Patents

Literature

48results about How to "Full combustion reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

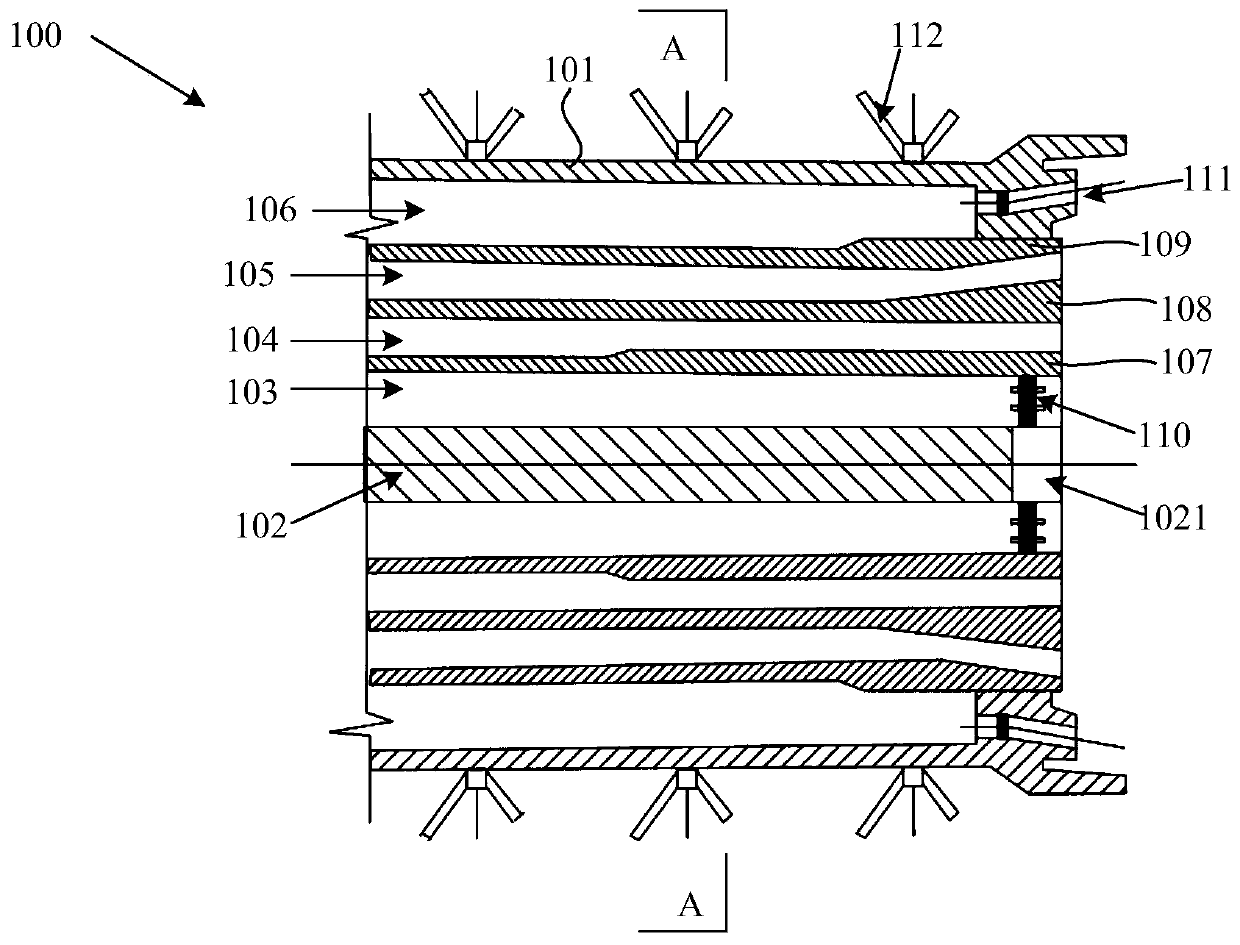

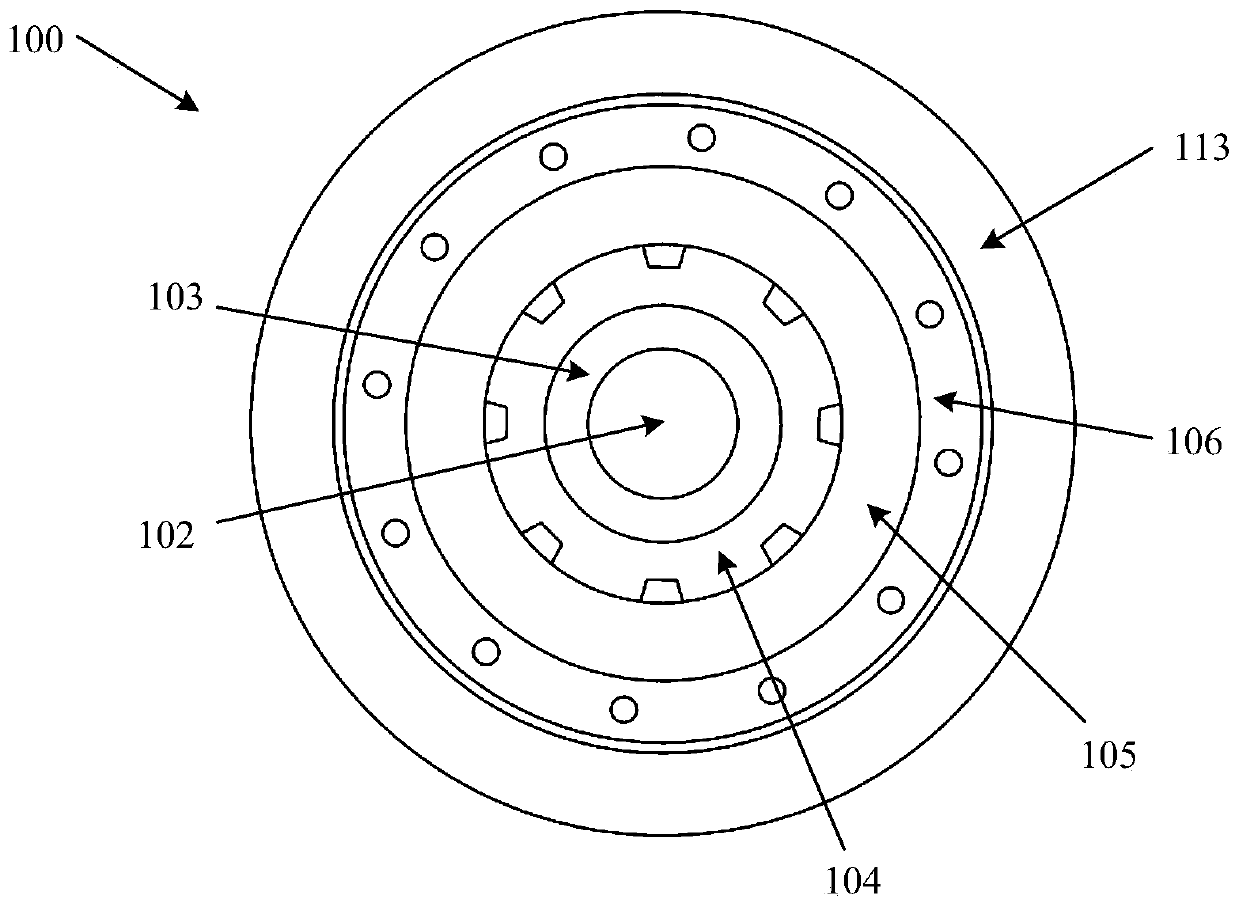

Combustor for treating waste gas and waste liquid of dinitrogen tetroxide and hydrazine propellants and control method

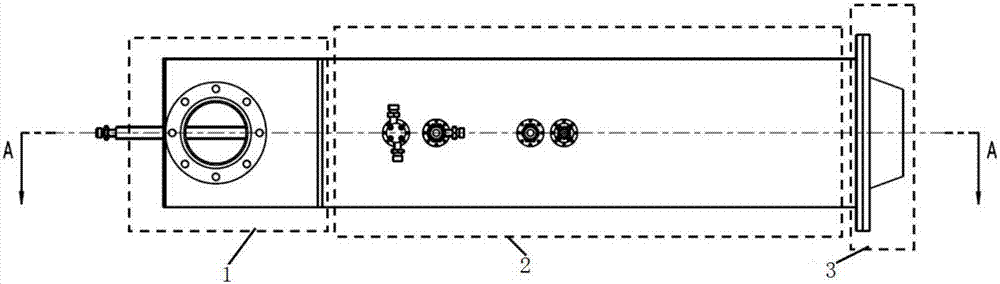

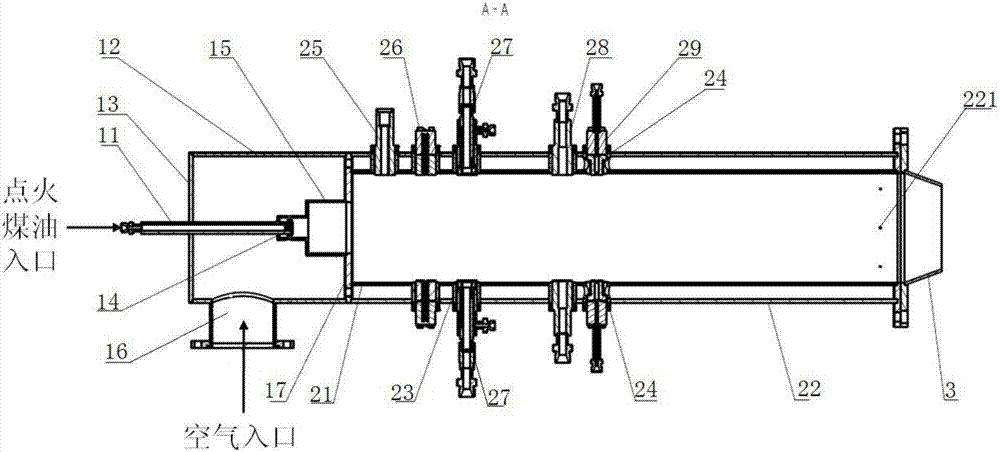

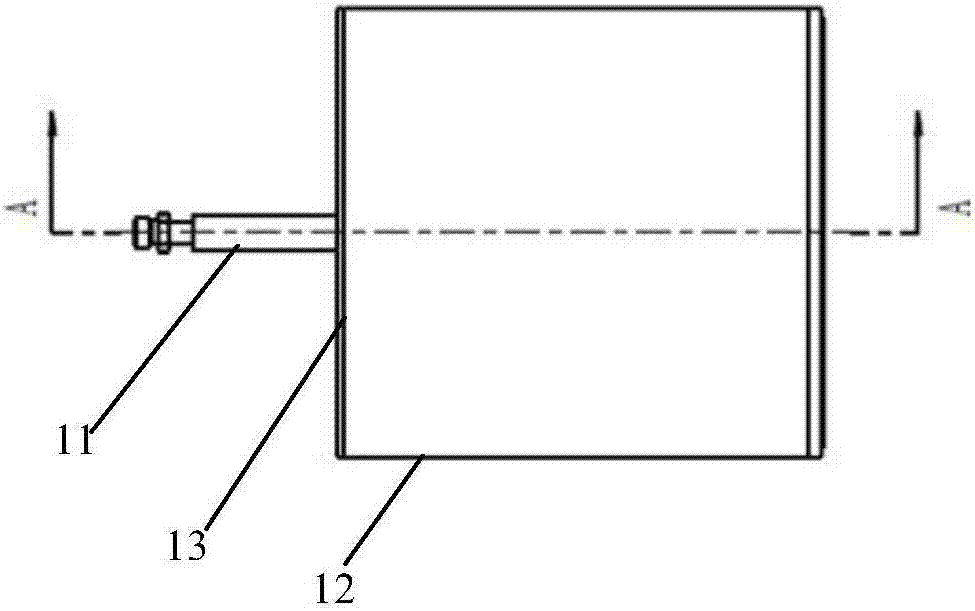

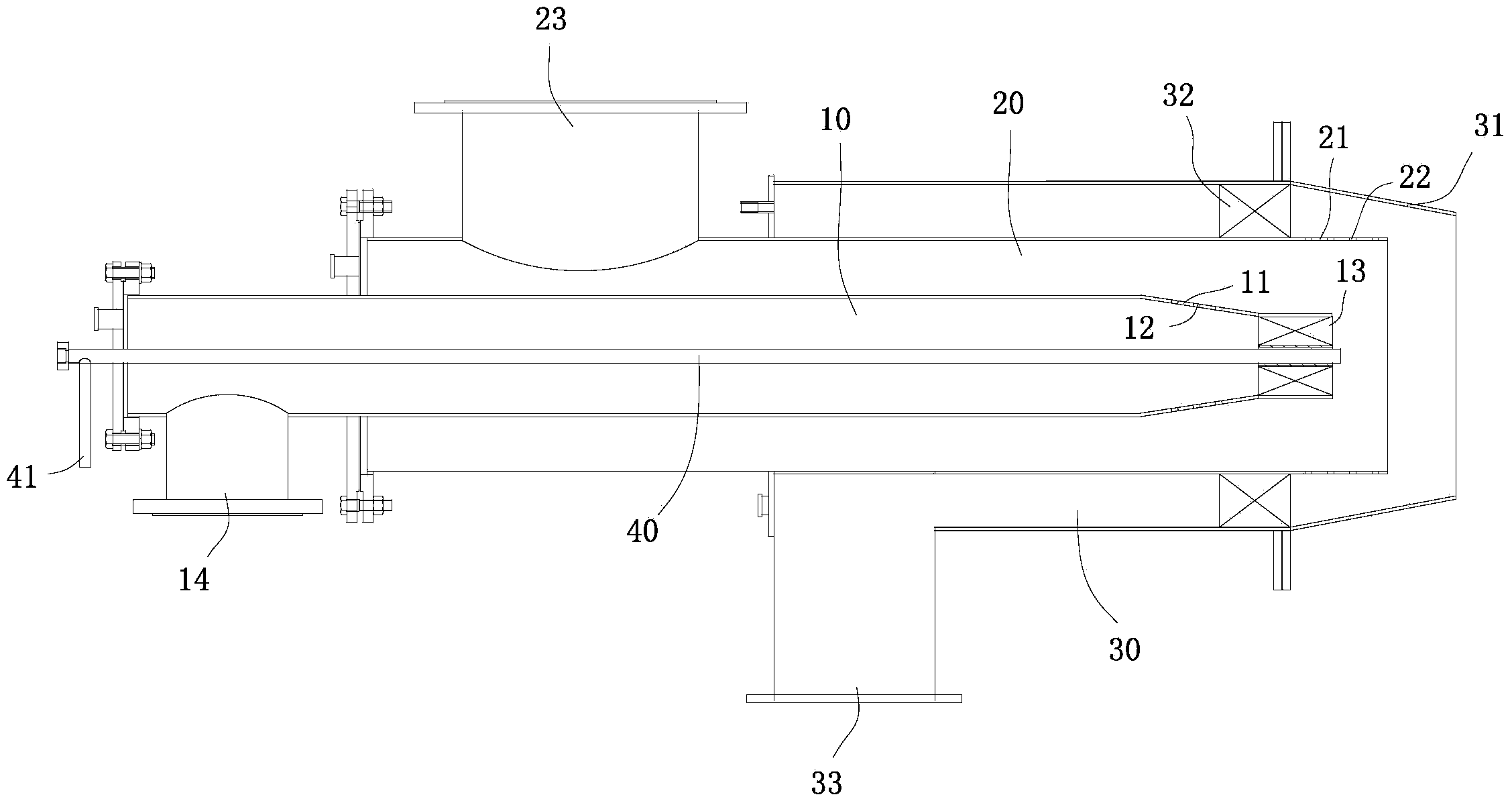

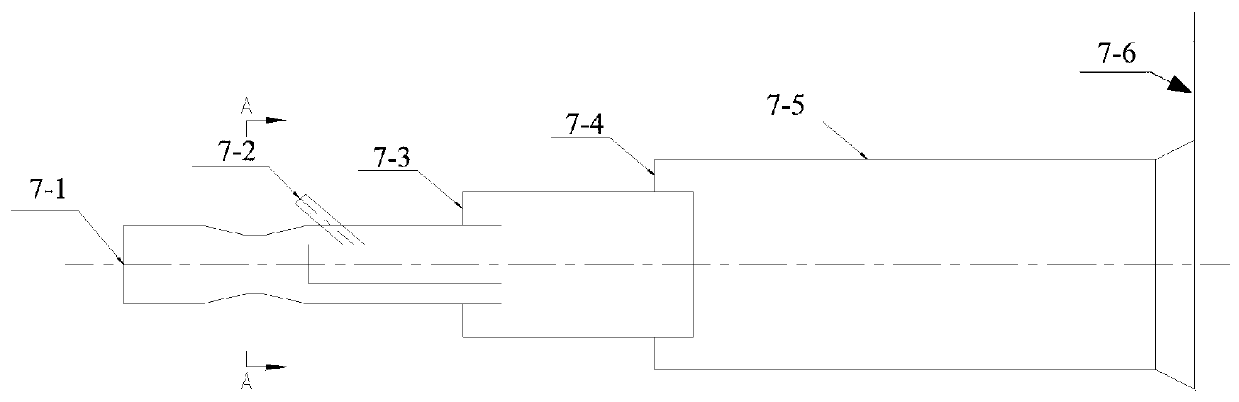

The invention provides a combustor for treating waste gas and waste liquid of dinitrogen tetroxide and hydrazine propellants and a control method. The combustor comprises a head for providing ignition premixed gas, a body for treating the waste gas and the waste liquid and a tail spray pipe. Kerosene and air are supplied by multiple paths; an ignition oxidant and ignition fuel are controlled to be in a partial fuel-rich state so as to guarantee reliable ignition; a two-stage sudden expansion structure plays a role in flame stabilizing; through grouped combustion and different nozzle structural modes, the waste gas and the waste liquid can be combusted fully, and it is guaranteed that the emission content of the dinitrogen tetroxide is smaller than 800 ppm and the emission content of the hydrazine propellants is smaller than 0.6 ppm. The combustor has the advantages of good structural strength, reliable ignition, complete gas combustion, nontoxic tail gas and the like and can be used for treating the waste gas and the waste liquid of the dinitrogen tetroxide and the hydrazine propellants.

Owner:XIAN AEROSPACE PROPULSION INST

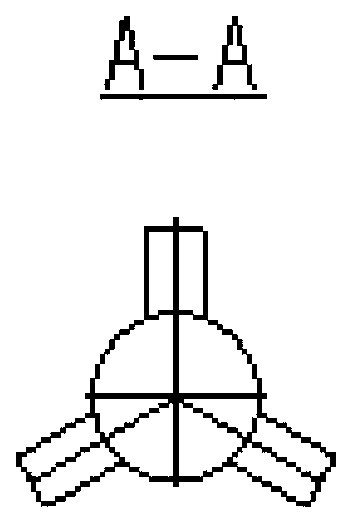

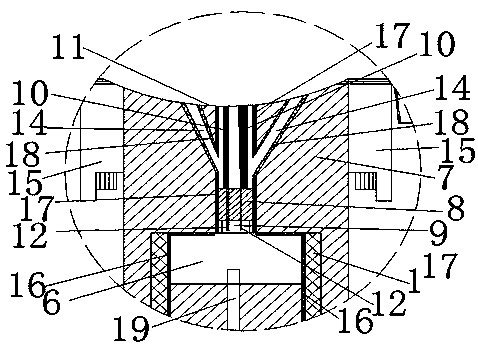

Biomass gas combustion device used for industrial boiler

The invention discloses a biomass gas combustion device used for an industrial boiler. The biomass gas combustion device used for the industrial boiler comprises an ignition channel, a primary wind channel, a fuel gas channel and a secondary wind channel, all of which are arranged concentrically from inside to outside, wherein the tail-end outlet of the primary wind channel is shrunk inwards to form a first shrinkage section and is provided with multiple first flow channels; the tail-end outlet of the primary wind channel is also provided with a primary wind swirler; the tail-end outlet of the fuel gas channel is provided with multiple second flow channels; the tail-end outlet of the secondary wind channel is shrunk inwards to form a second shrinkage section; a secondary wind swirler is arranged in the secondary wind channel and near the second shrinkage section; the arrangement of the first flow channels and the second flow channels enables the air at the tail-end outlets to be more sufficiently mixed with the fuel gas and enables the combustion reaction to be more complete, so that the combustion efficiency is improved efficiently; meanwhile, the air after passing through the primary wind swirler and the secondary wind swirler forms a recirculation zone which can suck partial high-temperature smoke, so that stable combustion of the fuel gas is guaranteed.

Owner:GUANGDONG ZHENGPENG BIOMASS ENERGY TECH

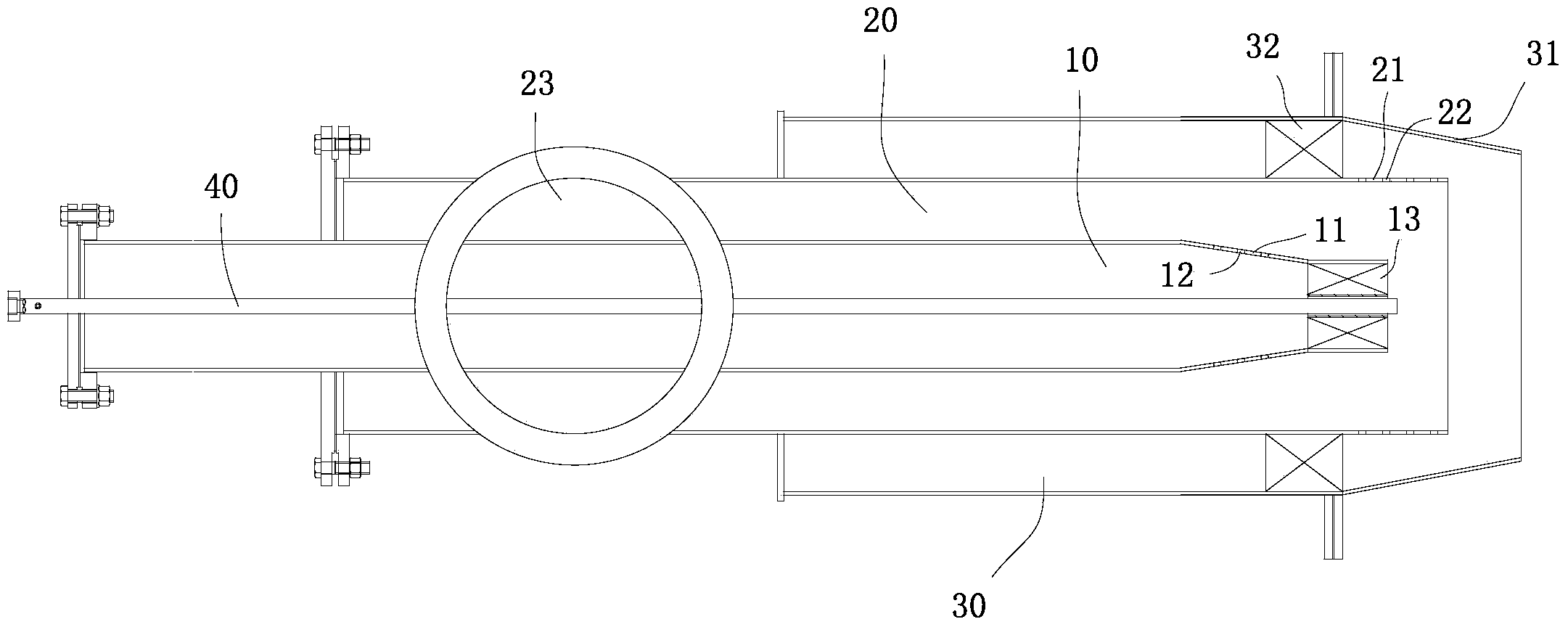

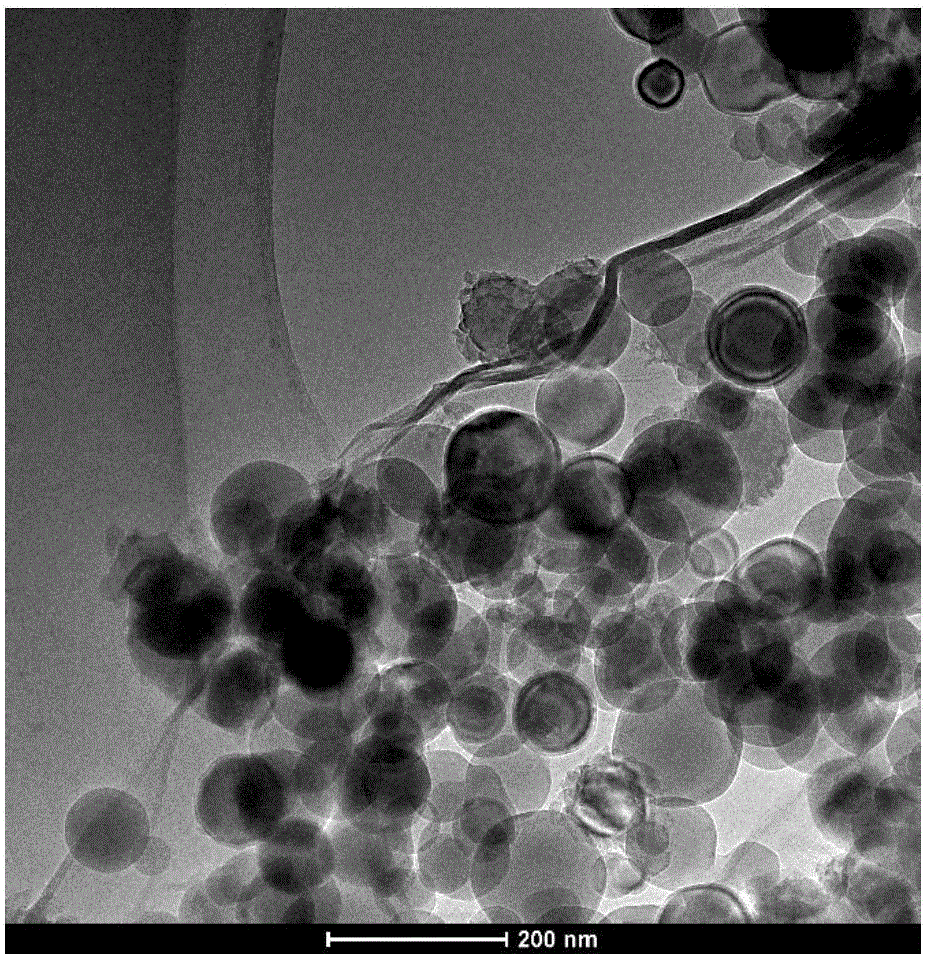

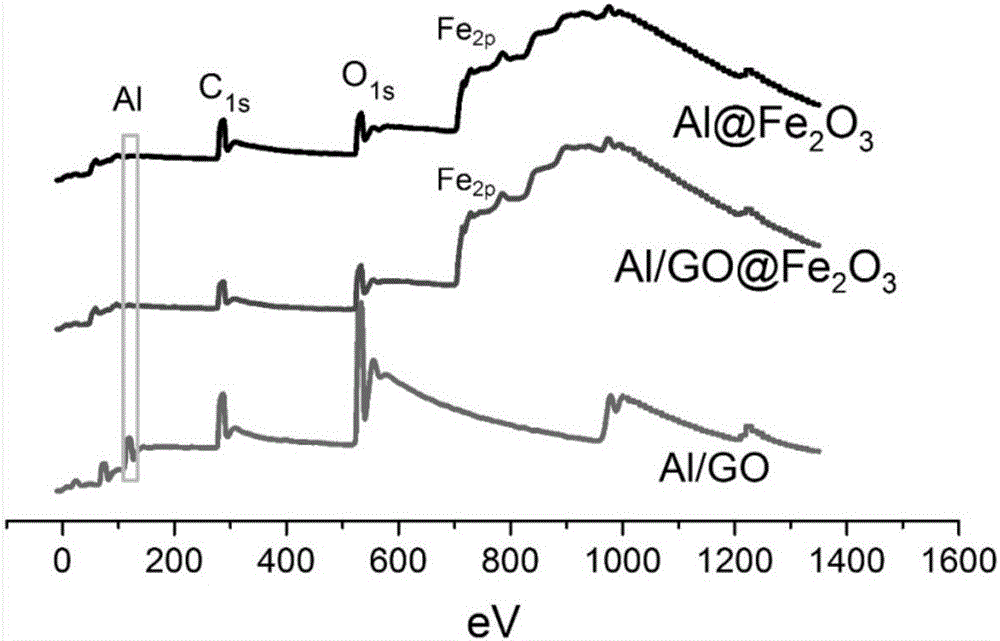

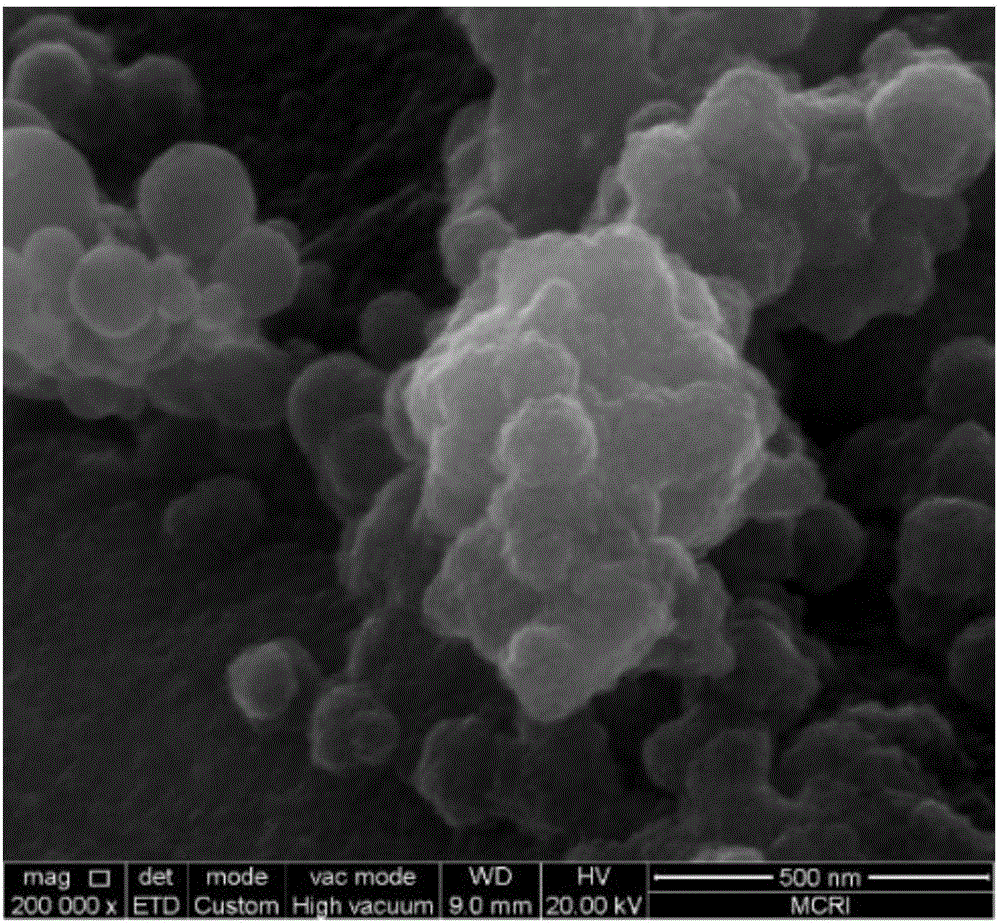

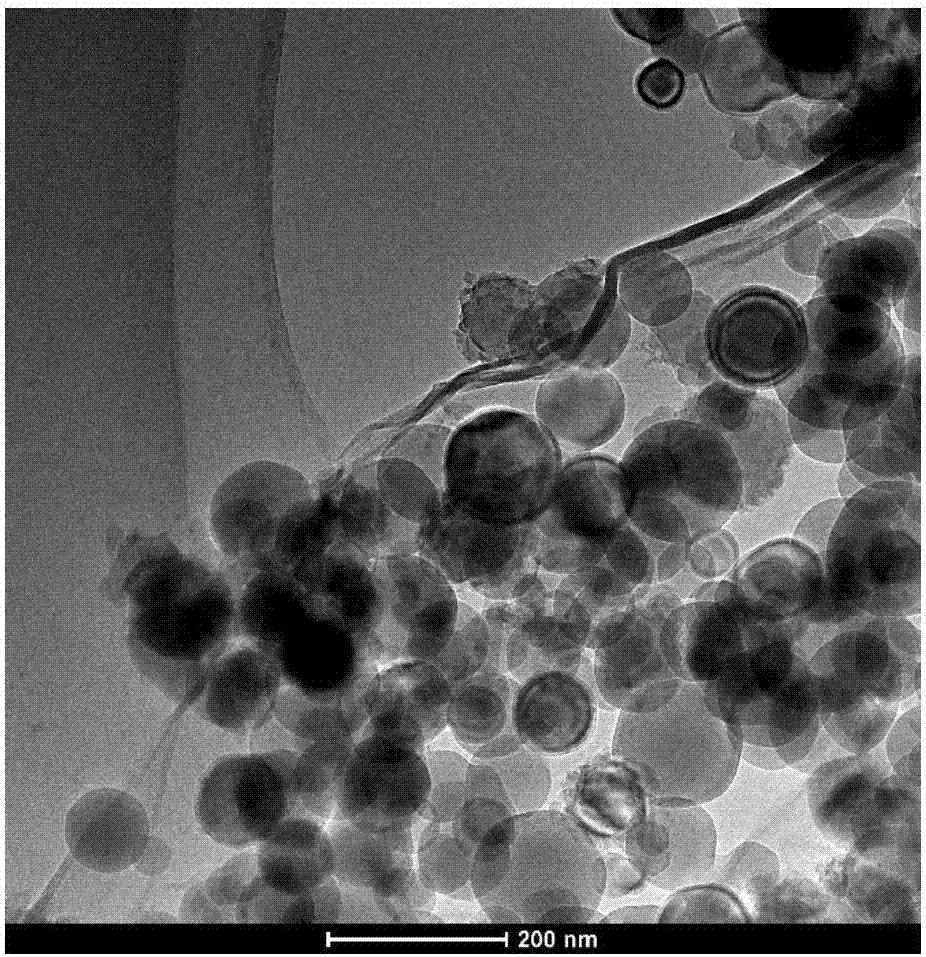

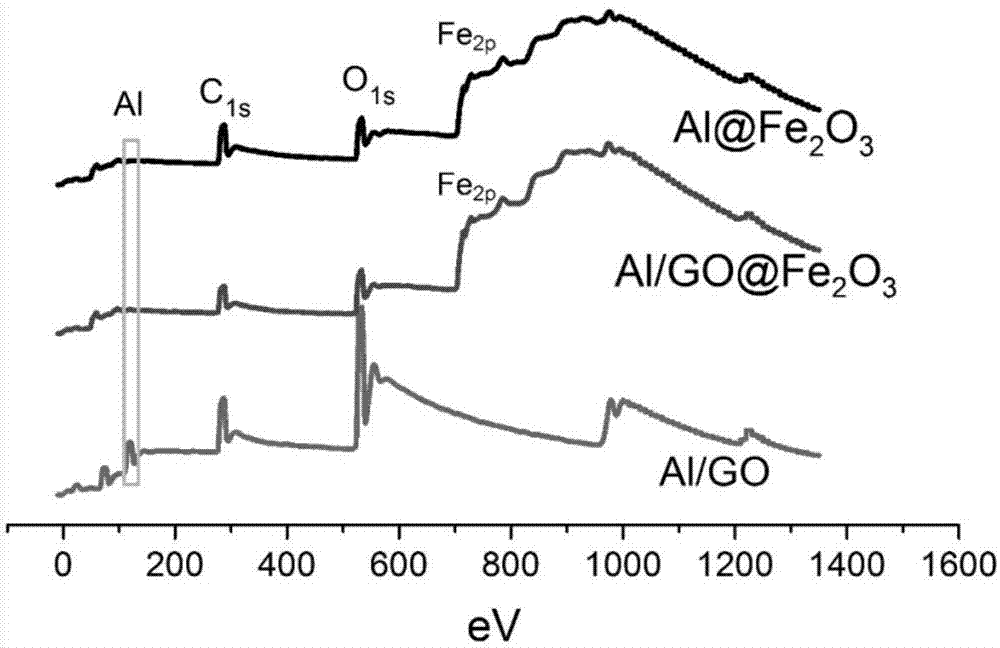

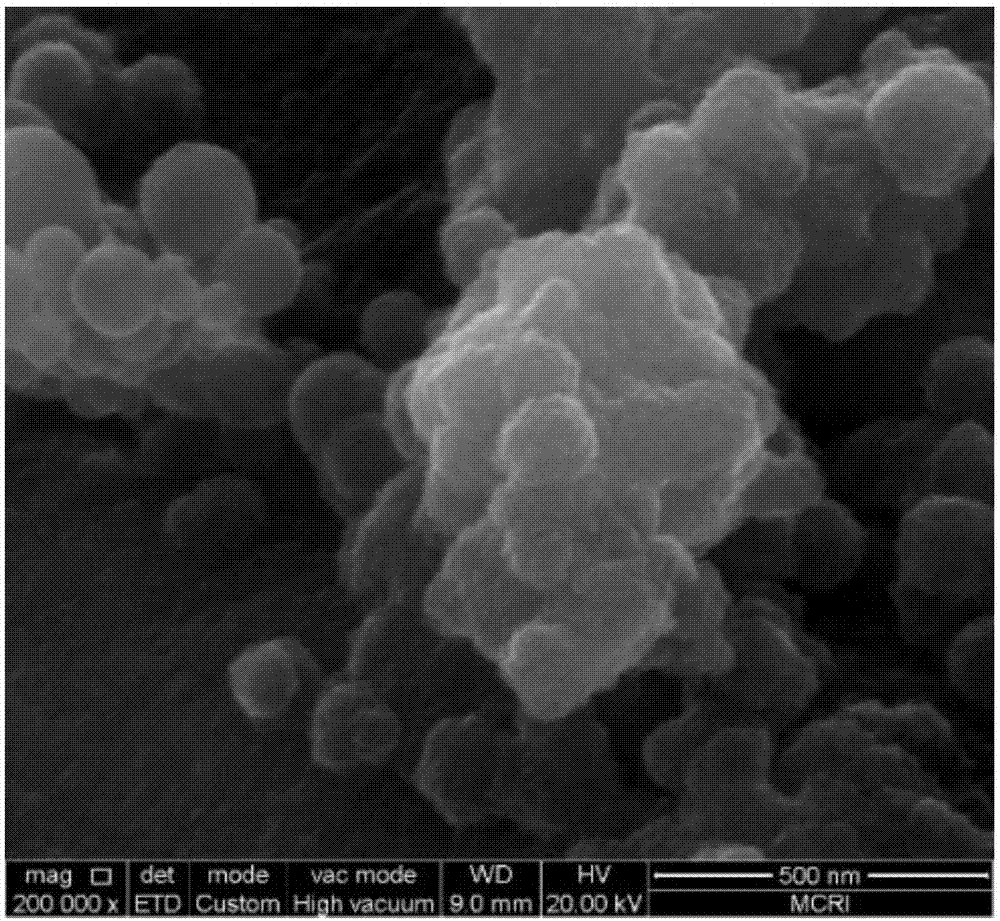

Method for preparing graphene nano-composite energetic material through atomic-layer deposition technology

ActiveCN105839078ASolve the problem of fragmentationEvenly dispersedNanotechnologyChemical vapor deposition coatingChemical reactionGas phase

The invention discloses a method for preparing a graphene nano-composite energetic material through an atomic-layer deposition technology. The method includes the steps that graphene loaded nanometer metal compound powder is prepared through an ultrasonic-assisted solution mixing and in-situ reduction method, so that even scattering of nanometer metal on the surface of graphene is achieved; and then, the gas-phase atomic-layer deposition technology is adopted, two different precursors pass through a reaction cavity alternately, the precursors make contact with the surface of the graphene / nanometer metal compound powder fully, a chemical reaction is set off, and oxides are generated. By means of the method, the oxides wrap the graphene surface and the nanometer metal surface evenly. According to the graphene nano-composite energetic material prepared through the method, the affinity between the oxides and the nanometer metal surface is increased, and spatial arrangement is improved. Due to the addition of the graphene, the scattering situation of the nanometer metal is improved, and the energy release rate of the energetic material is increased. The method is high in automation degree and good in safety, the material can be directly used without after-treatment, and mass production of the graphene nano-composite energetic material is achieved easily.

Owner:XIAN MODERN CHEM RES INST

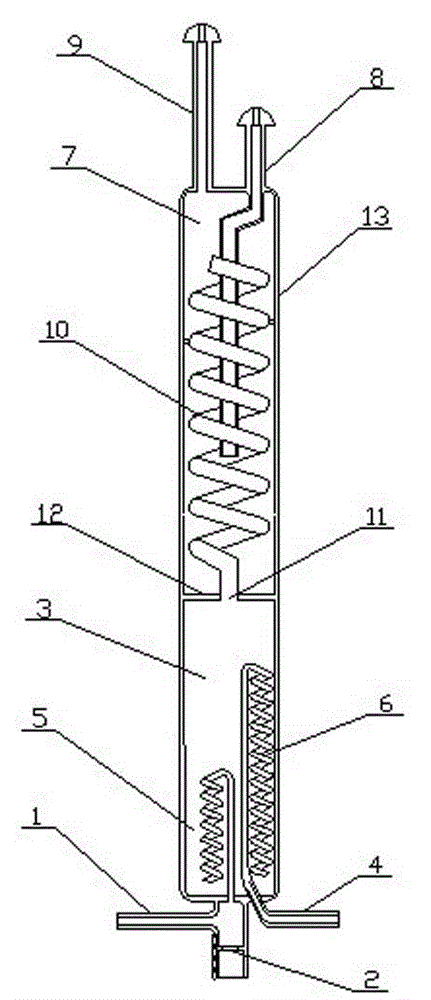

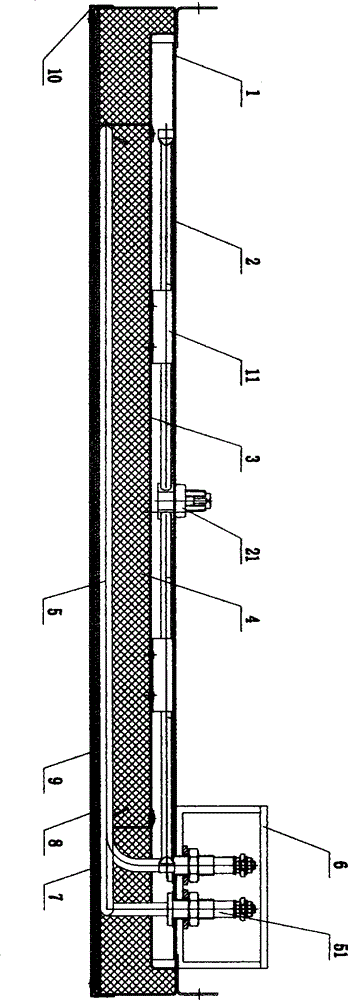

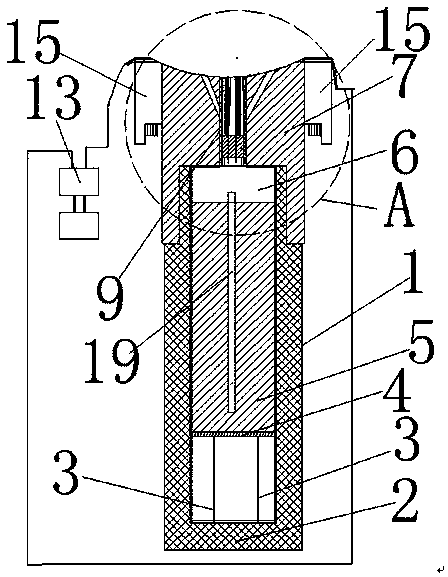

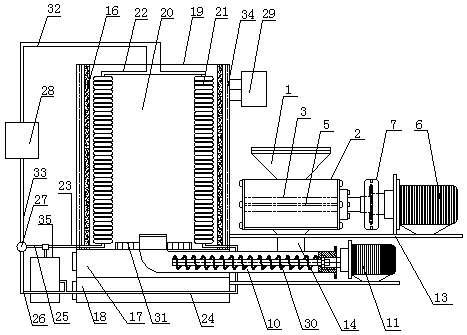

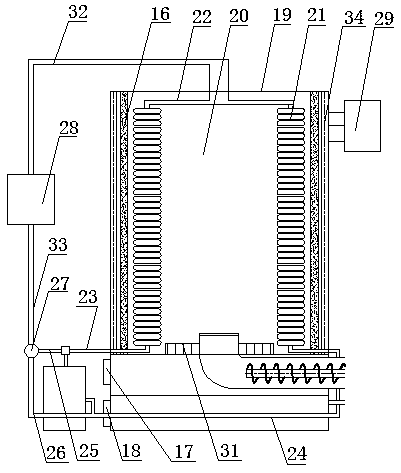

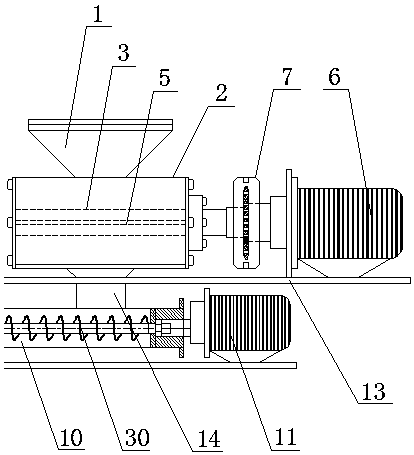

High-capacity quartz combustion tube for oil product analysis

InactiveCN103604904AFull combustion reactionBurn completelyChemical analysis using combustionPreparing sample for investigationCombustion chamberEngineering

The invention relates to a high-capacity quartz combustion tube for oil product analysis. The high-capacity quartz combustion tube is characterized by being provided with two combustion chambers, wherein a spiral carrier gas preheating tube and an oxygen preheating tube are arranged inside the first combustion chamber; a spiral combustion-supporting tube is arranged inside the second combustion chamber; the two adjacent combustion chambers are spaced by a partition plate with a through hole; a blowback oxygen inlet is formed at the outlet end of the combustion tube. The quartz combustion tube is mainly used for measuring the contents of total sulfur, total nitrogen and total chlorine in petrochemical products; conventional sample amount of 10-20 microlitres in oil product analysis is prominently improved by 5-10 times so as to be up to 100 microlitres, and carbon deposition is not caused, so that a measurement signal is relatively enhanced, and the low-content total sulfur, total nitrogen total sulfur and total chlorine detection sensitivity is prominently improved; the lower limit of detection is 0.05mg / L, and the detection limit is as low as 0.01mg / L.

Owner:江苏东华分析仪器有限公司

Cyclone concentrate spray nozzle

The invention discloses a cyclone concentrate spray nozzle, which comprises a material conveying pipe, wherein a center oil gun is coaxially arranged in the material conveying pipe, an air chamber is fixedly arranged at the outer side of the material conveying pipe, and is in an inverted truncated cone shape, a cyclone bird nest water jacket for forming cyclonic air is fixedly arranged at the lower end of the air chamber, a material conveying pipe outer layer for providing cooling air is arranged at the outer side of the material conveying pipe, a cyclone pipe for forming cyclonic air is fixedly arranged at the lower ends of the material conveying pipe and the material conveying pipe outer layer, the cyclone bird nest water jacket is arranged at the outer side of the material conveying pipe, an air outlet is formed by a gap between the cyclone bird nest water jacket and the the material conveying pipe, the directions of rotary air formed by the cyclone bird nest water jacket and the cyclone pipe are the same, and a high-speed rotary flow field is formed at the combining part of a material outlet. The cyclone concentrate spray nozzle has the advantages that by arranging the two cyclone mechanisms, the two types of cyclonic air are combined, the concentrate and reaction gas can be fully mixed, and the smoke dust rate is reduced; by increasing the negative pressure value at the material outlet, the problems of air returning and material returning are effectively reduced, and the production capacity of concentrate feeding is improved.

Owner:JINCHUAN GROUP LIMITED +1

Combined cooling, heating and power micro gas turbine device

PendingCN111075563AReduce volumeNo maintenanceContinuous combustion chamberEngine manufactureImpellerTurbine wheel

The invention provides a combined cooling, heating and power micro gas turbine device. The combined cooling, heating and power micro gas turbine device comprises a micro gas turbine; the micro gas turbine comprises a gas compressor, a turbine wheel and a combustion chamber assembly; the combustion chamber assembly comprises a combustion chamber, an air inlet cavity, an air inlet channel and an exhaust channel, the air inlet cavity comprises an internal air inlet cavity and an external air inlet cavity which are integrated, the air outlet end of the external air inlet cavity communicates with the air inlet end of the internal inlet cavity, the air inlet end of the external air inlet cavity communicates with the air inlet channel, the air inlet channel communicates with the gas compressor, the combustion chamber is arranged between the internal air inlet cavity and the external air inlet cavity, and an air outlet of the combustion chamber communicates with the exhaust channel; and an impeller of the gas compressor is coaxially connected with the turbine wheel through a rotating shaft, and the rim of the turbine wheel stretches into the exhaust channel. The combined cooling, heating and power micro gas turbine device has the advantages of being small in size, free of maintenance and high in heat exchange efficiency.

Owner:刘慕华

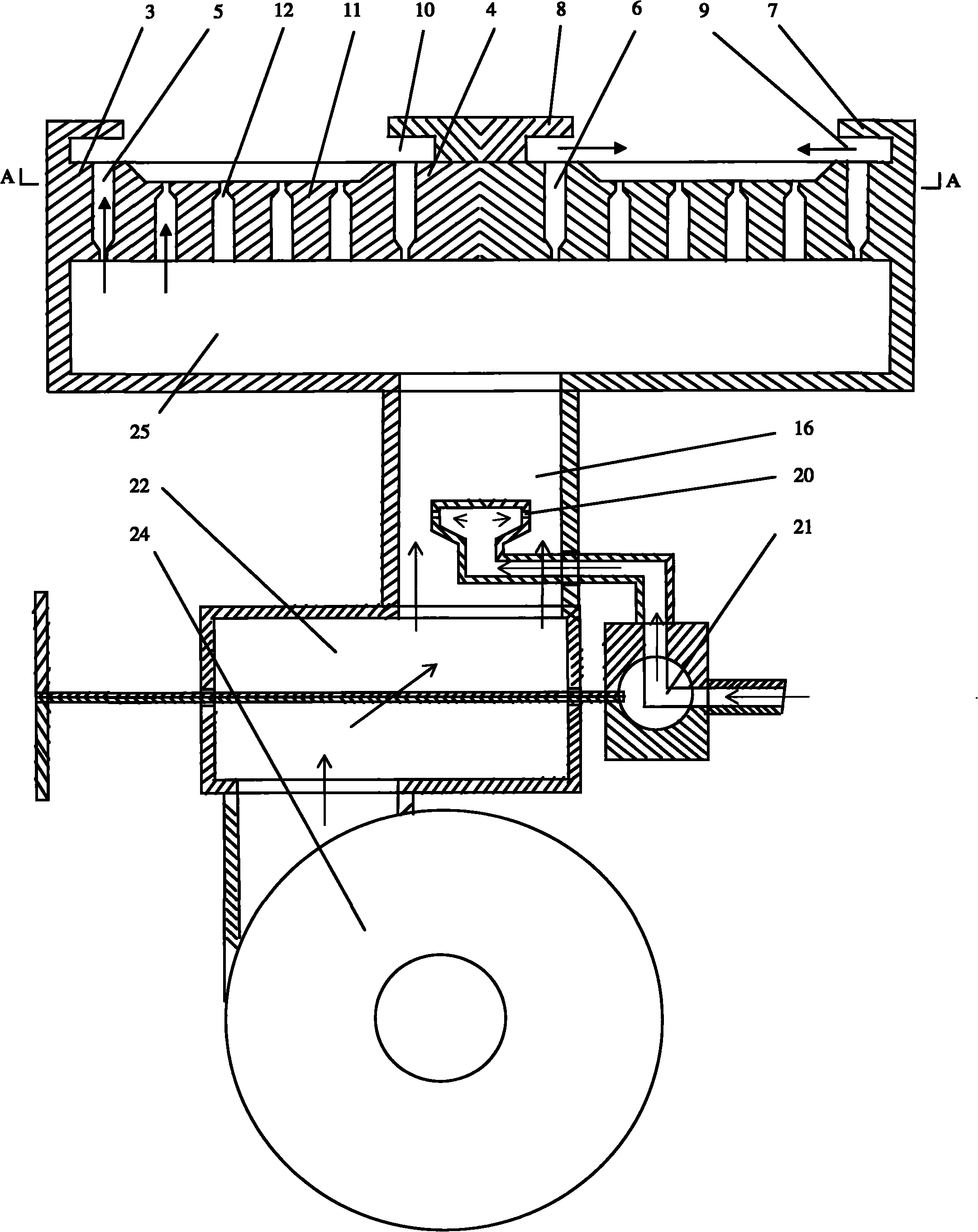

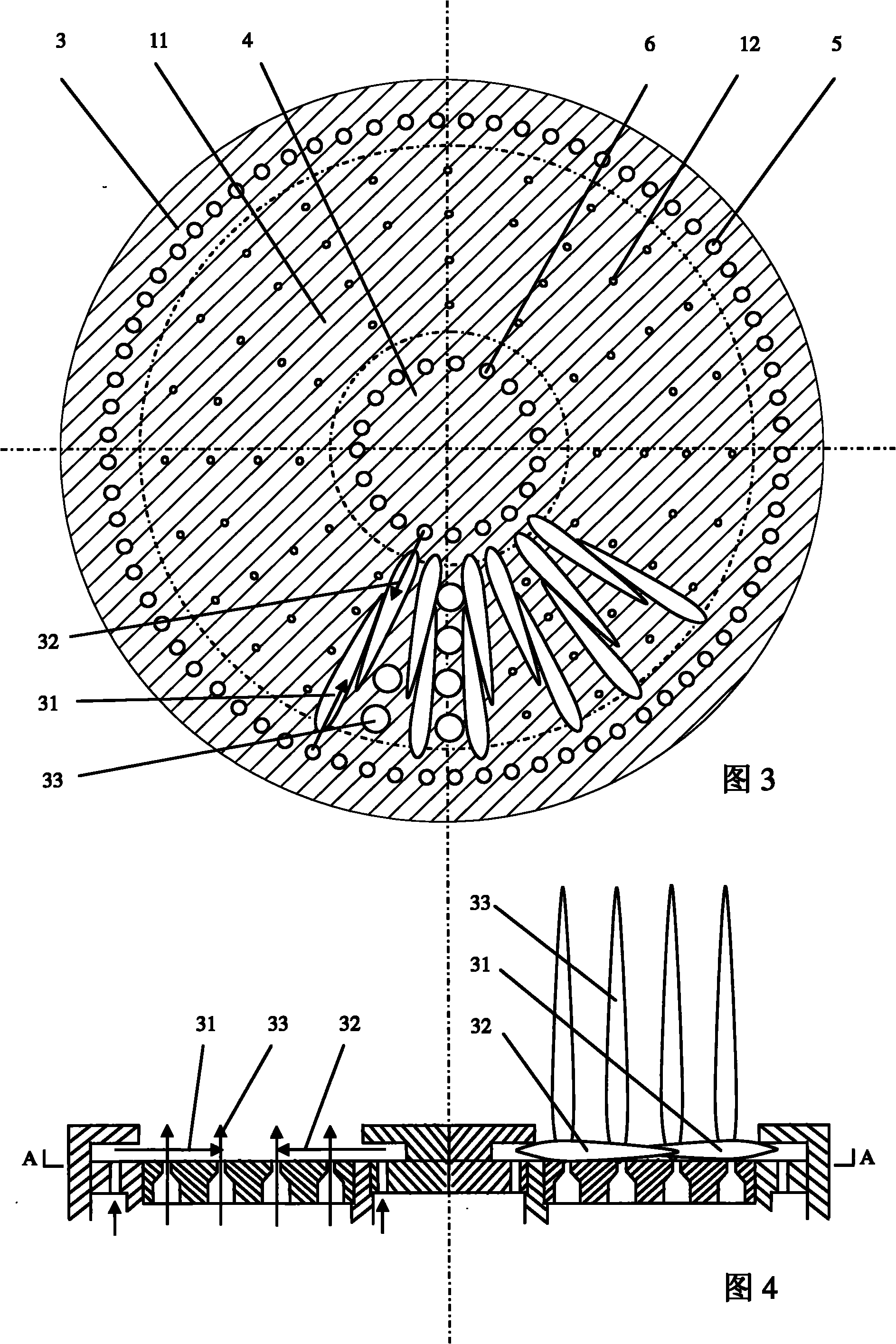

Combustor capable of improving combustion intensity and heat transfer intensity by utilizing auxiliary counter-flow flames

InactiveCN102052671AUniform combustion reactionStable combustion reactionGaseous fuel burnerCounter flowCombustor

The invention discloses a combustor capable of improving combustion intensity and heat transfer intensity by utilizing auxiliary counter-flow flames, which comprises auxiliary fire holes and main combustion fire holes. The combustor is characterized in that: auxiliary outer-circle fire caps, main combustion fire caps and auxiliary inner-circle fire caps are arranged to form a three-circle shape; the main combustion fire caps are positioned between the auxiliary outer-circle fire caps and the auxiliary inner-circle fire caps; an annular cavity between the auxiliary outer-circle fire cap and a corresponding outer-circle rectifier baffle plate is an outer-circle combustion diversion cavity; the annular cavity between the auxiliary inner-circle fire cap and a corresponding inner-circle rectifier baffle plate is an inner-circle combustion diversion cavity; and an opening of the outer-circle combustion diversion cavity is opposite to the opening of the corresponding inner-circle combustion diversion cavity. Outer-circle auxiliary flames flow relative to inner-circle auxiliary flames to form flame nets with more uniformly distributed heat on the surfaces of the main combustion fire caps, so that main combustion premixed gases flowing out of each gas orifice can obtain enough heat required by combustion, the combustion reaction of all the main combustion premixed gases is uniform, consistent and sufficient, and the combustion flames are stable. The main combustion premixed gases flow out at high flow rate and under high pressure, so the combustion intensity and flame temperature of the main combustion premixed gases are correspondingly high. Main combustion flames entrain the auxiliary flames by high kinetic energy to simultaneously transfer the heat, and the high-efficiency heat transfer can make the high temperature combustion flames rapidly reach the bottom of a roasting kettle.

Owner:李芳春

Electric heating washing type waste gas treatment device

PendingCN112121588AAvoid cloggingReduce water consumptionCombination devicesIncinerator apparatusThermodynamicsCombustion chamber

The invention relates to an electric heating washing type waste gas treatment device which comprises a first gas inlet, an electric heating device, a dust filtering device, an intelligent cooling water washing system and a gas outlet, the first gas inlet is formed in the electric heating device, and the electric heating device is arranged on the dust filtering device; the dust filtering device isarranged at the upper part of a water tank of the intelligent cooling water washing system; and the combustion chamber scaling removing device is arranged on the tee joint at the upper part of the first air inlet, is provided with a stainless steel brush, can reach the interior of the combustion chamber of the electric heating device and brushes away dust on the inner wall of the combustion chamber. According to the invention, silane dust adhered to the inner wall of the combustion cavity can be automatically cleaned at regular time; the water consumption of fresh water is reduced, and the operation cost is reduced; the low water level, the high water level and the ultrahigh water level in the water tank are controlled through the four floaters, and the safety performance of equipment in use is improved; a four-stage spraying system is adopted, so that the waste gas treatment efficiency is improved.

Owner:武汉更日敦科技有限公司 +2

Low-temperature catalysis type infrared gas heater and catalyst preparation process thereof

InactiveCN104100974AAvoid lostReduce consumptionGaseous fuel burnerMetal/metal-oxides/metal-hydroxide catalystsExcited stateGas heater

The invention discloses a low-temperature catalysis type infrared gas heater comprising a shell, a gas conduit, a gas homogenizing component, a dry type preheating electrical-heating pipe and an activated aluminum catalyst layer. The inside of the shell is of cavity structure. The gas conduit is arranged in the cavity structure of the shell, the gas homogenizing component is arranged on the lower portion of the gas conduit so as to homogenize gas released from the gas conduit, the dry type preheating electrical-heating pipe is arranged in the gas homogenizing component so as to preheat the catalyst layer and activating catalyst on the catalyst layer, the activated aluminum catalyst layer is arranged on the lower portion of the gas homogenizing component, the homogenized gas is catalyzed and combusted in the activated aluminum catalyst layer, a low-energy base is formed on the surface of the catalyst layer to generate vibrational-state products, and energy is released by infrared radiation. The low-temperature catalysis type infrared gas heater is energy saving, environment friendly, low in noise and high in efficiency.

Owner:王荣根

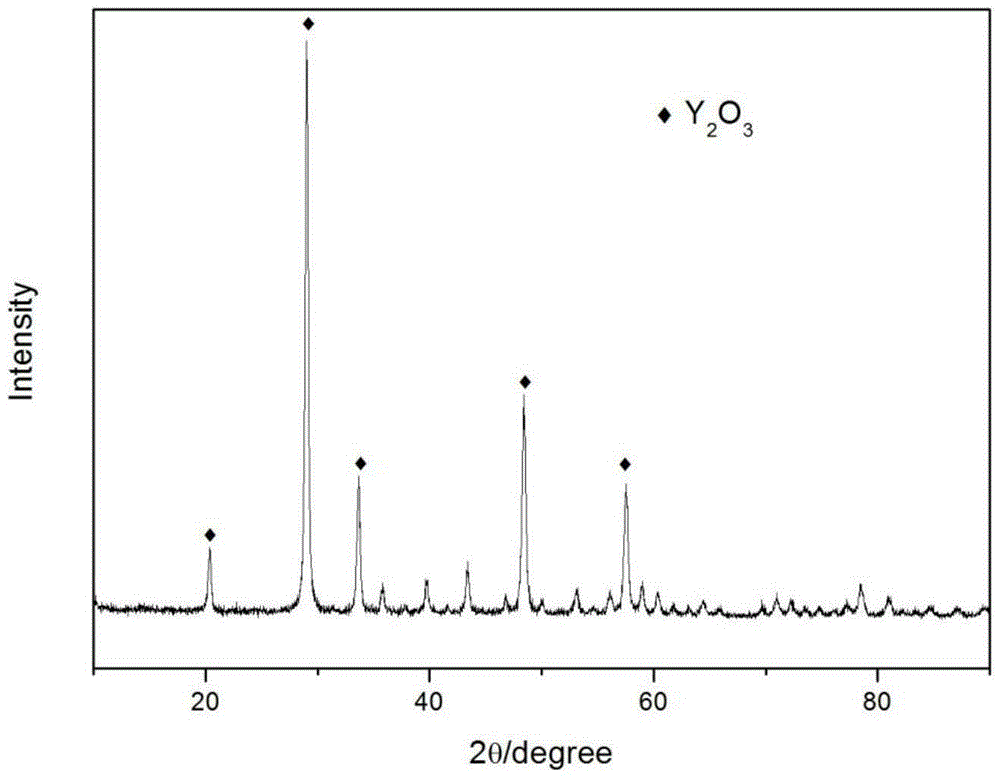

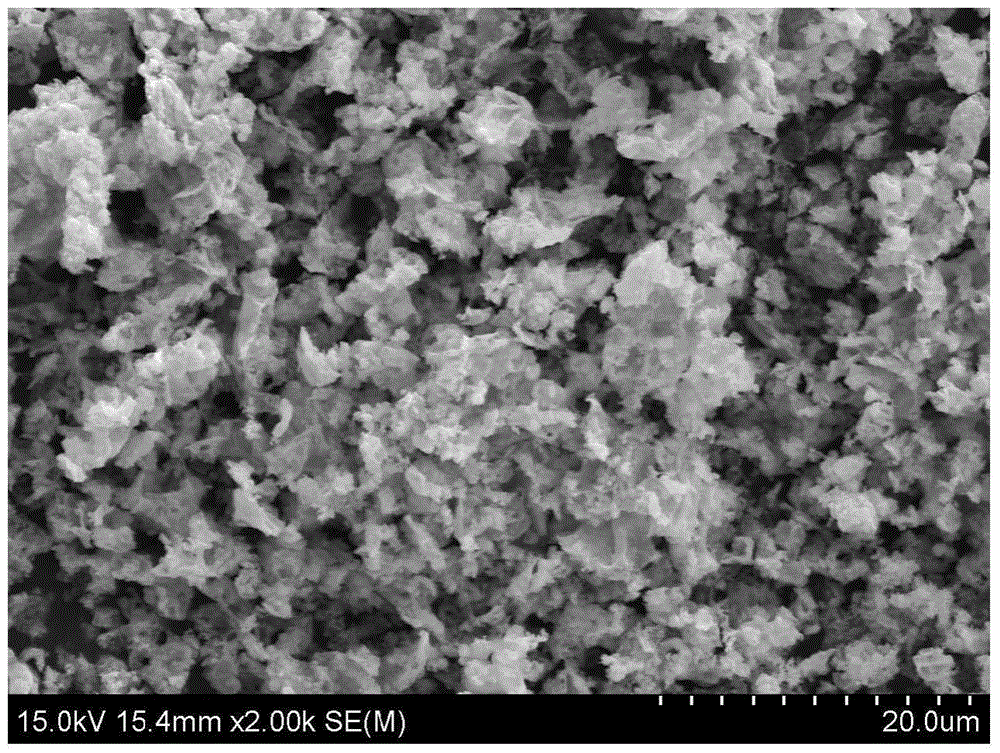

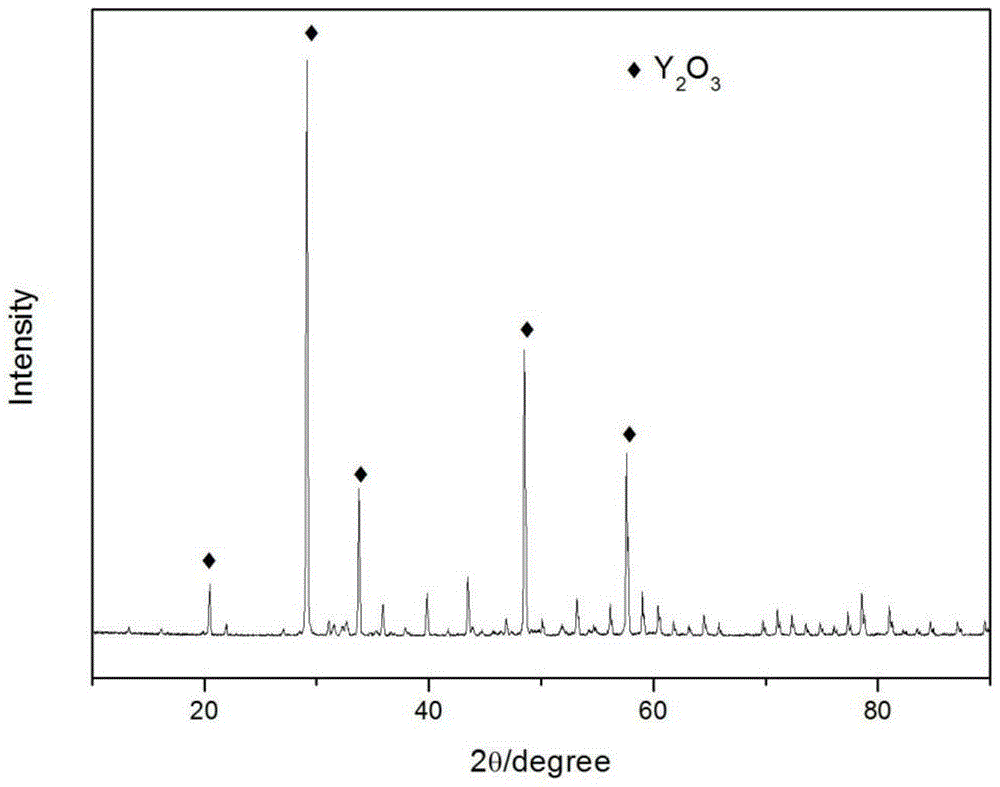

Preparation method of transparent ceramic for nuclear reactor observation window

ActiveCN105218097AComply with the requirements of viewing window materialMeet material requirementsNuclear reactorCombustion

The invention relates to a preparation method of transparent ceramic for a nuclear reactor observation window. The method comprises the following steps of firstly, mixing yttrium nitrate and yttrium acetate according to the mole ratio of 1:(0.4 to 0.6), then adding water, placing the obtained clarified precursor solution into a microwave oven and heating for 5 to 25 minutes; carrying out boiling, evaporating and self-propagating combustion to obtain Y2O3 nano powder with the particle size of 10 to 35nm; secondly, carrying out ball milling on the obtained Y2O3 nano powder, drying, dry-pressing molding, vacuum encapsulation and cold isostatic pressing to obtain a Y2O3 ceramic body; and then placing the Y2O3 ceramic body into a microwave sintering furnace for sintering at the temperature of 1,300 to 1,500DEG C to obtain the transparent ceramic. The preparation method disclosed by the invention is high in heating speed and is short in time; the ceramic can be quickly densified under normal pressure conditions; the prepared ceramic can be used as a nuclear reactor observation window material.

Owner:SHANDONG UNIV

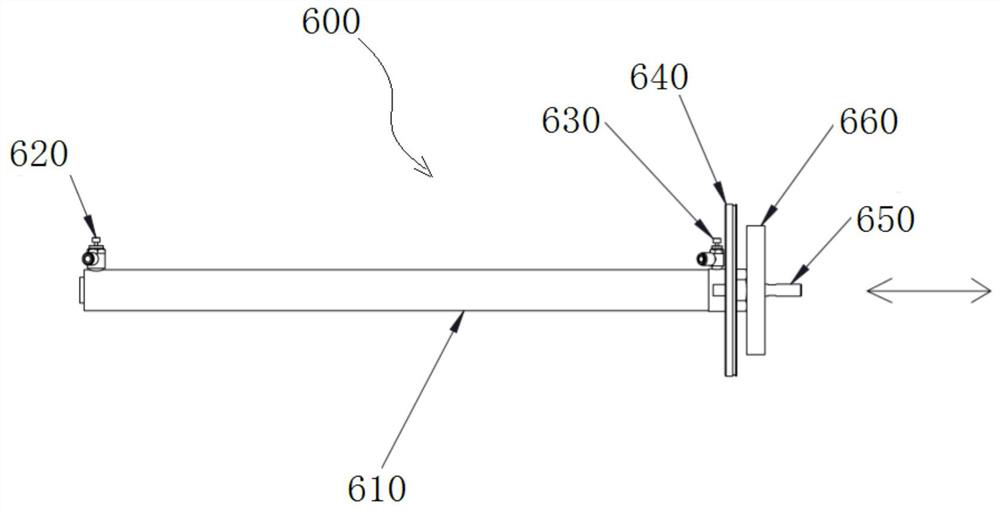

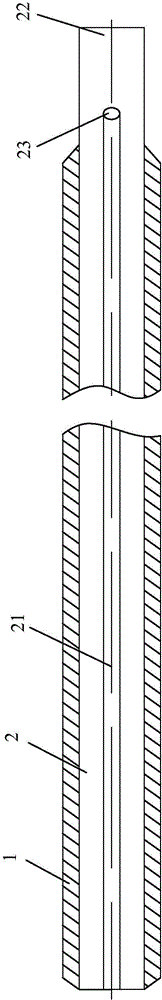

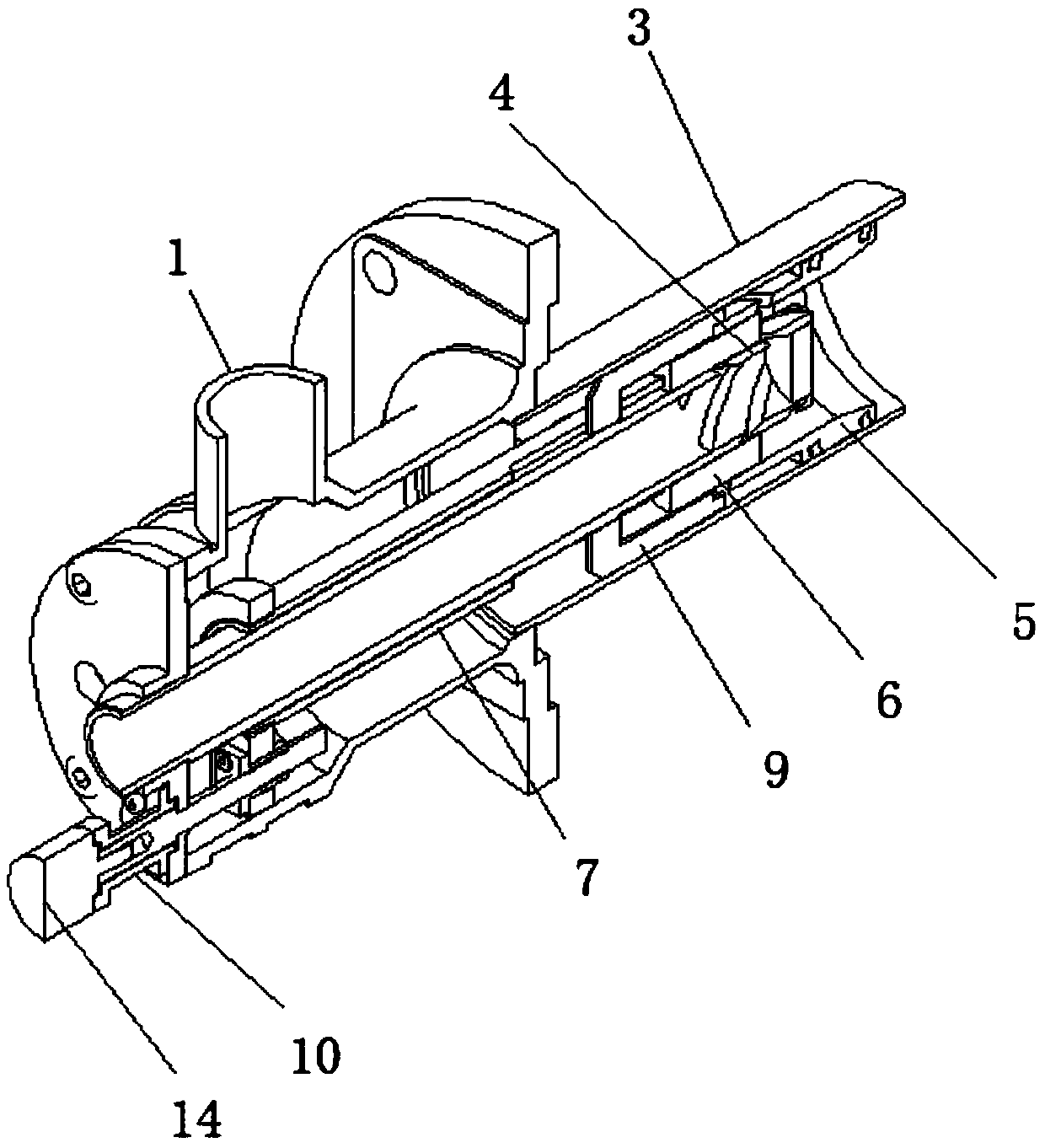

Arc planing and cutting system and arc planing and cutting bar thereof

InactiveCN105983797AFull combustion reactionHigh ambient temperatureArc welding apparatusWelding/cutting media/materialsCutting forceBiomedical engineering

The invention aims to provide an arc planning and cutting system and an arc planning and cutting bar thereof. A planning and cutting force of the arc planning and cutting bar can be promoted. In order to achieve the purpose, the arc planning and cutting bar comprises a core wire and a coating, wherein the core wire has a holding end and a part coated with the coating. The arc planning and cutting bar is characterized in that the core wire is provided with a gas inlet and a gas path, wherein the gas inlet is located at the holding end and the gas path extends to the tail end of the core wire along the center of the core wire.

Owner:KUNSHAN BANKNOTE PAPER

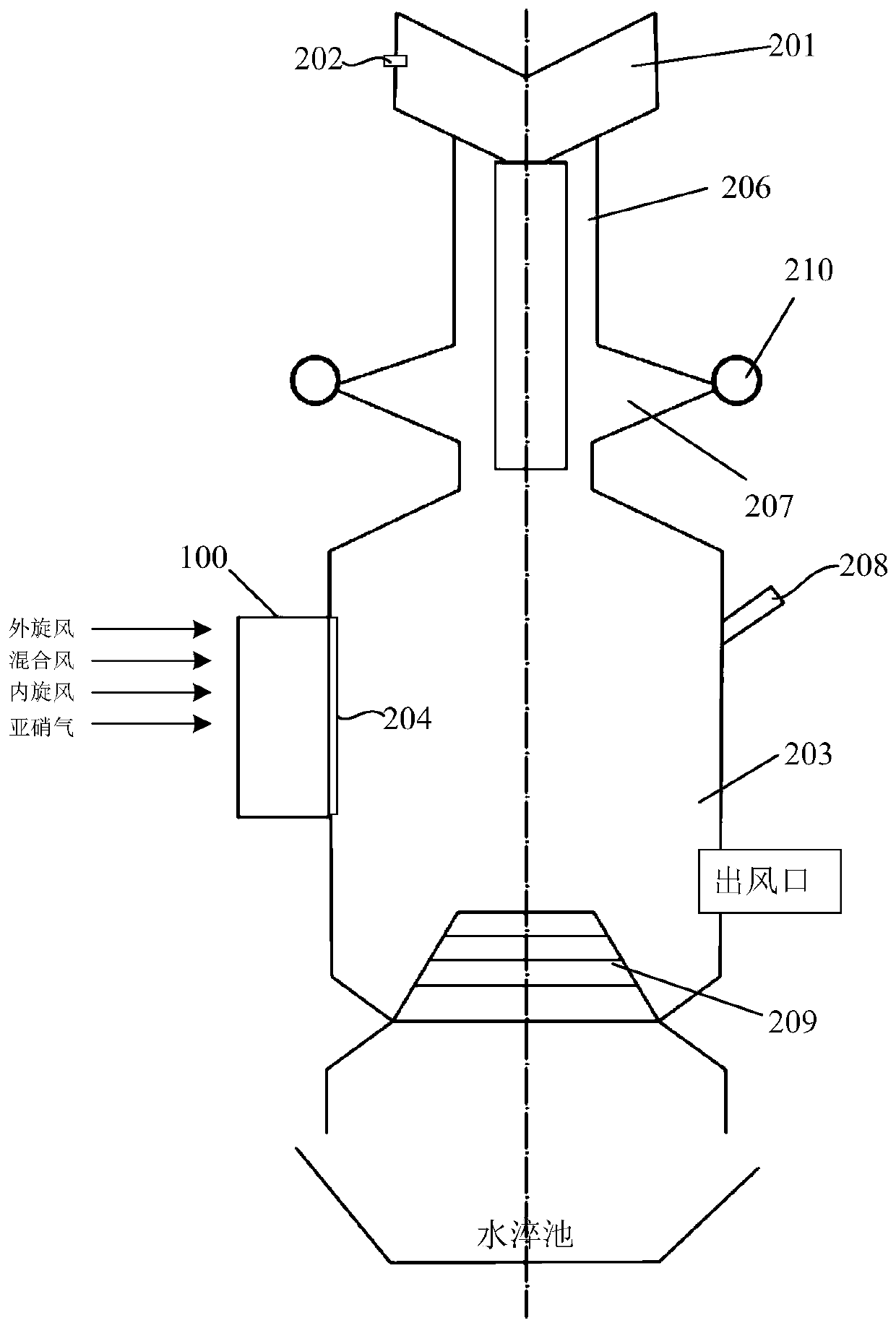

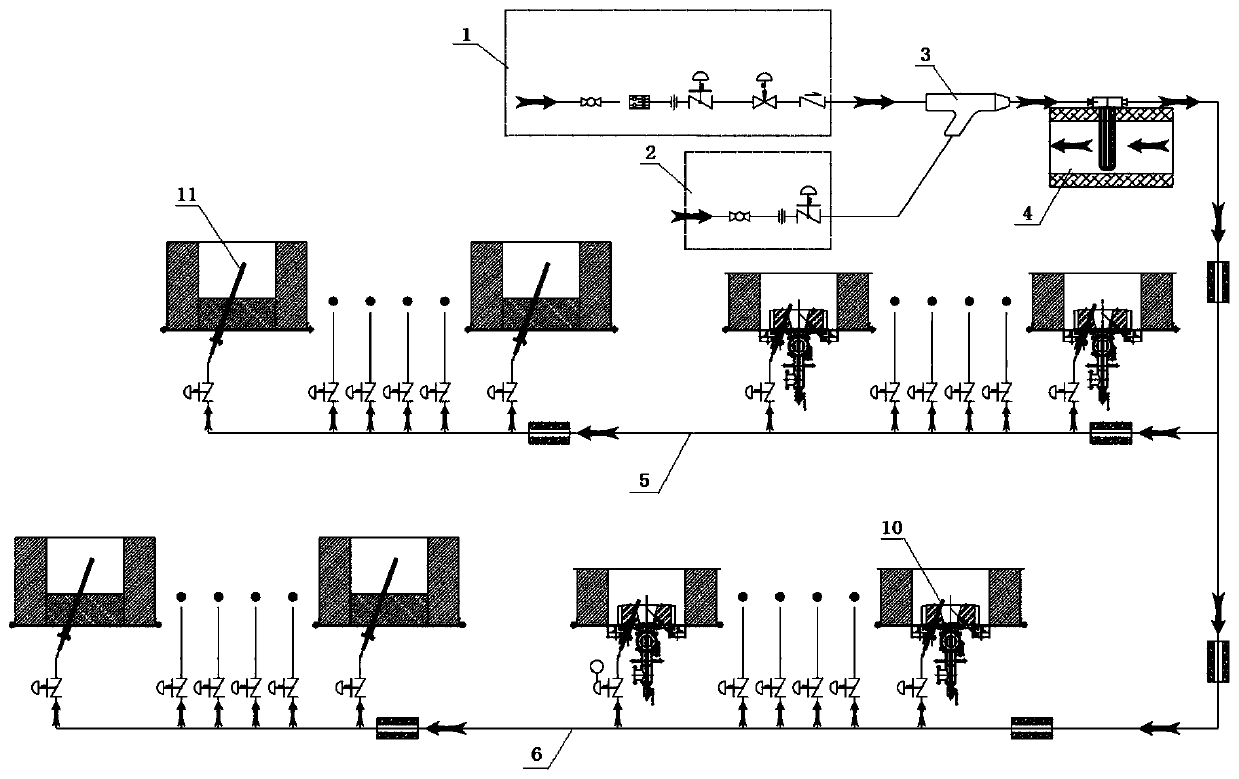

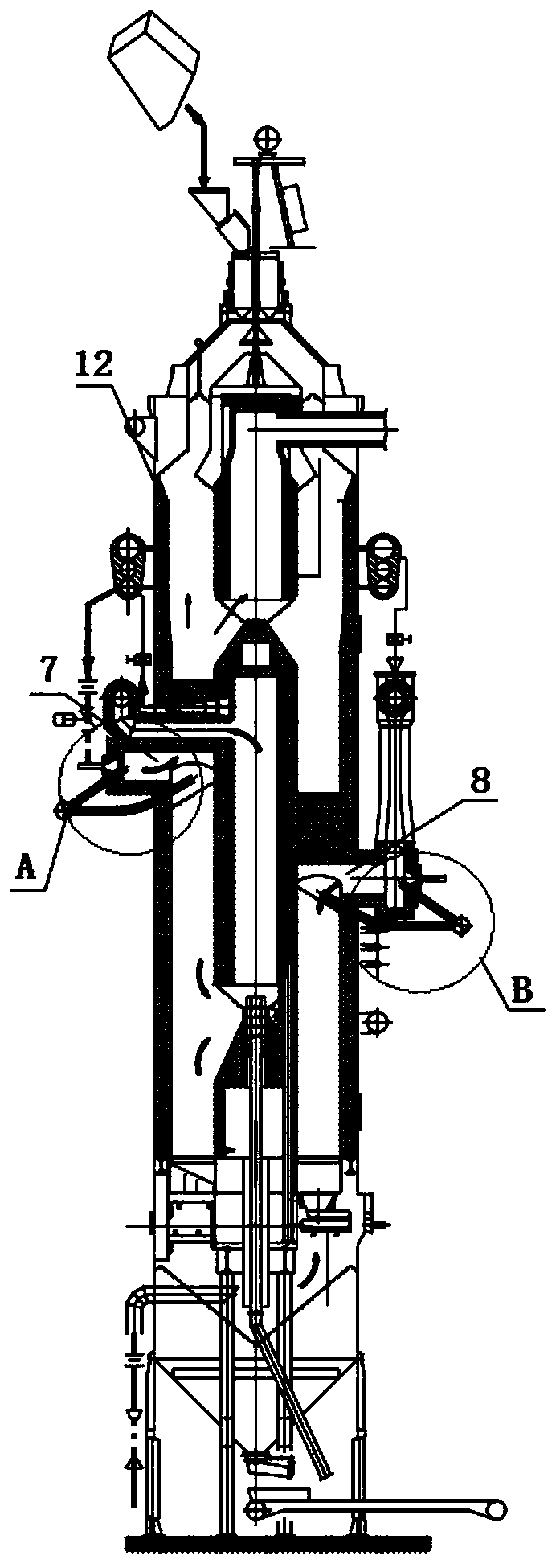

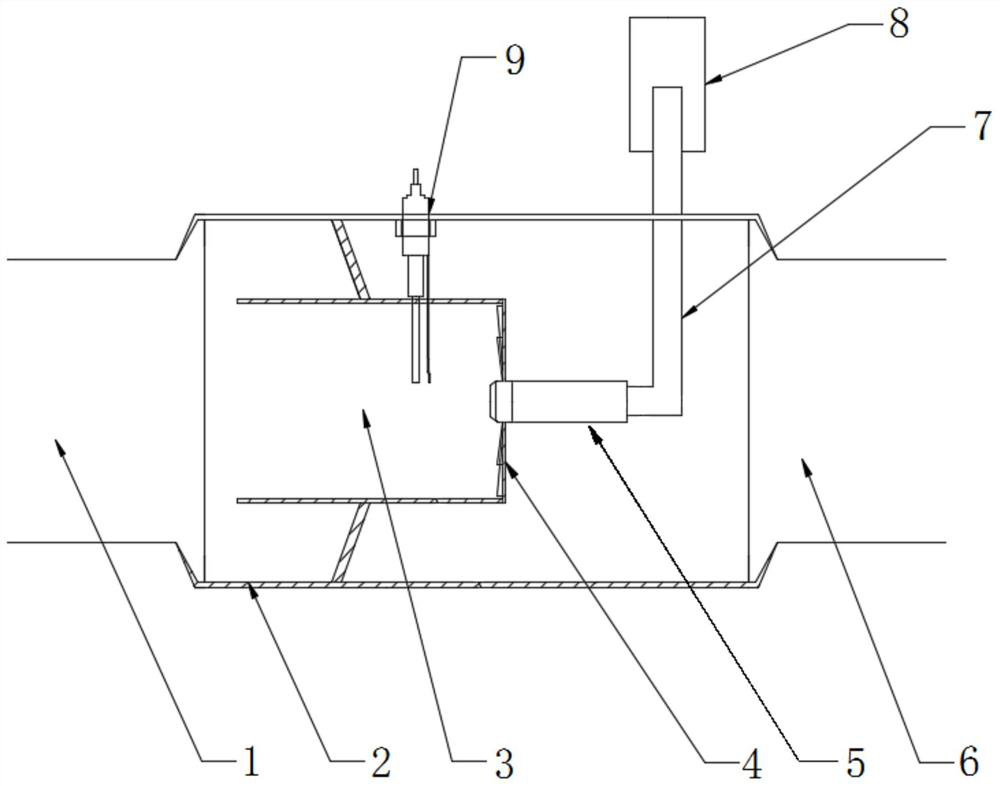

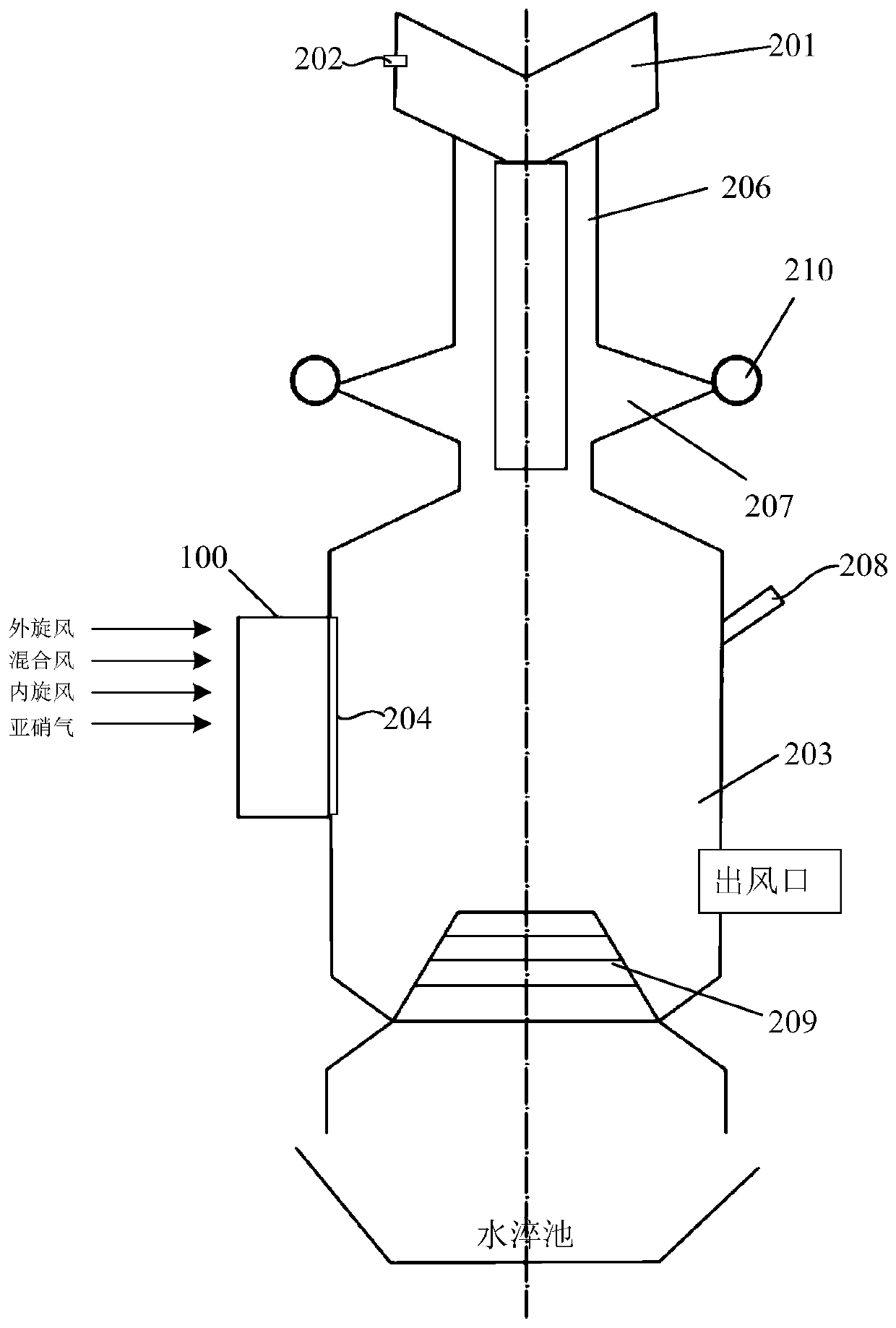

Three-waste integrated reactor and method for treating nitrite gas

PendingCN109974009AAvoid cloggingEffective destruction and decompositionIncinerator apparatusGratingCombustion chamber

The invention provides a three-waste integrated reactor. The three-waste integrated reactor and method for treating nitrite gas is vertically arranged and comprises a first combustion chamber arrangedat the top, the first combustion chamber is provided with a primary air inlet which is formed in the tangential direction and is used for spraying mixed air of waste solid and primary fuel gas into the first combustion chamber; the reactor further comprises a second combustion chamber, the second combustion chamber is provided with a secondary air inlet which is tangential to the second combustion chamber and is used for spraying mixed air of waste solid and secondary fuel gas into the second combustion chamber; a waste liquid filling port is formed in the second combustion chamber and is used for filling waste liquid into the second combustion chamber; a combustion descending channel is formed between the first combustion chamber and the second combustion chamber, and the combustion descending channel protrudes outwards to form a mixing chamber; and a grating tower is arranged at the bottom of the reactor, and a water quenching tank is arranged below the grating tower. According to the three-waste integrated reactor, the blockage of the dangerous waste incineration device can be effectively avoided, and meanwhile, the nitrite gas generated in the adipic acid production process can be sufficiently recovered.

Owner:北京科太亚洲生态科技股份有限公司

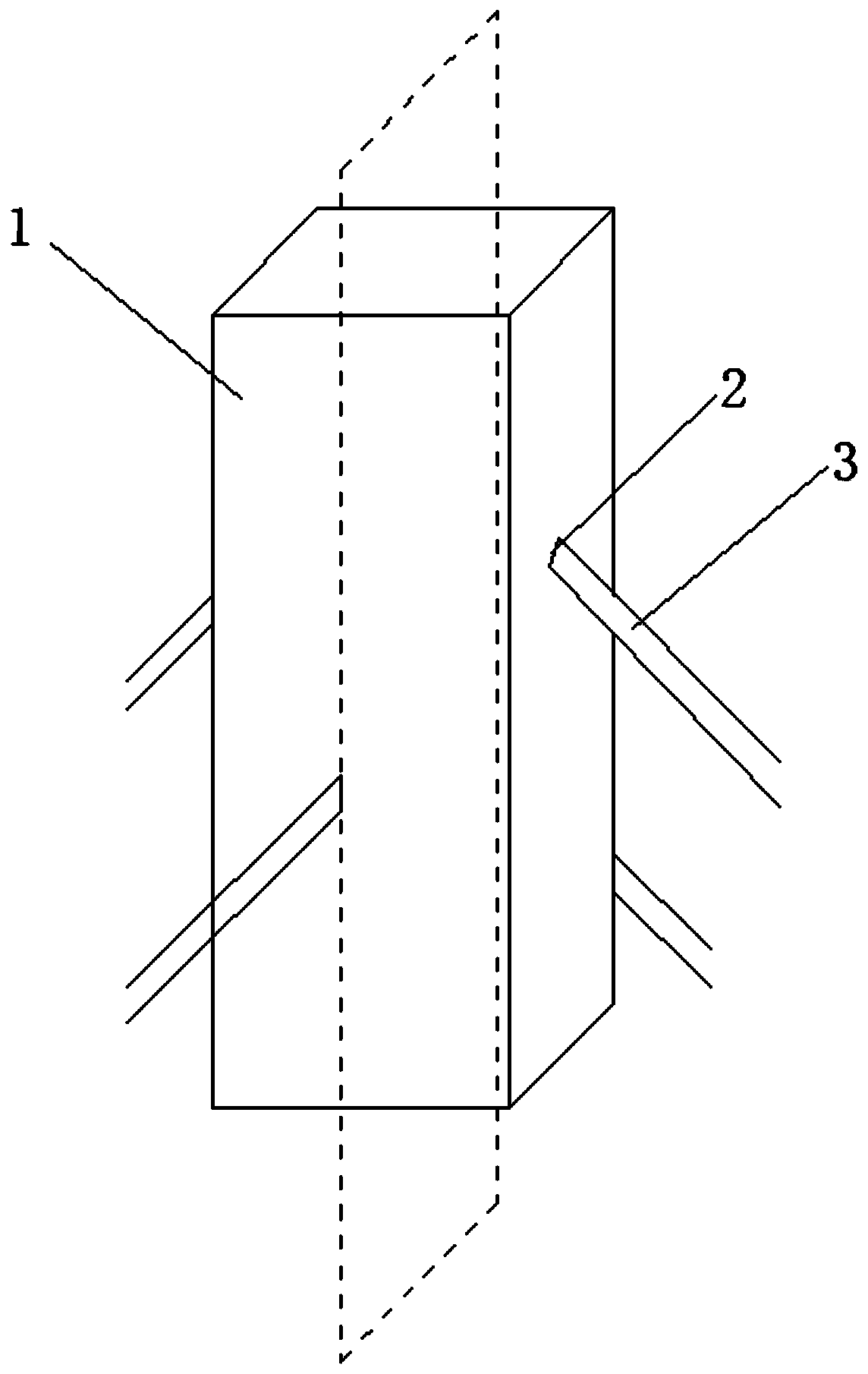

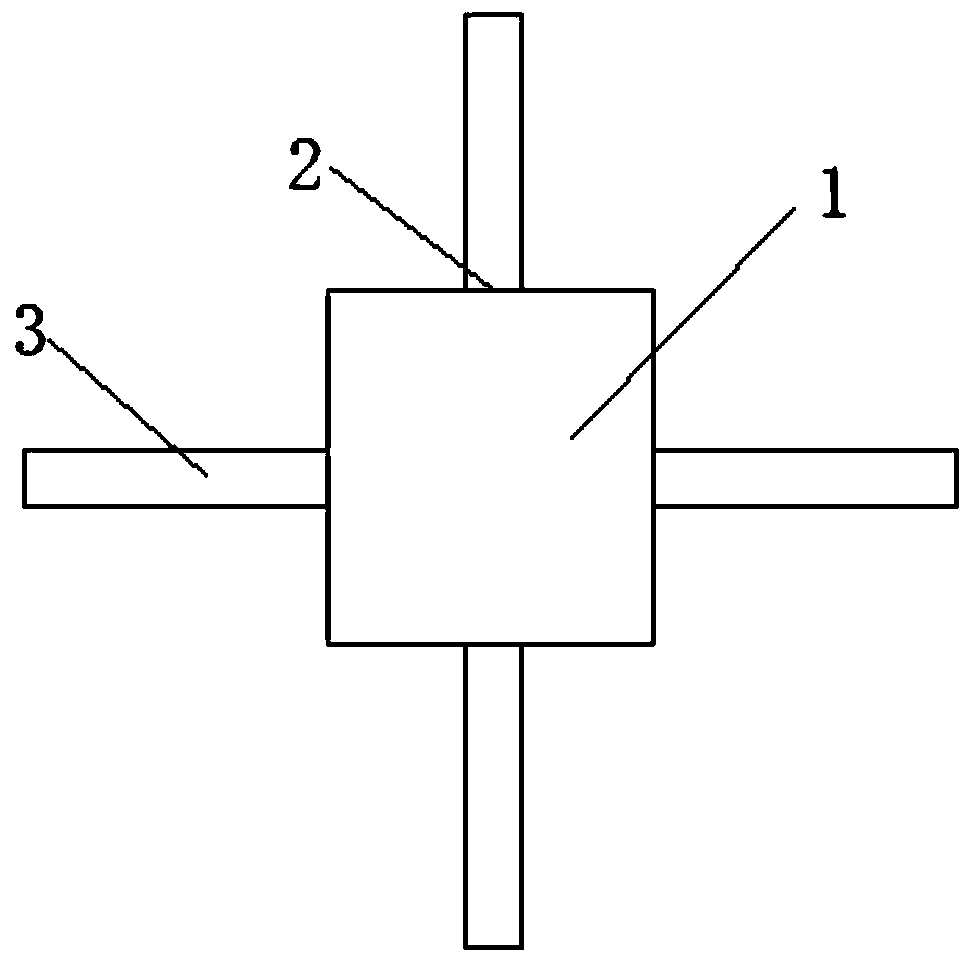

Impinging stream low-nitrogen combustion reaction device and reaction method thereof

PendingCN111578312AAvoid lossFull combustion reactionContinuous combustion chamberChemical/physical/physico-chemical stationary reactorsChemical industryEngineering

The invention relates to the technical field of chemical industry, and in particular to an impinging stream low-nitrogen combustion reaction device. The impinging stream low-nitrogen combustion reaction device comprises the following parts of a cylindrical or rectangular impinging stream reaction chamber, wherein the side of the impinging stream reaction chamber is uniformly opened with several layers of installation through holes from bottom to top; acceleration tubes installed in the installation through holes; an air flow channel installed on the top of the impinging stream reaction chamberand communicated with the impinging stream reaction chamber; a burner communicated with the other end of the air flow channel; and a boiler installed on the top of the burner and providing heat by the burner. The invention also discloses an impinging stream low-nitrogen combustion reaction method, which specifically comprises the following steps of introducing high-speed air and high-speed gas into the acceleration tubes in the same layer for collision to obtain a rising ion current; driving the turbulence fan to rotate by the rising ion current when passing through a turbulence fan so as toevenly mix the ions in the ion flow, and making the ion flow continue to rise into the burner; heating the burner to 1000 to 1100 DEG C to cause the ion flow to burn and release heat; and exhausting excess nitrogen and water.

Owner:江苏河海新能源技术发展有限公司

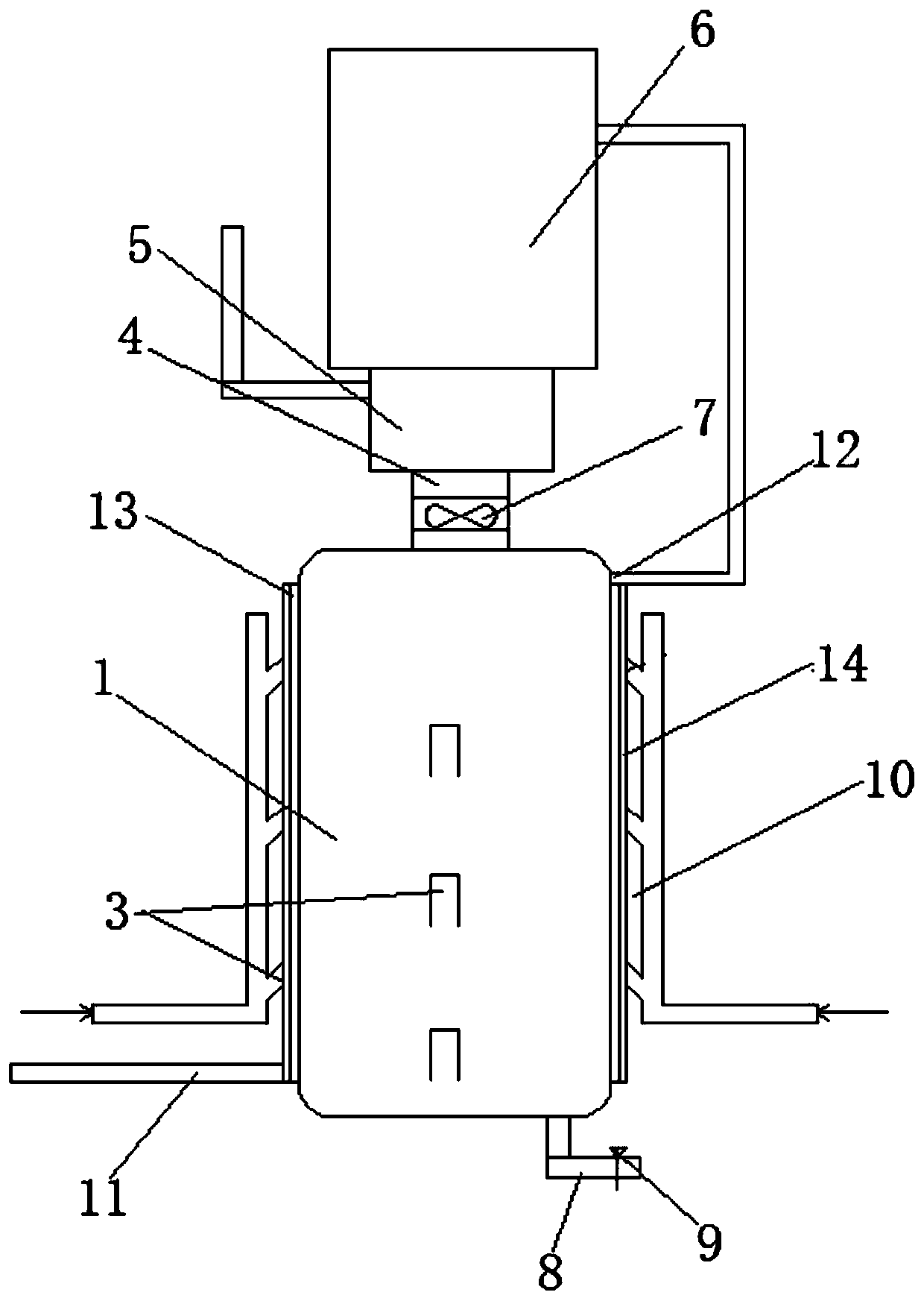

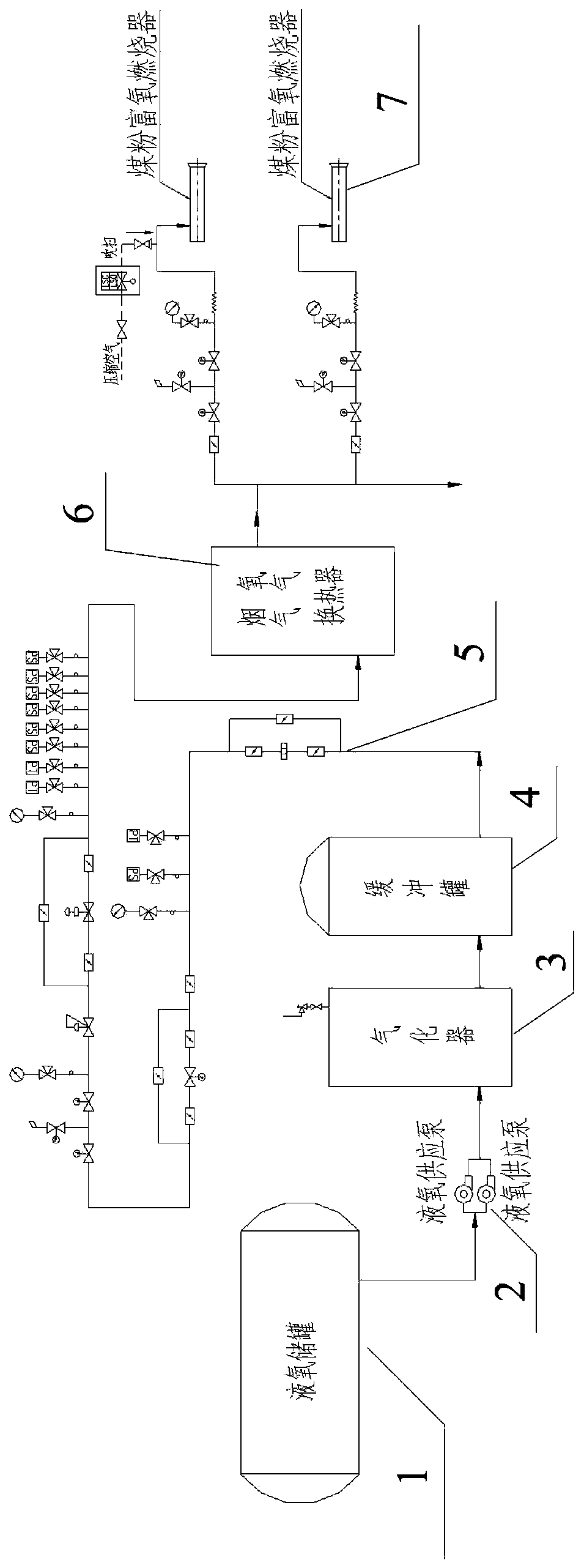

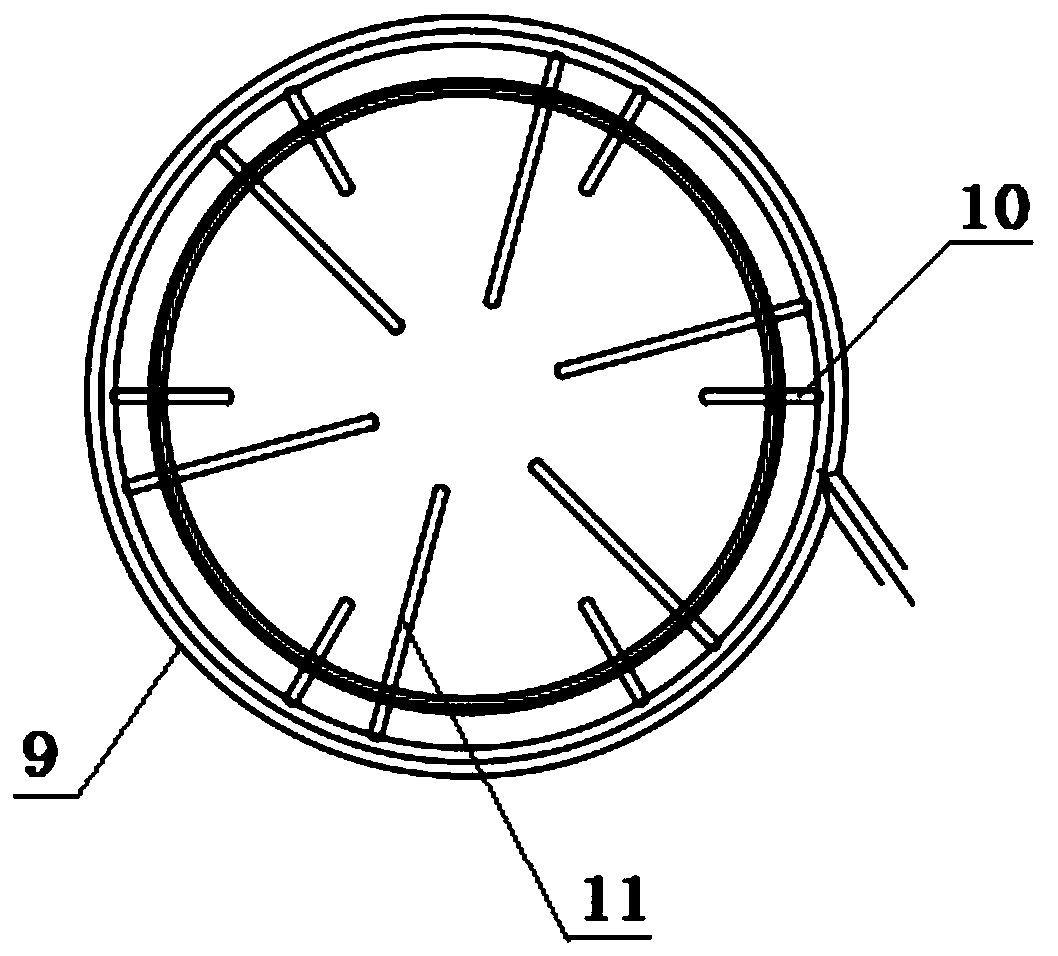

Pulverized coal oxygen-enriched burner meeting requirements of set deep peak load regulation, and system thereof

InactiveCN110207106ALow running costHigh operating costsPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationPressure stabilizationPeak load

The invention provides a pulverized coal oxygen-enriched burner meeting the requirements of set deep peak load regulation, and a system thereof, and belongs to the field of coal-fired power generation. The pulverized coal oxygen-enriched combustion system comprises a liquid oxygen storage tank, a liquid oxygen supply pump, a gasifier, a buffer tank, a pipeline valve, an exhaust gas and oxygen heatexchanger and the pulverized coal oxygen-enriched burner. Liquid oxygen stored in the liquid oxygen storage tank is conveyed to the gasifier through the liquid oxygen supply pump, evaporates to gasify into oxygen, is subjected to pressure stabilization in the buffer tank, and enters the exhaust gas and oxygen heat exchanger through the pipeline valve to be heated, and when the temperature reachesthe range from 650 DEG C to 700 DEG C, the oxygen enters the pulverized coal oxygen-enriched burner for ignition to form stable flames. According to the pulverized coal oxygen-enriched burner meetingthe requirements of set deep peak load regulation, and the system thereof, the oxygen-enriched burner carries out stable combustion during starting the low-load operation, the system has the self-stabilization combustion function, and has the advantages of being low in ignition temperature, high in combustion strength, high in combustion speed, high in temperature and complete in combustion reaction, and the boiler stable combustion and low-load operation cost is reduced.

Owner:HARBIN BOILER

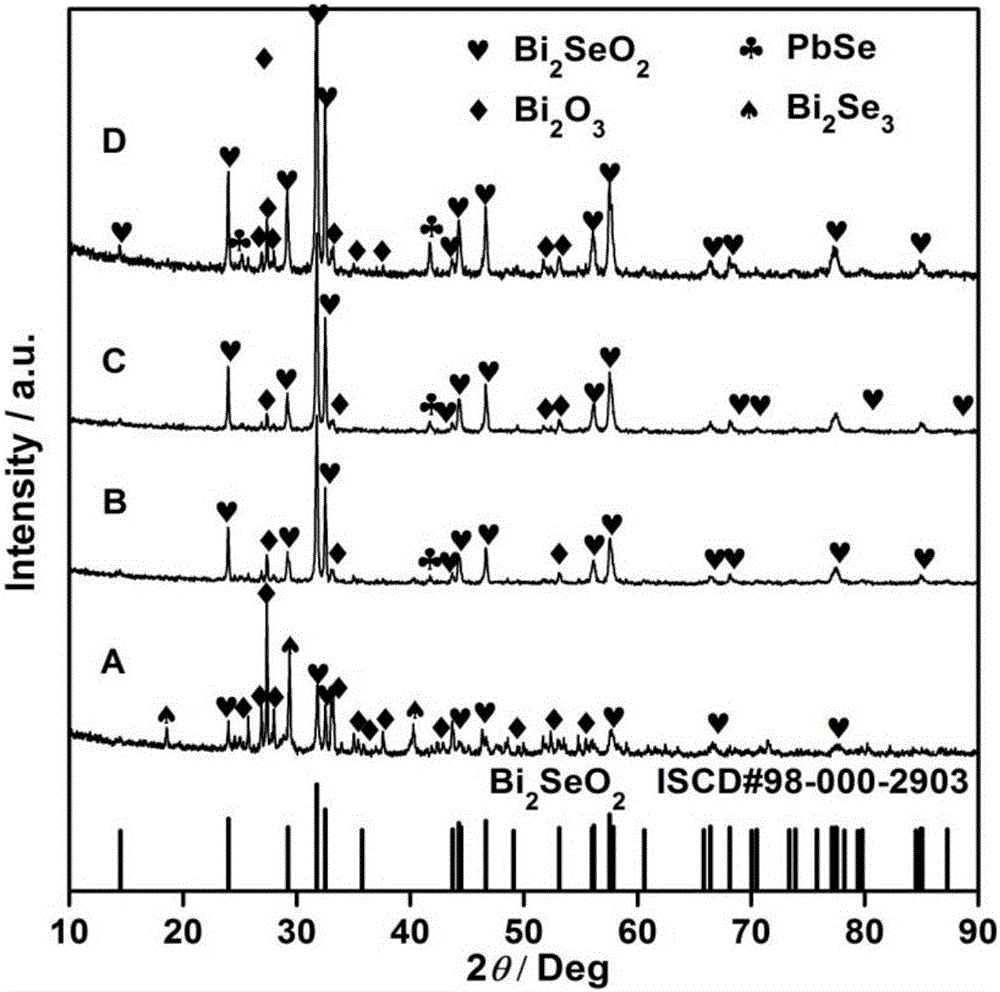

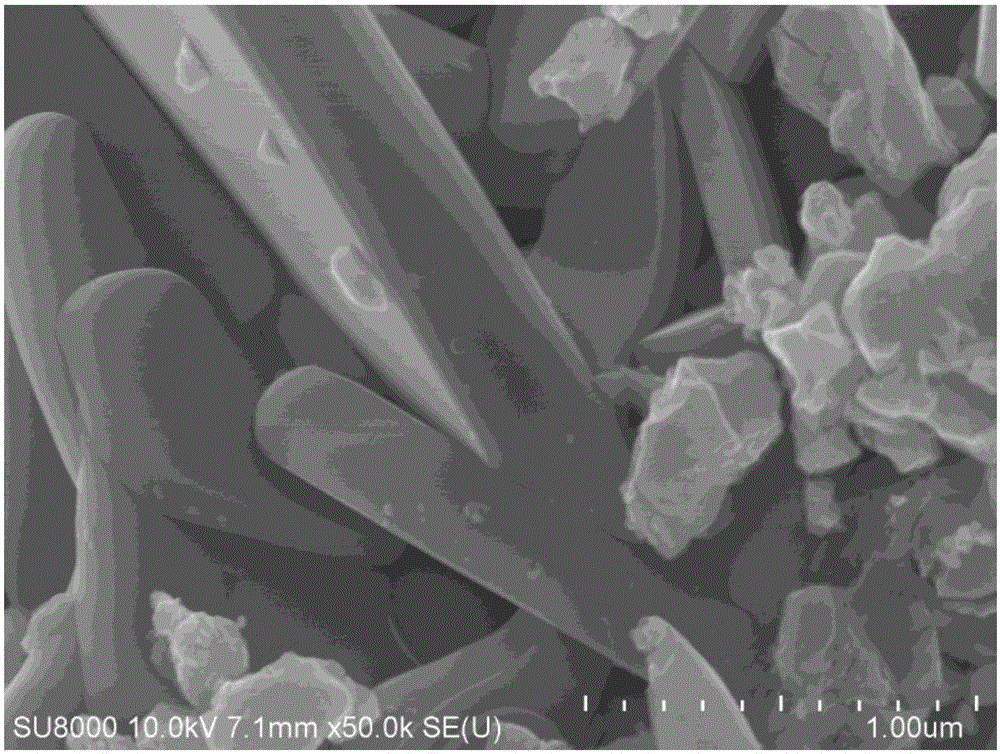

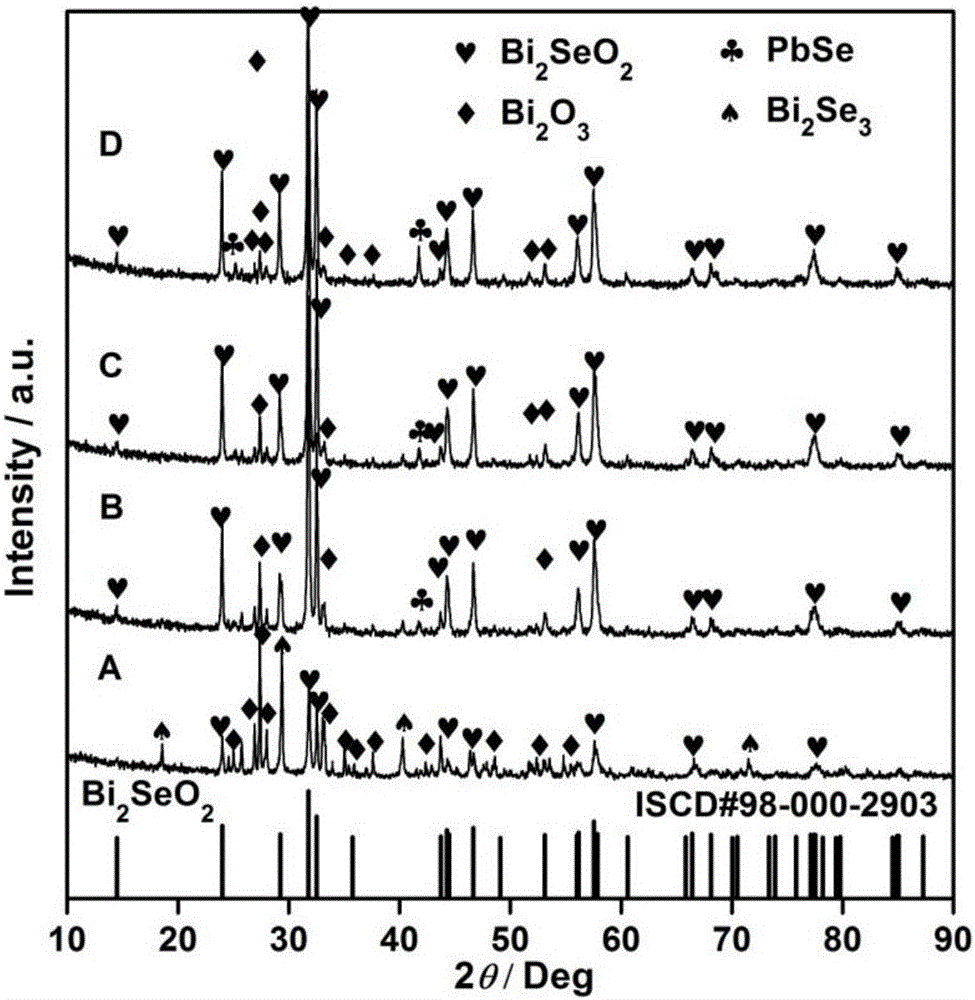

Combustion synthesis method of Bi2SeO2-based thermoelectric material and combustion improver for Bi2SeO2-based thermoelectric material

ActiveCN105152143AFull combustion reactionImprove thermoelectric performanceSelenium/tellurium compundsLead monoxideThermoelectric materialsCombustion

The invention discloses a combustion synthesis method of a Bi2SeO2-based thermoelectric material and a combustion improver for the Bi2SeO2-based thermoelectric material. By taking Bi, Se and Bi2O3 as raw materials, the method adopts a PbO compound as the combustion improver to promote combustion synthesis reaction to prepare the Bi2(1-x)Pb2xSeO2 thermoelectric material. The method disclosed by the invention has the advantages of being short in preparation time, simple in process, low in requirement on equipment, energy-saving and environmental-friendly, suitable for scaled production and the like, thereby laying a good foundation for scaled preparation and application of the Bi2SeO2-based thermoelectric material.

Owner:WUHAN UNIV OF TECH

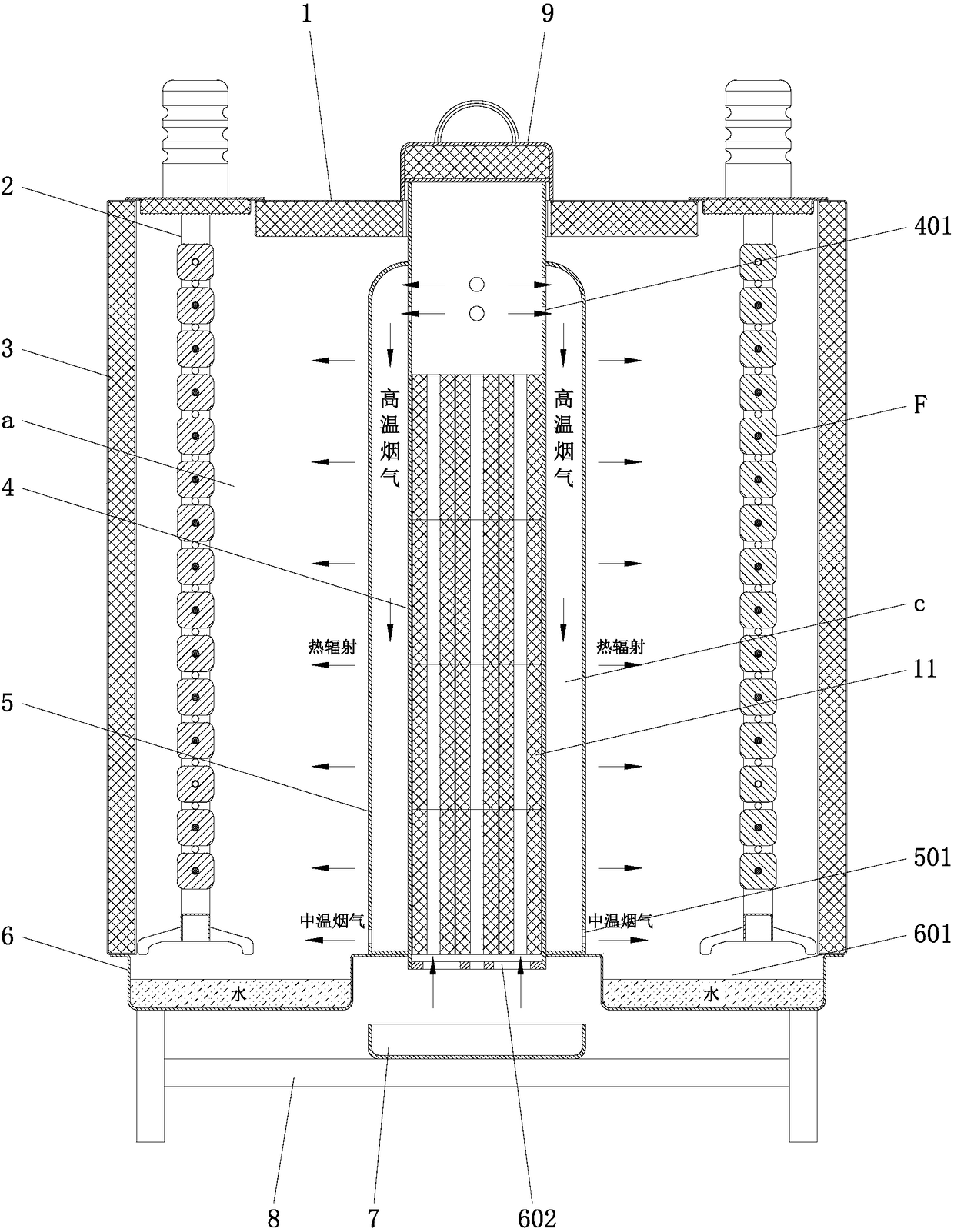

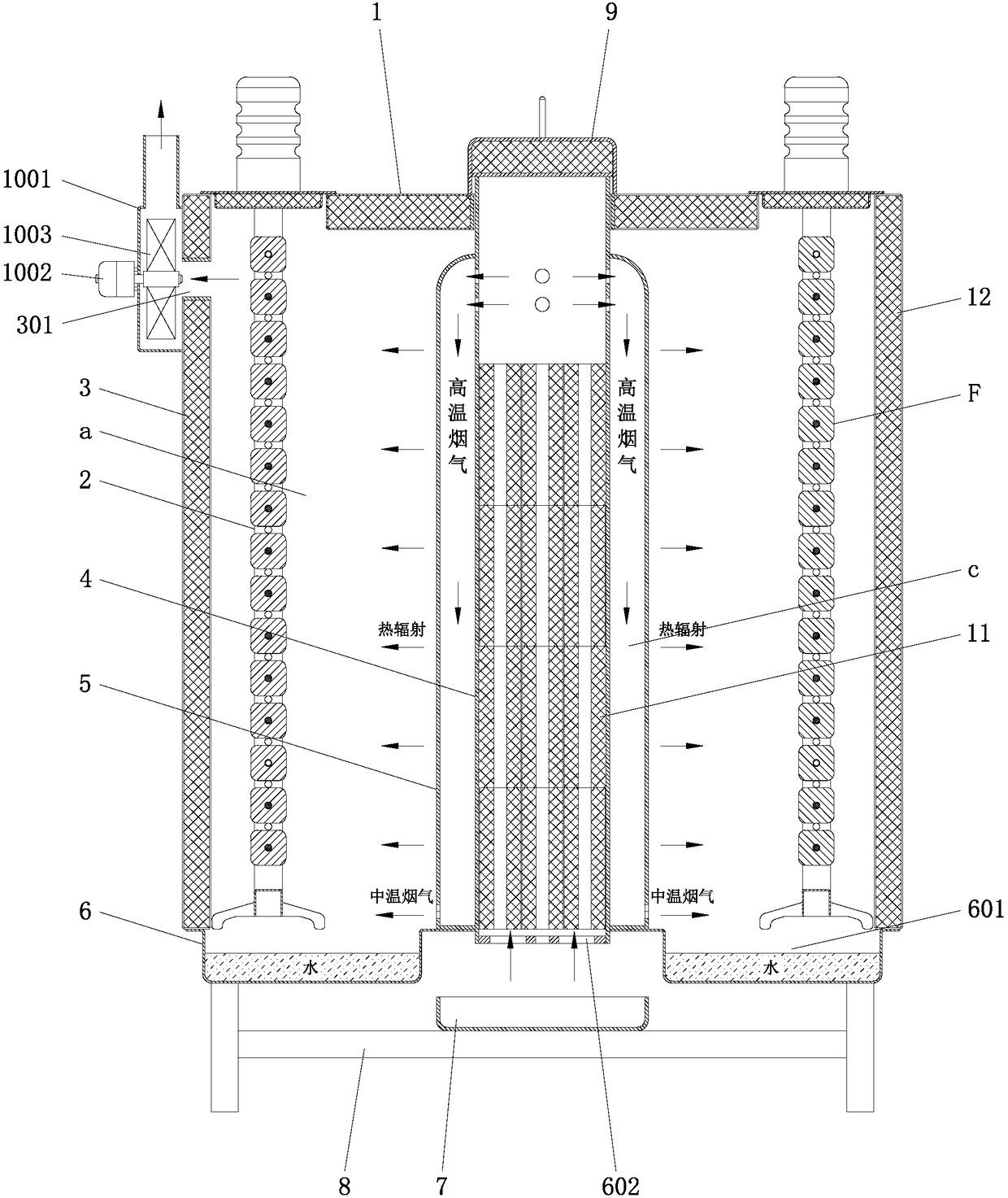

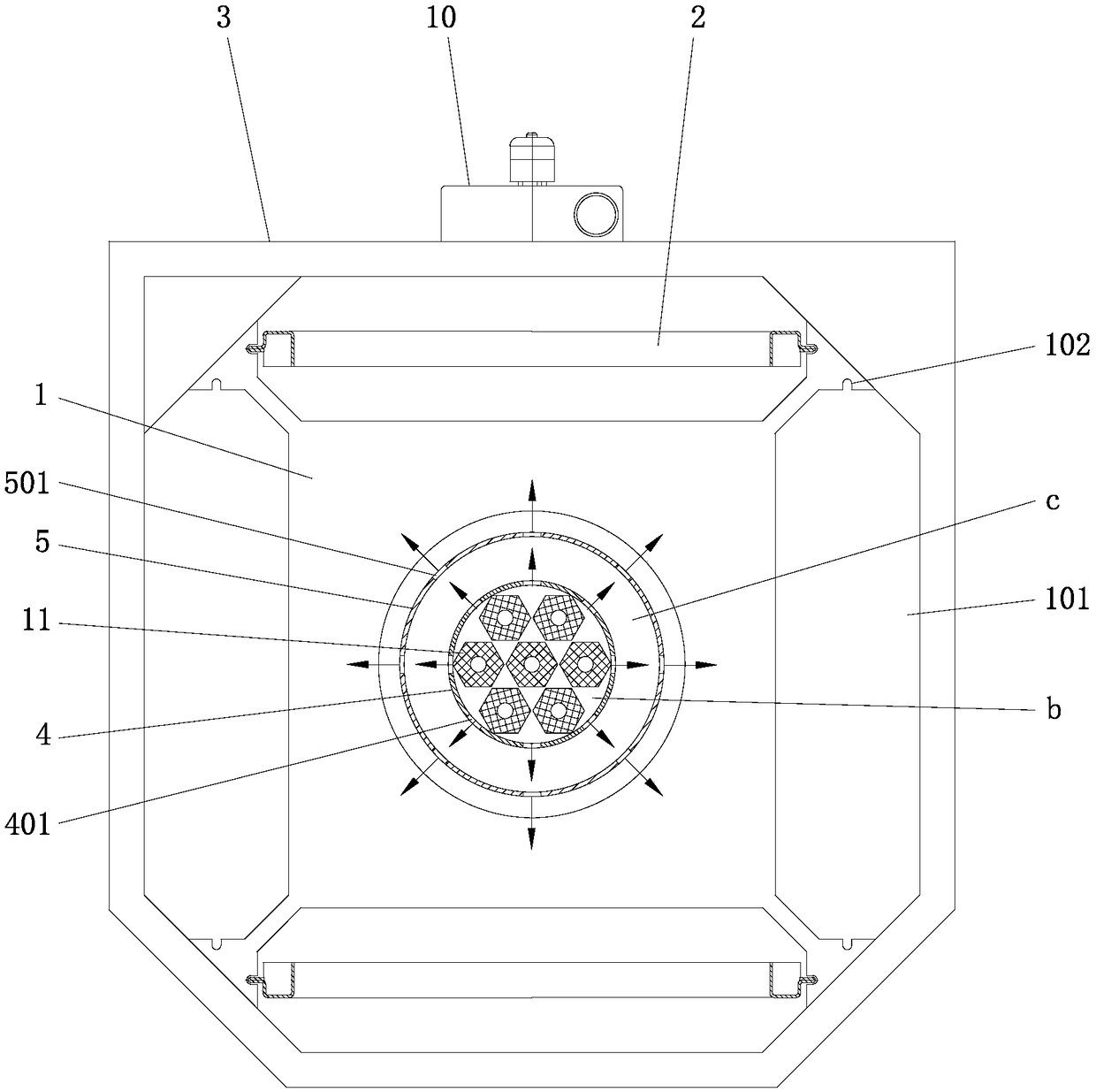

Forced-exhaust-type radiant carbon stove

InactiveCN108402111AReduce pollutionReduce contentOven air-treatment devicesCombustion chamberEngineering

The invention relates to a forced-exhaust-type radiant carbon stove. The forced-exhaust-type radiant carbon stove comprises a stove body, wherein a heating chamber is arranged in the stove body; a sleeve-type radiation mechanism is arranged in the heating chamber, and is composed of a combustion tube and a radiation tube; the radiation tube sleeves the outer side of the combustion tube, and a high-temperature smoke passage is formed between the combustion tube and the radiation tube; the inner chamber of the combustion tube is a combustion chamber, and a bottom of the combustion chamber communicates with the outside; high-temperature smoke outlets are formed in the combustion tube, and the combustion chamber communicates with the high-temperature smoke passage via the high-temperature smoke outlets; medium-temperature smoke outlets are formed in the radiation tube, and the high-temperature smoke passage communicates with the heating chamber via the medium-temperature smoke outlets; anda smoke exhaustion mechanism is arranged on the stove body. During operation, smoke produced by charcoal combustion in the combustion chamber enters the high-temperature smoke passage via the high-temperature smoke outlets, and then, enters the heating chamber via the medium-temperature smoke outlets; and then, forced exhaustion of the smoke in the heating chamber is realized by the smoke exhaustion mechanism. The forced-exhaust-type radiant carbon stove is capable of realizing completely enclosed radiant barbecue, and is convenient and practical in operation; moreover, the forced-exhaust-type radiant carbon stove is enhanced in heating performance, low in pollution, high in heat utilization rate, good in heating effect, and high in heating efficiency.

Owner:胡丽君

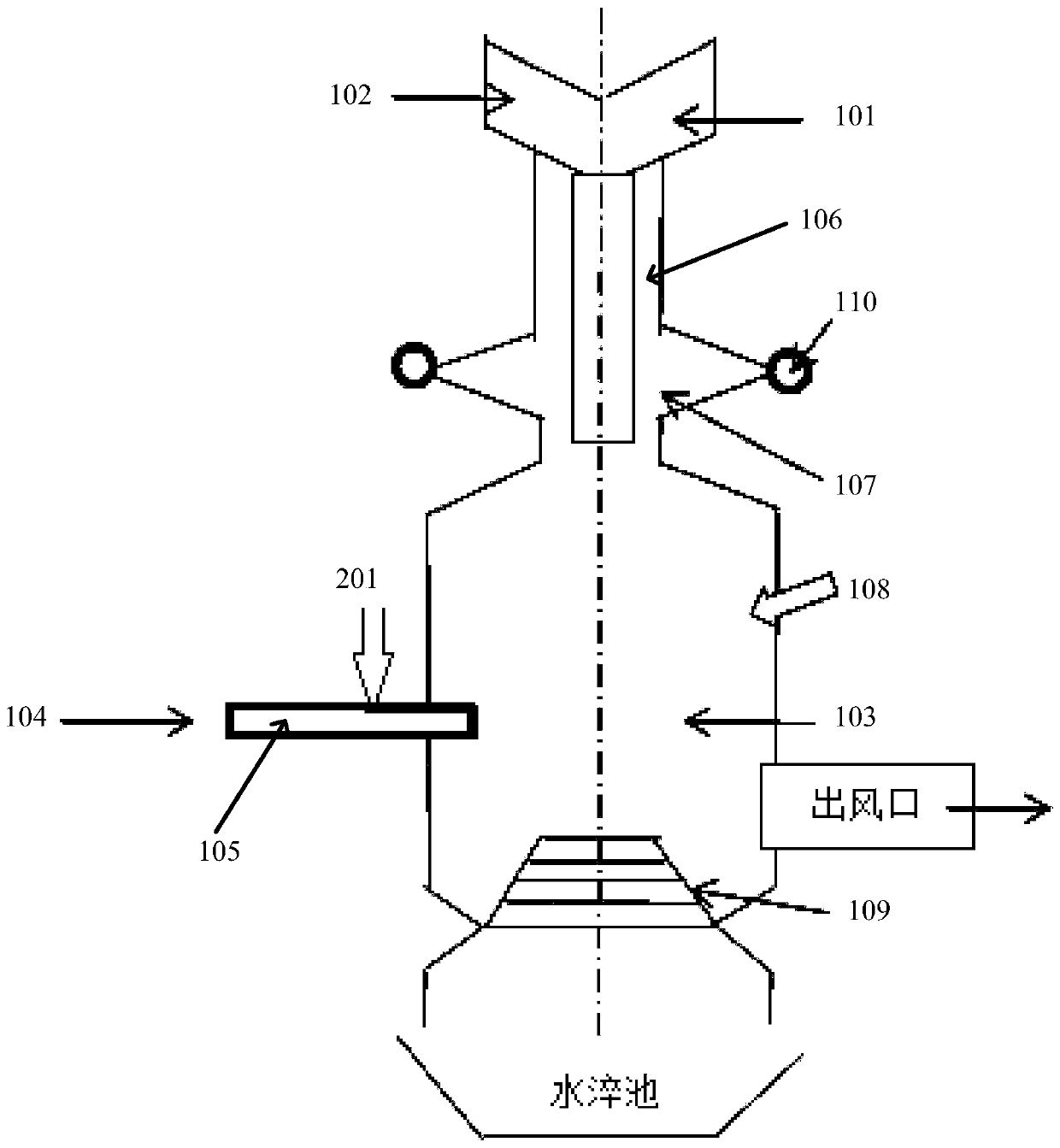

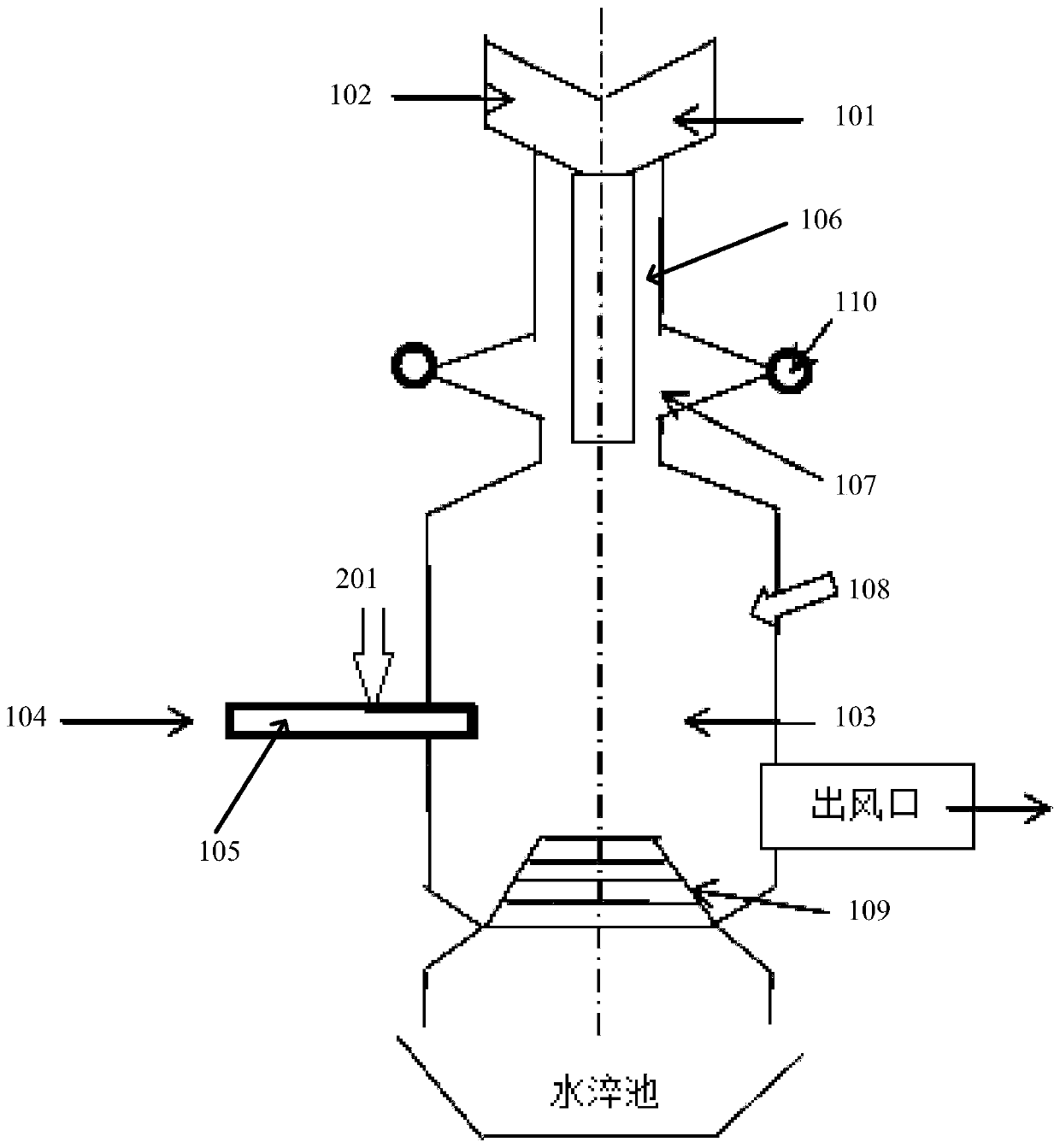

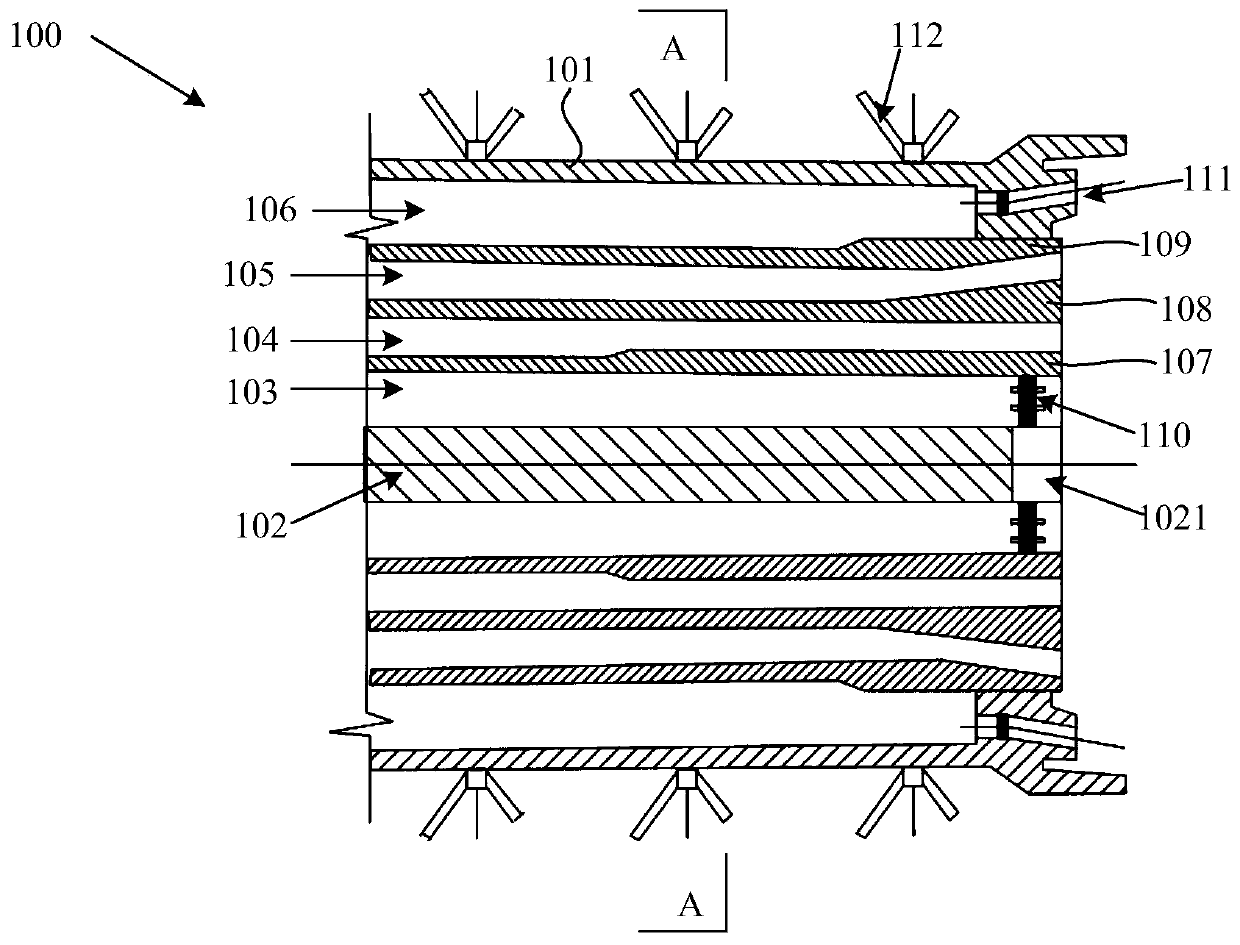

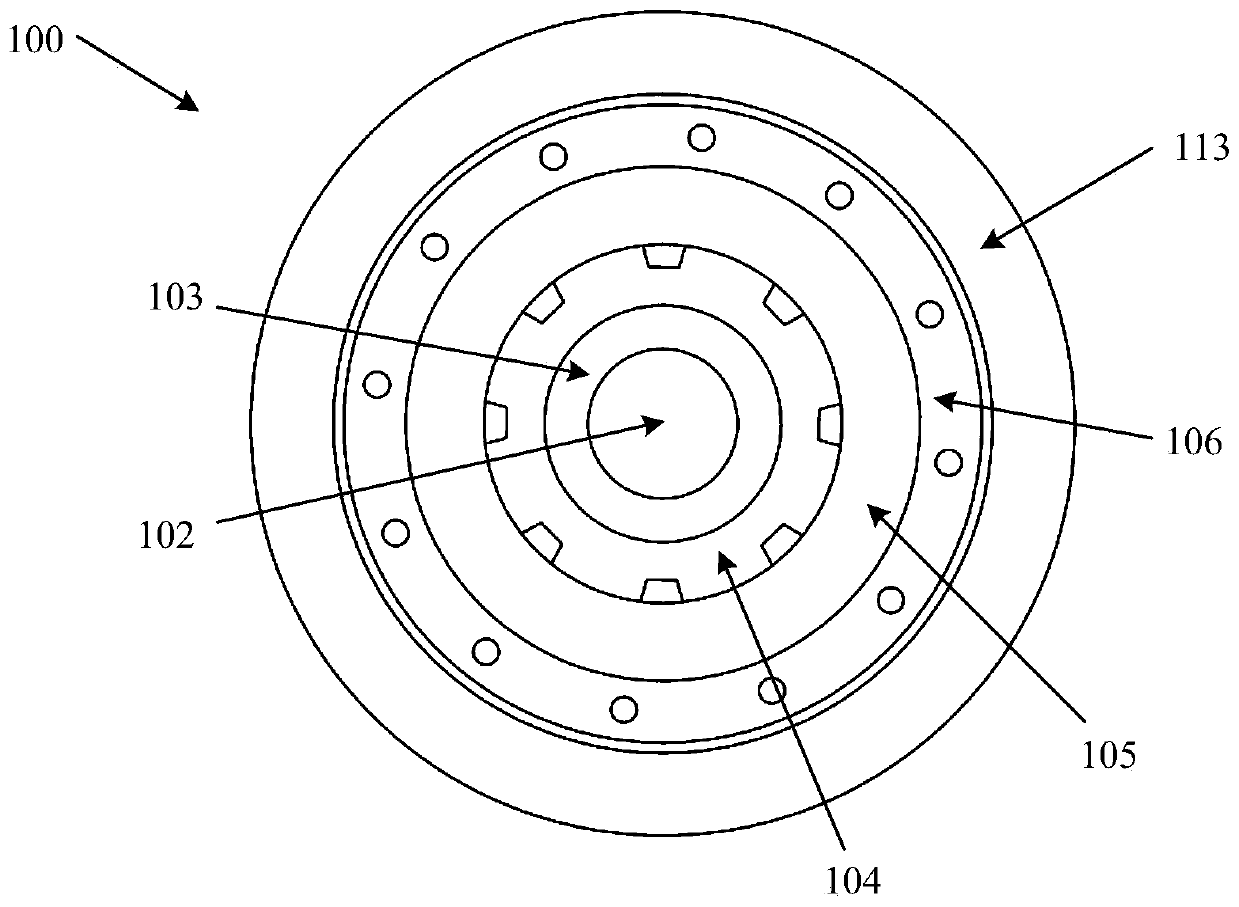

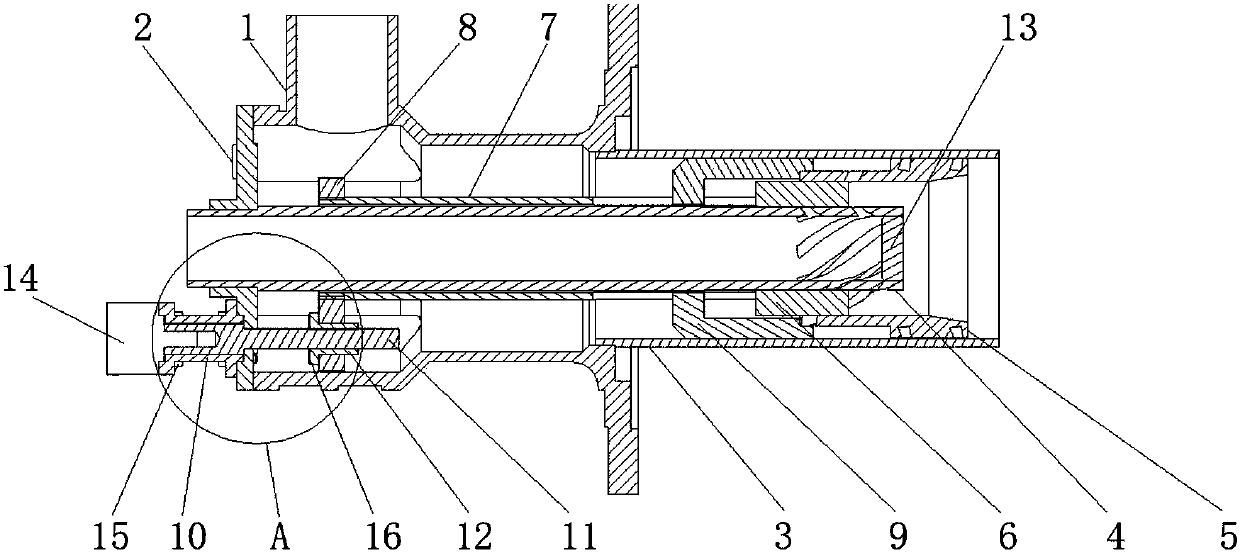

Combustion supporting device processing nitrous gas and three-waste integrated reactor

ActiveCN110081442AGive full play to the combustion-supporting effectAvoid cloggingIncinerator apparatusCycloneCombustion

The invention provides a combustion supporting device processing nitrous gas. The combustion supporting device processing nitrous gas comprises a shell. A column body is axially arranged at the centerof the shell. An ignition device is disposed at the bottom of the column body. The inner portion of the shell is divided by partition plates into a central ventilation channel, an inner cyclone air channel, a mixed air channel and an outer cyclone air channel from inside to outside. A bottom outlet of the outer cyclone air channel is provided with an outer cyclone nozzle, and the outer cyclone nozzle deviates outward and forms a certain angle with the axial direction of the combustion supporting device. Rotating wind blades are disposed at the bottom outlet of the central ventilation channel.When inner air, outer air and mixed air are sprayed out and leave the combustion supporting device, a high-speed rotating airflow is formed, so that mixed gas with the reducibility and the air with the oxidizing performance can quickly react and are burned rapidly. When N2O leaves the combustion supporting device, the N2O is completely wrapped in the middle of the combustion flame, the advantageof completely no escape is achieved, and after diffusion, the N2O enters the flame to assist combustion and participate in decomposition combustion.

Owner:北京科太亚洲生态科技股份有限公司 +1

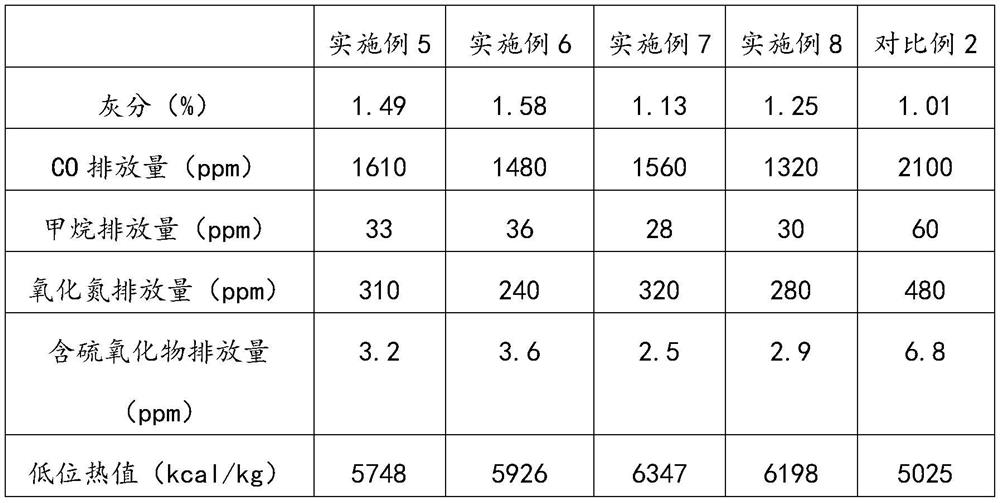

Biomass granular fuel and preparation method thereof

InactiveCN112111311AReduce porosityImprove molding rateBiofuelsSolid fuelsProcess engineeringEnvironmental engineering

The invention discloses a biomass granular fuel and a preparation method thereof, and relates to the field of development and utilization of waste biomass resources. The biomass granular fuel disclosed by the invention is prepared by the following steps: drying and crushing a biomass raw material to obtain powder, adding the lignin-based binder and the additive into the powder, uniformly stirringby virtue of a stirrer, mechanically compressing, granulating and cooling, thereby obtaining the biomass granular fuel. The lignin-based binder is obtained by adding a polyacrylic acid / urea polymer into a suspension containing lignin particles, adjusting the pH value, stirring, filtering, drying and crushing. According to the biomass granular fuel provided by the invention, by adding the lignin-based binder, the forming rate of the biomass granular fuel is increased, the biomass granular fuel is not easy to break in the transportation process, the combustion speed is stable, slag bonding is not liable to generate in the combustion process, the combustion efficiency is improved, the service life of a combustion device is prolonged, and the environmental pollution is reduced.

Owner:桃江县新辉生物质颗粒有限公司

Biomass granular fuel and preparation method thereof

ActiveCN108641773AIncrease the softening temperature of ash accumulationFully contactedBiofuelsSolid fuelsOxygenAlkali metal

The invention discloses a biomass granular fuel. The fuel comprises a biomass raw material and an additive, wherein the additive is a mixture of chitosan, calcium oxide and urea, and a weight of the additive is 0.5-4.8% of a weight of the biomass raw material. According to the fuel disclosed by the invention, a certain amount of chitosan, calcium oxide and urea are added into the biomass raw material as the additive, so that alkali metal elements in the biomass granular fuel can be fixed, and the problems of dust accumulation and slagging caused by alkali metals contained in the biomass granular fuel can be effectively improved; and addition of the chitosan, the calcium oxide and the urea can increase a contact area of the biomass granular fuel and oxygen, make a combustion reaction more sufficient, and prolong burning time, thereby improving burning efficiency. The invention also provides a preparation method of the biomass granular fuel.

Owner:湖北和泰生物能源有限公司

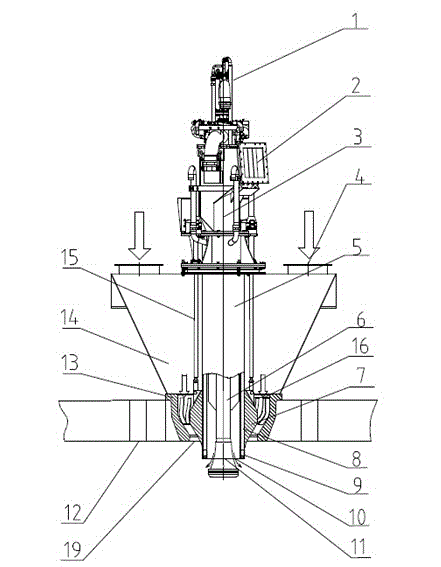

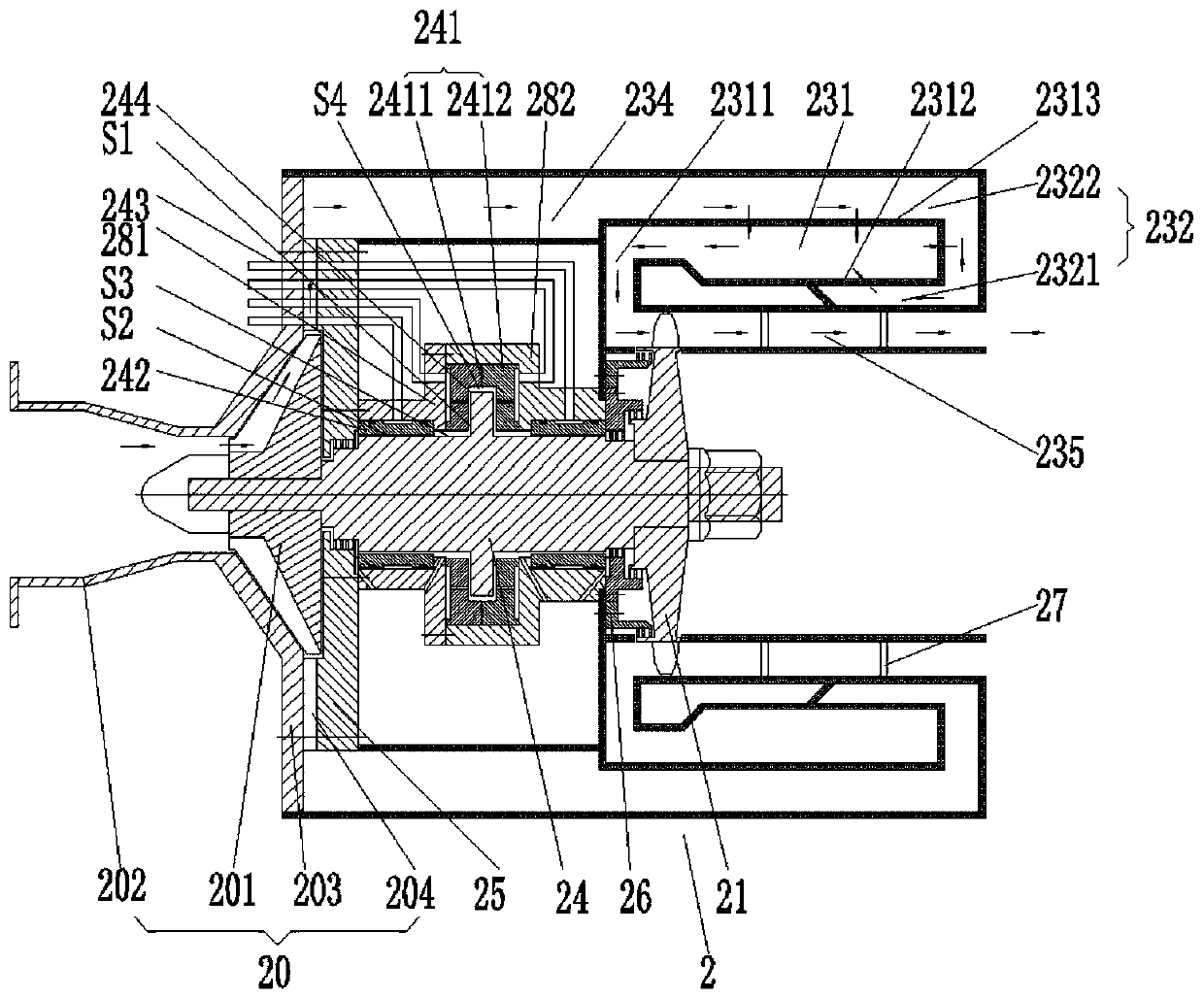

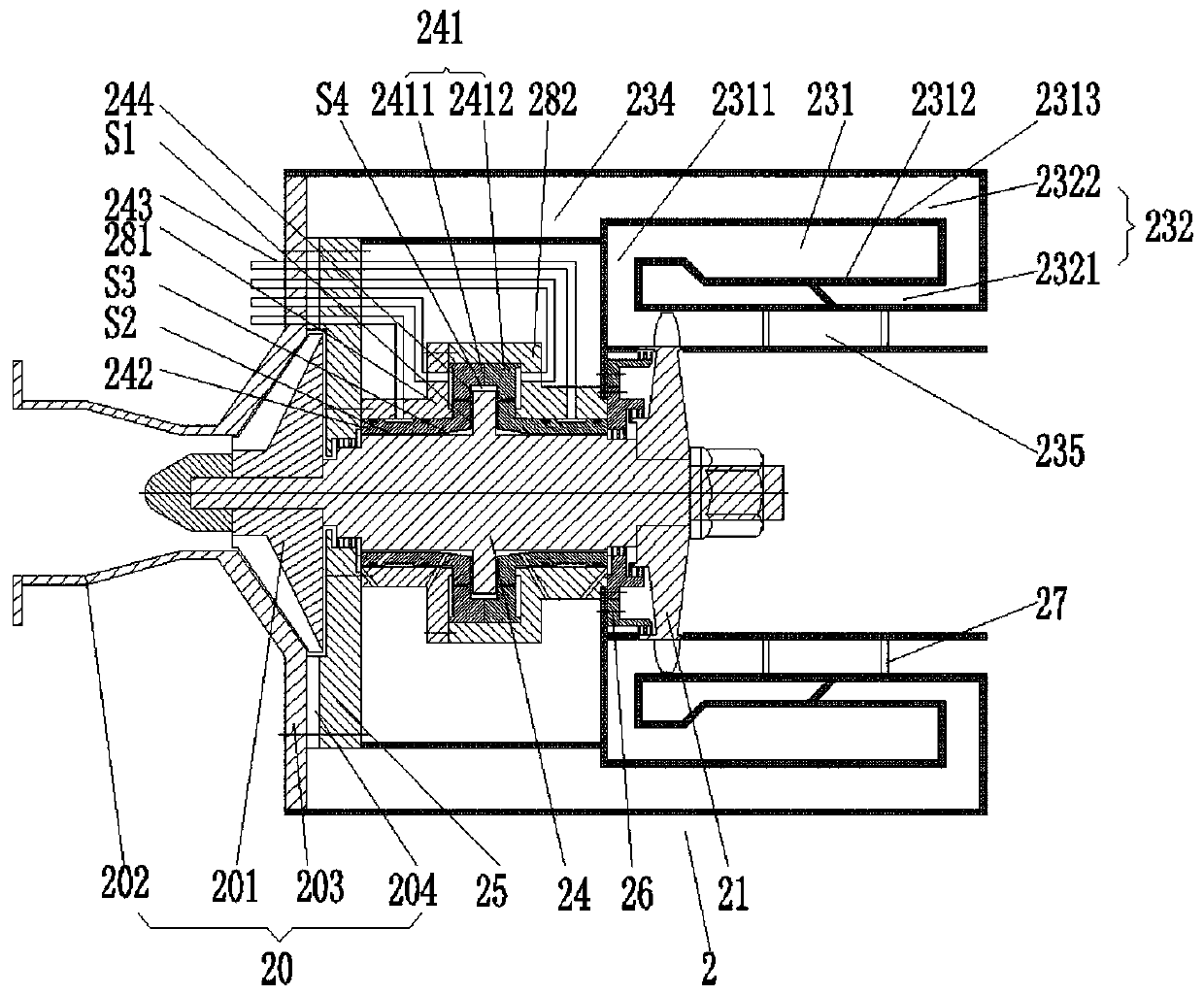

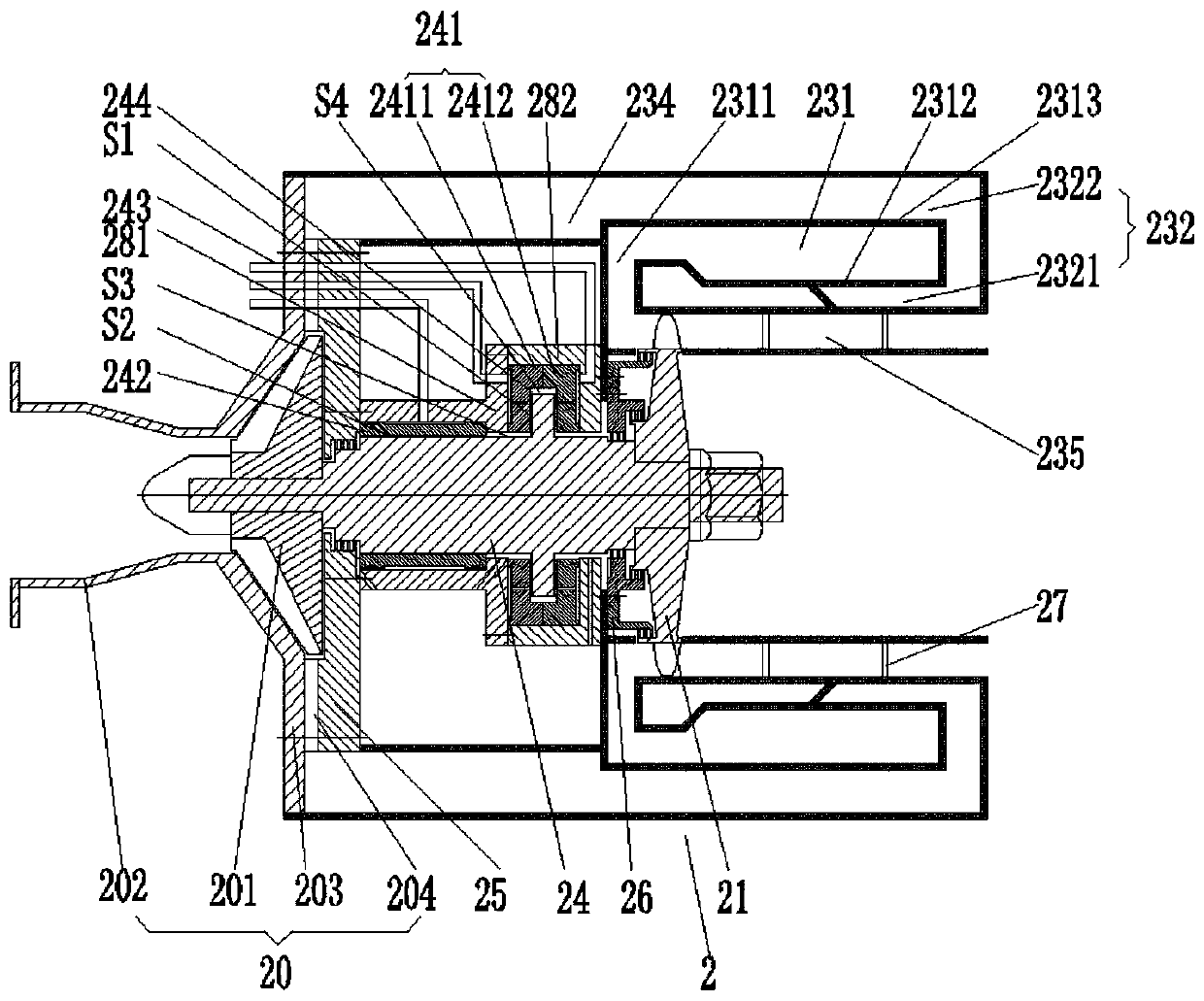

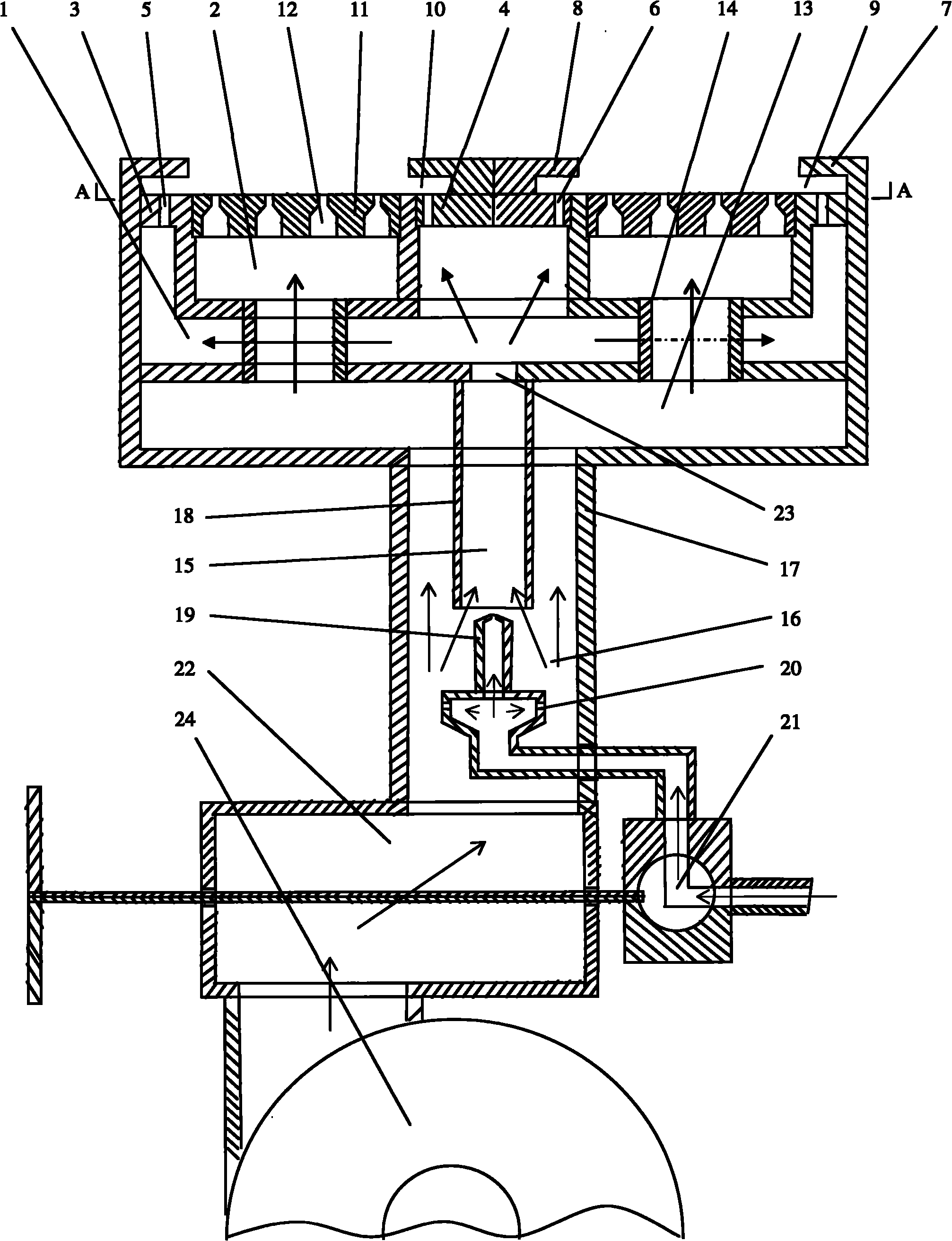

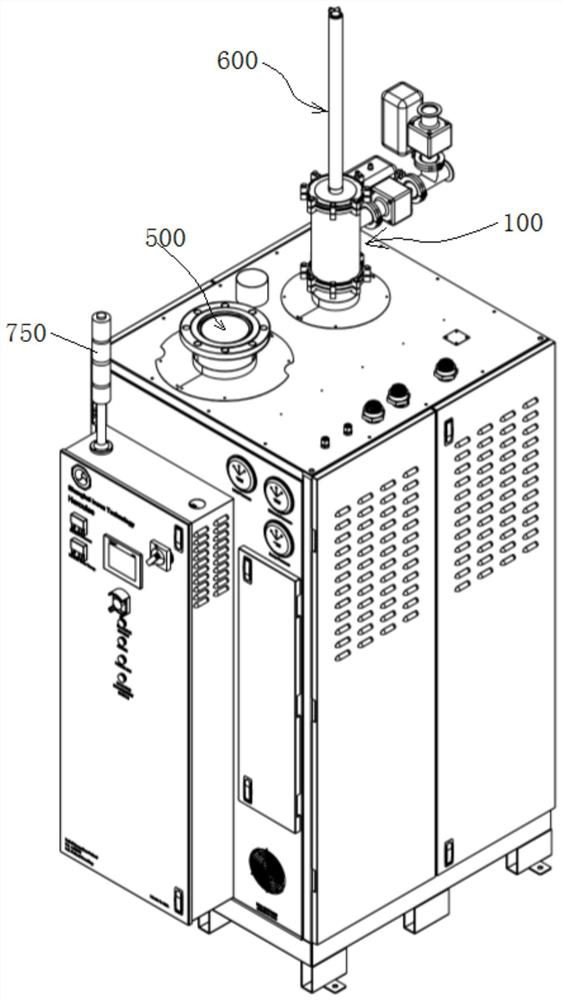

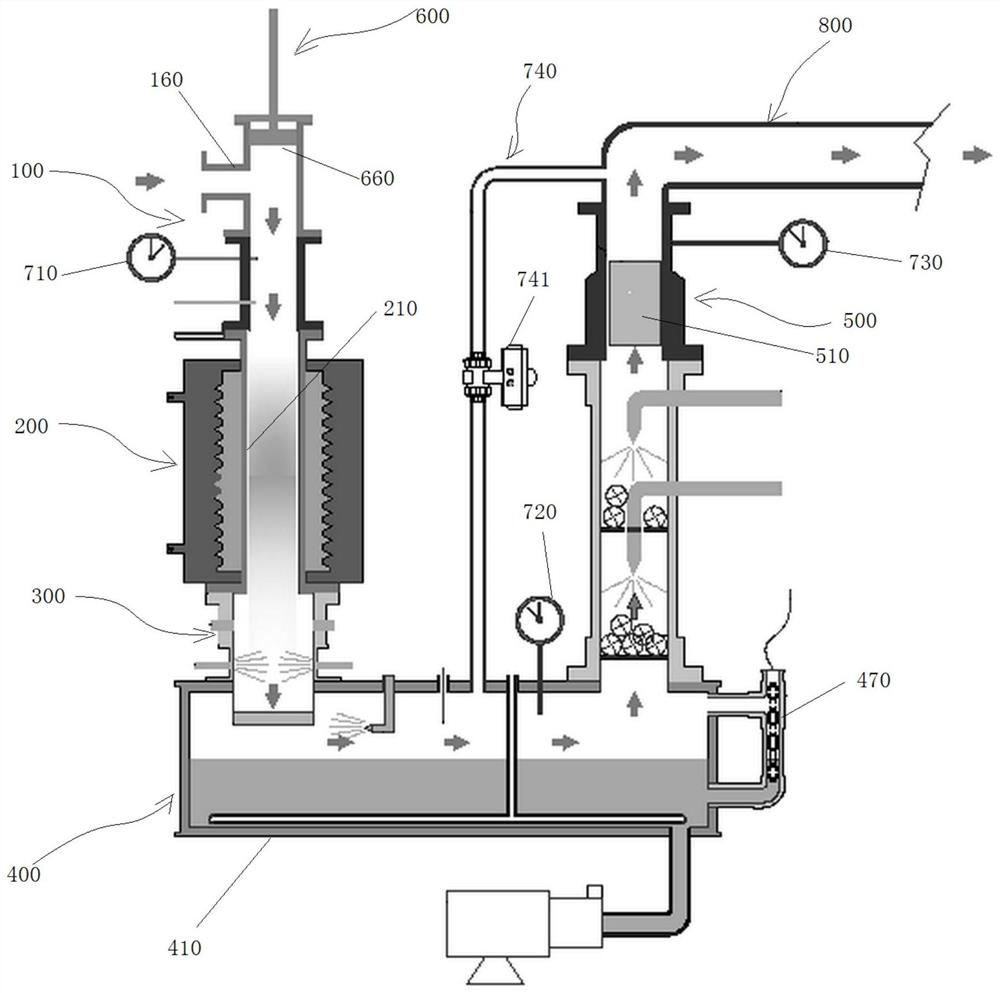

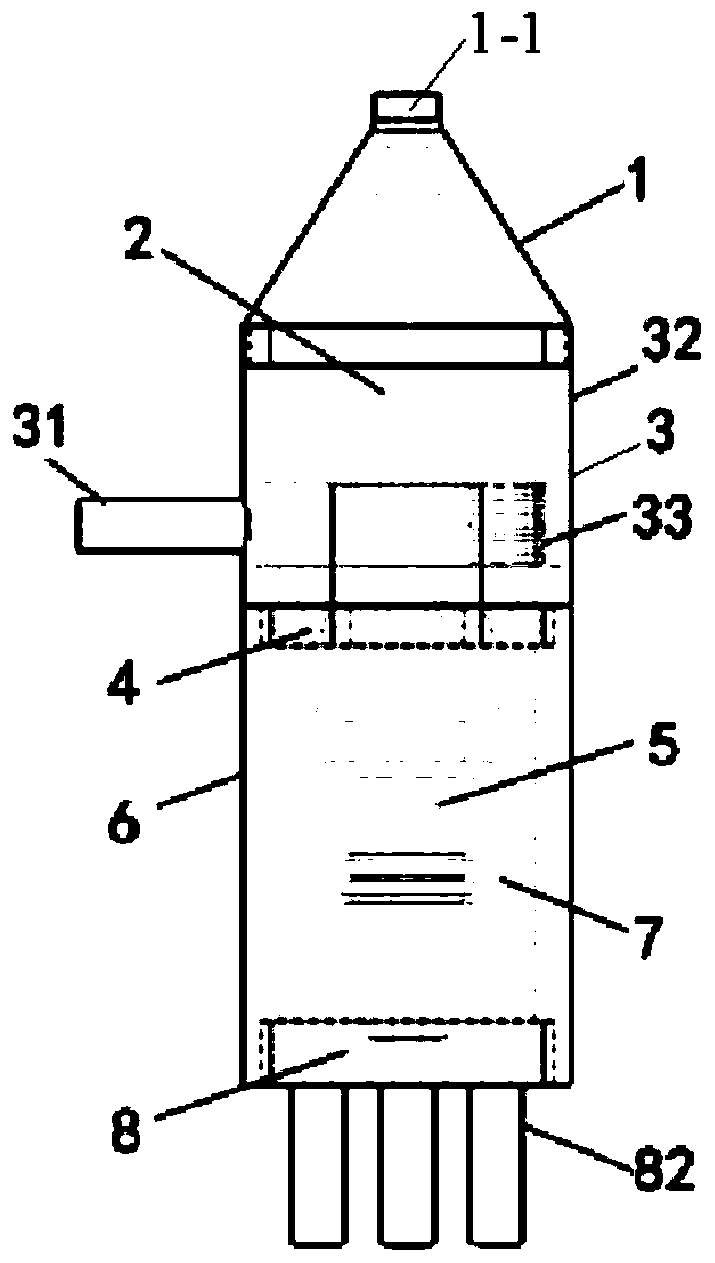

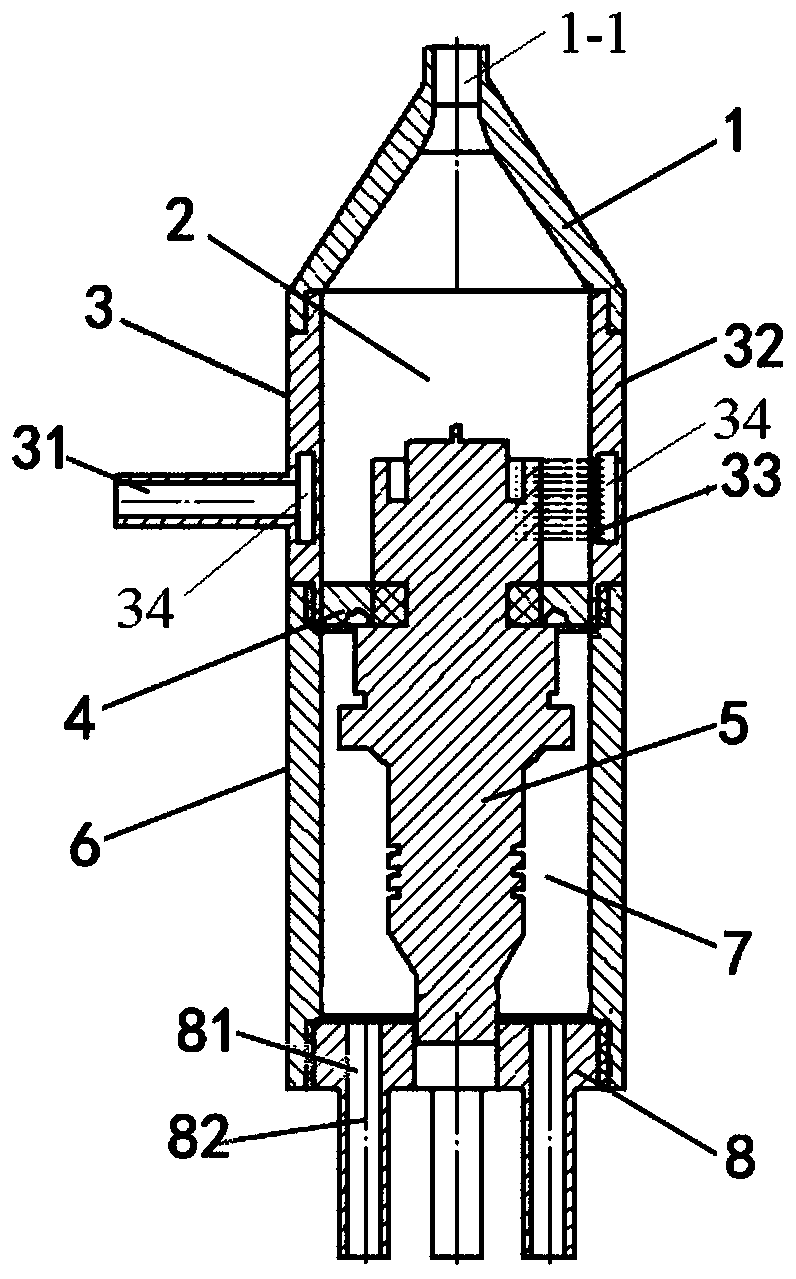

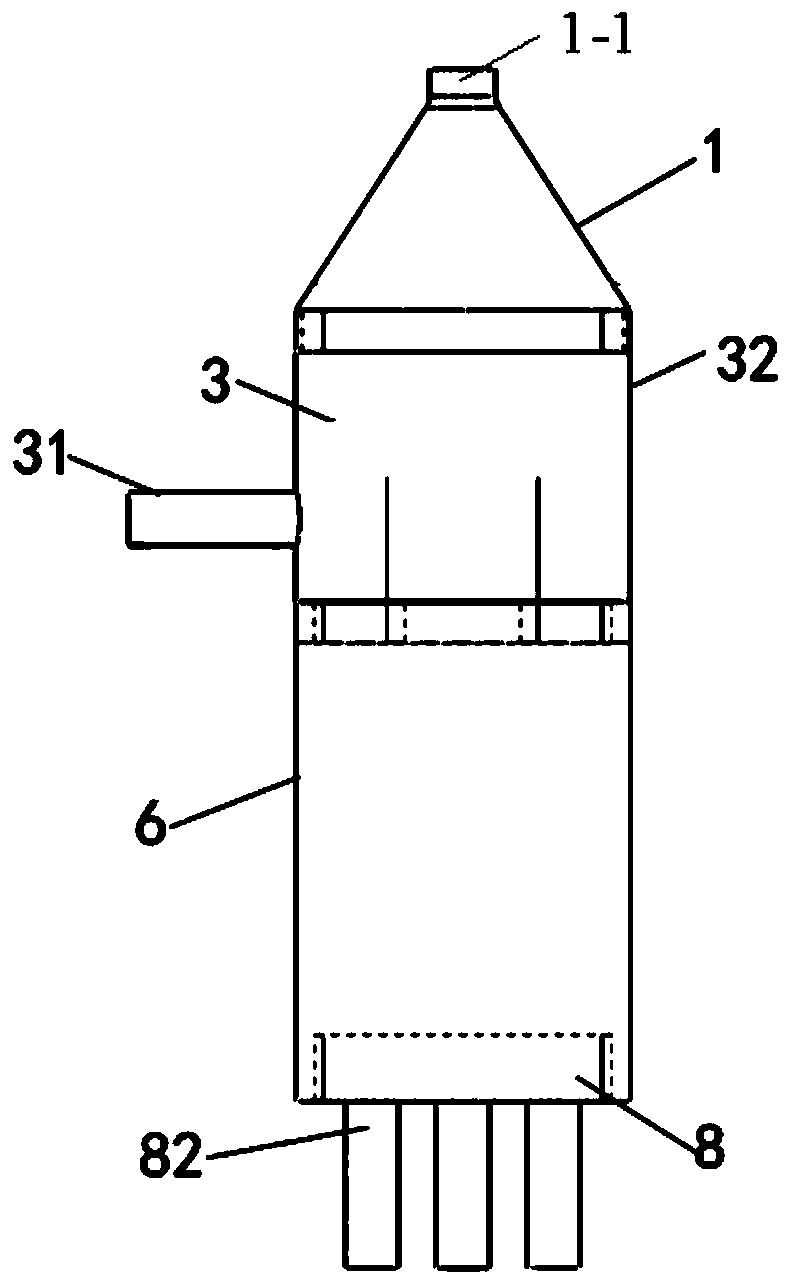

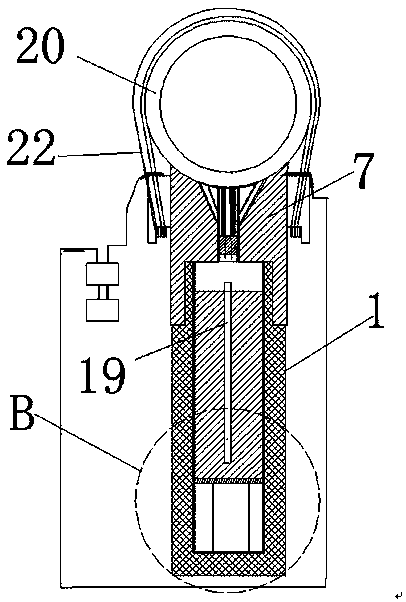

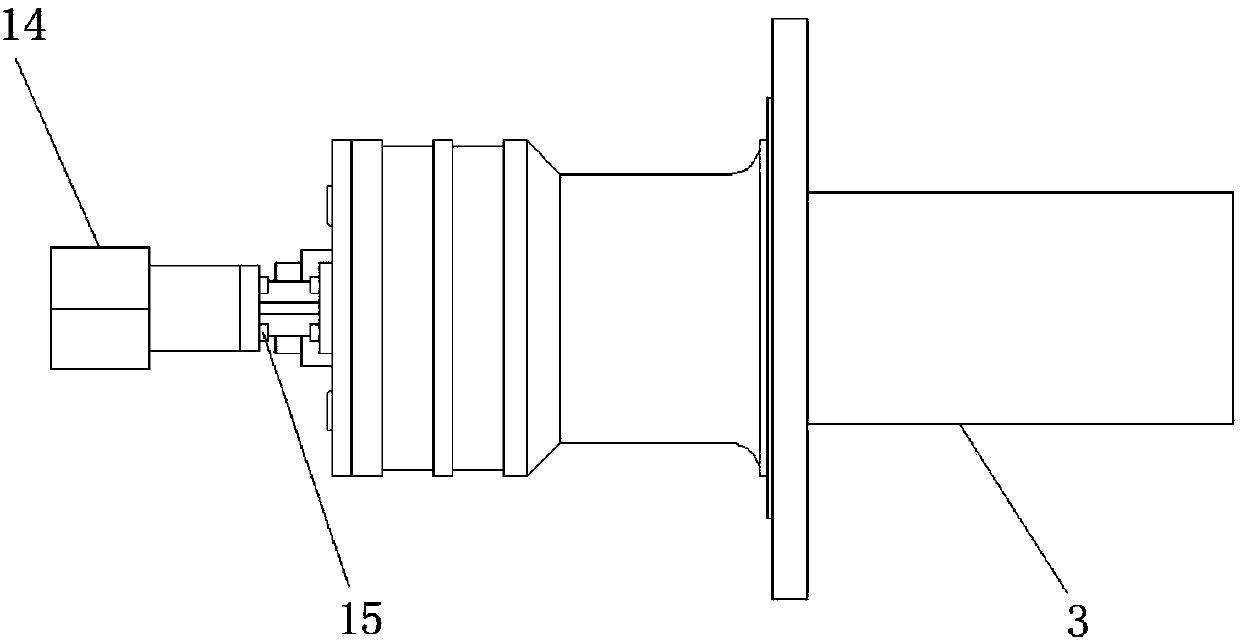

A kind of pre-combustion type plasma igniter and ignition method

ActiveCN107842427BRegion size increasesChemically activeTurbine/propulsion fuel supply systemsGas turbine plantsFuel oilHigh pressure

The invention discloses a pre-combustion type plasma igniter and an ignition method. The pre-combustion type plasma igniter comprises a shell, an oil conveying pipe, a hydrocyclone, a spark plug and agas channel base. A jetting opening is formed in the upper end of the shell. The hydrocyclone is arranged in the shell and connected with the shell. The hydrocyclone divides an inner cavity of the shell into a pre-combustion chamber and a rectification chamber. The spark plug is arranged on the inner cavity of the shell, penetrates the hydrocyclone and is connected with the hydrocyclone, and thehigh-voltage electrode of the spark plug is located in the pre-combustion chamber. An oil conveying cavity is formed in the shell wall of the portion, corresponding to the pre-combustion chamber, of the shell. The oil conveying pipe communicates with the oil conveying cavity. An atomizing hole is formed in the position, corresponding to the pre-combustion chamber, of the inner wall of the shell and communicates with the oil conveying cavity. The atomizing hole is used for atomizing fuel and then spraying the fuel to the pre-combustion chamber. The gas channel base is arranged at the lower endof the shell, connected with the shell, and used for providing combustion-supporting gas for the rectification chamber. A high-pressure lead of the spark plug penetrates the gas channel base and extends out of the shell. The igniter can ignite mainstream fuel oil in the pre-combustion chamber of an aircraft engine, and the reignition height of the aircraft engine is increased.

Owner:XI AN JIAOTONG UNIV

Combustion type steel component oriented cutting device

ActiveCN109623136AFull combustion reactionAvoid meltdownAlumino-thermic welding apparatusElectricityPunching

The invention discloses a combustion type steel component oriented cutting device. A bottom support sleeve, a top plate with a circular cross section, a cutting agent layer and an igniting agent layerare arranged in a charging barrel in sequence from bottom to top; a fixing device for fixing a top cover on objects to be punched is arranged on the radial peripheral surface of the top cover; a cylindrical through hole is formed in the center of the top cover; a cylindrical insulation plug is mounted in the through hole; the insulation plug is vertically provided with a top sleeve; two ignitionelectrodes are mounted in the center of the insulation plug, and are connected with electric ignition devices; and the top cover is provided with multiple punching holes. The cutting device is high inenergy density, high in combustion temperature, high in cutting speed and suitable for quick emergency hot cutting and underwater cutting of various steel structural parts under the conditions without electricity, gas and equipment in the fields or battlegrounds.

Owner:ARMY ENG UNIV OF PLA

Coal-saving agent and preparation method thereof

The invention belongs to the technical field of energy conservation and environmental protection, and in particular designs a coal-saving agent and a preparation method of the coal-saving agent. According to the invention, chitosan modified diatomite is taken as a carrier, so that effective components such as an oxidant, catalysts and a swelling agent can be effectively adsorbed to increase the loading amount of active components, so as to improve the combustion efficiency of coal; oxygen molecules adsorbed by a porous structure of the diatomite can be released when the coal is burned to promote a fully adequate combustion reaction; aluminum oxide and ferric oxide components contained in the diatomite can be used as the catalysts for the combustion reaction to effectively catalyze the coalcombustion reaction to reduce carbon monoxide emissions; calcium oxide and magnesium oxide components contained in the diatomite can effectively adsorb sulfur dioxide generated during combustion andreduce sulfur dioxide emissions in the presence of sodium hydroxide.

Owner:GUANGZHOU AUSPICIOUS CHEM

Sleeve kiln local oxygenation system

PendingCN111442649AReduce usageImprove combustion efficiencyMaintainance of heating chambersWaste heat treatmentCombustion chamberOxygen enhanced

The invention discloses a sleeve kiln local oxygenation system. The sleeve kiln local oxygenation system comprises an oxygen generation unit, an ejection unit, a heat exchange unit and an oxygenationunit, wherein the oxygen generation unit is used for producing pure oxygen, the inlet end of the ejection unit is connected with the oxygen generation unit, the inlet end of the heat exchange unit isconnected with the outlet end of the ejection unit, the heat exchange unit is arranged on a hot gas pipeline from an upper inner sleeve outlet flue of the sleeve kiln to the heat exchanger, the inletend of the oxygenation unit is connected with the outlet end of the heat exchange unit, the oxygenation unit is arranged outside a combustion chamber, the oxygenation unit comprises an oxygenation annular pipe, a plurality of oxygenation spray guns and a plurality of oxygenation spray pipes are arranged on the oxygenation annular pipe in the circumferential direction, the oxygenation spray guns are arranged on a combustion chamber panel, and the oxygenation spray pipes are arranged below an arch bridge. According to the sleeve kiln local oxygenation system, after local oxygen-enriched combustion, the combustion efficiency is improved, the combustion-supporting air volume and the use amount of fuel can be properly reduced, a better energy-saving effect can be achieved, the ignition temperature of the fuel in an oxygen-enriched state can be reduced, the combustion speed is increased, the combustion process is violent, the combustion reaction is sufficient and complete, and a better heatexchange effect is achieved.

Owner:JIANGSU ZHONGSHENGYUAN TECH CO LTD

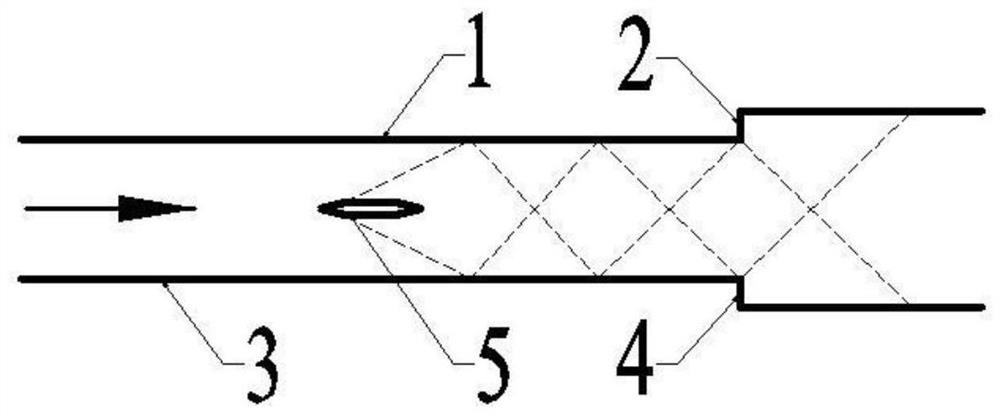

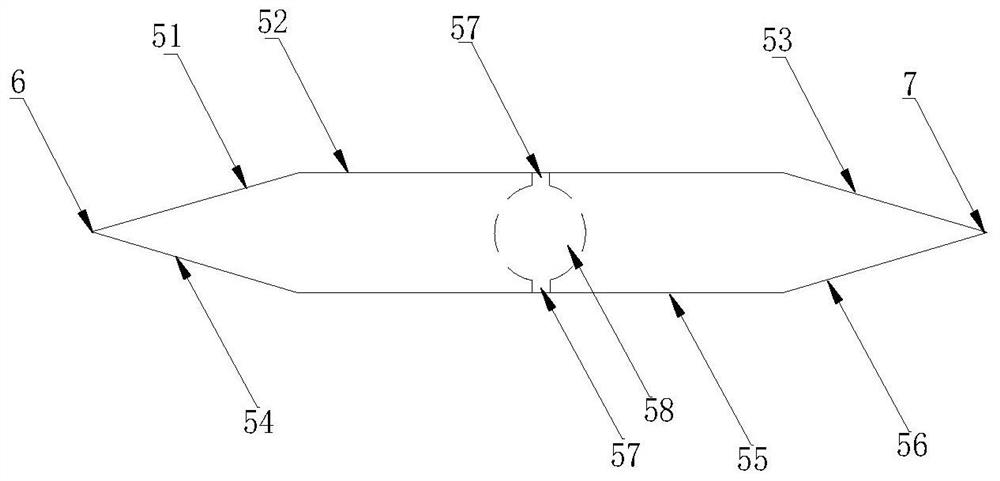

Combustor assisted without air source for engine

InactiveCN111997715AReduce particle contentFull combustion reactionExhaust apparatusSilencing apparatusThermodynamicsCombustor

The invention relates to the technical field of engines, in particular to a combustor assisted without an air source for an engine. The combustor comprises a shell, a fuel atomization structure and astable flame combustion chamber assembly, wherein the two ends of the shell are subjected to tapping and shrunk to form an air inlet and an air outlet, and the air inlet communicates with an exhaust pipeline of the engine; the fuel atomization structure provides atomized fuel for the stable flame combustion chamber assembly, and the spraying direction of the atomized fuel is the same with the flowdirection of the engine exhaust in the shell; and the stable flame combustion chamber assembly is arranged in the shell, and provides the space for the mixing and combustion of the atomized fuel andthe engine exhaust. The combustor assisted without the air source for the engine has the beneficial effects that the structure is simple, the engine exhaust changes the speed difference of the fuel through the expansion and shrinkage of the air inlet and the air outlet of the shell, so that the engine exhaust reacts with the full combustion of the fuel; and the atomized fuel and the engine exhaustare uniformly distributed and ignited in the stable flame combustion chamber assembly, continue to combust in the air outlet, and the combustion efficiency is improved.

Owner:山东盛锐达环保科技有限公司

Full-automatic energy-saving spray gun

InactiveCN107763620AReduced exhaust air volumeGood energy saving effectGaseous fuel burnerAir volumeEngineering

The invention discloses a fully automatic energy-saving spray gun, which comprises a spray gun seat, an adjusting pipe, a motor seat and a plug. One side of the spray gun seat is provided with a spray gun cover, and the other side of the spray gun seat is provided with a gun barrel. The inside of the gun barrel is inlaid with a spray gun nozzle, and the outside of the spray gun nozzle is inlaid with a regulator. One side, and the inside of the motor seat is inlaid with an adjusting screw, the outer side of the adjusting screw is installed with a nut sleeve, and one side of the nut sleeve is provided with a second screw. This fully automatic energy-saving spray gun solves the problem of insufficient laminar combustion and makes the combustion reaction more complete. The regulator adjusts the amount of gas while also adjusting the amount of air, and always ensures that the amount of air and gas are completely combusted. Proportional supply, the premix chamber required for complete combustion is formed between the air cap and the nozzle, which makes the fuel combustion of the device more complete.

Owner:丁光学

Organic heat carrier heating equipment

ActiveCN105135678BTake advantage ofClean up thoroughlyStorage heatersHeat carrierParticle combustion

The invention discloses an organic heat carrier heating device, which comprises a furnace body and a heat-conducting oil tank. The furnace body is provided with a furnace, the outer wall of the furnace is provided with a ring of heat-insulating jackets, and the bottom of the furnace body is respectively provided with air inlet cylinders. And ash chamber, including heating system, secondary circulation system, rotary quantitative feeding system and ash cleaning system; the advantage of the present invention is that it can feed quantitatively and orderly, strictly control the feeding speed and feeding amount, and prevent tempering The phenomenon occurs, the combustion reaction is sufficient, and the utilization rate of the combustion of biological particles in the furnace body is improved, the heat can be fully recycled for the second time, and the heating surface of the spirally coiled tube group can be made uniform, which greatly saves resources and saves biological energy. The usage of pellets saves cost.

Owner:ANHUI SANDING BOILER MFG CO LTD

A combustion chamber spanning support plate

The invention discloses a spanning support plate of a combustion chamber, which relates to the technical field of transcendental ramjet engines. The key points of the technical solution are: a support plate body installed in the middle of the combustion chamber, the support plate body includes a first inclined surface close to the upstream direction of the airflow and The second slope is located on the upper plane and the lower plane of the straight section of the support plate body, and the third slope and the fourth slope are close to the downstream direction of the airflow; the end of the support plate body close to the upstream direction of the airflow is composed of the first slope and the second slope The first cone angle; the end of the support plate body close to the downstream direction of the air flow is formed by the third inclined plane and the fourth inclined plane; the second cone angle is formed; the center of the support plate body is provided with an oil injection cavity. The middle part of the upper plane and the middle part of the lower plane are provided with injection holes communicating with the oil injection chamber. It is convenient to directly and quickly inject fuel into the middle of the combustion chamber, and at the same time, it can reduce the total pressure loss of the airflow caused by the intrusion of the support plate into the combustion chamber, prolong the residence time of the fuel in the combustion chamber, improve the mixing efficiency of fuel and airflow, and enhance the ignition capacity of the combustion chamber .

Owner:CHINA AERODYNAMICS RES & DEV CENT

A kind of biomass particle fuel and preparation method thereof

ActiveCN108641773BIncrease the softening temperature of ash accumulationFully contactedBiofuelsSolid fuelsEngineeringEnvironmental engineering

Owner:湖北和泰生物能源有限公司

A combustor for treating nitrous gas and a three-waste integrated reactor

ActiveCN110081442BImprove combustion efficiencyEasy to stir and mixIncinerator apparatusCombustionEngineering

Owner:北京科太亚洲生态科技股份有限公司 +1

A method for preparing graphene nanocomposite energetic materials using atomic layer deposition technology

ActiveCN105839078BSolve the problem of fragmentationEvenly dispersedNanotechnologyChemical vapor deposition coatingChemical reactionUltrasonic assisted

The invention discloses a method for preparing a graphene nano-composite energetic material through an atomic-layer deposition technology. The method includes the steps that graphene loaded nanometer metal compound powder is prepared through an ultrasonic-assisted solution mixing and in-situ reduction method, so that even scattering of nanometer metal on the surface of graphene is achieved; and then, the gas-phase atomic-layer deposition technology is adopted, two different precursors pass through a reaction cavity alternately, the precursors make contact with the surface of the graphene / nanometer metal compound powder fully, a chemical reaction is set off, and oxides are generated. By means of the method, the oxides wrap the graphene surface and the nanometer metal surface evenly. According to the graphene nano-composite energetic material prepared through the method, the affinity between the oxides and the nanometer metal surface is increased, and spatial arrangement is improved. Due to the addition of the graphene, the scattering situation of the nanometer metal is improved, and the energy release rate of the energetic material is increased. The method is high in automation degree and good in safety, the material can be directly used without after-treatment, and mass production of the graphene nano-composite energetic material is achieved easily.

Owner:XIAN MODERN CHEM RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com