Display device and manufacturing method thereof

A technology of a display device and a manufacturing method, applied in the field of display screens, can solve problems such as affecting production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

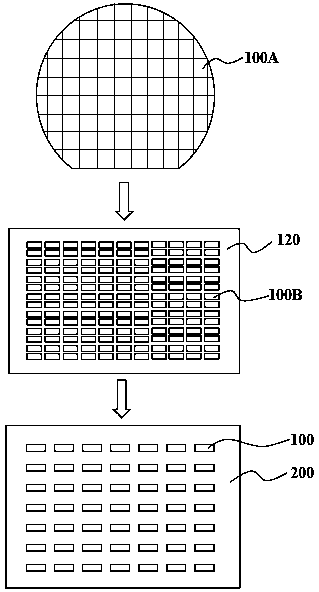

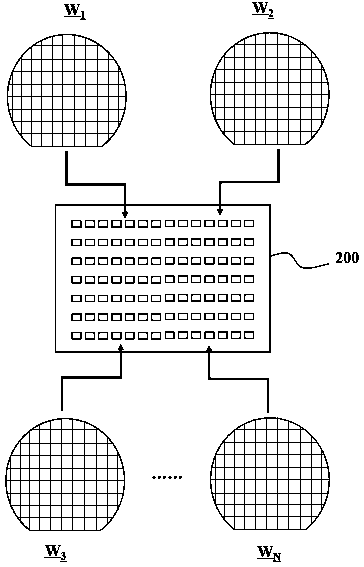

[0036] figure 2 A schematic diagram of a method for manufacturing an LED display screen implemented according to the present invention is shown. and figure 1The manufacturing method shown is completely different: after cutting the LED wafer into chips, step (2) is omitted in this method, that is, the LED chips are no longer rearranged, but the LED chips are assembled from W1~WN Chips are selected from among the wafers, and then placed directly on the circuit board 200 for installation. During the installation process, LED chips from different wafers can be mixed and arranged at the same time. The manufacturing method will be described in detail below in conjunction with the accompanying drawings.

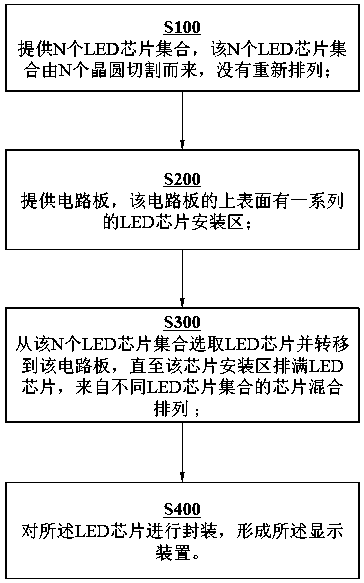

[0037] image 3 It is a flow chart of a manufacturing method of a light emitting diode display screen implemented according to the present invention. Such as image 3 As shown, the manufacturing method includes:

[0038] S100: Provide N LED chip sets, where the N LED chip set...

Embodiment 2

[0082] This embodiment provides an LED display screen, the LED display screen includes a display unit, the display unit includes a circuit board and a plurality of LED chips welded on the circuit board, the plurality of LED chips 100 are from different wafers, Chips from different wafers are mixed and arranged. The display unit is micro-modularized and includes a series of display sub-regions 100C, and the multiple display sub-regions constitute a required arrangement pattern. Each sub-region 100C can be an area such as M×N or M×K, wherein N is the number of LED chip sets, M and K are integers greater than 0, and the number of LED chips M×N or M×K is preferably 200 Below, preferably less than 100, such as 18, 24, 27, 36, 48, 54, or 72, or 81, etc., each sub-region 100C has the same LED chips and Arrangement order, the arrangement pattern of this sub-area can be selected according to the display requirements Figure 9~11 One of. Preferably, the display sub-areas are arranged...

Embodiment 3

[0087] This embodiment provides an LED display screen. Different from Embodiment 2, the LED chips in each display sub-area come from the same wafer, and each sub-area is randomly arranged, so that the chips in the screen are arranged in random numbers, and there is no Streaks or blocks of color difference / brightness and darkness, when modules and modules or screens are further assembled, there will be no streaks or block color differences / brightness and darkness.

[0088] Preferably, the number of LED chips in each sub-region is 1-25, preferably 4-16.

[0089] As a modification, the sub-regions can also be periodically arranged in the manner of horizontal reentry, vertical reentry, clockwise, counterclockwise, etc. Each period includes N sub-regions, and the LED chips in the N sub-regions are from N Each sub-region is preferably a region such as B×C, wherein B is an integer greater than 1, preferably 9-16, wherein the value of B:C is preferably 0.5-2. Preferably, there are so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com