Patents

Literature

181results about How to "Improve seawater corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

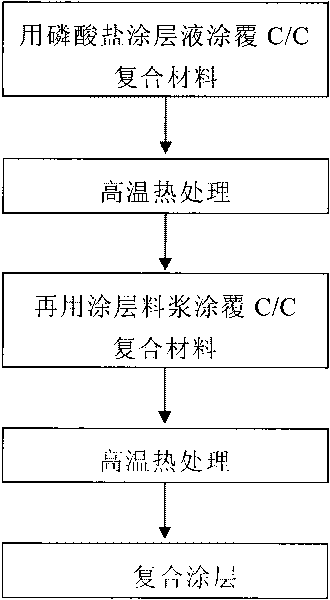

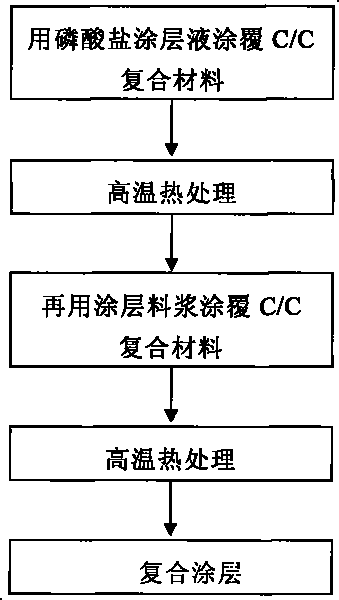

Surface anti-oxidation processing method for aircraft carbon brake disc

The invention discloses a surface anti-oxidation processing method for an aircraft carbon brake disc, which comprises the following steps: firstly, coating a layer of phosphate coating solution on the surface of a material needing to be processed, and forming a bottom phosphate coating through high temperature heat treatment; secondly, coating a layer of slurry coating which uses refractory ceramic powders as the main raw material and uses the phosphate coating solution as solution on the surface of the bottom phosphate coating; and finally forming a composite coating through the high temperature heat treatment. The composite coating of the invention has anticatalytic effect, and can improve the high temperature anti-oxidation capacity of C / C composite materials, such as the aircraft carbon brake disc and the like, under the condition of sea or salt spray pollution; and the ceramic component in the composite coating is melted and flows at high temperature so as to effectively heal the crackles in the coating, delay the time that oxygen is contacted with C / C materials, and improve the oxidation resistance of the composite coating.

Owner:XIAN CHAOMA SCI TECH

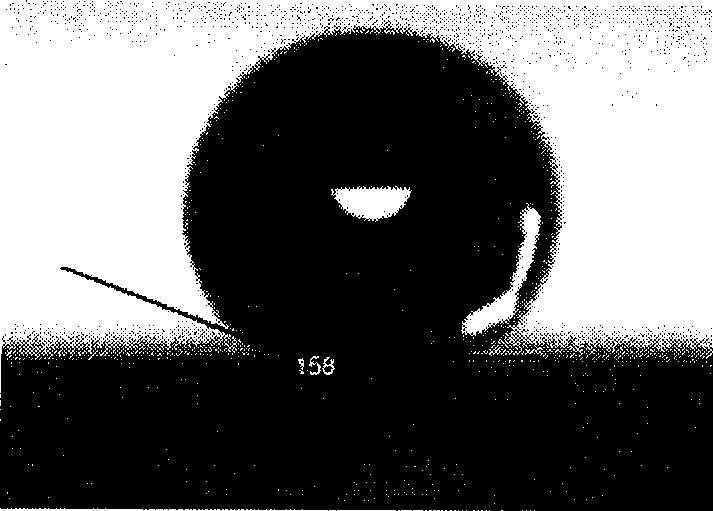

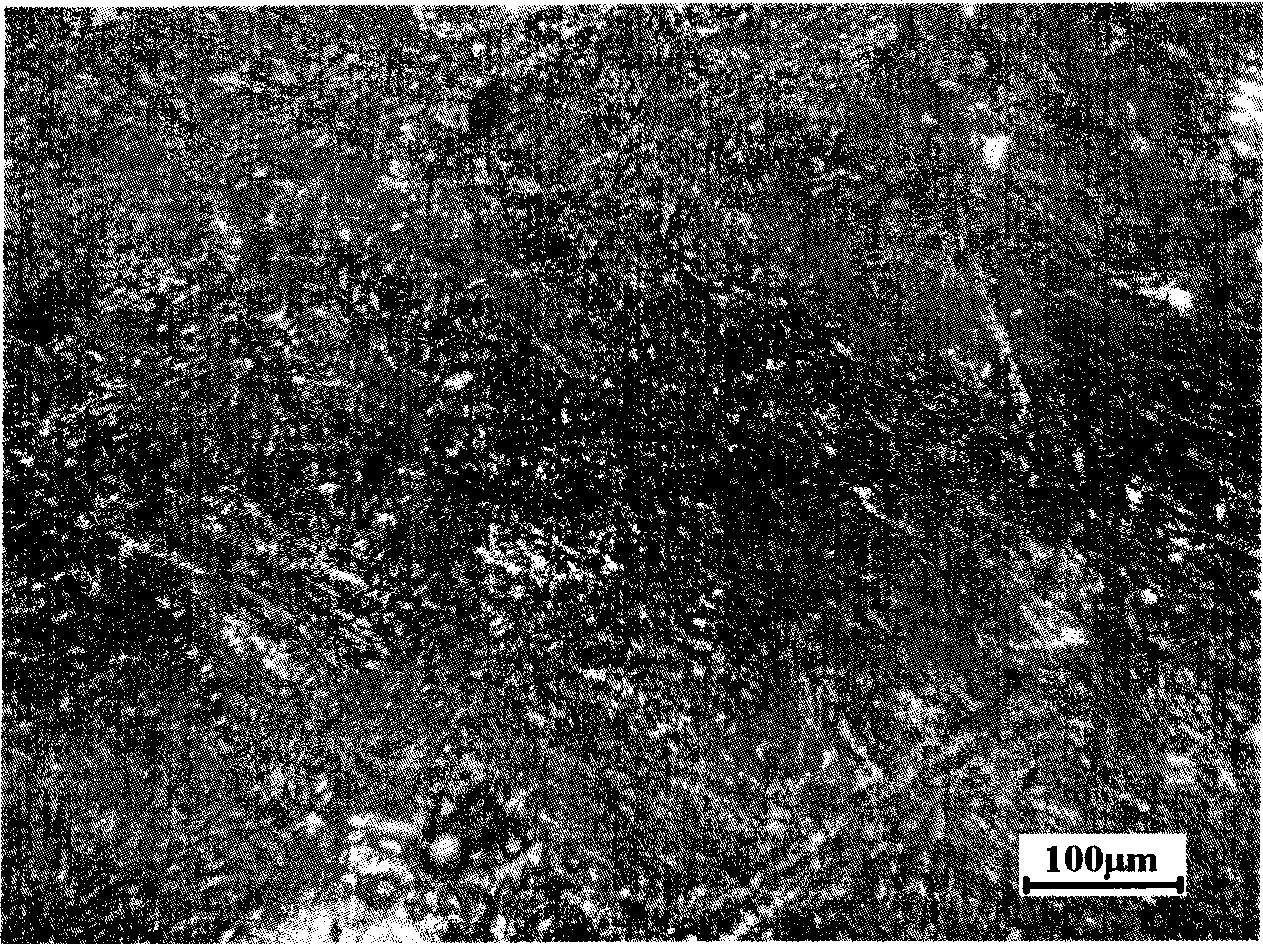

Surface treating method for sea water corrosion-resistant metal aluminum or aluminum alloy

InactiveCN101429672AImprove seawater corrosion resistanceEase of industrial applicationAnodisationMetallic aluminumElectrolysis

The invention relates to a method for treating the surface of seawater corrosion resistant metallic aluminum or aluminum alloy. The method comprises the following steps: 1) sand pellets are used to carry out gritting blasting treatment for the surfaces of aluminum and aluminium alloy through a spray gun so as to bring about the concave and convex surface topography in the micron order for aluminium and aluminium alloy; 2 the aluminium and aluminium alloy is cleaned after degreasing and is taken as the anode of an electrolytic bath, and nickel is taken as a cathode; the electrolyte is prepared and is added into the electrolytic bath, and a DC power supply is connected with the anode and the cathode so as to form nanometer holes on the aluminium or aluminium alloy surface; and 3 silicon fluoride is taken to carry out the surface finish of aluminum or aluminium alloy so as to reduce the surface free energy of aluminium or aluminium alloy. The method for adopting silicone fluoride to carry out the surface finish of aluminum or aluminium alloy comprises the following steps: heating up the aluminium or aluminium alloy processed in step 2 to 90 to 120 DEG C, keeping the temperature for 30 to 40 minutes, taking the aluminium or aluminum alloy out and cooling down the aluminium or aluminum alloy to a room temperature, and then carrying out surface finish through a soak method or a vapor plating method. The processed aluminium metal or aluminum alloy has good resistance to seawater corrosion.

Owner:SOUTHEAST UNIV

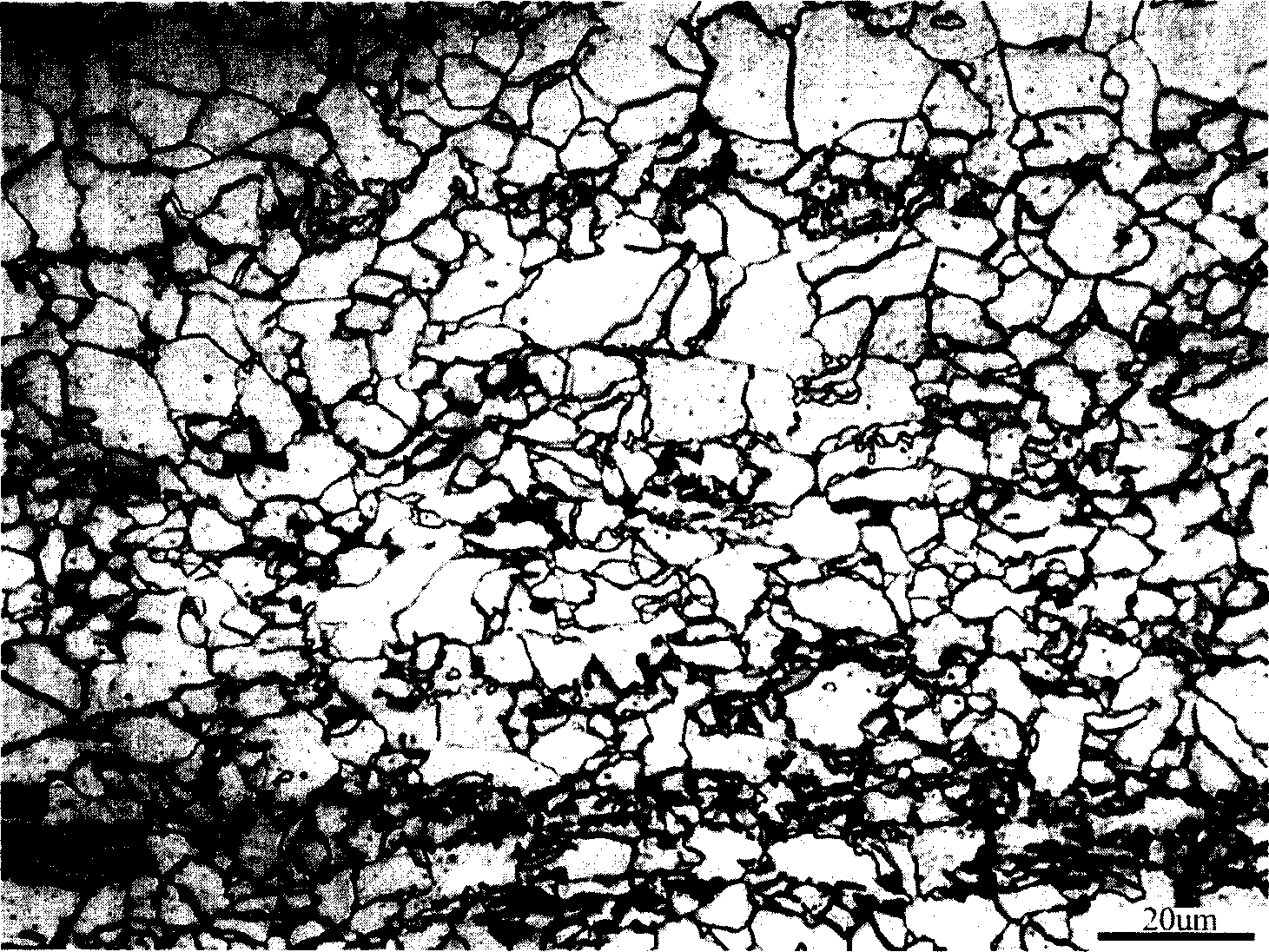

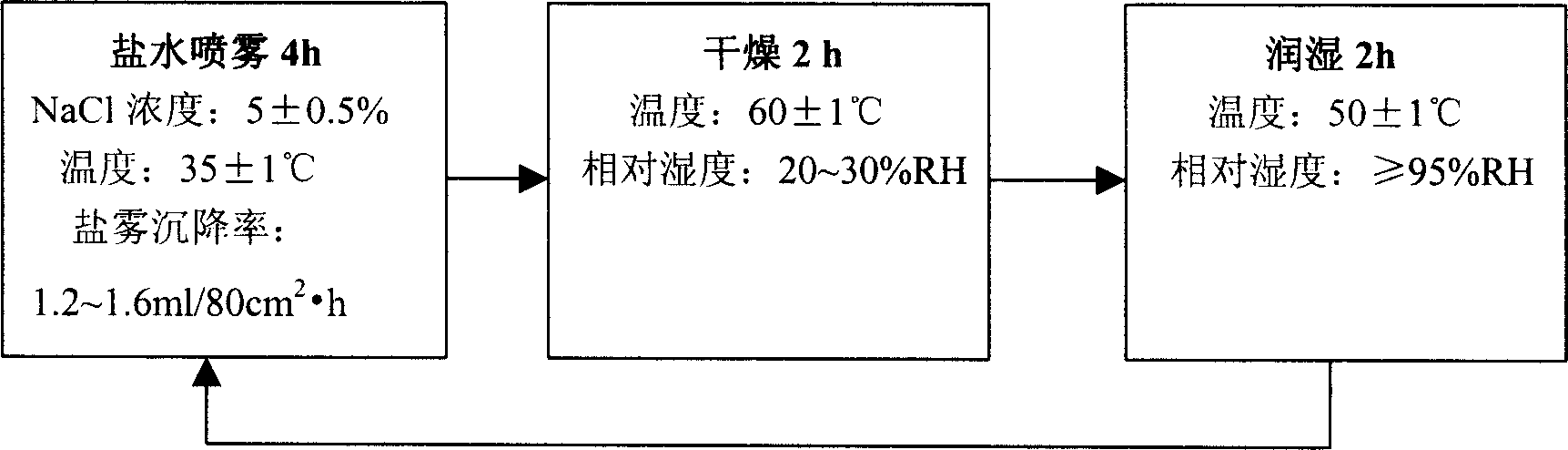

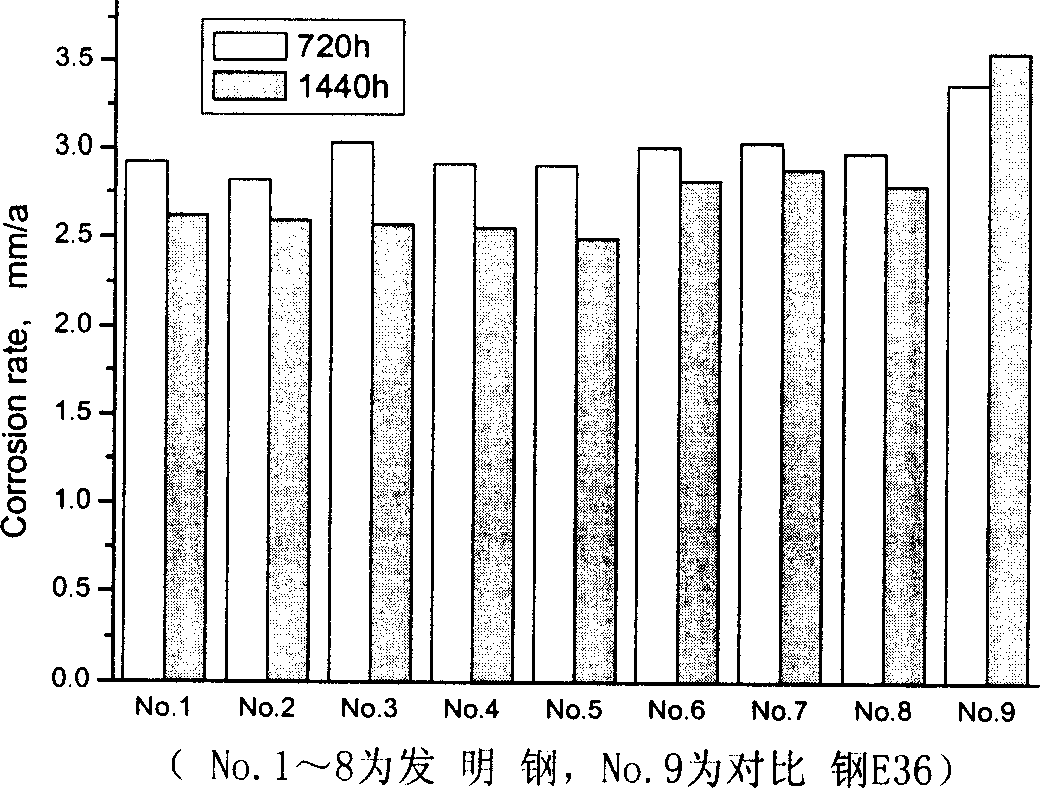

Sea water corrosion resistant steel for ocean drilling/production platform and preparation method thereof

InactiveCN1908217AReduce unevennessAvoid corrosionRoll mill control devicesWelding/cutting media/materialsChemical compositionImpurity

the invention discloses a marine exploiting platform steel of erosion property of sea water resistance, which comprises the following parts: 0.03-0.09% C, 0.90-1.60% Mn, 0.10-0.50% Si, 0.006-0.020% P, 0.004-0.100% Cr, 0.02-0.40% Cu, 0.010-0.060% Als, 0.005-0.060% Nb, 0.005-0.030% Ti, Fe and impurity. the manufacturing method comprises the following steps: desulfurizing; blowing; disposing through vacuum; casting continually; rolling.

Owner:武钢集团有限公司

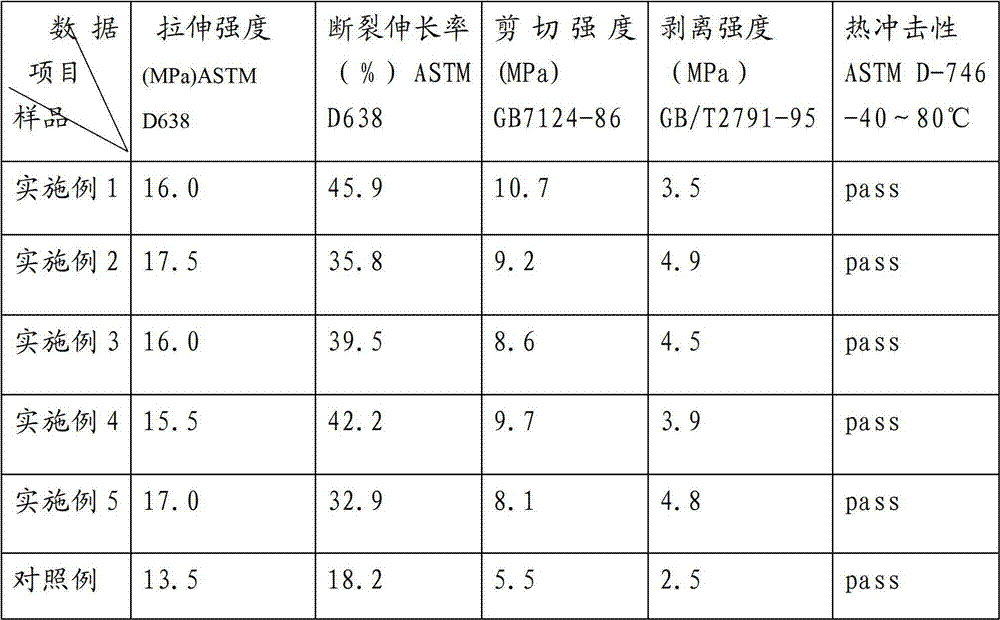

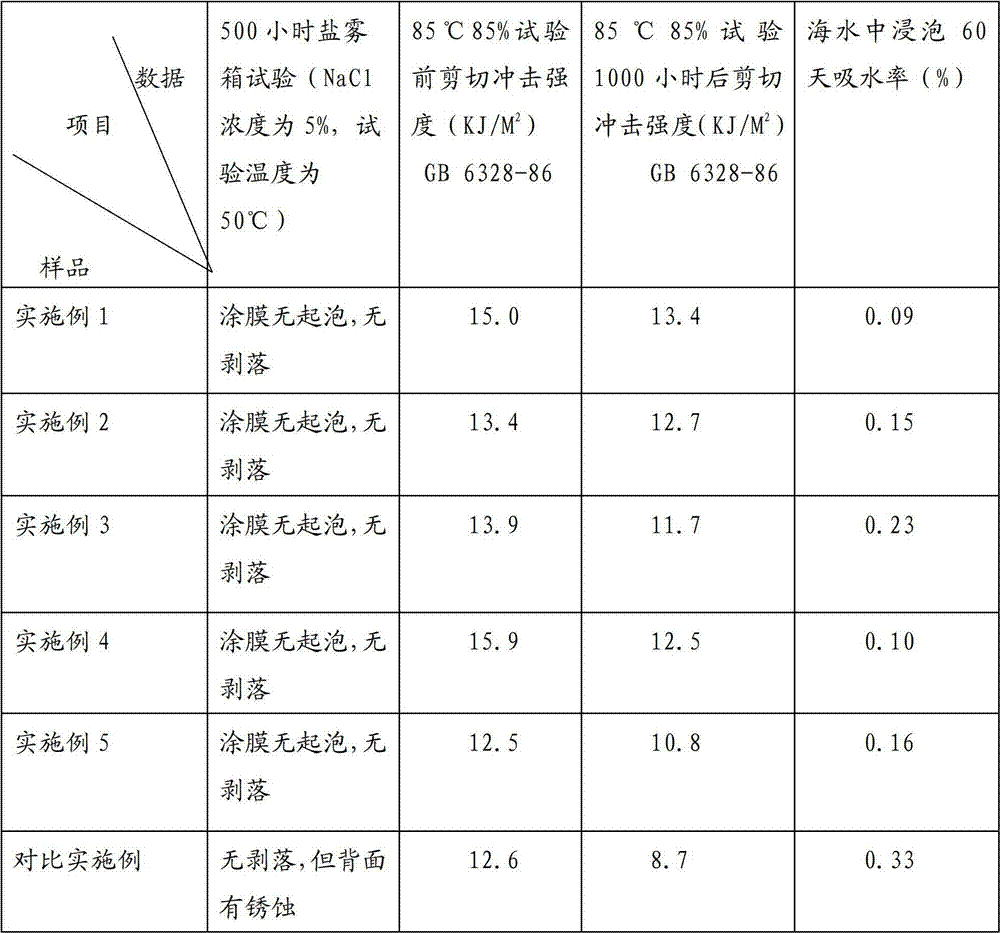

High elastic corrosion resistant epoxy sealant and preparation method thereof

InactiveCN102898988ANo foamingNo peelingNon-macromolecular adhesive additivesOther chemical processesCrack resistanceHigh intensity

The invention relates to a high elastic corrosion resistant epoxy sealant and a preparation method thereof. The epoxy sealant provided by the invention comprises a component A and a component B in a weight ratio of 100:20-100:25. The epoxy sealant provided by the invention has advantages of high strength, high elasticity, low heat release, cracking resistance, good sealing performance and seawater corrosion resistance, is convenient for construction, and greatly improves sealing of key parts of ship stern tube.

Owner:YANTAI DARBOND TECH

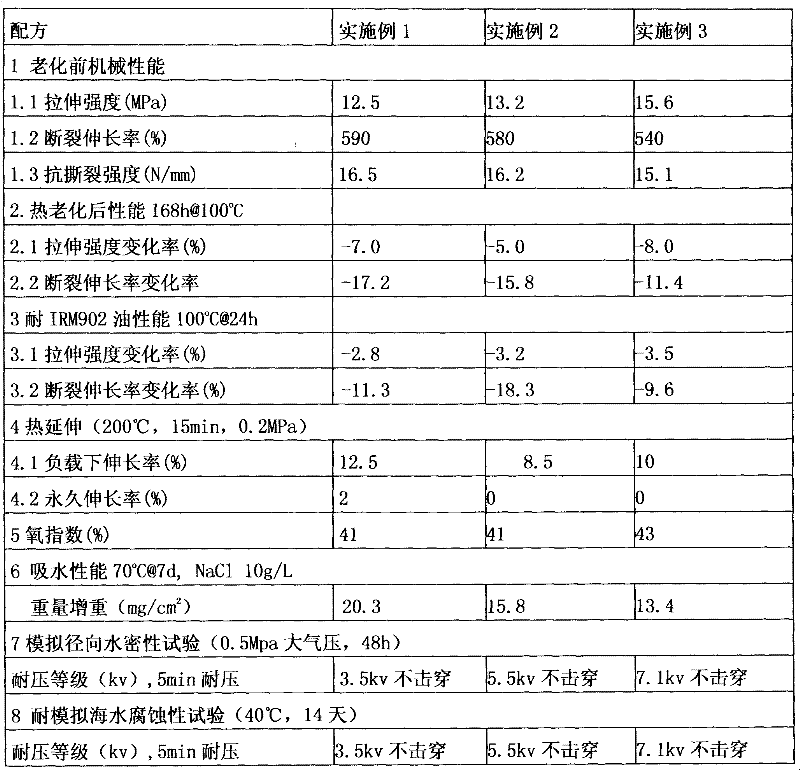

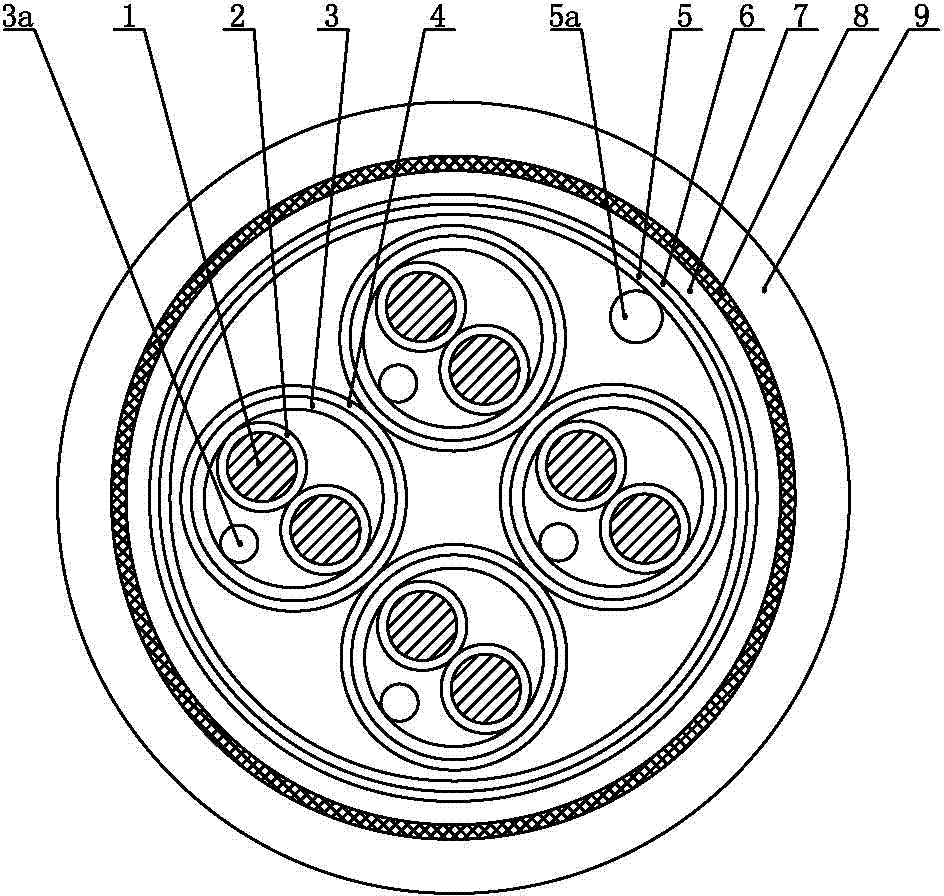

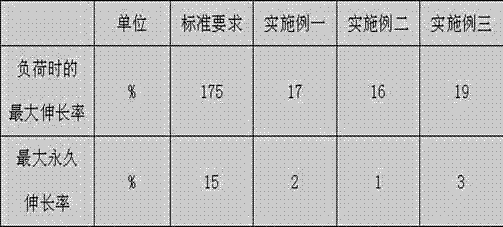

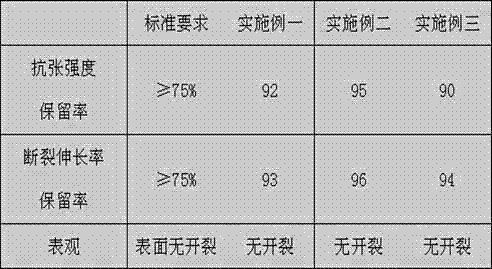

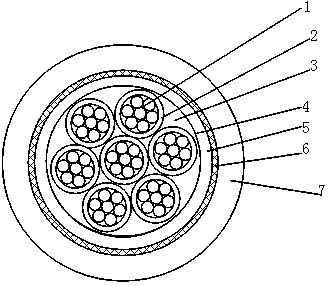

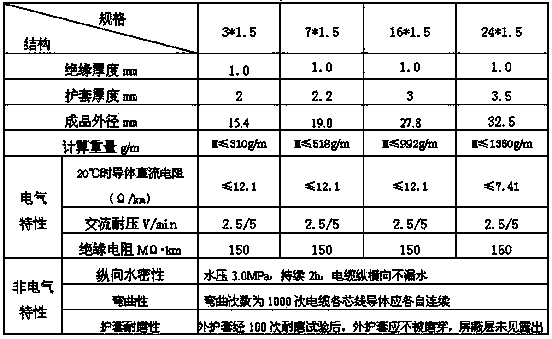

Waterproof and corrosion-resistant sheath material of degaussing cable and production method thereof

InactiveCN102417639AImprove water absorptionImprove mechanical propertiesRubber insulatorsInsulated cablesVulcanizationProcedure Agents

The invention discloses a waterproof and corrosion-resistant sheath material of a degaussing cable, which comprises the following components in part by weight: 100 parts of chloroprene rubber, 5-20 parts of vulcanizing agent, 0.5-5 parts of vulcanization accelerator, 0.5-5 parts of vulcanizing agent, 50-120 parts of filling agent, 15-40 parts of reinforcing agent, 1-5 parts of antiager, 5-15 parts of plasticizer, 5-20 parts of fire retardant, 1-5 parts of coupling agent and 2-6 parts of processing agent. The invention further discloses a production method of the waterproof and corrosion-resistant sheath material of the degaussing cable. Ships which use the sheath material of the invention have good water adsorption resistance, excellent mechanical property, flame resistance, weather resistance, seawater corrosiveness and the like when the ships are in the wet sea surface open-air environments or partially go deeply into the seawater, the performance requirement of the sheath material of the degaussing cable for the ship with the rated voltage of 0.6 / 1kv is satisfied, so the insulating layer of the cable is well protected, and the application of the degaussing cable on the ship is effectively ensured.

Owner:ZHONGTIAN TECH IND WIRE&CABLE SYST CO LTD

Self-compacting powder concrete for ocean engineering as well as preparation method and application

ActiveCN104876500AExtensive self-compactingImprove self-compactingSolid waste managementCalcium hydroxideUltimate tensile strength

The invention discloses self-compacting powder concrete for ocean engineering as well as preparation method and an application. According to the concrete, coal ash and limestone flour are simultaneously added, the precipitation amount of calcium hydroxide is reduced, and the problem in the prior art that the concrete is poor in corrosion resistance can be solved; moreover, the concrete is doped with nano-scale calcium carbonate and silica fume, so that the self-compacting property of the concrete structure is improved. The comprehensive cost of the concrete is low, the material source is wide, and a great amount of industrial wastes can be doped; the seawater corrosion resistance is good, the self-compacting property is good, the expandability is high, hydration heat is low, the adjusting range of the working expandability is large, the early strength is high, the strength of the concrete is greater than 50Mpa at the first day and greater than 130Mpa at the 28th day, and the self-compacting powder concrete is suitable for different types of ocean engineering.

Owner:黄贺明

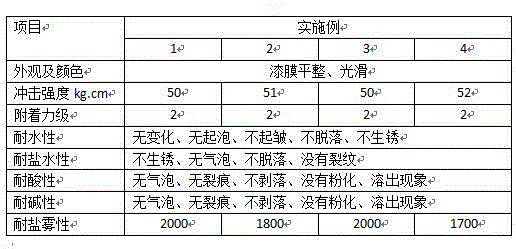

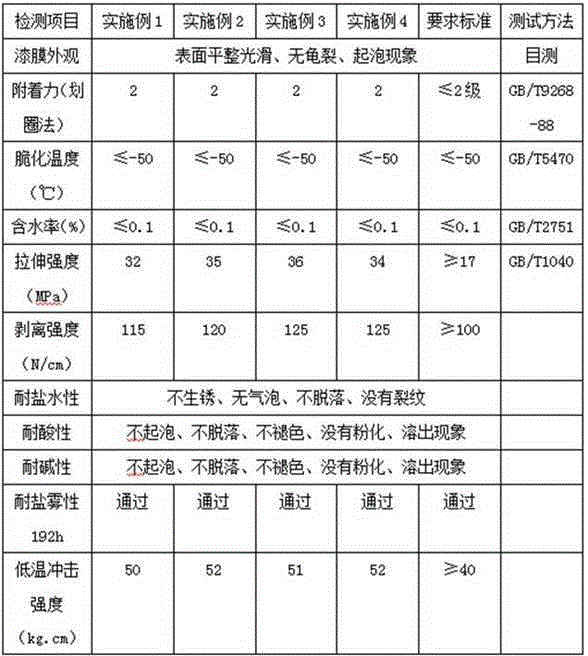

Ocean epoxy zinc-rich anti-corrosion powder coating and preparation method thereof

ActiveCN104087125AImprove conductivityImprove thermal conductivityAnti-corrosive paintsPowdery paintsEpoxyPolyvinyl alcohol

The invention provides an ocean epoxy zinc-rich anti-corrosion powder coating and a preparation method thereof. The coating is prepared from the following raw materials: E-12 epoxy resin, novolac epoxy, trimethyl hexamethylenedi, polyvinyl butyral, dimethyl imidazole, aminopropyl triethoxy silane, zinc powder, aluminum powder, graphene, ethylene bis stearamide, polyethylene wax powder, an antioxidant DNP, and compound filler. The preparation method comprises the following steps: uniformly mixing zinc powder, aluminum powder and graphene, adding aminopropyl triethoxy silane, stirring to disperse so as to obtain a component A, mixing the E-12 epoxy resin, novolac epoxy, polyvinyl butyral and polyethylene wax powder, preheating, cooling down to room temperature, mixing the component A, the mixture and the rest raw materials, carrying out melt extrusion by virtue of an extruder, tabletting, carrying out air cooling, grinding into powder, and sieving. The coating can protect a steel structure from being corroded by various corrosive media for a long term, is non-toxic, pollution-free and salt mist resistant, and has strong adhesive force and shock resistance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

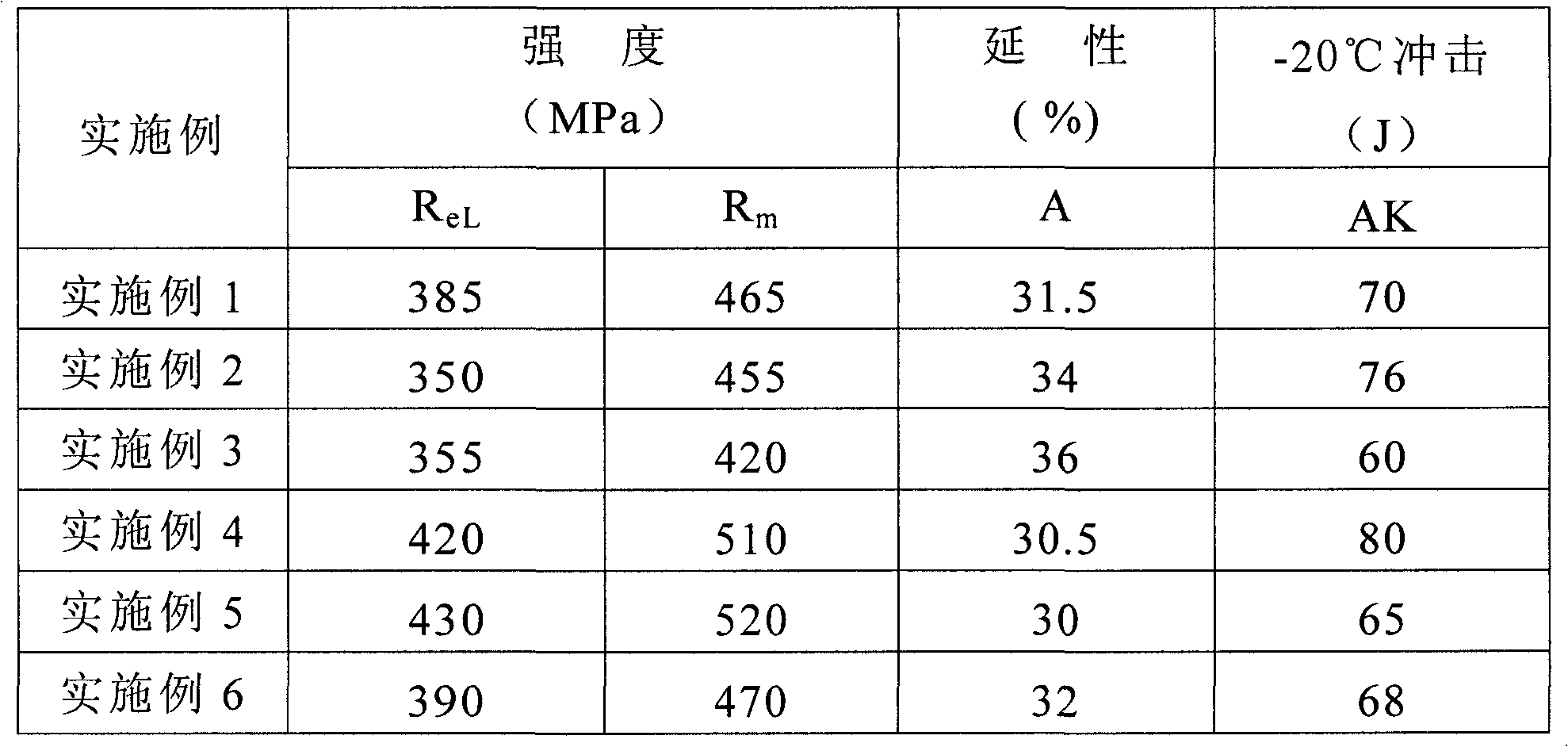

Reinforcing steel bar and preparation method thereof

ActiveCN104018091AImprove corrosion resistanceImprove seawater corrosion resistanceManufacturing convertersFurnace typesReinforced concreteRebar

The invention relates to a reinforcing steel bar. The reinforcing steel bar comprises the following components in percentage by weight: 0.005%-0.030% of C, 0.3%-0.6% of Si, 1.2%-2.5% of Mn, not greater than 0.01% of P, not greater than 0.01% of S, 8.0%-10.0% of Cr, 1.0%-3.0% of Mo, 0.2%-0.4% of Sn, 0.01%-0.05% of RE, and the balance of Fe and inevitable impurities. The invention further provides a preparation method for the reinforcing steel bar. The reinforcing steel bar disclosed by the invention has excellent comprehensive mechanical performance and corrosion resistance, prolongs service life of the reinforcing steel bar in seawater while satisfying requirements of an anti-seismic design, and can be widely applied to a reinforced concrete structure in a marine environment.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

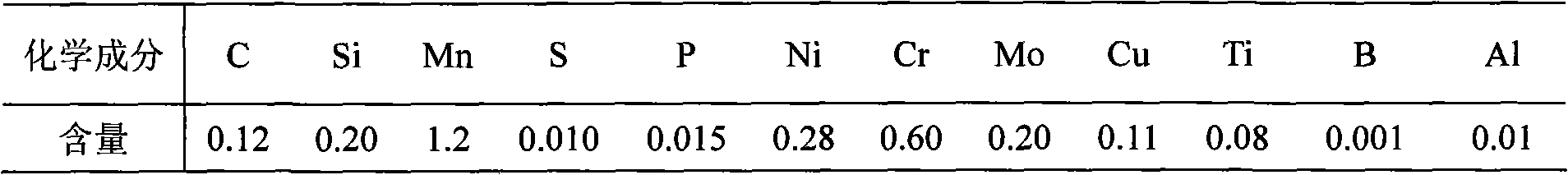

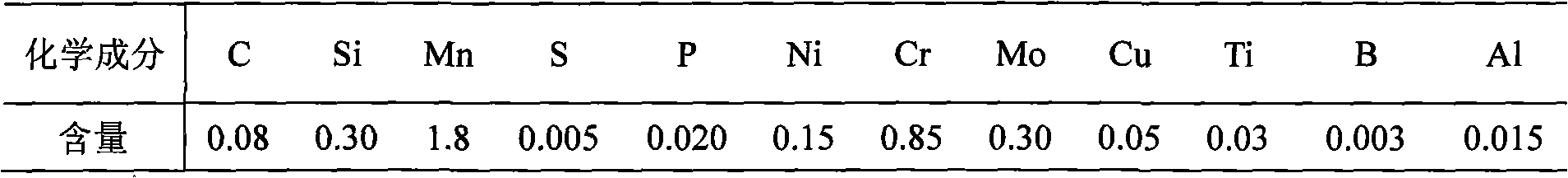

Seawater corrosion resistance submerged arc welding wire rod, welding wire and application thereof

ActiveCN101288924AImprove mechanical propertiesGood welding performanceArc welding apparatusWelding/cutting media/materialsWire rodImpurity

The invention provides a seawater corrosion resistant submerged arc welding wire rod and a welding wire thereof. Both the wire rod and the welding wire comprises the following elements (according to the weight percent): C is equal to or less than 0.12, Si is equal to or less than 0.3, Mn is 1.0 to 1.8, S is equal to or less than 0.020, P is equal to or less than 0.020, Cr is 0.60 to 1.50, Ni is 0.15 to 0.50, Mo is 0.10 to 0.30, Cu is 0.05 to 0.30, Ti is 0.01 to 0.08, B is equal to or less than 0.005, Al is equal to or less than 0.030, and the rest is Fe and inevitable impurity elements. The invention also provides the application of the welding wire to the submerged arc welding wire matched with the seawater corrosion resistant steel Q345C-NHY3. The deposited metal of the welding wire provided by the invention has the advantages of excellent dynamic performance, welding performance and seawater corrosion resistant performance, which can be used for welding the seawater corrosion resistant steel. The welding wire rod and the welding wire of the invention are applicable to the structure with high corrosion resistance requirement in the immersion zone and the splash zone of the sea.

Owner:BAOSHAN IRON & STEEL CO LTD

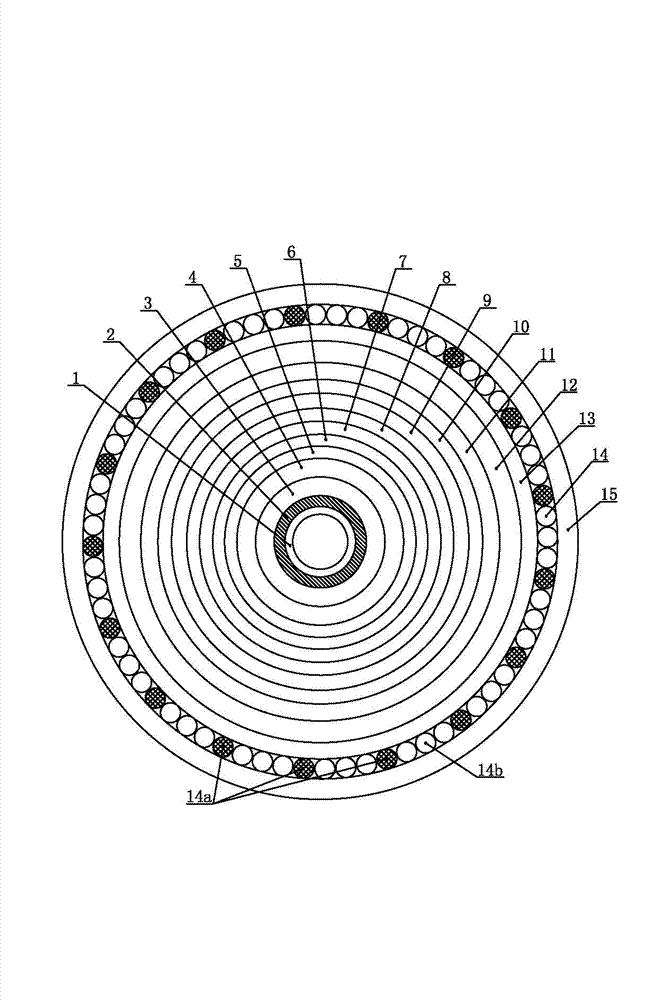

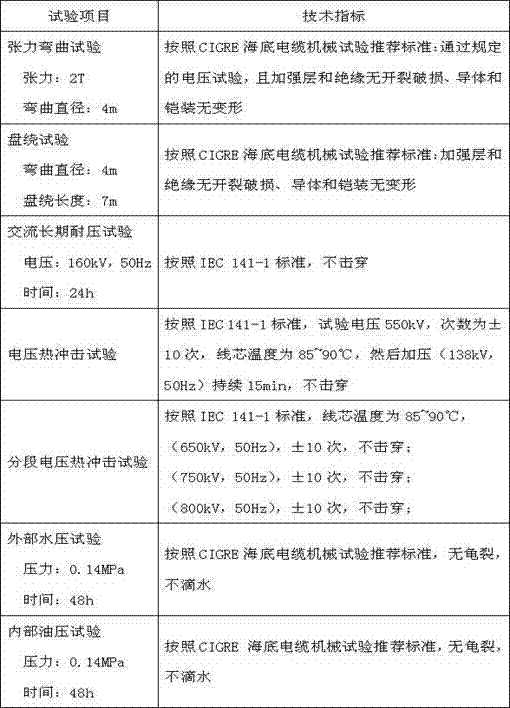

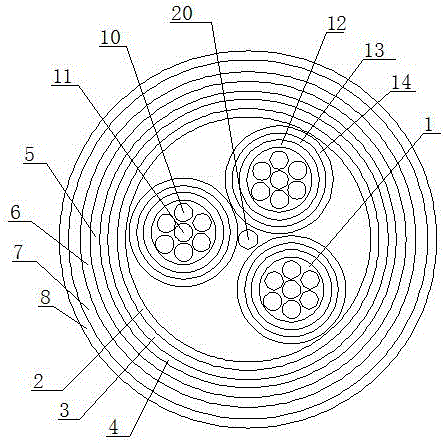

Submarine cable with increased current-carrying capacity

InactiveCN102969071AAvoid lossLarge carrying capacityPower cables with screens/conductive layersSubmarine cablesCopper wireHigh pressure

The invention relates to a submarine cable with an increased current-carrying capacity. Conductor layers comprising a plurality of annealed copper wires with high conductivity are tightly distributed at the periphery of a tin-plated copper spiral pipe; a carbon black paper conductor shielding layer, an oil-filled high-voltage cable paper insulating layer, a carbon black paper insulation shielding layer, a copper strip insulation shielding layer and a seamless lead-alloy sheath are wrapped at the periphery of the conductor layers sequentially; asphalt is evenly coated at the periphery of the seamless lead-alloy sheath; and a self-adhesive polyethylene strip inner cushion layer, double stainless steel strip strengthening layers, a self-adhesive polyethylene strip outer cushion layer, a non-woven fabric liner layer, a high-density polyethylene corrosion resisting layer, an armoured inner cushion layer formed by evenly soaking hemp ropes at intervals through polypropylene ropes in a concentric stranding manner, an armoured layer formed by uniform spacing of aluminum-magnesium-plated alloy steel wires and a copper wire in the concentric stranding manner and an outer protecting layer are wrapped at the periphery of the seamless lead-alloy sheath sequentially. The submarine cable has a larger current-carrying capacity and is excellent in water seepage resistance, seawater corrosion resistance, external water pressure resistance, voltage thermal shock resistance and tension bending resistance. In addition, the submarine cable also has the advantages of long service life and high reliability.

Owner:JIANGSU YUANYANG DONGZE CABLE

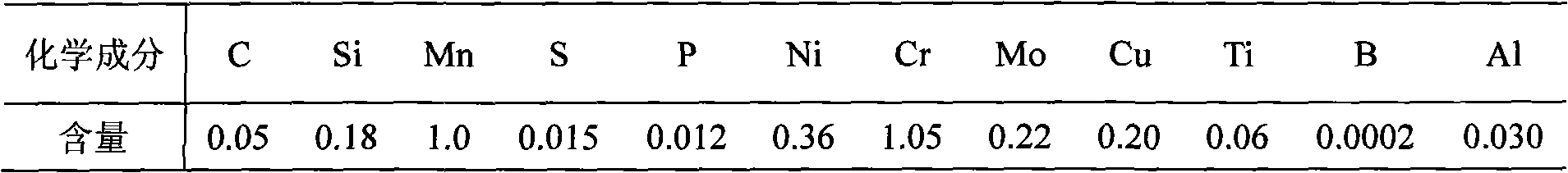

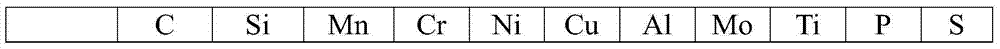

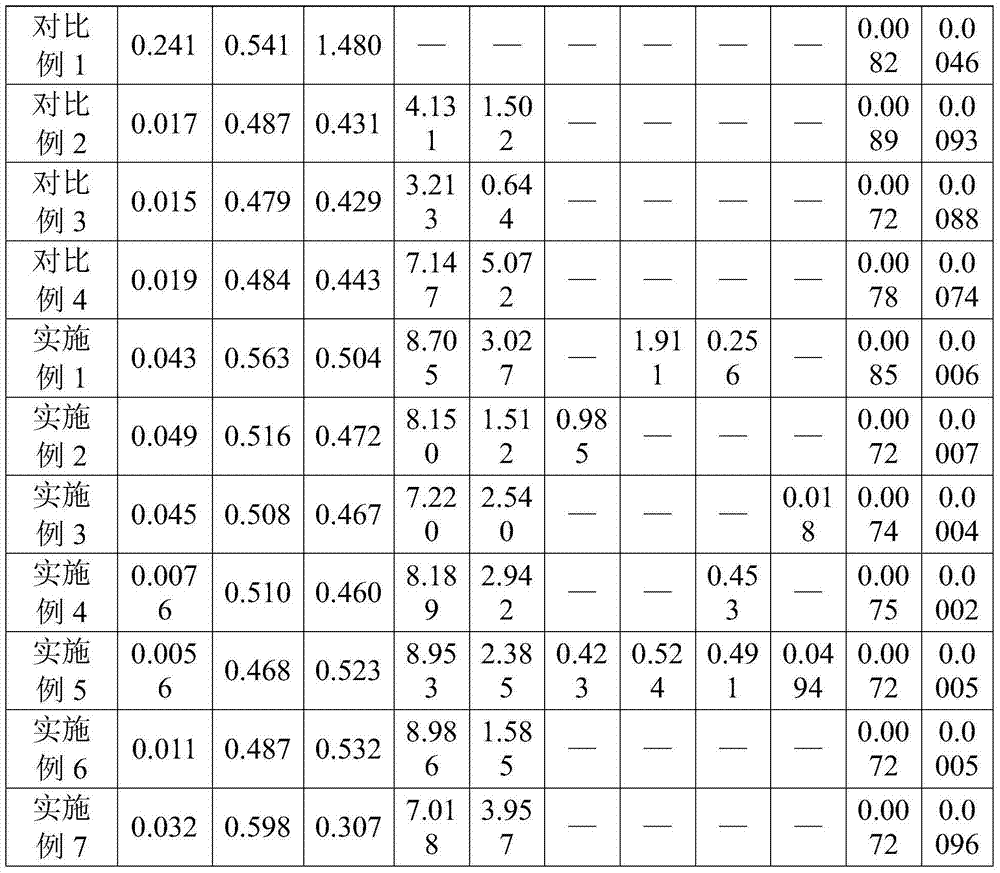

High-strength steel bar with high corrosion resistance and preparation method thereof

The invention discloses a high-strength steel bar with high corrosion resistance. The high-strength steel bar comprises the components of C, Si, Mn, P, S, Cr, Ni, Al, Cu, Mo, Ti and Fe. The invention further provides a preparation method of the high-strength steel bar with high corrosion resistance. The steel bar is stable in performance, has excellent corrosion resistance and high mechanical property, and can be widely applied to building engineering of coast and salt lake areas.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Aluminum alloy with high seawater corrosion resistance and plate-fin heat exchanger

ActiveUS20080283228A1Not be reduced to practiceImprove adhesionStationary conduit assembliesGlass/slag layered productsResin coatingFluorocarbon

An aluminum alloy for use in a plate-fin heat exchanger having a heat transfer portion with seawater as a coolant includes an organic phosphonic acid underlying coating disposed on the surface of the aluminum alloy and a fluorocarbon resin coating disposed on the organic phosphonic acid underlying coating, the fluorocarbon resin coating having an average thickness of 1 to 100 μm after drying. The aluminum alloy has improved durability of coating adhesion and excellent seawater corrosion resistance.

Owner:KOBE STEEL LTD

Whitening ultraviolet-proof double-shield instrument cable for ships and manufacturing method thereof

InactiveCN102969046AColor whiteGood physical and mechanical propertiesClimate change adaptationInsulated cablesCopper foilInsulation layer

The invention relates to a whitening ultraviolet-proof double-shield instrument cable for ships and a manufacturing method thereof. The cable is characterized in that a whitening ultraviolet-proof ethylene-propylene rubber insulation layer is extruded at the periphery of a tin-plated annealed stranded copper conductor to form an insulation wire core; every two insulation wire cores are twisted to form twisted wire pairs; each twisted wire pair is wrapped with a wire core copper foil polyester composite tape shielding layer at the periphery; the wire core copper foil polyester composite tape shielding layers are each wrapped with a wire core polyester tape at the periphery to form a pair-twist group; all the pair-twist groups are stranded to the right at 16-24 times of stranding lay ratio to form a cable core; the cable core is wrapped with a cable core copper foil polyester composite tape shielding layer at the periphery; the cable core copper foil polyester composite tape shielding layer is wrapped with a cable core polyester tape at the periphery; an inner sheath is extruded at the periphery of the cable core polyester tape; the inner sheath is coated with a copper alloy wire weaving armor layer at the periphery; and an outer sheath is extruded at the periphery of the copper alloy wire weaving armor layer. The insulation layer of the double-shield cable is white in color, good in mechanical property, excellent in anti-ultraviolet irradiation and anti-aging performance, and long in service life.

Owner:JIANGSU YUANYANG DONGZE CABLE

Epoxy powder primer used for anticorrosion paint for outer walls of deep sea oil transportation steel pipes and preparing method thereof

ActiveCN104530919AImprove adhesionInhibit expansionAnti-corrosive paintsPowdery paintsPolyvinyl butyralEpoxy

The invention provides an epoxy powder primer used for anticorrosion paint for outer walls of deep sea oil transportation steel pipes and a preparing method thereof. The epoxy powder primer comprises following raw materials by mass: 40-50 parts of E-12 epoxy resin, 10-25 parts of linear phenolic epoxy resin, 25-45 parts of a filler, 9-15 parts of a curing agent, 0.1-1 part of an antioxidant, 0.2-1 part of a coupling agent, 0.9-1.8 parts of benzoate, 0.3-1 part of a levelling agent, 1-3 parts of graphene, 1-2 parts of polyvinyl butyral, 3-5 parts of modified polytetrafluoroethylene wax micropowder, 0.2-0.4 part of rare earth chloride and 1-3 parts of pigment. The epoxy powder primer has excellent wear resistance, resistance to pressure, bending resistance and impact resistance, is excellent in adhesion force and fraction of coverage for steel pipes, and can effectively protect the steel pipes from being corroded by various corrosive media in sea water for a long term.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Aluminum alloy tube resistant to seawater corrosion and preparation method thereof

ActiveCN102465221AImprove seawater corrosion resistanceGood resistance to seawater corrosionRigid pipesDistillationMulti effect

The invention relates to an aluminum alloy tube resistant to seawater corrosion, in particular to an aluminum alloy tube with high seawater corrosion resistance. The aluminum alloy tube is manufactured from magnesium, aluminum and other raw materials through the steps of: melting, stirring, in-furnace modification treatment, impurity removal, fining treatment, online argon refining, purification treatment, casting, homogenization treatment, extrusion, cold drawing and the like. The aluminum alloy tube has the advantages of good seawater corrosion resistance and long service life, is particularly suitable for equipment for low-temperature multi-effect seawater distillation and seawater desalination treatment.

Owner:JIANGSU ASIA PACIFIC LIGHT ALLOY TECH CO LTD

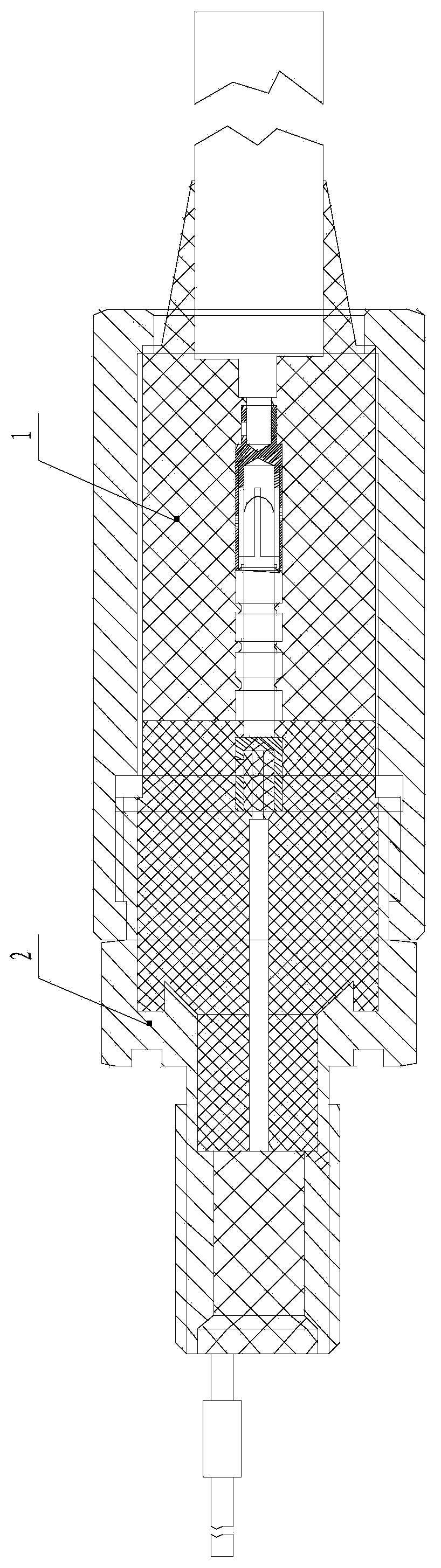

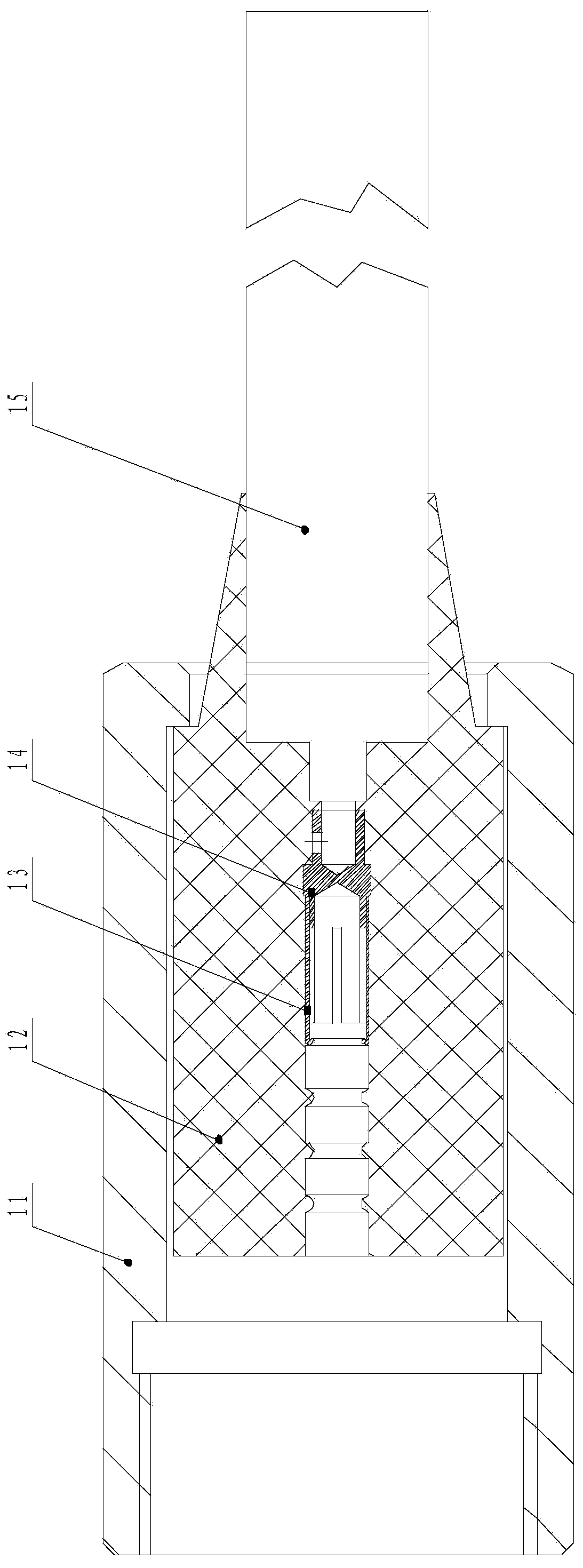

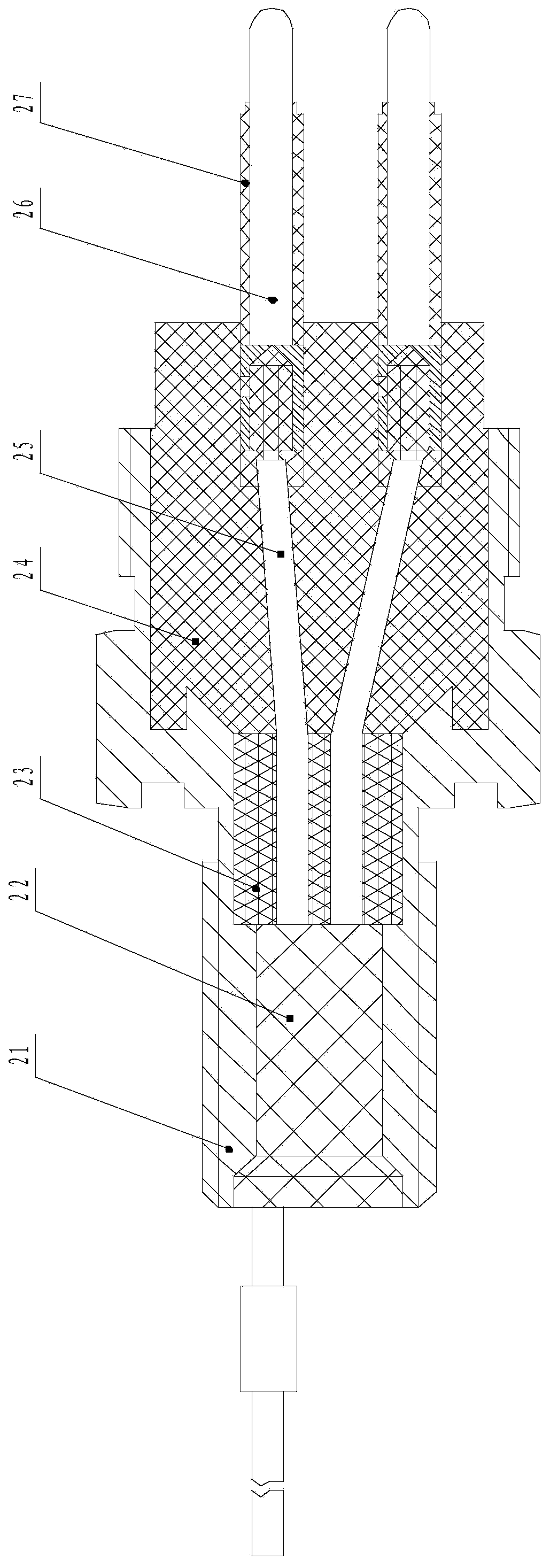

Manufacturing method of deep sea watertight electric connector

ActiveCN103414081AImprove sealingAvoid incomplete sealingLine/current collector detailsElectricityNuclear power

The invention discloses a manufacturing method of a deep sea watertight electric connector, and belongs to the technical field of underwater cable connecting equipment. The manufacturing method solves the problems that in the prior art, due to the fact that an O-type ring can be easily dropped in the using process of a traditional watertight electric connector, sealing is incomplete, water seepage is easily caused, and the traditional watertight electric connector cannot be used in the underwater severe environment. The manufacturing method mainly comprises the steps of manufacturing a plug, manufacturing a socket and assembling the plug and the socket. The deep sea watertight electric connector is mainly used in underwater cameras, underwater lamps, underwater robots, nuclear power station pool underwater lamps for lighting and underwater sensors.

Owner:济南无线电九厂有限公司

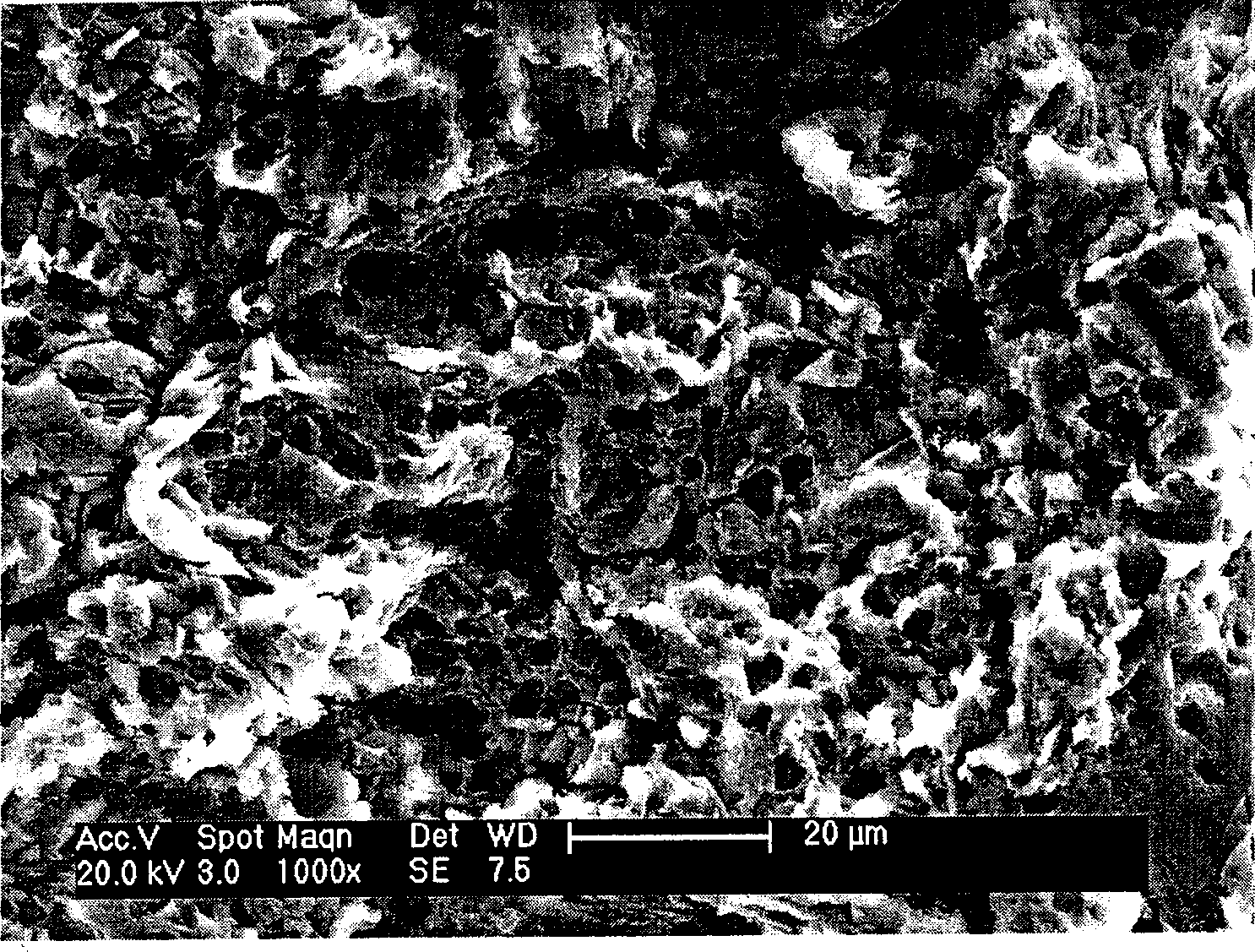

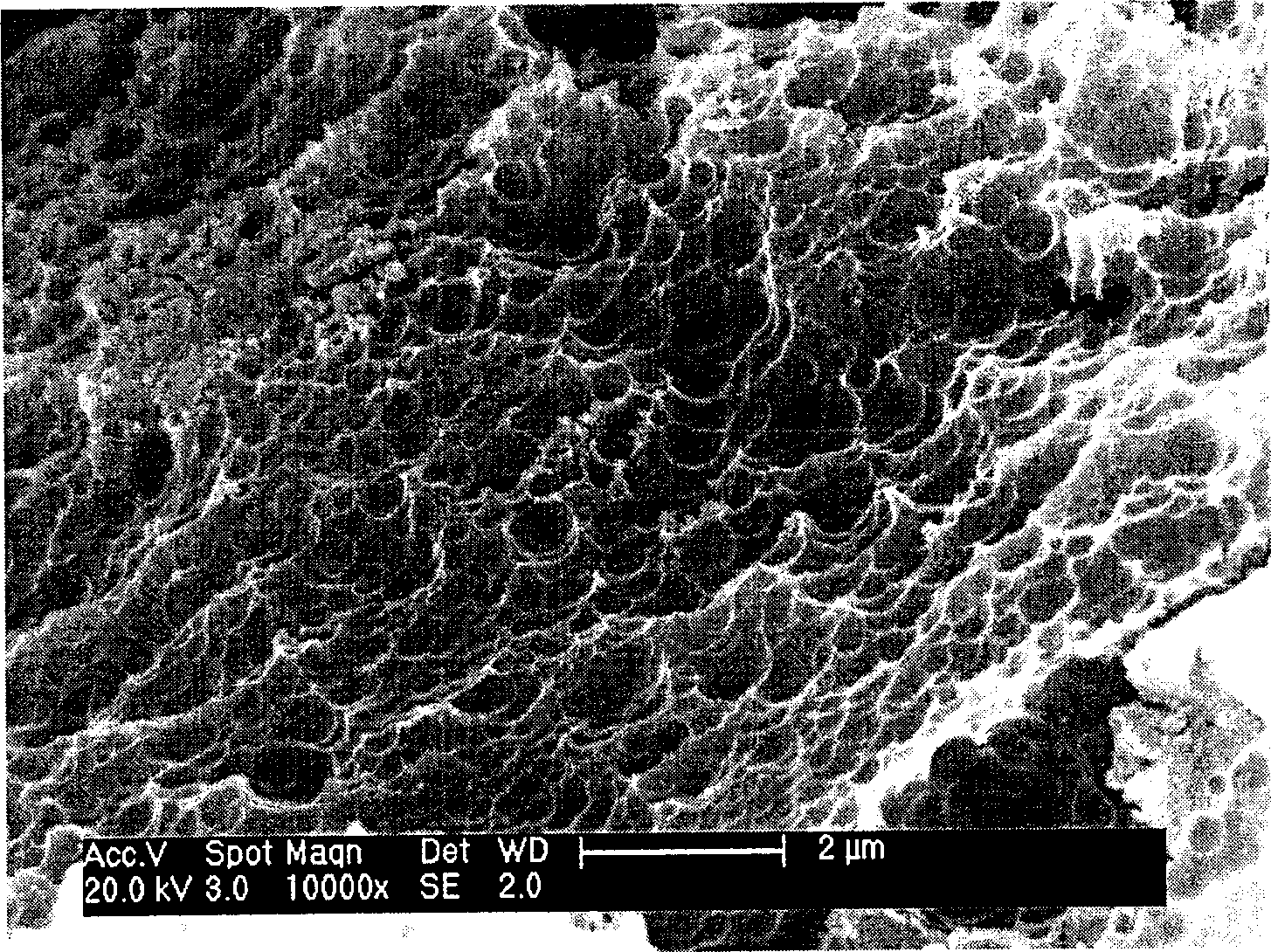

Anti-oxidization coating for airplane carbon/carbon brake disc and method of producing the same

InactiveCN101153123ALow priceThe implementation process is simpleBraking discsPretreated surfacesSolventPhosphoric acid

The present invention relates to anti-oxidant coating for plane carbon / carbon brake disc and the preparation method. In the preparation of the anti-oxidant coating for plane carbon / carbon brake disc, distilled water is used as solvent; phosphoric acid, phosphate and boron oxide are used as main components; the coating solution can be formed after stirring uniformly. The coating solution is uniformly painted on the part of the surface of a carbon brake disc to be painted in a brushing or spraying method. A layer of coating of thickness of about 50 Mu m to 300 Mu m can be formed after high-temperature solidification. The coating prepared in the method of the present invention has a dense surface, no crack or holes or other defects. The bonding performance between the coating and the carbon / carbon matrix is good. The coating has the characteristics of excellent performances of oxidation protection, and hot-wet, seawater-resistant, or smog-resistant oxide protection. The coating is suitable for the manufacture of plane carbon / carbon brake disc and the anti-oxidation treatment in repair.

Owner:XIAN CHAOMA SCI TECH

Low-alloy abrasion-proof and corrosion resistant steel and method for producing the same

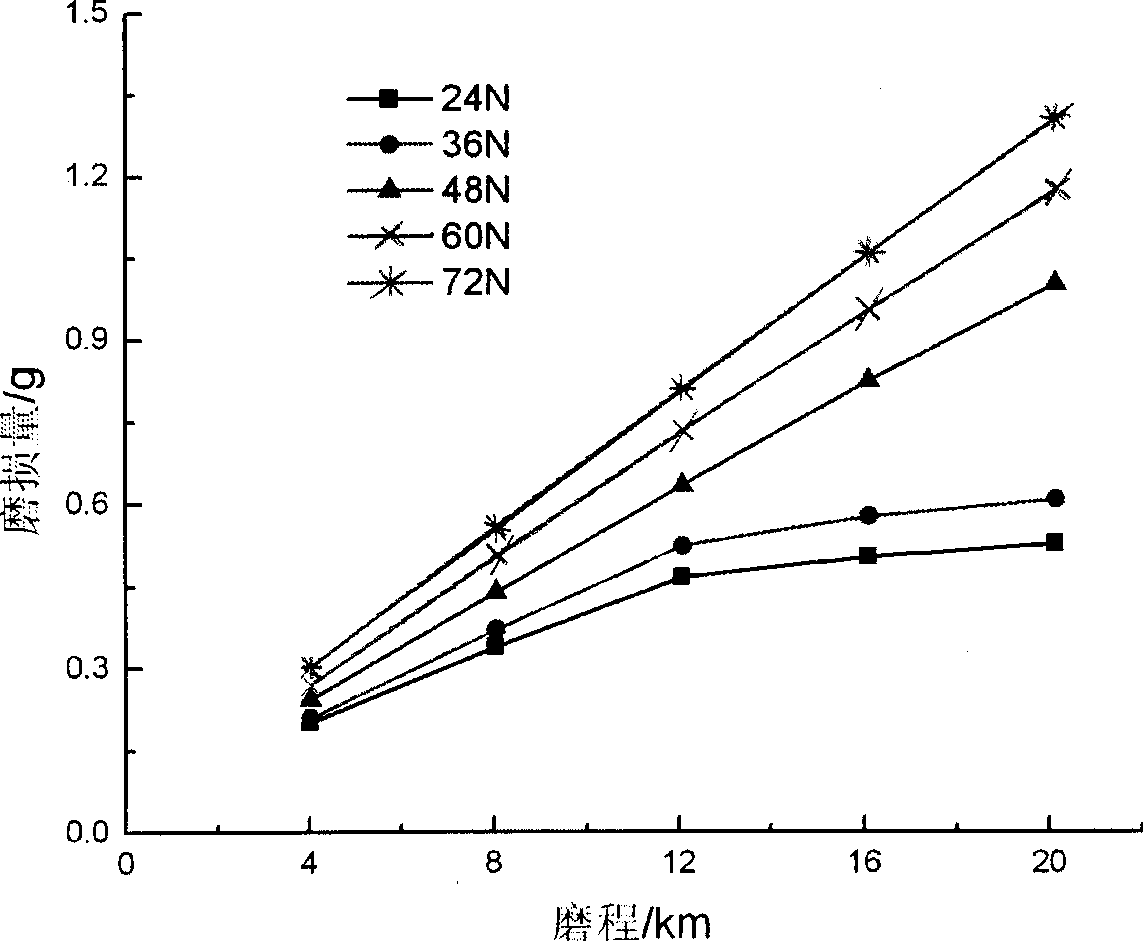

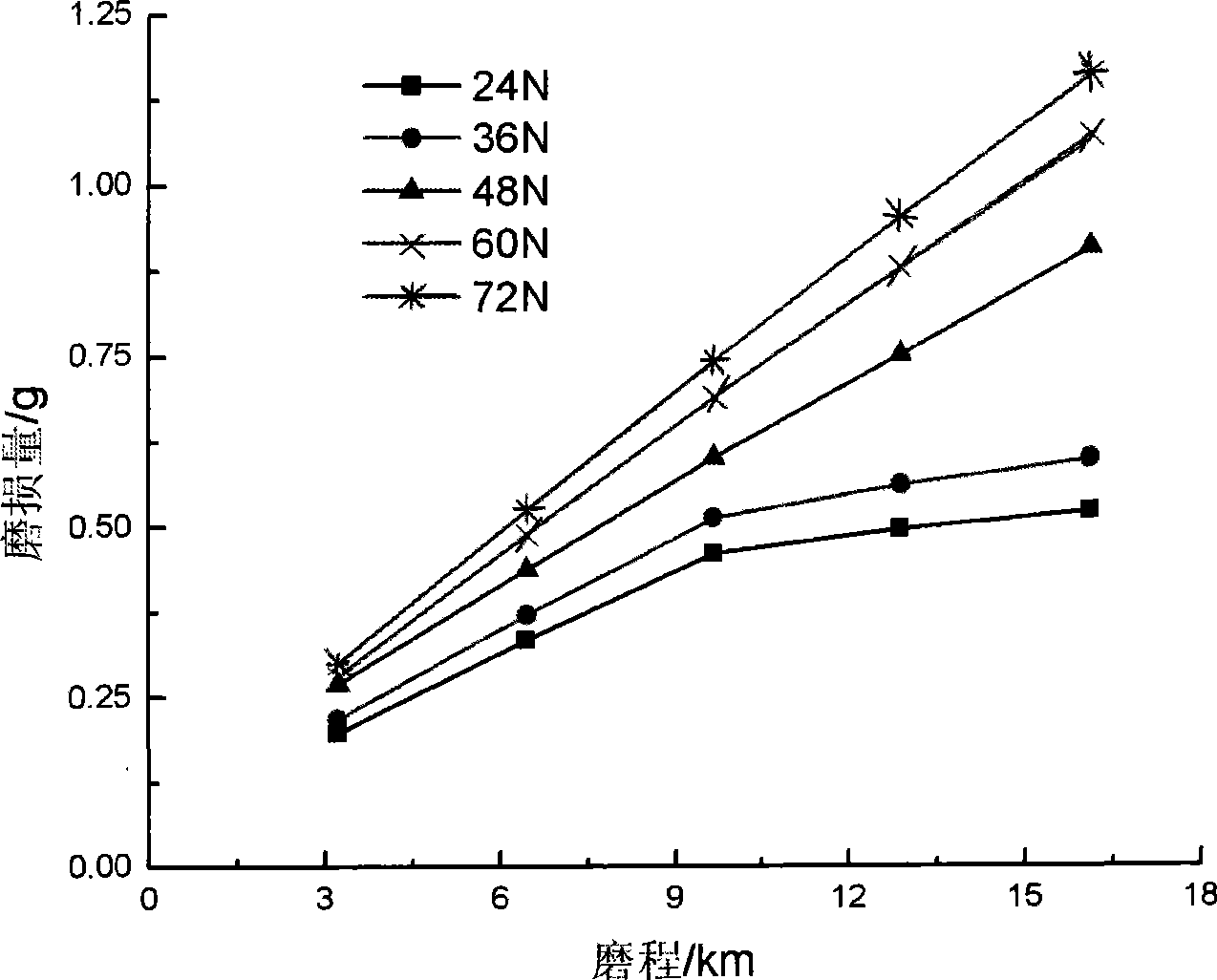

InactiveCN101423916AStrong resistance to seawater corrosionImprove corrosion resistanceElectric furnaceProcess efficiency improvementWear corrosionWear resistant

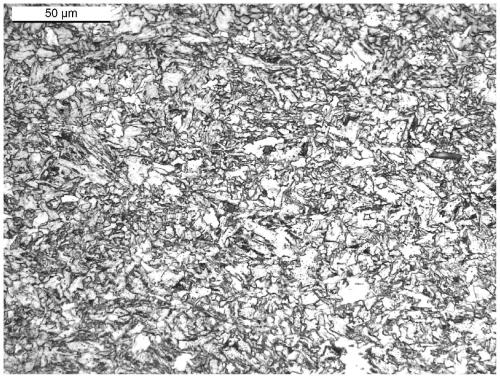

The invention relates to low alloy wearing resistance corrosion resistance steel which is suitably used in the ocean mud-sand wearing and corrosive environment, which is produced by the following steps: Mn-Si-Cr-Mo system non-carbide bainite alloy steel is taken as research basis, the carbon content and other alloy element contents are properly adjusted, elements of Al, Nb and rare earth contributing to improving the corrosion resistance of the alloy steel are added for modification, and the Mn-Si-Cr-Mo-Al system non-carbide bainite steel is formed by the progression quenching heat treatment process, so that the low alloy wearing resistance corrosion resistance steel is obtained. The steel has good obdurability, wearing resistant and corrosion resistant comprehensive performance and welding repair performances, and can be used to solve the problem of repairing worn blades of a centrifugal pump of a ship, and can also be applied to other ocean wearing resistance welding parts.

Owner:HOHAI UNIV +1

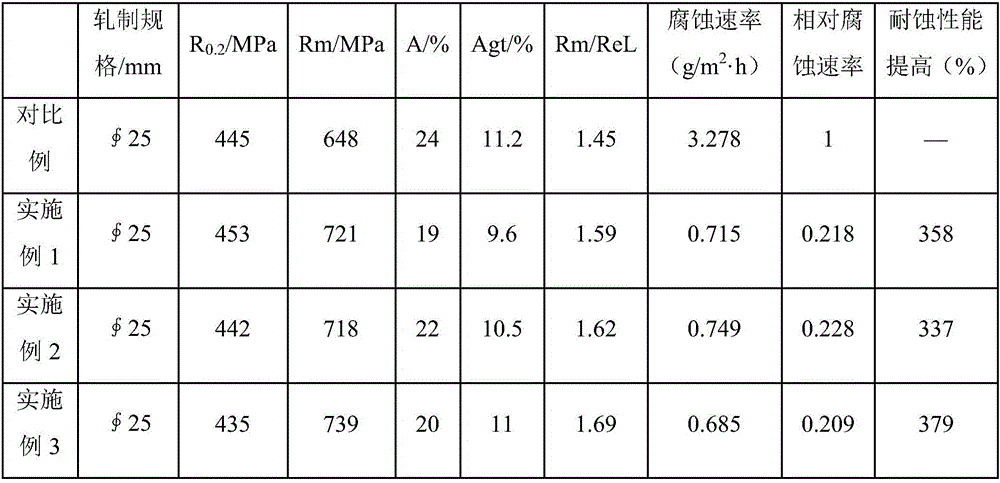

Anti-corrosion high strength-to-yield ratio earthquake-resistant reinforced bar and production method thereof

The invention provides an anti-corrosion high strength-to-yield ratio earthquake-resistant reinforced bar and a production method of the anti-corrosion high strength-to-yield ratio earthquake-resistant reinforced bar. The threaded reinforced bar includes basic ingredients, selectable ingredients and the balance Fe and inevitable impurities, wherein the basic ingredients comprise, by weight, 0.06-0.10% of C, 0.60-0.80% of Si, 0.60-1.00% of Mn, 0.01% or smaller of P, 0.01% or smaller of S, 3.20-3.50% of Cr, 0.70-0.90% of Al, 0.35-0.45% of Mo and 0.70-0.90% of Ni, and the selectable ingredients comprise any one or the combination of two of, by weight, 0.01-0.06% of V and 0.01-0.030% of Nb. The anti-corrosion high strength-to-yield ratio earthquake-resistant reinforced bar has the advantages that the sea water resistance of the reinforced bar is good and can be improved by three times or above compared with common threaded reinforced bars, the high elongation rate and the high strength-to-yield ratio are obtained, and the strength-to-yield ratio can reach 1.50 or above, and the earthquake resistance is excellent.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

PE sheath material for submarine cable and preparation method thereof

ActiveCN104829919AGood resistance to seawater corrosionImprove seawater corrosion resistanceMicrobial corrosionElectric cables

The invention provides a PE sheath material for a submarine cable. The PE sheath material comprises, by weight, 100 parts of PE, 8-12 parts of modified hemp fibers, 6-10 parts of modified magnesium oxide, 0.2-0.3 parts of an anti-oxidant, 9-10 parts of EVA, 2-3 parts of carbon black, 3-4 parts of calcium carbonate, 0.1-0.2 parts of a stabilizing agent and 0.1 parts of a coupling agent. The invention also provides a preparation method of the PE sheath material. The PE sheath material for a submarine cable has good sea water corrosion resistance and microbiological corrosion resistance, can effectively reduce corrosion damage and has a long service life.

Owner:青岛宏信塑胶造粒有限公司

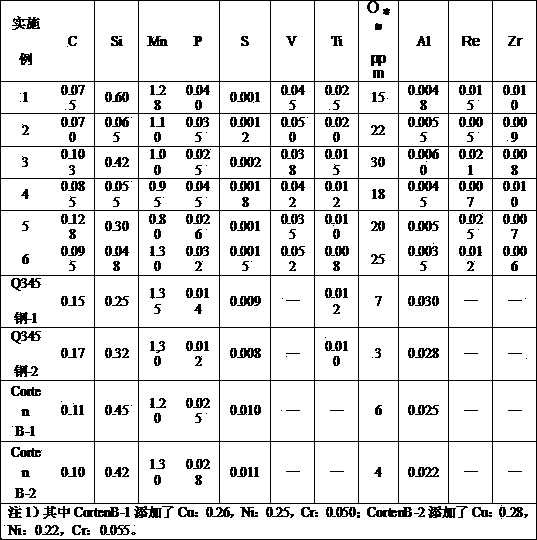

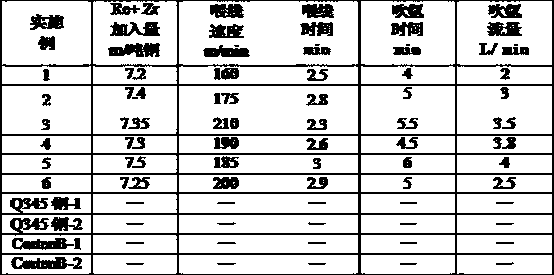

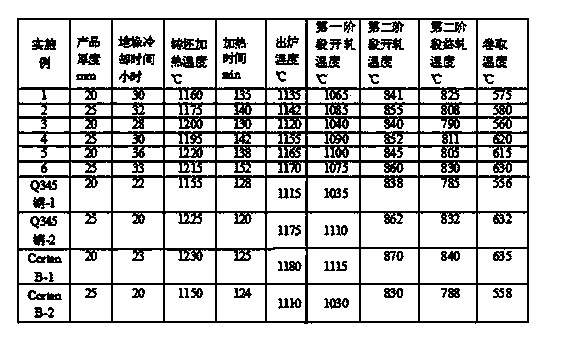

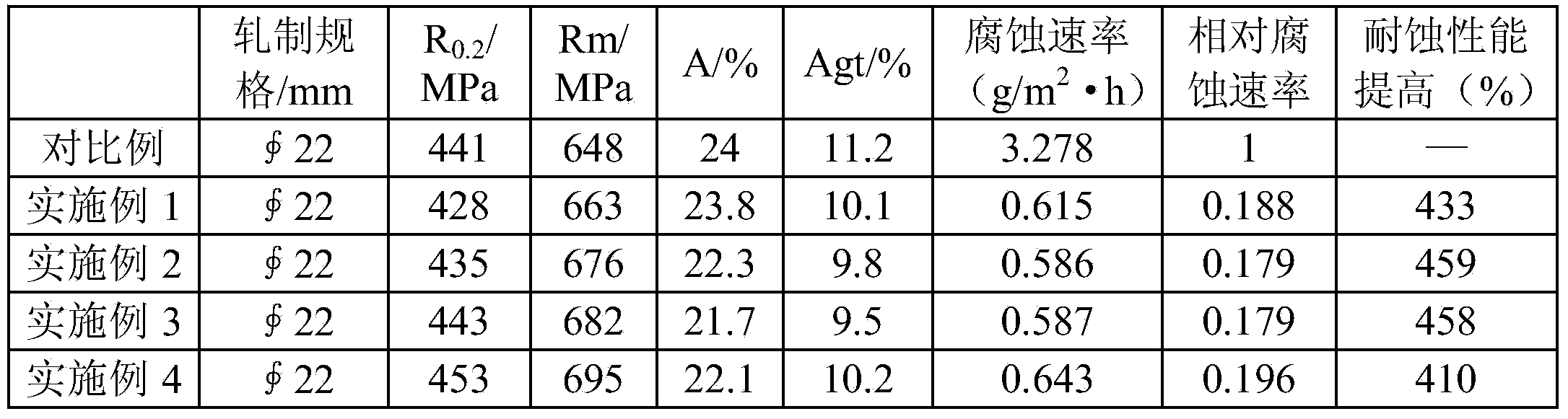

Anti-corrosion steel for bridge tubular pile and production method of anti-corrosion steel

ActiveCN103526112AReduce manufacturing costAdapt to large-scale production requirementsLaminar coolingRoom temperature

The invention discloses anti-corrosion steel for a bridge tubular pile. The anti-corrosion steel comprises the following components in percentage by weight: 0.07-0.13% of C, 0.30-0.65% of Si, 0.80-1.30% of Mn, 0.025-0.045% of P, less than or equal to 0.002% of S, not greater than 0.006% of Al, 0.035-0.050% of V, 0.008-0.025% of Ti, 0.005-0.02% of Re, 0.006-0.012% of Zr and 15-30ppm of dissolved [O]. A production method of the anti-corrosion steel comprises the following steps: performing converter smelting and continuous casting to obtain a blank; performing stack cooling on the casting blank; heating the casting blank; performing sectional rolling; performing conventional laminar cooling; coiling; and performing air cooling to room temperature. According to the anti-corrosion steel disclosed by the invention, the yield strength is greater than or equal to 390MPa, the tensile strength is greater than or equal to 510MPa, the elongation A is greater than or equal to 21%, the impact energy Akv at 0 DEG C is greater than or equal to 47J, the corrosion resistance is equivalent to that of the American Corten B steel, the thickness specification of a steel plate is 20-25mm, the production cost is low, and the large-scale production requirement is met; moreover, a straight welding pipe is replaced to manufacture the bridge steel tubular pile, the production efficiency can be remarkably improved, and the production cost of the steel tubular pile is lowered.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

400 MPa-level tungstenic corrosion-resistant twisted steel and preparation method thereof

The invention provides 400 MPa-level tungstenic corrosion-resistant twisted steel and a preparation method thereof. The twisted steel comprises the following components (wt%): 0.03%-0.05% of C, 0.3-0.6% of Si, 0.6-1.2% of Mn, smaller than or equal to 0.01% of P, smaller than or equal to 0.01% of S, 8.0-10.0% of Cr, 1.0-2.0% of W, one or a composition of 0.04-0.10% of V and 0.01-0.05% of RE and the balance of Fe and unavoidable impurities, wherein C, Si, Mn, P, S, Cr and W are basal components; and V and RE are optional components. The 400 MPa-level tungstenic corrosion-resistant twisted steel has the advantages that seawater corrosion resistance of the steel is improved by more than 4 times than that of common twisted steel, the performance is stable, structure mainly comprises ferrite and bainite, good strength and plasticity are ensured, and the 400 MPa-level tungstenic corrosion-resistant twisted steel can be widely applied to a reinforced concrete building structure in a marine environment.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Sea water corrosion-resistant steel with low cost

InactiveCN101787485ASimple ingredientsImprove seawater corrosion resistanceChemical compositionMetallurgy

The invention discloses a sea water corrosion-resistant steel with low cost. The steel comprises chemical components in percentage by weight: 0.06-0.15 C, 0.05-0.40 Si, 0.50-1.20 Mn, 0.010-0.030 P, not more than 0.020 S, 0.004-0.070 Als and 0.0040-0.0100 O. Verified by tests, the steel has the advantages of excellent corrosion-resistant performance, simple chemical components and fewer impurity contents. Compared with the traditional corrosion-resistant steel technology, the invention has lower production cost and is beneficial to popularization and application.

Owner:武钢集团有限公司

Anti-corrosion method for marine wind power jacket

InactiveCN109735840AImprove and enhance seawater corrosion resistanceImprove seawater corrosion resistanceArtificial islandsMetallic material coating processesAlloyBall mill

The invention discloses an anti-corrosion method for a marine wind power jacket. The anti-corrosion method for the marine wind power jacket comprises the following steps that aluminum-bronze alloy powder is put into a ball mill to be subjected to ball milling for 2-3 hours, the powder obtained after ball milling is put into a vacuum drying oven to be dried, and the powder is transferred to a rotating disc type powder feeder; the surface of a to-be-clad jacket is ground to remove rust, surface oil contaminants are cleaned with absolute ethyl alcohol, the jacket is installed on a high-speed laser cladding machining machine tool and clamped with a fixture, the positions of light spots and powder spots are adjusted, and 85% or above of energy of laser beams acts on the powder; the powder formsmolten drops before entering a molten pool; a little part of energy acts on the surface of the jacket to form a very shallow molten pool; and cladding is conducted by adopting a disc laser, and coaxial powder feeding is adopted as a powder feeding mode. According to the anti-corrosion method for the marine wind power jacket, the sea water corrosion resistance of the jacket is improved through a high-speed laser cladding technology, then the surface quality of the jacket is improved, and the problems such as pores, cracking, discoloring and bulging are prevented.

Owner:YANGJIANG HIGH POWER LASER APPLICAITON LAB CO LTD +1

Deep water seal rubber sleeve cable and manufacturing process thereof

ActiveCN104143390AGuaranteed reliabilityExcellent longitudinal watertightnessSubmarine cablesInsulated conductorsCable transmissionElectric power transmission

The invention discloses a deep water seal rubber sleeve cable and a manufacturing process thereof. A cable conductor is formed by twisting seven annealed copper wires and is coated with sealing glue. Insulation is achieved through irradiation crosslinking ethylene propylene rubber. Gaps among core wires are filled with water blocking glue when the core wires are twisted to form a cable core of a cable body. A water blocking wrapping band wraps the cable body. An irradiation crosslinking chloroprene rubber inner protective sleeve is arranged on the cable body in an extruding mode. A protective sleeve reinforcing layer is woven from tin-plated annealed copper wires coated with sealing glue. Finally, an irradiation crosslinking chloroprene rubber protective sleeve is arranged on the cable body in an extruding mode. The cable is reliable in longitudinal water-tightness performance, high in flexibility and resistant to seawater corrosion and deep water pressure; reliability of power transmission and control signal transmission can be normally kept under a certain water pressure condition. The cable can be used for cable transmission and control signal transmission of electrical instruments and power distribution units of underwater crafts, marine business, underwater equipment and marine survey systems and underwater mining devices.

Owner:安徽宏源特种电缆集团有限公司

Two-core photovoltaic composite submarine cable with rated voltage of 220 kV

ActiveCN105761828ANo magnetic damageImprove effective utilizationPower cables with screens/conductive layersSubmarine cablesElectrical conductorCopper wire

The invention relates to a two-core photovoltaic composite submarine cable with a rated voltage of 220 kV. The cable comprises a cable core and sheaths. The cable core consists of power control wire cores, a communication wire core, and a filling rope. The power control wire cores include conductors including copper wires and aluminium wires arranged at the centers of the conductors; the copper wires are arranged among the aluminium wires; conductor shielding layers are arranged outside the conductors; insulating layers are arranged outside the shielding layers; and water-blocking tapes are arranged outside the insulating layers. The communication wire core is arranged around the power control wire cores. A buffer layer, a lead sleeve, a non-metallic sheath, an anti-corrosion layer, an armored armor layer, an armored outer protection layer, and a lead alloy sheath are arranged outside the cable core successively. The provided cable has advantages of excellent anti-water-seepage, sea water-resistant, external water pressure-resistant, voltage thermal shock-resistant, and strain bending performances, long service life, and high reliability; and the effective usage rate of the power is improved; and the area occupation rate of the sea area is reduced.

Owner:ZHEJIANG CANYUAN HOME TEXTILE

Aluminium alloy material having an excellent sea water corrosion resistance and plate heat exchanger

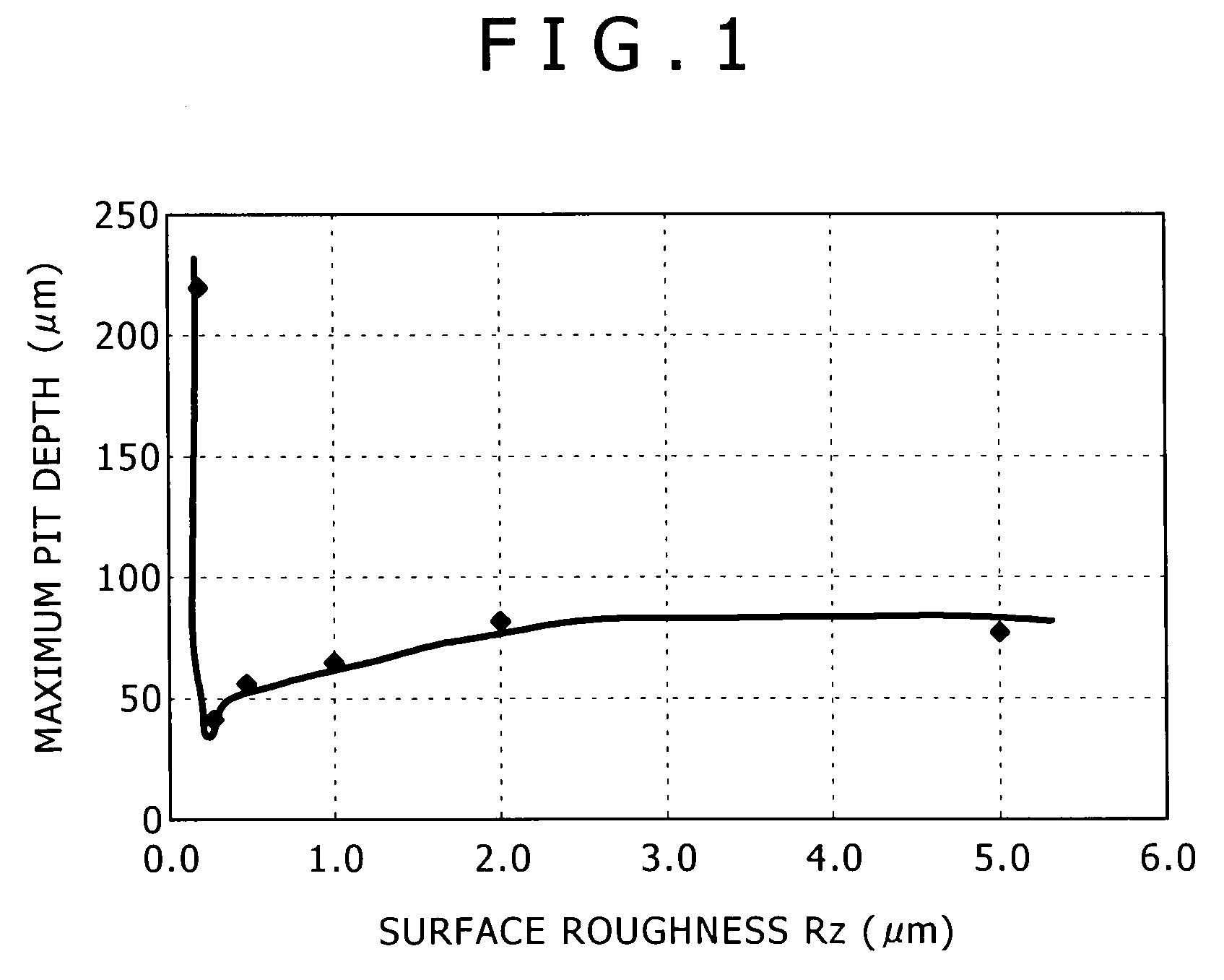

InactiveUS20090081449A1Not be reduced to practiceImprove adhesionSynthetic resin layered productsCorrosion preventionSurface roughnessPlate fin heat exchanger

An aluminium alloy material having an excellent sea water corrosion resistance comprises an aluminium alloy substrate whose ten-points average surface roughness Rz, which is the average of five greatest peak-to-valley separations on the surface, is controlled at 0.3 um or over, an organic phosphonic primer film formed on a surface of the aluminium alloy substrate, and a fluorine resin paint film formed on the primer film and having a dry average thickness of 1 to 100 μm. A plate heat exchanger having an excellent sea water corrosion resistance is also provided wherein the aluminium alloy material is used as a heat transfer unit using sea water as cooling water.

Owner:KOBE STEEL LTD

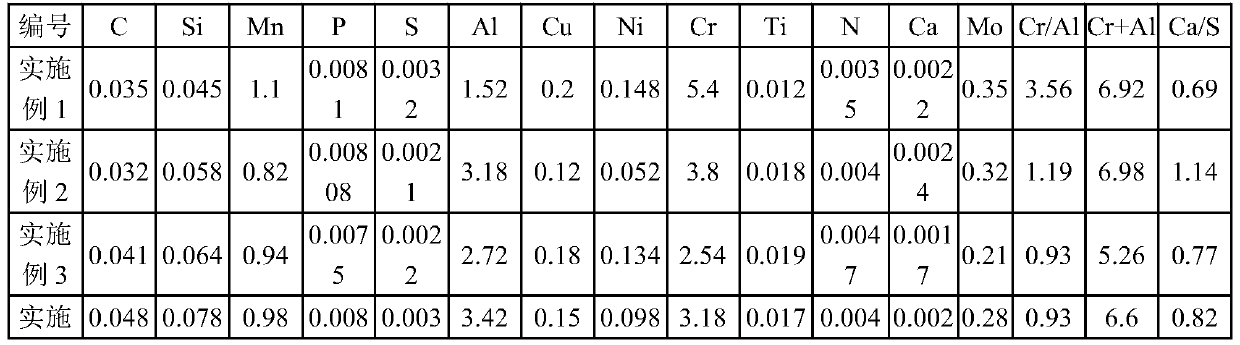

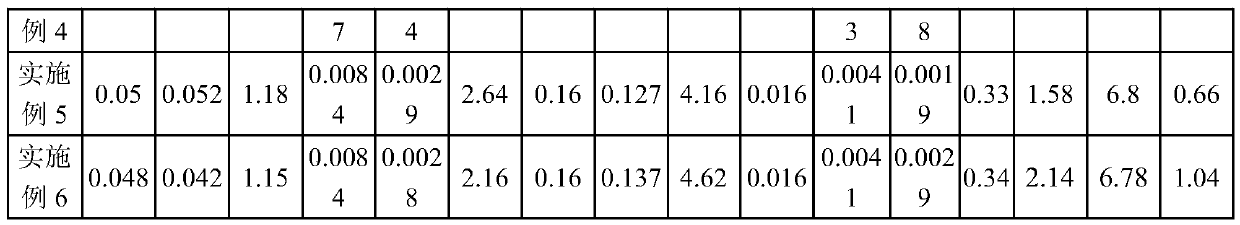

Seawater corrosion-resistant steel and manufacturing method thereof

The invention discloses seawater corrosion-resistant steel. The seawater corrosion-resistant steel comprises the following chemical elements in percent by mass: 0.03-0.05% of C, 0.04-0.08% of Si, 0.8-1.2% of Mn, 0.1-0.2% of Cu, 2.5-5.5% of Cr, 0.05-0.15% of Ni, 0.15-0.35% of Mo, 1.5-3.5% of Al, 0.01-0.02% of Ti, 0.0015-0.003% of Ca and the balance Fe and other inevitable impurities. In addition, the invention further discloses a manufacturing method of the seawater corrosion-resistant steel. The manufacturing method comprises the following steps of (1) smelting and casting; (2) reheating: reheating a casting blank to 1200-1260 DEG C; (3) rough rolling; (4) finish rolling; (5) coiling; and (6) carrying out cooling on the casting blank to room temperature. The seawater corrosion-resistant steel has good seawater corrosion resistance and excellent mechanical properties.

Owner:BAOSHAN IRON & STEEL CO LTD

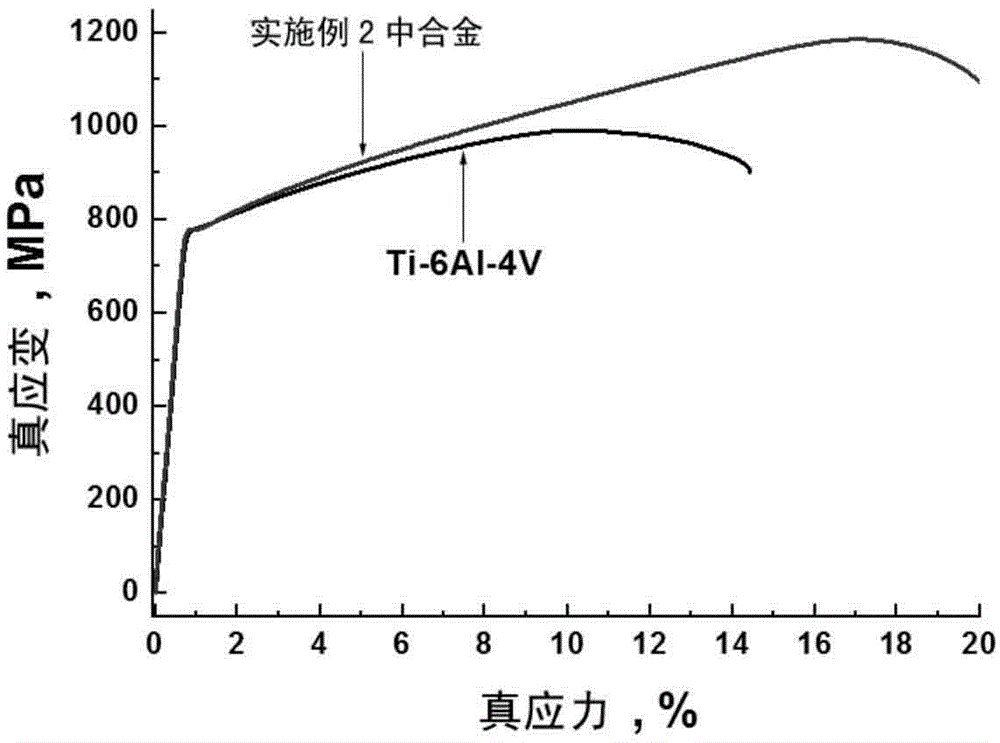

Novel low-cost high-plasticity sea-water-corrosion-resistant titanium alloy

The invention discloses a novel low-cost high-plasticity sea-water-corrosion-resistant titanium alloy, belonging to the technical field of a new titanium alloy. The novel low-cost high-plasticity sea-water-corrosion-resistant titanium alloy comprises the following elements by weight: 3.0-4.5% of Al, 2.0-3.0% of V, 0.5-1.5% of Fe, 0.5-2.0% of Cu and balance of Ti and impurity elements. Compared with Ti-6Al-4V alloy, the characteristics of the new alloy are as follows: (1) the raw materials are low in cost, hot workability plasticity is good, yield is high, and low is significantly reduced; (2) room temperature tensile strength of the new alloy after annealing is equal to that of the Ti-6Al-4V alloy, room temperature plasticity is higher, and the new titanium alloy is suitable for cold processing and warm processing forming of plates and pipes; and (3) corrosion resistance in seawater of the alloy is further improved. The titanium alloy is suitable for producing titanium alloy products such as rods, wires, plates, pipes,and the like, and can be widely used in the technical fields of aviation, spaceflight, ocean, and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

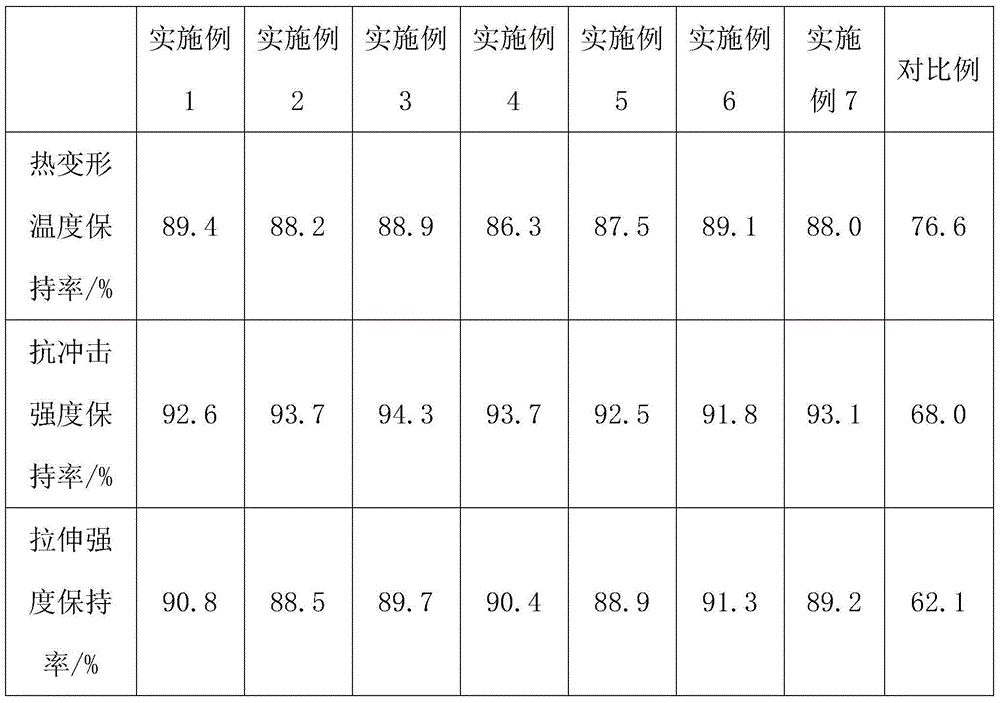

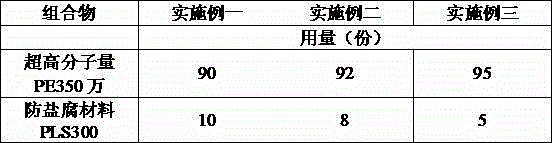

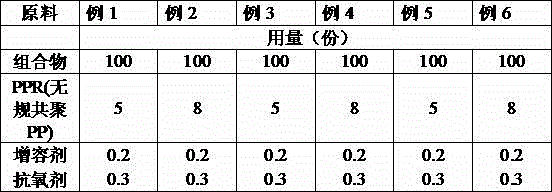

Marine wear-resistant ultrahigh-molecular-weight polyethylene composite material

The invention discloses a marine wear-resistant ultrahigh-molecular-weight polyethylene composite material. The composite material is prepared by mixing ultrahigh-molecular-weight polyethylene having the viscosity average molecular weight of 3000000-3500000 and a salt corrosion resistant material by an open mill to form a mixture, then adding a proper amount of a processing flow modifier, a compatibilizer and an antioxidant, and preparing by a twin-screw extruder. The composite material comprises the components in parts by weight: 80-90 parts of the ultrahigh-molecular-weight polyethylene, 5-10 parts of the salt corrosion resistant material, 5-10 parts of the processing flow modifier, 0.2-0.4 part of the compatibilizer, and 0.2-0.4 part of the antioxidant. The preparation comprises the steps: weighing the raw materials according to the proportion, firstly mixing in the open mill to form the mixture, again weighing the raw materials according to the proportion, extruding by the twin-screw extruder, and thus obtaining the product. The composite material can be widely used in the field of ship navigation. The preparation process is easy to control, high in production efficiency, and stable in quality.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com