Patents

Literature

34646results about "Metal rolling arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

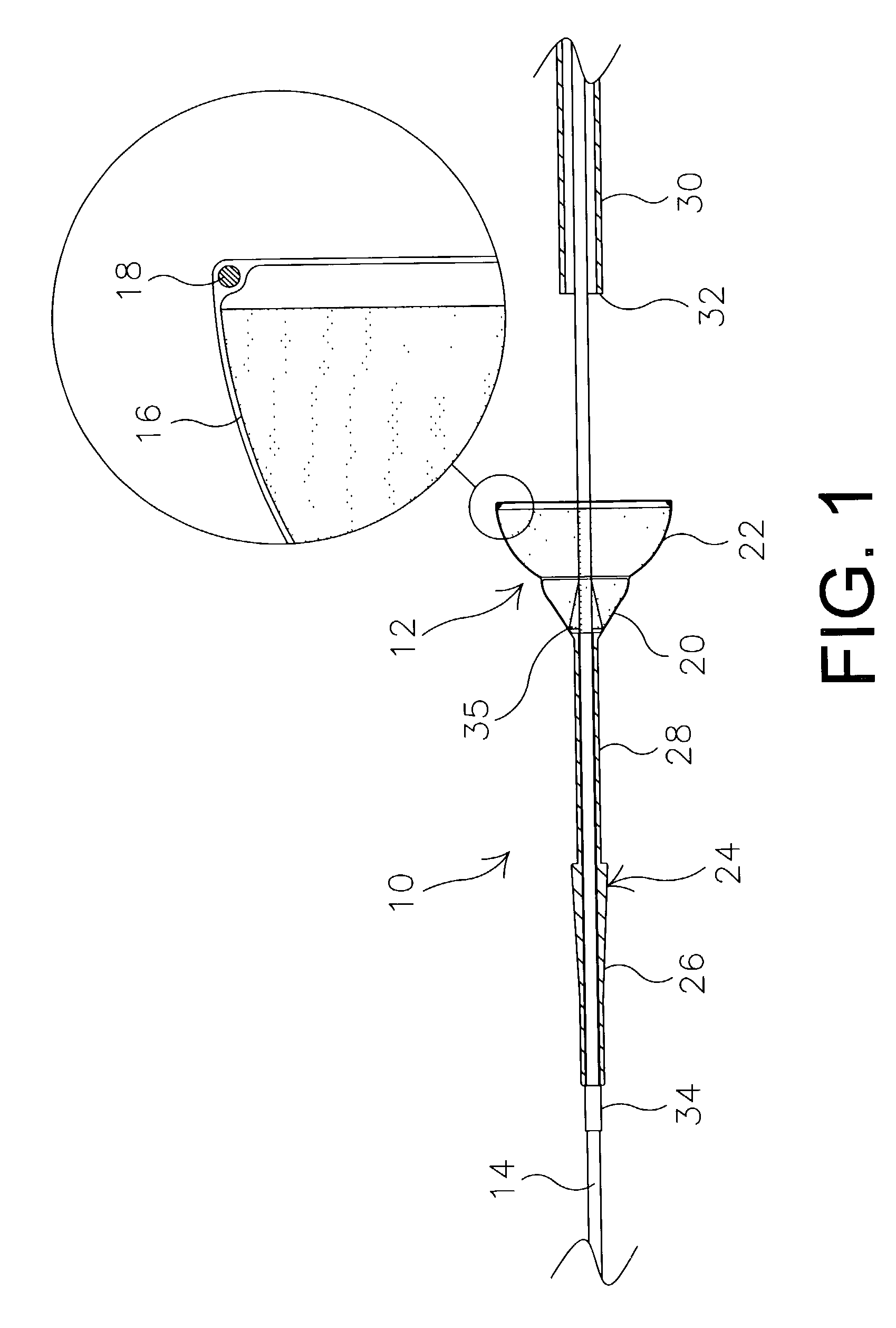

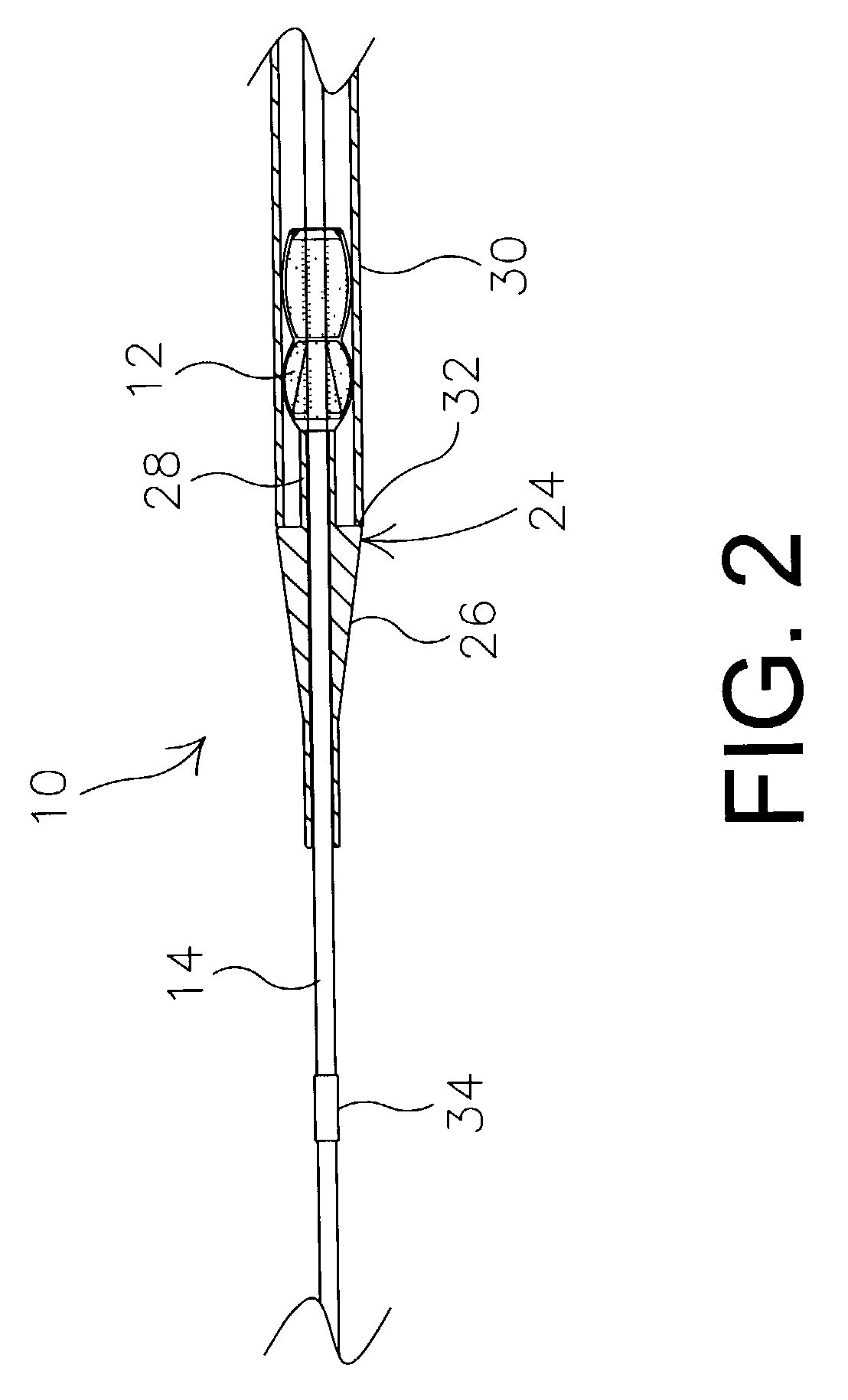

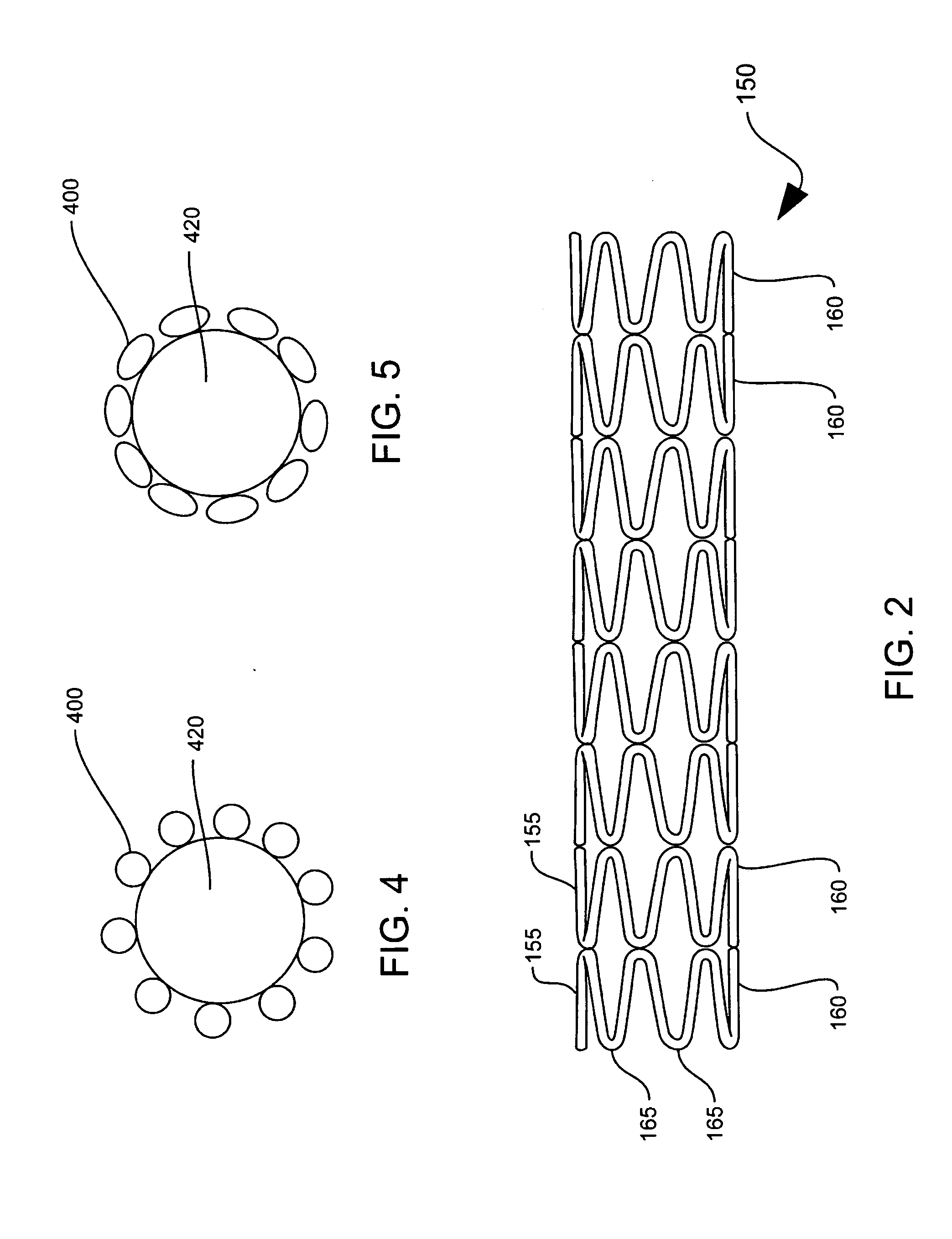

Method of making an embolic filter

Embolic protection filters and methods of making and using such devices are disclosed. An illustrative method of making a device for filtering embolic debris from a body may include the steps of molding a filter assembly that includes a distal tip and a filter portion, forming a plurality of apertures within the filter portion, and coupling a support member to the filter assembly that is adapted to shift the filter portion between a collapsed configuration and an expanded configuration.

Owner:BOSTON SCI SCIMED INC

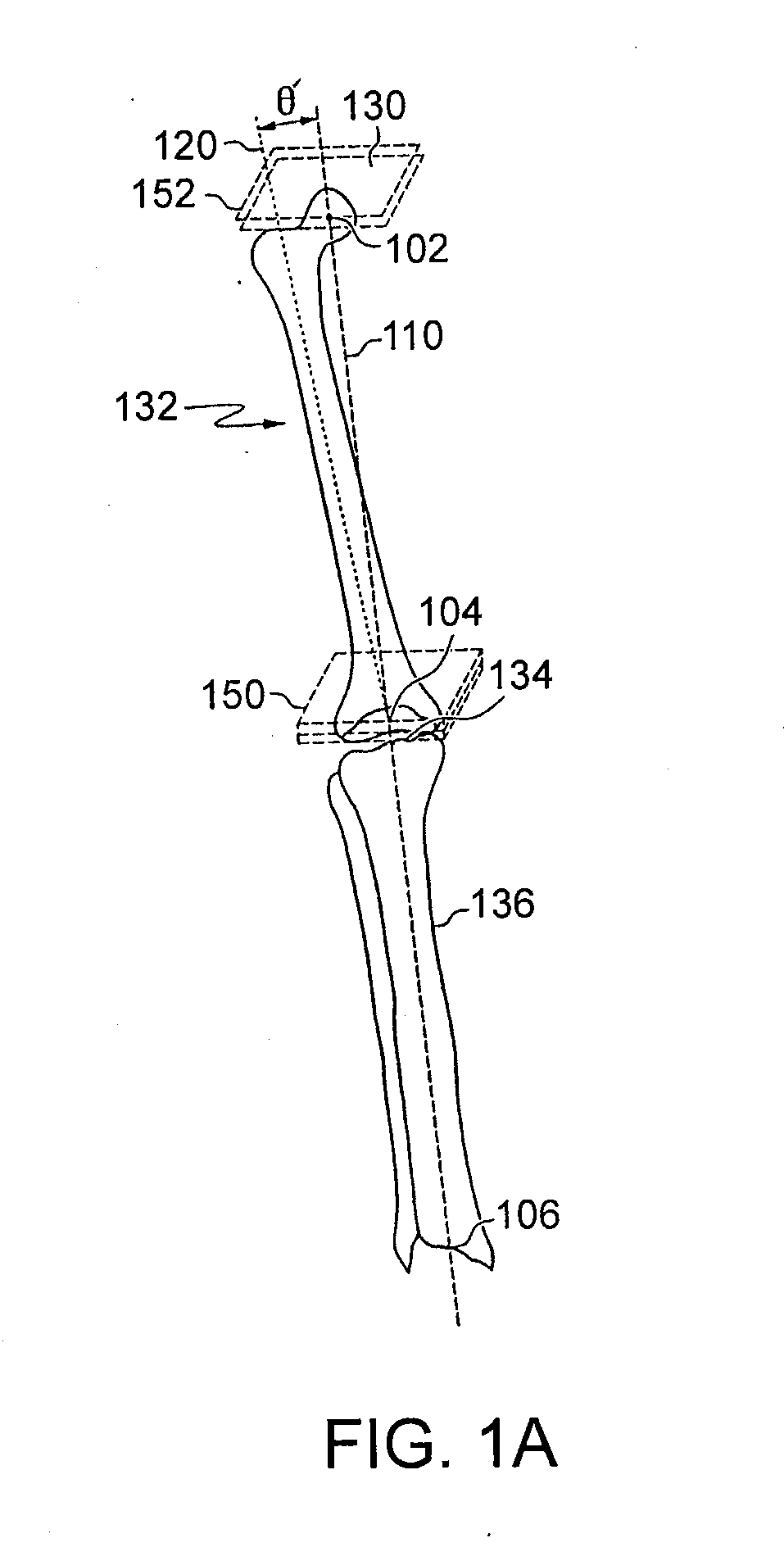

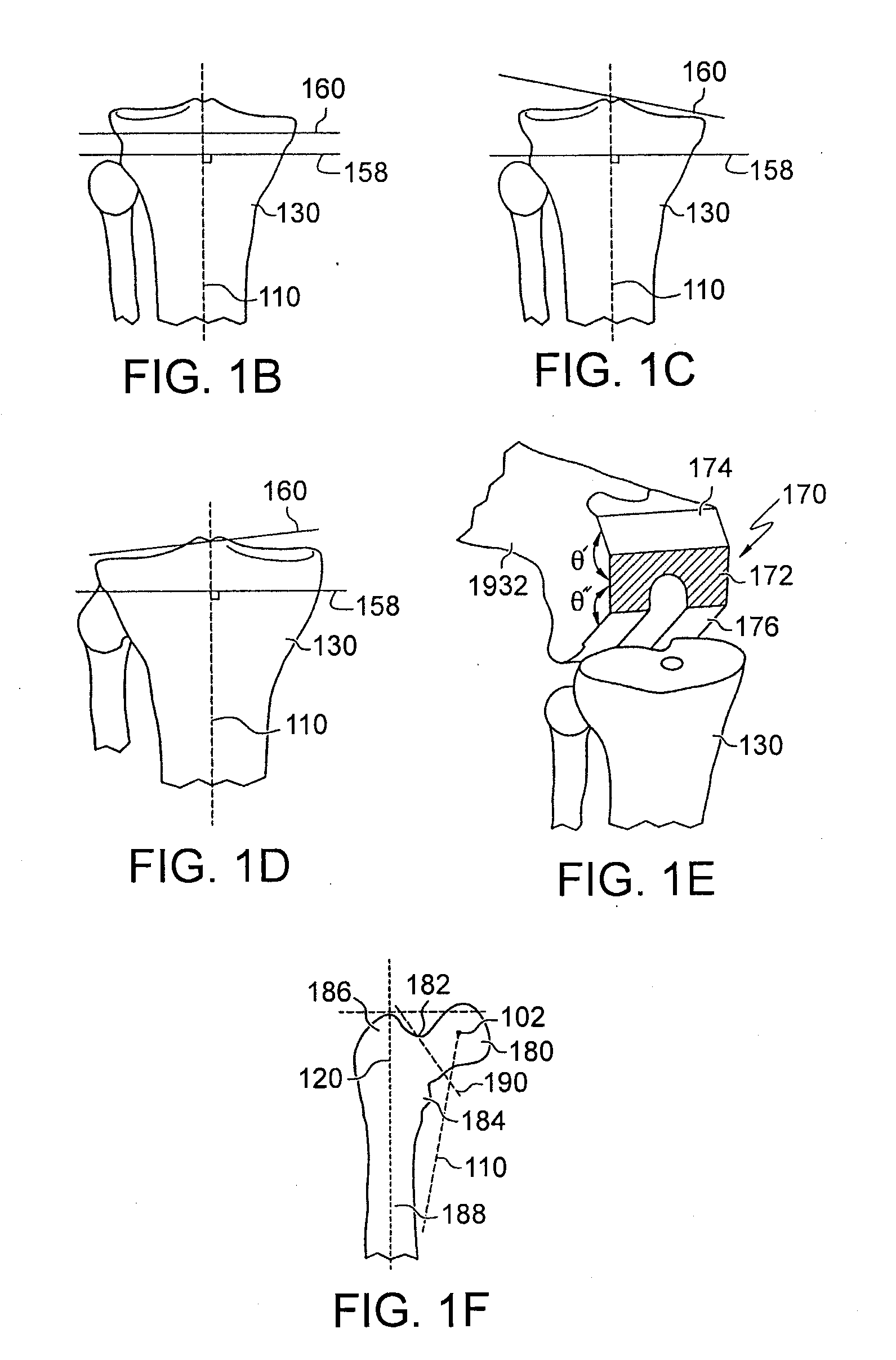

Surgical Tools Facilitating Increased Accuracy, Speed and Simplicity in Performing Joint Arthroplasty

InactiveUS20090307893A1Metal rolling stand detailsDiagnostic recording/measuringArticular surfacesArticular surface

Disclosed herein are tools for repairing articular surfaces repair materials and for repairing an articular surface. The surgical tools are designed to be customizable or highly selectable by patient to increase the speed, accuracy and simplicity of performing total or partial arthroplasty.

Owner:CONFORMIS

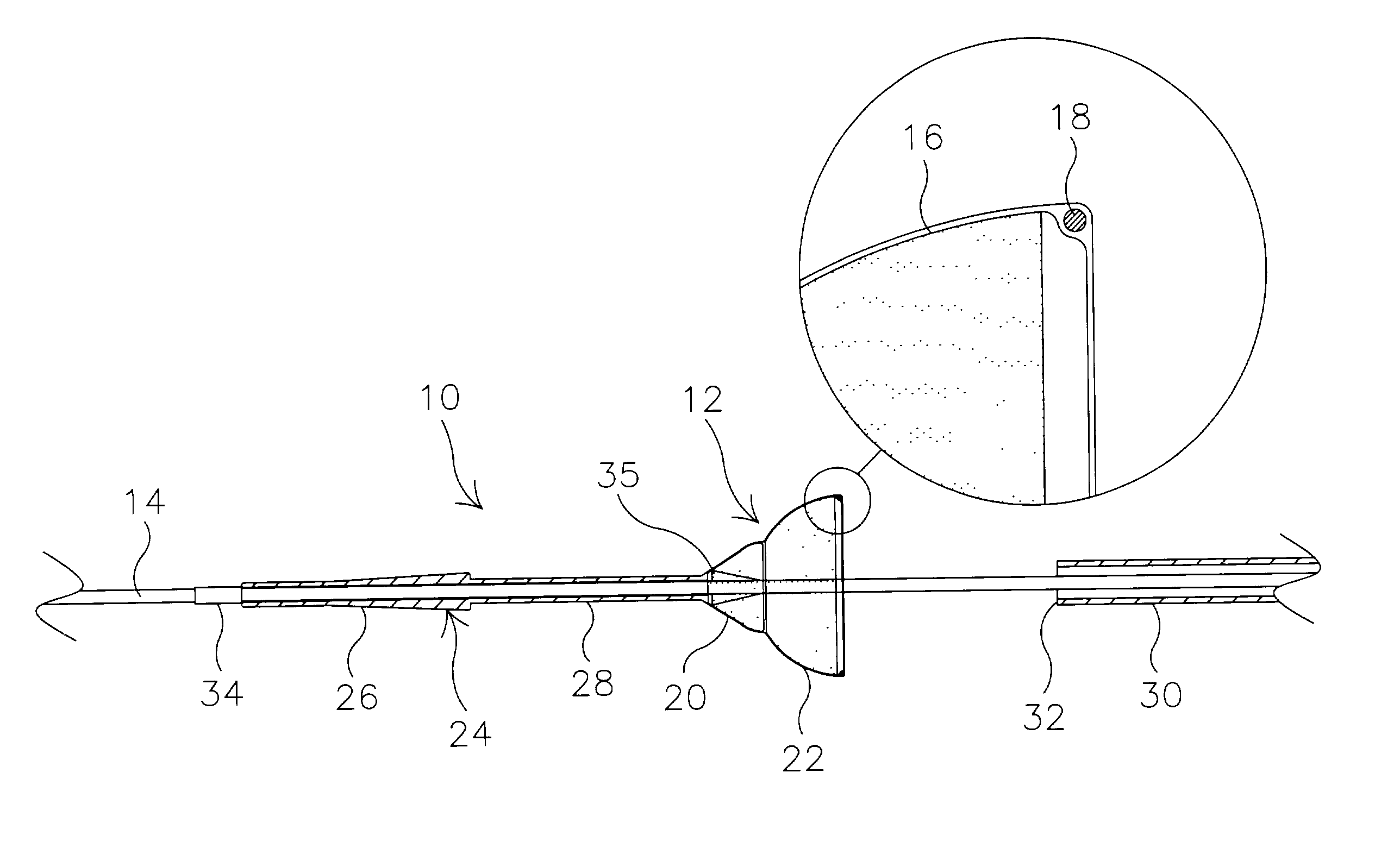

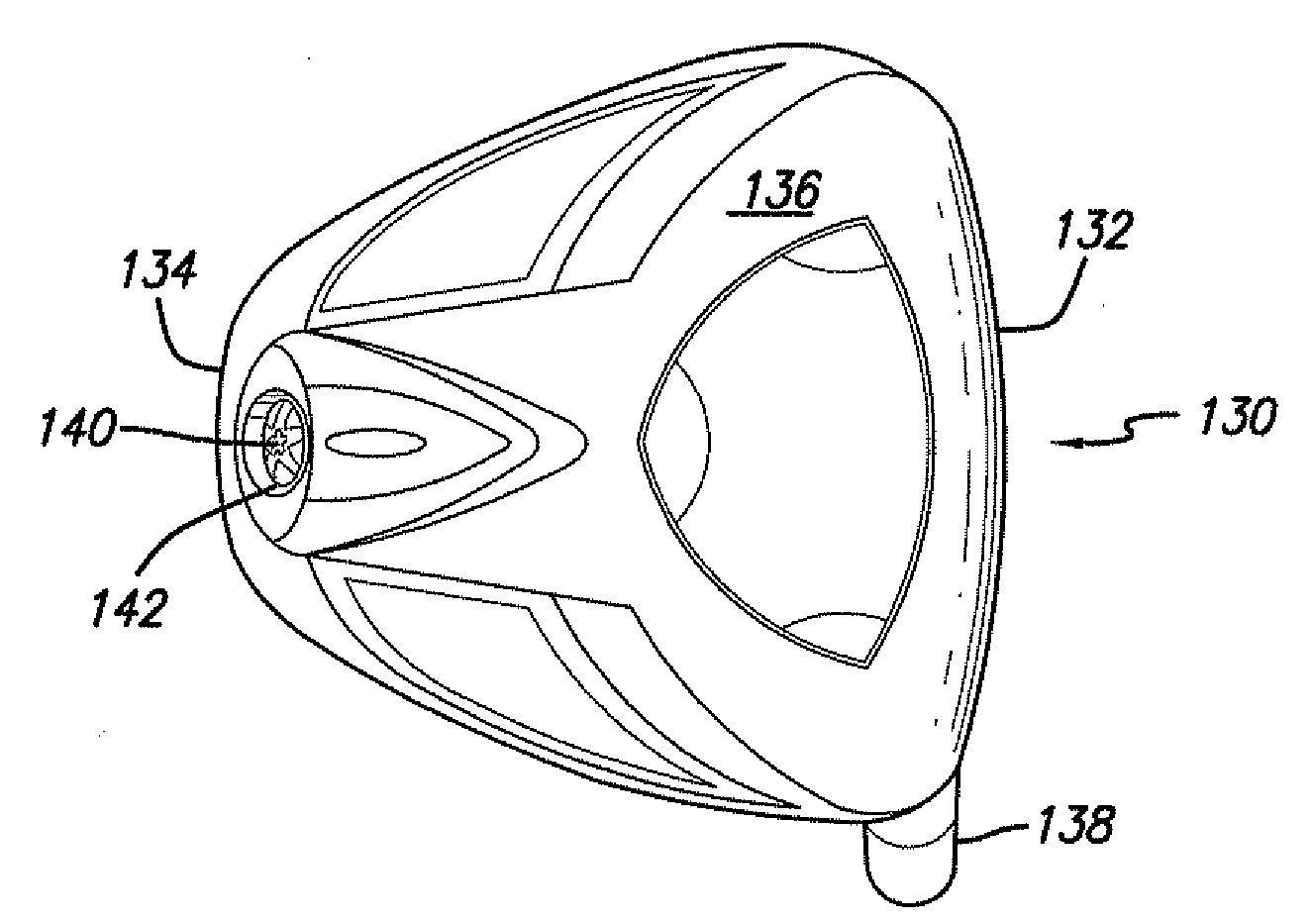

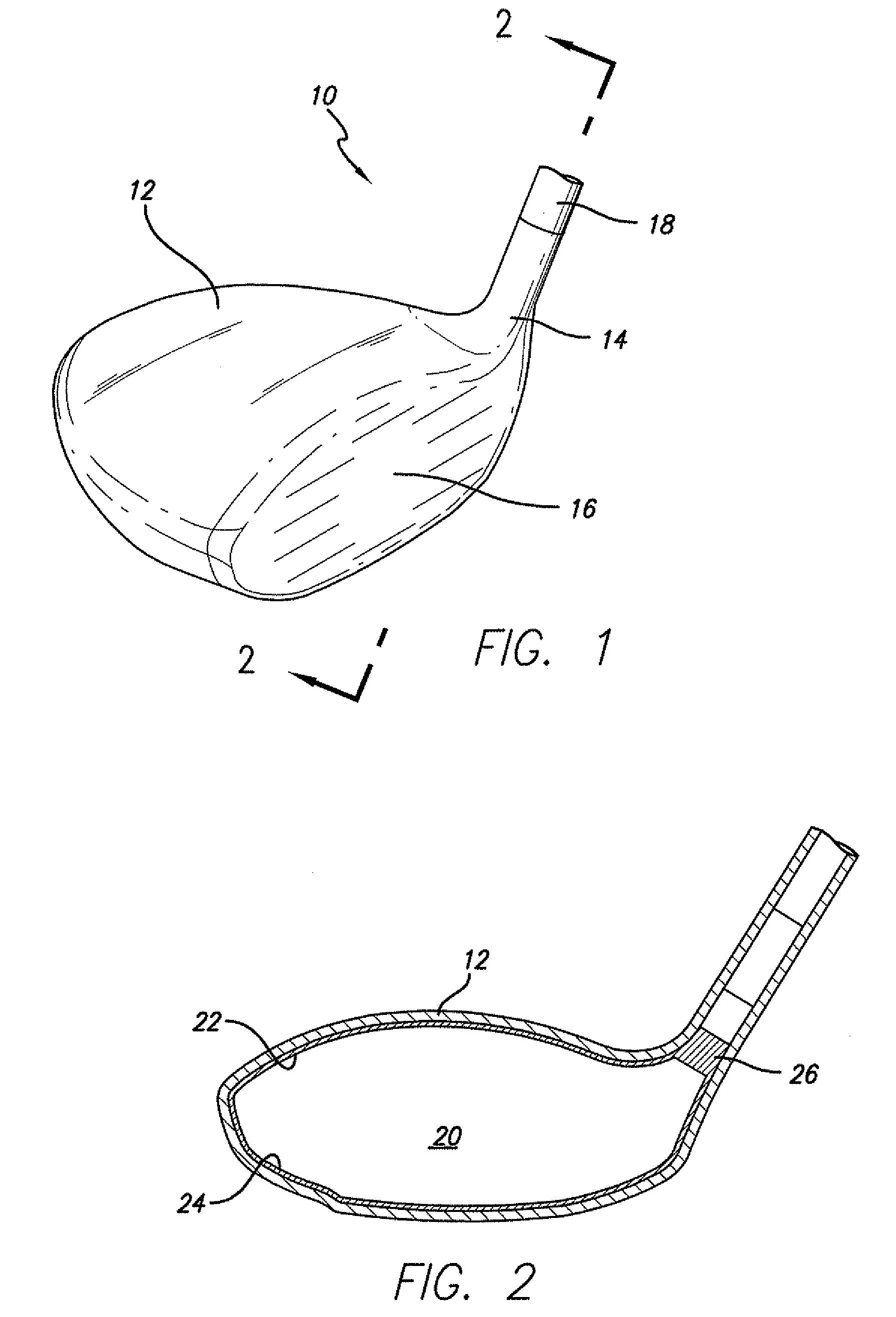

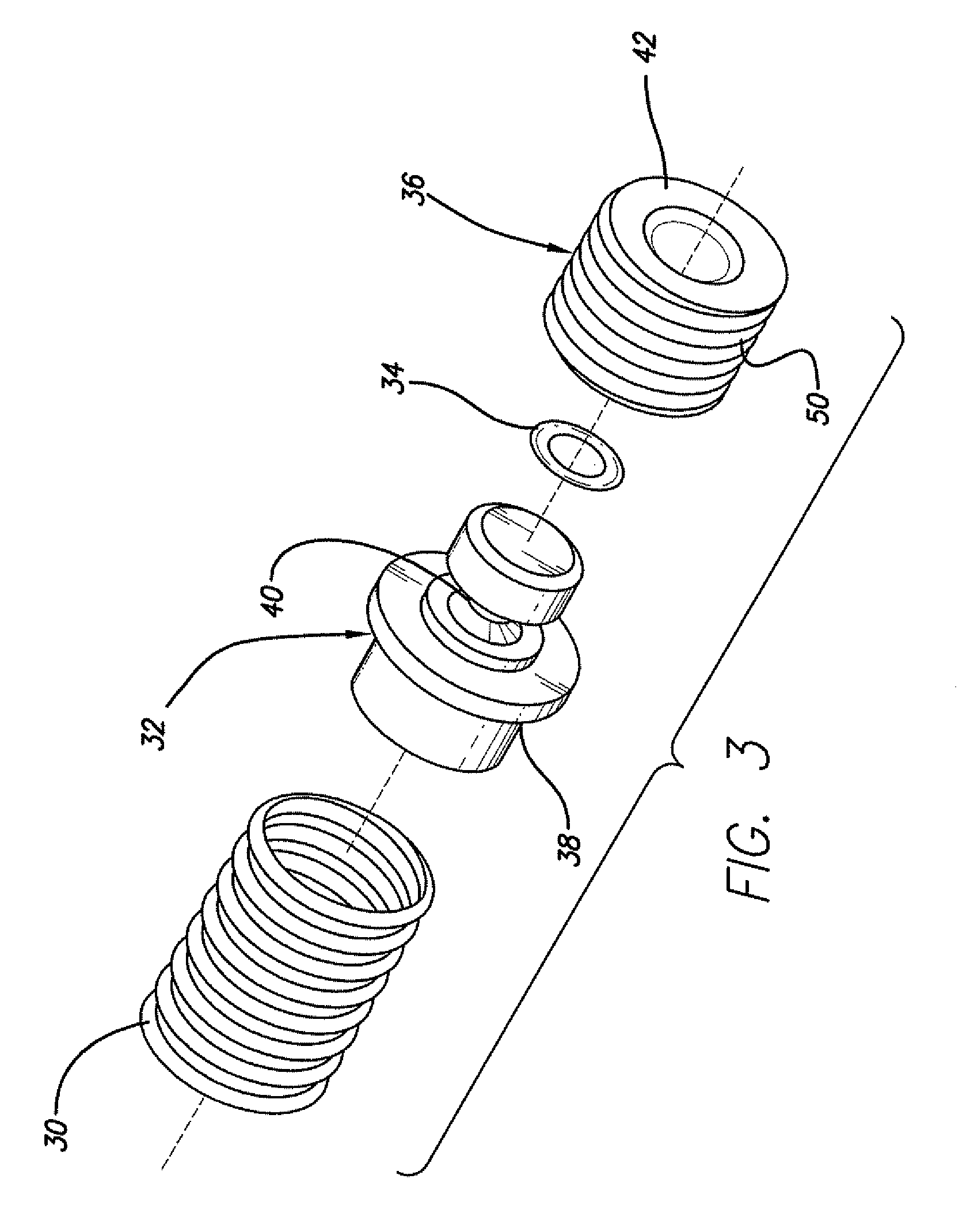

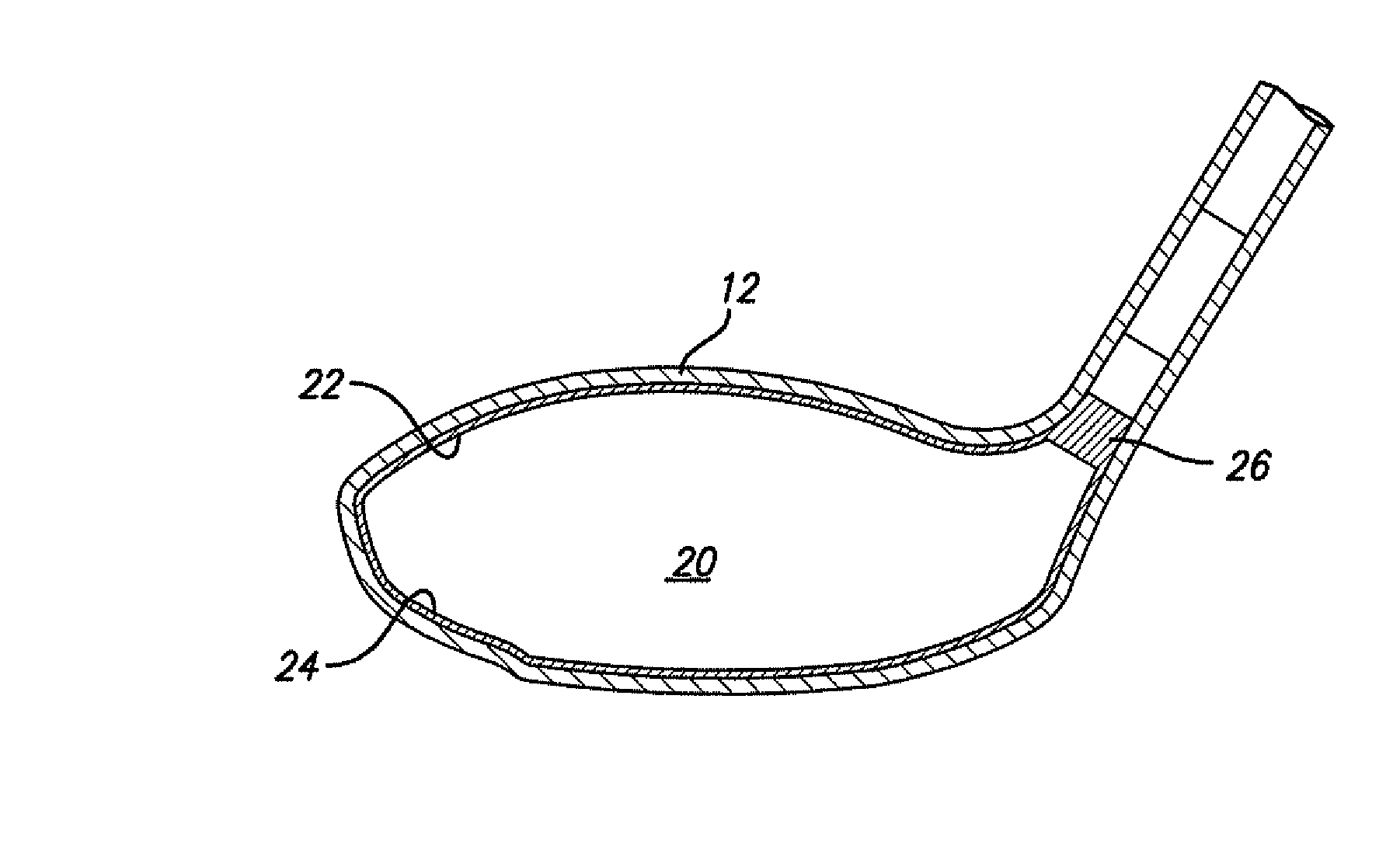

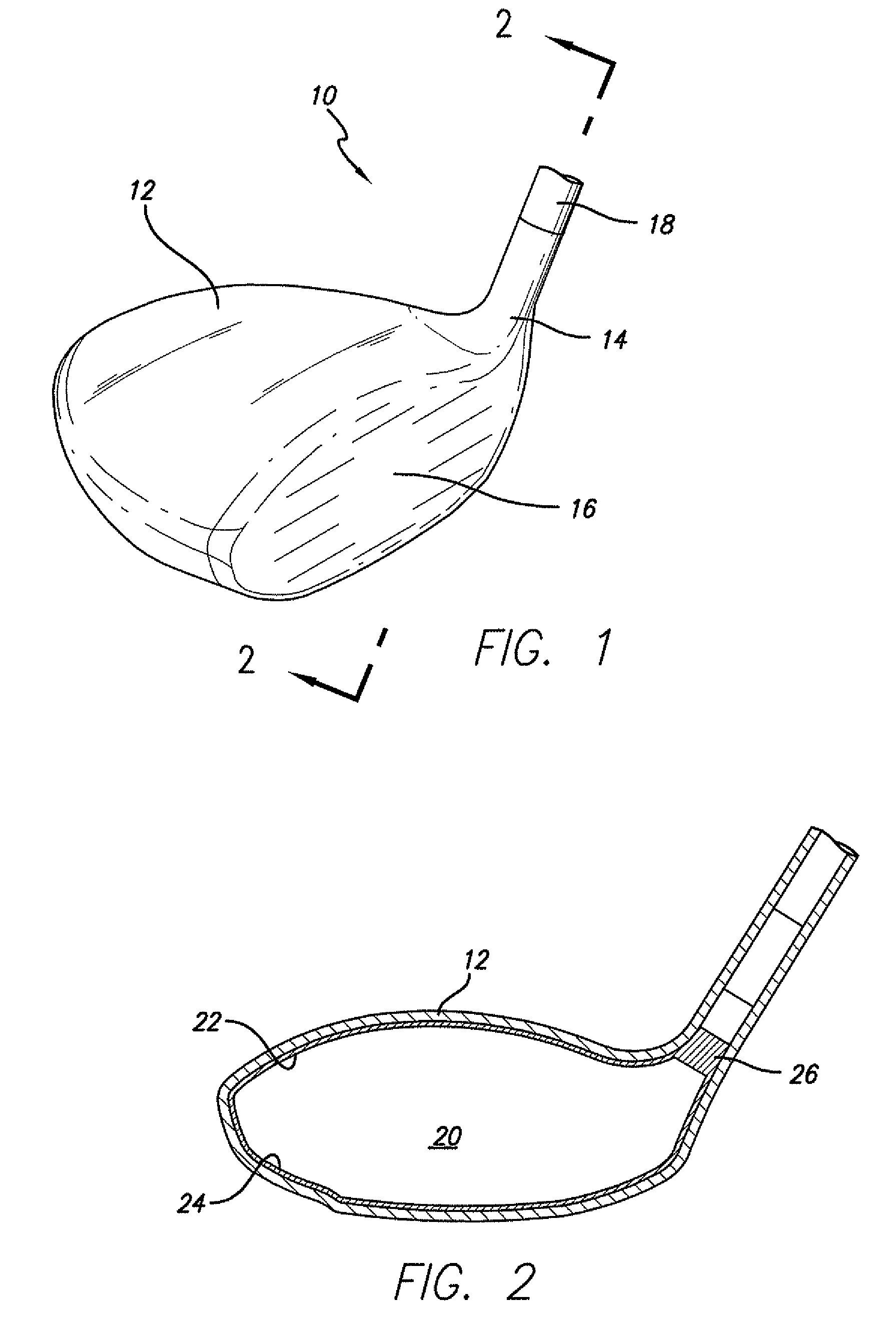

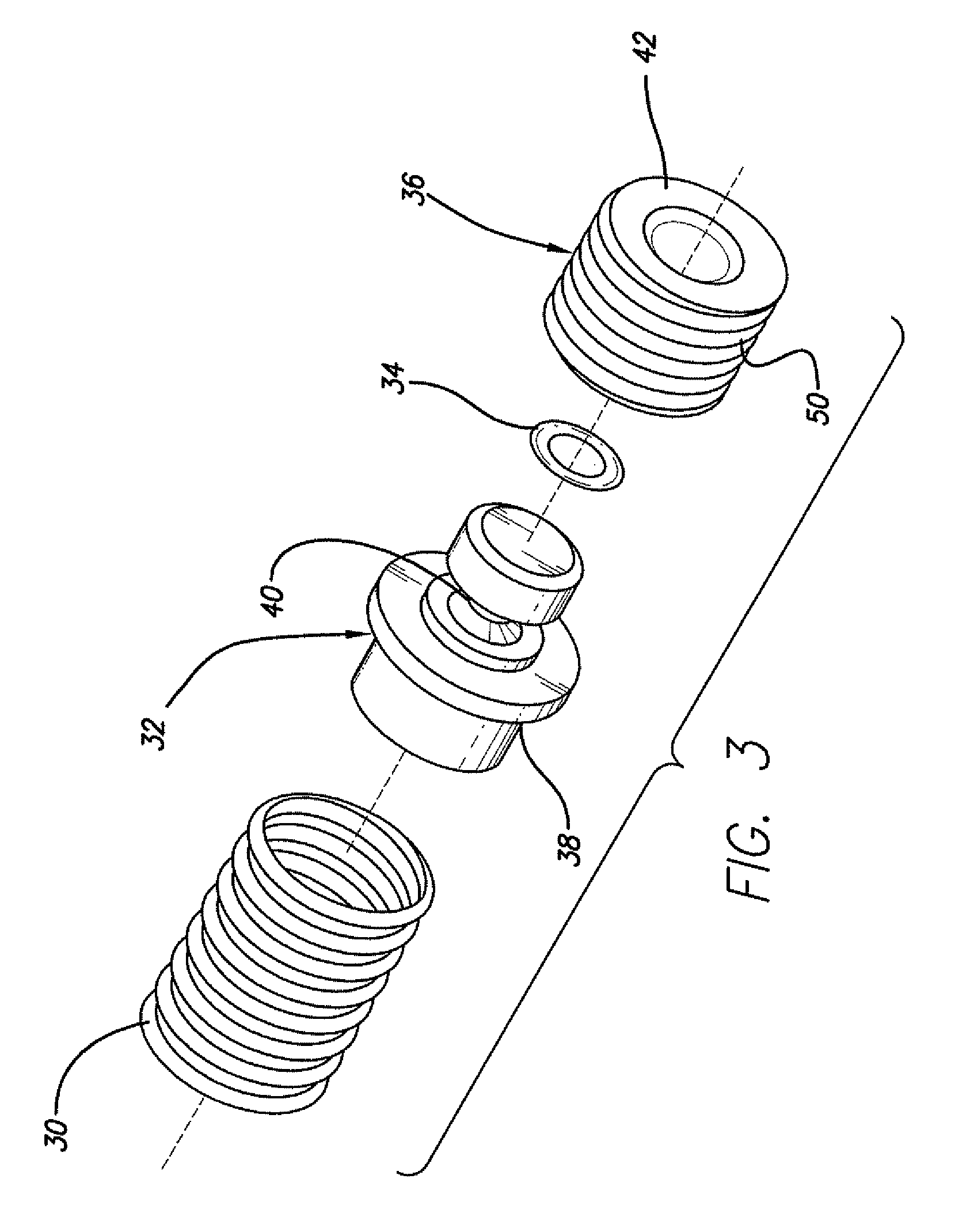

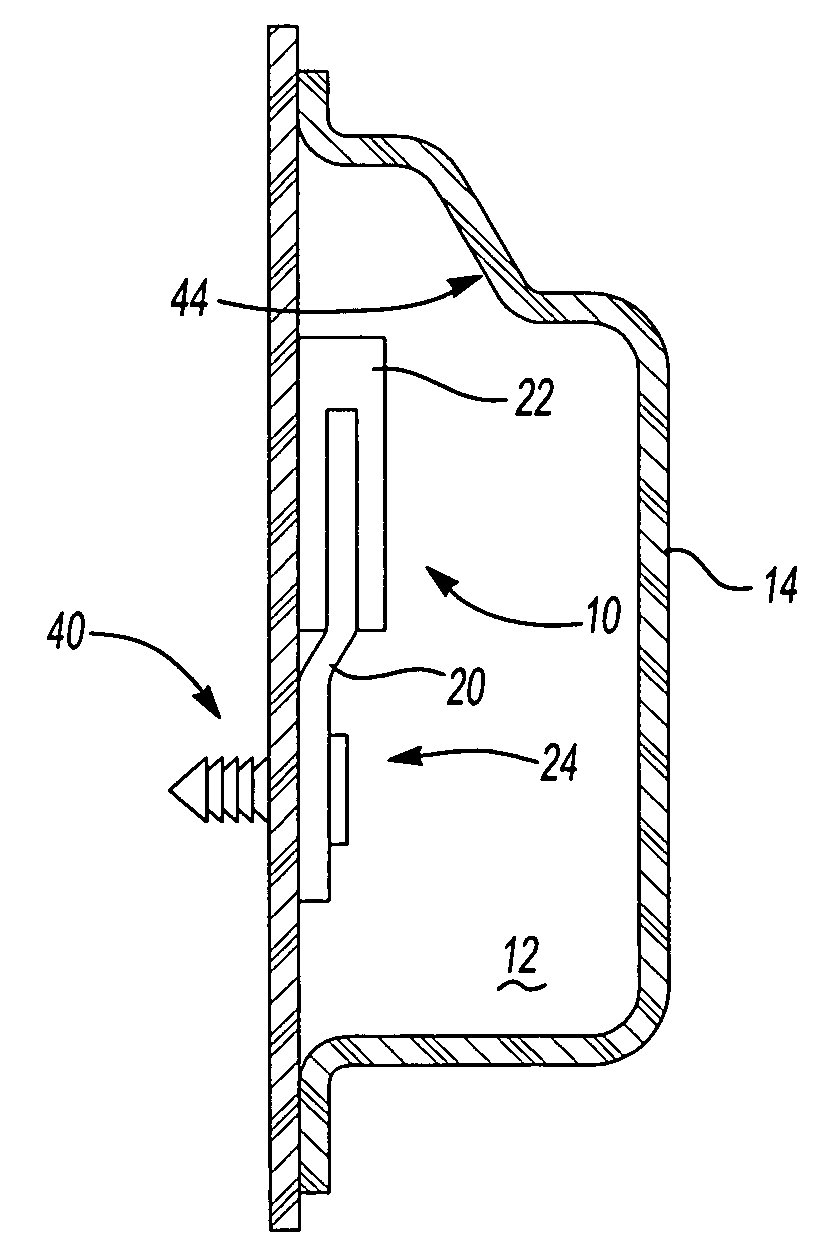

Golf club having a hollow pressurized metal head

ActiveUS20080188322A1Avoid passingPrevent escapeFilling using counterpressureMetal rolling stand detailsShell moldingPlastic materials

A golf club having a hollow golf club head which is filled with a gas under pressure. The interior surface of the golf club head is coated with a solidified layer of plastic material. The pressurized gas permits the use of thinner face plates by compensating for forces generated when the face plate strikes a golf ball. The plastic layer is preferably applied through the process of rotational molding using a thermoplastic material.

Owner:BLOWERS ALDEN J

Golf club having a hollow pressurized metal head

ActiveUS8663026B2Prevent escapeMetal rolling stand detailsPackaging under special atmospheric conditionsPlastic materialsEngineering

A golf club having a hollow golf club head which is filled with a gas under pressure. The interior surface of the golf club head is coated with a solidified layer of plastic material. The pressurized gas permits the use of thinner face plates by compensating for forces generated when the face plate strikes a golf ball. The plastic layer is preferably applied through the process of rotational molding using a thermoplastic material.

Owner:BLOWERS ALDEN J

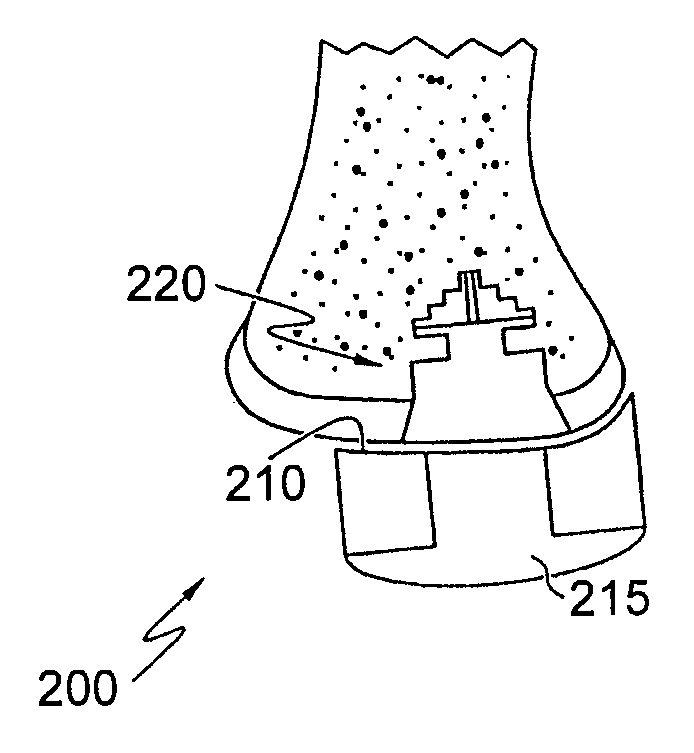

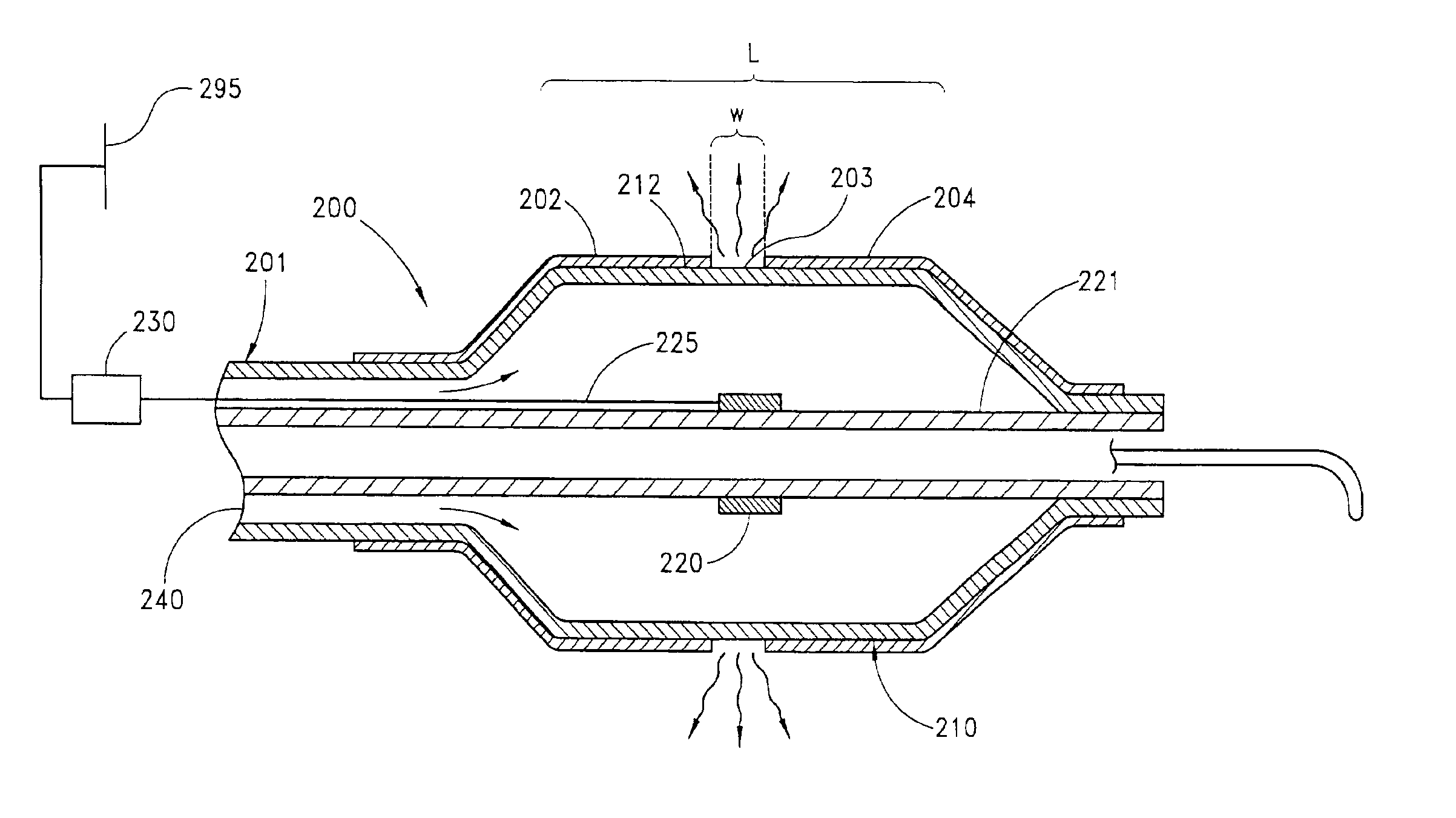

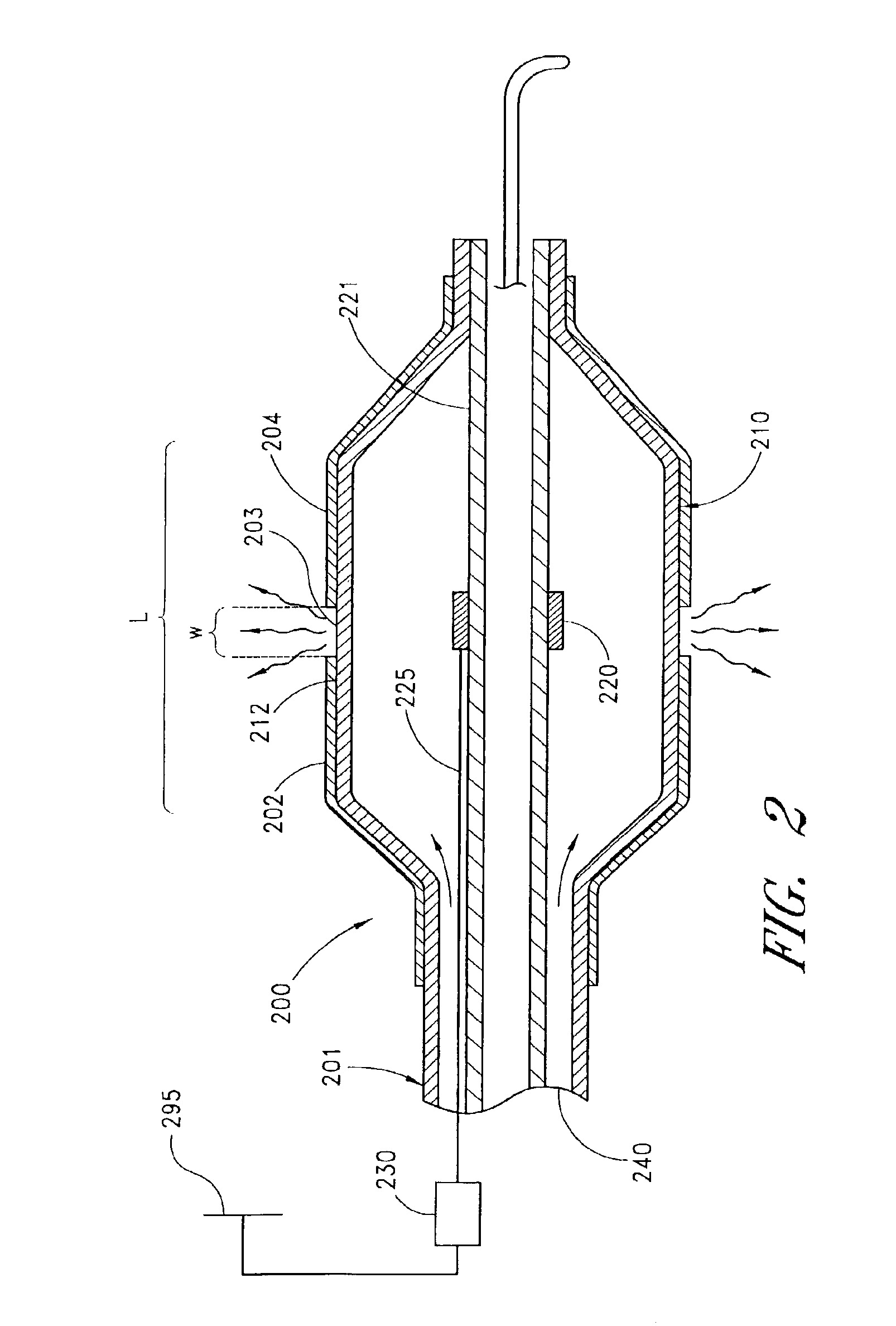

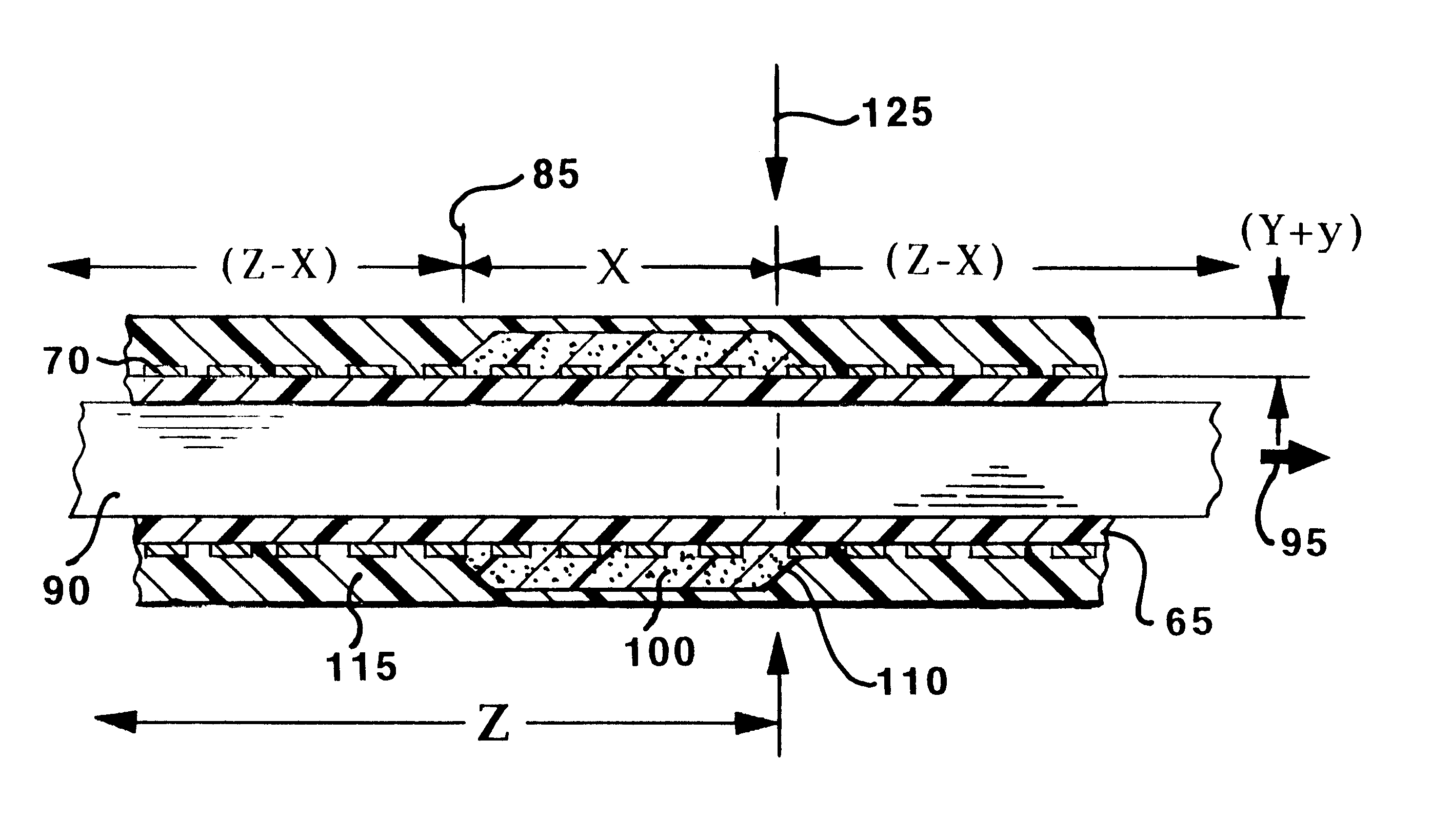

Circumferential ablation device assembly and methods of use and manufacture providing an ablative circumferential band along an expandable member

InactiveUS6954977B2Strong connectionConsistent positionElectrotherapyDiagnosticsFluoropolymerBalloon catheter

A medical balloon catheter assembly includes a balloon having a permeable region and a non-permeable region. The balloon is constructed at least in part from a fluid permeable tube such that the permeable region is formed from a porous material which allows a volume of pressurized fluid to pass from within a chamber formed by the balloon and into the permeable region sufficiently such that the fluid may be ablatively coupled to tissue engaged by the permeable region. The non-permeable region is adapted to substantially block the pressurized fluid from passing from within the chamber and outwardly from the balloon. The porous material may be a porous fluoropolymer, such as porous polytetrafluoroethylene, and the pores may be created by voids that are inherently formed between an interlocking node-fibril network that makes up the fluoropolymer. Such voids may be created according to one mode by expanding the fluoropolymer. The balloon may be formed such that the porous material extends along both the permeable and non-permeable regions. In one mode of this construction, the porous material is porous along the permeable region but is non-porous along the non-permeable region, such as for example by expanding only the permeable region in order to render sufficient voids in the node-fibril network to provide permeable pores in that section. The voids or pores in the porous material may also be provided along both permeable and non-permeable sections but are substantially blocked with an insulator material along the non-permeable section in order to prevent fluid from passing therethrough. The insulator material may be dip coated, deposited, or extruded with the porous material in order to fill the voids. The insulator material may in one mode be provided along the entire working length of the balloon and then selectively removed along the permeable section, or may be selectively exposed to only the non-permeable sections in order to fill the voids or pores there.

Owner:MAGUIRE MARK A +1

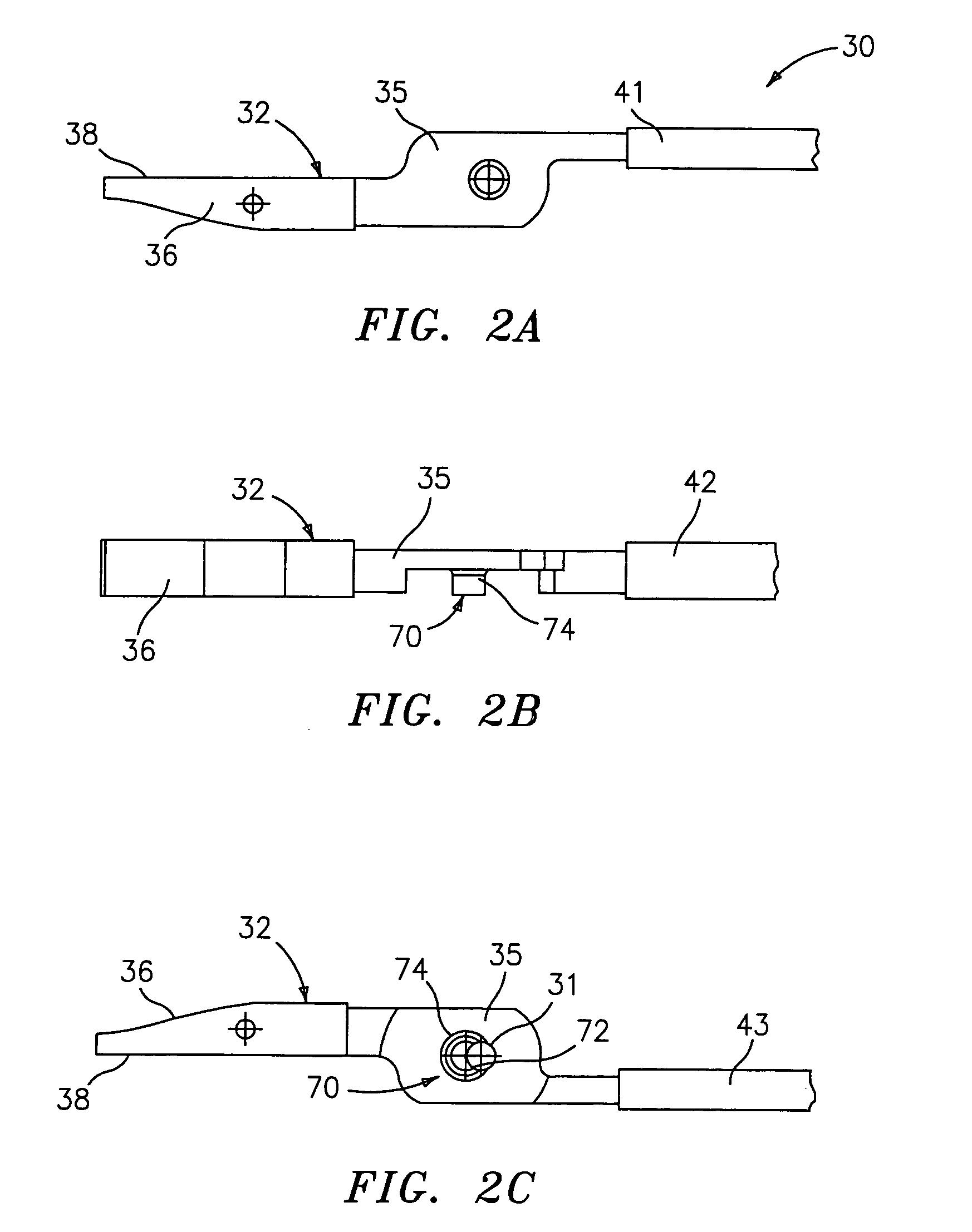

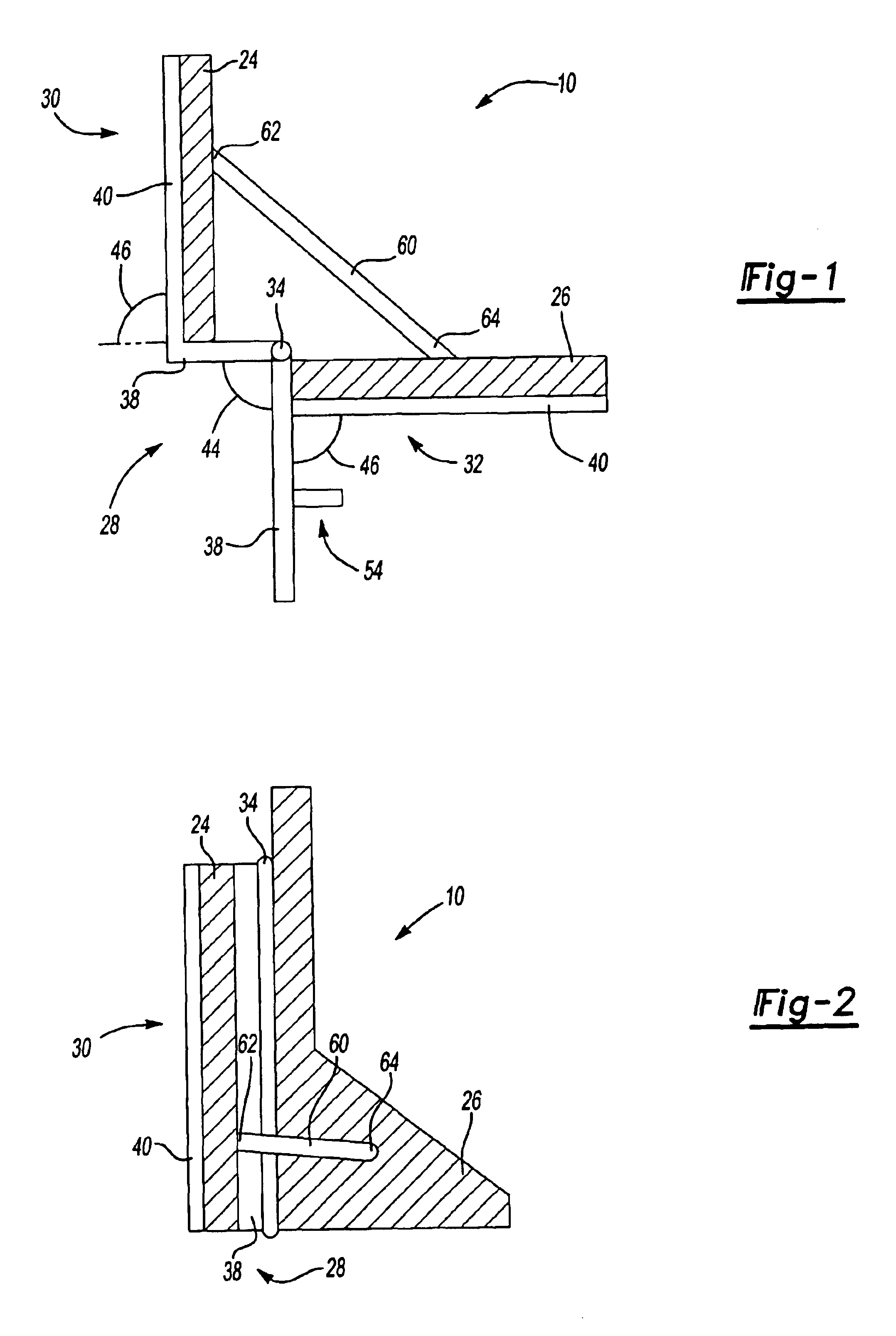

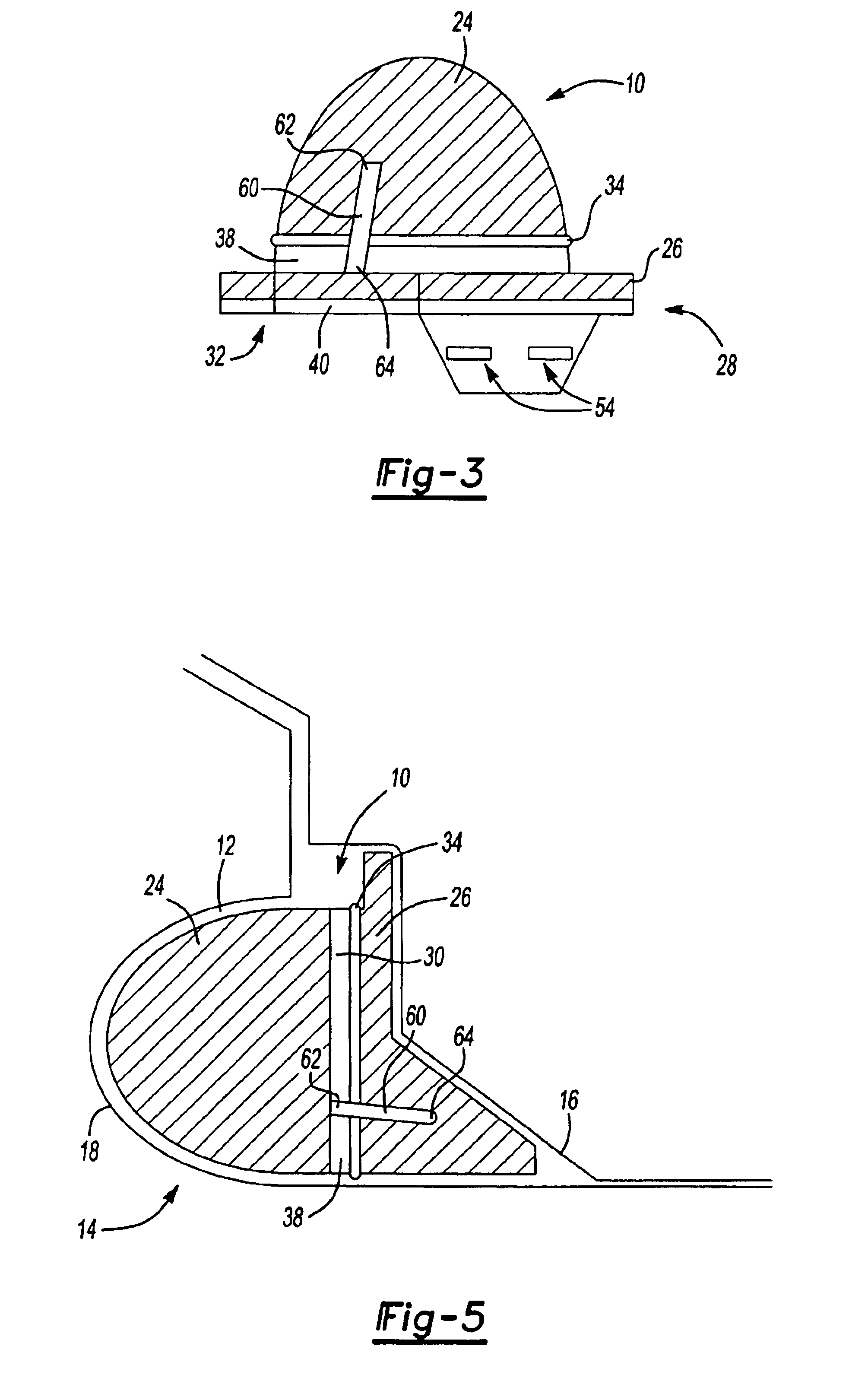

Molded insulating hinge for bipolar instruments

An electrosurgical instrument includes a pair of first and second elongated shafts each having an end effector attached to a distal end thereof and a handle. The handle is movable from a first position wherein the end effectors are disposed in spaced relation relative to one another to a second position wherein the end effectors are closer relative to one another. Each of the elongated shafts includes a hinge plate which mounts atop a pivot assembly for effecting movement of the end effectors relative to one another. The instrument also includes a hinge assembly made from an overmold composition which encapsulates and secures the hinge plates and the pivot assembly. The overmold composition is made from an electrically insulating material which insulates the end effectors from one another.

Owner:COVIDIEN AG

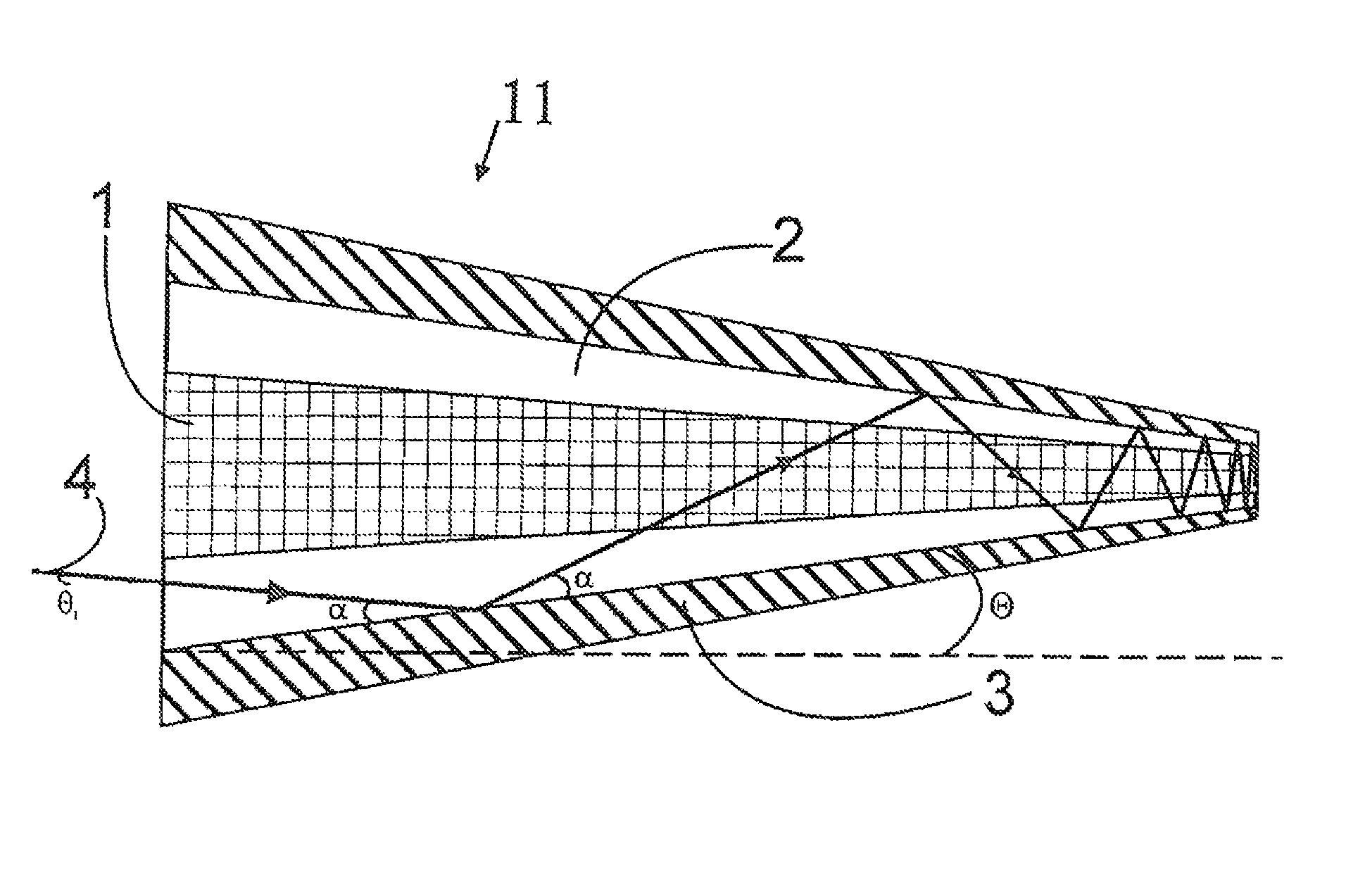

Active optical fiber and method for fabricating an active optical fiber

ActiveUS8433168B2Reduce the overall diameterLarge volumeLaser detailsMetal rolling stand detailsFiberActive core

A section of active optical fiber (11) which comprises an active core (1), an inner cladding layer (2) and an outer cladding layer (3). The diameter of said core 1) and the thickness of said inner cladding (2) change gradually along the length of said section of active optical fiber (11). This forms tapered longitudinal profile enabling a continuous mode conversion process along the length of the section of fiber (11). The method for fabricating a section of tapered active optical fiber comprises the steps of fabricating a preform for drawing active optical fiber from said preform, installing said preform into a drawing tower, drawing optical fiber in said drawing tower and altering at least one of the two parameters including the take-off preform speed and the take-up fiber speed during drawing of the optical fiber.

Owner:AMPLICONYX OY

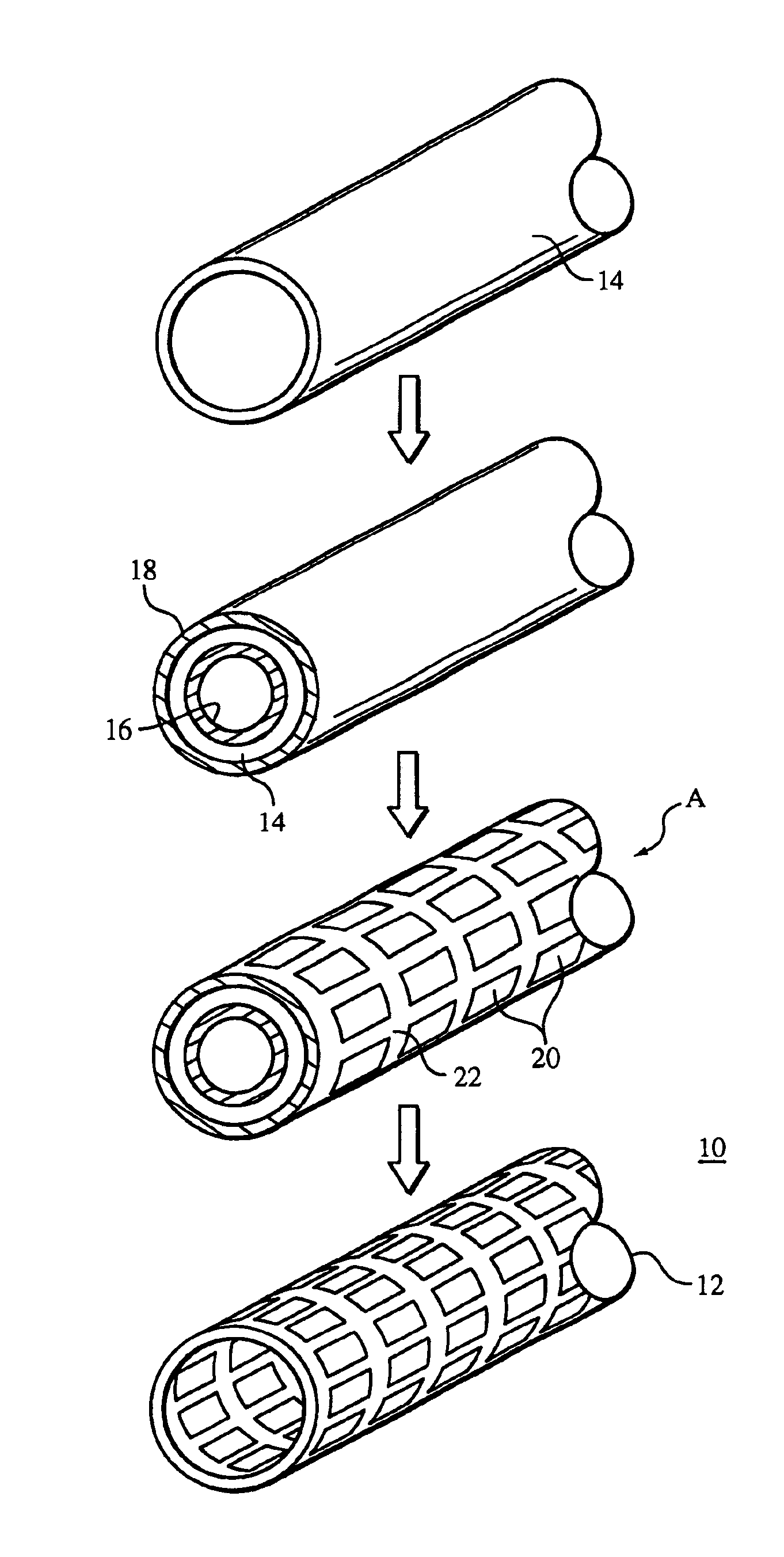

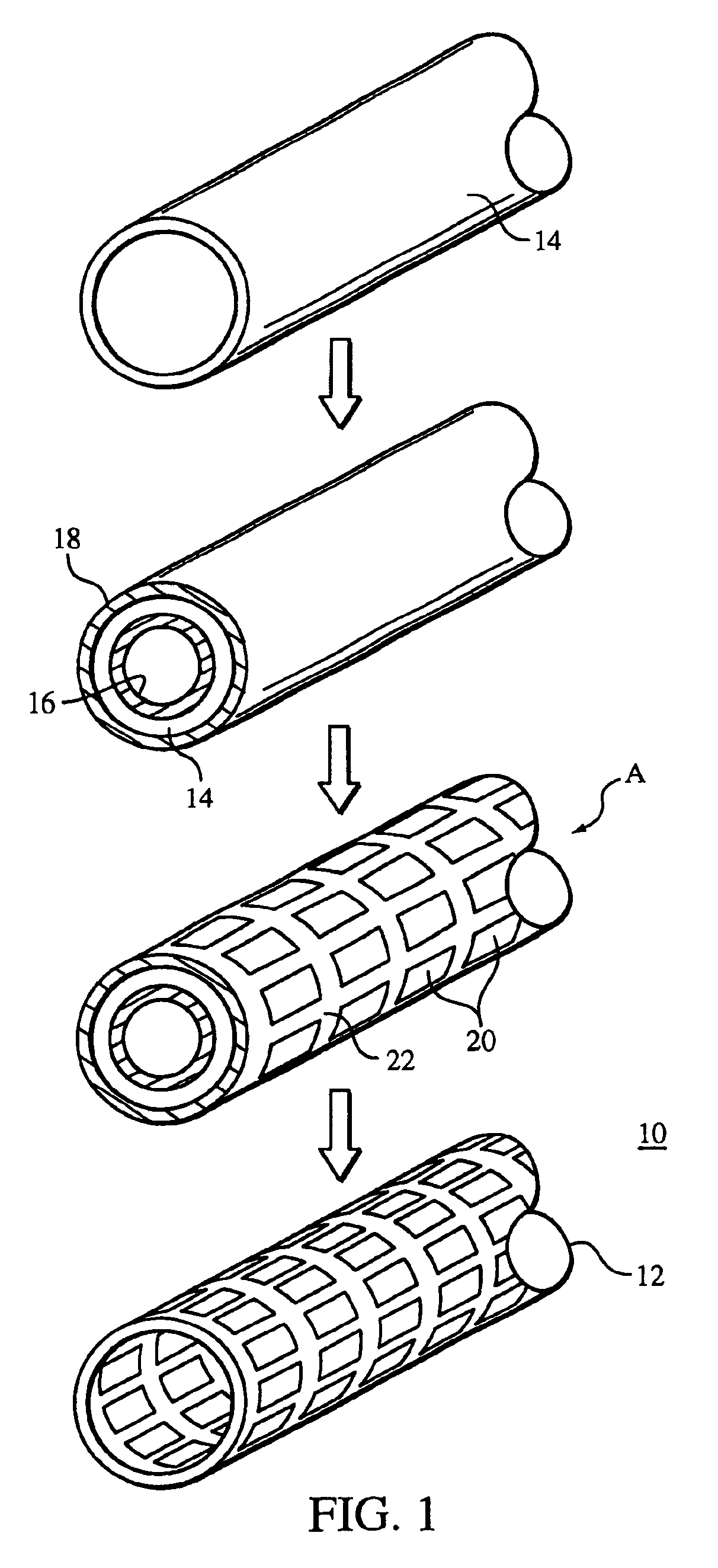

Methods of making medical devices

InactiveUS6865810B2Reduce the amount requiredEasy to disassemblePretreated surfacesAntithrombogenic treatmentInsertion stentMedical device

A method of making a stent includes providing a tubular member having a first layer, the first layer and the tubular member having different compositions, removing a portion of the tubular member, and removing a portion of the first layer from the tubular member.

Owner:BOSTON SCI SCIMED INC

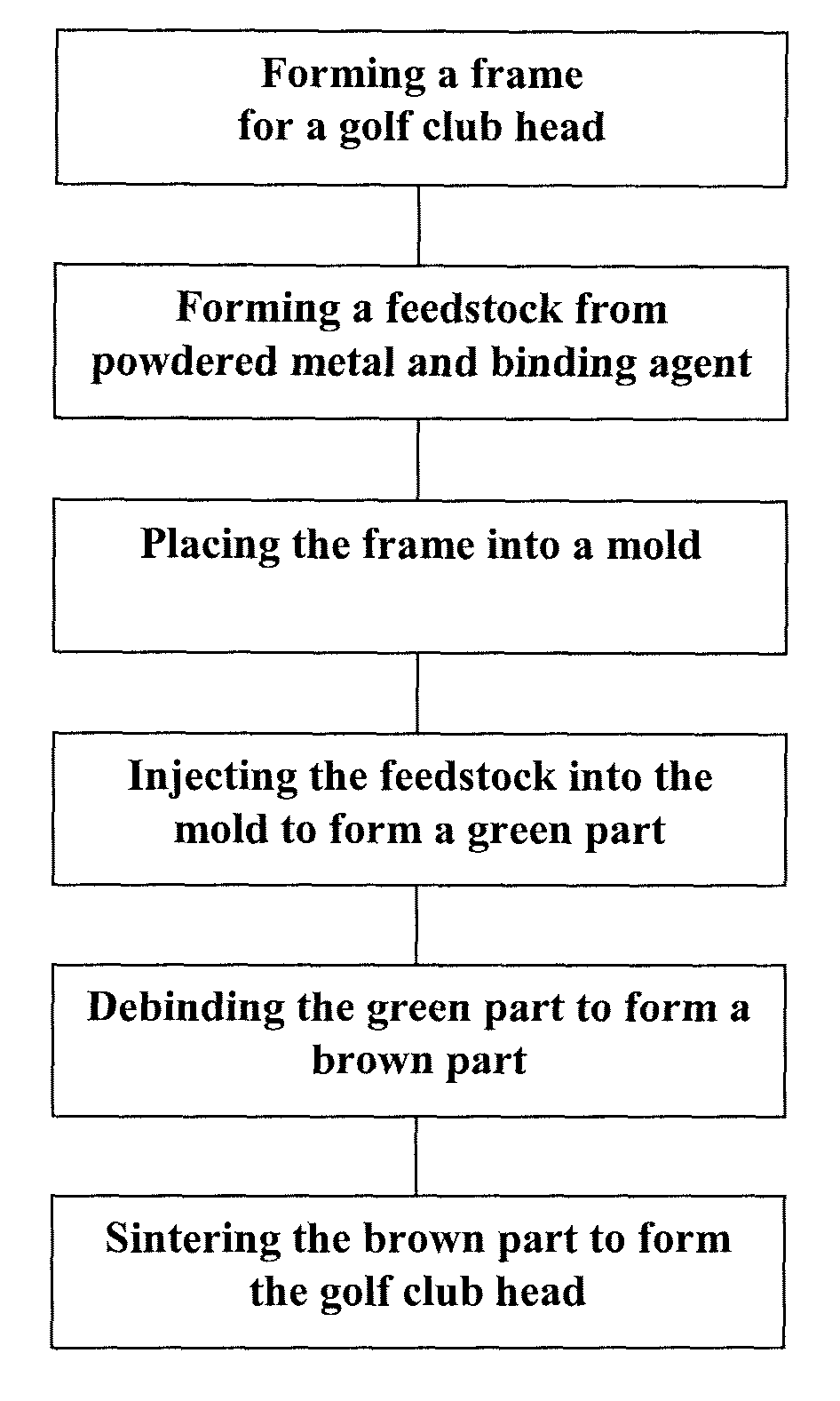

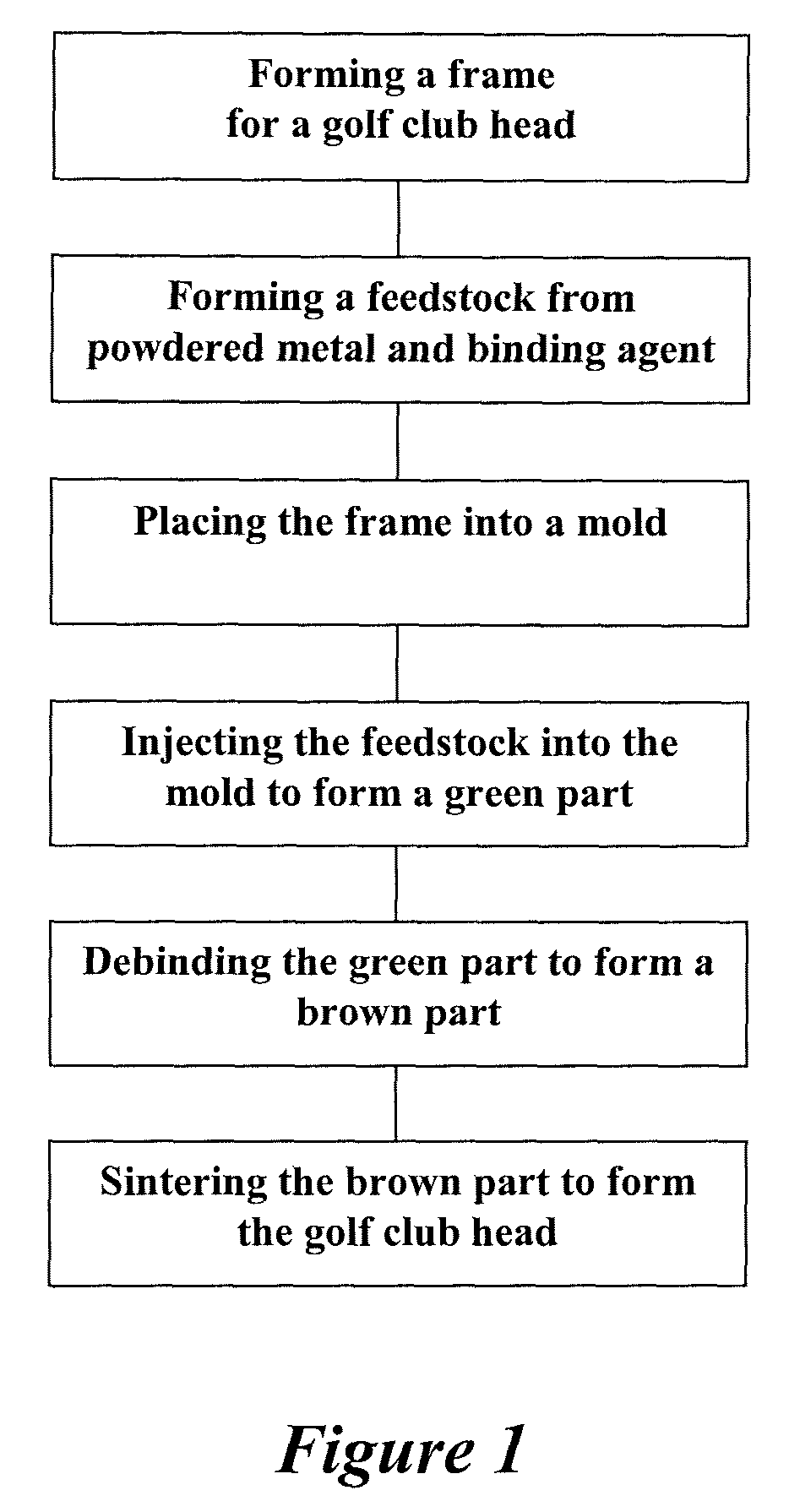

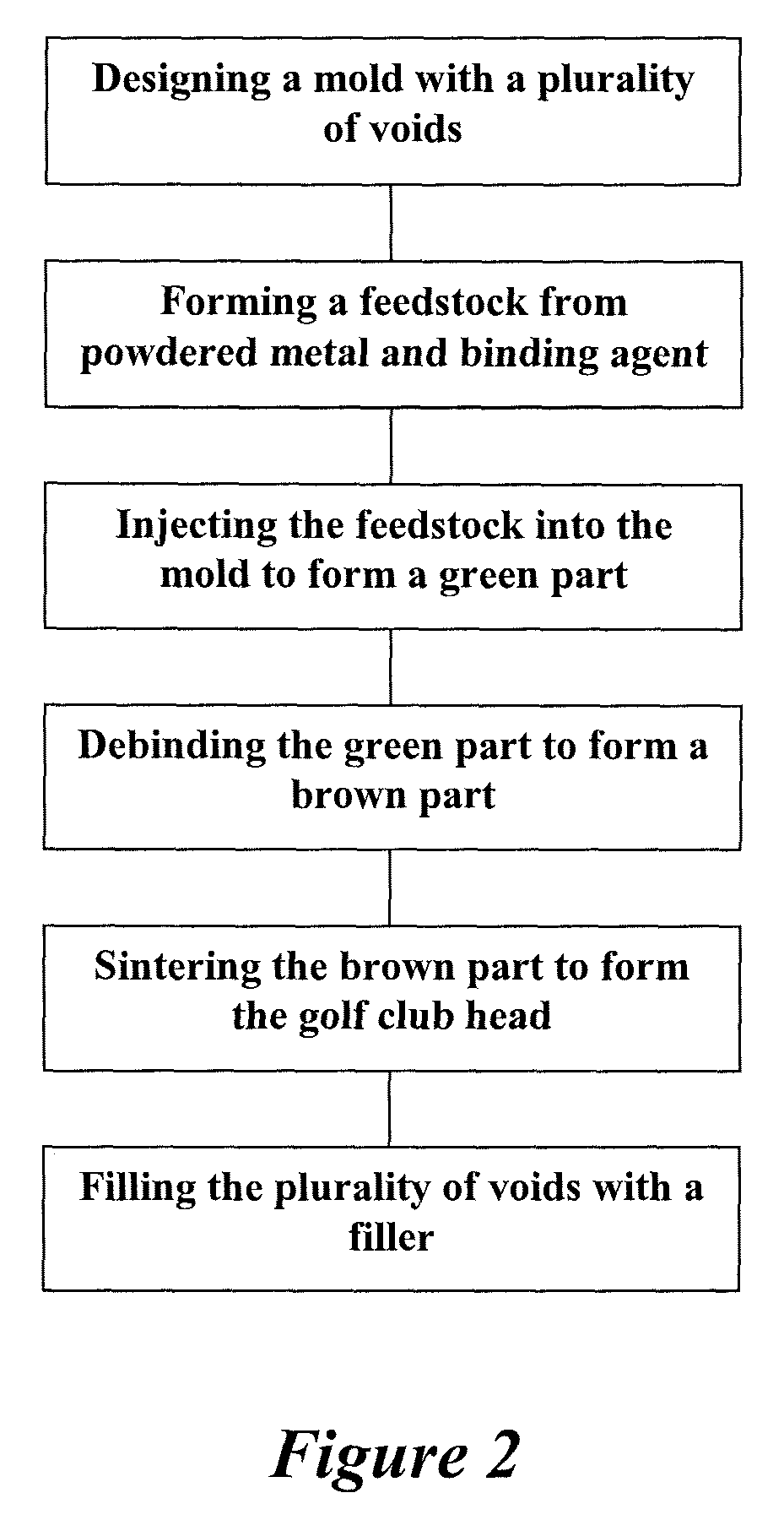

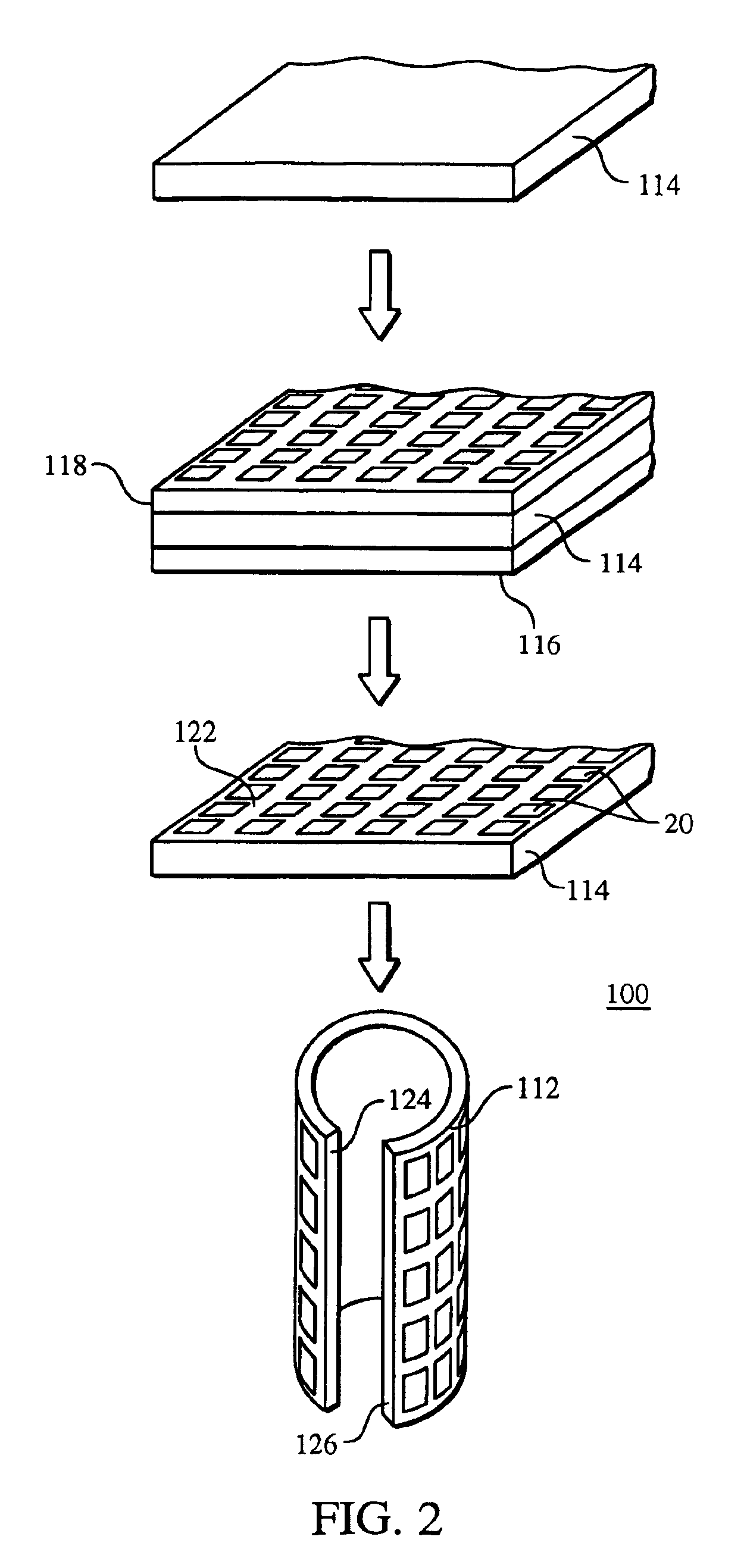

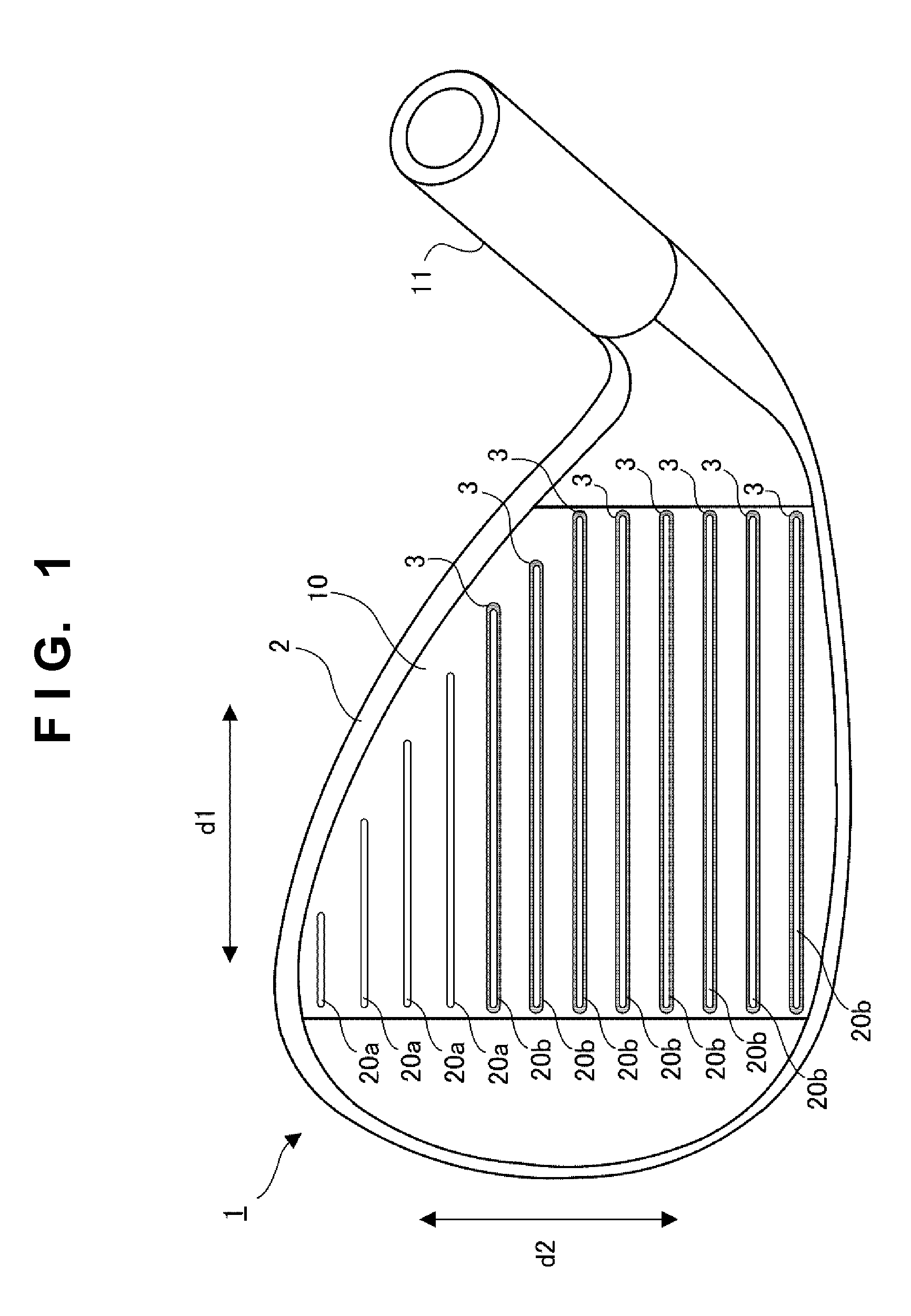

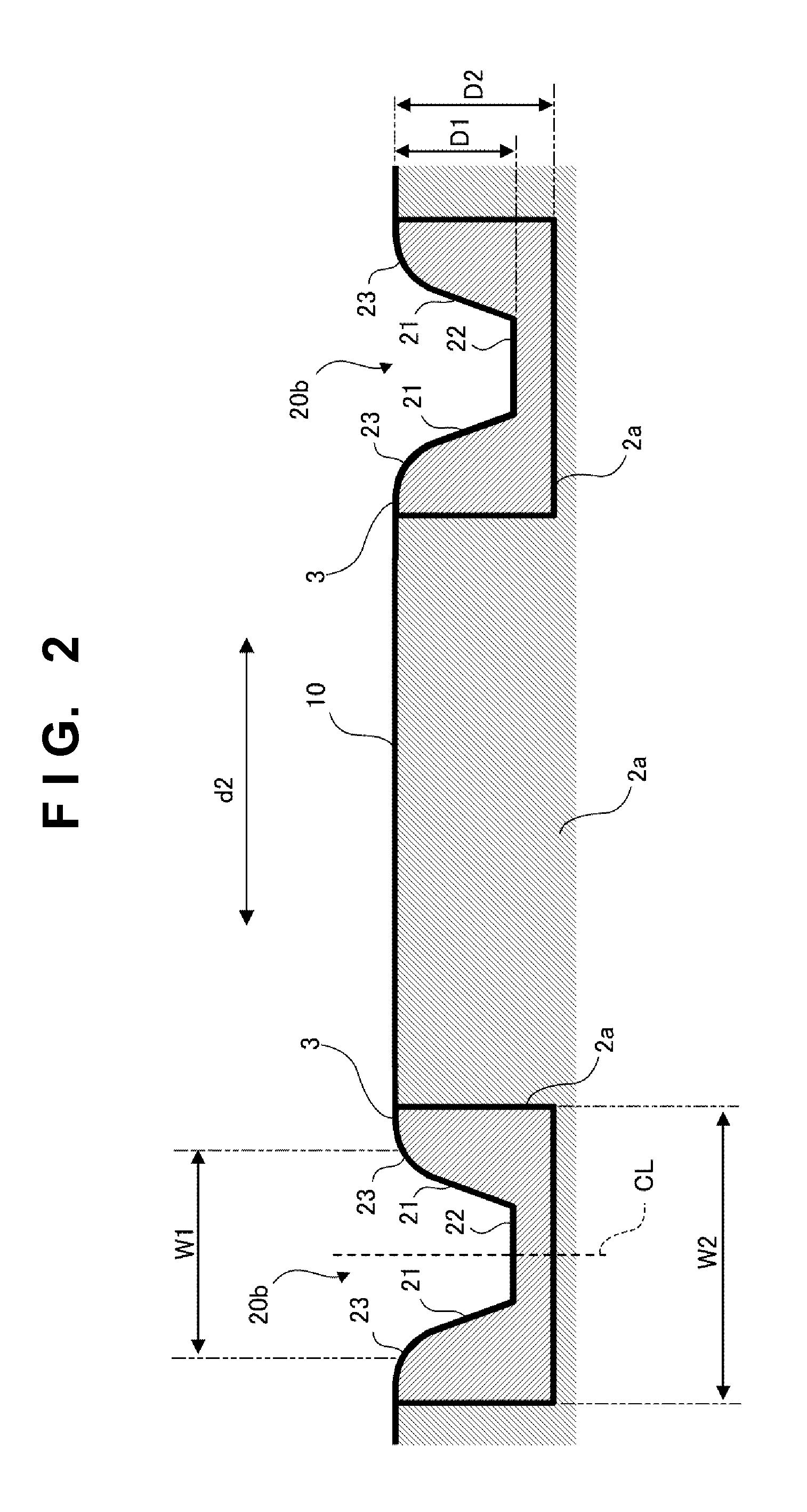

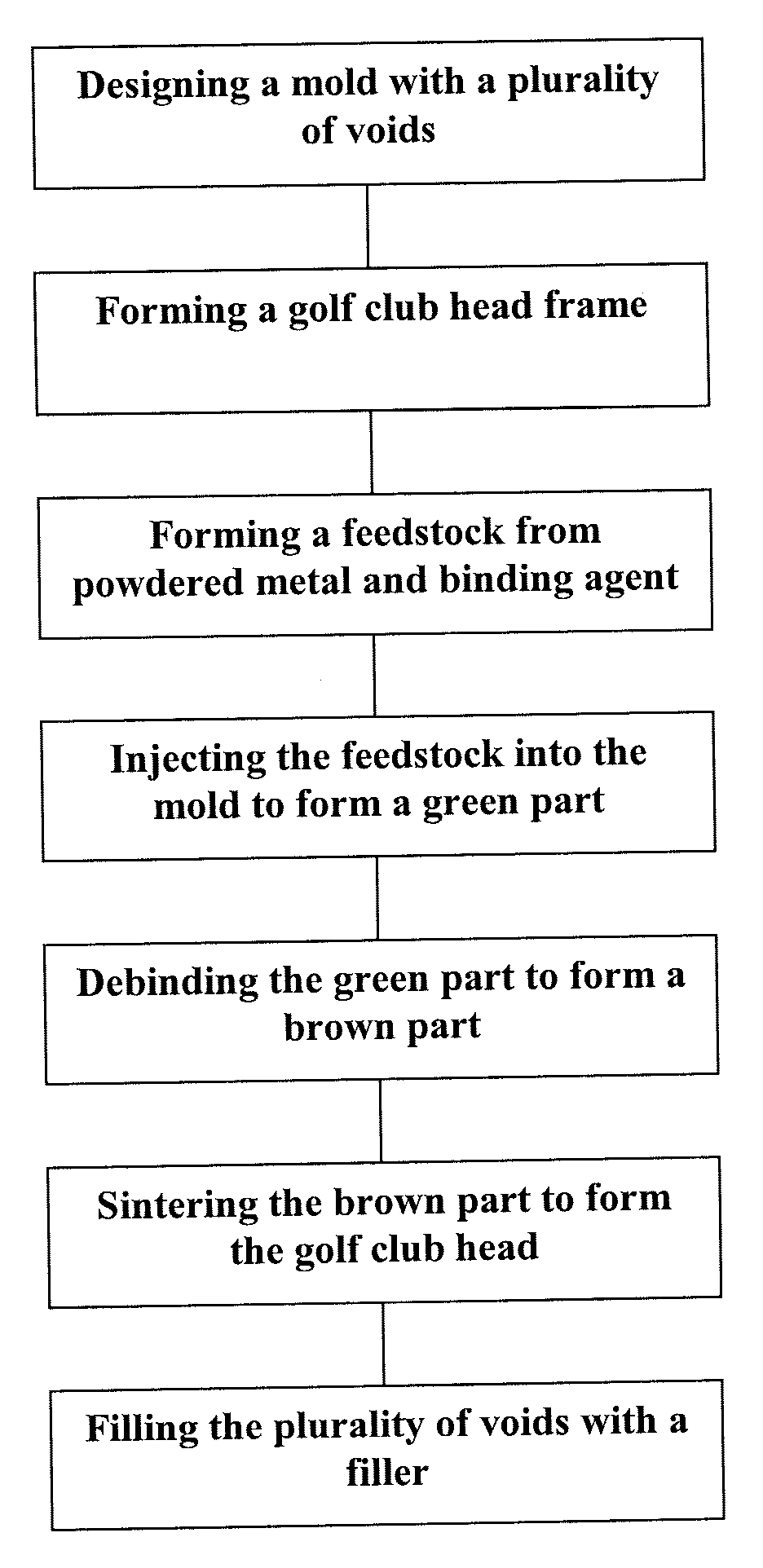

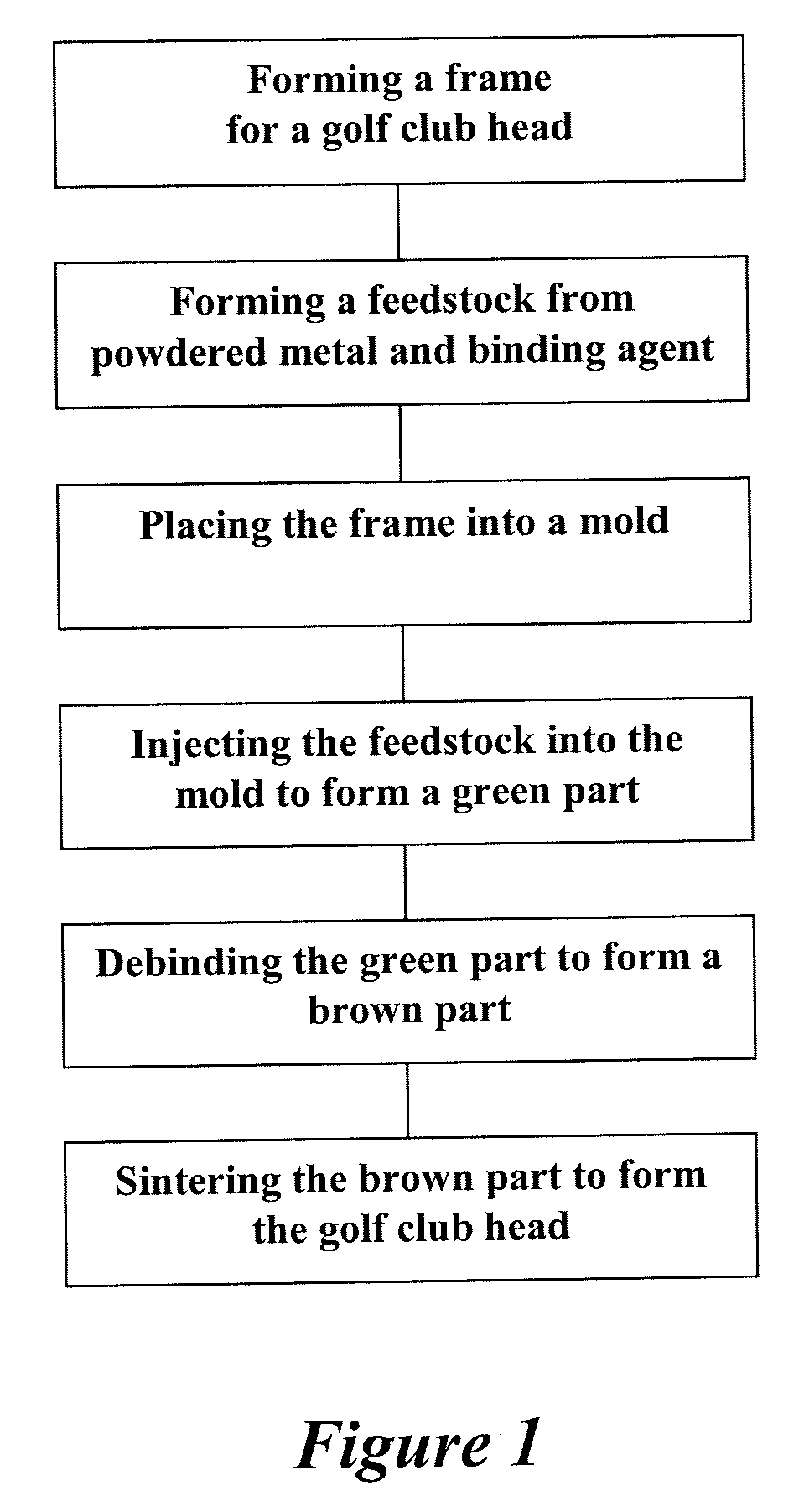

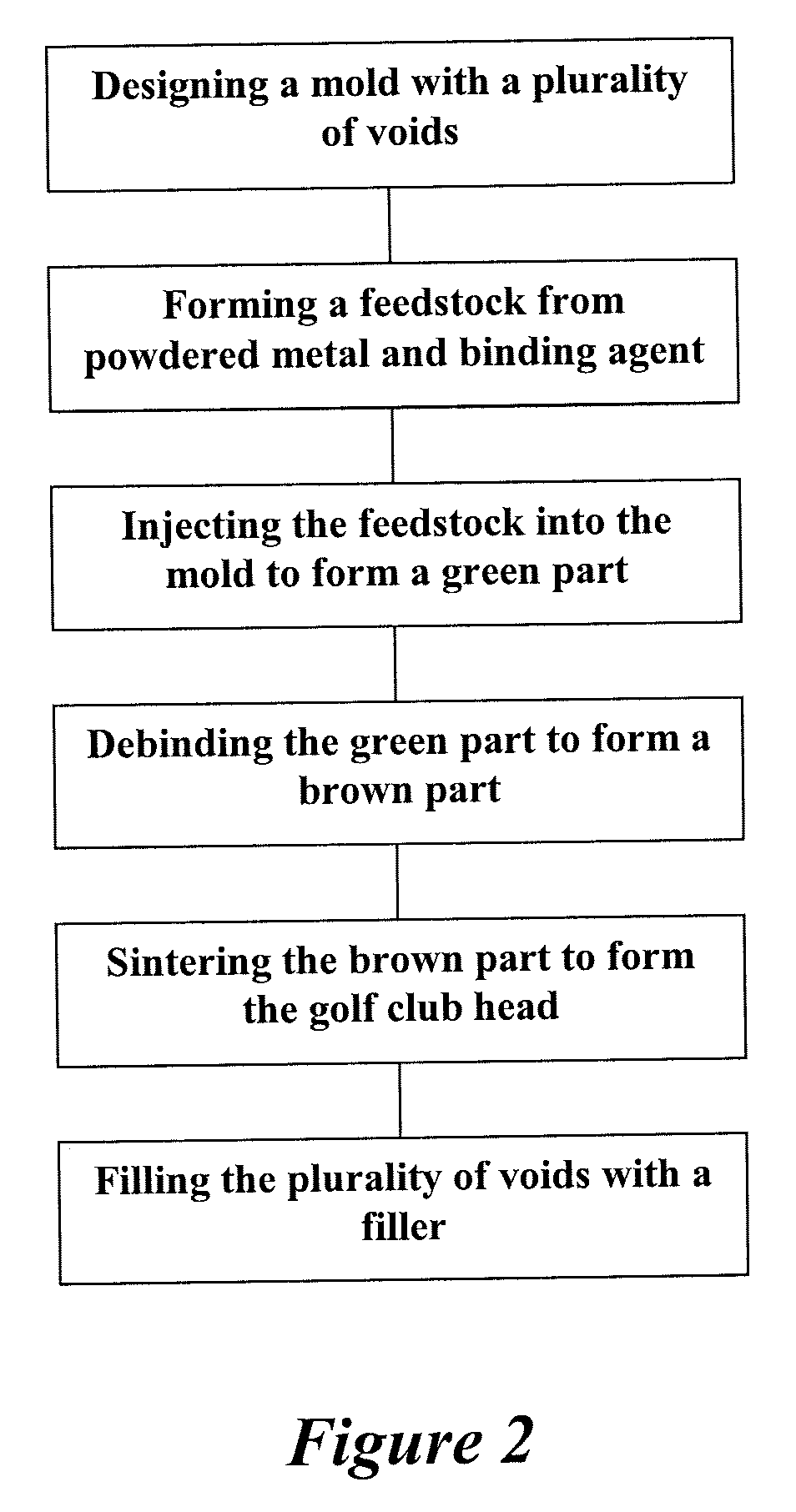

Manufacturing method and golf club head

ActiveUS20130303303A1Excellent abrasion resistanceImprove impact feelMetal rolling stand detailsMetal working apparatusEngineeringGolf Ball

This invention provides a method of manufacturing a golf club head including a face surface. This manufacturing method includes a step of forming a plurality of recessed portions in the face surface, included in a first member, to extend in the toe-to-heel direction, a fixing step of fixing, to the recessed portions, second members which are formed by a material different from that of the first member, and fill the recessed portions, and after the fixing step, a scoreline forming step of forming at least one scoreline in each of the second members, while not forming the scoreline in a portion, between the recessed portions, of the face surface of the first member.

Owner:BRIDGESTONE SPORTS

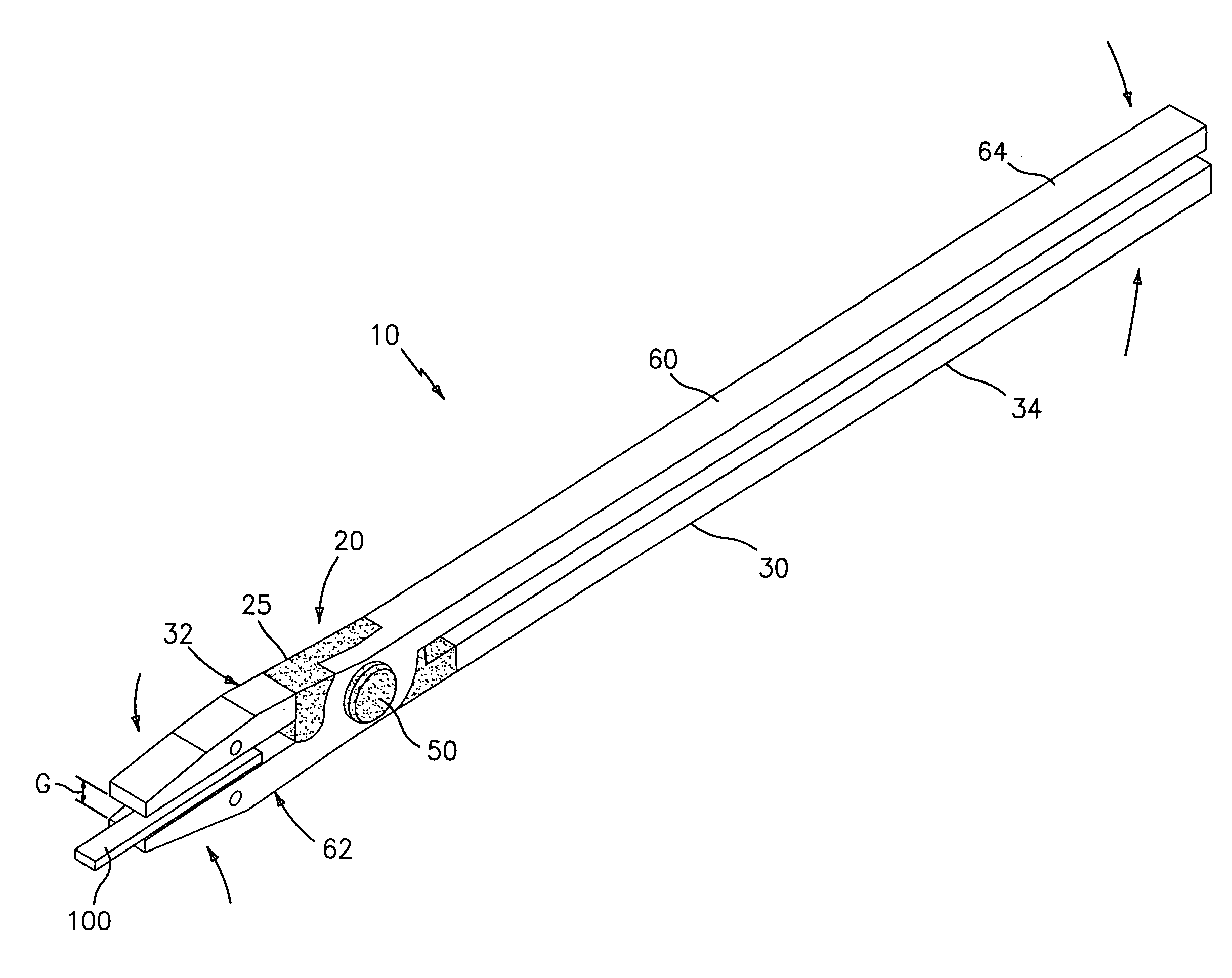

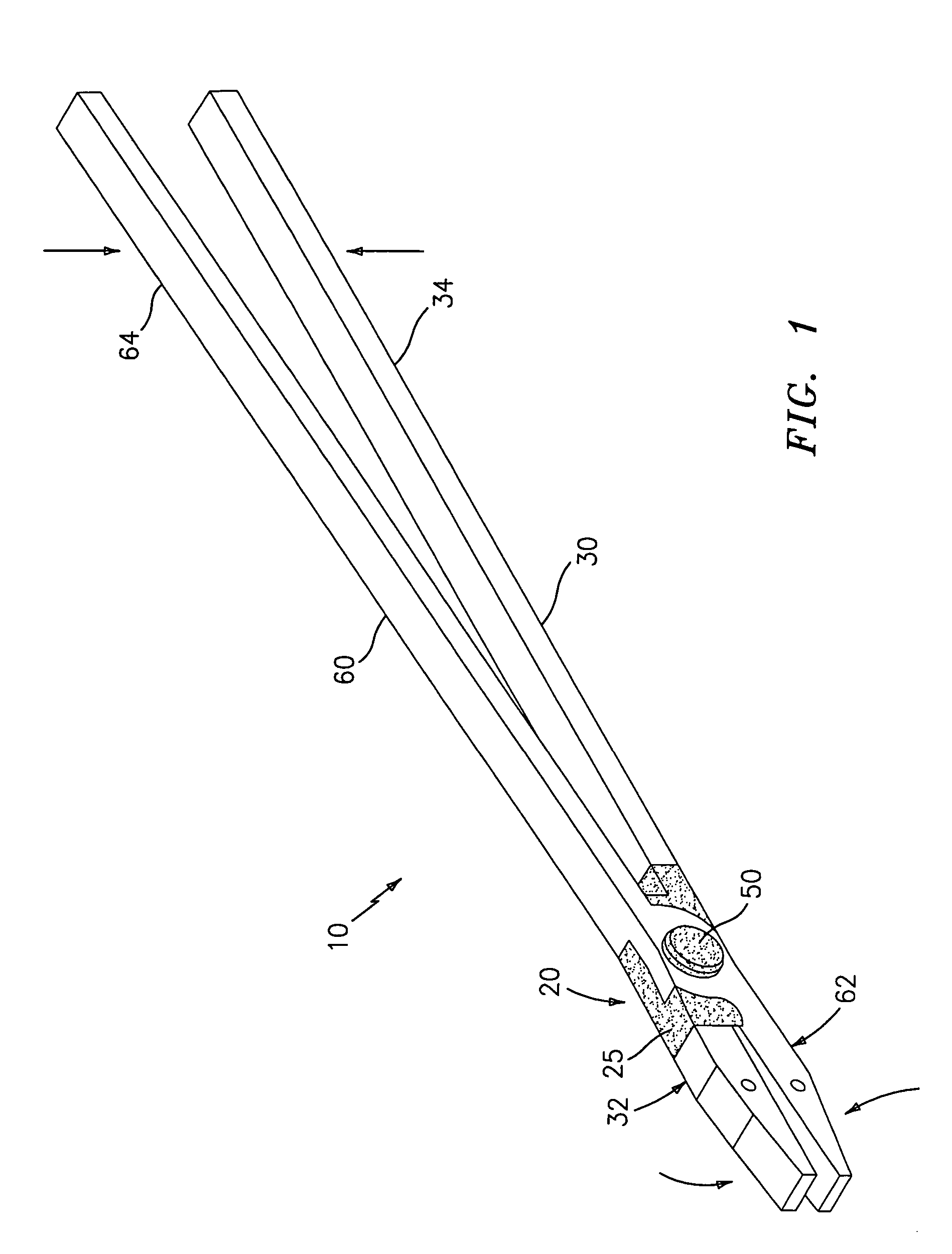

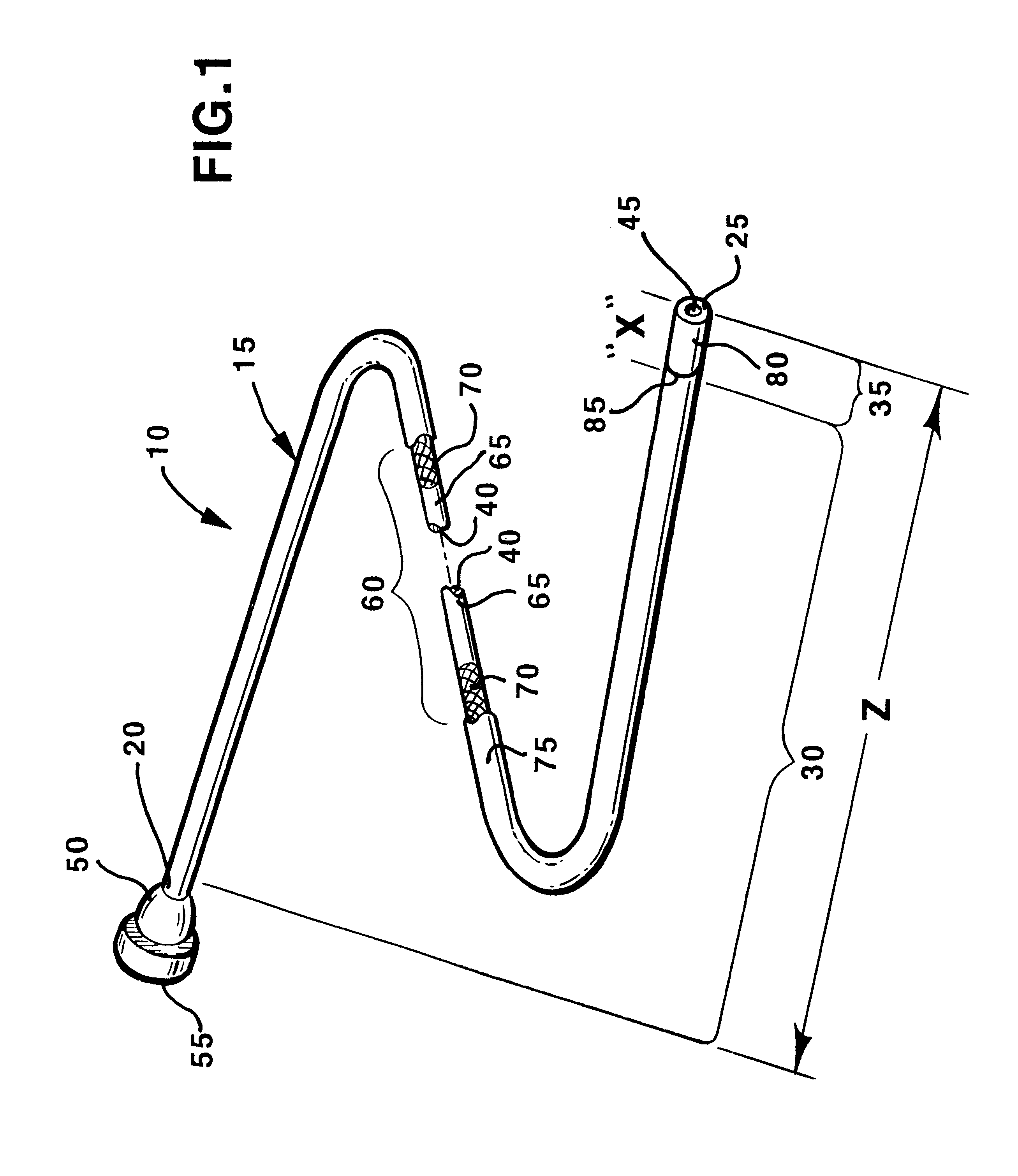

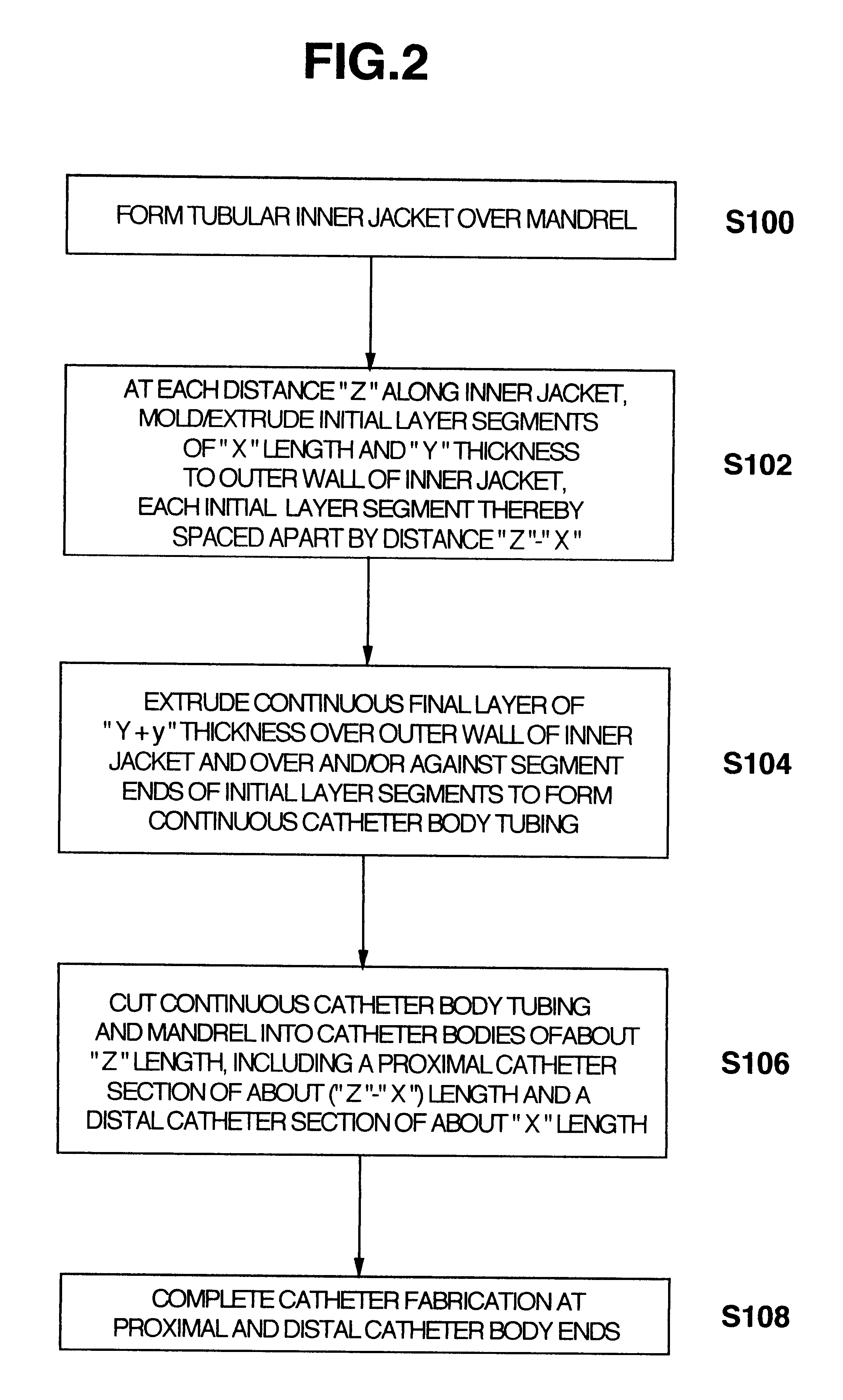

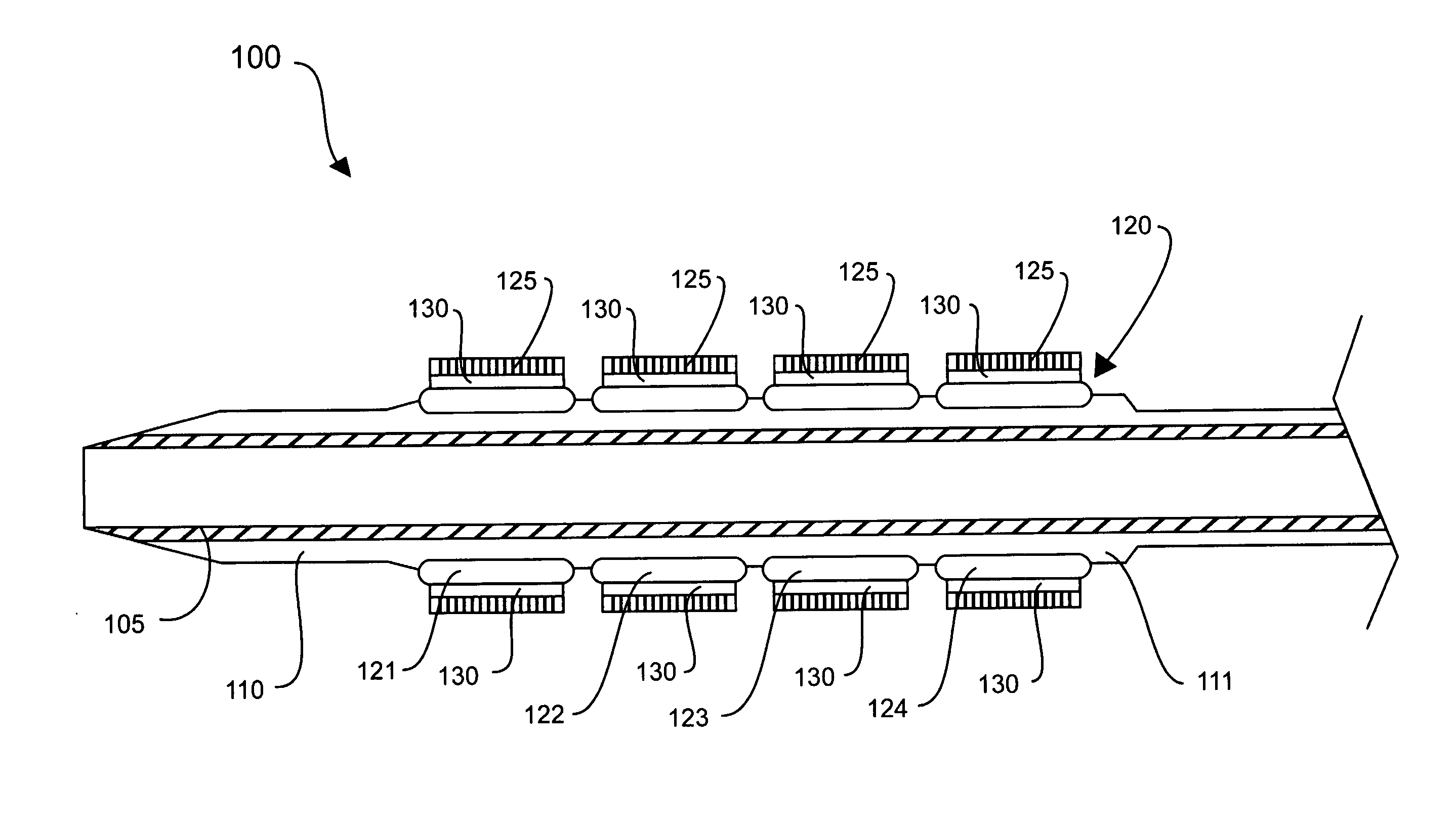

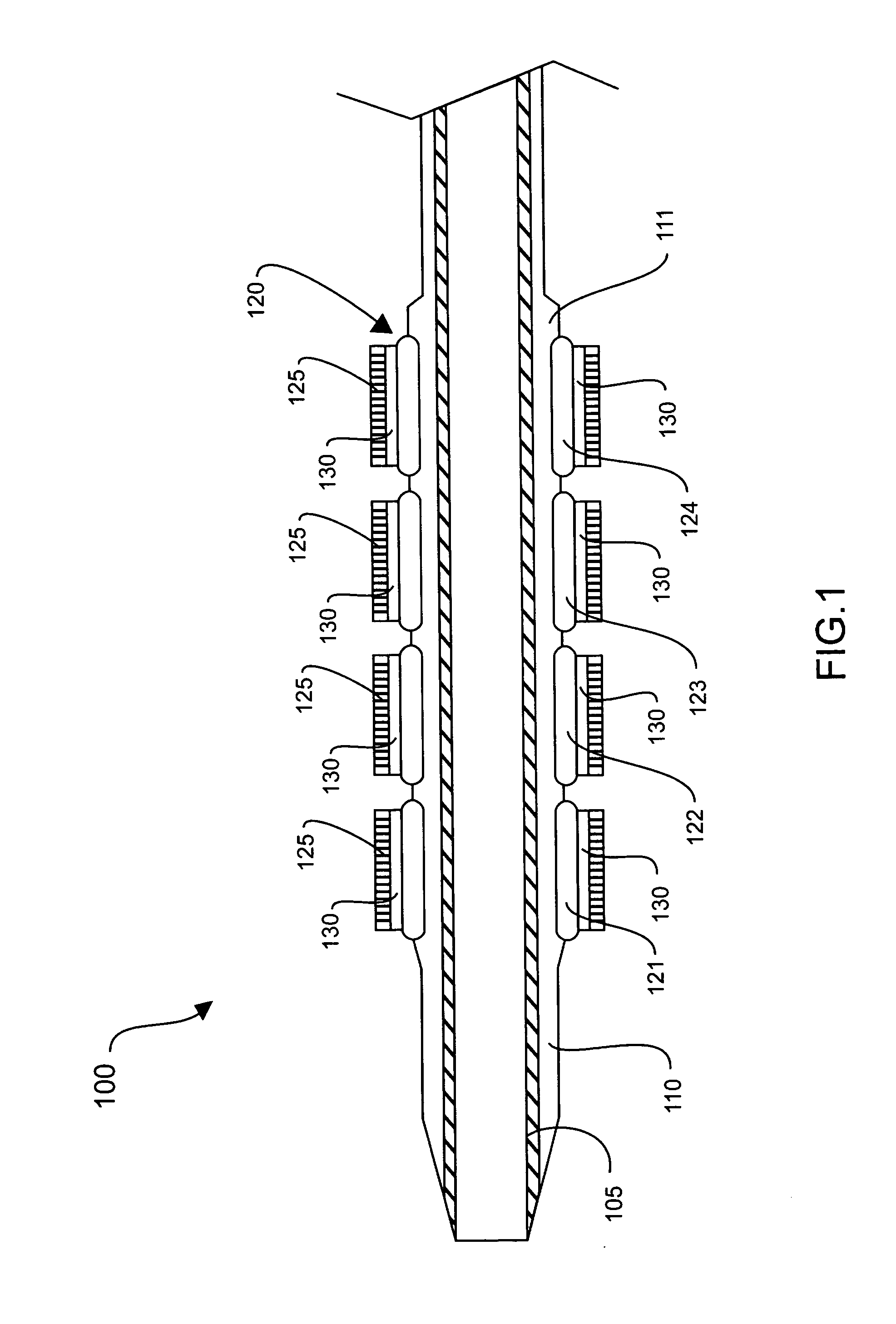

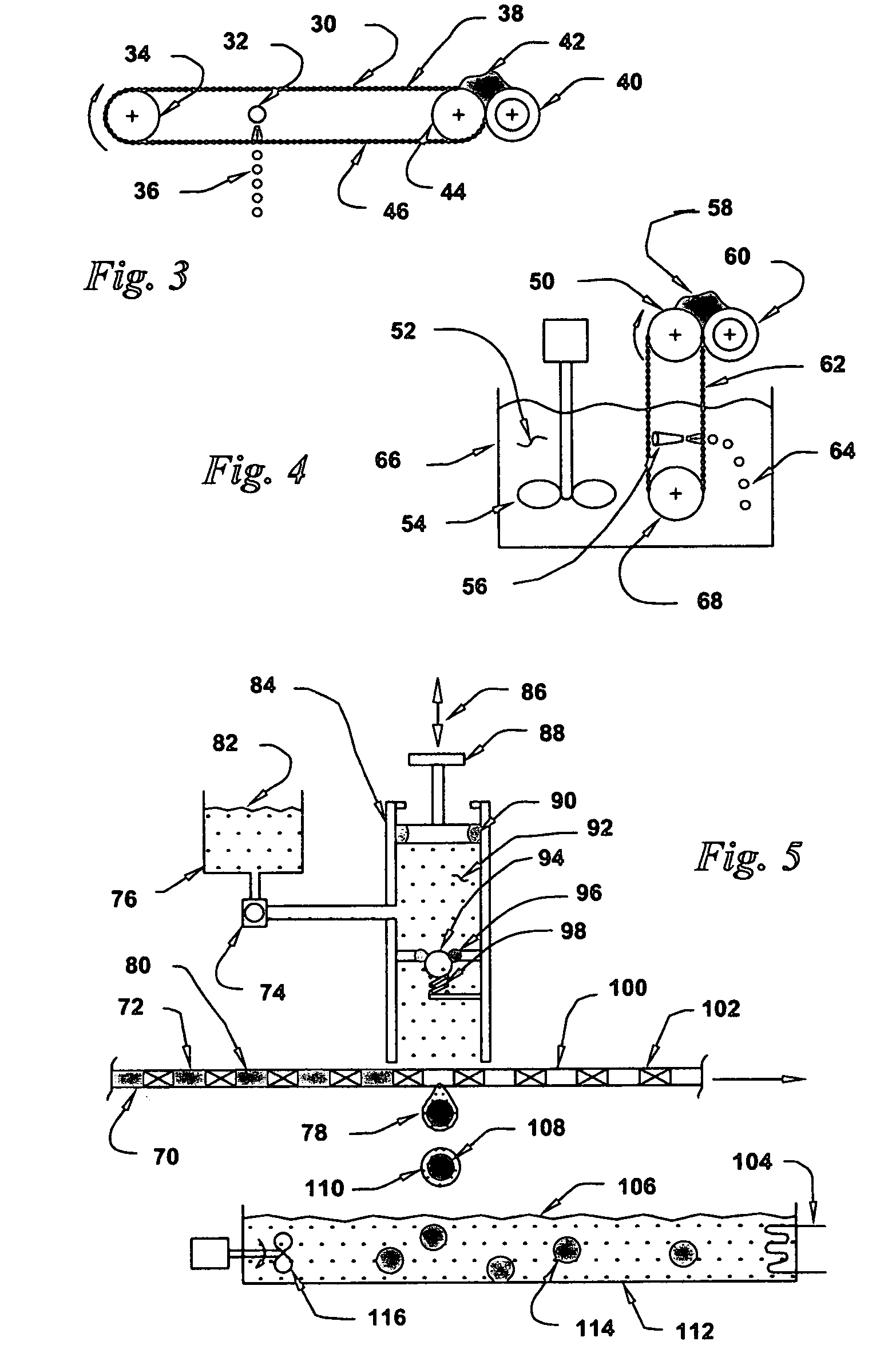

Multiple segment catheter and method of fabrication

Methods of fabricating medical vascular catheters adapted to be inserted into a blood vessel from an incision through the skin of a patient for introducing other devices or fluids for diagnostic or therapeutic purposes and particularly methods for fabricating such catheters with catheter bodies having catheter sections of differing flexibility are disclosed. Such catheter bodies having a proximal catheter body end and a distal catheter body end and formed of a proximal section and at least one distal section that have differing flexibilities are formed in a process comprising the steps of: (1) forming a continuous tubular inner jacket preferably of an inner liner and a reinforcement layer; (2) forming initial layer segments having an initial layer thickness along the length of the inner jacket from a material of first durometer hardness, whereby each initial layer segment is separated by a separation distance: (3) forming a final layer of a material of second durometer hardness with a second layer thickness over the tubular inner jacket along the separation distances and over and / or against the proximal and distal initial layer ends of the initial layer segments to form a continuous catheter body tubing; (4) severing the continuous catheter body tubing into catheter body lengths including a proximal catheter section formed of the material of second hardness and a distal catheter section of the material of first hardness; and (5) completing the catheter fabrication at the proximal catheter body end and the distal catheter body end. Centerless grinding of the catheter body or body tubing, formation of Intermediate catheter body sections, distal soft tips, and discontinuities in the reinforcement layer formed prior to step (2) are also disclosed.

Owner:MEDTRONIC INC

Stent with improved drug loading capacity

The present invention provides a method of forming a drug eluting stent, the method comprising coupling a stent framework to a mandrel, inserting the mandrel with stent framework into an open die, the die including a forming surface including a plurality of raised indention forming portions; closing the die against the stent framework; pressing the raised indention portions into the stent framework to form indentions in the stent framework; and inserting at least one drug polymer into the indentions formed in the stent framework.

Owner:MEDTRONIC VASCULAR INC

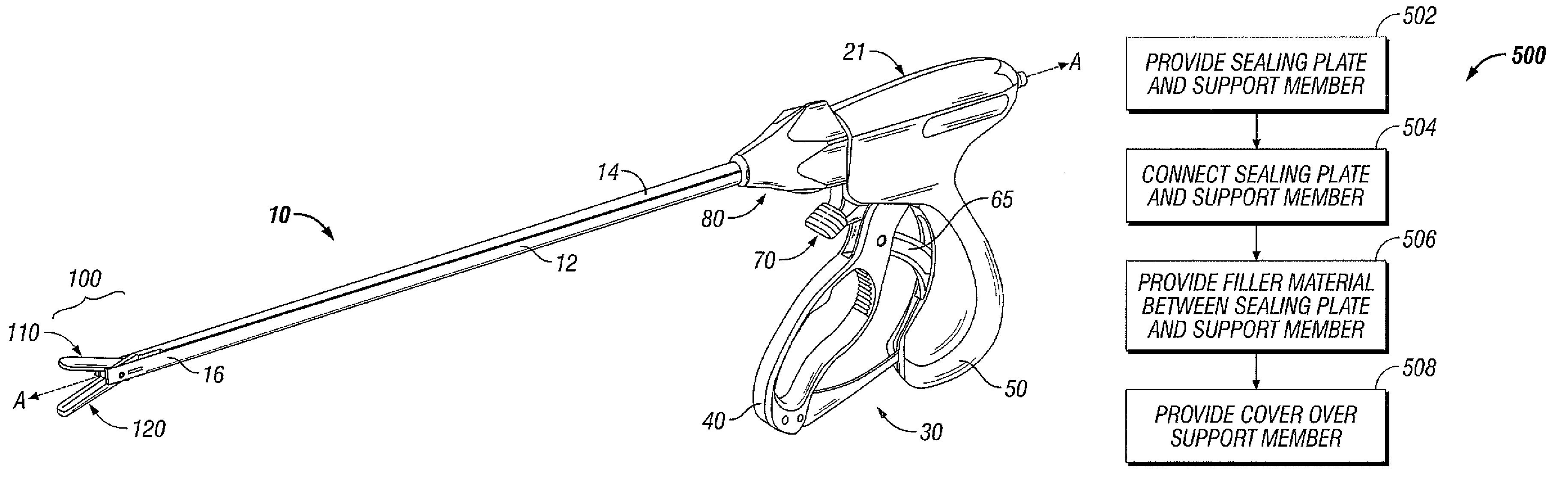

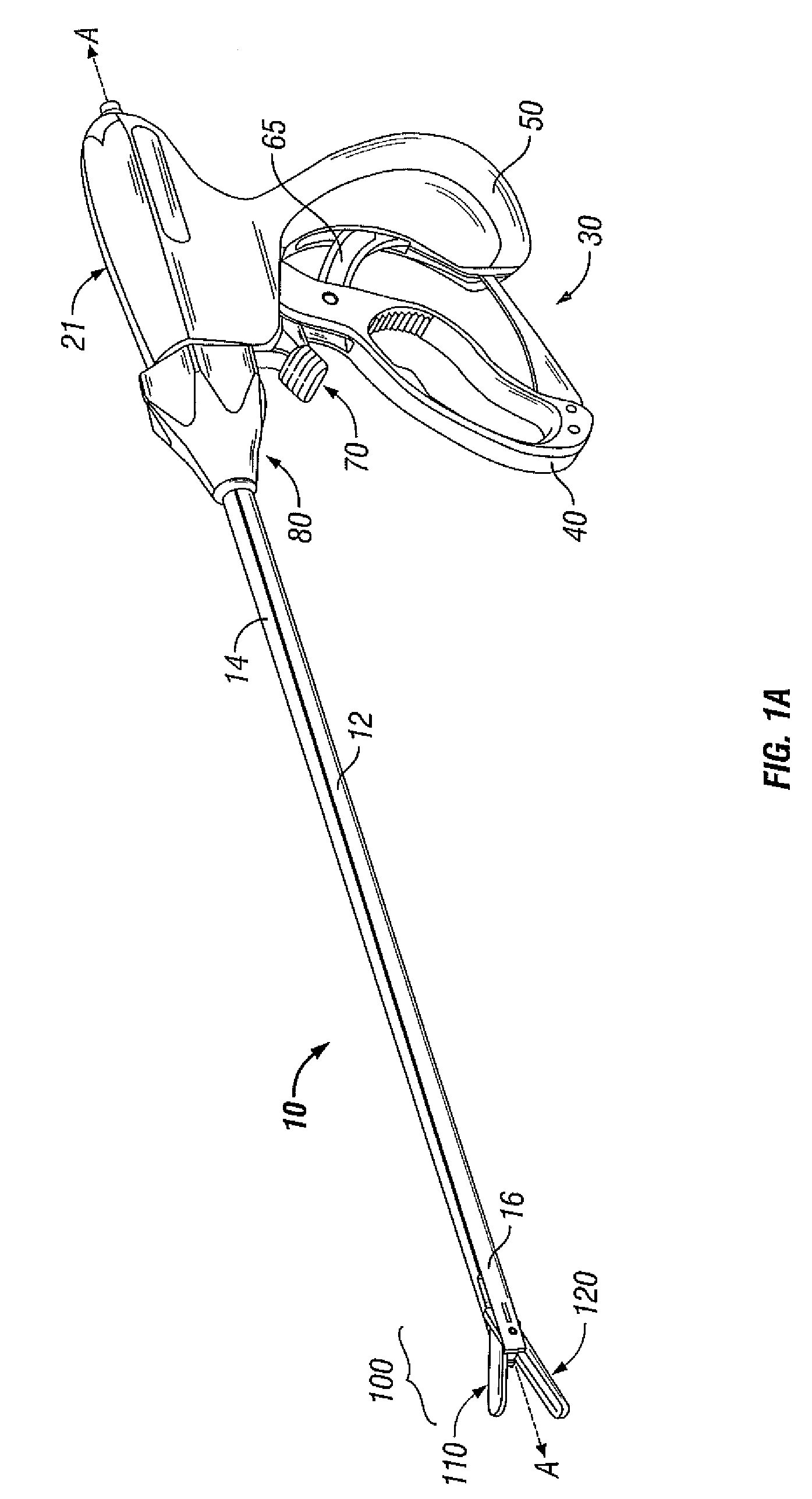

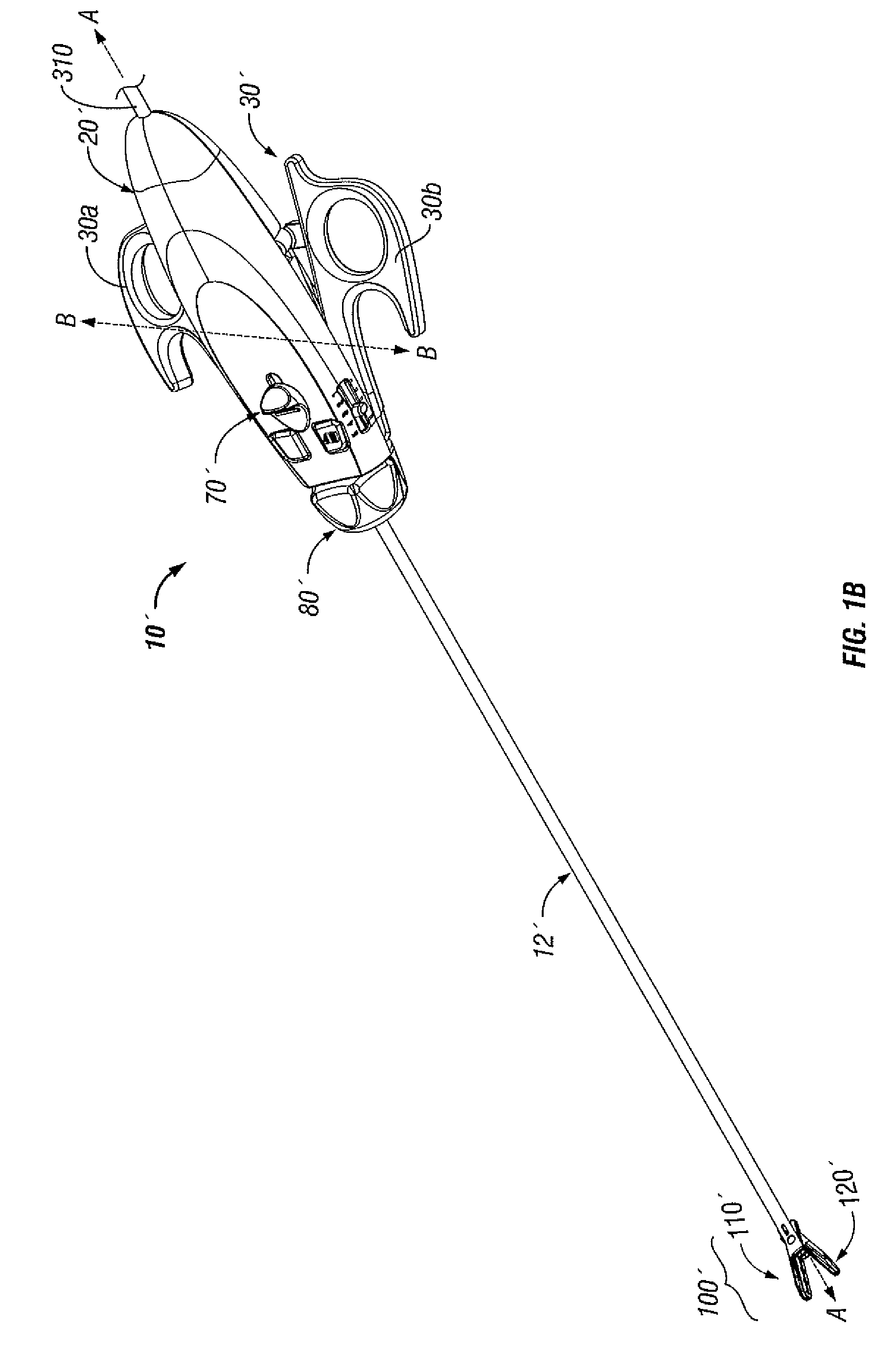

Monocoque jaw design

Owner:TYCO HEALTHCARE GRP LP

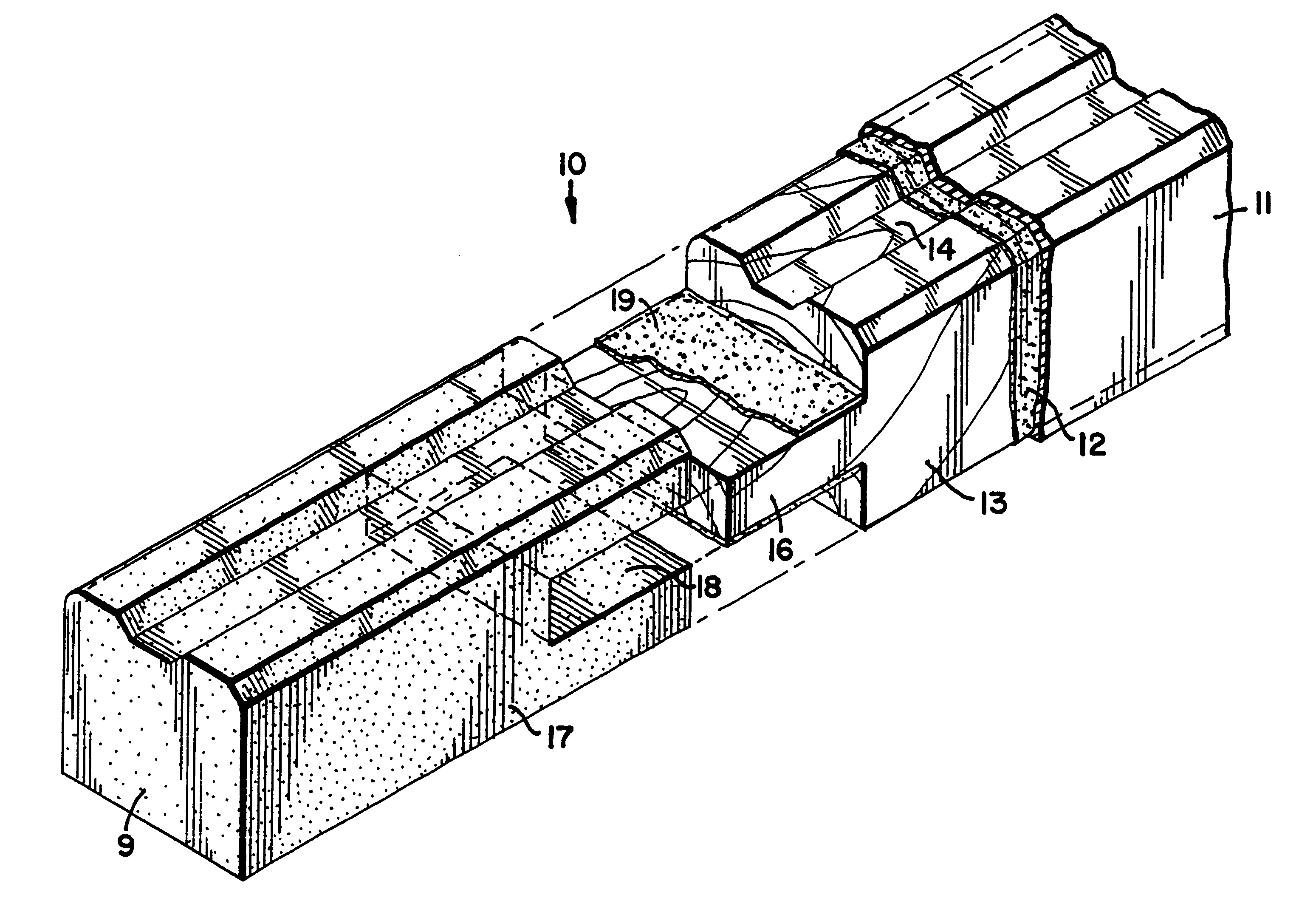

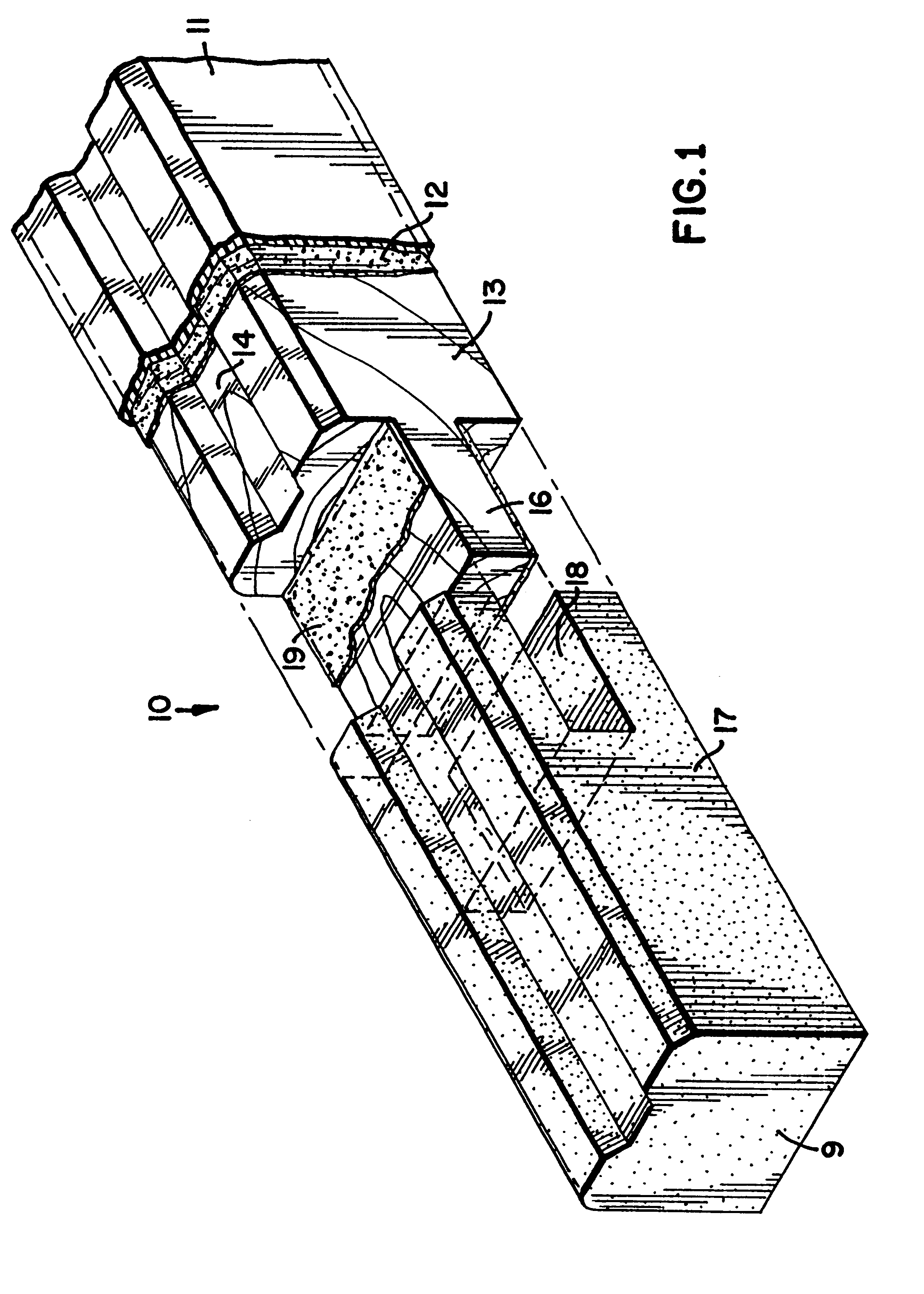

Polymer covered advanced polymer/wood composite structural member

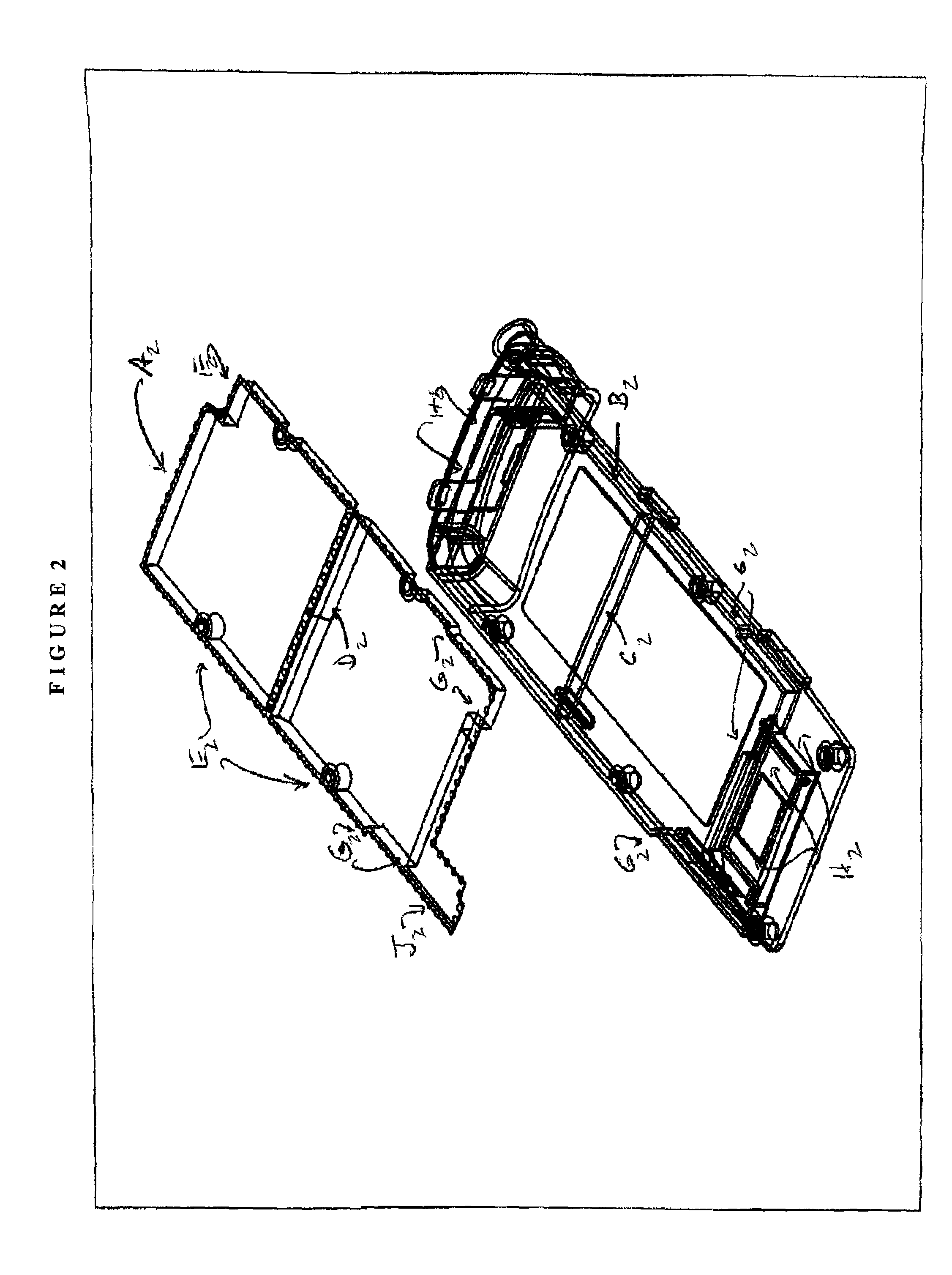

InactiveUS6357197B1Corner/edge jointsMetal rolling stand detailsComposite constructionMoisture absorption

A composite structural member of the invention comprises a linear member having a first end and a second end attached to each end of the linear member as an end piece or end cap structure. Covering the composite member is a thermoplastic envelope preferably adherently bonded to the composite member. The end caps or end pieces are preferably thermoplastic materials typically thermoplastic composites comprising a thermoplastic resin and a fiber. Such a member is environmentally stable, resists moisture absorption, forms strong mitered joints and can be used in the assembly of fenestration products for commercial and residential real estate.

Owner:ANDERSEN CORPORATION

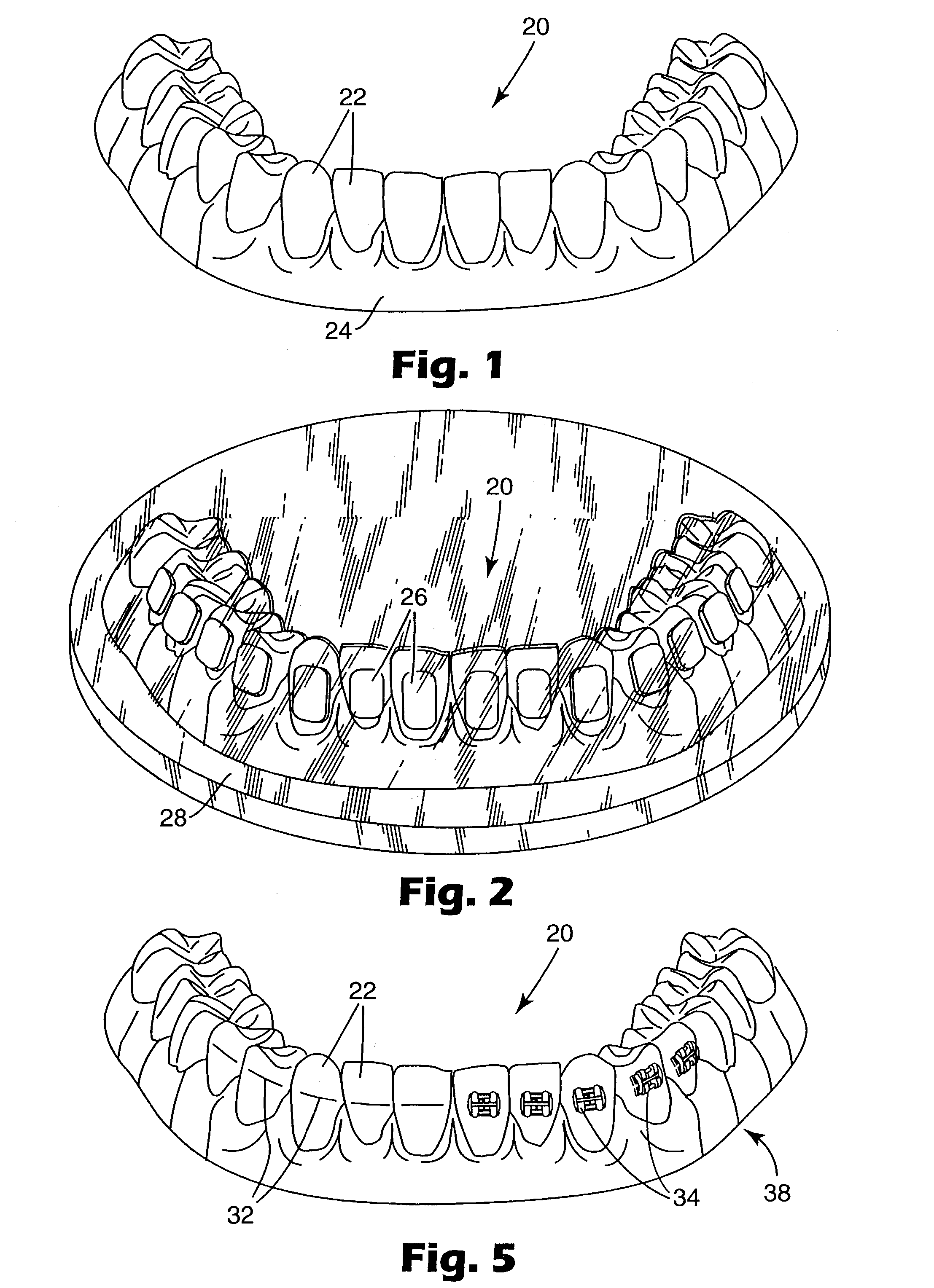

Method and apparatus for indirect bonding of orthodontic appliances

ActiveUS7020963B2Broaden applicationEasy to disengageBracketsAdditive manufacturing apparatusEngineeringAnodic bonding

Owner:3M INNOVATIVE PROPERTIES CO

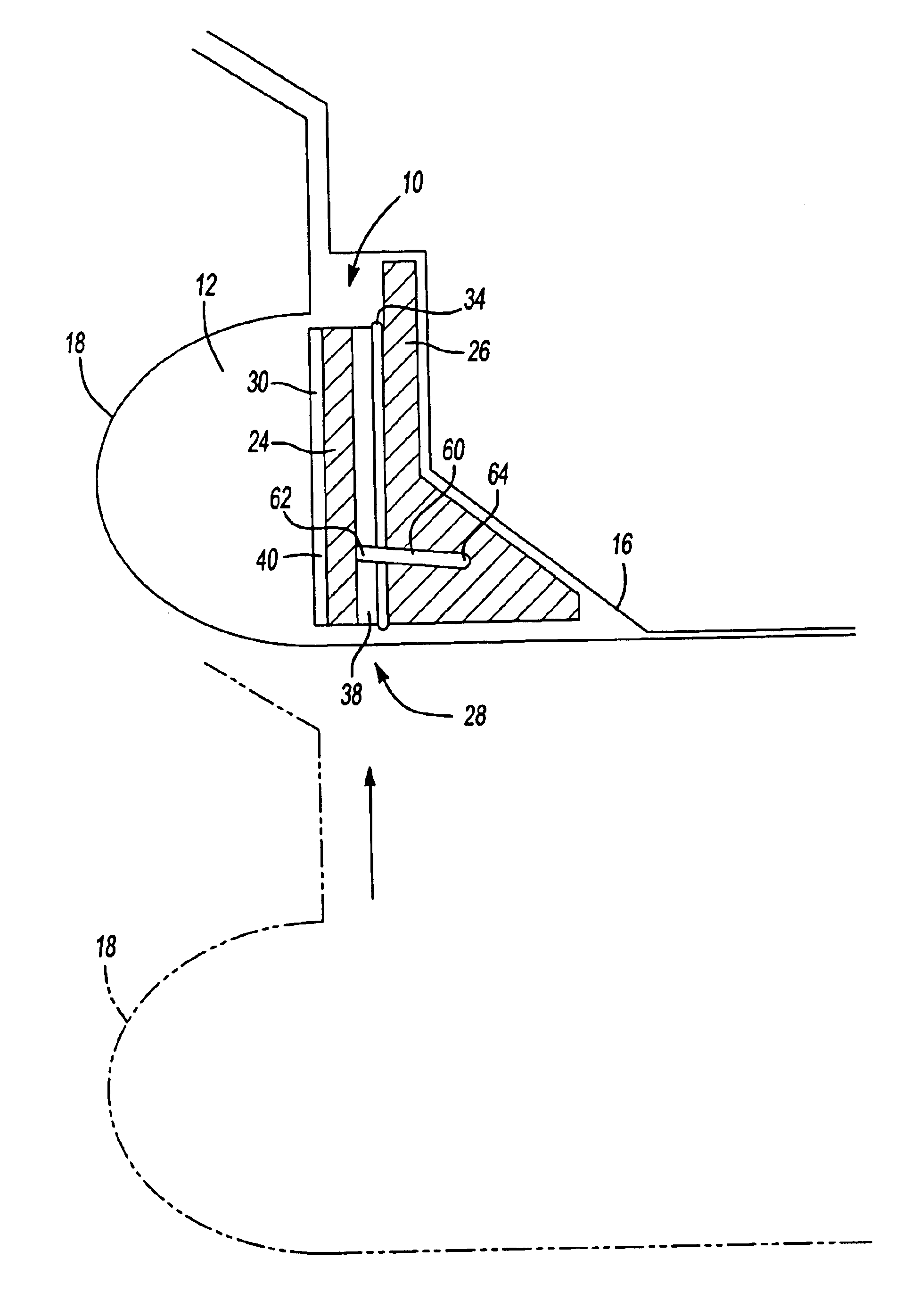

Dynamic self-adjusting assembly for sealing, baffling or structural reinforcement

There is disclosed a reinforced structural assembly and a method of using the assembly for sealing, baffling and / or reinforcing components of an automotive vehicle. The assembly generally includes at least a first mass of expandable material. Preferably, the first mass is movably (e.g., rotatably) connected to a second mass of material and / or another member. According to the method, the assembly is placed in a cavity of an automotive vehicle and the at least one mass is activated to expand. Preferably, upon activation, the first mass self adjusts by moving (e.g., rotating) relative to the second mass and / or the other member.

Owner:ZEPHYROS INC

Method for improving performance of 700MPa grade V-N micro-alloying high-strength weathering steel

InactiveCN101161849AImprove low temperature impact toughnessGood formabilityTemperature control deviceMetal rolling arrangementsChemical compositionHigh intensity

The invention discloses a method for improving the performance of 700 MPa grade V-N microalloyed high strength weathering steel. The method is specific to the characteristics of the sheet billet continuous casting and tandem rolling technology and metallurgy component, and adopts an electric furnace or a revolving furnace to smelt, refine, continuously cast sheet billet which directly enters into a roller hearth to heat after a casting blank concretes, or soaking furnace, hot rolling, laminar flow cooling and wind-up process flow. The chemical composition of molten steel is :C occupies less than or equal to 0.08Wt. percent, Si occupies from 0.25 to 0.75Wt. percent, Mn occupies from 0.2 to 2.0Wt.percent, P occupies less than or equal to 0.025Wt. percent, S occupies less than or equal to 0.040Wt. percent, Cu occupies from 0.25 to 0.60Wt. percent, Cr occupies from 0.30 to 1.25 Wt.percent, Ni occupies less than or equal to 0.65Wt. percent, V occupies from 0.02 to 0.20Wt. percent and N occupies from 0.015 to 0.030 Wt. percent. The invention takes full advantages of the characteristics of the sheet billet continuous casting and tandem rolling short flow process and adopts the V-N microalloyed technique to produce 700 MPa grade high strength weathering steel under the thinning function of VN and V (C, N) nanometer scale precipitate on crystal grain in casting blank of the sheet billet continuous casting and tandem rolling flow and the theory of precipitation strength. By the optimization design of the metallurgy component of V-N microalloyed 700MPa grade high strength weathering steel, the invention increases the low temperature impact ductility of coil of strip and improves the shaping property.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

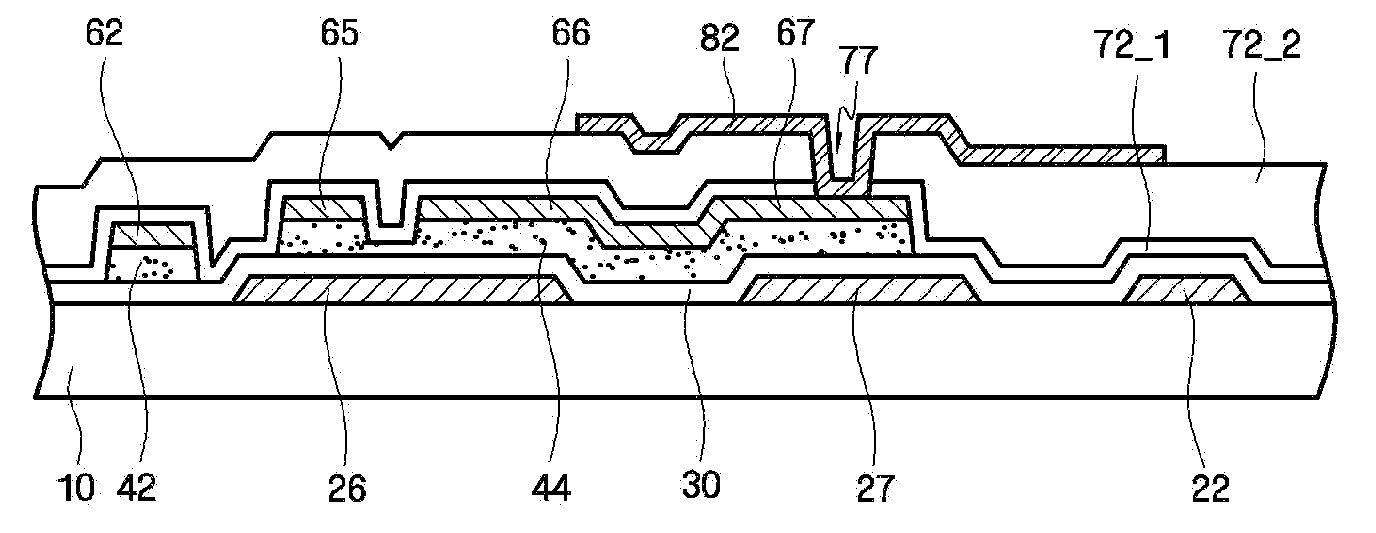

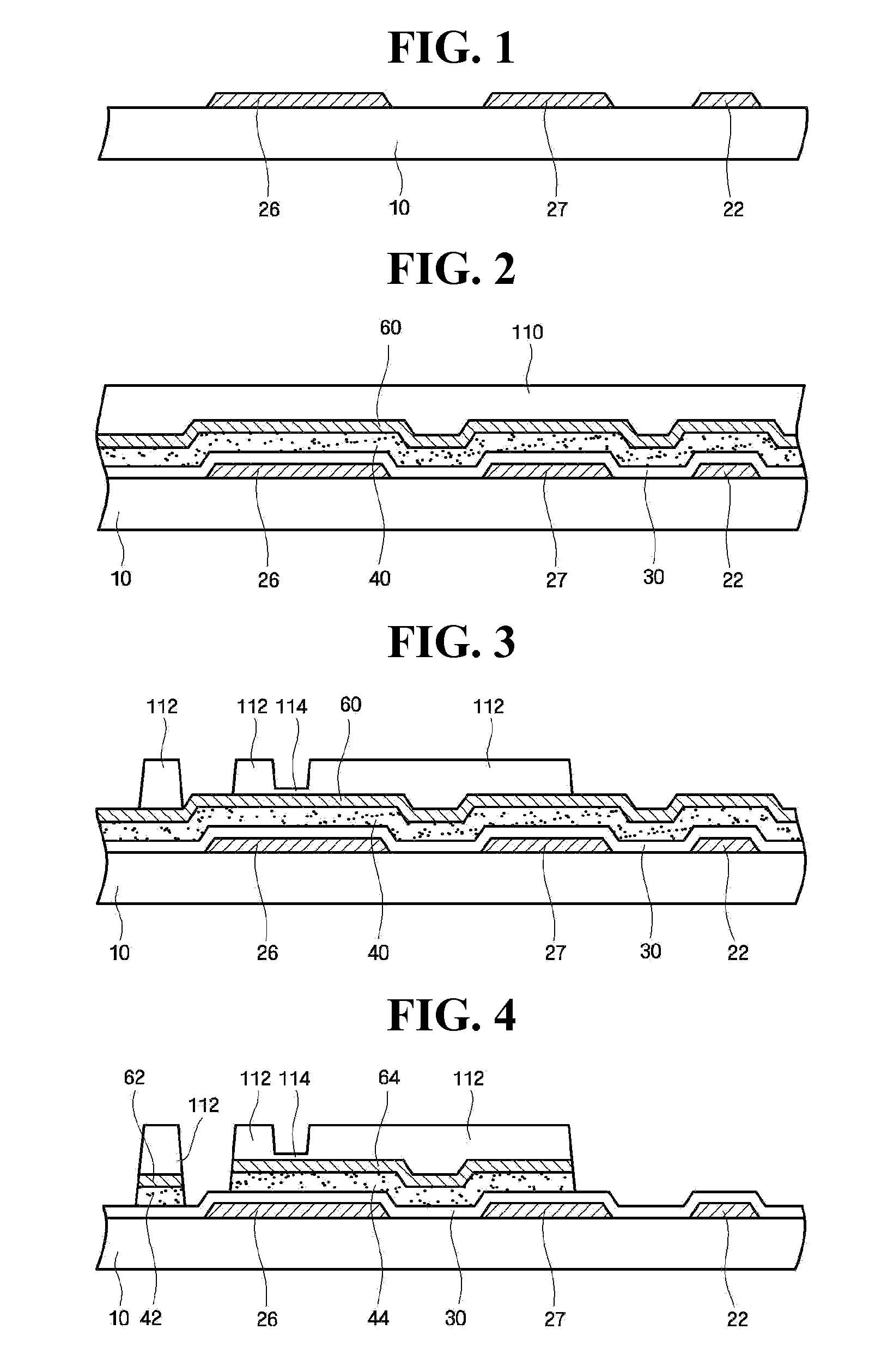

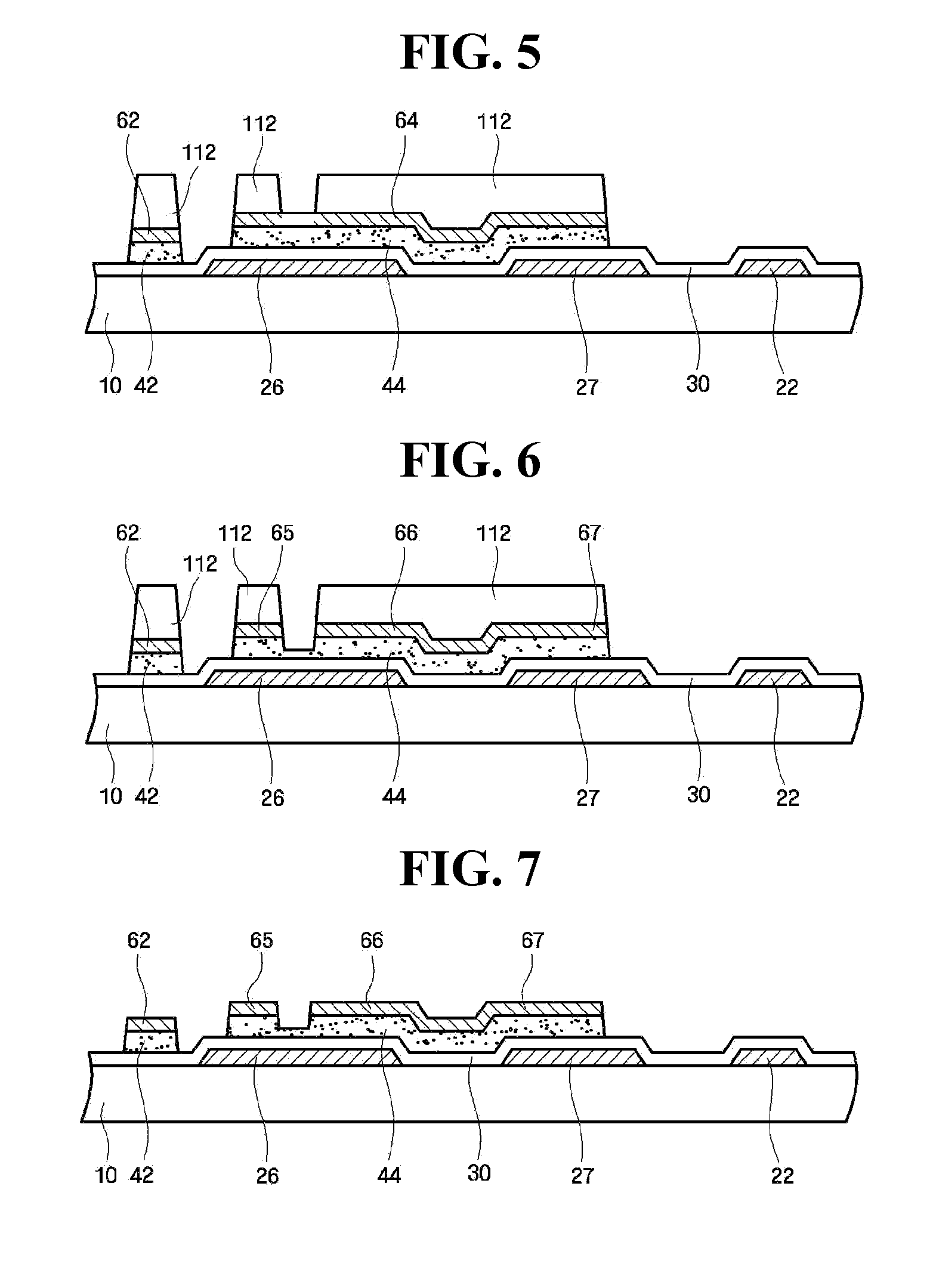

Method of manufacturing thin film transistor substrate

InactiveUS20080176364A1Enhance layeringImprove featuresTransistorSolid-state devicesActive layerPellicle membrane

The present invention provides a method for manufacturing a thin film transistor substrate including forming gate wires on an insulation substrate, forming oxide active layer patterns on the gate wires, forming data wires on the oxide active layer patterns so that the data wires cross the gate wires, forming a passivation film on the oxide active layer patterns and the data wires using a non-reductive reaction gas and SiH4, and forming pixel electrodes on the passivation film

Owner:SAMSUNG DISPLAY CO LTD

Method for producing 700Mpa V-N microalloyed high-strength air corrosion-resistant steel based on sheet bar continuous casting tandem rolling process

InactiveCN1884608AHigh strengthGood formabilityTemperature control deviceMetal rolling arrangementsSheet steelChemical composition

This invention exposed the producing method of V-N microalloyed high strength weathering steel which produced with near net shape con-casting technology. It is smelted in electric furnace or converter, refined, con-casted, casted, then directly sent into roller hearth furnace or soaking pit, hot-rolled, laminar cooled, coiled. The liquid steel's chemical elements are (Wt.%): C: <=0.08%, Si: 0.25- 0.75%, Mn: 0.8-2.0%, P: 0.070-0.150%, S: <=0.040%, Cu: 0.25-0.60 %, Cr: 0.30-1.25 wt%, Ni: <=0.65%, V: 0.05-0.20%, N: 0.015-0.030%. This invention can get the high intensity, formation, weathering, joining character stably. The alloying cost is relatively low. So it can be used to produce container, carriage, and other industry facility.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

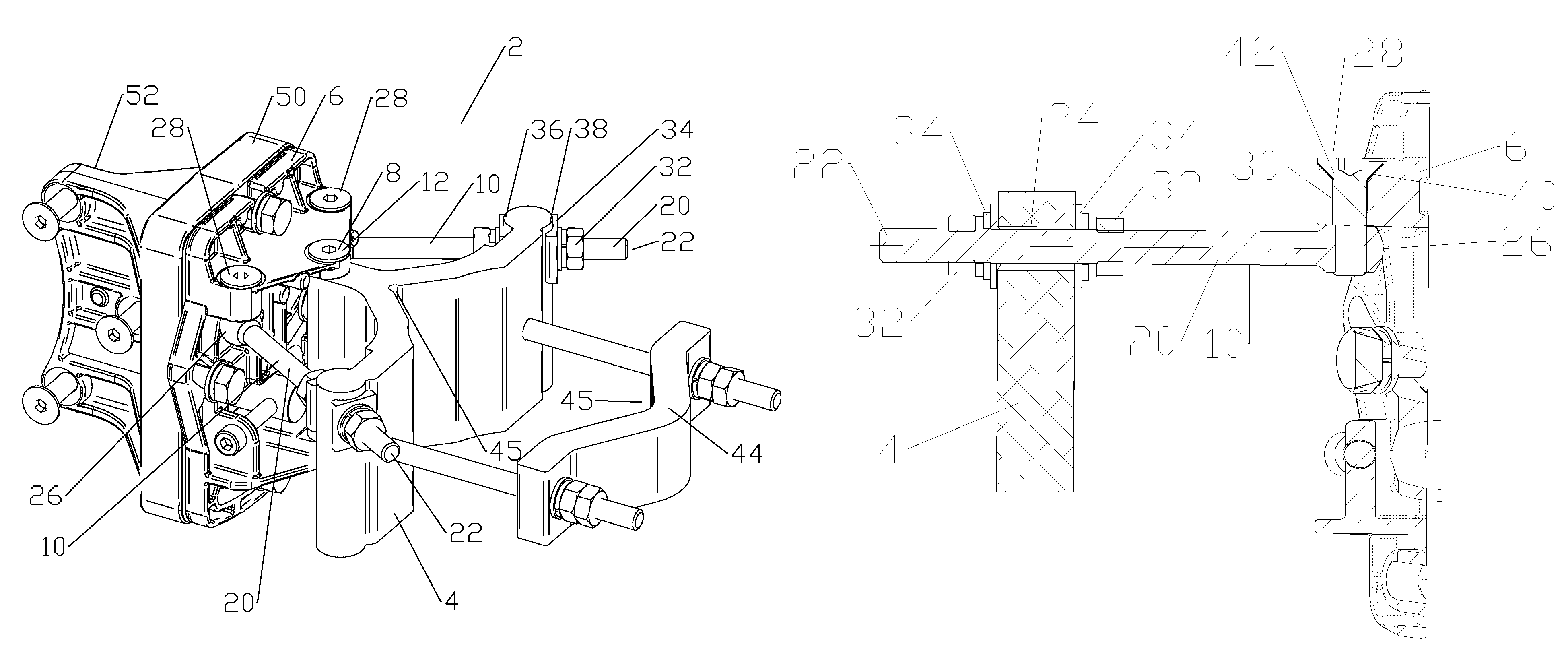

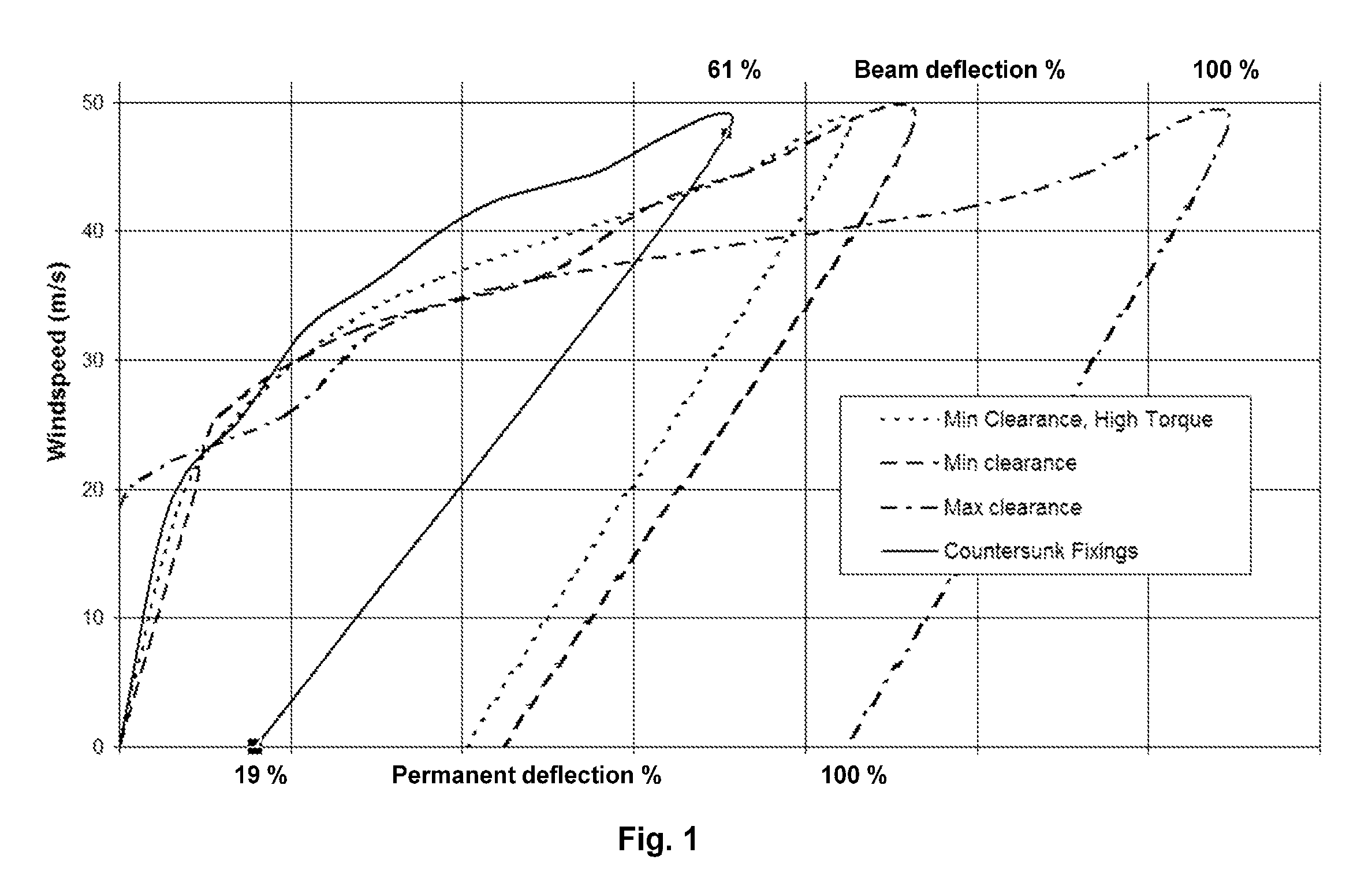

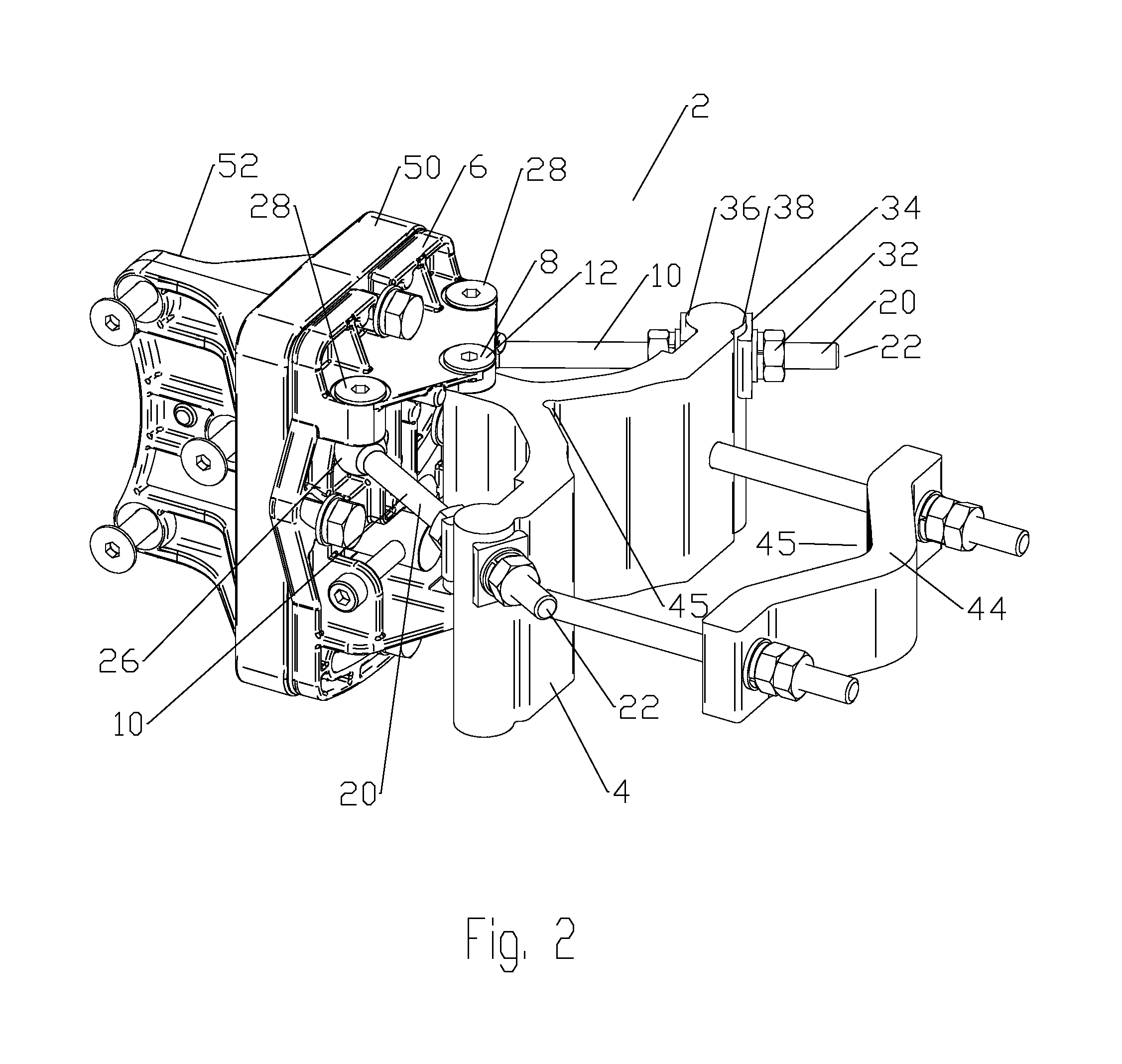

Alignment stable adjustable antenna mount

ActiveUS8866695B2Speed up preparationImprove alignment stabilityCandle holdersLighting support devicesEngineeringMechanical engineering

Owner:COMMSCOPE TECH LLC

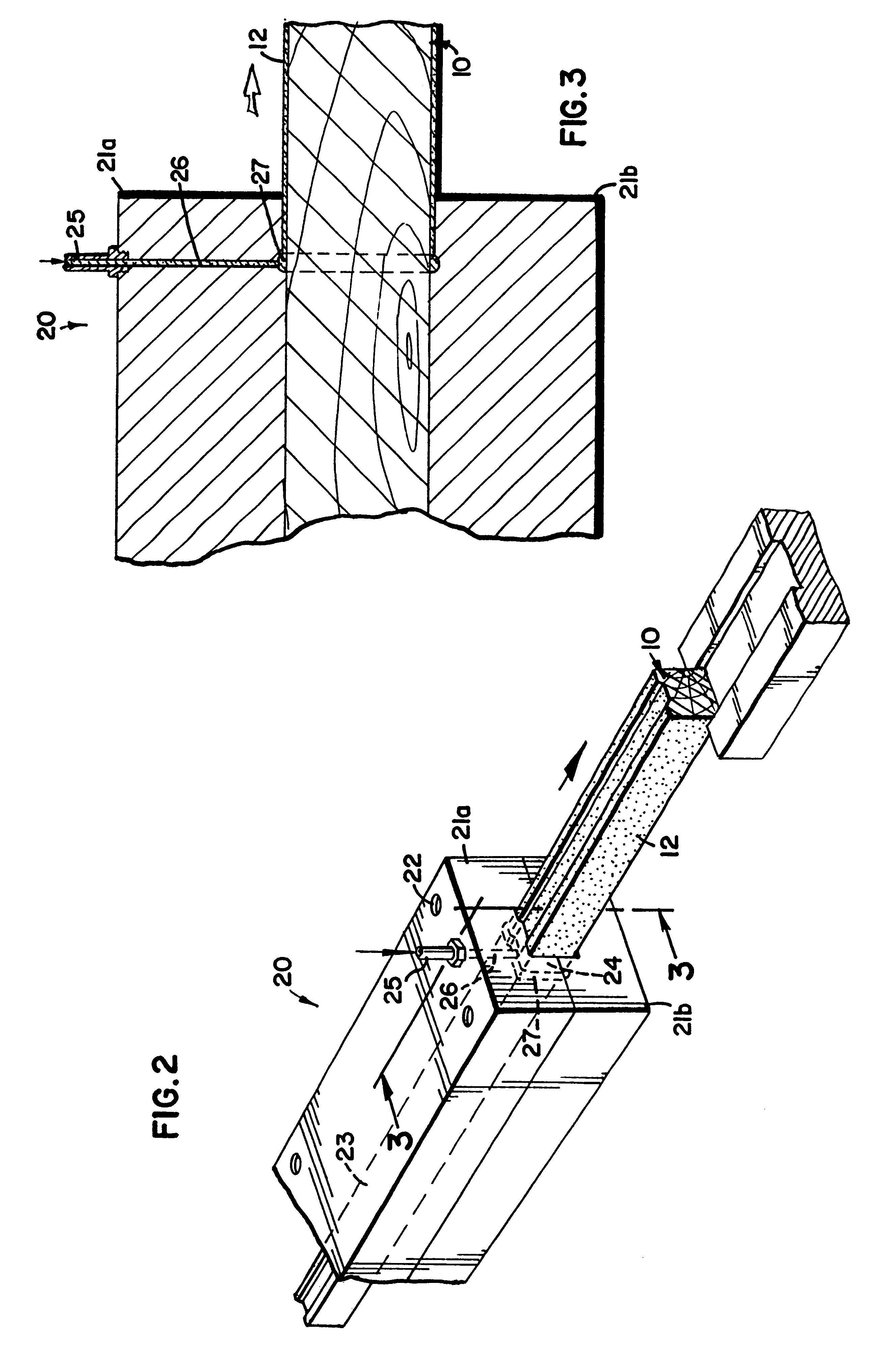

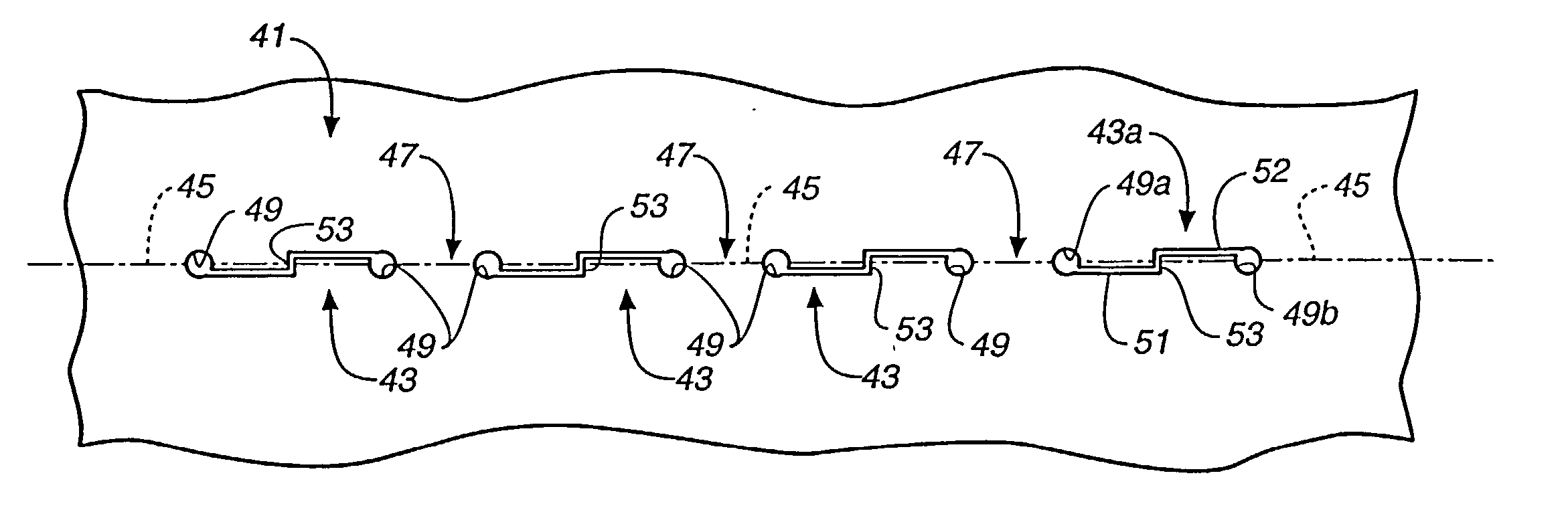

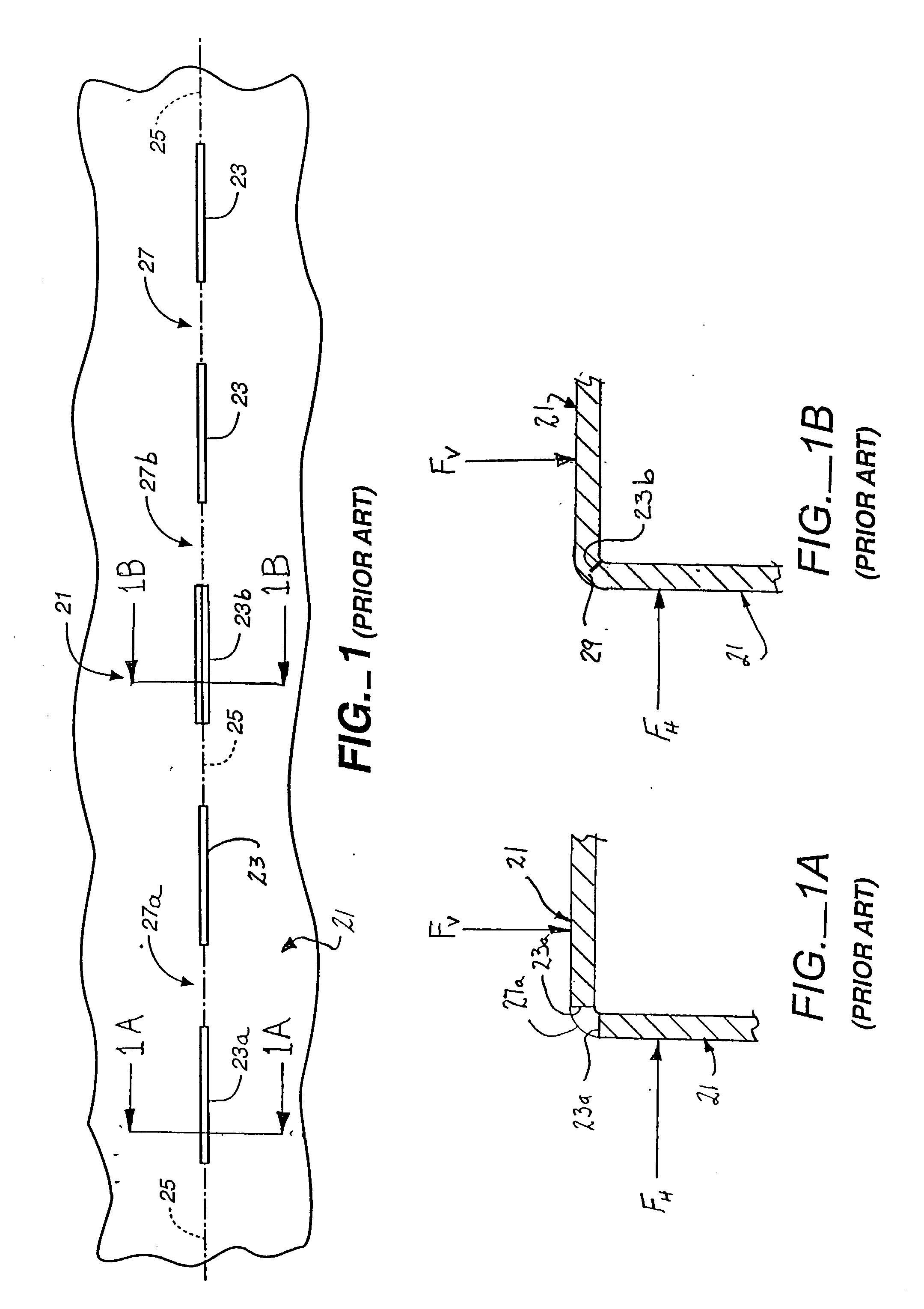

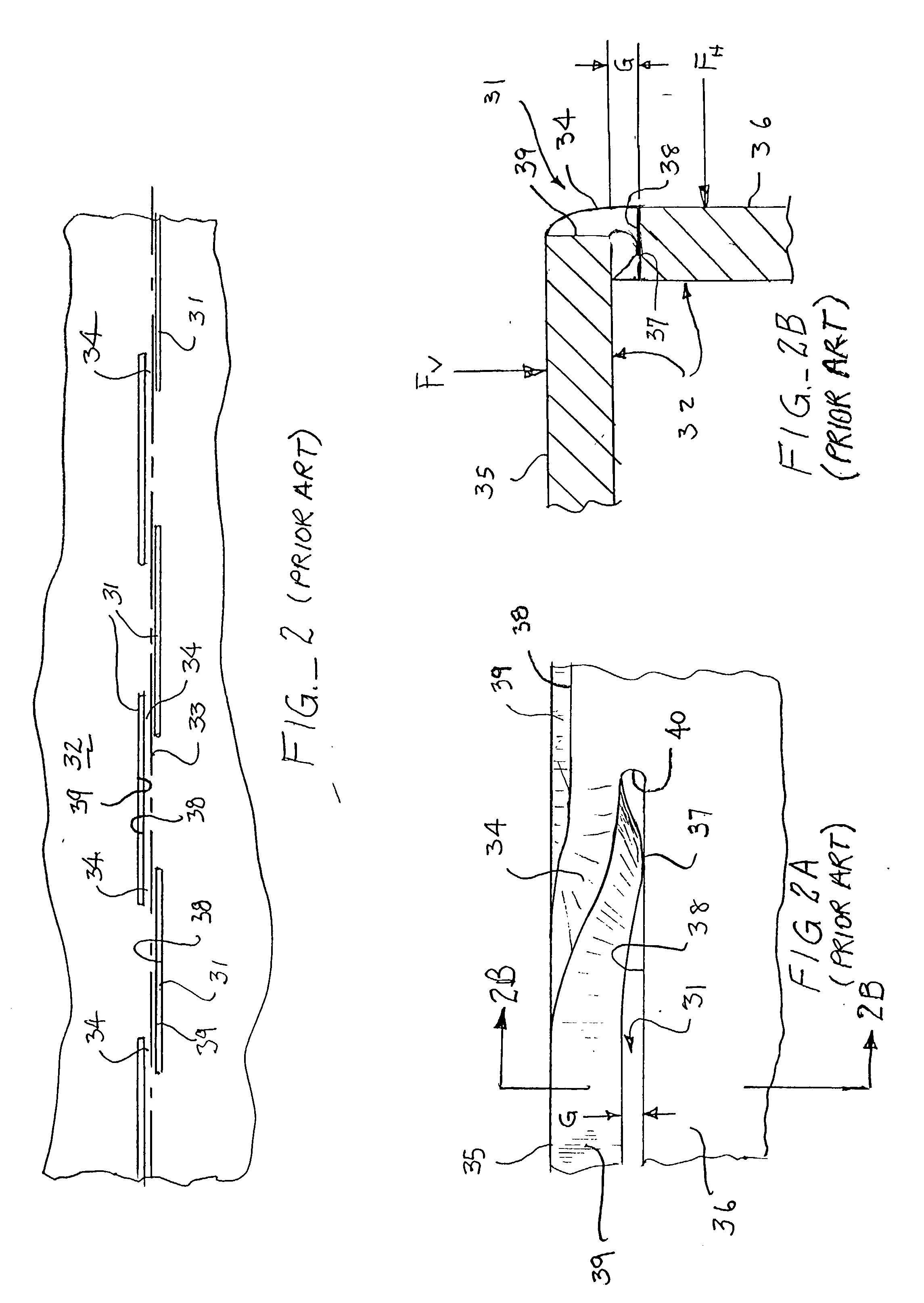

Method for precision bending of sheet of materials, slit sheets fabrication process

InactiveUS20030037586A1Reduce stress concentrationImprove accuracyAdditive manufacturing apparatusConstruction materialSheet materialEngineering

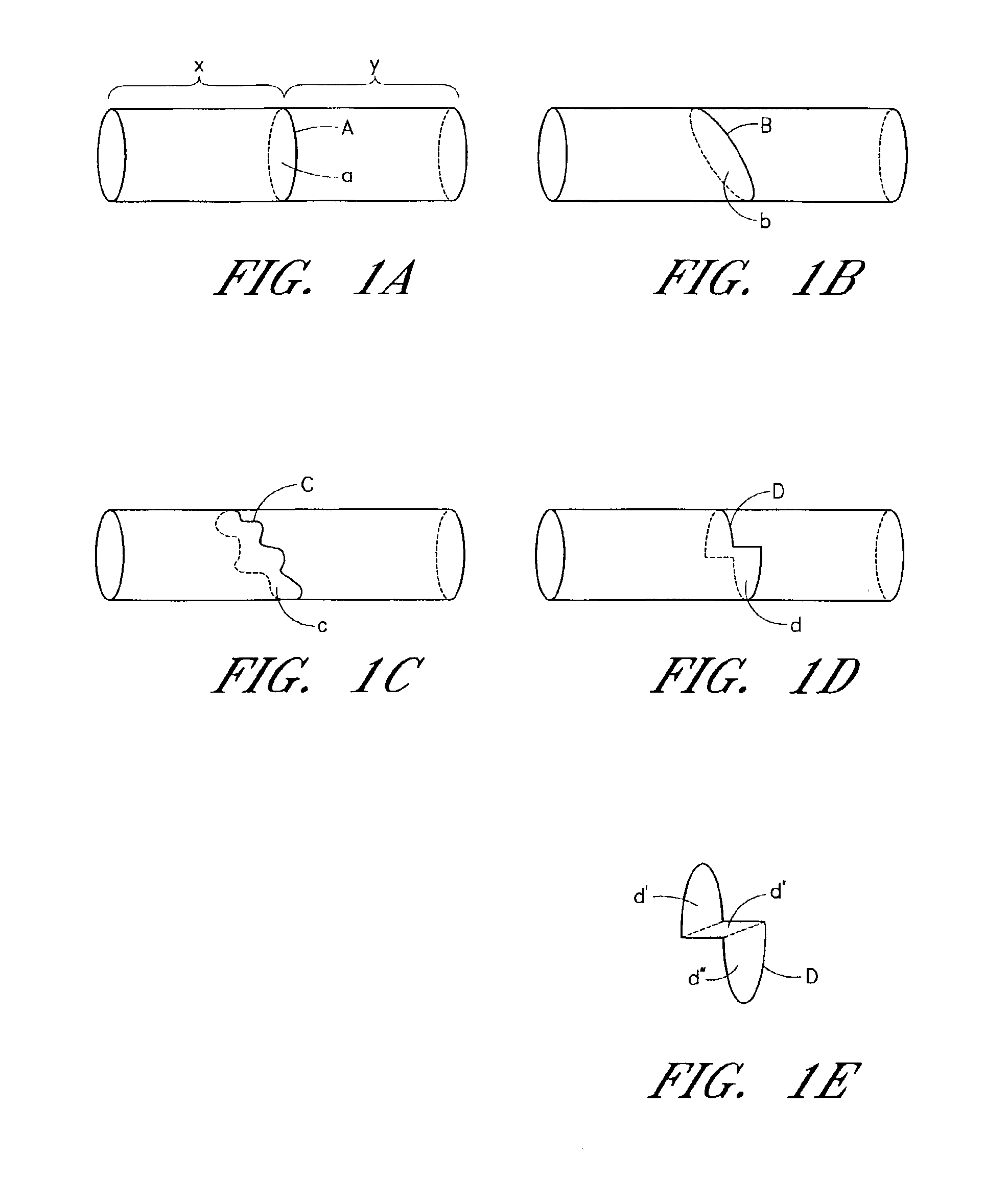

A method for precision bending of a sheet of material (41, 241, 341, 441) along a bend line (45, 245, 345, 445) and the resulting sheet are disclosed. A method includes a step of forming longitudinally extending slits (43, 243, 343, 443) through the sheet of material in axially spaced relation to produce precise bending of the sheet (41, 241, 341, 441) along the bend line (45, 245, 345, 445) with edges (257, 457) engaged and supported on faces (255, 455) of the sheet material on opposite sides of the slits. The edge-to-face contact produces bending along a virtual fulcrum position in superimposed relation to the bend line (45, 245, 345, 445). Several slit embodiments (43, 243, 343, 443) suitable for producing edge-to-face engagement support and precise bending are disclosed, as is the use of the slit sheets to enhance various fabrication techniques.

Owner:IND ORIGAMI INC CA US

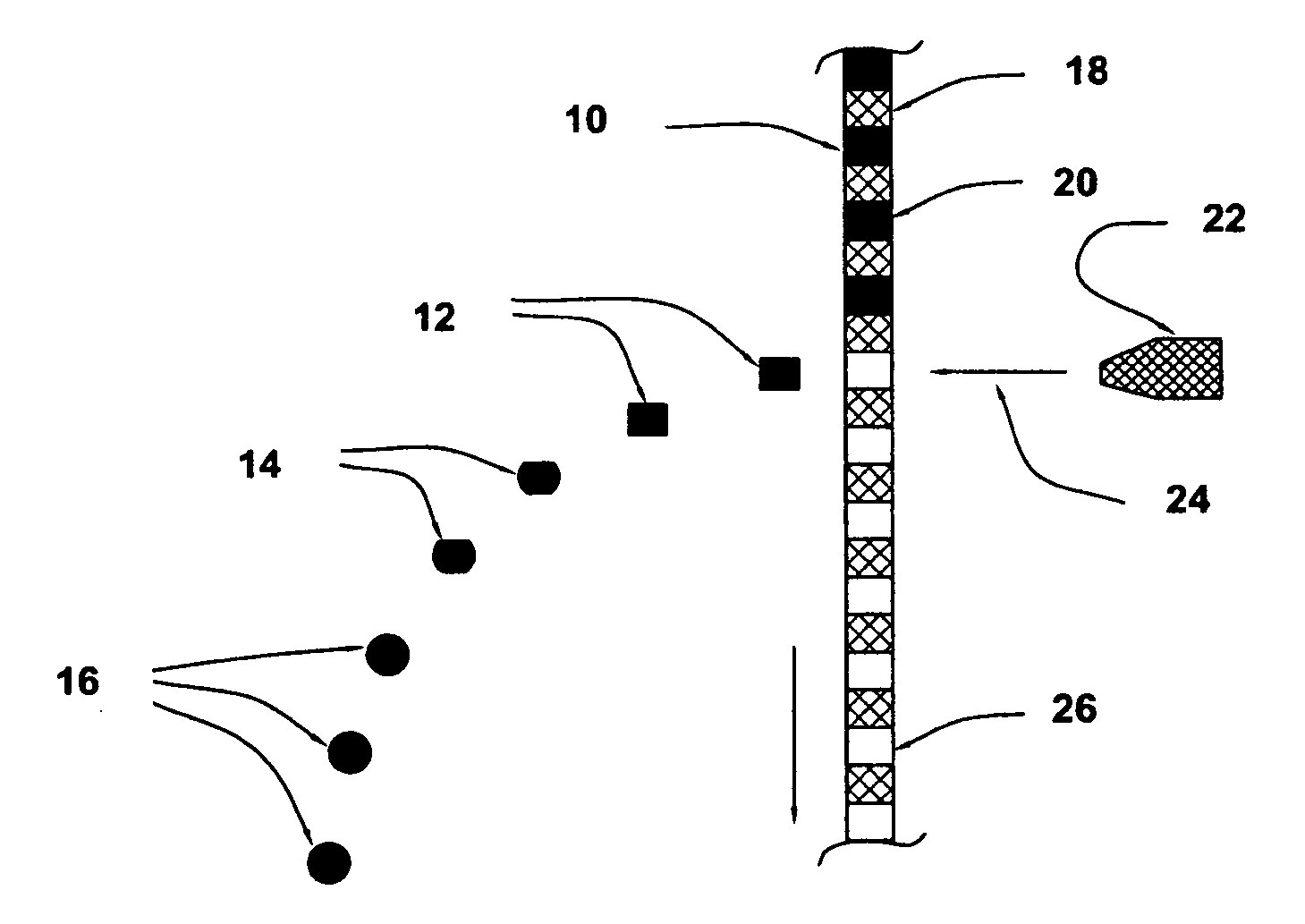

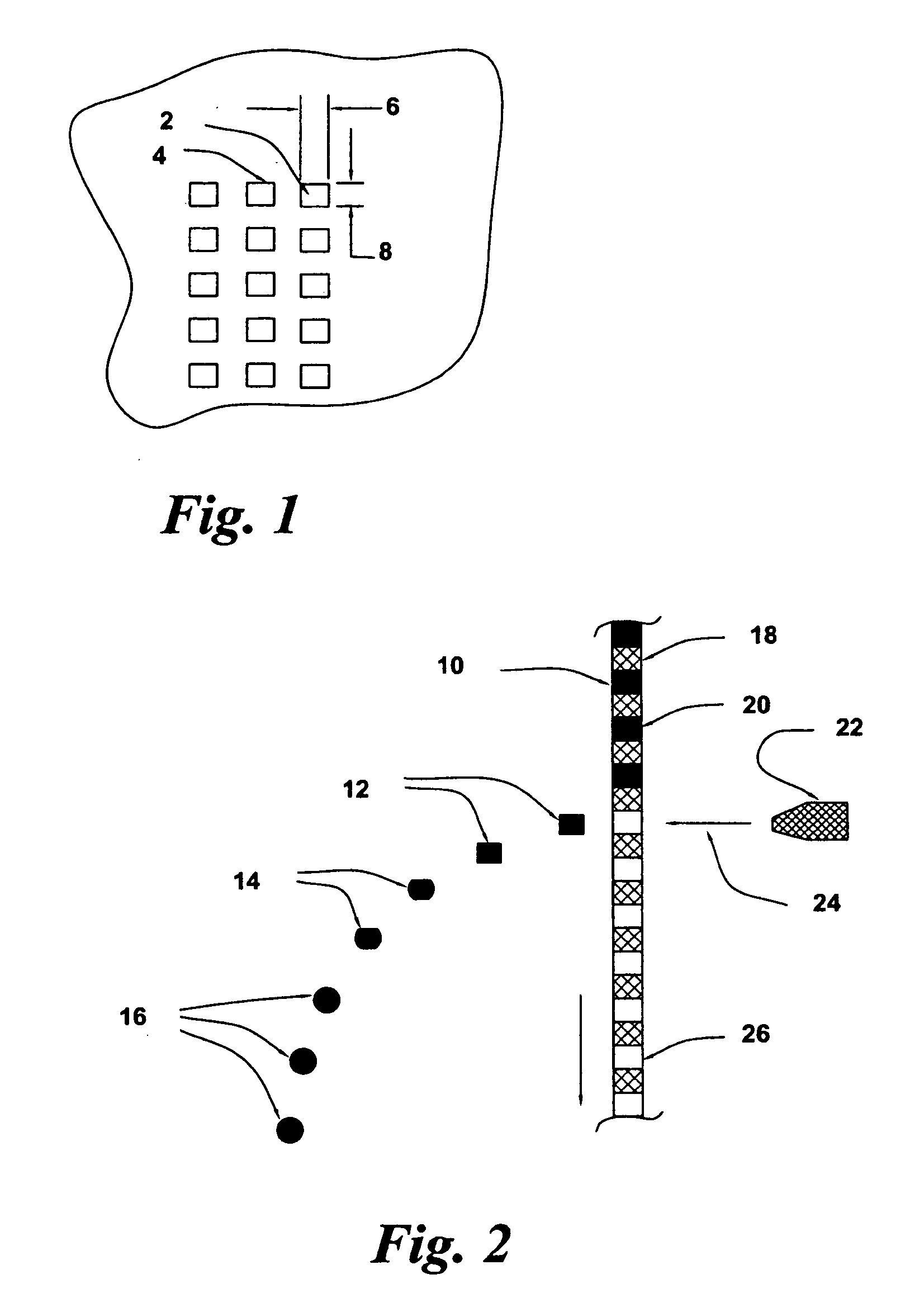

Equal sized spherical beads

InactiveUS20080299875A1Other chemical processesMetal rolling stand detailsSpherical shapedMaterials science

A method of producing equal-sized spherical shaped beads of a wide range of materials is described. These beads are produced by forming the parent bead material into a liquid solution and by filling equal volume cells in a sheet with the liquid solution. The sheet cells establish the volumes of each of the cell mixture volumes which are then ejected from the cells by an impinging fluid. Surface tension forces acting on the ejected equal sized solution entities form them into spherical beads. The ejected beads are then subjected to a solidification environment which solidifies the spherical beads. The beads can be solid or porous or hollow and can also have bead coatings of multiple material layers.

Owner:DUESCHER WAYNE O

Method for shielding an electronic component

Owner:PPG IND OHIO INC

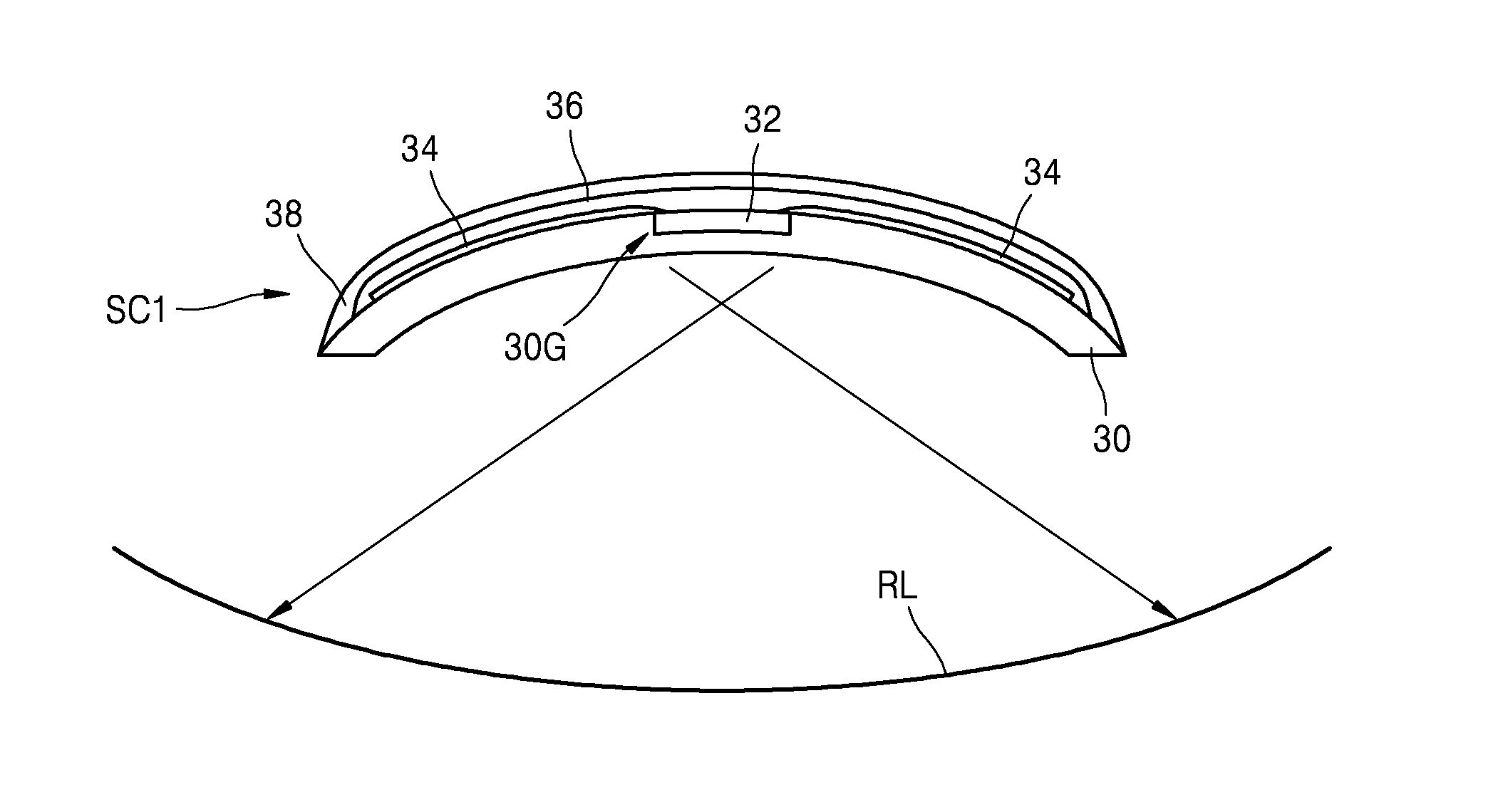

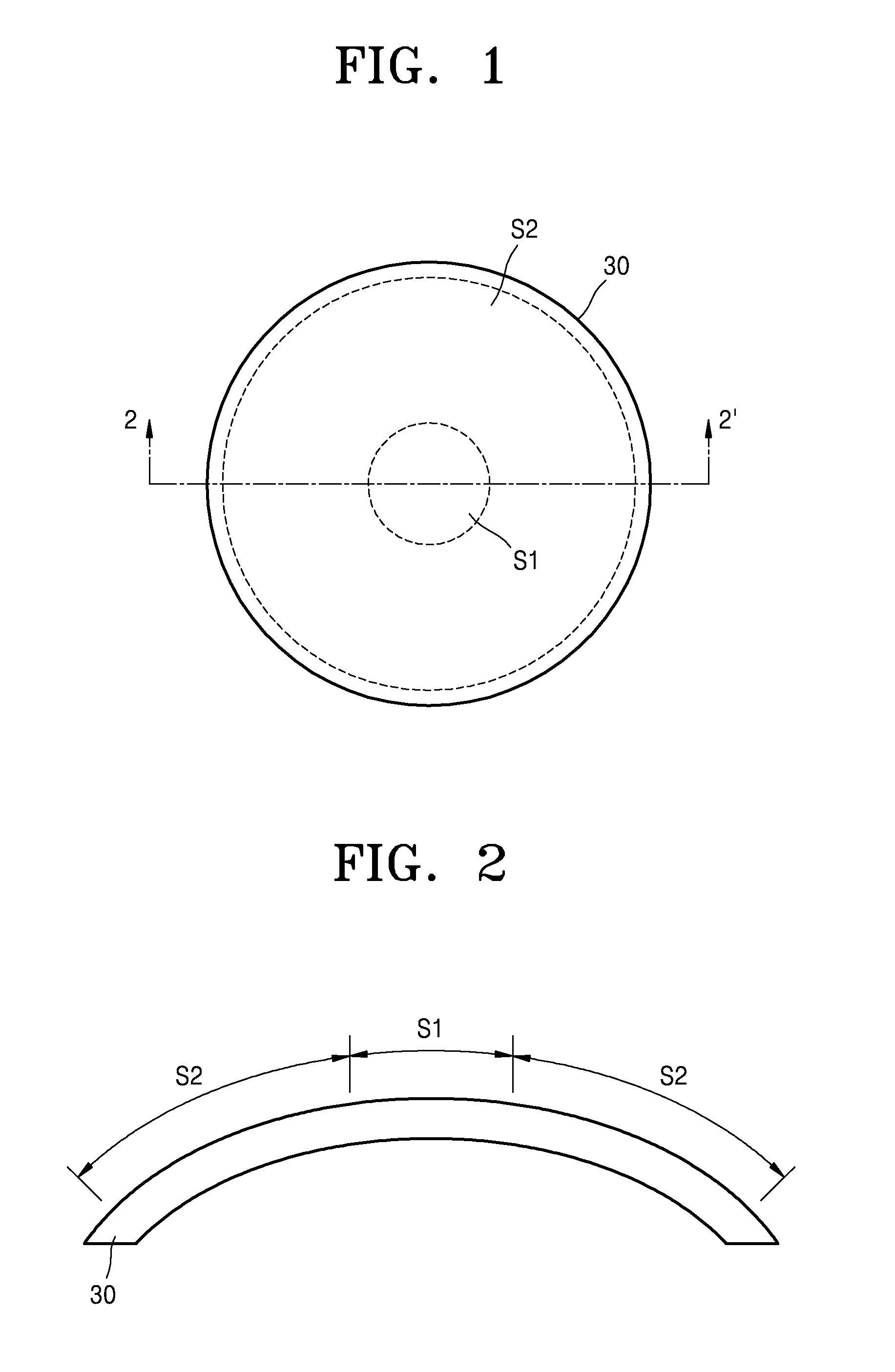

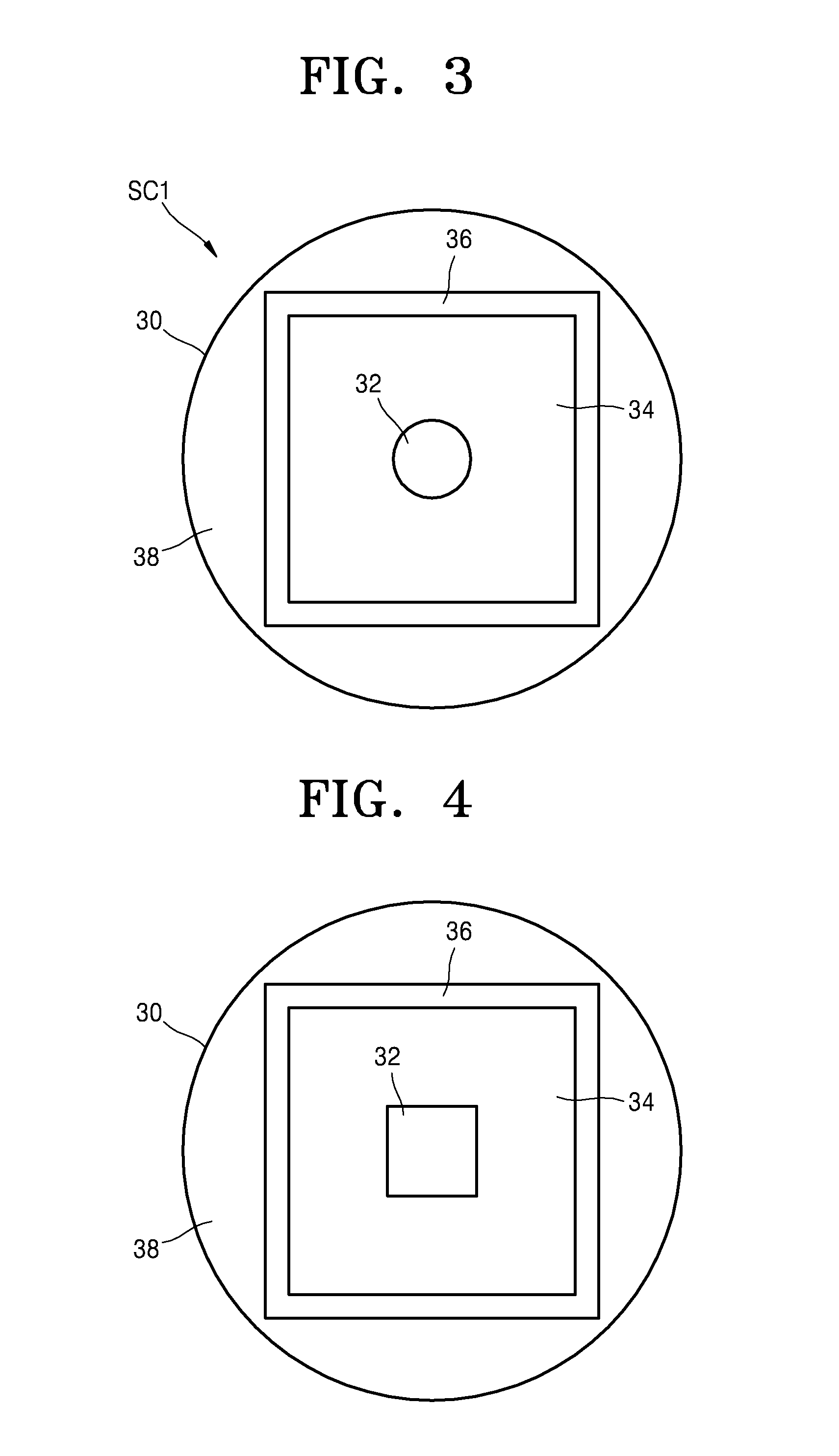

Smart contact lenses for augmented reality and methods of manufacturing and operating the same

ActiveUS20160091737A1Widen perspectiveSpectales/gogglesWave amplification devicesEngineeringContact lens

Example embodiments disclose a smart contact lens for augmented reality and methods of manufacturing and operating the smart contact lens. The smart contact lens includes a first contact lens, a display unit in a center region of the first contact lens, a peripheral device on the first contact lens and around the display unit, the peripheral device being connected to the display unit, and a passivation layer covering the display unit and the peripheral device. The method of manufacturing the smart contact lens includes forming a display unit; mounting the display unit in a center region of a first contact lens, forming a peripheral device on the first contact lens, around the display unit and in connection with the display unit, and forming a passivation layer to cover the display unit and the peripheral device.

Owner:SAMSUNG ELECTRONICS CO LTD

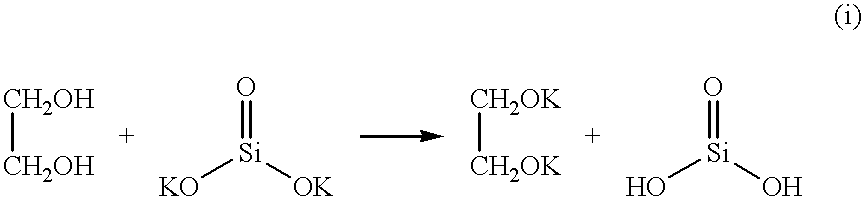

Aqueous compositions, aqueous cutting fluid using the same, method for preparation thereof, and cutting method using the cutting fluid

InactiveUS6221814B1Promote degradationSimple treatmentOther chemical processesWork treatment devicesActivated sludgeLiquid waste

An aqueous cutting fluid which can reduce the impact on working environment and the global environment, and can achieve both preventing precipitates from becoming a hard cake and keeping high dispersibility for abrasive grains is provided. Such an aqueous cutting fluid is obtained by a method comprising dispersing abrasive grains (G) in an aqueous composition comprising a dispersion medium (M) containing a hydrophilic alcohol compound such as ethylene glycol, a lipophilic alcohol compound such as propylene glycol and water, and silica colloid particles dispersed stably in the medium. The dispersion medium (M) is odorless and not flammable. The abrasive grains (G) may settle out after a time, but they do not closely contact with one another, and therefore the resulting precipitates do not become a hard cake, which allows the re-dispersion and reuse of precipitated grains. The instant aqueous cutting fluid is inherently low viscous, and the reduction of viscosity owing to the contamination of water and the increase of viscosity owing to contamination of shavings are both moderate. As a result, the cutting fluid has a long life. And articles which have been cut using the cutting fluid can be washed with water. Further, as the dispersion medium (M) is a biodegradable low molecular weight organic compound, a waste liquid from a process using the cutting fluid can be disposed with an activated sludge.

Owner:SHIN-ETSU HANDOTAI CO LTD +1

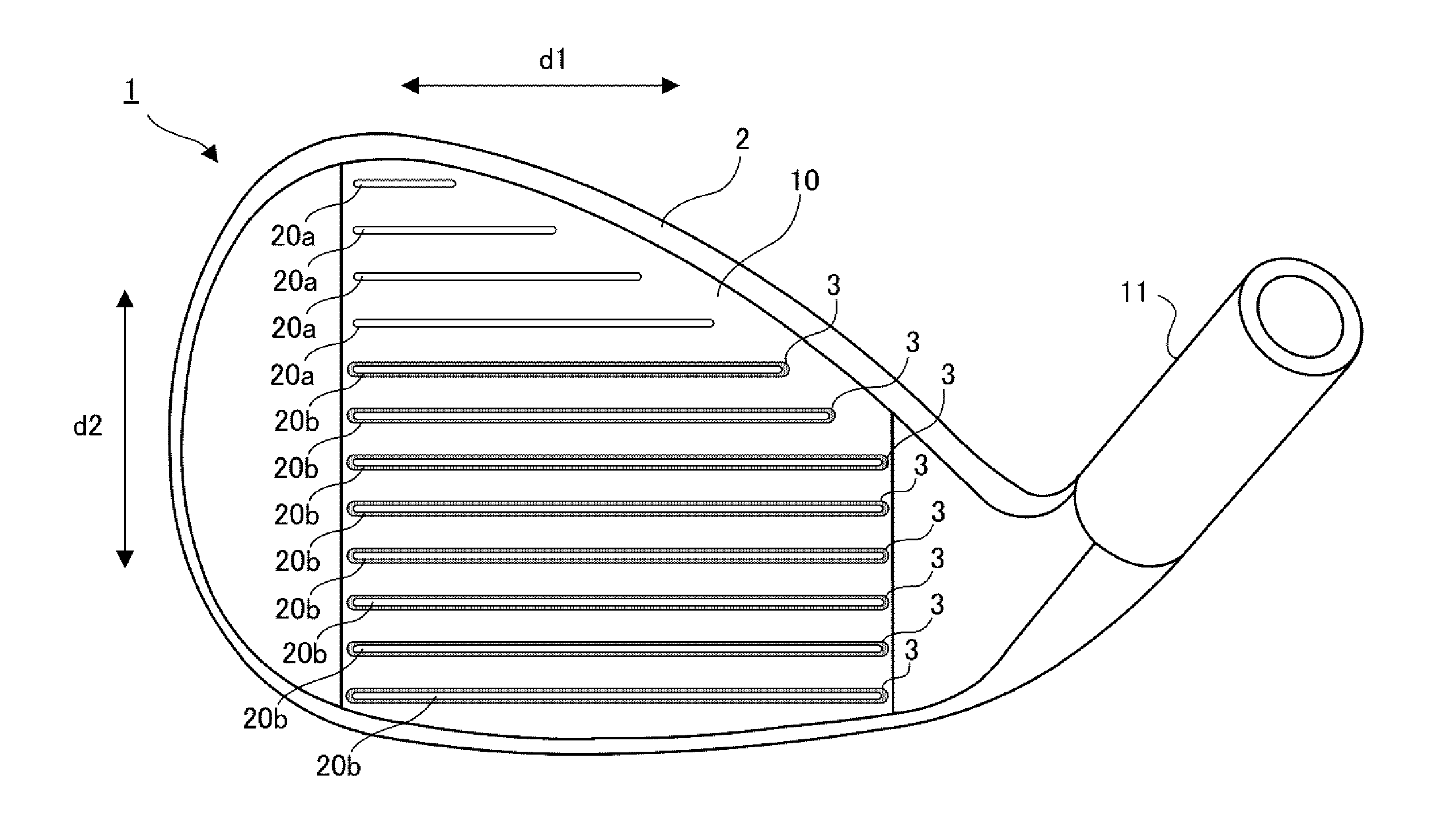

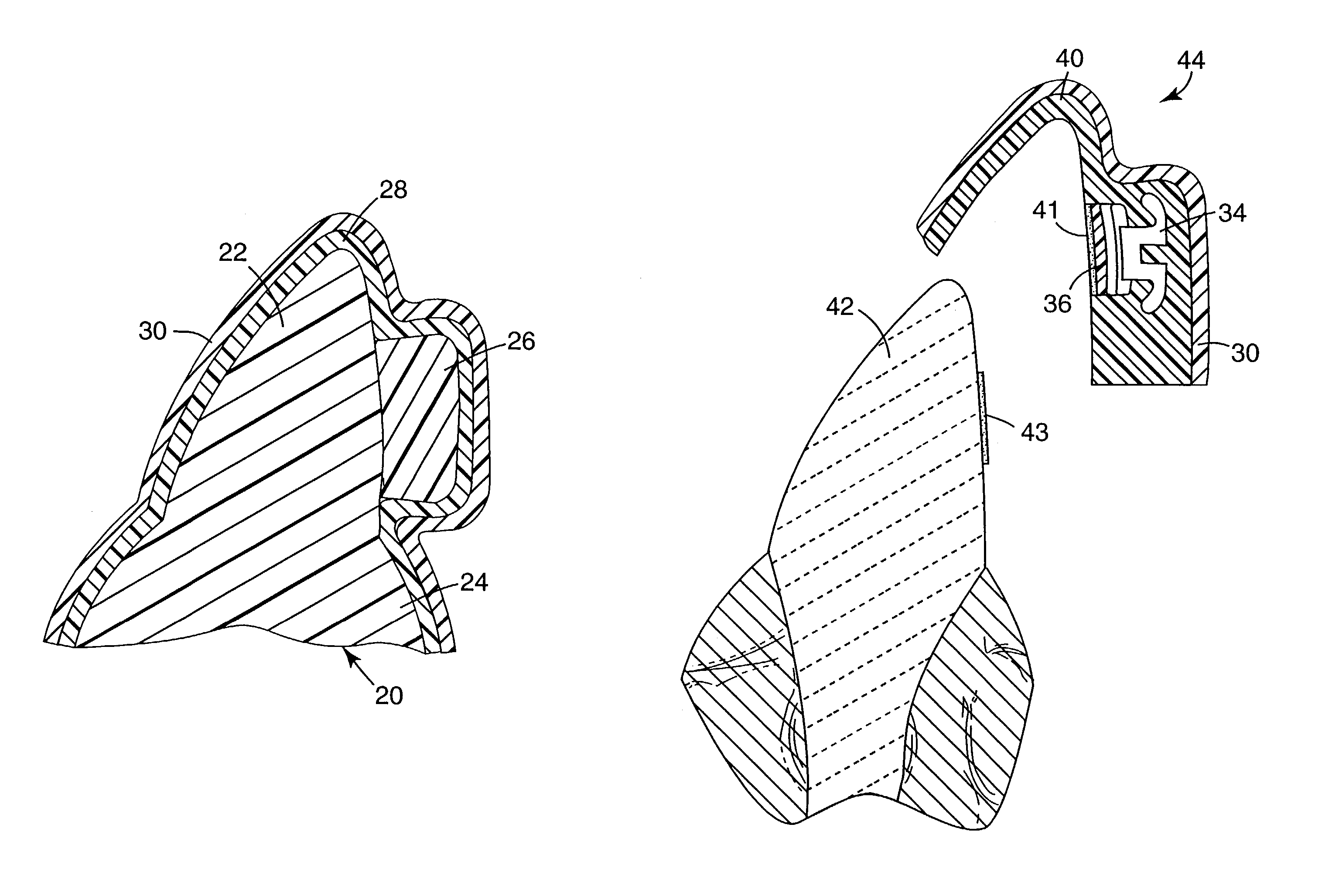

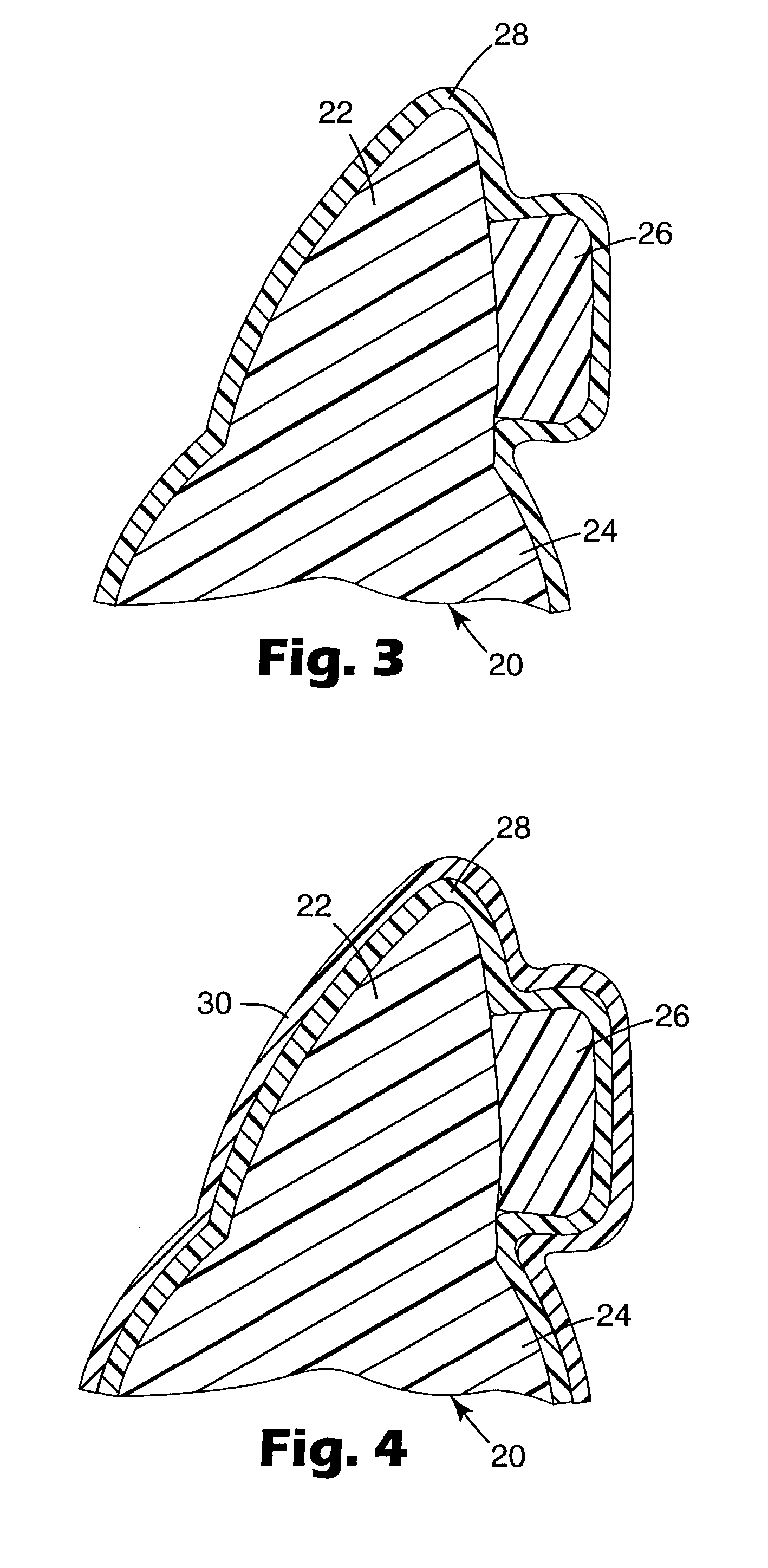

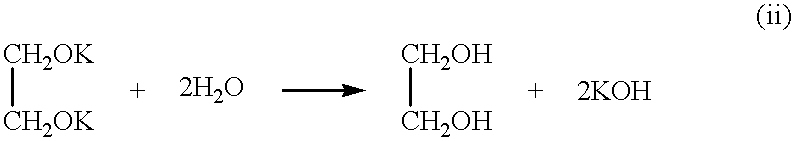

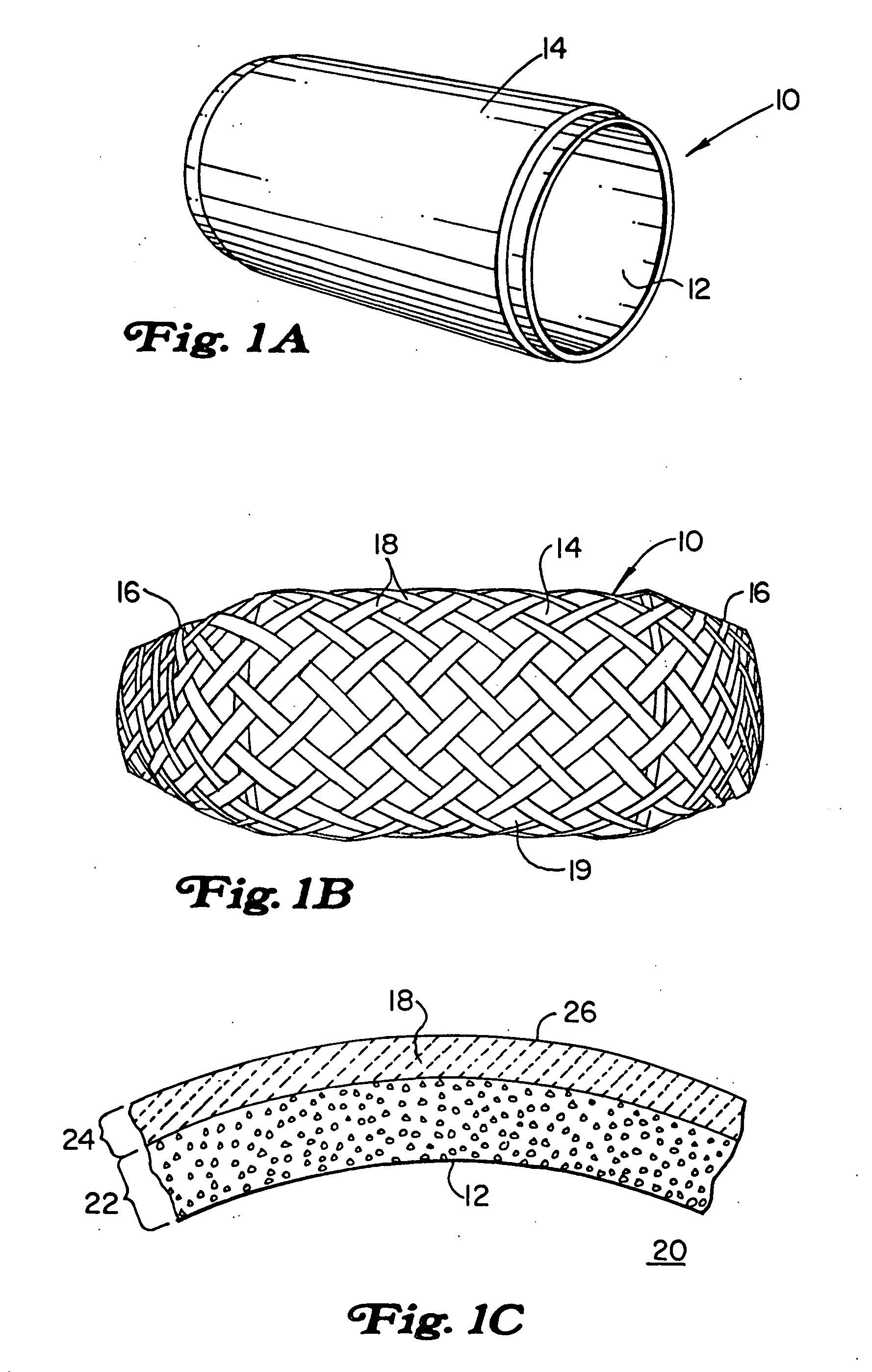

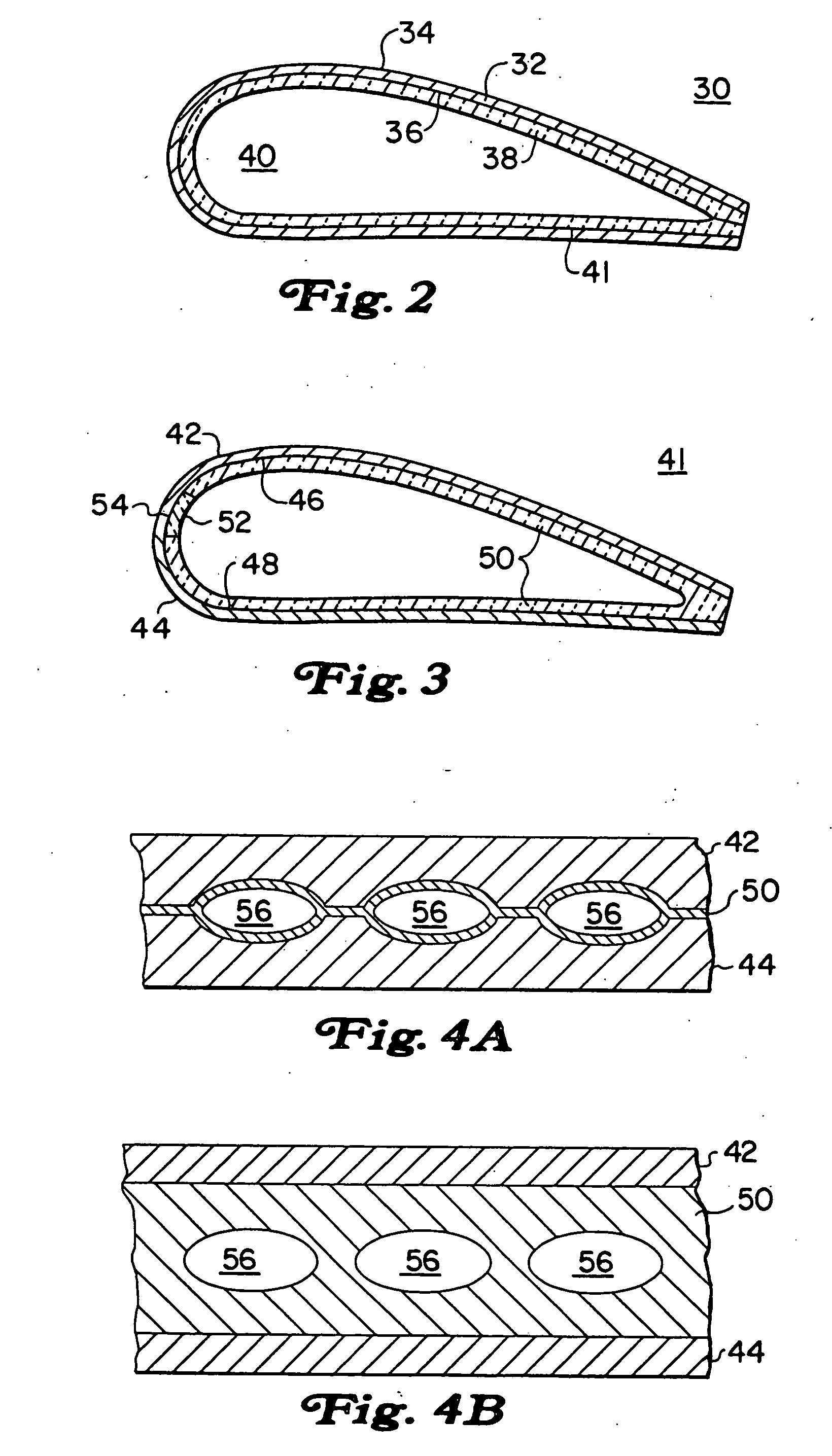

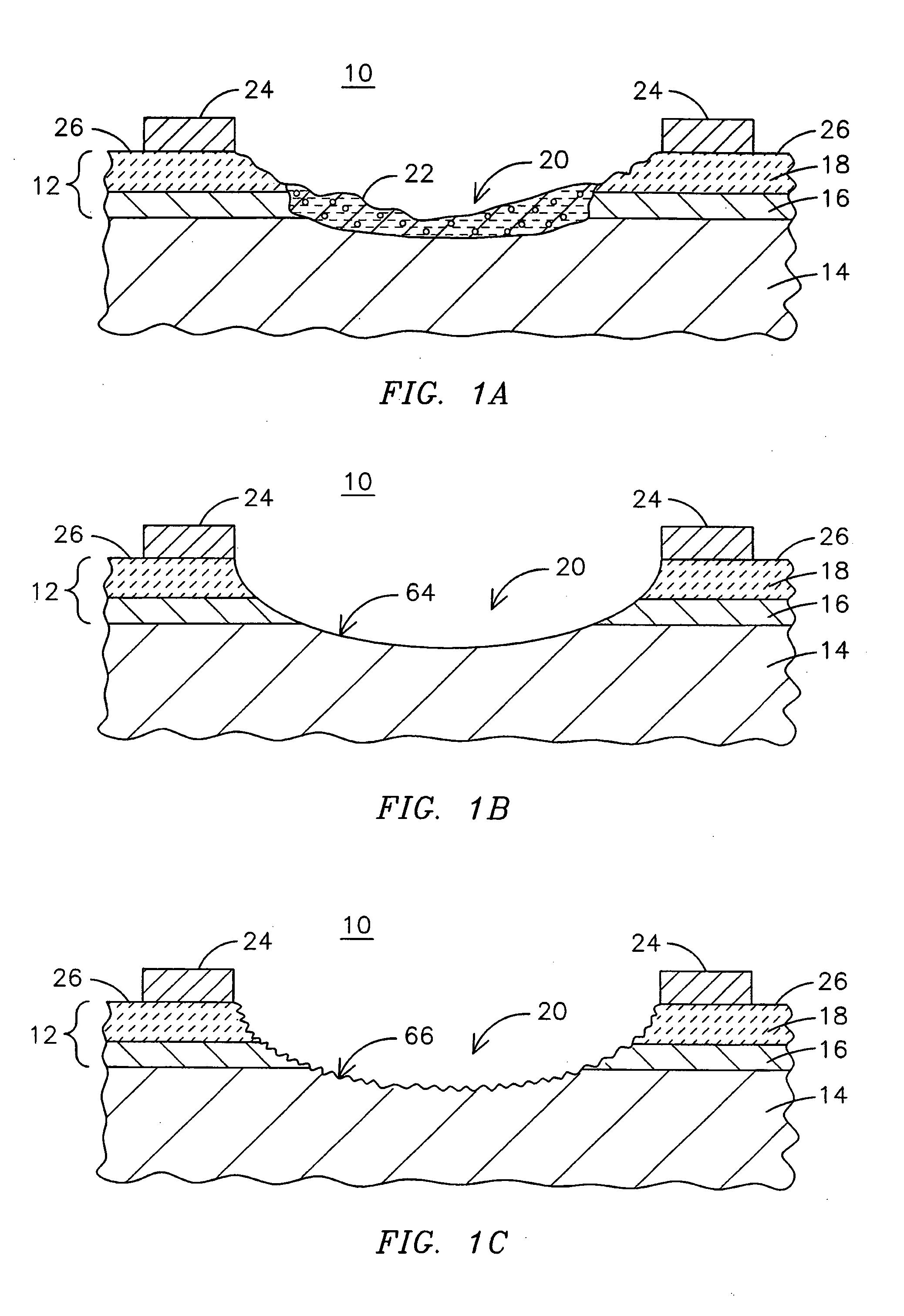

Composite structure formed by CMC-on-insulation process

ActiveUS20050076504A1Improved ceramic composite structureWood working apparatusCeramic layered productsCombustorEngineering

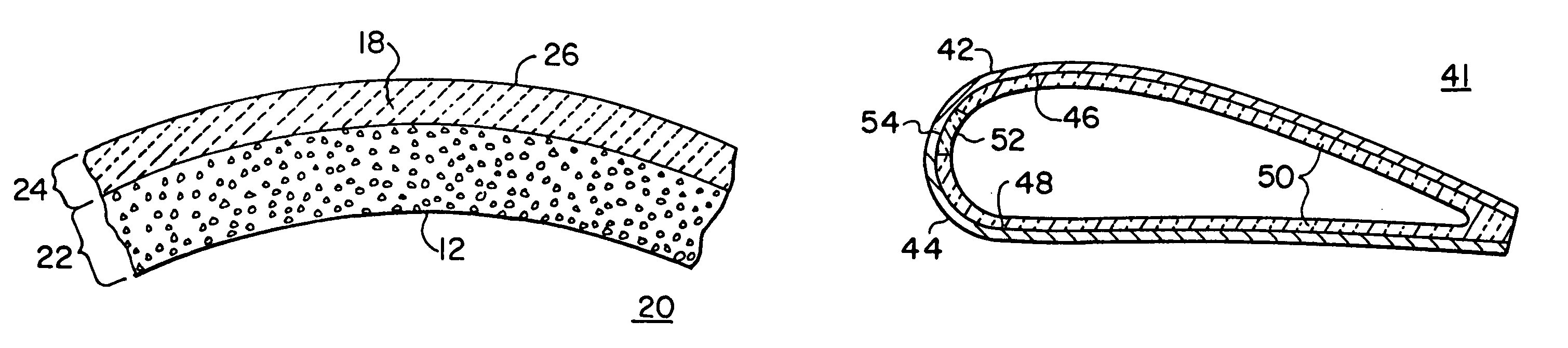

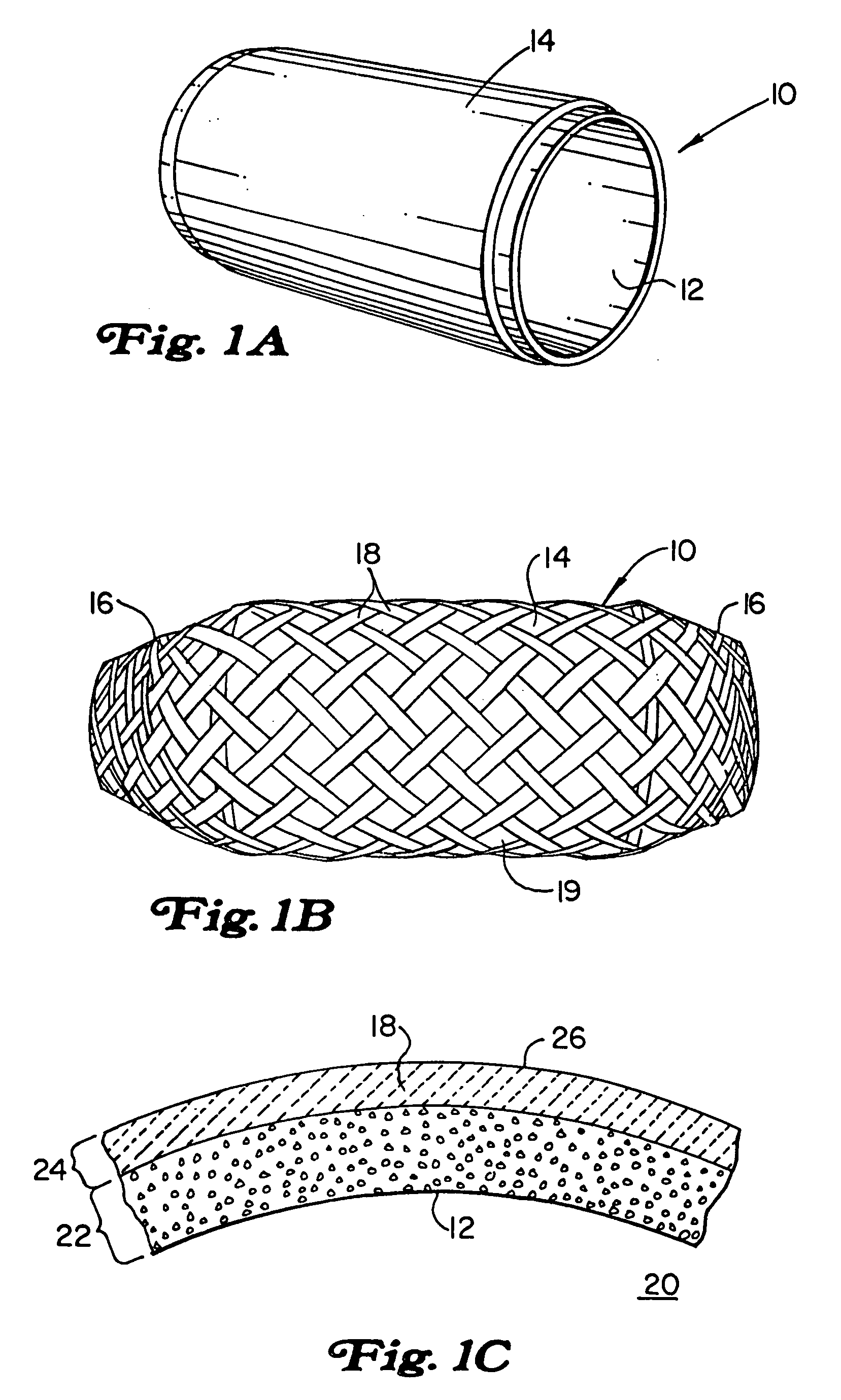

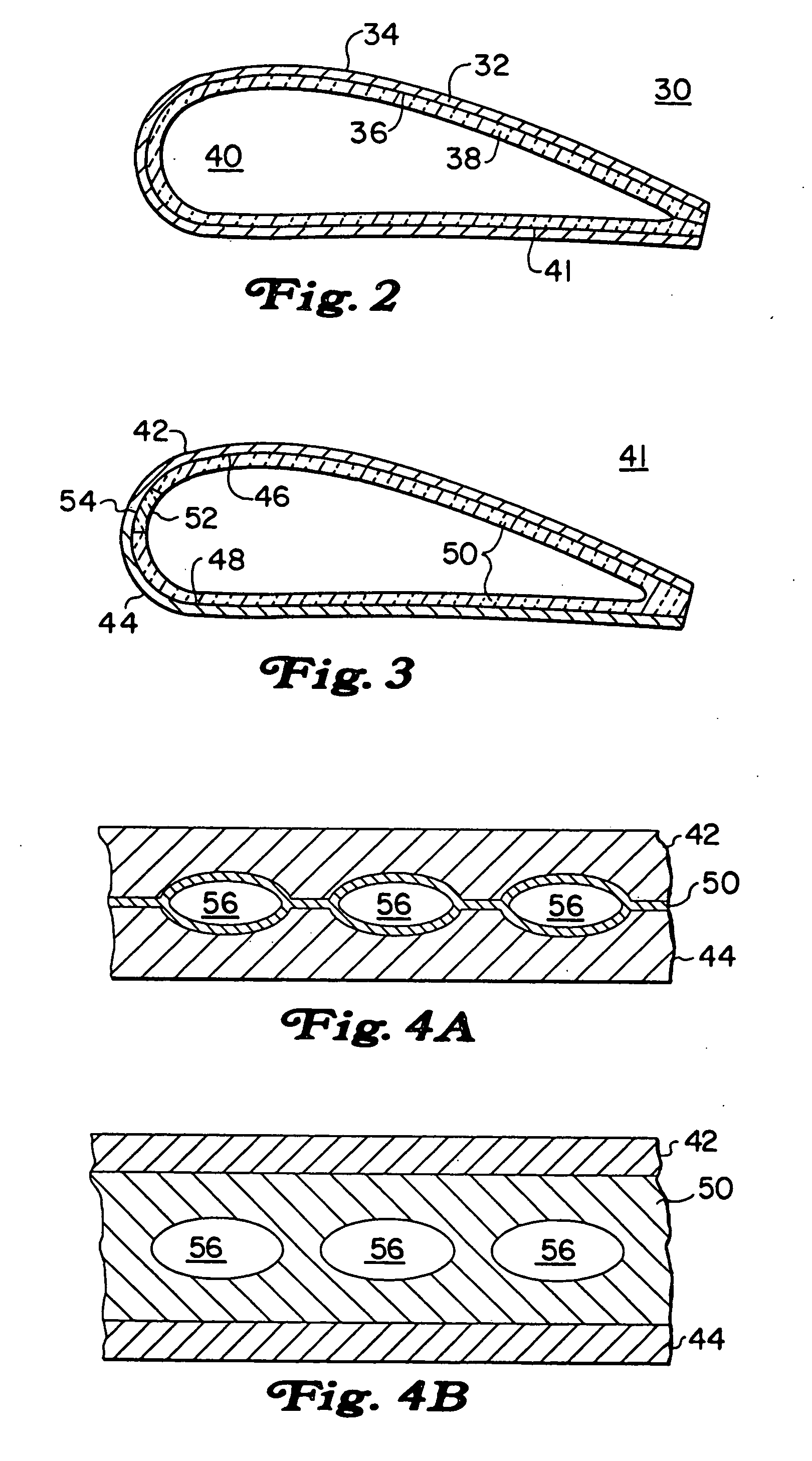

A method of manufacturing a composite structure uses a layer of an insulating material (22) as a mold for forming a substrate of a ceramic matrix composite (CMC) material (24). The insulating material may be formed in the shape of a cylinder (10) with the CMC material wound on an outer surface (14) of the cylinder to form a gas turbine combustor liner (20). Alternatively, the insulating material may be formed in the shape of an airfoil section (32) with the CMC material formed on an inside surface (36) of the insulating material. The airfoil section may be formed of a plurality of halves (42, 44) to facilitate the lay-up of the CMC material onto an easily accessible surface, with the halves then joined together to form the complete composite airfoil. In another embodiment, a box structure (102) defining a hot gas flow passage (98) is manufactured by forming insulating material in the shape of opposed airfoil halves (104) joined at respective opposed ends by platform members (109). A layer of CMC material (107) is then formed on an outside surface of the insulating material. A number of such composite material box structures are then joined together to form a vane ring (100) for a gas turbine engine.

Owner:SIEMENS ENERGY INC

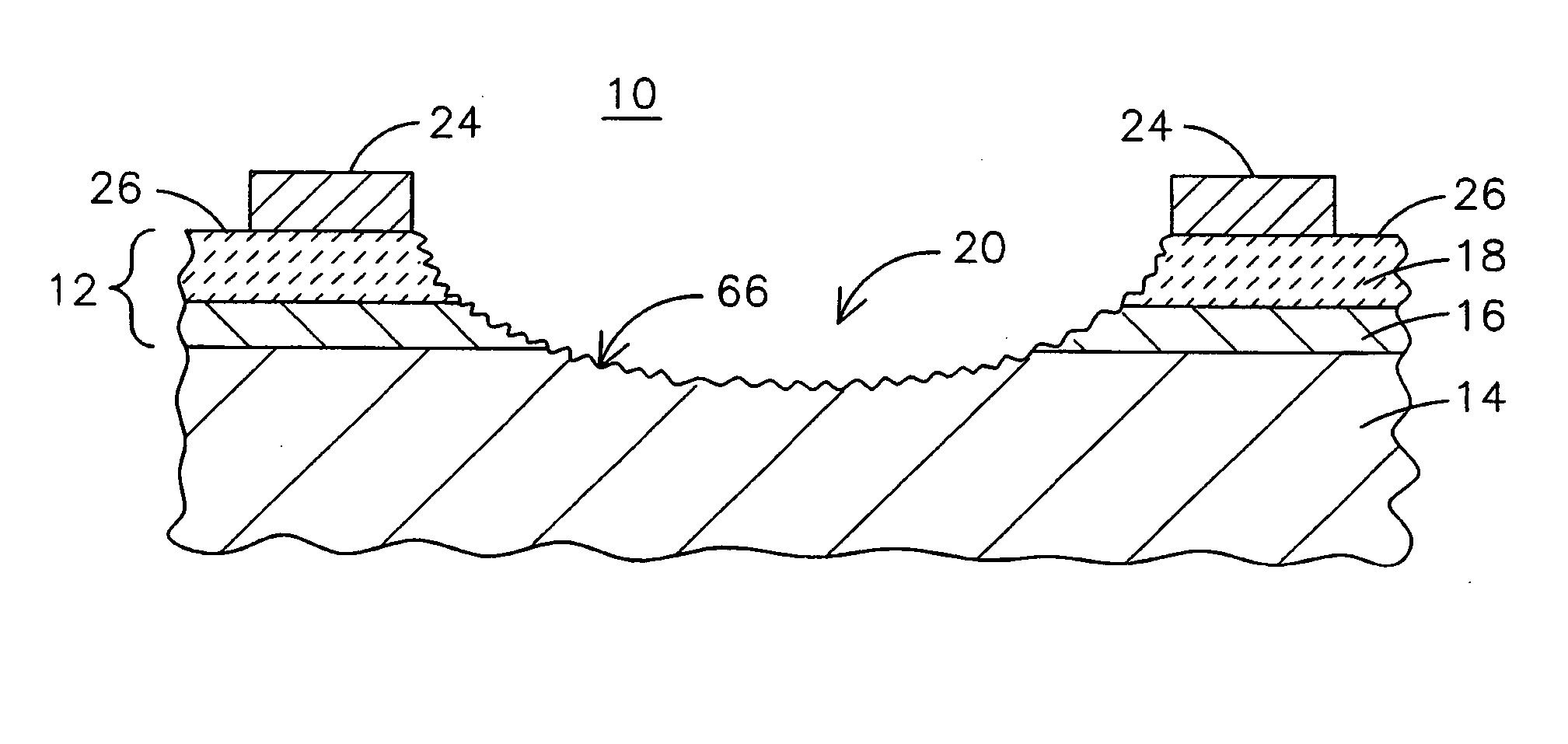

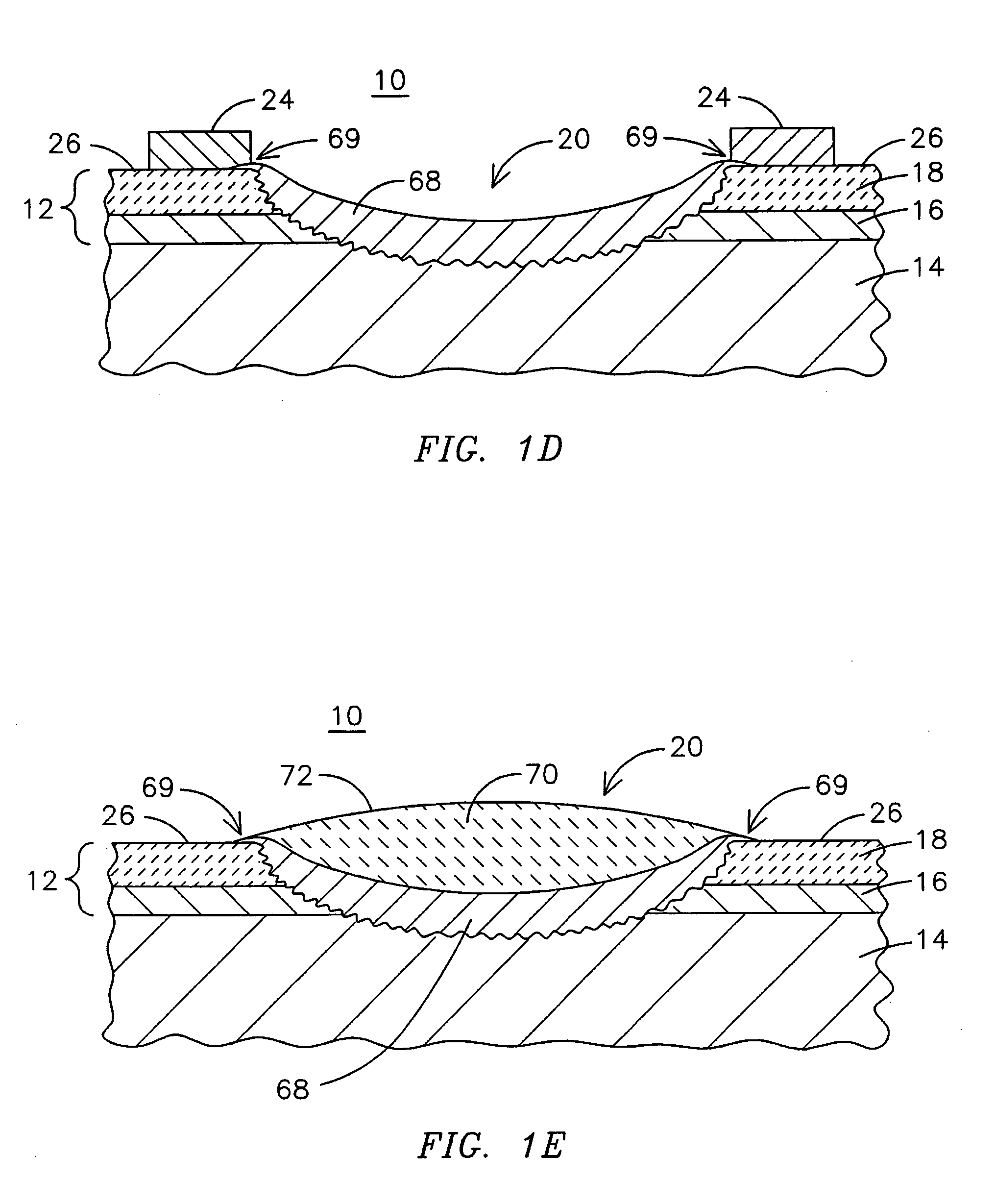

In-frame repair of gas turbine components

A method for in-frame repairing of a thermal barrier coating (12) on a gas turbine component includes cleaning a desired surface portion (10) of the component without removing the component from the gas turbine. The method also includes roughening the surface portion in-frame, applying a bond coat (68) to the surface portion in-frame, and applying a ceramic topcoat (70) to the bond coat, in-frame. A system (28) for cleaning the surface portion in-frame includes an abrasive media (34) having a state change characteristic occurring at a temperature lower than an operating temperature of the gas turbine so that the abrasive media changes from a solid state to another state allowing the media to exit the gas turbine during operation. The system also includes an abrasive media sprayer (36) to direct a spray of the abrasive media at the desired surface portion.

Owner:SIEMENS ENERGY INC

Composite structure formed by CMC-on-insulation process

A method of manufacturing a composite structure uses a layer of an insulating material (22) as a mold for forming a substrate of a ceramic matrix composite (CMC) material (24). The insulating material may be formed in the shape of a cylinder (10) with the CMC material wound on an outer surface (14) of the cylinder to form a gas turbine combustor liner (20). Alternatively, the insulating material may be formed in the shape of an airfoil section (32) with the CMC material formed on an inside surface (36) of the insulating material. The airfoil section may be formed of a plurality of halves (42, 44) to facilitate the lay-up of the CMC material onto an easily accessible surface, with the halves then joined together to form the complete composite airfoil. In another embodiment, a box structure (102) defining a hot gas flow passage (98) is manufactured by forming insulating material in the shape of opposed airfoil halves (104) joined at respective opposed ends by platform members (109). A layer of CMC material (107) is then formed on an outside surface of the insulating material. A number of such composite material box structures are then joined together to form a vane ring (100) for a gas turbine engine.

Owner:SIEMENS ENERGY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com