Impinging stream low-nitrogen combustion reaction device and reaction method thereof

A technology of impinging flow reaction and low-nitrogen combustion, applied in combustion methods, burners, combustion chambers, etc., to achieve uniform heat release and high heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is based on the ideal embodiment of the present invention as an inspiration. Through the following description, relevant workers can make various changes and modifications within the scope of not departing from the technical idea of the present invention. The technical scope of the present invention is not limited to the content in the specification, but must be determined according to the scope of the claims.

[0037] With reference to the following drawings, the present invention is further described:

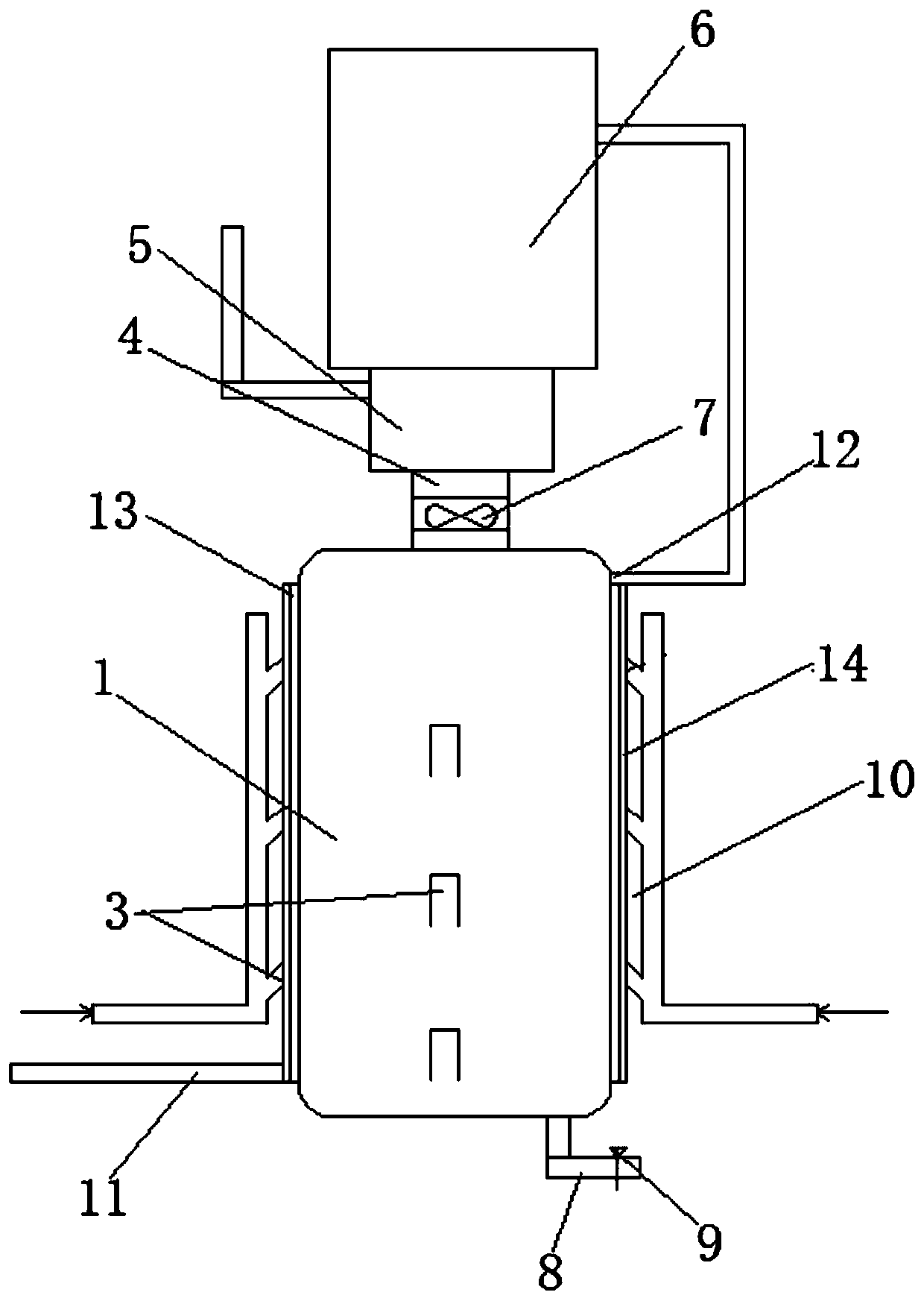

[0038] An impinging flow low-nitrogen combustion reaction device, comprising the following components:

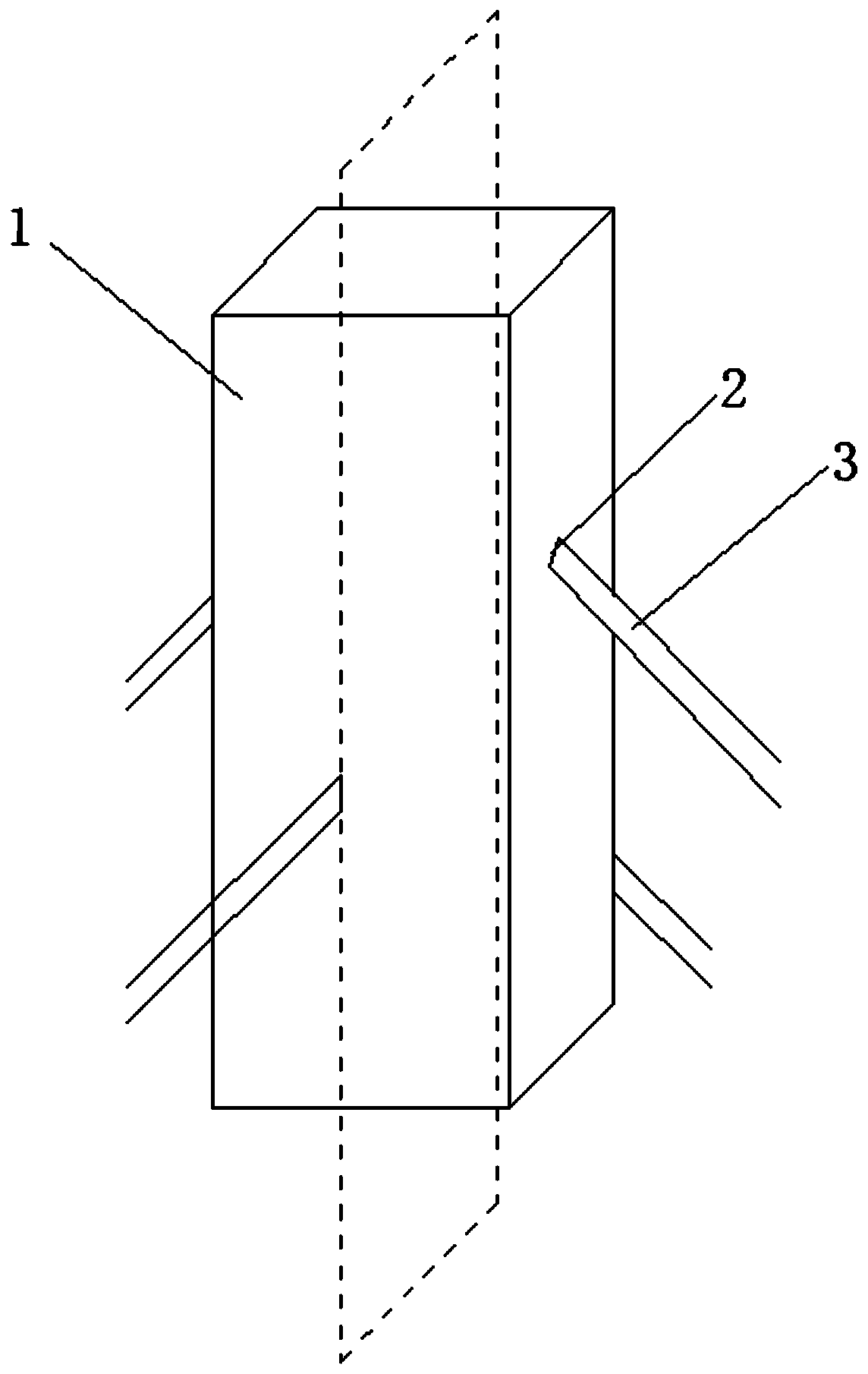

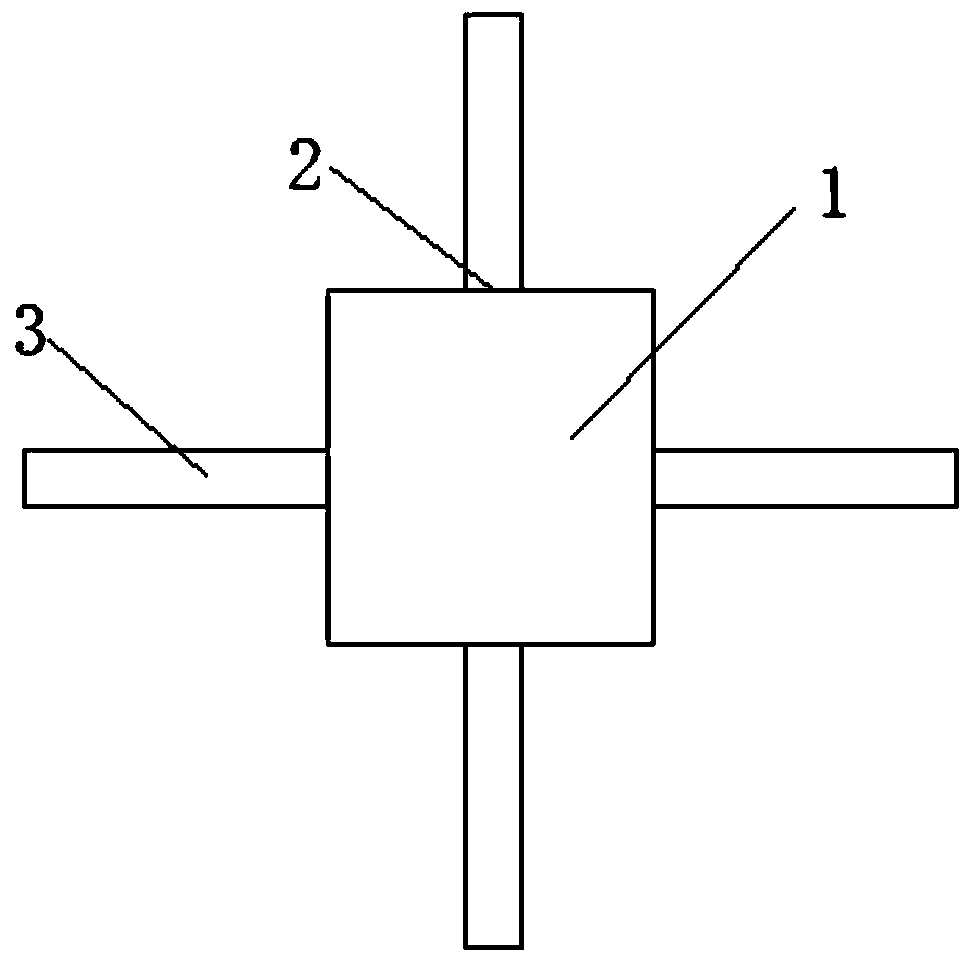

[0039] The impingement flow reaction chamber 1 of a cylinder or a cuboid, the side of the impingement flow reaction chamber 1 is evenly opened with several layers of installation through holes 2 from bottom to top, the installation through holes 2 of the same layer are of the same height and coaxial, and the installation through holes 2 of adjacent l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com