Patents

Literature

584results about How to "Meet size requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

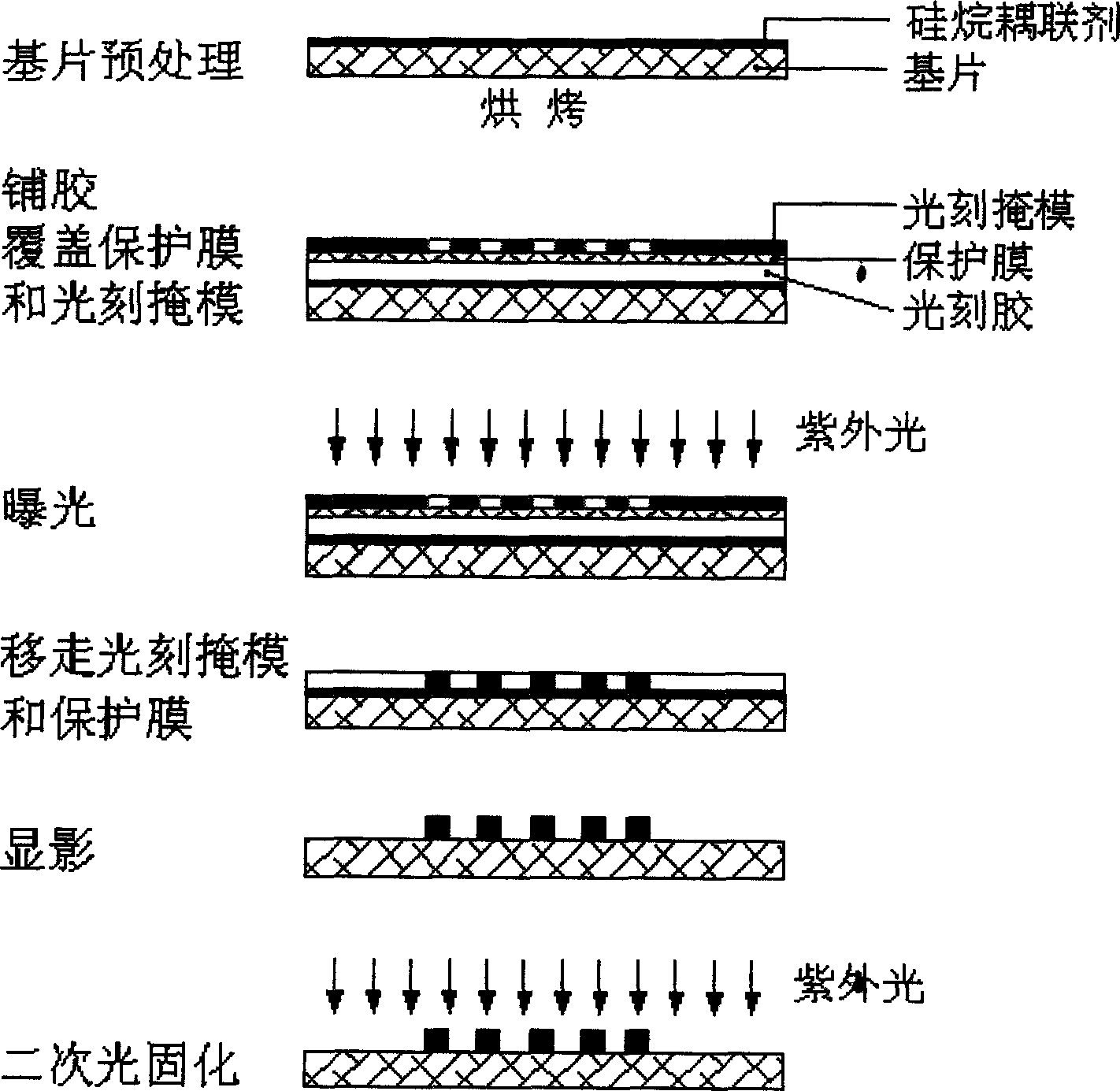

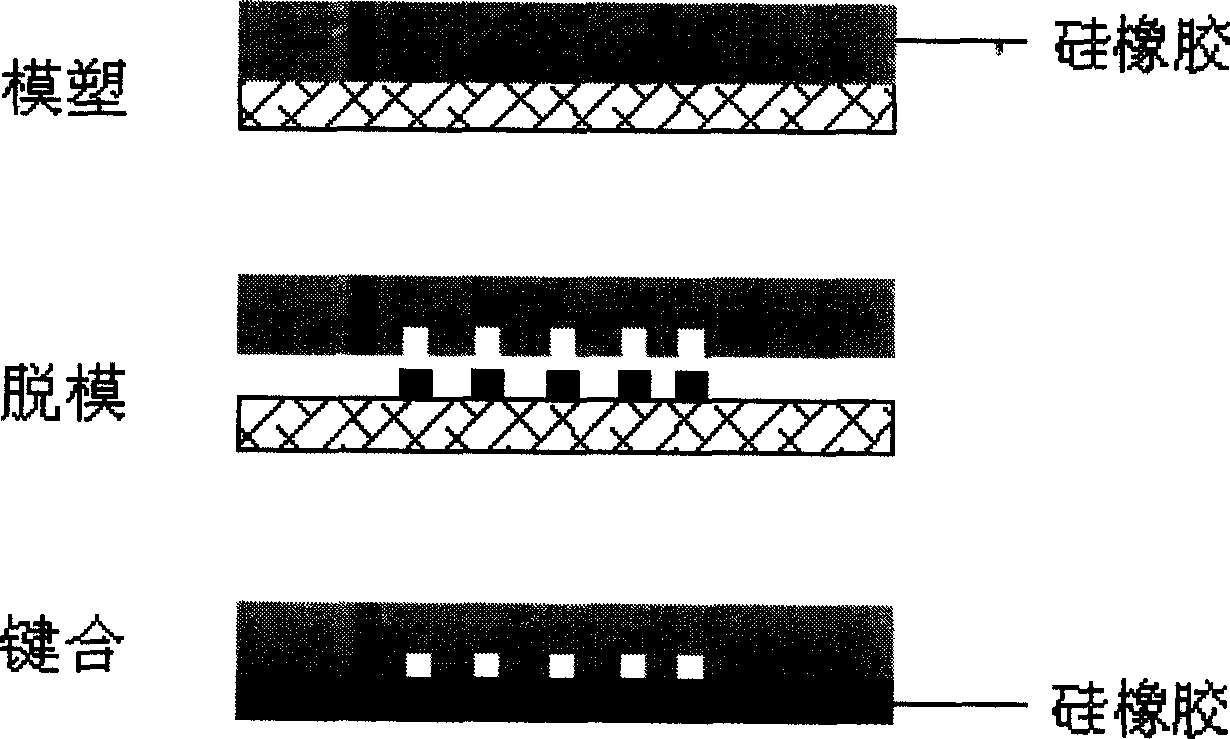

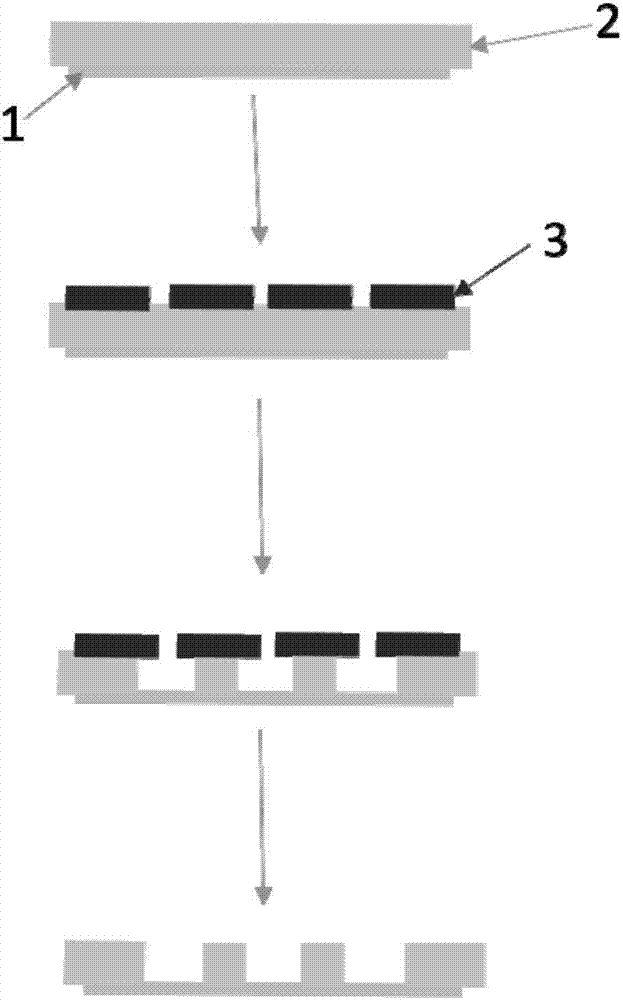

Method for making dimethyl silicone polymer micro flow control chip composite type optical cured resin die arrangement

InactiveCN1621945ASolve sticking problemsHigh speedPhotomechanical exposure apparatusMicrolithography exposure apparatusEtchingSilanes

The present invention discloses the making process of composite photocuring resin mold for preparing microfluid controlling chip of polydimethyl siloxane. The present invention adopts liquid photoresist of photosensitive epoxy resin as micro mold material, quartz glass as substrate, silane coupler coating on the substrate to increase the binding force between the mold structure and the substrate, plastic film of different thickness adhered around the substrate to control the thickness of photoresist, photoetching mask of photosensitive film from laser photoset, common ultraviolet lamp or ultraviolet laser as exposure light source, F46 film as exposure protecting film, absolute alcohol as developer, vibration for clear development contour and secondary photocuring after development to raise structure strength and structure-substrate binding force. The mold is used in copying microfluid control chip, biochip, soft mold for impression etching, etc.

Owner:XI AN JIAOTONG UNIV

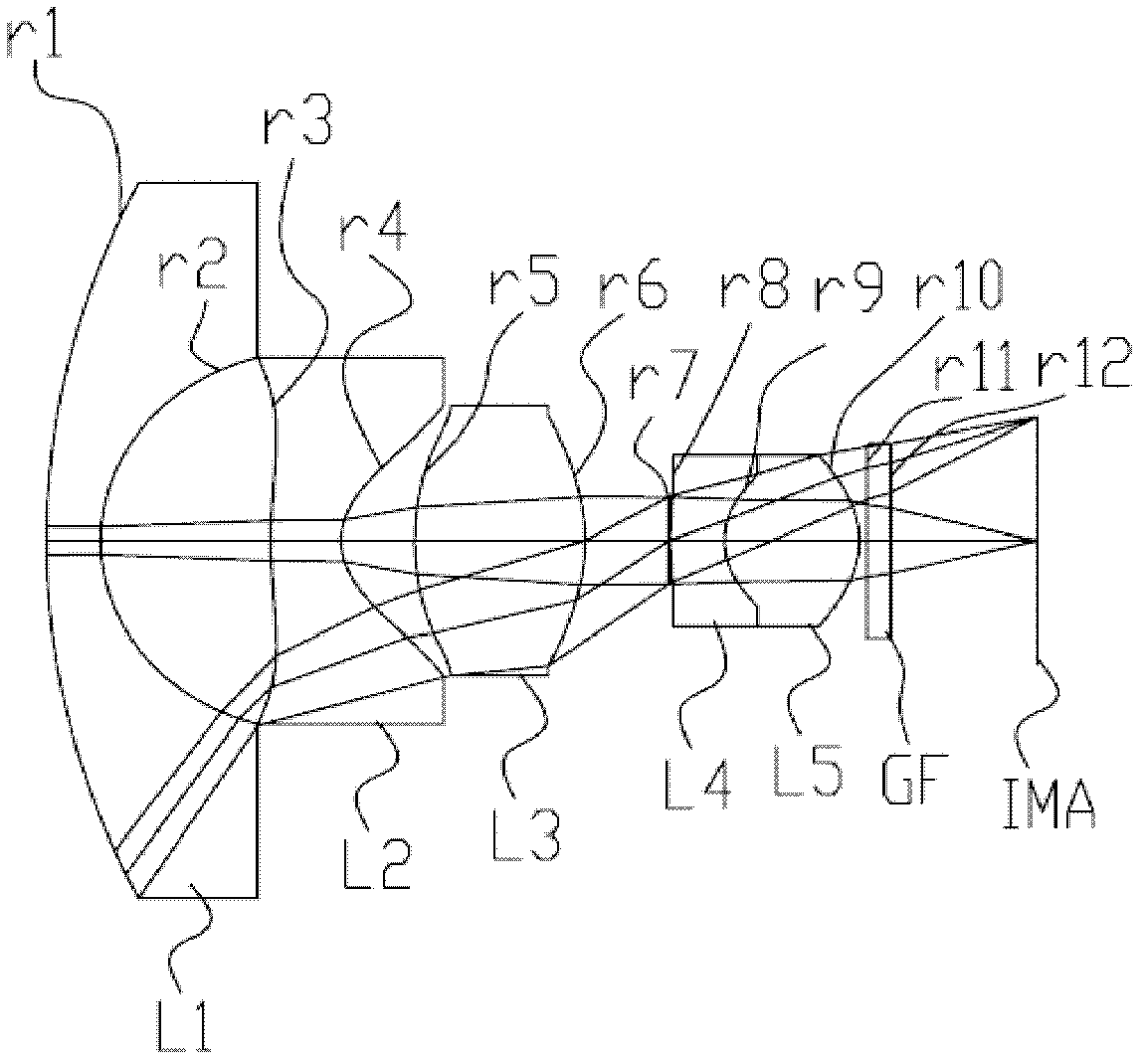

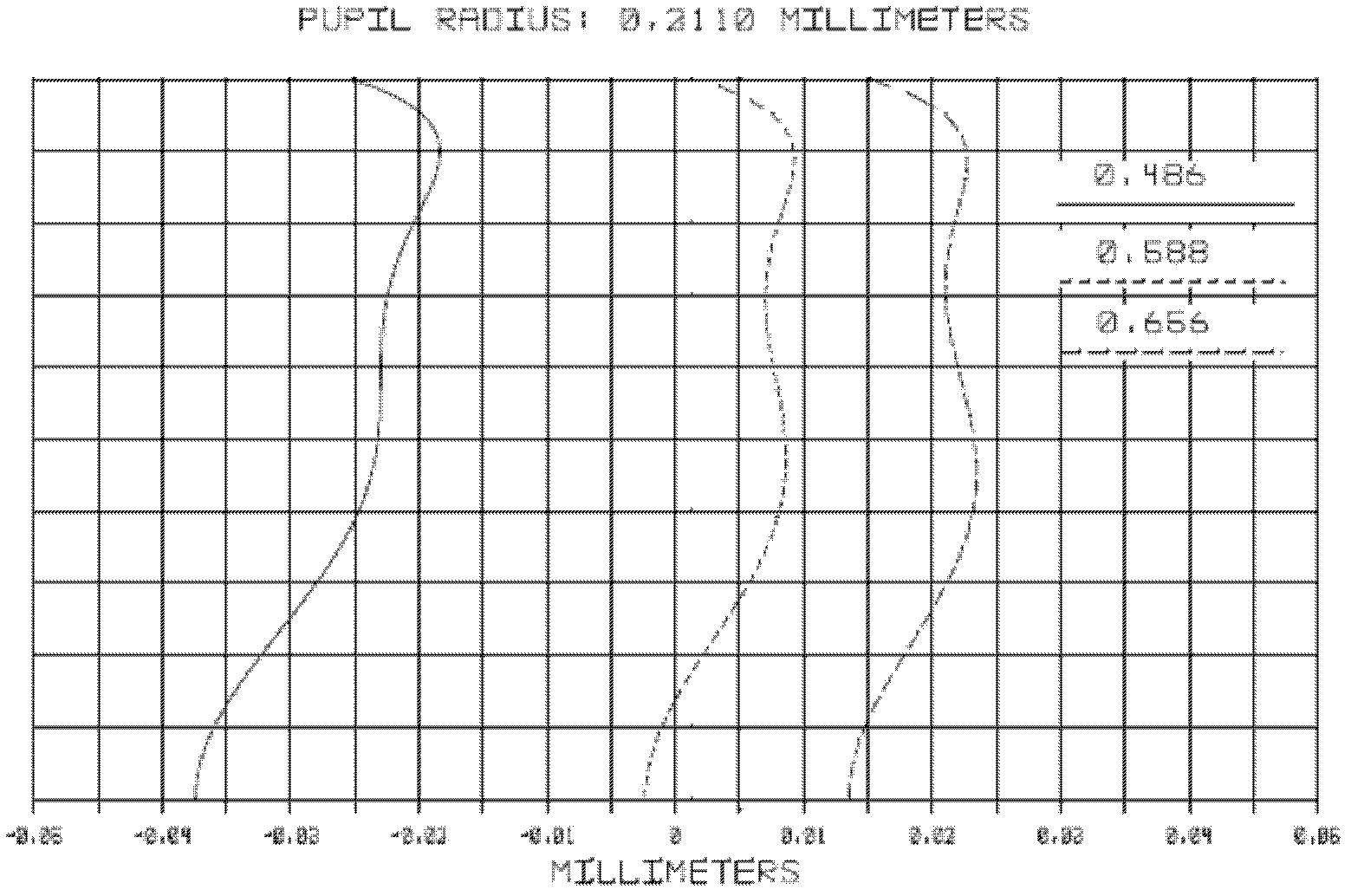

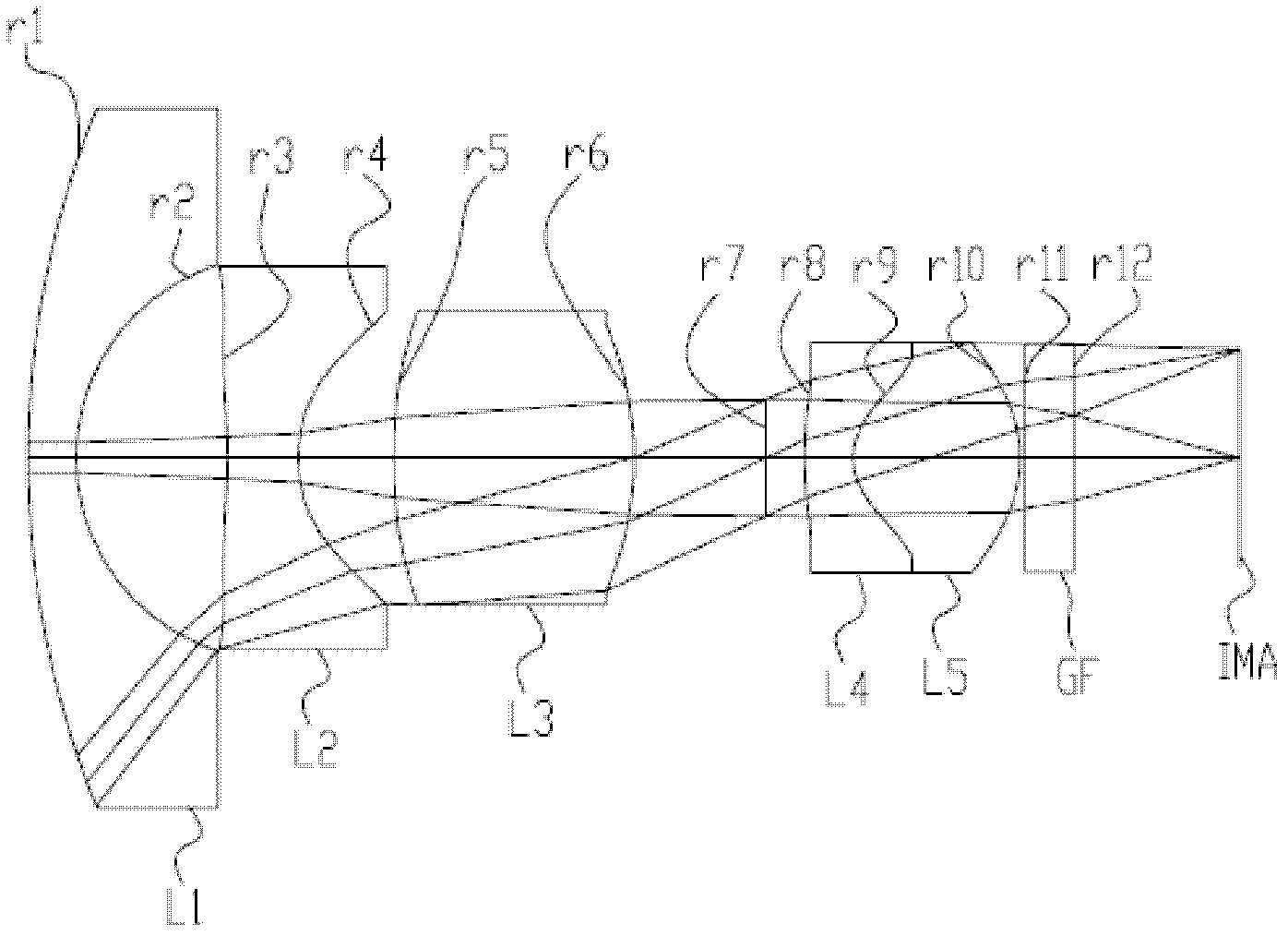

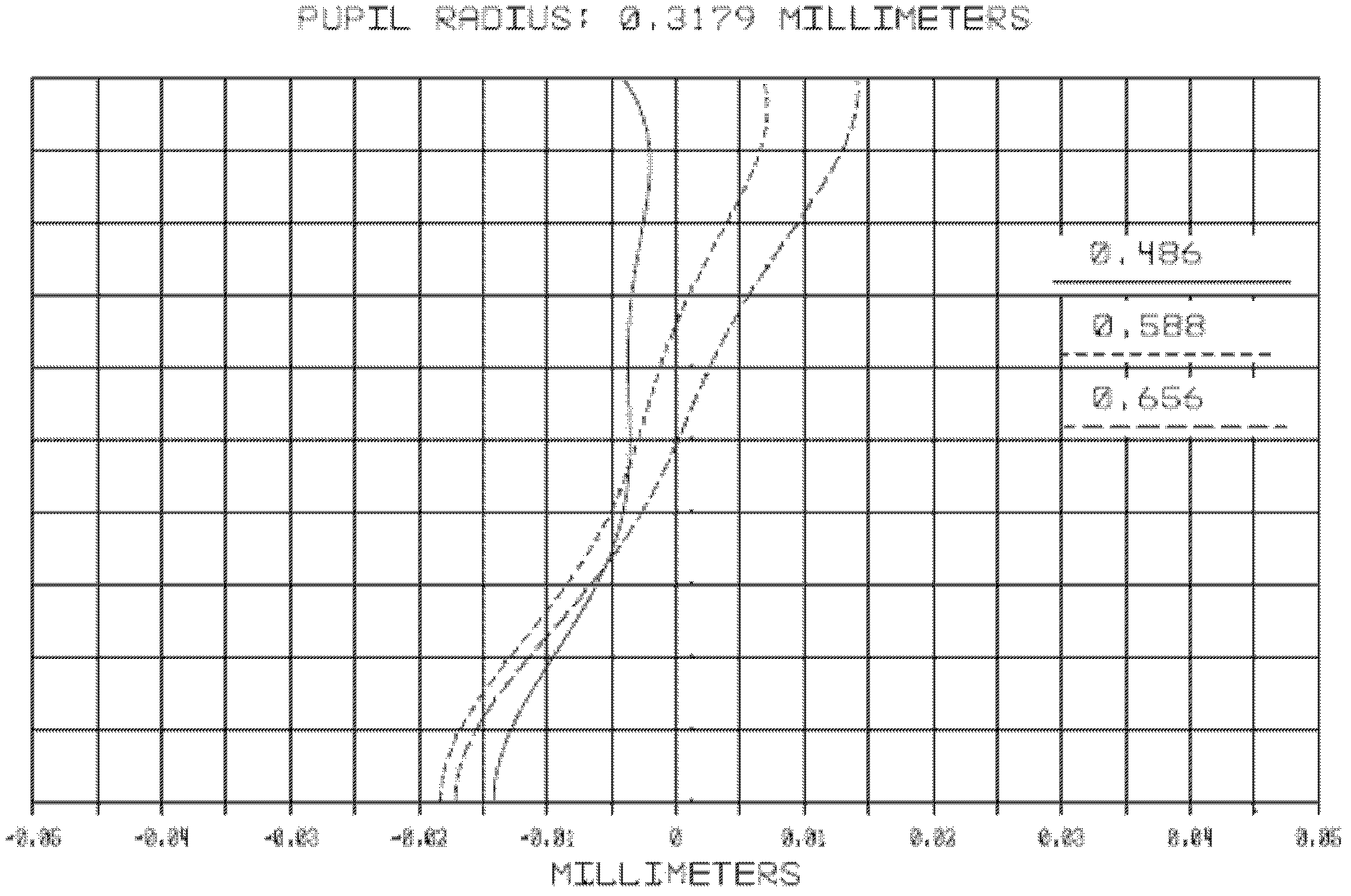

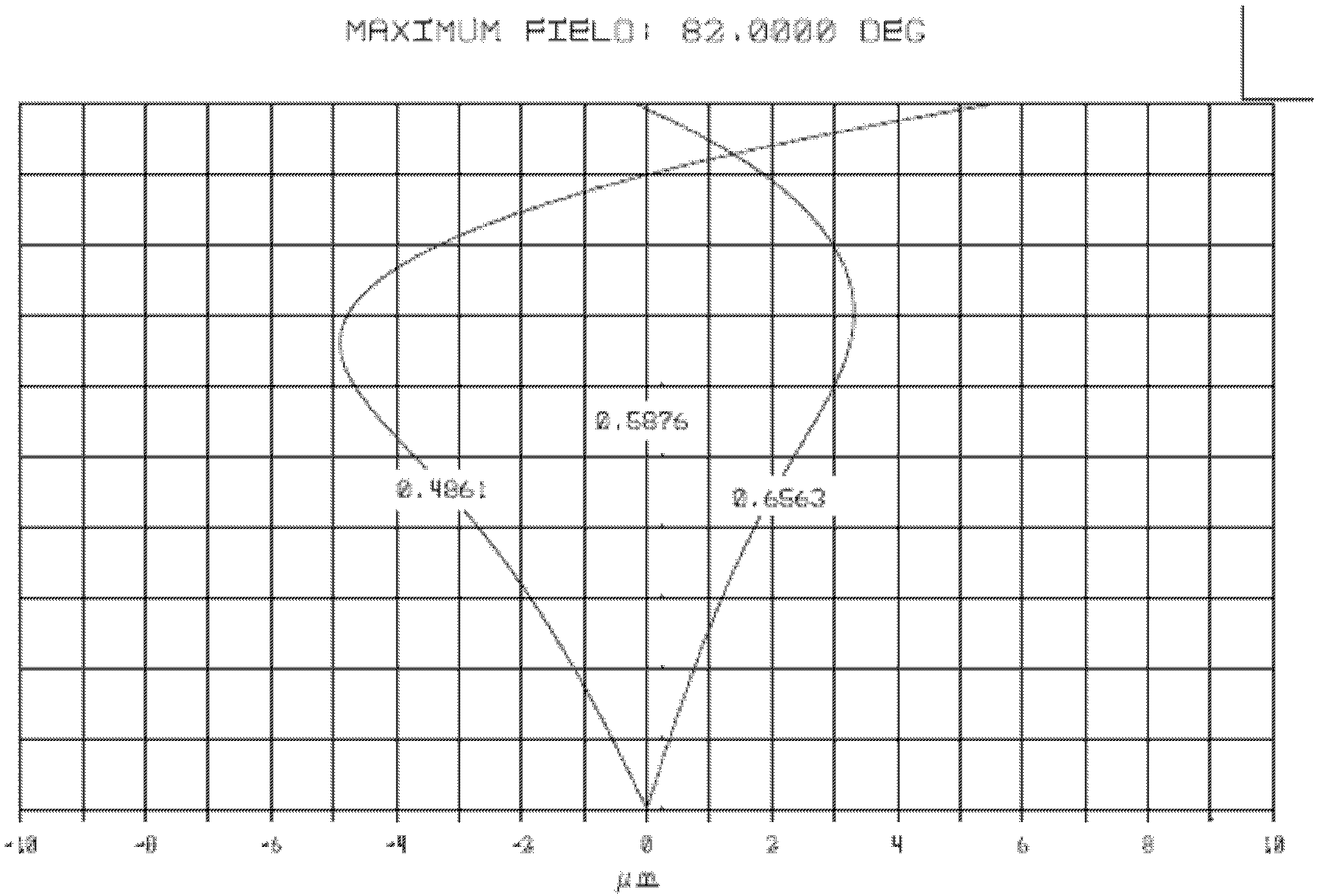

A super wide-angle lens

ActiveCN102289052AProtection against scratchesIncrease chromatic aberrationOptical elementsCamera lensLarge size

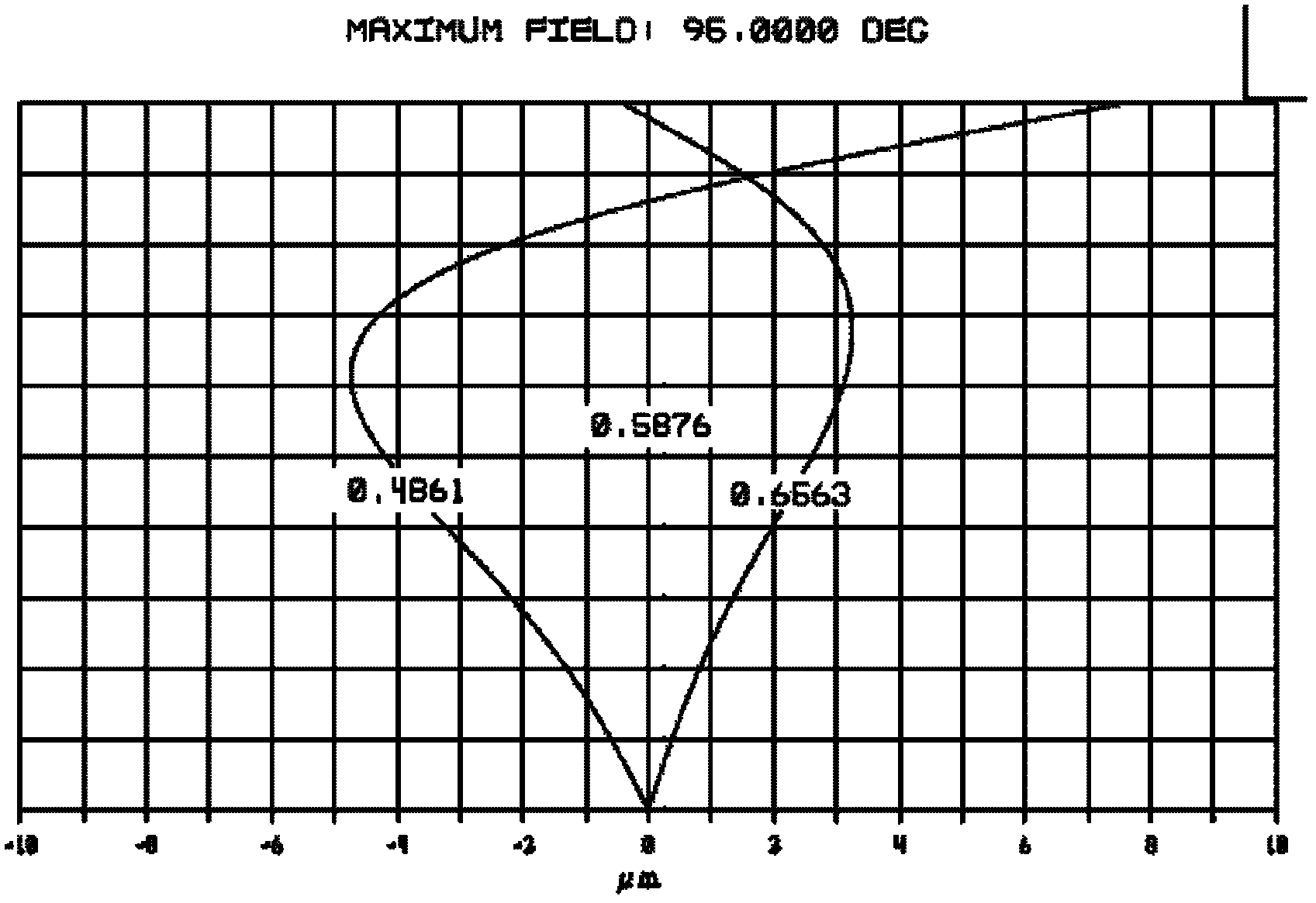

The invention discloses an ultra wide angle camera lens. The ultra wide angle lens comprises a first lens, a second lens, a third lens, a fourth lens and a fifth lens in sequence from an object space to an image space, wherein the first lens, the second lens and the fourth lens have negative focal power, the third lens and the fifth lens have positive focal power, the fourth lens and the fifth lens are adhered together to form a cemented lens with the positive focal power, the condition that BFL (Back Focal Length) / EFL (Effective Focal Length) is not smaller than 2.4 is also satisfied, BFL is a distance from an outermost point at the image space of a fifth lens element of the ultra wide angle camera lens to an imaging plane, and EFL is a focal length value of the ultra wide angle camera lens. In the invention, the ultra wide angle camera lens remains a longer BFL under the condition that a TTL (Total Length of Lens) is kept so as to meet requirements for larger sizes of electronic elements and devices at the periphery of an image sensor during the design of a camera; and the lens elements and optical filters are further from the image sensor due to longer BFL, so that the requirement for the surface cleanliness of the respective lens elements and optical filters can be effectively reduced, and the camera is easier to assemble and produce.

Owner:NINGBO SUNNY AUTOMOTIVE OPTECH

Method for treating the surface of a part made of a heat-structured composite material and use thereof in brazing parts made of a heat-structured composite material

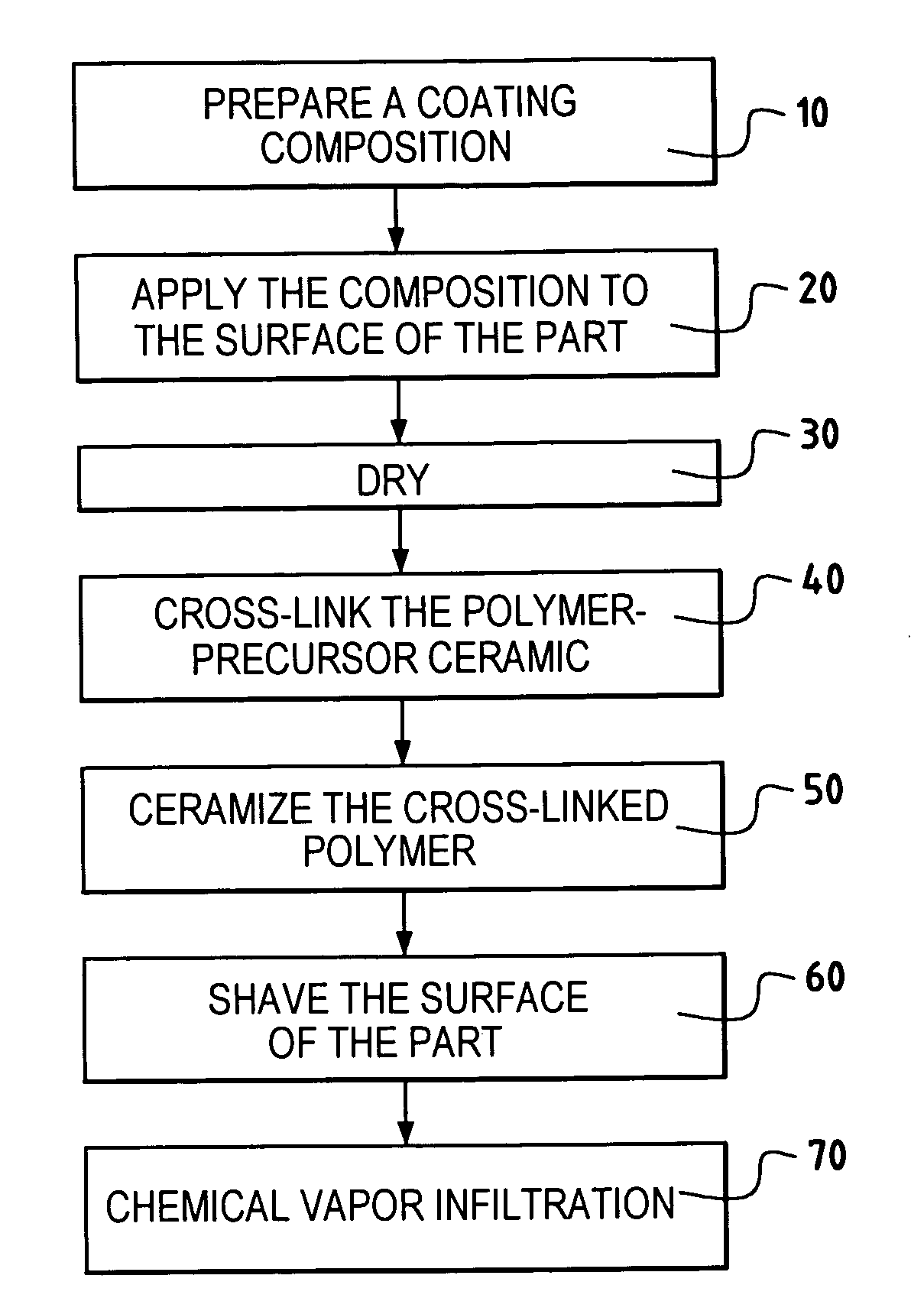

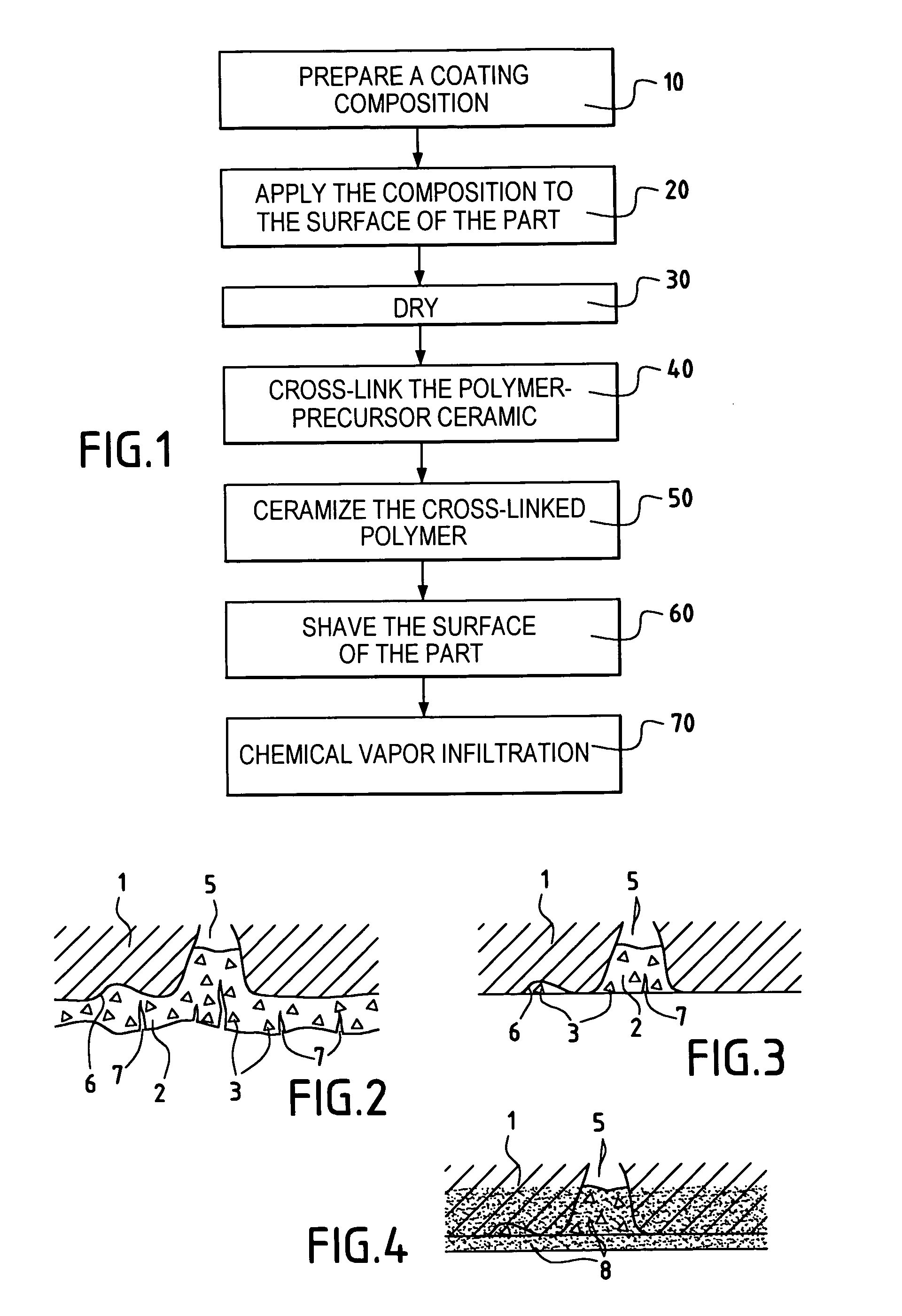

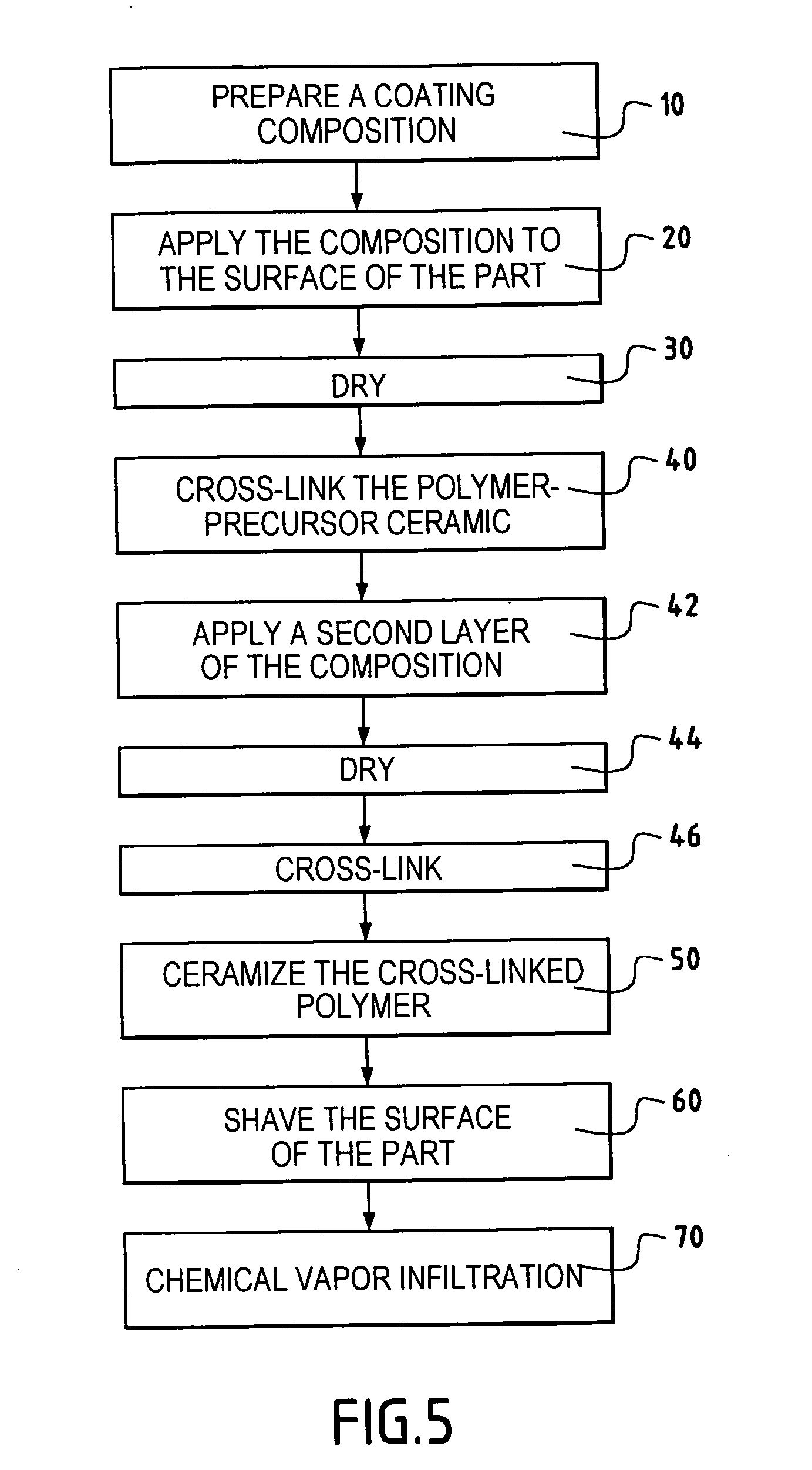

InactiveUS20060141154A1Satisfies dimensional requirementMeet size requirementsChemical vapor deposition coatingGas phasePrecursor polymer

A liquid composition is applied onto the surface of the part to be treated, the composition containing a ceramic precursor polymer and a refractory solid filler. After cross-linking, the polymer is transformed into ceramic by heat treatment, and subsequently ceramic is deposited by chemical vapor infiltration. Before the chemical vapor infiltration step, the surface of the part is shaved so as to return the composite part to its initial shape so that the chemical vapor infiltration forms a deposit that fills in the residual micropores in the shaved surface of the part.

Owner:SNECMA PROPULSION SOLIDE

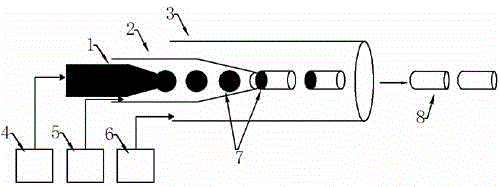

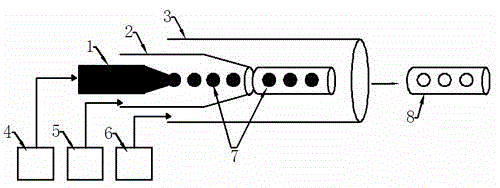

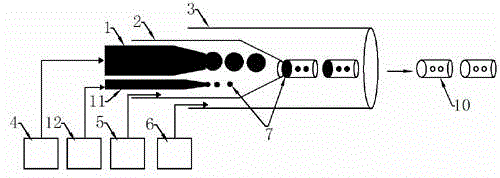

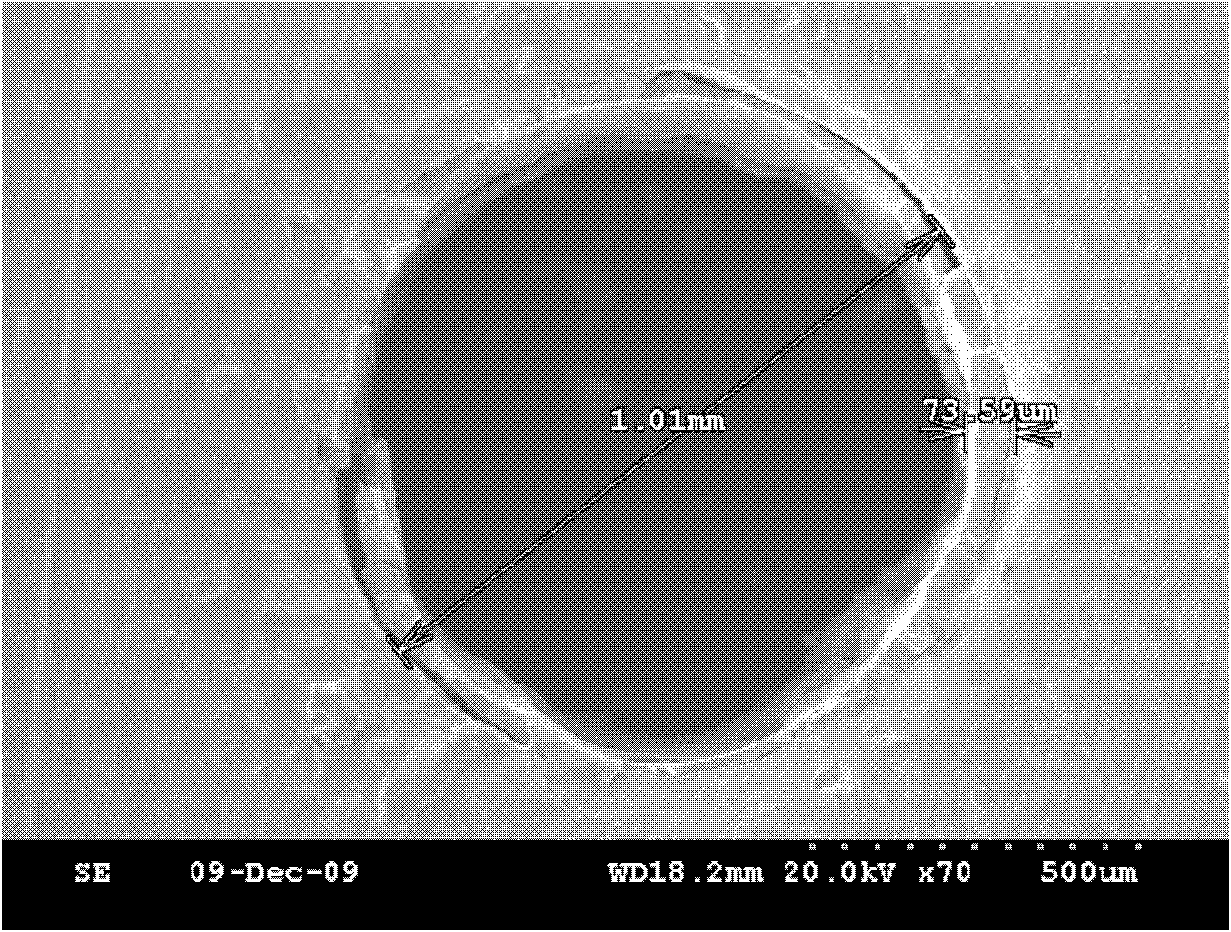

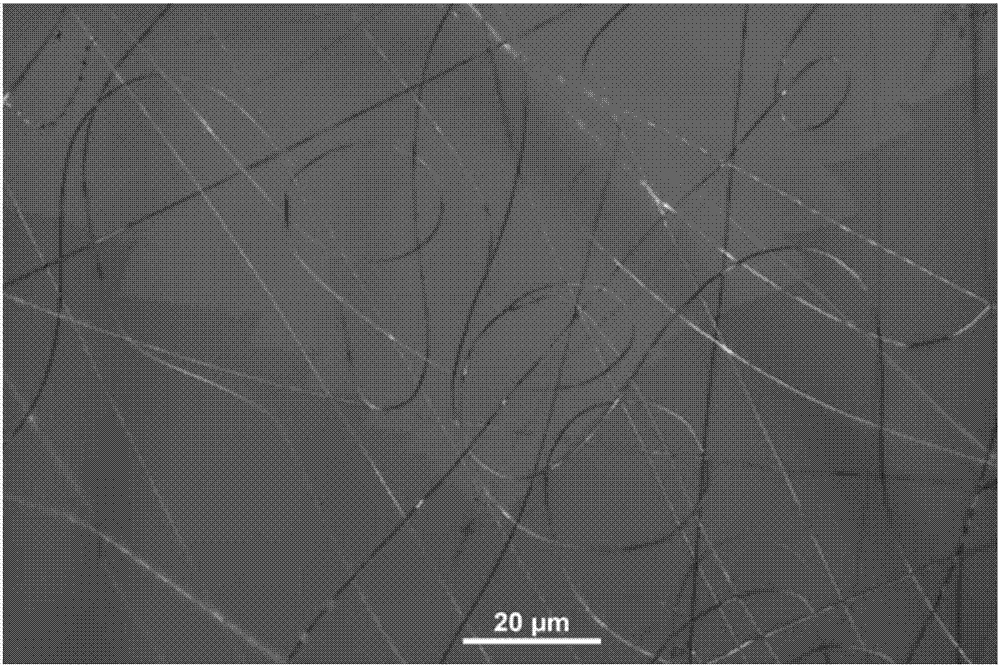

Calcium alginate fiber and preparation method thereof

InactiveCN103820880AUniform structureThe preparation method is simple and safeFilament/thread formingAlginate artificial filamentsFiber structureWater dynamics

The invention discloses a calcium alginate fiber and a preparation method thereof. The fiber is calcium alginate hydrogel with a porous structure, a rodlike structure or a rodlike and porous compound structure; the diameter of the fiber is 100-500mu m. According to the preparation method, on the basis of the action of hydrodynamics and by use of the chemical principle that sodium alginate reacts with calciumchloride to generate the calcium alginate hydrogel and the design of a microfluid device, sodium alginate solution and calciumchloride solution are mixed to generate gelation reaction; fibers with different structures and different sizes are generated by adjusting the flow velocity of internal-phase fluid. The preparation method disclosed by the invention has the advantages of simplicity, safety, lower cost and strong experimental repeatability; in the preparation process, a high-voltage electric field is not mentioned, so that the damage to cells is avoided and cell encapsulation can be realized. The prepared fiber structure has the advantages of uniformity, size controllability, good biocompatibility and broad application prospect; the prepared fiber structure can be directly applied to the fields of biomedicines such as cell culture and drug delivery.

Owner:SOUTHEAST UNIV

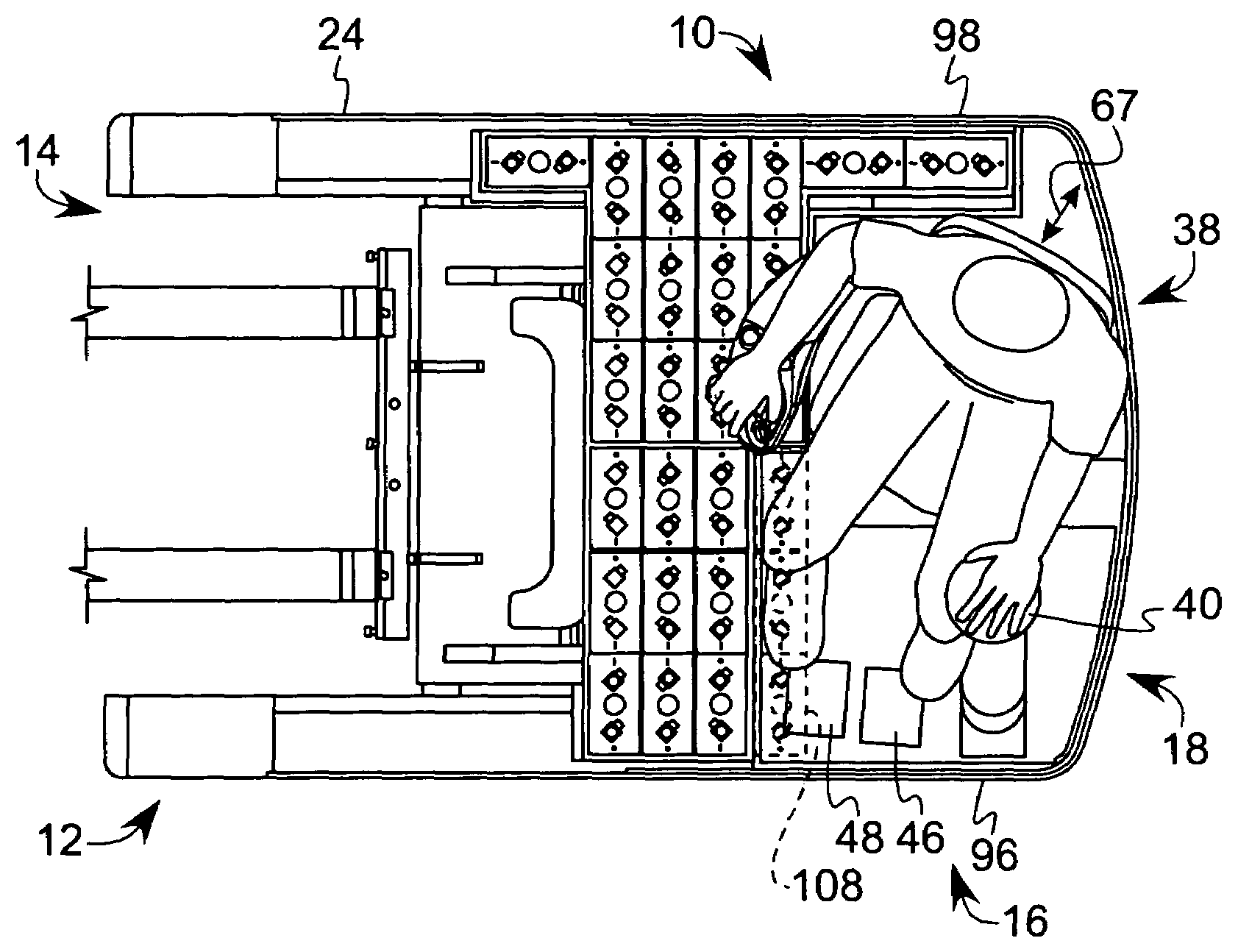

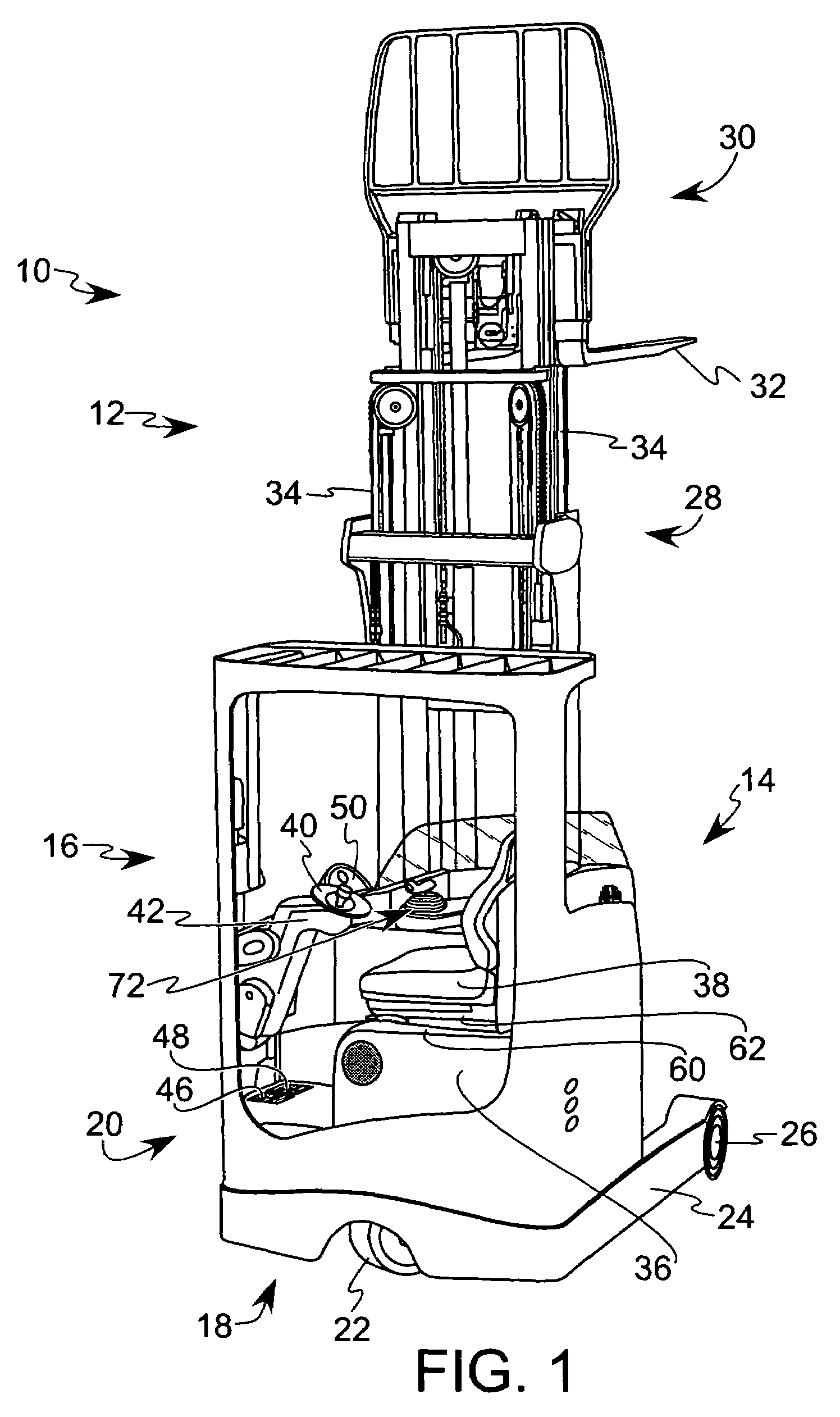

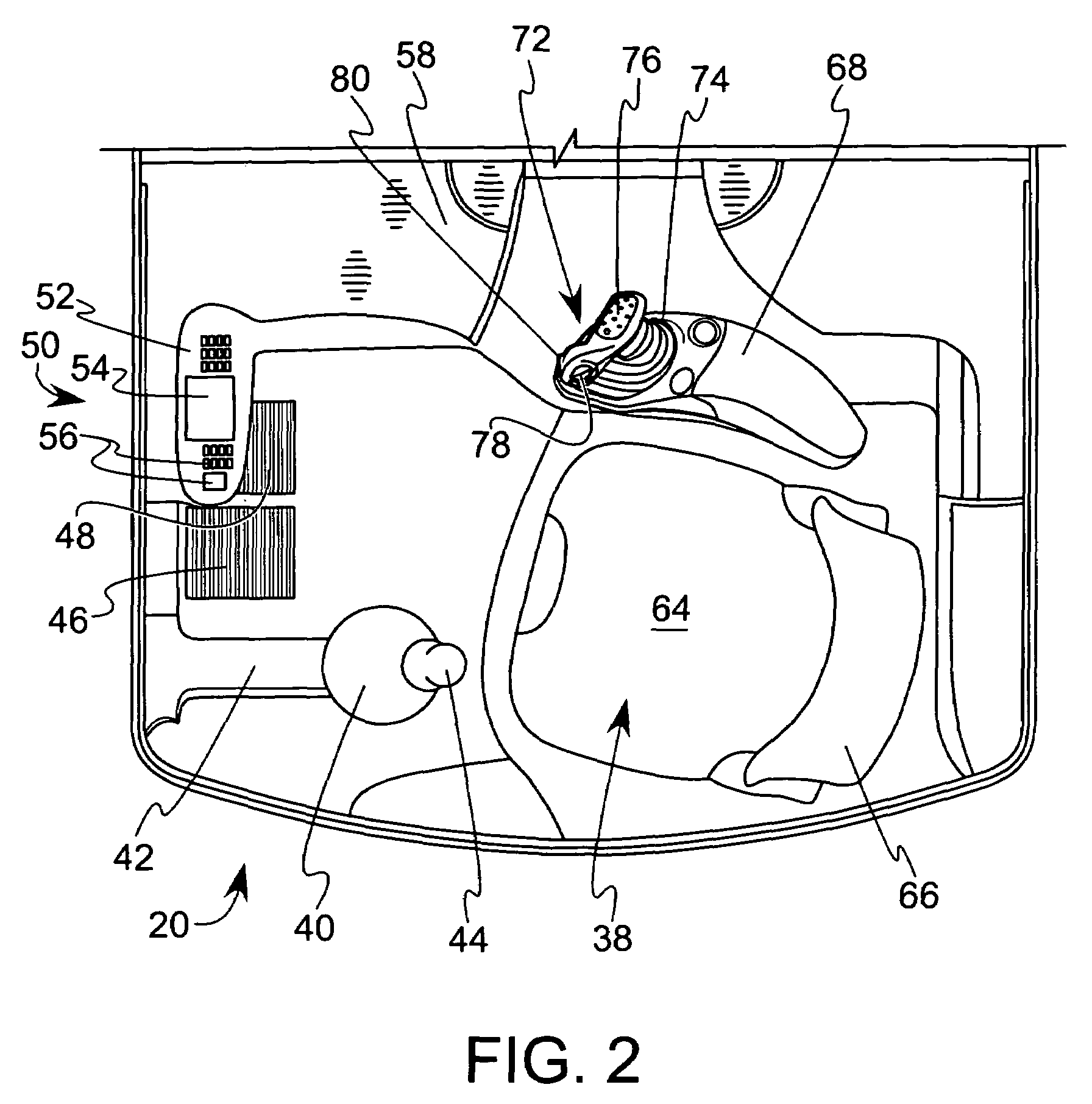

Industrial vehicle with shaped battery

InactiveUS7374004B2Available spaceImprove accommodationElectric propulsion mountingLifting devicesEngineeringSpace requirements

An industrial vehicle includes a battery that is shaped to expand or otherwise modify the space available within an operator's compartment. As a result, operator accommodations may be satisfied within the space requirements of the vehicle. The present invention further provides an industrial vehicle having an adjustable feature, such as a repositionable operator's seat and / or repositionable control element or operator control surface, and a shaped battery that enables or otherwise corresponds with the repositioning capability of the adjustable feature.

Owner:CROWN EQUIP CORP

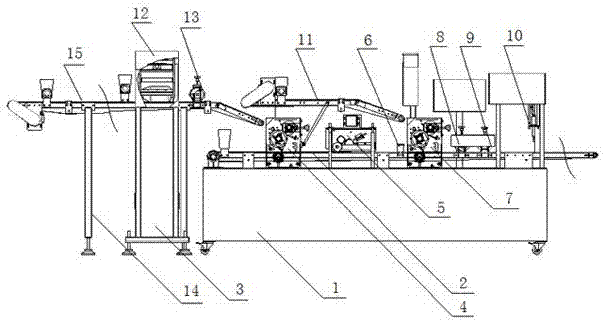

Double-layer fried bread stick machine and method of making fried bread sticks

ActiveCN107439626AEasy to startMeet size requirementsOil/fat bakingDough shaping and dividing combinationEngineeringConveyor belt

The invention discloses a double-layer fried bread stick machine. The method comprises a rack and a conveyor belt mounted on the rack, a front dough feeding mechanism located in a material feeding end of the conveyor belt, and a first dough pressing mechanism, an oil brushing mechanism, a water brushing mechanism, a second dough pressing mechanism, a round cutter mechanism, a medium press roller mechanism, a cutting table mechanism which are arranged from the material feeding end to a material discharging end; a rear dough feeding mechanism is located on the conveyor belt, and the output end of the rear dough feeding mechanism is located at an input end of the second dough pressing mechanism; a dough rolling mechanism and a three circular cutter mechanism are at least arranged on the front dough feeding mechanism. According to the double-layer fried bread stick machine, imitating manual rolling of the fried bread stick dough can be achieved; through brushing oil and water alternately, the edges of the fried bread sticks can rise easily when fried, the middle connections are good and do not explode, so that two layers of fried bread sticks stick well together, and it is not possible to cause dough stickiness for the fried bread sticks; the rising effect is good, it is ensured that the yield of finished products is 100%, the appearance is beautiful, the prepared double layer fried bread sticks are fed into a frying pan mechanism automatically, and the degree of automation is higher.

Owner:SUZHOU GUOEN FOOD MACHINERY

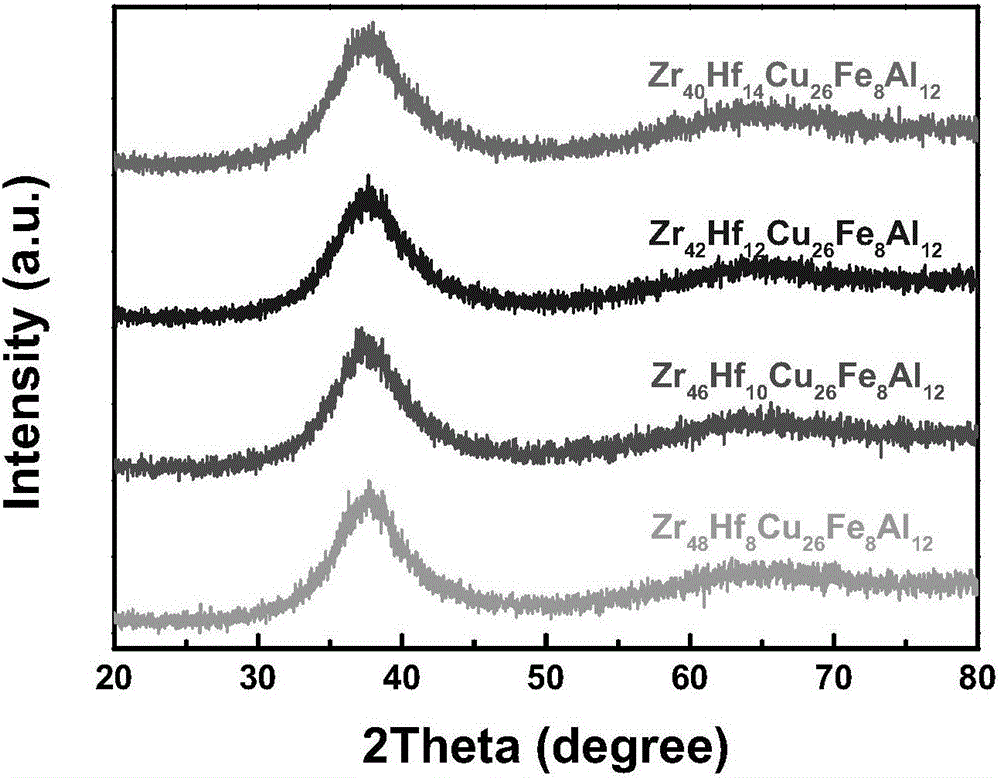

Beryllium-free nickel-free high-ductility zirconium-base block body amorphous alloy and preparation method thereof

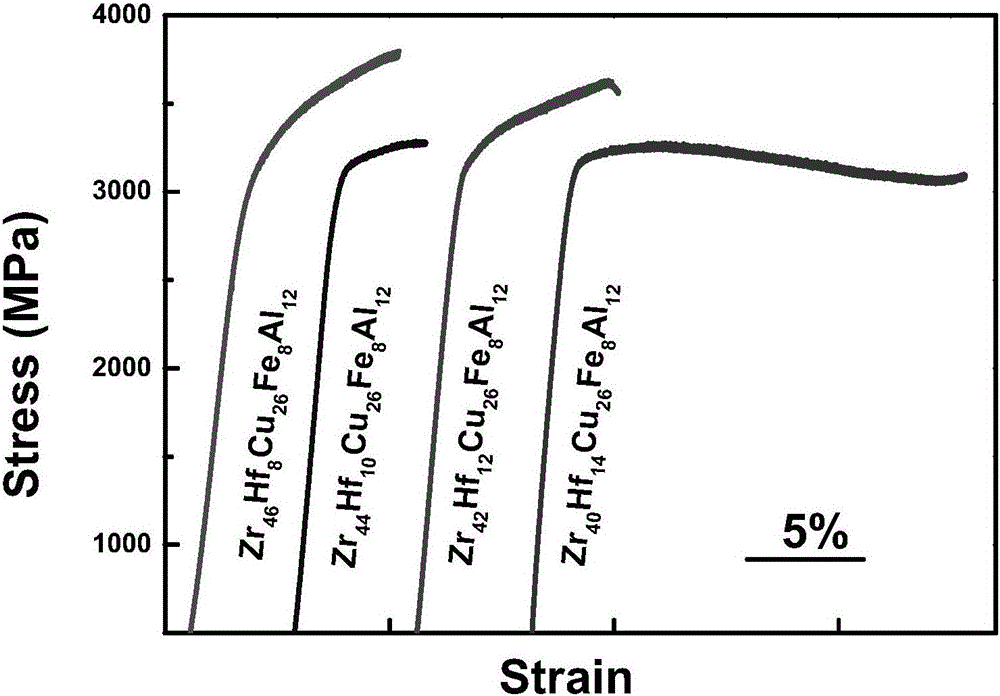

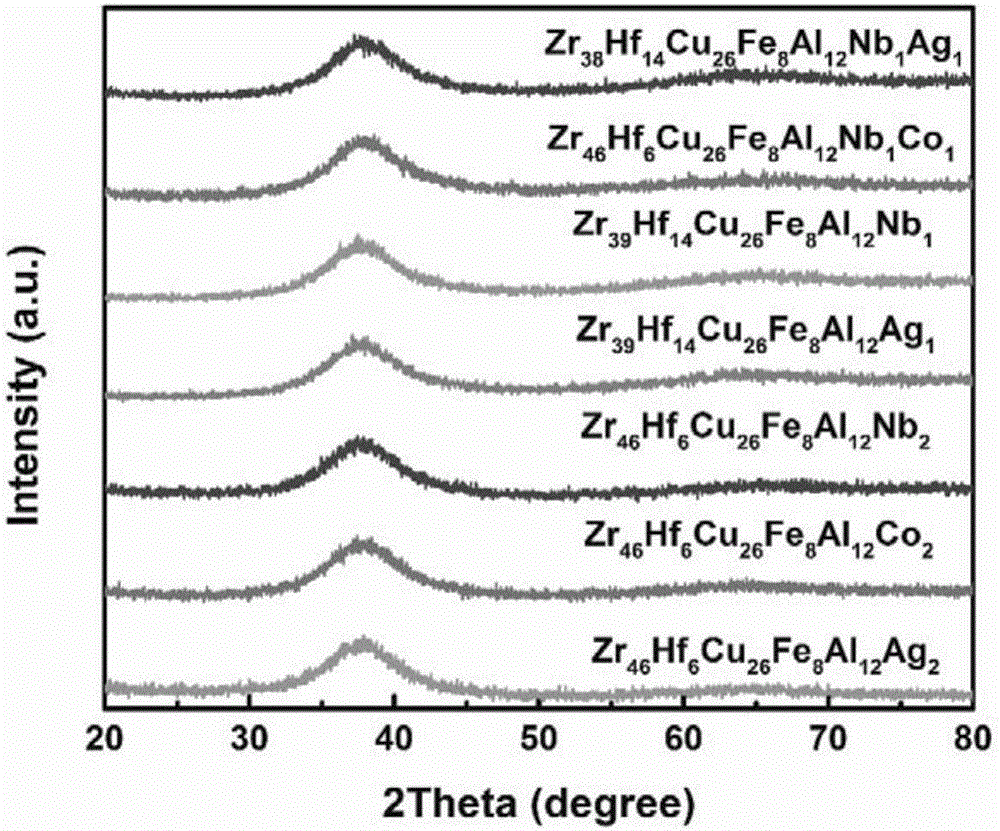

ActiveCN106756647AGood biocompatibilityWide temperature range of subcooled liquid phase regionBiocompatibility TestingNickel free

The invention provides a beryllium-free nickel-free high-ductility zirconium-base block body amorphous alloy and a preparation method thereof. The alloy comprises, by atom, 38-50% of Zr, 2-15% of Hf, 20-30% of Cu, 5-10% of Fe, 10-15% of Al, 0-5% of Co, 0-5% of Ag and 0-5% of Nb. The electric arc melting copper mould casting method is adopted for preparation. The amorphous alloy is free of metal elements such as Be and Ni, and biocompatibility of the zirconium-base alloy is improved. The high amorphous forming capacity is achieved, and the zirconium-base block body amorphous alloy with the critical size being no less than 5 mm can be prepared through the copper mould casting method. According to the beryllium-free nickel-free high-ductility zirconium-base block body amorphous alloy, high hardness is achieved, and vickers hardness is larger than 540 Hv; the plastic deformation capacity being larger than 3% is achieved; and the super-cooled liquid phase region range is wide and reaches 92 K at most. The beryllium-free nickel-free high-ductility zirconium-base block body amorphous alloy and the preparation method thereof has very wide application prospects in the fields of biomedical materials such as a precise complex medical component, a joint prosthesis and a human skeleton.

Owner:UNIV OF SCI & TECH BEIJING

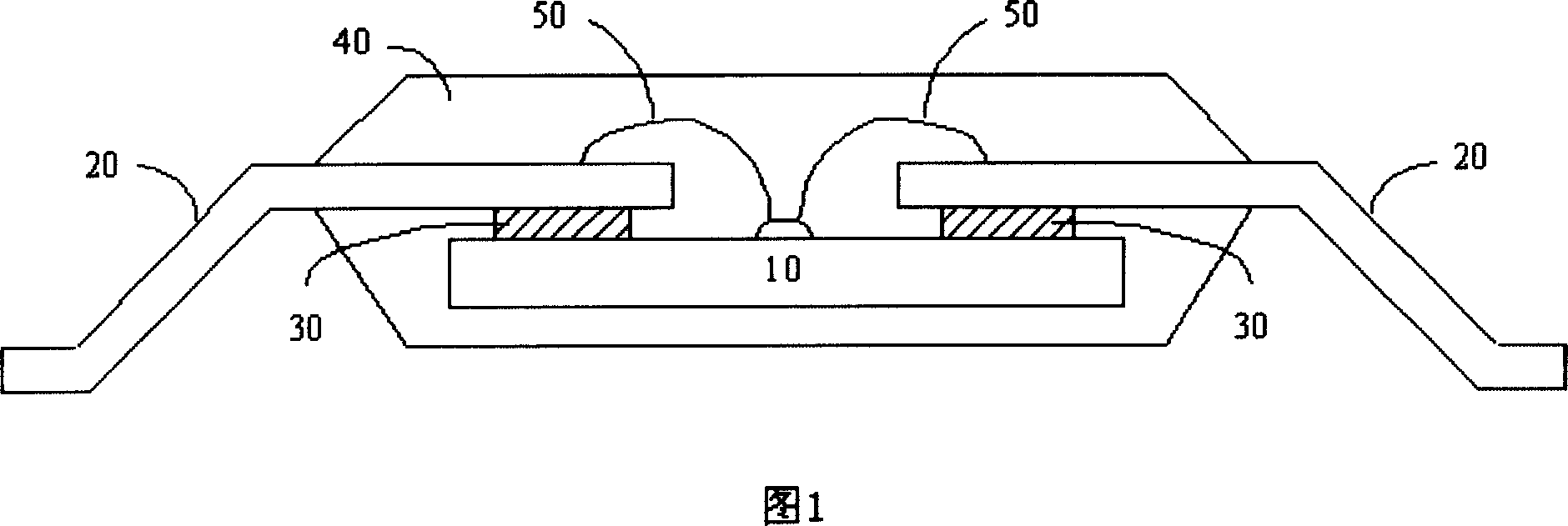

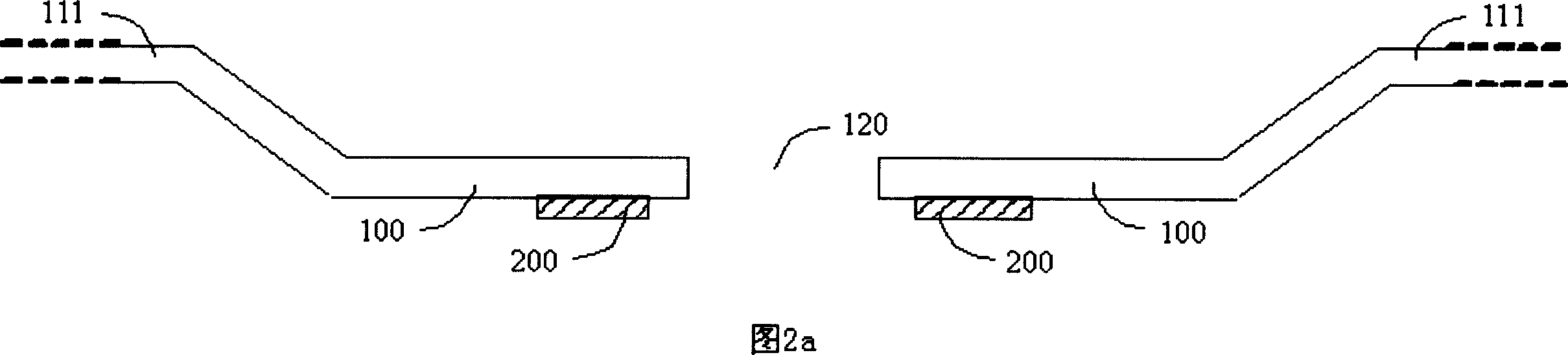

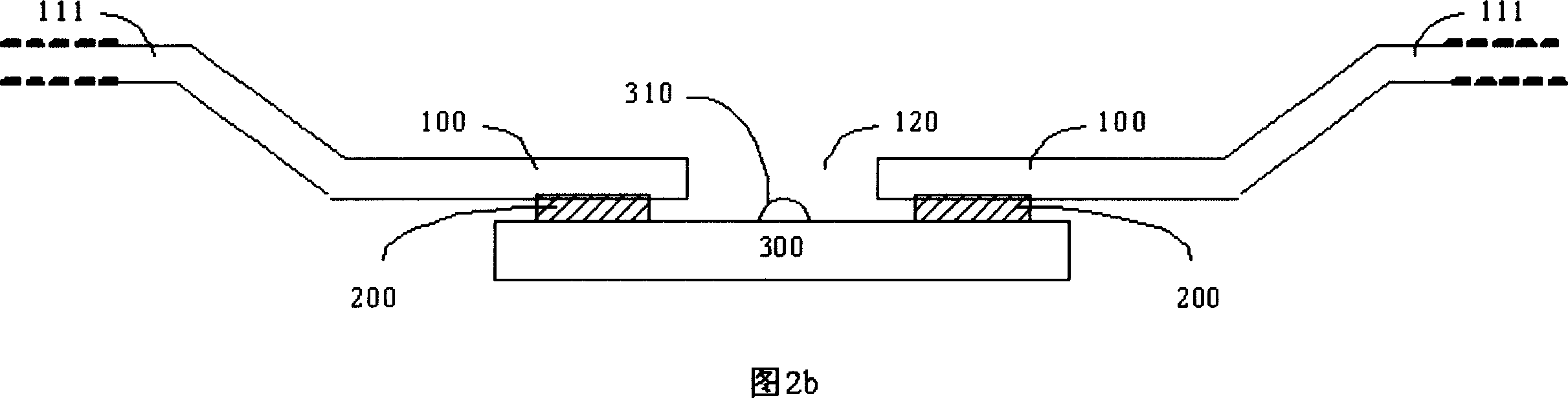

Lead frame chip-level encapsulation method

InactiveCN101055840AGuaranteed plating effectGuaranteed electrical stabilitySolid-state devicesSemiconductor/solid-state device manufacturingColloidLead frame

The invention proposes a lead frame type chip packaging method. The invention is similar to a conventional chip hook, but has a main difference that an inside pin of a lead frame is bended towords a side of the lead frame in addvance to form a space capable of supporting a chip and a lead, while an outside pin is directly exposed under a packaging colloid, and the outside pin is not bended and shaped when removing the frame. In addition, the packaged chip of the invention is face-down positioned on the lead frame, and the lead is connected to the lead frame via an opening of the lead frame by a solder pad positioned at a face of the chip, thereby the lead is under the lead frame. Another characteristic of the invention is that, after packaging, extravasated colloid or waste colloid are removed in a laser manner but only in a mechanical die or an electrolytic manner.

Owner:TITLE MAX TECH

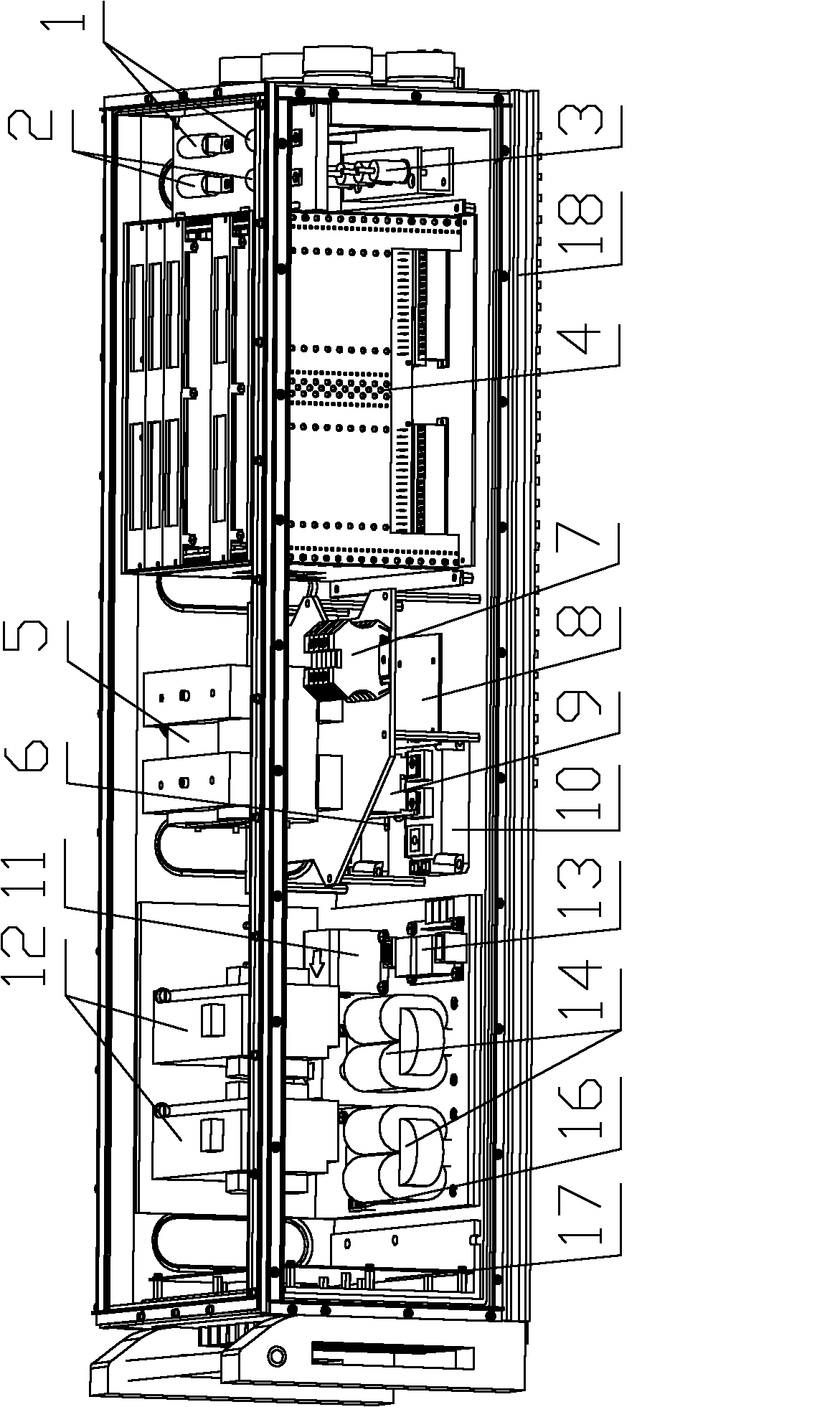

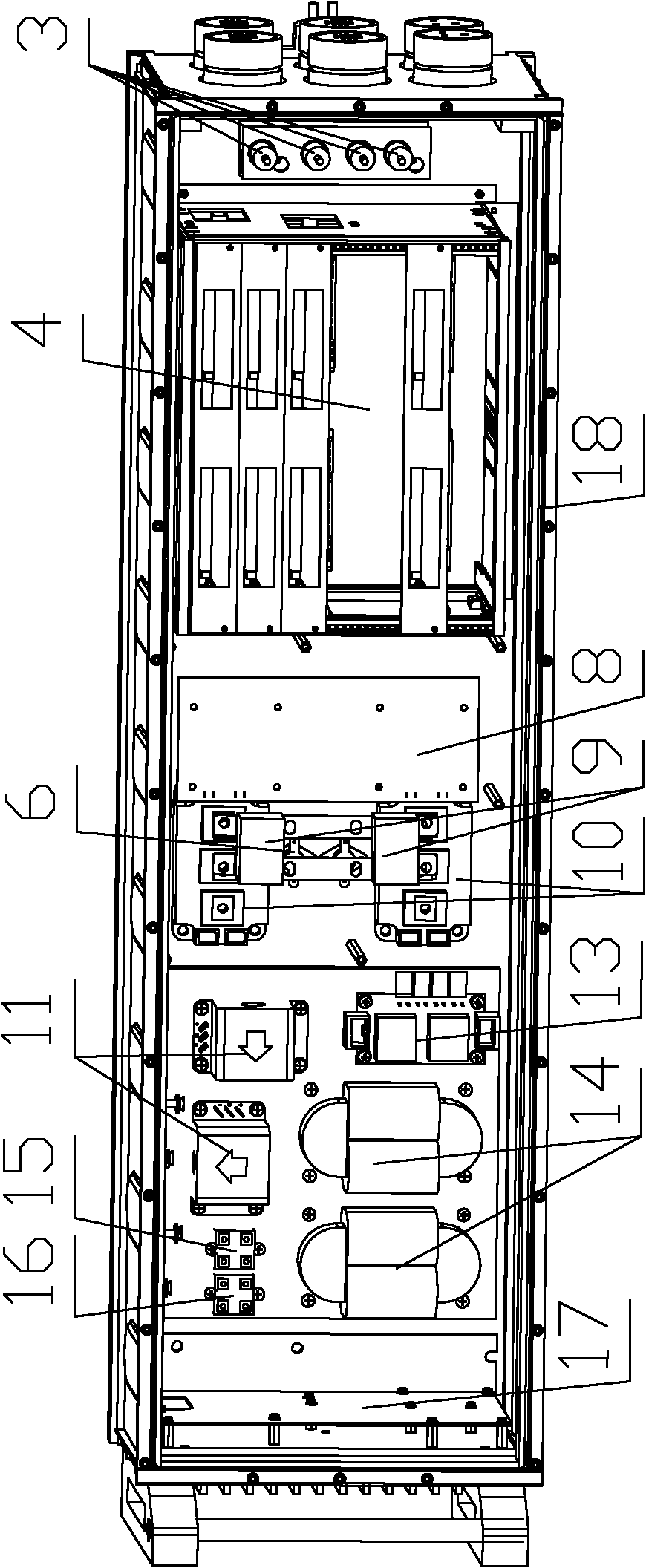

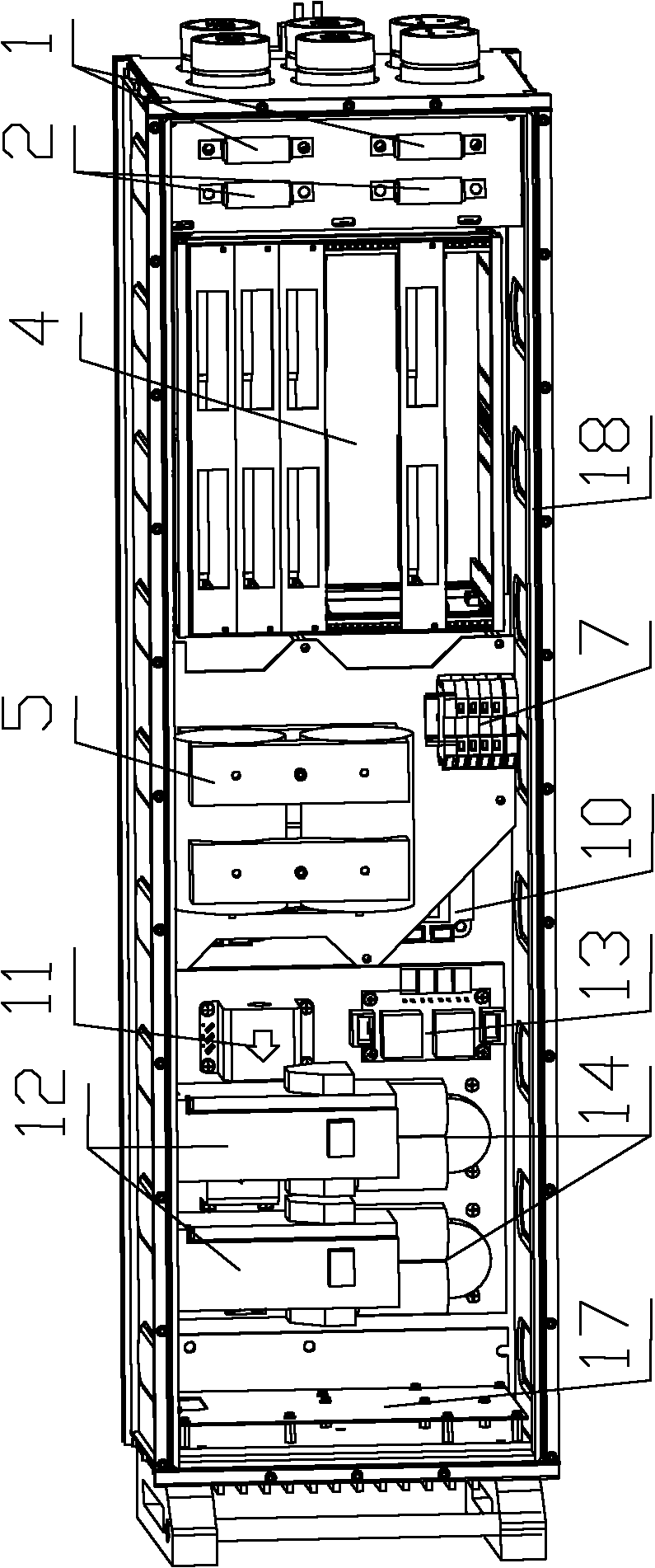

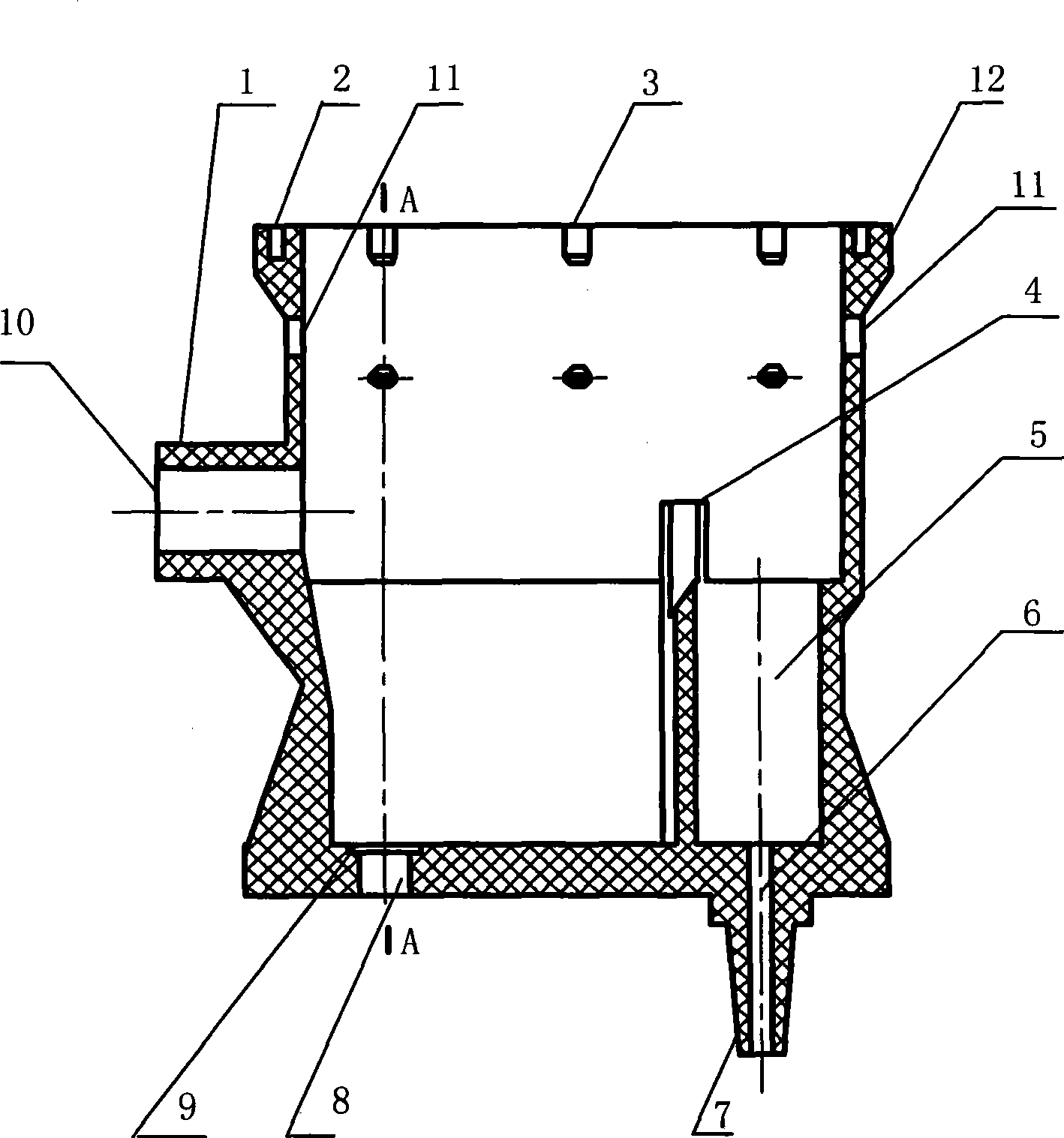

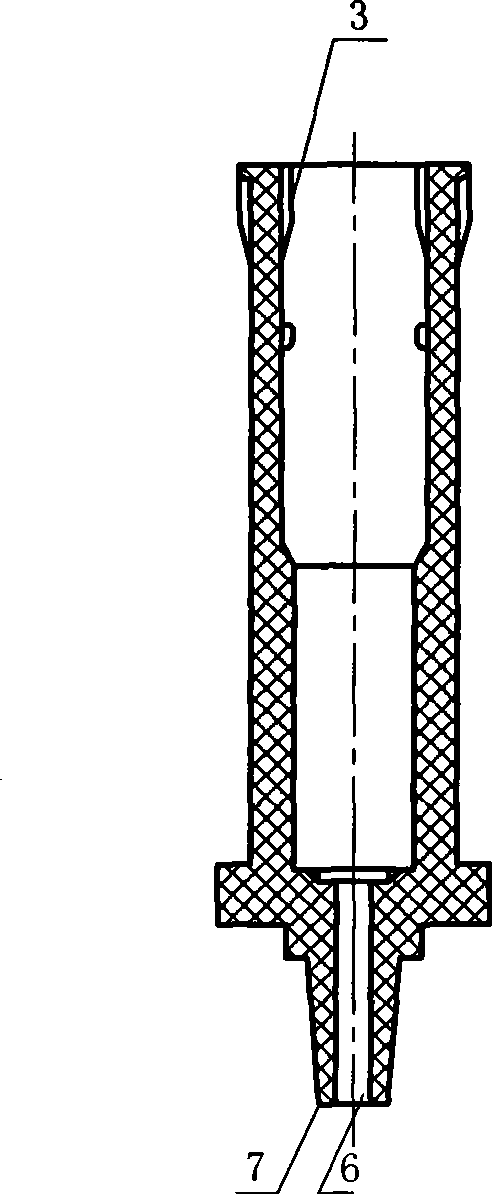

Suspension controller of magnetic suspension train

InactiveCN102005989ASave spaceReduce weightMagnetic holding devicesCooling/ventilation/heating modificationsMaglevResistor

The invention discloses a suspension controller of a magnetic suspension train, which comprises a box body and electric elements such as insulated gate bipolar transistor (IGBT), wherein the box body is cast by using an aluminum material, and the bottom of the box body is provided with radiation fins; a main circuit input end protective fuse and a control circuit input end protective fuse are arranged on an insulation board to form an insulation board component; a supported capacitor and a wiring terminal are mounted on an aluminum mounting board to form a mounting board component; and a current sensor, a voltage sensor circuit board, an output filter reactor, a charging resistor and a discharging resistor are mounted on the bottom face of an 'L'-shaped mounting board, a charging contact and a main contact are mounted on the side face of the 'L'-shaped mounting board, and thus, an 'L'-shaped mounting board component is formed. In the invention, the heating electric elements such as the IGBT are mounted on the bottom face of the box body and the heat of the electric elements can be dissipated by the box body, so it is unnecessary to configure a special radiator for the IGBT with the box body as the radiator; and thus, space is saved, and the suspension controller meets requirements on electrical performance as well as size and weight.

Owner:CHINA CNR CORPORATION

Method for preparing high molecular micro nanometer capsule

InactiveCN101053810AAchieve compatibilityMeet size requirementsMicroballoon preparationMicrocapsulesFreeze-dryingWater soluble drug

The invention relates to a preparation method of macromolecule micro / nano-capsules in the field of macromolecule functional material, which has the following steps: firstly, to prepare a water soluble medical solution and an oil soluble medical solution; to dissolve the macromolecule material into the oil soluble medical solution to form a polymer solution; after that, to inject the water soluble medical solution into the polymer solution to make a water-oil latex; to inject the latex into stabilizer solution to get water-oil-water dual latex; then to inject the dual latex into the curing agent solution to get a suspension of curing microcapsules; to centrifuge the suspension to get the microcapsules, which is washed and cooling dried to get a dry powder put into the sealing container; and lastly to get the micro / nano-capsules after vacuumizing, charging to standard atmospheric pressure at moment and sealed conserving. The grain size of micro / nano-capsules is nm degree to micron degree, and can be used in the regular ultrasonic radiography and molecule imaging. The invention realizes the compatibility of water soluble and oil soluble medicines, and has the effect of controlled release.

Owner:SHANGHAI JIAO TONG UNIV

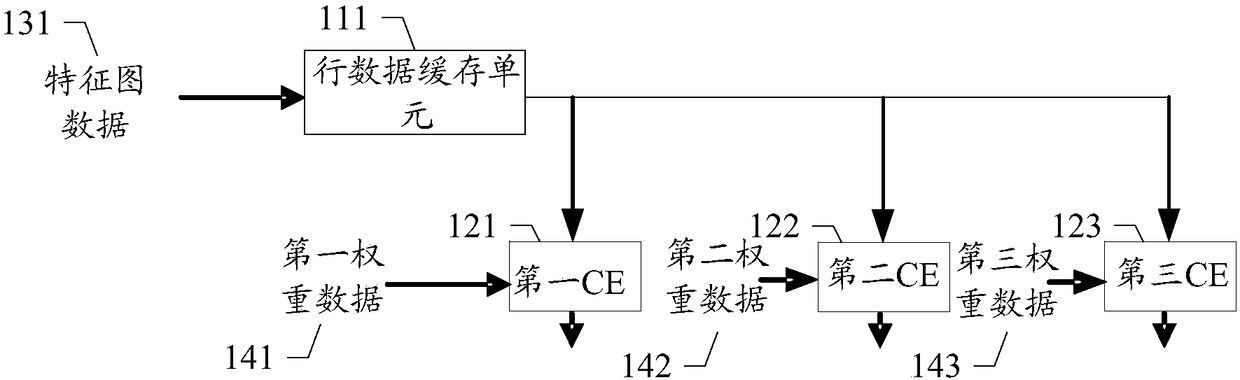

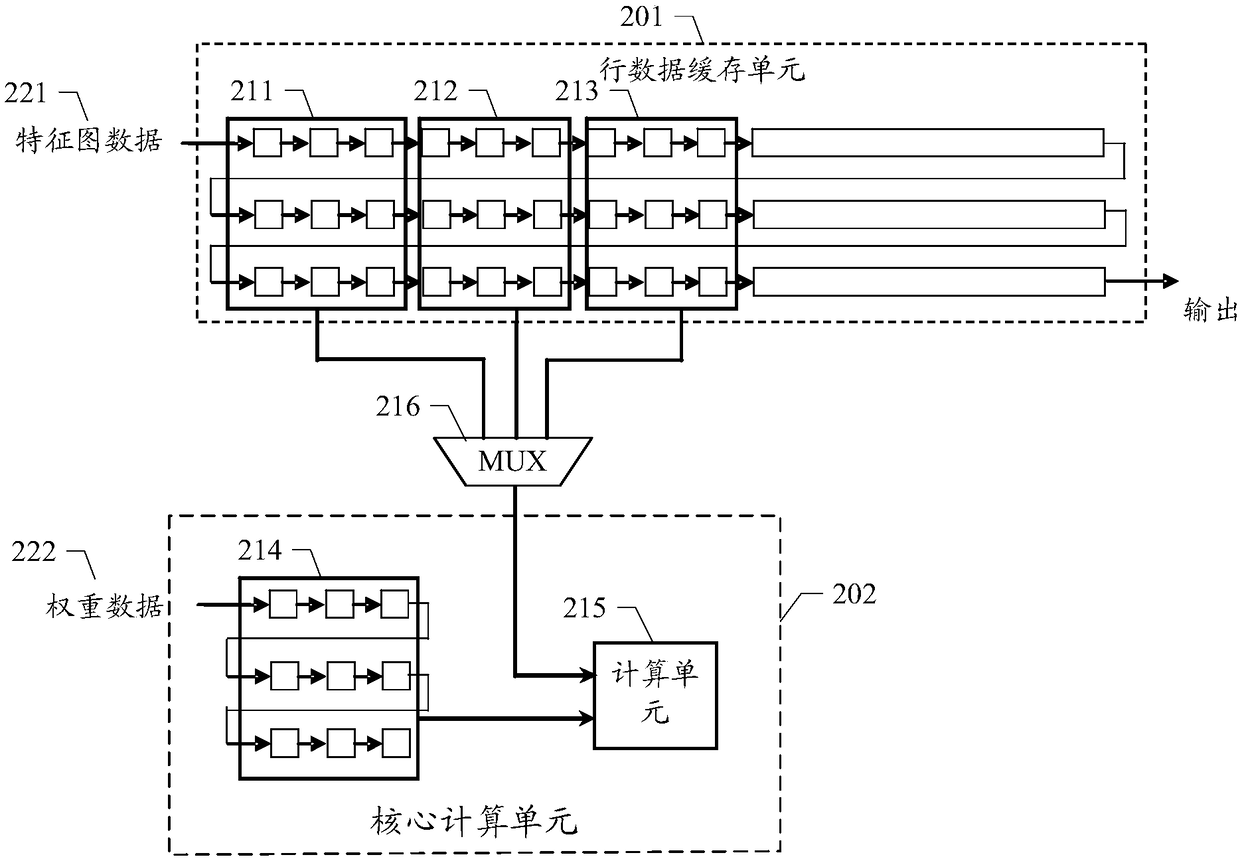

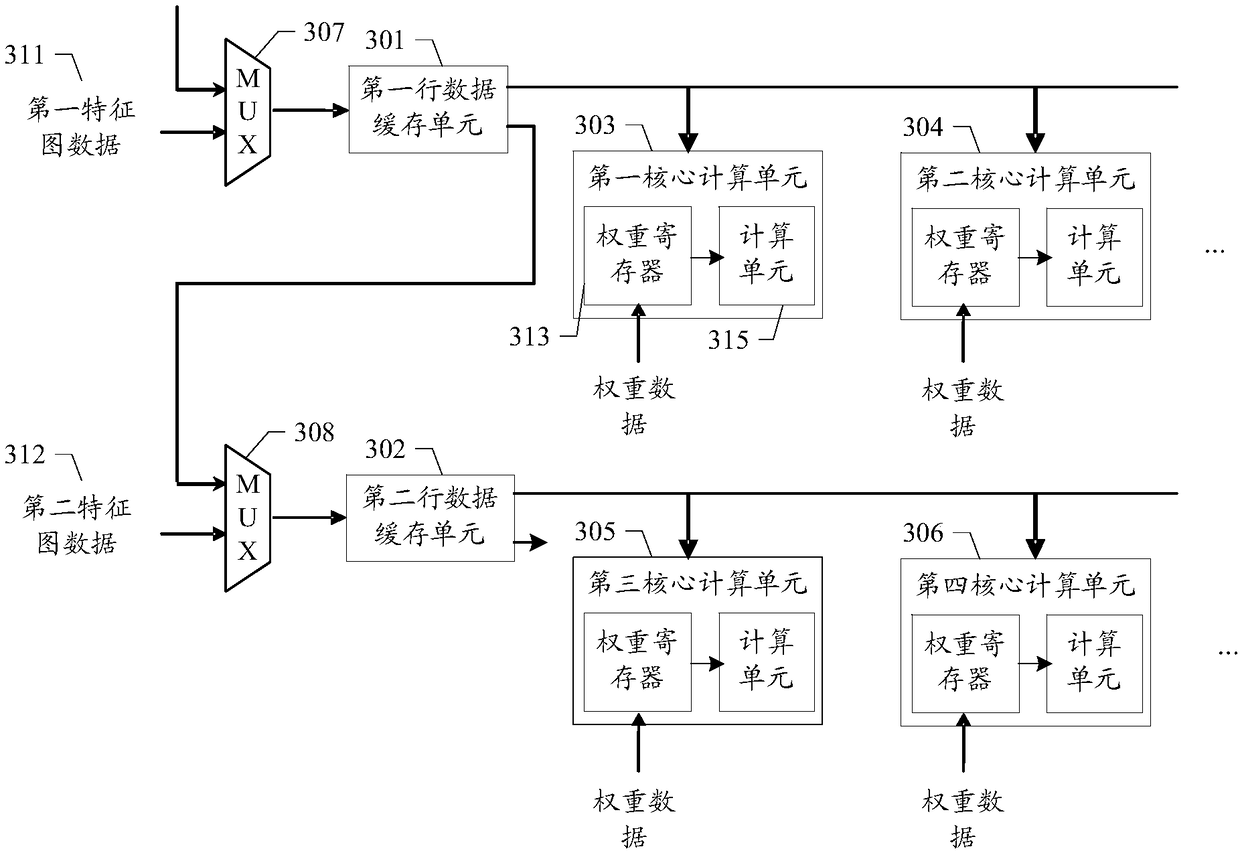

Operation device for convolution neural network

The invention relates to an operation device for a convolution neural network. The operation device comprises a plurality of row data caching units and a plurality of core computing units, wherein each row data caching unit receives externally inputted feature map data or feature map data outputted by other row data caching units via a first data selector, and each row data caching unit is provided with at least one data window; and each row data caching unit is coupled to at least one core computing unit. The core computing unit comprises a weight register and a computing unit, wherein the weight register is used for obtaining weight data; and the computing unit performs computation according to the feature map data in the data windows and weight data in the weight register. The scheme ofthe invention can realize the configurability of the number of the row data caching units and the number of the weight registers, thereby meeting requirements of users for different window sizes to be operated.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

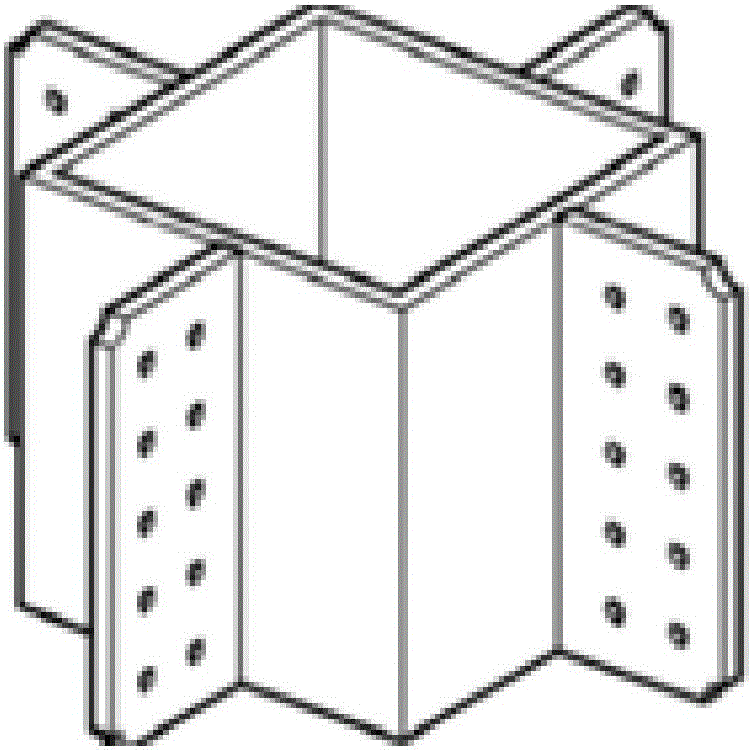

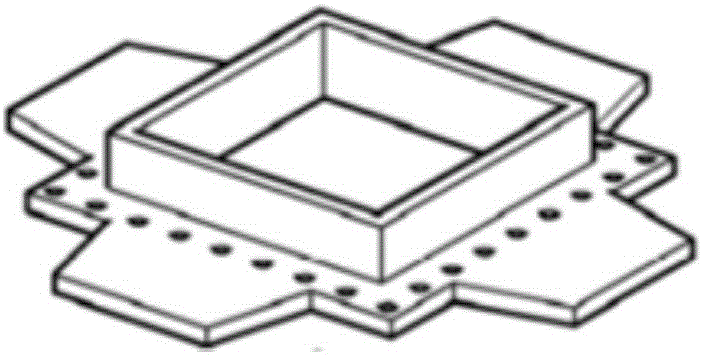

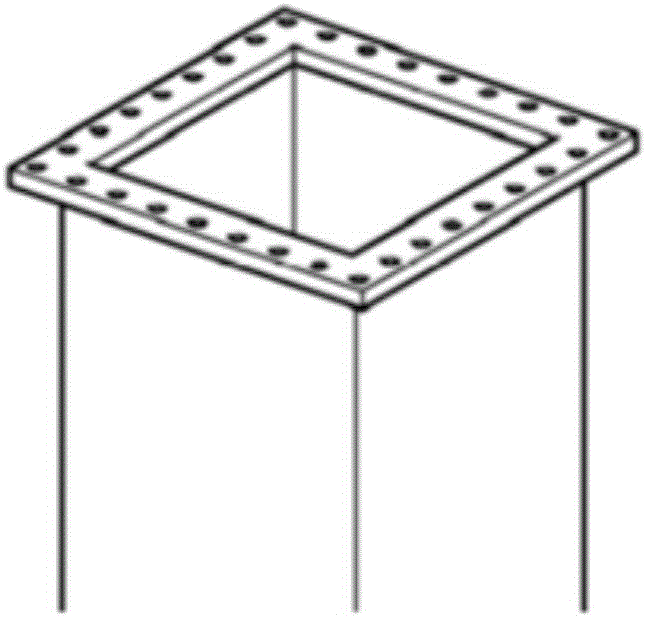

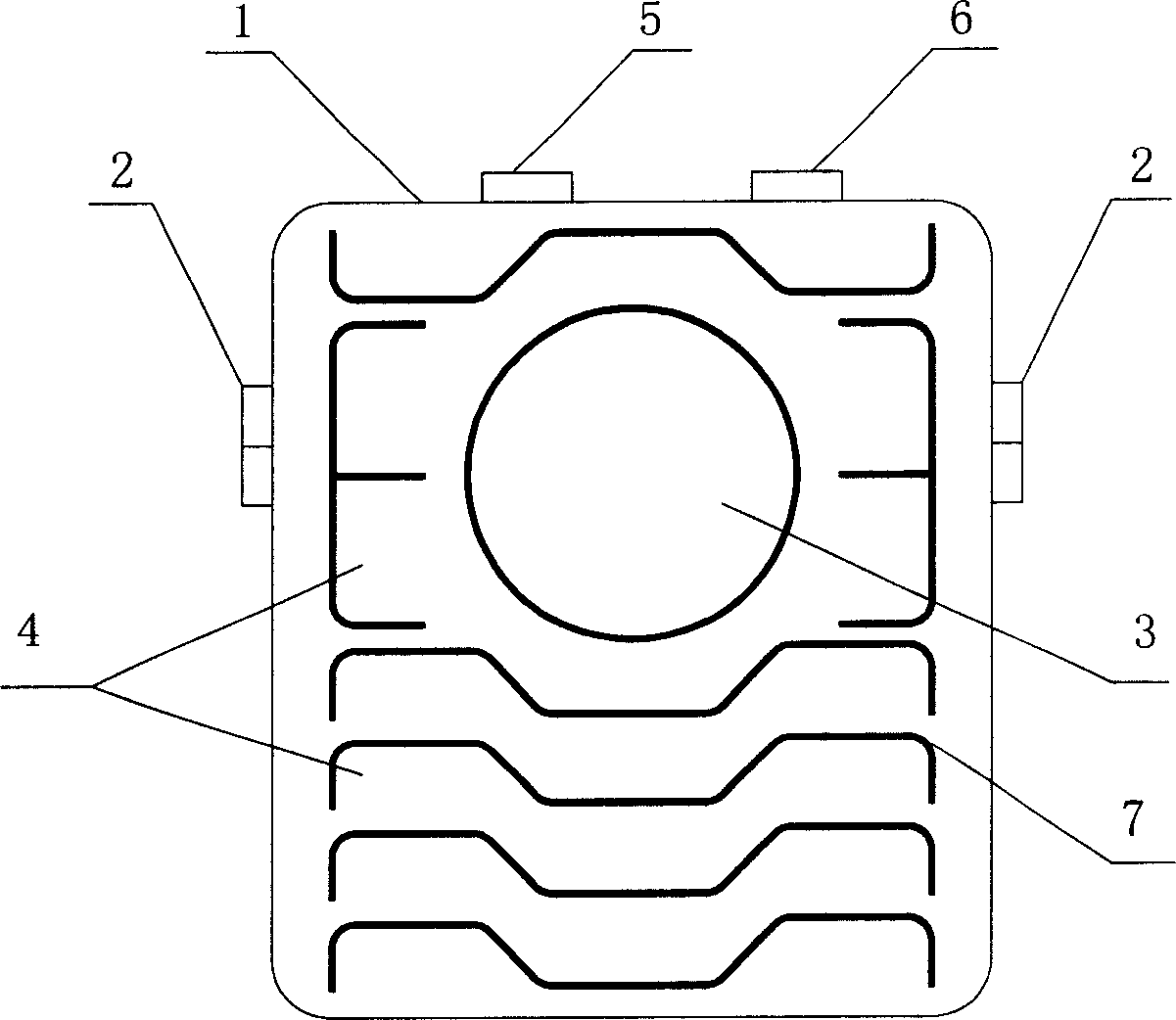

Assembling type embedded beam-column joint structure

InactiveCN106638958AEasy to process and manufactureIncrease productivityBuilding constructionsSteel columnsFlange

The invention discloses an assembling type embedded beam-column joint structure. The assembling type embedded beam-column joint structure is used for connecting steel beams and steel columns into a whole, the joint structure is constituted by a hollow cuboid-shaped core piece, and the four outer walls of the core piece are provided with connecting plates used for connecting the steel beams in a protruded mode correspondingly; two ranks of bolt holes are formed in the connecting plates corresponding to the steel beams, connecting pieces used for connecting the steel columns are symmetrically installed at the upper end and the lower end of the core piece, and flanges embedded with the steel columns are installed on the connecting pieces; and the connecting pieces and the steel columns are provided with bolt holes in a corresponding mode. While connecting safety and stability of the steel component beam columns are ensured by the structure, quick splicing can be conducted in a construction site; the overall property and the anti-seismic property are more excellent than traditional joints; and while stress concentration is reduced, the rule of connecting strengthening and component-constructing weakening is met, accordingly, structure damage caused by weak connecting is avoided, besides, the joint structure is very suitable for industrialization production, and construction is simple and rapid, so that the problems, caused by construction, of the joint quality and safety are reduced.

Owner:TIANJIN UNIV

A wide-angle lens with aspherical cemented lenses

ActiveCN102289053AMeet large size requirementsMeet size requirementsOptical elementsPhysicsWide-angle lens

The invention provides a wide-angle camera lens with an aspherical cemented lens. The wide-angle camera lens comprises a first lens, a second lens, a third lens, a fourth lens and a fifth lens in sequence from an object space to an image space, wherein the first lens, the second lens and the fourth lens have negative focal power, the third lens and the fifth lens have positive focal power, the fourth lens and the fifth lens are adhered together to form a cemented lens with the positive focal power, an adjoining plane of the cemented lens is at least a quadratic or above aspherical surface, the condition that BFL (Back Focal Length) / EFL (Effective Focal Length) is not smaller than 3.0 is also satisfied, BFL is a distance from an outermost point at the image space of a fifth lens element ofthe wide angle camera lens to an imaging plane, and EFL is a focal length value of the wide angle camera lens. The wide-angle camera lens can be used for realizing characteristics of a wide angle, small distortion, a large relative aperture, an ultra-long TTL (Total Length of Lens) and BFL under the condition of lower cost, and ensuring a comparatively perfect imaging definition within a wider temperature range, and is particularly suitable for outdoor monitoring under a relatively hostile environment and a vehicle-mounted camera system.

Owner:NINGBO SUNNY AUTOMOTIVE OPTECH

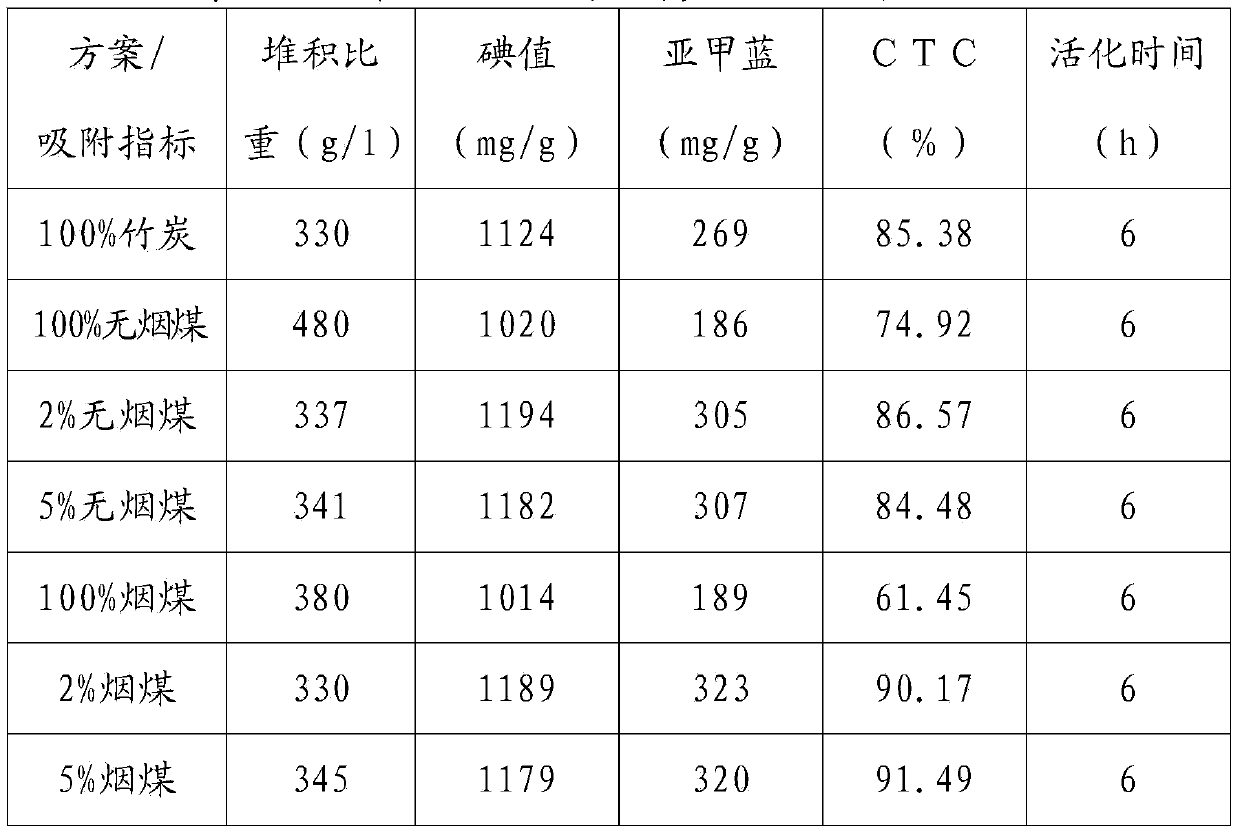

Preparation method of columnar bamboo activated carbon

ActiveCN104211061AMeet size requirementsMaximize fixed carbon contentCarbon compoundsActivated carbonPhysical chemistry

The invention belongs to the field of activated carbon production, and particularly relates to a preparation method of columnar bamboo activated carbon. The preparation method comprises the following steps: a primary anaerobic dry distillation process; drying and grinding; kneading; extruding and molding; conserving and sizing; a secondary anaerobic dry distillation process; and activation. Twice anaerobic dry distillation processes are adopted in the production process, a basic guarantee is provided for molding the columnar bamboo activated carbon by the primary anaerobic dry distillation process of the bamboo material, the strength of a columnar molding product is ensured by controlling the inventory and the kiln rotating speed by the secondary anaerobic dry distillation process, and meanwhile, 0.5-5% of coal particles are doped during activation, so that the gas atmosphere in the activating furnace is improved, the unsaturated basic structure of the columnar bamboo activated carbon is generated, the strength and the adsorption property of the columnar bamboo activated carbon are improved, the preparation process is simple, the product carbon does not need to be cleaned, environmental pollution and corrosion to equipment are reduced, and energy consumption in reaction is reduced.

Owner:NINGXIA HUAHUI ACTIVATED CARBON

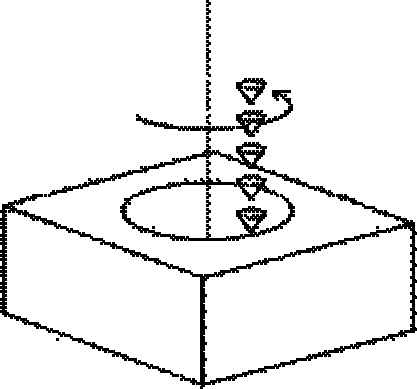

Millisecond laser processing and postprocessing process for no-recasting-layer micro-deep holes

InactiveCN102126087ASmooth holeClear outlineLaser beam welding apparatusHigh power lasersCeramic coating

The invention provides a millisecond laser processing and postprocessing process for no-recasting-layer micro-deep holes, which comprises the following steps of: spraying a high temperature resistant ceramic coating on the surface of a turbine blade, and performing micro-deep hole deep processing by using a high-power millisecond laser according to optimized laser parameters obtained through an orthogonal experiment to obtain micro-deep holes with the minimum recasting layer depth; soaking the processed micro-deep holes in chemical acid solution for corrosion; and obtaining the no-recasting-layer micro-deep holes. The micro-deep holes are processed by using parameter-optimized laser, and the micro-deep holes with the thinnest recast layer are obtained; the micro-deep holes are corroded by specially prepared acid solution for a certain period of time, and the recast layer is thoroughly etched off; and the composite processing method has the characteristics of low cost, high efficiency and simple operation, problems of recast layers and microcracks when the micro-deep holes are processed on metals through high-power laser are solved, and high-quality micro-deep holes with smooth hole walls and clear outlines are obtained.

Owner:XI AN JIAOTONG UNIV

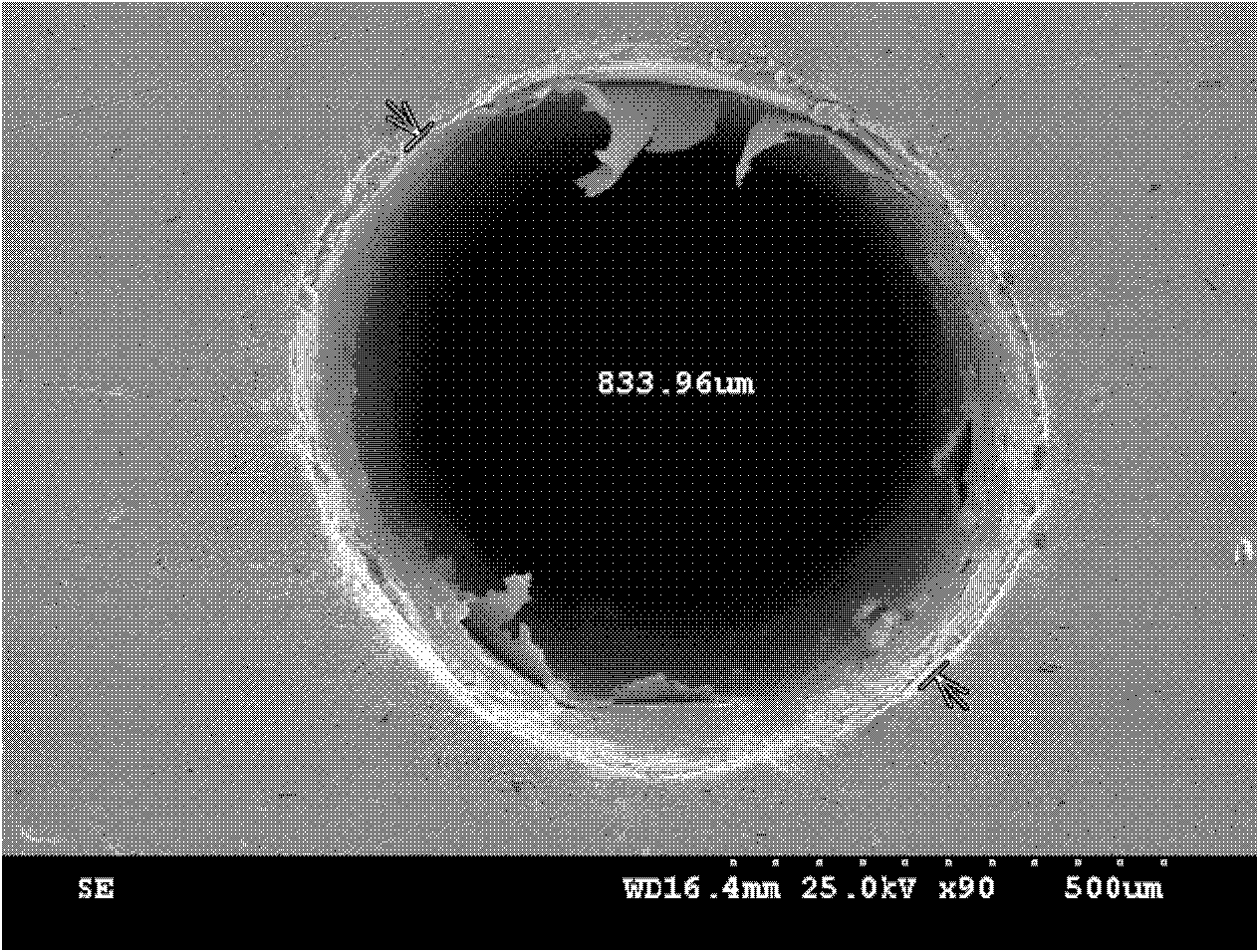

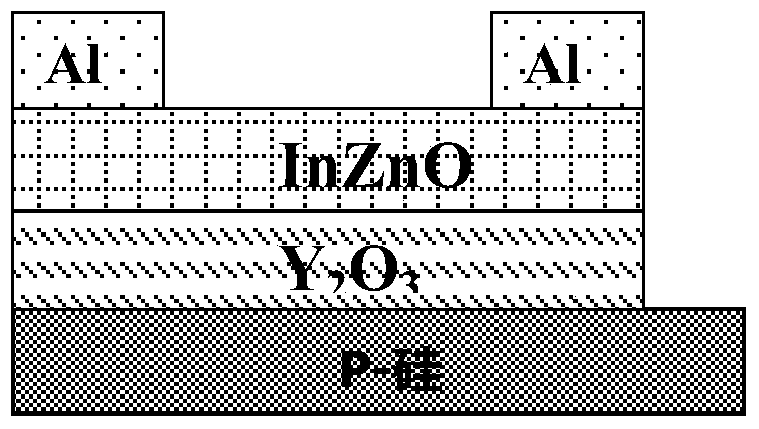

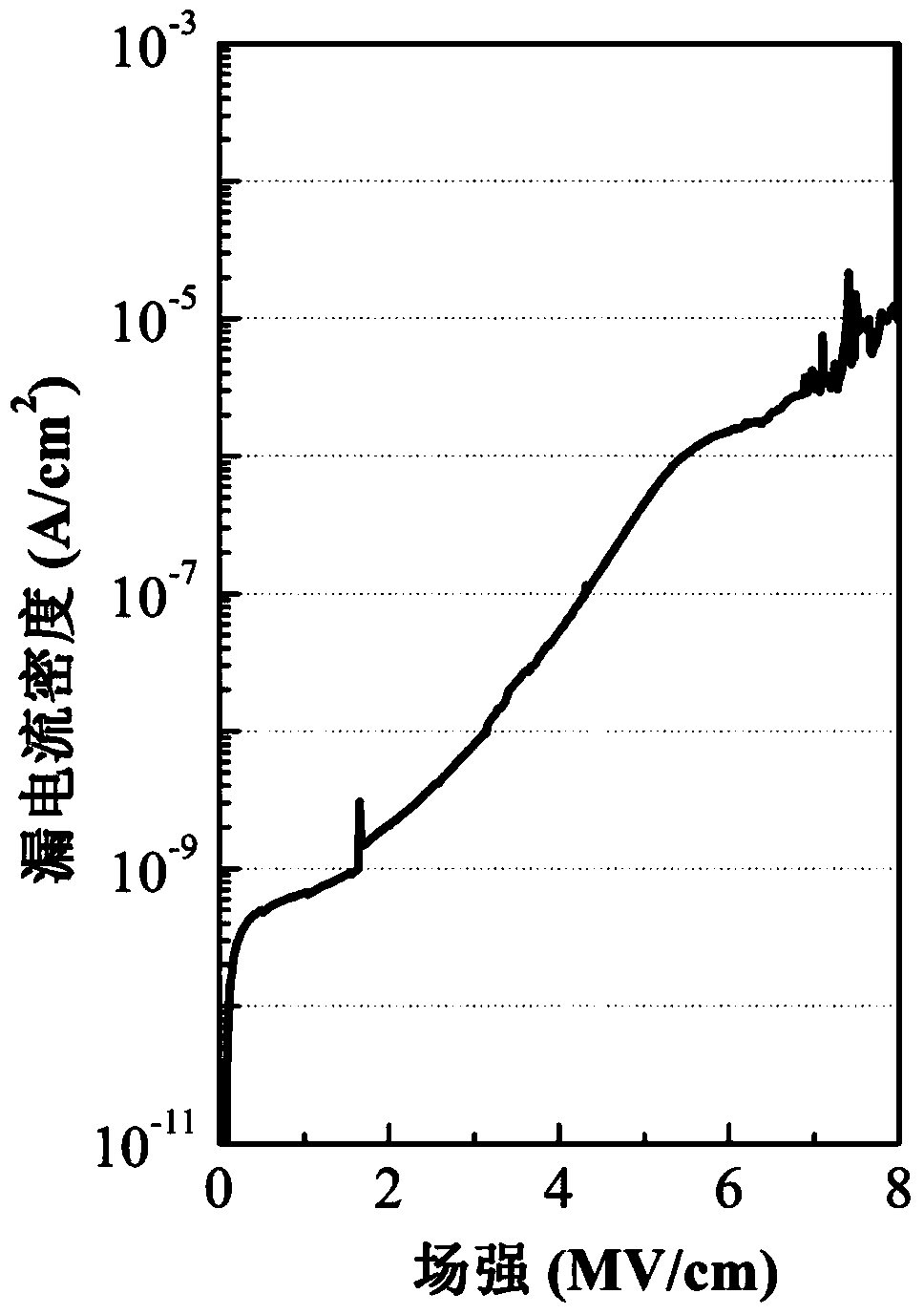

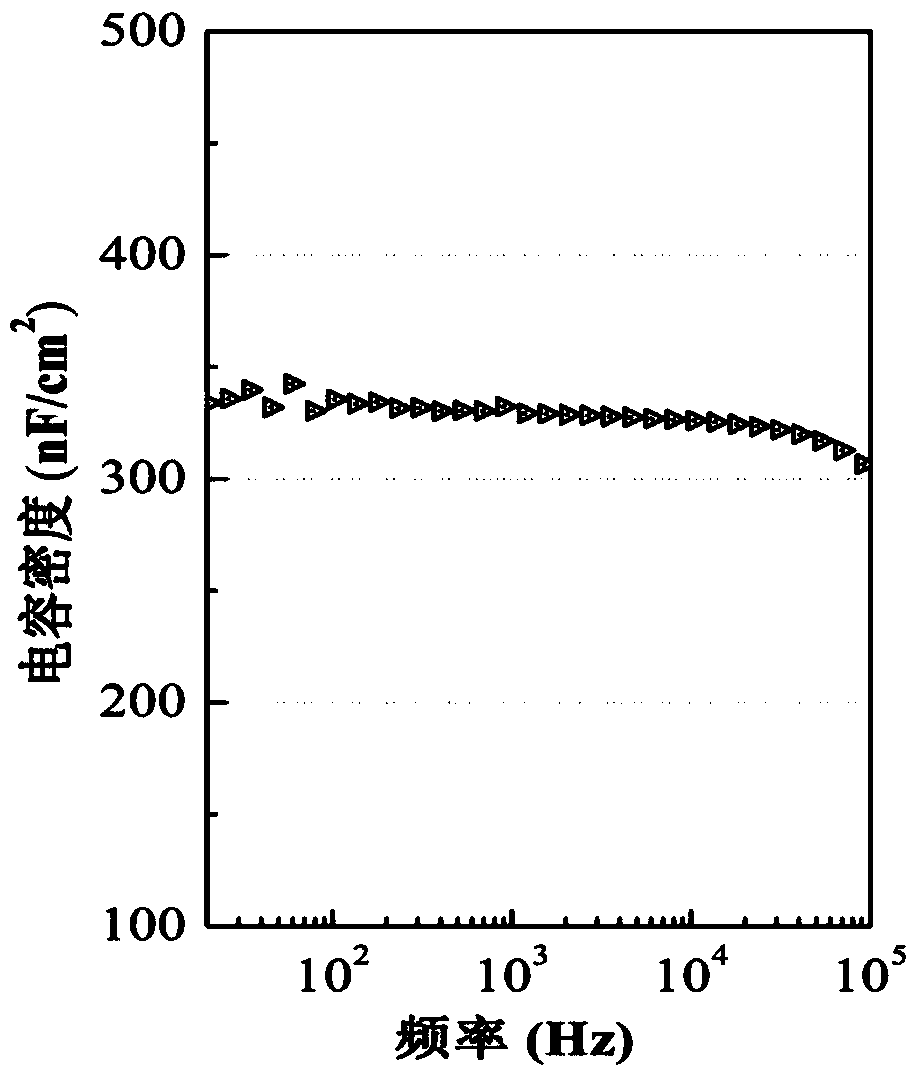

Preparation method for water solution thin film transistor

InactiveCN104201112ALow costAvoid high temperature impuritiesMaterial nanotechnologySemiconductor/solid-state device manufacturingIonYttrium

The invention belongs to the technical field of semiconductor thin film transistor preparation, and relates to a preparation method for a water solution thin film transistor. Firstly, yttrium nitrate is dissolved in deionized water, and a zirconia precursor solution is formed by magnetic force mixing; then, the surface of a low resistance silicon base is cleaned, and is coated with the precursor solution in a rotation manner; a Y2O3 film sample is obtained through baking and low temperature annealing; zinc nitrate and indium nitrate are respectively dissolved in deionized water, and an IZO water solution is formed through mixing; the Y2O3 film surface is coated with the IZO water solution in a rotation manner, is subjected to solidification treatment and low temperature annealing, so that an IZO gutter channel layer is obtained; finally, the vacuum thermal evaporation technology is adopted to prepare a metal source and an electric leakage pole on the IZO gutter channel layer, and the water solution thin film transistor based on ultrathin Y2O3 and high K dielectric layer is obtained. The overall embodiment is low in price; the technology is simple, the principle is reliable, the product performance is good, the preparation is environment-friendly, and the application prospect is wide.

Owner:QINGDAO UNIV

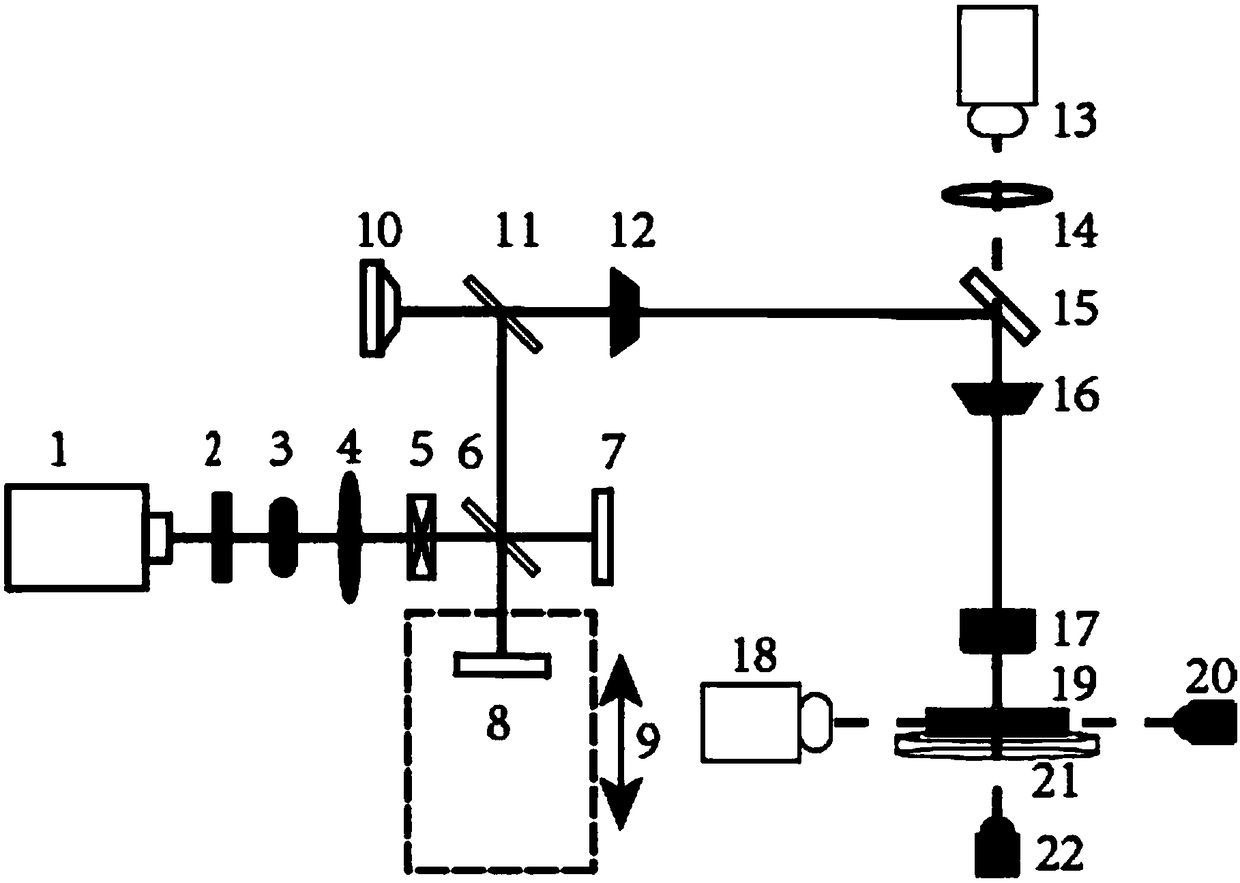

Polymer micro-channel machining method based on space-time shaping femtosecond laser

ActiveCN108723586AIncreased depth of reachImprove detection efficiencyLaser beam welding apparatusOptoelectronicsPulse sequence

The invention discloses a polymer micro-channel machining method based on space-time shaping femtosecond laser, and belongs to the field of laser application. The method comprises the following stepsthat step 1, a polymer substrate sample is prepared as a to-be-machined sample; step 2, repeat frequency of femtosecond laser monopulse is set as 10-20 Hz, and space-time shaping parameters are set that femtosecond laser monopulse shaping is modulated to be 1-3 pulse sequences, wherein each of the pulse sequences is composed of two sub-pulses, delay time between the two adjacent sub-pulses is -5ps-5ps, sub-pulse energy ratio is 1:1 or 2:1, total pulse energy is 30-50 muJ, and the distribution of sub-pulse light field is Bessel distribution; and step 3, according to the parameters, monopulse femtosecond laser is modulated as a space-time shaping double-pulse laser sequence, and the double-pulse laser sequence is focused on the surface of the to-be-machined sample prepared in the step 1 to form the polymer micro-channel by vertical machining. Local transient electron dynamics in material machining is effectively controlled by the space-time shaping, quality of the prepared polymer micro-channel is improved by vertical machining, and repeatability is high.

Owner:TSINGHUA UNIV

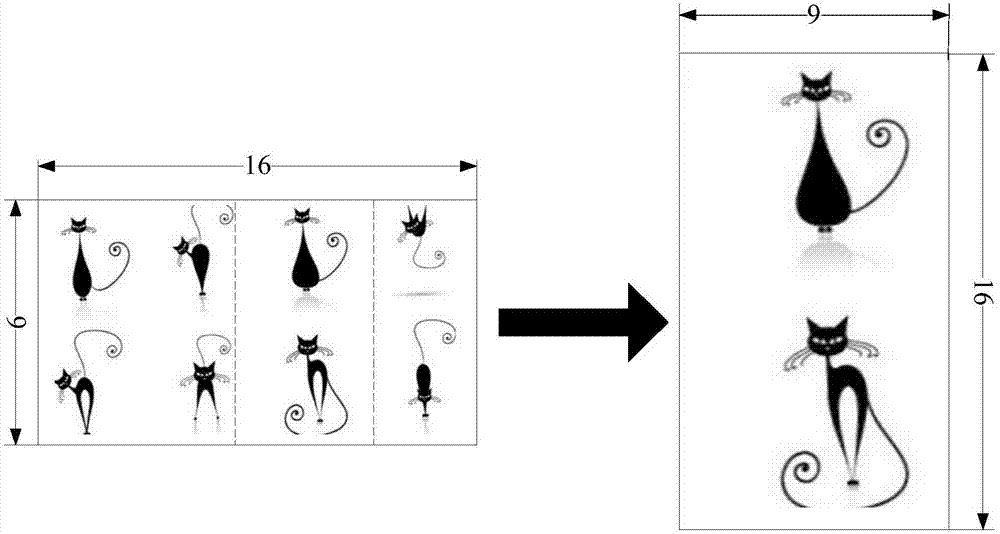

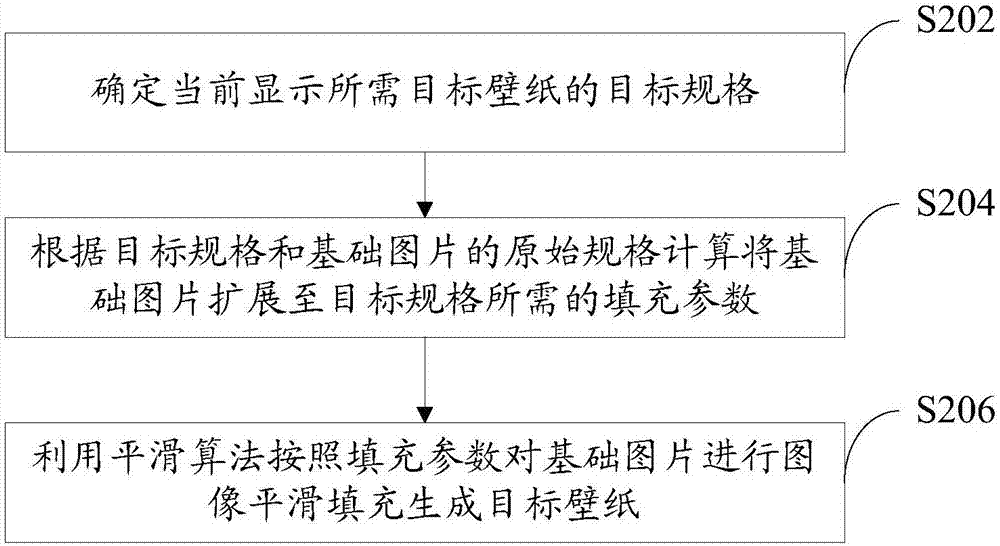

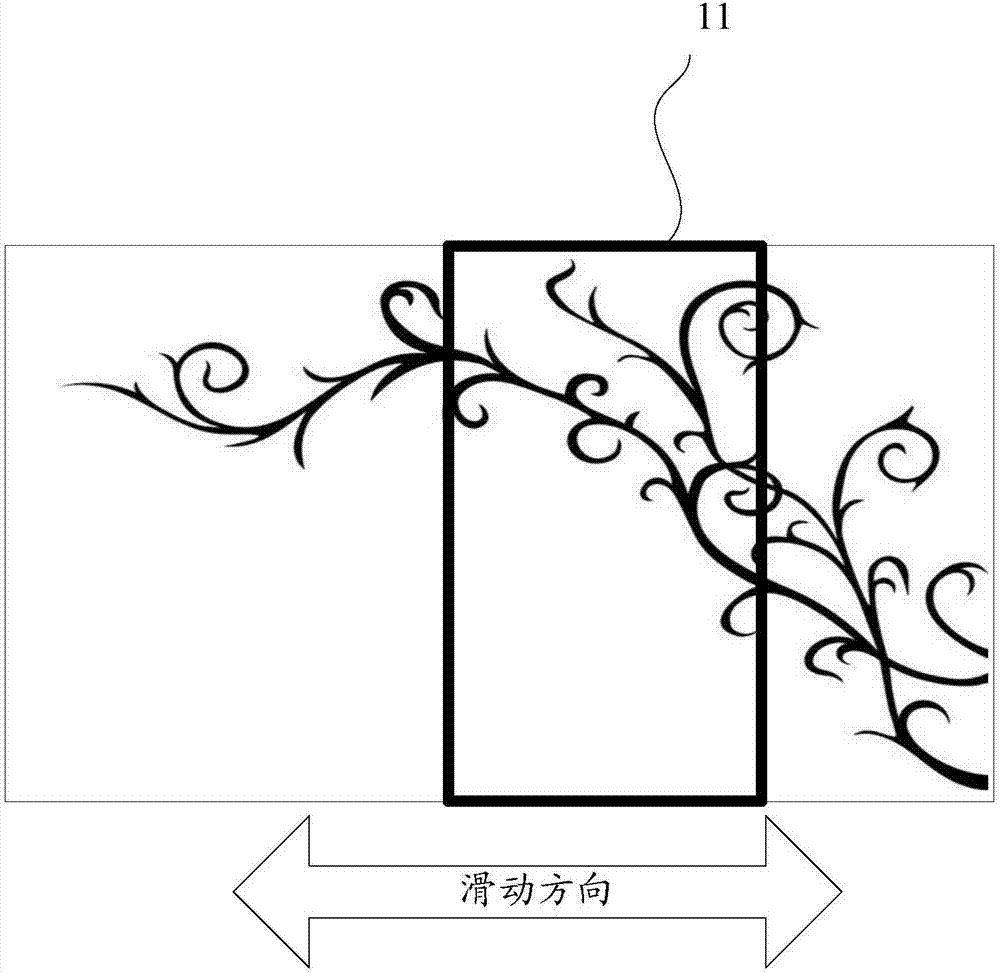

Terminal wallpaper generation method, terminal and computer readable storage medium

InactiveCN107368295ASame sizeMeet size requirementsImage enhancementSoftware engineeringImage resolutionAlgorithm

The invention discloses a terminal wallpaper generation method, a terminal and a computer readable storage medium. The method comprises the following steps of: firstly determining a target specification of target wallpaper required by the current display by the terminal; calculating a filling parameter required for extending a basic picture to the target specification according to the target specification of an original specification of the basic picture; and carrying out image smooth filling on the basic picture by the terminal according to a smooth algorithm and the filling parameter so as to generate the target wallpaper. In the method, the target wallpaper is not obtained through simply amplifying the basic picture, but the missing parts, relative to the target wallpaper, of the basic picture are filled by utilizing the smooth algorithm under the condition that the size of the basic picture is unchanged, so that the size of the filled basic picture can achieve the target specification. In the method, the size of the basic picture keeps unchanged, so that the image resolution, relative to the basic picture, of the generated target wallpaper is not reduced, and then better user experience can be provided for the users.

Owner:NUBIA TECHNOLOGY CO LTD

Nickel-removing solution for adverse chemical nickel plating layer of printed circuit board and preparation method thereof and method for removing adverse chemical nickel plating layer

The invention discloses nickel-removing solution for an adverse chemical nickel plating layer of a printed circuit board (PCB) and a preparation method thereof and a method for removing the adverse chemical nickel plating layer, and solves the technical problems of reducing the extra cost of the PCB and keeping the physical property of the PCB after reworking treatment. Each liter of nickel-removing solution contains 10 to 300 grams of sodium persulfate, 10 to 200 grams of sulfuric acid solution, 0.1 to 100 grams of alkyl ketone corrosion inhibitor and 0.1 to 50 grams of thiazole corrosion inhibitor. The method for removing the adverse chemical nickel plating layer comprises the following steps of: removing oil from an adverse nickel plating PCB, soaking the adverse nickel plating PCB into the nickel-removing solution, and taking the PCB out at a proper time calculated by removing 4 microns of a nickel layer every 15 minutes. Compared with the prior art, the method has the advantages of low cost, environmental protection, short nickel-removing time and constant nickel-removing speed; and the solution nearly does not damage a copper base material, and the copper loss of the naked copper base material in the nickel-removing solution is less than 0.5 micron per hour, so the integrity of a thin circuit can be well ensured.

Owner:SHENZHEN CHENGGONG CHEM

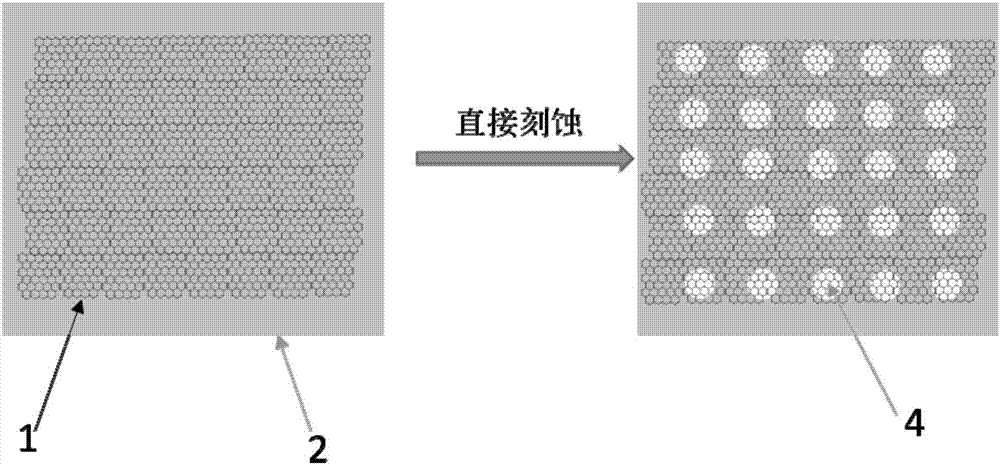

Method for preparing graphene-based support membrane of transmission electron microscope grid by directly etching metal substrate

ActiveCN106872501AIncrease the areaWon't breakMaterial analysis by measuring secondary emissionEtchingElectron microscope

The invention discloses a method for preparing a graphene-based support membrane of a transmission electron microscope grid by directly etching a metal substrate. The method comprises the following steps: (1) growing graphene on the surface of a metal substrate by a chemical vapor deposition method; (2) removing the graphene growing on the back of the metal substrate; (3) preparing a polymer fiber network on the surface of the graphene to form a metal substrate / graphene / polymer fiber network structure; (4) preparing a cyclic pattern on the back of the metal substrate by a photoetching method; and (5) removing the metal substrate exposed out of the cyclic pattern by an etching method, and then removing the cyclic pattern. The preparation method disclosed by the invention avoids the transfer process of the graphene and does not need an extra transmission grid, and can obtain a copper grid and the graphene support membrane meeting the sample preparation requirements of a transmission electron microscope through one-step etching; thus, high efficiency, low cost, and batch preparation can be achieved.

Owner:PEKING UNIV

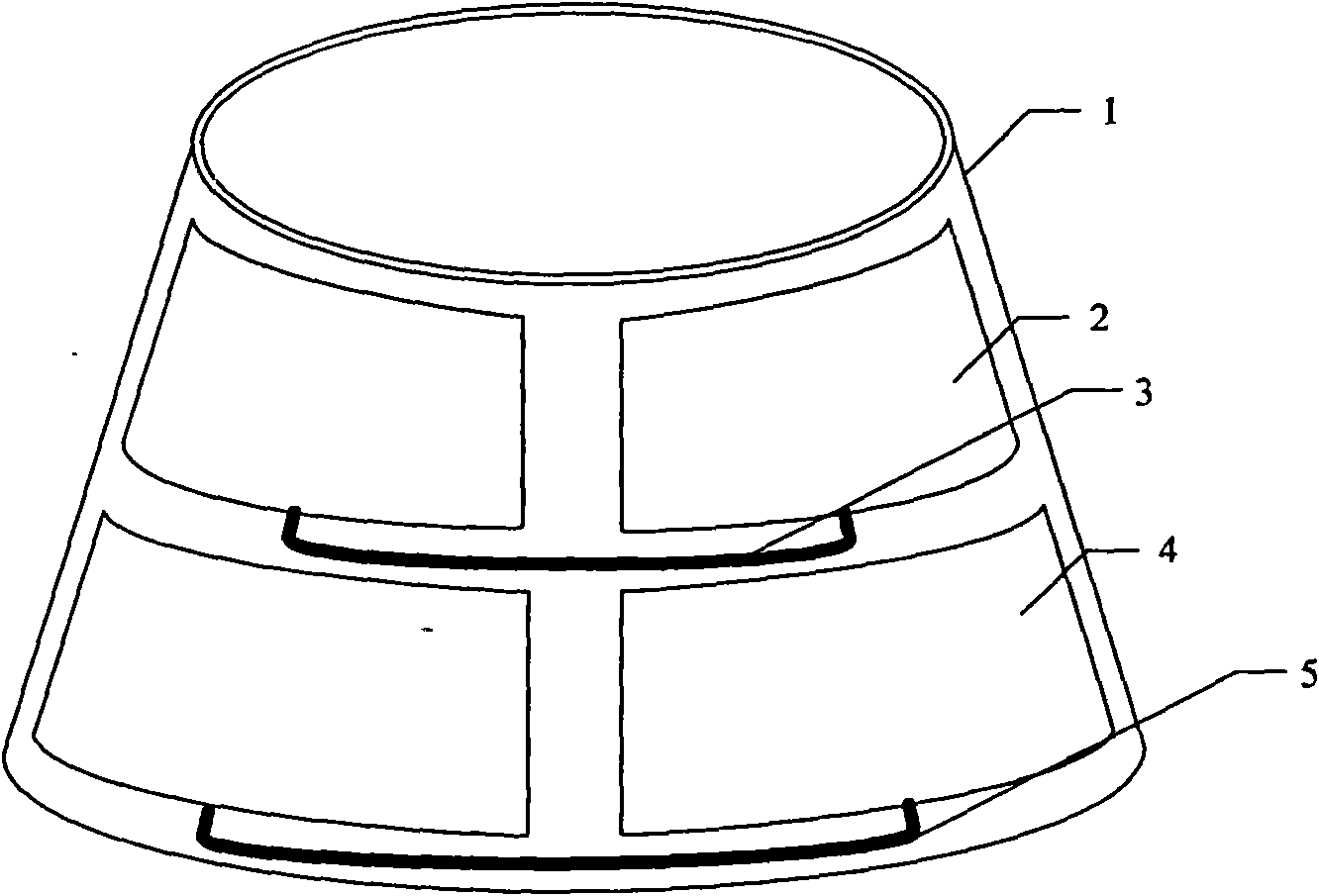

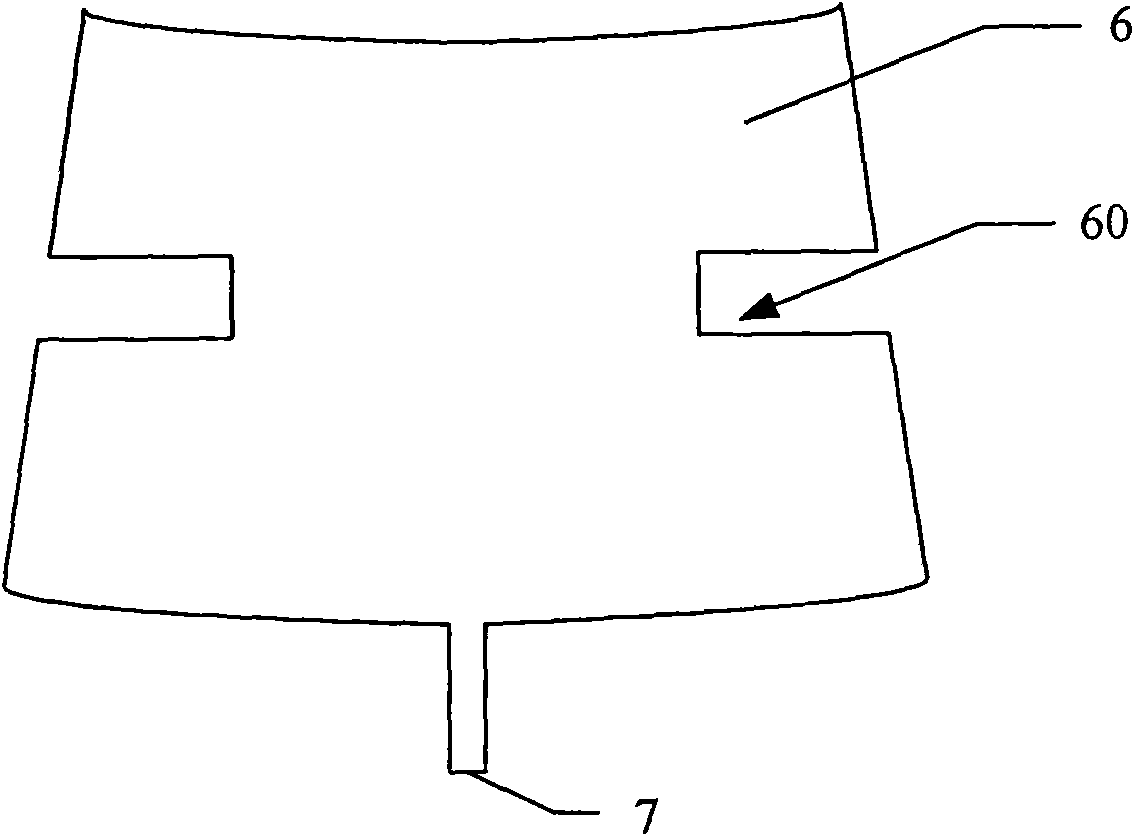

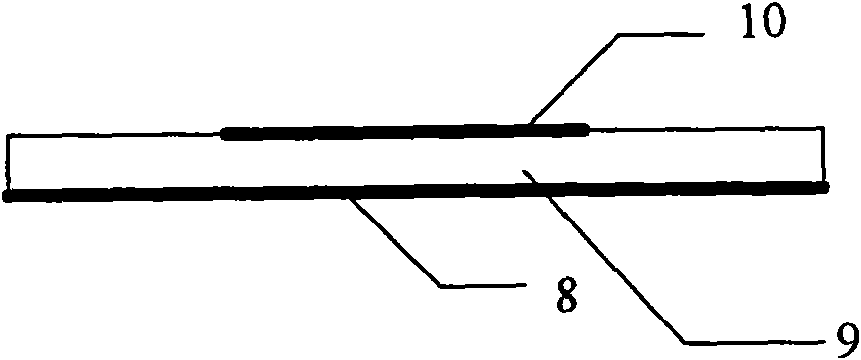

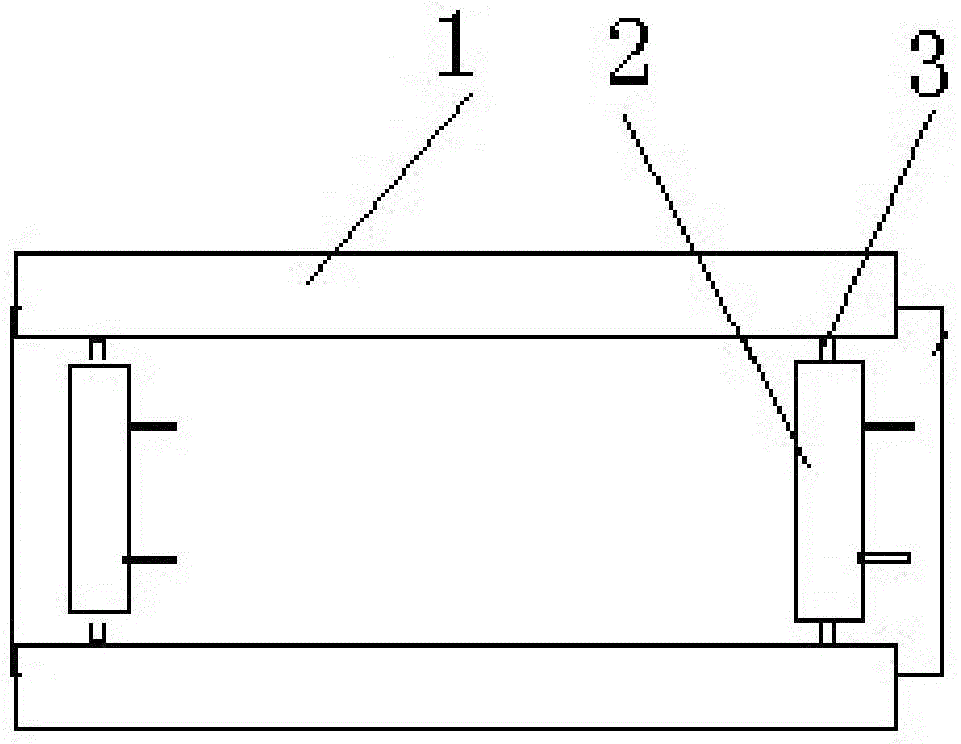

Taper conformal omnidirectional double-frequency micro-strip antenna array

InactiveCN101621158AAchieve conformalitySmall sizeSimultaneous aerial operationsRadiating elements structural formsOmnidirectional antennaMicrostrip antenna array

The invention relates to a taper conformal omnidirectional double frequency micro-strip antenna array which is characterized in that a high-frequency micro-strip antenna array (2) and a low-frequency micro-strip antenna array (4) which are arranged up and down and are conformal with a taper carrier (1) are arranged around the cone surface of the taper carrier (1), wherein the high-frequency micro-strip antenna array (2) is near the conic node end of the taper carrier (1), and the low-frequency micro-strip antenna array (4) is arranged below the high-frequency micro-strip antenna array (2); the high-frequency micro-strip antenna array (2) consists of a plurality of high-frequency micro-strip antenna elements (6) in parallel feed connection, and the low-frequency micro-strip antenna array (4) consists of a plurality of low-frequency micro-strip antenna elements (11) in parallel feed connection. The invention realizes the conformality of a micro antenna and omnidirectional antenna beam coverage on the taper carrier as a geometric structure, and gaps are arranged at a radiationless side of each micro-strip antenna unit, and sizes of the micro-strip antenna element are reduced so as tomeet the demand of axis sizes of the taper carrier.

Owner:南京卫邦电子科技有限公司

Antenna of handset, and built-in antenna type handset

InactiveCN1917281AEasy to installMeet functional requirementsAntenna supports/mountingsRadiating elements structural formsRadio frequencyFeed line

Characters of the antenna are that the antenna consists of metal layer of keyset of handset. The metal layer includes groove, grounding device, and feed line. The invention also discloses a handset with built-in antenna. The handset includes print circuit board, and metal layer of keyset. Being as antenna, the metal layer is in use for receiving and transmitting wireless signal. The metal layer includes groove in order to satisfy requirement of antenna size from frequency band. Being setup on the metal layer, the feed line unit connected to RF sect of print circuit board is in use for receiving and transmitting radio frequency. The grounding device setup on metal layer is connected to ground of the print circuit board.

Owner:HAIER GRP CORP +1

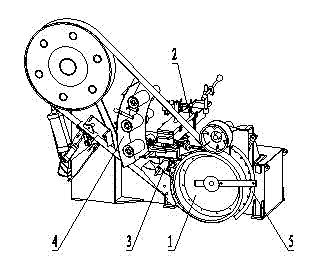

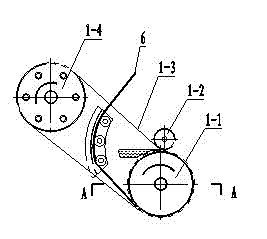

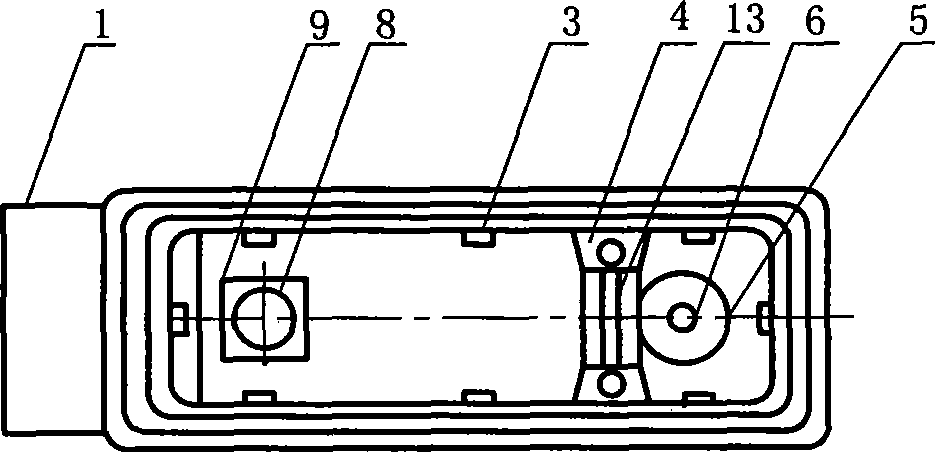

Manufacturing process and equipment for storage battery hauling net lead strip or net punching plate gate lead strip

ActiveCN102931416AReduce lead fume pollutionReduce lossElectrode carriers/collectorsMetal rolling arrangementsPunchingPollutant emissions

The invention discloses a manufacturing process for a storage battery hauling net lead strip or a punching net plate gate lead strip. The manufacturing process comprises the steps of melting electrolytic lead and adding alloy elements, conveying to the mixture to a continuous lead strip casting machine, and casting the mixture to a coarse alloy lead strip, then taking the coarse alloy lead strip as the raw materials and directly conducting cold rolling on the coarse alloy lead strip to be refined lead strip used for the hauling net or a punching net by the continuous lead strip casting machine. The manufacturing process comprises the steps of a. melting the electrolytic lead; b. conveying lead liquid; c. continuously casting to from the coarse alloy lead strip; d. continuously rolling to form the refined alloy lead strip; and e. rolling and storing. In addition, the invention also provides special manufacturing equipment. According to the manufacturing process and the manufacturing equipment, not only the discharging amount of pollutants such as lead fume can be obviously reduced, the energy consumption and the material loss also can be reduced, and the product quality and the production efficiency of the lead acid storage battery plate gate hauling net or the punching net lead strip can be improved.

Owner:BAODING GOLDEN SUNLIGHT POWER EQUIP TECH

Solid insulation complete enclosed switch isolation cover

ActiveCN101383488AReduce volumeMeet size requirementsSubstation/switching arrangement boards/panels/desksEngineeringGround contact

The invention relates to a solid insulating omniseal switch insulating cover which is a long barrel with a rectangular cross section; a big lug boss is arranged at one side of the long barrel, and a bipass bushing hole is arranged in the big lug boss and is communicated with the interior of the solid insulating omniseal switch insulating cover; a grounding contact head hole is arranged on the bottom surface of the solid insulating omniseal switch insulating cover which approaches to the bipass bushing hole, and a vacuum bubble cover is arranged on the bottom surface of the other side of the solid insulating omniseal switch insulating cover which approaches to the long barrel; the height of the vacuum bubble cover is less than the height of the lower end of a connecting terminal hole; a recess which is communicated with the width direction of the long barrel is arranged at the other side on the upper end of the vacuum bubble cover, which is far way from the long barrel, and a joint pin sleeve is arranged on the bottom surface of the long barrel which is arranged at the lower end of the vacuum bubble cover; a joint pin hole is arranged in the joint pin sleeve, leads to the vacuum bubble cover and is concentric with the central line of the vacuum bubble cover; an outward and downward flange is arranged at the circumference of an opening part of the upper end of the long barrel, and a seal groove is arranged on the flange. The invention strengthens the insulating level and reduces the volume of an isolating switch.

Owner:BEIJING SOJO ELECTRIC

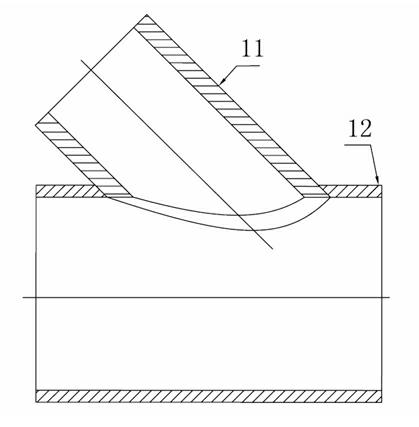

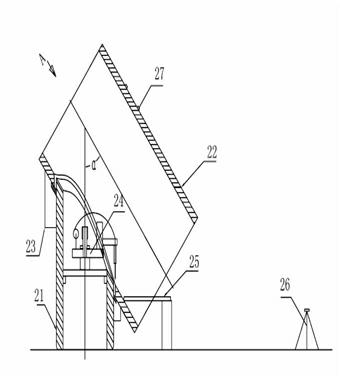

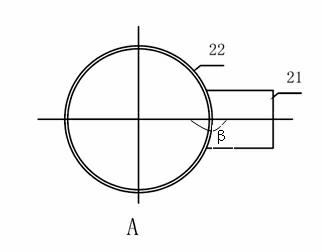

Method for controlling welding deformation of joint between inserted large inclined tube and barrel

InactiveCN102380690AControl welding deformationImprove pass rateArc welding apparatusEngineeringTotal station

The invention discloses a method for controlling welding deformation of a joint between an inserted large inclined tube and a barrel. The method comprises the following steps of: 1, forming a hole on the side part of the barrel; 2, assembling the inserted large inclined tube and the barrel, and welding a fixing rib plate on the outer side of the joint; 3, measuring the size of the joint between the barrel and the large inclined tube, and forming an angle alpha for counteracting the distortion allowance; 4, welding a lower welding line; 5, welding a middle lower welding line, measuring an included angle beta with a total station electronic tacheometer, and controlling the included angle beta at 180 degrees in the welding process; 6, welding a middle upper welding line, measuring an included angle beta, and controlling the included angle beta at 180 degrees in the welding process; and 7, welding an upper welding line. In the invention, the total station electronic tacheometer is used together with a rigid fixing method, and the welding deformation of the joint is controlled in the welding process of the inserted large inclined tube and the barrel, so that the product qualified rate is high, and the welding quality is effectively ensured; and the method is simple, and is very effective for controlling the welding deformation of a large inserted joint.

Owner:SHANGHAI BOILER WORKS

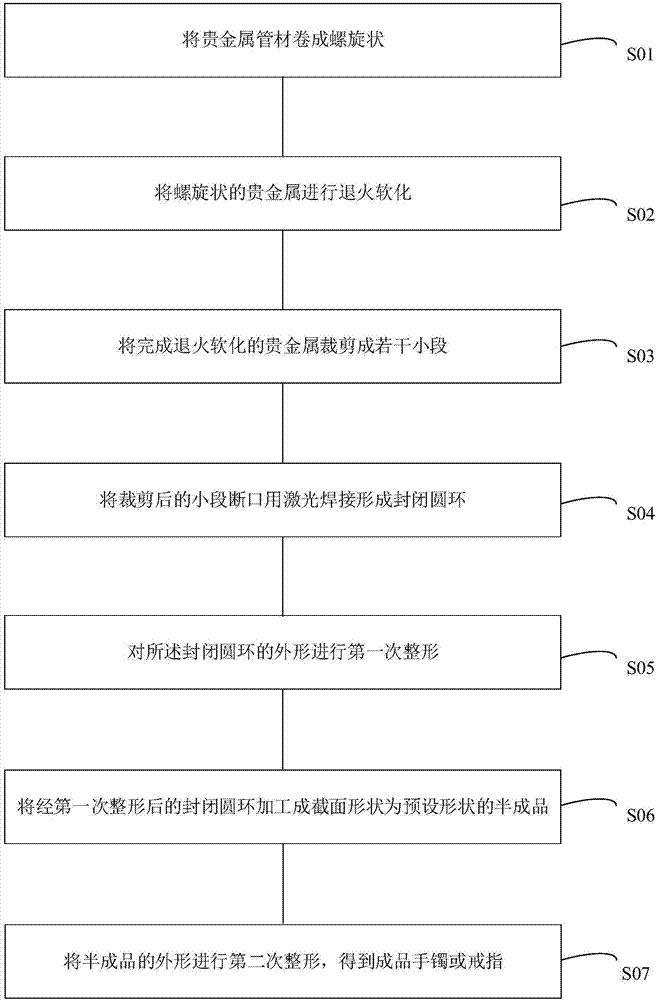

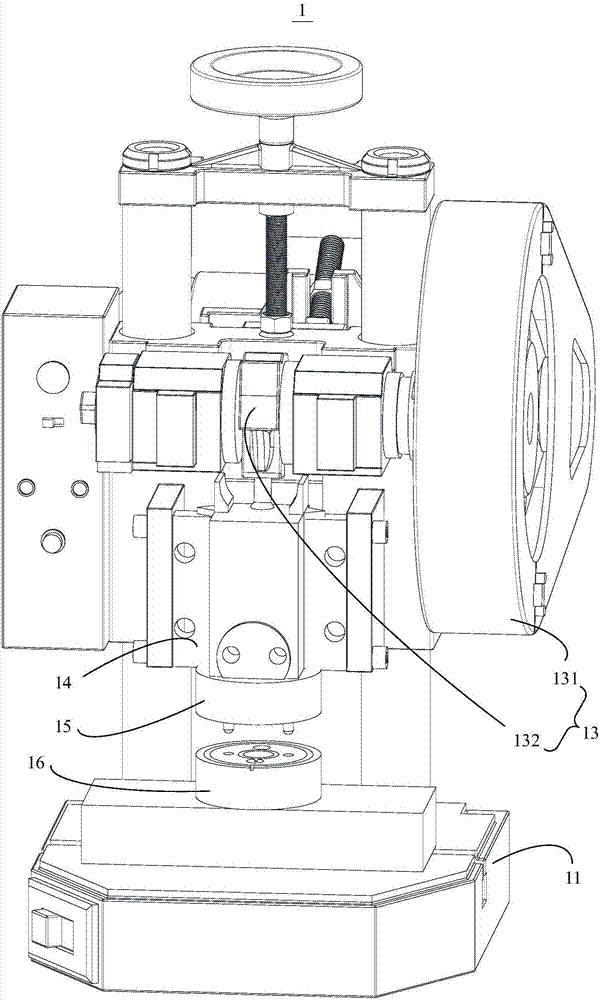

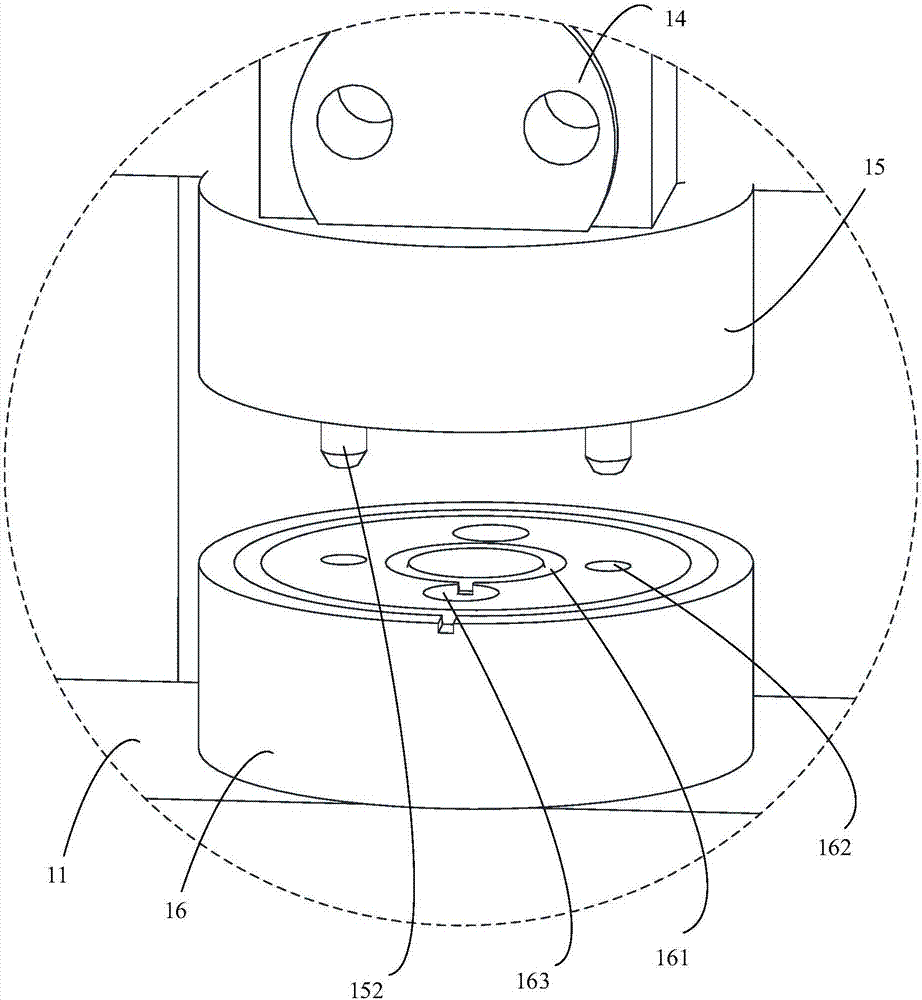

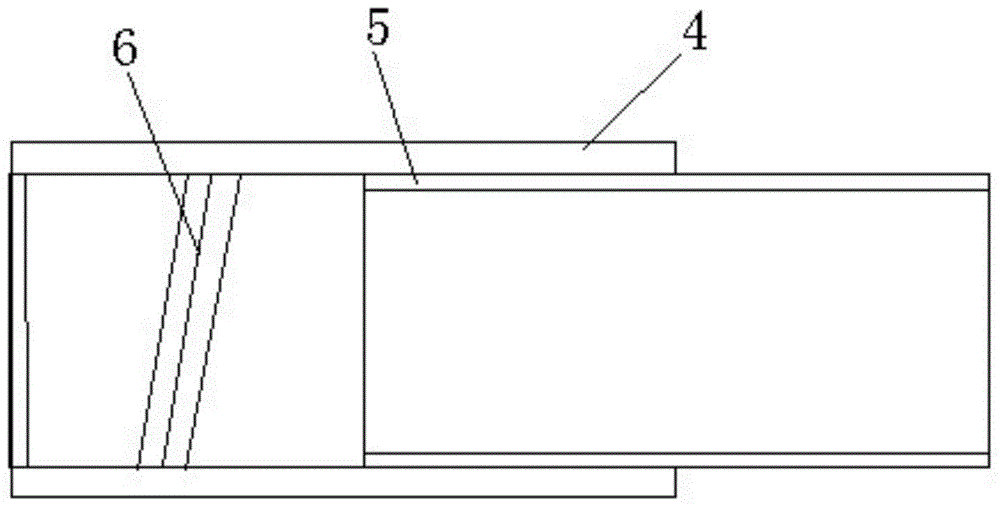

Processing technology for precious metal bracelet or ring, rounding equipment and arcing equipment

InactiveCN106862875AImprove machining accuracyWon't hurtBraceletsWrist-watch strapsMetallurgyWork in process

The invention discloses a processing technology for a precious metal bracelet or ring, rounding equipment and arcing equipment. The processing technology includes the following steps that a precious metal tubular product is rolled to be of a spiral shape; spiral-shaped precious metal is subjected to annealing softening; the precious metal subjected to annealing softening is cut into a plurality of small sections; the small sections of cut fractures are subjected to laser welding so that an enclosed circular ring can be formed; the appearance of the enclosed circular ring is subjected to primary shaping; the enclosed circular ring subjected to primary shaping is processed into a semi-finished product with the cross-section shape being a preset shape; and the appearance of the semi-finished product is subjected to secondary shaping, and accordingly a finished bracelet or ring product can be obtained. The processing technology aims to solve the problems that the precious metal bracelet or ring in the prior art is low in processing efficiency and poor in forming effect in the course of processing and the purity and precision cannot meet the requirements easily.

Owner:深圳市金银世界珠宝首饰有限公司

Method for arranging stainless steel sleeve in large-diameter cylinder block in sleeving way

The invention discloses a method for arranging a stainless steel sleeve in a large-diameter cylinder block in a sleeving way. The method comprises the following steps: firstly, performing boring machining on the inner wall of the cylinder block, manufacturing the stainless steel sleeve according to the size of the machined inner wall of the cylinder block, and machining a triangular thread on the inner wall of the cylinder block; secondly, arranging the stainless steel sleeve in the cylinder body in a sleeving way at the normal temperature, performing hot rolling on the stainless steel sleeve while heating, cooling to the normal temperature after the completion of hot rolling, and performing cold rolling on the stainless steel sleeve at the normal temperature; lastly, honing the inner wall of the stainless steel sleeve by using a honing head. The process is simple, the adhesion between the stainless steel sleeve and the inner wall of the cylinder block is high, and the inner wall of the stainless steel sleeve can meet the requirements of smooth finish and size.

Owner:BEIJING LANGDE COAL MINE MACHINERY +1

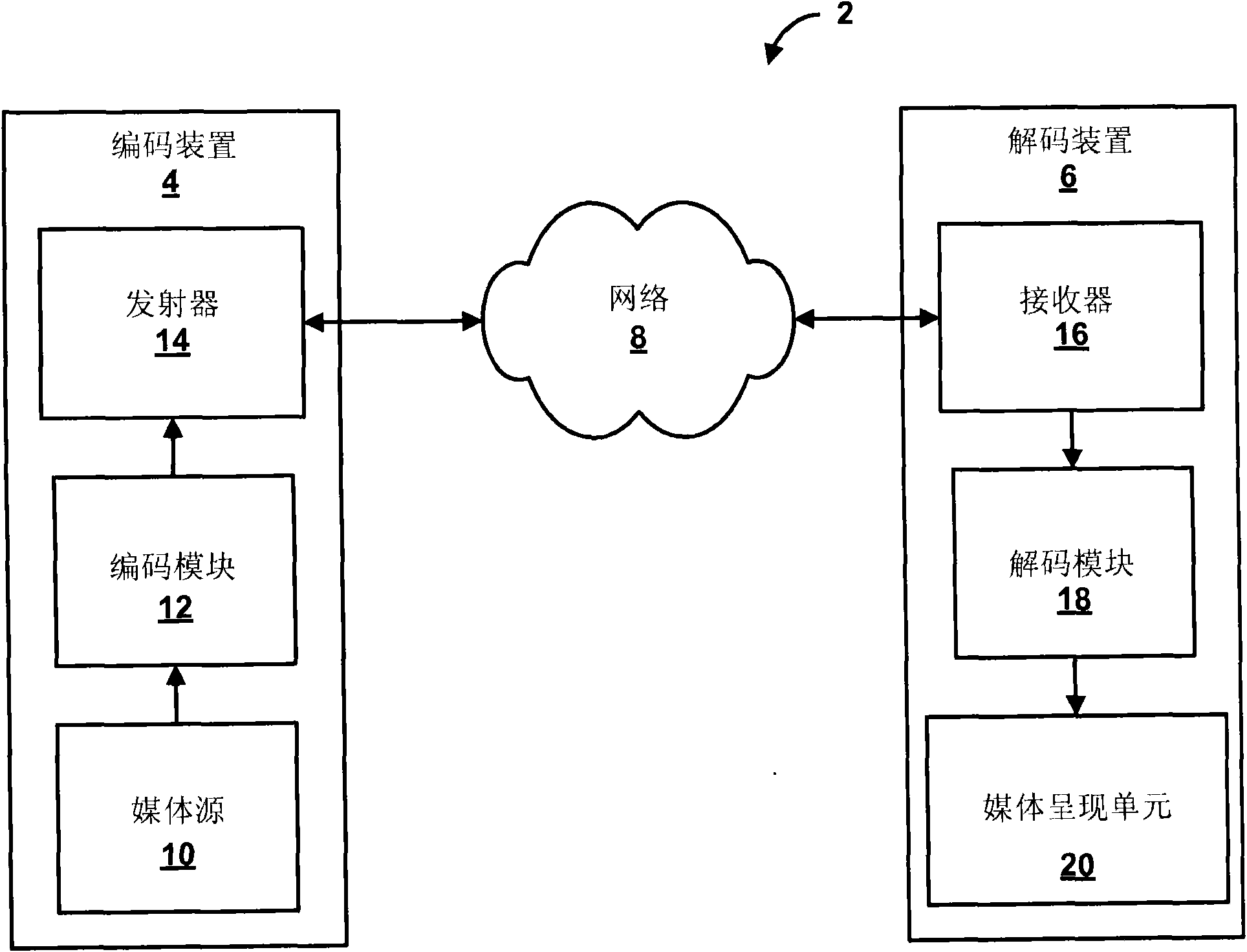

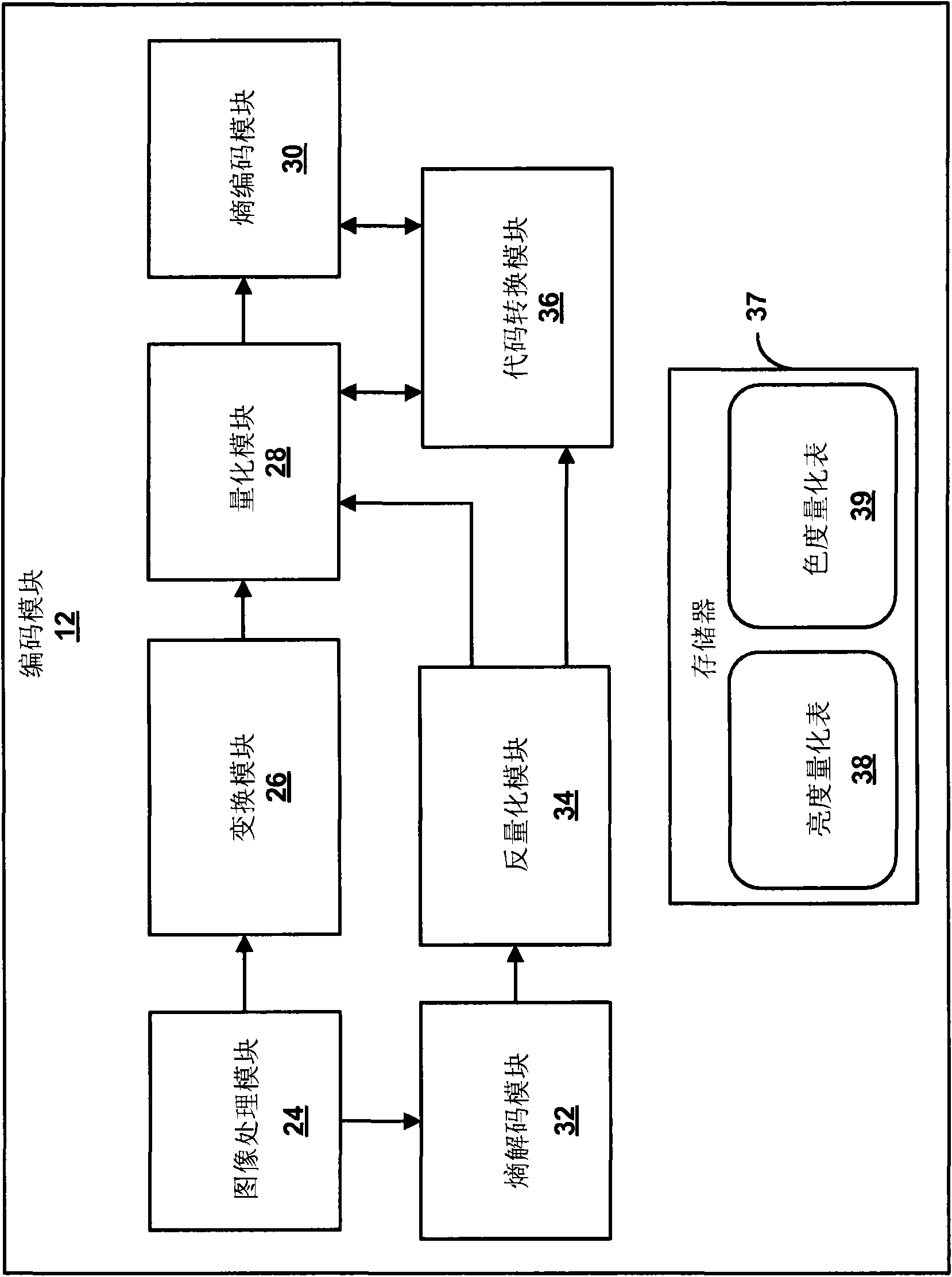

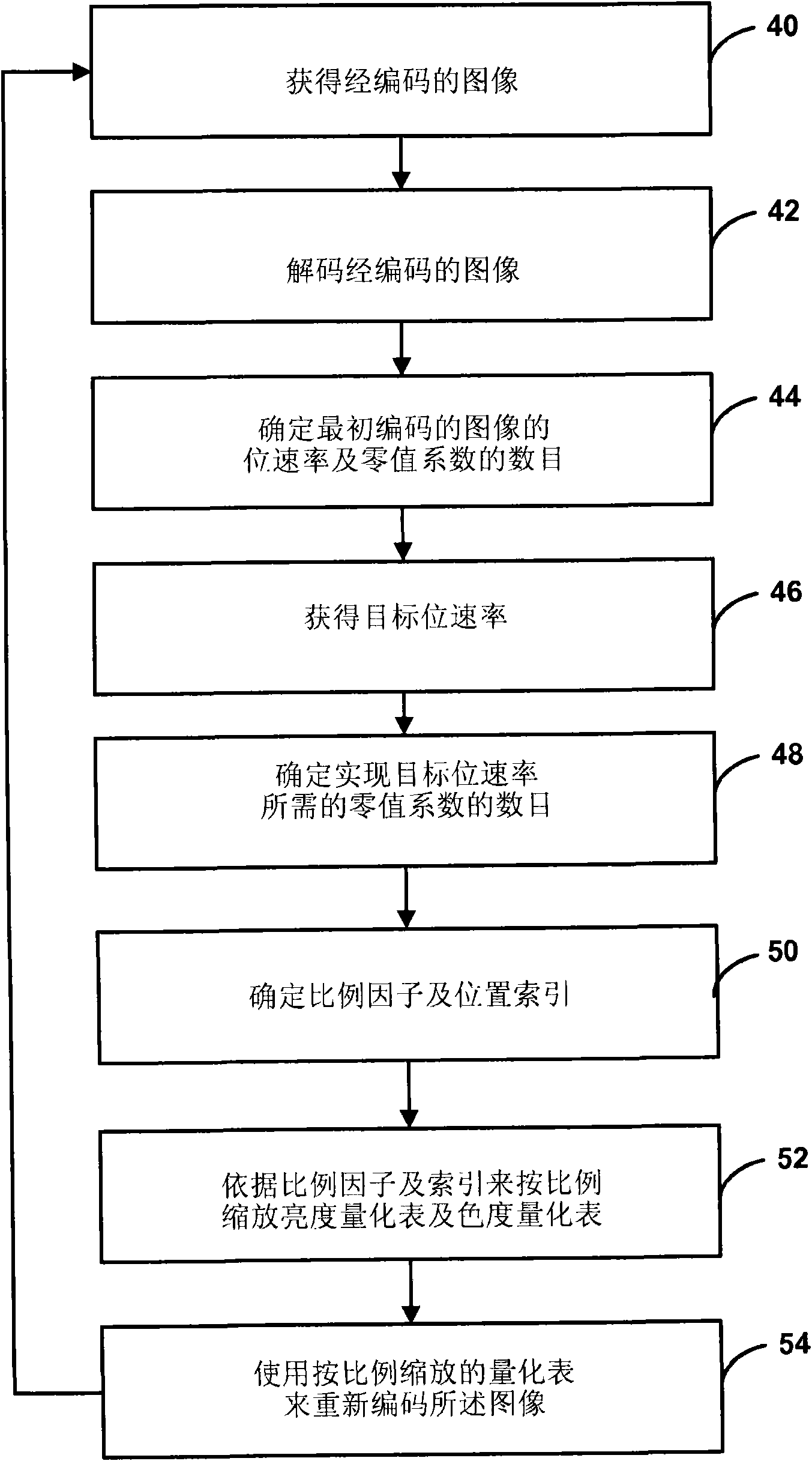

Bitrate reduction techniques for image transcoding

InactiveCN101682764AReduce sizeMeet size requirementsPulse modulation television signal transmissionDigital video signal modificationReduced sizeLinear relationship

This disclosure describes techniques for encoding data to compress image data to a reduced size. The techniques may be particularly effective in transcoding an image to a reduced size for transmission. An encoding device may transcode an image to an acceptable file size using bitrate control techniques that affect the entire image uniformly to transcode the image. For example, the encoding devicemay modify one or more quantization tables as a function of the near linear relationship between bitrate (R) and the number of zero-valued quantized transform coefficients to reduce the file size uniformly over the entire image. Alternatively, or additionally, the encoding device may transcode the image using bitrate control techniques that affect only specific localized regions of the image.

Owner:QUALCOMM INC

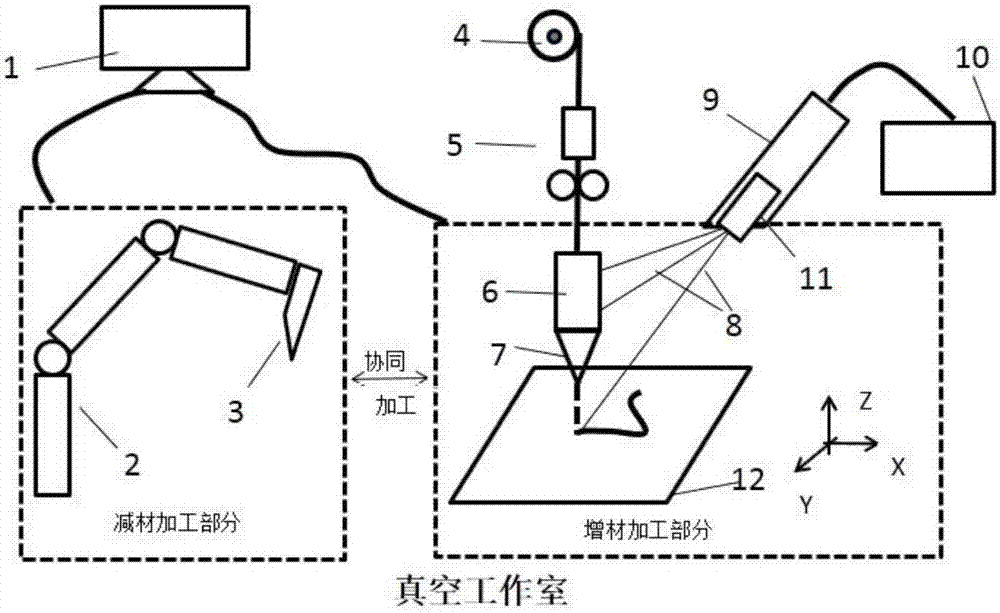

Additive and subtractive combined manufacturing device and method based on electron beam fuse

InactiveCN106862568AImprove practicalityAvoid error accumulationAdditive manufacturing apparatusTemperature controlComputer control system

The invention discloses an additive and subtractive combined manufacturing device and method based on electron beam fuse which are used for solving the technical problem of poor practicability of existing additive and subtractive combined machining systems and methods. According to the technical scheme, the device comprises an electron beam additive forming part, a subtractive machining part and an upper computer control system; the electron beam additive forming part comprises an electronic gun emitting the electron beams, an electronic gun deflection control system, a container for containing to-be-machined metal wires, a spray head and a metal wire feeding mechanism; the subtractive machining part comprises a mechanical arm, an internally-cooled cutter and an end effector mounted on the mechanical arm, the end effector of the mechanical arm is provided with a quick-change device, and subtractive machining is implemented; a cooling unit connected with the internally-cooled cutter is used for cooling the internally-cooled cutter and controlling the temperature of the internally-cooled cutter; and both the additive forming part and the subtractive machining part are placed in a vacuum chamber. With the device and the method, additive and subtractive combined machining is realized, and the practicability is high.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

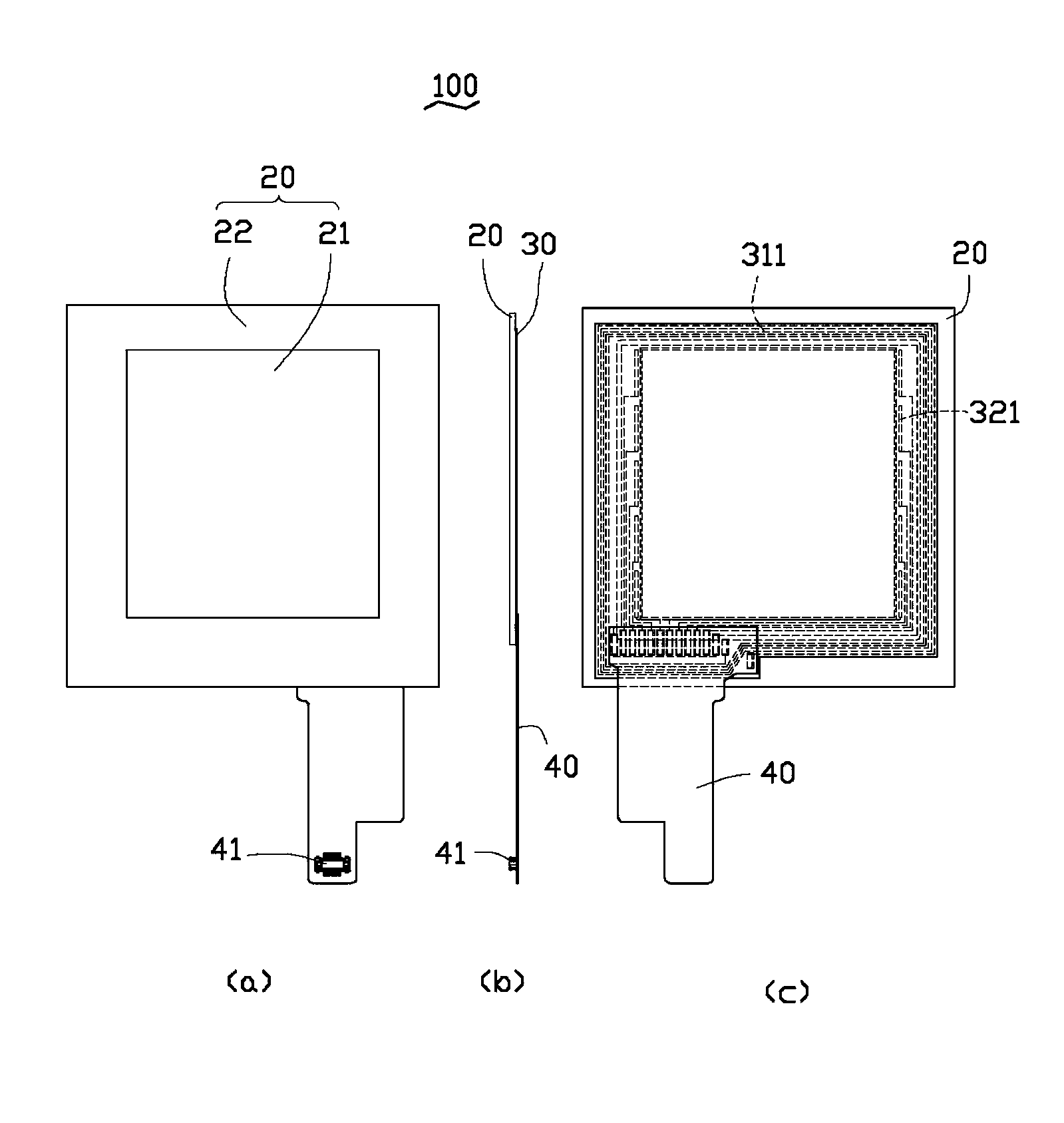

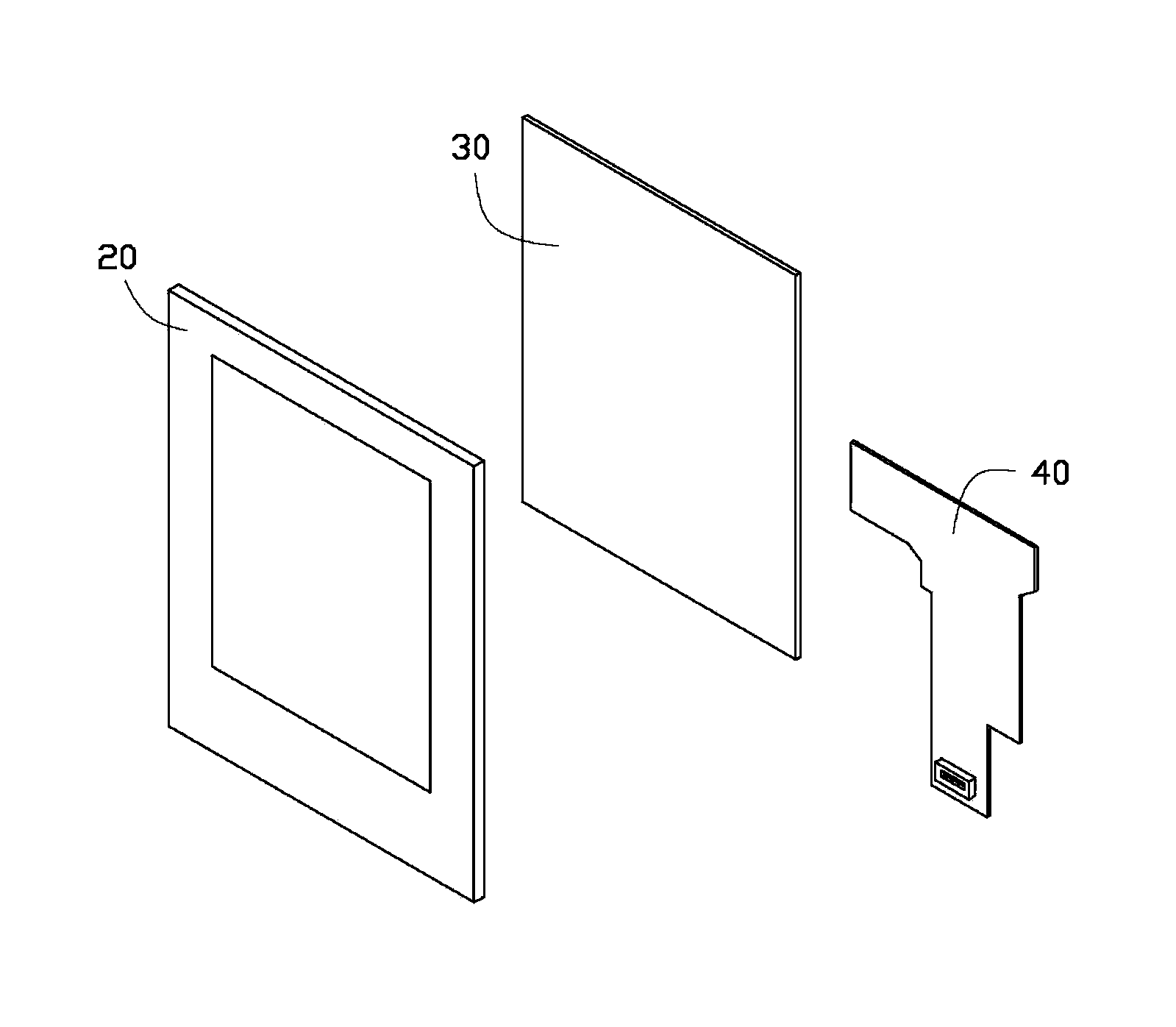

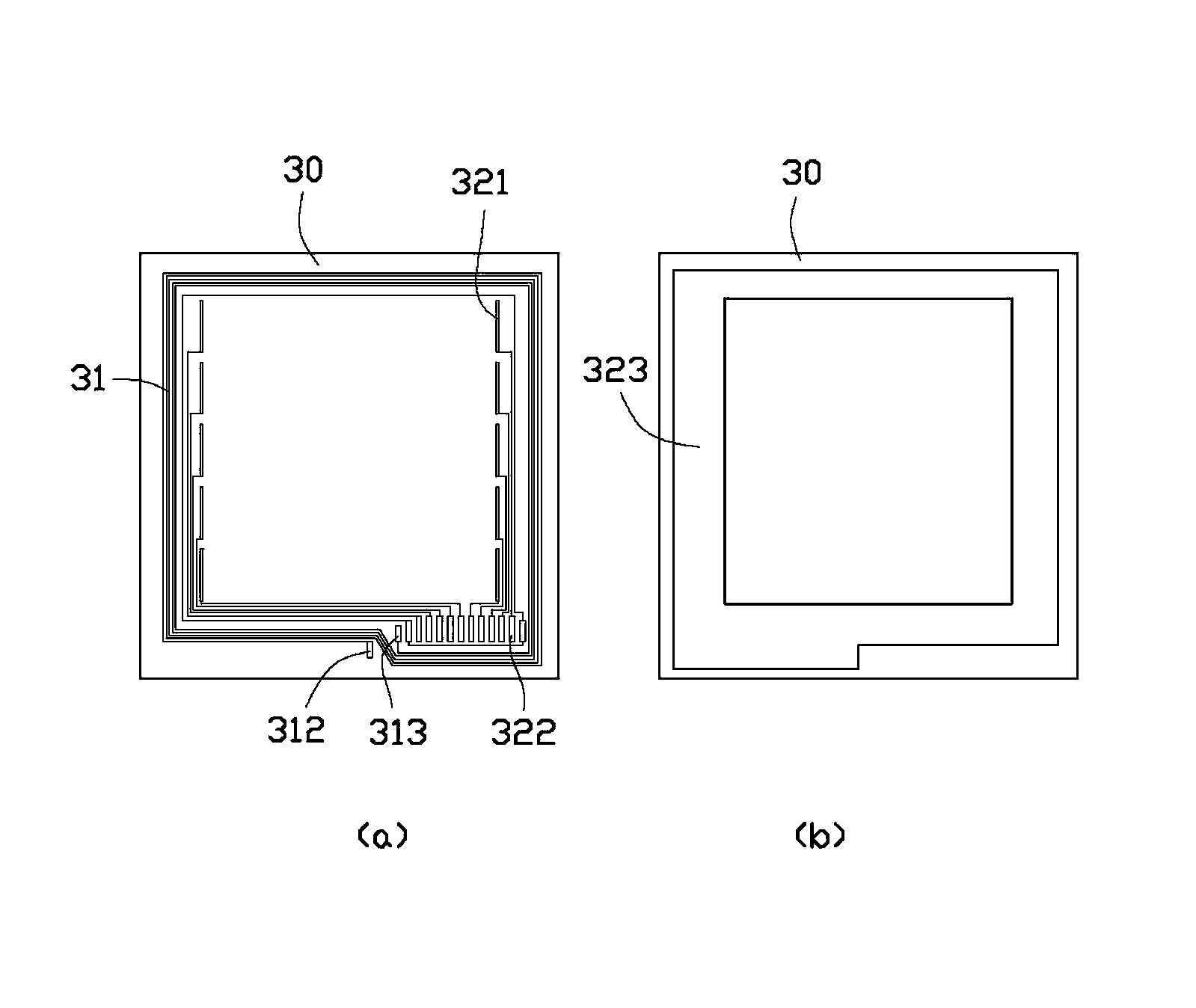

Portable electronic device with NFC antenna

InactiveCN103904411ASmall sizeAffect performanceAntenna supports/mountingsRadiating elements structural formsPrinted circuit board

A portable electronic device with an NFC antenna comprises a touch screen and a first printed circuit board arranged on the back side of the touch screen. The touch screen comprises a touch area and a non-touch area surrounding the touch area. The upper surface of the first printed circuit board, corresponding to the non-touch area of the touch screen, is imprinted with an NFC antenna and a touch-sensitive circuit side by side. The lower surface of the first circuit board, corresponding to the NFC antenna, is equipped with a shielding layer so as to isolate the NFC antenna from other components arranged below the first circuit board. According to the electronic device, the NFC antenna and the touch-sensitive circuit are printed on the circuit board side by side and are correspondingly adhered to the non-touch area of the touch screen. Thus, the NFC antenna keeps away from a main circuit board of the electronic device; the influence of components on the main circuit board on performance of the NFC antenna is avoided; the space occupied by the NFC antenna in the electronic device is saved; and then the electronic device is allowed to have a thin size.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com