Pre-coating liquid for transparent PI hardened film resistant to ultraviolet damp-heat aging and application of pre-coating liquid

A damp-heat aging and UV-resistant technology, applied in coatings, polyester coatings, etc., can solve the problems of hardened layer peeling off, hardened layer difficult to adhere, screen crease damage, etc. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

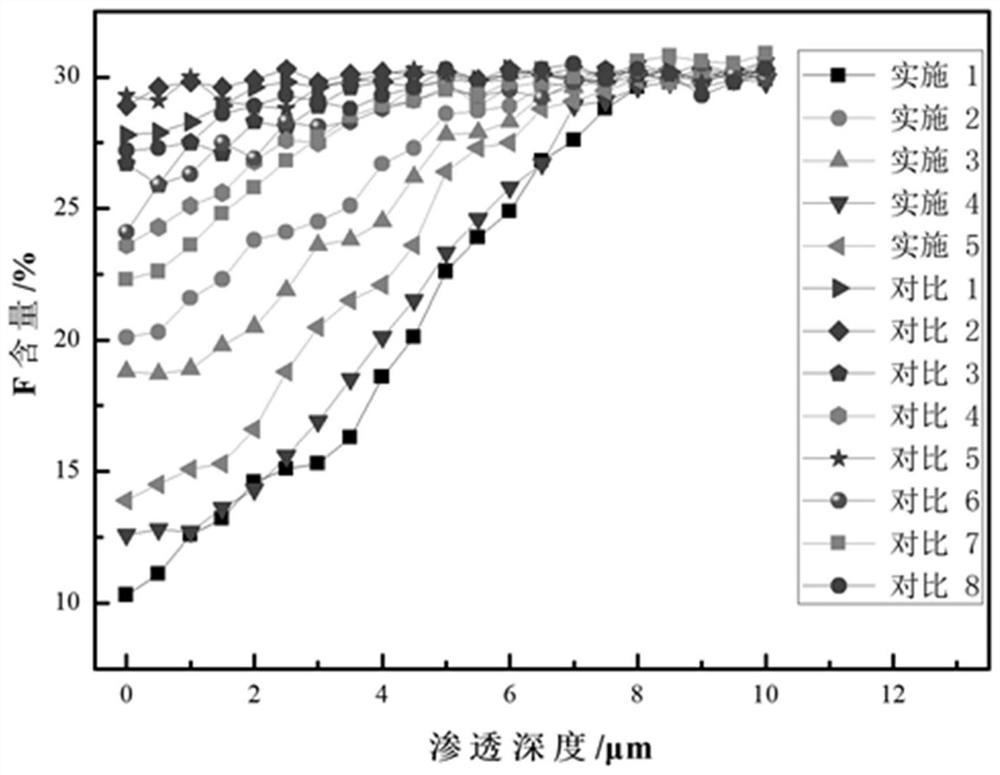

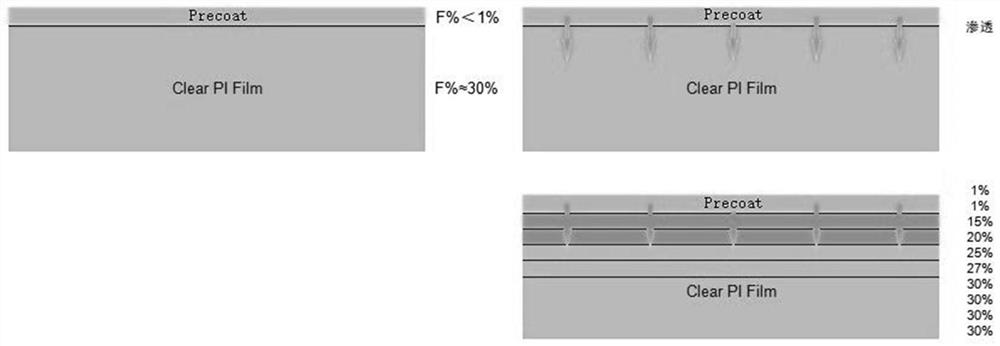

Examples

preparation example Construction

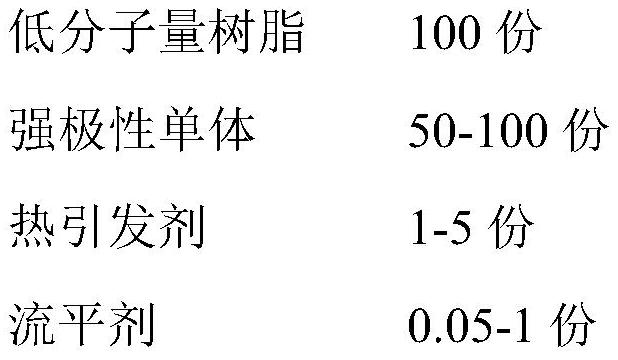

[0027] The preparation method of the pre-coating solution: Weigh the low molecular weight resin, strong polar monomer, thermal initiator, leveling agent and solvent in proportion, and mix them evenly.

[0028] The application of the precoating solution for the transparent PI cured film resistant to ultraviolet, humidity and heat aging includes the following steps:

[0029] (1) Evenly coat the pre-coating solution on the transparent PI substrate, and then heat-cure to obtain the pre-coating layer;

[0030] (2) Evenly coat a layer of hardening solution on the surface of the pre-coating layer, and then solidify to obtain a hardened layer. After the hardened layer cools down, attach a protective film.

[0031] Drying conditions of the precoat:

[0032] Condition 1: The distance from the coating head to the drying tunnel is 2.5 meters, the drying tunnel has 16 sections, each section is 2.5 meters, the vehicle speed is 10 m / min, and the drying tunnel pressure is 1.01-1.05ATM.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com