Application of 4-P-PDOT in acceleration of banana fruit ripening

A 4-P-PDOT, 1.4-P-PDOT technology, applied in the application, fruit and vegetable preservation, food preservation and other directions, can solve the problem of banana spoilage, ethylene decomposition is difficult to quantify, ripening process and ripening effect are difficult to control, etc. problem, to achieve the effect of wide application value and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

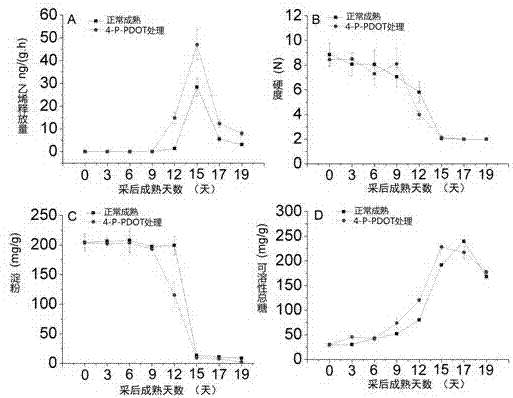

[0016] Example 1 Effect of 4-P-PDOT treatment on banana fruit ripening

[0017] The harvested banana fruits were divided into two groups: normal ripening group and 4-P-PDOT treatment group.

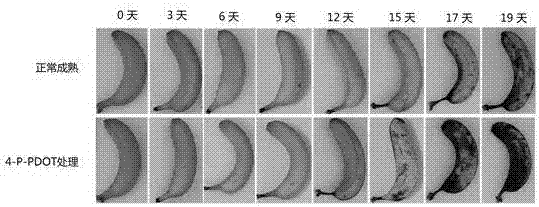

[0018] Normal ripening group: put the banana fruit in a culture room at 25°C until it matures naturally, observe and record the peel color of the banana fruit on day 0, day 3, day 6, day 9, day 12, day 15, day 17 and day 19 The change.

[0019] 4-P-PDOT treatment group: Banana fruits were soaked in 30 μM 4-P-PDOT solution for 2 hours, and then placed in a 25°C culture room. 12 days, 15 days, 17 days, 19 days observed and recorded the change of banana fruit peel color.

[0020] The results showed that under normal ripening conditions, the banana fruit gradually changed from green to yellow after harvesting, reached a full yellow state at 15 days after harvesting, and black spots appeared at 17 days after harvesting. Under the condition of 4-P-PDOT treatment, the banana fruit gradually c...

Embodiment 2

[0021] Example 2 Effect of 4-P-PDOT treatment on banana fruit ripening

[0022] The experimental method is the same as in Example 1, except that the only difference is that the concentration of the 4-P-PDOT solution used in the 4-P-PDOT treatment group of the present embodiment is 100 μM, and the soaking time of the banana fruit in the 4-P-PDOT solution for 6h.

Embodiment 3

[0023] Example 3 Effect of 4-P-PDOT treatment on ethylene release and quality of banana fruit

[0024] Under normal maturation and 4-P-PDOT treatment (the treatment method is the same as in Example 1), samples were taken at time points of 0 day, 3 days, 6 days, 9 days, 12 days, 15 days, 17 days, and 19 days, and the determination Relevant physiological indicators (including banana fruit ethylene release, banana fruit firmness, etc., each treatment was measured 3 times at each stage).

[0025] Ethylene release from banana fruit: determined according to the instructions of the ethylene detector of Shenzhen Kernuo Electronic Technology Co., Ltd., each treatment was measured 3 times at each stage.

[0026] The hardness of banana fruit was determined according to the instructions of the hardness tester of Hangzhou Top Instrument Co., Ltd. Each treatment was tested 3 times at each maturity level.

[0027] Determination of banana fruit starch content: take 0.5g banana pulp, grind i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com