Calcium alginate microcapsule with high core material content

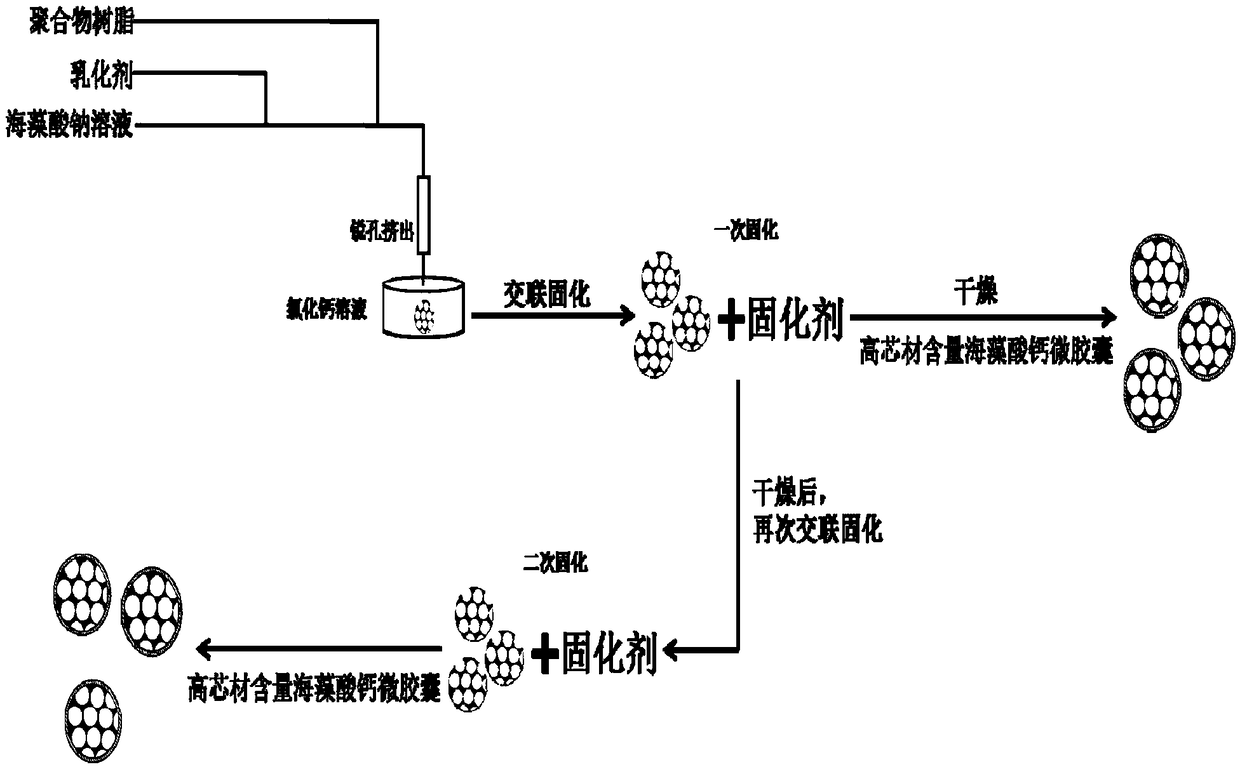

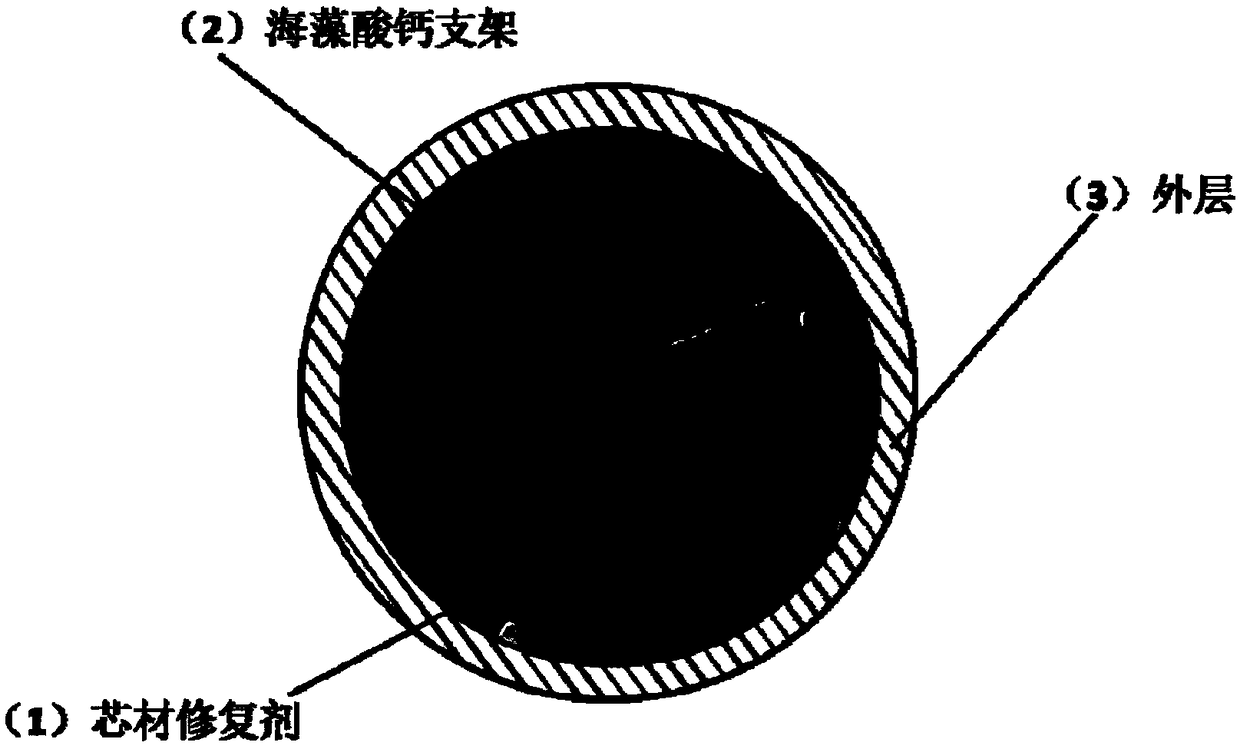

A technology of calcium alginate and microcapsules is applied in the field of concrete crack repair, which can solve the problems of microcapsules bonding and difficult to disperse, and achieves the effects of maintaining integrity, reducing influence and reducing interface voids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Weigh 17.5 g of sodium alginate solid, add it to 500 mL of deionized water, stir, and after the sodium alginate solid is completely dissolved, a 0.035 g / mL sodium alginate solution is obtained;

[0036] In a water bath at 55°C, add the above-mentioned sodium alginate solution and 1.875g of sodium dodecylbenzenesulfonate to the four-necked flask and stir; then add 75.0g of E-51 bisphenol A epoxy resin, and stir at a speed of 600r / min Stir for 1.5 hours, and get epoxy resin-sodium alginate mixture after cooling.

[0037] (2) Weigh 9.0g of calcium chloride solid and add it to 300mL of deionized water. After the calcium chloride is completely dissolved, a 0.03g / mL calcium chloride solution is obtained; drip the mixed solution obtained in step (1) through a syringe Add it to the above calcium chloride solution, and after the dropwise addition, continue to react for 3 hours to obtain primary calcium alginate microcapsules.

[0038] (3) Take out the primary calcium algina...

Embodiment 2

[0043](1) Weigh 7.5g of sodium alginate solid, add it to 500mL of deionized water, stir, and after the sodium alginate solid is completely dissolved, a 0.015g / mL sodium alginate solution is obtained;

[0044] In a water bath at 55°C, add the above-mentioned sodium alginate solution and 0.375g of sodium dodecylbenzenesulfonate to the four-necked flask and stir; then add 150.0g of E-51 bisphenol A epoxy resin, and stir at a speed of 600r / min Stir for 1.5 hours, and get epoxy resin-sodium alginate mixture after cooling.

[0045] (2) Weigh 3.0 g of calcium chloride solid, add it to 300 mL of deionized water, and after the calcium chloride solid is completely dissolved, obtain a 0.01 g / mL calcium chloride solution; pass the mixed solution obtained in step (1) through a syringe Add it dropwise into the above calcium chloride solution, and after the dropwise addition is completed, continue to react for 3 hours to obtain primary calcium alginate microcapsules.

[0046] (3) Take out t...

Embodiment 3

[0051] (1) Weigh 7.5g of sodium alginate solid, add it to 500mL of deionized water, stir, and after the sodium alginate solid is completely dissolved, a 0.015g / mL sodium alginate solution is obtained;

[0052] In a water bath at 55°C, add the above-mentioned sodium alginate solution and 2.00 g of emulsifier to the four-necked flask and stir; then add 85.0 g of 531 urea-formaldehyde resin glue, stir at a stirring speed of 600 r / min for 1.5 h, and obtain urea-formaldehyde resin-seaweed after cooling Sodium acid mixture.

[0053] (2) Weigh 7.5g of calcium chloride solid and add it to 300mL deionized water. After the calcium chloride solid is completely dissolved, a 0.025g / mL calcium chloride solution is obtained; pass the mixed solution obtained in step (1) through a syringe Add it dropwise into the above calcium chloride solution, and after the dropwise addition is completed, continue to react for 3 hours to obtain primary calcium alginate microcapsules.

[0054] (3) Take out t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com