Electric heating washing type waste gas treatment device

A waste gas treatment device, electric heating device technology, applied in the direction of combined devices, lighting and heating equipment, combustion methods, etc., can solve the problems of reducing the concentration, easy to get stuck in the scraper, uncontrollable liquid level, etc., to reduce the chance of entering the water tank , improve processing efficiency and avoid water pump damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific technical solutions of the present invention will be described in detail below through examples. It should be noted that the following examples can only be used to explain the technical solutions of the present invention and should not be construed as limitations on the present invention.

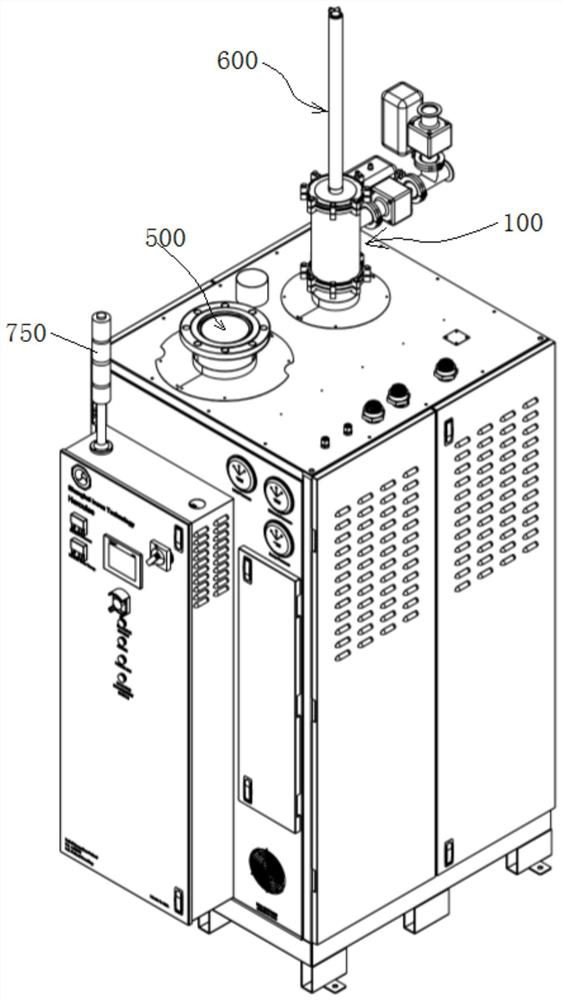

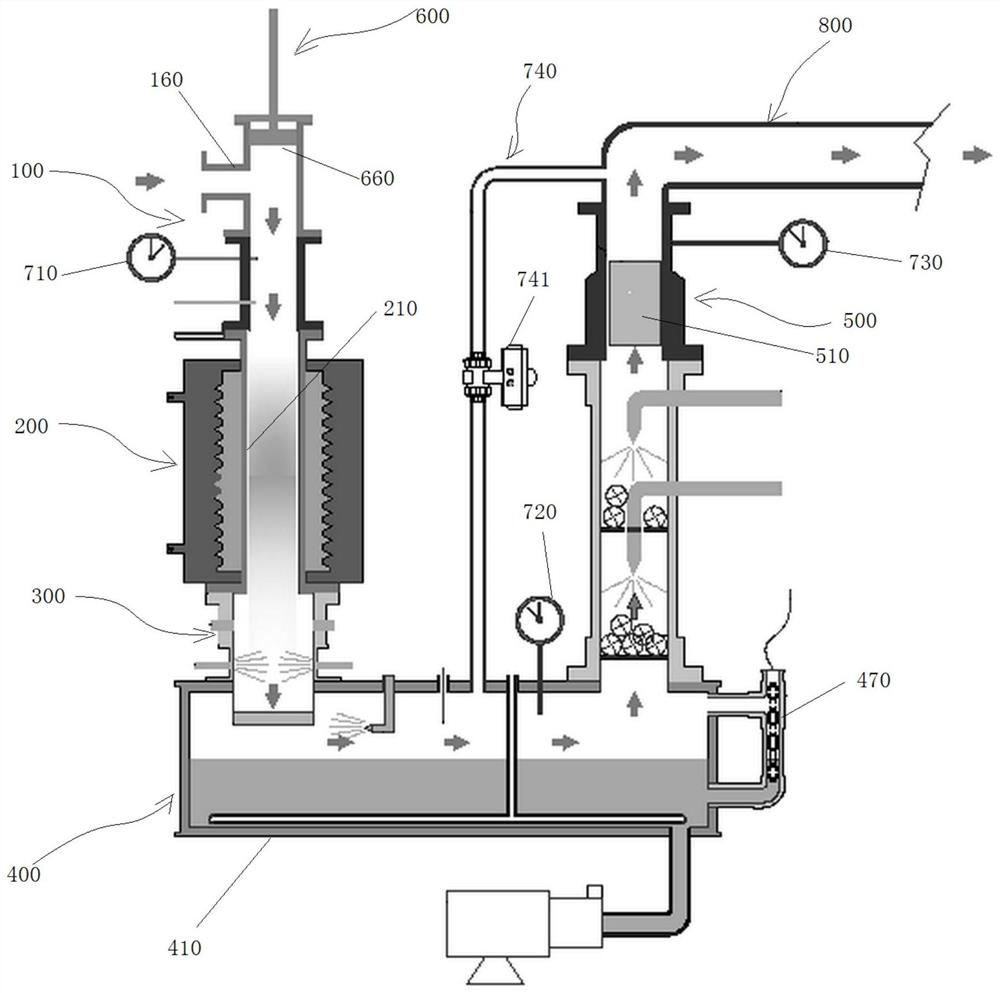

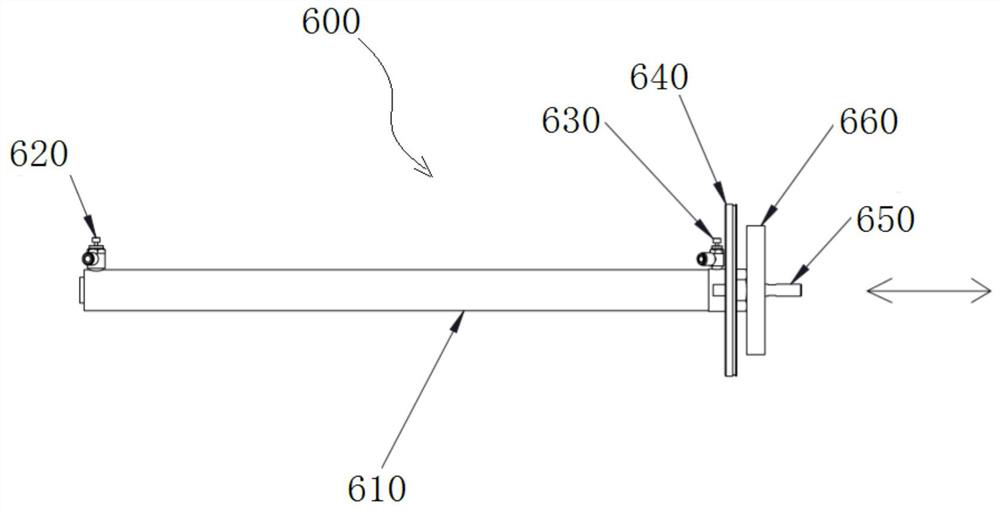

[0050] like figure 1 As shown, it is a schematic diagram of the appearance of an embodiment of the electric heating water washing waste gas treatment device of the present invention, as figure 2 As shown, it is a schematic structural diagram of an embodiment of the electric heating water washing waste gas treatment device of the present invention. The electric heating water washing waste gas treatment device includes a first air inlet 100, an electric heating device 200, a dust filter device 300, an intelligent cooling water washing System 400 and air outlet 500, the first air inlet 100 is arranged on the electric heating device 200, the electric heating device 200 is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com