Patents

Literature

11175results about "Vehicle cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

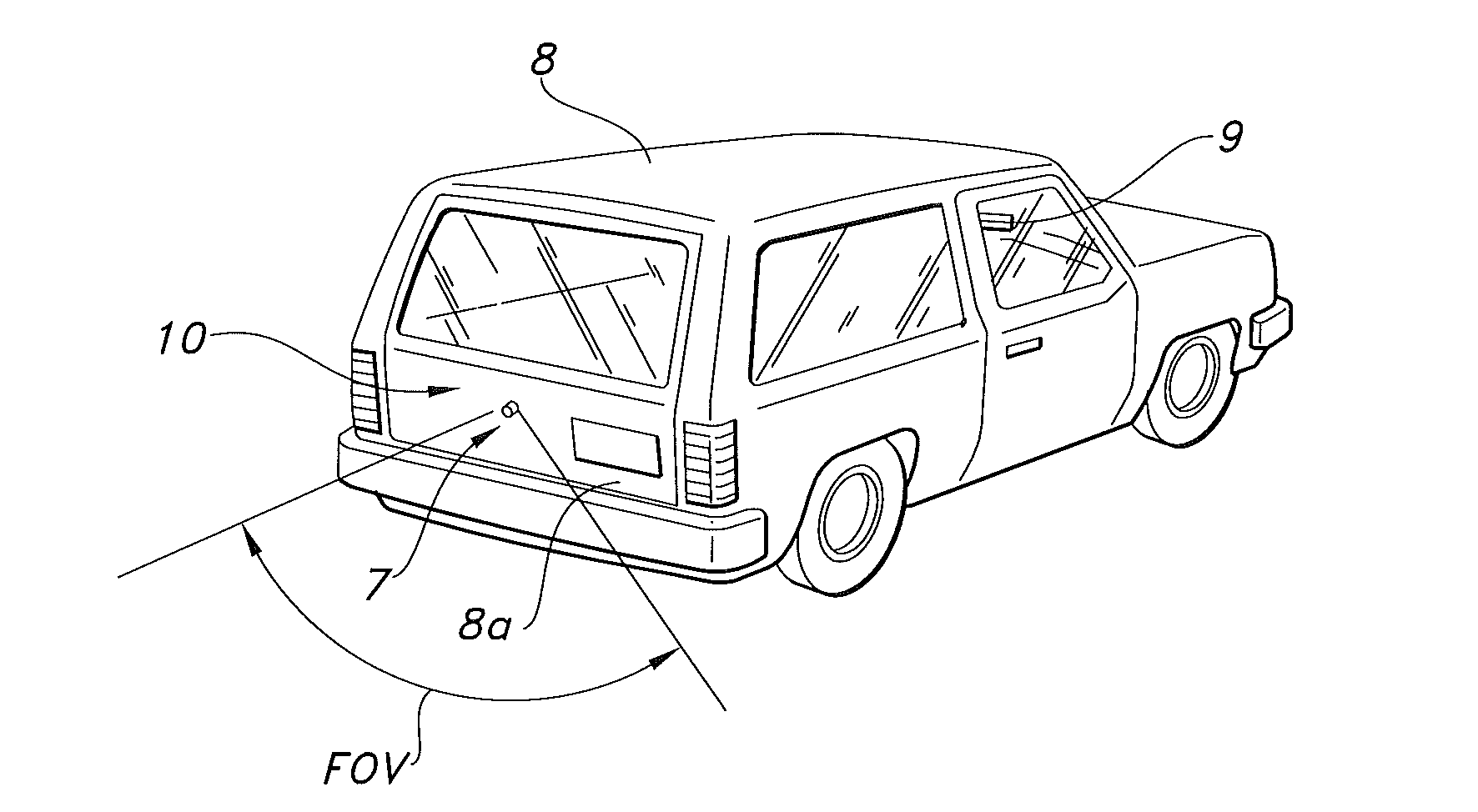

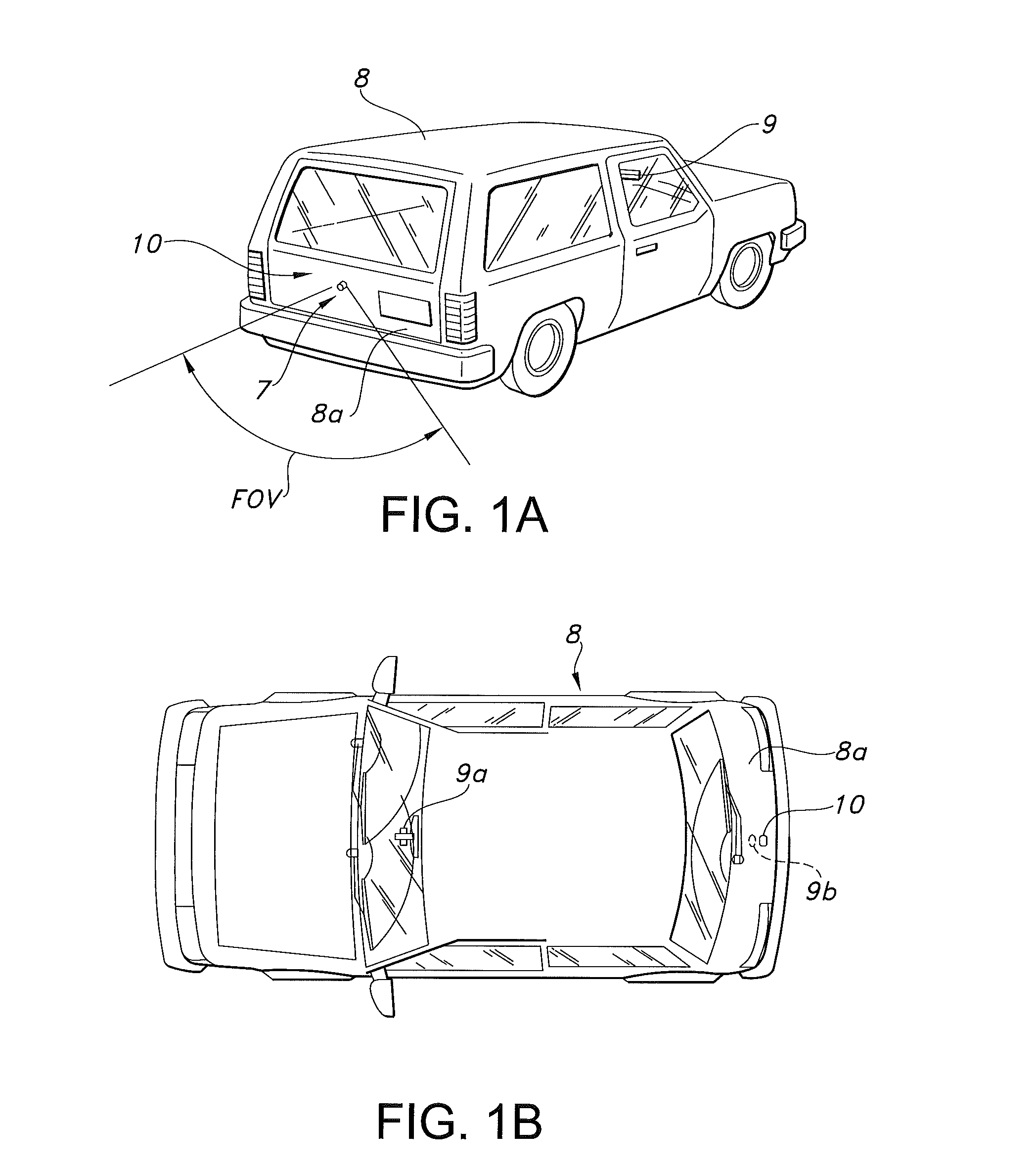

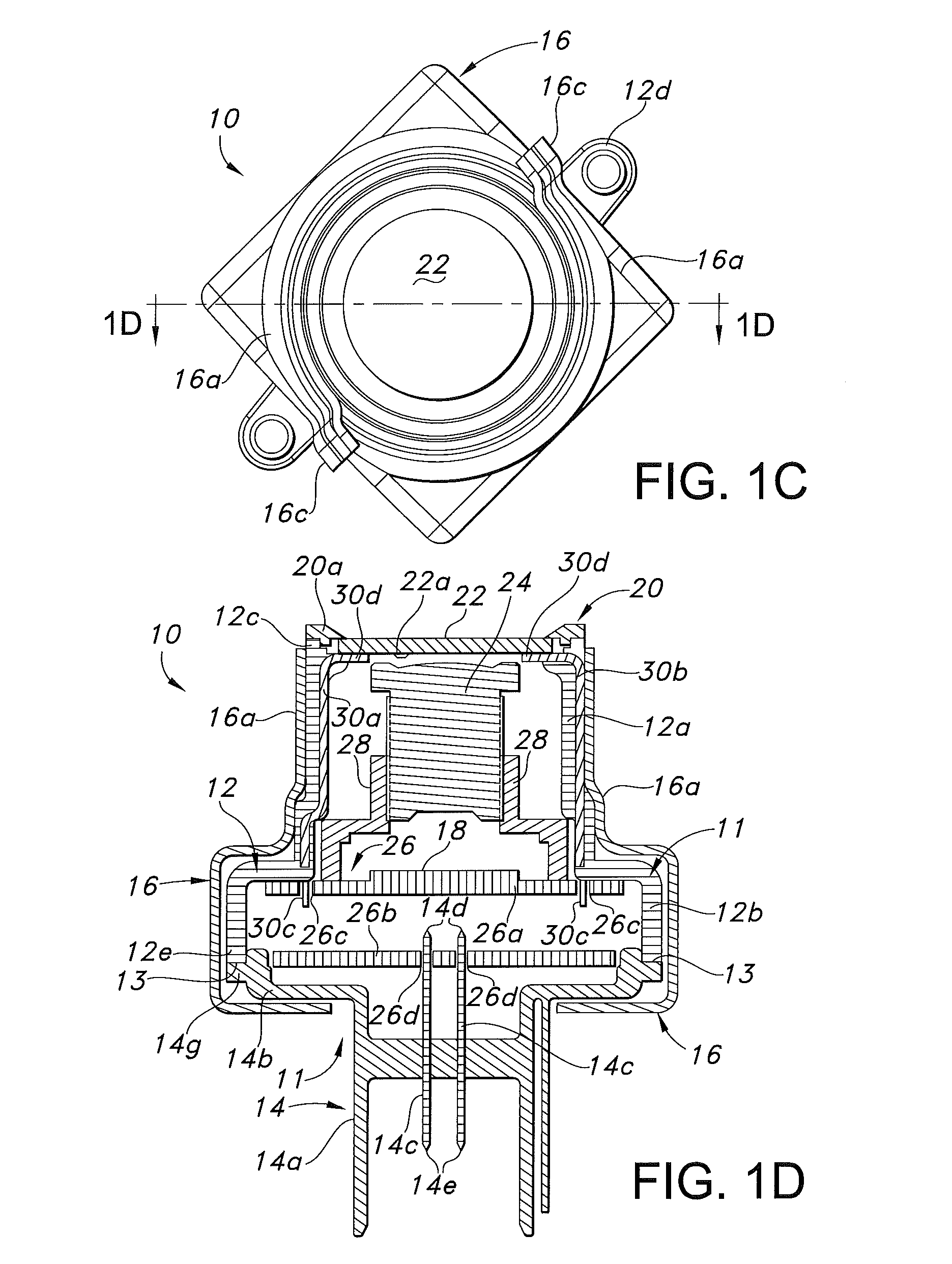

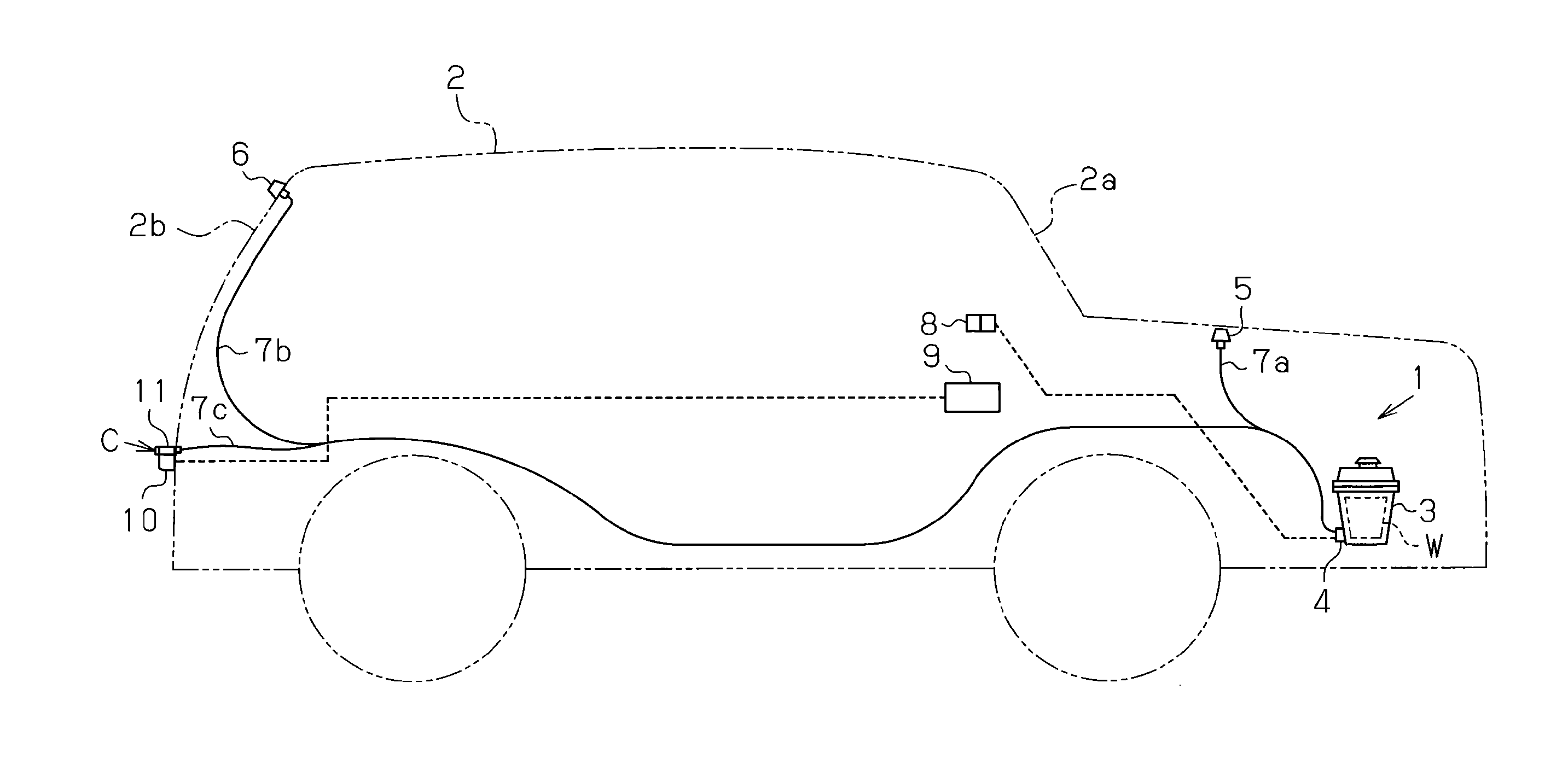

Imaging system for vehicle

ActiveUS20060171704A1Reduce vibration effectsReduce foggingTelevision system detailsPrintersWater vaporEngineering

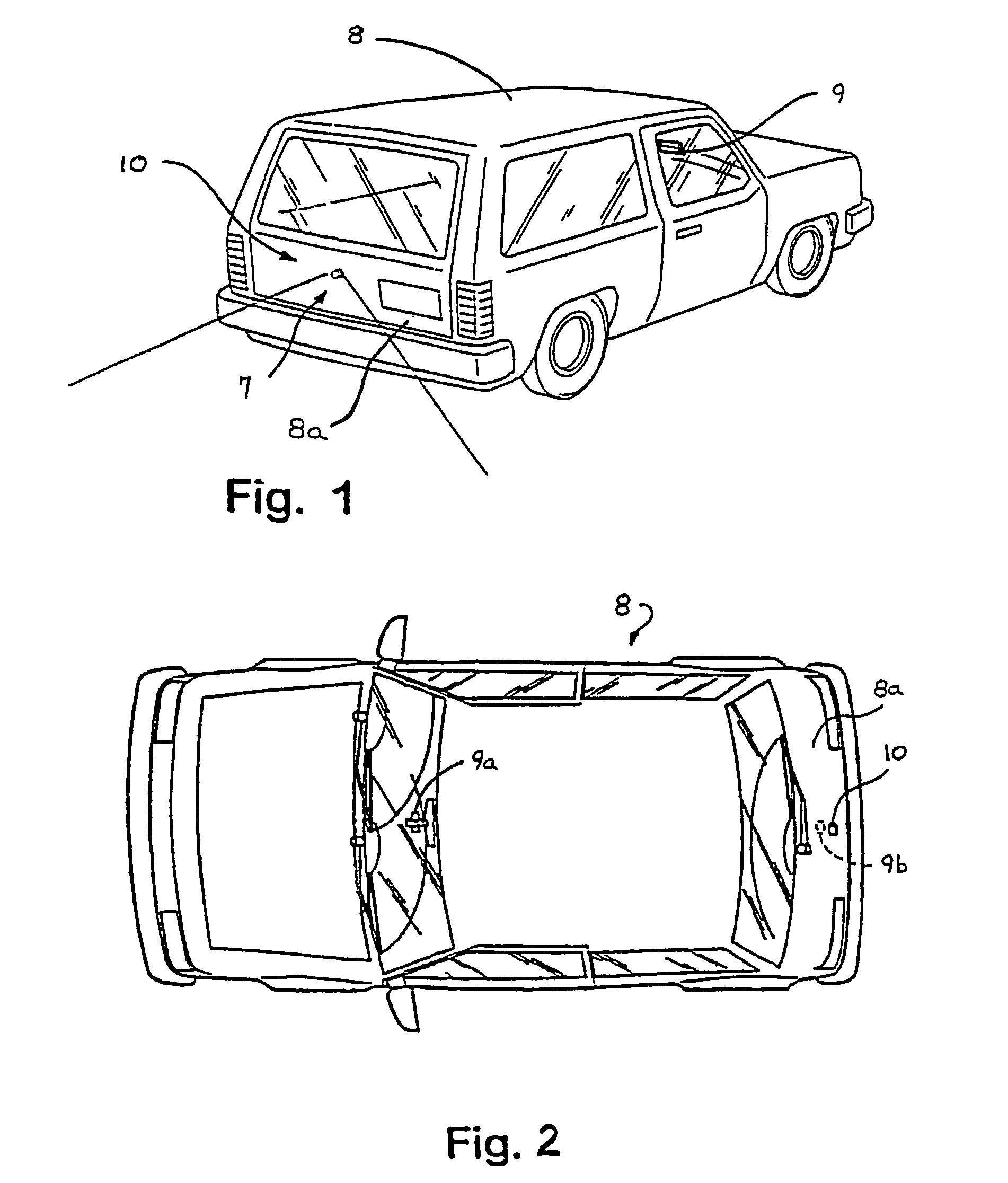

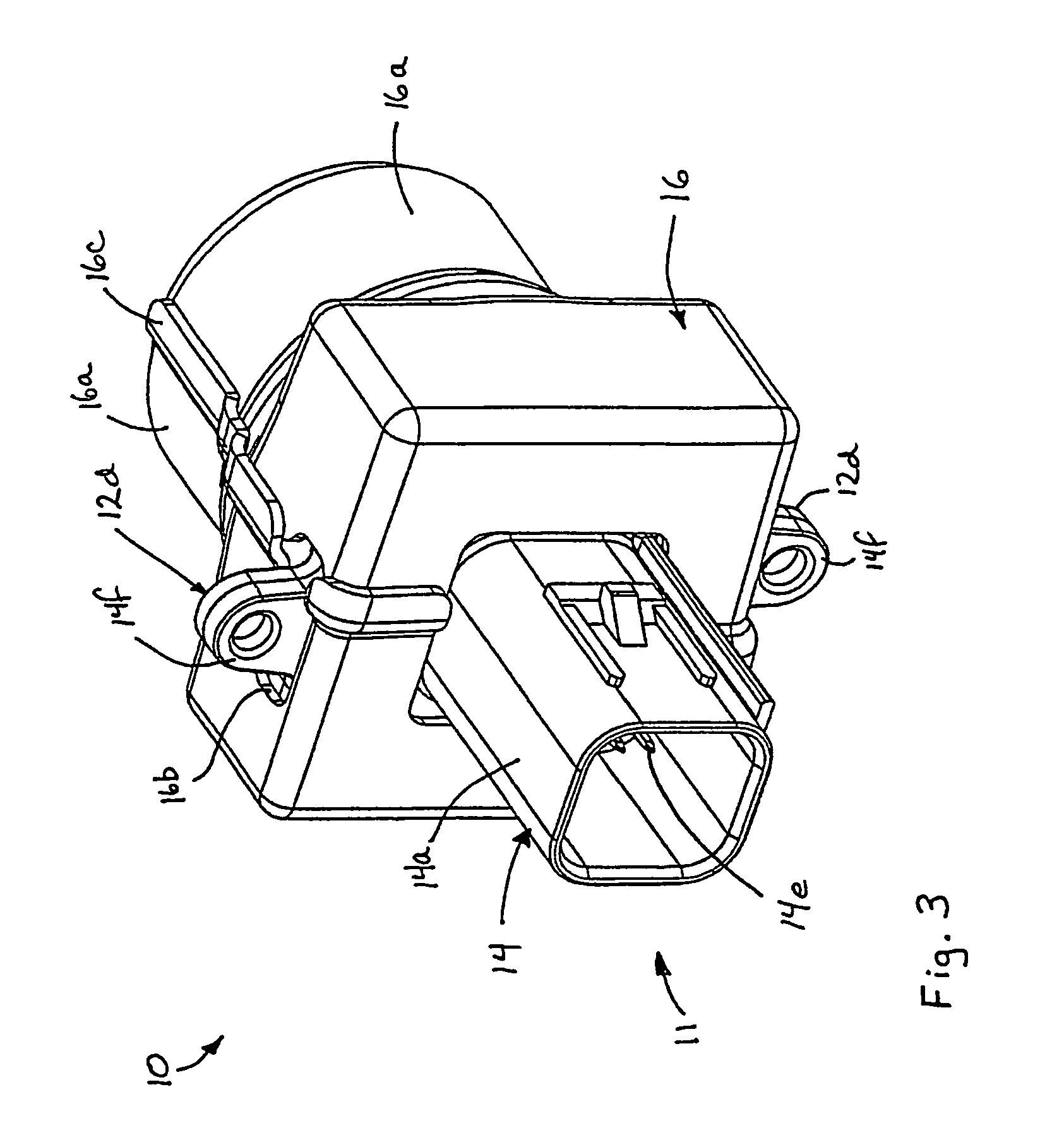

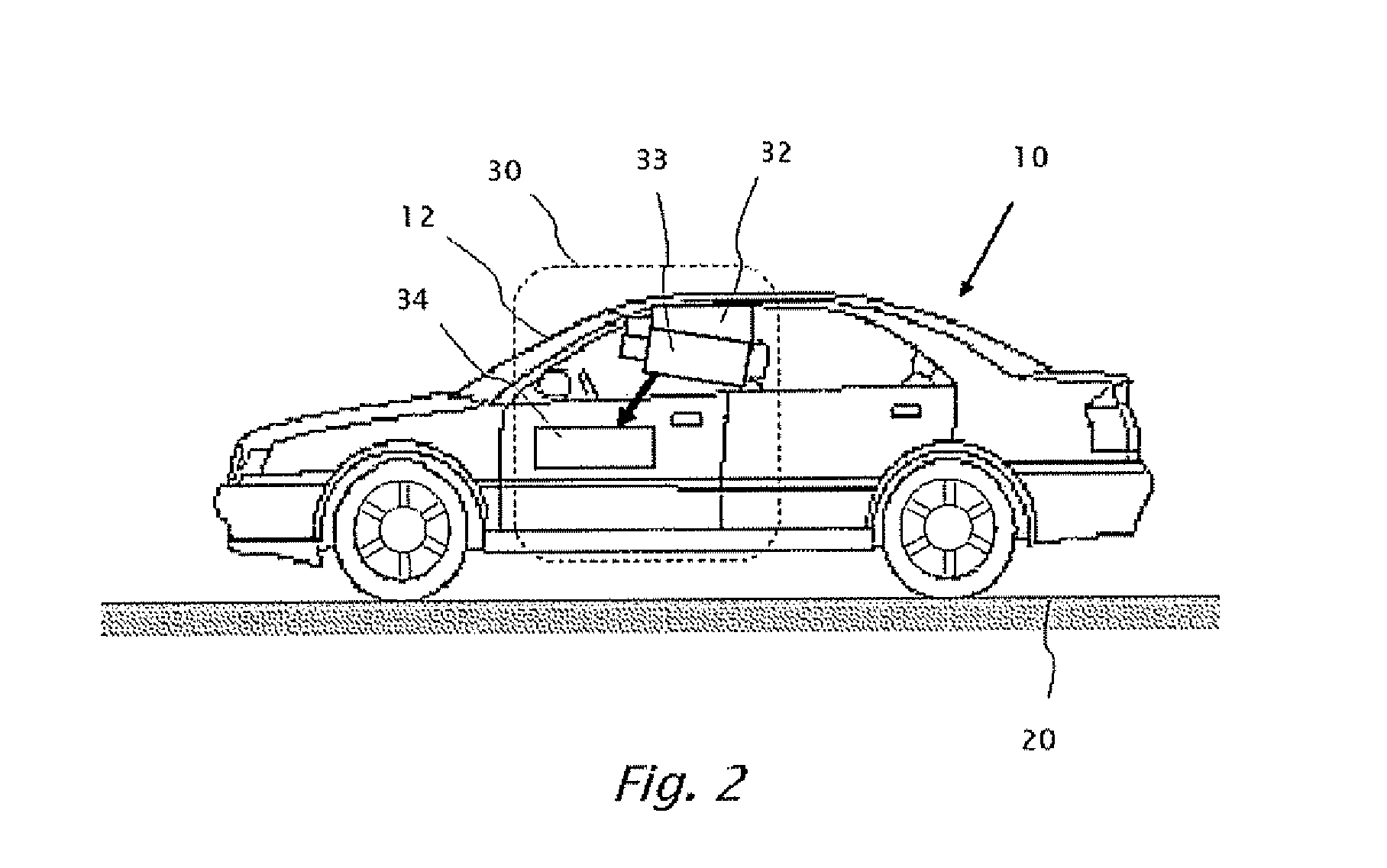

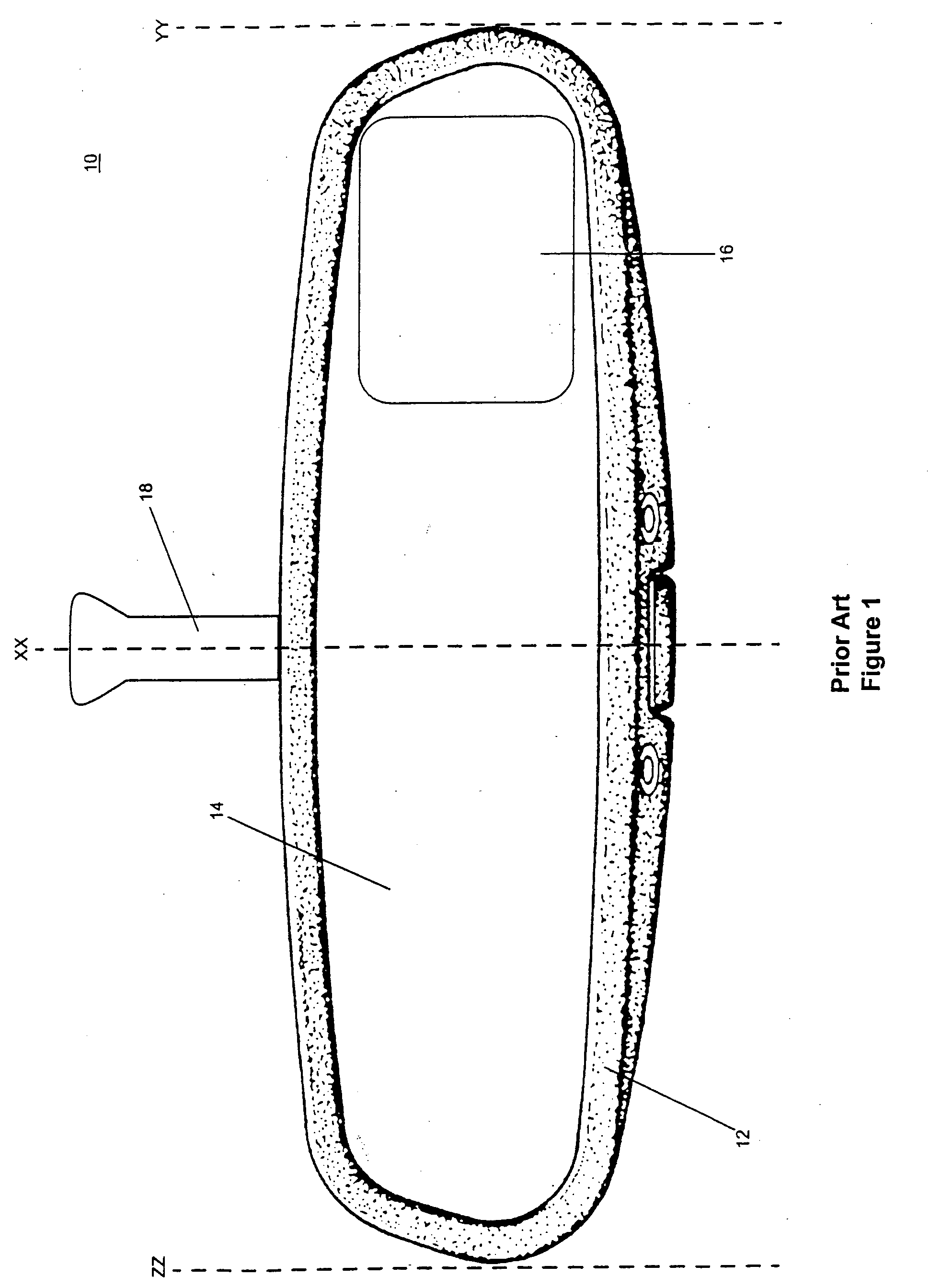

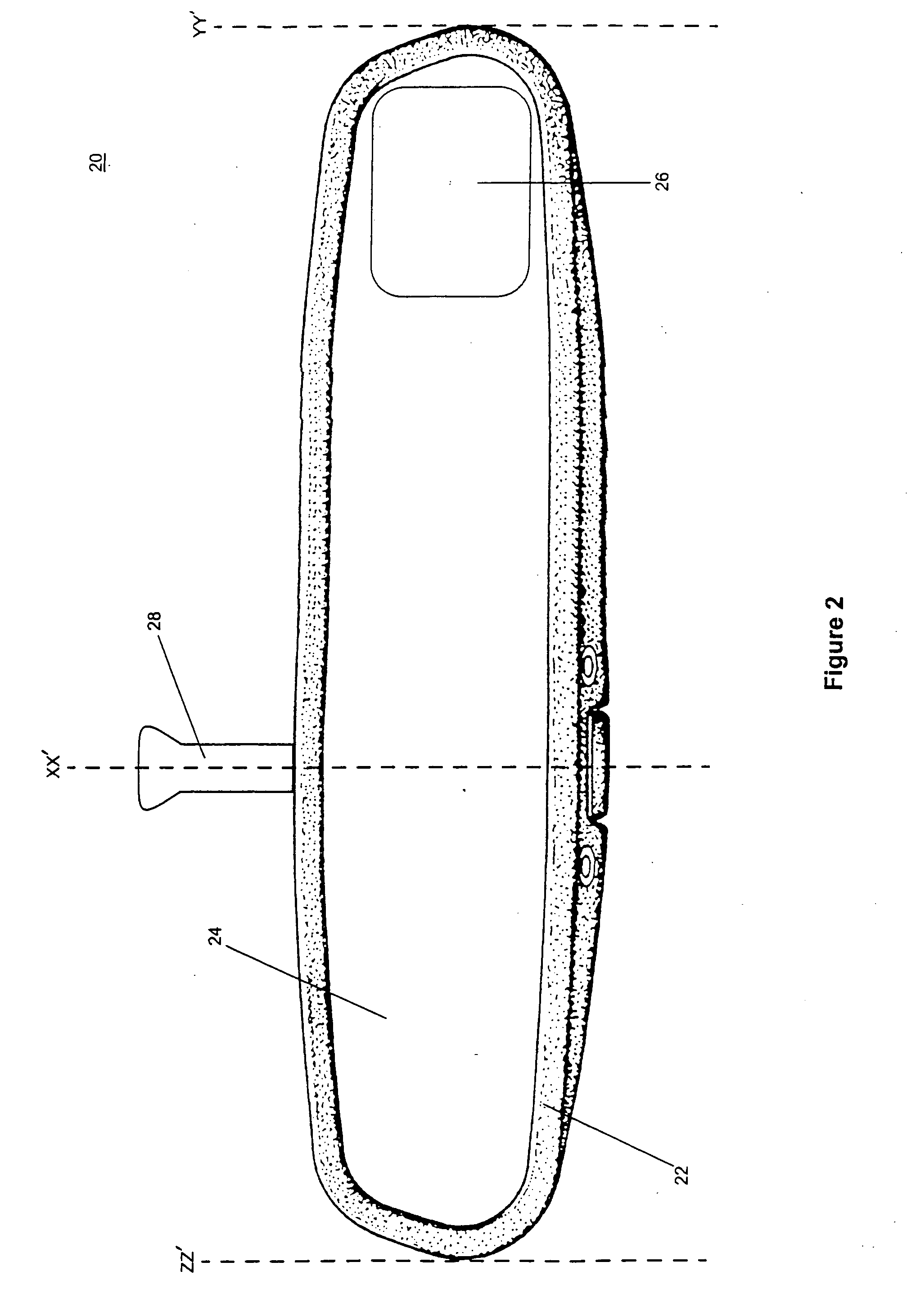

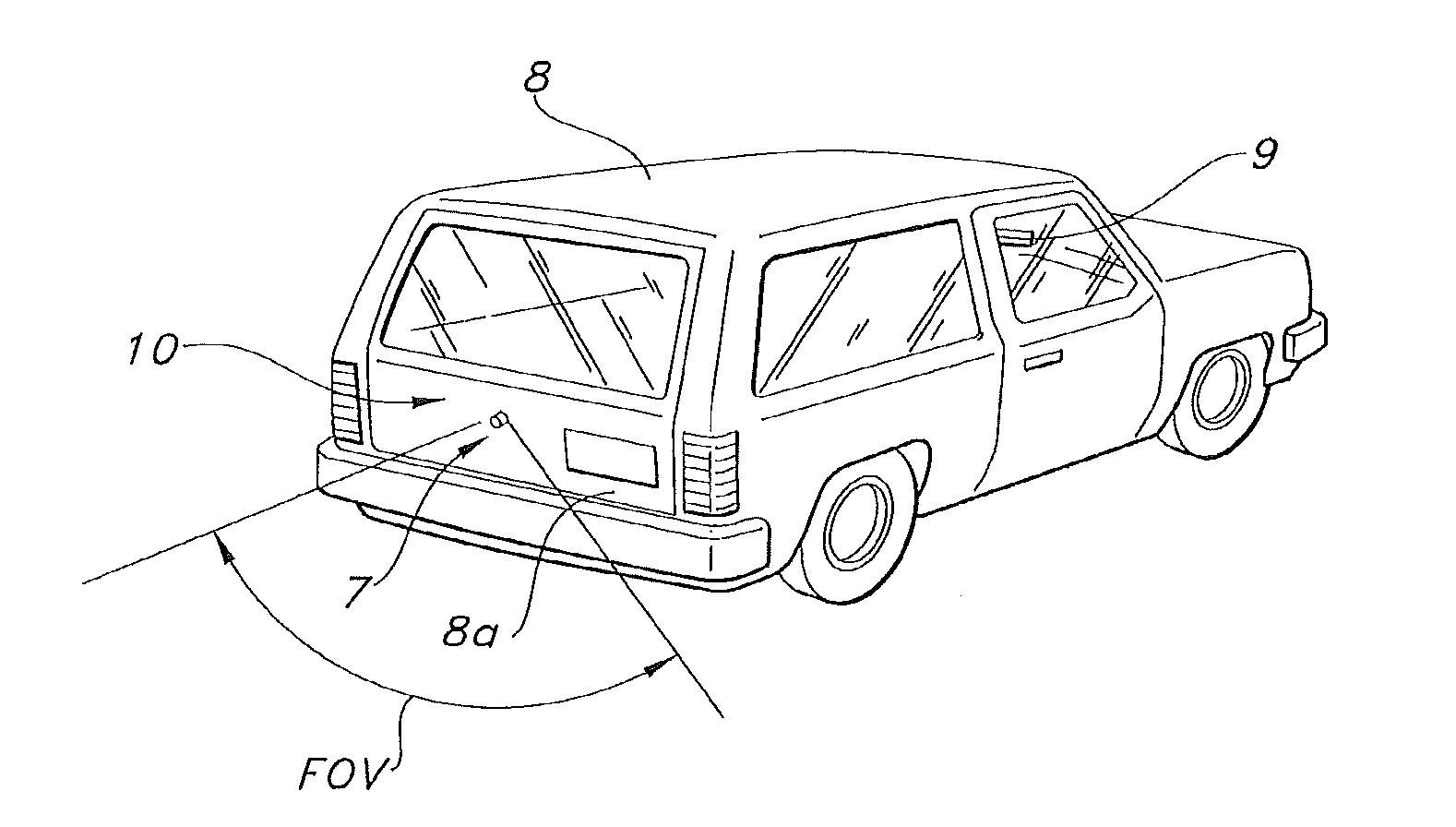

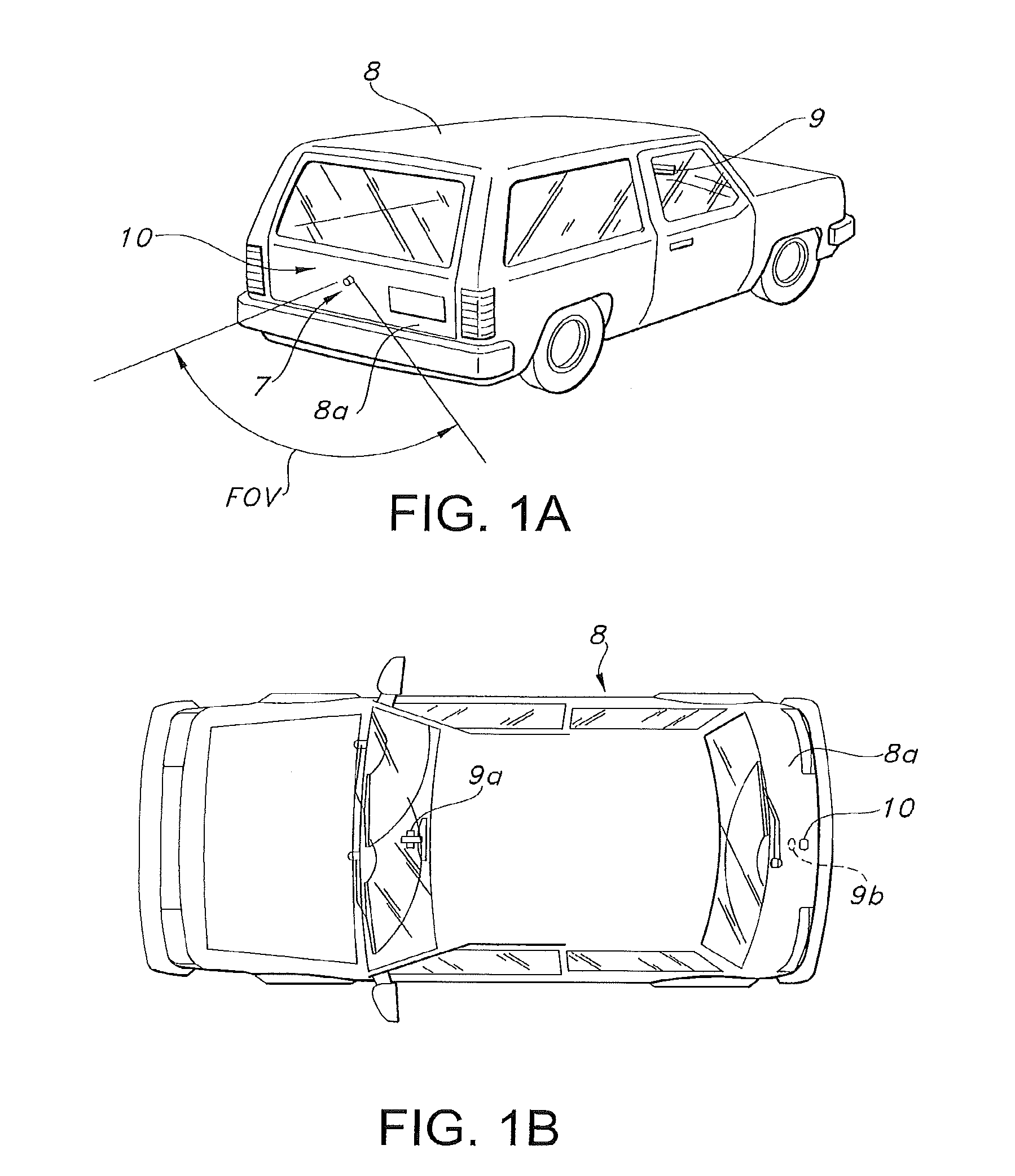

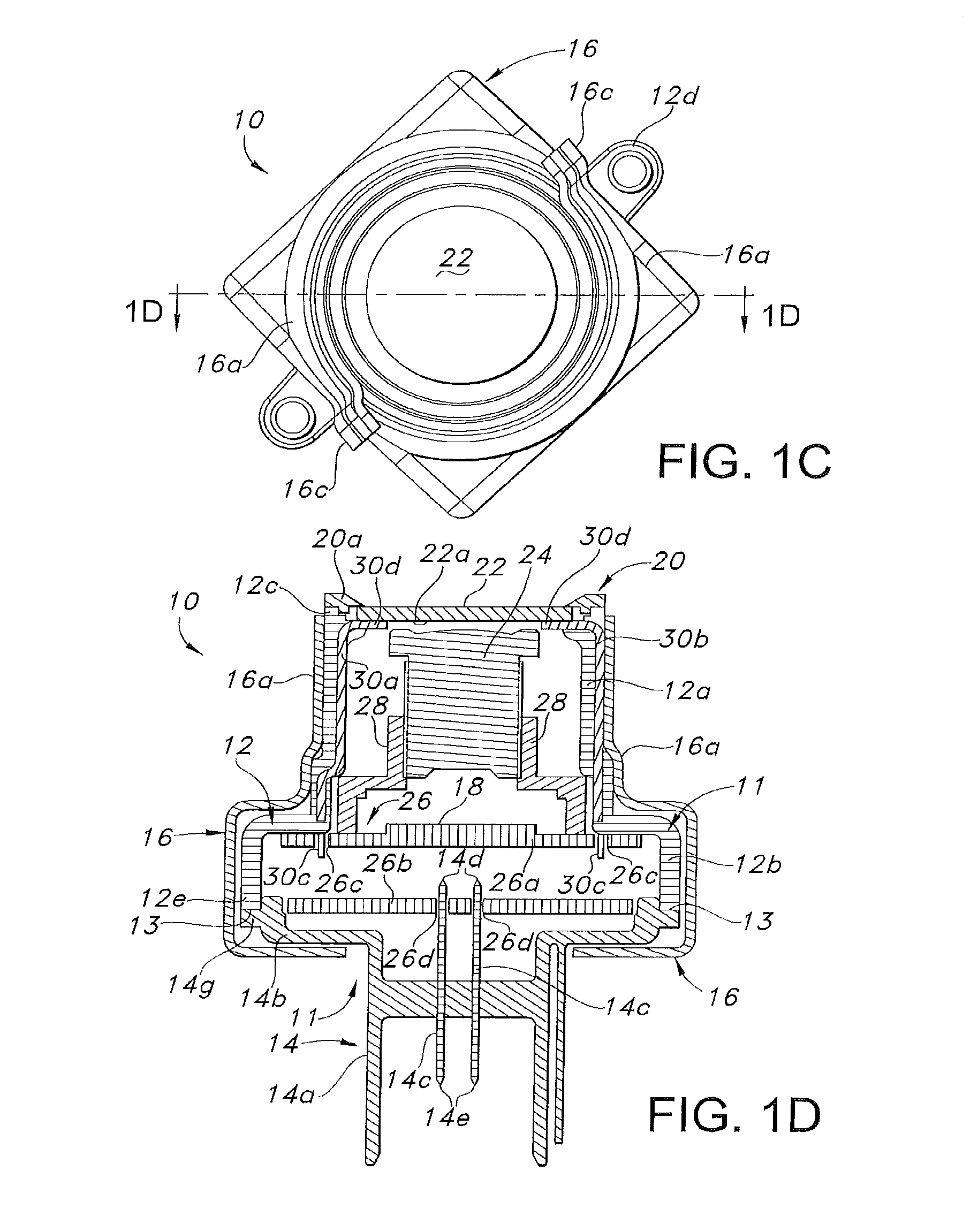

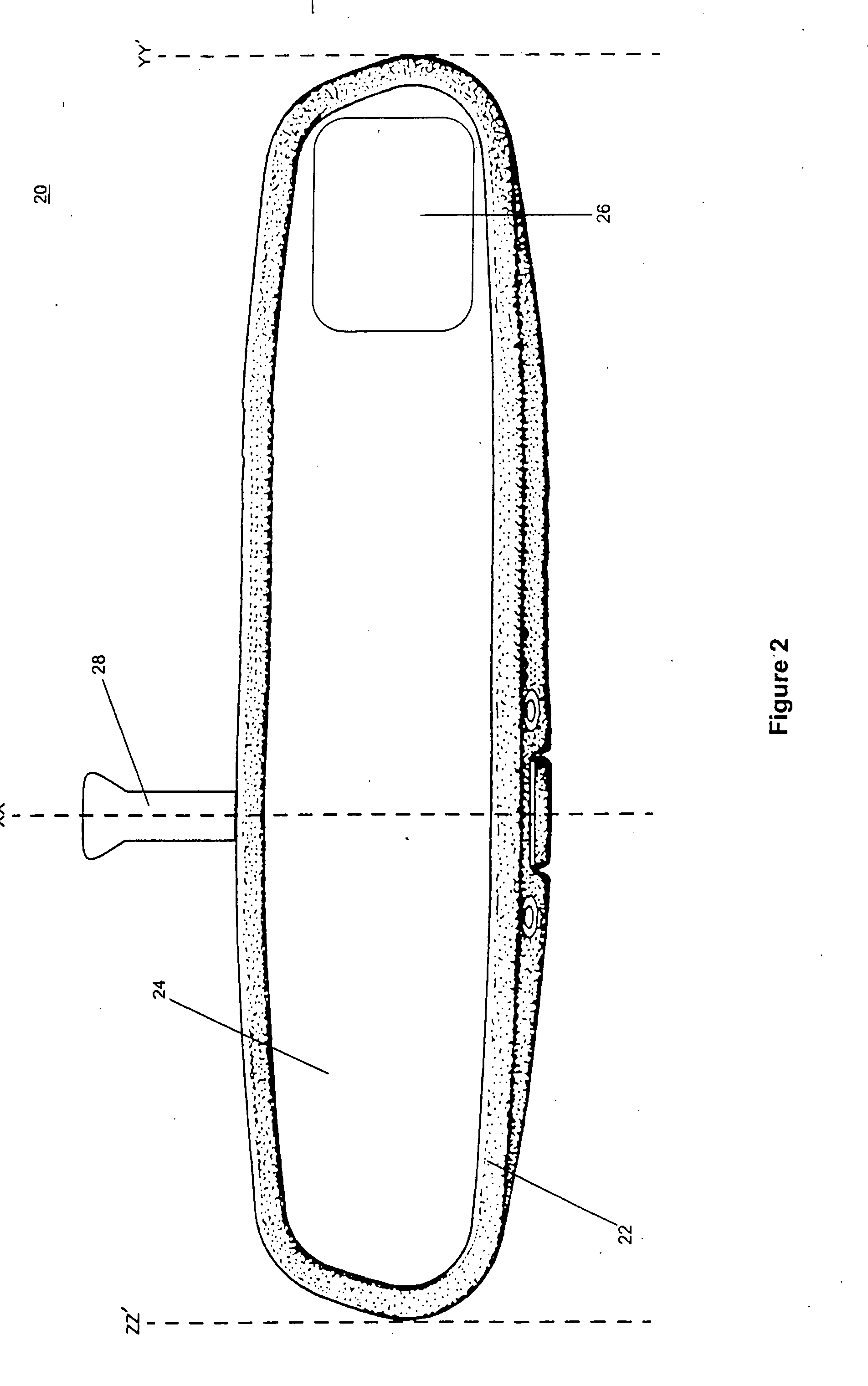

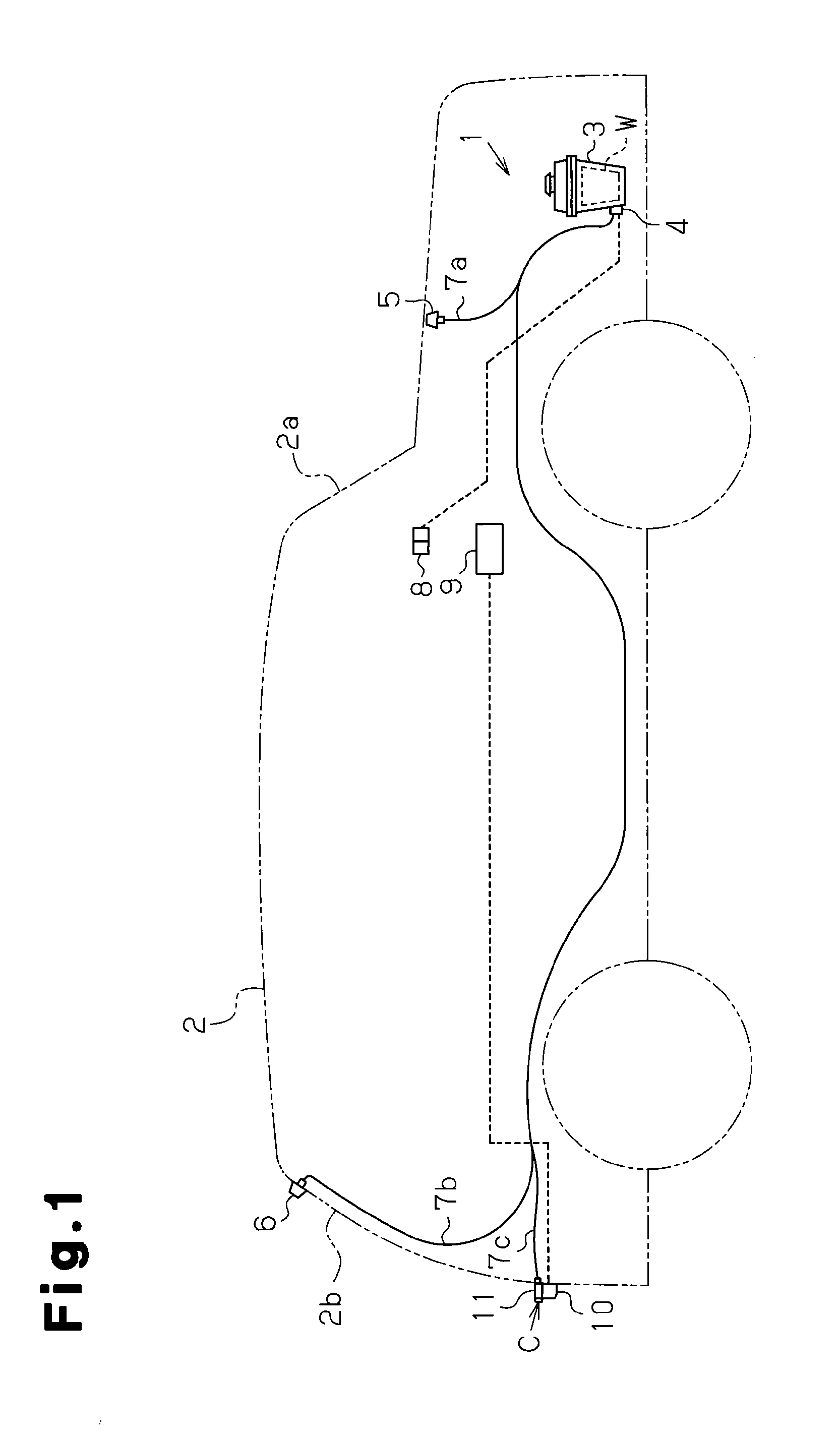

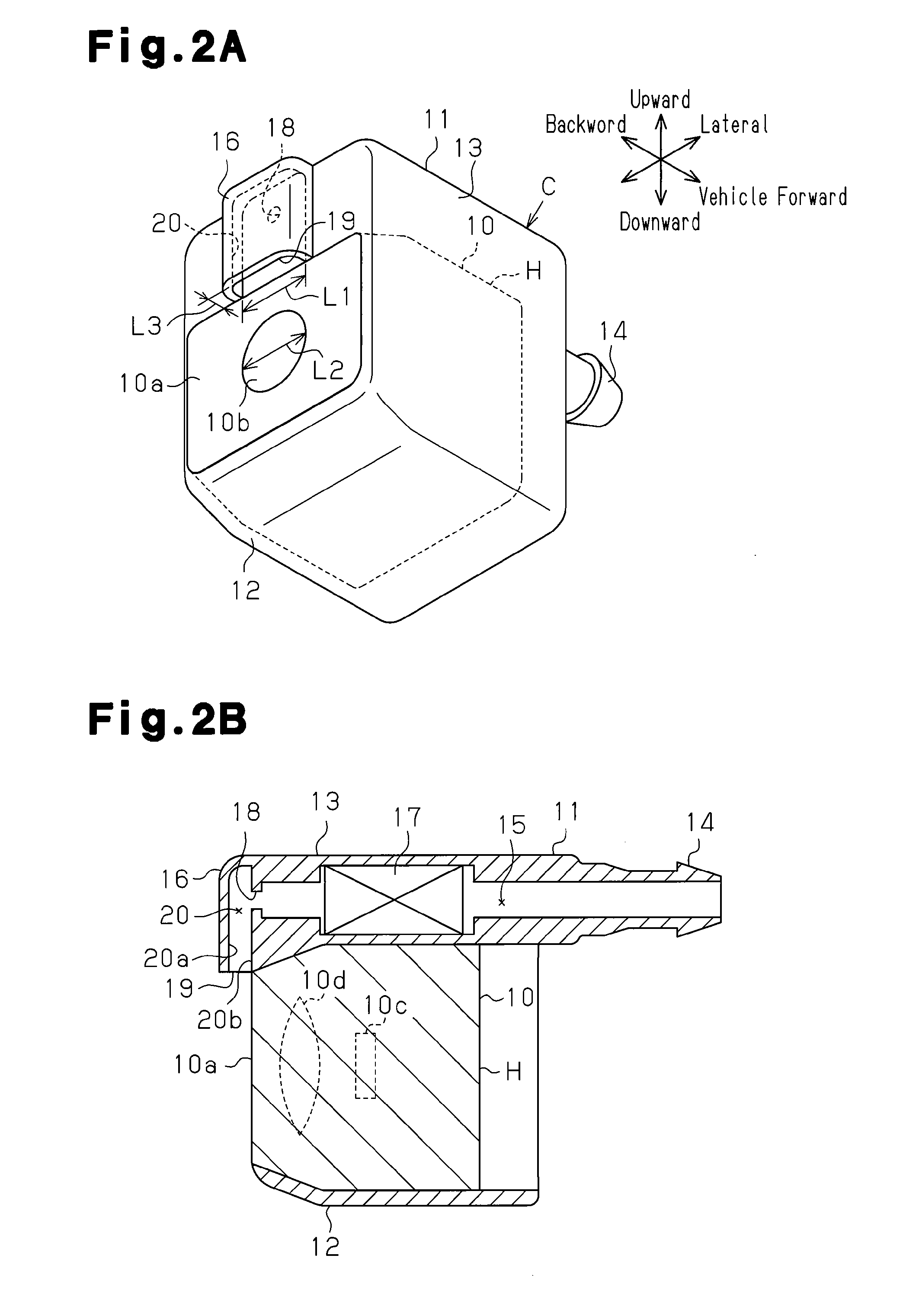

An imaging system for a vehicle includes a camera module positionable at the vehicle and a control. The camera module includes a plastic housing that houses an image sensor, which is operable to capture images of a scene occurring exteriorly of the vehicle. The control is operable to process images captured by the image sensor. The portions of the housing may be laser welded or sonic welded together to substantially seal the image sensor and associated components within the plastic housing. The housing may include a ventilation portion that is at least partially permeable to water vapor to allow water vapor to pass therethrough while substantially precluding passage of water droplets and / or other contaminants. The housing may be movable at the vehicle between a stored position and an operational position, where the image sensor may be directed toward the exterior scene.

Owner:MAGNA ELECTRONICS

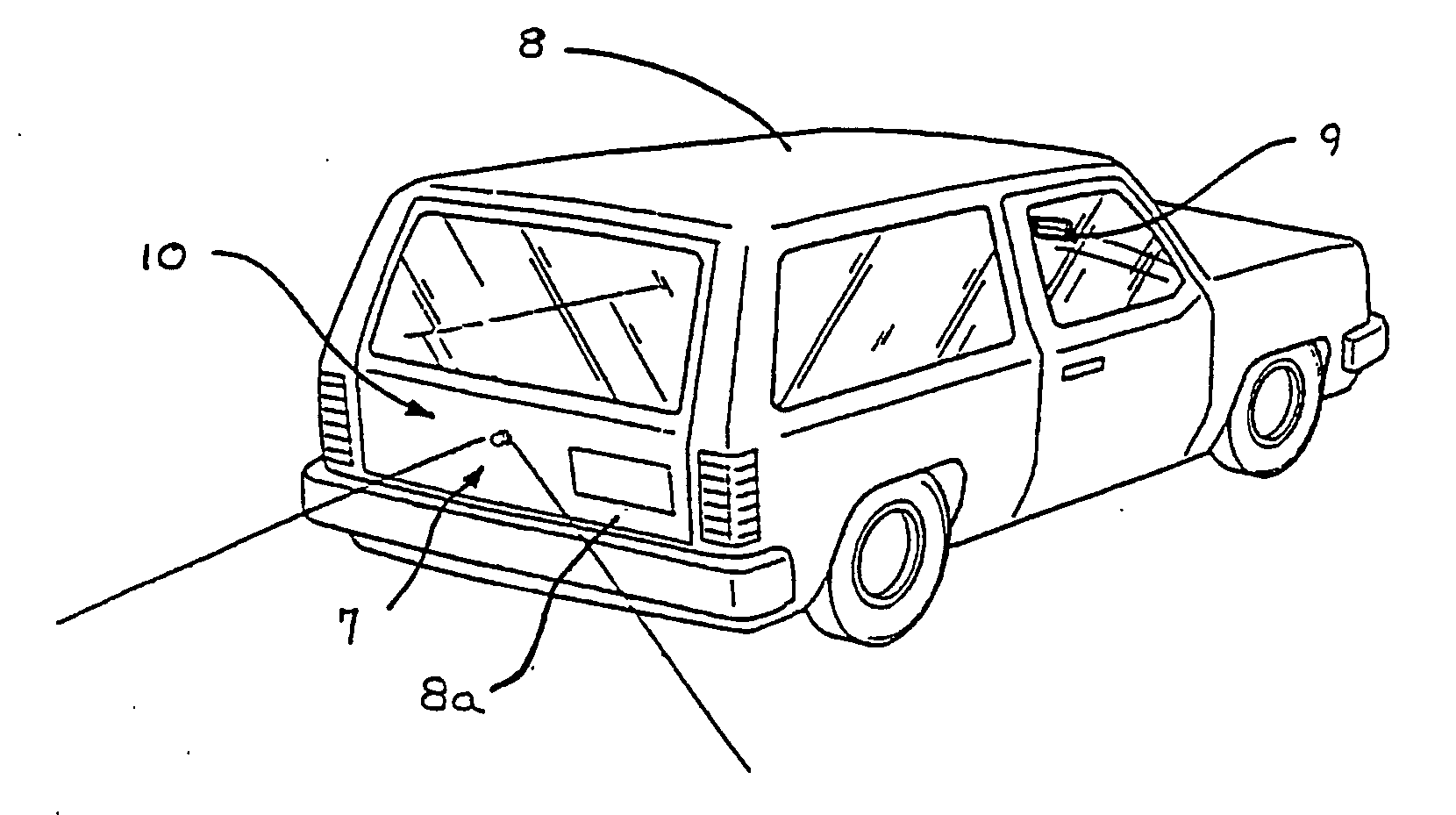

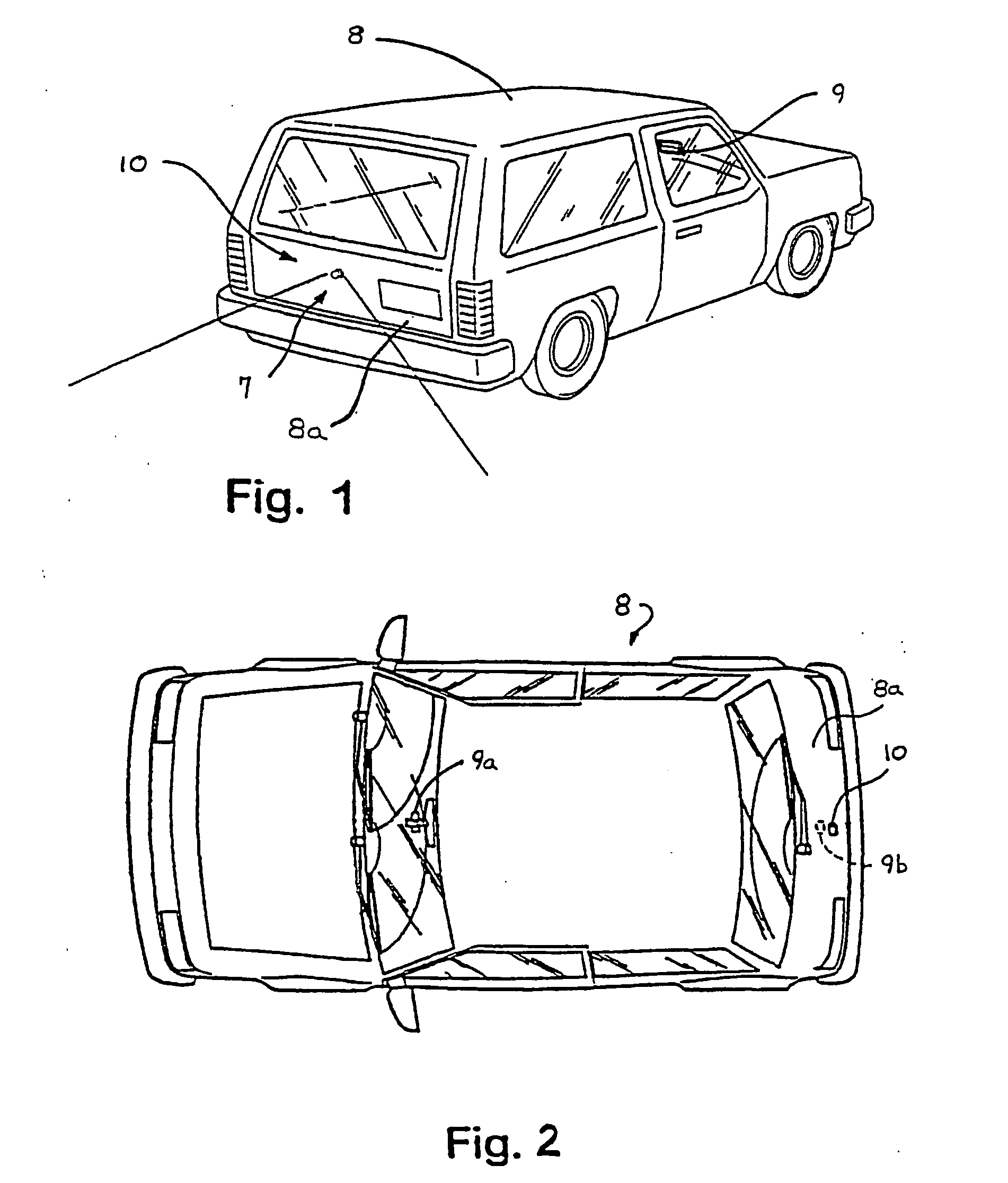

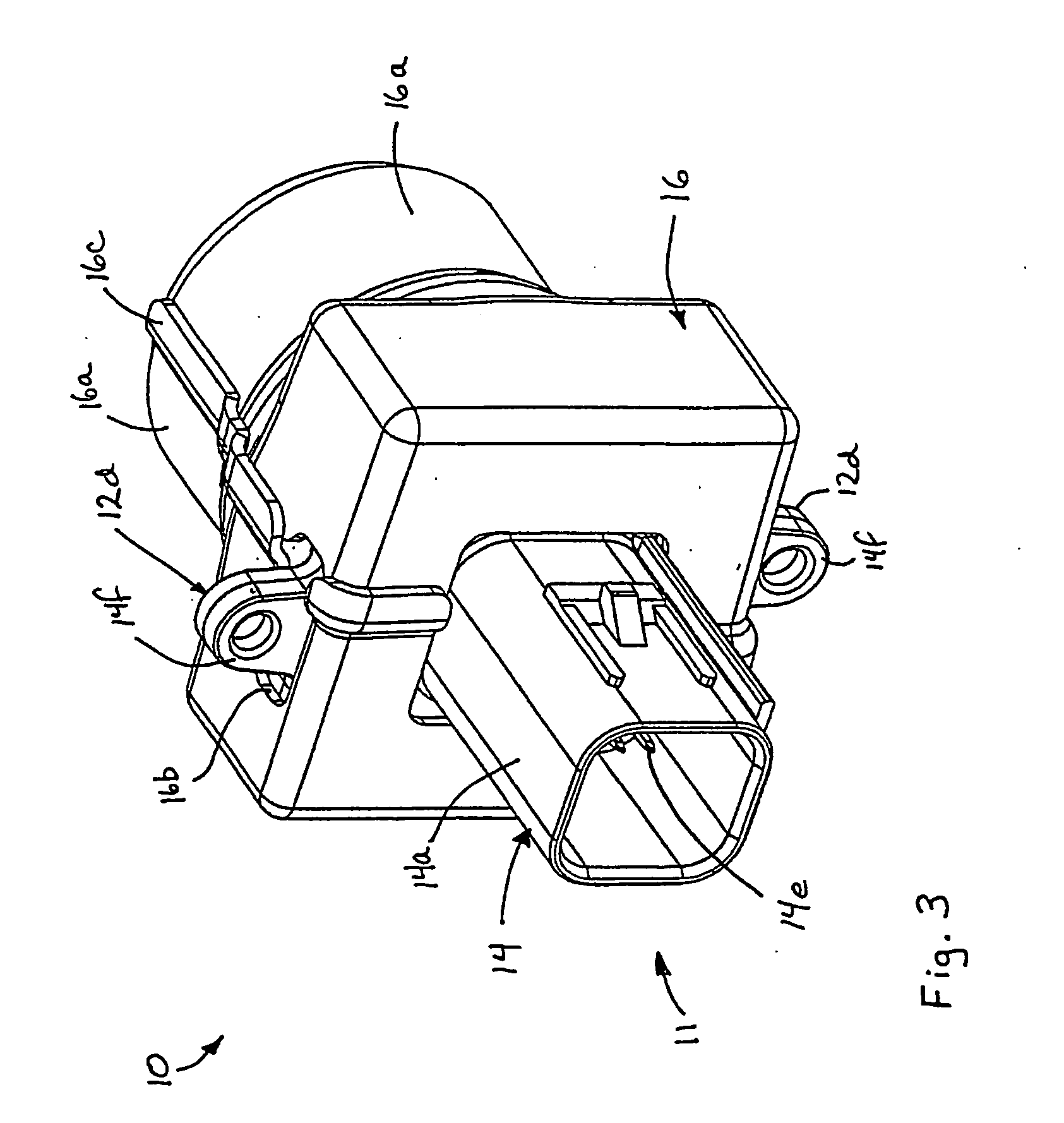

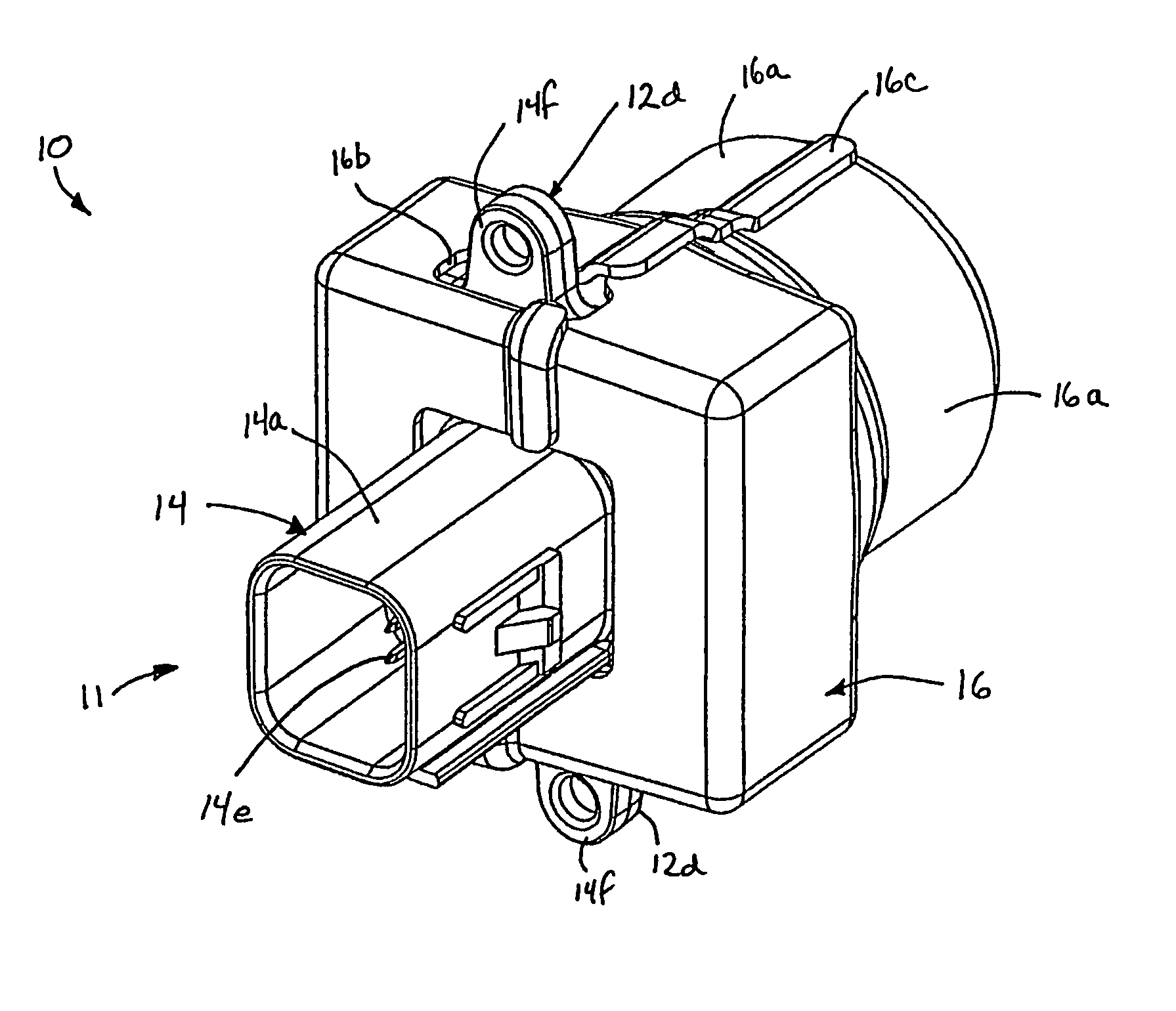

Imaging system for vehicle

ActiveUS7965336B2Reduce vibration effectsReduce foggingTelevision system detailsPrintersWater vaporCamera module

An imaging system for a vehicle includes a camera module positionable at the vehicle and a control. The camera module includes a plastic housing that houses an image sensor, which is operable to capture images of a scene occurring exteriorly of the vehicle. The control is operable to process images captured by the image sensor. The portions of the housing may be laser welded or sonic welded together to substantially seal the image sensor and associated components within the plastic housing. The housing may include a ventilation portion that is at least partially permeable to water vapor to allow water vapor to pass therethrough while substantially precluding passage of water droplets and / or other contaminants. The housing may be movable at the vehicle between a stored position and an operational position, where the image sensor may be directed toward the exterior scene.

Owner:MAGNA ELECTRONICS

Moisture sensor and windshield fog detector

InactiveUS6097024AAutomatic detectionLower performance requirementsTelevision system detailsImage enhancementControl signalEngineering

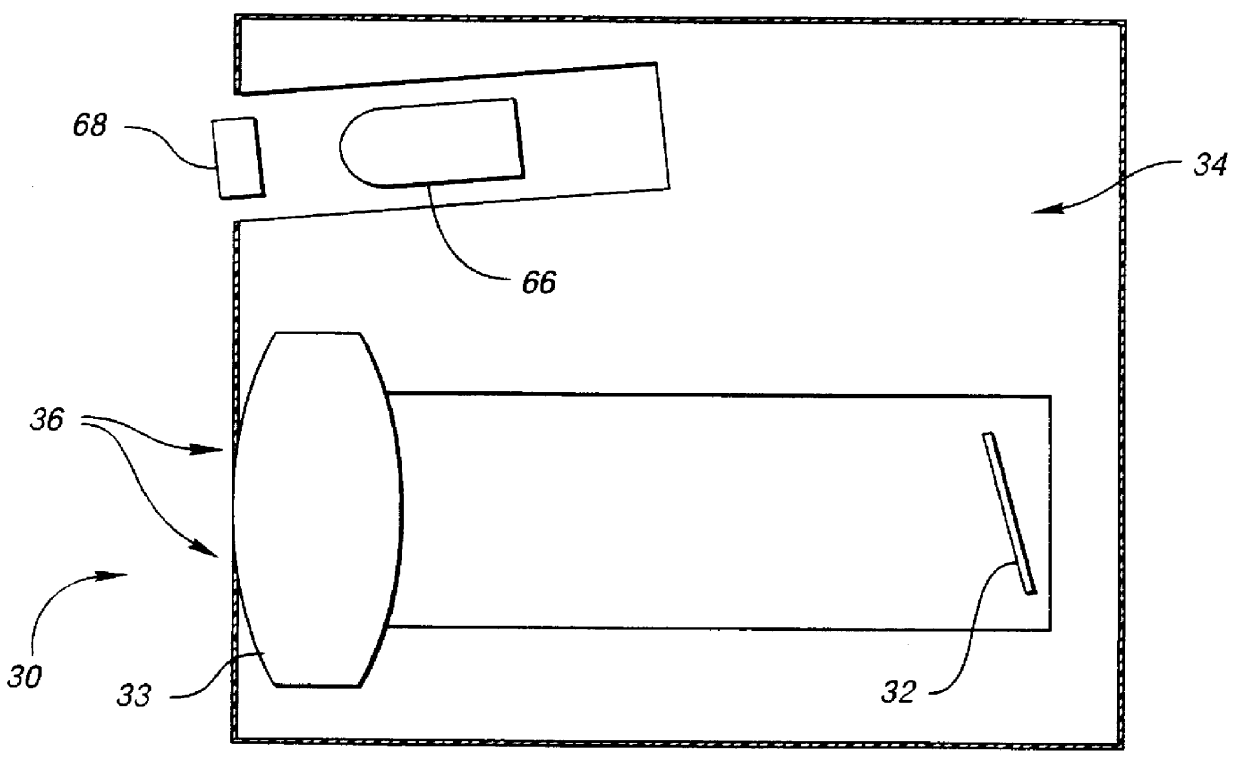

A control system for automatically detecting moisture on the windshield of a vehicle. The automatic moisture detecting system includes an optical system for imaging a portion of the windshield on to an image array sensor, such as a CMOS active pixel sensor. The voltages of each of the pixels which represents the illumination level is converted to a corresponding gray scale value by an analog digital converter. The gray scale values corresponding to the image are stored in memory. The spatial frequency composition of the gray scale values are analyzed to determine the amount of rain present. In order to provide a control signal to control the operation of the windshield wipers of the vehicle as a function of the amount of moisture present. The system is also adapted to detect the level of fog both on the interior of the windshield as well as the exterior of the windshield. By providing a system for automatically detecting the presence of fog on the interior and exterior of the windshield, serious performance limitations of known automatic rain sensors are eliminated.

Owner:GENTEX CORP

Vehicle control system and method

InactiveUS6302545B1Improve reliabilityAccurately determinedImage enhancementTelevision system detailsMirror reflectionControl signal

A vehicle control system and method includes structure and steps for capturing an image of a front seat of the vehicle and outputting image data corresponding thereto. A processor is provided which receives the image data output form the imaging device, compares the received image data with stored image data, and outputs a vehicle equipment control signal based on the comparison. Preferably, the vehicle equipment control signal controls one or more of airbag activation, mirror reflectance, vehicle lights activation, and vehicle intruder alarms. Preferably, the imaging device comprises a single chip camera disposed adjacent the vehicle rearview mirror.

Owner:DONNELLY CORP

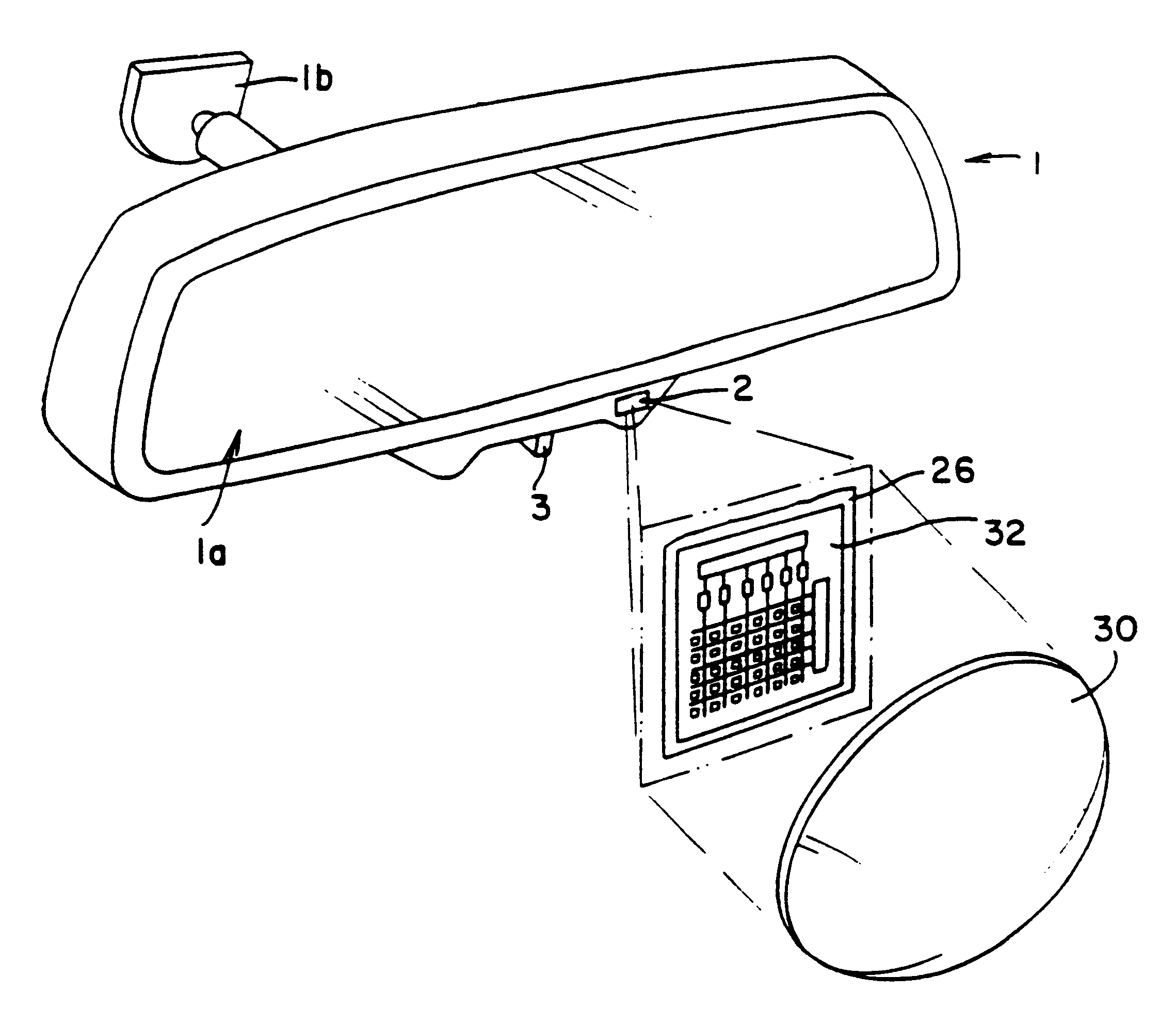

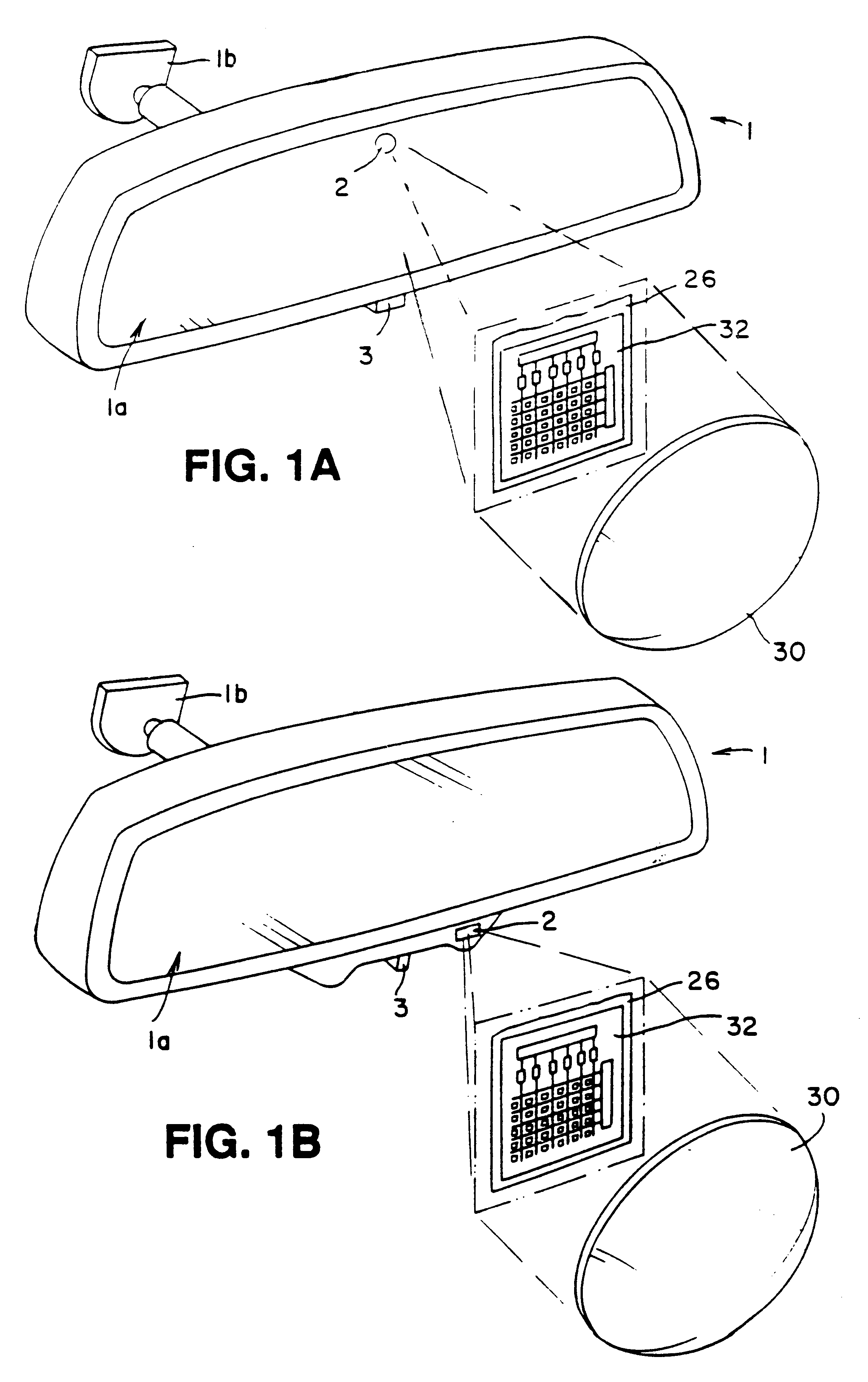

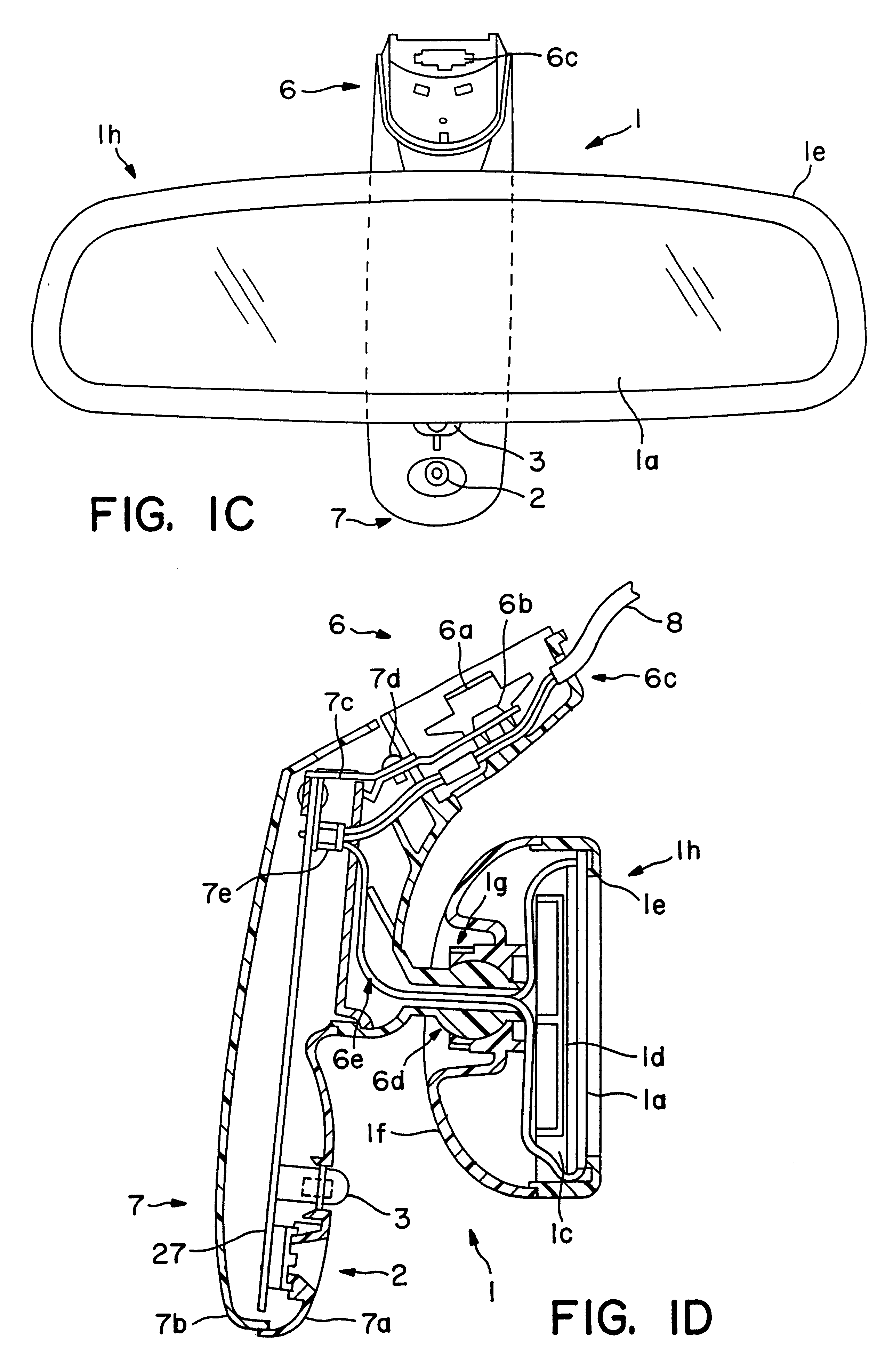

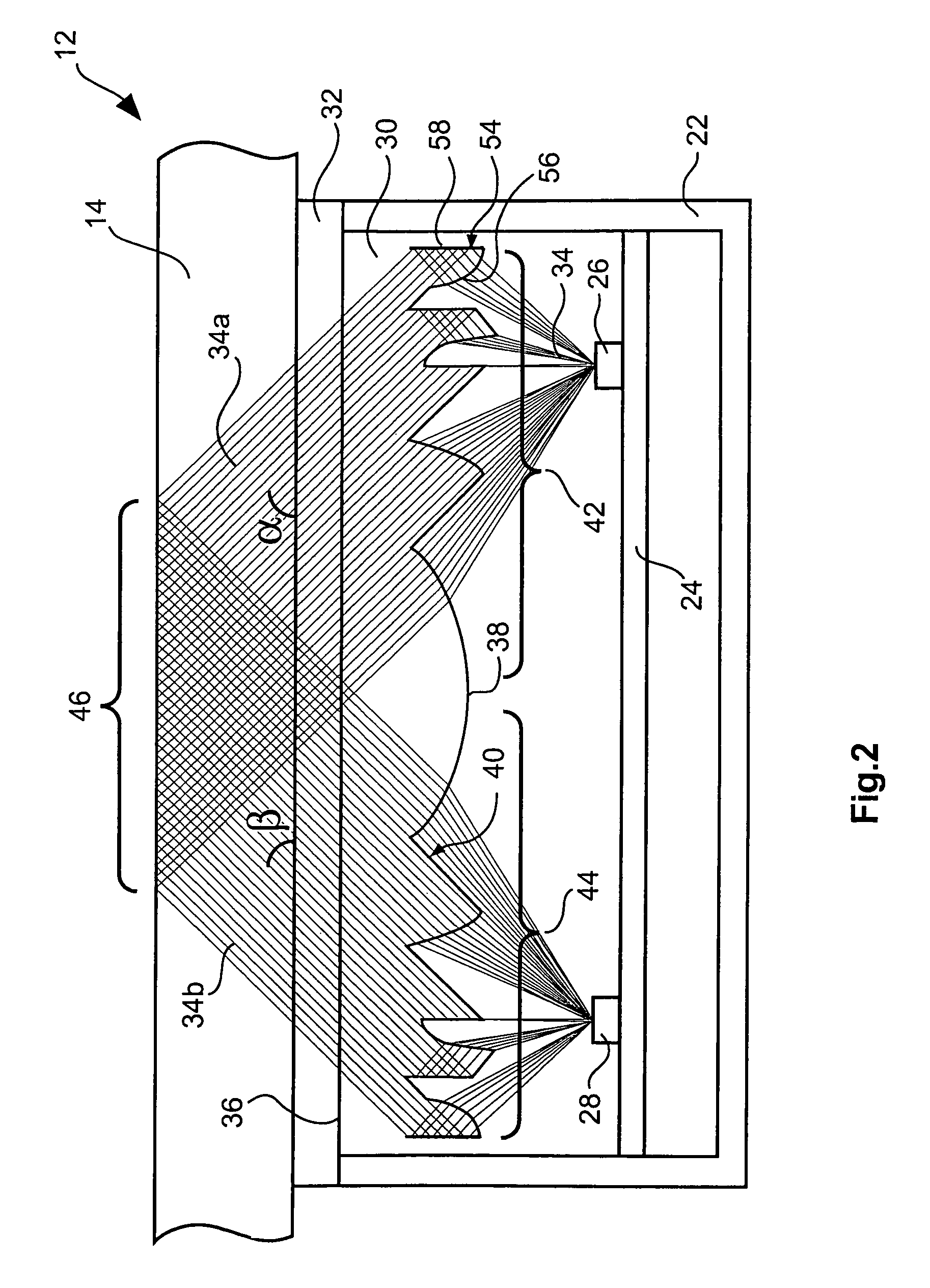

Rain sensor mounting system

InactiveUS6968736B2Economic and convenience and flexibility benefitLarge range of motionPayment architectureVehicle cleaningComputer moduleRain sensor

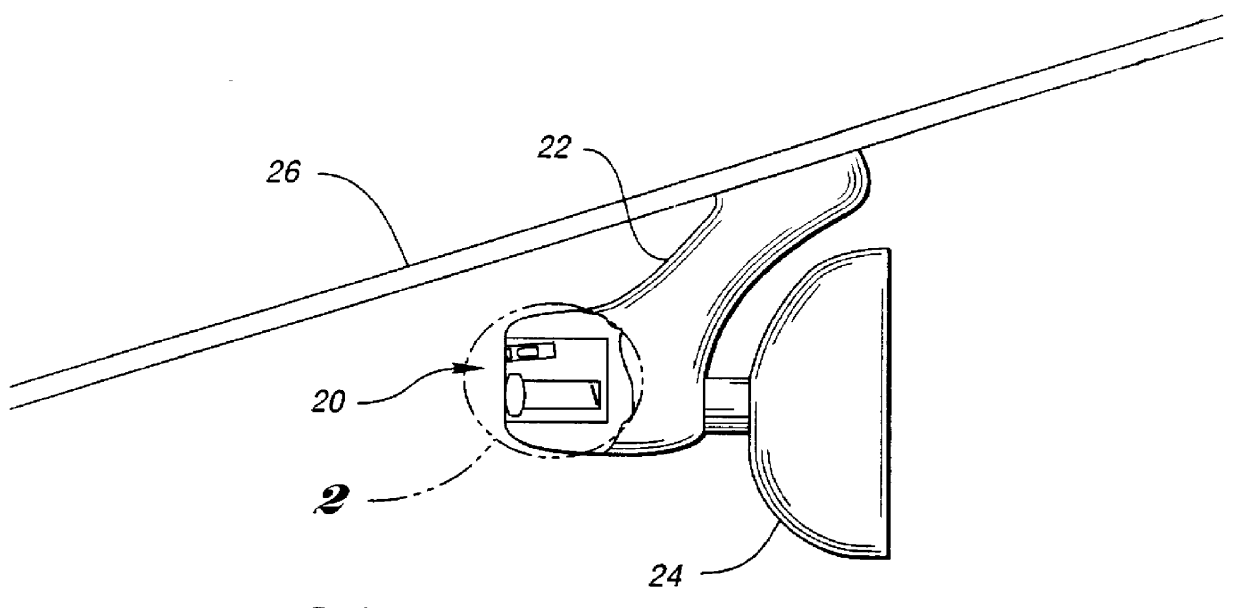

A vehicular rain sensor mounting system comprises a module assembly adapted for attachment to an attachment member on the inner surface of a vehicle windshield. The module assembly comprises a first side configured to be generally adjacent the inner surface of the vehicle windshield and a second side generally opposing the first side. A rearview mirror assembly mounting member is provided at the second side. The system further comprises a rearview mirror assembly having a mirror mount adapted for attachment to the rearview mirror assembly mounting member provided at the second side of the module assembly. The module assembly includes a rain sensor having a detecting surface. The detecting surface of the rain sensor contacts the inner surface of the windshield when the module assembly is attached to the attachment member on the inner surface of the vehicle windshield.

Owner:DONNELLY CORP

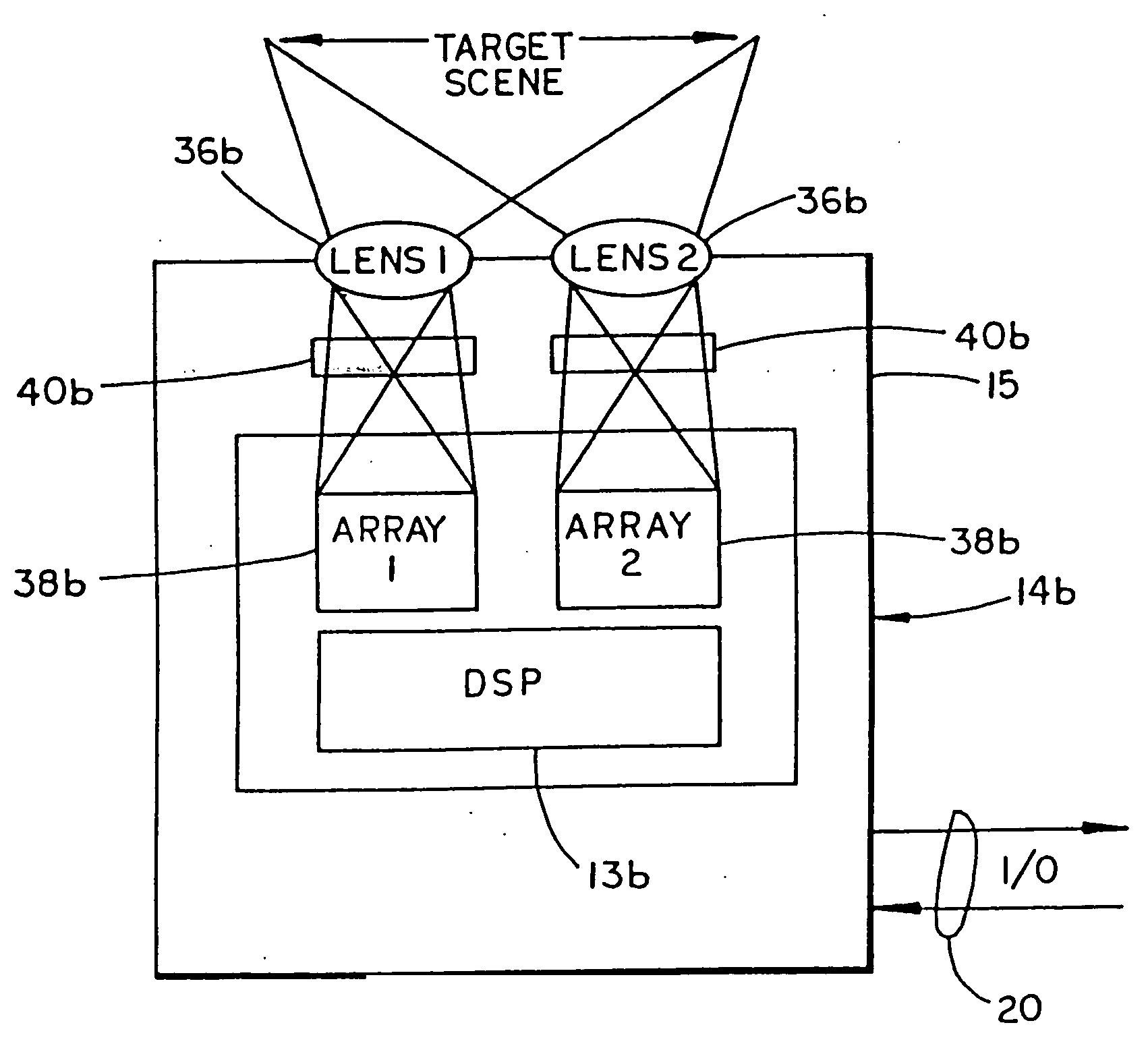

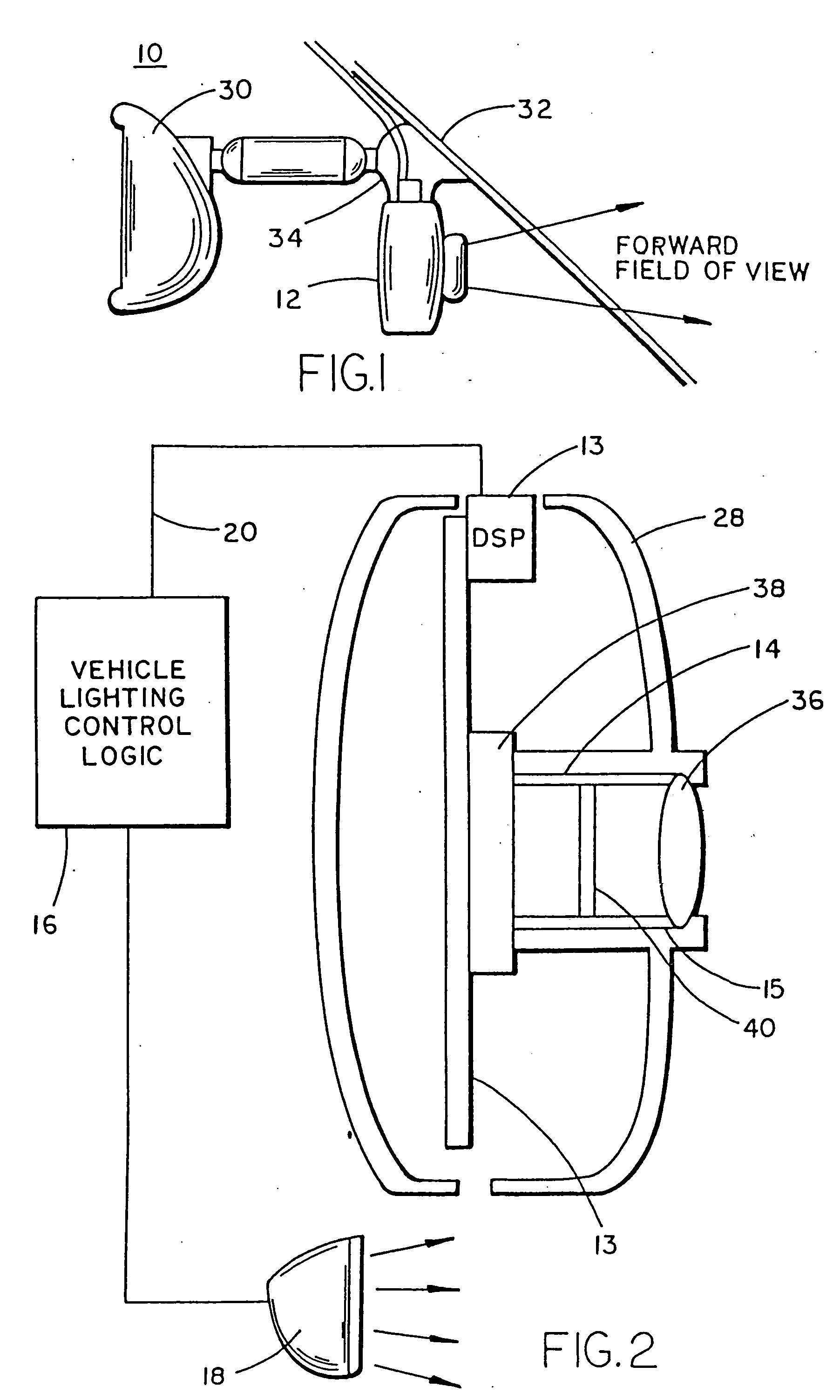

Image processing system to control vehicle headlamps or other vehicle equipment

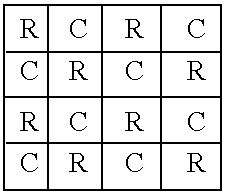

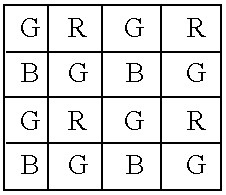

InactiveUS6631316B2Reduce complexityLow costTelevision system detailsDigital data processing detailsImaging processingComputer graphics (images)

An imaging system of the invention includes an image array sensor including a plurality of pixels. Each of the pixels generate a signal indicative of the amount of light received on the pixel. The imaging system further includes an analog to digital converter for quantizing the signals from the pixels into a digital value. The system further includes a memory including a plurality of allocated storage locations for storing the digital values from the analog to digital converter. The number of allocated storage locations in the memory is less than the number of pixels in the image array sensor. According to another embodiment, an imaging device includes an image sensor having a plurality pixels arranged in an array; and a multi-layer interference filter disposed over said pixel array, said multi-layer interference filter being patterned so as to provide filters of different colors to neighboring pixels or groups of pixels.

Owner:GENTEX CORP

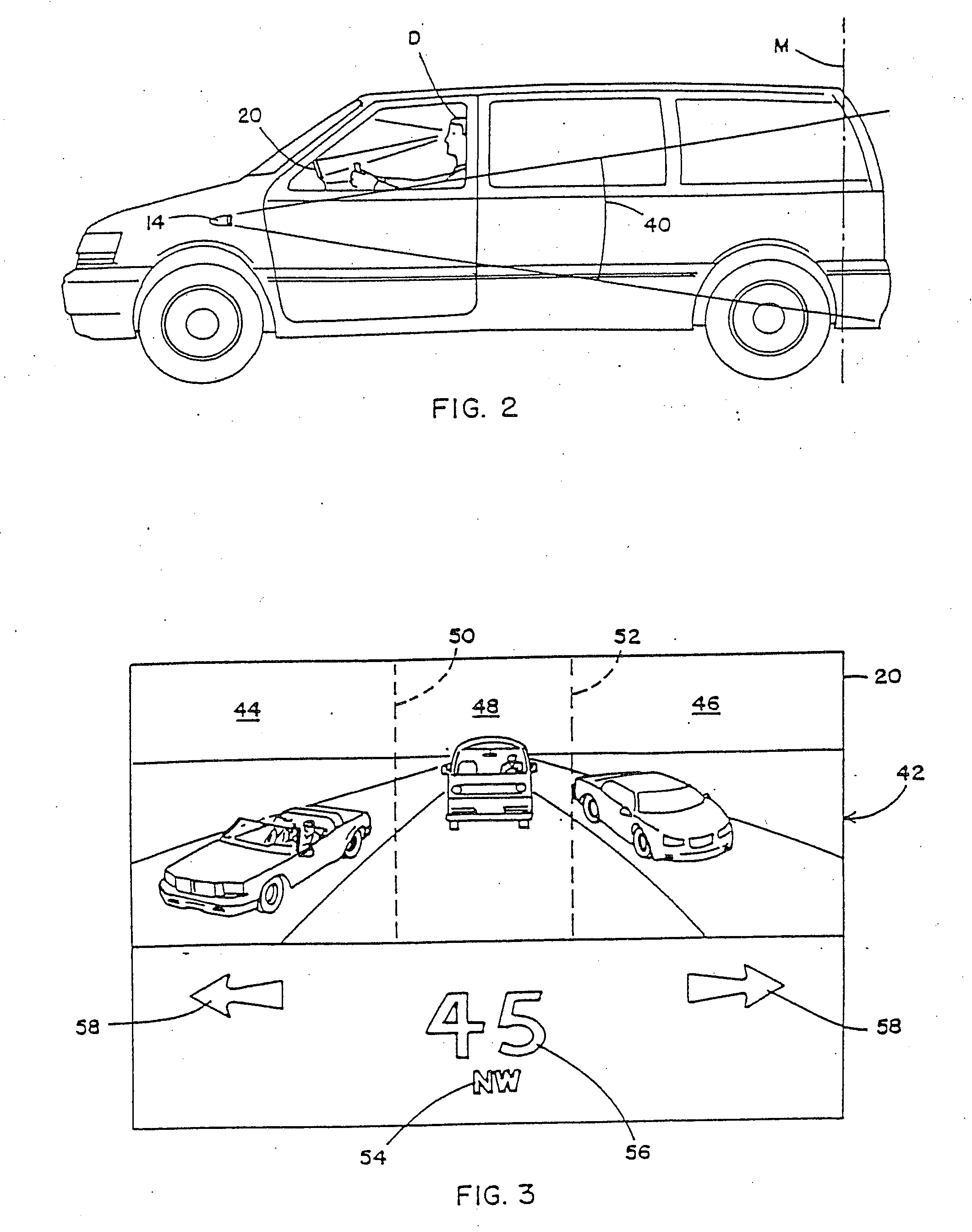

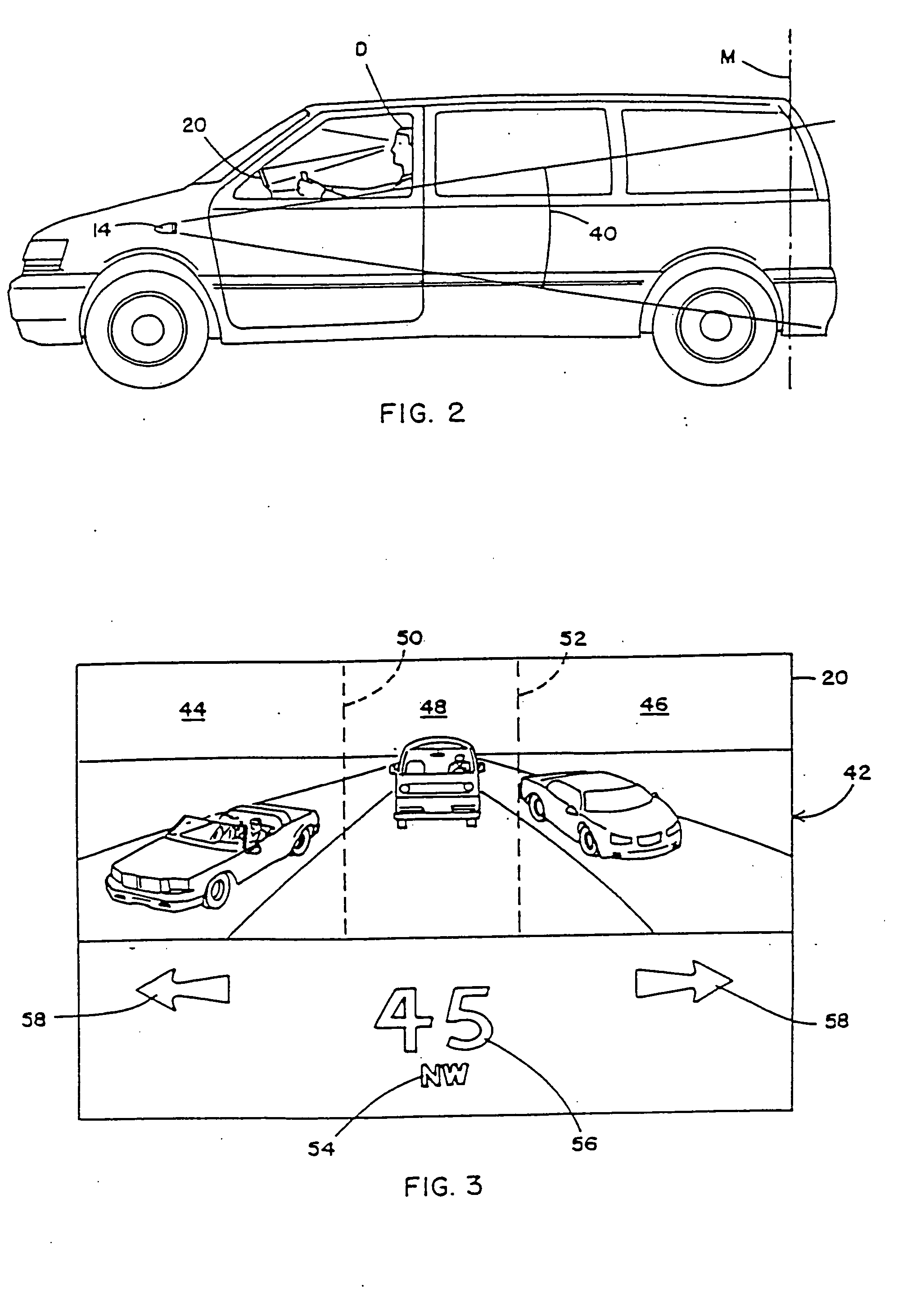

Image sensing system for a vehicle

InactiveUS20070120657A1Easy to explainRemove distortionVehicle seatsVehicle headlampsDriver/operatorDisplay device

An image sensing system for a vehicle includes an imaging sensor and a logic and control circuit. The imaging sensor comprises a two-dimensional array of light sensing photosensor elements formed on a semiconductor substrate, and has a field of view exterior of the vehicle. The logic and control circuit comprises an image processor for processing image data derived from the imaging sensor. The image sensing system may generate an indication of the presence of an object within the field of view of the imaging sensor. Preferably, video images may be captured by said imaging sensor and may be displayed by a display device for viewing by the driver when operating the vehicle. The logic and control circuit may generate at least one control output, and the at least control output may control an enhancement of the video images.

Owner:DONNELLY CORP

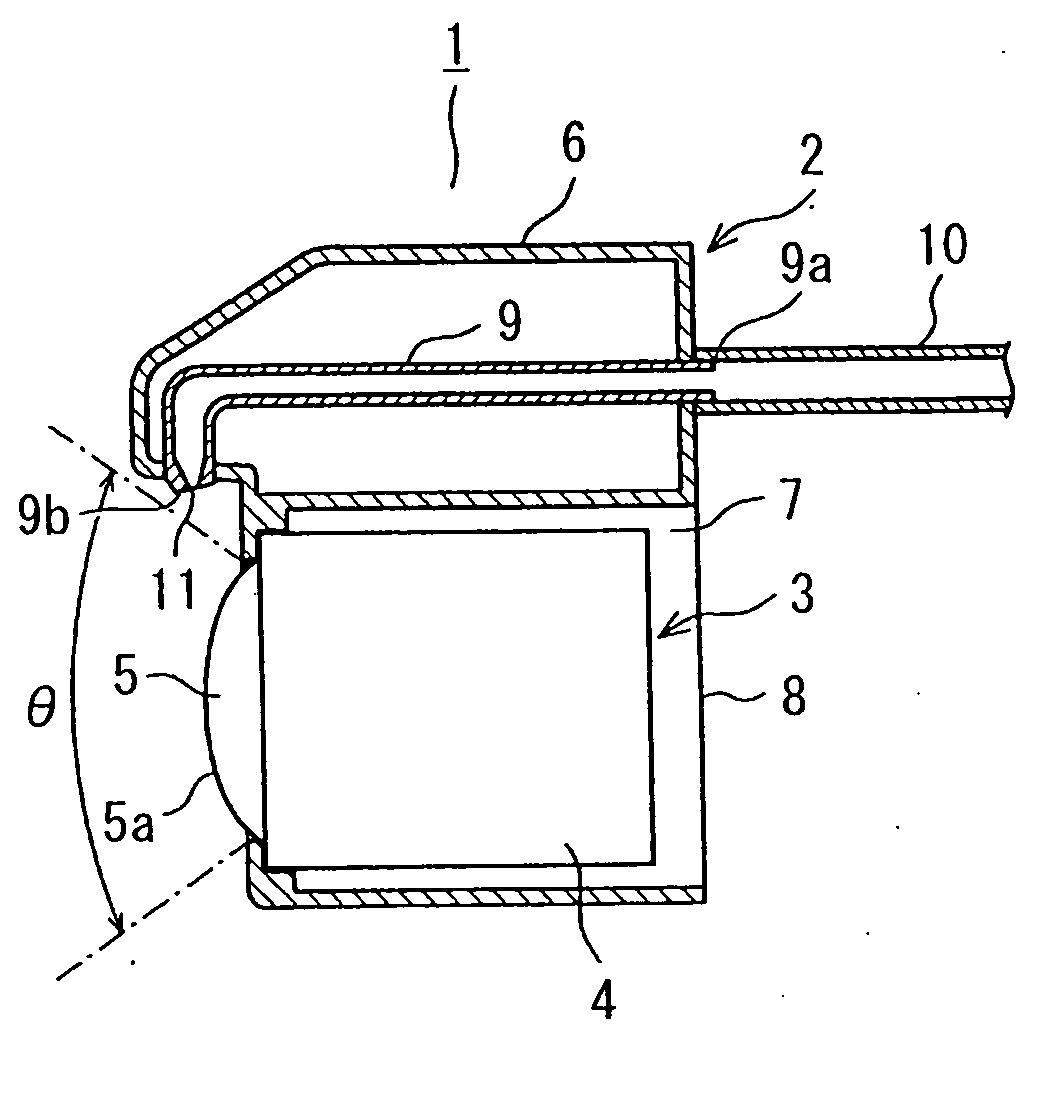

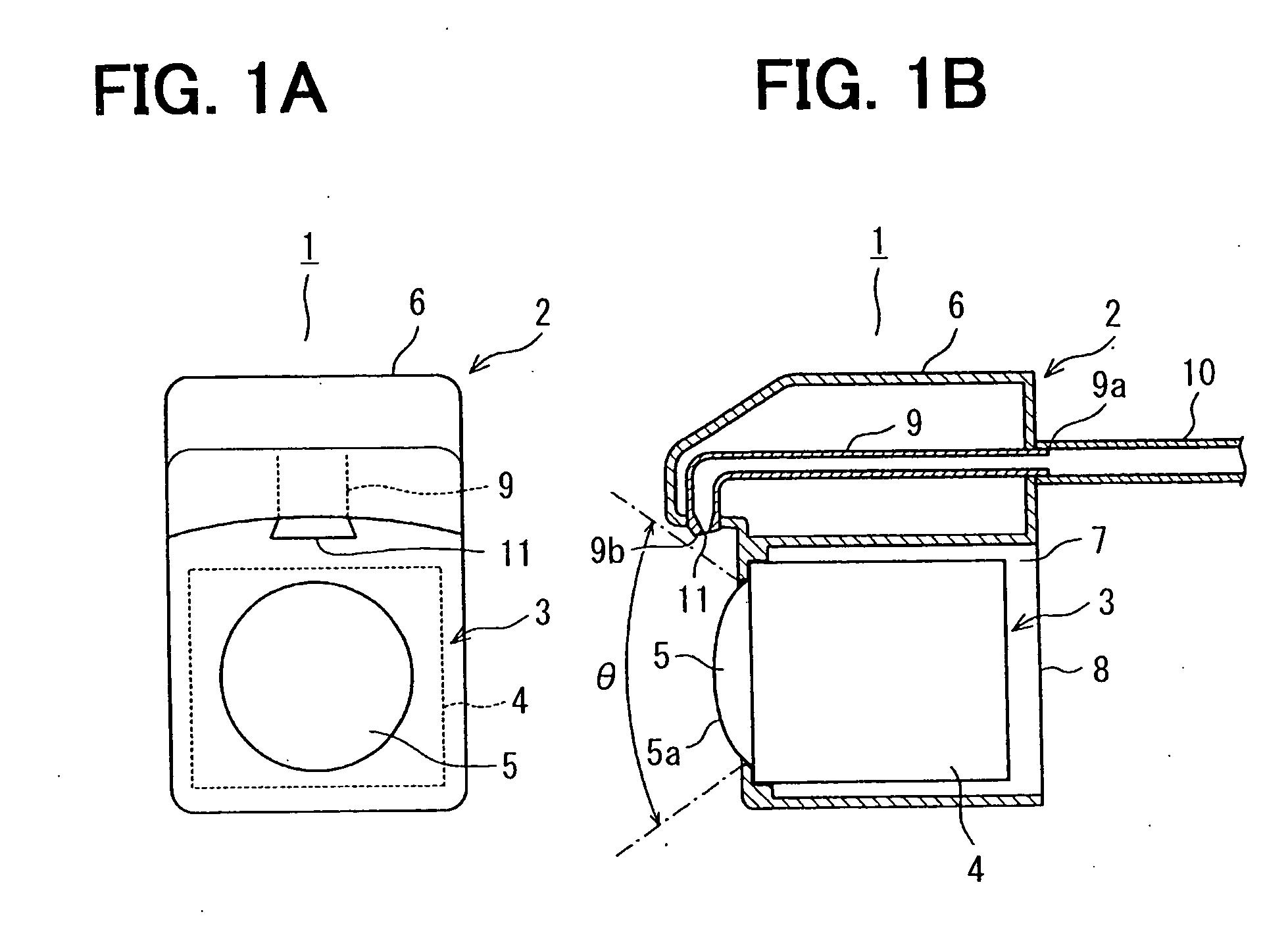

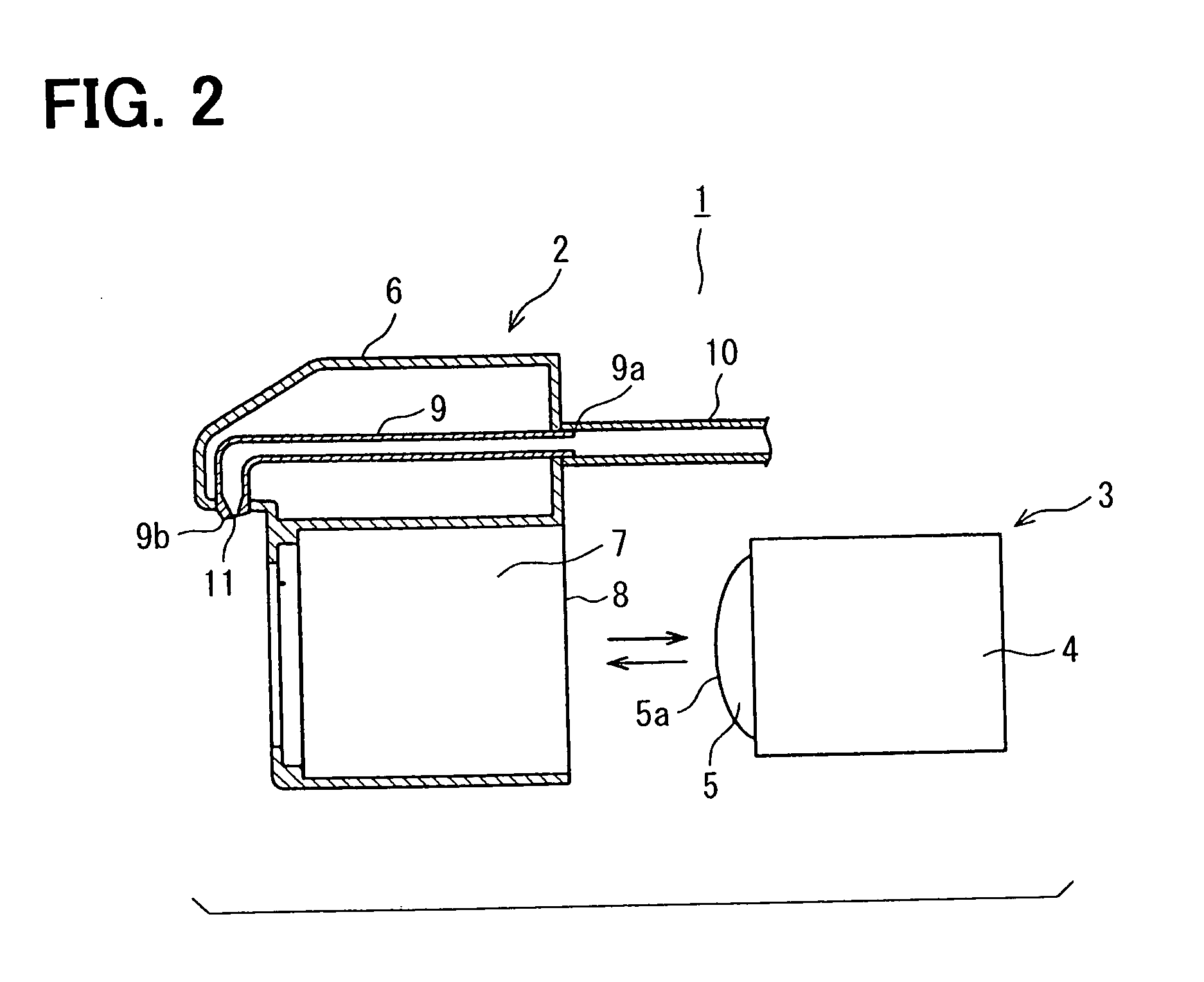

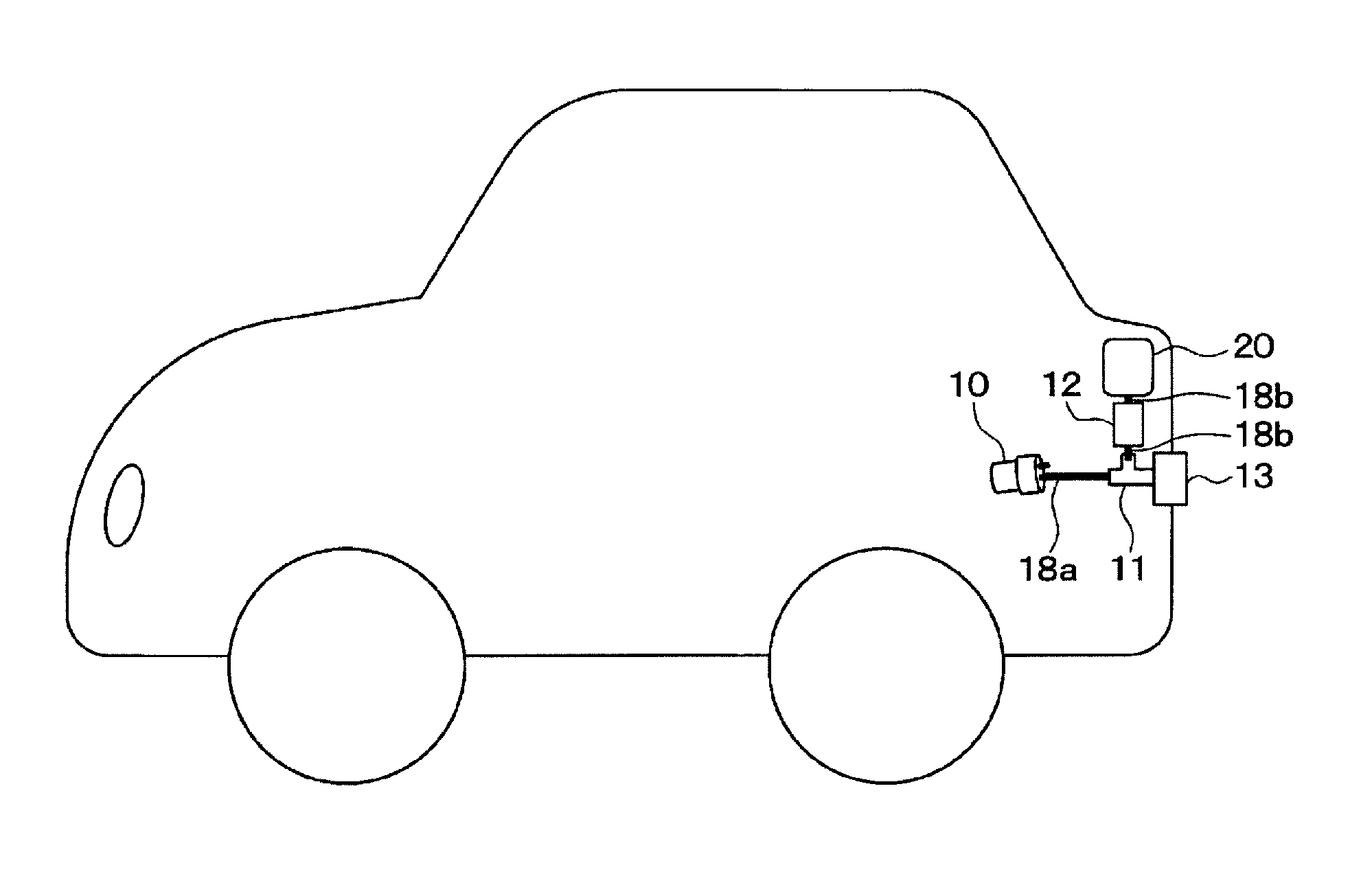

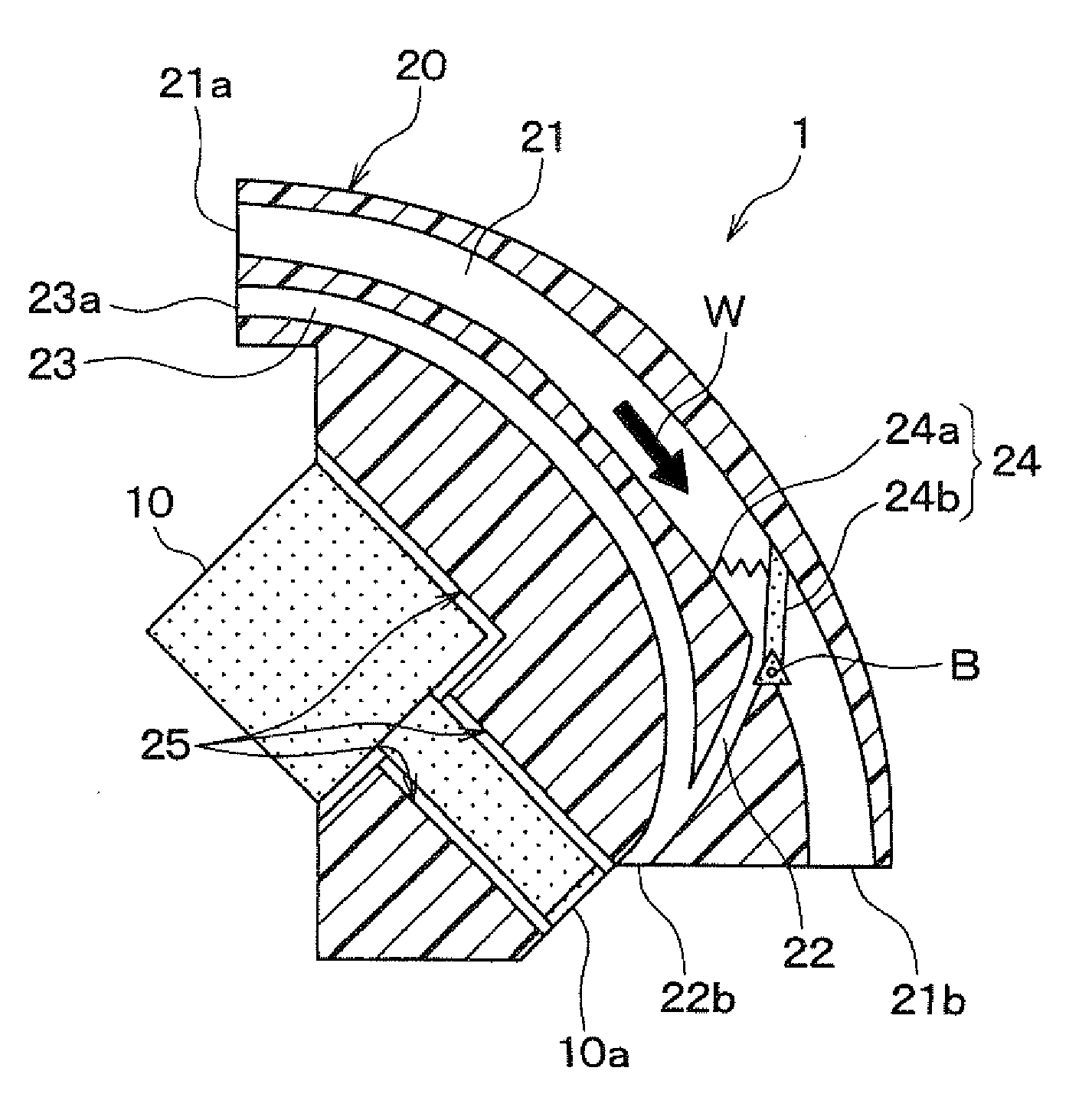

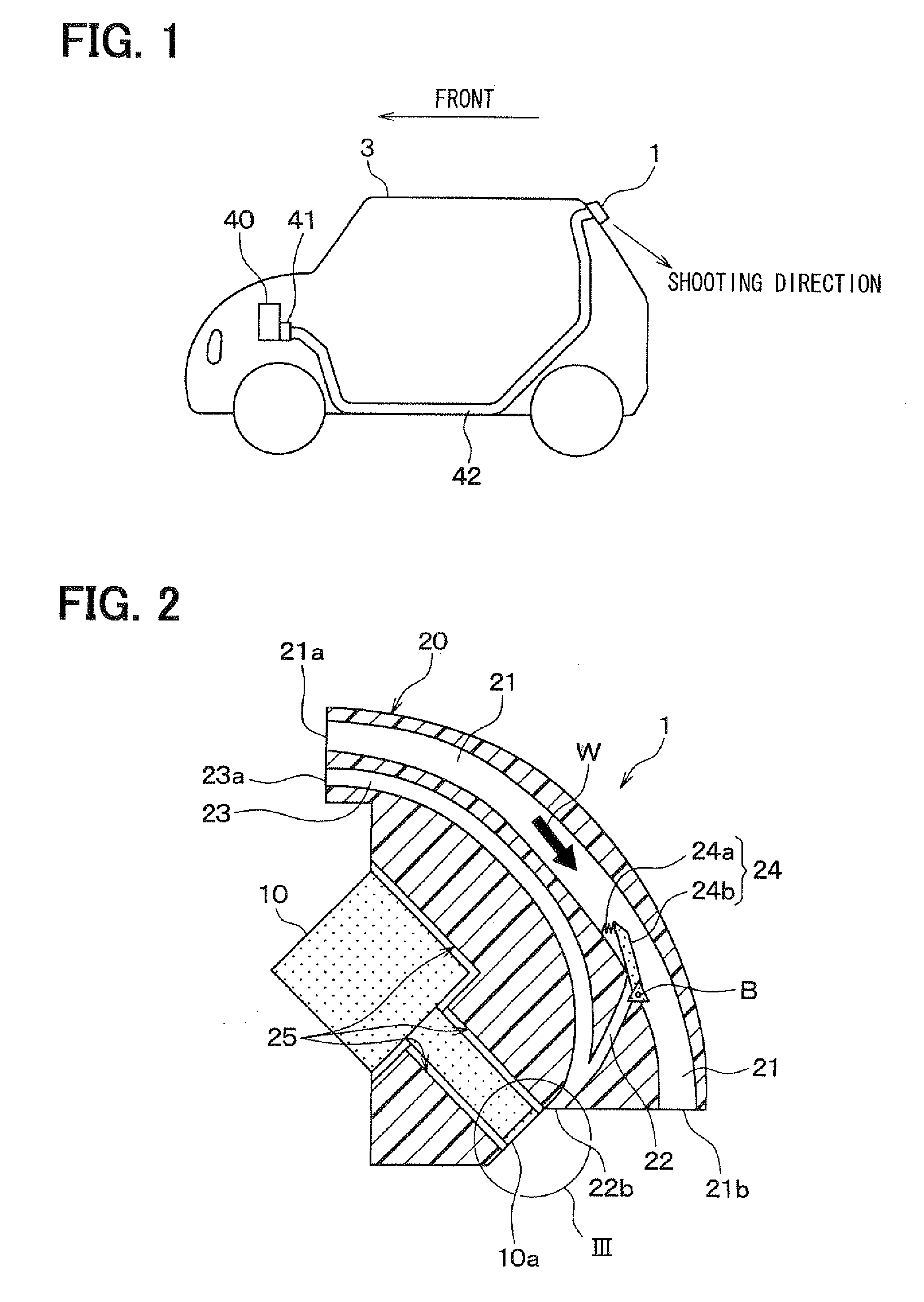

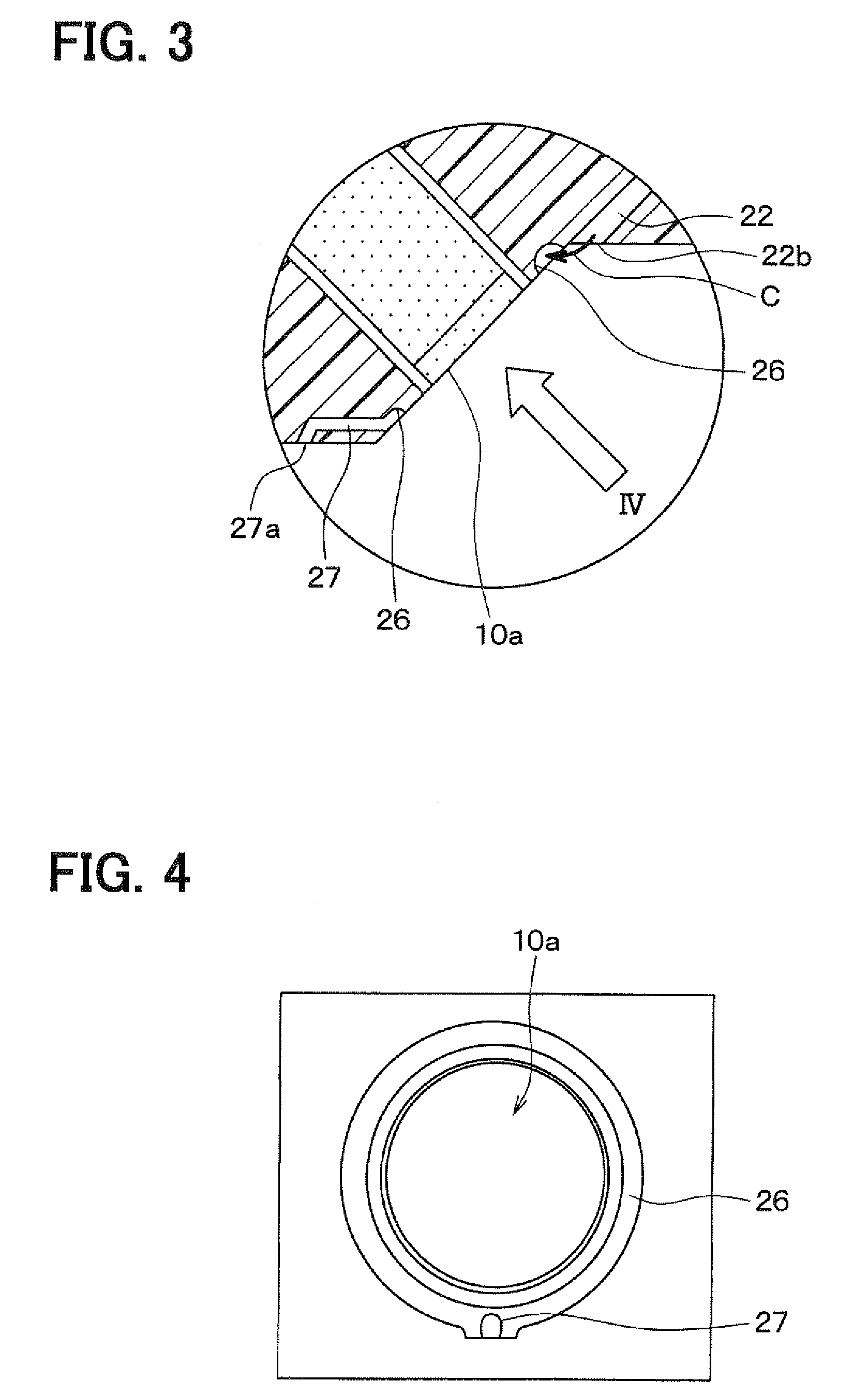

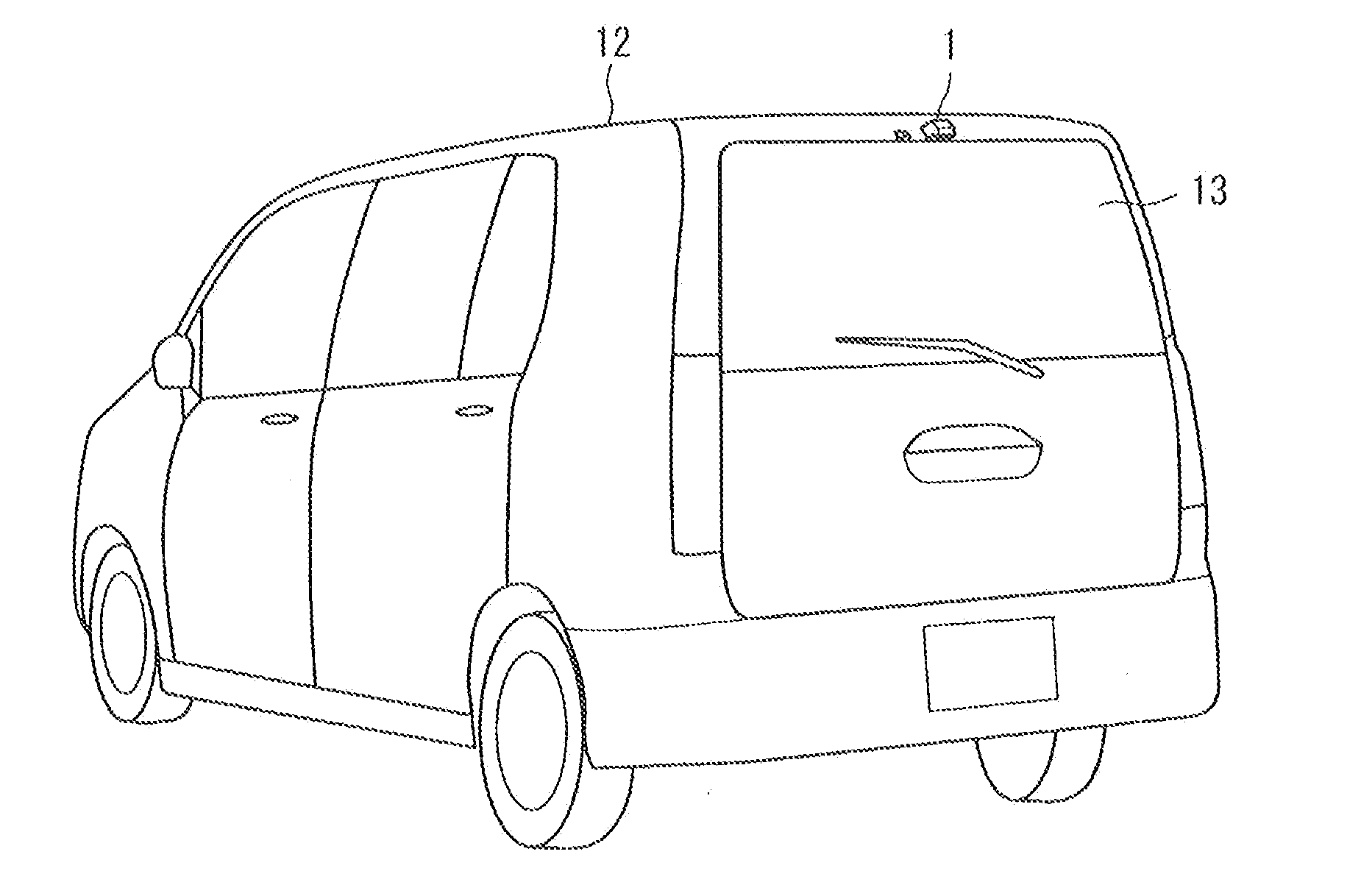

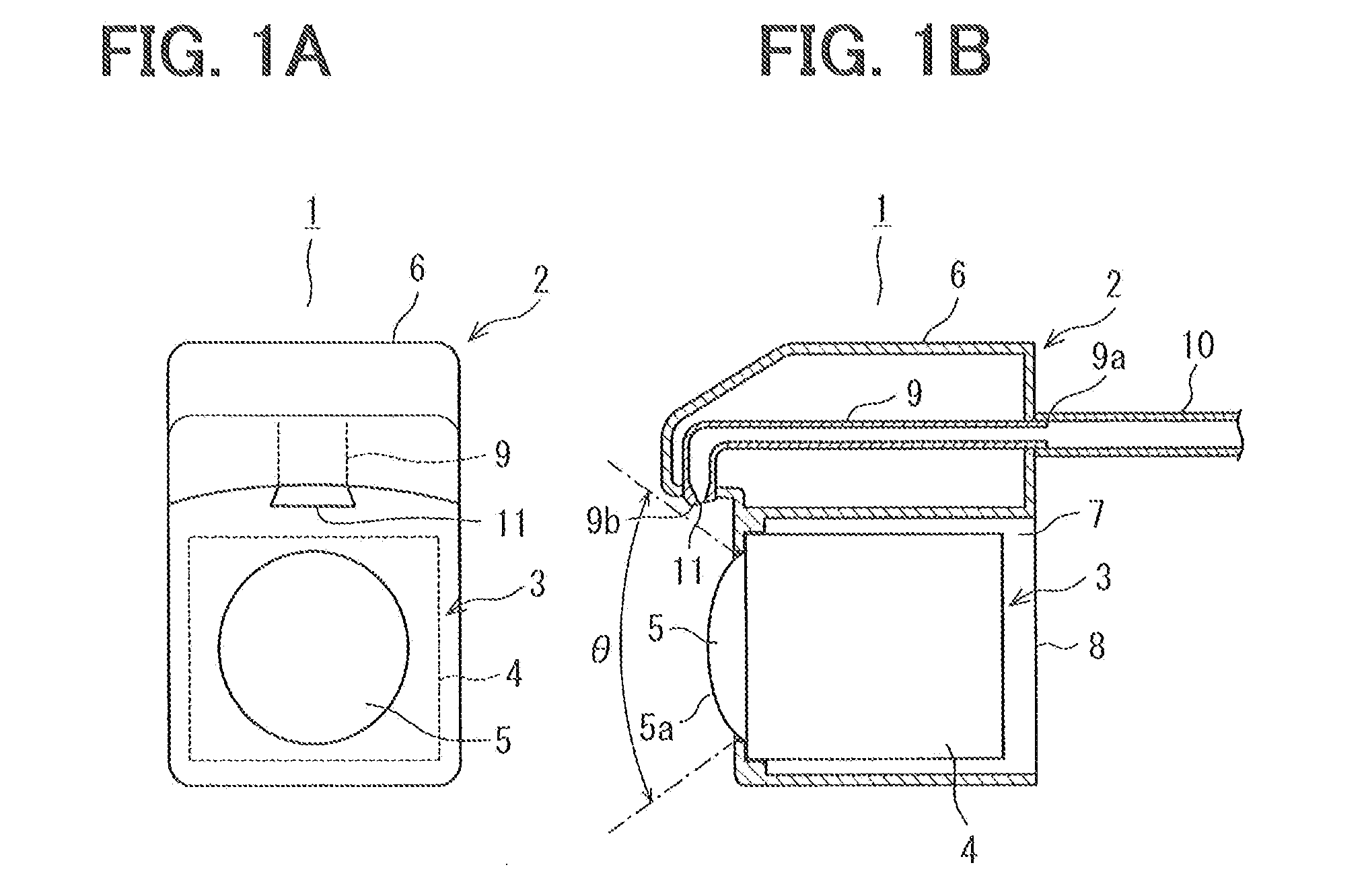

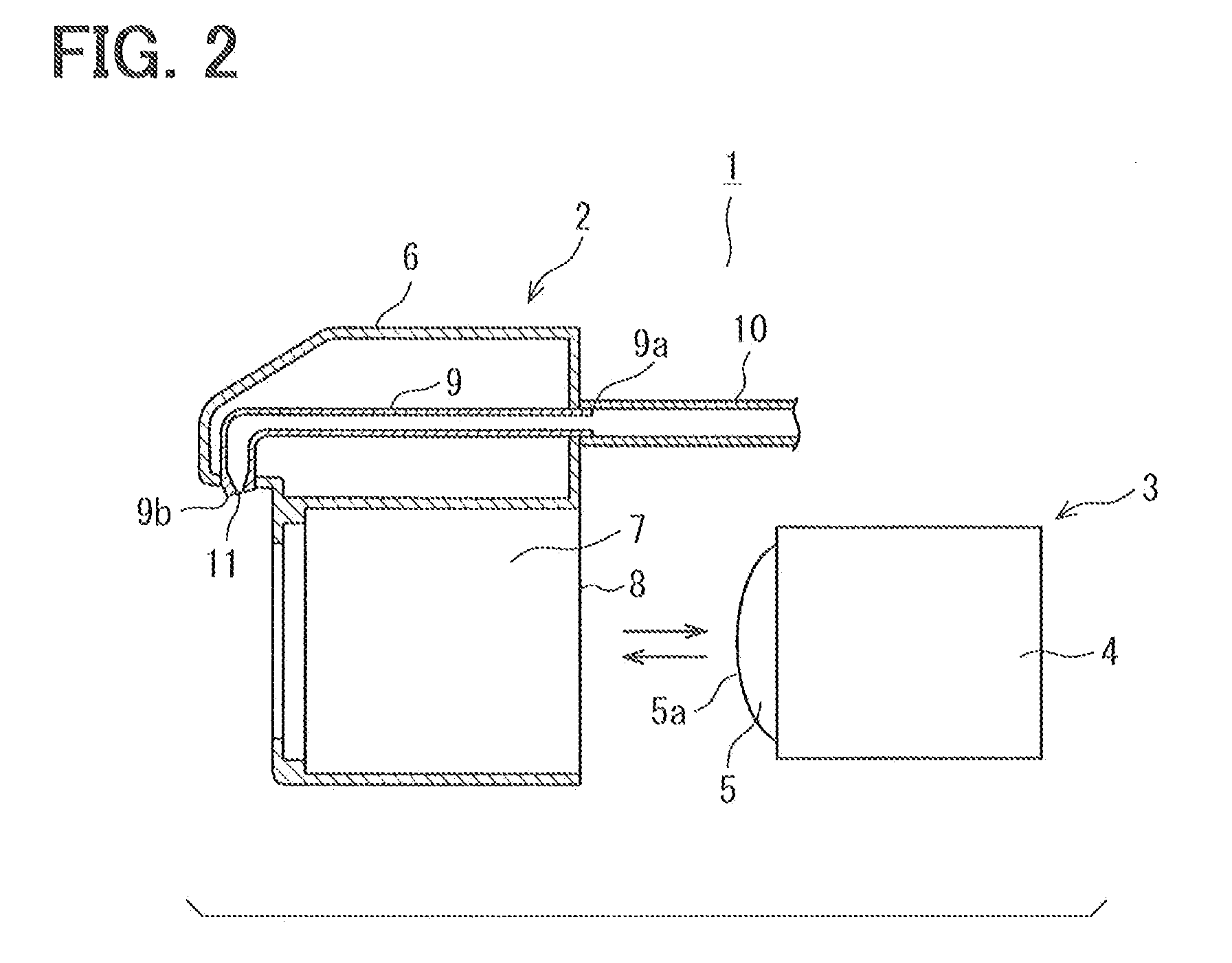

On-board optical sensor cover and on-board optical apparatus

An on-board optical sensor apparatus includes an optical sensor, an optical sensor cover, and a controller. The optical sensor has a lens. The optical sensor cover includes a holder and a washer nozzle. The holder holds the optical sensor. The washer nozzle performs a washing operation to wash a lens surface of the lens of the optical sensor or a glass surface of a cover glass located facing the lens by spraying a washer fluid, supplied from a washer fluid tank, onto the lens surface or the glass surface. The controller controls the washing operation of the washer nozzle.

Owner:DENSO CORP

Image sensing system for a vehicle

InactiveUS20070109406A1Easy to explainRemove distortionVehicle seatsVehicle headlampsLight sensingControl circuit

An image sensing system for a vehicle includes an imaging sensor comprising a two-dimensional array of light sensing photosensor elements. The system includes a logic and control circuit comprising an image processor for processing image data derived from the imaging sensor. The logic and control circuit generates at least one control output for controlling at least one accessory of the vehicle. The imaging sensor is disposed at an interior portion of the cabin of the vehicle and preferably has a field of view exterior of the vehicle through a window of the vehicle.

Owner:DONNELLY CORP

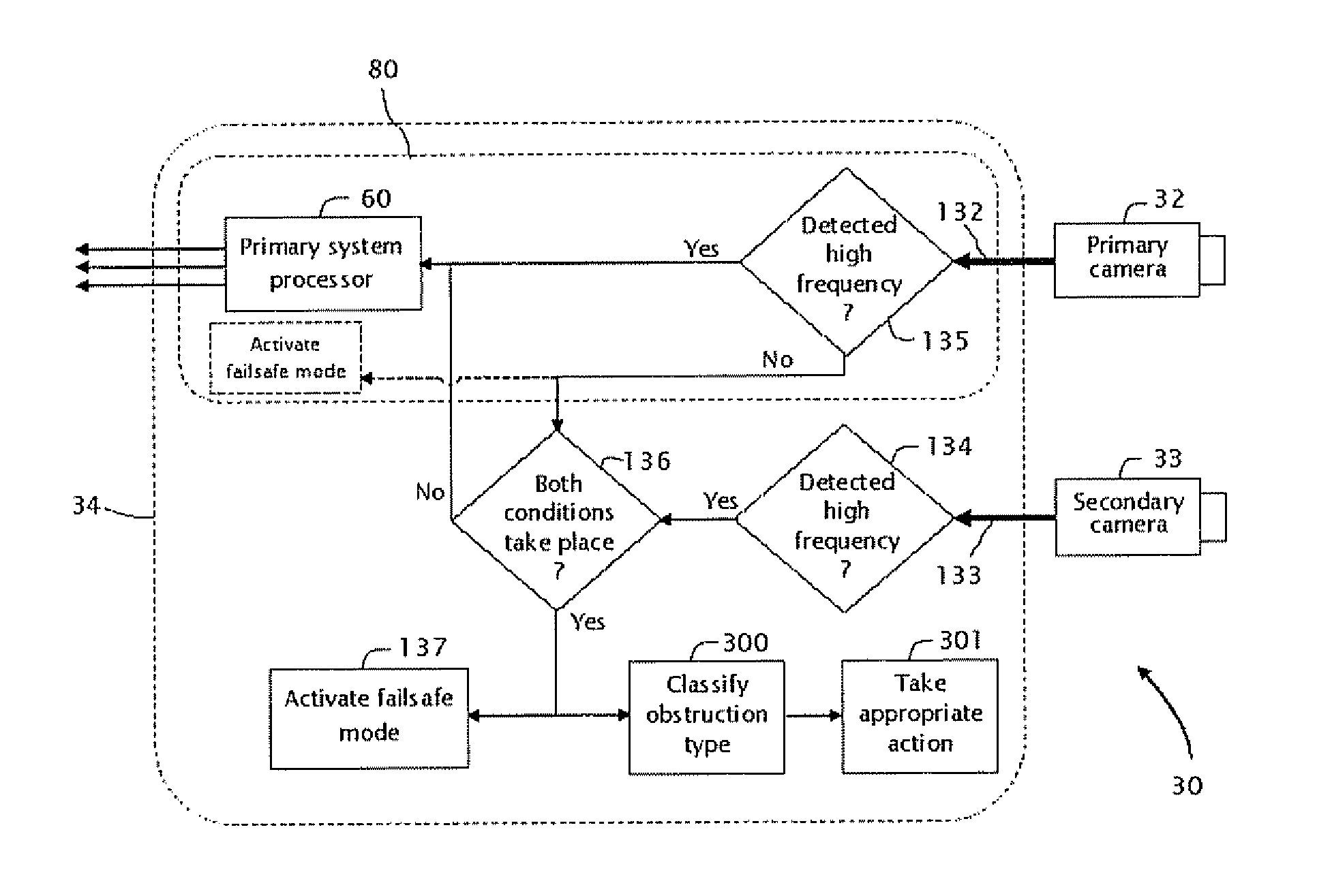

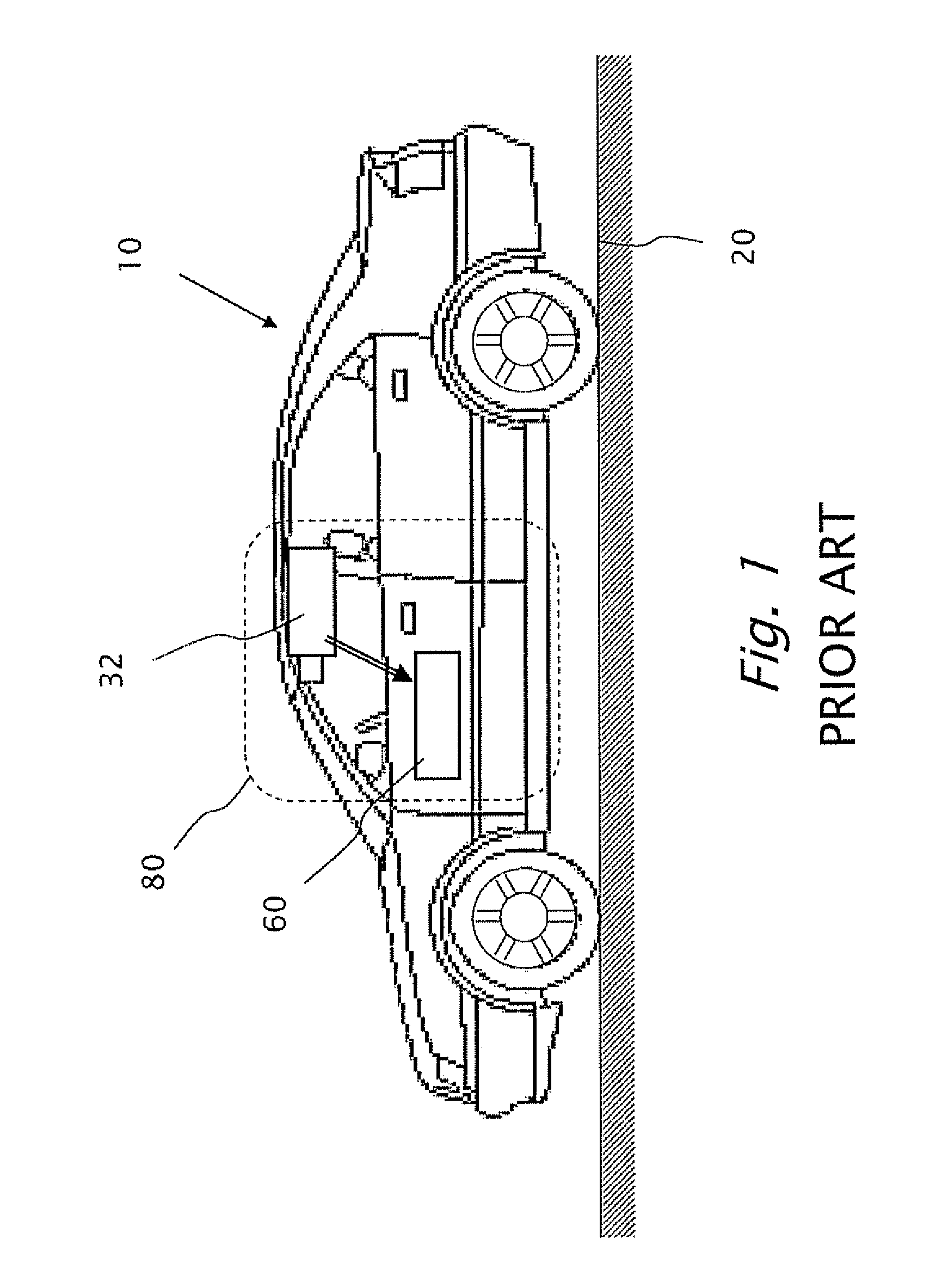

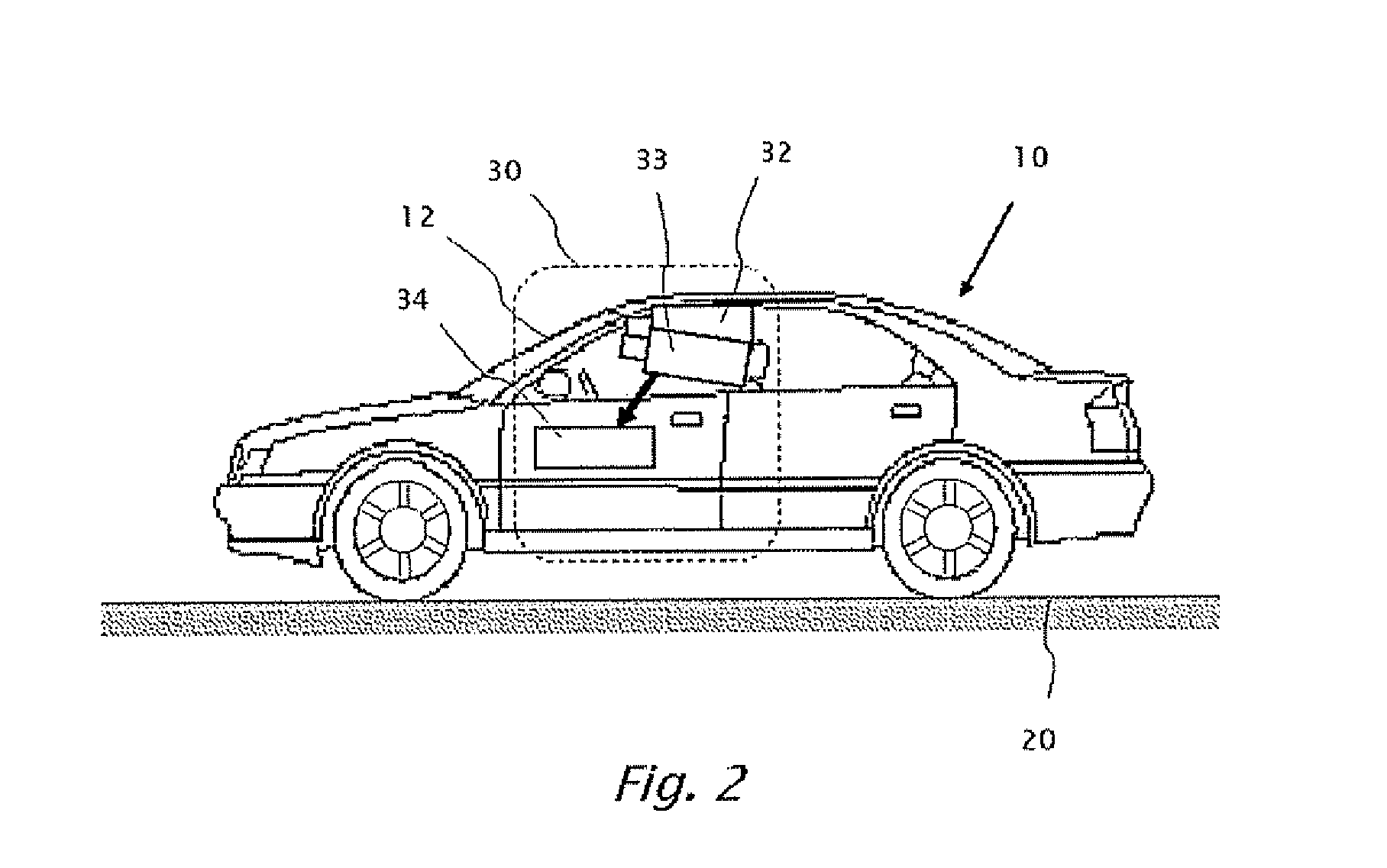

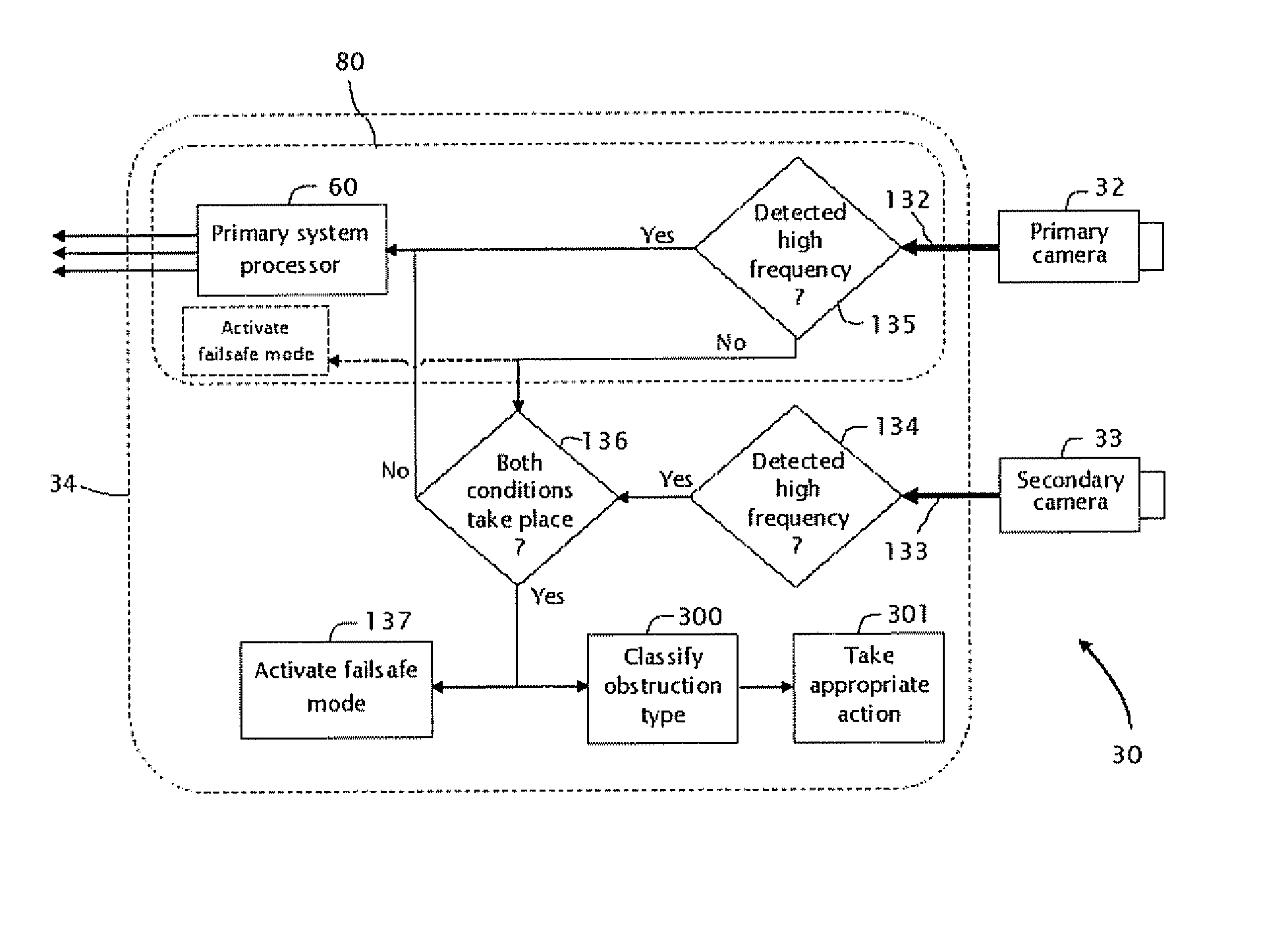

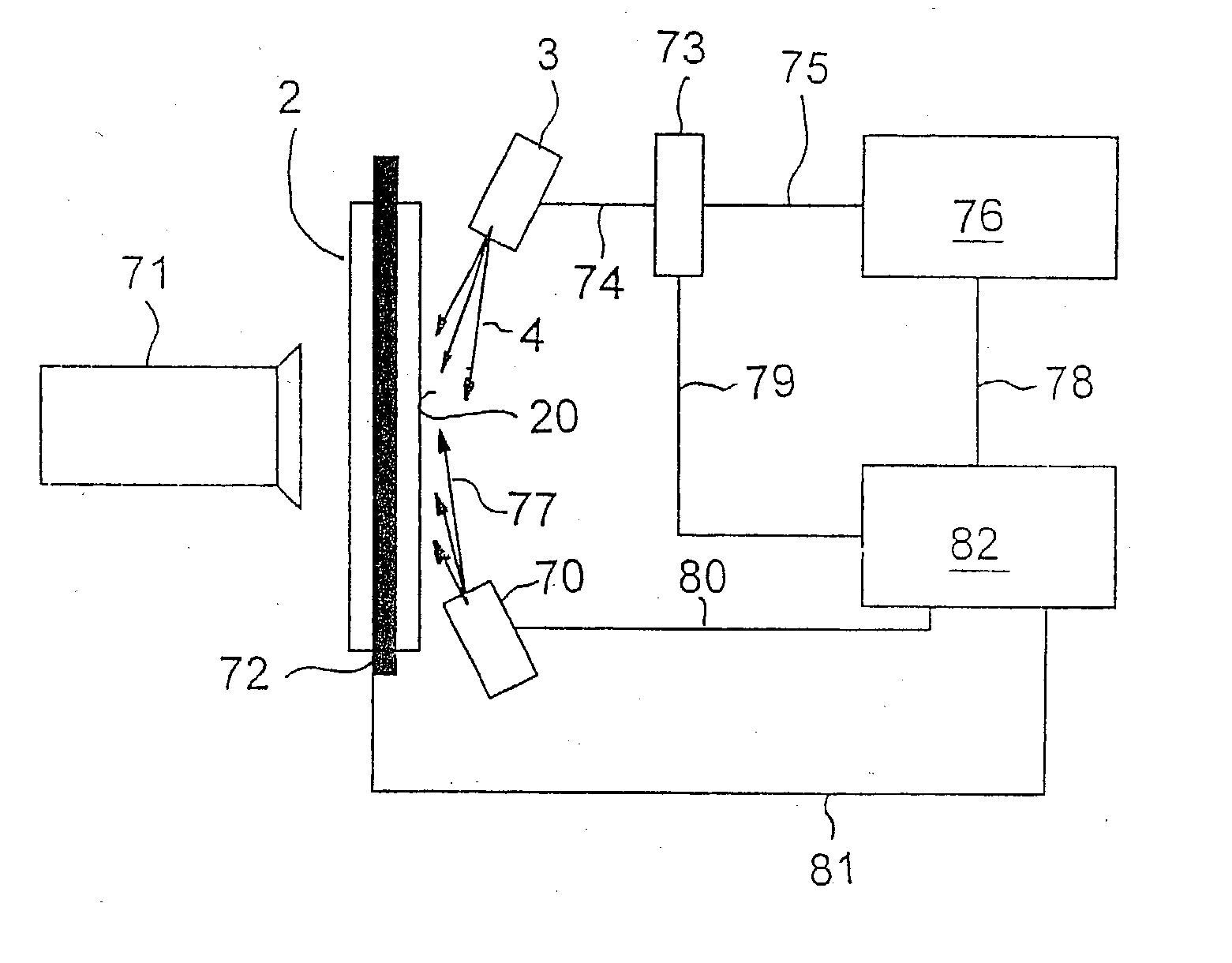

Systems and methods for detecting obstructions in a camera field of view

ActiveUS8553088B2Avoid identificationIncrease blockingVehicle headlampsCharacter and pattern recognitionField of viewImaging data

A system mounted on a vehicle for detecting an obstruction on a surface of a window of the vehicle, a primary camera is mounted inside the vehicle behind the window. The primary camera is configured to acquire images of the environment through the window. A secondary camera is focused on an external surface of the window, and operates to image the obstruction. A portion of the window, i.e. window region is subtended respectively by the field of view of the primary camera and the field of view of the secondary camera. A processor processes respective sequences of image data from both the primary camera and the secondary camera.

Owner:MOBILEYE VISION TECH LTD

Systems and methods for detecting obstructions in a camera field of view

ActiveUS20070115357A1Avoid identificationIncrease blockingVehicle headlampsCharacter and pattern recognitionField of viewImaging data

A system mounted on a vehicle for detecting an obstruction on a surface of a window of the vehicle, a primary camera is mounted inside the vehicle behind the window. The primary camera is configured to acquire images of the environment through the window. A secondary camera is focused on an external surface of the window, and operates to image the obstruction. A portion of the window, i.e. window region is subtended respectively by the field of view of the primary camera and the field of view of the secondary camera. A processor processes respective sequences of image data from both the primary camera and the secondary camera.

Owner:MOBILEYE VISION TECH LTD

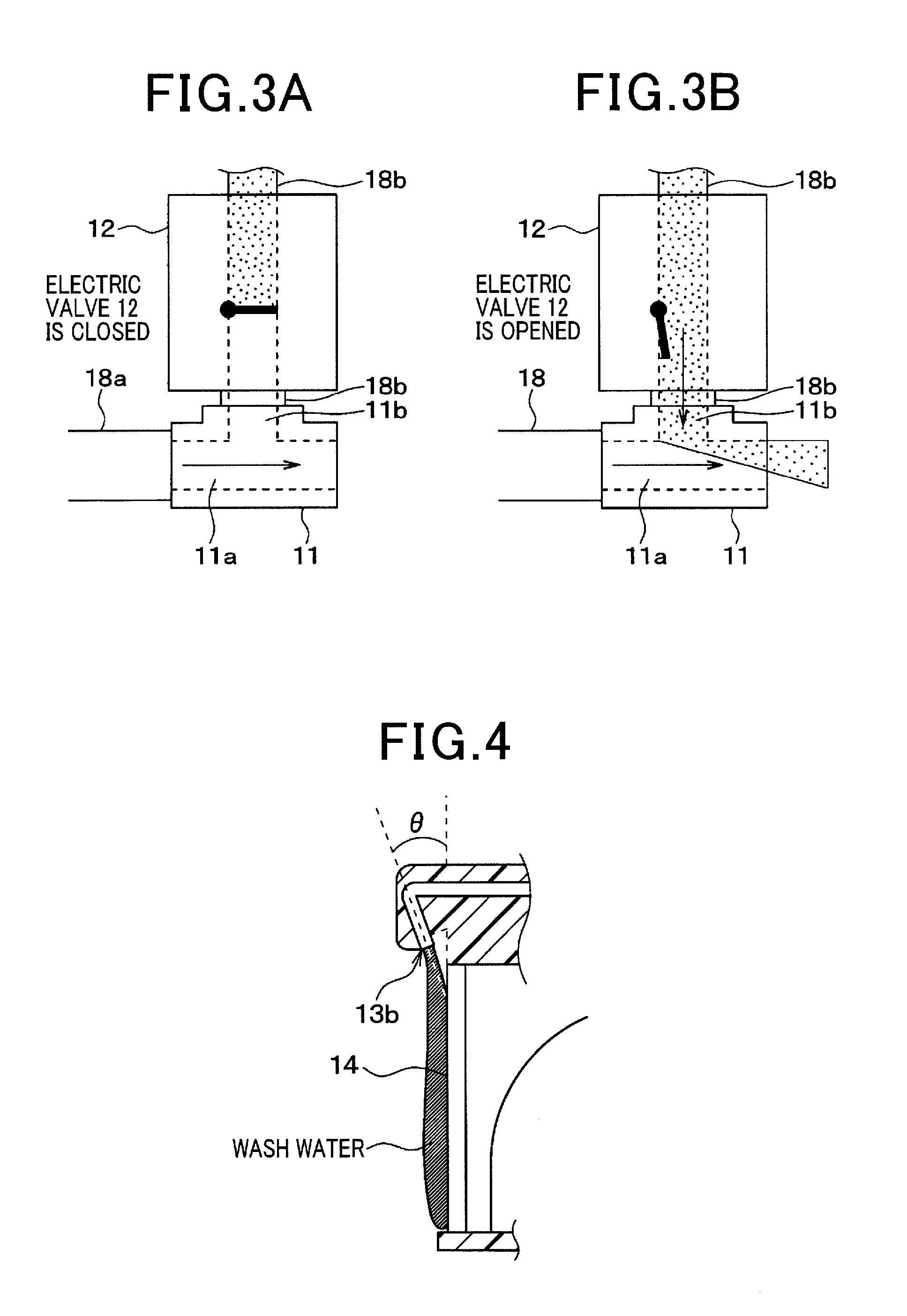

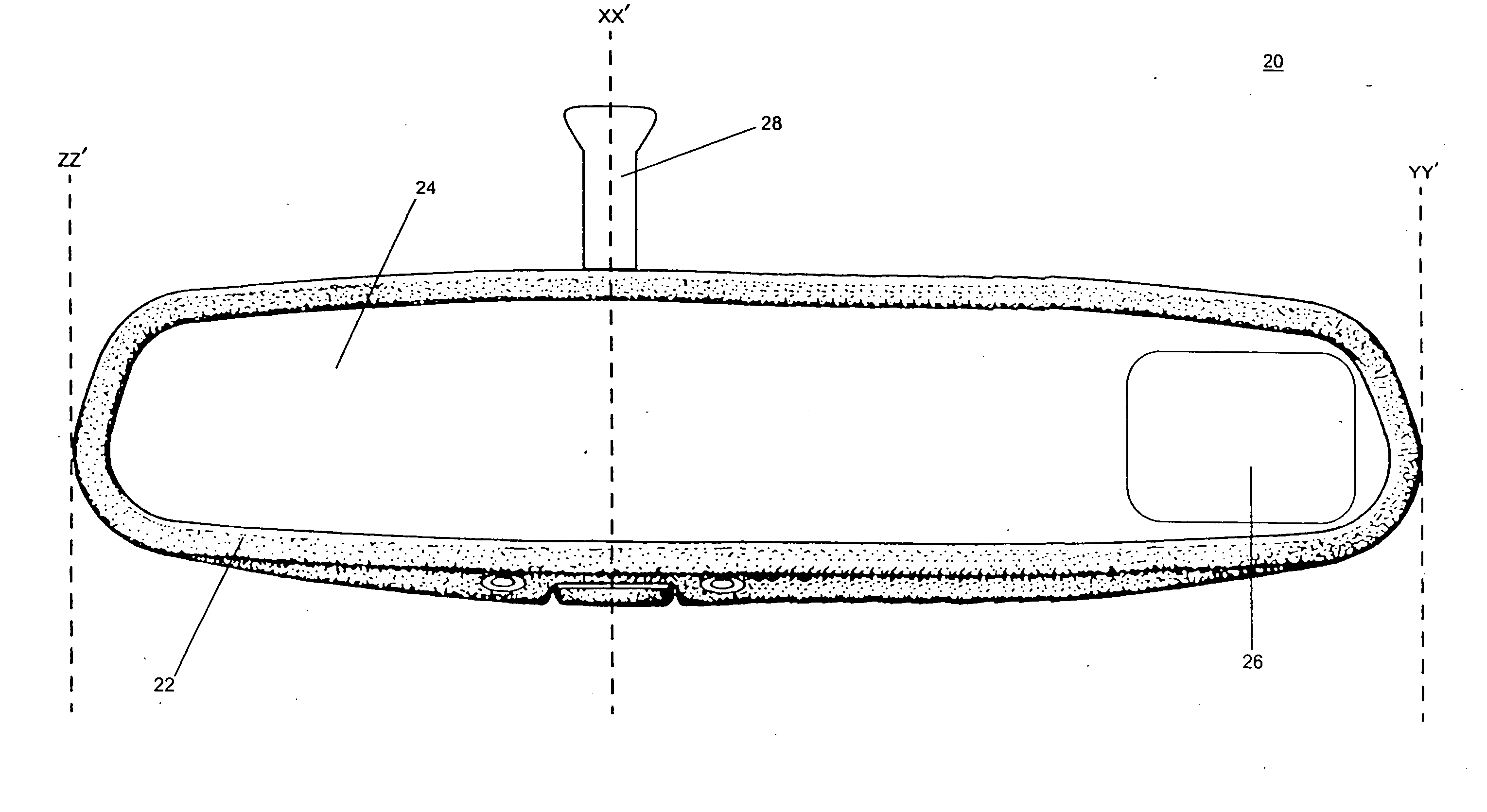

Video mirror system suitable for use in a vehicle

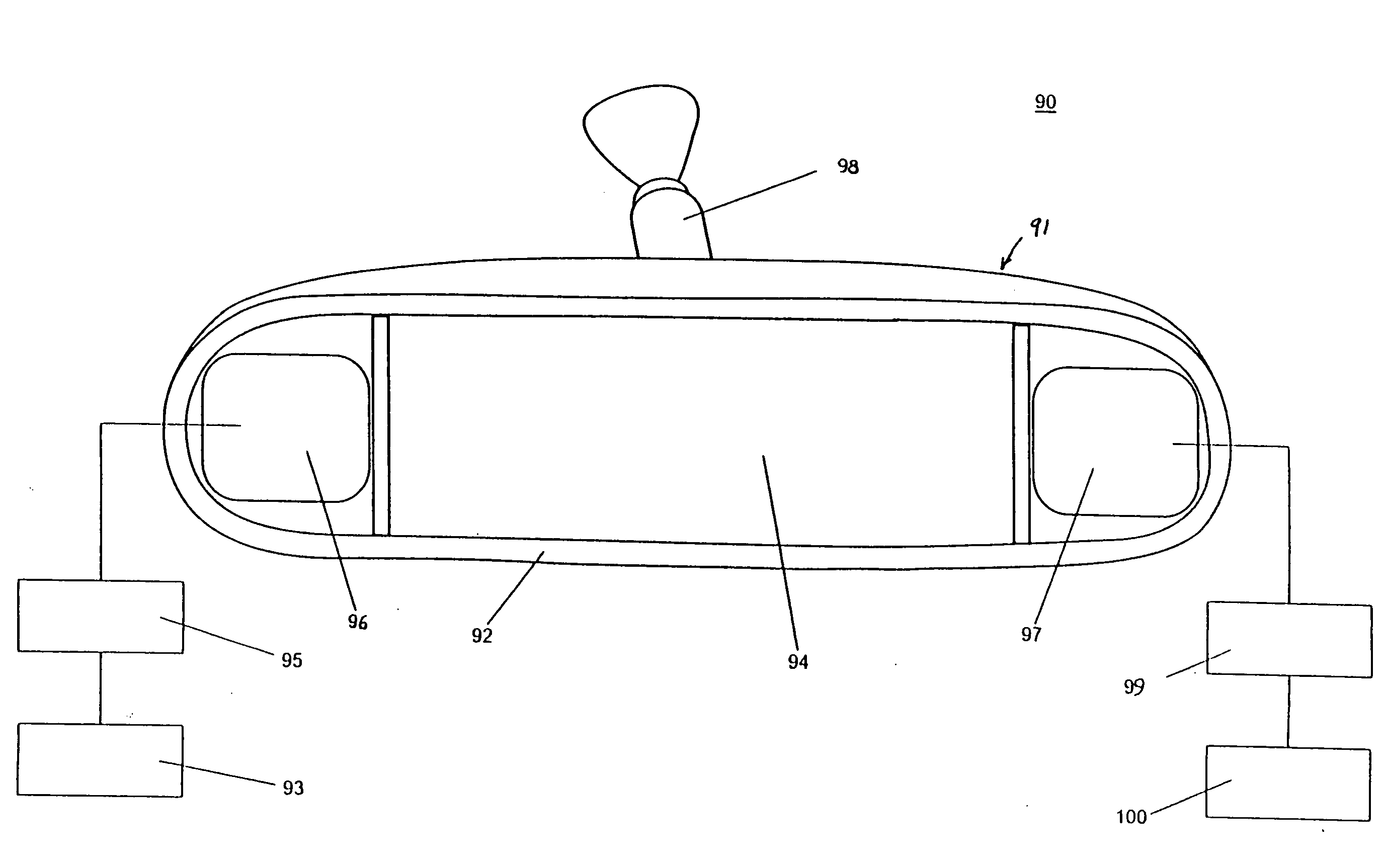

InactiveUS20070171037A1Maximizes rearward field of viewEasy to displayTelevision system detailsDashboard fitting arrangementsElectricityIn vehicle

A vehicular video mirror system comprises an interior electrochromic mirror having a transflective mirror reflector and a video screen disposed behind the mirror reflector so that its presence is substantially unobservable to a driver of the vehicle until the video screen is actuated to emit light that passes through the electrochromic reflective element to be viewed by the driver of the vehicle. Common control circuit circuitry may control dimming of the electrochromic medium and actuation of the video screen. The control circuitry may receive a signal indicative of selection of a reverse gear of the vehicle by the driver and actuates the video screen in order to display video images captured by a video imaging device disposed to the rear of the vehicle and having a field of view rearward of and external to the vehicle.

Owner:DONNELLY CORP

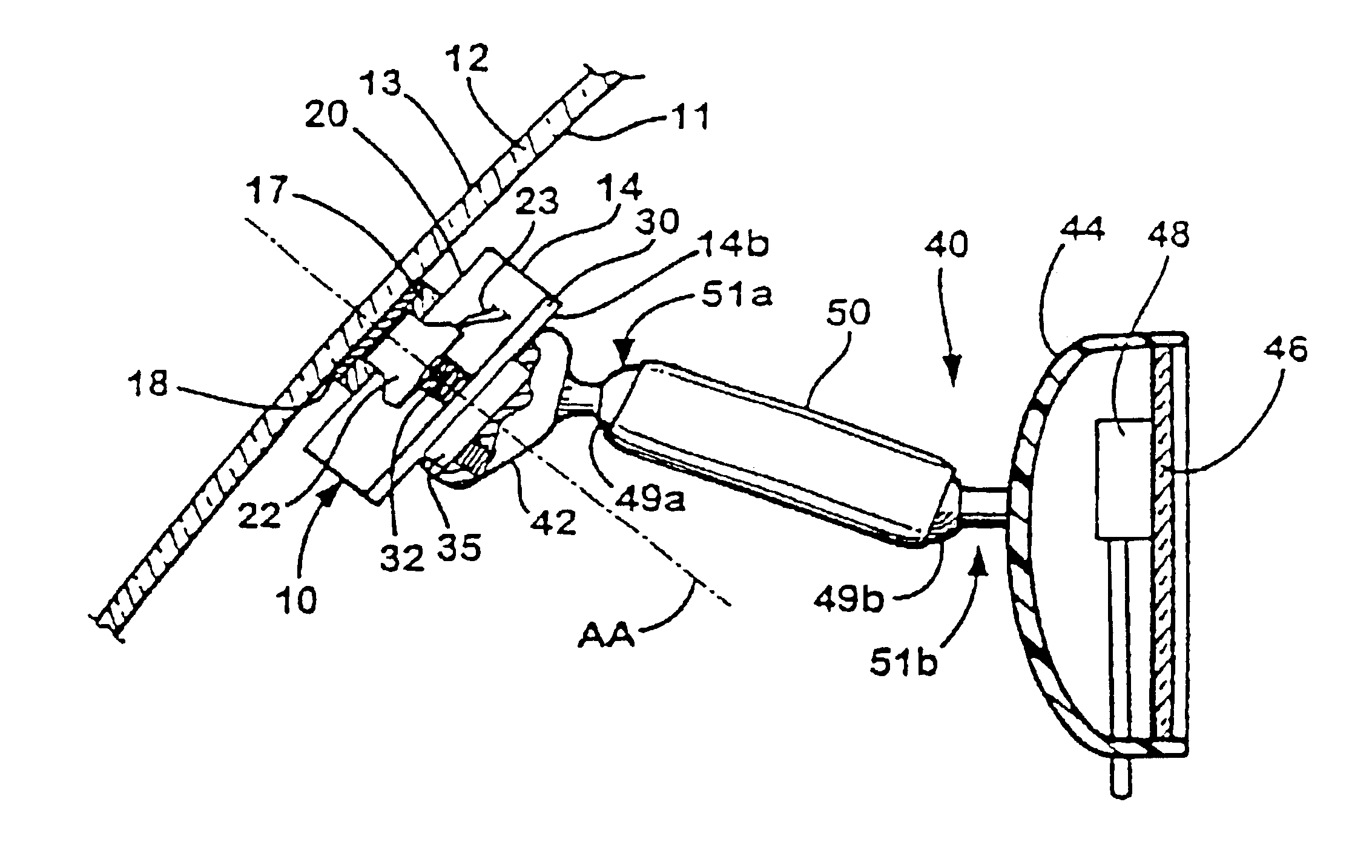

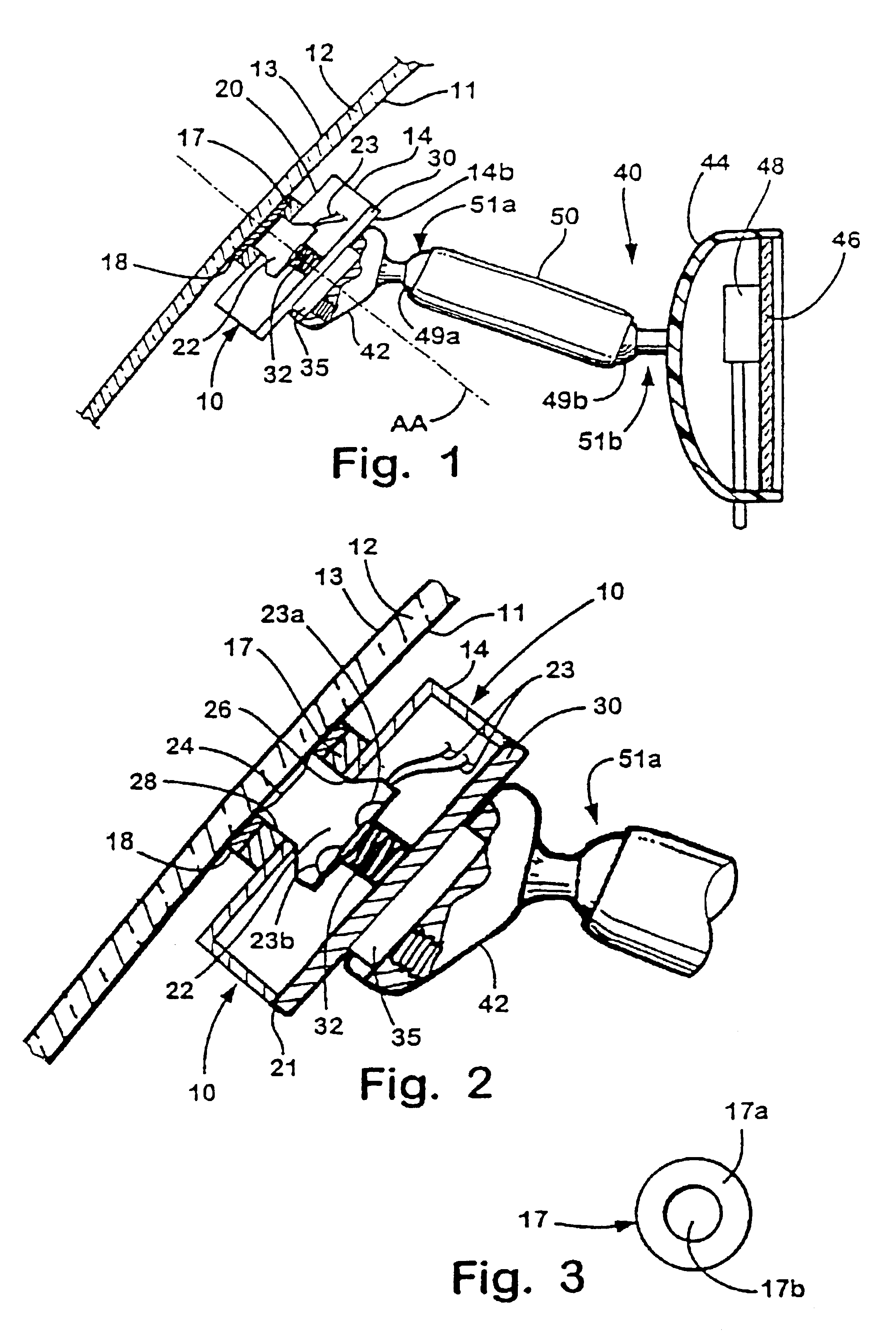

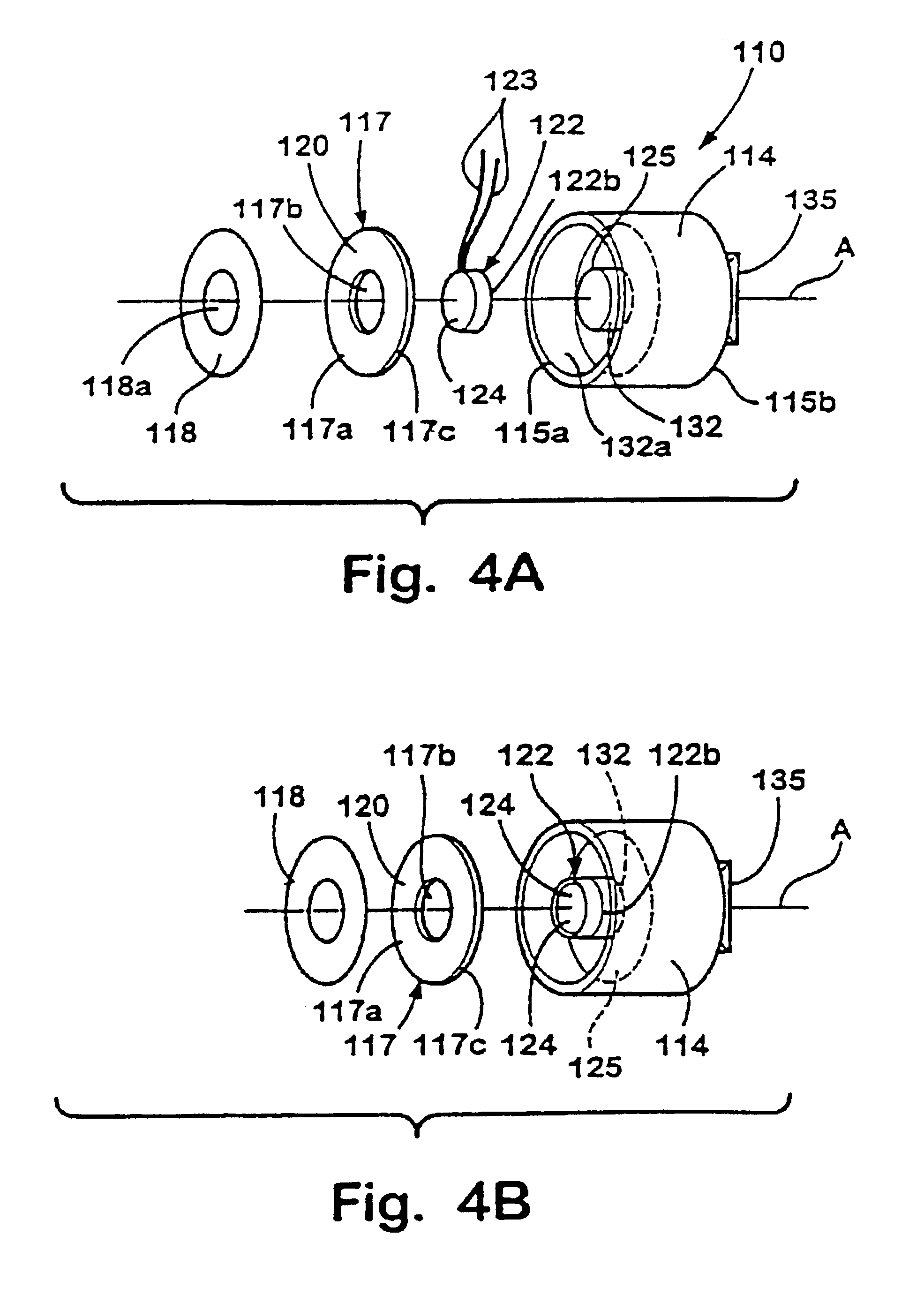

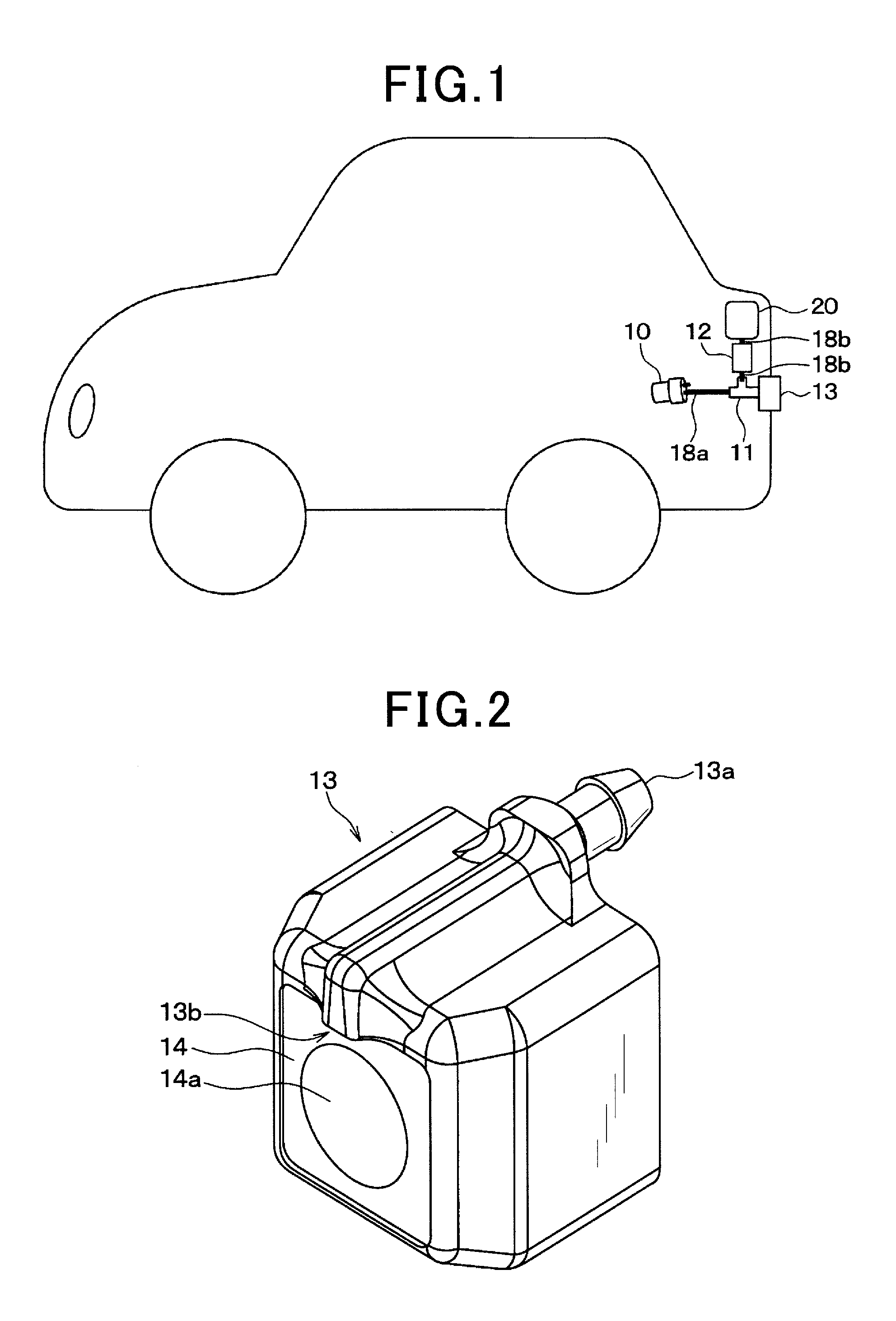

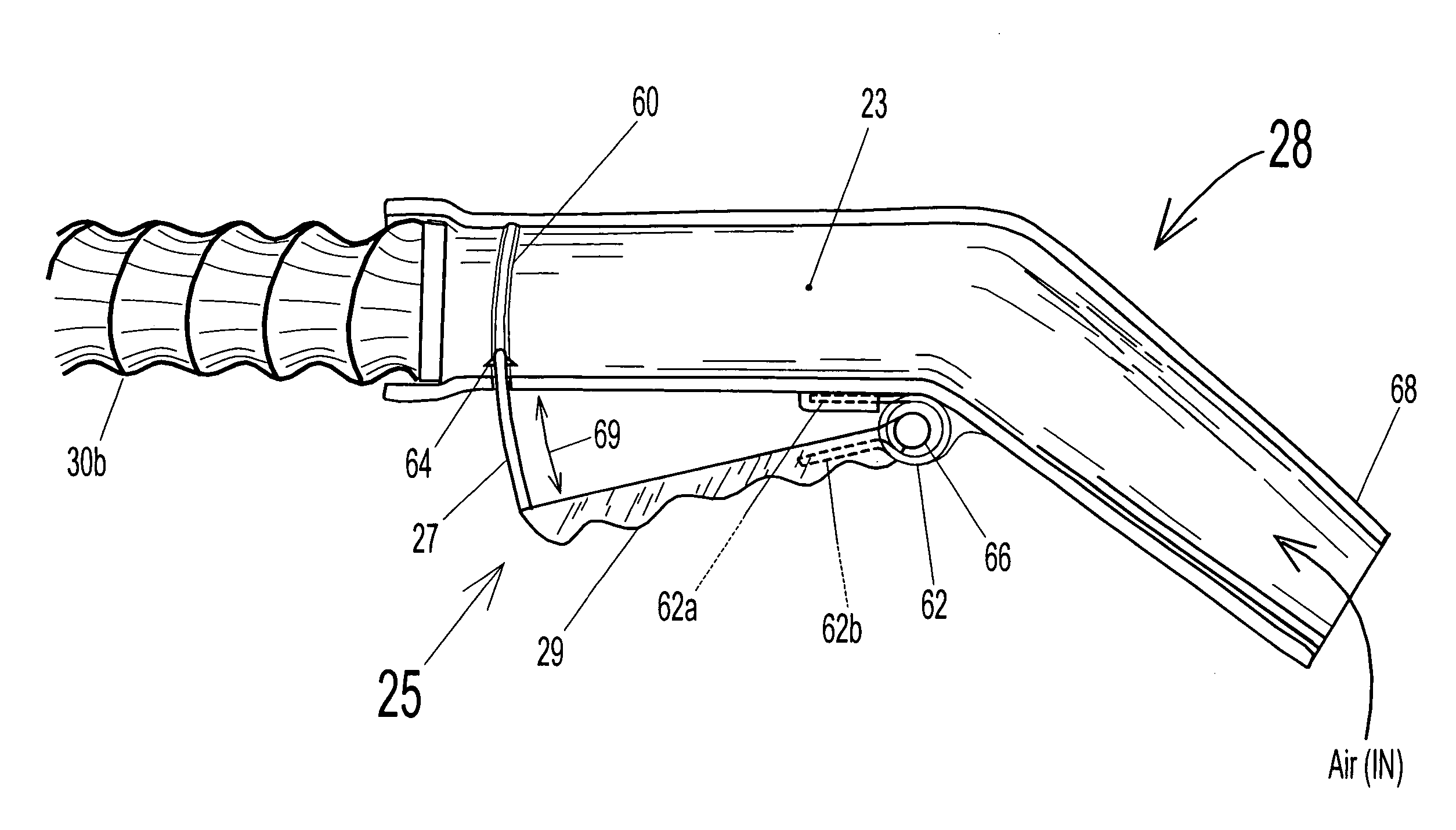

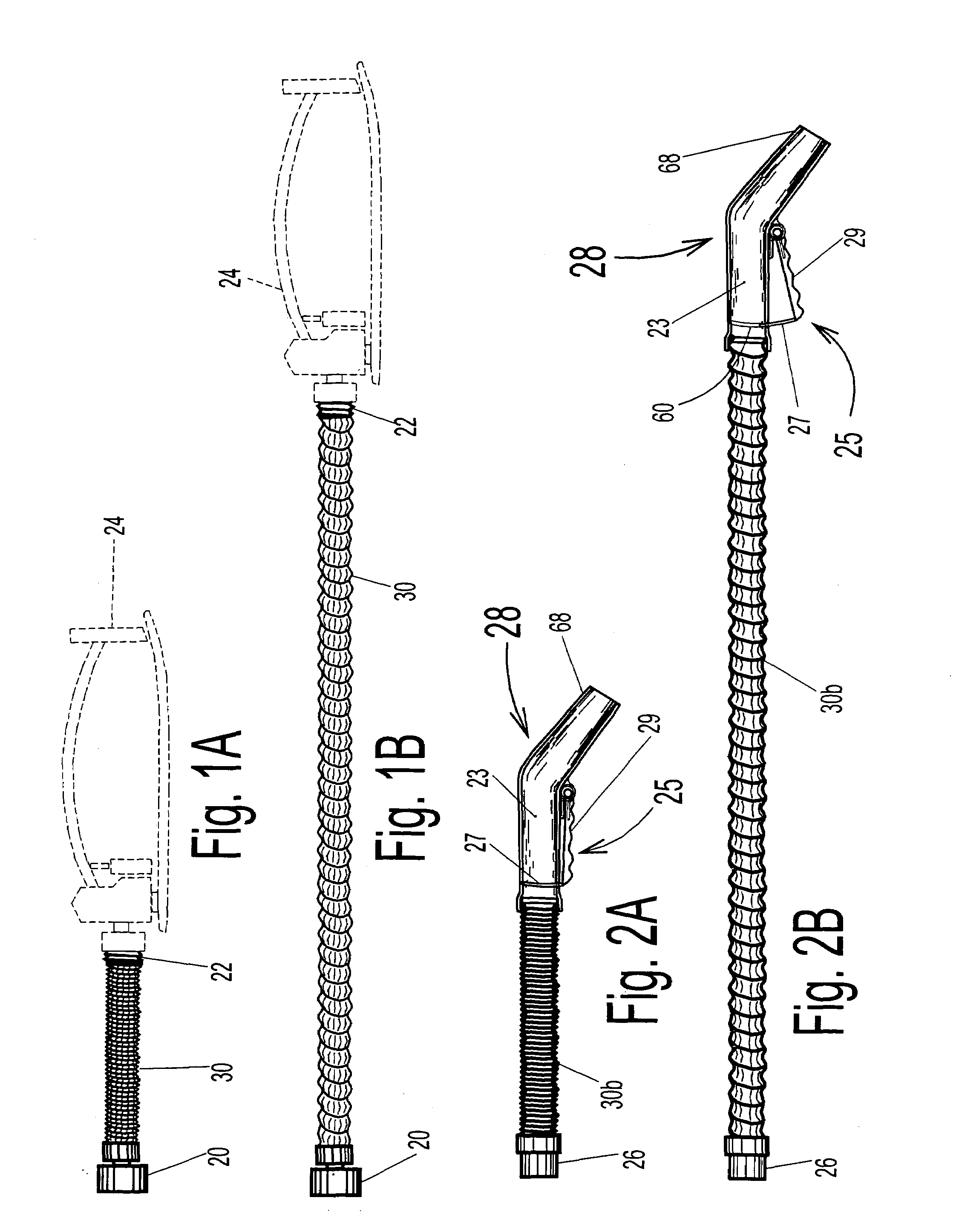

Integrated automotive system, nozzle assembly and remote control method for cleaning an image sensor's exterior or objective lens surface

ActiveUS20140060582A1Easy to cleanPromote effectiveElectrostatic cleaningSpray nozzlesCamera lensRemote control

An external lens washing system has an aiming fixture configured to support and constrain an external lens which is exposed to the elements and apt to become soiled with debris. A nozzle assembly is configured to be supported and aimed toward the external lens by the aiming fixture and has at least one laterally offset washing nozzle projecting from the aiming fixture to a spray washing fluid toward the external lens surface, spraying at a shallow, glancing spray aiming angle to impinge upon and wash the lens external surface. Optionally, an integrated image sensor and lens washing assembly is configured for use with a remote control method for cleaning an exterior objective lens surface and includes a sealed image sensor housing assembly including an integral, remotely controllable lens cleaning system with an optimized configuration for aiming one or more cleansing sprays from one or more laterally offset fluidic oscillators.

Owner:DLHBOWLES INC

Camera washing device for camera lens

ActiveUS20130092758A1Reduce water consumptionShorten the time periodSpray nozzlesVehicle cleaningCamera lensWash water

A camera washing device has an air pump, a wash water tank storing wash water, an injection nozzle with an injection part, a junction joint having a high-pressure air passage and a wash water passage, and an electromagnetic valve. The air pump generates and supplies high-pressure air to the high-pressure air passage. When the control part instructs the electromagnetic valve to be switched to an open state, the wash water and the high-pressure air are mixed in the junction joint to generate water particles. The generated water particles are supplied to the injection nozzle. When the electromagnetic valve is switched to the open state after injecting the high-pressure air only to a lens of a rear camera, the injection part injects the water particles to the lens of the camera.

Owner:DENSO CORP

Video mirror system suitable for use in a vehicle

InactiveUS20070132567A1Maximizes rearward field of viewVariable reflectivityTelevision system detailsDashboard fitting arrangementsElectricityIn vehicle

A vehicular video mirror system comprises an interior electrochromic mirror having a transflective mirror reflector and a video screen disposed behind the mirror reflector so that the presence of the video screen is substantially unobservable to a driver of the vehicle until the video screen is actuated to emit light that passes through the electrochromic reflective element to be viewed by the driver of the vehicle. Control circuitry receives a signal indicative of selection of a reverse gear of the vehicle by the driver and actuates the video screen in order to display video images captured by a video imaging device disposed to the rear of the vehicle and having a field of view rearward of and external to the vehicle.

Owner:DONNELLY CORP

Washer nozzle-equipped camera apparatus and washer nozzle

A washer nozzle-equipped camera apparatus includes a camera and a washer nozzle. The washer nozzle has a window spray outlet for spraying a washer fluid, supplied from a supply unit such as a pump, on a window of a vehicle. The washer nozzle further has a window duct for carrying the washer fluid to the window spray outlet. The washer nozzle further has a camera spray outlet for spraying the washer fluid on a lens of the camera. The washer nozzle further has a camera duct for carrying the washer fluid to the camera spray outlet.

Owner:DENSO CORP +1

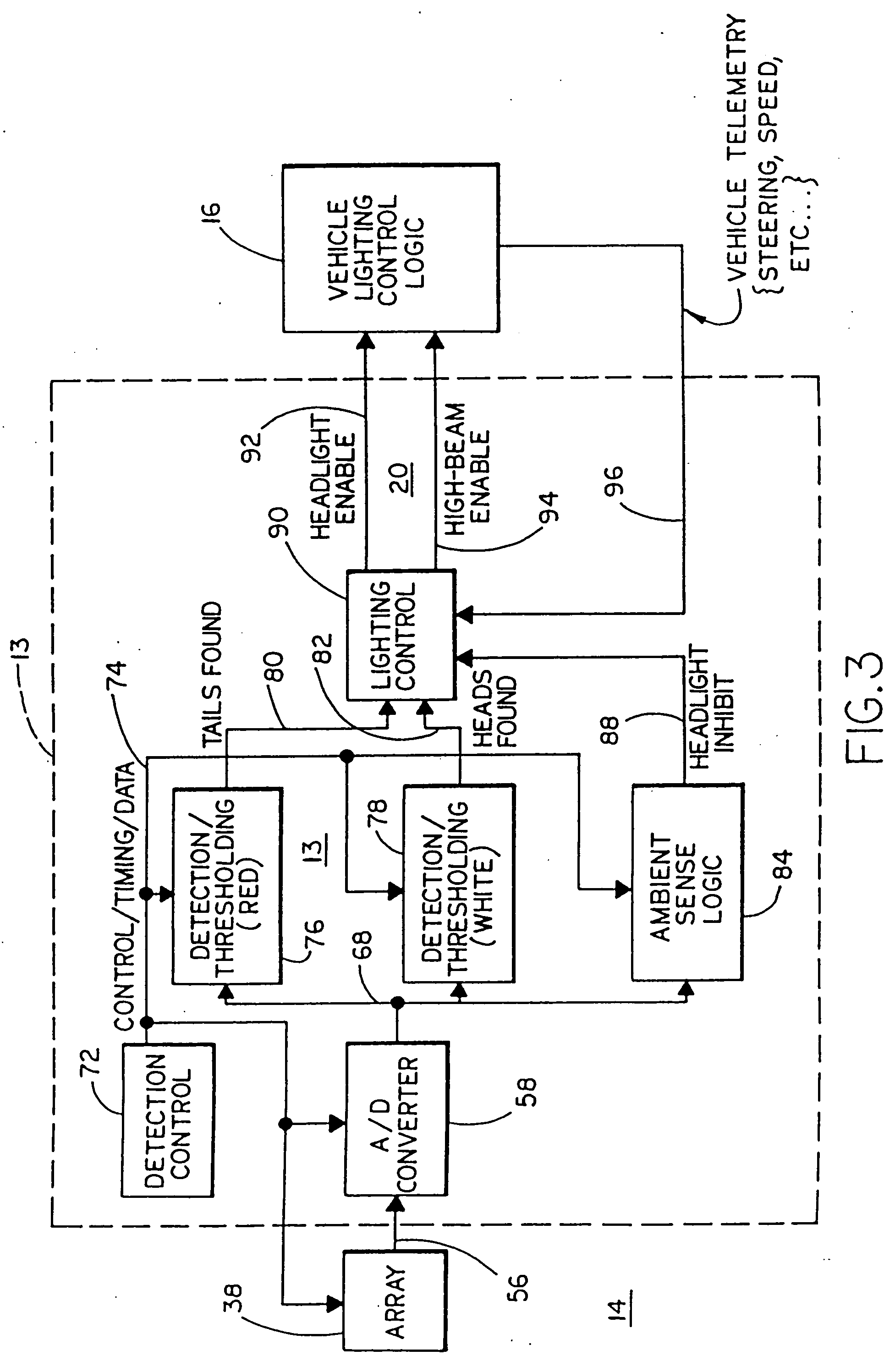

Vehicle headlight control using imaging sensor

InactiveUS20070023613A1Photometry using reference valueVehicle headlampsField of viewSpectral signature

A vehicle headlamp control method and apparatus includes providing an imaging sensor that senses light in spatially separated regions of a field of view forward of the vehicle. Light levels sensed in individual regions of the field of view are evaluated in order to identify light sources of interest, such as oncoming headlights and leading taillights. The vehicle's headlights are controlled in response to identifying such particular light sources or absence of such light sources. Spectral signatures of light sources may be examined in order to determine if the spectral signature matches that of particular light sources such as the spectral signatures of headlights or taillights. Sensed light levels may also be evaluated for their spatial distribution in order to identify light sources of interest.

Owner:MAGNA ELECTRONICS

On-board optical sensor cover and on-board optical sensor apparatus

An on-board optical sensor cover includes a holder and a washer nozzle. The holder holds an optical sensor. The optical sensor has a lens and is mounted above a window of a vehicle outside the vehicle. The washer nozzle performs a washing operation to wash a lens surface of the lens of the optical sensor held in the holder or a glass surface of a cover glass located facing the lens if the cover glass exists by spraying a washer fluid, supplied from a washer fluid tank, onto the lens surface or the glass surface. The optical sensor cover is located above the window outside the vehicle so that the washer fluid spayed from the washer nozzle flows to a window surface of the window after washing the lens surface or the glass surface.

Owner:DENSO CORP

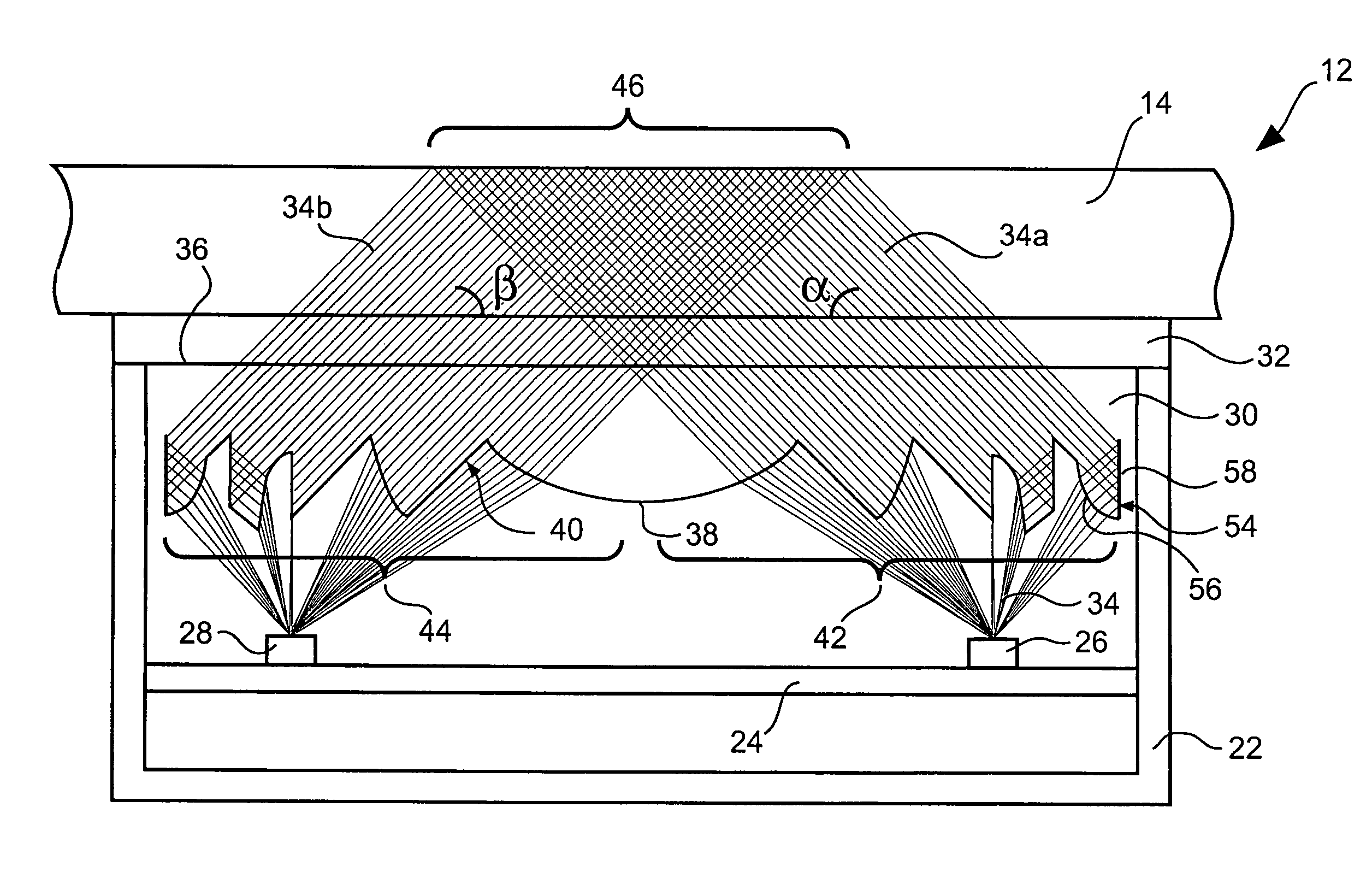

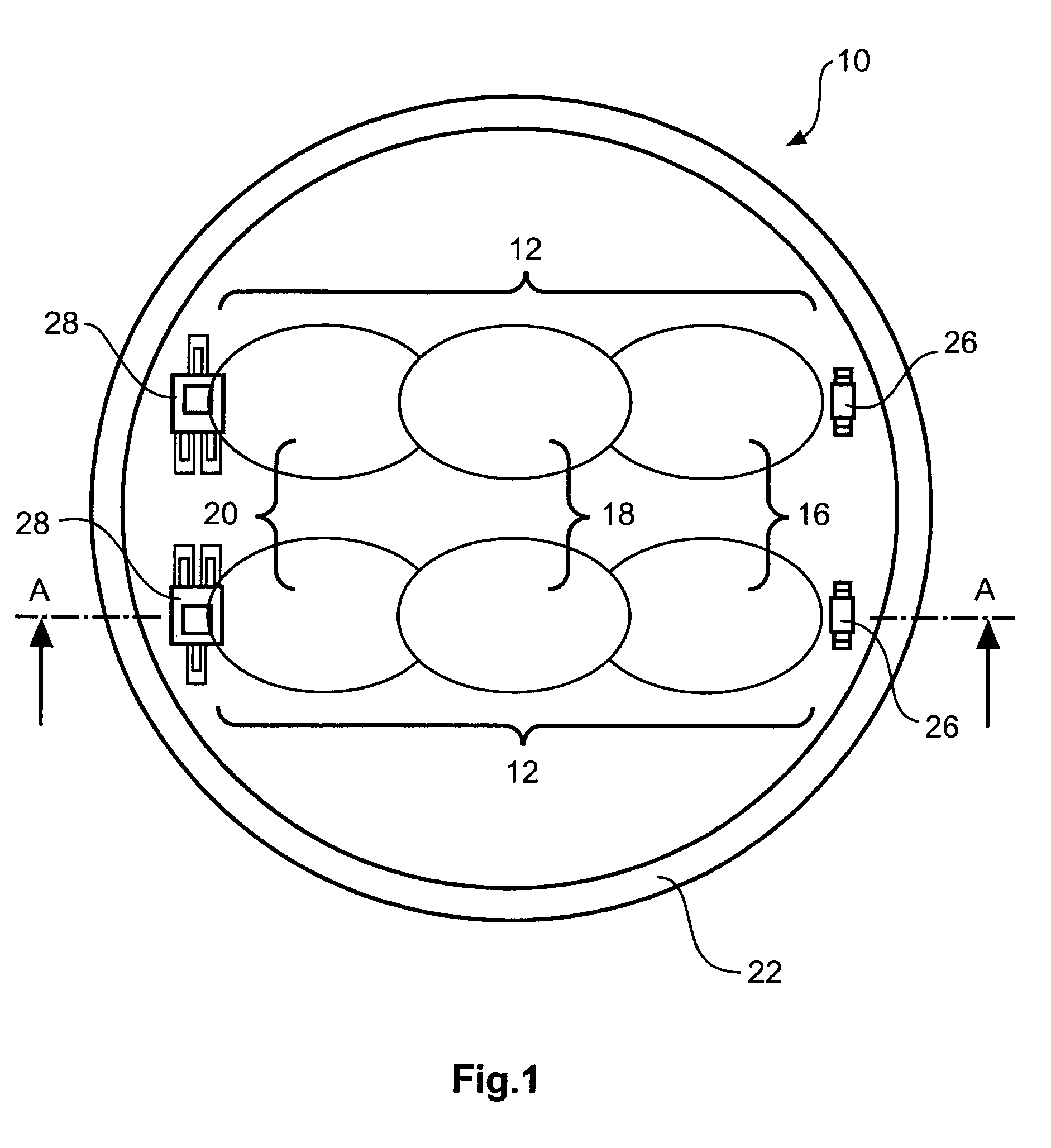

Optical sensor device for detecting wetting

InactiveUS7751054B2Small thicknessIncrease the areaScattering properties measurementsPhotoelectric discharge tubesFresnel lensElectrical conductor

An optical sensor device (10) is able to be coupled to a window (14), in particular to a windscreen of a motor vehicle. The optical sensor device (10) comprises a sensor unit (12), which includes a emitter (26), a receiver (28) and a light conductor unit (30). By the light conductor unit (30), a light beam (34) emitted by the emitter (26) is coupled into the window (14), coupled out of the window (14) and directed onto the receiver (28). The light conductor unit (30) includes Fresnel lens regions and associated reflecting regions.

Owner:TRW AUTOMOTIVE ELECTRONICS & COMPONENTS GMBH & CO KG

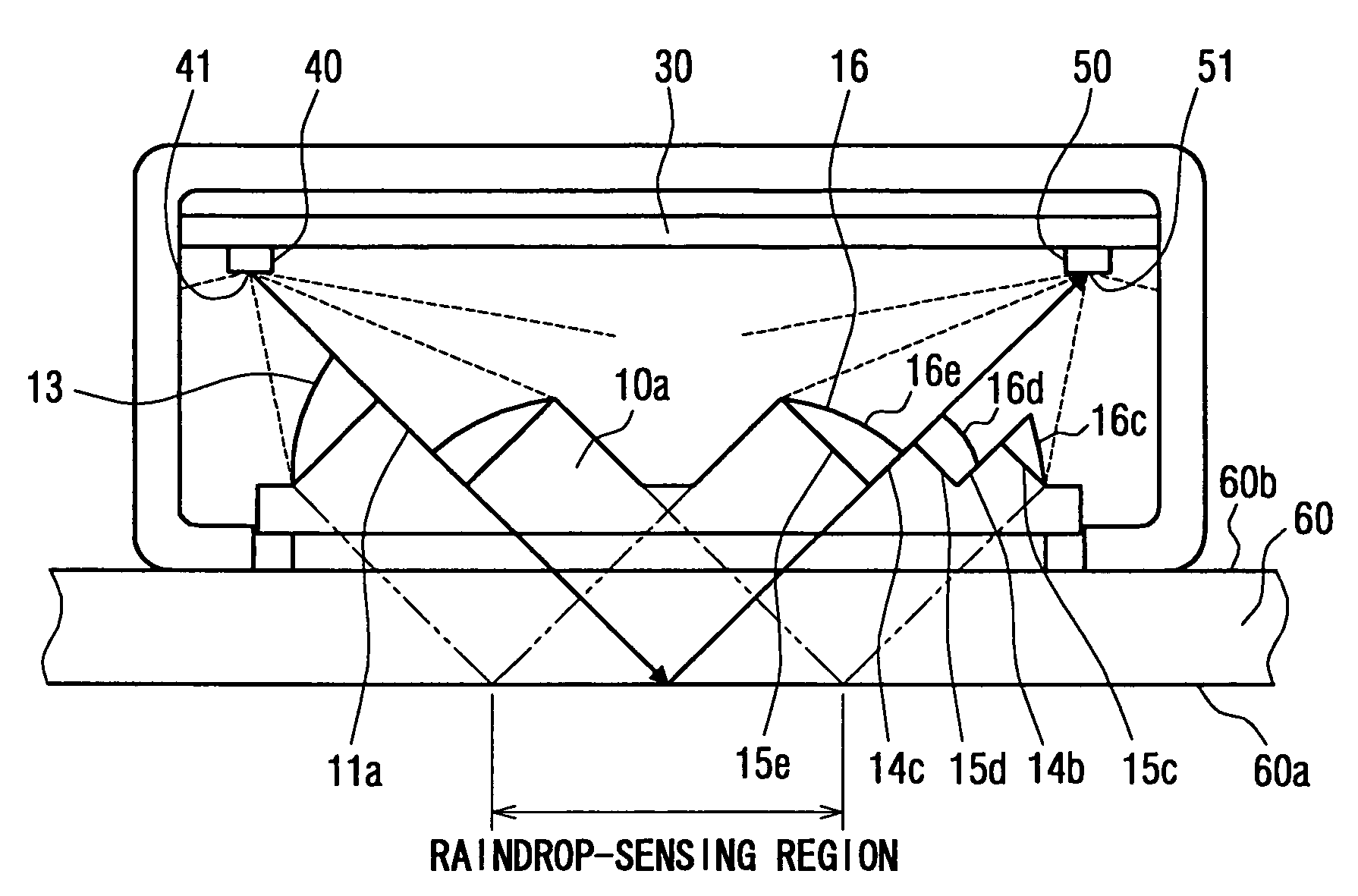

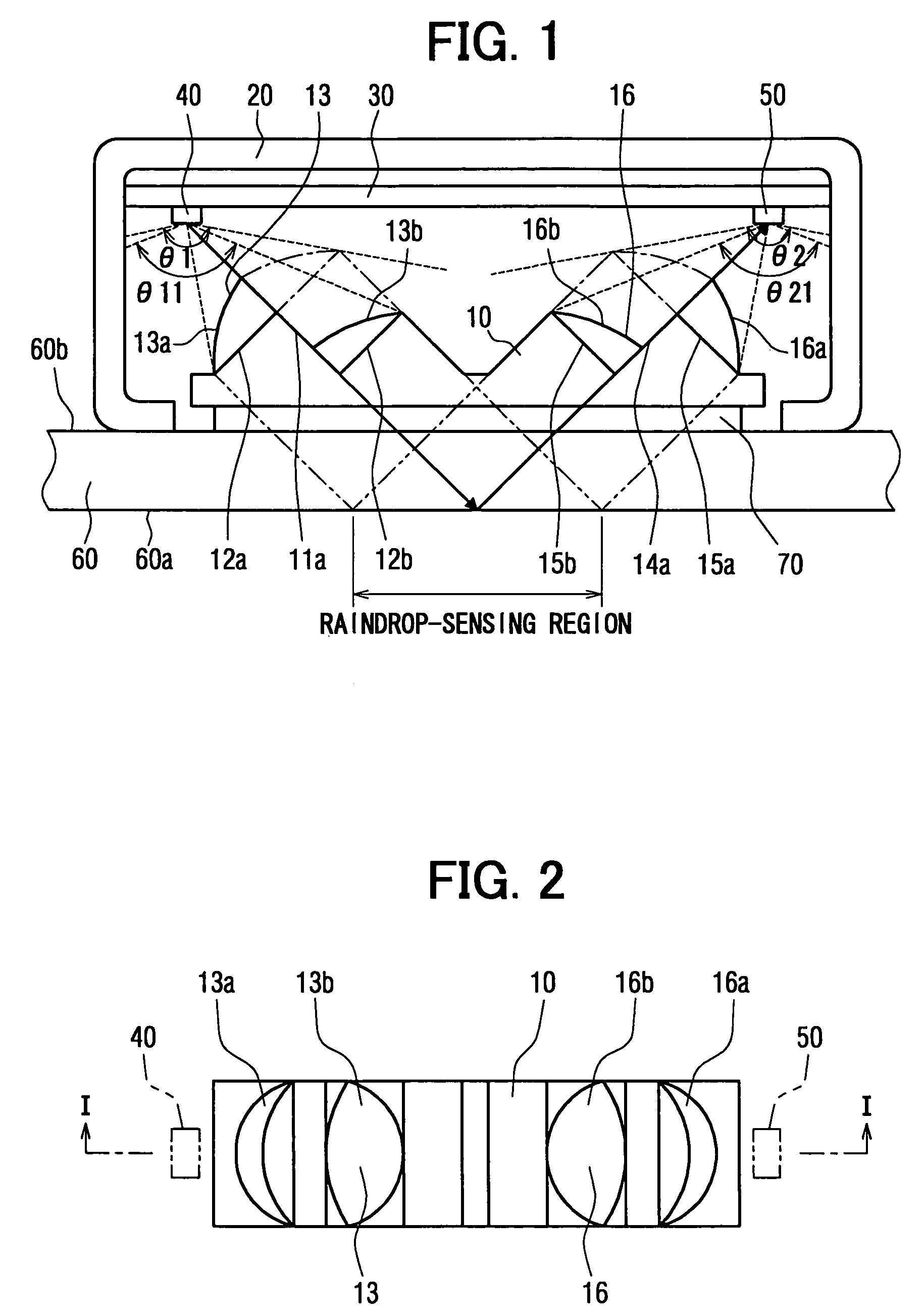

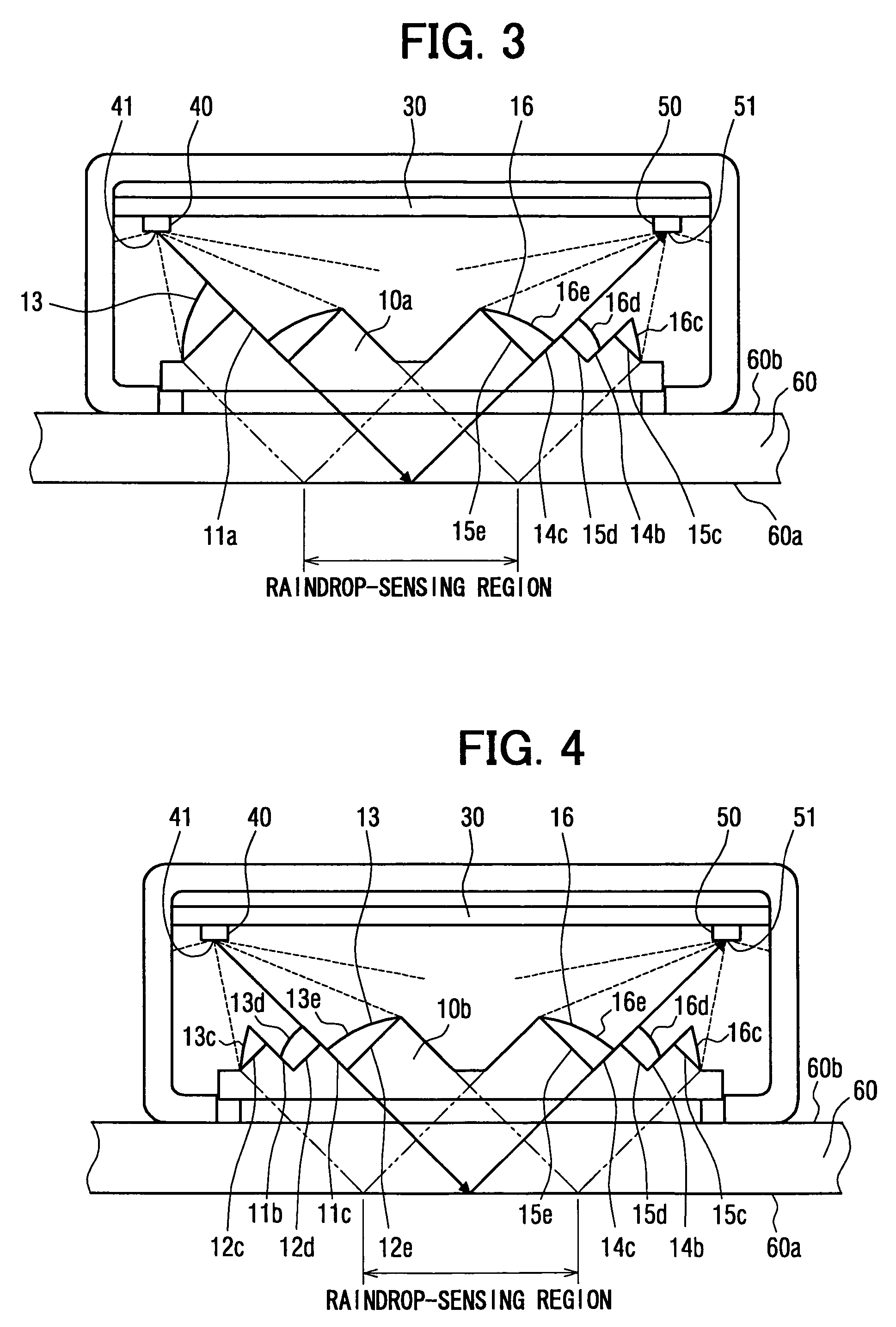

Raindrop sensor

ActiveUS7309873B2Phase-affecting property measurementsInvestigating moving fluids/granular solidsLight guideLight beam

A raindrop sensor includes a light-emitting element, a light-receiving element and a light guide body. The light-emitting element and the light-receiving element face a transparent panel. The light guide body, which is mounted on the transparent panel, includes an input lens, an input side dividing surface, an output lens and an output side dividing surface. The input lens collimates light emitted by the light-emitting element to form an input side collimated light beam. The output lens receives the collimated light beam, which is collimated by the input lens and is reflected by a reference surface of the transparent panel, to which the raindrop attaches. The output lens converges the reflected collimated light beam toward the light-receiving element. An intersection between an imaginary extension of the input side dividing surface and an imaginary extension of the output side dividing surface is located on the reference surface of the transparent panel.

Owner:DENSO CORP

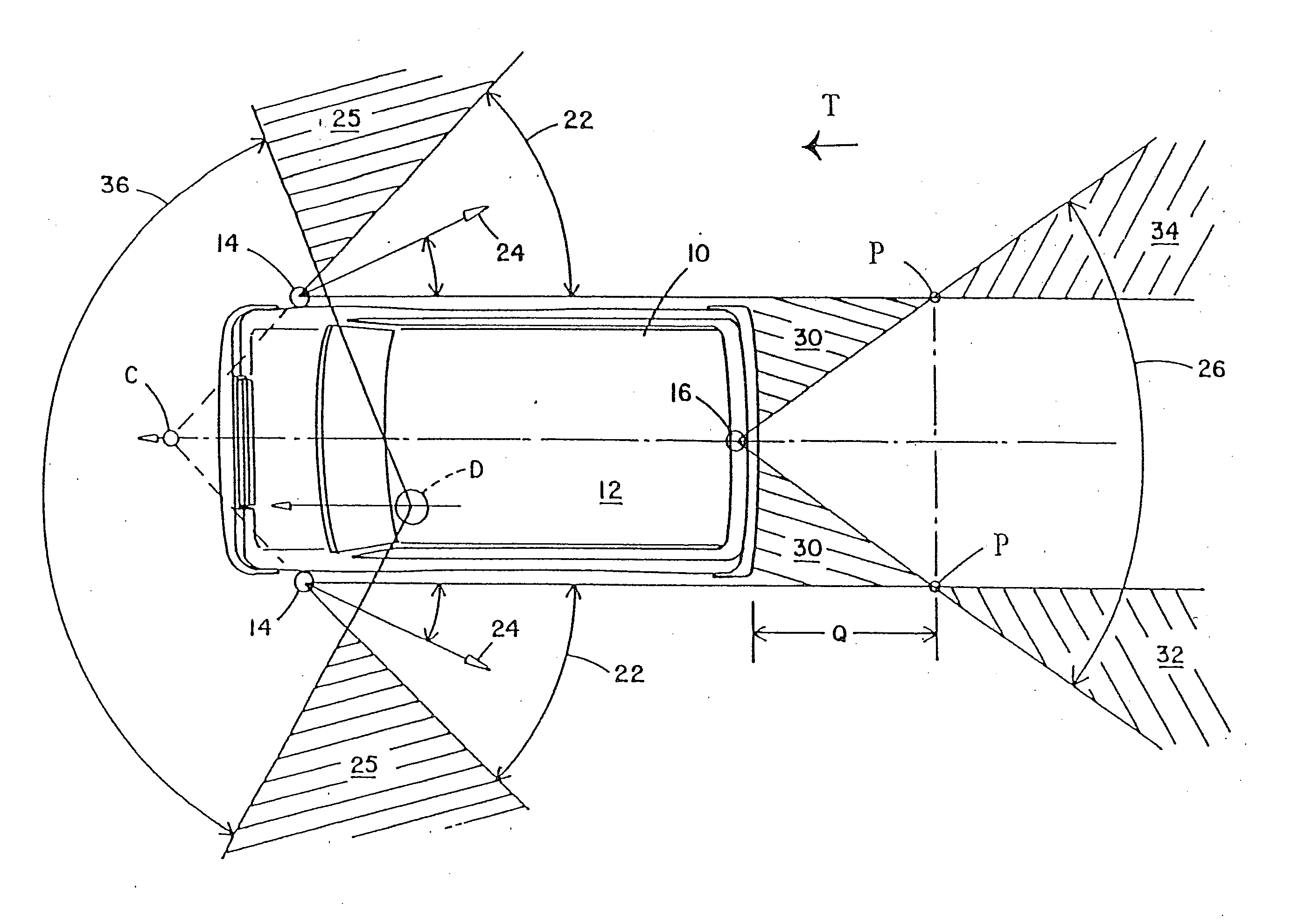

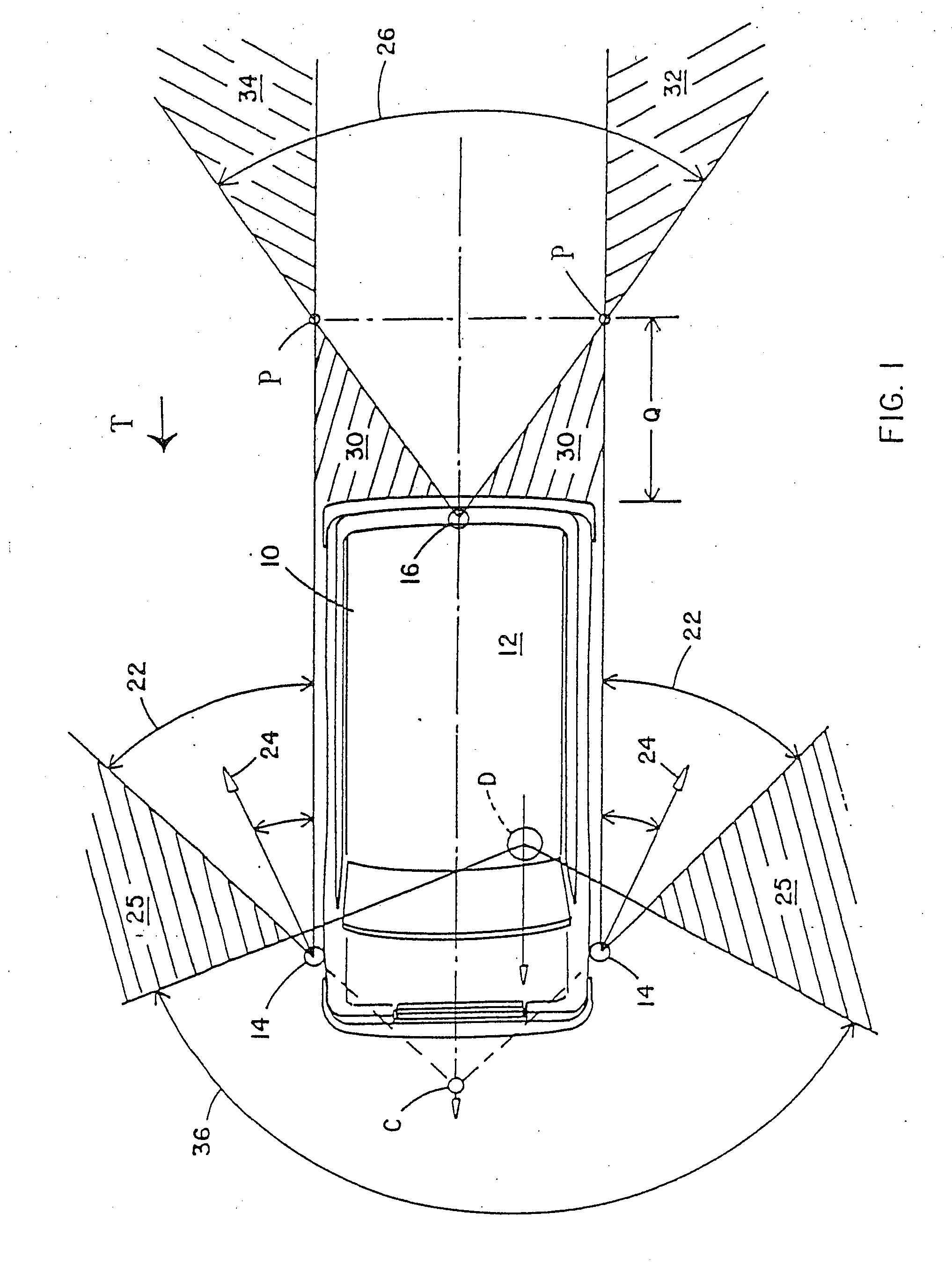

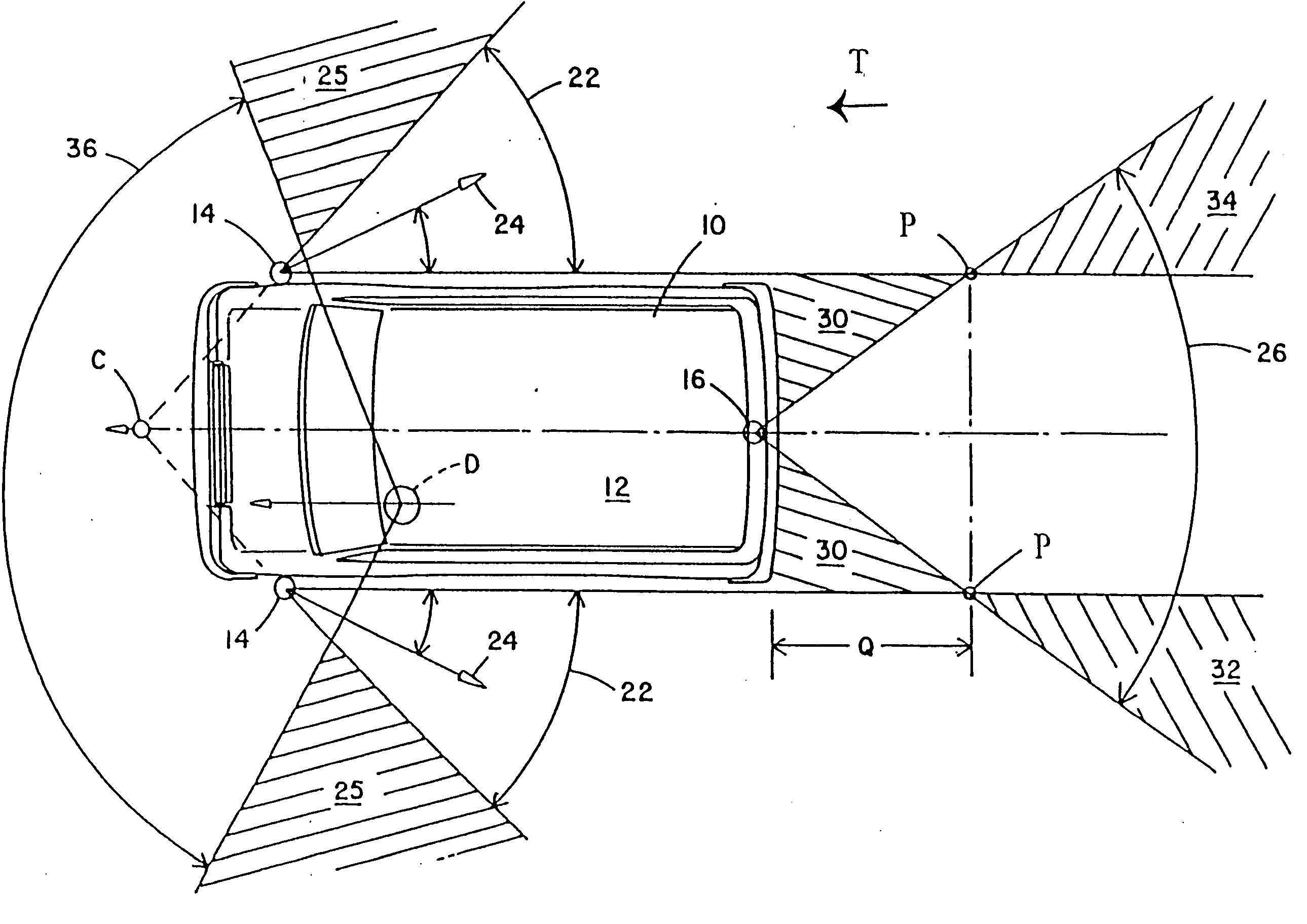

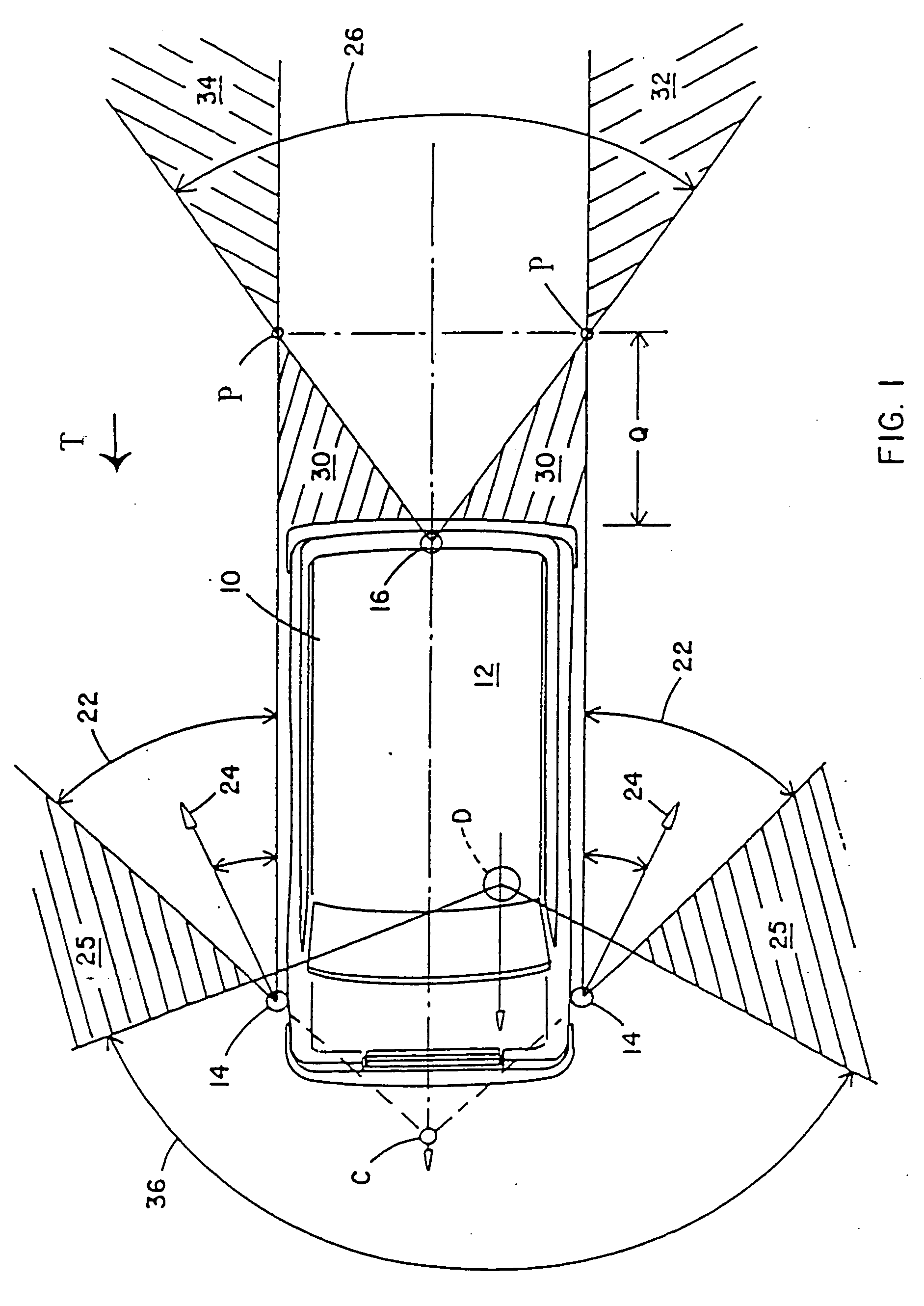

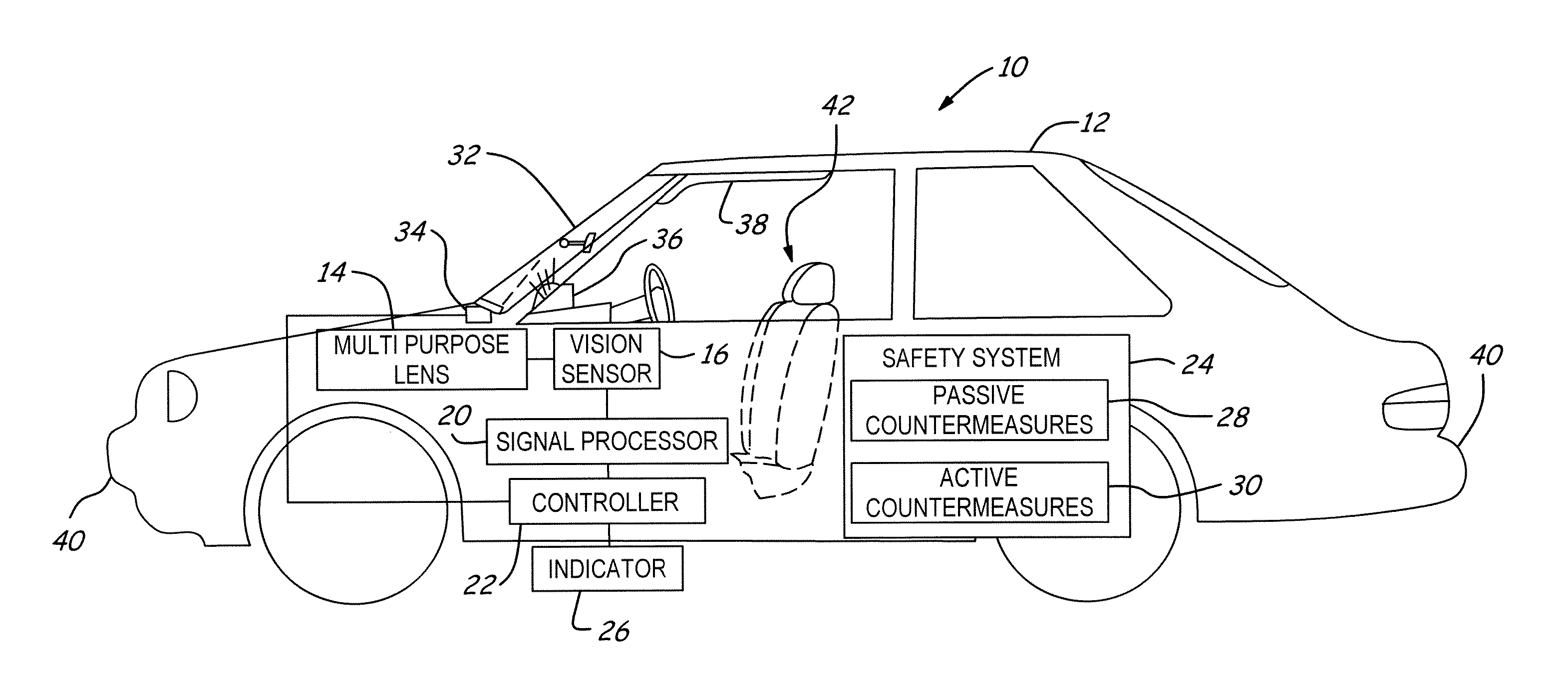

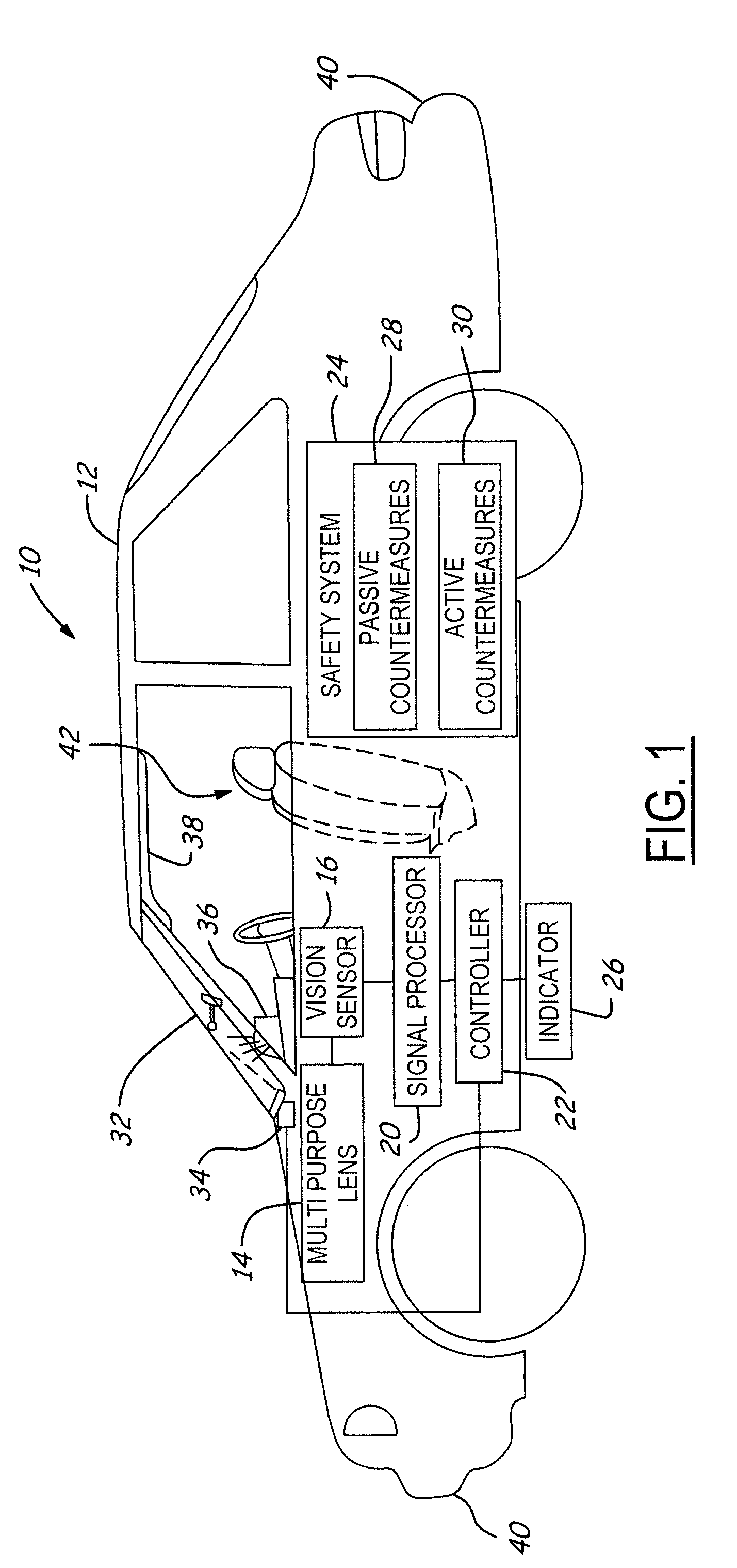

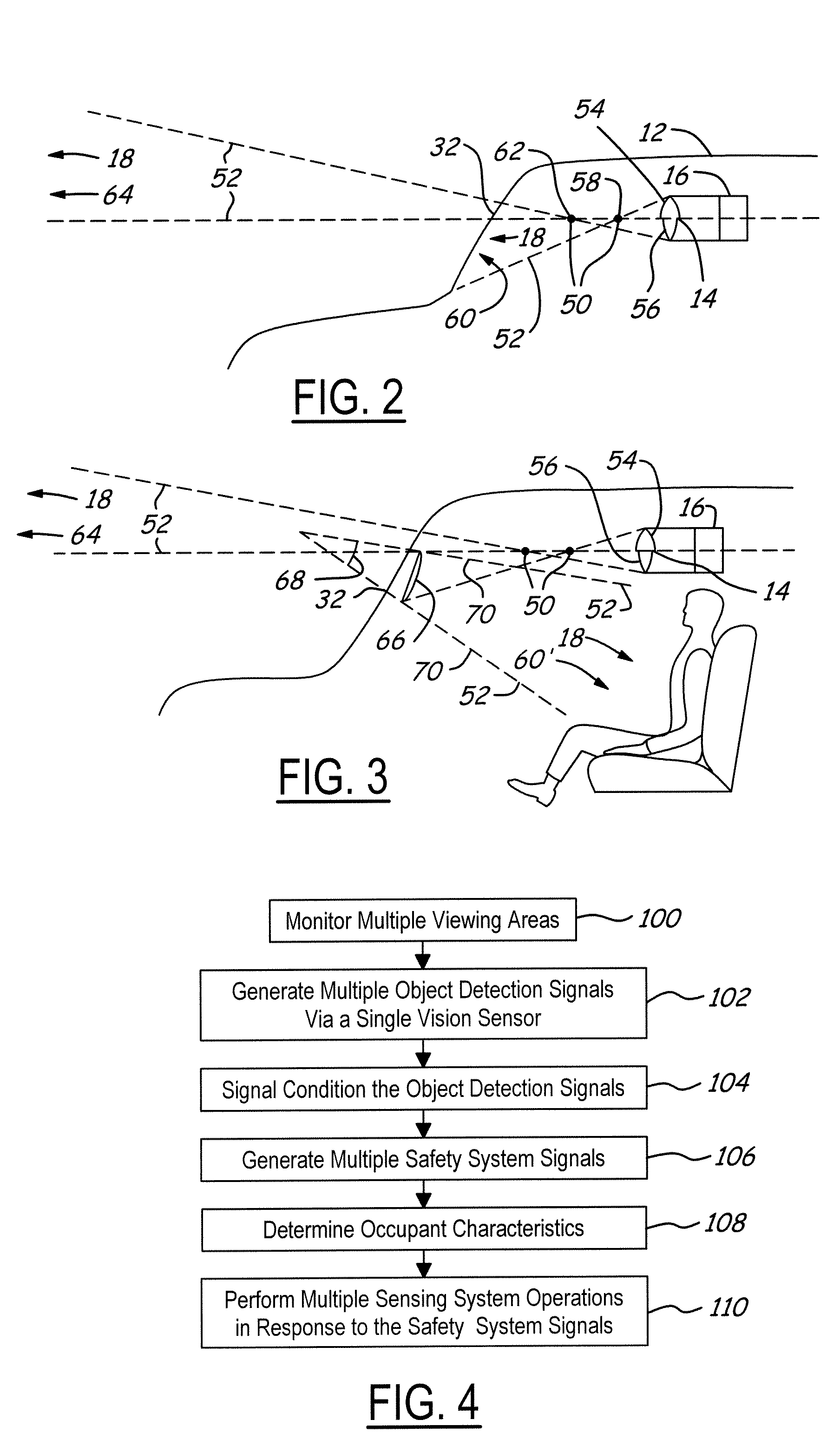

Multipurpose vision sensor system

InactiveUS6958683B2Low costMinimize the numberDigital data processing detailsPedestrian/occupant safety arrangementEngineeringVision sensor

A multipurpose sensing system (10) for a vehicle (12) includes an optic (14) that is directed at multiple viewing areas (18). A vision sensor (16) is coupled to the optic (14) and generates multiple object detection signals corresponding to the viewing areas (18). A controller (22) is coupled to the vision sensor (16) and generates multiple safety system signals in response to the object detection signals.

Owner:FORD GLOBAL TECH LLC

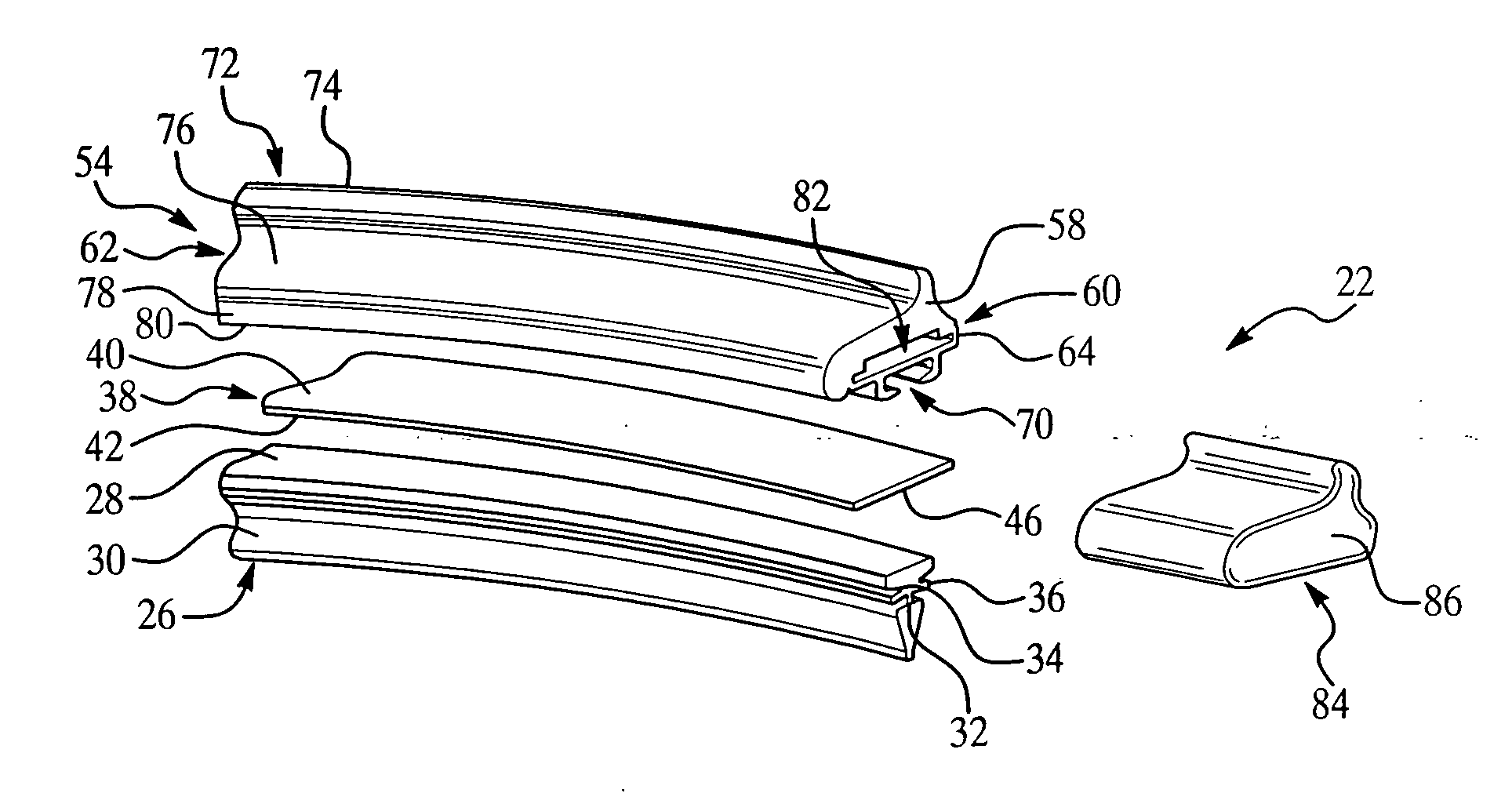

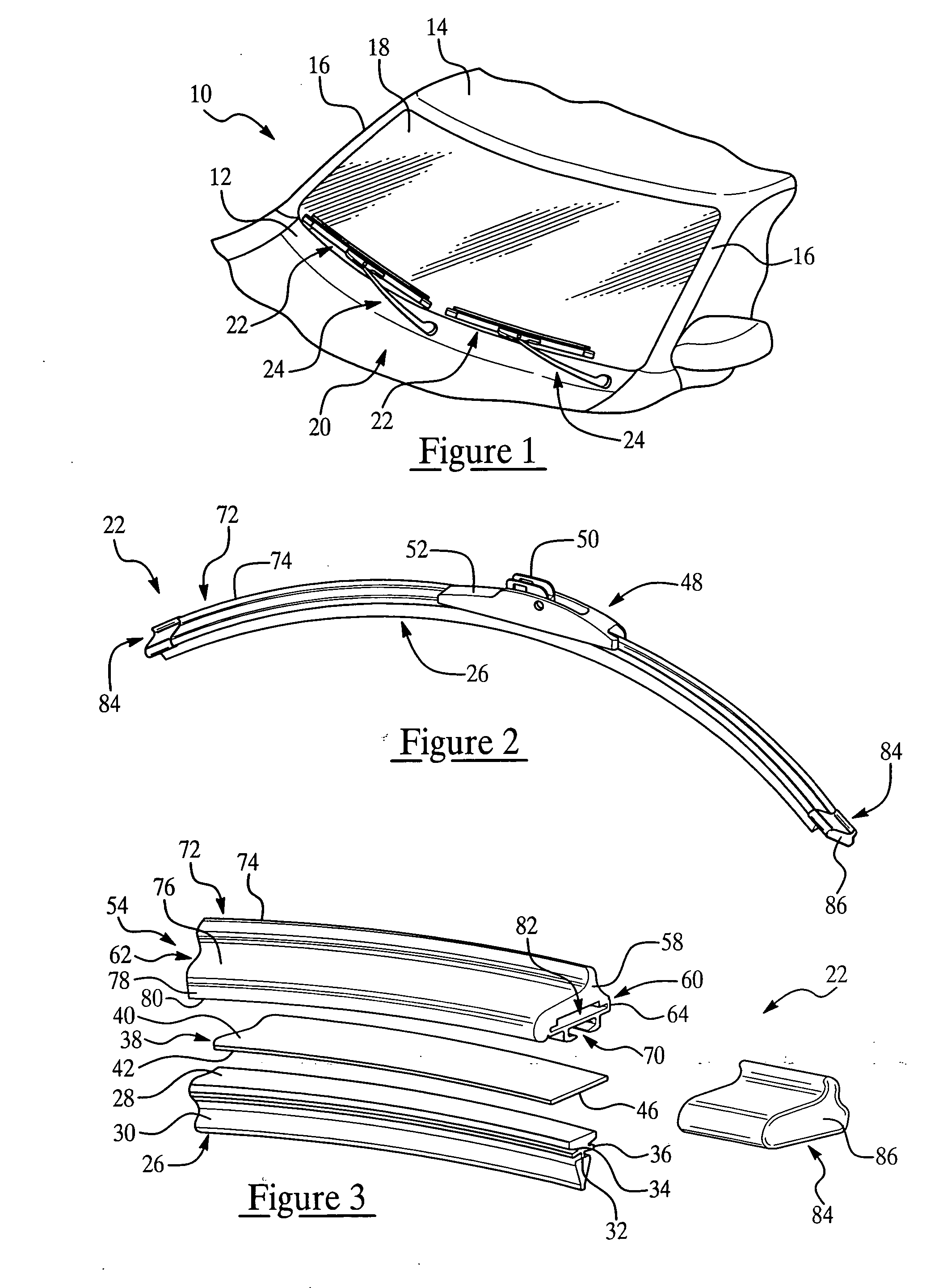

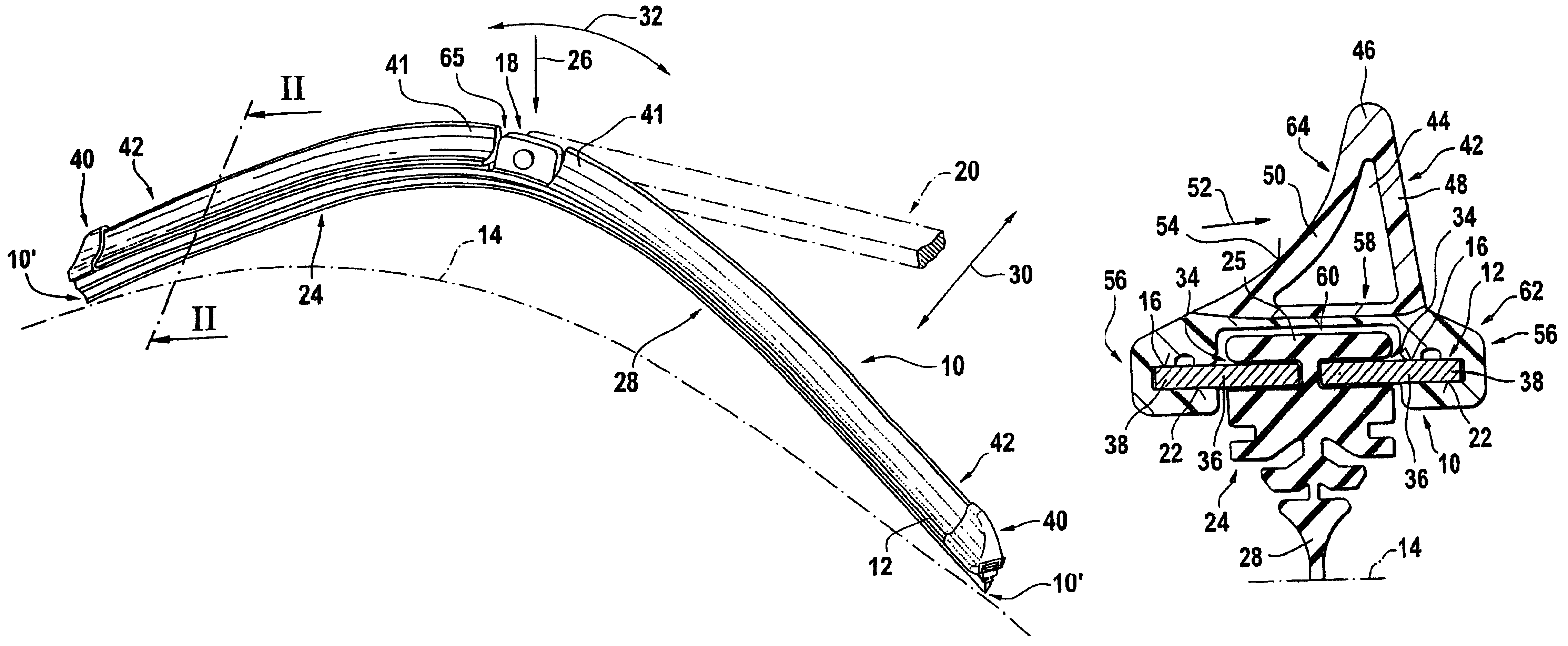

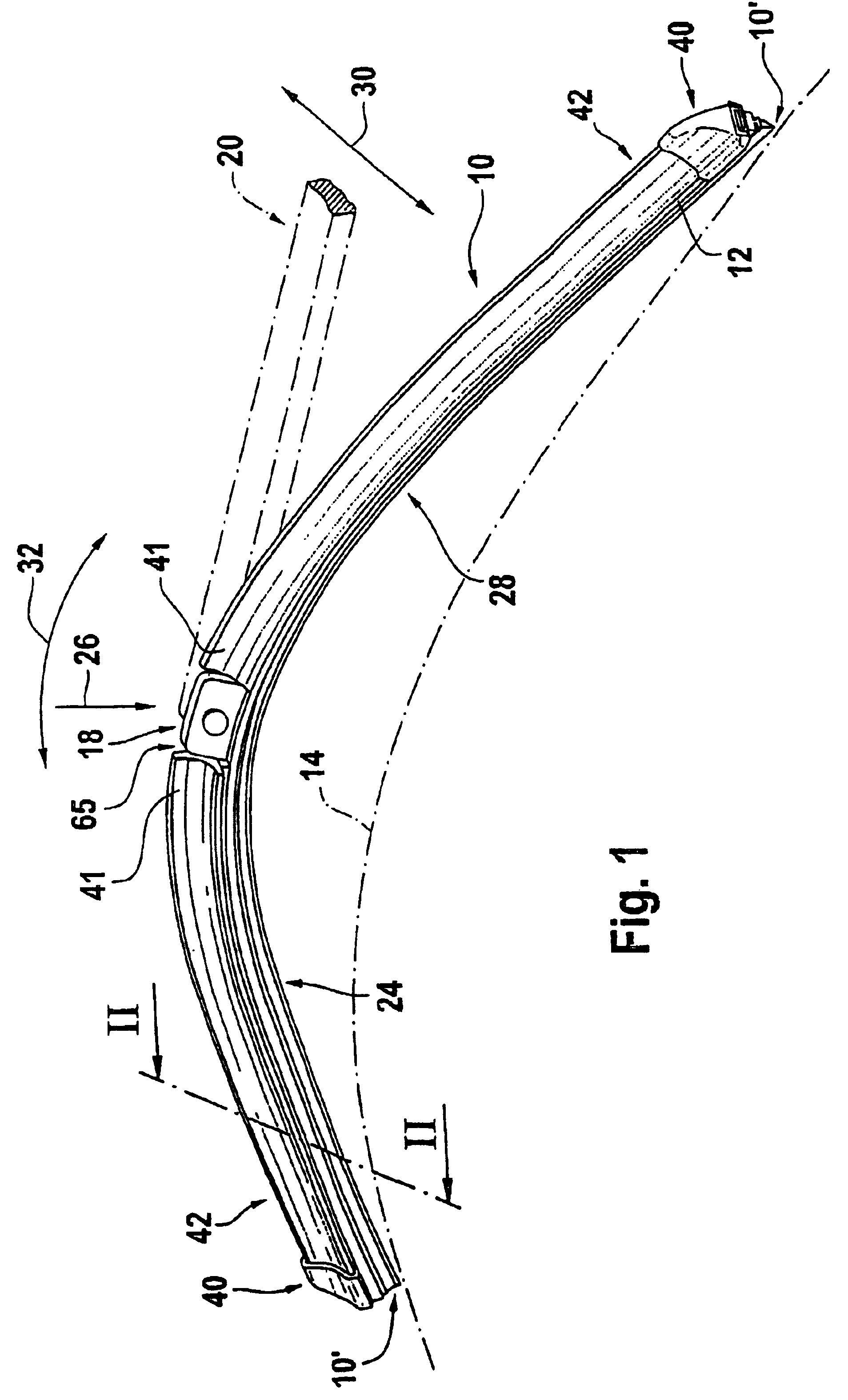

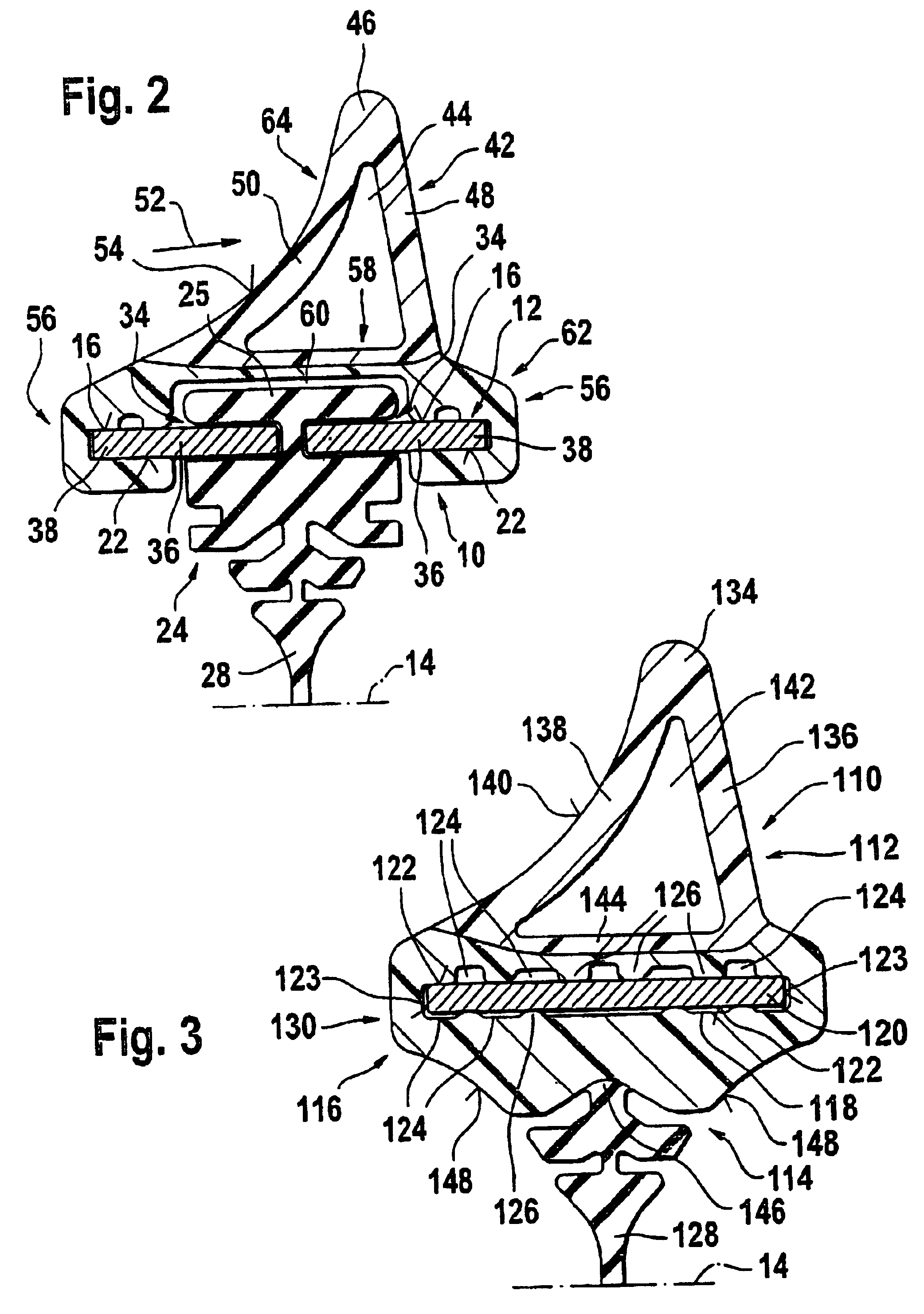

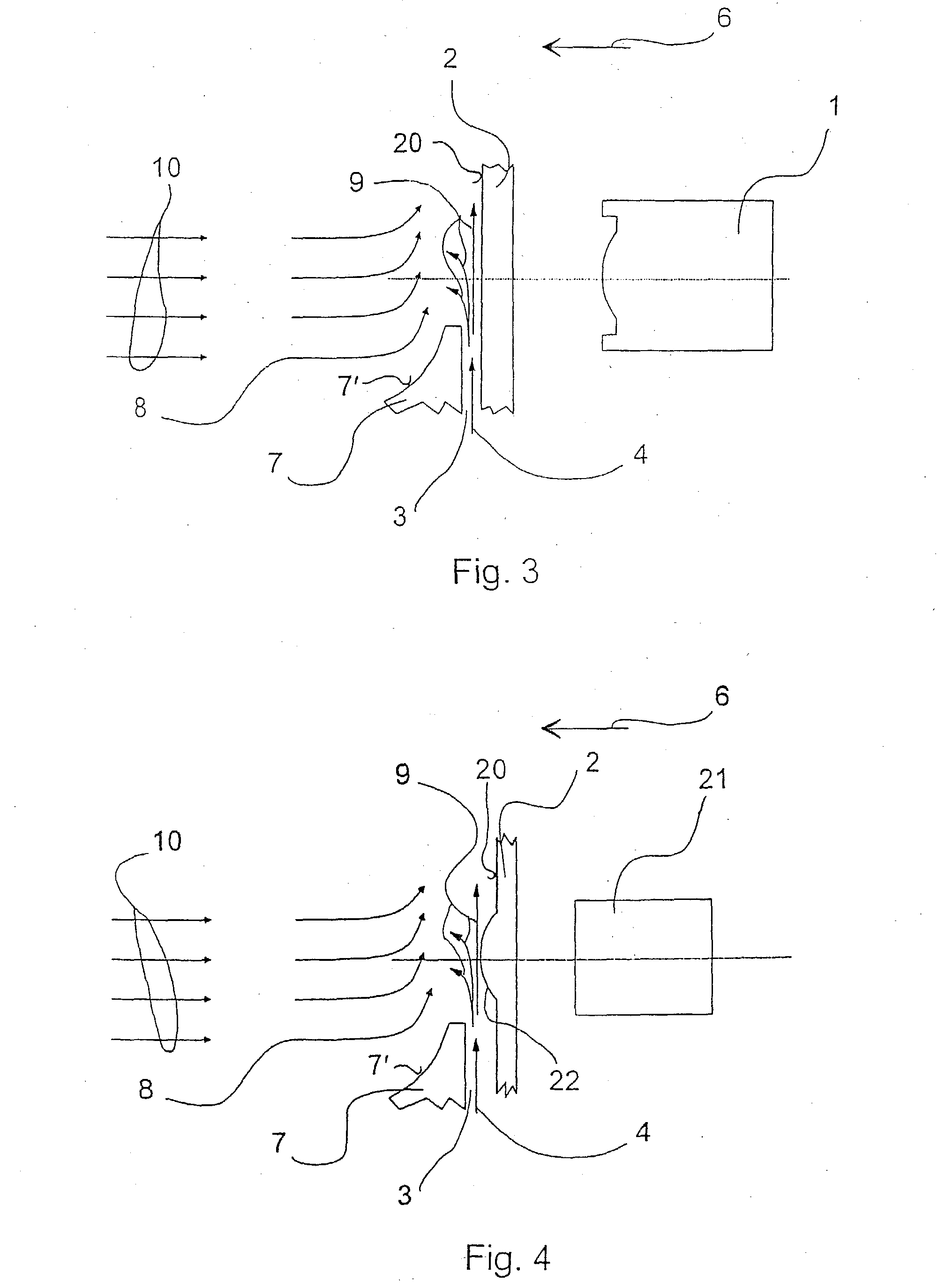

Beam blade windshield wiper assembly having an airfoil

ActiveUS20070174989A1Reduces wind liftImprove wiping effectWindow cleanersVehicle cleaningLeading edgeEngineering

A beam blade wiper assembly including a rubber wiping element and an elongated beam having first and second longitudinal ends. The wiper assembly also includes an airfoil having an attachment portion and an upper portion extending between first and second distal ends. The attachment portion includes a flat rib and a pair of legs adapted to operatively engage the rubber wiping element. The upper portion includes a solid base having a leading edge that extends from the base toward the wiping element. The base and the rib define a space that receives the elongated beam. The base and the elongated beam define a cavity that provides flexibility between the upper portion and the attachment portion during wiper operation. The upper portion further includes a spoiler that extends from the base in a manner opposite to the leading edge.

Owner:TRICO PROD CORP

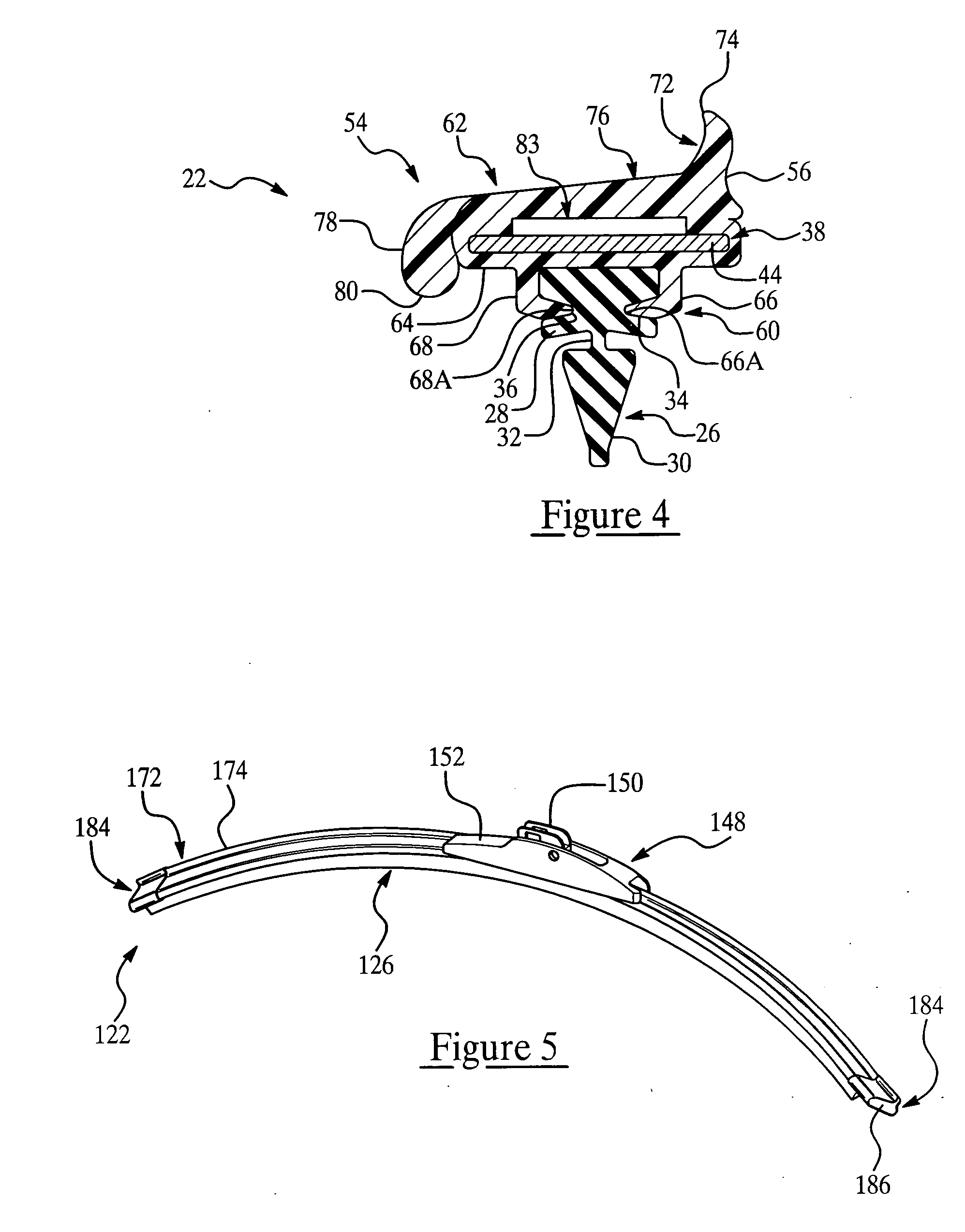

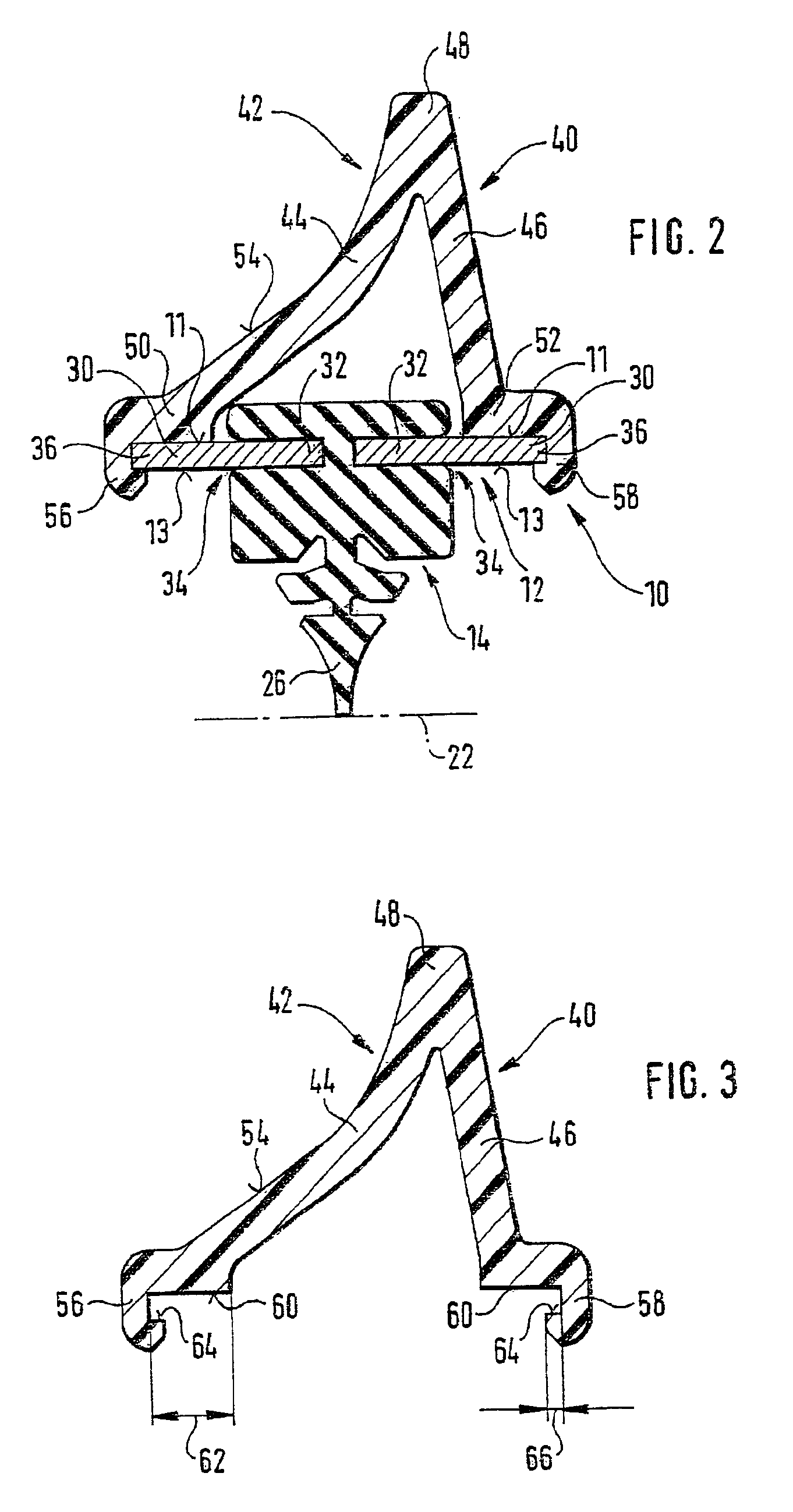

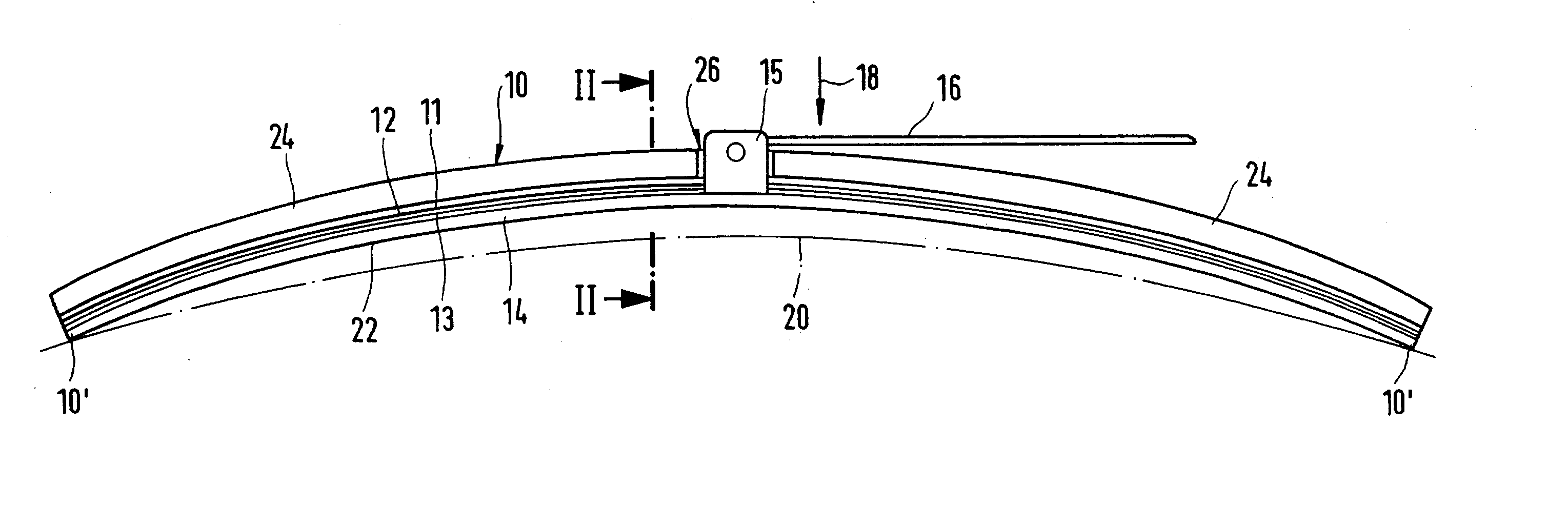

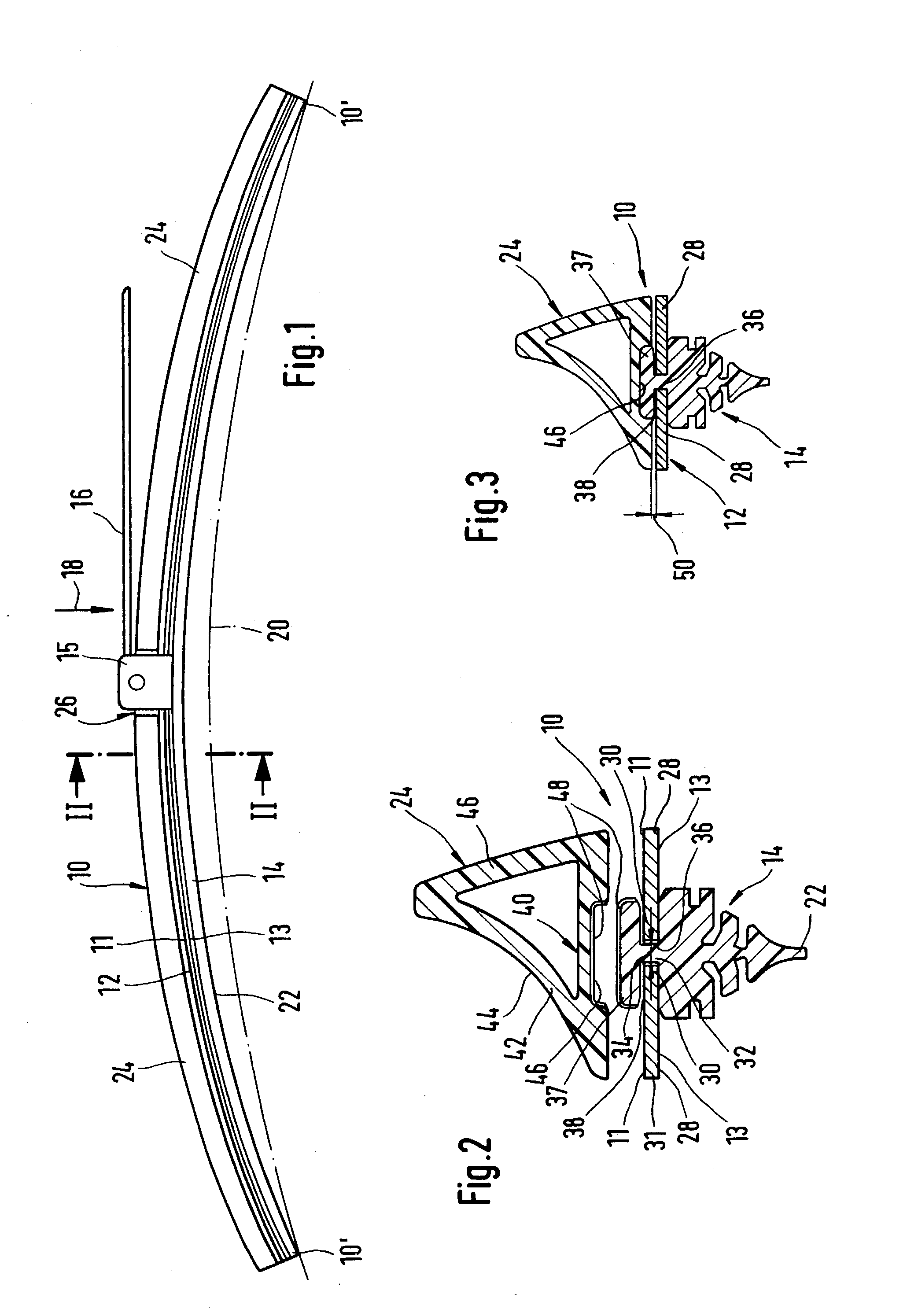

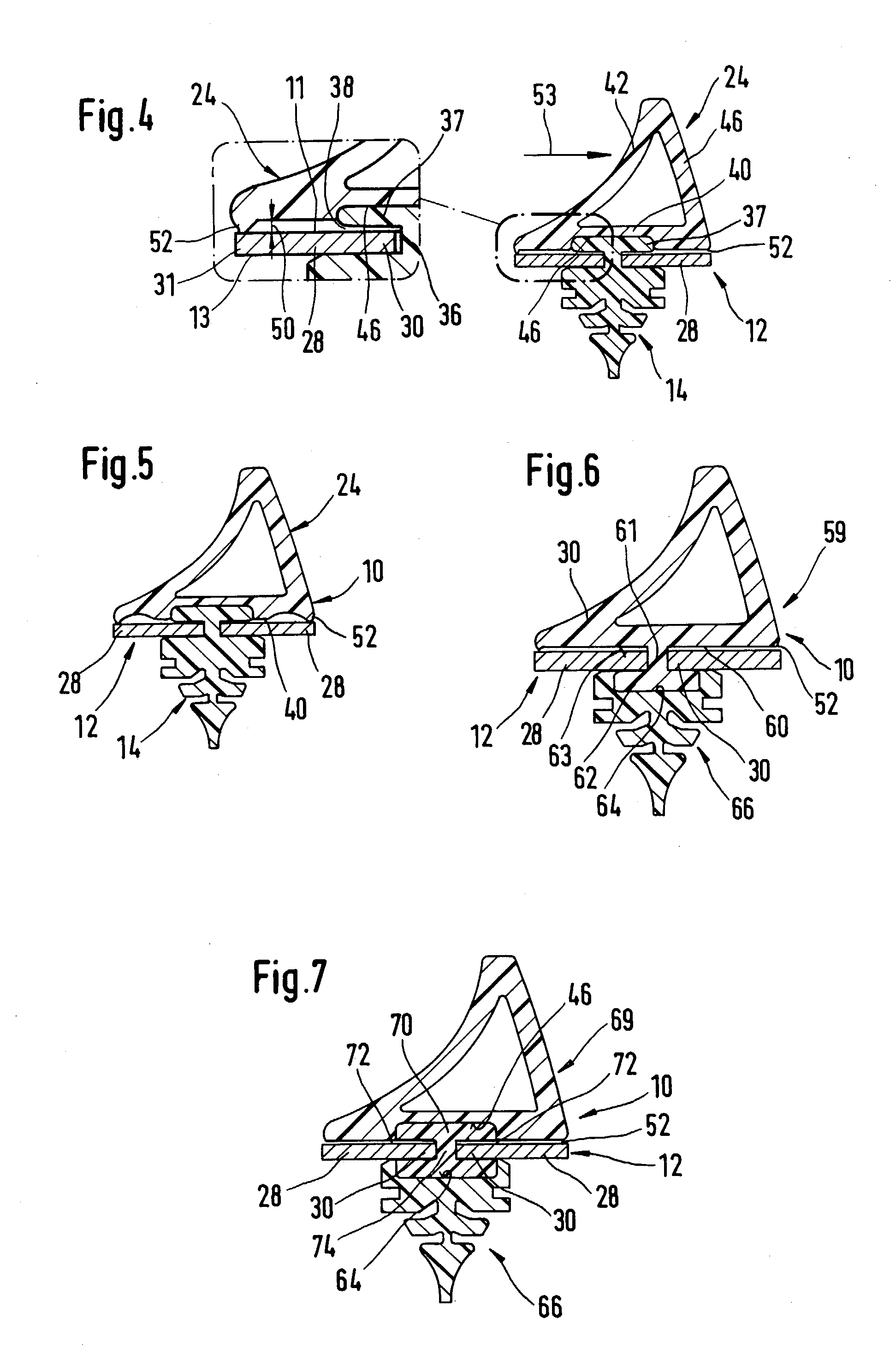

Wiper blade for cleaning screens in particular on motor vehicles

InactiveUS6944905B2Reduce weightSave materialWindow cleanersVehicle cleaningBand shapeMotorized vehicle

A wiper blade for cleaning motor vehicles is proposed, which is provided with a band-like, elongated, spring-elastic support element (12). The lower band surface (13) of the support element (12) oriented toward the window (22) has an elongated, rubber-elastic wiper strip (14), which can be placed against the window (22), disposed on it so that the longitudinal axes of these two parts are parallel and the upper band surface (11) of the support element (12) has a wind deflection strip (42) disposed on it, which extends in the longitudinal direction of the support element, is provided with an attack surface (54) oriented toward the main flow of the relative wind, and is comprised of an elastic material. A considerable weight savings for the wiper blade is achieved if the wind deflection strip (42, 142, or 242) has two diverging legs (44, 46), viewed in cross section, which are connected to each other at a common base (48) and whose free ends (50, 52) oriented toward the window (22) are supported on the wiper blade (10), and the attack surface (54) is embodied on the outside of the one leg (44).

Owner:ROBERT BOSCH CORP

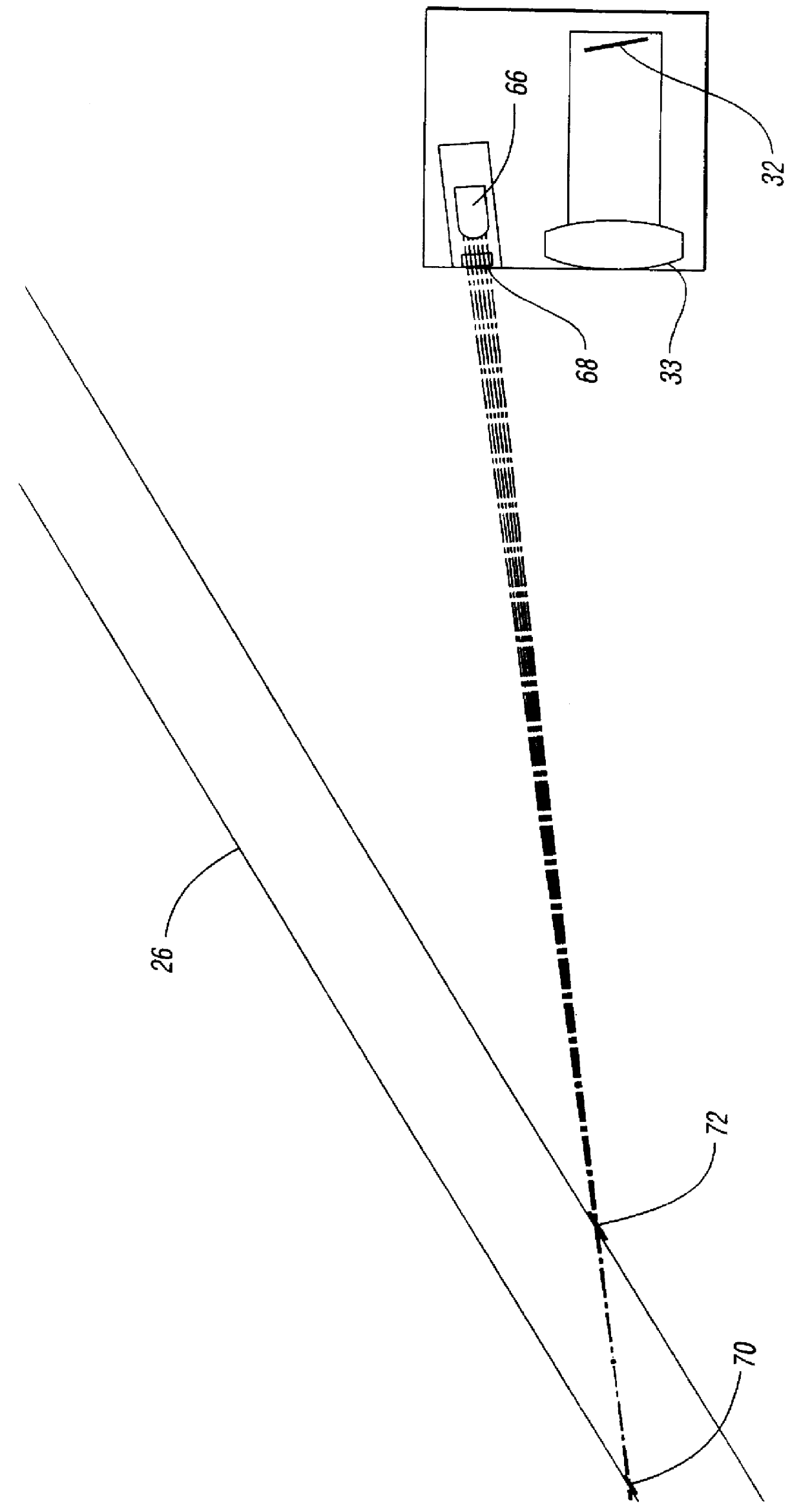

Integrated Automotive System, Pop Up Nozzle Assembly and Remote Control Method for Cleaning a Wide Angle Image Sensors Exterior Surface

ActiveUS20150138357A1Promote effectiveTelevision system detailsSpray nozzlesCamera lensRemote control

A pop-up external lens washing system has an extendable aiming fixture configured to aim a lens cleaning spray at an external lens which is exposed to the elements and apt to become soiled with debris. The extendable nozzle assembly is configured to be aimed toward the external lens by the extended aiming fixture during the washing operation only and has at least one laterally offset washing nozzle projecting from the aiming fixture to a spray washing fluid toward the external lens surface, spraying at a shallow, glancing spray aiming angle to impinge upon and wash the lens external surface.

Owner:DLHBOWLES INC

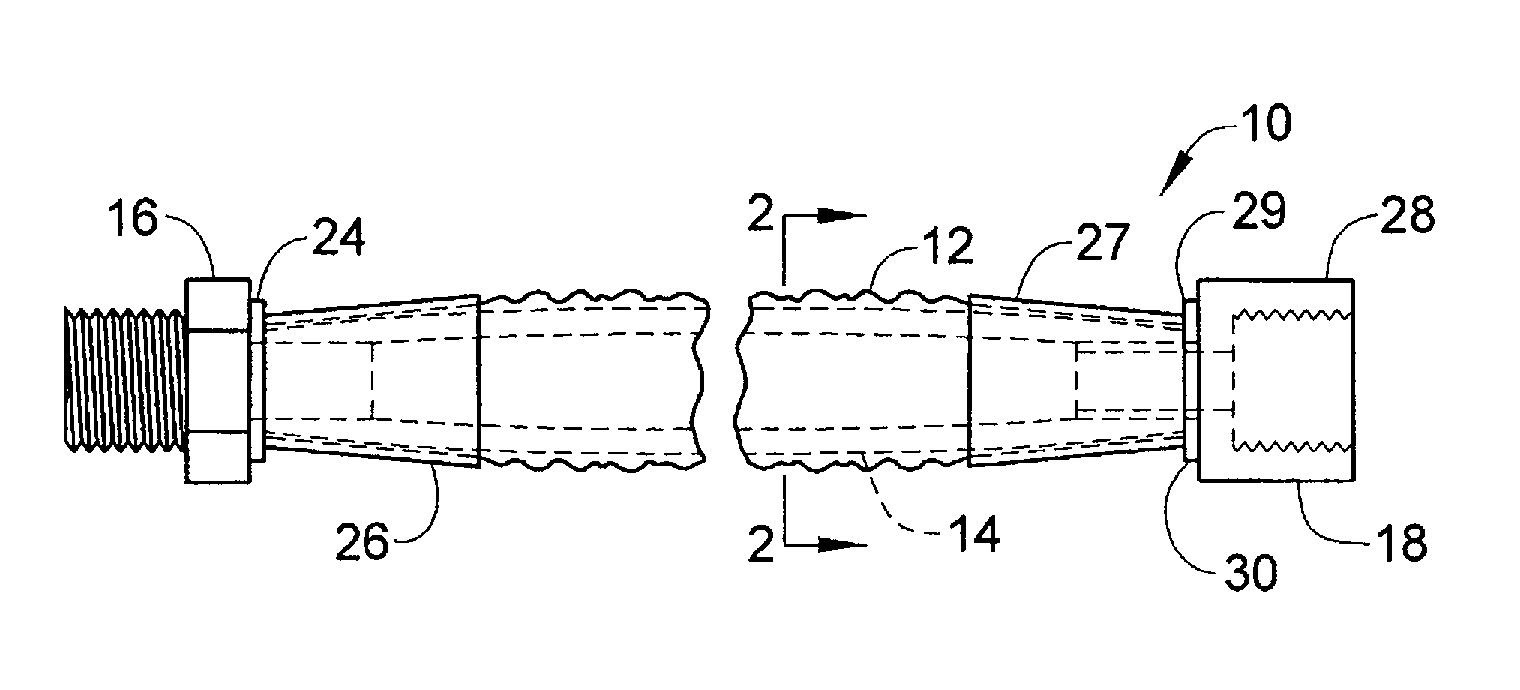

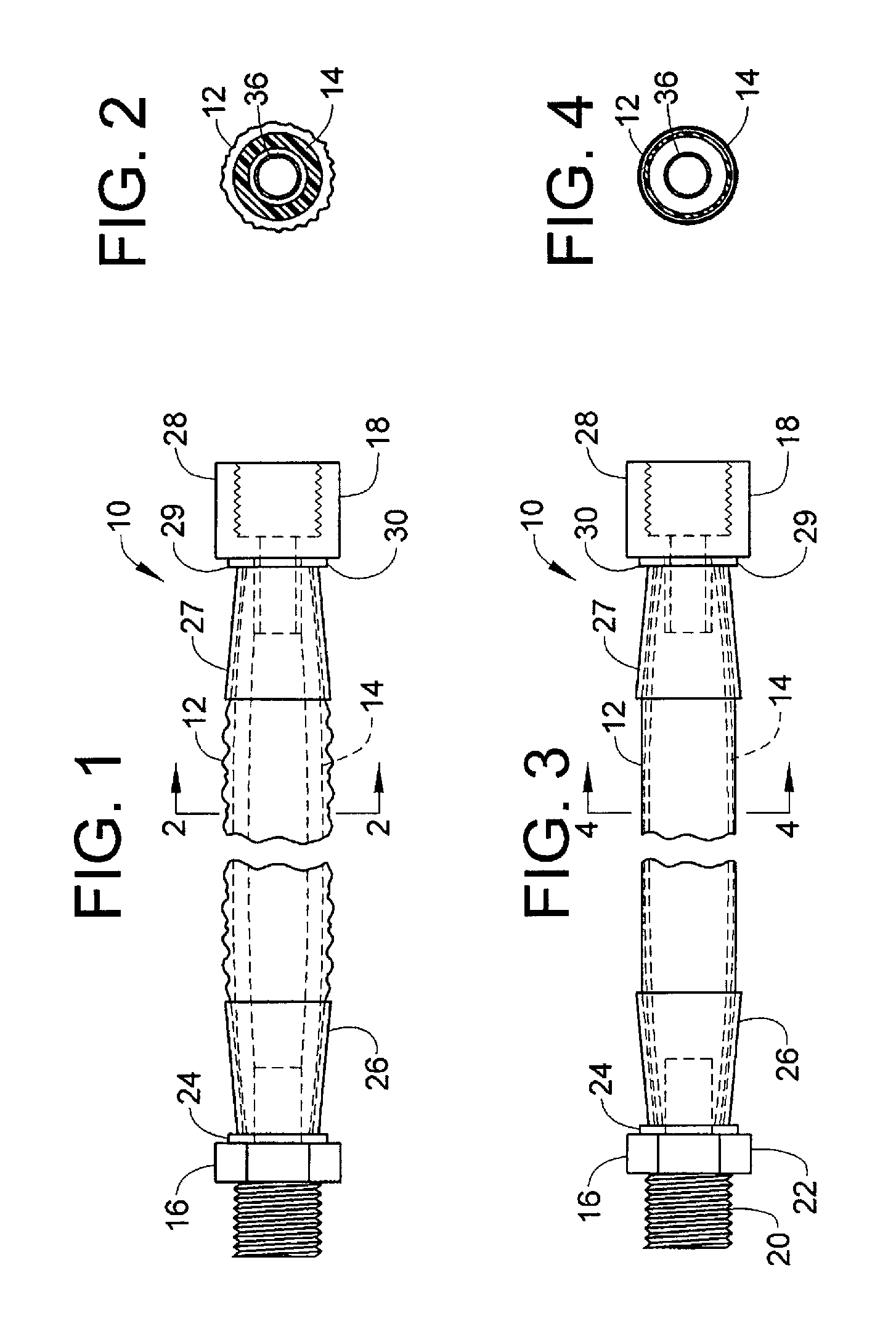

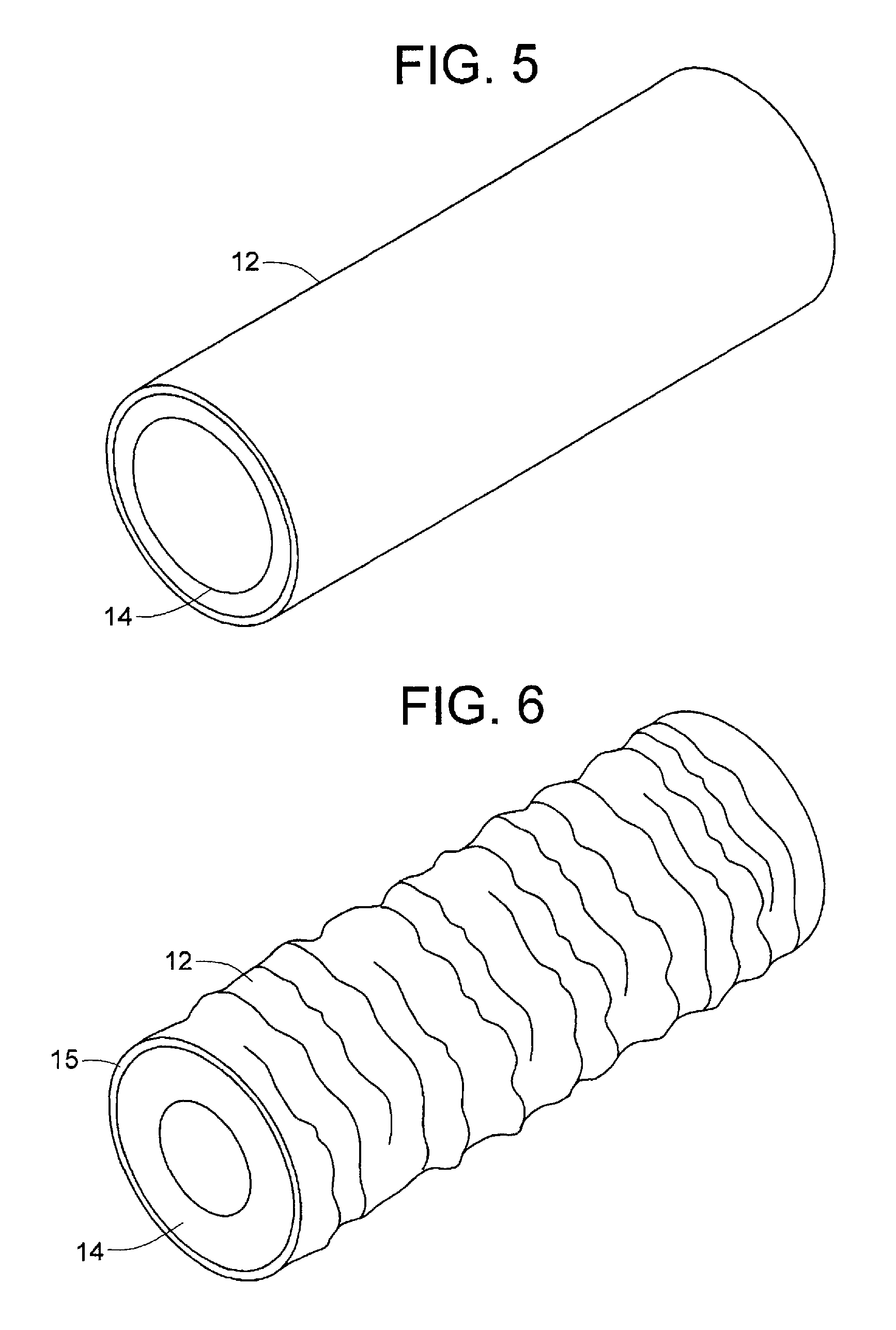

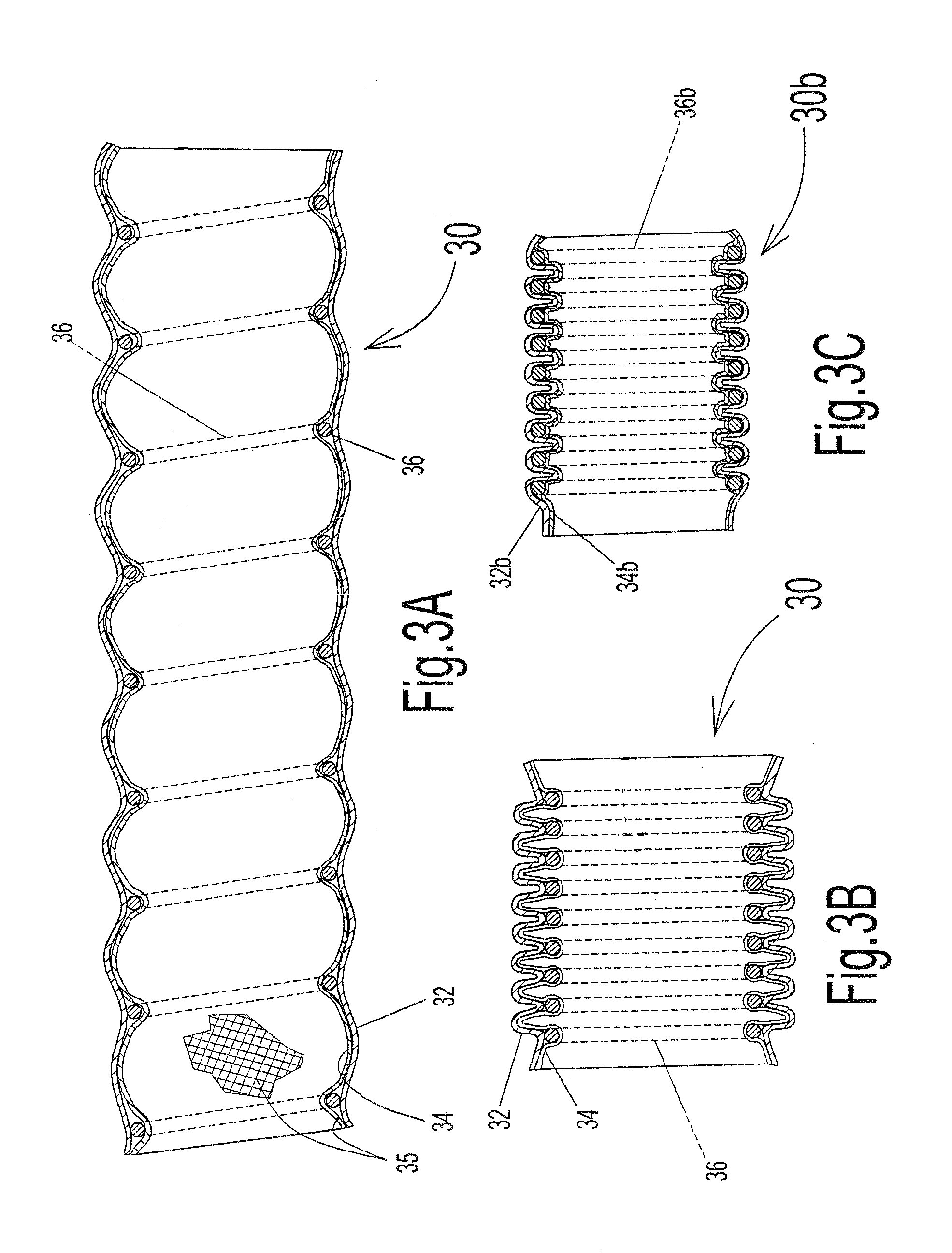

Expandable and contractible hose

A hose which automatically expands longitudinally and automatically expands laterally upon the application of a fluid pressure is disclosed. The hose can automatically expand longitudinally up to six times its unexpanded or contracted length. Upon release of the fluid pressure within the hose, the hose will automatically contract to a contracted condition. The hose includes an inner tube made from an elastic material and an outer tube made from a non-elastic material. The inner tube is positioned concentrically within the outer tube in both a contracted condition and an expanded condition. The outer tube is secured to the inner tube only at a first end of the inner and outer tubes and at a second end of the inner and outer tubes. The outer tube moves laterally and longitudinally with respect to the inner tube when the tubes are transitioning between a contracted condition and an expanded condition.

Owner:TELEBRANDS CORP

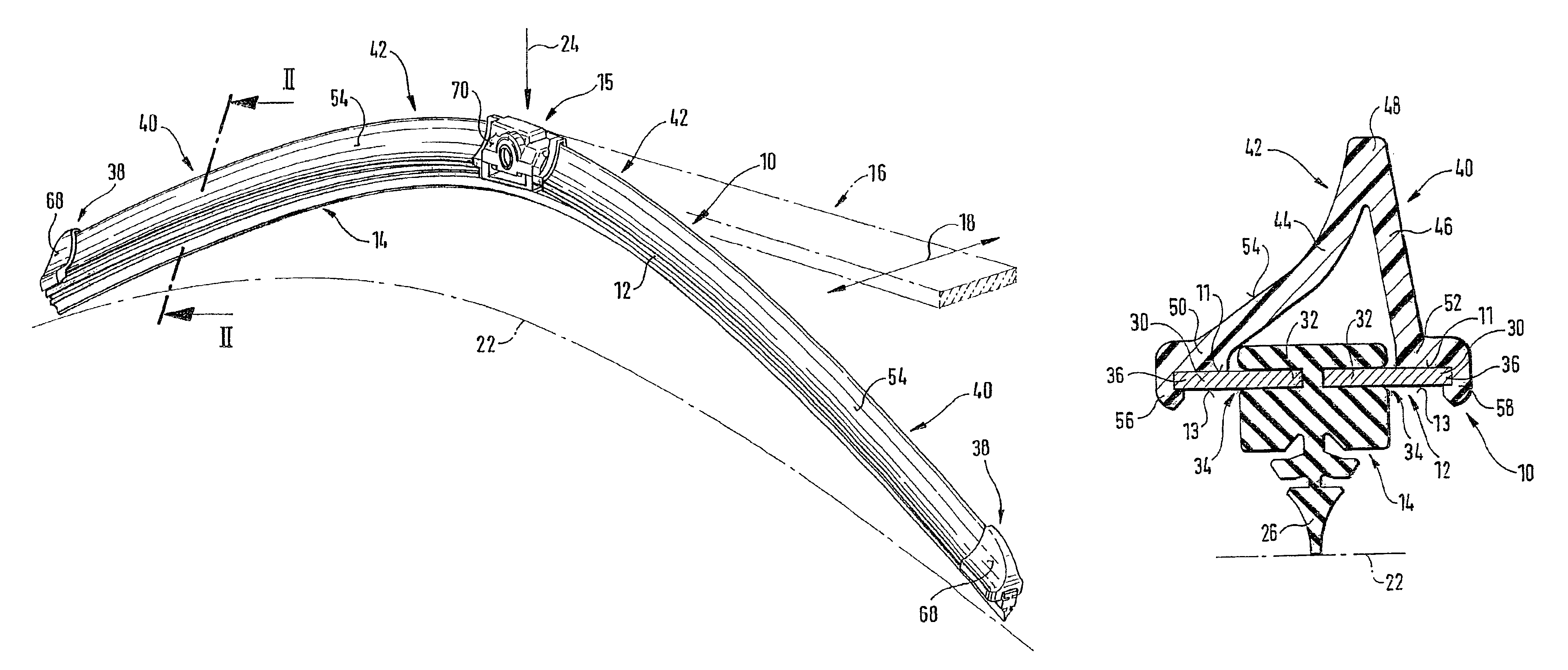

Wiper blade to clean windshields, in particular of automobiles

A wiper blade is proposed with which to clean windshields, in particular of automobiles. The wiper blade (10) has an elongated belt-shaped, flexible spring support element (12), with a separate first component designed as an elastic rubber wiper strip (14) that can be pressed against the windshield (20) located at the bottom belt surface (13) of the support element and with a separate second component located at the other upper belt surface (11) of the support element (12) that is designed as a wind deflection strip (24) that extends at least along a longitudinal section of the wiper blade (10). A particularly low-disruption wiper blade results if the two components (14, 24) are connected together at their sides facing one another.

Owner:ROBERT BOSCH CORP

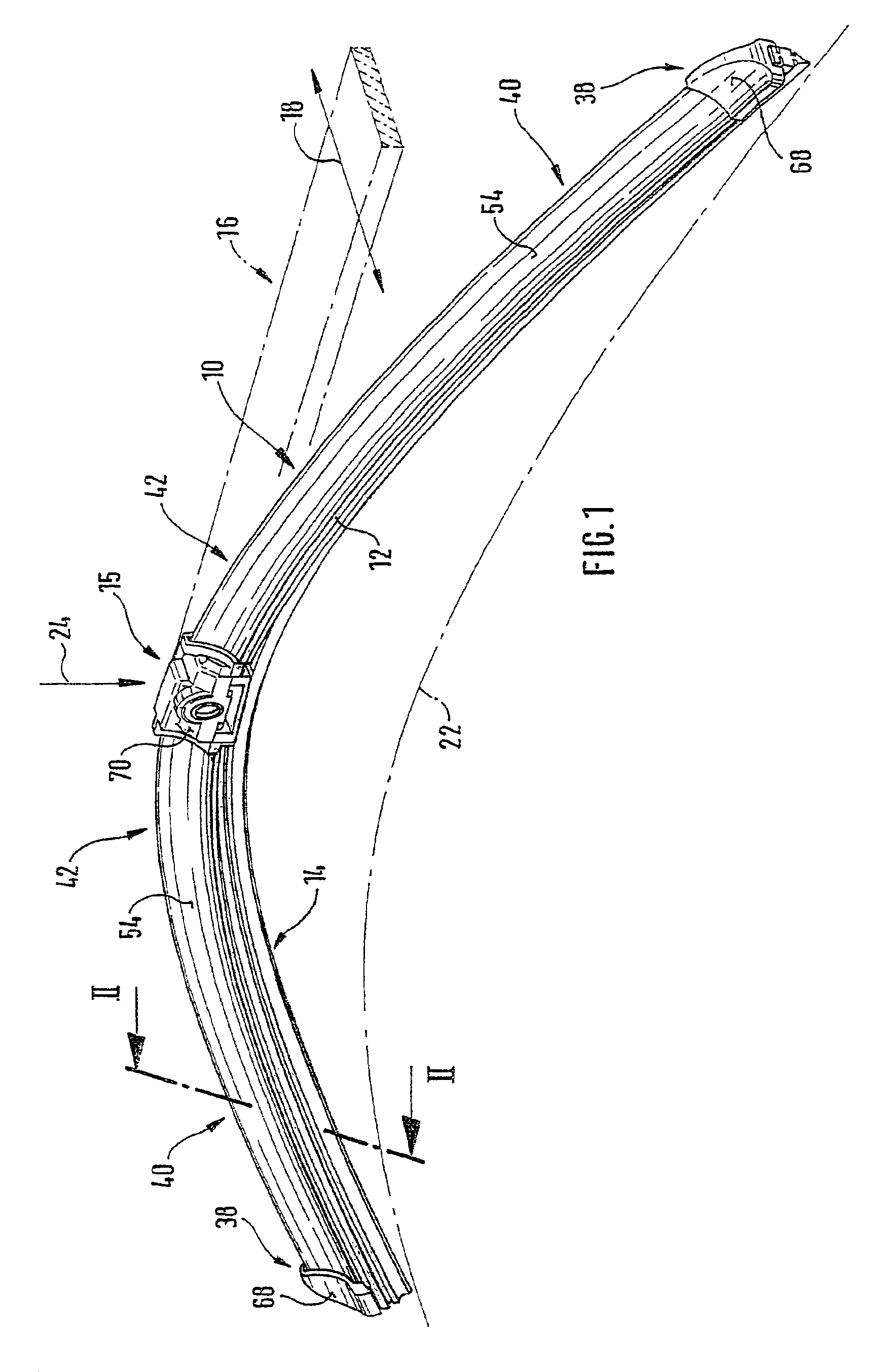

Wiper blade for cleaning panes, in particular of a motor vehicle

The invention relates to a wiper blade that cleans panes, in particular of motor vehicles. The wiper blade (10) comprises a strip-shaped, elongated, elastically resilient support element (12), the lower strip surface of which faces the pane (14) and is provided with an elongated, elastic wiper strip (24) running parallel to the longitudinal axis. The upper strip surface (16) of the element is provided with a wind deflector strip (42), which consists of an elastic material, extends in the longitudinal direction of the support element and has an oncoming stream surface (54) that faces the principal flow direction, (arrow 52), of the air stream. A particularly advantageous wiper blade, which is cost-effective to produce, can be achieved if the wind deflector strip, (when viewed in cross-section), comprises two limbs (48, 50), diverging from a common base (46) but mutually attached thereto, the free ends of said limbs facing the pane (14) and being supported on the wiper blade and if in addition, the oncoming stream surface (54) is configured on the external face of one limb (50) and the cross-sectional profile of the wind deflector strip is the same over its entire length.

Owner:ROBERT BOSCH CORP

Linearly retractable pressure hose

A linearly self-actuated hose for use in transporting fluids (liquids, gases, solid particles, and combinations of these three). Hose (30) has a biasing spring (36) that extends along its full length, and can comprise single or multiple springs and / or multiple diameter spring coils. Spring (36) is covered with hose cover material (32) on the outside and hose cover material (34) on the inside to form a sealed hose and are bowed inward or outward radially between the individual spring coils depending on the intended use of hose (30) to give the cover materials room to move out of the way when the hose retracts and the coils of spring (36) are forced close together. The Linearly Retractable Hose is operated by changing internal pressure within the hose relative to the ambient pressure on the exterior of the hose. Control of fluid pressure within hose (30) is what allows the hose to operate as an automatically extendable and retractable hose. The biasing of spring (36) depends on the type of use for the hose. For hose (30b), which will be used as a vacuum hose then the biasing spring (30b) must exert an extending force on the cover material (opposite that for a pressure hose). If the hose is to be used as a pressure hose (garden hose, etc.), spring (36) will need to have a bias that exerts a retracting force on cover materials (32) and (34).

Owner:TELEBRANDS CORP

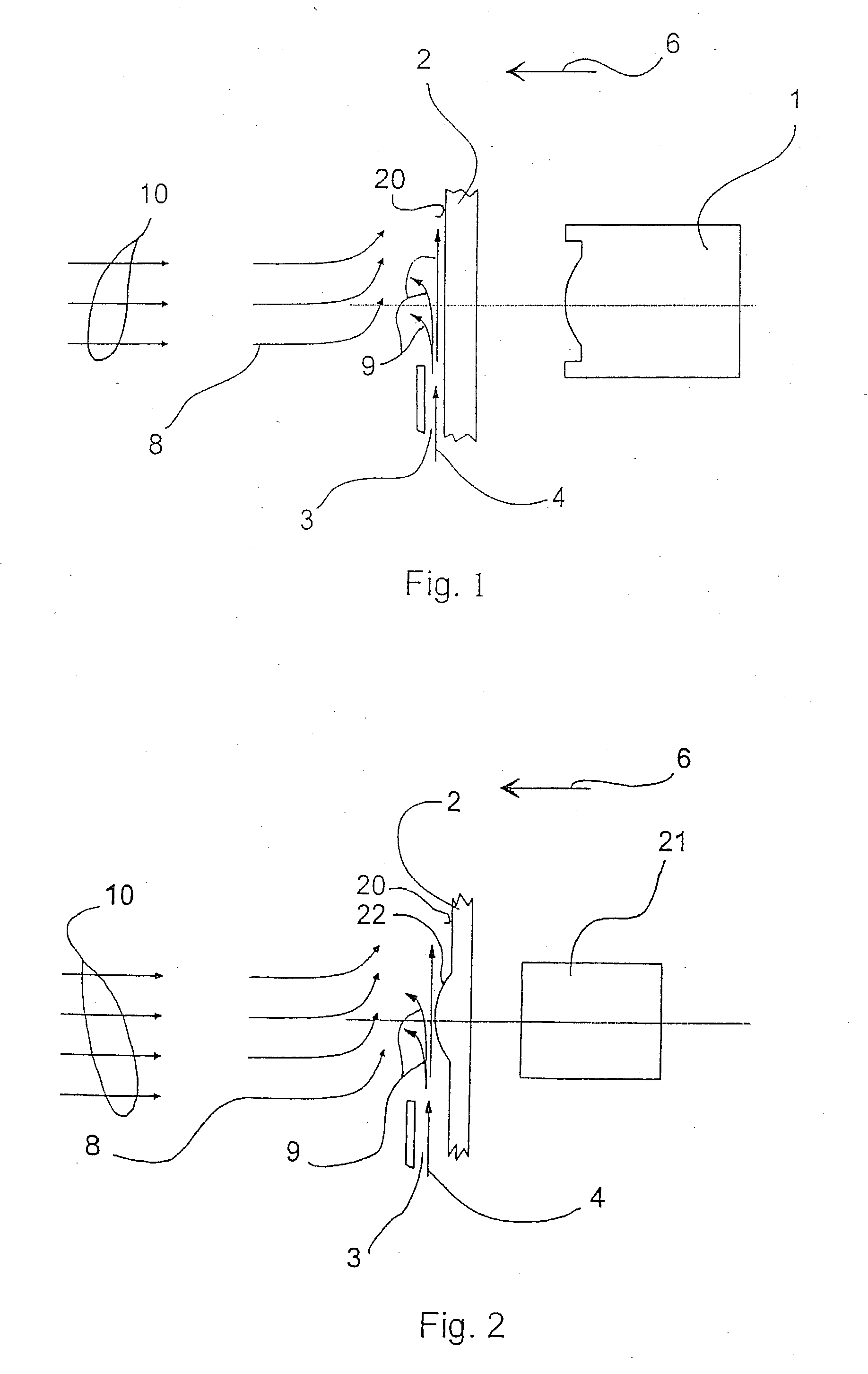

Device for keeping clean optical elements on motor vehicle clean, in particular covers for sensors or cameras

The invention relates to a device for keeping optical elements (1) clean in motor vehicles, in particular sensor or camera covers. This is done according to the present invention by applying a directed stream of gas, in particular a stream of air (4), to the transparent cover (2) in such a way that when the cover moves (6) relative to the surroundings no ambient atmosphere (10), in particular no ambient air, reaches the surface (20) of the cover. According to one embodiment, using a nozzle (3) pressurized air (4) is blown in, producing a transverse air stream (9). It is also possible, using a cover, to form a buffer space in front of the cover in addition to the transverse air stream. In a further refinement, a cleaning nozzle and a heater for the cover can be provided, in order to also be able to perform cleaning when soiling has occurred during stationary operation and to remove icing at low temperatures. To this end the cleaning fluid and / or the supplied air may also be pre-heated.

Owner:ROBERT BOSCH GMBH

Washer nozzle for vehicle mounted camera, vehicle mounted camera, and washer device for vehicle

InactiveUS20110292212A1Reliable washingAvoid flowSpray nozzlesColor television detailsForeign matterOnboard camera

A washer nozzle removes foreign matter on an image capturing surface of a camera mounted to the outside of a vehicle by supplying washer fluid to the image capturing surface. The washer nozzle includes an inside spray hole and a discharge portion. The inside spray hole sprays the washer fluid introduced into the washer nozzle. The discharge portion receives washer fluid sprayed from the inside spray hole. The discharge portion has a passage extending in a direction intersecting the spray direction of the washer fluid and a discharge port connected to the passage. The discharge portion discharges, from the discharge port, washer fluid sprayed from the inside spray hole along the image capturing surface, while filling the passage with the washer fluid, thereby washing the image capturing surface.

Owner:ASMO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com