Patents

Literature

158results about How to "Solve sticking problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

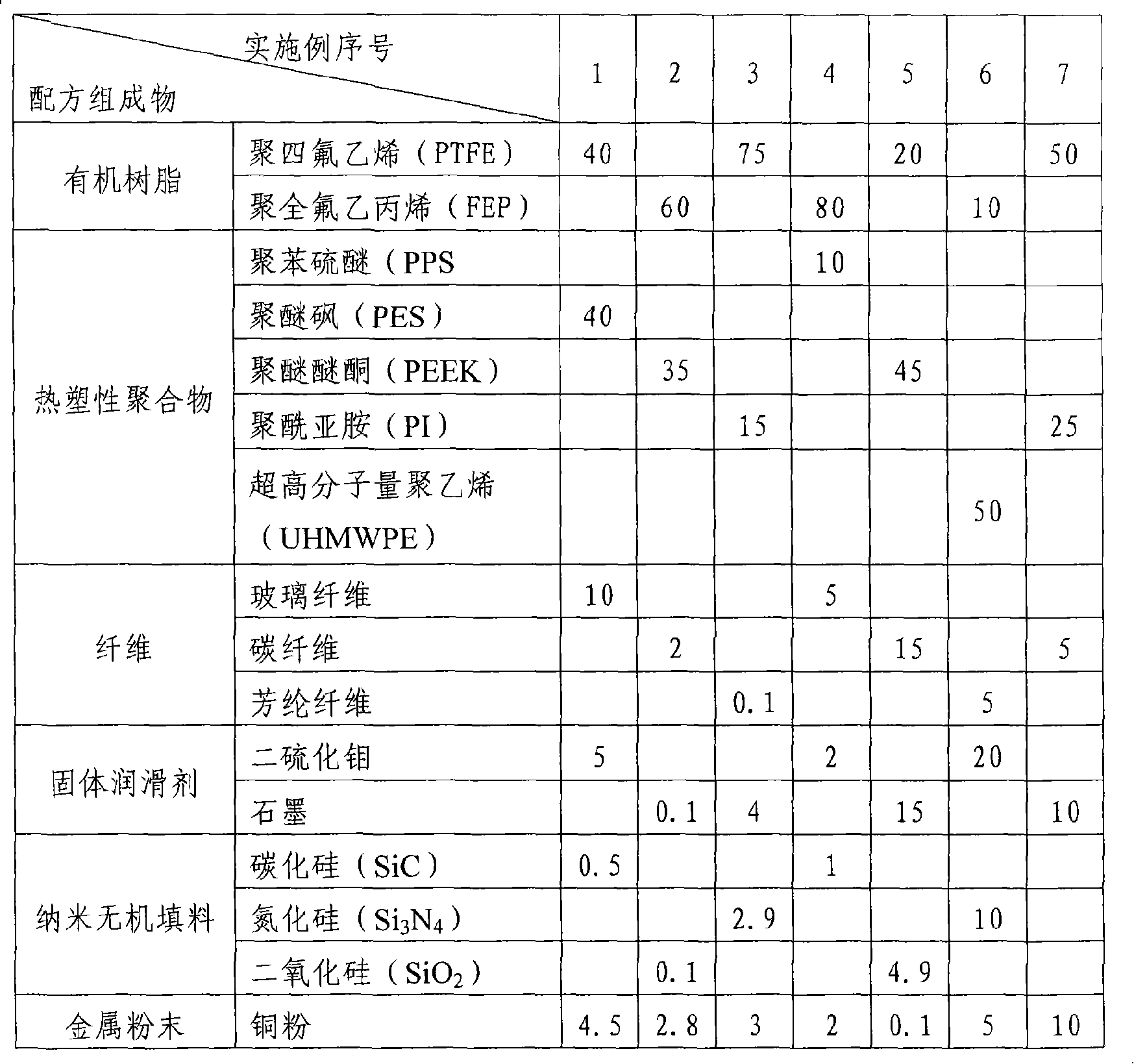

Self-lubricating sliding bearing material and its preparation method

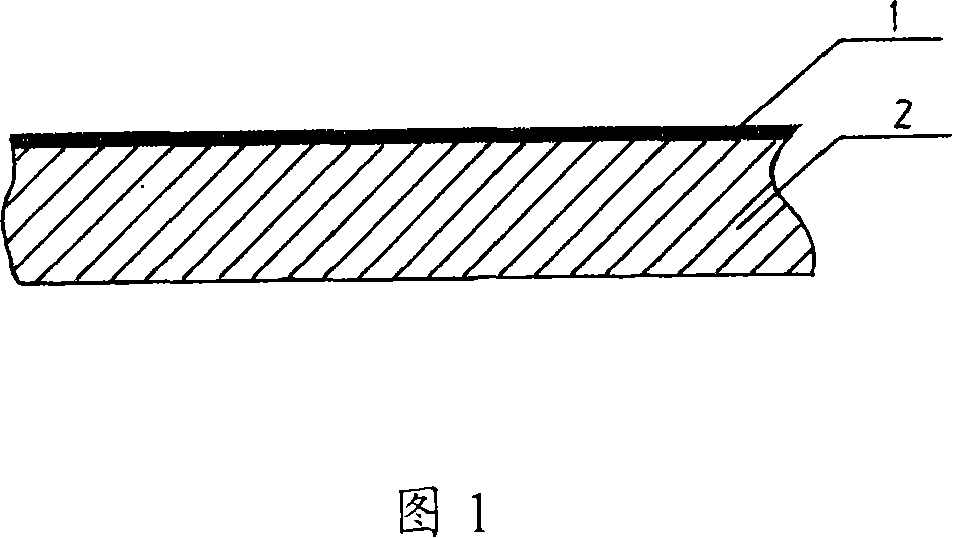

ActiveCN101126417AImprove carrying capacityReduce frictionBearing componentsCarrying capacityMetal sheet

The invention discloses a self-lubrication sliding bearing material and the preparation method, the self-lubrication sliding bearing material includes a self-lubrication sliding layer made of composite material which adopts the organic resin as the basis and a metal substrate, the sliding layer and the metal substrate are directly adhered together. During the preparation, the composite material for the self-lubrication sliding layer is blended proportionally and is laid on the metal sheet after being mixed mechanically, the surface of the metal sheet is treated, and then the metal sheet is sintered in a sintering furnace, then rolled immediately after the sintering process so that the surface coat is adhered on the metal substrate. The sliding bearing made of the material provided by the invention has the characteristics of higher carrying capacity and low friction and good wearing resistance, the metal substrate and the self-lubrication sliding layer can be stably adhered with each other, and is suitable for the dry friction and boundary or fluid friction conditions.

Owner:COB PRECISION PARTS

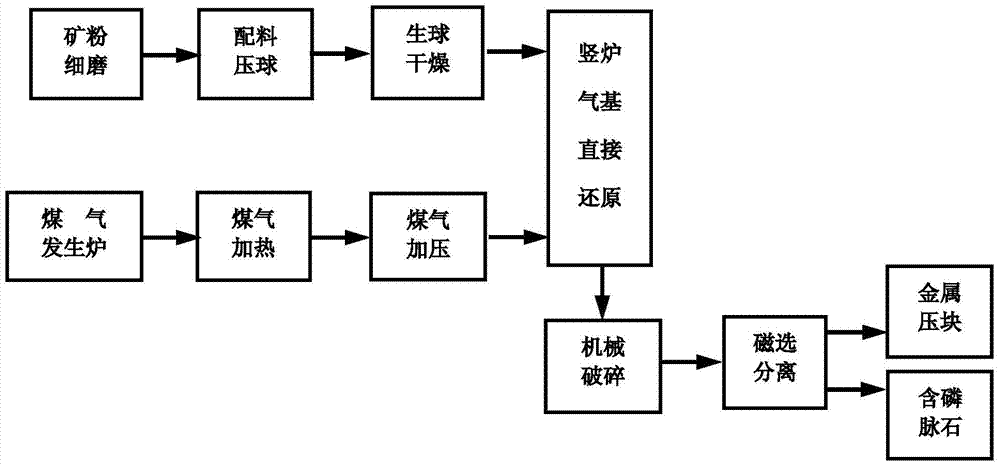

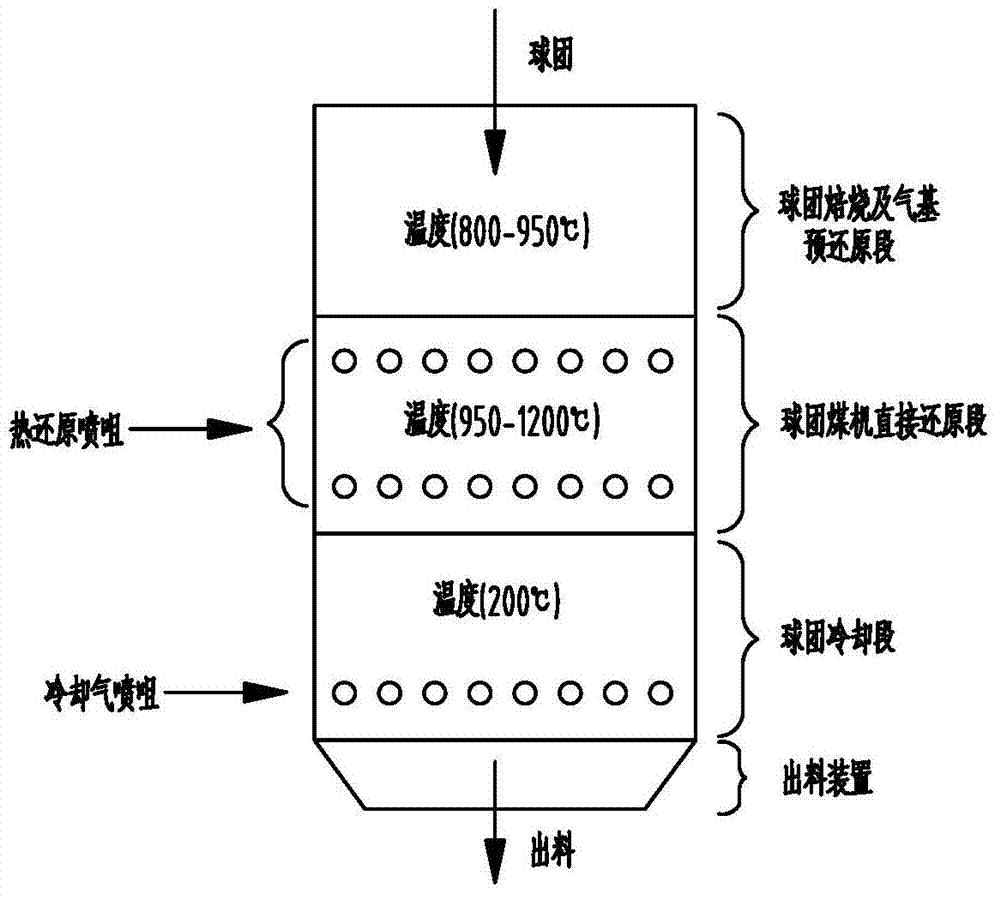

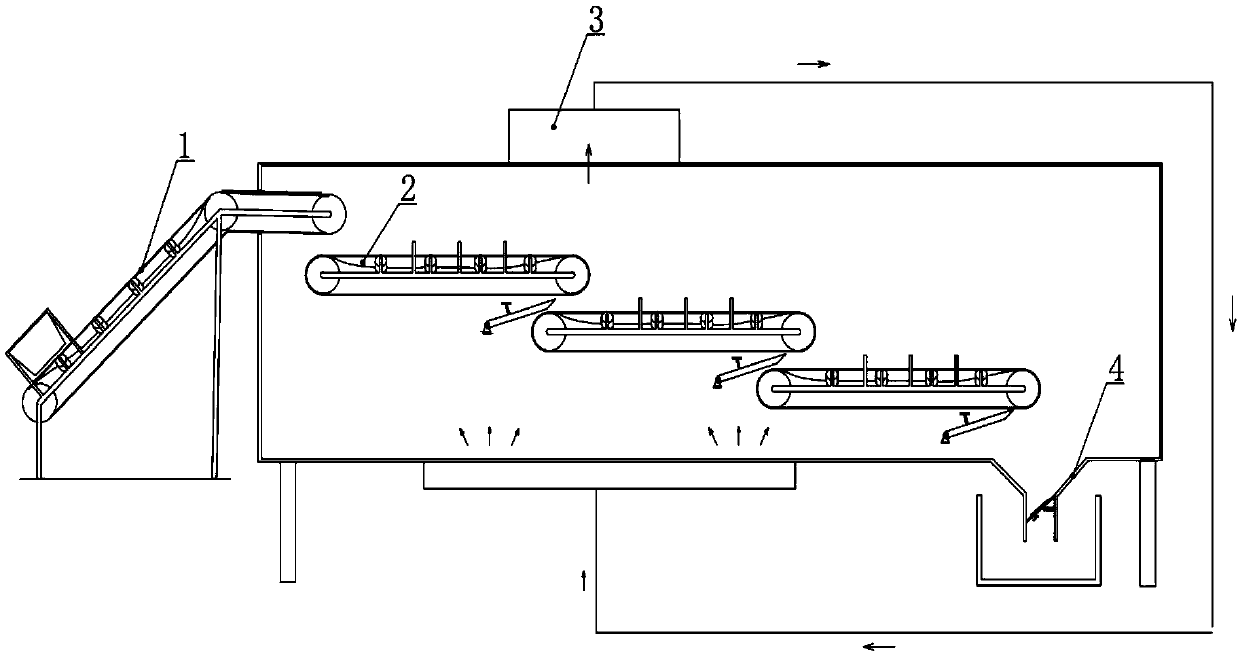

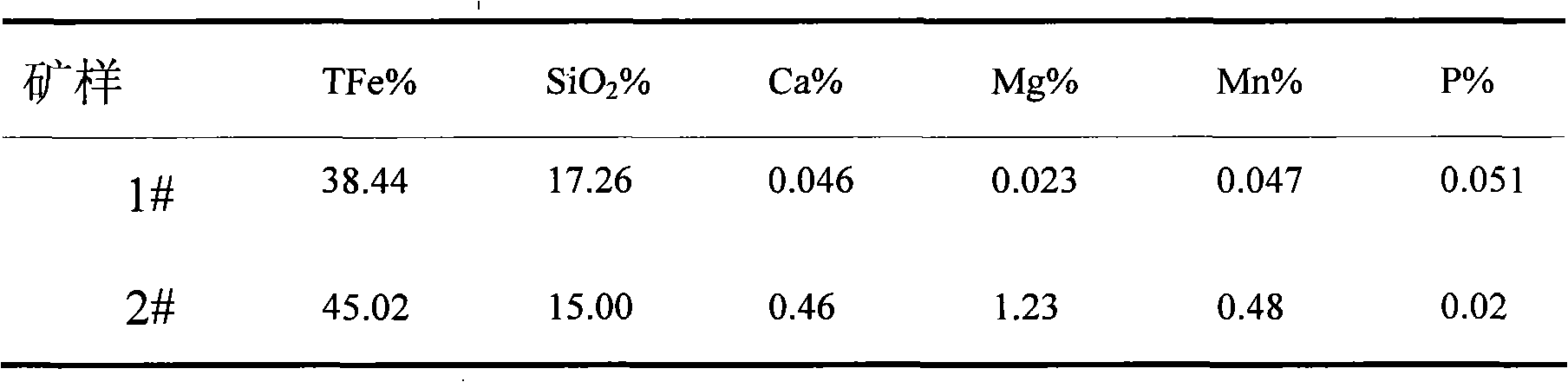

Method for preventing pellets from high temperature reduction bonding in high phosphorus oolitic hematite treatment shaft furnace

ActiveCN103667687ARelieve stickingGood for magnetic separationShaft furnaceDecreased energyShaft furnace

The invention discloses a method for preventing pellets from high temperature reduction bonding in a high phosphorus oolitic hematite treatment shaft furnace, belonging to the technical field of direct-reduction ironmaking. High phosphorus oolitic hematite powder, pulverized coal, a dephosphorization agent and a bonding agent are mixed together according to a proper ratio, the mixture is milled and pressed into balls so as to prepare cold bound pellets, and the bound pellets are dried or maintained and are further conveyed into a direct-reduction shaft furnace; in the direct-reduction shaft furnace, the pellets are subjected to hot coal gas roasting, gas-based prereduction, coal-based direct reduction and cooling process from top to bottom, temperature range of gas-based prereduction and coal-based direct reduction for the bound pellets is 850-1200 DEG C, and standing time in the shaft furnace is 1-5 hours; the reduction gas comprises H2 and CO in a ratio of 1.2-4; the reduced pellets are sealed and cooled, at the outlet of a cooling section, temperature of the bound pellets is controlled to be 100-200 DEG C, and the bound pellets are further smashed, magnetically separated and briquetted, wherein TFe in the obtained iron product is not less than 88%, and phosphorus content is less than 0.3%. The method has the advantages of decreasing energy consumption of reduction process of the shaft furnace.

Owner:韩其平

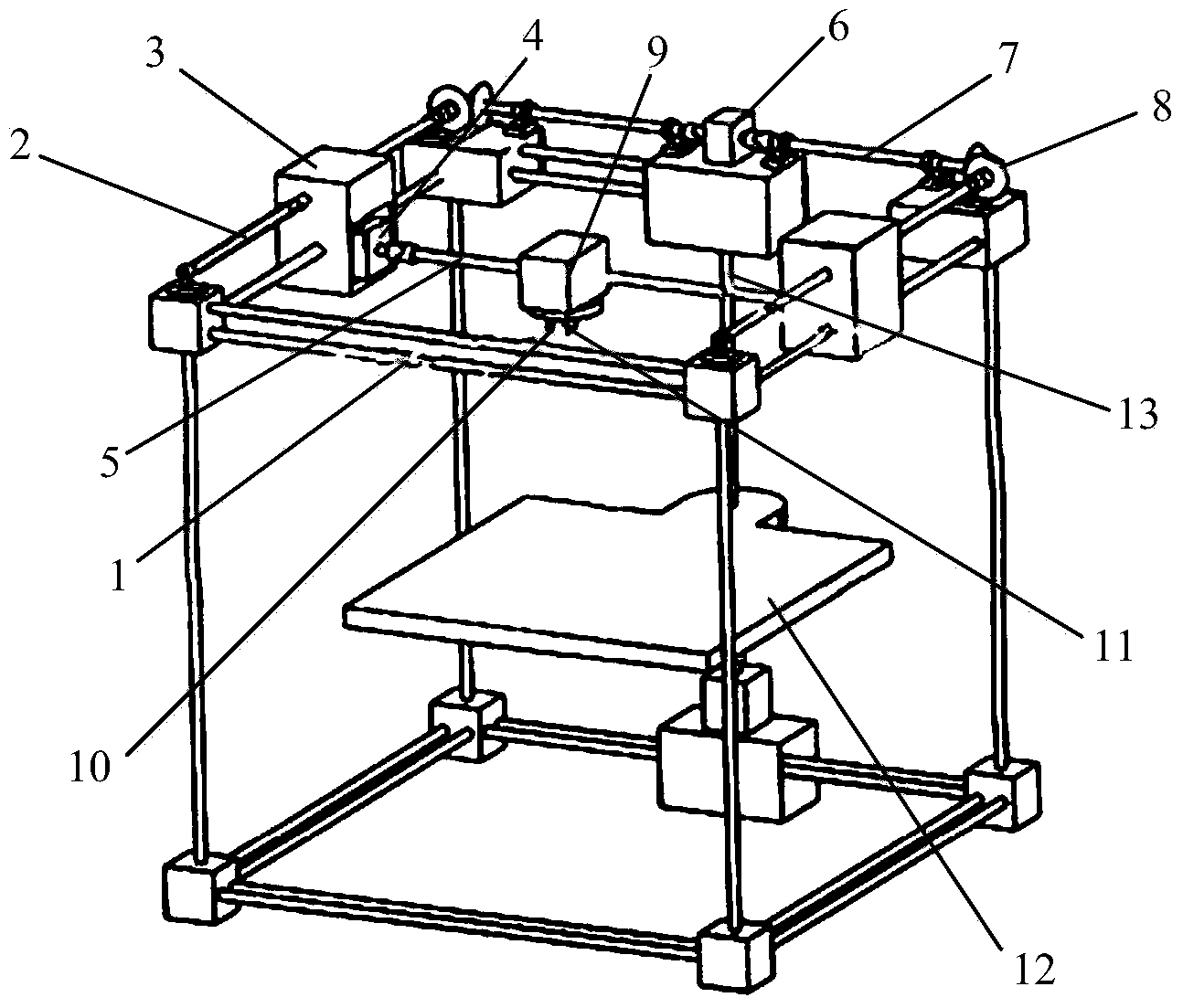

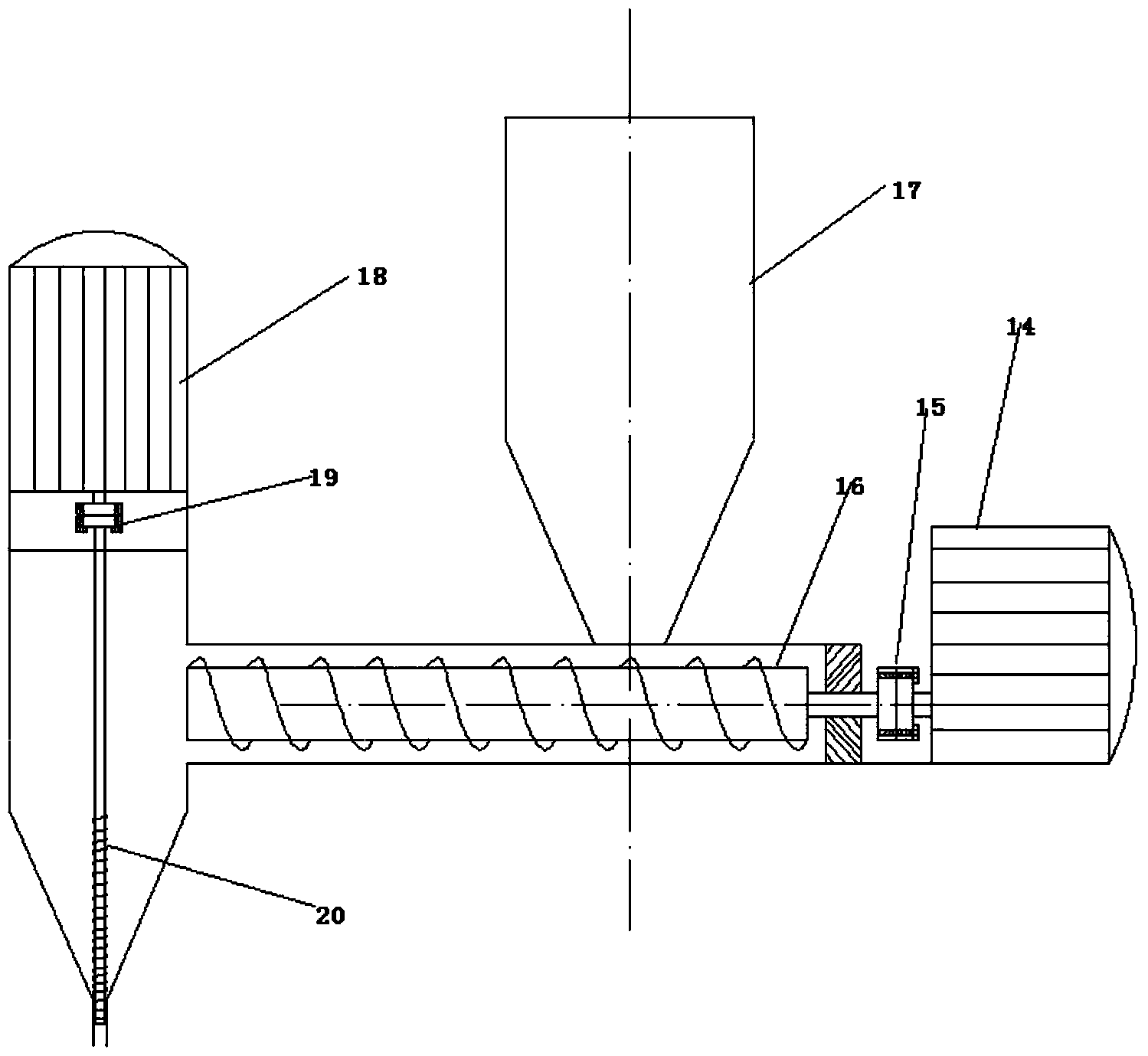

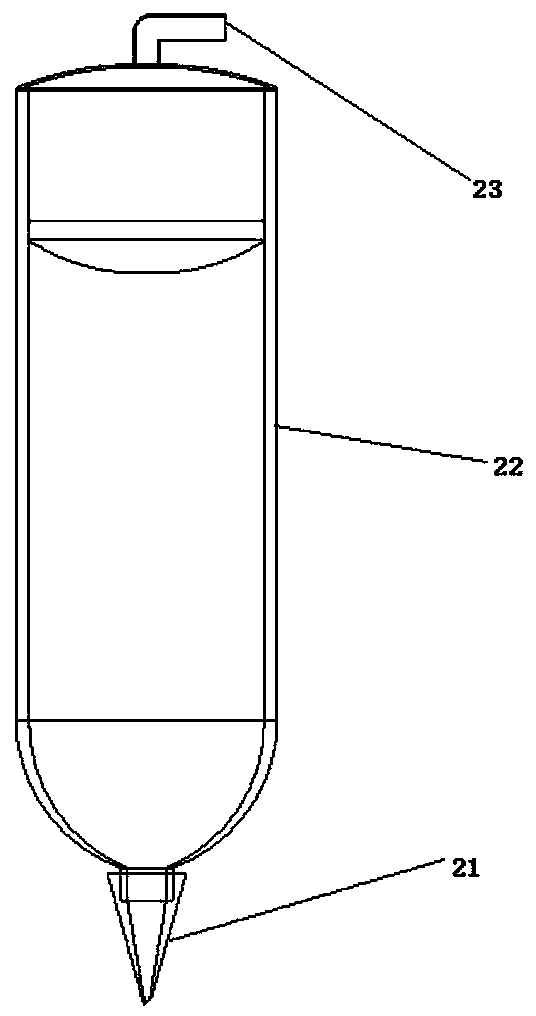

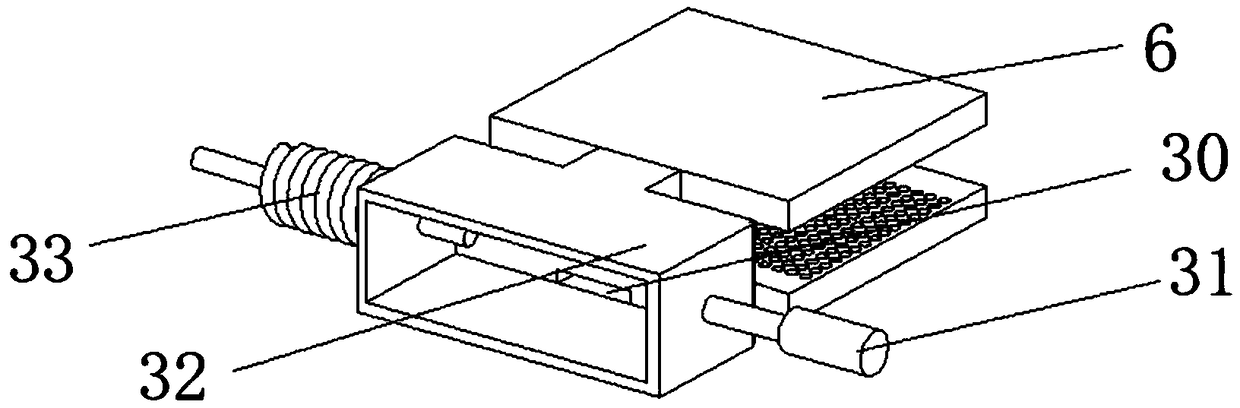

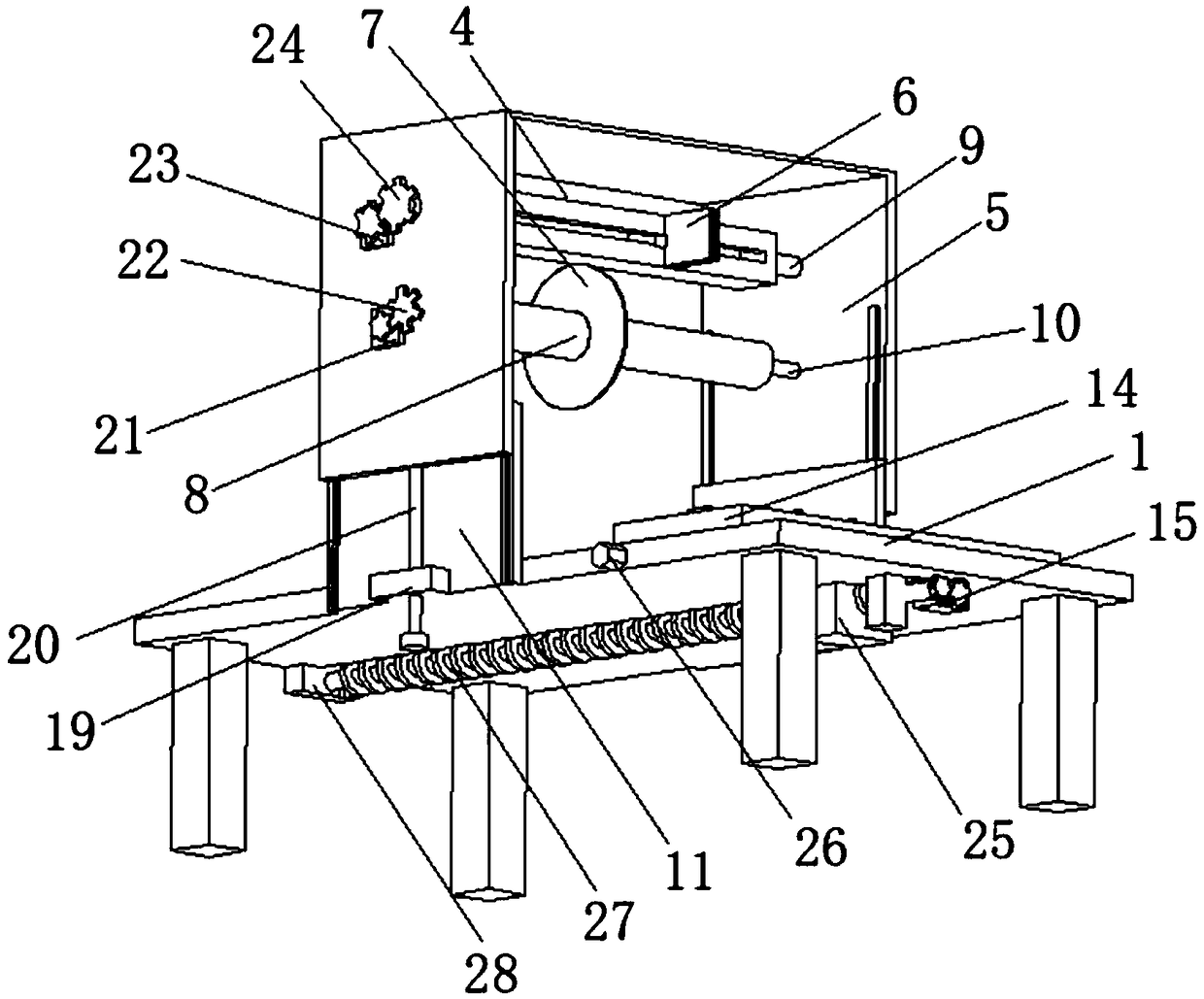

Controllable powder spray food 3D (three-dimensional) printing equipment and method

ActiveCN103932367AImprove efficiencyImprove printing efficiencyFood shapingSpray nozzleBonding problems

The invention discloses controllable powder spray food 3D (three-dimensional) printing equipment and printing method. A powder feeding device is used for pushing powdery food to an outlet through a horizontally-placed screw rod, and the powder feeding speed at the outlet is controlled by using a vertically placed spiral screw rod. Various powdery foods can be effectively bonded together, and a liquid feeding nozzle can rotate around a powdery food nozzle, so that the liquid feeding nozzle can be always kept behind a powder spout when the powdery food spout moves towards any direction, thereby ensuring the maximum bonding rate of powdery foods. By adopting the printing method, the food printing efficiency and bonding firmness can be increased greatly, the bonding problem of powdery foods in the 3D printing industry is solved effectively, and the application field of 3D printed foods is expanded.

Owner:XI AN JIAOTONG UNIV +1

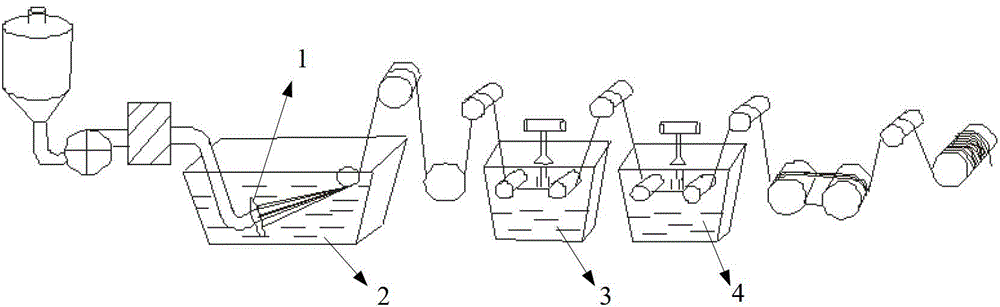

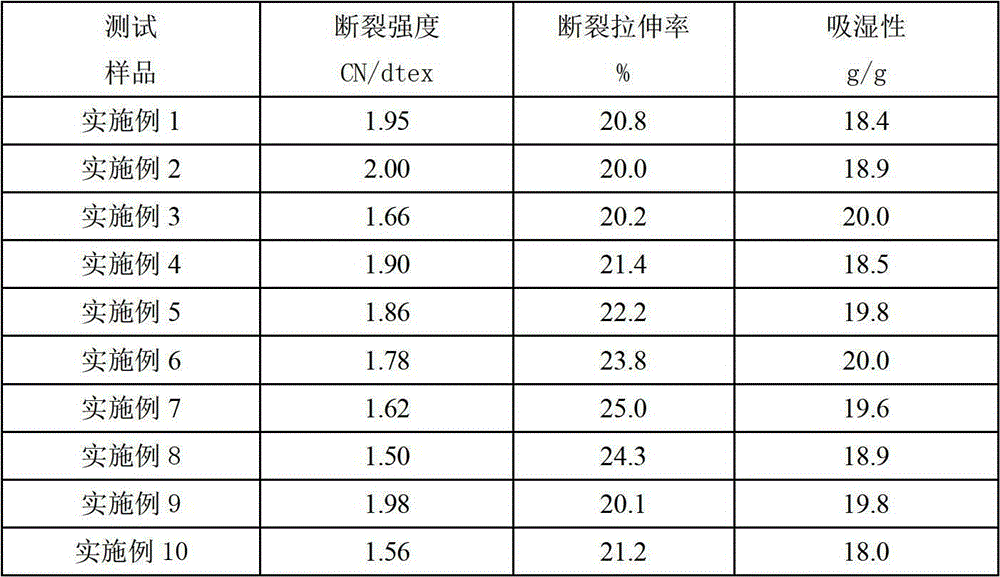

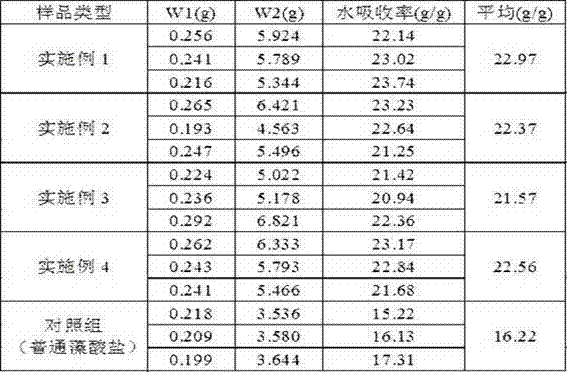

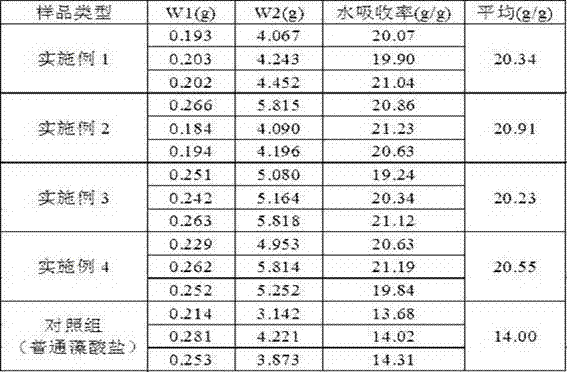

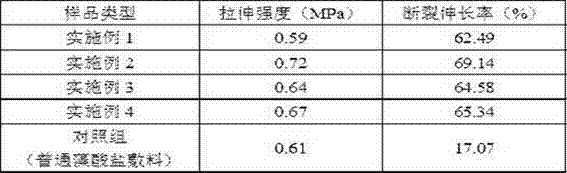

Blend fibers of alginate and sodium carboxymethyl cellulose and preparation method and application thereof

ActiveCN103060946AInsufficient improvementExcellent hygroscopicityConjugated cellulose/protein artificial filamentsAbsorbent padsFiberCarboxymethyl cellulose

The invention relates to the fiber field and discloses blend fibers of alginate and sodium carboxymethyl cellulose and a preparation method and application of the blend fibers. The blend fibers are formed by preparation from alginate and sodium carboxymethyl cellulose, and in preparation, the mass ratio of alginate to sodium carboxymethyl cellulose is 3-19:1. The preparation method of the blend fibers includes: preparing a blend spinning solution, enabling the blend spinning solution to pass through a spinning nozzle and then enter a coagulation bath, and then obtaining the blend fibers through drafting, washing, spinning dividing, drying and winding. Due to the fact the unique spinning dividing step is added to the process, the problem that fibers are prone to bonding with each other is solved, and the spinning dividing step is favorable for subsequent product processing. Compared with fibers of a single component, the blend fibers has the respective advantages of two kinds of single components, overcomes the defects caused by the single component and is better in both hygroscopicity and physical mechanical performance. Dressings made from the blend fibers can better meet the requirements of clinical medicine.

Owner:WINNER MEDICAL CO LTD

Waste salt recycling process and special device thereof

InactiveCN107321755AFully mineralizedHigh net salt puritySolid waste disposalTransportation and packagingFlame arresterPollutant emissions

The invention discloses a waste salt recycling process and a special device thereof. According to the process, a waste salt supply system, a waste salt melting system, a tail gas treatment system and a molten salt cooling and pelleting system are included. The special device comprises a waste salt feeder, a waste salt distributor, a drying, preheating and melting integrated salt-melting furnace, a belt cooling and pelleting machine, an RTO furnace, a filter, a fire arrester, an alkaline washing tower and the like. By means of the waste salt recycling process and the special device thereof, organic matter in waste salt is completely burnt out, the recycling standard is met, organic matter generated in the purifying process of waste salt is further treated in a thermal destruction mode, and emission of secondary pollutants like waste water and waste gas in the utilization process of the waste salt is avoided. Meanwhile, the vertical salt-melting furnace is adopted, the waste salt drying, preheating and melting processes are achieved in the furnace, high investment and waste gas pollution caused by equipment units for drying, grinding and the like are reduced, and the problem that it is difficult for the device to operate continuously and stably due to salt adhesion is solved.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

Lithium ion battery anode material and lithium ion battery and anode containing the material

InactiveCN101207204AIncrease capacityLower internal resistanceActive material electrodesSecondary cellsPolyethylene oxidePhosphate

The invention relates to lithium ion battery positive pole material, which includes lithium metal phosphate, bonding agent and electric conducting agent. The invention is characterized in that the positive pole active material also includes dispersing agent, and the dispersing agent is selected from one or more of polyacrylamide, polyacrylate, polyurethane, polyvinylpyrrolidone, polyisobutylene succimide, polyethylene oxide ether, hydroxy ethyl cellulose, dodecyl polyethylene oxide ester, fatty acid polyethylene oxide ester, alkoxy poly epoxy acrylate, poly caprolactone, polystyrene-ethylene pyrrolidone, polystyrene-N and N-divinyl acrylamide. The battery of the positive pole material provided by the invention, and the capacity, the internal resistance, charging and the heavy current discharging performance and the cycle performance of the battery are obviously improved.

Owner:BYD CO LTD

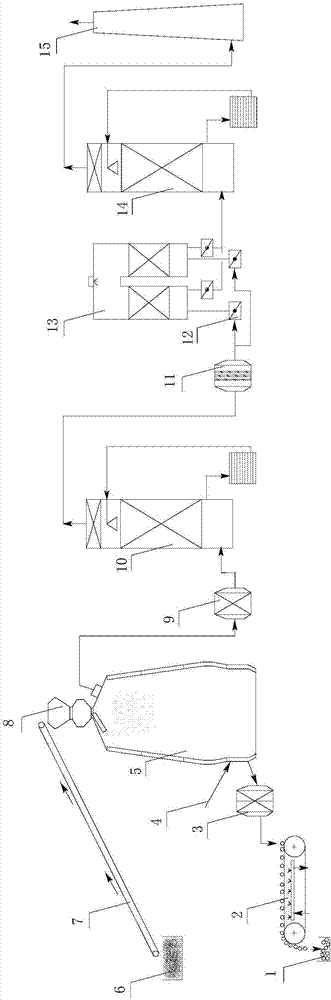

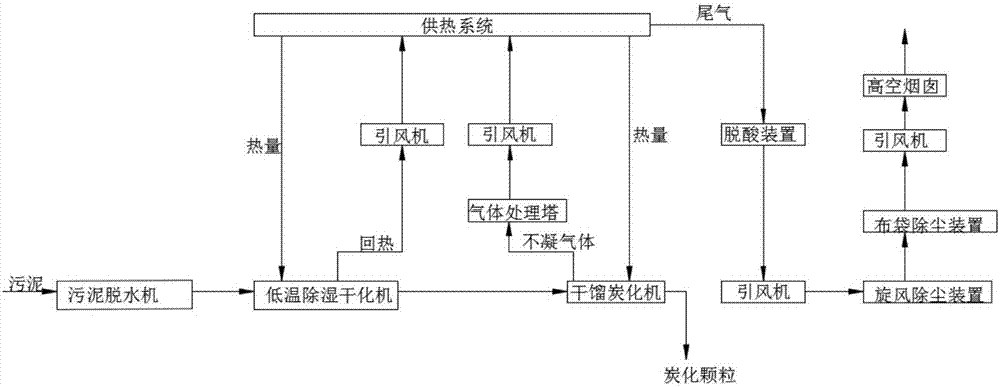

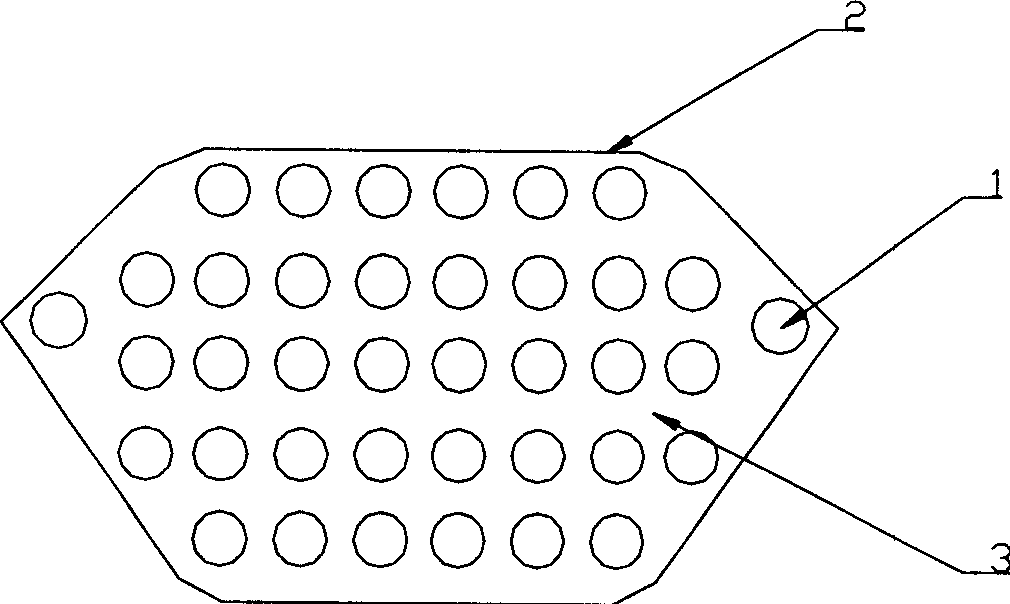

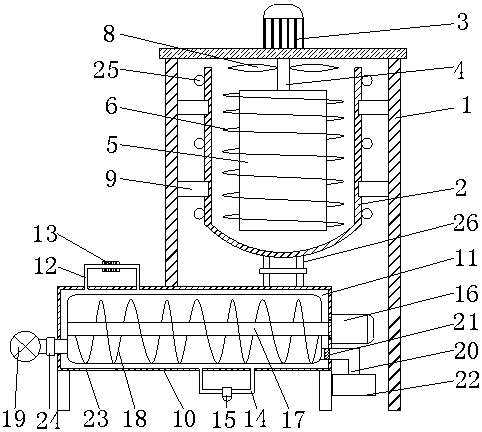

Sludge drying and carbonizing equipment and technology

PendingCN107337335AImprove energy efficiencySolve sticking problemsSludge treatment by de-watering/drying/thickeningSpecial form destructive distillationSludgeCarbonization

The invention discloses sludge drying and carbonizing equipment and technology. The equipment comprises a sludge concentration dewatering device, a low-temperature drying device, a sludge dry distillation and carbonization device, a heating system and an exhaust gas treatment system. A dehydration body, a low-temperature dehumidification dryer and a sludge carbonization main furnace are arranged sequentially in the feeding direction of a wet sludge material. Compared with an existing carbonization process, the treatment technology of the sludge of with moisture content of 95%-99.2% has the advantages as follows: a material obtained after the sludge is treated by the low-temperature drying device can directly enter the sludge dry distillation and carbonization device to be treated, a carbonization auxiliary furnace system is not needed to be added for drying and carbonizing the sludge, and accordingly, small floor area is occupied, the comprehensive investment cost is low, secondary harm to the environment is not easily produced, the energy use rate of the low-temperature drying device is higher, the problem of sludge sticking generated by a carbonization auxiliary furnace can be solved, and the equipment has higher market value and broader application fields.

Owner:上海净泥新能源科技有限公司

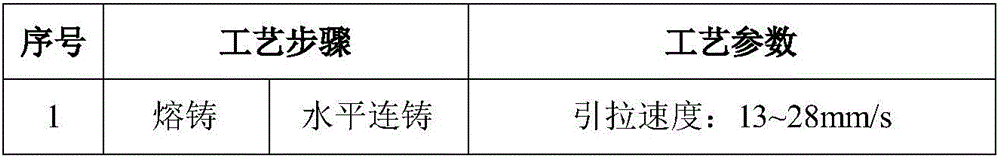

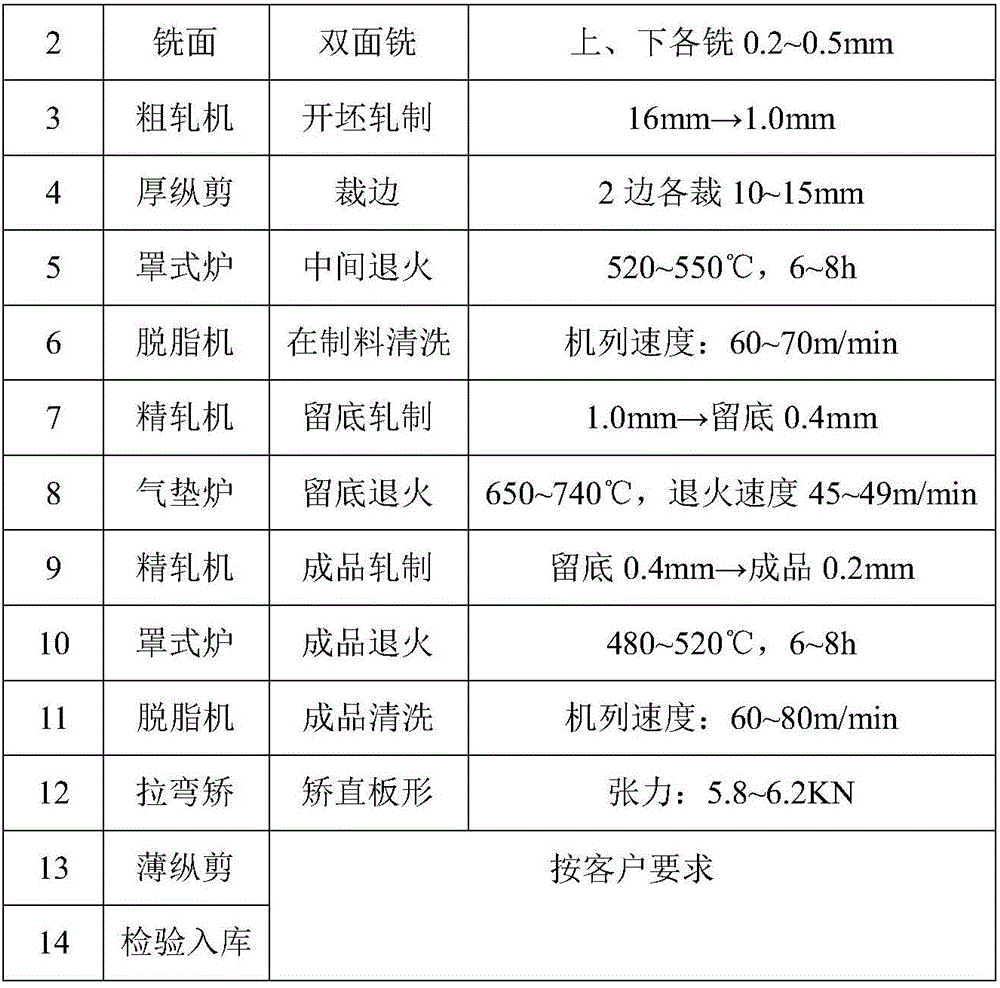

High-performance tin-phosphor bronze strip and production method thereof

The invention discloses a high-performance tin-phosphor bronze strip and a production method thereof. The high-performance tin-phosphor bronze strip comprises, by weight percent, 9% to 11% of Sn, 0.03% to 0.35% of P, not larger than 0.2% of Zn, not larger than 0.1% of Fe, not larger than 0.2% of Pb and the balance copper. Through the strict control over a casting technology, a rolling technology and an annealing technology of a tin-phosphor bronze alloy, a high-performance tin-phosphor bronze strip alloy product with the tin content ranging from 9% to 11% can be produced, and the application requirement of an IT industry and an electrommunication industry for a high-elasticity, high-strength and high-hardness copper alloy can be met.

Owner:安徽鑫科铜业有限公司

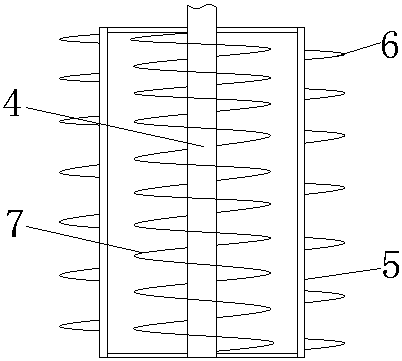

Production method of vanadium nitride

ActiveCN101948977AFacilitate the reduction reactionReduce water contentNitrogen-metal/silicon/boron binary compoundsMetallurgyVanadium nitride

The invention relates to a production method of vanadium nitride. The production method includes that: powdery vanadium oxide, carbon powder and catalyst are mixed and pressed into raw material spheres, the surface of raw material sphere is wrapped with vanadium nitride superfine powder and is added into a vertical furnace continuously, meanwhile nitrogen is introduced into the vertical furnace to be taken as reaction gas, material is heated to 1200-1600 DEG C, reduction and nitridation reactions are taken place on the material in the temperature range, time duration is less than 40-60min, and the material is cooled to certain temperature under protective atmosphere and then is taken out the furnace, thus obtaining the vanadium nitride product. The invention can solve the problem of bonding while discharging which is caused by the vertical furnace; and the invention has the advantages that production cycle is short, utilization ratio of energy and gas is high, production efficiency is high, production mode is flexible, product quality is high, and production cost is low.

Owner:江阴市中赢有色金属新材料有限公司

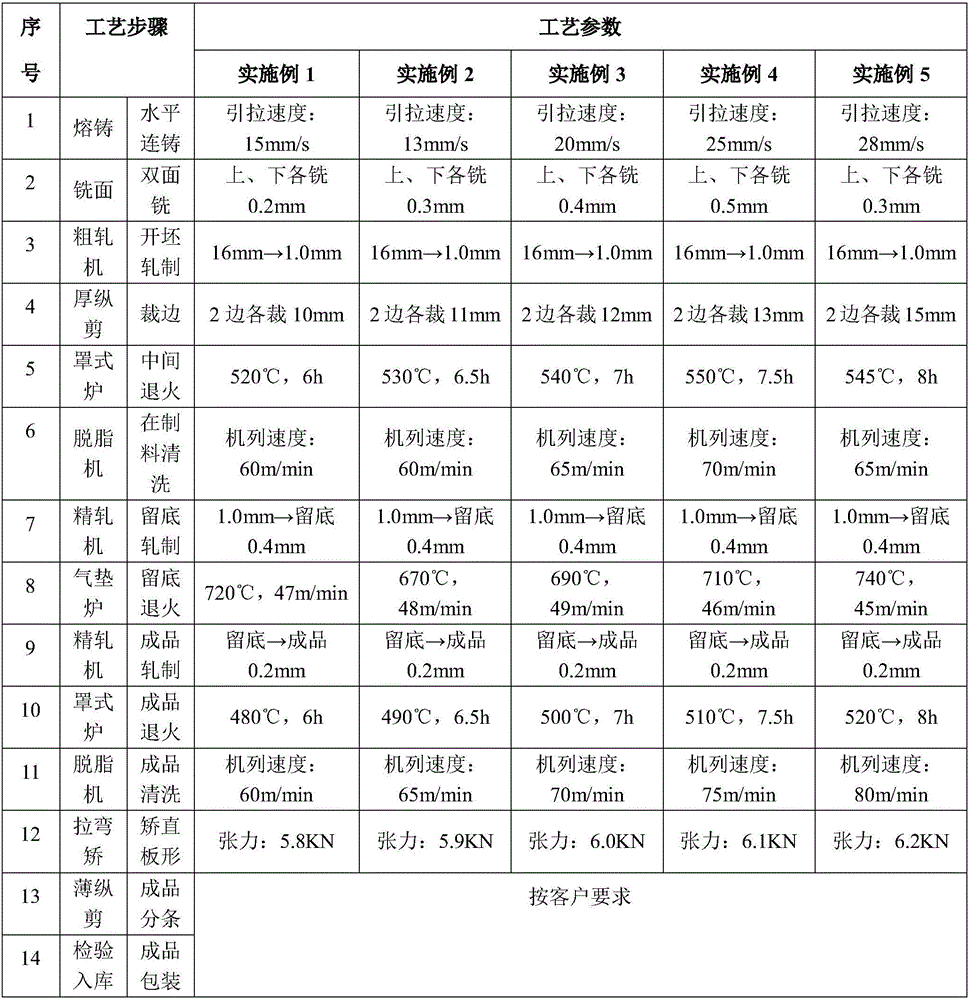

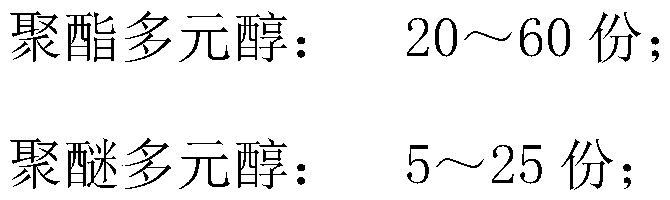

Reactive polyurethane hot melt adhesive for sealing household appliances, and preparation method thereof

ActiveCN111019582ASolve sticking problemsImprove assembly efficiencyPolyureas/polyurethane adhesivesAldehyde/ketone condensation polymer adhesivesPolyesterPolymer science

The invention discloses a reactive polyurethane hot melt adhesive for sealing household appliances. The reactive polyurethane hot melt adhesive is characterized by comprising, by weight, 20-60 parts of polyester polyol, 5-25 parts of polyether polyol, 0-15 parts of thermoplastic resin, 0-15 parts of tackifying resin, 0-5 parts of an adhesion promoter, 0-2 parts of an antioxidant, 0-2 parts of an ultraviolet light absorber, 0-0.5 part of a stabilizer, 10-40 parts of diisocyanate, 0-1 part of a catalyst and 0-5 parts of a silane coupling agent; and the polyester polyol is any one or more of crystalline polyester polyol and amorphous polyester polyol. The invention also discloses a preparation method of the reactive polyurethane hot melt adhesive. The hot melt adhesive provided by the invention effectively improves the sealing assembly efficiency of current household appliance parts, and solves the problem of bonding of the reactive polyurethane hot melt adhesive to galvanized iron and coating aluminum.

Owner:康达新材料(集团)股份有限公司

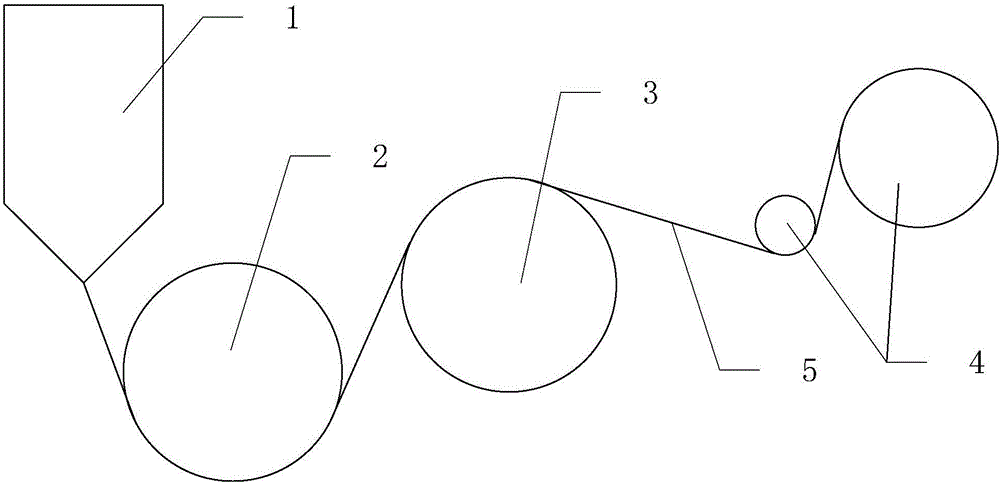

Preparation method of plain weave type wire-drawing screen cloth composite material

ActiveCN107263998AFlat surfaceLarge amount of pasteLamination ancillary operationsLaminationWeather resistanceWear resistance

The invention relates to a wire-drawing screen cloth technology, in particular to a wire-drawing screen cloth composite material and a preparation method thereof. The preparation method comprises the following steps: 1, preparing an outer-layer gray film and an inner-layer gray film, wherein the outer-layer gray film and the inner-layer gray film are melted and laminated to obtain PVC gray films; 2, respectively coating two side surfaces of plain weave type wire-drawing screen cloth with first layers of paste and then with second layers of paste, and heating and plasticizing the pasted wire-drawing screen cloth at 130 to 140 DEG C for 2 to 3 minutes; 3, laminating the upper and lower layers of PVC gray films at a nearly melted state with the wire-drawing screen cloth, so as to obtain the plain weave type wire-drawing screen cloth composite material. The plain weave type wire-drawing screen cloth composite material has the beneficial effects that the two side surfaces of the wire-drawing screen cloth are respectively coated with the paste agents, and then the wire-drawing screen cloth is laminated with the PVC gray films, so that the problem of air leakage is solved; the outer layers of the PVC gray films are modified into anti-UV layers, so that the plain weave type wire-drawing screen cloth composite material is high in weather resistance and wear resistance and high in elasticity; the inner layers of the PVC gray films can be firmly adhered with the pasted wire-drawing screen cloth.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

Manufacturing method of flexible display

ActiveCN103531722ASolve the separation problemFacilitate strippingSolid-state devicesSemiconductor/solid-state device manufacturingDisplay devicePolymer thin films

The invention discloses a manufacturing method of a flexible display, wherein the method comprises the following steps: etching a glass substrate to form a channel used for auxiliary fixation of an organic polymer thin layer, and cleaning the glass substrate; coating one face, provided with the channel, of the glass substrate with an organic polymer potion to form the flattened organic polymer thin layer; machining a TFT device on the organic polymer thin layer; machining an OLED lighting device on the TFT device; pasting a flexible packaging film used for preventing the devices from contacting air on the surface of the organic polymer thin layer provided with the OLED lighting device; and cutting the flexible packaging film along the edges of the flexible display with a designed size, and putting the glass substrate into a liquid or steam environment to enable the flexible display to fall off from the glass substrate, thereby forming the flexible display. The method provided by the invention ensures that the flexible display falls off from the glass substrate very well, operation is convenient, cost is low, and the lighting device is prevented against bad influences.

Owner:TCL CORPORATION

Preparation method of soft hygroscopic composite alginate dressing

InactiveCN106894111AGood flexibilityImprove antibacterial propertiesAbsorbent padsConjugated artificial filamentsBrown seaweedPolymer science

The invention discloses a preparation method of a soft hygroscopic composite alginate dressing. The preparation method includes: subjecting sodium alginate extracted from brown seaweed and carboxymethyl chitosan to cross-linking modification to form carboxymethyl chitosan / sodium alginate mixed liquid; adding propylene glycol alginate, stirring, and mixing well to form wet-process spinning dope; taking calcium chloride solution as solidification liquid for first solidification bath and one of zinc chloride solution, magnesium chloride solution and copper chloride solution as solidification liquid for second solidification bath for wet-spinning to obtain fiber; subjecting the fiber to needle-punched nonwoven cloth processing, slitting, packaging and sterilizing processes to obtain the soft hygroscopic composite alginate dressing. The alginate dressing prepared by the method has functions of absorbing liquid, maintaining moisture, resisting bacteria and stopping bleeding; due to spatial effect of carboxymethyl in the dressing, acting force among fiber macromolecules is weakened, so that flexibility of the fiber is enhanced, personalized needs of patients on the dressing are met better, and the alginate dressing has good application prospect.

Owner:GUANGDONG TAIBAO MEDICAL SCI TECH

Method for smelting crude lead in oxygen-enriched side-blowing smelting furnace

InactiveCN102776383AEmission reductionSimplify the melting processProcess efficiency improvementLead smeltingPhysical chemistry

The invention relates to a method for smelting crude lead in an oxygen-enriched side-blowing smelting furnace, belonging to the technical field of lead smelting. The method comprises the process steps of: 1) crude lead material preparation: proportioning lead-containing materials, quartz stones and limestone flux according to silicate degree being 0.9-1.3 percent, evenly mixing and crushing the lead-containing materials and the flux to grain size being less than or equal to 40mm; 2) crude lead smelting preparation: melting partial crude lead materials to a depth of 300-400mm in the oxygen-enriched side-blowing smelting furnace; and 3) crude lead smelting: continuously feeding the crude lead materials into a hearth and then controlling smelting air-coal ratio, temperature and high-pressure oxygen-enriched air supply, wherein molten lead sinks down and automatically flows into a furnace bed for heat preservation and storage through a siphon port, the molten lead automatically flows into a casting mold to form ingots when the depth of the stored molten lead reaches an overflow port, and the accumulated floating lean slag is discharged and is introduced into the crude lead material preparation process. The method for smelting crude lead in the oxygen-enriched side-blowing smelting furnace has the advantages that the investment is small, the smelting efficiency is high, the energy consumption is low, the arrangement is facilitated, the treatment capacity is high, the method is suitable for mass production, the materials are not required to be granulated, bricked, dried and stored, and the quantity of flue dust is small.

Owner:杨龙安

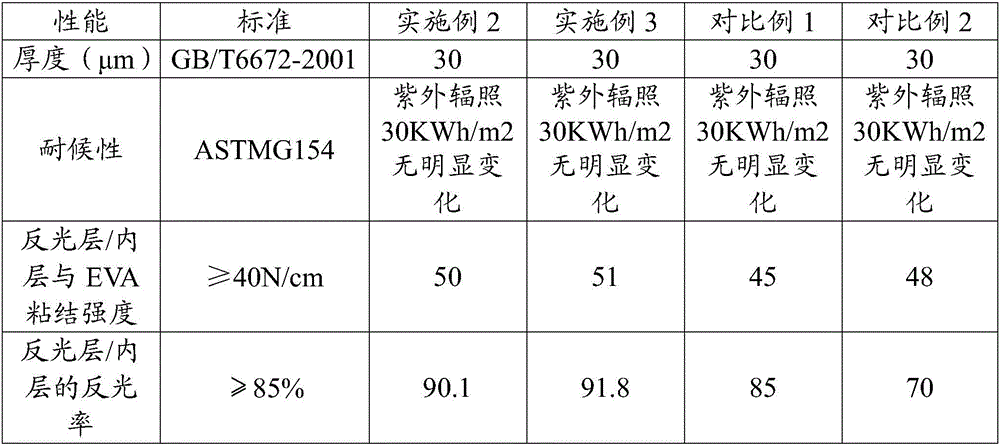

Polyvinylidene fluoride (PVDF) thin film for single-sided frosted and high-reflection solar backplate and preparation method of PVDF thin film

ActiveCN105895722ASolve sticking problemsImprove reflectivityFinal product manufactureSynthetic resin layered productsInter layerLight reflection

The invention belongs to the technical field of an optical film, in particular relates to a polyvinylidene fluoride (PVDF) thin film for a single-sided frosted and high-reflection solar backplate and a preparation method of the PVDF thin film. The PVDF thin film comprises an outer layer, an intermediate layer, an inner layer and a light reflection layer which are formed by melting extrusion and are sequentially combined from one side to the other side, the materials of the outer layer and the inner layer are polyvinylidene fluoride, one surface, far away from the intermediate layer, of the outer layer is a frosted surface, and the material of the light reflection layer is a crylic acid grafted polyvinylidene fluoride copolymer. The preparation method comprises the following steps of allowing the raw materials of the outer layer, the intermediate layer, the inner layer and the light reflection layer thin film to sequentially pass through an extruding machine, a multi-layer co-extrusion machine head, a cooling roller and a traction winding mechanism for combination and formation, wherein the cooling roller comprises a polishing roller and an embossing roller. In the technical scheme provided by the invention, the PVDF film layer is modified by introducing crylic acid graft, the problem of EVA bonding is solved, the reflective rate of a surface, close to EVA, of a backlight film is also improved, and the light utilization degree is improved.

Owner:SUZHOU GOLDEN TECH MATERIAL

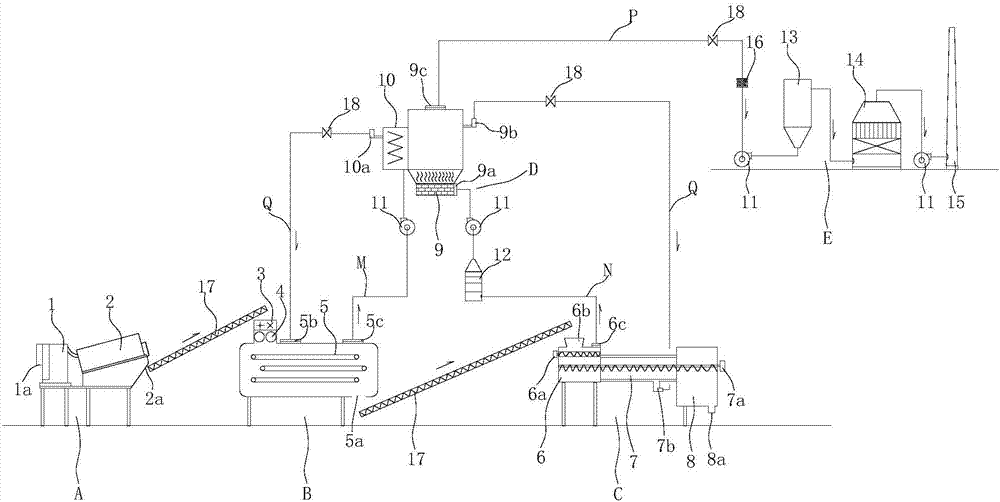

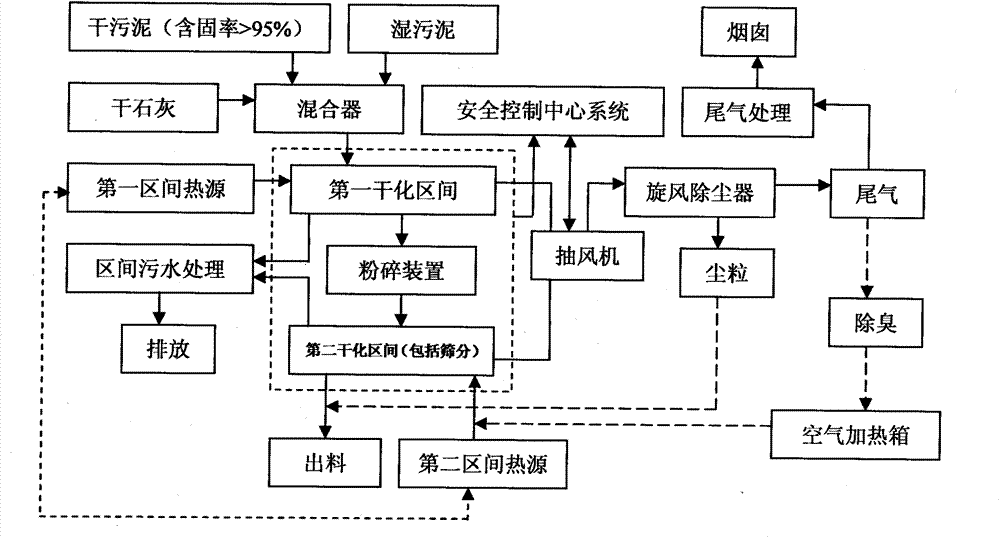

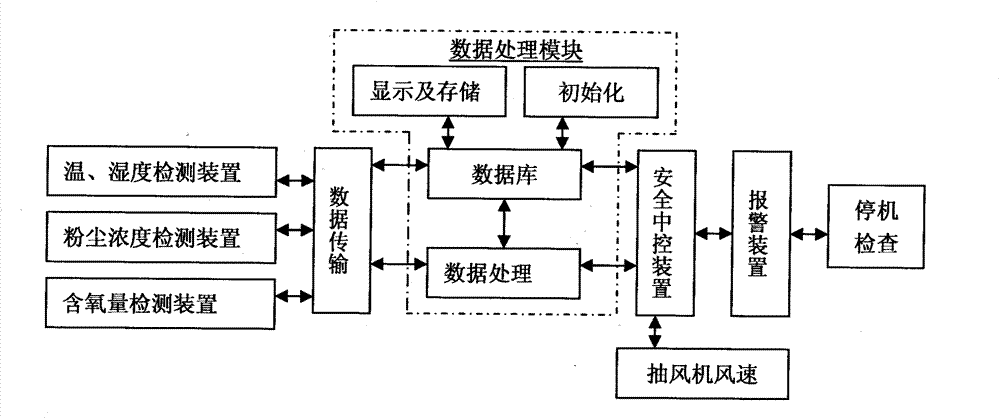

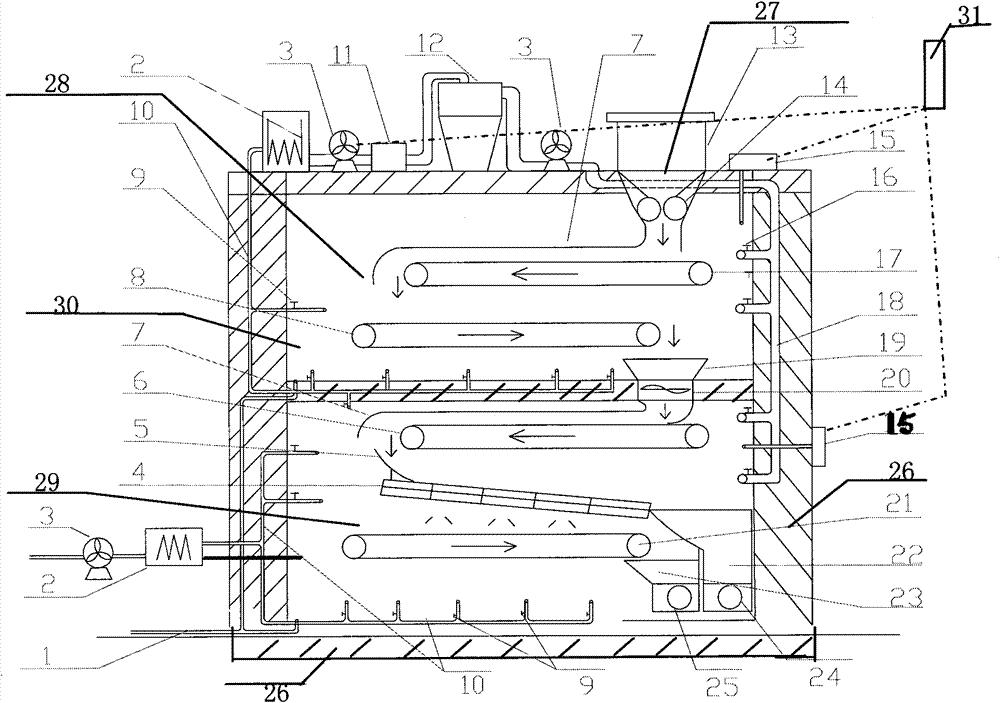

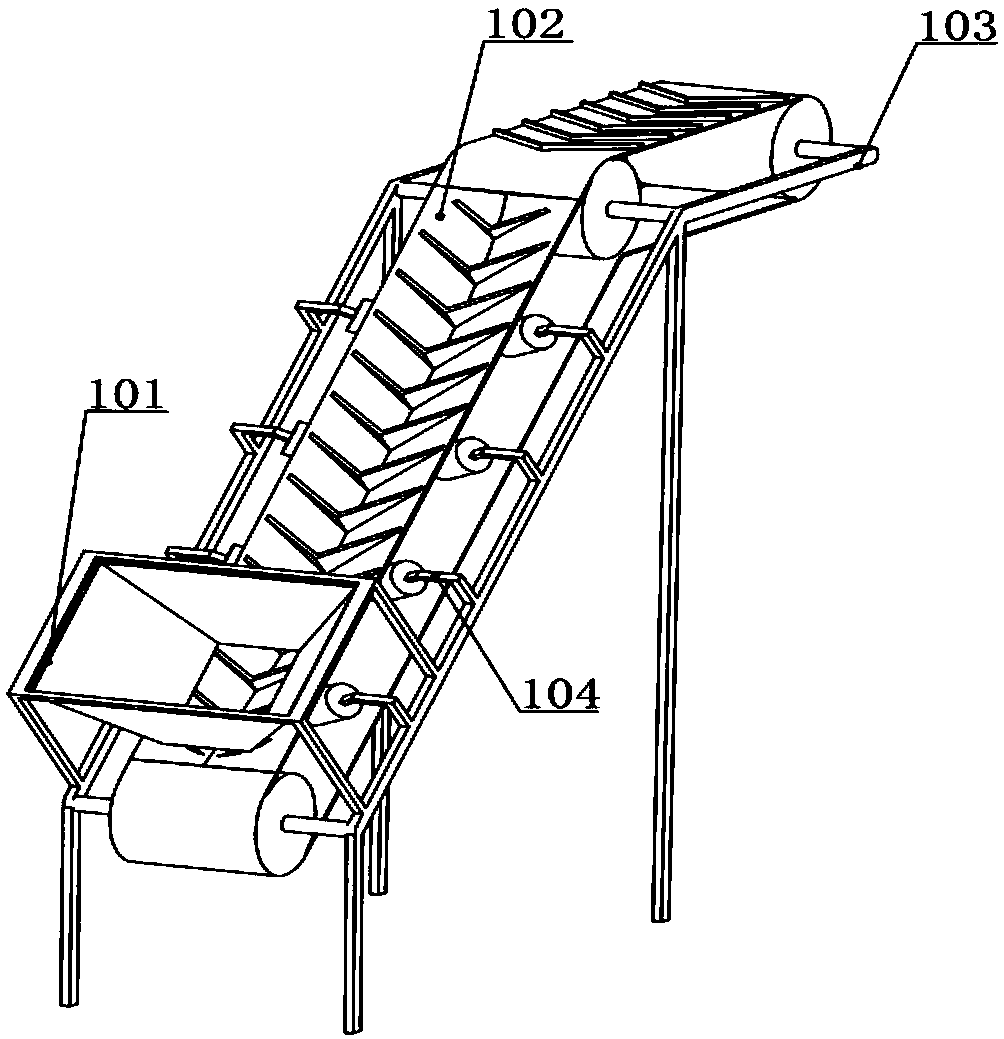

Vertical inter-partition sludge drying method and equipment with crushing and safety monitoring functions

InactiveCN103803769ASolve the costSolve cohesionSludge treatment by de-watering/drying/thickeningRefluxThermal insulation

The invention discloses a vertical inter-partition sludge drying method and equipment with crushing and safety monitoring functions. The method comprises the following steps: dividing a sludge drying process into a dried material back-mixing stage, a first drying stage, a crushing treatment stage, a second drying stage and a final screening and discharging stage, wherein the sludge drying operation is performed under monitoring of a safety monitoring system. The equipment comprises a heating box provided with multiple energy interfaces, a rolling plodder, a drying box (a crusher, a metallic screen and a conveyer belt are arranged in the drying box, and the interior of the drying box is partitioned into two intervals by a thermal insulation material and the crusher position in the middle), an exhaust fan, a dust remover, a deodorization device, a water vapor reflux pipe and is also equipped with a safety control center system. According to the sludge drying equipment, the drying method can be effectively performed. The problems of cost, adhesion and safety during sludge drying are appropriately solved, the drying efficiency is high, the discharging uniformity is high, and the sludge resource recycling value is high.

Owner:CHONGQING JIAOTONG UNIVERSITY

Wire type magnetic slot-wedge preparation process

InactiveCN1829049ASolve sticking problemsHigh bonding strengthWindingsManufacturing dynamo-electric machinesCohesive strengthUltimate tensile strength

The present invention discloses a high cohesive strength, high efficiency, low temperature rise, small iron loss and capable of continuously mechanical productive wire type magnetic wedge manufacturing method, which contains magnetic wedge adhesive preparation and wire type magnetic wedge moulding two steps. The present invention mainly solves wire, glass fabric cementing with adhesive problem, through using varnished cloth compound wire and glass fabric to replace the wire, raising cohesive strength, and solving problem s of iron loss and teeth pulsation loss increment, motor temperature rise raising, descent efficiency, electromagnetism noises increasing and poor starting performance.

Owner:上海电气集团上海电机厂有限公司

Method for preventing directly reduced metallic pellets from bonding

Belonging to the technical field of metallurgy, the invention relates to a method for preventing directly reduced metallic pellets from bonding. The method comprises the steps of: (1) mixing anthracite carbon powder, lime powder, clay and bentonite uniformly so as to prepare peritoneal powder; (2) making a material to be reduced into mineral powder pellets; (3) placing the peritoneal powder into the pelletizing disc of a pelletizer, then putting the mineral powder pellets to be reduced on the peritoneal powder in the pelletizing disc, and initiating the pelletizer so as to prepare composite pellets; (4) subjecting the composite pellets and a pulverized coal reducing agent to a reduction reaction at a temperature of 1180-1220DEG C for 3-4h, thus obtaining metallic iron pellets. The method of the invention solves the bonding problem of directly reduced metallic pellets, and is especially suitable for producing high density metallic pellets, and also especially suitable for production of metallic pellets with high grade iron ore powder.

Owner:辽宁博联特冶金科技有限公司

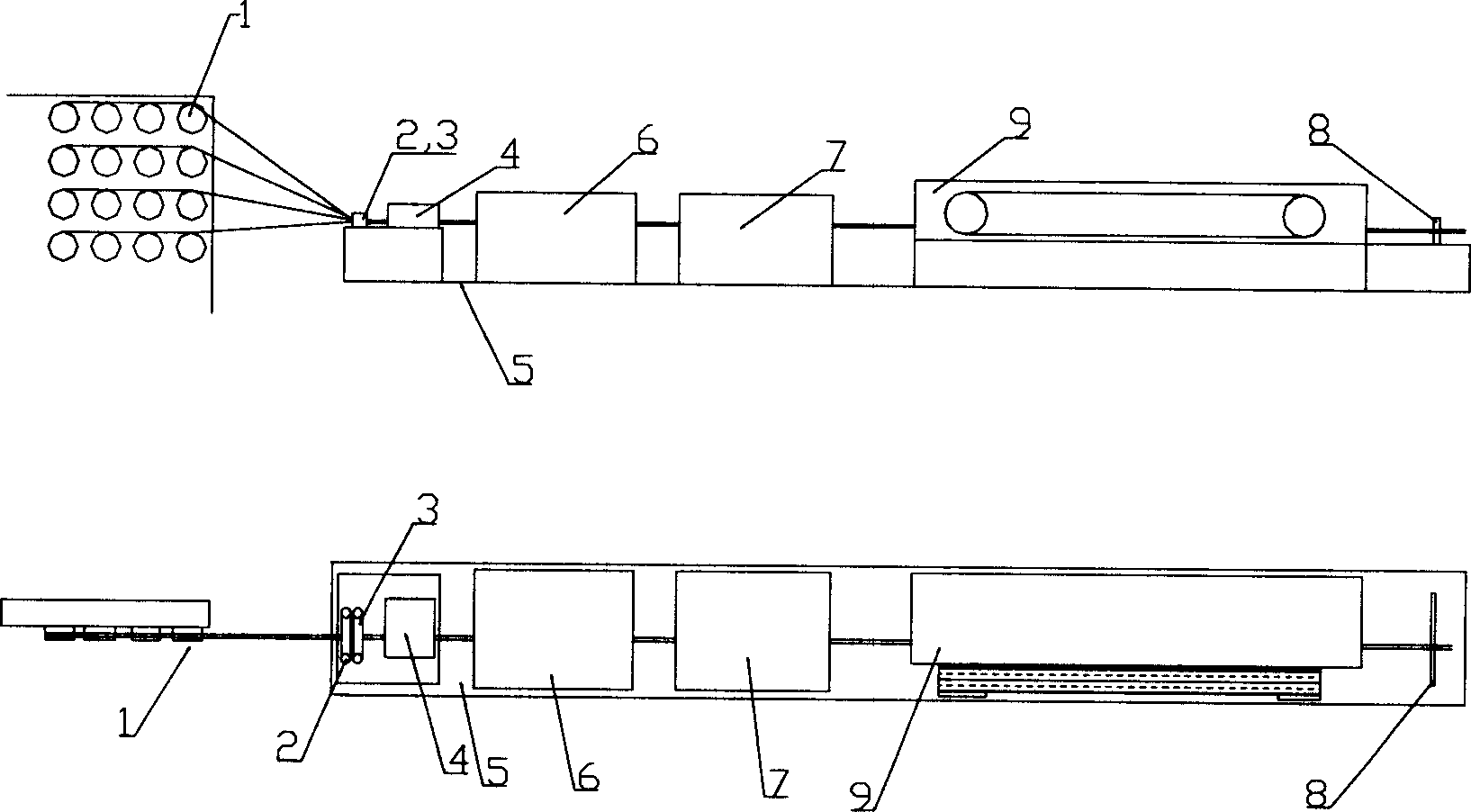

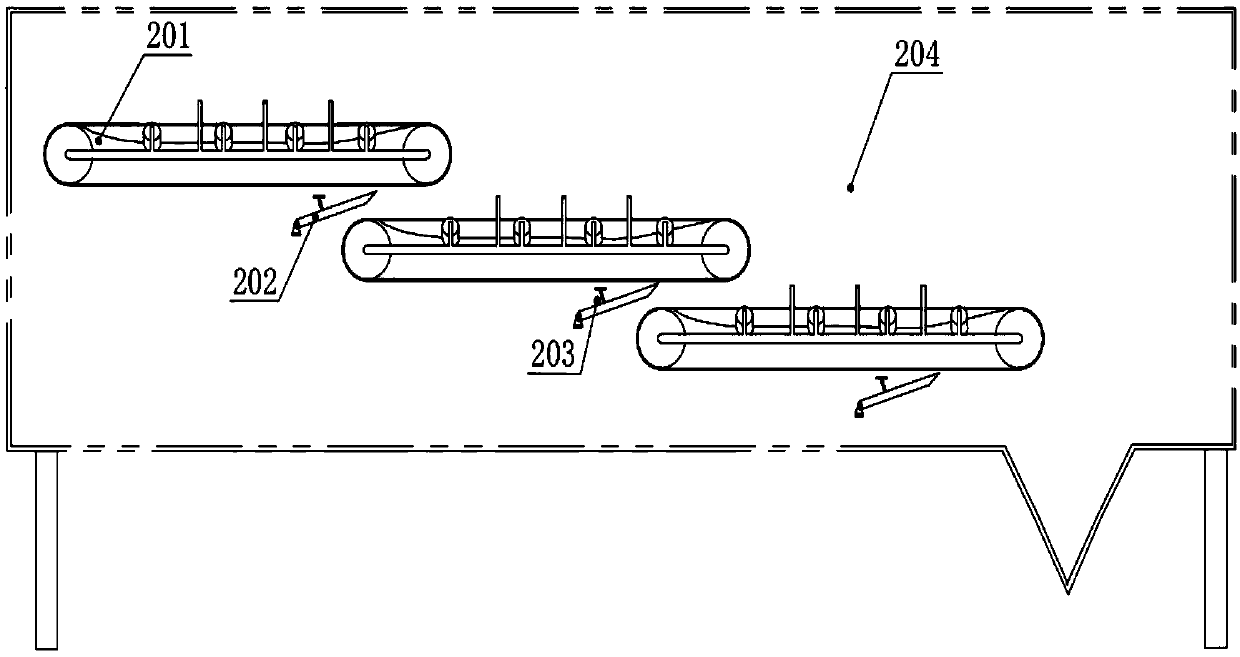

Novel low-temperature hot wind sludge drier

PendingCN109516668ASolve the problem of fouling and sludge stickingIncrease contact areaSludge treatment by de-watering/drying/thickeningGas treatmentWind circulationAir heating

The invention discloses a novel low-temperature hot wind sludge drier. The novel low-temperature hot wind sludge drier comprises a feeding uniform distribution system, a sludge drying chamber, a sludge conveying self-cleaning system, a hot wind circulation uniform distribution system and a discharging collecting system; the feeding uniform distribution system comprises a fixing frame, a feeding conveying belt arranged on the fixing frame, a loader and a roller, the loader and the roller wrapped by the feeding conveying belt are mounted on the fixing frame, and the top end of the feeding conveying belt extends into the sludge drying chamber; the sludge conveying self-cleaning system comprises a drying conveying net belt, an anti-adhesion scraping plate and a material stirring harrow, and the material stirring harrow and the anti-adhesion scraping plate are mounted above and below the drying conveying net belt respectively; the hot wind circulation uniform distribution system sequentially comprises a dust removing device, a dehumidifying device and an air heating device; the discharging collecting system comprises a material collecting groove formed in the bottom of the sludge dryingchamber and an unloading door arranged at the bottom of the material collecting groove. The novel low-temperature hot wind sludge drier can effectively solve the problems that dust accumulates on theconveying net belt and the conveying net belt is adhered in the sludge drying process, and has the functions of dust removal and dehumidification.

Owner:HUNAN UNIV +1

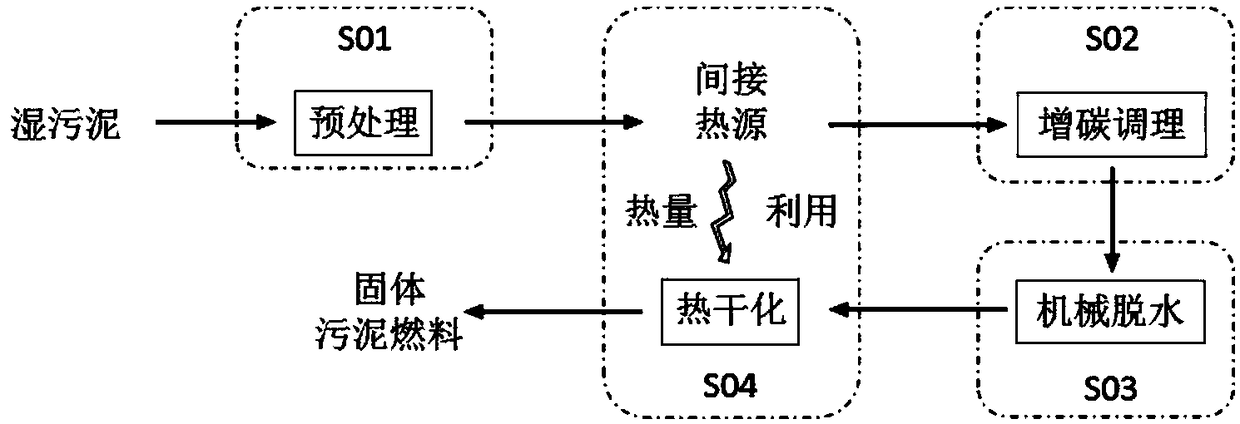

Method simultaneously for moisture removal and solid fuel preparation from sludge and products

ActiveCN108358421AChange fuel propertiesLower ignition pointSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningBound waterSludge

The invention provides a method simultaneously for moisture removal and solid fuel preparation from sludge. The method comprises the following steps: step S01: subjecting wet sludge to pretreatment under heating so as to obtain heat conditioned sludge; step S02: cooling the heat conditioned sludge so as to obtain cold sludge, adding a carburetting conditioning agent into the cold sludge, and carrying out uniform mixing so as to obtain carburetted conditioned sludge; step S03: subjecting the carburetted conditioned sludge to dehydration treatment; and step S04: subjecting the dehydrated carburetted conditioned sludge to heat drying so as to obtain a solid sludge fuel. Through combined application of a heat conditioning process and a conditioned sludge sensible heat direct utilization systemin pretreatment of the sludge, the method provided by the invention avoids the problem of excessively high energy consumption, and integrates advantages like improvement of sulfur-fixing, chlorine-fixing, nitrogen-fixing and phosphorus-fixing abilities of modified heat-conditioned sludge and reduction of the content of bound water in a reasonable energy consumption range.

Owner:HUAZHONG UNIV OF SCI & TECH

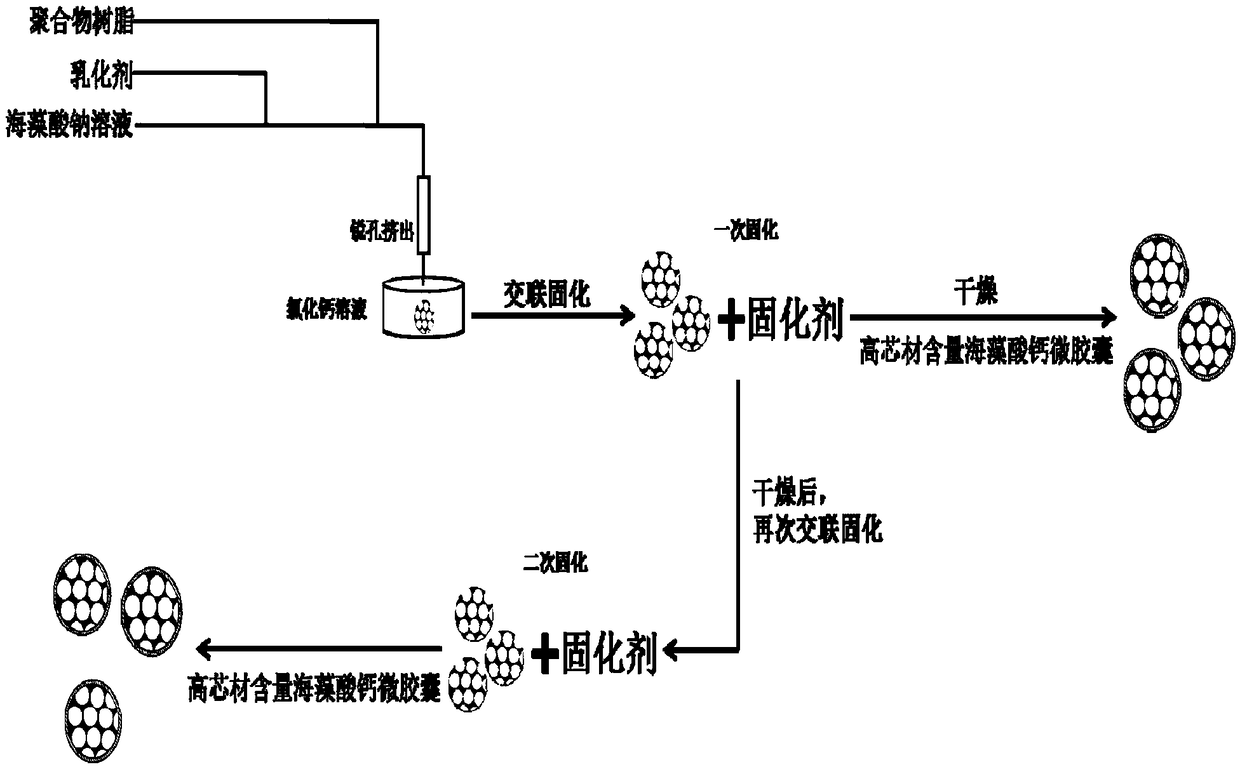

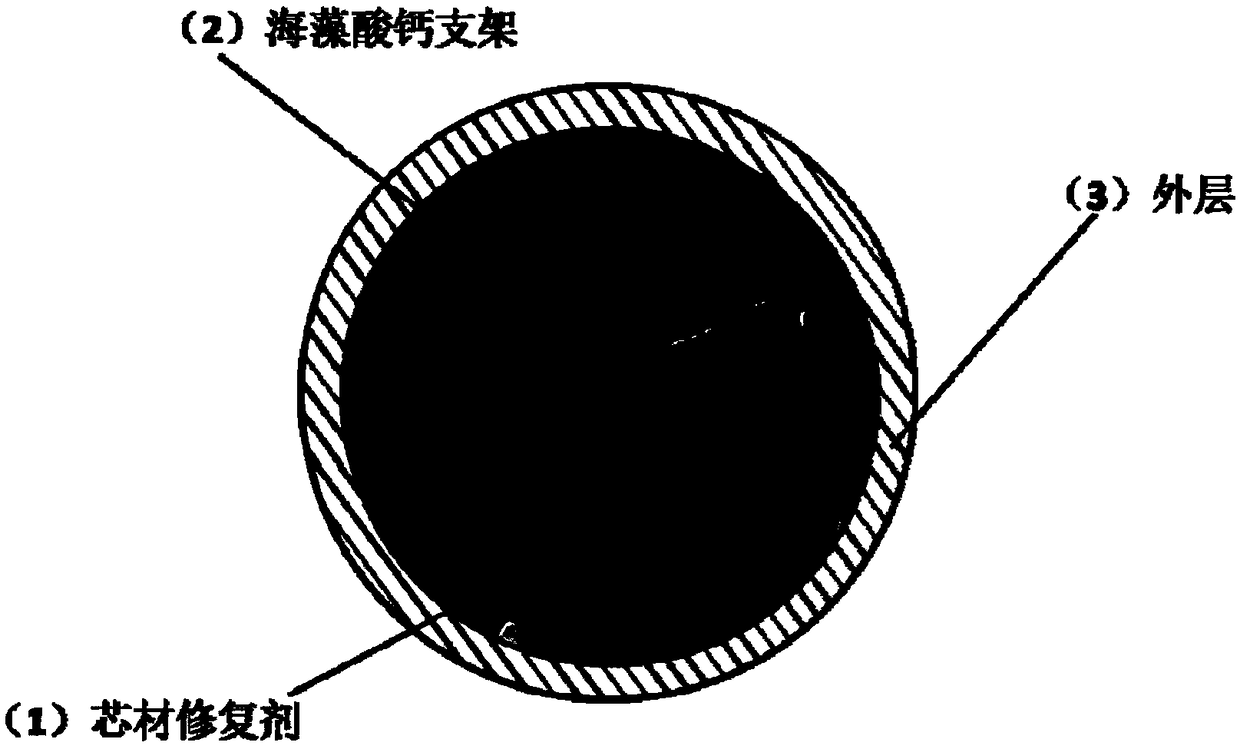

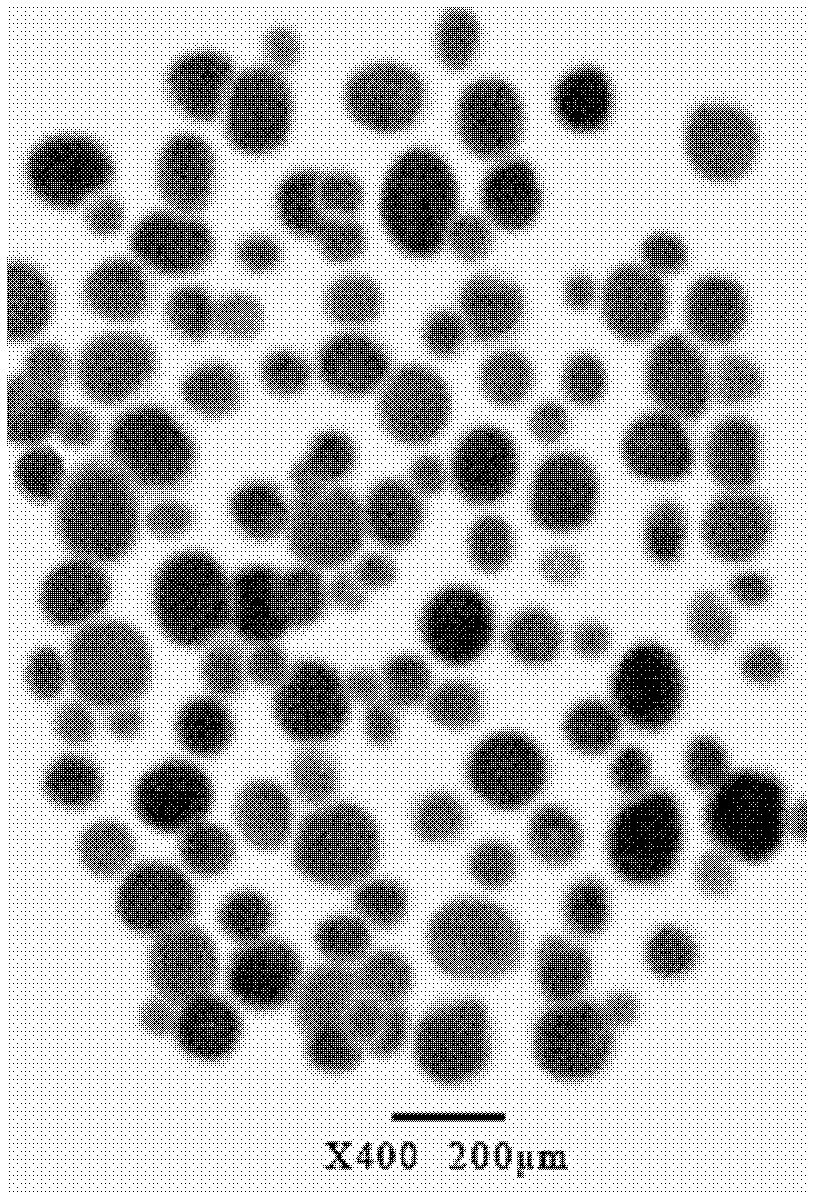

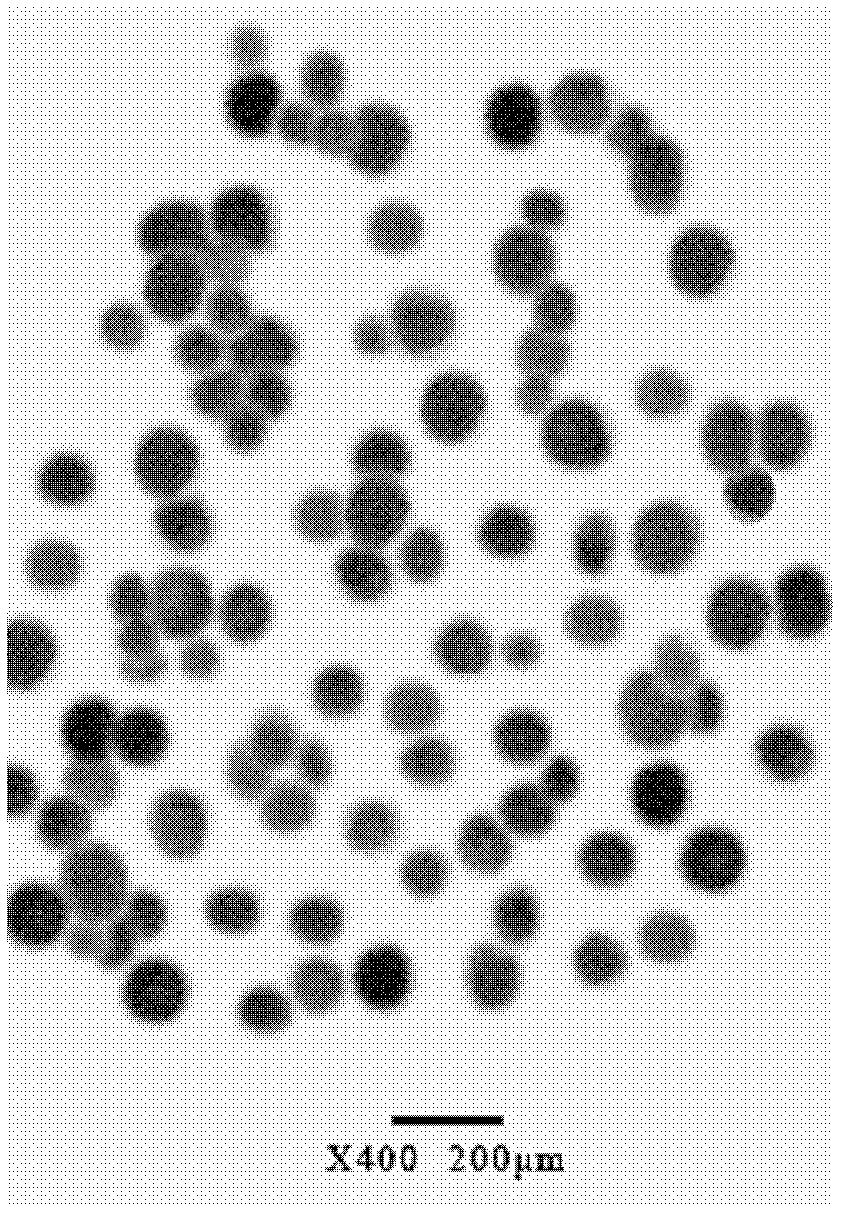

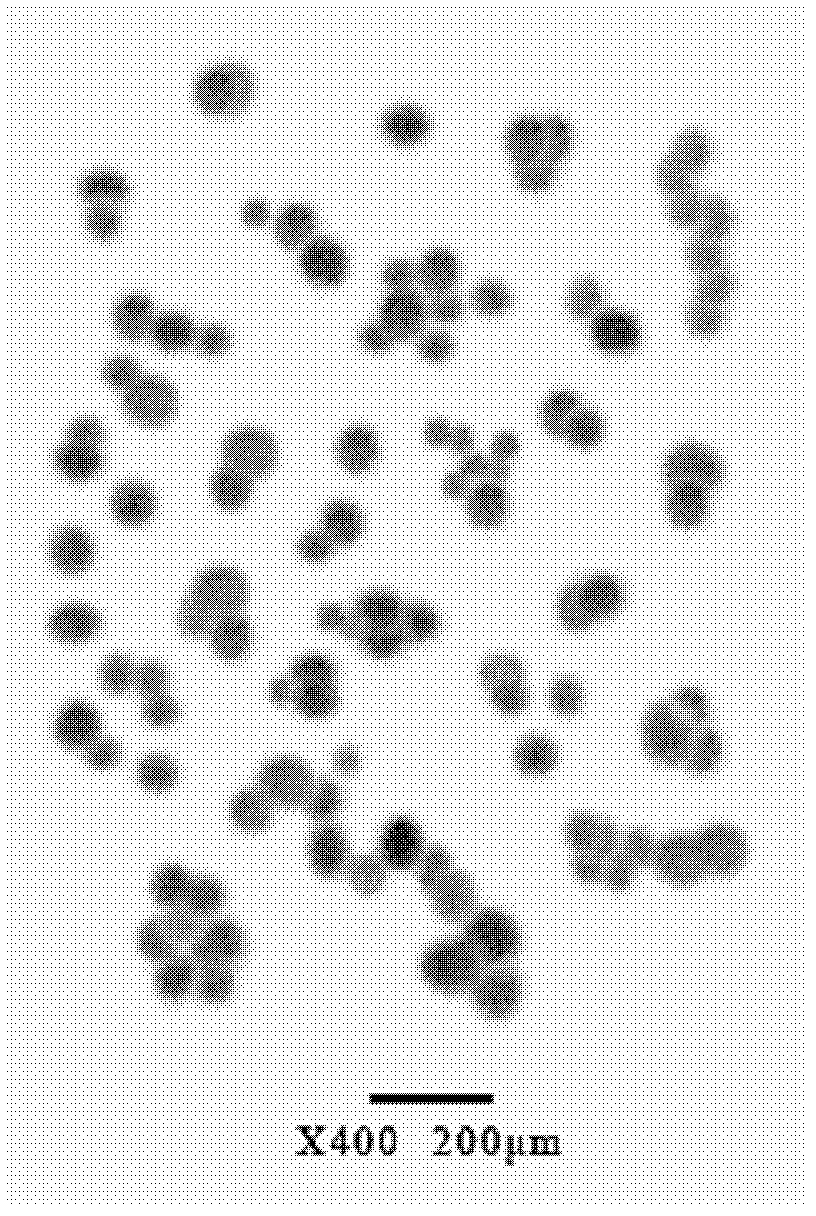

Calcium alginate microcapsule with high core material content

ActiveCN109250940ASolve the problem of fragmentationReduce interfacial voidsPolymer sciencePolymer resin

The invention relates to a calcium alginate microcapsule with high core material content. The calcium alginate microcapsule with high core material content comprises a polymer outer layer, a calcium alginate bracket and a core material repairing agent. Curable polymer resin is the core material repairing agent and fills interconnected channels of the calcium alginate bracket; an outermost layer isa cured polymer resin layer. The preparation method comprises the steps: firstly, primarily prepared calcium alginate microcapsules with high core material content are prepared by a sharp hole-coagulation bath method; secondly, the outer-layer polymer resin is cured to obtain the calcium alginate microcapsule with high core material content and with the structure. The microcapsule has water absorption and controllable volume swelling rate, has the content of the polymer core material of 65%-95%, and can be used for self-repairing of cracks in a cement matrix.

Owner:BEIJING UNIV OF TECH

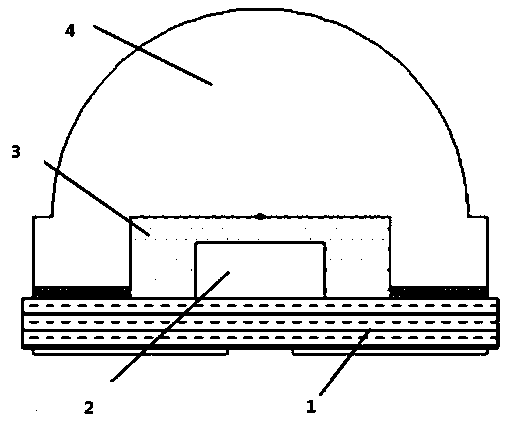

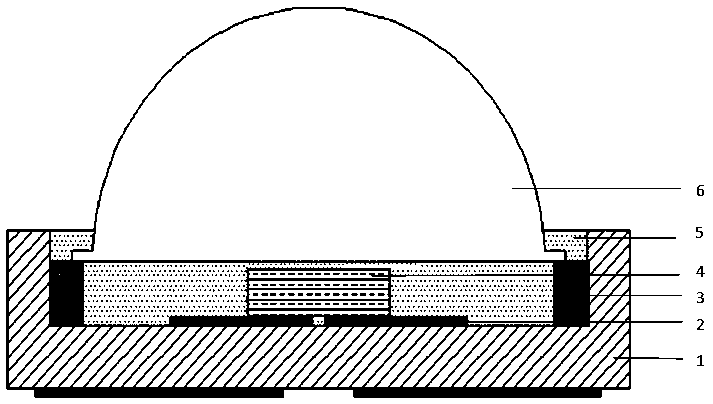

Ultraviolet light source packaging element

PendingCN110915006ANo air entrapmentEfficient exclusionSaving energy measuresSemiconductor devicesUltraviolet lightsFluorine containing

An ultraviolet light source packaging element comprises a base frame, an optical element and an LED chip. A groove is formed in the center of the base frame, and the LED chip is fixed at the bottom inthe groove; the groove part below the optical element is filled with the fluorine-containing resin, which covers part of the upper surface the optical element by filling a through hole structure in the optical element or a gap formed between the edge of the optical element and the inner side wall of the groove. The through hole structure in the optical element or the gap formed between the edge of the optical element and the inner side wall of the groove is filled to cover part of the upper surface of the optical element; on one hand, the fluorine-containing resin is put into a packaging bodyin a liquid form, gas generated in the curing process can be discharged through the through hole and the gap, and residual bubbles are avoided as much as possible; on the other hand, the fluorine-containing resin covers part of the outer surface of the optical element to form a buckling effect, and the reliability is improved.

Owner:QUANZHOU SANAN SEMICON TECH CO LTD

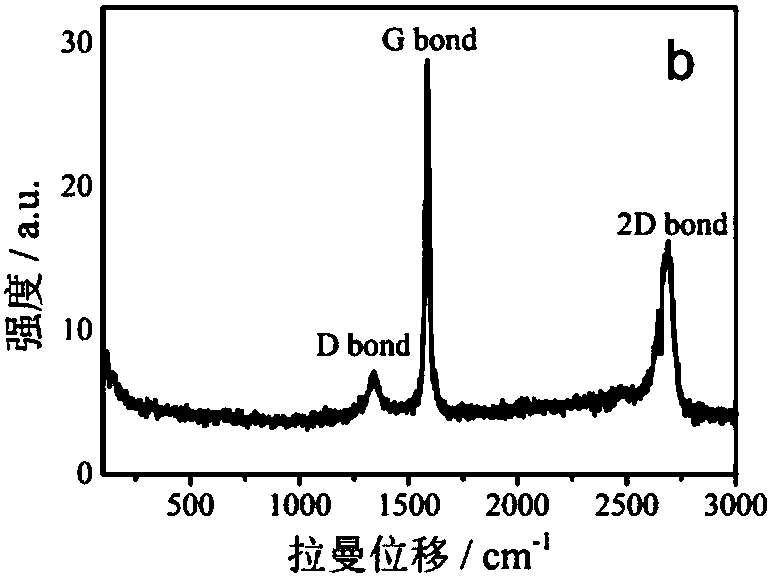

Preparation of intermediate-temperature graphene/silver composite conductive slurry and application thereof

InactiveCN108305702AGood chemical stabilityImprove conductivityConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersMetallurgyBond properties

The graphene has high chemical stability, high electrical conductivity and high mechanical flexibility. However, after the graphene is dispersed in a conductive slurry, bridge connection type contactbetween layers of the graphene can not be formed easily and thus a perfect conductive path can not be formed easily; and a large contact resistance exists at the layer connection part, so that the surface resistance of the conductive coating can not be reduced easily. According to the invention, graphene prepared by a liquid phase ultrasonic stripping method and nano silver powder are used as conductive fillers and low-temperature glass powder is used as a binder; the graphene, the low-temperature glass powder, and other organic solvents and additives are fixed to prepare a graphene / silver composite conductive slurry having the high-temperature bonding property; the conductive slurry is coated on the surface of a ceramic sheet; and after sintering for a period of time at a high temperature, a graphene / silver composite conductive coating having the excellent bonding force and excellent electrical conductivity is formed on the surface of the ceramic sheet.

Owner:林荣铨

Traditional Chinese medicine decoction piece drying machine

PendingCN108592563APlay the role of stirring and dryingDry evenlyDrying gas arrangementsDrying solid materialsSpiral bladeEngineering

The invention discloses a traditional Chinese medicine decoction piece drying machine. The traditional Chinese medicine decoction piece drying machine comprises a support and a stirring bucket; a first motor is arranged on the top of the support, the output end of the first motor is fixedly connected with a rotating shaft, a fan blade is fixedly connected to the outer surface of the rotating shaft, the bottom of the fan blade is provided with an inner cylinder fixedly connected to the rotating shaft, the outer surface of the inner cylinder is fixedly connected with an outer spiral blade, the interior of the inner cylinder is provided with an inner spiral blade fixedly connected to the surface of the rotating shaft, a heat exchange pipe is fixedly connected to the outer surface of the stirring bucket, the bottom of the stirring bucket is fixedly connected with a conveying pipe, the bottom of the conveying pipe is fixedly connected with a drying cylinder, and the inner wall of the dryingcylinder is fixedly connected with a circular water pipe. Through the first motor, the rotating shaft, the heat exchange pipe, the fan blade, the inner cylinder, the outer spiral blade, the inner spiral blade, the circular water pipe, a temperature rise pipe, a heater, a power pipe and a water pump, the problems that drying is not uniform, after packaging, bonding is prone to happening, drying isnot thorough, and the production efficiency of traditional Chinese medicine decoction pieces is reduced are solved.

Owner:新乡市雷公饮片有限责任公司

Method for producing iron ore concentrate by magnetizing and reducing limonite through biomass

The invention discloses a method for producing iron ore concentrate by magnetizing and reducing limonite through biomass, and belongs to the technical field of production of iron ore concentrate from low-grade limonite. The method comprises the following steps of: weighing raw materials of low-grade limonite, biomass raw material powder and an initiating additive in a weight ratio of 100:(10-30):(0.5-4), and uniformly mixing; and roasting the mixed material at the temperature of between 400 and 600DEG C, and performing dry-process or wet-process magnetic separation on roasting sand to obtain the iron ore concentrate. In the method for preparing fine iron powder by magnetizing and reducing lean iron ore through biomass, renewable energy of biomass replaces coal to reduce and magnetize the lean iron ore, the lean iron ore resources widely distributed in China can be utilized, the reduction temperature can be reduced to below 600 DEG C when the biomass is adopted for reduction, the problem of caking of silicate in the reduction process is prevented, equipment manufacture and maintenance are facilitated, the investment is saved, and the aims of saving energy and reducing production cost are fulfilled.

Owner:TSINGHUA UNIV

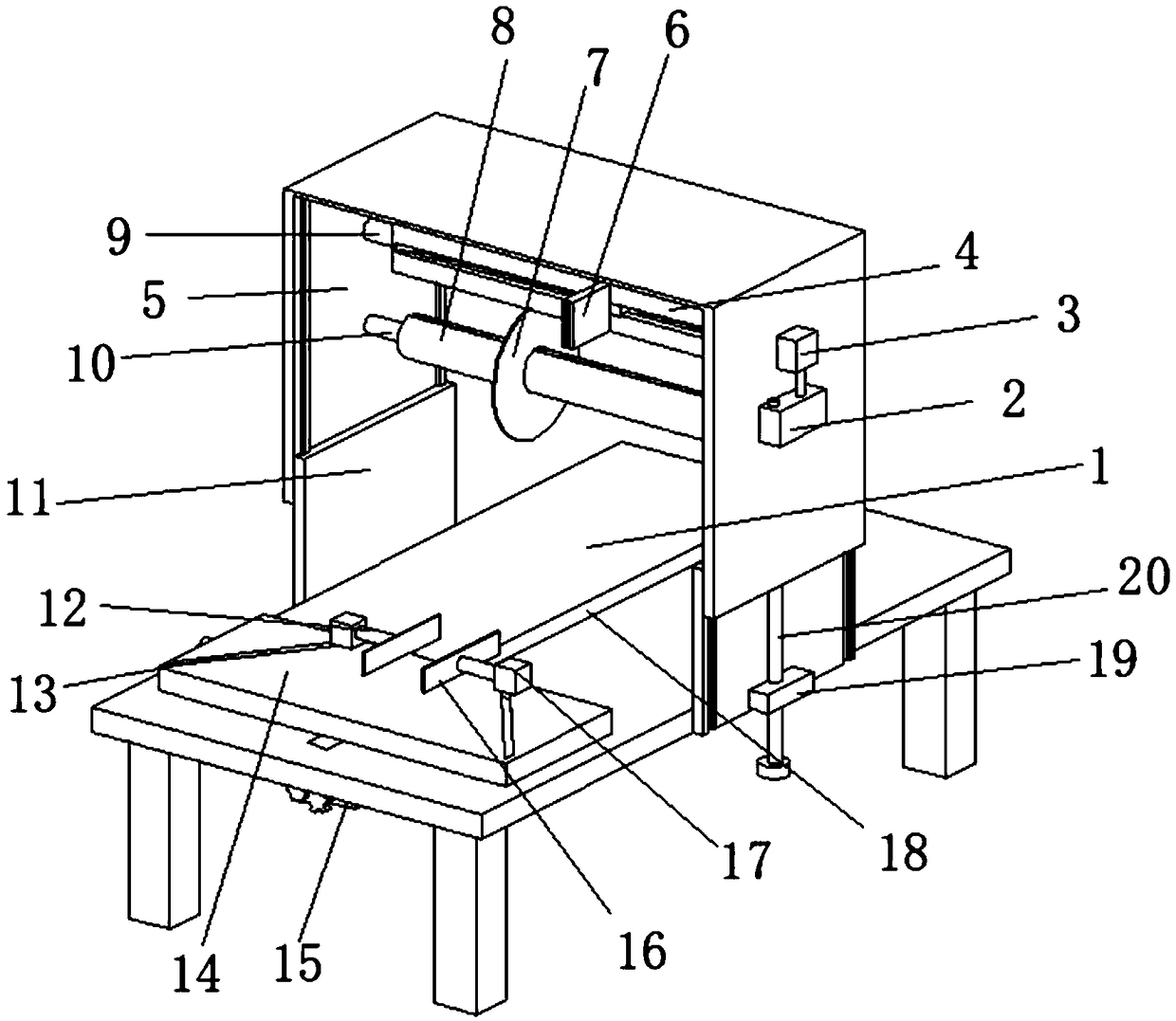

Anti-sticking pastry slicer

The invention discloses an anti-sticking pastry slicer. The anti-sticking pastry slicer comprises a workbench; a through slot is horizontally arranged at the middle of an upper surface of the workbench; a slider at the bottom of a tray is in sliding connection with the interior of the through slot; a nut fixing block is arranged on a lower surface of the slider at the bottom of the tray; the nut fixing block is in threaded connection with a side of a lead screw; both left and right ends of the lead screw are respectively connected with lead screw fixing blocks at both left and right ends of the bottom of the workbench via bearings; a lead screw gear is arranged at the left end of the lead screw; a conveyor motor is arranged at the left end of the bottom of the workbench; a conveyor motor gear is arranged on an output shaft of the conveyor motor; the conveyor motor gear is meshed with the lead screw; and support plates are respectively arranged at the middle of both the front and rear sides of the workbench. The anti-sticking pastry slicer is easy to operate, high in practicability, and capable of cleaning up residues on a slicer as well as preventing adhering of the residues on theslicer.

Owner:安徽品滋味食品股份有限公司

Calcium carbonate, rubber and polyvinyl chloride composition and preparation method thereof

InactiveCN102321313AStable physical and mechanical propertiesImprove impact performancePhysical chemistryPolyvinyl chloride

The invention provides a calcium carbonate, rubber and polyvinyl chloride composition and a preparation method thereof; the composition comprises the following components by weight: 100 parts of initial composition of calcium carbonate and rubber, and 50-200 parts of polyvinyl chloride. The preparation process of the invention is simple; the cost is greatly reduced; the impurities in the product are less; polyvinyl chloride particles are used as a physical isolating agent, which solves the problem of bonding of the initial composition during drying; the drying process is simple and practical, avoids the pollution and energy consumption of large drying equipment; the cost is effectively controlled; the composition of the invention is applicable to polyvinyl chloride toughening modification, can increase the impact strength of polyvinyl chloride from 3.7 kJ / m2 to 48 kJ / m2 while the tensile strength and flexural modulus are almost maintained constant.

Owner:SHANGHAI HUAMING HI TECH GRP +1

Automobile dash board sound insulation pad making process

ActiveCN104908393AHigh strengthSolve sticking problemsLamination ancillary operationsSynthetic resin layered productsUltrasonic weldingManufactured material

The invention relates to an automobile dash board sound insulation pad making process. The process comprises the main steps of (1) carrying out host press molding on a felt layer; (2) carrying out plastic sucking molding on an EVA layer; (3) adhering the felt layer and the EVA layer; (4) carrying out PU foam molding; (5) carrying out hot press molding on a PVC sponge layer; (6) carrying out ultrasonic welding; and (7) cutting by a water jet scalpel. According to the process, the sound insulation pad making process is optimized, the sound insulation pad making speed is high, the sound insulation pad making efficiency is high, the precision is good, the made sound insulation pad integrates the advantages of various raw materials, and the sound absorption performance, the sound insulation performance, the heat insulation performance and the ageing resistance can be greatly improved.

Owner:JIANGSU QISHENG MODERN NEW MATERIAL

Method for preparing carrageenan fibers with alkaline dissolution process

ActiveCN102304772ALow viscosityReduce heating and insulation requirementsWet spinning methodsSpinning solutions preparationFiberPolymer science

The invention discloses a method for preparing carrageenan fibers with an alkaline dissolution process. The method comprises the following steps of: (1) adding carrageenan to aqueous alkali with the concentration of 2-8mol / L, and stirring and dissolving at room temperature to obtain carrageenan aqueous alkali with the mass percentage concentration of 3-10%; (2) filtering and defoaming the carrageenan aqueous alkali to obtain a spinning solution; (3) spinning the filtered and defoamed spinning solution into a coagulation bath at the room temperature and a spinning speed of 10-80m / min through awet spinning machine, coagulating and drawing to obtain insoluble carrageenan fibers, and washing, dehydrating and drying the carrageenan fibers to obtain fiber materials. According to the method forpreparing the carrageenan fibers with the alkaline dissolution process, the carrageenan is dissolved by the aqueous alkali, and all operations can be carried out at the room temperature, thus the requirements on temperature rise and heat insulation of the spinning device are largely reduced, and the problems of spinneret plate stoppage due to gelatinization and the fiber adhesion during post-treatment can be solved; and in addition, the flexibility and the glossiness of the obtained fibers are largely higher than the flexibility and the glossiness of the water-soluble spinning fibers.

Owner:青岛源海新材料科技有限公司

Environmental protection type printable top sheet of laminated molding card, preparation method and application

InactiveCN1727202AFlat surfaceHigh bonding strengthDuplicating/marking methodsEngineeringCompanion animal

An environment protection type printable surface film for certificate card is composed of a surficial protecting layer (polyethanediol tere-phthalate (PET) film) and a functional printing-adhering layer containing special osmotic cross-linking assistant. Its advantages are high adhesion and transparency, and high print clearness.

Owner:上海浮托实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com