Beryllium-free nickel-free high-ductility zirconium-base block body amorphous alloy and preparation method thereof

A technology of amorphous alloy and high plasticity, which is applied in the field of high plasticity Zr-based bulk amorphous alloy, which can solve the problems of material catastrophic fracture, achieve wide temperature range, facilitate superplastic forming processing, and have excellent biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Preparation and Properties of Zr-Hf-Cu-Fe-Al System Bulk Amorphous Alloy

[0027] Design Zr a f b Cu 26 Fe 8 al 12 Amorphous alloy composition, where a=46,44,42,40; b=54-a. Get the composition as Zr 46 f 8 Cu 26 Fe 8 al 12 、Zr 44 f 10 Cu 26 Fe 8 al 12 、Zr 42 f 12 Cu 26 Fe 8 al 12 and Zr 40 f 14 Cu 26 Fe 8 al 12 alloy.

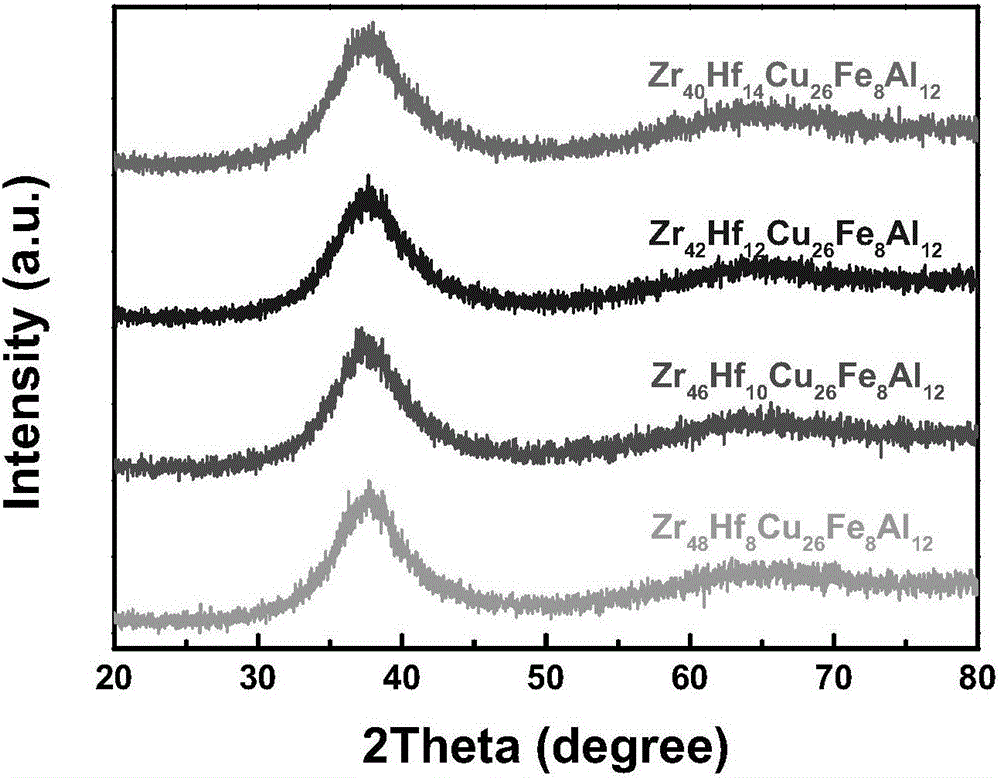

[0028] like figure 1 Shown, Zr 46 f 8 Cu 26 Fe 8 al 12 、Zr 44 f 10 Cu 26 Fe 8 al 12 、Zr 42 f 12 Cu 26 Fe 8 al 12 and Zr 40 f 14 Cu 26 Fe 8 al 12 The XRD pattern of the alloy 5mm sample has only the typical diffuse scattering peaks of the amorphous, indicating that the 5mm alloy is in the amorphous phase, and the alloy has a strong ability to form amorphous.

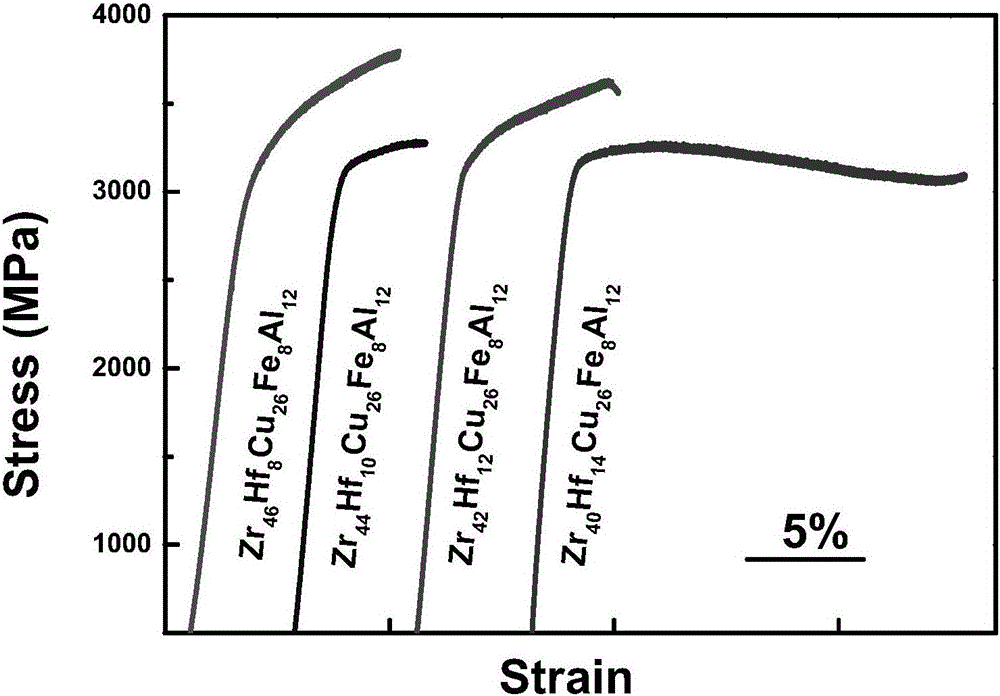

[0029] The compressive stress-strain curve of the alloy is given by figure 2 shown. It can be seen that the alloy does not undergo catastrophic fracture immediately after reaching the yield strength, but undergoes a period of plastic deform...

Embodiment 2

[0030] Example 2: Preparation and properties of Zr-Hf-Cu-Fe-Al-L1 series bulk amorphous alloy

[0031] Design Zr a f b Cu26 Fe 8 al 12 L1 g Amorphous alloy composition, wherein L1 is one of Ag, Co, Nb, a=39; b=14; g=1 or a=39,46; b=6; g=2. Prepare the alloy composition as Zr 46 Cu 26 Fe 8 al 12 f 6 Ag 2 , Zr 46 Cu 26 Fe 8 al 12 f 6 co 2 , Zr 46 Cu 26 Fe 8 al 12 f 6 Nb 2 , Zr 39 Cu 26 Fe 8 al 12 f 14 Ag 1 and Zr 39 Cu 26 Fe 8 al 12 f 14 Nb 1 .

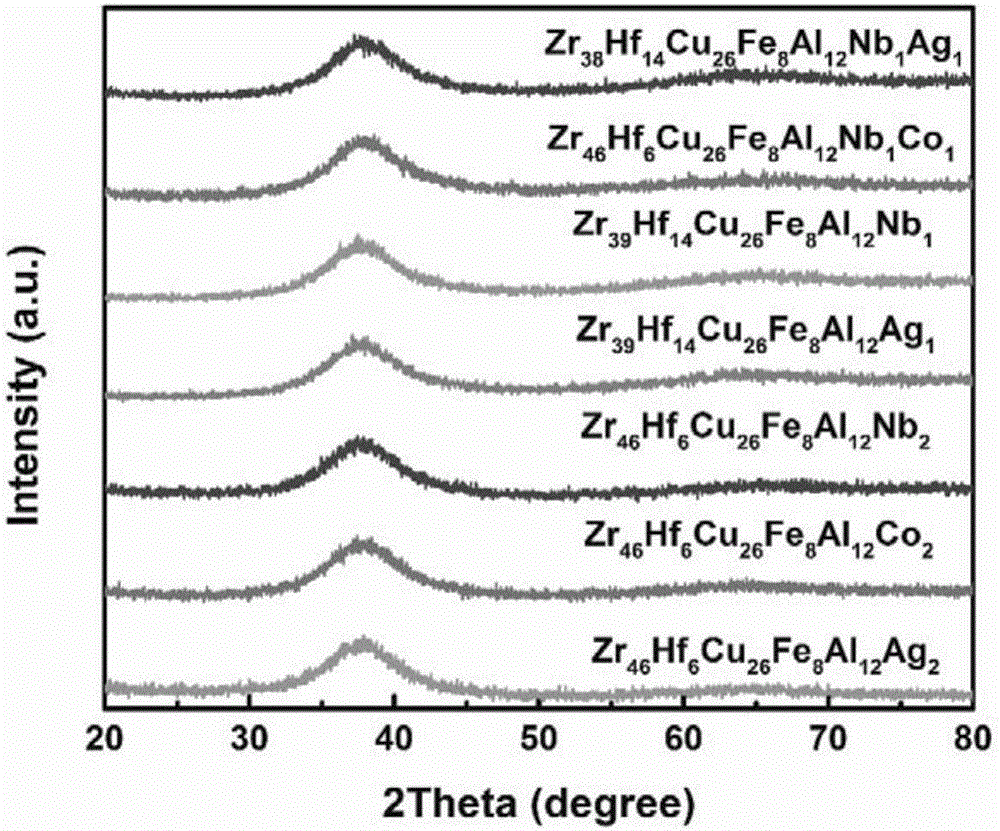

[0032] image 3 Zr shown a f b Cu 26 Fe 8 al 12 L1 g The XRD pattern of the 5mm sample of the alloy shows that there are only diffuse scattering peaks typical of amorphous in the XRD pattern of the 5mm sample, indicating that the 5mm alloy is in the amorphous phase, and the alloy has a strong ability to form amorphous.

[0033] Such as Figure 4 Zr shown a f b Cu 26 Fe 8 al 12 L1 g Vickers hardness of the alloy, the hardness of the amorphous alloy is greater than 550Hv, among which Zr has...

Embodiment 3

[0034] Example 3: Two of the preparation of Zr-Hf-Cu-Fe-Al-L2 series bulk amorphous alloy and its properties, a=38; b=14; g=2 or a=46; b=6 ; g=2, the atomic fractions of the two elements in L2 are the same. Prepare the alloy composition as Zr 46 Cu 26 Fe 8 al 12 f 6 Nb 1 co 1 and Zr 38 Cu 26 Fe 8 al 12 f 14 Nb 1 Ag 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com