Patents

Literature

32results about How to "Does not affect wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tire tread material with high wet and skid resistance and preparation method of material

ActiveCN103159998AImprove wet skid resistanceReduce rolling resistanceRolling resistance optimizationRolling resistanceStearic acid

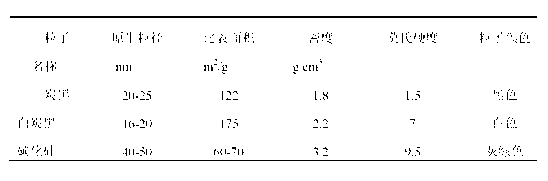

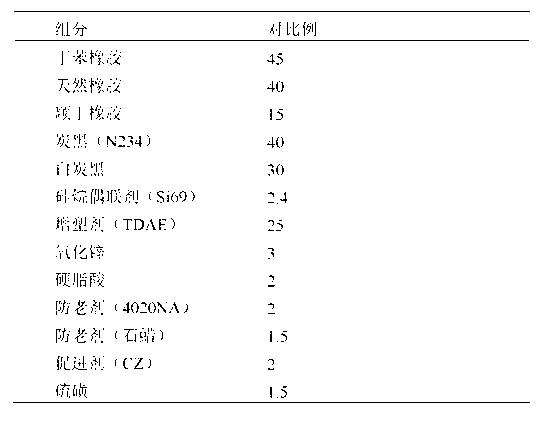

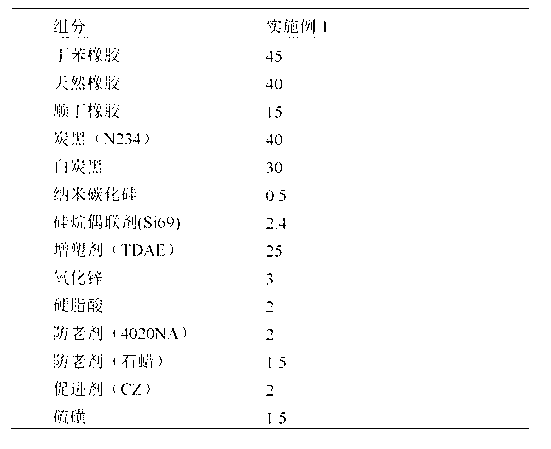

The invention relates to the technical field of rubber and particularly relates to a preparation method of a tire tread composite material with high wet and skid resistance. The composite material is characterized by containing the following materials in parts by weight: 100 parts of dienes rubber (concretely including styrene butadiene rubber, butadiene rubber, natural rubber, integrated rubber and a composite of the integrated rubber), 50-80 parts of stuffing (concretely including carbon black, white carbon black and a composite of the white carbon black), 0-6.4 parts of silane coupling agent, 0.5-3 parts of silicon carbide,10-40 parts of plasticizer, 2-5 parts of zinc oxide, 1-3 parts of stearic acid, 2-4 parts of anti-aging agent, 2-4 parts of accelerant and 1-3 parts of sulphur. By adoption of the material prepared by the method, the rolling resistance of a tire can be reduced, the wear-resisting property of the tire tread is not affected simultaneously, and especially, the wet and skid resistance of the tire is greatly increased by utilizing the nano silicon carbide material.

Owner:BEIJING UNIV OF CHEM TECH

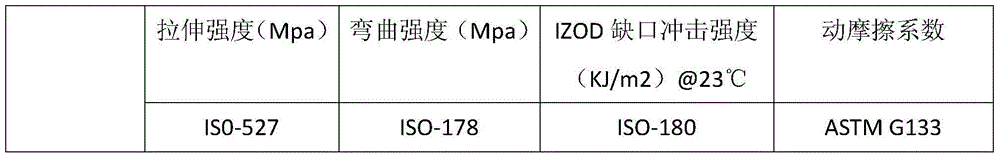

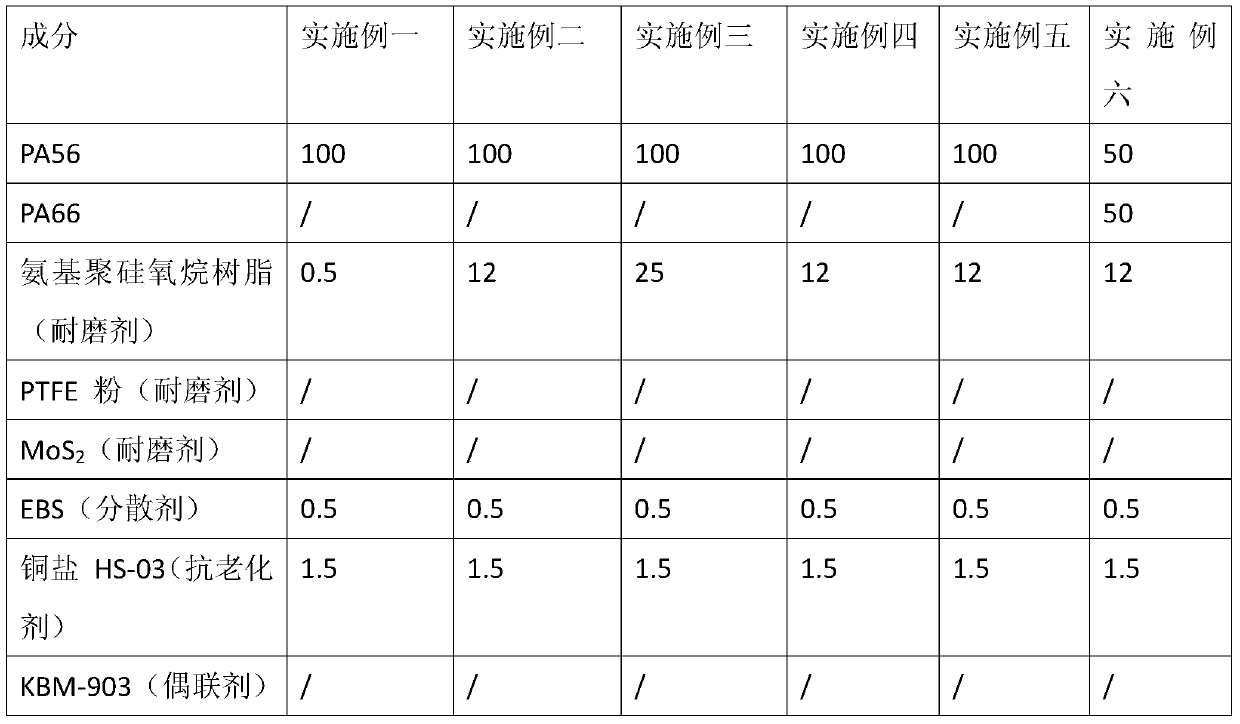

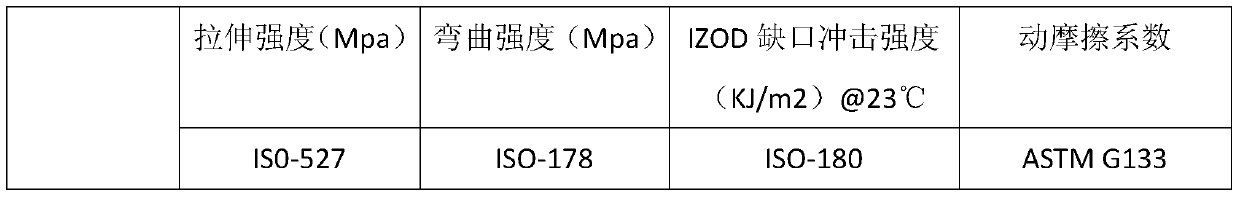

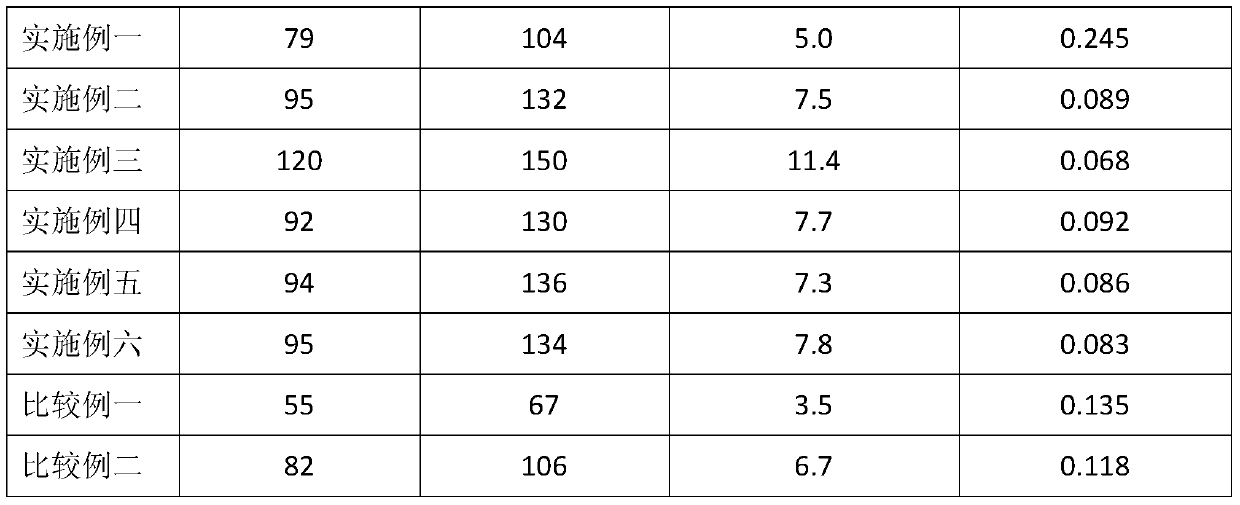

Highly wear-resistant bio-based polyamide composite material and preparation method thereof

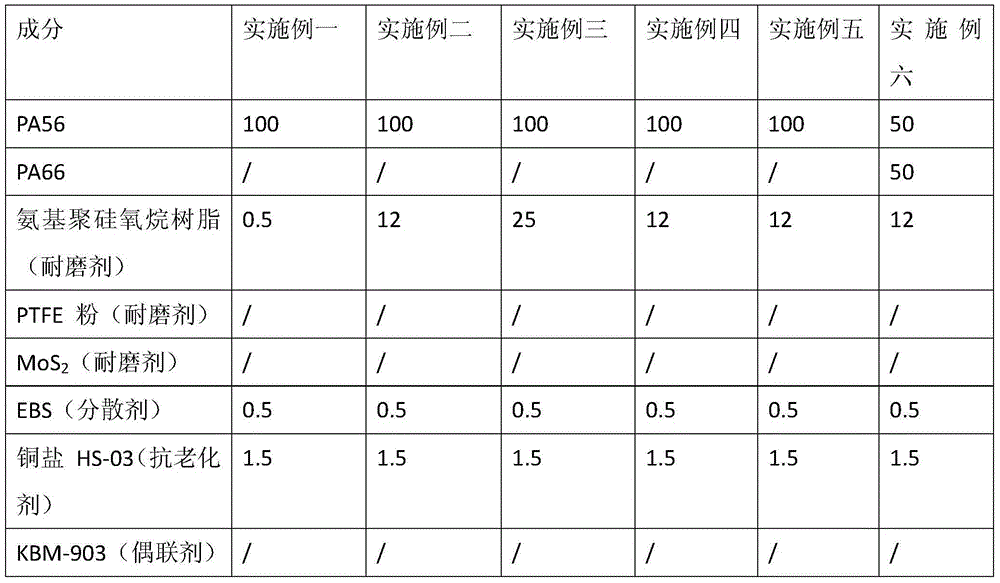

The invention provides a highly wear-resistant bio-based polyamide composite material and a preparation method thereof. The bio-based polyamide composite material contains polyamide resin and a wear-resisting agent. Production raw materials of the polyamide resin comprise pentanediamine and diacid. A weight ratio of the polyamide resin to the wear-resisting agent is 100: 0.5-25. The preparation method comprises the following steps: at least mixing the polyamide resin and amino polysiloxane at room temperature; and successively carrying out extrusion granulation at 220 to 300 DEG C, cooling and drying so as to obtain the highly wear-resistant bio-based polyamide composite material. The polyamide composite material provided by the invention has good mechanical properties and wear resistance; the wear-resisting agent amino polysiloxane does not influence the color of the polyamide composite material and poses no restriction to application occasions of the polyamide composite material; and the the preparation method provided by the invention has the advantages of easiness, low cost and accordance with production requirements of industrialization.

Owner:CATHAY R&D CENT CO LTD +1

Antifogging agent and application method

InactiveCN110257009AImprove hydrophilicityImprove mechanical propertiesOther chemical processesActive agentSolvent

The invention relates to a functional assistant, in particular to a reusable, safe and environment-friendly antifogging agent and an application method thereof. The antifogging agent comprises, by mass, 0.01-10% of nanocellulose, 0.1-30% of inorganic nanoparticles, 0-2% of surfactants, 0-1% water-soluble polymers, 0-50% of water-soluble solvents and the balance of water. The antifogging agent is mainly made from the nanocellulose which is blended with the inorganic nanoparticles, the water-soluble polymers, the surfactants, the solvents and the like, and has the advantages of water jet resistance, friction resistance and the like. When an antifogging coating is contaminated by grease and dust to disable the antifogging effect, due to the high friction resistance of the antifogging coating, users can slightly wipe away the grease and the dust by hands or wetted soft cloth, and accordingly, the antifogging effect is reactivated.

Owner:浙江跃维新材料科技有限公司

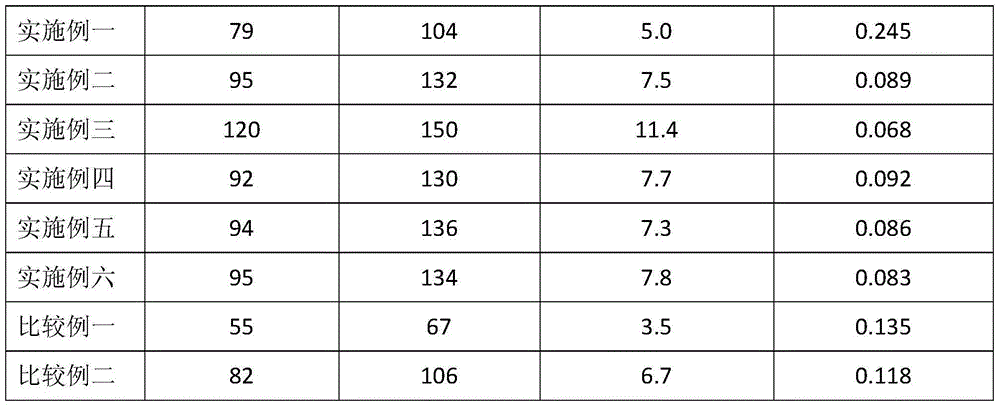

Wear-resistant glaze for glazed bricks, and preparation method thereof

The invention discloses a wear-resistant glaze for glazed bricks, and a preparation method thereof. The wear-resistant glaze is prepared from raw glaze powder, No.1 frit powder and No.2 frit powder, wherein the raw glaze powder comprises, by weight, 8-12% of kaolin, 10-18% of calcined kaolin, 12-20% of quartz, 12-20% of dolomite, 8-15% of calcined talc, 8-15% of nepheline, 5-10% of zinc oxide, 3-6% of barium sulfate and 6-12% of strontium carbonate. The raw materials of the No.1 frit powder comprise zircon sand and barium sulfate, and raw materials of the No.2 frit powder comprise kaolin, calcined talc, fluorite and barium sulfate. The glaze disclosed by the invention contains barium sulfate, so that the color development condition can be improved, the problem of color difference of red and yellow ceramic ink-jet inks during firing of a product is avoided, and the transparency of the wear-resistant glaze is improved under the condition that the hardness and the wear resistance are notinfluenced.

Owner:佛山市东鹏陶瓷发展有限公司 +1

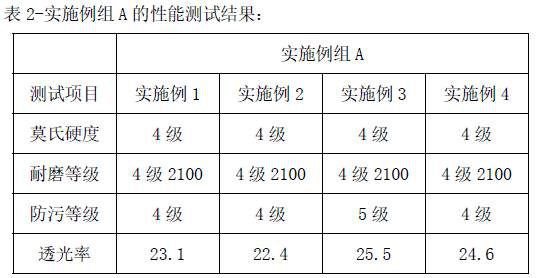

High-slippery-resistance tire tread rubber composite material and preparation method thereof

InactiveCN105646972AIncrease Tanδ valueTanδ value decreasedRolling resistance optimizationRolling resistancePolymer science

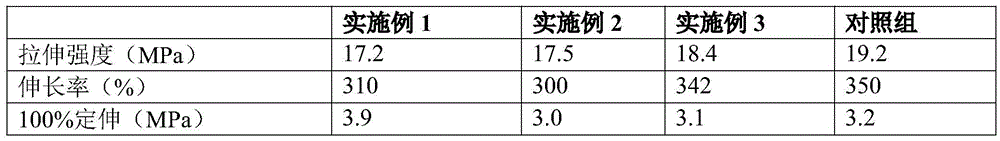

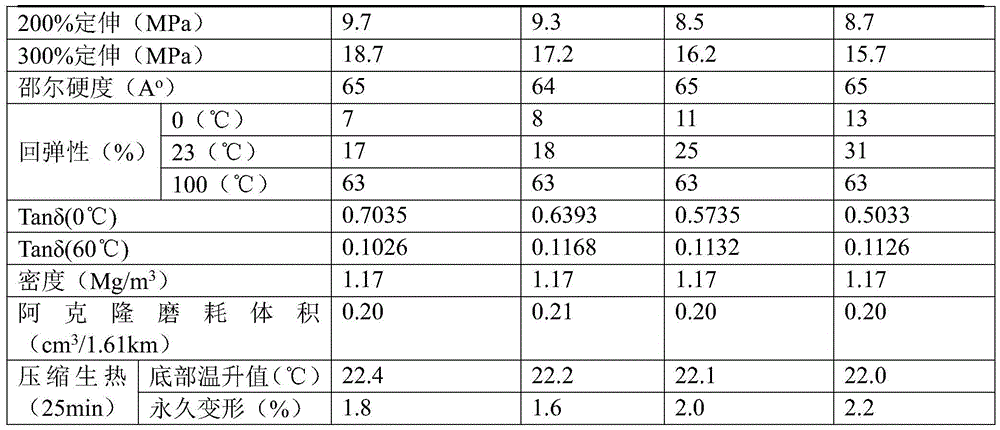

The invention relates to a high-slippery-resistance tire tread rubber composite material and a preparation method thereof and belongs to the technical field of rubber. The rubber composite material is prepared from, by weight, 100 parts of diolefine containing rubber (specifically including solution polymerized styrene-butadiene rubber, butadiene rubber and rare earth 3,4-isoprene rubber), 30-70 parts of a plasticizer, 50-120 parts of white carbon black, 5-30 parts of carbon black, 0.5-20 parts of a silane coupling agent, 0.5-3 parts of stearic acid, 2-5 parts of zinc oxide, 1-3 parts of sulfur, 1-5 parts of an anti-aging agent and 1-5 parts of an accelerant. By introducing the rare earth 3,4-isoprene rubber to a rubber formula of the rubber composite material, a Tan delta value when the rubber composite material is at 0 DEG C is remarkably improved, and meanwhile the Tan delta value when the rubber composite material is at 60 DEG C is reduced. Accordingly, the slippery-resistance performance of tires is improved, and the rolling resistance of the tires is reduced on the premise that the abrasion resistance performance of the tires is not affected.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +1

Environment-friendly high-performance organic high-temperature-resistant paint

InactiveCN105462485ADoes not affect adhesionDoes not affect weather resistancePolyester coatingsMulticolor effect coatingsTemperature resistanceWear resistance

The invention discloses an environment-friendly high-performance organic high-temperature-resistant paint. The paint comprises, by weight, 40 to 100 parts of resin, 10 to 20 parts of high-temperature-resistant pigments, a filling material and an auxiliary agent. According to the invention, through addition of the high-temperature-resistant pigments, the paint has various colors instead of a single color and is high-temperature resistant; and while having diversified colors and high temperature resistance, the paint is not influenced in the original adhesion, weatherability, wear resistance and high temperature resistance.

Owner:王寿高

Procuring composite layer tread rubber for tyre retreading

InactiveCN101570604AIncrease elasticityLow heat generationTyresRubber layered productsRubber materialSulfur

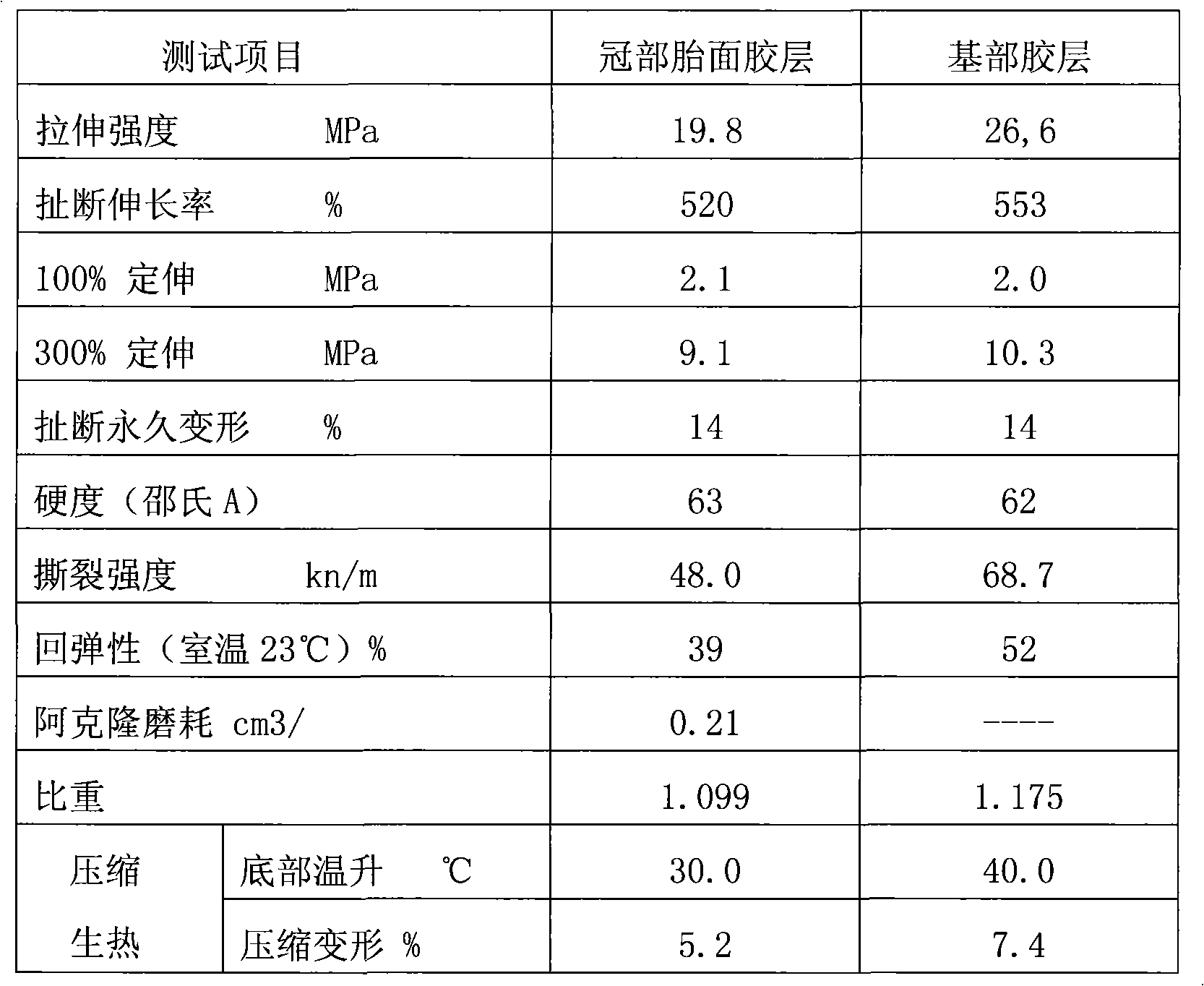

The invention relates to a procuring composite layer tread rubber for tyre retreading. A basal rubber layer is connected on the inner surface of a tread rubber layer at the crown part, the basal rubber layer is provided with different formula component materials to meet the performance requirements of high elasticity and lower heating, therefore, the cost of the rubber material used for the tread rubber is effectively reduced and the normal use of the retreaded tyre is also ensured. The basal rubber layer comprises the following formula components according to the parts by weight: 100 of rubber, 25-45 of black carbon, 5-10 of white carbon black, 3-5 of activating agent, 2-5 of antioxidant, 1-3 of sulfur and 1-3 of promoter. In the formula of the basal rubber layer, the high wear-resistant black carbon and other components are not included, therefore, the basal rubber layer does not have the performance indexes of abrasion resistance and tear resistance, and the contact friction with the ground is realized through the tread rubber layer at the crown part.

Owner:SAILUN GRP CO LTD

Copper alloy wear-resistant material and manufacturing method thereof

The inventive copper alloy wear-resistant material and manufacturing method thereof relate to the field of metal wear-resistant materials, aiming at solving the technical problems of high content of precious metals, high manufacturing cost, high price and prominent influence of production mode on the wear resistance of the copper alloy wear-resistant material, in the production field of the conventional copper alloy wear-resistant material. The inventive copper alloy wear-resistant material comprises the following ingredients based on weight ratio: 54%-57% of Cu, 3%-5% of Al, 3.5%-5.5% of Mn, 0.5%-1.3% of Si, 0.7-1.5% of Fe, not more than 1% of impurities, and Zn as the balance. The invention is suitable for the production field of alloy wear resistant material.

Owner:CHENGDU HAONENG TECH CO LTD

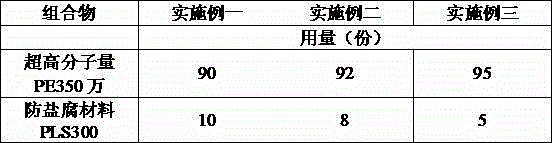

Marine wear-resistant ultrahigh-molecular-weight polyethylene composite material

The invention discloses a marine wear-resistant ultrahigh-molecular-weight polyethylene composite material. The composite material is prepared by mixing ultrahigh-molecular-weight polyethylene having the viscosity average molecular weight of 3000000-3500000 and a salt corrosion resistant material by an open mill to form a mixture, then adding a proper amount of a processing flow modifier, a compatibilizer and an antioxidant, and preparing by a twin-screw extruder. The composite material comprises the components in parts by weight: 80-90 parts of the ultrahigh-molecular-weight polyethylene, 5-10 parts of the salt corrosion resistant material, 5-10 parts of the processing flow modifier, 0.2-0.4 part of the compatibilizer, and 0.2-0.4 part of the antioxidant. The preparation comprises the steps: weighing the raw materials according to the proportion, firstly mixing in the open mill to form the mixture, again weighing the raw materials according to the proportion, extruding by the twin-screw extruder, and thus obtaining the product. The composite material can be widely used in the field of ship navigation. The preparation process is easy to control, high in production efficiency, and stable in quality.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

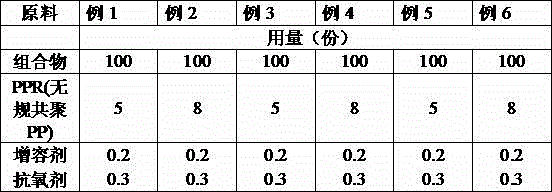

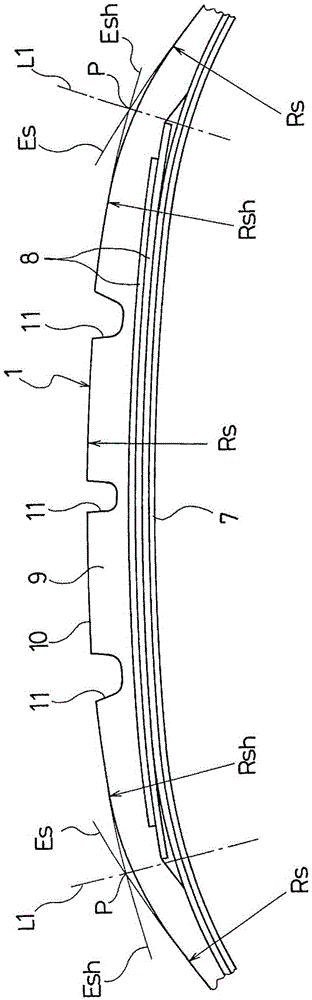

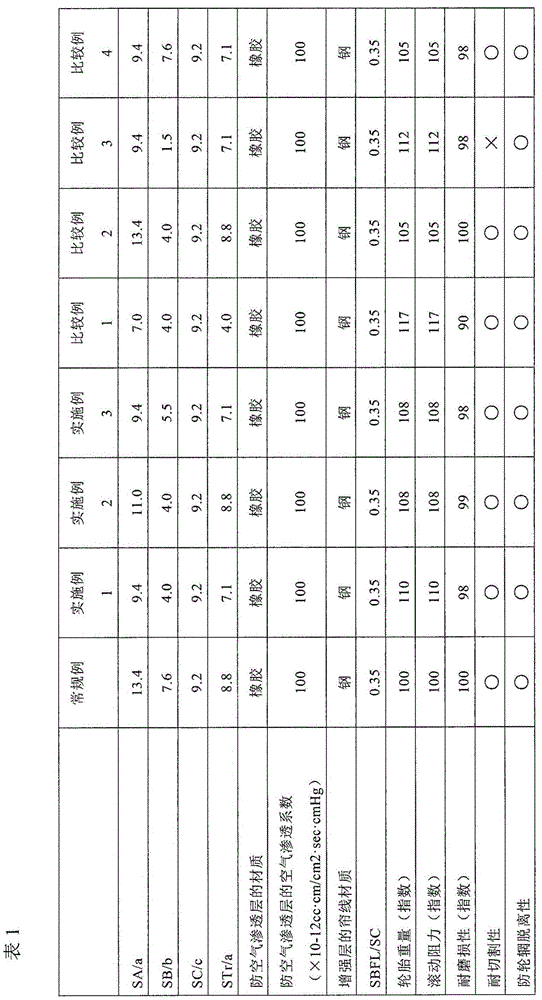

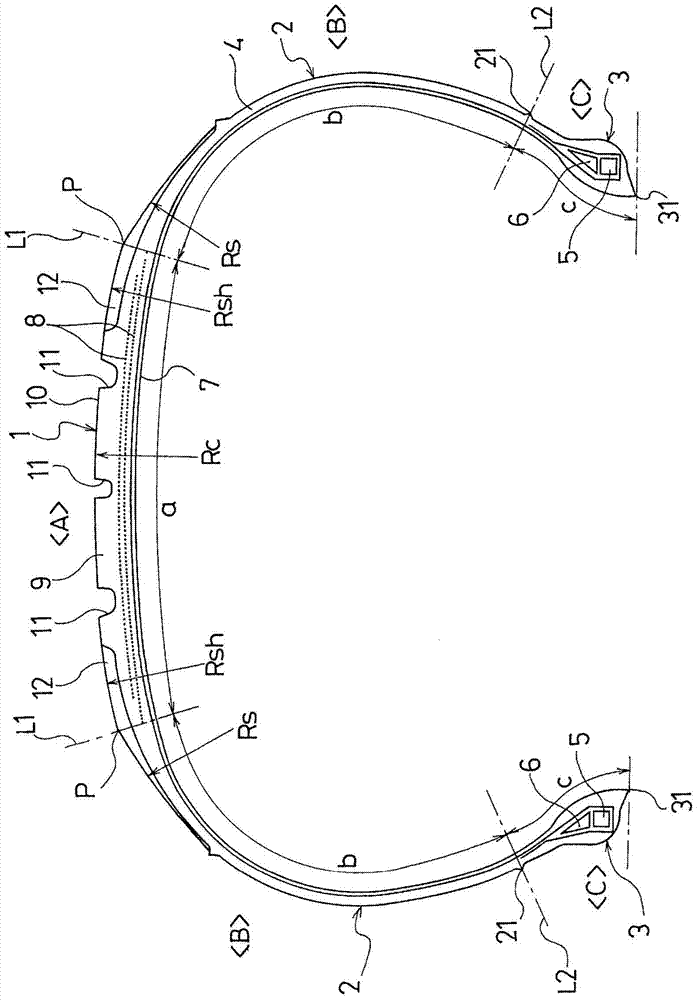

Automobile pneumatic tire

ActiveCN105408130AReduce weightIncrease fuel consumptionWithout separate inflatable insertsPneumatic tyre reinforcementsTire beadRolling resistance

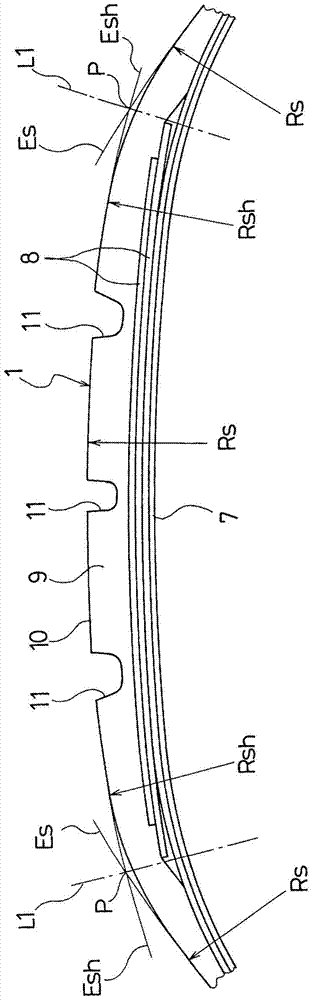

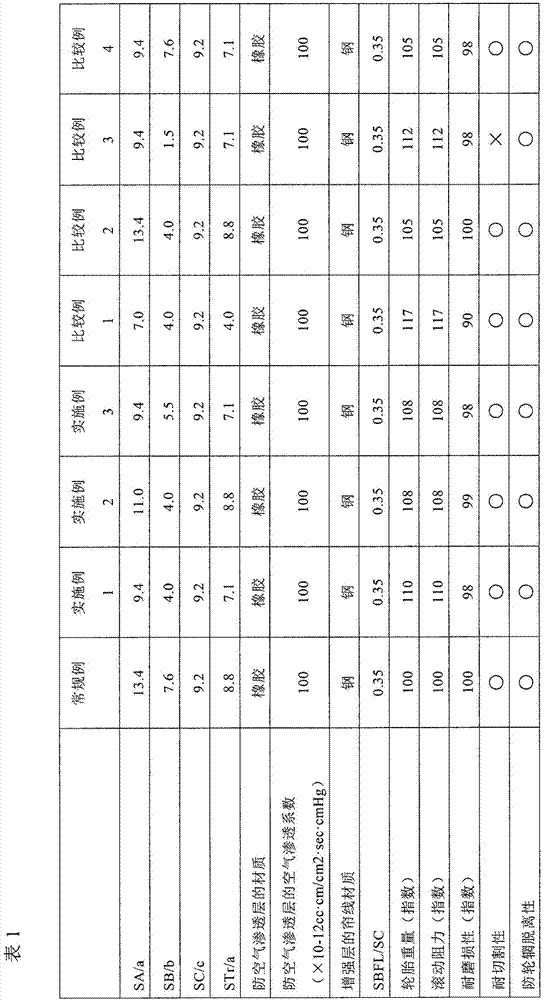

Provided is an automobile pneumatic tire such that the tire weight and rolling resistance can be greatly decreased without detracting from necessary tire performance. In a pneumatic tire, at least one layer of a carcass layer is installed between a pair of bead portions, a bead core is embedded in each bead portion, at least one layer of a reinforcement layer is disposed on an outer periphery side of the carcass layer, and a tread rubber layer is layered on the outer periphery side of the reinforcement layer. When a pair of first boundary lines is defined that passes a point of intersection of an extension of a side arc forming a tread profile and an extension of a shoulder arc and orthogonal to a tire inner surface, a pair of second boundary lines is defined passing a rim check line and orthogonal to the tire inner surface, a first region is partitioned between the pair of first boundary lines, a second region is partitioned between the first boundary lines and the second boundary lines, a third region is partitioned closer to a bead toe than to the second boundary lines, the first to the third regions have cross sectional areas (mm2) of SA, SB, and SC, respectively, and the first to the third regions respectively have periphery lengths (mm) of a, b, and c along the tire inner surface, the relationships 7.5 <= SA / a <= 11.5 and 2.0 <= SB / b <= 6.0 are satisfied with respect to the ratios SA / a and SB / b.

Owner:YOKOHAMA RUBBER CO LTD

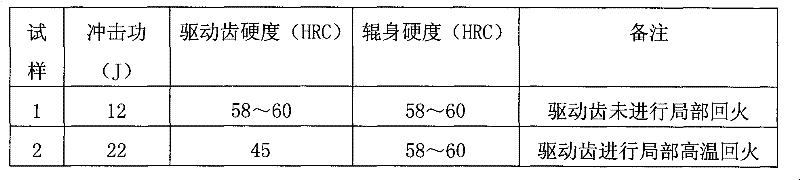

Heat treating method for driving roll and driving gear of rolling mill

InactiveCN102312057ADoes not affect strengthDoes not affect wear resistanceFurnace typesHeat treatment furnacesRoom temperatureOil cooling

The invention relates to a heat treating method for a driving roll and a driving gear of a rolling mill. The heat treating method comprises the following steps: I insulating the driving roll in a salt bath furnace at the temperature of 980 DEG C-1080 DEG C for 40-50 minutes, then suspending into quenching oil with the temperature of 20 DEG C-80 DEG C for cooling, cooling the roll to the temperature below 120 DEG C, II putting the driving roll into a nitrate furnace with the temperature of 510 DEG C-600 DEG C for tempering three times, wherein each time lasts 3.5-5 hours, air cooling after the first two times tempering, performing the third tempering after cooling the temperature of roll lower than 60 DEG C; cooling to the room temperature after performing the third tempering; III carrying out a partial high-temperature tempering to the driving gear of the tempered roll, immersing the whole driving gear into the nitrate furnace with the temperature of 560 DEG C-680 DEG C for 1-4 hours and then oil cooling, cooling the roll to the temperature below 40 DEG C. According to the invention, the driving gear processed by the heat treatment method has high impact resistance.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

High-flowability nylon composite material and preparation method thereof

InactiveCN107722621AImprove liquidityLiquidity will not affectHeat-exchange elementsGlass fiberWear resistant

The invention discloses a high-flowability nylon composite material, which is prepared from nylon, a heat conduction wear-resistant filling material, a first flowability enhancing agent and a second flowability enhancing agent, wherein the first flowability enhancing agent is nanometer ultrafine talcum powder; the heat conduction wear-resistant filling material is prepared from aluminum hydroxide,nanometer particulate alpha-Al2O3 and magnesium hydroxide. The invention discloses a preparation method of the high-flowability nylon composite material. The method comprises the following steps of proportioning and mixing the nylon, the heat conduction wear-resisting filling material, the first flowability enhancing agent, the second flowability enhancing agent, a coupling agent, an antioxidantand a lubricating agent to obtain a mixed material; adding the mixed materials into a double-screw extruder for fusion plasticization; then, adding glass fiber into a mold head of the double-screw extruder for extrusion; performing cooling, palletization and drying to obtain the high-flowability nylon composite material. The high-flowability nylon composite material provided by the invention has good flowability; in addition, the mechanical strength is unchanged; the high heat conduction, flame-retardant and wear-resistant performance is realized; the preparation method is simple; the cost islow.

Owner:广州维邦新材料科技有限公司

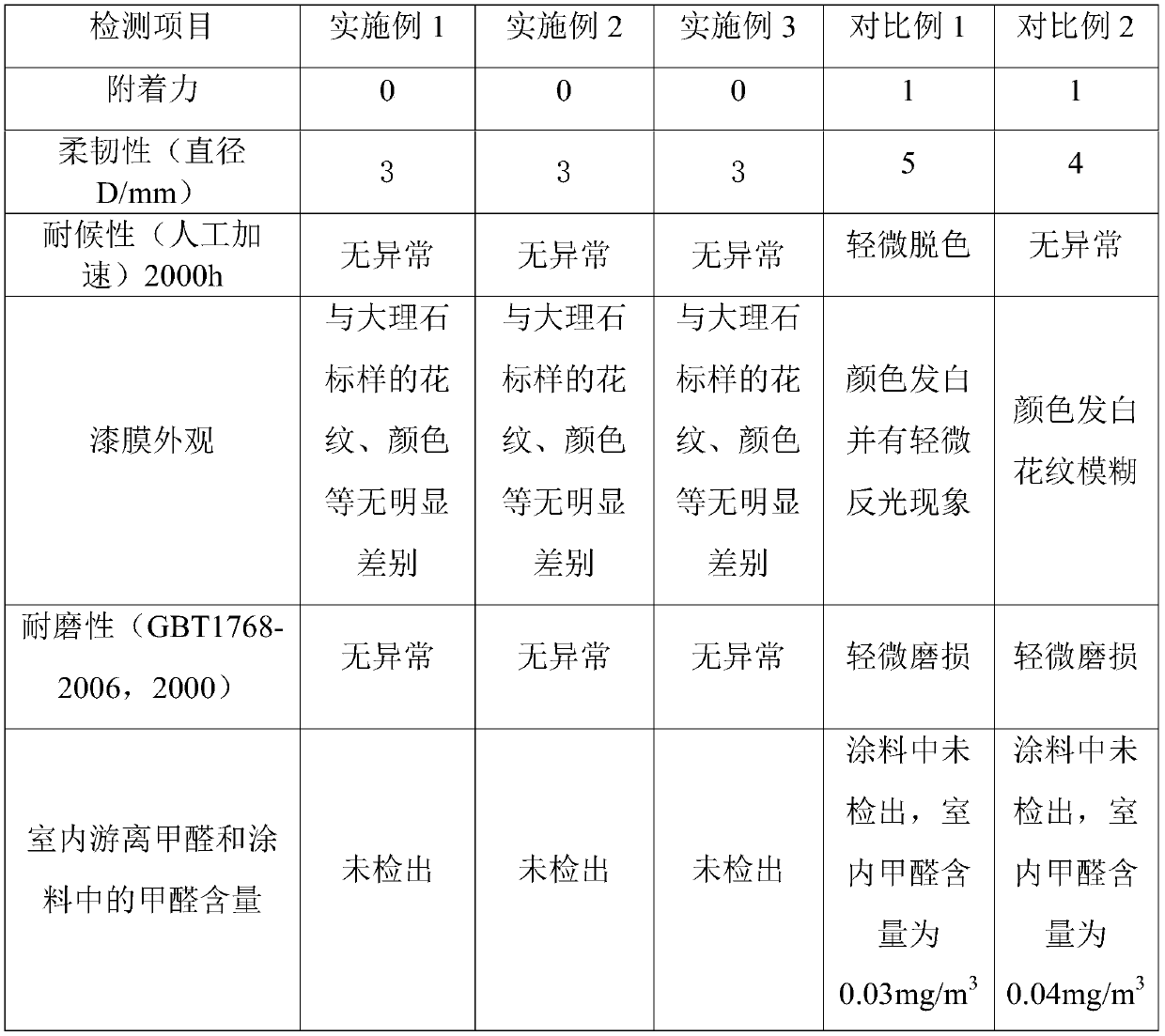

Sand-in-water coating and preparation method thereof

The invention relates to the technical field of coatings, and particularly discloses a sand-in-water coating and a preparation method thereof. The sand-in-water coating comprises, by weight, 20-30 parts of a protective glue, 50-60 parts of a toning base paint and 15-25 parts of a continuous phase. The sand-in-water coating has the advantages of strong adhesive force, high toughness, good wear resistance and good weather resistance, and a film formed by the coating can achieve the natural effect and beauty of marble textures.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

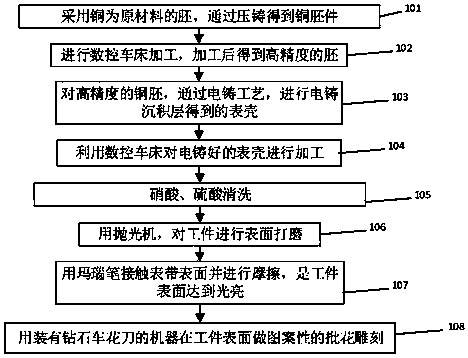

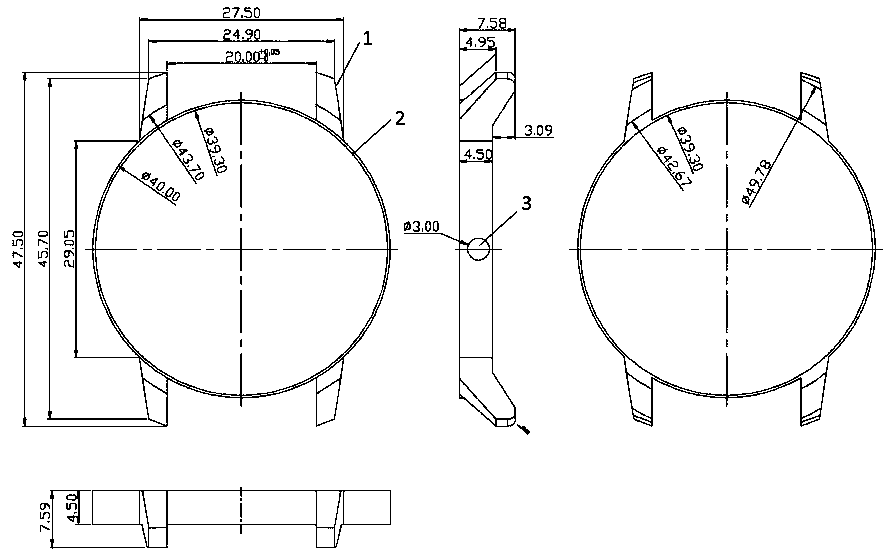

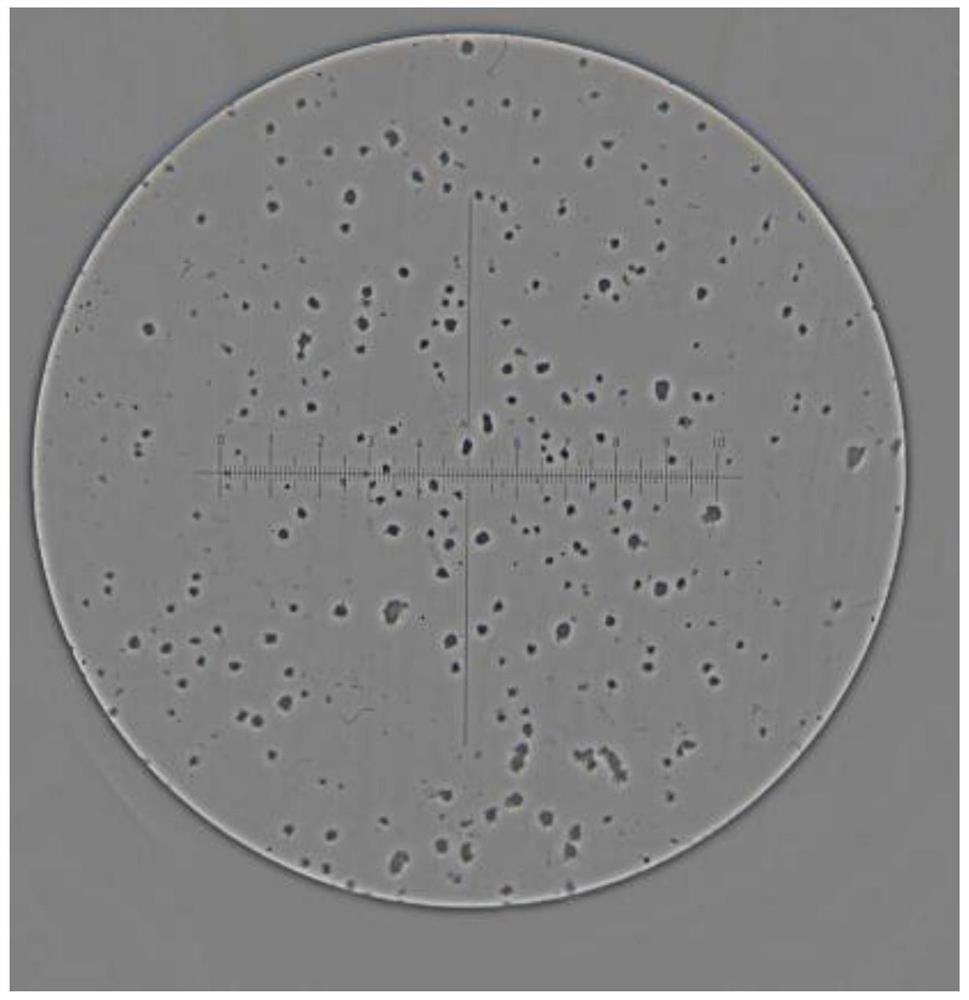

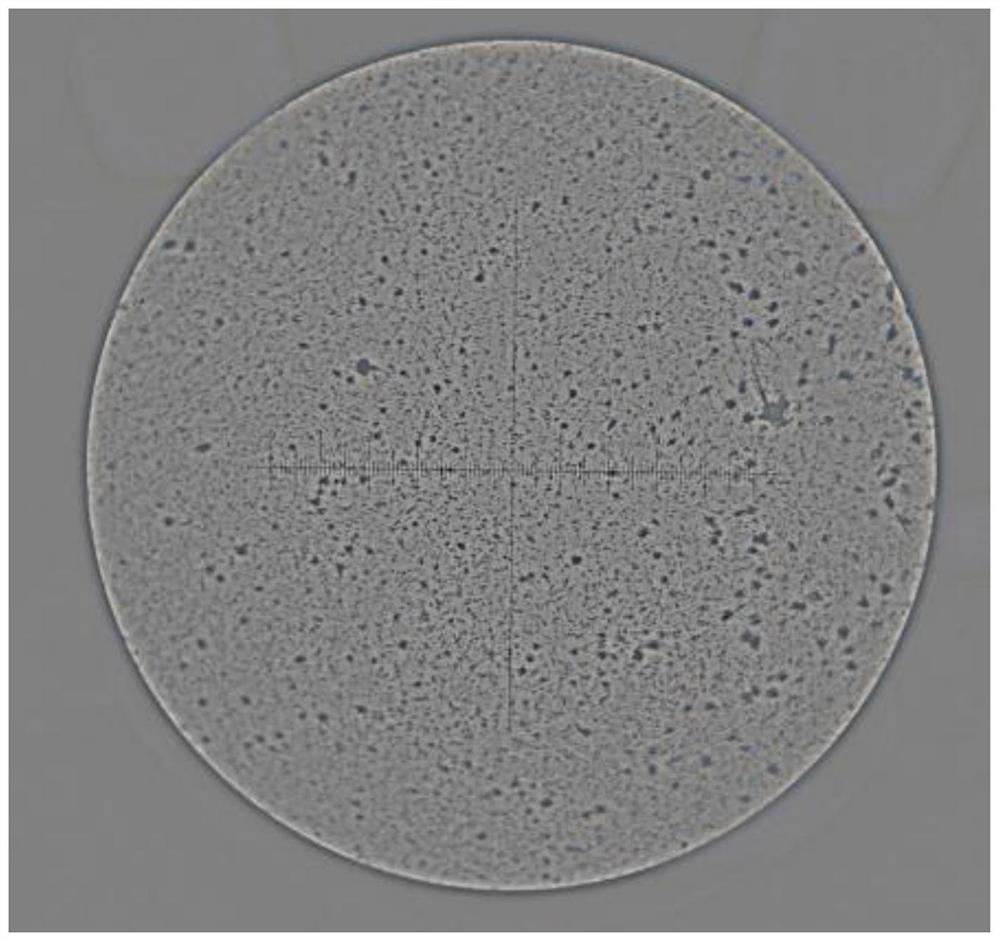

Manufacturing method of watchcase

InactiveCN110629256ADoes not affect hardnessDoes not affect wear resistanceClockwork casesElectroforming processesCopper nitrateElectroforming

The embodiment of the invention discloses a manufacturing method of a watchcase. The manufacturing method of the watchcase comprises the steps that a copper blank is machined according to an electroforming dimension and a matching position, so that a higher-precision blank is obtained; the higher-precision blank is electroformed through a pure gold electroforming process to make sure that an electroforming sedimentary layer of the electroformed blank is less than 0.5 mm, so that the watchcase is formed; gold or other precious metal is used during electroforming; the watchcase is machined according to the requirements for an assembly dimension, the matching position and the like; after nitric acid is heated to be boiled, the machined watchcase and the nitric acid are completely dissolved toform copper nitrate and are washed with water, then protective copper on the inner wall of the machined watchcase is heated and dissolved with sulfuric acid, and the watchcase is cleaned with water and then is dried to obtain a workpiece; and the workpiece is polished, so that the surface of the polished workpiece is glossy. By adopting the manufacturing method of the watchcase in the embodimentof the invention, the watchcase with light weight and good manufacturing precision can be manufactured.

Owner:深圳市元福珠宝首饰有限公司

Self-lubricating wear-resistant material and preparation process thereof

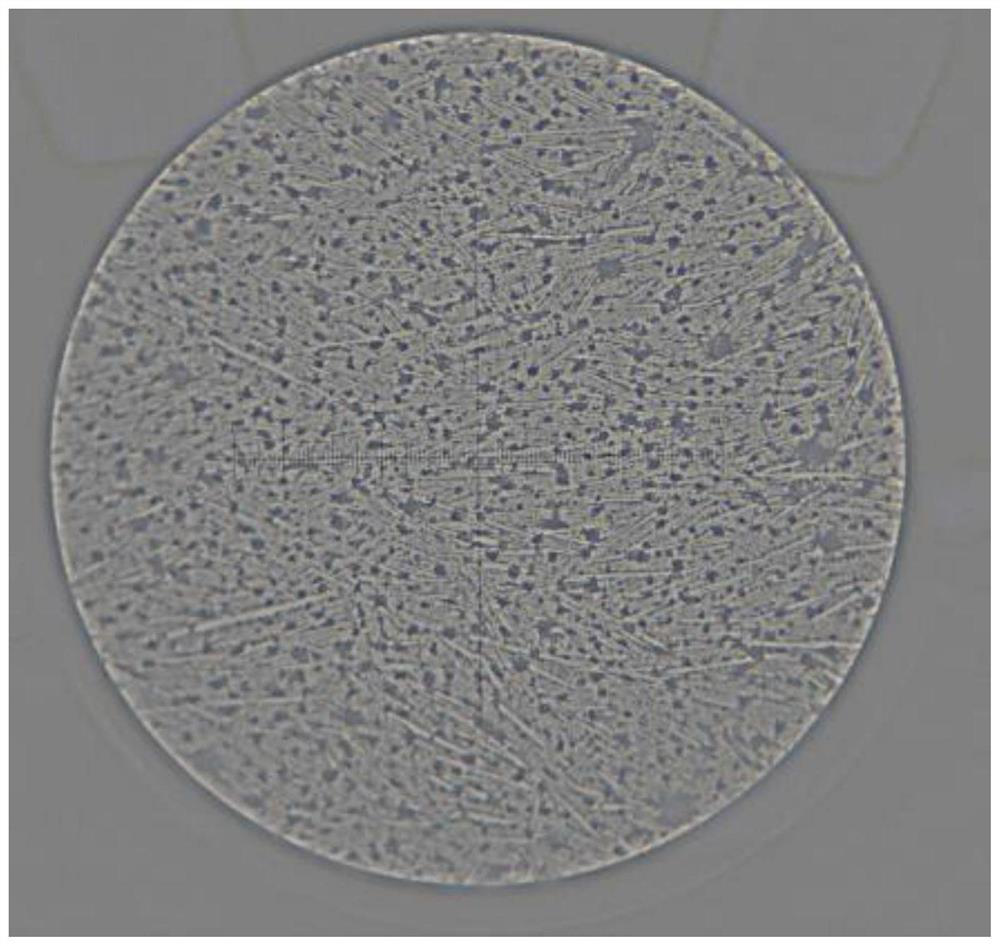

InactiveCN112575238ADoes not affect wear resistanceImprove the lubrication effectEutectic transformationGraphite

The invention discloses a preparation process of a self-lubricating wear-resistant material. The preparation process comprises the following steps: heating a raw material so that the raw material forms molten iron, wherein the raw material contains carbon atoms, the carbon atoms are in a supersaturated state, then the carbon atoms in the raw material are in a local aggregation state, and part of the carbon atoms are in a free state; cooling the heated molten iron, wherein the carbon atoms are still in a supersaturated state, and the carbon atoms in a free state are preferentially separated outto form graphite; further cooling the molten iron so as to precipitate primary cementite from the raw material from which graphite is removed; enabling at least part of the primary cementite to formcementite and austenite through eutectic transformation; and further cooling the molten iron to convert the austenite into martensite. According to the preparation process, graphite, cementite and martensite are separated out at a time, meanwhile, the graphite is obtained without annealing treatment, and then the wear resistance of the wear-resistant material is not affected.

Owner:杨洪根 +1

A kind of coating sealing material, its preparation method and its application

InactiveCN105001781BLong-term protectionDoes not affect wear resistanceAnti-corrosive paintsAnhydrous ethanolCeramic coating

The invention discloses a coating layer sealing material including an organic silicon resin hole sealing agent A, a micron-size talcum powder B, a mixture C, an auxiliary agent and an anhydrous ethanol solvent, the mass ratio of the organic silicon resin hole sealing agent A to the micron-size talcum powder B to the mixture C is 100 to (40-60) to (60-120), the auxiliary agent accounts for 5-7% of the total mass, and the mass ratio of the organic silicon resin hole sealing agent A to the anhydrous ethanol solvent is 1 to (1-1.3); the mixture C includes modified nano-size silicon dioxide and micron-size titanium dioxide, wherein the content of the modified nano-size silicon dioxide accounts for 50-100% of the total mass of the mixture C. The invention also discloses a preparation method of the coating layer sealing material, and a use of the coating layer sealing material for sealing treatment of a plasma sprayed ceramic coating layer. The coating layer after being sealed by the material has both excellent corrosion resistance and water biological adsorption resistance.

Owner:HOHAI UNIV

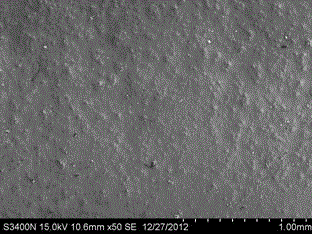

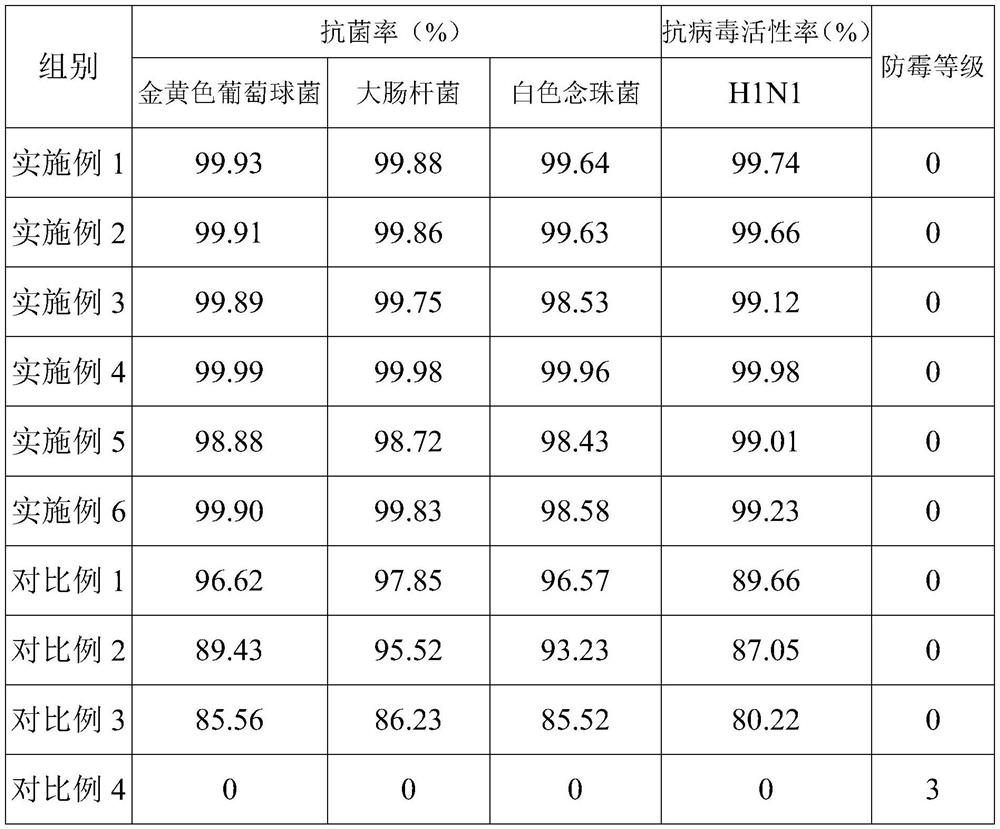

Nano composite antibacterial powder and application thereof in ceramic tea set

InactiveCN112956494AImprove performanceAchieve antibacterialBiocideFungicidesAnti bacterialAntibacterial agent

The invention provides nano composite antibacterial powder and application thereof in a ceramic tea set. The nano composite antibacterial powder comprises nano metal oxide, silver-doped nano bismuth tungstate and a silver-loaded antibacterial agent. The invention also provides an antibacterial and antiviral glaze, an antibacterial and antiviral tea set and a preparation method of the antiviral tea set. The nano composite antibacterial powder disclosed by the invention has good antibacterial and antiviral properties through the synergistic effect of the nano metal oxide, the silver-doped nano bismuth tungstate and the silver-loaded antibacterial agent. the ano composite antibacterial powder is added into ceramic glaze, and after spraying and calcining, blank glaze with antibacterial and antiviral effects can be formed on the surface of a tea set, so that the overall antibacterial effect of the tea set is realized, the antibacterial time is relatively long, and the strength, wear resistance and appearance of the tea set are not influenced; and the preparation method of the antibacterial and antiviral tea set is simple, efficient, energy-saving and environment-friendly, does not need an additional treatment process, and is very high in application value.

Owner:同曦集团有限公司

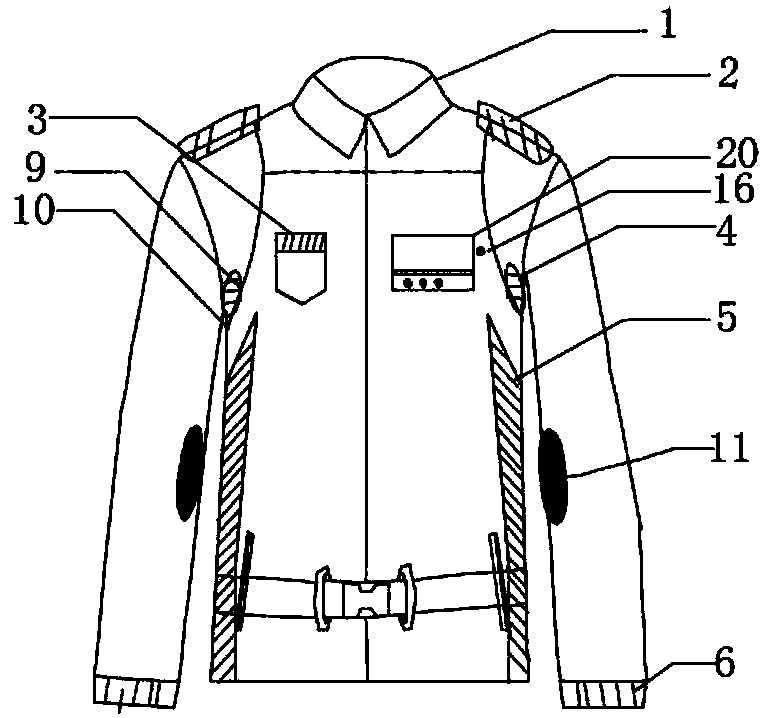

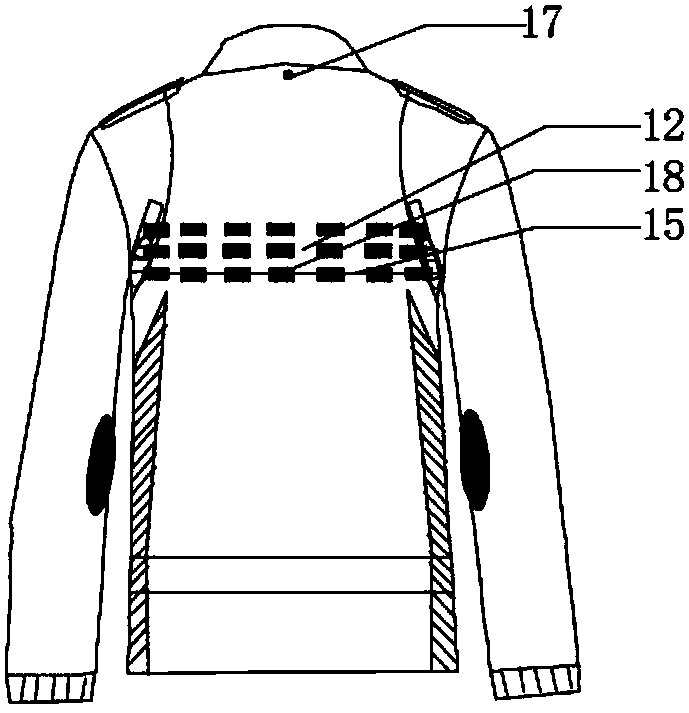

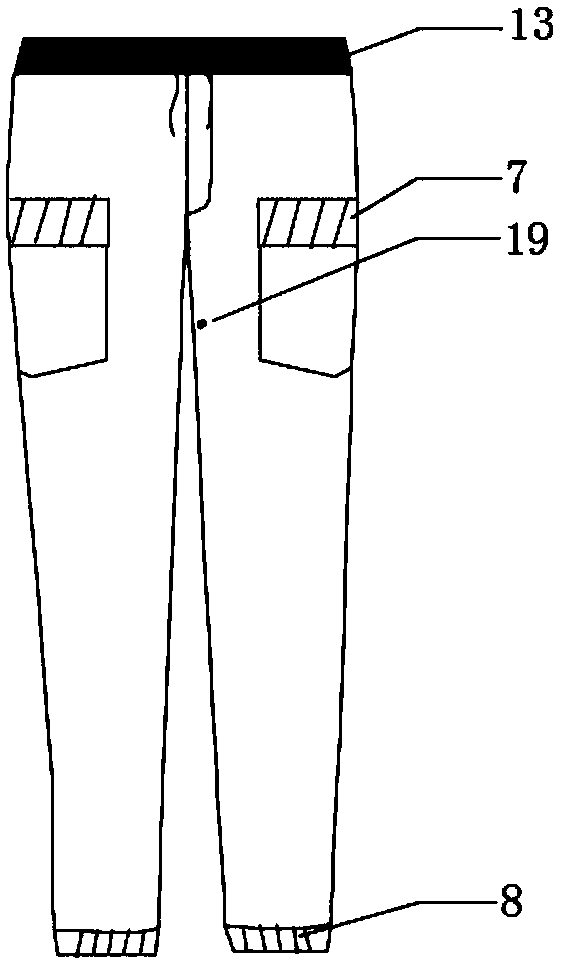

Novel temperature-adjustable intelligent military training clothing system device

InactiveCN108402554AReal-time monitoring of physiological dataCompact structureDiagnostic recording/measuringSensorsDisplay deviceBlood pressure

The invention relates to a novel temperature-adjustable intelligent military training clothing system device. The device comprises a temperature adjusting module, a sensor and a displayer which are arranged on a clothing coat and trousers. The temperature adjusting module comprises a structural temperature adjusting module and a chemical temperature adjusting module. For the structural temperatureadjusting module, an air-permeable mesh fabric is arranged on the corresponding part of clothing, for the chemical temperature adjusting module, a temperature-adjusting fabric containing phase-changematerials is arranged on the corresponding part of the clothing, the sensor comprises a temperature and humidity sensor arranged on the corresponding part of the clothing, a contact end, a heart ratesensor, a respiratory rate sensor and a blood pressure sensor. Relevant parameters are divided according to the security level and displayed on the displayer. By means of the temperature adjusting module, the sensor and the displayer, the temperature-adjustable intelligent military training clothing system device can adjust the local temperature of a human body, monitor and display physiologicaldata of the human body in real time, and issue a warning when the relative value exceeds the security level range, and safe, comfortable and intelligent wearing experience is provided for the human body.

Owner:JIANGNAN UNIV

Tire tread rubber with low rolling resistance

InactiveCN106118081AAbrasion resistance does not affectReduce the ratioSpecial tyresRolling resistance optimizationEpoxyWax

The invention relates to tire tread rubber with low rolling resistance, belonging to the technical field of a tire rubber formula. The tire tread rubber comprises 2-5 parts of natural rubber, 3-6 parts of styrene-butadiene rubber, 0.1-0.5 part of phenolic resin, 1-2 parts of epoxy resin, 2-4 parts of stearic acid, 2-4 parts of wax, 1-3 parts of an anti-aging agent, 21-35 parts of carbon black N330, 2-7 parts of white carbon black, 0.5-1 part of sulfur, 1.5-2.5 parts of an accelerating agent, 15-35 parts of aromatic oil and 4-15 parts of hard clay. By virtue of reasonable formula combination, the proportion of carbon black in the system is reduced, the rolling resistance of a finished product of a tire in use can be greatly reduced, and the wear resistance of the tire tread can not be influenced.

Owner:SICHUAN YUANXING RUBBER

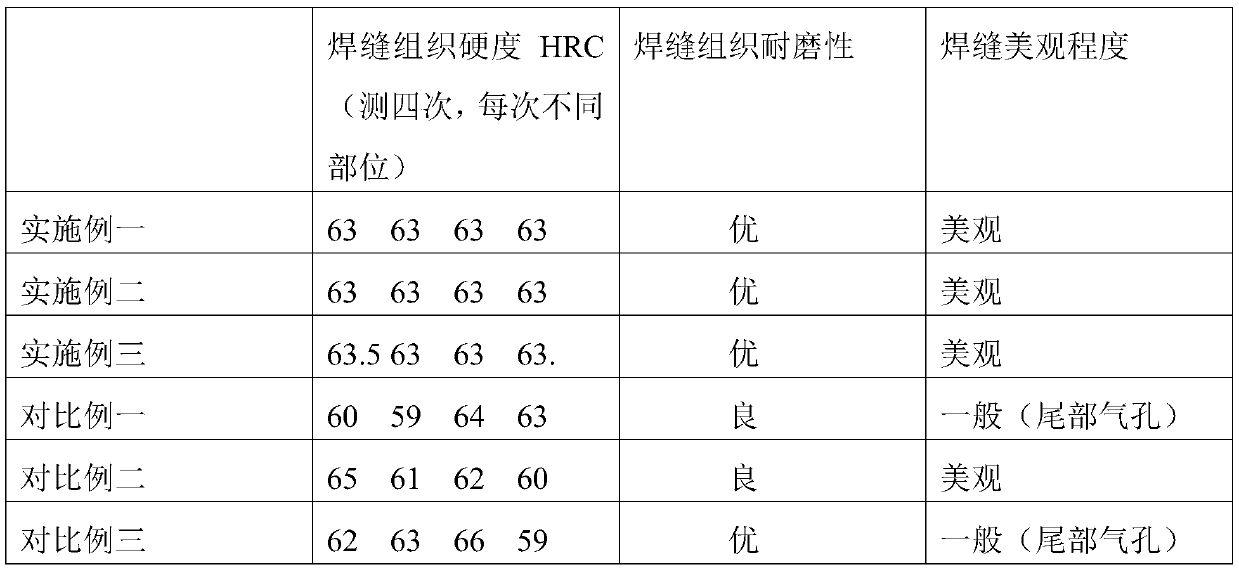

Surfacing flux-cored wire and manufacturing method thereof

InactiveCN110253177ADoes not affect wear resistanceSolve the problem of stomataWelding/cutting media/materialsSoldering mediaGraphiteHardness

The invention discloses a surfacing flux-cored wire and a manufacturing method thereof. The surfacing flux-cored wire consists of the following components in percentage by mass: 3-7% of marbles, 4-8% of fluorite, 2-6% of silicate, 5-9% of graphite, 10-20% of chromium metal and 60-70% of high carbon ferro-chrome, based on 100% in total. The surfacing flux-cored wire disclosed by the invention can be used to obtain a very uniform welding seam texture in case of not adding other alloy elements, so that hardness of the welding seam texture can be guaranteed, and wear resistance of the welding seam texture is improved.

Owner:株洲湘江电焊条有限公司

High wear resistance aluminium bronze and manufacturing method thereof

The invention discloses high wear resistance aluminium bronze and a manufacturing method thereof. The high wear resistance aluminium bronze is made from QAl10-4-4 as raw materials, and finally obtained after the processes of solid solution, hot water cooling, cold treatment, aging heat preservation and spheroidizing and slow cooling treatment. The strengthening phase in the high wear resistance aluminium bronze is of the spheroidized state. The high wear resistance aluminium bronze has uniform structure, high hardness, good abrasive resistance, and spheroidized structure.

Owner:NINGBO HUACHENG VALVE

Pneumatic tires for passenger cars

ActiveCN105408130BReduce weightIncrease fuel consumptionWithout separate inflatable insertsPneumatic tyre reinforcementsTire beadRolling resistance

The present invention provides a pneumatic tire for passenger vehicles that can significantly reduce tire weight and rolling resistance without affecting desired tire performance. At least one carcass ply is spanned between a pair of bead parts, a bead core is embedded in each bead part, at least one reinforcing layer is arranged on the outer peripheral side of the carcass ply, and a tread rubber layer is laminated on the outer peripheral side of the reinforcing layer In the pneumatic tire, a pair of first boundary lines orthogonal to the inner surface of the tire are defined by the intersection of the extension line of the side arc and the extension line of the shoulder arc that constitute the tread profile, and a pair of first boundary lines orthogonal to the inner surface of the tire is defined by the rim detection line. For the second boundary line, divide the first area between a pair of first boundary lines, divide the second area between the first boundary line and the second boundary line, divide the third area on the toe side of the second boundary line, divide the first The cross-sectional area (mm2) from the region to the third region is respectively set as SA, SB, and SC, and the edge lengths (mm) along the inner surface of the tire from the first region to the third region are respectively set as a, b, and c, the ratio SA / a, SB / b satisfy the relationship of 7.5≤SA / a≤11.5, 2.0≤SB / b≤6.0.

Owner:THE YOKOHAMA RUBBER CO LTD

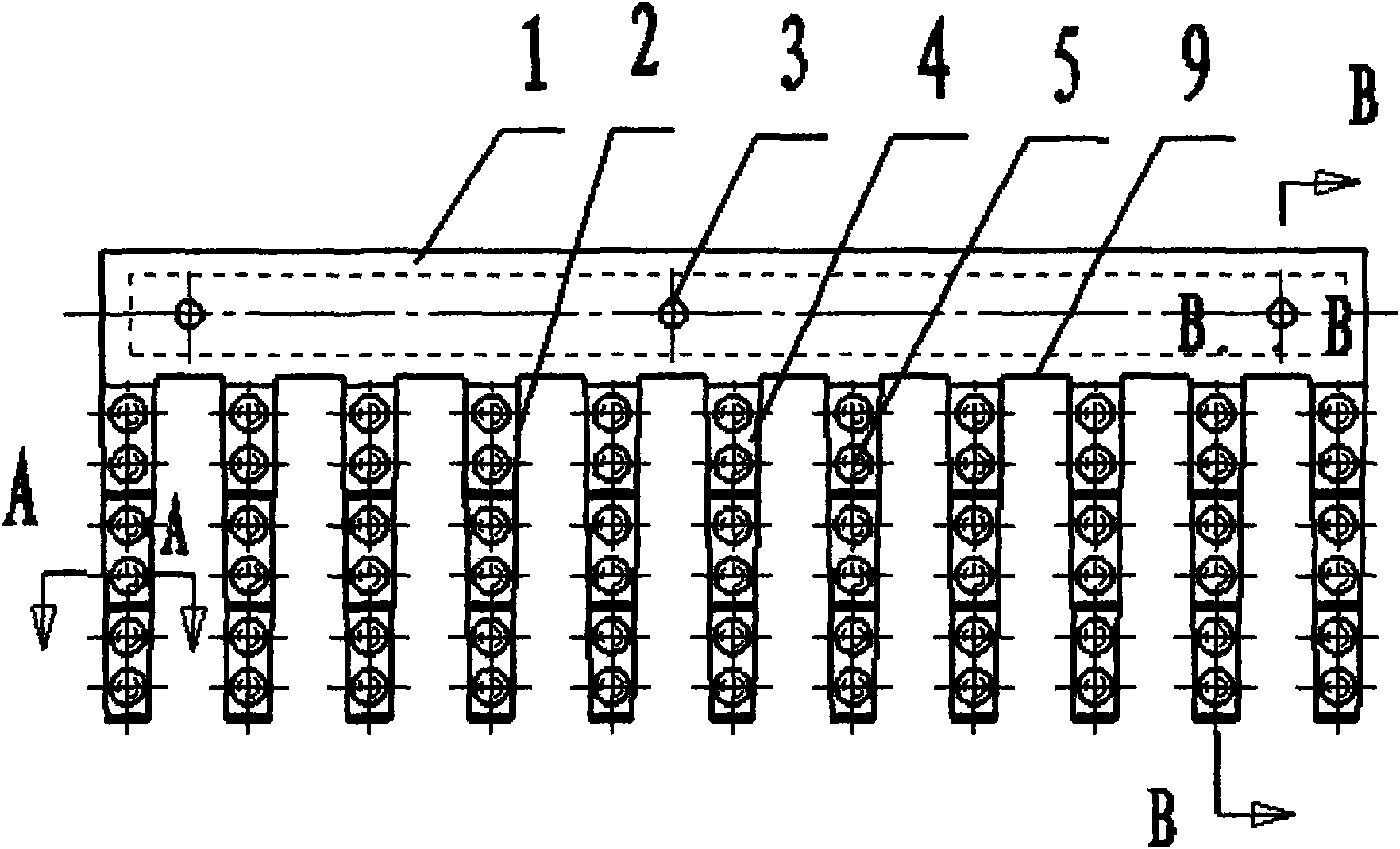

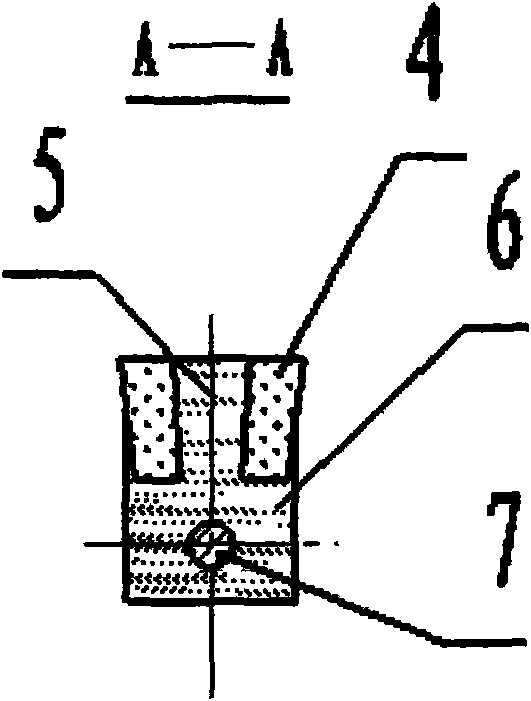

Abrasion-resistant grate bar

The invention relates to a comb-tooth grate bar of a comb-tooth sieve plate used for sieving a material. The grate bar consists of a substrate made of a macromolecular elastic material, an abrasion-resistant composite layer, a fixed steel plate vulcanized in the root of the comb-tooth grate bar and the like, wherein the abrasion-resistant composite layer is on the upper part of a comb-tooth part,is adhered to the substrate and is provided with a big end up taper hole; and the hole is filled with a substrate material and is connected with the substrate to form a whole. The abrasion-resistant composite layer is made of ceramics or a hard alloy abrasion-resistant material; the inside of the macromolecular elastic material on the lower part of the abrasion-resistant composite layer is vulcanized with a spring steel wire; and one end of the spring steel wire is 2 to 20 mm away from the edge of the abrasion-resistant grate bar. The lateral surface of the abrasion-resistant composite layer has a big end up obliqueness, and a part of the lower part is coated by the macromolecular elastic material. The comb-tooth sieve plate manufactured by the abrasion-resistant comb-tooth grate bar provided by the invention is good in abrasion resistance and difficult in causing a falling-off problem of the composite layer, so the service life of the sieve plate can be prolonged greatly, and meanwhile a sieve hole of the sieve plate is difficult to be blocked. Thus, the abrasion-resistant grate bar has good popularization and application prospects.

Owner:ZHENGZHOU UNIV

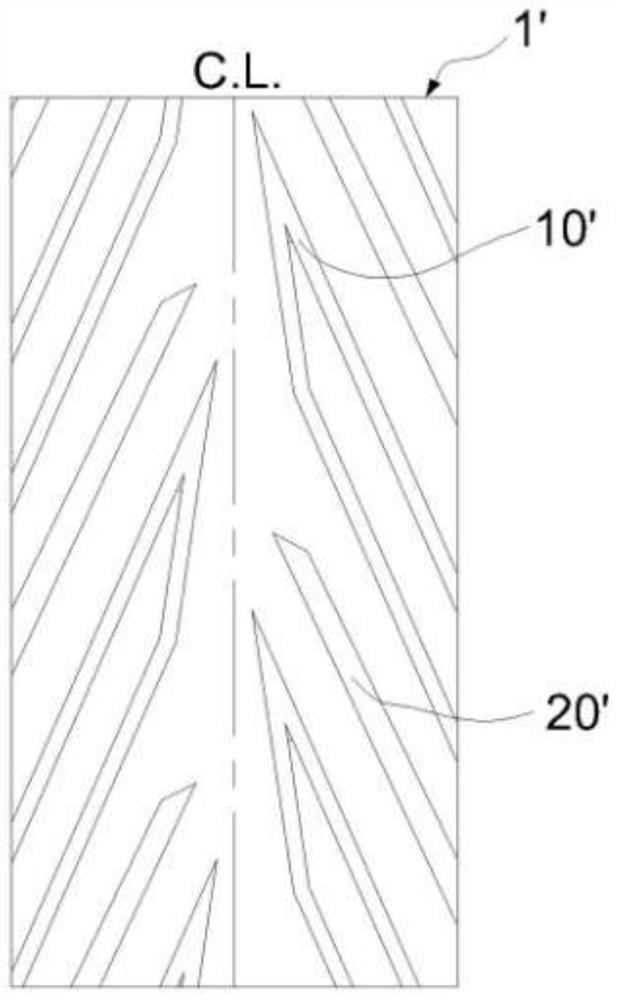

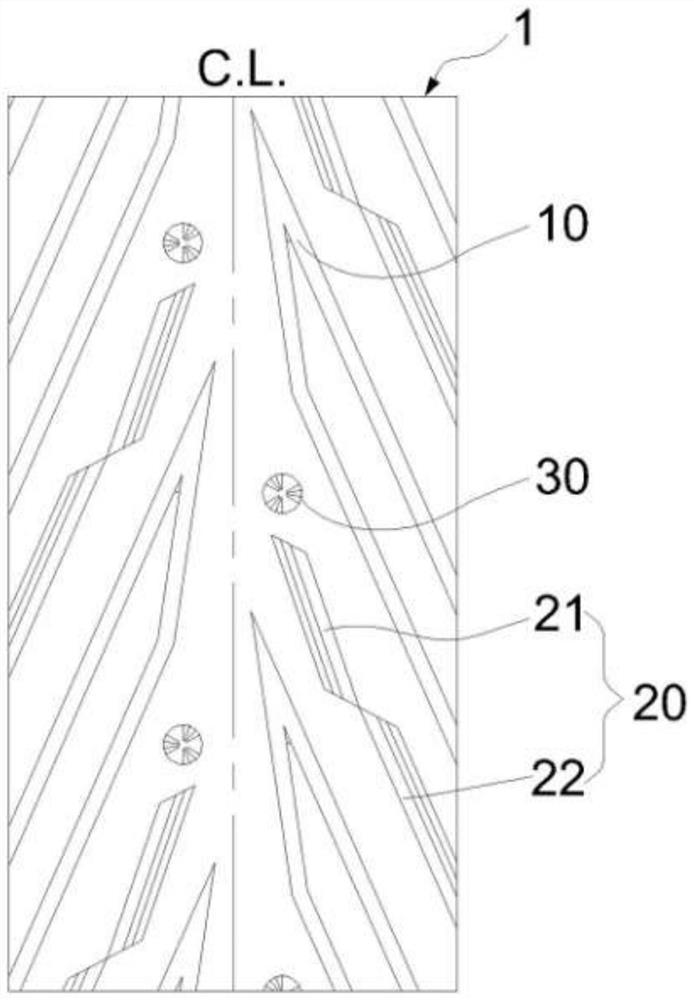

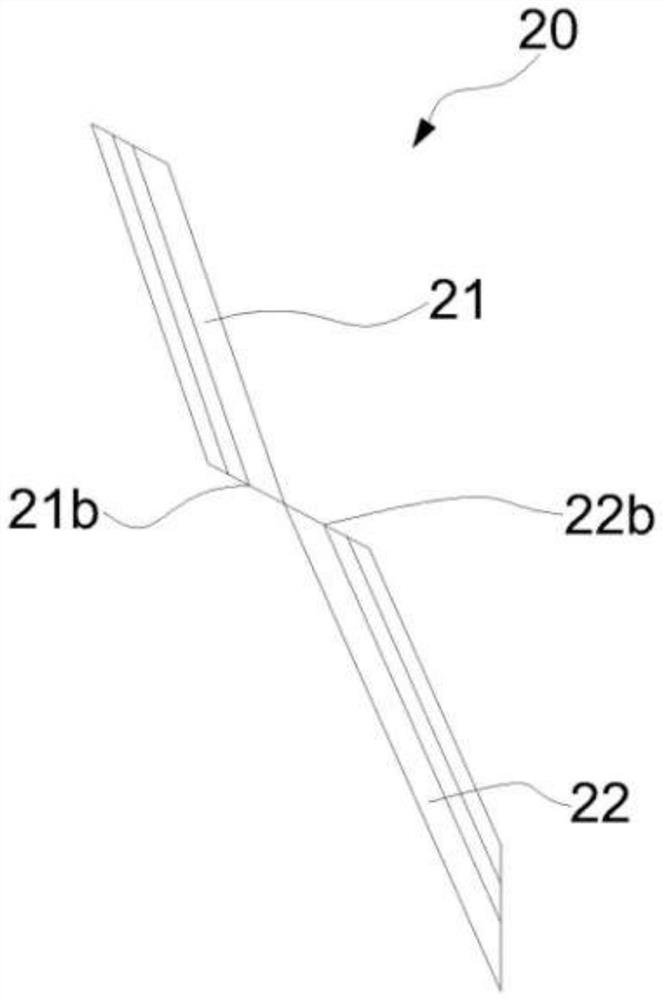

Pneumatic tire for electric two-wheeled vehicle

PendingCN113771558ADoes not affect wear resistanceDoes not affect dragBicycle tyresTyre tread bands/patternsAutomotive engineeringCentral plane

The invention provides a pneumatic tire for an electric two-wheeled vehicle. The tread patterns arranged on the two sides of the tread are symmetrical about the center plane of the tire and are staggered in the circumferential direction of the tire, and each tread pattern comprises a bent main groove, an inclined main groove and a center anti-skid suction cup; the inclined main grooves are arranged at intervals in the circumferential direction of the tire; bent main grooves are formed between the adjacent inclined main grooves in the circumferential direction. The bent main groove is formed by mutually connecting at least two sections of grooves, the inclined main groove is a disconnected two-section type groove and is formed by diagonally arranging an upper groove and a lower groove in a staggered manner, and the outer endpoint of the rear grounding end of the upper groove is overlapped with the inner endpoint of the front grounding end of the lower groove; the center anti-skid suction cups are close to the center plane of the tire and arranged in the circumferential direction of the tire at intervals, and each center anti-skid suction cup comprises a concave arc disc and at least two rotating ladders arranged at the bottom of the arc disc at intervals along the arc outline of the center anti-skid suction cup. The pneumatic tire does not influence wear resistance, rolling resistance performance and drainage performance on a dry land, and can effectively prevent stone from being clamped and improve the problem of slipping on a wet land.

Owner:CHENG SHIN RUBBER XIAMEN IND

A kind of diamond composite sheet and its preparation method

The invention discloses a diamond compact and a preparation method thereof. The preparation method of the diamond compact comprises the steps that a cemented carbide substrate with a geometric patterngroove in the back face, a cemented carbide block and a brazing sheet different from cemented carbide materials in color are prepared; diamond micro-powder is loaded into a metal cup and then is compacted, then the cemented carbide substrate is loaded, the brazing sheet is arranged in the geometric pattern groove of the cemented carbide substrate, then the cemented carbide block is arranged on the brazing sheet, the cemented carbide block and the geometric pattern groove form a geometric pattern seam, a middle cup and a large cup are sleeved, and an assembled suite is obtained; the suite is subjected to vacuum treatment, then the suite is sintered, and the diamond compact with a geometric pattern logo is obtained. According to the preparation method, the diamond compact with the geometricpattern logo on the back face can be prepared, and accordingly different diamond compacts can be distinguished from different geometrical pattern logos.

Owner:SHENZHEN HAIMINGRUN SUPERHARD MATERIALS

A kind of high wear-resistant bio-based polyamide composite material and preparation method thereof

The invention provides a highly wear-resistant bio-based polyamide composite material and a preparation method thereof. The bio-based polyamide composite material contains polyamide resin and a wear-resisting agent. Production raw materials of the polyamide resin comprise pentanediamine and diacid. A weight ratio of the polyamide resin to the wear-resisting agent is 100: 0.5-25. The preparation method comprises the following steps: at least mixing the polyamide resin and amino polysiloxane at room temperature; and successively carrying out extrusion granulation at 220 to 300 DEG C, cooling and drying so as to obtain the highly wear-resistant bio-based polyamide composite material. The polyamide composite material provided by the invention has good mechanical properties and wear resistance; the wear-resisting agent amino polysiloxane does not influence the color of the polyamide composite material and poses no restriction to application occasions of the polyamide composite material; and the the preparation method provided by the invention has the advantages of easiness, low cost and accordance with production requirements of industrialization.

Owner:CATHAY R&D CENT CO LTD +1

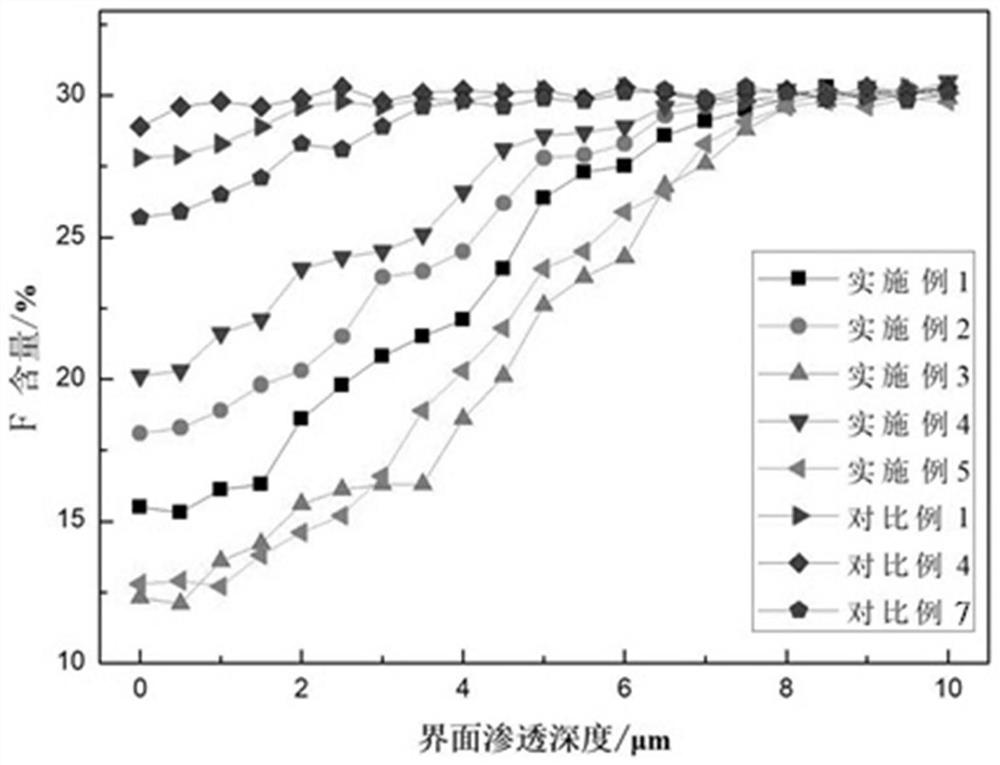

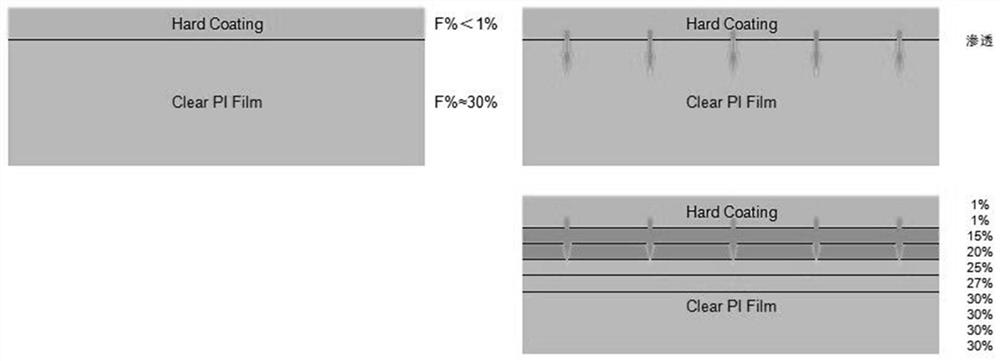

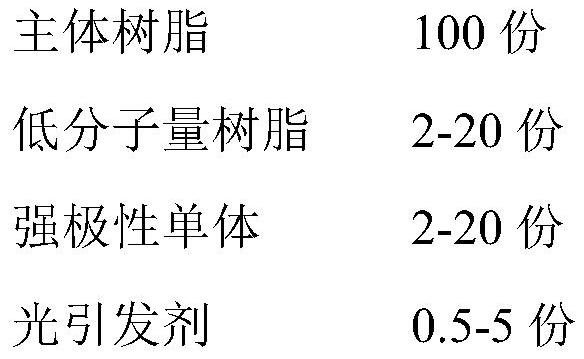

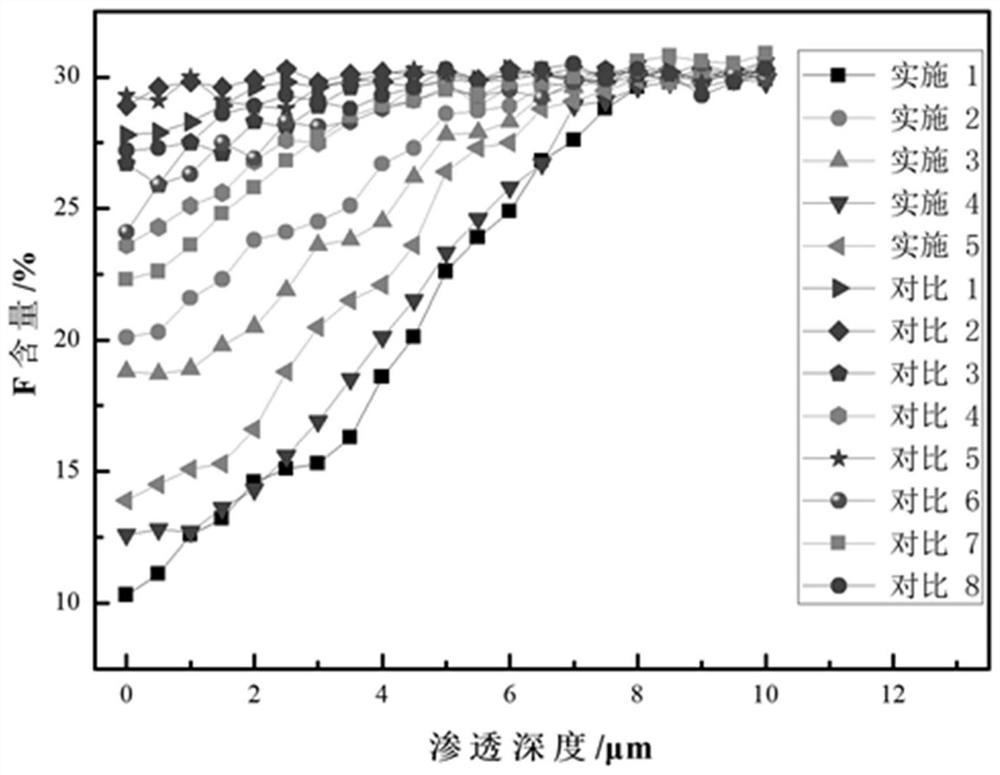

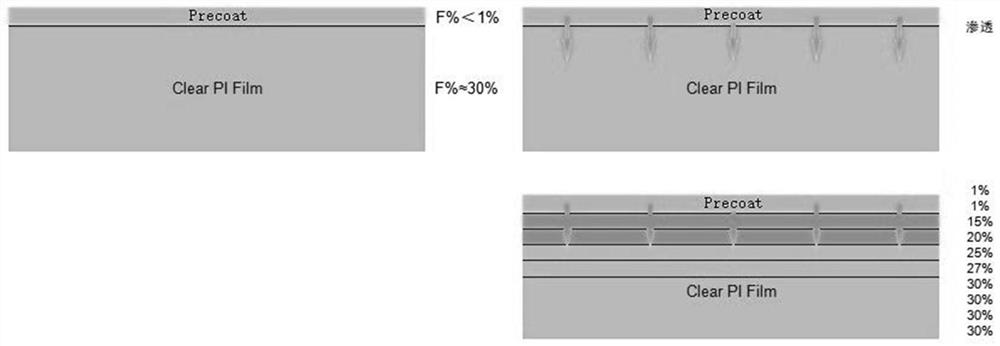

Transparent PI hardened coating resistant to ultraviolet damp-heat aging and preparation method of transparent PI hardened coating

ActiveCN112574664ADoes not affect hardnessDoes not affect wear resistanceBio-packagingPolyurea/polyurethane coatingsImideUv absorbance

The invention belongs to the technical field of transparent polyimide hardened coatings, and particularly relates to a transparent PI hardened coating resistant to ultraviolet damp-heat aging. Hardening liquid for preparing the transparent PI hardened coating is prepared from the following components in parts by weight: 100 parts of matrix resin, 2-20 parts of low molecular weight resin, 2-20 parts of strong polar monomer, 0.5-5 part of photoinitiator, 0.1-2 part of thermal initiator, 0.05-1 part of leveling agent, 0.05-1 part of ultraviolet absorbent, 0.05-1 part of antioxidant and 100-200 parts of solvent. According to the invention, a proper amount of low molecular weight resin and strong polar monomer are added into the hardening liquid, and the hardening liquid can gradually permeateinto the transparent PI base material by adopting a curing mode of combining thermocuring and photocuring, so that the adhesive force between the hardened coating and the transparent PI base layer isimproved; and therefore, the ultraviolet and damp-heat resistance of the PI hardened film is improved on the premise of not influencing the comprehensive properties such as hardness and wear resistance of the hardened coating.

Owner:新纶光电材料(常州)有限公司

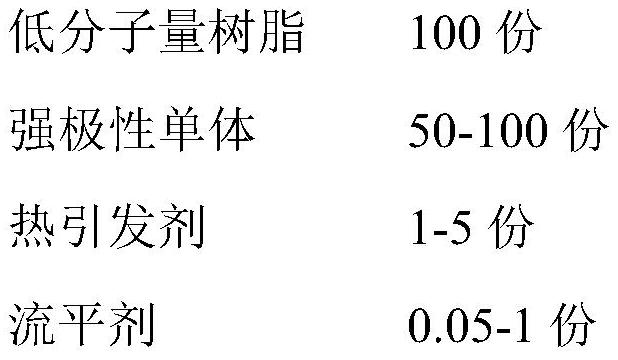

Pre-coating liquid for transparent PI hardened film resistant to ultraviolet damp-heat aging and application of pre-coating liquid

ActiveCN112574604ADoes not affect hardnessDoes not affect wear resistancePolyester coatingsImidePolymer science

The invention belongs to the technical field of pre-coating liquid for transparent polyimide hardened films, and particularly relates to pre-coating liquid for a transparent PI hardened film resistantto ultraviolet damp-heat aging and application of the pre-coating liquid. The pre-coating liquid is prepared from the following components in parts by weight: 100 parts of low molecular weight resin,50-100 parts of a strong polar monomer, 1-5 parts of a thermal initiator, 0.05-1 part of a leveling agent and 1000-1500 parts of a solvent. The pre-coating liquid contains a proper amount of low-molecular-weight resin and a strong-polarity monomer, and the low-molecular-weight resin and the strong-polarity monomer are matched with each other, so that the pre-coating liquid can permeate into the transparent PI base material, permeate and bite the transparent PI base material alternately, and the pre-coating layer is firmly attached to the surface of the base material through curing crosslinking, thereby enhancing the adhesive force between the hardened coating and the transparent PI base layer. The composition of the pre-coating liquid determines that a good binding force exists between the pre-coating layer and the hardened layer, so that the ultraviolet and damp-heat resistance of the PI hardened film is improved, and the comprehensive properties such as hardness and wear resistanceof the hardened layer are not influenced.

Owner:新纶光电材料(常州)有限公司

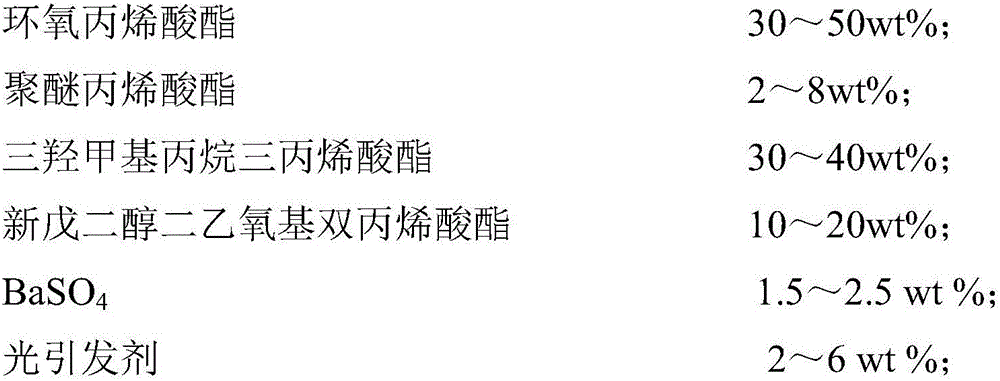

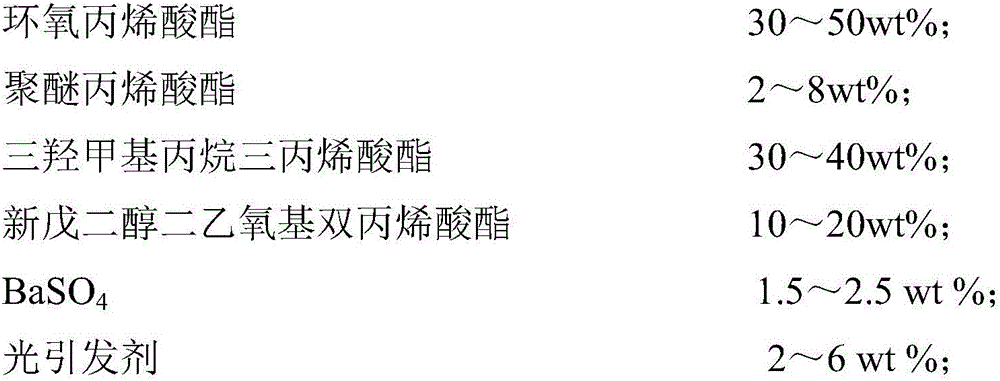

High-performance double-layer PET film

InactiveCN106188599ADoes not affect wear resistanceCure as soon as possiblePolyether coatingsEpoxy resin coatingsOrganic filmWear resistant

The invention provides a high-performance double-layer PET film which comprises a PET base material and an anti-scraping wear-resistant layer coating the PET base material. The anti-scraping wear-resistant layer comprises 30-50 wt% of epoxy acrylate, 2-8 wt% of polyether acrylate, 30-40 wt% of trimethylol propyl triacrylate, 10-20 wt% of neopentyl glycol diacrylate, 1.5-2.5 wt% of BaSO4 and 2-6 wt% of photoinitiator. BaSO4 is first subject to surface treatment through SiO2. By selection of an appropriate diluent, epoxy acrylate serves as a main body prepolymer to be crosslinked with polyether acrylate and filled with inorganic particle barium sulfate, a prepared coating has good performance of adhering to base material PET, the obtained double-layer PET film is excellent in various mechanical properties, and development of the high-performance organic film is promoted.

Owner:SUZHOU KECHUANG ELECTRONICS MATERIAL CO LTD

Organic-inorganic hybrid sealing agent for plasma sprayed ceramic coating, preparation method and application thereof

ActiveCN108003783BDoes not affect wear resistanceAccelerated corrosionLiquid surface applicatorsAnti-corrosive paintsCeramic coatingSealant

The invention discloses an organic-inorganic hybrid sealant for a plasma spraying ceramic coating. The organic-inorganic hybrid sealant comprises a precursor A, a methyl silicone resin film forming agent B, absolute ethyl alcohol, ammonia water and deionized water; the precursor A comprises ethyl orthosilicate and methyl triethoxysilane with a molar ratio of 100:(60-200); the molar ratio of the precursor A to the absolute ethyl alcohol to the ammonia water to the deionized water is 1: (30-35):(2-3):(5-7); and the addition amount of the methyl silicone resin film forming agent B accounts for 1-5% of the total mass of the organic-inorganic hybrid sealant for the coating. The invention further discloses a preparation method of the organic-inorganic hybrid sealant for the plasma spraying ceramic coating and application of the sealant to sealing treatment of the plasma spraying ceramic coating. The sealant disclosed by the invention is capable of taking a long-acting effect on protecting the plasma spraying ceramic coating used in a water environment and incapable of affecting the wear resistance of the ceramic coating.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com