Patents

Literature

23166results about How to "Save material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

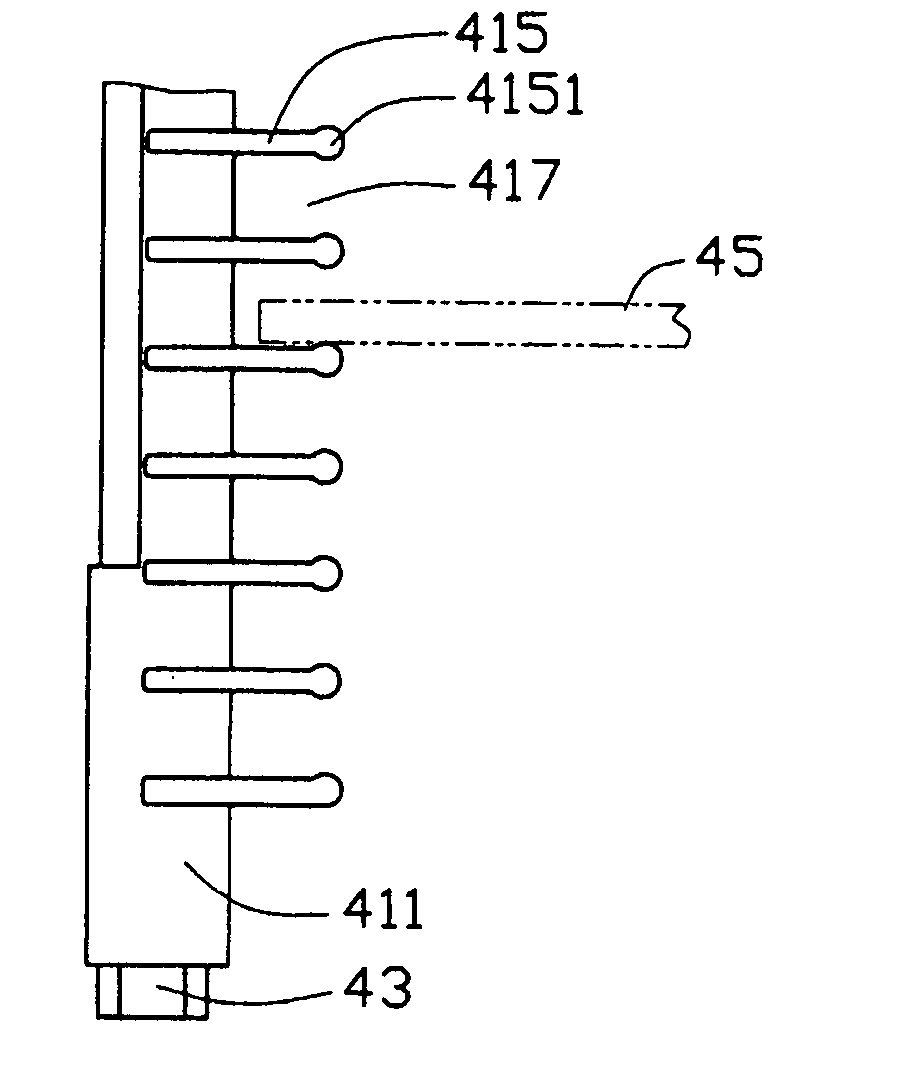

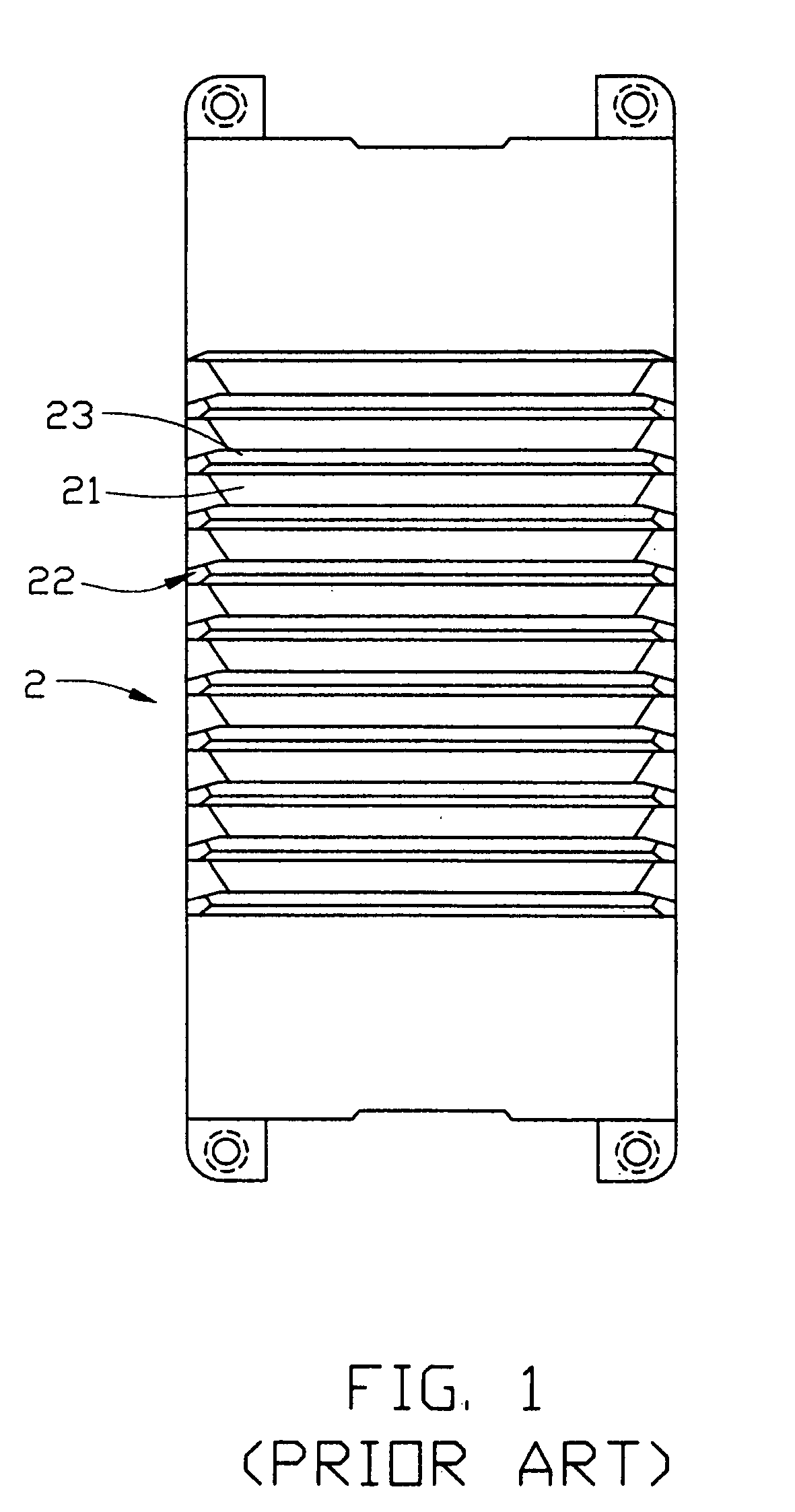

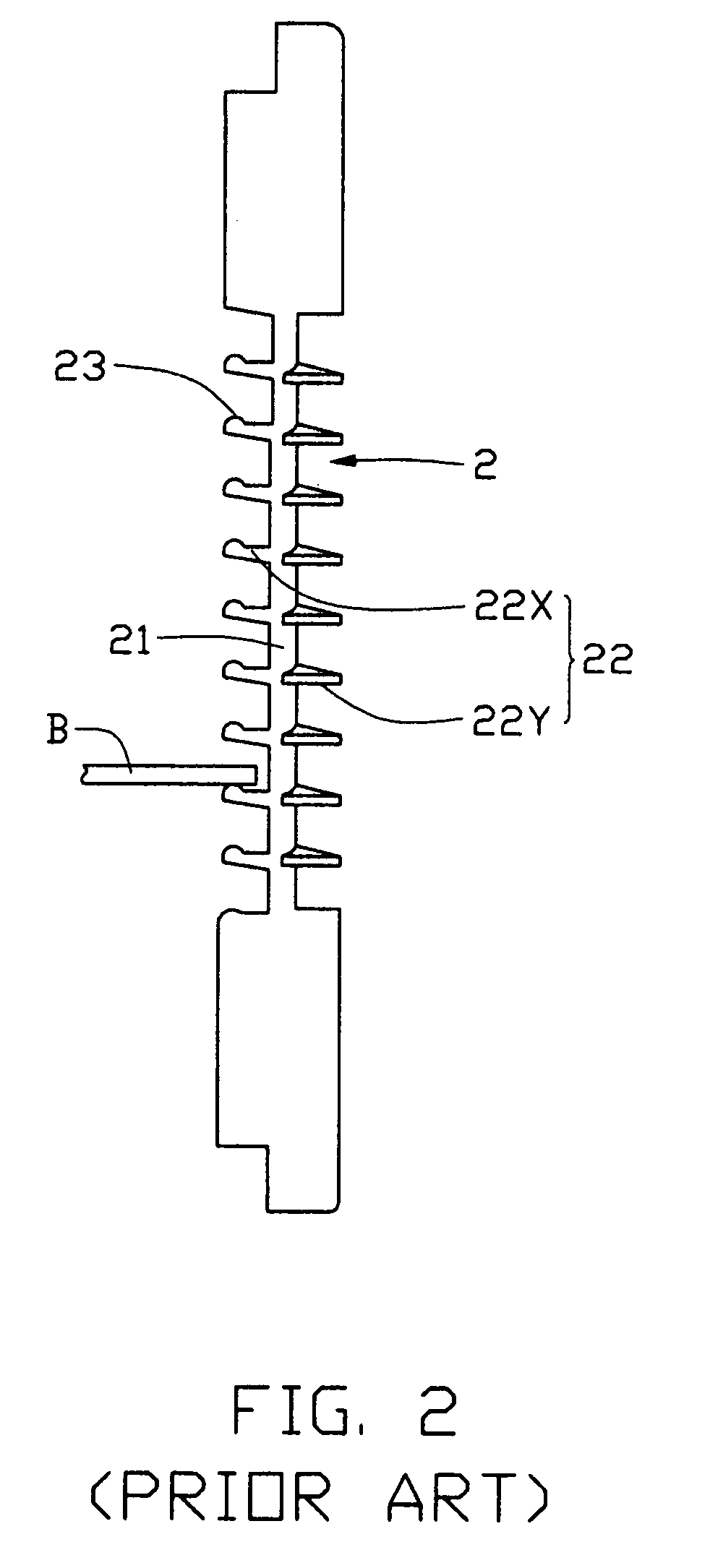

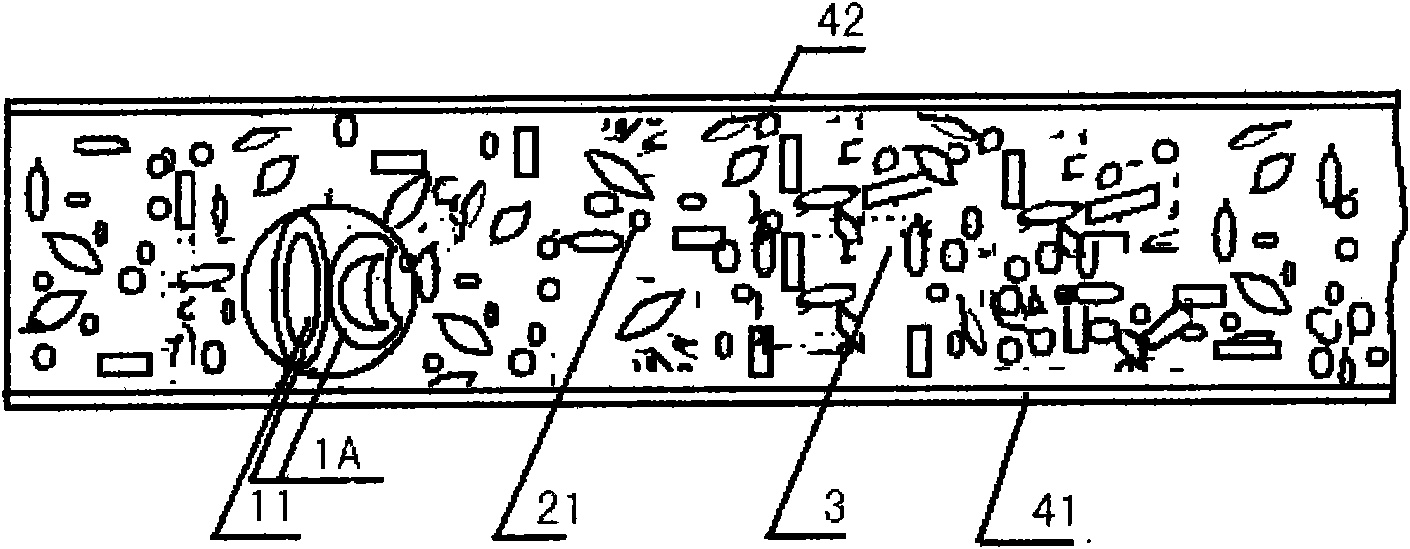

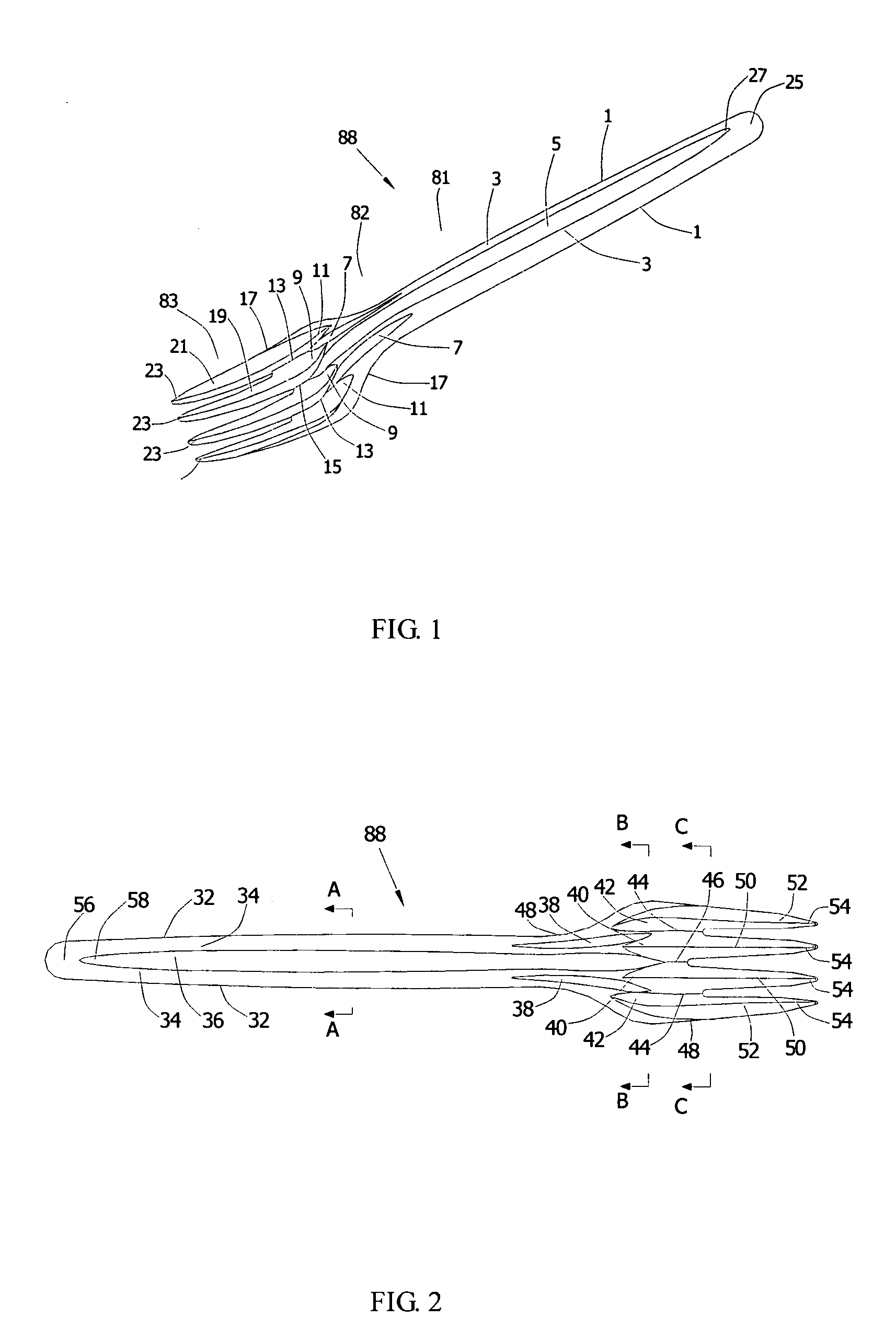

Substrate supporting rod and substrate cassette using the same

InactiveUS20050023231A1Improve rigiditySave materialLiquid surface applicatorsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

A substrate-supporting rod (4) comprises a resin body (41) and a metal rod (43). The resin body (41) includes a body portion (411) being cylinder-shaped and having a first through hole (413) in a direction of the axis thereof and a number of shelves (415, 415′) arising from said body portion (411) and extending in parallel and inwardly of a cassette (5) at a predetermined pitch. The metal rod (43) is received in the first through hole (413) of the body portion (411) so as to increase the rigidity of the substrate-supporting rob (4). A projection (4151) is defined on the end of each shelf (415, 415′) to support a substrate (45). Further, the body portion (411) is molded from an electrically conductive resin so that not only the cassette (5) can be protected against static discharge but also resin material is saved and cost is decreased.

Owner:FOXSEMICON INTEGRATED TECH INC

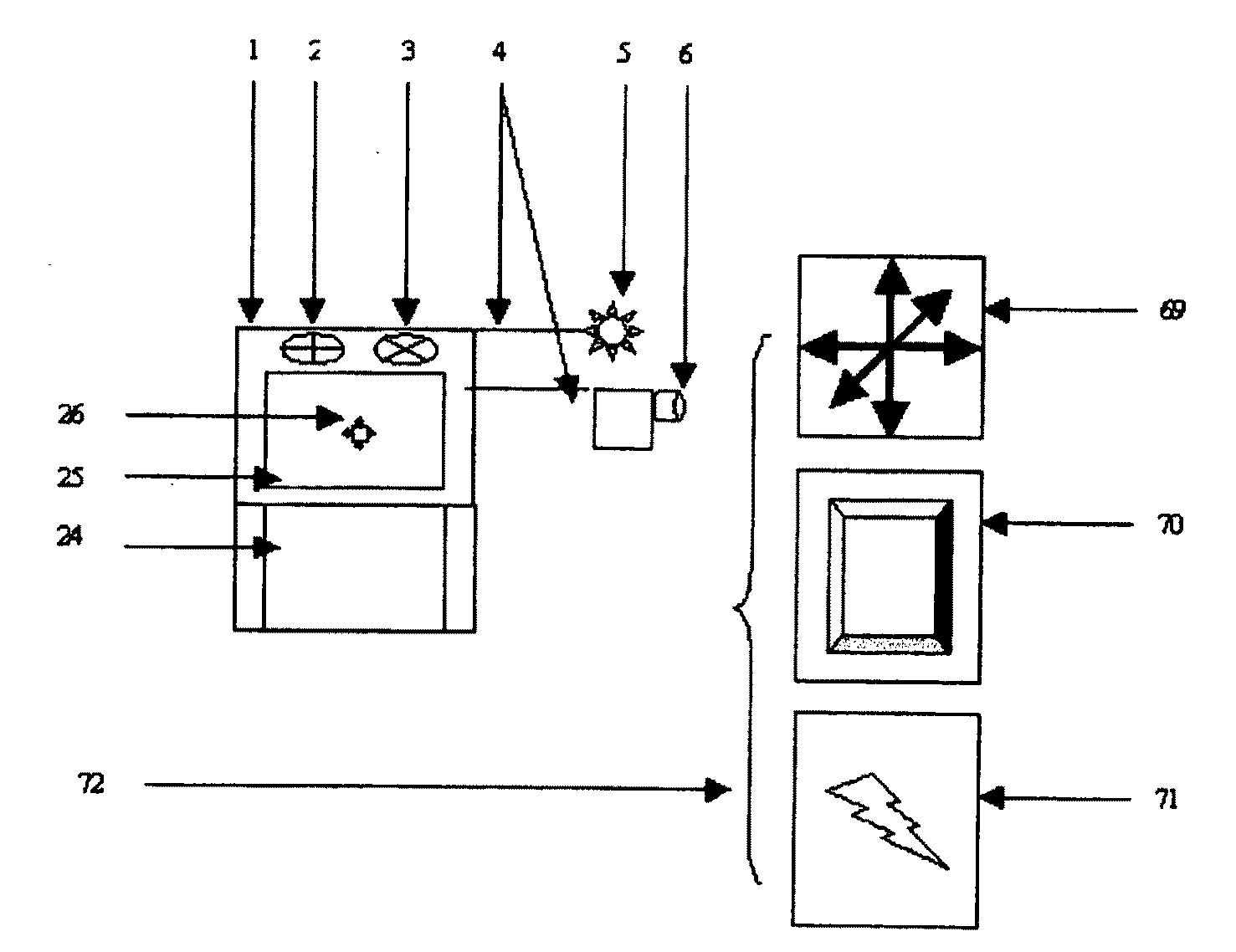

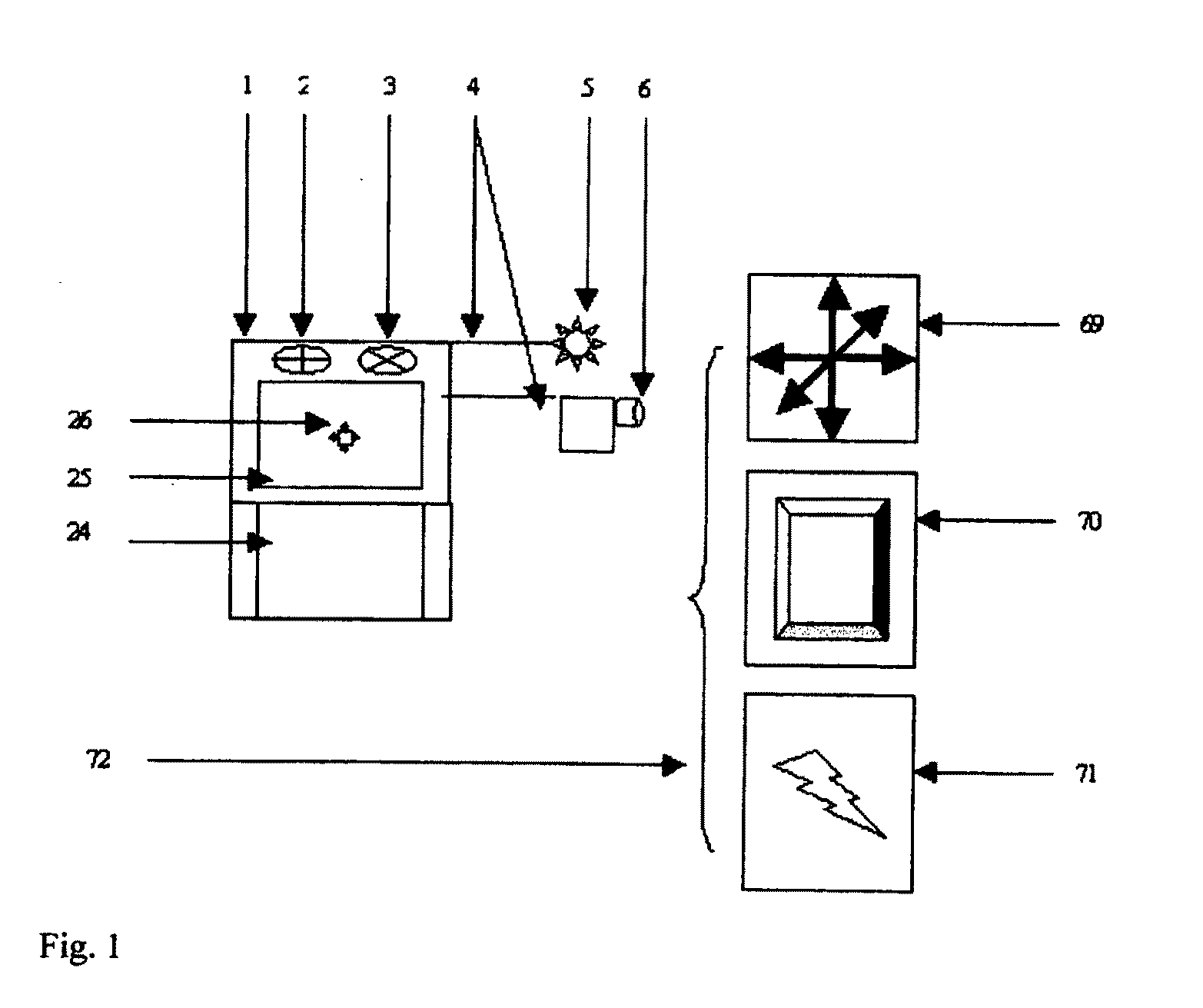

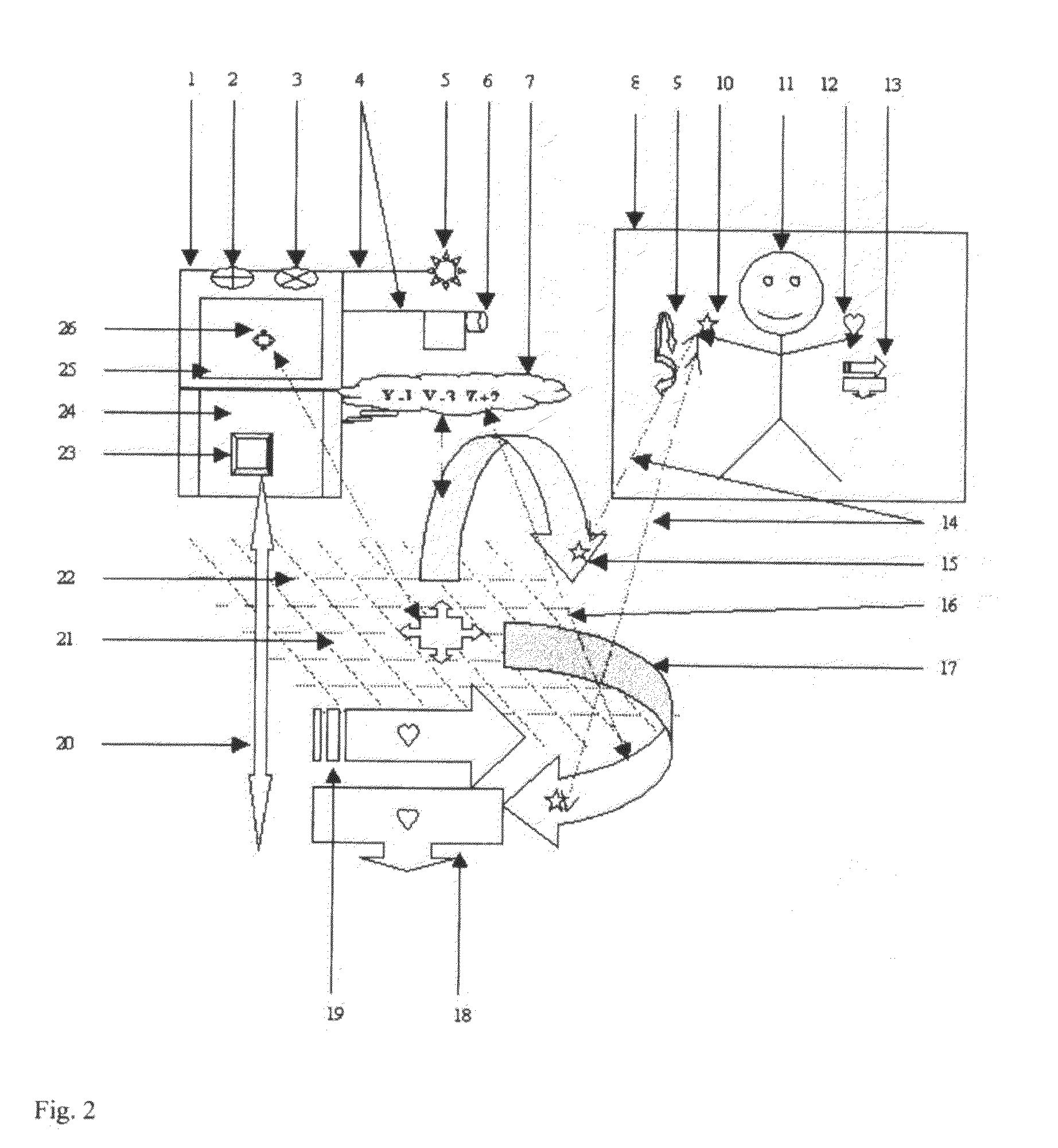

Intelligent robotic interface input device

InactiveUS20100103106A1Shorten the timeSave spaceProgramme controlInput/output for user-computer interactionVirtual spaceVision sensor

Universal Video Computer Vision Input Virtual Space Mouse-Keyboard Control Panel Robot has computer system use video vision camera sensors, logical vision sensor programming as trainable computer vision seeing objects movements X, Y, Z dimensions' definitions to recognize users commands by their Hands gestures and / or enhance symbols, colors objects combination actions to virtually input data, and commands to operate computer, and machines. The robot has automatically calibrated working space into Space Mouse Zone, Space Keyboard zone, and Hand-Sign Languages Zone between user and itself. The robot automatically translate the receiving coordination users' hand gesture actions combinations on the customizable puzzle-cell positions of working space and mapping to its software mapping lists for each of the puzzle-cell position definition and calibrate these user hand and / or body gestures' virtual space actions into entering data and commands to computer meaningful computer, machine, home appliances operations.

Owner:CHIU HSIEN HSIANG

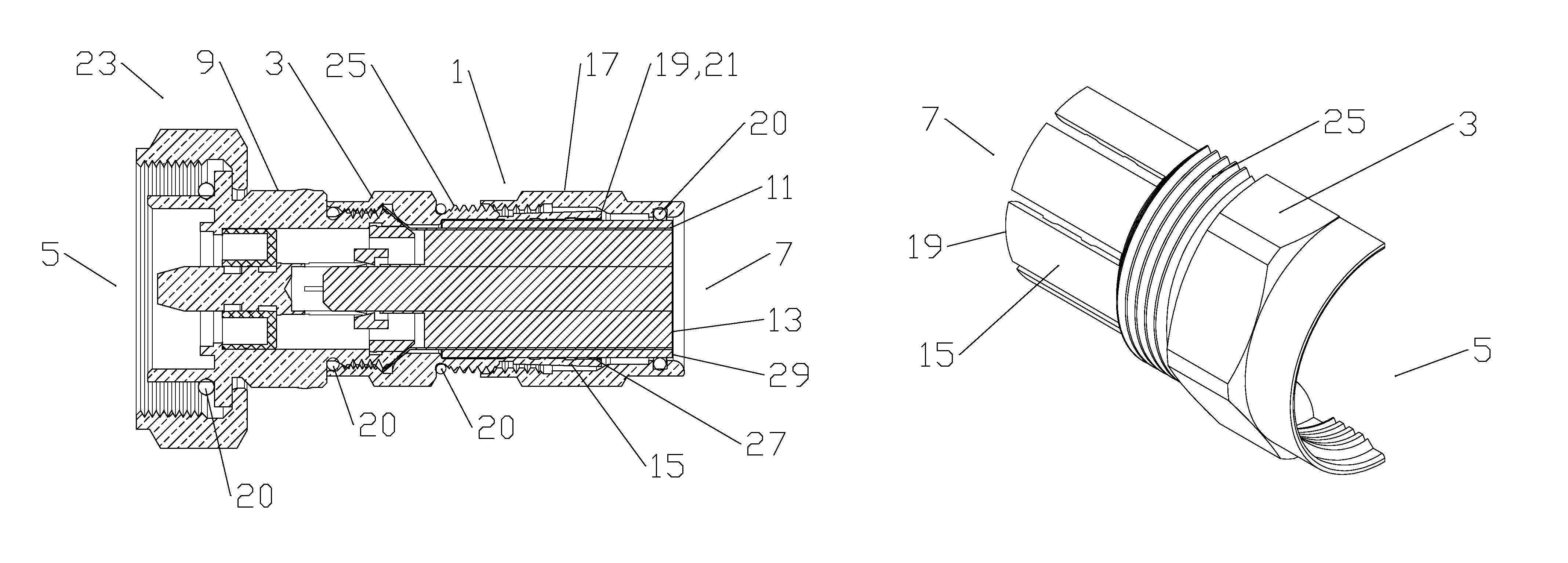

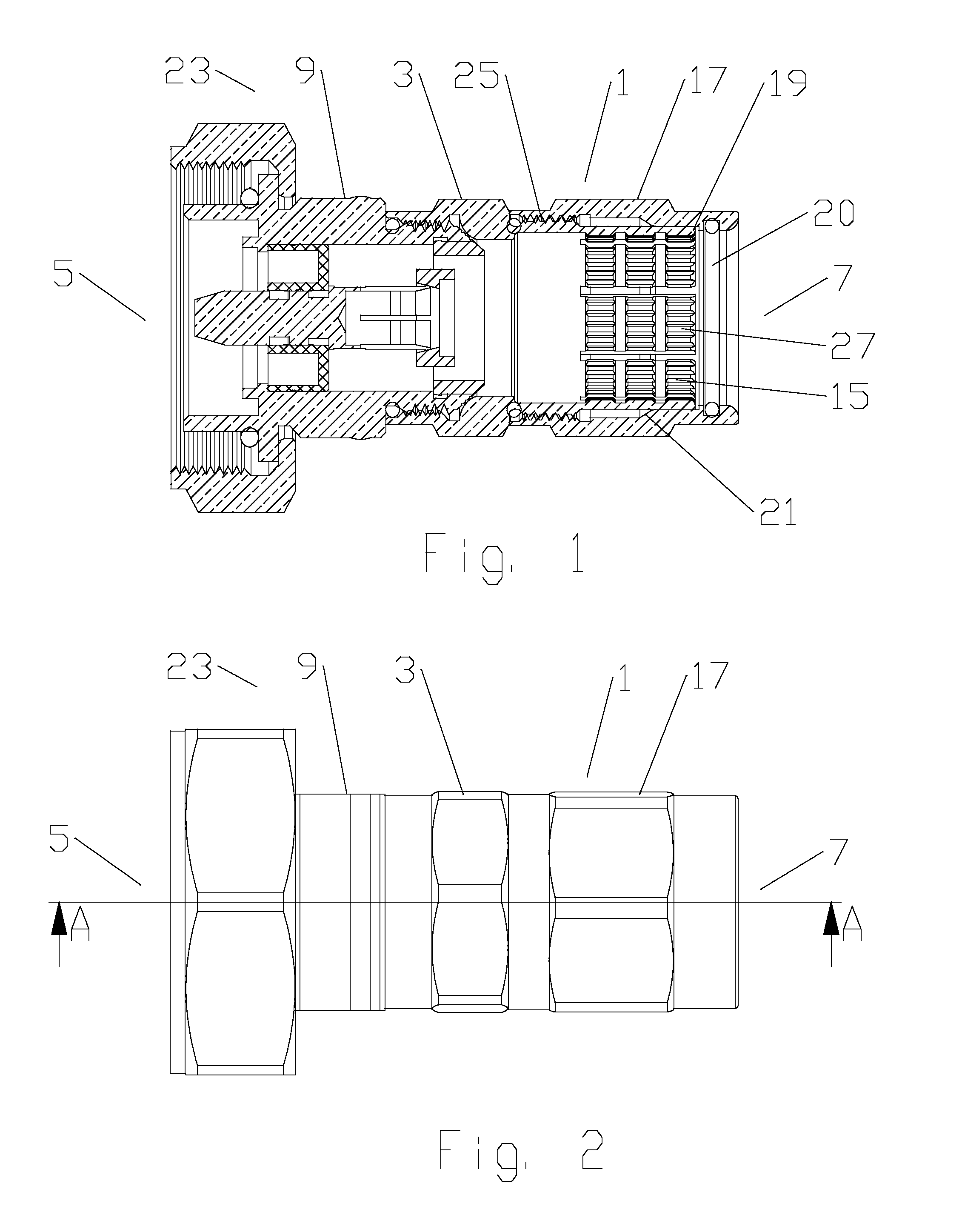

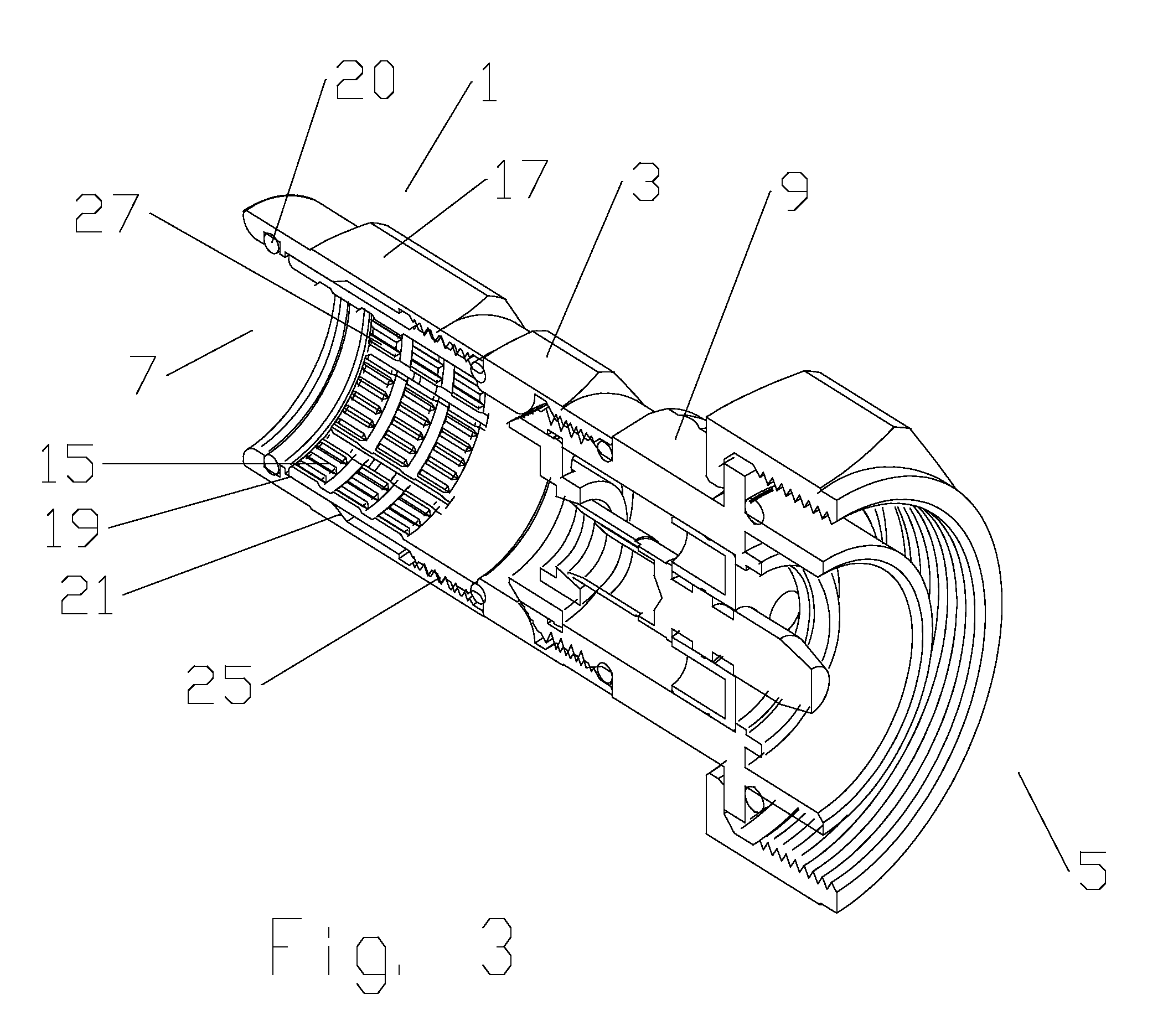

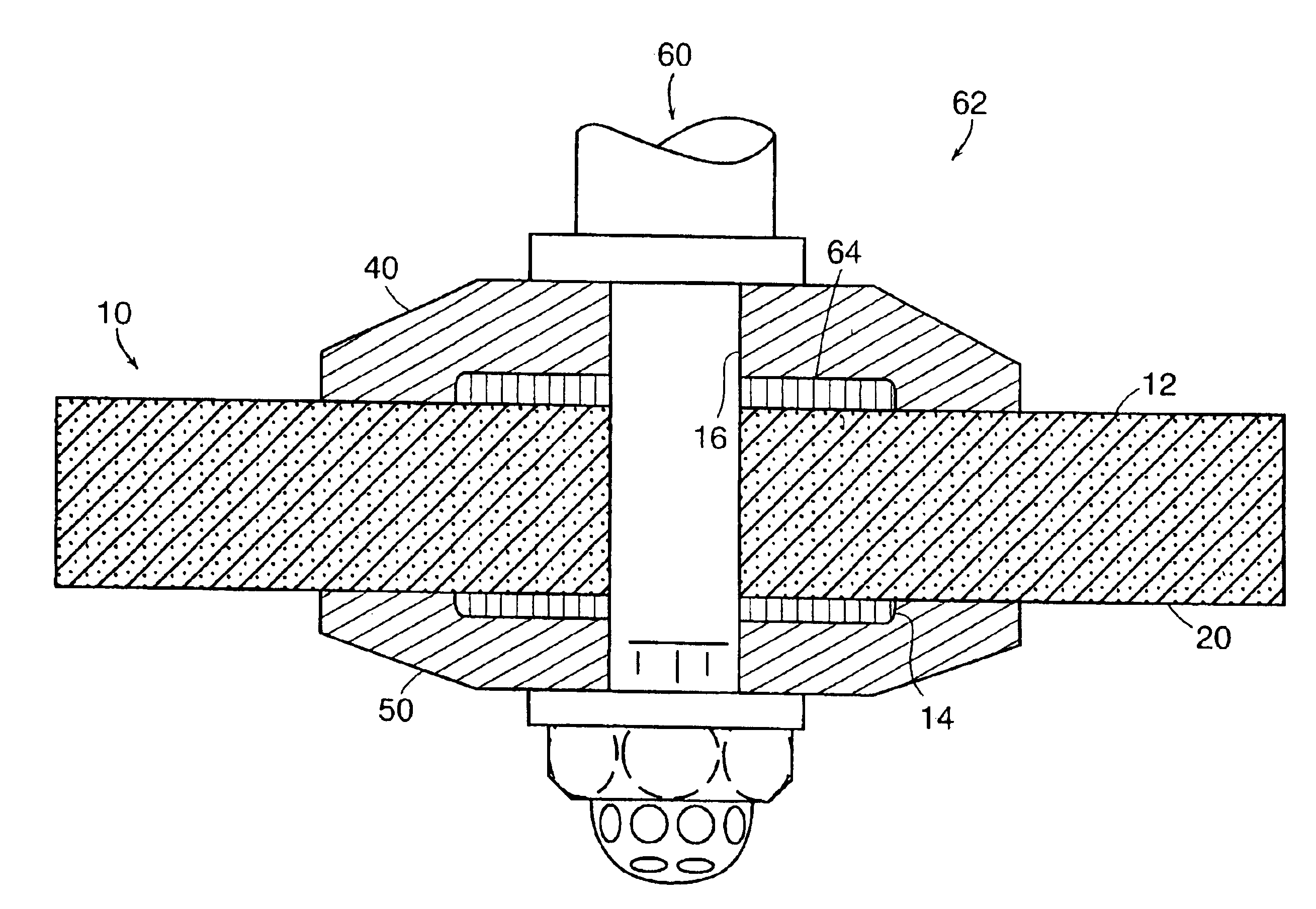

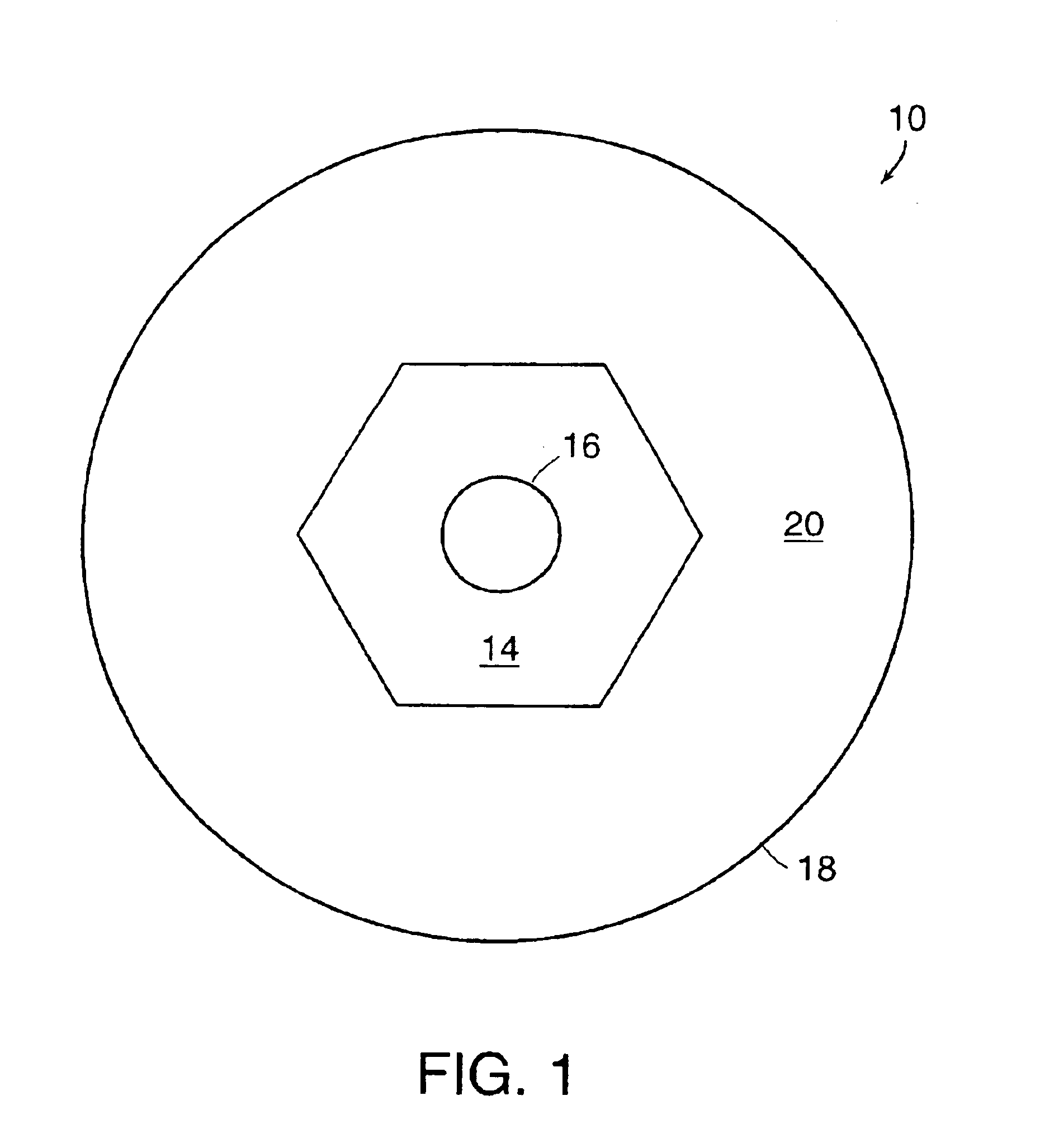

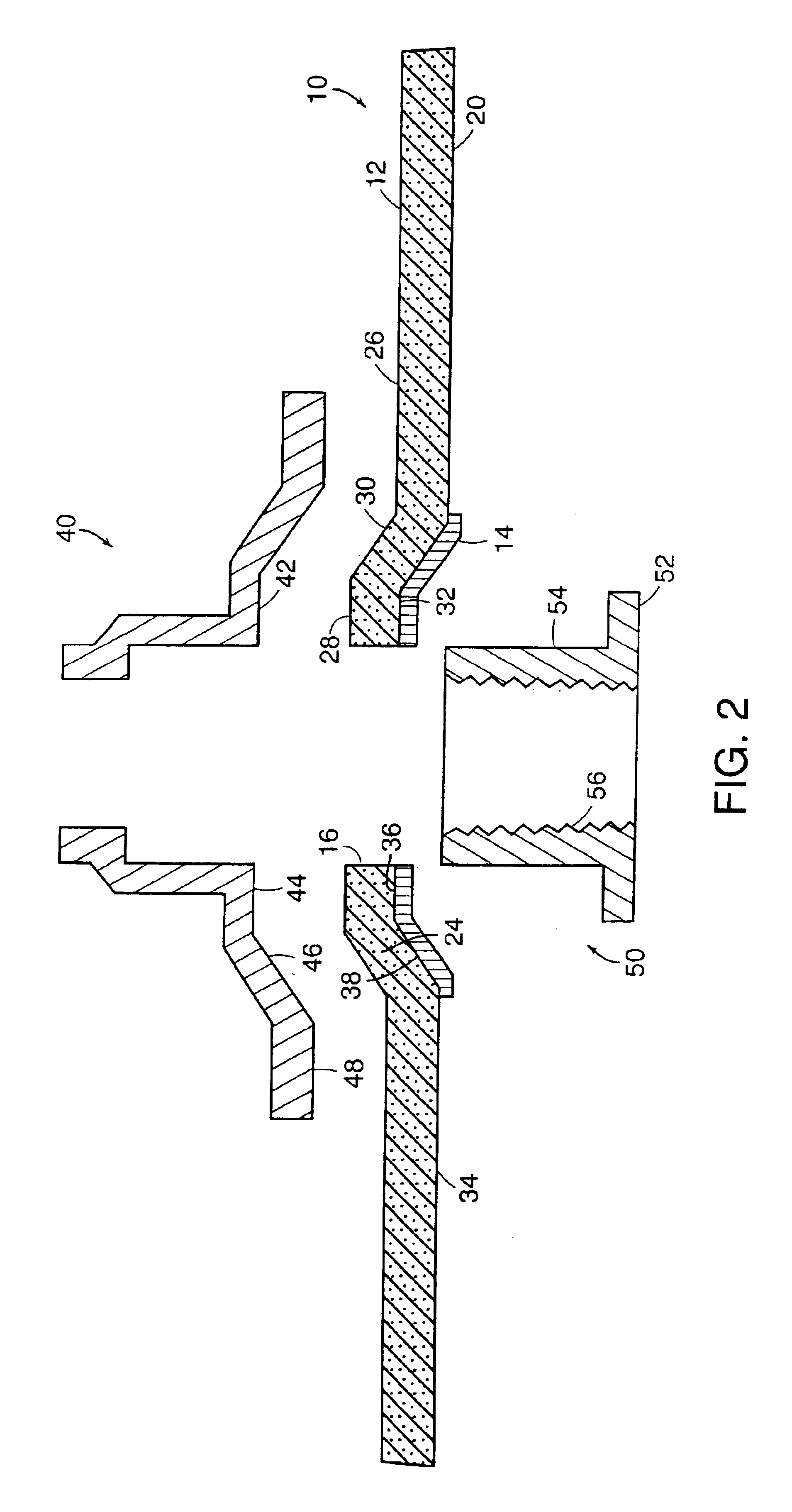

Coaxial connector with a coupling body with grip fingers engaging a wedge of a stabilizing body

ActiveUS7927135B1Easy to assembleEasy to processElectrically conductive connectionsTwo pole connectionsMaximum diameterMachining

A stabilizing coupling body assembly for a connector is provided with a monolithic coupling body dimensioned to couple with a cable end of a connector body of the connector. A plurality of grip fingers extends from a cable end of the coupling body, the grip fingers dimensioned for insertion within a bore of a stabilizing body. The stabilizing body is coupled to a cable end of the coupling body. A distal end of the grip fingers is proximate an annular wedge surface of the bore of the stabilizing body. The wedge surface is provided with a taper between a maximum diameter proximate a connector end and a minimum diameter proximate a cable end. The grip fingers are driven radially inward as the stabilizing body is advanced axially towards the coupling body. Methods of manufacture include forming elements of the coupling body assembly via injection molding and / or machining.

Owner:COMMSCOPE TECH LLC

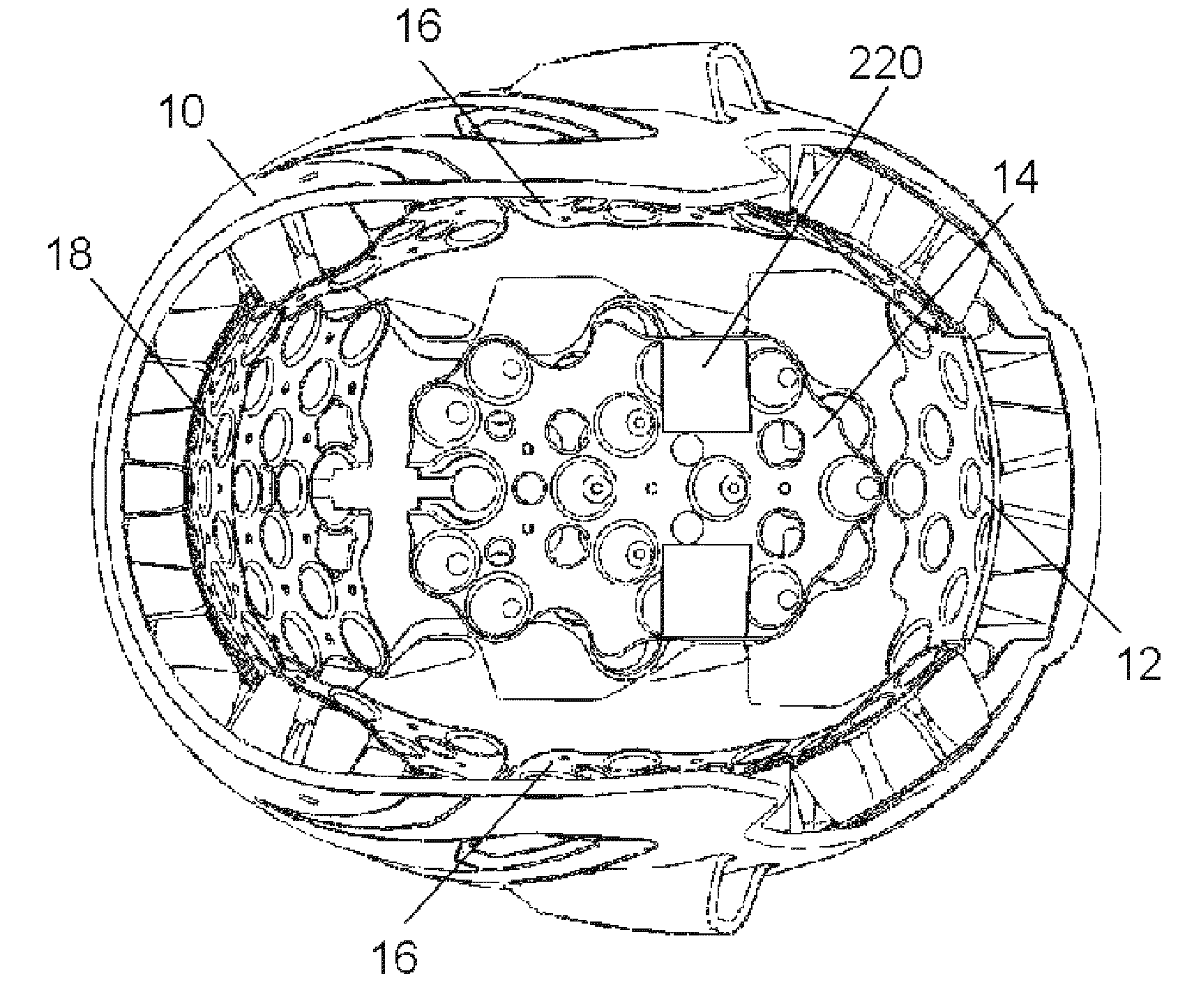

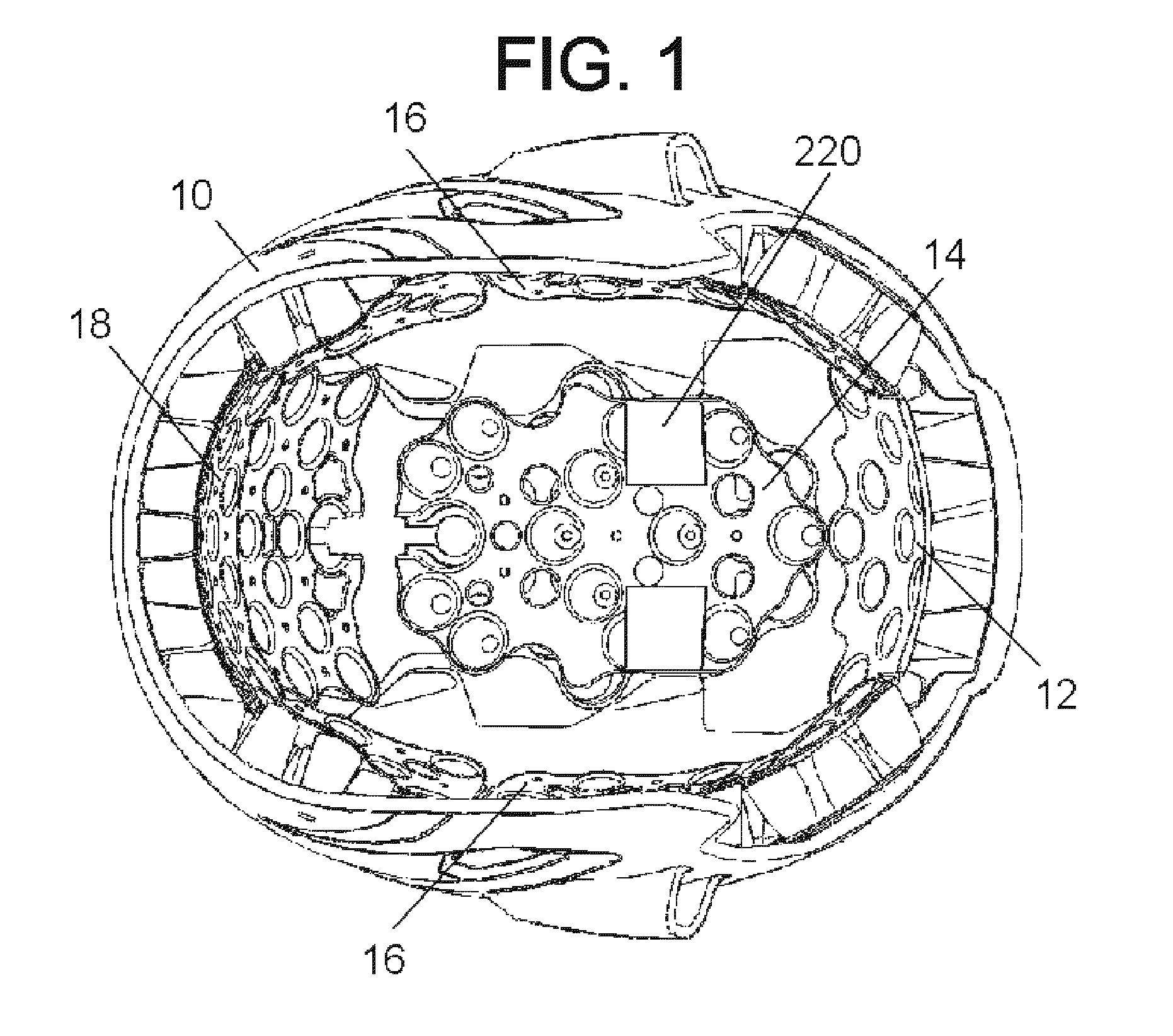

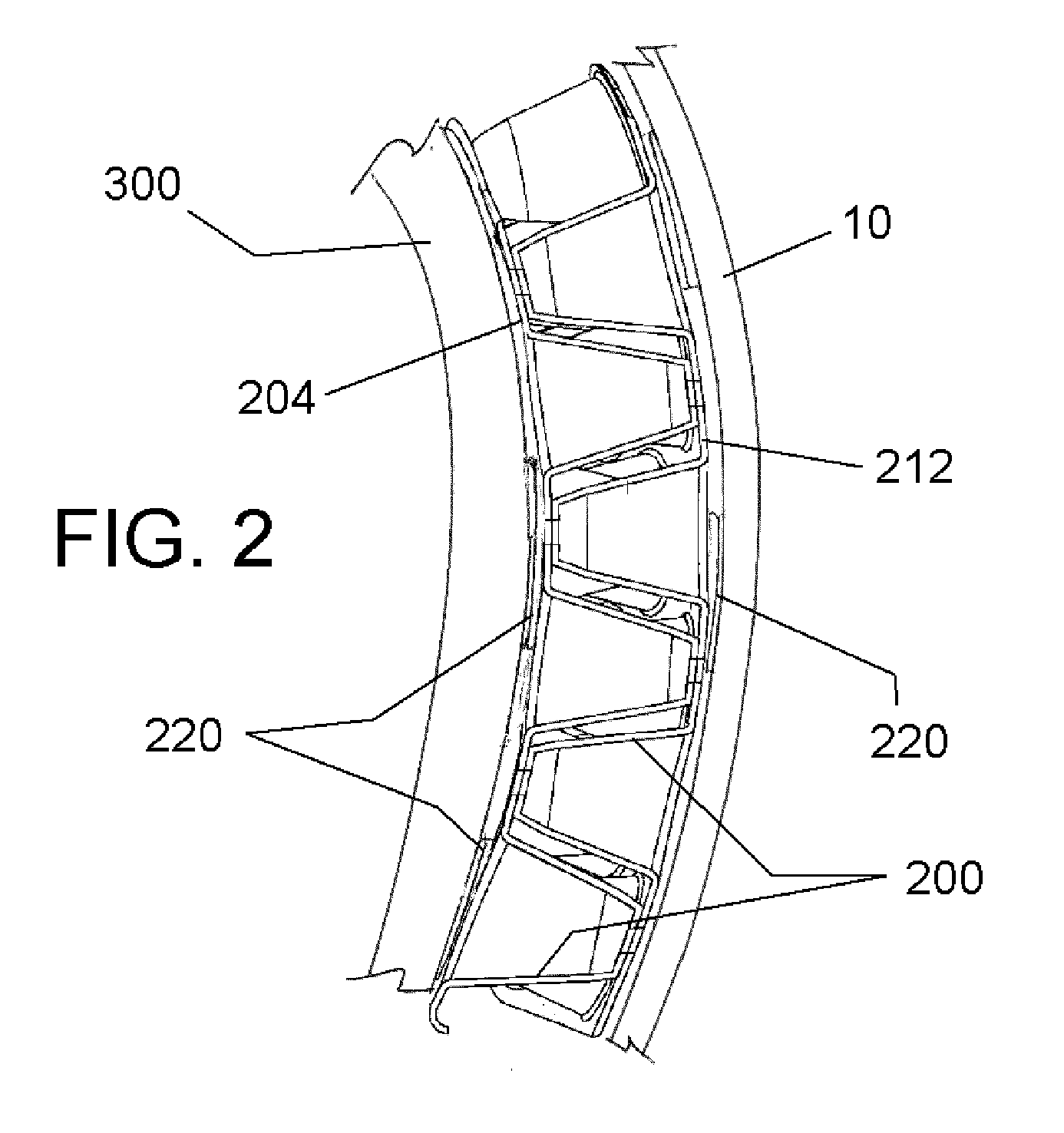

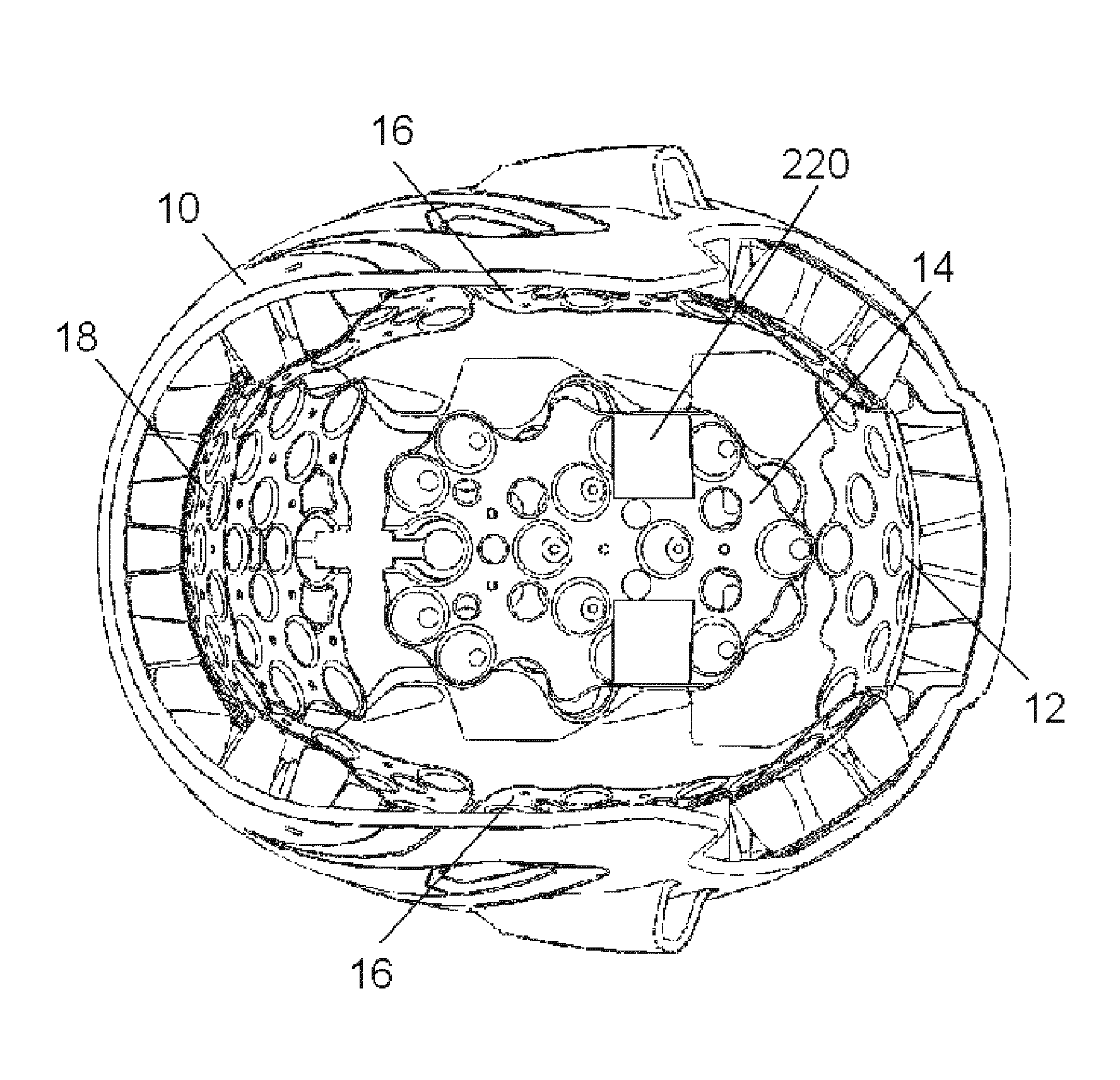

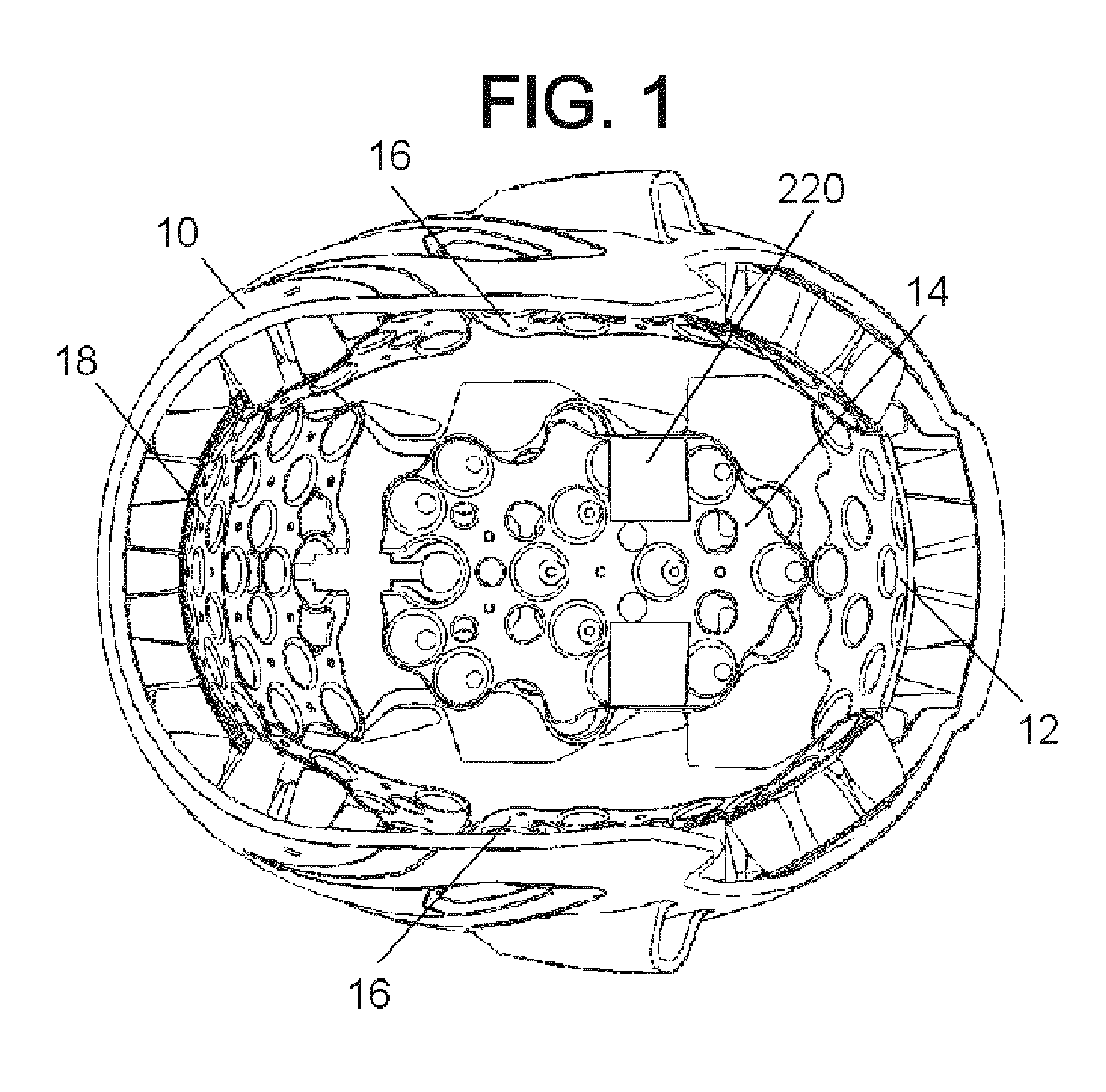

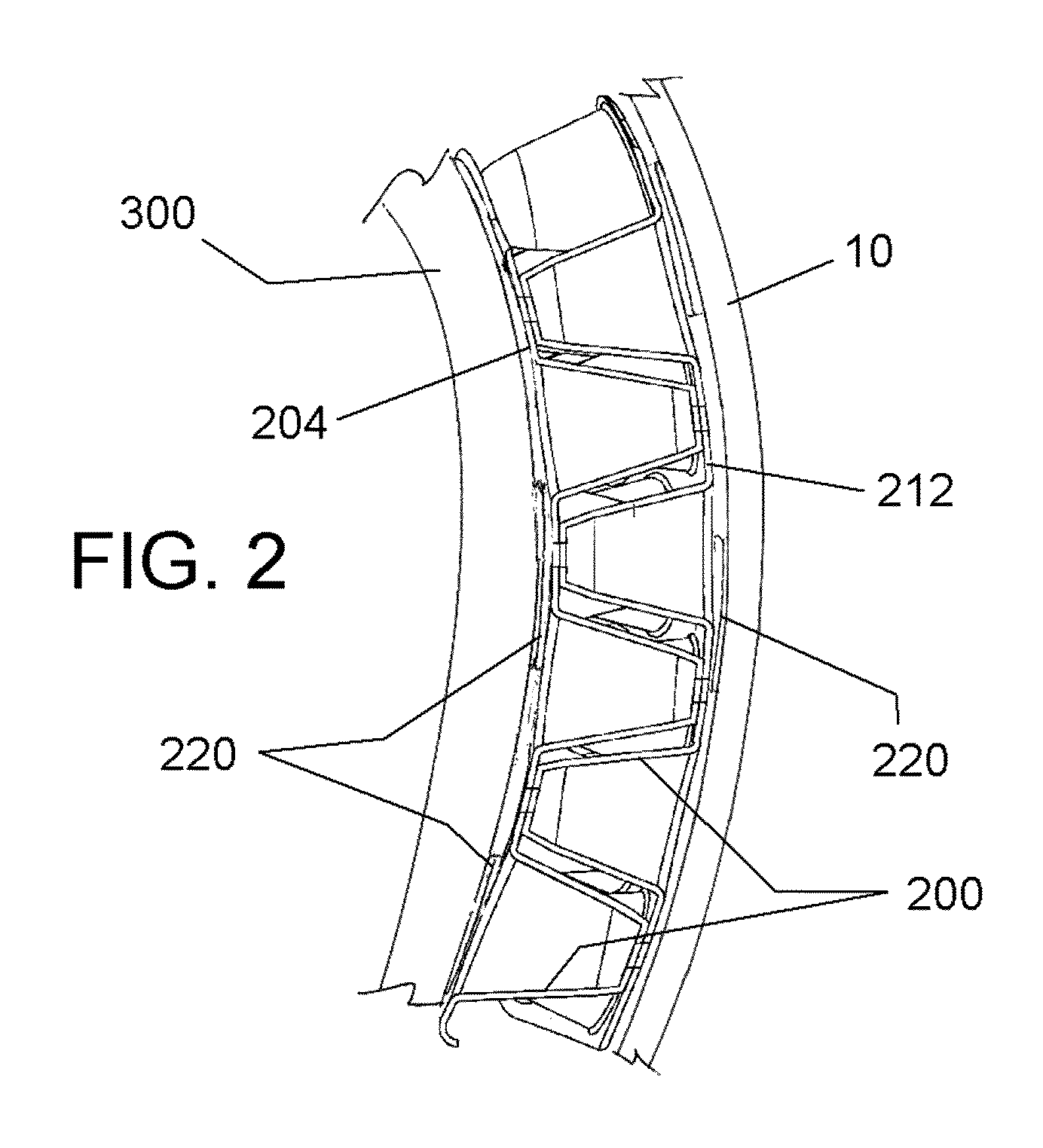

Protective arrangement

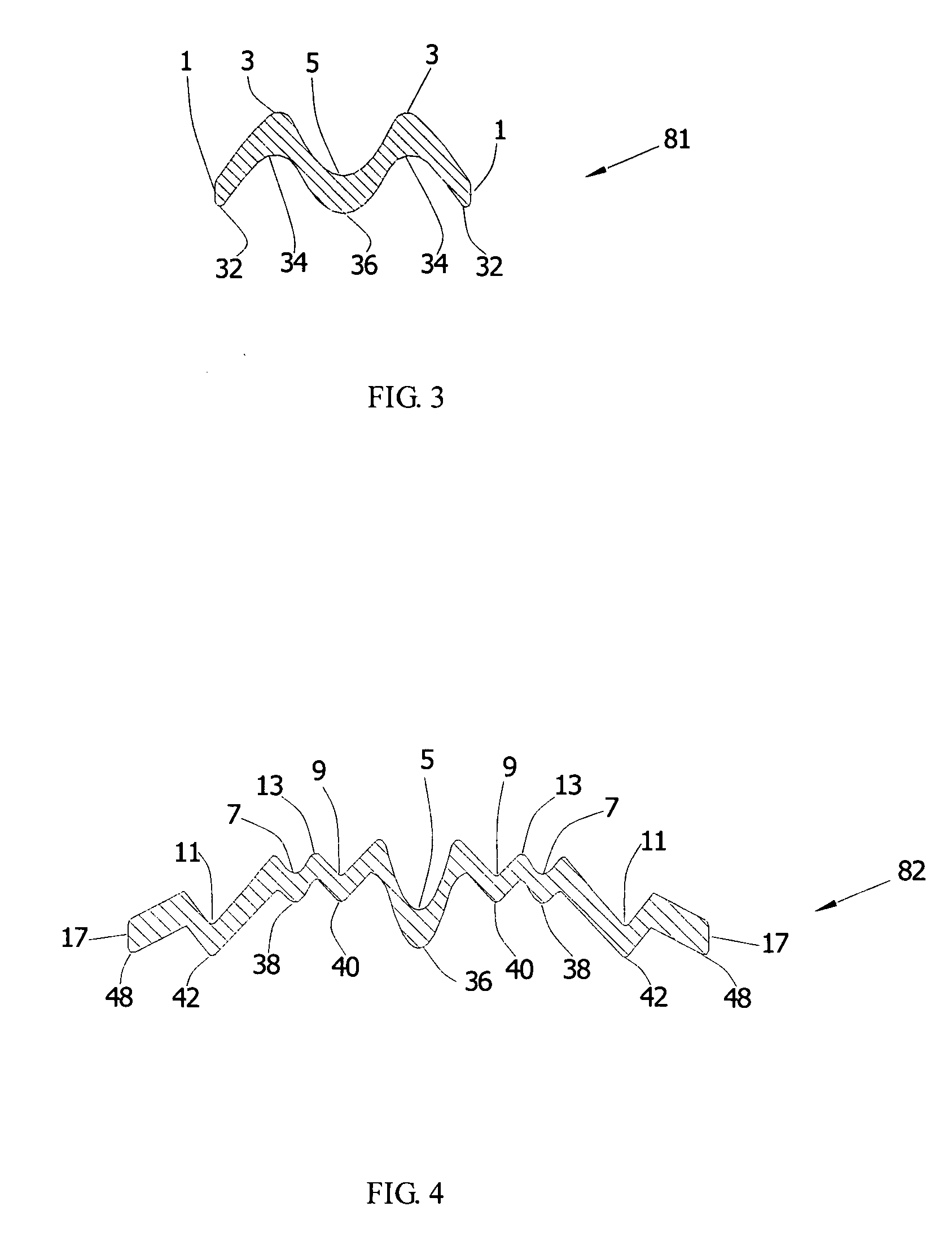

ActiveUS20100299812A1Save materialSave weightChemical protectionHeat protectionEngineeringMechanical engineering

A protective arrangement has a rigid shell to cover a body part and at least one impact absorbing pad removably attached to the inner surface of the rigid shell. The pad has an outer part made of an outer curved sheet and an inner part made of an inner sheet that is parallel to and spaced inwardly from the outer sheet to define a space. The inner and outer sheets have a plurality of spaced apart projecting hollow protrusions extending to the other sheet, the protrusions of one sheet alternating with the protrusions of the other sheet to form an impact absorbing pattern of alternating protrusions in the space between the sheets.

Owner:SCHUTT SPORTS IP LLC

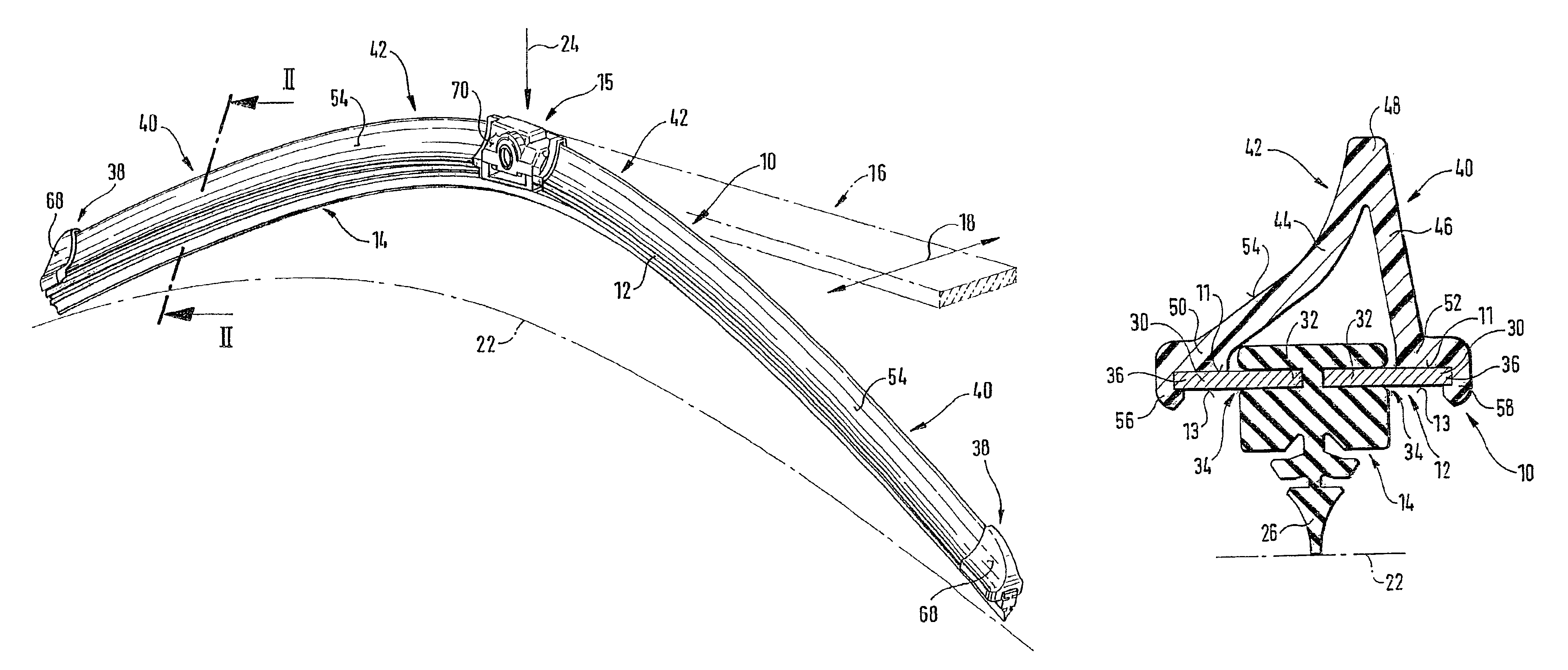

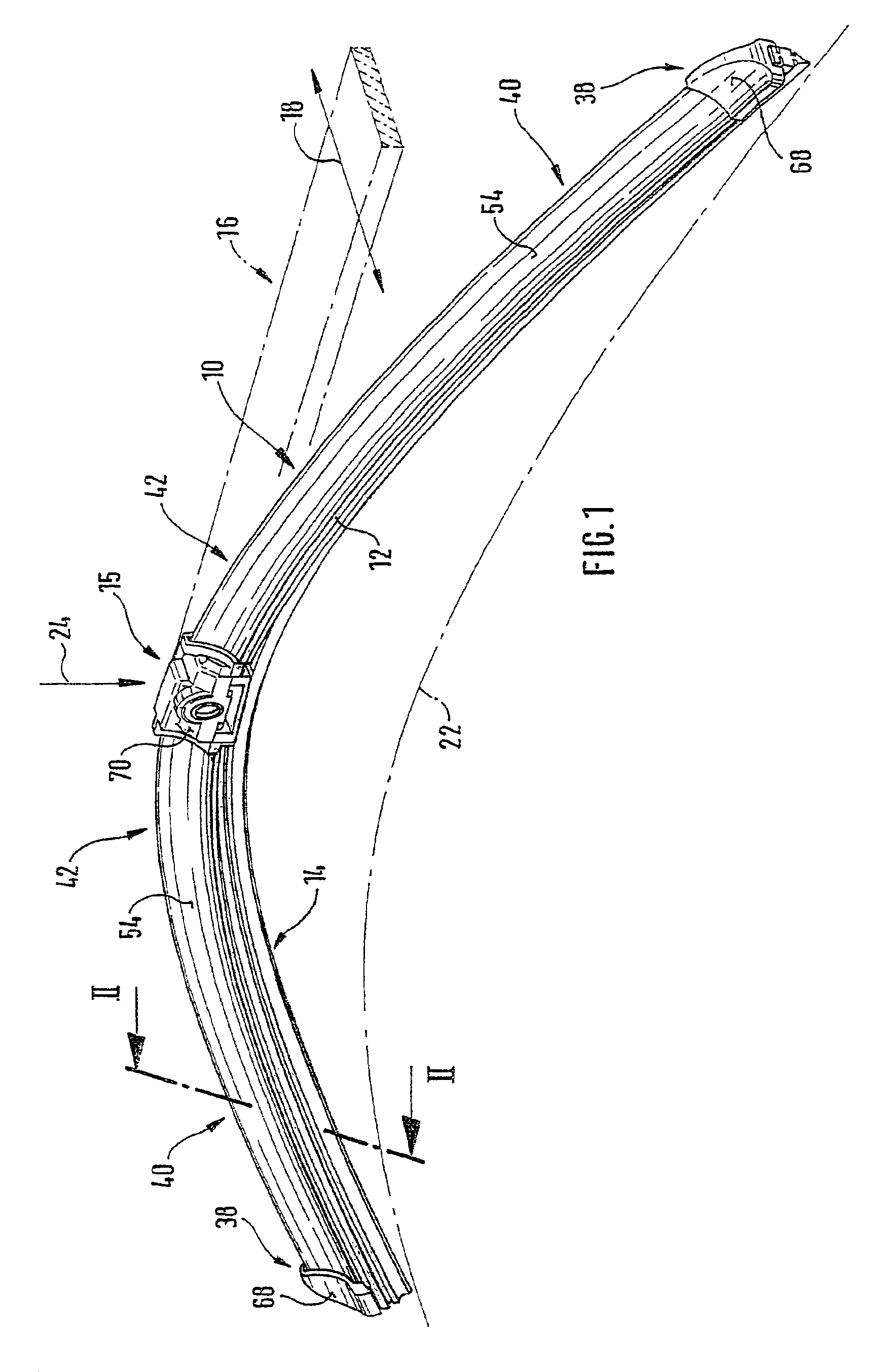

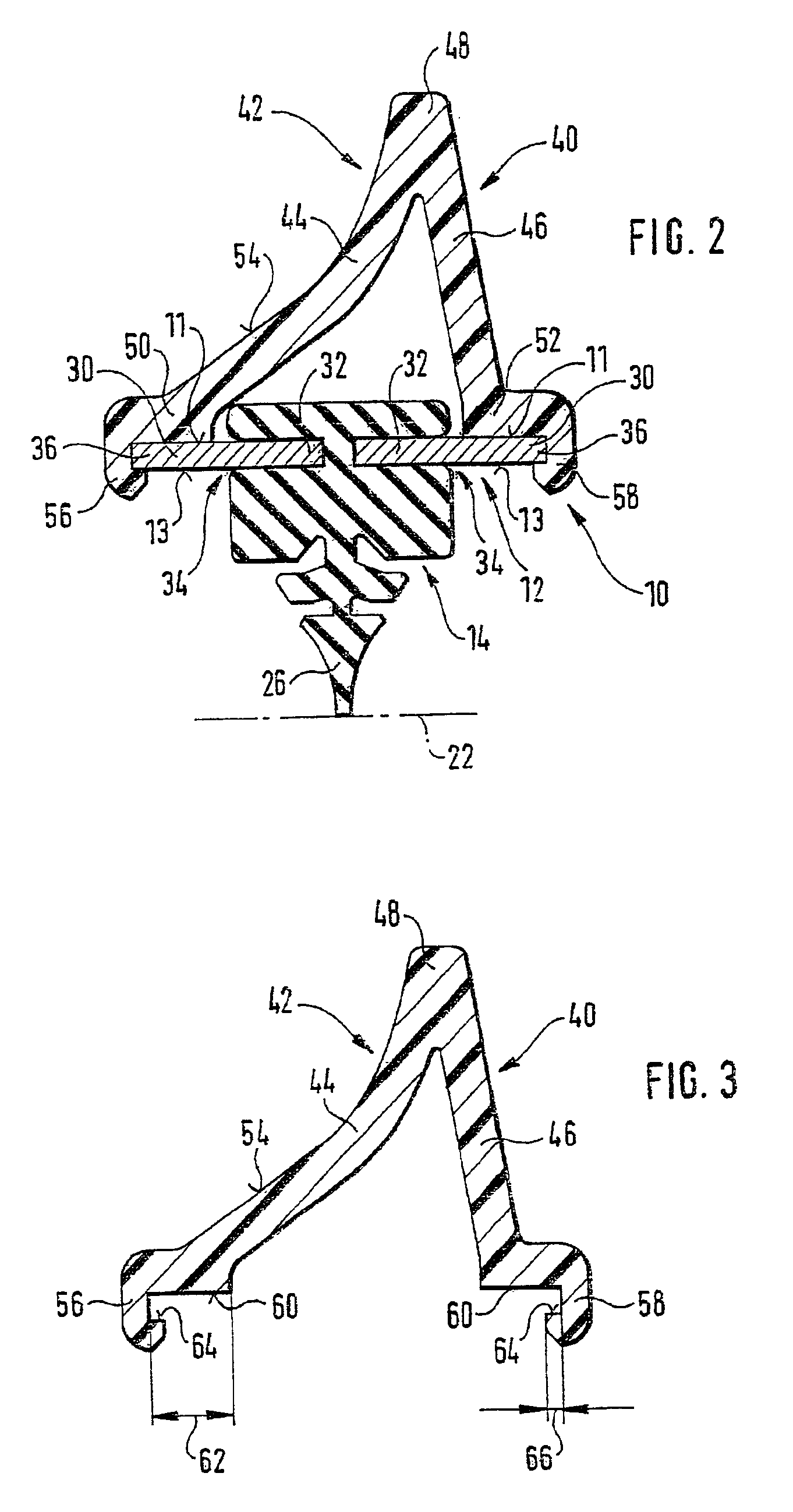

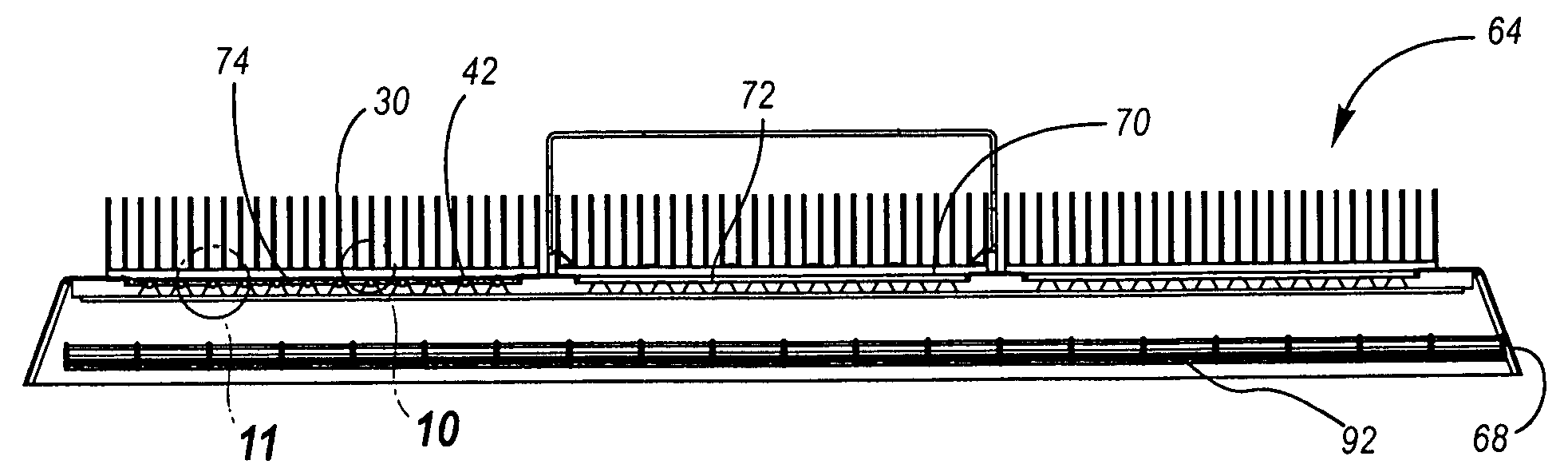

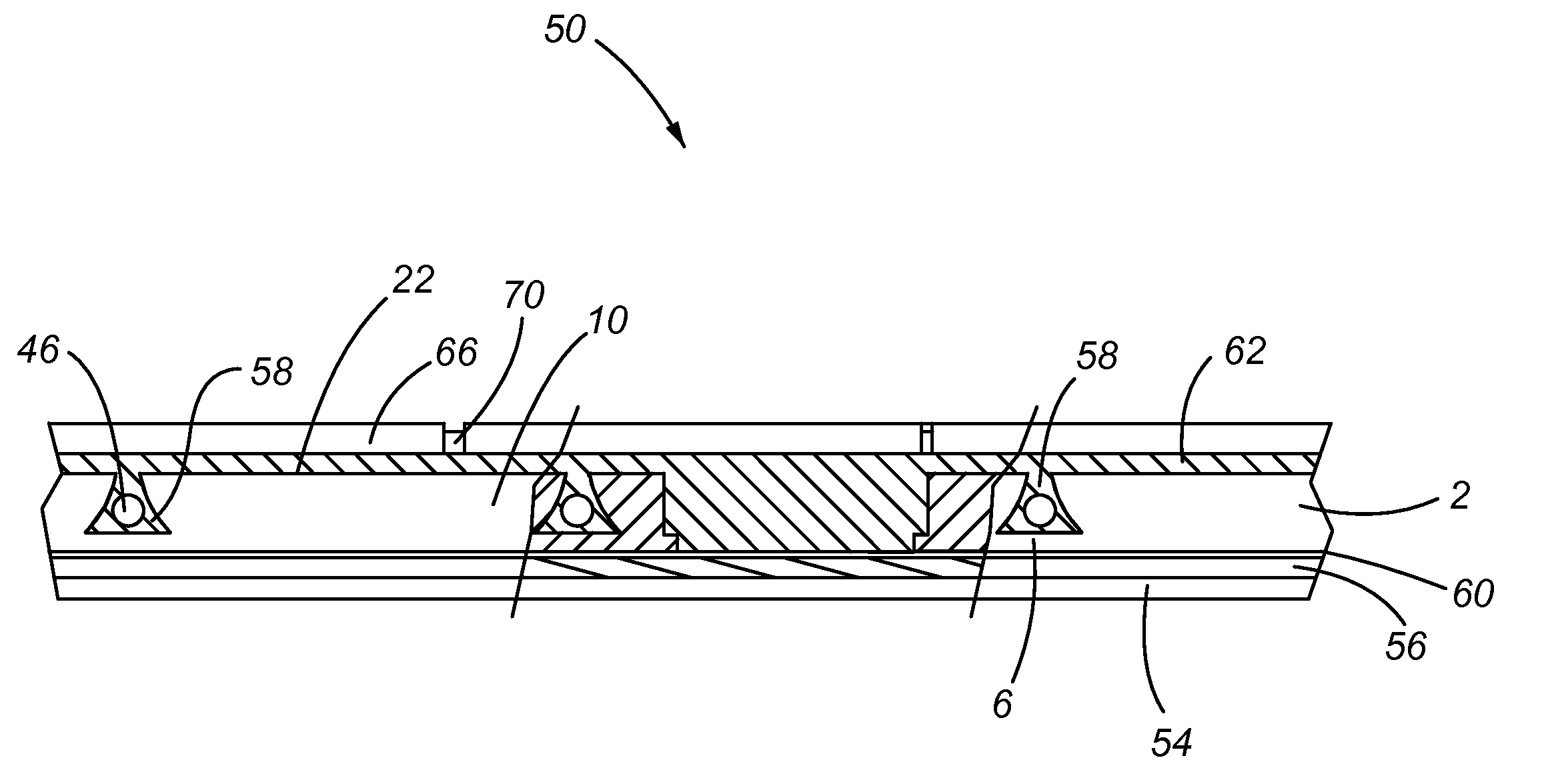

Wiper blade for cleaning screens in particular on motor vehicles

InactiveUS6944905B2Reduce weightSave materialWindow cleanersVehicle cleaningBand shapeMotorized vehicle

A wiper blade for cleaning motor vehicles is proposed, which is provided with a band-like, elongated, spring-elastic support element (12). The lower band surface (13) of the support element (12) oriented toward the window (22) has an elongated, rubber-elastic wiper strip (14), which can be placed against the window (22), disposed on it so that the longitudinal axes of these two parts are parallel and the upper band surface (11) of the support element (12) has a wind deflection strip (42) disposed on it, which extends in the longitudinal direction of the support element, is provided with an attack surface (54) oriented toward the main flow of the relative wind, and is comprised of an elastic material. A considerable weight savings for the wiper blade is achieved if the wind deflection strip (42, 142, or 242) has two diverging legs (44, 46), viewed in cross section, which are connected to each other at a common base (48) and whose free ends (50, 52) oriented toward the window (22) are supported on the wiper blade (10), and the attack surface (54) is embodied on the outside of the one leg (44).

Owner:ROBERT BOSCH CORP

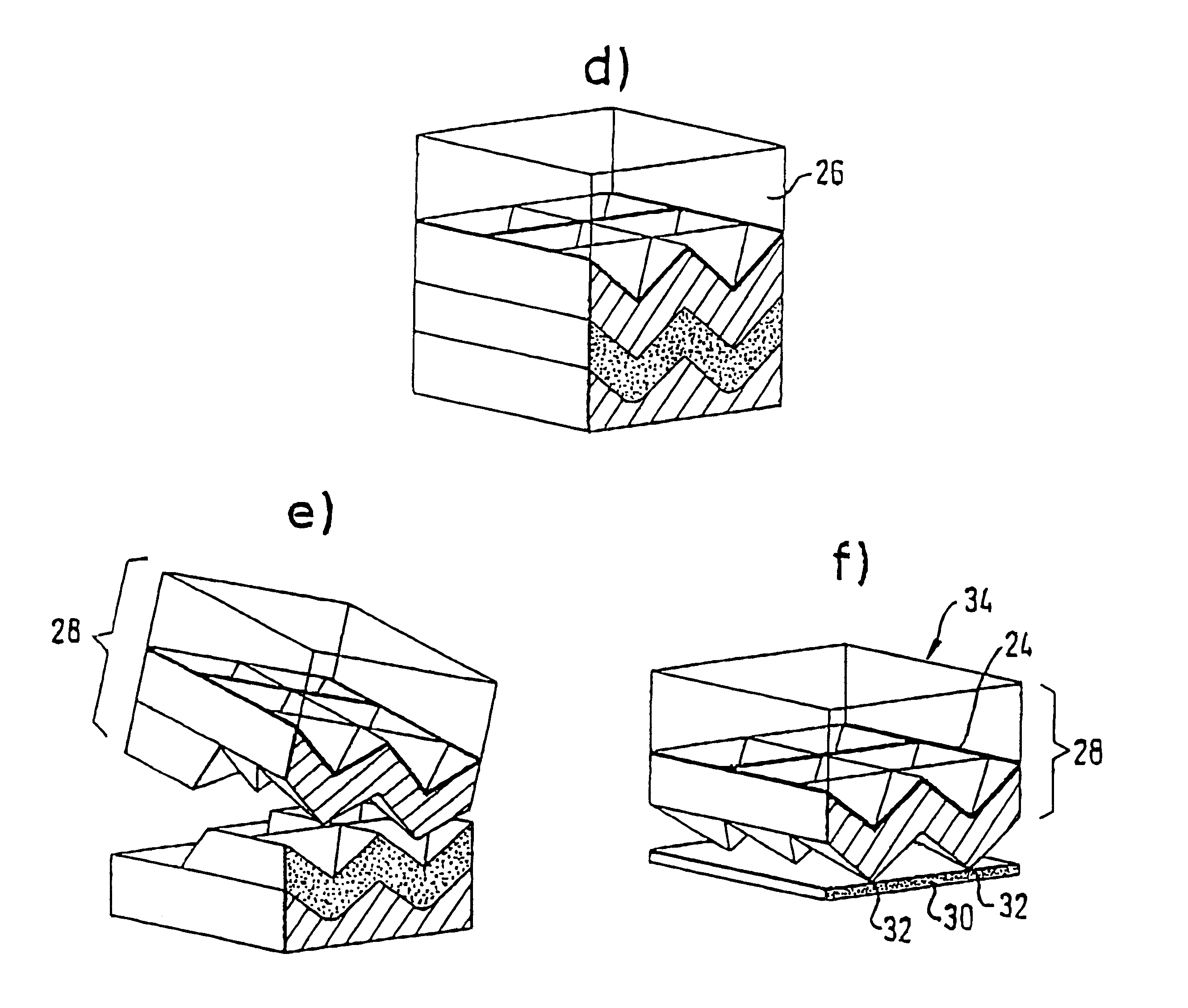

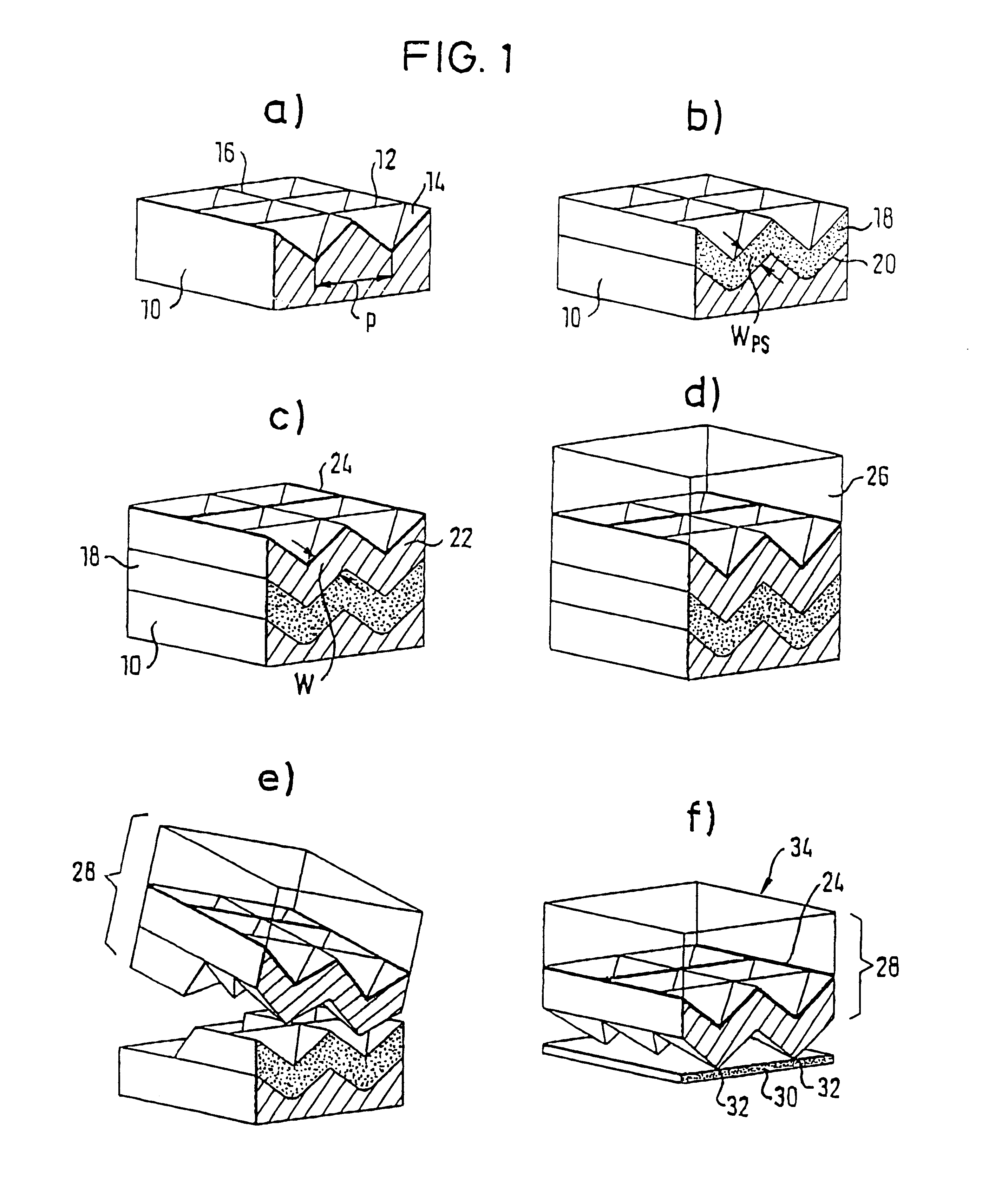

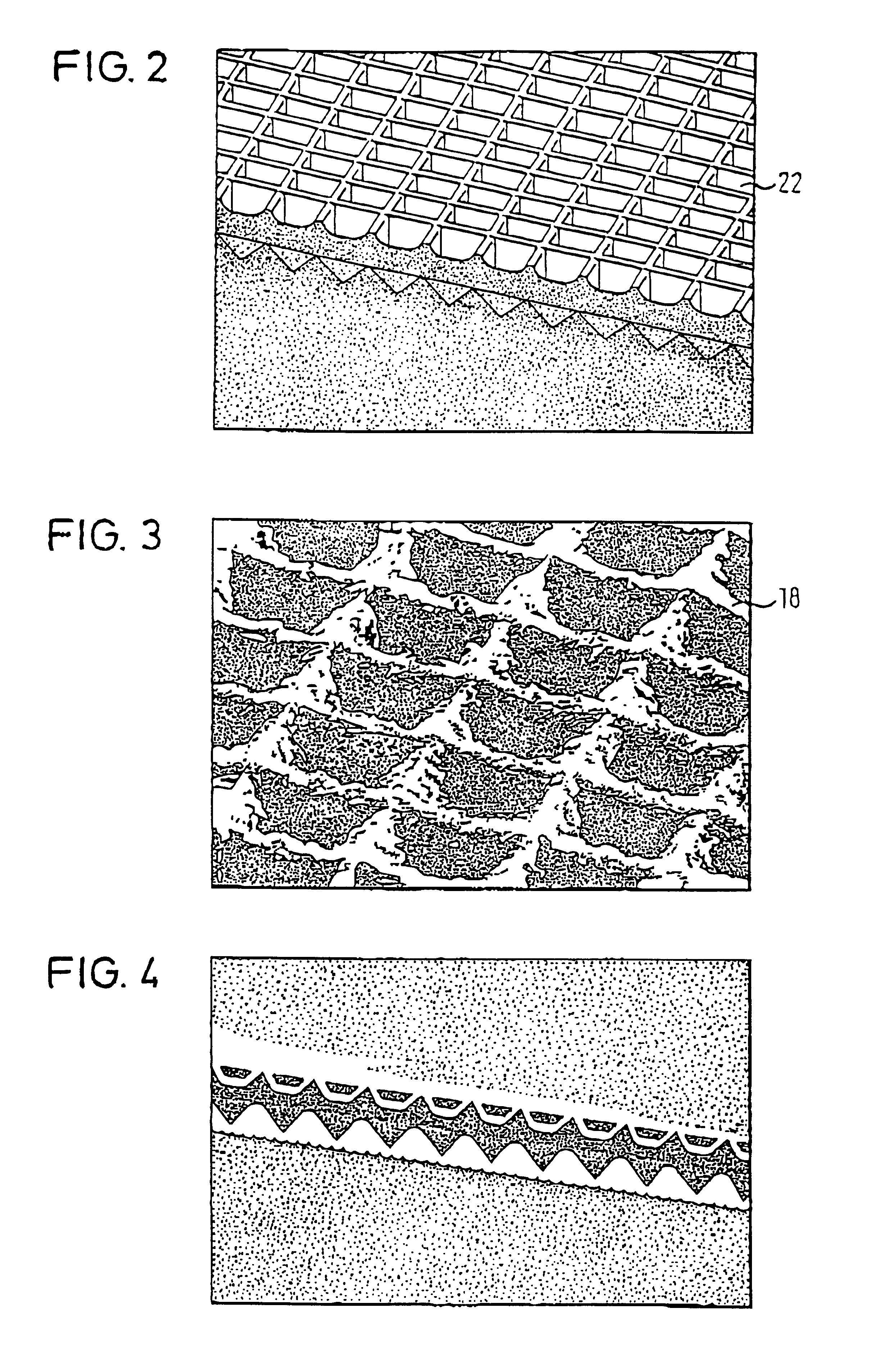

Method for producing layered structures on a substrate, substrate and semiconductor components produced according to said method

InactiveUS6645833B2Easy to make costExcellent technical characteristicPolycrystalline material growthFinal product manufacturePorous layerSingle crystal

The invention relates to a method of manufacturing layer-like structures in which a material layer having hollow cavities, preferably a porous material layer, is produced on or out of a substrate consisting, for example, of monocrystalline p-type or n-type Si and in which the layer-like structure, or a part of it, is subsequently provided on the cavity exhibiting or porous material layer. The layer-like structure, or a part of it, is subsequently separated from the substrate using the layer having the hollow cavities, or porous layer, as a point of desired separation, for example through the production of a mechanical strain within or at a boundary surface of the cavity exhibiting or porous layer. The method is characterized in that the surface of the substrate is structured prior to the production of the porous layer, or in that the surface of the porous layer is structured.

Owner:MAX PLANCK GESELLSCHAFT ZUR FOERDERUNG DER WISSENSCHAFTEN EV

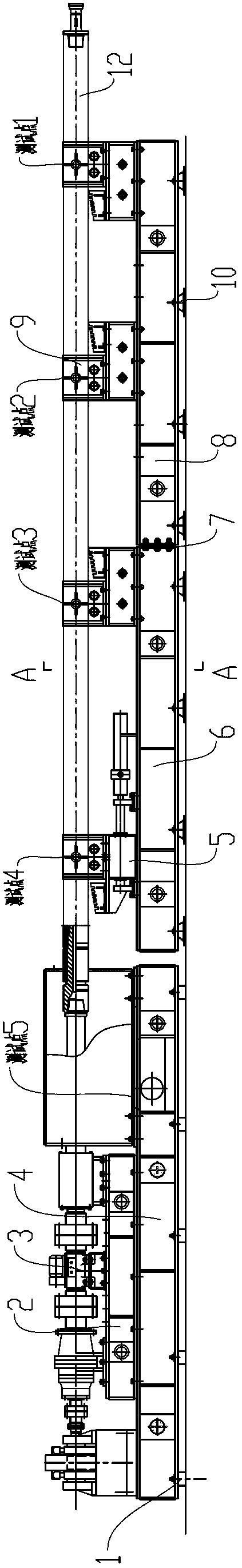

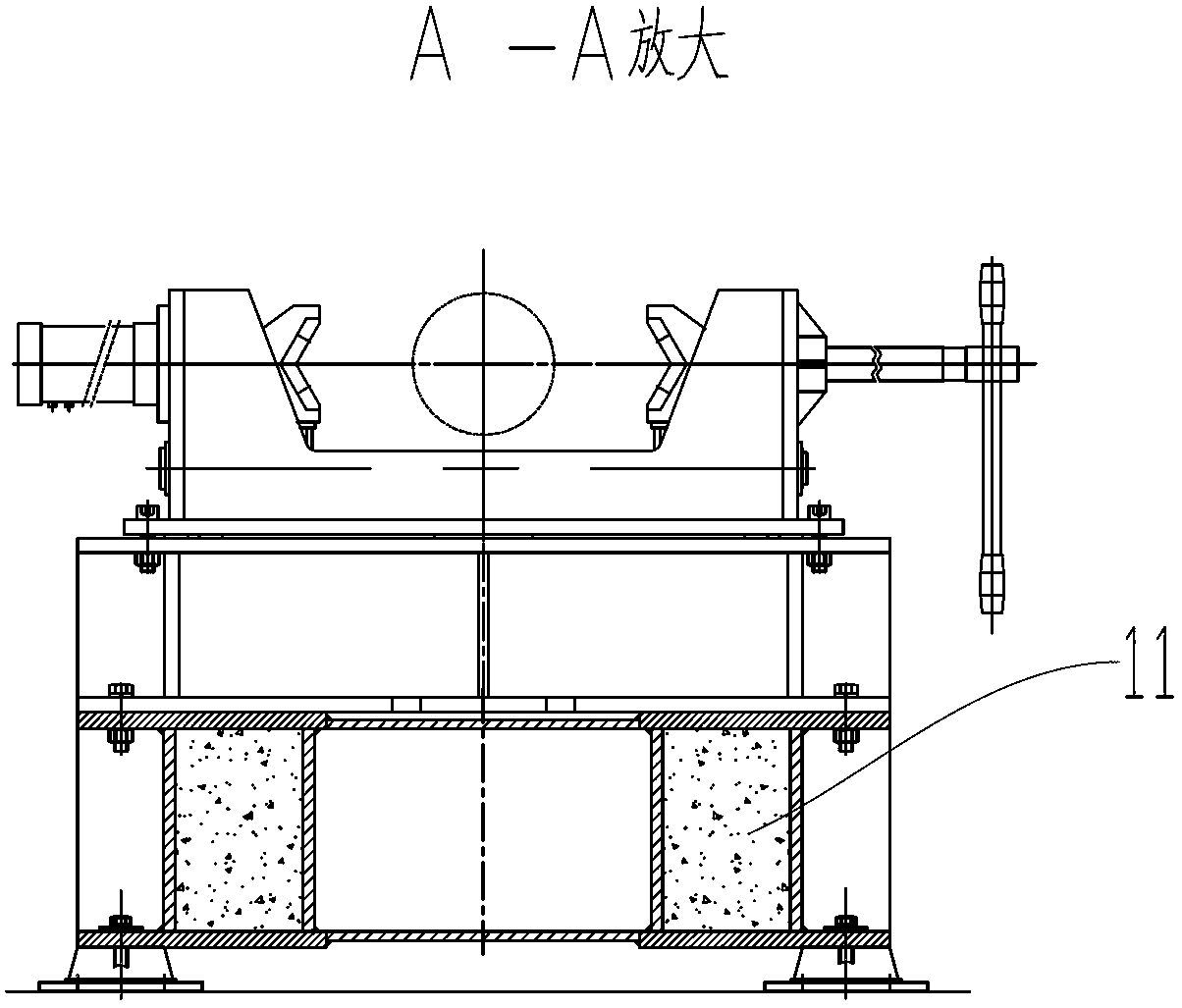

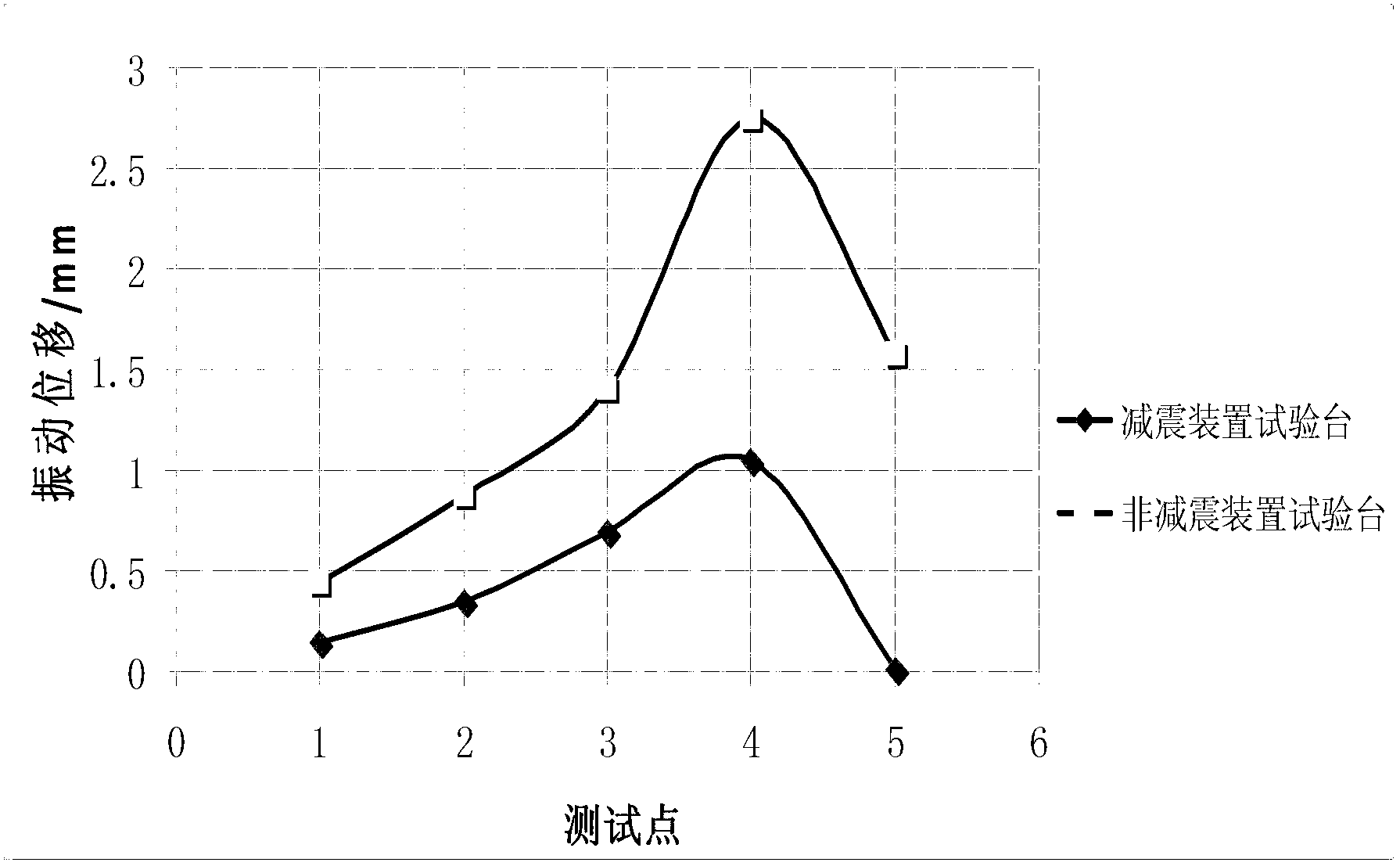

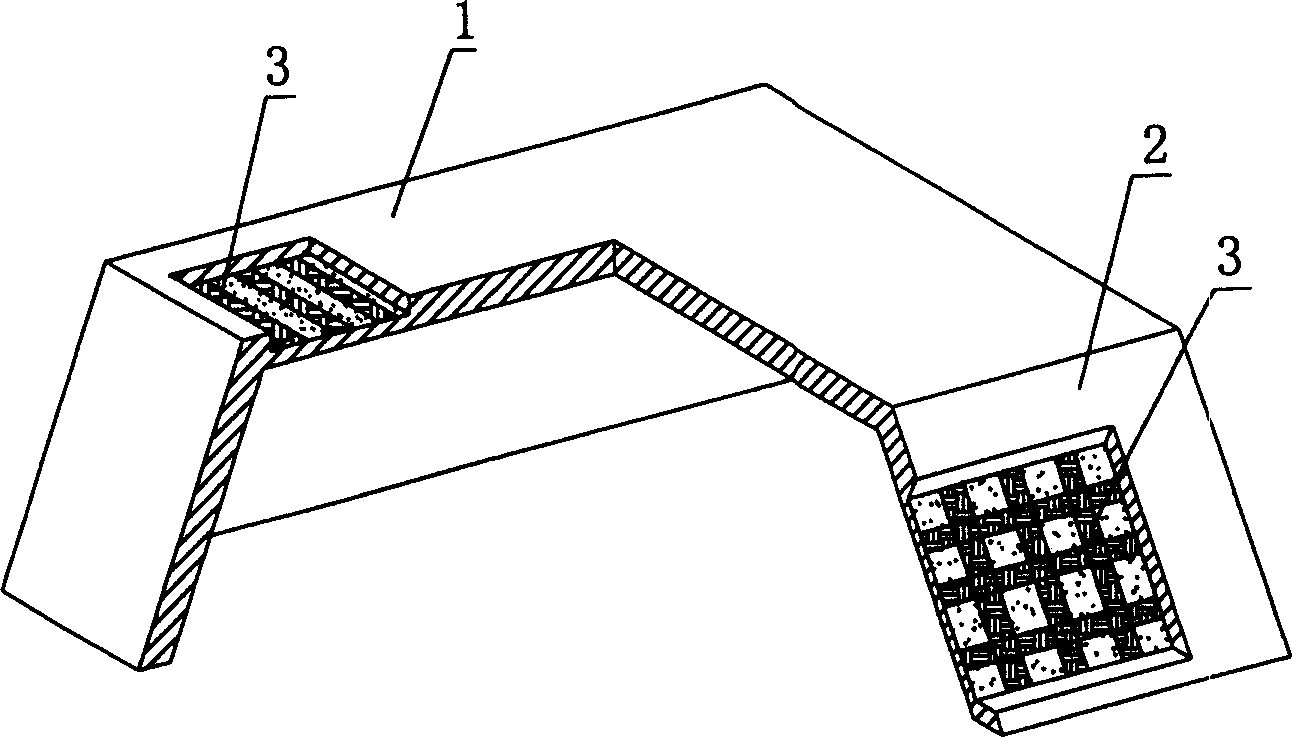

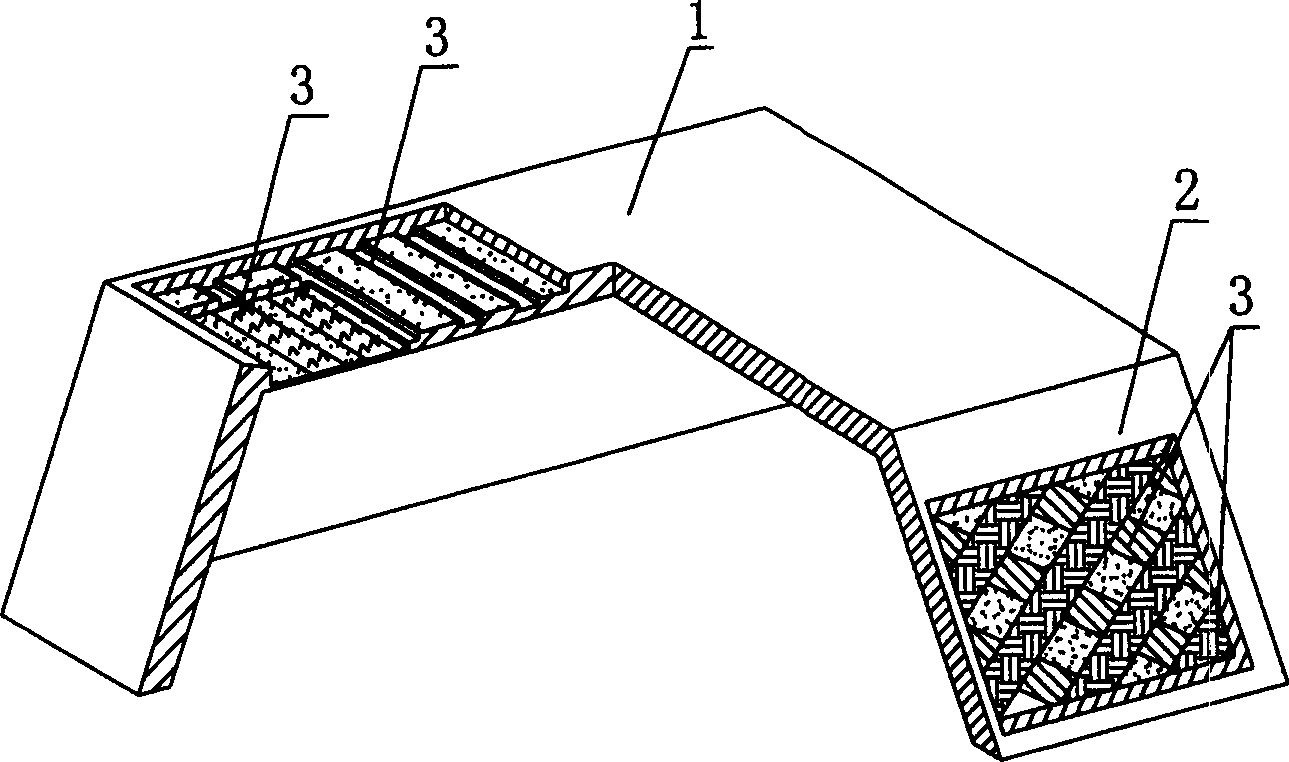

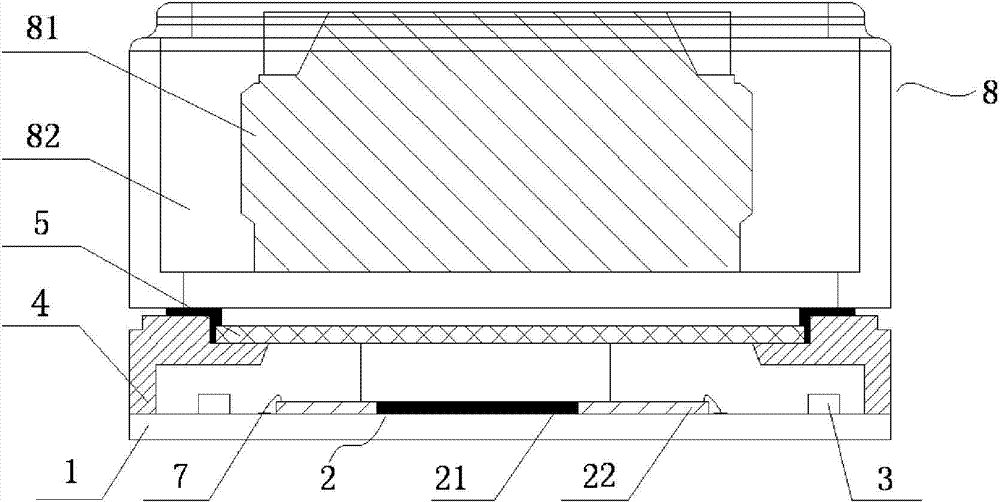

Combined vibration damper of screw drill complete machine test-bed and manufacturing method thereof

ActiveCN103245523AAchieve test accuracyThe test data is accurateStructural/machines measurementVibration attenuationResonance

The invention discloses a combined vibration damper of a screw drill complete machine test-bed and a manufacturing method thereof. The combined vibration damper comprises a vibration attenuation base which comprises a loading system base, a first clamping system base and a second clamping system base, wherein the loading system base is arranged on an equipment foundation in a rigidity way; the first clamping system base and the second clamping system base are connected into a whole through a bolt and are arranged on the equipment foundation through a rubber vibration attenuation block; an interval of 30-50 mm is reserved between the loading system base and each clamping system base; the first clamping system base and the second clamping system base are respectively internally provided with a plurality of cubic cavities with an equal size; the volume of each cubic cavity is 0.1-0.2 cubic meter; discrete type balance weight sand is respectively filled into the cubic cavities, and the filling efficiency is 80-90 %; and the weight of the balance weight sand is 25-35 % of the total weight of the whole device. The test-bed is capable of restraining resonance and testing precisely in the testing process by the combined vibration damper, and the usage precision of surrounding working devices is not affected.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

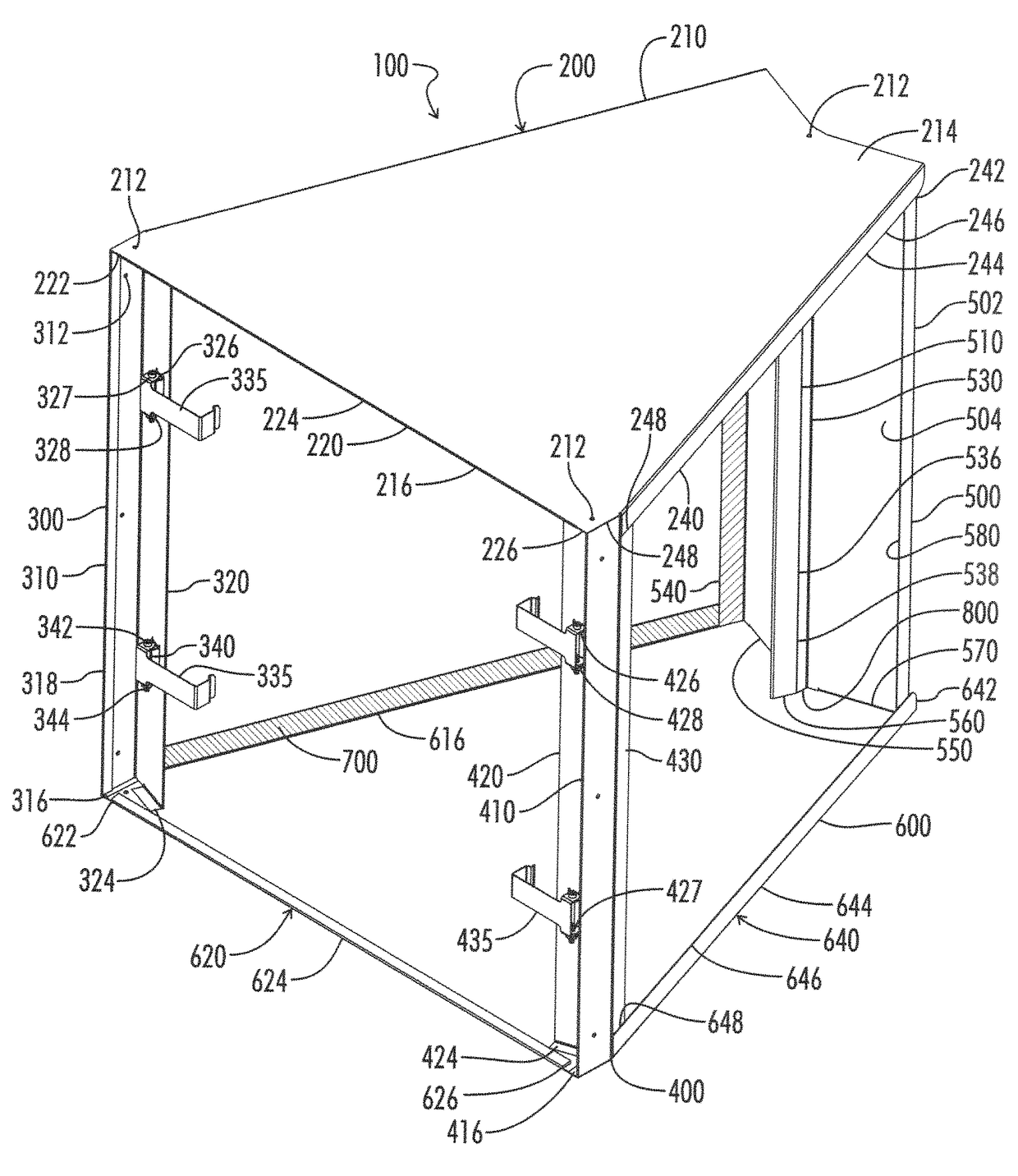

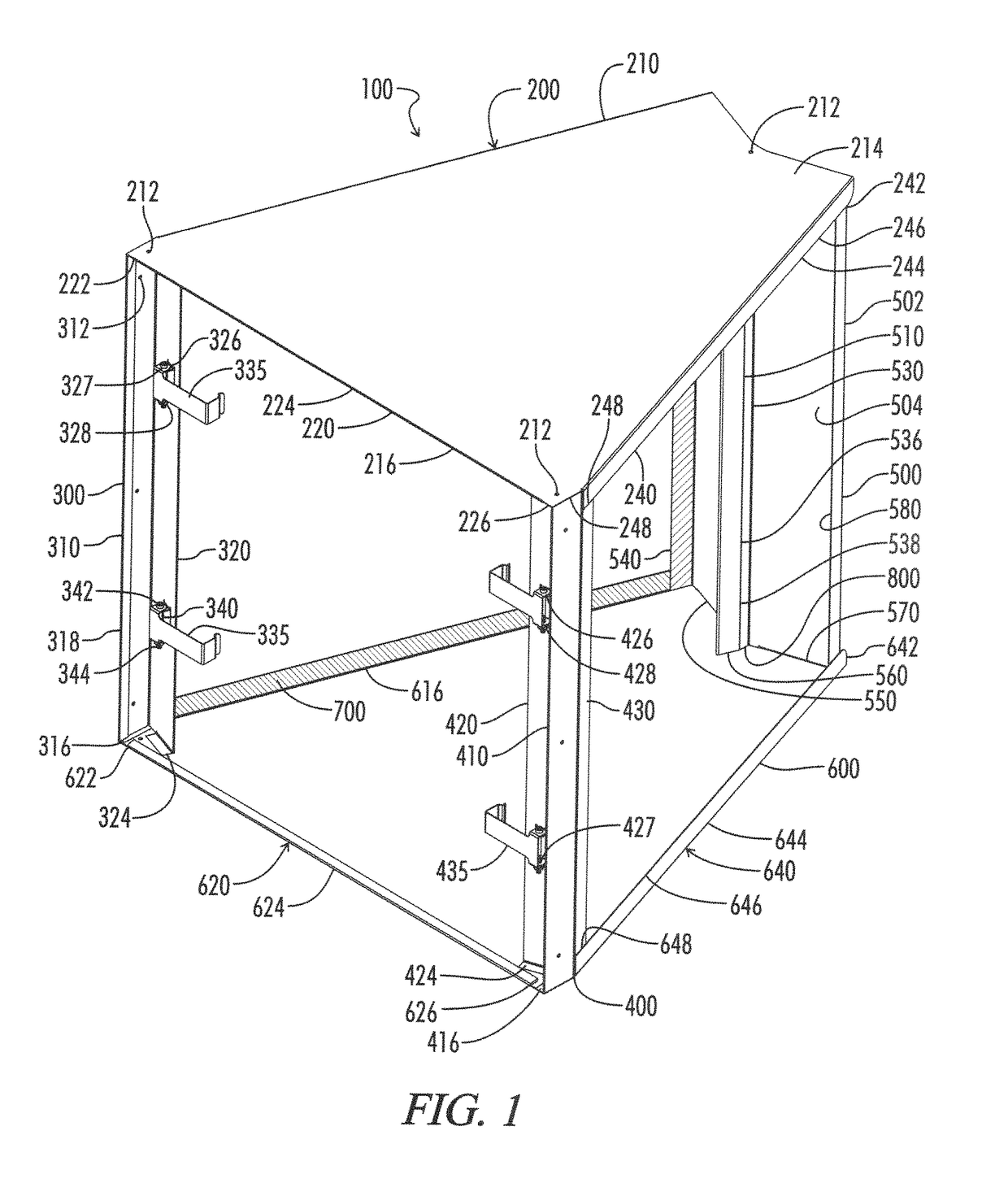

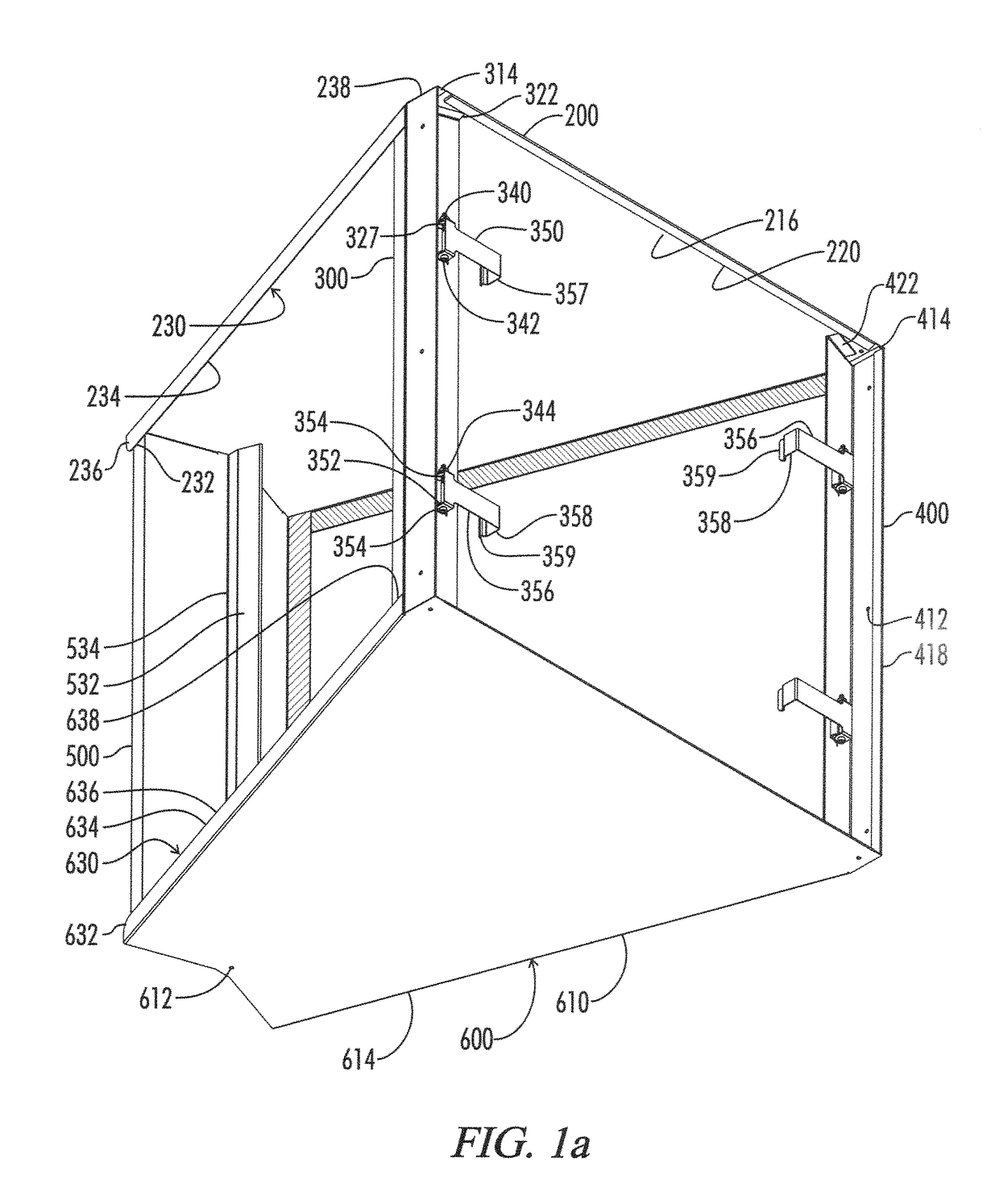

Modular air filter housing

ActiveUS9764266B1Improve sealingImprove efficiencyDispersed particle filtrationTransportation and packagingAir filterMechanical engineering

An air filter module for modularly mounting angled air filters. The module includes a top plate, bottom plate, left and right front corners with the corners defining perpendicular side walls, angled filter end retention walls, angled side walls, and a back wall with angled side walls, parallel end retention walls, and a positioning guide. The positioning guide is constructed from clips or a guide face and an inner side positioning wall.

Owner:CARTER SCOTT

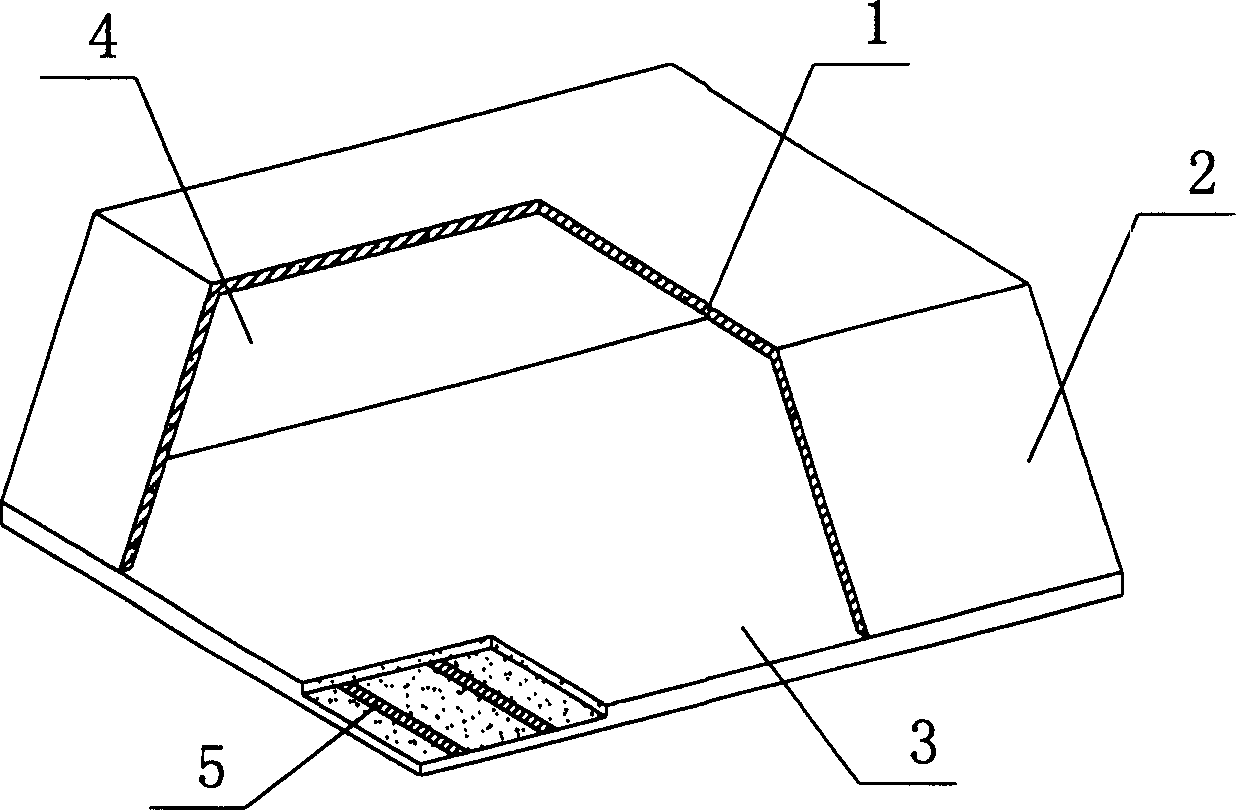

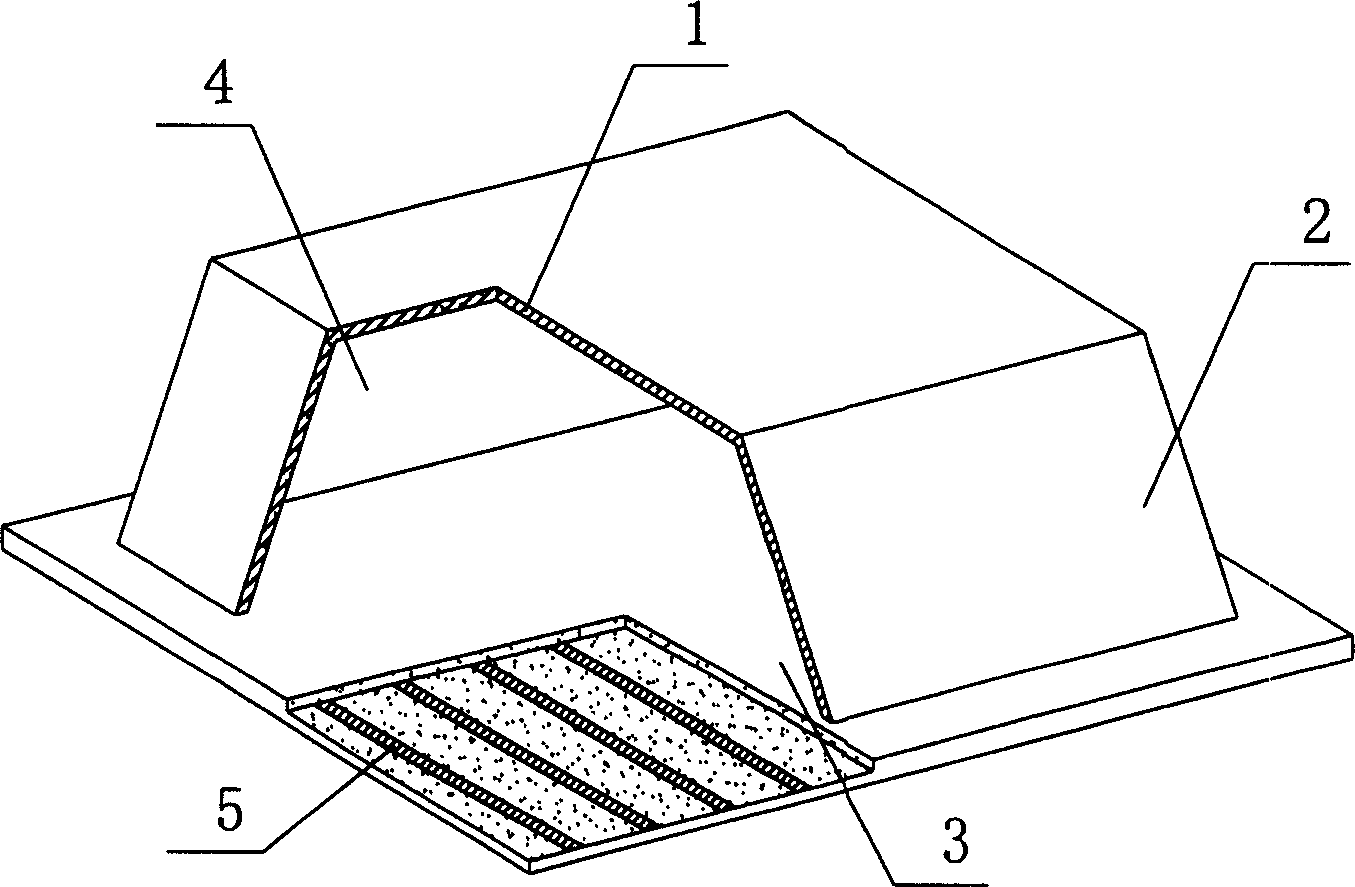

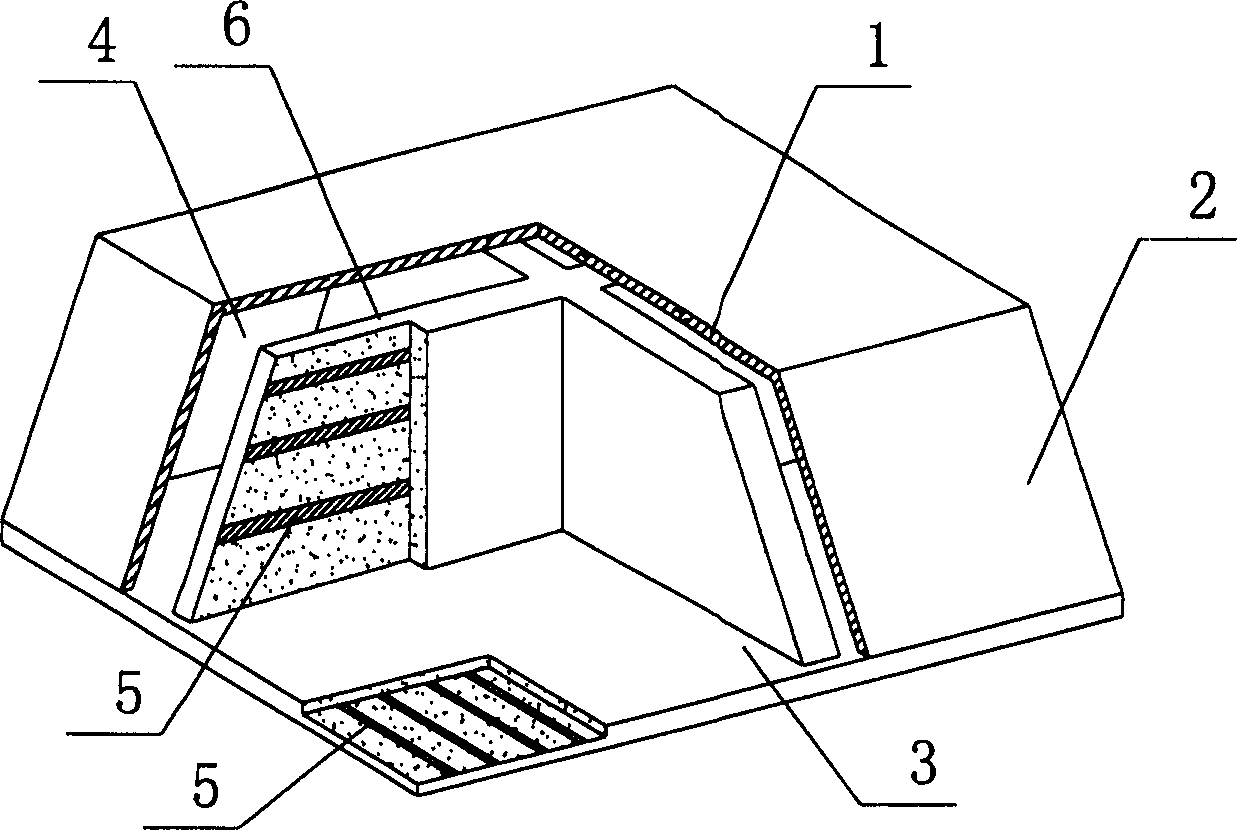

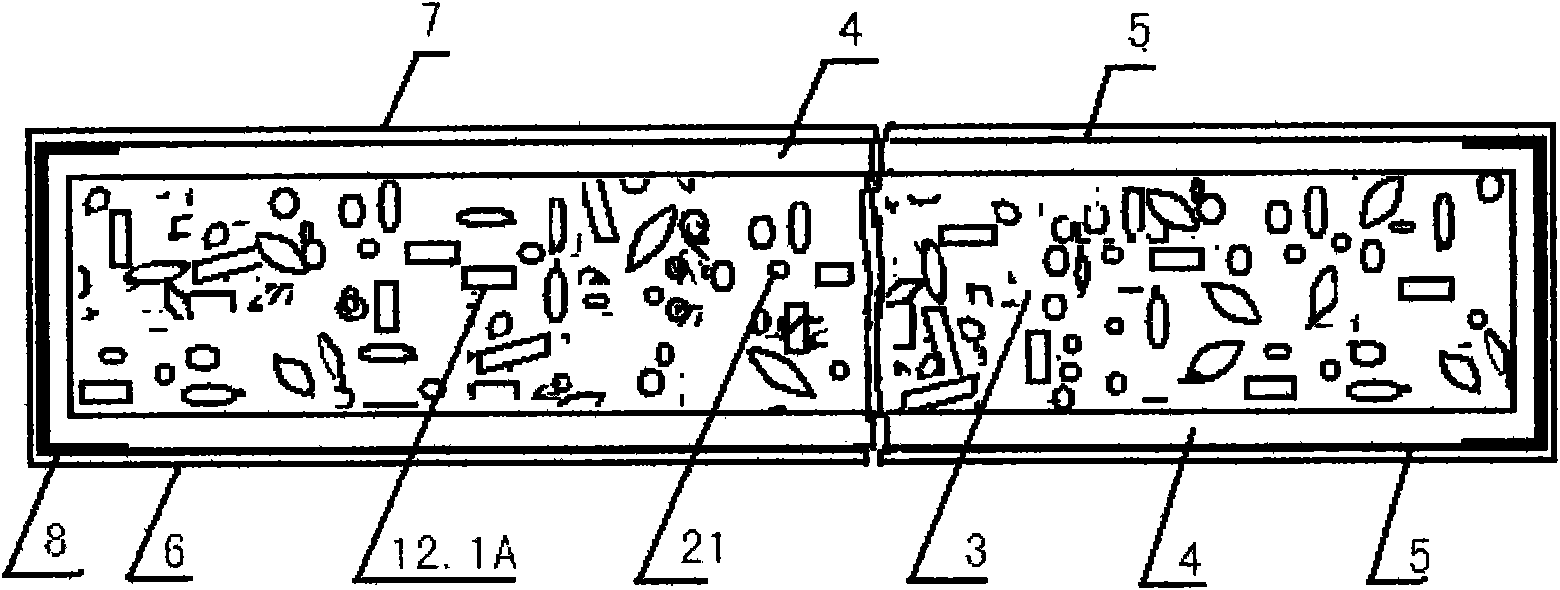

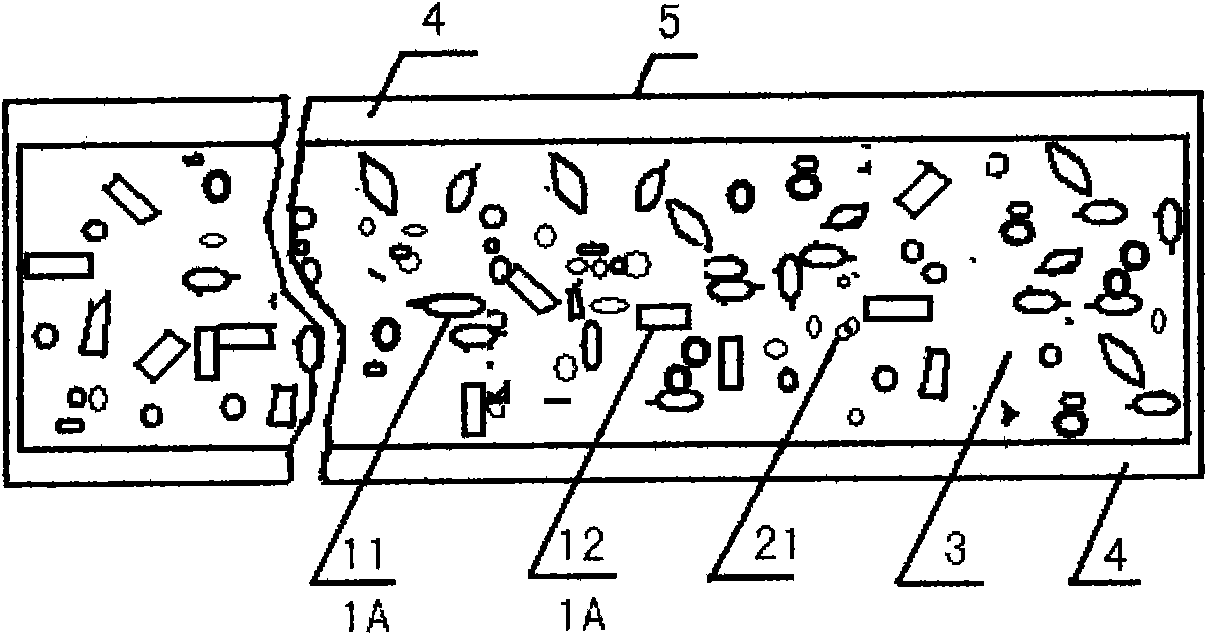

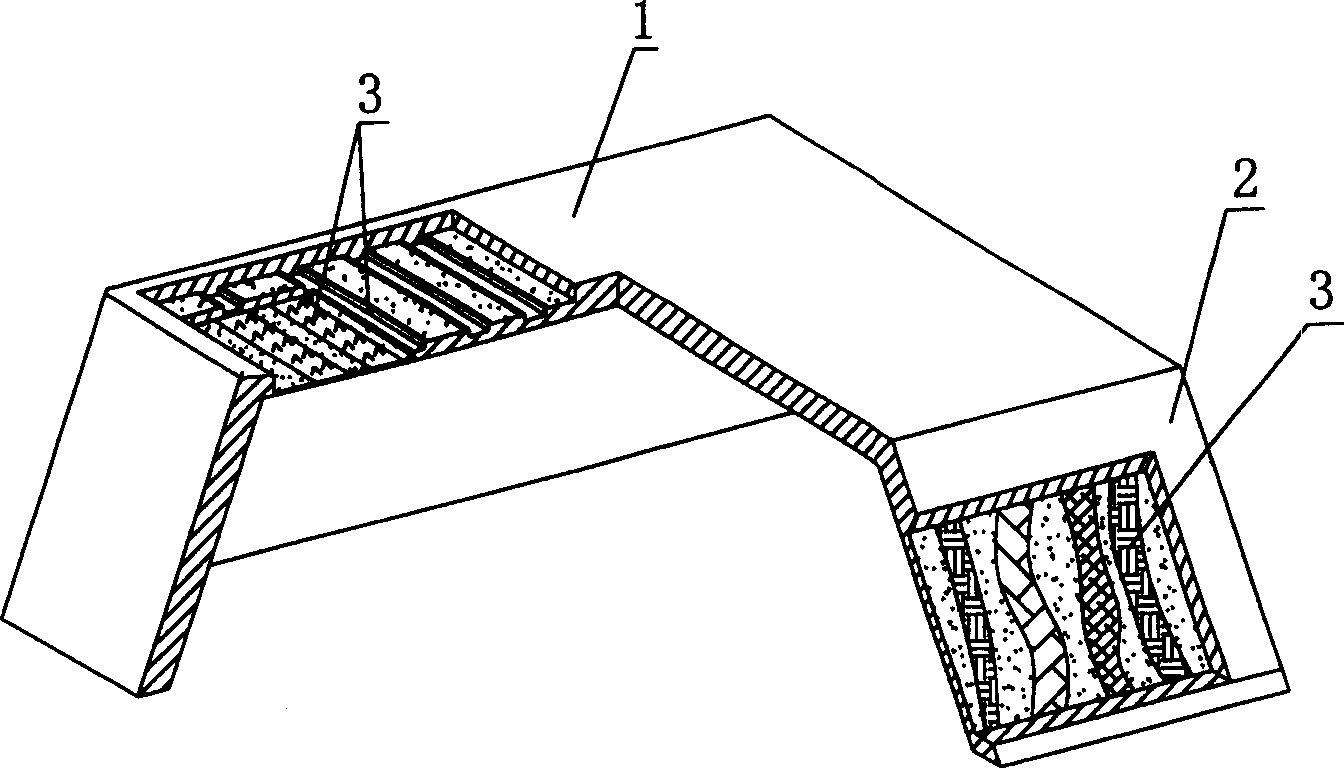

Thin-wall form member for hollowing out concrete

A thin-wall hollow form for concrete to in-situ pour hollow non-beam floor is composed of top plate, peripheral wall and bottom plate, and is characterized by that its bottom plate contains at least one thin strip for improving its resistance to impact and collision. Its advantages are simple structure, high strength, toughness and resistance to deformation and vibration, light weight and low cost.

Owner:湖南邱则有专利战略策划有限公司

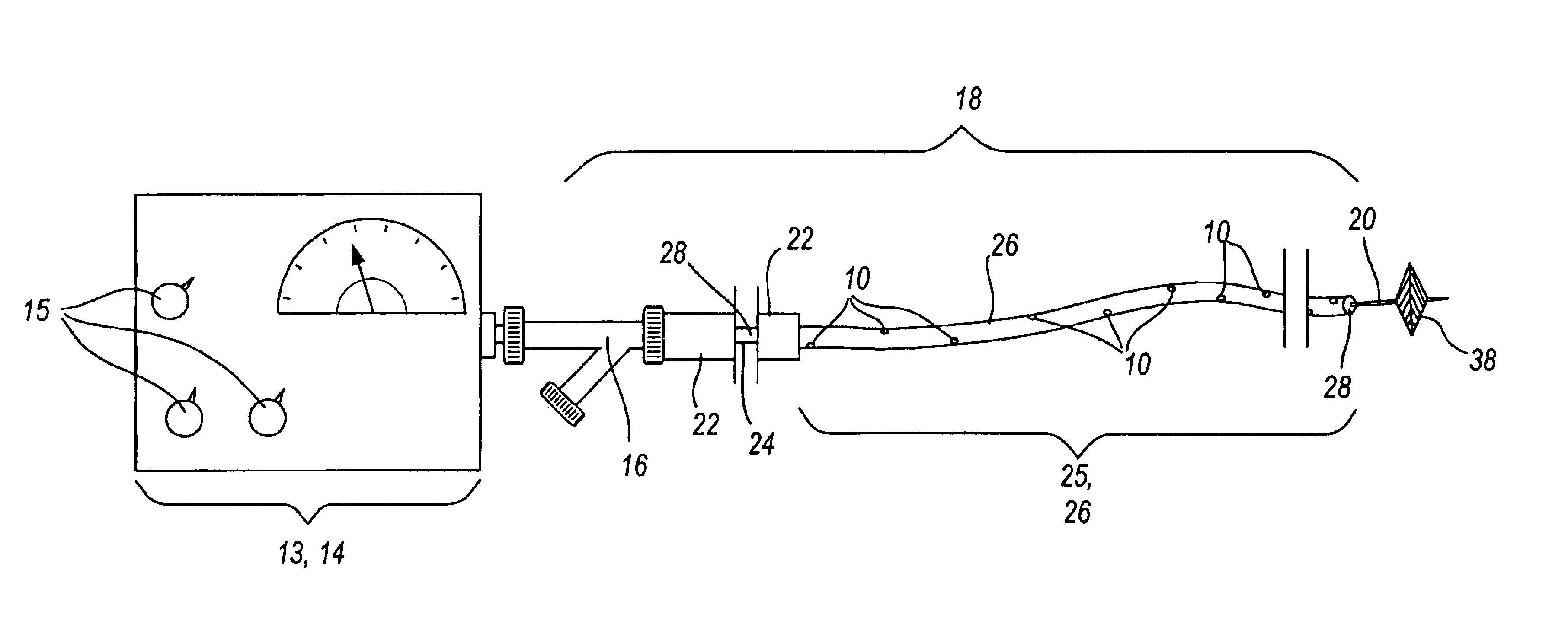

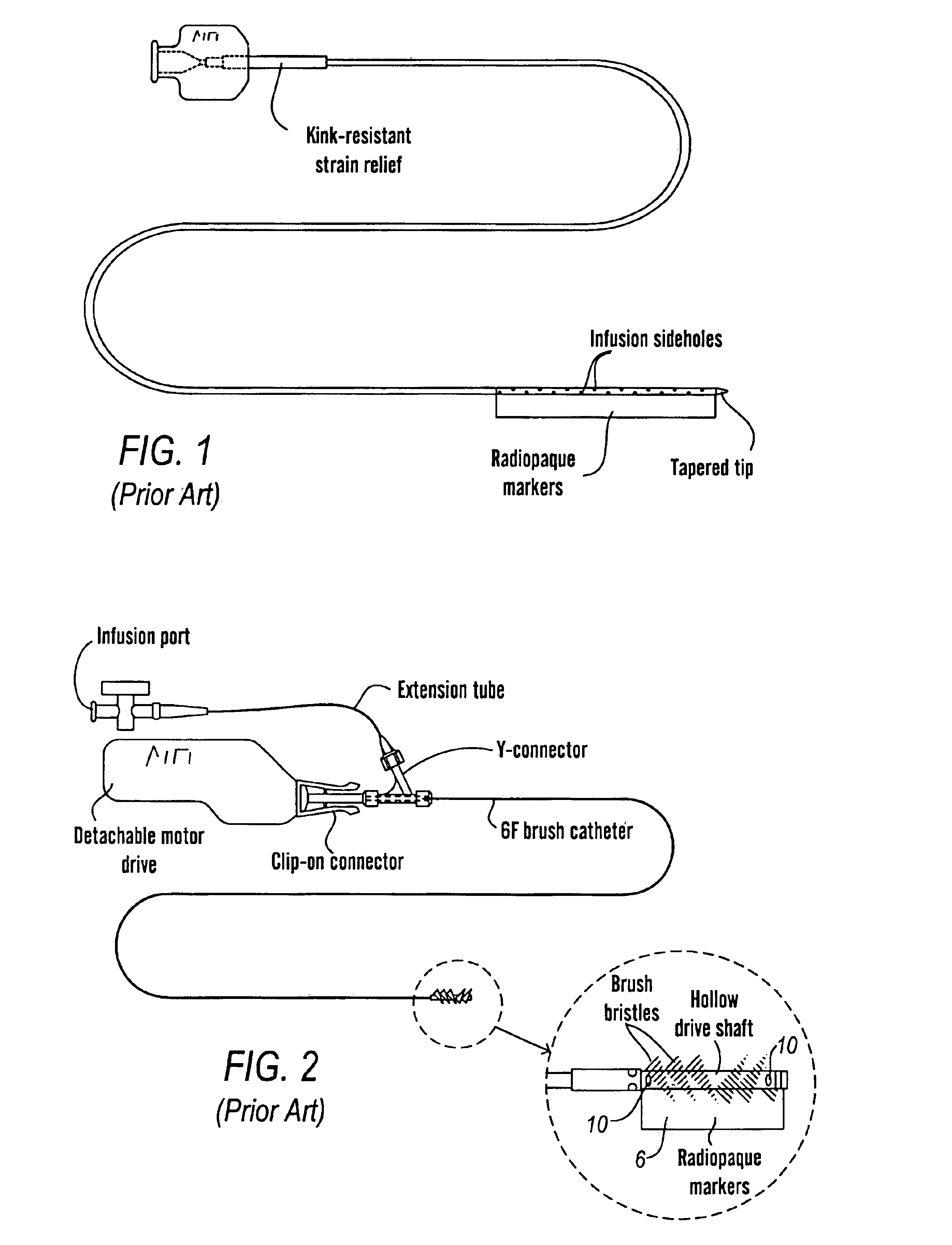

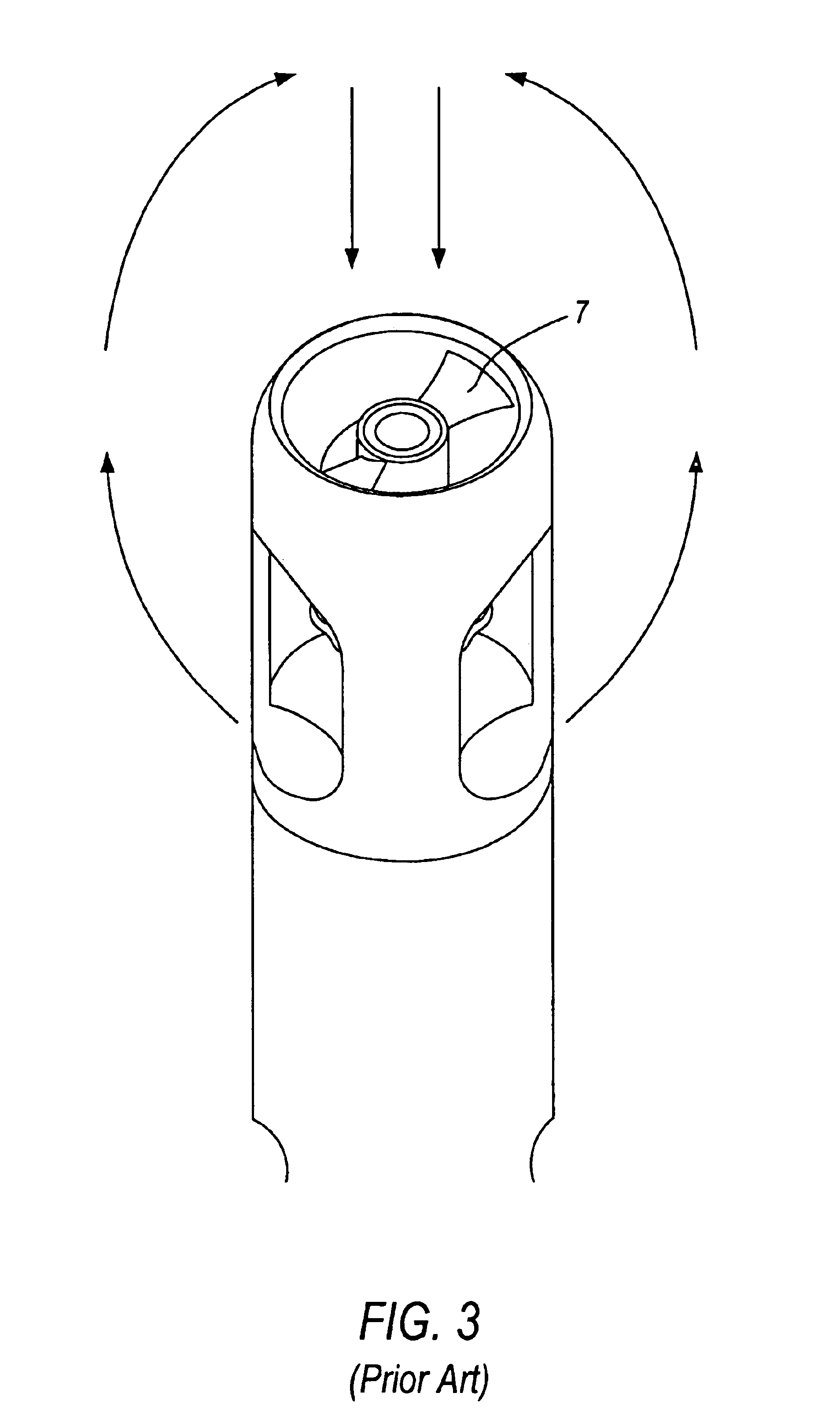

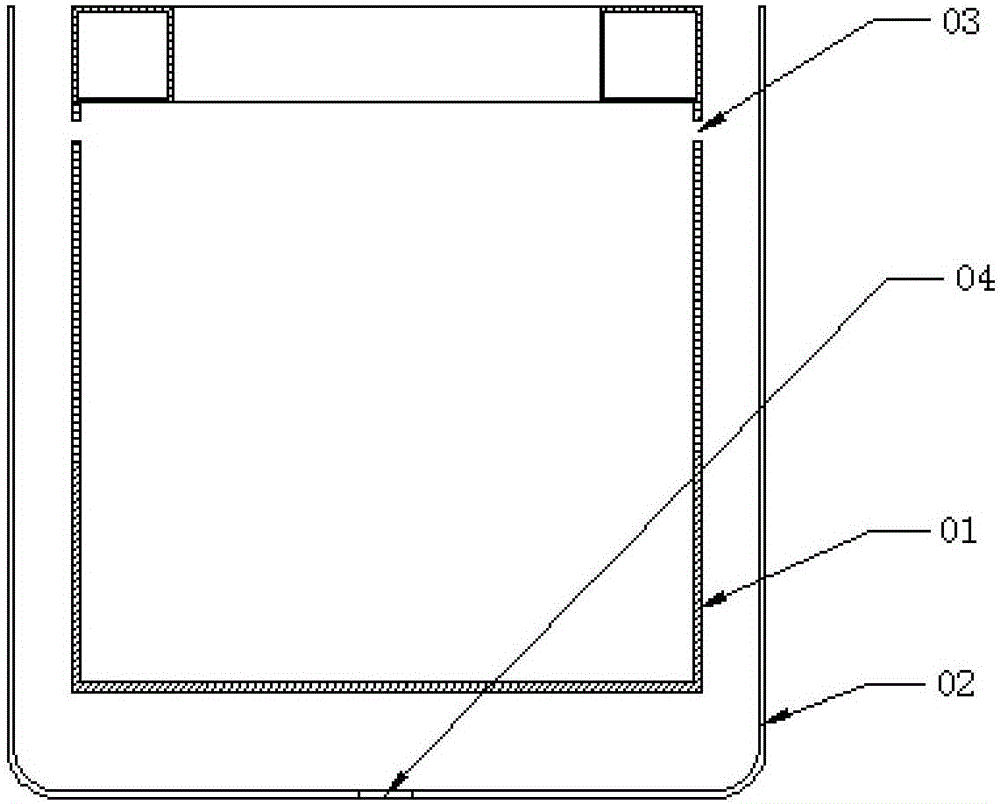

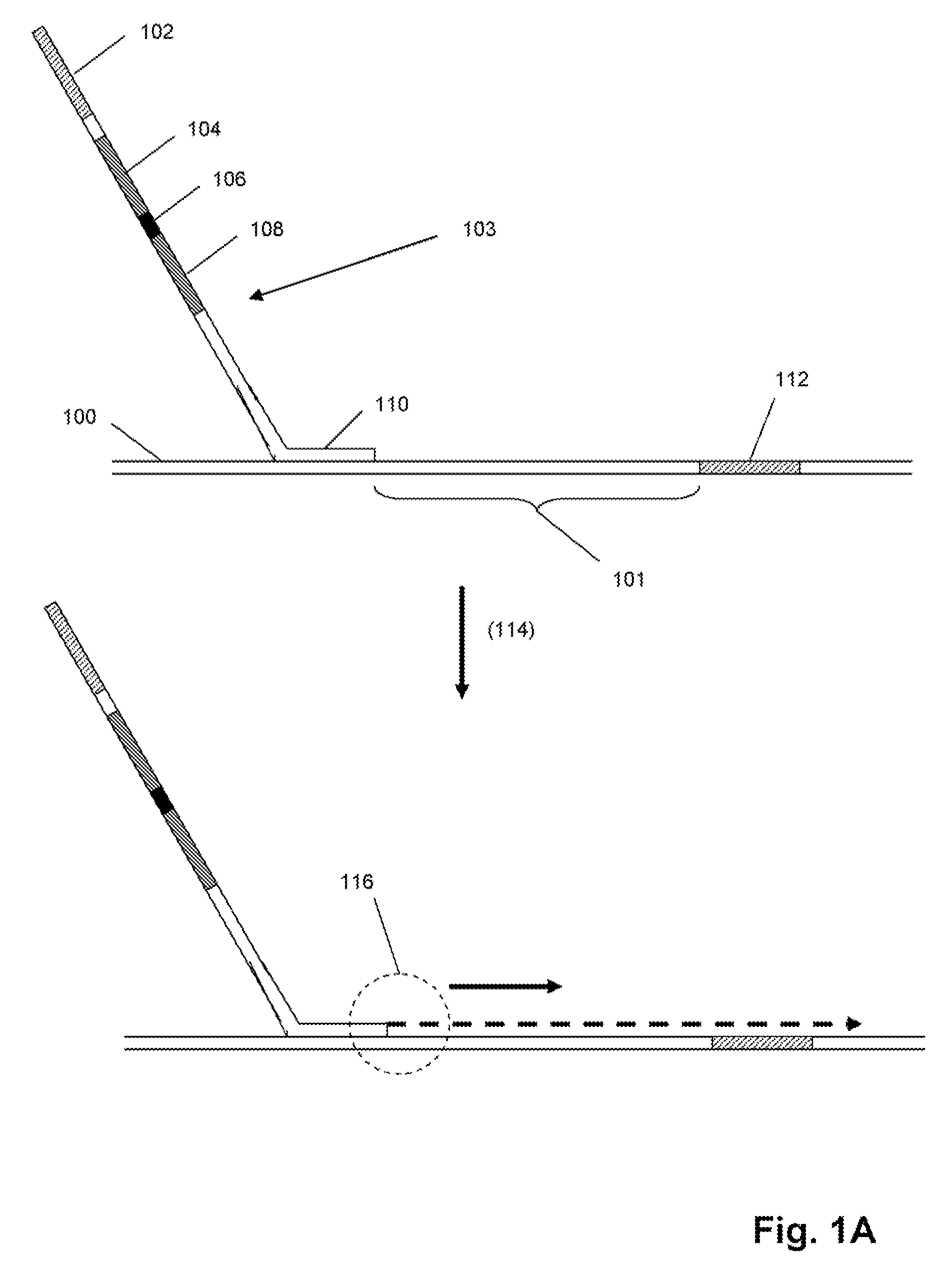

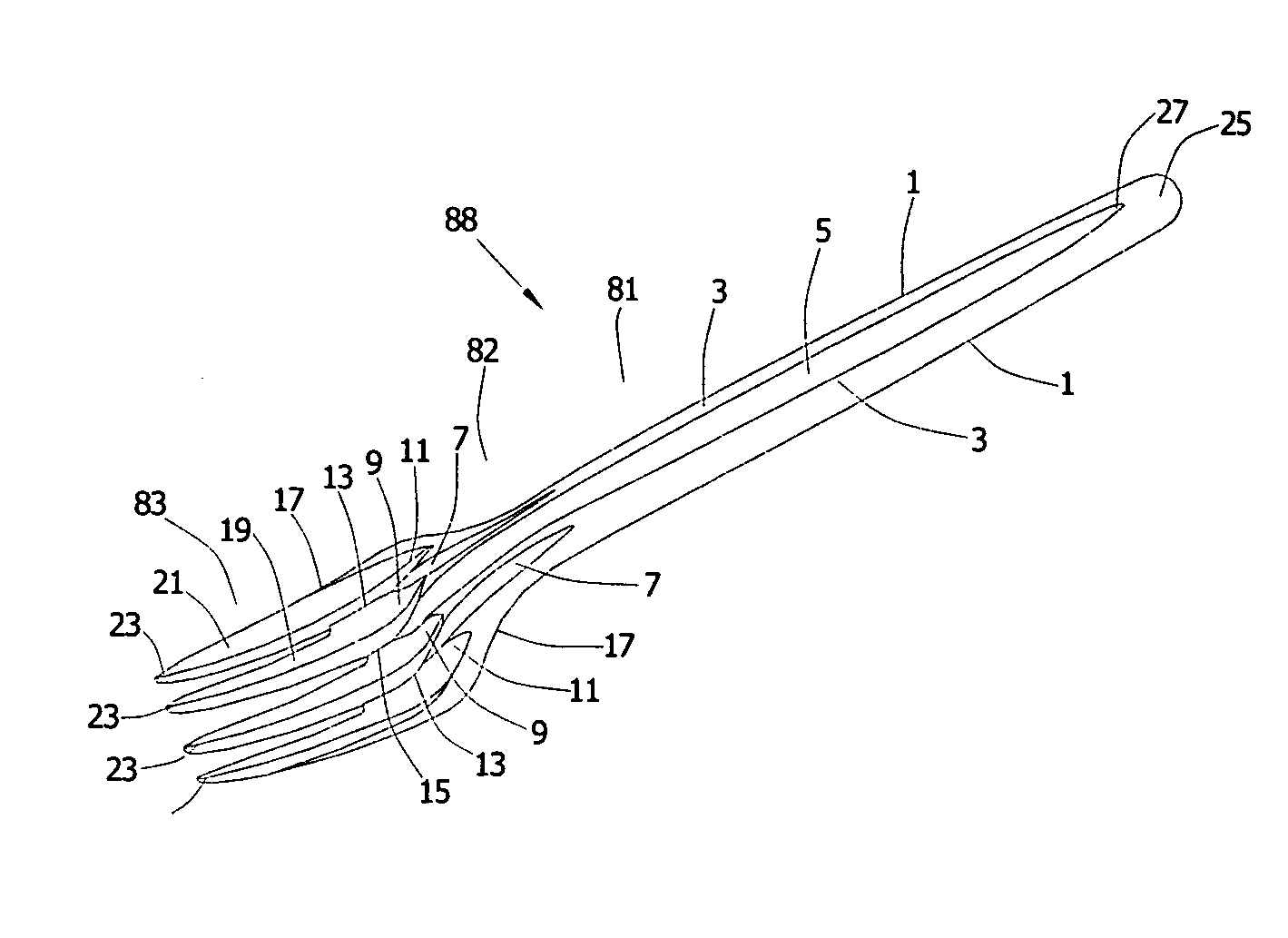

Mechanically active infusion catheter

A device and method to dissolve or eliminate blood clots from a patient relies upon a non-rapid moving mechanism to physically dissolve clots without damaging endothelium of the arteries and veins of a patient. In one embodiment, in addition to mechanical agitation of a clot, a thrombolytic agent is administered simultaneously with such agitation. Preferably, intermittent agitation is utilized over a prolonged period of time to effectuate clot removal.

Owner:COOK MEDICAL TECH LLC

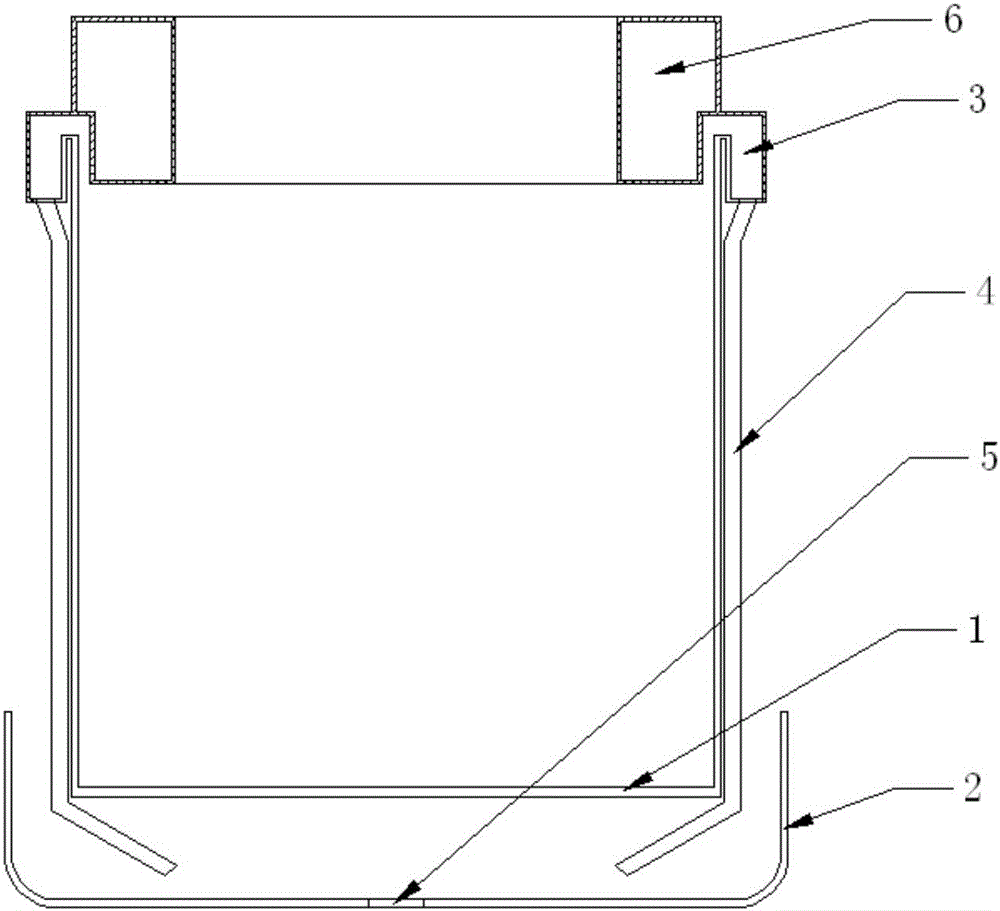

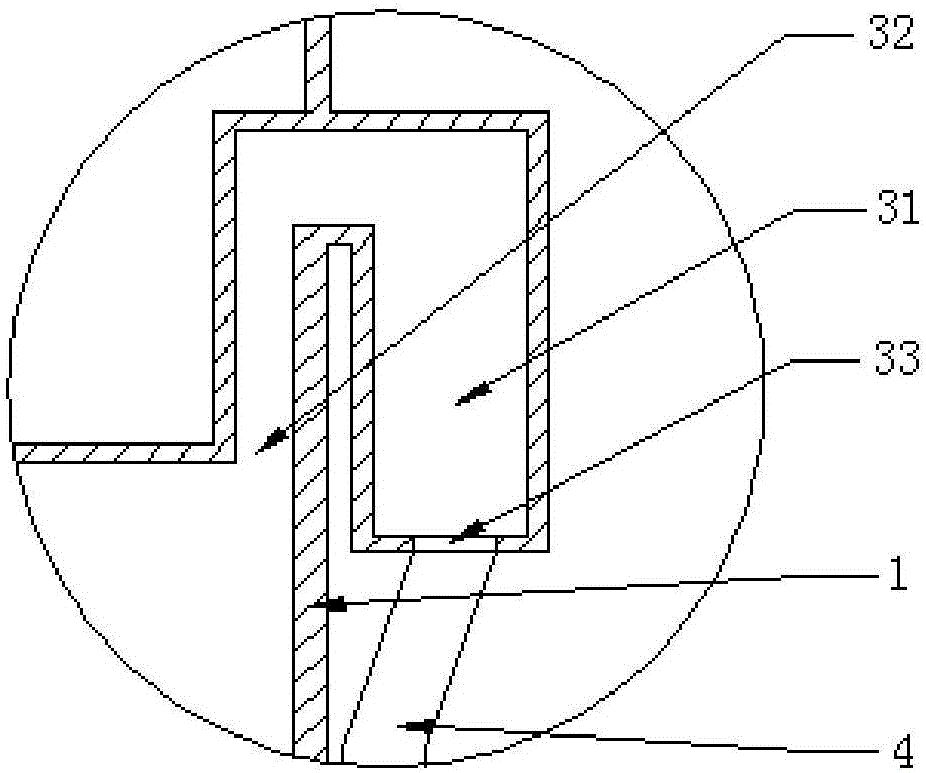

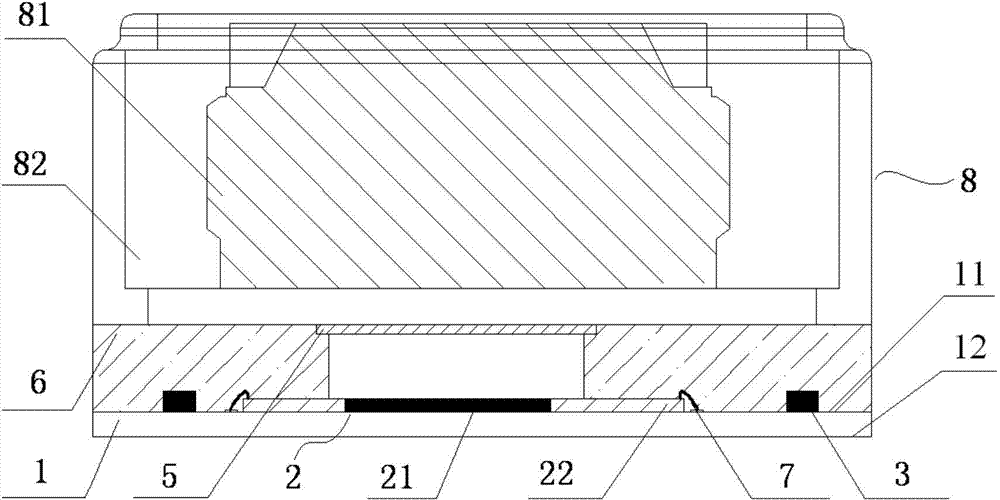

Hole-free inner barrel washing machine

InactiveCN105714514ALower the altitudeLow costOther washing machinesTextiles and paperWater dischargePulp and paper industry

The invention discloses a hole-free inner barrel washing machine and relates to the technical field of washing machines. Under the condition of saving water, the problems that the water is easy to splash when the water is discharged above an inner barrel and bacteria are easy to breed in an outer barrel are solved, and the cost of the washing machine is saved. The hole-free inner barrel washing machine comprises the inner barrel and the outer barrel, wherein a water collection ring is arranged at a barrel opening of the inner barrel; the water collection ring comprises a water collection cavity, and a water collection hole and a water discharging hole which are communicated with the water collection cavity; the water collection hole is arranged toward the inner part of the inner barrel; the water discharging hole is formed towards a gap between the inner barrel and the outer barrel; the water discharging hole is connected with a water discharging pipe; and the water discharging pipe extends downwards to the bottom of the outer barrel. The hole-free inner barrel washing machine is used for discharging the water of the washing machine.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

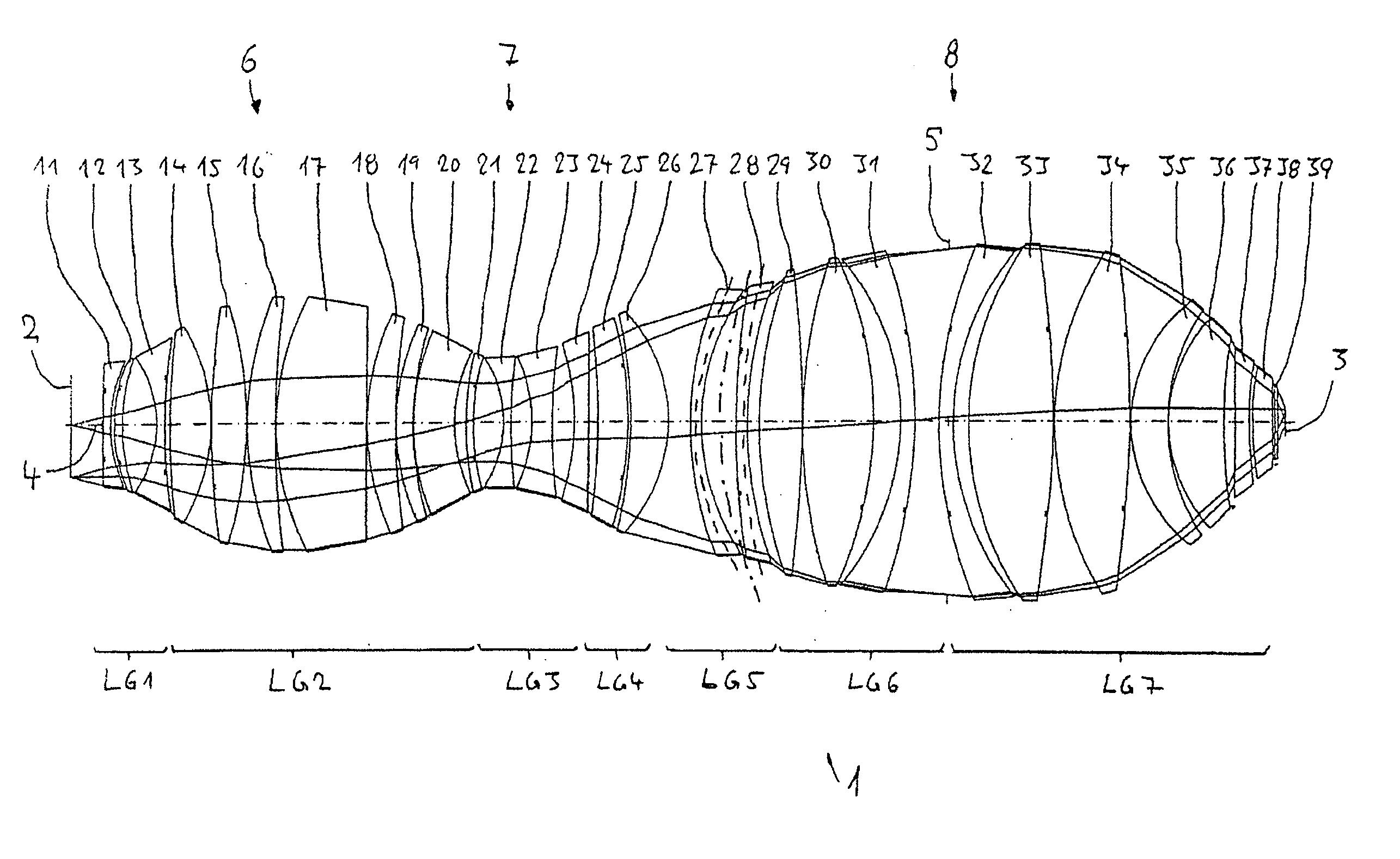

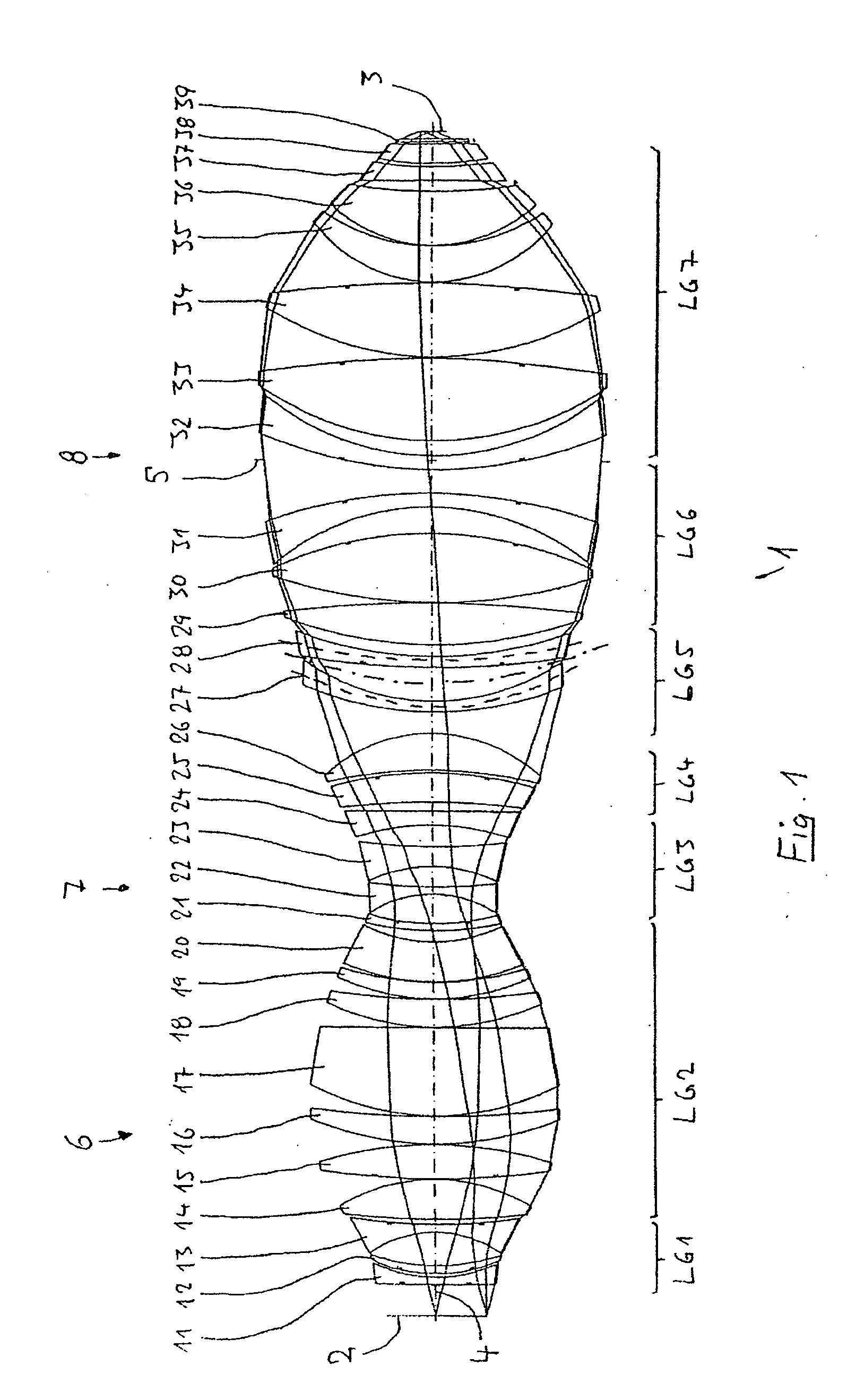

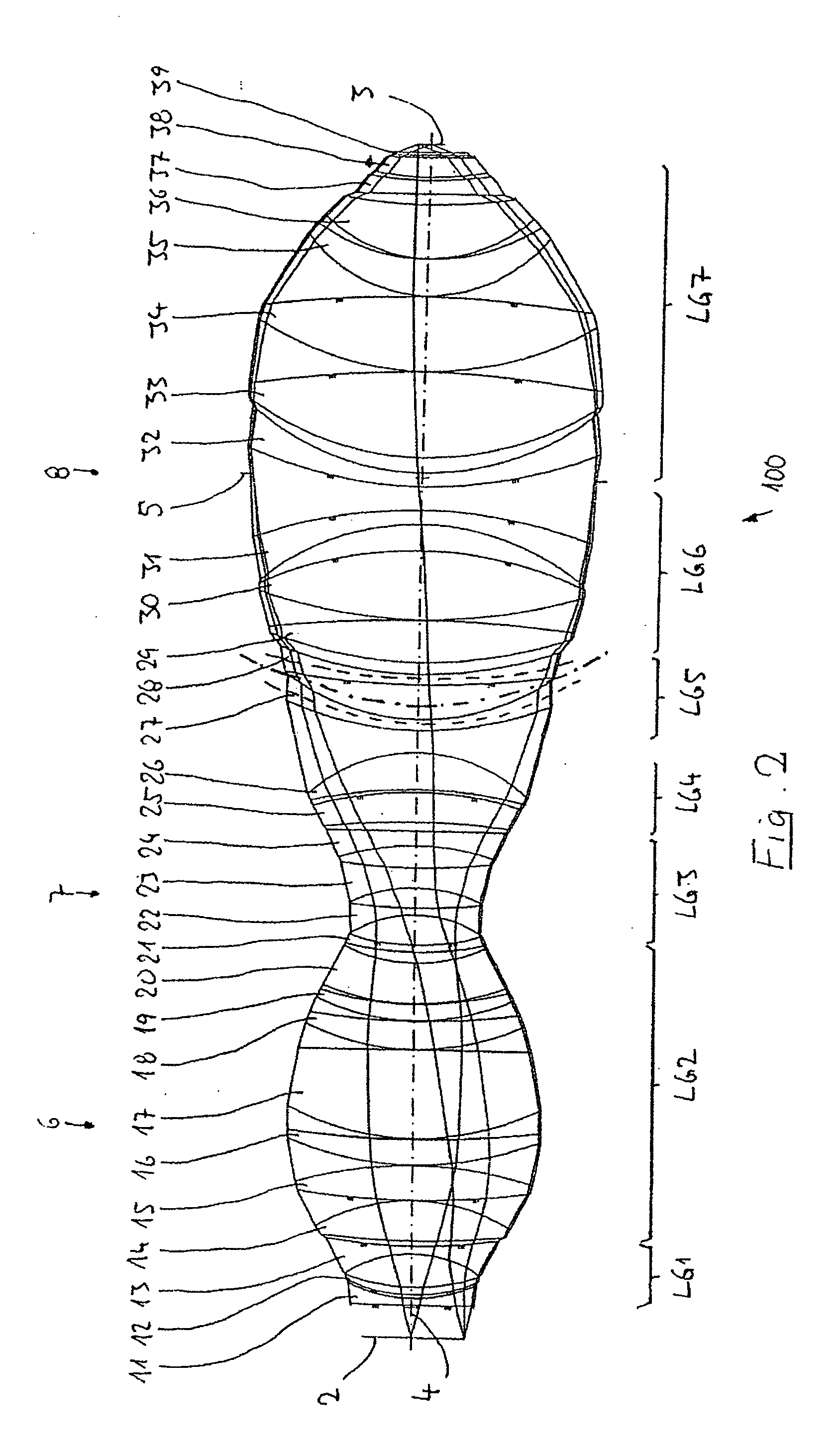

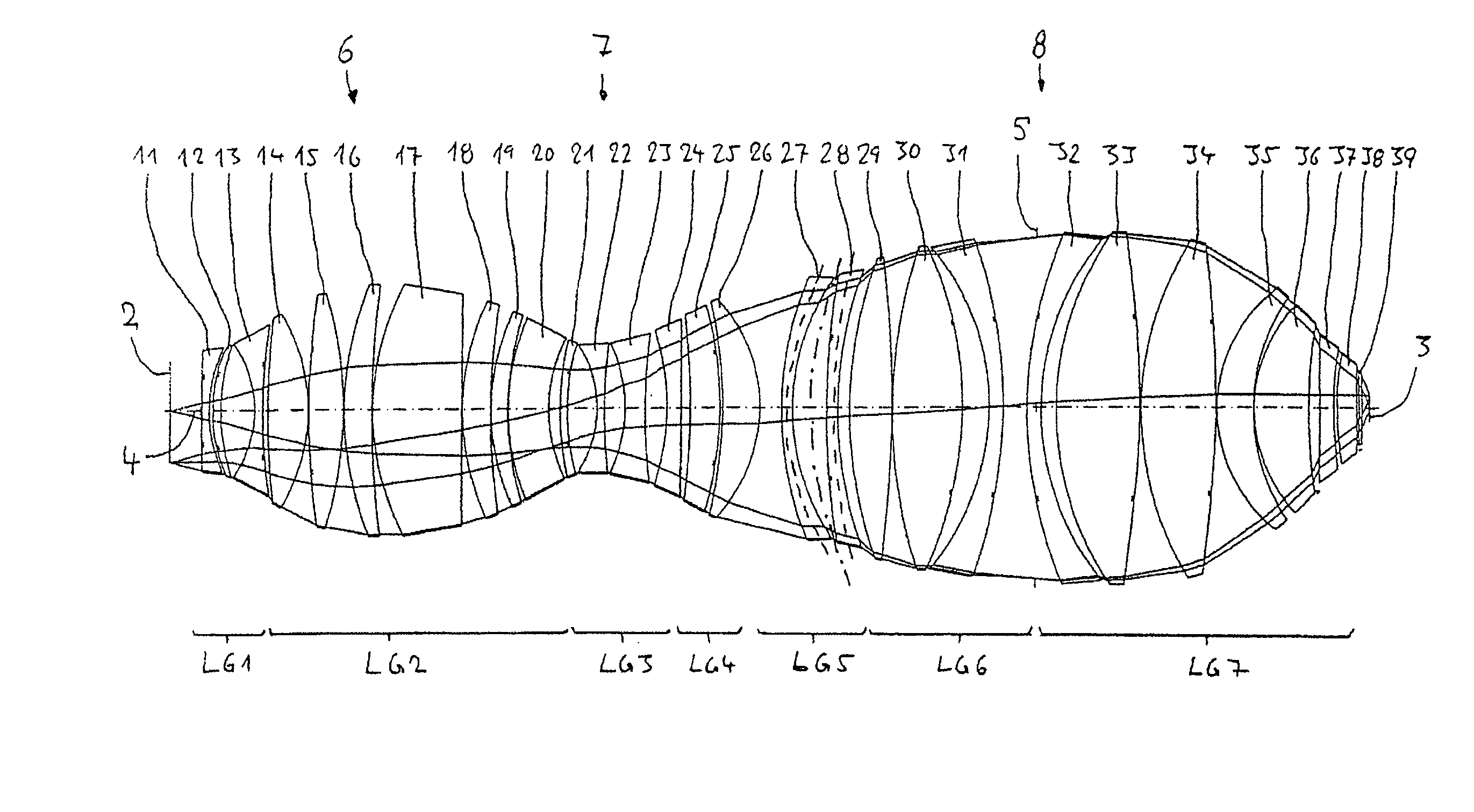

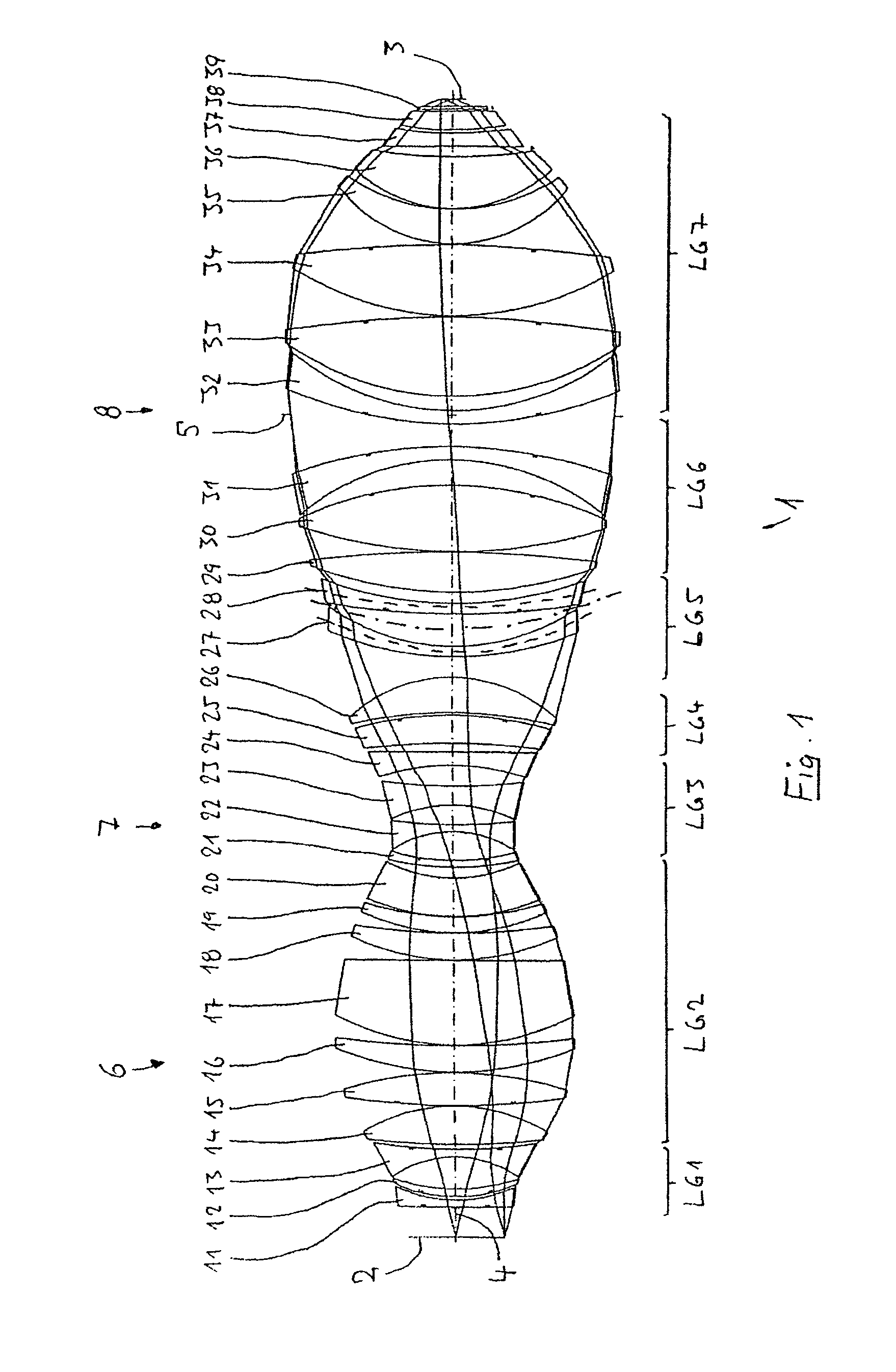

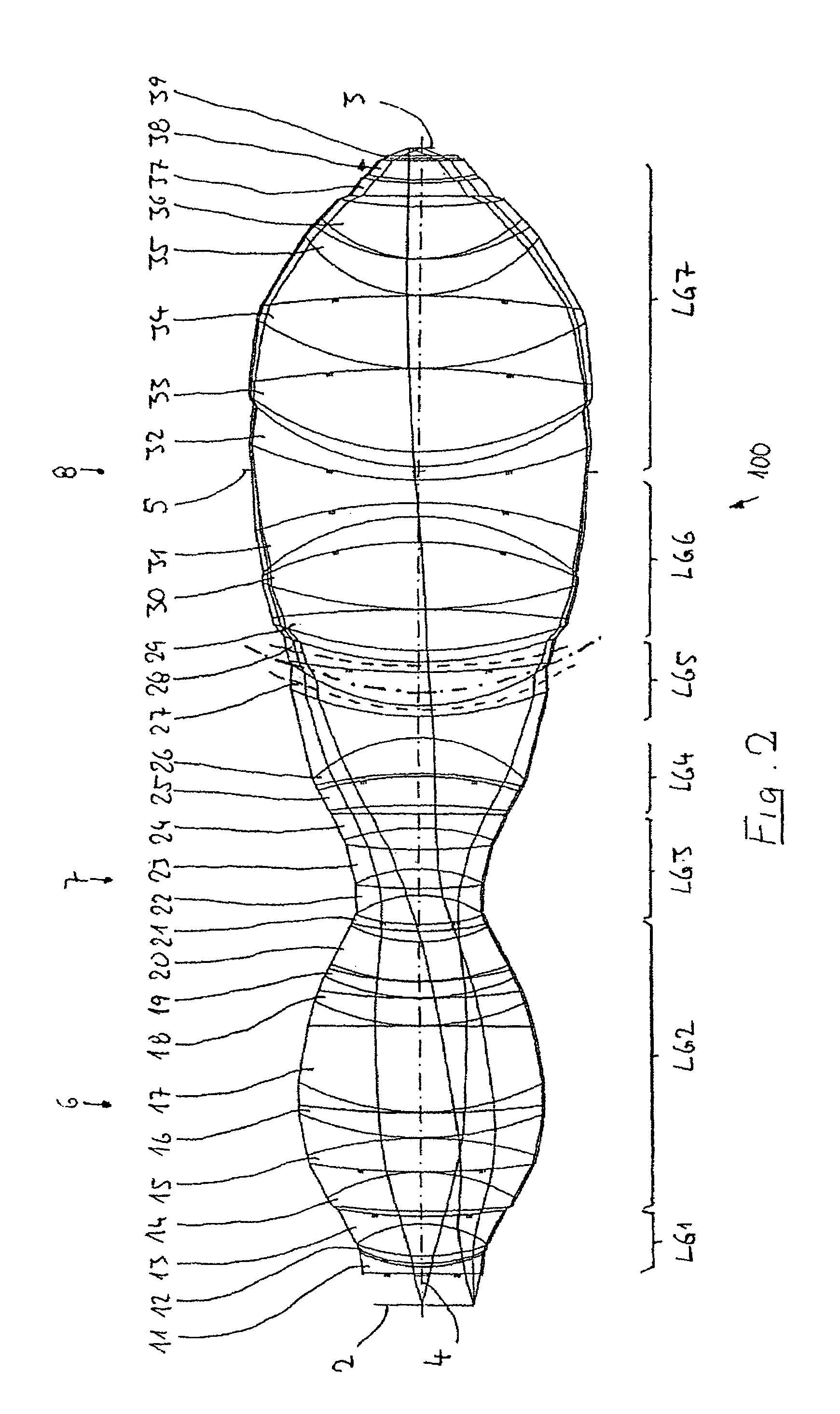

Very-high aperture projection objective

InactiveUS20050111108A1High image-side numerical apertureImproved chromatic correctionPhotomechanical exposure apparatusMicrolithography exposure apparatusHigh numerical apertureImage plane

A very-high aperture, purely refractive projection objective is designed as a two-belly system with an object-side belly, an image-side belly and a waist (7) situated therebetween. The system diaphragm (5) is seated in the image-side belly at a spacing in front of the image plane. Arranged between the waist and the system diaphragm in the region of divergent radiation is a negative group (LG5) which has an effective curvature with a concave side pointing towards the image plane. The system is distinguished by a high numerical aperture, low chromatic aberrations and compact, material-saving design.

Owner:CARL ZEISS SMT GMBH

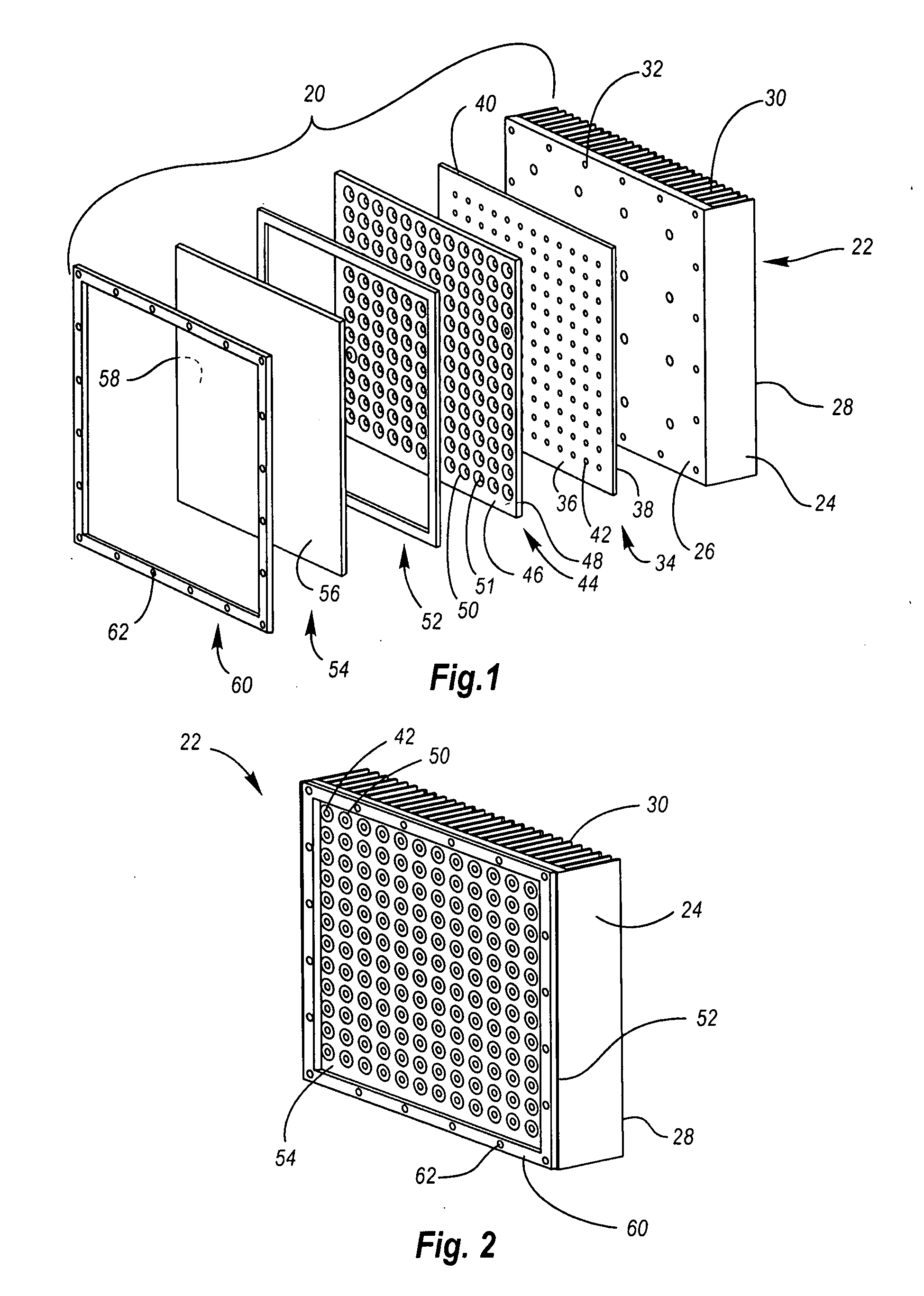

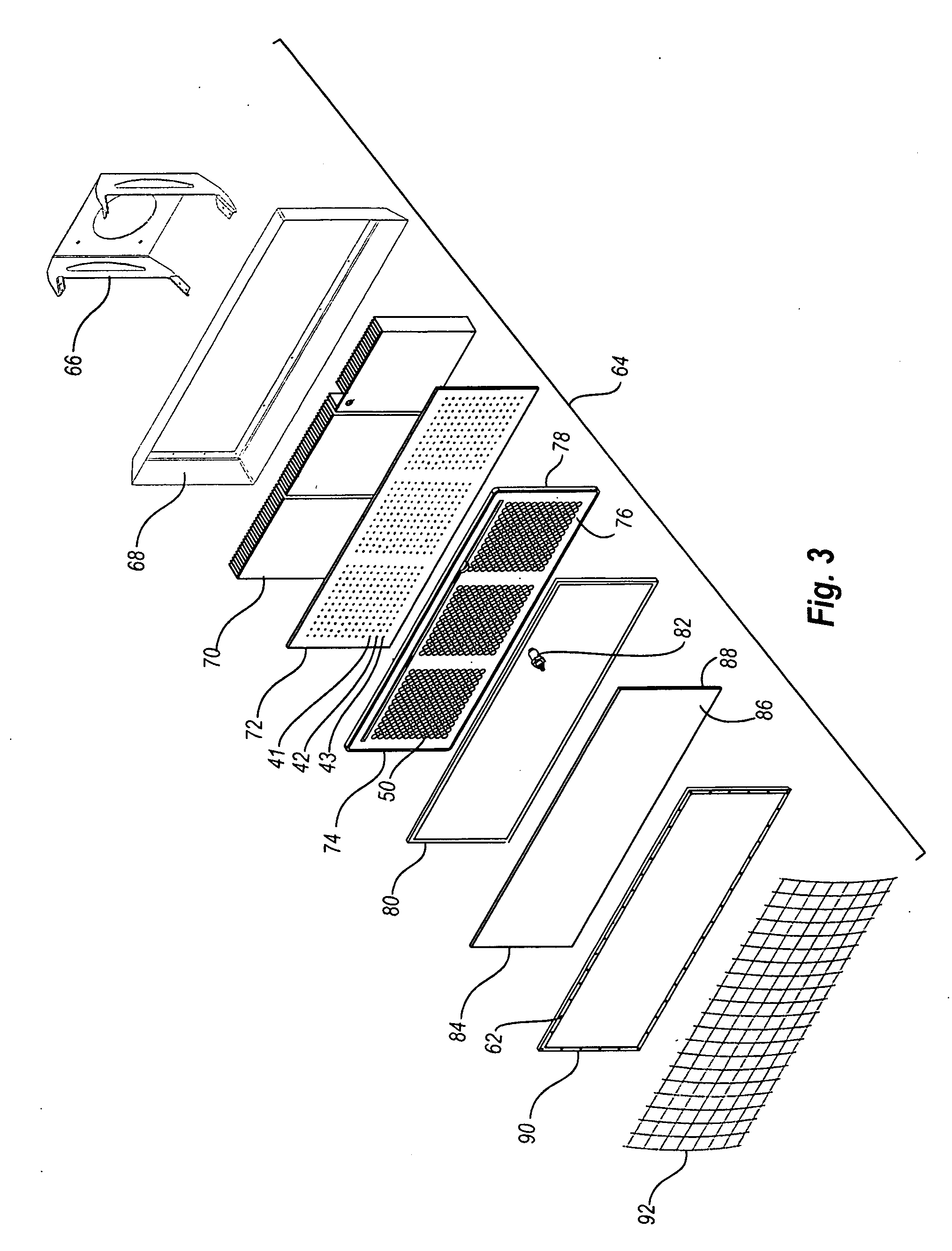

Submersible High Illumination LED Light Source

InactiveUS20090180281A1Low costReduce maintenancePlanar light sourcesMechanical apparatusElectrical connectionEngineering

A submersible high illumination light source assembly is disclosed, comprising at least one module. A module comprises a heat sink having a front surface and a rear surface. A printed circuit board comprising one or more electrical connections sized and shaped to couple with a plurality of high-illumination light emitting diode (LED) lamps is in thermal communication with the front surface of the heat sink. The plurality of high-illumination LED lamps are coupled in electronic communication with the printed circuit board via the one or more electrical connections. At least one reflector is sized and shaped to accept the insertion of one or more of the plurality of high-illumination LED lamps. A window is in watertight communication with the reflector plate. The submersible high illumination light source assembly operates both when submerged underwater and exposed to air.

Owner:LIGHTS CAMERA ACTION

Environment-friendly light heat-insulating material and manufacturing method thereof

The invention relates to an environment-friendly light heat-insulating material for fireproof doors and buildings, and a manufacturing method thereof. The manufacturing method is characterized by comprising the following steps of: pretreating plant hollow core bodies and / or flexible porous fillers by using a water glass adhesive; mixing with inorganic fire-resistant hollow particles; and performing mould pressing, shaping and drying to obtain the environment-friendly light heat-insulating material. The hollow core bodies and the flexible porous fillers are arranged multidirectionally; one layer of water glass adhesive is arranged at least on the surfaces of the hollow core bodies and the flexible porous fillers; and discontinuous holes are reserved between the hollow core bodies and / or the flexible porous fillers and the inorganic fire-resistant hollow particles. Preferably, the hollow core bodies are rice husks and straw sections; and the flexible porous fillers are foam and fibers. Renewable plant resources and recovered foam and fiber waste are adopted, so the environment-friendly light heat-insulating material is energy-saving and environment-friendly; and a large number of sealed holes are formed among the material particles through the penetration and coating of the modified water glass adhesive, and a heat-insulating hydrophobic corrosion-resistant multi-effect protective layer is provided, so the environment-friendly light heat-insulating material has good fireproof, heat-insulating and heat-preserving effects, high weather resistance, combined rigidity and toughness, low density and low cost.

Owner:重庆恒宏致嘉全过程建设项目管理有限公司

Thin-wall form for filling concrete

A thin-wall form for filling concrete in it to in-situ pour hollow non-beam floor is composed of top plate and peripheral wall, and is characterized by that at least one of said top plate and peripheral wall contains at least one thin strip for improving its resistance to impact and collision. Its advantages are simple structure and high resistance to deformation and vibration.

Owner:湖南邱则有专利战略策划有限公司

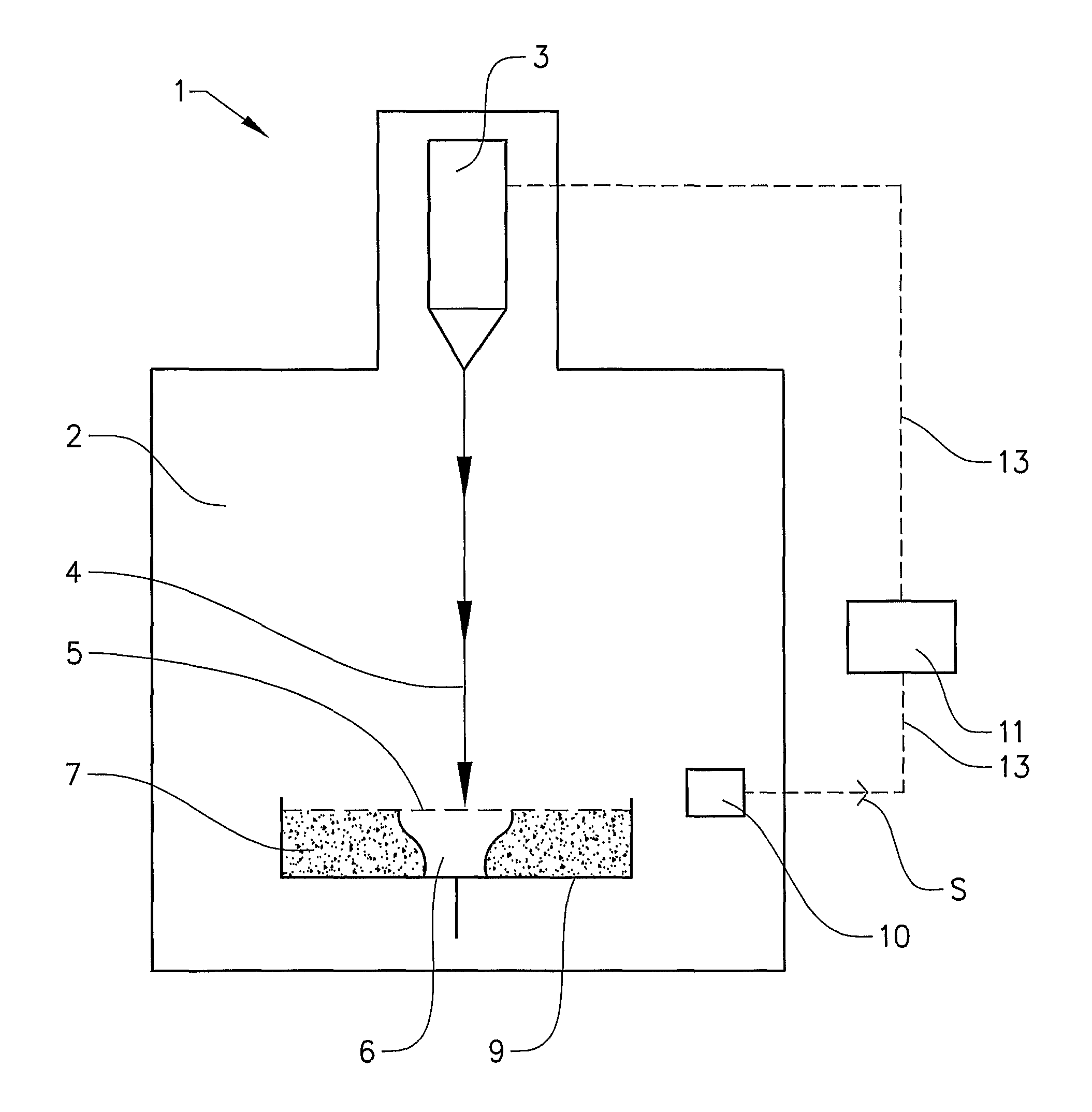

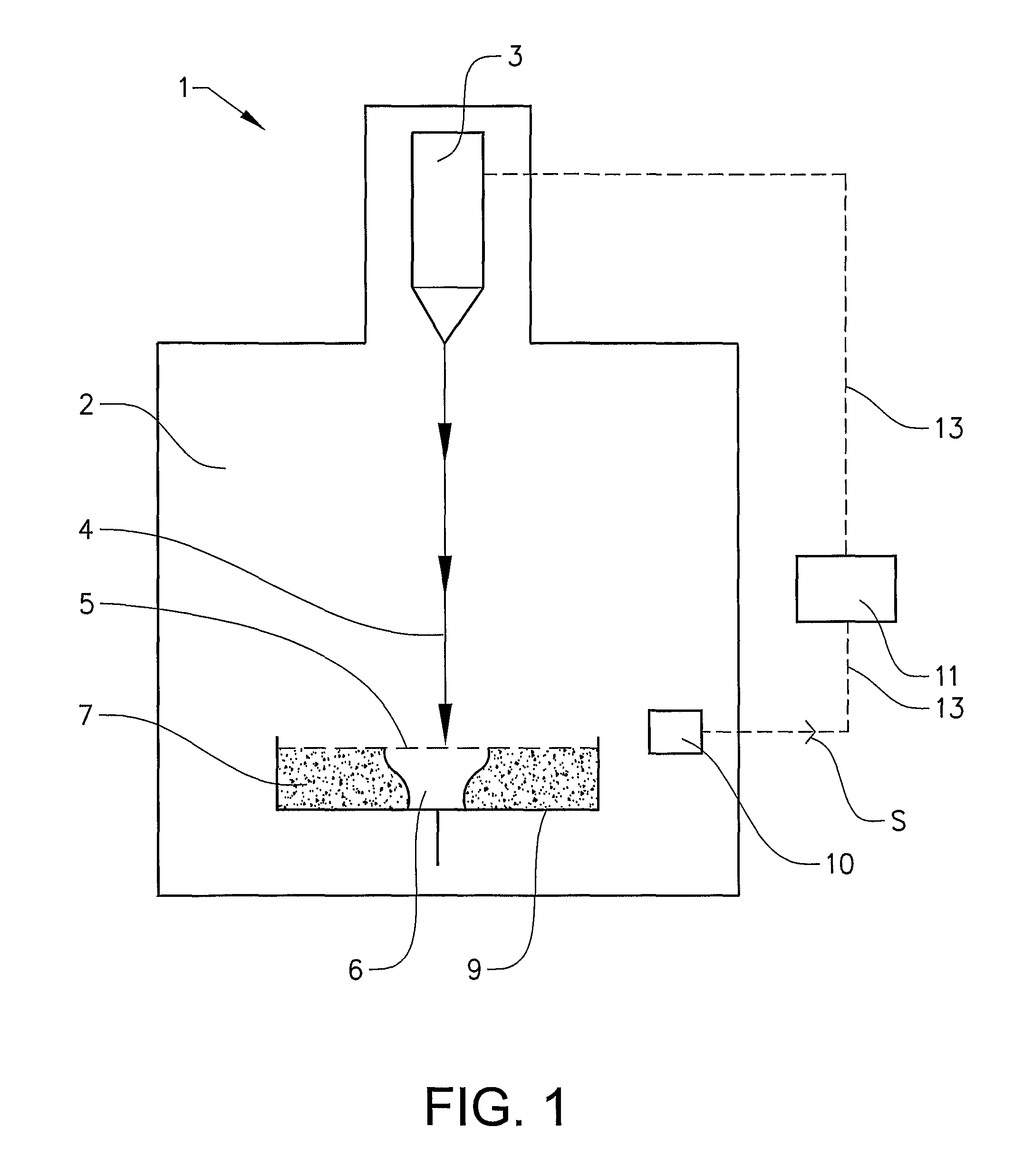

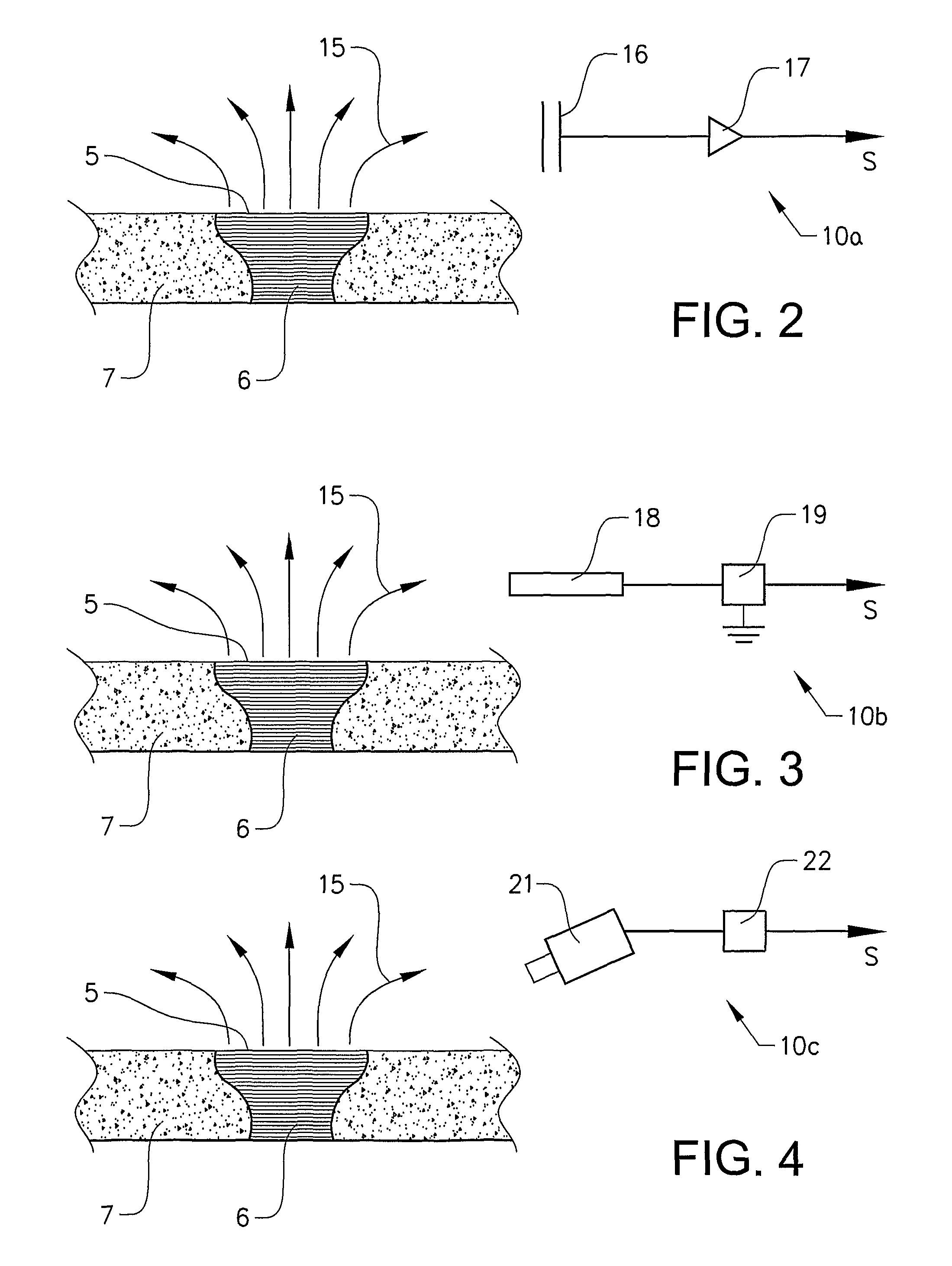

Method and apparatus for producing three-dimensional objects

ActiveUS8992816B2Save materialShorten the timeAdditive manufacturing apparatusIncreasing energy efficiencyMaterials scienceCharged particle

Owner:ARCAM AB

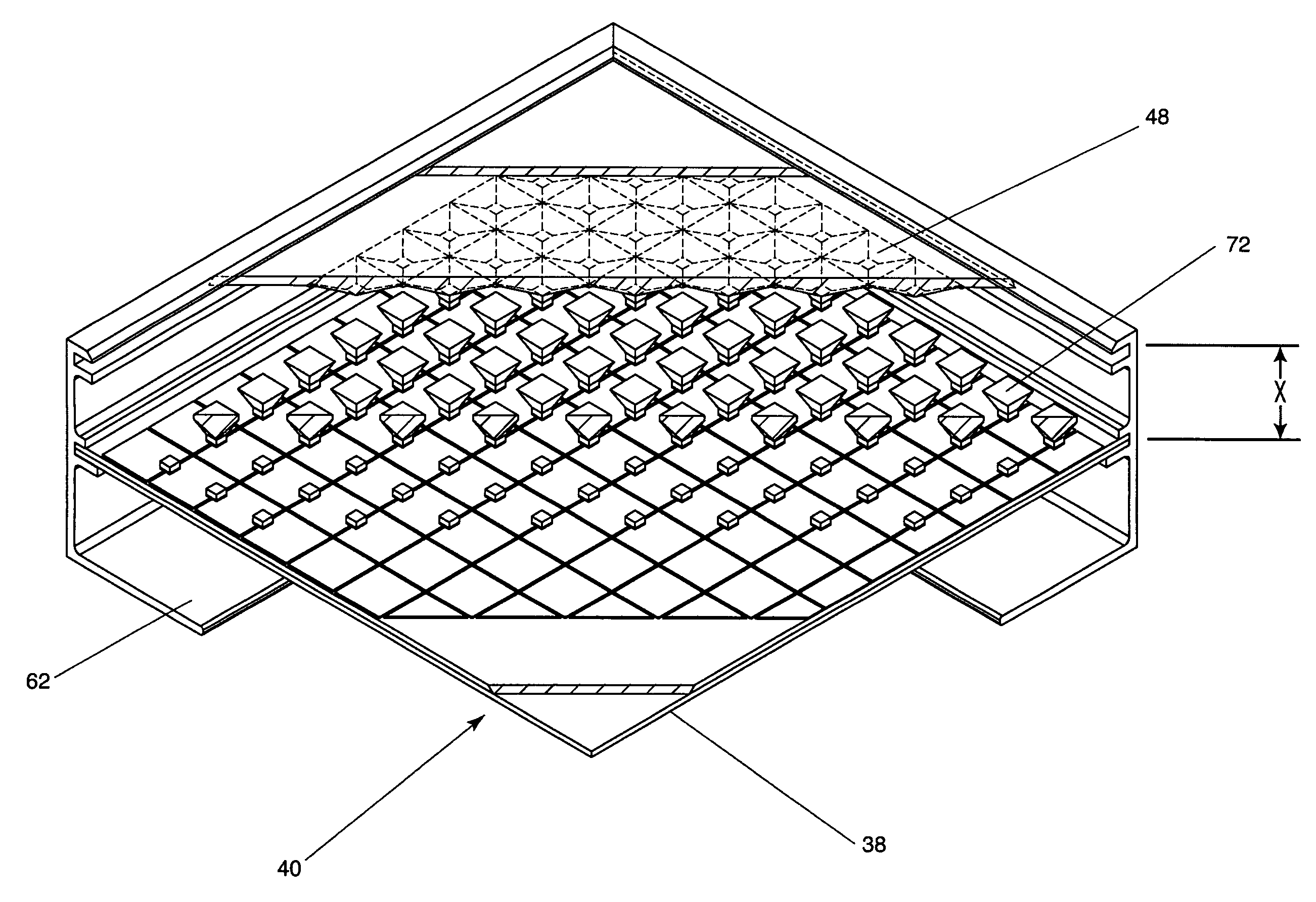

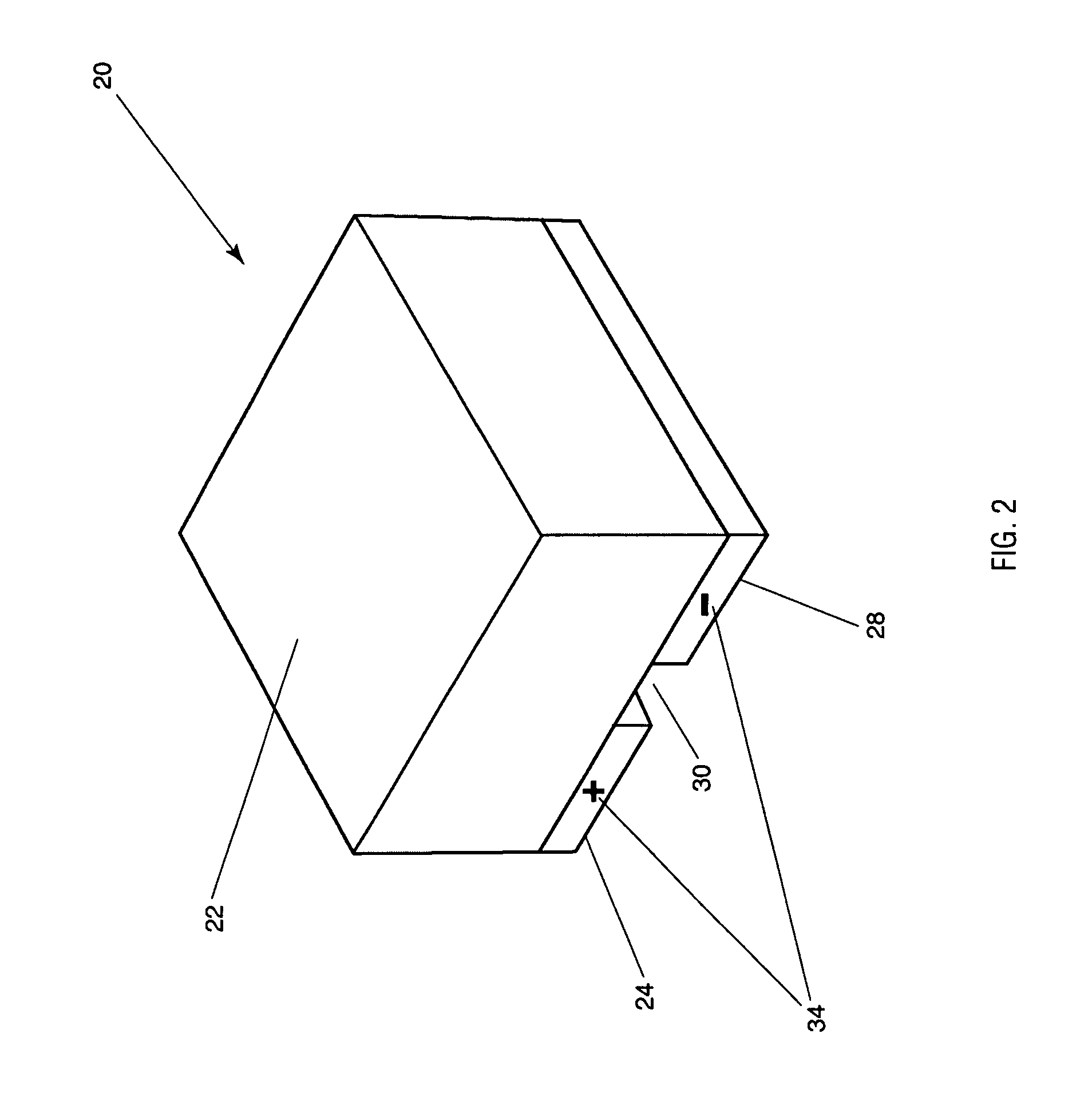

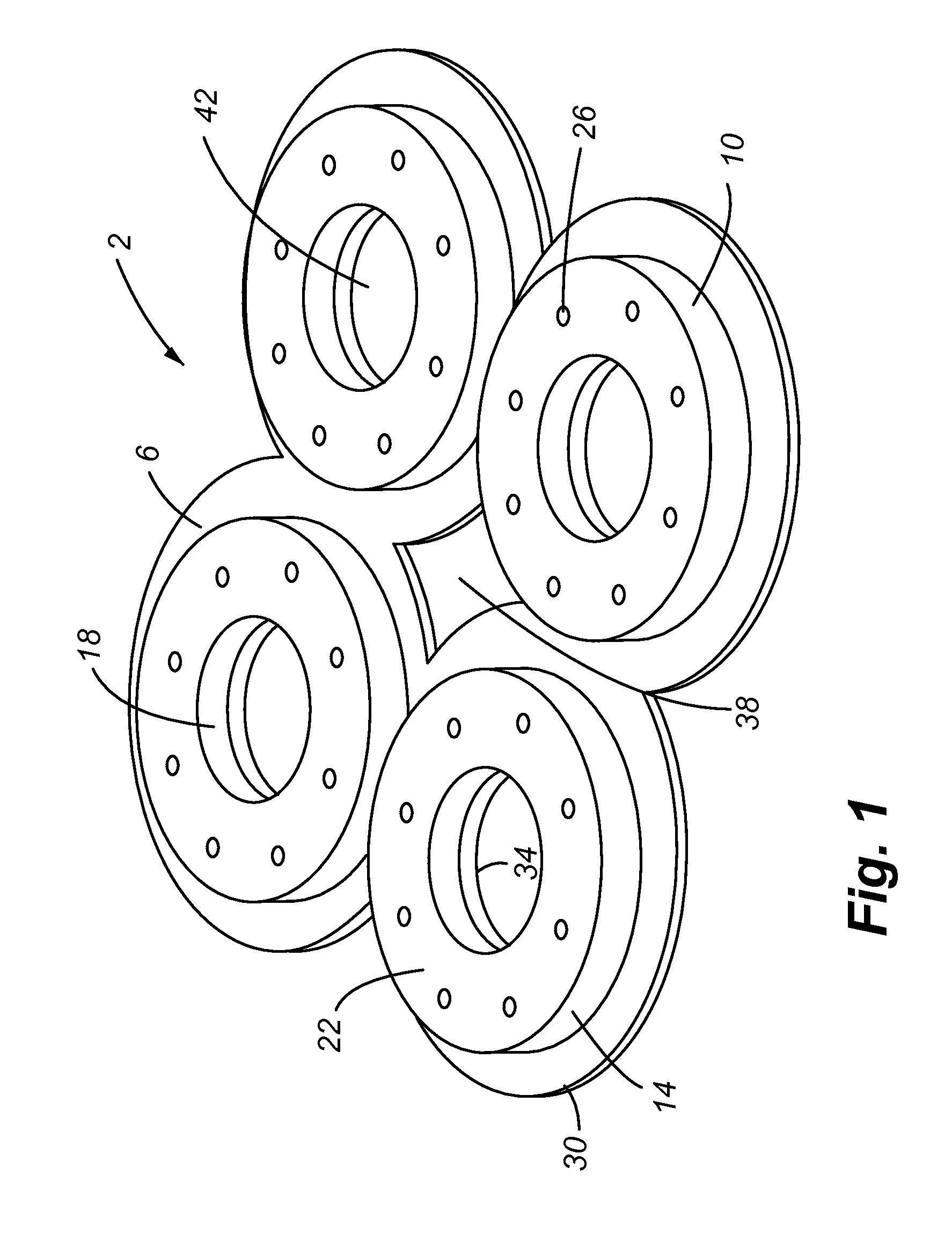

Reinforced abrasive wheels

InactiveUS6942561B2Minimize empty spaceSaving in layer materialGrinding machine componentsRevolution surface grinding machinesGlass fiberEngineering

In a depressed-center abrasive wheel assembly a reinforcement layer of polygonal shape is located between a front face of the abrasive wheel and a front flange. The reinforcement layer is dimensioned to entirely cover the depressed center portion of the wheel. An example of polygonal reinforcement layer has a hexagonal shape and is made of fiberglass cloth. A polygonal shape reinforcement layer can also be employed between the front flange and the front face in an abrasive flat wheel assembly that employs a wheel without internal reinforcement.

Owner:SAINT GOBAIN ABRASIVES INC

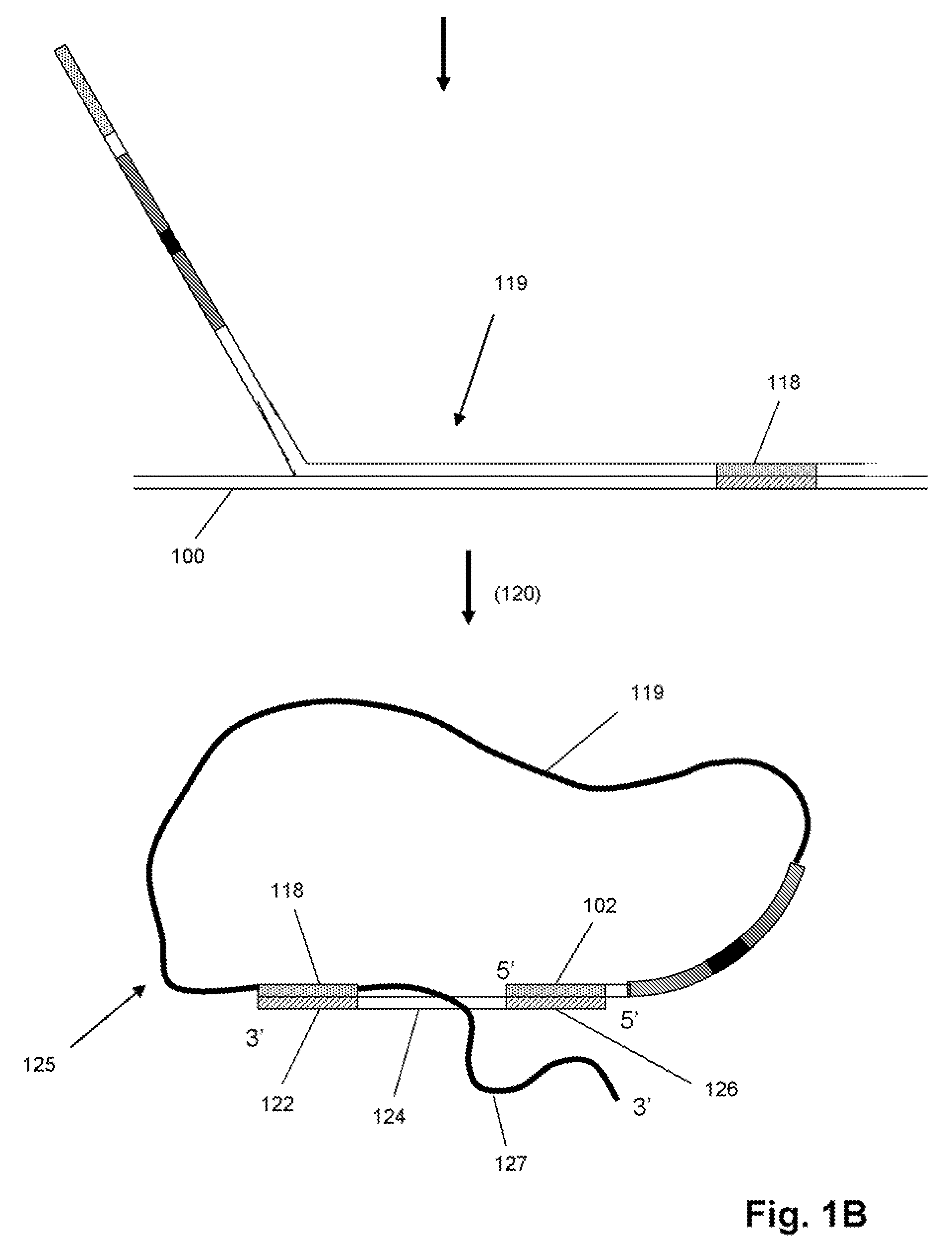

Selected amplification of polynucleotides

InactiveUS8137936B2Reducing background and spurious amplificationSave materialMicrobiological testing/measurementFermentationPolynucleotideDouble stranded

The invention provides methods and compositions for selectively amplifying one or more target polynucleotides in a sample. In one aspect, a plurality of selection oligonucleotides are provided that are capable of simultaneously annealing to separate regions of a target polynucleotide to form a complex that is enzymatically converted into a closed double stranded DNA circle that incorporates the sequence region between the two separate regions. Sequences that fail to form such complexes may be removed by nuclease digestion and the sequences of the remaining DNA circles may be amplified by a variety of techniques, such as rolling circle replication after nicking, PCR amplification after linearization, or the like.

Owner:MACEVICZ STEPHEN C

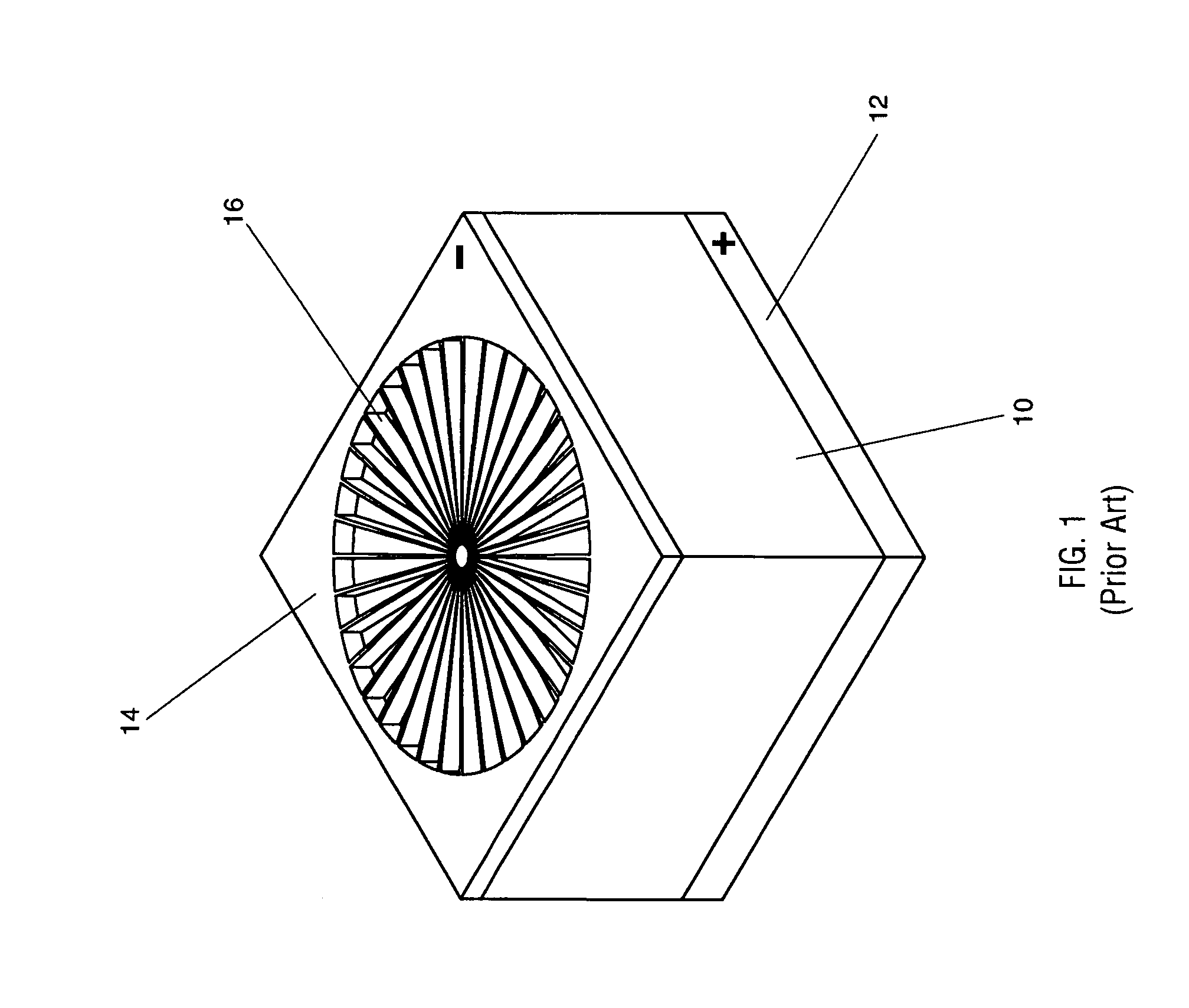

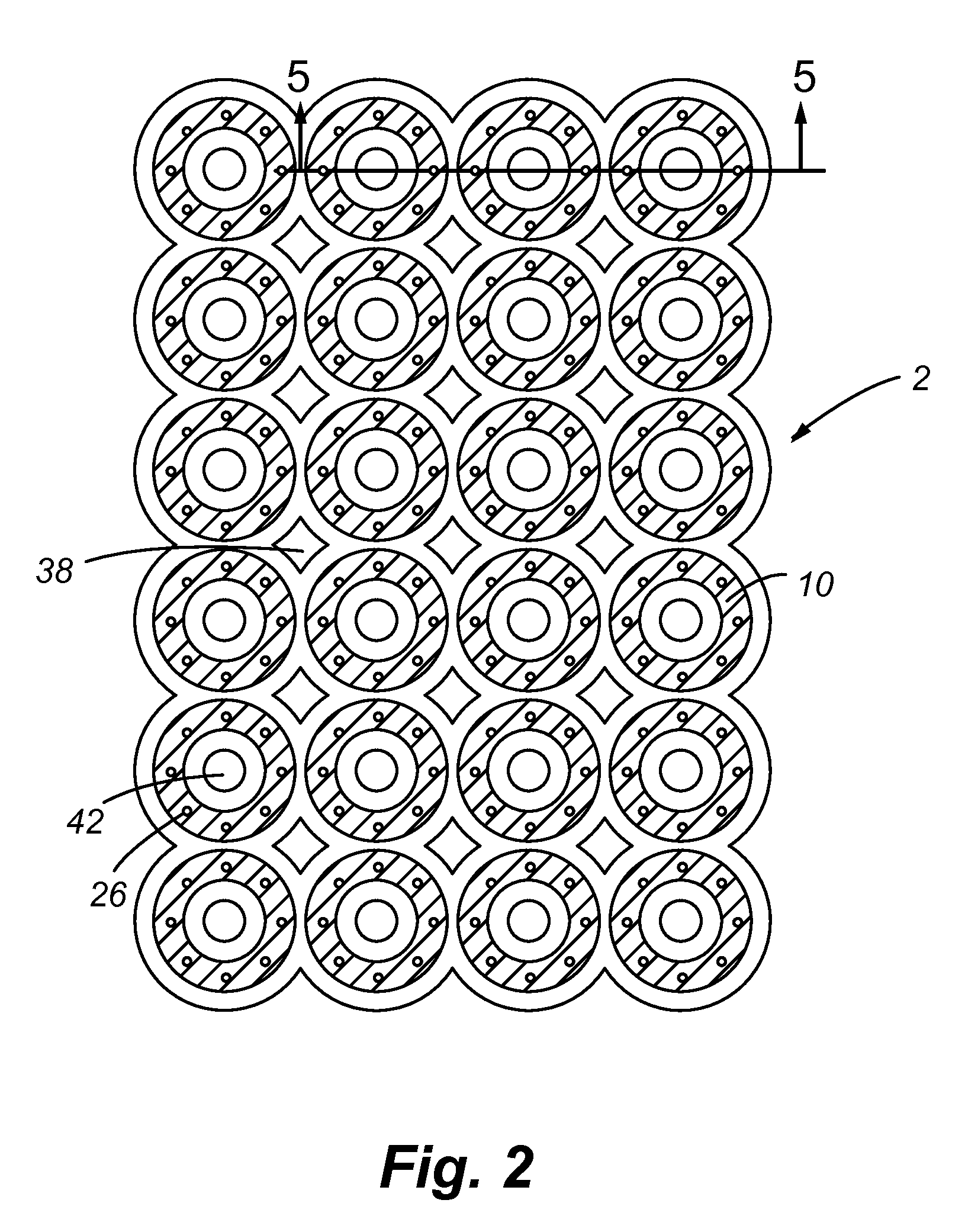

Fly's Eye Lens Short Focal Length Solar Concentrator

InactiveUS20080185034A1Solve the large heat dissipationShort focal lengthPrinted circuit assemblingPV power plantsElectrical conductorSurface mounting

A compact solar concentrator photovoltaic module assembly includes a plurality of rear contact solar cells configured in a matrix array on a substrate. The substrate is comprised of conductors laminated to an insulator sheet to form a receiver sheet. A lens sheet on which many lenses have been formed is disposed in a fixed spaced relation to the substrate and operates to focus sunlight onto the active surfaces of the PV cells. The overall thickness of the concentrator module is less than four inches thick. The receiver sheet may be assembled using standard, surface mount printed circuit board assembly techniques. The receiver sheet may have a secondary optical element and may also serve as part of the encapsulant for environmental protection.

Owner:CORIO RONALD P

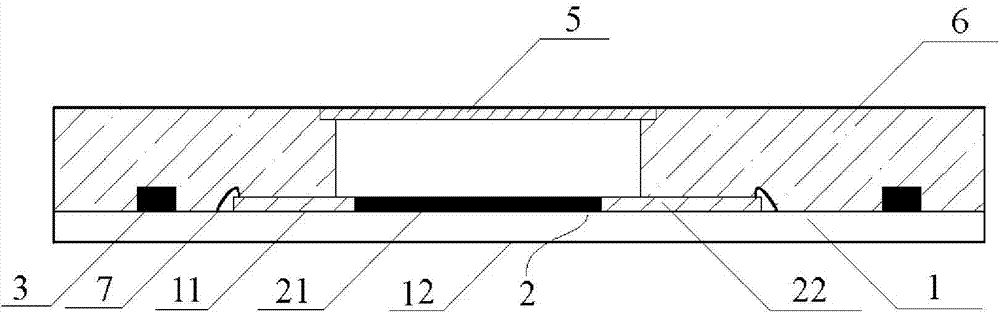

Camera module, and encapsulating structure and encapsulating method thereof

ActiveCN103700634ASmall enclosed spaceNot easy to fall intoTelevision system detailsSemiconductor/solid-state device detailsElectricityImaging quality

The invention provides a camera module, and an encapsulating structure and an encapsulating method thereof. The encapsulating structure of the camera module comprises a circuit board, an image sensing chip, a passive element, an encapsulating part and an infrared filter, wherein the circuit board is provided with a first surface and a second surface; the image sensing chip and the passive element are arranged on the first surface of the circuit board, and the image sensing chip is provided with a sensing region and a non-sensing region and electrically connected with the circuit board; the encapsulating part is arranged on the first surface of the circuit board and at least part of the non-sensing region of the image sensing chip and encompasses the passive element; the infrared filter is arranged on the encapsulating part and located in a position above the sensing region of the image sensing chip, and forms an enclosure space together with the encapsulating part and the sensing region of the image sensing chip. The infrared filter of the encapsulating structure of the camera module is smaller in size so as to facilitate material saving and cost reduction; besides, impurities such as dust are unlikely to fall or be left in the enclosure space, so that the imaging quality is high.

Owner:NANCHANG OFILM HUAGUANG TECH CO LTD

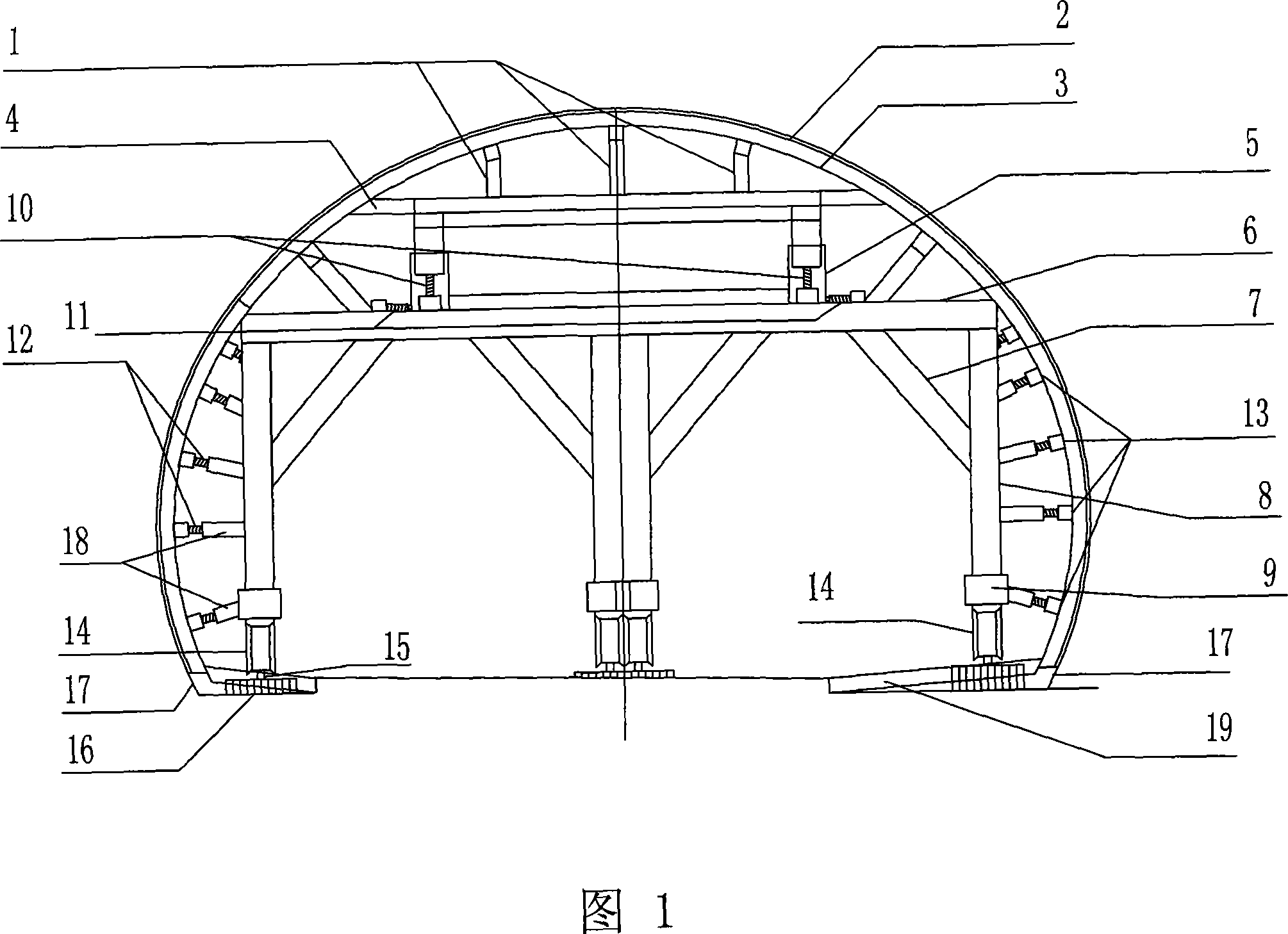

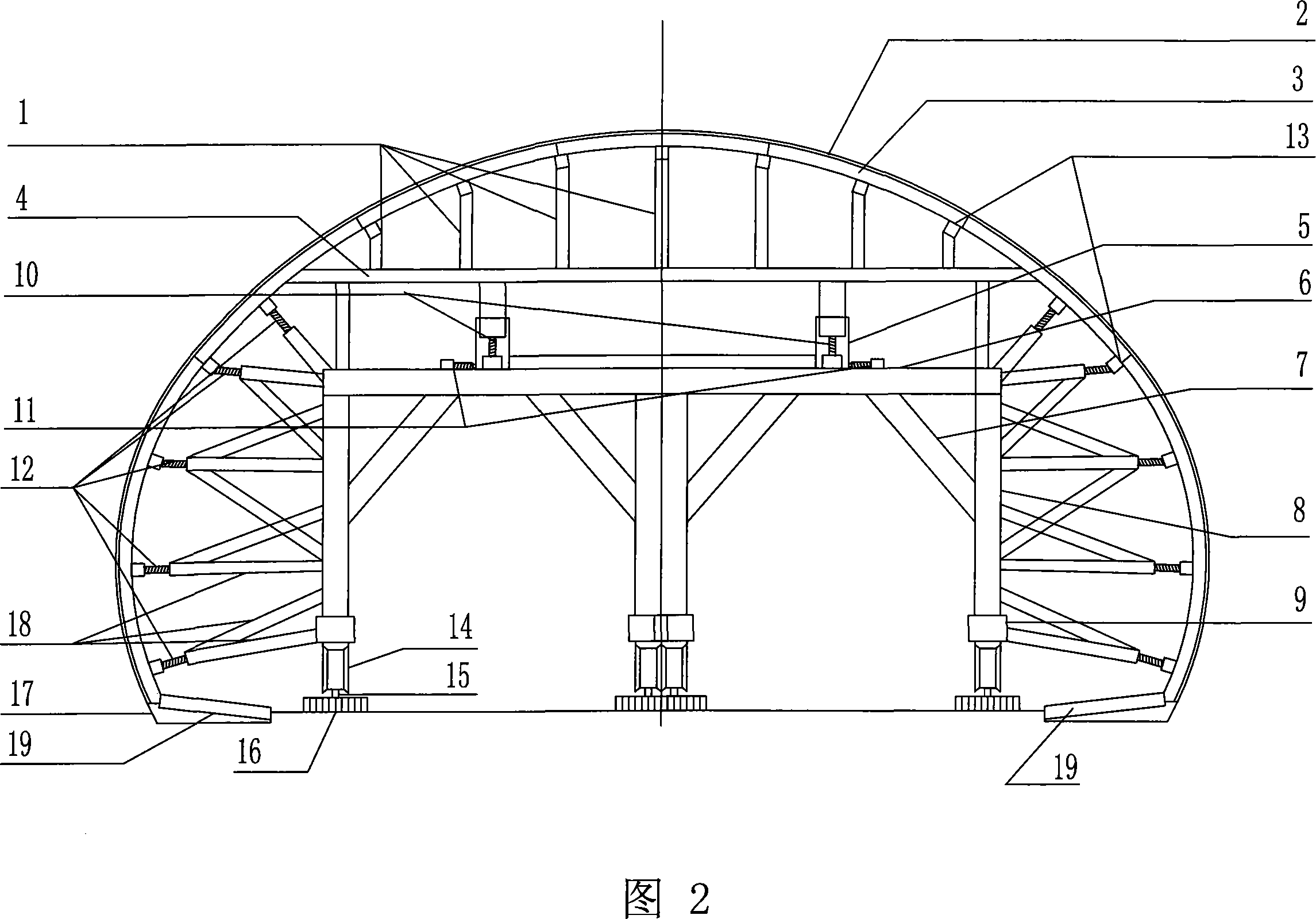

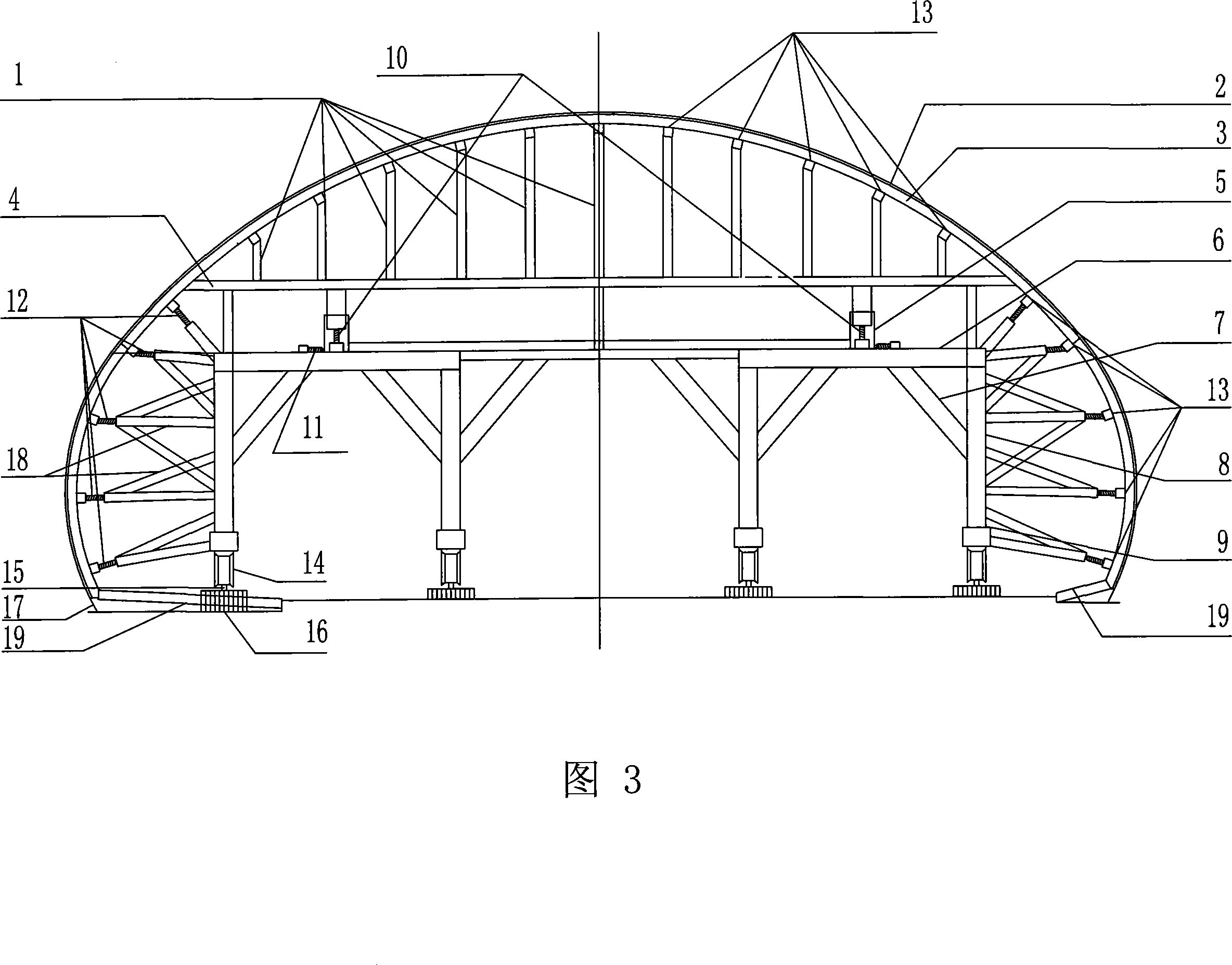

Construction method for large section and multiple sections tunnel lining

ActiveCN101230785AImprove construction progressQuick disassemblyUnderground chambersTunnel liningAssembly lineConstruction management

The invention discloses a large cross-section and multiple cross-section tunnel lining construction method. Combined type lining trolleys are chosen to carry through the trolley assembly lining to the cross-section, and adding a gantry mounting on the basis of a normal trolley single gantry mounting can form an assembled and detachable lining trolley. Steel molding plates, road wheels, main gantry mountings, etc. are listed in unchanged components in the process of the assembly trolleys with different cross-sections, and lateral adjusting driving screws, upper platform chord members, upper platform upright posts, lining steel arches, etc. are listed in adjustable components. In the process of the construction from one cross-section to another cross-section, the unchanged components do not change, and only the changeable components are carried through the refitting and assembly. The construction method has the characteristics of fast construction progress, low cost, easy control of site construction management, etc., can save a great deal of manpower, physical resources and financial resources and obtain good technical economic effect, and has the remarkable economic, social and environmental benefits; the invention is especially adapted to the large cross-section and multiple cross-section type lining construction of tunnels and underground constructions.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

Protective arrangement

ActiveUS8069498B2Save materialSave weightChemical protectionHeat protectionMechanical engineeringEngineering

Owner:SCHUTT SPORTS IP LLC

Very-high aperture projection objective

InactiveUS7154676B2Increase the number ofImproved chromatic correctionPhotomechanical exposure apparatusMicrolithography exposure apparatusHigh numerical apertureImage plane

A very-high aperture, purely refractive projection objective is designed as a two-belly system with an object-side belly, an image-side belly and a waist (7) situated therebetween. The system diaphragm (5) is seated in the image-side belly at a spacing in front of the image plane. Arranged between the waist and the system diaphragm in the region of divergent radiation is a negative group (LG5) which has an effective curvature with a concave side pointing towards the image plane. The system is distinguished by a high numerical aperture, low chromatic aberrations and compact, material-saving design.

Owner:CARL ZEISS SMT GMBH

Coating material for protecting metals, especially steel, from corrosion and/or scaling, method for coating metals and metal element

InactiveCN101360796AVarious usabilityImprove conductivityPretreated surfacesAnti-corrosive paintsAfter treatmentSpot welding

The invention surprisingly finds that when a suitable binder including a suitable filler is used during the high temperature treatment of a curing process, the coating materials of the invention change in such a manner that electrically conducting reactive layers are formed that allow welding and especially spot welding together with the metal substrate even after treatment at temperatures of more than 800 DEG C.

Owner:NANOX

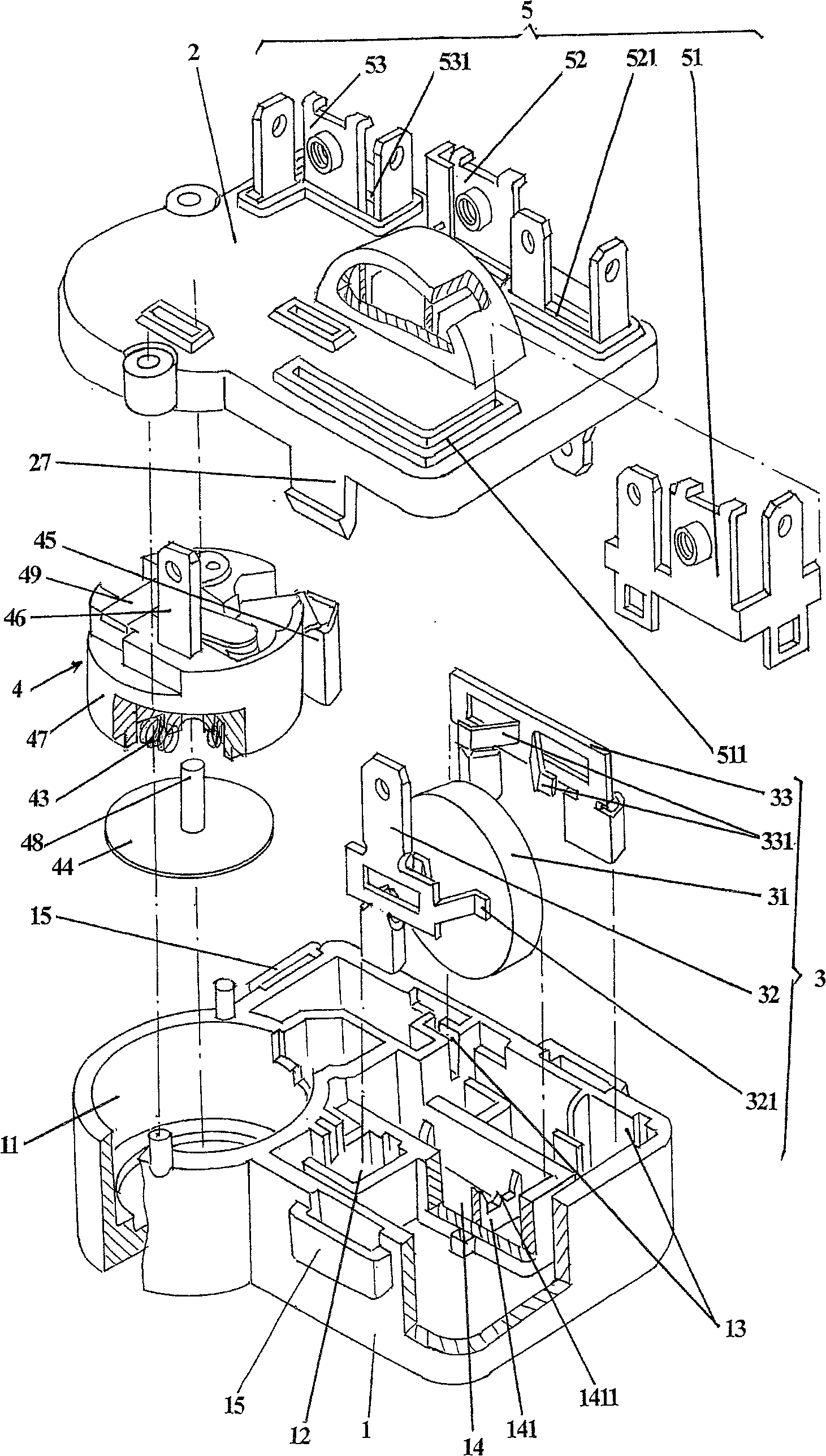

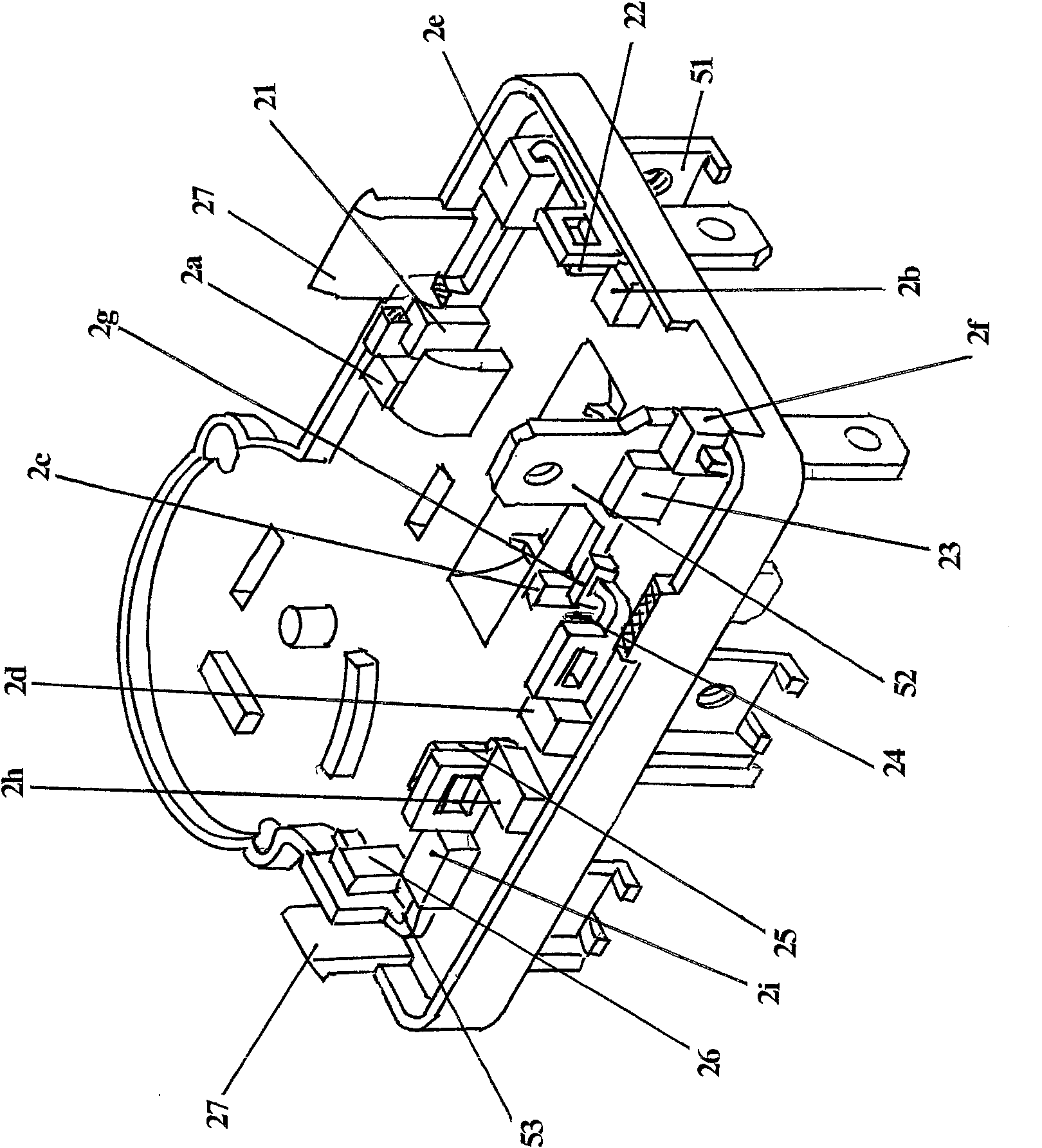

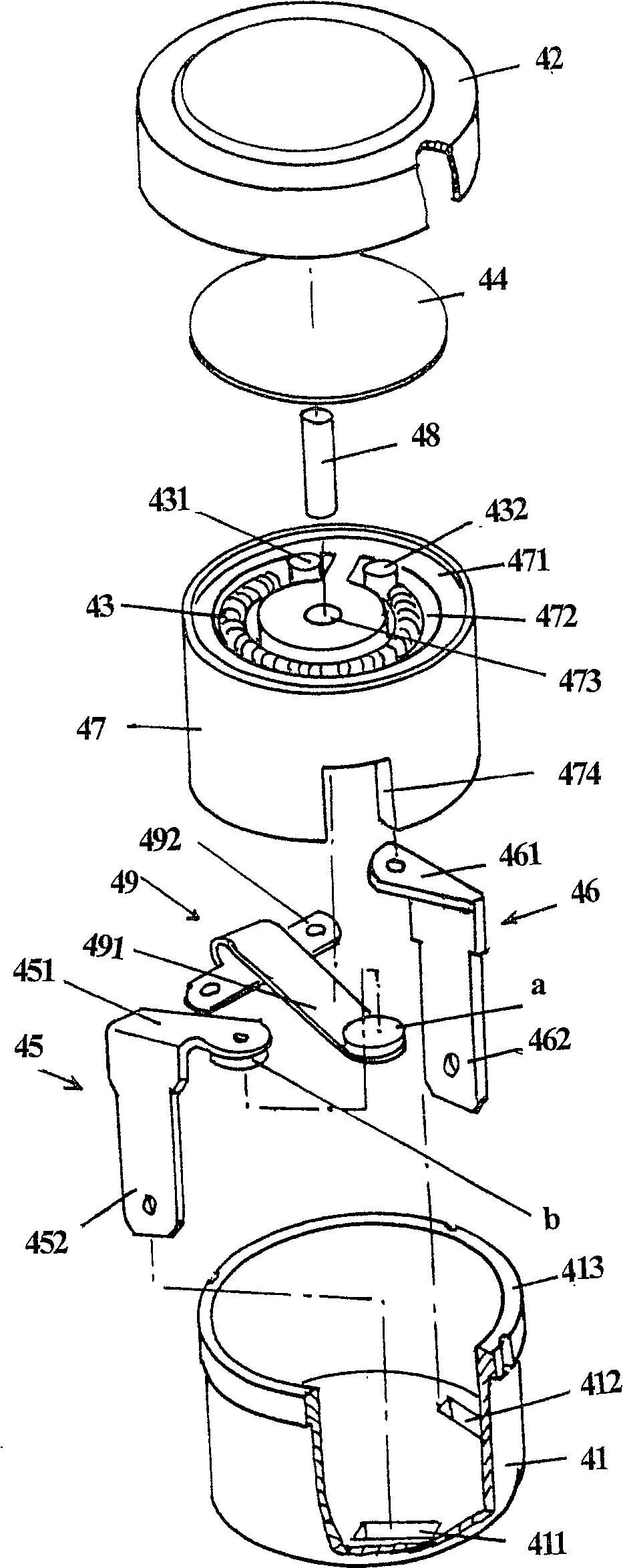

Energy-saving type integral single phase AC electric motor starting and protection device

ActiveCN100581043CReduce power consumptionReduce contact areaSingle-phase induction motor startersStarter detailsRefrigeration compressorElectric machine

An starter and protector for an energy-saving integral single-phase alternating current motor, belonging to cold compressor motor protecting equipment technology field, includes a housing, a cover, a motor protector mounted in the housing, a motor starter mounted on the housing, and a plug-in sheet mechanism composed of a L plug-in sheet, a N plug-in sheet and an earthing plug-in sheet. The motor starter includes a first pin, a second pin and a positive temperature coefficient thermistor, and is characterized in that the two ends of the positive temperature coefficient thermistor are equipped with a supporting wall separately, wherein the pair of the supporting walls being parallel with each other, a rostellum being arranged on the basic centered position of the upper side of each supporting wall, the two bottom sides of the positive temperature coefficient thermistor contacting the rostellum, and the two sides of the positive temperature coefficient thermistor holding with the first and the second pins separately. The invention has well energy-saving effect, and has substantial deflated volume, which being help to save the material for manufacturing the positive temperature coefficient thermistor.

Owner:CHANGSHU TIANYN ELECTROMECHANICAL

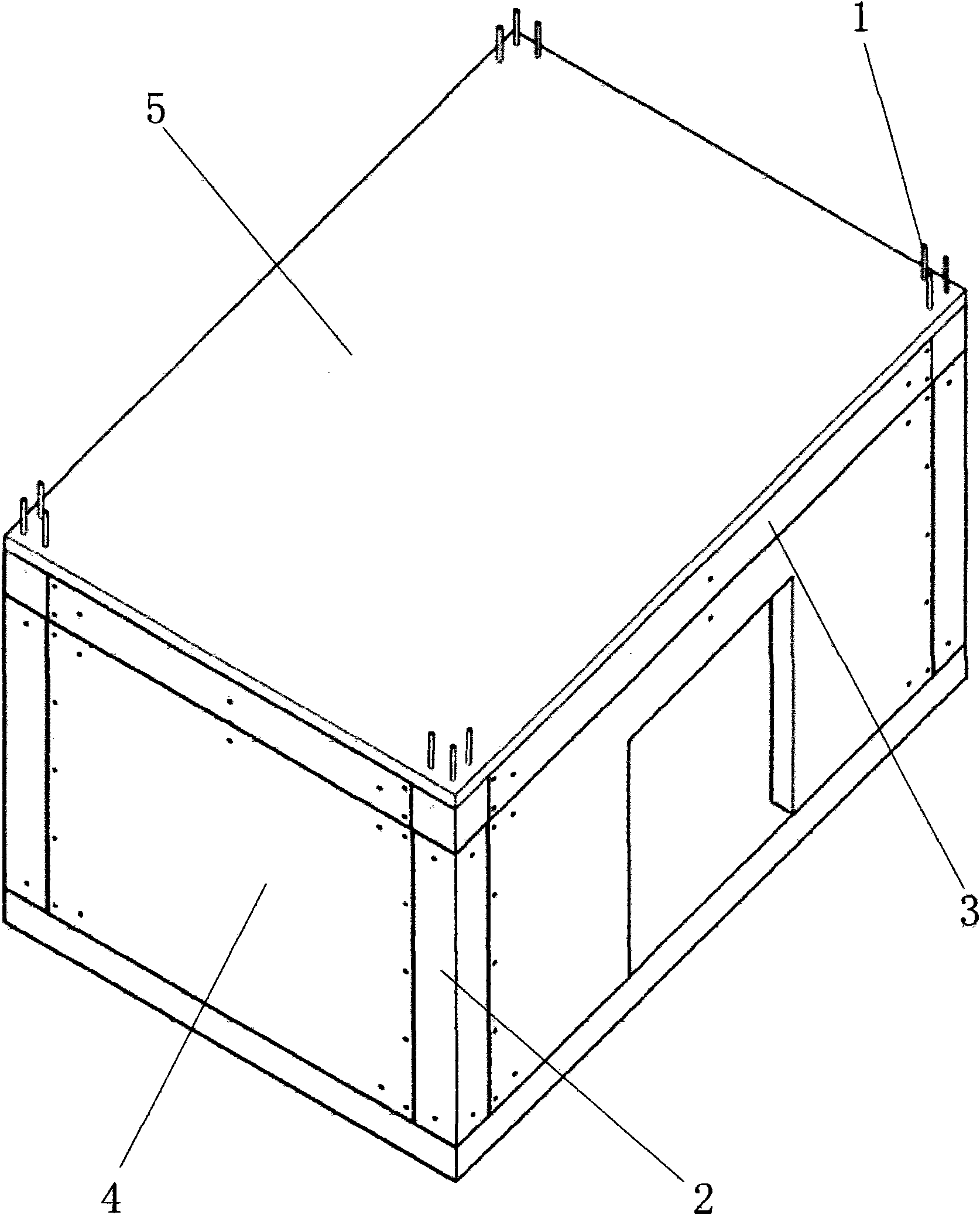

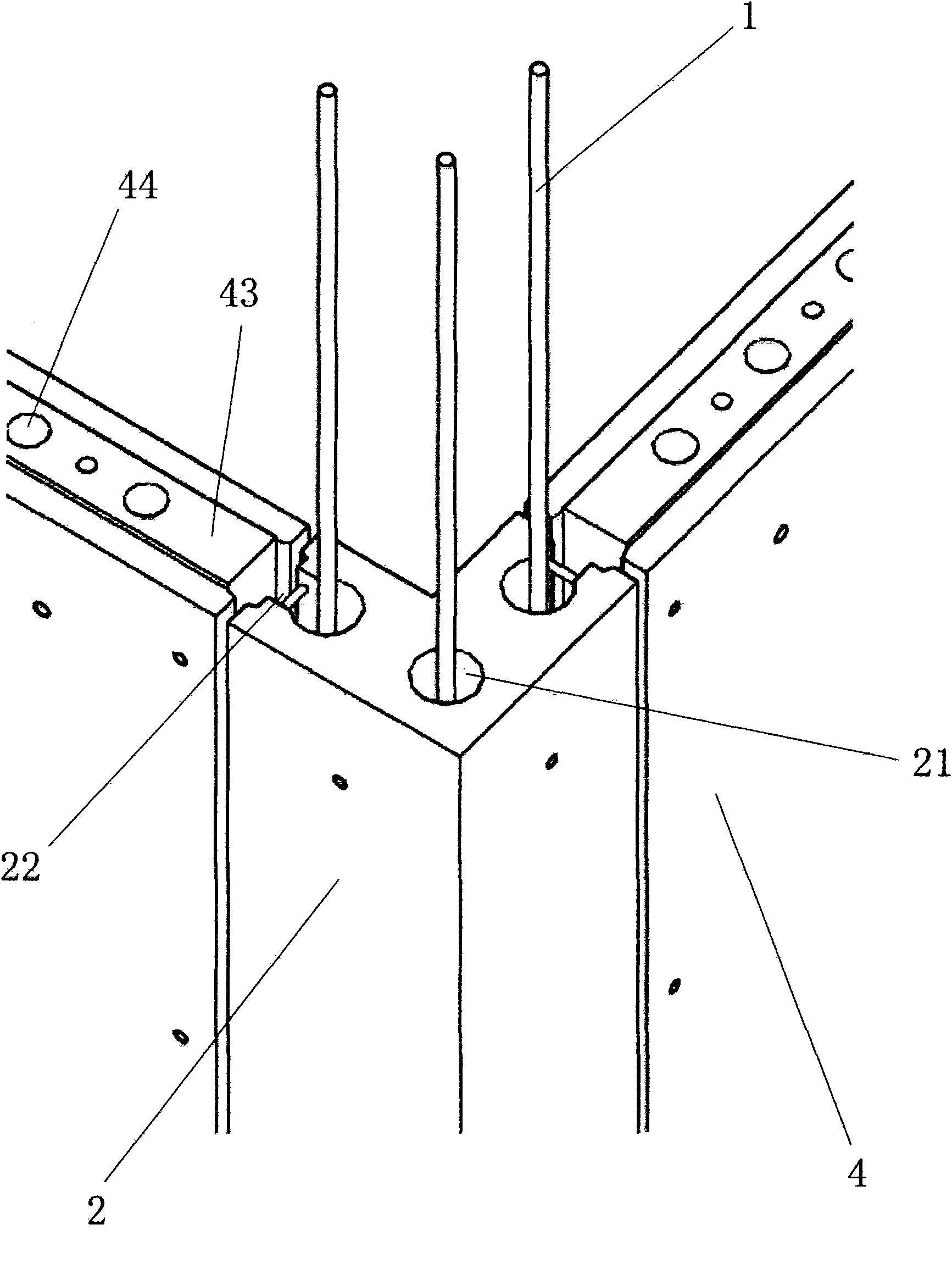

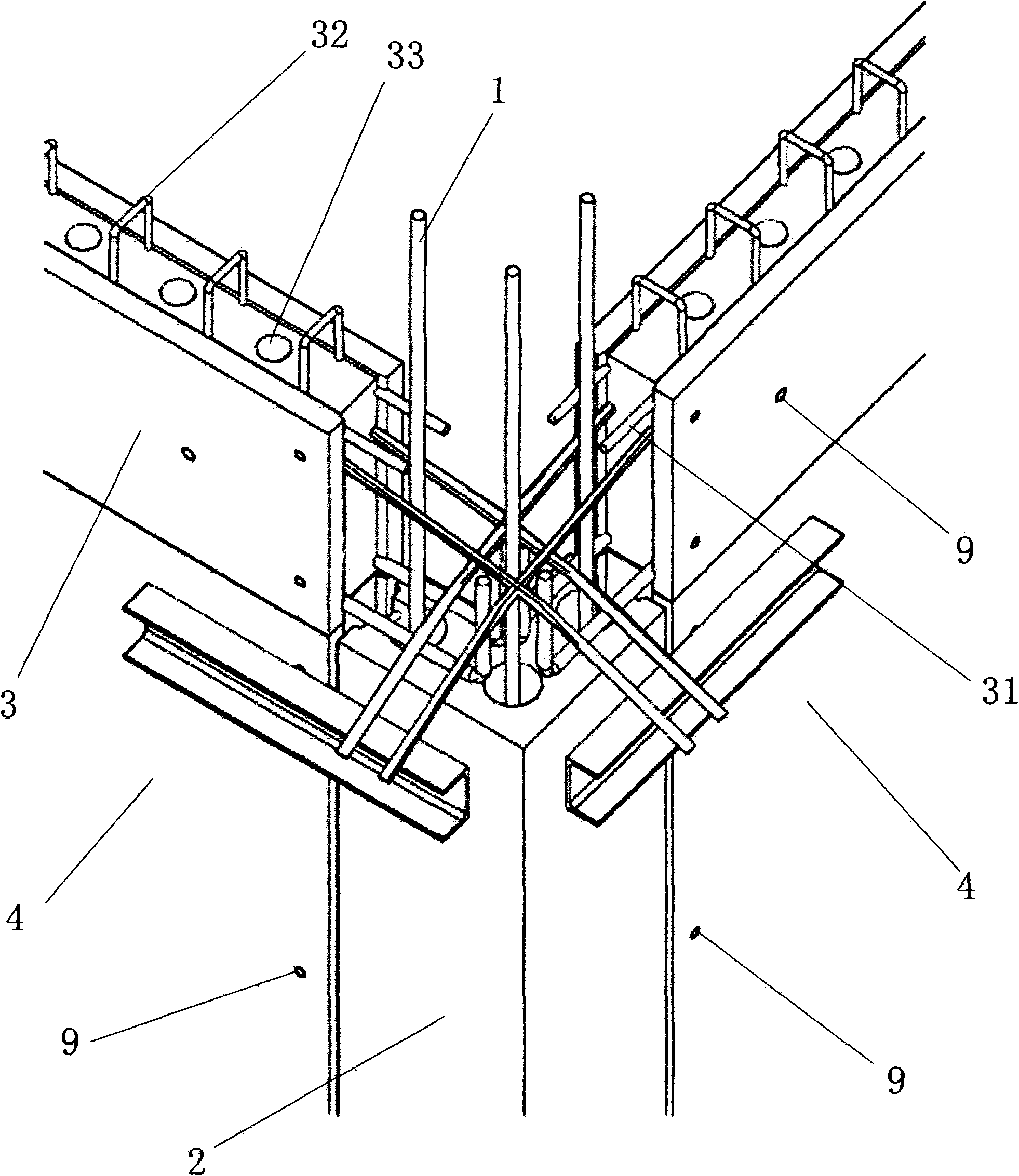

Full-fabricated assembly overall reinforced concrete house and building method thereof

InactiveCN101806095ASmall sizeNo secondary plastering requiredBuilding material handlingFloor slabReinforced concrete

The invention discloses a full-fabricated assembly overall reinforced concrete house which comprises a plurality of column ribs arranged at intervals and respectively and fixedly connected with a foundation, a plurality of column bodies prefabricated in a modularized way, a plurality of wall bodies prefabricated in the modularized way, and a floor slab prefabricated in the modularized way. The invention aims to overcome the defects of the prior art, and improve the full-fabricated assembly overall reinforced concrete house which has simple structure, is convenient to install, saves building materials, is quick to build, and has good overall safety performance. Another purpose of the invention is to provide a method for building the house.

Owner:ZHONGSHAN FAST LIVING PREFABTED HOUSING

Tableware

InactiveUS20050155229A1Improve handling strengthCheap manufacturingKitchen equipmentMetal working apparatusWave structureEngineering

The present invention relates to tableware. The tableware includes a handle and a holding section connected with the handle. The cross-section of the handle is “M”-shaped, with a “V”-shaped groove extending from the middle of the handle to the holding section, and at least one V-shaped groove being positioned in the middle of the holding section. The above-mentioned parts make up the strengthened tableware. The “M”-shaped and “W”-shaped grooves strengthen the handle, the palm and the finger of the tableware. On the other hand, the manufacturing and concave points located at the “M”-shaped groove of the front surface and the “W”-shaped groove of the back surface of the tableware enable the tableware to overlap closely and steadily because of a parallel-wave structure principle. Different types or the same type of tableware can overlap closely.

Owner:LEE CHING MOU

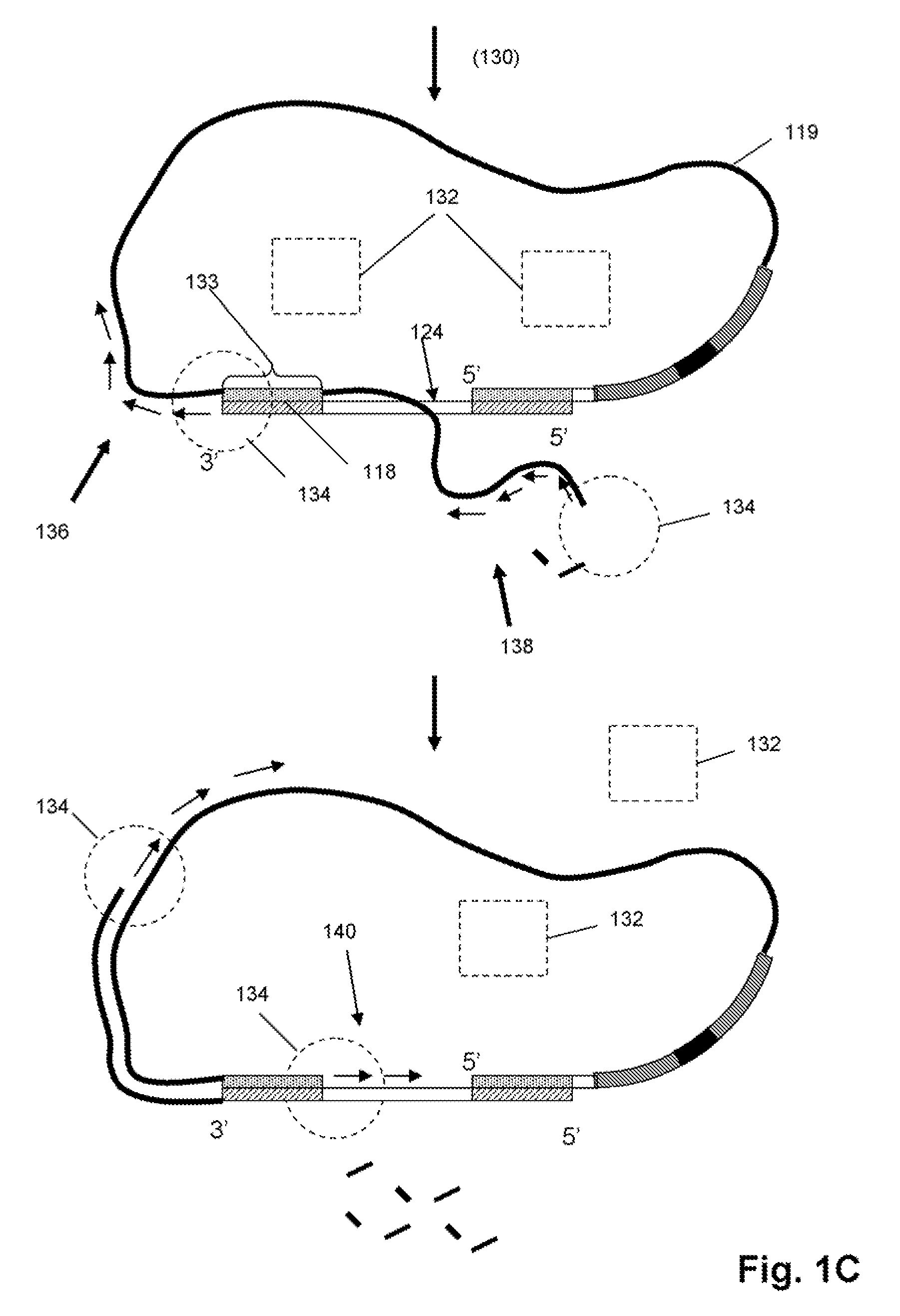

Method and apparatus for positioning heating elements

ActiveUS20110047907A1Enhance bondingDecrease weightDomestic stoves or rangesCovering/liningsAdhesiveBiomedical engineering

An underlayment system is provided that includes a plurality of bosses that emanate form a common base member. The bosses and bases preferably include an opening therethrough that will allow for subsequent layers of adhesive to interact and bond to each other. The bosses are also spaced in such a way to help secure a wire snugly therebetween.

Owner:PROGRESS PROFILES

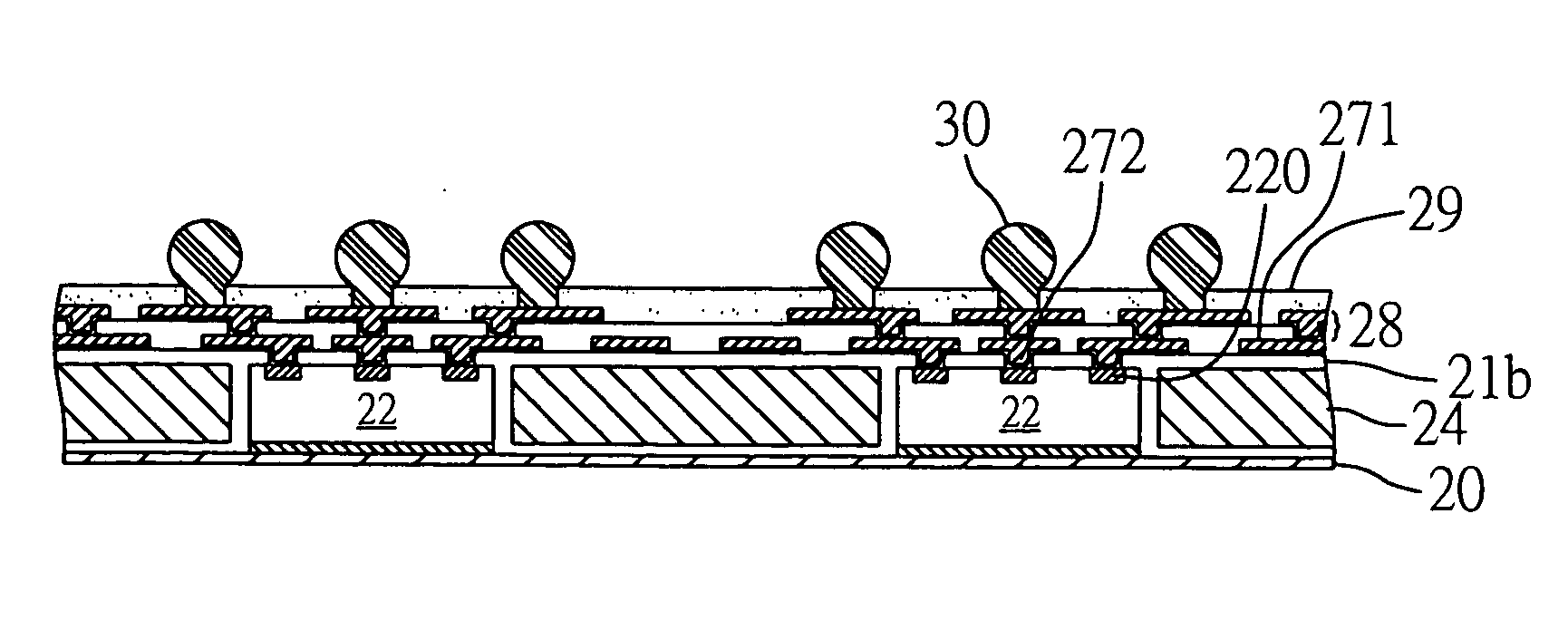

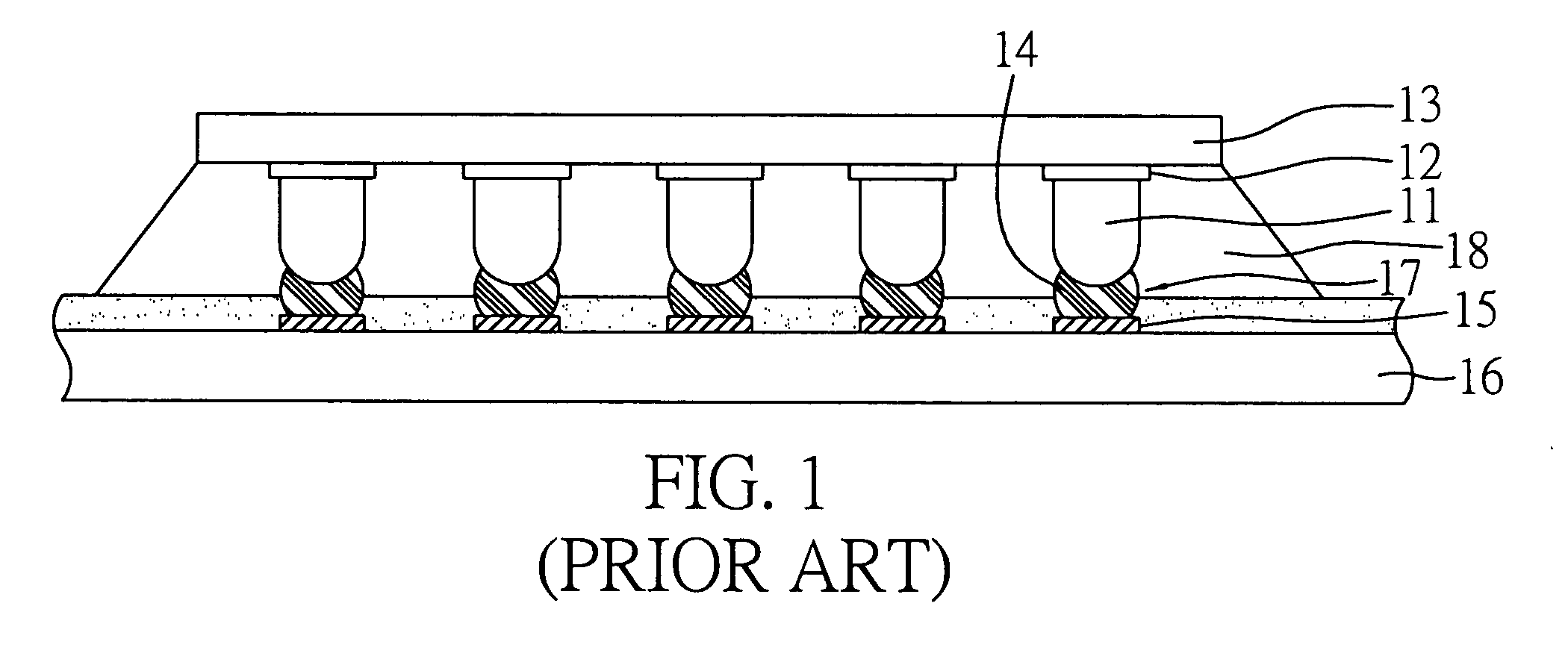

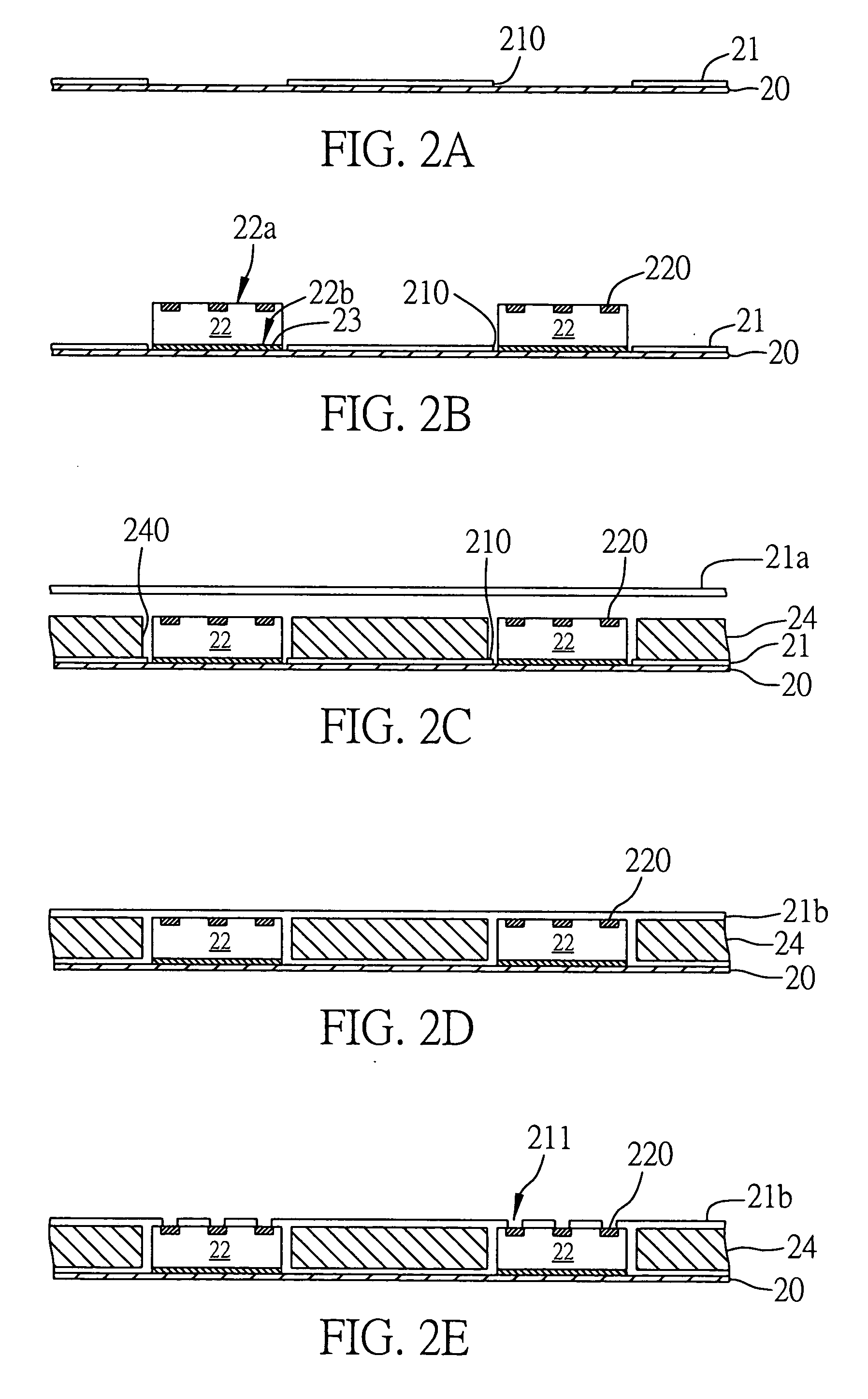

Semiconductor package substrate with embedded chip and fabrication method thereof

ActiveUS20060115931A1Improve performanceGreat flexibilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor chip

A semiconductor package substrate with embedded chip and a fabrication method thereof are provided. A first insulating layer is applied on a metallic board, and formed with at least one opening for exposing a portion of the metallic board. At least one semiconductor chip is mounted on the exposed portion of the metallic board. A support plate is mounted on the first insulating layer, and formed with a through cavity at a position corresponding to the opening of the first insulating layer, for receiving the chip in the through cavity. A second insulating layer is applied on the chip and the support plate. Insulating materials of the insulating layers fill a gap between the chip and the support plate. A circuit layer is formed on the second insulating layer, wherein the circuit layer is electrically connected to the chip by conductive structures formed in the second insulating layer.

Owner:PHOENIX PRECISION TECH CORP

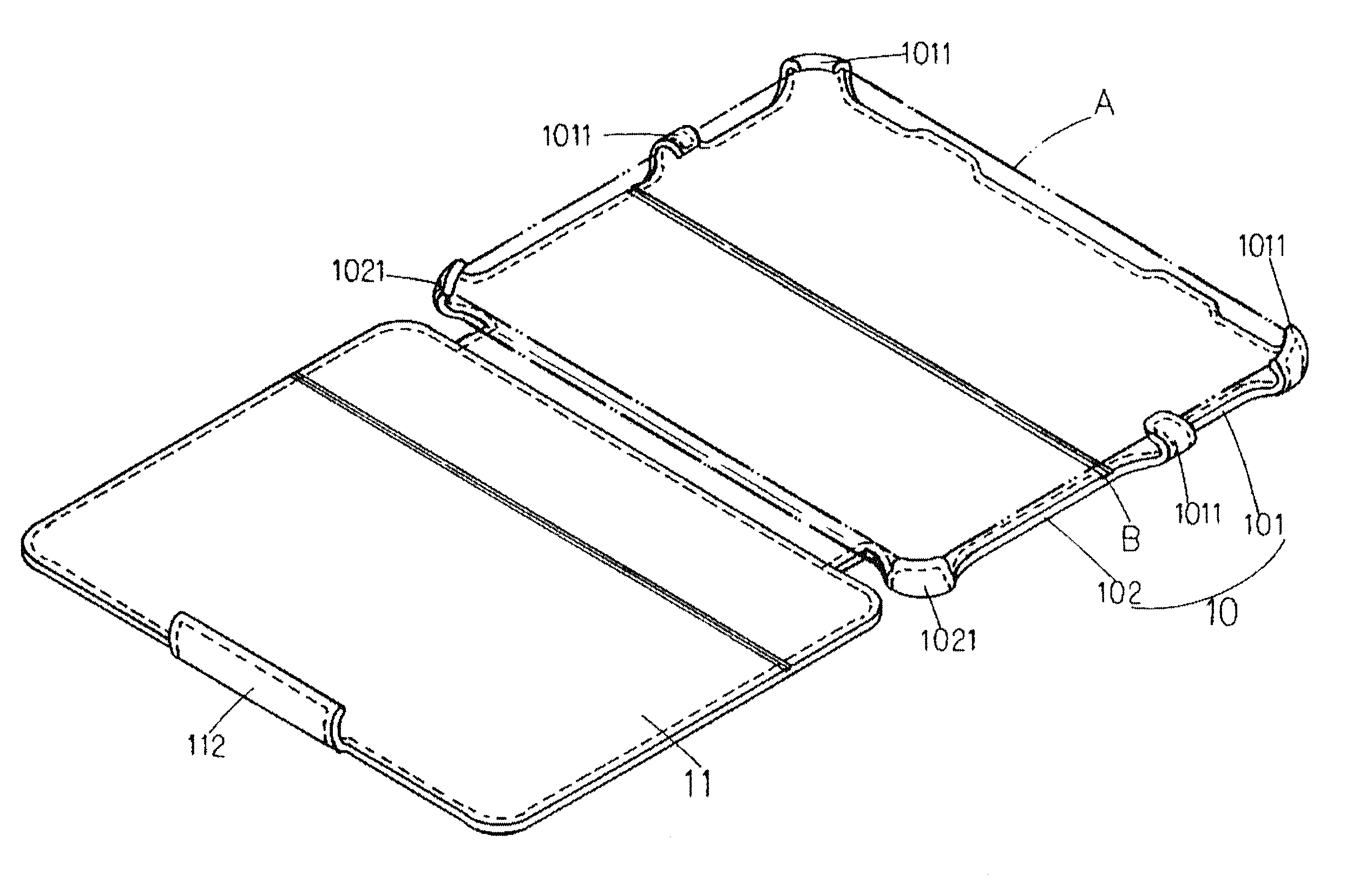

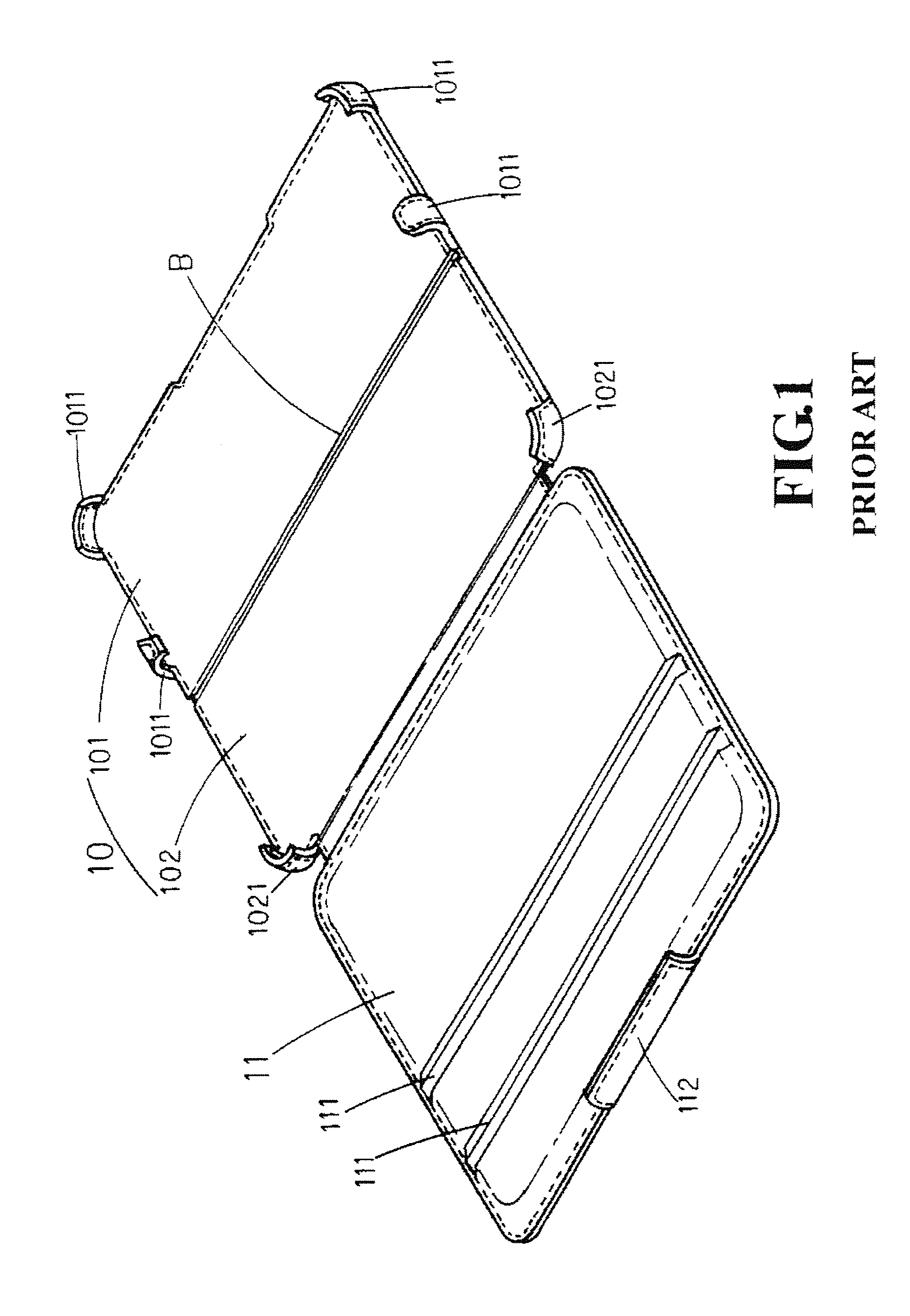

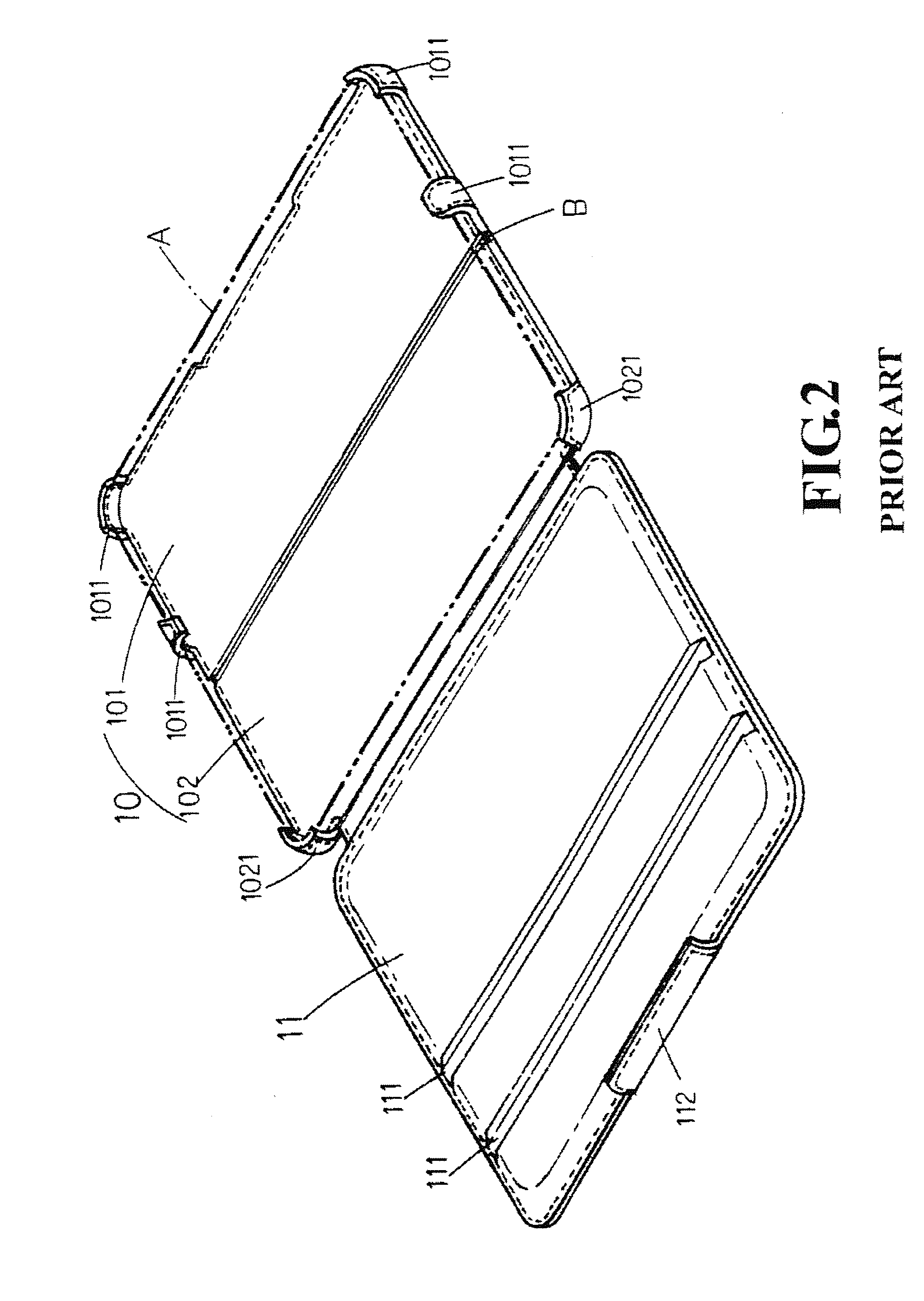

Protective cover unfolding and positioning device

InactiveUS20130140194A1Simpler and cheap to manufactureSave materialDigital data processing detailsOther accessoriesPeripheralEngineering

A protective cover unfolding and positioning device has a position restoring element installed at a folding portion adjacent to upper and lower support portions of a first protective plate for providing a restoring resilience for bending or folding the upper and lower support portions. A telecommunication product or an electronic device may be disposed obliquely on a peripheral surface of a second protective plate peripheral surface, The weight of the telecommunication product or electronic device exerted on the first protective plate upper, the lower support portions and the restoring resilience provided by the position restoring element to the upper and lower support portions Maintain stability of the that the telecommunication product or electronic device.

Owner:HAN HSIU PING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com