Patents

Literature

188results about How to "Reduce sorting costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

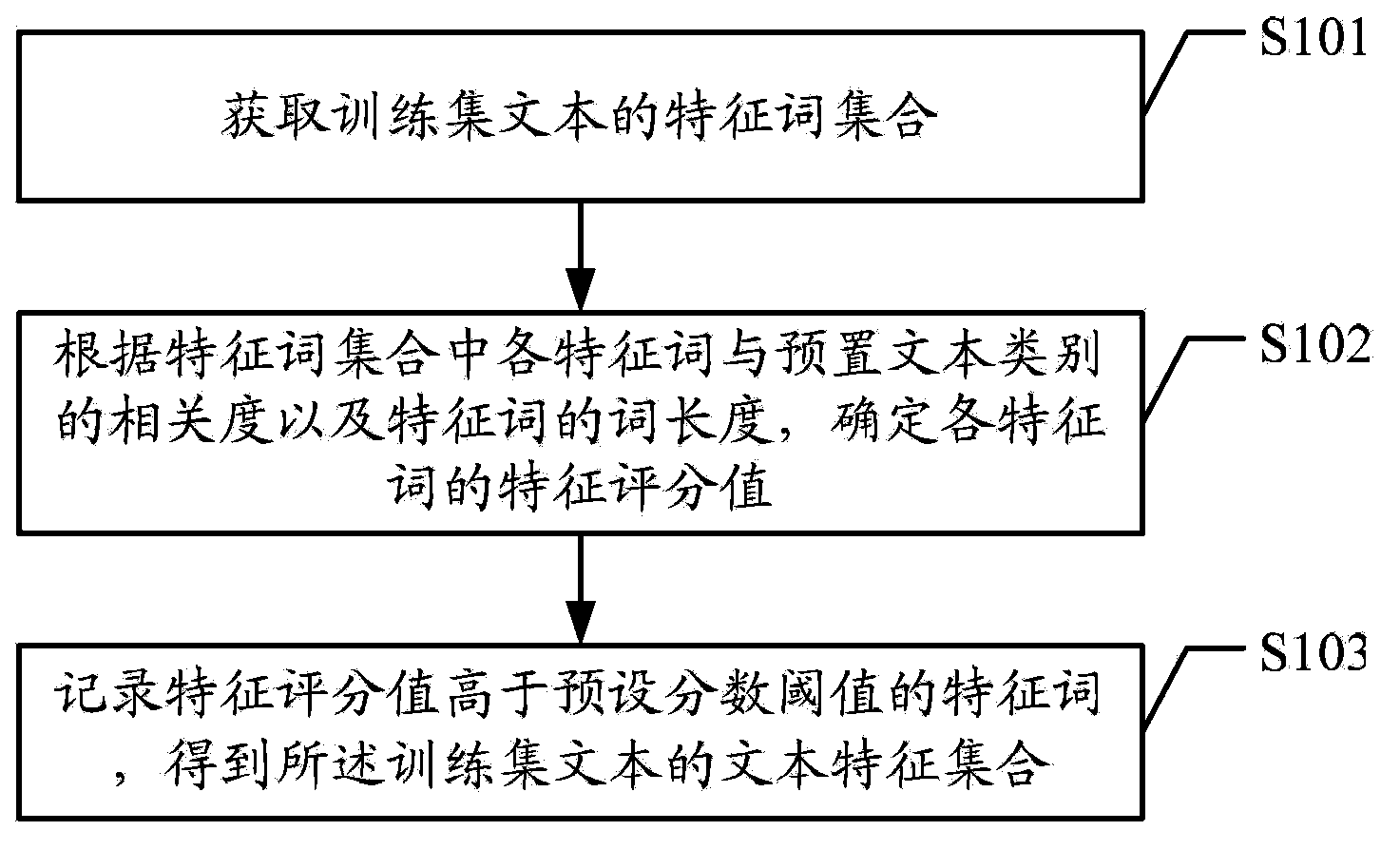

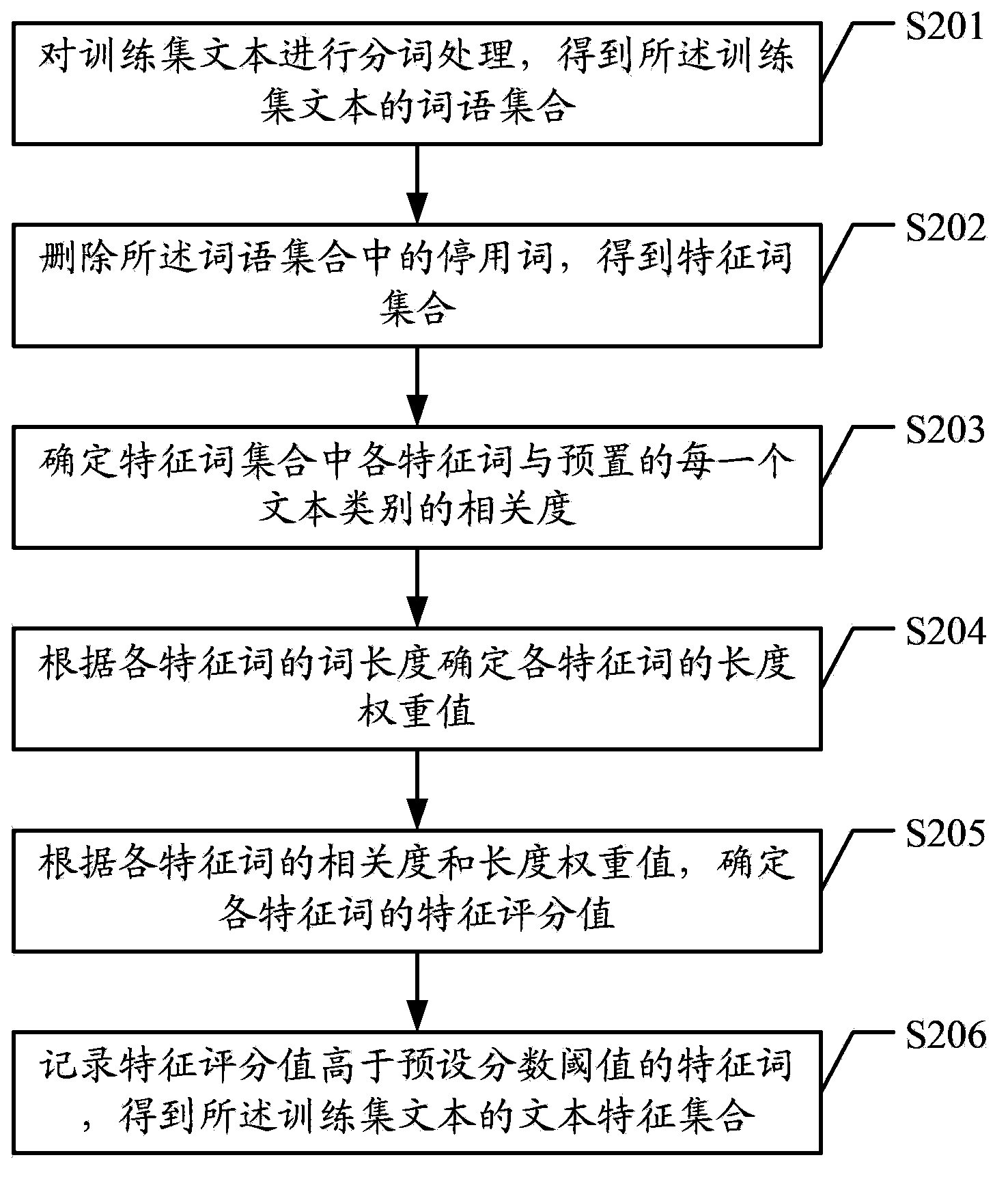

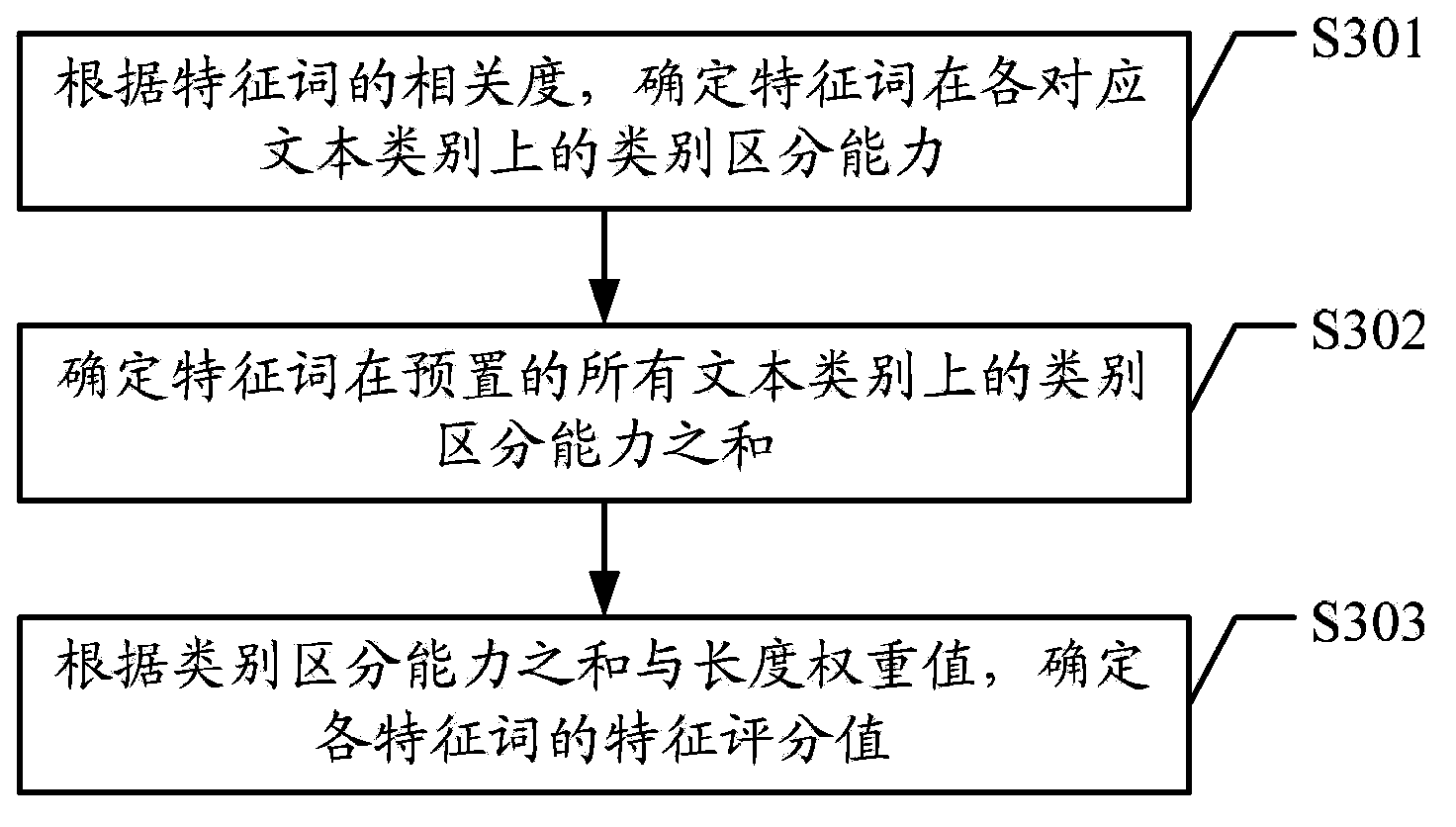

Text classification feature extraction method, classification method and device

ActiveCN103902570AReduce the numberReduce sort run timeSpecial data processing applicationsText database clustering/classificationFeature setText categorization

The embodiment of the invention discloses a text classification feature extraction method and a classification method and device. The text classification feature extraction method includes the steps of obtaining a feature word set of training set texts, confirming feature grading values of the feature words according to relevance of feature words in the feature word set and preset text categories, recording the feature words whose grading values are higher than a preset score threshold value, and obtaining a text feature set of the training set texts. According to the text classification feature extraction method and the classification method and device, the number of the feature words can be effectively reduced on the situation that the feature words capable of expressing text information are obtained, and accordingly when texts are classified, classification operation time is conveniently reduced, calculation time and space expenditures are reduced, and calculation cost is saved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

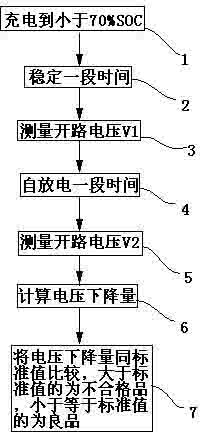

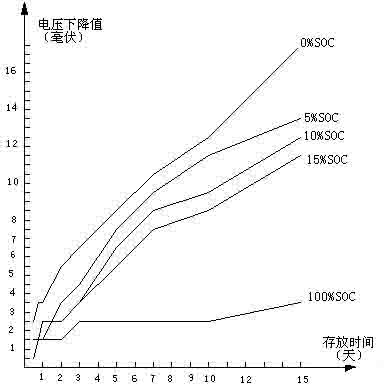

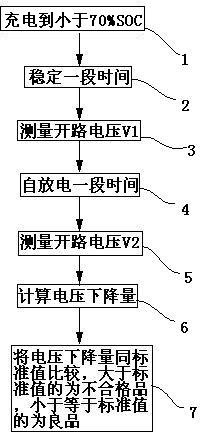

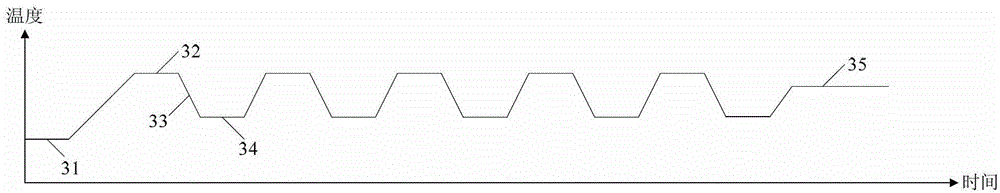

Method for detecting and sorting self-discharge performance of lithium iron phosphate battery

ActiveCN102303023AHigh sorting accuracyReduce sorting timeSortingLithium vanadium phosphate batteryElectricity

The invention relates to a method for detecting and sorting self-discharge performance of a lithium iron phosphate battery. The method comprises the following steps of: charging to less than 70 percent of a SOC ( State Of Charge); 2, storing for a period of time, wherein the period of time is called as a stabilization time; 3, testing an open-circuit voltage of the battery, wherein the tested voltage in the step is called as V1; 4, storing for one period of time, wherein the period of time is called as a self-discharge time; 5, testing an open-circuit voltage of the battery, wherein the tested voltage in the step is called as V2; 6, calculating a voltage drop amount of the battery, the voltage drop amount is called as a delta V, wherein the delta V is equal to the V1 minus the V2; and 7, determining that a battery of which the delta V is greater than a standard value is an unqualified product, and determining that a battery of which the delta V is smaller than the standard value is a good product. According to the method provided by the invention, the self-discharge performance of the lithium iron phosphate battery can be sorted in a short time without needing a high temperature aging, the problem of high detection cost caused by shortening the detection time by using the traditional method needing using the high temperature aging to accelerate the electricity discharge speed is solved.

Owner:WANXIANG 123 CO LTD

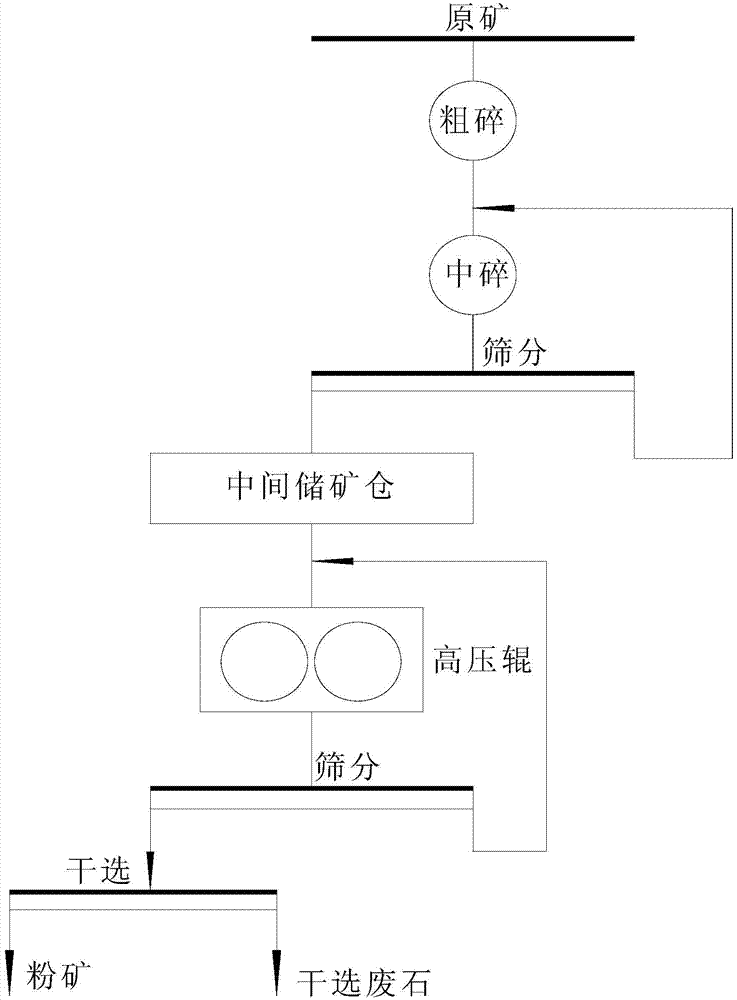

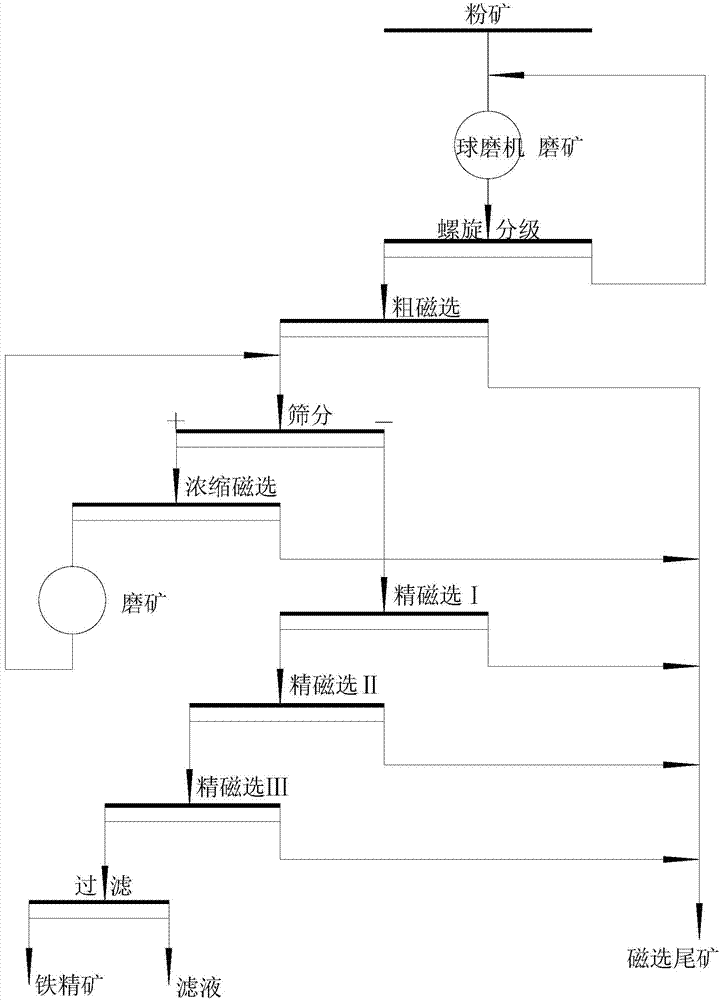

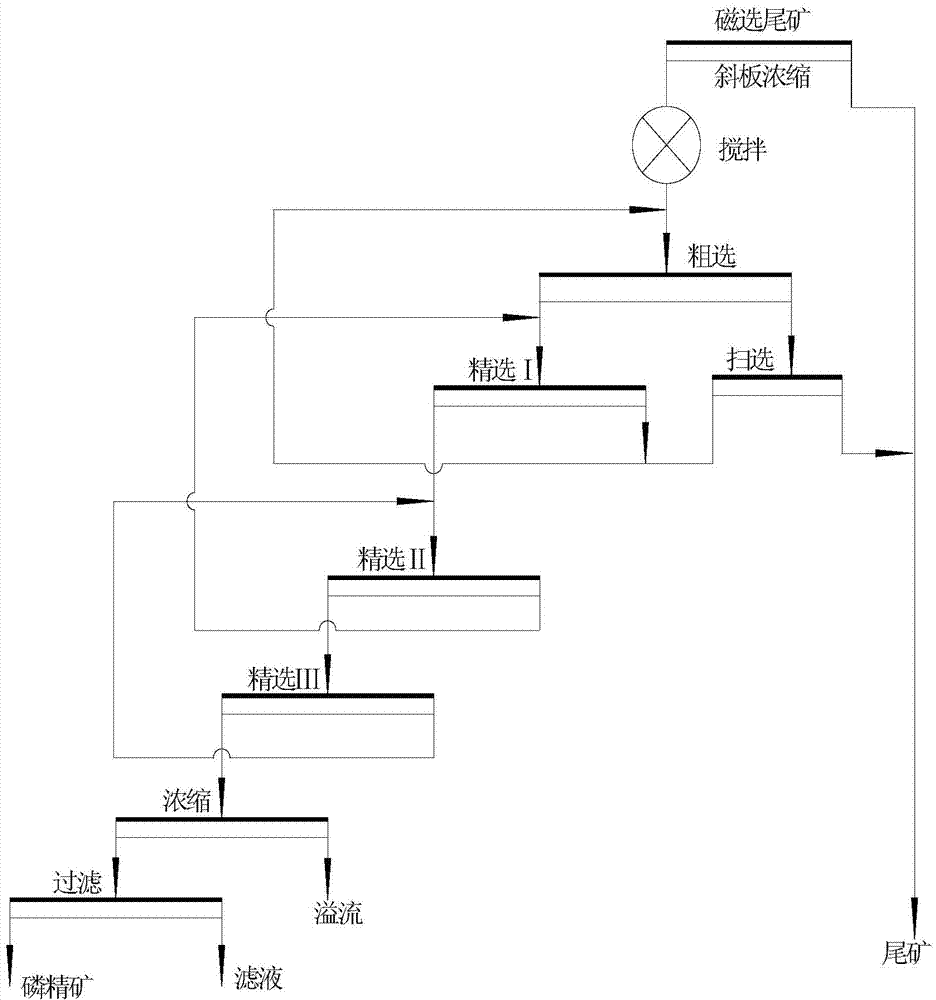

Combined beneficiation method and combined beneficiation system for comprehensive recovery of associated iron-phosphate minerals

The invention belongs to the technical field of efficient development of ultralow-grade ore resources and comprehensive utilization of associated minerals, and in particular relates to a combined beneficiation method and a combined beneficiation system for comprehensive recovery of associated iron-phosphate minerals. The combined beneficiation method for the comprehensive recovery of the associated iron-phosphate minerals comprises the following steps: sequentially performing three-section and two-closed-loop crushing and screening flow on raw ores, and performing dry separation to obtain fine ores; performing two-section closed-loop ore-grinding flow on the fine ores, performing fine magnetic separation for three times, and concentrating by using a wash mill to separate iron ore concentrate and discharge tailings; performing one-time roughing, one-time scavenging and three-time concentrating on the tailings at the temperature of 10-15 DEG C to obtain phosphate ore concentrate by floatation. Compared with the prior art, the invention provides a comprehensive recovery scheme for magnetic iron ore resources and phosphate ore resources in ultralow-grade associated iron-phosphate minerals. According to the scheme, the separation cost is low, the efficiency is high, energy is saved, the space occupation is low, and the comprehensive recovery of the magnetic iron ores and the phosphate ores can be realized.

Owner:中冶沈勘工程技术有限公司

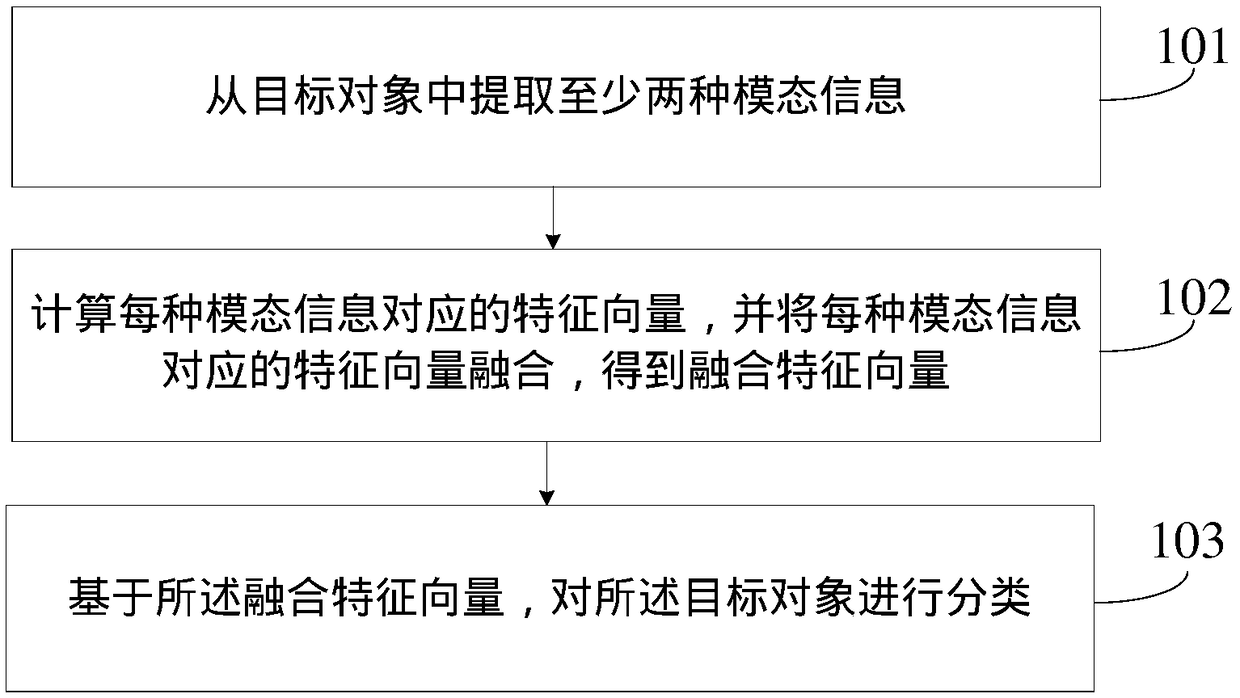

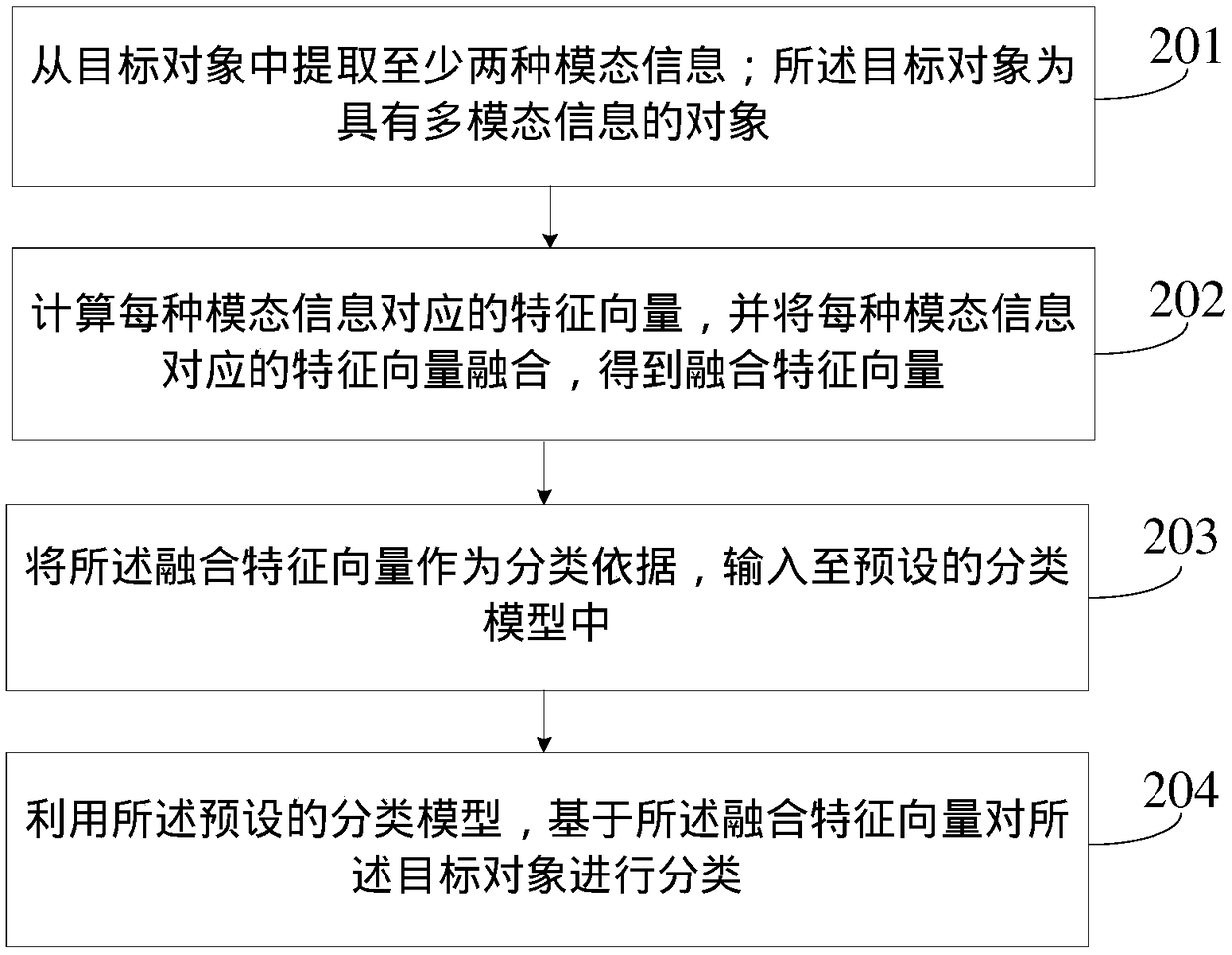

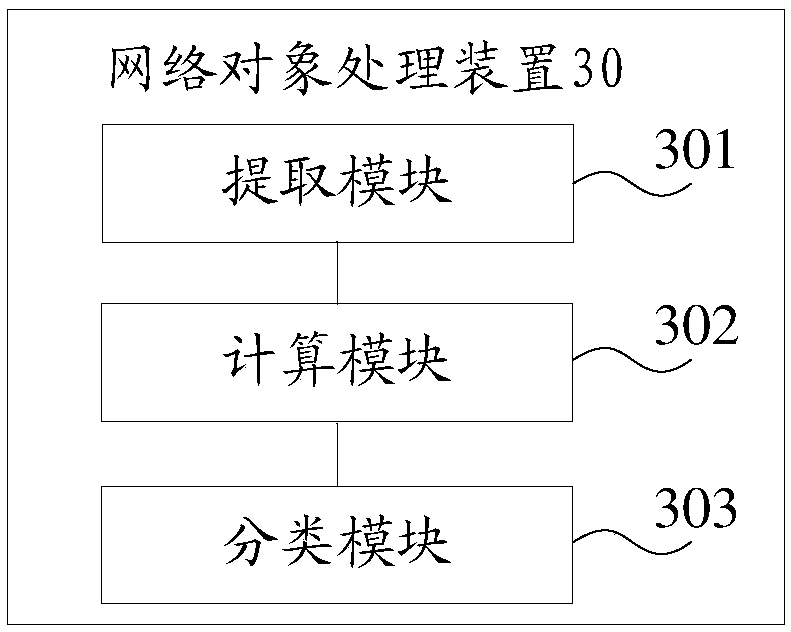

Network object processing method and device

ActiveCN108763325ASimplify the classification processReduce sorting costsCharacter and pattern recognitionSpecial data processing applicationsFeature vectorComputer terminal

The invention provides a network object processing method and device, and belongs to the technical field of computers. In the embodiment of the invention, at least two types of modal information can be firstly extracted from a target object, then feature vectors corresponding to all the modal information can be calculated, the feature vectors corresponding to all the modal information can be fusedfor obtaining a fused feature vector, and finally, the target object is classified on the basis of the fused feature vector. The fused feature vector can represent features corresponding to all the modal information, thus in the embodiment of the invention, a terminal can simplify a classification process while the target object is classified on the basis of all the information features of the target object, and classification costs are reduced.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

Method for recovering valuable elements in waste lithium ion battery electrode material

ActiveCN107955879AReduce sorting costsReduce recycling costsWaste accumulators reclaimingProcess efficiency improvementSlagElectrical battery

The invention discloses a method for recovering valuable elements in waste lithium ion battery electrode materials. The method comprises steps of roasting the waste lithium ion battery electrode materials in an inert gas atmosphere, the roasting temperature is 200 -600 DEG C, the time is 30-360 minutes, and the roasting slag is obtained; mixing the obtained roasting slag and an acidic solution with [H+] concentration of 0.5~8 mol / L according to the mass ratio of 1:3~10; leaching at the leaching temperature of 30-90 DEG C and leaching time of 1-8 hours, leach liquor and leach residues are filtered to be obtained; the leach liquor is used for recovering nickel, cobalt, manganese, aluminum and lithium, and the leach residues are used for preparing negative electrode materials. According to the method for recovering valuable elements in waste lithium ion battery electrode materials, a leaching reducing agent does not need to be additionally added, the battery sorting and recycling costs are reduced, the positive and the negative electrode materials can be recovered at the same time, and the economic benefits of lithium battery recovery can be improved.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

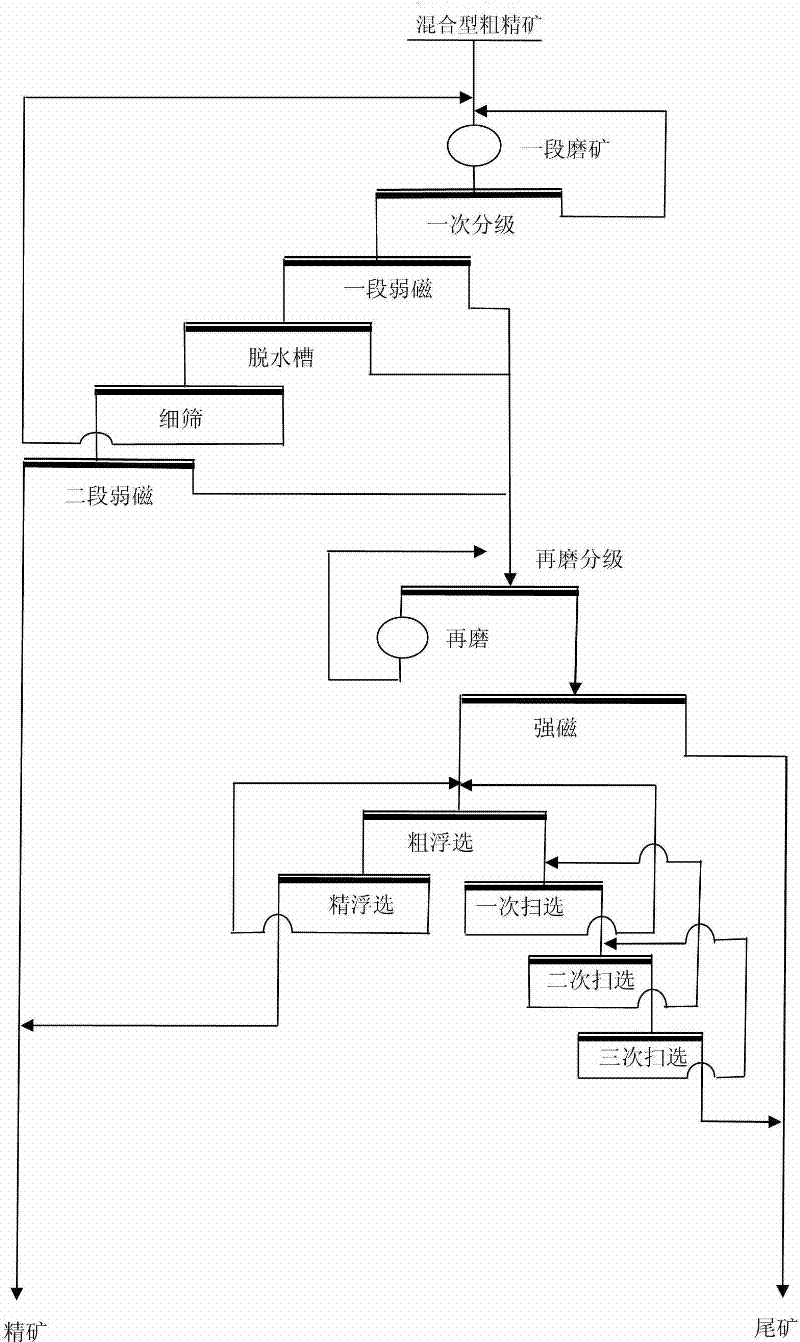

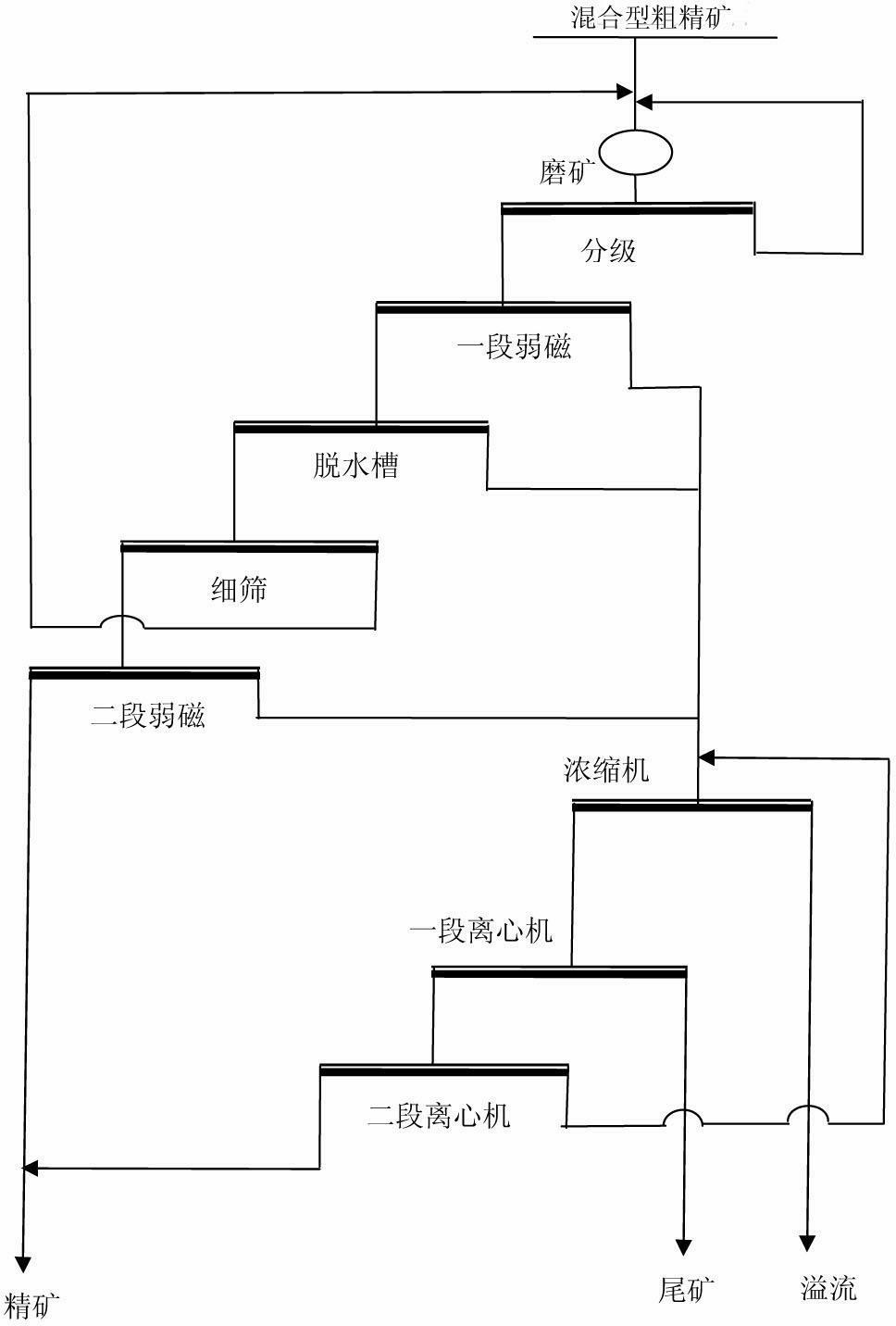

Mineral separation process for magnetic hematite rough concentrates

ActiveCN102441481ATo achieve the purpose of increasing iron and reducing siliconSolve the technical problems of improving the quality of coarse and concentrated oresFlotationMagnetic separationHybrid typeEngineering

The invention relates to a mineral separation process for magnetic hematite rough concentrates, which comprises the following steps of: feeding the magnetic hematite rough concentrates into a closed circuit grinding system; once grading, overflowing and feeding into weak magnetism at first section; feeding the concentrates in the weak magnetism at the first section into a dewatering tank; feedingthe concentrates in the dewatering tank into a fine sieve; returning rough particle products on the sieve into the first section for grinding; feeding fine particle products under the sieve into weakmagnetism at second section; mixing tailings in the weak magnetism at the second section, tailings in the weak magnetism at the first section and tailings in the dewatering tank to obtain low intensity magnetic separation tailings; concentrating the low intensity magnetic separation tailings by a concentrating machine; feeding into a closed circuit regrinding system; grading, overflowing and feeding again into strong magnetism; concentrating strong magnetic concentrates by the concentrating machine; feeding into a negative ion reverse flotation process including one-time rough separation, one-time fine separation and three-time scavenging; combining the strong magnetic tailings with the floatation tailings to obtain final tailings; and combining the concentrates in the weak magnetism at the second section with the flotation concentrates to obtain final concentrates. The mineral separation process provided by the invention is simple, high-efficiency, particularly low-cost, good in effect and high in concentrate quality and metal recovery rate, and realizes high-efficiency utilization of resources.

Owner:ANSTEEL GRP MINING CO LTD

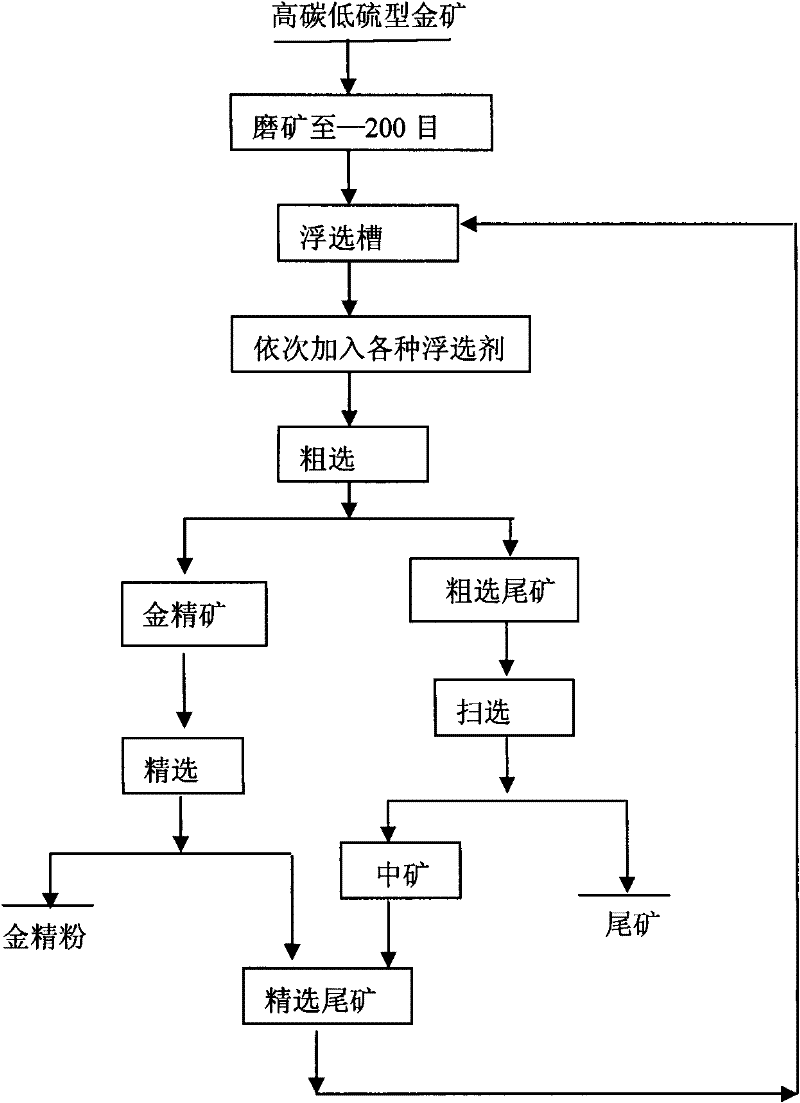

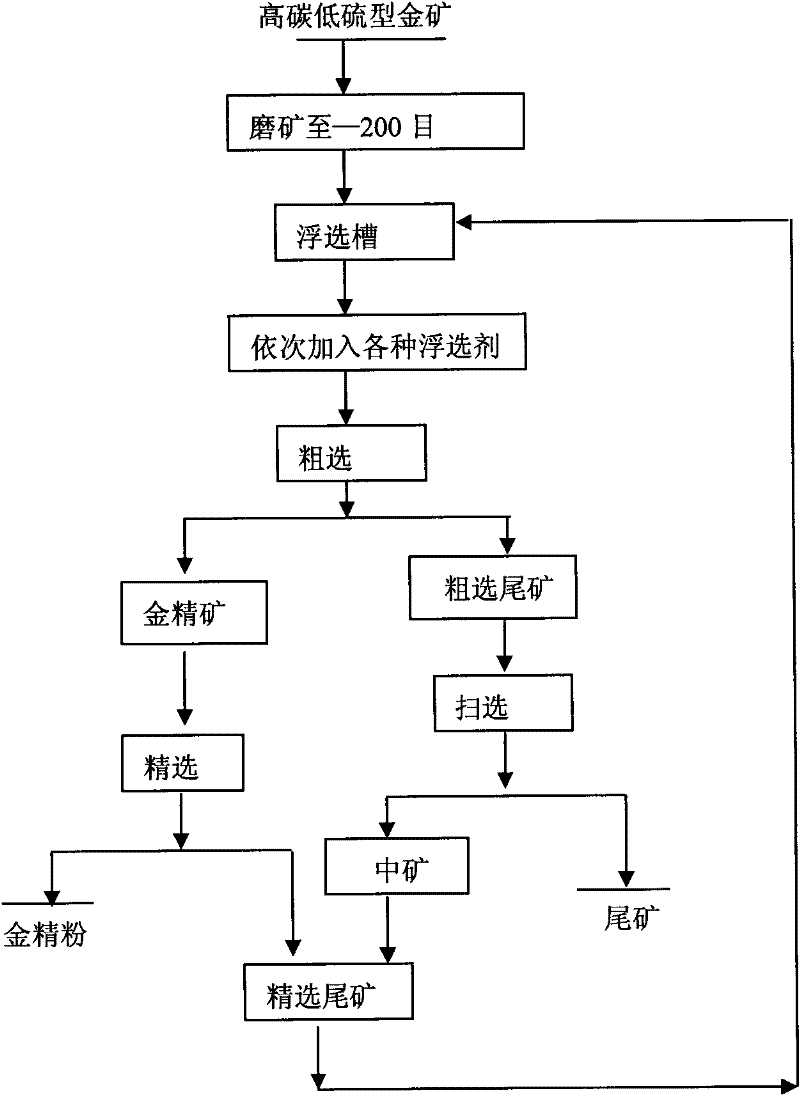

High-carbon and low-sulfur type gold ore floating agent and floating method thereof

InactiveCN102049355ASolve difficult dippingSolving Difficult Flotation ProblemsFlotationScavengerFoaming agent

The invention relates to a high-carbon and low-sulfur type gold ore floating agent and a floating method thereof. The floating agent comprises an activating agent, an adjusting agent, a foaming agent and a collecting agent. The floating method comprises the following steps: smashing and grinding each of high-carbon and low-sulfur type gold ores into 200 meshes and adding the activating agent, theadjusting agent, the foaming agent and the collecting agent in sequence for uniform agitation after size mixing; roughing to obtain gold concentrate ores and rougher tailings, obtaining gold concentrate powder and cleaner tailings after the gold concentrate ores are chosen; obtaining scavenger gold ores and tailings after the rougher tailings are scavenged; discarding the tailings; and returning the scavenger gold ores and the cleaner tailings into a flotation tank for re-separation. The invention solves the problem that the high-carbon and low-sulfur type gold ore is hard to soak and float, so that the explored high-carbon and low-sulfur type gold ore is developed and utilized. Compared with the prior art, the floating method has short sorting process, simple process, relatively low sorting cost, high recovery rate and easiness in operation.

Owner:JILIN UNIV

Method and device for cargo sorting under conditions of large cargo amount and large cargo owner amount

ActiveCN104174599ASave on shippingImprove sorting efficiencySortingIndustrial engineeringBatch Number

The invention discloses a method and a device for cargo sorting and especially relates to a method and a device for cargo sorting under conditions of a large cargo amount and a large cargo owner amount. The method for cargo sorting adopts a receiving-type sorting method and a distribution-type sorting method. In receiving-type sorting, cargoes supplied by all suppliers are orderly arranged according to cargo owner numbers so that a rule of cargo arrangement based on the cargo owner numbers is formed; then a sorting process round is carried out several times, wherein in the each sorting process round, a sorting process is carried out several times so that the cargoes belonging to the same service station are sorted, then the cargoes sorted by the sorting process rounds are orderly arranged according to service station numbers, a part of the cargoes belonging to a service station in a corresponding-level region are sorted in each sorting process and the rest of the cargoes are stayed in original positions; and the sorted cargoes are arranged in a type number order and the same type of the cargoes are orderly arranged according to the cargo owner numbers so that a rule of cargo arrangement based on cargo types is formed. In distribution-type sorting, batch numbers are used as main sorting basis and city numbers are used as minor sorting basis.

Owner:吴宁飞

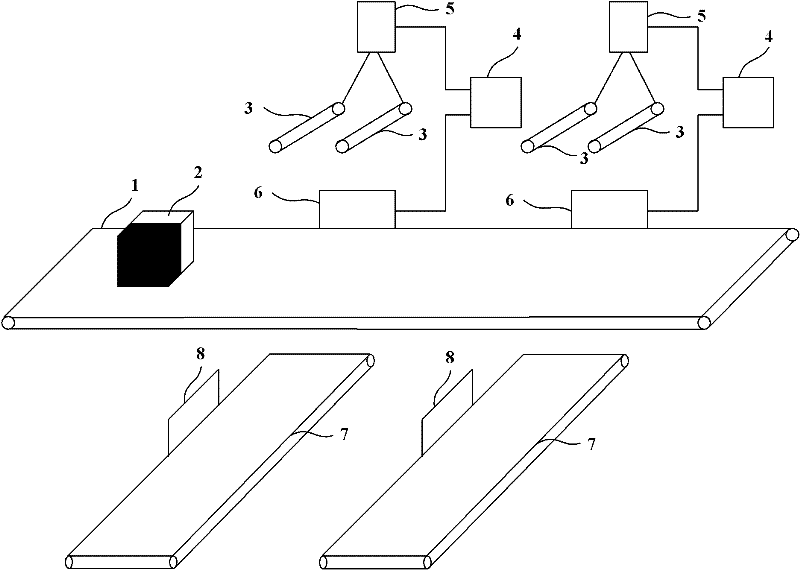

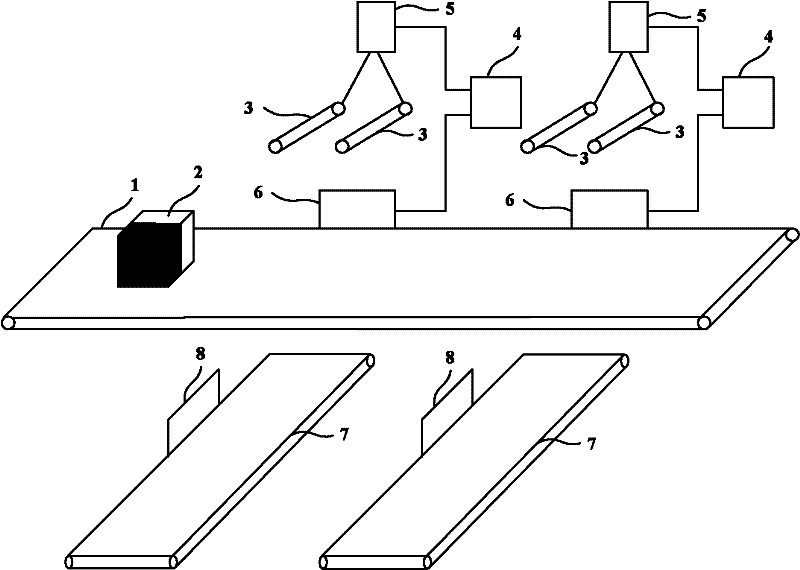

Logistic sorting system based on color sensor

The invention discloses a logistic sorting system based on a color sensor, belonging to the technical filed of identifying and sorting objects. The logistic sorting system comprises a main transmission belt and a plurality of control units, wherein the control unit comprises a branch transmission belt, a motor, a pushing rod mechanism, the color sensor and a controller; the branch transmission belt is positioned under one side of the main transmission belt, and the transmission direction of the branch transmission belt is vertical to that of the main transmission belt; the pushing rod mechanism is positioned at the other side of the main transmission belt and corresponds to the branch transmission belt; the pushing rod mechanism is positioned above the plane of the main transmission belt and is connected with the motor; the color sensor is positioned above the main transmission belt and corresponds to the branch transmission belt; the detection direction of the color sensor is opposite to the transmission direction of the main transmission belt and is inclined downwards; and the color sensor is connected with the controller which is connected with the motor. In the logistic sorting system, expresses are quickly identified by the color sensor, so that the sorting efficiency of the expresses is improved, and the sorting cost is reduced.

Owner:BEIJING JIAOTONG UNIV

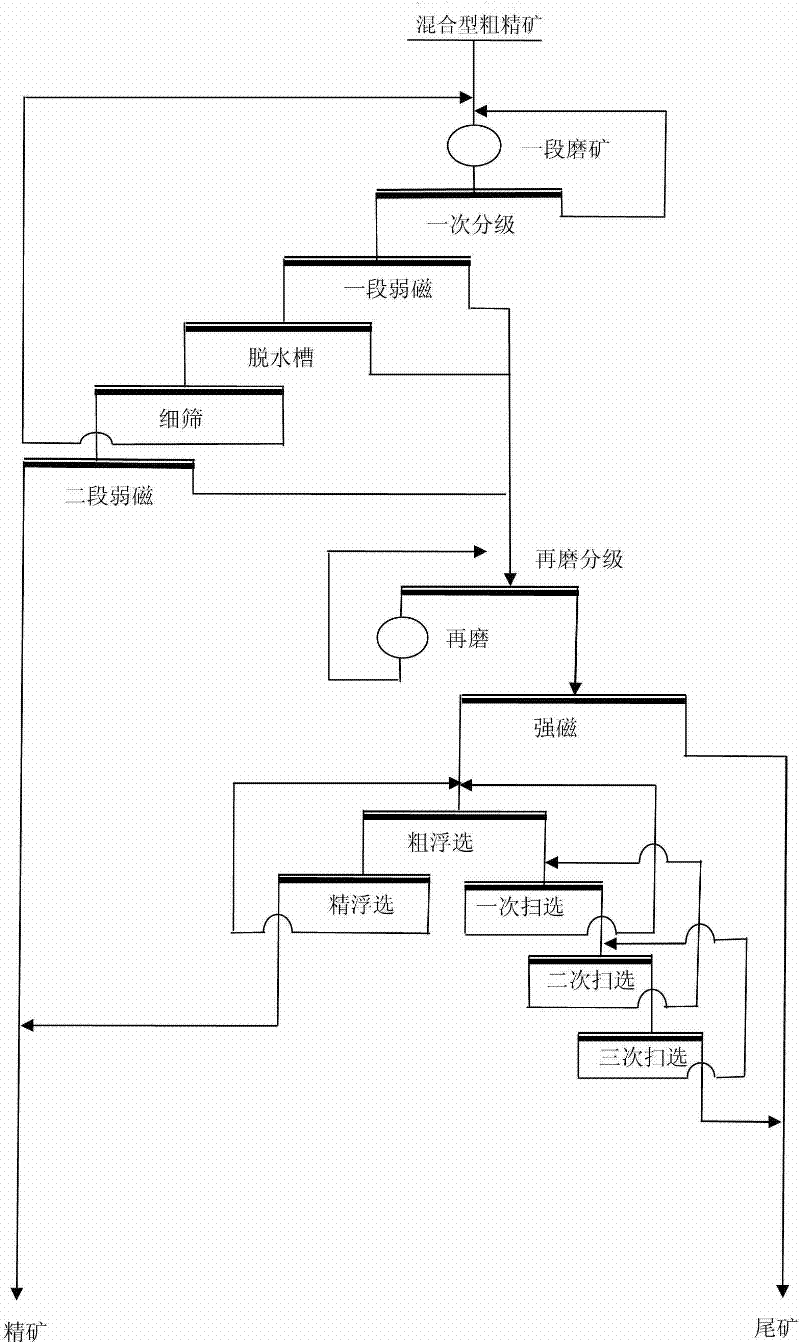

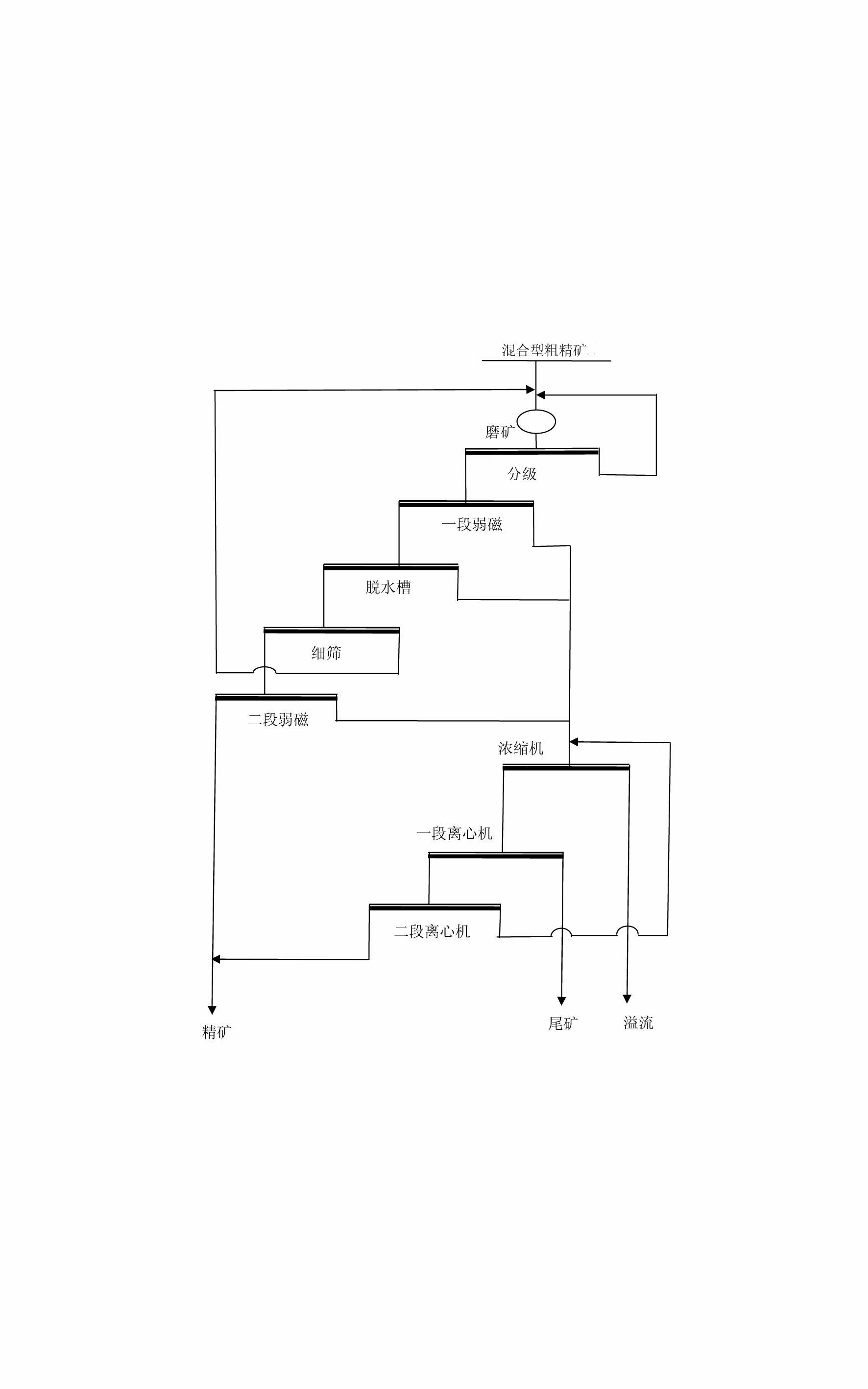

Magnetism-gravity combined separation technology for magnetic hematite mixed type rough concentrate

ActiveCN102430468AEmbodies the depth of selectionRealize the purpose of improving quality and removing impuritiesSievingScreeningHybrid typeSeparation technology

The invention relates to a magnetism-gravity combined separation technology for magnetic hematite mixed type rough concentration. The technology is characterized by comprising the following steps of: feeding the magnetic hematite mixed type rough concentration into a closed-circuit grinding system; feeding first-section weak magnetism through primary classification overflow; feeding the concentrate of the first-section weak magnetism into a dehydration tank; feeding the concentrate of the dehydration tank into a fine sieve; returning the coarse-grain product on the sieve to the grinding system; feeding the fine-grain product below the sieve to second-section weak magnetism; mixing the tailings of the second-section weak magnetism with the tailings of the first-section weak magnetism and the tailings of the dehydration tank to obtain weak-magnetic separation tailings; concentrating the weak-magnetic separation tailings by a concentrator, and feeding into a first-section centrifugal machine for roughing; feeding the concentrate of the first-section centrifugal machine into a second-section centrifugal machine for selection; discarding the tailings of the first-section centrifugal machine; mixing the concentrate of the second-section centrifugal machine with the second-section weak-magnetism concentrate to obtain the final concentrate; and returning the tailings of the second-section centrifugal machine to the concentrator. The technology provided by the invention is simple and efficient, has low separation cost, a good effect and high concentrate grade and metal recovery rate, and realizes efficient utilization of resources.

Owner:ANSTEEL GRP MINING CO LTD

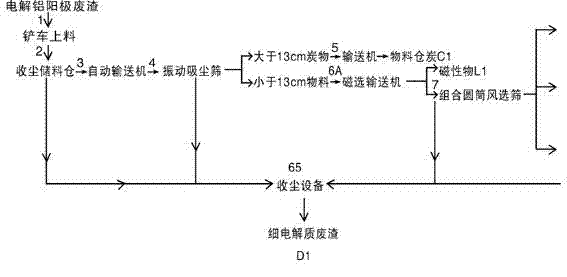

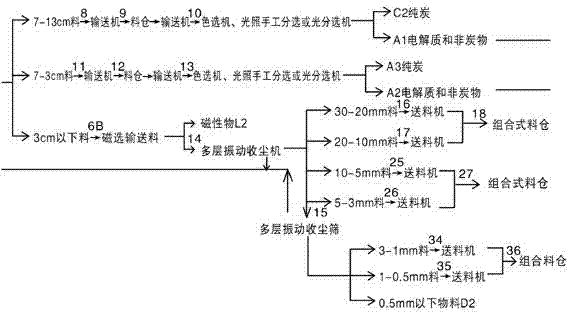

Electrolytic aluminum anode waste separating and recovering method

InactiveCN102389891AReduce sorting costsLabor demand is smallSievingScreeningChemical reactionChemical separation

An electrolytic aluminum anode waste separating and recovering method relates to the field of waste recovery and utilization. The method comprises the following steps: a, screening and classification are performed on waste materials; b, materials of which F is greater than F1 are divided into carbon objects and amorphous carbon objects through manual separation, and the separation of a color sorting machine or an optical separator; c, magnetic objects and nonmagnetic objects are separated during material conveying; d, carbon is extracted through respective electric separation equipment from the material of which the F is less than or equal to F3 and is less than or equal to F2 after screening and classifying; e, a material of which the F is less than the F3, and other amorphous carbon materials separated out from other links can be separated into carbon and amorphous carbon materials through crushing and flotation; f, the amorphous carbon materials in e is added with fluorine and chlorhydric acid for reaction so as to obtain cryolite; and g, purer cryolite is obtained after separation, water scrubbing, dewatering and drying. The invention has the benefits as follows: various material separation and purification from waste can be accomplished by using a series of processes such as optical separation, color selection, manual separation, magnetic separation, electric separation, floatation, chemical reaction and the like, so as to meet the requirements of industrial application. The separation cost during the entire process is low, the demand for labor force is low, and industrial automation continuous production is achieved.

Owner:巨锋

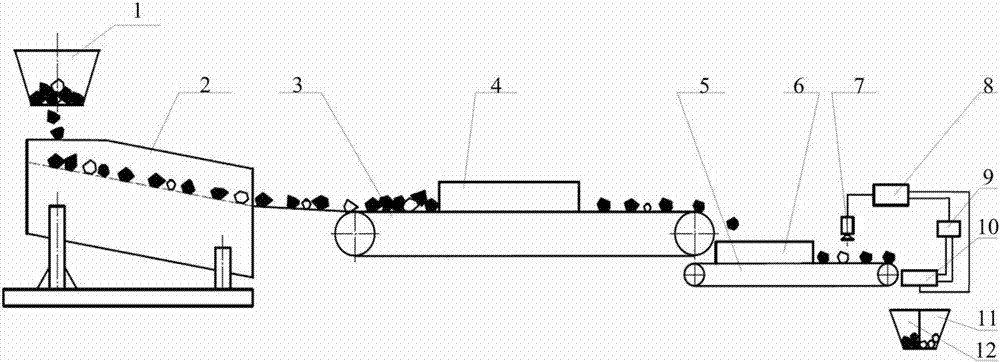

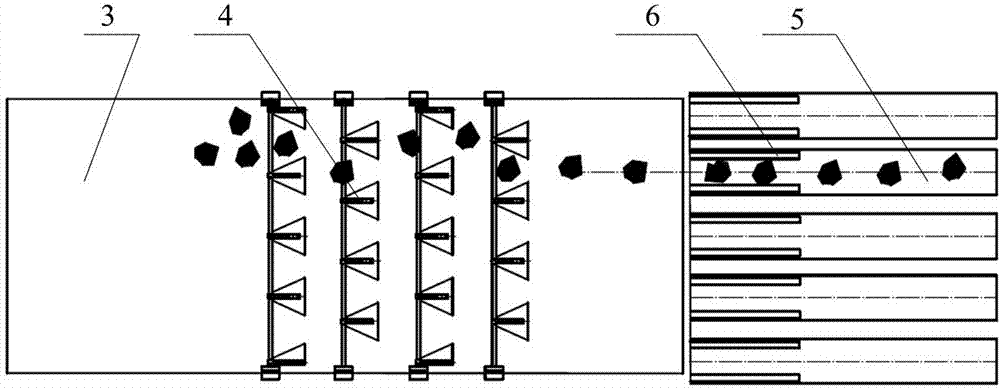

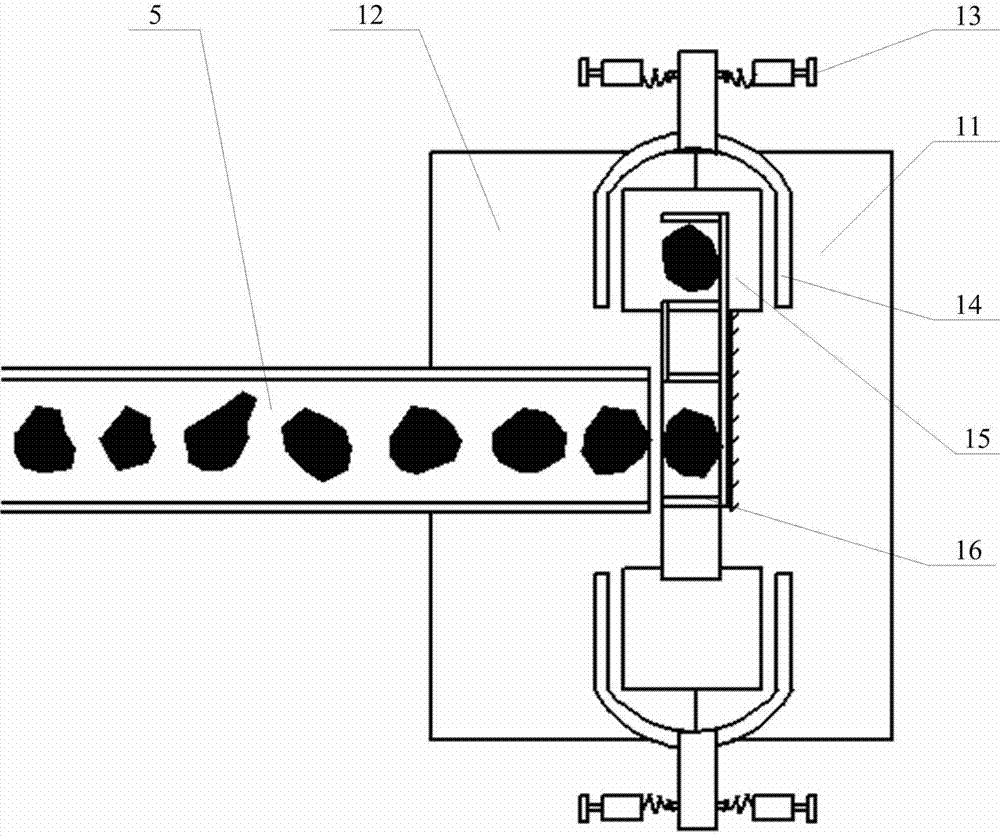

Intelligent coal gangue separating machine

InactiveCN104492725AAchieving identifiabilityRealize sortingSortingProcess engineeringPersonal computer

The invention relates to an intelligent coal gangue separating machine which comprises a raw coal feeding hopper, a screening device, a primary conveyer belt conveyor and a secondary conveyer belt conveyor, a coal gangue identifying mechanism and a coal gangue separating mechanism, wherein a sequencing mechanism is arranged on the primary conveyer belt conveyor, an aligning mechanism used for carrying raw coal blocks conveyed by the primary conveyer belt conveyor, the coal gangue identifying mechanism comprises a raw coal block volume measuring device, an industrial personal computer, a weighing platform and a feeding device; the industrial personal computer is respectively connected with the raw coal block volume measuring device, a PLC and the weighing platform, the PLC is connected with the feeding device, the feeding device is arranged between the tail part of the secondary conveyer belt conveyor and the weighing platform; the coal gangue separating mechanism is a mechanical executing mechanism used for separating coal gangue on the weighing platform. The intelligent coal gangue separating machine is high in separating efficiency, free from pollution and high in automaton degree, can be used for separating coal and coal gangue, and has a wide application prospect in other mineral separation fields.

Owner:郑州大河智信科技股份公司

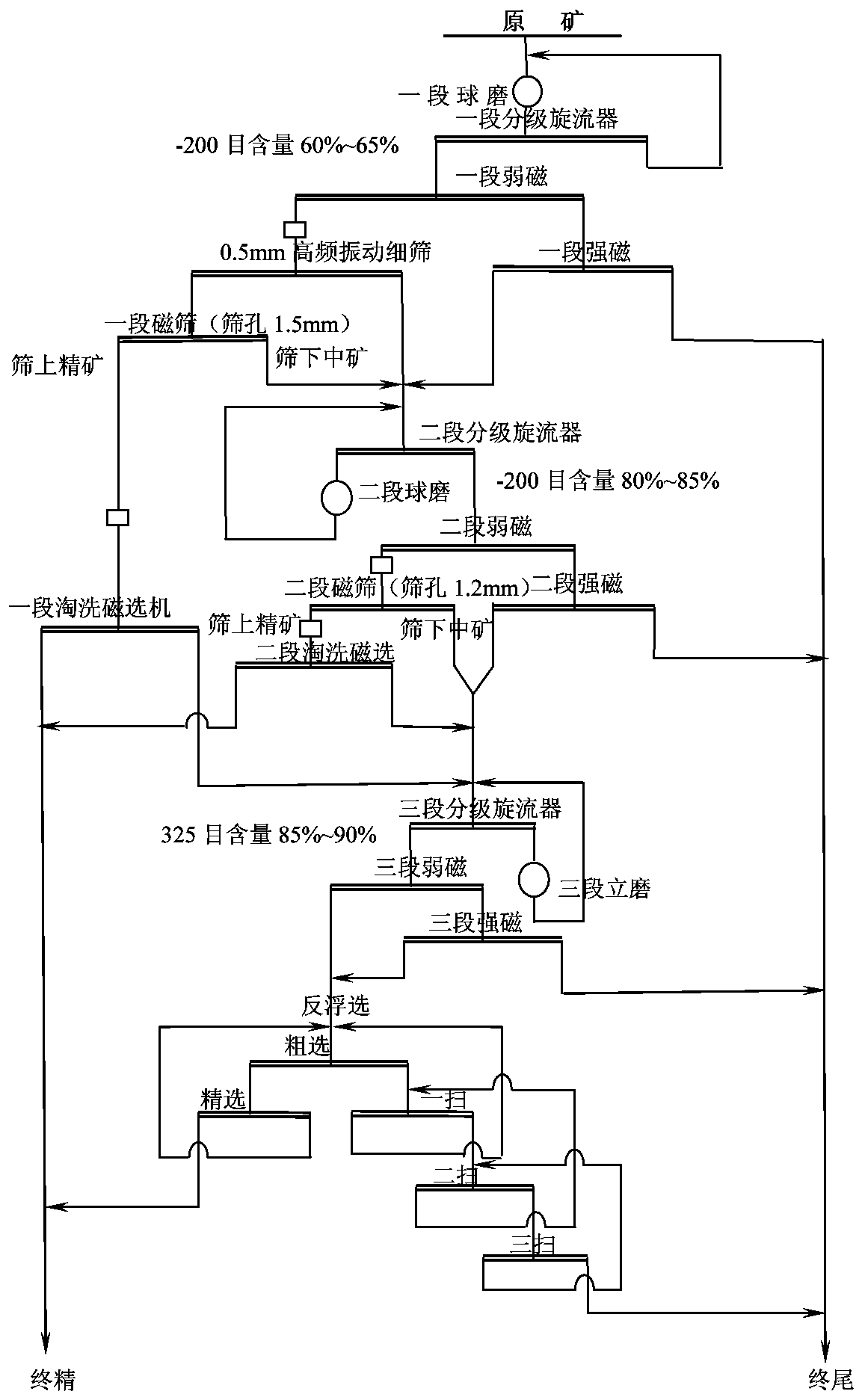

Separation process for magnetic red mixed ore based on iron material disseminated particle size treatment

ActiveCN109351467AReduce grinding energy consumptionReduce overgrindingSolid separationOre concentrateSeparation process

The invention relates to a separation process for magnetic red mixed ore based on iron material disseminated particle size treatment. The process comprises the operation of feeding the mixed ore withthe grade of 27%-29% and with magnetite as a main raw material into first-section closed circuit ore grinding operation to obtain a primary grading overflow product, and is characterized by further comprising first-section weak magnetic and strong magnetic operation, fine screening operation, first-section magnetic separation and first-section washing magnetic separation operation, second-sectionclosed circuits ore grinding operation, second-section weak magnetic strong magnetic operation, second-section magnetic separation and washing magnetic separation operation, third-section closed circuit ore grinding, third-section weak magnetic strong magnetic operation and reverse flotation operation. The final concentrate with the grade of 66%-66.5% is obtained through the operation. Compared with the prior art, the separation process has the advantages that 1) an efficient separation process which is characterized in that the concentrate can be obtained once dissociation is achieved and segmented ore grinding, segmented concentrate taking and segmented tailings discharging are achieved is provided for the magnetic red mixed ore with the non-uniform iron material disseminated particle sizes, so that overgrinding is reduced, and energy conservation and consumption reduction are achieved; 2) magnetic separation equipment is adopted for upgrading, and three sections of ore grinding is carried out by adopting vertical mills; and 3) the process is simple in structure, free of middling circulation, easy to implement on site and easy to produce and manage.

Owner:ANSTEEL GRP MINING CO LTD

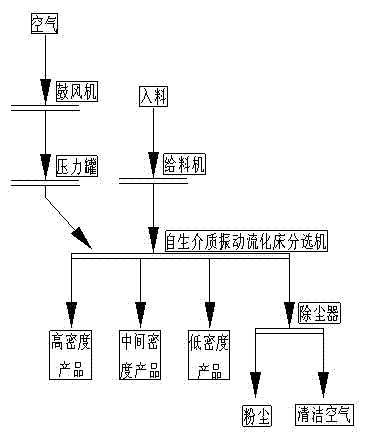

Authigenic medium vibrated fluidized bed dry separating method and separating machine

ActiveCN102921636AImprove reliabilityReduce sorting loadGas current separationHigh densityDust control

Owner:CHINA UNIV OF MINING & TECH

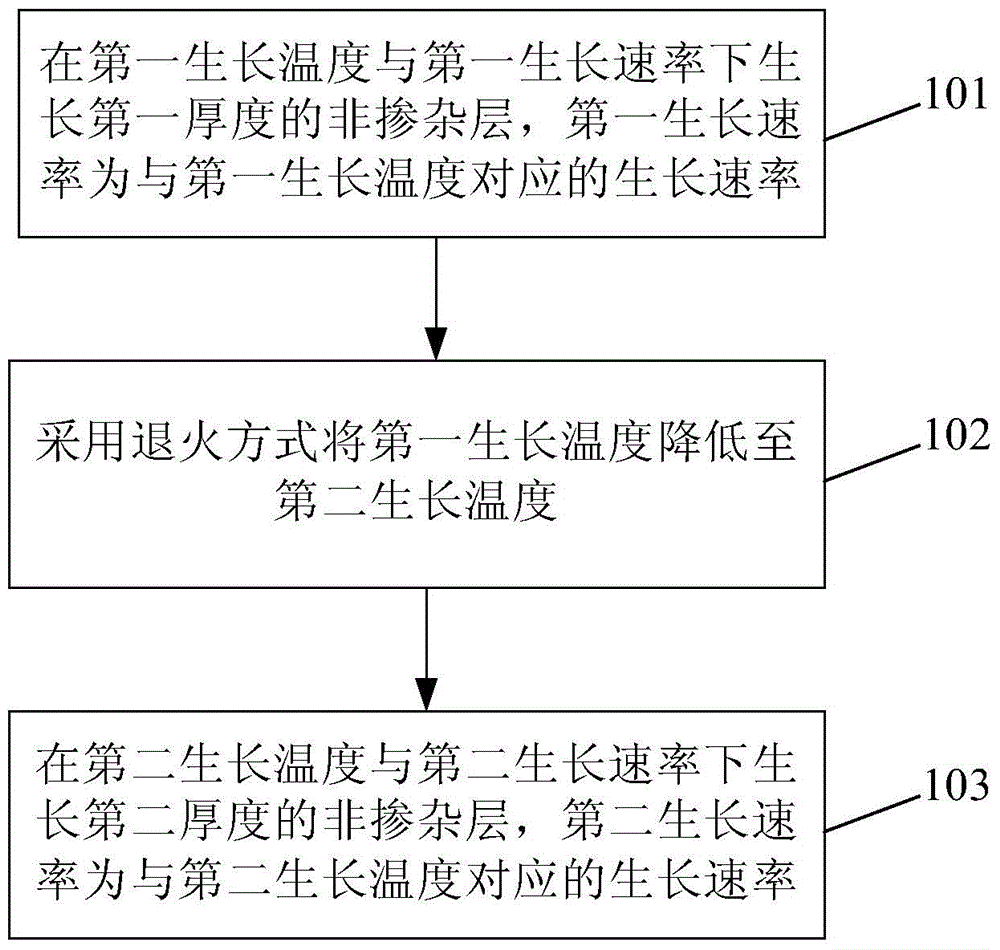

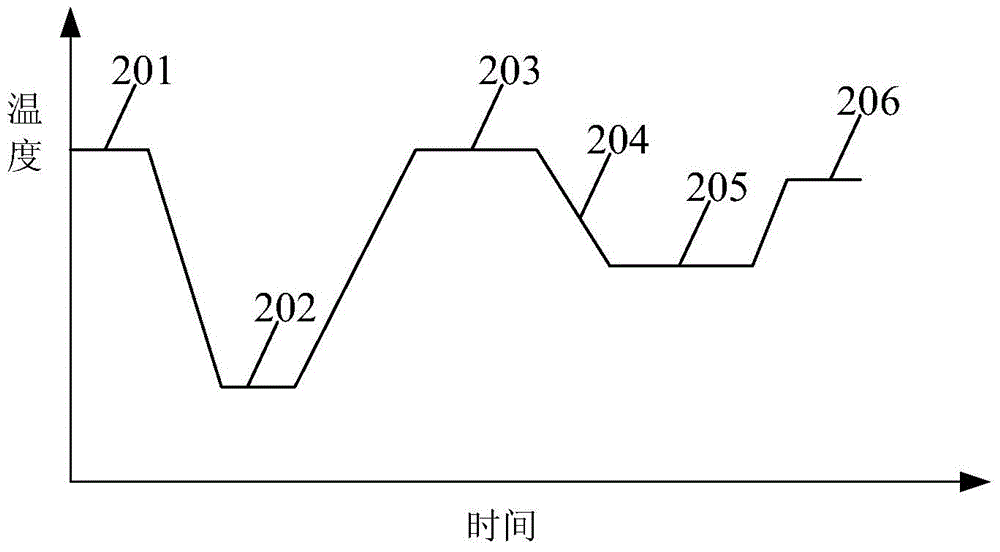

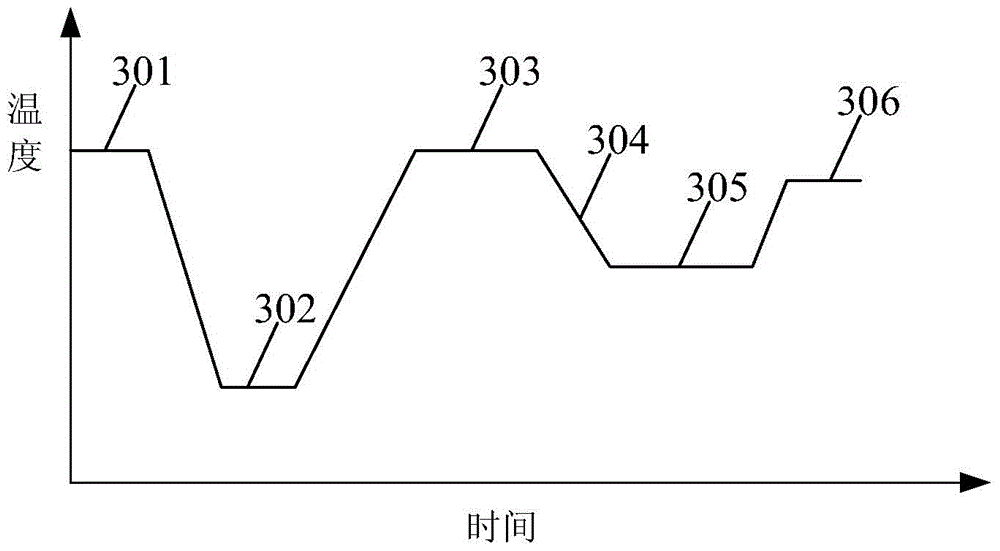

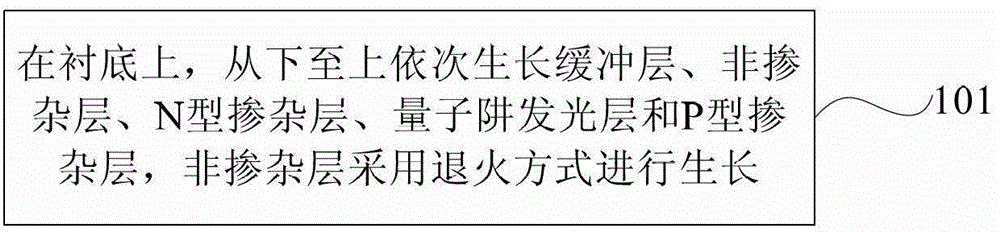

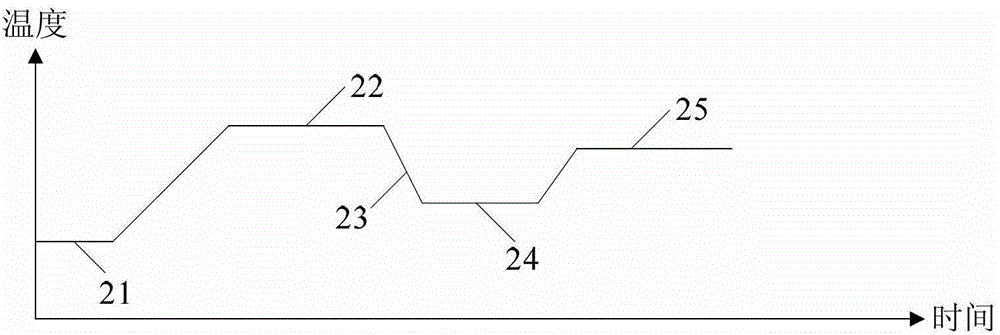

Light-emitting diode epitaxial growth method

The invention provides a light-emitting diode epitaxial growth method. The method comprises the steps that a buffer layer, a non-doping layer, an N-type doping layer, a quantum well light-emitting layer and a P-type doping layer are sequentially grown on a substrate from bottom to top; the non-doping layer grows through the mode that the annealing process and adjustment on growth environment in a reaction chamber are performed alternatively; the growth environment comprises the growth temperature and the growth rate. The non-doping layer grows through the growth mode that the annealing process and the adjustment on the growth temperature and the growth rate of the non-doping layer in the reaction chamber are carried out alternatively, the epitaxial warping degree at the high temperature can be effectively improved, and therefore the epitaxial wavelength distribution evenness and LED quality can be improved. Further, the test and sorting cost can be reduced.

Owner:EPITOP PHOTOELECTRIC TECH

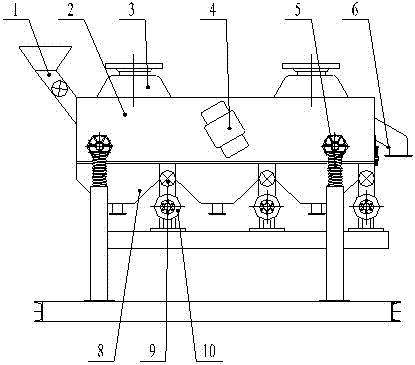

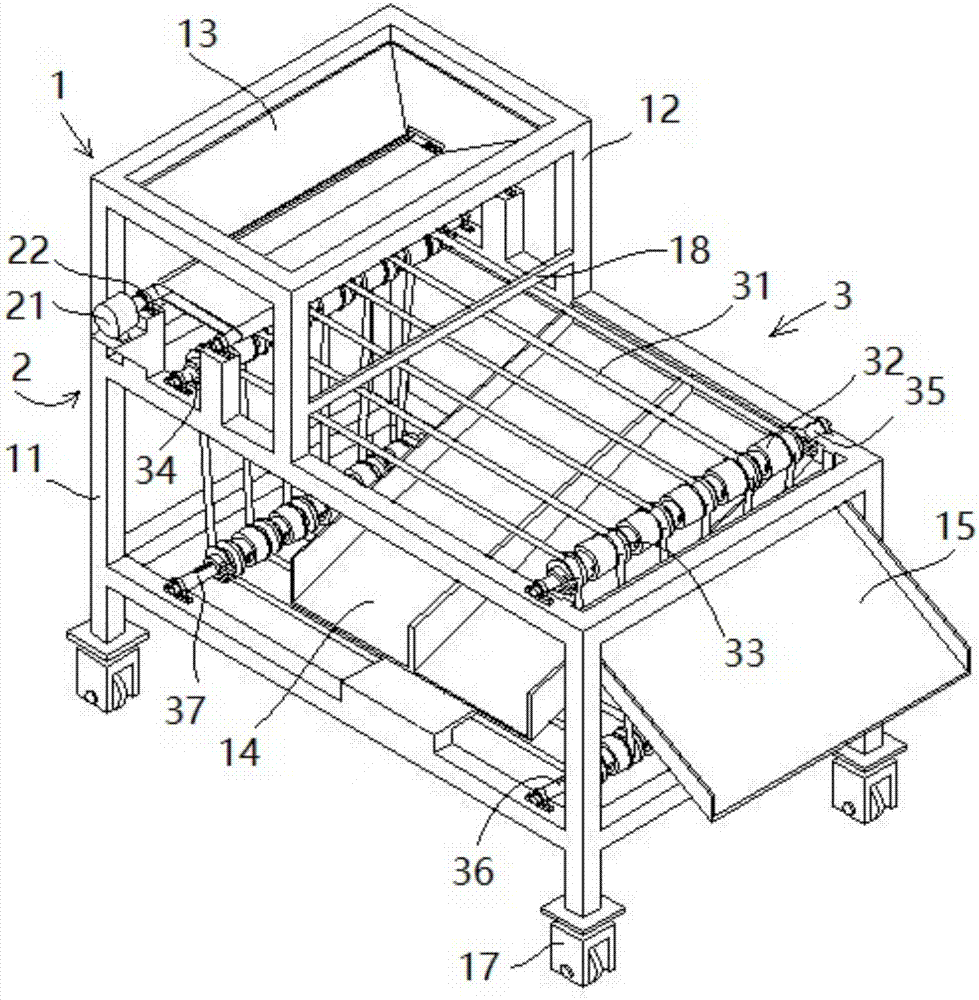

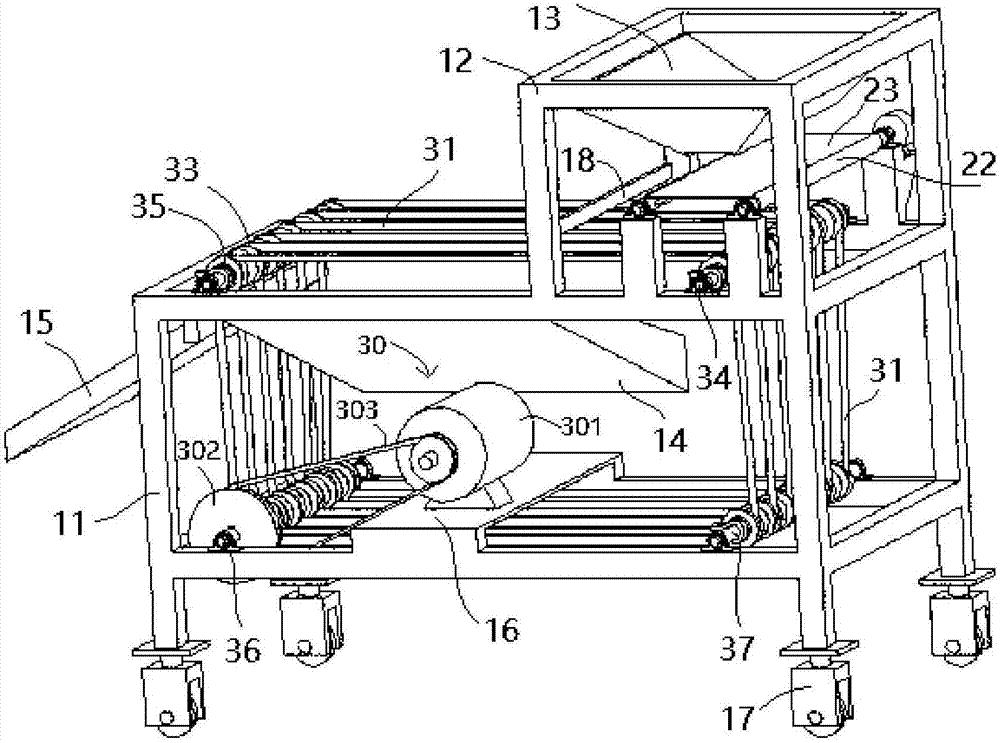

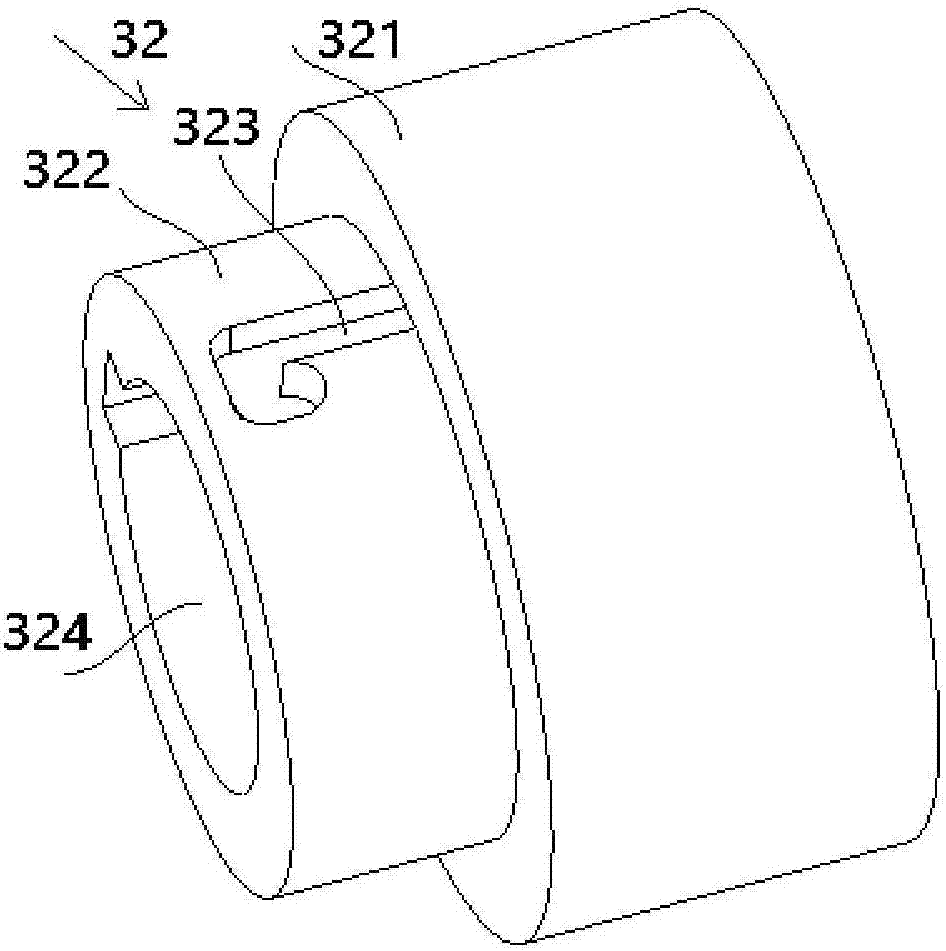

Fruit classification equipment

ActiveCN107051886AReduce sorting costsMeet sorting requirementsClimate change adaptationGradingAgricultural engineeringMachine

The invention discloses fruit classification equipment, and belongs to the field of screening equipment. The fruit classification equipment comprises a machine body, and a screening module mounted on the machine body; the machine body comprises an upper frame and a lower frame; the upper frame is arranged at one end of the upper end surface of the lower frame; a feed port for feeding fruits is formed in the upper end of the upper frame; a conveying belt device for horizontally conveying the fruits fed from the feed port to the screening module is arranged rightly below the feed port; the conveying belt device is fixed on the upper frame; the screening module is mounted on the lower frame, and is positioned below the conveying belt device; and the screening module is arranged in the length direction of the lower frame, and comprises a driving device, a first transmission shaft, a second transmission shaft, a circular belt, a clamping port sleeve and a synchronous belt wheel. The automatic fruit sorting machine can adjust the distance, and is liable to carry.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

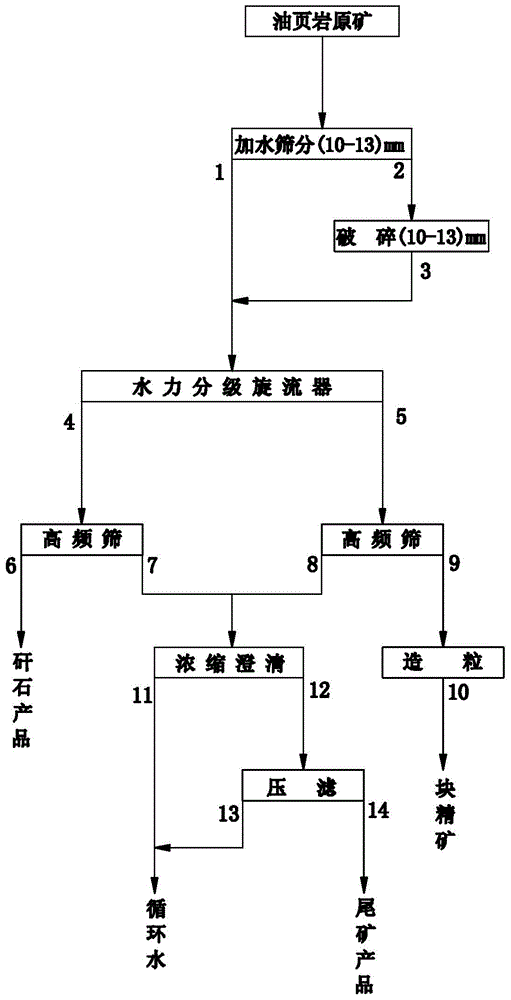

Oil shale tailings beneficiation process

ActiveCN104984819AHigh oil contentImprove resource utilizationSievingScreeningOil shale industryOil shale gas

The invention relates to an oil shale tailings beneficiation process and belongs to the oil shale industrial field. The oil shale tailings beneficiation process is especially suitable for the oil shale tailings processing utilization industry. The process includes the following steps that: water is added in oil shale raw ores, and the oil shale raw ores are subjected to 10-to-13mm screening, and plus-sieve products which are larger than 10 to 13 mm are crushed and are mixed with minus-sieve products which are smaller than 10 to 13 mm, the crushed plus-sieve products and the minus-sieve product are subjected to separation through adopting a hydrocyclone, underflow products are dehydrated through a high-frequency screen, so that gangue products can be obtained, and overflow products are dehydrated through the high-frequency screen and granulated so as to form nubbly concentrate products, all slime water generated by all the products that pass through the high-frequency screen is thickened and clarified, and precipitates are subjected to filter pressing, so that tailings products can be obtained; and clarified water and filtered liquid can be adopted as circulating water. According to the oil shale tailings beneficiation process, after being crushed, the oil shale tailings are subjected to separation through adopting the hydrocyclone, and therefore, the oil shale tailings beneficiation process is simple, efficient and economical, and has a higher economic value. With the oil shale tailings beneficiation process adopted, problems of complex production process, high production investment and low separation efficiency can be solved, and the concentrate yield of oil shale can be effectively improved.

Owner:JINYITONG SCI ANDTECH BEIJING CO LTD

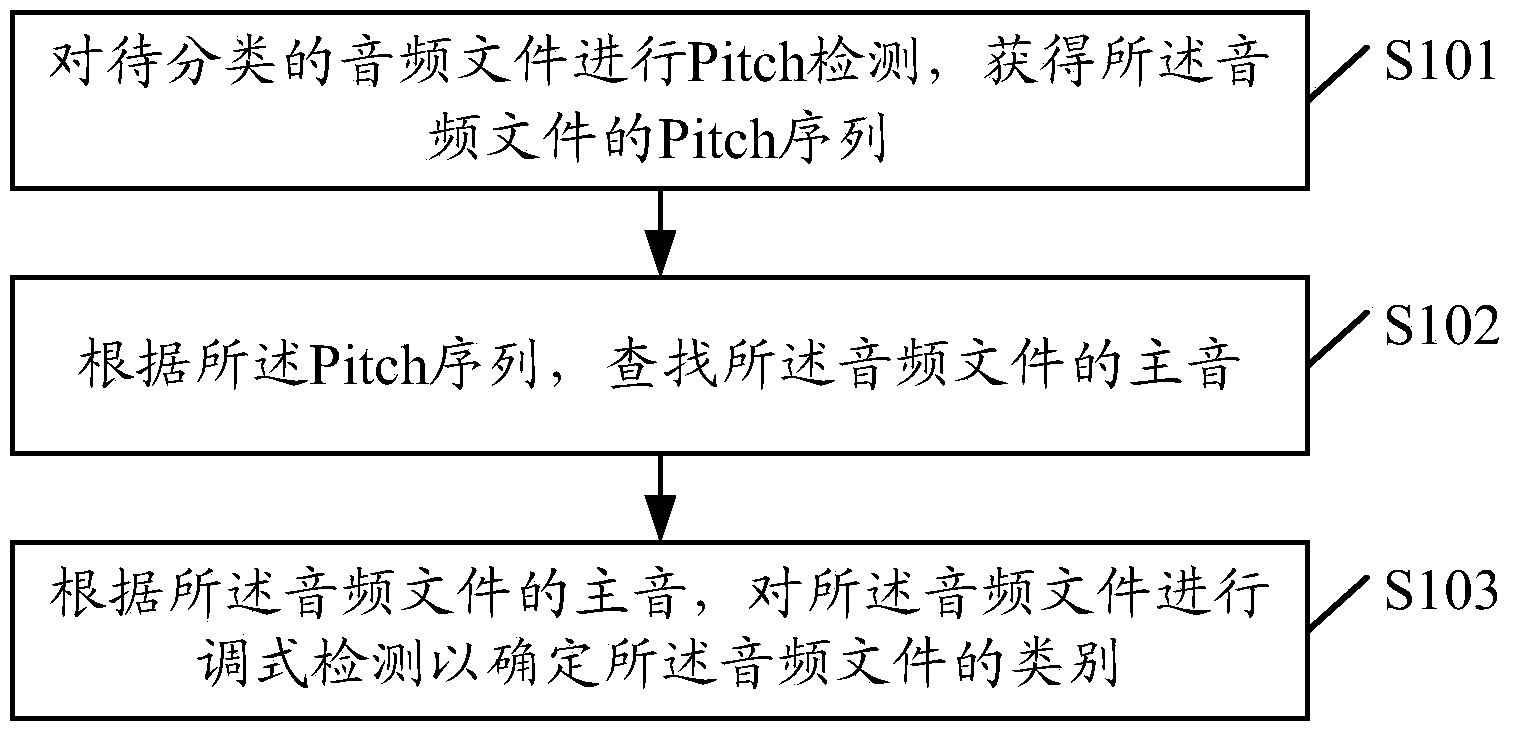

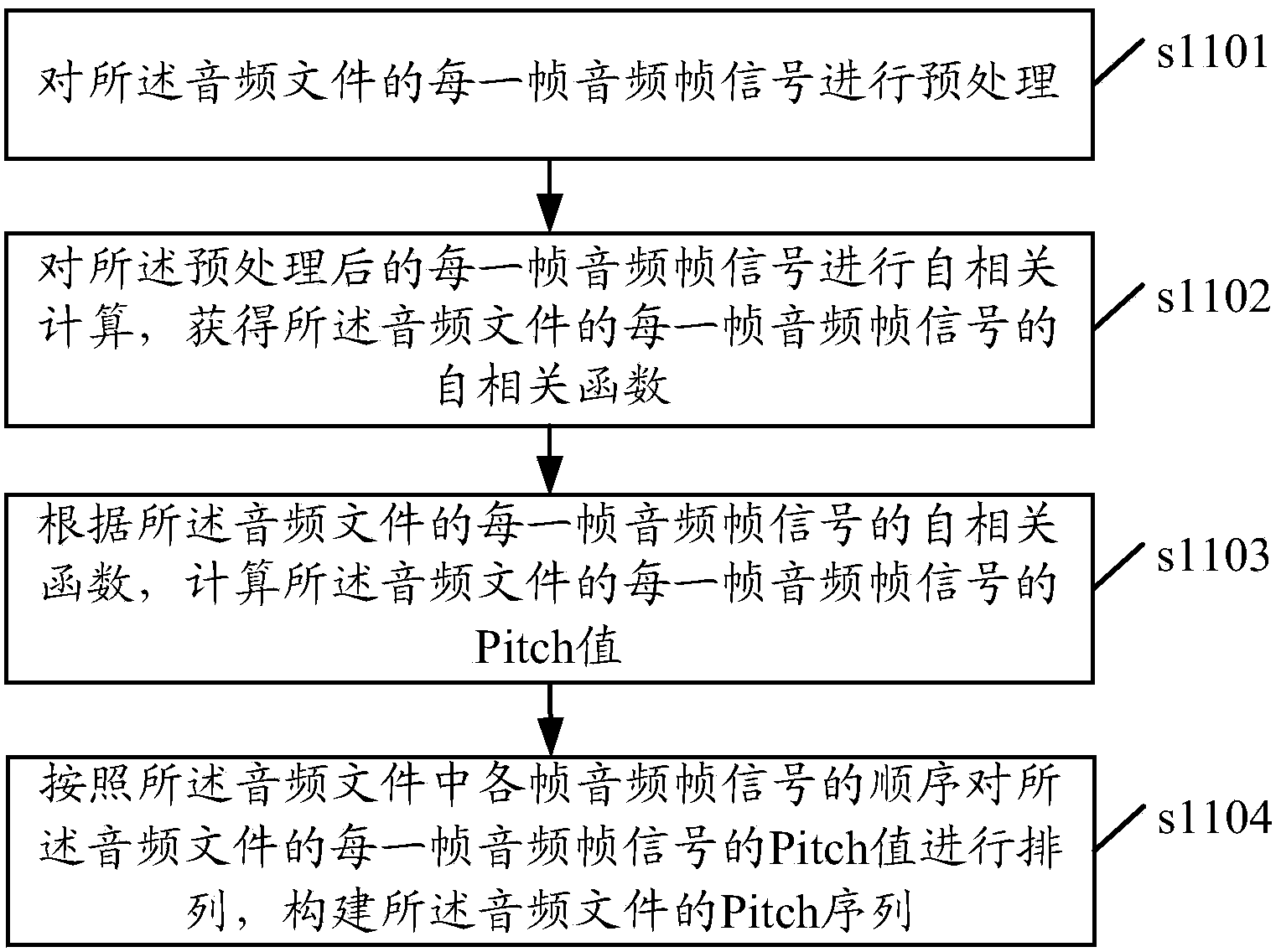

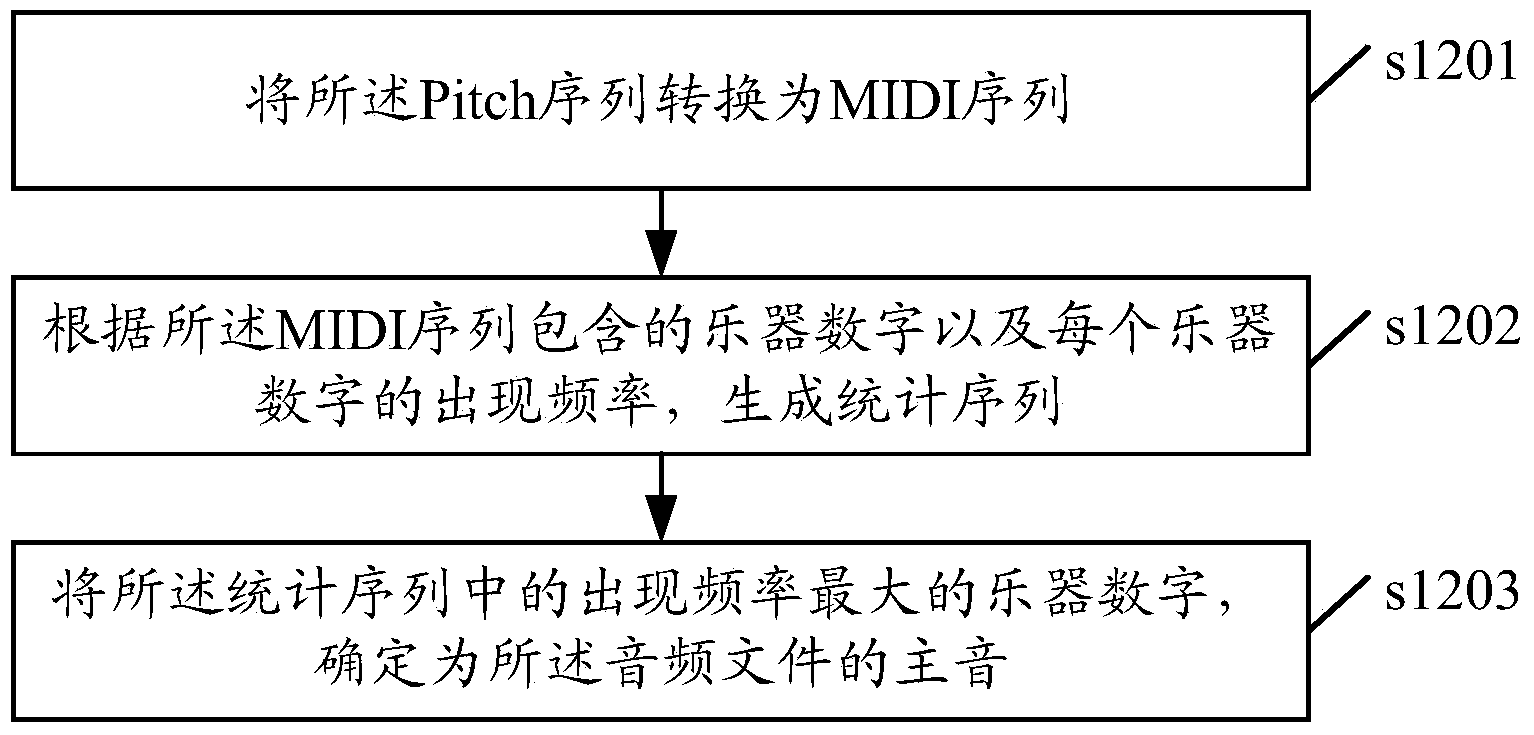

Audio classifying method and device

ActiveCN104091594AAvoid resource consumptionReduce sorting costsSpeech recognitionSpeech recognition

The embodiment of the invention provides an audio classifying method and device. The method comprises the steps that Pitch detection is carried out on an audio file to be classified, so as to acquire the Pitch sequence of the audio file; according to the Pitch sequence, the tonic of the audio file is searched; and according to the tonic of the audio file, mode detection is carried out on the audio file to determine the classification of the audio file. According to the invention, the classifying cost of the audio file can be reduced; the classifying efficiency is improved; and the intelligence is enhanced.

Owner:GUANGZHOU KUGOU TECH

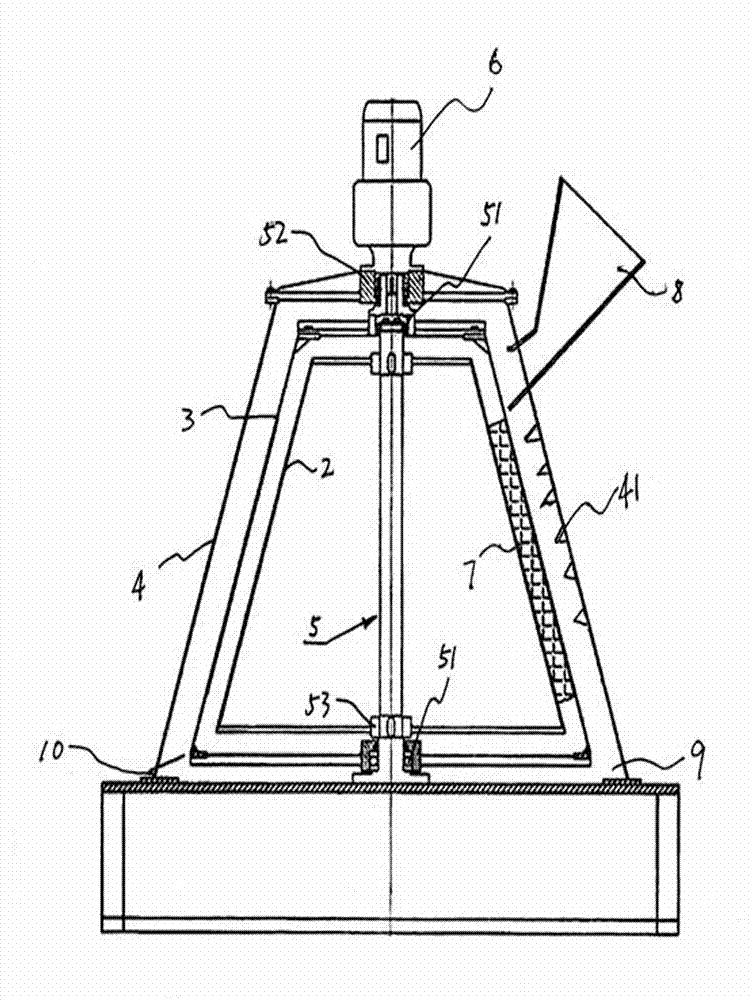

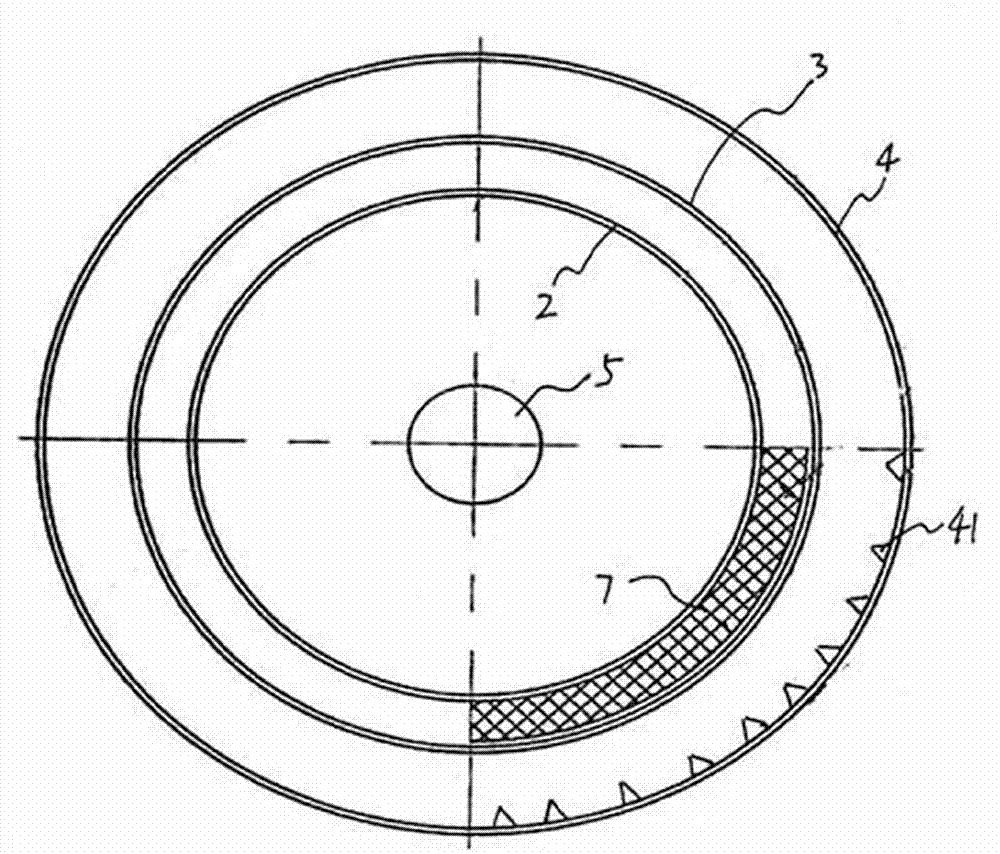

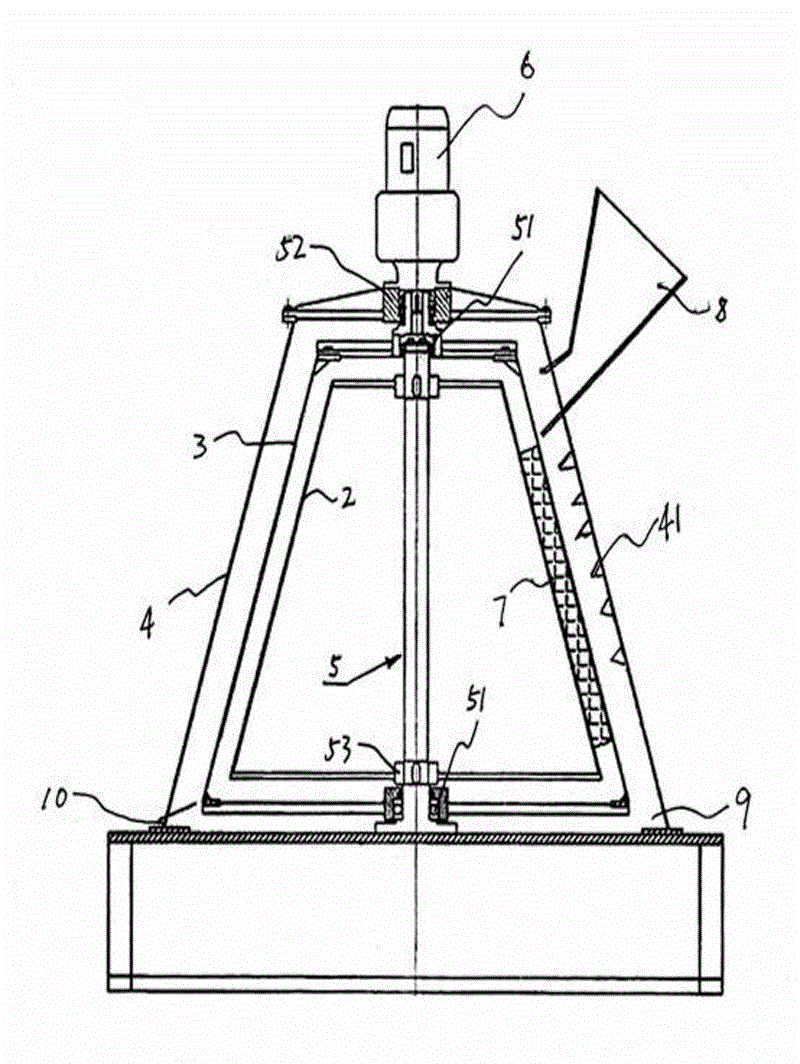

Vertical magnetic separator

InactiveCN102698869ASave drying programReduce sorting costsMagnetic separationMagnetic separatorStructural engineering

The invention relates to a vertical magnetic separator which comprises a circular-truncated-cone-shaped inner barrel, a circular-truncated-cone-shaped outer barrel and a circular-truncated-cone-shaped rotating barrel, wherein the circular-truncated-cone-shaped inner barrel is installed on a machine frame and defined by a vertical shaft, a certain distance is reversed between the circular-truncated-cone-shaped outer barrel and the circular-truncated-cone-shaped inner barrel, the circular-truncated-cone-shaped rotating barrel is installed between the circular-truncated-cone-shaped inner barrel and the circular-truncated-cone-shaped outer barrel, and a magnet is installed on a part of the outer surface of the circular-truncated-cone-shaped inner barrel. The centrifugal force generated in the rotating process of the circular-truncated-cone-shaped rotating barrel enables mineral powder or gangue powder falling on the circular-truncated-cone-shaped rotating barrel to be impacted onto the surface of the circular-truncated-cone-shaped outer barrel under effect of the centrifugal force and then rebound back to the circular-truncated-cone-shaped rotating barrel, so that the mineral powder or the gangue powder can be changed to be in loose conditions from sticky conditions, and separation efficiency can be improved through repeated magnetic separation.

Owner:王永强

Method for recovering valuable components in mixed slag containing copper and iron

InactiveCN107699704AAchieve recyclingSolve pollutionRecycling and recovery technologiesProcess efficiency improvementLead smeltingZinc

The invention relates to a method for recovering valuable components in mixed slag containing copper and iron. The method for recovering the valuable components in the mixed slag containing copper andiron comprises the steps of S1, slag mixing, specifically, copper slag is added into a smelting reaction device, and one or more of lead smelting slag, blast furnace slag, steel slag and iron alloy slag are added at the same time so as to form mixed slag, the slag is heated to be in a molten state to form reaction slag, the reaction slag is evenly mixed and monitored in real time, the mixed reaction slag is regulated and controlled to meet a condition a and a condition b, and thus reacted slag is obtained; and S2, separation and recovery. By adoption of the method for recovering the valuablecomponents in the mixed slag containing copper and iron, copper, iron, zinc, lead, gold, silver, phosphorus, calcium and silicon in non-ferrous metallurgical slag and ferrous metallurgical slag are comprehensively utilized, and the problems of accumulation of a large quantity of slag and environmental pollution in the prior art are solved.

Owner:NORTHEASTERN UNIV

Light-emitting diode epitaxial growth method

The invention provides a light-emitting diode epitaxial growth method. The method comprises the step of growing a buffer layer, undoped layers, an N-type doped layer, a quantum well light-emitting layer and a P-type doped layer on a substrate successively from bottom to up, wherein the undoped layers are grown through the annealing method. According to the light-emitting diode epitaxial growth method provided in the invention, the undoped layers are grown alternately through the annealing method, so the warping degree of the substrate in high-temperature conditions can be effectively improved, and the temperature uniformity of the bottom portion of the substrate can be improved, so that the wavelength distribution uniformity and the LED quality can be improved. Additionally, the test and sorting cost can be reduced to a certain extent.

Owner:EPITOP PHOTOELECTRIC TECH

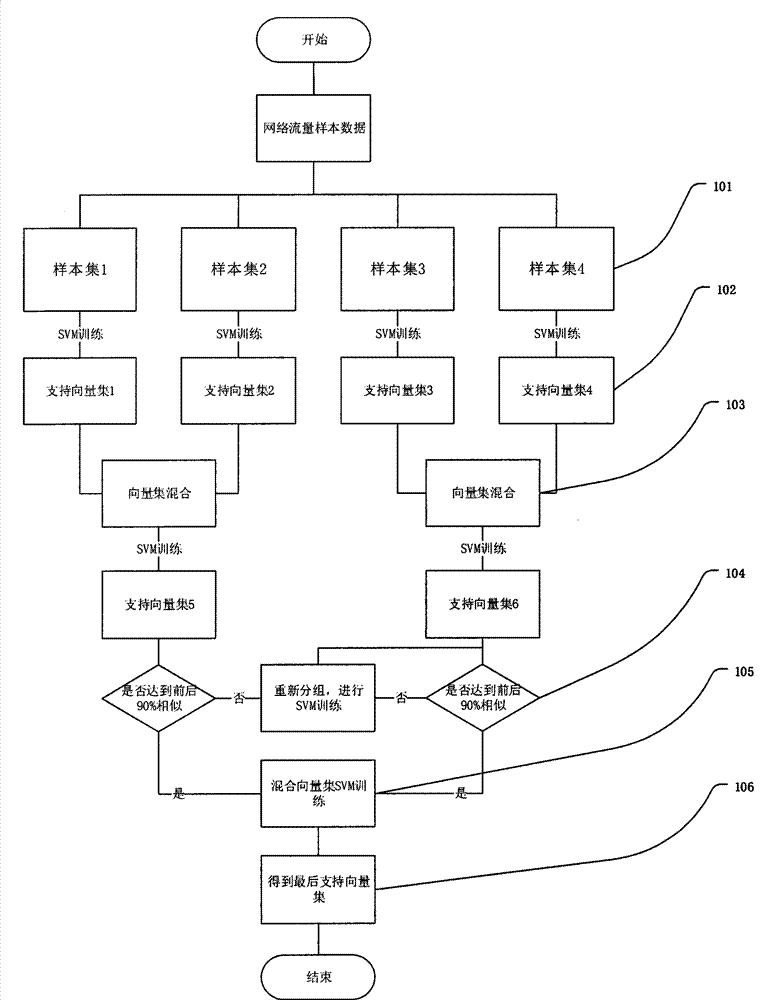

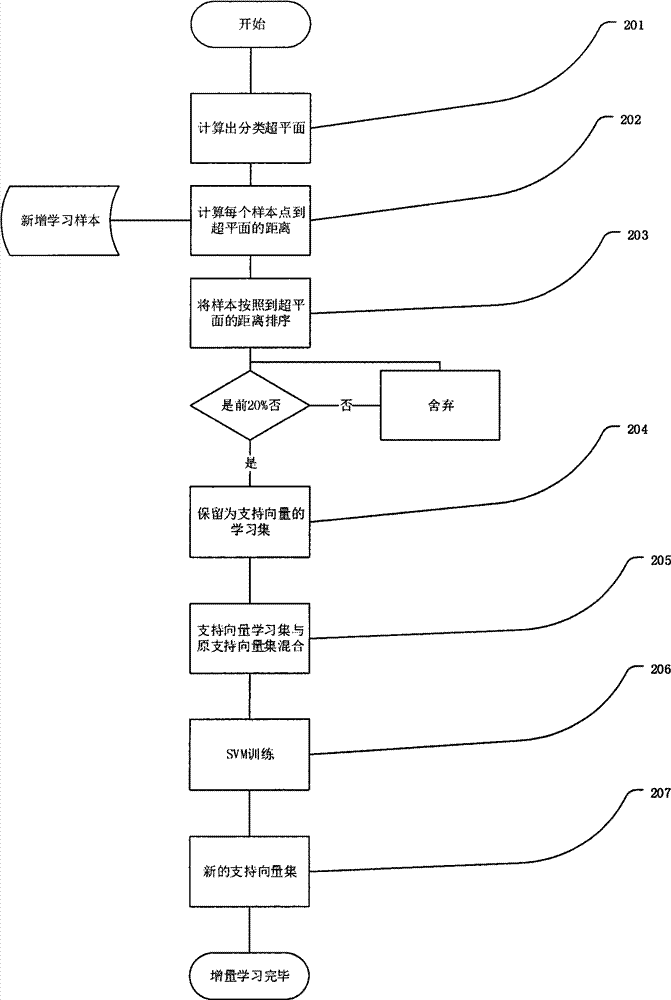

SVM network business classification method

ActiveCN104751200AImprove training efficiencyShorten the timeCharacter and pattern recognitionSvm classifierClassification methods

The invention provides an SVM network business classification method. The method includes 1, utilizing a serial segmentation feedback method to train an initial SVM classifier of network business, and acquiring a classification hyperplane; 2, by means of the effective boundary elimination method, eliminating sample points useless for classification hyperplane construction, and acquiring the optimal classification hyperplane. The efficient method is adopted to optimize the machine learning algorithm, on the premise of guaranteeing the constant classification accuracy, the training time of the machine learning classifier is shortened effectively, and the classification cost of network traffic data is reduced.

Owner:CHINA ELECTRIC POWER RES INST +3

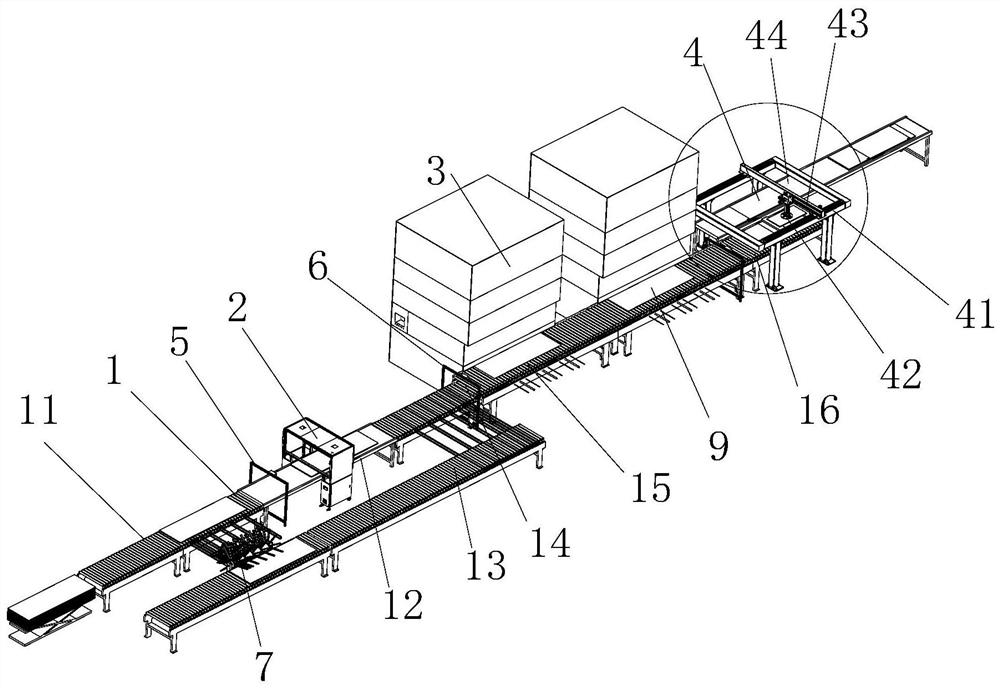

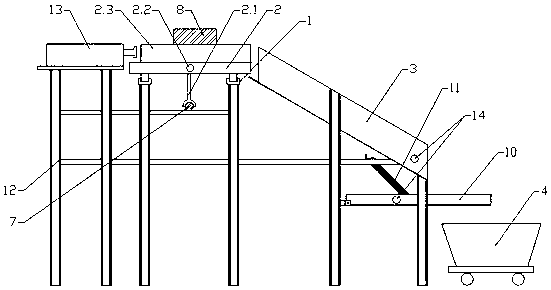

Intelligent sorting system and working method thereof

PendingCN112452792AAchieve storageIncrease storage capacityConveyorsPackagingControl engineeringPalletizer

The invention provides an intelligent sorting system and a working method thereof. The intelligent sorting system comprises a conveying mechanism, a detecting mechanism, a storing and sorting mechanism, a stacking mechanism and a control mechanism. The conveying mechanism is used for conveying plates, the detecting mechanism is used for detecting the plates on the conveying mechanism, the storingand sorting mechanism is used for sorting and storing the plates, the stacking mechanism is used for stacking and sub-packaging the plates on a stacking conveying line, and the control mechanism is connected with the conveying mechanism, the detecting mechanism, the storing and sorting mechanism and the stacking mechanism and controls operation of all the mechanisms. According to the intelligent sorting system, all the mechanisms cooperate with one another to achieve automation of plate sorting, the plates are stored, sorted and output in different hoppers, the rotary hoppers are large in plate storage amount and small in occupied area, the space utilization rate is increased, the plate sorting efficiency is improved, and the plate sorting cost is reduced.

Owner:中科元象(常州)智能装备有限公司

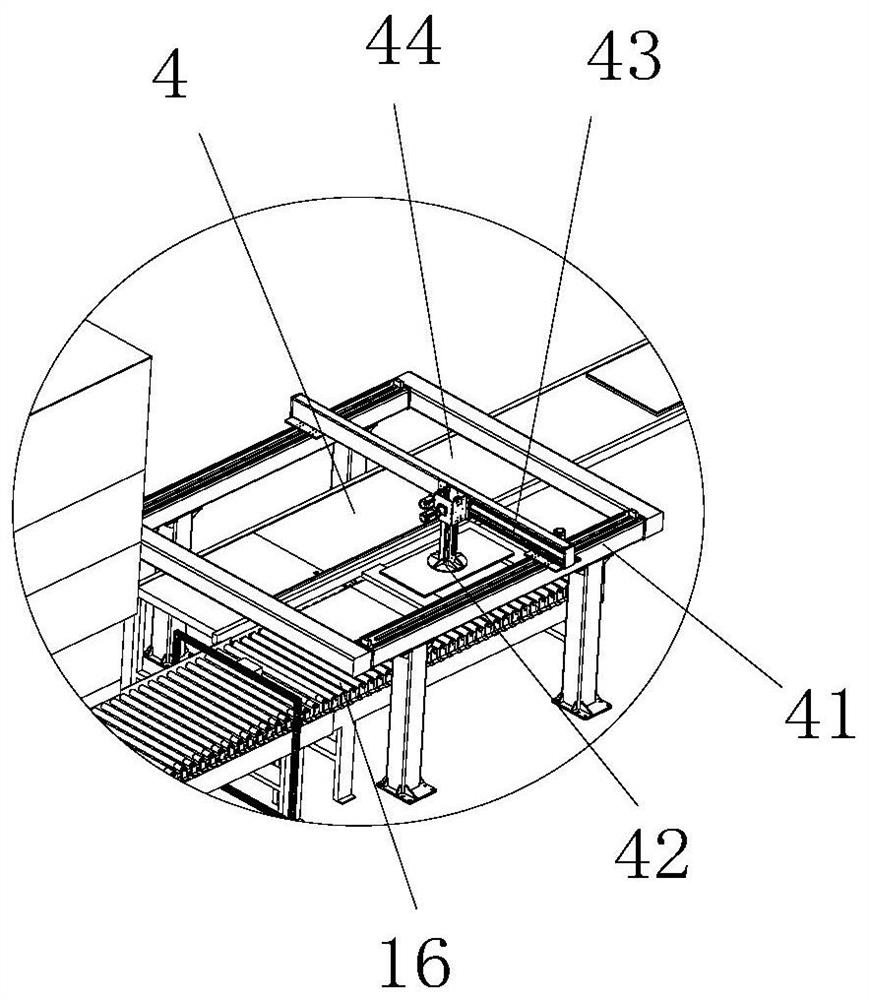

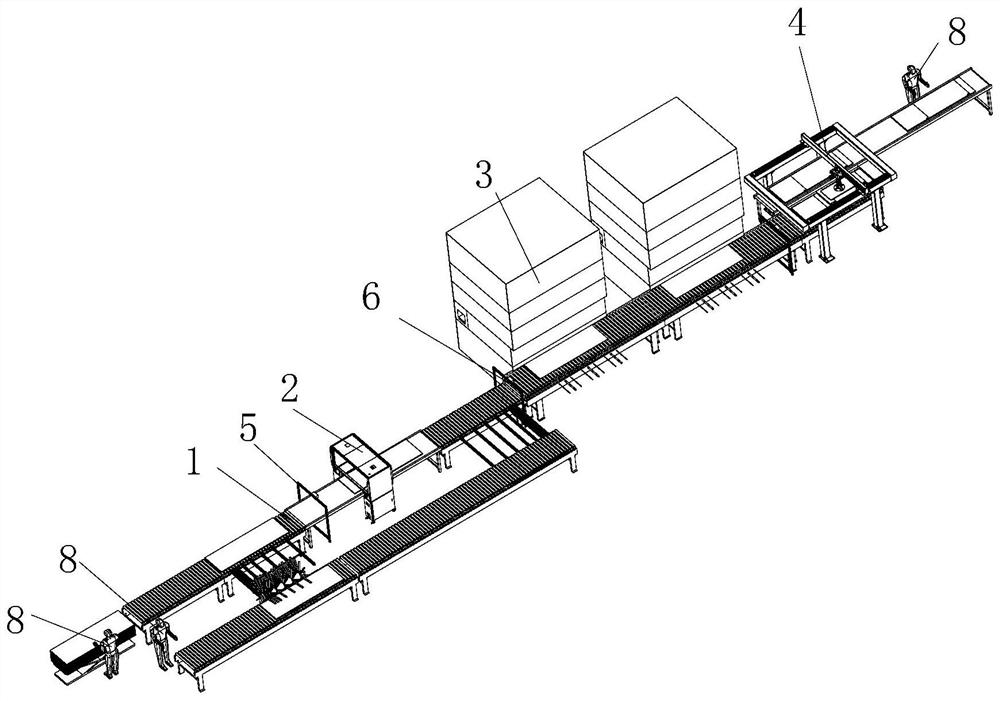

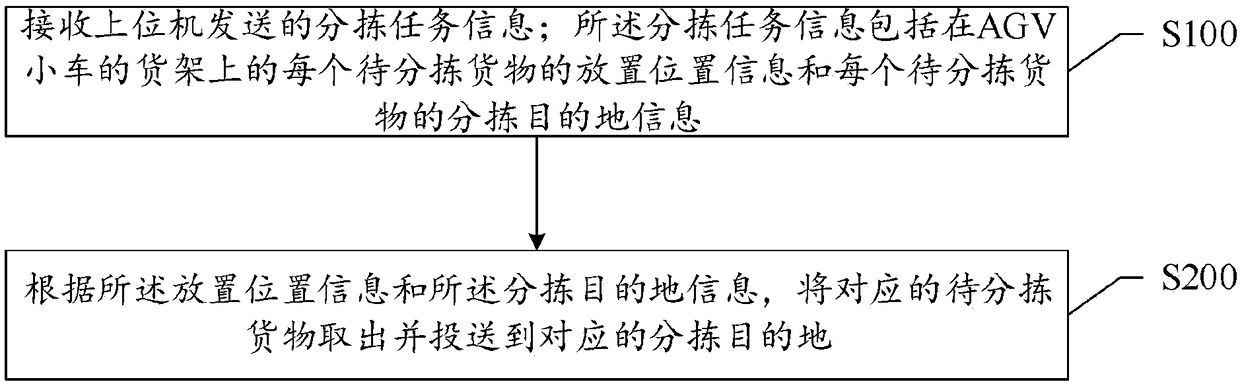

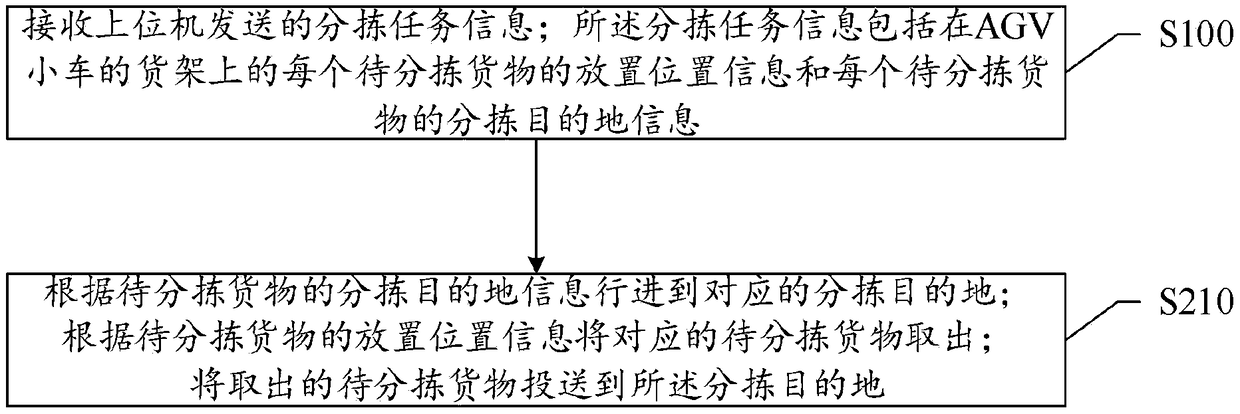

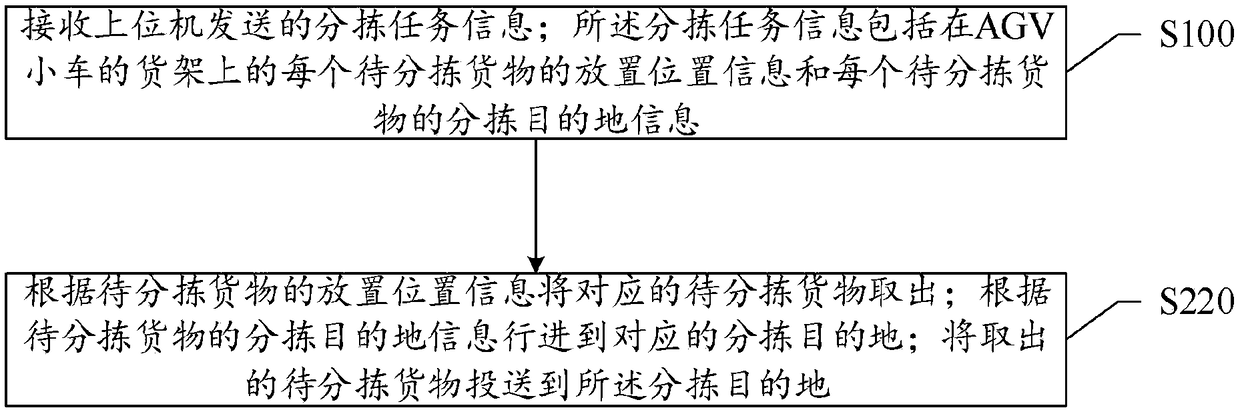

Goods sorting method based on automatic guided vehicle (AGV)

Owner:SHANGHAI ATOVO ROBOTICS CO LTD

Method of separating and purifying zircon fron basic rock

InactiveCN1752019AImprove sorting efficiencyReduce sorting costsZirconium sulfatesDiiodomethaneMagnetic stirrer

A process for separating zircon from basic rock and purifying it includes such steps as crushing and pulverizing basic rock, magnetic stirring while removing strong magnetic substance by U-shaped magnet, using three magnetic rods to respectively remove weak magnetic, strong electromagnetic and weak electromagnetic minerals, using miniature shaker to remove the most of light mineral, electromagnetically fine separation by multi-purpose magnetic analyzer, using heavy diiodomethane solution for separation in separating funnel to remove light minerals and examine by binocular microscope. Its advantages are high purity (more than 99%) and short period.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

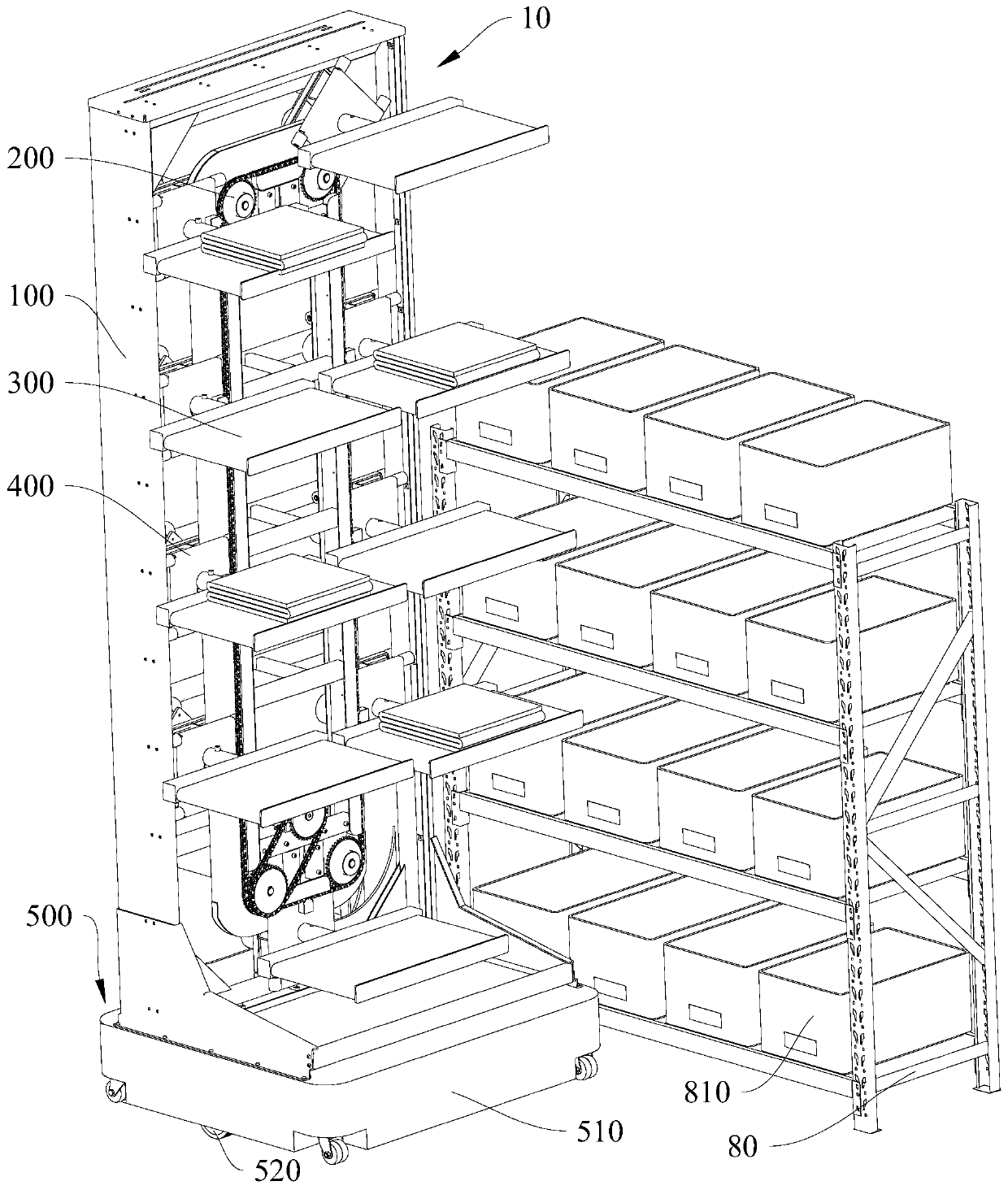

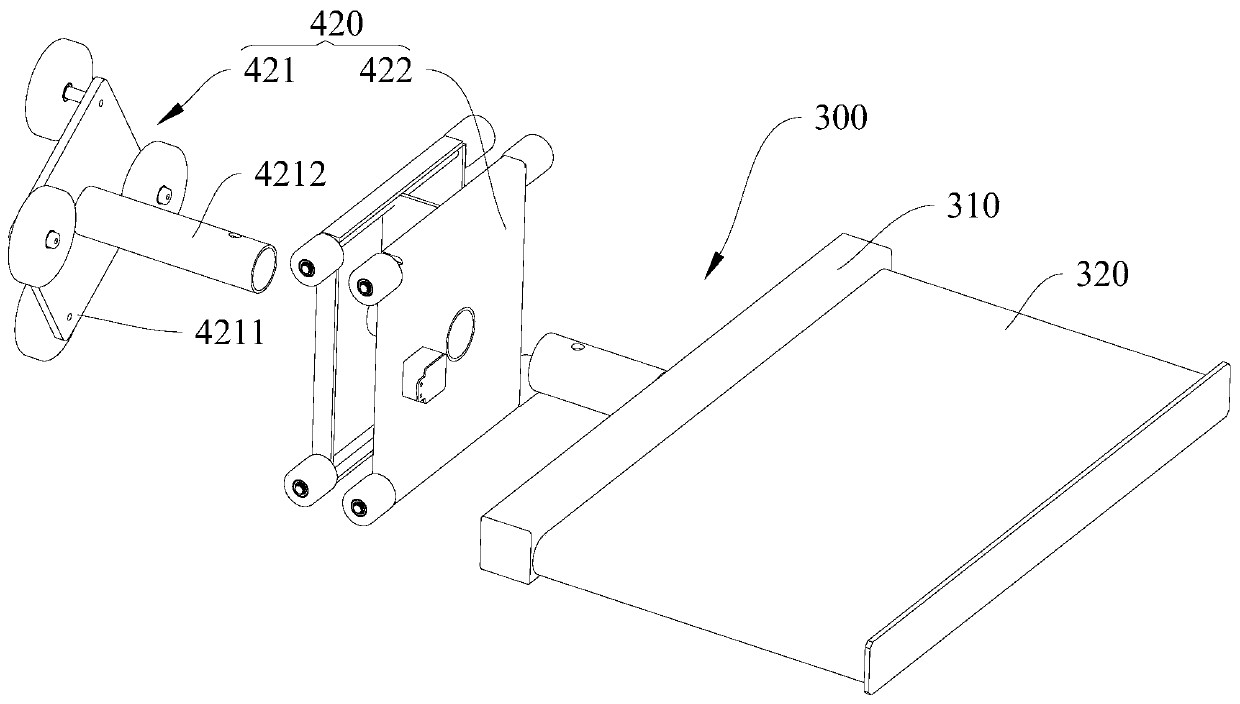

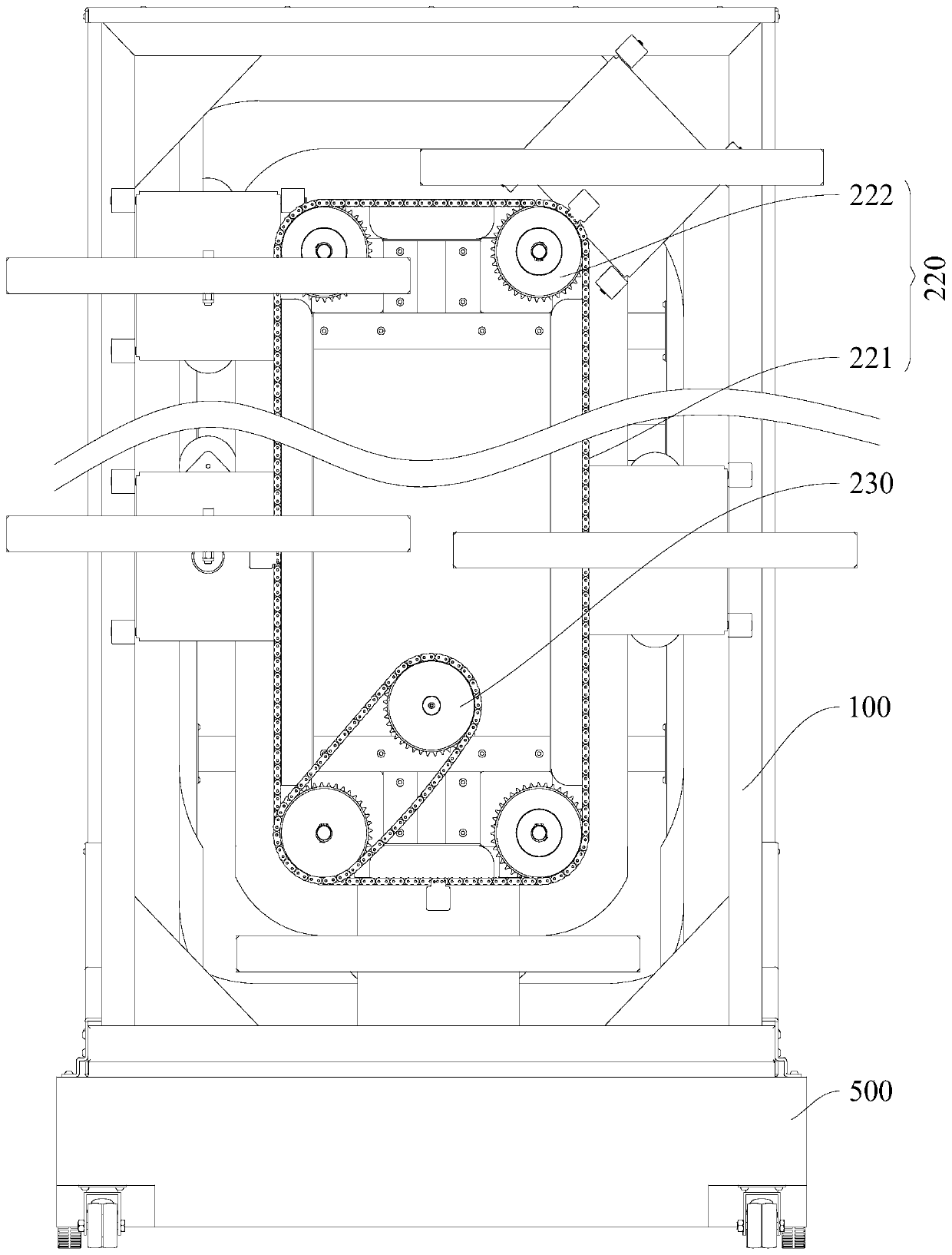

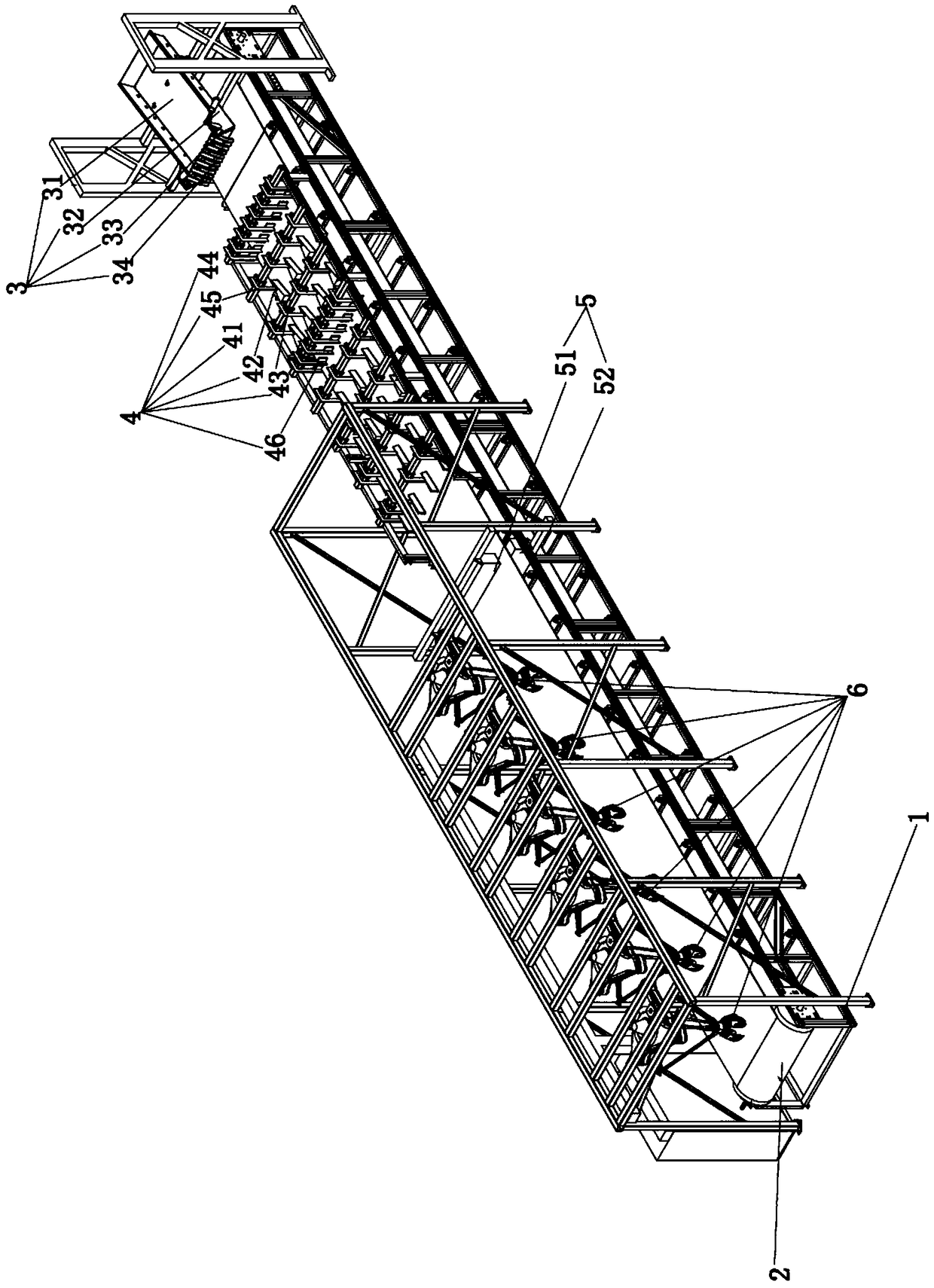

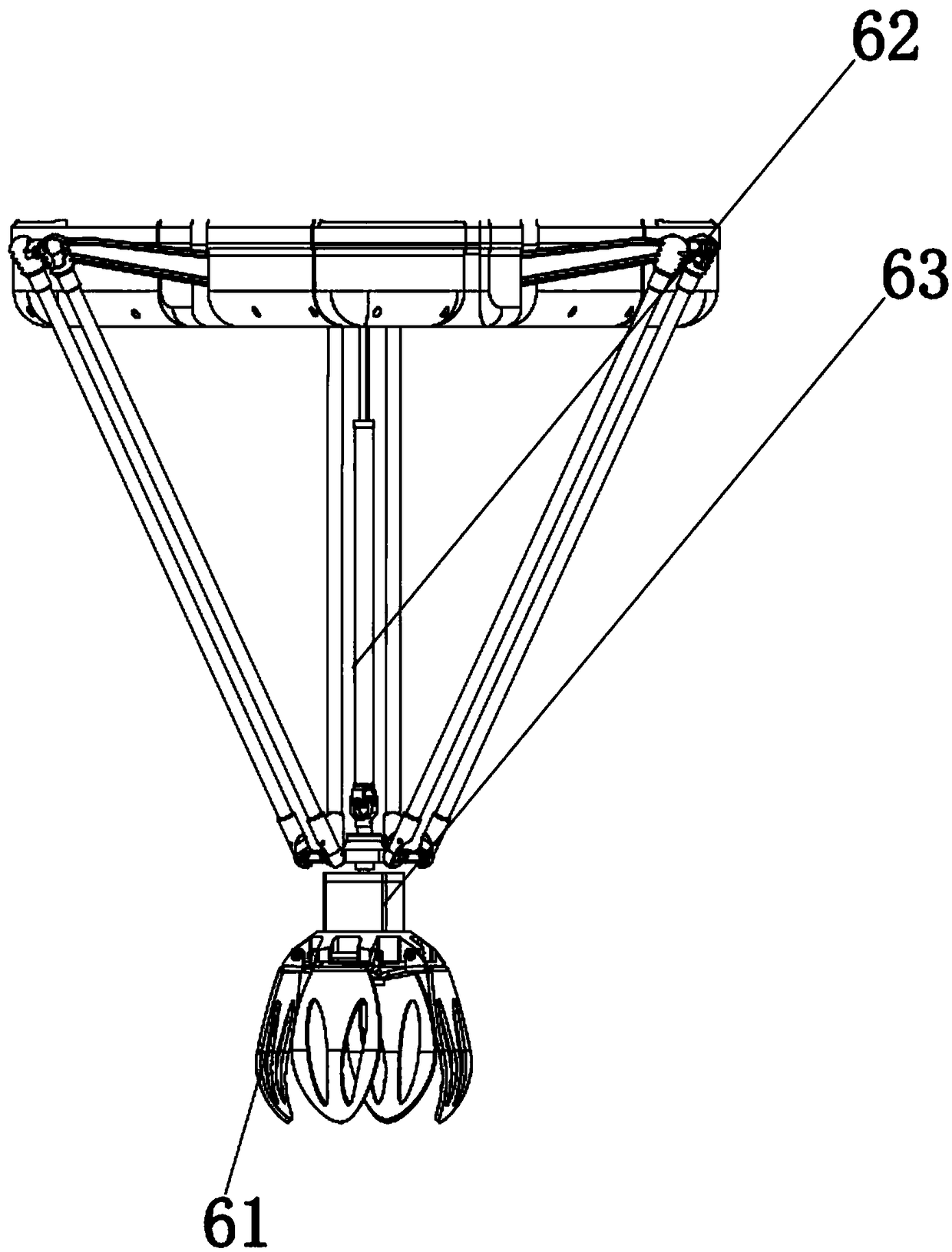

Sorting robot and sorting method

ActiveCN110589327AReduce sorting costsImprove sorting efficiencySortingStorage devicesCost of goodsIndustrial engineering

The invention relates to a sorting robot and a sorting method. The sorting robot is used for delivering specific goods to be sorted to a specific sorting position, and a sorting action table bearing the specific goods to be sorted corresponds to the specific sorting position. The sorting method comprises the following that S10, the sorting action table receives the goods to be sorted; S30, the sorting action table rises and falls to the height of the corresponding sorting position driven by a circulating lifting mechanism; and S50, the sorting action table performs the action of delivering thegoods to be sorted on the sorting action table to the corresponding sorting position. According to the above sorting robot and the sorting method, the cooperation between the circulating lifting mechanism and a sorting mechanism realize the automation of goods sorting, so that the cost of goods sorting is reduced and the efficiency of goods sorting is greatly improved; and at the same time, the sorting mechanism moves to different heights driven by the circulating lifting mechanism, and then can deliver the goods to be sorted to the sorting positions with different heights, so that the universality is strong and the area of the sorting position is reduced.

Owner:HAI ROBOTICS CO LTD

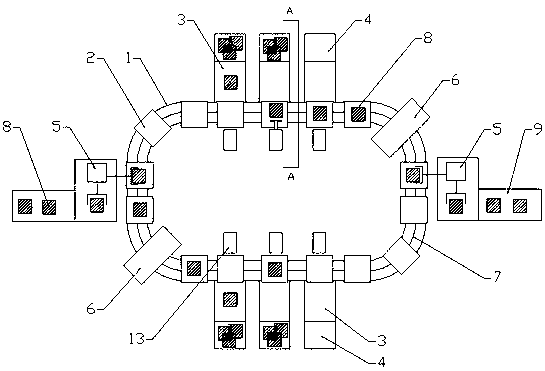

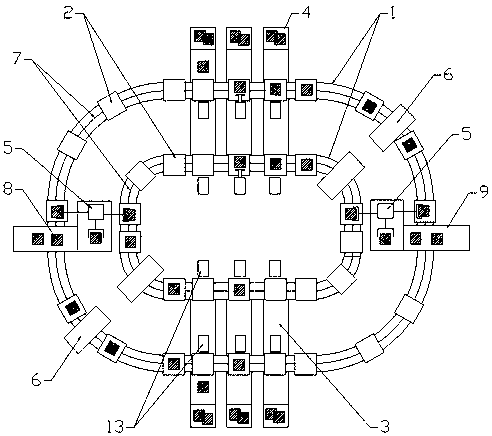

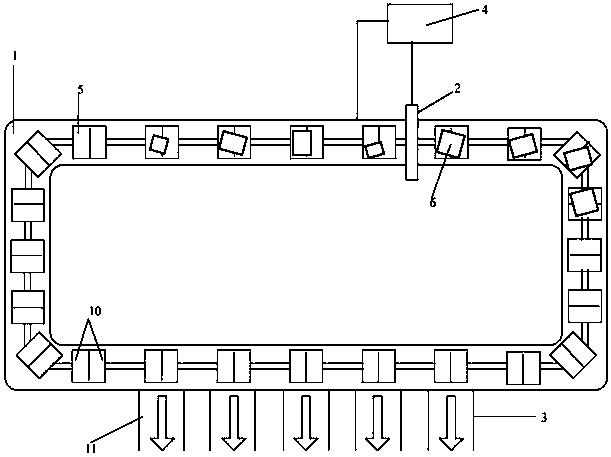

Unmanned logistics express platform system

The invention discloses an unmanned logistics express platform system. The unmanned logistics express platform system comprises a bracket, the bracket is provided with an annular track and a power belt, a certain number of power trolleys are distributed on the annular track, and the bottoms of the power trolleys are provided with power connecting devices to be connected with the power belt, a plurality of sliding channels are arranged on the outer side of a straight line section of the annular track, the lower ends of the sliding channels are provided with express storing devices, and an air cylinder structure is arranged to make express packages on the power trolleys fall into the sliding channels; and one side of an arc section of the annular track is provided with at least one multi-armrobot platform, mechanical arms of robots place the express packages on the power trolleys in a certain direction, and a scanning device is arranged at the position, behind the multi-arm robot platforms, of the upper portion of the annular track in the moving direction of the power trolleys. The unmanned logistics express platform system is small in floor area, can continuously sort express in large quantities, the processing ability is high, unmanned sorting of express is realized, the sorting efficiency is improved, and sorting errors and the sorting cost are reduced.

Owner:浙江佳成通跨境供应链管理有限公司

Sorting system for coal gangues

ActiveCN108722905AImprove sorting rateHigh degree of automationSortingEngineeringUltimate tensile strength

The invention discloses a sorting system for coal gangues. The sorting system for the coal gangues comprises a frame, a conveyor belt, a buffering discharging unit, a queuing unit, a detecting unit and a robot grabbing unit, wherein the conveyor belt is positioned on the frame; and the buffering discharging unit, the queuing unit, the detecting unit and the robot grabbing unit are sequentially arranged on the conveyor belt in the feeding direction. The sorting system for the coal gangues has the advantages of being high in sorting rate, low in sorting cost, low in working intensity, environmentally friendly, and high in automation degree.

Owner:孙金虎

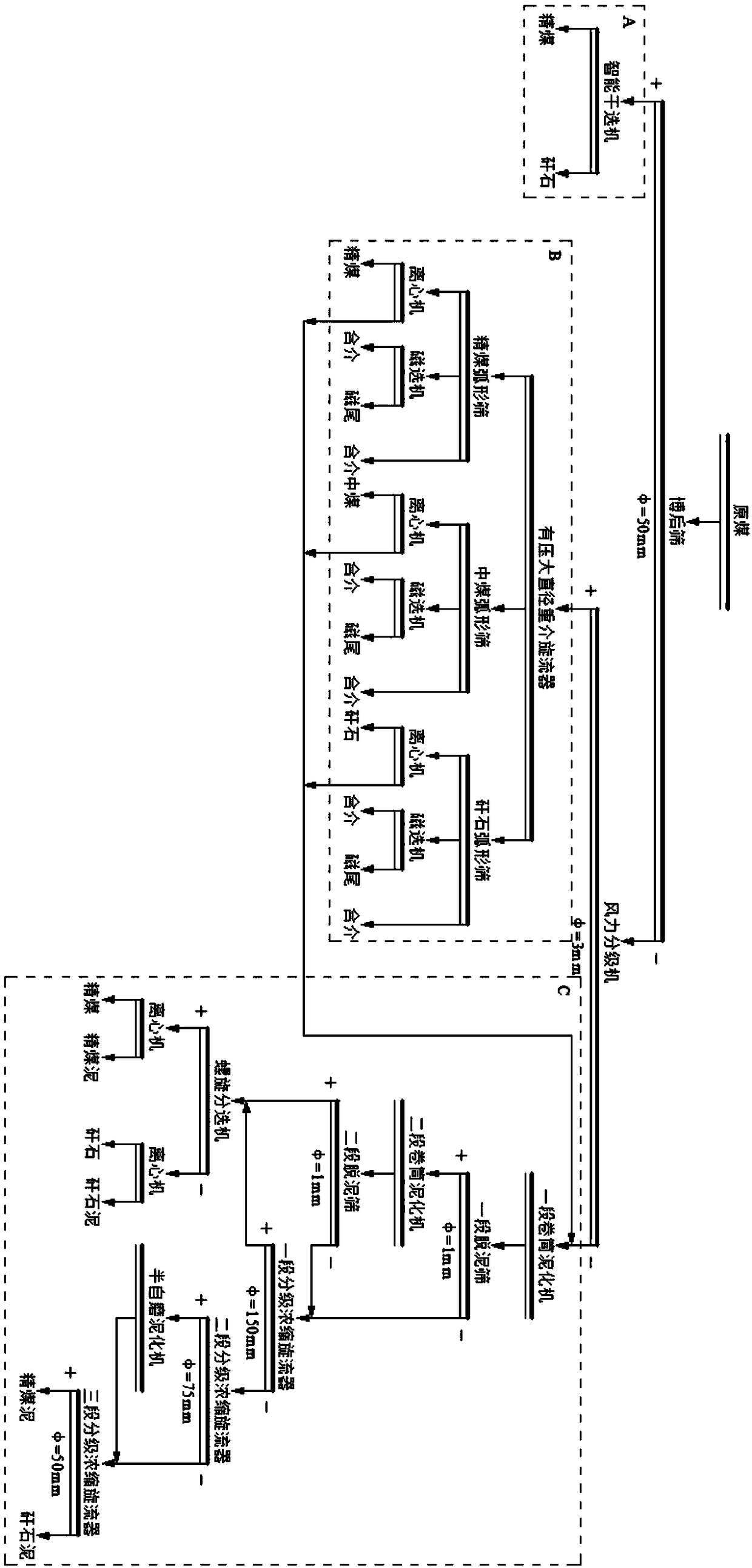

Long flame coal washing system and method

ActiveCN108745622AQuality improvementHigh recovery rateWet separationSeparation technologyEngineering

The invention relates to a long flame coal washing system and method, and belongs to the technical field of raw coal separation. The problems that in the prior art, a long flame coal separation technology is low in separation efficiency, low in washed coal recovery rate and high in washing cost are solved. The long flame coal washing system comprises a drying separation device, a pressurized densemedia separation device and an argillization separation device. Raw coal enters one of the drying separation device, the pressurized dense media separation device and the argillization separation device according to the different particle sizes. The long flame coal washing method comprises the steps of drying separation operation, pressurized dense media separation operation and argillization separation operation. The raw coal enters into one of the drying separation operation, the pressurized dense media separation operation and the argillization separation operation according to the different particle sizes. The long flame coal washing system and method can be used for providing the long flame coal washing method for coal mining enterprises.

Owner:湖南兴辉洗选药剂科技开发有限公司 +1

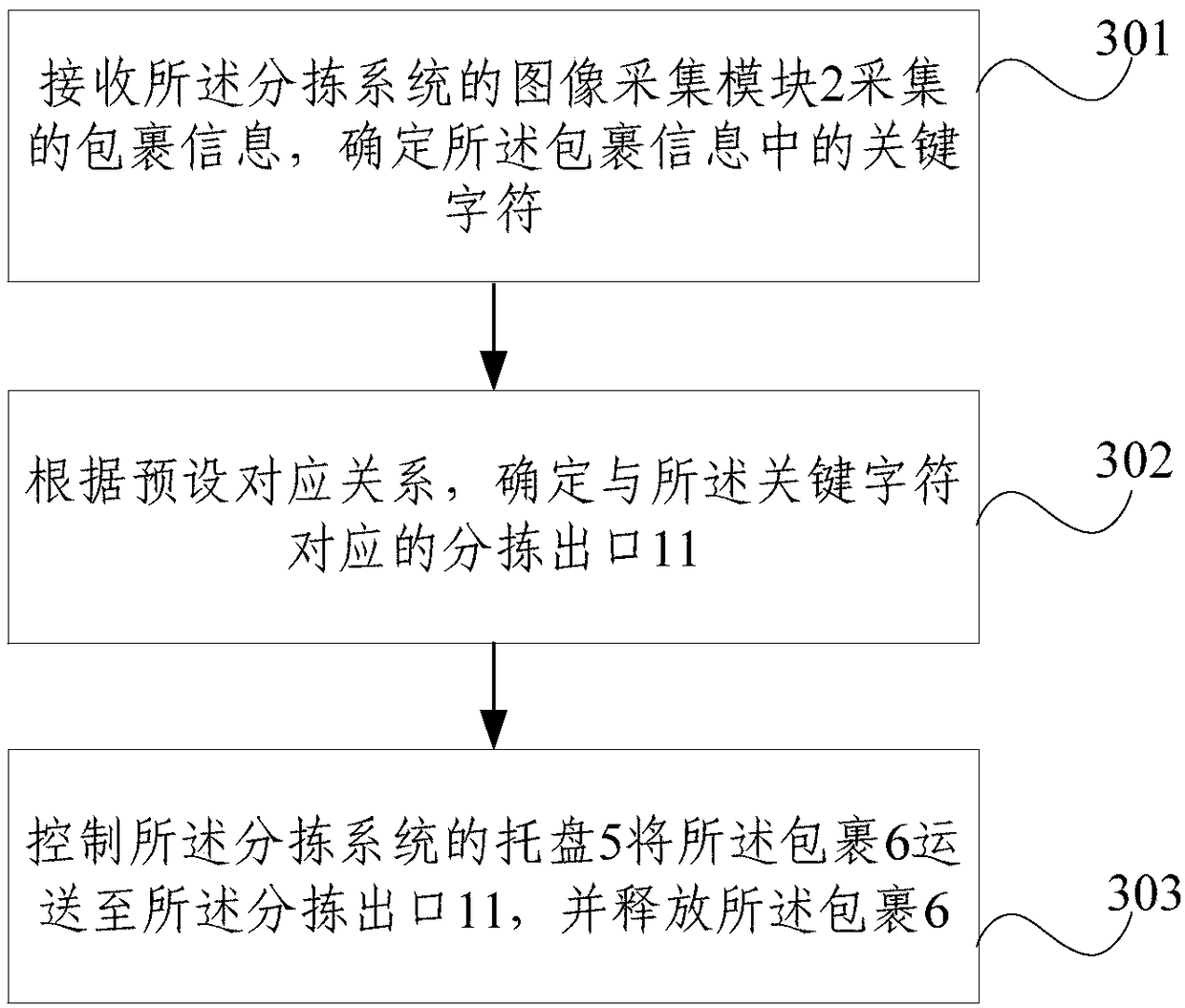

Sorting system and sorting method

The embodiment of the invention provides a sorting system and a sorting method. The sorting system comprises a conveying belt which comprises at least two trays used for carrying packages, an image collecting module used for collecting package information of the packages facing the image collecting module on the trays and collecting first identification numbers of the trays of the packages, an exit module which is arranged in the second preset direction of the conveying belt and comprises at least two sorting exits, and a system controlling module which is used for receiving the package information and the first identification numbers collected by the image collecting module to determine key characters in the package information. According to preset corresponding relationship, the sortingexit corresponding to the key characters is determined. The target tray corresponding to the first identification numbers is controlled to convey the packages to the sorting exits and release the packages. The integration and automation degree is high, the sorting cost and breaking rate can be lowered, and sorting efficiency can be improved.

Owner:杭州视语智能视觉系统技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com