Patents

Literature

30results about How to "Does not affect heat resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diaphragm, preparation method of diaphragm and lithium ion battery

ActiveCN104157810AImprove heat resistanceNot easy to fall offSecondary cellsCell component detailsPolymer sciencePolymer substrate

A separator and a method for preparing the separator are provided. The separator includes a polymer substrate,a ceramic layer provided on the polymer substrate and an infiltration part formed between the polymer substrate and the ceramic layer. The polymer substrate contains a base polymer and a first curing resin. The infiltration part has at least a portion infiltrated into the polymer substrate. Each of the infiltration part and the ceramic layer independently contains ceramic particles and a second curing resin.A battery including the separator is also provided.

Owner:BYD CO LTD

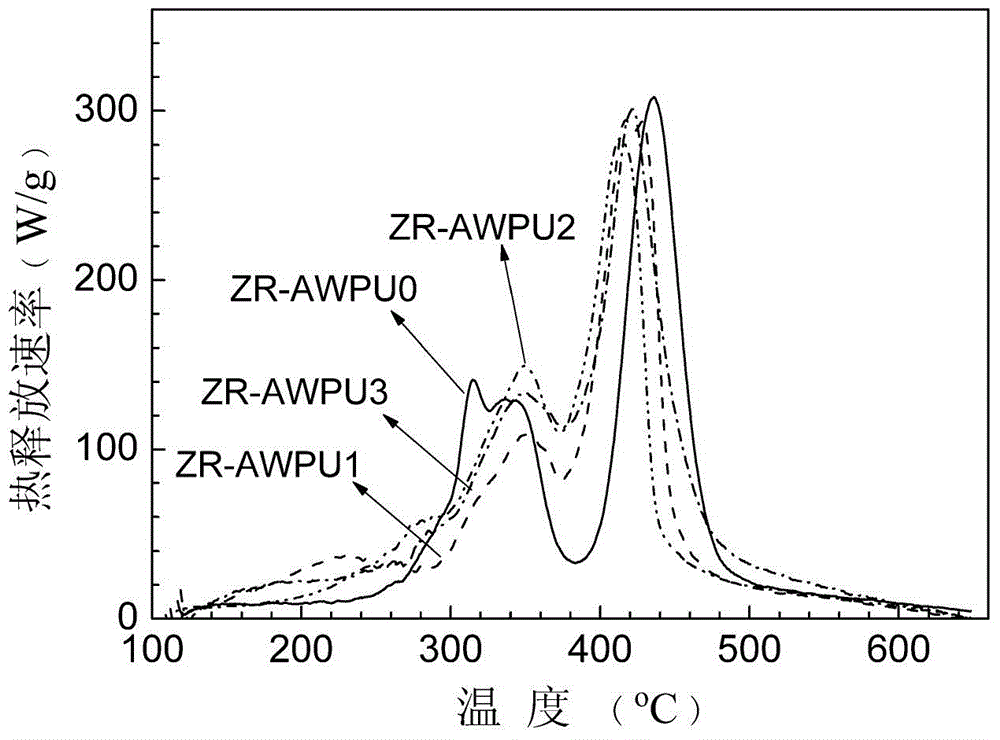

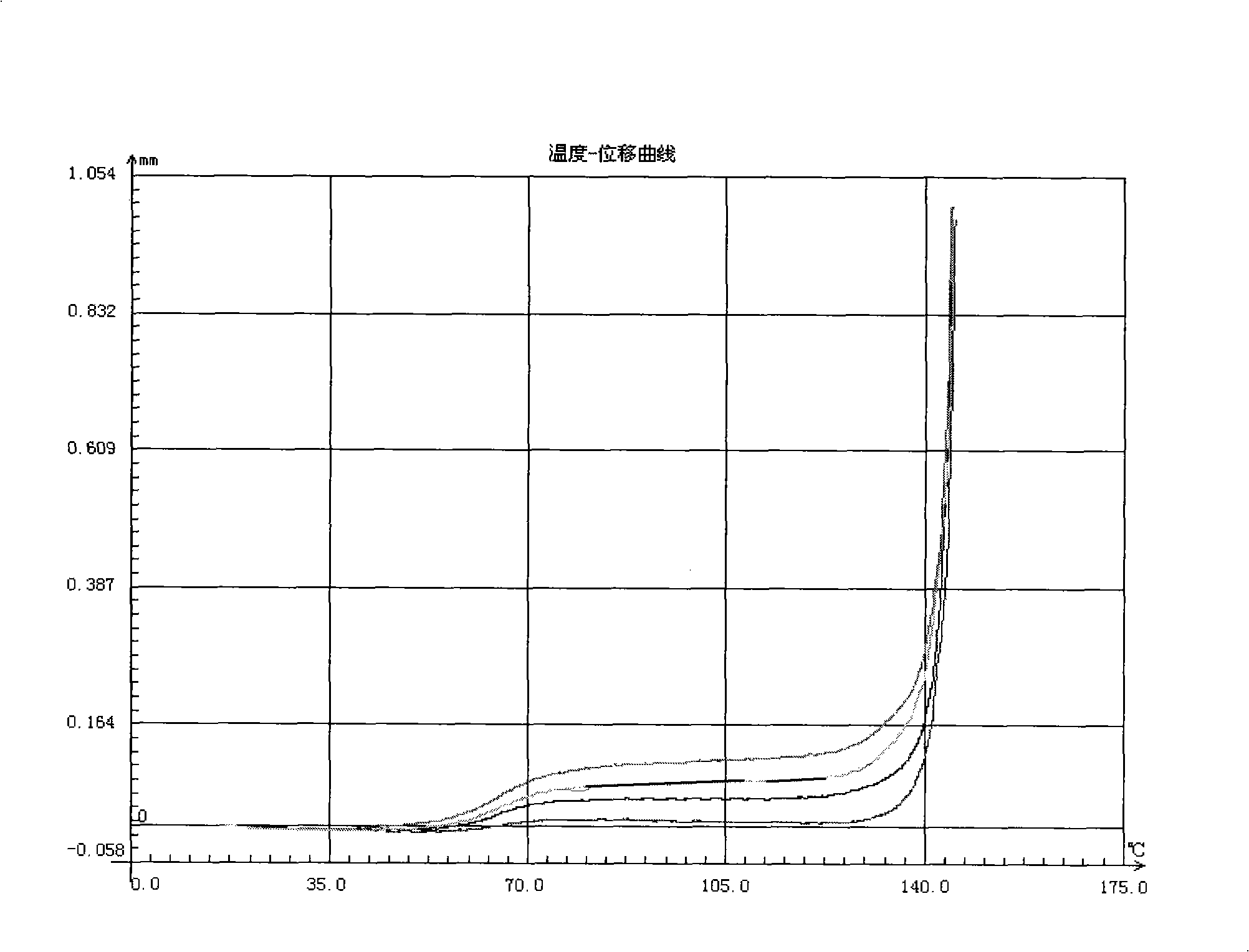

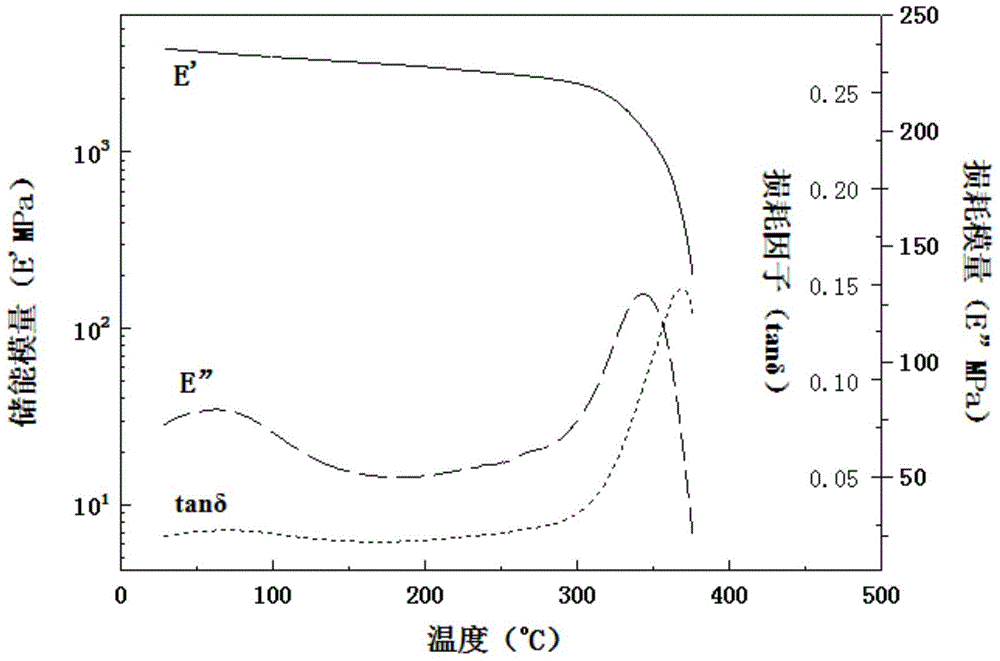

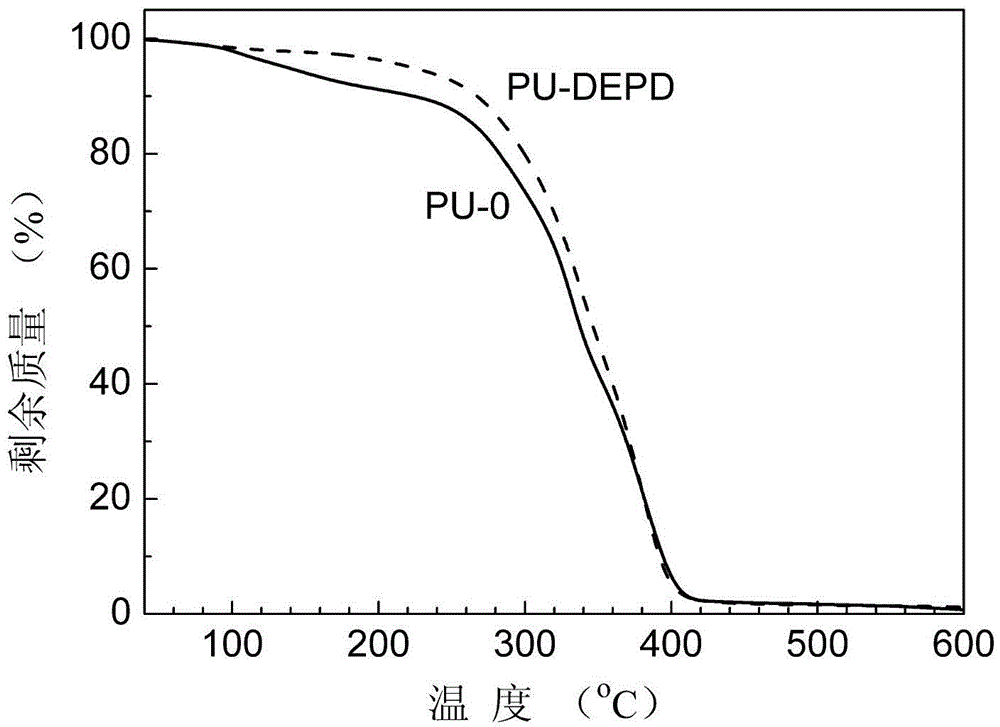

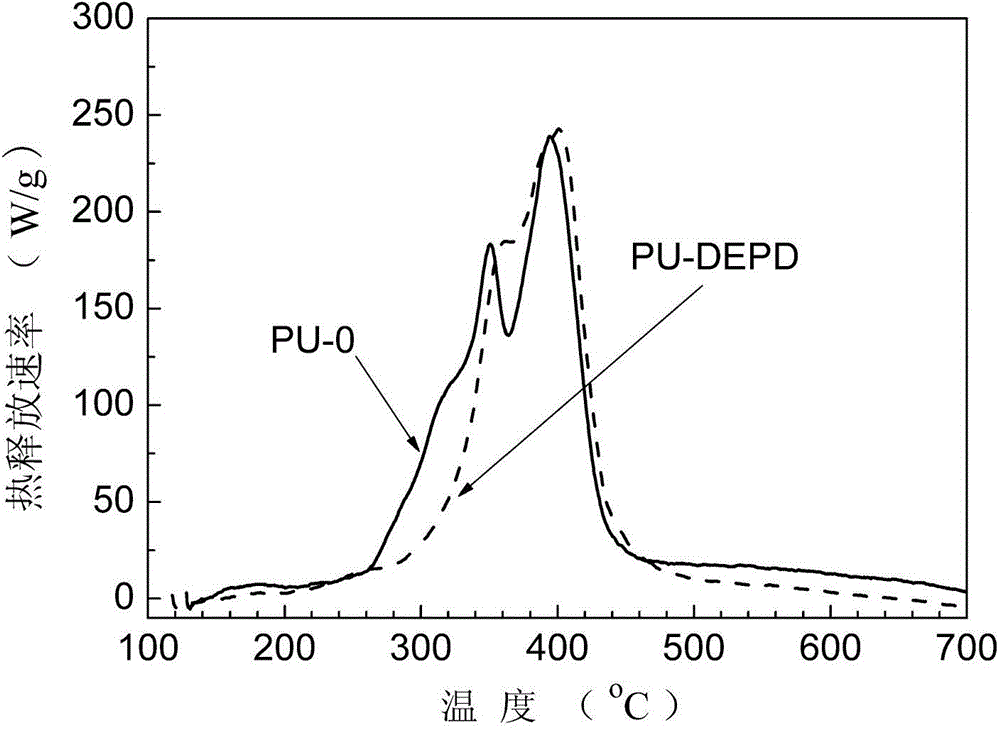

Method for preparing flame-retardant waterborne polyurethane containing phosphaphenanthrene and/or phenyl phosphate groups

InactiveCN104592475ANon-corrosive generationEvenly distributedGroup 5/15 element organic compoundsPolymer scienceAlcohol

The invention discloses a method for preparing flame-retardant waterborne polyurethane containing phosphaphenanthrene and / or phenyl phosphate groups. The method is characterized by comprising the following step of reacting dihydric alcohol as a reactant which contains phosphaphenanthrene and / or phenyl phosphate groups and of which the hydroxyl groups are symmetric with diisocyanate, macromolecular dihydric alcohol, anionic or cationic hydrophilic chain extender and the like to synthesize flame-retardant waterborne polyurethane. According to the method, since flame-retardant dihydric alcohol is used as one of chain extenders, flame-retardant dihydric alcohol ca partially or totally substitute other small molecular chain extenders, phosphorus-containing flame-retardant groups are controllable in content and difficult to migrate and are evenly distributed, and the flame-retardant property of waterborne polyurethane can be enduringly retained. According to the structural characteristics of selected flame-retardant dihydric alcohol, by virtue of one and a combination of two or more of flame-retardant groups, phosphorus in the flame-retardant groups can be alone located at a main chain, side chains or simultaneously located at the main chain and the side chains of the polyurethane molecule chain as desired so as to meet the requirements of different flame-retardant properties or other properties such as mechanics, toughness and plasticity.

Owner:UNIV OF SCI & TECH OF CHINA

High thermotolerance polylactic acid composite material filled by french chalk and method for preparing same

InactiveCN101333331AImprove mechanical propertiesImprove heat resistanceHeat resistanceMechanical property

The invention relates to polylactic acid composite material which takes heat resistant talcum powder as filler and a preparation method thereof. The polylactic acid composite material contains(based on weight portion) 59-98 portions of semi-crystalline poly-L-lactic acid, 1-40 portions of modified talcum powder, 0.1-1.0 portions of heat stabilizer, 0.2-1.5 portions of talcum powder surface passivator and 0.05-1.0poritons of lubricant. The polylactic acid composite material is prepared through the following steps: firstly, preparing modified talcum powder; then batching according to the composition of the polylactic acid composite material, stirring and mixing to be even, putting the mixture into a kneader, and melting and blending under 160-200DEG C; hot press molding under 10-20MPa and finally annealing under 100-120 DEG C. The composite material is applicable in automobile and house appliance fields. The polylactic acid composite material can not only be biologically degraded but also has excellent mechanical property and heat resistance. The filler adopted by the invention is low in cost, simple in preparation process and short in process period and can be realized in large-scale industrial production.

Owner:SHANGHAI UNIV

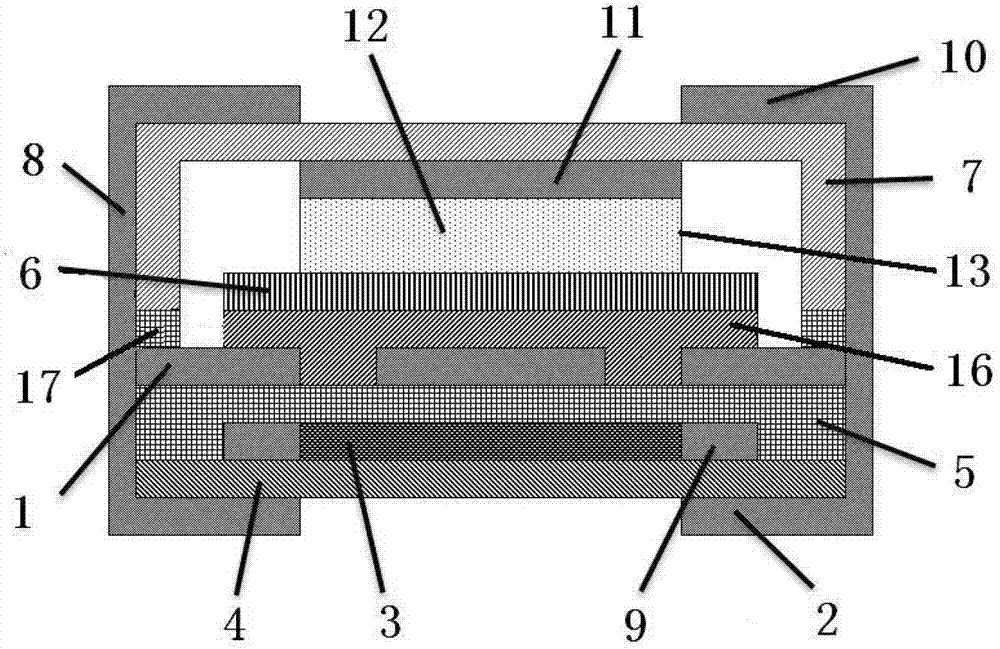

Diaphragm, preparing method of diaphragm and lithium ion battery

ActiveCN104078633AGood heat resistanceImprove heat resistanceCell seperators/membranes/diaphragms/spacersSecondary cellsCeramic particlePolymer substrate

The invention provides a diaphragm, a preparing method of the diaphragm and a lithium ion battery comprising the diaphragm. The diaphragm comprises a polymer substrate and slurry layers positioned at the inside and on the surface of the substrate; each slurry layer comprises ceramic particles and curing resin; the curing resin is obtained through performing cross-linking and curing reaction on curing agents or initiating agents positioned inside the substrate and cross-linking resin positioned in the slurry layers; the high-temperature-resistant performance of the diaphragm is excellent; a heat-resistant layer cannot easily fall; and the winding, the preparation and the practical application are easier.

Owner:BYD CO LTD

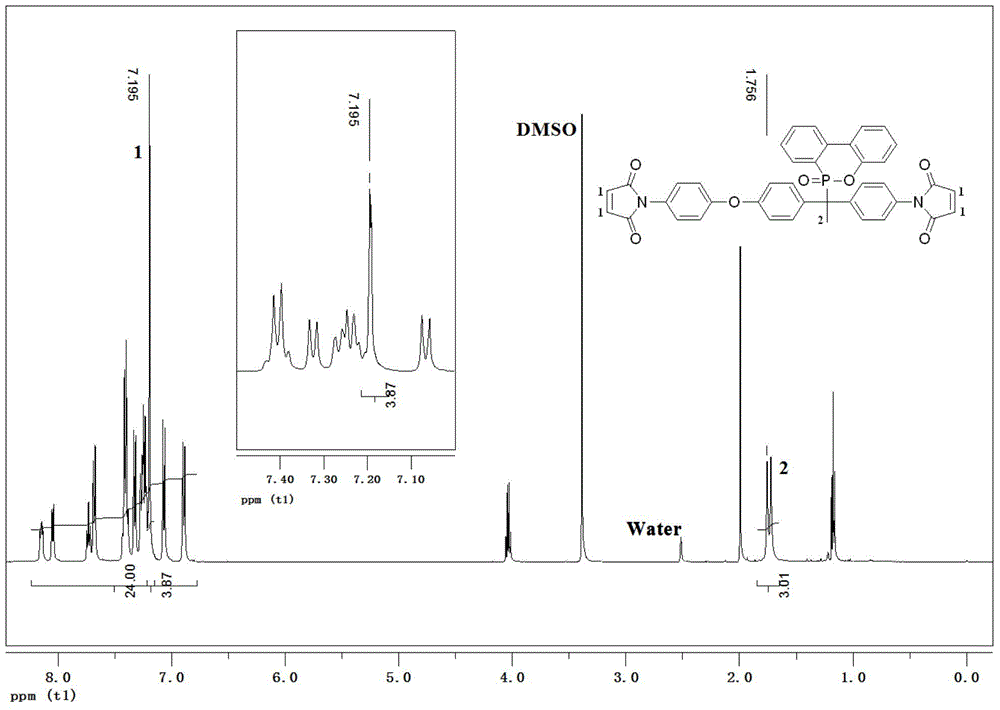

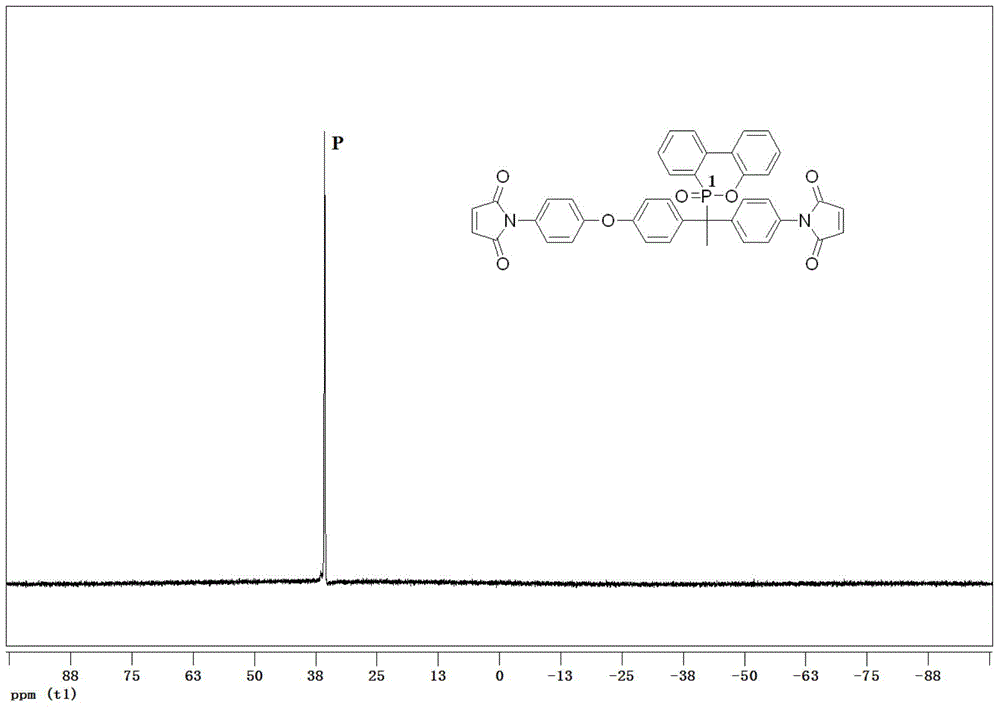

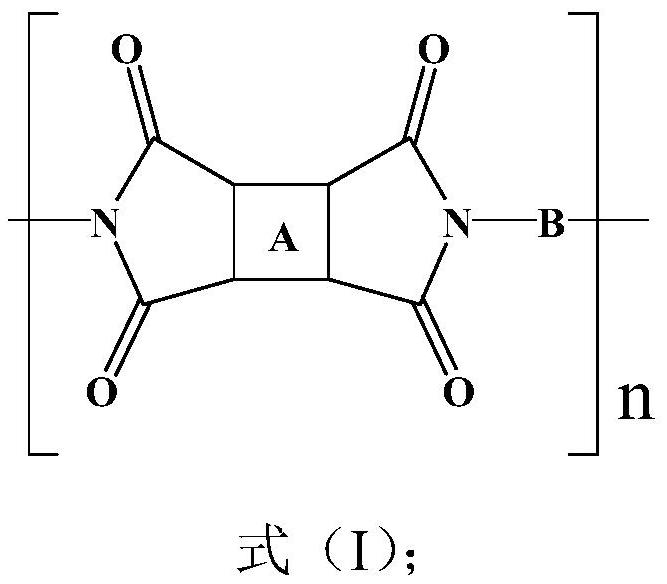

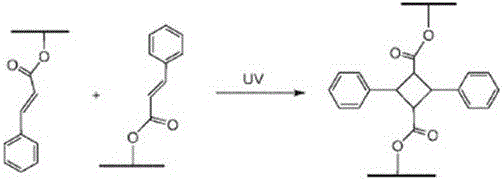

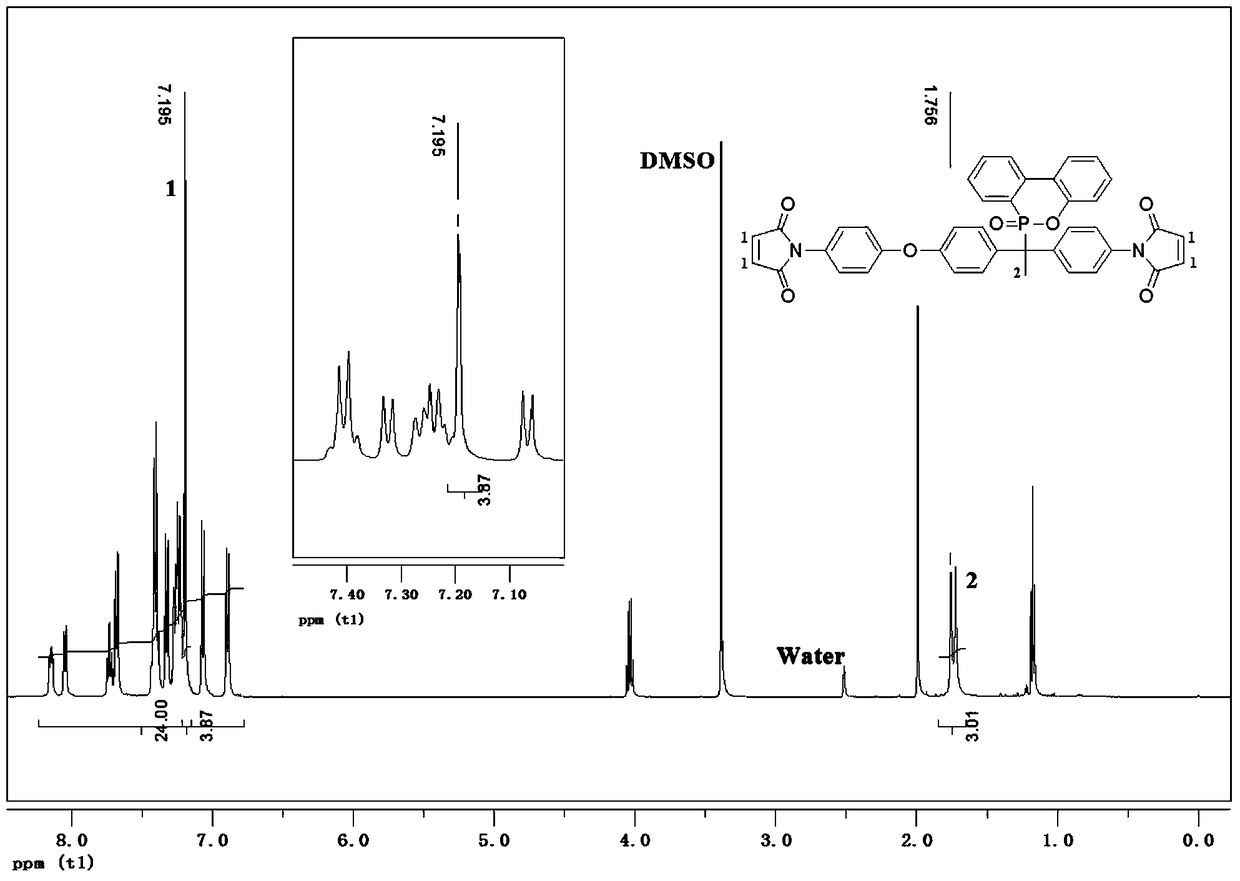

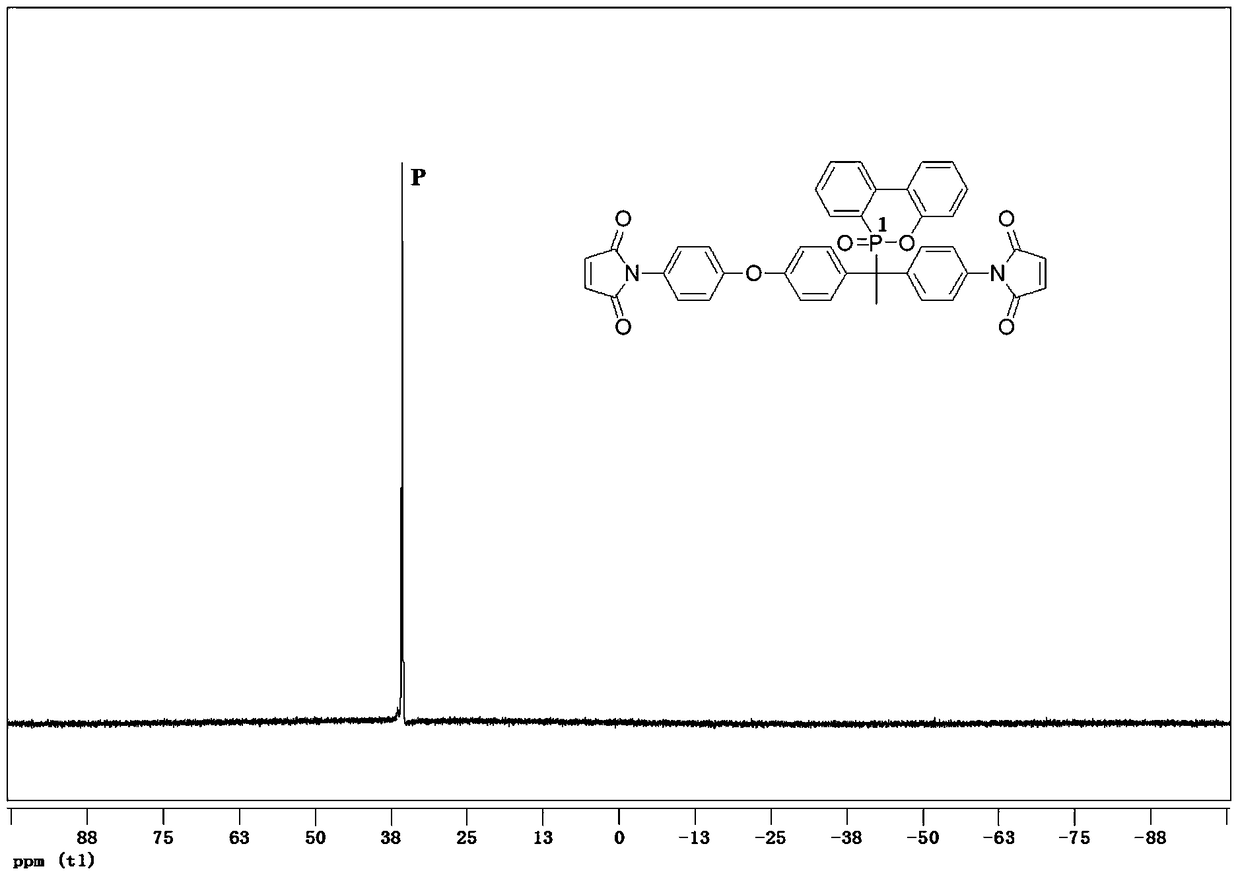

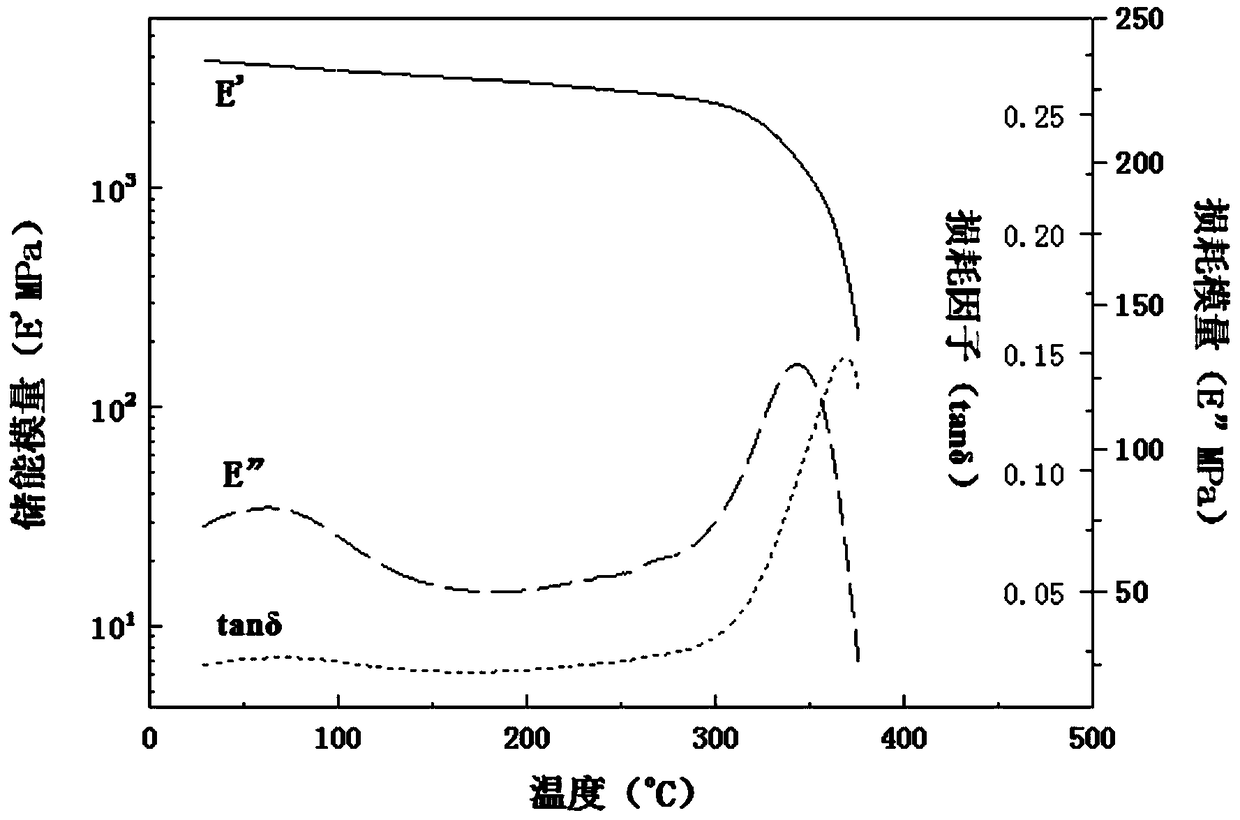

Bismaleimide containing 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and asymmetric in molecular structure as well as preparation method and application of bismaleimide in preparation of composite resin

ActiveCN104447869AImprove solubilitySolve solubilityGroup 5/15 element organic compoundsOrganic solventResin-Based Composite

The invention relates to the field of micro-electronic packaging materials, and discloses bismaleimide containing 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and asymmetric in molecular structure, as shown in a general formula (II) shown in specification, as well as a preparation method and application of the bismaleimide in preparation of composite resin. The bismaleimide containing DOPO and asymmetric in molecular structure disclosed by the invention is soluble in such conventional organic solvents as acetone, so as to facilitate processing and using; the bismaleimide containing DOPO and asymmetric in molecular structure disclosed by the invention can be used for further preparing cyanate ester composite resin, and a cured product is good in thermal stability and flame retardance; and as a base material for packaging in the micro-electronic packaging field, the bismaleimide has good application prospect.

Owner:FUDAN UNIV

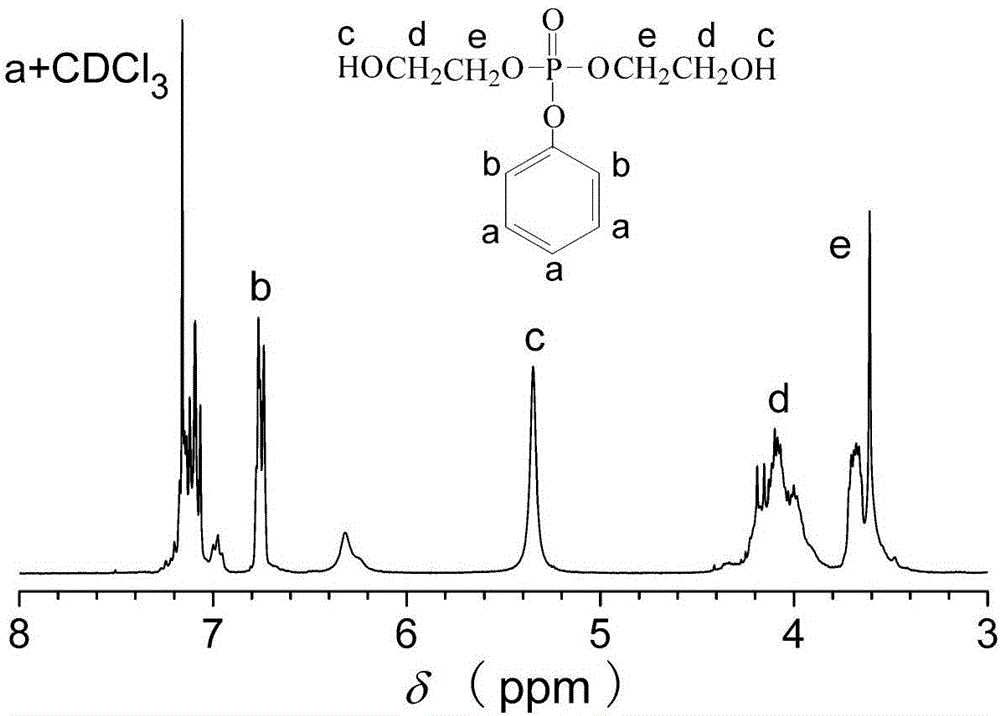

Flame-retardant glycol containing phenyl phosphate-based symmetrical structure and preparation method thereof

InactiveCN104592297AHas flame retardant propertiesRegular structureGroup 5/15 element organic compoundsEthyl acetateTetrahydrofuran

The invention discloses reaction-type flame-retardant glycol containing a phenyl phosphate-based symmetrical structure and a preparation method thereof. The preparation method is characterized by comprising the following steps: reacting phenyl dichlorophosphate with dihydric alcohol in a tetrahydrofuran or ethyl acetate solution in the presence of triethylamine, placing the tetrahydrofuran or ethyl acetate solution of dihydric alcohol and triethylamine into an ice-water bath, stirring and dropwise adding the tetrahydrofuran or ethyl acetate solution of phenyl dichlorophosphate; and filtering a precipitate and then removing the solvent in the filtrate to obtain the product with a structural general formula specified in the description, wherein n is an integer ranging from 2 to 6. According to the preparation method disclosed by the invention, micromolecular dihydric alcohol is introduced in the phenyl dichlorophosphate group in a manner of chemical bonding, so that the obtained dihydric alcohol molecular structure contains both the phenyl dichlorophosphate group and two hydroxyl groups with symmetrical structures and same reaction activity, and can partially or completely replace the micromolecular dihydric alcohol without a flame-retardant characteristic, so that the prepared polymer material has a flame-retardant characteristic; the raw materials in the preparation method disclosed by the invention are easily available, synthesis and post-treatment processes are simple, the cost is low, and the yield can achieve more than 90%.

Owner:UNIV OF SCI & TECH OF CHINA

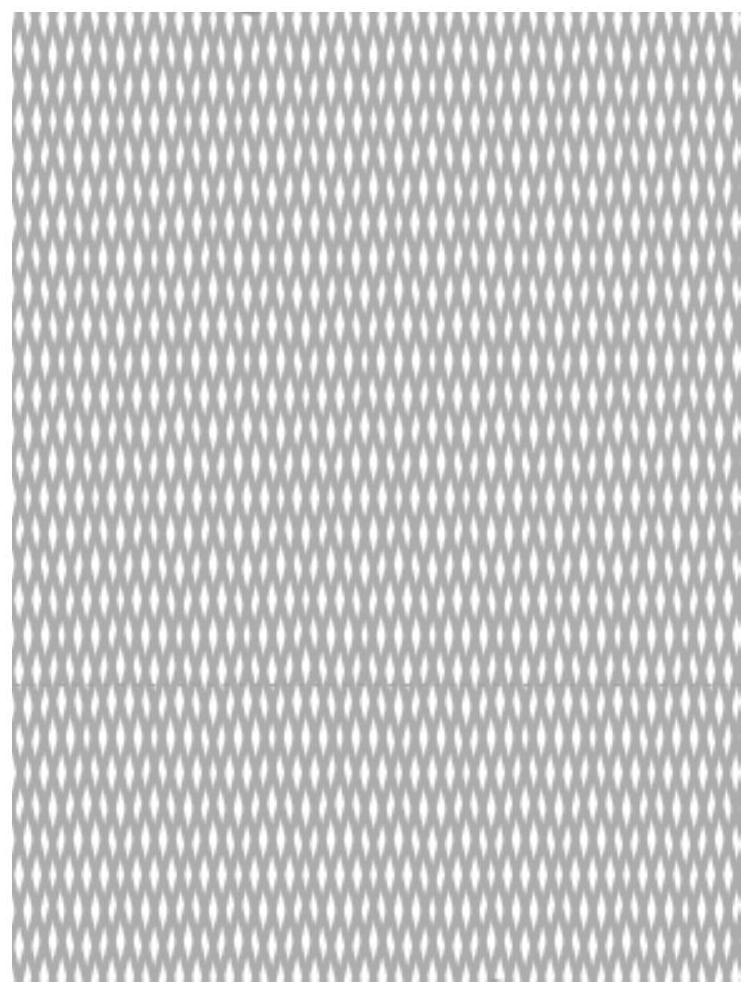

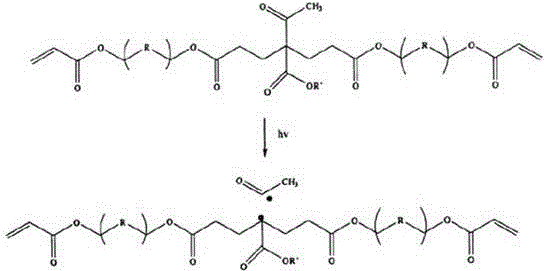

Toughening material of composite material and preparation method toughening material

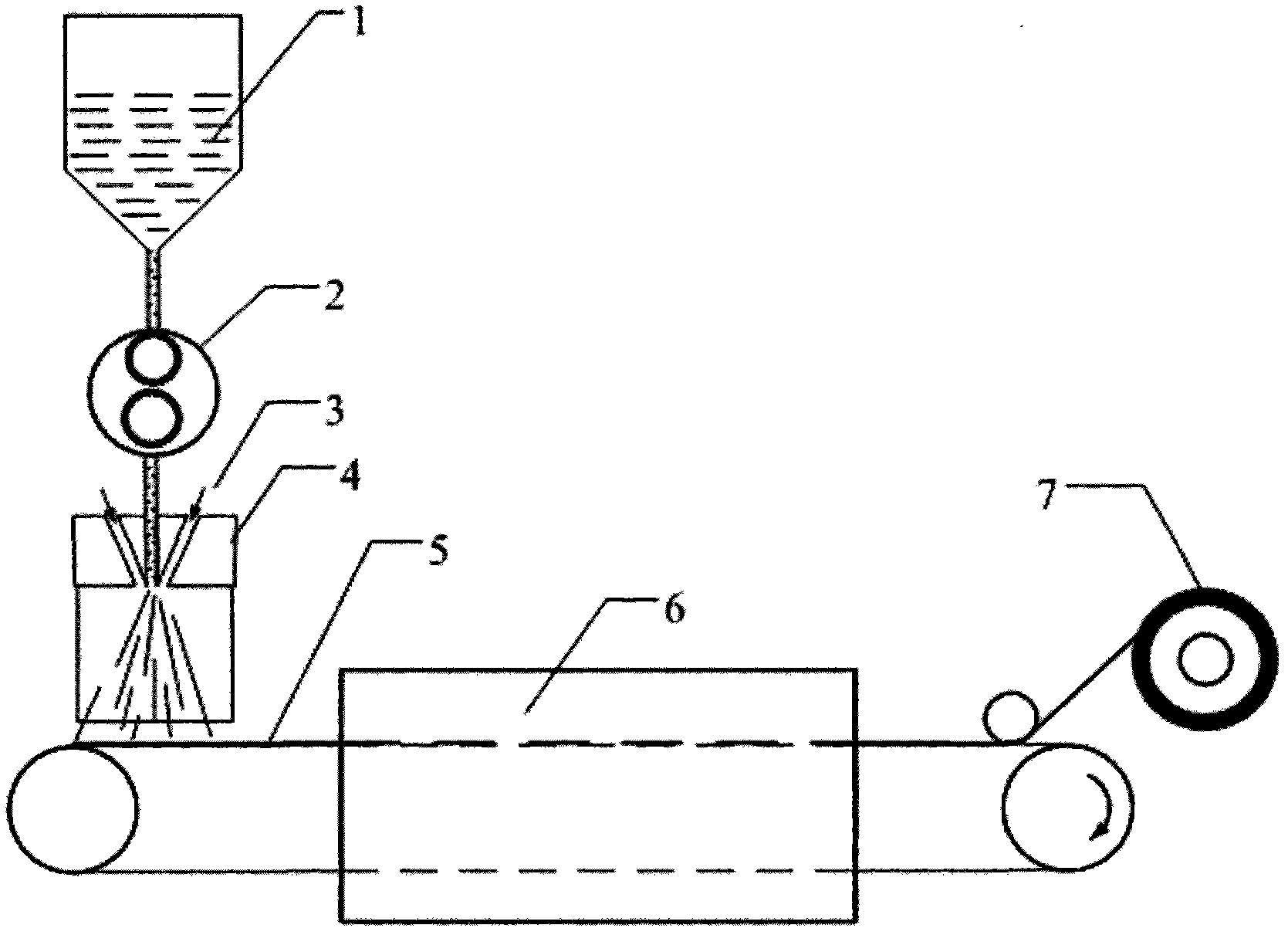

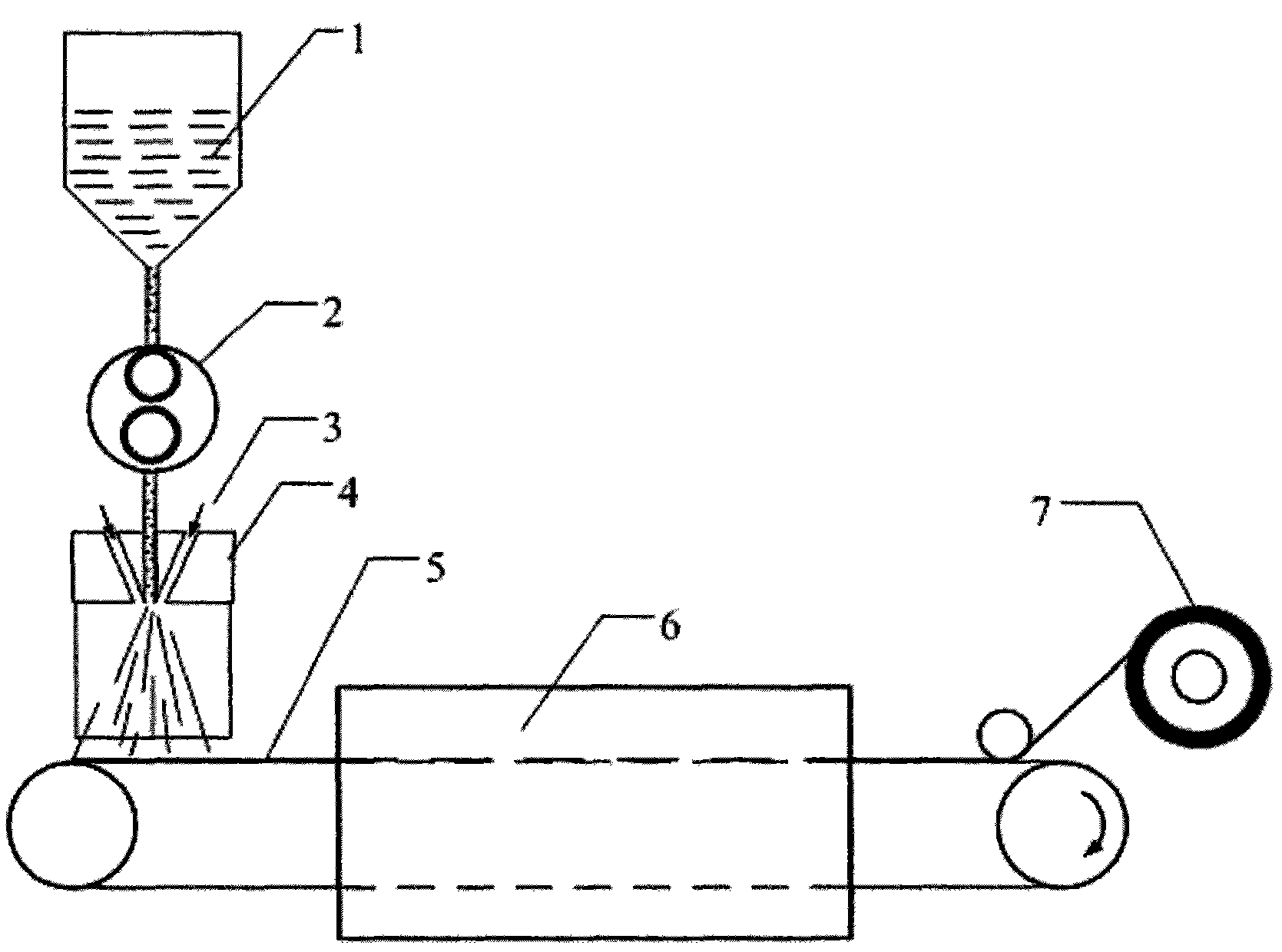

ActiveCN102505355AThe overall thickness is thinSmall fiber diameterNon-woven fabricsYarnPolymer science

The invention belongs to a composite material high performance technology, relates to toughening material of composite material and a preparation method of the toughening material. The toughening material is made of non-woven cloth comprising thermoplastic polymer fiber, the thickness of the non-woven cloth is 5 to 50 micrometers, and the fiber diameter of the non-woven cloth is about 0.2 to 5 micrometers. The preparation method comprises the steps as follows: yarns are sprayed out through solution; the yarns are deposited to become the non-woven cloth; and then the fiber non-woven cloth toughening material is formed through drying and collection. The method adopting a solution spray process to prepare the non-woven cloth toughening material can effectively improve the preparation efficiency, and realize the mass manufacture of the toughening material. The toughening material prepared by the method can obviously improve the compression performance of impacted resin matrix composites, and compared with the prior art, the method has the advantages that the compression strength of the impacted resin matrix composites is improved by 50 to 150 percent, the heat resisting property and the mechanical property of composite material, as well as the flowing of resin during the forming of the composite material, are not affected, and the yield and the quality stability of the composite material are improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Halogen-free flame retardant highlight polypropylene and preparation method thereof

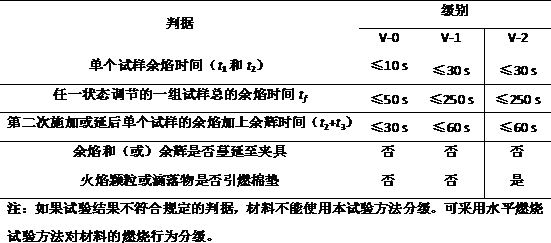

The invention relates to the technical field of thermoplastic high polymer material modification and discloses halogen-free flame retardant highlight polypropylene applied to household appliances, electronics and the like. The halogen-free flame retardant highlight polypropylene comprises the following materials: polypropylene, a nucleating agent, a halogen-free flame retardant, a superfine barium sulphate filling agent, an antioxidant and a processing aid. The invention also discloses a preparation method of the halogen-free flame retardant highlight polypropylene. The invention aims at providing high-glossiness, halogen-free and flame retardant modified polypropylene which can be applied to a bread maker, a water dispenser, a shell of an electric appliance and the like.

Owner:广东波斯科技股份有限公司

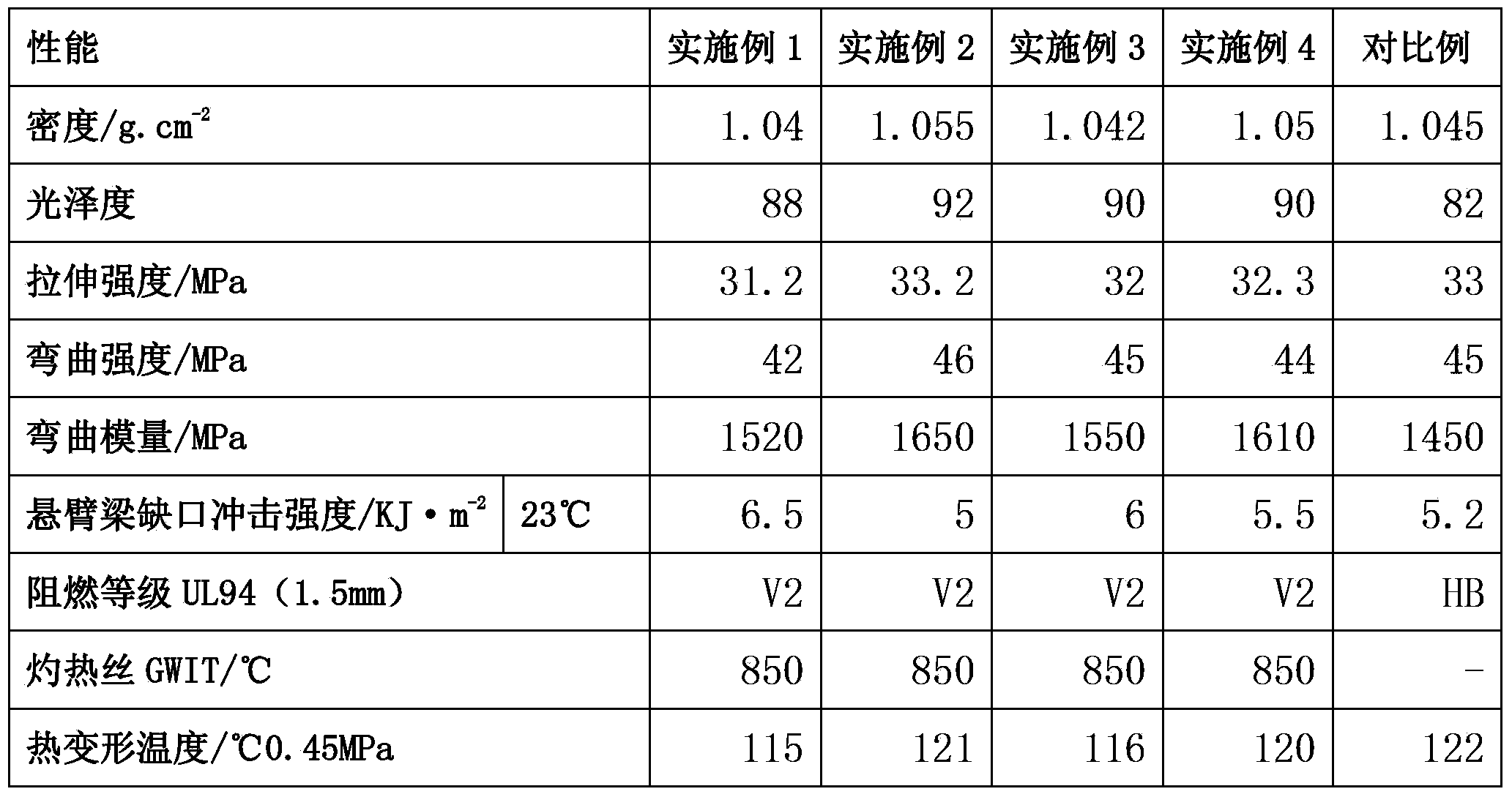

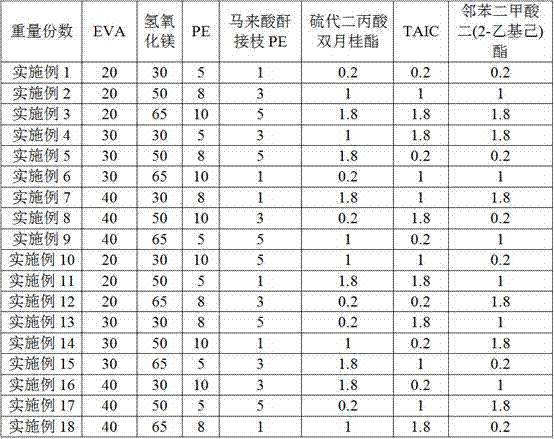

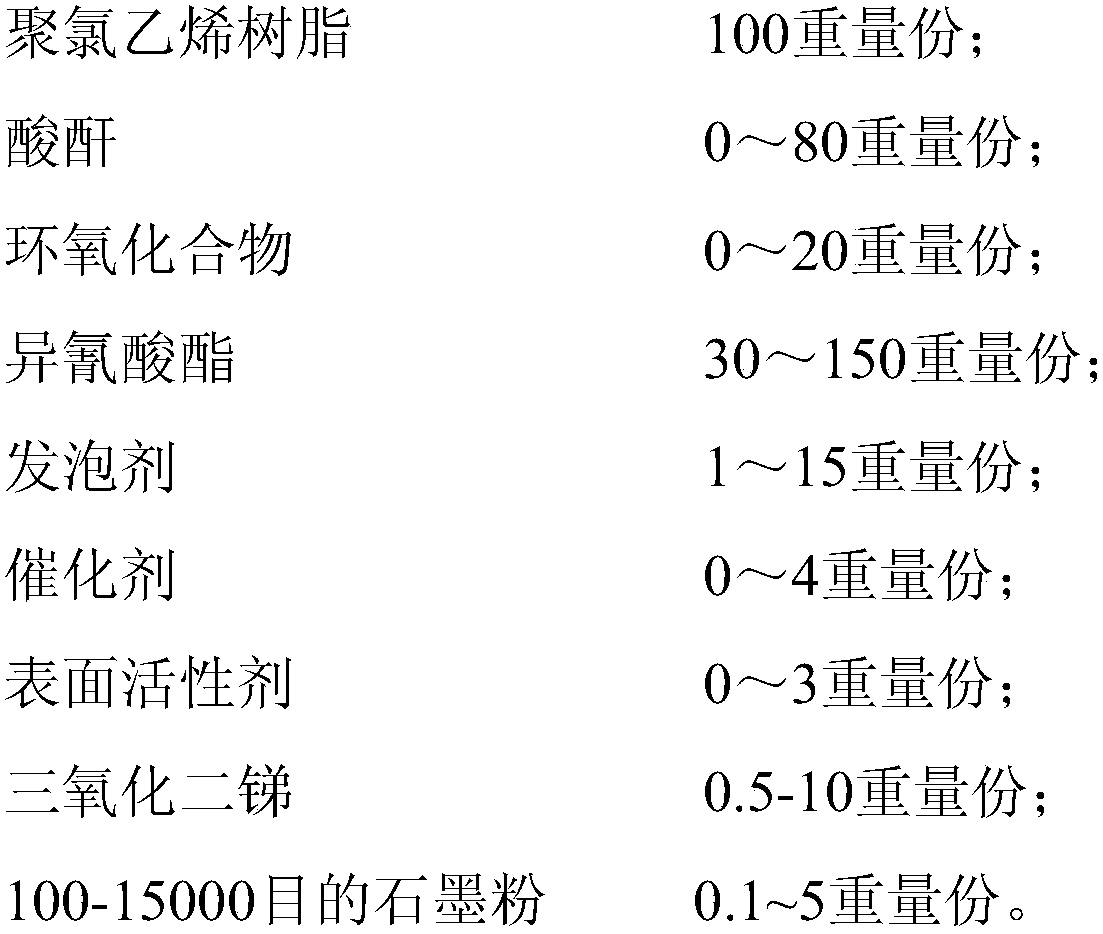

150 DEG C heat-resistant crosslinked low-smoke halogen-free electronic wire material and preparation method thereof

The invention discloses a 150 DEG C heat-resistant crosslinked low-smoke halogen-free electronic wire material and a preparation method thereof and aims to solve the problem that in order to achieve a certain flame-retardant effect, the usage of inorganic filler in an existing wire and cable insulating material exceeds 50% universally, so that the mechanical property is not good enough, particularly, the flexibility of the electronic wire material is affected as the elongation at break is relatively low. The key point of the technical scheme is as follows: the material comprises the following components in parts by weight: 20-40 parts of EVA, 5-10 parts of PE, 1-5 parts of grafted PE, 30-65 parts of inorganic filler, 0.2-1.8 parts of an antioxidant, 0.2-1.8 parts of a crosslinking agent and 0.2-1.8 parts of a plasticizer. By adopting the formula, the flame retardance of the electronic wire material is improved, the elongation at break of the electronic wire material is improved, and the mechanical property of the electronic wire material is ensured.

Owner:惠州市展创新材料科技有限公司

Organic titanium epoxy resin catalytic ester cyanate system

An ester cyanate resin system with organic titanium epoxy resin as catalyst is characterized by taking organic titanium modified epoxy resin as catalyst, which is obtained by reacting tetrabutyl titanate with hydroxyl in glycidol ether epoxy resin structure, and consisting of ester cyanate resin 70-99.99% and organic titanium epoxy resin catalyst 0.01-30%. It can improve curing process of resin system, lower curing temperature, shorten curing time and cost low.

Owner:AVIC COMPOSITES

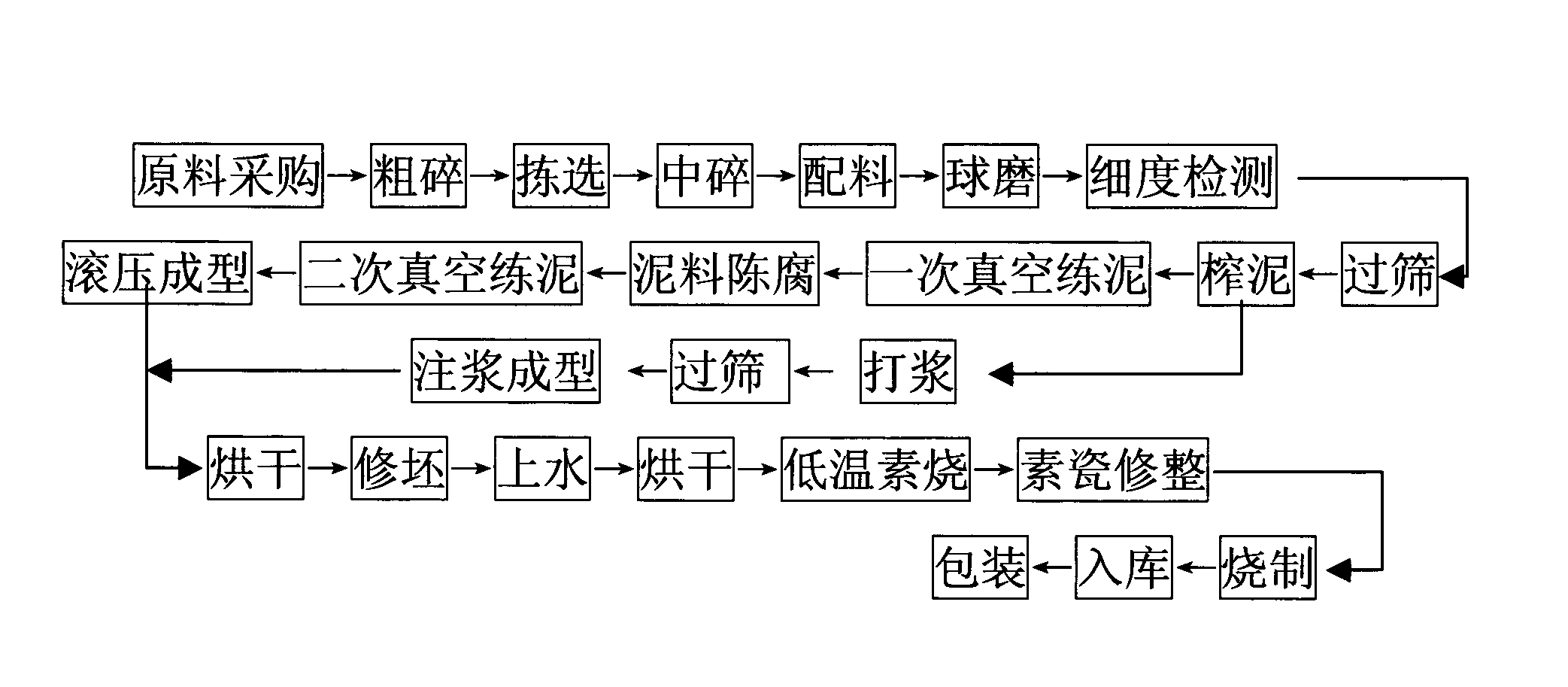

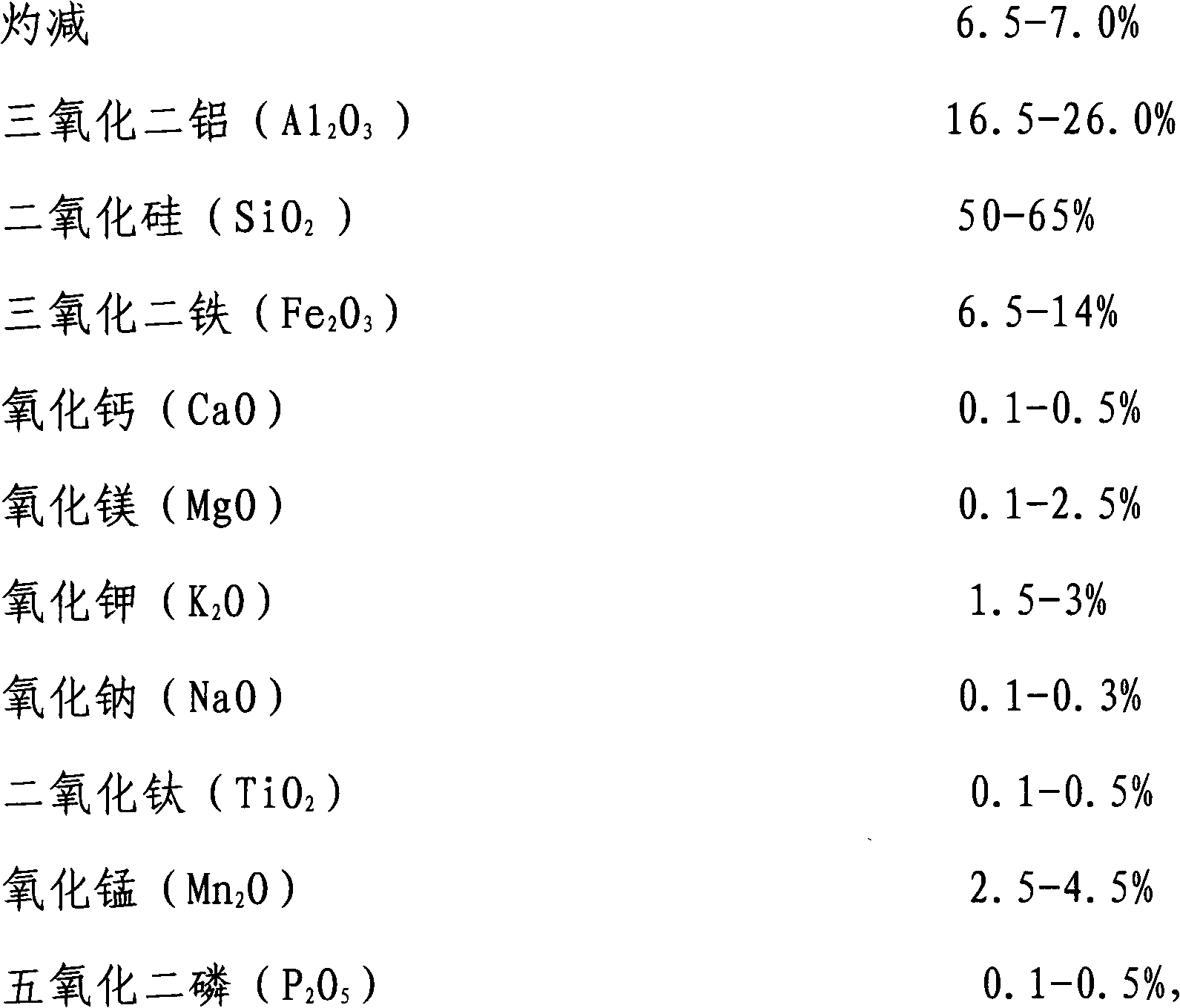

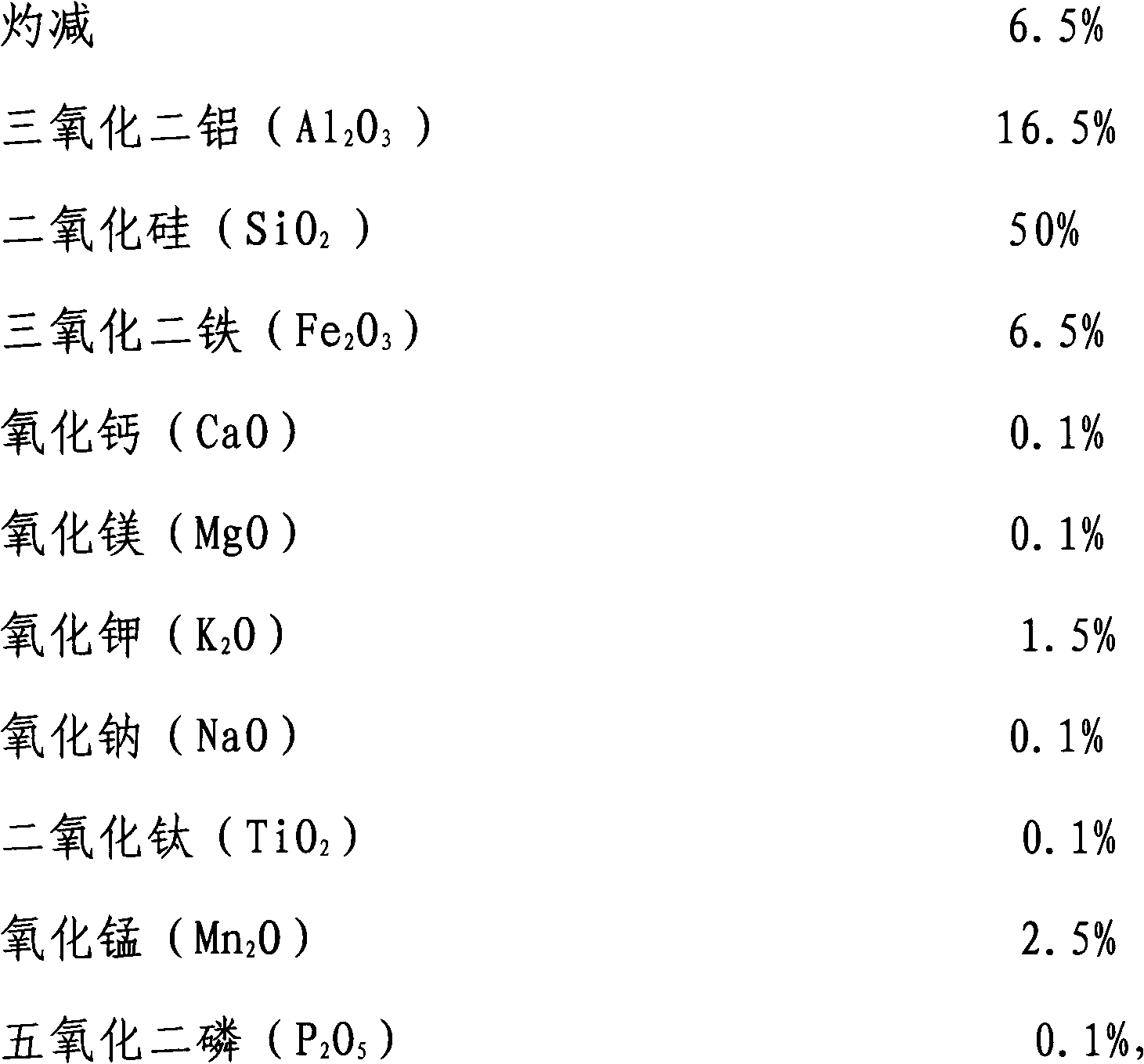

Iron-manganese heat resistant cooker and production technology thereof

The invention belongs to the technical field of ceramic materials, and provides a novel iron-manganese heat resistant cooker and a production technology thereof. A low expansion coefficient raw material such as spodumene is not required in the formula of the product; the heat conductivity coefficient of the ceramic ware is greatly improved by improving the heat conductivity coefficient and the thermal shock resistance of ceramic; the sintering temperature is low, and the maturing temperature is wide in range and is 1,160 to 1,230 DEG C; the product is high in superior quality, can be quickly sintered, can tolerate the heat exchange of 500 to 20 DEG C without cracking, has the advantages of low energy consumption, high heat conductivity, high impact strength, thermal shock resistance and the like, and can be used for directly steaming, boiling, stewing and stir-frying food over a heat source; and the cooker keeps the cooking flavor of the conventional ceramic ware, does not decompose nutritional components in the food, and is an ideal multifunctional cooking ware for modern families, hotels and restaurants.

Owner:邱东烽

Graphene nonstick paint

ActiveCN103214897BGood construction performanceImprove performanceCoatingsPolymer scienceHigh energy

The invention discloses a graphene nonstick paint, and aims to solve the problem of high energy consumption caused by weak thermal conductivity of an existing nonstick paint. The invention employs graphene to modify a nonstick paint, and the addition of the graphene accounts for 0.1-5wt% of the nonstick paint. The graphene nonstick paint provided by the invention can substantially improve heat conduction effect of a nonstick coating, save energy and reduce consumption, without influencing other indexes of the coating, such as viscosity, adhesive force, heat resistance, friction resistance and corrosion resistance.

Owner:NINGBO MORSH NEW MATERIALS

Halogen-free flame retardant composition and two applications thereof

PendingCN112280098ADoes not affect heat resistanceImprove flame retardant performancePolymer scienceHalogen

The invention discloses a halogen-free flame retardant composition, which comprises the following components by weight: 50-100 parts of anhydrous piperazine cyanurate; and 0-50 parts of a phosphorus-containing metal compound. The invention also aims to disclose an application of the halogen-free flame retardant composition in high-processing-temperature flame-retardant thermoplastic resin and an application of anhydrous piperazine cyanurate in a high-processing-temperature resin flame retardant. The halogen-free flame retardant composition disclosed by the invention is a flame retardant composition with a wide application range.

Owner:ZHUHAI WANTONG CHEM

Composite non-sticky coating material

InactiveCN106280617AImprove conductivityUse less materialFireproof paintsAnti-corrosive paintsSodium bicarbonatePolyvinyl alcohol

The invention discloses a composite non-sticky coating material. The composite non-sticky coating material is prepared from 10-12 parts of graphene oxide, 8-10 parts of polyethylene, 8-9 parts of wood fiber, 6-8 parts of polyvinyl chloride, 7-9 parts of kieselguhr, 5-8 parts of dimethyl phosphite, 6-8 parts of sodium bicarbonate, 6-7 parts of terpene resin, 5-7 parts of rosin, 4-5 parts of mica powder, 5-8 parts of silicon dioxide, 6-8 parts of titanium oxide, 5-10 parts of bentonite, 6-8 parts of activated carbon, 5-6 parts of ethylenediaminetetraacetic acid, 4-5 parts of sodium citrate, 3-5 parts of acrylic acid, 4-6 parts of ferrocene, 8-10 parts of polyurethane, 8-10 parts of polyvinyl alcohol resin, 3-5 parts of sodium carboxymethylcellulose, 2-3 parts of nanometer titania, 3-4 parts of nanometer aluminum powder, 4-5 parts of nanometer copper powder and 2-3 parts of nanometer silver powder. The composite non-sticky coating material has the good conductivity, few materials are adopted, the conductive effect of a non-sticky coating can be remarkably improved, energy conservation and dissipation reduction are achieved, and various other indexes such as non-stickiness, adhesive force, heat resistance, friction resistance and corrosion resistance of the non-sticky coating are not affected.

Owner:李兆源

Polyphenylene sulfide composite non-woven fabric as well as preparation method and application thereof

PendingCN113026212AGood compatibilityLower spinning temperatureNew-spun product collectionFibre typesEpoxyCompression molding

The invention relates to a polyphenylene sulfide composite non-woven fabric as well as a preparation method and application thereof, and belongs to the technical field of carbon fiber reinforced polyphenylene sulfide composite materials. The preparation method comprises the following steps of mixing polyphenylene sulfide, polyethersulfone and epoxy resin to prepare composite fibers, arranging the composite fibers into a net-shaped structure by using a winding machine, and then forming a PPS composite non-woven fabric which can be laid on the surface of the carbon fibers through setting. The preparation method has the beneficial effects that the epoxy resin can effectively improve the PPS / PES compatibility and reduce the PPS / PES spinning temperature in the early spinning process, the fracture toughness of the mixed thermoplastic resin is improved, the epoxy resin can be separated out in the later setting and net forming process, the heat resistance of the final thermoplastic composite material is not influenced, and the specific surface area of the prepared polyphenylene sulfide composite non-woven fabric is far higher than that of a polyphenylene sulfide film, so that carbon fibers can be rapidly infiltrated more easily in the compression molding process of a thermoplastic composite material.

Owner:上海碳纤维复合材料创新研究院有限公司

Method for enhancing surface abrasion resistance of liquid molding composite material

ActiveCN102924741BImprove surface abrasion and wear resistanceImprove compatibilitySynthetic resin layered productsLaminationAviationHeat resistance

The invention belongs to liquid molding resin-base composite material surface abrasion resistance technology, and relates to a method for enhancing surface abrasion resistance by preforming an abrasion-resistant layer on a liquid molding composite material surface. The method comprises the following steps: preparing an abrasion-resistant layer prepreg from an abrasion-resistant resin matrix and reinforcing fibers or fabric thereof, carrying out prepolymerization on the abrasion-resistant layer prepreg at 100-150 DEG C, directly attaching the prepolymerized prepreg onto a dry fiber preformed body surface, and carrying out co-curing and molding with the dry fiber preformed body by a liquid molding technique. The resin matrix used by the abrasion-resistant composite material can be structurally compatible with the present typical liquid molding matrix resin for aviation on the molecular level, and participates into the curing reaction of the resin; and the heat resistance, mechanical properties and molding processibility of the original matrix resin and composite material thereof can not be influenced.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

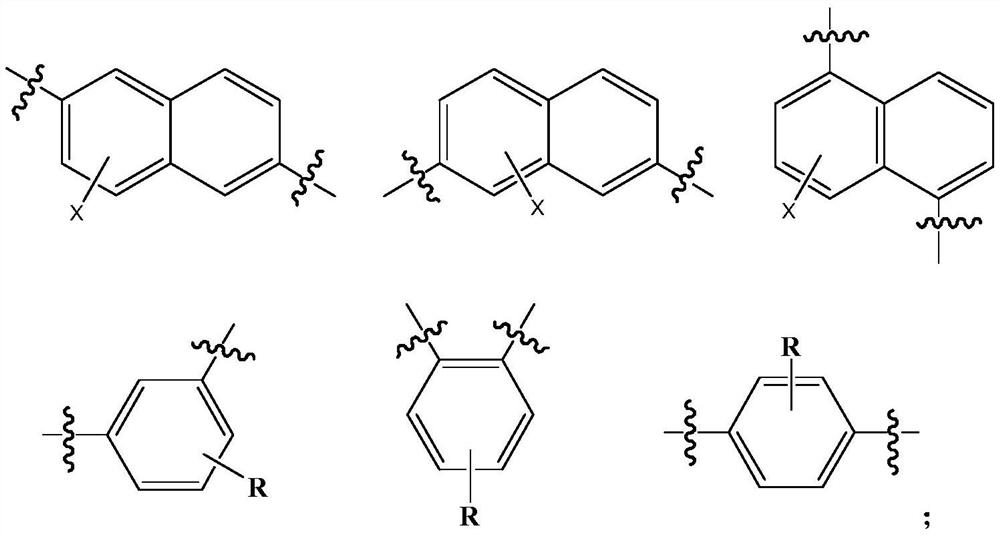

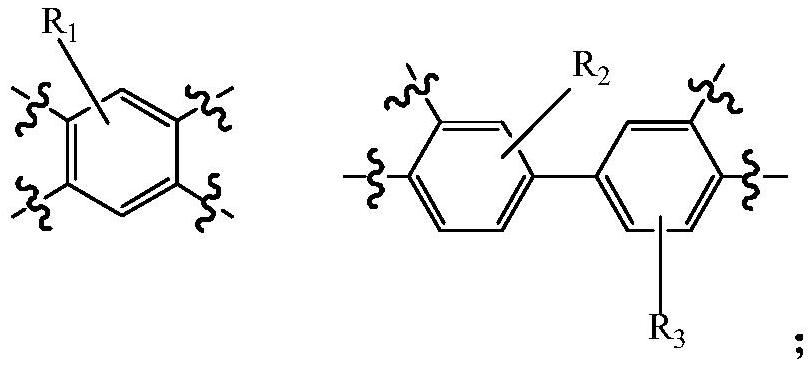

Polyimide resin, polyimide film and preparation method and application thereof

The invention relates to a polyimide resin, a polyimide film and a preparation method and application thereof, the polyimide resin has a structural general formula as shown in formula (I), in the formula, A is a dianhydride residue, and B is a diamine residue; a fluorine side group is introduced into an aromatic ring, so that the water absorption and moisture absorption of diamine can be greatly reduced, and the water absorption of the polyimide film is reduced; and a fluorine side group on fluorine-containing diamine directly replaces a hydrogen atom on a benzene ring, the heat resistance and the coefficient of thermal expansion (CTE) of polyimide cannot be affected, the prepared polyimide film is good in heat resistance and low in coefficient of thermal expansion, the application field of polyimide can be expanded through introduction of the fluorine-containing side group, the polyimide can be used in display substrates, solar cell substrates, and the like, the tensile strength of the prepared film is larger than or equal to 300 MPa, and the elastic modulus of the film is larger than or equal to 8 GPa.

Owner:BEIJING BAYI SPACE LCD MATERIALS TECH

Environment-friendly peroxy-vulcanized EPDM material suitable for automatic demolding and preparation method of environment-friendly peroxy-vulcanized EPDM material

The environment-friendly peroxy-vulcanized EPDM material suitable for automatic demolding comprises the following raw materials in parts by weight based on 100 parts of raw rubber: 90-105 parts of ethylene propylene diene monomer rubber; the rubber composition is prepared from the following components in parts by weight: 30 to 40 parts of carbon black N550, 40 to 50 parts of carbon black N774, 10 to 20 parts of argil N85, 10 to 30 parts of polyisobutene, 2 to 5 parts of zinc oxide, 0.5 to 2 parts of stearic acid, 0.6 to 0.8 part of anti-aging agent SP-P, 1.5 to 3 parts of peroxy vulcanizing agent BIBP and 5 to 15 parts of peroxy assistant crosslinking agent cis-butadiene rubber BR9000. The release effect of the EPDM peroxy vulcanization formula can be greatly improved under the condition that no auxiliary agent is added, the release agent is suitable for automatic production, and the raw material cost can be reduced to a certain extent.

Owner:XIAMEN MAIHUA RUBBER PROD CO LTD

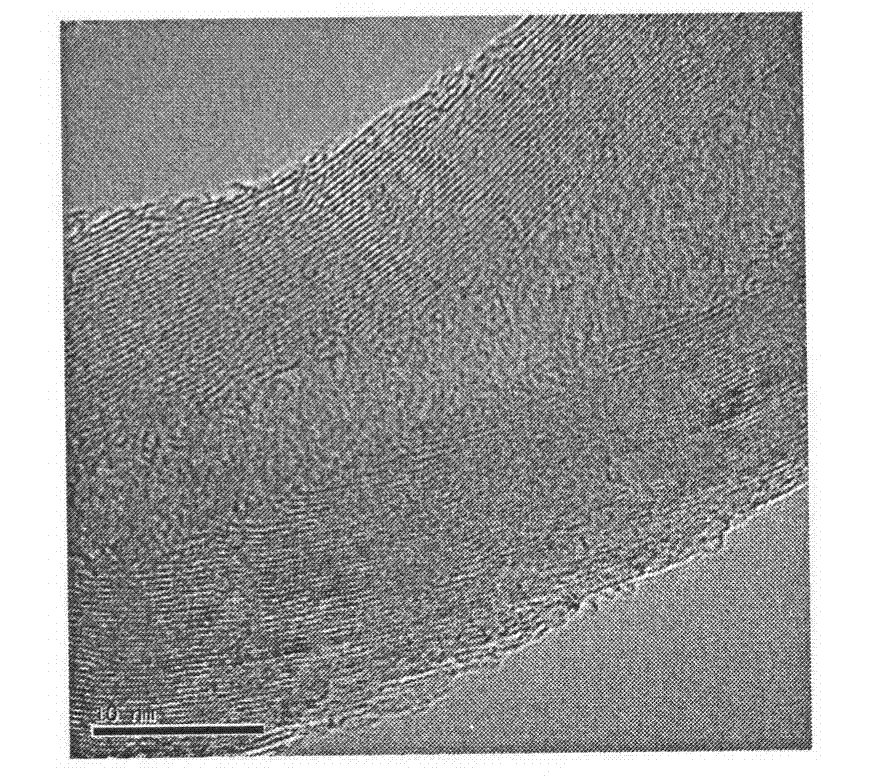

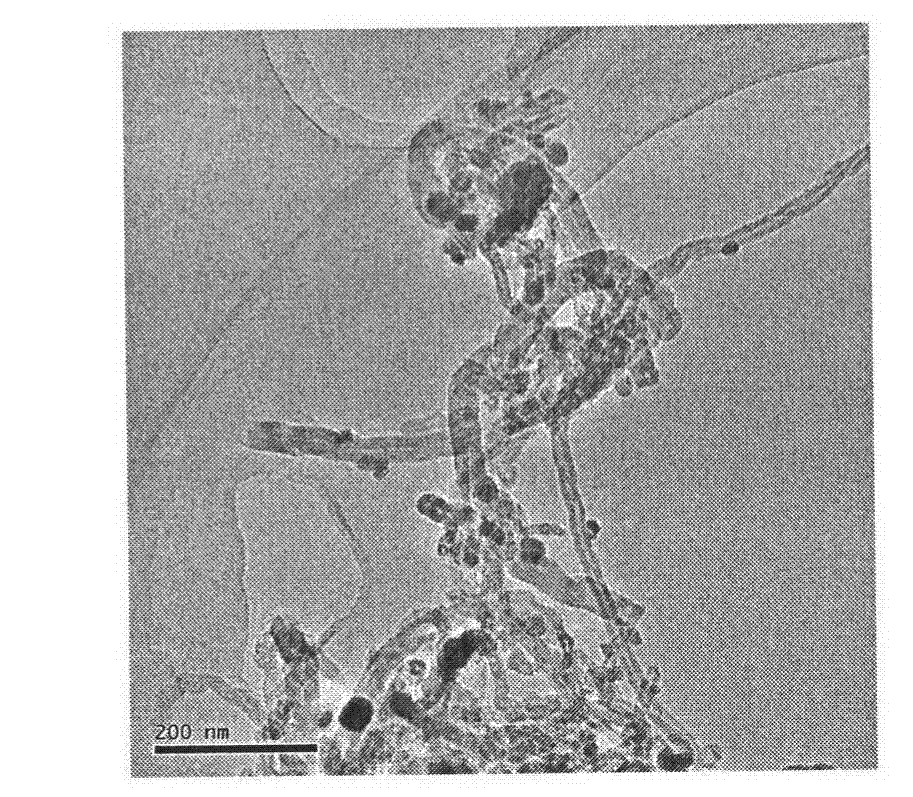

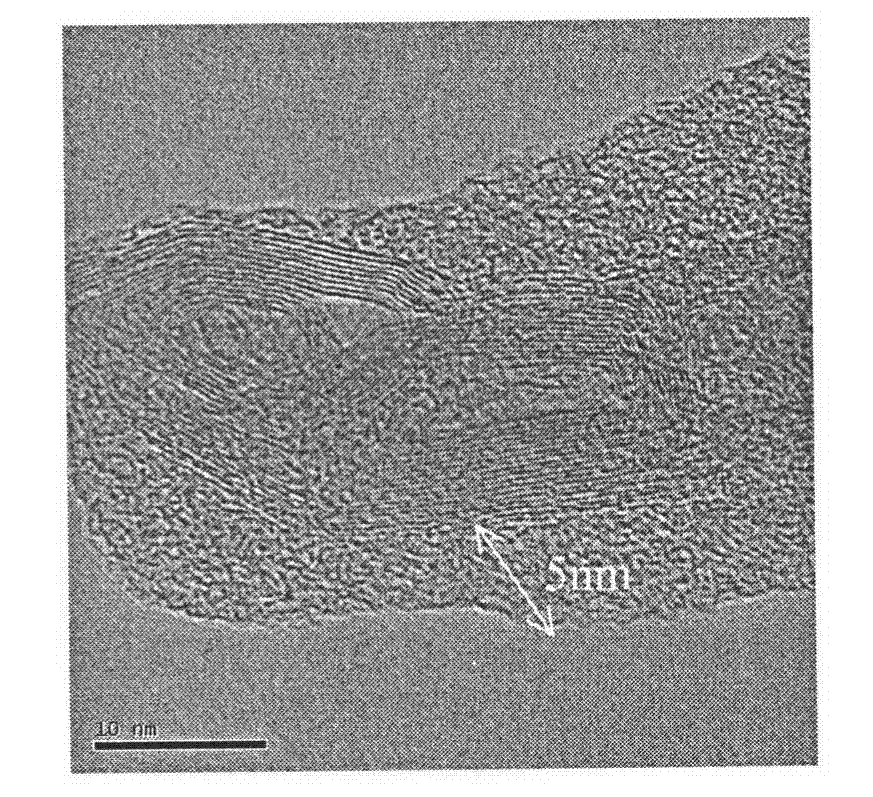

Method for preparing modified carbon nanotube and ferrite and polyimide composite absorbing material

InactiveCN102329425BTo achieve the effect of surface modificationDoes not affect heat resistanceOther chemical processesIn situ polymerizationModified carbon

The invention discloses a method for preparing a modified carbon nanotube and ferrite and polyimide composite absorbing material. The method comprises the following steps of: modifying carbon nanotubes by using argon plamas, and preparing the modified carbon nanotubes and ferrite into composite powder by using a chemical coprecipitation method; and preparing the composite powder, 4,4-dioctyldiphenylamine and pyromellitic dianhydride into the modified carbon nanotube / ferrite / polyimide composite absorbing material by using an in situ polymerization method. The method has the advantages that: onthe premise of not influencing good heat resistance of polyimide, the mechanical properties of the composite material are improved, and the light and high-frequency absorbing material is prepared. Bythe method for preparing the modified carbon nanotube and ferrite and polyimide composite absorbing material, the mechanical properties of the composite material are improved, and the prepared composite material with wave-absorbing performance can be widely applied to the field of aerospace.

Owner:TIANJIN UNIV

A separator, its preparation method and a lithium-ion battery

ActiveCN104078633BImprove heat resistanceNot easy to fall offCell seperators/membranes/diaphragms/spacersSecondary cellsPhysical chemistryLithium-ion battery

Owner:BYD CO LTD

A diaphragm, its preparation method and a lithium-ion battery

ActiveCN104157810BImprove heat resistanceNot easy to fall offSecondary cellsCell component detailsCross-linkPolymer science

The invention provides a diaphragm, a preparation method thereof and a lithium ion battery containing the diaphragm. The diaphragm includes a polymer matrix and a slurry layer located inside and on the surface of the matrix; the polymer matrix contains a polymer substrate and a cured resin, and the slurry layer contains ceramic particles and a cured resin; the cured resin passes through the polymer The base material and the paste layer can be obtained by self-initiating UV-curable cross-linking resin cross-linking and curing. The prepared separator has excellent high-temperature resistance, the heat-resistant layer is not easy to fall off, and is easier to wind, prepare and apply.

Owner:BYD CO LTD

Organic titanium epoxy resin catalytic ester cyanate system

An ester cyanate resin system with organic titanium epoxy resin as catalyst is characterized by taking organic titanium modified epoxy resin as catalyst, which is obtained by reacting tetrabutyl titanate with hydroxyl in glycidol ether epoxy resin structure, and consisting of ester cyanate resin 70-99.99% and organic titanium epoxy resin catalyst 0.01-30%. It can improve curing process of resin system, lower curing temperature, shorten curing time and cost low.

Owner:AVIC COMPOSITES

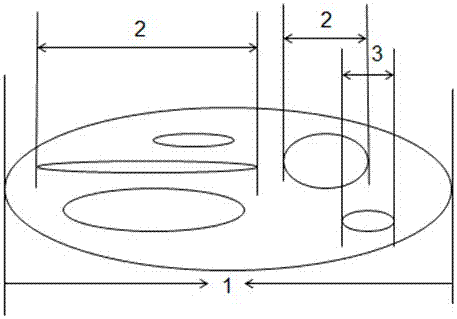

A kind of polycarbonate composition and preparation method thereof

ActiveCN104987687BOvercoming the disadvantages of reducing flame retardancyImprove toughness and strengthHeat resistanceDiameter ratio

Disclosed is a polycarbonate composition, comprising the following components in parts by weight: a. 30.4 parts to 80.2 parts of polycarbonate; b. 8.4 parts to 49.6 parts of a butadiene copolymer; c. 5.4 parts to 25.2 parts of a flame retardant; and d. 0 parts to 9.6 parts of other additives, where the sum of the parts by weight of the four components, a, b, c, and d, is 100 parts. In the present invention, by selecting the butadiene copolymer composition to be in the formula of the polycarbonate composition, where the structure of a polybutadiene copolymer in the composition is a large sea-island structure rubber phase, 1 to 50 small sea-island structures are present within the large sea-island structure rubber phase, and, when the diameter ratio of 90% or more of the large sea-island structure rubber phase to the small sea-island structures therein of the least diameter is 1.01-80, the impact strength of the polycarbonate composition can be significantly increased without affecting the flame retardancy, fluidity, and heat resistance of the composition, which is especially suitable in scenarios of increase requirements on the use environment.

Owner:KINGFA SCI & TECH CO LTD

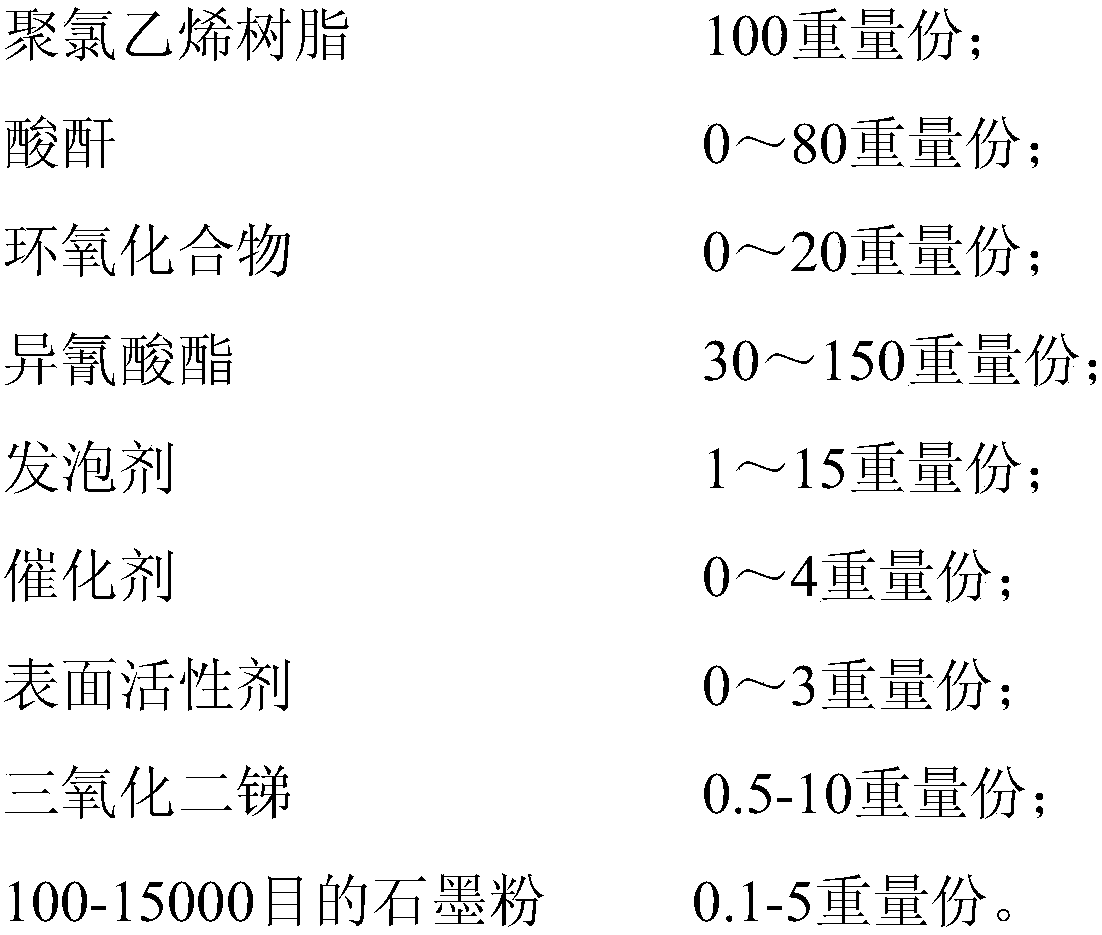

A flame-retardant and heat-insulating polyvinyl chloride foam material and its preparation method

The invention discloses a flame-retardant heat-insulating polyvinyl chloride foam material and a preparation method thereof, belongs to the technical field of foam materials, and aims to solve the problems of relatively poor heat-insulating performance and relatively poor heat resistance of the foam materials since flame retardants added into the foam materials are mostly organic small molecular substances and are added in a large quantity, and the heat conductivity of the foam materials are difficult to lower in the prior art. The polyvinyl chloride foam material is prepared from the following components in parts by weight: 100 parts of polyvinyl chloride resin, 0 to 80 parts of acid anhydride, 0 to 20 parts of epoxy compound, 30 to 150 parts of isocyanate, 1 to 15 parts of foaming agent, 0 to 4 parts of catalyst, 0 to 3 parts of surfactant, 0.5 to 10 parts of antimony trioxide, and 0.1 to 5 parts of graphite powder of 100 to 15,000 meshes. The foam material has good flame retardant property, low heat conductivity, and superior heat-insulating performance and heat resistance.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

150°C heat-resistant cross-linked low-smoke halogen-free electronic wire material and manufacturing method thereof

The invention discloses a 150 DEG C heat-resistant crosslinked low-smoke halogen-free electronic wire material and a preparation method thereof and aims to solve the problem that in order to achieve a certain flame-retardant effect, the usage of inorganic filler in an existing wire and cable insulating material exceeds 50% universally, so that the mechanical property is not good enough, particularly, the flexibility of the electronic wire material is affected as the elongation at break is relatively low. The key point of the technical scheme is as follows: the material comprises the following components in parts by weight: 20-40 parts of EVA, 5-10 parts of PE, 1-5 parts of grafted PE, 30-65 parts of inorganic filler, 0.2-1.8 parts of an antioxidant, 0.2-1.8 parts of a crosslinking agent and 0.2-1.8 parts of a plasticizer. By adopting the formula, the flame retardance of the electronic wire material is improved, the elongation at break of the electronic wire material is improved, and the mechanical property of the electronic wire material is ensured.

Owner:惠州市展创新材料科技有限公司

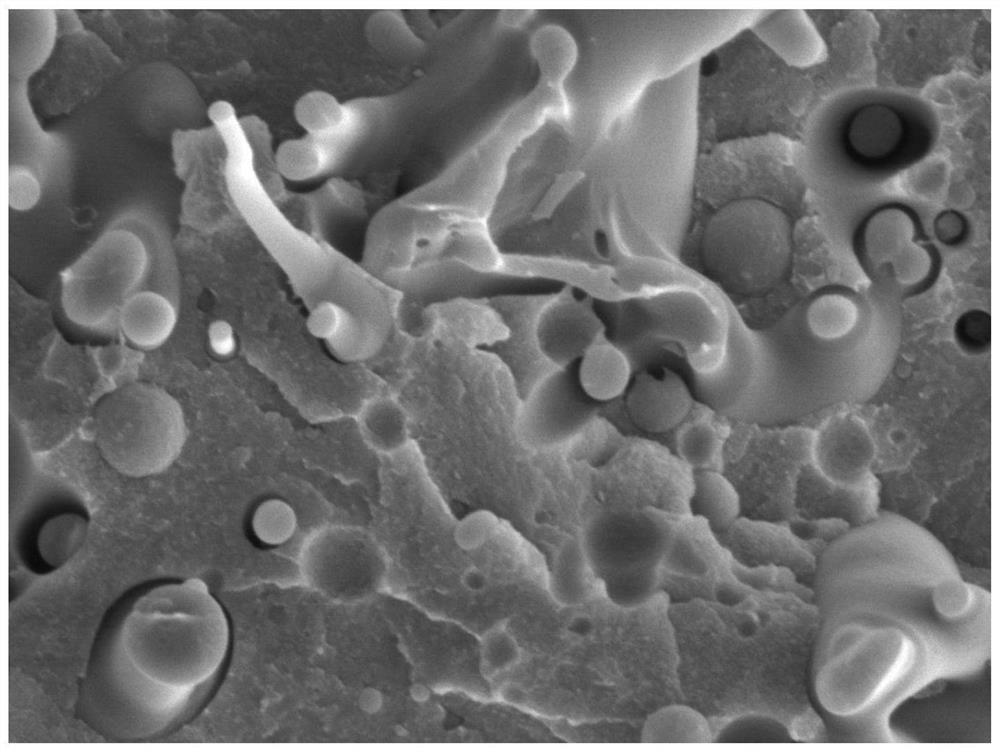

Preparation method of rigid nanoparticle interlayer modified liquid-state molded composite material

The invention belongs to the technical field of liquid-state molded composite material manufacturing, and relates to a preparation method of an inorganic rigid nanoparticle interlayer modified liquid-state molded composite material. The invention prepares a liquid-state molded composite material interlayer modifier by mixing inorganic rigid nanoparticles and substrate resin, and no surface treatment is needed. According to the invention, the interlayer modifier is directly adhered to a surface of a continuous fabric surface by the bonding effect of a coating layer of the substrate resin, and thus the scouring effect of the flowing of the resin on interlayer rigid nanoparticles during the liquid-state molding process is prevented; nanoparticles are directly introduced into a weak interlayer part of the composite material, which effectively prevents the extension of interlayer cracks of the composite material, and thus improves the interlayer performance of the composite material. Additionally, the added rigid inorganic nanoparticles do not participate the chemical reaction of the original resin substrate; no chemical dosage ratio is involved; and the process properties of the RTM resin system and the heat resistance of the composite material are not influenced.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

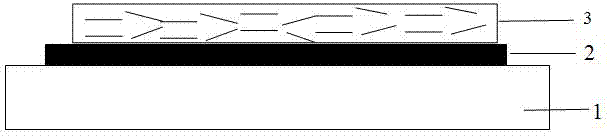

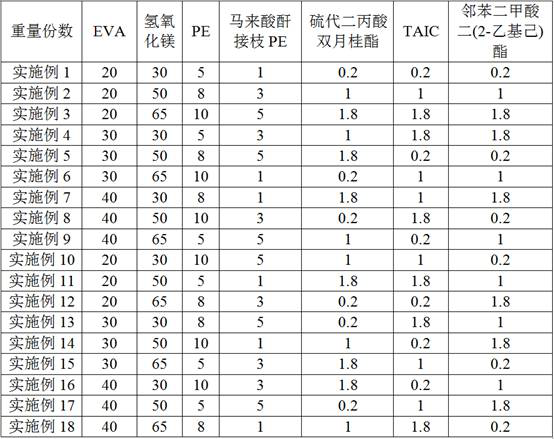

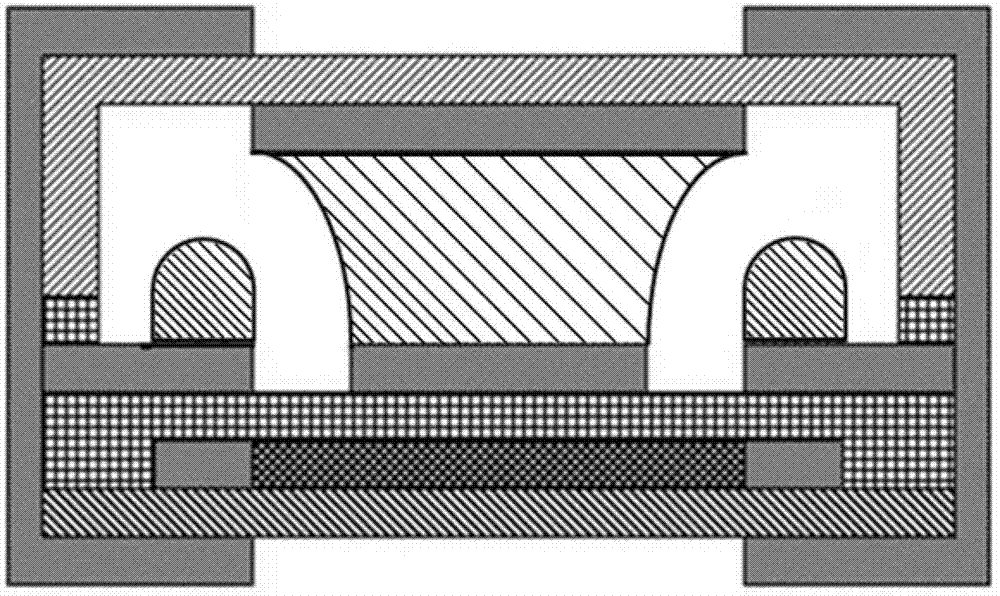

Over-current over-voltage protective element and manufacture method thereof

ActiveCN103236380BDoes not affect heat resistanceGood heat insulationFuse device manufactureSputteringElectricity

The invention discloses an over-current over-voltage protective element and a manufacture method thereof. The over-current over-voltage protective element comprises a bearing plate, a fuse, an upper cover plate and end electrodes. A middle electrode of the bearing plate is divided into at least three isolated areas. The fuse covers the middle electrode so that the mutually isolated areas of the middle electrode are electrically connected. The upper cover plate is in a channel structure open to the bearing plate, and an open end of the upper cover plate is adhered with the bearing plate to form a cavity. The end electrodes are disposed on two sides of the bearing plate and the upper cover plate so that an upper electrode, the middle electrode and a lower electrode are electrically connected. The over-current over-voltage protective element made of high-temperature-resistant polymer material has unaffected heat resistance and is also well heat-insulating. The fuse is directly connected with the electrodes by vacuum sputtering, vacuum evaporation or plating, and drifting of the fuse caused by partial melting of the melt after being heated is avoided. A gap is added above the fuse, so that the melt fuse can be well absorbed by the gap and no tin arch occurs.

Owner:NANJING SART SCI & TECH DEV

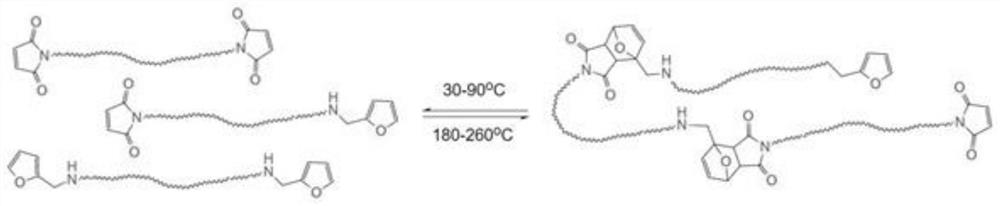

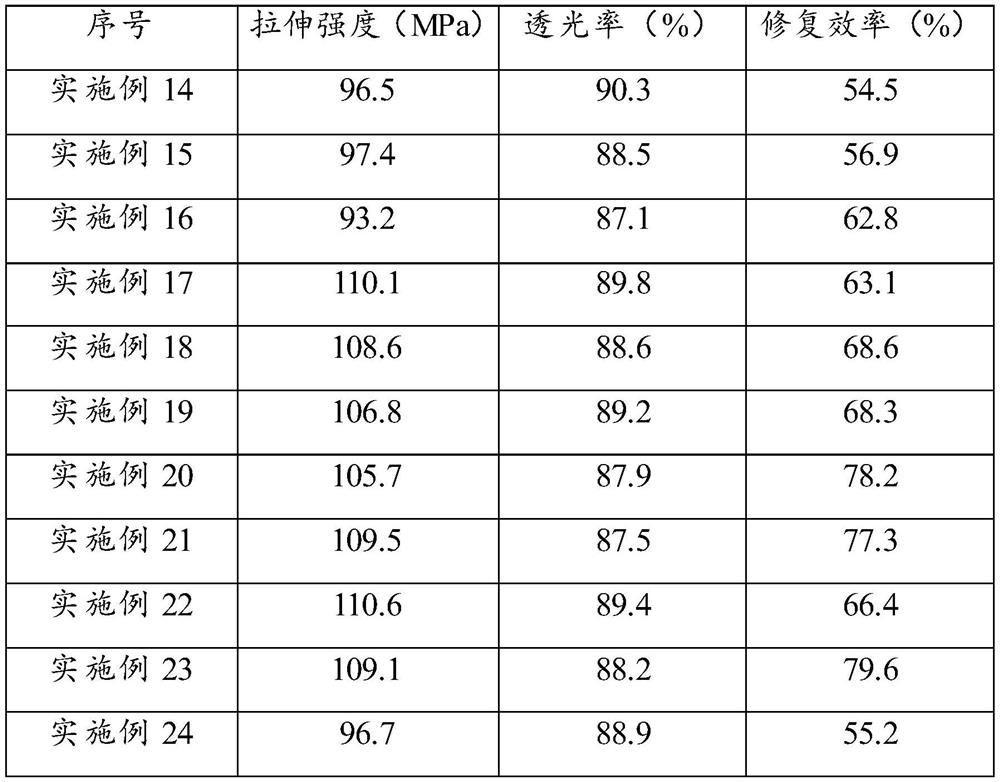

Polyimide resin with self-healing function, polyimide film and preparation method, and flexible foldable display cover base film

The invention provides a polyimide resin with self-repairing function, a polyimide film, a preparation method and a flexible foldable display screen cover plate base film, and relates to the field of material technology. The polyimide resin is mainly made of raw materials such as diamine monomer, dianhydride monomer, end-capping agent, dehydrating agent and catalyst. Among them, furfurylamine and maleic anhydride are used as end-capping agents, which can be used in polyimide The structure of conjugated diene and substituted olefin is introduced into the main structure of the resin. Based on the dynamic reversible Diels-Alder reaction, the cyclohexene structure is cracked at a higher temperature to generate furfurylamine and maleic anhydride, and furfurylamine and maleic anhydride are generated during the cooling process. The amine and maleic anhydride react spontaneously to produce a cyclohexene structure, thereby realizing self-healing of the polyimide resin. The present invention also provides a polyimide film with self-repair function, which is made of the above-mentioned polyimide resin. The polyimide film has self-repair function, and the repair effect does not decrease with the increase of repetition times.

Owner:NINGBO CHANGYANG TECH

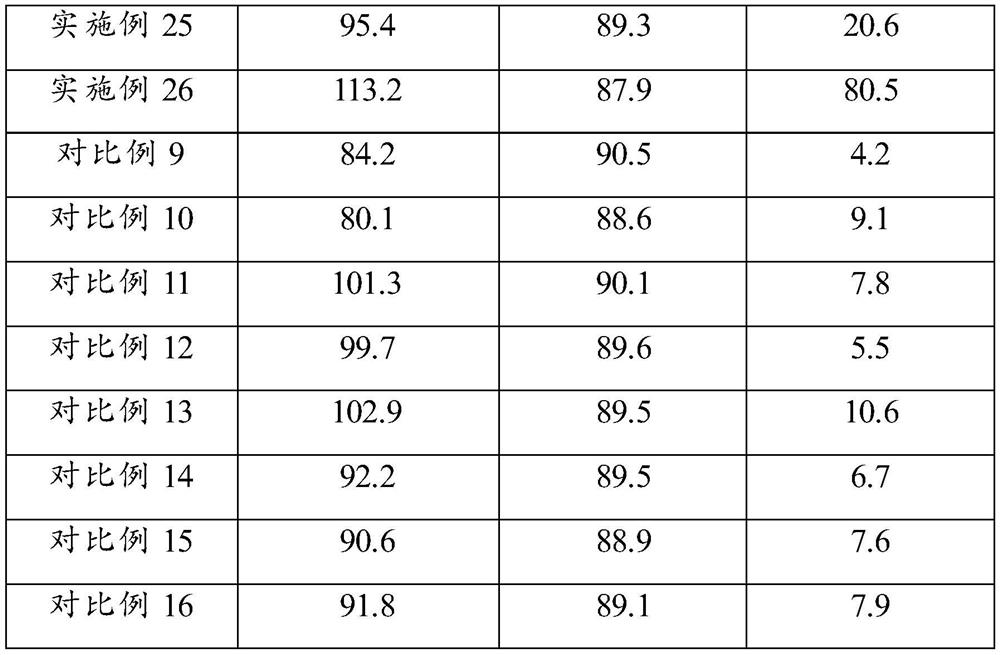

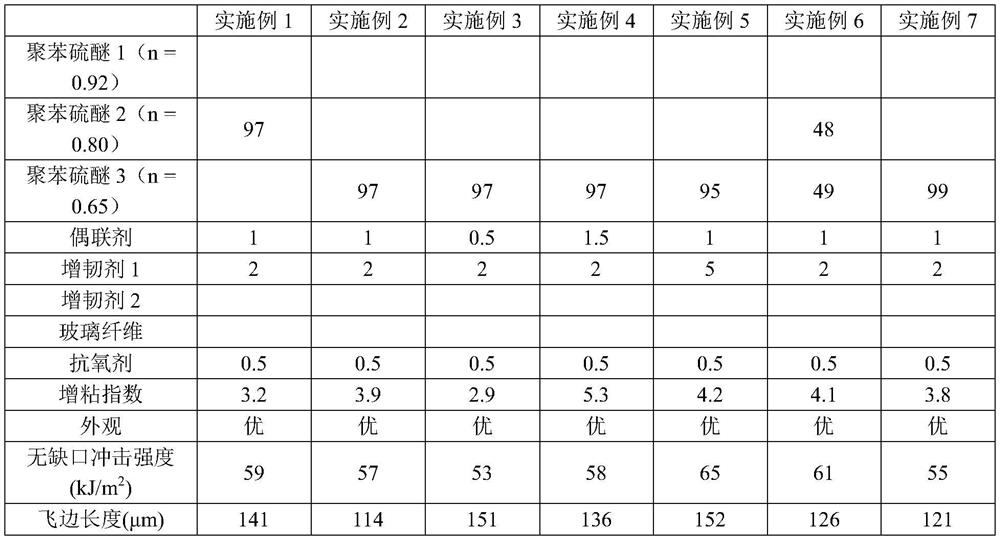

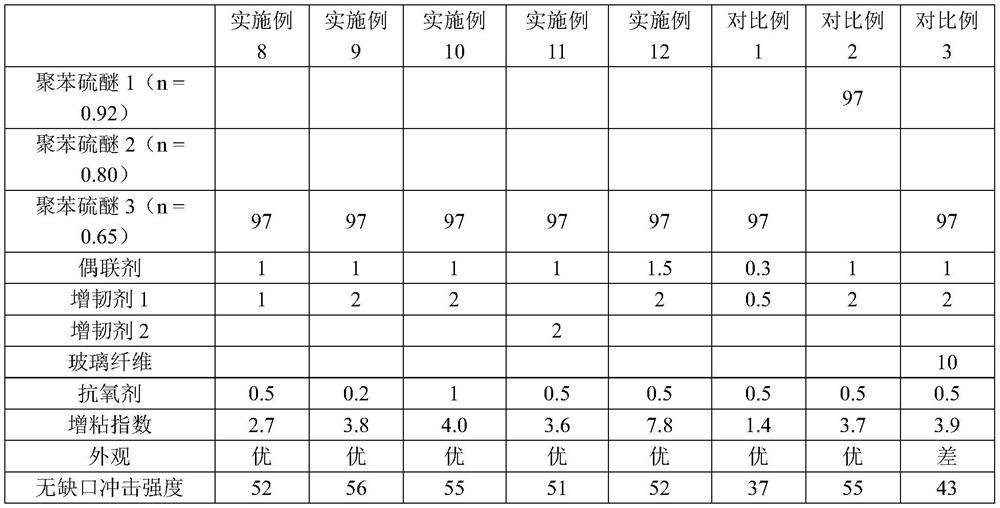

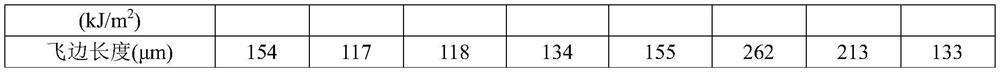

Low-flash high-toughness good-surface polyphenylene sulfide composition as well as preparation method and application thereof

PendingCN114525032ADoes not affect heat resistanceDoes not affect solvent resistancePhotovoltaic energy generationPhysical chemistryAnoxomer

The invention discloses a low-flash high-toughness good-surface polyphenylene sulfide composition as well as a preparation method and application thereof. The polyphenylene sulfide composition is prepared from the following components in parts by weight: 95 to 99 parts of polyphenylene sulfide, 1 to 5 parts of a toughening agent, 0.5 to 1.5 parts of a coupling agent and 0.2 to 1 part of an antioxidant. The power law index of the polyphenylene sulfide is 0.5 to 0.9. The tackifying index of the polyphenylene sulfide composition is 2 to 8. The polyphenylene sulfide composition disclosed by the invention has low flash and relatively high impact strength on the premise of not influencing high heat resistance, solvent resistance and dimensional stability of the polyphenylene sulfide composition, and has a good application prospect in the field of electronic appliances.

Owner:KINGFA SCI & TECH CO LTD

A dopo-containing bismaleimide with asymmetric molecular structure, its preparation method and its application in the preparation of composite resin

ActiveCN104447869BImprove solubilityEasy to processGroup 5/15 element organic compoundsOrganic solventResin-Based Composite

The invention relates to the field of micro-electronic packaging materials, and discloses bismaleimide containing 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and asymmetric in molecular structure, as shown in a general formula (II) shown in specification, as well as a preparation method and application of the bismaleimide in preparation of composite resin. The bismaleimide containing DOPO and asymmetric in molecular structure disclosed by the invention is soluble in such conventional organic solvents as acetone, so as to facilitate processing and using; the bismaleimide containing DOPO and asymmetric in molecular structure disclosed by the invention can be used for further preparing cyanate ester composite resin, and a cured product is good in thermal stability and flame retardance; and as a base material for packaging in the micro-electronic packaging field, the bismaleimide has good application prospect.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com