Anti-impact MPP (molypermalloy powder core) electric protection tube

A technology for power protection and impact resistance, which is applied in the field of impact-resistant MPP power protection tubes, can solve problems such as difficulty in fluidity and mechanical properties, high flexibility of PP molecular chains, and high elasticity of melt extrusion, so as to improve rigidity, The effect of increasing the number of spherulites and improving the degree of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

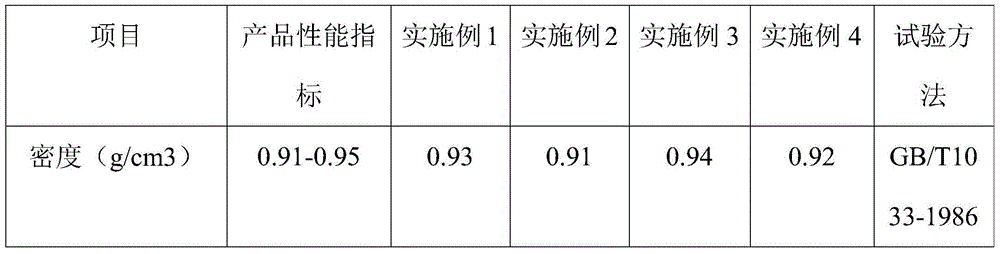

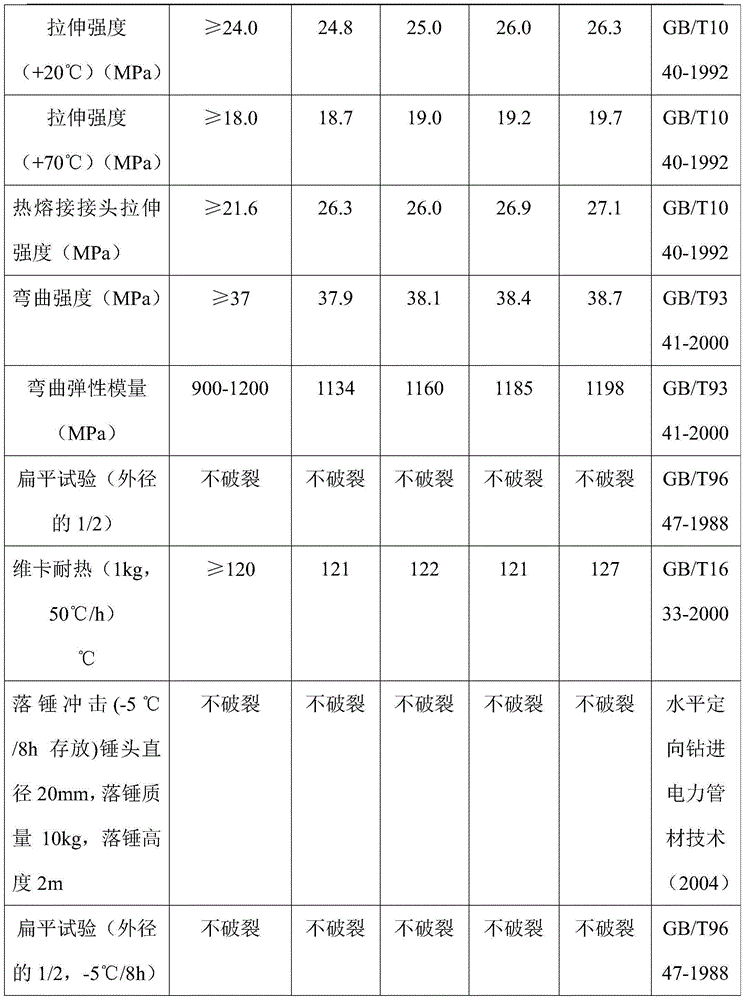

Examples

Embodiment 1

[0031] The impact-resistant MPP power protection pipe of the present invention has a raw material composition as shown in Example 1 in Table 1, wherein the modified hectorite is prepared according to the following process: 100 parts of hectorite are dispersed in 400ml of distilled water , to obtain a hectorite dispersion; dissolve 4 parts of octadecyldimethylbenzyl ammonium chloride in 78ml of distilled water to obtain a modifier solution; adjust the pH of the hectorite dispersion to 8, and heat it to 68°C Add the modifier solution and keep stirring for 4 hours, then filter, wash and dry to obtain the modified hectorite;

[0032] The novel organic montmorillonite was prepared according to the following process: add 200ml of distilled water into a three-neck flask, add 10 parts of sodium-based montmorillonite, heat to 70°C, add dropwise an aqueous solution containing 16 parts of CTAB, and keep stirring for 3 hours. After drying, grinding, and sieving, the modified organomontmor...

Embodiment 2

[0036] The impact-resistant MPP power protection pipe of the present invention has a raw material composition as shown in Example 2 in Table 1, wherein the modified hectorite is prepared according to the following process: disperse 80 parts of hectorite in 405ml of distilled water , to obtain a hectorite dispersion; dissolve 4.3 parts of cetyltrimethylammonium bromide in 50ml of distilled water to obtain a modifier solution; adjust the pH of the hectorite dispersion to 7, and add the modifier after heating to 69°C The neutralizing agent solution was incubated and stirred for 4.6h, then filtered, washed, and dried to obtain the modified hectorite;

[0037] The novel organic montmorillonite was prepared according to the following process: add 10 parts of sodium-based montmorillonite to a three-neck flask after adding 100 ml of distilled water, add 10 parts of CTAB aqueous solution dropwise after heating to 90° C., and keep stirring for 2 hours. After drying, grinding, and sievin...

Embodiment 3

[0043] The impact-resistant MPP power protection pipe of the present invention has a raw material composition as shown in Example 3 in Table 1, wherein the modified hectorite is prepared according to the following process: 85 parts of hectorite are dispersed in 500ml of distilled water , to obtain a hectorite dispersion; 5 parts of dodecyltrimethylammonium bromide and 5 parts of hexadecyltrimethylammonium bromide are dissolved in 100ml distilled water to obtain a modifier solution; adjust hectorite The pH of the dispersion is 8, heated to 80°C, adding a modifier solution and stirring for 8 hours, then filtering, washing, and drying to obtain the modified hectorite;

[0044] The new organic montmorillonite was prepared according to the following process: add 185 ml of distilled water into a three-necked flask, add 18 parts of sodium montmorillonite, heat to 72 °C, add dropwise an aqueous solution containing 20 parts of CTAB, and keep stirring for 2.3 hours , obtained modified o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com