Integrated nitrogen and phosphorus recovery device in struvite method

A recovery device and struvite method technology, applied in chemical instruments and methods, inorganic chemistry, phosphorus compounds, etc., can solve the problems of large investment in supporting equipment, increased operation difficulty, high energy consumption, etc., to reduce operating costs and Difficulty of operation, maintaining supersaturation, increasing recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

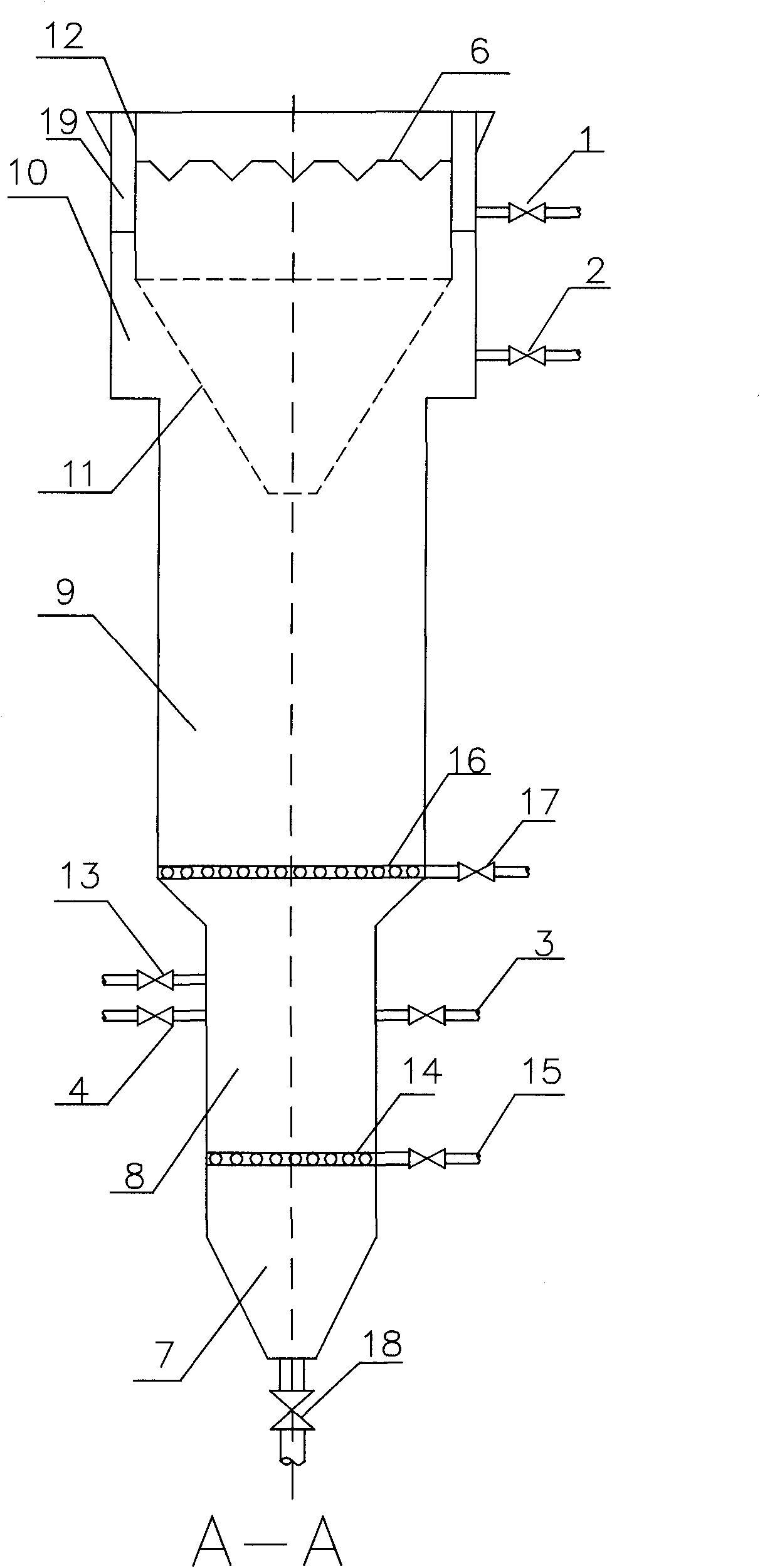

[0046] The wastewater from the fermentation pond of chicken farms has a COD (chemical oxygen demand) concentration of about 10000mg / L, ammonia nitrogen of 3000-4000mg / L, and total phosphorus of 400-500mg / L. 2 □6H 2 O and Na 2 HPO 4 □12H 2 O is a precipitating agent, and 10% NaOH solution is used to adjust the pH value for denitrification and phosphorus removal of struvite and recovery.

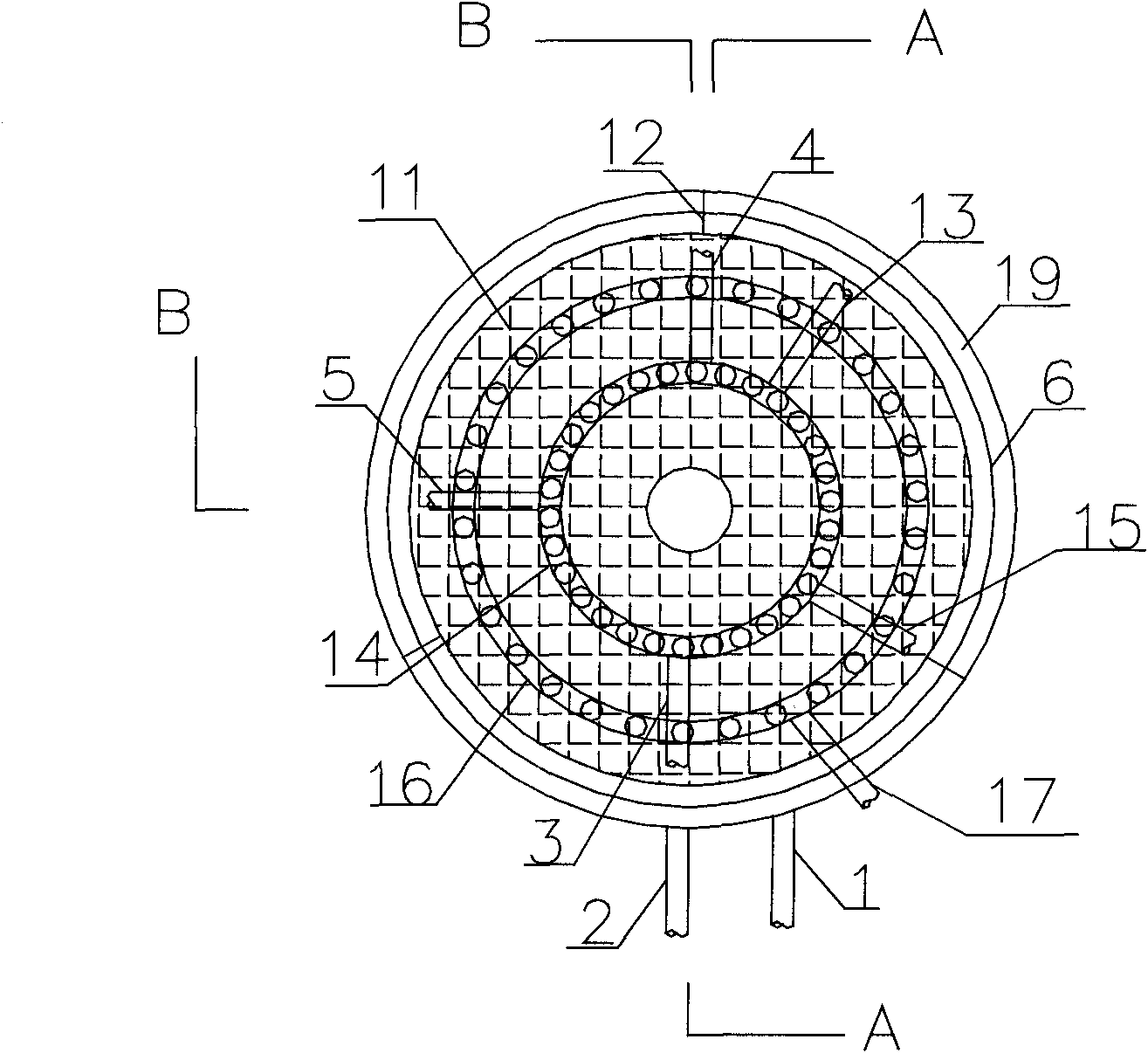

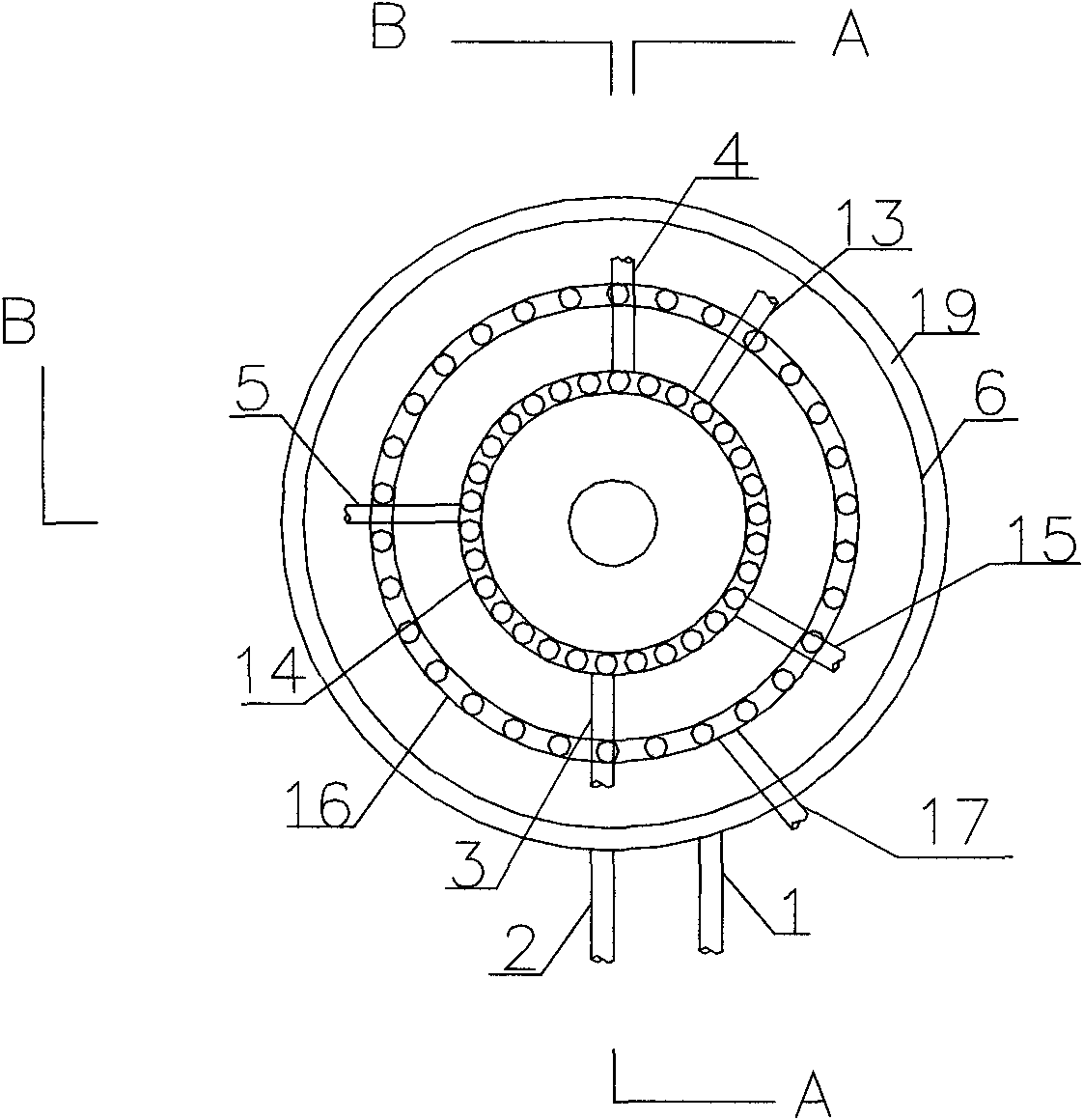

[0047] The total height of the reactor is 52cm, the effective height is 49cm, and the total volume is 4L. There is a conical funnel at the bottom to collect the sediment. The volume of the funnel is 0.09L. The height of the buffer layer at the upper end of the funnel is 3cm. The height of the crystal growth area is 20cm, the diameter is 11cm, and the bottom is equipped with annular aeration to scour the inner wall to prevent struvite crystals from scaling on the inner wall of the crystal growth area. The mixed reaction zone and the crystal growth zone have different cross-sectional areas,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com