Patents

Literature

121results about How to "High Vickers hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

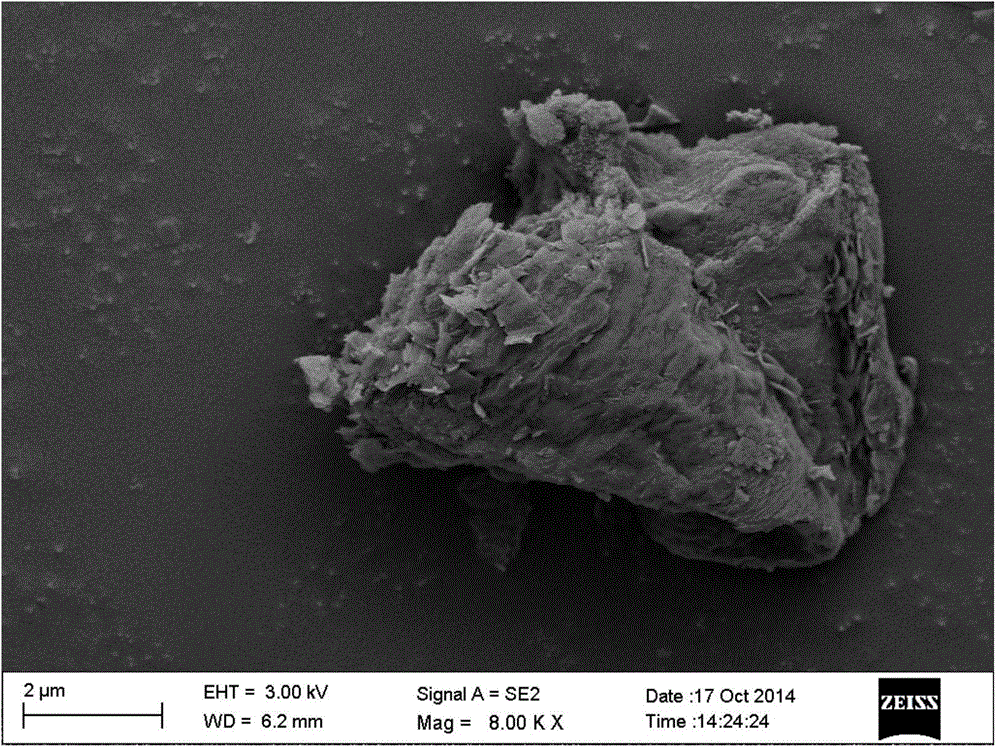

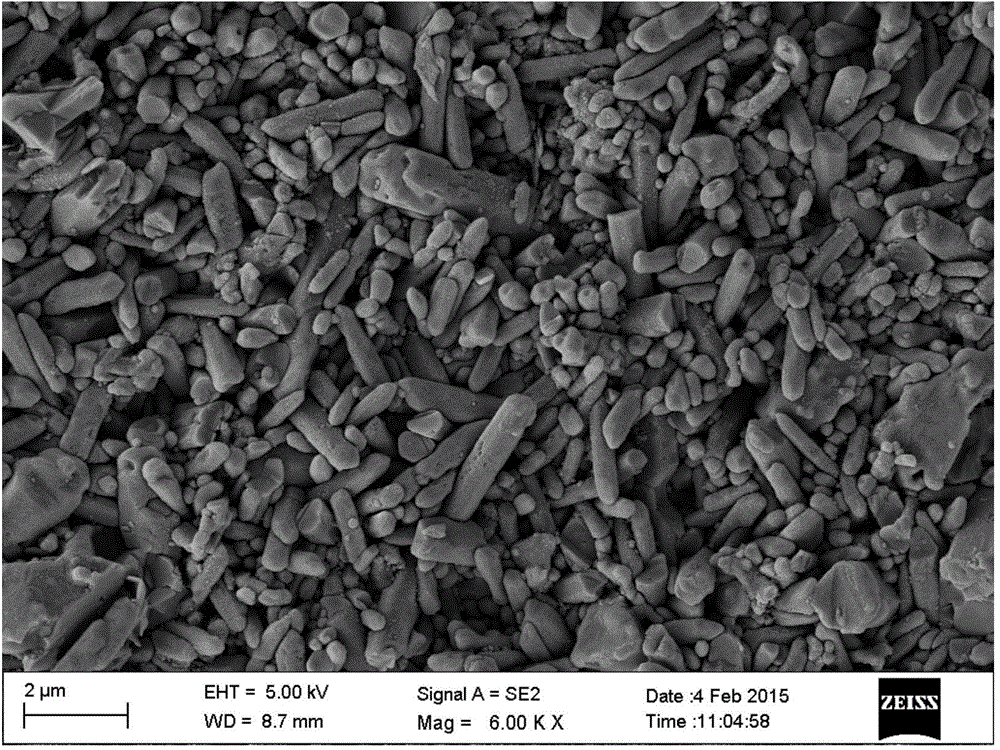

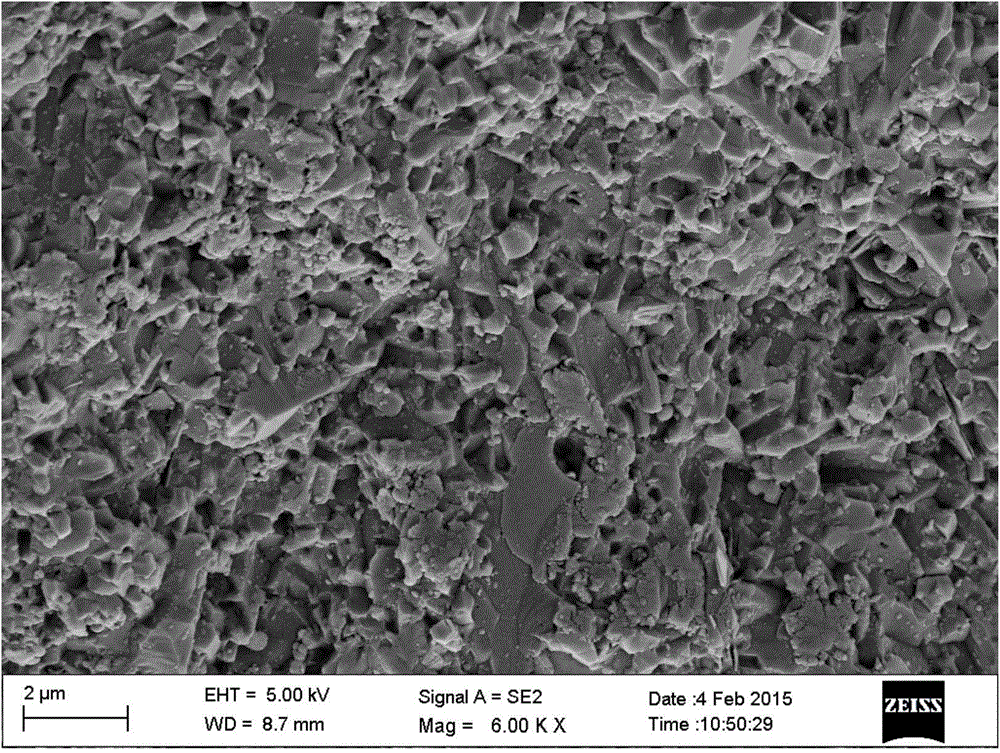

Preparation method of silicon nitride-based self-lubricating ceramic cutter material containing alumina-coated hexagonal boron nitride composite powder

ActiveCN104892005AHigh Vickers hardnessImprove toughness and strengthHexagonal boron nitrideBoron nitride

The invention relates to a preparation method of a silicon nitride-based self-lubricating ceramic cutter material containing alumina-coated hexagonal boron nitride composite powder. The silicon nitride-based self-lubricating ceramic cutter material comprises, by volume, 57-70% of micrometer silicon nitride, 5-15% of nanometer silicon nitride, 5-15% of micrometer titanium carbide, 3.2% of alumina, 4.8% of yttrium oxide, and 2-15% of alumina-coated hexagonal boron nitride. The preparation method comprises preparing alumina-coated hexagonal boron nitride composite powder with particle sizes of 4-12 micrometers, weighing micrometer silicon nitride, nanometer silicon nitride and micrometer titanium carbide, respectively preparing their suspension liquids, carrying out ultrasonic dispersion, carrying out mixing, adding alumina and yttrium oxide into the mixture, carrying out ultrasonic dispersion for 15-20min to obtain a composite suspension liquid, carrying out ball milling, adding the alumina-coated hexagonal boron nitride composite powder into the composite suspension liquid, carrying out ball milling, carrying out vacuum drying to obtain mixed powder and carrying out vacuum hot pressing sintering molding. The silicon nitride-based self-lubricating ceramic cutter material containing alumina-coated hexagonal boron nitride composite powder can improve ceramic cutter mechanical properties and guarantee self-lubricating performances.

Owner:QILU UNIV OF TECH

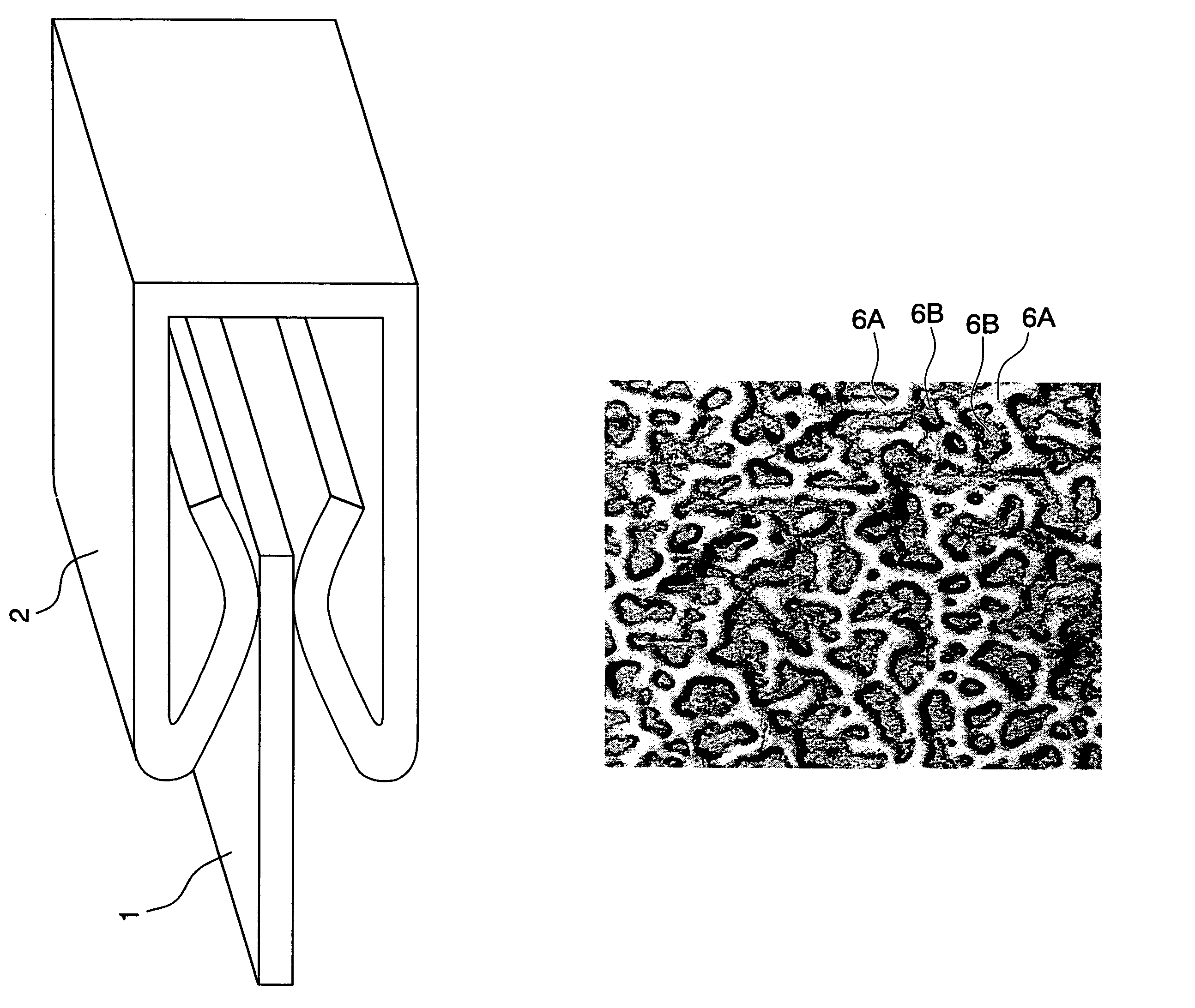

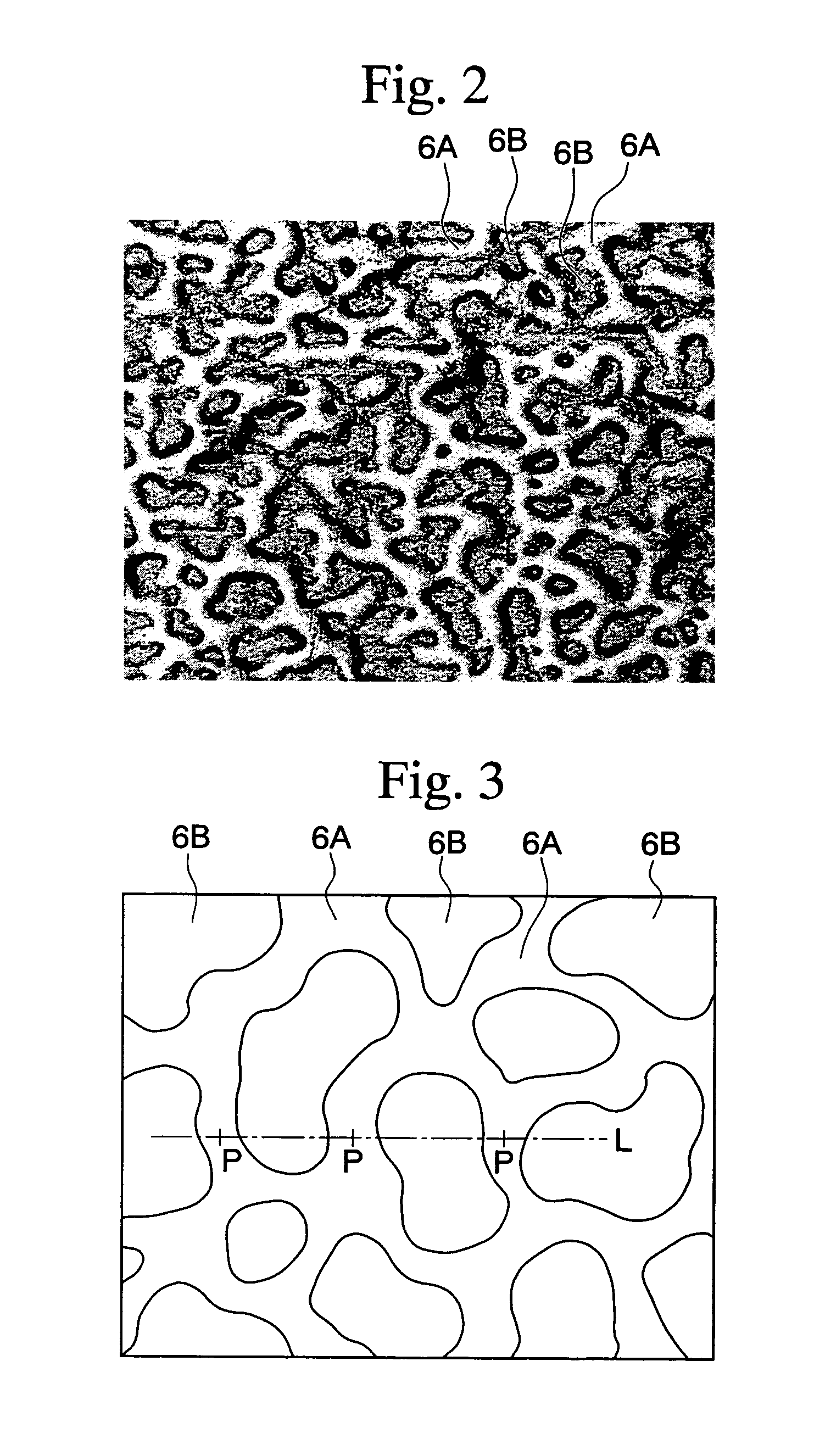

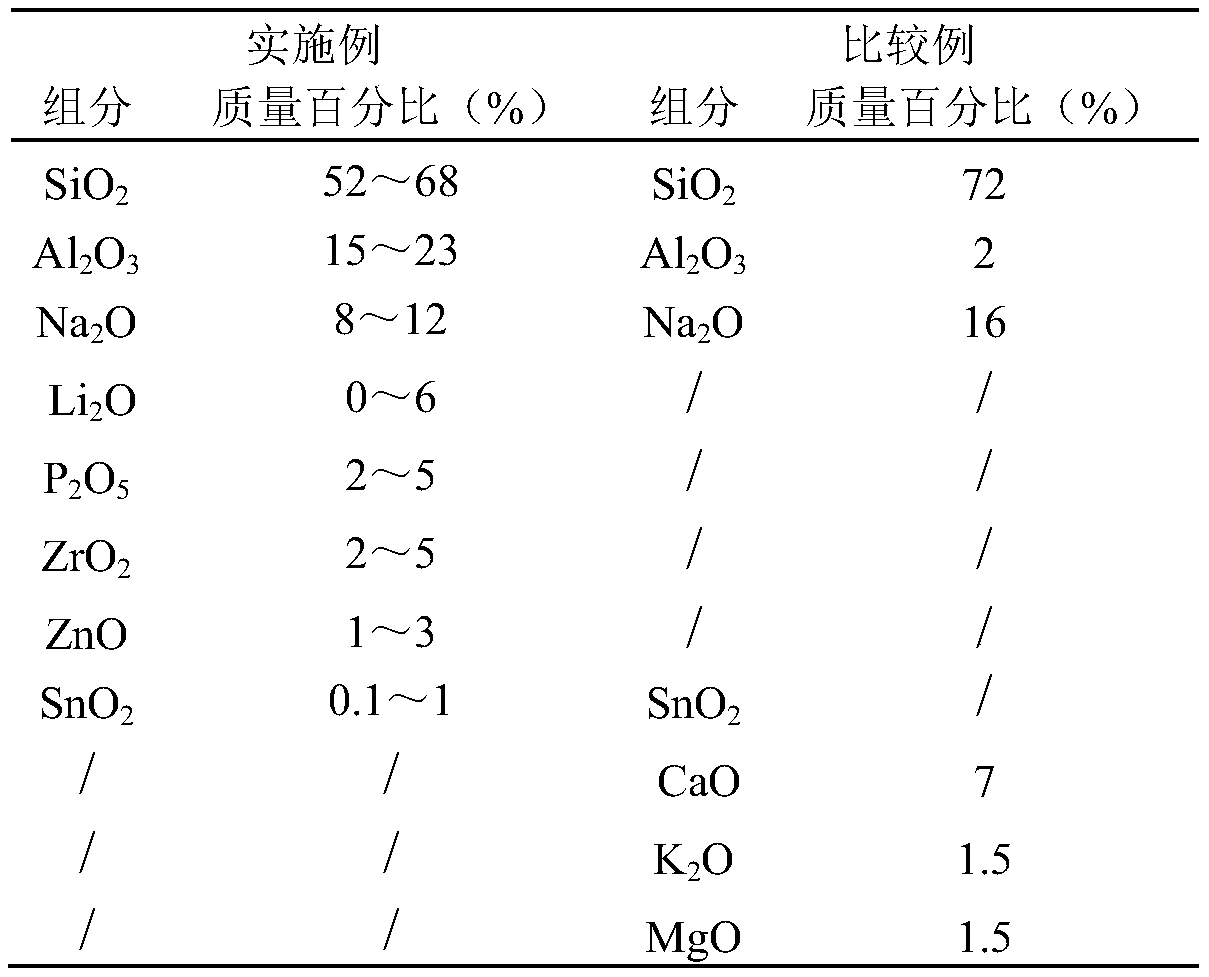

Plated material and method of manufacturing the same, terminal member for connector, and connector

ActiveUS7029760B2Excess wear can be preventedEasy to slideContact materialsSingle bars/rods/wires/strips conductorsHardnessAlloy

A plated material reduces insertion and withdrawal forces when used in a connector. A terminal member for a connector and a connector therewith are also provided. The plated material comprises a substrate 3 made of Cu or a Cu alloy and a metal plating layer 6 formed on the surface of the substrate 3. A soft region 6A spreading in a network-shape and a hard region 6B surrounded by the network of the soft region 6A coexists in the metal plating layer 6. The soft region 6A has a Vickers hardness of 20 to 250, while the hard region 6B has a Vickers hardness of 60 to 700, which is at least 30 higher than that of the soft region 6A. An average size of the network of the soft region 6A is from 5 to 500 μm.

Owner:MITSUBISHI SHINDOH CO LTD

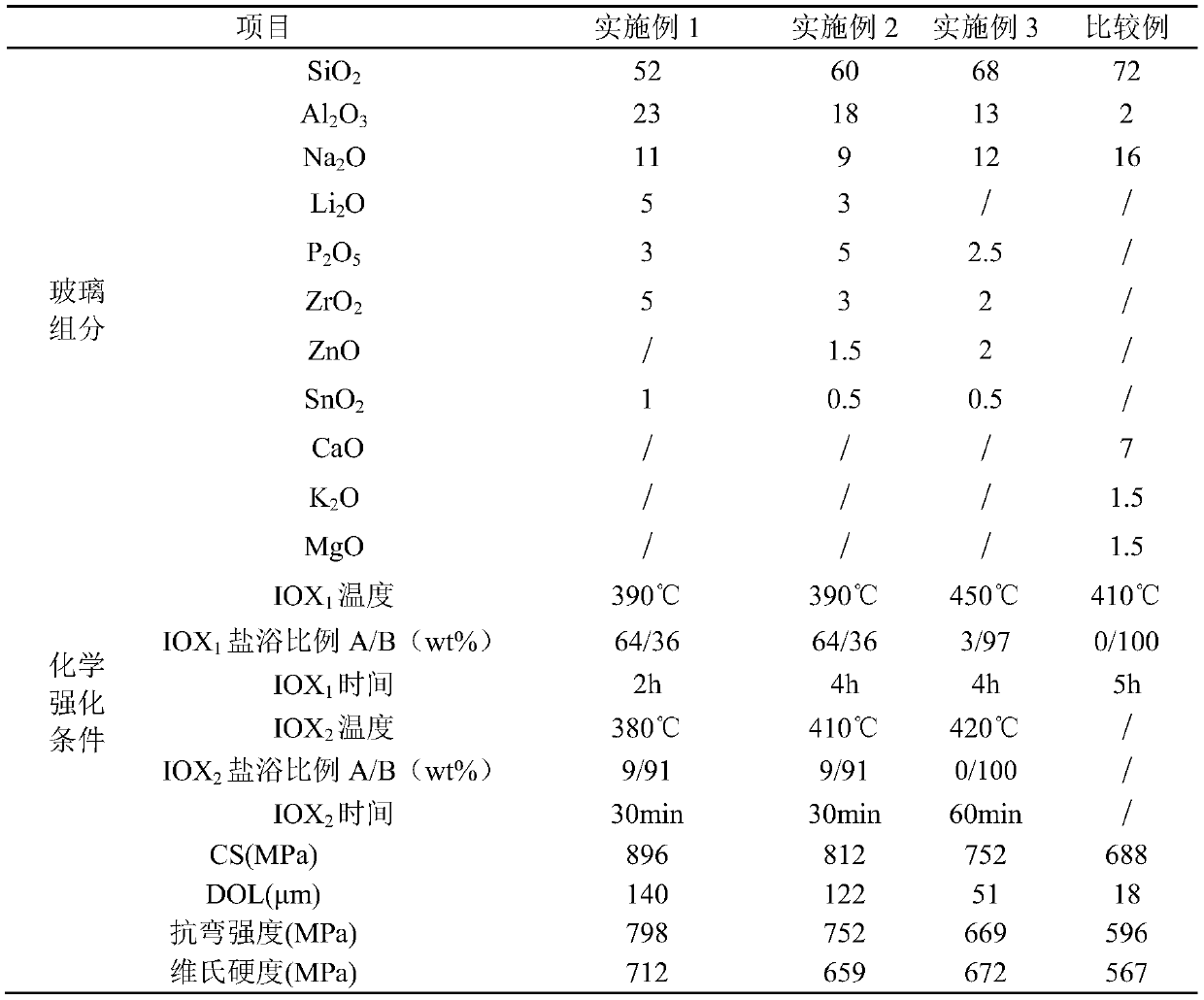

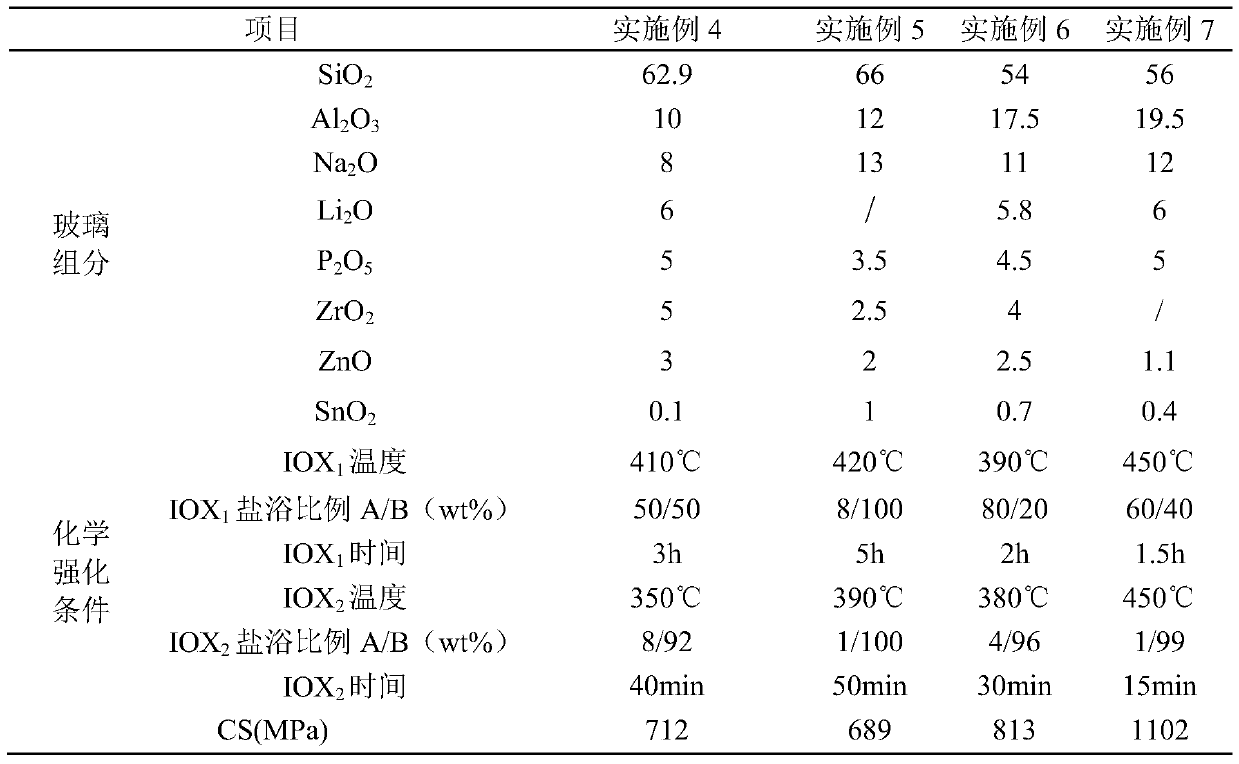

Alkali-containing alumina silicate glass, and product, strengthening method and application thereof

The invention relates to alkali-containing alumina silicate glass, and a product, a strengthening method and application thereof. The alkali-containing alumina silicate glass is sequentially subjectedto ion exchange in a salt bath of sodium nitrate and potassium nitrate at 350-450 DEG C for two times to obtain the chemically strengthened alumina silicate glass product. The glass comprises 52-68%of SiO2, 10-23% of Al2O3, 8-13% of Na2O, 0-6% of Li2O, 2-5% of P2O5, 0-5% of ZrO2 and 0-3% of ZnO. The surface pressure stress of the chemically strengthened alumina silicate glass product is greaterthan 600 MPa, the stress layer compression depth thereof is greater than 50 micrometers, the bending strength thereof is greater than 600 MPa, and the Vickers hardness thereof is greater than 600 MPa.The chemically strengthened alkali-containing alumina silicate glass product is applied to an electronic device.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

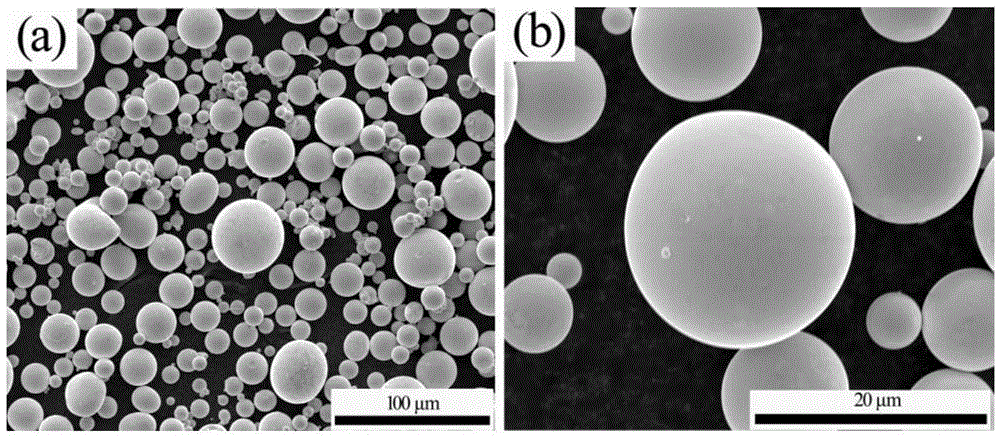

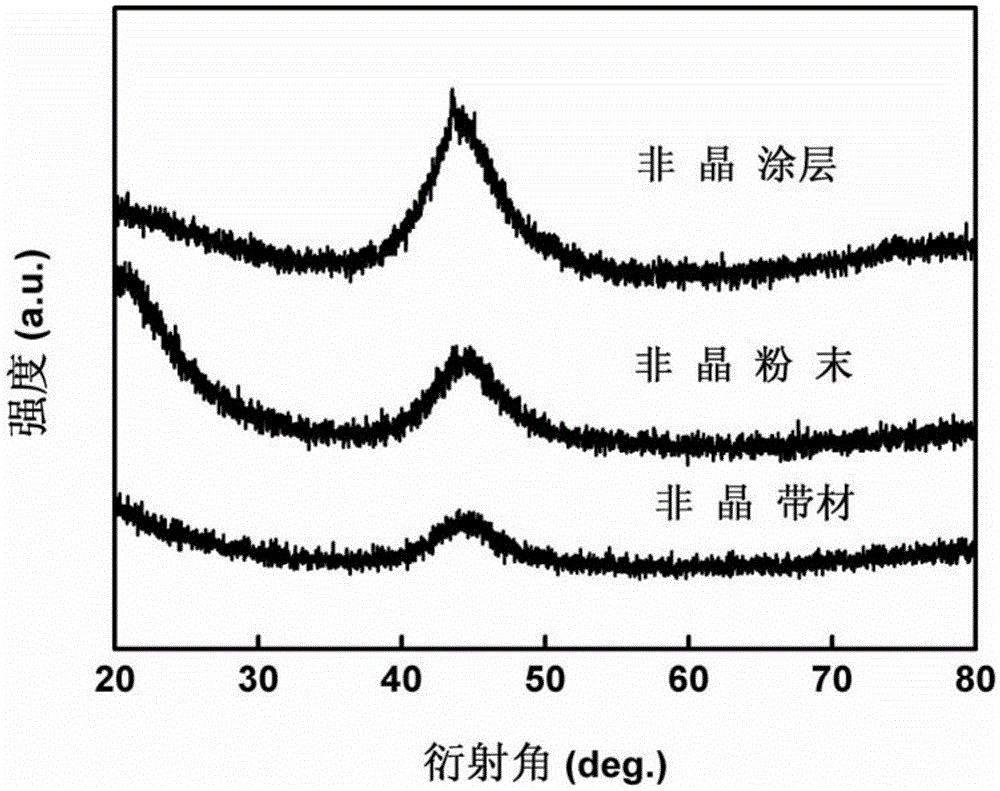

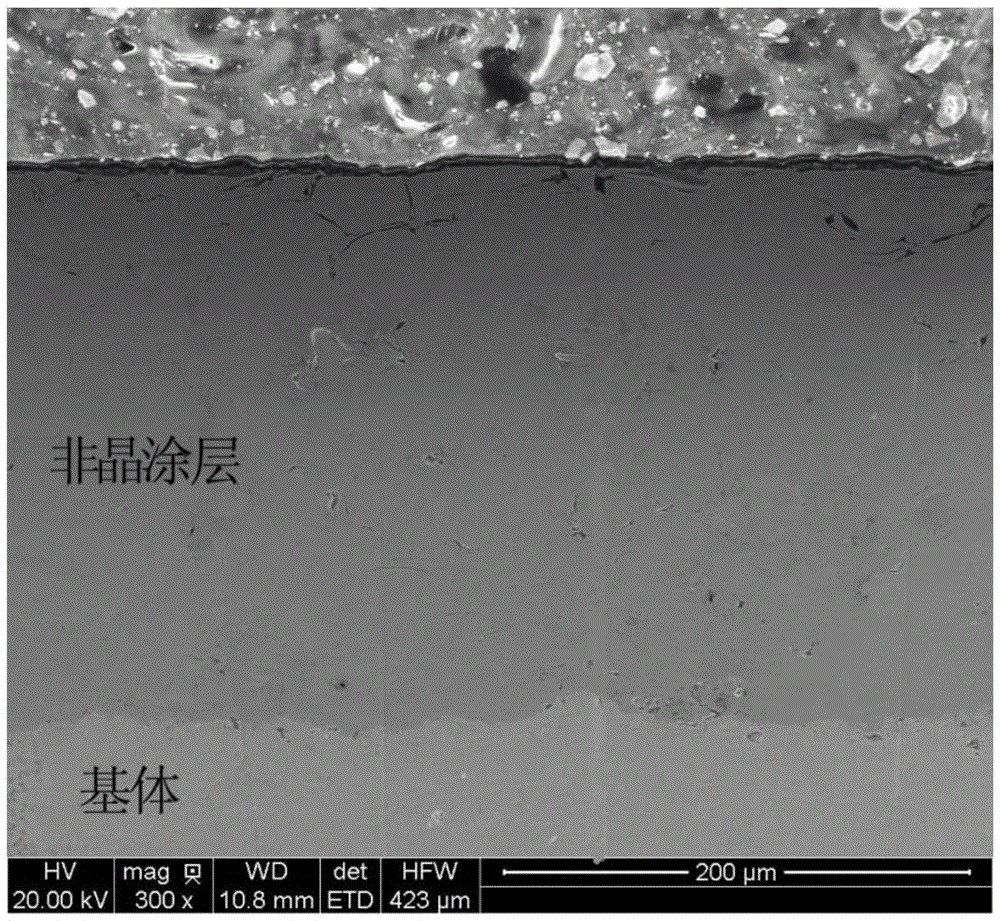

Iron-base amorphous alloy, powder material of alloy and wear-resisting anticorrosion coating of alloy

The invention provides an iron-base amorphous alloy. The chemical formula of the iron-base amorphous alloy is FeaCrbNicModPeCfBgSih, wherein a, b, c, d, e, f, g and h are molar contents of corresponding atoms, b is larger than or equal to 5 and smaller than or equal to 15, c is larger than or equal to 2 and smaller than or equal to 15, d is larger than or equal to 2 and smaller than or equal to 8, e is larger than or equal to 6 and smaller than or equal to 12, f is larger than or equal to 2 and smaller than or equal to 6, g is larger than or equal to 3 and smaller than or equal to 6, h is larger than or equal to 1 and smaller than or equal to 5, and the balance is iron. According to the chemical formula, compounding and smelting are carried out to obtain an ingot casting; then, resmelting is carried out, and through vacuum spraying and cooling, a powder material of the iron-base amorphous alloy is obtained. By means of the supersonic speed flame spraying technology, the iron-base amorphous alloy powder is sprayed to the surface of a base body to prepare an iron-base amorphous alloy coating. The coating is high in amorphous content, low in porosity and oxygen content and high in diamond pyramid hardness and has the good wear-resisting anticorrosion performance and has the wide application prospect in fields of energy, chemical engineering, national defense, aerospace, ships and the like.

Owner:NINGBO INNOVATION CENT FOR APPLIED MAGNETICS CO LTD

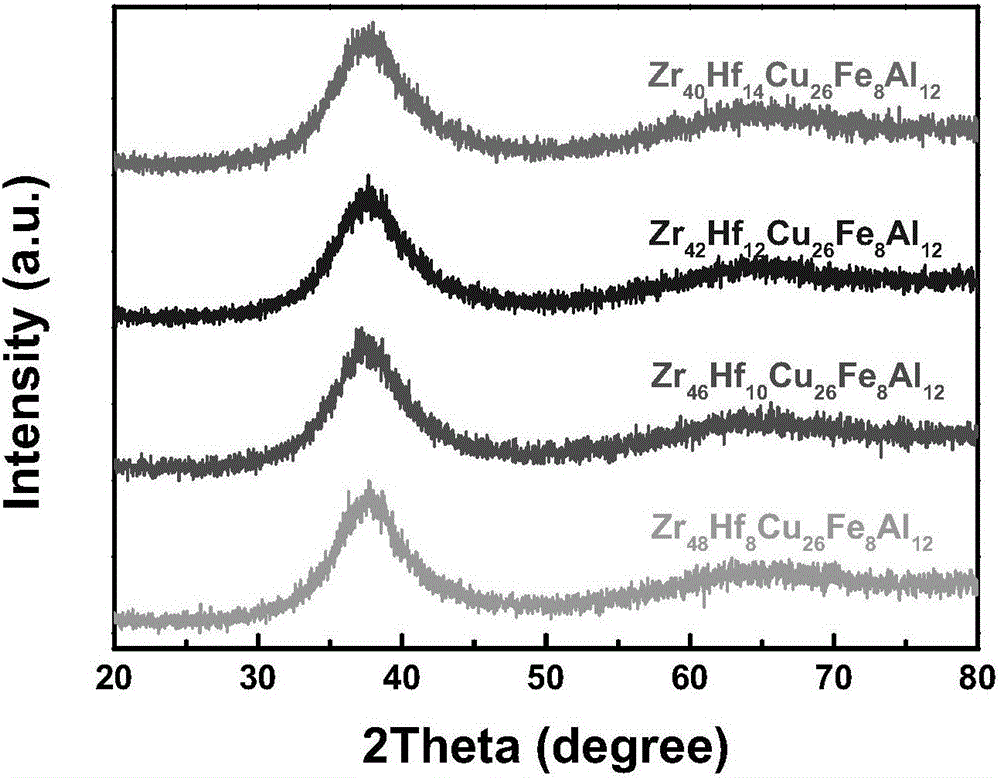

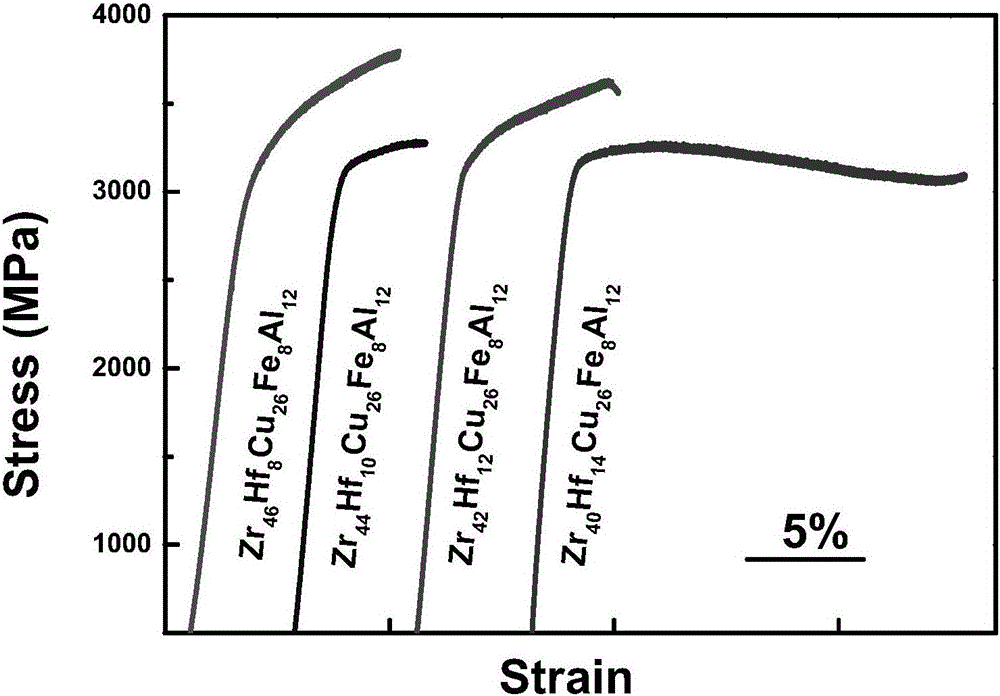

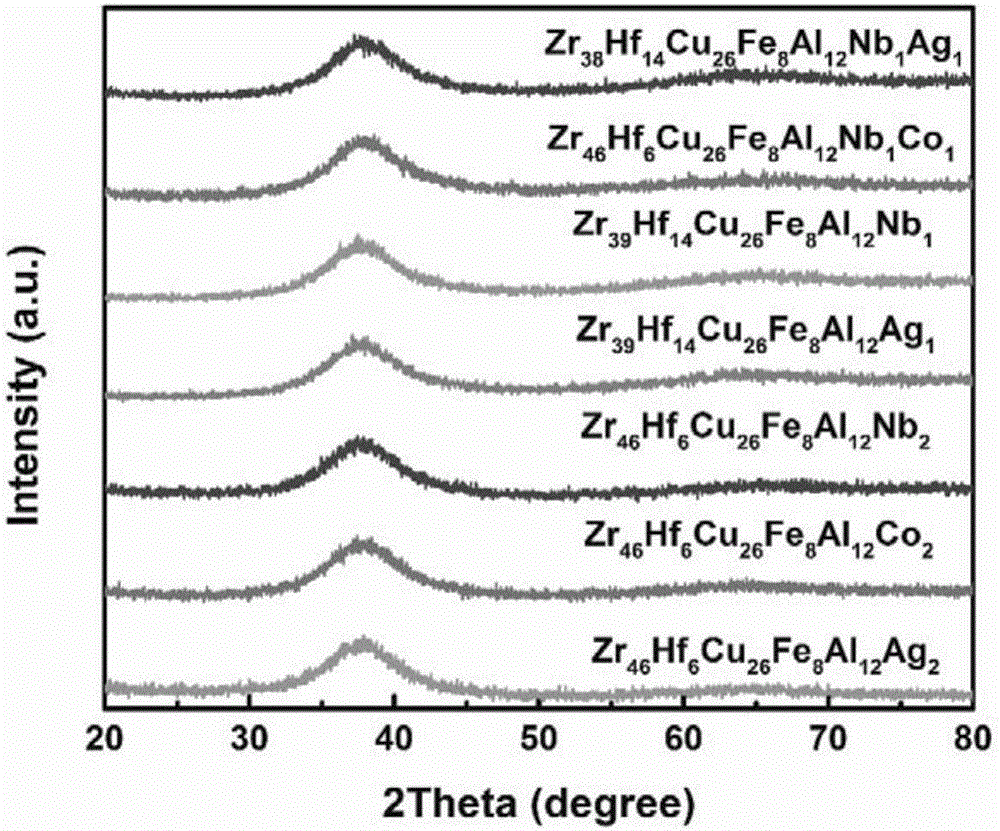

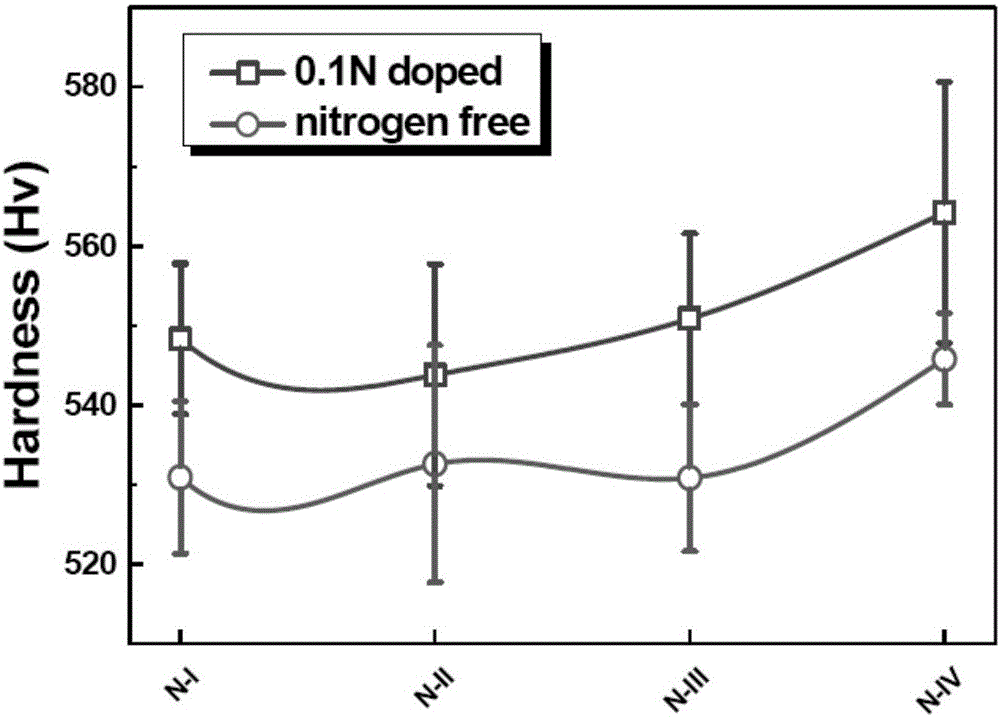

Beryllium-free nickel-free high-ductility zirconium-base block body amorphous alloy and preparation method thereof

ActiveCN106756647AGood biocompatibilityWide temperature range of subcooled liquid phase regionBiocompatibility TestingNickel free

The invention provides a beryllium-free nickel-free high-ductility zirconium-base block body amorphous alloy and a preparation method thereof. The alloy comprises, by atom, 38-50% of Zr, 2-15% of Hf, 20-30% of Cu, 5-10% of Fe, 10-15% of Al, 0-5% of Co, 0-5% of Ag and 0-5% of Nb. The electric arc melting copper mould casting method is adopted for preparation. The amorphous alloy is free of metal elements such as Be and Ni, and biocompatibility of the zirconium-base alloy is improved. The high amorphous forming capacity is achieved, and the zirconium-base block body amorphous alloy with the critical size being no less than 5 mm can be prepared through the copper mould casting method. According to the beryllium-free nickel-free high-ductility zirconium-base block body amorphous alloy, high hardness is achieved, and vickers hardness is larger than 540 Hv; the plastic deformation capacity being larger than 3% is achieved; and the super-cooled liquid phase region range is wide and reaches 92 K at most. The beryllium-free nickel-free high-ductility zirconium-base block body amorphous alloy and the preparation method thereof has very wide application prospects in the fields of biomedical materials such as a precise complex medical component, a joint prosthesis and a human skeleton.

Owner:UNIV OF SCI & TECH BEIJING

Optical Glass and Optical Element

Owner:KONICA MINOLTA OPTO

Method for producing multi-metal wear-resistant steel pipe

The invention discloses a method for producing a multi-metal wear-resistant steel pipe, and the method belongs to the technical field of production of tubes and pipes. The mixing of materials is firstly carried out: the following components by weight content are taken and evenly mixed: 58-61 percent of copper chrome alloy power, 16-18 percent of iron oxide powder, 22-24 percent of aluminium powder and 0.001-0.005 percent of nano-silicon carbide powder; then a seamless steel pipe or a straight seam steel pipe with the wall thickness of 3-5mm is further taken and cut into the appropriate length; then the steel pipe is fixed on a pipe molding machine to lead the steel pipe to rotate at the speed of 1000-1400rpm; the composition is further sent into an inner cavity for centrifugal casting, thereby leading the thickness of a multi-metal layer which is evenly distributed on the pipe wall to be 3-15mm; the rotation state of the steel pipe is continuously kept, and the steep pipe is removed after the curing of the inner wall of the steel pipe or the direct cooling to the room temperature. The method can line the thicker multi-metal layer in the thin-walled steel pipe, and the produced steel pipe has the advantages of great strength, good toughness and wear resistance.

Owner:YANGZHOU JUYE WEAR-RESISTANT COMPOSITE MATERIAL CO LTD

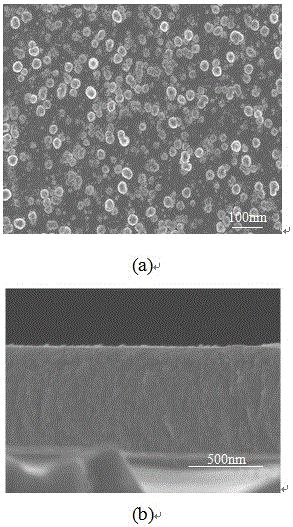

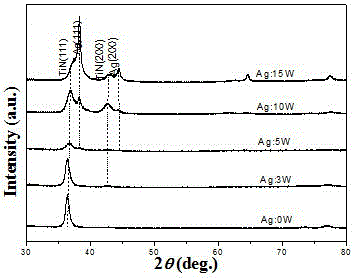

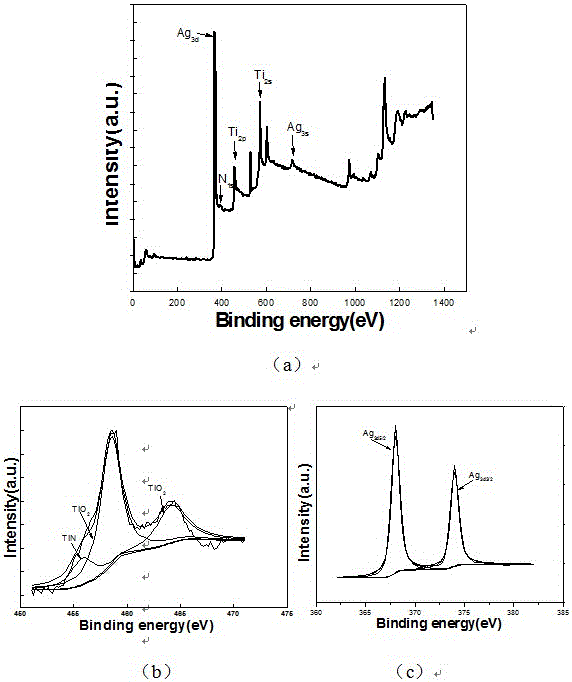

TiN-Ag nano composite coating and preparation and application thereof

InactiveCN105862001AHigh Vickers hardnessEvenly dispersedVacuum evaporation coatingPharmaceutical delivery mechanismComposite filmHardness

The invention discloses a TiN-Ag nano composite coating and a preparation and application thereof. The TiN-Ag nano composite coating is characterized by being a composite film obtained by magnetron co-sputtering deposition; and a certain substrate temperature is kept in the sputtering process, and the obtained thickness is between 0.5[mu] m and 1[mu] m. The negative bias voltage of a substrate in the preparation process is adjusted by experiments; for an obtained TiN-Ag nano composite coating, the hardness of the substrate is remarkably improved; Ag elements are uniformly distributed in a TiN film, so a contact angle of the TiN film is significantly smaller than that of a TiN film in which no Ag is doped, good hydrophilicity is obtained and cell compatibility is improved; and the TiN-Ag nano composite coating is expected to improve application of a titanium alloy in biomedicine. The material formed by the method disclosed by the invention is stable in structure, the method can be repeated, and preparation conditions are controllable.

Owner:TIANJIN NORMAL UNIVERSITY

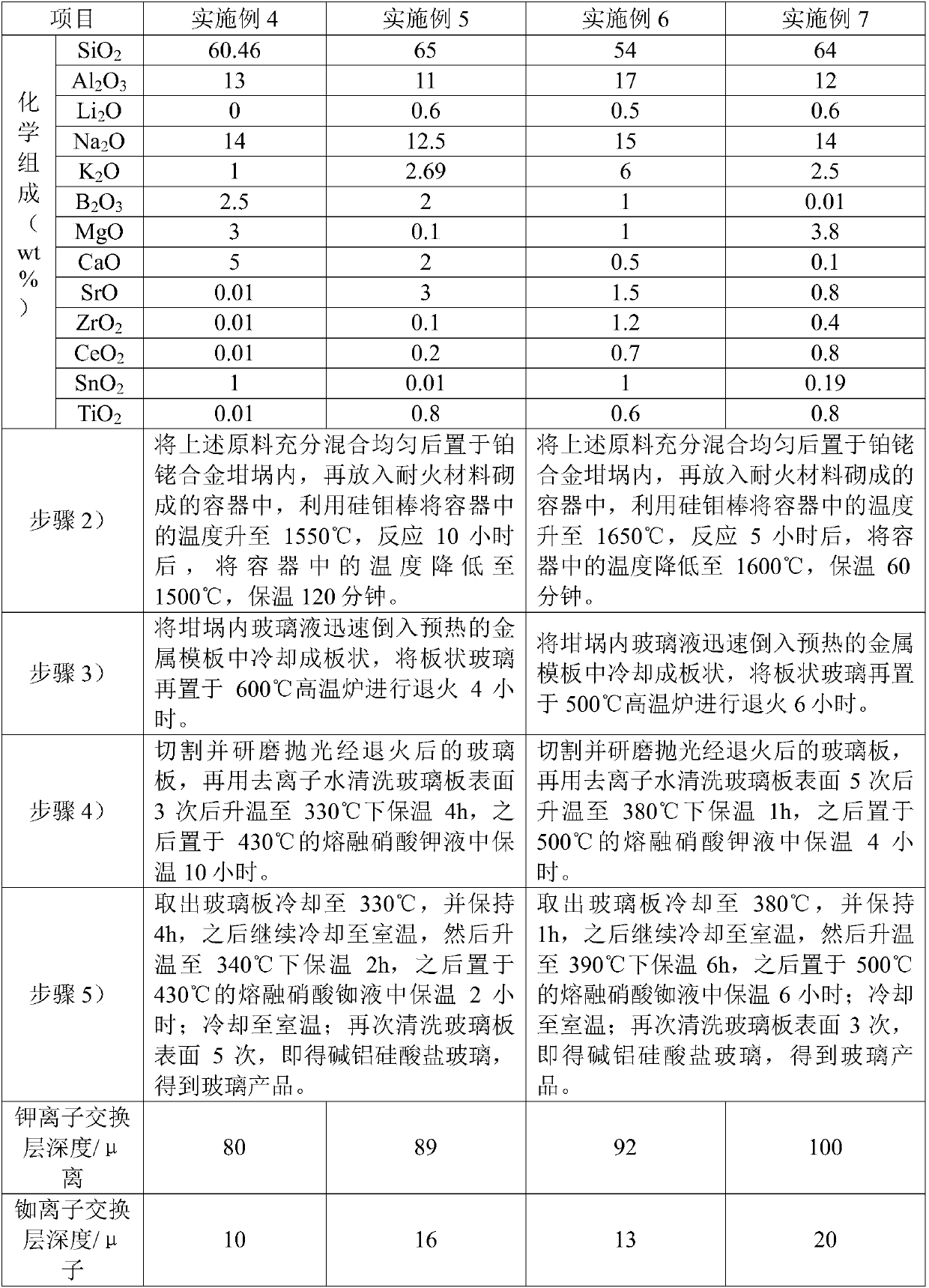

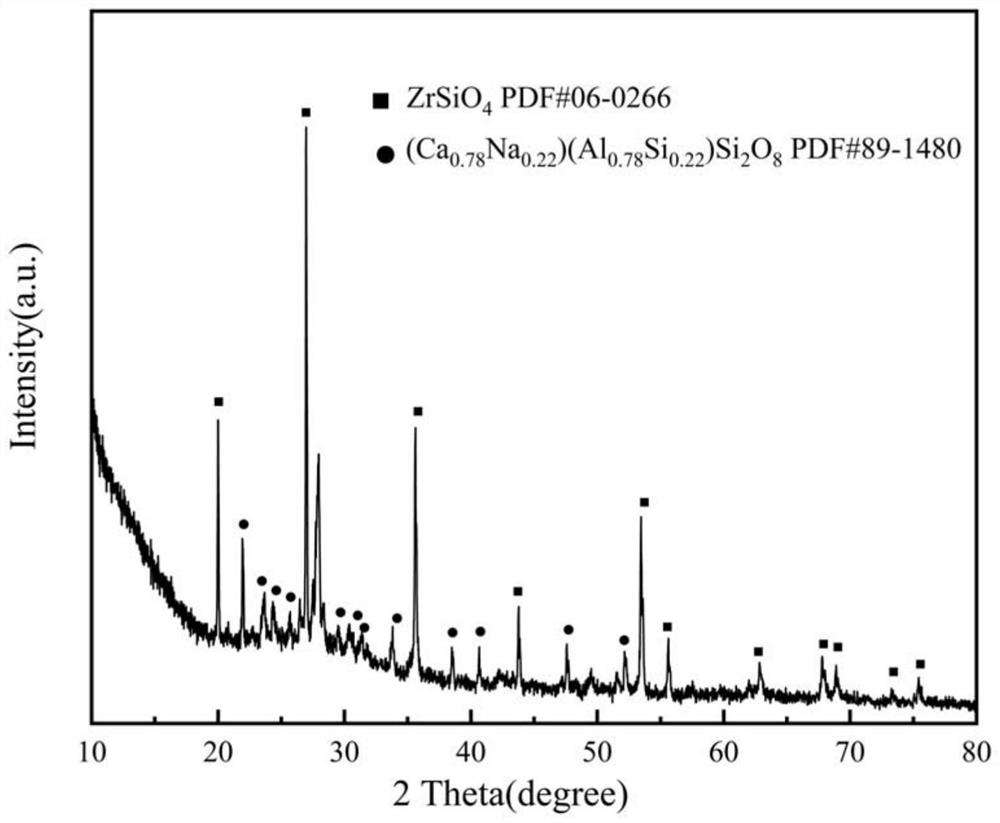

Spinel transparent microcrystalline glass with low melting temperature, preparation method and performance enhancing method thereof

The invention belongs to the field of inorganic materials, and relates to spinel transparent microcrystalline glass with a low melting temperature, a preparation method and a performance enhancing method thereof. The oxide component of the microcrystalline glass comprises: 48-55 mol% of SiO2, 14-17 mol% of Al2O3, 2-12 mol% of Na2O, 8-16 mol% of MgO, 2-12 mol% of ZnO, 0.5-4.5 mol% of TiO2, 0.1-3 mol% of ZrO2, and 0.5-1 mol% of Sb2O3. According to the invention, the spinel transparent microcrystalline glass is obtained through glass component design and heat treatment process control, has the melting temperature of less than 1500 DEG C and the transmittance of more than 80% in a visible light region, has the main crystal phases of magnesia-alumina spinel (MgAl2O4) and zinc-alumina spinel (ZnAl2O4), and has the Vickers hardness (Hv) of 800 kgf / mm<2>, wherein the Vickers hardness (Hv) can be improved by more than 15% after ion exchange with a KNO3 molten salt.

Owner:WUHAN UNIV OF TECH

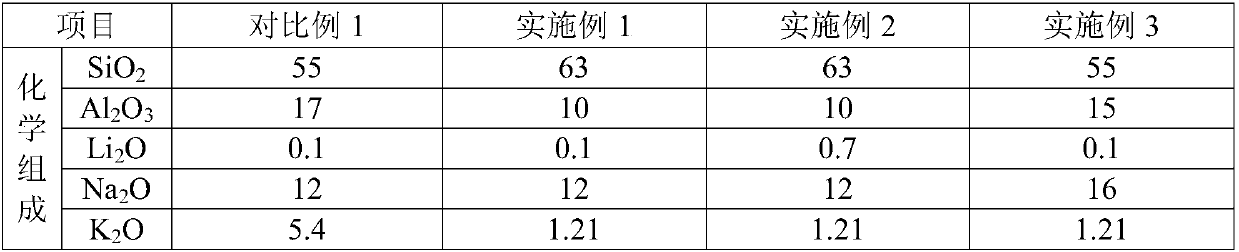

High-strength glass for display device and preparation method of glass

The invention discloses a high-strength glass for a display device and a preparation method of the glass. The strength of the glass can be improved from two aspects of component design and strengthening method, wherein the components exert a significant synergistic effect; through the introduction of new components CeO2 and TiO2, and the content relationships among various components are defined,in particular (Na2O+K2O) / Al2O3 and K2O / (Na2O+Li2O) are maintained in a certain range, the amount of ion exchange and the depth of the ion exchange are improved, and through the definition of the synergistic effect among the TiO2, ZrO2 and the CeO2, the thermal stability and the performance of ion exchange of the glass are improved. Finally, through the adoption of twice ion exchange, the mechanical property of the glass is greatly improved, so that the glass provided by the invention has relatively high surface compressive stress, Vickers hardness and excellent strain point and thermal stability, has the properties of compression resistance, scrape resistance and scratch resistance, and can be widely applied to a protective cover plate of the display device.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

Recycling method of toughened waste glass

The invention provides a recycling method of toughened waste glass. The recycling method comprises the following steps: A, preheating; B, ion exchange of mixed molten salt: the preheated glass is subjected to ion exchange by the mixed molten salt consisting of lithium nitrate and sodium nitrate for 4 hours or longer at 380-480 DEG C; C, water cleaning: molten salt of lithium nitrate and sodium nitrate on the surface of the glass after ion exchange is removed by water washing; D, annealing at high temperature; E, re-toughening: chemical toughening is performed on the annealed glass again aftersecondary processing and / or cutting, and a recycled glass product is obtained. According to the recycling method, surface stress of the glass toughened primarily can be eliminated by the aid of the ion exchange action of sodium nitrate and lithium nitrate in the mixed molten salt, so that the glass annealed at high temperature can be directly processed secondarily and / or cut without cracking, andthe size of the expanded glass after original high-temperature annealing and re-toughening is effectively controlled.

Owner:LENS TECH

Sanitary ceramic glaze with colorful effect, preparation method thereof and sanitary ceramic

The invention discloses a sanitary ceramic glaze with a colorful effect. The sanitary ceramic glaze mainly comprises the following raw materials in percentage by weight: 16%-28% of quartz, 18%-27% ofpotassium feldspar, 0.4%-0.8% of dolomite, 3%-4% of kaolin, 3.2%-4.2% of zinc oxide, 9%-11% of aluminum oxide, 9.5%-11.5% of zirconium silicate and 15%-30% of wollastonite. Correspondingly, the invention further discloses a preparation method of the sanitary ceramic glaze with a colorful effect, and a sanitary ceramic. The Vickers hardness of the sanitary ceramic glaze surface can be effectively improved, and meanwhile, the glaze surface has a colorful flashing effect under the irradiation of lamplight and has an outstanding decorative function.

Owner:景德镇乐华陶瓷洁具有限公司

Preparation method of antibacterial cobalt chromium alloy porcelain artificial tooth

ActiveCN103060618AQuickly vaporize and eliminateEasy feedingImpression capsFoundry mouldsSand blastingCobalt-chrome

The invention discloses a preparation method of an antibacterial cobalt chromium alloy porcelain artificial tooth. Cobalt chromium alloy consists of Cr, Mo, W, Mn, Nb, Si, Ag, Cu, Ce and Co. The preparation method comprises the following steps: (1) manufacturing a lost foam pattern, then coating a coating on the surface, putting into a sand box after the coating is dried, filling sand and compacting, and putting into a pouring table with a vibration device; (2) putting ingot metal, intermediate alloy and other raw materials into an induction furnace for melting according to the mixture ratio, testing and adjusting ingredients after solution is uniform, then adjusting the pouring temperature, ensuring that the pouring temperature is about 30-40 DEG C higher than that of an alloy melting point and preparing to pour; (3) starting the vibration device, so that the vibration frequency is about 140-160 Hz, and the amplitude of vibration is about 4-6 mm and then pouring the solution in the step (2); and (4) sand-blasting, ultrasonic cleaning and conventional porcelain-baking after cooling and cleaning. The prepared artificial tooth has the advantages of excellent performance and good antibacterial effect.

Owner:GUANGZHOU NALIAN MATERIAL TECH CO LTD

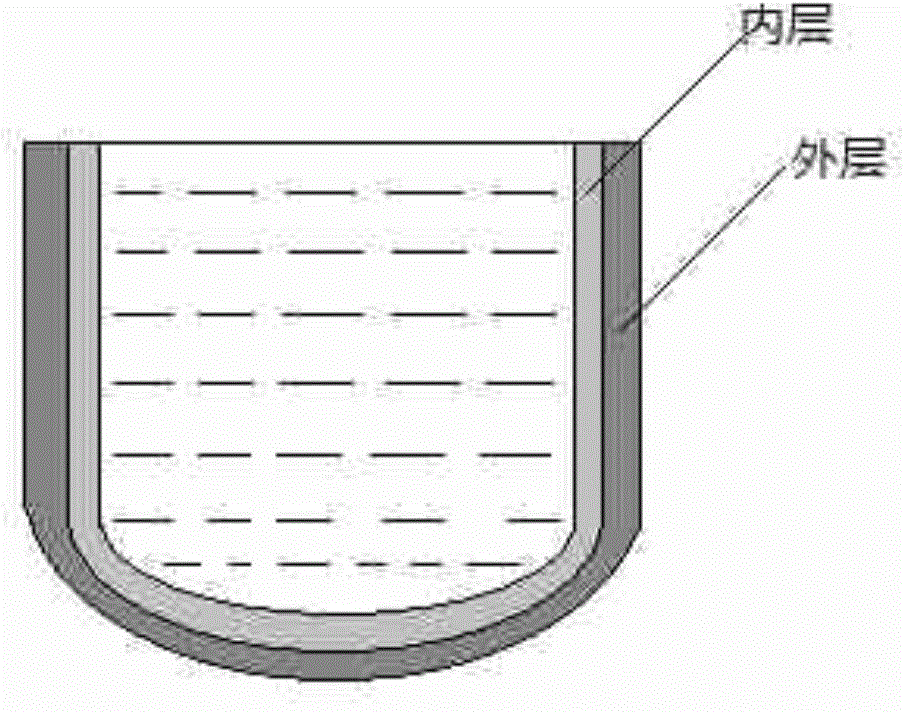

Quartz crucible for single crystal growth and preparation method of quartz crucible for single crystal growth

InactiveCN104389014AImprove interface connection performanceHigh strengthBy pulling from meltSilicon dioxideSingle crystal growth

The invention discloses a quartz crucible for single crystal growth. The quartz crucible comprises an inner layer and an outer layer, wherein the inner layer is prepared from silicon dioxide particles being 0.5mm-2mm, nano silicon dioxide being smaller than 100nm, the outer layer is prepared from silicon dioxide particles being 0.5mm-2mm, nano silicon dioxide being smaller than 100nm, a stable-phase substance and silicon nitride in proportion; the stable-phase substance is any one of titanium oxide, zirconium oxide, aluminum oxide, titanium nitride, aluminum nitride and zirconium nitride. According to the quartz crucible for single crystal growth and the preparation method of the quartz crucible for single crystal growth disclosed by the invention, the quartz crucible production is divided into inner layer production and outer layer production, wherein the inner layer is made from synthesized quartz, and the particle sizes of the quartz particles including large particles and small particles are controlled; in the outer layer, the quartz strength is controlled by adding a reinforcing phase which is natural silica sand silicon dioxide, and a stable phase. According to a preparation method of the quartz crucible, physical properties such as high strength, good durability and high outer-layer viscosity of the quartz crucible can be provided, and cracking and silicon leakage of the quartz crucible due to high-temperature heating can be prevented.

Owner:JIANGSU UNIV OF SCI & TECH

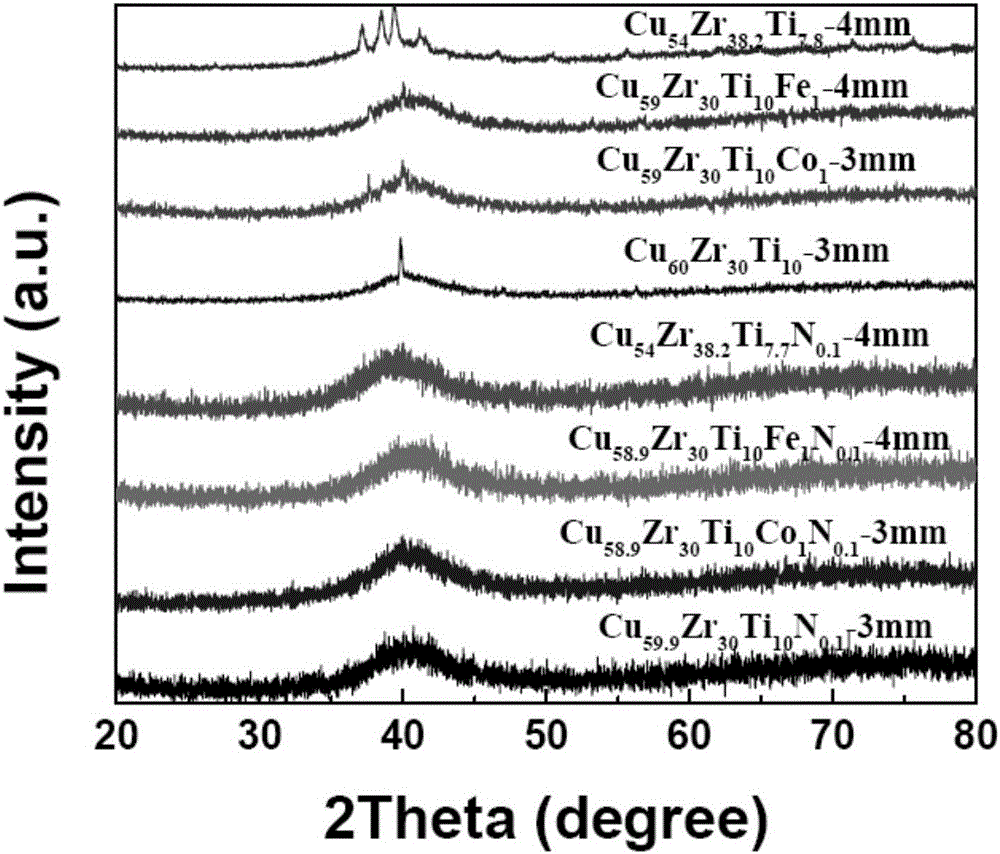

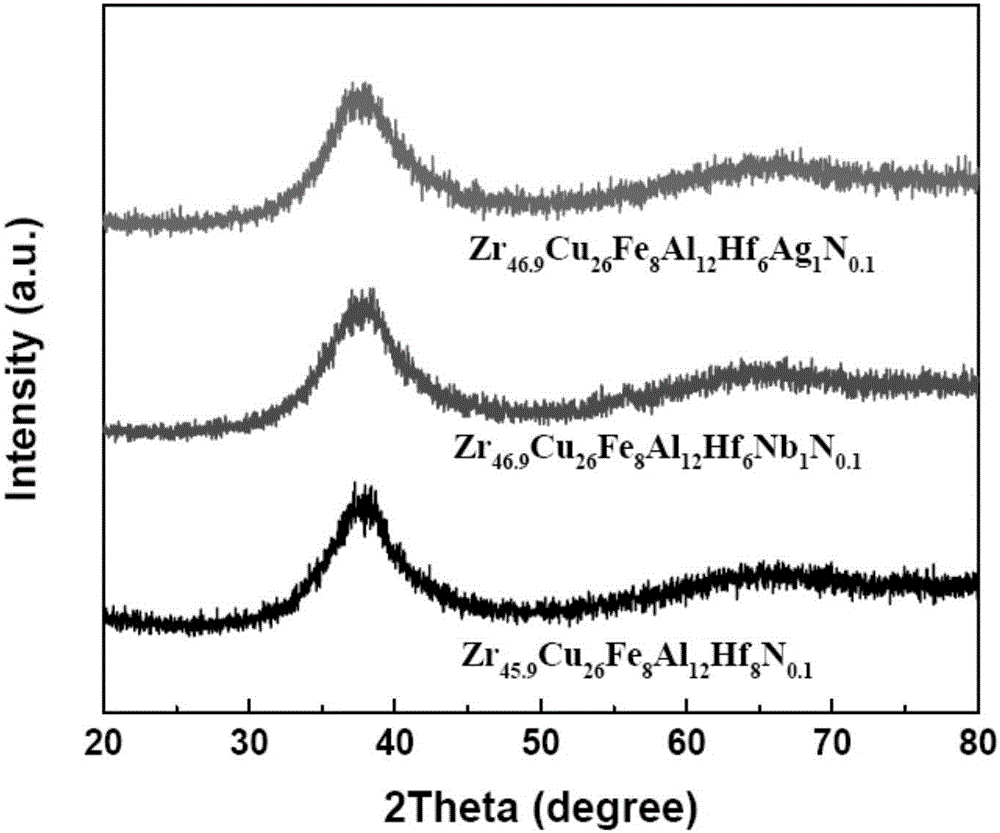

N-containing Be-free Ni-free high-hardness Zr matrix body amorphous alloy and preparation method thereof

ActiveCN106702292AGood biocompatibilityStrong Amorphous Formation AbilityRare-earth elementBiocompatibility Testing

The invention relates to an N-containing Be-free Ni-free high-hardness Zr matrix body amorphous alloy. The expression of the alloy in atomic percentage is Zr Cu A <c> B <d> X <e>Z <f> N<g>, wherein A is one of Hf and Ti; B is a IIIA group element; X is one or more elements of VIII group elements or rare-earth elements except Ni; Z is one or more elements of IB group elements and VB group elements; a+b+c+d+e+f+g=100%, a is greater than or equal to 25 %, and is lower than or equal to 65 %; b is greater than or equal to 15 %, and is lower than or equal to 65 %; c is greater than or equal to 5 %, and is lower than or equal to 15 %; d is greater than or equal to 0, and is lower than or equal to 15 %; e is greater than or equal to 0, and is lower than or equal to 15 %; f is greater than or equal to 0, and is lower than or equal to 10 %; and g is greater than or equal to 0.05 %, and is lower than or equal to 0.5 %. The N-containing Be-free Ni-free high-hardness Zr matrix body amorphous alloy disclosed by the invention does not contain a metallic element Be and a metallic element Ni, so that the biocompatibility of a Zr -base alloy is improved; the N-containing Be-free Ni-free high-hardness Zr matrix body amorphous alloy has high glass forming ability, and the Zr matrix body amorphous alloy of which the critical dimension is not less than 2mm can be prepared through adopting a copper mold suction casting method; and compared with a N-free amorphous alloy, the N-containing Be-free Ni-free high-hardness Zr matrix body amorphous alloy has the advantage that the vickers hardness of an alloy system is not less than 540Hv.

Owner:UNIV OF SCI & TECH BEIJING

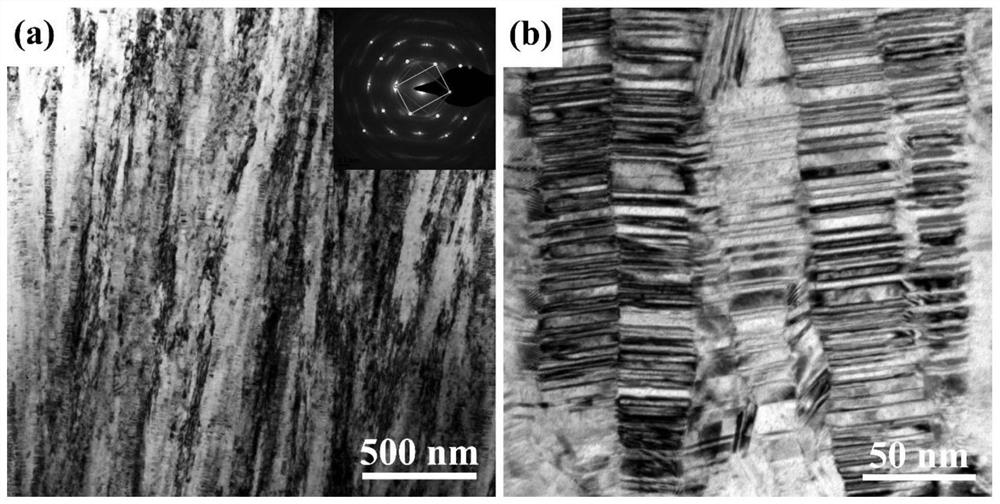

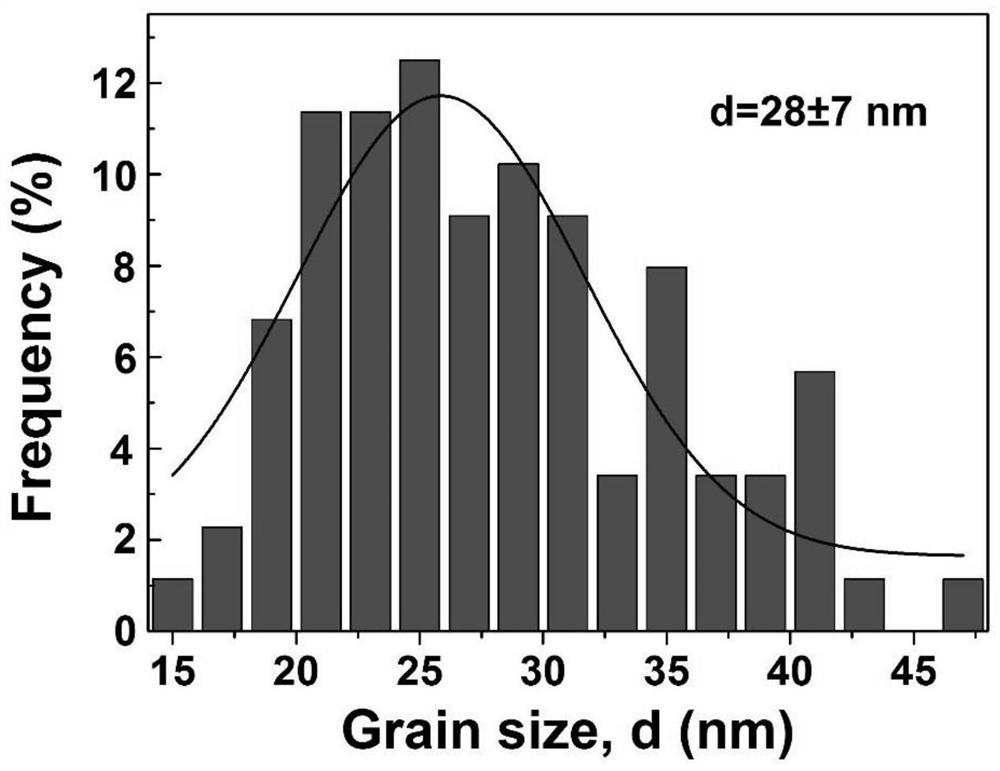

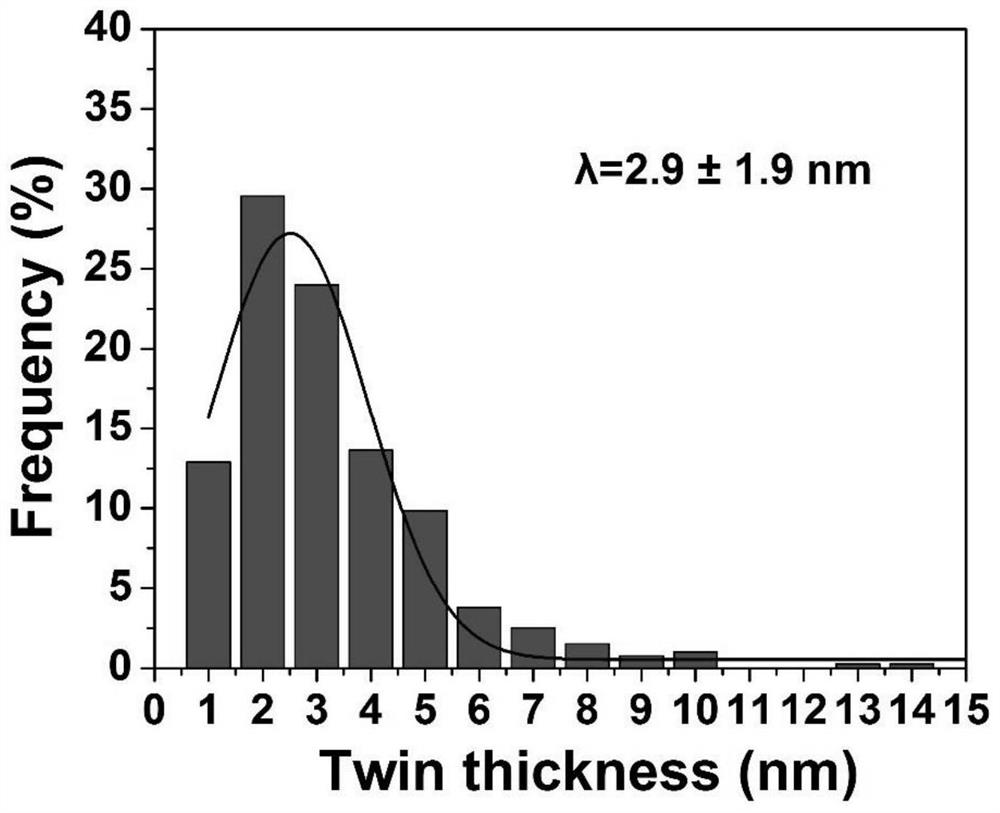

Nano twin-crystal nickel with extremely small twin-crystal lamella thickness and ultrahigh strength and preparation thereof

The invention relates to a superhard nanocrystal metal material, in particular to nano twin-crystal nickel with extremely small twin-crystal lamella thickness and ultrahigh strength and a preparationmethod thereof. The nano twin-crystal nickel with a thickness of hundreds of microns to millimeters is prepared by utilizing an electrolytic deposition technology, wherein a microstructure of the nanotwin-crystal nickel is composed of columnar crystal particles with lengths of 200-3000 nm and widths of about 10-50 nm, twin-crystal lamella structures with high density and consistent orientation are contained in columnar crystals, a thickness of each twin-crystal lamella structure is 0.5-10 nm, the crystal particles with the twin-crystal structures can account for 100% of the crystal particlesof a whole sample, a room-temperature microhardness of a material can reach 8.5 GPa or above and is 1.5-2 times or above that of common electroplating nano nickel, and after annealing is carried out at 250 DEG C for half an hour, the hardness is increased to 9.6 GPa and a structure roughening temperature can reach 350 DEG C or above and is 150 DEG C or above higher than a structure roughening temperature of common nanocrystal nickel. A prepared nanocrystal coating can be applied to wear-resistant protection of metal materials such as copper, nickel, alloys of the copper and nickel, and stainless steel, and can also be applied to the fields of micromechanical systems (MEMS) and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High porosity foam nickel base alloy and preparation method thereof

The invention provides a high porosity foam nickel base alloy and a preparation method thereof. The foam nickel base alloy is composed of the following elements in percentages by weight: 63.0-97.5% of Ni, 2-35% of Cr or Al and 0.5-2.0% of Si. The preparation method comprises the following steps: coating a soft polyurethane foaming plastic with aqueous resin slurry comprising Cr or Al powder, Si powder and carboxymethylcellulose and drying the plastic; electroplating the plastic in a watt plating solution for 2-6 hours; heating the plastic in a non-oxidized atmosphere; and alloying the plastic in a vacuum or inertial atmosphere for 5-20 hours. The foam nickel base alloy framework is level in surface, free of cracks, high in porosity, good in trafficability characteristic, high in mechanical strength and excellent in oxidation resistance. The preparation method is free of hexavalent Cr pollution, easy to realize a design of alloy component and prepare high Cr or high Al foam Ni base alloy, simple in process and suitable for scaled production.

Owner:CHANGDE LYRUN MATERIAL

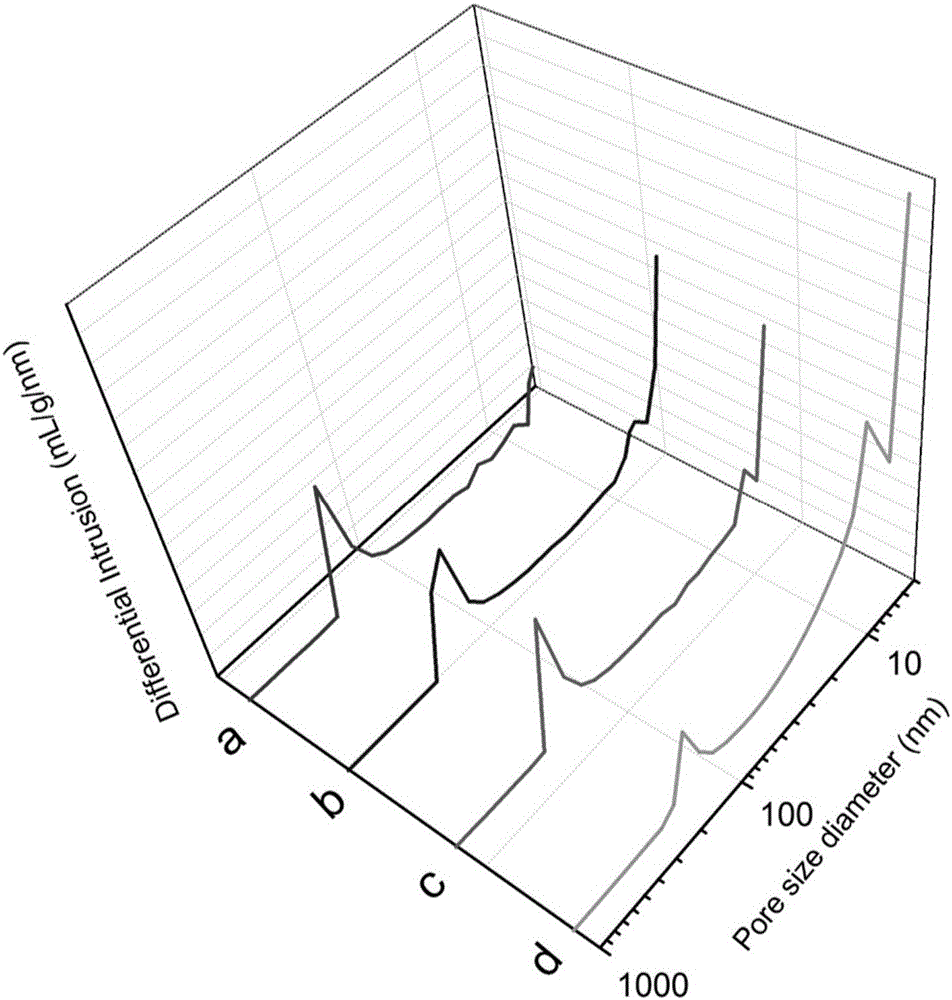

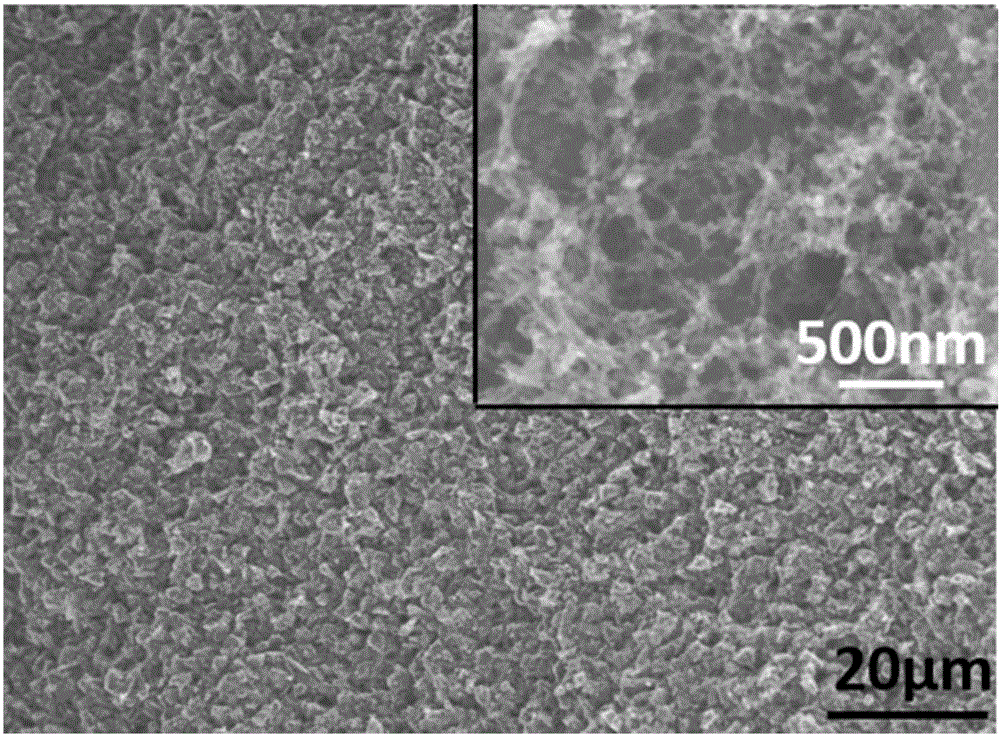

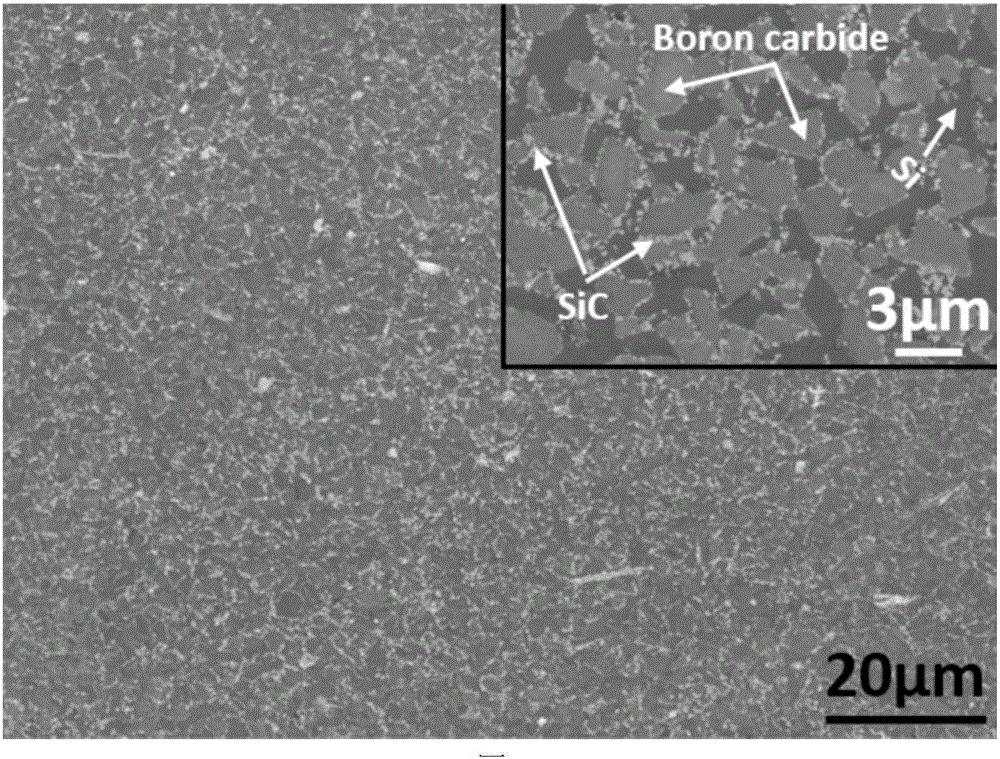

Gel casing preparation method of reaction-sintered boron carbide ceramic composite material

A gel casing preparation method of reaction-sintered boron carbide ceramic composite material includes the steps of firstly, mixing resorcinol, formaldehyde and sodium carbonate with deionized water, and adding B4C powder to form B4C mixed slurry; secondly, performing vacuum degassing and injection molding sealing on the mixed slurry; performing sol gelation in water bath, and aging for 4-50 hours; drying under normal pressure, and performing high-temperature carbonization to obtain a B4C / C biscuit; thirdly, placing silicon on the B4C / C biscuit, performing high-temperature infiltration to obtain a sintered body, and cooling to remove redundant silicone to obtain the reaction-sintered boron carbide ceramic composite material. The method has the advantages that the mesoporous carbon is introduced during the formation of the biscuit, and the B4C / C biscuit with an even structure and a controllable hole structure is obtained; the strength of the B4C / C biscuit is 10-50MPa, machining is facilitated, and the B4C / C biscuit can be used for preparing products of complex shapes; the Vickers hardness of the reaction-sintered boron carbide ceramic composite material is 17-26GPa, the bending strength of the reaction-sintered boron carbide ceramic composite material is 255-484MPa, and the fracture toughness of the reaction-sintered boron carbide ceramic composite material is 3-5MPa.m<1 / 2>.

Owner:NORTHEASTERN UNIV

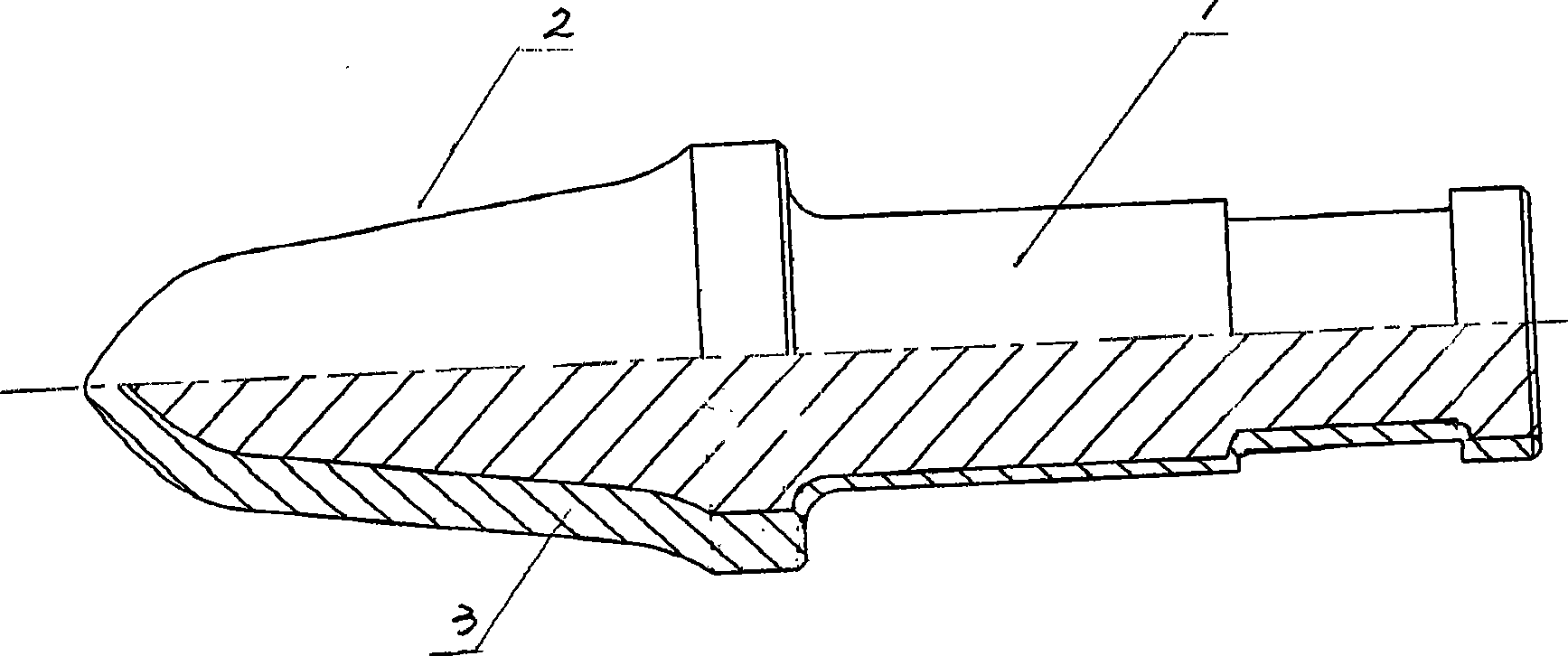

Integral conical pick and method for producing the same

InactiveCN101509376ANot easy to damageExtended service lifeMetal-working apparatusSlitting machinesChemical treatmentEngineering

The invention relates to a one-piece conical cutting pick and a production method thereof, in particular to a conical cutting pick on a coal mining heading machine and a production method thereof. The conical cutting pick comprises a conical cutting pick body which includes a tooth body and a tooth top. The conical cutting pick is characterized in that the tooth body and the tooth top are of the same material and form a whole. The surface of the conical cutting pick body has a wear layer. The conical cutting pick is made by carbon tool steel bars through the steps of precision forging, spheroidizing annealing, machining, chemical processing, high frequency processing, quenching, underhardening and finishing, etc. The one-piece conical cutting pick is not easy to damage and has long service life.

Owner:丽叶卫健国际商贸(无锡)有限公司

Preparation method of Si-B-C-N (silicon-boron-carbon-nitrogen) ceramic with PBSZ (polyborosilazane) as additive

The invention provides a preparation method of Si-B-C-N (silicon-boron-carbon-nitrogen) ceramic with PBSZ (polyborosilazane) as an additive and belongs to the technical field of preparation methods of the Si-B-C-N ceramic. The method comprises steps as follows: S1, cubic silicon powder, hexagonal boron nitride powder, graphite powder and PBSZ are weighed in the mole ratio and in percentage by mass and taken as raw materials for standby use; S2, the raw materials weighed in S1 are put in a ball milling tank, high-energy ball milling is performed under the protection of the argon atmosphere, and ceramic powder containing amorphous Si-B-C-N is obtained; the ball-to-powder ratio of a ball material is (10-90):1, the ball milling diameter is 5-9 mm, and the ball milling time lasts 10-60 h; S3, the amorphous Si-B-C-N ceramic powder obtained in S2 is mixed with PBSZ, ball milling is performed under the protection of the argon atmosphere, and SiBCN compound powder is obtained; the ball-to-powder ratio is (1-20) :1, the ball milling diameter is 5-9 mm, and the ball milling time lasts 10-30 h; S4, the SiBCN obtained in S3 is subjected to spark plasma sintering, and the Si-B-C-N ceramic material with PBSZ as the additive is obtained.

Owner:HARBIN INST OF TECH

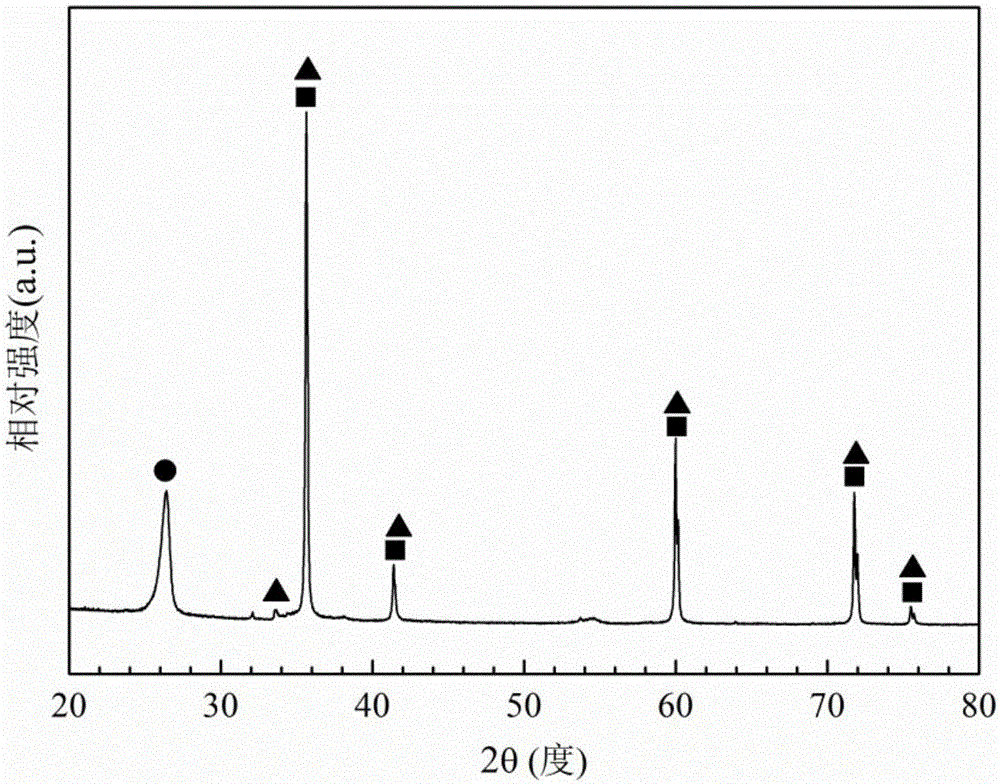

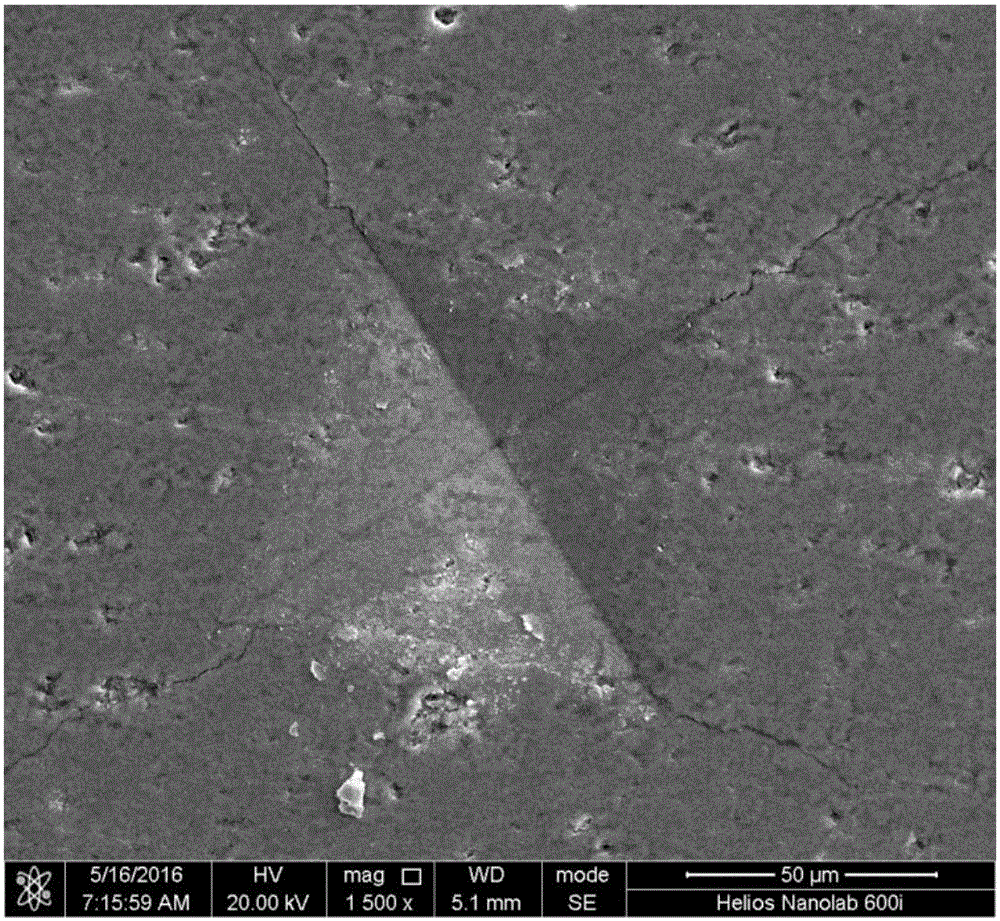

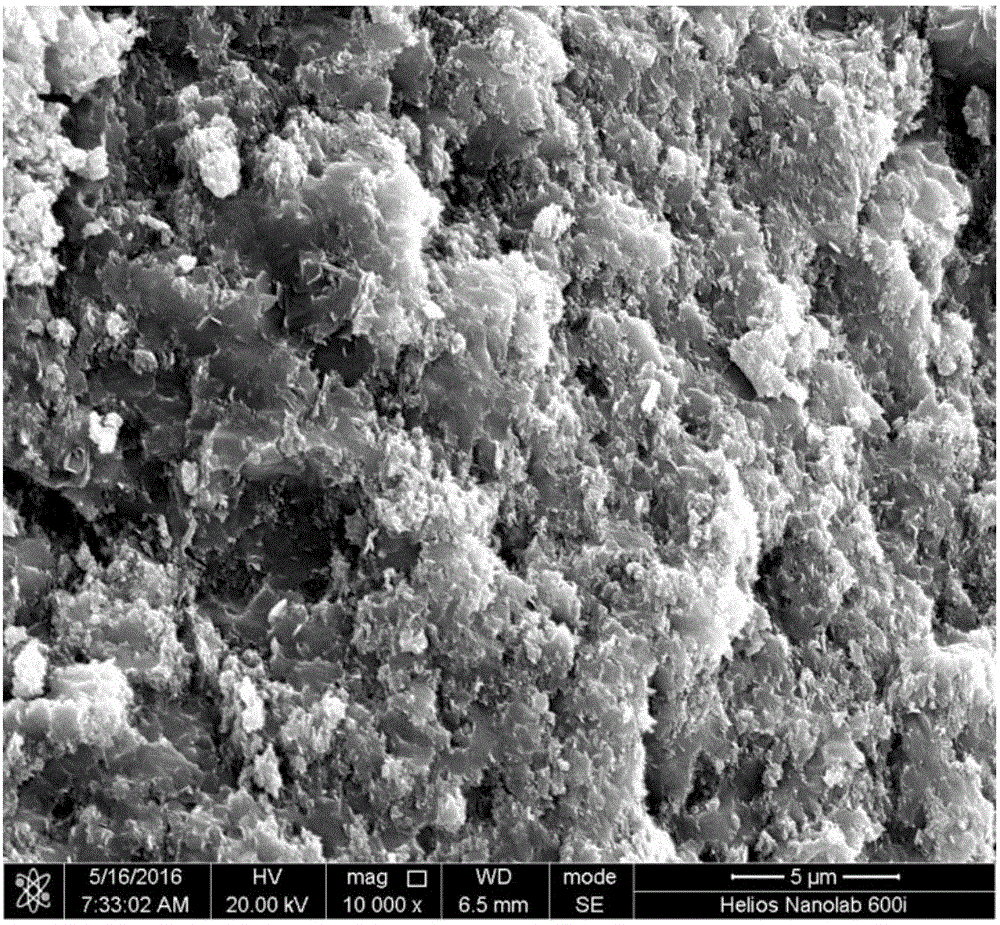

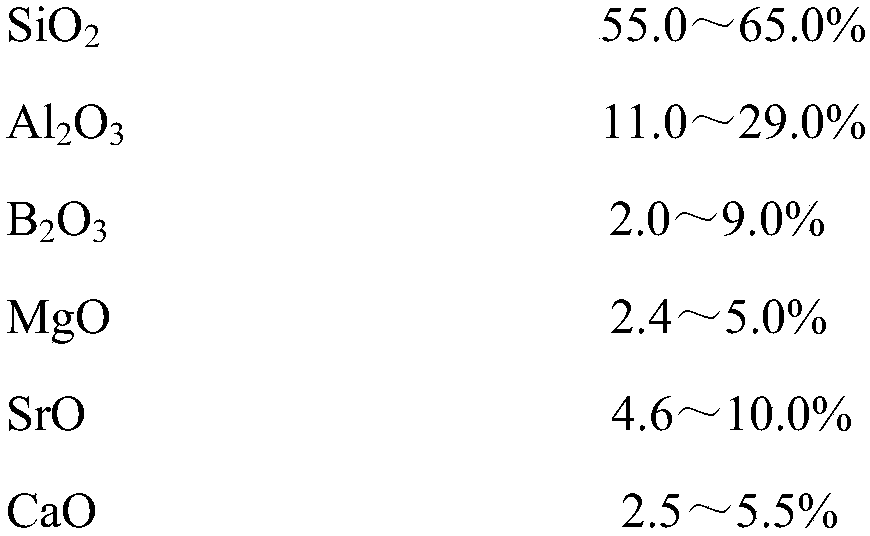

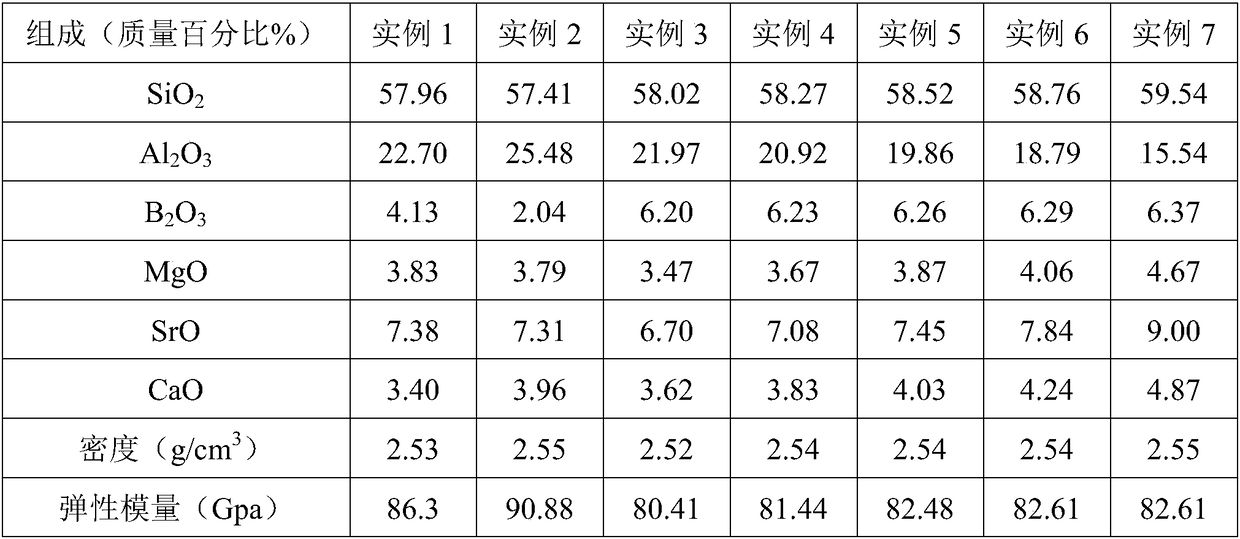

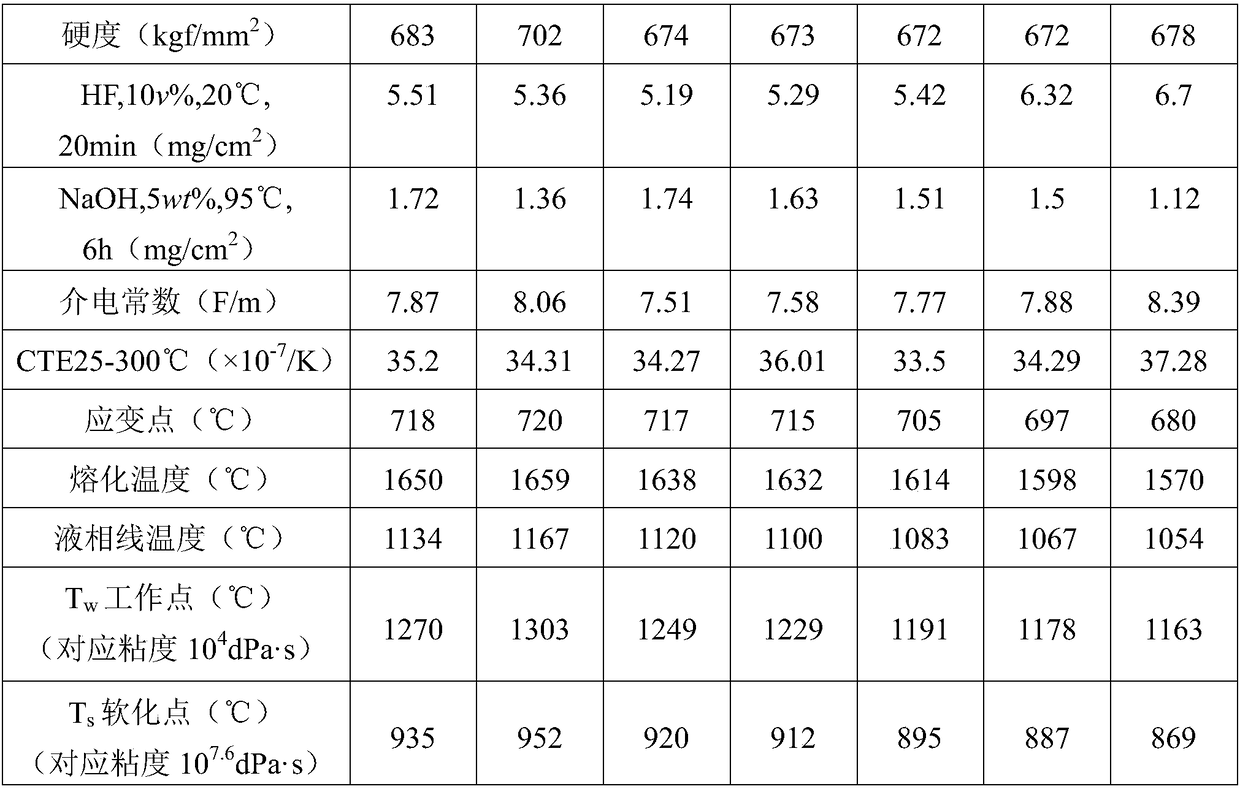

High-hardness alkali-free aluminoborosilicate glass suitable for float process production, and preparation method and application of aluminoborosilicate glass

InactiveCN108911501AReduce high temperature viscosityLower melting temperatureSolid-state devicesGlass shaping apparatusAlkali freeThin-film-transistor liquid-crystal display

The invention discloses high-hardness alkali-free aluminoborosilicate glass suitable for float process production and a preparation method of the aluminoborosilicate glass. Based on the content of oxides, the glass comprises the following components in percentage by mass: 55.0-65.0% of SiO2, 11.0-29.0% of Al2O3, 2.0-9.0% of B2O3, 2.4-5.0% of MgO, 4.6-10.0% of SrO and 2.5-5.5% of CaO. The inventionprovides substrate glass, especially substrate glass suitable for thin film transistor-liquid crystal display (TFT-LCD), wherein the Vickers hardness is higher than 670 kgf / mm<2>, the strain point exceeds 680 DEG C, the melting temperature is 1620-1660 DEG C, the annealing temperature is 700 DEG C, and the glass can be produced by a float process, has high elastic modulus and good chemical stability, and can be widely applied to panel display elements or other optoelectronic devices.

Owner:WUHAN UNIV OF TECH

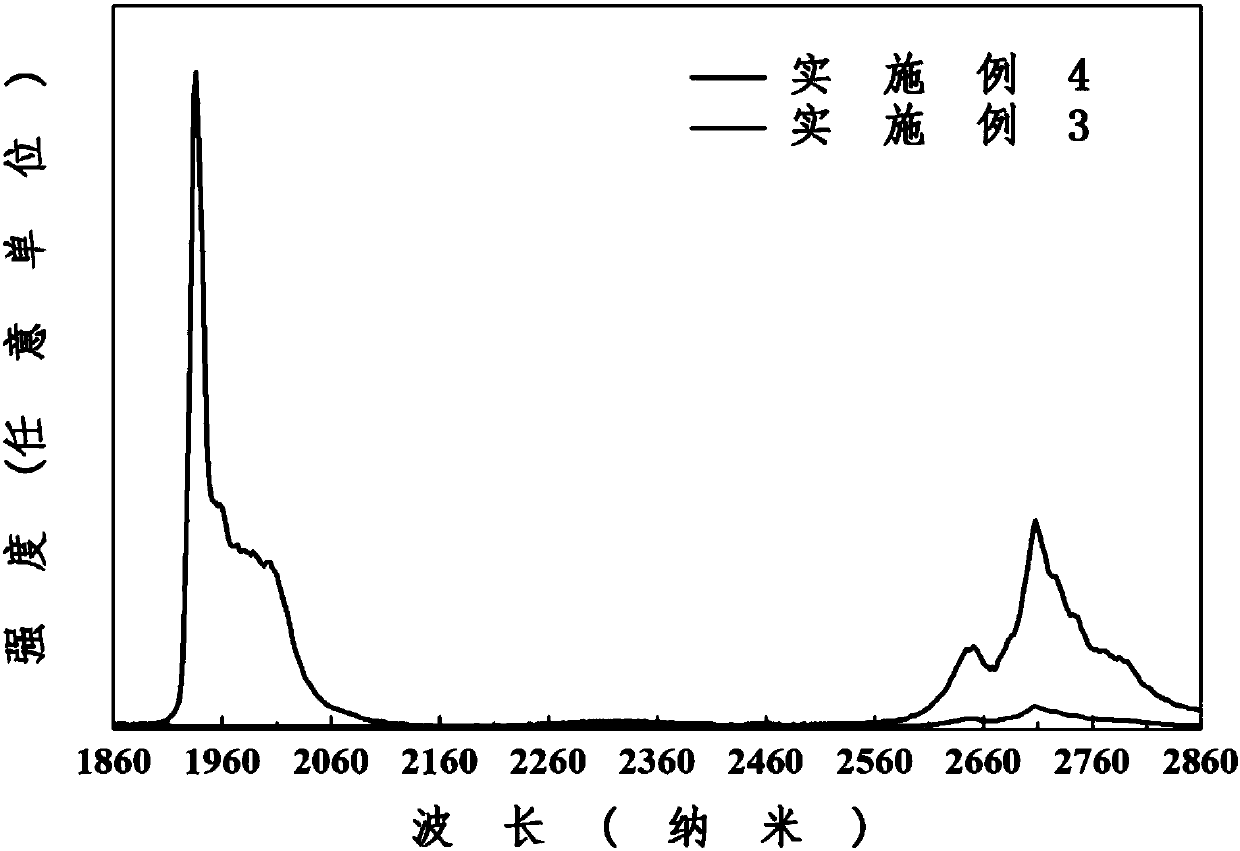

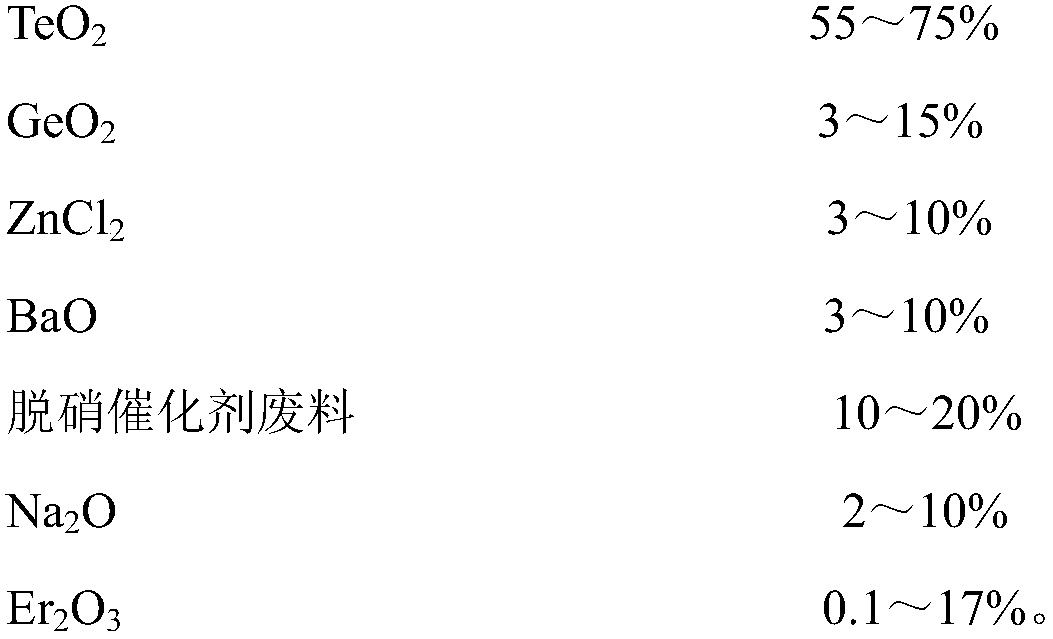

High-doped erbium intermediate infrared tellurium germinate glass and preparation method thereof

The invention discloses high-doped erbium intermediate infrared tellurium germinate glass. The high-doped erbium intermediate infrared tellurium germinate glass comprises the components of TeO2, GeO2,ZnCl2, BaO, a denitration catalyst waste, Na2O, and Er2O3. According to the glass prepared through a melting method, the intermediate infrared light intensity is high, the doping concentration of rare earth is high, the glass is excellent in thermal stability, and is quite promising high-optical quality glass; the wasted denitration catalyst waste is used to strengthen the hardness of the glass and improve the thermal stability of the glass, the preparation method is simple and convenient, the preparation period is short, and the glass is expected to be applied to national defence industry aswell as military and civil fields.

Owner:CHINA JILIANG UNIV

Antibacterial cobalt-chromium alloy porcelain false tooth

ActiveCN103083101AWell fedLess loose defectsImpression capsArtificial teethCobalt chromium alloyAntibacterial effect

The invention discloses an antibacterial cobalt-chromium alloy porcelain false tooth. The false tooth comprises a cobalt-chromium alloy serving as a base material, and a porcelain layer on the surface of the cobalt-chromium alloy; the cobalt-chromium alloy is composed of the following components in parts by weight: 27.5 to 28.5 parts of Cr, 9.5 to 11.5 parts of Mo, 3 to 5 parts of W, 2.5 to 3.5 parts of Mn, 1.5 to 2.5 parts of Nb, 1 to 2 parts of Si, 0.8 to 1.2 parts of Ag, 1.5 to 2.5 parts of Cu, 0.5 to 0.7 parts of Ce, and the balance of Co; the cobalt-chromium alloy has the tensile strength of more than about 960MPa, the yield strength of more than about 730MPa, and the vickers hardness of more than about 550HV. The cobalt-chromium based alloy of the false tooth is casted and formed by the evanescent mode process; and the prepared false tooth is excellent in performance and good in antibacterial effect.

Owner:珠海新茂义齿科技有限公司

Method for preparing SiCp/AZ61 magnesium-based nano composite material using ultrasonic wave

The invention relates to a method for preparing SiCp / AZ61 magnesium-based nano composite material using ultrasonic wave, belonging to the metal material preparation field, comprising the following steps: adding nano SiC powder into alcohol solution and performing ultra sonic dispersion pretreatment of the mixture, drying and grinding the pretreated mixture; heating the AZ61 magnesium alloy into a crucible to melt, and insulating the crucible at temperature rang of 640 DEG C -650 DEG C, making an amplitude transformer under the melted mixture surface and performing ultrasonic treatment of the mixture at 600W-650W for 5-10 minutes; cladding the pretreated nano SiC powder according to the weight percent of 0.1-2.0% by the tinfoil, adding the clad SiC powder into the AZ 61 magnesium alloy melt mass, continuously performing ultrasonic treatment of the mixture at 600W-650W for 15-20 minutes; casting and sampling the mixture. The nano SiC granules has uniform dispersion in matrix, increased tensile strength by 13.5-25%, increased Vickers hardness by 16.8-42.4%, higher ductility of matrix, simple preparation technology, safety, reliability and no three-waste pollution.

Owner:NANCHANG UNIV

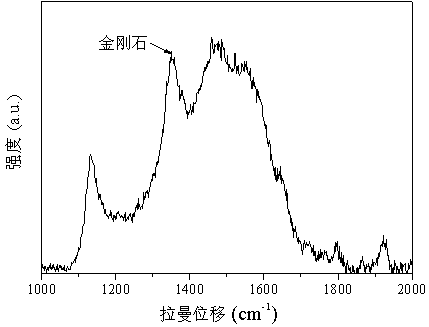

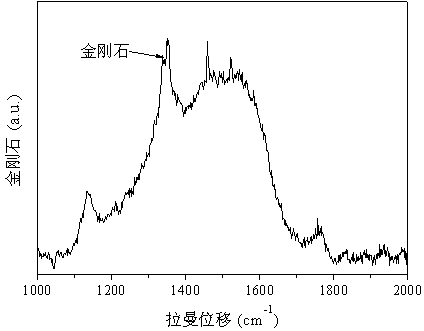

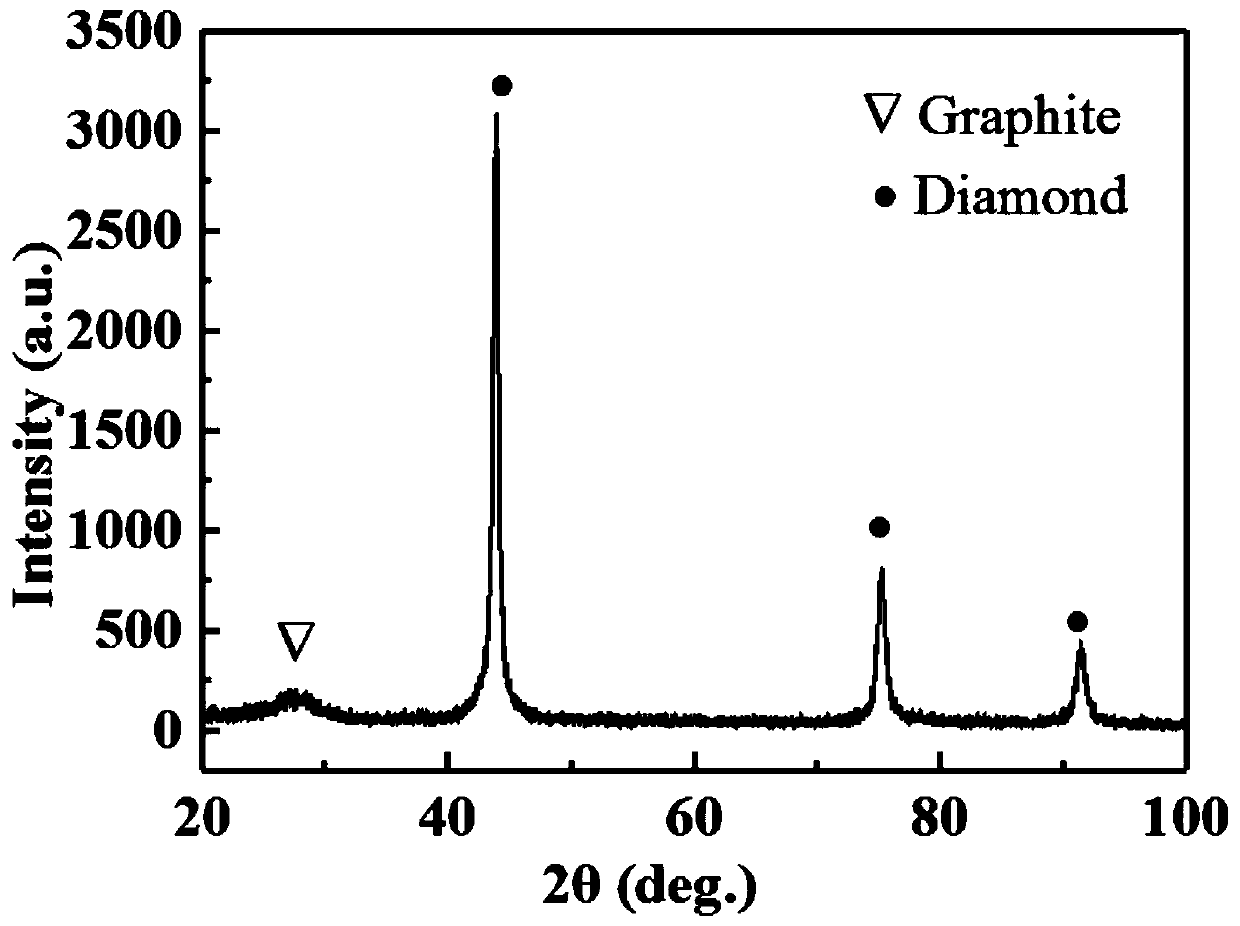

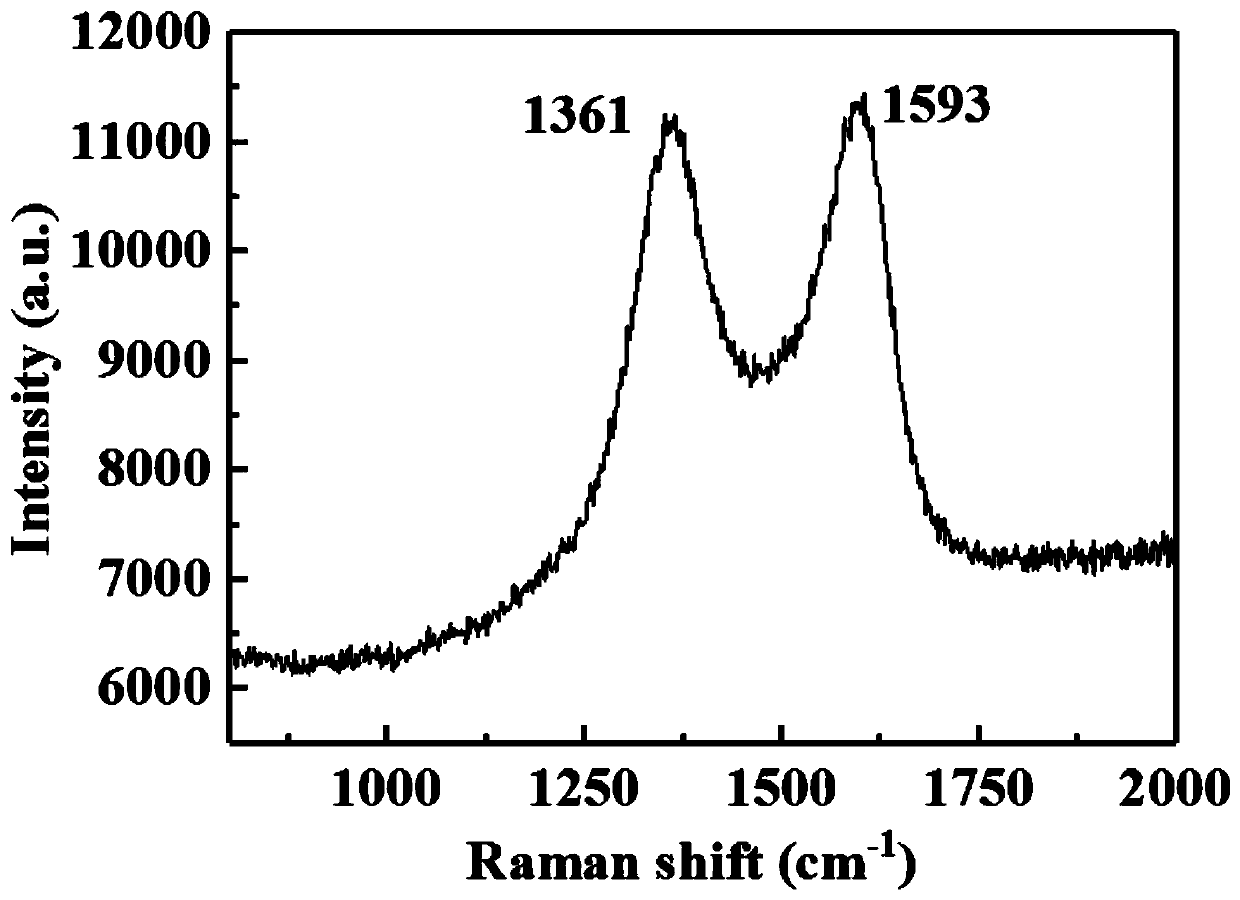

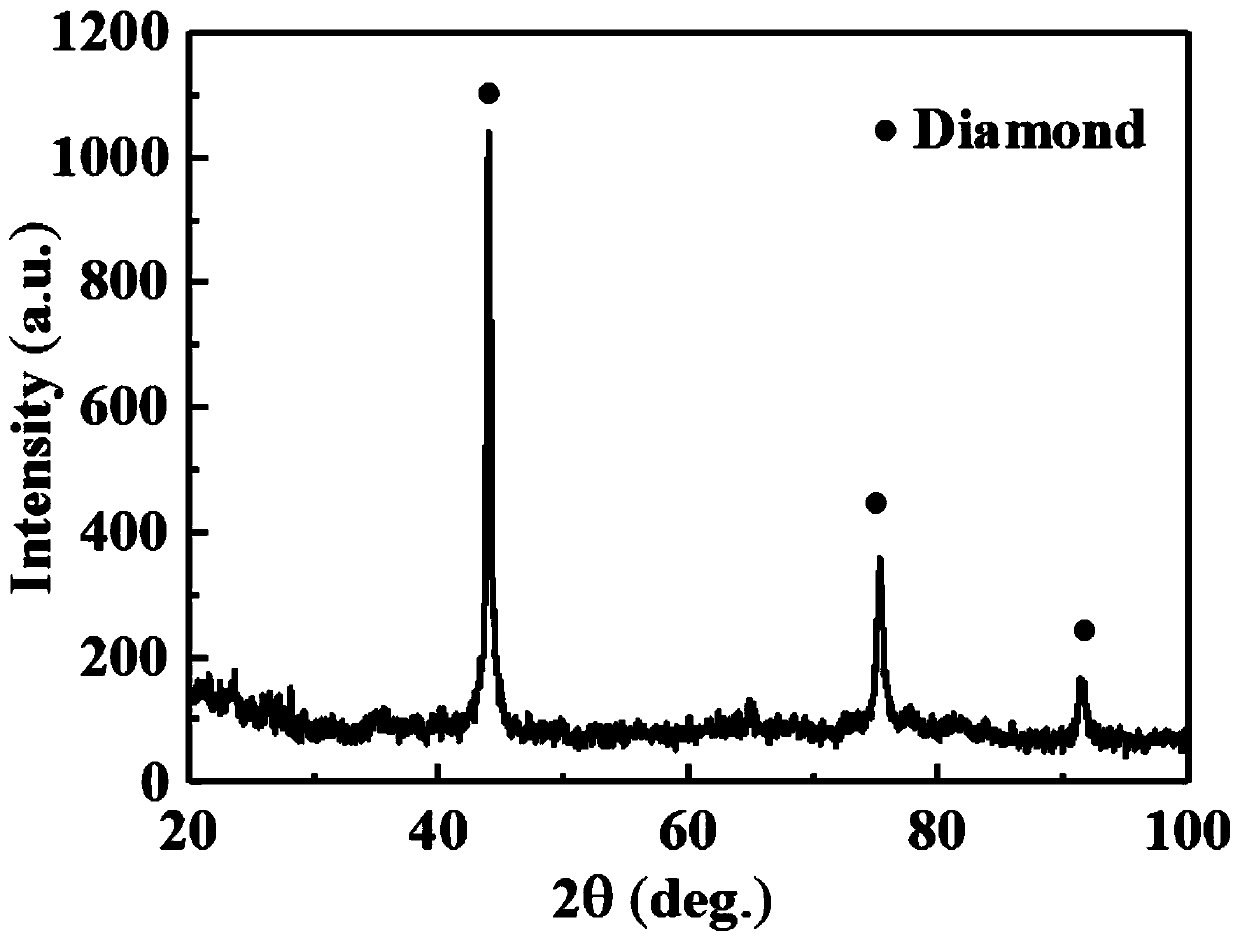

Method for preparing diamond film on stainless steel surface with Cr/CrAlN as transition layer

ActiveCN110629194AStrong membrane bindingNo sheddingVacuum evaporation coatingSputtering coatingHardnessDiamond thin film

The invention discloses a method for preparing a diamond film on a stainless steel surface with Cr / CrAlN as a transition layer. The method is characterized by comprising the following steps of S1, pretreatment of a stainless steel sample, wherein the stainless steel sample is polished with abrasive paper, ultrasonically treated with acetone and absolute ethyl alcohol, and then dried for later use;S2, deposition of the Cr / CrAlN layer on the stainless steel surface, wherein the stainless steel sample treated in step S1 is placed on a sample table of a magnetron sputtering device, Cr and Al target materials are mounted on a target base, and a Cr film and a CrAlN film are deposited on the surface of a stainless steel substrate, so that the stainless steel sample comprising the Cr / CrAlN transition layer is obtained; and S3, preparation of the diamond film on the stainless steel surface, wherein the stainless steel sample, comprising the Cr / CrAlN transition layer, obtained in step S2 is ultrasonically crystallized, and the diamond film is deposited by means of a heating wire through HFCVD, so that the diamond film is prepared on the stainless steel surface with Cr / CrAlN as the transition layer. By the adoption of the technique, the bonding force between the diamond film and stainless steel is high, and the film does not fall under a load with the Rockwell hardness of 150K.

Owner:ZHEJIANG UNIV OF TECH

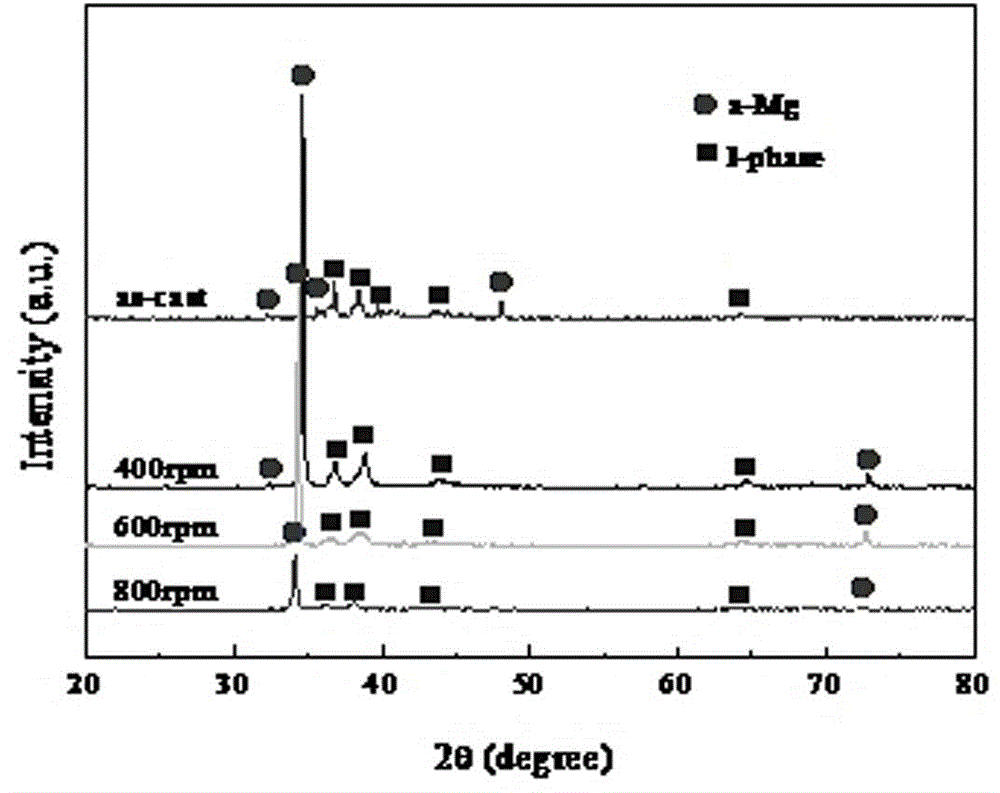

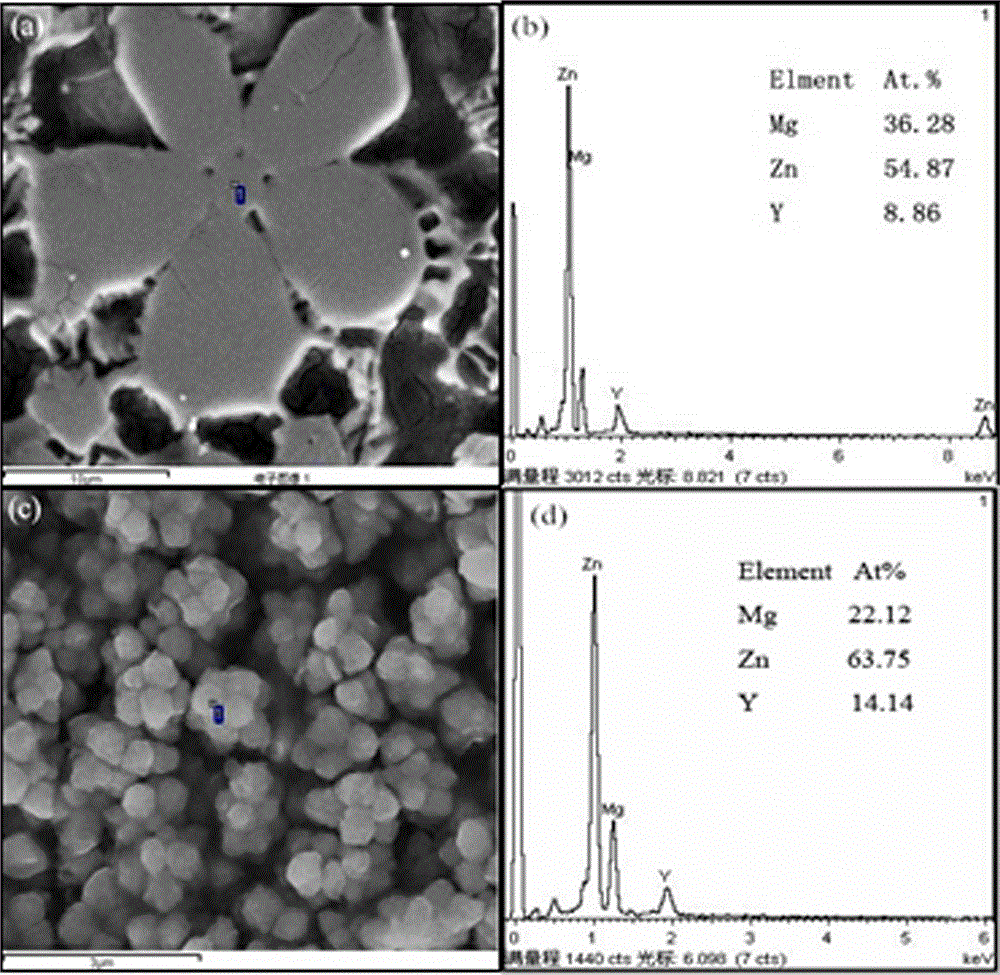

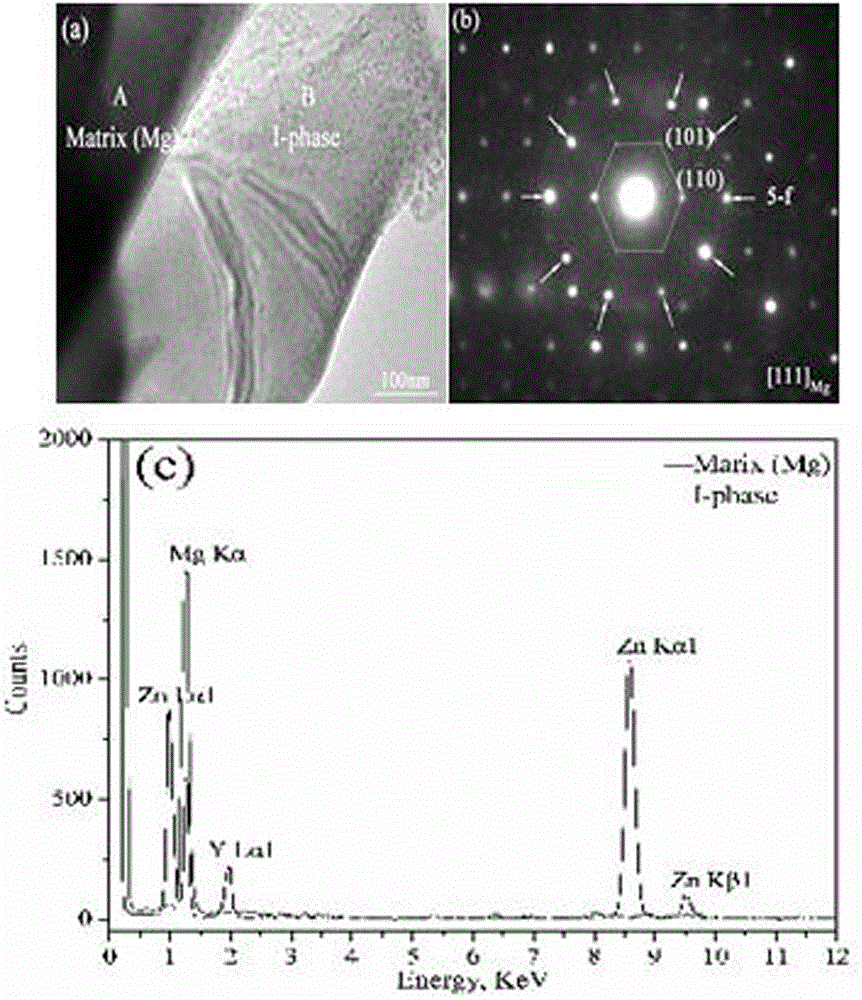

Mg-Zn-Y magnesium alloy and preparation method thereof

ActiveCN104152747AIncrease the volume fraction of quasicrystalline phaseOvercoming the problem of low quasi-crystal integral fractionCorrosion resistantMagnesium alloy

The invention provides an Mg-Zn-Y magnesium alloy. The Mg-Zn-Y magnesium alloy comprises the following components in percentage by mass: 55.50-56.00% of Zn, 11.50-13.00% of Y, and the balance of magnesium and trace impurity elements; and the quasicrystal volume fraction of the Mg-Zn-Y magnesium alloy is 26.8-51.3%. The invention further provides a preparation method of the Mg-Zn-Y magnesium alloy; a fast solidification spraying method is adopted; the operation is simple and convenient; and the promotion and application are convenient. The Mg-Zn-Y magnesium alloy prepared by the fast solidification spraying method increases the quasicrystal phase volume fraction, solves such problems as lower magnesium alloy quasicrystal content and uneven tissue distribution in an existing preparation method, and improves the corrosion resistance and Vickers hardness.

Owner:UNIV OF JINAN

Micro-nano polycrystalline diamond composite material and preparation method thereof

The invention discloses a micro-nano polycrystalline diamond composite material and a preparation method thereof. The micro-nano polycrystalline diamond composite material comprises the following components: carbon nano onions and micron diamond, wherein the mass percent of the micron diamond is 20-50wt.%, and the balance is the carbon nano onions; and the Vickers hardness of the micro-nano polycrystalline diamond composite material ranges from 30 GPa to 200 GPa. The preparation method comprises the following steps: carrying out annealing treatment on detonation nano diamond powder to preparecarbon nano onions; adding micron diamond crystal grains for mixing, wherein the mass percent of the micron diamond is 20-50wt.%; a mixture formed by the micron diamond and the carbon nano onions is filled into a WC hard alloy die to be pre-pressed, the pre-pressing pressure is 400-600 MPa, and pre-pressing is conducted for 10-30 s; and a pre-pressed sample is put into a mold for high-temperatureand high-pressure sintering, and the micro-nano polycrystalline diamond composite material is prepared. The Vickers hardness of the micro-nano polycrystalline diamond is nearly one time higher than the Vickers hardness of a common PCD, and the performance of the micro-nano polycrystalline diamond is obviously improved.

Owner:YANSHAN UNIV

Optical glass and optical element

Owner:KONICA MINOLTA OPTO

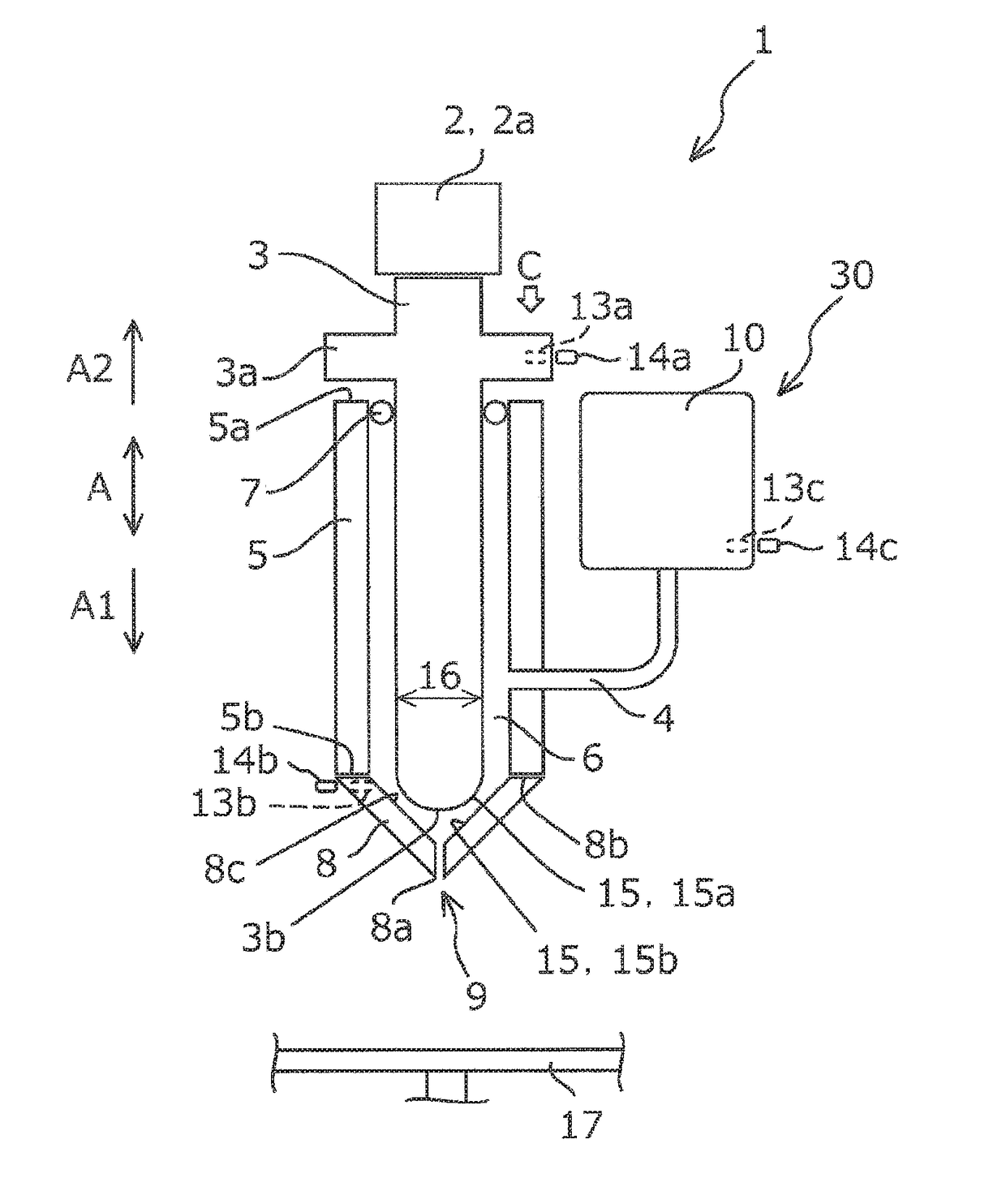

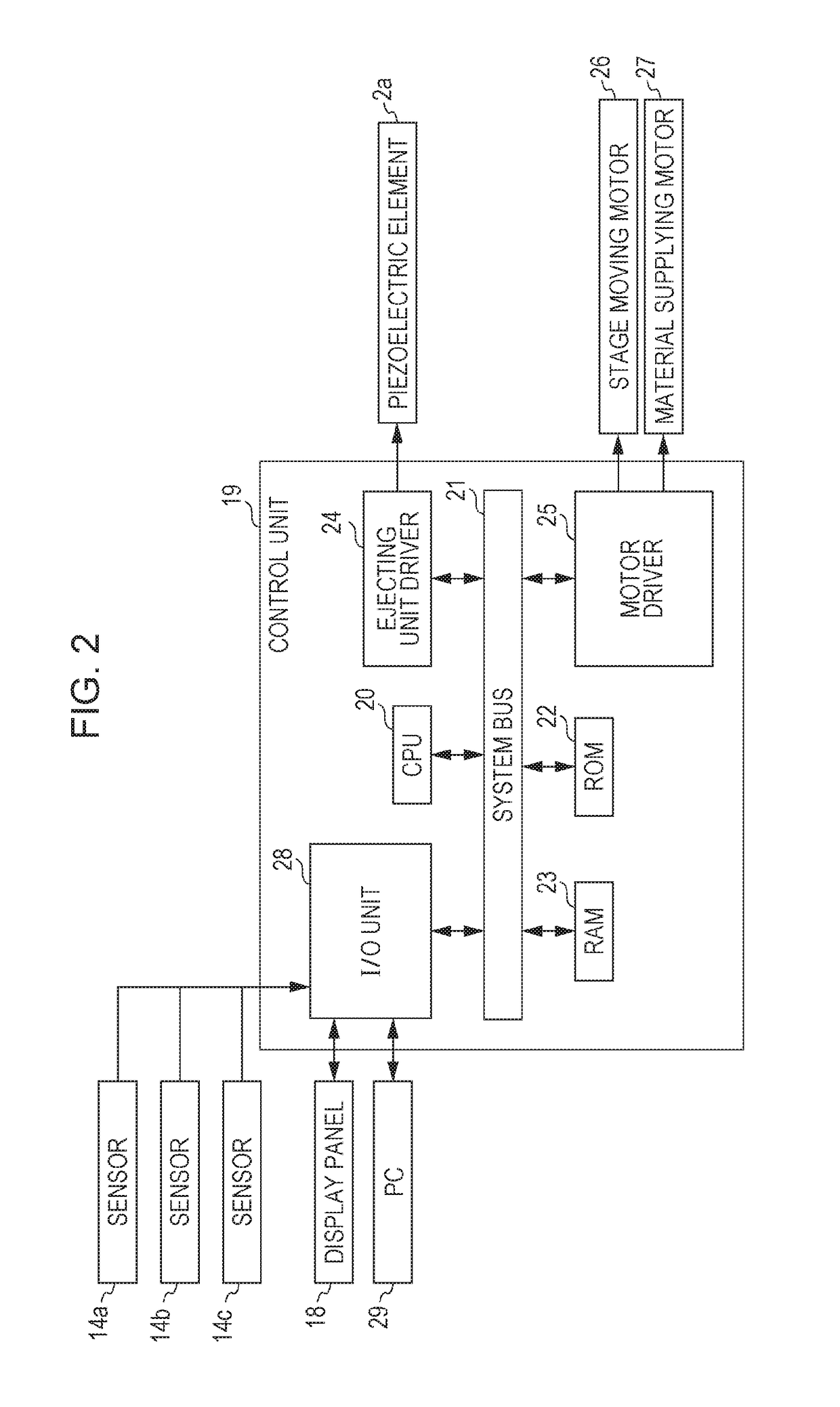

Fluid material ejecting apparatus

InactiveUS20180085825A1Stably ejectedHigh Vickers hardnessAdditive manufacturing apparatusCeramic shaping apparatusHardnessPiston

A fluid material ejecting apparatus includes a material chamber to which a fluid material containing at least one of metal particles and ceramic particles is supplied, a valve seat constituting a part of the material chamber and including an ejection port, a piston movable in the material chamber in directions toward and away from the ejection port, and a driver of the piston. The driver is configured to cause the piston to contact the valve seat from a position away from the valve seat and move in the direction toward the ejection port so as to slide along the valve seat, to thereby eject the fluid material through the ejection port. Sliding surfaces of the piston and the valve seat via which the piston and the valve seat contact each other have a higher Vickers hardness than the particles contained in the fluid material.

Owner:SEIKO EPSON CORP

Full-dehydration high-hardness highly corrosion-resistant galvanizing method

The invention discloses a full-dehydration high-hardness highly corrosion-resistant galvanizing method. Plating liquid is formed by 180-250 g / L of potassium chloride, 50-80 g / L of zinc chloride, 10-20 g / L of dibutyltin dilaurate, 30-45 g / L of boric acid, 10-50 ml / L of stabilizer, 0.5-5 ml / L of brightener, 10-50 ml / L of softener and 1-5 ml / L of polyethylene glycol 600. Electroplating is carried out for 2-10 min with the current density of 0.5-2 A / dm2, and a zinc-tin alloy plating layer 1-10 micron thick is obtained. The plating liquid is stable, the obtained plating layer is high in Vickers hardness and bright, and the corrosion resistance is above 72 h in neutral salt mist.

Owner:扬州市佳佳镀锌有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com