Patents

Literature

65results about How to "Does not affect hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

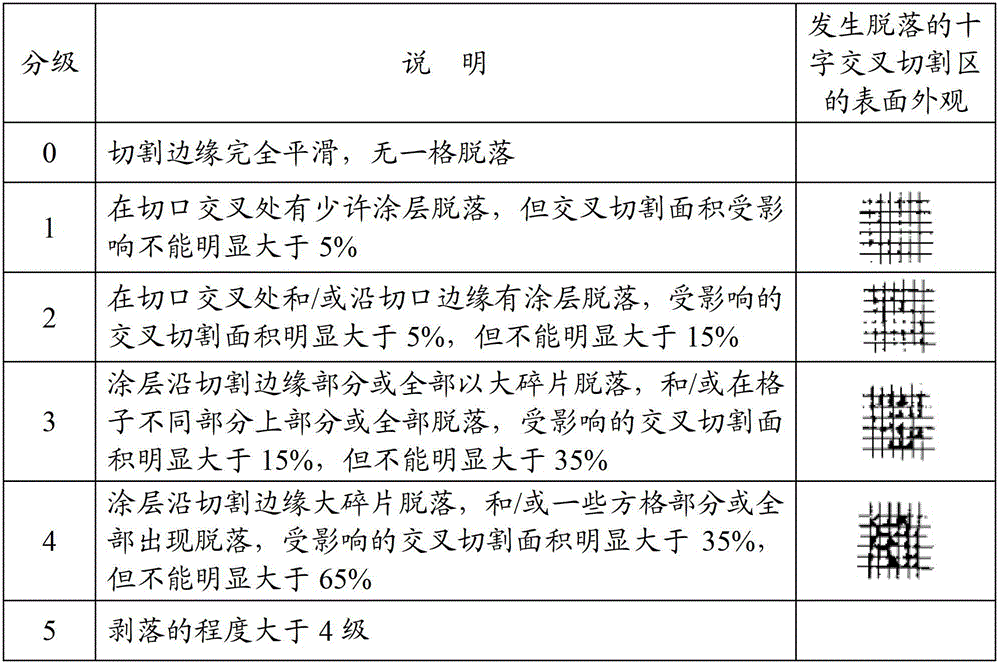

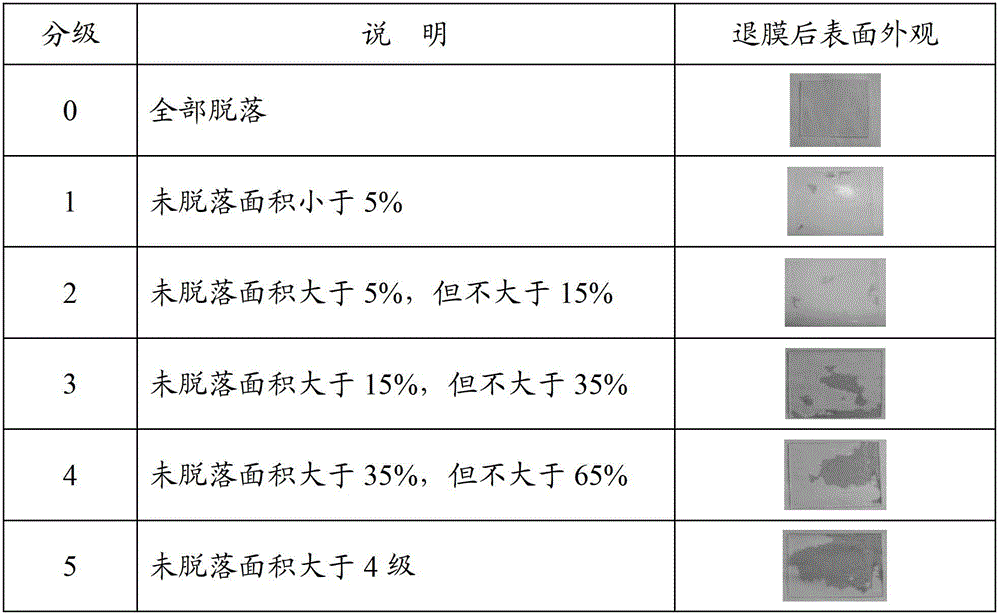

Glass protecting ink and preparation method thereof

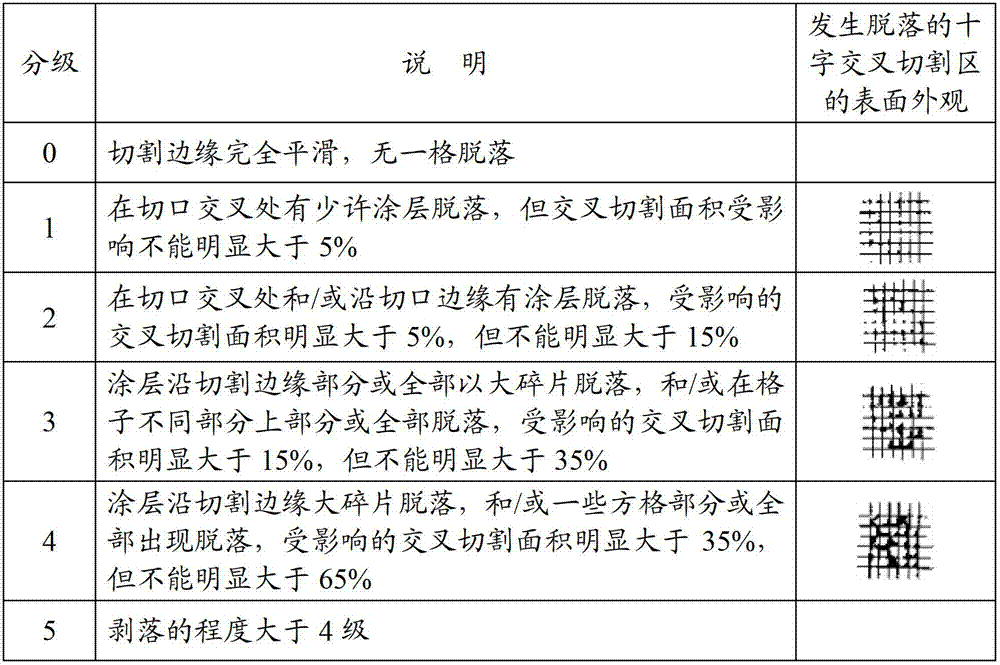

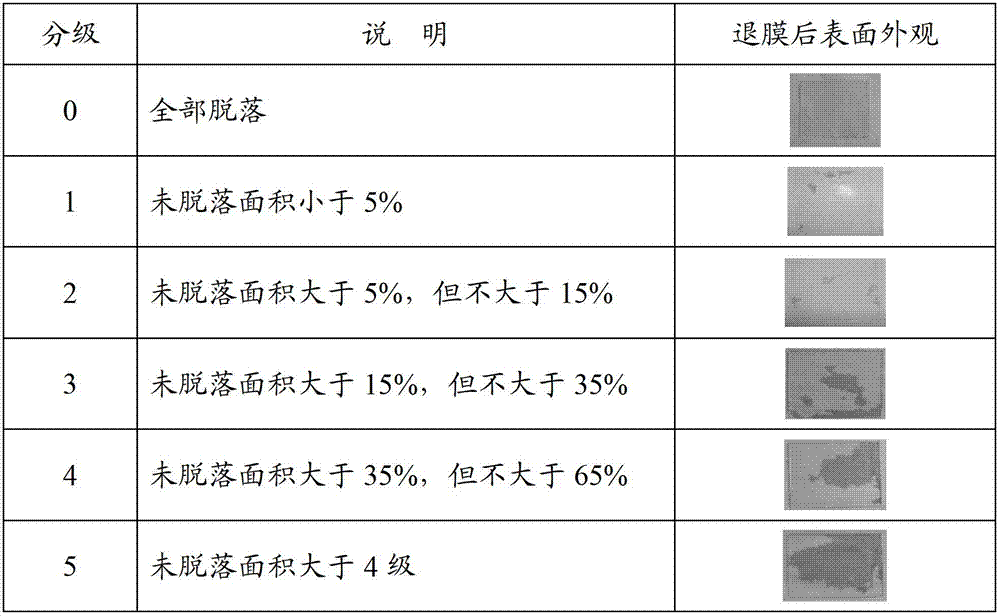

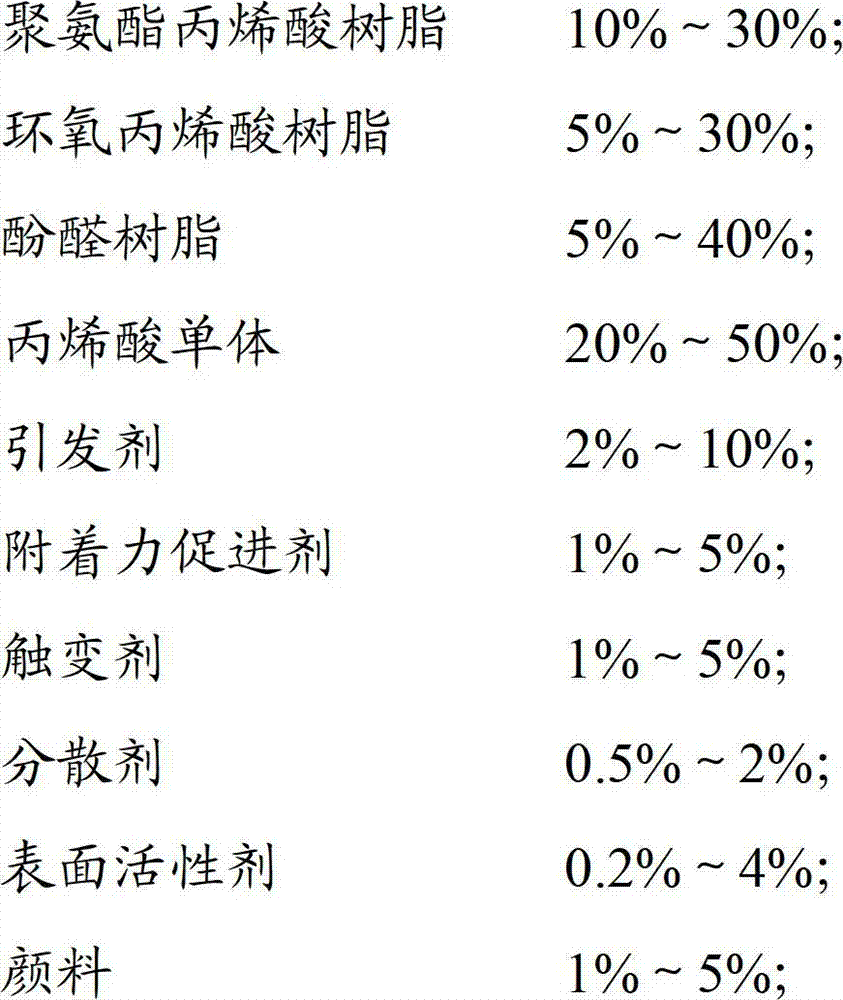

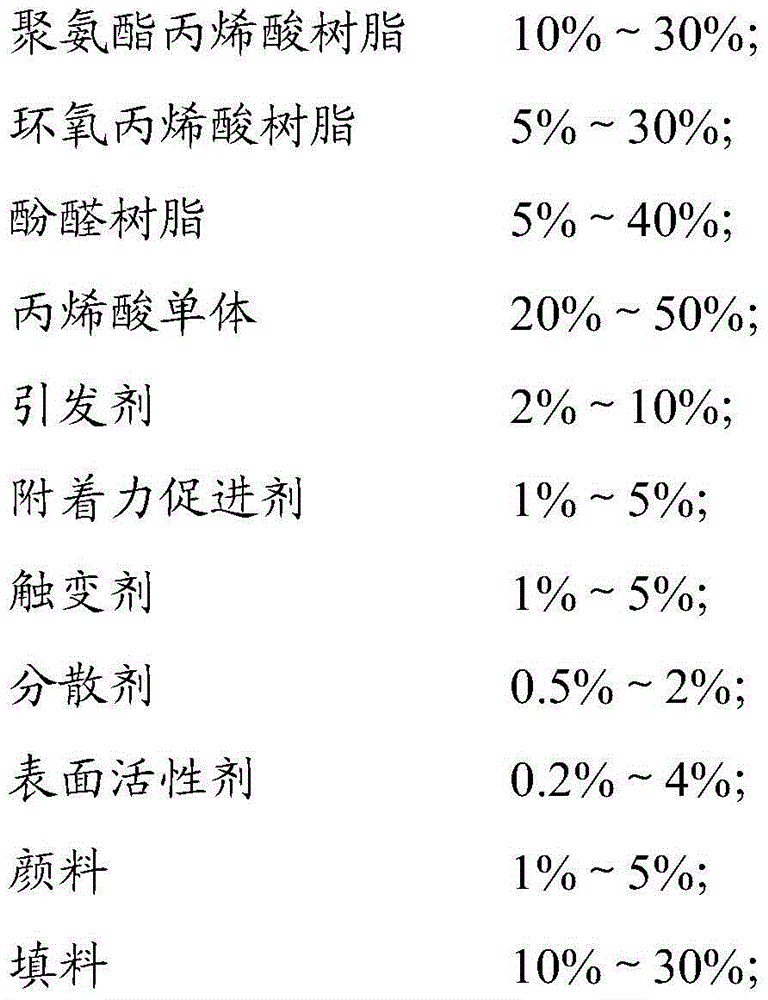

The invention discloses a glass protecting ink and a preparation method thereof. The glass protecting ink comprises the following components in percentage by weight: 10%-30% of polyurethane acrylate, 5%-30% of epoxy acrylic resin, 5%-40% of phenolic resin, 20%-50% of acrylic monomer, 2%-10% of initiator, 1%-5% of adhesion promoter, 1%-5% of thixotropic agent, 0.5%-2% of dispersing agent, 0.2%-4% of surface active agent, 1%-5% of pigment and 10%-30% of filler. The glass protecting ink disclosed by the invention has a good glass protecting performance, is easy to strip, and is convenient to operate.

Owner:FOSHAN 3Q ELECTRONICS MATERIALS

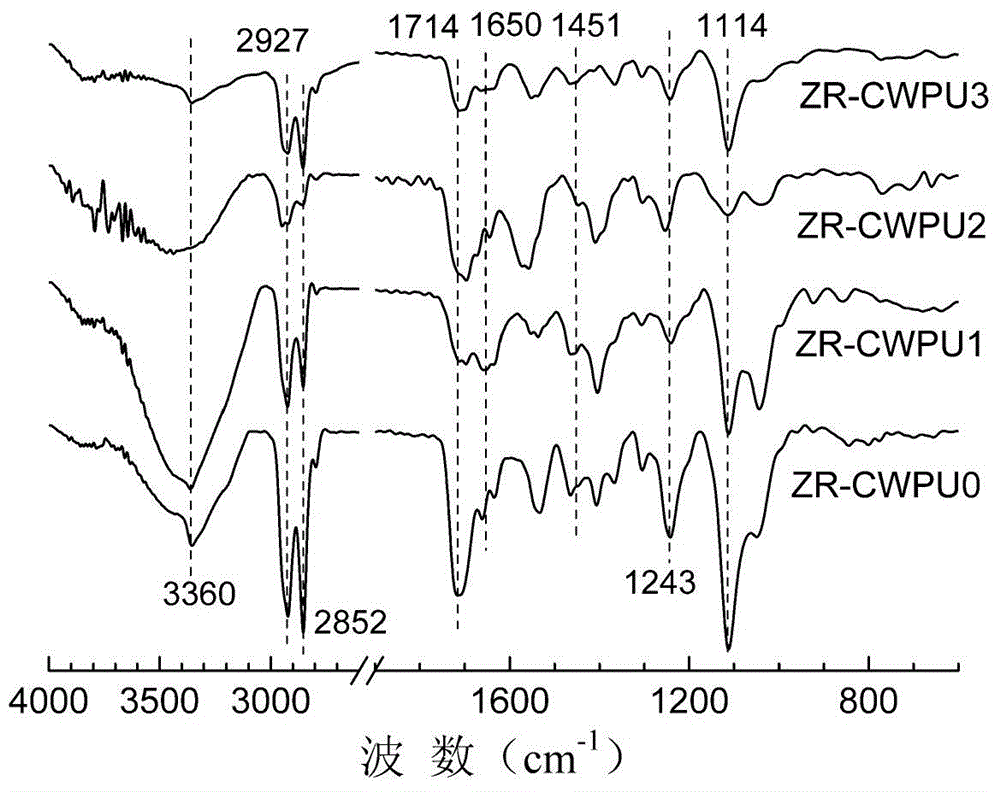

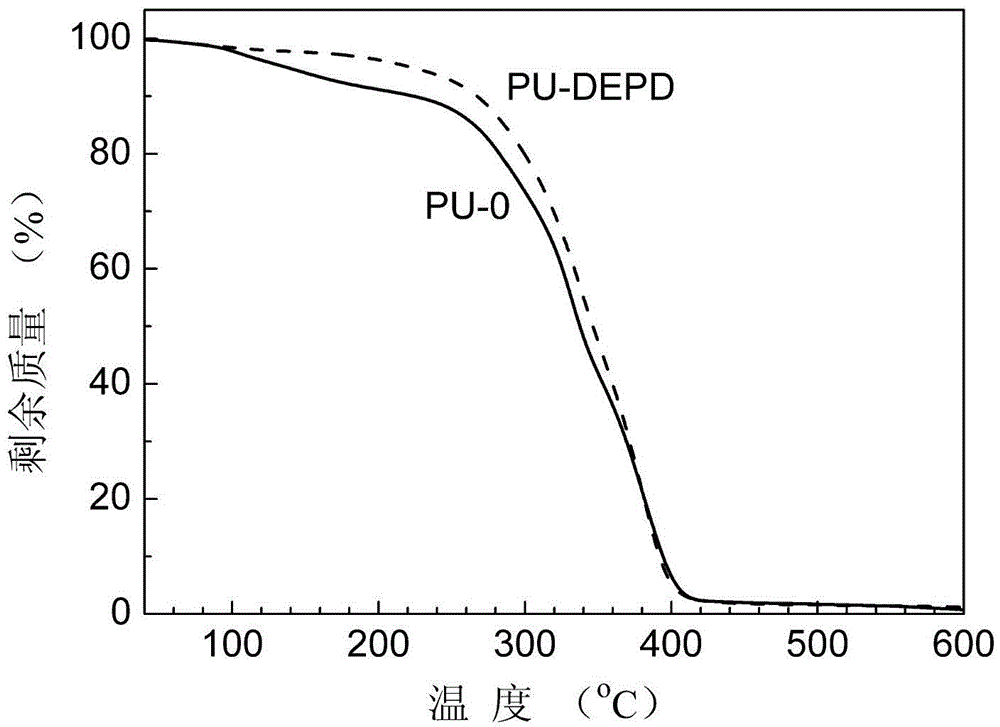

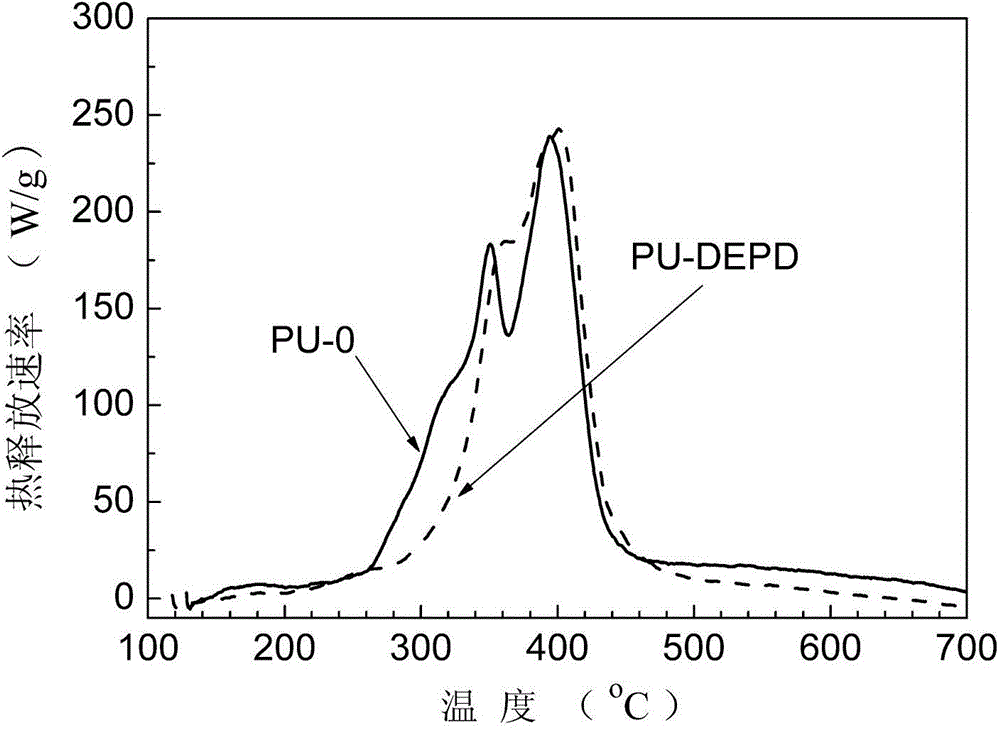

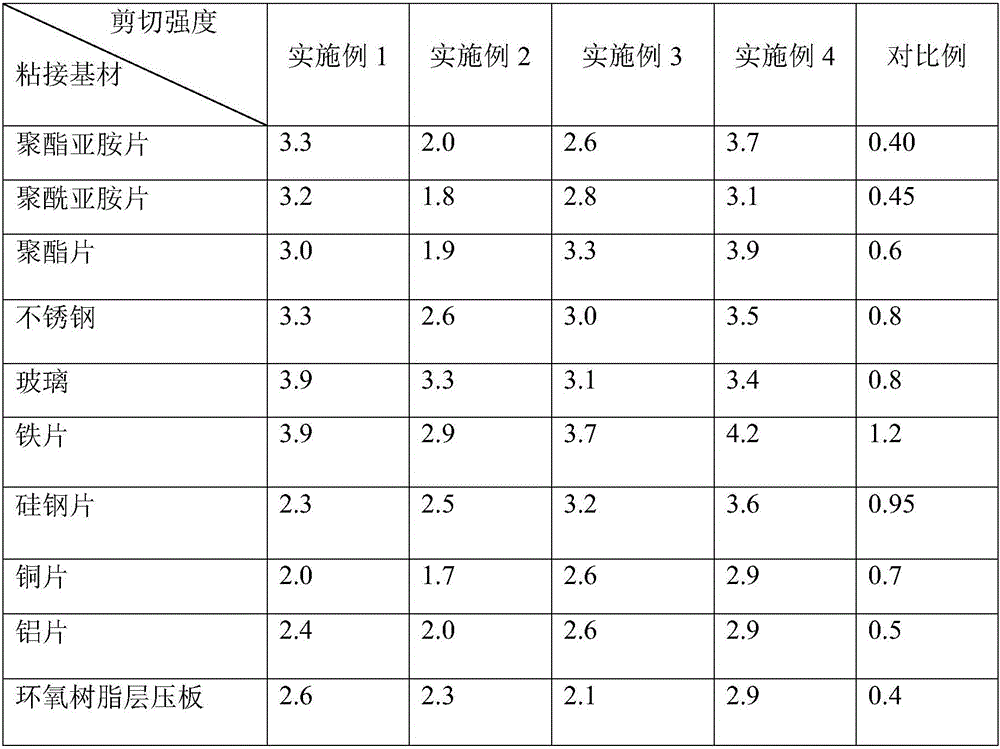

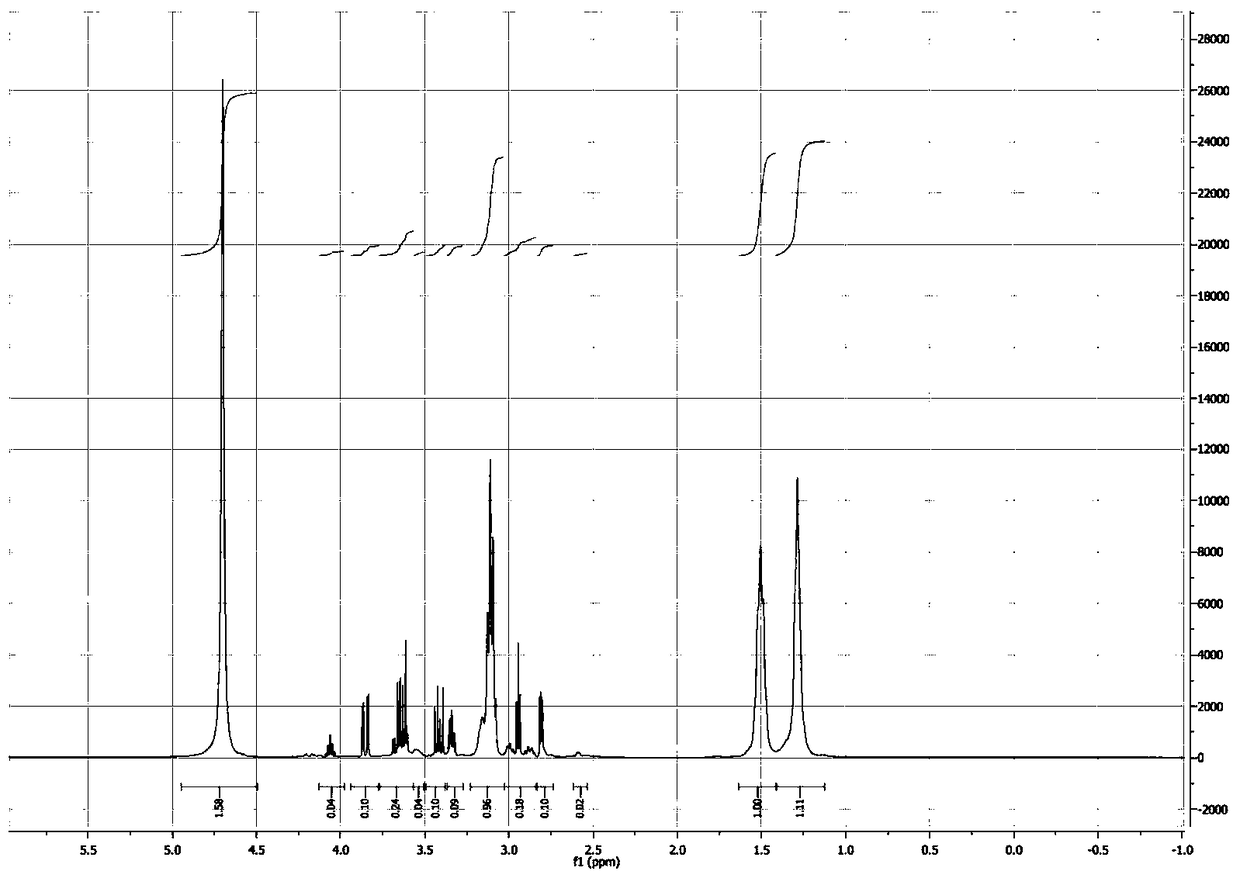

Method for preparing flame-retardant waterborne polyurethane containing phosphaphenanthrene and/or phenyl phosphate groups

InactiveCN104592475ANon-corrosive generationEvenly distributedGroup 5/15 element organic compoundsPolymer scienceAlcohol

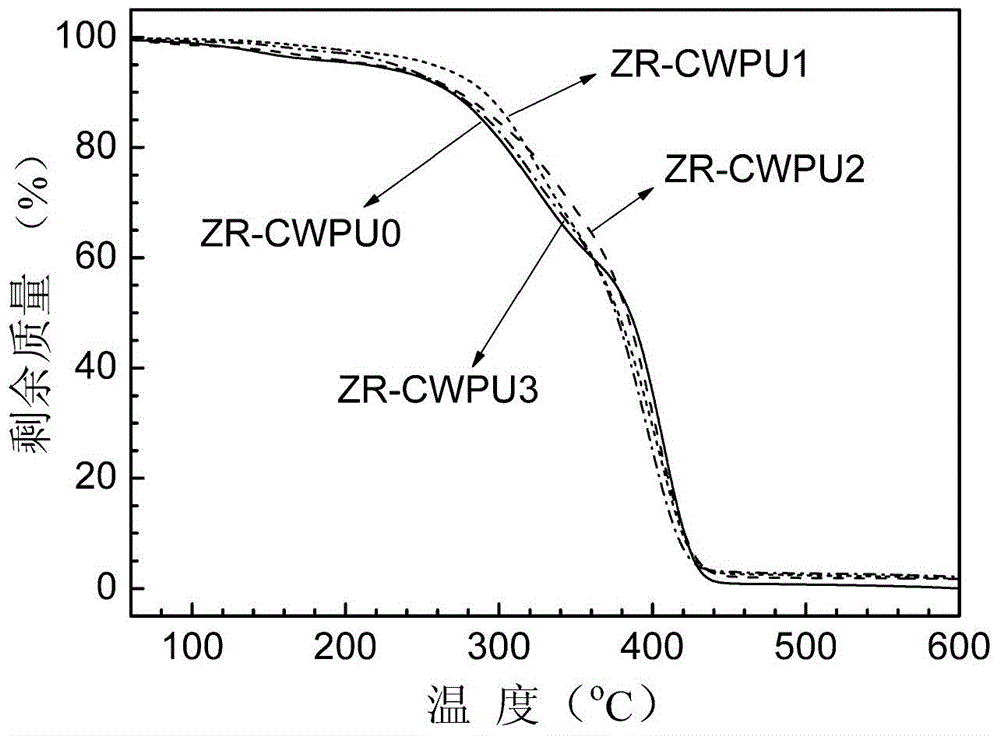

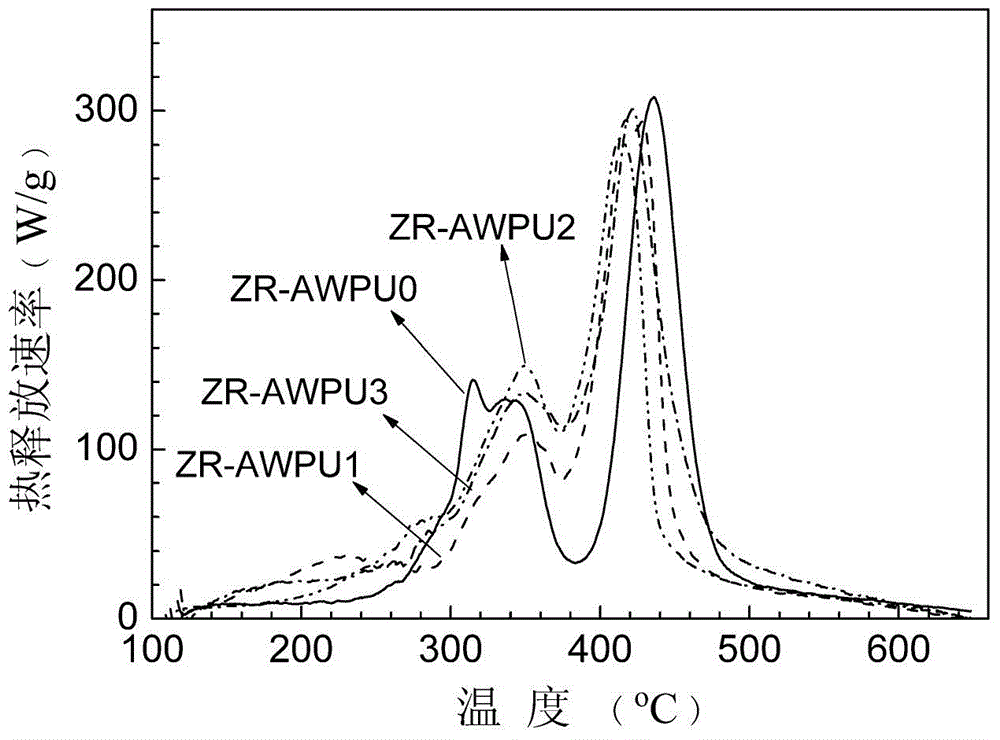

The invention discloses a method for preparing flame-retardant waterborne polyurethane containing phosphaphenanthrene and / or phenyl phosphate groups. The method is characterized by comprising the following step of reacting dihydric alcohol as a reactant which contains phosphaphenanthrene and / or phenyl phosphate groups and of which the hydroxyl groups are symmetric with diisocyanate, macromolecular dihydric alcohol, anionic or cationic hydrophilic chain extender and the like to synthesize flame-retardant waterborne polyurethane. According to the method, since flame-retardant dihydric alcohol is used as one of chain extenders, flame-retardant dihydric alcohol ca partially or totally substitute other small molecular chain extenders, phosphorus-containing flame-retardant groups are controllable in content and difficult to migrate and are evenly distributed, and the flame-retardant property of waterborne polyurethane can be enduringly retained. According to the structural characteristics of selected flame-retardant dihydric alcohol, by virtue of one and a combination of two or more of flame-retardant groups, phosphorus in the flame-retardant groups can be alone located at a main chain, side chains or simultaneously located at the main chain and the side chains of the polyurethane molecule chain as desired so as to meet the requirements of different flame-retardant properties or other properties such as mechanics, toughness and plasticity.

Owner:UNIV OF SCI & TECH OF CHINA

Technique of preparing amlodipine besylate tablets

ActiveCN101161241AHigh dissolution rateImprove finenessOrganic active ingredientsPill deliverySolubilityAir volume

A preparation technology of amlodipine besylate is disclosed in the present invention, the technology is with amlodipine besylate, filler, disintegrating agent, lubricant etc. as main components. By using grinding and sieving; reasonably controlling particle water; repeatedly feeling fluidized bed granulating technology parameter, controlling spraying speed, spraying pressure and air quantity, under the situation of non-affecting tablet content and hardness, increasing the solubility of product greatly, thereby promoting the internal quality and curative effect of the product.

Owner:YANGZIJIANG PHARMA GROUP SHANGHAI HAINI PHARMA

Method for sealing micro-arc oxidation films

InactiveCN101649480ADoes not affect hardnessDoes not affect ceramic textureAnodisationMicro arc oxidationPlasma electrolytic oxidation

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Wear-resistant glaze for glazed bricks, and preparation method thereof

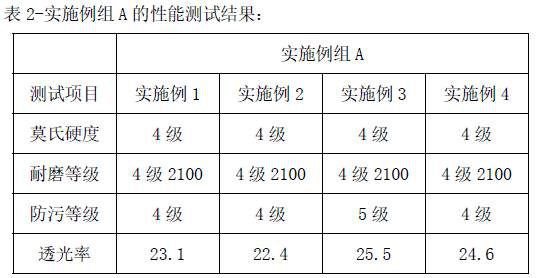

The invention discloses a wear-resistant glaze for glazed bricks, and a preparation method thereof. The wear-resistant glaze is prepared from raw glaze powder, No.1 frit powder and No.2 frit powder, wherein the raw glaze powder comprises, by weight, 8-12% of kaolin, 10-18% of calcined kaolin, 12-20% of quartz, 12-20% of dolomite, 8-15% of calcined talc, 8-15% of nepheline, 5-10% of zinc oxide, 3-6% of barium sulfate and 6-12% of strontium carbonate. The raw materials of the No.1 frit powder comprise zircon sand and barium sulfate, and raw materials of the No.2 frit powder comprise kaolin, calcined talc, fluorite and barium sulfate. The glaze disclosed by the invention contains barium sulfate, so that the color development condition can be improved, the problem of color difference of red and yellow ceramic ink-jet inks during firing of a product is avoided, and the transparency of the wear-resistant glaze is improved under the condition that the hardness and the wear resistance are notinfluenced.

Owner:佛山市东鹏陶瓷发展有限公司 +1

Method for sealing micro-arc oxidation films

InactiveCN101649479ADoes not affect hardnessDoes not affect ceramic textureAnodisationPolyesterPlasma electrolytic oxidation

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

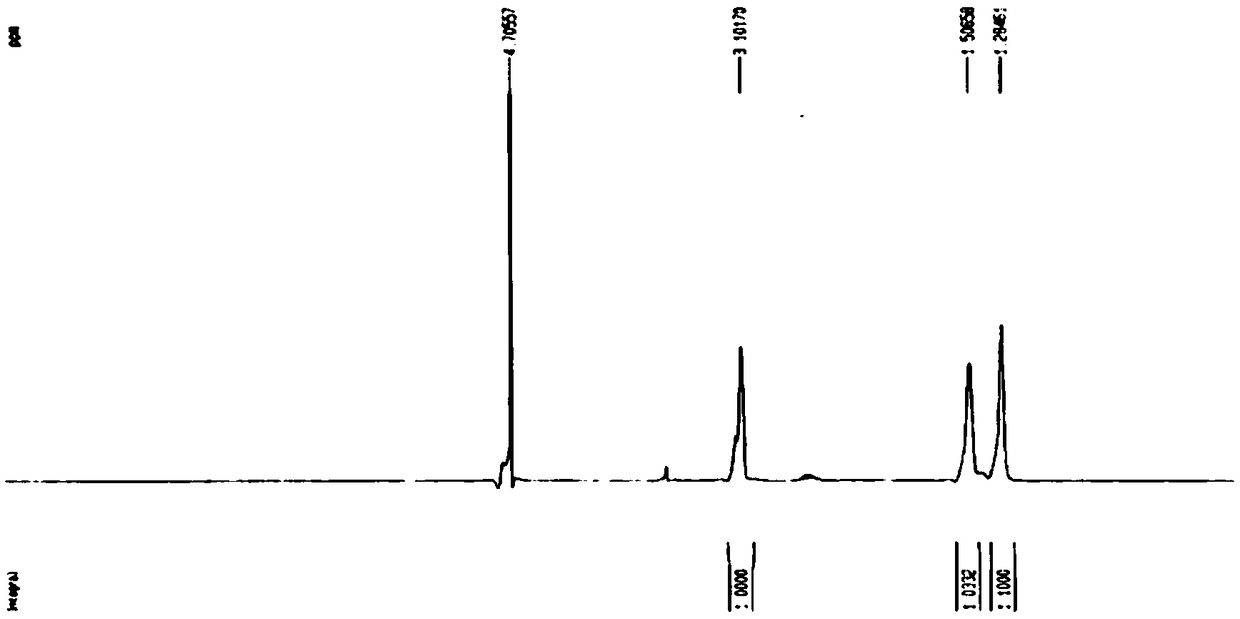

Flame-retardant glycol containing phenyl phosphate-based symmetrical structure and preparation method thereof

InactiveCN104592297AHas flame retardant propertiesRegular structureGroup 5/15 element organic compoundsEthyl acetateTetrahydrofuran

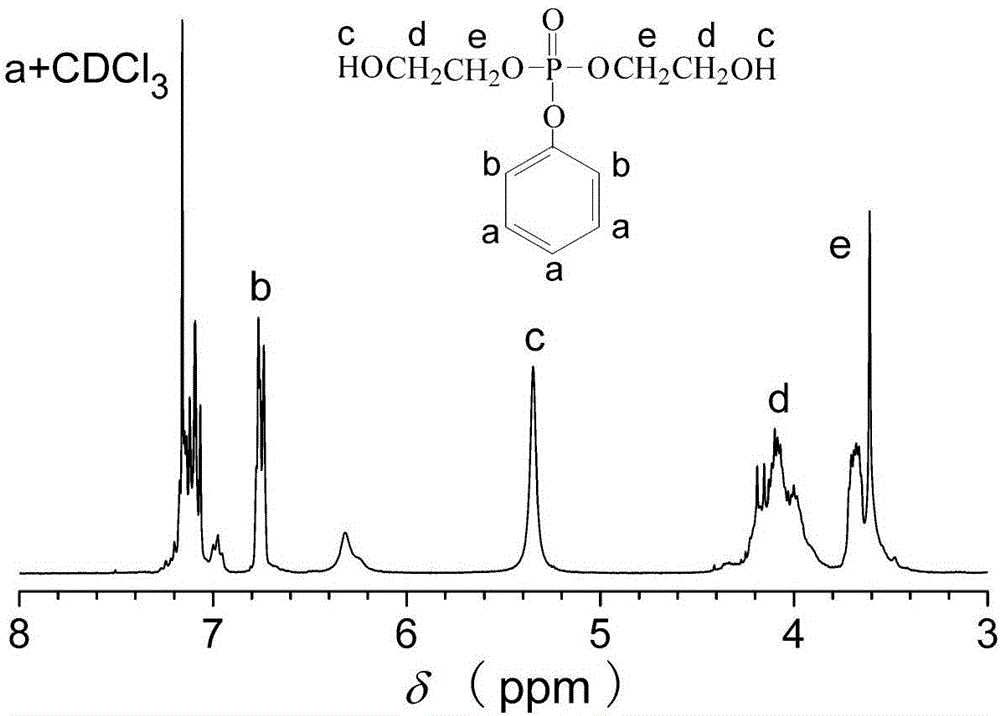

The invention discloses reaction-type flame-retardant glycol containing a phenyl phosphate-based symmetrical structure and a preparation method thereof. The preparation method is characterized by comprising the following steps: reacting phenyl dichlorophosphate with dihydric alcohol in a tetrahydrofuran or ethyl acetate solution in the presence of triethylamine, placing the tetrahydrofuran or ethyl acetate solution of dihydric alcohol and triethylamine into an ice-water bath, stirring and dropwise adding the tetrahydrofuran or ethyl acetate solution of phenyl dichlorophosphate; and filtering a precipitate and then removing the solvent in the filtrate to obtain the product with a structural general formula specified in the description, wherein n is an integer ranging from 2 to 6. According to the preparation method disclosed by the invention, micromolecular dihydric alcohol is introduced in the phenyl dichlorophosphate group in a manner of chemical bonding, so that the obtained dihydric alcohol molecular structure contains both the phenyl dichlorophosphate group and two hydroxyl groups with symmetrical structures and same reaction activity, and can partially or completely replace the micromolecular dihydric alcohol without a flame-retardant characteristic, so that the prepared polymer material has a flame-retardant characteristic; the raw materials in the preparation method disclosed by the invention are easily available, synthesis and post-treatment processes are simple, the cost is low, and the yield can achieve more than 90%.

Owner:UNIV OF SCI & TECH OF CHINA

Hole-sealing method of micro-arc oxidation coating

InactiveCN101613870ADoes not affect hardnessDoes not affect ceramic textureAnodisationEpoxyMicro arc oxidation

The invention relates to a sealing method of a micro-arc oxidation coating. An oxide film is sealed by a mixture of polyurethane resin, epoxy resin and curing agent as a sealing agent in a spraying way; and the sealing agent forms a film layer on the surface of the oxide film after the hole sealing.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

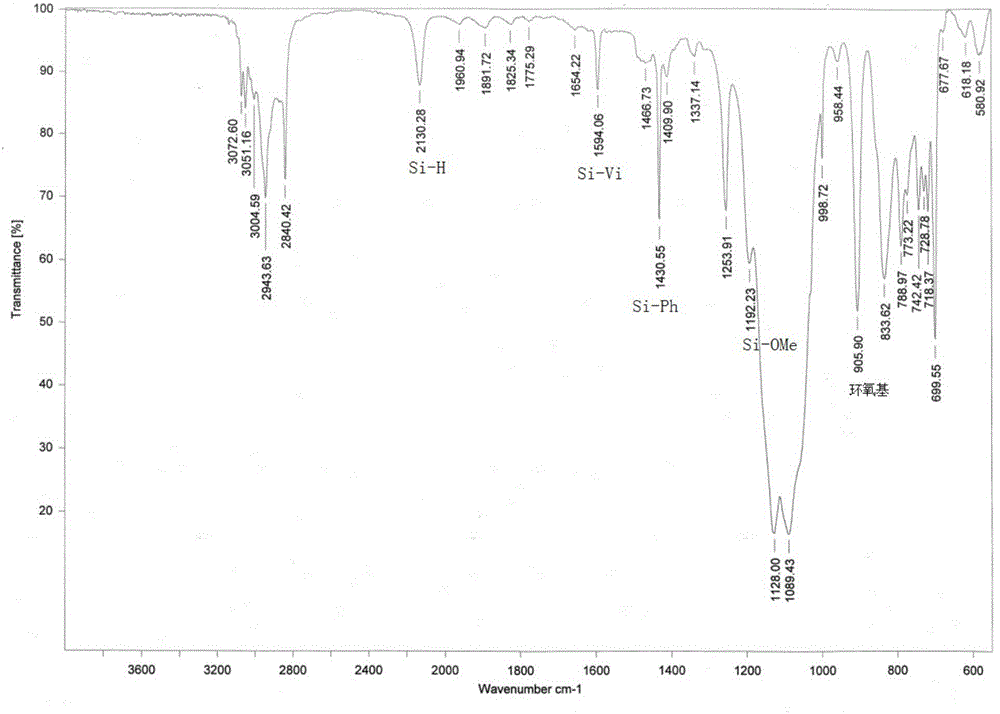

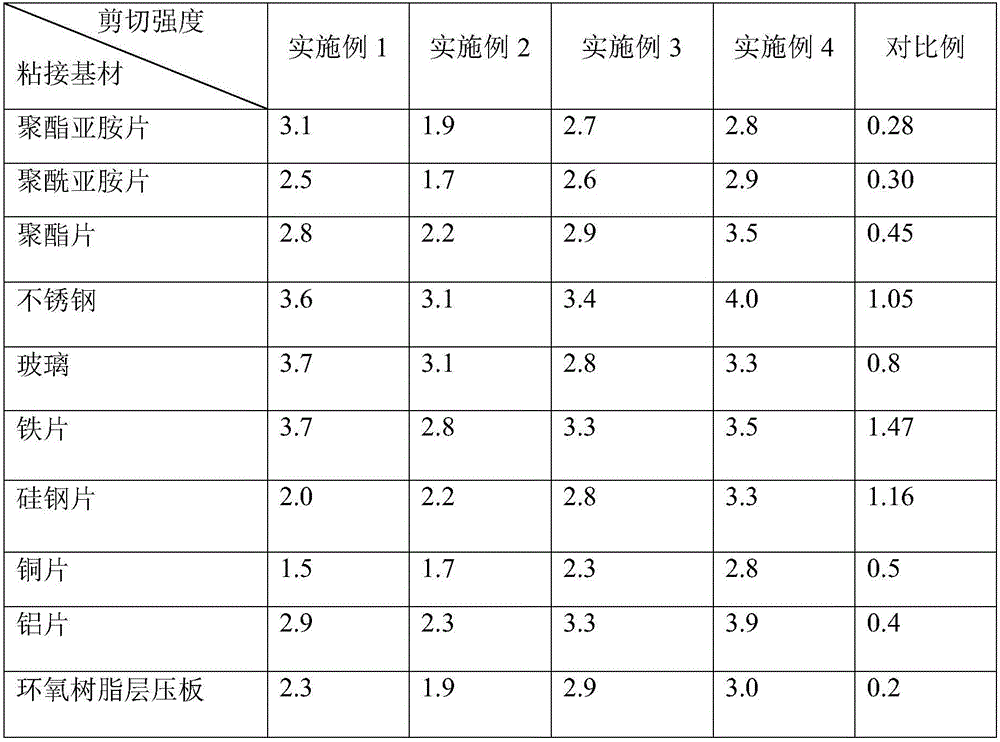

Tackifier for addition type organosilicon impregnating resin and preparation method thereof

The invention relates to a tackifier for addition type organosilicon impregnating resin and a preparation method thereof. The molecular formula of the tackifier is (Me2R1SiO0.5)a(MeR2SiO)b(PhSiO1.5)c(R3SiO1.5)d, wherein a, b, c and d represent the mole number of each chain link of the tackifier; and it is at least guaranteed that in R1 and R2, vinyl and hydrogen groups coexist. The tackifier is obtained by hydrolytic condensation of silane monomers containing hydrogen groups, vinyl, phenyl groups and other reactive groups under the effect of a catalyst. The prepared tackifier can remarkably improve high temperature adhesive properties of the addition type organosilicon impregnating resin, the tackifier and the impregnating resin are good in compatibility, the appearance, hardness and other mechanical properties of the resin are not affected after the mixing, and the tackifier has important application to motor and engine insulation impregnation.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

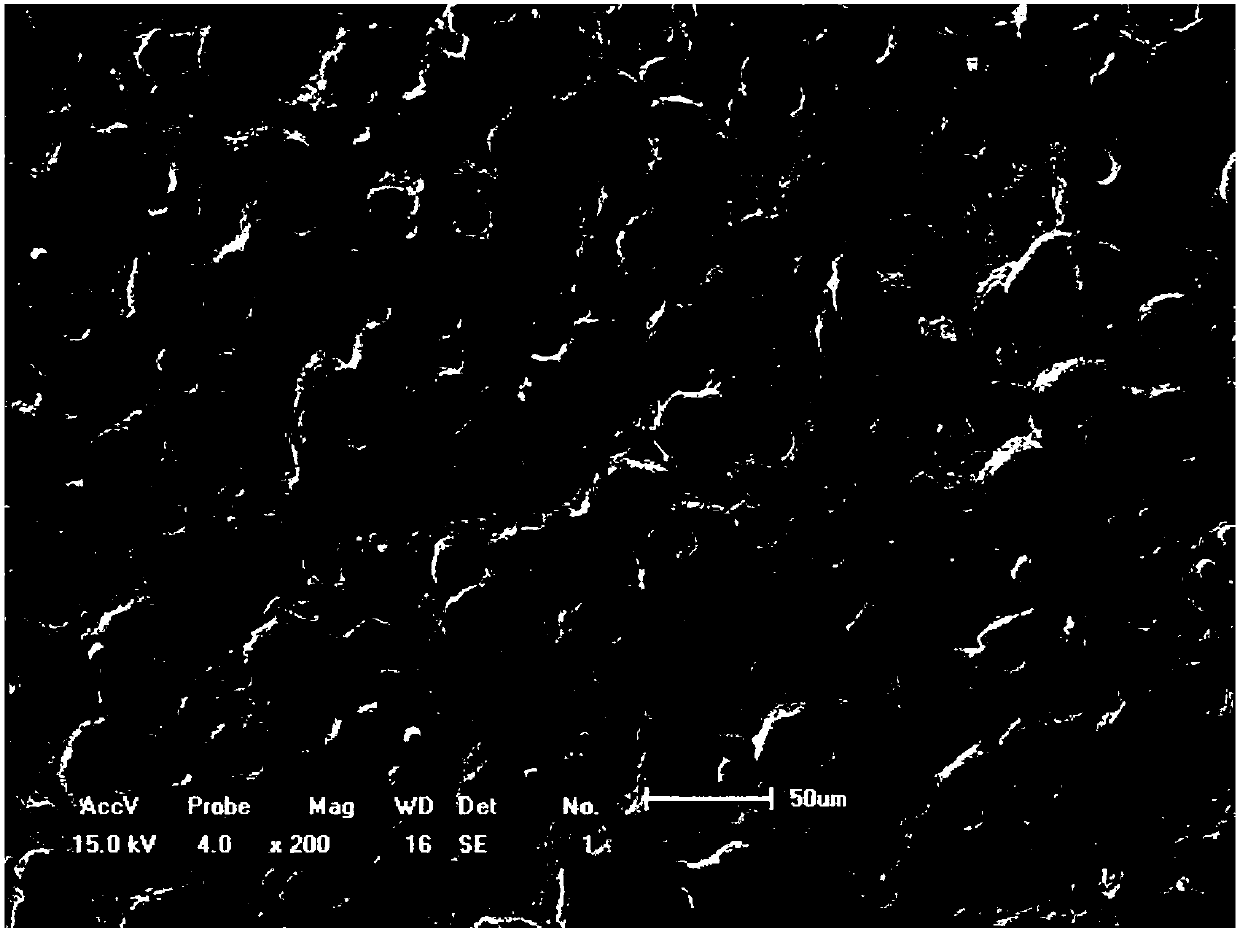

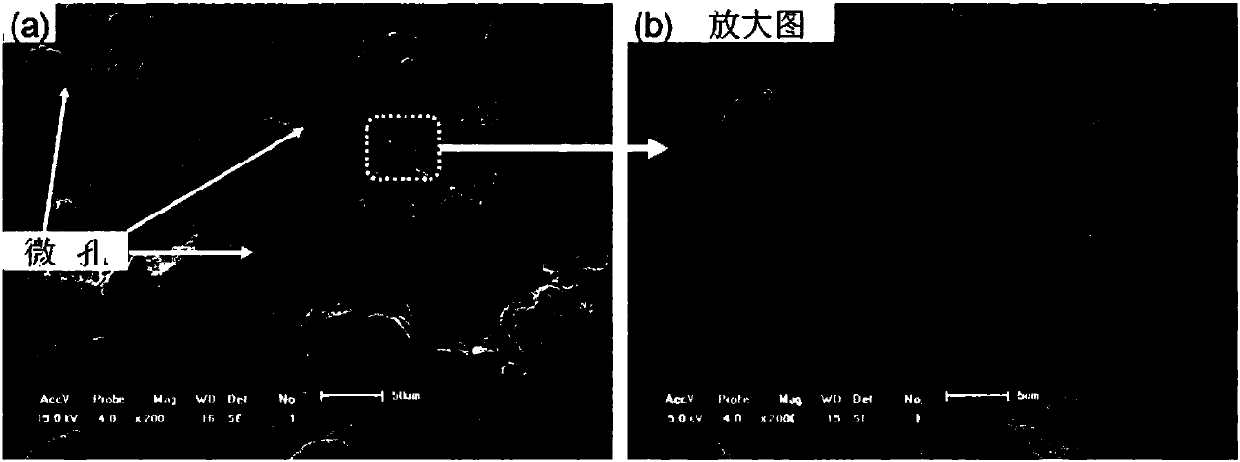

Magnesium alloy surface micro arc oxidation ceramic layer hole sealing agent and hole sealing method

InactiveCN107904647AGood sealingImprove corrosion resistanceAnodisationMolten spray coatingMicro arc oxidationSodium stearate

The invention discloses a magnesium alloy surface micro arc oxidation ceramic layer hole sealing agent and a hole sealing method. The magnesium alloy surface micro arc oxidation ceramic layer hole sealing agent comprises, by weight, 5-30 parts of sodium stearate, 5-20 parts of sodium metaaluminate, 1-5 parts of sodium dodecyl benzene sulfonate, 20-50 parts of ethanol with the mass fraction being 98% and 20-50 parts of deionized water. According to the hole sealing method, a magnesium alloy surface micro arc oxidation ceramic layer to be subjected to hole sealing is soaked in the magnesium alloy surface micro arc oxidation ceramic layer hole sealing agent to be subjected to hole sealing treatment, the temperature of the hole sealing agent is 25-30 DEG C, and the soaking time is 1-5 h. The magnesium alloy surface micro arc oxidation ceramic layer hole sealing agent and the hole sealing method have a good hole sealing effect on the magnesium alloy surface micro arc oxidation ceramic layer, the hole sealing agent is environment-friendly and non-toxic, the hole sealing process is simple and easy to operate, and the corrosion resistant performance of the magnesium alloy surface micro arcoxidation ceramic layer can be effectively improved.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Wear-resistant antibacterial sole material

The invention discloses a wear-resistant antibacterial sole material. The sole material is prepared from, by weight, 90-96 parts of isoprene rubber, 76-80 parts of hydrogenated nitrile rubber, 20-24 parts of methylpropanediol, 8-9 parts of aniline, 12-14 parts of ethyl acetate, 10-12 parts of calcium zinc salt, 8-9 parts of white carbon black and 20-24 parts of naphthenic oil. The sole material enables antimicrobial and wear-resistant performances of soles to be greatly improved without affecting due elasticity, hardness and other performances of the soles, and is applicable to industrial production.

Owner:WUJIANG XINXU PLASTIC SHOES COMPLETE

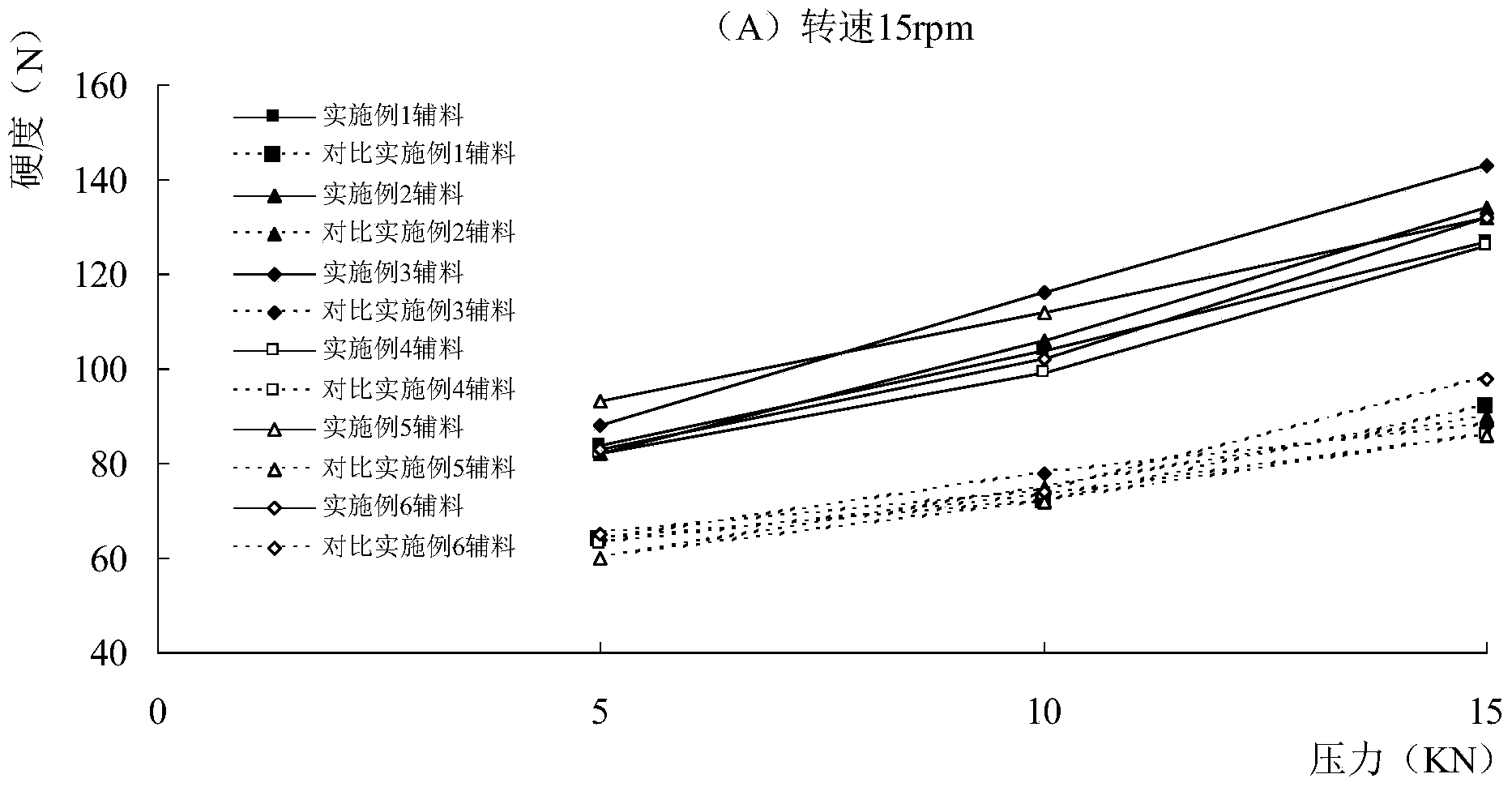

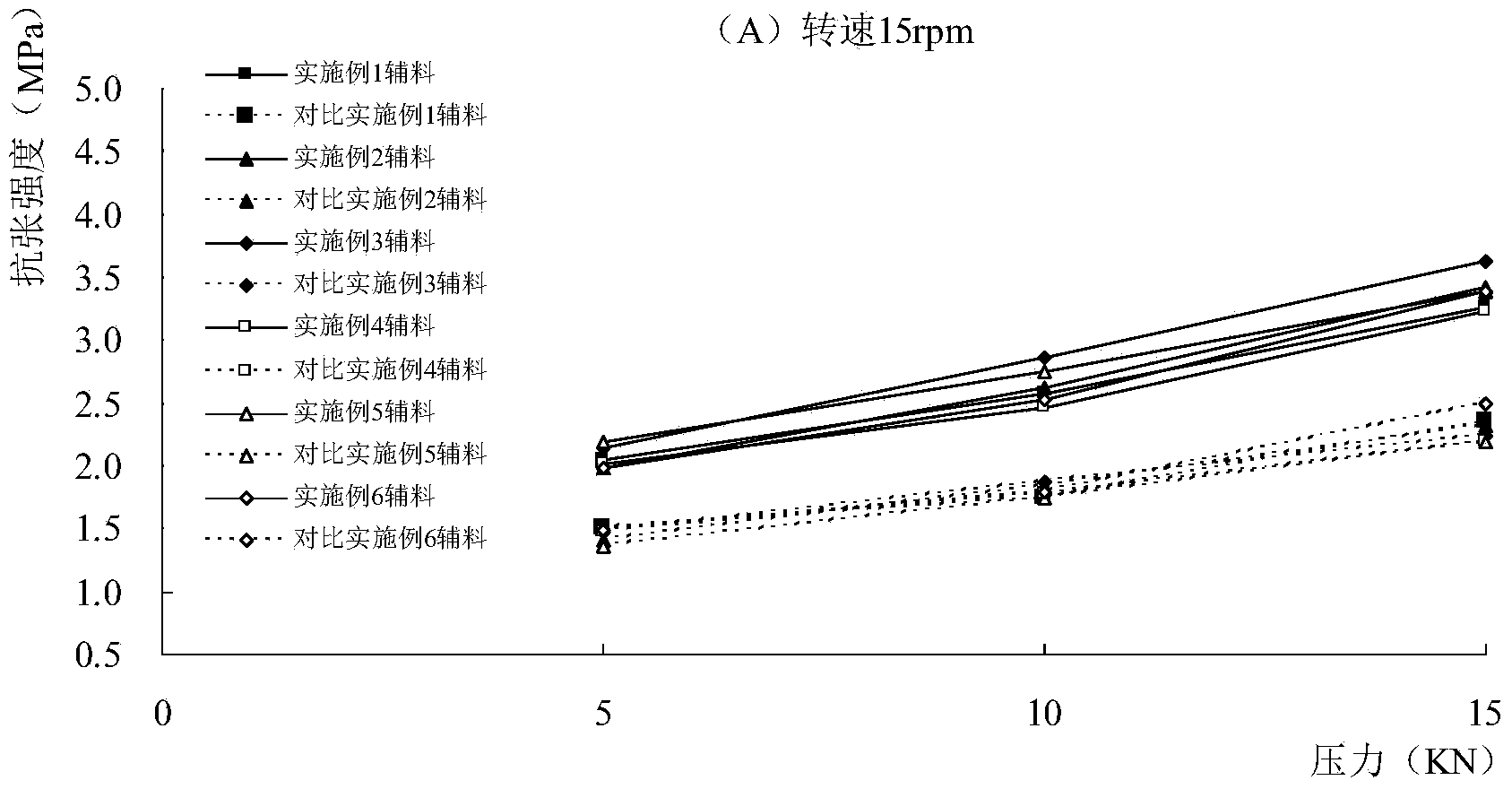

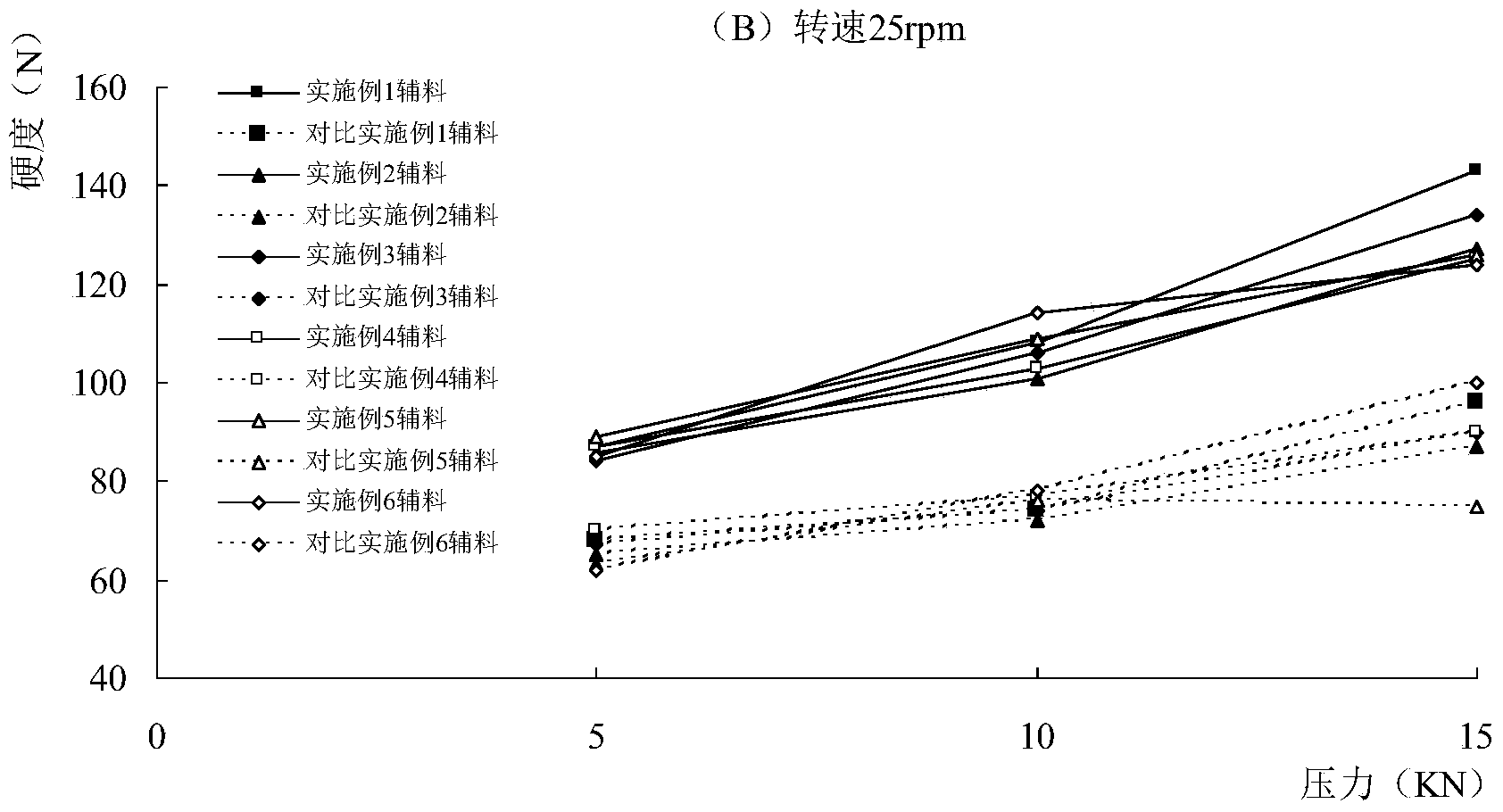

A premix auxiliary material and a preparation technology thereof

InactiveCN103637994AGood liquidityStrong compressibilityPharmaceutical non-active ingredientsPill deliveryFriabilityGlyceryl behenate

The invention discloses a premix auxiliary material. The premix auxiliary material comprises polyvinylpyrrolidone, glyceryl behenate, and a pharmaceutical adjuvant filler and a pharmaceutical adjuvant disintegrant, wherein the weight ratio of the filler, the disintegrant, the polyvinylpyrrolidone and the glyceryl behenate is (80-98.5):(10-0.5):(5-0.5):(5-0.5). The premix auxiliary material comprising the polyvinylpyrrolidone and the glyceryl behenate is good in fluidity, strong in compressibility and good in lubricating effect. The mixing uniformity, the medicine content, the tablet hardness, and the like would not change with prolongation of the total mixing time. The premix auxiliary material is prone to enlargement. Indexes comprising fluidity, the Carr's index, compressibility, friability, etc. of the premix auxiliary material provided by the invention are superior to corresponding indexes of auxiliary materials mixed physically. Uncontrollable factors of the technology are reduced, thus facilitating large-scale production. The premix auxiliary material can be used for direct compression of tablets or encapsulation of capsules.

Owner:SHANDONG UNIV

Anti-aging antistatic sole material

InactiveCN102863664ADoes not affect elasticityDoes not affect hardnessSolesAdhesiveMaterials science

The invention discloses an anti-aging antistatic sole material which is prepared by raw materials in parts by weight: 80-86 parts of chloroprene rubber adhesive, 75-78 parts of chlorosulfonated polyethylene adhesive, 5-10 parts of diethylene glycol, 6-8 parts of dimethylformamide, 2-3 parts of dicumyl peroxide, 16-18 parts of carbon black, 12-14 parts of calcium sulfate and 20-25 parts of naphthenic oil. With the adoption of the anti-aging antistatic sole material, antistatic property and anti-aging property are substantially improved on the premise of being free of influences on elasticity, hardness and other performances; and the anti-aging antistatic sole material is applicable to industrial production.

Owner:WUJIANG XINXU PLASTIC SHOES COMPLETE

Method for sealing micro-arc oxidation films

InactiveCN101649481ADoes not affect hardnessDoes not affect ceramic textureAnodisationMicro arc oxidationPlasma electrolytic oxidation

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Coffee grounds shoe material and preparation method thereof

PendingCN111484662AGood deodorizing effectHigh peel strengthTextile/flexible product manufactureFootwearPtru catalystActive agent

The invention relates to the technical field of shoe materials. The invention relates to coffee grounds, in particular to coffee grounds shoes and a preparation method thereof. The formula comprises the following raw materials in parts by weight; 4-8 parts of coffee grounds, 30-40 parts of polyethylene, 1-3 parts of a chain extender, 1-5 parts of an antioxidant, 16-20 parts of deionized water, 1-5parts of modified SBS, 8-12 parts of isocyanate, 0.05-1.0 part of a surfactant, 0.1-0.4 part of a first catalyst and 0.05-0.1 part of a second catalyst. The shoe material disclosed by the invention is prepared by taking coffee grounds as raw materials, so that the recycling property of wastes is improved, and the prepared shoe material has excellent peel strength, thermal aging resistance, waterresistance and deodorization effect, can be naturally decomposed after being used, and does not pollute the environment; the preparation method is simple, efficient, convenient to operate and control,high in product quality, low in cost and beneficial to industrial production.

Owner:广东粤盛新材料科技有限公司

Air-permeable sole material and preparation method thereof

The invention relates to an air-permeable sole material and a preparation method thereof. The air-permeable sole material comprises the following components in parts by weight: 88 parts of ethylene-propylene-diene monomer, 20 parts of carbon black, 22 parts of petroleum wax, 36 parts of polystyrene, 67 parts of natural 3L rubber, 8 parts of magnesia and 11 parts of calcium-zinc salt. The preparation method of the air-permeable sole material comprises the following steps of: mixing the raw materials according to the parts by weight, adding the mixture to an internal mixer for internal mixing, then granulating the mixture after internal mixing through a granulator to obtain granules, cooling the granules in a water tank, and drying at room temperature. By using the material provided by the invention, on the premise of not influencing the elasticity, hardness and other properties of the sole, the air permeability of the sole is greatly improved; and the material is nontoxic and pollution-free as well as safe and environment-friendly.

Owner:WUJIANG XINXU PLASTIC SHOES COMPLETE

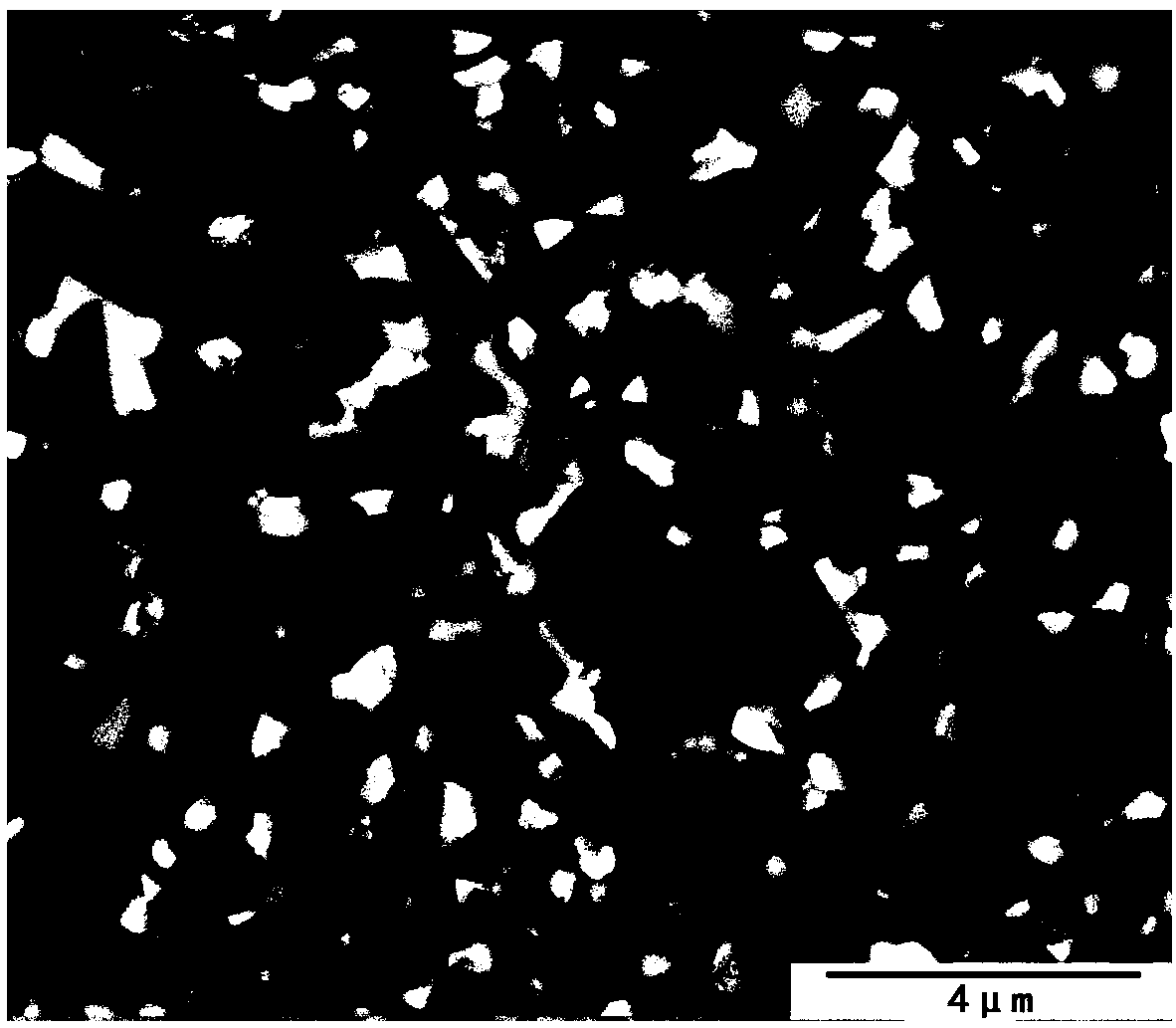

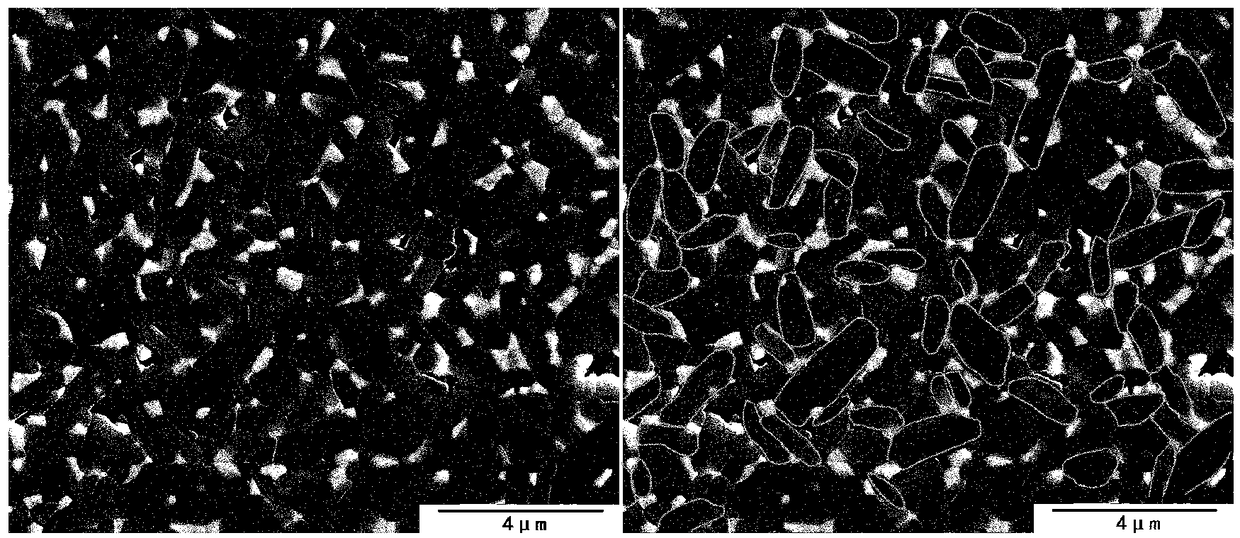

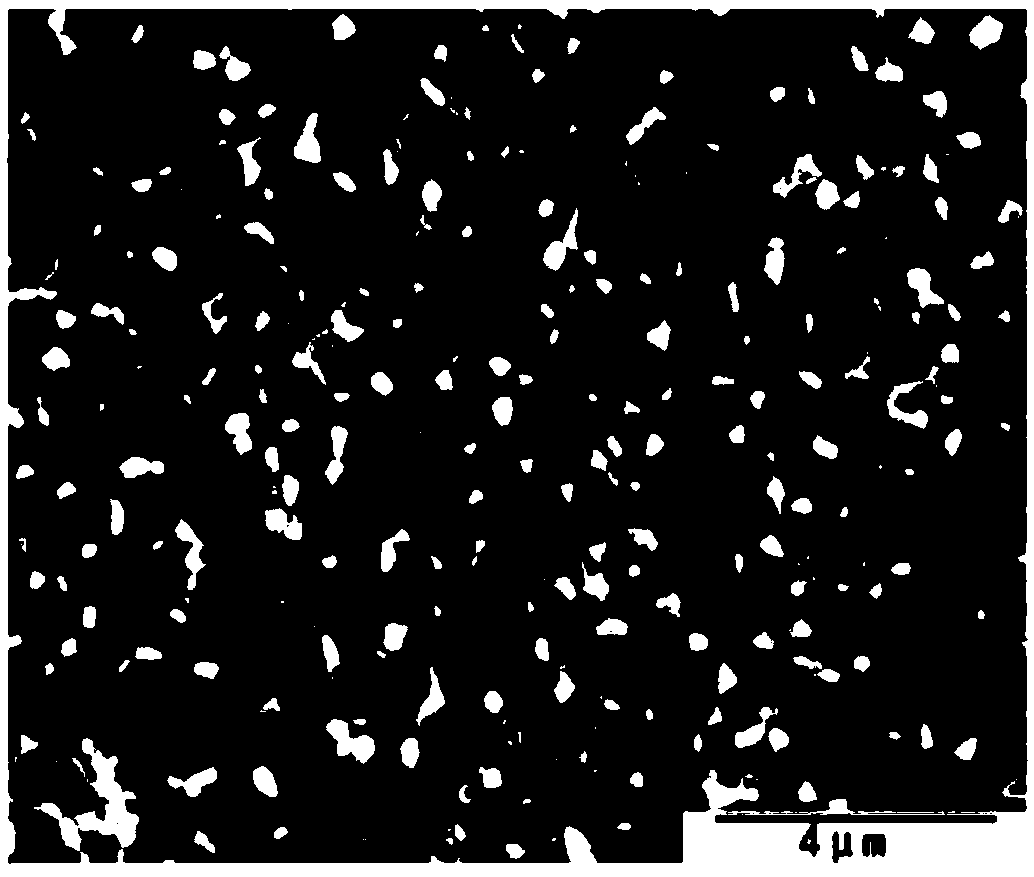

Zirconium dioxide toughened flaky aluminum oxide-based composite ceramic and preparation method thereof

The invention relates to zirconium dioxide toughened flaky aluminum oxide-based composite ceramic and a preparation method thereof. The invention discloses a preparation method of the zirconium dioxide toughened flaky aluminum oxide-based composite ceramic. The preparation method comprises the following steps: successively adding a first dispersing agent, Al2O3 powder and ZrO2 powder, mixing, adding a second dispersing agent, sintering to obtain the ZrO2 toughened flaky Al2O3-based composite ceramic, wherein the first dispersing agent is prepared from PAA and PEG; and the second dispersing agent is prepared from AMP and PEG. The preparation method is simple in operation, the preparation cost is reduced, Al2O3 crystal grains in a ZTA composite ceramic matrix has the directional growth, hascertain length-to-diameter ratio, and is of a flaky structure; and by adopting the structure, the probability of the crack deflection and crack bridging in the breaking process can be increased, so that on the premise of not influencing the hardness of the ZTA composite ceramics, the breaking toughness and strength of the ZTA composite ceramic can be significantly improved, and the problems that the shape of the existing ZTA composite ceramic matrix Al2O3 is of an isometric morphology and the toughness is poor can be solved.

Owner:GUANGDONG UNIV OF TECH

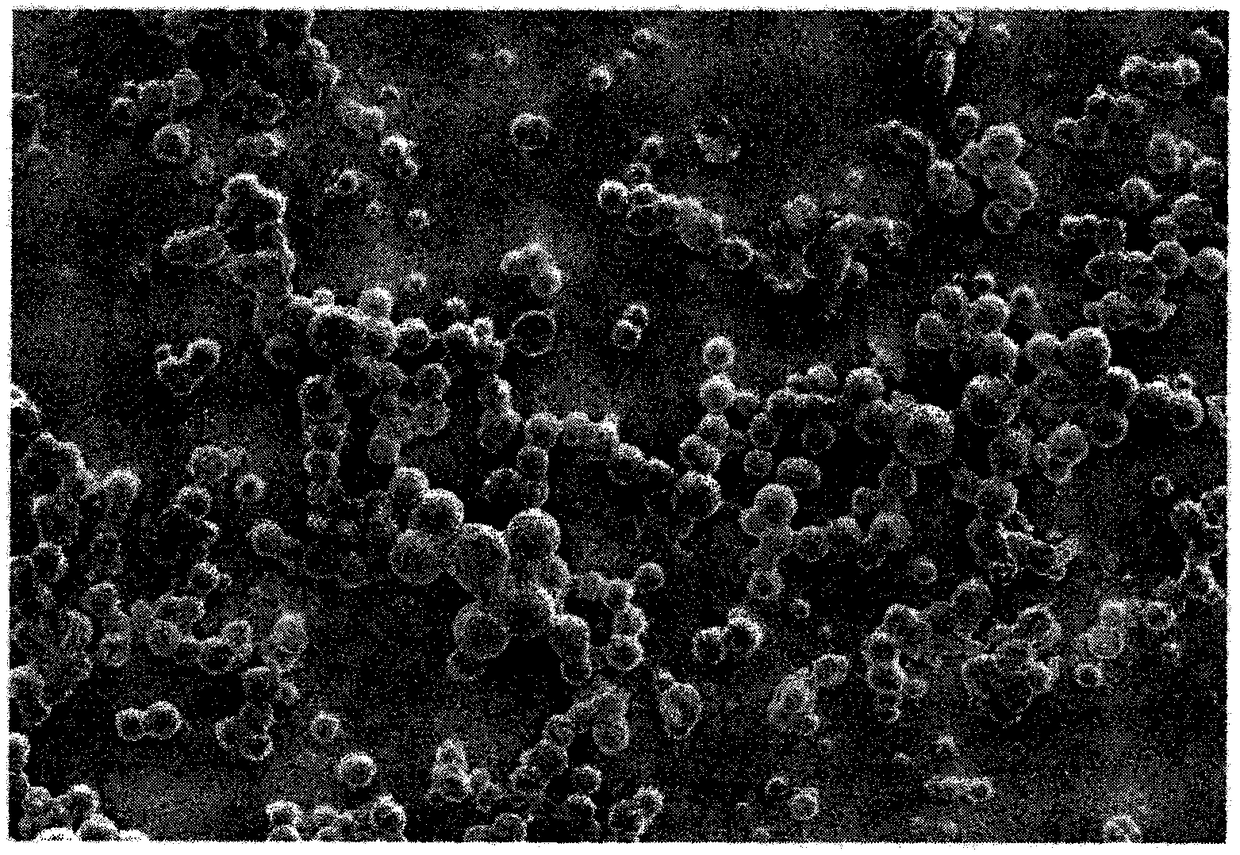

Hydrophobic, scratch-resistant and light-resistant UV-LED curing oil polish for paper packaging printed matters

ActiveCN108373782AImprove scratch resistanceImprove wear resistanceEpoxy resin coatingsPolyester coatingsPolyesterMaterials science

The invention discloses hydrophobic, scratch-resistant and light-resistant UV-LED curing oil polish for paper packaging printed matters. 1-10% by mass of Al2O3 or ZrO2 or SiO2 which has powder particle diameters D50 of 10-40nm and has dispersion properties improved by plasma polymerization is added into oil polish. The nanometer powder can absorb the impact energy and slowly release the energy sothat the surface of the cured film has elasticity, the hardness is not influenced and the scratch resistance and wear resistance of the surface of the cured film are observably improved. Through synergism of the inorganic nano-powder and the leveling agent, a random island-like distributed rough surface is formed on the cured film and the surface hydrophobic effects are obtained. Through use of polyester acrylate with low viscosity and nine functional groups, a highly reactive monomer, a photoinitiator and reactive amine, the reactivity of the oil polish is improved and the oil polish can be fast cured under weak LED illuminance. The cured oil polish has various performances meeting the various performance requirements on cigarette paper packaging of oil polish.

Owner:广西真龙彩印包装有限公司

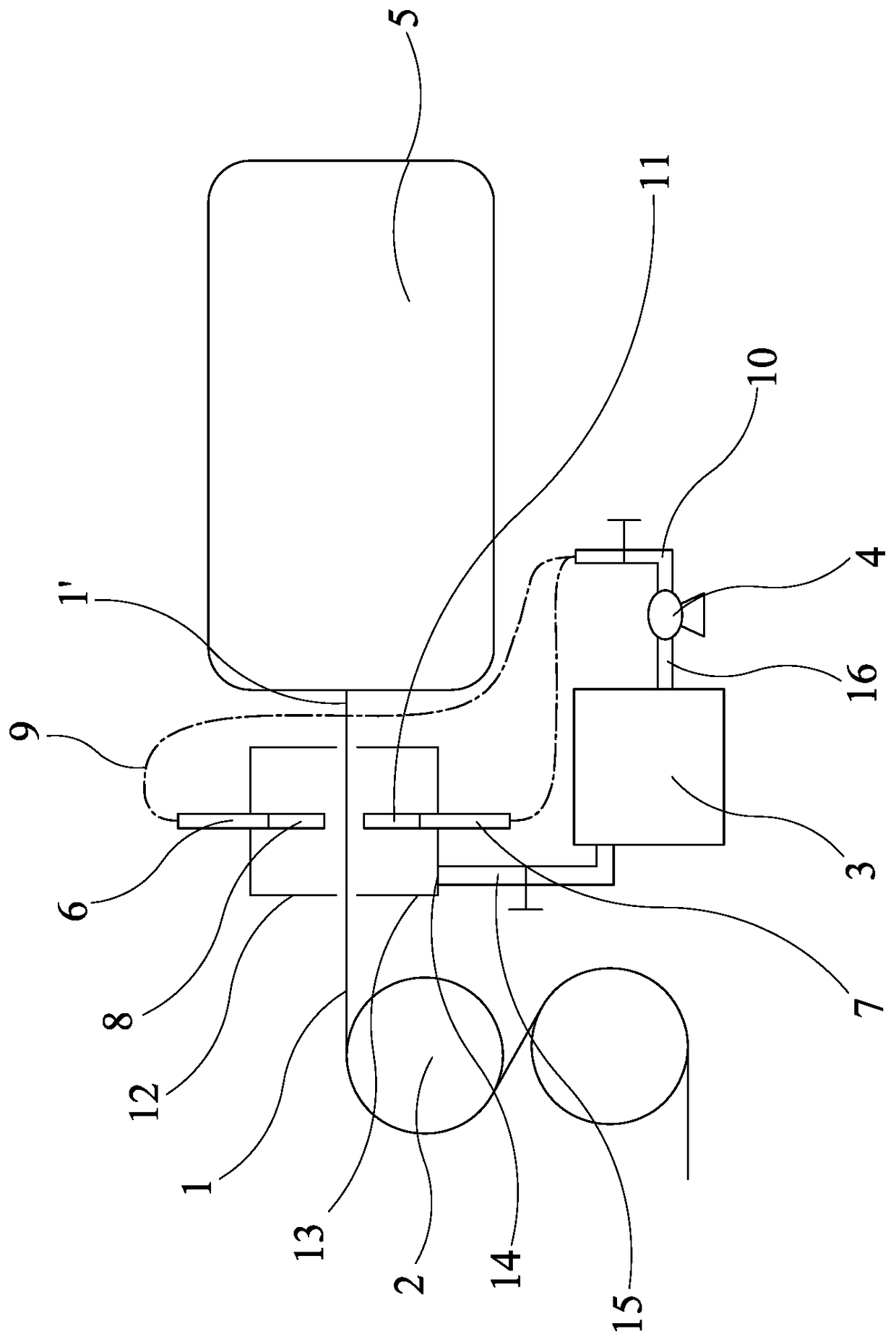

Water-repellent and oil-proof treatment method and device for filter cloth

PendingCN109351051ADoes not affect water and oil repellencyDoes not affect consumptionDispersed particle filtrationMembrane filtersWater resourcesWastewater

The invention discloses a water-repellent and oil-proof treatment method and device for filter cloth. The method comprises the steps that water-repellent and oil-proof liquid is prepared, subjected topressurized atomization and uniformly sprayed to the upper and lower surfaces of the filter cloth, and the treated filter cloth is dried. The device comprises winding rollers, a treatment assembly, asolution container, a pressure pump and a setting machine, and the filter cloth sequentially passes through the winding roller, the treatment assembly and the setting machine. The treatment assemblycomprises upper liquid spraying pipes and lower liquid spraying pipes, the upper liquid spraying pipes and the lower liquid spraying pipes are arranged at the upper and lower portions of the filter cloth and connected to a liquid outlet pipe of the pressure pump; the pressure pump is connected with the solution container through a liquid inlet pipe, and the solution container contains the water-repellent and oil-proof liquid. By means of the method and device, the water-repellent and oil-proof effect of the filter cloth is not influenced, and the treatment efficiency and the production efficiency are effectively improved; the method and the device have the advantages that the drying temperature is low, the energy consumption can be reduced, the energy is saved, and the color and harness ofthe product are not influenced; the consumption of water resources in the treatment process is greatly reduced, and the emission of wastewater is reduced.

Owner:XIAMEN ZHONGCHUANG ENVIRONMENTAL TECH CO LTD

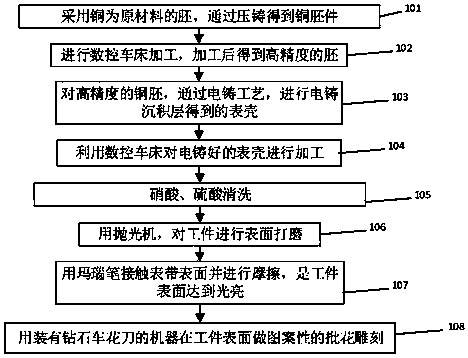

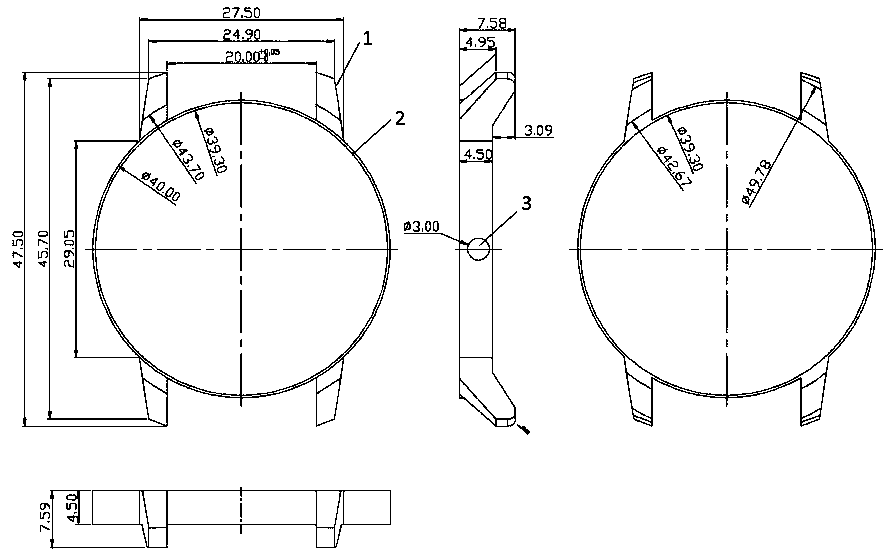

Manufacturing method of watchcase

InactiveCN110629256ADoes not affect hardnessDoes not affect wear resistanceClockwork casesElectroforming processesCopper nitrateElectroforming

The embodiment of the invention discloses a manufacturing method of a watchcase. The manufacturing method of the watchcase comprises the steps that a copper blank is machined according to an electroforming dimension and a matching position, so that a higher-precision blank is obtained; the higher-precision blank is electroformed through a pure gold electroforming process to make sure that an electroforming sedimentary layer of the electroformed blank is less than 0.5 mm, so that the watchcase is formed; gold or other precious metal is used during electroforming; the watchcase is machined according to the requirements for an assembly dimension, the matching position and the like; after nitric acid is heated to be boiled, the machined watchcase and the nitric acid are completely dissolved toform copper nitrate and are washed with water, then protective copper on the inner wall of the machined watchcase is heated and dissolved with sulfuric acid, and the watchcase is cleaned with water and then is dried to obtain a workpiece; and the workpiece is polished, so that the surface of the polished workpiece is glossy. By adopting the manufacturing method of the watchcase in the embodimentof the invention, the watchcase with light weight and good manufacturing precision can be manufactured.

Owner:深圳市元福珠宝首饰有限公司

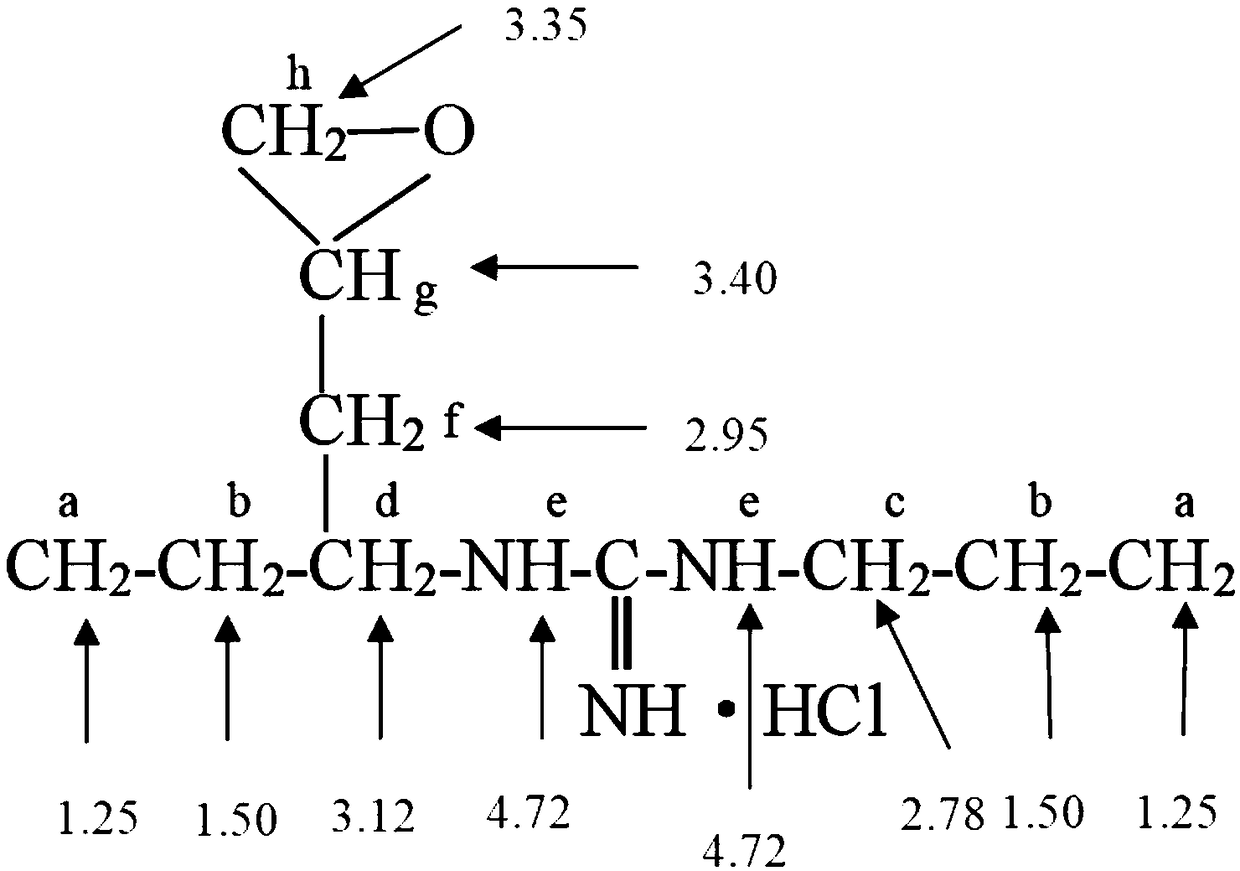

Polyepoxypropylhexylguanidine hydrochloride and preparation method thereof

InactiveCN109503832AImprove antibacterial propertiesRapid sterilizationPolyethylene terephthalatePolyvinyl chloride

The invention belongs to the technical field of plastic antibacterial agents, and particularly relates to polyepoxypropylhexylguanidine hydrochloride and a preparation method thereof. The preparationmethod of the polyepoxypropylhexylguanidine hydrochloride has the advantages that the technology is simple, and the cost is low. The polyepoxypropylhexylguanidine hydrochloride prepared by the preparation method has the advantages that the purity is high, and the yield rate can stably reach 90.0% to 95.0%; the sterilizing effect is excellent, and the poison and irritation are avoided; the polyepoxypropylhexylguanidine hydrochloride can be used as an antibacterial agent to be added into PP (polypropylene), PE (polyethylene), PET (polyethylene terephthalate), PVC (polyvinyl chloride) and other plastics to further prepare the antibacterial plastics, and the influence on the appearance, transparency, plasticity, hardness and other properties of the plastic is avoided; the polyepoxypropylhexylguanidine hydrochloride and the plastic can generate grafting copolymerizing reaction at the temperature of 160 DEG C, and the polyepoxypropylhexylguanidine hydrochloride cannot be dissolved out by thewater-based and oil-based solvents after combining, so that the prepared antibacterial plastic can realize lasting antibacterial characteristic.

Owner:上海高聚生物科技有限公司

Two-component waterborne coating and preparation method thereof

InactiveCN109054615ASmall molecular weightGood construction performancePolyurea/polyurethane coatingsHigh humidityDistilled water

The invention discloses a two-component waterborne coating. The two-component waterborne coating comprises a component A and a component B according to parts by weight. The component A is prepared from the following raw materials in parts by weight: 40.0-60.0 parts of waterborne hydroxyacrylic acid dispersion, 3.0-6.0 parts of waterborne functional resin, 20.0-30.0 parts of waterborne color paste,3.0-6.0 parts of functional cosolvent, 0.3-0.6 part of thickener, 0.2-0.4 part of substrate wetting agent, 0.1-0.3 part of leveling agent, 0.1-0.3 part of defoamer, 4.0-10.0 parts of distilled water.The component B is prepared from the following raw materials in parts by weight: 15-25 parts of waterborne polyisocyanate curing agent. The waterborne coating prepared by the scheme is relatively wide in construction window, is still capable of constructing and obtaining good coating film in the severe high-temperature, low-temperature and high-humidity environment, and shows good property; the appearance, the drying speed, the hardness and the water resistance of the coating film achieve ideal effects.

Owner:商丘市博大化工有限公司

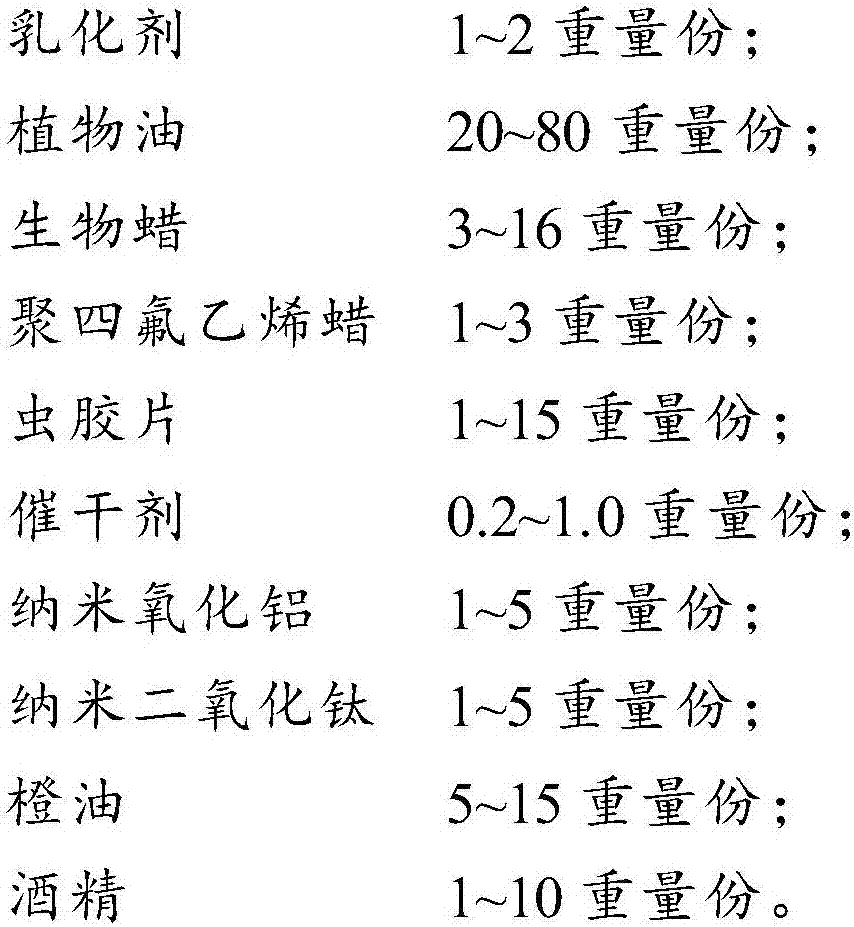

Water-based wax oil composition and preparation method thereof

InactiveCN107955530AImprove wear resistanceImprove aging resistanceShellac coatingsWax coatingsWaxWater based

The invention provides a water-based wax oil composition which comprises, by weight, 5-20 parts of water, 1-2 parts of emulsifier, 20-80 parts of plant oil, 3-15 parts of biological wax, 1-3 parts ofpolytef wax, 1-16 parts of shellac, 0.2-1.0 part of drier, 1-5 parts of nano alumina, 1-5 parts of titanium dioxide, 5-15 parts of orange oil and 1-10 parts of alcohol. Mutual cooperation and use of the above components, and a paint film formed by the water-based wax oil composition has high wear resistance and aging resistance, has self-cleaning ability and is environment-friendly and harmless.

Owner:广东顺德三阳化学有限公司

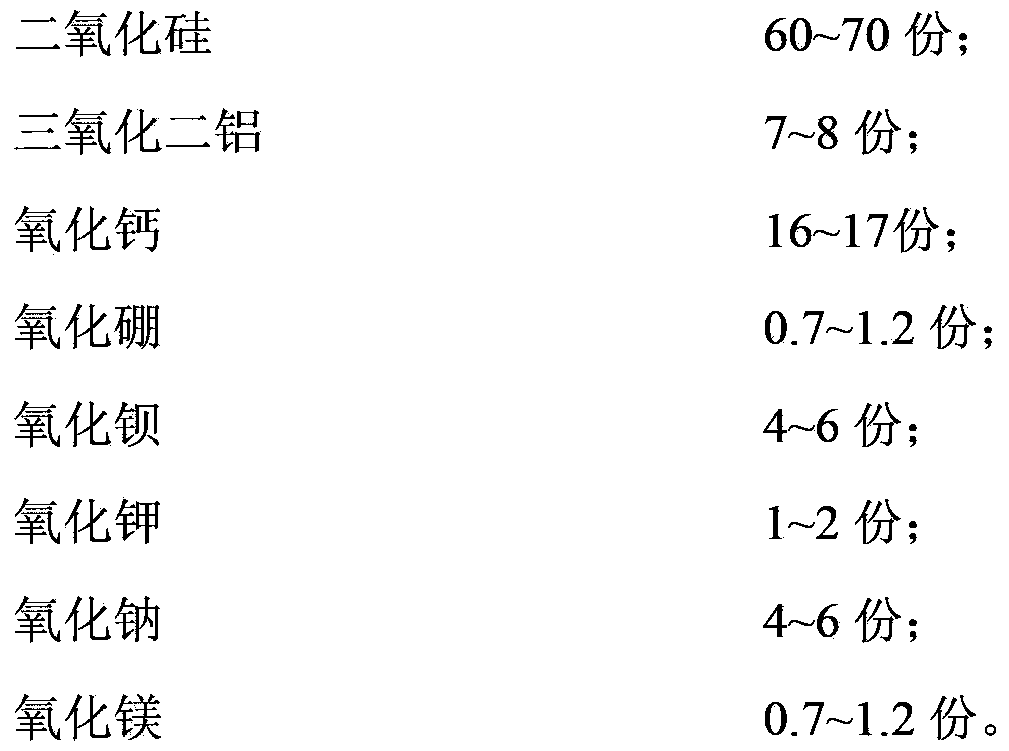

Zinc oxide-free microcrystalline

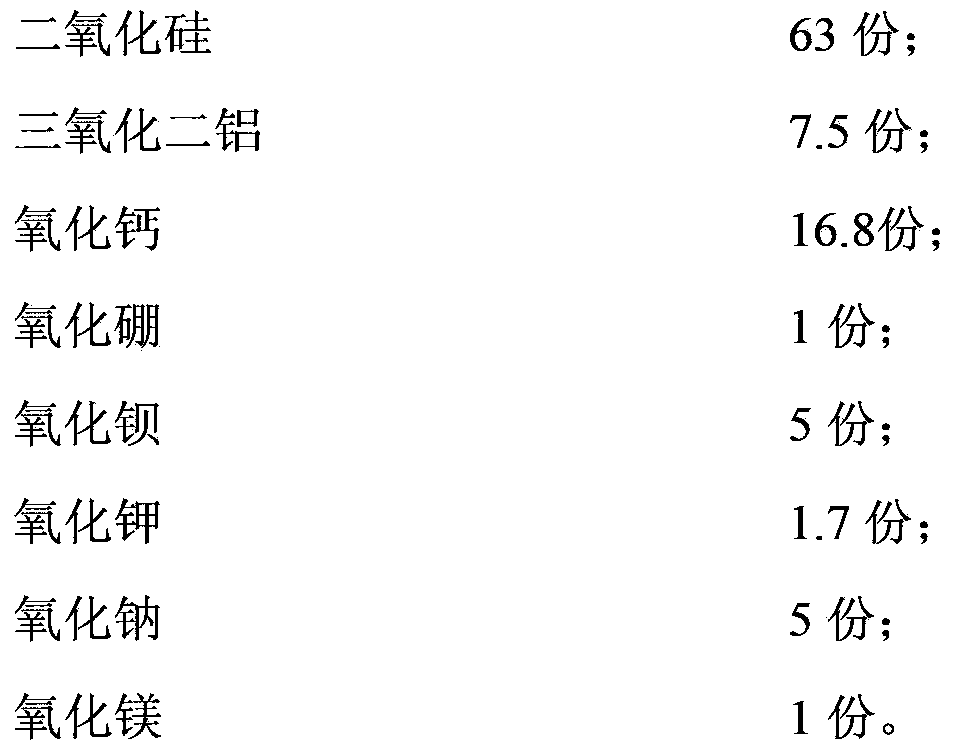

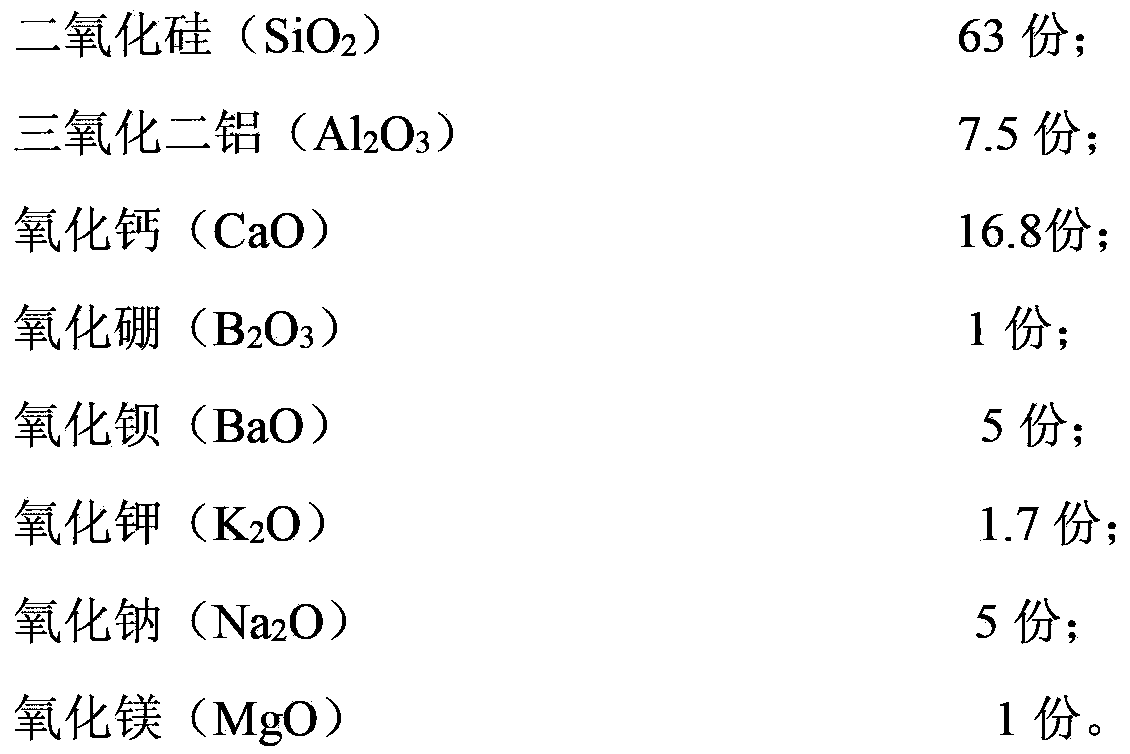

The invention relates to zinc oxide-free microcrystalline comprising the following components by weight: 60-70 parts of silica; 7-8 parts of aluminum oxide; 16-17 parts of calcium oxide; 0.7-1.2 parts of boron oxide; 4-6 parts of barium oxide; 1-2 parts of potassium oxide; 4-6 parts of sodium oxide; and 0.7-1.2 parts of magnesium oxide. The materials of the zinc oxide-free microcrystalline do not contain zinc oxide, and has no effect on microcrystalline hardness, the enterprise production cost is reduced, and the zinc oxide-free microcrystalline has the advantages of low cost and convenient production, improves the enterprise production efficiency, and greatly satisfies the demand of people for the microcrystalline in living and production.

Owner:TIANJIN JUHUAJING TECH DEV

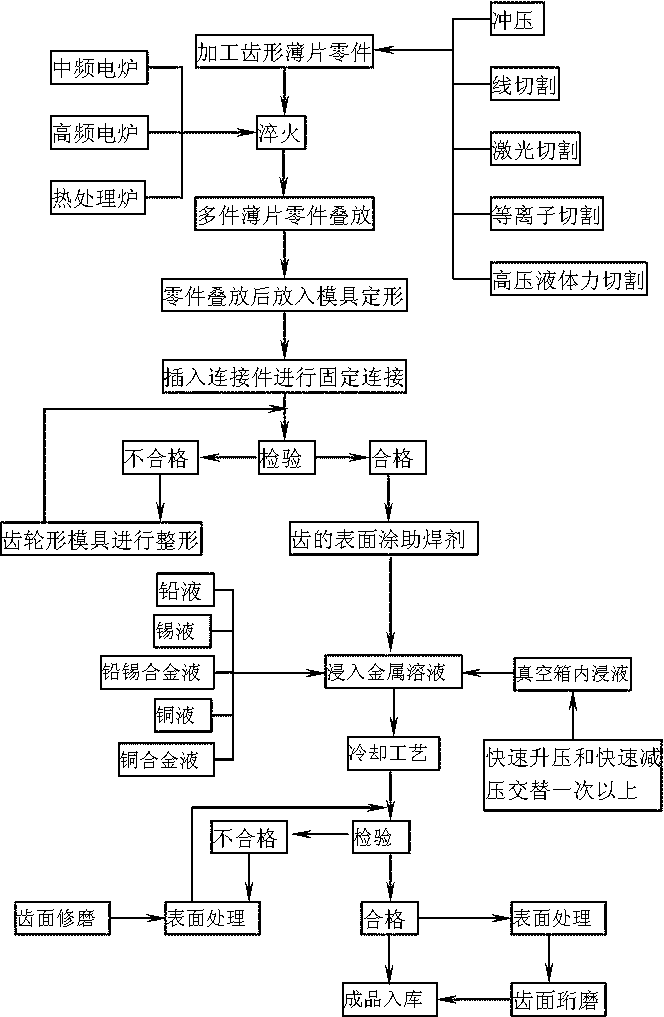

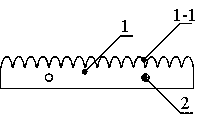

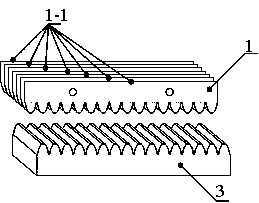

Gear speed changing box

The invention relates to a gear speed changing box, in particular to a speed changing box of a gear. The gear is formed by laminating a plurality of quenched sheet parts with teeth, and gaps of the gear are filled with a metal solution. The speed changing box comprises a box body, a shaft and the gear, the shaft is installed in the box body, and the gear is arranged on the shaft. The gear speed changing box is characterized in that the gear is a multilayer gear; the gear comprises a gear body, and the gear body is formed by laminating the multiple quenched sheet parts with the teeth; at least one connecting hole is formed in each sheet part, the connecting holes are laminated to form a through hole after the sheet parts are laminated, and the connecting holes are fixedly connected into the gear body through connecting pieces; and then the gear body is soaked into a metal solution, the gear body is taken out from the metal solution to be cooled, the metal solution solidifies into metal to be injected into the positions between the sheet parts of the gear body and the surface of the gear body, and the technical aim of rapidly manufacturing the gear with the high physical property in a low-cost manner is achieved.

Owner:QUZHOU YOUDE IND DESIGN

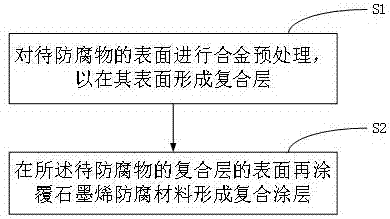

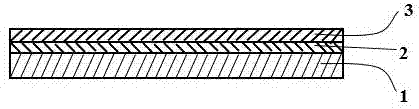

Trail traffic buckle accessory alloy pretreatment and graphene material compound corrosion resistance technology

InactiveCN107418345ASolving Galvanic Corrosion ProblemsImprove comprehensive anti-corrosion abilitySolid state diffusion coatingAnti-corrosive paintsCorrosion resistantPre treatment

The invention relates to a trail traffic buckle accessory alloy pretreatment and graphene material compound corrosion resistance technology which comprises the following steps: S1, performing alloy pretreatment on the surface of a to-be-corrosion resistant object to form a compound layer on the surface thereof; and S2, then coating the surface of the compound layer of the to-be-corrosion resistant object with a graphene corrosion-resistant material to form a compound coating. The compound corrosion resistance technology comprises the S1 of obtaining the compound layer (an alloy co-diffusing layer). The alloy co-diffusing layer can be combined with a metal matrix firmly, so that the electrochemical corrosion problem can be solved. Meanwhile, the problem of collision in a construction process is solved without affecting the hardness of metal. The alloy co-diffusing layer can be combined with the graphene corrosion-resistant coating well, so that the comprehensive corrosion-resistant ability of a product is improved. By combining the two, corrosion-resistance and collision resistance of the product can be solved at the same time.

Owner:戴鹏 +1

Method for improving water permeability resistance performance of outer layer of fire protective clothing and recovering original appearance of outer layer of fire protective clothing

ActiveCN103721355AImprove water resistanceImprove surface moisture resistanceChemical protectionHeat protectionWaxHydrostatic pressure

The invention relates to a method for improving the water permeability resistance of an outer layer of fire protective clothing and recovering the original appearance of the outer layer of the fire protective clothing. According to the method, strong glue spray processing, lustering wax spray processing and first time waterproof spray processing are carried out on the outer layer of the fire protective clothing, the processed outer layer of the fire protective clothing maintains high surficial humidity resistance (spray rating is larger than or equal to four), higher water permeability resistance is provided (hydrostatic pressure reaches 5-8kPa), the icing resistance capacity is improved, and working efficiency of firefighters under low-temperature environment in cold region is guaranteed. Cleaning agent processing is carried out on the outer layer of the fire protective clothing by using the method continuously to remove sprayed glue, sprayed wax and sprayed agents effectively, finally second time waterproof spray processing is carried out to recover the surficial humidity resistance of the fire protective clothing, the original appearance of the fire protective clothing is recovered thereby, and normal use of the fire protective clothing by the firefighters under non-low-temperature environments can be guaranteed.

Owner:应急管理部天津消防研究所

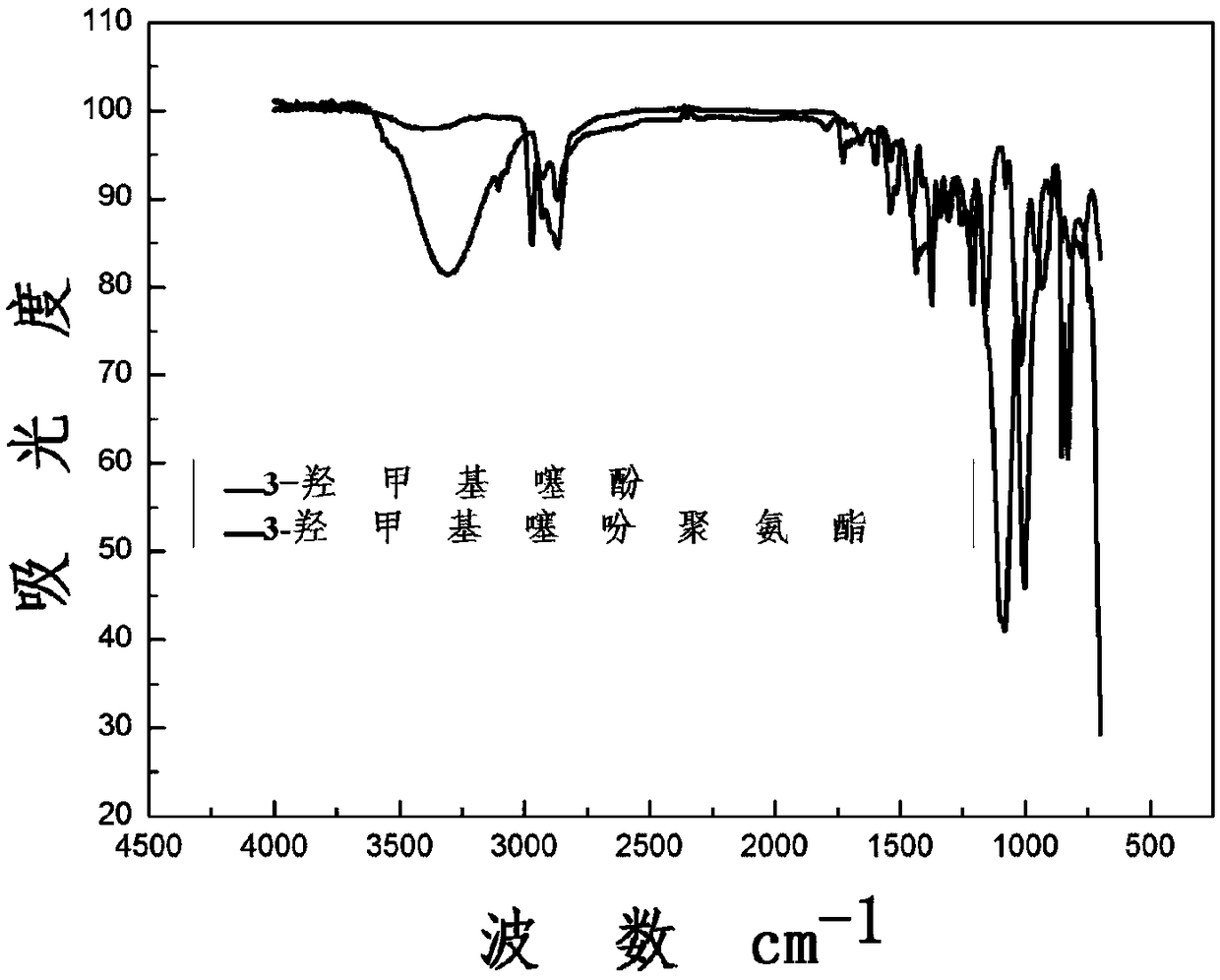

A kind of preparation method of anti-mildew polyurethane prepolymer

The invention discloses a preparation method of a mildew-resistant polyurethane prepolymer. The preparation method comprises the following steps: 1) adding polyether polyol to a reaction vessel, performing vacuum-pumping, controlling the temperature and performing stirring with a stirrer; 2) in the protection of nitrogen, cooling the system, adding diisocyanate and a proper amount of a catalyst, controlling the temperature, and increasing the stirring speed; 4) according the NCO content in the system, slowing adding a silane coupling agent to the reaction system, and continuously performing stirring; 5) adding a certain amount of hydroxyl (or amino) thiophene oligopolymer to the system, and continuously performing stirring; and 6) after the reaction is over, vacuumizing the system to remove bubbles and obtaining a target product. The obtained polyurethane prepolymer is excellent in mildew resistance without mechanical property being affected.

Owner:SOUTH CHINA UNIV OF TECH

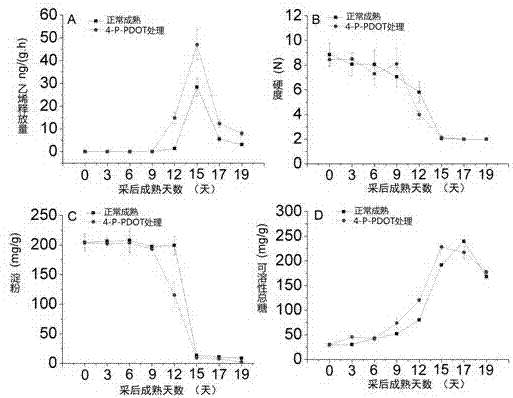

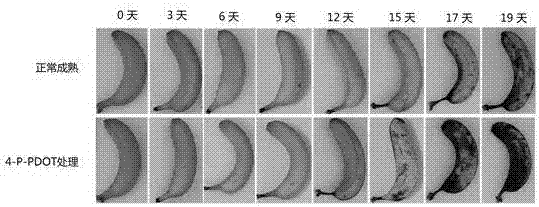

Application of 4-P-PDOT in acceleration of banana fruit ripening

InactiveCN106922810ADoes not affect hardnessQuality is not affectedFruit and vegetables preservationEndogenous ethyleneRipening

The invention belongs to the technical field of acceleration of fruit ripening, and discloses an application of 4-P-PDOT in acceleration of banana fruit ripening. The banana fruits treated by the 4-P-PDOT have increased endogenous ethylene release amounts, and turn yellow ahead of time; moreover, the hardness, the starch and the soluble sugar qualities of the treated banana fruits are not affected. The invention further provides a method for accelerating ripening of the banana fruits. The method comprises the following steps: soaking harvested banana fruits in a 4-P-PDOT solution for a certain period of time, air-drying the soaked banana fruits, and carrying out normal-temperature storage. Compared with existing methods for accelerating ripening of the banana fruits, the method is simple in operation, safe, effective, and free of damages to the qualities of the banana fruits; moreover, the method has practical and wide application values.

Owner:INST OF TROPICAL BIOSCI & BIOTECH CHINESE ACADEMY OF TROPICAL AGRI SCI

Glass protecting ink and preparation method thereof

The invention discloses a glass protecting ink and a preparation method thereof. The glass protecting ink comprises the following components in percentage by weight: 10%-30% of polyurethane acrylate, 5%-30% of epoxy acrylic resin, 5%-40% of phenolic resin, 20%-50% of acrylic monomer, 2%-10% of initiator, 1%-5% of adhesion promoter, 1%-5% of thixotropic agent, 0.5%-2% of dispersing agent, 0.2%-4% of surface active agent, 1%-5% of pigment and 10%-30% of filler. The glass protecting ink disclosed by the invention has a good glass protecting performance, is easy to strip, and is convenient to operate.

Owner:FOSHAN 3Q ELECTRONICS MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com