Patents

Literature

797results about How to "Improve toughness and strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three-dimensional printing forming material with toughness and high adhesive property and preparation method thereof

The invention discloses a three-dimensional printing forming material with toughness and high adhesive property. The three-dimensional printing forming material comprises a powder material and an adhesive material and is characterized in that the powder material comprises the following components in parts by weight: 40-85 parts of polyamide resin, 5-40 parts of pigments, 5-30 parts of filler, 1-6 parts of pigment and filler dispersing and wetting aid, 0.1-1.5 parts of flatting agent and 0.1-0.5 part of degassing agent; the adhesive material comprises the following components in parts by weight: 60-95 parts of epoxy resin, 5-40 parts of filler, 1-10 parts of toughening agent, 0.1-1.5 parts of flatting agent, 1-4 parts of pigment and filler dispersing and wetting aid, 0.1-0.5 part of degassing agent and 0.1-0.5 parts of powder flowing aid; and when the three-dimensional printing forming material is used, 1 part by weight of powder material and 0.01-0.5 part by weight of adhesive material are cooperatively used. A solid component printed by using the material disclosed by the invention has the advantages of higher adhesion strength and firmness, good flexibility and scratching resistance.

Owner:ZHONGSHAN POLYTECHNIC

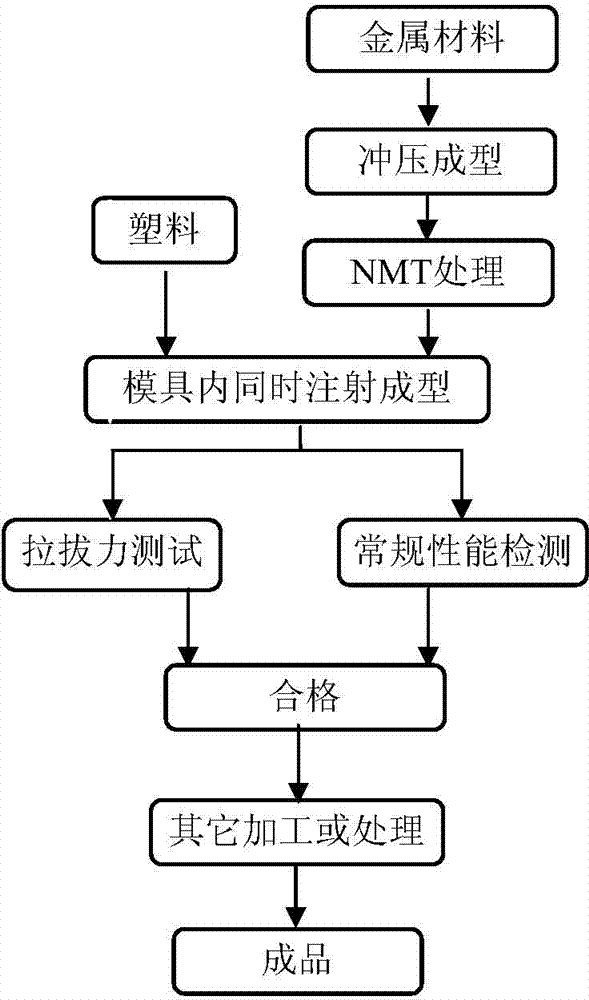

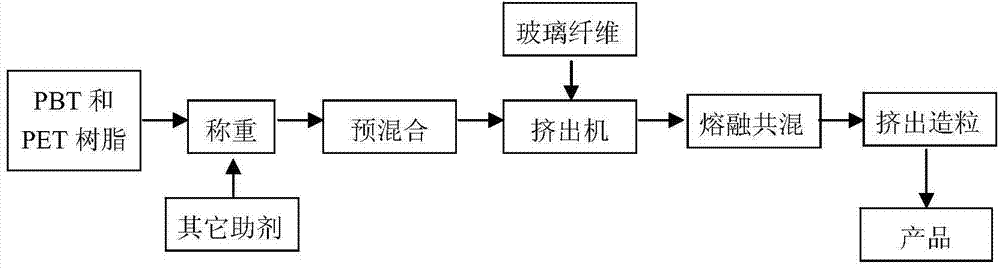

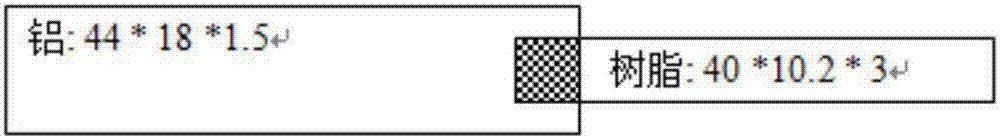

PBT (polybutylece terephthalate) engineering plastic composition used for NMT (Nano Molding Technology)

ActiveCN104845297AImprove mechanical propertiesImprove heat resistanceAntioxidantPolyethylene glycol

The invention provides a PBT (polybutylece terephthalate) engineering plastic composition used for a NMT (Nano Molding Technology) and a preparation method thereof. The PBT engineering plastic composition used for the NMT comprises the following components in parts by mass: 60 parts of PBT resin, 5 to 60 parts of PET (polyethylene glycol terephthalate) resin, 10 to 16 parts of glass fibers, 5 to 15 parts of flexibilizer, 0.3 to 3 parts of antioxidants, 0.3 to 2 parts of heat stabilizers, and 0.5 to 3 parts of lubricants, wherein the flexibilizers are selected from the mixture of at least two of unsaturated carboxylic ester, unsaturated carboxylic ester copolymers, saturated carboxylic acid vinyl ester, saturated carboxylic acid vinyl ester copolymers, unsaturated epoxy compounds, unsaturated epoxy copolymers, unsaturated carboxylic acid, unsaturated carboxylic acid copolymers, unsaturated acid anhydride or unsaturated acid anhydride copolymers. The bond force between the PBT engineering plastic composition and a metal material is excellent, and the NMT process requirements can be met; meanwhile, excellent mechanical performance and heat resistance are realized.

Owner:SHENZHEN HALCYON NEW MATERIALS

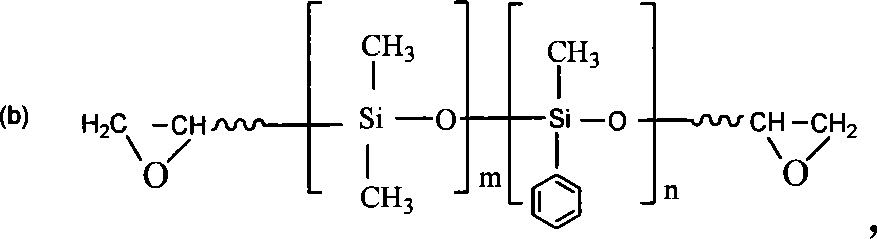

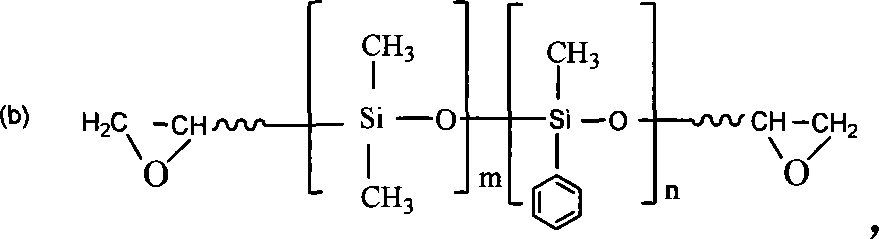

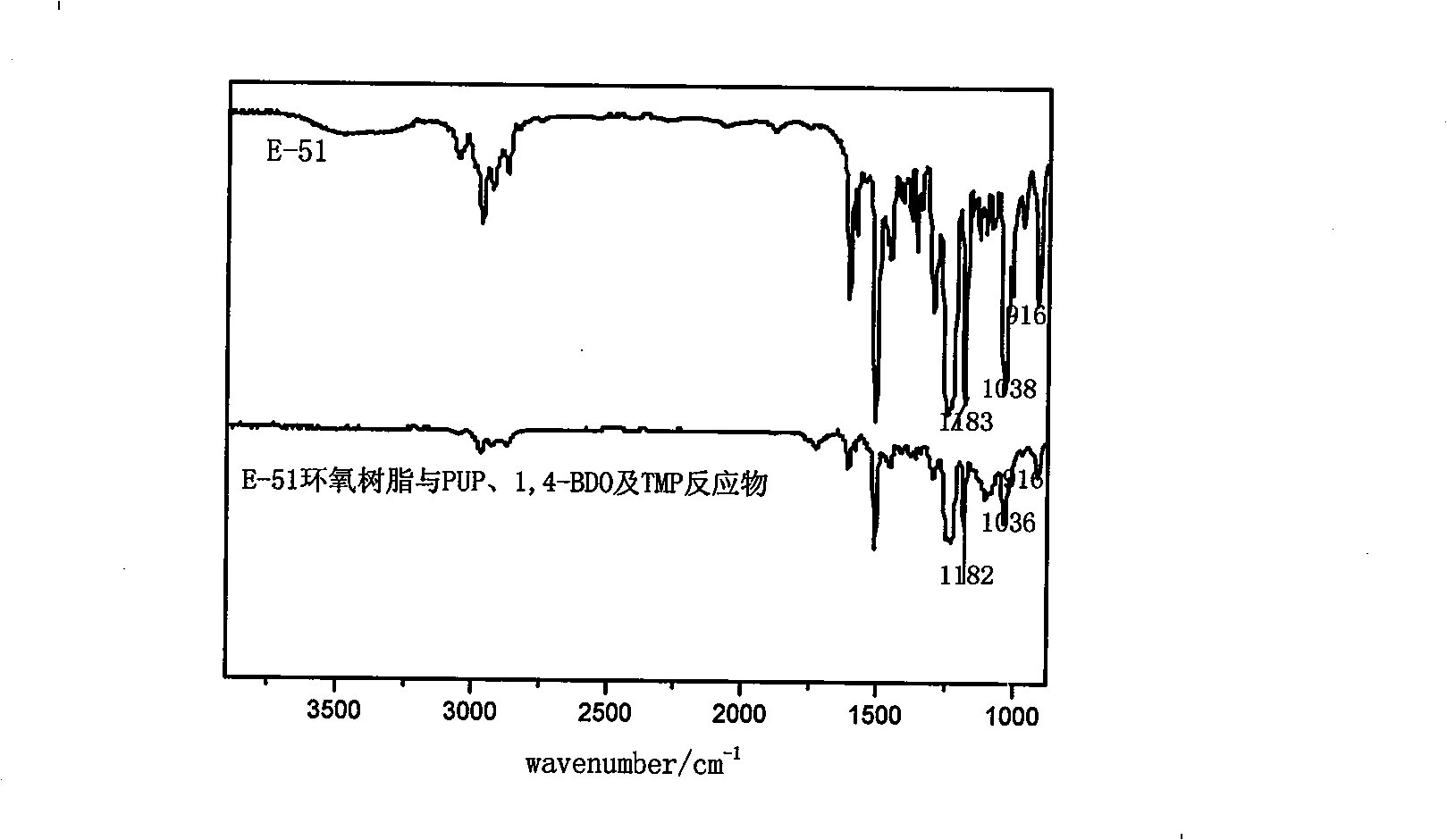

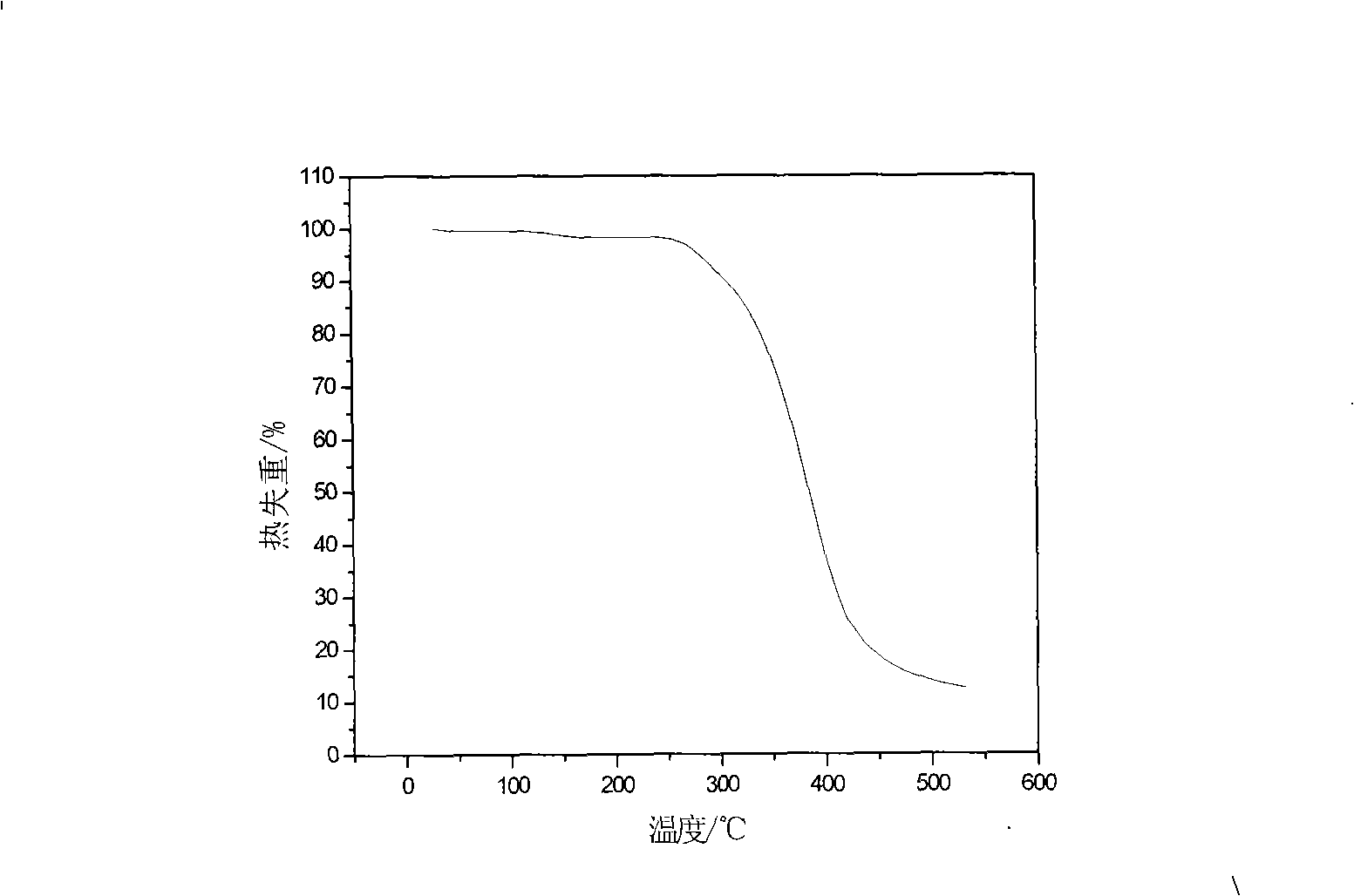

Method for preparing epoxy resin adhesive

InactiveCN101186796AGood compatibilityImprove toughness and strengthNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyDecomposition

The invention discloses a process for preparing epoxy resin adhesive. epoxy phenyl silicone oil(PEPDMS) is employed as a toughening modifier of the epoxy-resin binder, the mixing compatibility of organosilicon resin and epoxide resin are improved by introducing phenyl group to the molecular structure of the naphthene-base silicone oil, simultaneously, the impact ductility and bending intensity of solidifying matters can be increased owing to the mutual function of the soft Si-O-Si chain and the rigid phenyl group, thereby the invention has the function of toughening and strengthening, and the invention has the advantages of sound fire-resisting property and electricity-air insulating property. The beginning heat decomposition temperature is more than 400 DEG C, volume resistivity is more than 10 17 omega, cm under indoor temperature, the consumption of medium is less than 2% under indoor temperature and in 155 DEG C, and the invention is in particular adaptable for casting and packaging of electronic materials and the manufacture of electrical resistant materials.

Owner:SHANGHAI JIAO TONG UNIV

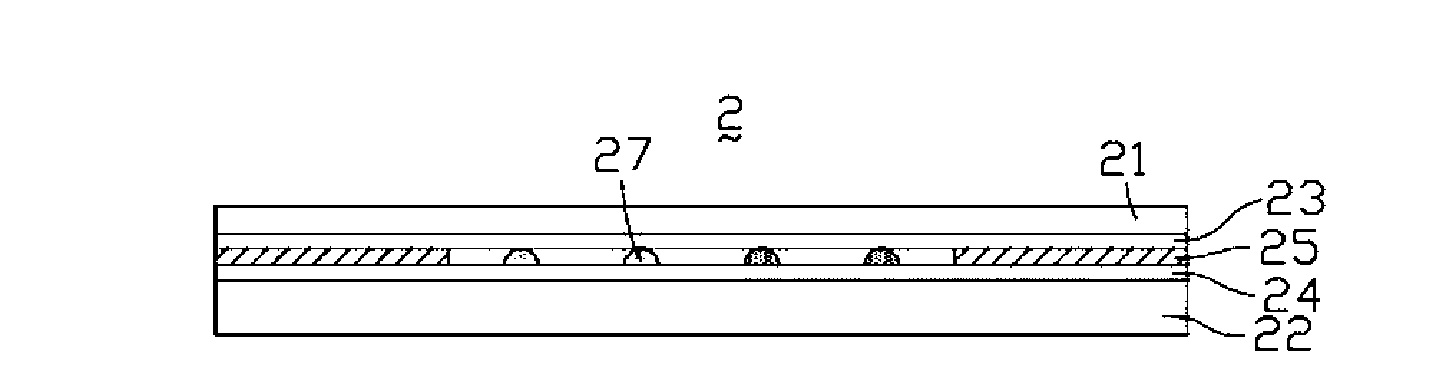

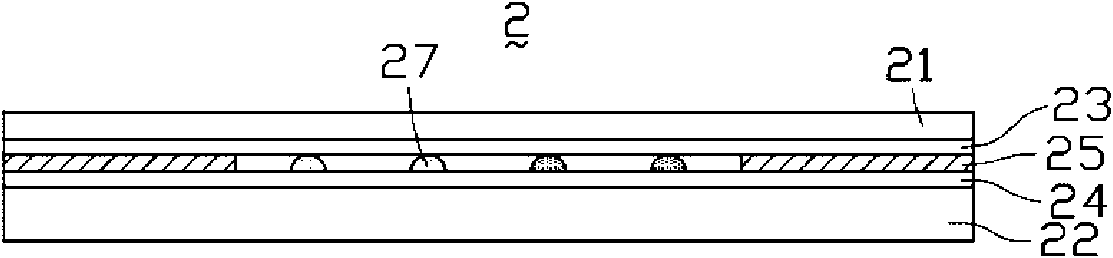

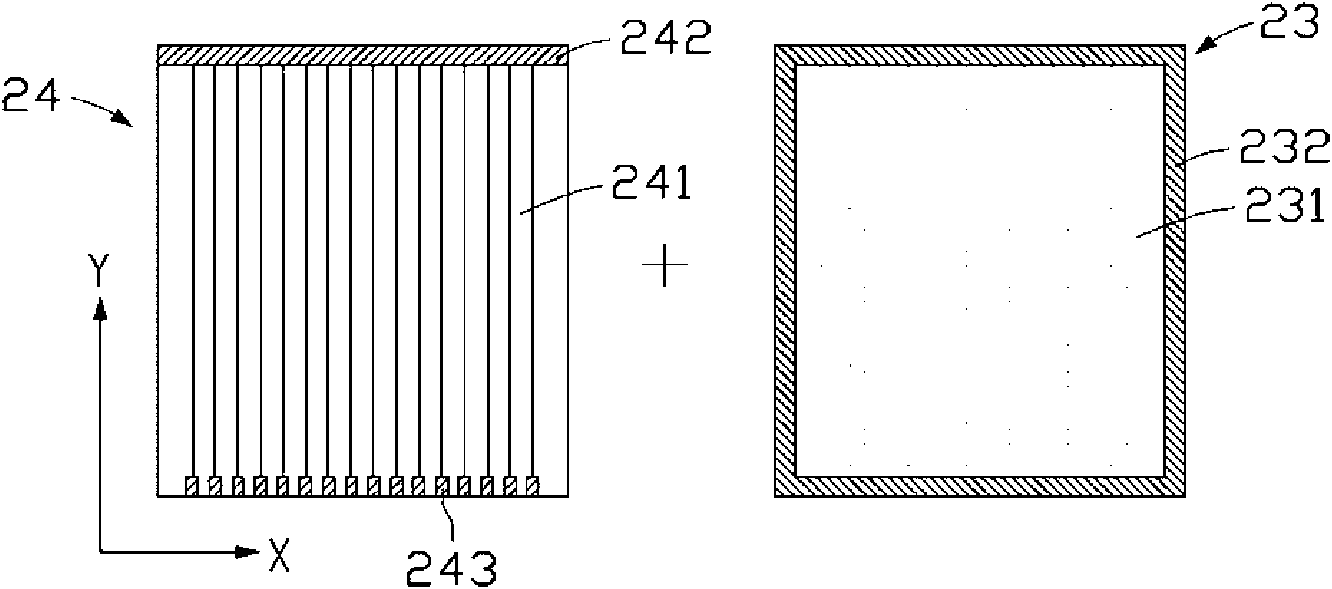

Touch screen and driving method thereof

ActiveCN101937279ASimple structureWith multi-touch operationConductive layers on insulating-supportsNanoinformaticsOptoelectronicsPhysics

Owner:INNOCOM TECH (SHENZHEN) CO LTD +1

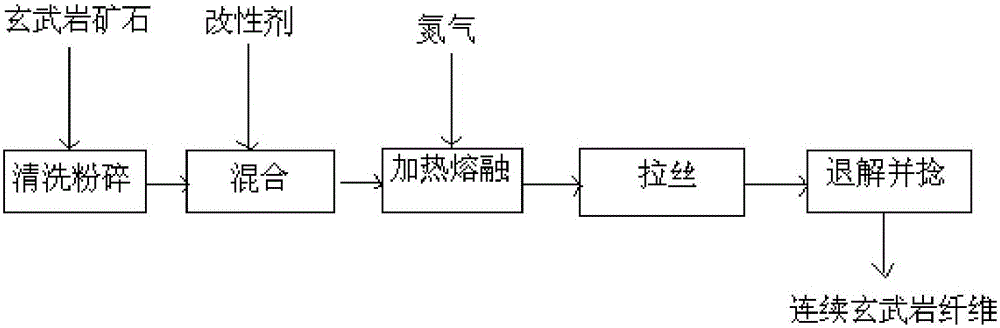

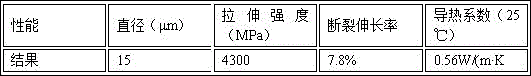

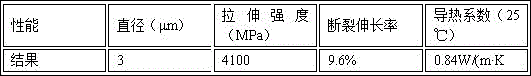

Preparation method of continuous basalt fibers

ActiveCN105837024ASolve the defect that is easy to breakImprove toughness and strengthGlass making apparatusPolymer scienceBasalt fiber

The invention discloses a preparation method of continuous basalt fibers. A modifier in basalt can fast transfer heat so that heat in the basalt fibers is easily transferred to the fiber surfaces, cooling curing rates inside and outside the fibers are the same, fiber toughness and strength are improved, and basalt fibers bear uniform load in stretching and are not easily broken so that the continuous basalt fibers are prepared. The preparation method has simple processes and substantial effects, is suitable for large scale industrial production and has a wide market application prospect.

Owner:江苏狮腾工程材料有限公司

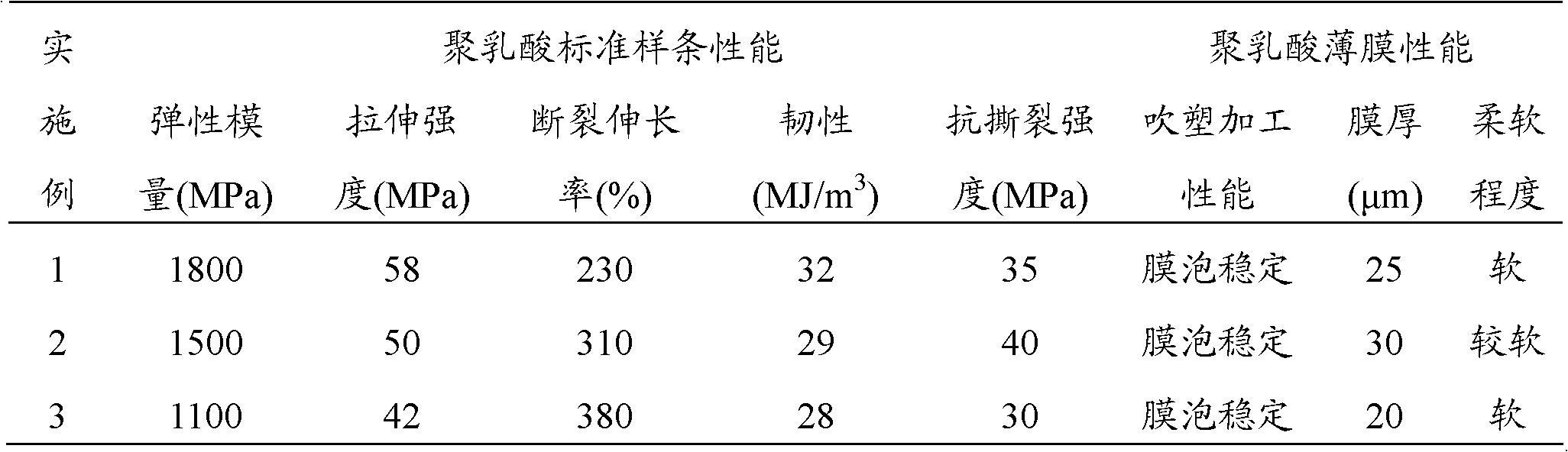

Polylactic acid composition and polylactic acid product

InactiveCN102618003AGood comprehensive mechanical propertiesImprove blow molding processabilityPlasticizerPolylactic acid

The invention provides a polylactic acid composition and a polylactic acid product. The polylactic acid composition comprises the following components by weight percent: 50 to 80 percent of polylactic acid, 0 to 35 percent of adipic acid-polybutylene terephthalate, 0 to 35 percent of poly(butylene succinate), 0.05 to 0.5 percent of peroxide, 0.05 to 0.5 percent of chain extendor and 3 to 15 percent of plasticizer, wherein the content of the adipic acid-polybutylene terephthalate and the content of the poly(butylene succinate) are not 0 percent. The mechanical properties such as melt strength, elongation at break, tenacity and anti-tear strength of the polylactic acid composition provided by the invention are improved, so that the polylactic acid composition with better comprehensive mechanical properties can be obtained, and the polylactic acid composition has more stable processability and better film forming stability.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

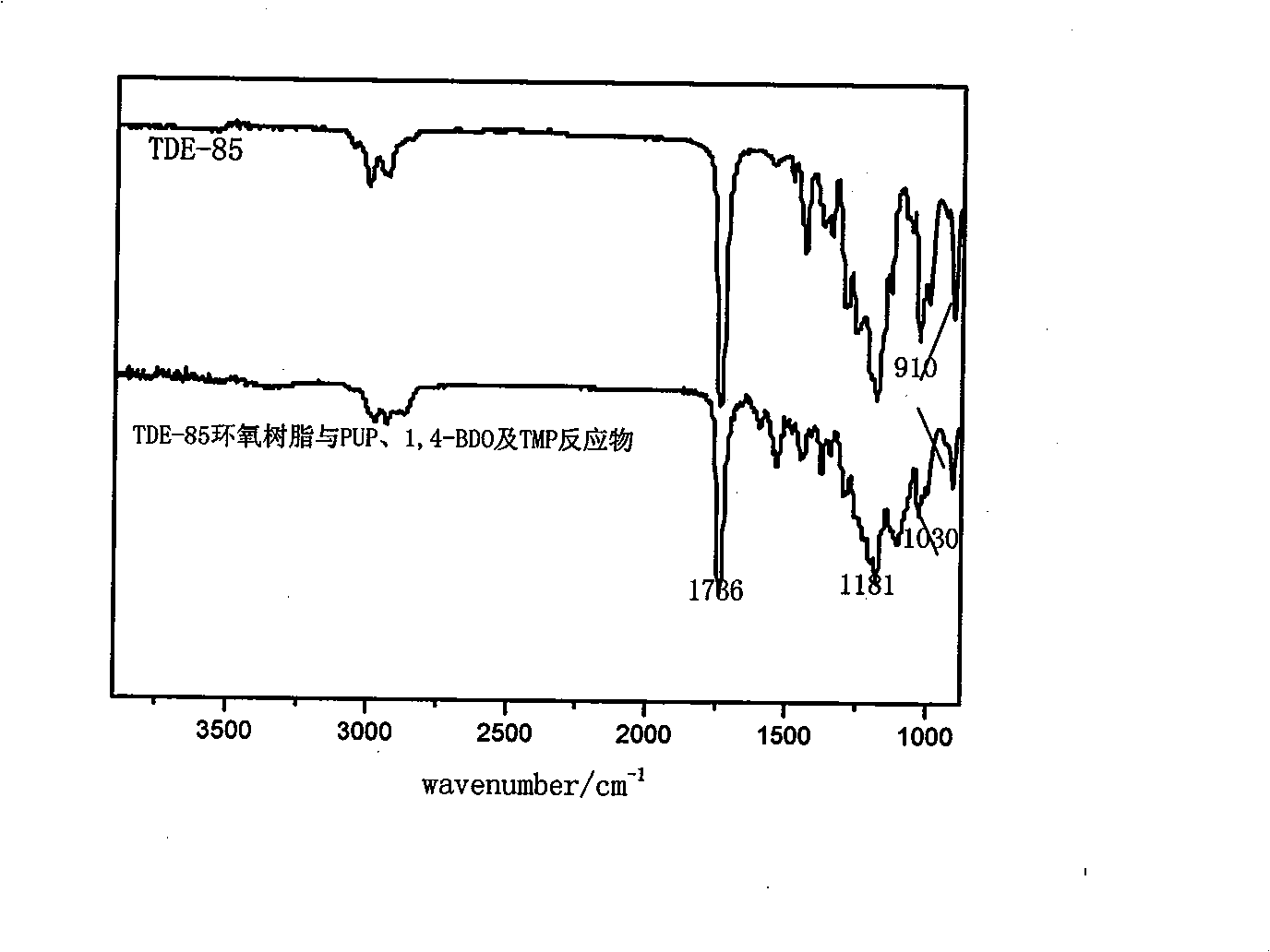

High temperature resistant, high strength modified epoxy resin adhesive and preparation thereof

InactiveCN101407708AGood high temperature resistanceImprove flexibilityEpoxy resin adhesivesChemistryDiol

The invention discloses a high-temperature-resistant and high-strength modified epoxy resin structured adhesive. First, polyether diols and 2, 4-tolylene diisocyanate are reacted to prepare polyurethane prepolymer (PUP); 1, 4-butanediol and trimethylolpropane are added into the prepared PUP and, after agitation, the mixture is added into TDE-85 / E-51 epoxy resin; then, a curing agent is added into the TDE-85 / E-51 epoxy resin and, and finally, a curing accelerator is added. The prepared adhesive has high tenacity, excellent high-temperature resistance and high reaction activity. After curing, the tensile and shear strength of the adhesive reach 22.81MPa at room temperature and 12.85MPa at high temperature of 160 DEG C, and the peel strength reaches 51.68N / cm, therefore, the adhesive can be widely applied to the adhesion of metals, porcelain, plastics and wood and the like.

Owner:CENT SOUTH UNIV

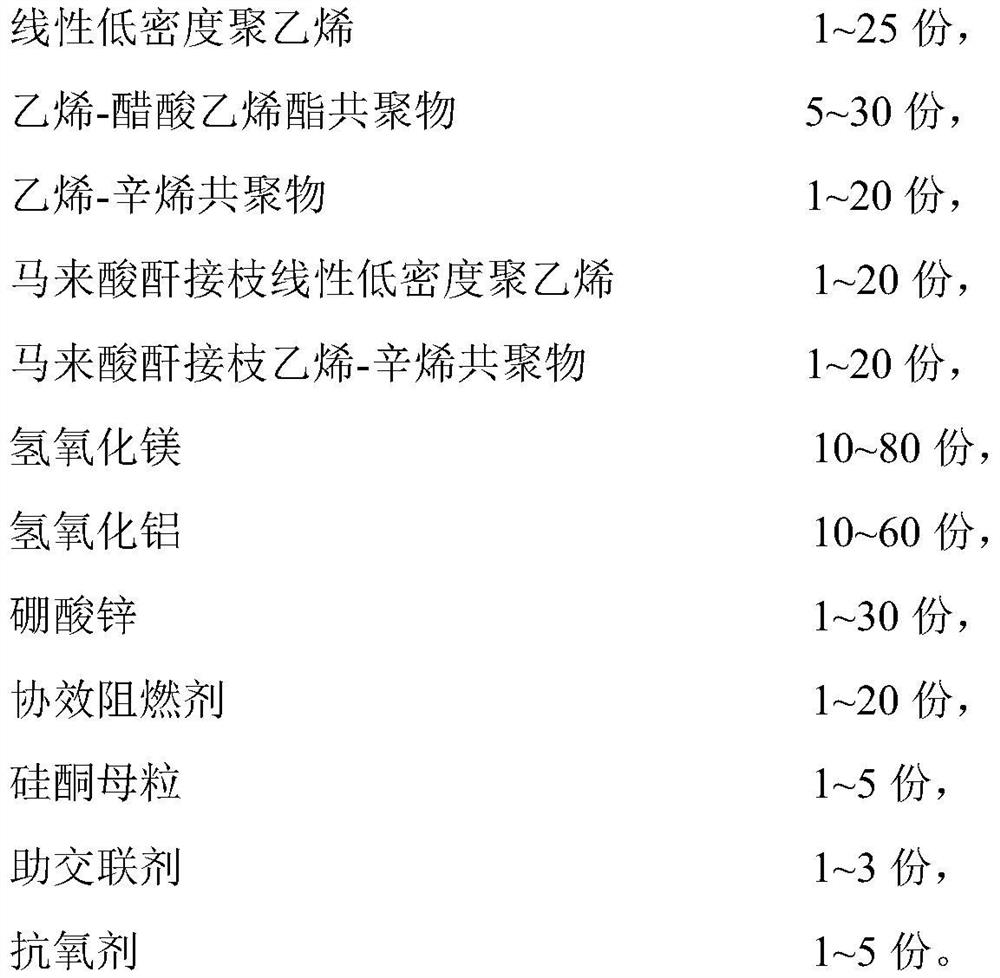

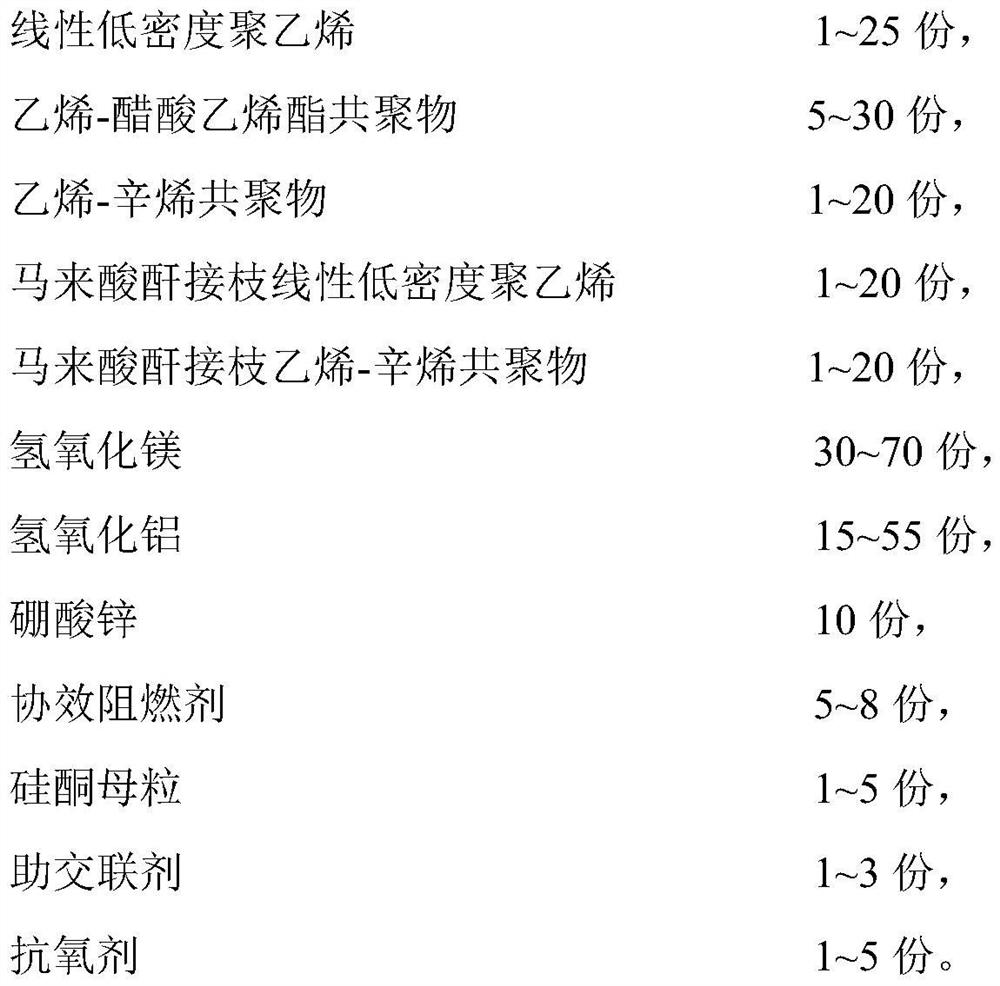

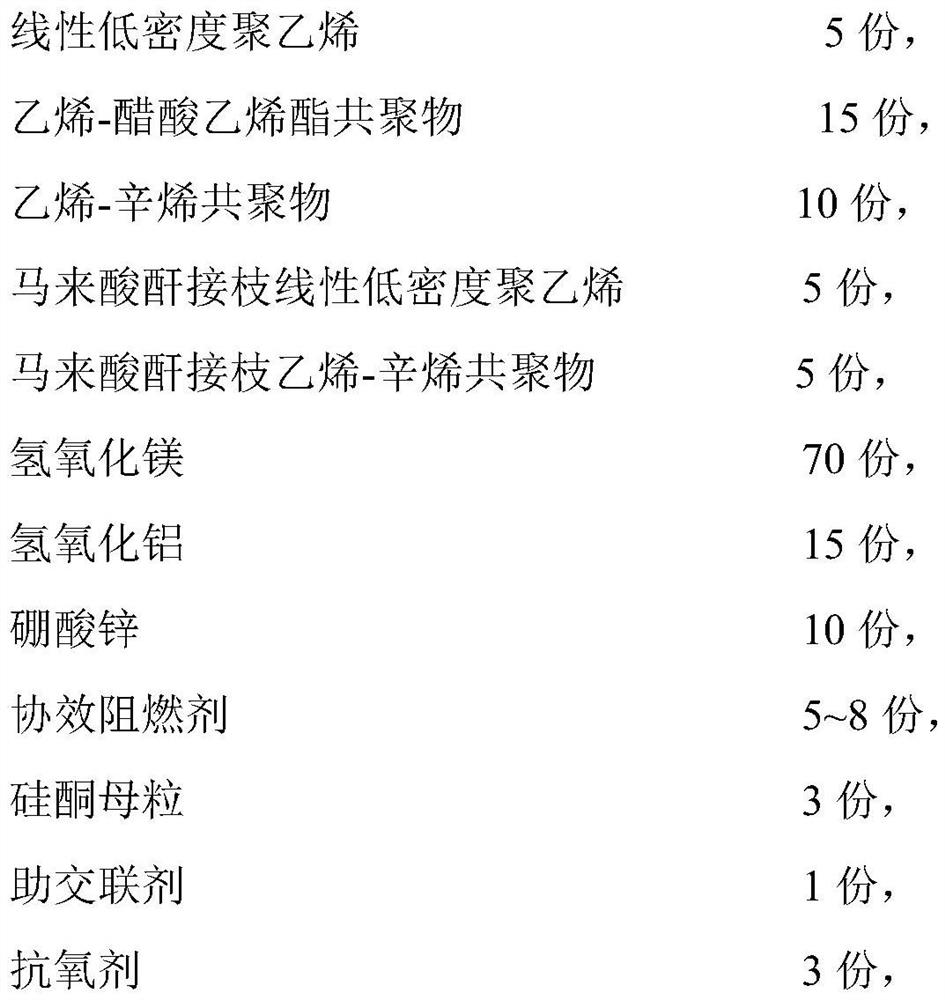

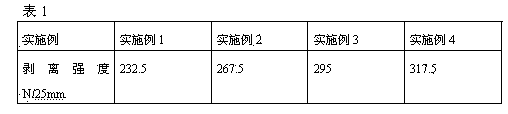

Irradiation crosslinking low-smoke halogen-free polyolefin cable material as well as preparation method and application thereof

PendingCN112759823AImprove toughness and strengthHigh mechanical strengthPlastic/resin/waxes insulatorsCross-linkLinear low-density polyethylene

The invention discloses an irradiation crosslinking low-smoke halogen-free polyolefin cable material as well as a preparation method and application thereof. The irradiation crosslinking low-smoke halogen-free polyolefin cable material is prepared from the following components in parts by weight: 1 to 25 parts of linear low-density polyethylene, 5 to 30 parts of ethylene-vinyl acetate copolymer, 1 to 20 parts of ethylene-octylene copolymer, 1 to 20 parts of maleic anhydride grafted linear low-density polyethylene, 1 to 20 parts of maleic anhydride grafted ethylene-octylene copolymer, 30 to 80 parts of magnesium hydroxide, 10 to 30 parts of aluminum hydroxide, 1-30 parts of zinc borate, 1-20 parts of a synergistic flame retardant, 1-5 parts of silicone master batch, 1-3 parts of an assistant crosslinker and 1-5 parts of an antioxidant. Specific preparation raw materials are adopted for modifying the low-smoke halogen-free polyolefin cable material, the defects of flame retardance and mechanical performance of an existing flame-retardant wire and cable material are overcome, the cable material with good mechanical performance and flame retardance is provided, and the low-smoke halogen-free polyolefin cable material is suitable for being widely applied to preparation of wires or cables.

Owner:KINGFA SCI & TECH CO LTD +1

High peel strength acrylate adhesive

InactiveCN103834307AImprove toughness and strengthHigh peel strengthOrganic non-macromolecular adhesiveEpoxyElastomer

The invention discloses a high peel strength acrylate adhesive which belongs to the technical field of two-component acrylate adhesives, and mainly solves the problems that second generation acrylate structural adhesives in the prior art are poor in toughness, and have the peel strength of only 50-100N / 25mm. The high peel strength acrylate adhesive is mainly characterized by including a main agent component which comprises 25 to 60 parts of acrylate monomers containing at least one vinyl, 0 to 25 parts of methacrylic acid, 0 to 25 parts of an elastomer, 5 to 15 parts of epoxy resin, 0.5 to 8 parts of an initiator and 0.1 to 5 parts of a stabilizer; and a curing agent component which comprises 25 to 60 parts of the acrylic monomers containing at least 1 vinyl, 0 to 25 parts of the methacrylic acid, 0 to 25 parts of the elastomer and 1-10 parts of an accelerant. The high peel strength acrylate adhesive is characterized by significantly improving the toughness and the peel strength of the adhesive, the peel strength can reach 200-300N / 25mm, and the high peel strength acrylate adhesive is mainly used as a high peel strength acrylate adhesive.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD

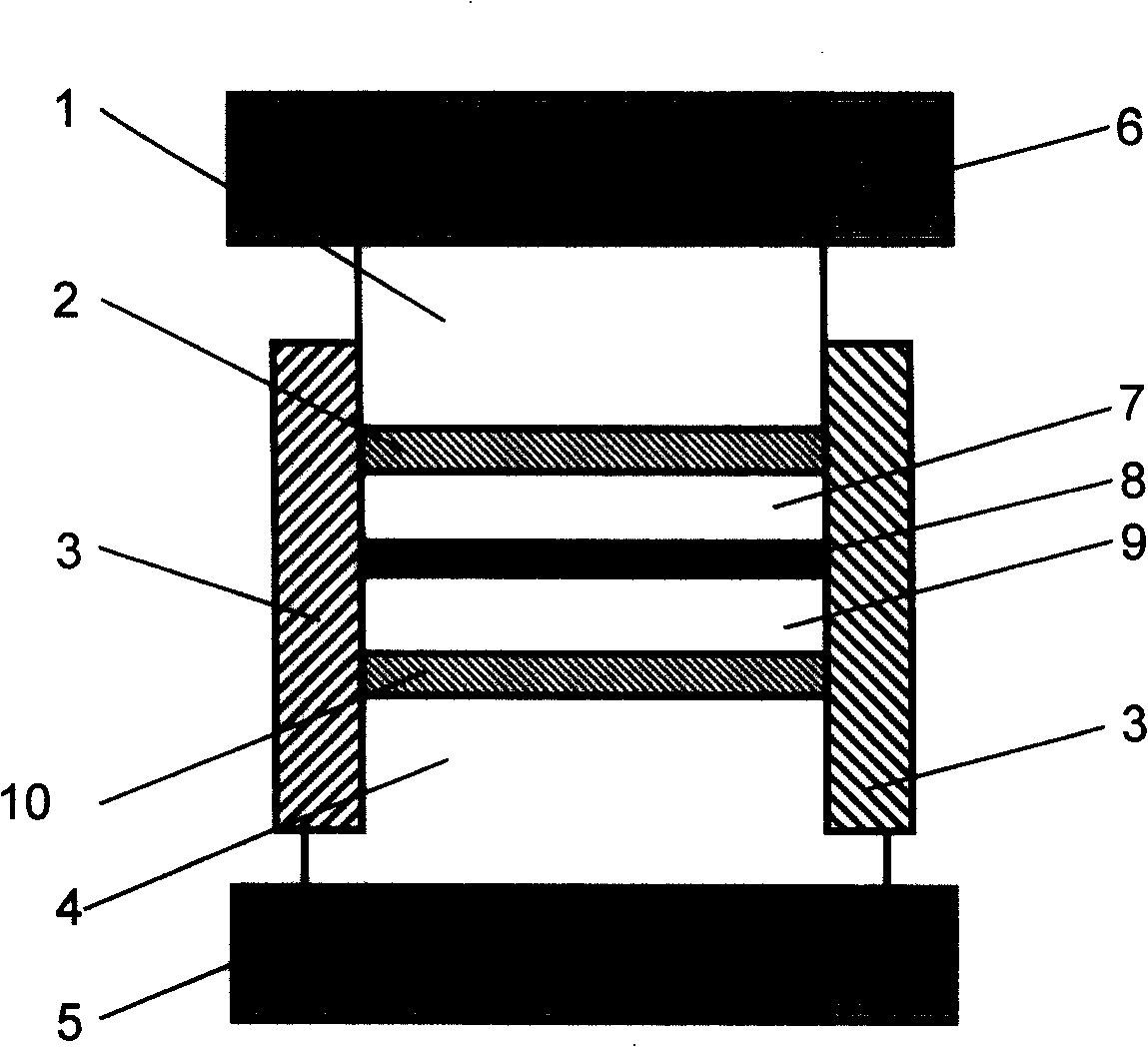

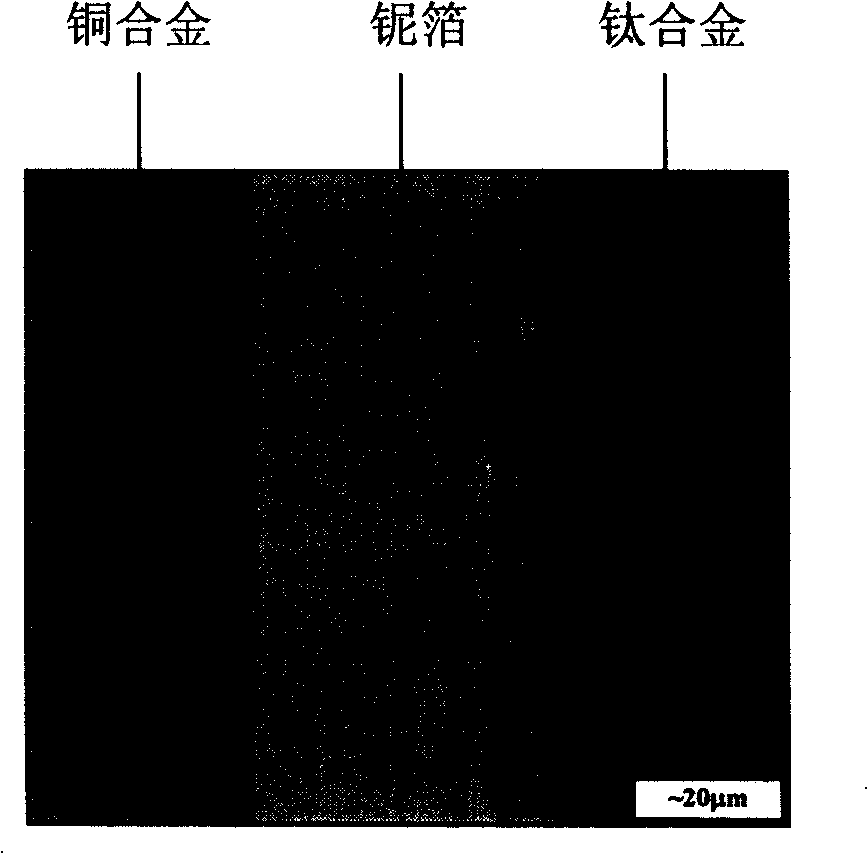

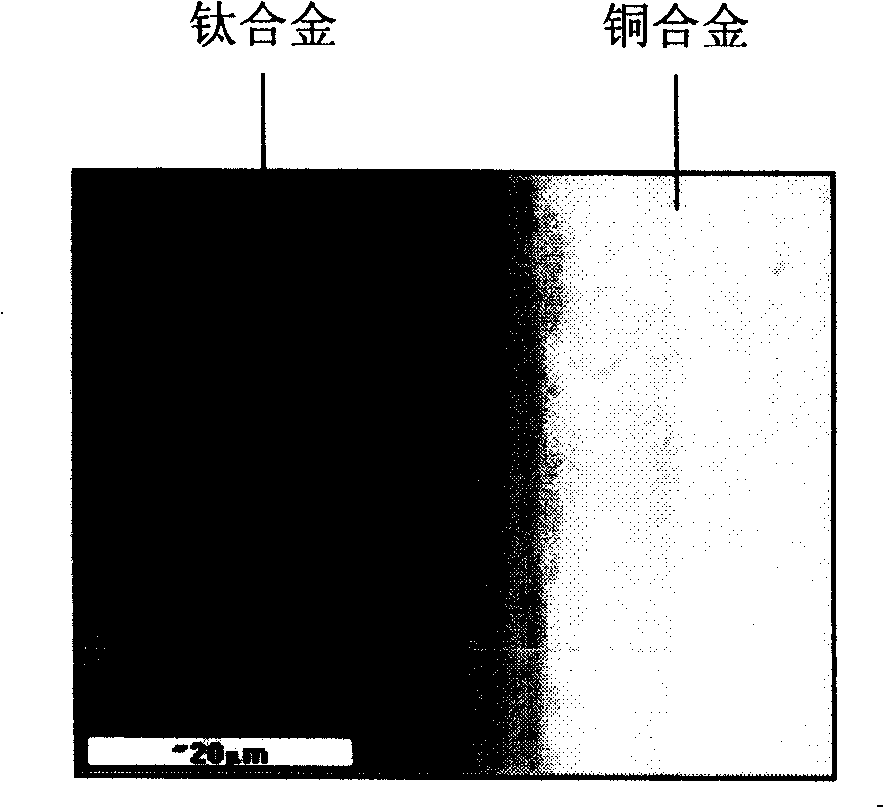

Method diffusion welding titanium alloy and copper alloy using niobium central layer

InactiveCN101254572AImprove toughness and strengthHigh bonding strengthNon-electric welding apparatusNiobiumAxial pressure

The invention relates to a method for welding titanium alloy and copper alloy. A method for diffusion-welding titanium alloy and copper alloy by using niobium intermediate layer is characterized in that the method comprises the following steps: (1) selecting niobium foil or powder as the intermediate layer for connecting a titanium alloy sheet and a copper alloy sheet, and cleaning the surfaces to be welded of the titanium alloy sheet and the copper alloy sheet; (2) arranging the niobium intermediate layer between the titanium alloy sheet and the copper alloy sheet, putting the whole into a graphite mold, transferring the graphite mold into a vacuum welding furnace, and applying a pre-pressure of 0.5 to 2 MPa to compress the mold; and (3) vacuuming the vacuum welding furnace, heating when the vacuum degree is larger than 5*10<-3> Pa with a speed of 2 to 10 DEG C / min to 700 to 850 DEG C, keeping the temperature for 30 to 60 min, applying an axial pressure of 5 to 10 MPa before keeping the temperature, decreasing the temperature when reaching the temperature-keeping time, discharging the pressure and cooling. The method can achieve high-strength connection between titanium alloy and copper alloy, and is suitable for high-strength connection of various kinds of titanium and copper alloys.

Owner:WUHAN UNIV OF TECH

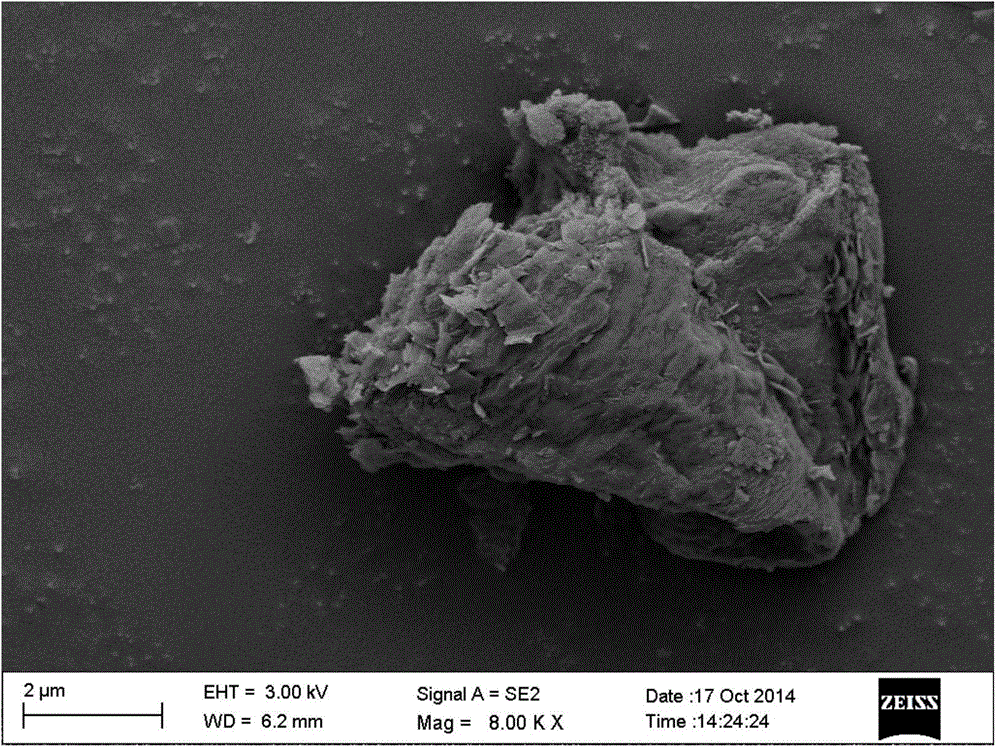

Preparation method of silicon nitride-based self-lubricating ceramic cutter material containing alumina-coated hexagonal boron nitride composite powder

ActiveCN104892005AHigh Vickers hardnessImprove toughness and strengthHexagonal boron nitrideBoron nitride

The invention relates to a preparation method of a silicon nitride-based self-lubricating ceramic cutter material containing alumina-coated hexagonal boron nitride composite powder. The silicon nitride-based self-lubricating ceramic cutter material comprises, by volume, 57-70% of micrometer silicon nitride, 5-15% of nanometer silicon nitride, 5-15% of micrometer titanium carbide, 3.2% of alumina, 4.8% of yttrium oxide, and 2-15% of alumina-coated hexagonal boron nitride. The preparation method comprises preparing alumina-coated hexagonal boron nitride composite powder with particle sizes of 4-12 micrometers, weighing micrometer silicon nitride, nanometer silicon nitride and micrometer titanium carbide, respectively preparing their suspension liquids, carrying out ultrasonic dispersion, carrying out mixing, adding alumina and yttrium oxide into the mixture, carrying out ultrasonic dispersion for 15-20min to obtain a composite suspension liquid, carrying out ball milling, adding the alumina-coated hexagonal boron nitride composite powder into the composite suspension liquid, carrying out ball milling, carrying out vacuum drying to obtain mixed powder and carrying out vacuum hot pressing sintering molding. The silicon nitride-based self-lubricating ceramic cutter material containing alumina-coated hexagonal boron nitride composite powder can improve ceramic cutter mechanical properties and guarantee self-lubricating performances.

Owner:QILU UNIV OF TECH

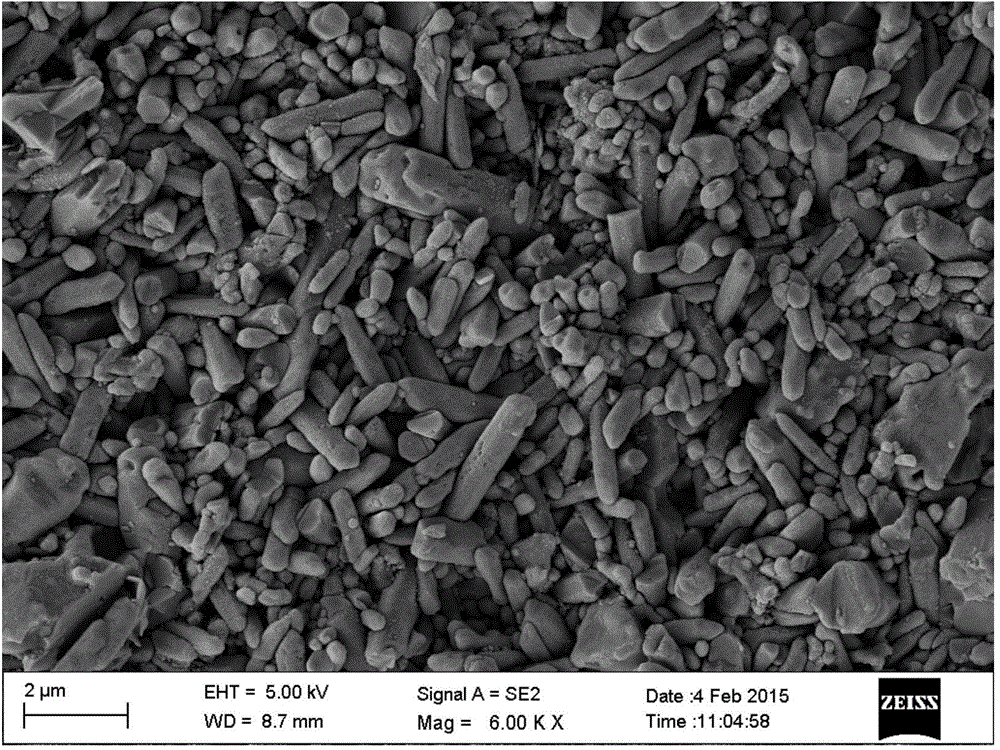

Crosslinked alginate-bacterial cellulose sponge and preparation method thereof

ActiveCN103536954AImprove mechanical propertiesSimple structureAbsorbent padsBandagesPolymer scienceFreeze-drying

The invention relates to the field of a biomedical material, and particularly discloses a crosslinked alginate-bacterial cellulose sponge and a preparation method thereof. The crosslinked alginate-bacterial cellulose sponge takes an alginate biomaterial and bacterial cellulose as raw materials. The crosslinked alginate-bacterial cellulose sponge is characterized in that a sponge product is prepared from the alginate biomaterial and the bacterial cellulose in manners of crosslinking and freeze-drying after being compounded, wherein the alginate biomaterial accounts for 80-95% of the sponge product in mass fraction; the bacterial cellulose accounts for 5-20% of the sponge product in mass fraction. The crosslinked alginate-bacterial cellulose sponge is abundant in used material sources, low in cost, controllable to process, and simple in production technology; the prepared crosslinked alginate-bacterial cellulose sponge has good mechanical property, liquid absorption property, water retention capacity and air permeability, and is applicable to bleeding healing of large seepage or a bleeding wound.

Owner:山东颐诺生物科技有限公司

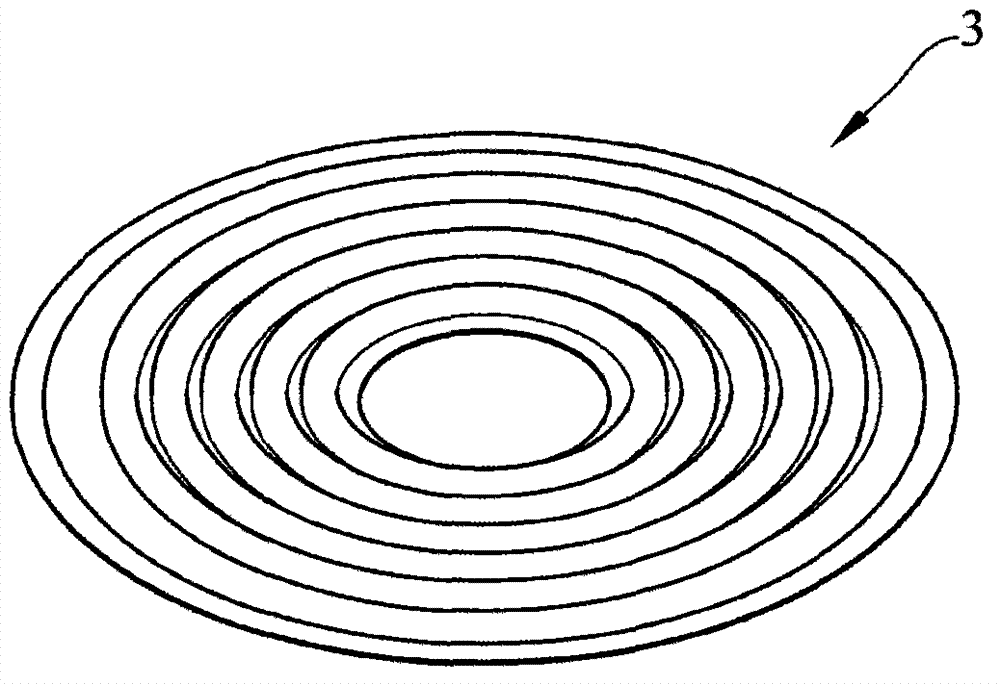

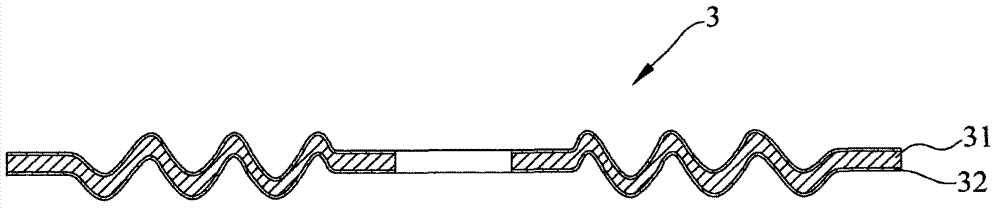

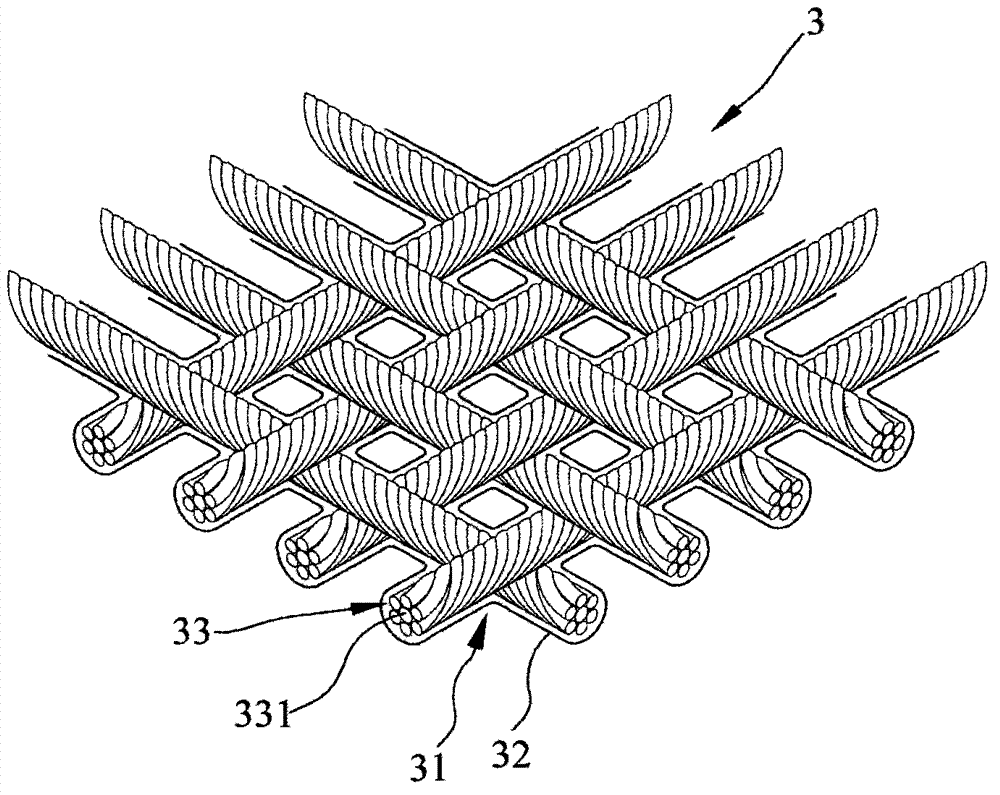

Horn elastic wave and manufacturing method thereof

InactiveCN103596114AImprove lateral force resistanceIncrease elasticityElectrical transducersYarnAramides

The invention discloses a horn elastic wave and a manufacturing method thereof. The horn elastic wave comprises a fiber cloth body which is formed through weaving a plurality of line bodies. The plurality of line bodies are a single line body individually formed by a single fiber or are formed by multiple fibers through a multi-strand twist yarn mode. The fiber at least comprises a first fiber. The first fiber is made by one of cotton, a polyester fiber and an aromatic polyamide fiber or a combination of the cotton, the polyester fiber and the aromatic polyamide fiber. When the first fiber is simultaneously made by the cotton, the polyester fiber and the aromatic polyamide fiber, any material can individually account for 0-100% of whole weight of a fiber cloth body. When the first fiber does not account for 100% of the whole weight of the fiber cloth body, the fiber cloth body further comprises a second fiber and a resin solid shape layer, wherein the second fiber is made by one of rayon, tough silk, linen, acryl, a rubber and an artificial fiber or a combination of the above materials; the resin solid shape layer is sticked and combined to the fiber cloth body; and the fiber cloth body maintains a preset configuration after a molding method is used.

Owner:大原博

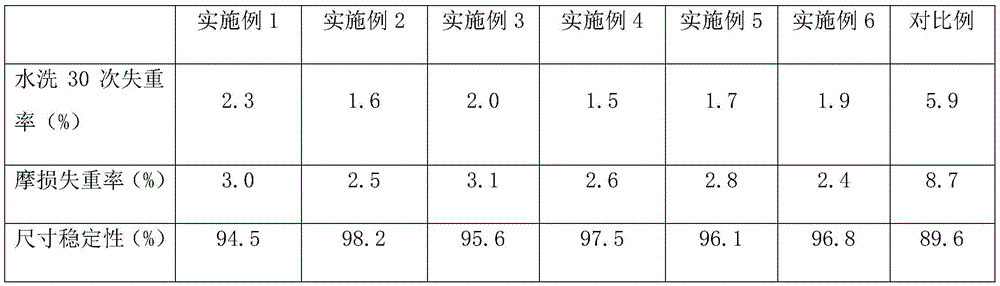

Fabric post-finishing agent based on modified silk fibroin solution and preparation method of fabric post-finishing agent

ActiveCN105544210ASkin-friendlyHigh affinityBiochemical fibre treatmentGrip property fibresDissolutionSolvent

The invention provides a fabric post-finishing agent based on a modified silk fibroin solution and a preparation method of the fabric post-finishing agent. The preparation method comprises the following specific operational steps: (1) removing impurities from waste silk, putting the impurity-free waste silk in a sodium bicarbonate solution for boiling and degumming, taking out and wringing out the degummed waste silk, washing with clean water till the greasy feel is eliminated, putting the primarily treated waste silk in the sodium bicarbonate solution again for boiling and degumming, taking out and wringing out the degummed waste silk again, washing again with clean water till the greasy feel is eliminated, putting the secondarily treated waste silk in an oven for drying, so as to obtain degummed silk; (2) putting the degummed silk in a lithium bromide solution for standing and dissolution, taking out the treated silk, and performing cooling, dialysis and concentration to obtain a silk fibroin solution; and (3) adding glycerin and gelatin into the silk fibroin solution, uniformly stirring to form a membrane solution, adjusting the pH value of the membrane solution and then adding glutaraldehyde and chitosan, uniformly stirring, and finally mixing the treated membrane solution with a solvent containing additives, so as to obtain the fabric post-finishing agent. The fabric post-finishing agent obtained according to the preparation method covers the fabric surface in the form of a composite membrane; and the preparation method is beneficial to improvements in the membrane forming property, the ductility and the like of a silk fibroin finishing agent.

Owner:SUZHOU INSILK CO LTD

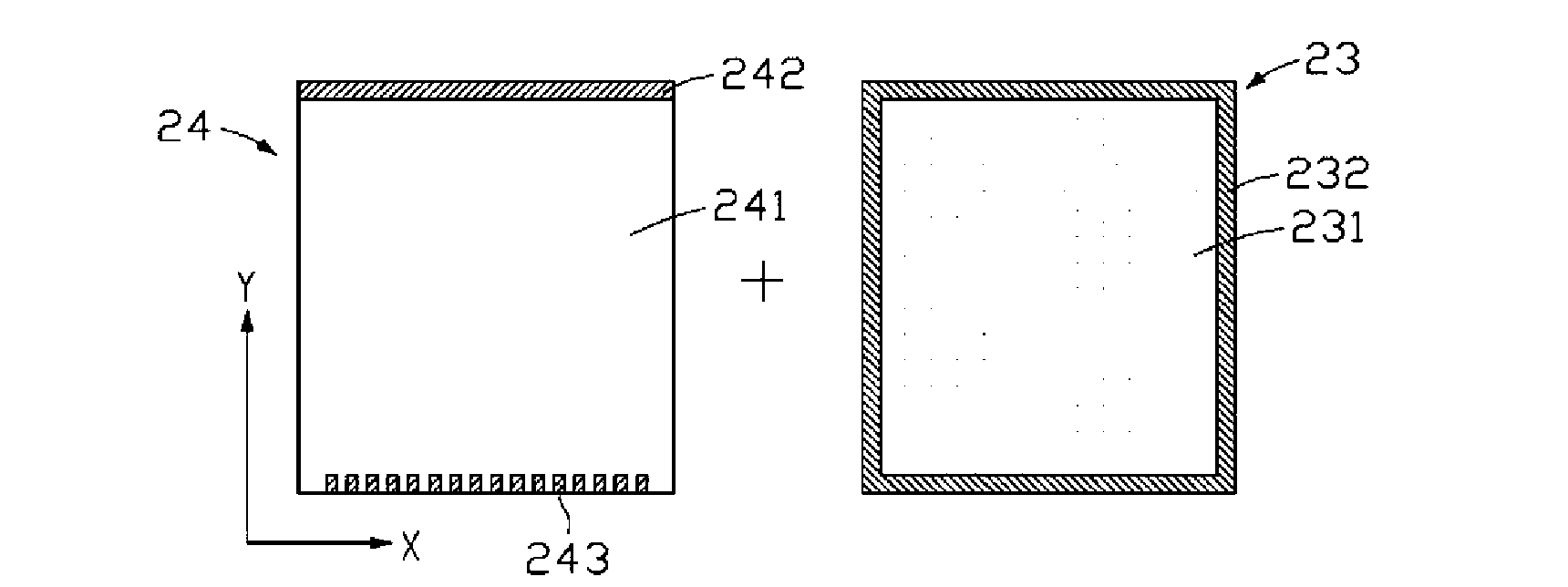

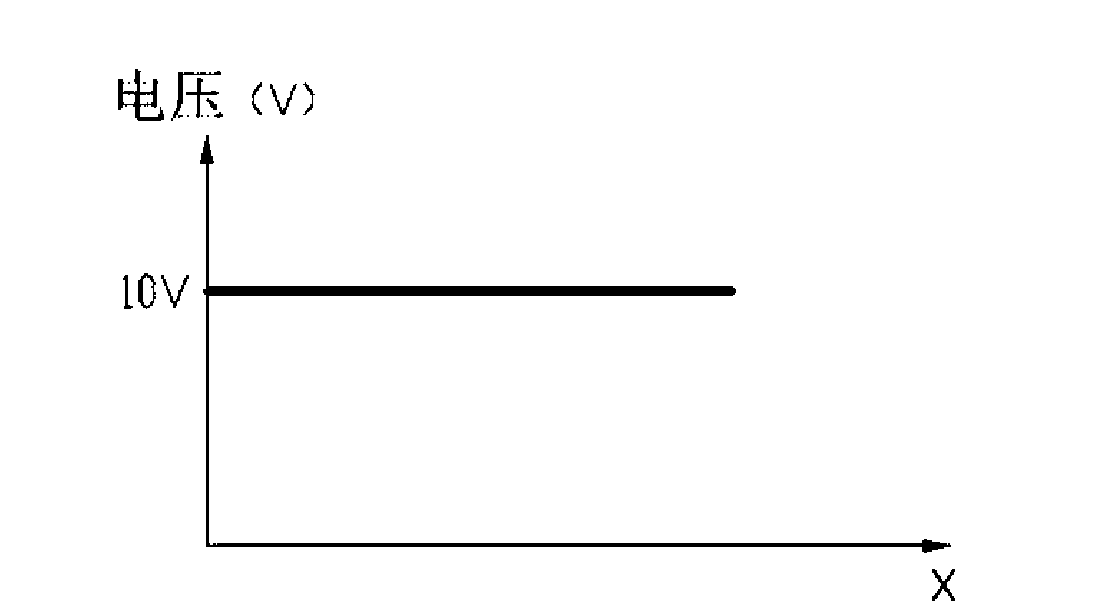

Multipoint touch screen and driving method thereof

ActiveCN101901069ASimple structureSimple driving methodInput/output processes for data processingElectrically conductiveEngineering

The invention provides a multipoint touch screen which comprises a first baseplate, a second baseplate, a first transparent conducting layer and a second transparent conducting layer, wherein the first baseplate and the second baseplate are oppositely arranged, the first transparent conducting layer is arranged on the inner surface of the first baseplate, and the second transparent conducting layer is arranged on the inner surface of the second baseplate. The resistivity of the second transparent conducting layer along a first direction is larger than the resistivity thereof along a second direction. The second transparent conducting layer is a carbon nanotube film, furthermore, carbon nanotubes in the carbon nanotube film are preferentially oriented and arranged along a single direction, and the single direction is parallel to the second direction of the second transparent conducting layer. The invention also provides a driving method of the multipoint touch screen.

Owner:INNOCOM TECH SHENZHEN +1

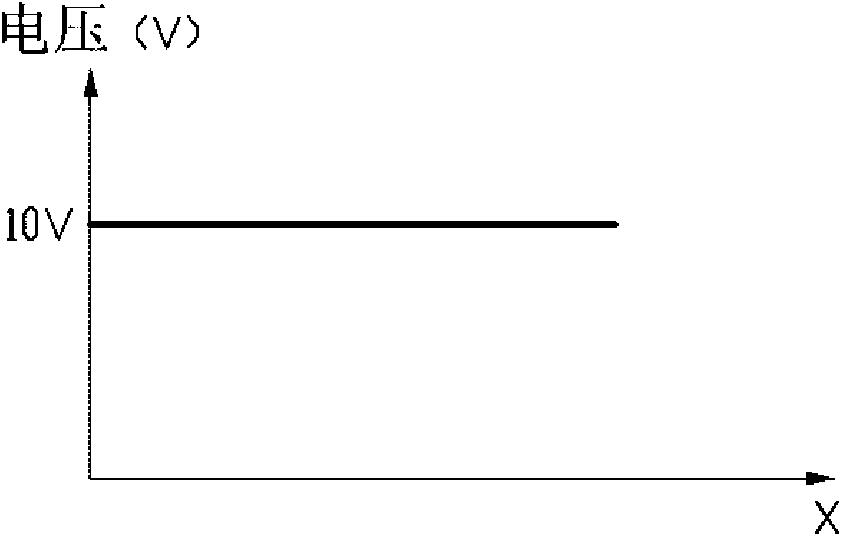

Anti-icing cable

ActiveCN105390189AAchieving Hydrophobic PropertiesAchieve strengthPower cables with screens/conductive layersInsulated cablesGlass fiberAntioxidant

The invention discloses an anti-icing cable. The cable comprises a core, a shielding layer and an anti-icing layer arranged in sequence from inside to outside, wherein the anti-icing layer comprises the following raw materials by weight: 60-75 parts of fluorosilicon resin, 20-30 parts of methyl vinyl silicone rubber, 10-15 parts of SiO2-glass fiber gel, 5-8 parts of polypropylene fiber powder, 3-5 parts of nano SiO2, 4-6 parts of nano TiO2, 0.5-1 part of a dispersing agent, 0.5-1.5 parts of a flame retardant, 1-2 parts of a silane coupling agent and 1-2 parts of an antioxidant. The anti-icing cable has excellent hydrophobic property and anti-icing performance, and is excellent in insulating performance, high in compressive strength, high in flexibility and anti-aging; and the anti-icing layer of the anti-icing cable can replace the insulating layer in the cable and a sheath outside the cable, so that the cable mass is lowered and the service life of the cable is prolonged.

Owner:STATE GRID HENAN DENGZHOU POWER SUPPLY CO

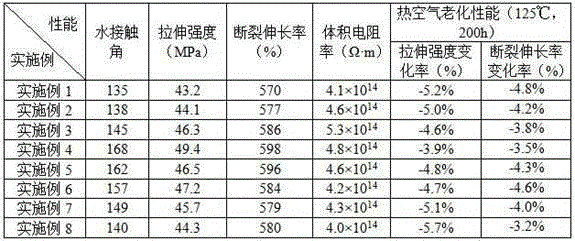

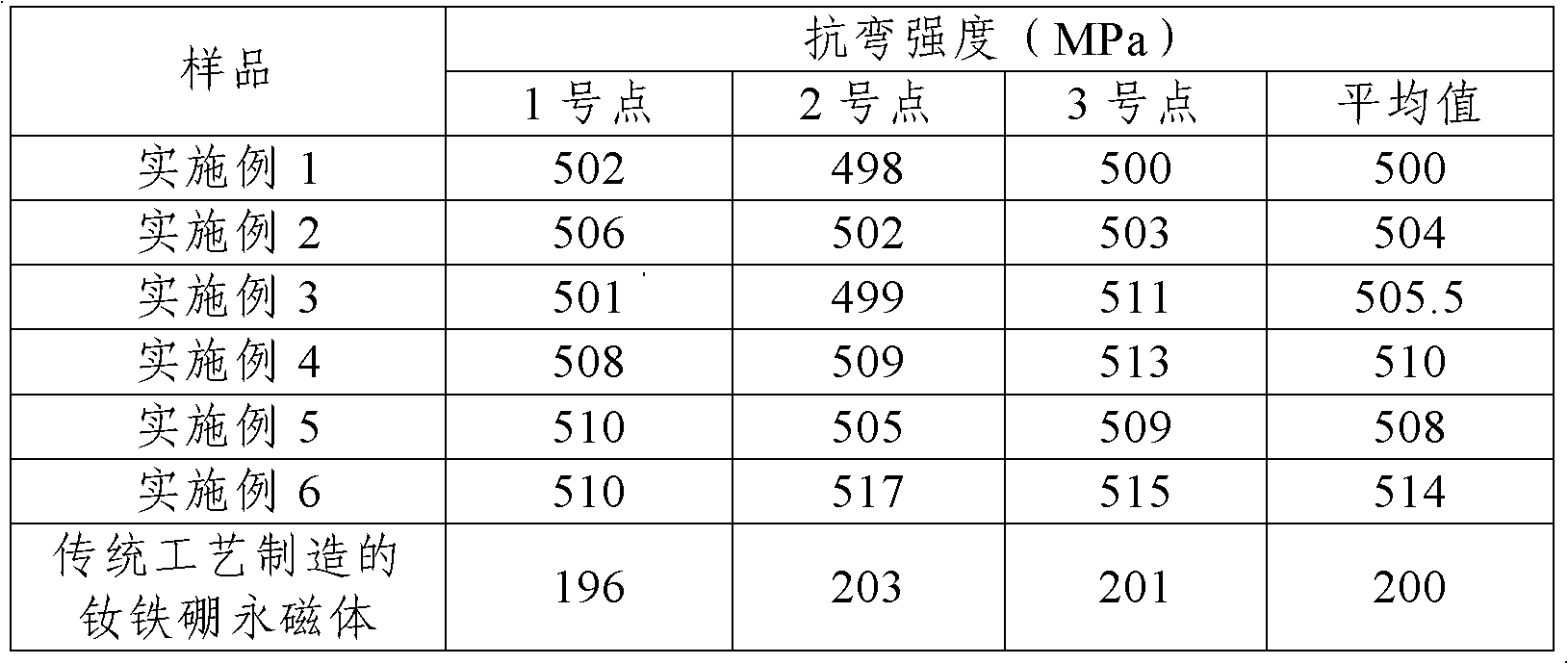

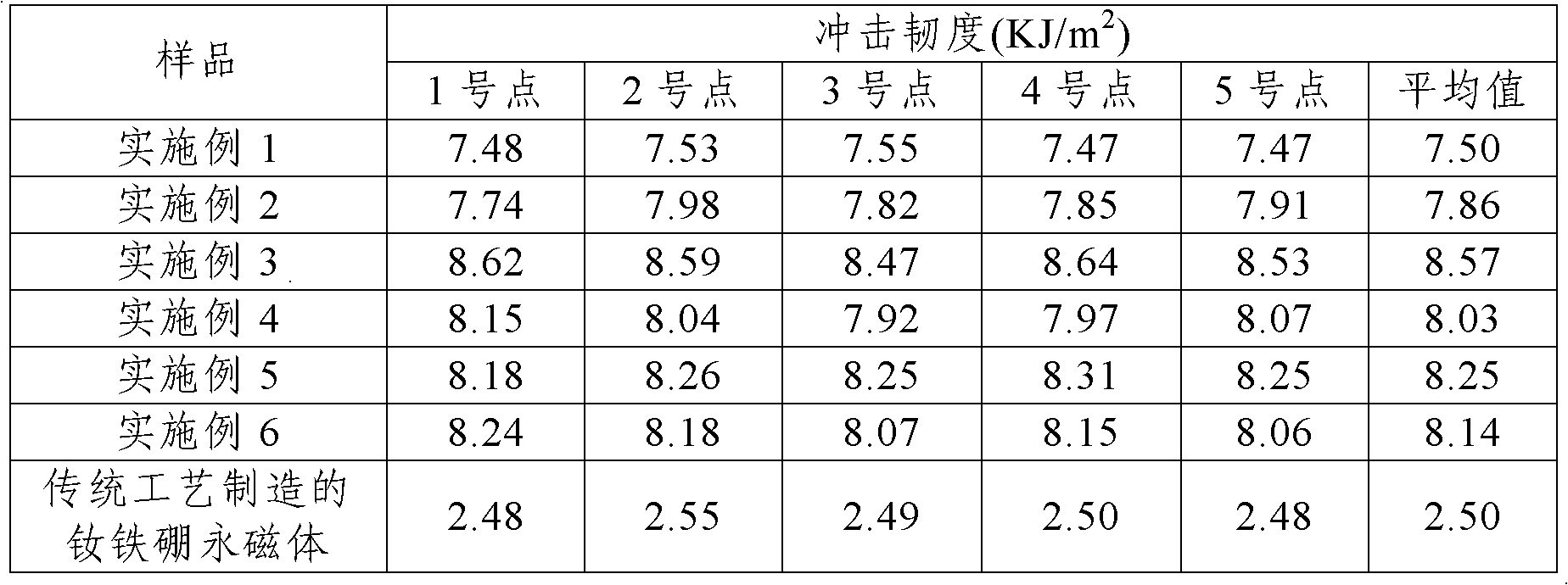

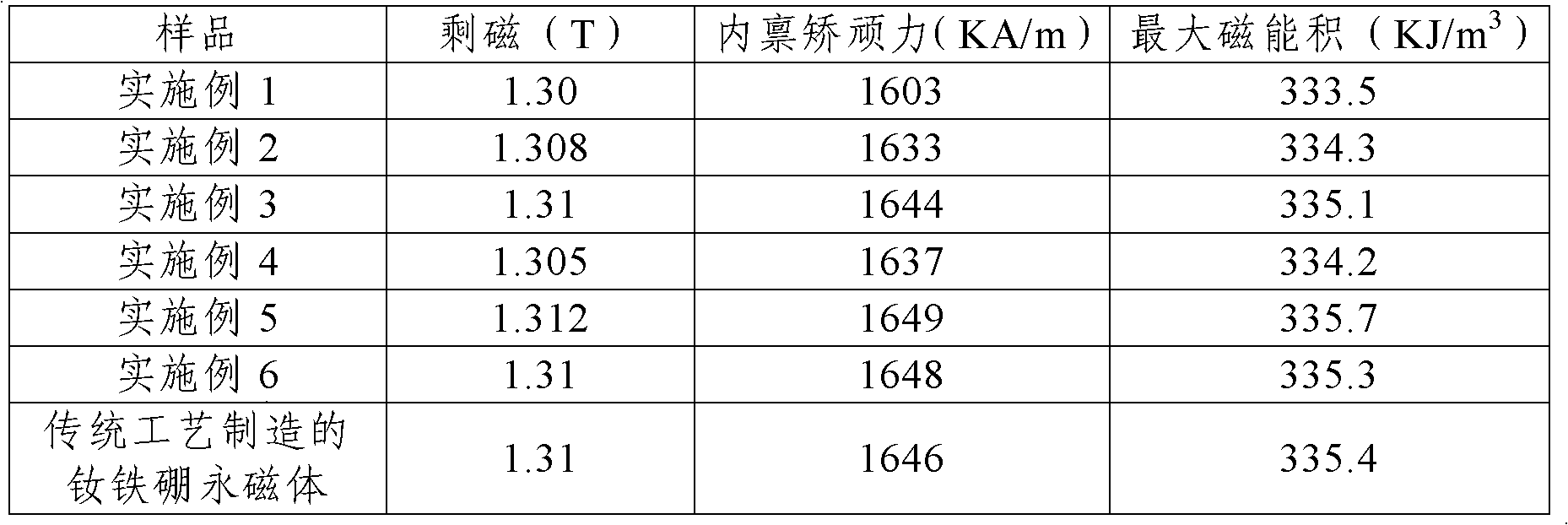

Manufacturing method of high-mechanical-strength sintered neodymium iron boron permanent magnets

ActiveCN102568738AAvoid coarseningHigh strengthPermanent magnetsInductances/transformers/magnets manufactureRare-earth elementCobalt

The invention discloses a manufacturing method of high-mechanical-strength sintered neodymium iron boron permanent magnets, which includes: firstly, utilizing rare-earth elements, iron, titanium, cobalt and boron iron alloy as raw materials and weighing the raw materials; secondly, mixing the weighed raw materials and disposing the same in a vacuum melting induction furnace, and preparing quick-hardened tablets by means of quick hardening process; thirdly, saturating the quick-hardened tablets to absorb hydrogen at the room temperature and dehydrogenating the same to prepare hydrogen decrepitation powder, then preparing magnetic powder by the hydrogen decrepitation powder through jet mill process; fourthly, molding the magnetic powder in an oriented manner, pressing to form magnets, disposing the magnets into a vacuum sintering furnace to be sintered in a vacuum environment, and performing tempering heat treatment to obtain blanks; and fifthly, machining the blanks, cleaning and removing oil, scouring to obtain high-mechanical-strength sintered neodymium iron boron permanent magnets with bending resistance strength not lower than 500MPa and impact toughness not lower than 7.5KJ / m2. By the manufacturing method, processing difficulty of the sintered neodymium iron boron permanent magnets is reduced greatly, application range of the sintered neodymium iron boron permanent magnets is broadened and economic potential thereof is high.

Owner:西安西工大思强科技股份有限公司

Carbon fiber composite material laminated plate with piezoelectric damping and preparation method thereof

InactiveCN102700203AExcellent piezoelectric damping performanceIncrease dampingSynthetic resin layered productsLaminationCarbon nanotubeGreek letter sigma

The invention provides a carbon fiber composite material laminated plate with piezoelectric damping and a preparation method thereof, and relates to a carbon fiber composite material laminated plate and a preparation method thereof. The invention aims to solve the problems that a polarization process is complex and a practical application is bad in the prior art. The carbon fiber composite material laminated plate comprises piezoelectric ceramic powder, carbon nano-tube and bismaleimide carbon fiber prepreg. The preparation method comprises the following steps of: preparing bismaleimide resin solution into the carbon fiber prepreg; grinding the polarized piezoelectric ceramic into the piezoelectric ceramic powder, and mixing the piezoelectric ceramic powder with the bismaleimide resin solution and the acidized carbon nano-tube so as to obtain pre-mixing sizing material after ultrasound; and laying the carbon fiber prepreg in a mold, painting the pre-mixing sizing material on the carbon fiber prepreg, and placing the carbon fiber prepreg into a hot press for processing so as to obtain the product. The damping los factor Delta tan sigma of the carbon fiber composite material laminated plate is more than or equal to 0.016 under a normal temperature, and the interlayer strength is improved by 3%-7%. The carbon fiber composite material laminated plate is applied to fields of aerospace crafts, naval vessels which have special usage requirements on material mechanical property and vibration and noise reduction.

Owner:HARBIN INST OF TECH

Storing up and luminous dimension stoney and manufacturing method

InactiveCN1660712ABreak through the brittle characteristics and the bottleneck of secondary processingImprove featuresFilling materialsCeramic

A light-accumulating luminescent stone is prepared through choosing silicon contained aggregate (granite, quartz sand, marble, glass, or ceramics), pulverizing, classifying, proportionally mixing, adding light accumulating and emitting material, filler and functional material (nano material, pigment and resin or cement), stirring, vibration moulding, curing and drying. It has low luminous time.

Owner:李明禹

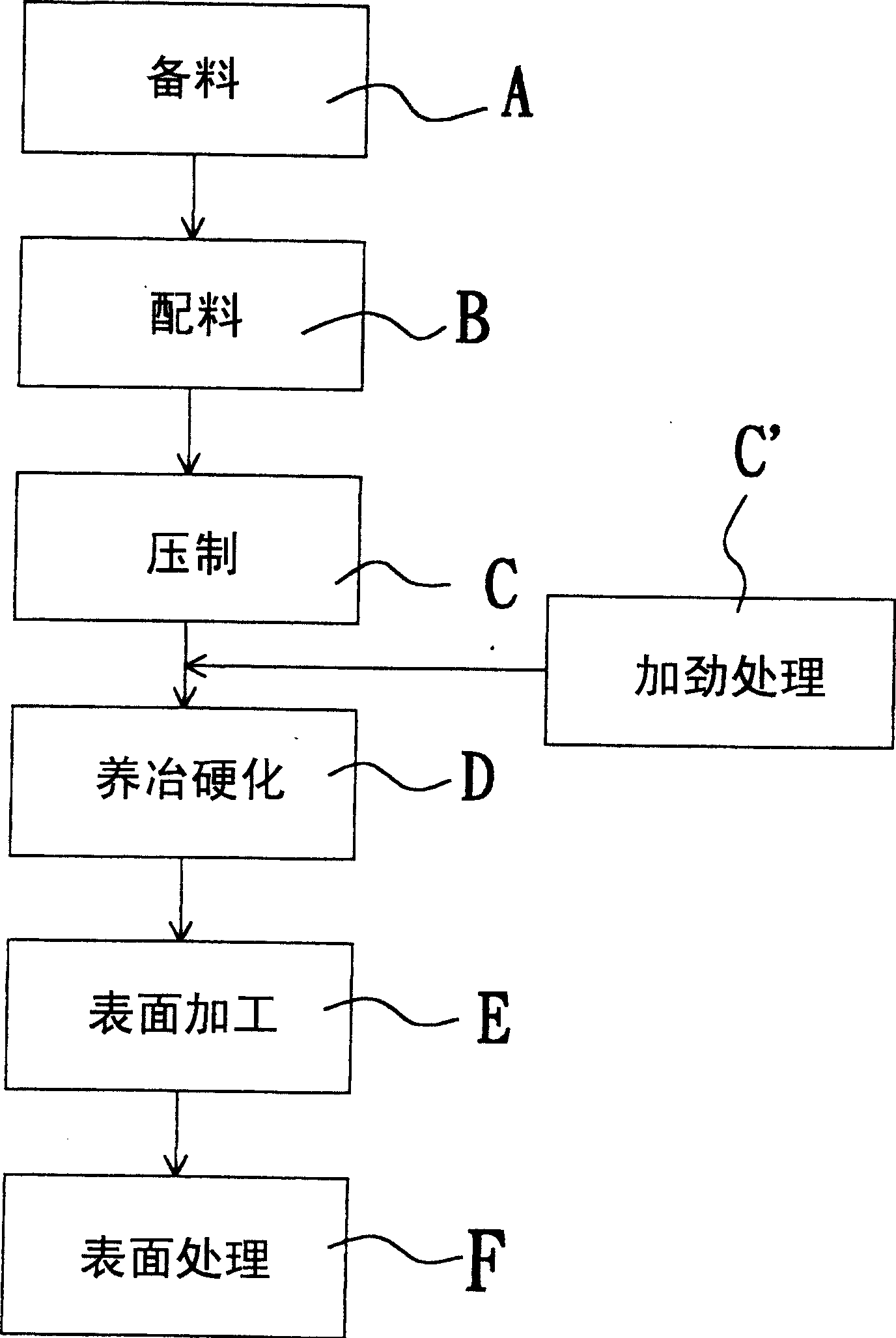

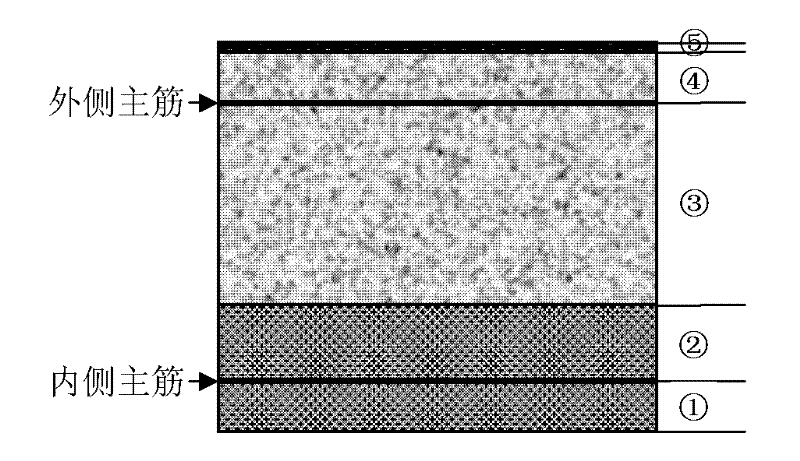

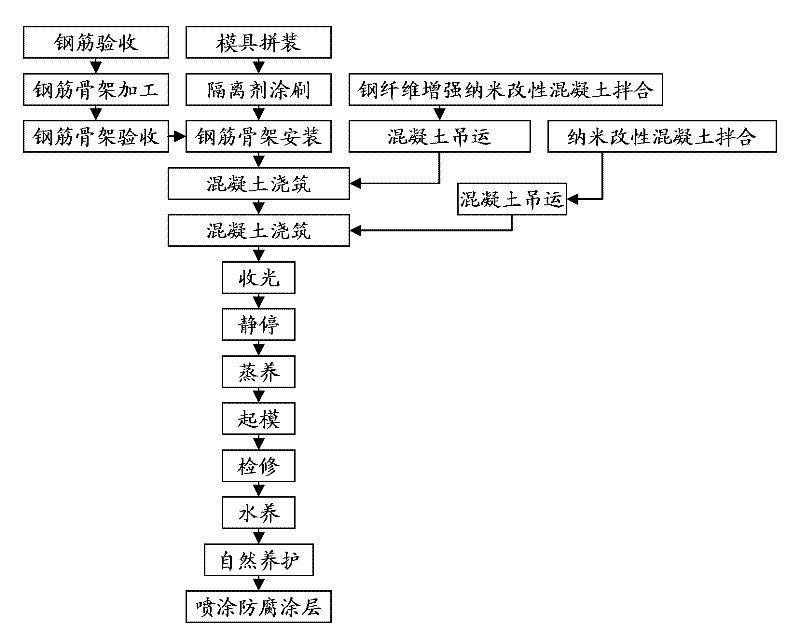

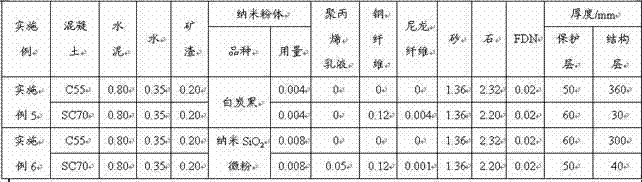

High-performance functionally-gradient shield lining segment and preparation method thereof

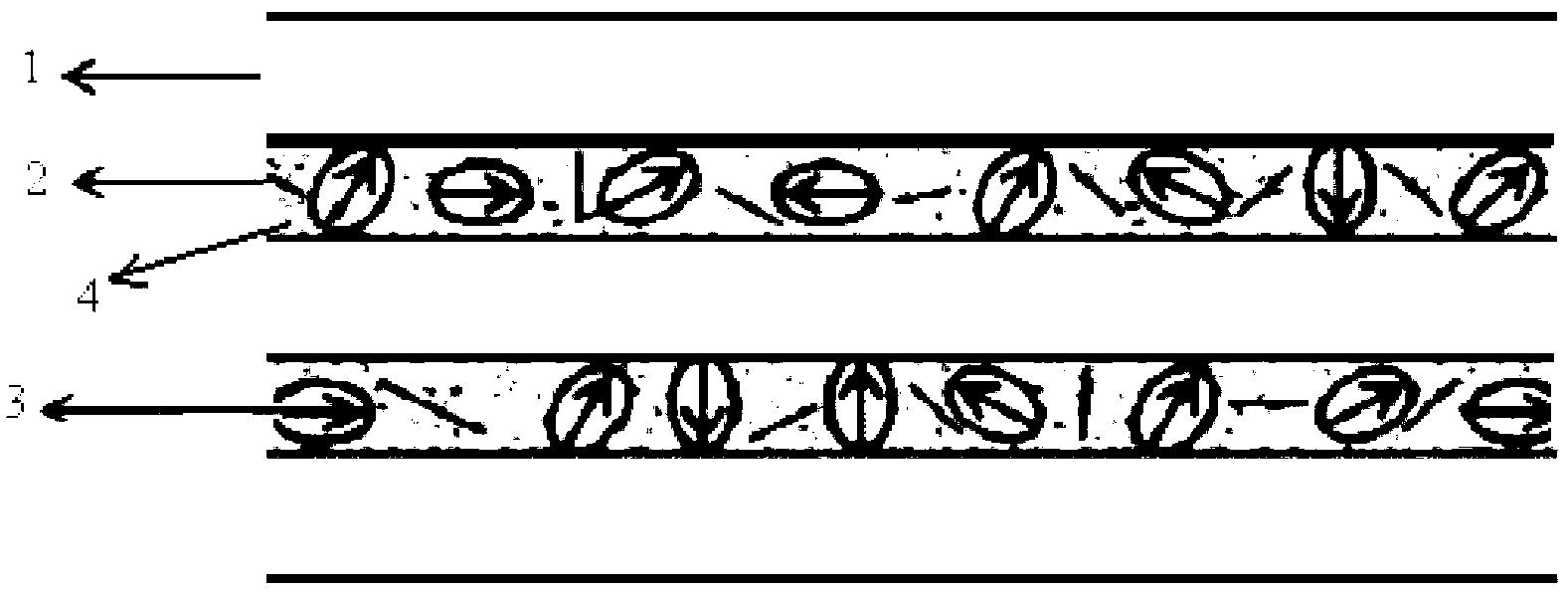

InactiveCN102207000AReduce breakage rateImproves carbonation resistanceUnderground chambersWater-setting substance layered productFiberReinforced concrete

The invention discloses a high-performance functionally-gradient shield lining segment and a preparation method thereof. The high-performance functionally-gradient shield lining segment, from top to bottom, sequentially comprises an external nano-modified concrete protection layer, an external nano-modified concrete structure layer, an internal steel fiber reinforced nano-modified concrete toughening structure layer and an internal steel fiber reinforced nano-modified concrete toughening protection layer, wherein the external nano-modified concrete protection layer and the external nano-modified concrete structure layer are connected into a whole; and the internal steel fiber reinforced nano-modified concrete toughening structure layer and the internal steel fiber reinforced nano-modifiedconcrete toughening protection layer are connected into a whole. The invention effectively solves the problems that the existing reinforced concrete segment is easy to damage, poor in durability and low in cost and the like because the existing reinforced concrete segment is completely prepared from high-toughness concrete.

Owner:ZHEJIANG UNIV OF TECH +1

Nylon/ethane-ethenol copolymer commixed type lamination barrier material and its preparation method

Owner:武汉中泽恒远生物材料技术有限公司

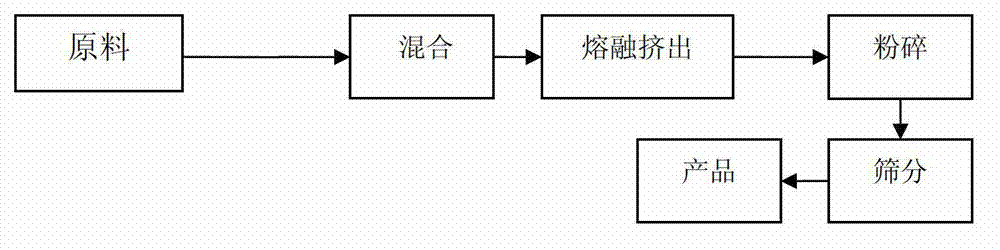

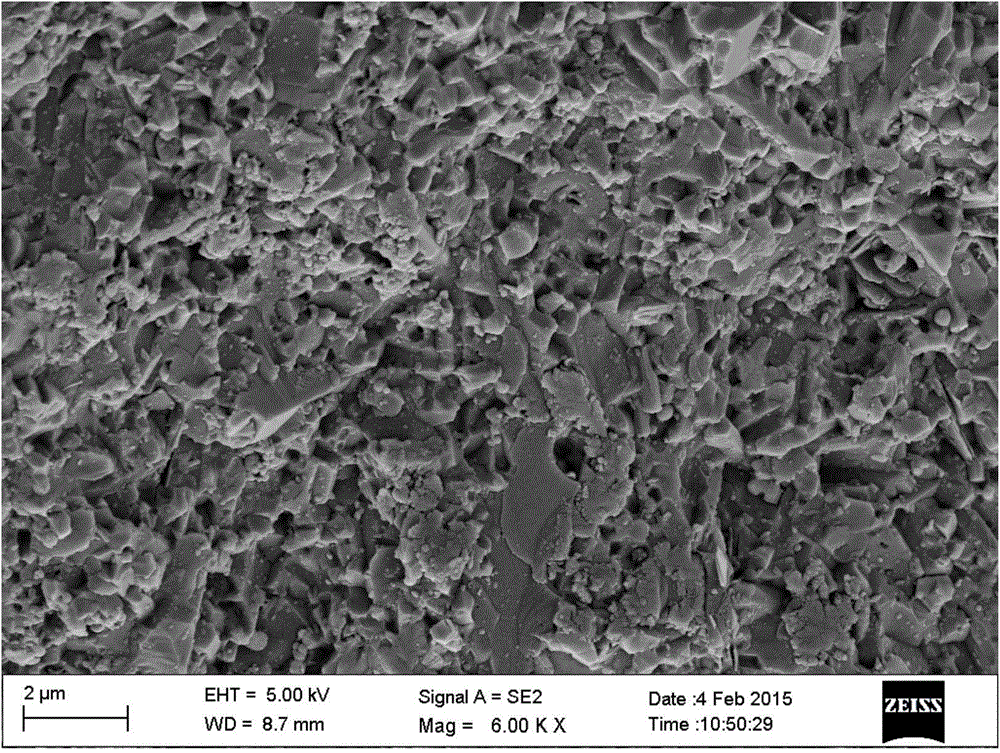

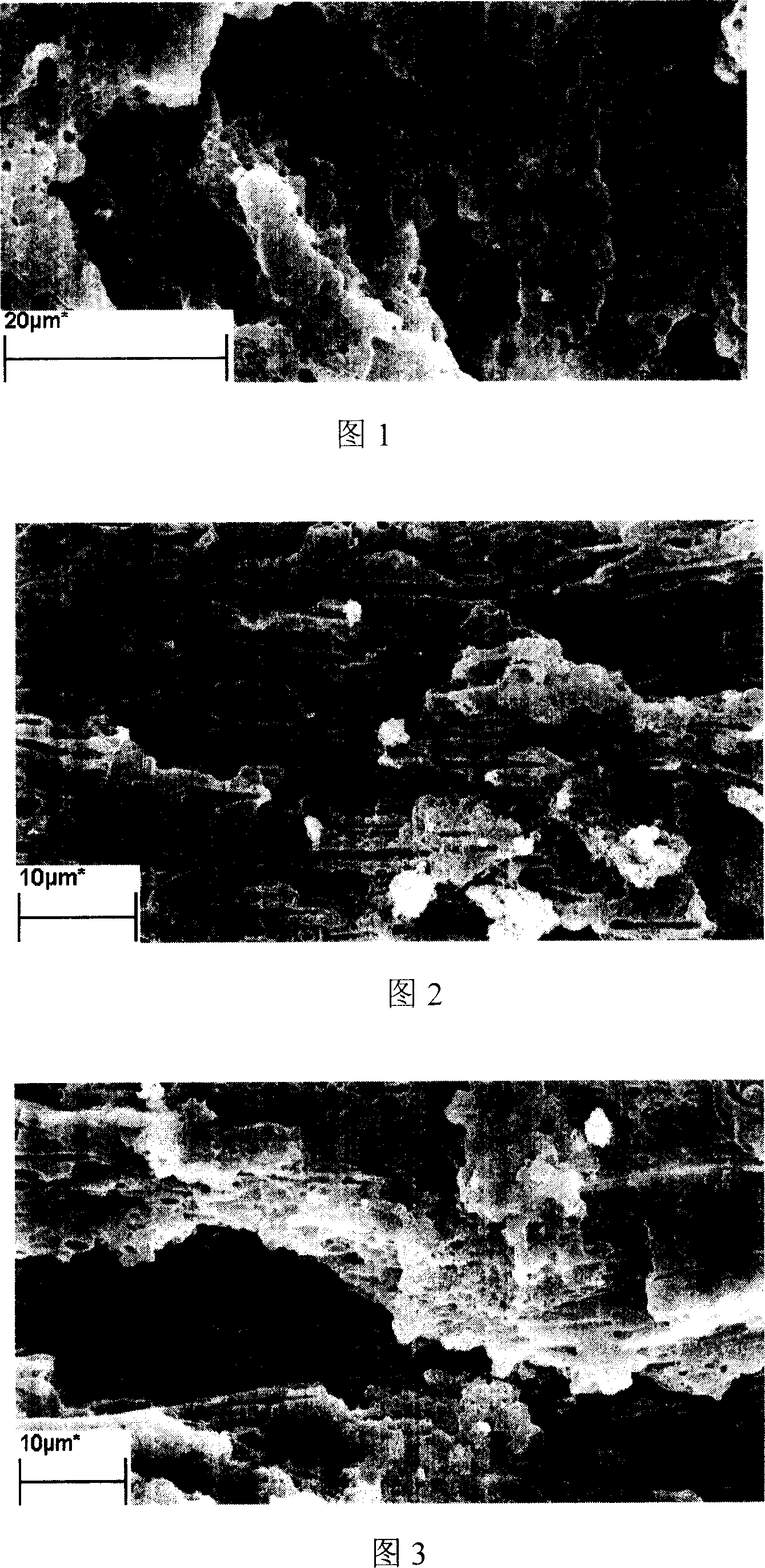

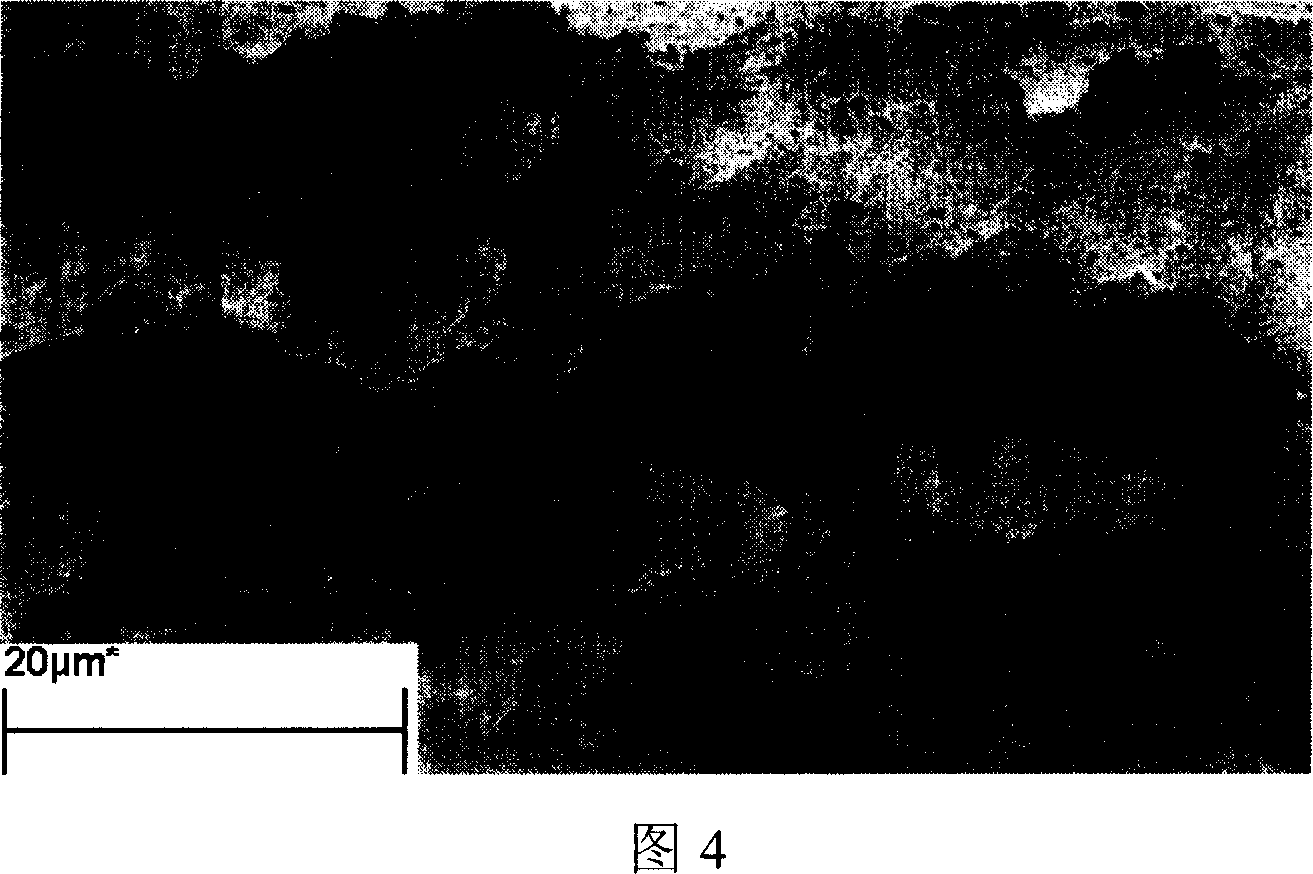

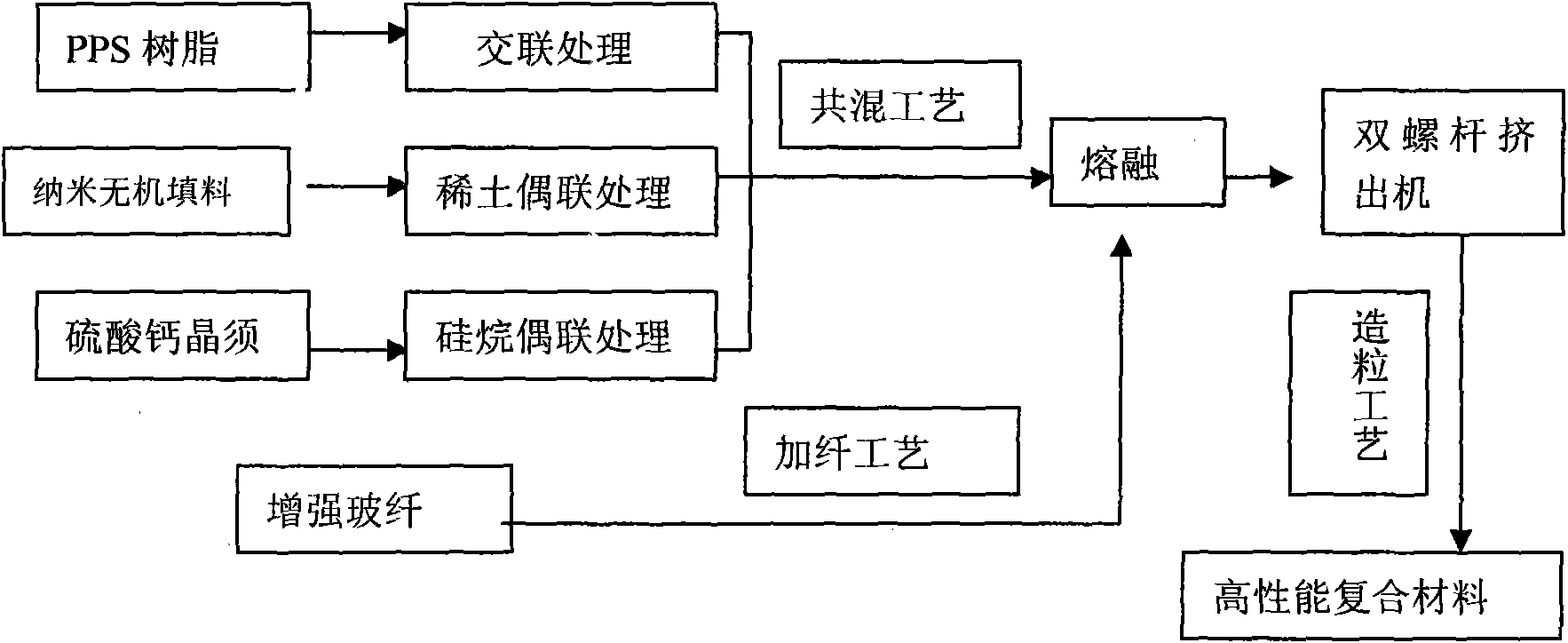

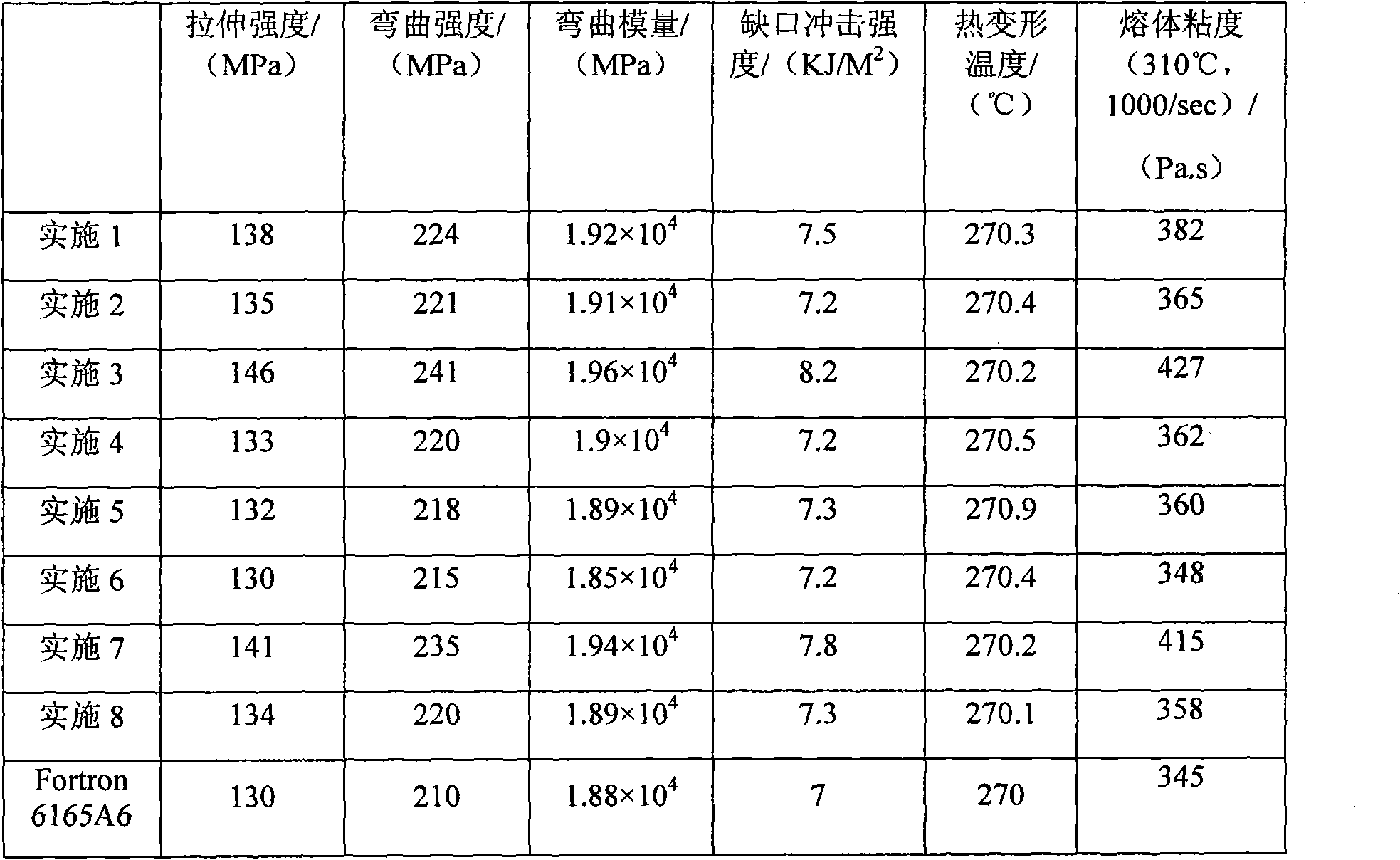

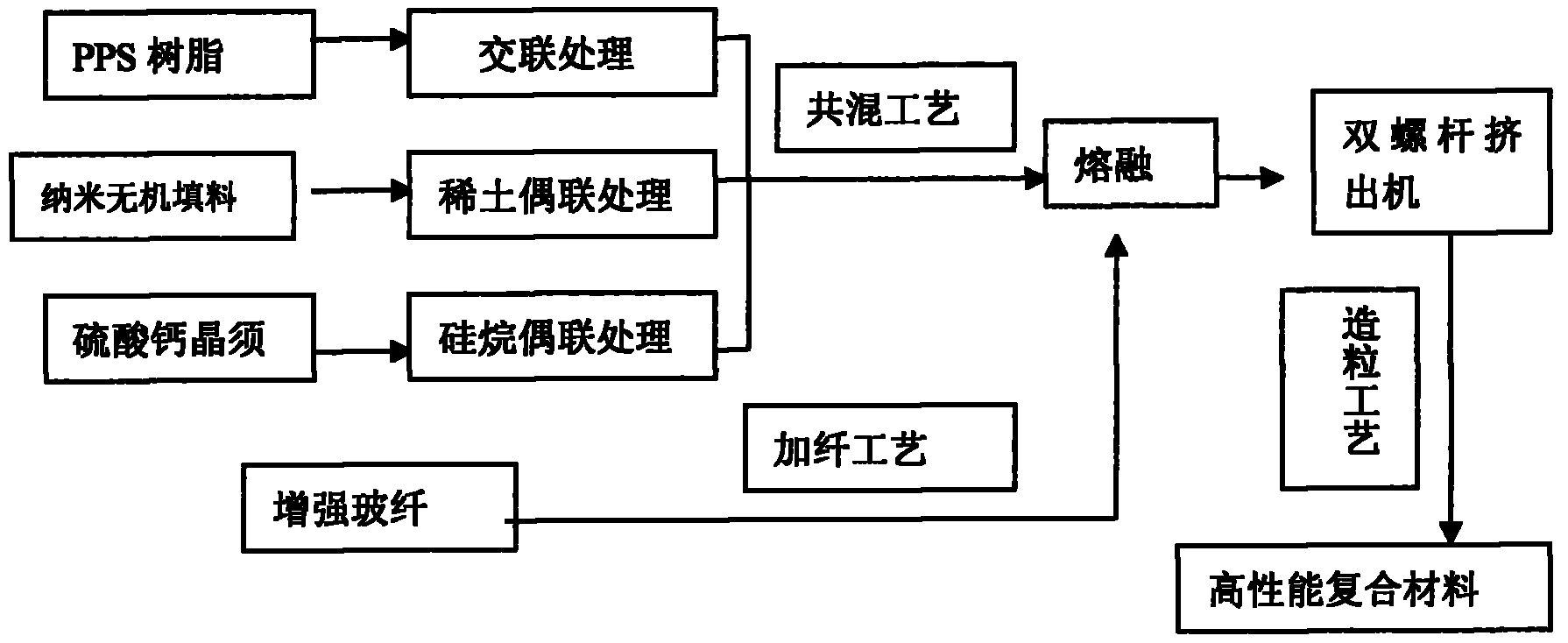

Polyphenylene sulfide nano whisker composite material and preparation method thereof

The invention discloses a polyphenylene sulfide nano whisker composite material and a preparation method thereof. The composite material comprises the following raw material components in percentage by mass: 24 to 39 percent of polyphenylene sulfide(PPS), 15 percent of calcium sulfate whisker, 40 percent of glass fiber(GF), 2.5 to 17.5 percent of nano inorganic filler, 0.8 to 2.5 percent of rare-earth coupling agent (DN-930), 0.5 percent of silane coupling agent (KH-550) and 0.5 percent of antioxidant (1010). The preparation method comprises the following steps: crosslinking PPS resin; preparing the nano inorganic filler treated by the rare-earth coupling agent and the calcium sulfate whisker treated by the silane coupling agent; mixing the materials; and extruding the mixture to form grains of the polyphenylene sulfide nano whisker composite material. The obtained polyphenylene sulfide nano whisker composite material has the advantages of high mechanical strength, good material flow rate and low unit production cost.

Owner:四川华通特种工程塑料研究中心有限公司

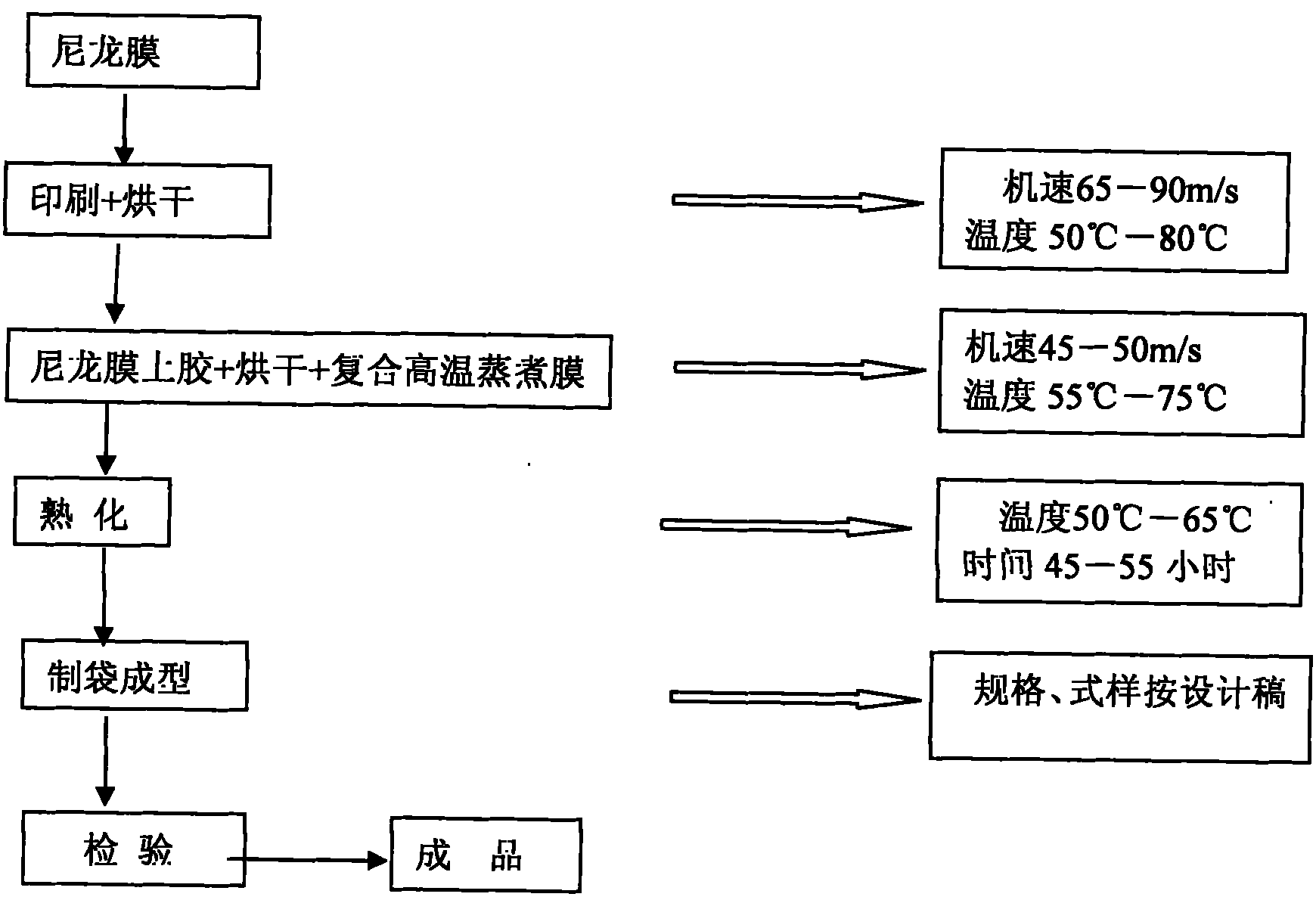

Manufacturing method of vacuum cooking and packaging bag for food

InactiveCN101837855AIncrease air flowImprove toughness and strengthLamination ancillary operationsBagsCompound aEngineering

The invention relates to a manufacturing method of a vacuum cooking and packaging bag for food, which comprises the following steps: selecting and proportioning raw materials and controlling the process flow; compounding a BOPA with an RCPP; firstly, delivering the printed BOPA into a compounding process; and proportioning a polyurethane glue and a solvent by weight; stirring uniformly and gluing on the BOPA; and manufacturing and forming a bag by heating in a drying tunnel, aging at constant temperature and heat sealing. After the food is packaged in vacuum, the vacuum package can resist high-temperature cooking and sterilizing at 135 DEG C for 30 minutes, and the packaging bag can not loose or leak air, can ensure the quality of the food and prolong the preservation and quality guarantee period of the food.

Owner:赵秀雄

Anti-impact MPP (molypermalloy powder core) electric protection tube

The invention discloses an anti-impact MPP (molypermalloy powder core) electric protection tube. The anti-impact MPP electric protection tube is prepared from the following raw materials in parts by weight: 90-110 parts of polypropylene, 5-15 parts of ethylene-propylene-diene monomer, 10-25 parts of talcum powder, 3-10 parts of brucite powder, 5-12 parts of modified micro silicon powder, 0.8-2 parts of colouring agent, 5-15 parts of nano mica, 0.5-2 parts of antioxidant, 0.5-2 parts of polytetrafluoroethylene, 10-25 parts of modified shell powder, 5-15 parts of modified hectorite, 5-25 parts of novel organic montmorillonite, 5-18 parts of melamine cyanurate, 10-25 parts of modified crystal whisker, 15-30 parts of long glass fiber, 3-8 parts of expandable graphite and 5-20 parts of intumescent flame retardants. The anti-impact MPP electric protection tube has excellent impact resistance, flame retardance, ageing resistance, cold resistance and heat resistance.

Owner:安徽宁国市高新管业有限公司

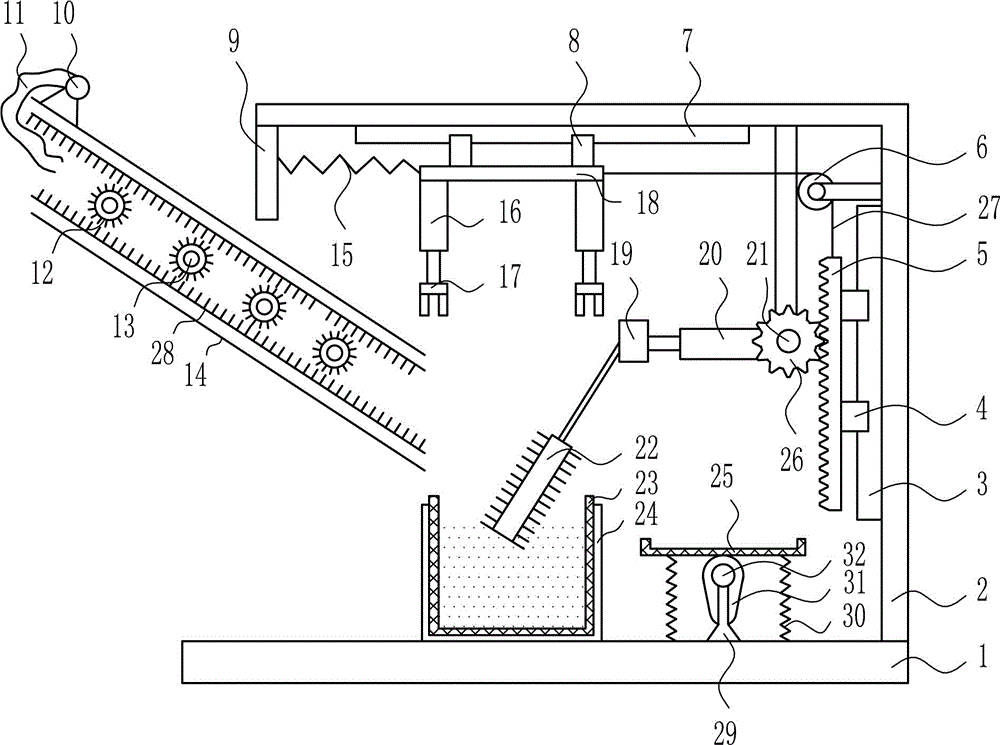

Fast cleaning device for sport tennis balls

InactiveCN106180031AIncrease the speed of drippingFast dryingCleaning using toolsGear wheelMaterial resources

The invention relates to a cleaning device, in particular to a fast cleaning device for sport tennis balls. The fast cleaning device for the sport tennis balls is thorough in cleaning, capable of protecting fluff on the surfaces of the tennis balls, and high in working efficiency. In order to achieve the technical purposes, the fast cleaning device for the sport tennis balls comprises a base plate, a right support, a first slide rail, first slide blocks, a rack, a guide wheel, second slide blocks, a support rod, a water pump, a flexible pipe, first hairbrushes, first motors, a transfer passage, a first spring, first electric push rods, thumb cylinders, a movable plate, a connecting device, a filter case, a cleaning case, a storing case, a gear, a stay cord and the like; and the cleaning case, the filter case and the storing case are sequentially arranged on the base plate from left to right. By utilization of the fast cleaning device for the sport tennis balls, the effects that cleaning is thorough, the fluff on the surfaces of the tennis balls can be protected, and the working efficiency is high are achieved, manpower and material resources are saved, time for cleaning the tennis balls is reduced, and the tennis balls are clean.

Owner:叶明

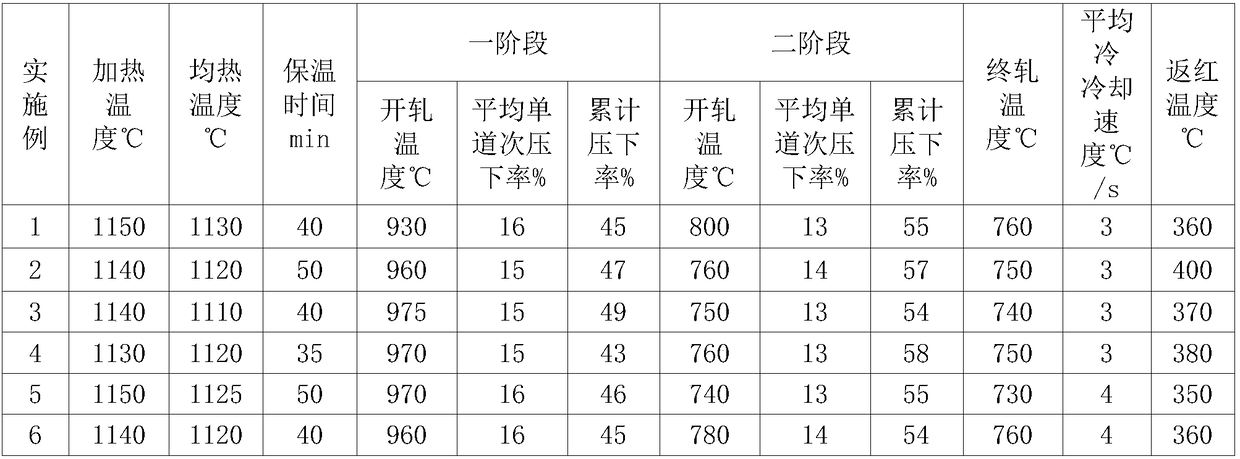

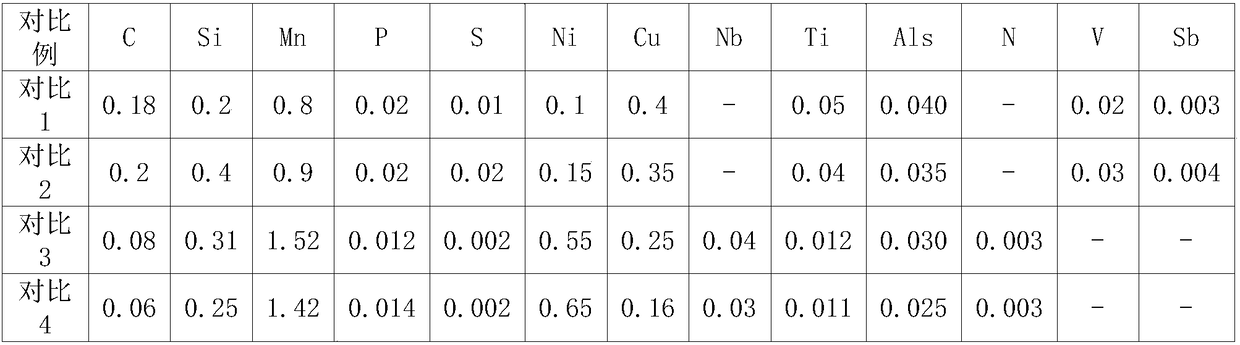

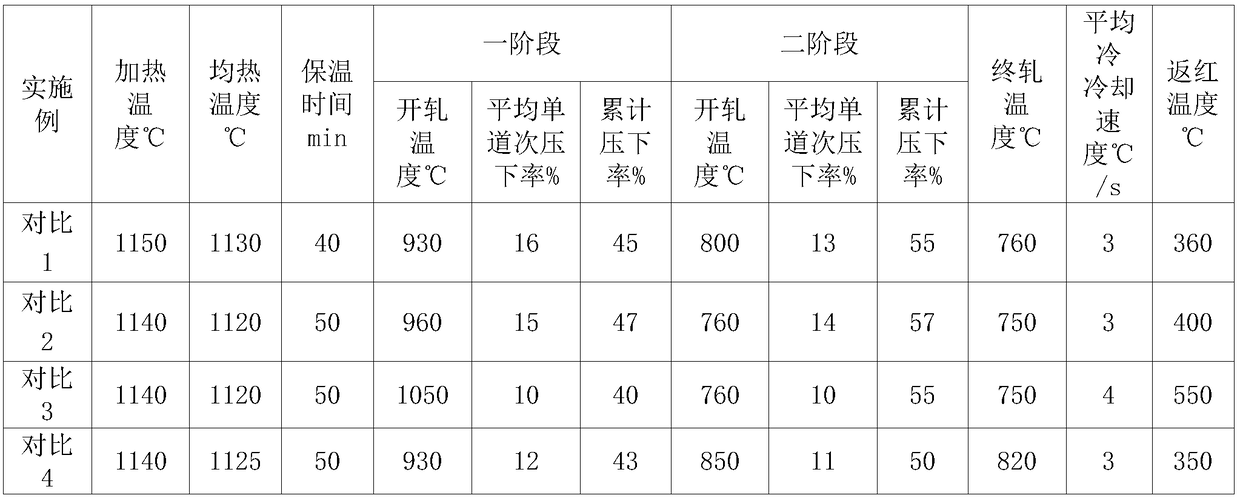

High-strength thick steel plate with excellent crack-arrest property and manufacturing method thereof

The invention relates to a high-strength thick steel plate with an excellent crack-arrest property. The steel plate has the following characteristics: a wide-plate tensile value Kca for determining the crack-arrest property is larger than 6000 N / mm<1.5>; yield strength at the positions, which are respectively 1 / 4 and 1 / 2 the thickness of the steel plate away from the surface of the steel plate, isno less than 460 MPa; tensile strength is 570 to 720 MPa; Charpy impact energy at minus 40 DEG C is no less than 200 J; and a zero-ductility transition temperature is less than minus 60 DEG C. The steel plate provided by the invention comprises the following components by weight: 0.04 to 0.16% of C, 0.1 to 0.5% of Si, 0.9 to 1.6% of Mn, 0.1 to 0.3% of Cu, 0.2 to 0.9% of Ni, no more than 0.02% ofP, no more than 0.02% of S, 0.01% to 0.05% of Als, 0.002 to 0.010% of N, 0.02% to 0.05% of Nb and 0.01 to 0.03% of Ti, with the balance being Fe and unavoidable impurities. According to the invention,through optimization of chemical components of a high-strength steel plate and adoption of controlled rolling and controlled cooling processes for controlling the microscopic structure and grain sizein a plate thickness direction, the crack-arrest steel plate with high yield and stable strength and toughness is obtained. The high-strength thick steel plate provided by the Invention is used as container vessel steel, and has the characteristics of excellent crack-arrest toughness, high yield strength, excellent low-temperature toughness and large thickness.

Owner:ANGANG STEEL CO LTD

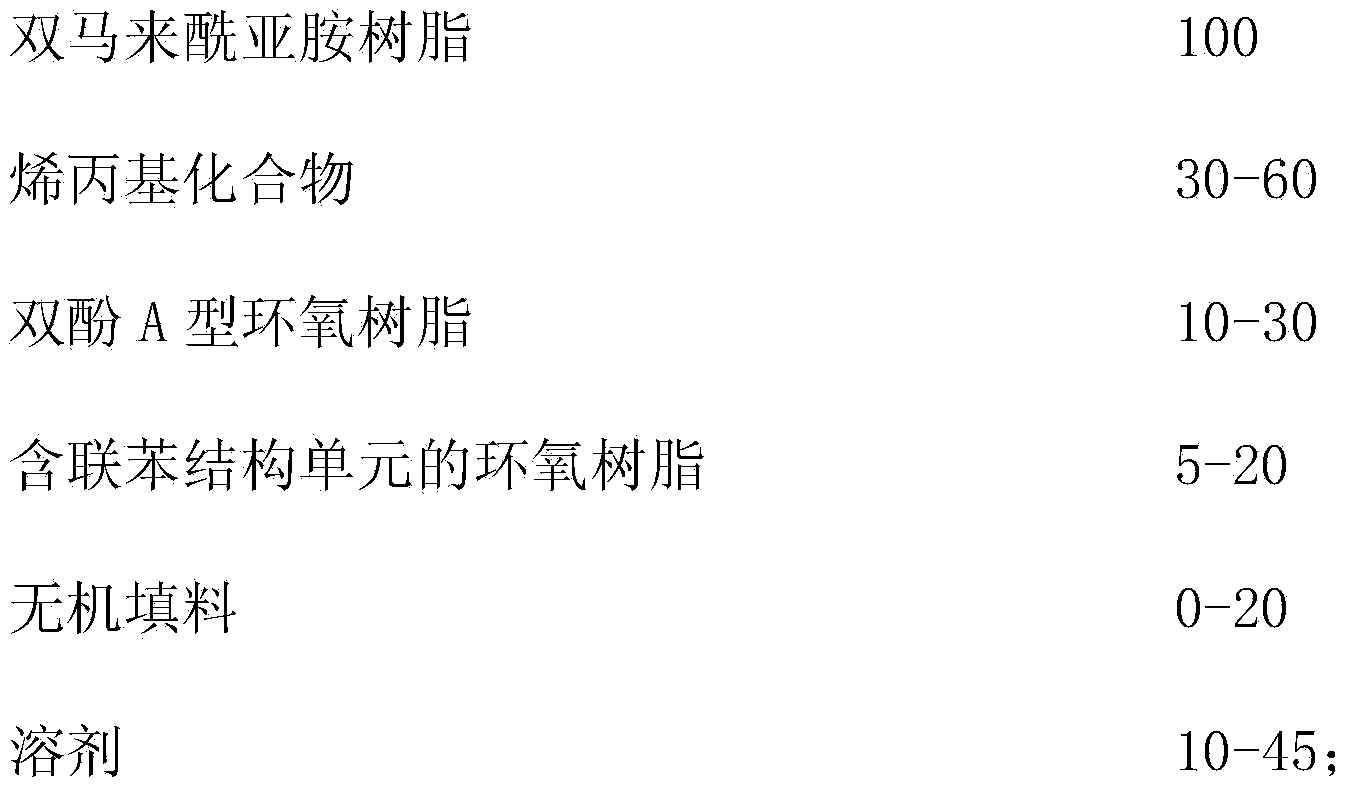

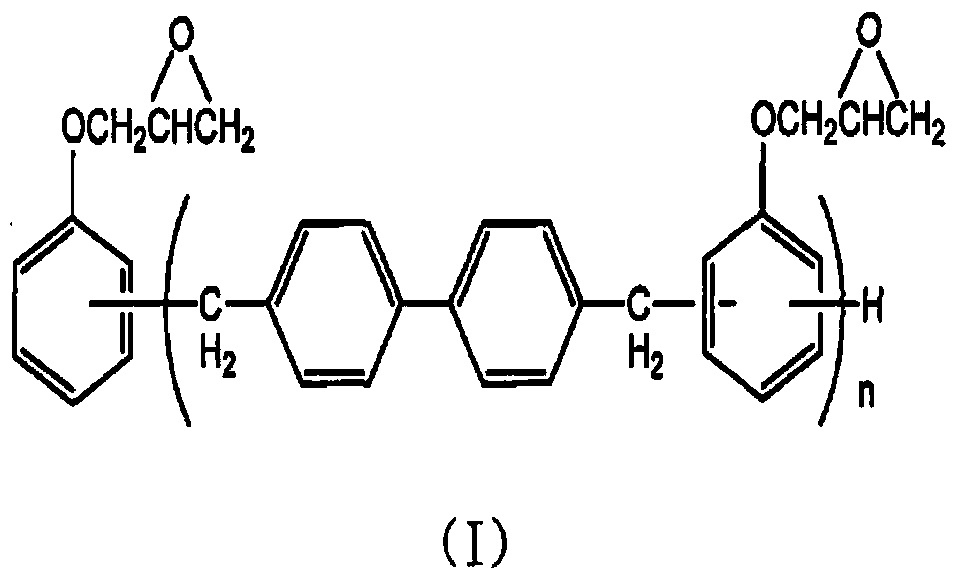

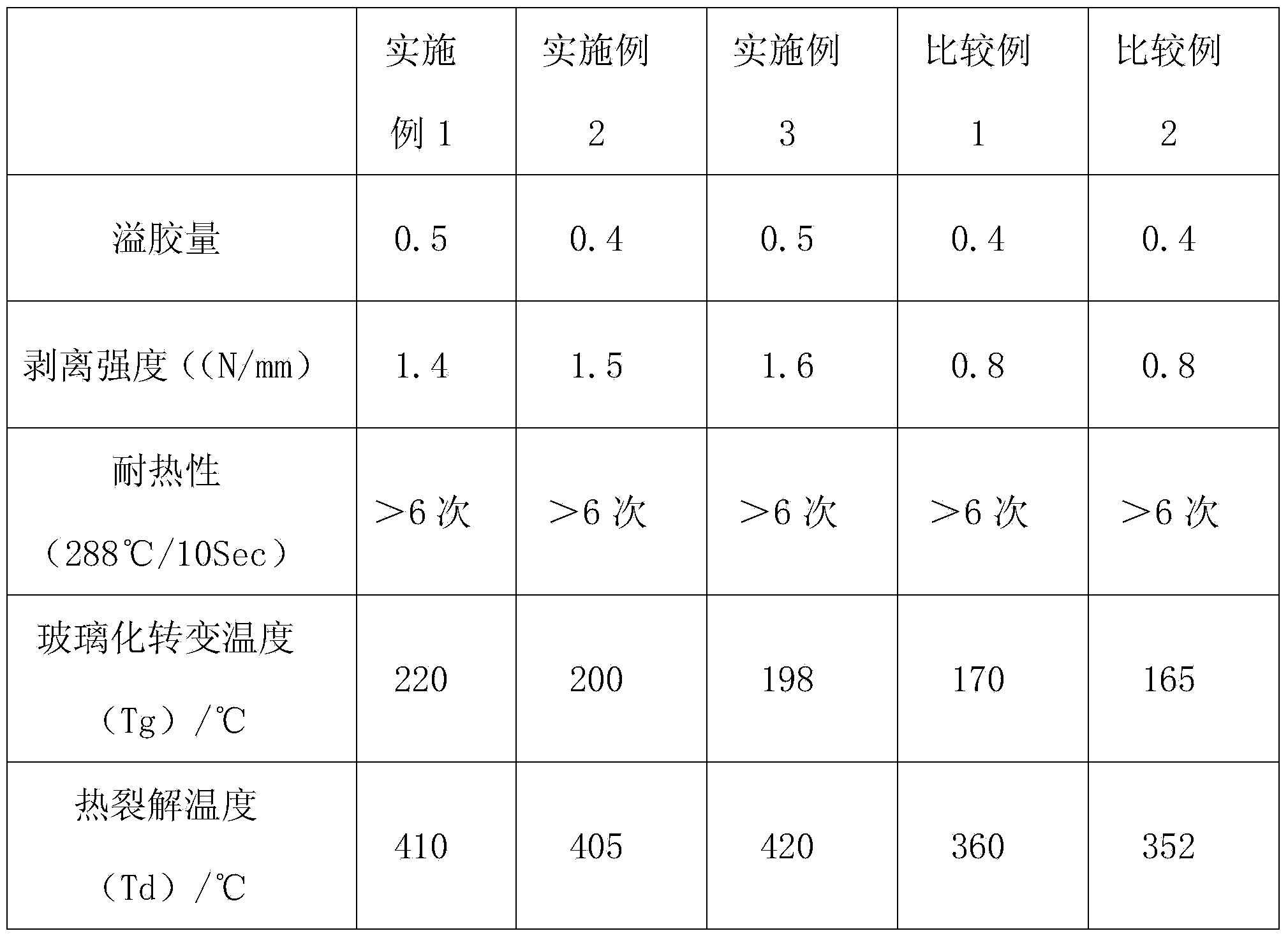

Low resin fluidity prepreg and preparation method thereof

The invention provides a low resin fluidity prepreg, which has an enhanced material and thermosetting resin composition, the enhanced material is electronic grade glass fiber cloth, and the thermosetting resin composition is composed of 100 parts of bimaleimide resin, 30-60 parts of allyl compound, 10-30 parts of bisphenol A epoxy resin, 5-20 parts of epoxy resin containing a biphenyl structure unit, 0-20 parts of inorganic filling material and 10-45 parts of solvent. The low resin fluidity prepreg has the advantages of high flexibility and bonding strength, no glue flowing condition, and long-term preservation, the disadvantages that reliability of a rigid-flex combined printed circuit board made by the same kind products is decreased due to low bonding degree of the same kind products can be solved, the transition temperature of the solidified glass can reach as high as more than 200 DEG C, so that the heat resistance and processing toughness of the rigid-flex combined printed circuit board are increased.

Owner:VENTEC ELECTRONICS SUZHOU

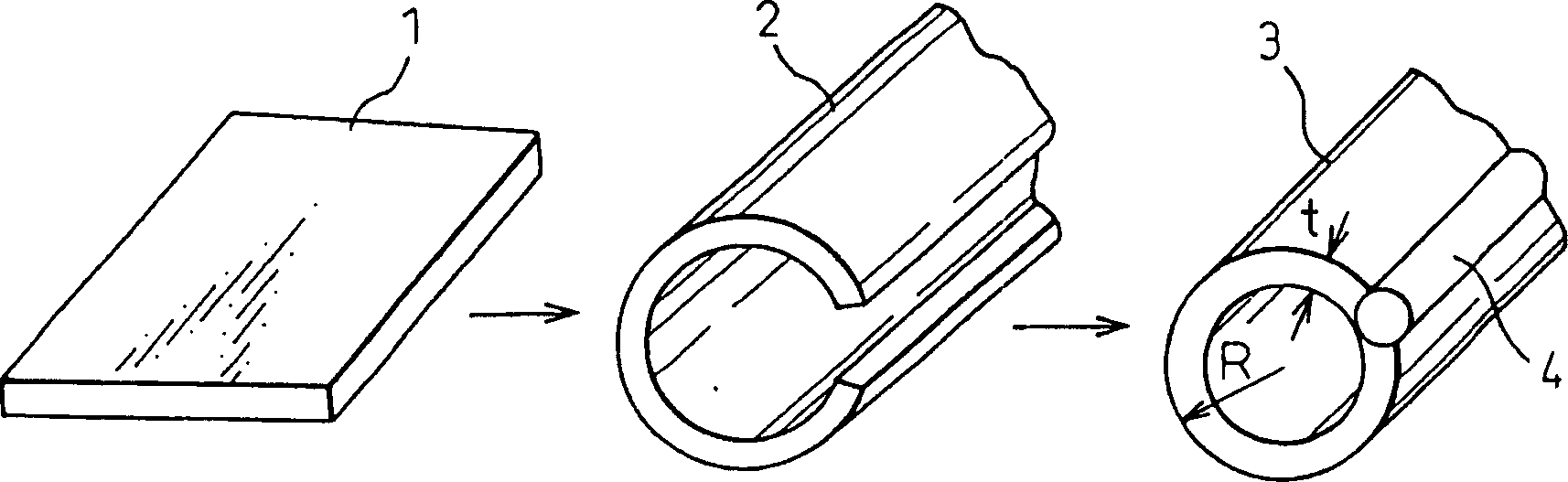

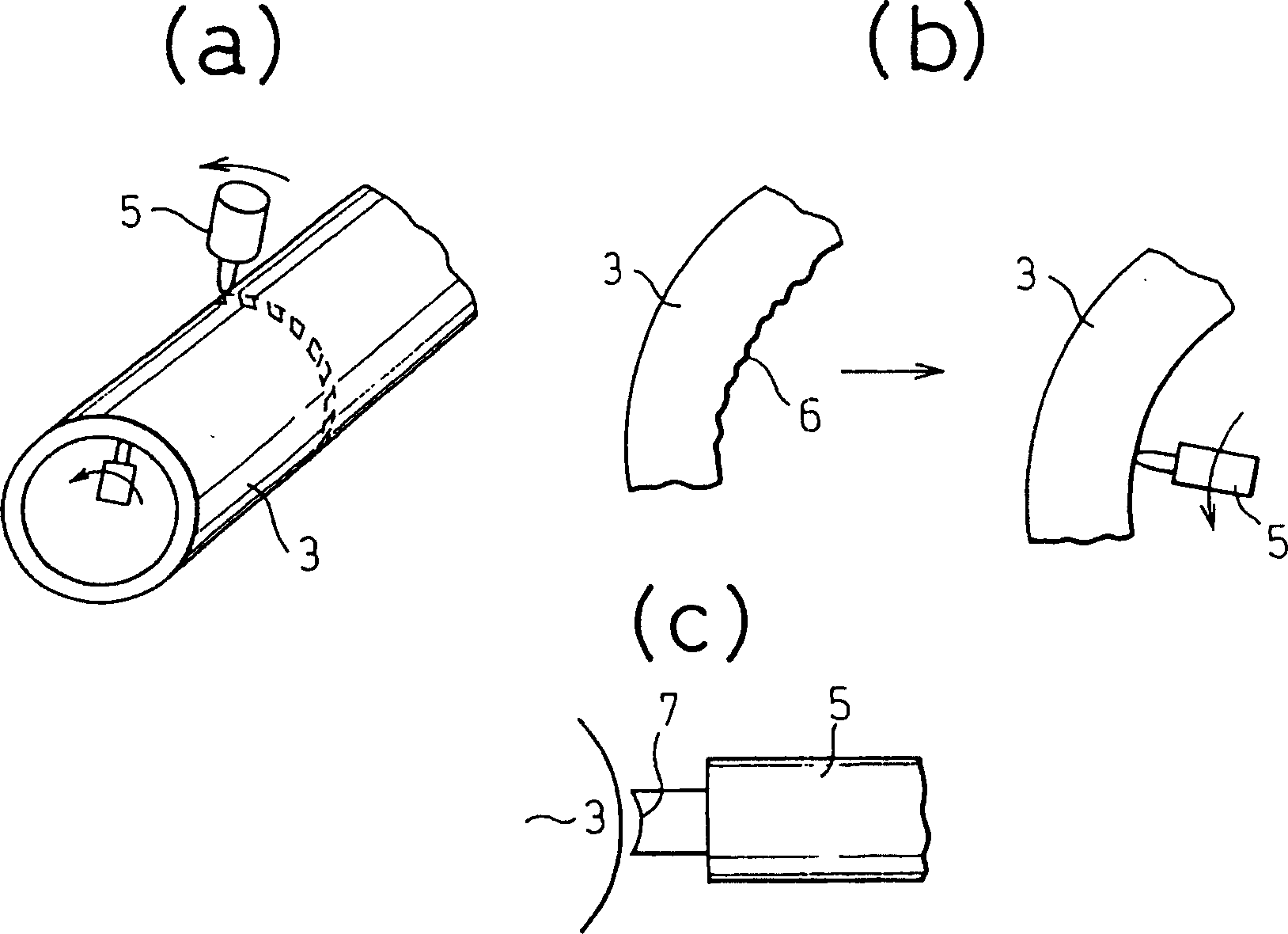

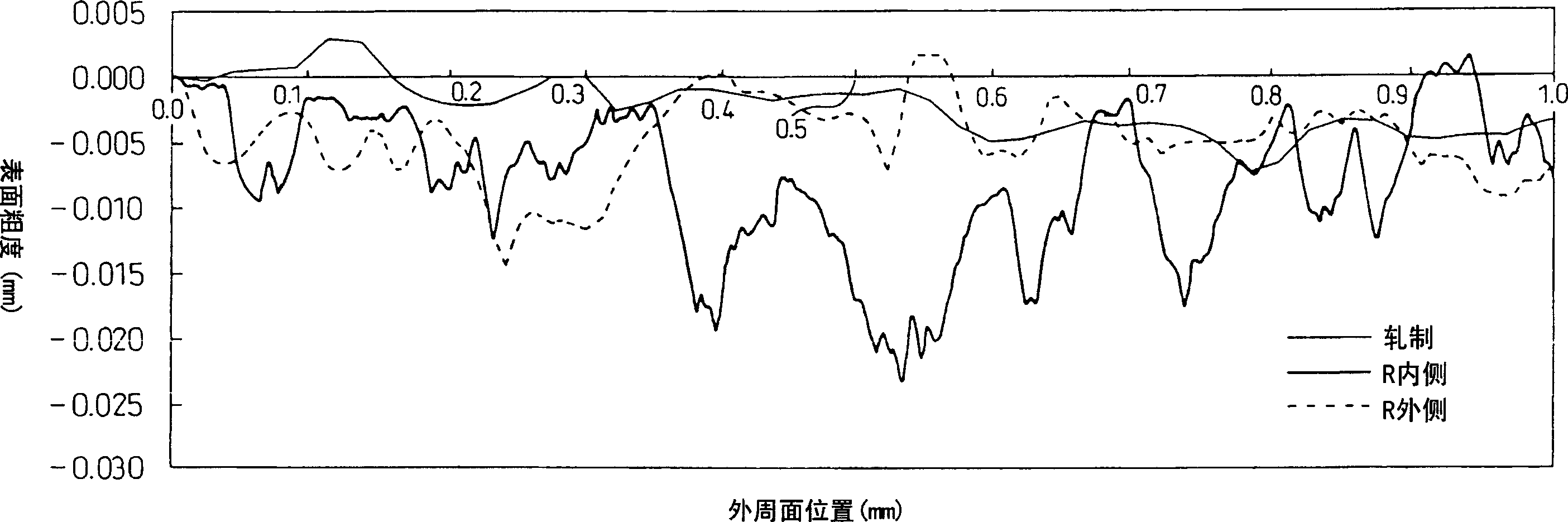

Method of increasing strength of cold worked part by ultrasonic shock treatment, and metal product with high fracture toughness and fatigue strength

ActiveCN1714162AReduce residual stressImprove toughness and strengthFatigue IntensityUltrasonic impact treatment

The invention provides a method for improving the strength of a cold-worked part by ultrasonic impact treatment. By implementing ultrasonic impact treatment on the surface of the stretched side of the metal cold-bending process, the surface hardness can be made higher than that of the surface without ultrasonic impact treatment. The surface hardness is increased by more than 10%, and the tensile residual stress can be reduced, and the fracture toughness and fatigue strength can be improved.

Owner:NIPPON STEEL CORP

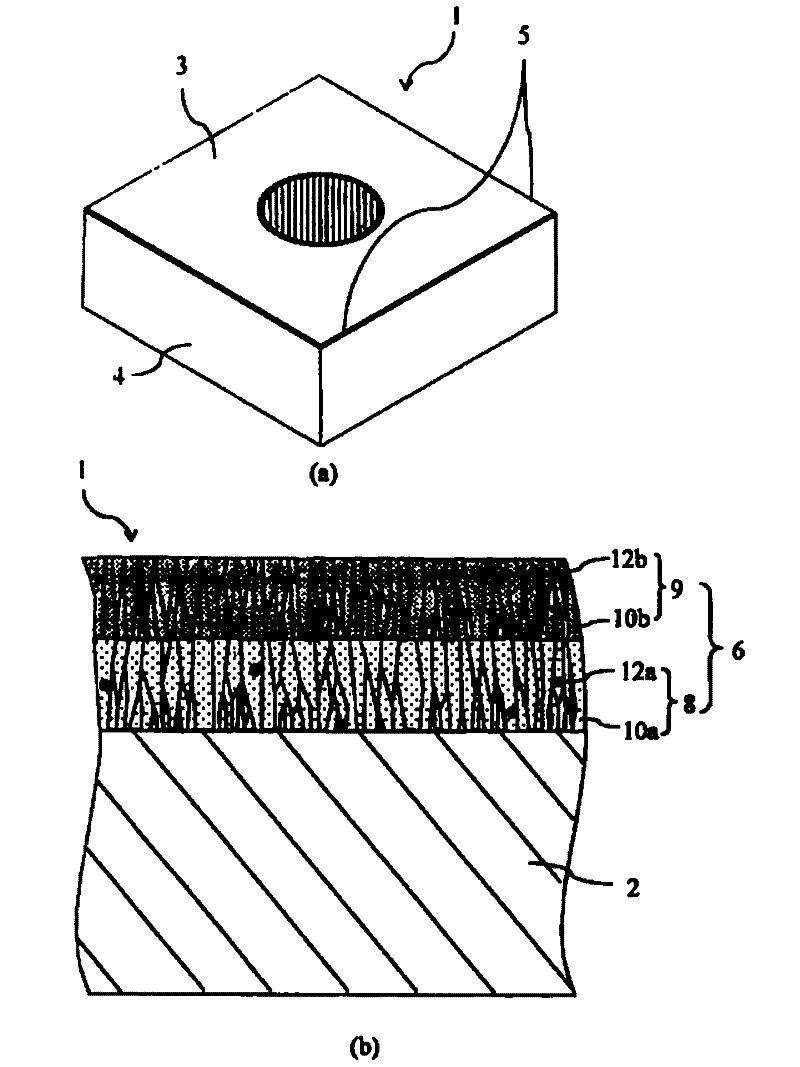

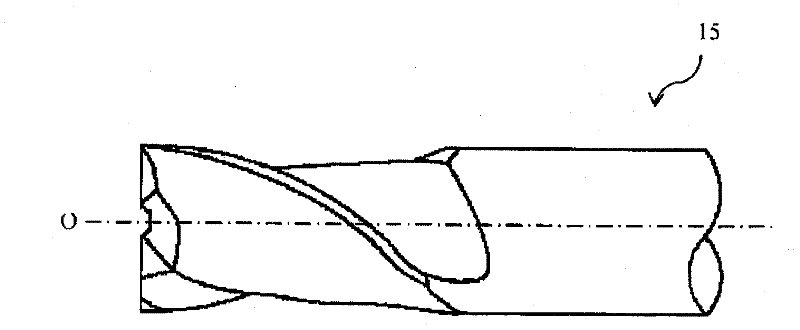

Surface covered tool

ActiveCN102196874AThe average crystal width is smallReduce distribution densityMilling cuttersVacuum evaporation coatingVolumetric Mass DensityUpper floor

Disclosed is a surface covered tool, such as a cutting tool (1), wherein the surface of a base body (2) is covered with a cover layer (6), the cover layer (6) is composed of a lower layer (8) and an upper layer (9), and the lower layer (8) and the upper layer (9) are both composed of columnar particles (10) extending perpendicularly to the surface of the base body (2). The average crystal width of the columnar particles (10b) constituting the upper layer (9) is smaller than the average crystal width of the columnar particles constituting the lower layer, dispersed particles containing tungsten exist in both the lower layer and the upper layer, and the distribution density of the dispersed particles existing in the upper layer is smaller than the distribution density of the dispersed particles existing in the lower layer. The surface covered tool is provided with the cover layer which improves abrasion resistance and defect resistance.

Owner:KYOCERA CORP

Special PU (polyurethane) plate for automobile roof and prepared by one-step wet method

The invention discloses a special PU (polyurethane) plate for an automobile roof and prepared by a one-step wet method. The special PU plate is prepared by uniformly mixing the following raw materials in parts by weight, namely 100 parts of a mixture of polyether polyol and polyester polyol, 1-3 parts of mixed sillicon oil, 0.1-0.5 part of amine catalyst, 5-20 parts of mixed foaming agent, 0.1-0.3 part of delaying catalyst and 1.0-2.0 parts of pore forming agent, to obtain a material A, performing reaction of the material A and 140-175 parts of modifying material B to obtain a big foamed block, and slicing. The special PU plate is applicable to the automobile roof manufactured by the one-step wet method; and the special PU plate is good in toughness, high in size stability and low in cost.

Owner:YANTAI ZHENGHAI HIGH TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com