Patents

Literature

461 results about "Centerless grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

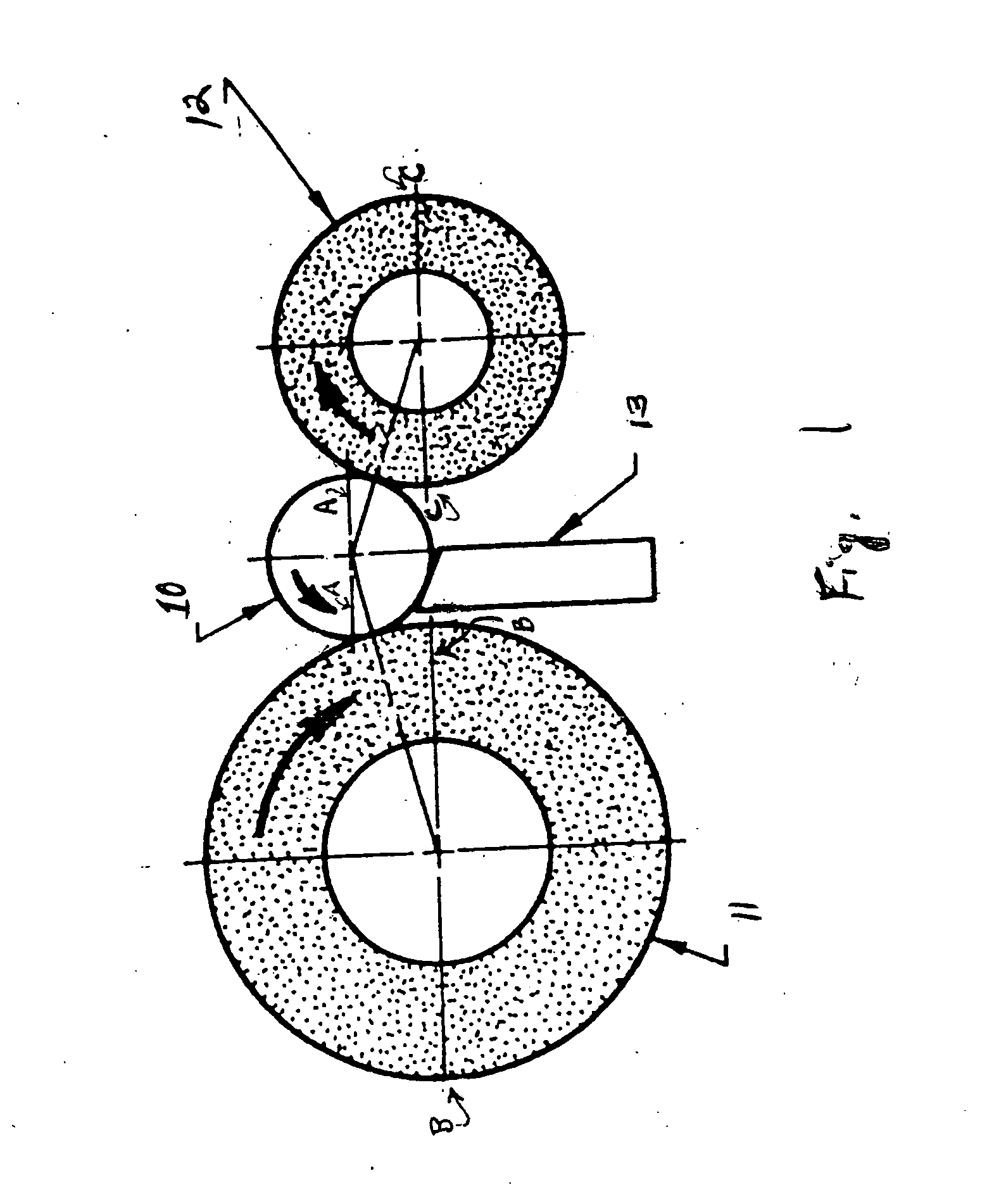

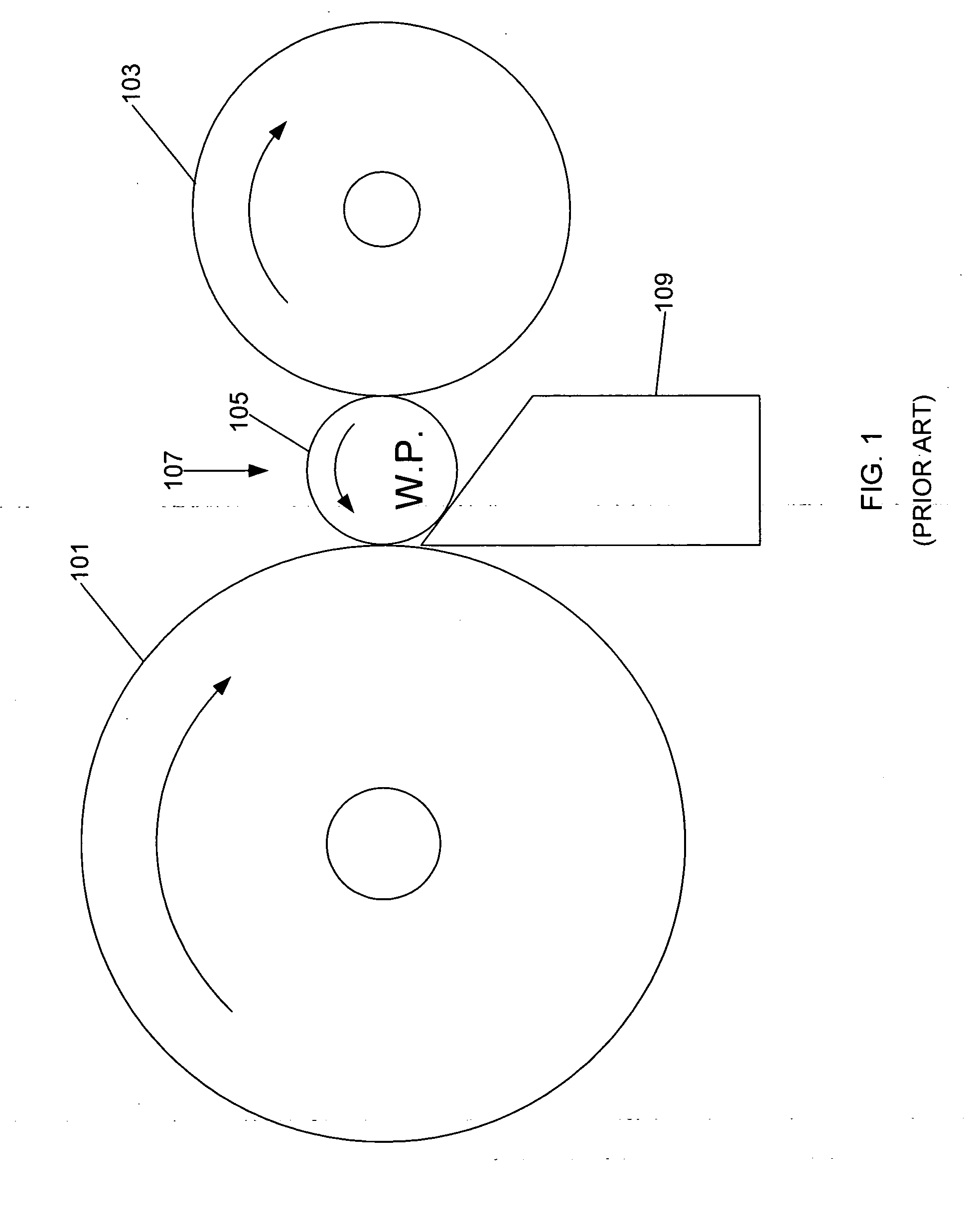

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. Centerless grinding differs from centered grinding operations in that no spindle or fixture is used to locate and secure the workpiece; the workpiece is secured between two rotary grinding wheels, and the speed of their rotation relative to each other determines the rate at which material is removed from the workpiece.

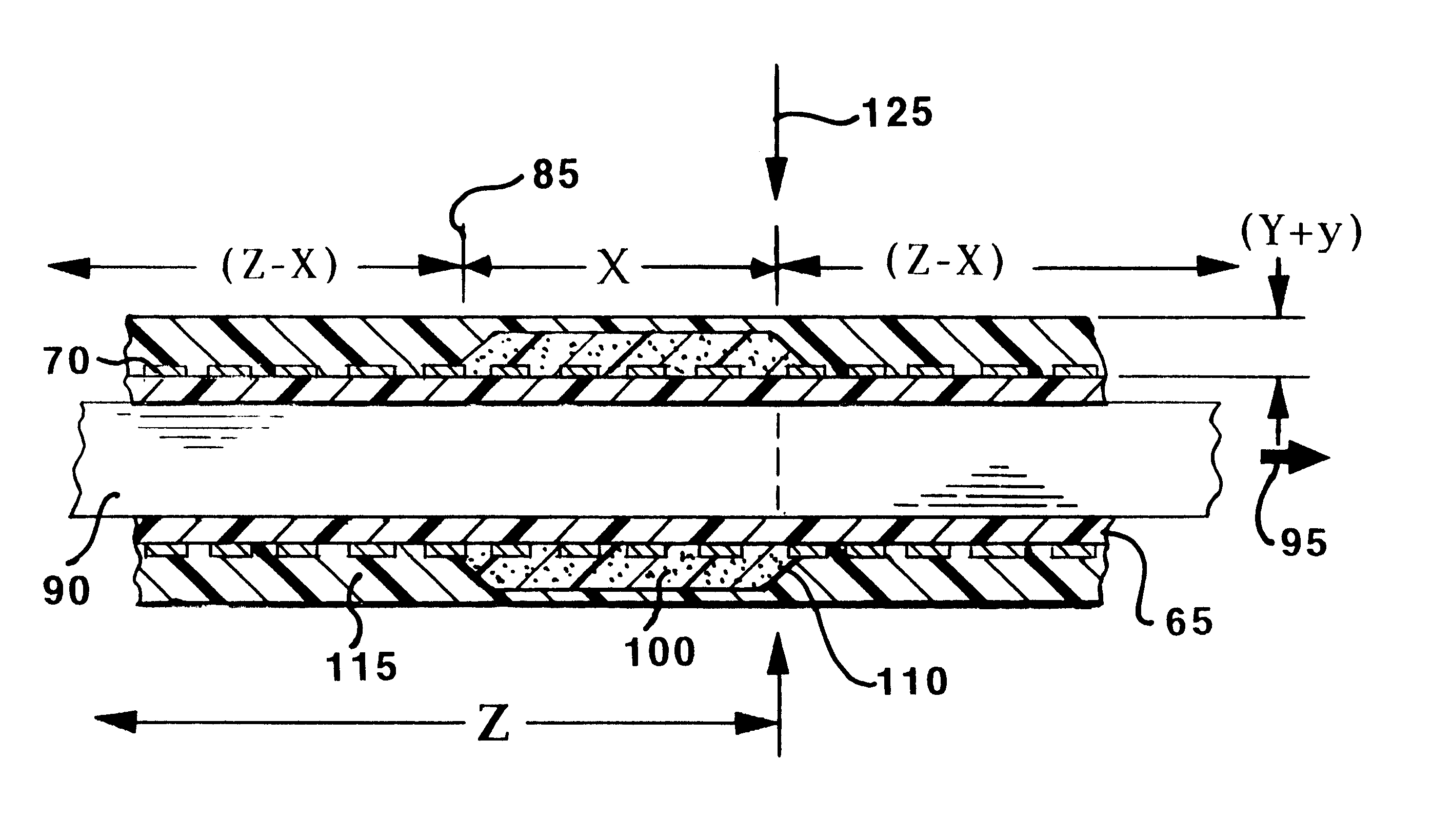

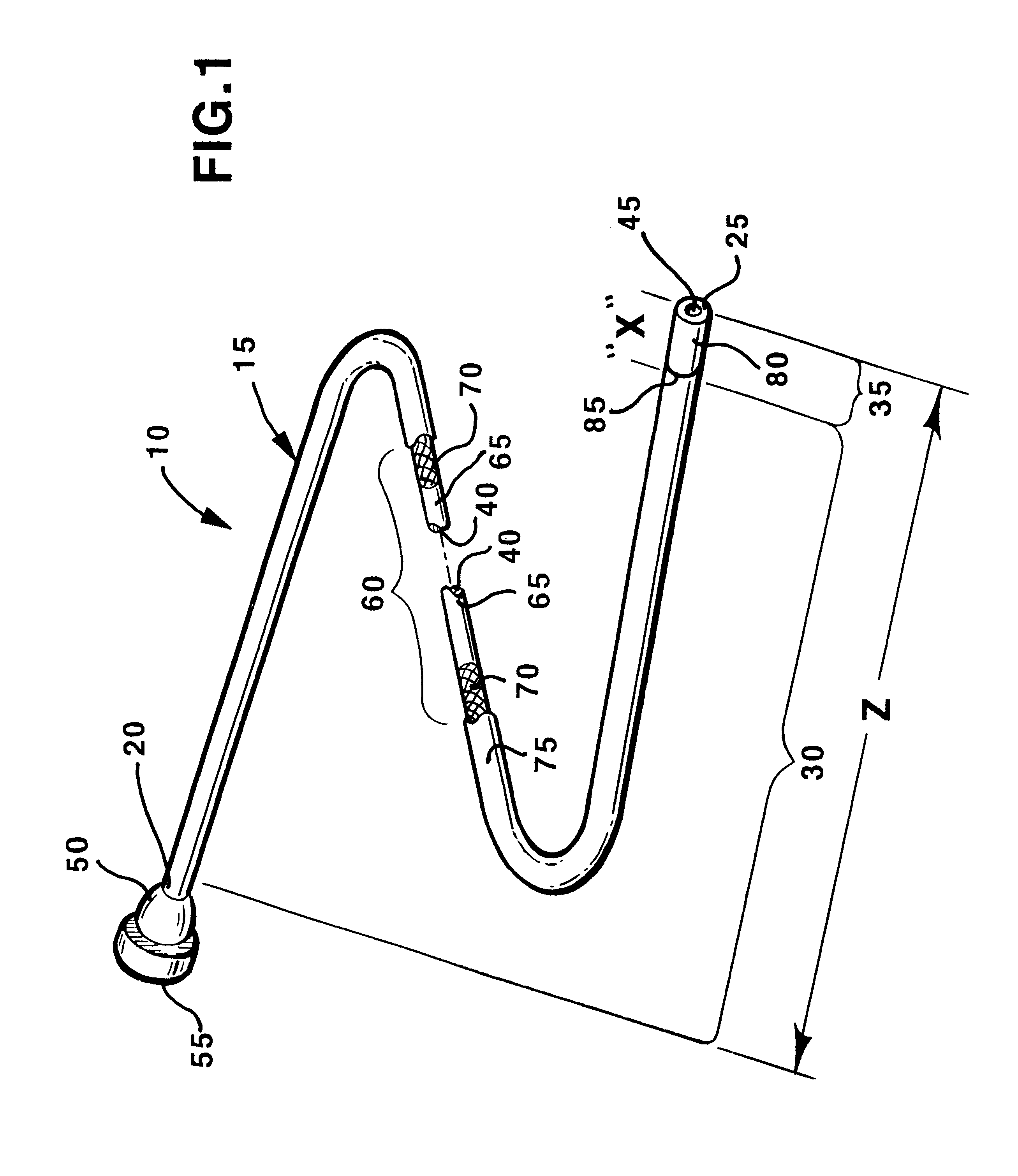

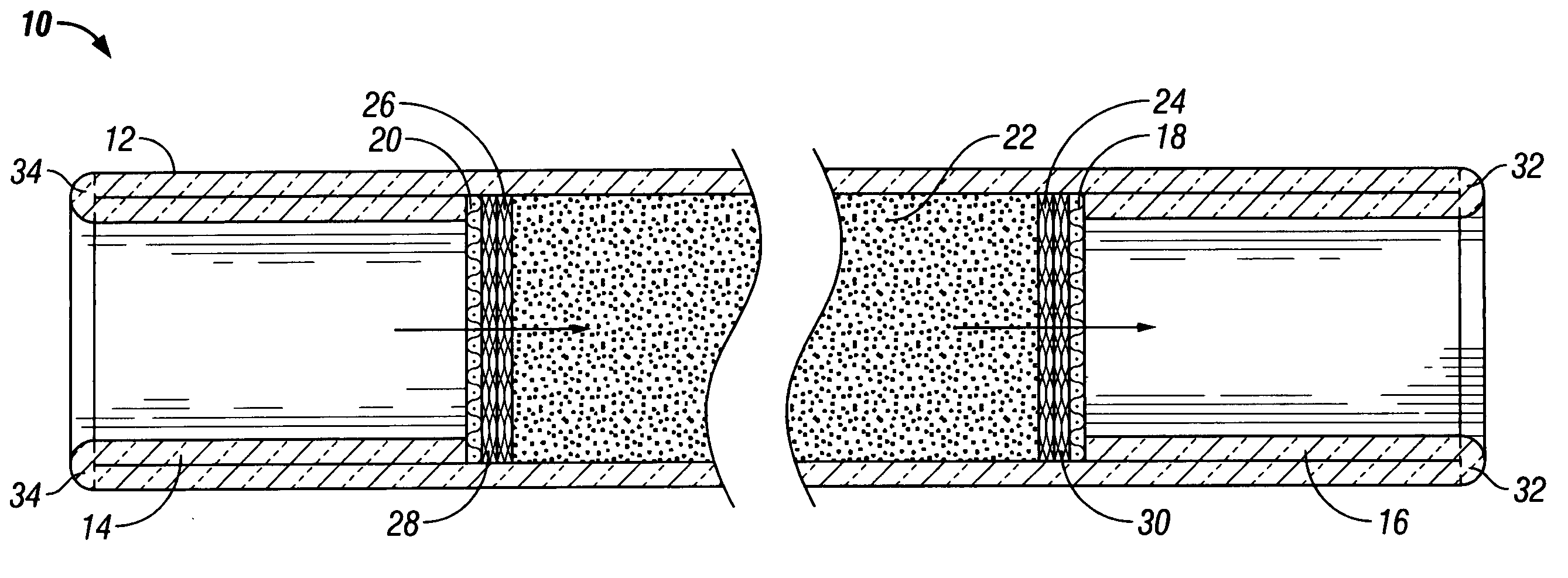

Multiple segment catheter and method of fabrication

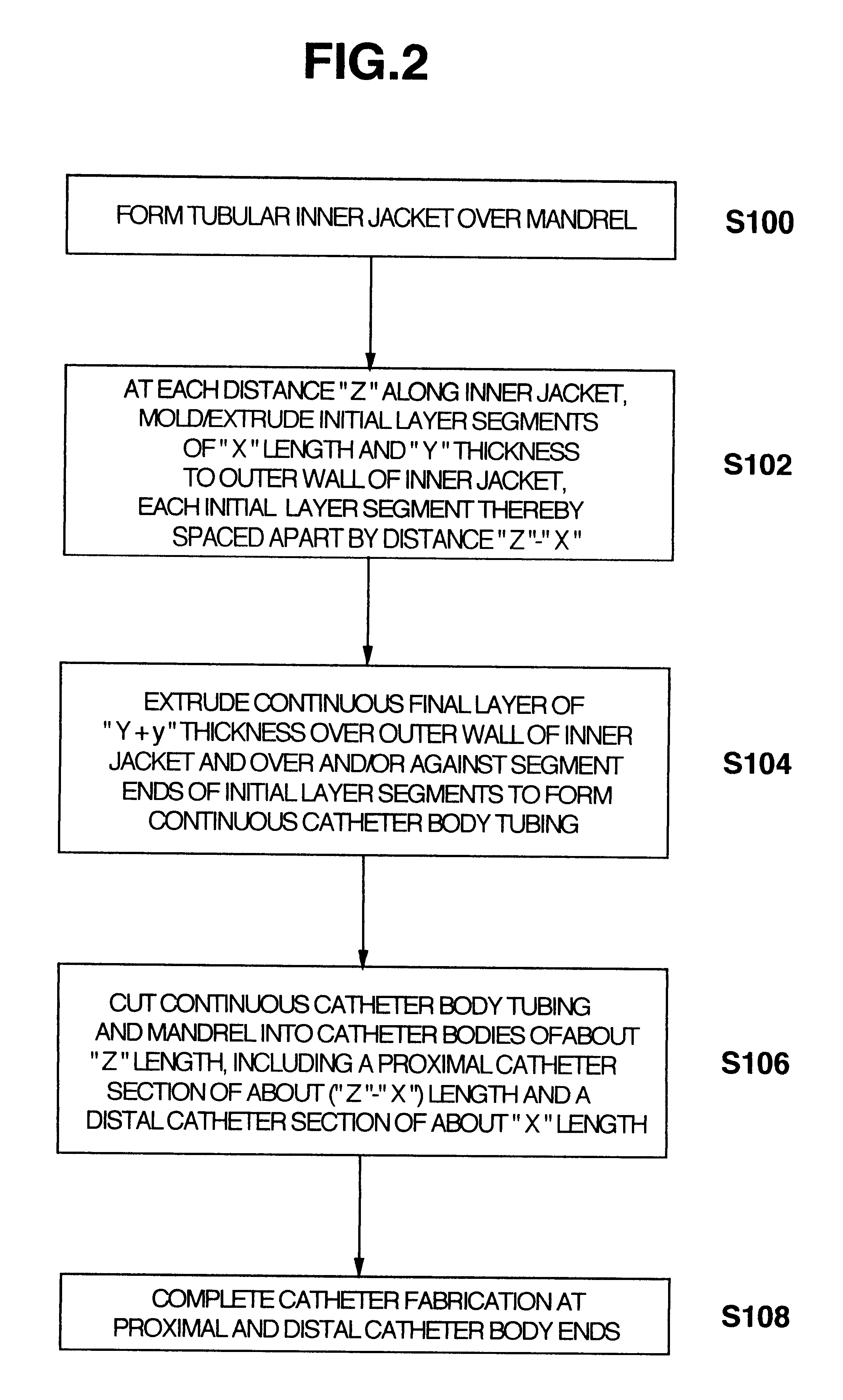

Methods of fabricating medical vascular catheters adapted to be inserted into a blood vessel from an incision through the skin of a patient for introducing other devices or fluids for diagnostic or therapeutic purposes and particularly methods for fabricating such catheters with catheter bodies having catheter sections of differing flexibility are disclosed. Such catheter bodies having a proximal catheter body end and a distal catheter body end and formed of a proximal section and at least one distal section that have differing flexibilities are formed in a process comprising the steps of: (1) forming a continuous tubular inner jacket preferably of an inner liner and a reinforcement layer; (2) forming initial layer segments having an initial layer thickness along the length of the inner jacket from a material of first durometer hardness, whereby each initial layer segment is separated by a separation distance: (3) forming a final layer of a material of second durometer hardness with a second layer thickness over the tubular inner jacket along the separation distances and over and / or against the proximal and distal initial layer ends of the initial layer segments to form a continuous catheter body tubing; (4) severing the continuous catheter body tubing into catheter body lengths including a proximal catheter section formed of the material of second hardness and a distal catheter section of the material of first hardness; and (5) completing the catheter fabrication at the proximal catheter body end and the distal catheter body end. Centerless grinding of the catheter body or body tubing, formation of Intermediate catheter body sections, distal soft tips, and discontinuities in the reinforcement layer formed prior to step (2) are also disclosed.

Owner:MEDTRONIC INC

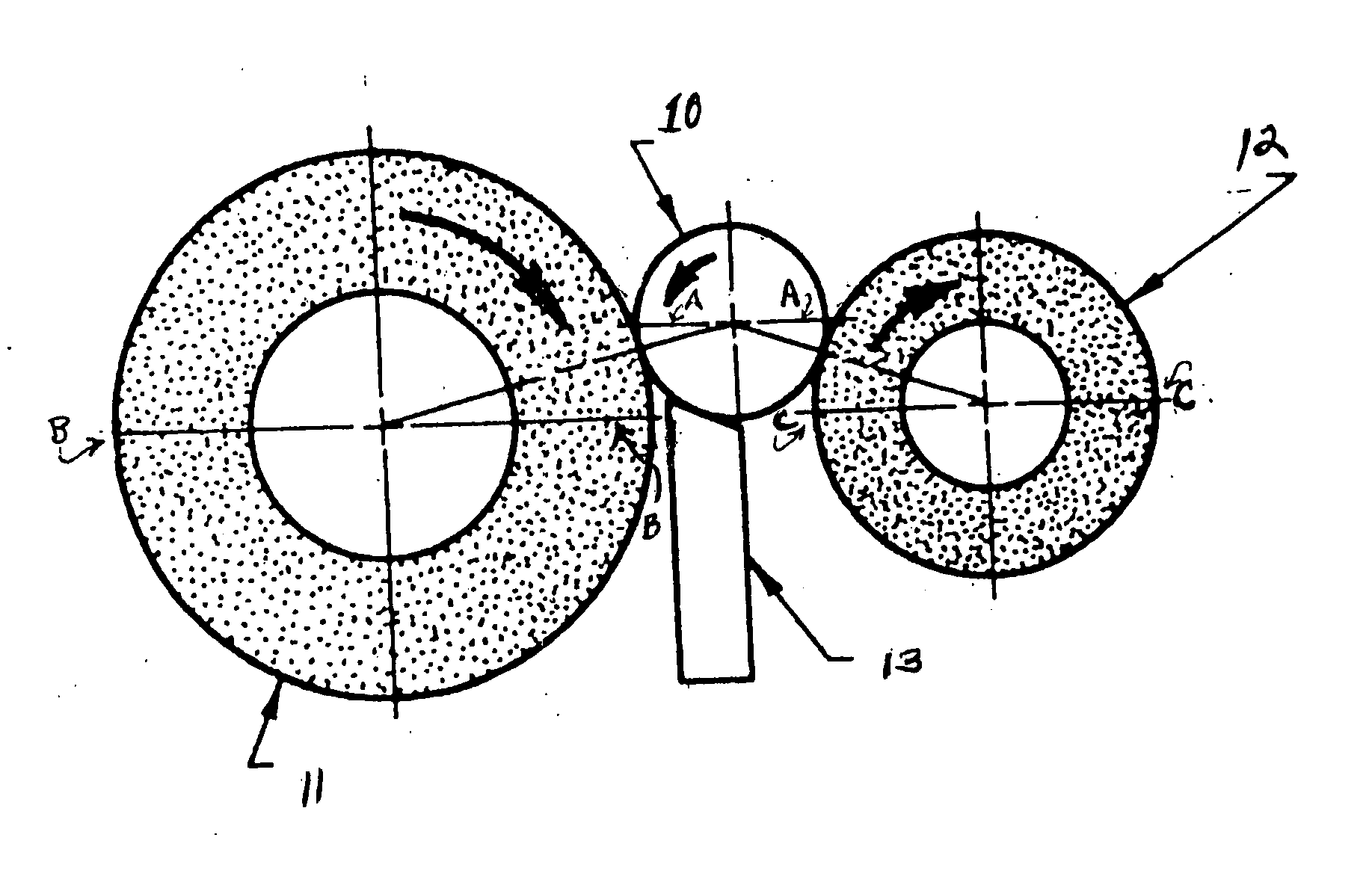

Method of centerless grinding

Organic bonded abrasive tools, having controlled microstructures, comprise a relatively low volume percentage of abrasive grain and a relatively low hardness grade, but are characterized by the excellent mechanical strength and efficient grinding performance of much harder grade, lower porosity tools, especially in versatile grinding processes, such as centerless grinding. A method for centerless grinding with these tools is provided. Methods for making the abrasive tools utilizing agglomerated abrasive grain are described.

Owner:SAINT GOBAIN ABRASIVES INC

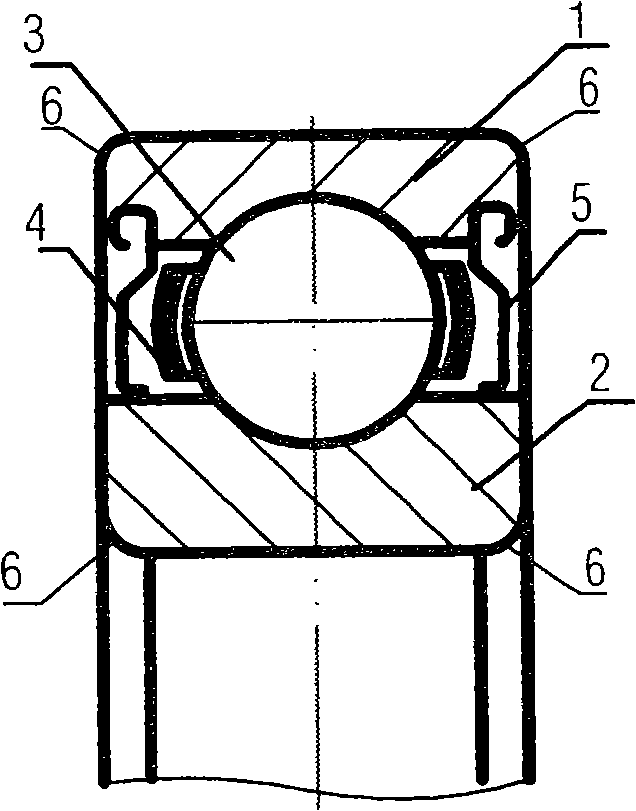

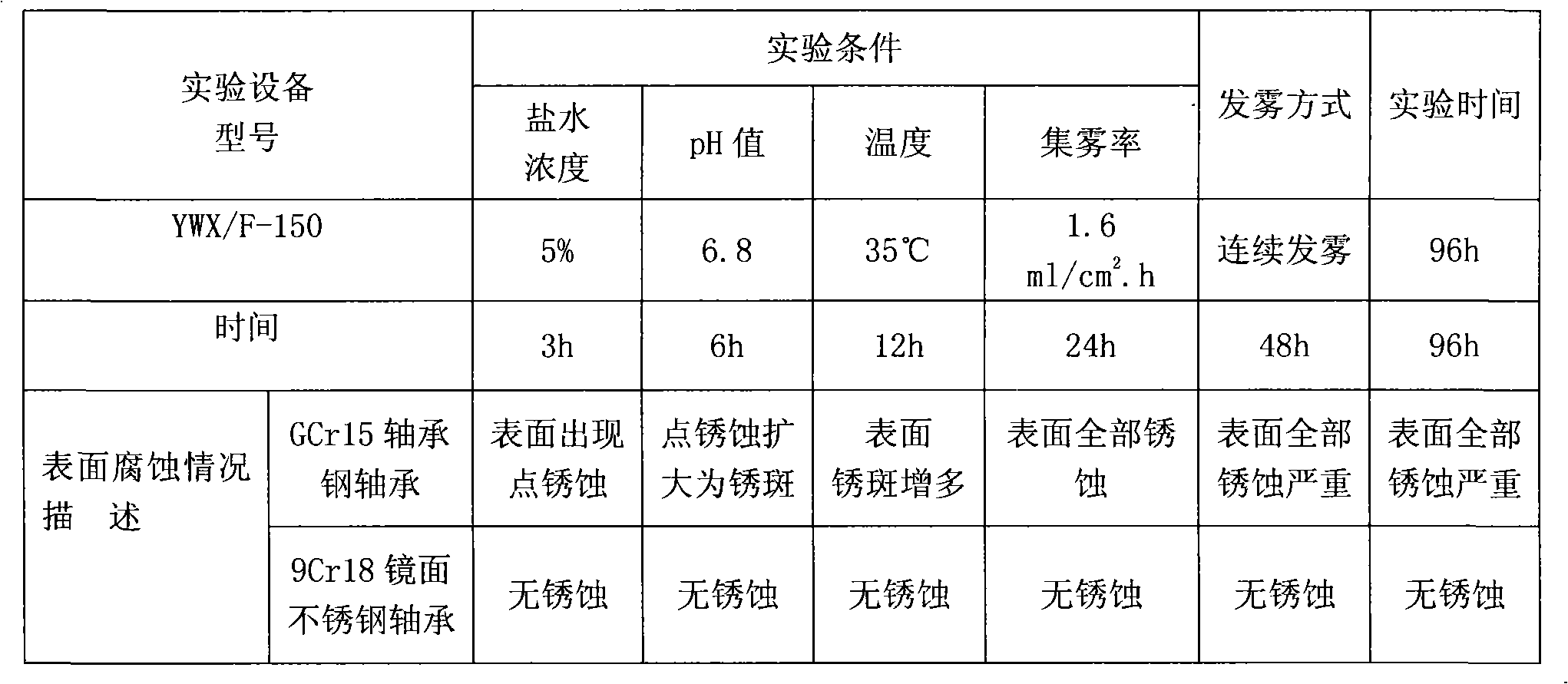

Mirror face stainless steel bearing and process thereof

InactiveCN101280808AImprove corrosion resistanceCorrosion resistantBearing componentsWaxPharmaceutical industry

The invention discloses a mirror finished stainless steel bearing and a process technology thereof, which comprise molding of an inner ring and an outer ring of a bar stock, turning operation, heat treatment, plane centerless grinding, coarsely grinding the channels of the inner and the outer rings, heat treatment, finely grinding the channels of the inner and the outer rings, heat treatment, grinding the channels of the inner and the outer rings, assembly and pressing fit a dust cap. The mirror finished stainless steel bearing and the process technology thereof are characterized in that: 9Cr18 stainless steel is adopted as the bar stock; liquid casting passivation is carried out before fine grinding of the channels of the inner and the outer rings; uniform burnishing treatment with a waxing machine is carried out to the inner ring surface, the two end surfaces and the two chamfers of the inner ring and the outer ring surface, the two end surfaces and the two chamfers of the outer ring after grinding the channels of the inner and the outer rings; the dust cap and a retainer adopt material of stainless steel 304, coated with a vacuum ion coating and colored into golden. The mirror finished stainless steel bearing of the invention has strong corrosion resistance and long service life and can be widely used in special environment, such as food machinery, chemical dyeing, marine equipment, pharmaceutical industry, assembly line of IT industry, etc.

Owner:余姚市曙光不锈钢轴承有限公司

Centerless grinder

ActiveUS20050148288A1Edge grinding machinesRevolution surface grinding machinesCenterless grindingCollet

A centerless grinder for grinding an elongated workpiece includes a grinding wheel having a working surface with a plurality of raised areas extending circumferentially around at least a portion of the working surface. A platform is provided having an elongated top surface for supporting the workpiece substantially adjacent to the working surface of the grinding wheel and a front surface with a plurality of lateral grooves for receiving the raised areas on the working surface of the grinding wheel such that movement of the platform toward the working surface into a working area adjacent to the grinding wheel enables the raised areas to pass into the lateral grooves and grind the workpiece. The centerless grinder further includes a first spindle and collet in front of the working area and a second spindle and collet behind the working area, for grinding both ends of an elongated workpiece without removing the workpiece from the grinder, and a wire spool assembly for grinding wire stock directly from the wire spool.

Owner:ROYAL MASTER GRINDERS INC

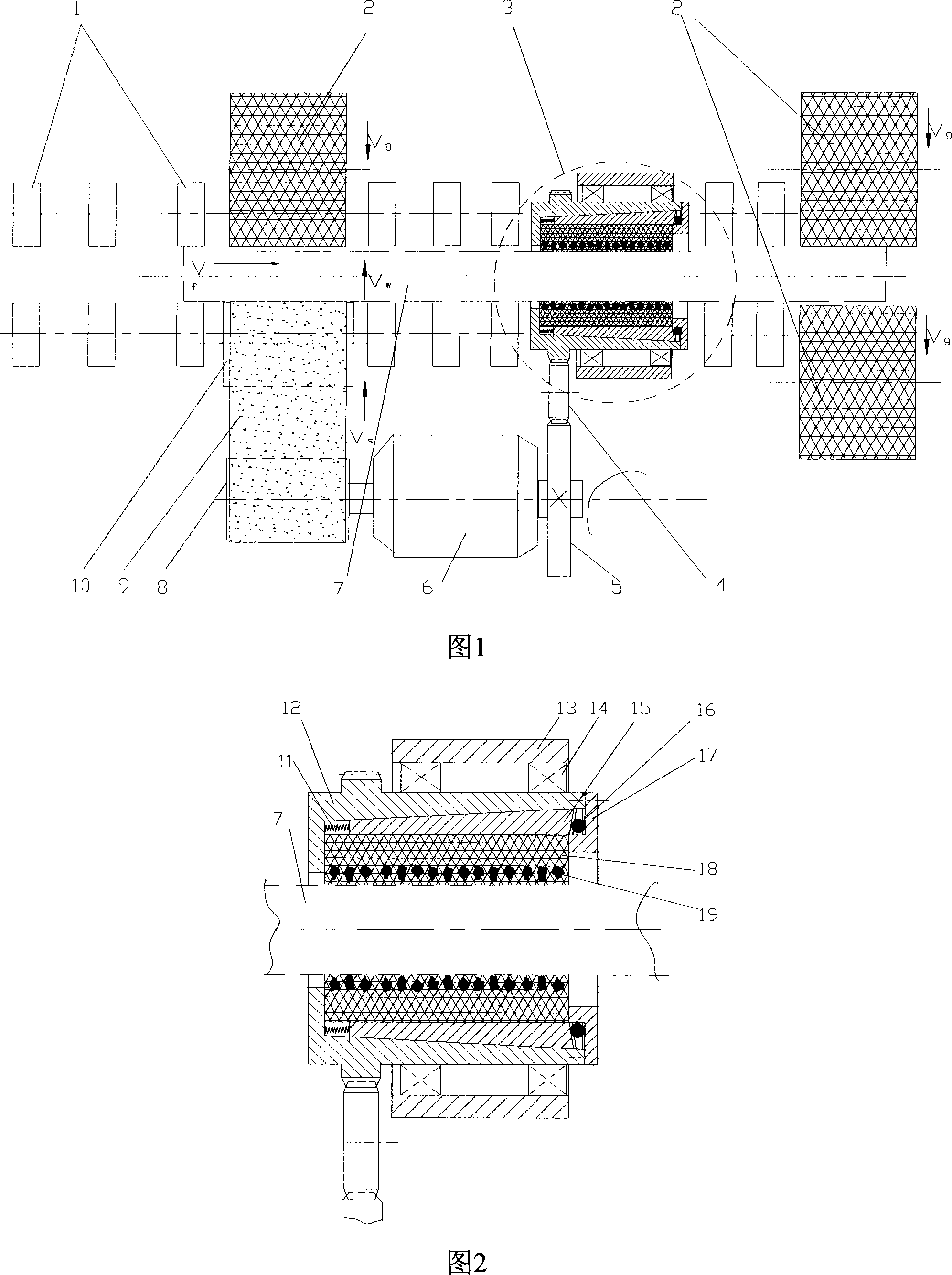

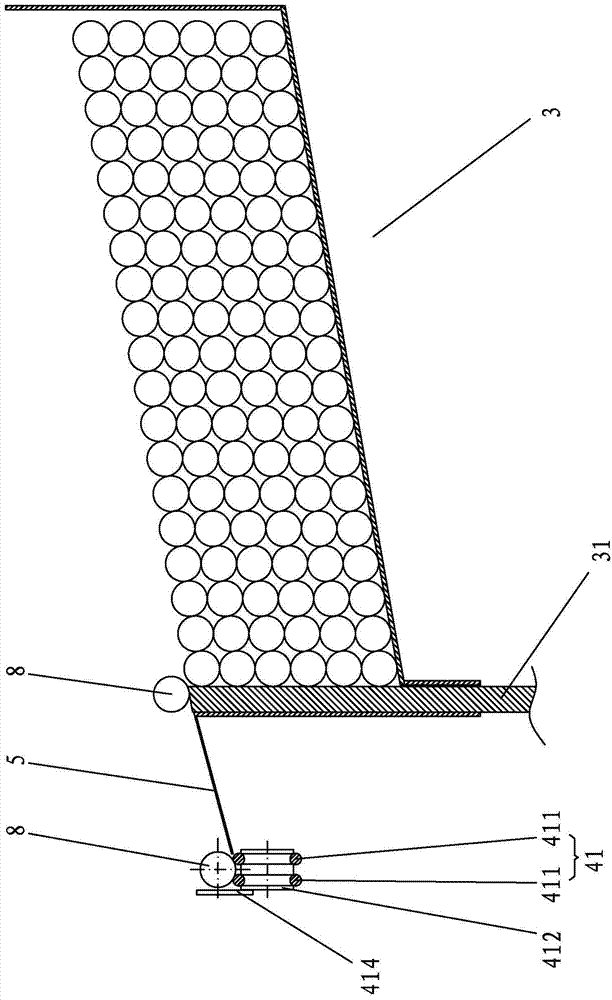

Wide/fine machining integrated processing device for emery belt centerless grinding and polishing

InactiveCN101195205AImprove grinding efficiencyImprove securityPolishing machinesBelt grinding machinesDrive wheelGear wheel

The invention discloses a process device with the combination of rough machining and fine machining of centreless grinding and lapping and polishing of an abrasive belt. The device comprises a piece riding wheel, a guide wheel, an abrasion head, a transition gear, a fixing gear, a two-shaft motor, a centreless abrasive head of the abrasive belt, and a supporting member of the piece riding wheel, wherein the centreless abrasive head of abrasive belts is composed of an abrasion head driving gear, the abrasive belt and an abrasive head contacting gear, and the abrasion head driving gear is connected with the abrasive head contacting gear via the abrasive belt. One end of the two-shaft motor is in fixed connection with the abrasive head driving gear, and the other end is connected with a fixed gear which is matched with the transition gear. The transition gear is matched and connected to the abrasive head. The device resolves the problems of poor rigidity, a lot of process procedures, a plurality of devices, much transport, complex operation, inconvenient installation and the like in the prior art of the coarse grinding, fine grinding, polishing and the like of the outer circle with elongated circular rods. The device increases the integral efficiency, reduces manufacture cost, enlarges the manufacture range and combines the rough process, semi-fine process, fine process, lapping and polishing.

Owner:GUANGDONG IND TECHN COLLEGE

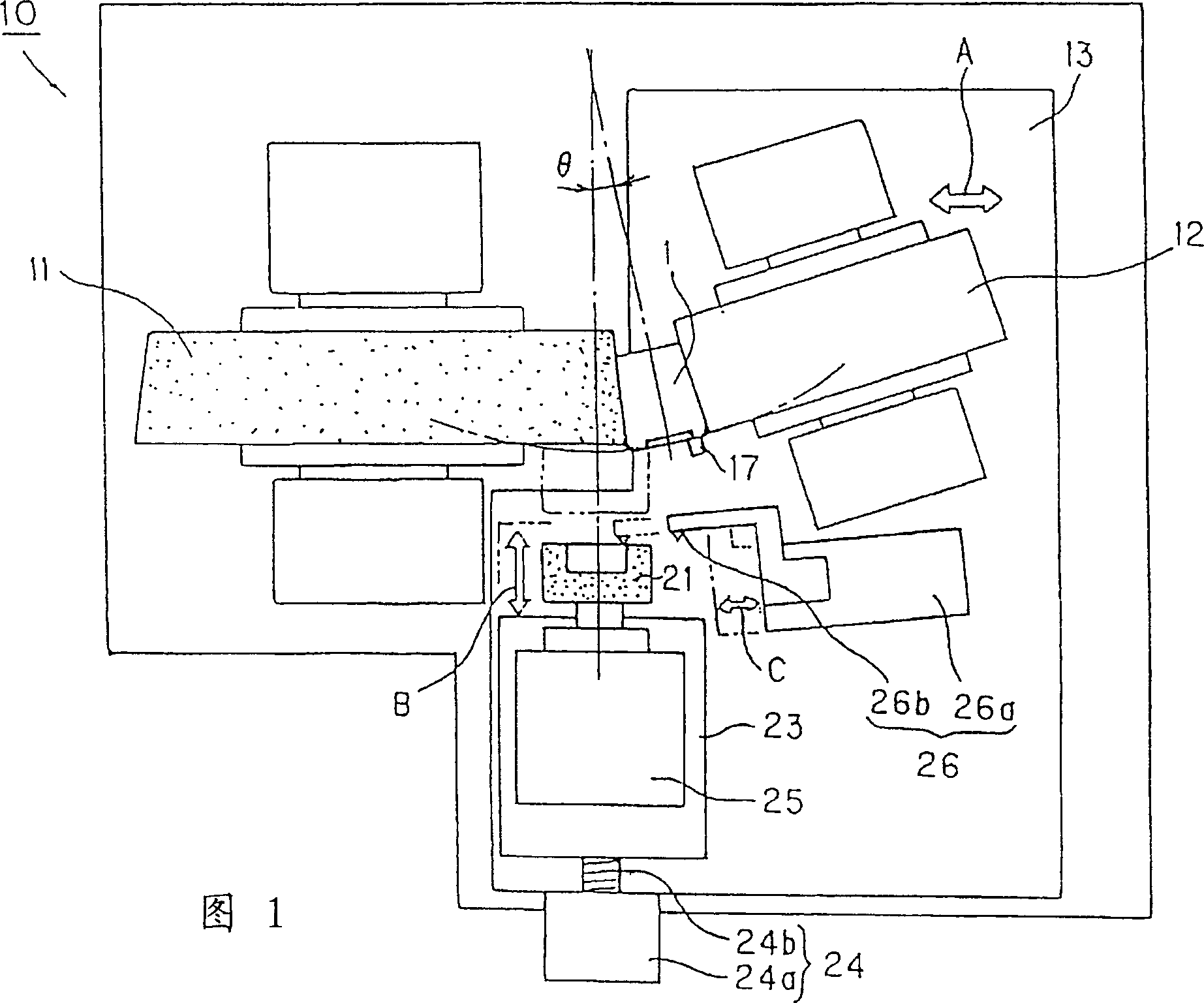

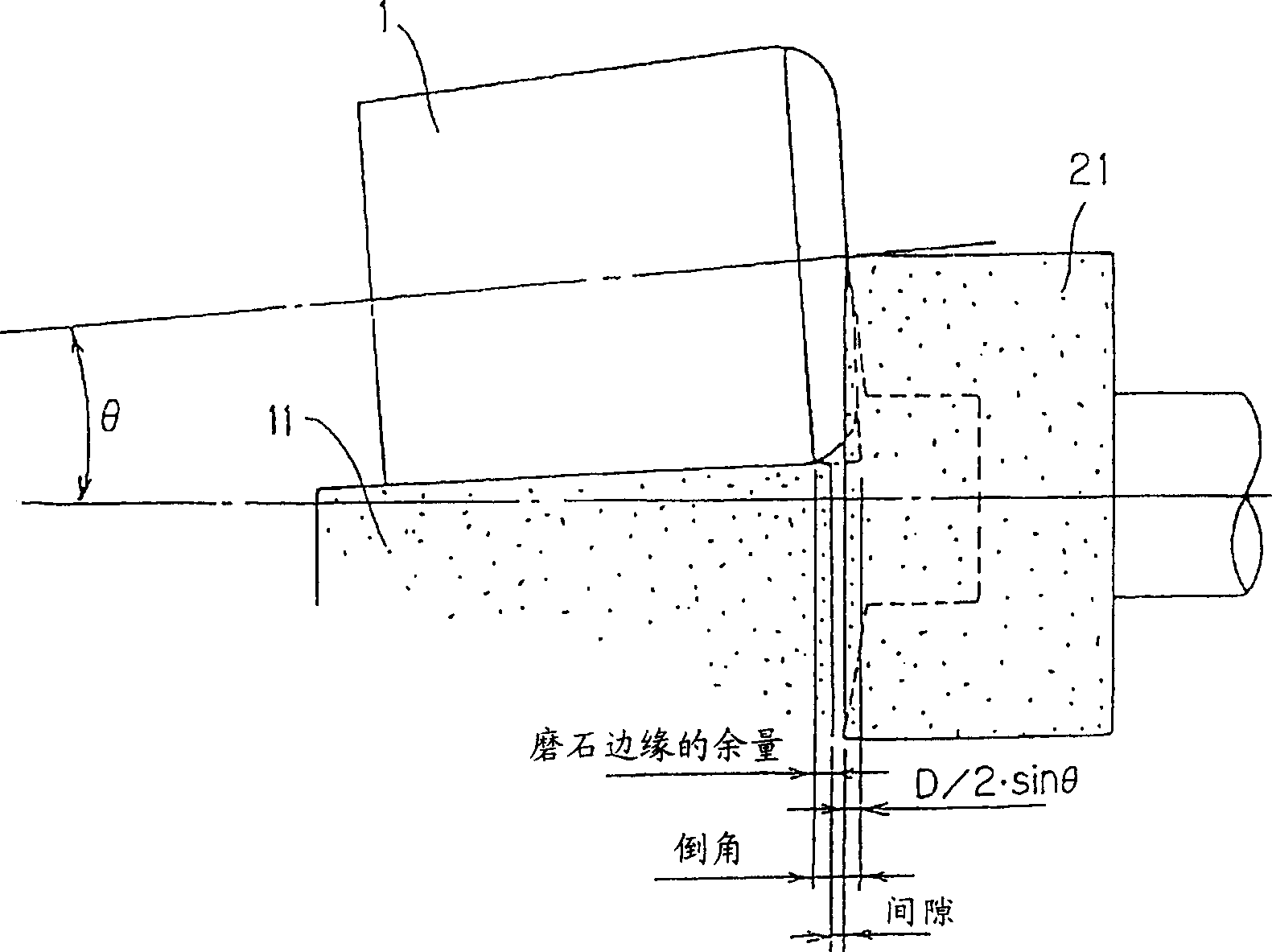

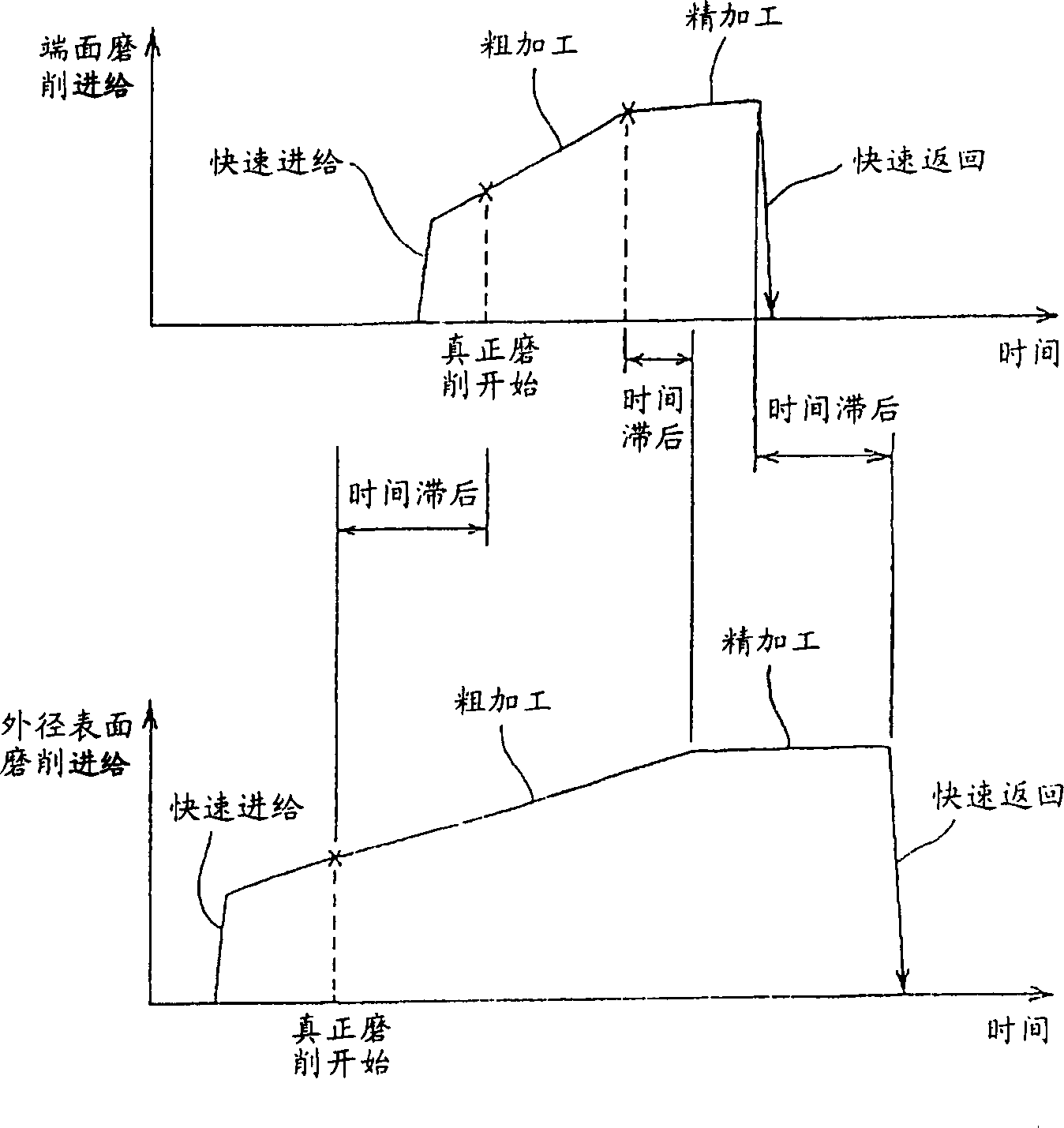

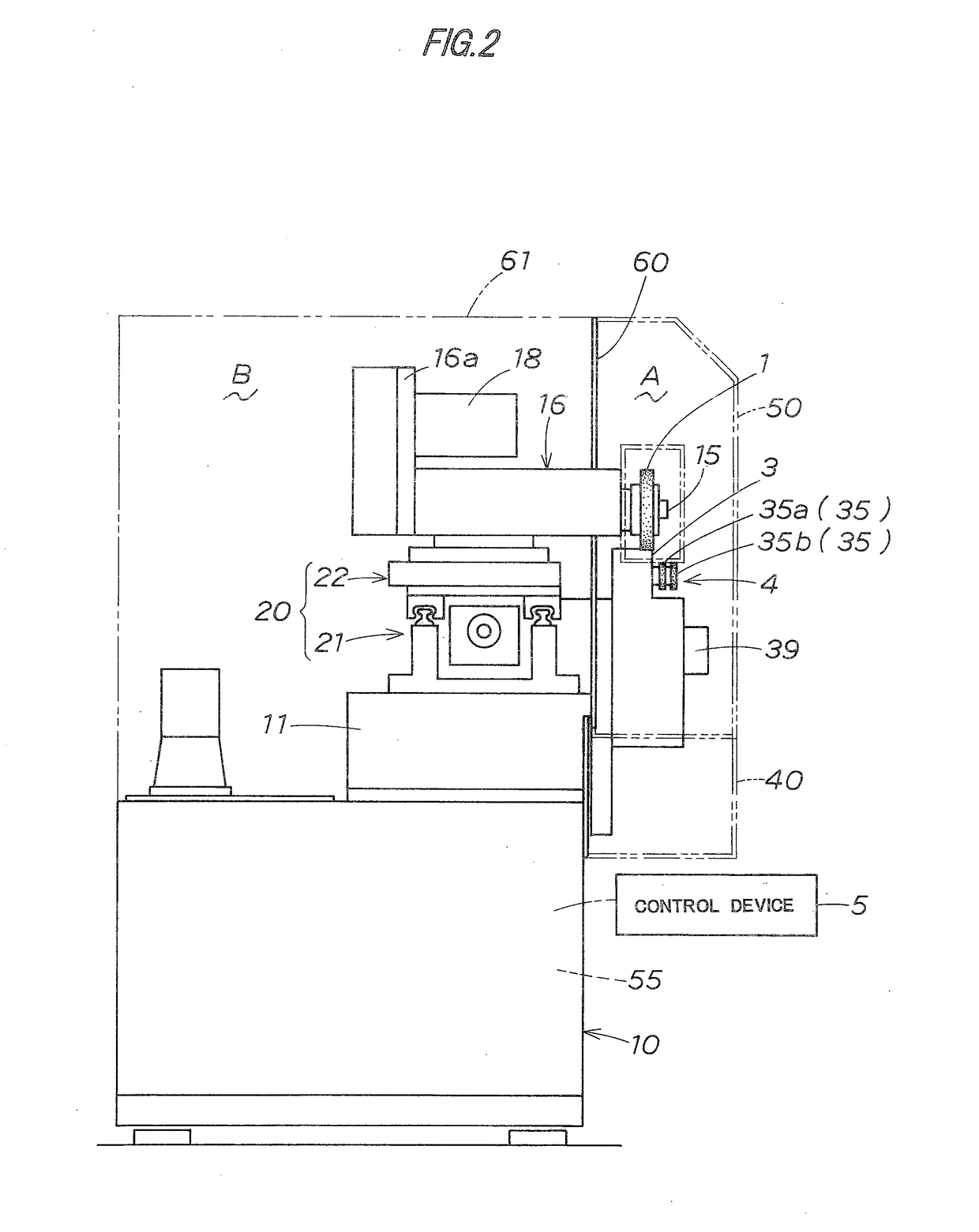

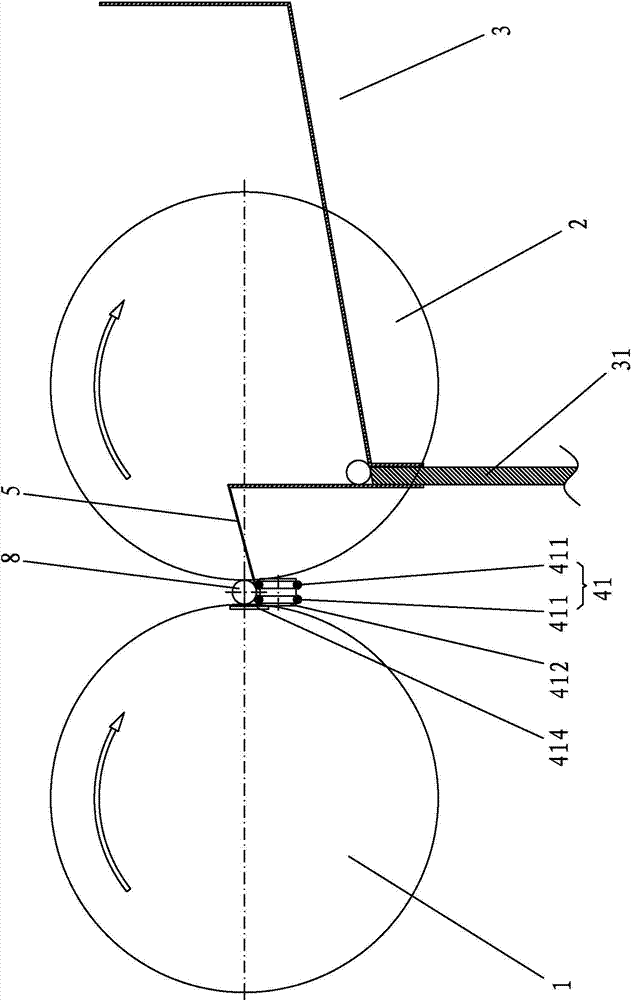

Centerless grinding apparatus and centerless grinding process

InactiveCN1448247ASimple structureShorten the time periodRevolution surface grinding machinesAbrasive surface conditioning devicesEngineeringSurface grinding

Owner:NSK LTD

Preparation method and application of heat-resistant titanium alloy wires

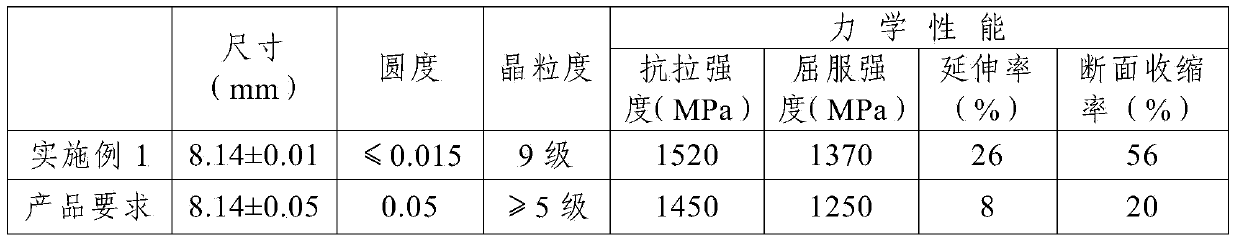

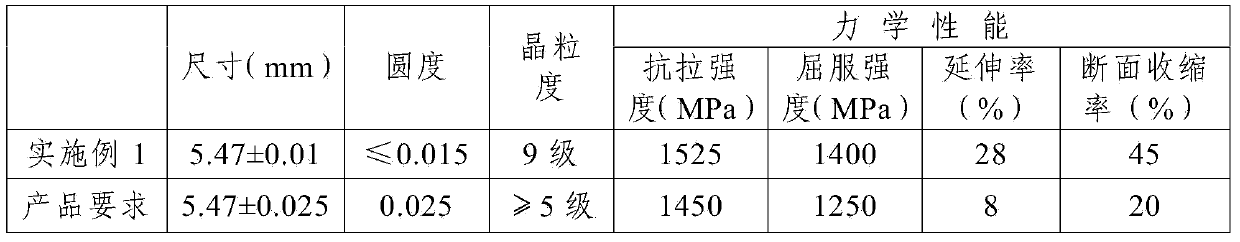

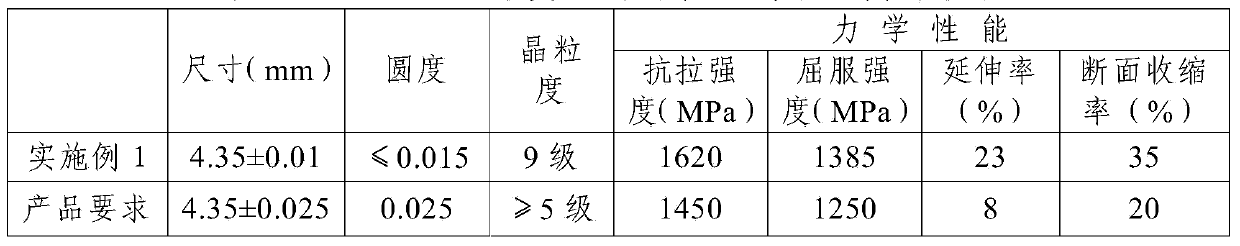

ActiveCN109355530ADifferent tensile strength matchingPlastic different matchingTitanium alloyHeat treated

The invention provides a machining and manufacturing method and application of heat-resistant titanium alloy Ti60 wires. The method comprises the steps that Ti60 titanium alloy ingot castings are smelted by adopting a vacuum consumable smelting technology; the smelted Ti60 titanium alloy ingot castings are forged into rods by adopting a free forging technology; the Ti60 titanium alloy rods are finish-forged into thick rod blanks by adopting a finish forging technology; the Ti60 titanium alloy thick rod blanks are rolled into straight strip wire blanks by adopting a hot rolling technology; surface treatment is conducted on Ti60 titanium alloy annealing wire blanks, and pre-oxidation oxidation film hanging treatment is conducted after defects on the surfaces of the wire blanks are removed; continuous high-temperature drawing deformation is conducted on the Ti60 titanium alloy wire blanks obtained after surface treatment by adopting a straight wire drawing machine; the drawn wires are straightened by adopting electric heating tension; and annealing heat treatment is conducted on the straightened wires, and finally centerless grinding is conducted. According to the machining and manufacturing method and application of the heat-resistant titanium alloy Ti60 wires, through combination of different heat machining and heat treating technologies, different matching combinations of the tensile strength, the plasticity and the shearing strength can be obtained, and the heat-resistant titanium alloy Ti60 wires can be used for manufacturing advanced aerospace fasteners such as rivets, bolts and nuts and are used in the temperature range of 600-650 DEG C.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

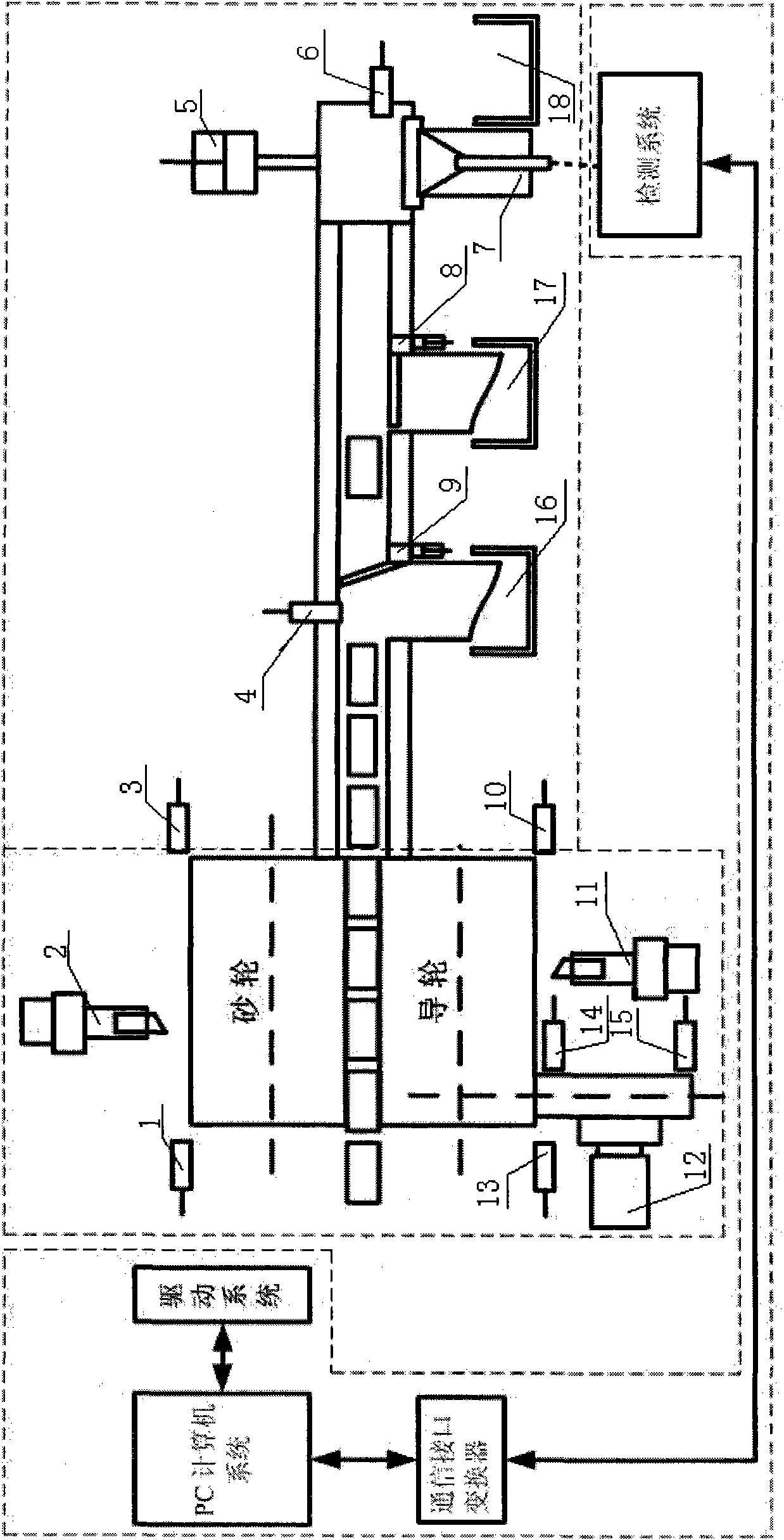

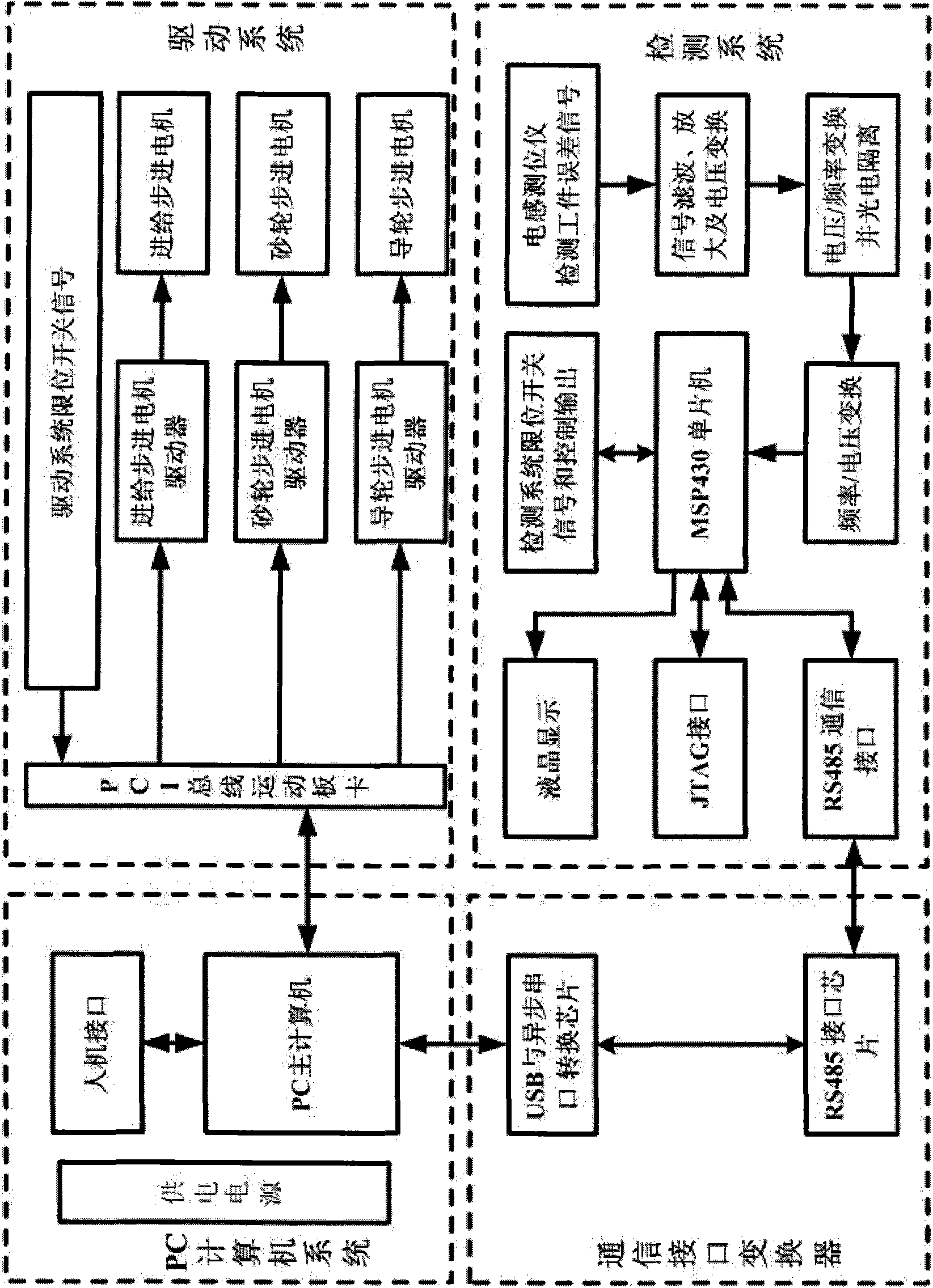

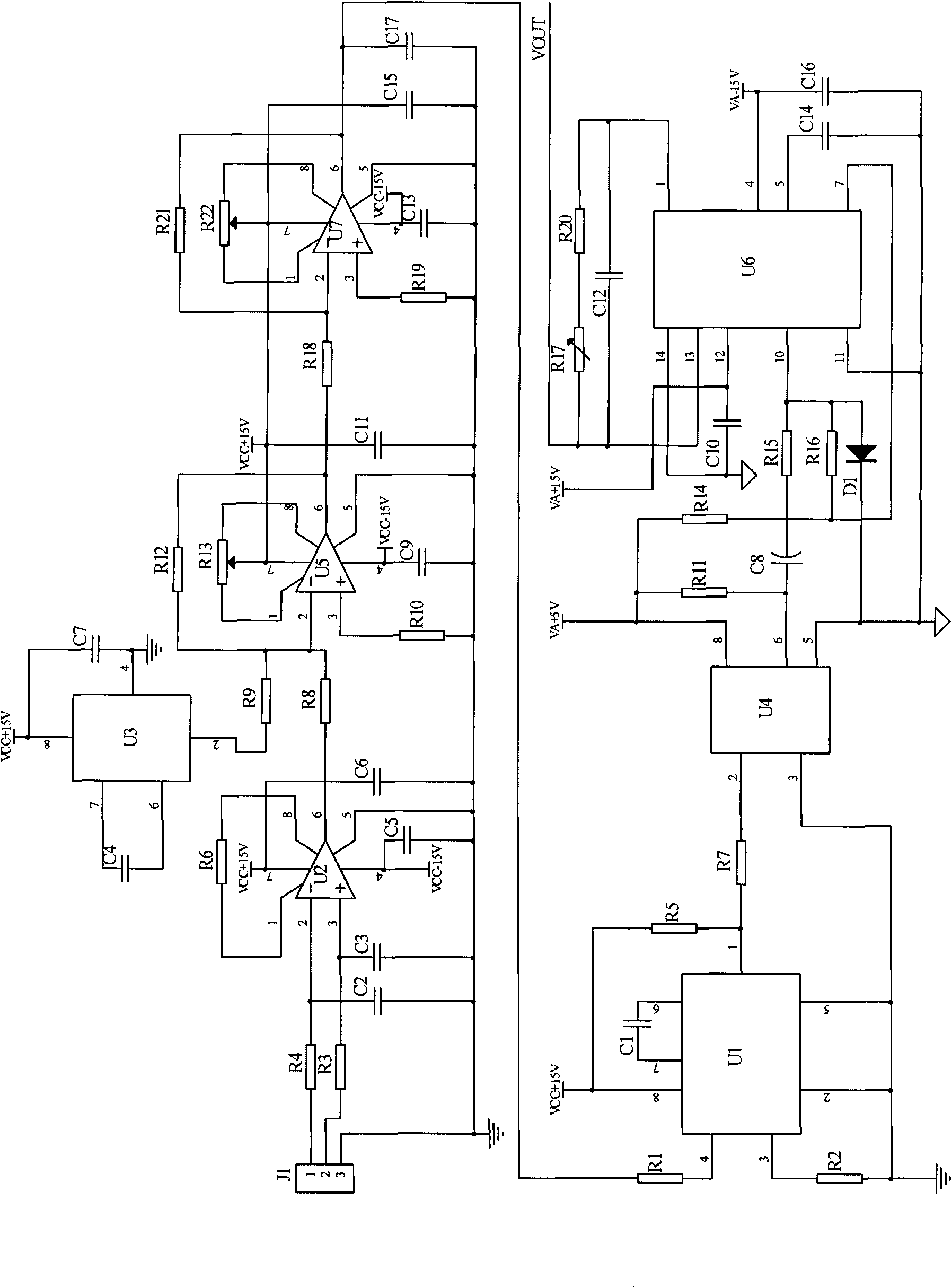

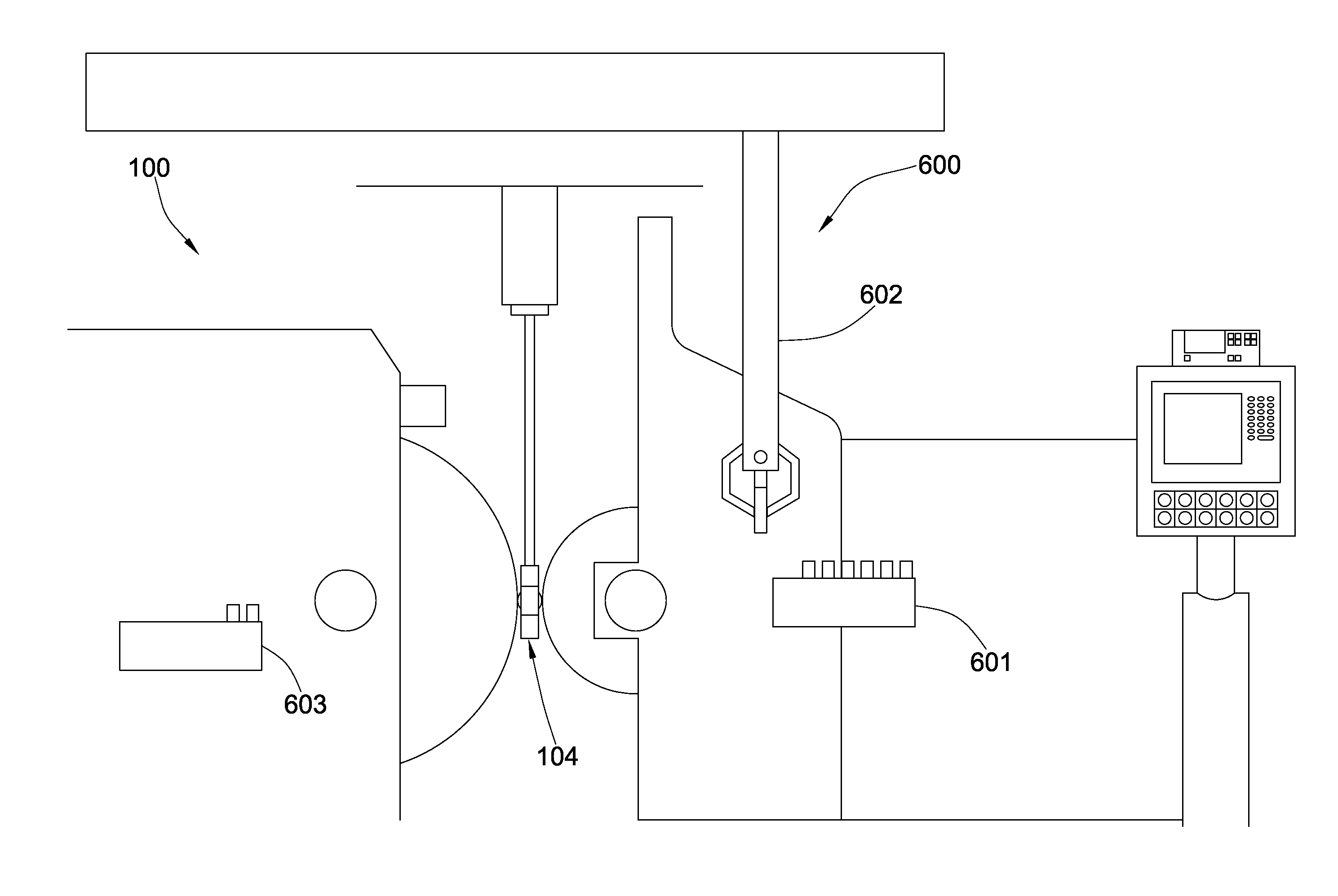

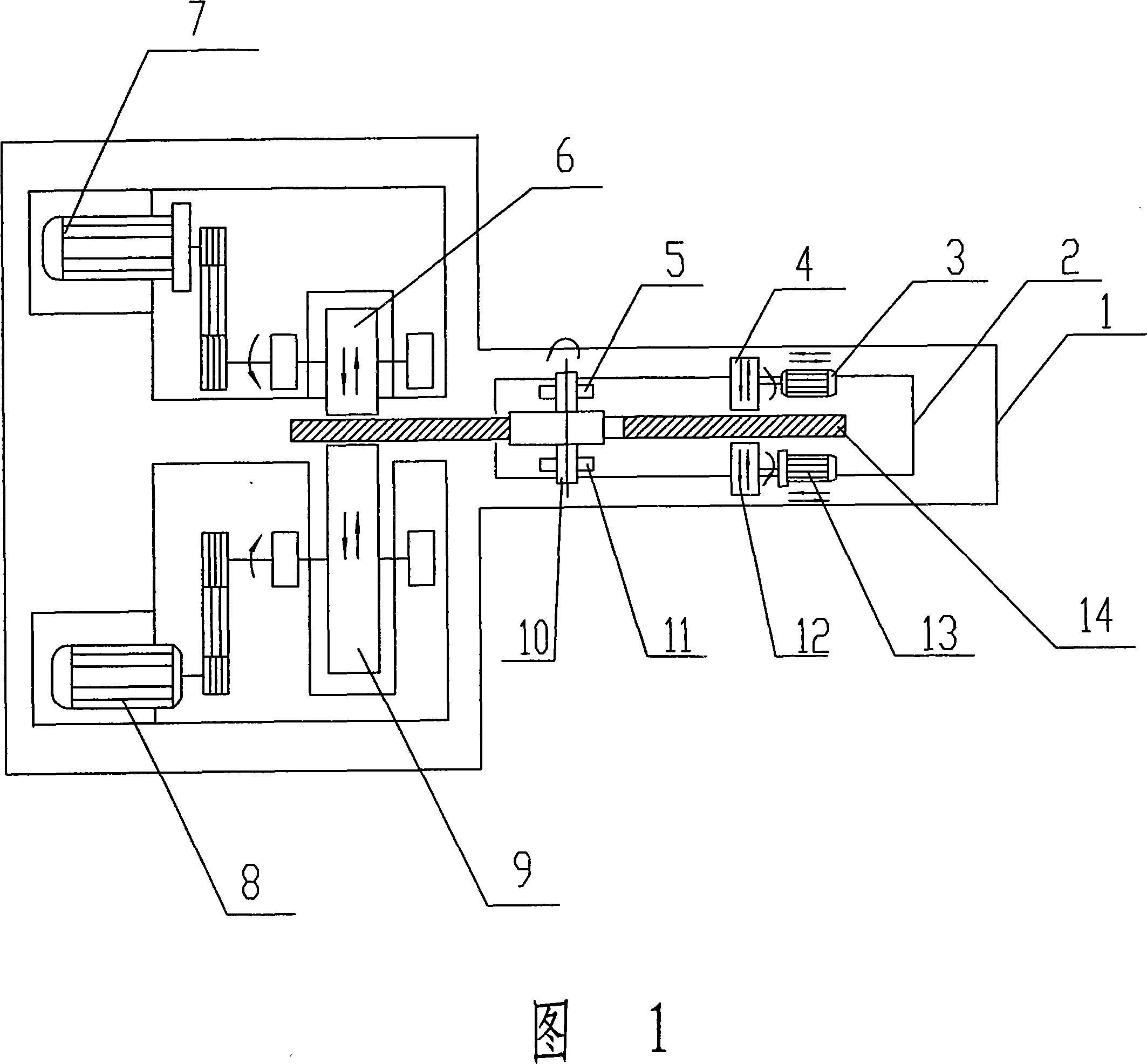

Coreless abrasive machining measurement and control system and corresponding coreless abrasive machining method

InactiveCN101559578AEasy to transformEasy to adjustGrinding feed controlUsing electrical meansCommunication interfaceControl system

The invention relates to a coreless abrasive machining measurement and control system and a corresponding coreless abrasive machining method. Combining with the fact that the coreless abrasive machining workpiece errors are mainly caused by the abrasion of a grinding wheel and a guide wheel, the coreless abrasive machining method samples and processes error signals through a workpiece error detection system in a coreless abrasive machining system, and sends the error signals to a PC computer system through a communication interface converter, and the PC computer system calculates the adjustedquantity and outputs signals to control a grinding wheel finisher, a guide wheel finisher and a feed mechanism driving system so as to achieve the finishing of the grinding wheel and the guide wheel and the adjustment of the feed mechanism. The measurement and control system and the method are mainly used for solving the problems that the prior system and the implement method thereof have a complex control method and are designed integrally.

Owner:HENAN UNIV OF SCI & TECH

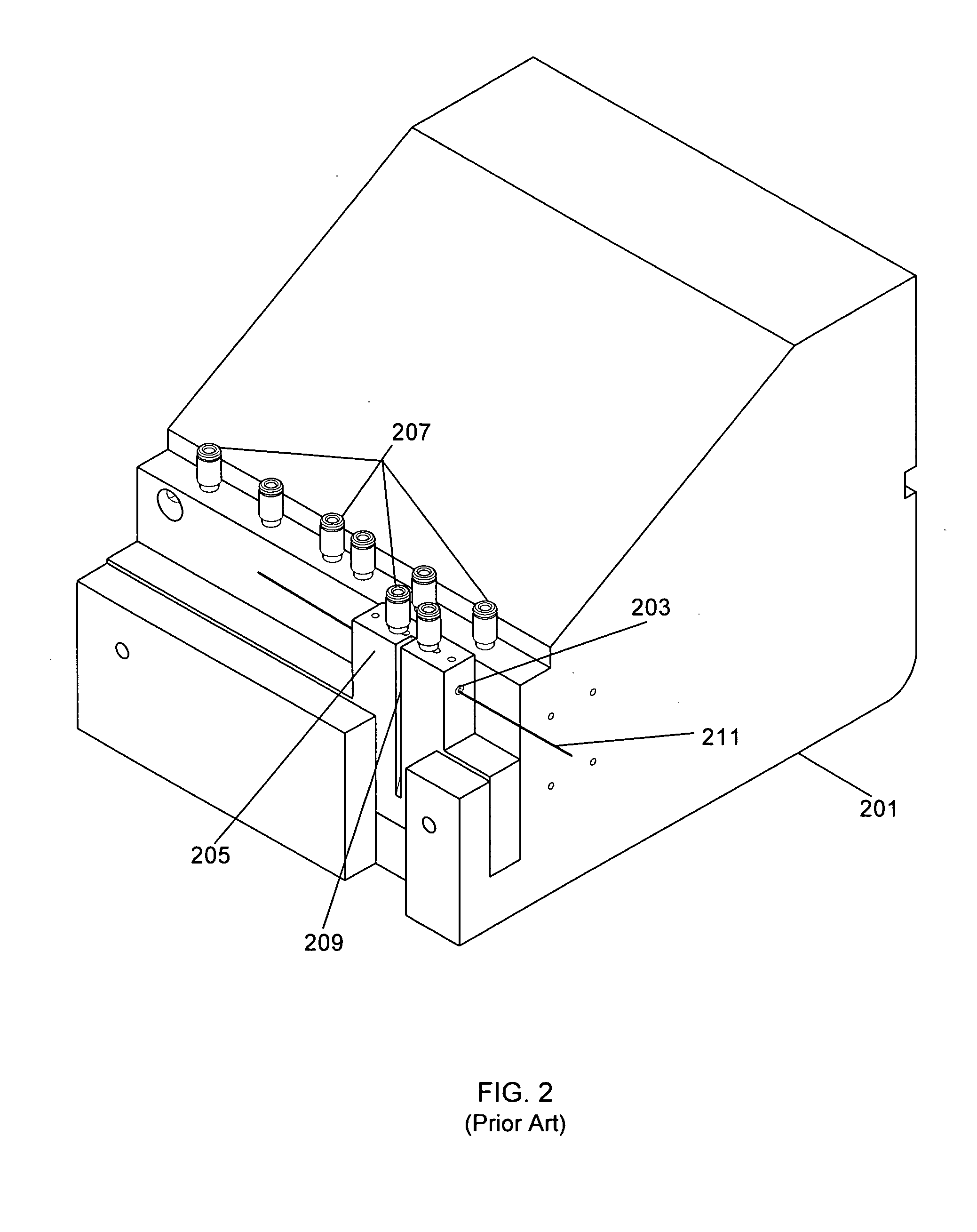

Centerless ground thermal desorption tube and method without frit

InactiveUS20050180893A1Easy constructionThe material is lowAnalysis using chemical indicatorsWithdrawing sample devicesFritSorbent

A centerless ground thermal desorption tube comprises an outer barrel and one or more inner spacers insertably positioned within the outer barrel. A suitable sorbent material is positioned within the outer barrel which may be held in place by friction and / or with glass wool plugs, and / or screens, and / or the inner spacers. In one preferred embodiment one glass inner spacer is fused to one end of a glass outer barrel prior to the glass outer barrel being centerless ground to a high precision. The sorbent and / or any wool plugs and / or screens are inserted into a second opposite end of the outer barrel after the centerless grinding process. A second glass is fused to the second end of the glass outer barrel whereby the glass fusing may change the precise tolerance of the centerless ground glass outer barrel at the second end only.

Owner:HANDLY ROBERT A

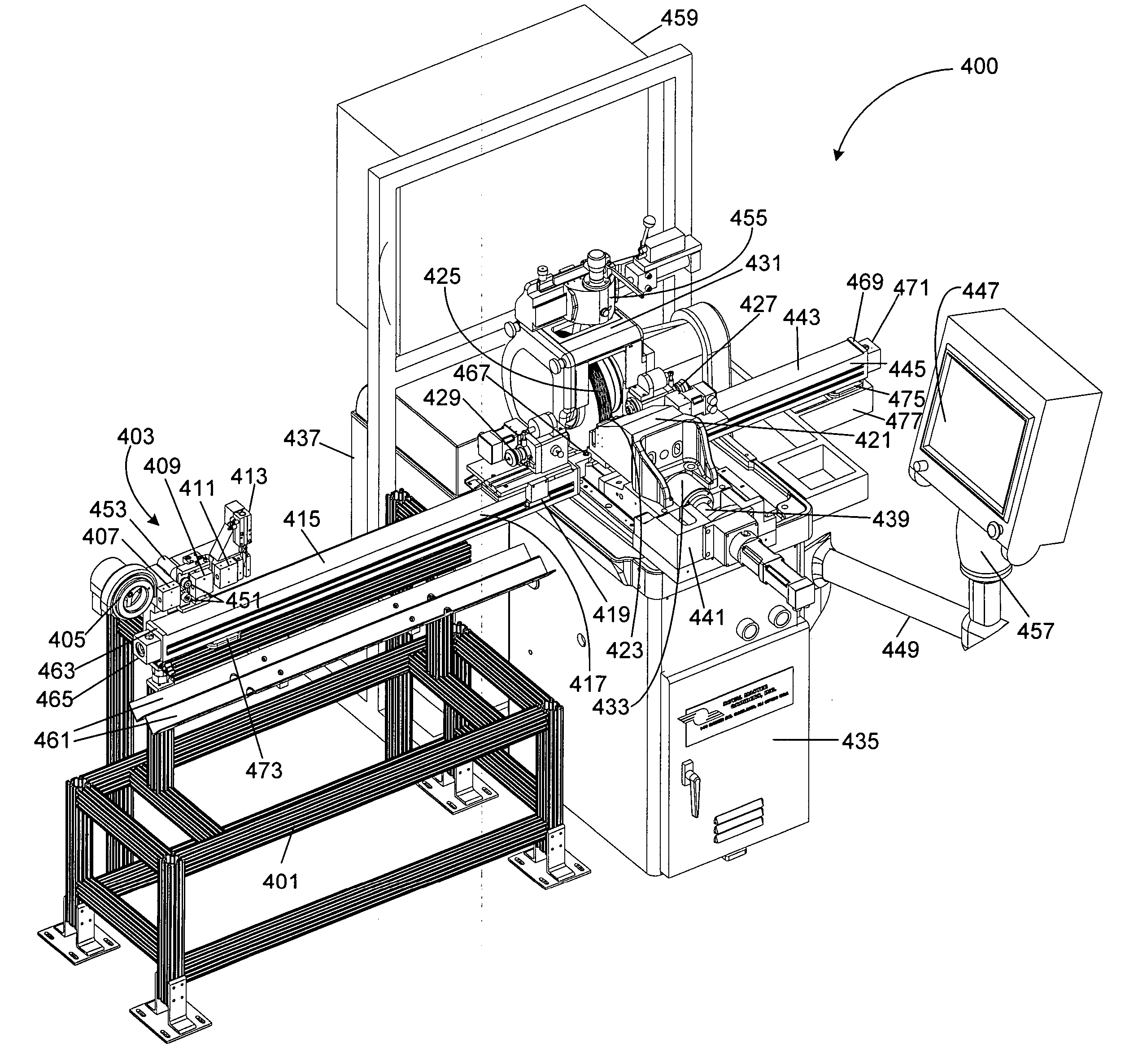

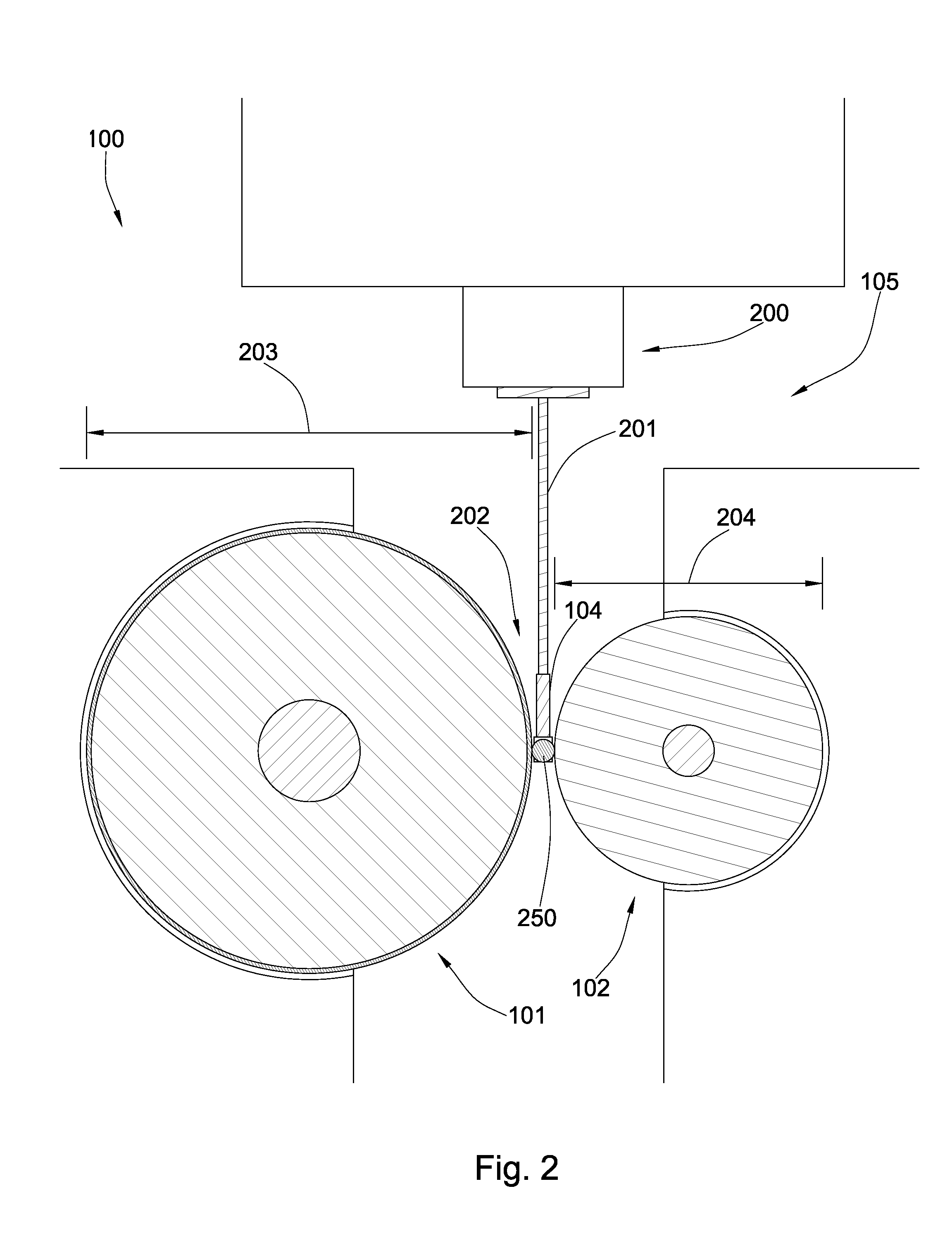

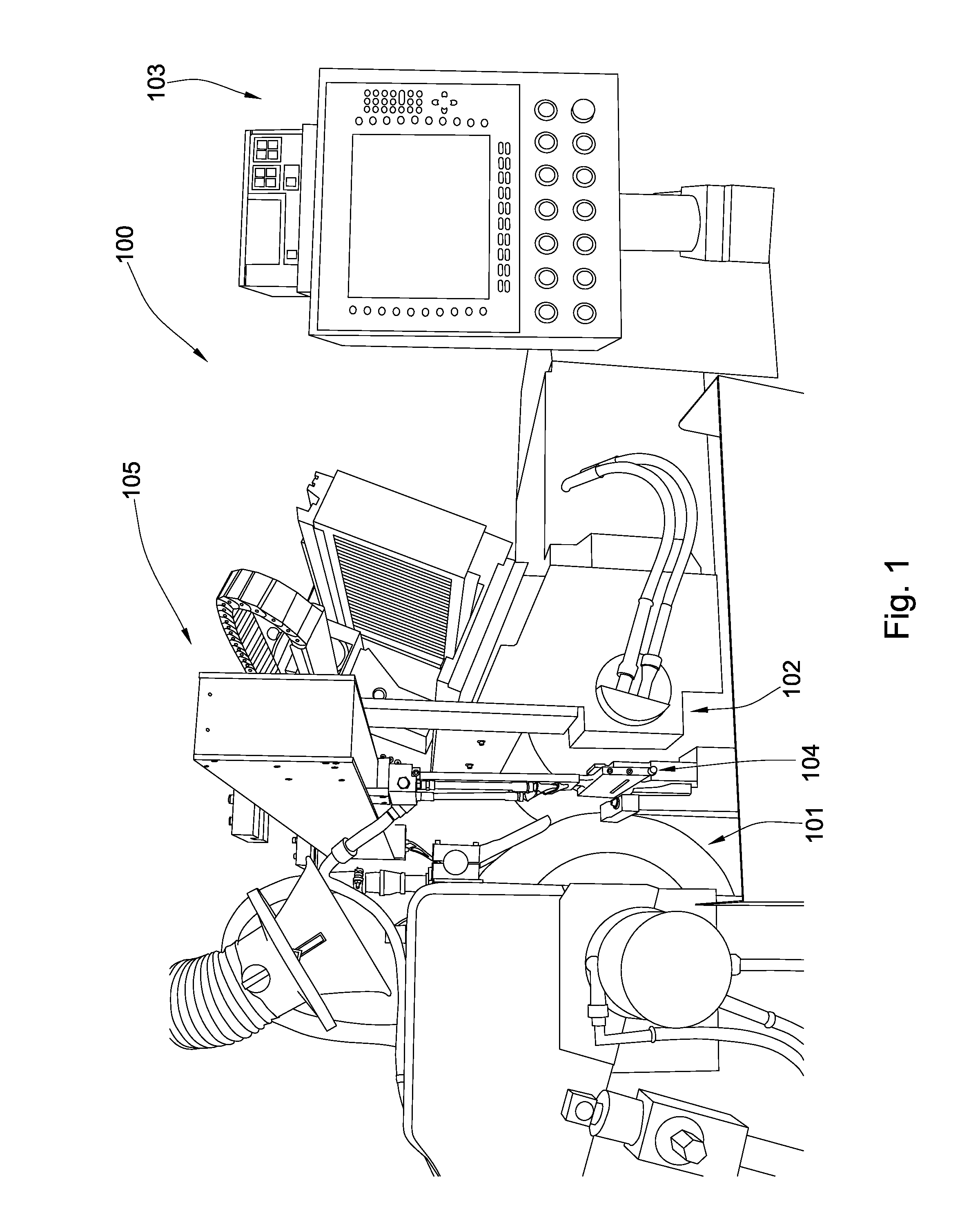

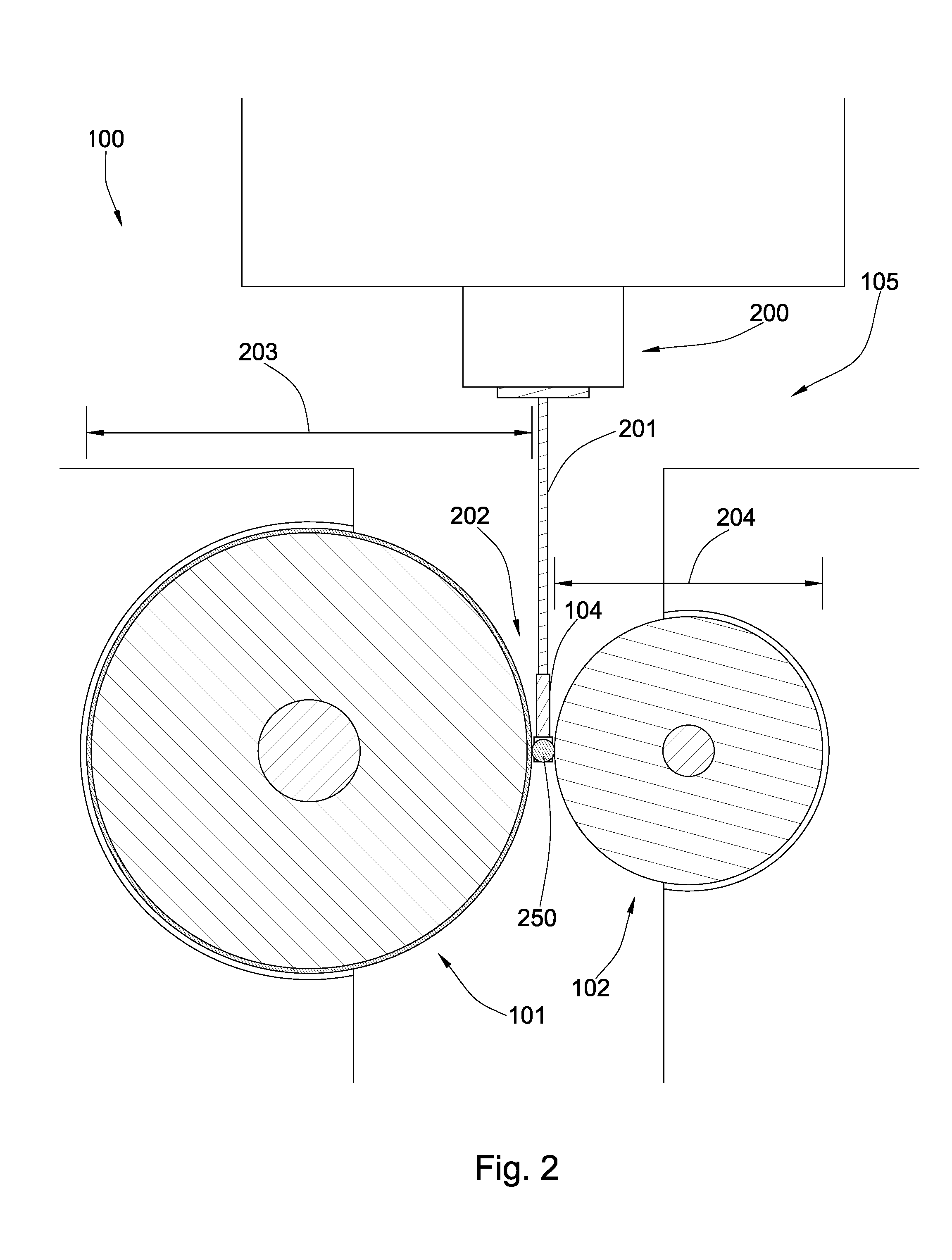

O.D. Centerless Grinding Machine

InactiveUS20080293328A1Avoid uneven wearEdge grinding machinesRevolution surface grinding machinesMechanical engineeringElectronic equipment

In one aspect of the present invention, an outer diameter (O.D.) centerless grinding machine for use in grinding a diamond workpiece has a grinding wheel positioned parallel to a regulating wheel which is adapted to press a cylindrical workpiece into the grinding wheel as the regulating wheel rotates. Electronic equipment may be adapted to adjust a pressure of the regulating wheel against the grinding wheel. Also, a carrier may be adapted to house the workpiece, the carrier being attached to a translation mechanism adapted to move the carrier between the wheels such that the workpiece is in contact with both wheels.

Owner:NOVATEK IP

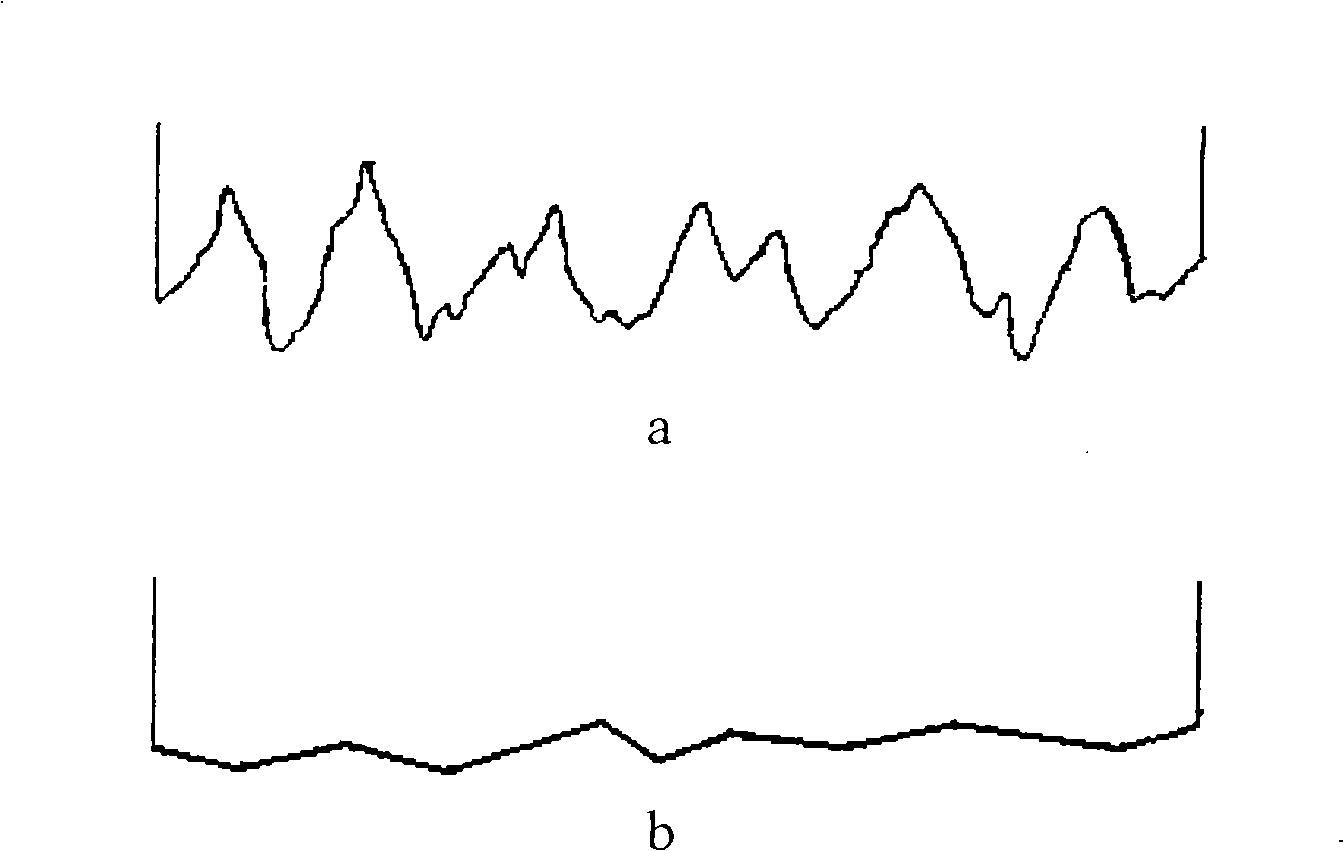

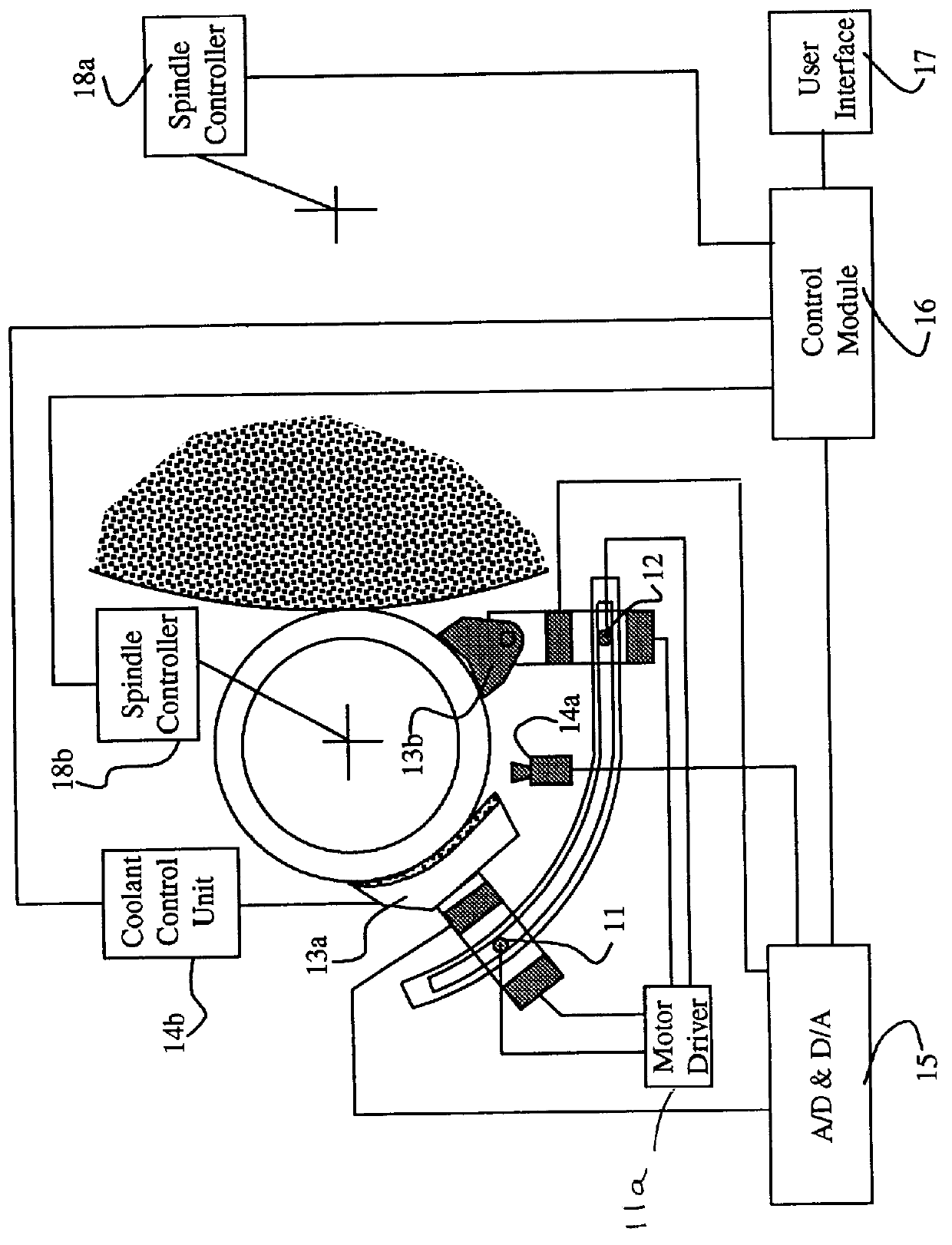

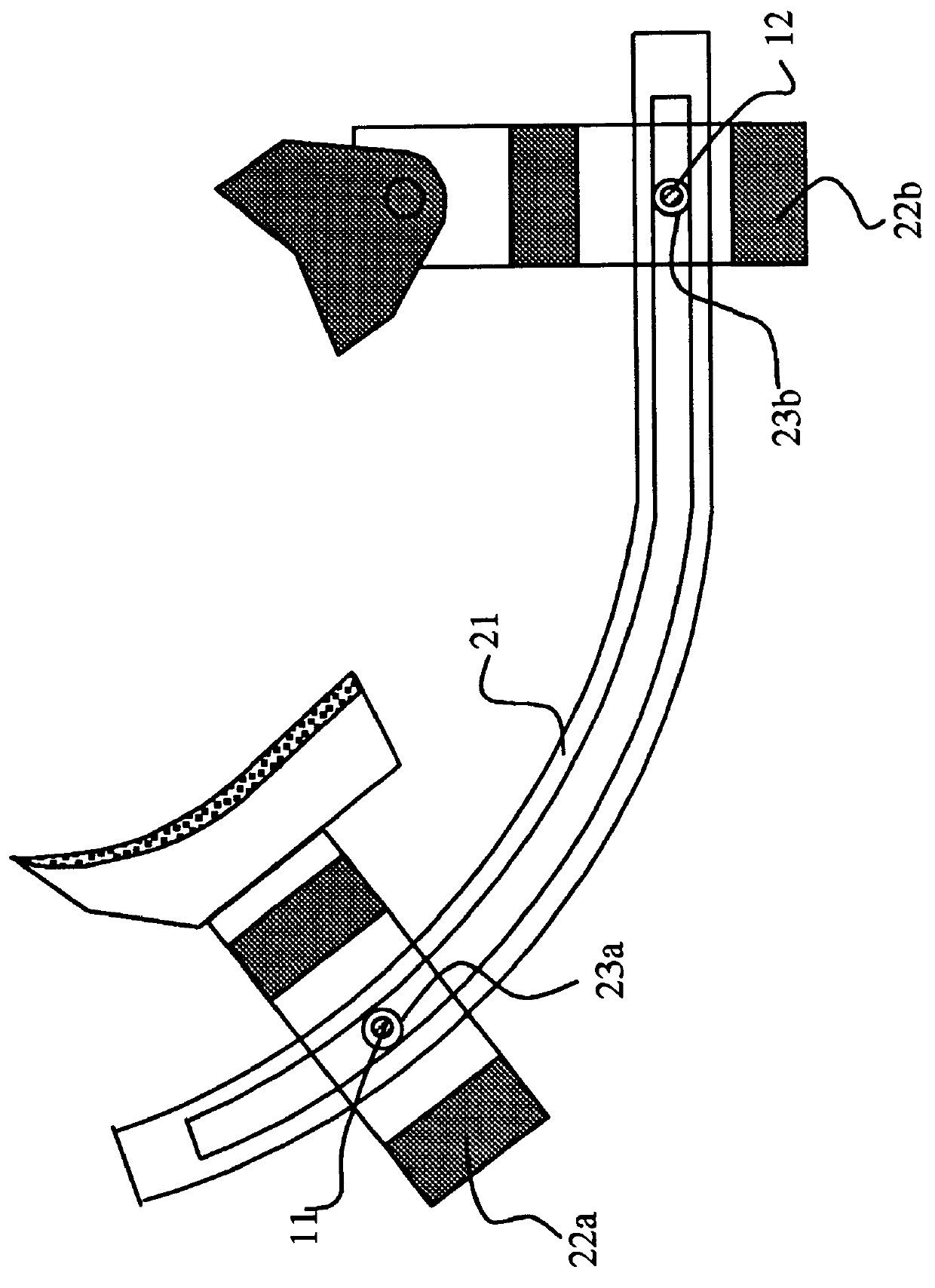

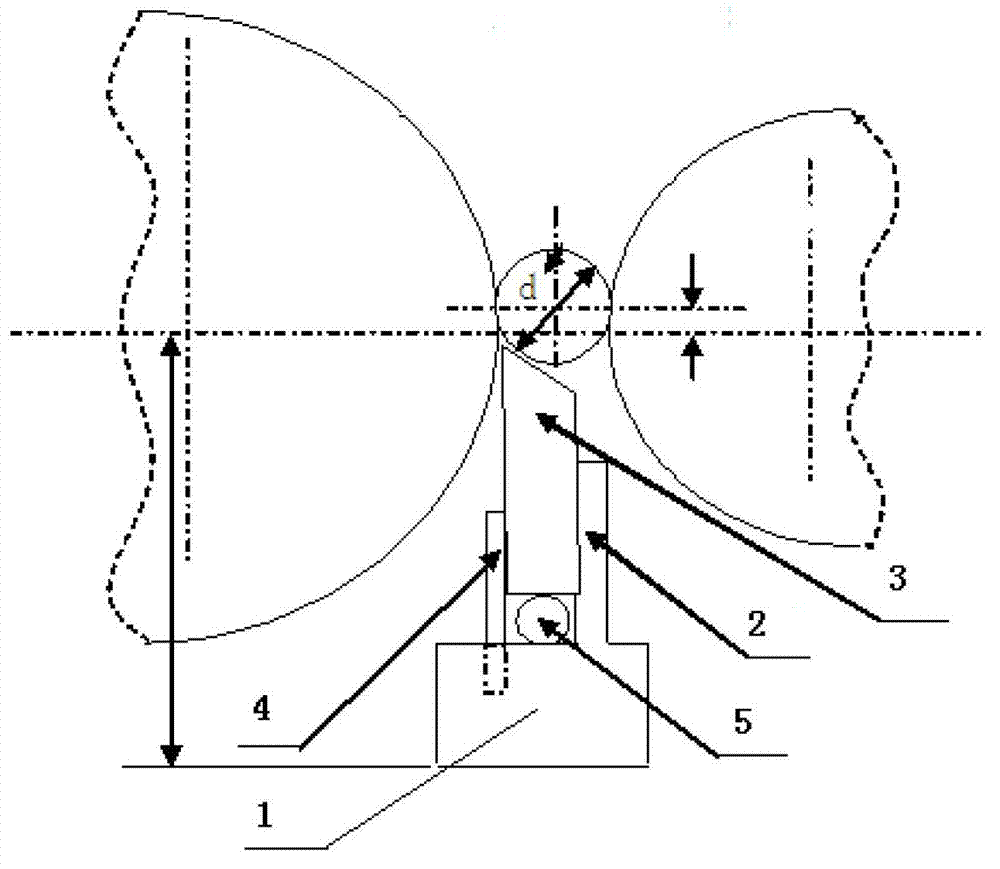

Apparatus and method for lobing and thermal-damage control in shoe centerless grinding

InactiveUS6148248AProgramme controlRevolution surface grinding machinesAutomatic controlVision based

A control system by which, the lobing and thermal-damage on a component surface will be eliminated and a component of a circular cross-section is capable of being ground with ultra-precision and high quality surface finish. The system includes (i) an automatic controlled supporting device, by which the periphery support of circular component of any size is auto-formed in a most stable work-holding condition; (ii) a flexible rear-shoe with active filtering mechanism, by which the high frequency lobing will be removed and the heat generated in the contact area between the workpiece and rear-shoe will be reduced by the self-lubrication of rear-shoe; (iii) an on-line vision-based temperature monitoring and control device, by which the overheat on the workpiece is controlled; (iv) an on-line phase precession lobing control algorithm, by which the lobing will be effectively suppressed in a rounding process.

Owner:XINAOMDT TECH

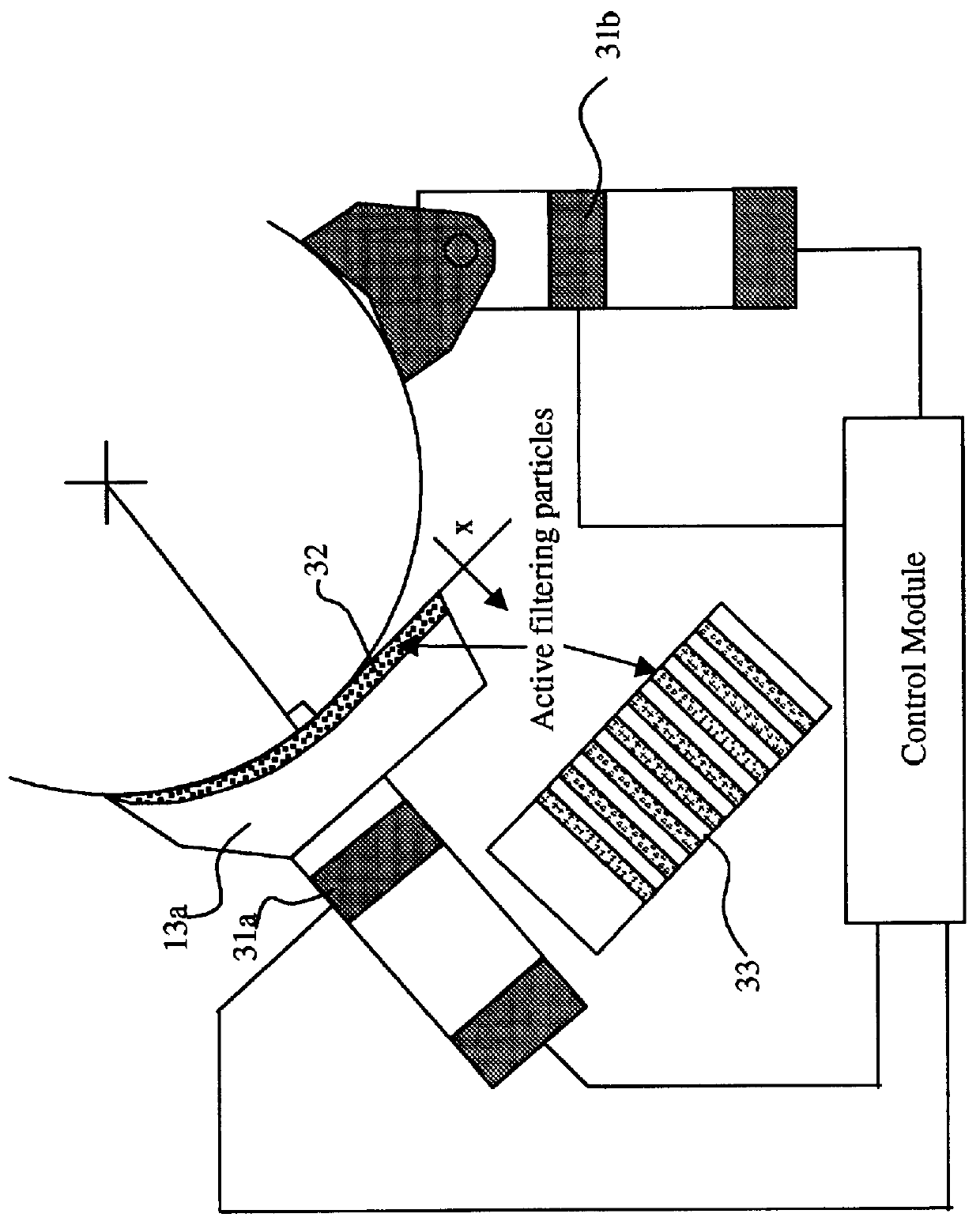

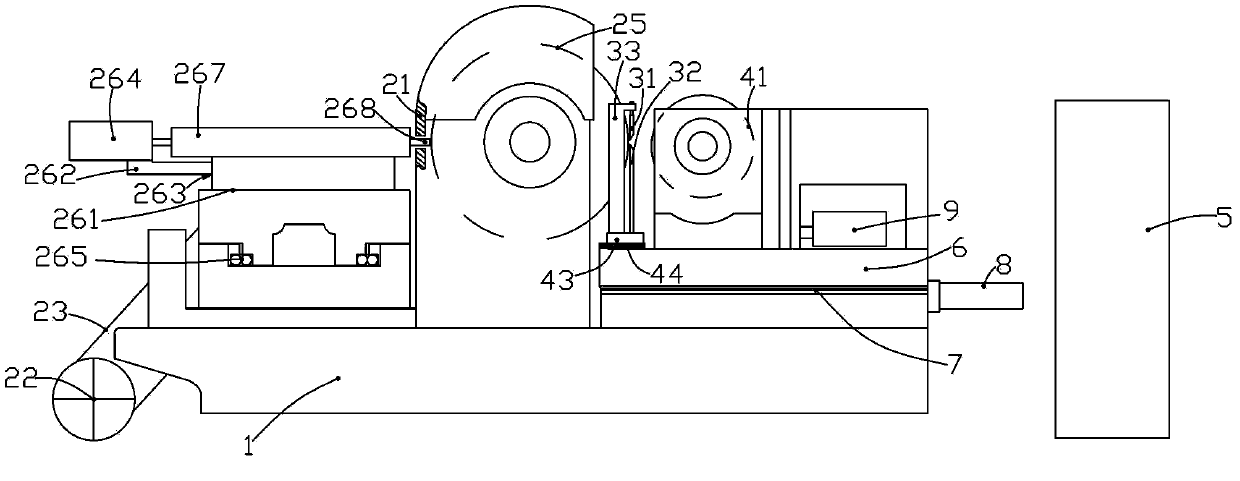

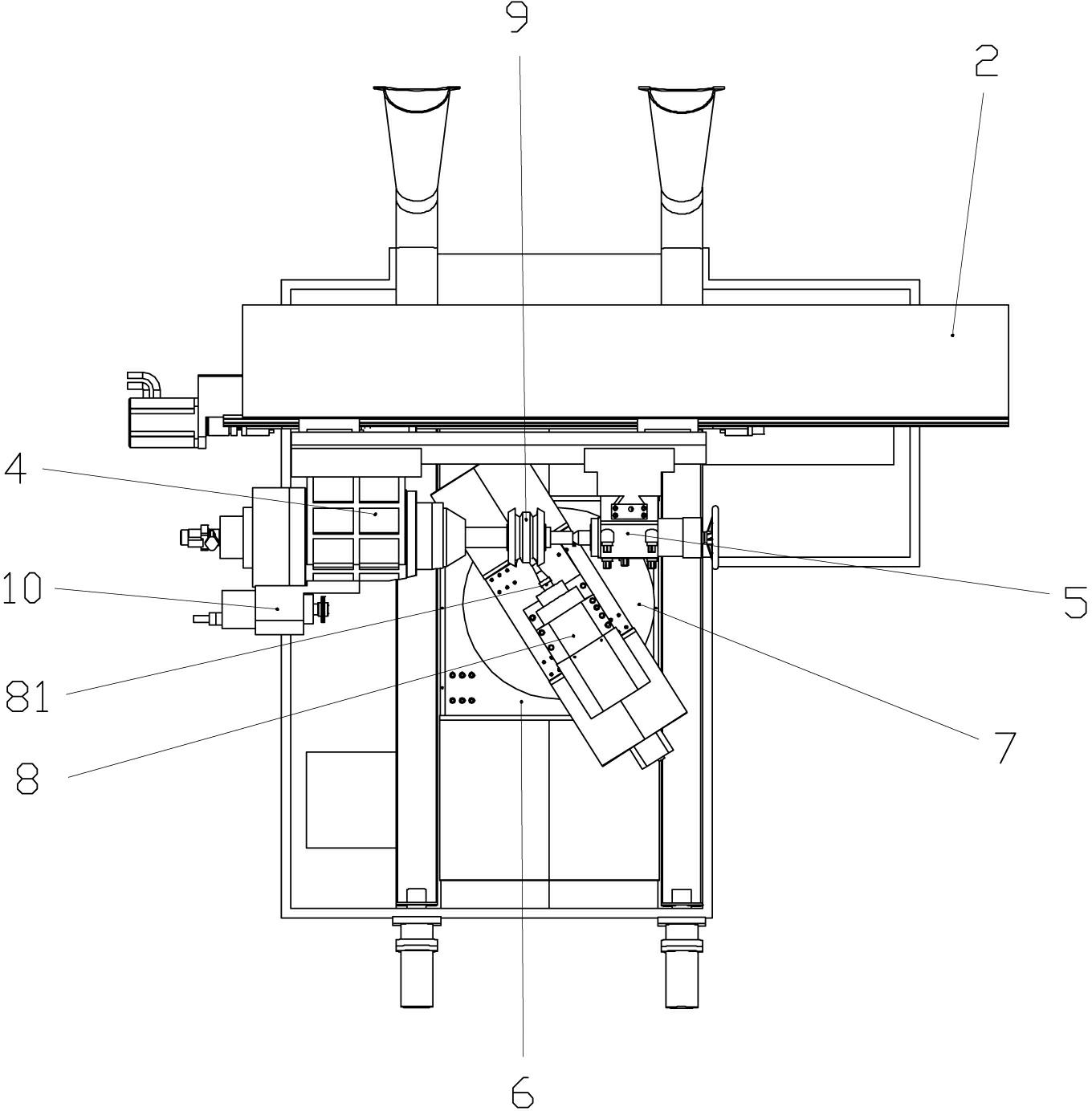

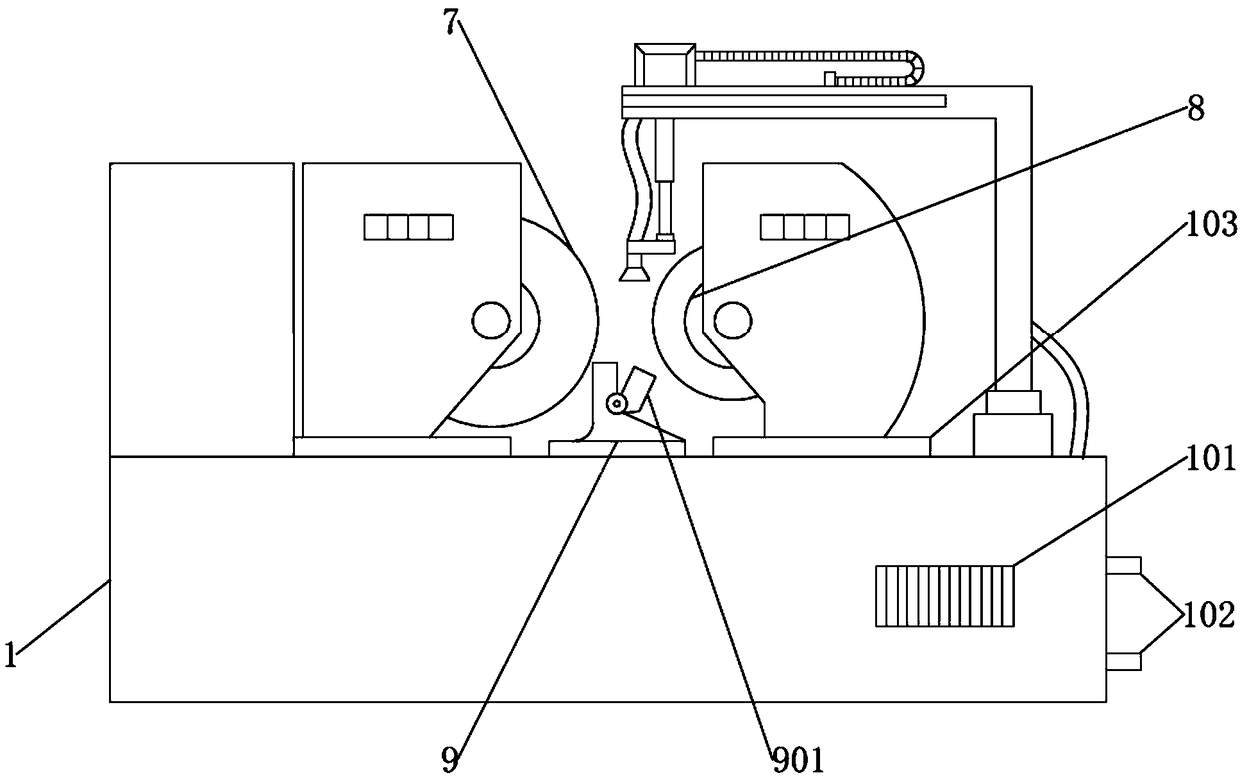

Centerless grinding machine device

InactiveCN105150037ARealize automatic trimmingRealize automatic compensationRevolution surface grinding machinesGrinding drivesMachining processManipulator

The invention aims at providing a centerless grinding machine device. The centerless grinding machine device comprises a grinding wheel, a guiding wheel, a workpiece, a layer board, a machine body, a grinding wheel dresser, a guiding wheel dresser, a guiding wheel feeding mechanism, a grinding wheel feeding mechanism, servo motors, mechanical arms and a control cabinet. The workpiece is borne by the layer board. The grinding wheel and the guiding wheel are located on the two sides of the layer board respectively. The grinding wheel feeding mechanism is used for controlling feeding of the grinding wheel. The guiding wheel feeding mechanism is used for controlling feeding of the guiding wheel. The mechanical arms are located on one side of the grinding wheel and one side of the guiding wheel. The mechanical arms are controlled by CNC to grab the workpiece to finish feeding and discharging operation. The centerless grinding machine device has the beneficial effects that the feeding devices are driven through the servo motors, and automatic dressing and automatic compensating of a centerless grinding machine are achieved; the mechanical arms are controlled by CNC to carry out automatic feeding and discharging, the auxiliary time in the machining process is greatly shortened, and the labor intensity of workers is relieved; and the labor cost is reduced, and the machining precision and the productive efficiency are improved.

Owner:TIANJIN HUATIAN CENTURY MACHINERY

O.D. centerless grinding machine

InactiveUS7677954B2Avoid uneven wearEdge grinding machinesRevolution surface grinding machinesMechanical engineeringElectronic equipment

In one aspect of the present invention, an outer diameter (O.D.) centerless grinding machine for use in grinding a diamond workpiece has a grinding wheel positioned parallel to a regulating wheel which is adapted to press a cylindrical workpiece into the grinding wheel as the regulating wheel rotates. Electronic equipment may be adapted to adjust a pressure of the regulating wheel against the grinding wheel. Also, a carrier may be adapted to house the workpiece, the carrier being attached to a translation mechanism adapted to move the carrier between the wheels such that the workpiece is in contact with both wheels.

Owner:NOVATEK IP

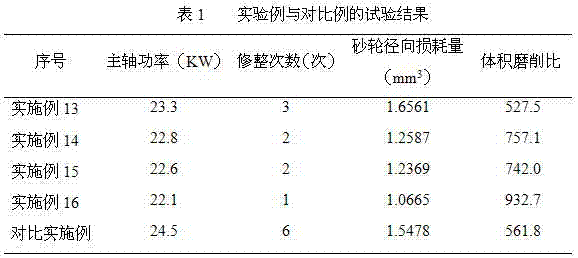

High self-sharpening resin binder diamond centerless grinding wheel and manufacturing method thereof

The invention discloses a high self-sharpening resin binder diamond centerless grinding wheel, comprising a basic body and an abrasive layer. The abrasive layer is made by raw materials in the following parts by weight, 15-25 parts of resin powders, 10-35 parts of micron-order boron carbide, 45-65 parts of polycrystalline diamond, 1-5 parts of FeCrAl alloy fibers, and 1-2 parts of a wetting agent. Compared with a conventional resin binder diamond centerless grinding wheel, the high self-sharpening resin binder diamond centerless grinding wheel is advantaged by high self-sharpening, few grinding wheel dressing frequency, and high durability, and working efficiency is improved. In addition, an improved mixing process is high in efficiency and mixing homogeneity is good, and volume production can be realized, and production efficiency is improved. A mixing process comprises respectively performing dry ball milling by using the abrasive and a binder, and filling the wetting agent to mixing in a machine in a three-dimensional manner, so that mixing efficiency and mixing uniformity effect are improved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

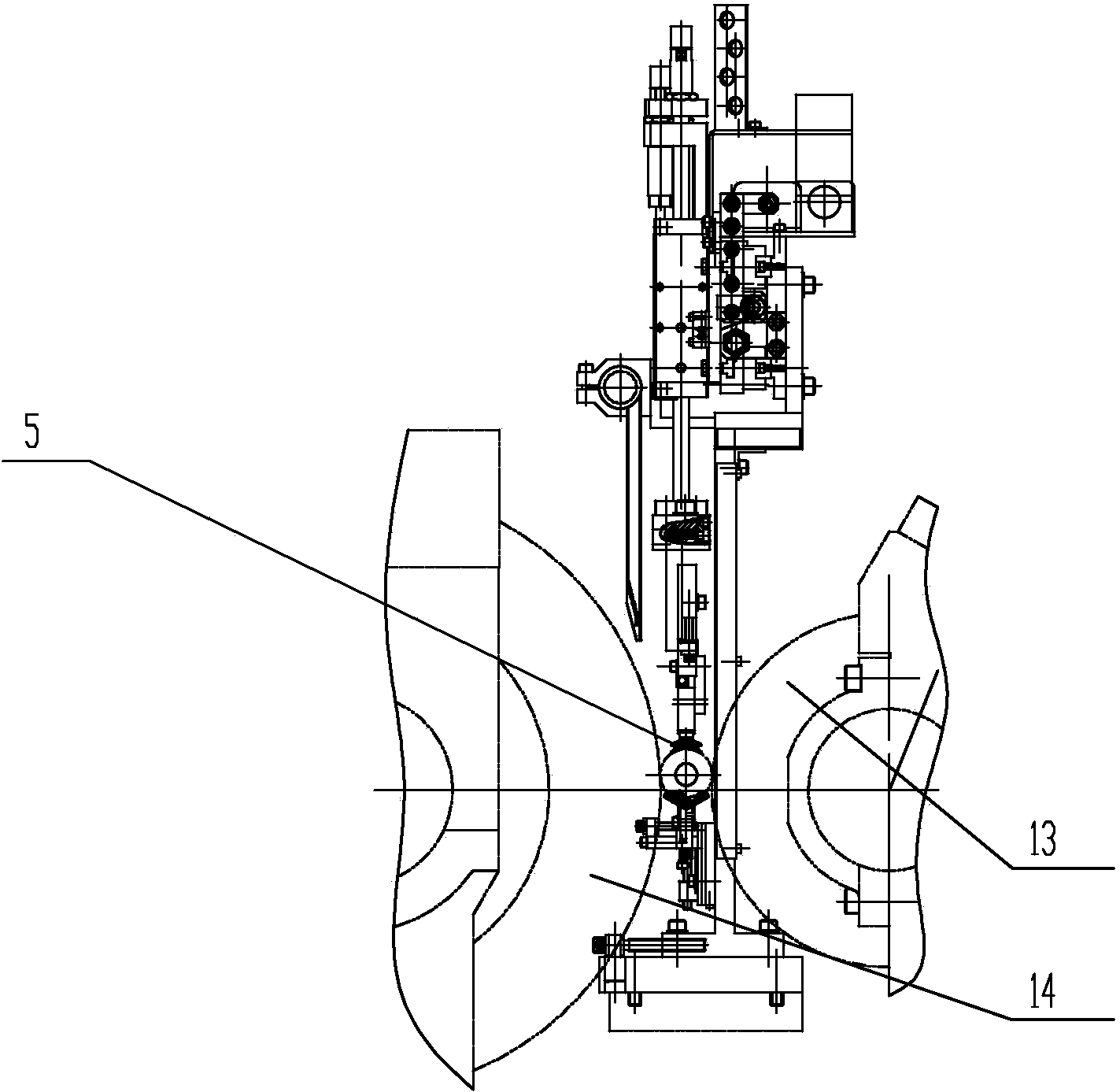

Centerless grinding machine for conical rollers

ActiveCN103394978ANot easy to wearImprove grinding accuracyGrinding carriagesRevolution surface grinding machinesElectrical controlEngineering

A centerless grinding machine for conical rollers comprises a grinding wheel mechanism, a composite base, a guide plate and guide frame mechanism and a guide wheel mechanism. The grinding wheel mechanism is fixed onto a machine body, the composite base matches with the machine body through a MV guide rail, and the guide plate and guide frame mechanism is arranged on the composite base by a cross roller guide rail through a guide plate and guide frame base. The cross roller guide rail is also adopted on a sliding rail in a grinding wheel dressing part of the grinding wheel mechanism, a grinding wheel spindle adopts a double-support ceramic bearing bush, and the end portion of a grinding wheel dressing pen is provided with a King Kong pen point. The grinding wheel dressing part, the composite base and the guide plate and guide frame base are driven by servo motors, and each servo motor and driving motor are under servo control through a electrical control cabinet. The centerless grinding machine is high in degree of automation, fine in accuracy and consistency of grinding machining, convenient to adjust, mount and maintain, high in grinding efficiency, and lower in equipment failure rate, maintenance load, and maintenance cost.

Owner:临清市宏森轴承有限公司

Preparation method of Ti-6Al-4V alloy welding wire suitable for repair welding of titanium alloy casting

ActiveCN106041369ARealize mass productionMeet performance requirementsWelding/cutting media/materialsSoldering mediaTi 6al 4vStress relief

The invention relates to a preparation method of a Ti-6Al-4V alloy welding wire suitable for repair welding of a titanium alloy casting and belongs to the technical field of nonferrous metal material preparation. The preparation method comprises the steps that S1, alloy welding wire raw materials are mixed and pressed into electrodes, and an alloy cast ingot is formed through smelting; S2, homogenizing annealing is conducted; S3, billet forging is conducted; S4, forging is conducted, and flaw detection is conducted through ultrasonic waves; S5, large deformation is conducted once, rolling is conducted twice, and heating and heat preservation are conducted; S6, hot drawing and finishing rolling are conducted, and surface treatment is conducted; S7, temperature-control hot drawing is conducted; S8, annealing is conducted after cold drawing; and S9, sliding block straightening is conducted, straightening and cutting-off are conducted, and a finished product is obtained through stress relief annealing and polishing. The preparation method has the beneficial effects that nonuniformity, caused by quenching, of alloy components and structures in the caisting process is eliminated; and the contaminated surfaces of wire materials are removed in a centerless grinding mechanical mode, surface impurities are removed, further corrosion of the surfaces of the wire materials is prevented during subsequent storage, and the quality of the wire materials is stabilized and improved easily.

Owner:DALIAN SUNNY TITANIUM IND

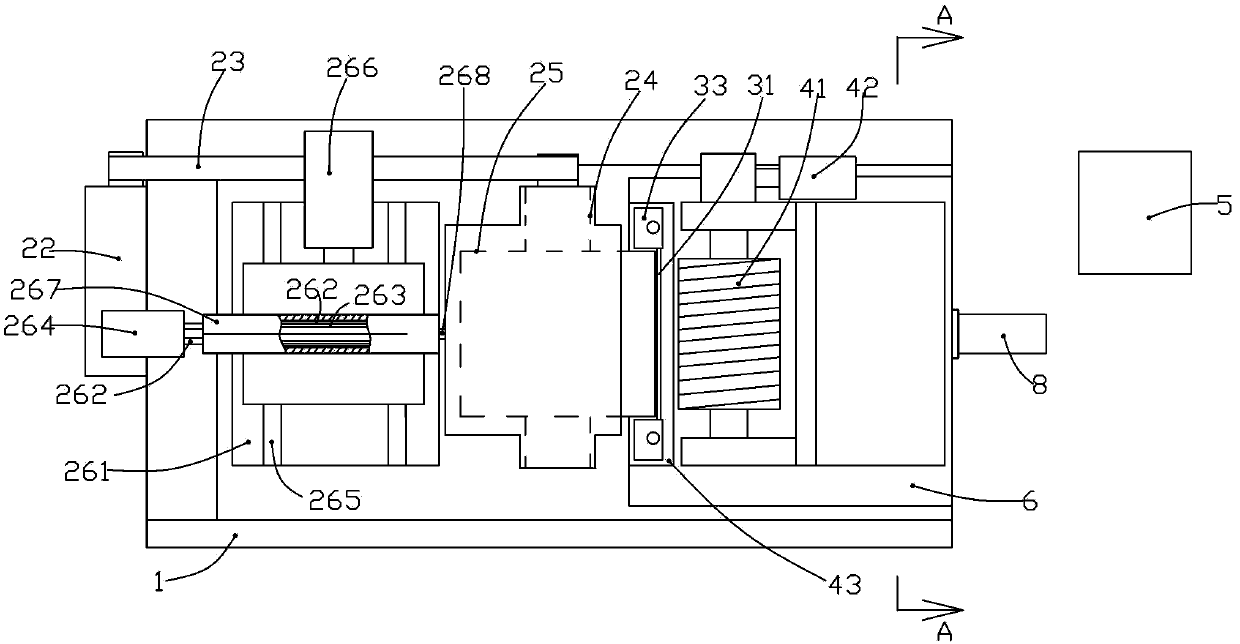

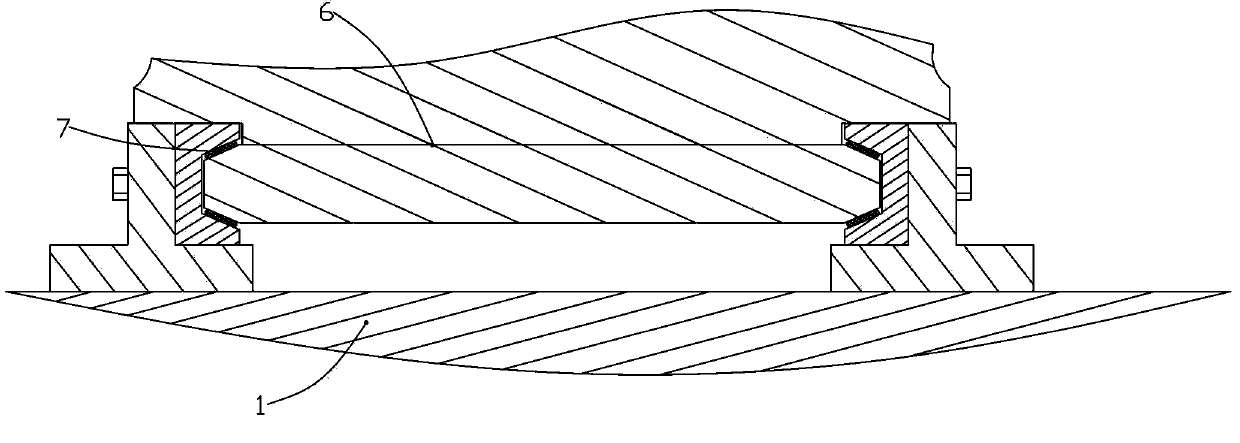

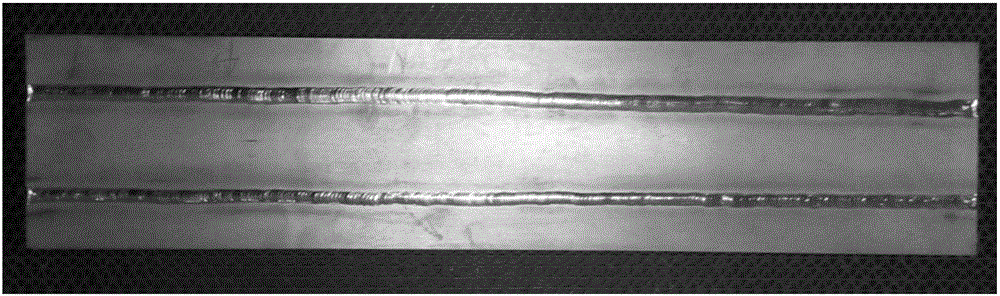

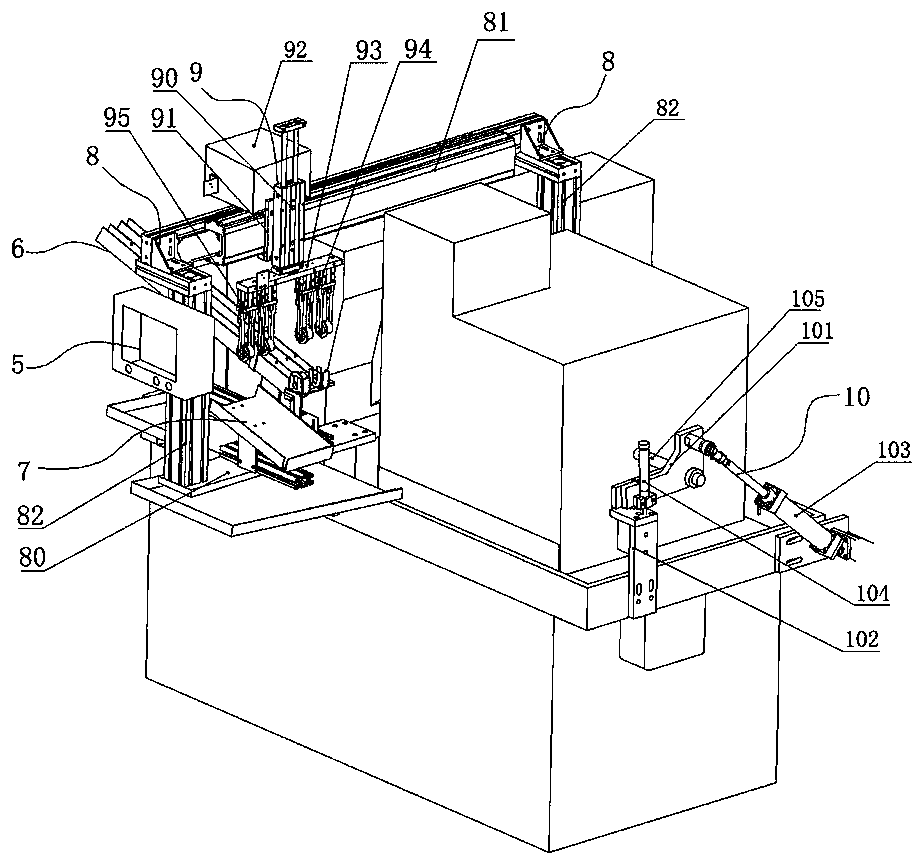

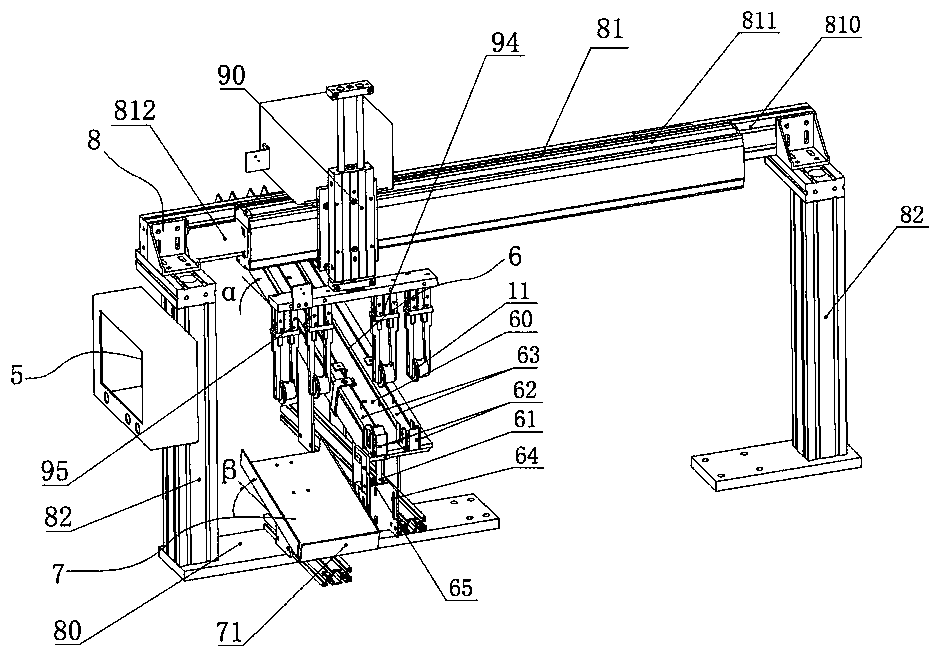

Machining process of loading and unloading conveying device and step shaft sleeves of centerless grinding machine

ActiveCN108436627ASwing neatlyGuarantee processing qualityRevolution surface grinding machinesEngineeringMachining process

The invention relates to the field of machining of centerless grinding machines, in particular to a machining process of a loading and unloading conveying device and step shaft sleeves of a centerlessgrinding machine. The centerless grinding machine comprises a grinding machine base, a grinding wheel, an adjusting wheel and a workpiece bracket; the loading and unloading conveying device comprisesa control cabinet, a feeding mechanism, a discharge bin, a loading and unloading conveying mechanism, a loading and unloading clamping mechanism and a pushing device; the control cabinet is electrically connected with the feeding mechanism, the loading and unloading conveying mechanism and the loading and unloading clamping mechanism; the feeding mechanism takes the charge of tidily placing the step shaft sleeves in sequence; the loading and unloading conveying device is an operating procedure of supporting the loading and unloading clamping mechanism, so that the step shaft sleeves are smoothly loaded and unloaded on the grinding machine, and the manual loading time is saved; through cooperation of the pushing device and the discharge bin, full-automatic grinding is realized, so that thelabor intensity of operators is effectively reduced; and a loading clamping hand and an unloading clamping hand can once clamp at least two step shaft sleeves, so that one half of the machining timeis saved, the labor productivity is improved, and the batch production is achieved.

Owner:CHONGQING ELECTROMECHANICAL VOCATIONAL INST

Preparation method of nickel-based high-temperature alloy Inconel718 spring wire

ActiveCN103924178ASimplify pre-lubrication processSimplify the acid-base cleaning processAcid washingSolid solution

The invention discloses a preparation method of a nickel-based high-temperature alloy Inconel718 spring wire. The method comprises the following steps: I, drawing a nickel-based high-temperature alloy Inconel718 bar by using a roller die for to obtain a wire blank; II, carrying out a solid solution heat treatment on the wire blank and hardening and acid dipping in sequence; III, carrying out the steps I and II for 0-4 times to the acid-dipped wire blank, then, drawing by using the roller die with the total processing rate being greater than or equal to 25%, and then carrying out electric heating tension straightening; and IV, grinding the wire blank on a centerless grinding machine to obtain the Inconel718 spring wire. The method disclosed by the invention is simple in process, easy to realize and high in production efficiency and hardly causes environmental pollution. The spring wire prepared by the method is high in dimensional precision, good in surface quality, uniform in texture and excellent in mechanical property. The method can be widely applied to the processing industry of deformed nickel-based high-temperature alloy wires.

Owner:西安诺博尔稀贵金属材料股份有限公司

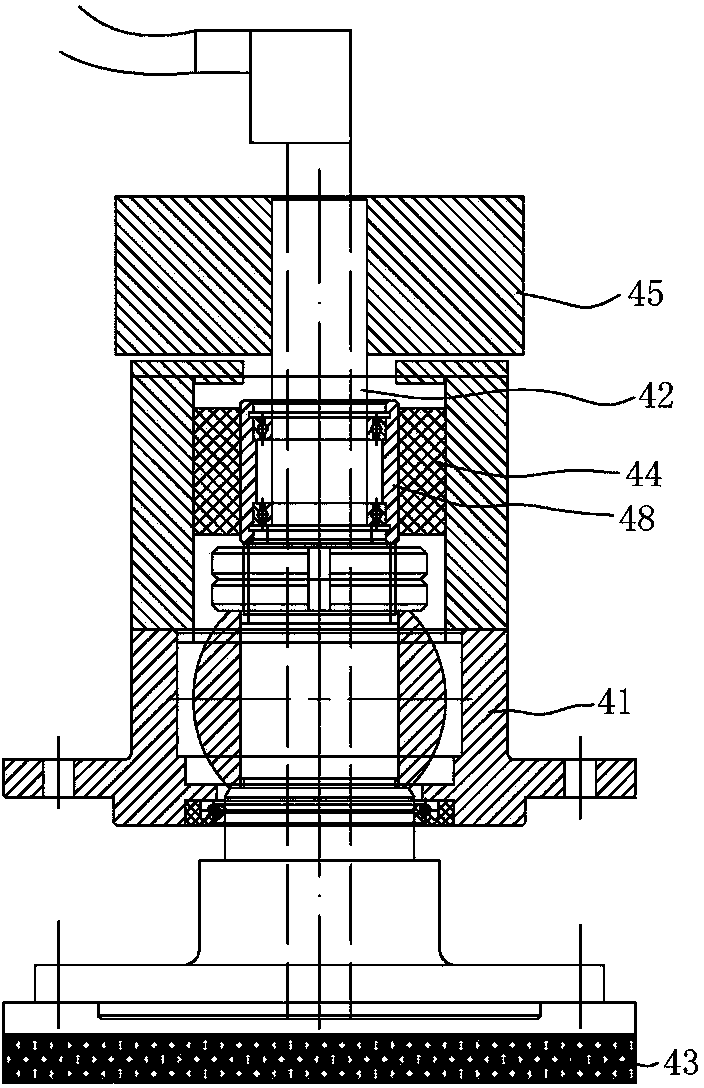

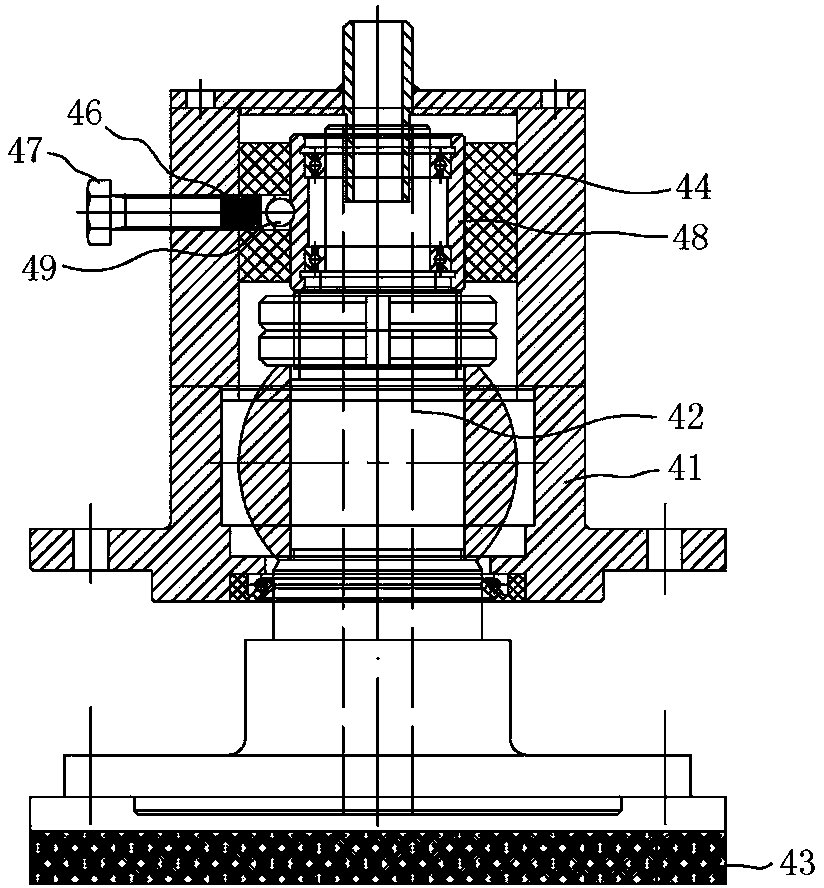

Stepless grinding and polishing device

InactiveCN103801999AUniform wearNo abnormal wear and tearGrinding machine componentsPlane surface grinding machinesFree rotationEngineering

The invention discloses a stepless grinding and polishing device. The stepless grinding and polishing device comprises a main shaft and a revolution plate connected to the lower section of the main shaft. A plurality of grinding head installation positions are arranged on the revolution plate. A stepless grinding head is arranged in each grinding head installation position. Each stepless grinding head comprises a grinding head fixing base with a shaking space. Grinding blocks are connected with the lower ends of grinding wheel shafts. The middle sections of the grinding wheel shafts are provided with spherical motion pairs, wherein the spherical motion pairs are located in the shaking spaces, and gaps are reserved between the spherical motion pairs and the peripheral walls of the shaking spaces. The upper sections of the grinding wheel shafts are connected with the grinding head fixing bases in an elastic mode. In the working process, the grinding method that revolution and free rotation are integrated and the grinding blocks can rotate in all directions in the free rotation process is achieved for the stepless grinding heads, and therefore the surface of a plate to be machined can have a certain profiling function, the surface of the plate can not be easily pressed and damaged, the rough grinding and polishing effects are good, and work efficiency is high. The stepless grinding and polishing device is suitable for machining surfaces of building ceramics, stone materials and decorative plates.

Owner:广东工科机电有限公司

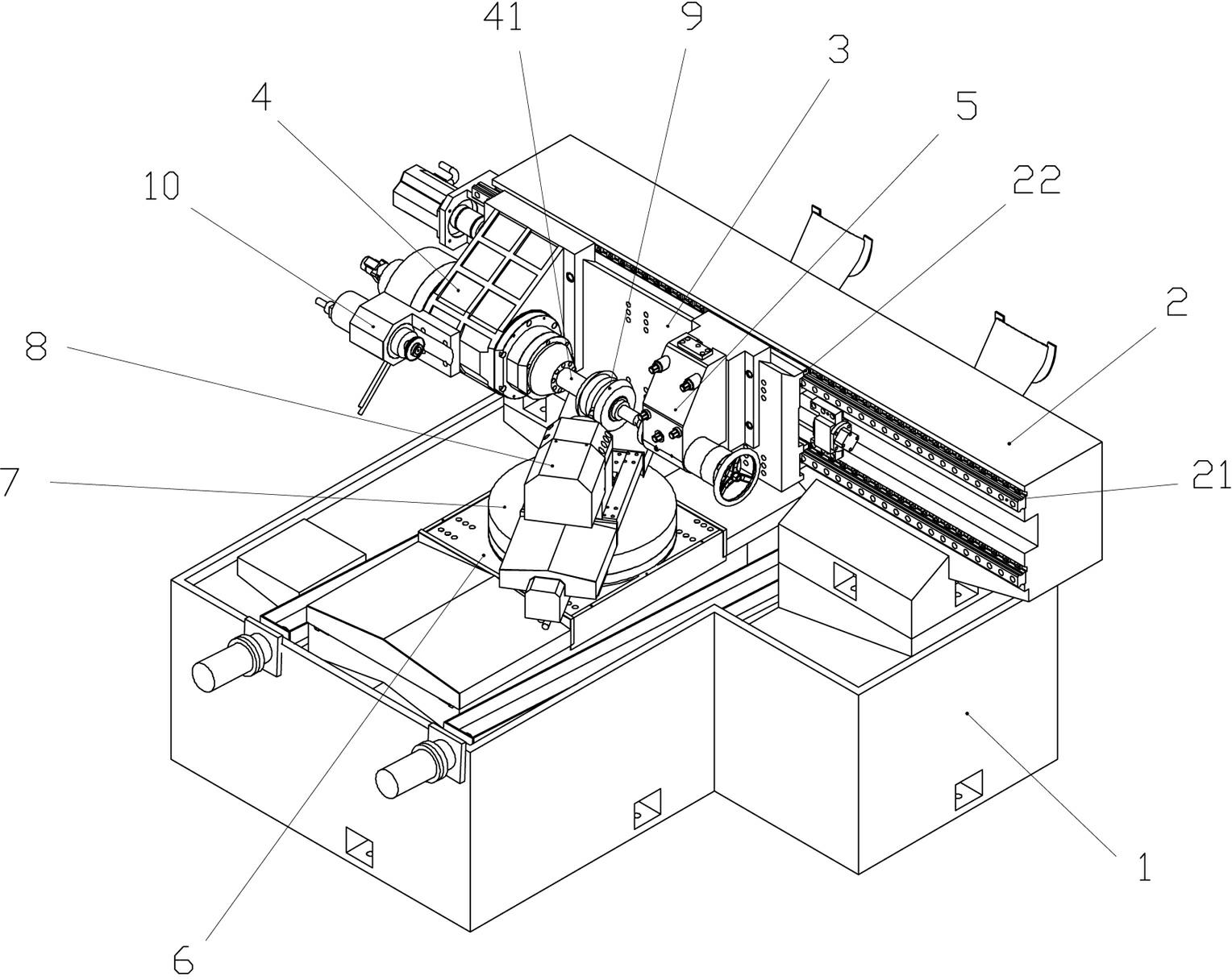

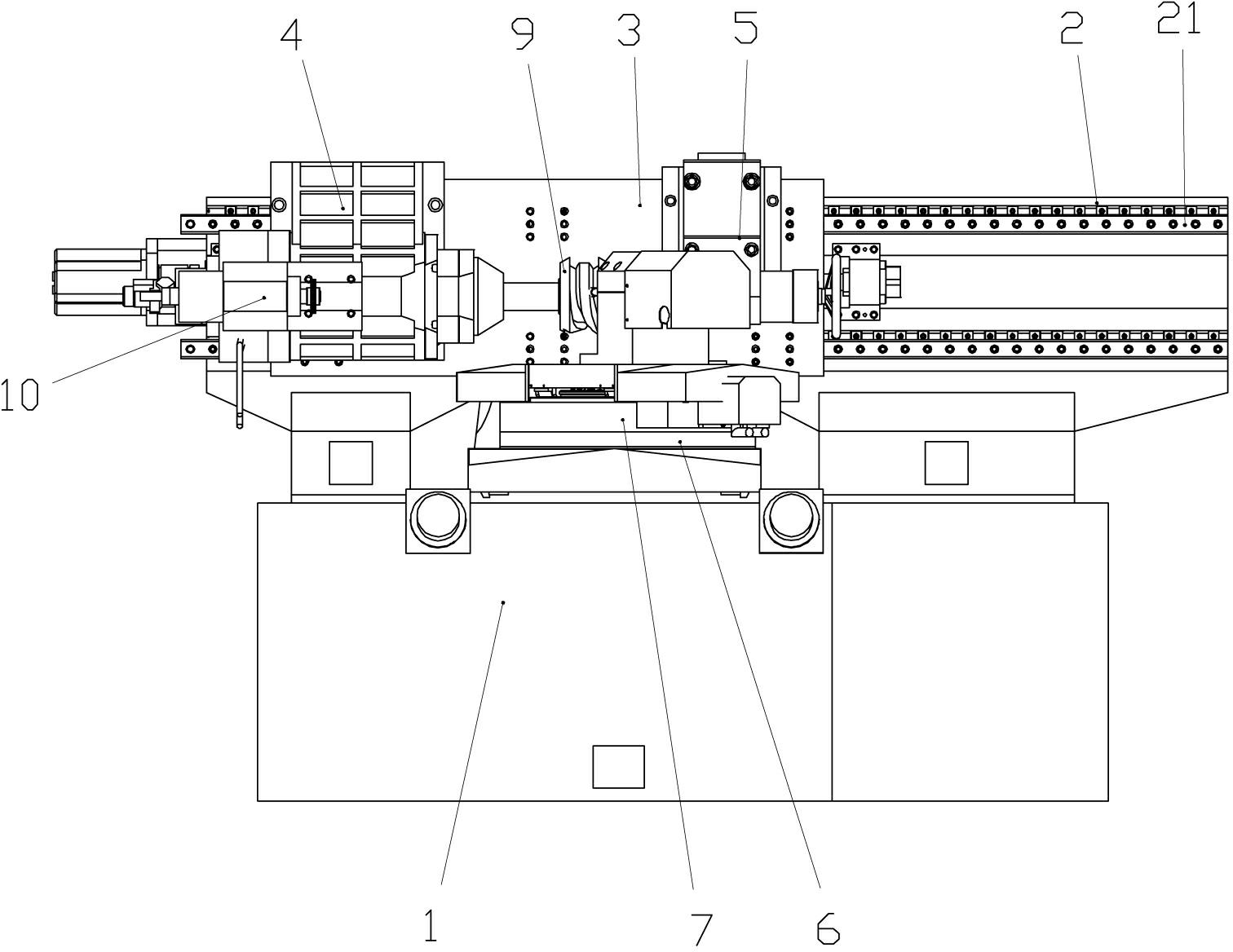

Special numerical-control grinding and milling machine for cams with arc-shaped surfaces

InactiveCN102554627ARealize continuous grinding and millingOther manufacturing equipments/toolsNumerical controlMilling cutter

A special numerical-control grinding and milling machine for cams with arc-shaped surfaces comprises a machine body, a crossbeam is arranged on the machine body along an X-direction, an X-direction slide plate is disposed at the front end of the crossbeam, a workpiece spindle box and a tailstock are oppositely arranged on the X-direction slide plate along the X-direction, a workpiece spindle is arranged in the workpiece spindle box, a Y-direction slide plate is disposed on one side, which is positioned on the X-direction slide plate, of the machine body along a Y-direction, a rotating table is arranged on the Y-direction slide plate, a cutter spindle box is arranged on the rotating table, and a cutter spindle is disposed in the cutter spindle box. When the special numerical-control grinding and milling machine is used, a grinding wheel or milling cutter mounted on the cutter spindle can rotate around the axis of the cutter spindle and simultaneously can swing around the central axis of the rotating table in a reciprocating manner along with rotation of the rotating table. Accordingly, the grinding wheel or milling cutter is equivalently used as a roller of a driven plate of a cam shaft with an arc-shaped surface. Simultaneously, the workpiece (the cam with the arc-shaped surface) is driven by the workpiece spindle to rotate in the process, and an inner groove of the cam with the arc-shaped surface can be continuously ground and milled only by means of rotation of the workpiece spindle and rotation of the rotating table during processing.

Owner:GUANGZHOU CITY AGILE MFG

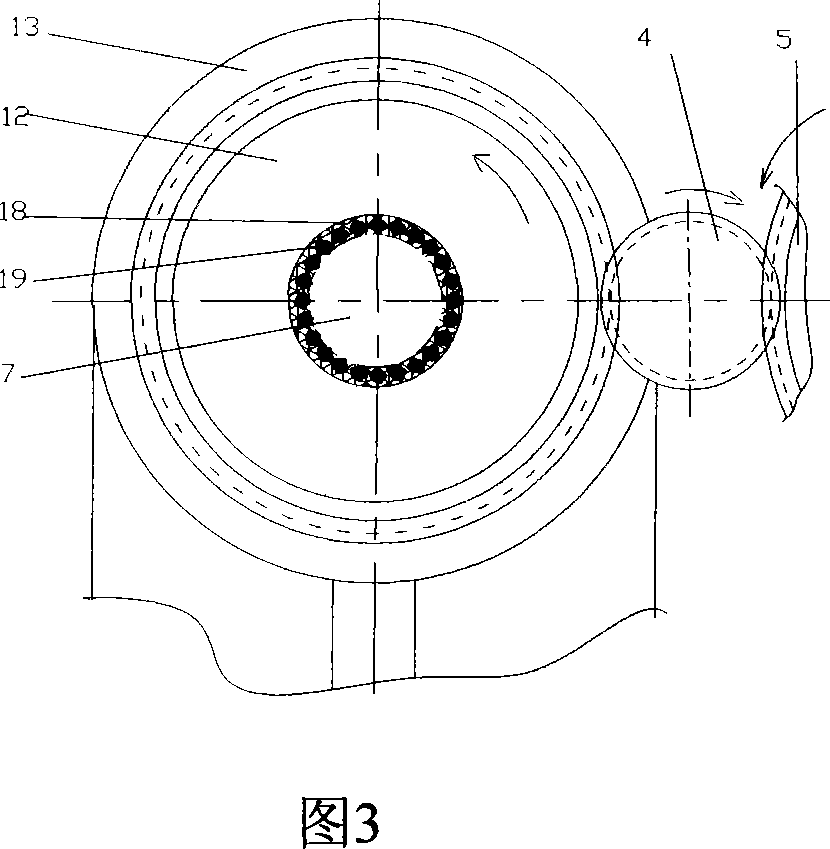

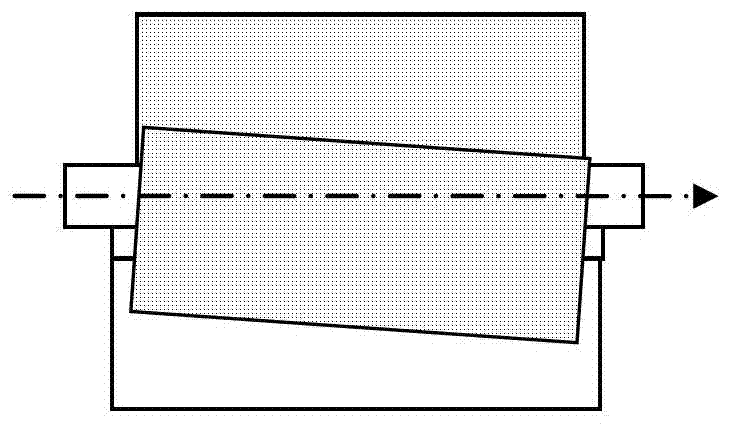

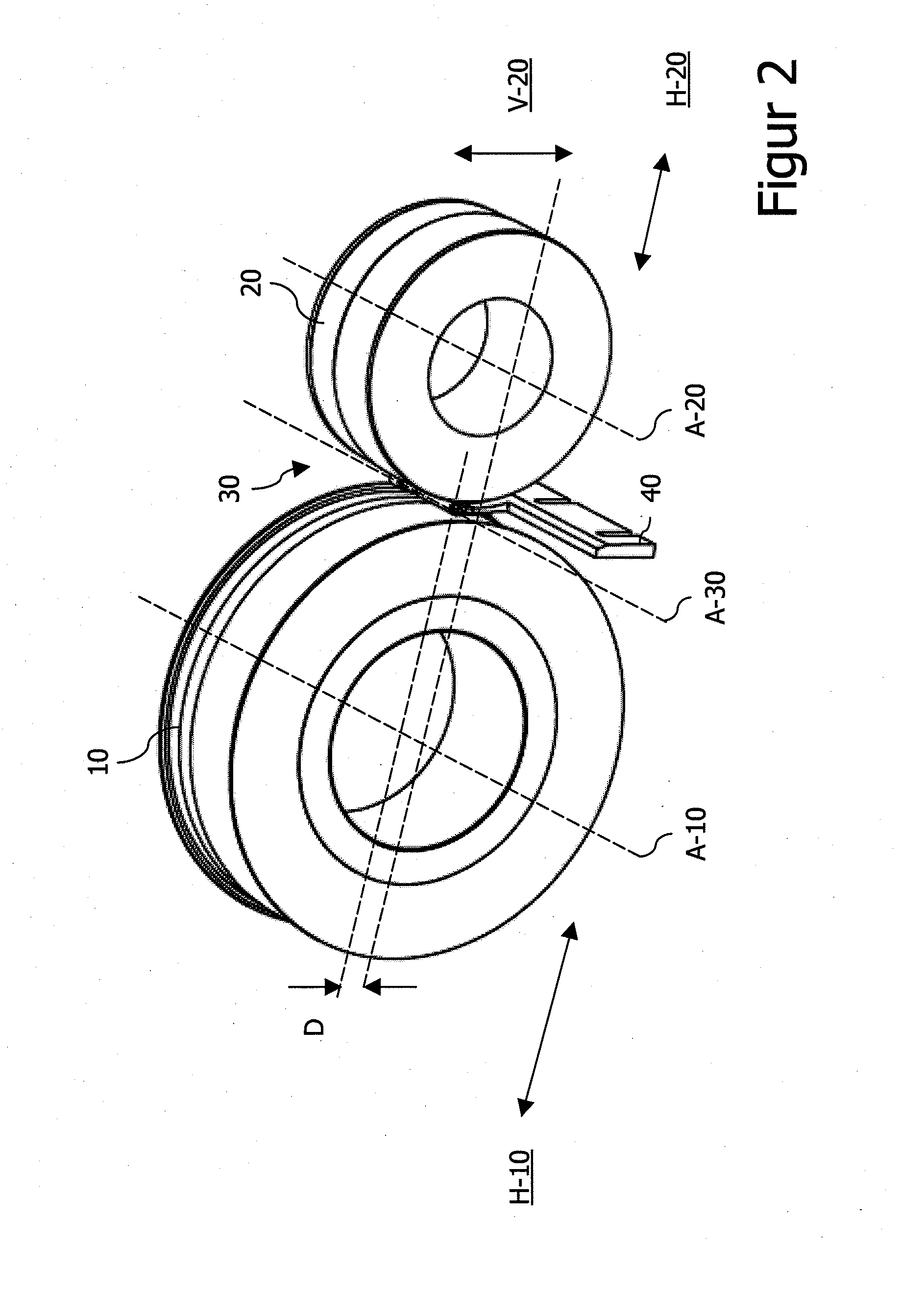

Circular saw blade profile centerless grinding machine and method for centerless grinding circular saw blade profile

InactiveCN101157189AReduce processing costsReduce consumptionPlane surface grinding machinesDrive wheelCircular saw

The invention relates to a grinding machine, in particular to a circular saw blade flank center-less grinding machine and the method thereof to centre-less grinding of the circular saw blade flank. A saw blade feeding operating platform which can be moved from side to side is arranged on one side at the upper part of the machine seat of the grinding machine, a saw blade supporting bracket is arranged on the operating platform, a core axle for suspending the saw blade is arranged on the saw blade supporting bracket, a driving wheel and a motor which rotate with the blade with in a fricative way are installed on the two sides of the saw blade on the operating platform; an abrasion wheel and a back wheel which are provided with independent driving motors and respectively arranged on the both side of the saw blade are installed on the other side of the upper part of the machine seat side by side, axial lines of the two wheels are paralleled, and kept parallel with the plane of the saw blade, the rotating speed of the back is lower than the rotating speed of the abrasion wheel, and clearance which can be grinded, adjusted, and installed into the saw blade is arranged between the two wheels. The invention extends the rod center-less grinding principle, the double side grinding can be finished through a double-face alternate grinding method, and clamped and fixed through the floating of the saw blade, on the basis of ensuring the processing efficiency and processing precision, the production cost can be saved, the energy consumption can be saved, and the processing cot of the saw blade can be decreased.

Owner:TANGSHAN METALLURGICAL SAW BLADE

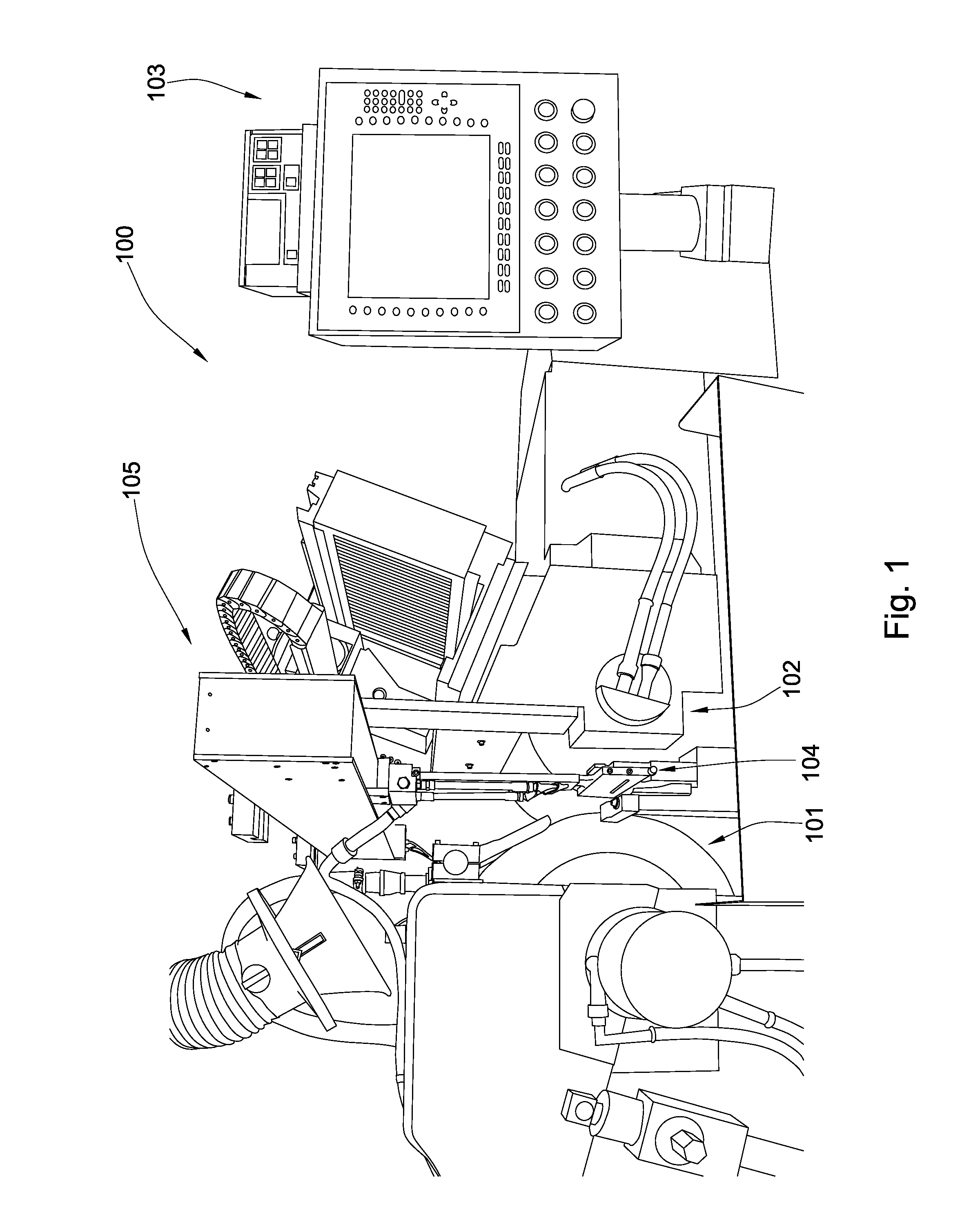

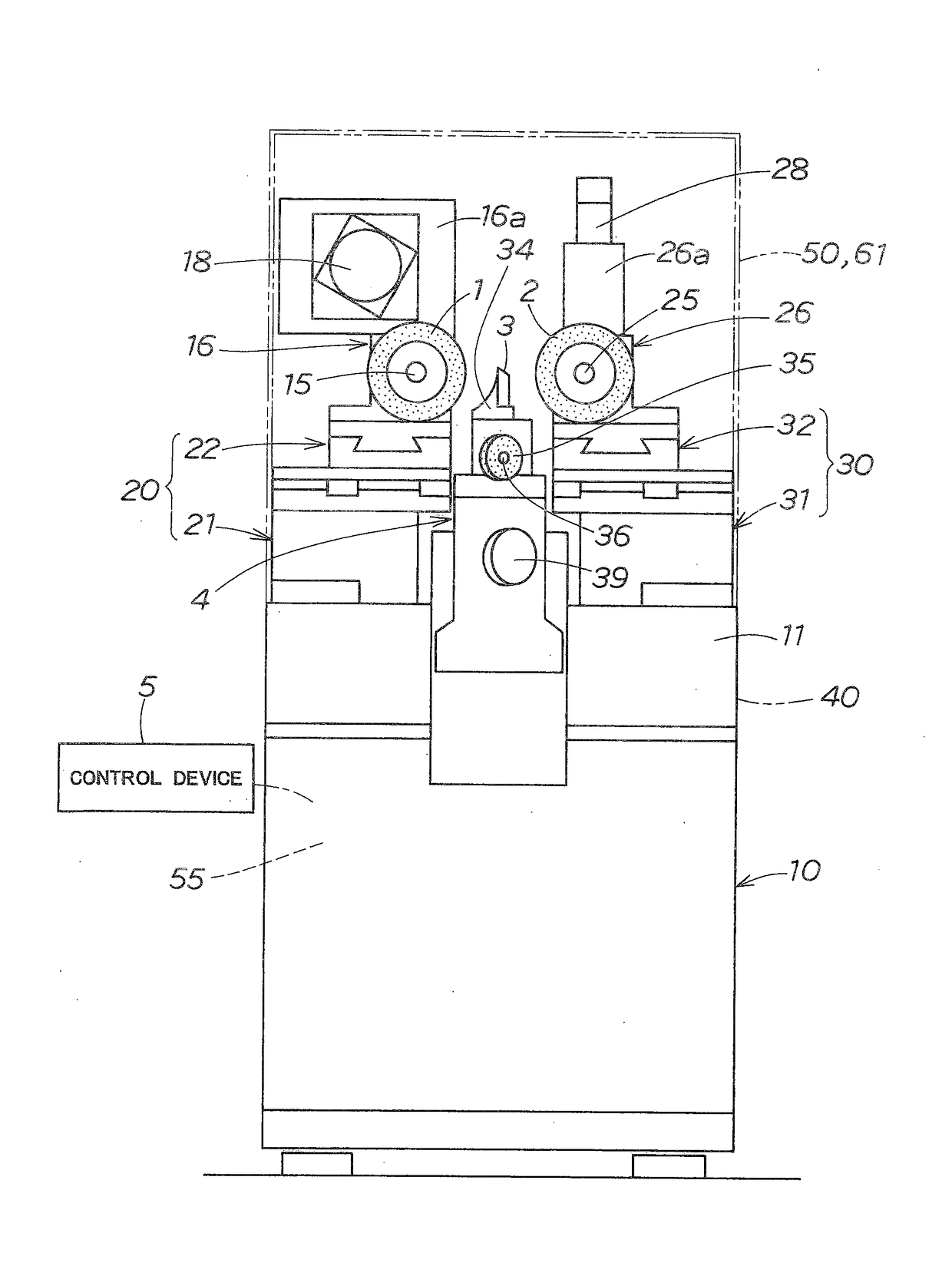

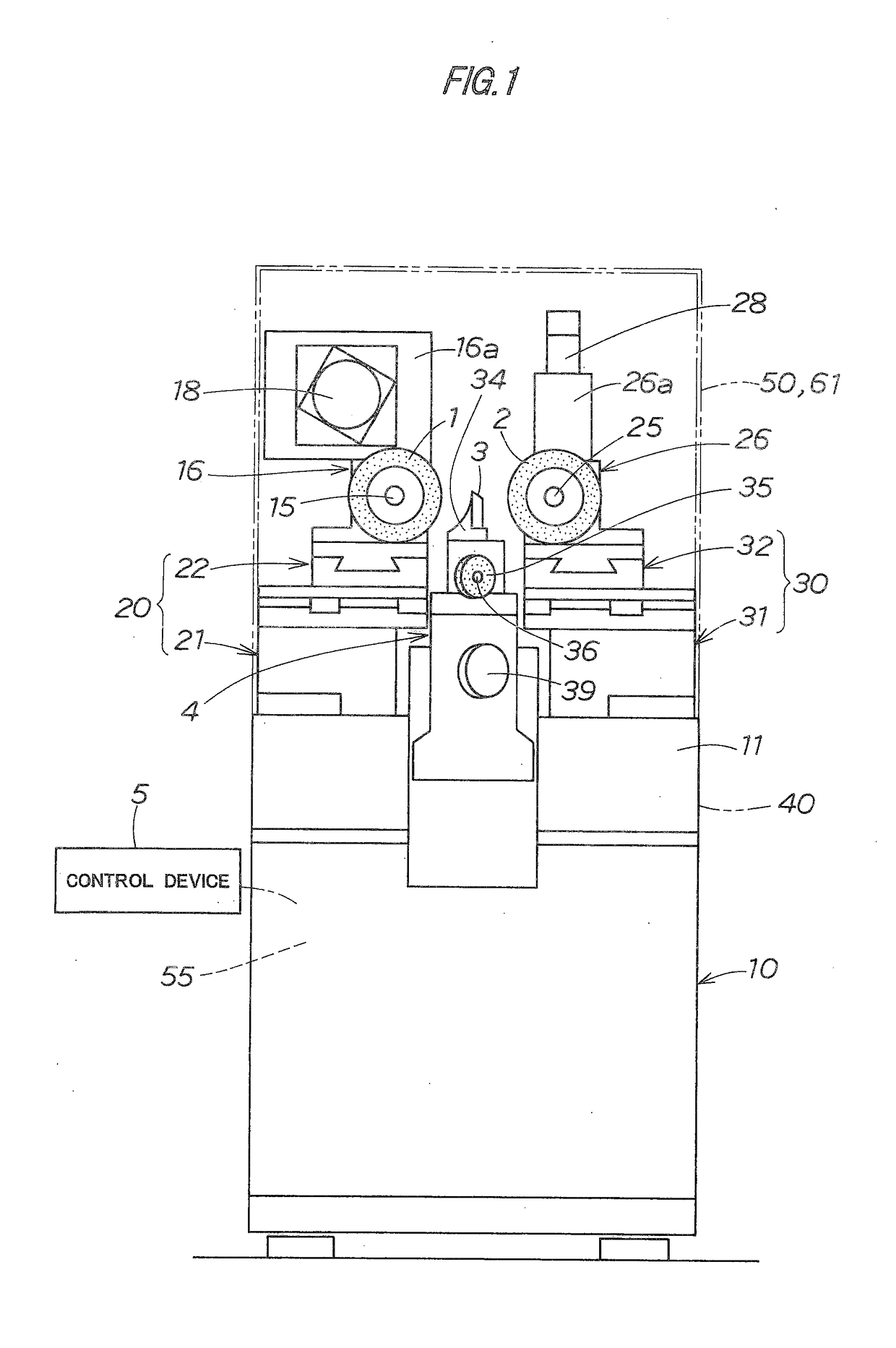

Centerless grinding machine

ActiveUS20170106488A1Easy to operateEasy to prepareGrinding carriagesRevolution surface grinding machinesEngineeringMechanical engineering

A space-saving centerless grinding machine having high operability is obtained by devising the configuration of component units around the basic configuration of the machine. A dressing means for performing a dressing process for a grinding wheel and a regulating wheel comprises a single dressing unit. The dressing unit is located at a lower position between the grinding wheel and the regulating wheel, and thus eliminates the need for right and left dresser spaces for grinding wheels that have most seriously affected the breadthwise dimension of a conventional centerless grinding machine, leading to space saving and a considerable reduction in the breadthwise dimension of the centerless grinding machine.

Owner:KOYO MASCH IND CO LTD

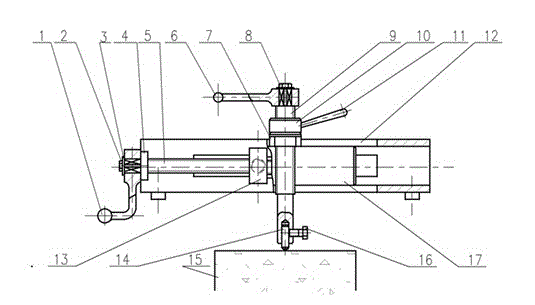

Bar centerless grinding technology and special knife board adjusting device thereof

InactiveCN102773776ASimple structureEasy to debug and maintainRevolution surface grinding machinesEngineeringMachining

The invention relates to a bar centerless grinding technology and a special knife board adjusting device thereof; the bar centerless grinding technology comprises the following steps of: firstly carrying out rough machining on a bar so as to enable the workpiece allowance to be between 0.3mm and 0.5mm, the roundness error is below 0.10mm and the straightness accuracy is within 1mm / m; the bar centerless grinding technology and the special knife board adjusting device thereof disclosed by the invention can efficiently eliminate or reduce the original roundness error of a bar blank, thereby controlling the roundness error of a workpiece finished product, improving the product percent of pass and saving the production cost; the whole process flow is simple in process and easy to operate; and the special knife board adjusting device is simple in structure, and convenient to debug and maintain.

Owner:BAOSTEEL DEV CO LTD

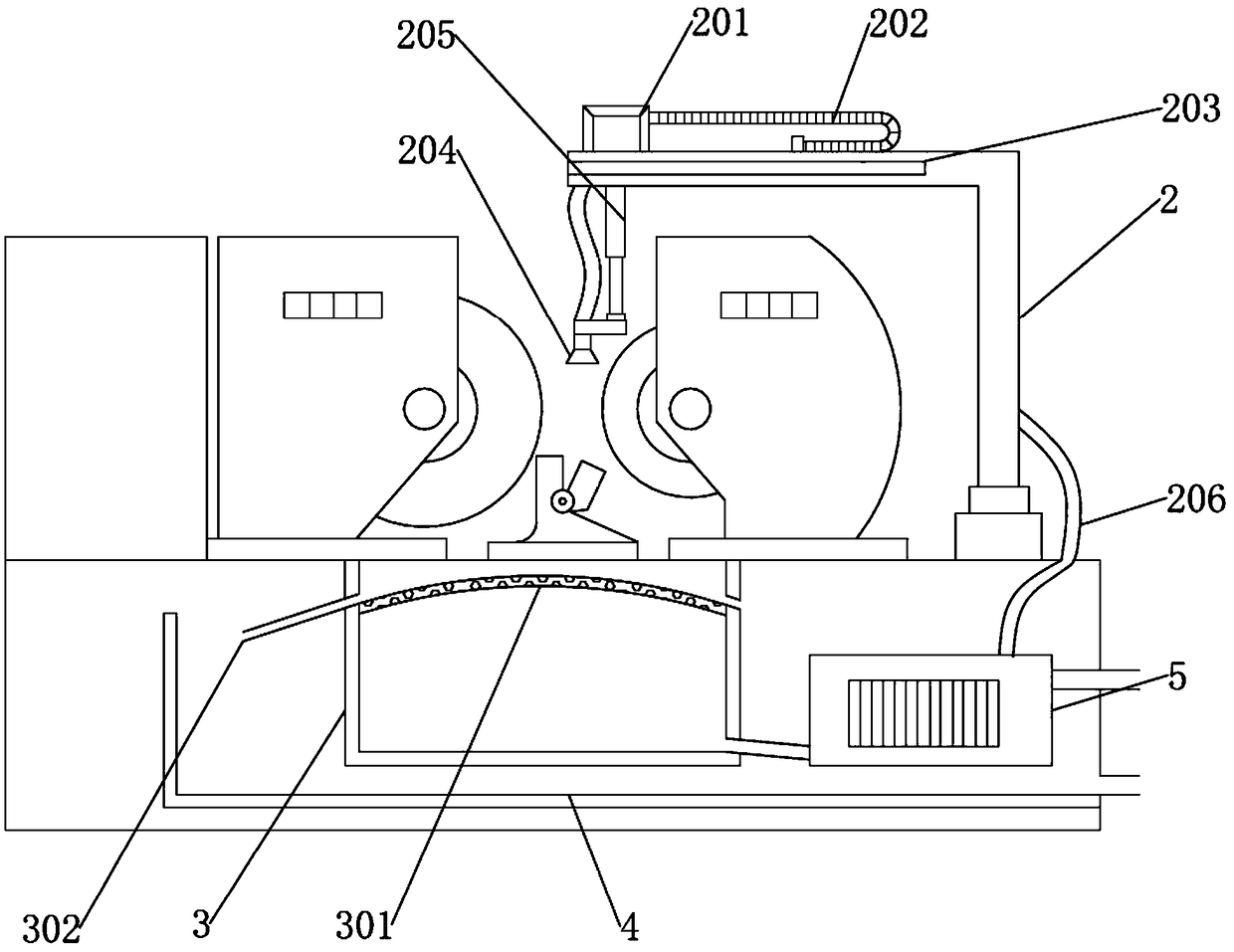

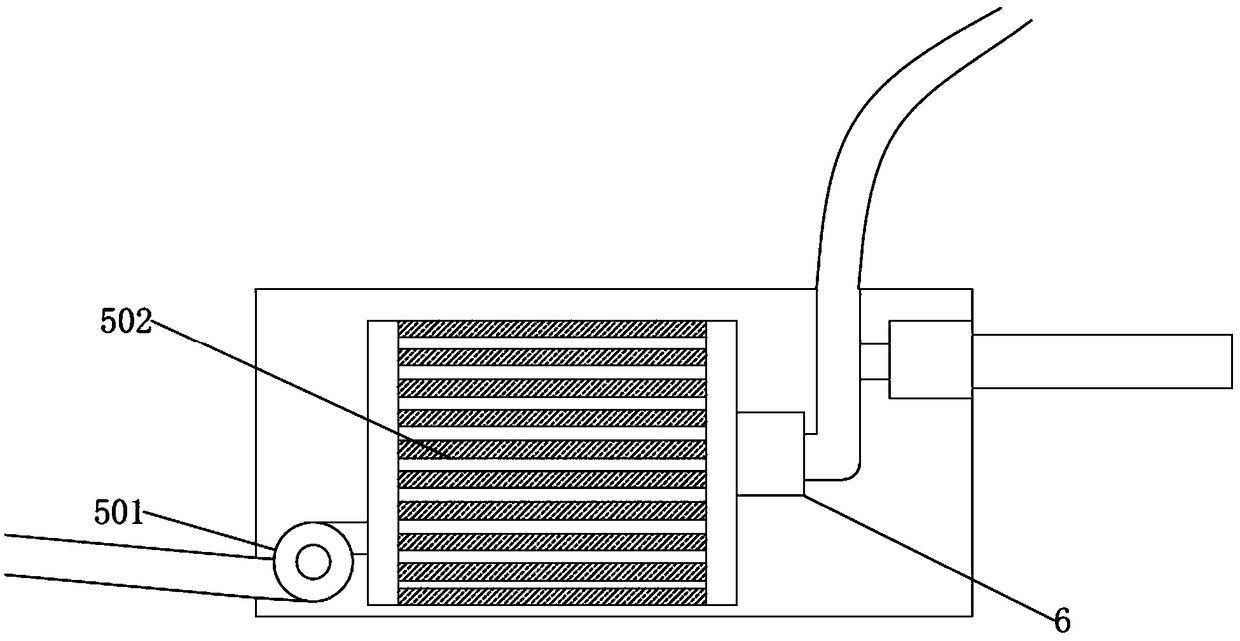

Centerless grinding machine

InactiveCN108788961AAchieve the effect of reuseGrinding effectRevolution surface grinding machinesGrinding/polishing safety devicesEngineeringWater level

The invention discloses a centerless grinding machine. The centerless grinding machine comprises a grinding machine base, a water collecting water tank, a grinding wheel and a metal chip filtering plate, two grinding wheel adjusting sliding rails are fixedly installed on the upper surface of the grinding machine base, a water cooling system is connected to the upper surface of the grinding machinebase in an inserted mode, a horizontal rod is welded to the top of the water cooling system, and a water level adjusting sliding block is connected to the upper surface of the horizontal rod in a sliding mode; and one side of the water cooling system is connected with a water supply pipe in an inserted mode, and the water collecting water tank is fixedly installed inside the grinding machine base. According to the centerless grinding machine, the metal chip filtering plate is fixedly connected to the center of the inner part of the water collecting water tank, cooling liquid flowing down after grinding through the centerless grinding machine can be filtered through the metal chip filtering plate, scrap iron left by grinding through grinding wheel inside the cooling liquid is filtered, sothat the situation that the scrap iron is sprayed onto the grinding wheel again after passing through the water cooling system, then scratches are left on the surface of a ground workpiece is avoided,and the problem that the interior of the cooling liquid cannot be secondarily utilized due to the residual scrap iron is solved.

Owner:MAANSHAN YASHIDA INTELLIGENT TECH CO LTD

Guide wheel modifier for centerless grinding machine

InactiveCN103056774ASimple structureLow input processing costAbrasive surface conditioning devicesEngineeringProcessing cost

The invention relates to a guide wheel modifier, specifically relates to a guide wheel modifier for a centerless grinding machine and belongs to the technical field of bearing processing and centerless grinding. The guide wheel modifier comprises a modifier body, a horizontal moving mechanism and a vertical moving mechanism, and the horizontal moving mechanism and the vertical moving mechanism are arranged on the modifier body. The manufacture structure of the guide wheel modifier for the centerless grinding machine is simple, investing processing costs are much lower than those of an old guide wheel modifier, height adjustment and horizontal moving of a diamond pen are flexible by means of a bidirectional adjustable mechanism, and more importantly, the problem of frequent maintaining in the past is solved; and the operation is convenient, an operator can master work methods after the operator is slightly trained and guided, work efficiencies are greatly improved, and subsidiary work time is reduced.

Owner:WAFANGDIAN BEARING GRP CO LTD

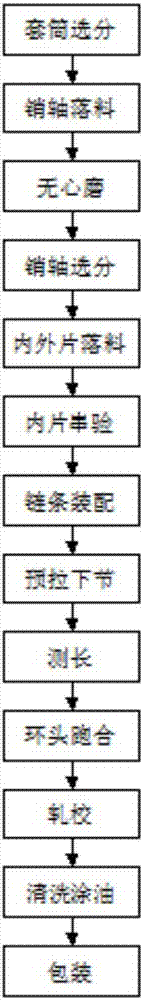

Assembly method of timing chain

The invention discloses an assembly method of a timing chain in the technical field of chain assembly. The assembly method comprises the steps of sleeve sorting, pin shaft blanking, centerless grinding, pin shaft sorting, inner and outer piece blanking, inner piece string checking, chain assembly, lower section pre-stretching, length measurement, ring head closing, rolling inspection, cleaning, oil removal and packing. Raw materials with defects on the surfaces are eliminated in the raw material selecting phase to greatly improve the pass percent in the raw material primary production phase; through the procedures of lower section pre-stretching, ring head closing and finished product length measurement, the pass percent of timing chain products is guaranteed; inner and outer chain platesof the timing chain and a cover plate are riveted through cover pieces to guarantee flexibility of each chain link of the timing chain and to prevent the tooth jumping phenomenon; and the assembly method of the timing chain prevents the defects of high operation difficulty, low assembly efficiency and easy generation of wrong operations in a traditional chain assembly method through pairing and marking, and is flexible and accurate in assembly mode and high in assembly efficiency.

Owner:NANJING LIMIN MACHINERY

Preparation method of titanium alloy bar of universal resetting screw seat

ActiveCN111534715AEffective grain size refinementReduce residual stressWire straightening devicesTemperature control deviceOrthopedic departmentManufactured material

The invention belongs to the technical field of machining of medical titanium alloy materials and particularly relates to a preparation method of a titanium alloy bar of a universal resetting screw seat. The chemical ingredients of titanium alloy comprise, by mass percentage, 5.9%-6.4% of Al, 3.9%-4.4% of V, 0.15%-0.22% of Fe, 0.09%-0.13% of O, not larger than 0.05% of C, not larger than 0.005% ofH, not larger than 0.01% of N and the balance Ti. The preparation method comprises the steps that firstly, a round bar blank is obtained through the procedures of smelting, forging, and rolling; thena beta single-phase section homogenization annealing treatment process is adopted to obtain a homogeneous fine-grained acicular martensite structure, an electrifying straightening and hyperbolic straightening combined process is used for straightening, the electrifying straightening temperature is controlled to be less than 780 DEG C, and a balanced residual stress state is obtained; and finally,stress relief annealing and centerless grinding are conducted to obtain the finished bar. The preparation method of the titanium alloy bar of the universal resetting screw seat can produce a medicalTi-6Al-4V alloy bar basically free of stress, the Ti-6Al-4V alloy bar has excellent fatigue life, and a qualified raw material is provided for manufacturing of universal resetting screw seats of orthopedic medical instruments.

Owner:中科锐金山东钛业科技有限公司

Novel centerless grinding device for pole blank

InactiveCN103692299ANovel and reasonable structureLow degree of mechanizationRevolution surface grinding machinesGrinding feedersEngineeringMaterial storage

The invention provides a novel centerless grinding device for a pole blank. The novel centerless grinding device for the pole blank comprises a grinding mechanism and a feeding mechanism, wherein the feeding mechanism comprises a material storage box and a conveyer, the material storage box is open and oblique, the conveyer comprises a conveyer belt, the bottom wall of the material storage box is provided with a propping plate, the upper end of the propping plate is oblique, and an oblique guide plate is arranged between the upper edge of the lowest box side wall and the conveyer belt. Therefore, the novel centerless grinding device for the pole blank breaks through the construction form of tradition centerless grinding device, the propping plate props the pole blank to be higher than the upper edge of the lowest box side wall, the pole blank rolls to the oblique guide plate and further rolls to the conveyer belt, and then is conveyed to the grinding mechanism by the conveyer belt for grinding; when material at the lower end of the material storage box reduces, the material at the higher end automatically rolls to supplement; compared with prior art, the feeding mechanism of the novel centerless grinding device for the pole blank can feed the grinding mechanism organically and continuously, and the whole device has high degree of mechanization, much smoother grinding, high efficiency and strong practicability.

Owner:QUANZHOU FENGYUAN MACHINERY

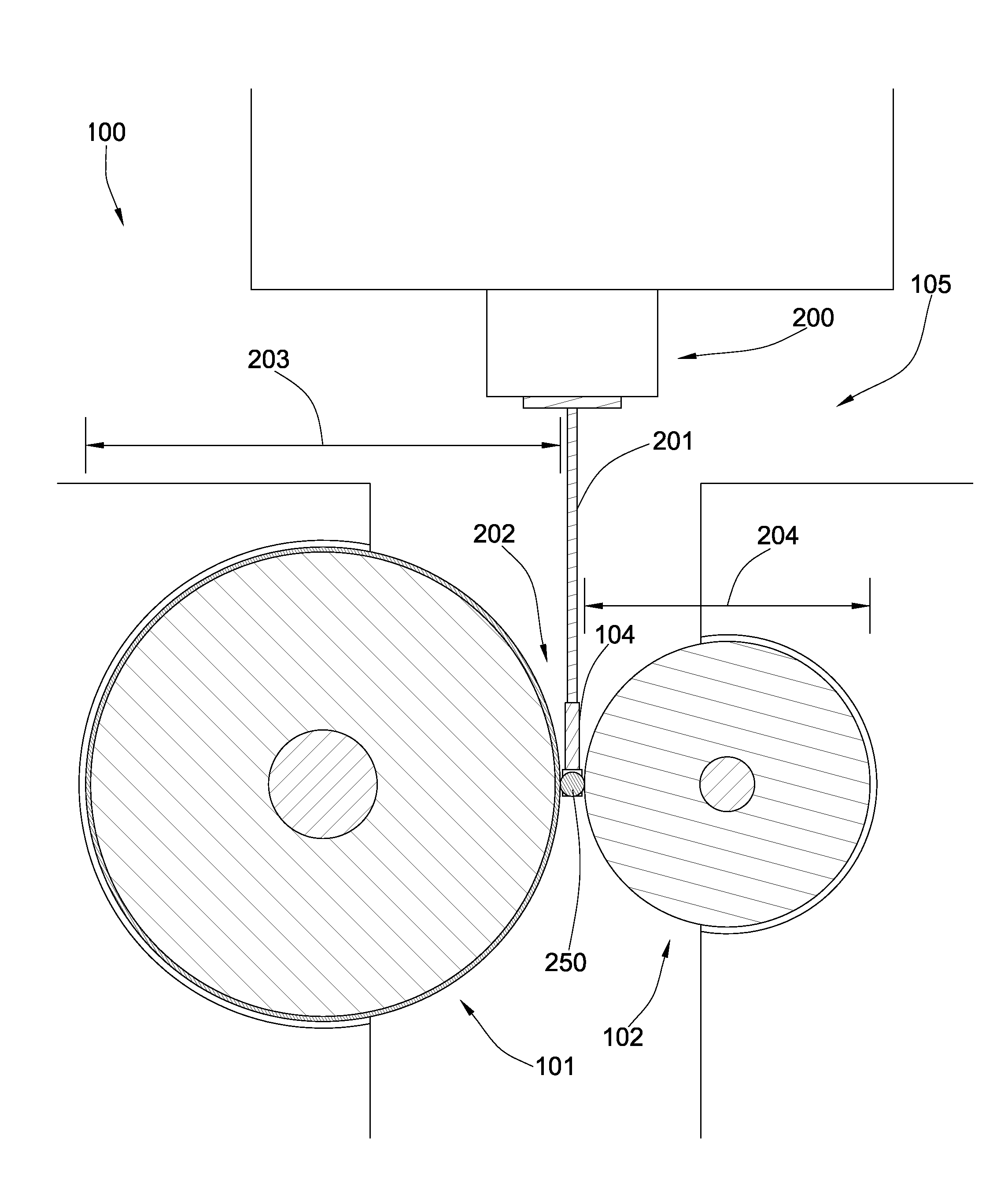

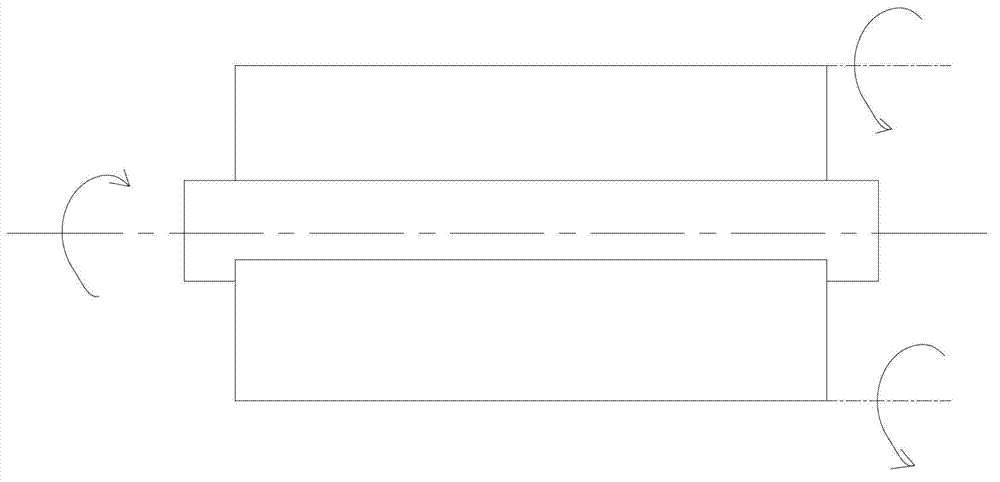

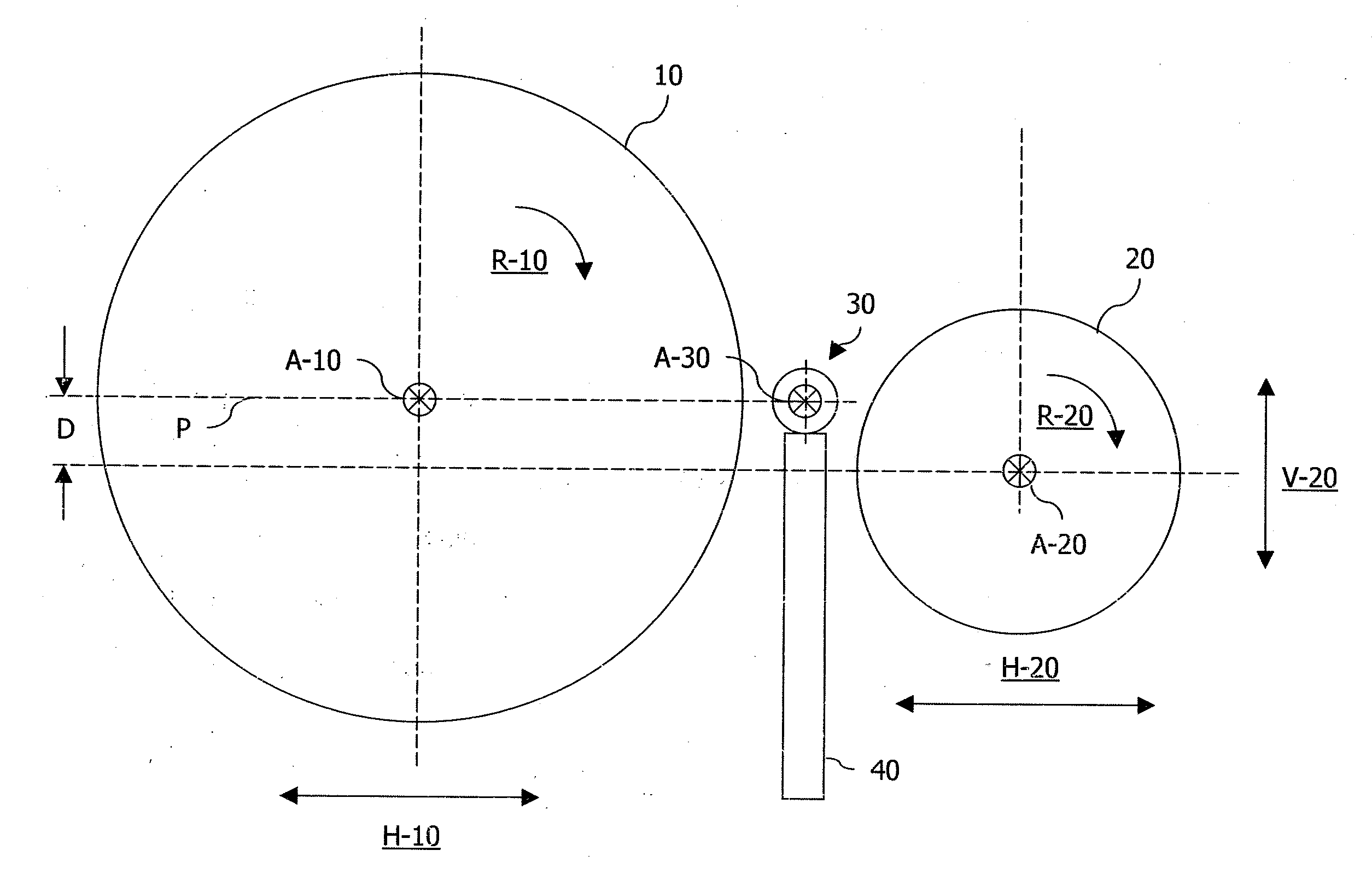

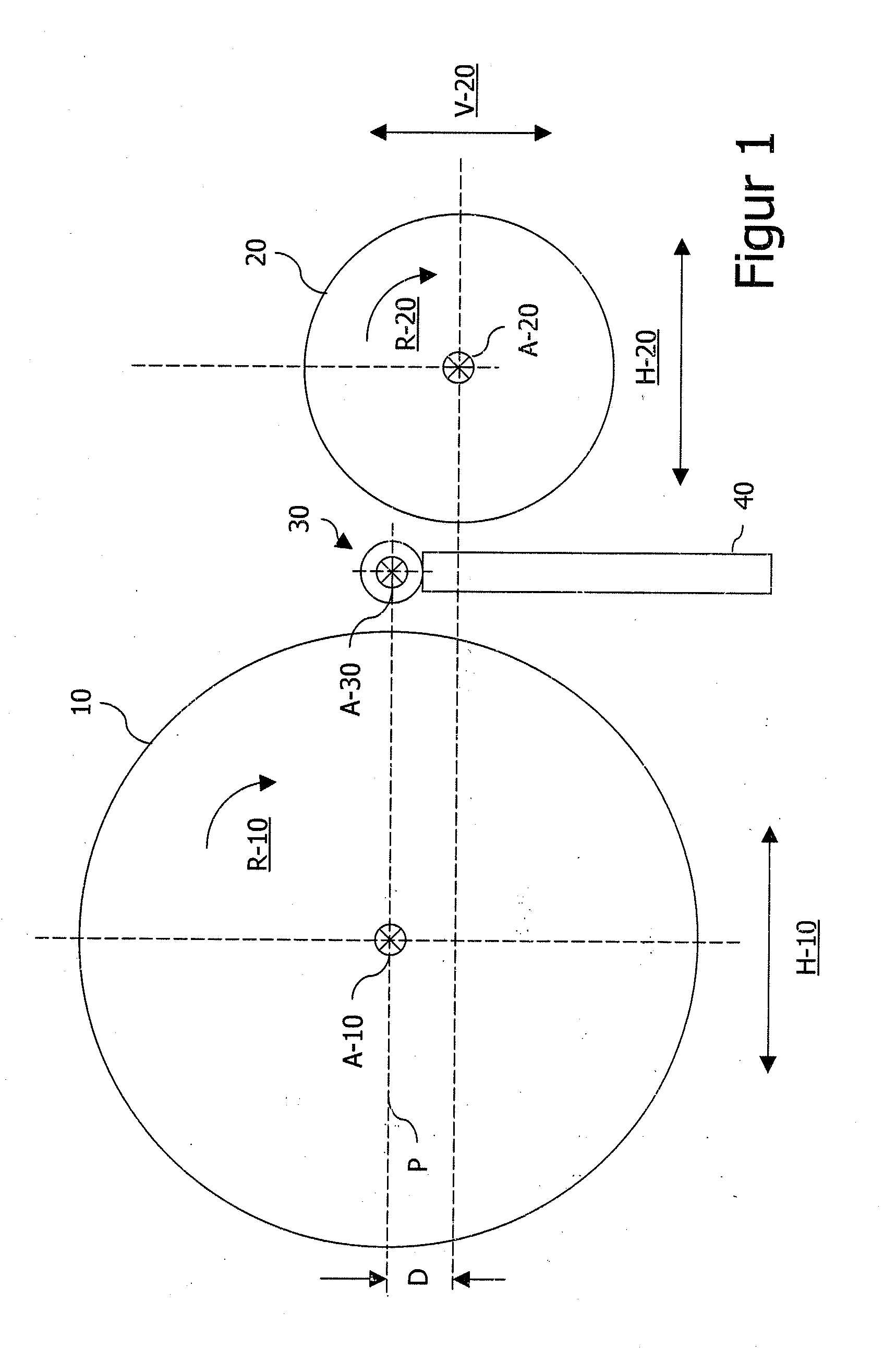

Centerless cylindrical grinding machine and centerless grinding method with height-adjustable regulating wheel

ActiveUS20110306273A1Effective controlEasy to carryEdge grinding machinesRevolution surface grinding machinesRotational axisKinematics

The present invention pertains to a centerless cylindrical grinding machine with a grinding wheel and a regulating wheel that can be laterally displaced toward a work piece that can be held between these wheels, and with a rest blade for supporting the work piece that is realized rigid in the vertical direction and arranged and dimensioned such that a rotational axis of the work piece and a rotational axis of the grinding wheel lie in a common plane, wherein a height adjustment of the rotational axis of the regulating wheel beyond the plane is kinematically decoupled from the lateral displacement of the regulating wheel and can be varied in order to position the regulating wheel on the supported work piece.

Owner:TSCHUDIN URS

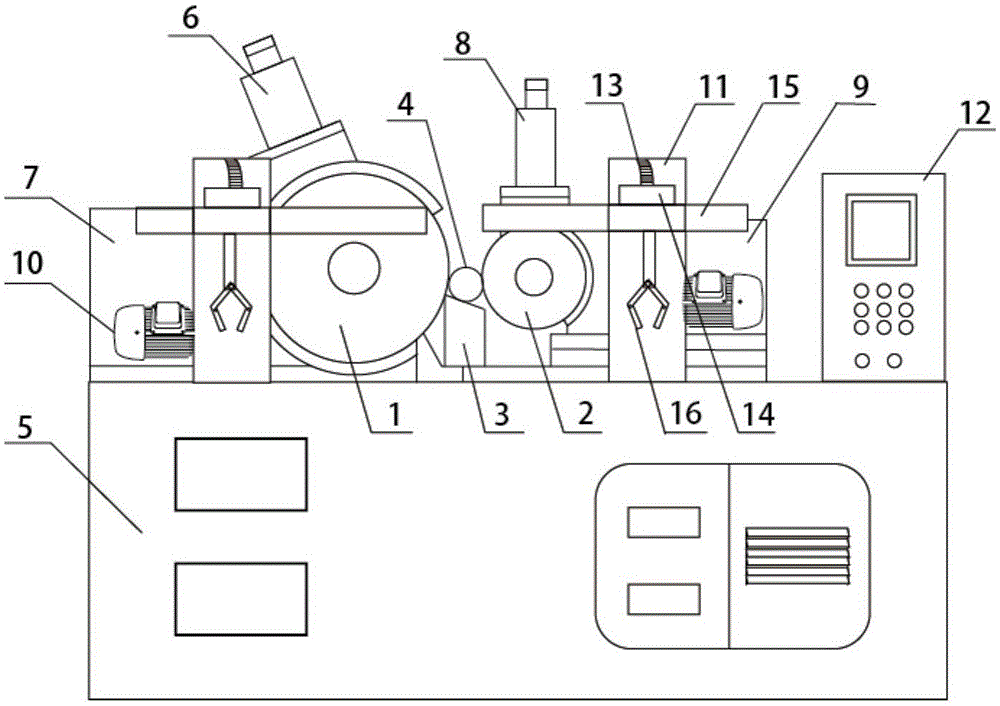

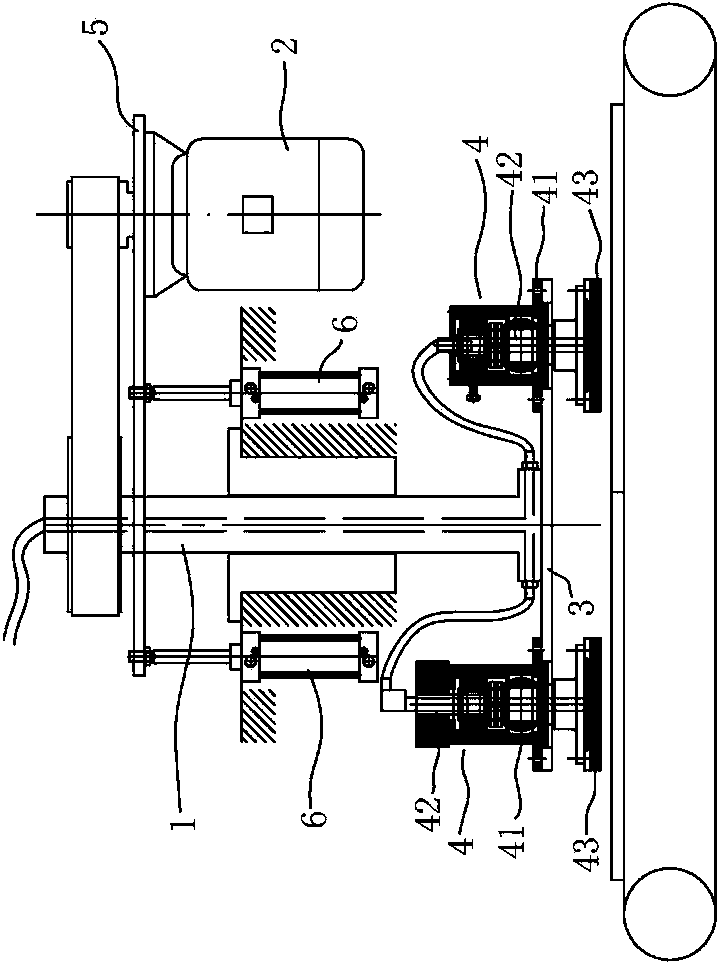

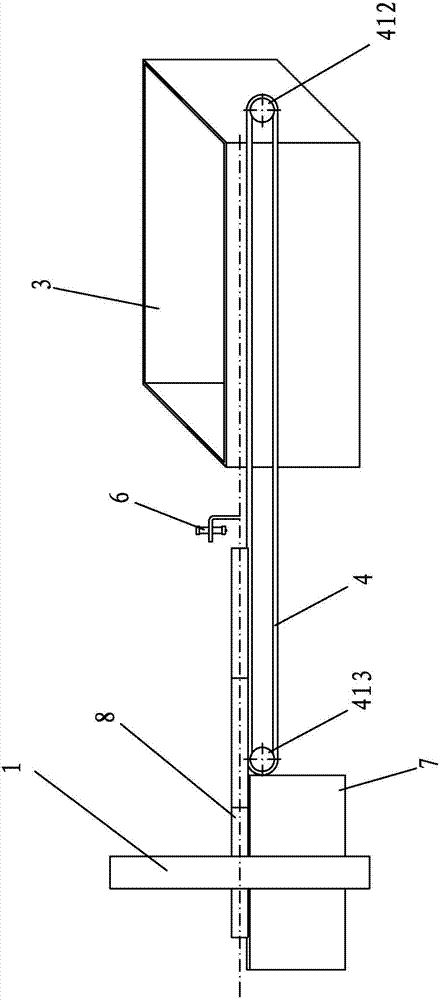

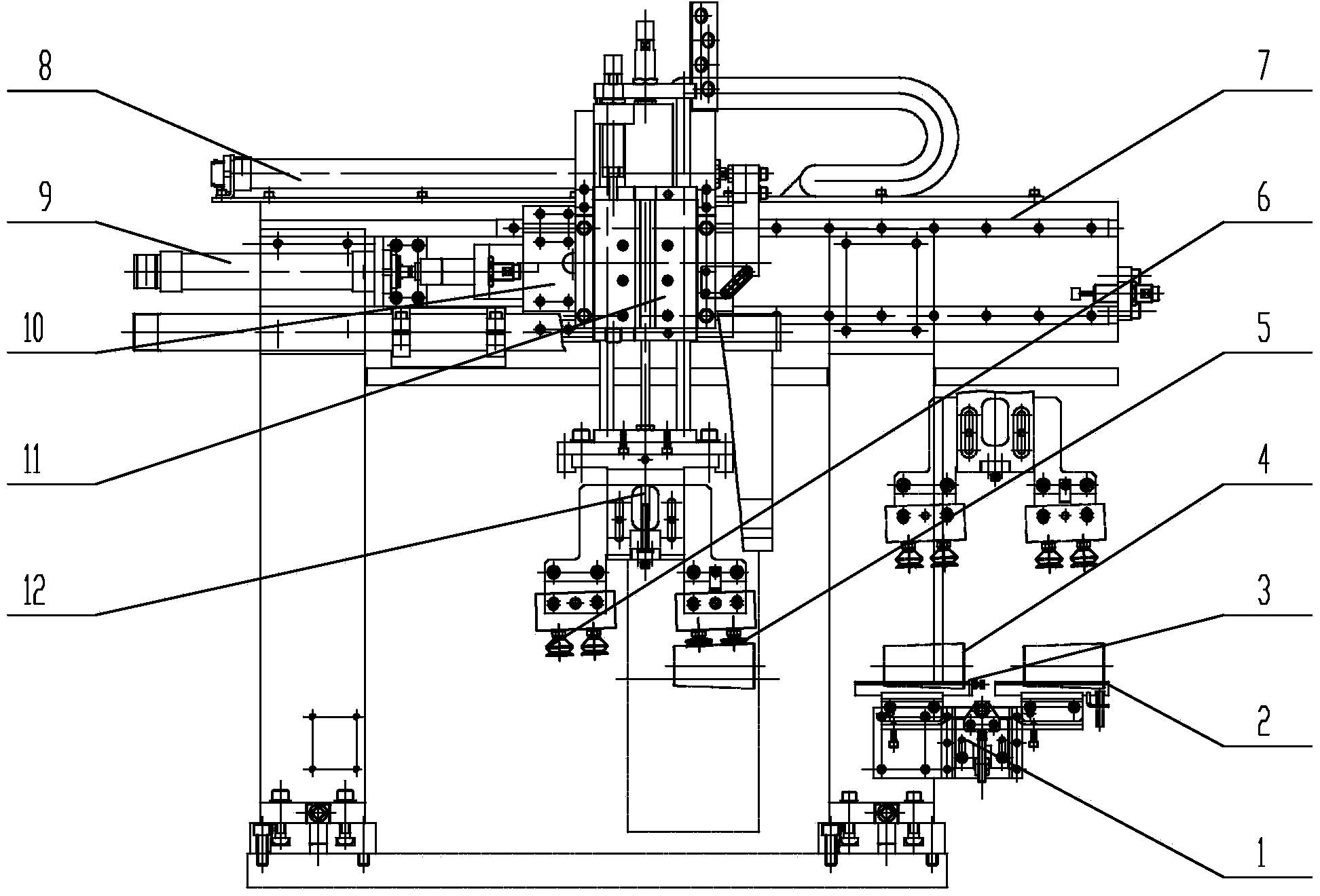

Feeding and discharging device for centerless grinding machine for performing plunge-cut grinding on bearing rollers

ActiveCN103659492AAvoid bumpingSimple structureRevolution surface grinding machinesGrinding feedersEngineeringSlide plate

The invention belongs to the technical field of machining equipment, and relates to a centerless grinding machine, in particular to a feeding and discharging device for a centerless grinding machine for performing plunge-cut grinding on bearing rollers. The feeding and discharging device comprises a grinding frame, wherein a transverse guide track is fixed on the upper portion of the grinding frame; a sliding plate is slidably arranged on the guide track; a first cylinder is arranged on the top of the grinding frame; a piston rod of the first cylinder is connected to the sliding plate; a guiding cylinder is arranged on the sliding plate; a piston rod of the guiding cylinder faces the vertical direction; the lower end of the piston rod of the guiding cylinder is fixedly connected with a mechanical arm; the mechanical arm is provided with two support arms; and a discharging sucker and a feeding sucker are respectively arranged on mounting workstations of the two support arms.

Owner:无锡市明鑫机床有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com