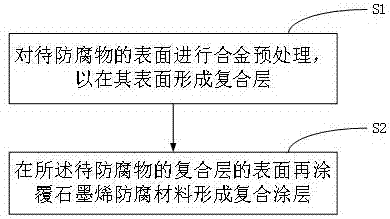

Trail traffic buckle accessory alloy pretreatment and graphene material compound corrosion resistance technology

A technology of rail transit and graphene, which is applied in metal material coating technology, anti-corrosion coatings, coatings, etc., can solve the problems of easy damage or falling off, and the loss of protection of the steel substrate, so as to solve the problems of anti-corrosion and anti-collision, and improve the comprehensive Anti-corrosion ability, the effect of solving electrochemical corrosion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The preparation method of graphene anticorrosion material in described step S21 comprises:

[0058] The preparation procedure of graphene anticorrosion material is as follows:

[0059] In step S211, the mixture of additives and solvents is put into the reactor for stirring, the stirring tangential speed is controlled between 15-25 m / s, and the pigment is added after stirring for 15-60 min.

[0060] Step S212, adding the composite resin and graphene to the mixed solution in step S211, adding a rust remover and antirust agent, controlling the temperature of the reaction kettle to be between 25 and 60°C, and stirring at a low speed at a tangential speed of 5 to 15 m / s 10-30 min to prepare the graphene anti-corrosion material;

[0061] In the step S22, the graphene anti-corrosion material is coated, that is

[0062] The graphene material is coated on the rail transit buckle parts after alloy pretreatment by air spraying, brushing or roller coating, and then dried or dried...

Embodiment 1

[0090] First, alloy pretreatment, namely

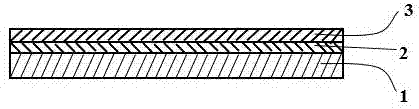

[0091] Put rail transit buckle fittings into 60g / L NaOH solution, soak for 10 minutes, and remove surface oil. Take out the rail buckle accessories, rinse with cold water, and let it dry naturally. Then put the rail transit buckle fittings into the zinc powder, and at 300~500°C, the active metal atoms diffuse from the surface to the inside, and at the same time, the iron atoms in the rail transit buckle fittings diffuse from the inside to the outside to form a composite layer , the thickness of the composite layer is 20~100 um; finally rinse with water and dry naturally.

[0092] Then, the anti-corrosion treatment of graphene anti-corrosion material, namely

[0093] Put the mixture of additives and solvents into the reaction kettle for stirring, the stirring tangential speed is controlled at 15 m / s, after stirring for 15 minutes, add the pigment, then add the composite resin, graphene and rust remover and antirust agent in turn, con...

Embodiment example 2

[0098] First, alloy pretreatment, namely

[0099] Put rail transit buckle fittings into 60g / L NaOH solution, soak for 10 minutes, and remove surface oil. Take out the rail buckle accessories, rinse with cold water, and let it dry naturally. Put the rail transit buckle accessories into the aluminum powder, and at 300~500°C, the active metal atoms diffuse from the surface to the inside, and at the same time, the iron atoms in the rail transit buckle accessories diffuse from the inside to the outside to form a composite layer , the thickness of the composite layer is 20~100 um; finally rinse with water and dry naturally.

[0100] Then, the anticorrosion treatment of graphene material, namely

[0101] Put the mixture of additives and solvents into the reaction kettle for stirring, the stirring tangential speed is controlled at 25 m / s, after stirring for 60 min, add the pigment, then add the composite resin, graphene and rust remover and antirust agent in turn, control the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com