Patents

Literature

55results about How to "To achieve a mixed effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pollution-free method for planting dendrobium nobile lindl

ActiveCN103999672AHigh in nutrientsImprove medicinal effectFertilising methodsCultivating equipmentsBiotechnologyDendrobium candidum

The invention relates to a method for planting dendrobium nobile, in particular to a pollution-free method for planting the dendrobium nobile lindl. The pollution-free method for planting the dendrobium nobile lindl comprises the steps of tissue culture seedling breeding, site selection, ground cultivation under a greenhouse, matrix laying, field planting of seedlings, daily planting environment management, daily management and harvest and storage. After tissue culture seedling transplanting, the survival rate is high, growth is fast, the yield is high, nutrition ingredients of the dendrobium nobile lindl are close to those of wild dendrobium nobile lindl, the medicinal value is high, pesticide application is reduced, and plant diseases and insect pests seldom occur.

Owner:普洱市民族传统医药研究所

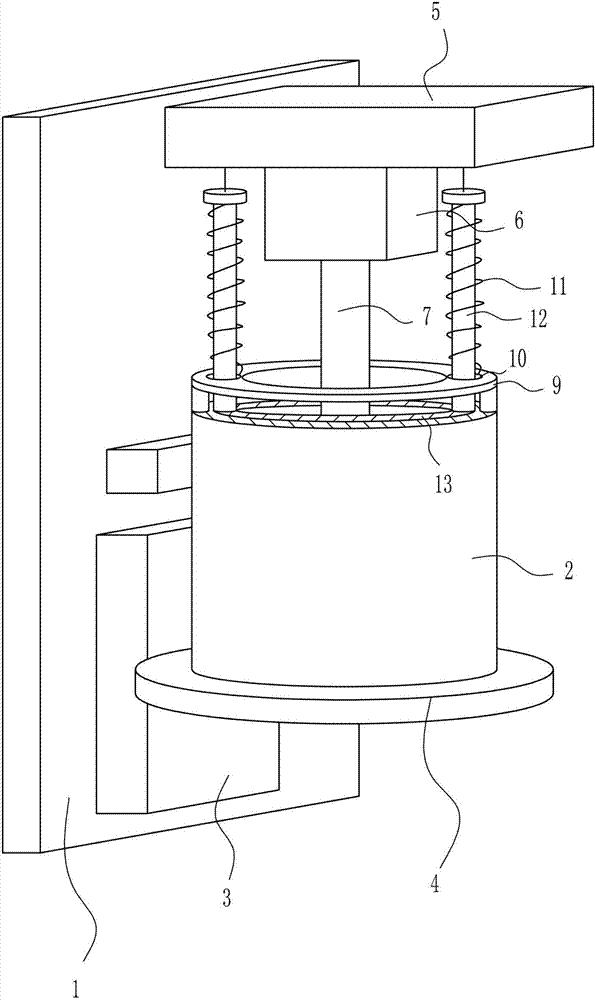

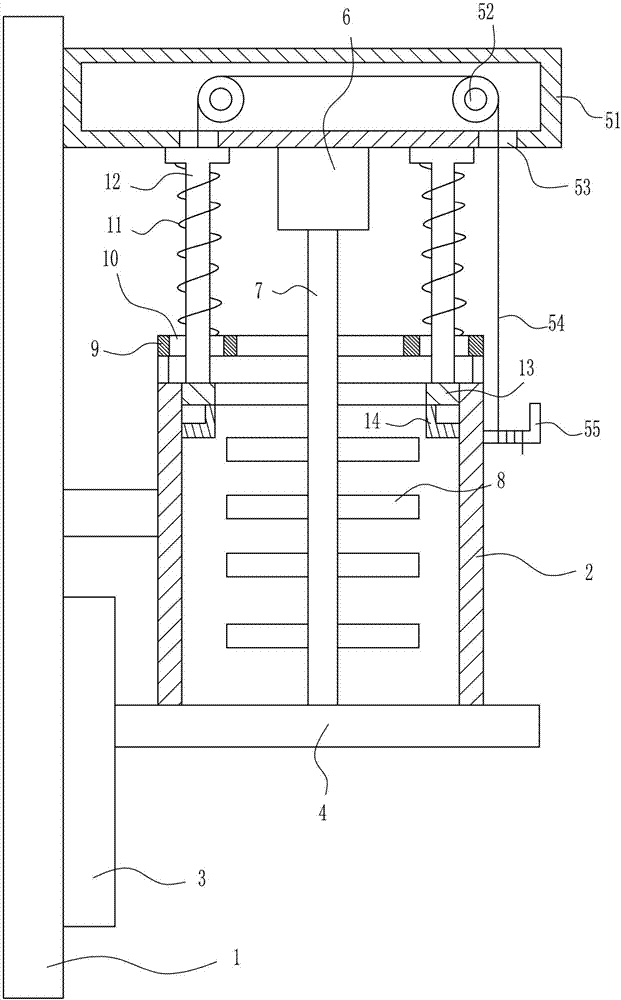

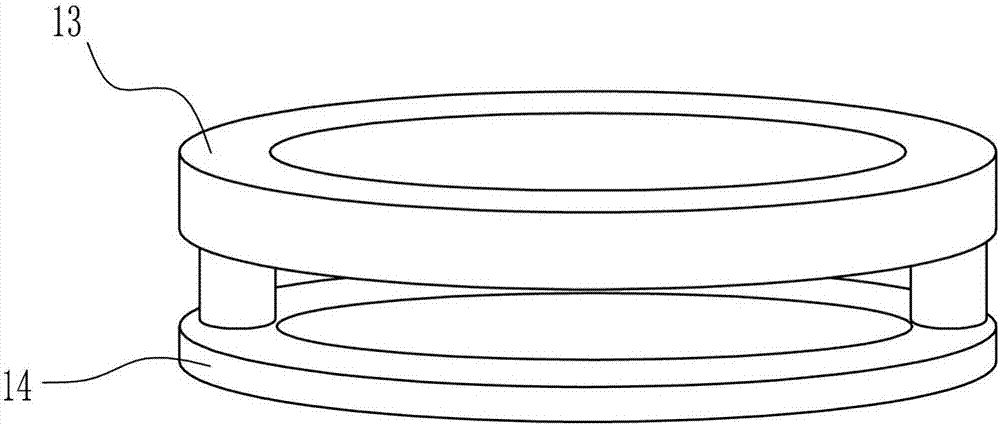

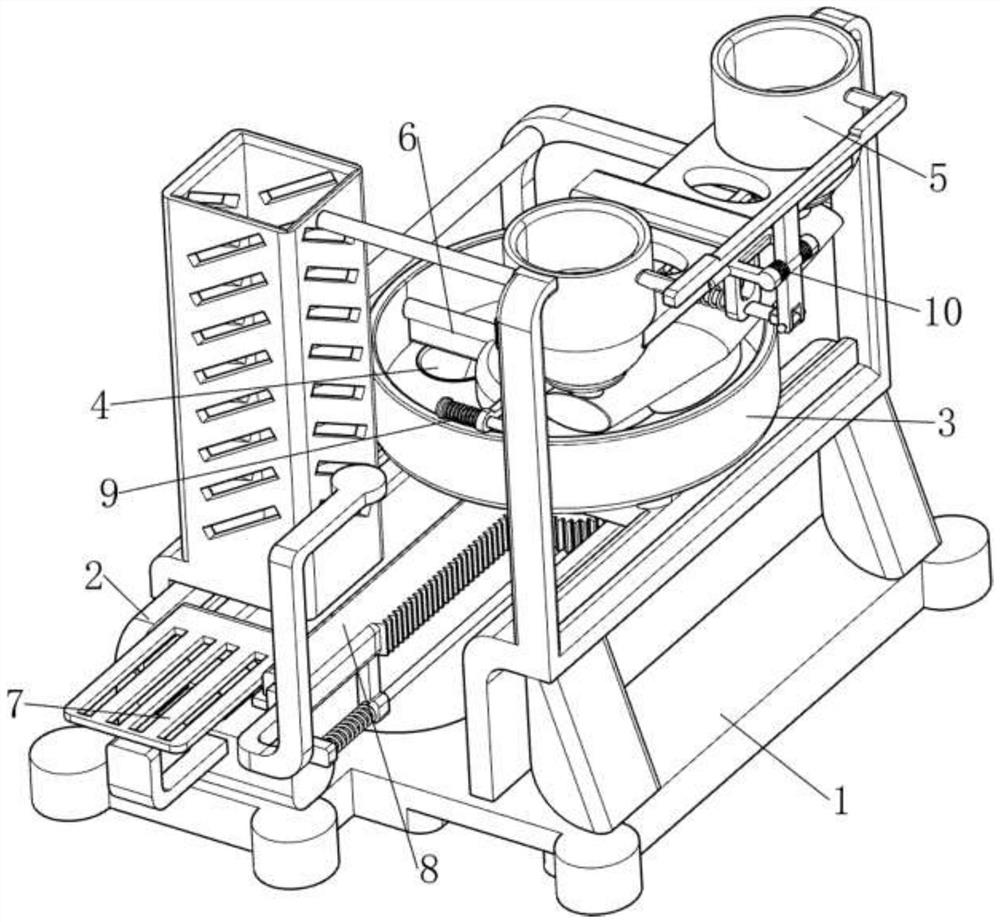

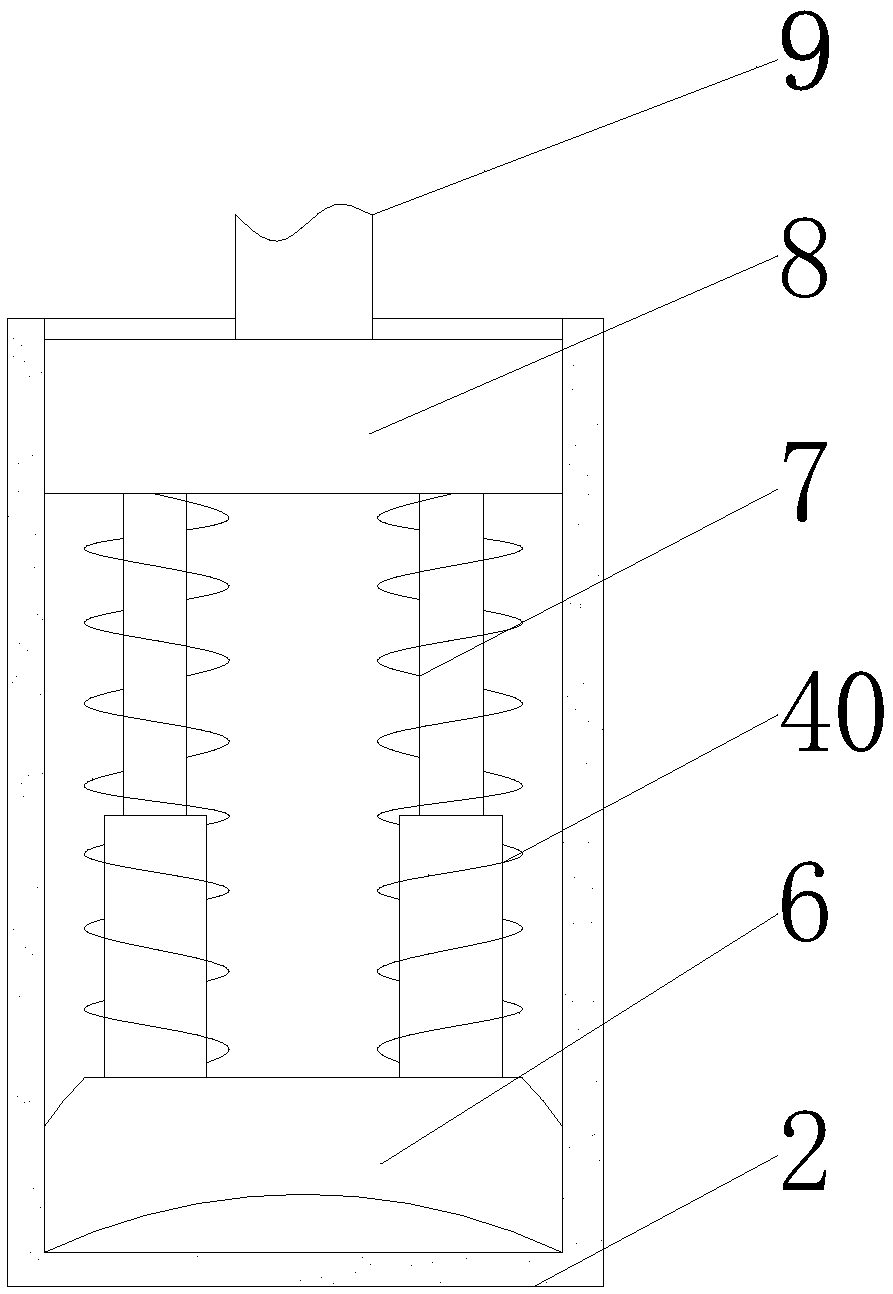

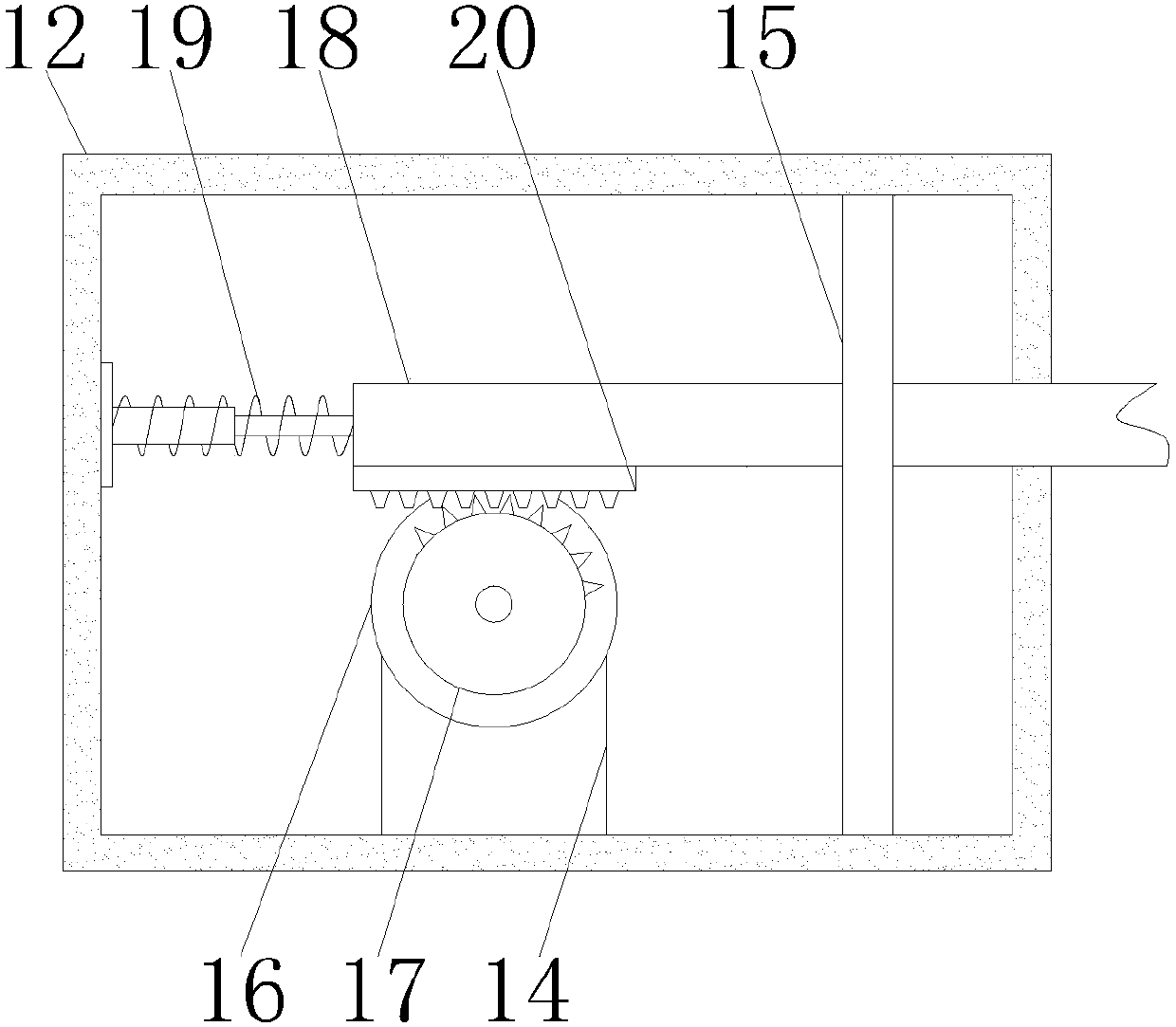

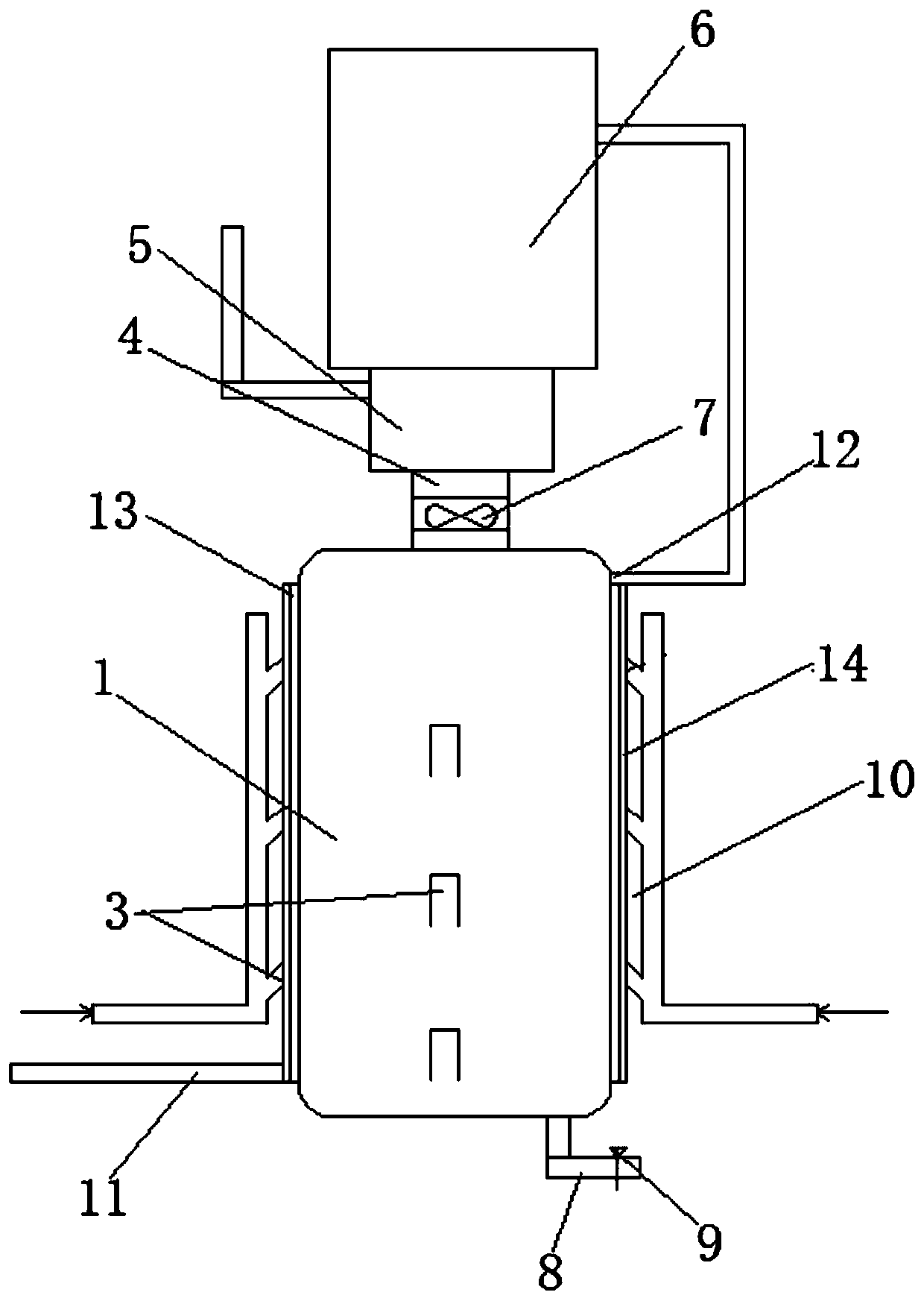

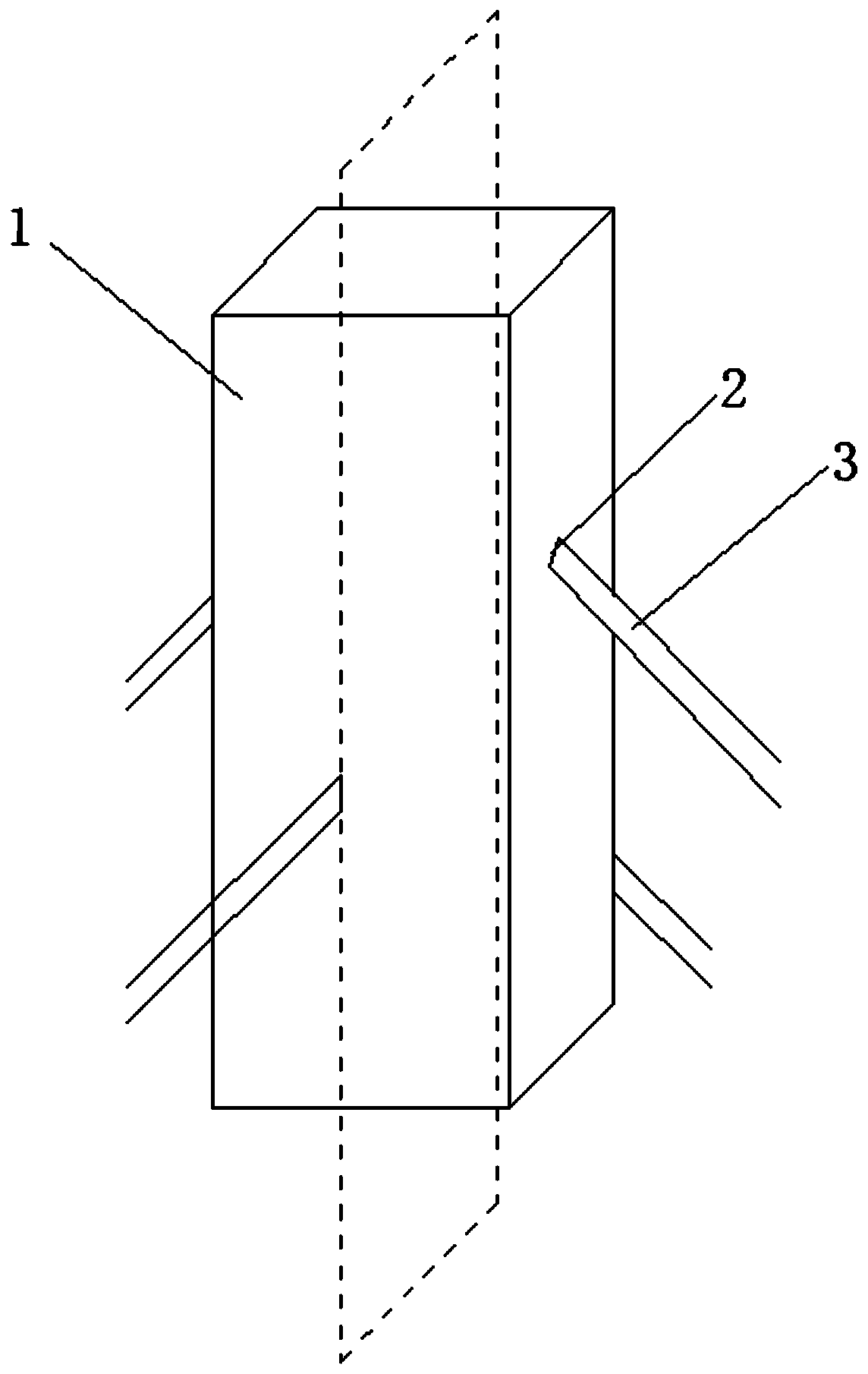

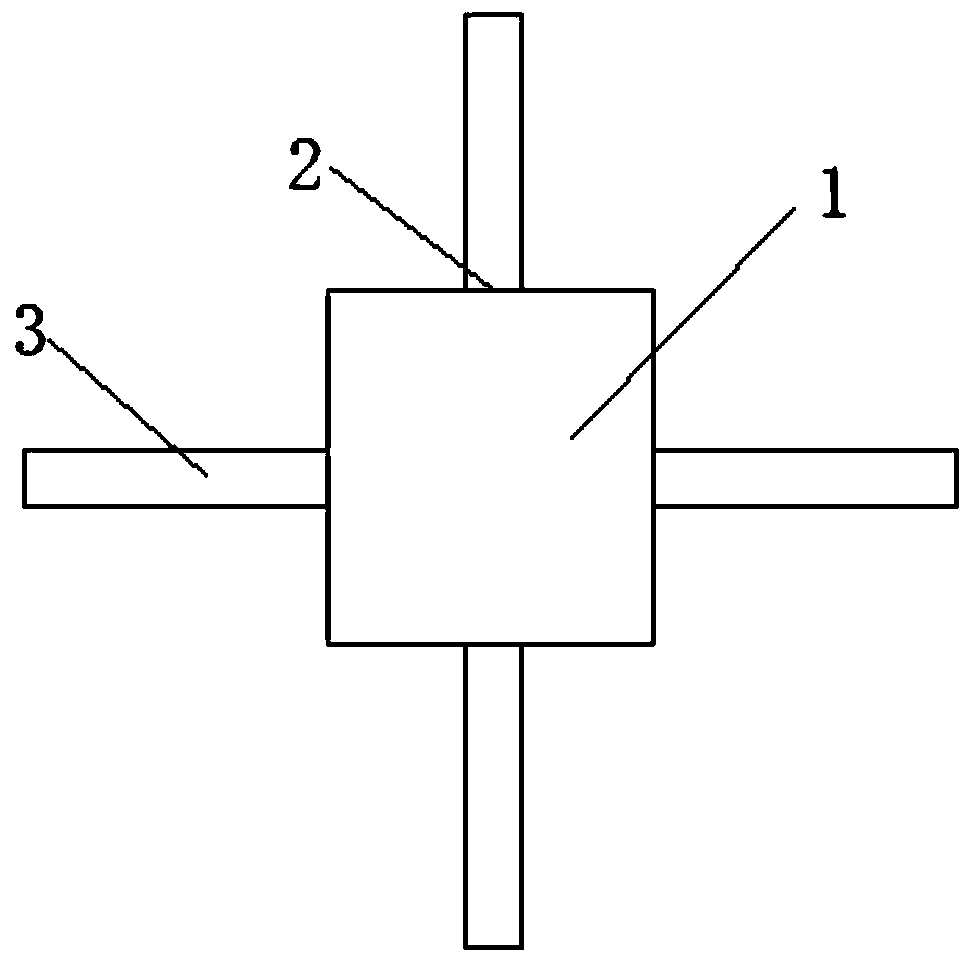

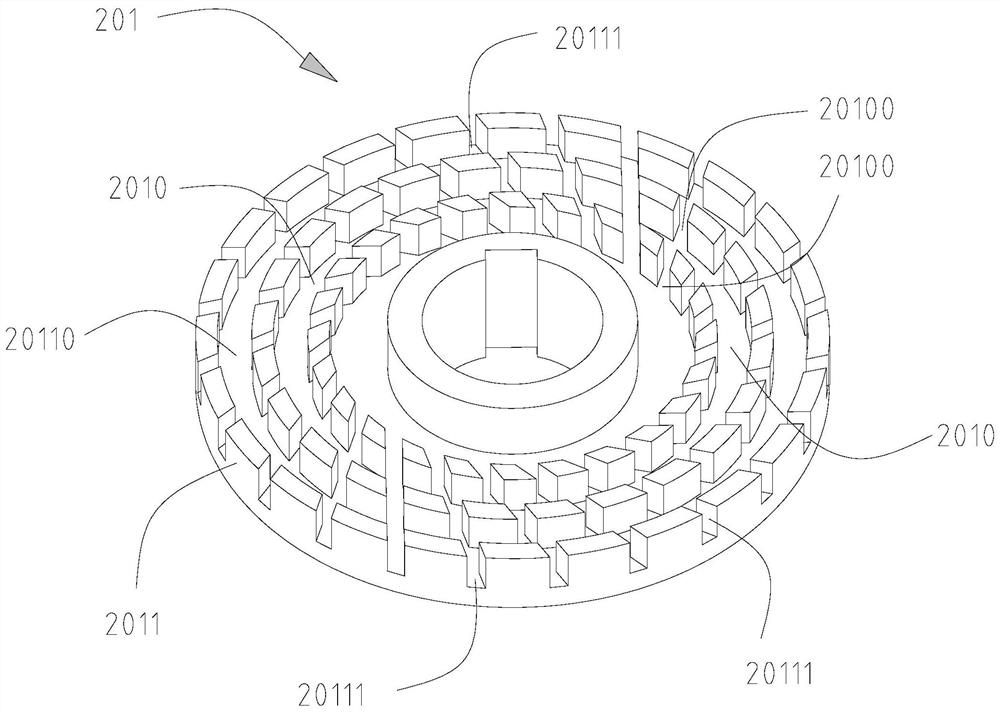

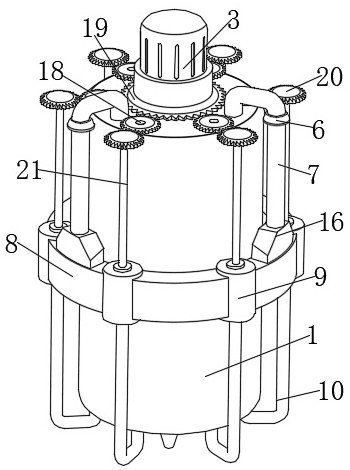

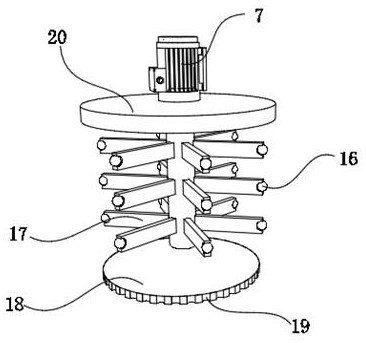

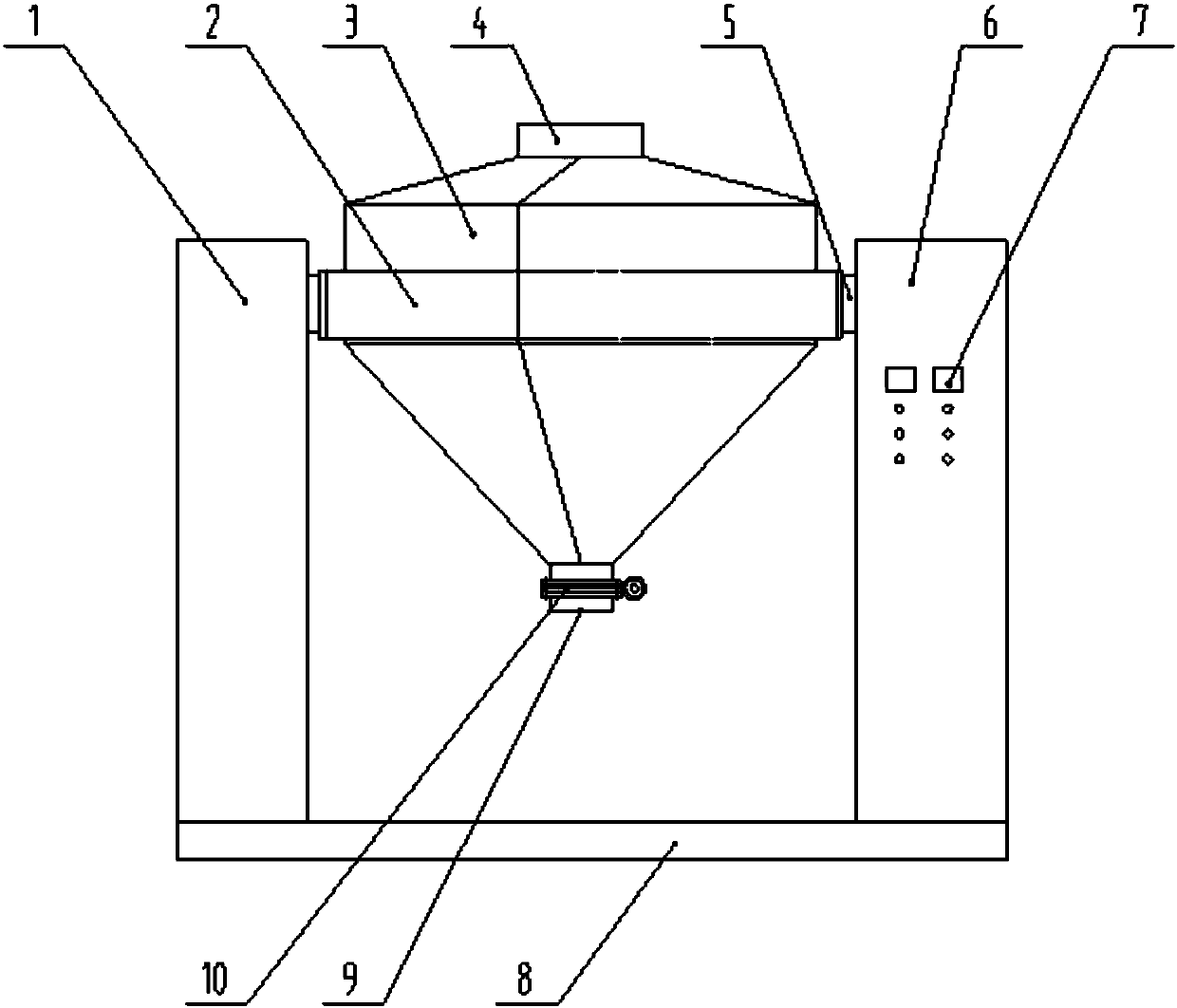

Raw material mixing device for manufacturing steel backing of disc type brake pad

InactiveCN106943920AEasy to cleanNo residueTransportation and packagingRotary stirring mixersMixing tankBrake pad

The invention relates to a raw material mixing device and particularly relates to a raw material mixing device for manufacturing a steel backing of a disc type brake pad. According to the raw material mixing device, raw material residue can be avoided, and the raw material mixing device is easy to take and use. The raw material mixing device for manufacturing the steel backing of the disc type brake pad comprises a support plate, a mixing tank, a rotating mechanism, a baffle, a lifting mechanism, a first motor, a first rotating rod, a stirring rod, an annular guide plate, a first spring, a lifting rod and the like, wherein the mixing tank is connected to the middle of the right wall of the support plate, the rotating mechanism is connected to the lower part of the right wall of the support plate, and the baffle is connected to the upper part of the right side of the rotating mechanism. According to the raw material mixing device, the first motor is firstly designed so as to drive a first rotating rod to rotate clockwise, and then the first rotating rod drives the stirring rod to rotate clockwise so as to stir and mix.

Owner:来安县华鹏摩擦材料厂

Preparation method of cladding material of lithium ion battery

The invention belongs to the technical field of a lithium ion battery, and particularly relates to a preparation method of a cladding material of a lithium ion battery. The preparation method comprises the following steps: stirring a core layer material in a stirring tank; making a cladding layer material into a solution, sol, gel or an emulsion; placing the cladding layer material into an atomizing machine, spraying the cladding layer material onto the surface of the core layer material, and continuously stirring the material; and drying, calcining and crushing the material to obtain the cladding material of the lithium ion battery. Compared with a solid-solid mixing way of the prior art, the mixing way provided by the invention ensures more uniformity in cladding; compared with a liquid-liquid mixing way and a conventional solid-liquid mixing way, the mixing way provided by the invention has the advantages that only the solvent in the sprayed solution is consumed, so that the application amount of the solvent is greatly reduced, and the energy consumption of the subsequent drying process can be reduced.

Owner:HUNAN LIFANG NEW ENERGY SCI & TECH

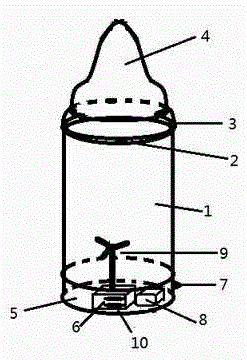

Automatic stirring feeding bottle

InactiveCN105726340ATo achieve a mixed effectSave milking timeFeeding-bottlesAutomatic testingBottle

The invention discloses an automatic stirring feeding bottle, comprising: a bottle body, a sealing ring, a bottle ring, a nipple, a base, a battery slot, a button, a motor module, stirring blades, and a battery, the sealing ring is located outside the mouth of the bottle body, and the The pacifier is set in the bottle ring, the bottle ring is installed outside the sealing ring, the base is located under the bottle body, the battery slot is located under the base, the battery is installed in the battery slot, and the button is located on the side of the base. The motor module is located between the base and the bottom of the bottle body, the stirring blade is installed on the motor module, and the stirring blade is located inside the bottom of the bottle body. The invention has the advantages of automatically stirring the feeding bottle, the battery supplies power to the motor module, presses the button, starts the motor module, the motor module drives the stirring blades to rotate rapidly, instantly completes the mixing of milk powder and water, saves milk preparation time, does not need manual stirring, and is clean and hygienic.

Owner:NANJING COLLEGE OF CHEM TECH

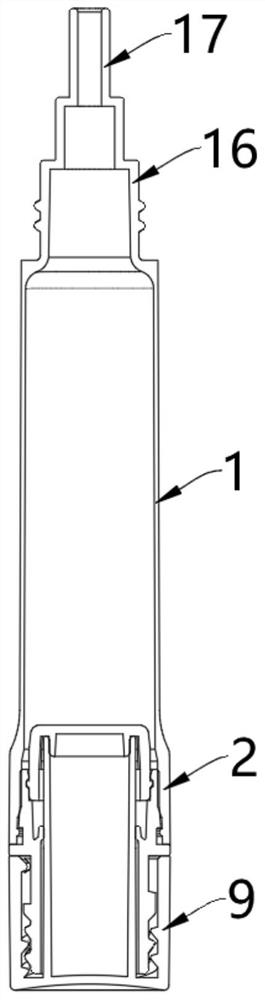

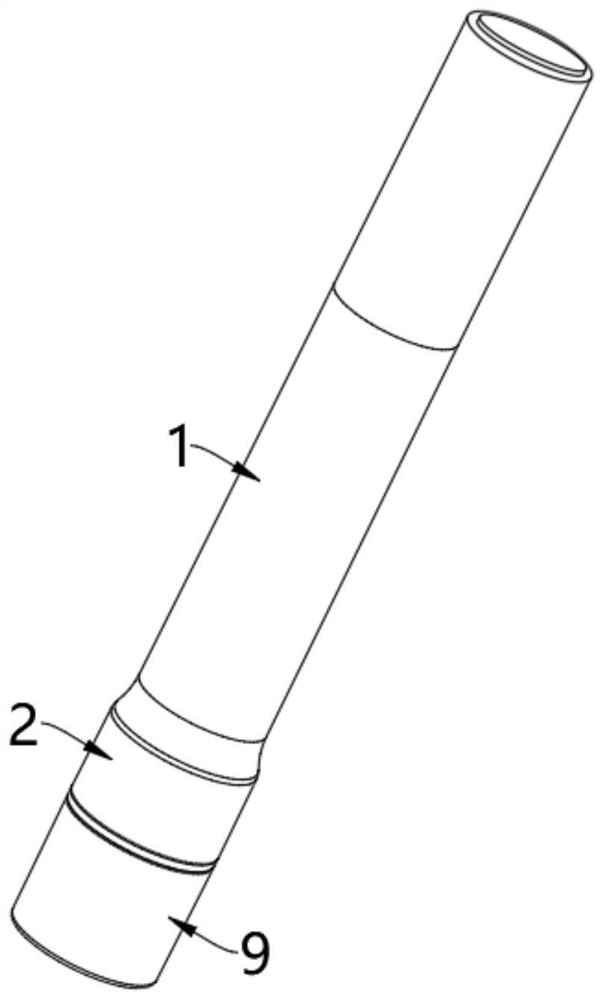

Liquid-magnetization-based high-concentration gas-liquid two-phase mixed atomizer

InactiveCN106694268AReduce usageImprove solubilityLiquid spraying apparatusHigh concentrationMagnetization

The invention discloses a liquid-magnetization-based high-concentration gas-liquid two-phase mixed atomizer. The liquid-magnetization-based high-concentration gas-liquid two-phase mixed atomizer comprises a liquid inlet pipe, a liquid speed adjusting valve, a laval pipe, a magnetization mixer, a primary atomizer, an atomization nozzle, a compressed air pipe and a gas distribution valve. The liquid inlet pipe communicates with the liquid speed adjusting valve, the laval pipe, the magnetization mixer, the primary atomizer and the atomization spray head sequentially. The novel structure is reasonable in design and convenient to use, dissolution of ozone in water can be increased in a magnetized water mode, and thus the concentration of ozone water is increased so as to ensure the disinfection effect. The atomization effect is ensured in a secondary atomization mode, meanwhile, due to arrangement of a rotational flow channel, jet flow at a nozzle is stable, speed fluctuation is not generated, and the equipment cost is reduced.

Owner:合肥九州龙腾科技成果转化有限公司

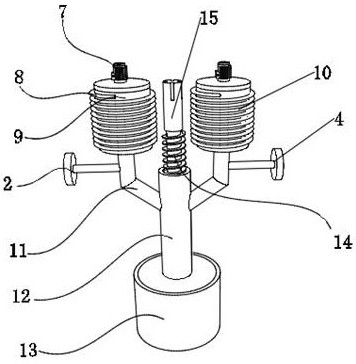

Face beautifying instrument capable of improving use efficiency of essence

InactiveCN112169163ATo achieve a mixed effectMedical devicesVibration massageElectric machineryEngineering

The present invention discloses a face beautifying instrument capable of improving use efficiency of essence. The face beautifying instrument capable of improving use efficiency of essence comprises ahandheld handle, a working block is fixedly arranged at an upper end of the handheld handle, a first sliding cavity is formed in the working block, two liquid inlets which are located in the workingblock, provided with upward openings and communicating with the first sliding cavity are formed in the first sliding cavity in a bilateral symmetry mode, and a mixing cavity is arranged at a lower side of the liquid inlets. Through cooperation of motors and pull lines, inlet gates are automatically opened when the device is used, so that a user is allowed to pour essence into the device, a mixingeffect of the essence and a diluent is achieved through work of stirring fan blades in the mixing cavity, then under driving of a cam and an extrusion plate, an effect that the mixed liquid is sprayedto a face of a user through a pressure spraying block is achieved, and under actions of the motors and a vibration block, two face beautifying modes of vibration and rotary massage of the user are provided.

Owner:佛山市九真饰品有限公司

Ball mill

The invention discloses a ball mill. The ball mill comprises a rack, a first speed reducing wheel, a main transmission motor, a first synchronous belt, a second speed reducing wheel, a second synchronous belt, a third speed reducing wheel, a main shell, stirring blades, a main stirring shaft, a joint flange, a water heat preservation side wall and stirring teeth, wherein the second speed reducing wheel is driven to rotate by the main transmission motor; the first speed reducing wheel and the second speed reducing wheel simultaneously rotate and drive the third speed reducing wheel to rotate; the main stirring shaft is driven to rotate by the third speed reducing wheel; the stirring blades and the stirring teeth are driven to rotate by the main stirring shaft; the raw material is stirred by the stirring blades, so that the raw material can be uniformly mixed so as to achieve the required mixing effect; steel balls are arranged in a milling cavity; the steel balls strike each other by virtue of rotation of the stirring teeth, so that the fine milling effect of a medium is achieved; the main transmission motor, a slurry feeding pump, the water heat preservation side wall and a water heat preservation base plate are controlled by a PLC system; the temperature can be automatically controlled; the temperature of the medium is controlled to be incapable of exceeding the standard. The ball mill is low in energy consumption, low in noise and high in productivity, and is operated by one button.

Owner:苏州明锦机械设备有限公司

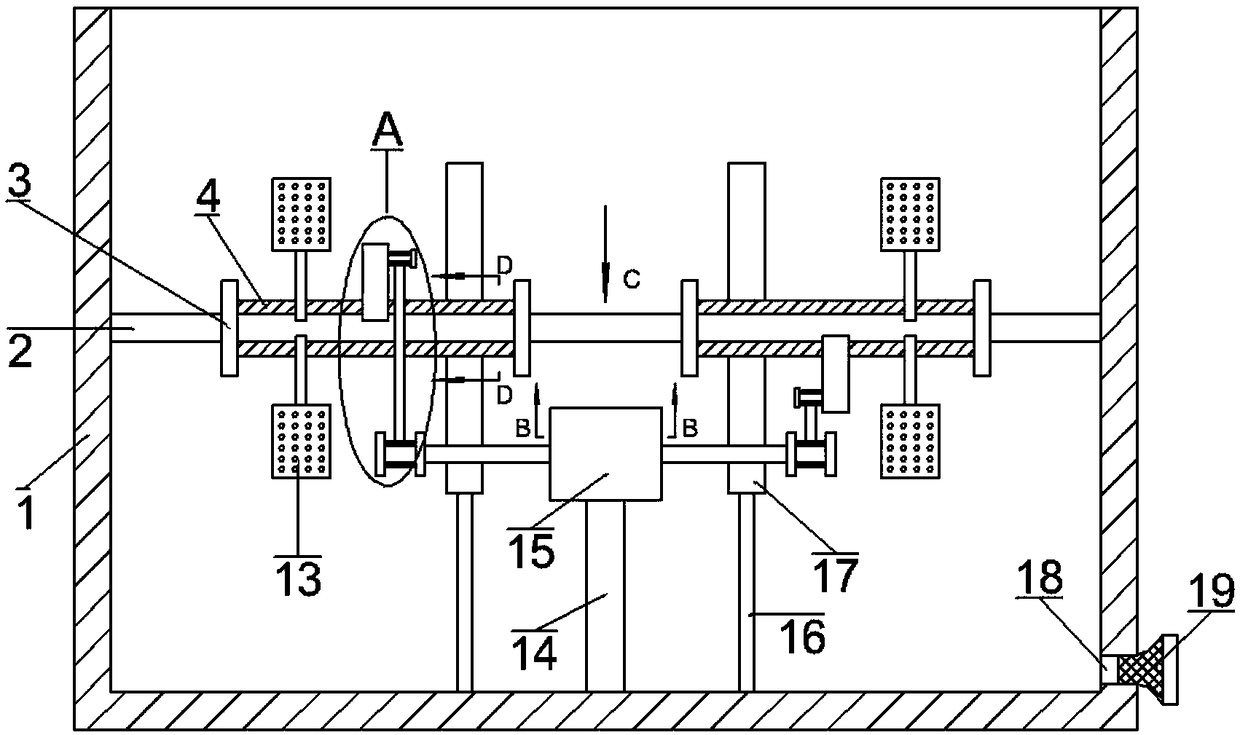

Mixing and stirring device for soil remediation

InactiveCN106823964ANovel structurePracticalTransportation and packagingContaminated soil reclamationSoil remediationEngineering

The invention discloses a mixing and stirring device for soil remediation. The mixing and stirring device comprises a base, wherein rolling wheels are fixedly mounted at the bottom of the base; a first box body and a second box body are sequentially connected to the top of the base from left to right; the top of the first box body is communicated with a feeding pipe; a supporting plate is fixedly connected with the upper part of one side, far away from the second box body, of the first box body; the top of the supporting plate is fixedly connected with a first motor; a U-shaped groove and an inclined plate are fixedly connected in the first box body in sequence from top to bottom; one end of the inclined plate penetrates through the first box body and the second box body in sequence and extends into the second box body. The mixing and stirring device for the soil remediation is novel in structure and high in practicability, and is convenient to operate; the effect of mixing soil with a remediation medicament is realized; the first box body is combined with the second box body, so that the effect of stirring for a plurality of times is realized under the action of the first motor and a second motor; the medicament can be in contact with the soil very well, and the mixing time is saved.

Owner:青岛恒新辉瑞工业技术有限公司

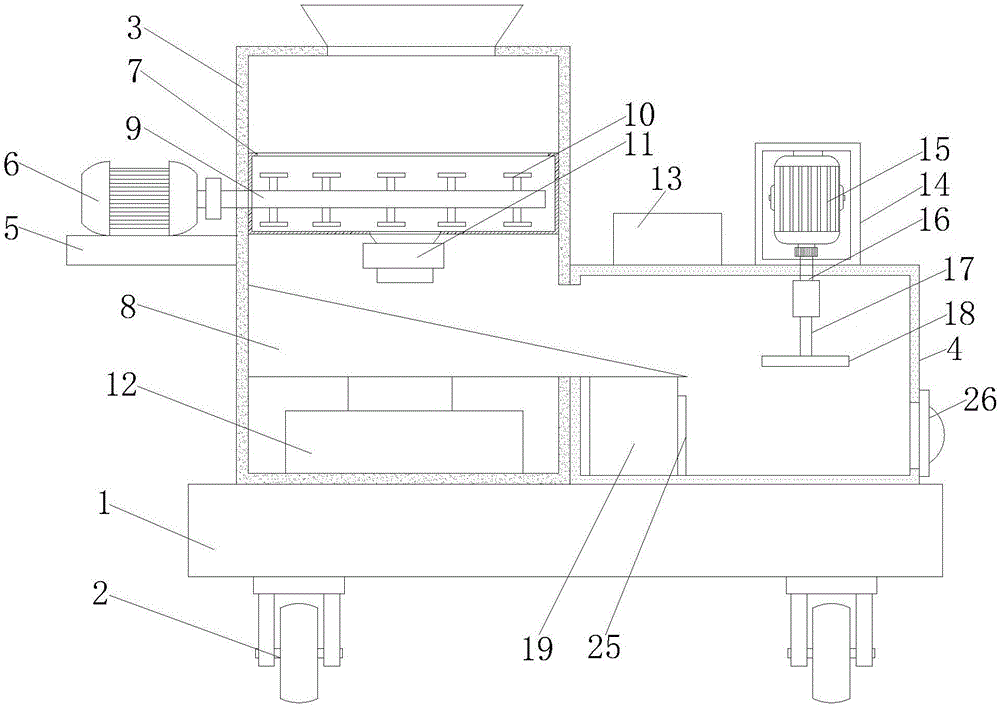

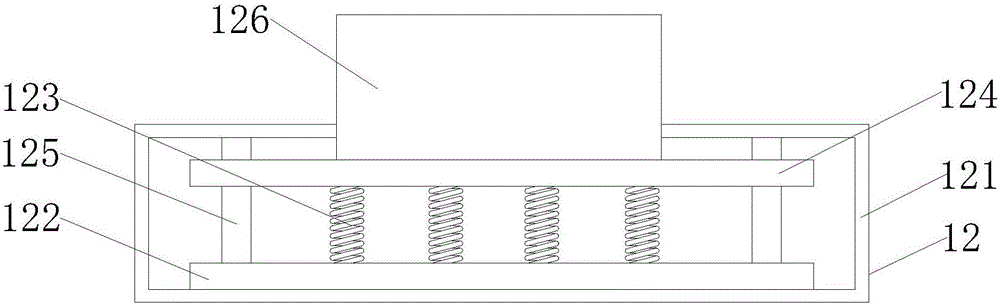

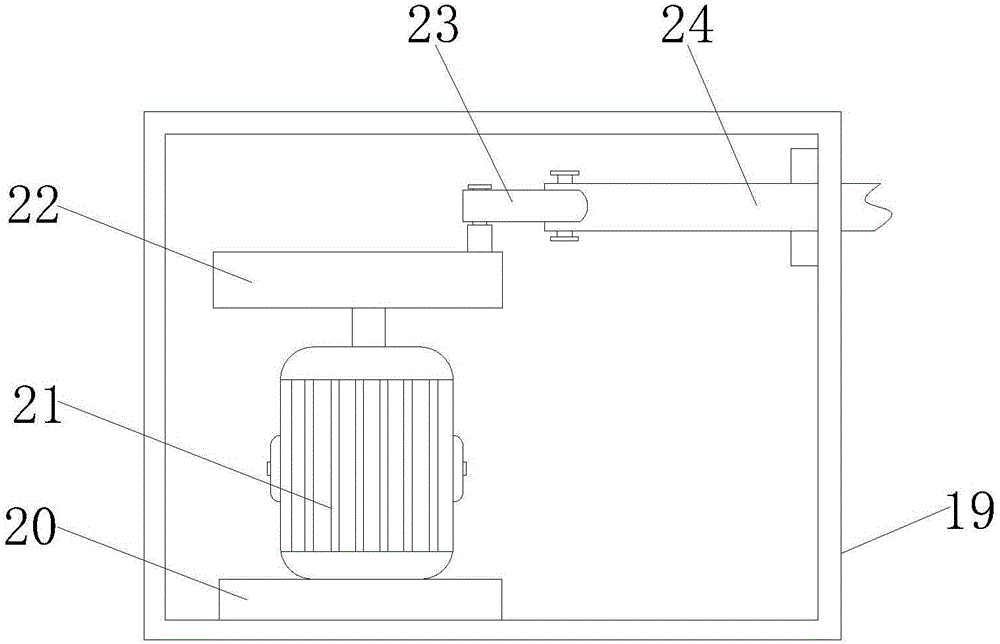

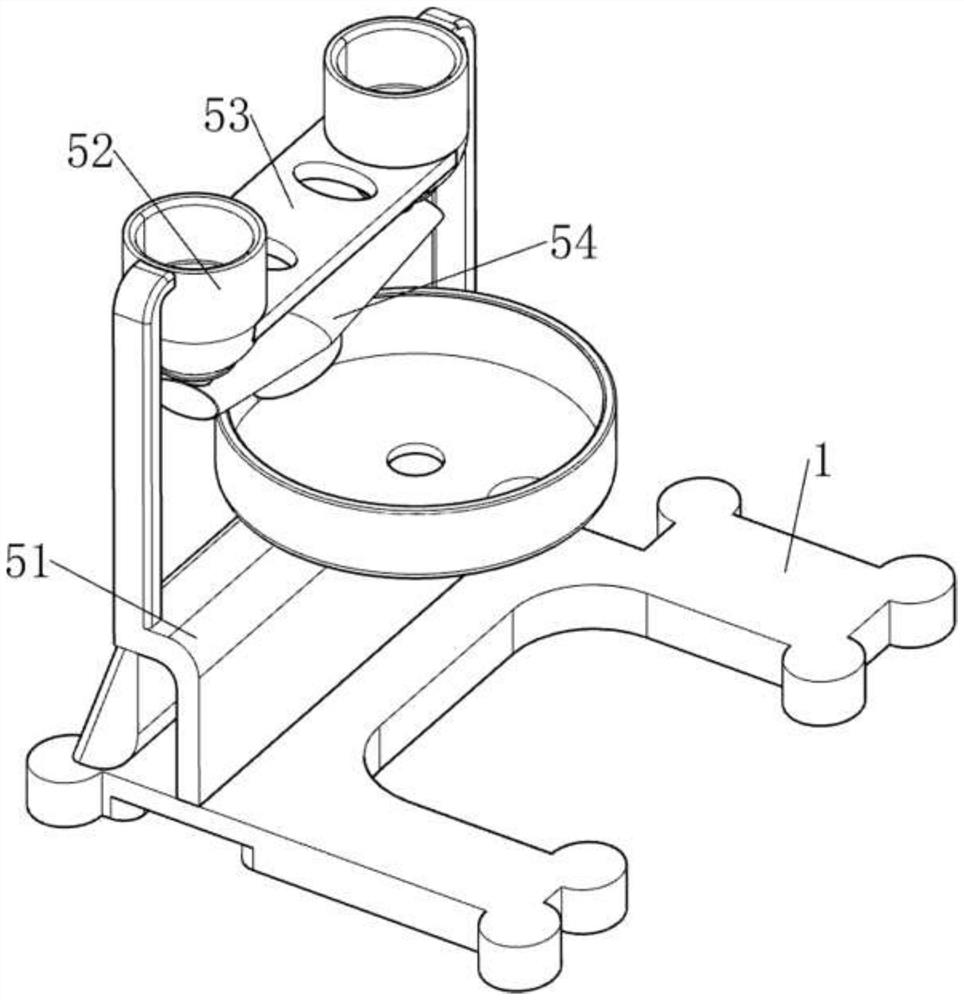

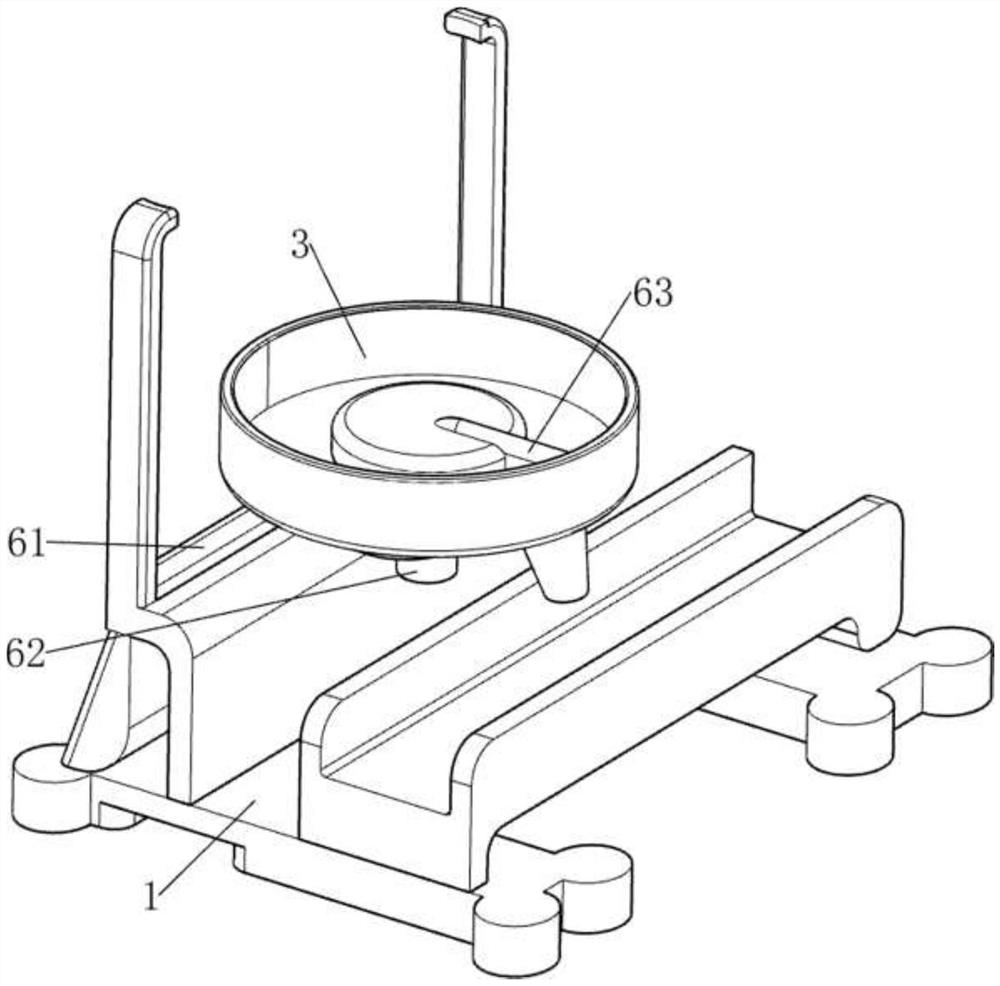

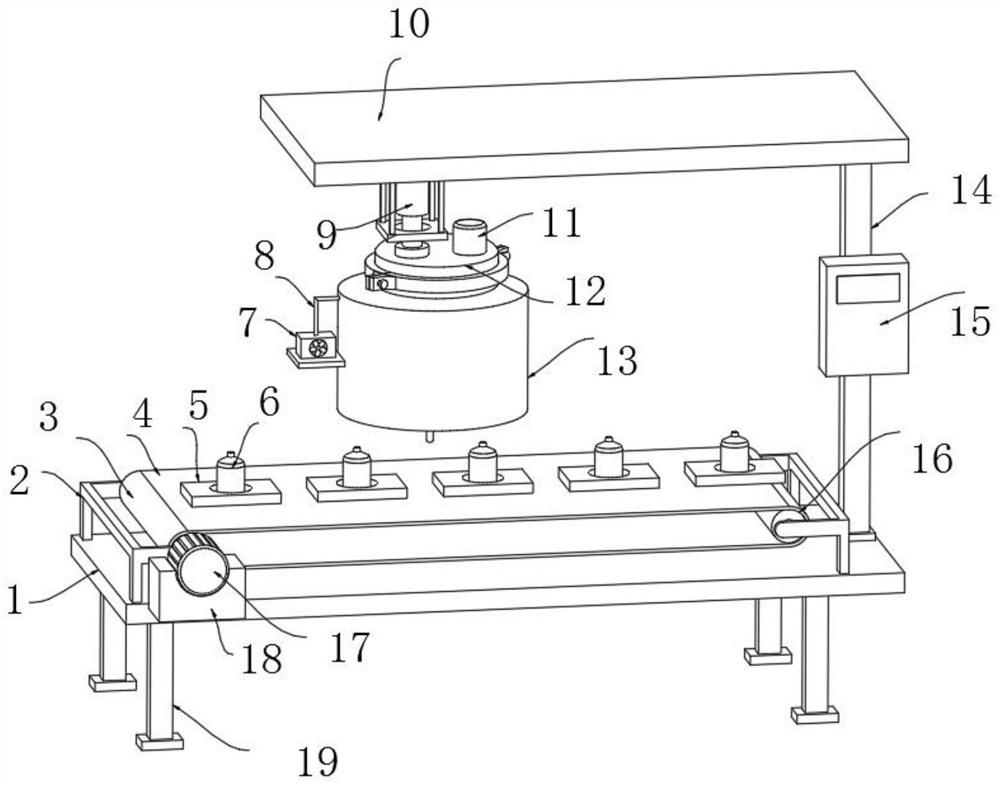

Quantitative mixing and packaging equipment for pet food processing

ActiveCN113022972ATo achieve the cutting effectTo achieve a mixed effectFood processingRotary stirring mixersEngineeringMechanical engineering

The invention relates to packaging equipment, in particular to quantitative mixing and packaging equipment for pet food processing. The invention provides the quantitative mixing and packaging equipment for pet food processing, which has an automatic mixing and packaging function. The quantitative mixing and packaging equipment for pet food processing comprises: a bottom plate and a material pushing frame, wherein the material pushing frame is arranged on the bottom plate; a discharging mechanism arranged on the bottom plate; a mixing mechanism arranged in the middle of the discharging mechanism; and a material mixing frame arranged on the mixing mechanism, wherein a discharging port is formed in the material mixing frame. By means of the discharging mechanism, people only need to place two kinds of pet food on the discharging mechanism for discharging, and therefore the discharging effect is achieved.

Owner:临沂华众宠物用品有限公司

Medical breathing device

The invention discloses a breathing device for medical use, which comprises a base, and the top of the base is fixedly installed with a shock absorbing tube, a fixed box, a pole and a controller in order from left to right, and the bottom of the inner cavity of the shock absorbing tube is fixedly installed There is a shock-absorbing sheet, and spring rods are fixedly installed on both sides of the top of the shock-absorbing sheet, and a buffer block is fixedly installed on the top of the spring rod, and a bracket is fixedly installed on the top of the buffer block, and one side of the bracket A horizontal plate is fixedly installed, and a support rod is fixedly installed on the bottom of the horizontal plate, and the bottom end of the support rod is fixedly connected with one side of the bracket. The medical breathing device, through the improvement of the motor box and the drug tube, achieves the effect of facilitating the patient's breathing, so that it is also convenient to add an appropriate amount of medicine to the patient's breathing gas, thus facilitating the treatment of the patient and the medical staff. The operation is convenient for users and also provides a comfortable treatment environment for patients.

Owner:青岛恒新辉瑞工业技术有限公司

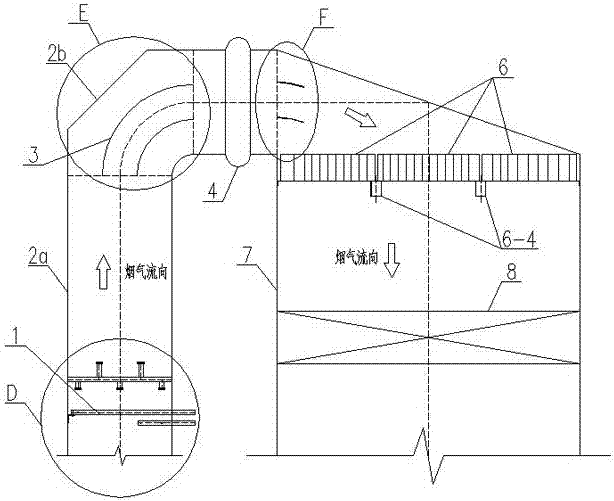

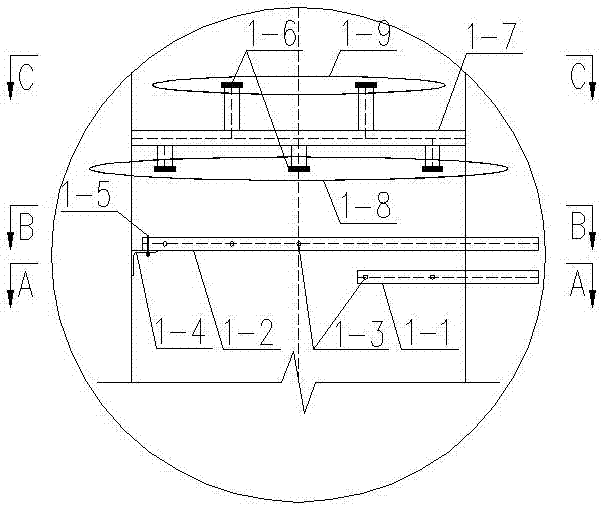

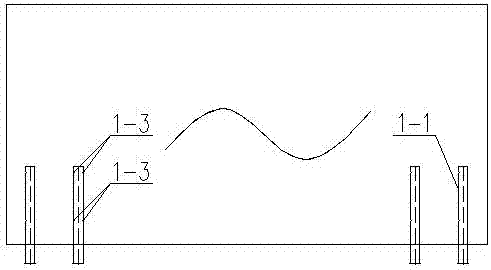

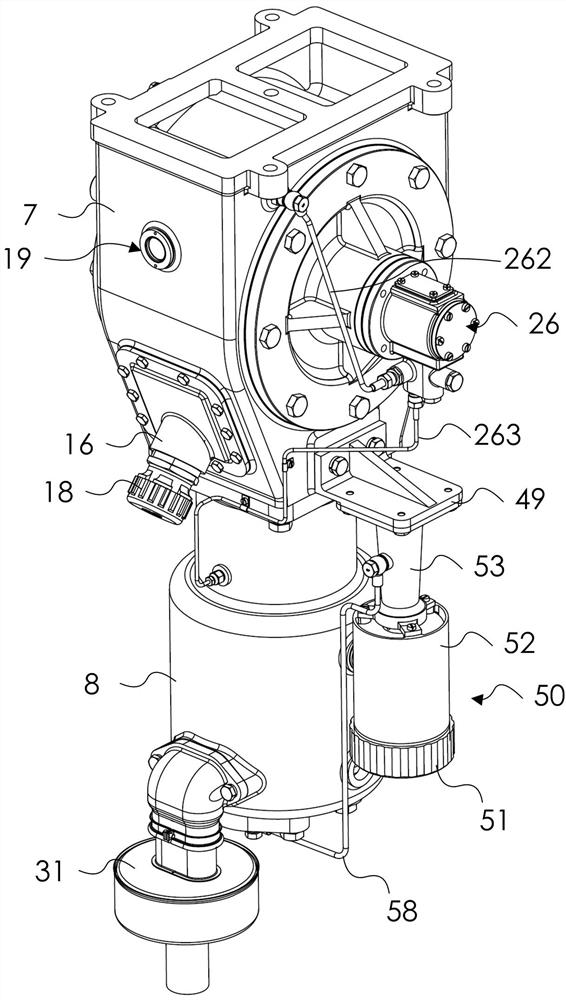

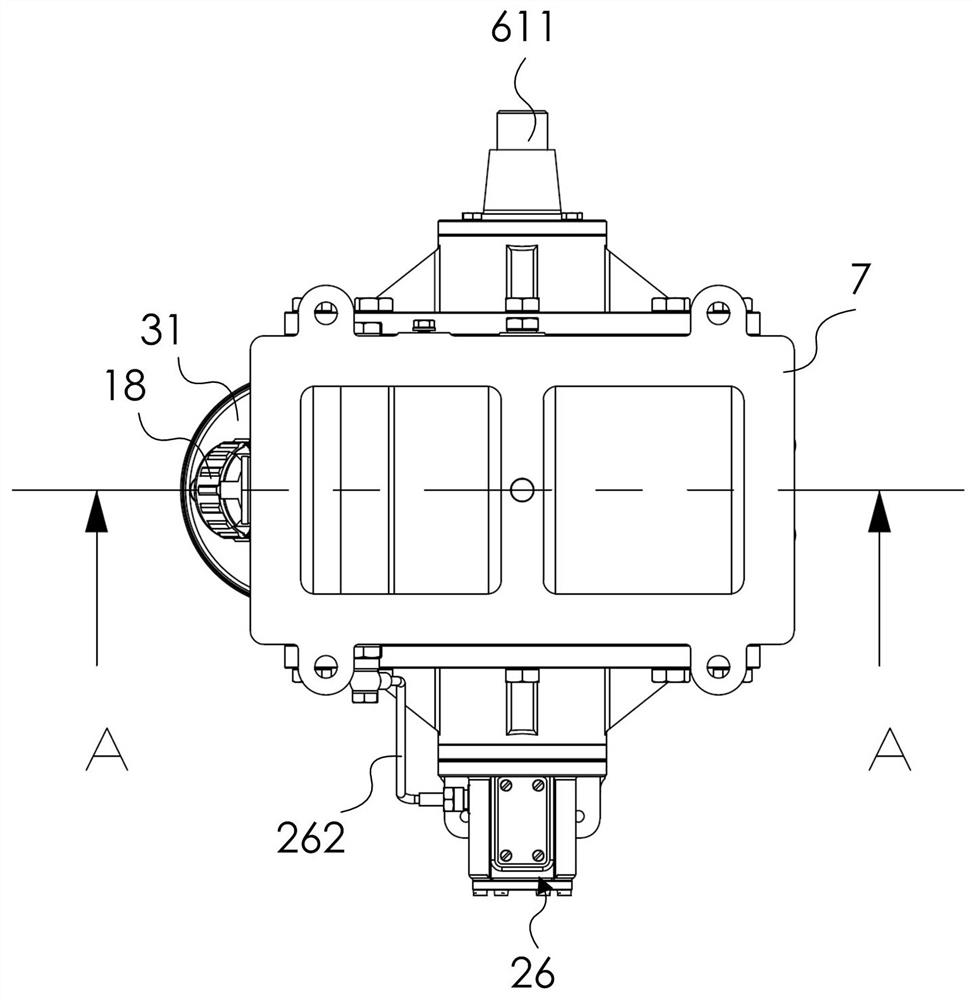

SCR denitrification ammonification and flow field homogeneous structure and operating method thereof

PendingCN107126835AEfficient mixingImprove the flow fieldGas treatmentDispersed particle separationMixed flowFlue gas

The invention provides an SCR denitrification ammonification and flow field homogeneous structure and an operating method thereof. The structure has the advantages of high mixing uniformity between ammonia gas and flue gas, reasonable flow field, low local resistance and simple configuration. Ammonification pipe series are fixed in a linear-segment flue; the ammonification pipe series are provided with ammonification holes; the outer bend of the bend flue is composed of an outer-chamfer plate; the inner bend of the bend flue is composed of an inner arc plate; a front guide plate is fixed in the bend flue; a back guide plate is fixed to the inside of an inlet of a reactor; and a rectifier unit module is fixed in the reactor. Ammonia gas is quickly ejected via the ammonification holes of the ammonification pipe series, and is subjected to opposed-flow diffusion and taken away by the flue gas; ammonia molecules are further diffused under the barrier action of mixed flow plates of mixed flow assemblies, are divided to the two sides of the mixed flow plates at higher speed, are subjected to slow guiding after sufficient mixing, and finally, are uniformly dispersed in the flue gas; and the flue gas is adjusted and distributed uniformly by the rectifier unit module and reaches the catalyst on the first layer.

Owner:CHINA UNITED ENG

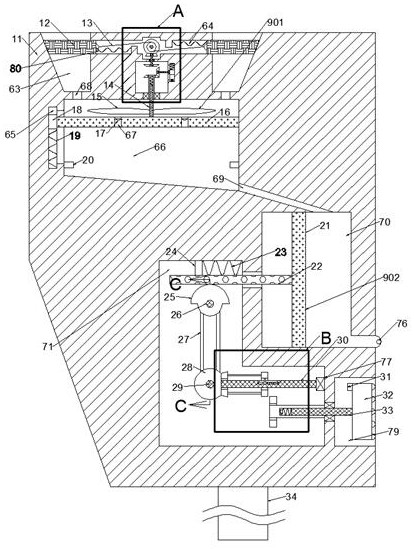

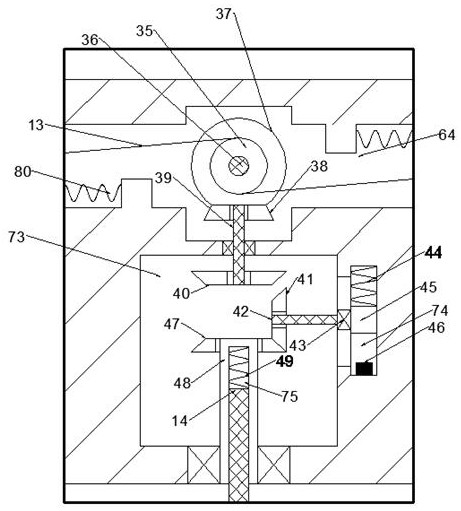

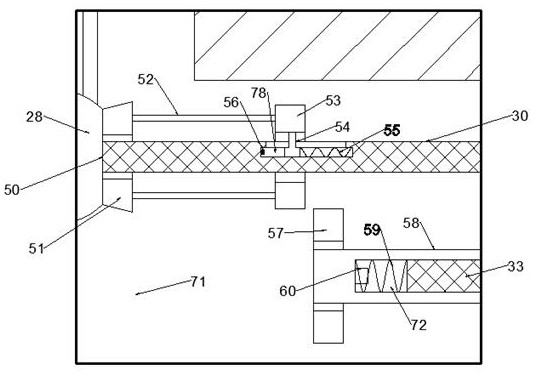

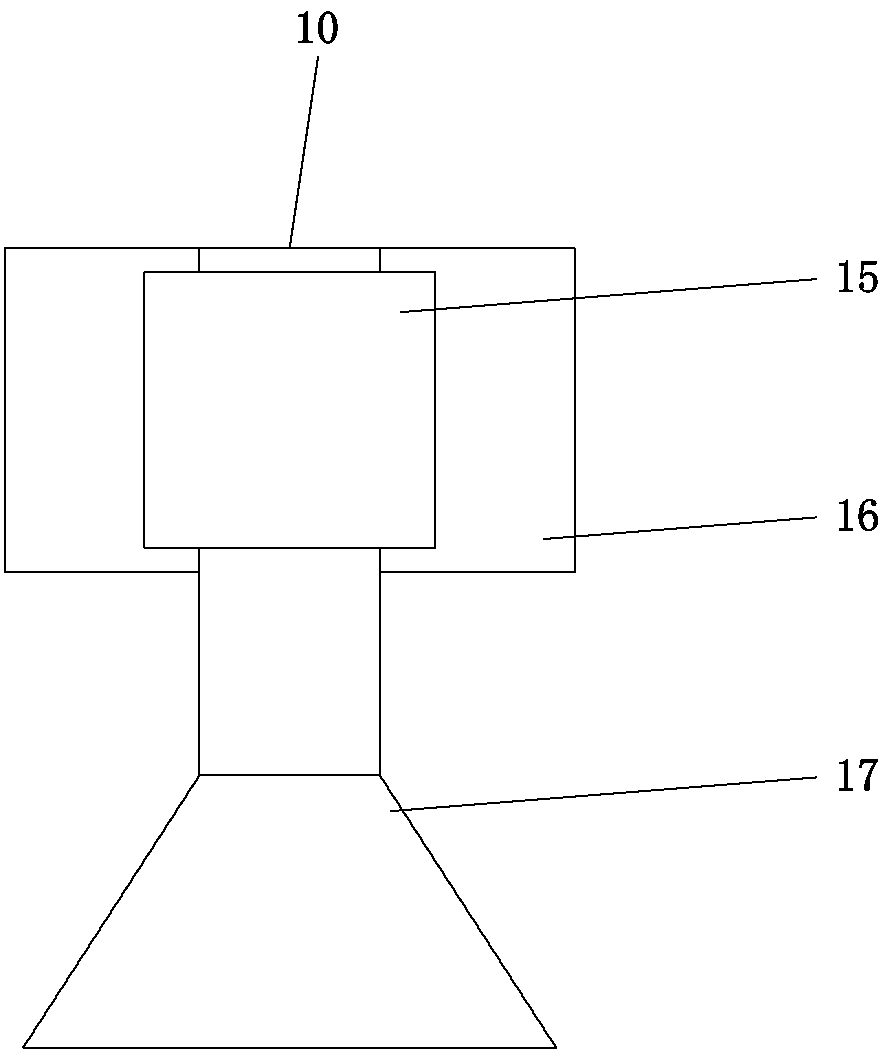

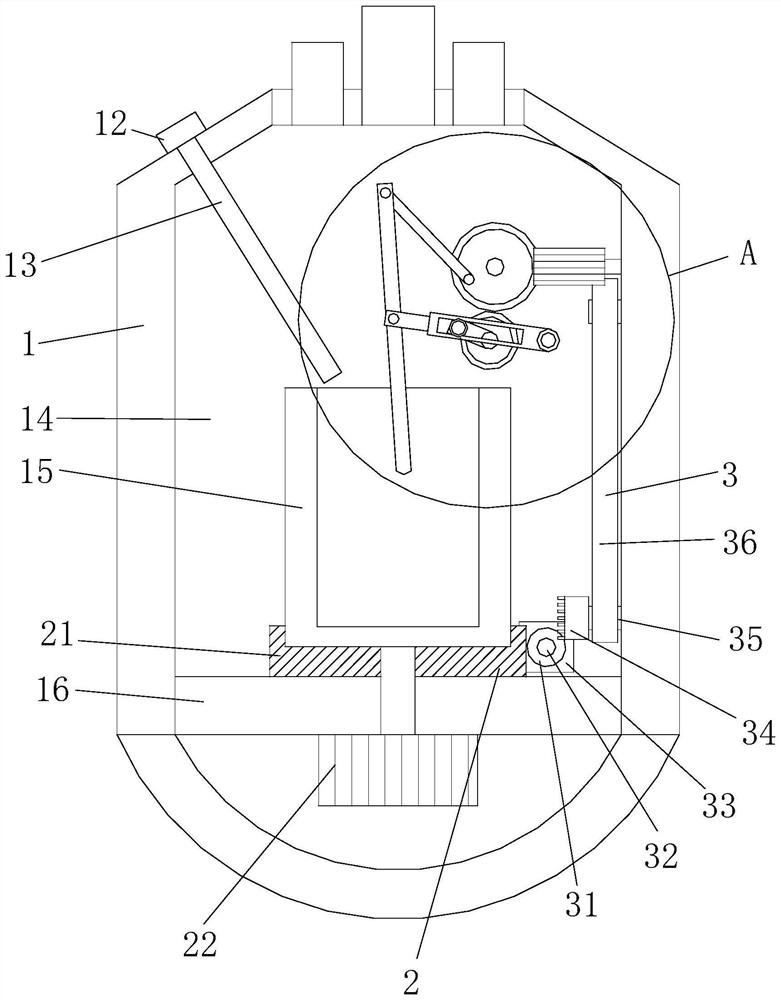

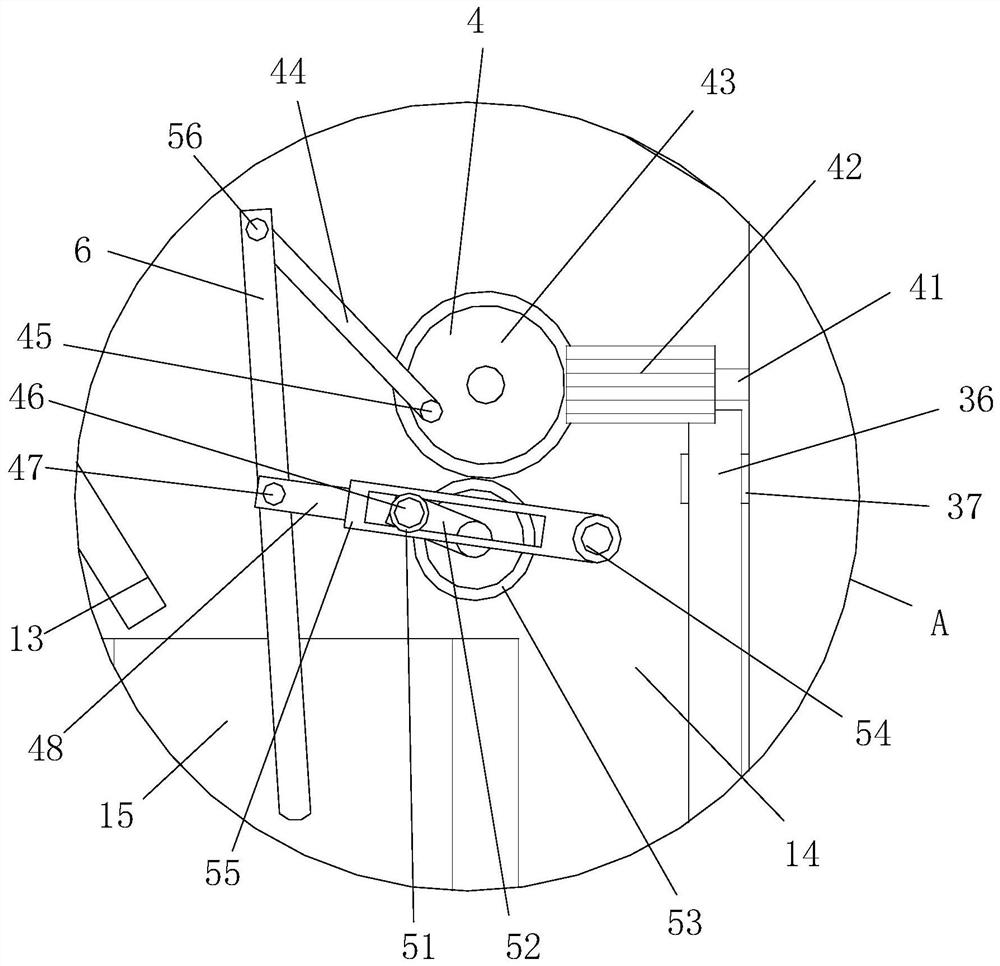

Mixing equipment for industrial liquid material based on double-slide-block crank structure

InactiveCN108854804AAchieve staggered rotationRealize reciprocating motionTransportation and packagingMixer accessoriesReciprocating motionEngineering

The invention provides mixing equipment for an industrial liquid material based on a double-slide-block crank structure. The mixing equipment comprises a casing, wherein a first horizontal post is fixedly connected onto the side wall in the casing; a pair of first baffle plates are symmetrically arranged on the first horizontal post; a first sleeve is sleeved on the first horizontal post between the two first baffle plates; a rotating plate is fixedly connected onto the first sleeve; a second horizontal post is fixedly connected onto the side wall of the rotating plate. The mixing equipment has the following beneficial effects that a reciprocating driving device can realize the front and back reciprocating movement of a third horizontal post; the third horizontal post drives the rotating plate and the first sleeve to rotate around the first horizontal post through a connecting rod; the rotating plate at the left side drives the first sleeve to firstly rotate in a clockwise direction (right view) and to then rotate in an anticlockwise direction (right view); the rotating plate at the right side drives the first sleeve to firstly rotate in the anticlockwise direction (right view) andto then rotate in the clockwise direction (right view); through the work in such a way, the staggered rotation of the two first sleeves can be realized.

Owner:陈晨

High-strength ceramsite and preparation process thereof

PendingCN112960964AHigh strengthHigh refractorinessCeramic materials productionCeramicwareExpanded clay aggregateRefuse Disposals

The invention discloses a high-strength ceramsite and a preparation process thereof. Wet mud powder obtained after filter pressing of mud and powder generated in the gravel aggregate processing process is directly used as a main raw material, small amounts of a pore-forming agent and a fluxing agent are added, kneading, granulation, preheating and high-temperature roasting are carried out to prepare the artificial light bone ceramsite, and the ceramsite is spherical and subsphaeroidal, is hard in skin, and fully filled with fine pores. The prepared ceramsite is high in density, high in strength, low in heat conductivity coefficient, high in refractoriness, good in chemical stability and non-toxic and harmless, the problem that aggregate processing garbage is difficult to treat can be solved, waste is turned into wealth, and good social benefits and environmental protection benefits are achieved.

Owner:杭州奥兴筑友科技有限公司

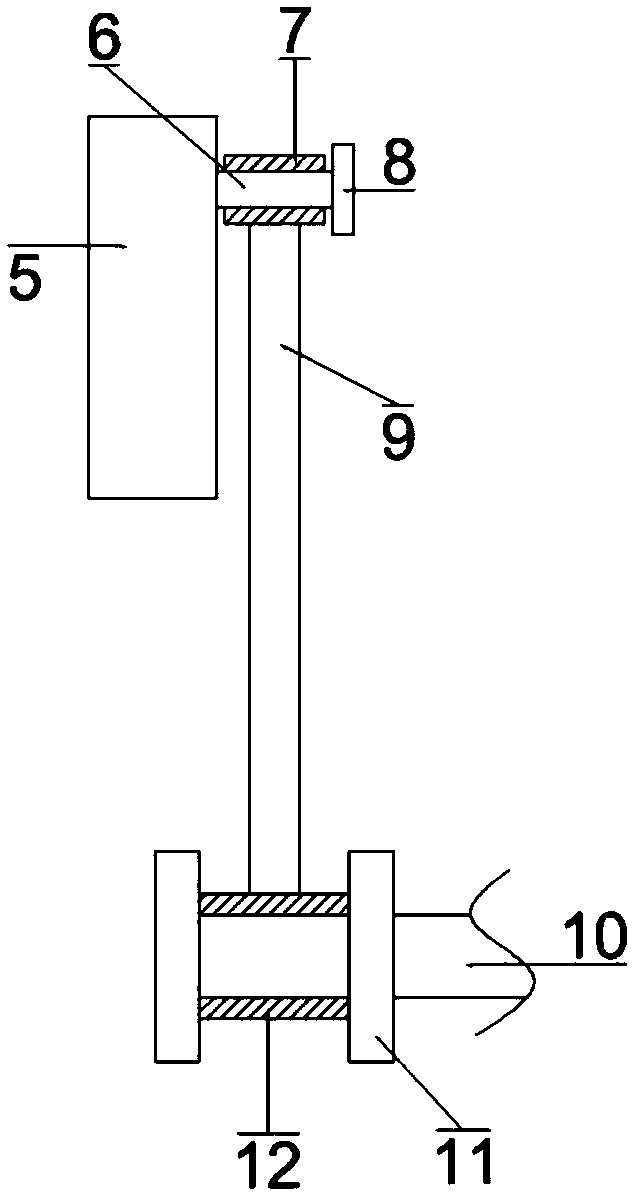

Sow feed mixing method and mixing equipment

ActiveCN112717811ASimple structureIngenious designRotating receptacle mixersShaking/oscillating/vibrating mixersElectric machineMixing effect

The invention discloses a sow feed mixing method and mixing equipment. The mixing equipment comprises supporting columns, a first motor, a fixing piece and a mixing assembly. The mixing assembly is installed on the fixing piece, the supporting columns are located on the two sides of the fixing piece, the first motor is installed on one supporting column, one side of the fixing piece is connected with the first motor, and the other side of the fixing piece is connected with the other supporting column through a rotating rod. The mixing assembly comprises a second motor, a first mixing chamber and a second mixing chamber. The mixing equipment is simple in structure and ingenious in design, multiple raw materials can be mixed through the first mixing chamber and the second mixing chamber, the raw materials in the second mixing chamber can be conveyed into the first mixing chamber through the circulating mechanism, mixing of the multiple raw materials is guaranteed, and the expected mixing effect is achieved.

Owner:TWINS GRP

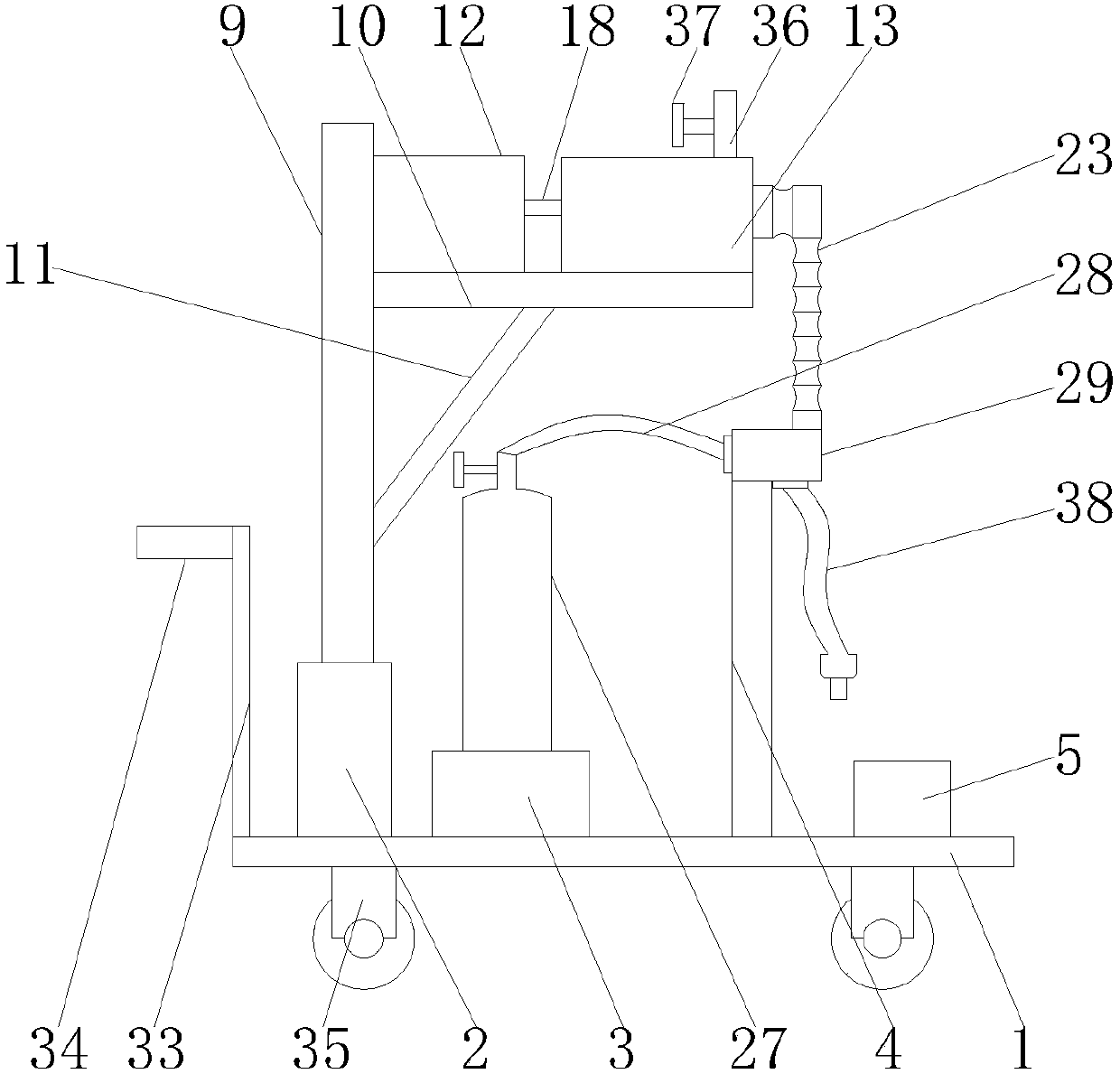

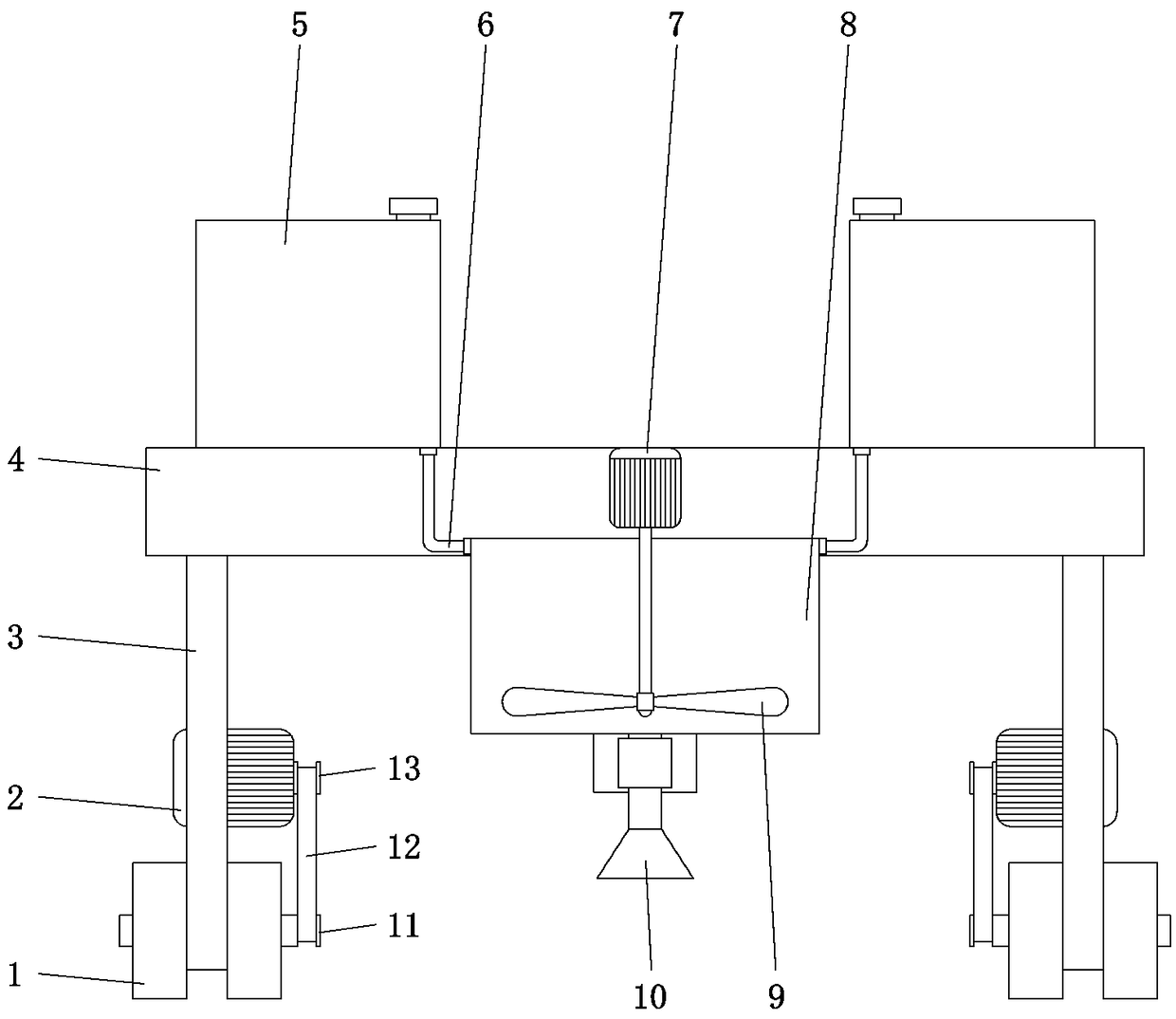

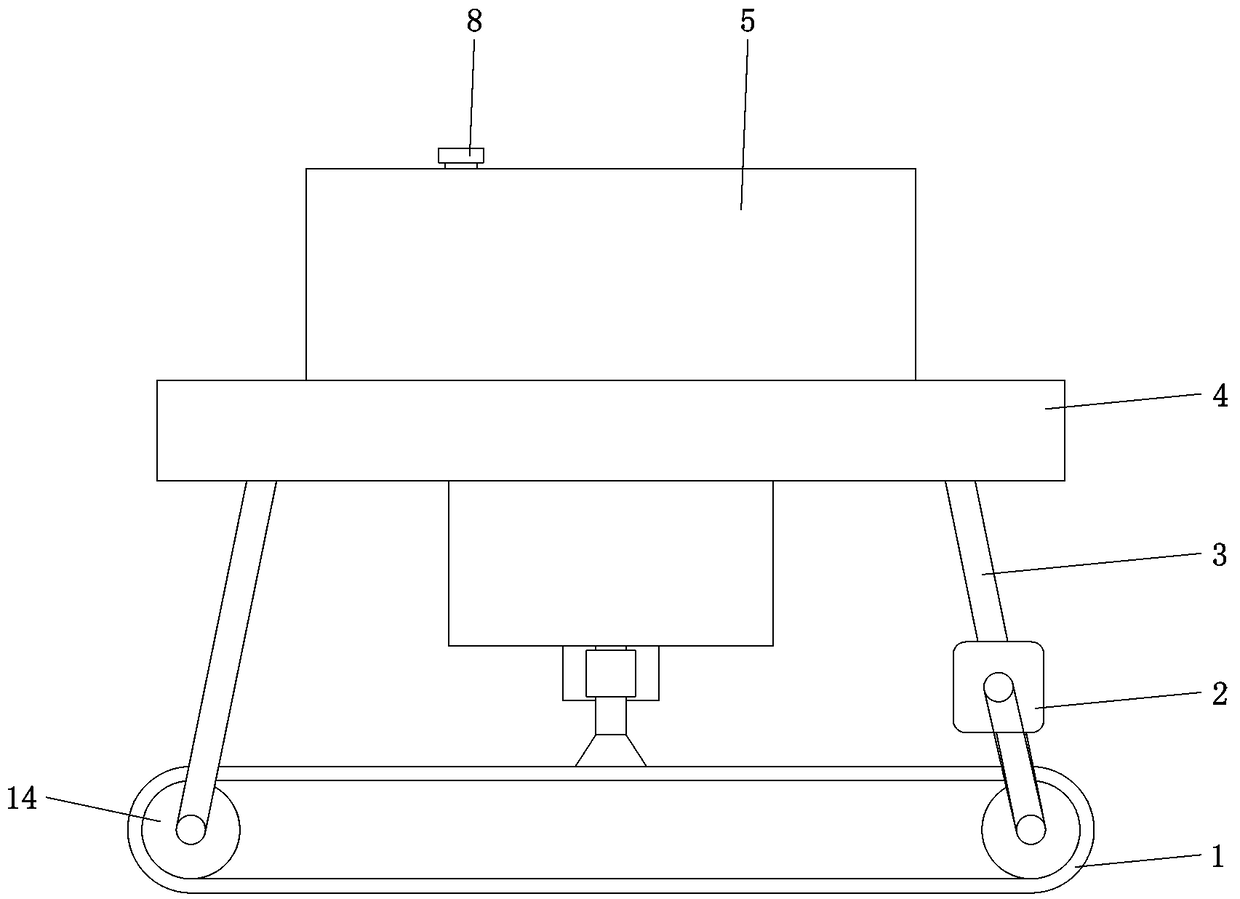

Modern agricultural planting efficient fertilization device with automatic mixing function

PendingCN108093808ATo achieve a mixed effectGood effectRotary stirring mixersTransportation and packagingDrive wheelEngineering

The invention discloses a modern agricultural planting efficient fertilization device with automatic mixing function. The device consists of crawler belts, support columns, a support plate, temporarystorage boxes and a mixing box. The support columns are mounted at the lower surface of the mounting plate, wheel rotating shafts are inserted at the ends of the support columns, and driving wheels are sleeved outside the wheel rotating shafts, driving motors are welded to the front end surfaces of the support columns, and motor rotation shafts are mounted at the output ends of the driving motors,the mixing box is mounted at a middle position on the lower surface of the support plate, a liquid discharge apparatus is mounted at a middle position of the mixing box lower end, a pump installationbox is disposed outside the liquid discharge apparatus, and the pump installation box is welded to the lower surface of the mixing box, a middle position inside the support plate is equipped with a stirring motor, and the stirring motor output end is equipped with a stirring shovel, and both sides at the upper end of the support plate are equipped with the temporary storage boxes. The efficient fertilization device provided by the invention can achieve convenient mixing of fertilizer and ejection through the liquid discharge apparatus, and the equipment has automatic mixing function.

Owner:四川绅裕建设工程有限公司

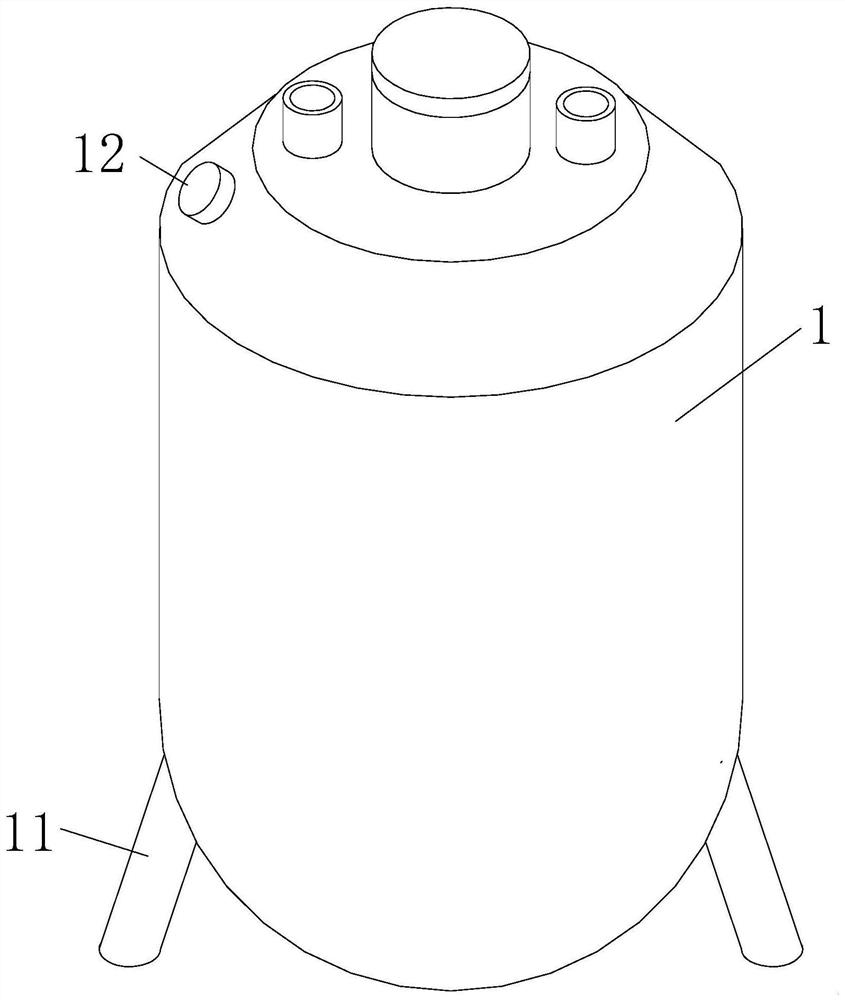

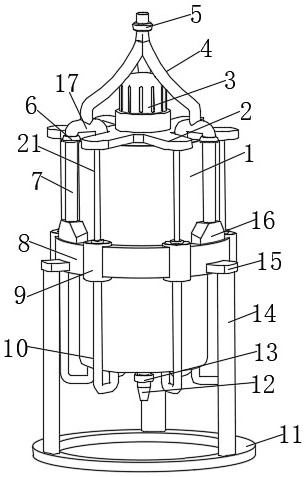

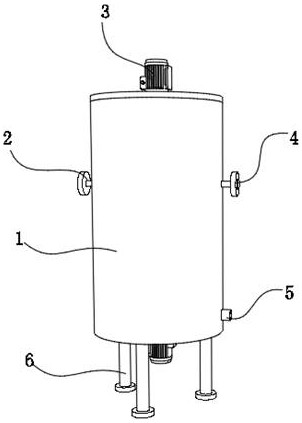

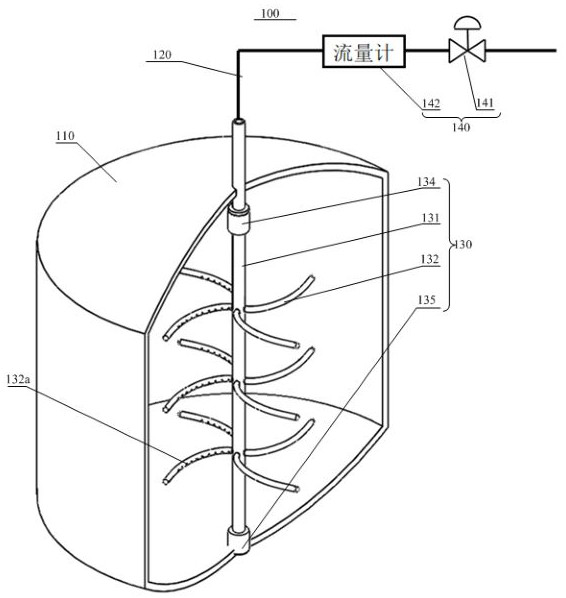

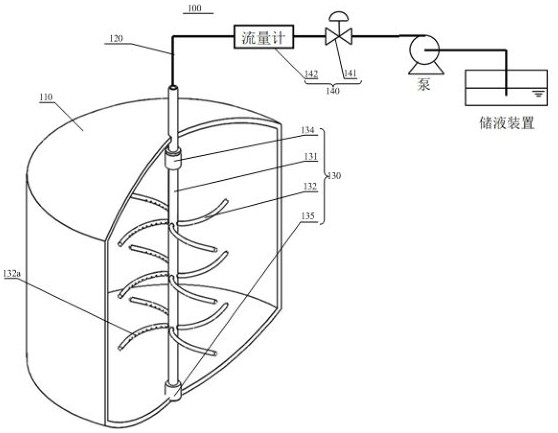

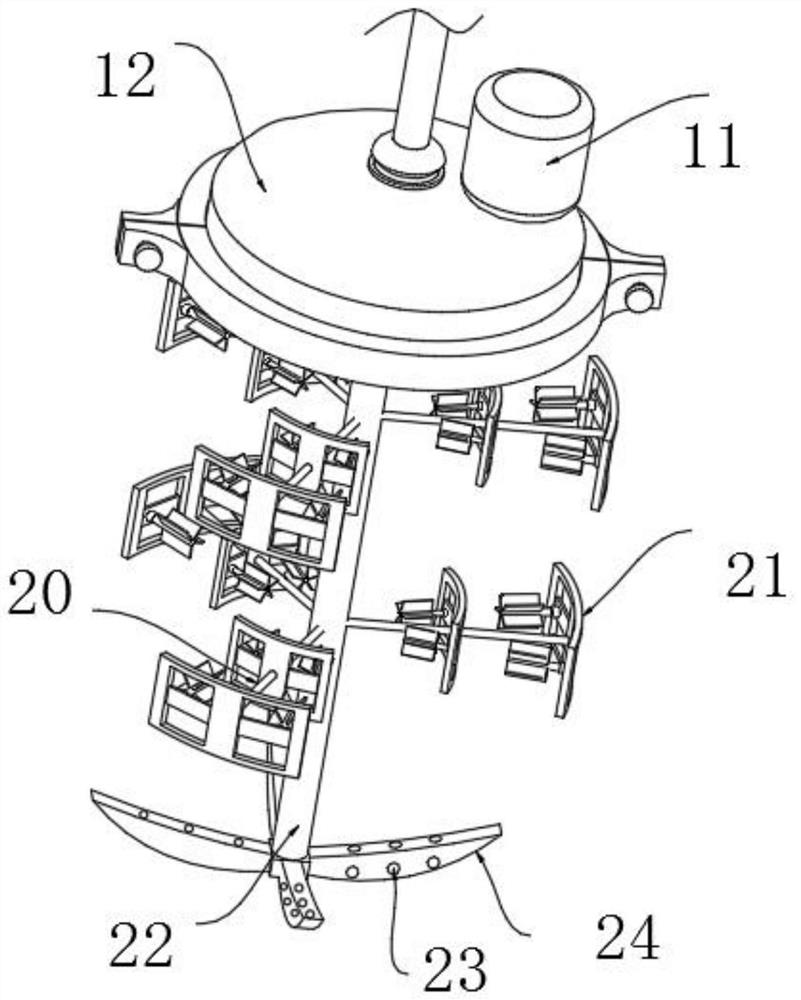

Enzymatic microbial strain liquid fermentation system

InactiveCN113105993AImprove qualityAccelerate mixing and dissolvingBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyEngineering

The invention relates to the technical field of strain liquid fermentation, and discloses an enzymatic microbial strain liquid fermentation system. The system comprises a tank body and a fermentation barrel; an inner chamber is formed in the tank body, a plug cover is movably clamped to the upper end of a feeding pipe, a partition plate is fixedly connected to the inner wall of the inner chamber, and a transverse rotating mechanism is arranged above the partition plate; the transverse rotating mechanism is fixedly connected with the fermentation barrel, the transverse rotating mechanism is externally connected with the transmission mechanism in a meshed mode, the longitudinal stirring mechanism is movably arranged above the transmission mechanism, strain liquid is placed into the fermentation barrel, then external feeding can be conducted through the feeding pipe, and when the strain liquid is added into the fermentation barrel, the rotating motor is started, and at the moment, strains are longitudinally stirred by matching with the stirring wings while being transversely rotated by the fermentation barrel, so that the effect of three-dimensional liquid mixing of the strains is achieved, mixing and dissolving of strain liquid and fed materials are accelerated, and the quality of the fermented strain liquid is improved.

Owner:北京金华雅轩健康科技有限公司

Impinging stream low-nitrogen combustion reaction device and reaction method thereof

PendingCN111578312AAvoid lossFull combustion reactionContinuous combustion chamberChemical/physical/physico-chemical stationary reactorsChemical industryEngineering

The invention relates to the technical field of chemical industry, and in particular to an impinging stream low-nitrogen combustion reaction device. The impinging stream low-nitrogen combustion reaction device comprises the following parts of a cylindrical or rectangular impinging stream reaction chamber, wherein the side of the impinging stream reaction chamber is uniformly opened with several layers of installation through holes from bottom to top; acceleration tubes installed in the installation through holes; an air flow channel installed on the top of the impinging stream reaction chamberand communicated with the impinging stream reaction chamber; a burner communicated with the other end of the air flow channel; and a boiler installed on the top of the burner and providing heat by the burner. The invention also discloses an impinging stream low-nitrogen combustion reaction method, which specifically comprises the following steps of introducing high-speed air and high-speed gas into the acceleration tubes in the same layer for collision to obtain a rising ion current; driving the turbulence fan to rotate by the rising ion current when passing through a turbulence fan so as toevenly mix the ions in the ion flow, and making the ion flow continue to rise into the burner; heating the burner to 1000 to 1100 DEG C to cause the ion flow to burn and release heat; and exhausting excess nitrogen and water.

Owner:江苏河海新能源技术发展有限公司

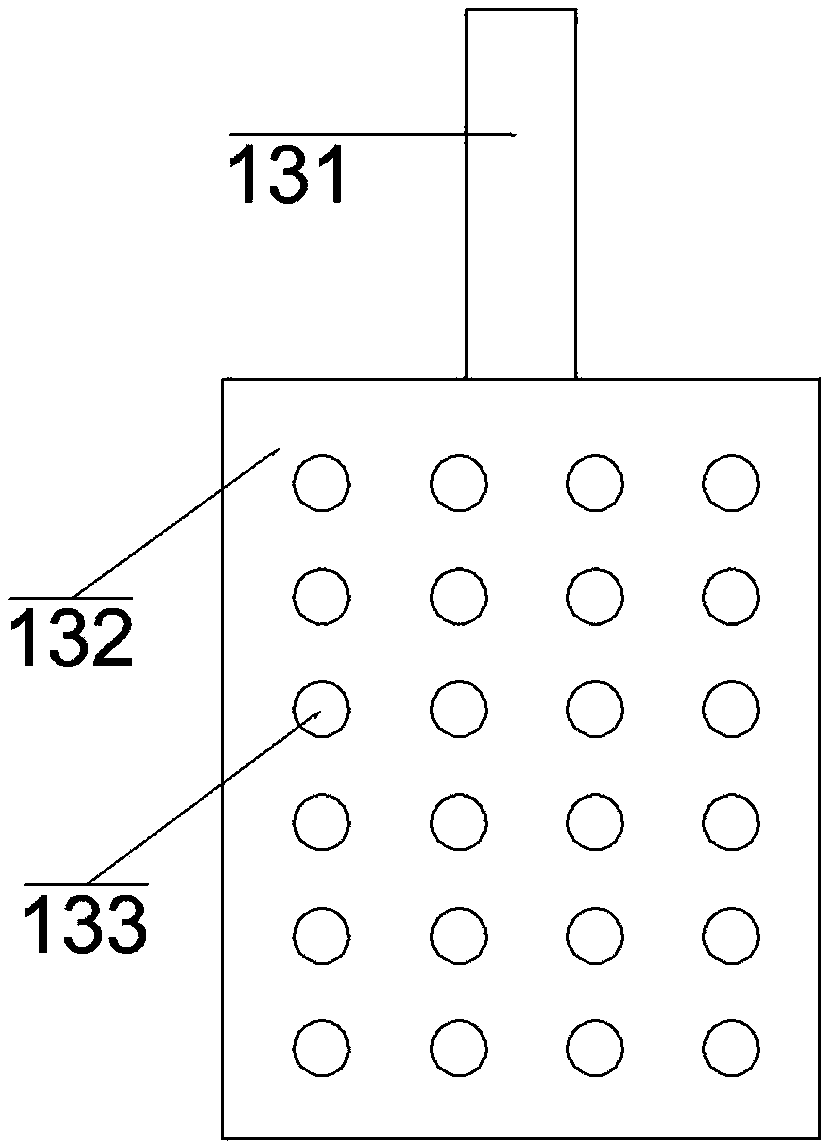

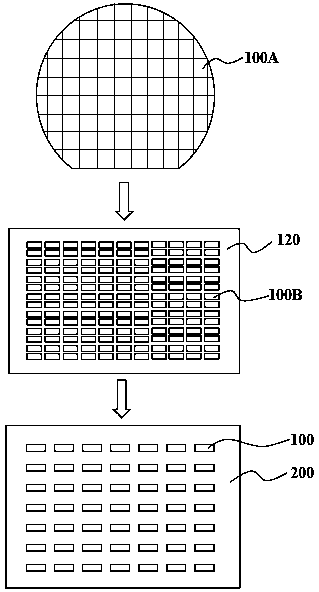

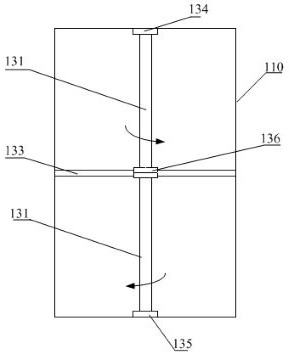

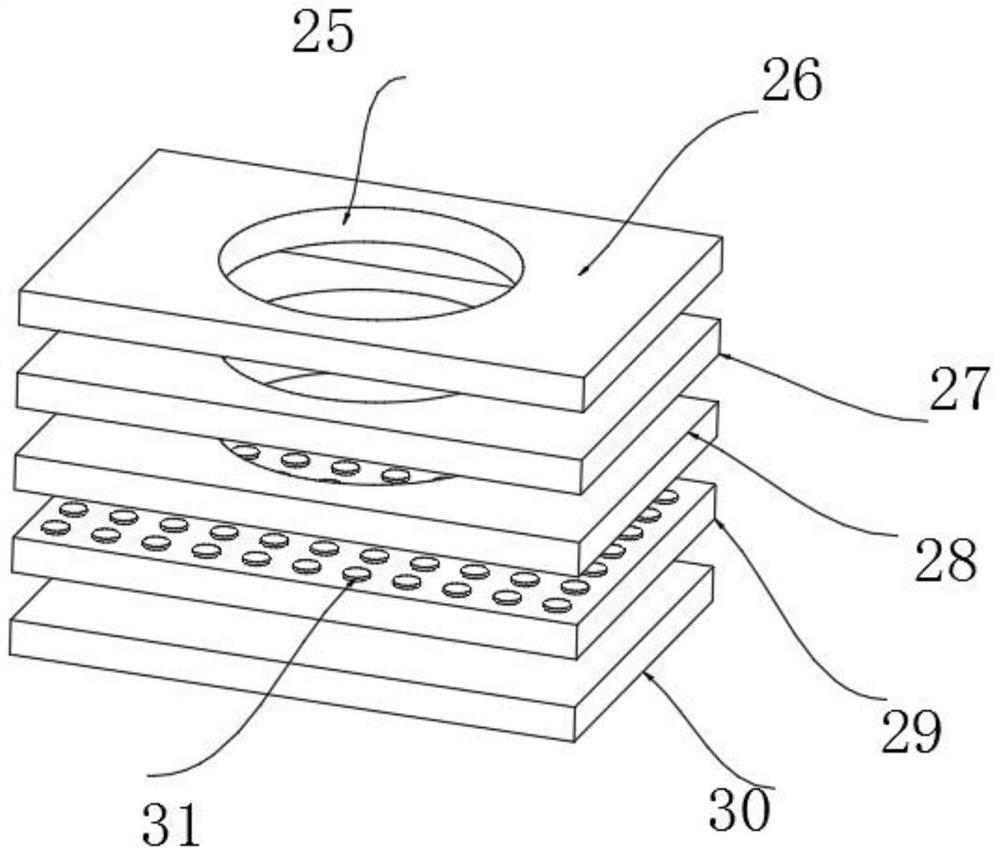

Display device and manufacturing method thereof

ActiveCN111201595ABrightness does not appeNo color differenceSolid-state devicesSemiconductor/solid-state device manufacturingWaferDisplay device

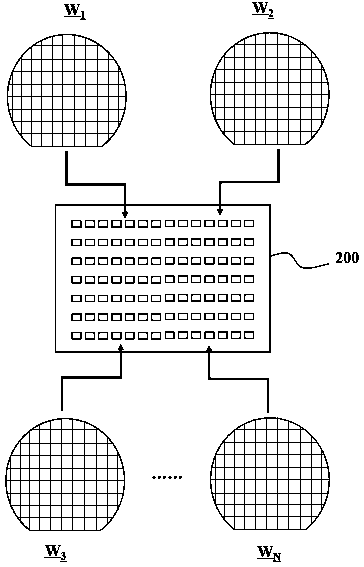

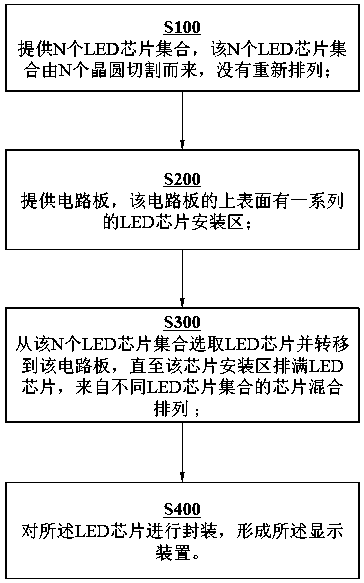

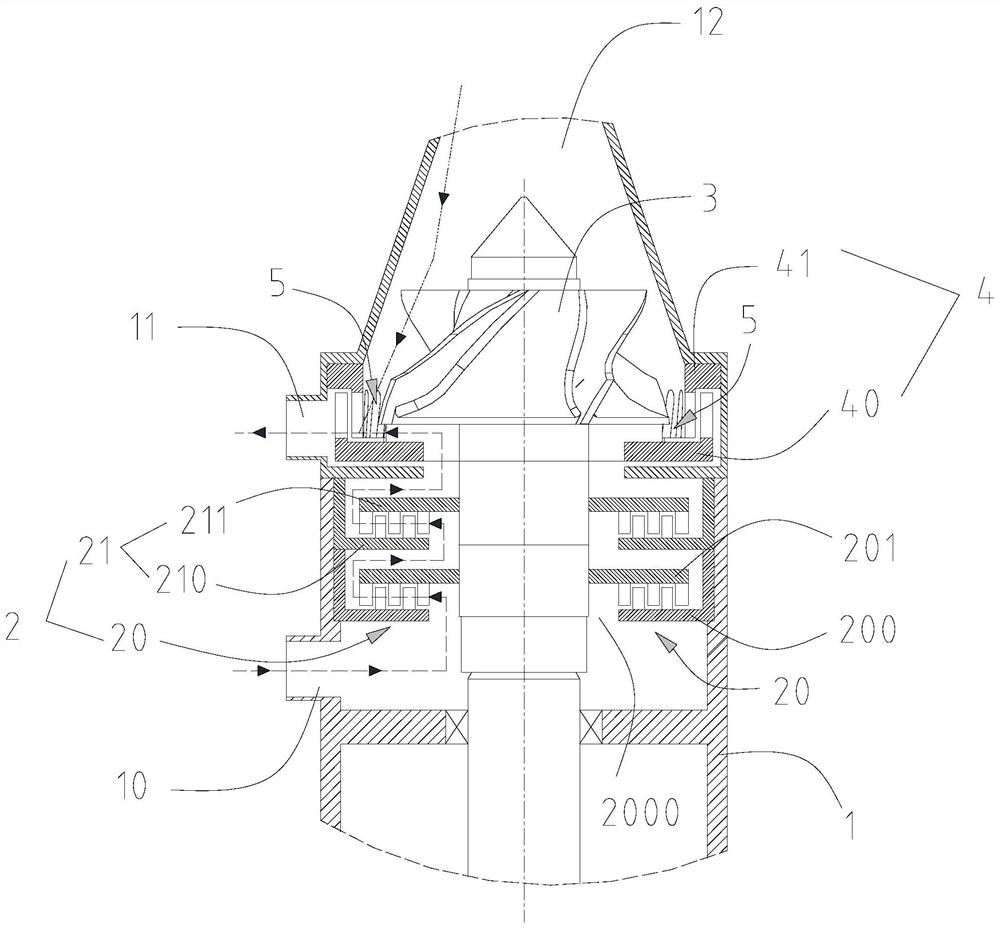

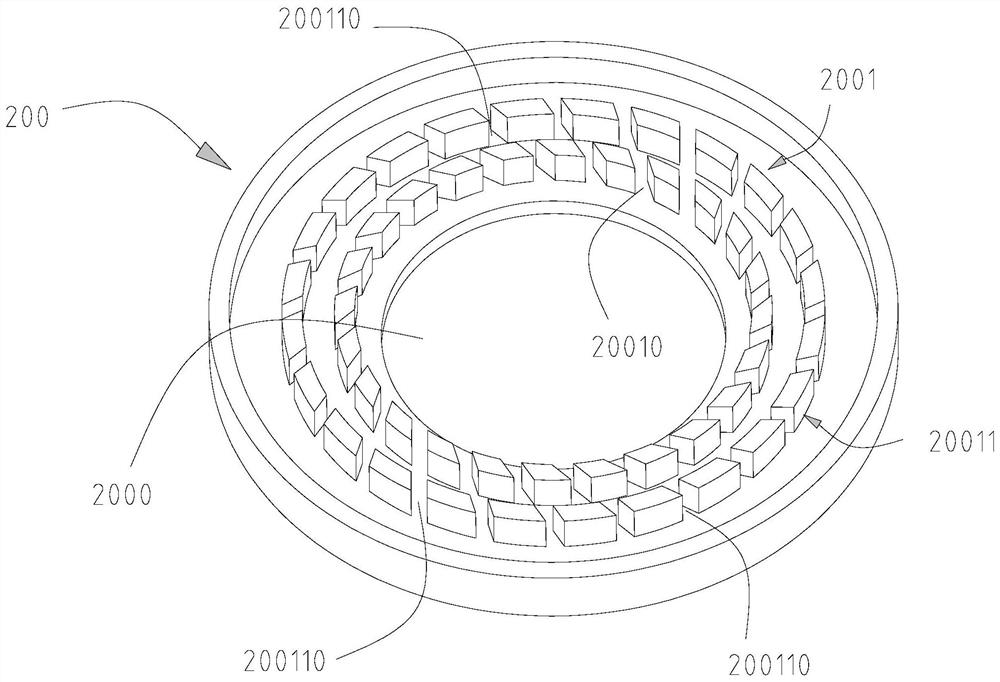

The invention discloses a manufacturing method of a display device. The method comprises the following steps: providing N LED chip sets, wherein the N LED chip sets are formed by cutting N wafers andare not rearranged, the first LED chip set is produced from the first wafer, the second LED chip set is produced from the second wafer,..., the Nth LED chip set is produced from the Nth wafer, and N is an integer greater than 2; providing a circuit board (200), wherein the upper surface of the circuit board (200) is provided with a series of LED chip mounting areas (210); selecting LEDs from the NLED chip sets and transferring to the circuit board (200) until the chip mounting area (210) is full of the LED chips, and arranging the chips from different LED chip sets in a mixed mode; and packaging the LED chip to form the display device. The invention further provides a display device.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

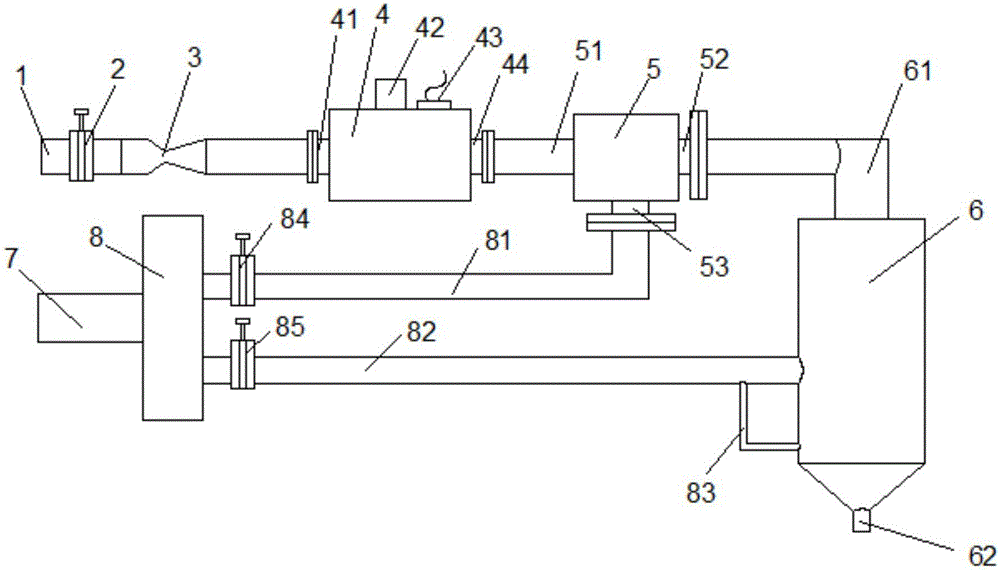

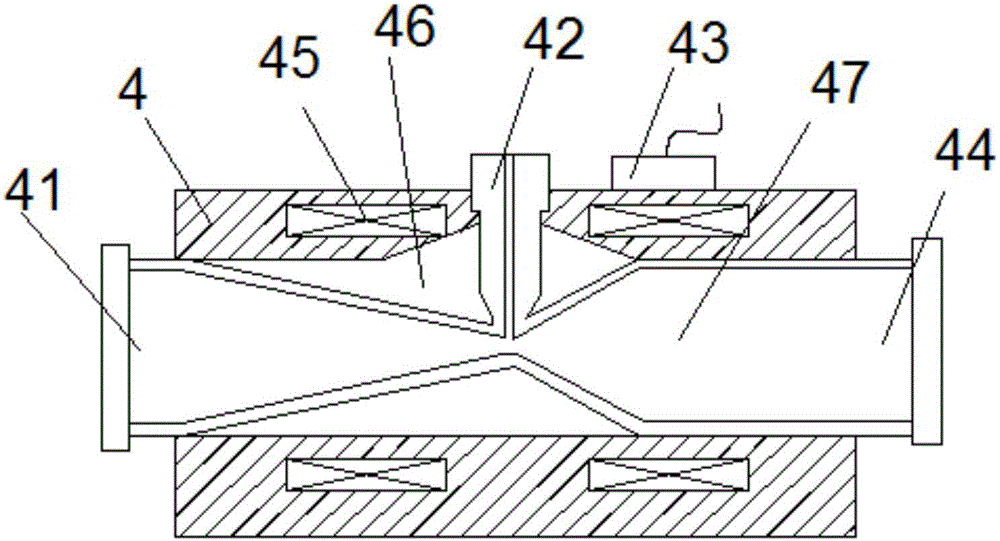

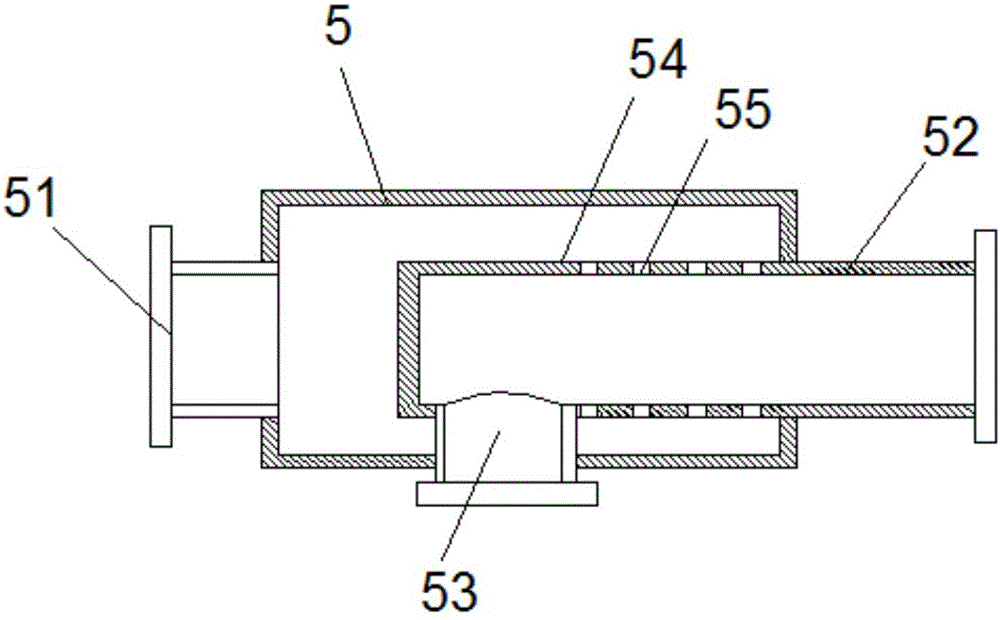

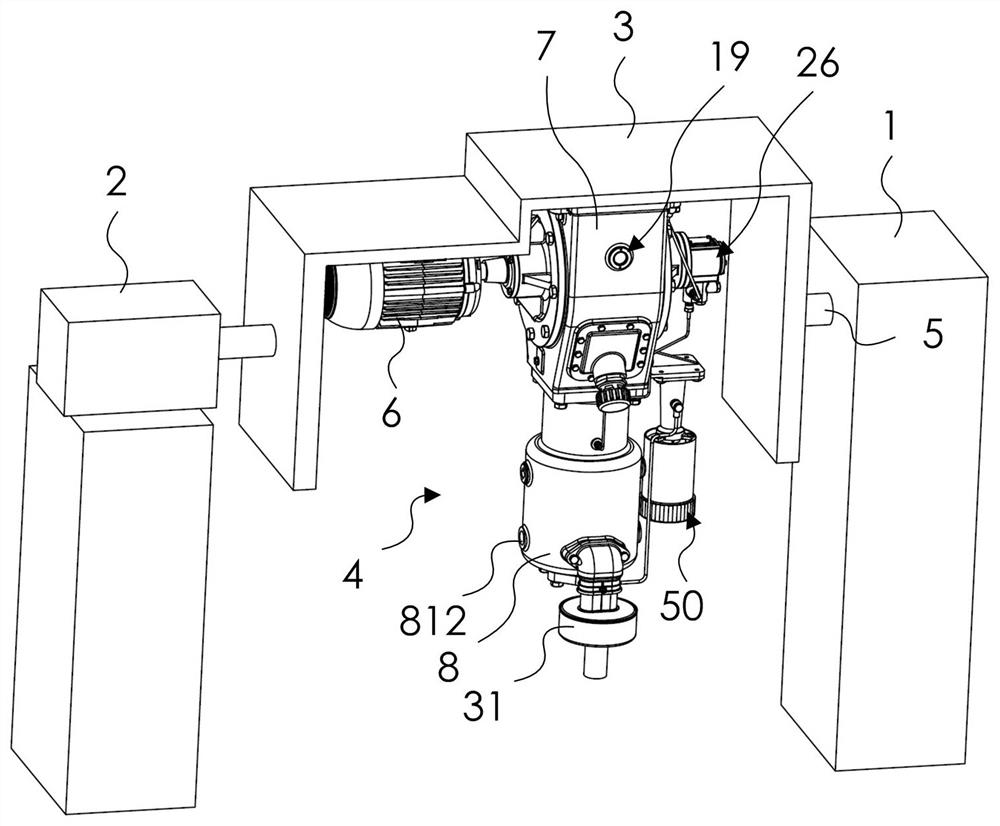

Powder-liquid mixing machine

PendingCN113499698AOvercoming Congestion and Dispersion ContradictionsOvercoming technical difficultiesMixing methodsMixersPhysicsEngineering

The invention discloses a powder-liquid mixing machine which comprises a main shell, a liquid dispersing device, a powder conveying device and a mixing device; a liquid dispersing area and a powder-liquid mixing area are formed in the main shell; the liquid dispersing device is used for dispersing to-be-mixed liquid in the liquid dispersing area and enabling the dispersed to-be-mixed liquid to enter the powder-liquid mixing area; the powder conveying device is used for conveying to-be-mixed powder into the powder-liquid mixing area; and the mixing device is used for mixing the to-be-mixed powder entering the powder-liquid mixing area and the to-be-mixed liquid entering the powder-liquid mixing area and discharging the mixed powder and the mixed liquid. During use, to-be-mixed slurry is dispersed in the liquid dispersing area through the liquid dispersing device and then enters the powder-liquid mixing area, and to-be-mixed powder conveyed by the powder conveying device is mixed through the material mixing device, so that the effect that to-be-mixed liquid is dispersed firstly and then mixed with the to-be-mixed powder is achieved; and the technical difficulties of blockage and dispersity contradiction of high-viscosity mixed materials are overcome.

Owner:ONGOAL MATERIAL AUTOMATION EQUIP

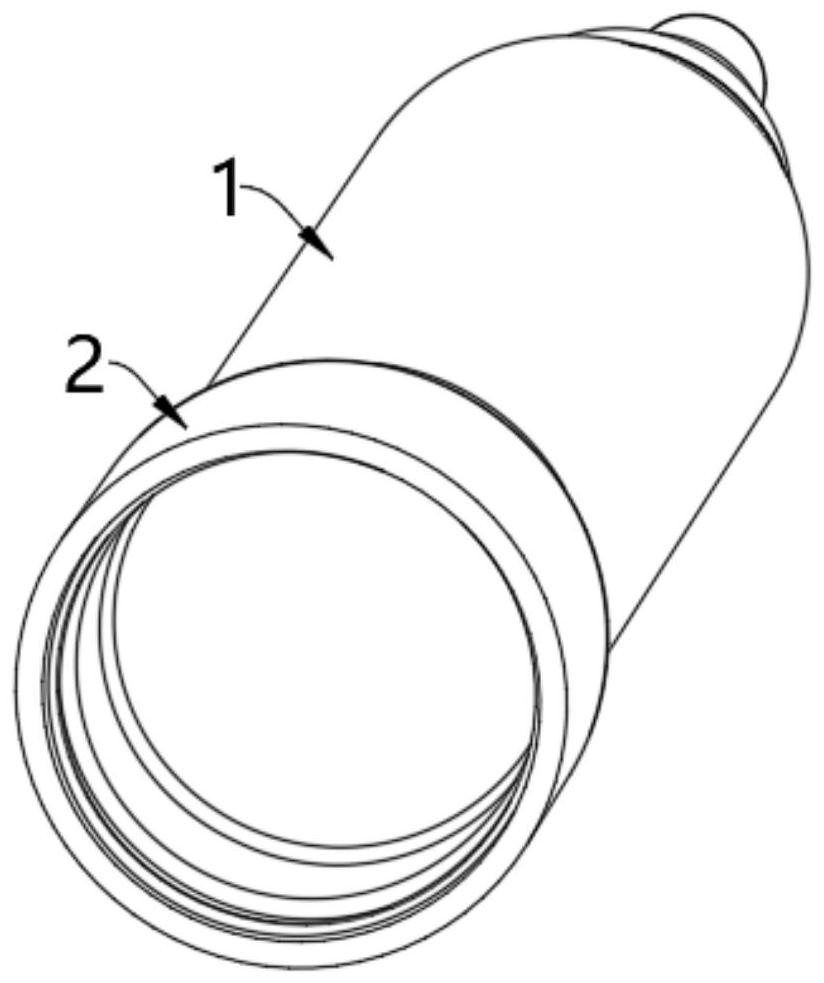

Rotating type self-mixing double-agent package

InactiveCN113816015AReduce complexityReduce manufacturing costPackaging toiletriesPackaging cosmeticsManufacturing engineeringShelf life

The invention relates to the technical field of packaging bottles, and discloses a rotating type self-mixing double-agent package which comprises a bottle body and a first stock bin formed in the bottle body. A nesting sleeve is fixedly installed at the bottom of the bottle body, a connecting piece is embedded in the inner wall of the nesting sleeve, a sealing plate is arranged at the top end of the connecting piece, a charging barrel is movably arranged in the connecting piece, the top end of the charging barrel is movably arranged on the sealing plate, and a second stock bin is formed in the charging barrel. Different liquids are stored in the first stock bin and the second stock bin respectively, when mixing is needed, a lower cover is directly screwed, the structural complexity is effectively reduced, the production cost is low, independent storage of two kinds of cosmetics with different characters can be effectively achieved, storage and transportation of the cosmetics are facilitated, the overall shelf life and service life are prolonged, the operation is very convenient during mixing, the complicated mixing operation of a traditional double-agent package is abandoned, and the rotating type self-mixing double-agent package has high popularization and application values and market competitiveness.

Owner:郗大伟

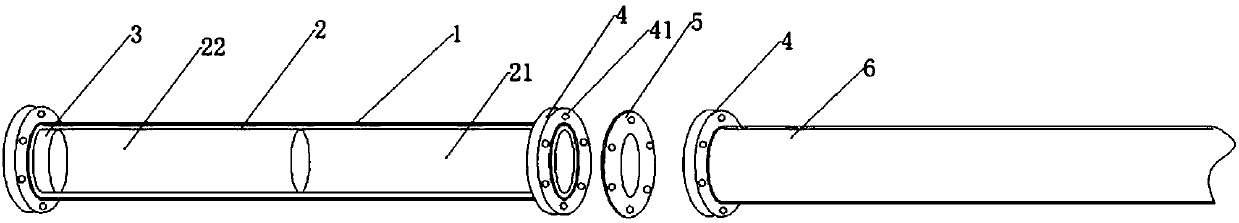

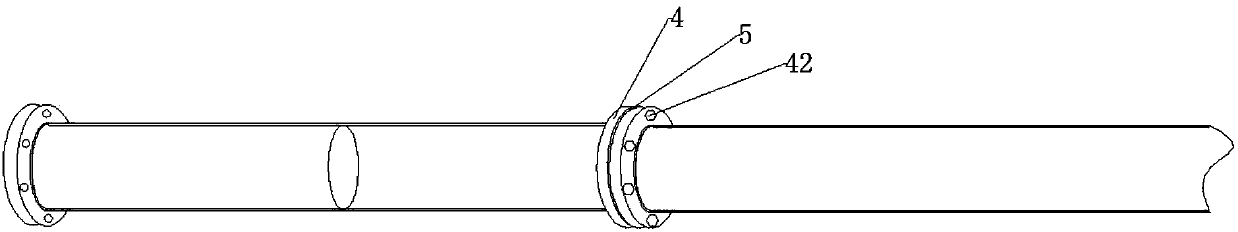

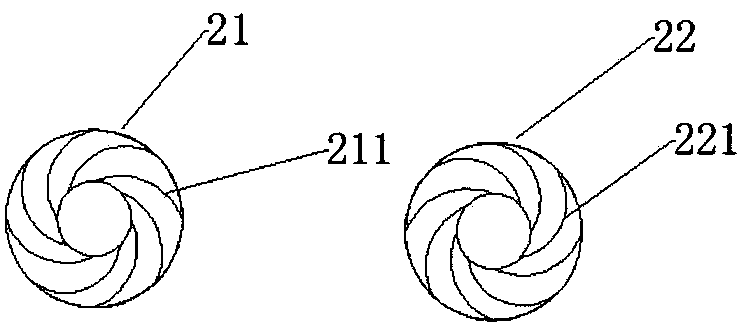

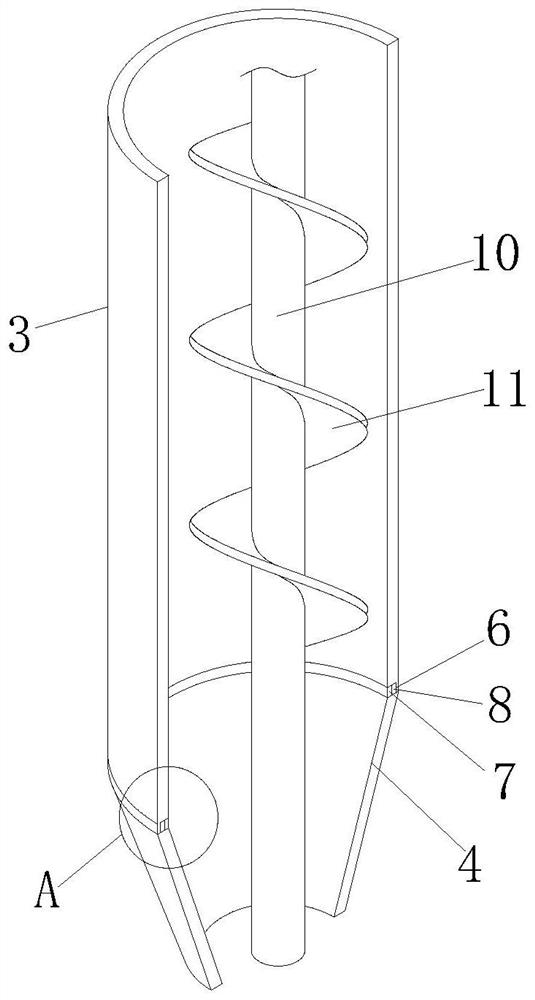

Double-spiral-pipeline oil mixing method and double-spiral-pipeline oil mixing device

PendingCN107837701APrevent leakageThe principle is simpleFlow mixersMixing methodsScrew threadClockwise

The invention discloses a double-spiral-pipeline oil mixing method and a double-spiral-pipeline oil mixing device. The device mainly consists of a sleeve and an inner pipe, wherein the inner pipe is arranged in the sleeve, the outer diameter of the inner pipe is equal to the inner diameter of the sleeve, and the outer wall of the inner pipe is completely fitted with the inner wall of the sleeve; the inner wall of the inner pipe is provided with threads including clockwise rotating threads and counterclockwise rotating threads, and the clockwise rotating threads are connected with the counterclockwise rotating threads. The device provided by the invention is simple as well as simple and convenient to operate; by clockwise and counterclockwise twisting an oil product, flowing in an oil conveying pipeline, along the opposite directions, the oil product is subjected to forward and reverse intense turbulent flow and to be fully mixed, so that the mixing effect of the oil product is improved.

Owner:QINZHOU UNIV

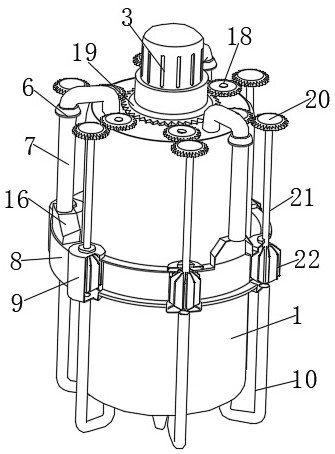

Stirring equipment for biological pharmacy

ActiveCN112791656ATo achieve the initial mixing effectTo achieve a mixed effectFlow mixersRotary stirring mixersBiotechnologyPharmacy

The invention relates to the technical field of biopharmacy, in particular to stirring equipment for biological pharmacy. The stirring equipment comprises a stirring cylinder; a squeezing and pushing disc is horizontally arranged in the stirring cylinder, the outer side of the squeezing and pushing disc is fixedly sleeved with a sealing ring, and the sealing ring is in sliding close contact with the inner wall of the stirring cylinder; a driving sleeve head is vertically and fixedly mounted in the middle of the extruding and pushing disc, a reciprocating screw rod matched with the driving sleeve head is inserted into the inner side of the driving sleeve head and is vertically and rotatably mounted between the two ends in the stirring barrel, and the top end of the reciprocating screw rod extends to the exterior of the stirring barrel to be connected with an output shaft of a driving motor; a plurality of limiting sliding rods are vertically connected between the two ends in the stirring barrel at equal intervals in the circumferential direction, and the extruding and pushing disc is arranged on the outer sides of the multiple limiting sliding rods in a sliding and sleeving mode. The invention has a dual-circulation mixing and stirring effect, the mixing and stirring time of multiple pharmaceutical liquid raw materials is effectively shortened, and the mixing and stirring uniformity of the multiple pharmaceutical liquid raw materials is improved.

Owner:广州加泰医药科技有限公司

Raw material mixing device for glass manufacturing

InactiveCN112371045APrevent solidificationReduce consumptionTransportation and packagingMixer accessoriesProcess engineeringGlass manufacturing

The invention discloses a raw material mixing device for glass manufacturing, and relates to the technical field of glass manufacturing. The problem of energy waste is solved. The device specificallycomprises a heat preservation chamber, a base is fixedly connected to the bottom of the heat preservation chamber, a discharge port is formed in the outer wall of the heat preservation chamber, a stirring barrel is fixedly connected to the inner wall of the bottom of the heat preservation chamber, a mixing pipe is fixedly connected to the top of the stirring barrel, and a guide pipe is fixedly connected to the outer wall of the mixing pipe. By arranging a first heating barrel and a second heating barrel, raw materials needing to be mixed are put into the first heating barrel and the second heating barrel correspondingly, the different raw materials in the first heating barrel and the second heating barrel are heated through heating coils, the melting points of the different raw materials can be heated correspondingly, energy consumption is effectively reduced, and meanwhile, the proportion of the mixed raw materials is adjusted through a first adjusting valve and a second adjusting valve, so that the mixing proportion meets the glass manufacturing requirement, the heat preservation chamber gathers heat, and the guide pipe and a component below the guide pipe are located in a high-temperature environment.

Owner:TAIWAN GLASS YUEDA AUTO GLASS CO LTD

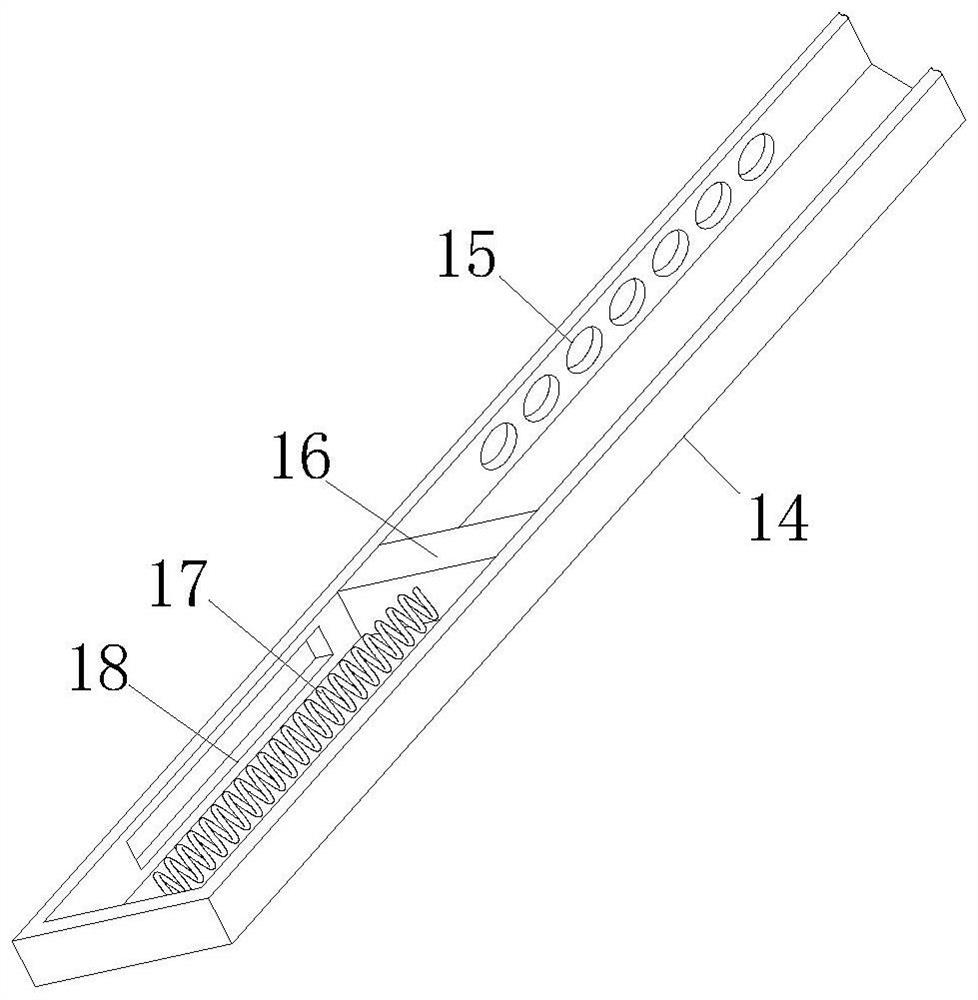

Garden pesticide application configuration mechanism

InactiveCN106889043ATo achieve a mixed effectEasy to operateTransportation and packagingMixersRubber ringIsolation layer

The invention discloses a garden pesticide application configuration mechanism. The garden pesticide application configuration mechanism comprises a mixing cavity, sealing covers sleeving two sides of the mixing cavity, a filtering cavity disposed at an inner side of the mixing cavity, a pesticide storage cavity disposed over the filtering cavity, and a detachable pesticide injection part installed over the pesticide storage cavity. The detachable pesticide injection part comprises an outer cylinder, a piston installed in the outer cylinder, and a handle disposed at the top of the piston. An isolation layer is disposed between the pesticide storage cavity and the filtering cavity. An outer side of the filtering cavity is provided with a fine screen mesh. A rubber ring is disposed between the pesticide storage cavity and the detachable pesticide injection part. The rubber ring is provided with small holes. According to the garden pesticide application configuration mechanism, the sealing covers at the two sides of the pesticide mixing cavity can be detached to connect more pesticide mixing cavities, the effect of mixing multiple pesticides is achieved, and the pesticides having different proportions can be configured according to crops. The garden pesticide application configuration mechanism is simple in operation, and the pesticide mixing can be controlled.

Owner:谢东梅

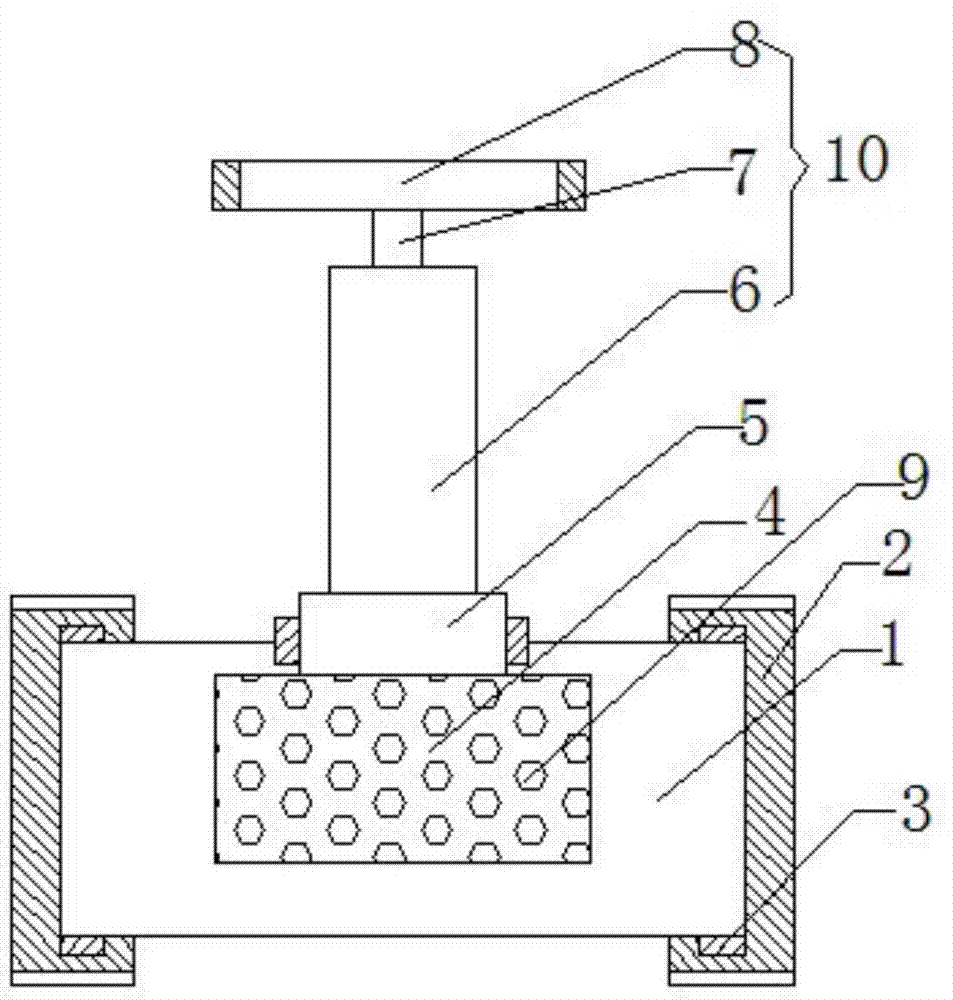

Stirring device and stirring method

InactiveCN114733400ASimple structureTo achieve a mixed effectFlow mixersRotary stirring mixersThermodynamicsElectric machinery

The invention provides a stirring device and a stirring method. The stirring device comprises a stirring tank, a liquid inlet pipeline and a stirring assembly rotationally arranged in the stirring tank; the stirring assembly is provided with a fluid feeding channel, the fluid feeding channel is respectively communicated with the liquid inlet pipeline and the stirring tank so as to form jet flow in the stirring tank, and the jet flow can push the stirring assembly to rotate so as to stir fluid in the stirring tank. According to the stirring device, jet flow of fluid is used as a power source, the stirring assembly is pushed to rotate to achieve stirring, and the effect of multi-phase fluid mixing is achieved; meanwhile, mutual mixing of multi-phase fluid can be increased through the jet flow effect of the fluid, and therefore it is guaranteed that fluid mixing operation is safely, efficiently and economically operated. The stirring device is simple in structure, a motor is not needed, energy consumption and noise pollution are reduced, and the safety risk of electrical equipment when a traditional motor stirrer is used in an anti-explosion area is fundamentally eradicated.

Owner:CHINA AVIATION OIL CO LTD ZHEJIANG BRANCH

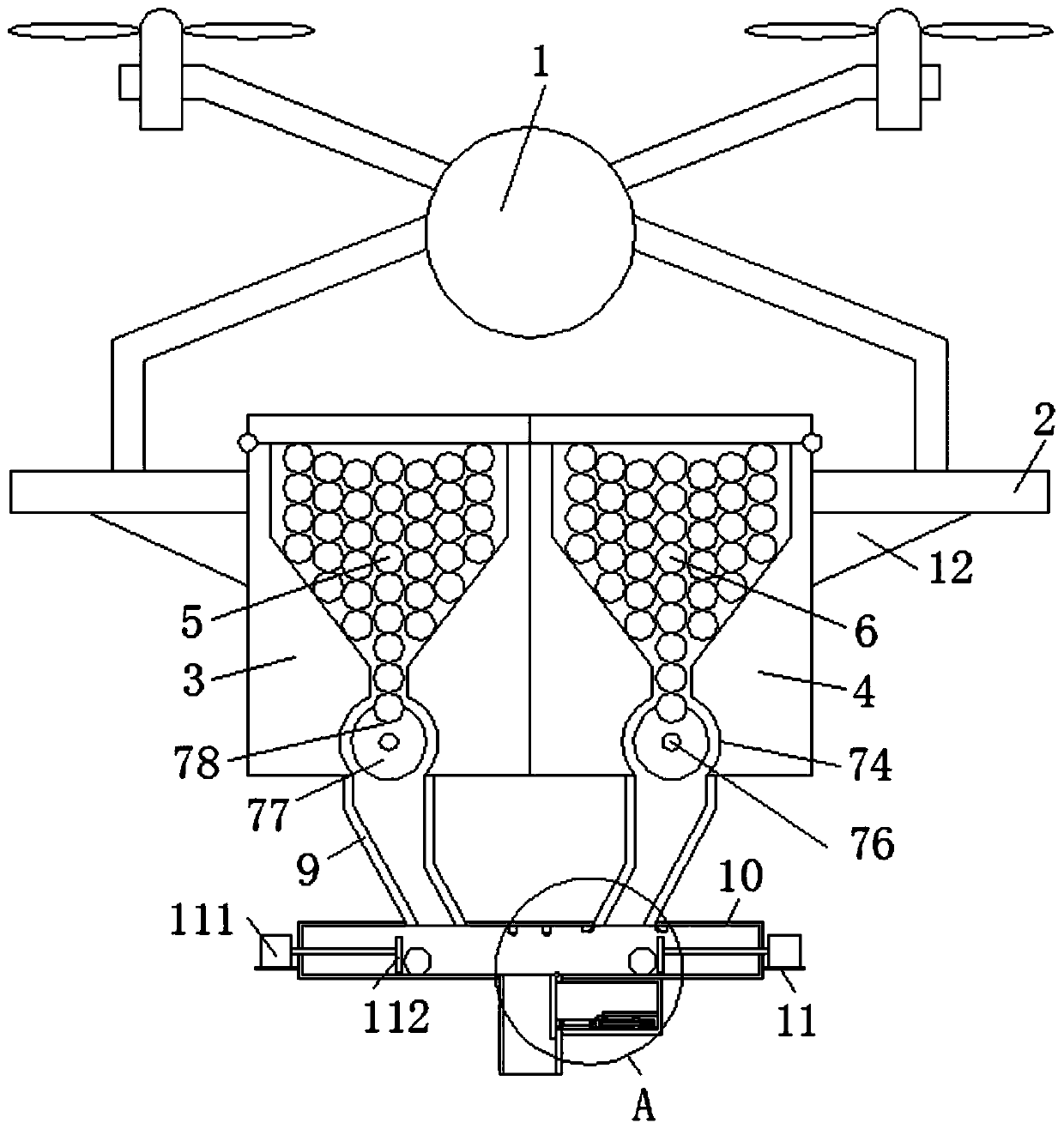

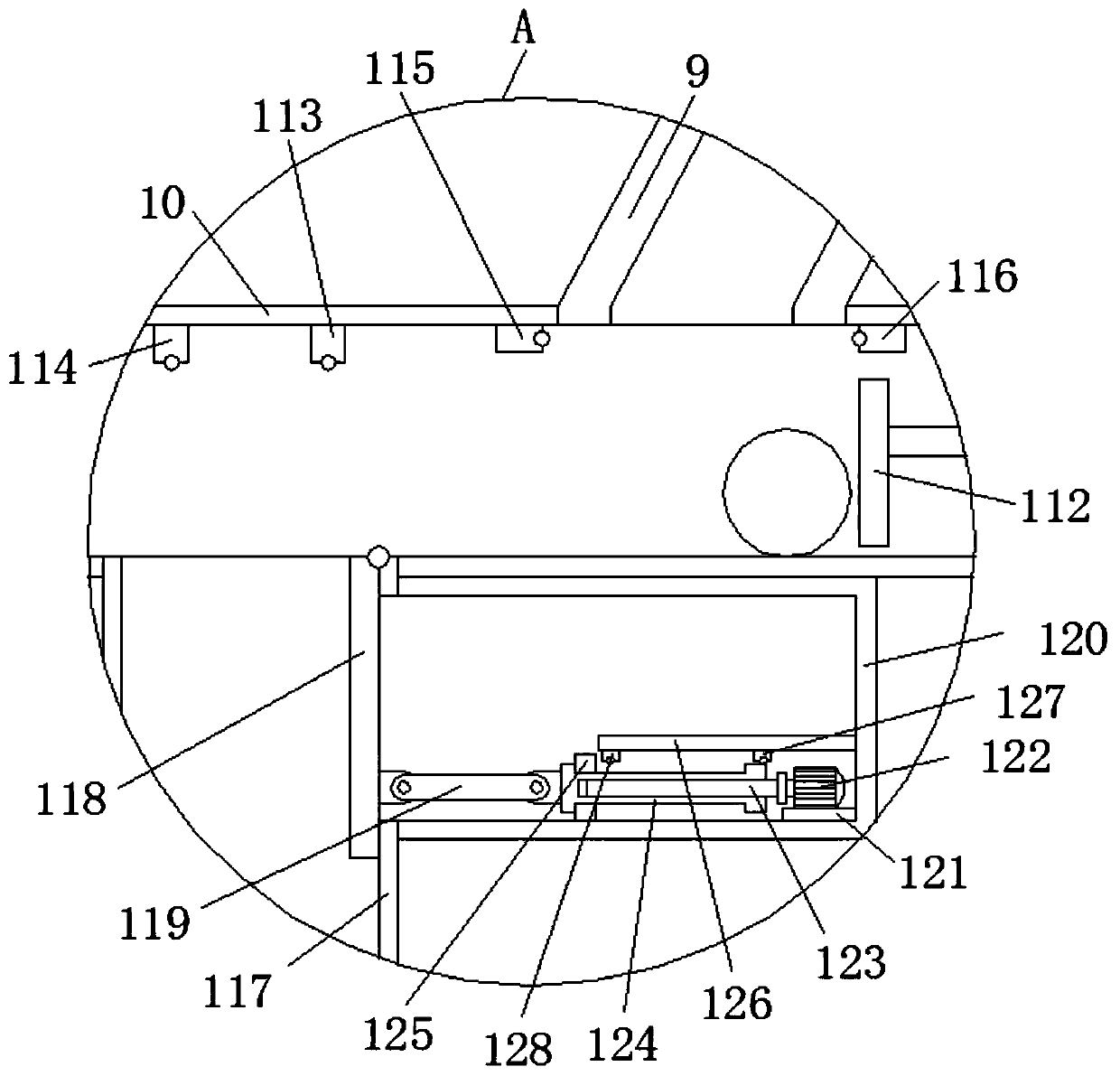

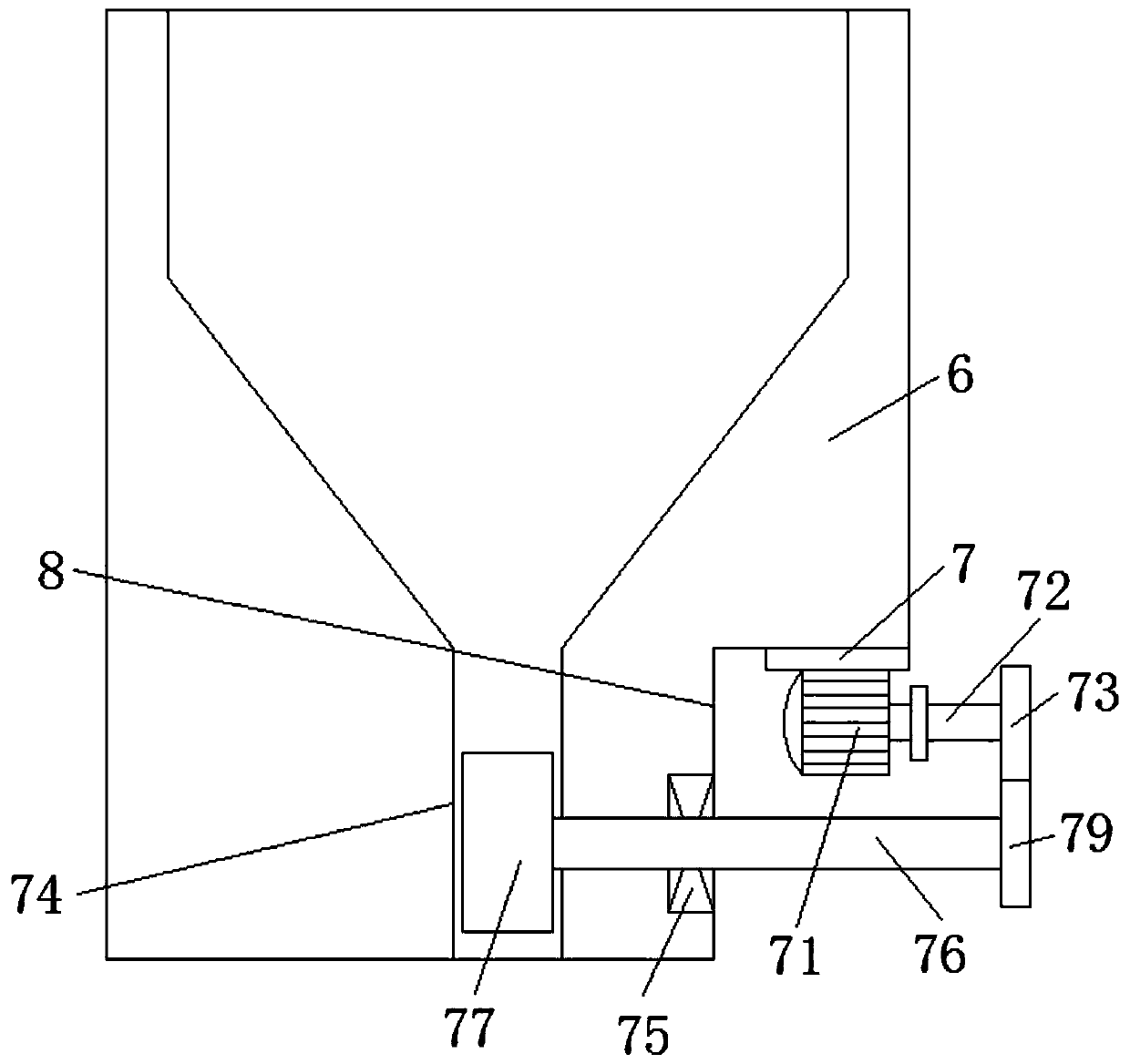

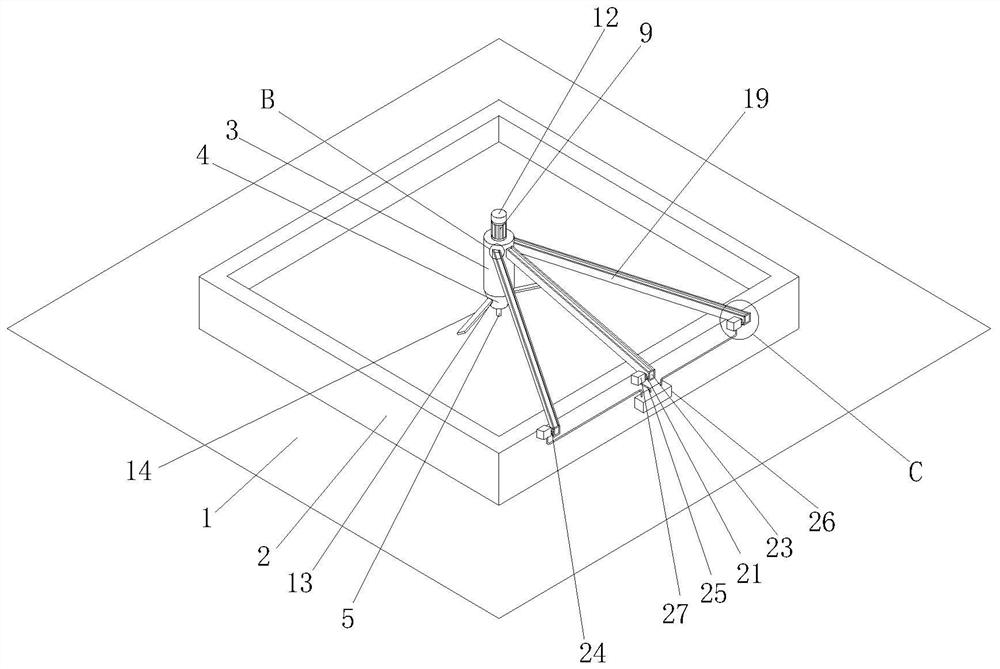

Seeding device used for agricultural unmanned aerial vehicle

ActiveCN110562457AReduce controlTo achieve a mixed effectAircraft componentsRemote controlled aircraftAgricultural engineeringEngineering

The invention belongs to the technical field of agricultural equipment and particularly relates to a seeding device used for an agricultural unmanned aerial vehicle. The seeding device comprises the unmanned aerial vehicle. Connecting blocks are fixedly connected with the bottom of the unmanned aerial vehicle. The surface of one of the connecting blocks is fixedly connected with a seed storage box, and the surface of the other connecting block is fixedly connected with a balance weight nutrition box. By means of the seeding device used for the agricultural unmanned aerial vehicle, one ends oftwo discharging pipes fixedly communicates with a mixing pipe, and a mixing device is arranged in the mixing pipe. The mixing device comprises installation bottom plates, the surfaces of the two installation bottom plates are fixedly connected with the two ends of the mixing pipe, and therefore the effect of controlling mixing of seeds and balance weight particles is achieved, the weight of the seeds is increased, and the falling speed is increased in the falling process; and the phenomenon that during normal seeding, the seeds are small in mass and small in size, during seeding, due to the too long falling time of the seeds in the scattering process, the seeds are likely to be blown away by air, consequently, the seeds are deviated from the seeding position, and the seeding effect is pooris avoided.

Owner:南京精微迅智能科技有限公司

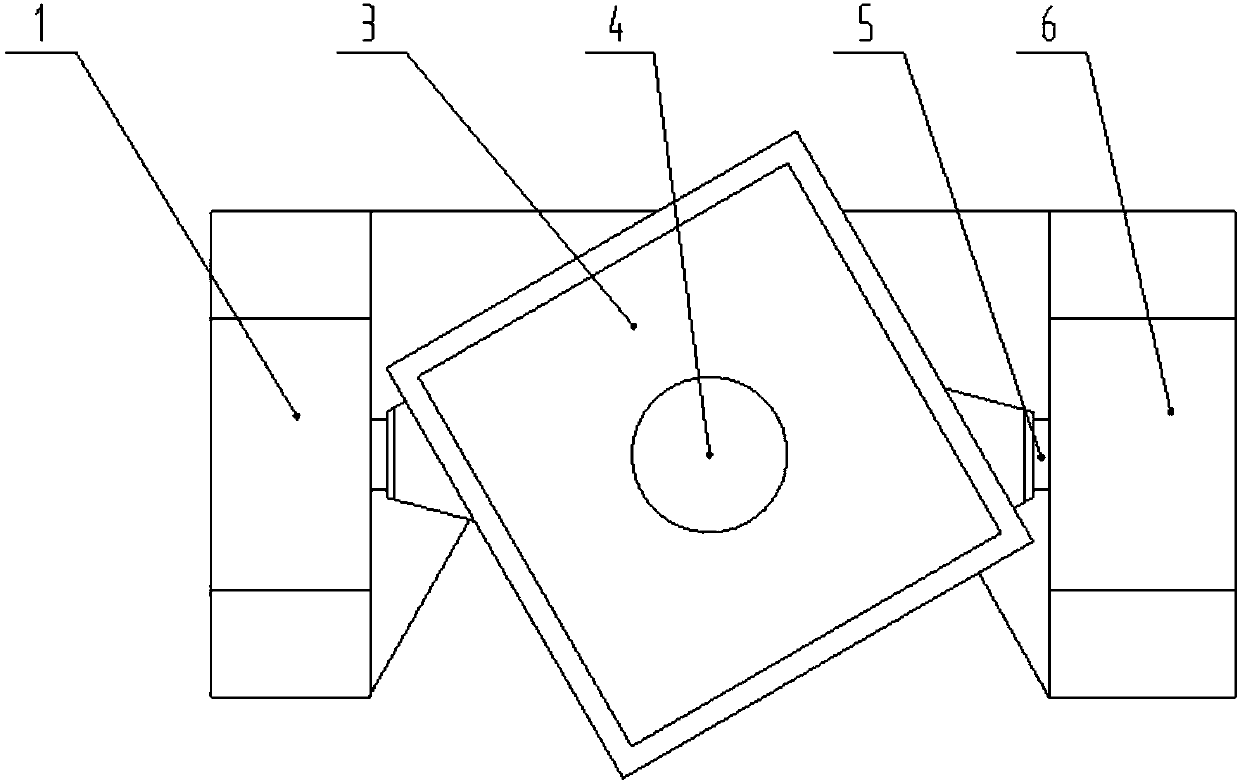

Square cone mixing machine

PendingCN110339762ATo achieve a mixed effectImprove uniformityRotating receptacle mixersShaking/oscillating/vibrating mixersPulp and paper industryReducer

The invention discloses a square cone mixing machine. The square cone mixing machine comprises a left bracket, a right bracket, a material cylinder and a frame. The left bracket is mounted on one endpart of a base, the right bracket is mounted on the other end part of the base, and rotating shafts are installed at two ends of the frame; the frame, the left bracket and the right bracket are connected by matching the rotating shafts with bearings; the material cylinder is fixed into the frame, the material cylinder is a cone body with the tip end facing downward and the upper part protruding, afeeding hole is formed in the upper end of the material cylinder, and a discharging hole is formed in the lower end of the material cylinder; and a motor and a reducer are installed in the right bracket, and a shaft of the reducer and the rotating shafts on the frame are connected through belts. The square cone mixing machine has the effects of fully mixing smashed powder materials with differentproportion and adding and mixing other additive raw materials.

Owner:NANJING SHENPENG MACHINERY EQUIP

Household canning and boxing device convenient for internal cleaning

PendingCN113697744AAvoid uneven distribution of micro-ingredientsLight in massFilling device cleaningElectric machineryWorkbench

The invention belongs to the technical field of white spirit production, and particularly relates to a household canning and boxing device convenient for internal cleaning. The household canning and boxing device comprises a workbench, supporting legs are arranged at four corners of the outer wall of the bottom of the workbench, a fixed plate is arranged on the outer wall of the top of the workbench, a top plate is arranged on the outer wall of the top of the fixed plate, an electric sliding rail is arranged on the outer wall of the bottom of the top plate, a hydraulic rod is slidably connected to the inner wall of the electric sliding rail through a sliding block, and a sealing cover is arranged on the outer wall of the bottom of the hydraulic rod. According to the household canning and boxing device convenient for internal cleaning provided by the invention, a motor is turned on, the motor drives a rotating rod to rotate, then the rotating rod drives a stirring rod to rotate, the stirring rod can conduct certain mixing on white spirit during canning, thereby avoiding uneven distribution of trace components in the white spirit and reducing the quality of the white spirit; and in addition, a cleaning plate is of an arc-shaped structure, and is close to the inner wall of a canned box, the inner wall of the canned box can be conveniently, rapidly and effectively cleaned, and convenience and practicability are achieved.

Owner:贵溪市塘湾五谷丰酒厂

A kind of method of planting dendrobium officinale without pollution

ActiveCN103999672BHigh in nutrientsImprove medicinal effectFertilising methodsCultivating equipmentsNutritionInsect pest

The invention relates to a planting method of Dendrobium officinale, in particular to a method for planting Dendrobium candidum without pollution. Solving the planting method of Dendrobium candidum, a method for planting Dendrobium candidum without pollution, comprising the following steps: 1. tissue culture seedling propagation; 2. site selection; 3. ground cultivation under a greenhouse; 4. laying substrate; ⑦Daily management; ⑧Harvesting and preservation. After transplanting, the tissue culture seedlings have high survival rate, fast growth, high yield, close to wild Dendrobium candidum in nutritional content, high medicinal value, less pesticide use, and less occurrence of diseases and insect pests.

Owner:普洱市民族传统医药研究所

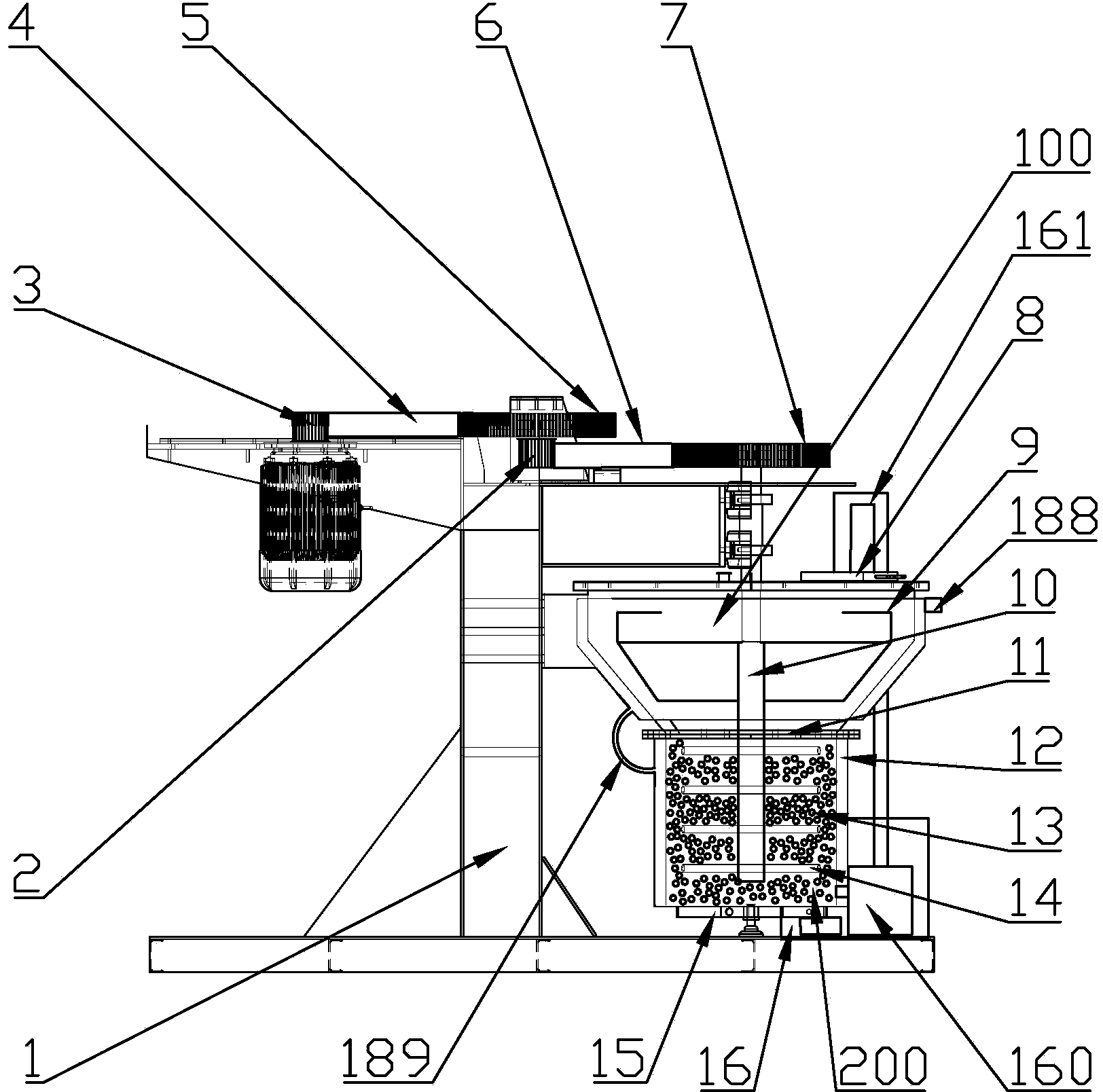

High-efficiency feed mixing and feeding device for aquaculture

ActiveCN114190318AImprove the breeding effectServe evenlyRotary stirring mixersTransportation and packagingAquatic speciesDrive motor

The invention relates to the technical field of aquaculture equipment, and discloses a high-efficiency feed mixing and putting device for aquaculture, the high-efficiency feed mixing and putting device for aquaculture comprises a foundation and a culture pond arranged in the foundation and used for culturing aquatic species, in the high-efficiency feed mixing and putting device for aquaculture, a mixed material can fall into a collection bottom cover after being stirred and mixed; when a driving motor is started to drive a mixing mechanism to rotate, a feeding box on a collecting bottom cover is driven by a driving shaft to rotate, and materials falling into the collecting bottom cover flow into the feeding box through a discharging groove; when the feeding box rotates at a high speed, centrifugal force can be generated, so that feed is firstly discharged through a plurality of groups of discharging holes to be close to the position near the periphery of the mixing device, and when the feeding box rotates at a high speed, a guide block can extrude a spring in the feeding box; at the moment, the feed can fully extrude the material guide block and is uniformly and rotatably thrown and scattered through the throwing groove, so that the effects of uniformly throwing the feed and improving the breeding property of aquatic organisms are achieved.

Owner:江西省水产科学研究所江西省鄱阳湖渔业研究中心江西省渔业资源生态环境监测中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com