Patents

Literature

2251results about How to "Reduce recycling costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High wear-resistant wood-plastic composite and preparation method thereof

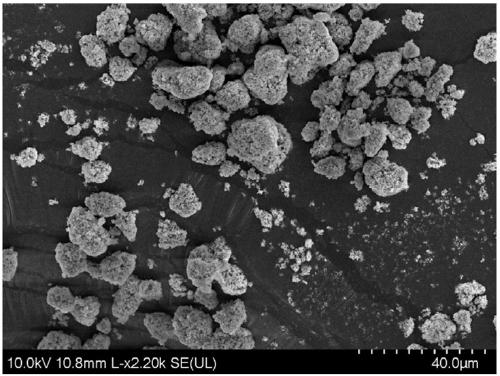

The invention provides a high wear-resistant wood-plastic composite and a preparation method thereof, and relates to a composite obtained by mixing modified plant fiber powder, modified nano ceramics particles and plastic powder. The high wear-resistant wood-plastic composite comprises the modified plant fiber powder, the modified nano ceramics particles, the recycled plastic powder and the like, wherein the modified nano ceramics particles comprises modified nano Al2O3, modified nano Si3N4, modified nano SiC or the mixture thereof, which can obviously improve the microhardness of the wood-plastic composite, reduce the wear rate and improve the mechanical property. The high wear-resistant wood-plastic composite is prepared from the components by the common melt-mixing method in the plastic processing. The surface hardness and the wearability of the wood-plastic composite are greatly increased, and the strength and the toughness are also greatly improved, so that the overall performance of the wood-plastic composite is greatly enhanced. The wood-plastic composite can be used in the fields of construction material, furniture, package and the like.

Owner:GUANGDONG XINXIU NEW MATERIAL CO LTD

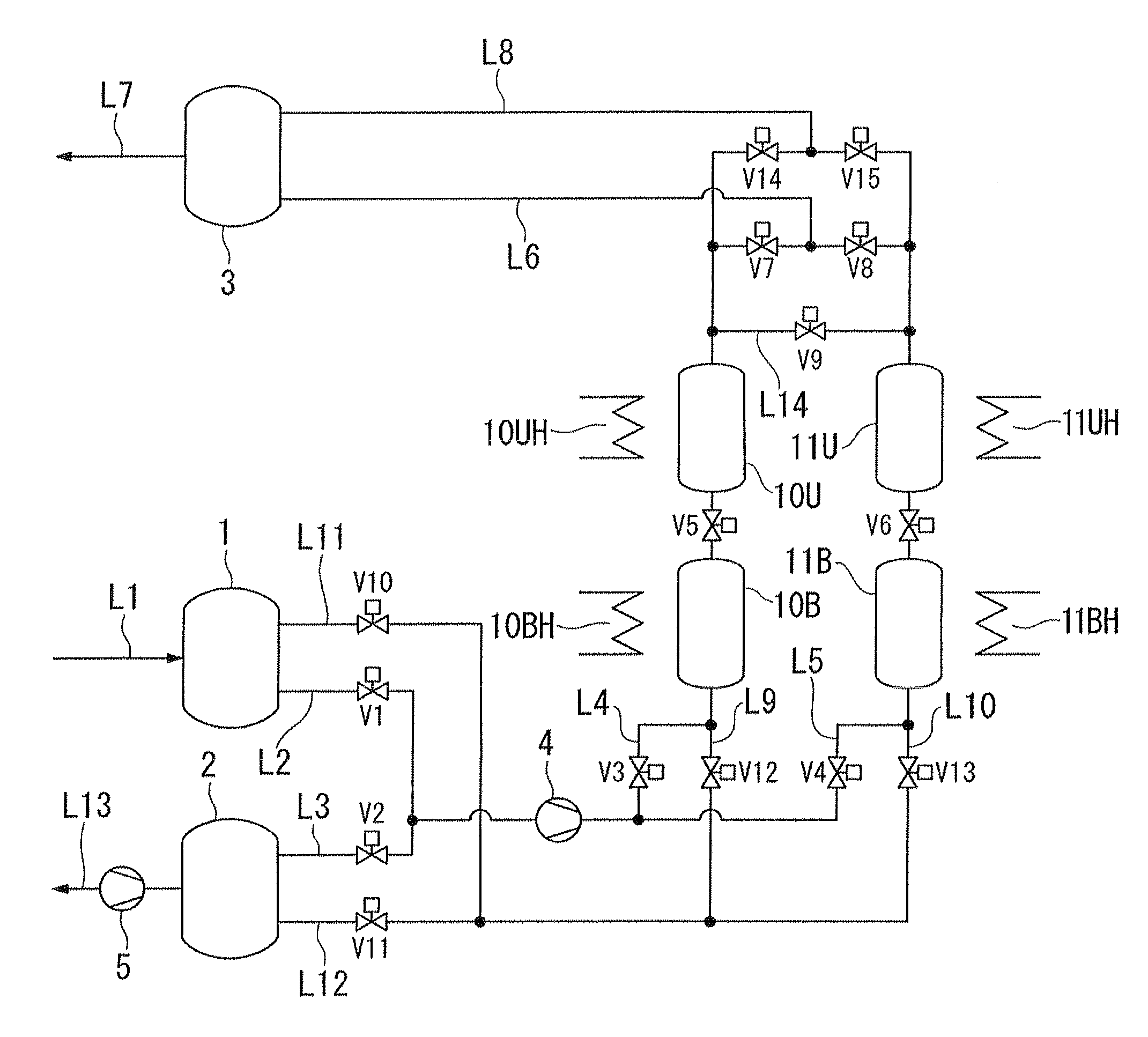

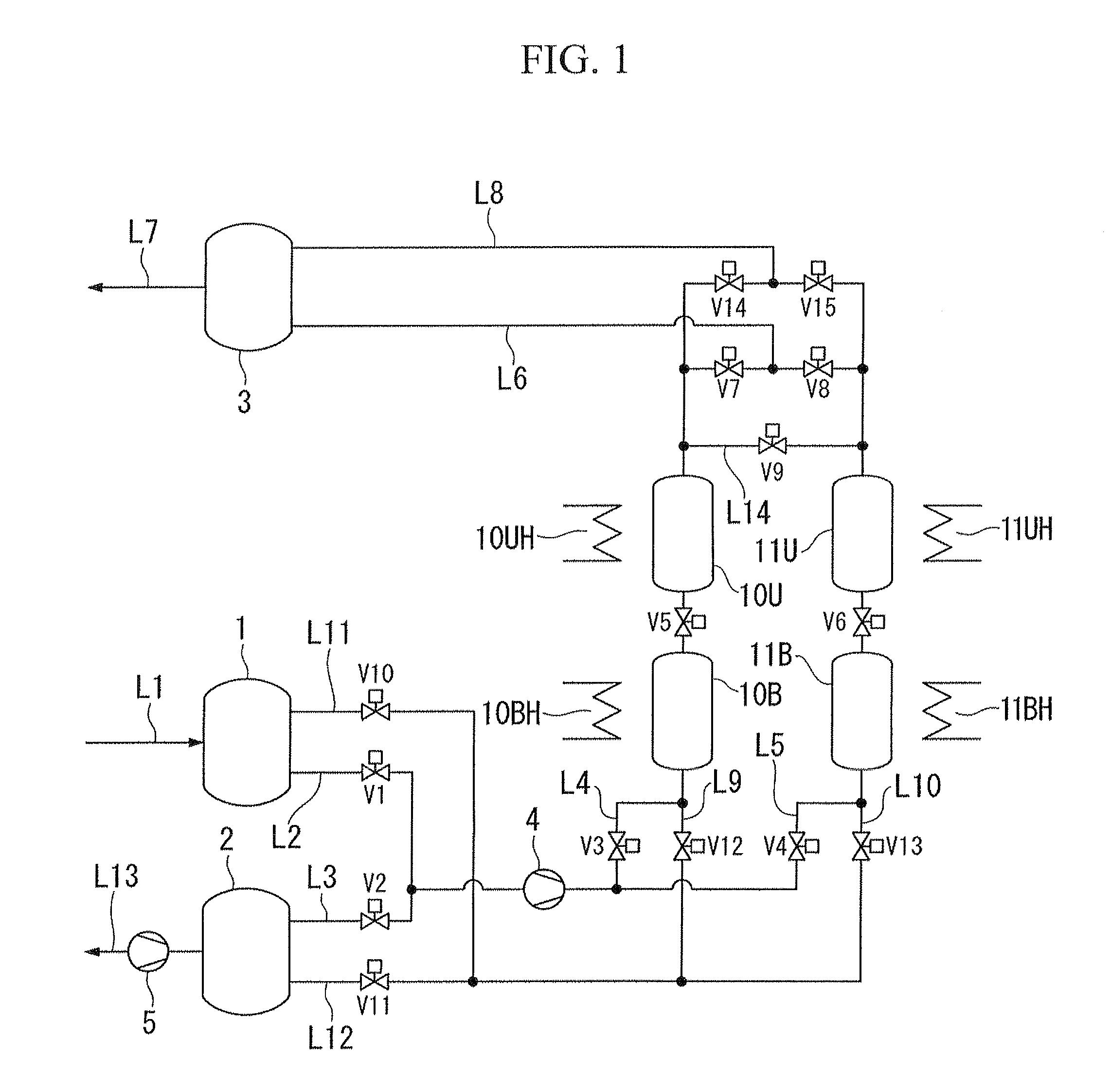

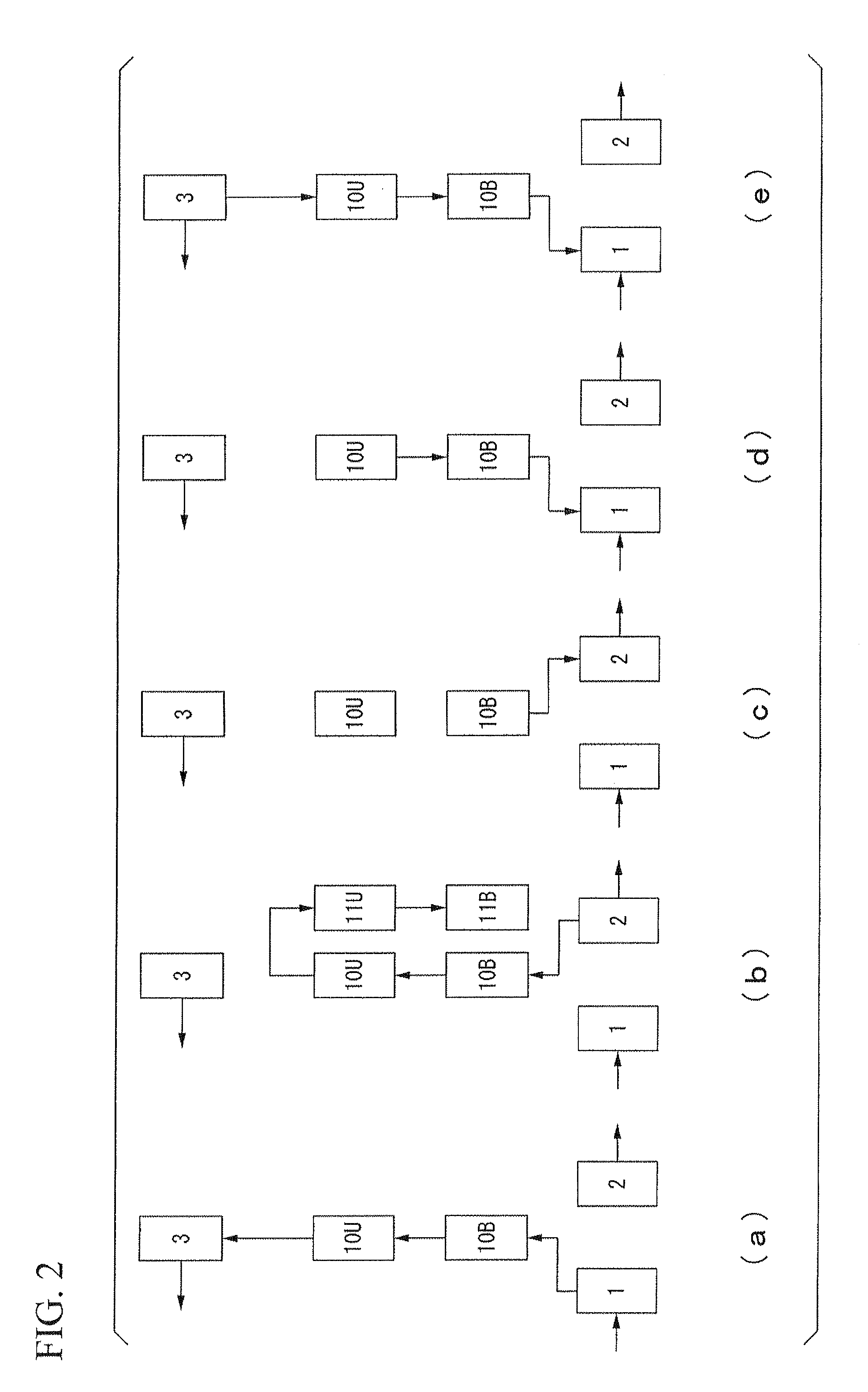

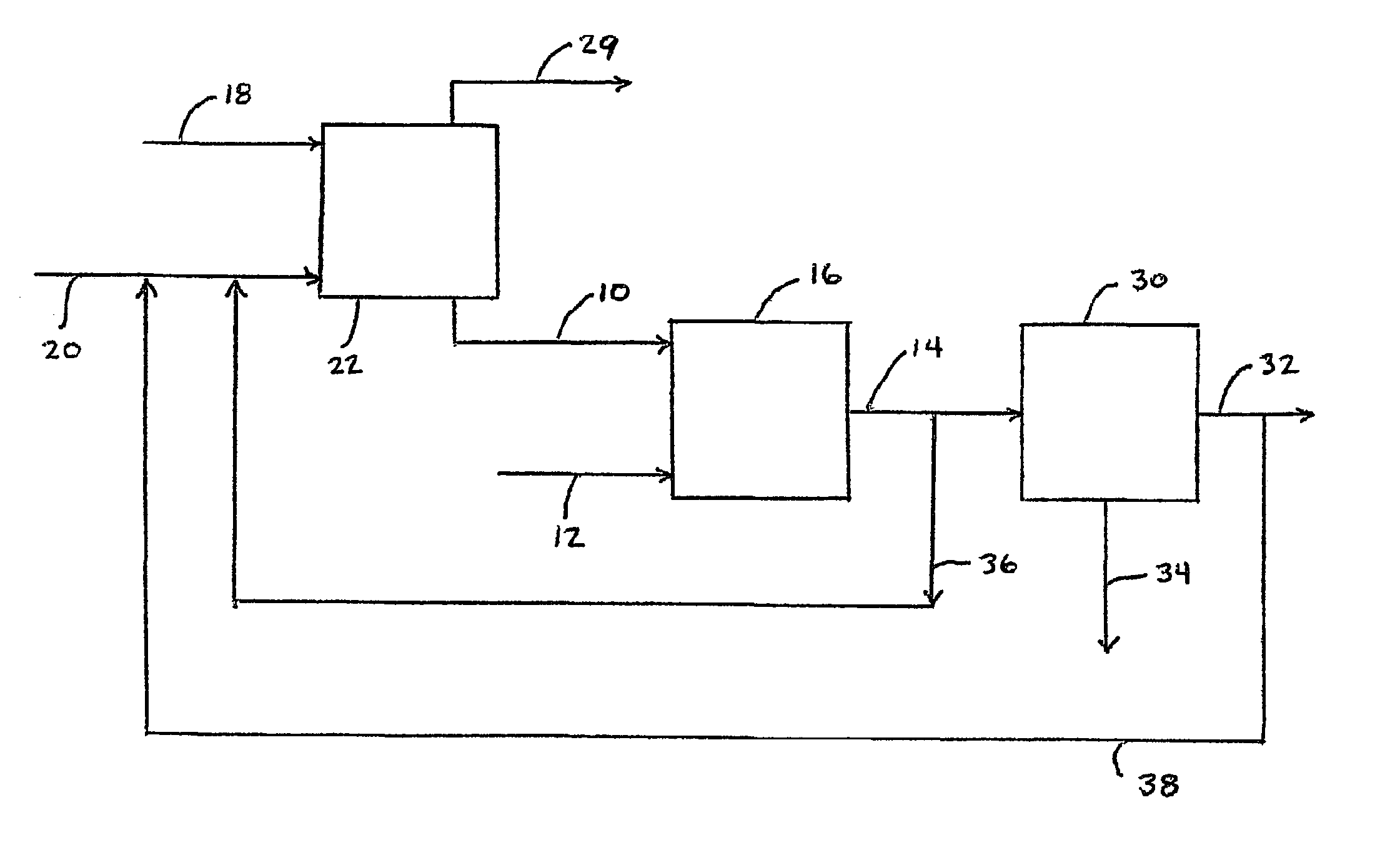

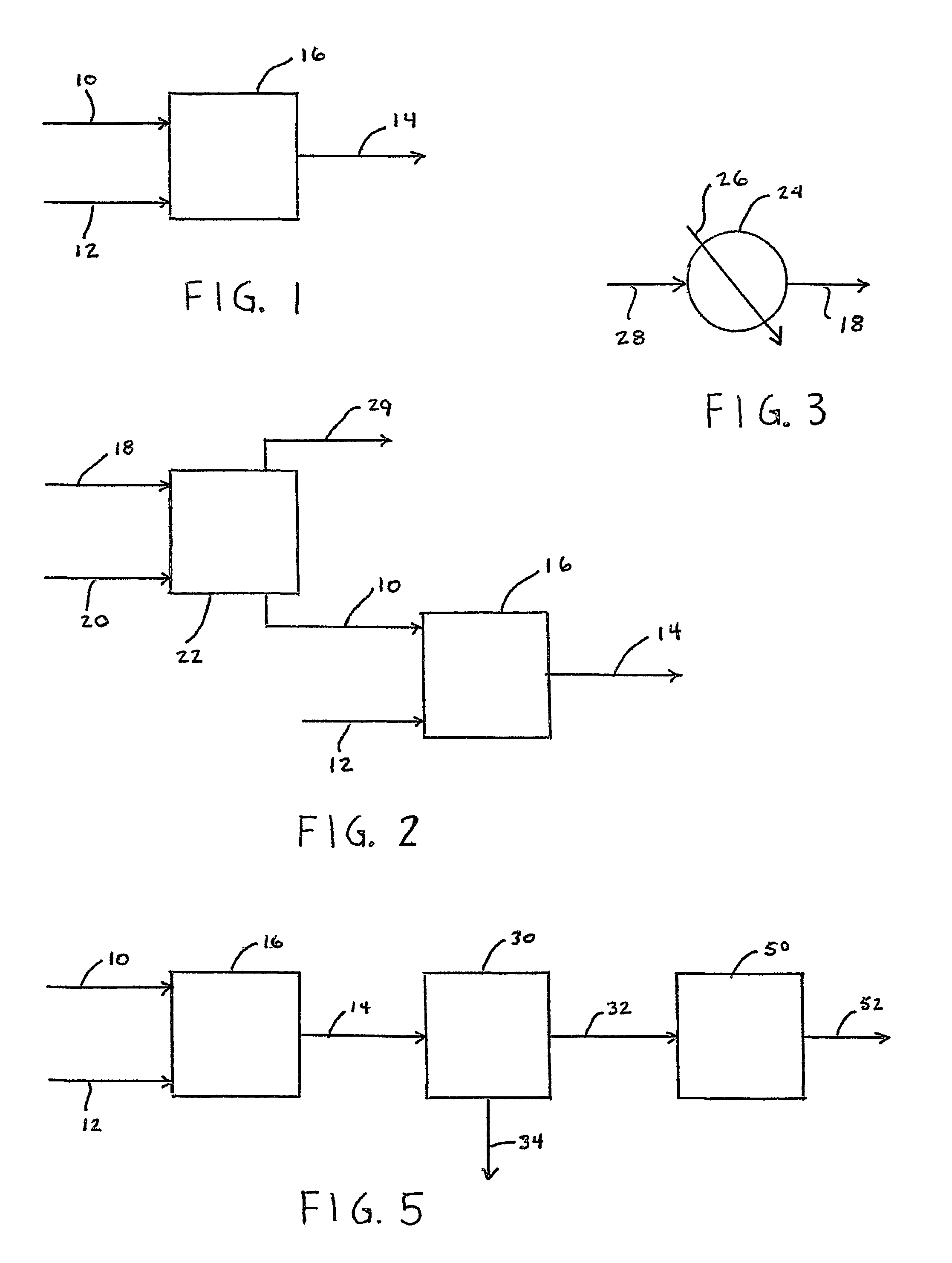

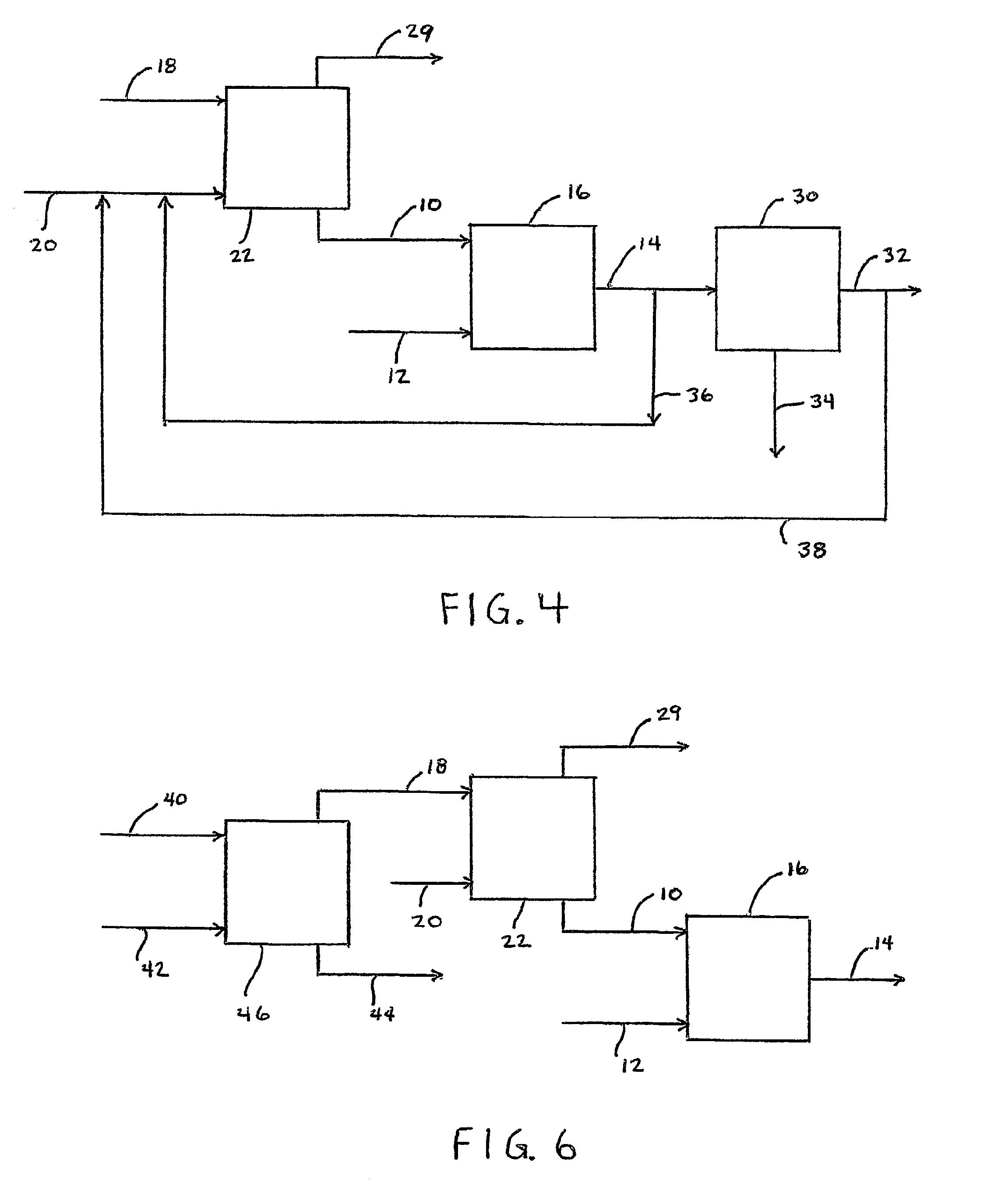

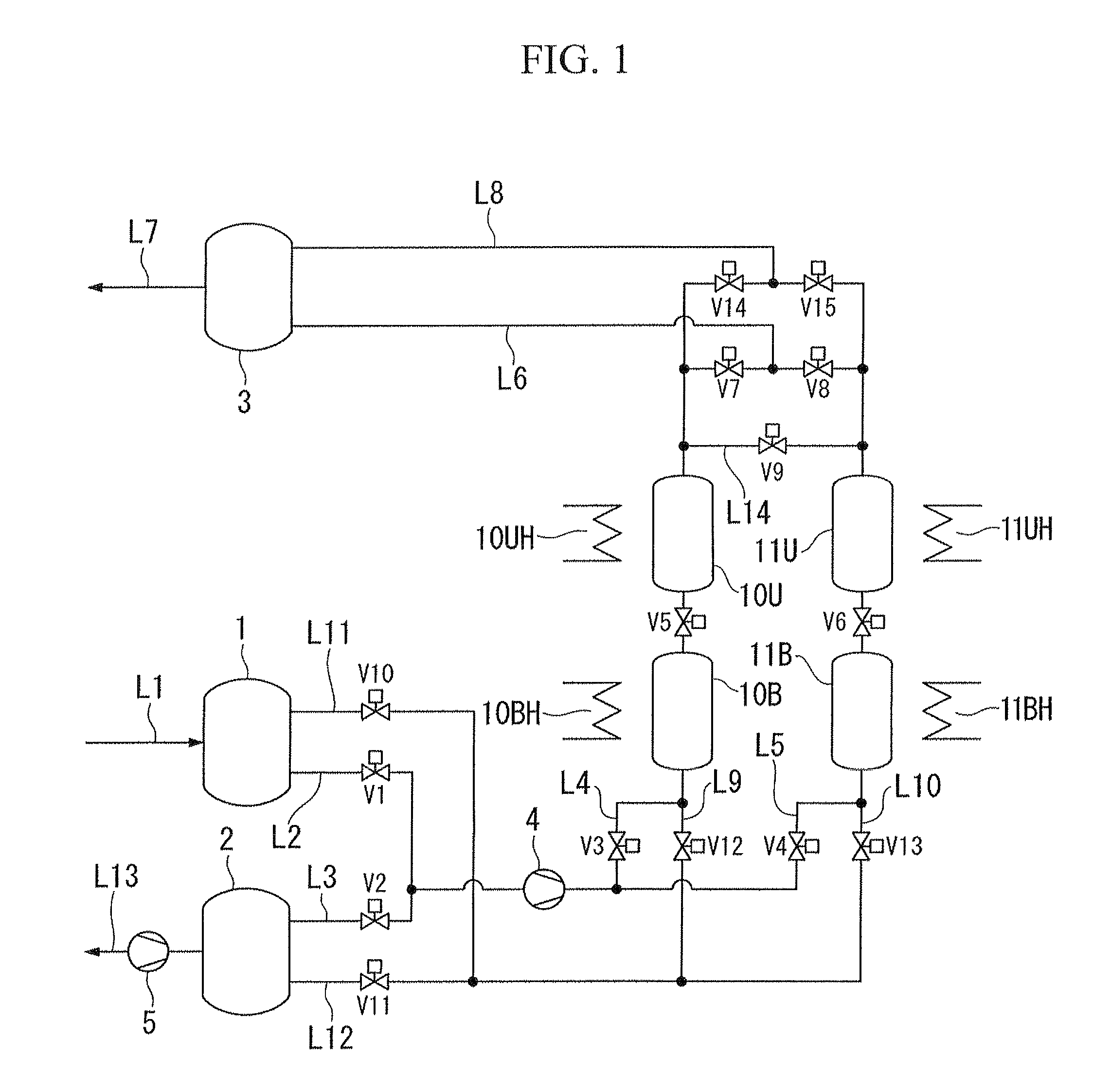

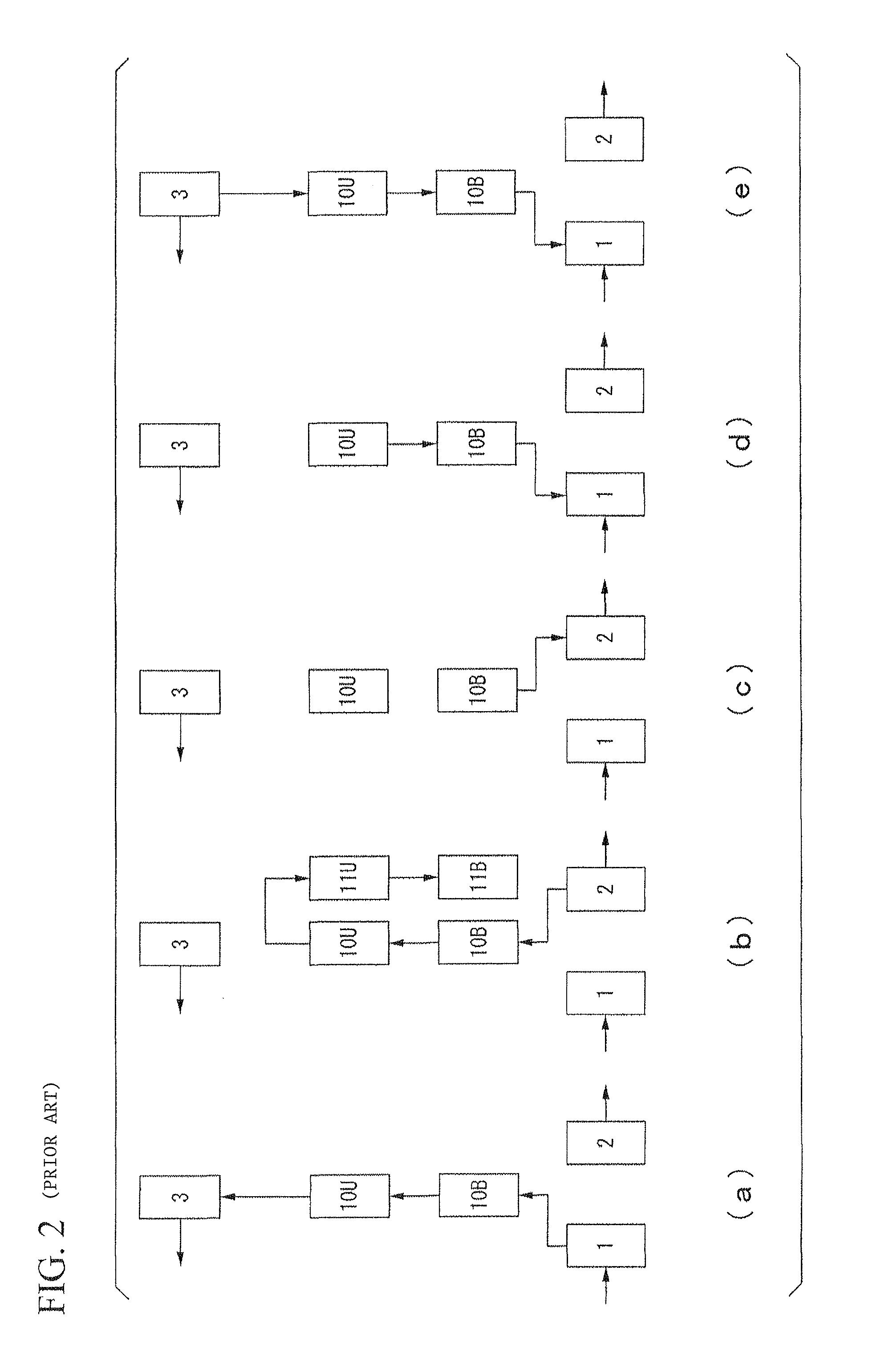

Pressure swing adsorption-type gas separation method and separation apparatus

InactiveUS20120024152A1Stable separationStable collectionGas treatmentIsotope separationChemistryPressure swing adsorption

Owner:NIPPON SANSO CORP

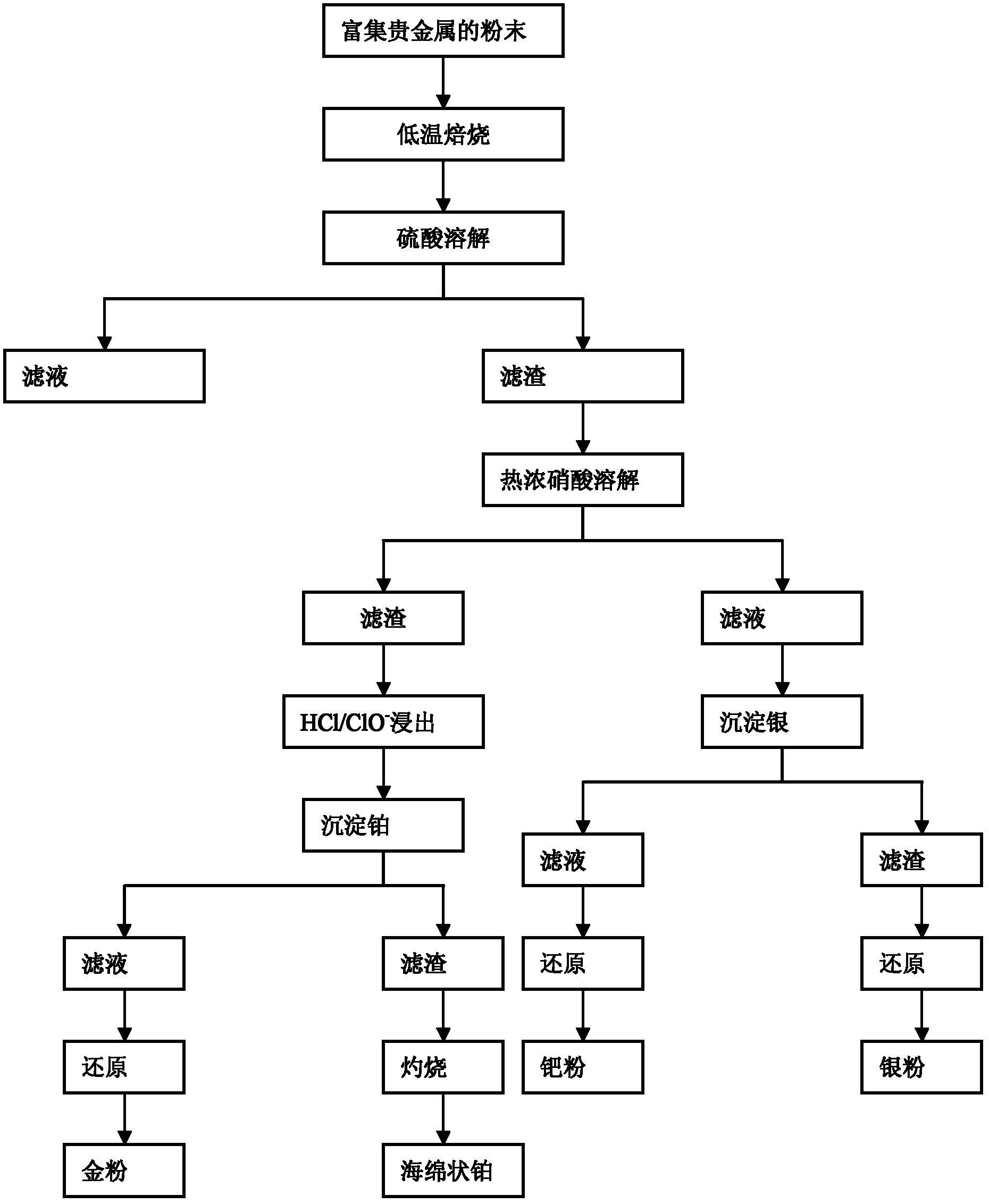

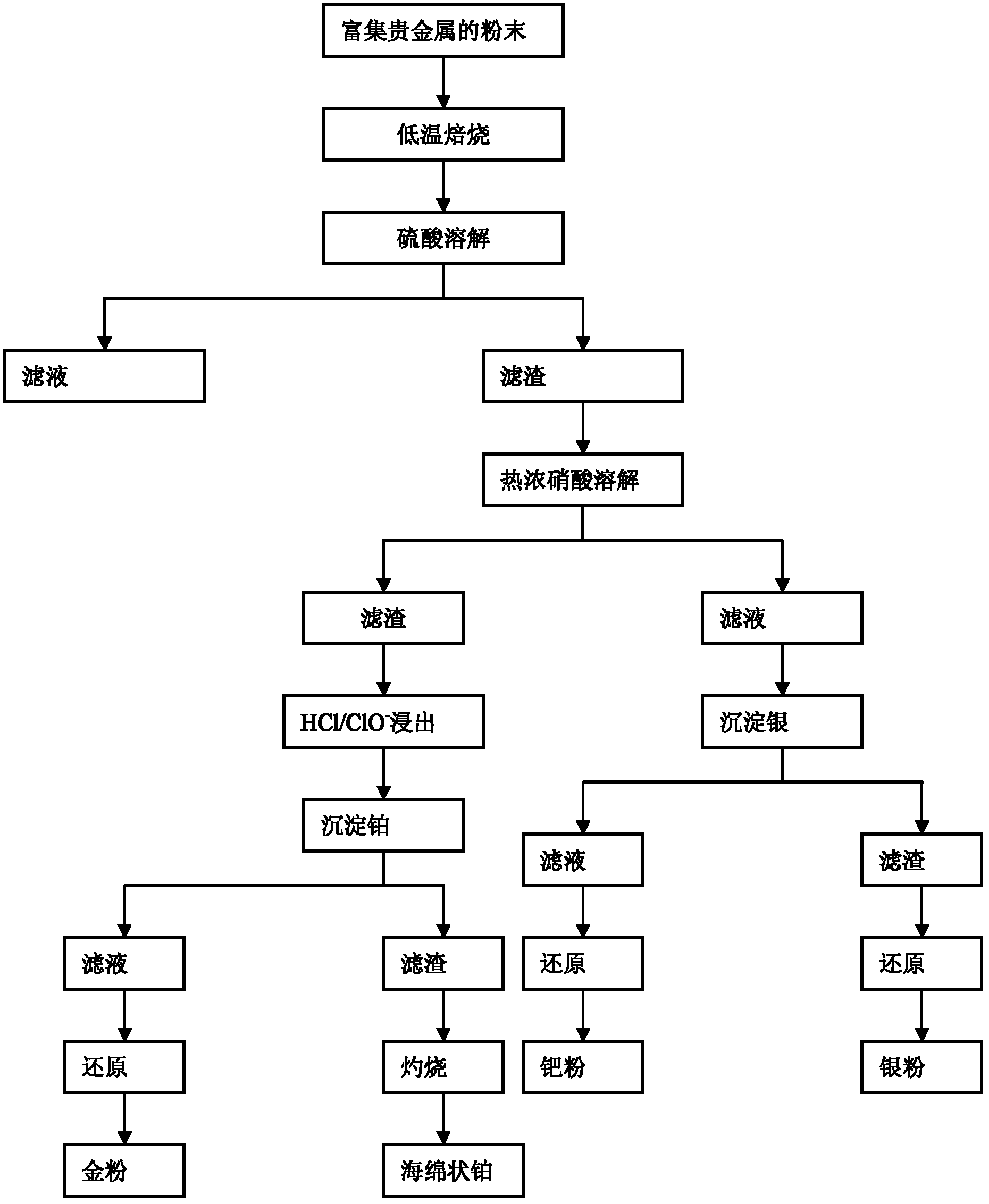

A method for recovering gold, palladium, platinum and silver from waste circuit boards

ActiveCN102277497AEmission reductionIncrease profitProcess efficiency improvementElectronic waste recyclingPlatinumCopper

The invention relates to the field of industrial waste recycling and in particular relates to a method of reclaiming gold, palladium, platinum and silver from a waste circuit board. The method comprises the following steps: (1) removing impurities of a waste circuit board which is subjected to extraction of copper, nickel, lead and tin; (2) separating and reclaiming palladium and silver; and (3) separating and reclaiming platinum and gold. Compared with the prior art, the method provided by the invention has the advantages of lower reclaiming cost, higher recycling rate and higher purity of the reclaimed metals.

Owner:荆门格林循环电子废弃物处置有限公司

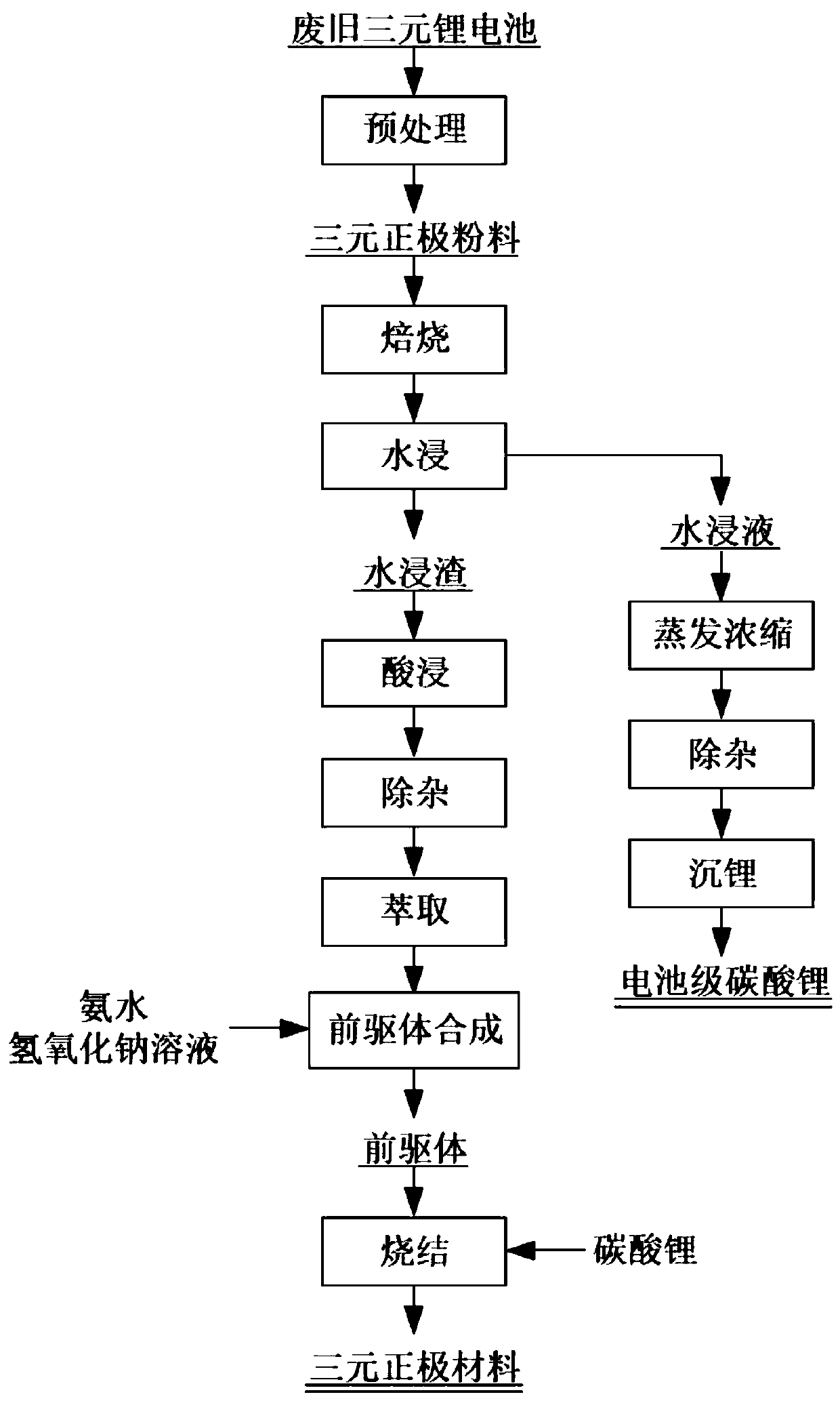

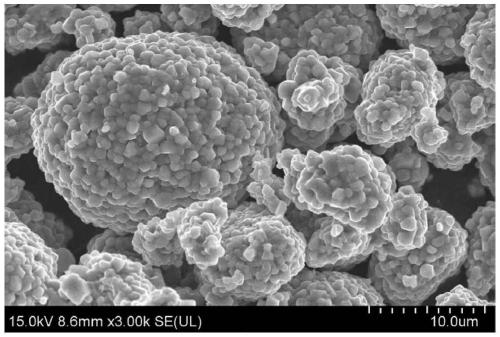

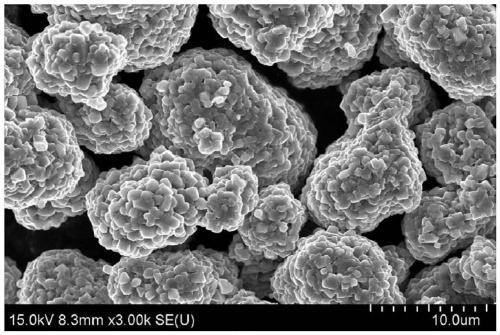

Method for preparing ternary positive electrode material through recovering waste ternary lithium battery

ActiveCN111206148AHigh recovery rateReduce recycling costsCell electrodesWaste accumulators reclaimingManganese sulphatePregnant leach solution

The invention provides a method for preparing a ternary positive electrode material through recovering a waste ternary lithium battery. The method comprises the following steps of 1) mixing pretreatednickel cobalt lithium manganate waste positive electrode powder with sulfate, and roasting to obtain a roasted product; 2) immersing the roasted product in water to obtain water immersion liquid andwater immersion slag; wherein the water immersion liquid contains lithium salt; 3) reacting the water immersion slag with an acid solution and hydrogen peroxide to obtain a nickel-cobalt-manganese leaching solution; 4) removing impurities from the nickel-cobalt-manganese leaching solution, then extracting cobalt, manganese and nickel, and saponifying and reversely extracting obtained organic phaseto obtain a nickel sulfate solution, a cobalt sulfate solution and a manganese sulfate solution; and 5) co-precipitating the nickel sulfate solution, the cobalt sulfate solution and the manganese sulfate solution with a sodium hydroxide solution and ammonia water, mixing obtained precursor with lithium carbonate, sintering, and screening iron to obtain the ternary positive electrode material. According to the method, lithium is extracted firstly, so that the influence of a lithium element on subsequent nickel-cobalt-manganese extraction is reduced, the impurity content in the ternary positiveelectrode material is reduced, and the recovery rate of nickel-cobalt-manganese is greatly improved; and meanwhile the recovery rate of the lithium can be improved.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

Method for recycling electrolyte of waste lithium ion battery

ActiveCN102496752AEasy to handleSimple processWaste accumulators reclaimingBattery recyclingSocial benefitsHydrogen fluoride

The invention discloses a method for recycling the electrolyte of a waste lithium ion battery. The method mainly comprises the following steps of: collecting and cleaning the lithium ion battery; after discharge, putting the lithium ion battery in a drying room or a glove box under protection of inert gas; opening the battery, carefully taking out the electrolyte and placing in a material tank; performing high-vacuum decompressed rectification and separation to obtain the organic solvent contained in the electrolyte; performing rectification and purification for recycling; putting a rough product of lithium hexafluorophate into a dissolution kettle, and adding a hydrogen fluoride solution for dissolving the recycled lithium hexafluorophate; filtering the solution and then putting into a crystallization kettle for crystallization and purification; and screening, drying, packaging and recycling to obtain the product lithium hexafluorophate. The method has simple technology, is practical, efficient, clean and environment-friendly and easy to control, and realizes close integration of economic benefits and environmental social benefits.

Owner:CHINA NAT OFFSHORE OIL CORP +1

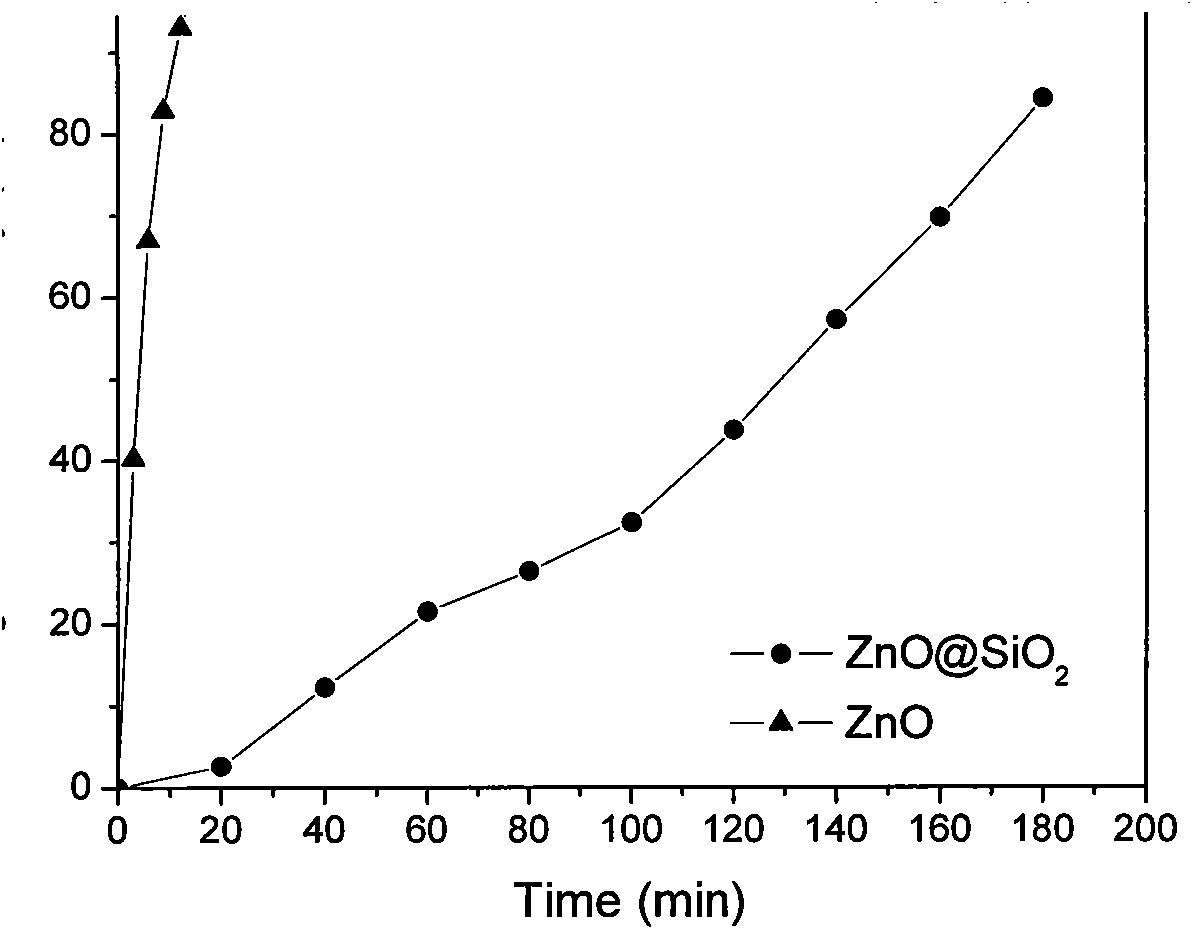

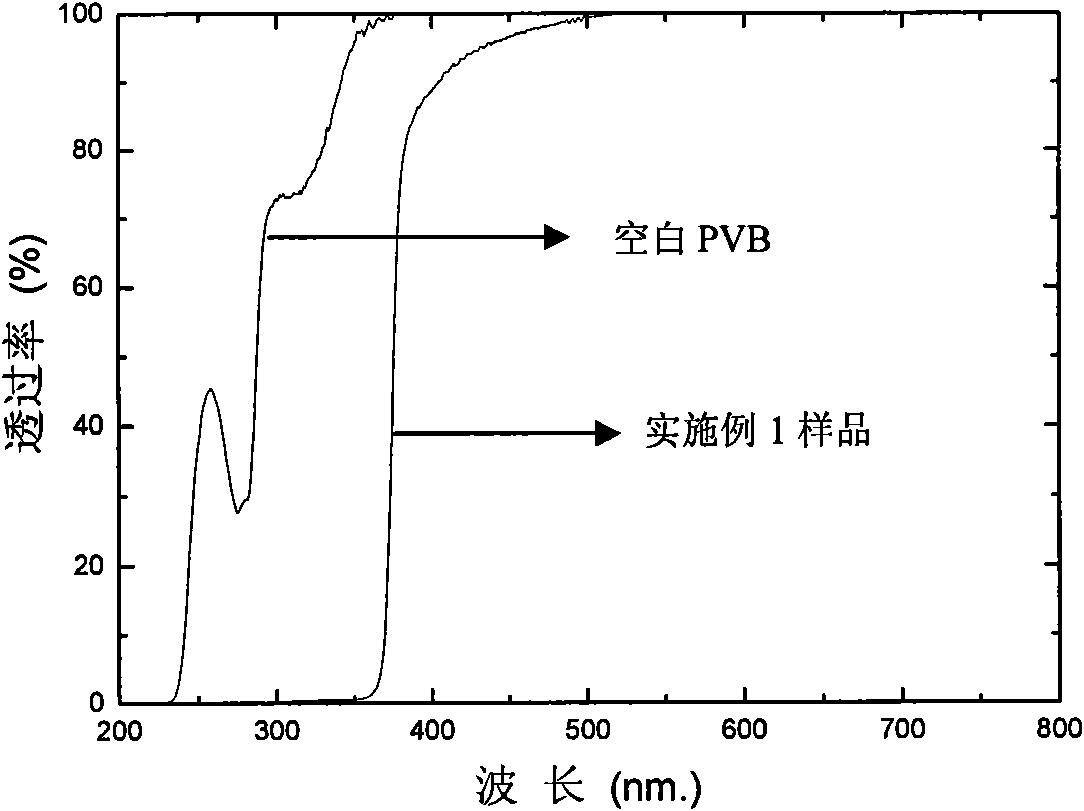

High-transparency ultraviolet-blocking energy-saving film and solution-fusion preparation method thereof

The invention discloses a high-transparency ultraviolet-blocking energy-saving film and a solution-fusion preparation method thereof, which belong to the field of composite films. The film comprises the following components: 50 to 99.8 weight percent of thermoplastic polymer, 0.2 to 50 weight percent of metallic oxide nanoparticles (which at least comprise one kind of composite metallic oxide nanoparticles with a core-shell structure) and 0 to 39.9 weight percent of plastic assistant. The film is prepared by a solution-fusion mixing process which comprises the following steps of: transferring the metallic oxide nanoparticles from an initial disperse system to a solvent system capable of dissolving the thermoplastic polymer to prepare metallic oxide nanoparticle / thermoplastic polymer / solvent dispersion; and drying the obtained dispersion by atomization to obtain a dry powdered master batch and preparing the energy-saving film from the master batch, the thermoplastic polymer and the assistant by using the fusion mixing process. The film in the invention has high transparency, high ultraviolet light shielding performance and good energy-saving effects and is simple in preparation process, low in cost and suitable for industrial production.

Owner:BEIJING UNIV OF CHEM TECH

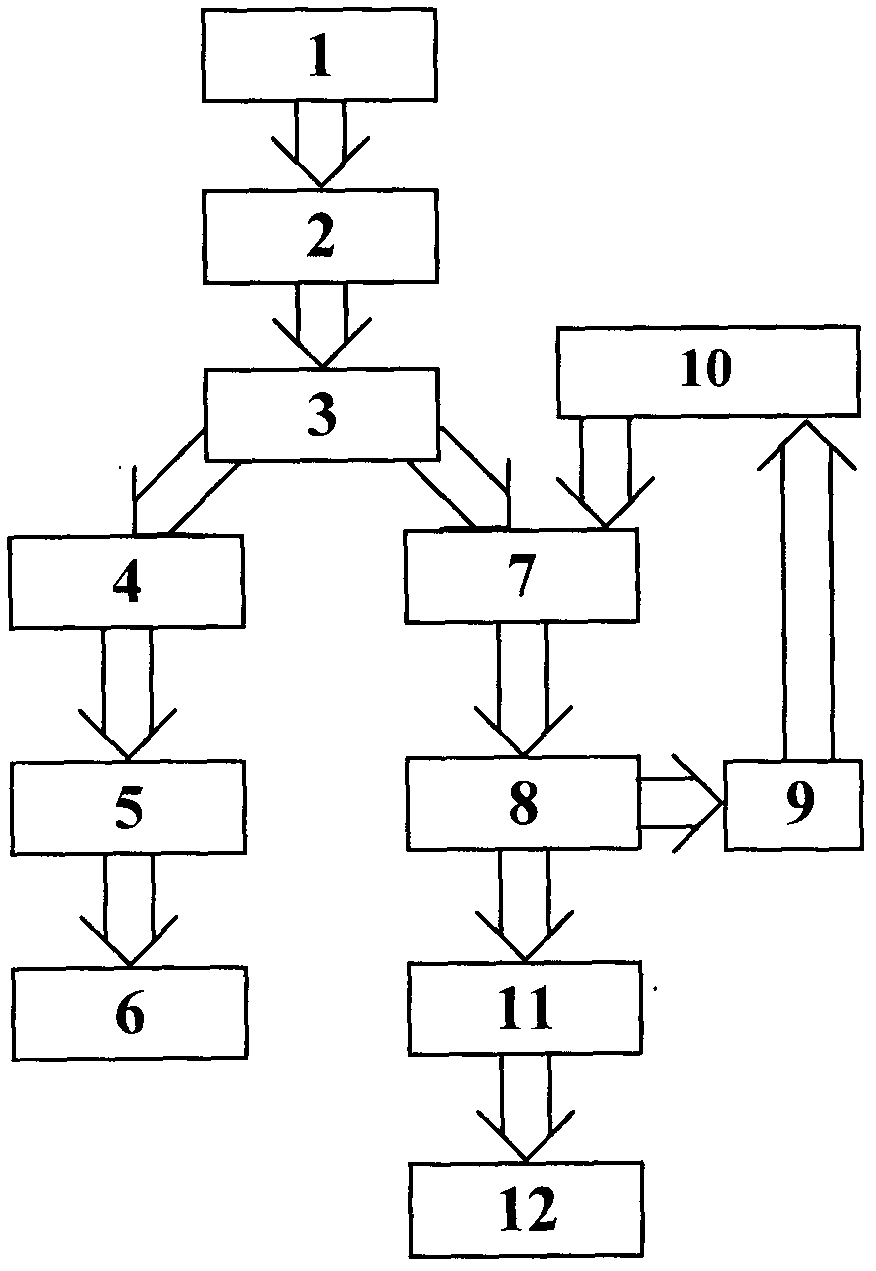

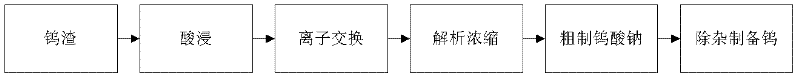

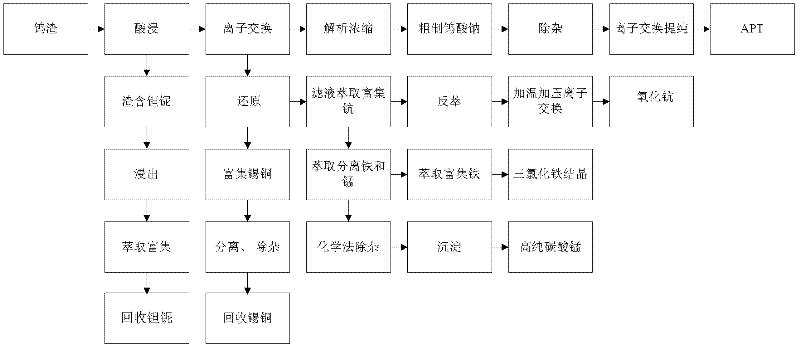

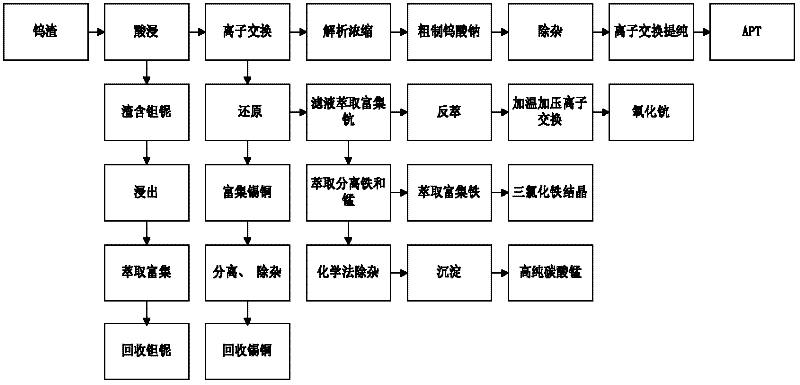

Tungsten slag treatment method

ActiveCN102212697ASolve the problem of secondary pollutionReduce recycling costsProcess efficiency improvementSlagFiltration

The invention discloses a tungsten slag treatment method. The tungsten slag treatment method comprises the following steps of: dissolving: mixing tungsten slag and 15 to 30 percent HCl solution of 50 to 65 DEG C, adding a tungsten stabilizing agent, and performing filtration after the reaction is finished to obtain acid solution; and reclaiming tungsten: adsorbing the tungsten in the acid solution by adopting weak alkali acrylic acid series anion exchange resin to obtain tail solution I, resolving the exchange resin by using sodium hydroxide solution to obtain sodium tungstate, and reclaimingthe tungsten from the sodium tungstate. By using the technical scheme, the tungsten slag is leached at a low temperature under normal pressure by adopting the HCl solution, and the tungsten is directly reclaimed by a one-step method under the acid condition; and the process is simple and low in reclamation cost.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

Universal method and apparatus for conversion of volatile compounds

InactiveUS7029589B2Increase usageAvoid oversaturationPaint waste treatmentUsing liquid separation agentCompound aOxidizing agent

Owner:MCGINNESS MICHAEL P

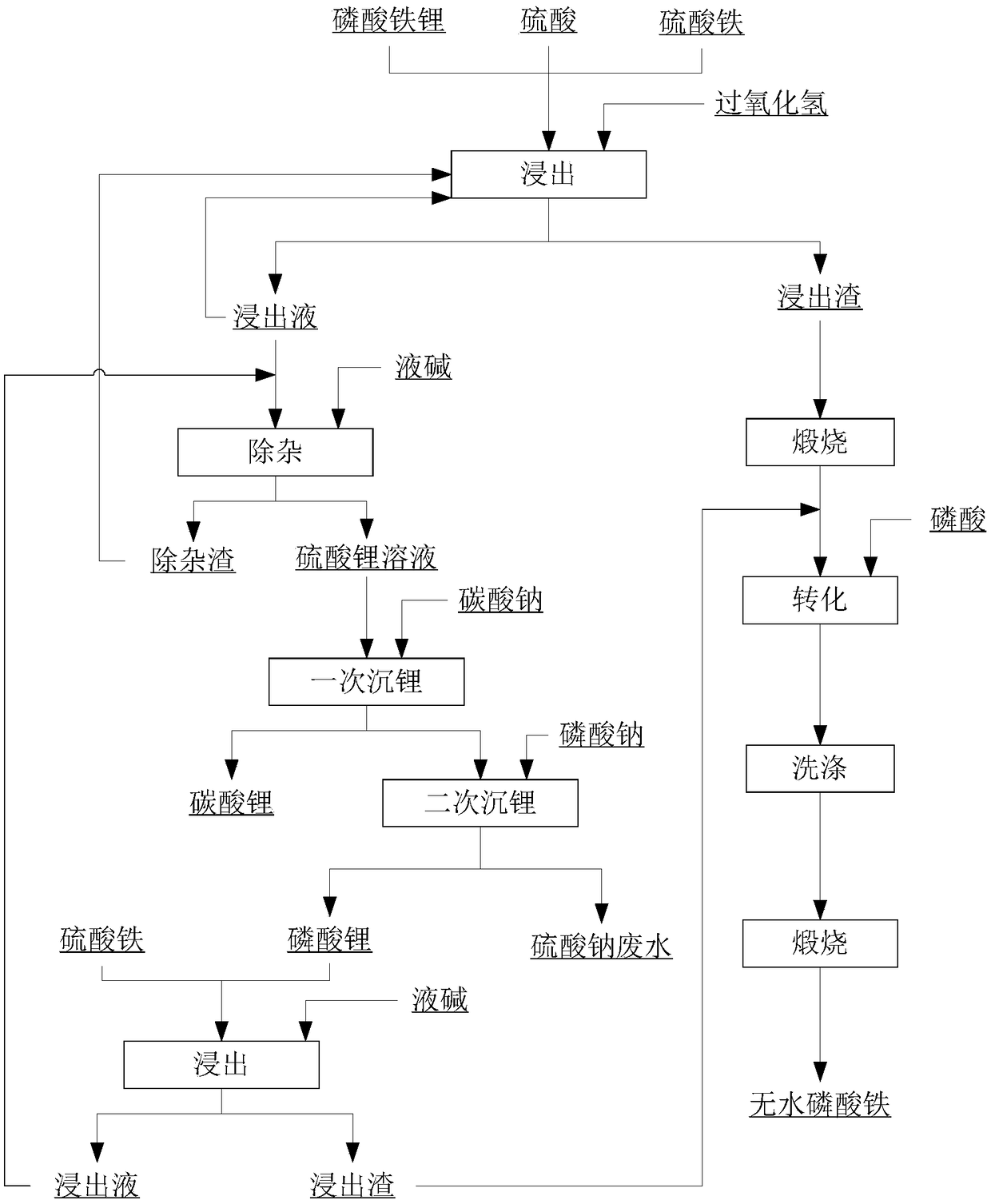

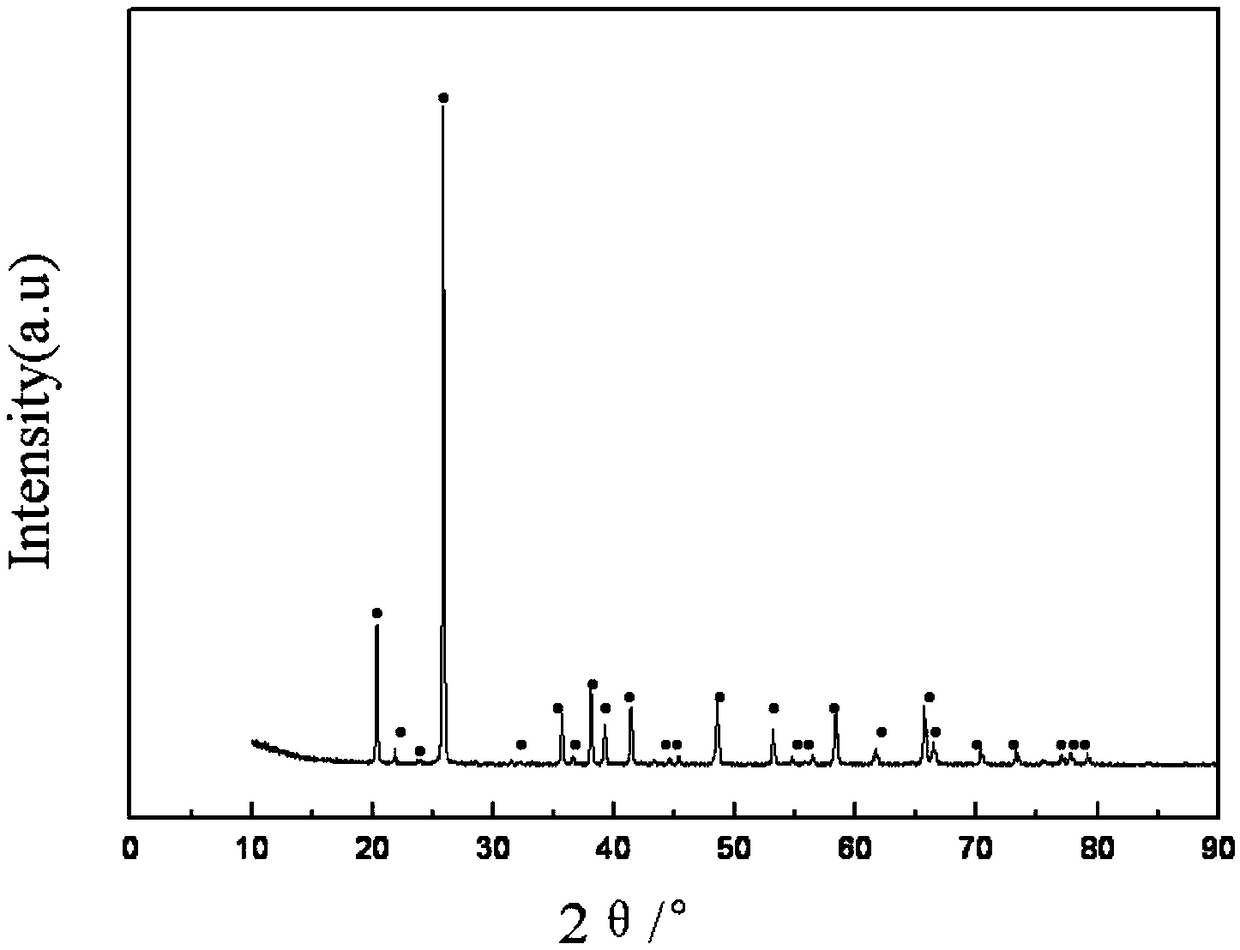

Method for recovering lithium from lithium iron phosphate

ActiveCN108899601ADoes not affect the leaching rateHigh purityWaste accumulators reclaimingProcess efficiency improvementFerric hydroxideIron sulphate

The invention discloses a method for recovering lithium from lithium iron phosphate. The method disclosed by the invention comprises the following steps: dissolving waste lithium iron phosphate slag with sulfuric acid and ferric sulfate, leaching iron, lithium and phosphorus, adding an oxidizing agent, reacting iron and phosphate radicals to produce an iron phosphate precipitate and a small amountof ferric hydroxide, converting lithium into a water-soluble lithium sulfate solution, filtering to obtain the lithium sulfate solution, adding sodium carbonate into the lithium sulfate solution to prepare a lithium carbonate product, and adding sodium phosphate or phosphoric acid to prepare lithium phosphate; dissolving the lithium phosphate with ferric sulfate again to obtain the lithium sulfate solution and a compound taking iron phosphate as a principle component, returning the lithium sulfate solution to the system to prepare lithium carbonate, and calcining the iron phosphate slag to remove organic matters and carbon in the slag; and slurrying to prepare cell grade iron phosphate. According to the method for recovering lithium from lithium iron phosphate disclosed by the invention,the lithium is totally converted into the product lithium carbonate in the method, the process flow is short, the cost is low, the lithium recovery rate is 97%, the metal lithium in the lithium iron phosphate can be effectively recovered, and all the slag is converted into the cell grade iron phosphate.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

Method for recycling metal in waste LiMn1-x-yNixCoyO2 battery and preparing LiMn1-x-yNixCoyO2

ActiveCN104538695AImprove performanceReduce recycling costsCell electrodesWaste accumulators reclaimingHydrogen SulfateFiltration

A method for recycling metal in a waste LiMn1-x-yNixCoyO2 battery and preparing LiMn1-x-yNixCoyO2 comprises the steps that a waste lithium ion battery is discharged and dismantled, or positive electrode leftover materials and positive electrode fragments are collected, and waste positive plates are obtained; waste LiMn1-x-yNixCoyO2 powder is obtained through the calcinations, water dissolution and the filtration of the waste positive plates; the waste LiMn1-x-yNixCoyO2 powder and potassium pyrosulfate are mixed according to a certain proportion and calcinated, the calcinated products are leached by water, a potassium carbonate solution is added into the solution, then the filtration is carried out, the proportion of Li, Ni, Co and Mn in filter residues is adjusted by supplying carbonate, ball-milling, compressing and the calcinating are carried out on the Li, the Ni, the Co and the Mn, and LiMn1-x-yNixCoyO2 positive materials are regained. Composition adjustment is carried out on filtrate with sulfuric acid, and potassium hydrogen sulfate is obtained after the crystallization treatment is carried out.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Pressure swing adsorption-type gas separation method and separation apparatus

InactiveUS8657922B2Stably separate and collectIncrease valueGas treatmentIsotope separationChemistryPressure swing adsorption

Owner:NIPPON SANSO CORP

Method for recovering positive pole material of Li-ion battery

InactiveCN101212074AImprove recycling efficiencyShorten production timeSolid waste disposalWaste accumulators reclaimingOrganic solventAlcohol

The invention relates to a method for recycling anode material of a lithium ion battery, which includes the processes: organic solvent is used for soaking anode plates of the battery so as to separate the anode material from a current collector; the current collector is taken out and filtered to obtain anode active substances; the anode active substances are parched. The organic solvent is the mixed solvent of the N, N - dimethylformamide and liquid alcohol and / or liquid ketone. By adopting the mixed solvent, the invention greatly promotes the recycling efficiency of the anode material; in the method of the invention, the recycling rate of the anode material is higher by over 20 per cent compared with the prior art in the situation of adopting different used organic solvent but other same conditions; besides, by adopting the method provided by the invention, the needed production time is greatly shortened and the production efficiency is promoted.

Owner:SHANGHAI BYD

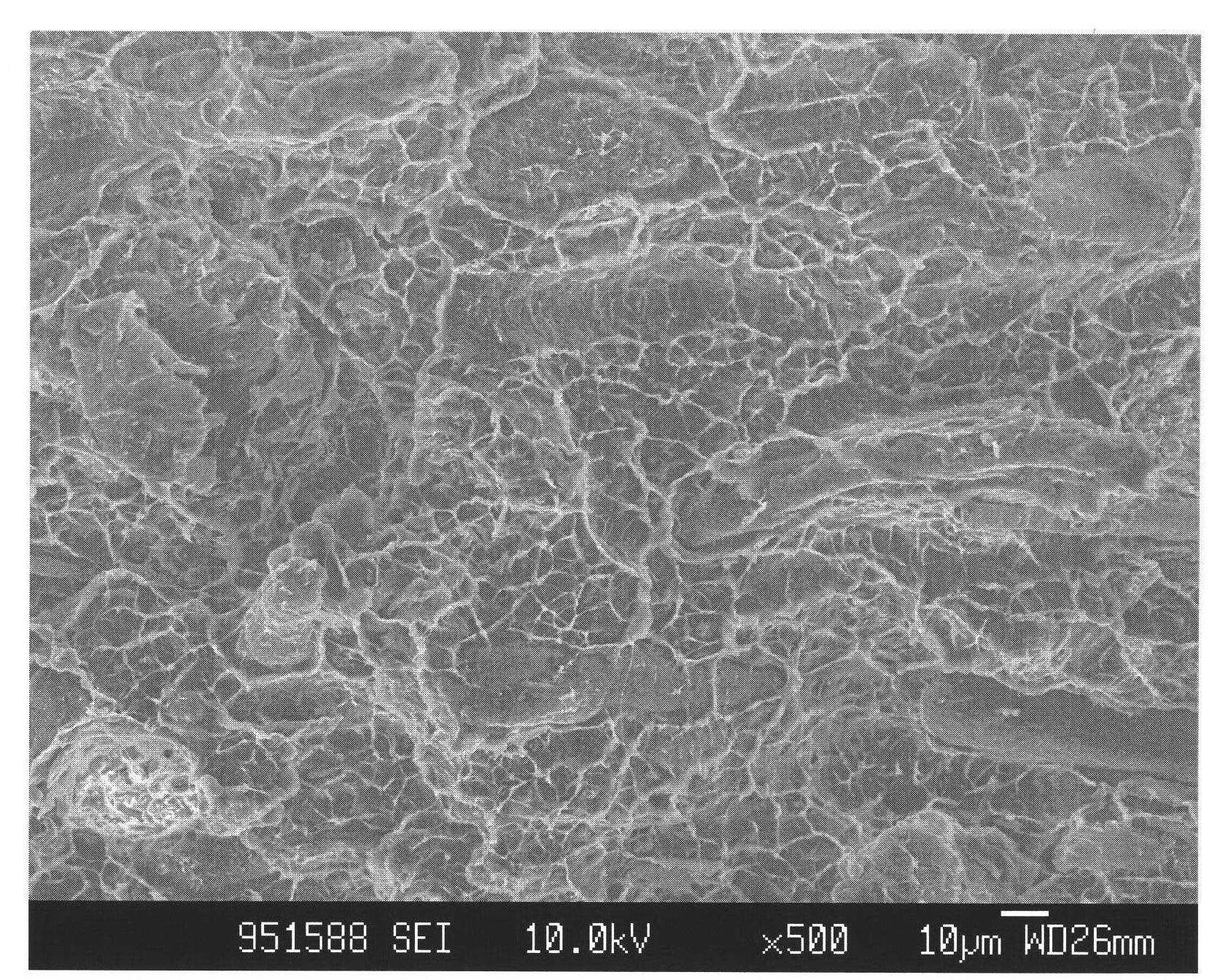

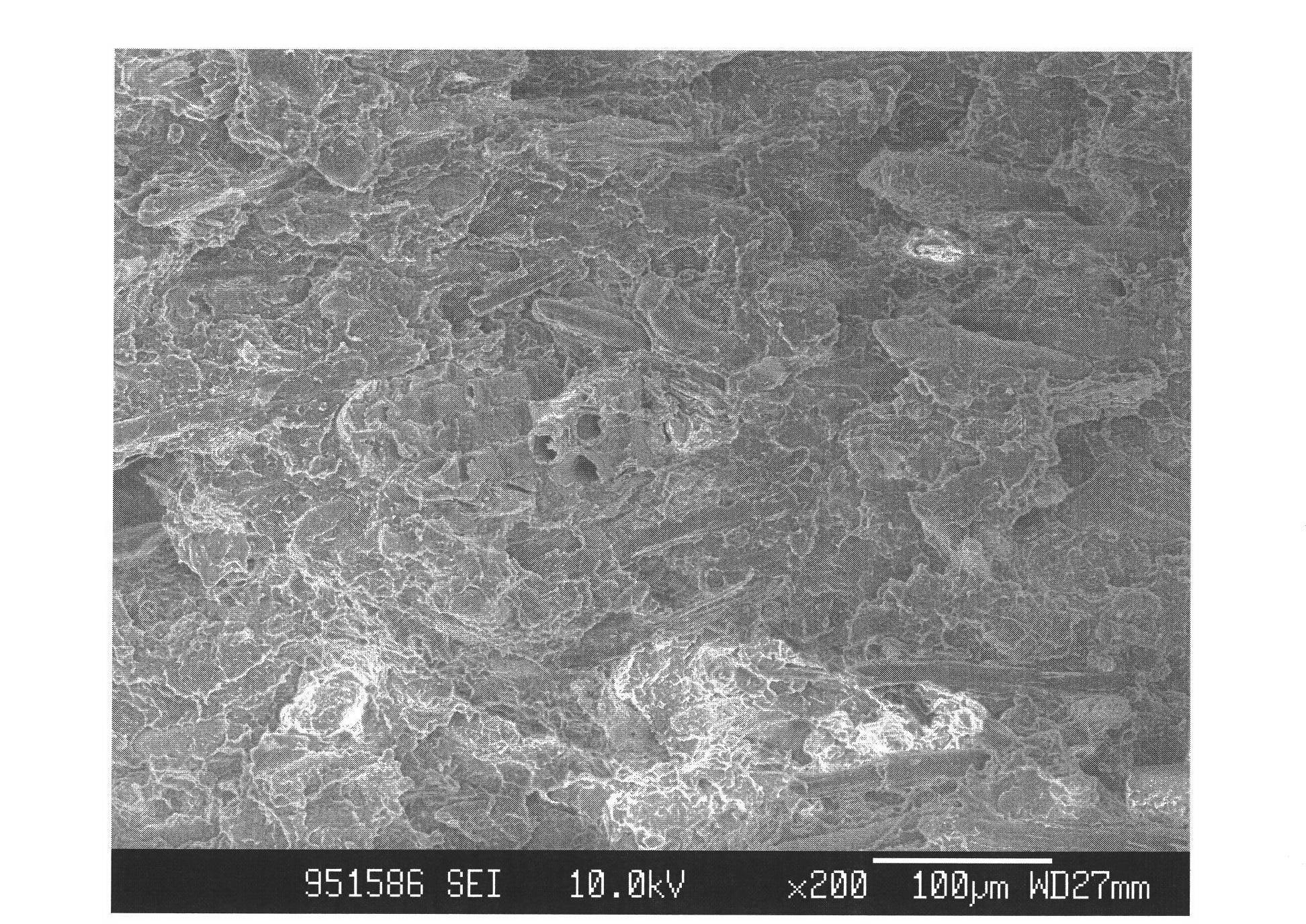

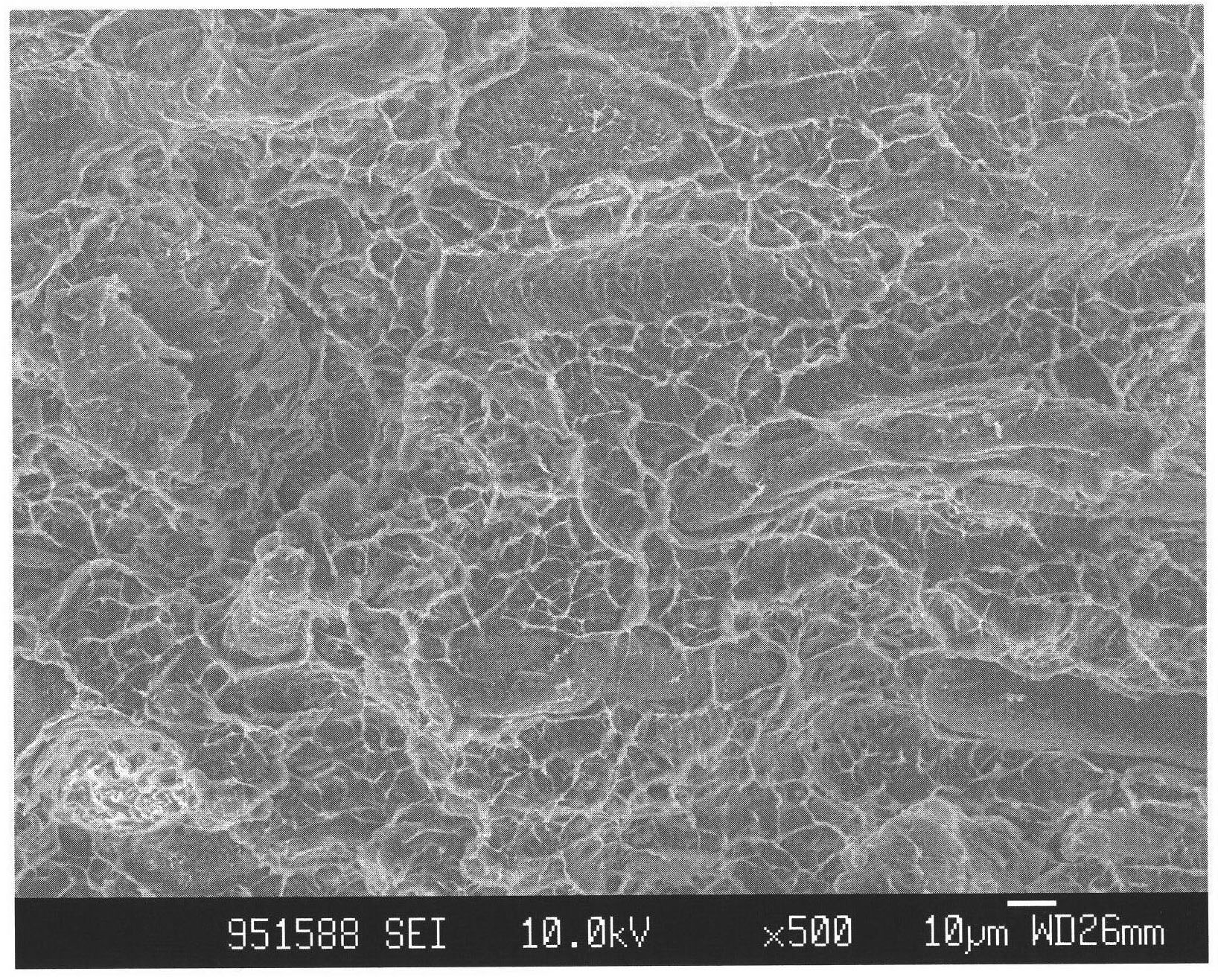

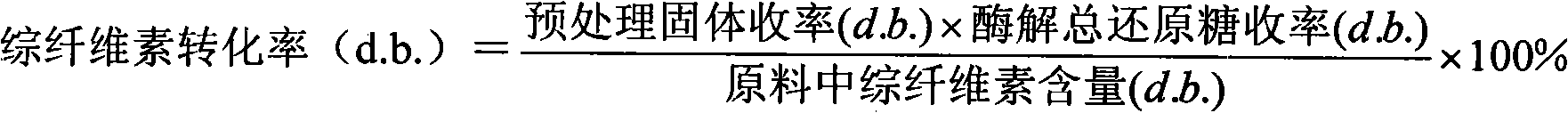

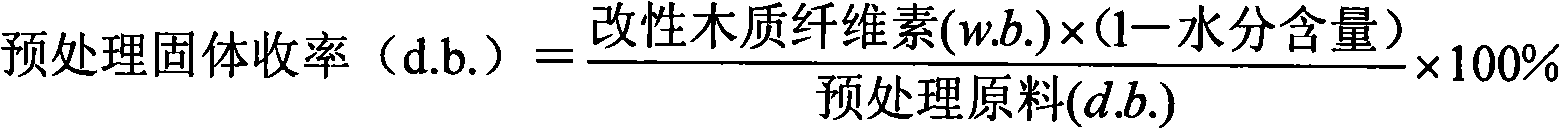

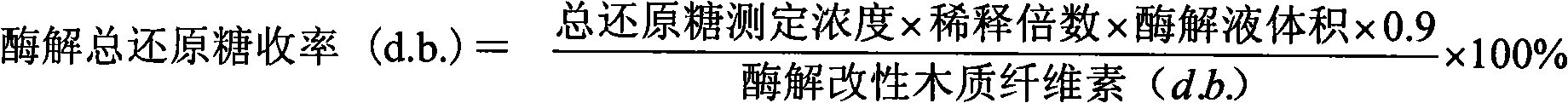

Pre-treatment method for highly-effective saccharification of lignocellulose

InactiveCN101255479AReduce the cost of trainingImprove securitySugar derivativesSugar derivatives preparationCelluloseLiquid glucose

The invention discloses a pretreatment method for effectively saccharifying lignocellulose, particularly discloses a pretreatment method of lignocellulose with room-temperature light-concentration lye, characterized in the method comprises the steps of coarse grinding, lye wetmilling, alkali recovery and enzymolysizing. The ground lignocellulose is mixed with univalent metal lye having a concentration of 0.1% to 3%, solid and liquid are separated under room temperature after wet grinding, wherein the liquid is used for recovering univalent metal lye, and the solid, namely the modified lignocellulose, is used for further enzymolysizing for preparing liquid glucose. According to the invention, lignocellulose is used as the raw material, room temperature condition without external heating can be selected, low-concentration lye is pretreated, the lye can be effectively recovered, the enzymolysis efficiency is improved, the glucose yield is increased, the cost is lowered, the economical efficiency is enhanced, and drawbacks of high energy consumption, low glucose recovery rate, and high equipment requirements in current lignocellulose pretreatment method are made up.

Owner:NANJING TECH UNIV

Method for reclaiming valuable metals from waste lithium batteries

ActiveCN101921917AReduce recycling costsSimple methodProcess efficiency improvementBattery recyclingCopperCobalt

The invention discloses a method for reclaiming valuable metals from waste lithium batteries, which comprises the following steps of: crushing discharged waste lithium batteries, calcining at the high temperature of 350-400 DEG C to obtain a material containing cobalt, copper and aluminum, adding 5-10% sodium hydroxide solution to the material, making the sodium hydroxide solution react with the material for 2-3 hours, filtering alkaline liquor, washing and drying to obtain a material containing cobalt and copper; adding sulfuric acid with a certain concentration and Na2S2O3 to the material containing cobalt and copper, mixing, dissolving, adding an extractant to extract copper, and adding an extractant to the copper-extracted solution to extract cobalt. The method is simple and effective and has low reclamation cost.

Owner:深圳前海吉祥环保科技有限公司

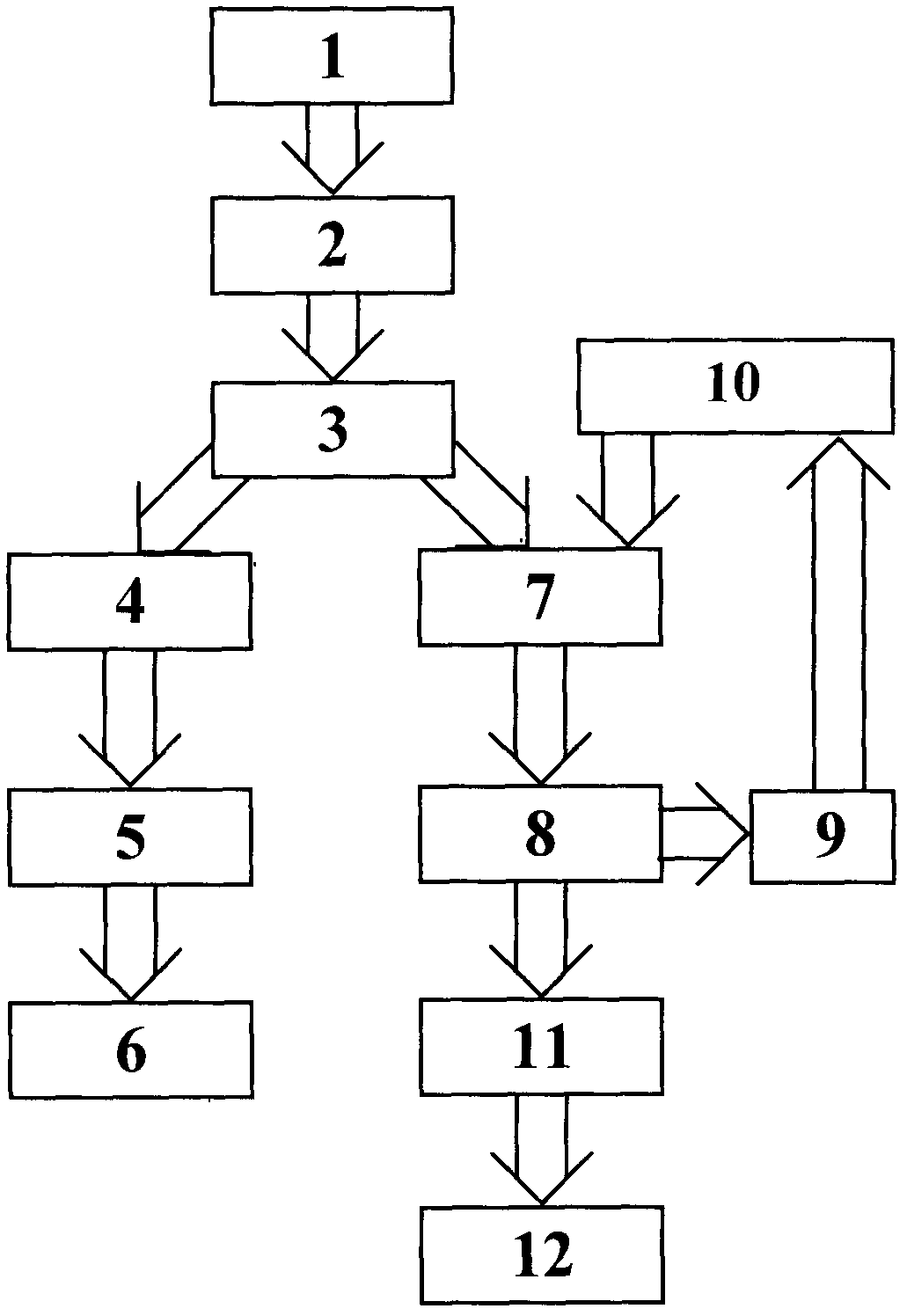

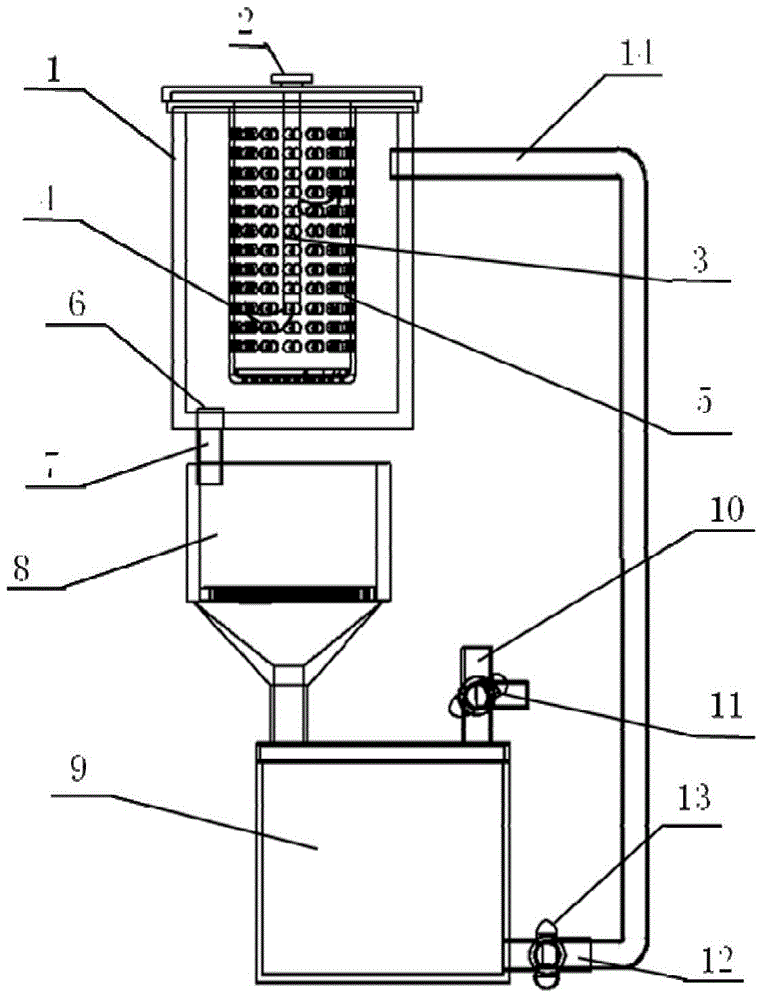

Recycling method and recycling device for cathode material and anode material of spent lithium-ion battery

ActiveCN104577246AEasy to operateReduce operating proceduresWaste accumulators reclaimingBattery recyclingRecovery methodFilter system

The invention discloses a recycling method and a recycling device for a cathode material and an anode material of a spent lithium-ion battery. The recycling method comprises the following steps: discharging the spent lithium-ion battery; removing a shell; crushing an inner core of the battery into broken pieces of 2 to 4 cm; immersing the broken pieces into a polar solvent system; stirring for 2 to 10 minutes with the assistance of mechanical stirring to separate and recycle the cathode material, the anode material, diaphragms, foil materials and the like. The recycling device comprises a separation system, a filtering system and a solvent cyclic utilization system. The recycling method and the recycling device are easy to operate; the cathode material and the anode material can be recycled simultaneously; the operating processes are reduced; the work efficiency is improved; the separation effect is good; the filtered solvent can be reutilized directly; the recycling method and the recycling device are environment-friendly; the recycling cost is reduced.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

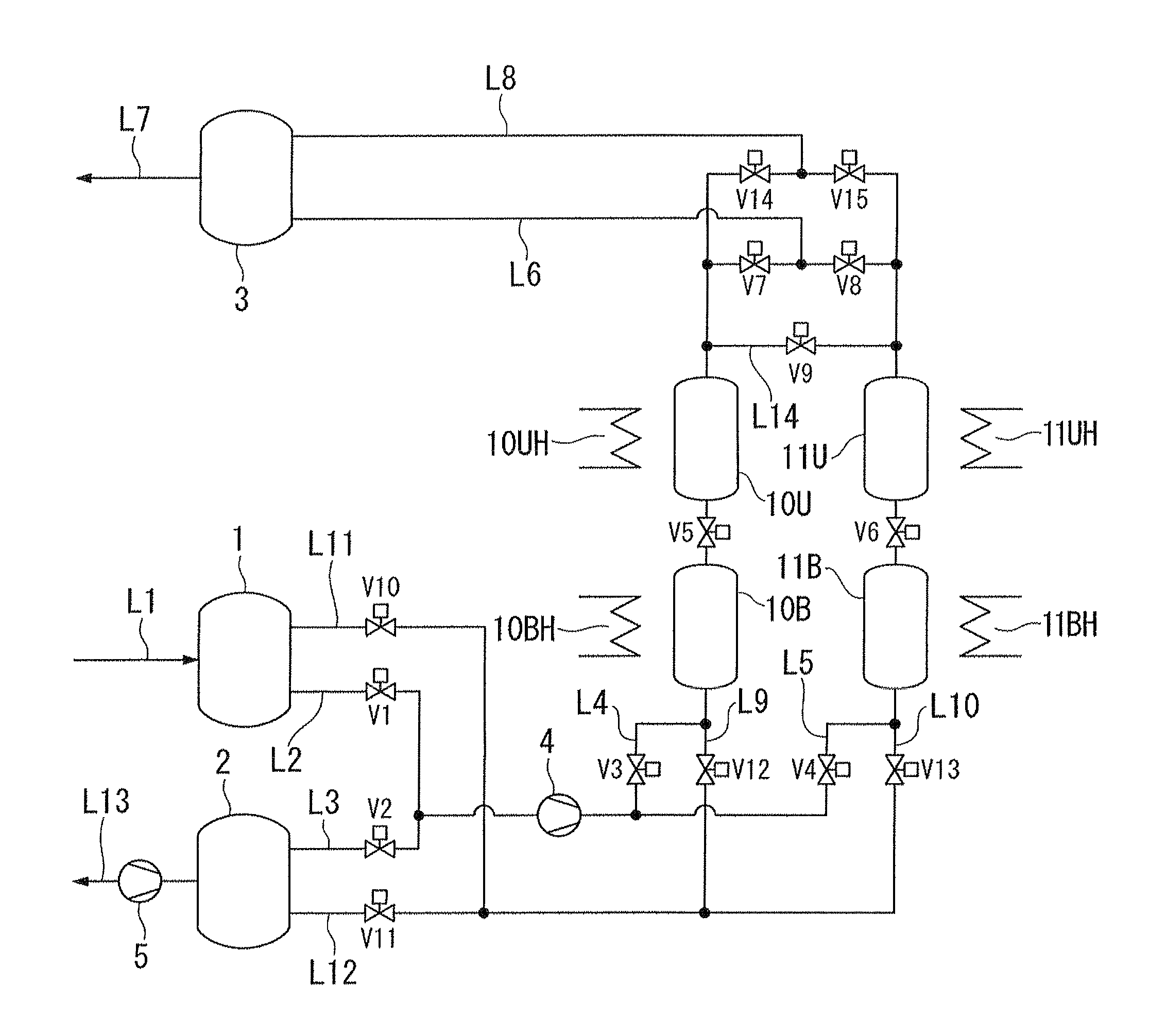

Deep treatment process of oily wastewater

ActiveCN102060350ASolving Deep Processing ChallengesImplement deep processingFatty/oily/floating substances removal devicesCombustible gas purificationActivated carbonSorbent

The invention relates to a deep treatment process of oily wastewater, which is characterized in that an absorption system and a regeneration system are provided in the process, wherein the absorption system is formed by a series of absorption tower groups with columns in series used for realizing parallel operation, the absorption tower groups are used for alternately performing deep treatment on oily yielding water with a low concentration of 30-50 mg / L of a traditional process, the absorption operation is carried out at normal temperature, the oil content in the yielding water is controlled to be lower than 1 mg / L through the treatment of a group of the absorption towers with columns in series, and an absorbing agent is made of modified fly ash, activated carbon and an expanded graphite absorbing material; when the yielding water in a group of the absorption towers exceeds a treatment requirement, the group of the absorption towers is switched to a biological regeneration system, and other absorption tower groups are simultaneously switched to the absorption system for continuous absorption; and saturated absorption towers are used for performing in-situ regeneration on the saturated absorbing agent by utilizing degradation ability of high temperature-resistant and efficient petroleum hydrocarbon for degrading bacteria.

Owner:CHINA NAT OFFSHORE OIL CORP +2

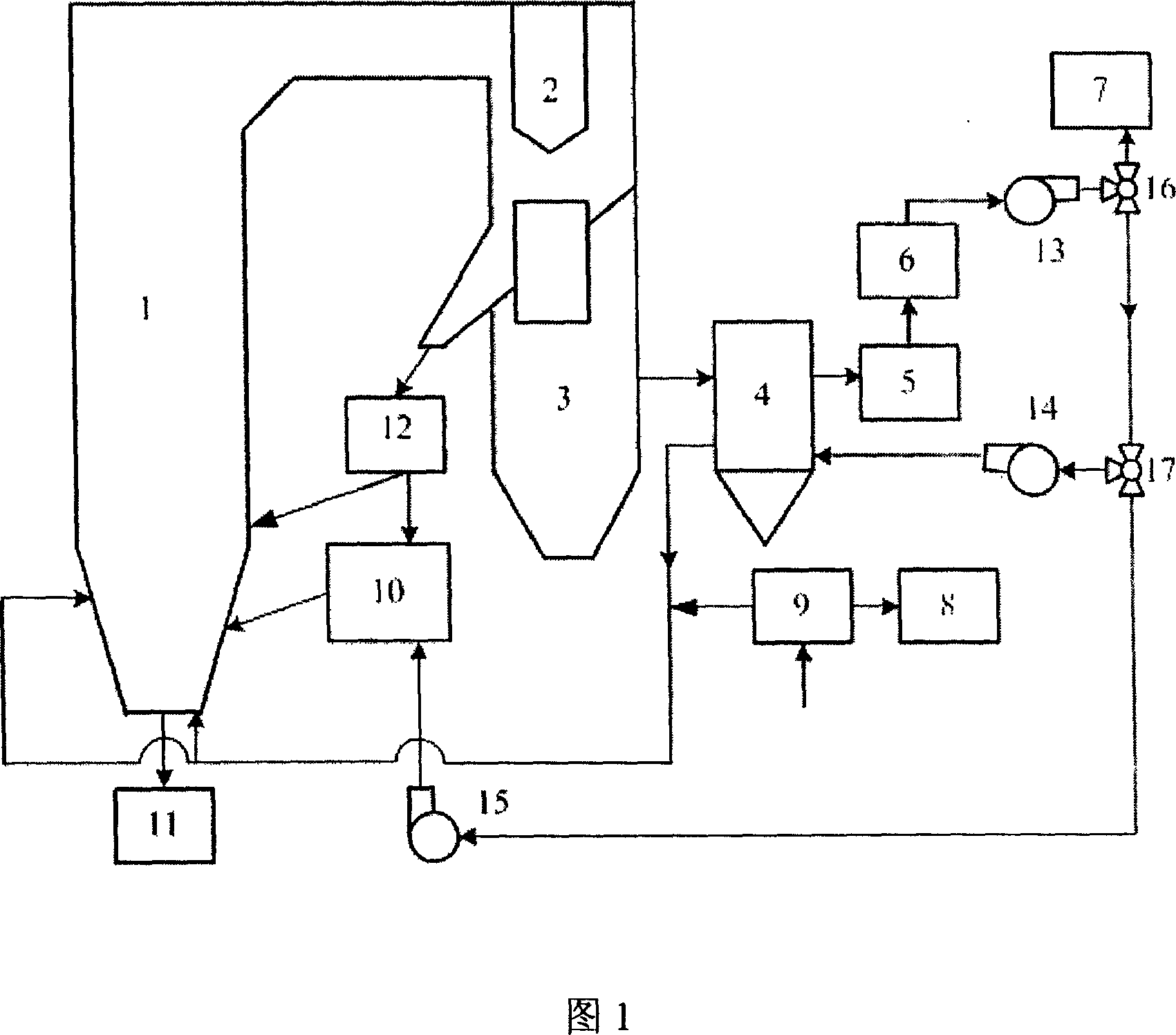

Boiler system of circulating fluid bed burning in oxygen enrichment

InactiveCN1959208AOvercome the problem of difficult temperature controlIncrease concentrationFluidized bed combustionIndirect carbon-dioxide mitigationHigh concentrationFluidized bed

A circulation fluidized-bed boiler of rich-oxygen combustion type is prepared as utilizing circulation fluidized-bed boiler with external fluidized bed heat exchanger to carry out combustion in mode of mixing mixture gas of high concentration oxygen from air separate and recirculation smoke from boiler tail with fuel, controlling load and firepot temperature of said boiler by regulating flow rate of fly ash particles entering into external fluidized bed heat exchanger.

Owner:HUAZHONG UNIV OF SCI & TECH

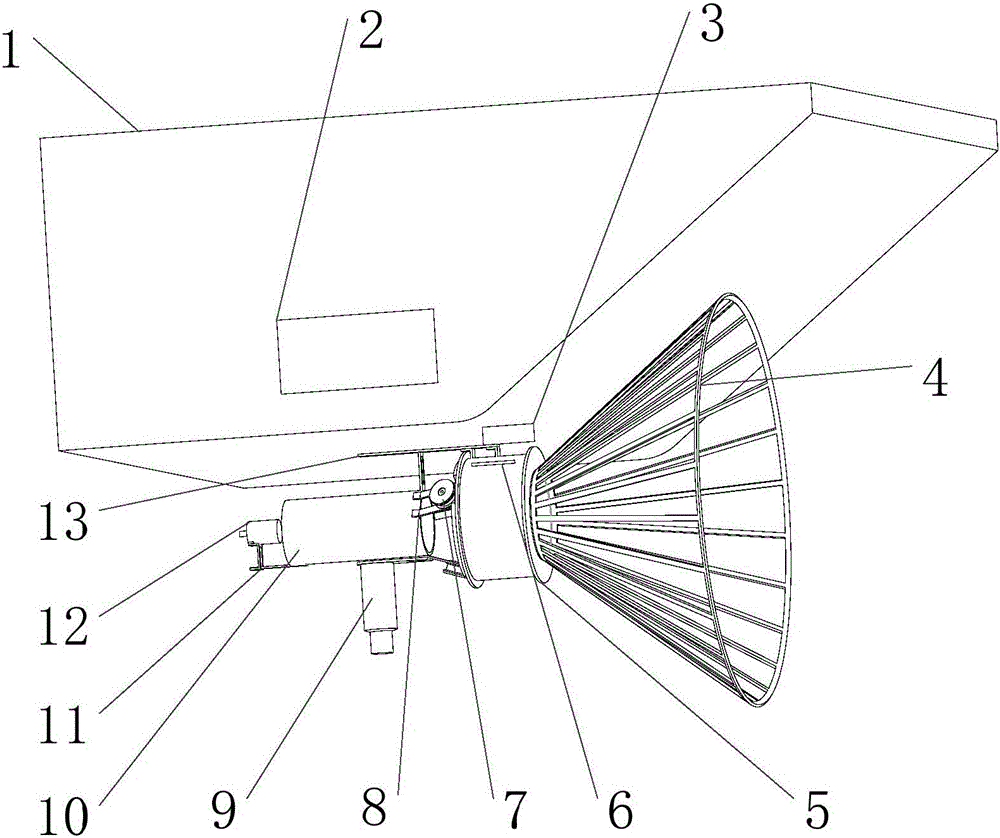

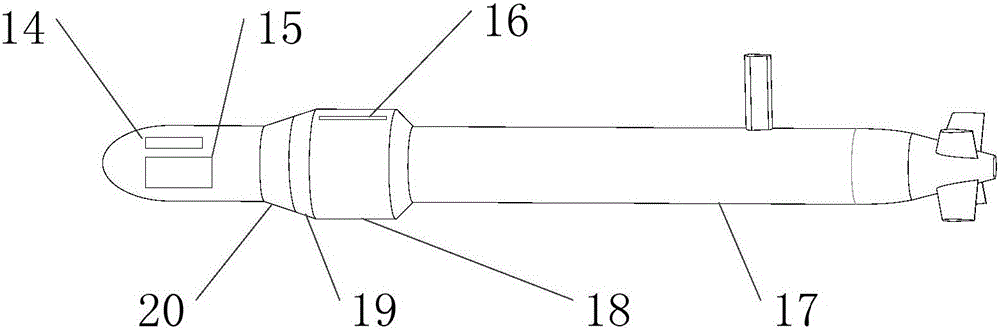

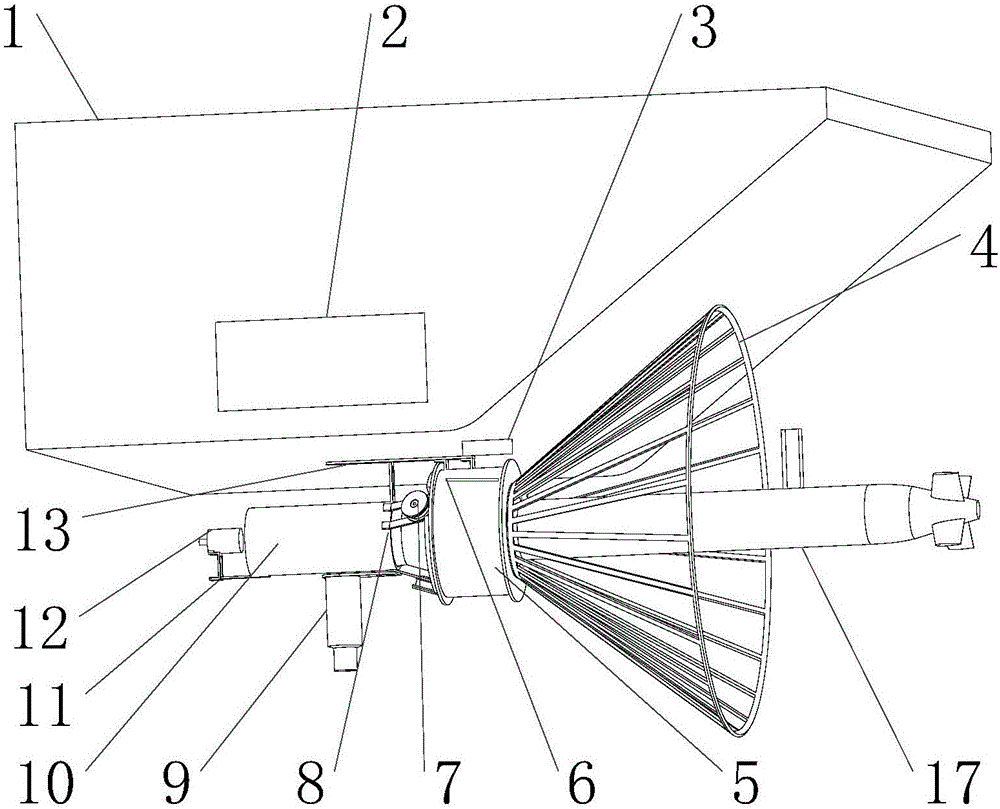

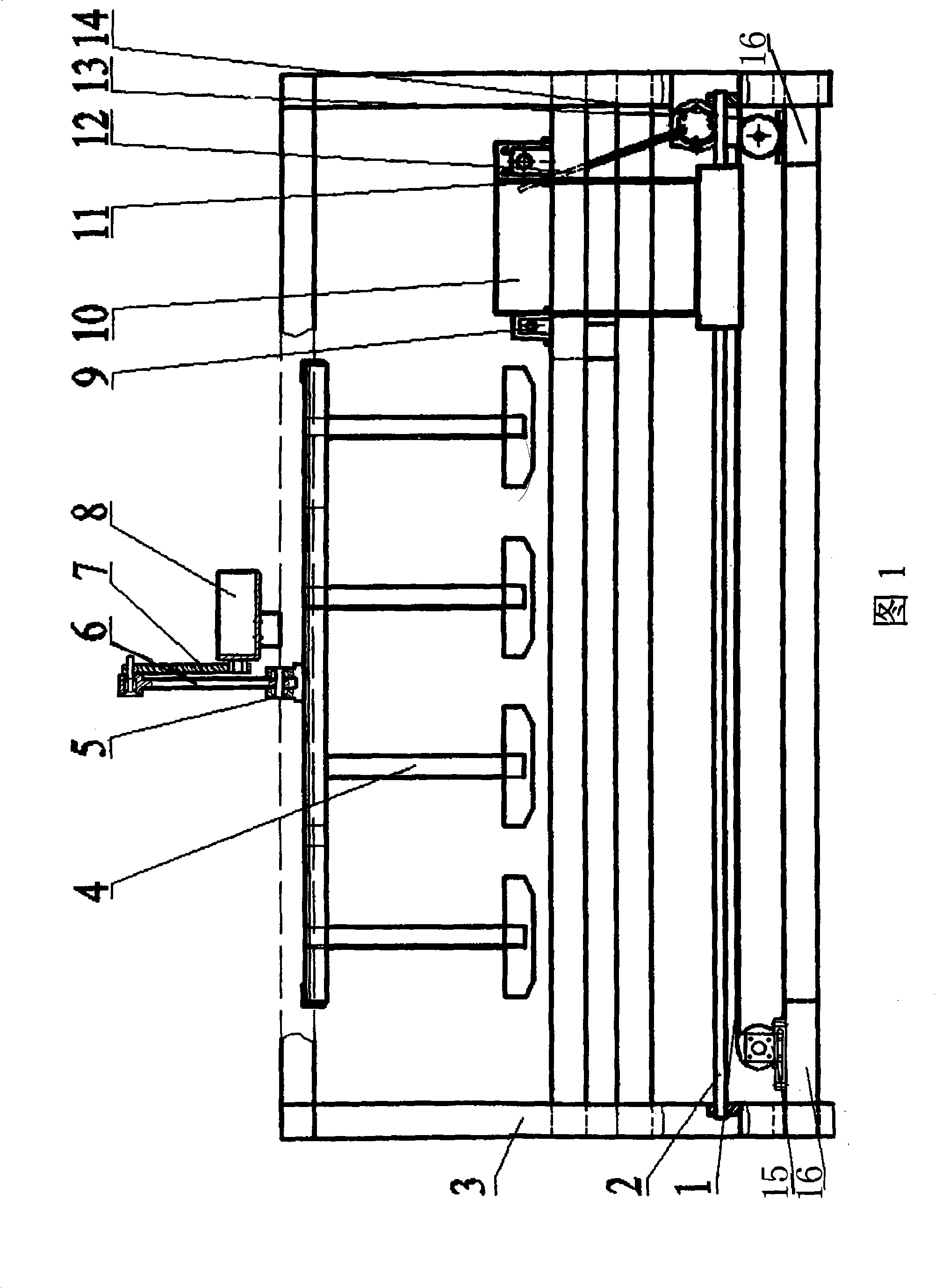

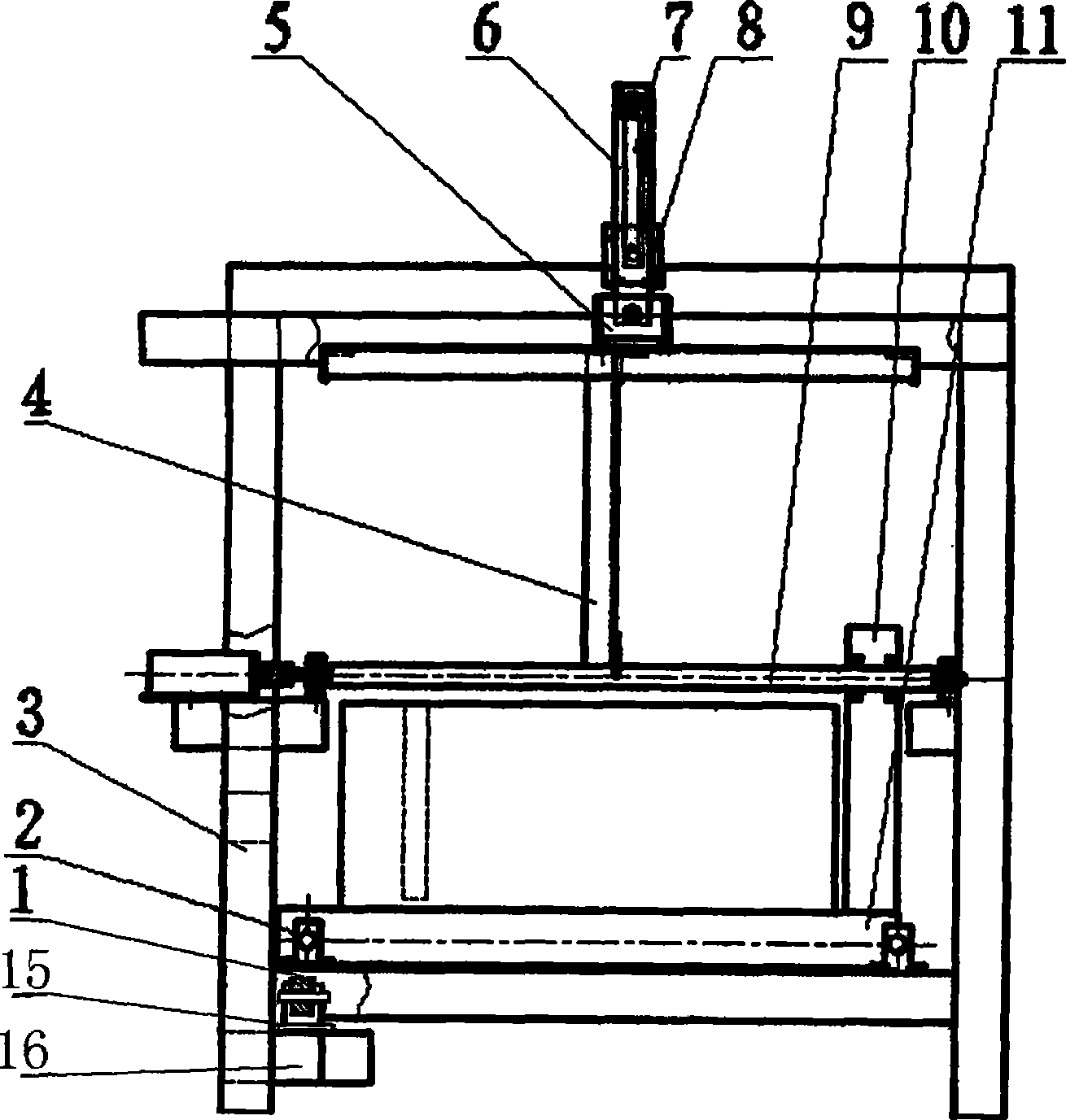

Underwater non-contact mobile docking device for underwater unmanned vehicle and water surface mobile platform

ActiveCN105775079AIncrease flexibilityReduce recycling costsUnderwater vesselsUnderwater equipmentElectric energyProtection KIT

The invention discloses an underwater non-contact mobile docking device for an underwater unmanned vehicle and a water surface mobile platform. The underwater non-contact mobile docking device comprises a water surface mobile platform side part and an underwater unmanned vehicle side part, wherein the water surface mobile platform side part mainly comprises a water surface mobile platform ship body, a non-contact docking main control unit, a flared guide hole, a non-contact electric energy transmission primary coil, a water surface mobile platform side signal transmission antenna, an electromagnet locking unit, a water surface mobile platform side acoustic communication positioning module and a cylindrical guide port; the underwater unmanned vehicle side part mainly comprises a visual guide assembly, an underwater unmanned vehicle side acoustic communication module, an underwater unmanned vehicle side signal transmission antenna, an underwater vehicle main body, a non-contact electric energy transmission secondary coil, an electromagnet locking block and a conical protection sleeve. By adopting the underwater non-contact mobile docking device, the detection range and relevant detection task execution flexibility of the underwater unmanned vehicle are enlarged and improved, and the recovery cost of the underwater unmanned vehicle is lowered.

Owner:ZHEJIANG UNIV

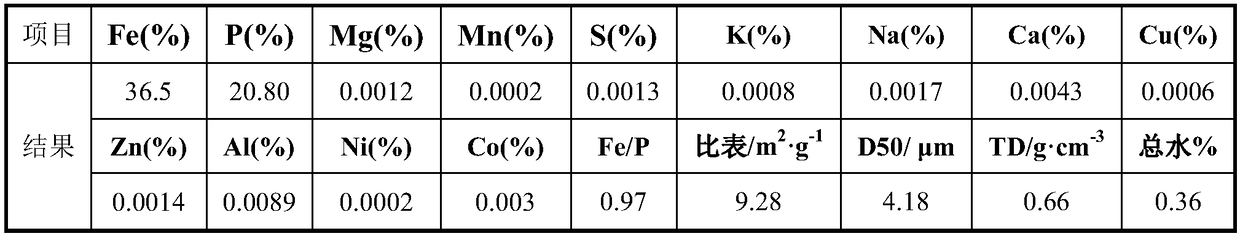

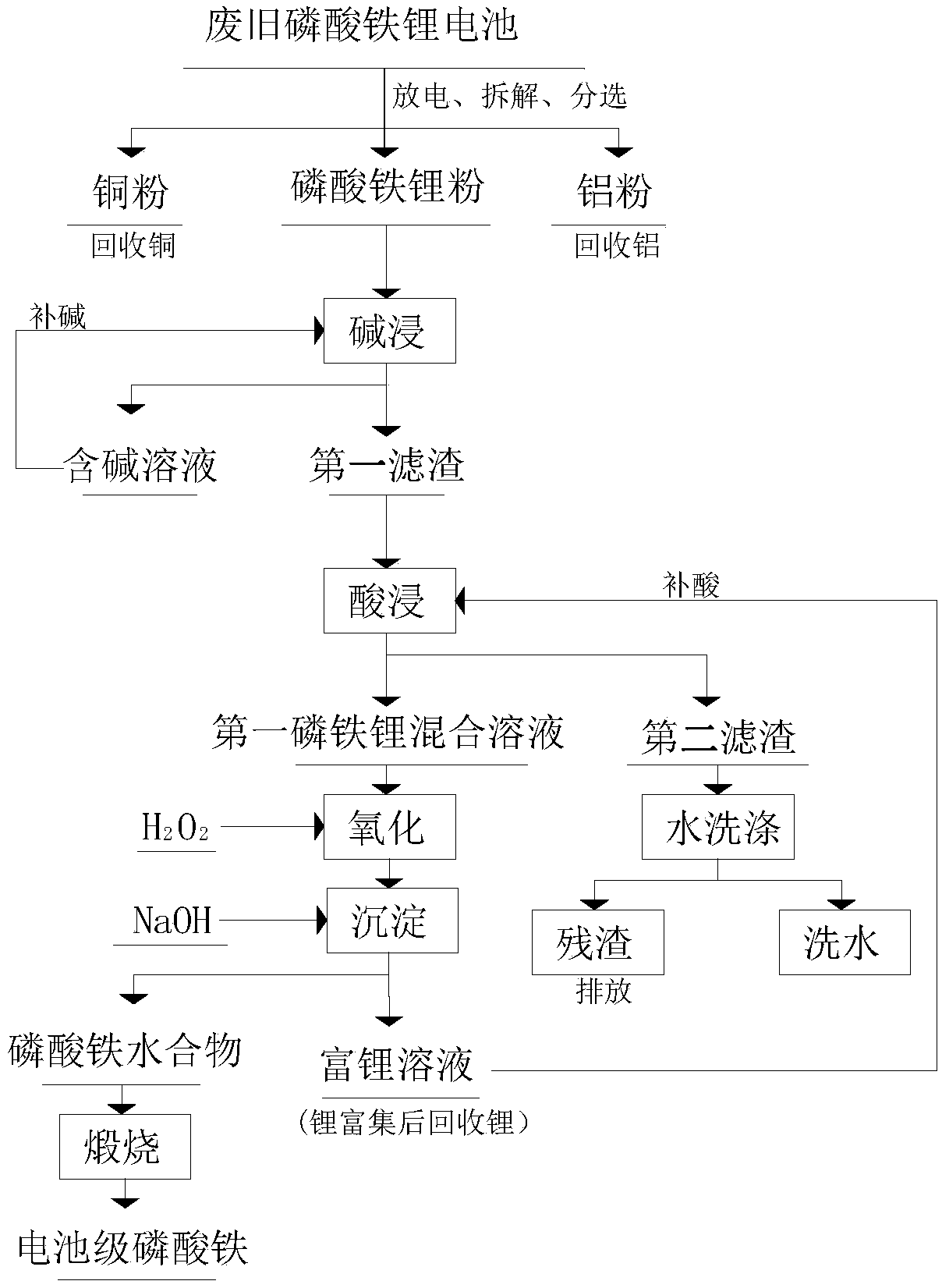

Method for preparing battery grade iron phosphate from waste and old lithium iron phosphate batteries

ActiveCN109179358AEfficient removalHigh purityPhosphorus compoundsLithium iron phosphatePhosphoric acid

The invention discloses a method for preparing battery grade iron phosphate from waste and old lithium iron phosphate batteries and relates to the technical field of battery recovery. The method can prepare anhydrous battery grade iron phosphate by battery disassembly and separation, alkali leaching, acid leaching, oxidation, precipitation and calcination. Through alkali leaching and then acid leaching and precipitation, impurities such as aluminum in lithium iron phosphate can be removed and the purity of iron phosphate can be improved. The alkali leaching solution and the lithium-rich solution can be reused so that a recovery cost is reduced. After repeated acid supply, the lithium-rich solution immerses novel filter wastes so that the concentration of lithium in the solution and the recovery rate of lithium can be increased and the recovery cost of lithium can be reduced. pH at the precipitation end point is low in a range of 1.0-2.5 so that the formation trend of iron hydroxide isreduced. The aging process after the precipitation reaction can improve the purity of iron phosphate and the produced iron phosphate meets the industry standards. The whole process is carried out at alow temperature so that the corrosion of the solution to the equipment is delayed and the energy consumption and recycling cost are reduced.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

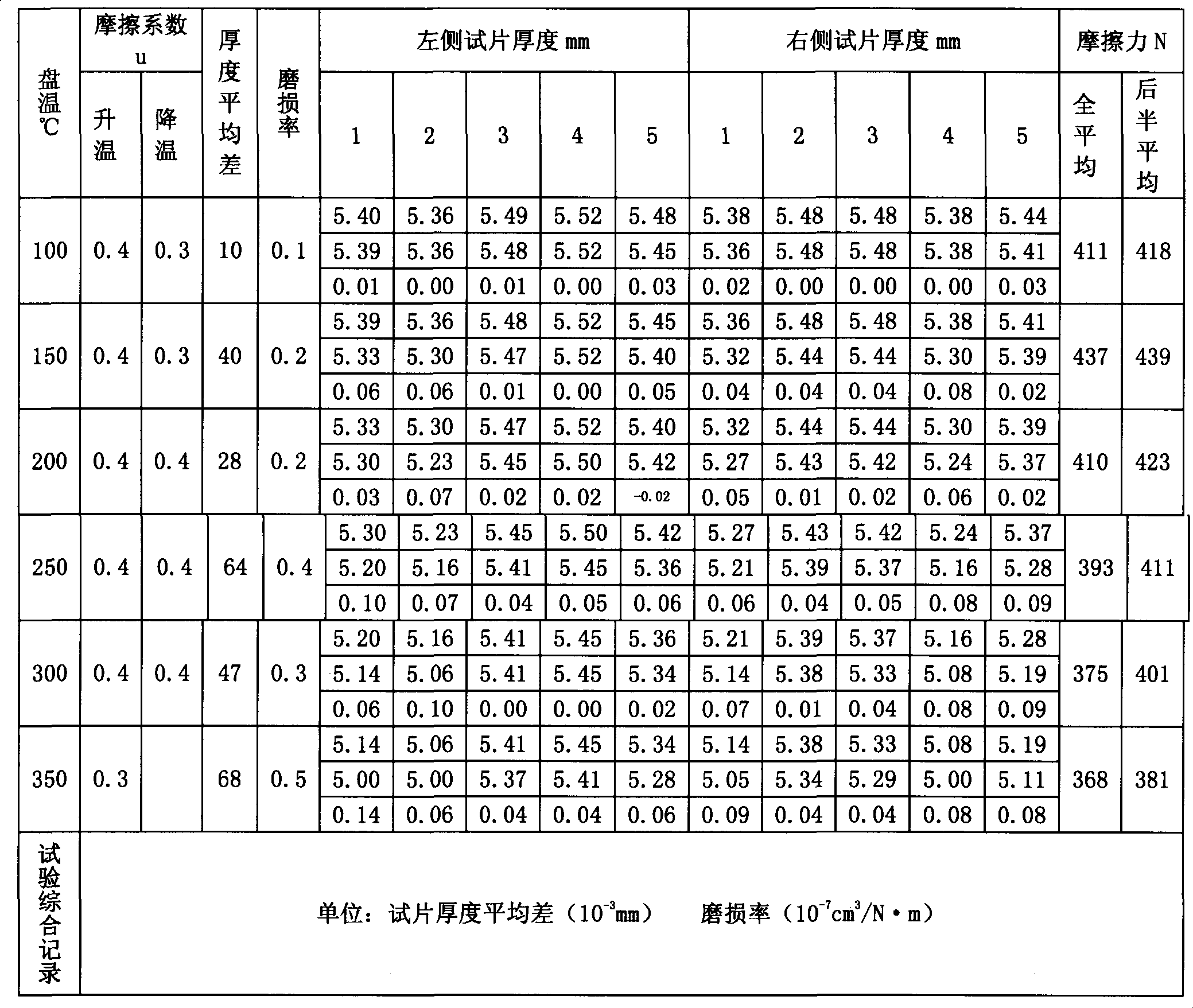

Method for preparing brake pad friction material by using rice and wheat straws

InactiveCN103820078AAbundant resourcesReduce recycling costsOther chemical processesFriction liningFiberAtmospheric pollution

The invention discloses a method for preparing a brake pad friction material by using rice and wheat straws and relates to the technical field of composite materials. The brake pad friction material has the following formula: 15 percent of toughened fibers, 16 percent of modified resin, 14 percent of a friction increase agent, 9 percent of sulfur and tin powder, 1.6 percent of carbon black, 2.5 percent of zinc oxide, 8.9 percent of barium sulfate, 10 percent of rice and wheat straw carbon powder, 6 percent of aluminum hydroxide, 14 percent of modified li beads and 3 percent of zinc stearate. The materials are uniformly mixed and stirred, pressed in a mold and subjected to machining such as grinding and chamfering according to a technical requirement to obtain a braking pad. According to the method, the rice and wheat straws are used as raw materials to prepare carbon powder which replaces graphite in a friction material formula, so that the atmospheric pollution caused by severe combustion of straws in each year is alleviated, the production cost of the brake pad is reduced, and the brake performance and the braking effect are enhanced; the friction coefficient is stable; the brake pad is simple in structure, low in brake noise, environment-friendly and pollution-free.

Owner:YANCHENG XINHAO MACHINERY

Automatic sorting garbage bin

InactiveCN101391693AReduce labor intensityReduce recycling costsWaste collection and transferRefuse receptaclesPlastic bagCompressibility

The invention discloses an automatically-classifying garbage bin belonging to the garbage classifying-recycling apparatus field. The automatically-classifying garbage bin utilizes a hall-sensor proximity switch for detecting metals, a mechanical knocking means for leading the detected matter to sound and a follow-up circuit for collecting and processing the sound signals so as to distinguish glasses, plastic and other varieties; simultaneously garbage with low recycling value of the garbage with less volume, plastic bags with better compressibility or paper bags and the like are all classified as the garbage of other varieties for disposal. The automatically-classifying garbage bin comprises a belt wheel, an optical bar, a mechanical frame, a low press plate, a connecting block, a linkage rod, a crank, a screw rod, a compressing plate, a conveying box, a knocking rod and an electromagnet. Compared with the existing art, the garbage bin has the advantages that the labor intensity for people is reduced; the recycling cost is saved; and the accuracy of garbage classification is enhanced.

Owner:TSINGHUA UNIV

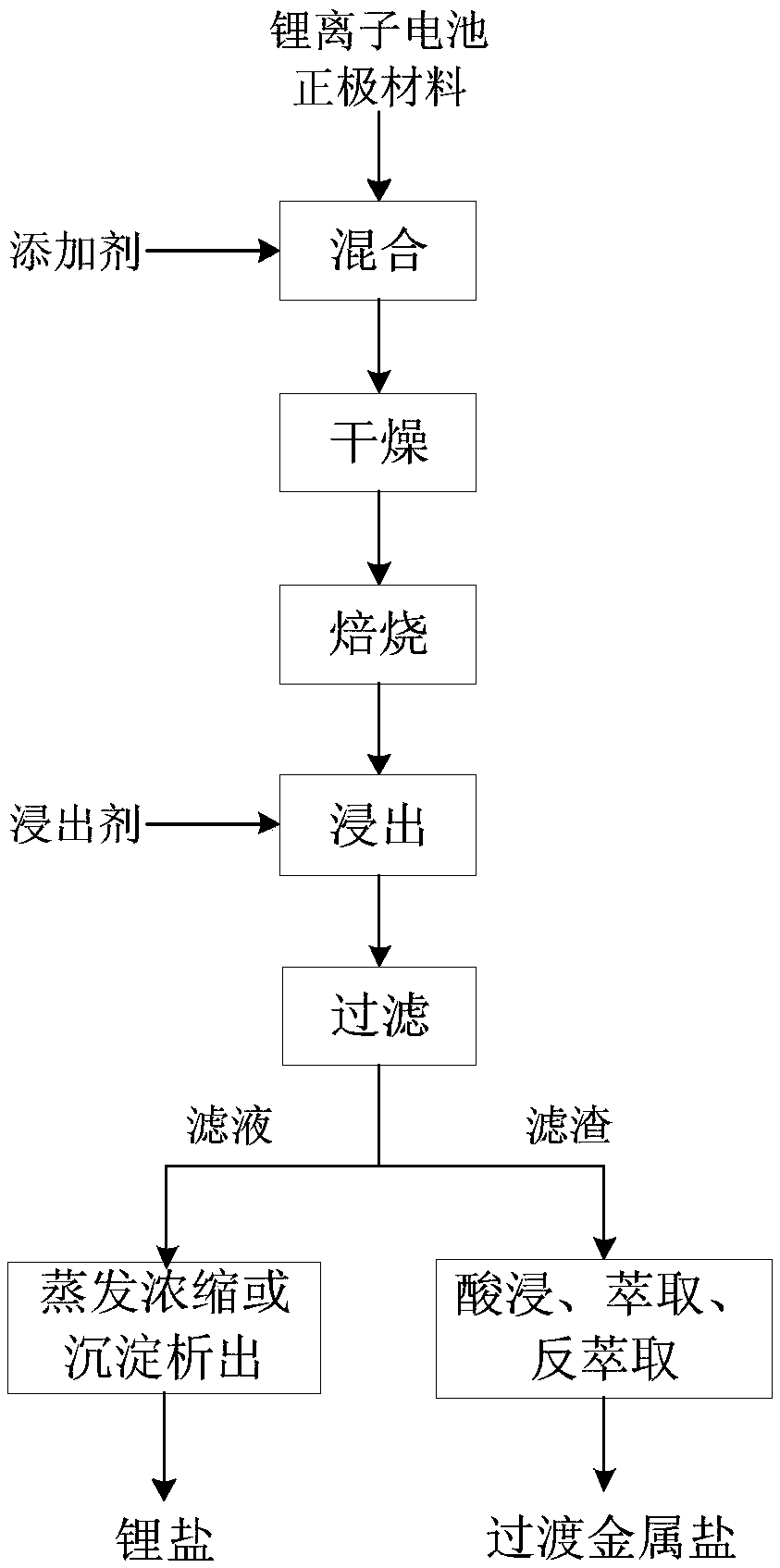

Method for selectively recycling positive electrode materials for lithium ion batteries

ActiveCN108832215AImplement selective extractionEasy to separateWaste accumulators reclaimingProcess efficiency improvementLiquid wasteSlag

The invention provides a method for selectively recycling positive electrode materials for lithium ion batteries. The method comprises the following steps: carrying out transformation processing aftermixing the recycling positive electrode materials for lithium ion batteries with an additive; leaching an obtained transformation product with a leaching agent, and carrying out solid-liquid separation to obtain a lithium-rich solution and a solid slag; and preparing the obtained lithium-rich solution into a lithium salt and the obtained solid slag into a transition metal salt. According to the method, recycling of valuable metals in the positive electrode materials for lithium ion batteries is realized by using in situ crystal transformation and mild leaching methods, particularly, selectiveextraction for lithium is realized, the recycle rate reaches 95% or above, and the recycle rate of other valuable metals such as nickel, cobalt and manganese reaches 98% or above; the method is shortin flow, other impurity ions are not introduced, the product purity is high, secondary pollution and liquid waste disposal can also be avoided, the recycle cost is saved, and the method is easy to realize industrial application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for separating and recovering nickel, cobalt, magnesium, iron and silicon from nickel-bearing laterite

InactiveCN101525690AImprove leaching rateHigh dissolution rateProcess efficiency improvementSlagLaterite

A method for separating and recovering nickel, cobalt, magnesium, iron and silicon from nickel-bearing laterite is disclosed; nickel, cobalt, magnesium and iron therein are leached out by using high-temperature peracid, leachate is pre-neutralized via serpentine powder, after the pre-neutralization, the leachate is neutralized by magnesite powder for de-ironing, and the scum is delivered for ironmaking after being dewatered by smoke gases in a fluidized bed furnace for making sulfuric acid, the de-ironed clear nickel liquid uses magnesite powder to precipitate nickel carbonate, and the precipitated liquid is concentrated and crystallized to obtain magnesium sulfate heptahydrate. The leached slag mainly contains silicon and can be used for making white carbon black. The invention can sufficiently recover and utilize nickel, cobalt, magnesium, iron and silicon in the nickel-bearing laterite, and the invention is simple in technology, low in energy consumption and pollution-free on environment.

Owner:广西冶金研究院有限公司 +1

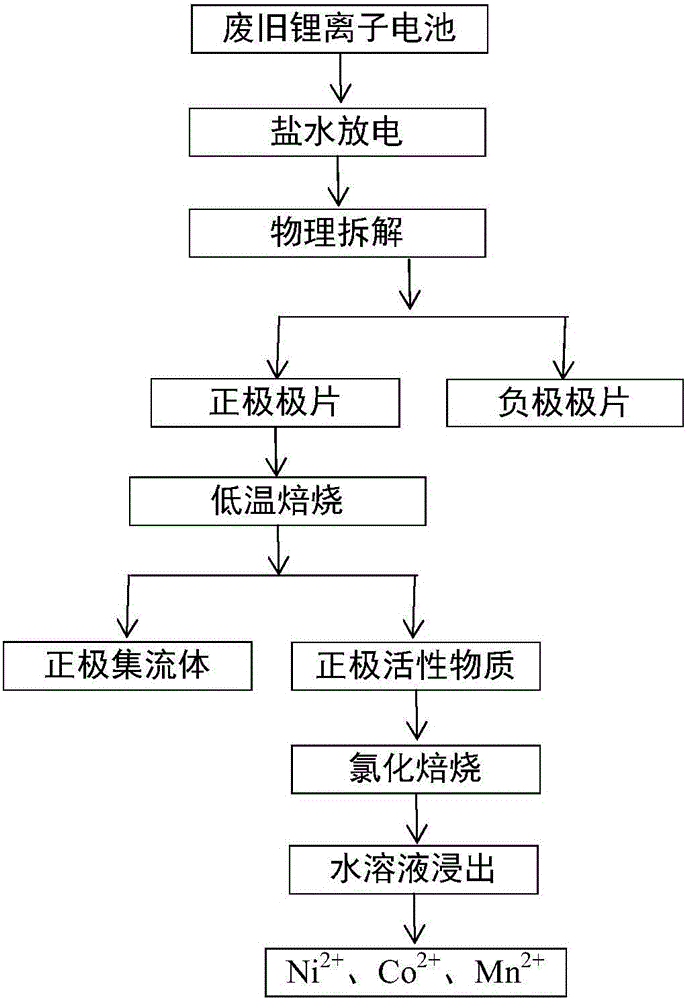

Method for recovering valuable metals from cathode materials of waste lithium ion batteries

InactiveCN106848469AEfficient recyclingReduce recycling costsWaste accumulators reclaimingBattery recyclingMetal leachingChloride

The invention discloses a method for recovering valuable metals from cathode materials of waste lithium ion batteries. The method comprises the following steps: the waste lithium ion batteries are discharged and dismantled, and cathode plates are separated out; the cathode plates are subjected to pyrolysis for glue removal, and current collectors and active materials are separated out; the active materials are mixed with chloride for chloridizing roasting; a solid product of chloridizing roasting is leached with water, and aleachate containing valuable metal ions is obtained. The method overcomes the defect that a large quantity of mineral acids and bases is needed to be consumed in the traditional metal leaching and recovering process of the cathode materials of the waste lithium ion batteries, adopts simple process, is low in cost and environment-friendly and has great industrial application value.

Owner:CENT SOUTH UNIV +1

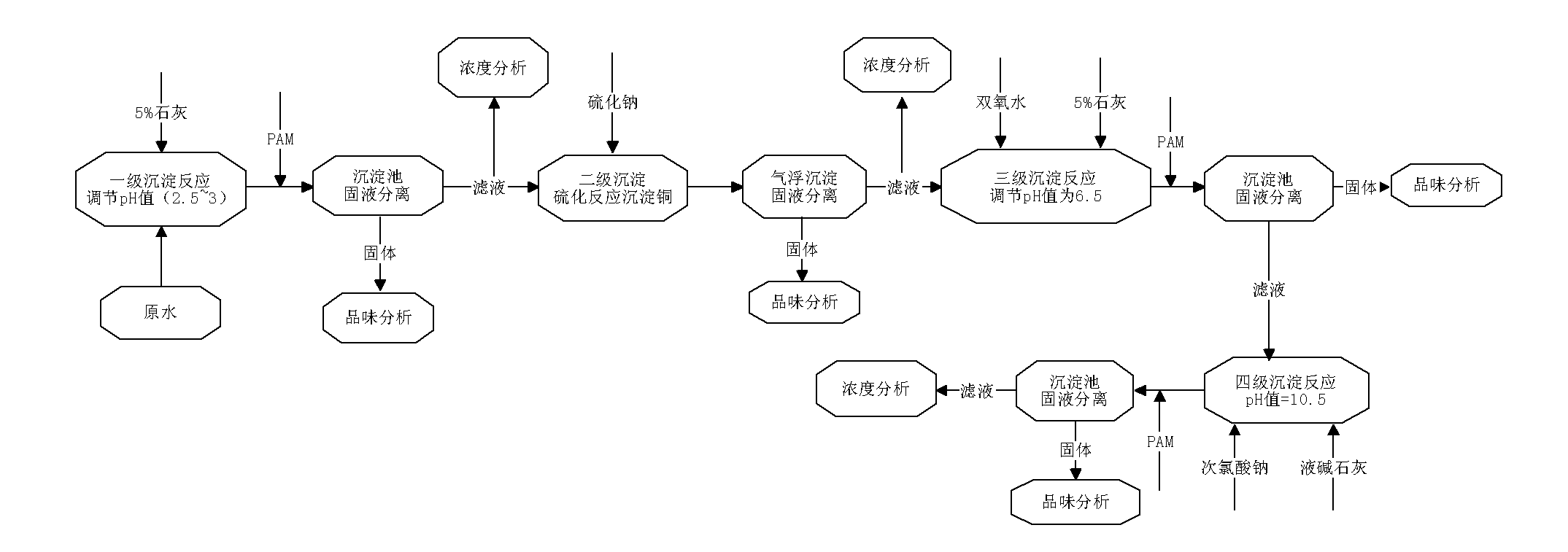

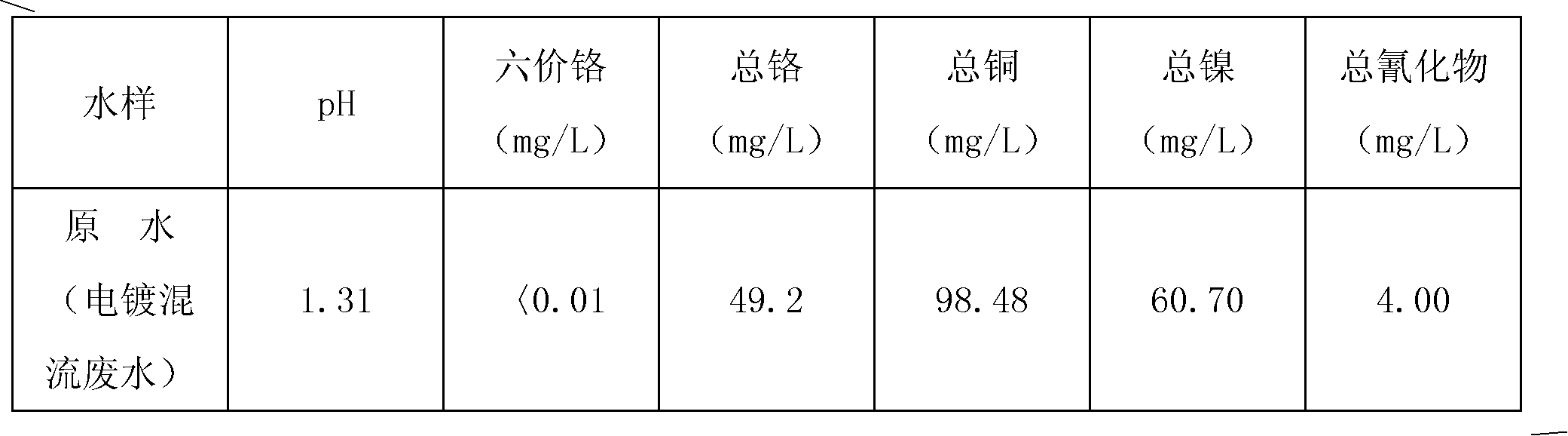

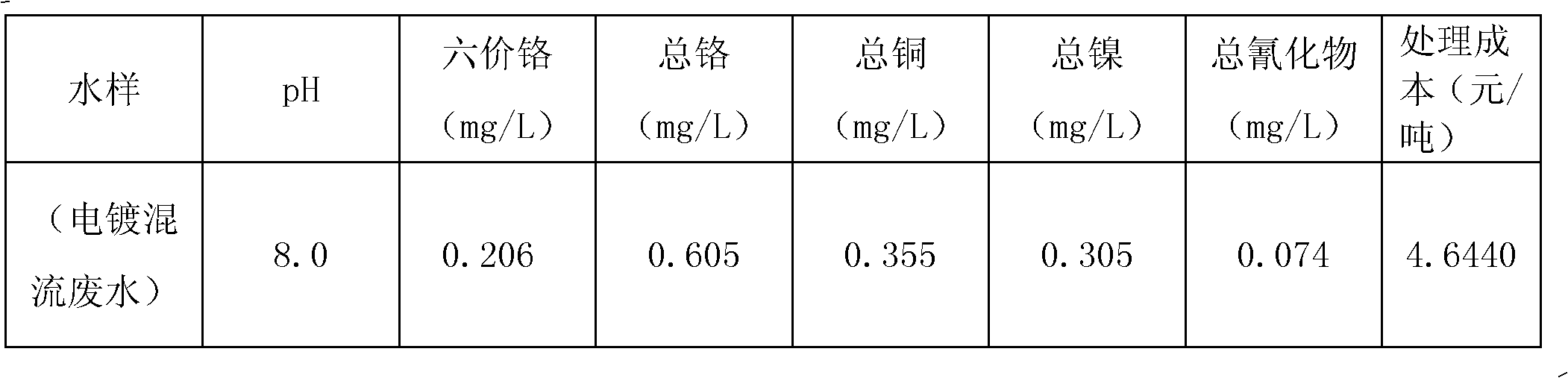

Recovery method of copper-nickel heavy metals in electroplated mixed-flow waste water

ActiveCN102557299AReduce lossesReduce loss rateWaste water treatment from metallurgical processMultistage water/sewage treatmentRecovery methodCopper sulfide

The invention relates to a recovery method of copper-nickel heavy metals in electroplated mixed-flow waste water. The recovery method comprises the following steps of: using lime to adjusting the pH value to be 2.5-3 in the electroplated mixed-flow waste water containing copper and nickel, adding a flocculating agent PAM (polyacrylamide), generating precipitate, and carrying out solid-liquid separation; then adding sodium sulfide, generating copper sulfide precipitate, and carrying out solid-liquid separation; then adding hydrogen peroxide for preventing complexation, using the lime to adjusting the pH value to be 6.5, simultaneously precipitating copper and chromium ions, adding the flocculating agent PAM, and carrying out solid-liquid separation; then using the lime to adjusting the pH value to be 10.5, simultaneously adding sodium hypochlorite for preventing complexation, generating precipitate containing nickel hydroxide, adding the flocculating agent PAM, carrying out solid-liquid separation, and recovering nickel mud; and finally, adjusting the pH value of the discharged water to be 8 by adding sulfuric acid, and realizing standard discharging. The recovery method has the advantages that the process is simple and convenient, the operation is easy, the recovery cost is low and the recovery rate is higher.

Owner:ZHEJIANG HI TECH ENVIRONMENTAL TECH

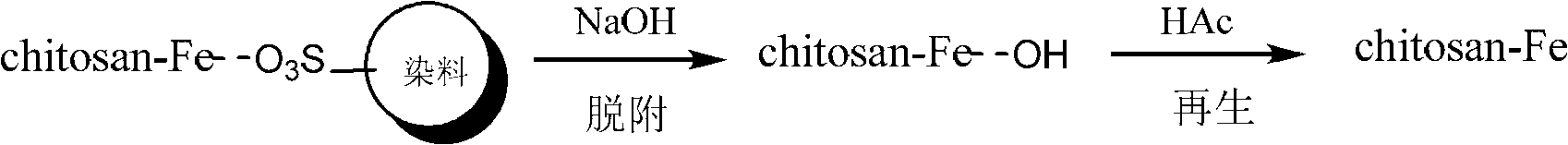

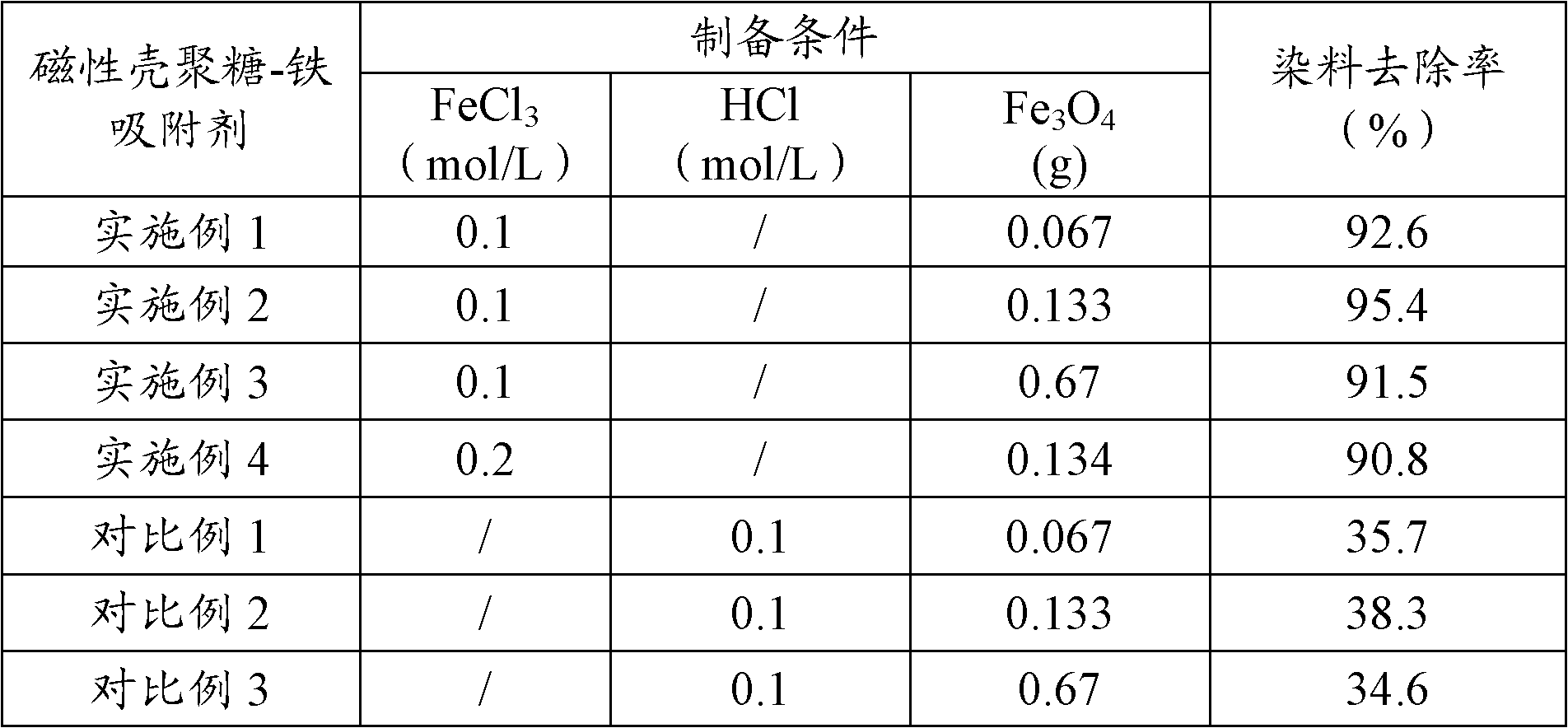

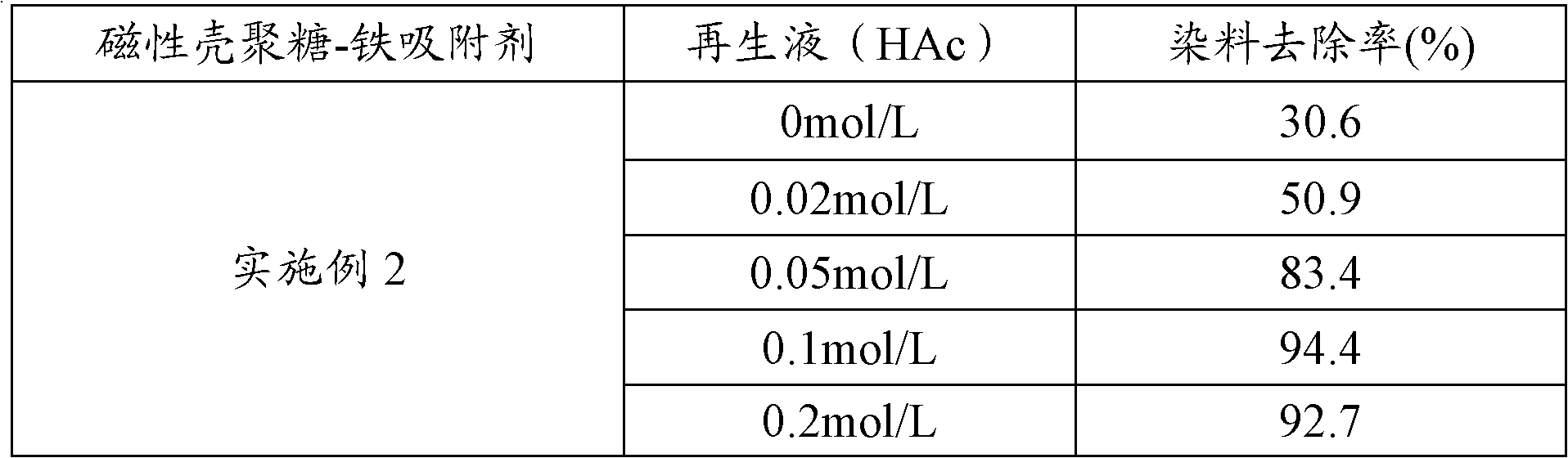

Method for removing sulfonic-group-containing dye in alkaline waste water by using magnetic chitosan adsorbent

InactiveCN102107980AQuick removalEasy to separateOther chemical processesMultistage water/sewage treatmentCross-linkSorbent

The invention discloses a method for removing sulfonic-group-containing dye in alkaline waste water by using a magnetic chitosan adsorbent, which comprises the following steps: (1) dissolving chitosan in an iron chloride water solution, stirring, adding ethanol to precipitate a solid, filtering out the solid, washing, mixing the solid with nano magnetic ferroferric oxide, carrying out cross-linking reaction with a glutaric dialdehyde water solution, and carrying out after-treatment to obtain a magnetic chitosan adsorbent; (2) adding the obtained magnetic chitosan adsorbent into an alkaline waste water solution containing the sulfonic-group-containing dye, stirring, carrying out magnetic separation, and drying to obtain the dye-adsorbed magnetic chitosan adsorbent; and (3) adding the dye-adsorbed magnetic chitosan adsorbent into a water solution containing a desorbing agent, stirring, and filtering to obtain a dye recovered solution and the recovered magnetic chitosan adsorbent. The method disclosed by the invention is simple to operate, has the advantages of environment friendliness and low cost, and has wide industrial application prospects.

Owner:ZHEJIANG UNIV

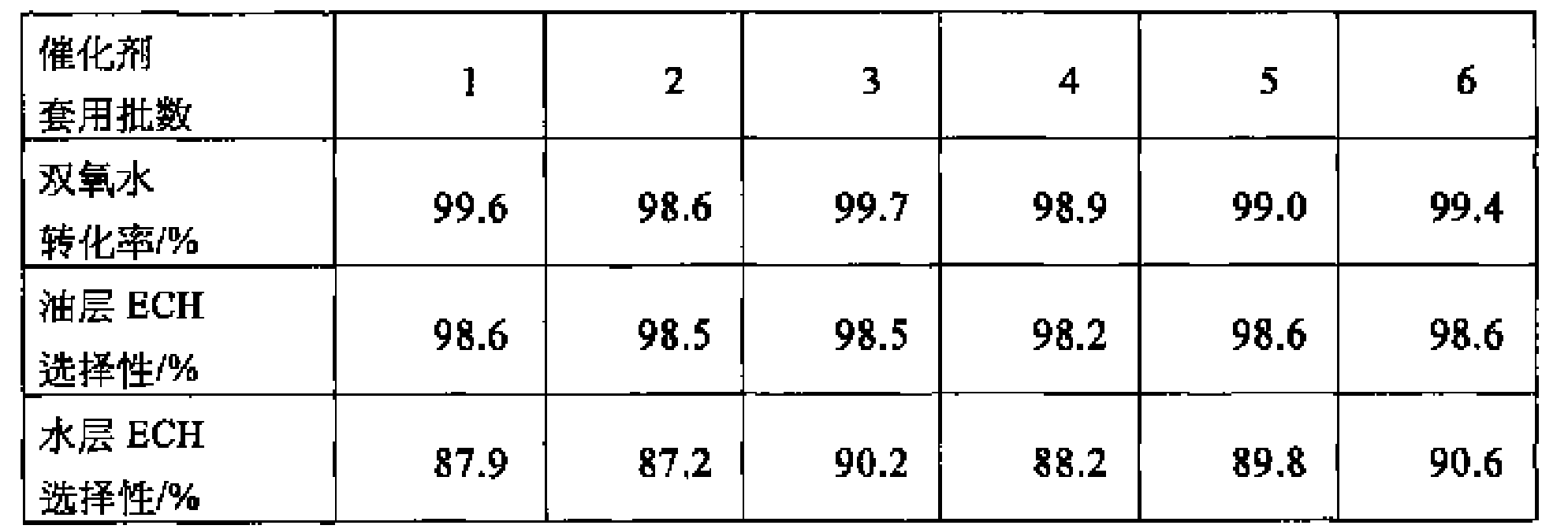

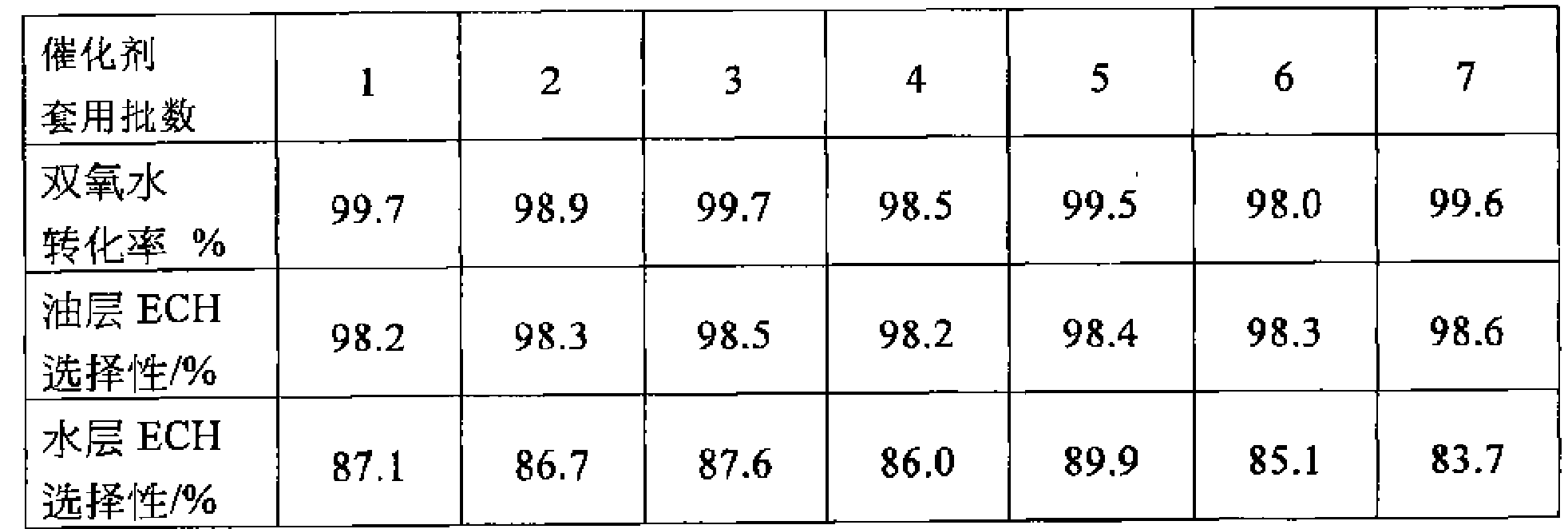

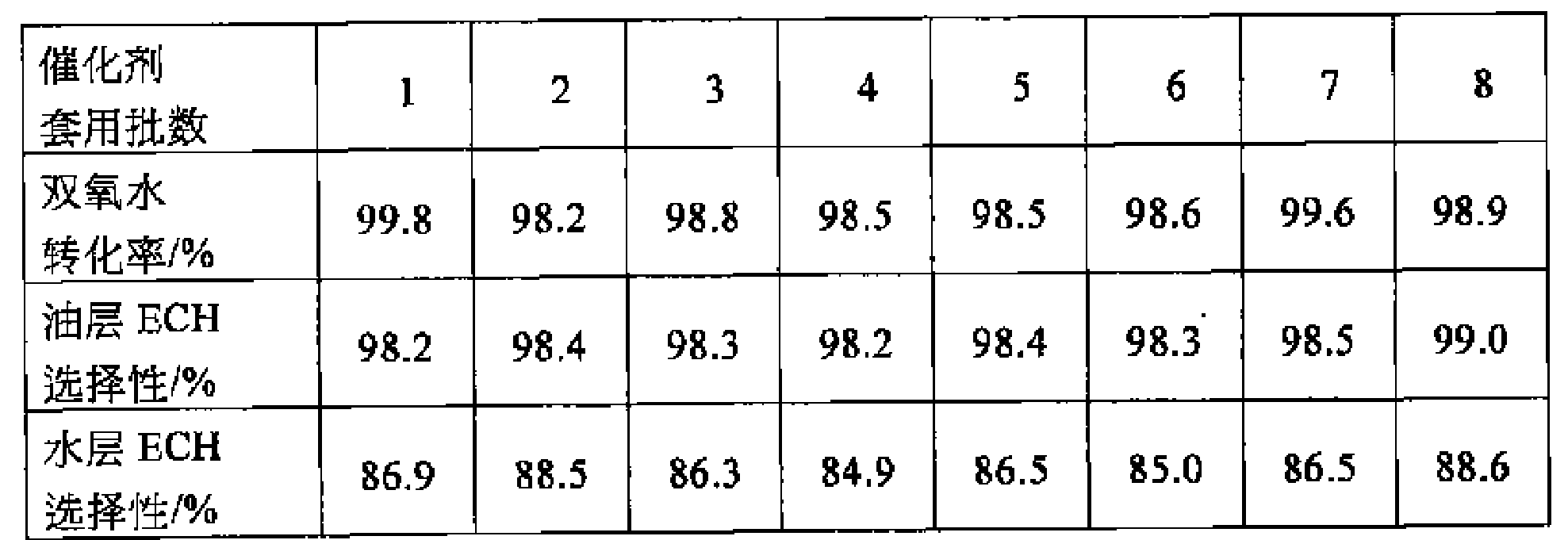

Method for regenerating titanium-silicon molecular sieve catalyst

ActiveCN101480623AGood regeneration performanceImprove securityOrganic chemistryMolecular sieve catalystsDecompositionSolvent

The invention provides a catalyst used as a titanium-silicate molecular sieve in the process of preparing epoxide from olefin and hydrogen peroxide. The invention is characterized by comprising the following steps: washing with or without a small amount of methanol solvent; purging the catalyst cake with steam directly after reaction; extracting few organic matters absorbed in the catalyst; then stirring in a regenerating kettle and dropwise adding H2O2 with a certain concentration simultaneously; removing the organic matters and low polymers absorbed on the catalyst and in a pore path through oxidative decomposition; and finally, washing with a small amount of methanol or deionized water to remove the organic acid generated by oxidation on the surface of the catalyst. The regenerated catalyst can be circularly used for the epoxidation reaction of olefin to stably maintain the activity of the epoxidation reaction.

Owner:JIANGSU YANGNONG CHEM GROUP +2

Method for recovering valuable elements in waste lithium ion battery electrode material

ActiveCN107955879AReduce sorting costsReduce recycling costsWaste accumulators reclaimingProcess efficiency improvementSlagElectrical battery

The invention discloses a method for recovering valuable elements in waste lithium ion battery electrode materials. The method comprises steps of roasting the waste lithium ion battery electrode materials in an inert gas atmosphere, the roasting temperature is 200 -600 DEG C, the time is 30-360 minutes, and the roasting slag is obtained; mixing the obtained roasting slag and an acidic solution with [H+] concentration of 0.5~8 mol / L according to the mass ratio of 1:3~10; leaching at the leaching temperature of 30-90 DEG C and leaching time of 1-8 hours, leach liquor and leach residues are filtered to be obtained; the leach liquor is used for recovering nickel, cobalt, manganese, aluminum and lithium, and the leach residues are used for preparing negative electrode materials. According to the method for recovering valuable elements in waste lithium ion battery electrode materials, a leaching reducing agent does not need to be additionally added, the battery sorting and recycling costs are reduced, the positive and the negative electrode materials can be recovered at the same time, and the economic benefits of lithium battery recovery can be improved.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

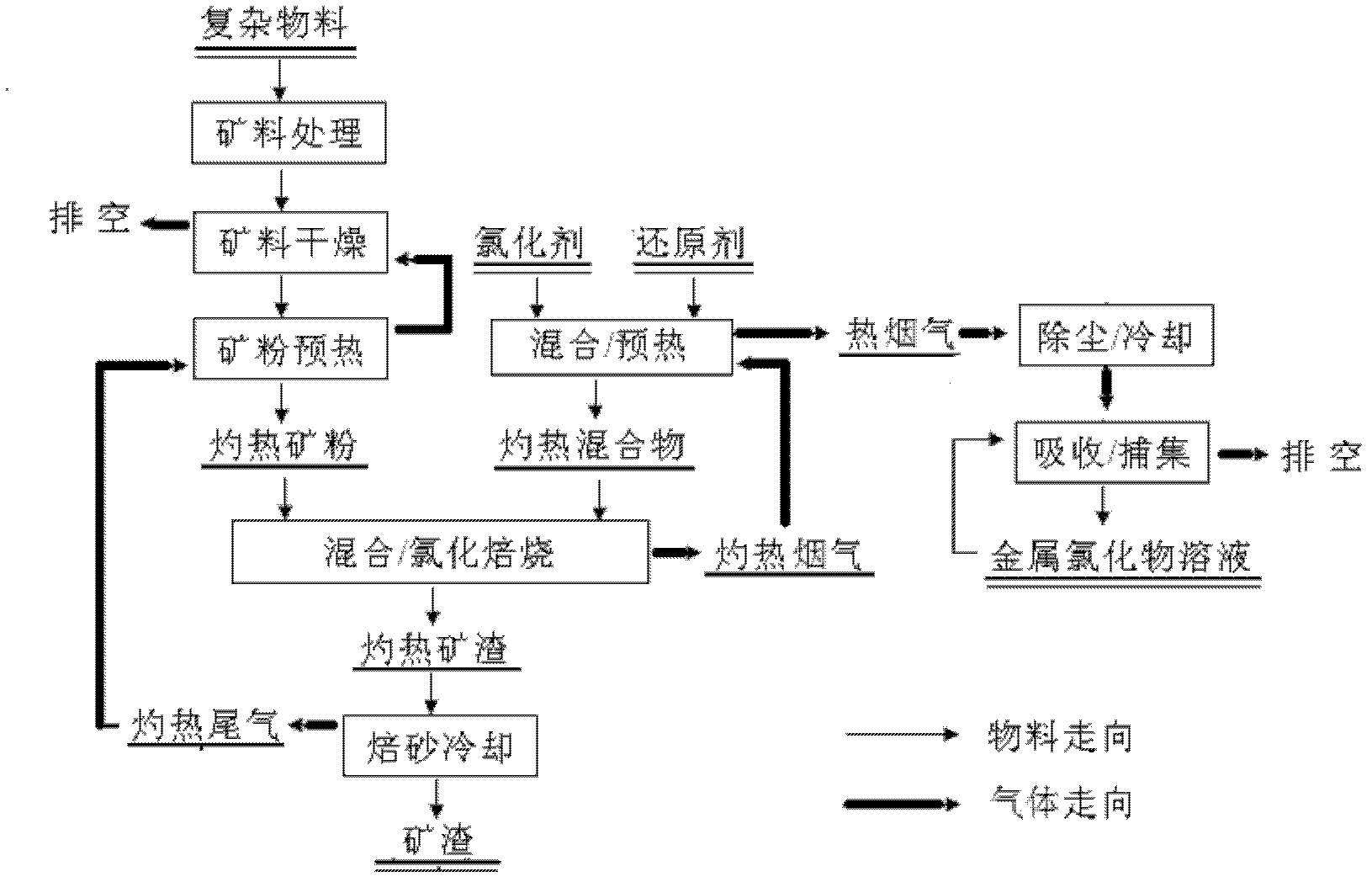

A method for processing low-content non-ferrous metal materials to extract non-ferrous metals

InactiveCN102277485ALow melting pointIncrease relative volatilityProcess efficiency improvementMetal chlorideFlue gas

The invention discloses a method for processing low-content non-ferrous metal materials to extract non-ferrous metals: (1) pretreatment: processing the low-content non-ferrous metal materials into powder materials with a water content not higher than 10% and a particle size of -60 mesh; ( 2) Preheating: Preheat the mixture of reducing agent and chlorinating agent and low-content non-ferrous metal materials to 500-800°C respectively; (3) High-temperature chlorination roasting: add to the preheated low-content non-ferrous metal materials 0~6wt% reducing agent and 4~10wt% chlorinating agent, carry out the chlorination roasting of valuable metals; roasting temperature 800~1100 ℃, roasting time 30~60min; (4) Valuable metal chloride capture recovery: chlorine After the high-temperature flue gas from chemical roasting is collected to remove mineral dust, it is cooled and wet-type collected to recover valuable metal chlorides. The economical and efficient extraction of valuable metals in low-content nonferrous metal materials is realized.

Owner:CENT SOUTH UNIV

Method for recycling silicon carbide and co-producing white carbon black from waste mortar for wire cutting

The invention discloses a method for recycling silicon carbide and co-producing white carbon black from waste mortar produced by cutting and machining monocrystalline silicon or polysilicon into silicon wafers, which comprises the following steps: utilizing organic and inorganic solvents to dissolve cutting solution molecules in the mortar; removing iron from solid-state sand through mixed acid for acid cleaning and a chelating agent; adding the high-concentration aqueous solution of sodium hydroxide in the solid-state sand so that the aqueous solution of the sodium hydroxide is reacted with silicon in the mortar to produce sodium silicate, and performing filtering to obtain the pure silicon carbide; adding a little amount of high modulus water glass into the aqueous solution of the sodium silicate; and finally performing acid precipitation to separate flocculent sediment out, and drying the flocculent sediment to obtain the white carbon black product, wherein dilute sodium chloride solution can be recycled as a diluent. The method in the invention is simple in process and moderate in reaction conditions, can effectively recycle the silicon carbide, effectively reduce the cost on recycling the waste mortar and preparing the white carbon black by utilizing wastewater, is the practicable technology which can make waste profitable, greatly reduce the discharge of the wastewater and create remarkable economic and social benefits.

Owner:滕州市产品质量监督检验所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com