Method for preparing graphene nano-composite energetic material through atomic-layer deposition technology

A technique of atomic layer deposition and nanocomposite, applied in the direction of nanotechnology, metal material coating process, coating, etc., can solve the problem of inability to control the affinity and spatial arrangement of metal fuel and oxidant, lack of effective distribution and load density Control and other issues, to achieve the effect of easy realization and promotion, improved spatial arrangement and affinity, and complete combustion reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

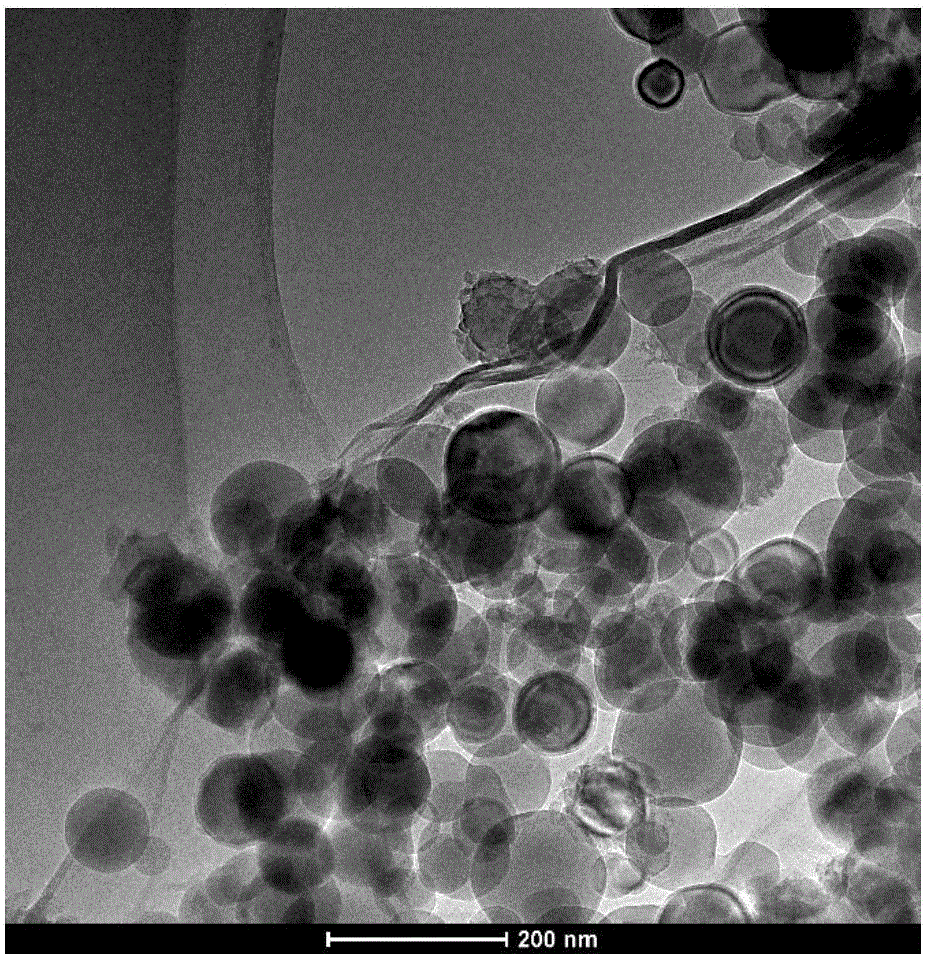

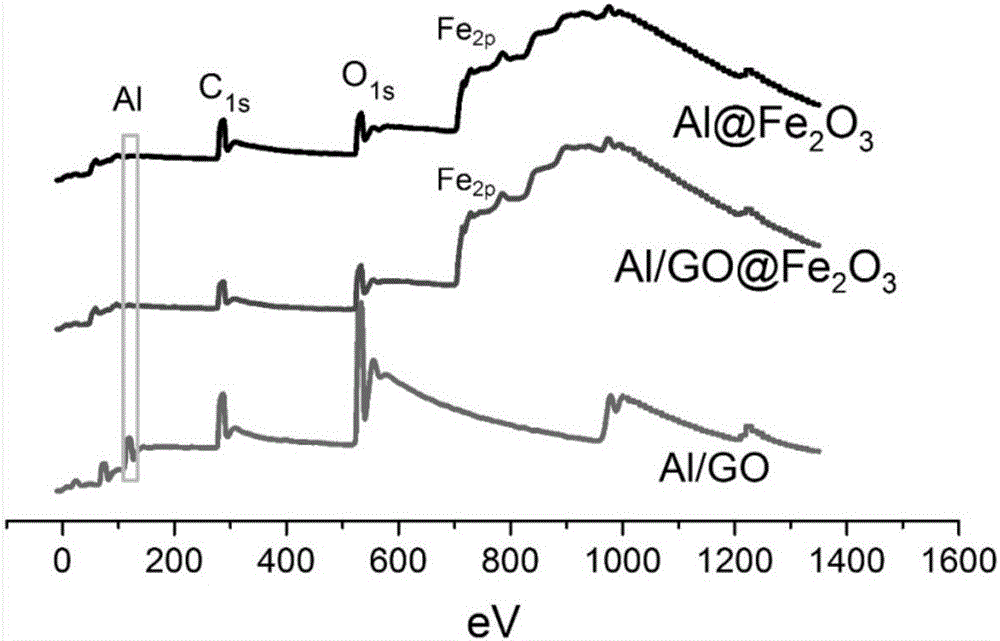

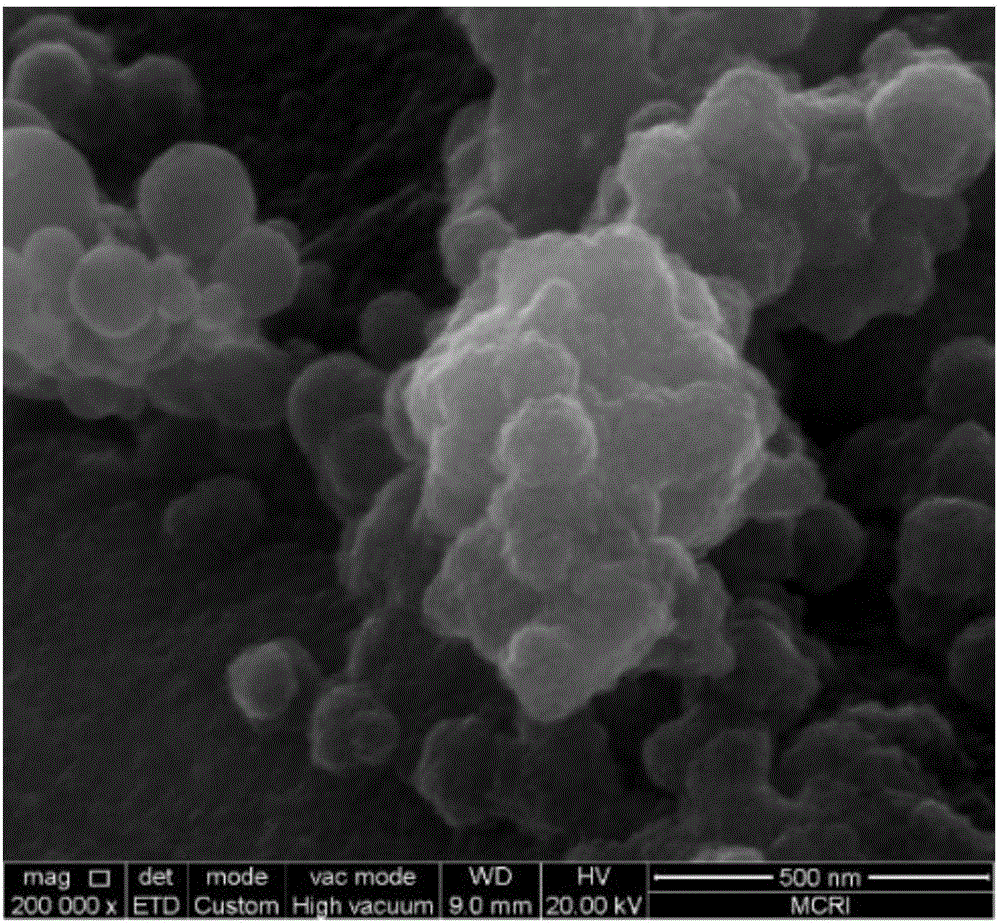

[0039] This embodiment provides a method for preparing a graphene-loaded nano-aluminum powder composite energetic material by atomic layer deposition technology, and the method specifically includes the following steps:

[0040] Step 1: Preparation of graphene-supported nano-aluminum powder

[0041] (1) Add 0.1 g of graphene oxide and 100 g of N,N-dimethylformamide into an ultrasonic reactor, and obtain graphite oxide at an ultrasonic power of 1000 W, a frequency of 200 Hz, a temperature of 60 ° C, and an ultrasonic dispersion time of 2 hours. Alkene suspension.

[0042] (2) Prepare N,N-dimethylformamide (100g) and isopropanol (100g) as a co-solvent, add 2g of nano-aluminum powder into the co-solvent, and disperse with the aid of ultrasound. The ultrasonic power is 1000W and the frequency is 200Hz. The temperature was 60° C., and the ultrasonic dispersion time was 2 hours to obtain a stable dispersed nano-aluminum powder suspension. Add 100 g of graphene oxide suspension to ...

Embodiment 2

[0057] This example provides a method for preparing a graphene-loaded nano-aluminum powder composite energetic material by atomic layer deposition technology. Step 1 of the method is the same as Step 1 in Example 1, except for Step 2.

[0058] Step 2: Preparation of graphene nanocomposite energetic materials by atomic layer deposition

[0059] The graphene-supported nano-aluminum powder is placed in the reaction chamber of the vapor phase atomic layer deposition system, and the reaction chamber is sealed. Nitrogen gas was introduced into the vapor deposition system and vacuumed, the pressure was controlled at 133Pa, and the temperature was controlled at 200°C.

[0060] Atomic layer deposition is performed on graphene-supported nano-aluminum powder to form a coating film. A cycle of atomic layer deposition growth includes the following four steps:

[0061] (1) Inject tris(2,2,6,6-tetramethyl-3,5-heptanedionate bismuth) Bi(thd) into the reaction chamber 3 , so that it will und...

Embodiment 3

[0069] This example provides a method for preparing a graphene-loaded nano-aluminum powder composite energetic material by atomic layer deposition technology. Step 1 of the method is the same as Step 1 in Example 1, except for Step 2.

[0070] Step 2: Preparation of graphene nanocomposite energetic materials by atomic layer deposition

[0071] The graphene-supported nano-aluminum powder is placed in the reaction chamber of the vapor phase atomic layer deposition system, and the reaction chamber is sealed. Nitrogen was introduced into the vapor deposition system and vacuumed, the pressure was controlled at 133 Pa, and the temperature was controlled at room temperature.

[0072] A cycle of atomic layer deposition of graphene-supported nano-aluminum powder includes the following four steps:

[0073] (1) Inject the first precursor tin tetrachloride (SnCl 4 ) to make it complex with graphene-loaded nano-aluminum powder

[0074] A saturated surface chemical reaction occurs on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com