High-performance double-layer PET film

A high-performance, double-layer technology, applied in coatings, epoxy resin coatings, polyether coatings, etc., can solve the problem that the anti-scratch and wear-resistant layer cannot protect the surface of the film, surface hardness, abrasion resistance and impact resistance. , can not meet the problems of high-end electronic optoelectronic products, etc., to achieve the effect of improving weather resistance and various mechanical properties, increasing light transmittance, and increasing polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

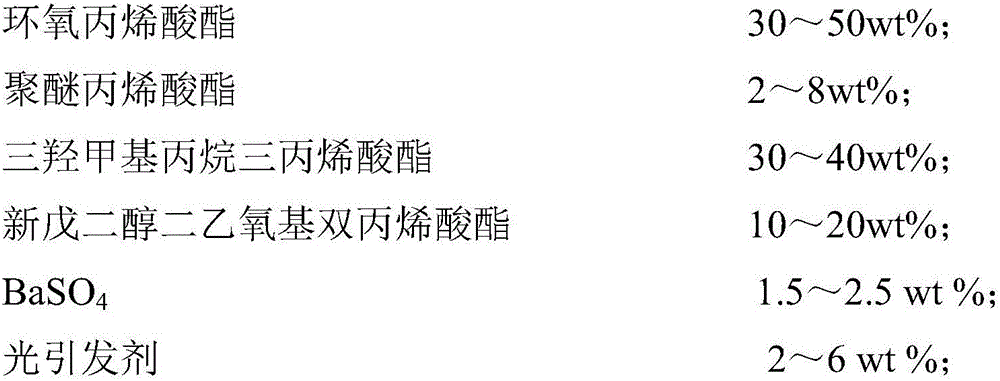

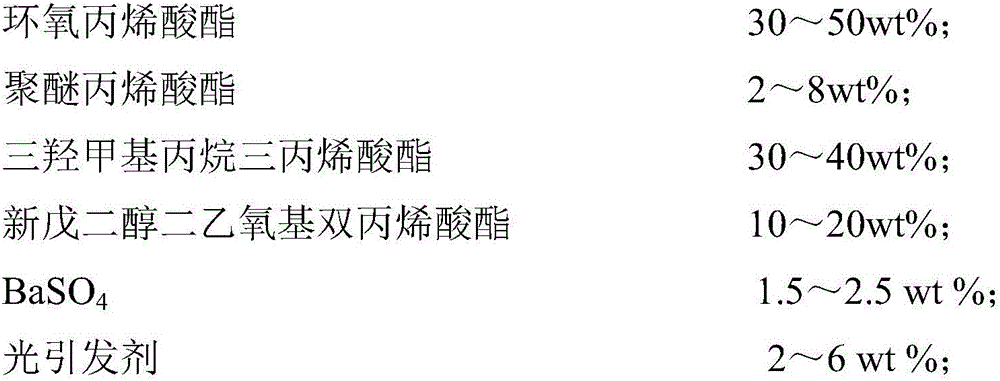

Method used

Image

Examples

example 1

[0027] A high-performance double-layer PET film, which includes a PET substrate and a scratch-resistant and wear-resistant layer coated on the PET substrate, wherein the scratch-resistant and wear-resistant layer includes: 39.5wt% epoxy acrylate; Ether Acrylate 2wt%; Trimethylolpropane Triacrylate 30wt%; Neopentyl Glycol Diethoxy Diacrylate 20wt%; BaSO 4 2.5wt%; 2-isopropylxanthone 6wt%;

[0028] Among them, the BaSO 4 First, surface treatment is required: under continuous stirring, the BaSO 4 Gradually add Na to the slurry 2 SiO 3 solution, while controlling the pH of the reaction system to be 8.7, and finally make silicon with Si(OH) 4 form precipitates wrapped in the BaSO 4 the surface of the particle.

[0029] Before the anti-scratch layer is coated on the PET substrate, the PET substrate is ultrasonically treated in an acetone solution with a pH of 10 for 15 minutes, and then placed in absolute ethanol for 20 minutes.

[0030] The BaSO 4 The particle size is 100 ...

example 2

[0032] A high-performance double-layer PET film, which includes a PET substrate and a scratch-resistant and wear-resistant layer coated on the PET substrate, wherein the scratch-resistant and wear-resistant layer includes: 43.5wt% epoxy acrylate; Ether Acrylate 8wt%; Trimethylolpropane Triacrylate 35wt%; Neopentyl Glycol Diethoxy Diacrylate 10wt%; BaSO 4 1.5wt%; Di-tert-butyl peroxide 2wt%;

[0033] Among them, the BaSO 4 First, surface treatment is required: under continuous stirring, the BaSO 4 Gradually add Na to the slurry 2 SiO 3 solution, while controlling the pH of the reaction system to be 9.2, and finally make the silicon with Si(OH) 4 form precipitates wrapped in the BaSO 4 the surface of the particle.

[0034] Before the anti-scratch layer is coated on the PET substrate, the PET substrate is ultrasonically treated in an acetone solution with a pH of 10 for 30 minutes, and then placed in absolute ethanol for 15 minutes.

[0035] The BaSO 4 The particle size ...

example 3

[0037]A high-performance double-layer PET film, which includes a PET substrate and a scratch-resistant and wear-resistant layer coated on the PET substrate, wherein the scratch-resistant and wear-resistant layer includes: 44wt% epoxy acrylate; polyether Acrylates 5wt%; Trimethylolpropane Triacrylate 30wt%; Neopentyl Glycol Diethoxy Diacrylate 15wt%; BaSO 4 2wt%; 4,4-dimethylaminobenzophenone 3wt%; benzophenone 1wt%;

[0038] Among them, the BaSO 4 First, surface treatment is required: under continuous stirring, the BaSO 4 Gradually add Na to the slurry 2 SiO 3 Solution, while controlling the pH of the reaction system to be 9, and finally make the silicon with Si(OH) 4 The form precipitates wrapped in the BaSO 4 the surface of the particle.

[0039] Before the anti-scratch layer is coated on the PET substrate, the PET substrate is ultrasonically treated in an acetone solution with a pH of 10 for 20 minutes, and then placed in absolute ethanol for 17 minutes.

[0040] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com