Method for making dimethyl silicone polymer micro flow control chip composite type optical cured resin die arrangement

A polydimethylsiloxane and microfluidic chip technology, applied in the field of micro-manufacturing, can solve the problems of pattern cracks, many processes, long time, etc., and achieves the effect of clean and clear structure outline and improved development speed and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] According to the above technical solution, the present invention provides a specific embodiment. It should be noted that the present invention is not limited to this embodiment, and the parameter transformation performed within the scope of the above technical solution belongs to the protection scope of the present invention.

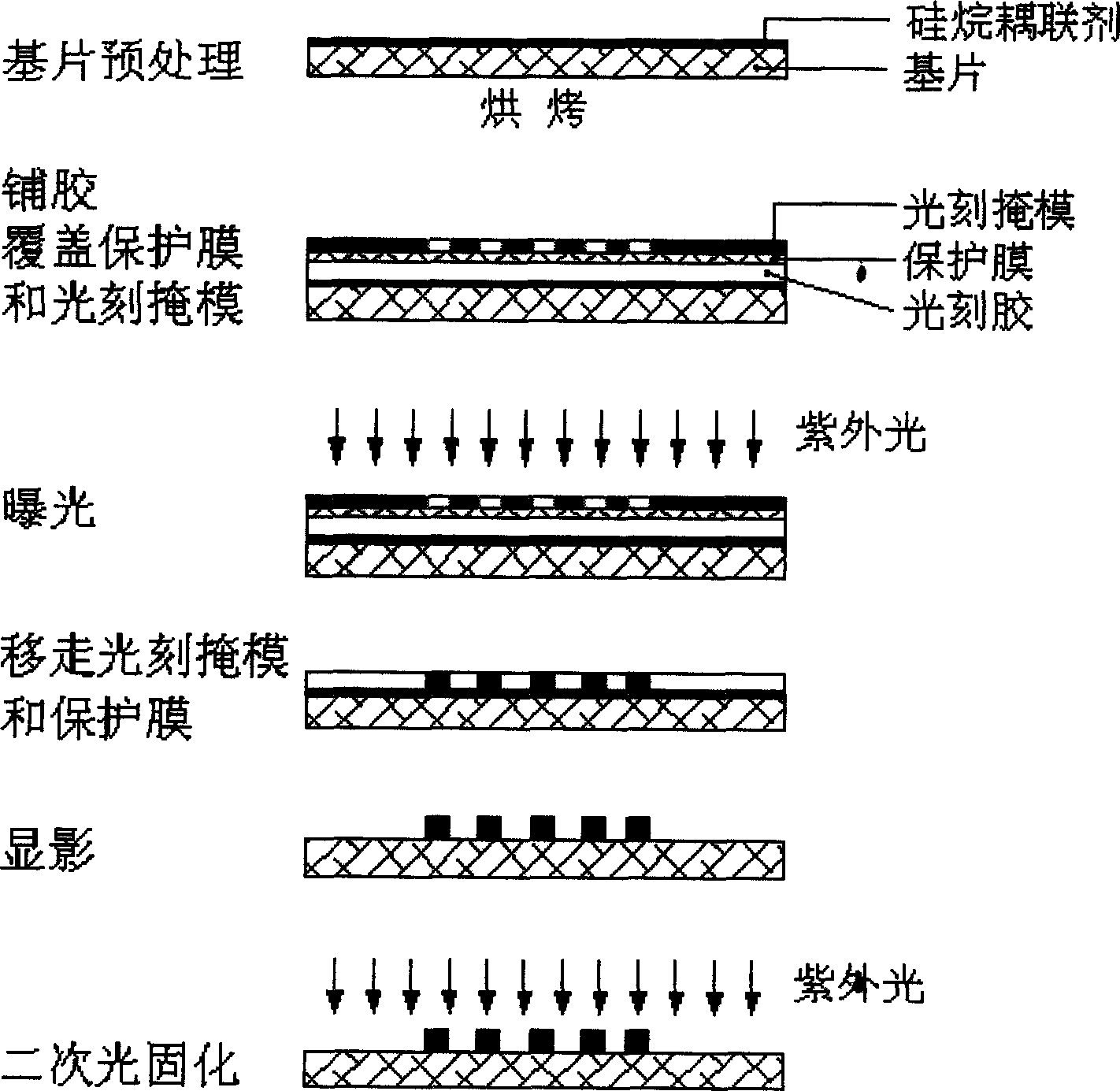

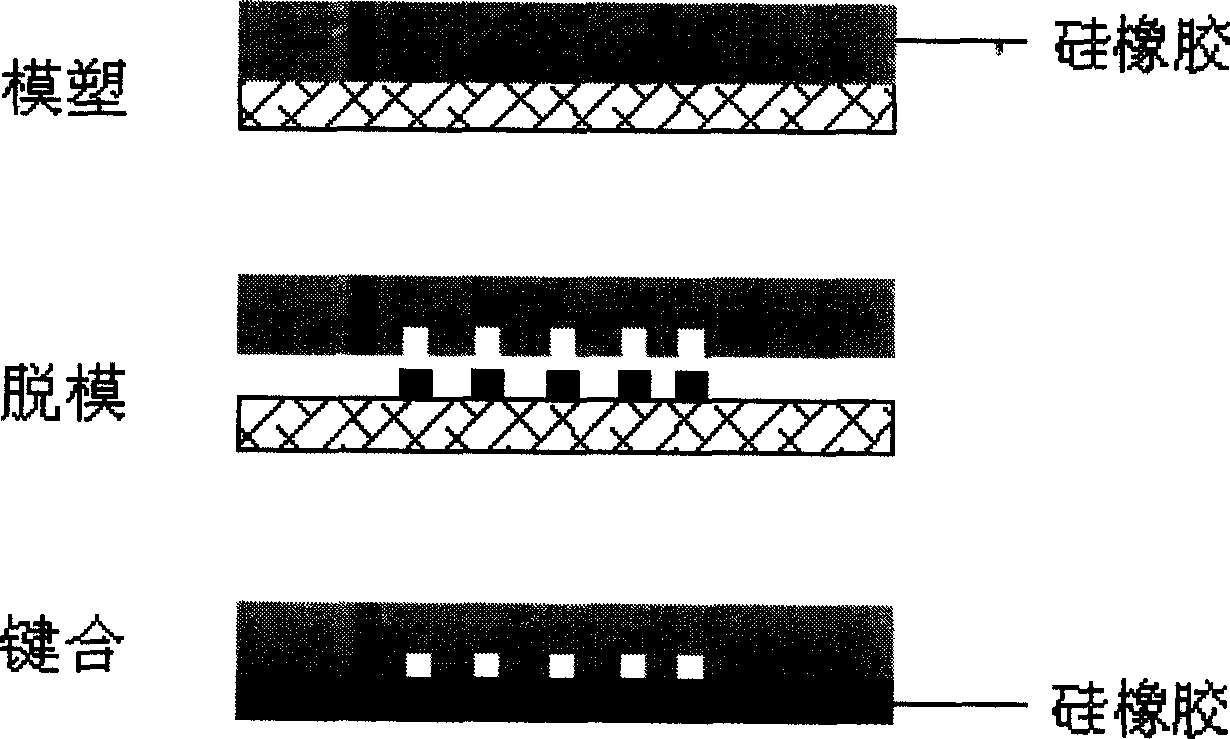

[0045] (1) Mold making

[0046] 1. Substrate pretreatment

[0047] Using quartz or glass as the substrate material, the substrate is pretreated to increase the bonding force between the photoresist and the substrate. The pretreatment method is to take a small amount of silane coupling agent (commercially available), evenly coat the substrate, put it into an oven, and bake at 120° C. for 40 minutes.

[0048] 2. Laying glue

[0049] A plastic sheet is pasted around the substrate to form a cavity, and after the photoresist is injected into the cavity, it is scraped off with a scraper.

[0050] 3. Exposure

[0051] Cover a layer of F46 protective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com