Method for preparing aluminum electrolytic cell TiB2 cathode coating by adopting plasma spraying technology

An aluminum electrolytic cell and cathode coating technology, which is applied in coating, metal material coating process, melt spraying, etc. Combined with weak and other problems, the effects of reducing industrial voltage and secondary reaction probability, improving aluminum electrolysis production, and reducing production and processing costs are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

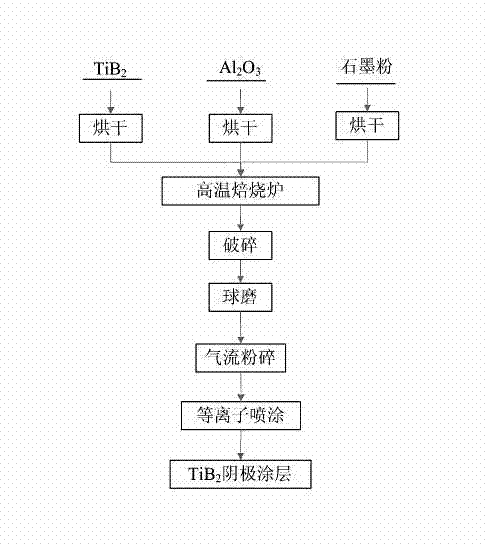

Image

Examples

Embodiment 1

[0023] TiB 2 、Al 2 o 3 , Put the graphite powder into a constant temperature drying oven, and dry at 120°C for 3-6 hours. TiB after drying 2 、Al 2 o 3 And graphite powder by mass percentage is: TiB 2 60%, Al 2 o 3 30% and graphite powder 10%, added to the medium frequency induction furnace to form a eutectic. Particle size D after crushing, ball milling and further ultra-fine crushing 50 It is a 400-mesh material, which is added to the hopper of the plasma spraying equipment.

[0024] Start the main control system and manipulator of the spraying equipment for plasma spraying. Process parameters: use argon as the main gas plus secondary gas as hydrogen to jointly feed powder, the flow rate of the main gas is 2000L / h, the flow rate of the secondary gas is 20L / h; the working current is 550A, the working voltage is 70V; the flow rate of the powder feeder is 240L / h; spraying The moving speed of the equipment is 0.02m / s, and the distance between the nozzle and the substra...

Embodiment 2

[0027] TiB 2 、Al 2 o 3 and graphite powder into a constant temperature drying oven, and dried at 120°C for 3-6 hours. TiB after drying 2 、Al 2 o 3 And graphite powder by mass percentage is: TiB 2 60%, Al 2 o 3 20% and graphite powder 20%, add to high temperature roasting furnace to form eutectic. After crushing, ball milling and further ultra-fine grinding, the particle size D 50 It is 500 mesh, and it is added to the hopper of the plasma spraying equipment.

[0028] Start the main control system and manipulator of the spraying equipment for plasma spraying. Process parameters: use argon as the main gas and secondary gas as hydrogen to jointly feed powder, the flow rate of the main gas is 2500L / h, the flow rate of the secondary gas is 30L / h; the working current is 600A, the working voltage is 72V; the flow rate of the powder feeder is 320L / h; spraying The moving speed of the equipment is 0.08m / s, and the distance between the nozzle and the substrate is 9cm. The res...

Embodiment 3

[0031] TiB 2 、Al 2 o 3 and graphite powder into a constant temperature drying oven, and dried at 120°C for 3-6 hours. TiB after drying 2 、Al 2 o 3 And graphite powder by mass percentage is: TiB 2 80%, Al 2 o 3 10% and graphite powder 10%, add to high temperature roasting furnace to form eutectic. After crushing, ball milling and further ultra-fine grinding, the particle size D 50 It is 500 mesh, and it is added to the hopper of the plasma spraying equipment.

[0032] Start the main control system and manipulator of the spraying equipment for plasma spraying. Process parameters: use argon as the main gas plus secondary gas as hydrogen to jointly feed powder, the flow rate of the main gas is 3000L / h, the flow rate of the secondary gas is 35L / h; the working current is 650A, the working voltage is 75V; the flow rate of the powder feeder is 350L / h; spraying The moving speed of the equipment is 0.04m / s, and the distance between the nozzle and the substrate is 10cm. The r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com