A kind of diamond composite sheet and its preparation method

A diamond composite sheet and diamond micropowder technology, applied in the field of diamond composite sheet and preparation, can solve the problems of indistinguishable, indistinguishable, mis-mixed diamond composite sheets, etc., and achieve the effect of clear pattern and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

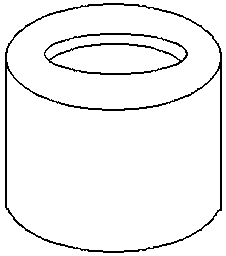

[0043] Manufacturers open molds to customize cemented carbide substrates, such as figure 1 As shown, the front tooth shape of the cemented carbide substrate is the same as that of the ordinary cemented carbide substrate, and the back of the cemented carbide substrate has a circular groove with a depth of 2mm and a diameter of 8mm; it is matched with a 7.95mm diameter , 2mm thick hard alloy block; prepare a piece of copper-based brazing sheet with a diameter of about 6mm and a thickness of 0.05mm; then sandblast the front of the hard alloy substrate and clean it for later use.

[0044] Put the prepared diamond powder into a metal cup and compact it, then put it into the cemented carbide substrate, and make the toothed side (front side) of the cemented carbide substrate contact with the diamond powder, and then place it on the hard alloy substrate. The copper-based brazing sheet is put into the circular groove on the back of the cemented carbide substrate, and then the hard allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com