Patents

Literature

40results about How to "Reduce production handling costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

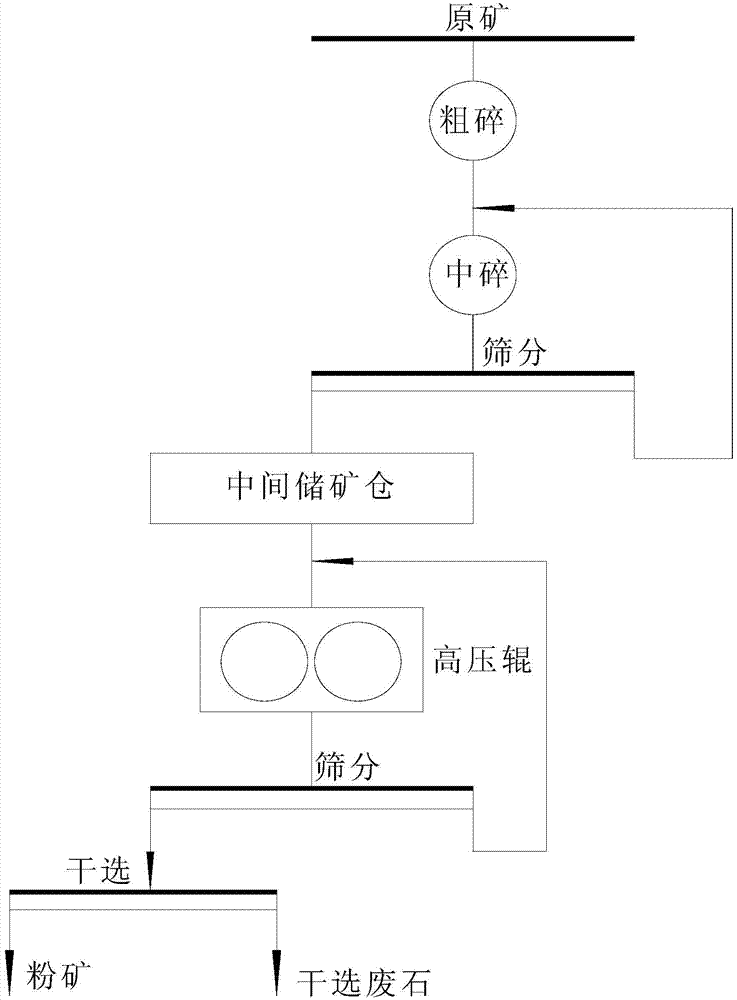

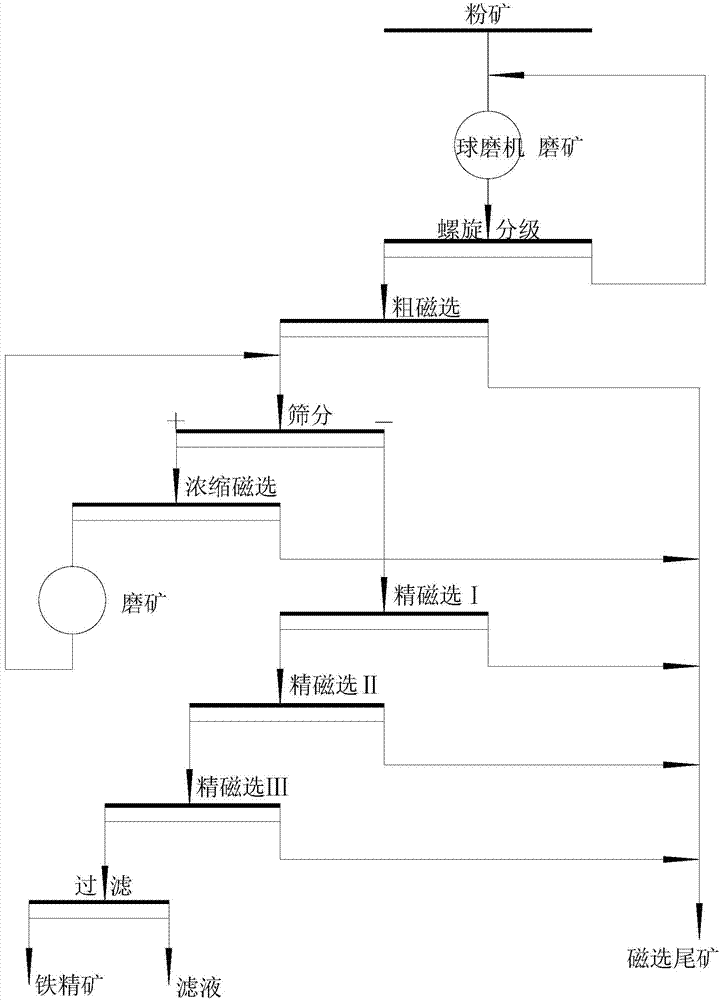

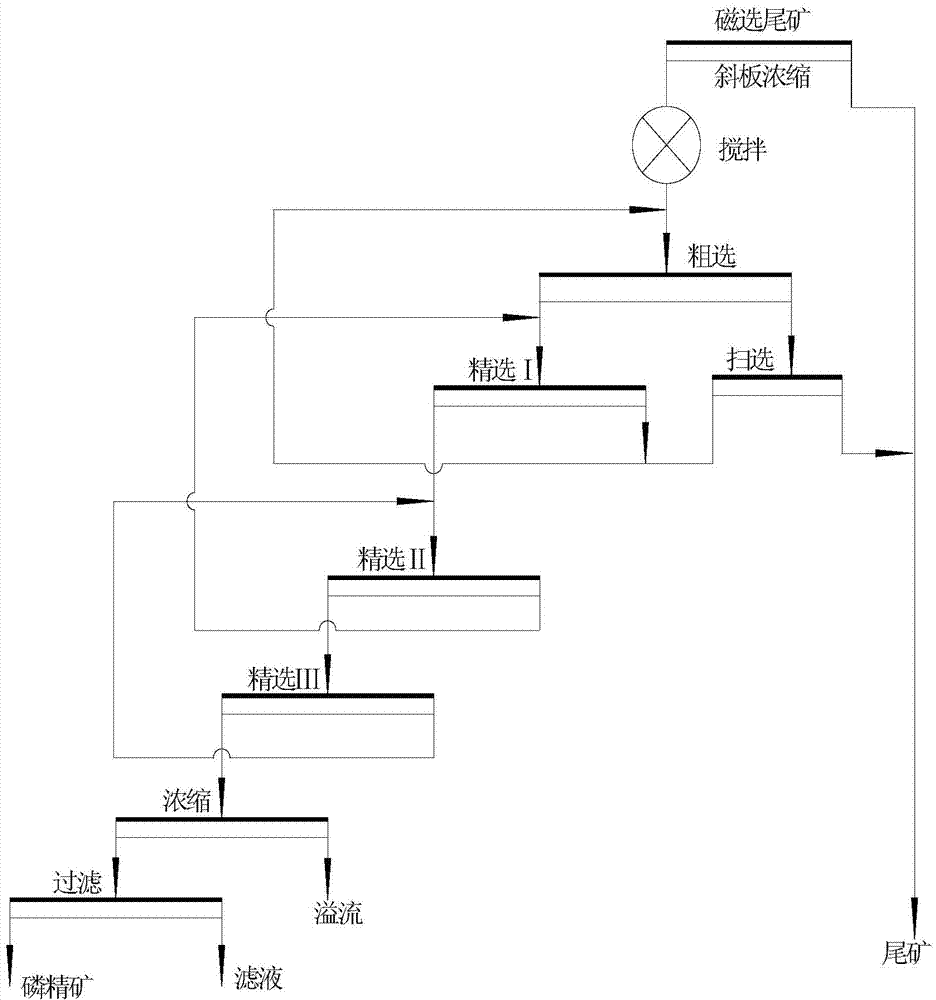

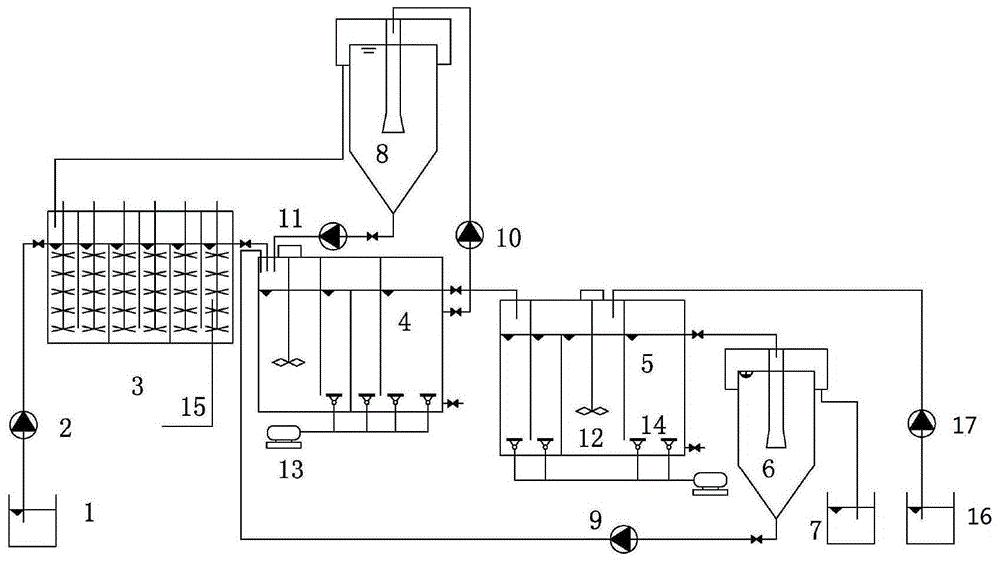

Combined beneficiation method and combined beneficiation system for comprehensive recovery of associated iron-phosphate minerals

The invention belongs to the technical field of efficient development of ultralow-grade ore resources and comprehensive utilization of associated minerals, and in particular relates to a combined beneficiation method and a combined beneficiation system for comprehensive recovery of associated iron-phosphate minerals. The combined beneficiation method for the comprehensive recovery of the associated iron-phosphate minerals comprises the following steps: sequentially performing three-section and two-closed-loop crushing and screening flow on raw ores, and performing dry separation to obtain fine ores; performing two-section closed-loop ore-grinding flow on the fine ores, performing fine magnetic separation for three times, and concentrating by using a wash mill to separate iron ore concentrate and discharge tailings; performing one-time roughing, one-time scavenging and three-time concentrating on the tailings at the temperature of 10-15 DEG C to obtain phosphate ore concentrate by floatation. Compared with the prior art, the invention provides a comprehensive recovery scheme for magnetic iron ore resources and phosphate ore resources in ultralow-grade associated iron-phosphate minerals. According to the scheme, the separation cost is low, the efficiency is high, energy is saved, the space occupation is low, and the comprehensive recovery of the magnetic iron ores and the phosphate ores can be realized.

Owner:中冶沈勘工程技术有限公司

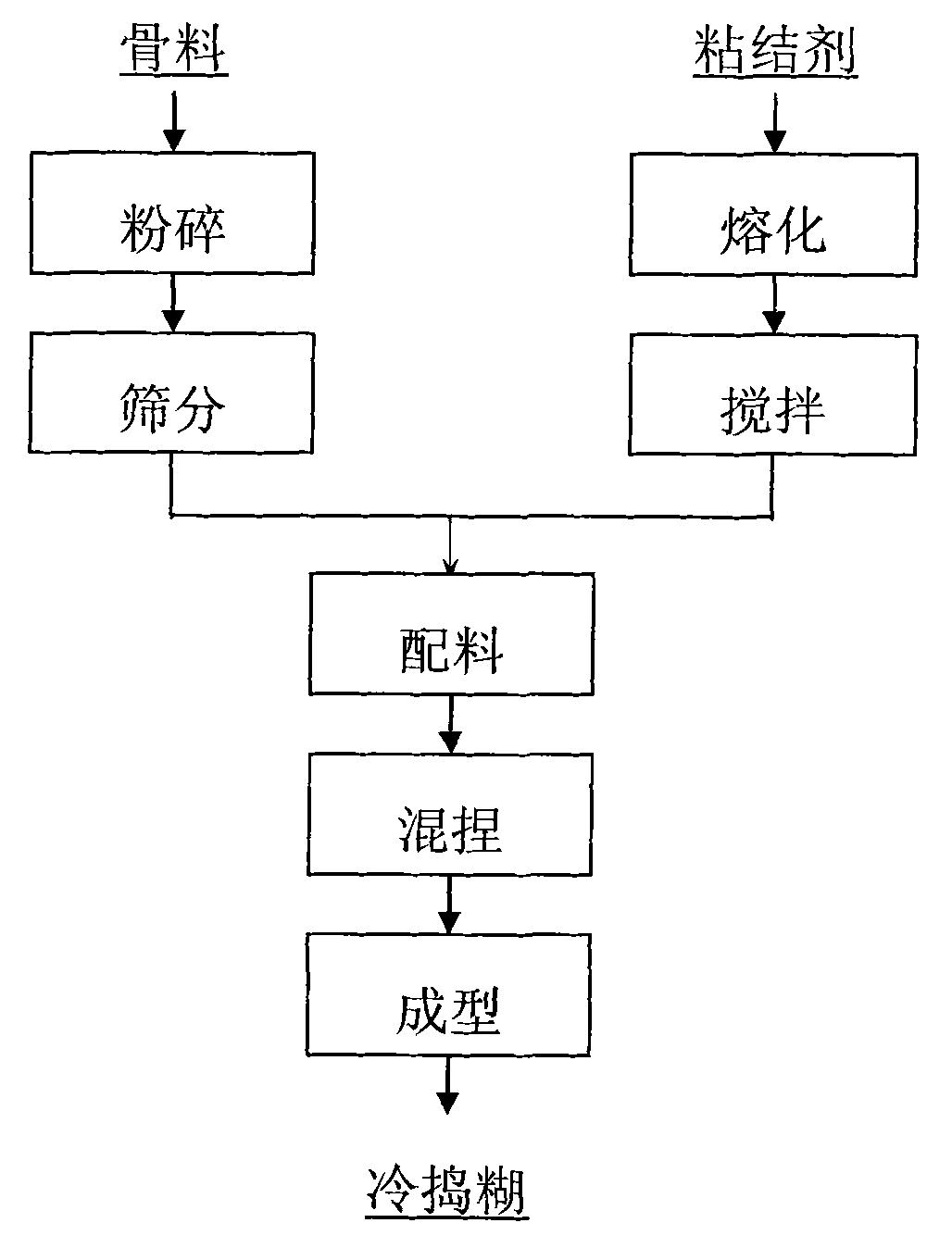

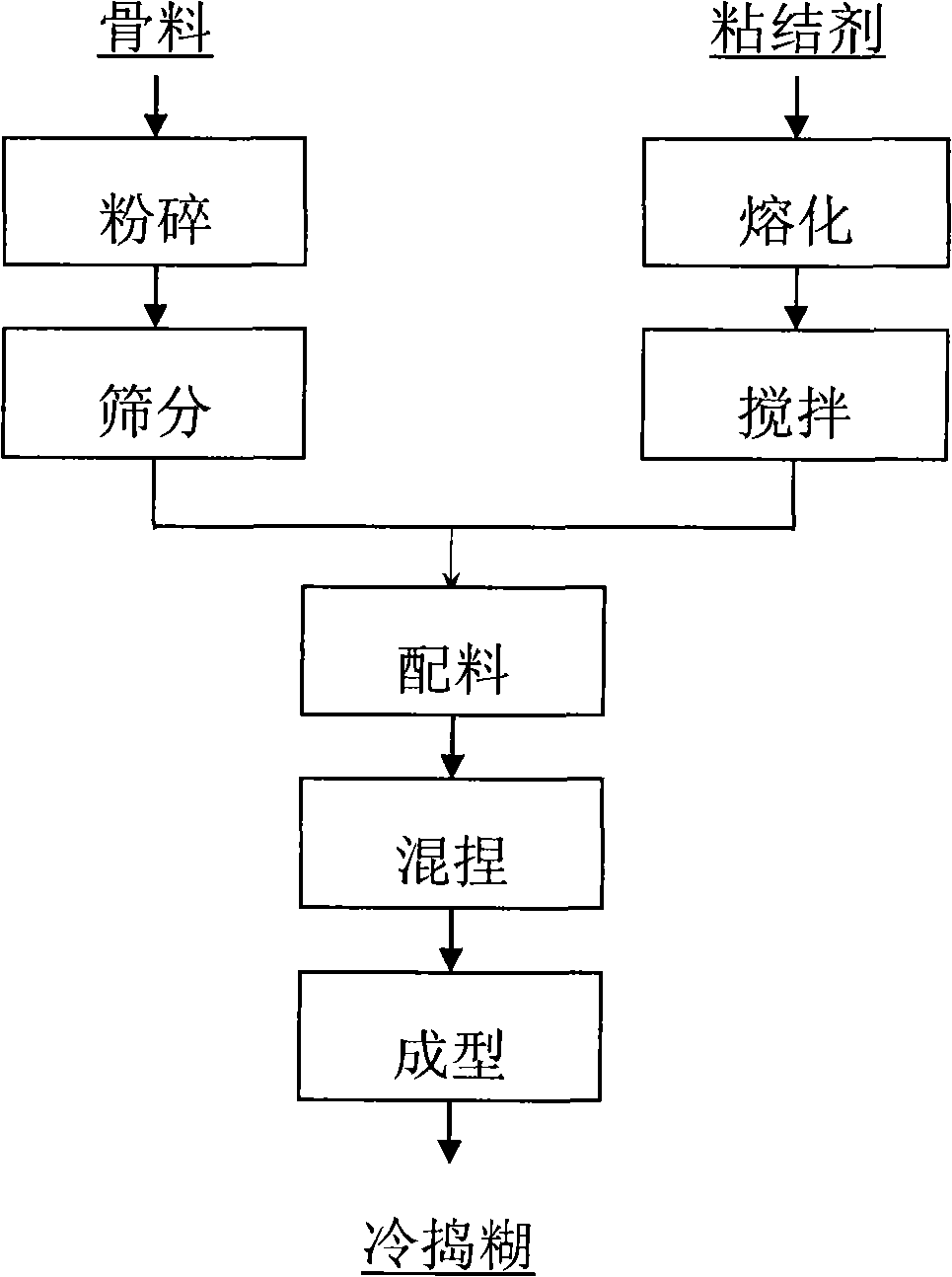

Method for preparing cold ramming paste for electrolytic aluminum

The invention discloses a method for preparing cold ramming paste for electrolytic aluminum. The method comprises the following steps of: crushing and ball-milling one or more mixed aggregates and feeding the aggregates into screening equipment to obtain aggregate powder with particle diameter of between 50 and 300 microns; meanwhile, heating and melting one or more mixed adhesives to obtain adhesive melt; then pouring the aggregate powder and the adhesive melt in a weight ratio of 5-20:1 into a kneading machine in sequence and uniformly mixing; keeping the kneading temperature to be between 80 and 200 DEG C and the kneading time to be between 1 and 18 hours; and taking the kneaded material out and guiding into a forming machine for forming to obtain a cold ramming paste product of a specified size, wherein the aggregates are one or a mixture of more of the normal calcined anthracite, electrically calcined anthracite, high-carbon graphite, metallurgical coke and petroleum coke; the carbon content of each aggregate is not less than 95 percent; and the adhesive is one or a mixture of more of phenolic resin, furfural resin, epoxy resin, furan resin, asphalt, coal tar and anthracene oil.

Owner:KUNMING METALLURGY INST

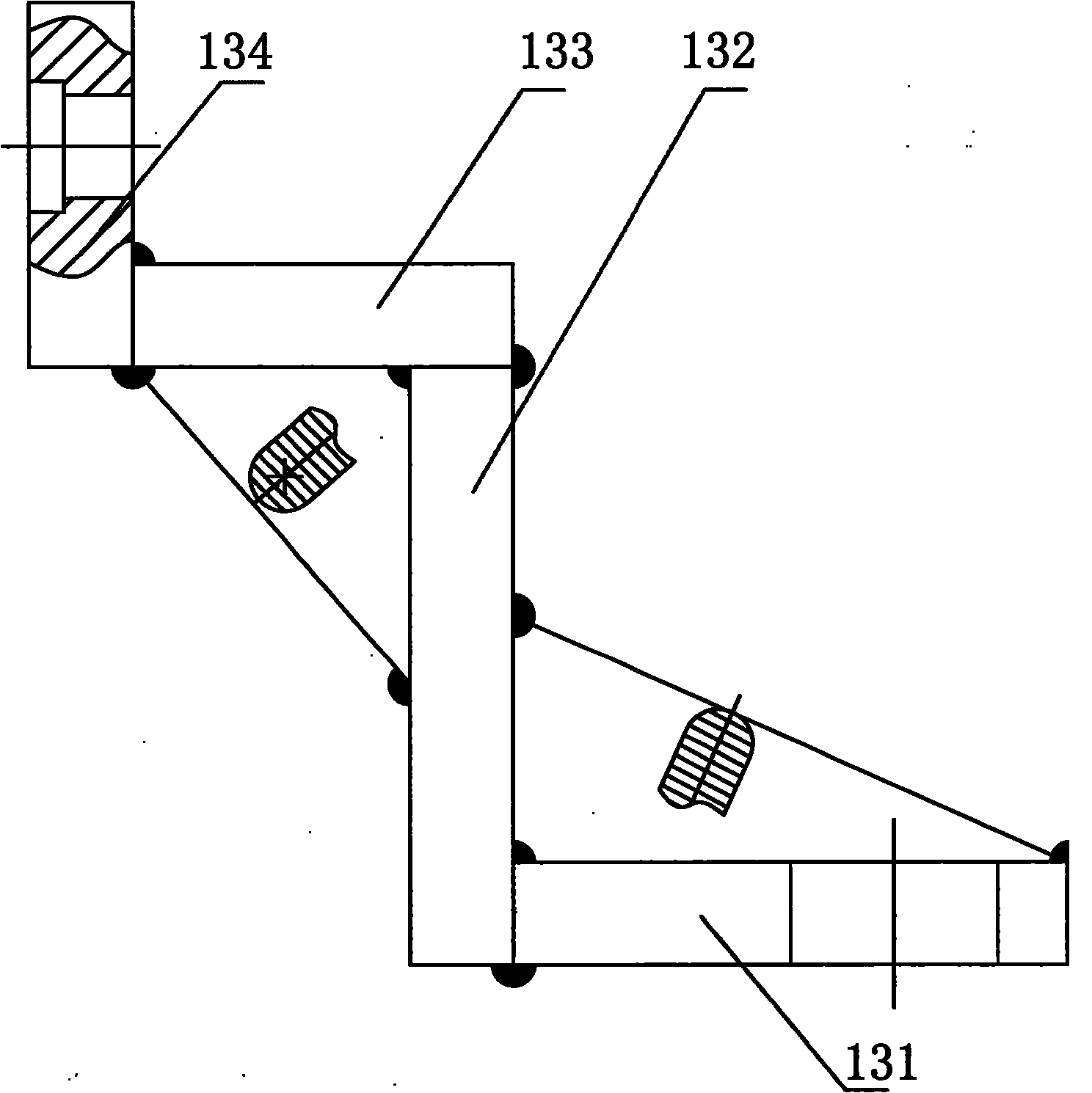

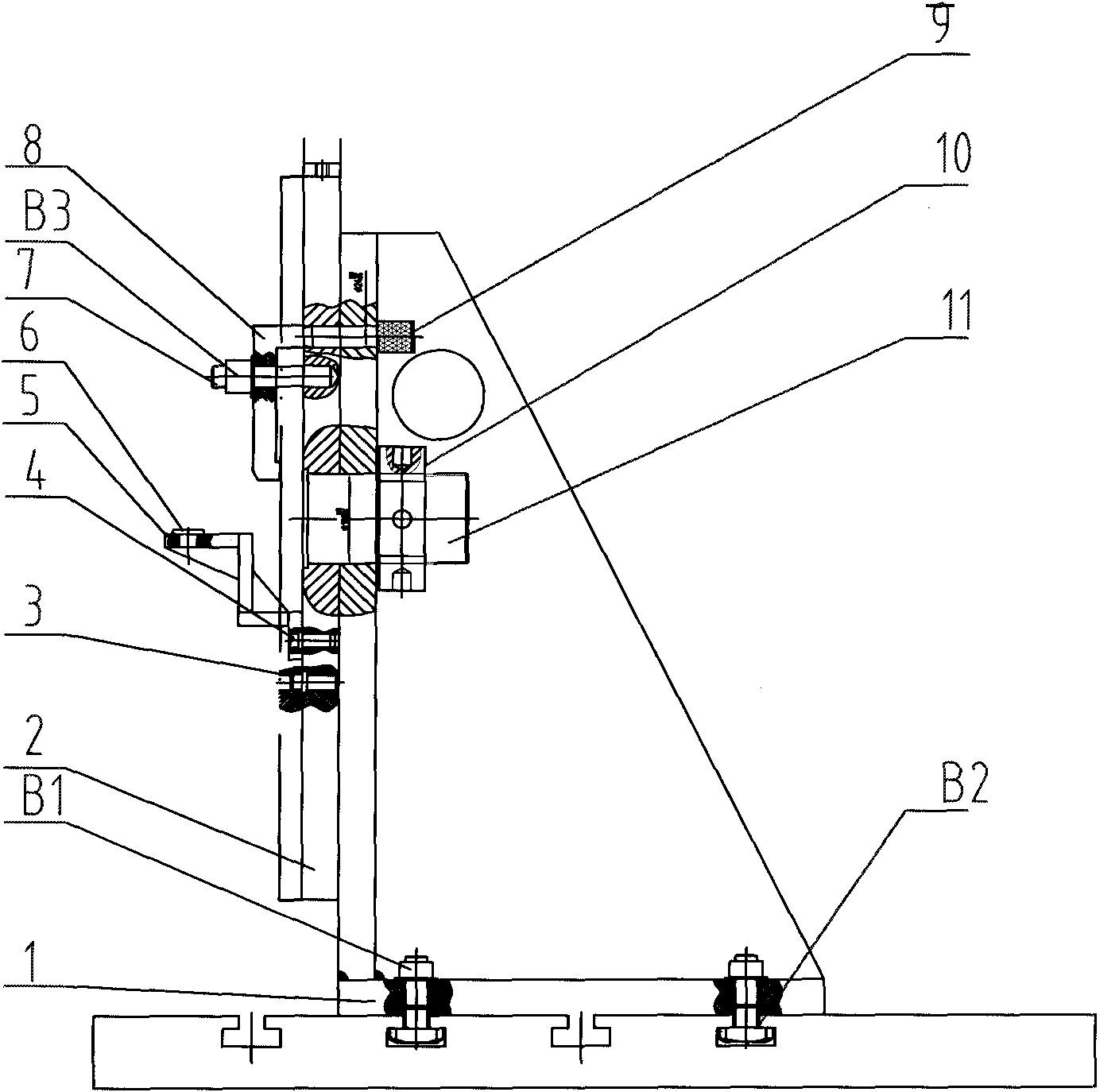

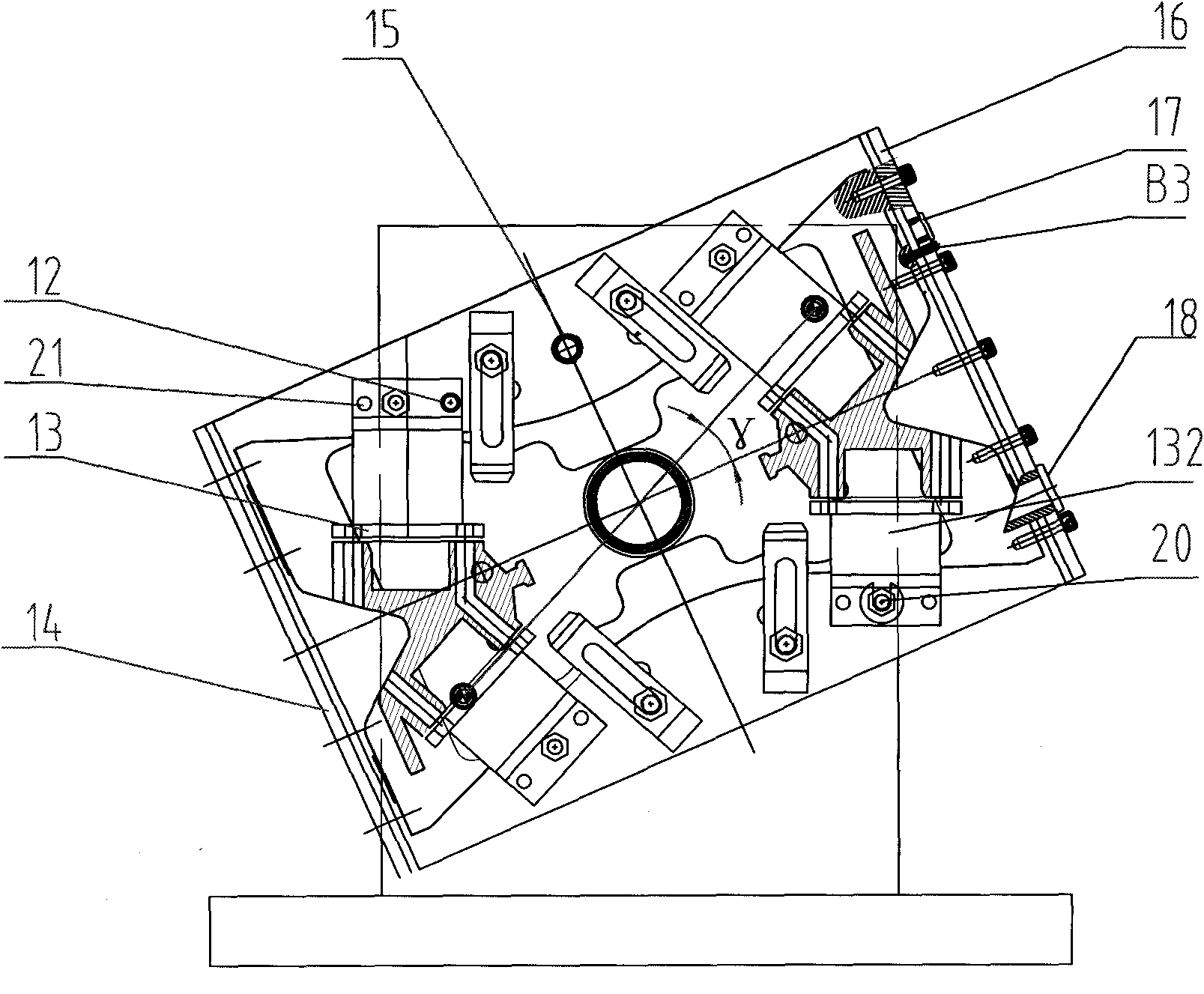

Combined fixture for cast crossbeams

InactiveCN101791767AUnified positioningReduce processDrilling/boring measurement devicesPositioning apparatusEngineeringMachining

The invention discloses a combined fixture for cast crossbeams, which comprises a fixed seat, a rotary plate, two end hole drill plates, at least two inclined hole drill plates and a plurality of clamping parts; the fixed seat is provided with a mounting surface connected with a drilling machine workbench and a fixing surface perpendicular to the mounting surface; the rotary plate is rotatably mounted on the fixing surface through a connecting shaft; the end hole drill plates are fixed on both sides of the rotary plate, and the surfaces of the end hole drill plates are provides with die holes corresponding to both sides of a cast crossbeam to be drilled; the inclined hole drill plates are mounted on the surface of the rotary plate, and each inclined hole drill plate is provided with drill plate holes corresponding to the positions and sizes of inclined holes; and the clamping parts are detachably mounted on the rotary plate, and are used for mounting the cast crossbeam on the rotary plate. The invention is integrated with multiple processes for machining, positioning is uniform, the number of processes is reduced, the carrying cost is reduced, and the efficiency is increased.

Owner:济南中森机械制造有限公司

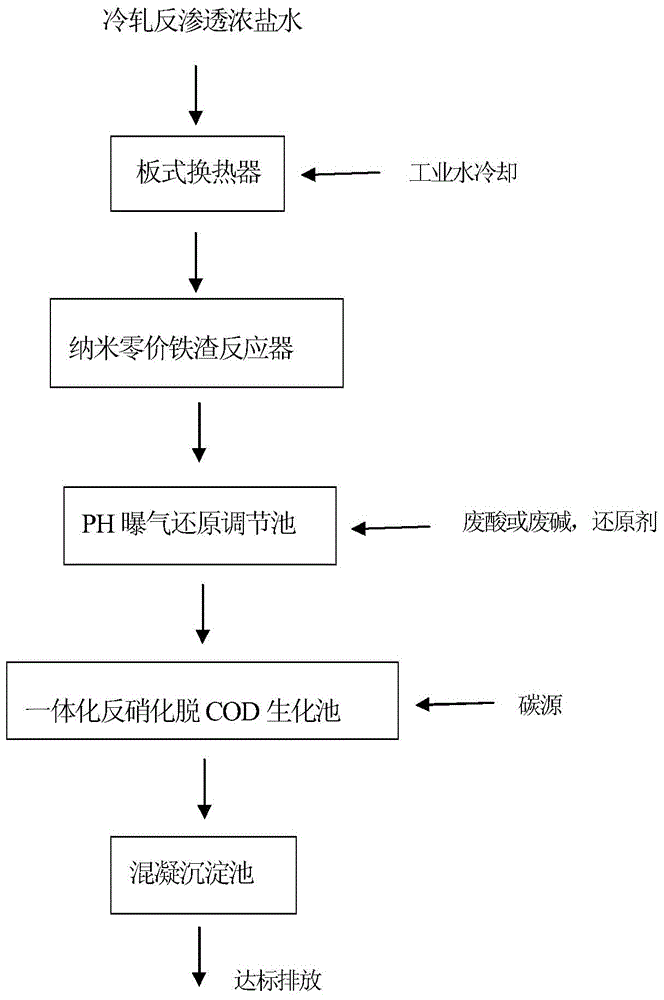

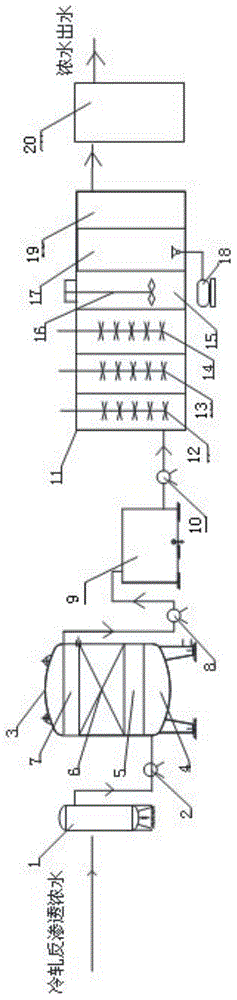

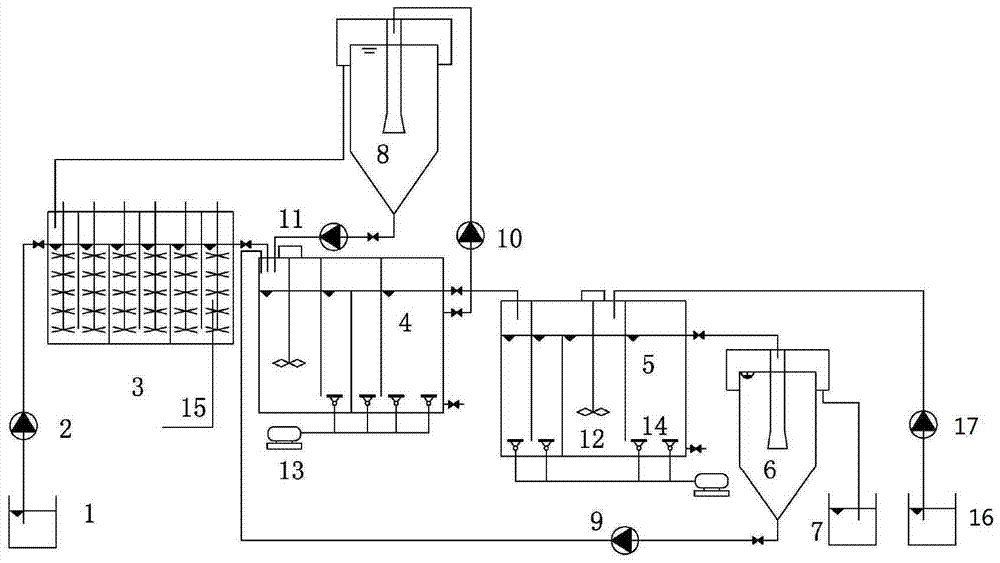

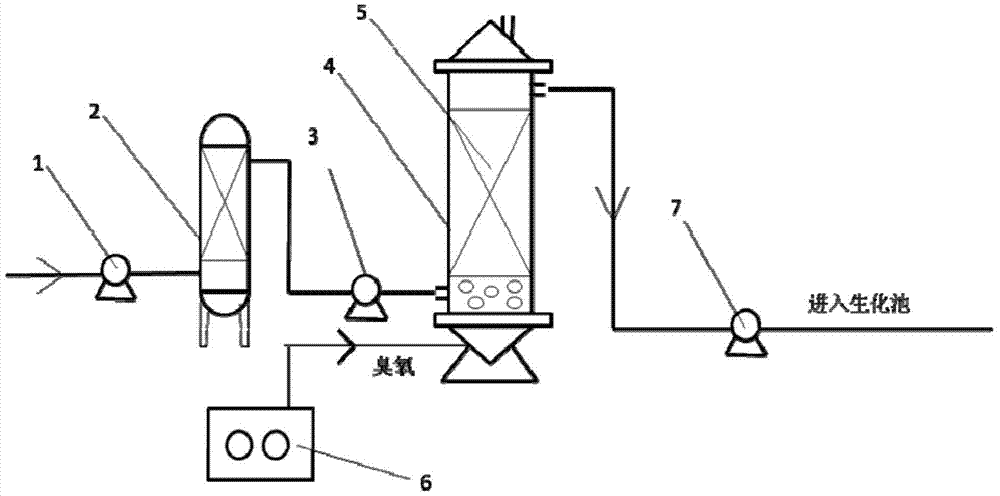

Processing system and method for cold rolling reverse osmosis strong brine

ActiveCN105016569ASolve the problem of meeting emission standardsReduce pollutionMultistage water/sewage treatmentReverse osmosisTotal nitrogen

The invention provides a processing system and method for cold rolling reverse osmosis strong brine. The processing system sequentially comprises a platy heat exchanger, a first-stage lifting pump, a nanometer zero-valent iron residue reactor, a second-stage lifting pump, a PH aeration reduction pool, a third-stage lifting pump, an integrated denitrification COD biochemical pool and a coagulative precipitation tank. The cold rolling reverse osmosis strong brine enters the zero-valent iron residue reactor after passing through the platy heat exchanger to be cooled so that heavy metal can be removed. The cold rolling reverse osmosis strong brine then enters the integrated denitrification COD biochemical pool after passing through the PH aeration reduction pool so that total nitrogen and organic matter can be removed. The cold rolling reverse osmosis strong brine finally enters the coagulative precipitation tank and can reach the standard and then be discharged after coagulating sedimentation. The processing system is low in one-time investment, easy to run and operate, low in production and processing cost and capable of processing environment-friendly steel waste water in a green and environment-friendly mode.

Owner:BAOSHAN IRON & STEEL CO LTD

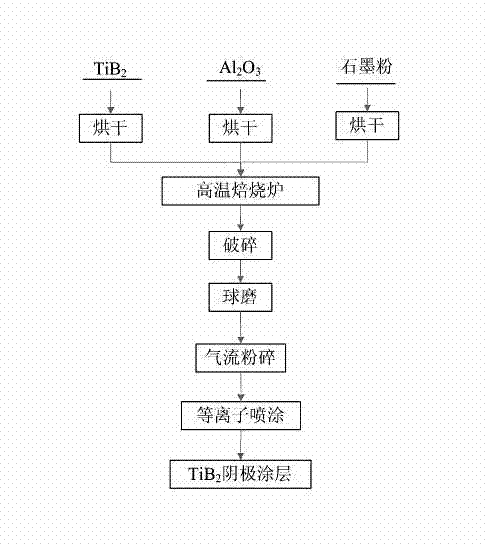

Method for preparing TiB2 cathode coating for aluminium electrolysis

The invention provides a method for preparing a TiB2 cathode coating for aluminium electrolysis. The method comprises the following steps: grinding such materials as TiB2, a carbon-based material, an additive and the like, then mixing the ground materials proportionally and further mixing the ground materials uniformly in mixing and kneading equipment to obtain a solid powder mixture; adding a diluent into an adhesive, continuously stirring the two materials until the two materials are fully mixed uniformly; and pouring the uniformly mixed mixture of the diluent and the adhesive into the mixing and kneading equipment, nixing the mixed mixture of the diluent and the adhesive with the solid powder mixture and stirring the materials until the materials are mixed uniformly, thus obtaining the TiB2 composite required for aluminium electrolysis. The method has the following beneficial effects: after the product produced by the method is used in an aluminium electrolytic cell, the service life of the aluminium electrolytic cell is greatly prolonged and simultaneously the current efficiency of an aluminium electrolysis process is greatly improved, thus lowering the production cost of aluminium per ton; and the method has the advantages of short process flow, low production treatment cost and low environmental pollution.

Owner:KUNMING METALLURGY INST

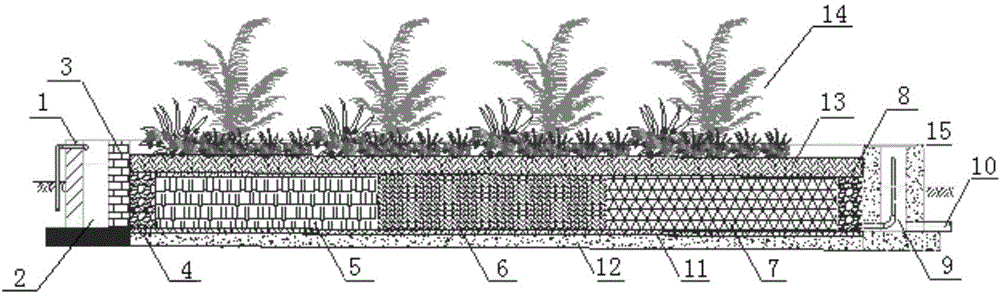

Ecological treatment system and method for cold-rolling reverse osmosis strong brine

ActiveCN105366872AEfficient removalLess one-time investmentWaste water treatment from metallurgical processMultistage water/sewage treatmentWater qualityManganese

Owner:BAOSHAN IRON & STEEL CO LTD +1

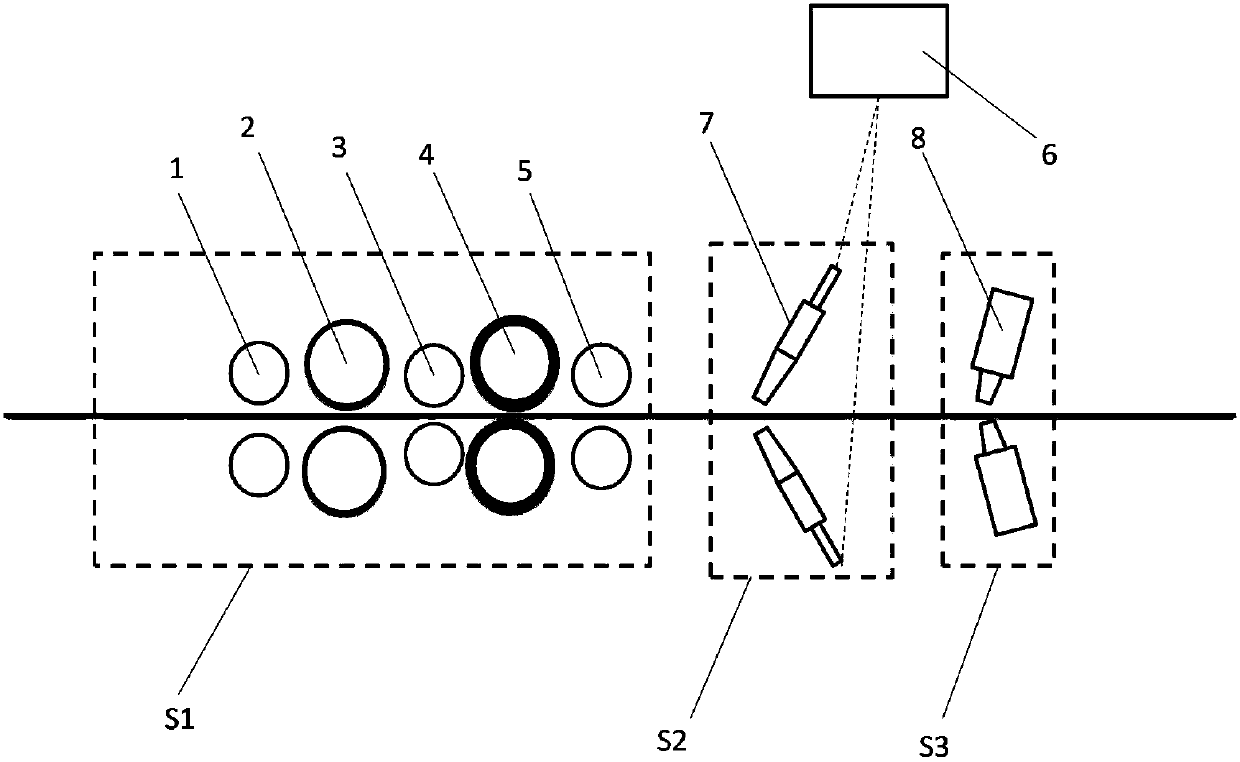

Long-acting anti-rust method and equipment for hot-rolled magnetic yoke steel

InactiveCN109097758AGood mechanical propertiesImprove rust resistanceMetallic material coating processesSocial benefitsLiquid storage tank

The invention provides long-acting anti-rust equipment for hot-rolled magnetic yoke steel. The long-acting anti-rust equipment of the hot-rolled magnetic yoke steel comprises first pinch rollers, up-down rough brushing rollers, second pinch rollers, up-down fine brushing rollers, third pinch rollers, antirust agent nozzles and purging nozzles according to the moving direction of the hot-rolled magnetic yoke steel; and in addition, an anti-rust agent liquid storage tank is further arranged and is connected with the anti-rust agent nozzles. The invention further provides an anti-rust method using the equipment. The rust-proof equipment and the rust-proof method are used, so that the hot-rolled magnetic yoke steel is not rusted for 72 hours under the conditions of the temperature of 49 DEG Cand the relative humidity of 98%, and the anti-rust effect is good. The long-acting anti-rust equipment and method effectively solve the problem that hot-rolled chromium-molybdenum low alloy steel iseasy to rust, and therefore, the long-acting anti-rust equipment and method belong to the environment-friendly production process of steel and iron, and have good social benefit and environmental benefit.

Owner:BAOSHAN IRON & STEEL CO LTD

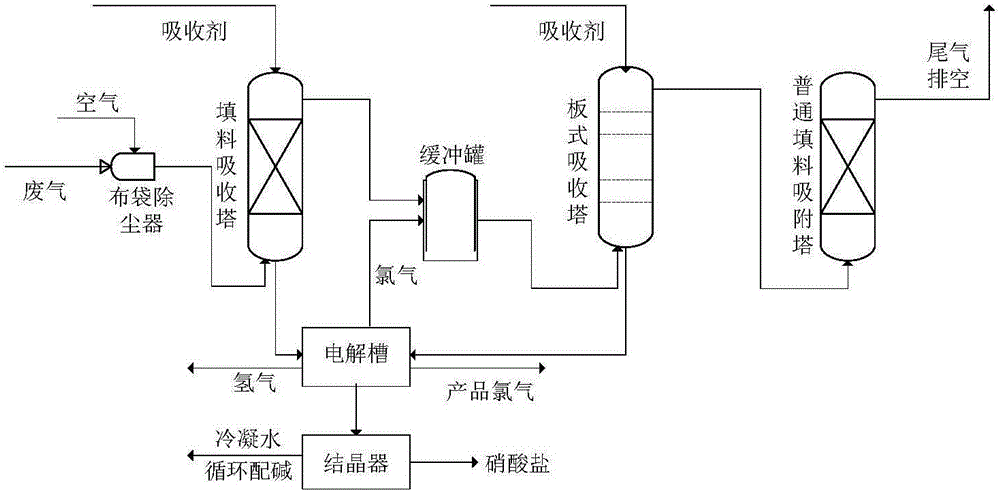

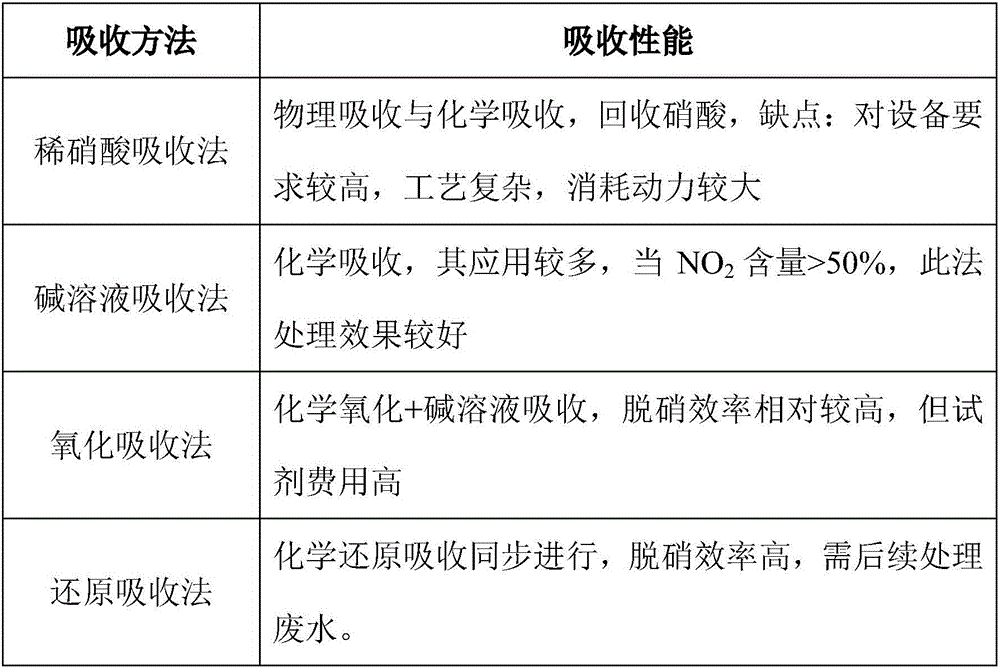

Chlorine containing high-concentration NOX waste gas treatment method

InactiveCN106582224AOvercome ClO

<sup>-</sup>

Decomposition to Oxygen DeficiencyStrong oxidation abilityGas treatmentDispersed particle filtrationHigh concentrationElectrolysis

The invention provides a chlorine containing high-concentration NOX waste gas treatment method. Chlorine containing high-concentration NOX tail gas, after undergoing bag-type dust removal, is sequentially processed by virtue of a packing absorbing tower and a plate absorbing tower under an ultraviolet light catalysis condition as well as a normal absorbing tower. The packing absorbing tower and the plate absorbing tower adopt wet dechlorination and denitration under the ultraviolet light catalysis condition, and the normal absorbing tower is a protection tower. In treated waste gas, the content of NOX is lower than 240mg / m<3> and the content of Cl2 is lower than 65mg / m<3>, up to national emission demand. The method has the advantages that by adopting ultraviolet catalytic oxidation wet dechlorination and denitration, by catalyzing an oxidation-reduction reaction between chlorine and NO in the waste gas, and by implementing an oxidizing process simultaneously in a gas phase and a liquid phase, the shortcoming of an existing wet method which is not high in denitration efficiency is overcome; a solution is purified after absorption liquid is electrolyzed, and the NOX is finally recovered in the form of nitrate, so that a degree of resource utilization is improved; and the absorption liquid in the system is recycled, so that secondary pollution is prevented.

Owner:WANHUA CHEM GRP CO LTD

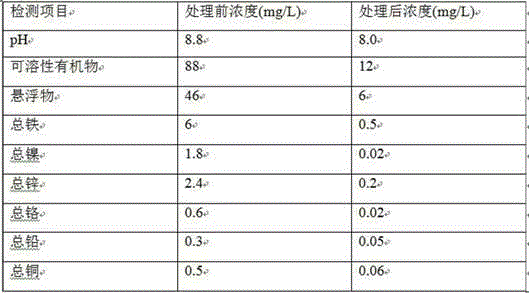

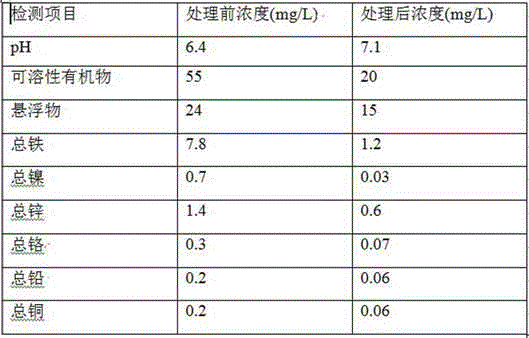

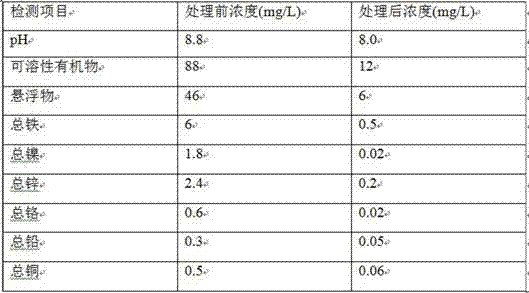

Method for removing dissolved organic matter and heavy metal ions in electroplating waste water

ActiveCN105293769ASolve the pollution of the environmentAvoid churnWater contaminantsWaste water treatment from metallurgical processActivated carbonGreen waste

The invention discloses a method for removing dissolved organic matter and heavy metal ions in electroplating waste water. The method involves a pH value regulation tank and a filler tower capable of effectively removing dissolved organic matter and heavy metal ions. Modified kieselguhr and activated carbon serve as double-layer filler of the filler tower, and after being adsorbed by the filler, electroplating waste water reaches the national emission standard. The method is an environment-friendly green waste water treatment process which is high in organic matter and metal heavy ion removal rate, low in one-time investment, easy to run and operate and low in production treatment cost.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

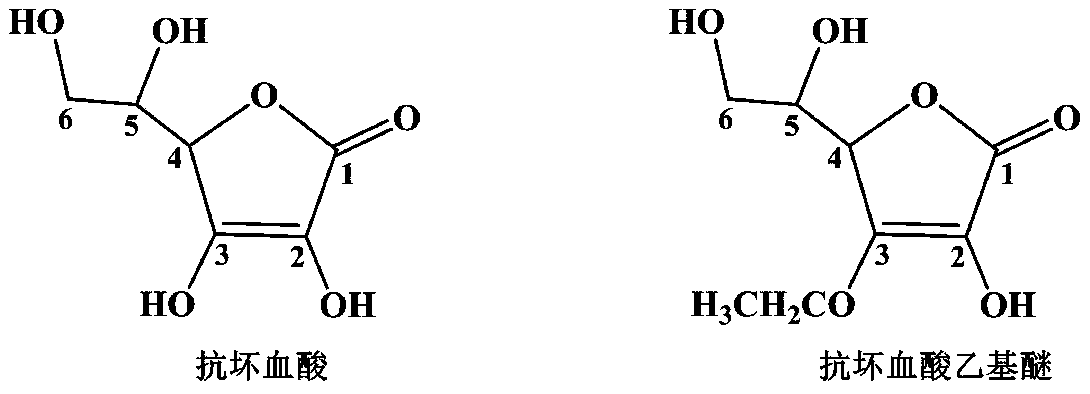

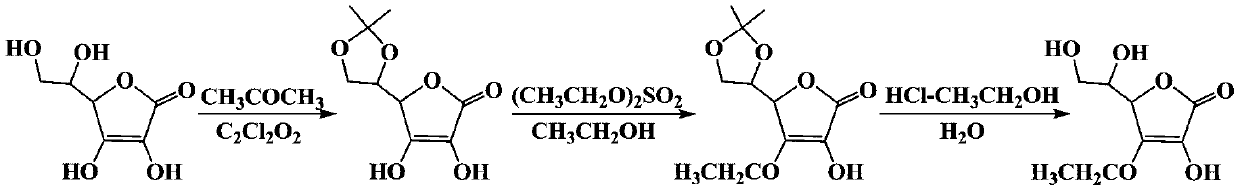

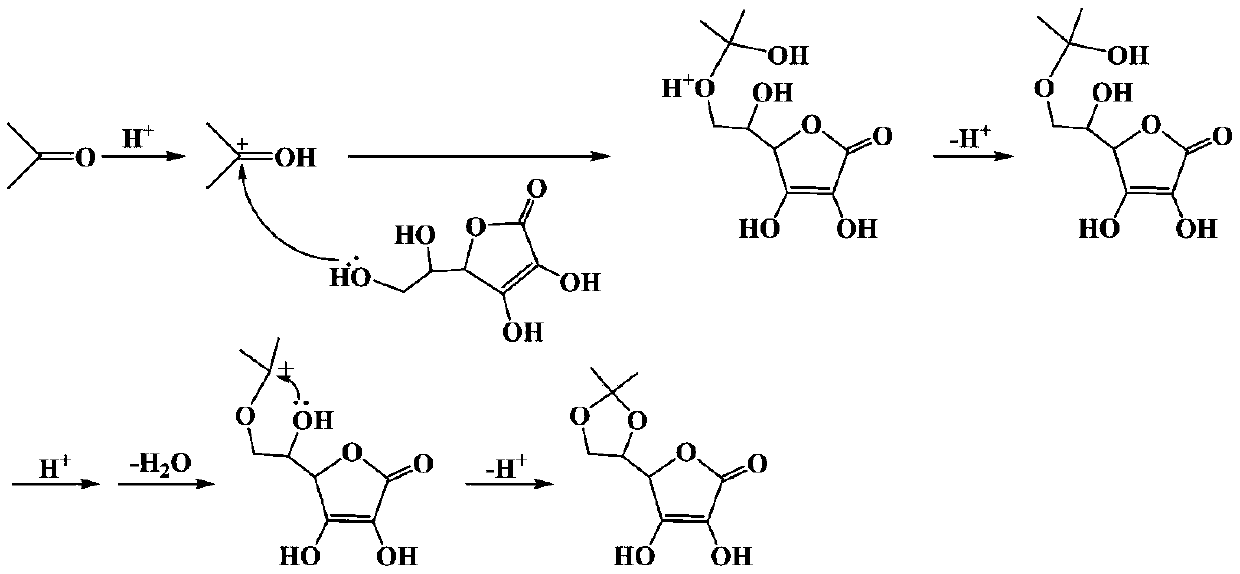

Preparation process of ascorbyl ethyl ether

ActiveCN111559995ASolving Recycling ProblemsReduce manufacturing costOrganic chemistryBulk chemical productionOXALIC ACID DIHYDRATEAlkaline earth metal

The invention relates to a preparation process of ascorbyl ethyl ether. The preparation process comprises the following steps: with ascorbic acid and acetone as raw materials, carrying out reacting for 8-10 hours under the catalysis of oxalyl chloride, and then carrying out filtering, washing and drying to obtain 5,6-O-isopropylidene-L-ascorbic acid; adding alkaline-earth metal oxide into mother liquor to remove oxalic acid, hydrogen chloride and moisture, and drying acetone with a molecular sieve for reuse; dissolving an ethylation reagent, inorganic base and 5,6-O-isopropyl-L-ascorbic acid in ethanol, carrying out reacting for 6-8 hours at 40-60 DEG C, and carrying out purifying to obtain 3-ethyl-5,6-O-isopropyl-L-ascorbic acid; removing isopropyl protecting groups through an alcohol solution of hydrogen chloride, carrying out concentrating, adding a solvent with low solubility, and conducting recrystallizing to obtain the ascorbyl ethyl ether. The process solves problems in recoveryand reuse of acetone, does not use toxic and harmful solvents and organic alkali, does not produce a large amount of waste liquid, and is economic and environment-friendly; technological process is easy to control; and the process is high in yield and easy to industrially popularize.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY +1

Processing system and processing method of strong brine from reverse osmosis of coking

ActiveCN105152453AReduce pollutionLess one-time investmentTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentSaline waterReflux

The invention provides a processing system of strong brine from reverse osmosis of coking. The processing system comprises a water inlet tank, which is connected to a filler tank, a large aerobic tank, a small aerobic tank, a biological sedimentation basin, and a water outlet tank in sequence through pipelines. The large aerobic tank is connected to a nitration sedimentation basin through pipelines, and the nitration sedimentation basin is connected to the filler tank. A sludge reflux pump is arranged at the bottom of the nitration sedimentation basin and is used for enabling sludge to get in the large aerobic tank. The small aerobic tank is connected to a carbon source dissolving tank through pipelines, and the carbon source dissolving tank pumps dissolved carbon sources into the small aerobic tank through a metering pump. According to the processing system, one-time investment is low; operation is simple, and the production and processing cost is relatively low. Environment-friendly green environment-protecting processing technology of iron and steel waste water is provided. Based on the quality and quantity of strong brine from reverse osmosis of coking, the economical and efficient processing system for discharging strong brine, up to the standard, from reverse osmosis is developed.

Owner:BAOSHAN IRON & STEEL CO LTD +1

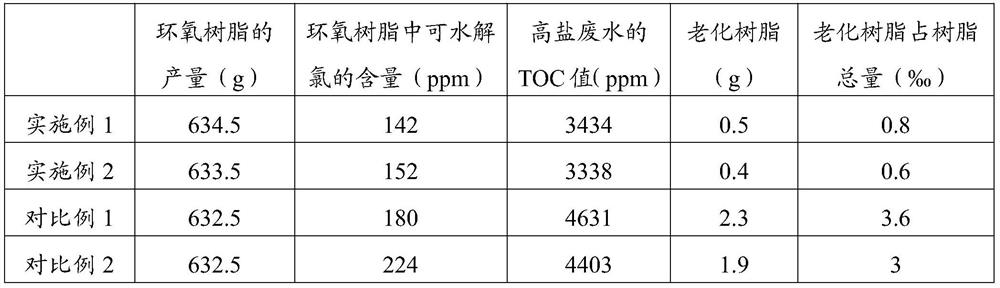

Refining method of epoxy resin

ActiveCN113248687AReduce the content of hydrolyzable chlorineIntensified generationPlastic recyclingEpoxyPtru catalyst

The invention provides a refining method of epoxy resin, and belongs to the field of chemical refining. In the staged refining process, the content of water in a system is reduced by pumping negative pressure to a certain vacuum degree and removing water and an organic solvent in the system, so that the reaction is promoted to proceed towards a crude epoxy resin dehydrochlorination ring-closure reaction, the content of hydrolyzable chlorine in the crude epoxy resin is remarkably reduced, by using a phase transfer catalyst and controlling the vacuum degree and temperature of each refining stage, the utilization rate of sodium hydroxide participating in ring-closure reaction is increased, and the use amount of sodium hydroxide is reduced, so that excessive condensation side reaction is avoided, the generation of aged resin is reduced, the content of organic matters in the generated high-salinity wastewater is reduced, and the production treatment cost and raw material consumption are reduced; and the TOC value in the generated high-salinity wastewater is as low as 3434ppm, the aged resin accounts for 0.8% o of the total amount of the resin, and the content of hydrolyzable chlorine in the epoxy resin product is as low as 142 ppm.

Owner:JIANGSU KUMHO YANGNONG CHEM CO LTD

Technical process of chrome plating overpassing hydraulic mechanical member

InactiveCN1928154AIncrease production capacityGood application effectLiquid/solution decomposition chemical coatingHigh resistanceAlloy

The present invention provides alloy plating solution and corresponding treating process for forming coating with high corrosion resistance, high hardness, high wear resistance and high erosion resistance. The present invention is used in hydraulic part production, and has the outstanding features of high plating speed, low material consumption, low power consumption and no pollution. The alloy plating solution is compounded through dissolving nickel sulfate, amino acetic acid, sodium hypophosphorite, graphite fluoride, boric acid, sodium saccharin, lead ion, ammonia water and sodium hydroxide in the weight ratio of 3 to 2.5 to 0.35 to 0.6 to 3 to 0.3 to 0.003 to 0.35 to 0.15 in pure water of 90 weight portions. During plating, the alloy plating solution is heated to 50-80 deg.c, and the plating time is determined based on thickness to be plated.

Owner:李天忠

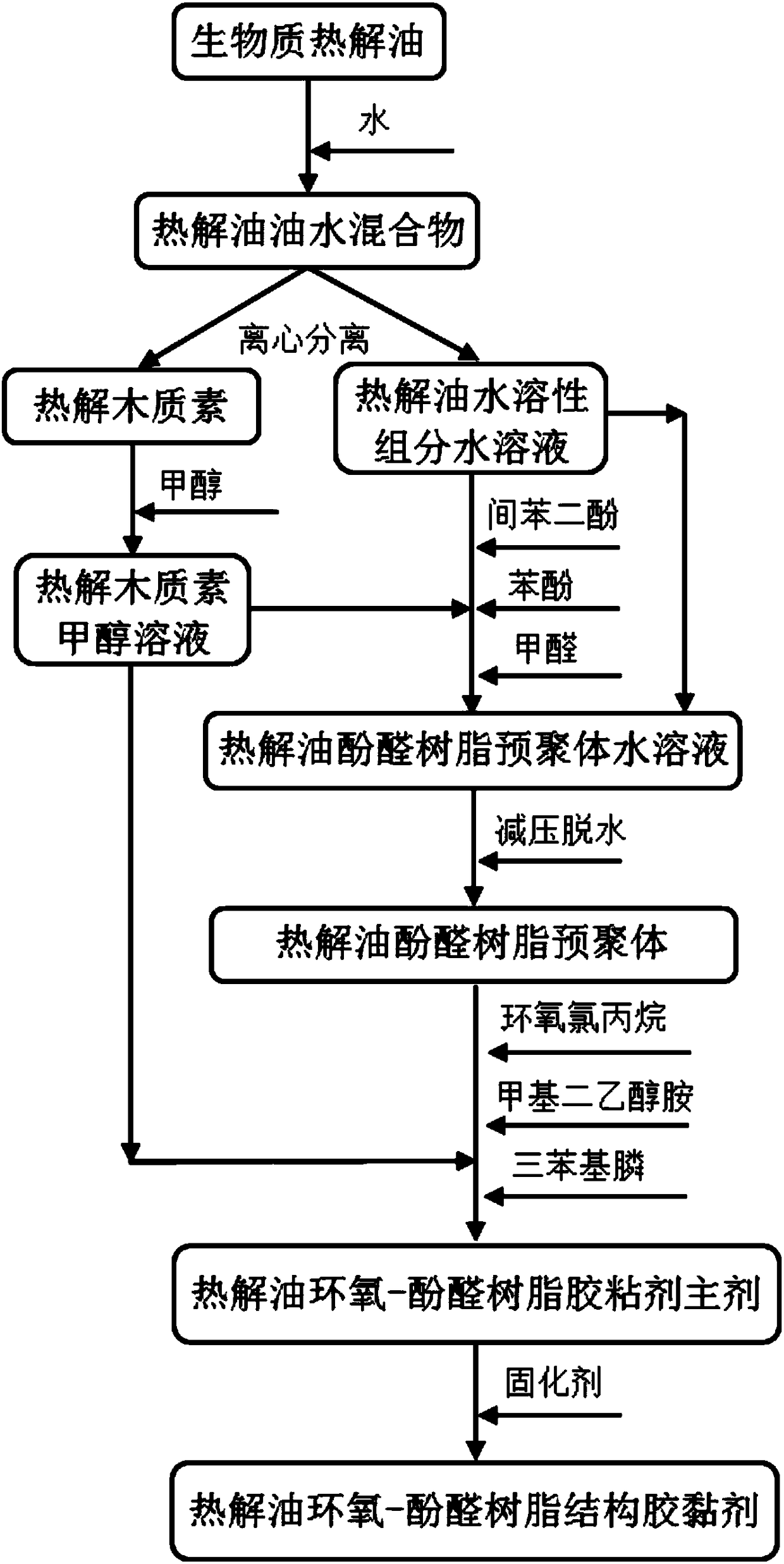

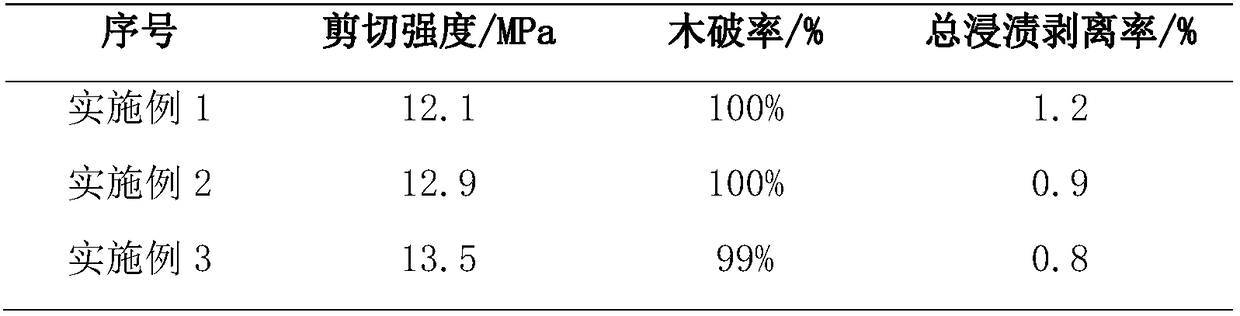

Preparation method of normal temperature curing biomass pyrolysis oil-based structure adhesive

ActiveCN108102591ABroaden the way of high-value utilizationWide variety of sourcesEpoxynovolac adhesivesEpoxyAdhesive system

The invention utilizes green renewable and cheap biomass pyrolysis oil as a raw material, performs step-by-step synthesis reaction with resorcinol, phenol, formaldehyde, epichlorohydrin and the like to prepare a normal temperature curing biomass pyrolysis oil-based structure adhesives. The adhesive of the invention not only converts agricultural and forestry waste into high-value-added green chemical raw materials, but also broadens use ways of high-valued biomass pyrolysis oil; also provides a new green adhesive for a structural adhesive industry, combines the advantages of epoxy resin and phenolic resin, has good mechanical strength, heat resistance and certain flexibility, improves wettability of a traditional structural adhesive, and easily infiltrates the surface of woods, has high strength of adhesive materials and high wood breakage rates, can well adapt to and meet the comprehensive requirements of a wood structure and other adhesive systems to the adhesive, and has important practical application value.

Owner:BEIJING FORESTRY UNIVERSITY

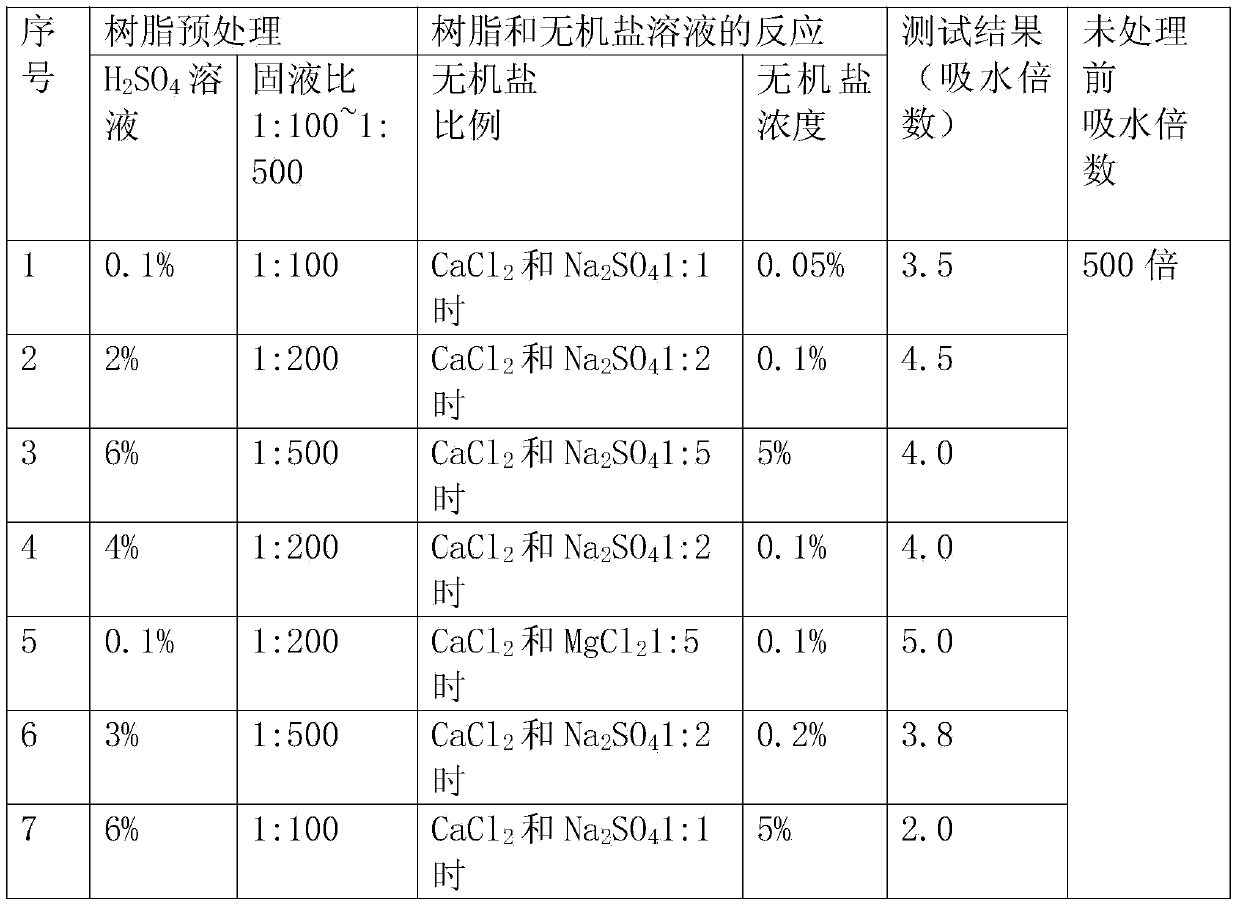

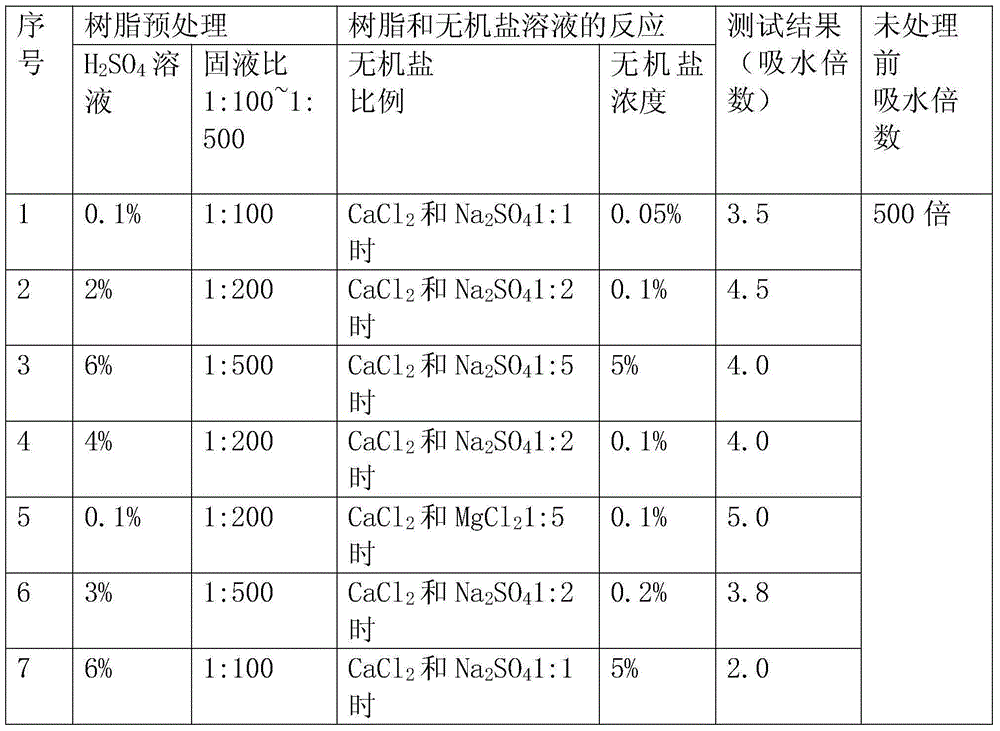

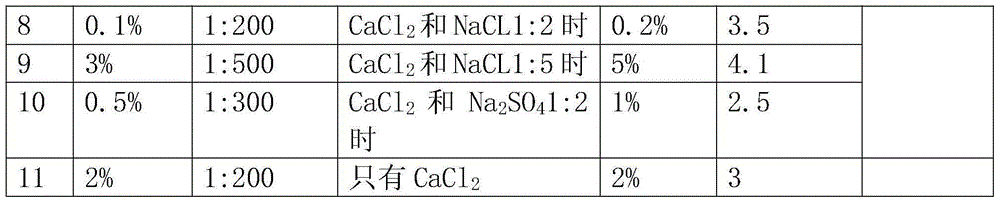

Method for destroying water absorbency of sodium polyacrylate resin and method for recovering waste/old water absorbing articles

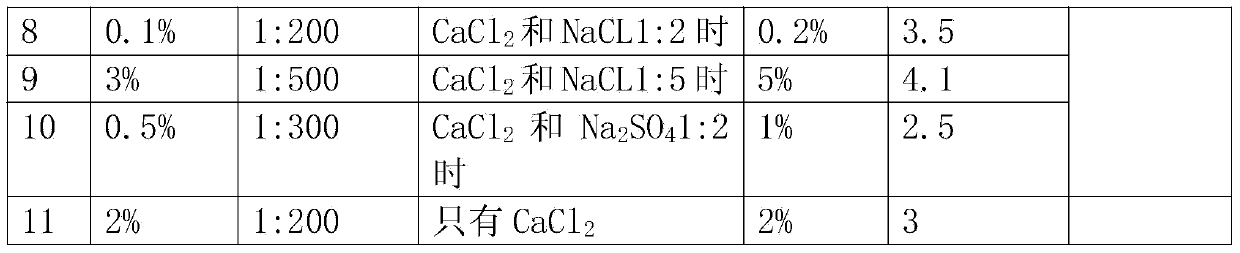

ActiveCN103627027ALow priceMeet the requirements of industrial productionPlastic recyclingInorganic saltsLiquid ratio

The invention discloses a method for destroying the water absorbency of sodium polyacrylate resin. The method comprises the following steps: (1) weighing inorganic salt containing CaCl2, and preparing a 0.05-5% solution from the inorganic salt; (2) weighing a sodium polyacrylate resin solid, adding a 0.1-6% H2SO4 solution according to the solid-to-liquid ratio of (1: 100) to (1: 500), and filtering, so as to obtain a pretreated sodium polyacrylate resin solid substance; (3) adding the resin solid substance into an inorganic salt mixed solution according to the solid-to-liquid ratio of (1: 50) to (1: 300), and filtering, thereby obtaining sodium polyacrylate resin with lowered water absorbency. The invention further discloses a method for recovering articles for physiological hygiene. The methods have the good effects that the water absorbency of the sodium polyacrylate resin is lowered to about 1% of the original water absorbency, and the problem of water resource waste during the recovery of waste / old water absorbing articles is solved.

Owner:青岛福创环境科技有限公司

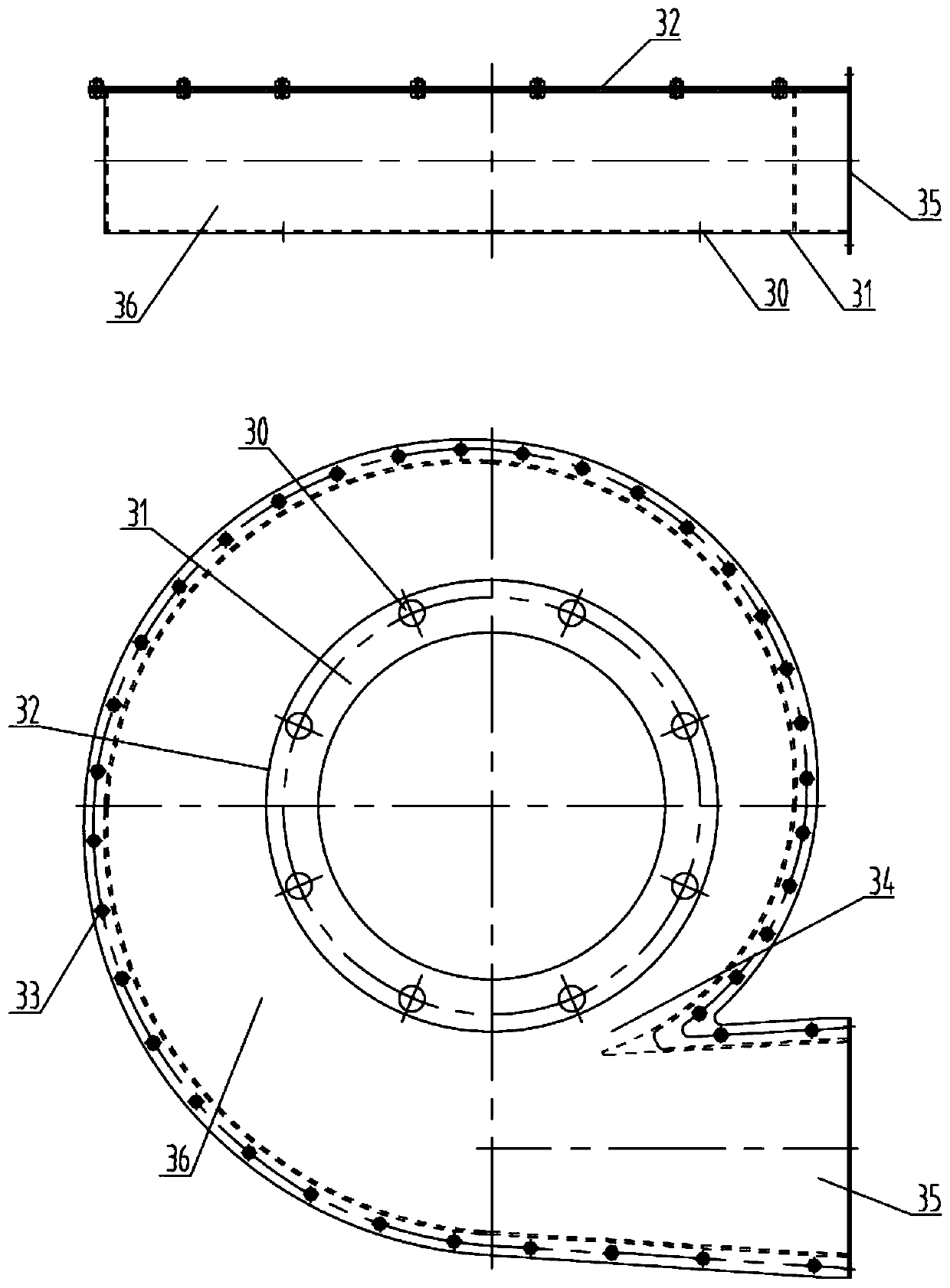

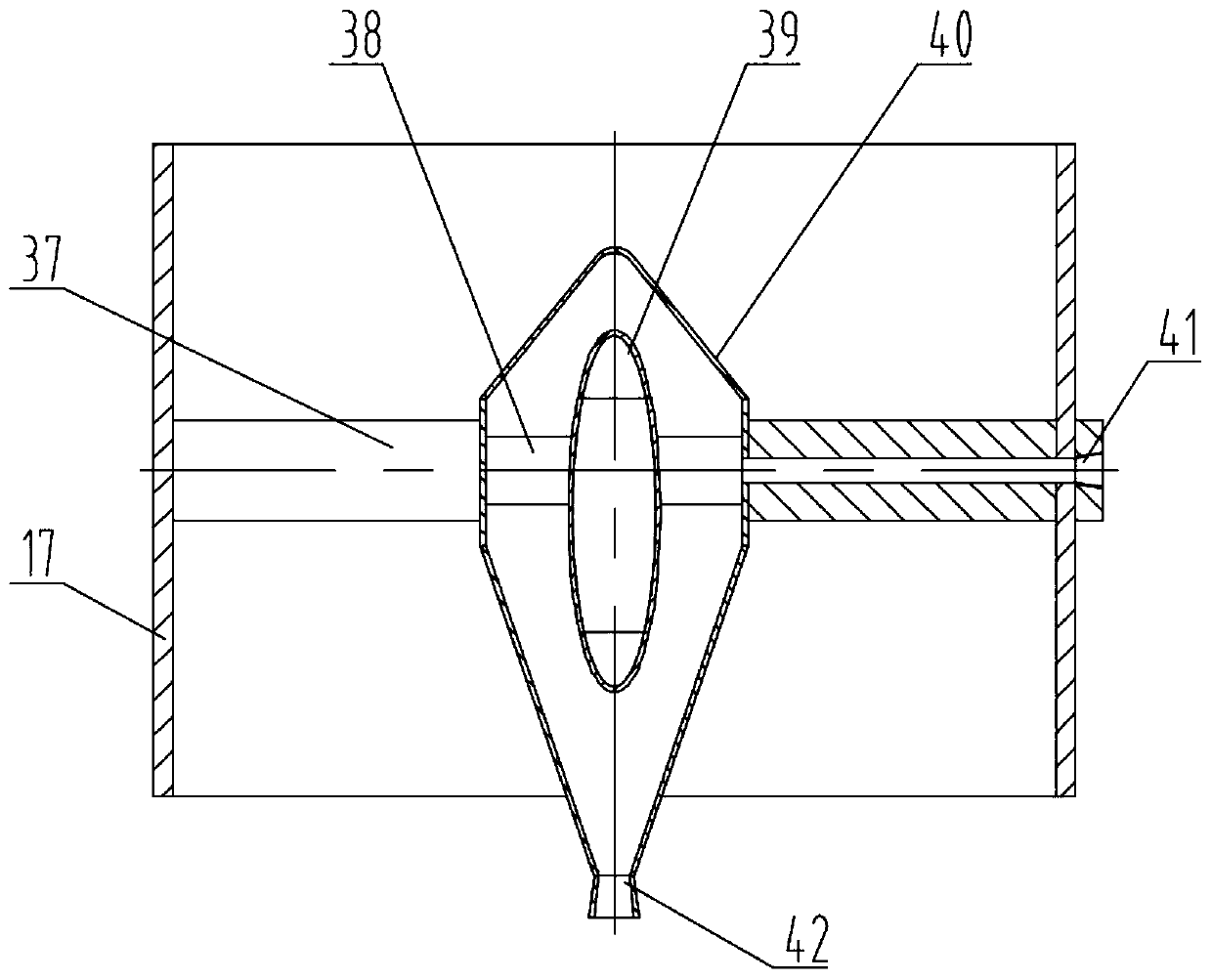

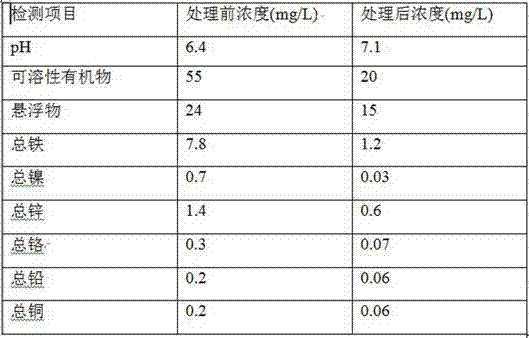

Beneficiation combined method and system for comprehensively recovered associated iron phosphate minerals

InactiveCN108906313AReduce production handling costsReduce processingMagnetic separationWet separationPrillIronstone

The invention discloses a beneficiation combined method and a system for comprehensively recovered associated iron phosphate minerals. The method comprises the steps of internally crushing the iron phosphate minerals through a crusher; sequentially carrying out 0.35mm to 0.45mm particle-size coarse crushing, 0.1mm to 0.15mm intermediate crushing, and 0.05mm to 0.09mm fine crushing; screening the fine-crushed powder ore, and obtaining undersize dried powdered ore and plus sieve powdered ore; placing the undersize dried powdered ore into a screening machine with a 0.4T to 1.2T high-intensity magnetic field, screening to obtain magnetic iron ore particles and powder, carrying out magnetic separation to screening a first dried iron ore concentrate, a first dried middling ore, and a first driedtailing, and returning the plus sieve powered ore back to the fine crushing step. The powered ore is dry-screened through sequentially carrying out the technological processes such as coarse crushing, intermediate crushing, fine crushing, screening, and dry screening on raw ore, so that the grinding particle size fineness is improved, the aim of more crushing and less grinding is achieved, the energy consumption and other raw material consumption during the mineral processing process are greatly reduced, the beneficiation cost is reduced, and the economic benefit is improved.

Owner:李建辉

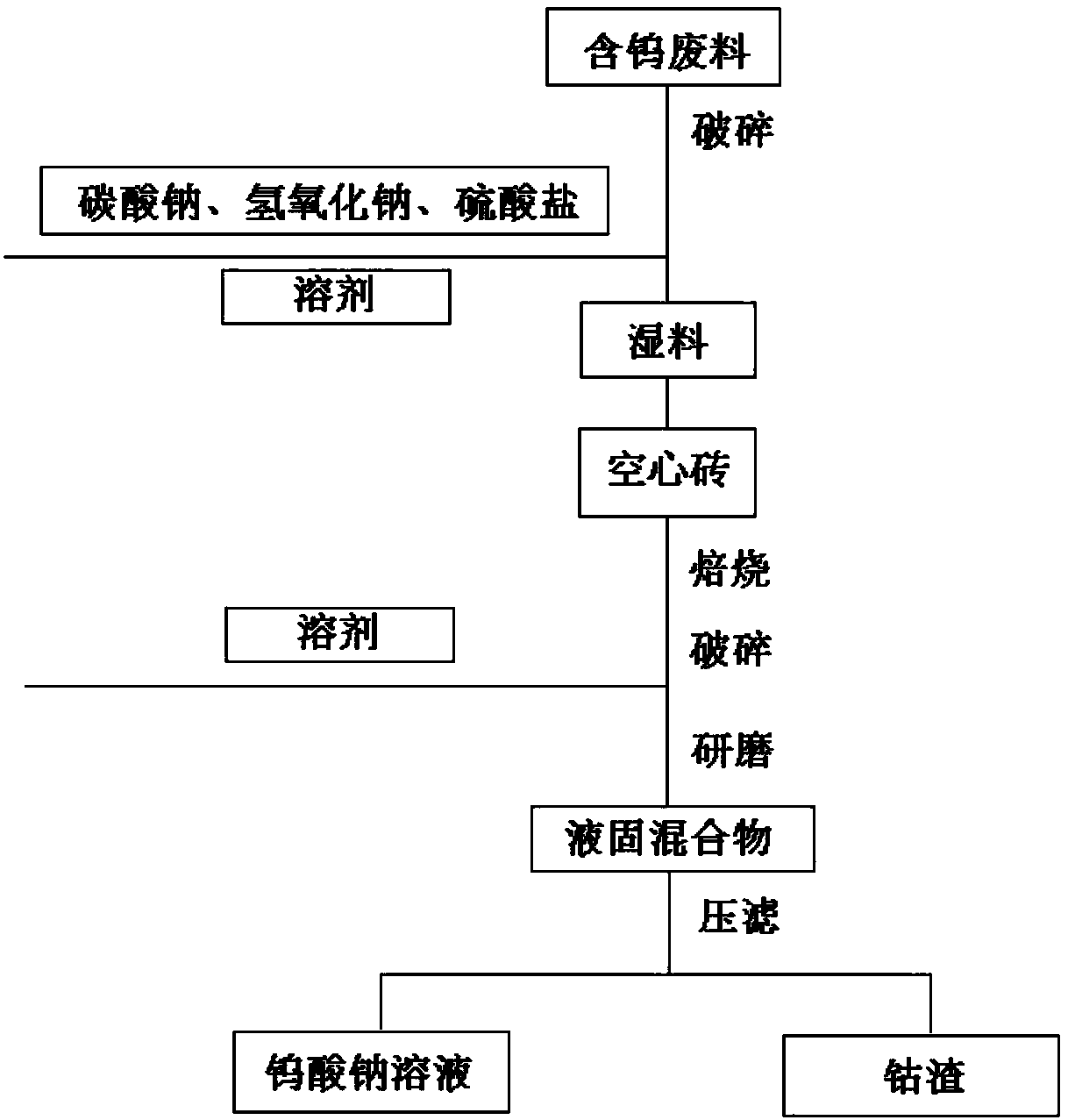

Method for extracting sodium tungstate from tungsten-containing waste material

The invention relates to a method for extracting sodium tungstate from a tungsten-containing waste material. The method comprises the following steps: (1) preparing a tungsten-containing waste material; (2) adding sodium carbonate, sodium hydroxide and sulfate into the blocky tungsten-containing waste material, mixing, and then adding a solvent, so that a wet material is prepared; (3) making the wet material into a hollow brick, and naturally drying; (4) roasting the naturally dried hollow brick, and then cooling to room temperature; and (5) crushing into a blocky brick, adding a solvent tiilthe liquid-solid ratio reaches (0.3-1):1, grinding, then adding a solvent till the liquid-solid ratio reaches (1-6):1, leaching for 5-30 minutes at the temperature of 50-120 DEG C, and carrying out filter pressing, so that a sodium tungstate solution and cobalt slag are obtained. The method provided by the invention has the advantages that sodium tungstate can be extracted from the tungsten-containing waste material with relatively high extraction efficiency, the production technical process is simplified, land occupied by equipment is reduced, and the industrial utilization value of the tungsten-containing waste material is comprehensively improved.

Owner:HUNAN LITIAN TUNGSTEN IND CO LTD

Injection molding machine waste gas zero-emission system and process

InactiveCN111228899ASave raw materialsReduce pollutionDispersed particle separationViscous flowFuel oil

The invention relates to an injection molding machine waste gas zero emission system and process, and belongs to the technical field of environmental protection. The zero emission system for the wastegas of the injection molding machine comprises the injection molding machine, an induced draft hood is arranged above the injection molding machine and connected with an induced draft fan, the induced draft fan is connected with a cyclone separator, the top of the cyclone separator is connected with a condenser, and the condenser is connected with a raw material collecting device through a pipeline A; the bottom of the cyclone separator is connected with the heavy oil adsorption tank through a pipeline B. The process comprises collecting waste gas generated by an injection molding machine andsucking the waste gas into a cyclone separator and separating the waste gas into two parts; wherein the recyclable waste gas is condensed into a viscous flow state material and then is collected; theorganic components in the waste gas, which cannot be recycled, by the heavy oil, and the adsorbed gas is discharged into an injection molding workshop. The system and process is scientific and reasonable in design and convenient to use, resources are saved, the production and treatment cost is reduced, environmental pollution is reduced, and energy conservation and environmental protection are achieved.

Owner:山东海众化工科技有限公司

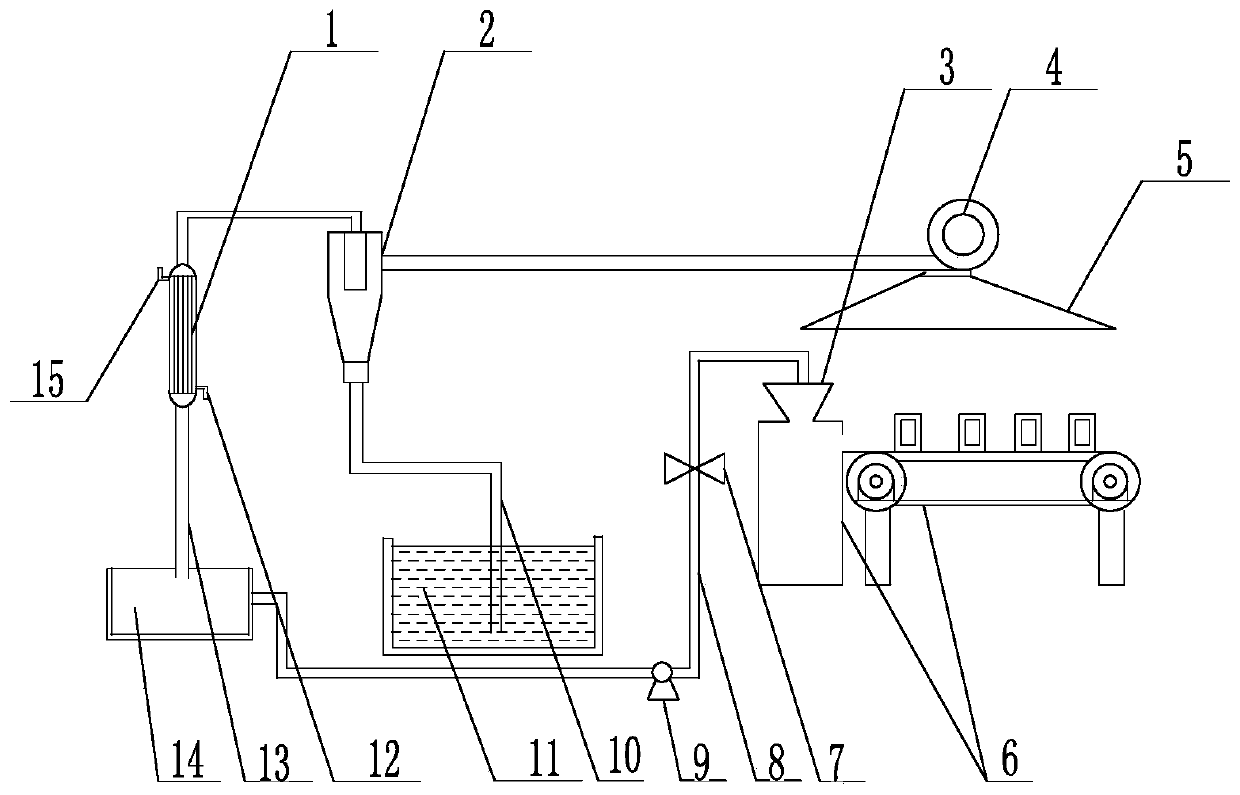

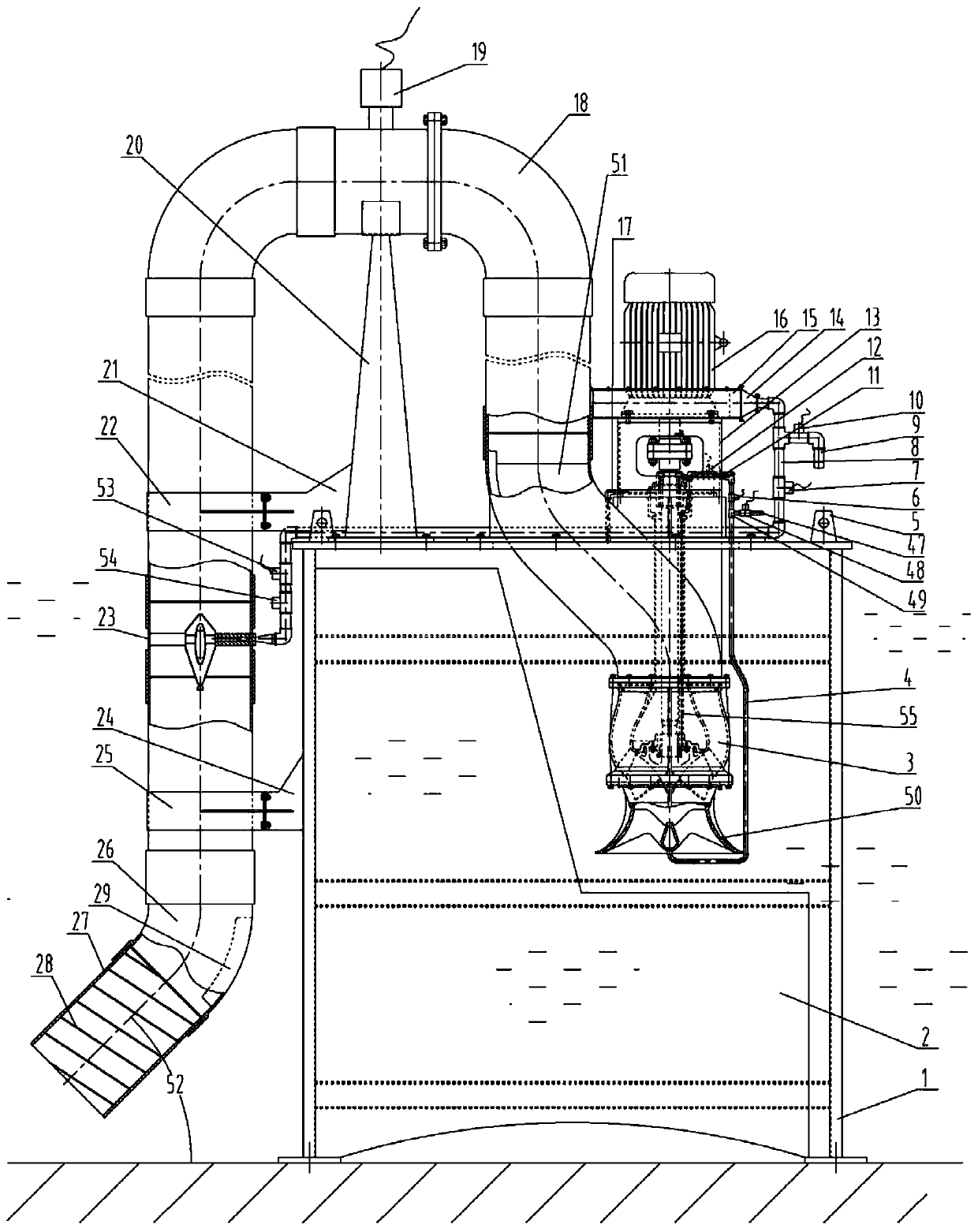

Forced circulation pump set equipment for water treatment system

PendingCN110240254AProcessing speedImprove processing effectWater treatment parameter controlPump componentsTreatment costsEngineering

The invention provides forced circulation pump set equipment for a water treatment system. The equipment comprises a pump set installation frame, a circulation pump, a water outlet pipe, a gas-liquid mixing device and a wind collecting device; and the circulation pump comprises an electromotor, a rotor component, a water outlet section and a suction section which cooperate in sequence from the top to the bottom. According to the equipment provided by the invention, the wind collecting device is arranged under the electromotor of the circulation pump, the electromotor of the circulation pump is provided with a fan for dissipating heat, when the circulation pump runs, the wind collecting device collects wind energy generated by the fan of the electromotor and sends the wind energy into the gas-liquid mixing device, the wind energy and a medium in the water outlet pipe are subjected to gas-liquid mixing circulation, the collected wind energy contains a large amount of oxygen, the oxygen can be oxidized with the medium, so that the equipment saves energy and reduces costs without the need of additionally adding oxygen production or wind production equipment; and the collected wind energy has air pressure and can generate jet action to drive the medium in the water outlet pipe to flow, so that the medium in the circulation pump and the water outlet pipe has siphon flow, acting of the electromotor on the circulation pump is reduced, energy consumption is reduced, and the production treatment costs of the medium are reduced.

Owner:GUANGZHOU XINHENG PUMP MFG

Method for destroying water-absorbing performance of sodium polyacrylate resin and method for recycling waste water-absorbing articles

ActiveCN103627027BLow priceMeet the requirements of industrial productionPlastic recyclingInorganic saltsLiquid ratio

The invention discloses a method for destroying the water absorbency of sodium polyacrylate resin. The method comprises the following steps: (1) weighing inorganic salt containing CaCl2, and preparing a 0.05-5% solution from the inorganic salt; (2) weighing a sodium polyacrylate resin solid, adding a 0.1-6% H2SO4 solution according to the solid-to-liquid ratio of (1: 100) to (1: 500), and filtering, so as to obtain a pretreated sodium polyacrylate resin solid substance; (3) adding the resin solid substance into an inorganic salt mixed solution according to the solid-to-liquid ratio of (1: 50) to (1: 300), and filtering, thereby obtaining sodium polyacrylate resin with lowered water absorbency. The invention further discloses a method for recovering articles for physiological hygiene. The methods have the good effects that the water absorbency of the sodium polyacrylate resin is lowered to about 1% of the original water absorbency, and the problem of water resource waste during the recovery of waste / old water absorbing articles is solved.

Owner:青岛福创环境科技有限公司

A treatment system and method for coking reverse osmosis concentrated brine

ActiveCN105152453BReduce pollutionLess one-time investmentTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentSaline waterSludge

The invention provides a coking reverse osmosis concentrated brine treatment system, which includes a water inlet tank, and the water inlet tank is sequentially connected with a filling tank, a large aerobic tank, a small aerobic tank, a biological sedimentation tank, and a water outlet tank through pipelines; The large aerobic tank is connected with the nitrification sedimentation tank through pipelines, and the nitrification sedimentation tank is connected with the packing tank, and a sludge return pump is arranged at the bottom of the nitrification sedimentation tank to allow the sludge to enter the large aerobic tank; the small aerobic tank passes through The pipeline is connected with the carbon source dissolving pool, and the carbon source dissolving pool pumps the dissolved carbon source into the small aerobic pool through the metering pump. Adopting the treatment system of the present invention has low one-time investment, simple operation and low production and treatment cost, and is an environment-friendly green treatment process for steel wastewater; according to the water quality and quantity of coking reverse osmosis concentrated brine, an economical and efficient treatment system has been developed. Reverse osmosis concentrated brine discharge treatment system up to standard.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Method for producing three-dimensional network solidification and sealing carbonaceous ceramsite by hot dipping of leather sludge

The invention provides a method for producing three-dimensional network solidification and sealing carbonaceous ceramsite by hot dipping of leather sludge. Then put it into a cracking furnace, and thermally crack it in isolation from air at 300-800°C until no cracking gas is produced, forming carbonaceous ceramsite with a large number of micropores on the surface; then impregnated in the impregnated material, using carbon The temperature of the ceramsite itself melts the impregnated material, infiltrates the carbonaceous ceramsite and enters the micropores of the carbonaceous ceramsite for heavy metal fixation and three-dimensional network sealing, and natural cooling, that is, the finished three-dimensional network is solidified and sealed carbonaceous ceramsite; The impregnating material is polymer resin. The cured metal ions of the present invention are basically unable to dissolve and have high safety. At the same time, the carbonaceous ceramsite has certain hydrophobicity, strong weather resistance and toughness, and has high application value in light building materials, water resistance, heat insulation materials and the like.

Owner:QUANZHOU NORMAL UNIV

A method for removing soluble organic matter and heavy metal ions in electroplating wastewater

ActiveCN105293769BSolve the pollution of the environmentAvoid churnWater contaminantsWaste water treatment from metallurgical processActivated carbonOrganic matter

The invention discloses a method for removing soluble organic matter and heavy metal ions in electroplating wastewater, which comprises an acid-base regulating tank and a packing tower for efficiently removing soluble organic matter and heavy metal ions. The packing tower uses modified diatomaceous earth and activated carbon as double-layer packing. After being adsorbed by the packing, the electroplating wastewater meets the national discharge standard. The method for treating electroplating wastewater of the invention has high removal rate of organic matter and heavy metal ions, low one-time investment, simple operation and low production and treatment cost, and is an environment-friendly green treatment process for electroplating wastewater.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

A cold-formed hot-rolled pickling high-strength steel antirust liquid, its preparation method and application

A cold-formed hot-rolled pickling high-strength steel antirust solution, its preparation method and application, relate to the technical field of antirust treatment in hot rolling, and the antirust solution includes microemulsion, phosphoric acid mixed solution and dimethyldichlorosilane , wherein, the microemulsion uses propylene glycol as a solvent and contains glucose and fatty acid methyl ester; the phosphoric acid mixed solution uses 0.5 to 2wt.% phosphoric acid solution as a solvent and contains lauric acid monoester, palmitic acid monoester and stearic acid triester. The anti-rust solution can be used for long-term rust prevention of cold-formed hot-rolled pickled high-strength steel. The cold-formed hot-rolled pickled high-strength steel after treatment has good mechanical properties and good anti-rust effect. Simple, low production and processing costs, belongs to the steel green environmental protection production process, has good social and environmental benefits.

Owner:BAOSHAN IRON & STEEL CO LTD

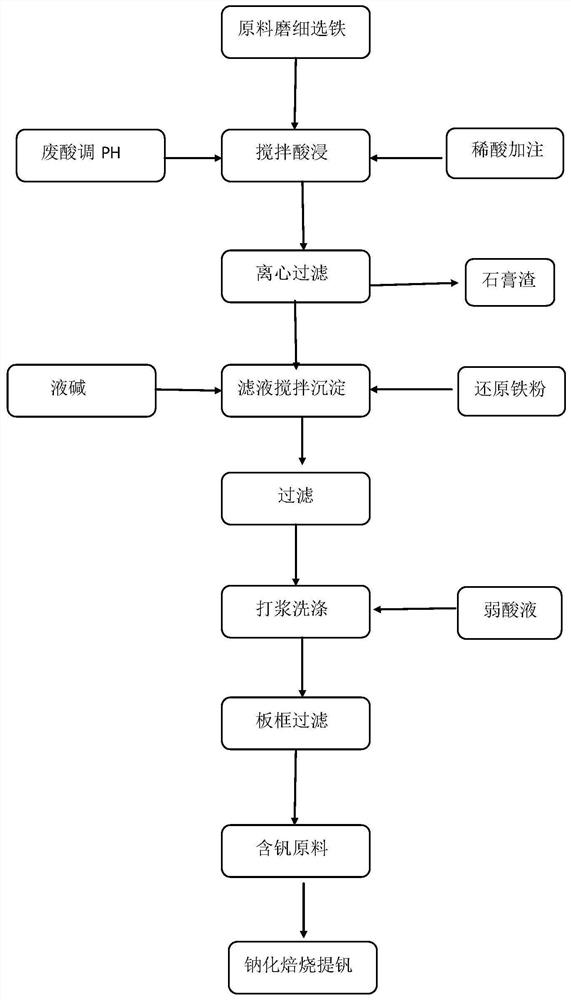

A method for comprehensively treating vanadium-containing slag and titanium dioxide waste acid

ActiveCN112830694BAvoid extracting vanadiumReduce production handling costsCement productionIron powderSlag

The invention discloses a method for comprehensively treating vanadium-containing slag and titanium dioxide waste acid. The flue in the white powder sprays the acid-containing wastewater produced in each titanium dioxide production process; 2) The premixed liquid and the waste acid are mixed and stirred to react to form a slurry. After the reaction is completed, the solid-liquid separation is completed, and the obtained solid is acidic high-sulfur gray-white Gypsum slag; the liquid is a vanadium-containing solution; the waste acid comes from the waste sulfuric acid that is difficult to reuse after acidolysis in the titanium dioxide industry by the sulfuric acid method; 3) Add iron powder to the obtained vanadium-containing solution for stirring and reduction, and then add liquid alkali to react The pH of the liquid is 3.8-4.5, and precipitation is performed to obtain a qualified slurry, and a vanadium-containing filter cake is obtained after solid-liquid separation. Through the method provided by the invention, vanadium-containing slag and titanium dioxide waste acid can be effectively treated, comprehensive recovery and utilization thereof can be realized, and the treatment cost can be reduced, so that the slag can be used for industrial-scale treatment.

Owner:攀枝花恒通钛业有限公司

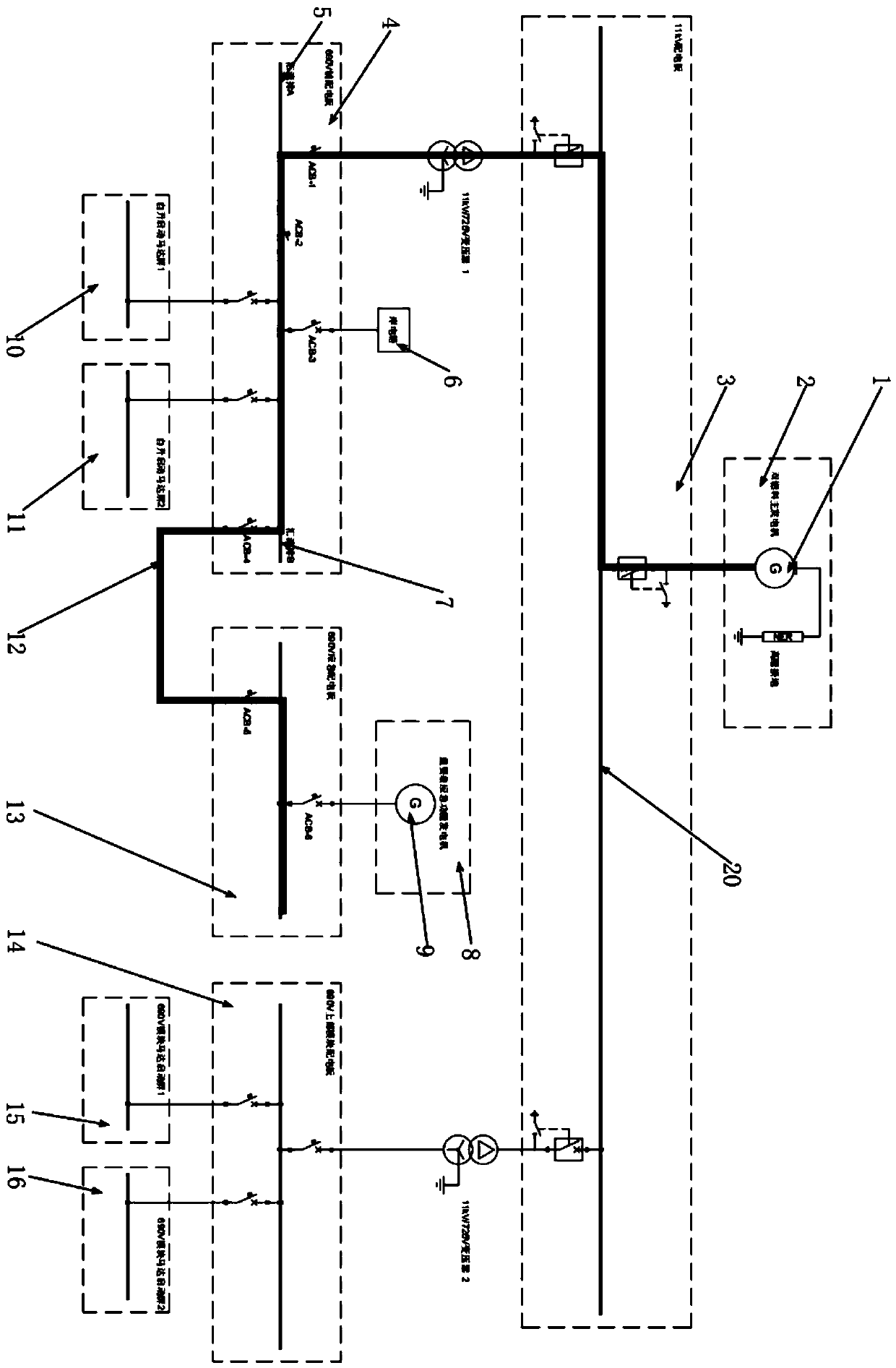

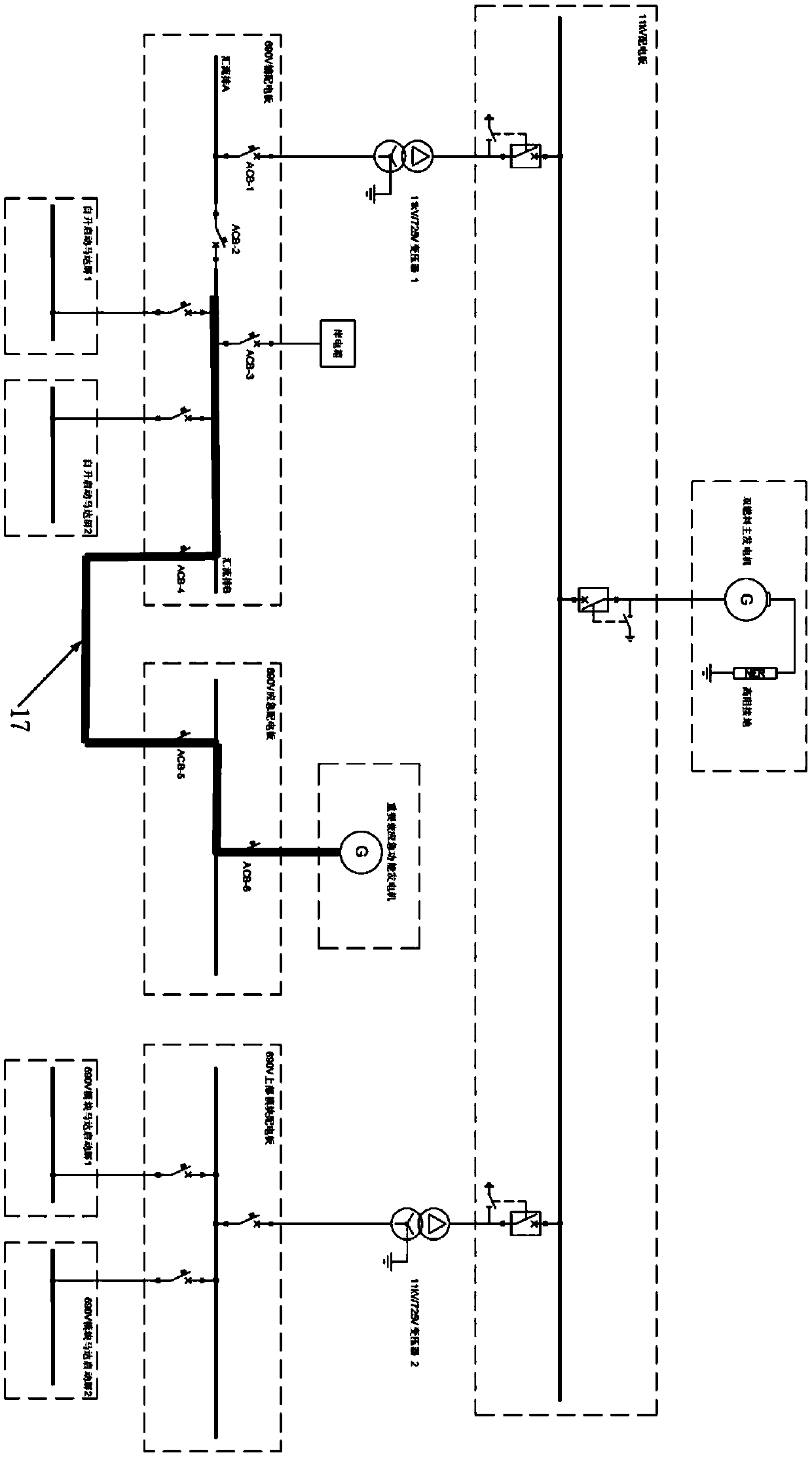

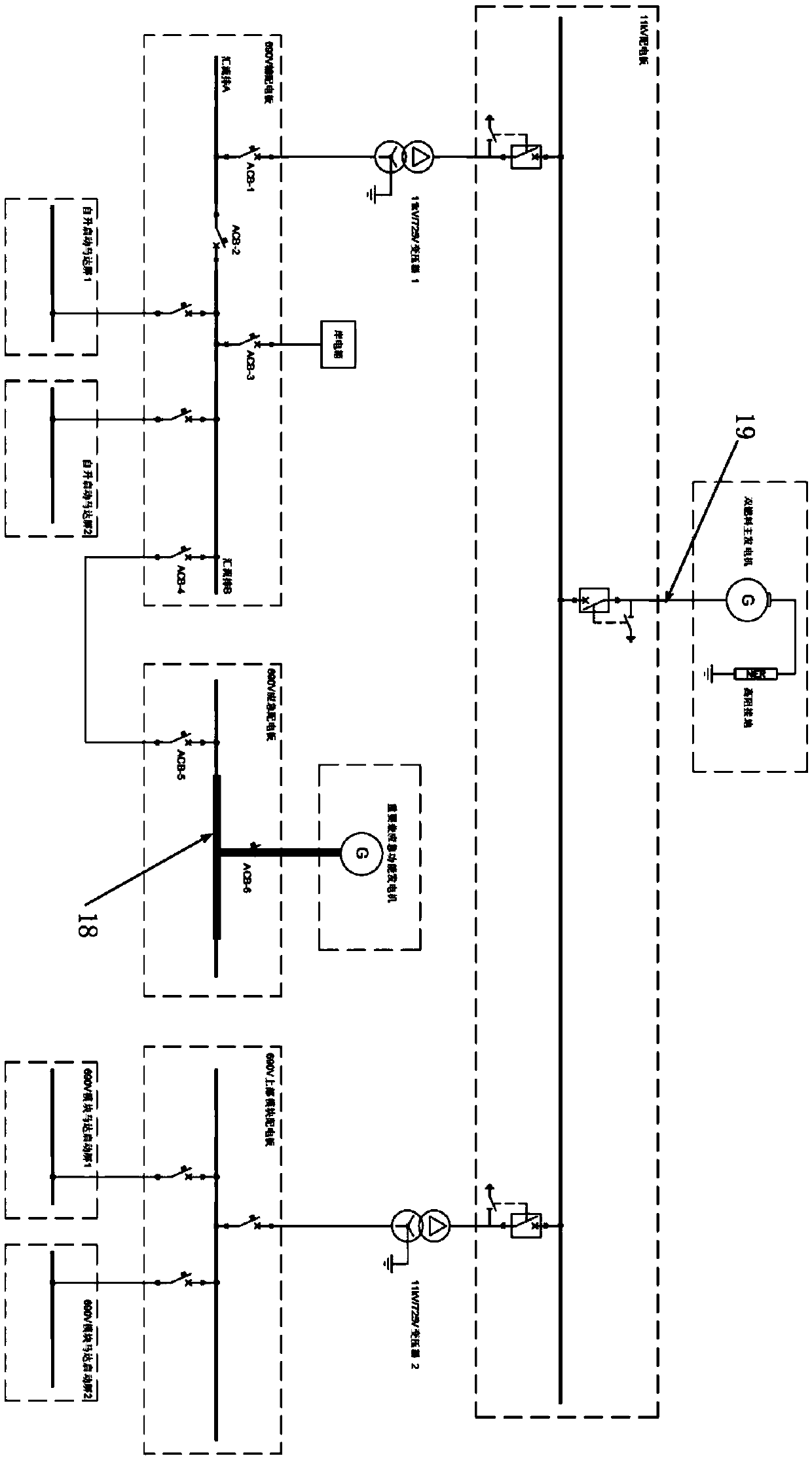

Self-elevating MOPU economical power system

PendingCN109638828AReduce operating costsReduce production handling costsAc network circuit arrangementsEmergency power supply arrangementsPower stationBusbar

The invention relates to the field of offshore ocean engineering and particularly relates to a self-elevating MOPU economical power system. The system comprises a main power station, an important andemergency power station and a power grid. The main power station is fixedly connected with a dual-fuel main generator. The dual-fuel main generator is electrically connected with an upper module powerdistribution system. One side, far away from a 690V upper module power distribution board, of a 11KV power distribution board, is electrically connected with a 690V marine auxiliary power distribution board. The 690V marine auxiliary power distribution board comprises a busbar A and a busbar B. One side, away from the busbar A, of the busbar B is electrically connected with a 690V emergency powerdistribution board. One end, away from the busbar B, of the 690V emergency power distribution board is electrically connected with the important and emergency power station. The power grid comprisesan L-shaped power supply mode, a reverse power supply mode and an emergency power supply mode. The system is suitable for a self-elevating oil-gas production processing platform and an economical power supply system in the offshore ocean engineering field. The system meets related laws and regulations, and reduces the project cost to the maximum extent.

Owner:上海中远船务工程有限公司

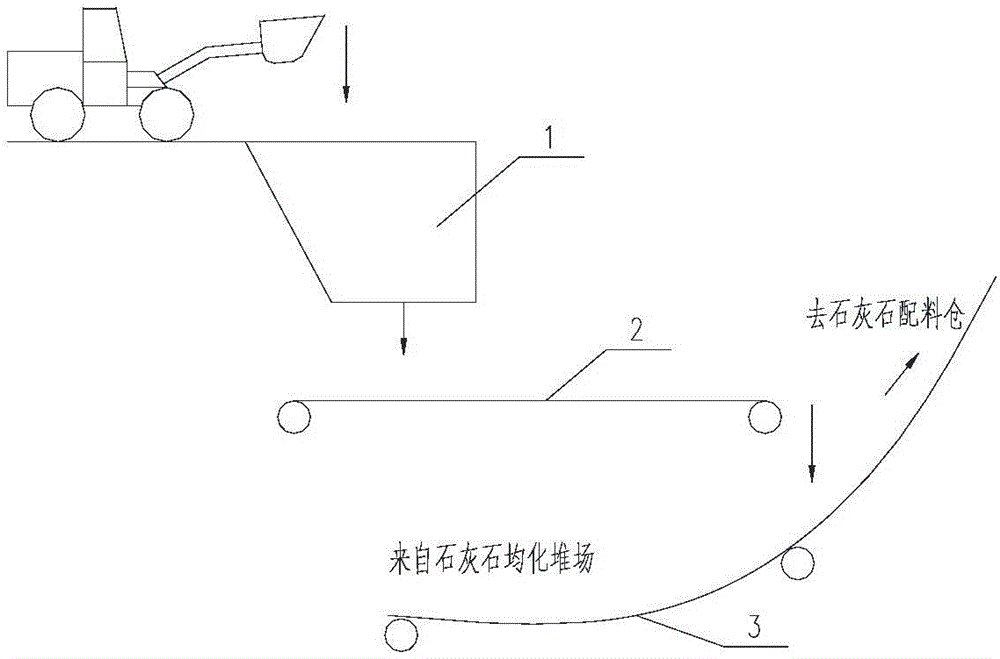

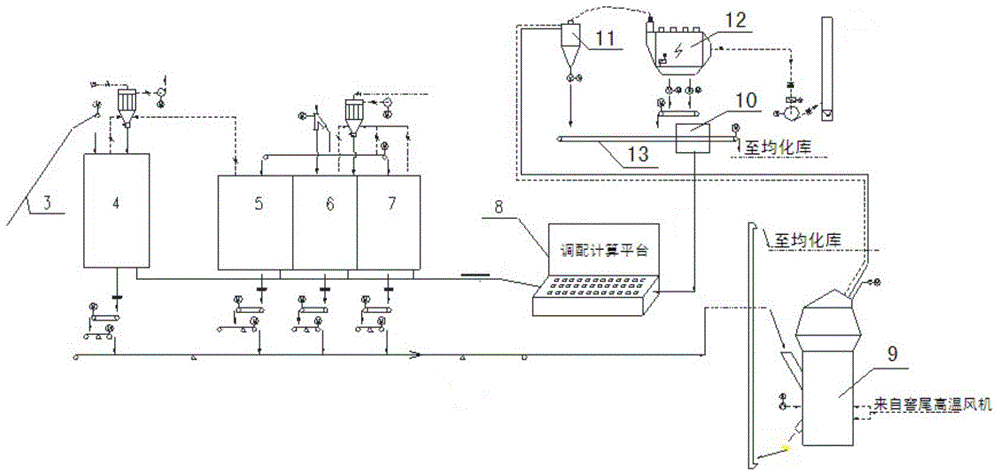

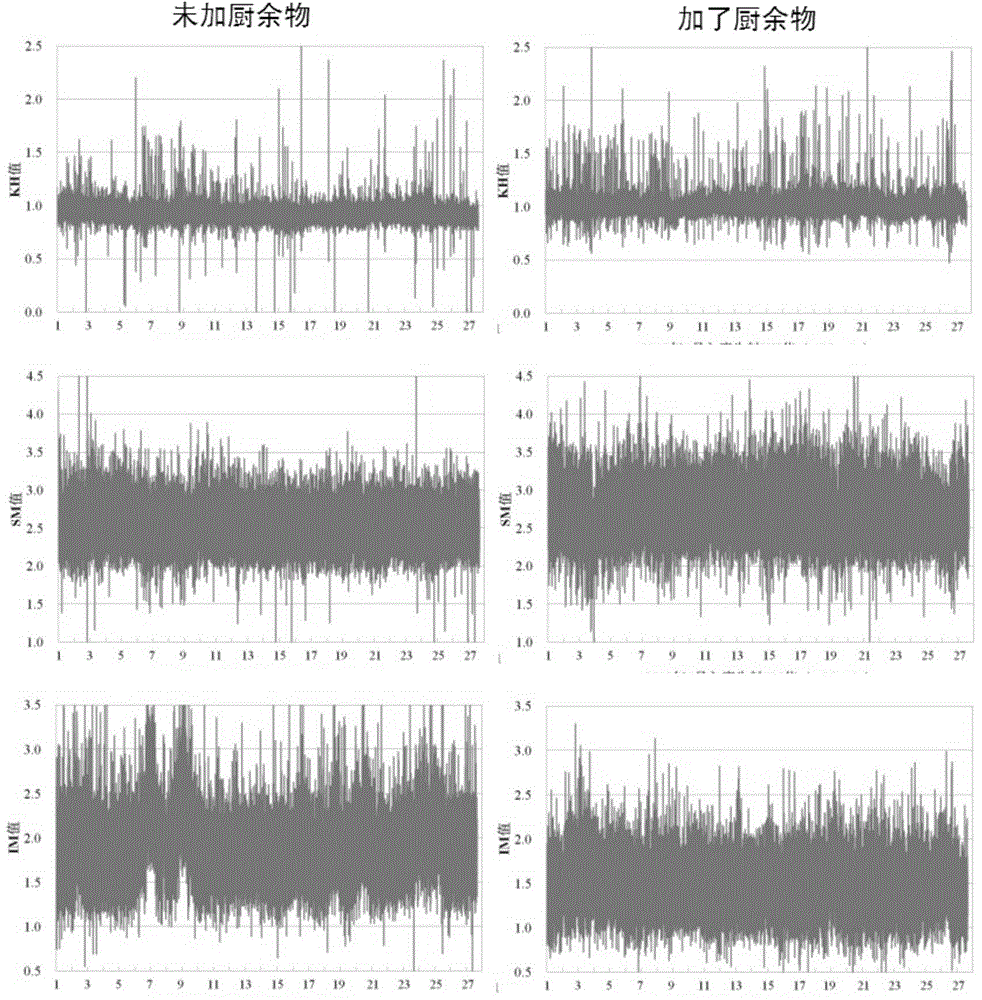

A method for improving the grindability of cement raw meal and reducing toc emission by using kitchen waste

ActiveCN103936310BImprove grindabilityReduce power consumptionClinker productionCombustionChemical composition

The invention discloses a method used for improving cement raw material grindability and reducing TOC discharge with kitchen waste. According to the method, the kitchen waste collected from municipal solid waste is mixed with raw materials which are used for preparing cement raw material; and an obtained mixture is delivered into a flour mill for grinding, wherein the outlet of the flour mill is provided with a gamma-Metric analyzer used for real-time monitoring on chemical components of the discharged cement raw material. According to the method, kitchen waste is added into a raw material grinding system so as to improve grindability of the cement raw material, and reduce power consumption of the flour mill; ash obtained via combustion of the kitchen waste can be used for replacing clay raw material; TOC discharge of a cement production system is reduced at the same time; a large amount of organic substances with relatively heat value are obtained via drying of the kitchen waste, and are burnt in a preheater so as to generate heat energy, so that the temperature of waste gas is increased, and waste heat power generation is increased; the kitchen waste is subjected to low-temperature drying grinding, a large amount of residual heat energy obtained via cerement plant waste heat power generation is recycled, a kitchen waste dewatering problem is solved, and processing cost of the kitchen waste is reduced.

Owner:SINOMA INT ENG

Method for preparing aluminum electrolytic cell TiB2 cathode coating by adopting plasma spraying technology

ActiveCN102864404BImprove corrosion abilityImprove corrosion resistanceMolten spray coatingAluminium electrolysisComposite cathode

Owner:KUNMING METALLURGY INST

Technical process of chrome plating overpassing hydraulic mechanical member

InactiveCN100467667CImprove corrosion resistanceImprove performanceLiquid/solution decomposition chemical coatingHigh resistanceAlloy

The present invention provides alloy plating solution and corresponding treating process for forming coating with high corrosion resistance, high hardness, high wear resistance and high erosion resistance. The present invention is used in hydraulic part production, and has the outstanding features of high plating speed, low material consumption, low power consumption and no pollution. The alloy plating solution is compounded through dissolving nickel sulfate, amino acetic acid, sodium hypophosphorite, graphite fluoride, boric acid, sodium saccharin, lead ion, ammonia water and sodium hydroxide in the weight ratio of 3 to 2.5 to 0.35 to 0.6 to 3 to 0.3 to 0.003 to 0.35 to 0.15 in pure water of 90 weight portions. During plating, the alloy plating solution is heated to 50-80 deg.c, and the plating time is determined based on thickness to be plated.

Owner:李天忠

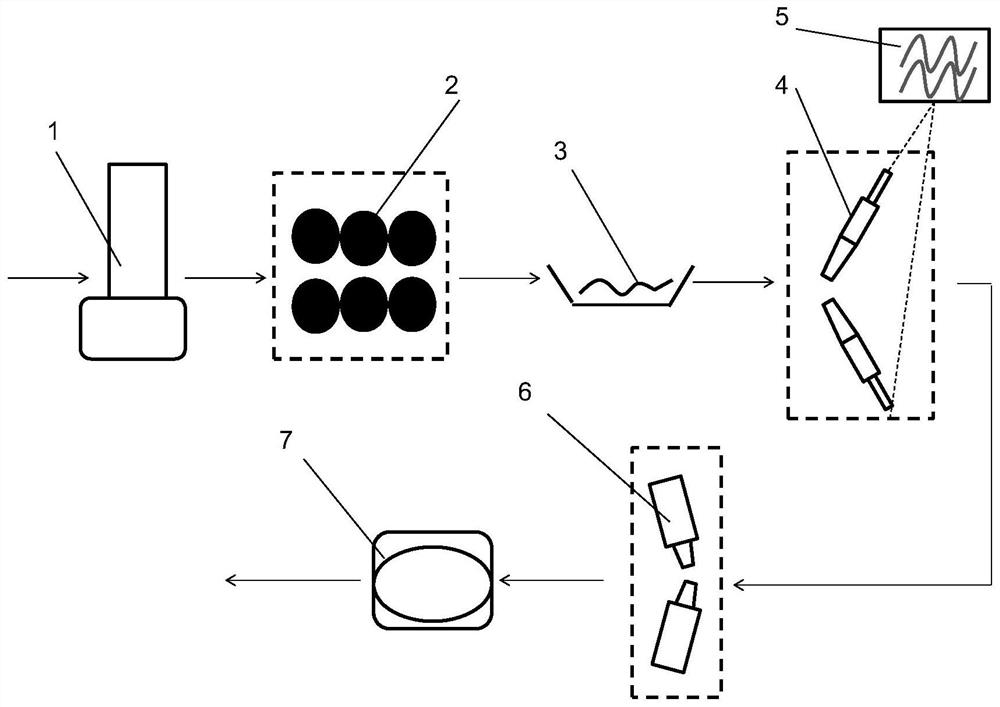

Treatment method and treatment system apparatus for improving biodegradability of surface finishing liquid wastewater

ActiveCN106976950AImprove BODImprove biodegradabilityMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationWater vaporCordierites

The invention provides a treatment method and a treatment system for improving the biodegradability of surface finishing liquid wastewater. According to the present invention, surface finishing liquid wastewater flows into a coarse sand filter to remove suspended matters and impurity particles from the wastewater, the surface finishing liquid wastewater outflowing from the coarse sand filter enters a contact reaction tower provided with an air source ozone generator from the bottom portion of the contact reaction tower, a cordierite honeycomb ceramic-supported ferromanganese catalyst filler is placed in the contact reaction tower, the ozone generated from the air source ozone generator enters the contact reaction tower from the bottom portion of the contact reaction tower, and the wastewater, the ozone and the catalyst are co-subjected to a water vapor heterogeneous catalytic reaction in the contact reaction tower so as to improve the biodegradability of surface finishing liquid wastewater, ie., the BOD / COD value in the surface finishing liquid wastewater can be increased. With the technical scheme of the present invention, the environmental pollution can be reduced, and the increasingly stringent environmental protection laws and regulations can be met.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com