Patents

Literature

237results about How to "Realize automatic compensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

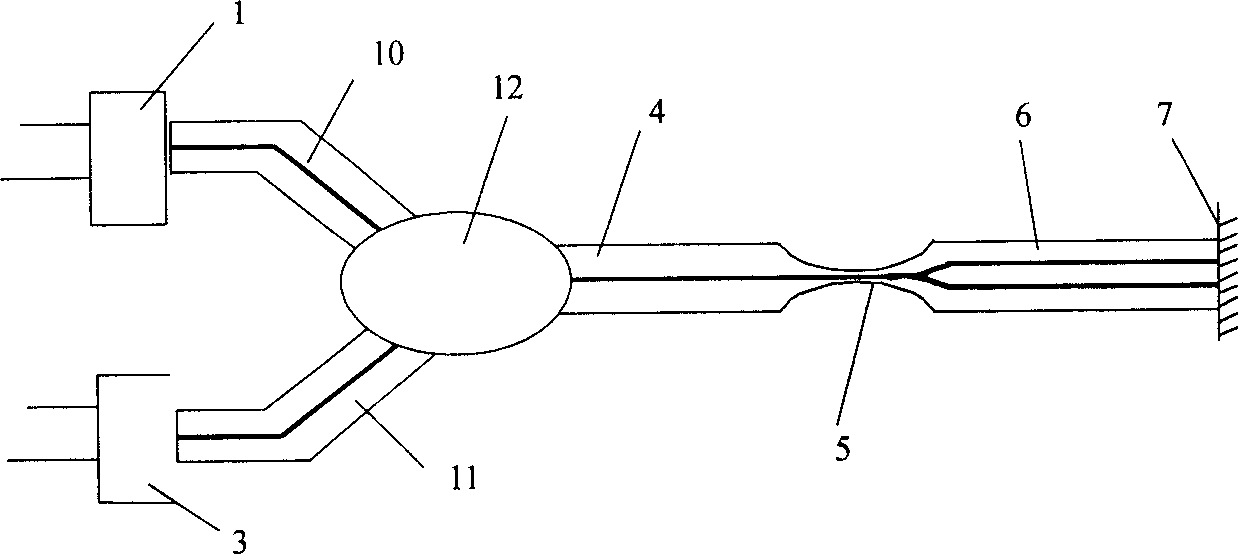

Michelson's interferometer integrated into single optical fiber

InactiveCN1908577AImprove stabilityReduce volumeUsing optical meansDual coreMichelson interferometer

The related Michelson interferometer with only one optical fiber comprises: integrating the co-light-path part of source input and signal output and two interference arms into one optical fiber; and using the integrated optical fiber with one segment as mono-core fiber and one segment as dual-core fiber to replace the conventional product. The advantages of this invention include: 1. well stability; 2. small size and compact structure; 3. low requirement to source coherence; and 4. automatic compensation for light path difference.

Owner:HARBIN ENG UNIV

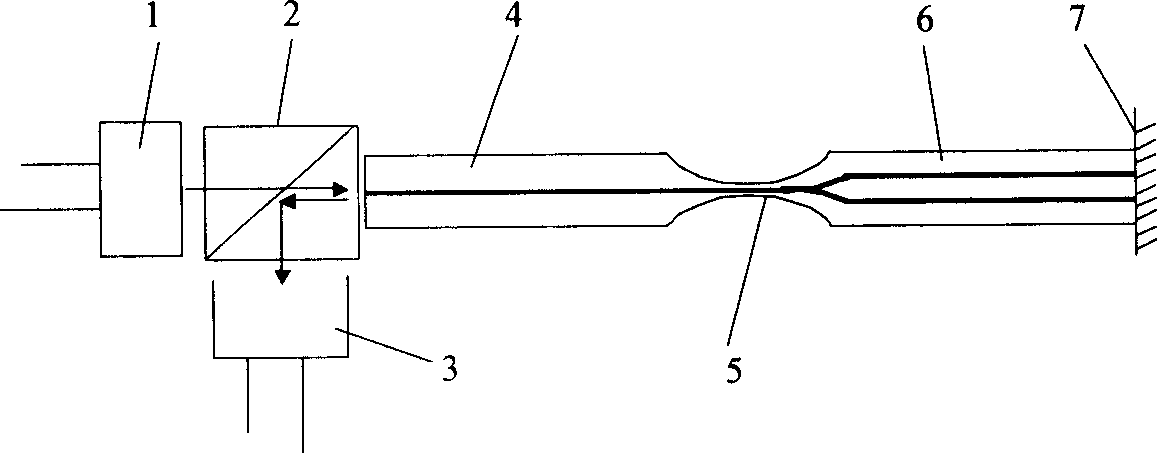

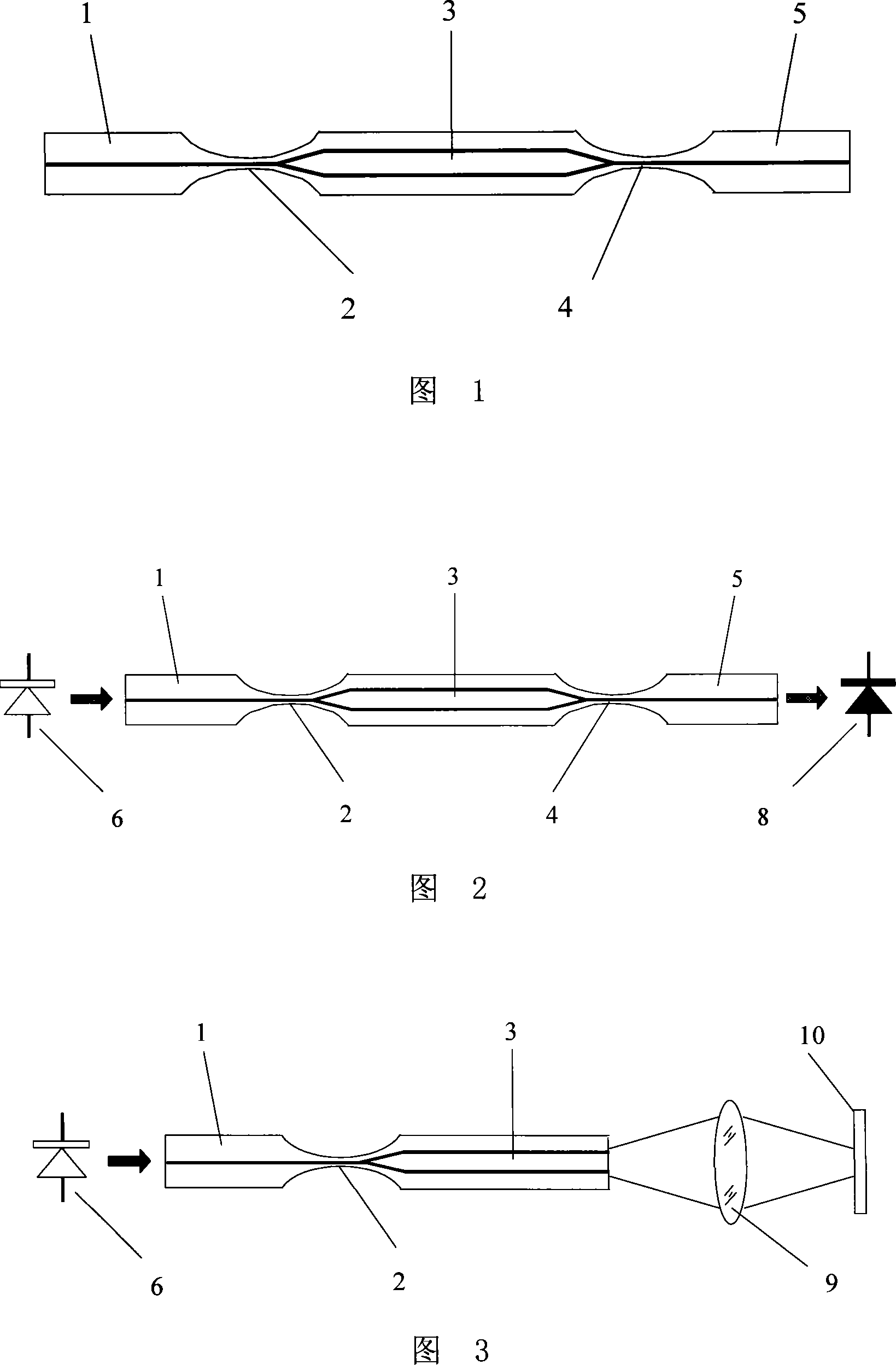

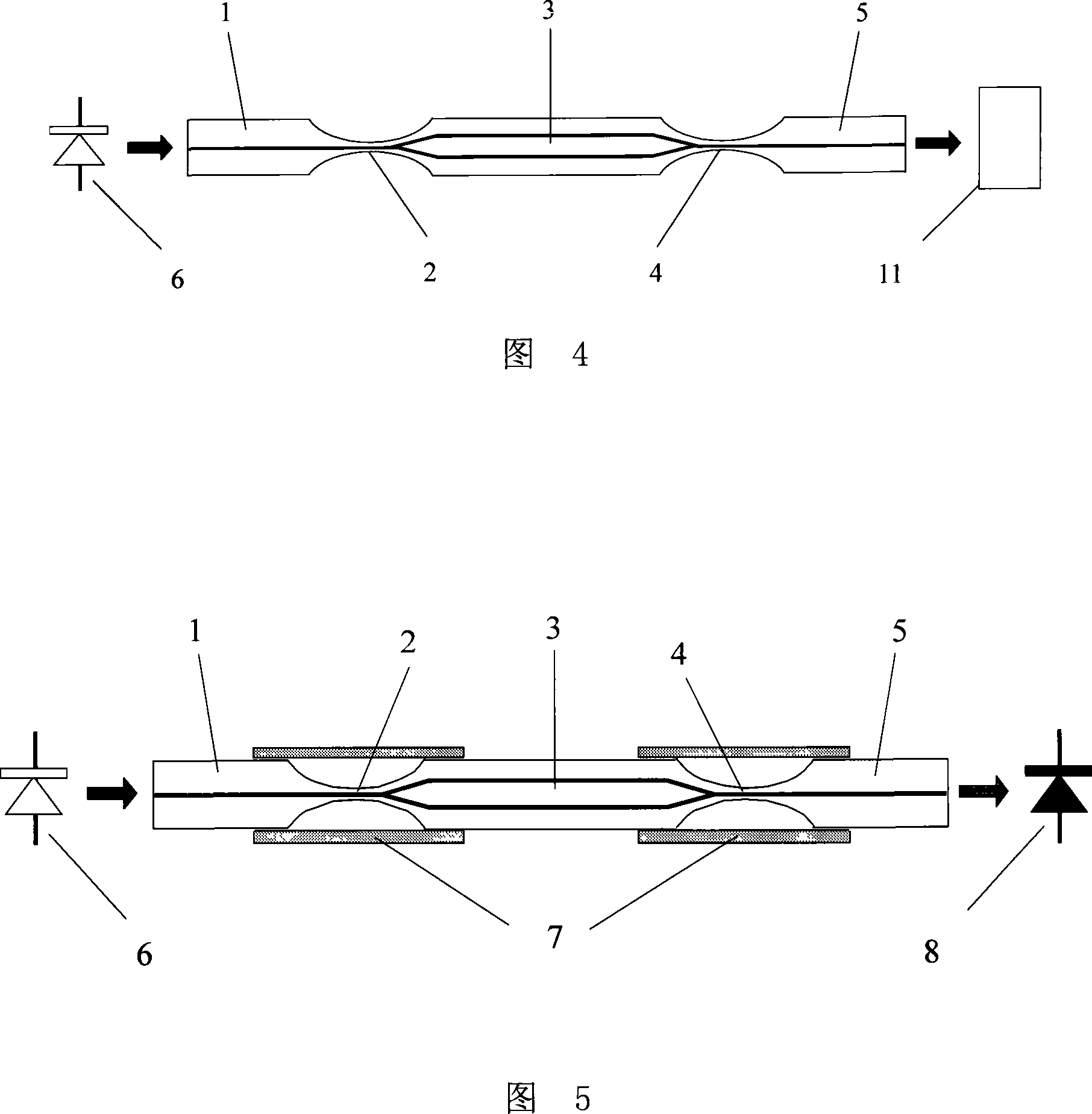

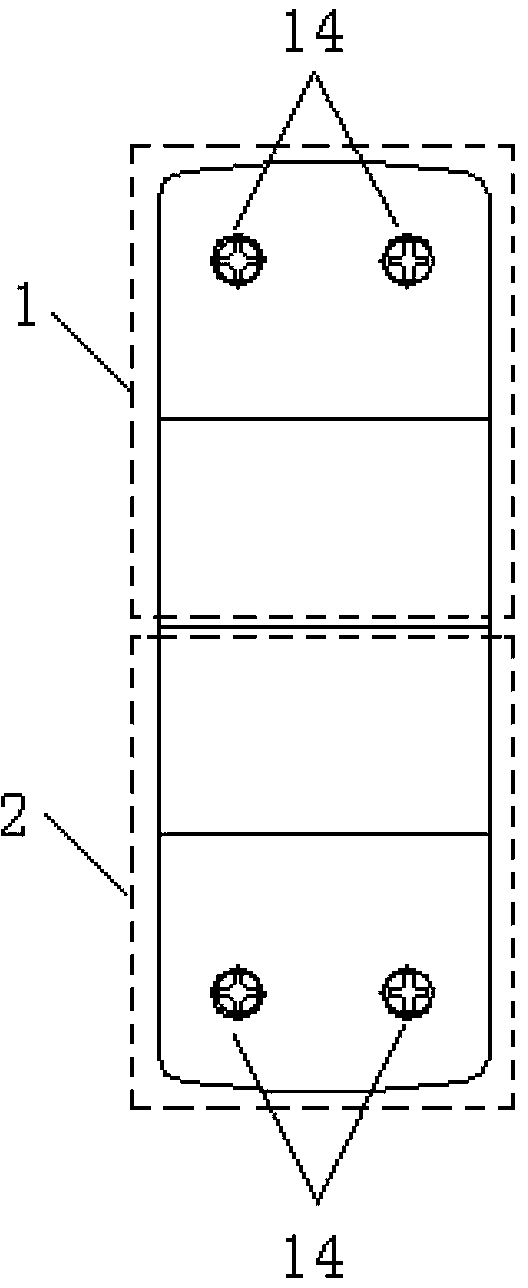

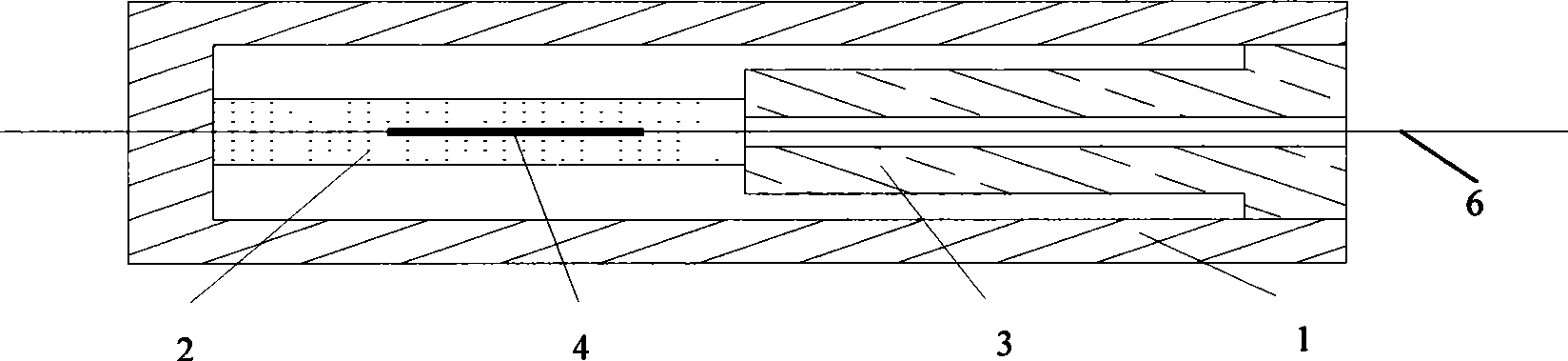

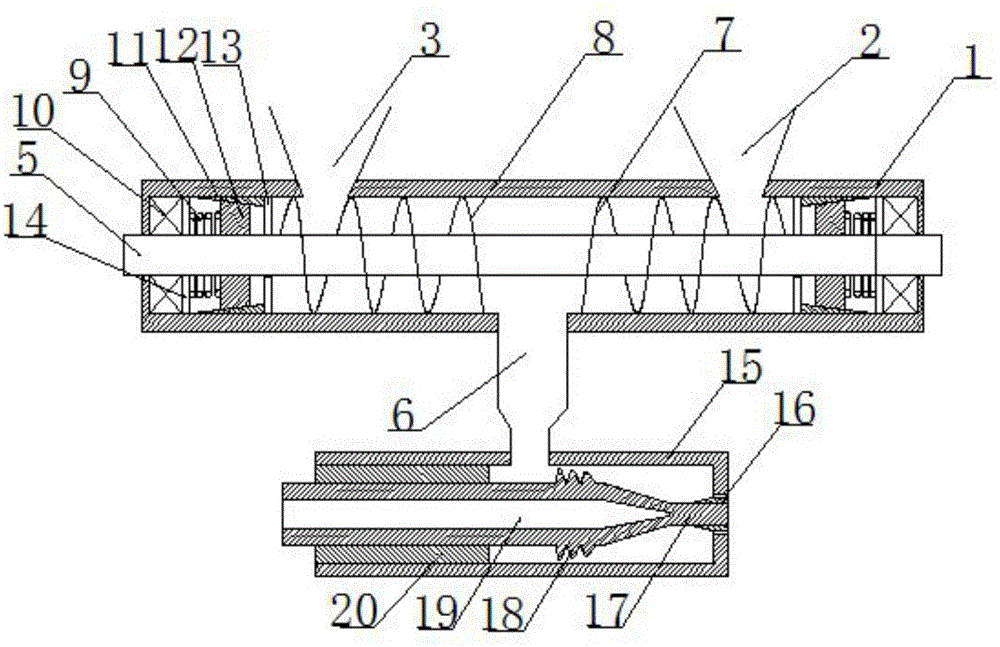

Fiber integrated type Mach-Zehnder interferometer and its production method

The invention discloses Mach-Zehnder interferometer integrated in an optical fiber and the manufacture method thereof; two sections of single core optical fibers are respectively provided on two sides Mach-Zehnder interferometer, and one section of two-core optical fiber in the middle of Mach-Zehnder interferometer are welded and tapered, and hence the Mach-Zehnder interferometer is formed; the Mach-Zehnder interferometer comprises a single mode single core input optical fiber (1), a light splitting taper-shaped coupling area (2), a single mode double-core optical fiber (3), a light composite taper-shaped coupling area (4) and a single mode single core output optical fiber (5); the single mode single core input optical fiber (1), the single mode single core output optical fiber (5) and the single mode double-core optical fiber (3) are connected with each other through the light splitting taper-shaped coupling area (2) and the light composite taper-shaped coupling area (4). The invention has the advantages that interferometer has great stability, avoids the variation positions of all moveable parts because of assembly, fixing and regulation, reduces the volume of the interferometer and makes the system more simple and more compact; as the optical path differences of two interference arms positioned in the double-core optical fiber are very small, the invention doesn't need huge mutual coherence of light source and can implement auto-compensation of optical paths of the two interference arms.

Owner:HARBIN ENG UNIV

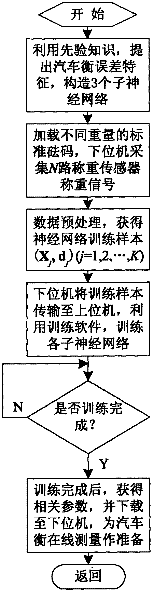

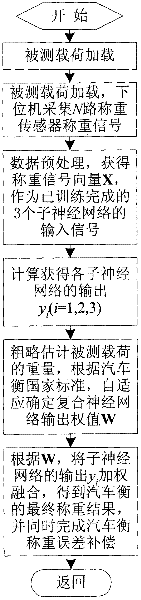

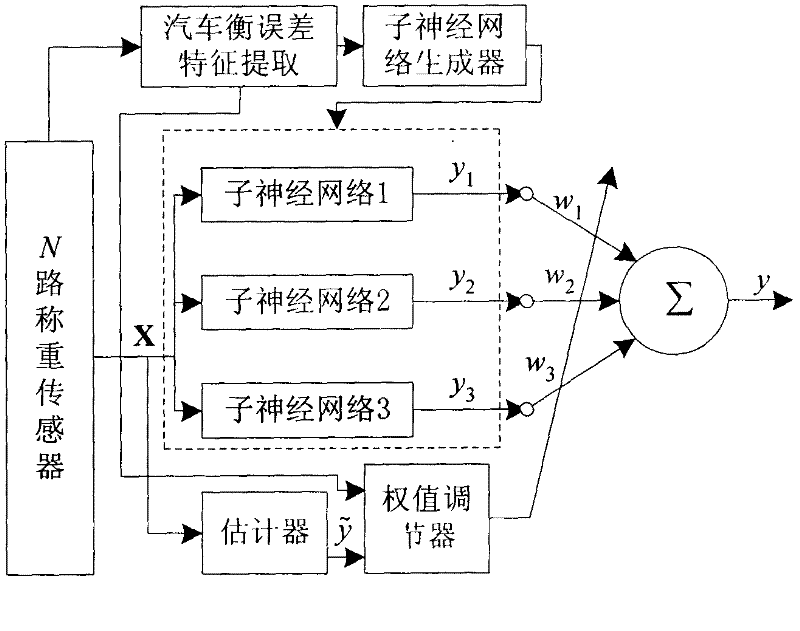

Weighing error automatic compensation method of vehicle scale

InactiveCN102506983ARealize automatic compensationImprove accuracyWeighing auxillary devicesNeural learning methodsEngineeringNetwork construction

The invention discloses a weighing error automatic compensation method of a vehicle scale, which comprises three aspects of composite neural network construction, neural network off-line training and vehicle scale on-line weighing. First, constructing three sub-neural networks according to priori knowledge; then utilizing standard weights of different tonnage and a weighing signal collecting circuit to train a sample and transmitting the sample to an upper computer, utilizing training software to finish off-line training of the three sub-neural networks, obtaining a corresponding parameter, and downloading the parameter to a lower computer to prepare for the on-line measurement of the vehicle scale; when the vehicle scale performs on-line measurement, utilizing the lower computer to first obtain a weighing signal vector through the weighing signal collecting circuit to serve as input of the three sub-neural networks and calculating the output of each sub-neural network; roughly estimating the weight of a tested load, and automatically obtaining the output weight of a composite neural network; and merging the output weighing of the sub-neural networks, obtaining a final weighing result, and simultaneously finishing the weighing error compensation of the vehicle scale. The weighing error automatic compensation method of the vehicle scale can achieve automatic compensation of an unbalance loading error and a linear error of the vehicle scale so as to greatly improve accuracy of the weighing result.

Owner:HUNAN NORMAL UNIVERSITY

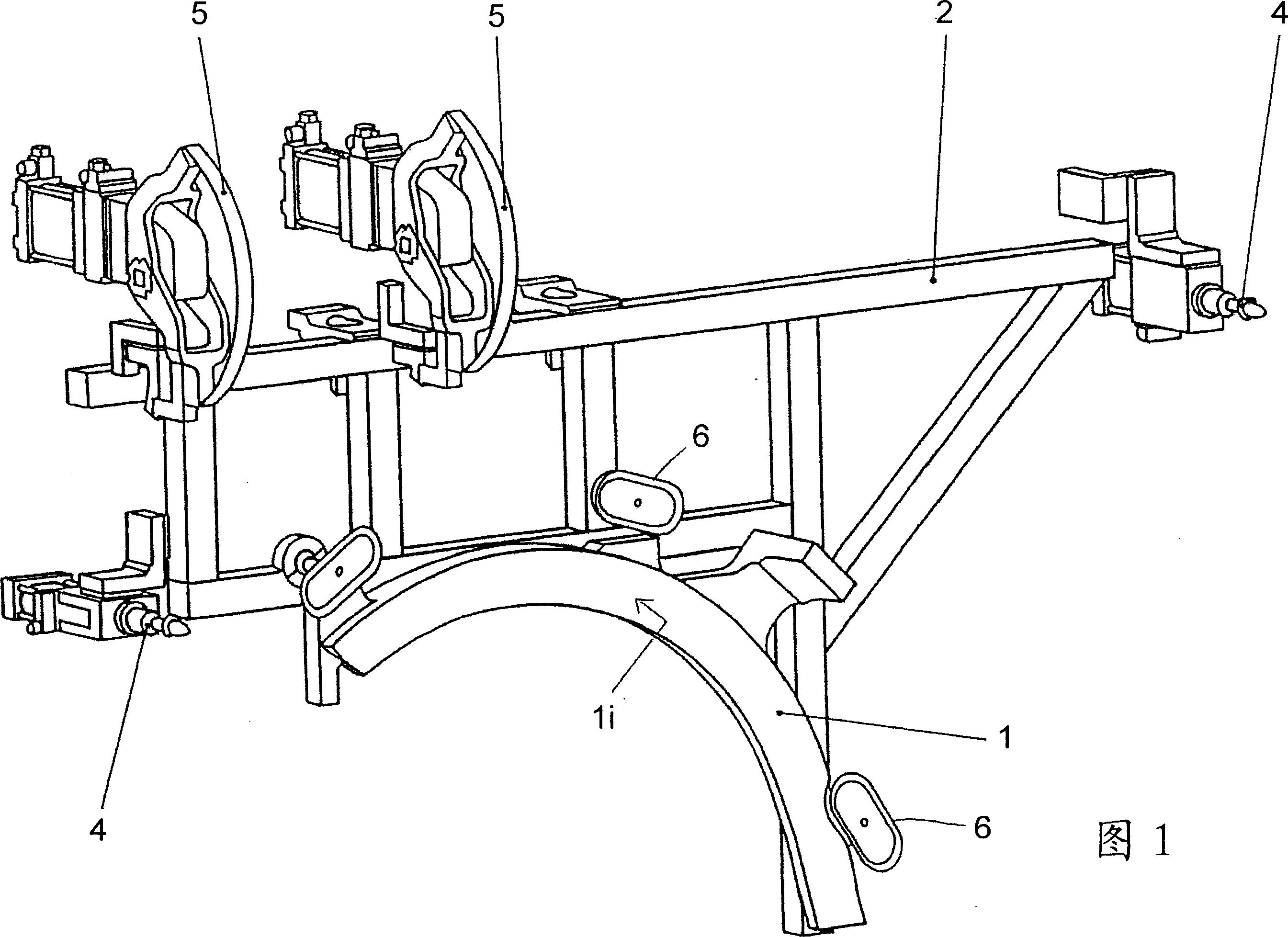

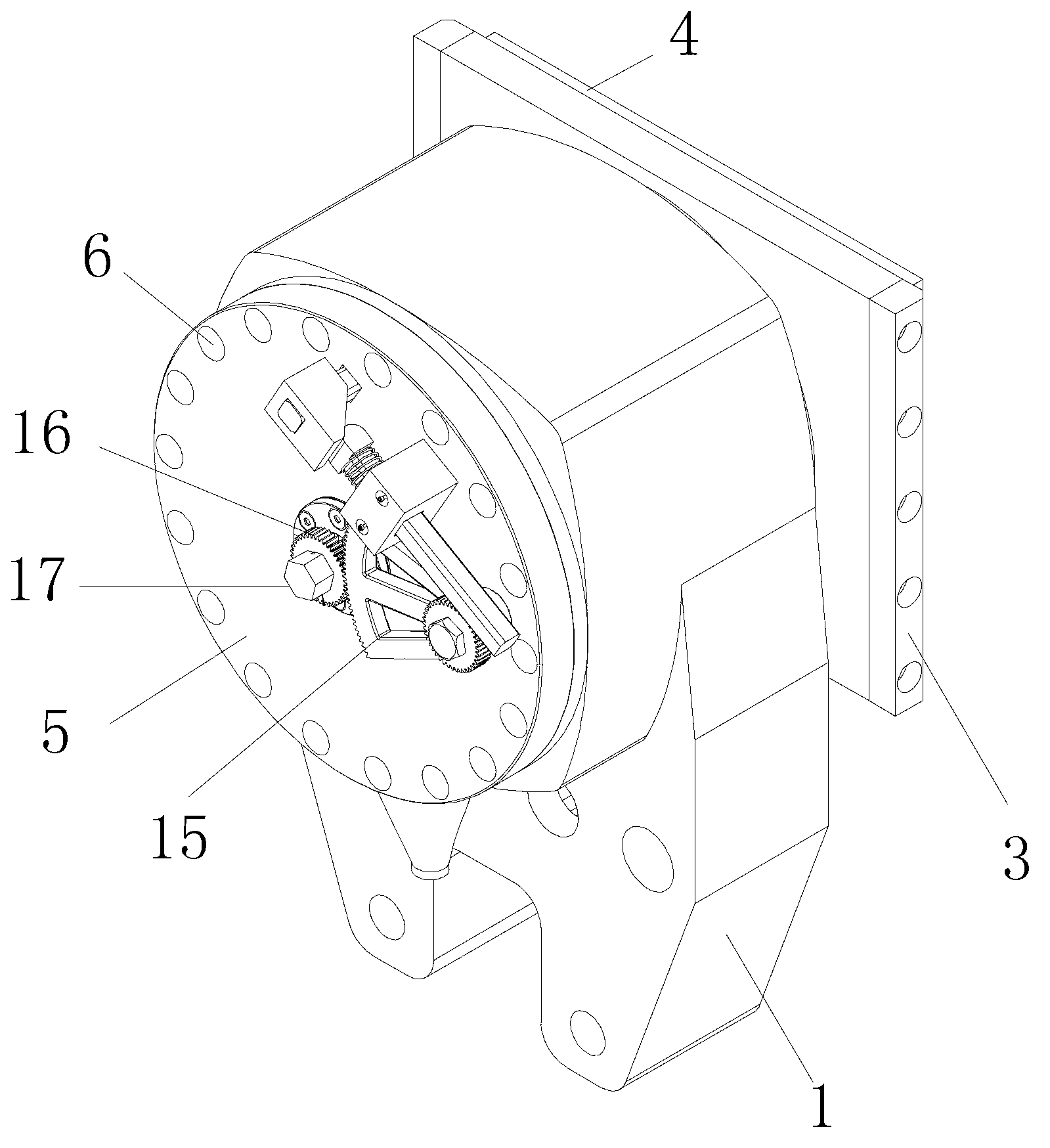

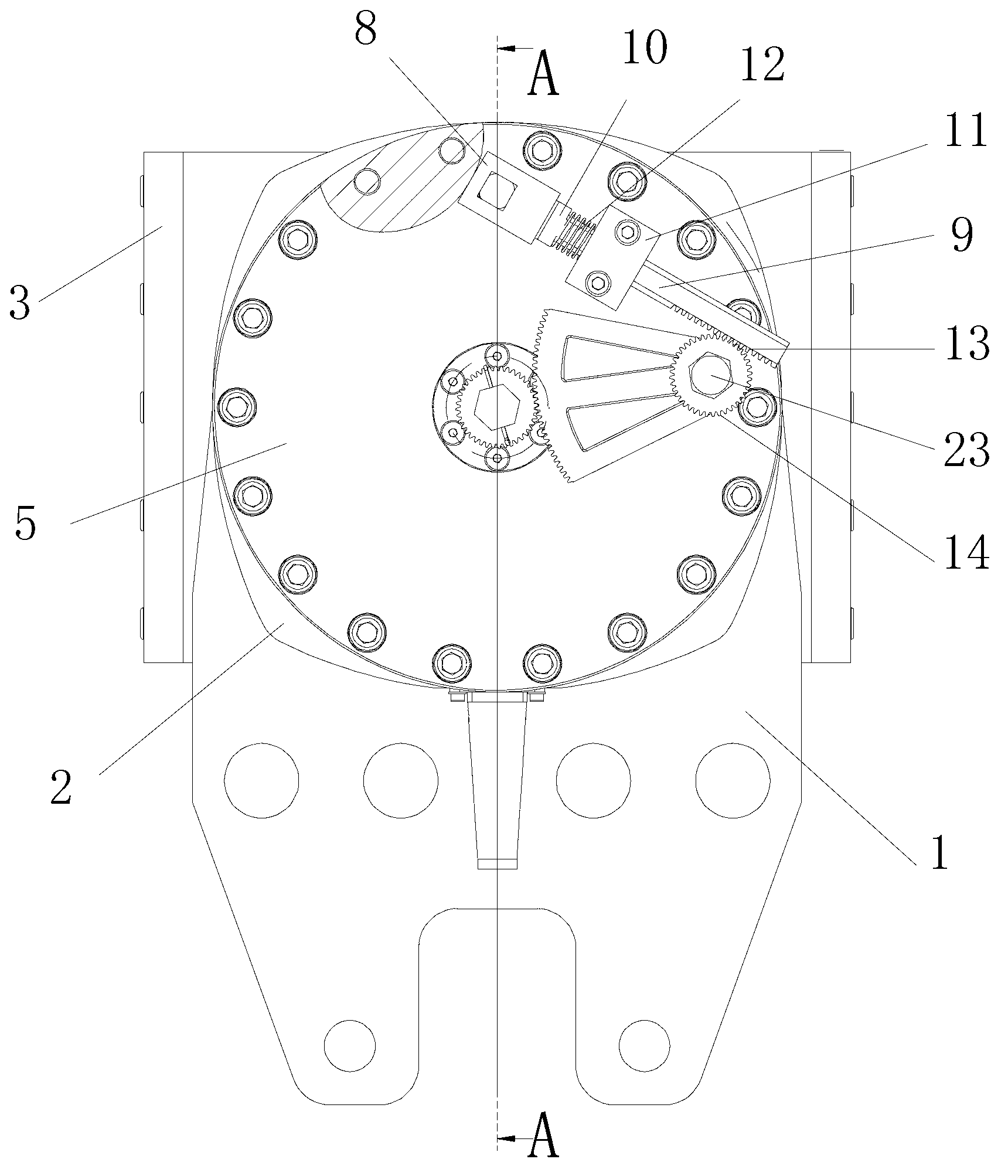

Follower rest for hydraulic automatically centering, automatically compensating and surface rolling

InactiveCN102513836ASimple structureEasy to operateLarge fixed membersEngineeringMechanical engineering

The invention provides a follower rest for hydraulic automatically centering, automatically compensating and surface rolling. Because three follower claw units enable workpiece to stress from three points, the three force forms a plane concurrent force system to achieve balance, thereby eliminating the shortcoming that the workpiece is easy to deform and bend caused by rolling by a single wheel. When the follower rest is used, the pressure is manually adjusted; and the too loose or too tight phenomenon of the common follower rest can be eliminated. When the diameter of the workpiece becomes little after turning, a hydraulic unit adjusts the pressure of the follower claw units to the workpiece so as to automatically compensate. When the surface size precision and the surface quality requirements of the workpiece are high, the hydraulic oil pressure is appropriately adjusted, so that three rolling wheels of the follower claw units simultaneously and evenly press the workpiece; the rotation of the workpiece drives the rolling wheels to rotate; and the follower rest rolls the surface of the workpiece during longitudinal moving. The follower rest provided by the invention has the functions of automatically centering, automatically compensating and pressing surface when the follower rest is used for turning an elongate shaft. The follower rest is convenient to use, high in stability and has relaxed requirements to tools.

Owner:CHANGCHUN UNIV OF SCI & TECH

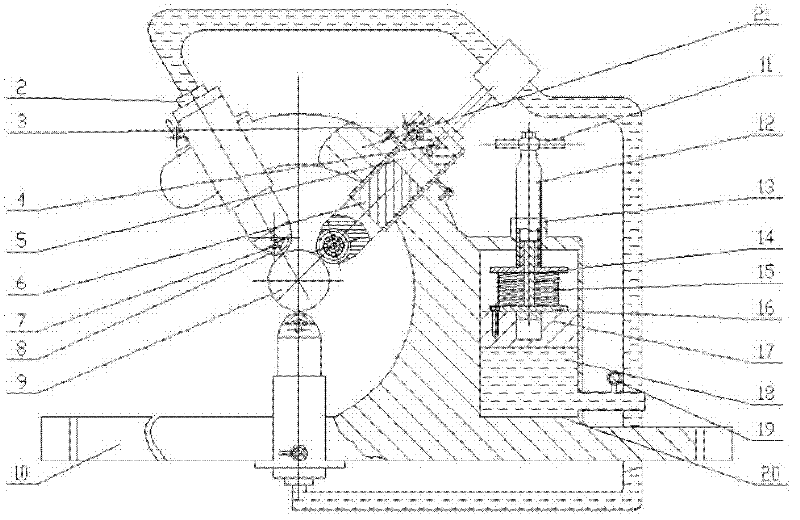

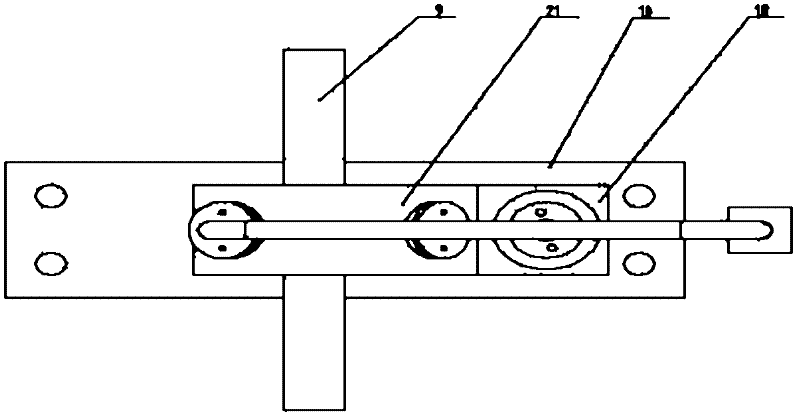

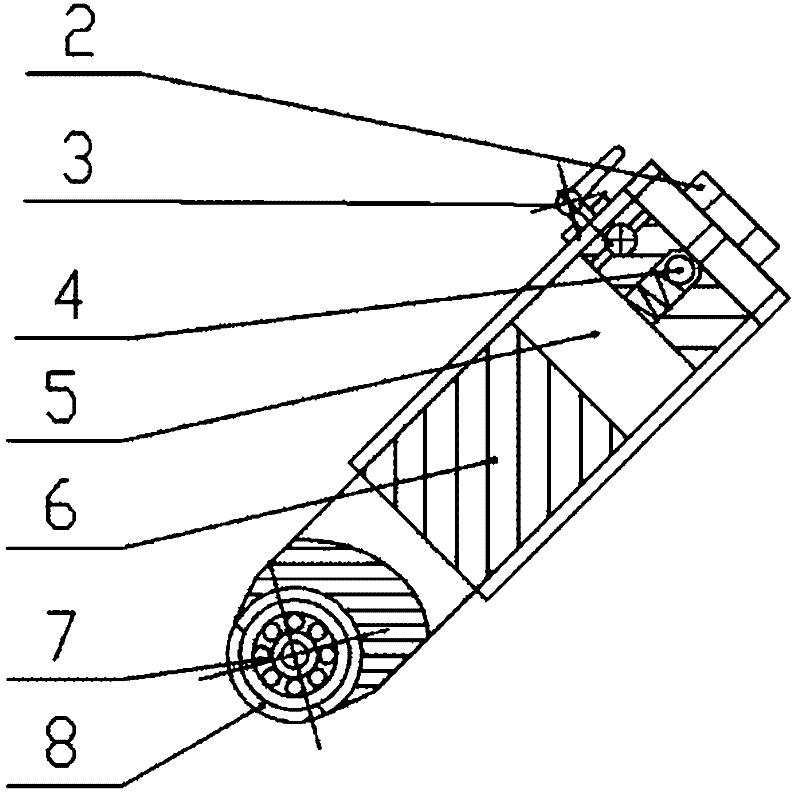

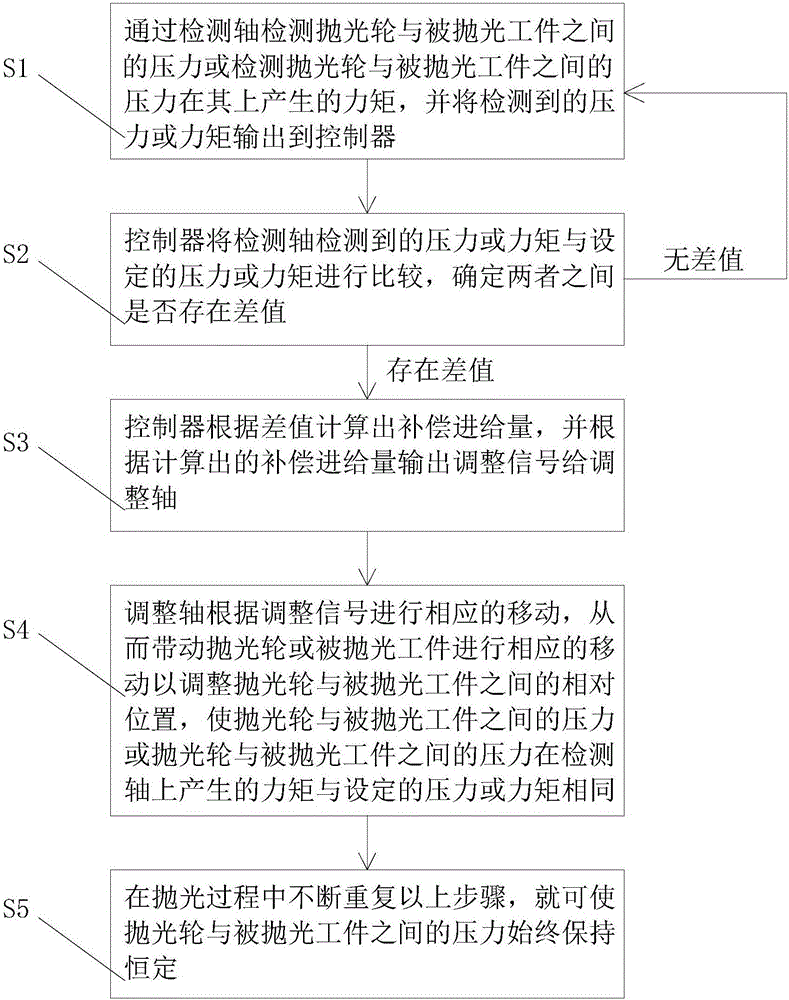

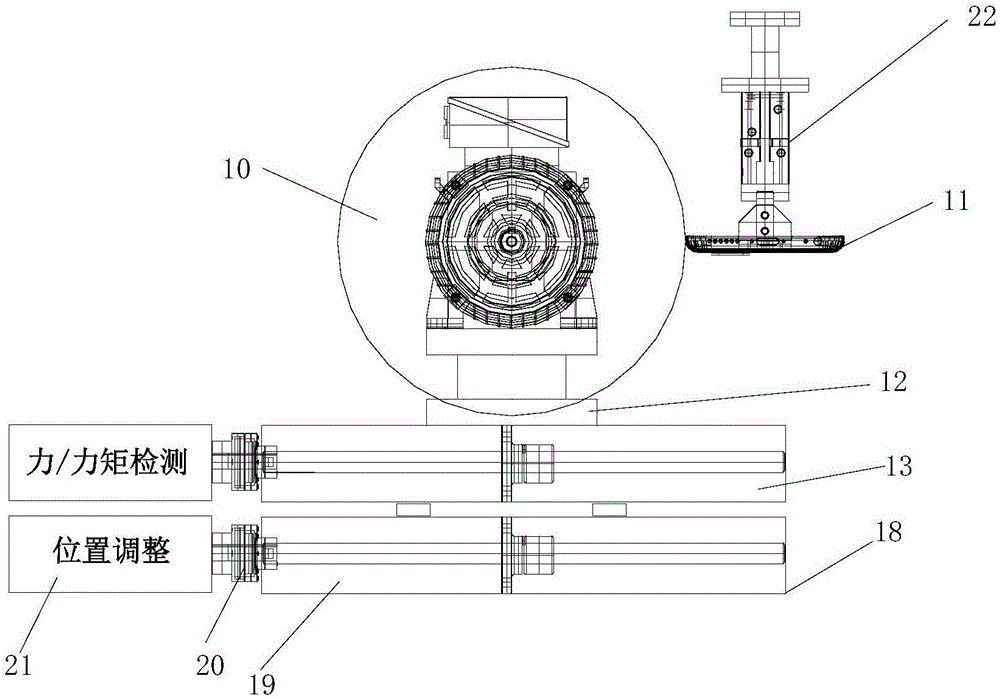

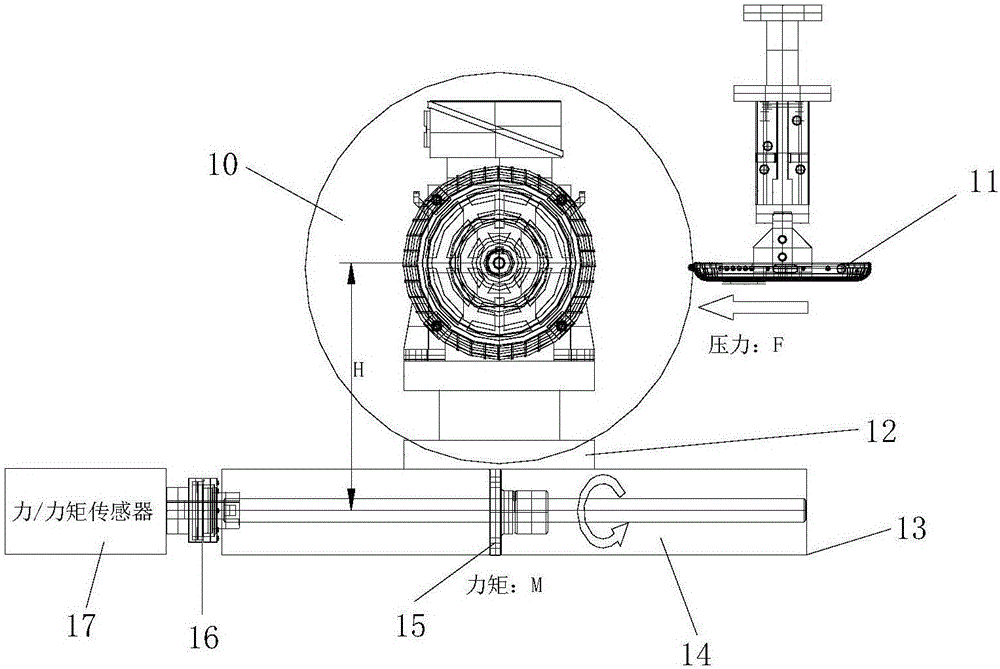

Method for detecting, controlling and automatically compensating pressure in polishing process

ActiveCN106553126AImprove qualityStable pressureGrinding feed controlNumerical controlEngineeringControl theory

Owner:TUNG HING AUTOMATION INVESTMENT LTD +1

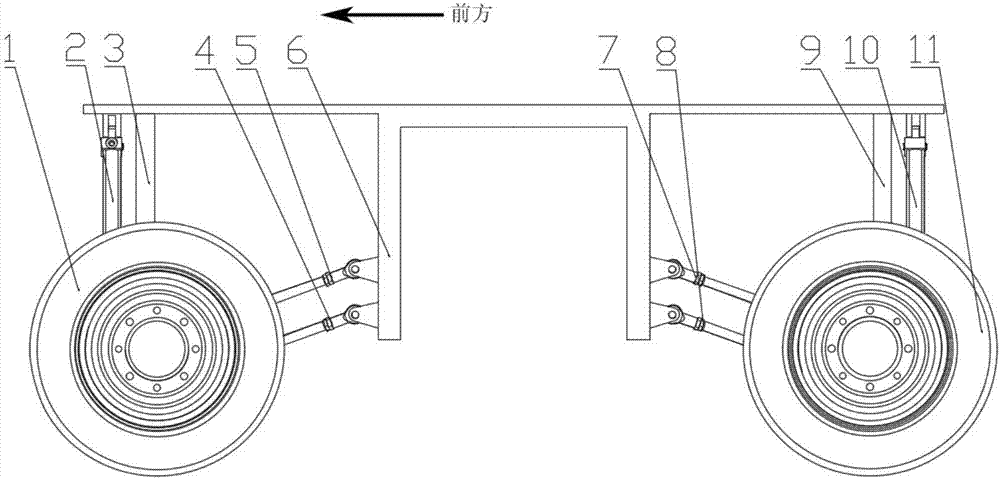

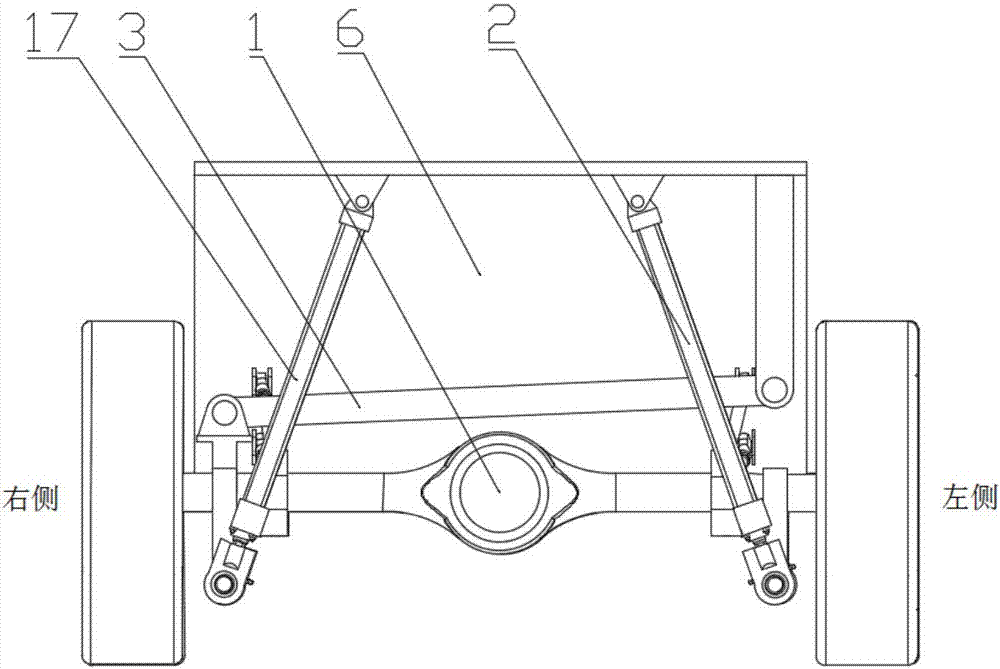

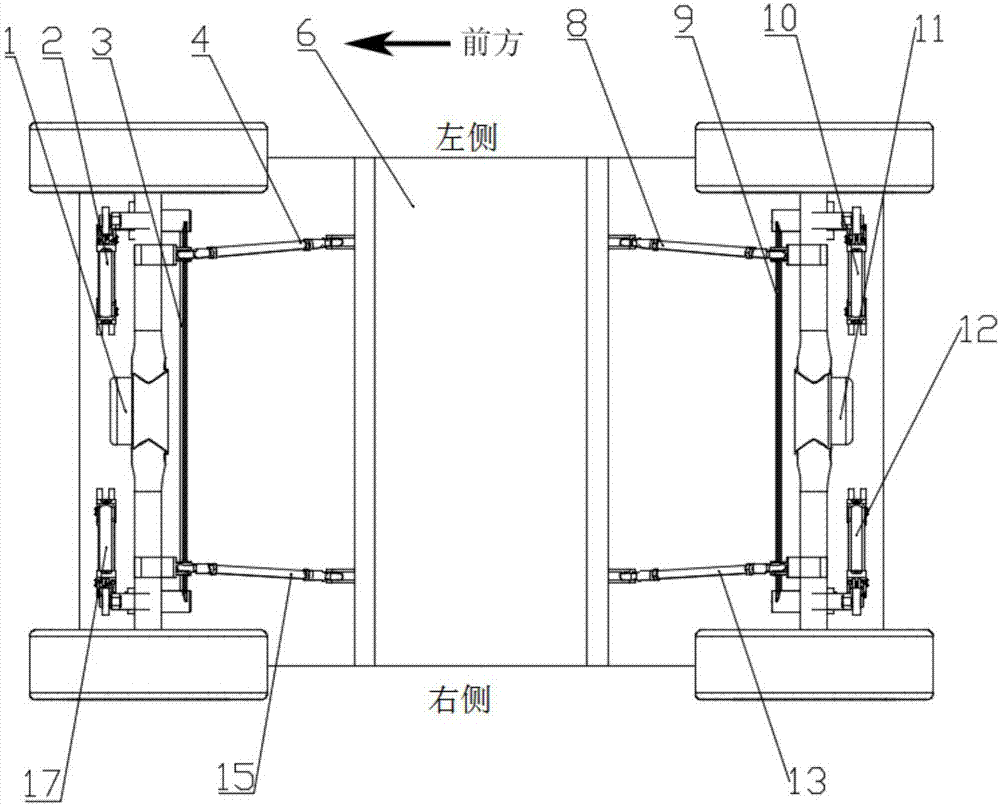

Hill and mountain tractor body attitude adjusting device and adjusting method

ActiveCN106938597AReal-time adjustmentHigh adjustment accuracyResilient suspensionsVehicle springsHydraulic cylinderAttitude control

The invention provides a hill and mountain tractor body attitude adjusting device and an adjusting method. Axle adjusting components of the hill and mountain tractor body attitude adjusting device are symmetrically mounted at the bottom of a body; the hill and mountain tractor body attitude adjusting device comprises axles, attitude adjusting hydraulic cylinders, stabilizers and variable connecting rod groups; the attitude adjusting hydraulic cylinders and the variable connecting rod groups are both symmetrically hinged between the body and the axles; each variable connecting rod group comprises two connecting rods, which are hinged between the body and the axles and parallel to each other in an up-and-down direction; the stabilizers are mounted between the body and the axles; an electronically controlled hydraulic system comprises a sensor, a signal collection unit, an attitude controller and an electronically controlled hydraulic valve which are connected with each other via signals; and the electronically controlled hydraulic valve controls the attitude adjusting hydraulic cylinders. According to the adjusting method, vehicle attitude information detected by the sensor is transmitted to the attitude controller by using the information collection unit, and then the electronically controlled hydraulic valve is controlled to adjust the attitude adjusting hydraulic cylinders, and finally, self-adjusting of body attitude is realized. According to the hill and mountain tractor body attitude adjusting device and the adjusting method, the body attitudes of wheeled vehicles are self-adjusted in real time to guarantee the running stability.

Owner:JILIN UNIV

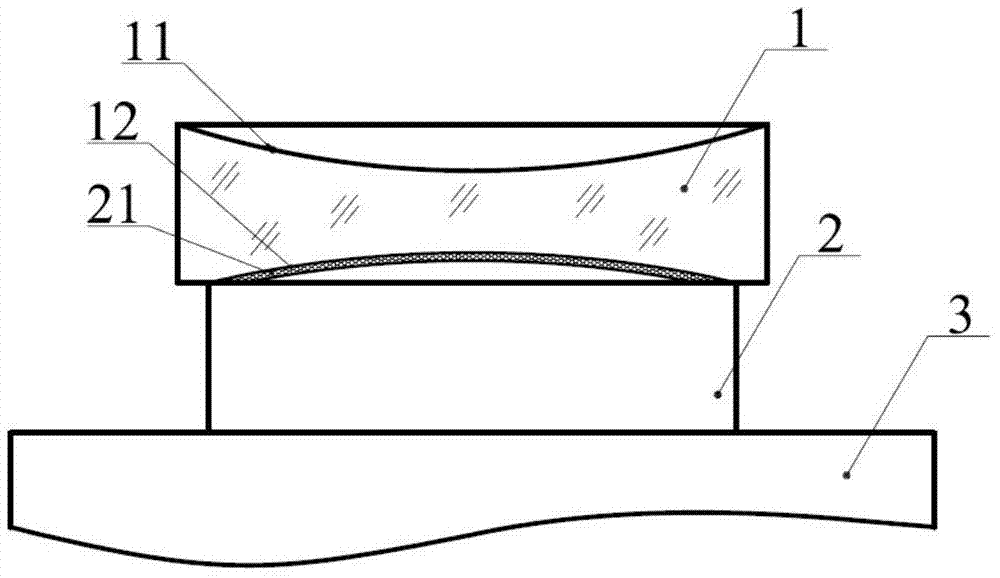

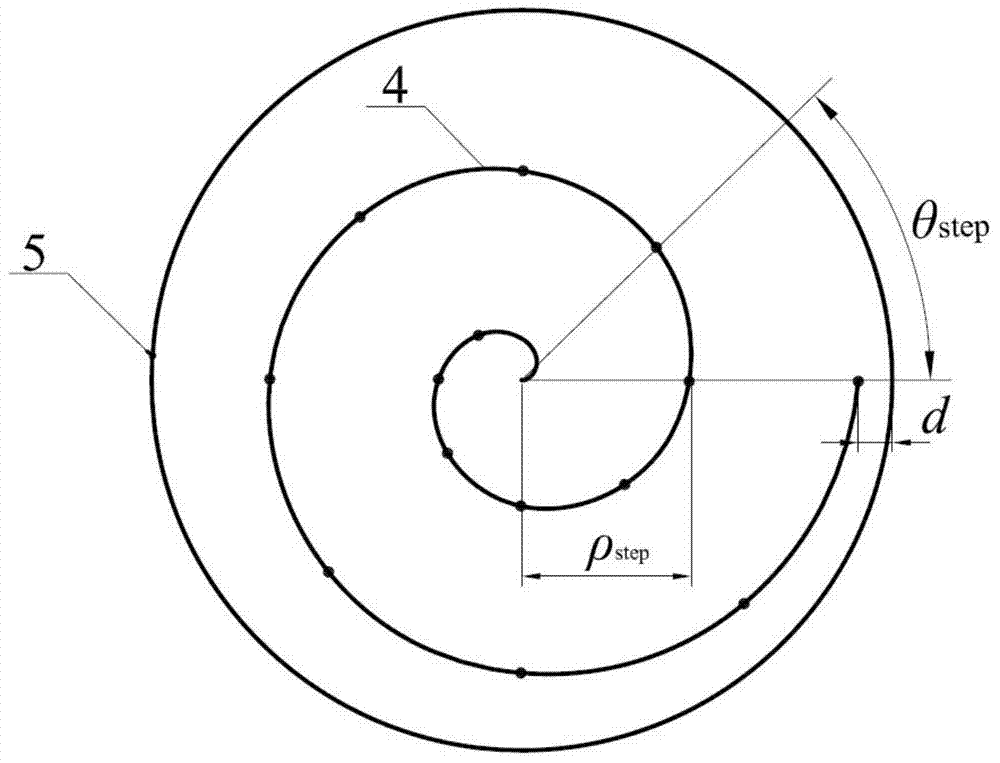

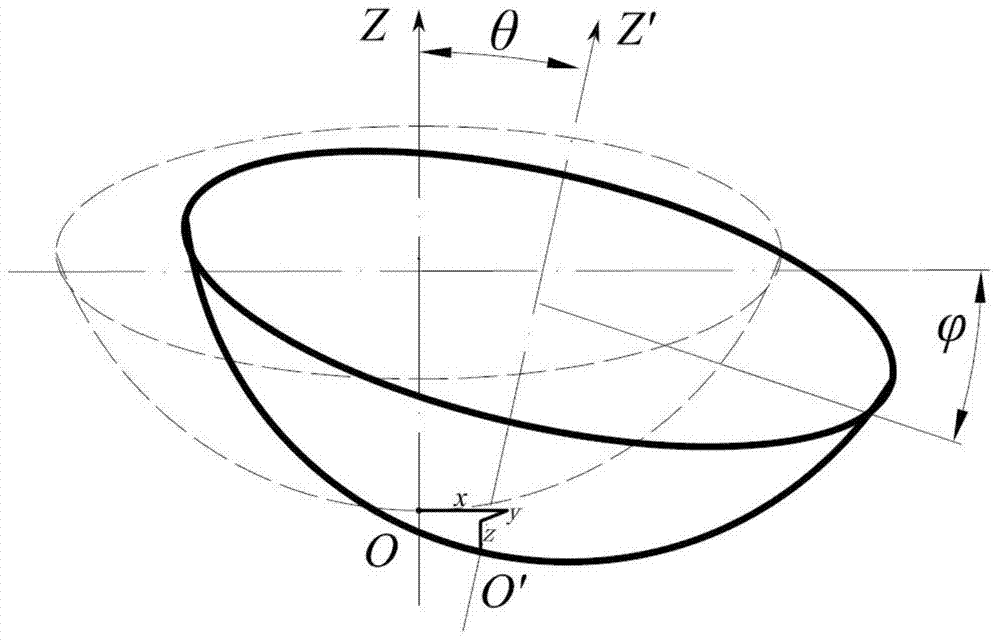

Method for automatically compensating pose errors in machining process of optical element

InactiveCN103592893ANo need to moveQuick and easy compensation processProgramme controlComputer controlMeasurement pointMathematical model

The invention discloses a method for automatically compensating pose errors in the machining process of an optical element, relates to the machining field of optical elements, and aims to provide a method for automatically eliminating installation errors without adjusting a workpiece. The method adopts the following steps that the optical element is firstly clamped on a working table of a machine tool, and the surface of the optical element is measured; actual position measuring points are then transformed to be theoretical position measuring points according to a pose error vector construction transformation matrix; an objective function for solving pose error vectors and a solving mathematic model are built, and the pose errors are solved; a transformation matrix is built according to solutions of the pose errors, and position vectors and direction vectors of resident points on machining paths are transformed respectively; finally, the transformed resident points are subjected to post-processing to obtain a machining program after pose error compensating. The method can accurately and rapidly compensate the pose errors of the optical element and is suitable for being applied to the field of optical machining controlled by a computer.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

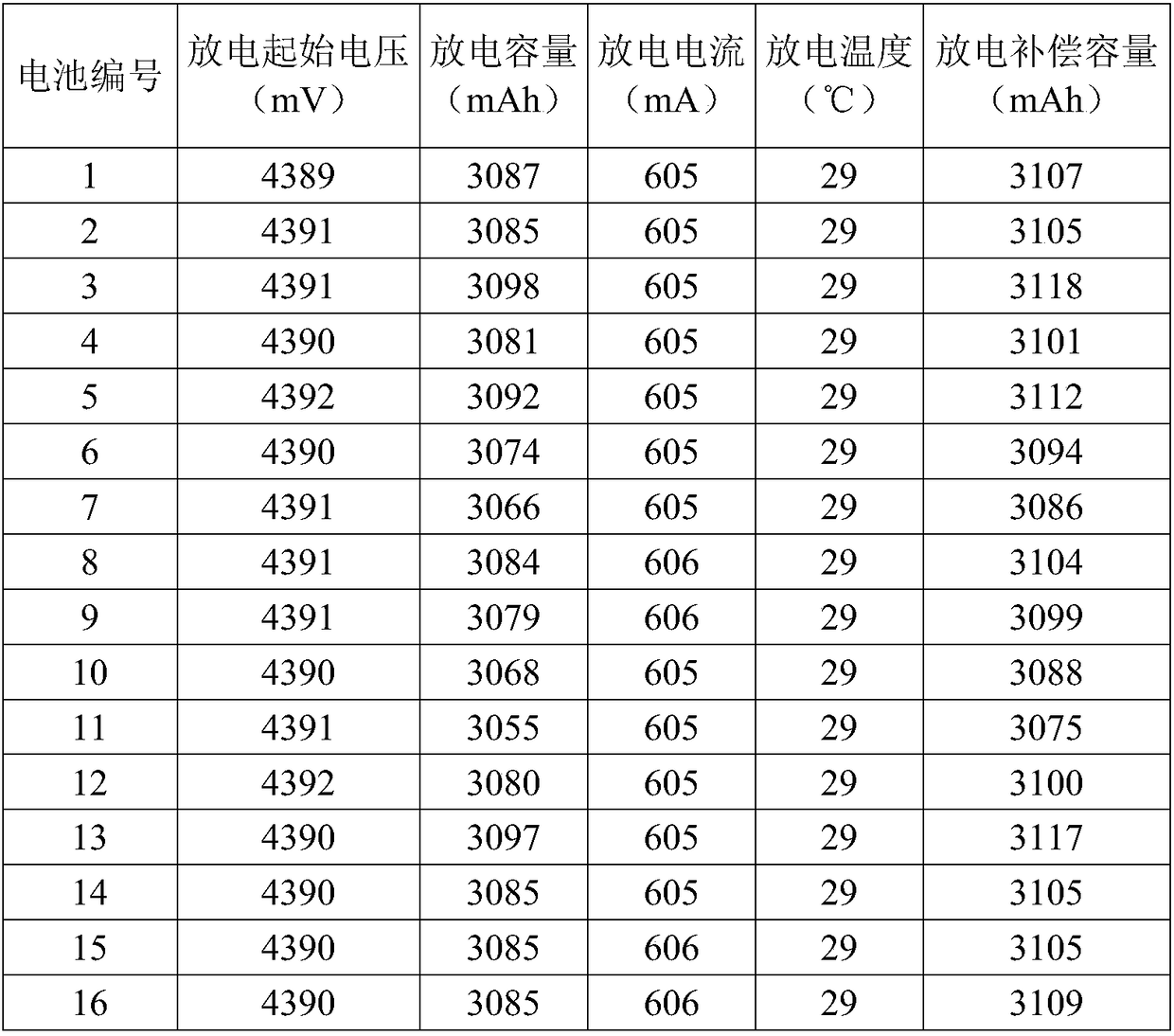

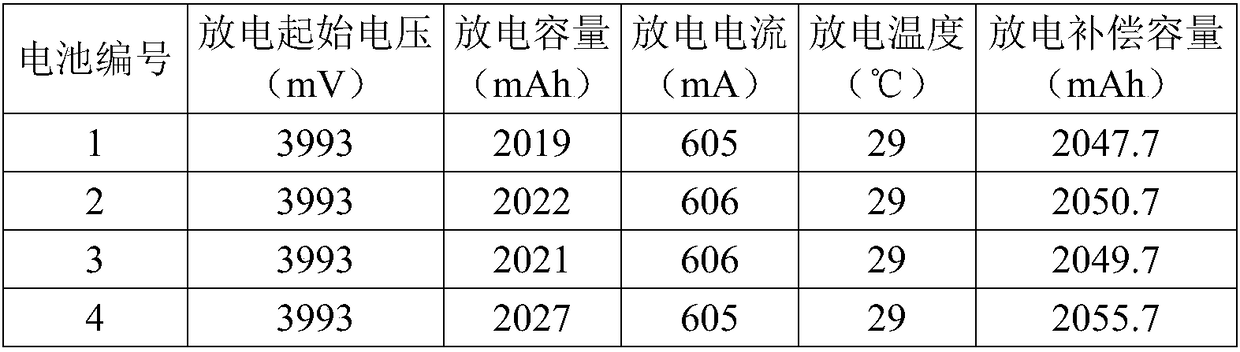

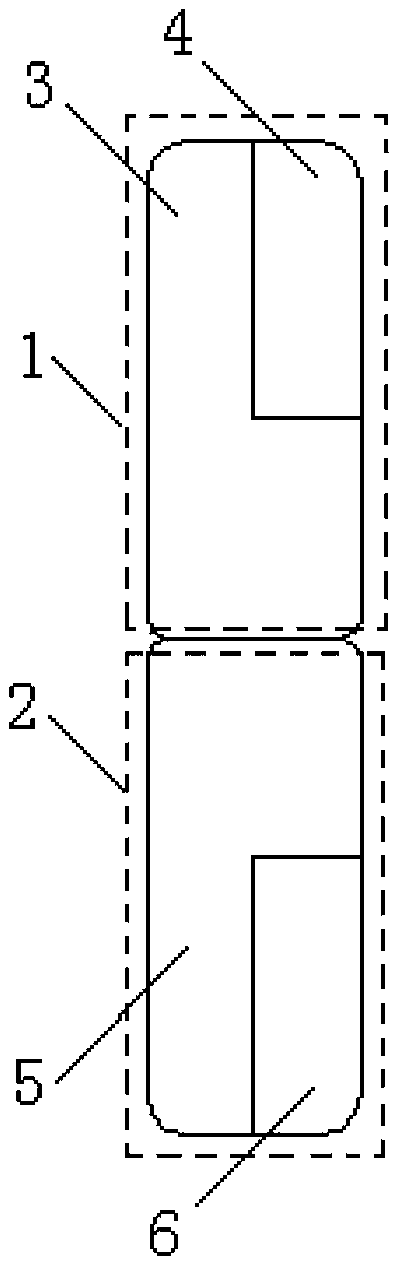

Capacity grading compensation method

ActiveCN108321444ANarrow down test conditions inconsistentLow costSecondary cells testingSecondary cells charging/dischargingTesting equipmentManufacture execution system

The invention belongs to the field of automatic manufacturing of lithium ion batteries and particularly relates to a capacity grading compensation method which comprises the following steps: performing battery cell capacity grading, at the same time monitoring and testing an ambient temperature, synchronously recording voltages and current of a battery cell in capacity grading, and compensating according to a capacity and temperature fitting curve till a capacity in an environment required by a customer, so as to effectively reducing the problems that testing conditions required by customers and manufacturers are not accordant. In addition, by adopting the method provided by the invention, automatic compensation can be achieved from local testing equipment to an MES (Manufacturing Execution System) simultaneously, by barcode tracing can be achieved, and the method is low in cost and high in efficiency.

Owner:DONGGUAN LIWINON ENERGY TECH

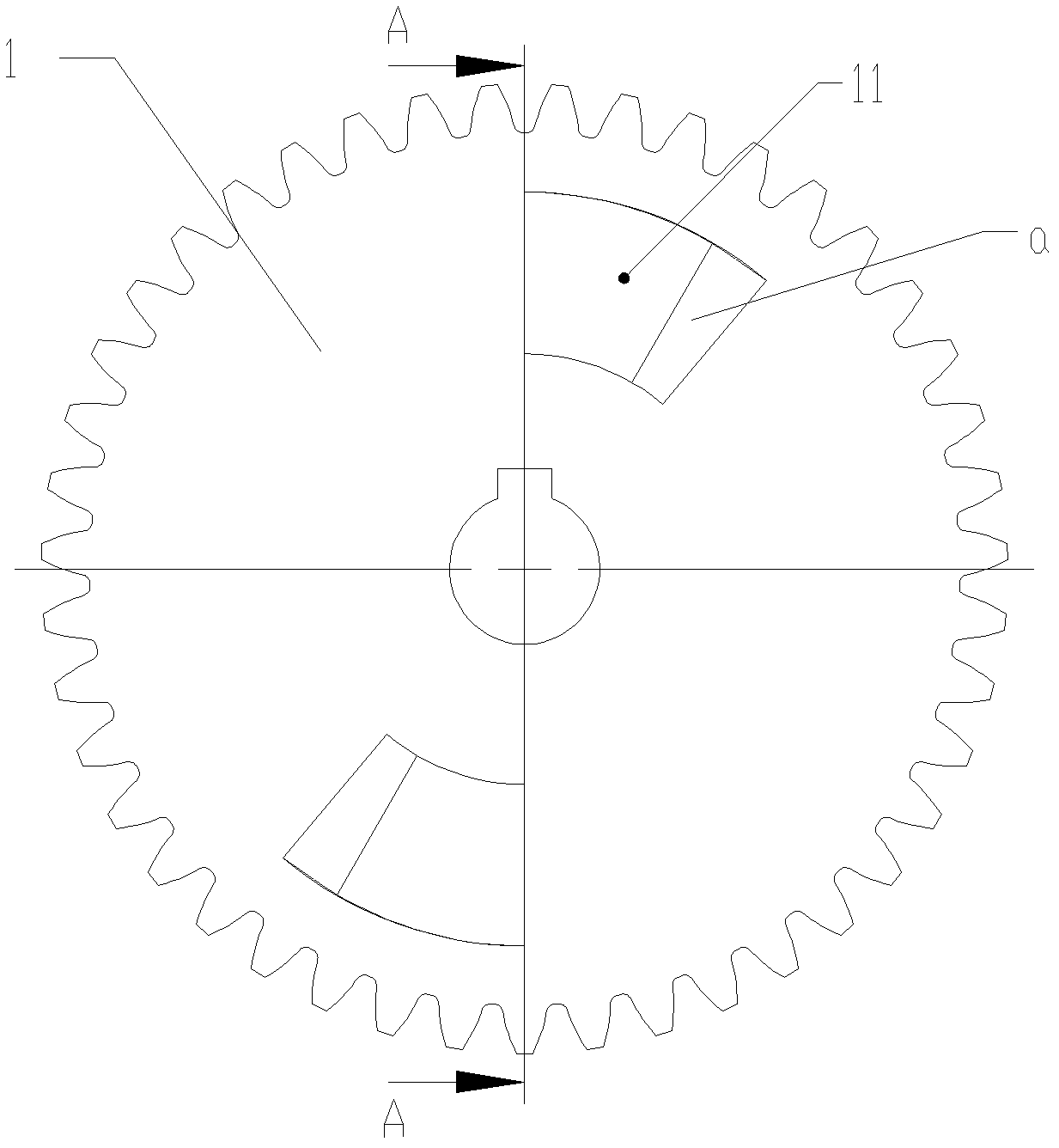

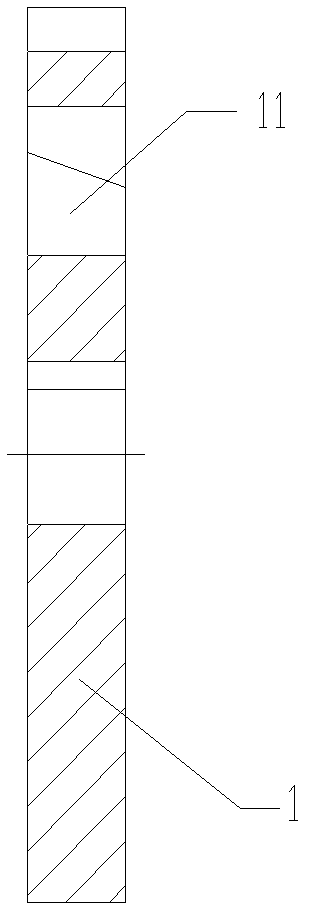

Gapless gear transmission device and method for removing gear transmission gap

InactiveCN102588559ARealize backlash-free transmissionRealize automatic compensationPortable liftingGearing elementsEngineeringBlock match

The invention relates to a gapless gear transmission device and a method for removing a gear transmission gap. The gapless gear transmission device comprises a third gear connected with an output shaft of a driving device, a first gear and a second gear, wherein the first gear and the second gear are simultaneously meshed with the third gear and installed on a gear shaft in parallel, gear modules of the first gear and the second gear are same, the first gear is fixed on the gear shaft through a key groove, and penetrated wedge-shape similar holes are arranged on a gear face of the first gear. The second gear is sleeved on the gear shaft and can rotate along the gear shaft, axial movement is achieved through a spring and an adjusting nut installed on the gear shaft, a wedge-shape similar protruding block matched with the wedge-shape similar holes is arranged on the second gear corresponding to the positions of the wedge-shape similar holes, and a junction surface of the holes and the protruding block is a spiral curved surface. Staggered angles between the first gear and the second gear are adjusted through mutual rotation between the wedge-shape similar holes and the wedge-shape similar protruding block, and a transmission gap between gears is removed. The gapless gear transmission device and the method are simple in structure, convenient to operate and wide in application scope.

Owner:北京华彩时尚服装设计有限公司

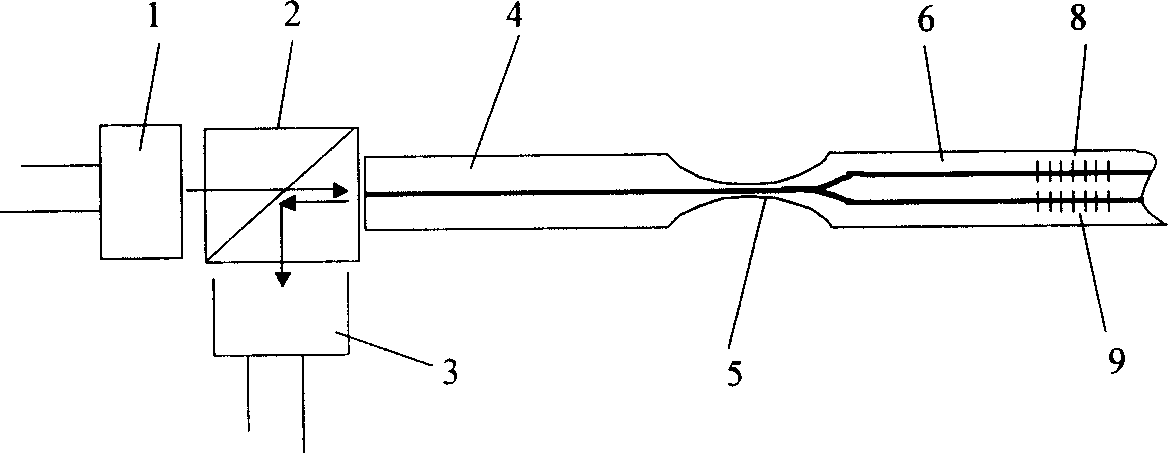

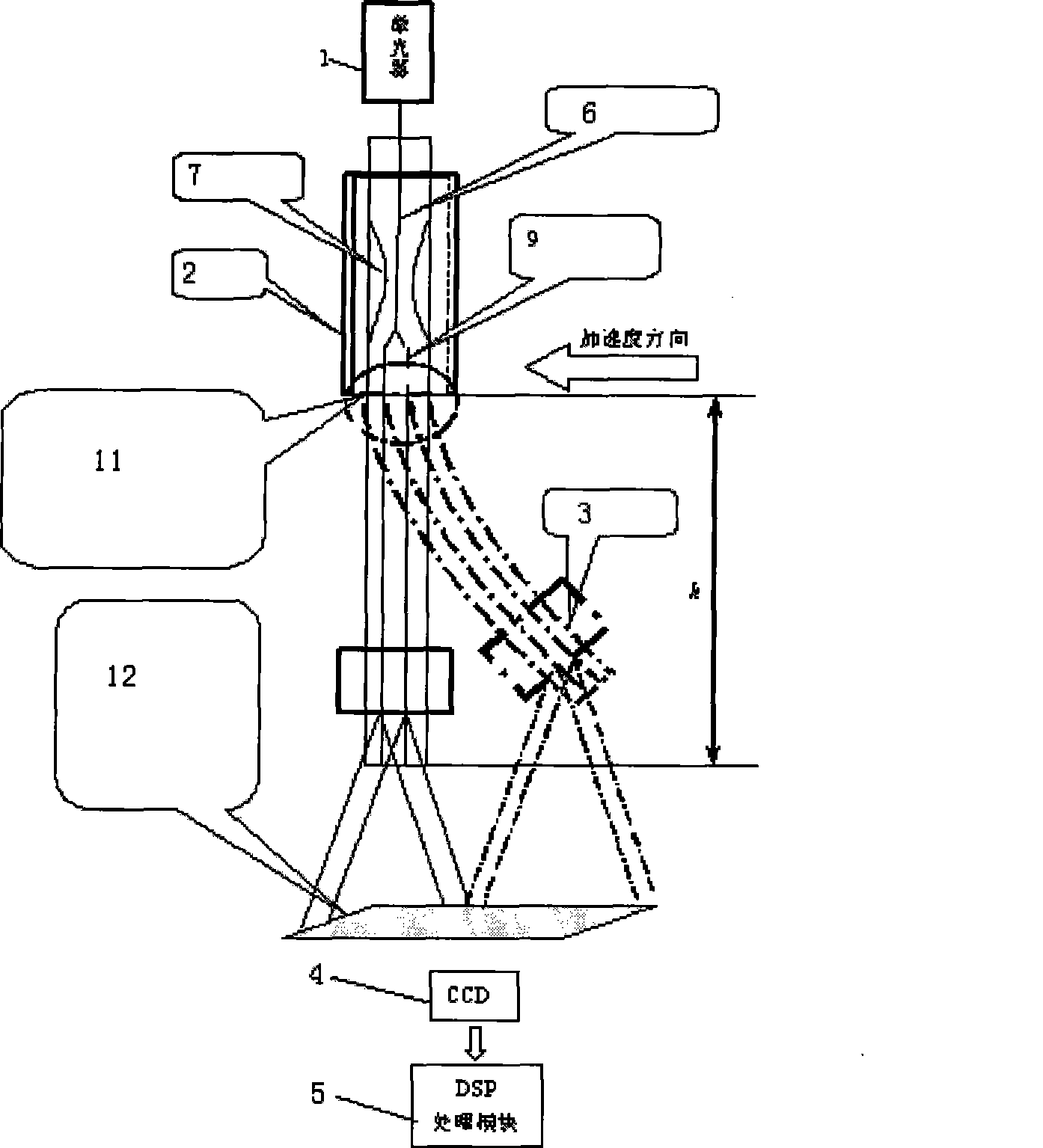

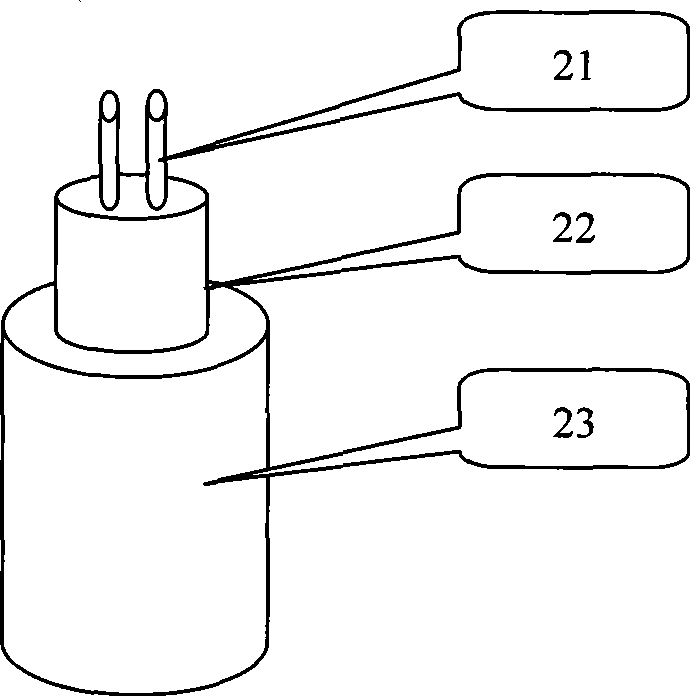

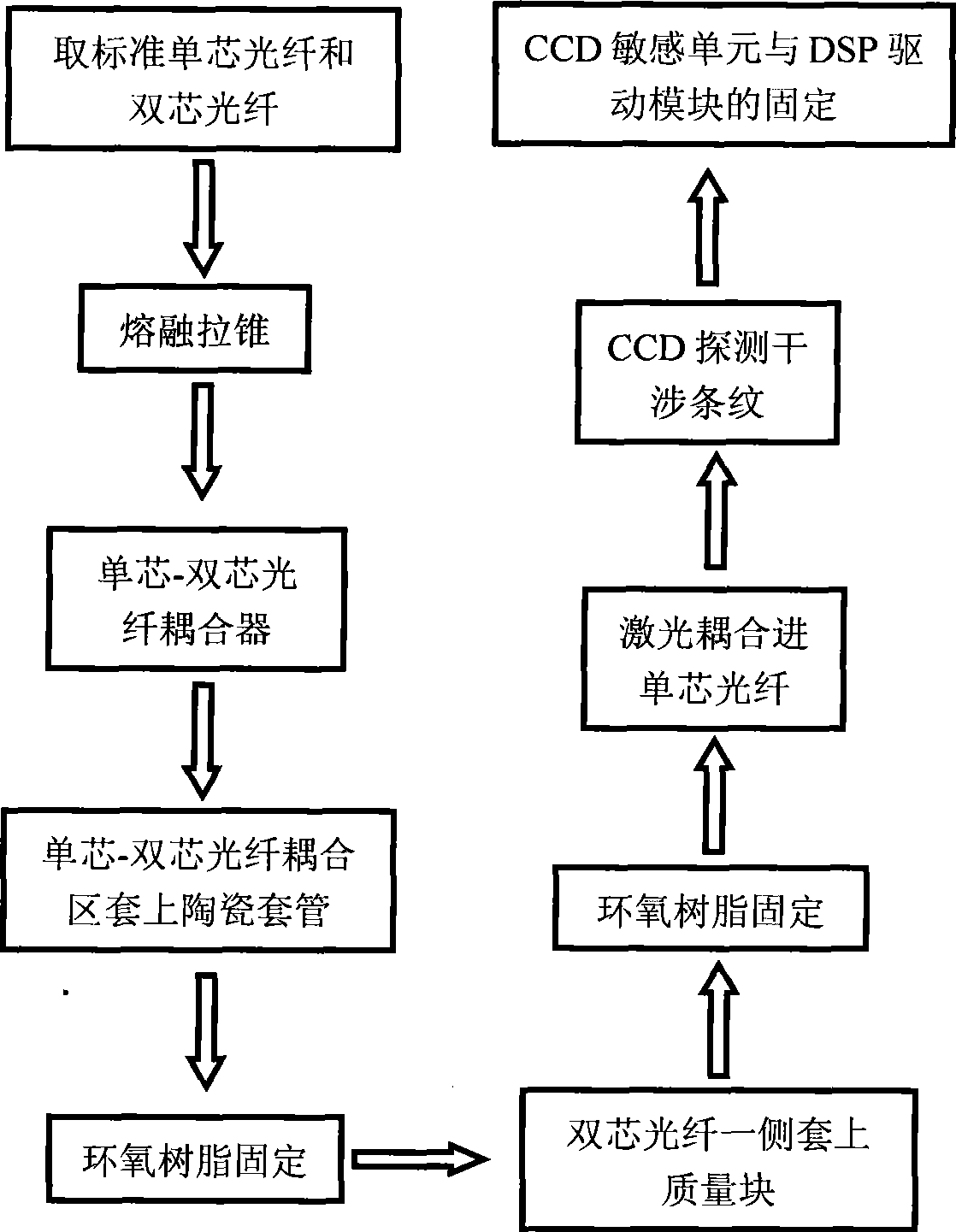

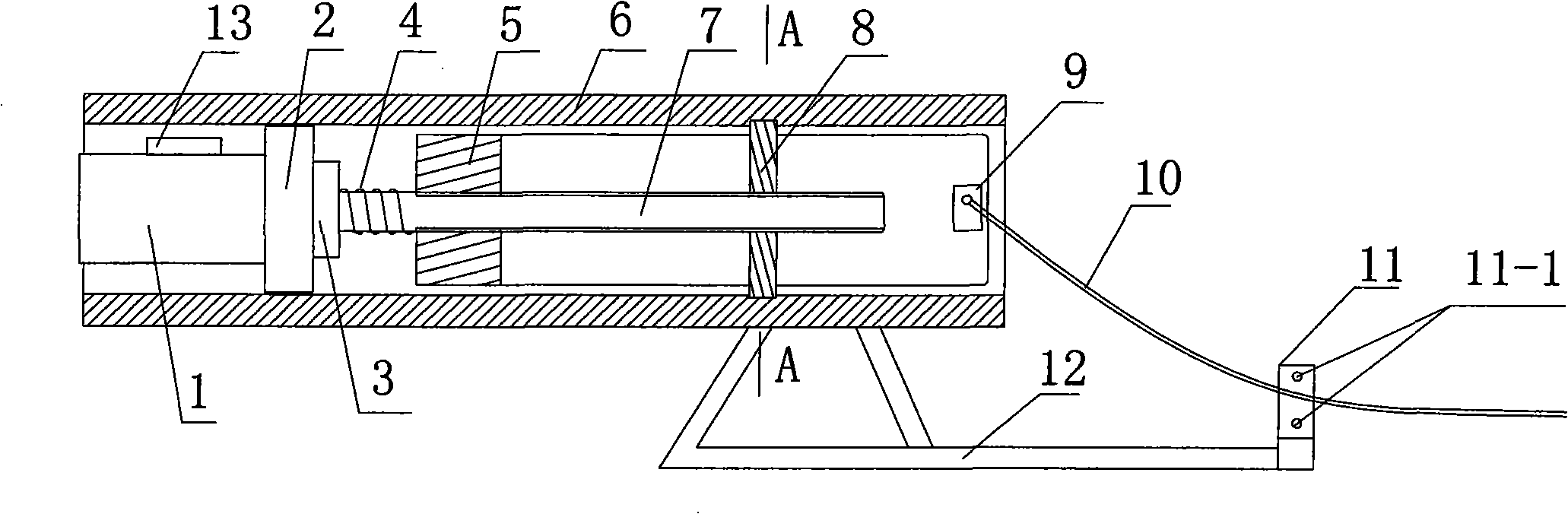

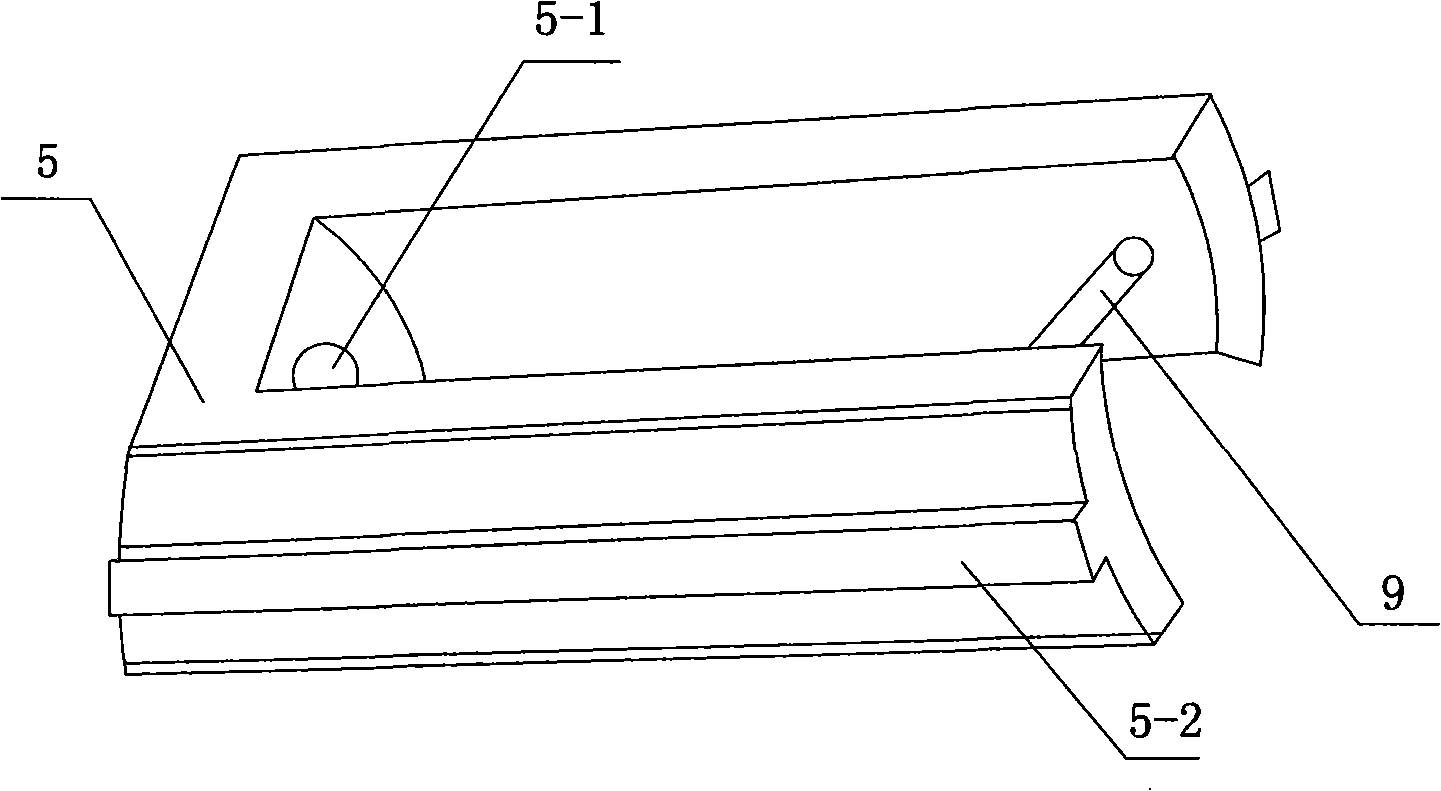

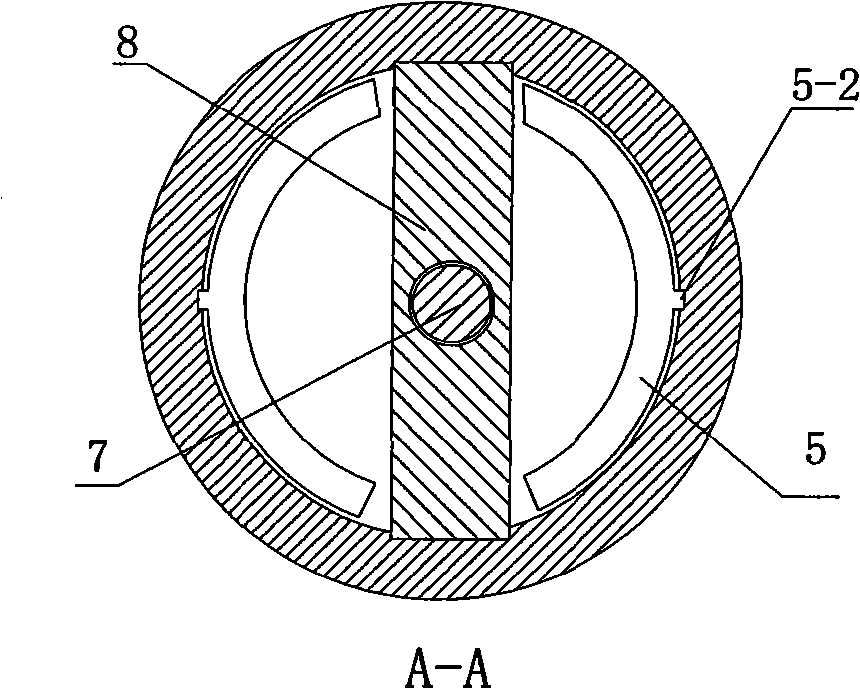

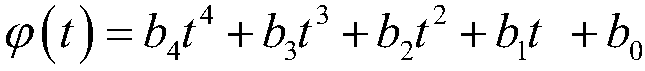

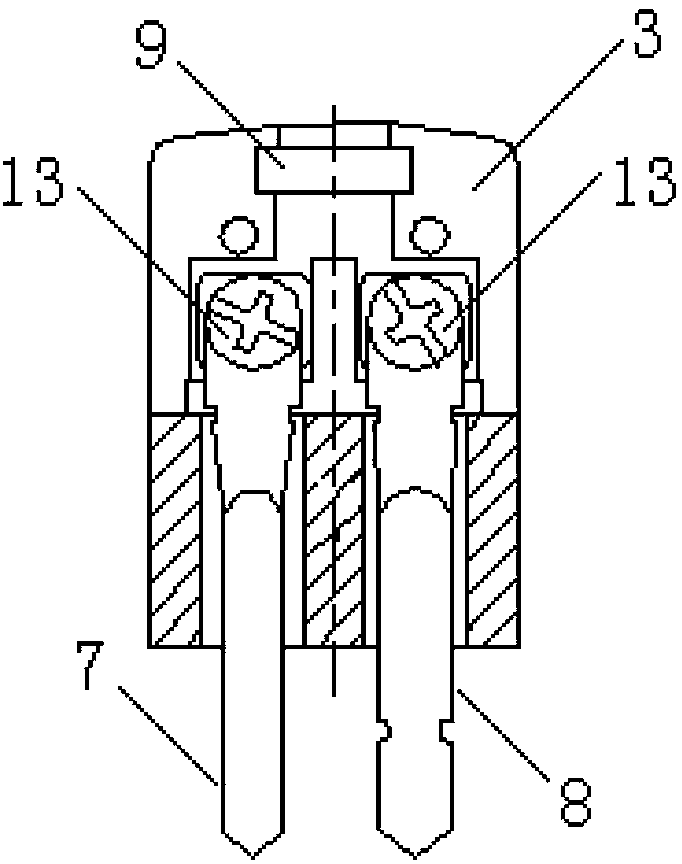

Double-core optical fiber integration type accelerometer and measuring method

InactiveCN101368978AReduce volumeRealize automatic compensationAcceleration measurement using interia forcesAccelerometerDual core

The invention provides a dual-core optical fiber integrated accelerometer and a measuring method thereof. A semiconductor optical laser device 1 is coupled at one end of a single-core optical fiber 6, a dual-core optical fiber 9 is coupled at the other end of the single-core optical fiber 6, a sleeve 8 is nested outside the coupled region 7 of the single-core optical fiber and the dual-core optical fiber, the sleeve 8 is rigidly connected with an exterior shell 2, a metal sleeve which is provided with a hole in the middle is nested at the other side of the dual-core optical fiber 9 as a weight block 3, a receiving device 4 with a plurality of interference fringes and a data processing module 5 are arranged in the exterior shell 2, and the receiving device 4 and the data processing module 5 are rigidly connected with the exterior shell 2, a data line and a power supply line are fetched out through a wire hole 10. The accelerometer has the advantages that the structure is simple and compact, the automatic compensation can be achieved, the accelerometer is suitable for various measuring occasions, and the measuring sensitivity is high.

Owner:HARBIN ENG UNIV

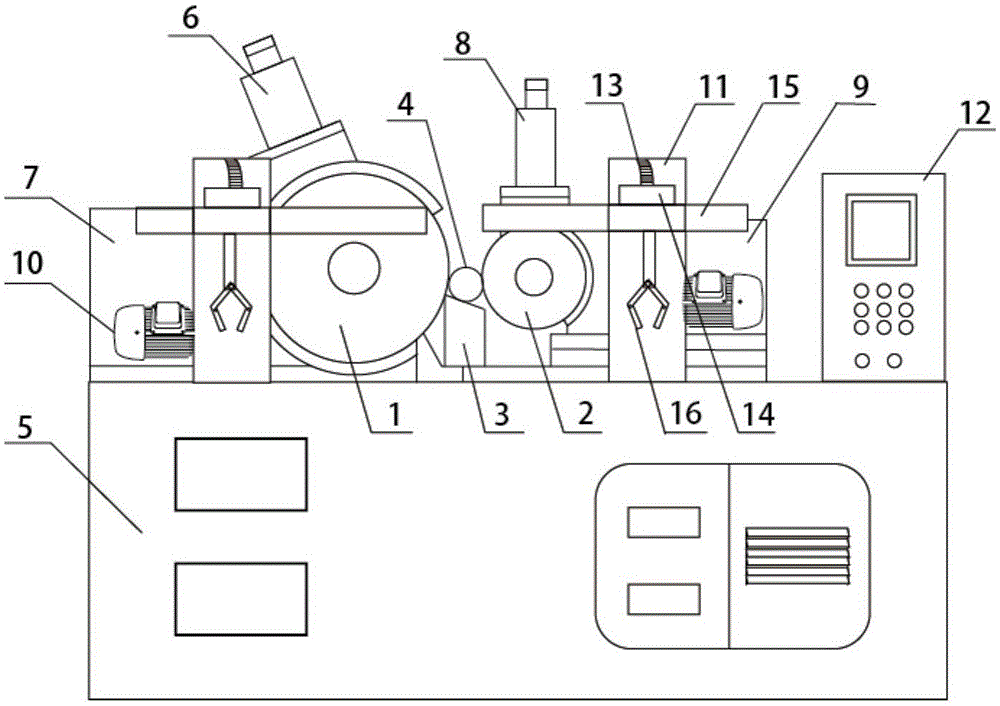

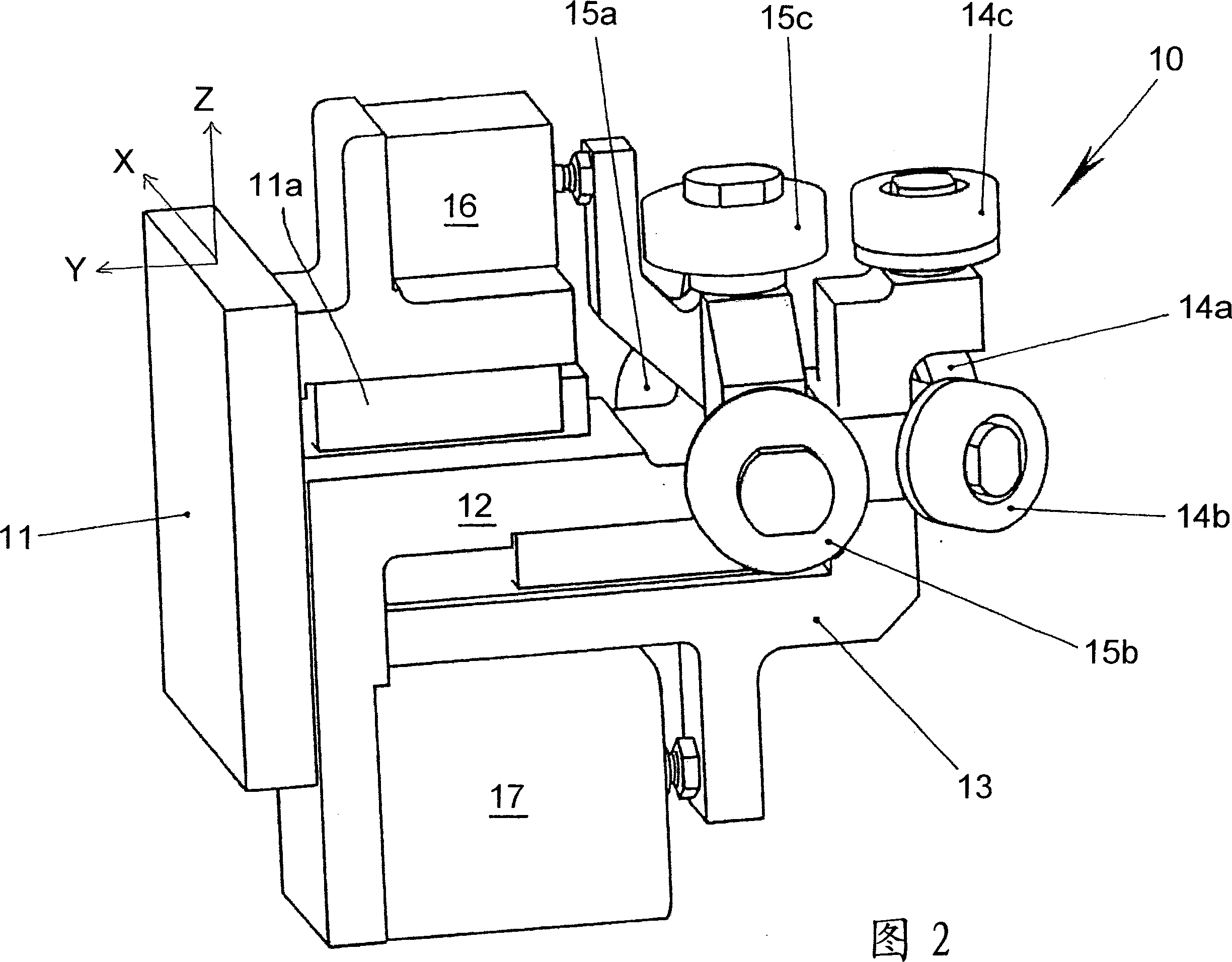

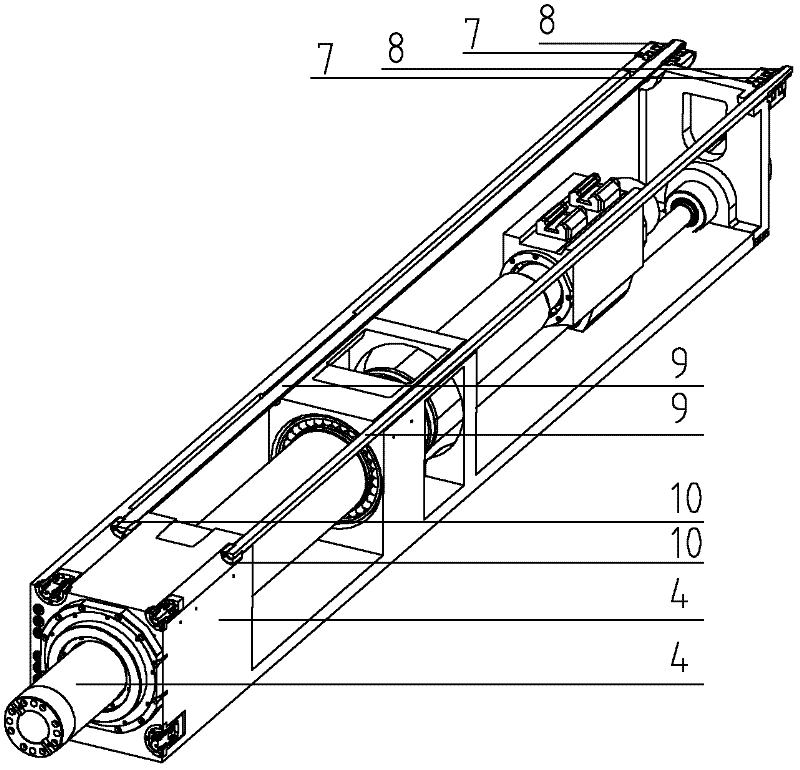

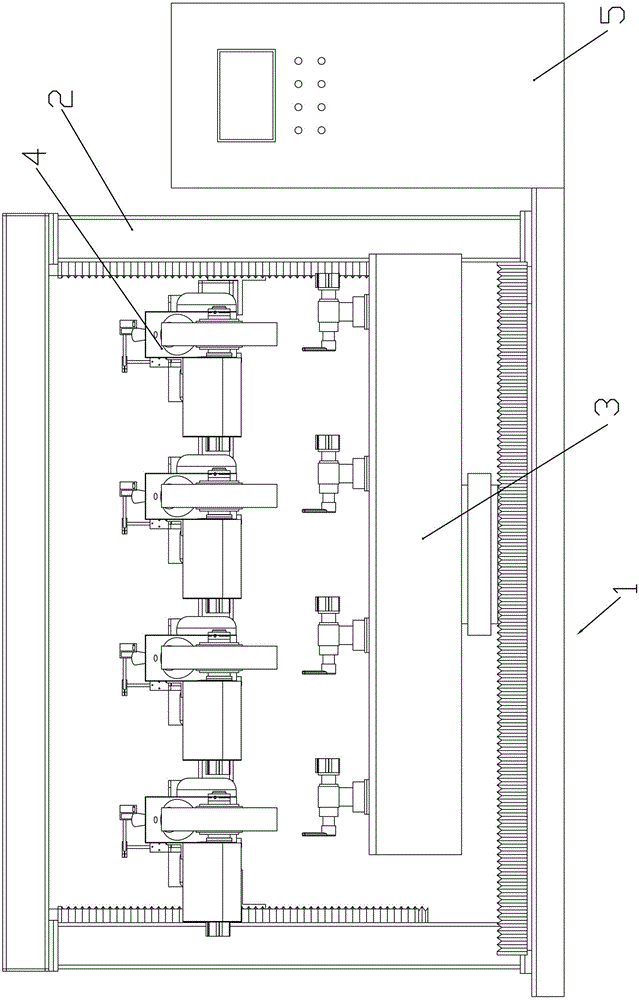

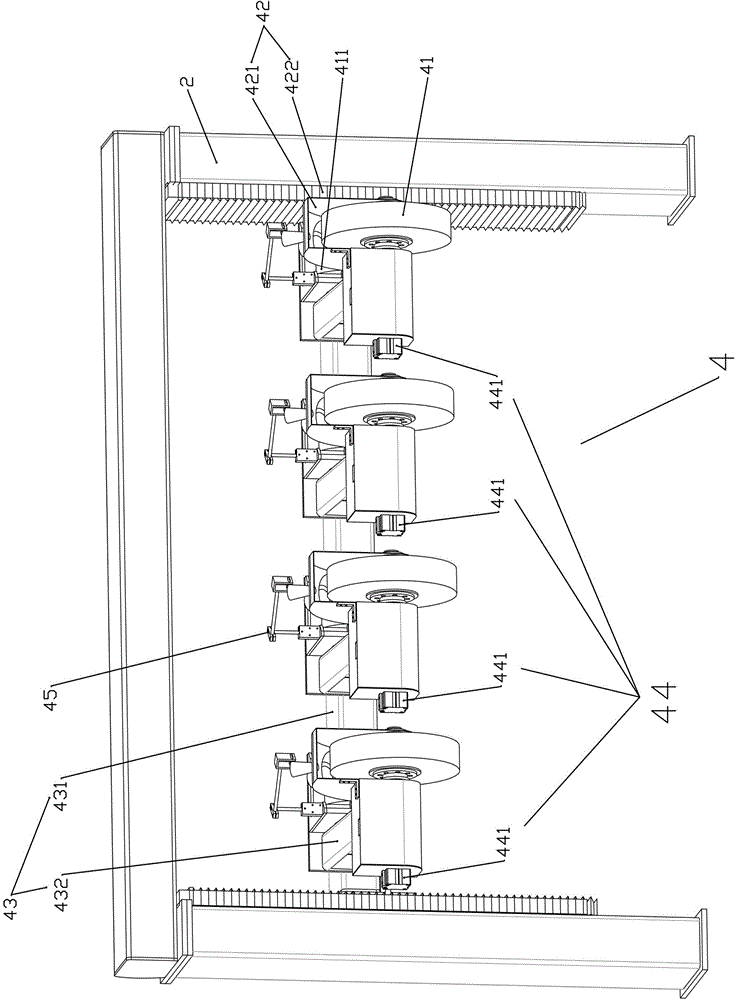

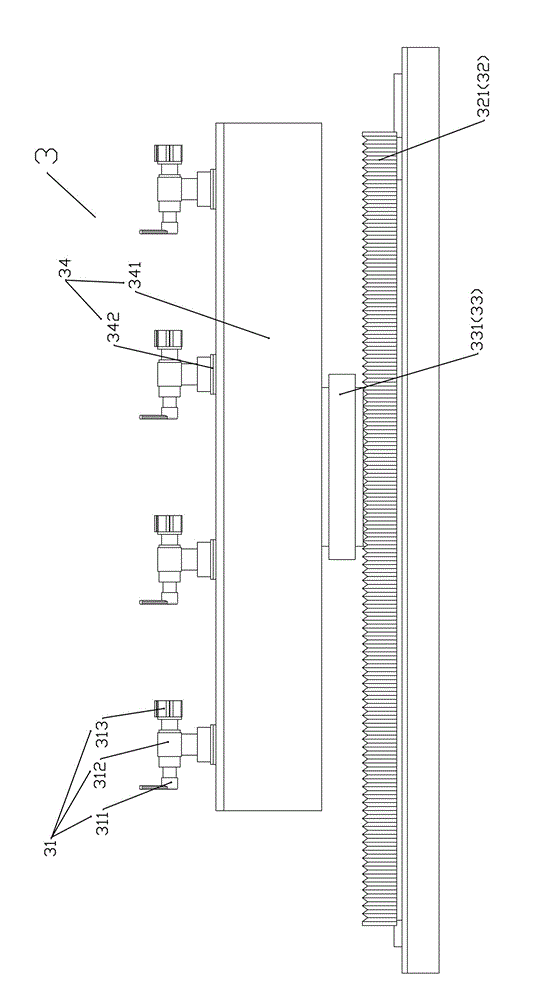

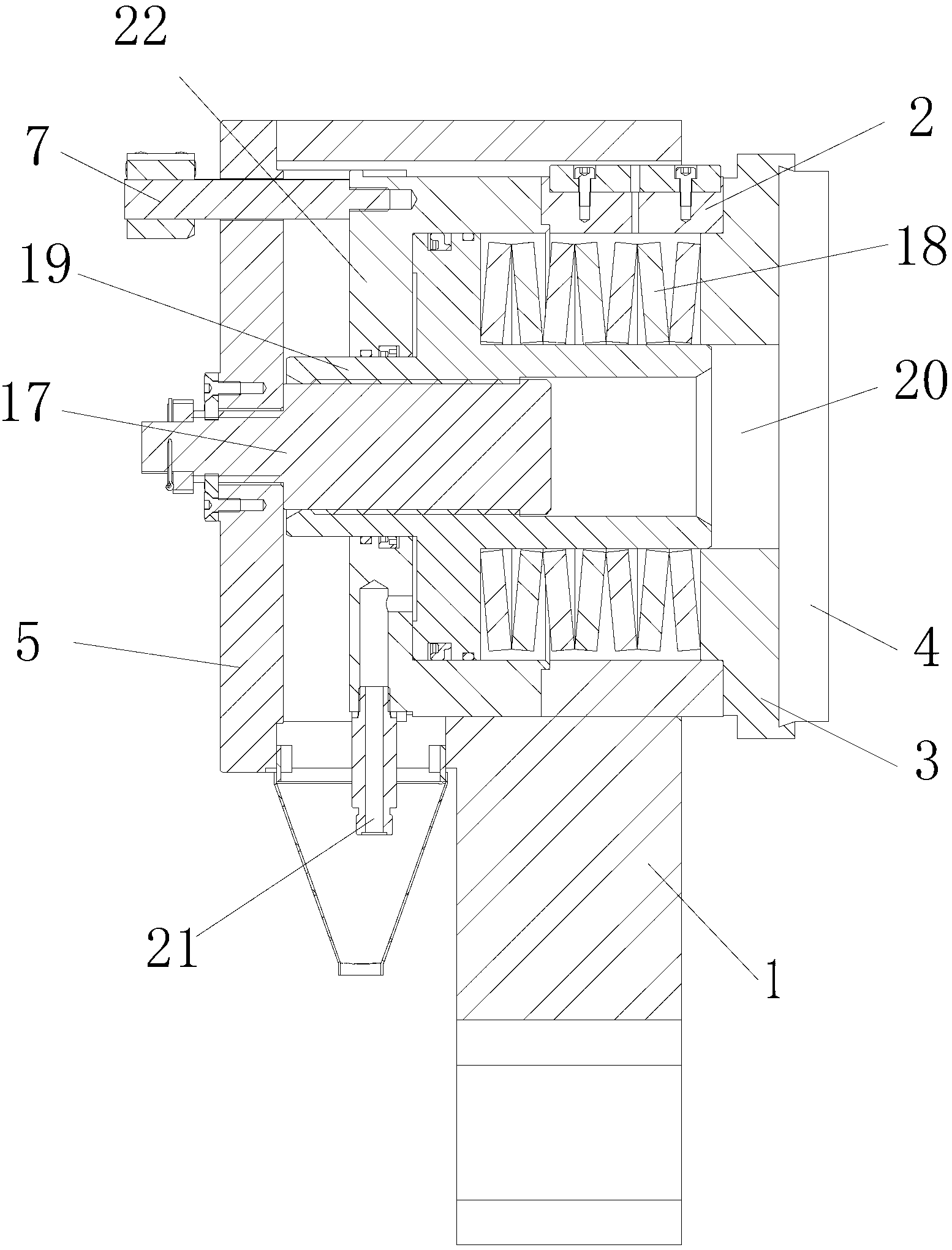

Centerless grinding machine device

InactiveCN105150037ARealize automatic trimmingRealize automatic compensationRevolution surface grinding machinesGrinding drivesMachining processManipulator

The invention aims at providing a centerless grinding machine device. The centerless grinding machine device comprises a grinding wheel, a guiding wheel, a workpiece, a layer board, a machine body, a grinding wheel dresser, a guiding wheel dresser, a guiding wheel feeding mechanism, a grinding wheel feeding mechanism, servo motors, mechanical arms and a control cabinet. The workpiece is borne by the layer board. The grinding wheel and the guiding wheel are located on the two sides of the layer board respectively. The grinding wheel feeding mechanism is used for controlling feeding of the grinding wheel. The guiding wheel feeding mechanism is used for controlling feeding of the guiding wheel. The mechanical arms are located on one side of the grinding wheel and one side of the guiding wheel. The mechanical arms are controlled by CNC to grab the workpiece to finish feeding and discharging operation. The centerless grinding machine device has the beneficial effects that the feeding devices are driven through the servo motors, and automatic dressing and automatic compensating of a centerless grinding machine are achieved; the mechanical arms are controlled by CNC to carry out automatic feeding and discharging, the auxiliary time in the machining process is greatly shortened, and the labor intensity of workers is relieved; and the labor cost is reduced, and the machining precision and the productive efficiency are improved.

Owner:TIANJIN HUATIAN CENTURY MACHINERY

Underwater separable connector test device

ActiveCN104296910APlay a guiding roleEasy to assemble and disassembleMachine part testingTesting dielectric strengthElectricityPore water pressure

The invention relates to the field of electrical connector test, and especially relates to an underwater separable connector test device. The underwater separable connector test device comprises a simulation container on which a pressure compensation device is arranged. The pressure compensation device is arranged on the simulation container of the underwater separable connector test device, so that the pressure compensation device can compensate the pressure of water in the simulation container after separation of a connector to enable the water pressure of the environment of the connector before and after separation to be basically the same, thereby improving the similarity of simulation of pressure in the using environment of an underwater separation connector.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

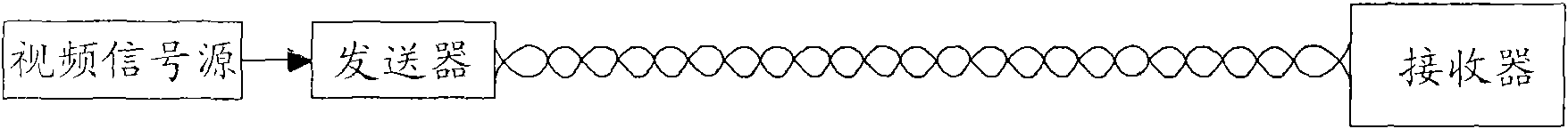

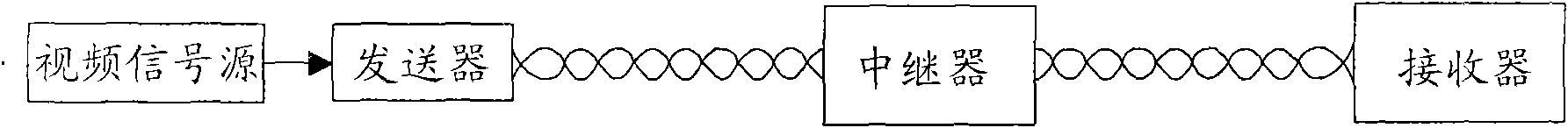

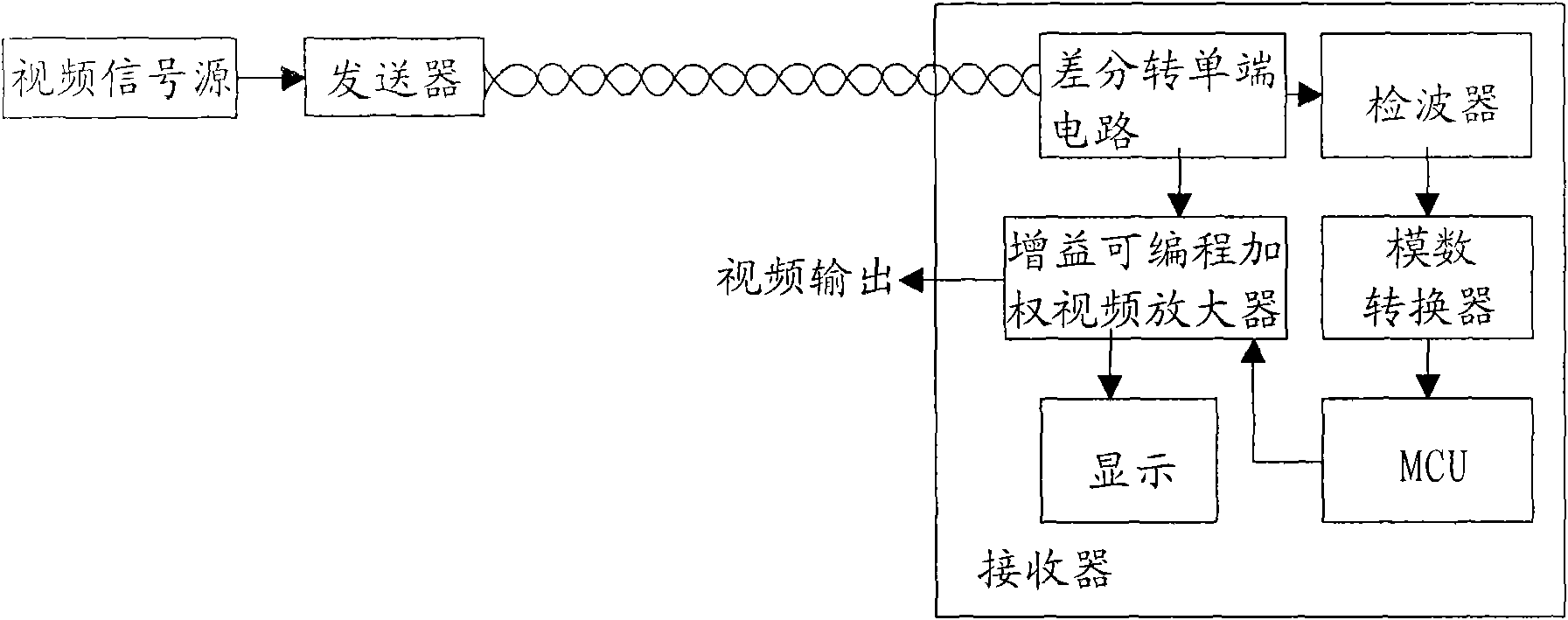

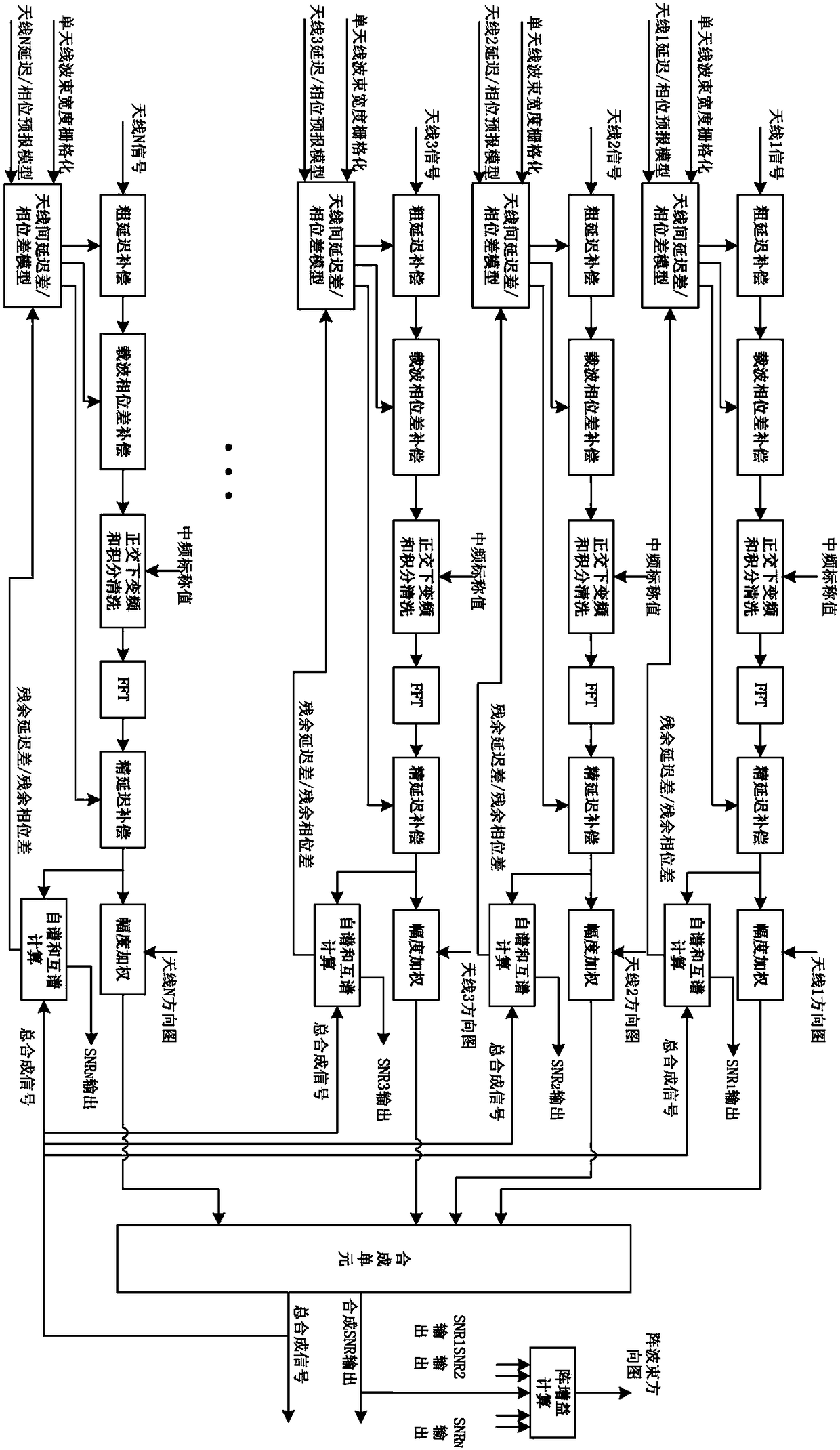

Automatic preamplification and precompensation twisted-pair video transmission method and system

ActiveCN101795385AImprove signal-to-noise ratioRealize automatic compensationElectrical cable transmission adaptationVideo outputTransceiver

The invention discloses an automatic preamplification and precompensation twisted-pair video transmission system. The basic structure of the system at least comprises a transmitter, two pairs of twisted pairs and a receiver, wherein the transmitter comprises at least one video input impedance matching circuit, whereas the receiver comprises at least one video output impedance matching circuit; the transmitter also comprises a multistage stepping adjustable gain video weighting amplifier, a reference signal generator, a multipath selective switch, a microprocessor and a data communication transceiver, and the receiver also comprises a signal amplitude detector, a microprocessor and a data communication transceiver, wherein the signal amplitude detector sends the amplitude of a reference signal to the microprocessor. The structure can effectively carry out automatic and accurate compensation on the loss of a video signal in twisted-pair transmission, reduce the engineering debugging difficulty and improve the capacity of resisting disturbance of video signal transmission. The invention also discloses the automatic preamplification and precompensation twisted-pair video transmission method.

Owner:厦门ABB智能科技有限公司

Automatic tensile-force compensator of soft part

InactiveCN101527439ARealize automatic compensationGuaranteed to workAdjusting/maintaining mechanical tensionTrolley linesReduction driveEngineering

The invention relates to an automatic tensile-force compensator of a soft part, which comprises an electric motor, a speed reducer, an axial positioning screw rod, a nut, a fixed sleeve and an infrared switch, wherein the electric motor is provided with a controller, the screw rod and the central thread hole of the nut form a spiral pair, the nut is provided with a connection member of a soft part and positioned in the fixed sleeve, the nut and the fixed sleeve are used cooperatively by tracks of mutual concave and convex close fit, and the nut slides along a fixed track. The invention changes the work mode of the passive adaptability compensation of the traditional potential-energy element compensator, and can timely and actively control the load change according to the using requirements.

Owner:CHANGZHOU MINGJIN SPRING +2

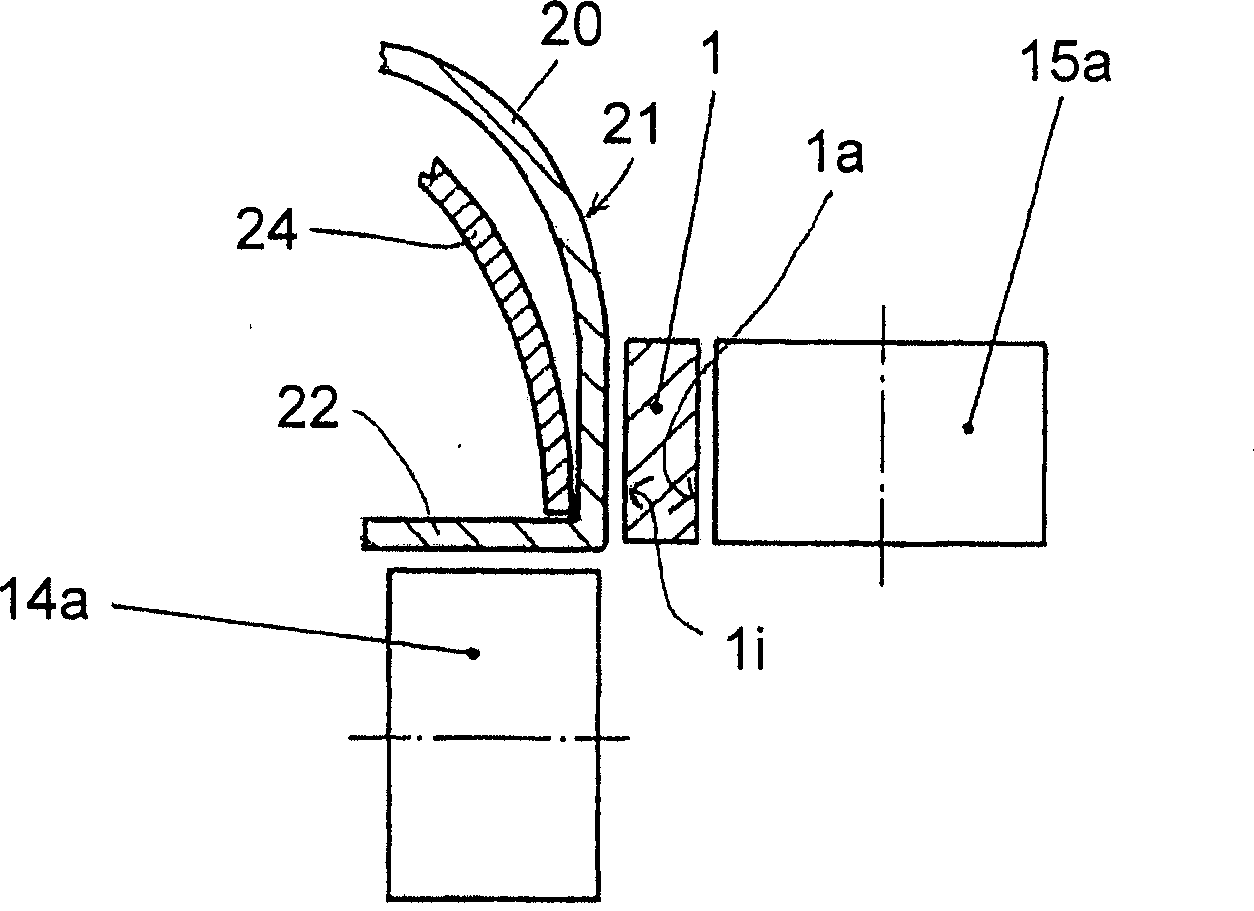

Flanging device and flanging method with component protection

Owner:FFTEDAG生产有限公司

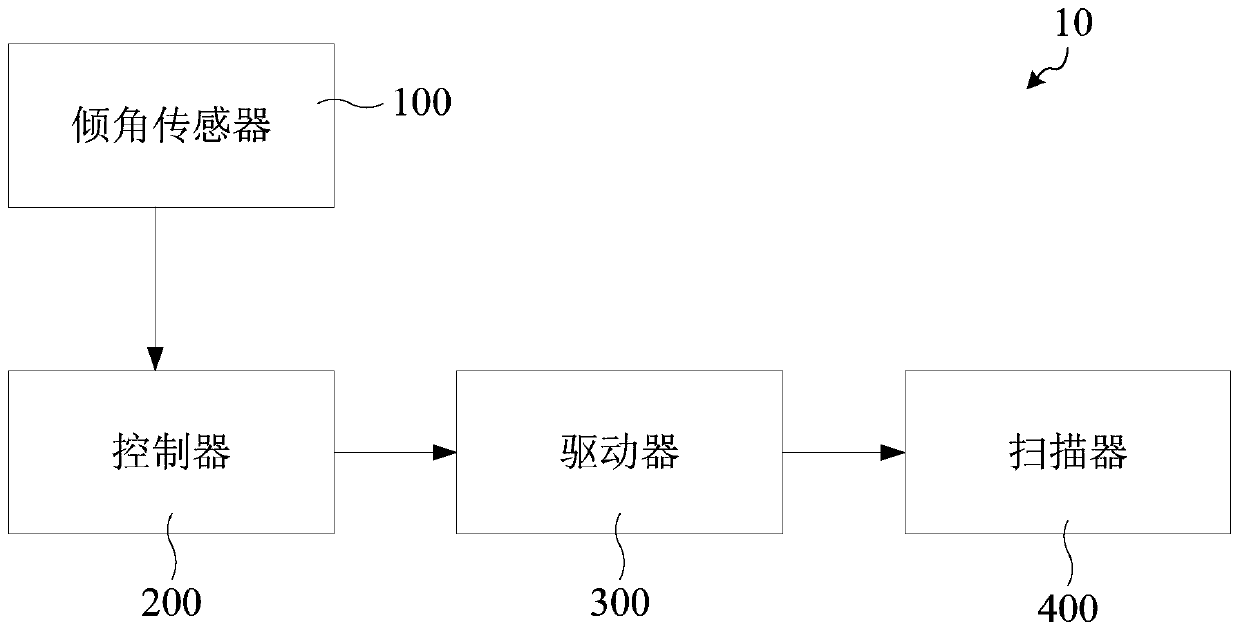

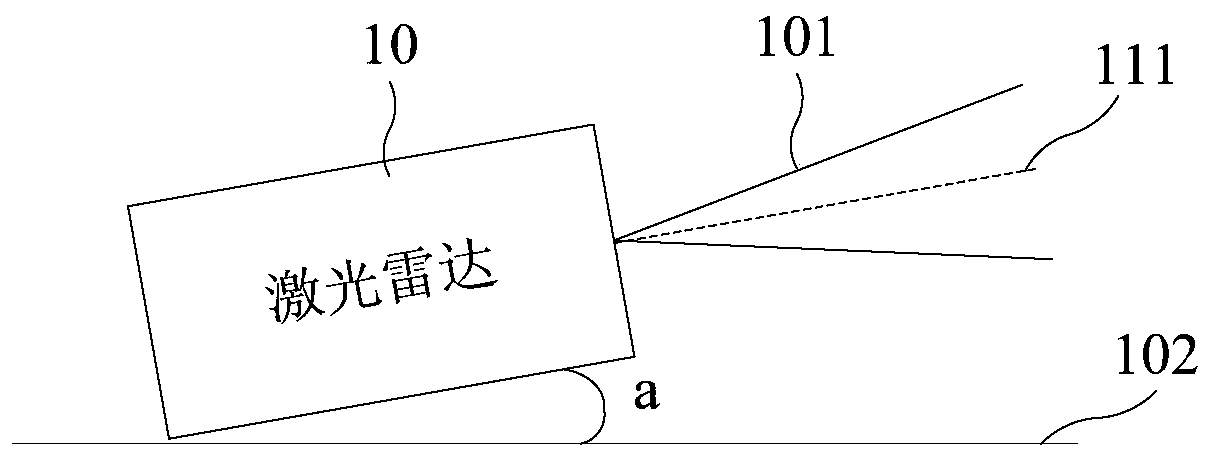

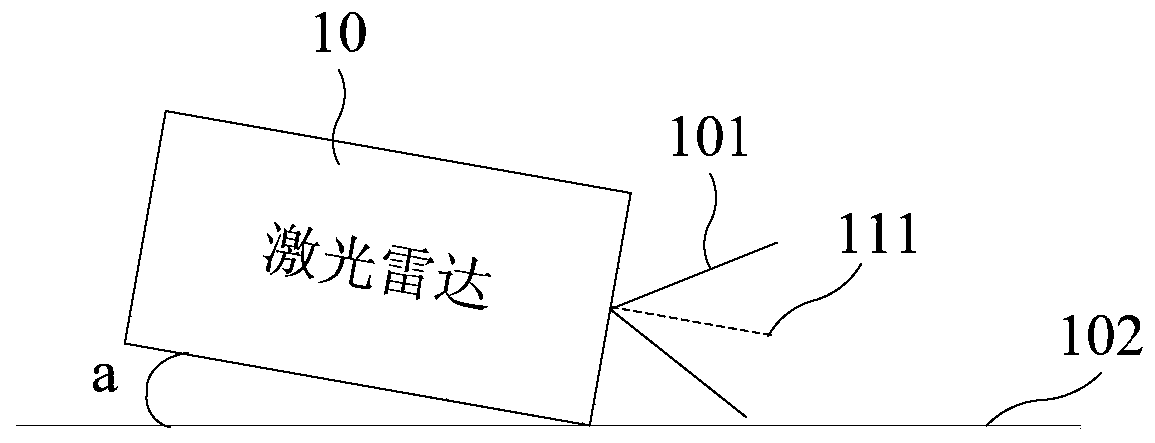

Laser radar, equipment and laser radar installation angle calibration method

PendingCN109870700ARealize automatic compensationNo labor consumptionElectromagnetic wave reradiationRadarOptoelectronics

The invention discloses a laser radar, equipment and a laser radar installation angle calibration method. The laser radar comprises a tilt angle sensor, a controller, a driver and a scanner, wherein the tilt angle sensor, the controller, the driver and the scanner are sequentially connected in series; the tilt angle sensor is used for detecting an installation angle of the laser radar; the controller is used for obtaining an actual deflection angle of the scanner according to the installation angle and a target inclination angle of a laser beam emitted by the scanner, and generating a drivinginstruction carrying the actual deflection angle; and the driver is used for driving the scanner to deflect the actual deflection angle according to the driving instruction. According to the technicalscheme provided by the embodiments of the invention, the automatic compensation of an installation error of the laser radar is realized, no manual consumption is generated, the man-hour is short, andthe measurement and debugging precision is high.

Owner:LEISHEN INTELLIGENT SYST CO LTD

Method for testing ultra-sparse antenna array transmit-receive beam pattern

ActiveCN108303602ASolve the problem that cannot be tested on the groundAchieve accurate estimatesWave based measurement systemsAntenna radiation diagramsRadarPhase difference

The invention discloses a method for testing an ultra-sparse antenna array transmit-receive beam pattern, and mainly solves the problem that an existing measuring method and system cannot carry out ground pattern testing on an ultra-sparse antenna array. The method includes the steps of using multiple antennas to receive echo signals of a same satellite, obtaining the delay difference and the phase difference between the antennas by utilizing an FX correlation synthesizer to serve as zero values of the antenna delay difference and the phase difference between antennas; performing rasterizationon the incoming wave direction in the width of the single-antenna beam on the basis, carrying out accurate compensation on the satellite signals received by the antennas through the corresponding delay difference and the phase difference, so that the test of the super-sparse antenna array transmit-receive beam pattern is achieved. The method has the advantages of high delay / phase measurement precision, and simple and reliable method. The method is more suitable for far-field pattern test of a regional antenna array, networked radar and other super-sparse and distributed antenna arrays.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Thermocouple cold junction compensation type combined socket connector

ActiveCN103389169ARealize automatic compensationEnsure high temperature resistanceThermometers using electric/magnetic elementsUsing electrical meansControl systemJunction temperature

The invention relates to a thermocouple cold junction compensation type combined socket connector which comprises a plugin male head and a plugin female head, wherein the plugin male head comprises a plugin male head bottom cover and a plugin male head upper cover; a male head inner core positive electrode and a male head inner core negative electrode are arranged in the plugin male head bottom cover side by side; the plugin female head comprises a plugin female head bottom cover and a plugin female head upper cover; the female head inner core positive electrode and the female head inner core negative electrode are arranged in the plugin female head bottom cover side by side. The socket connector has the benefits that through the utilization of the free connection or plug-in connection of a thermocouple temperature sensor and an armored compensation conducting wire cable, the cold junction of the thermocouple is stretched from an industrial site with frequent temperatures and considerable change to a central control room with a relatively constant temperature in a long distance; the long distance stretching of the thermocouple cold junction and the automatic compensation of the cold junction temperature are realized; with the help of the firm and durable properties of the armored compensation cable, the temperature measuring circuit is ensured to be high temperature resistant, the reliability of the running of the temperature measurement and control system can be obviously enhanced, and the service life can be obviously prolonged.

Owner:ZHEJIANG TAISUO TECH

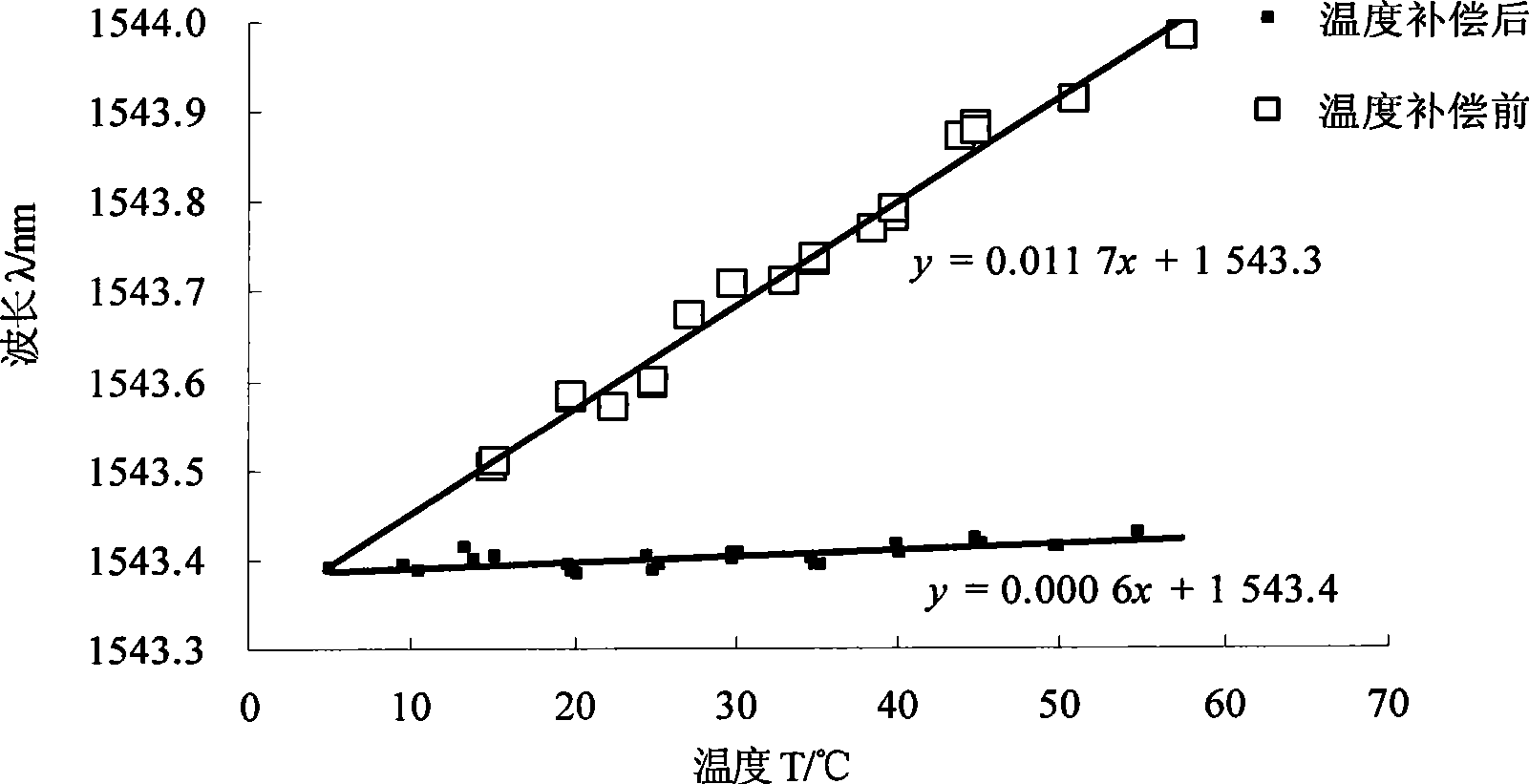

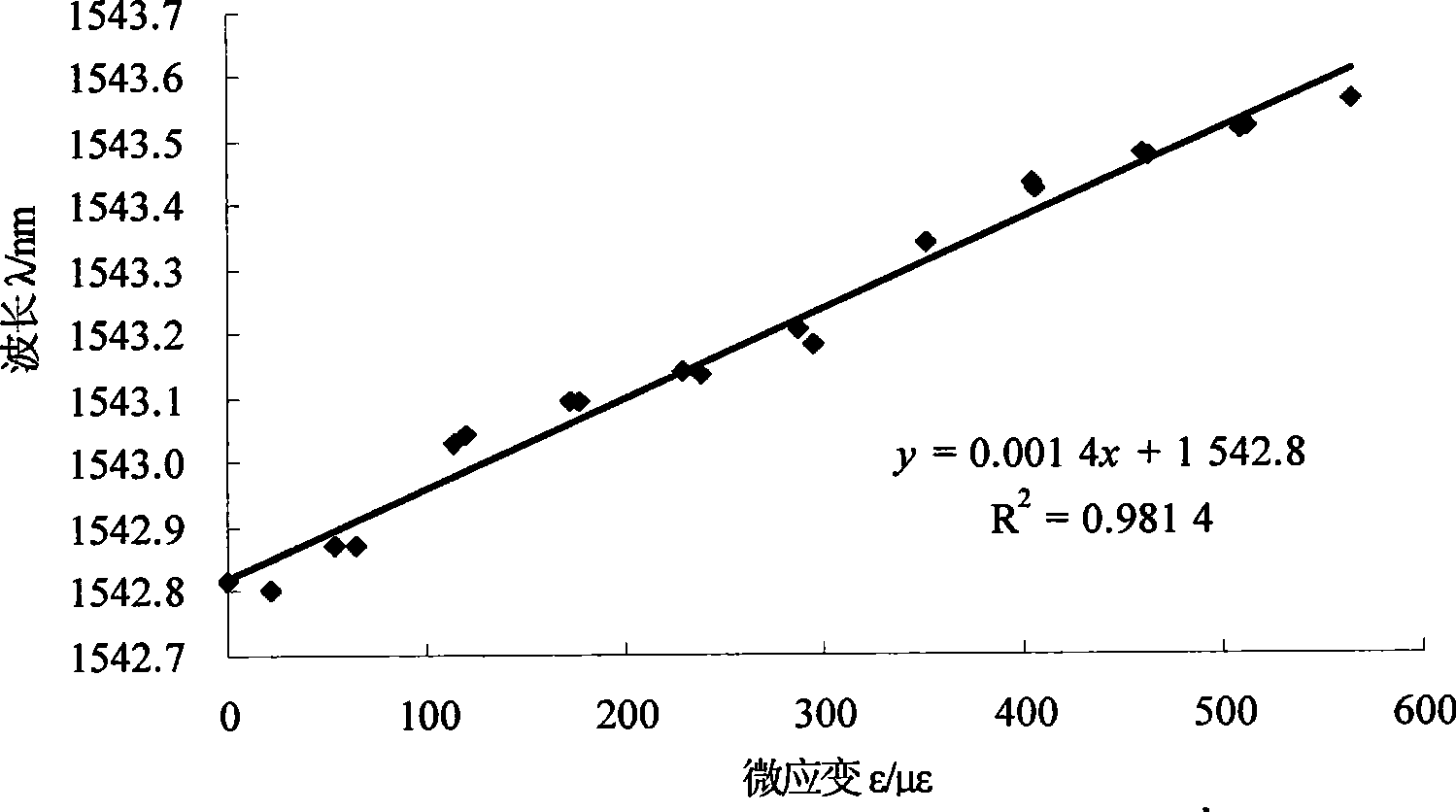

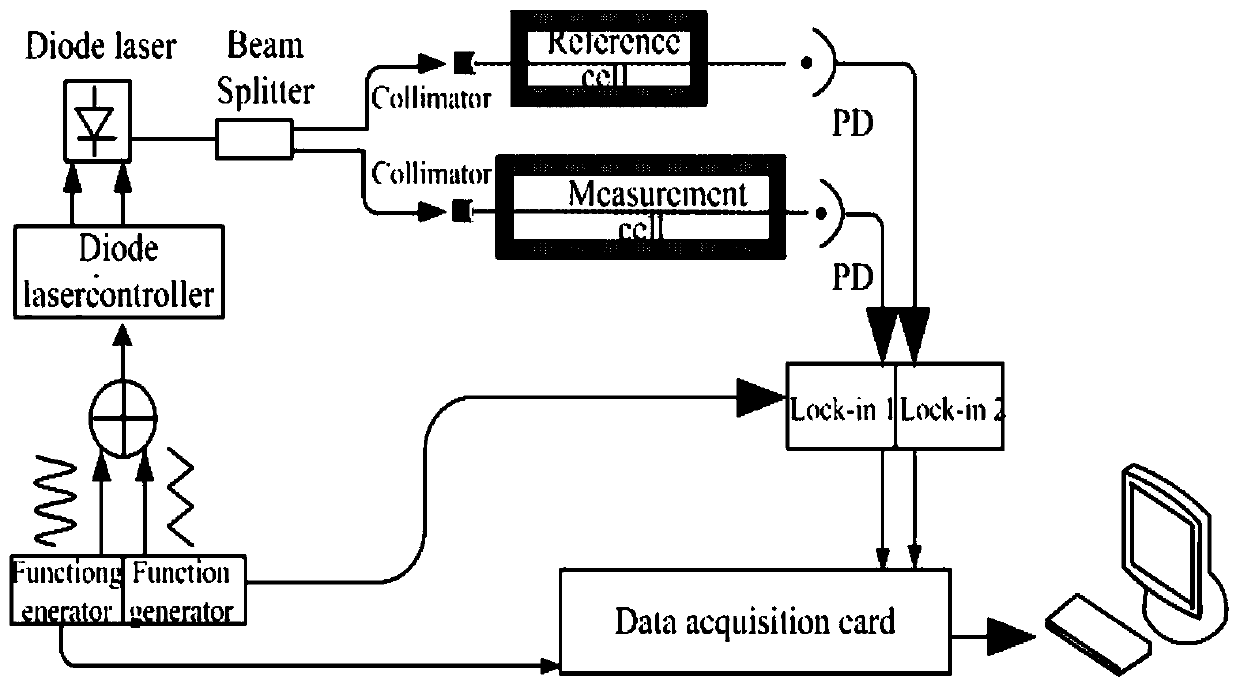

Optical fiber grating self-compensating strain transducer produced by on-line molding process

InactiveCN101382420ASolve the problem of unreliable bindingSolve easy creepUsing optical meansFiberGrating

The invention provides a fiber grating self-compensating strain transducer manufactured by adopting an online molding process, relating to the technical field of temperature transducers. A compensating device is composed of a part B and a solid body which are connected in series, wherein, the solid body is manufactured by adopting the online molding process for embedding and fixing the whole fiber grating in the solid body, and at least one of the cross-sectional area and thermal expansion coefficient of the part B and the solid body is different from each other. The strain transducer has the positive effects that: when the environmental temperature rises or falls, the automatic compensation to grating wavelength temperature drift can be realized by the effect of stress deformation, with precision compensation and good working stability; moreover, the strain transducer also has the advantages of small size, low cost, easy processing, good working stability, convenient use, stability and reliability, and long service life; the molding process of the strain transducer is simple and convenient, the compensation performance can be guaranteed to be reliable, and the problems that grating adhesive process has easy creep deformation, easy aging, unreliable grating combination, short service life and the like in the prior art are solved.

Owner:SHIJIAZHUANG RAILWAY INST

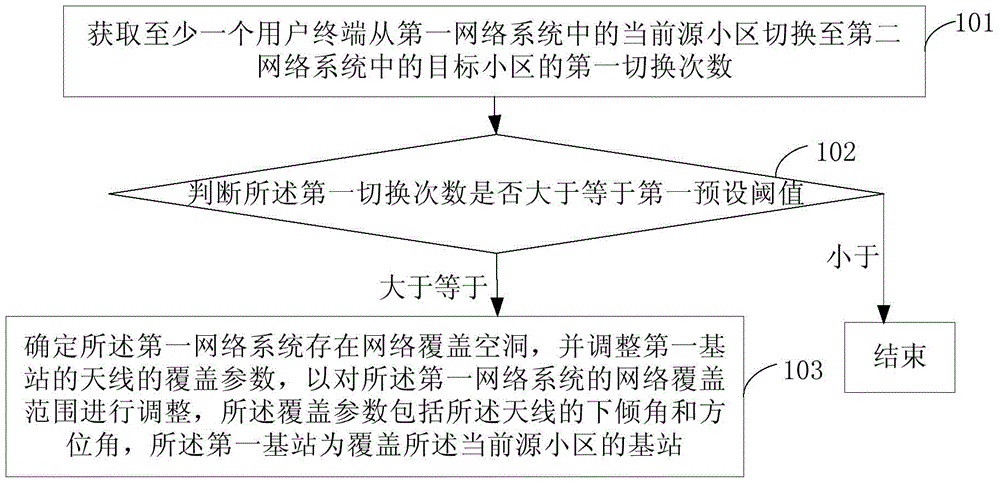

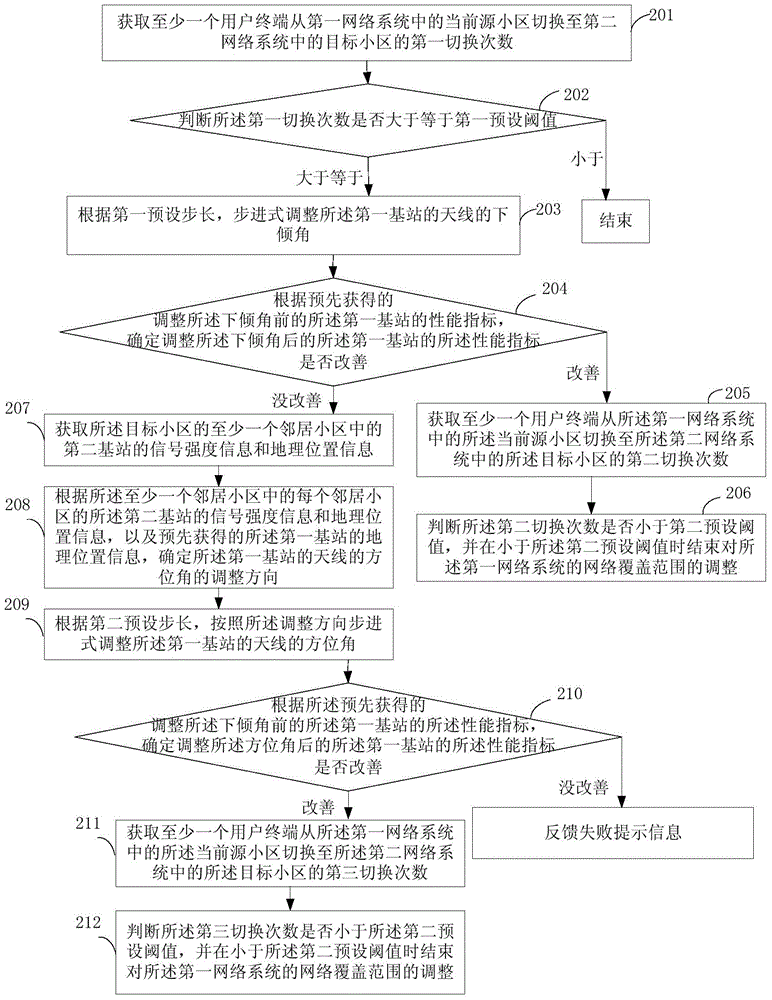

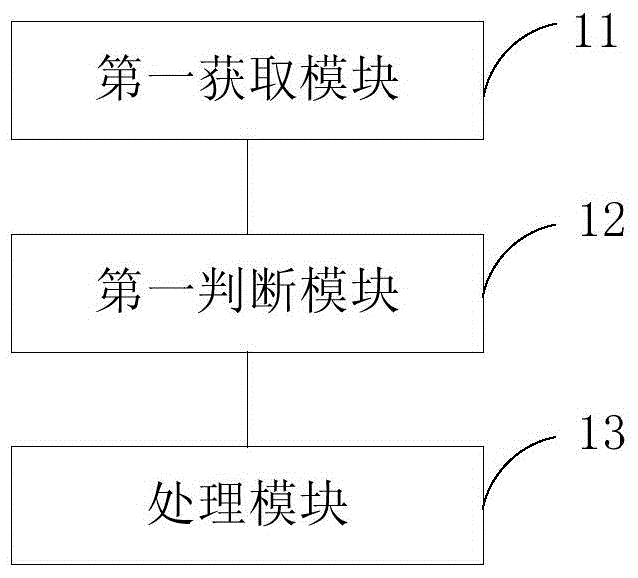

Network coverage hole processing method and device based on inter-system switching

InactiveCN104980939ARealize automatic compensationImprove processing efficiencyNetwork planningComputer terminalSwitching time

The invention provides a network coverage hole processing method and device based on inter-system switching. The method comprises: obtaining a first switching time of at least one user terminal switching from a current source cell in a first network system into a target cell in a second network system; judging whether the first switching time is larger than or equal to a first preset threshold; and if so, determining that the first network system has a network coverage hole, and adjusting coverage parameters of an antenna of a first base station to adjust the network coverage of the first network system, wherein the coverage parameters include a downward inclination angle and an azimuth angle of the antenna, and the first base station is a base station covering the current source cell. Whether the network coverage hole exists is judged in accordance with the inter-system switching time, when the network coverage hole exists, the coverage parameters of the base station are automatically adjusted to compensate the coverage hole without manual intervention, and thus the processing efficiency of compensating the network coverage hole is improved.

Owner:HUAWEI TECH CO LTD

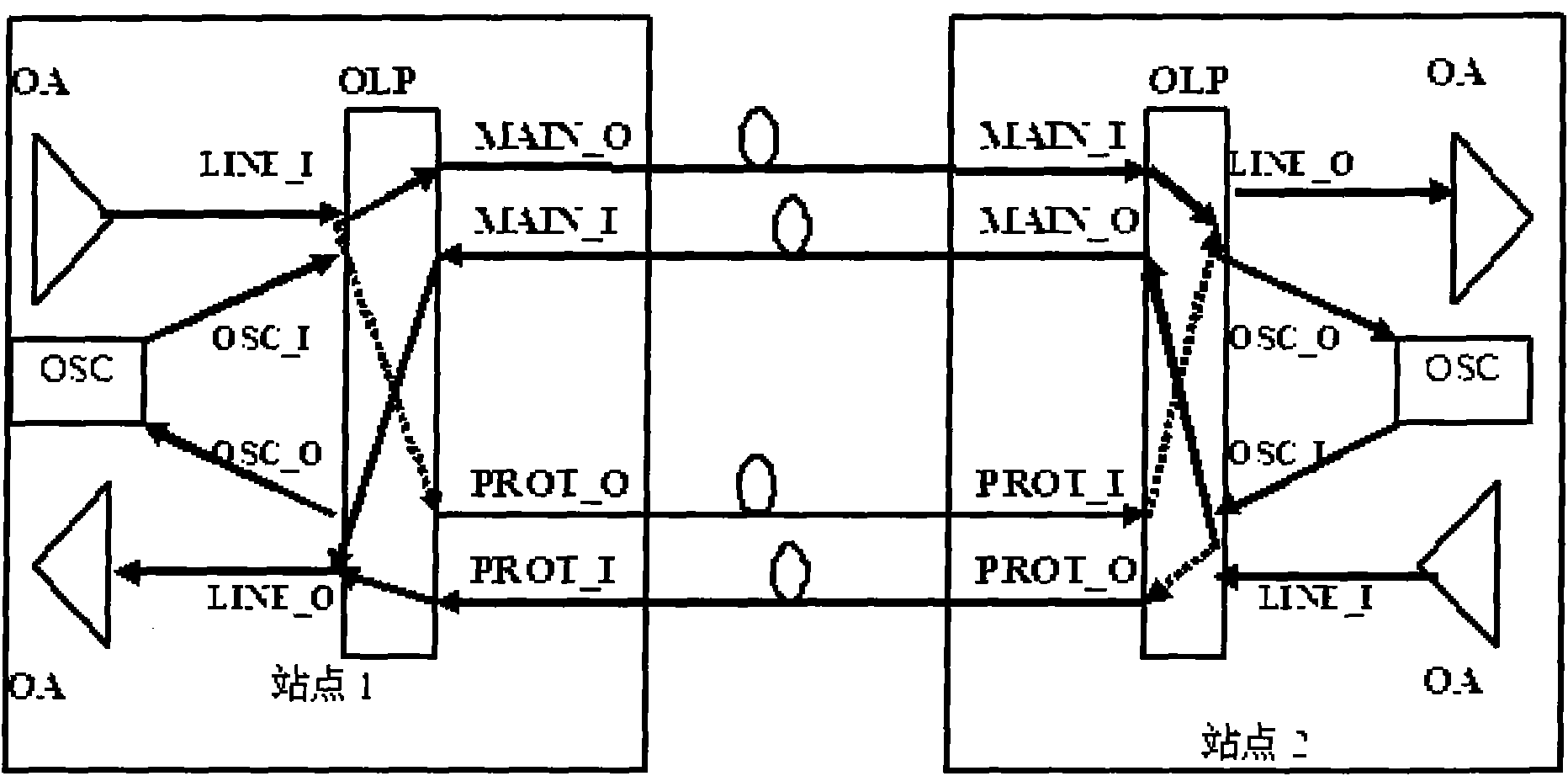

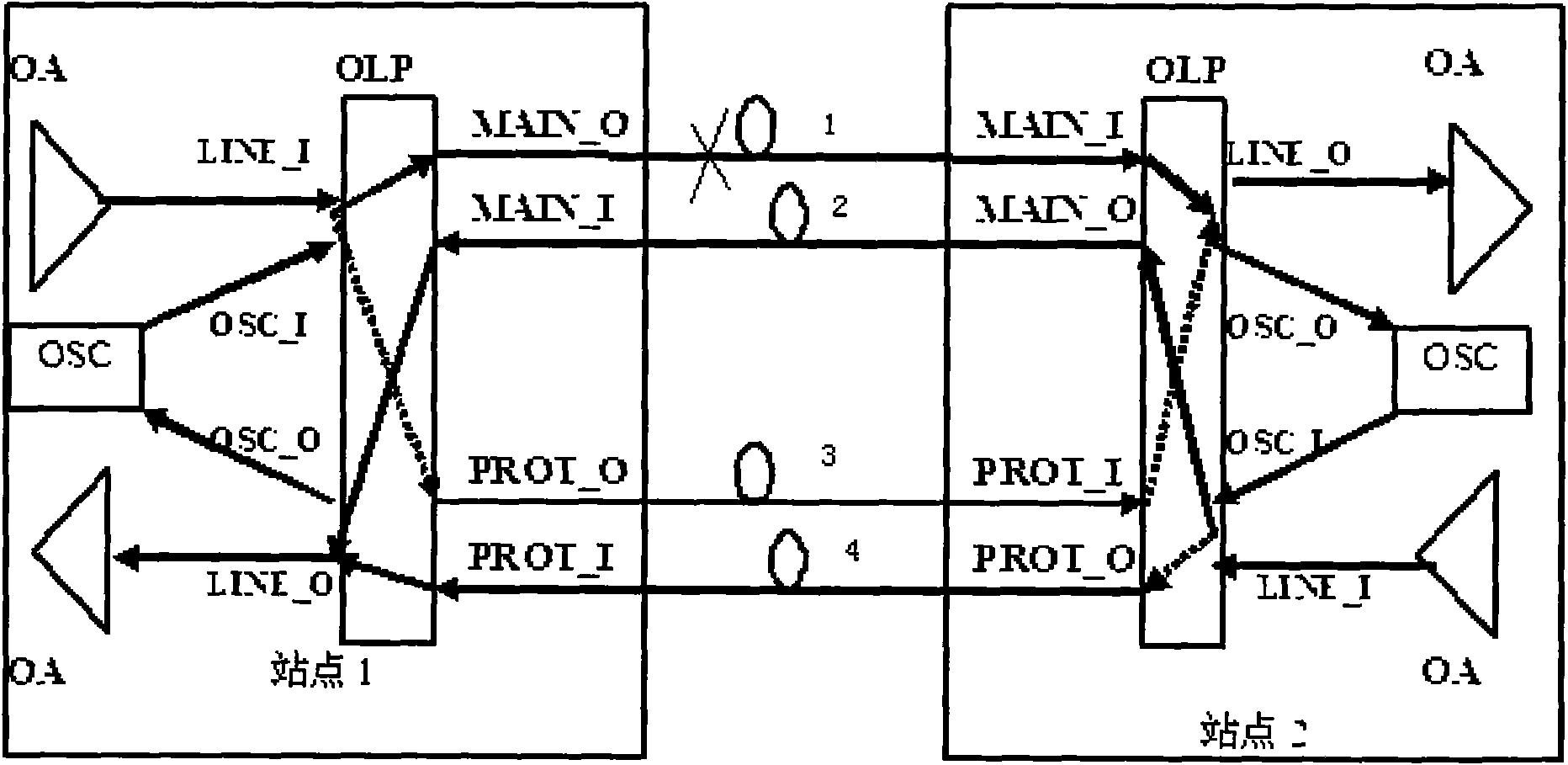

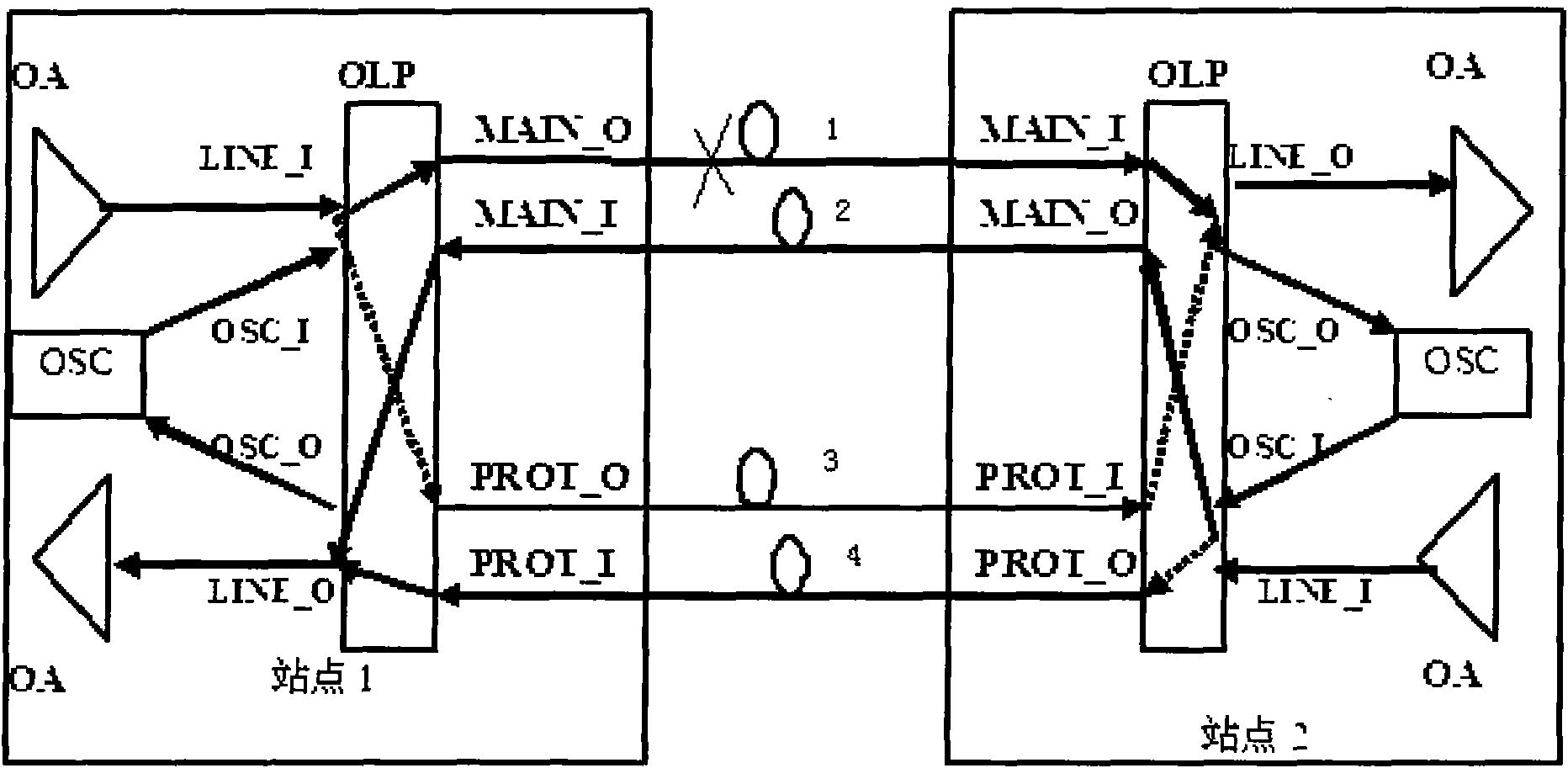

Method for compensating asymmetric line delay caused by OLP (Optical Line Protection) switching

InactiveCN102064901AReduce difficultySolve protection problemsTime-division multiplexCompensation effectByte

The invention discloses a method for compensating asymmetric line delay caused by OLP (Optical Line Protection) switching, which comprises the following steps of: setting a port of designated OSC (Optical Supervisory Channel) to work in the BC (Boundary Clock) or OC (Over Clock) mode, and enabling the corresponding OLP to have the automatic compensation function on the port; setting an OLP unit to work at asymmetric delay compensation values of different receiving and transmitting lines on an OSC designated port of a site with OLP; receiving the working state of the line and transmitting to the OSC at the same site in the form of switched bytes through a back plate by the OLP unit; and analyzing the received OLP switched bytes of the opposite site by the OSC, combining with the OLP switched bytes of the site, determining the actual working state of the OSC port at the site in the line protection section, and selecting the set corresponding compensation value to compensate on the slaveend. By applying the invention, asymmetric delay caused by OLP switching can be compensated in real time, the compensation effect is unrelated to the OLP section, and the stability of time synchronization during OLP switching is ensured.

Owner:FENGHUO COMM SCI & TECH CO LTD

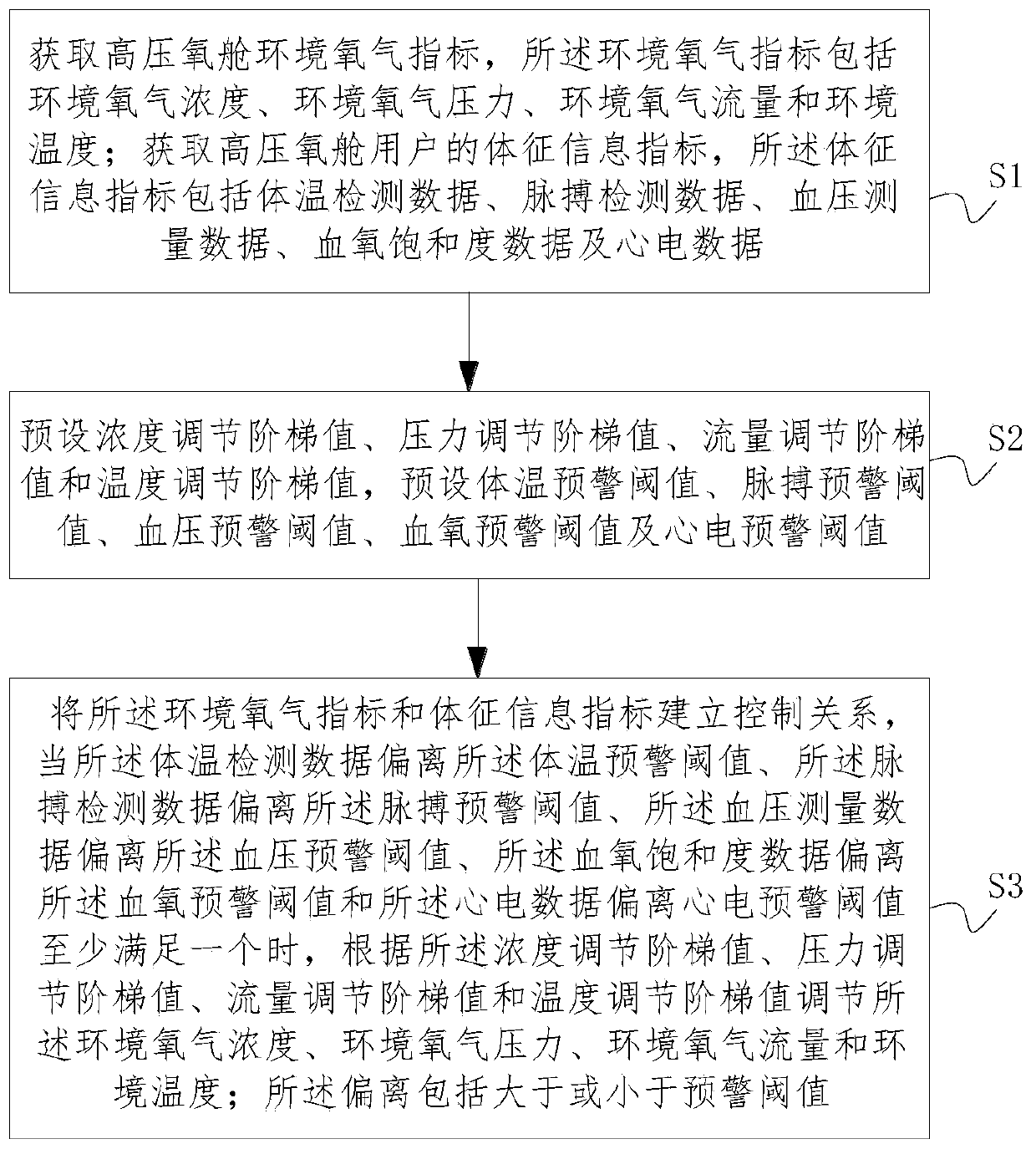

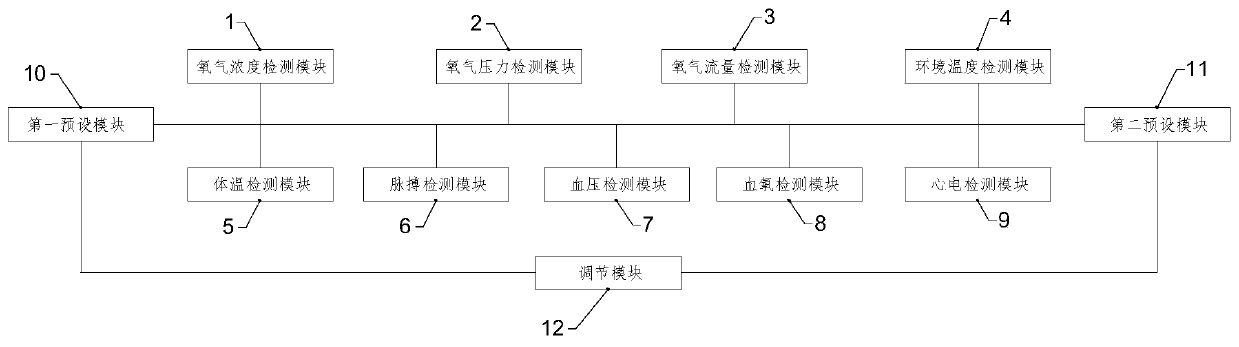

Hyperbaric oxygen chamber equipment operation monitoring method and system

InactiveCN110063859AImprove operational efficiencyRealize automatic compensationBreathing protectionMeasurement devicesFeedback controlAmbient oxygen

The embodiment of the invention discloses a hyperbaric oxygen chamber equipment operation monitoring method and system. The method comprises the steps that a hyperbaric oxygen chamber environmental oxygen index and a physical information index of a user are obtained, the control relationship is established between the environmental oxygen index and the physical information index, and when at leastone of the conditions that temperature detection data deviates from a body temperature early warning threshold value, pulse detection data deviates from a pulse early warning threshold value, blood pressure measurement data deviates from a blood pressure early warning threshold value, blood oxygen saturation data deviates from a blood oxygen early warning threshold value, and electrocardio data deviates from an electrocardio early warning threshold value is met, the environmental oxygen concentration, environmental oxygen pressure, environmental oxygen flow and environmental temperature are adjusted according to a concentration regulation step value, a pressure regulation step value, a flow regulation step value and a temperature regulation step value; deviations include greater or less than the early warning threshold value. Accordingly, by judging the oxygen pressure, concentration and flow in the hyperbaric oxygen chamber environment, equipment operation parameter real-time monitoring and feedback control is achieved, occurrence of dangerous accidents is avoided, the equipment operation is more efficient, and energy consumption is lowered.

Owner:烟台宏远氧业股份有限公司

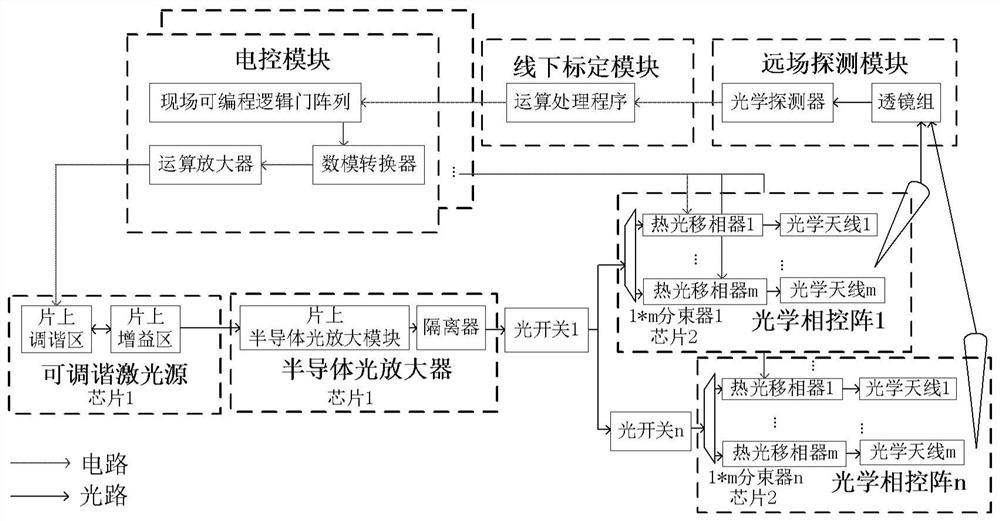

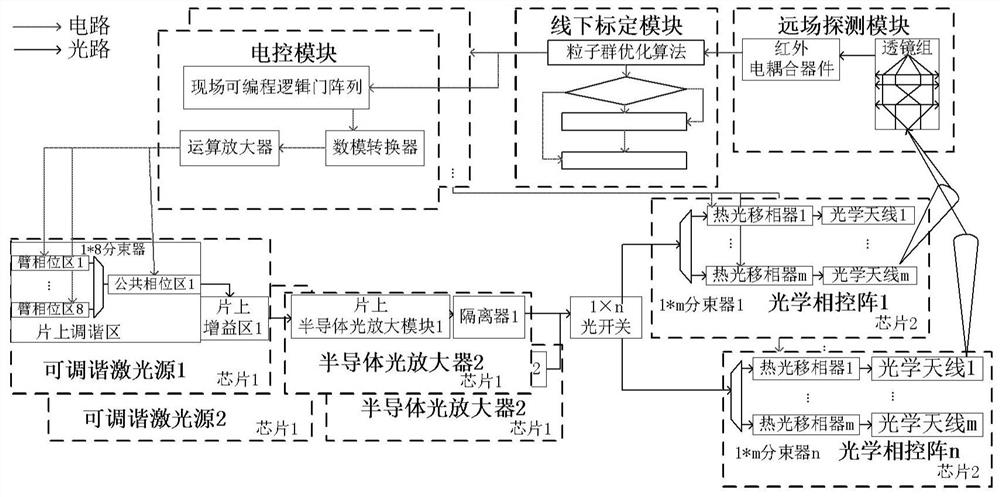

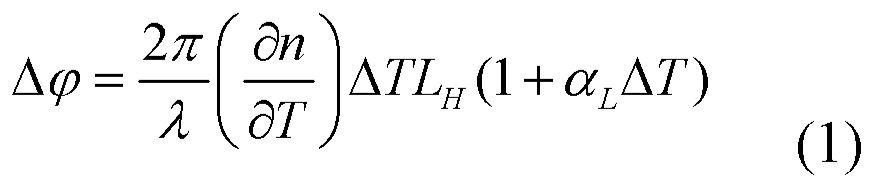

All-solid-state chip large-angle optical beam forming system

An all-solid-state chip optical beam forming system comprises a tunable light source, a semiconductor optical amplifier, an optical phased array, a far-field detection module, an offline calibration module and an electric control module, wherein the semiconductor optical amplifier amplifies the laser power from the tunable light source by injecting a proper driving current, and transmits the laserpower to the optical phased array through the on-chip waveguide; or the semiconductor optical amplifier and the tunable light source are integrated together and transmitted to the optical phased array through the coupling optical fiber; according to the optical phased array, single longitudinal mode laser enters from a cleavage surface and is equally divided into m paths of waveguides by a properamount of optical beam splitters, and the laser in each waveguide is equal in power; after passing through the thermal regulation electrodes loaded on the waveguides, the waveguides are arranged at certain intervals and radiated into a free space above the waveguides through gratings etched at the tail ends of the waveguides, and m paths of array element radiation beams are superposed to form a phased-array antenna directional diagram of a phase dimension; and the radiation direction of the grating at the tail end of the optical phased array waveguide is changed by tuning the wavelength of the light source.

Owner:AEROSPACE INFORMATION RES INST CAS

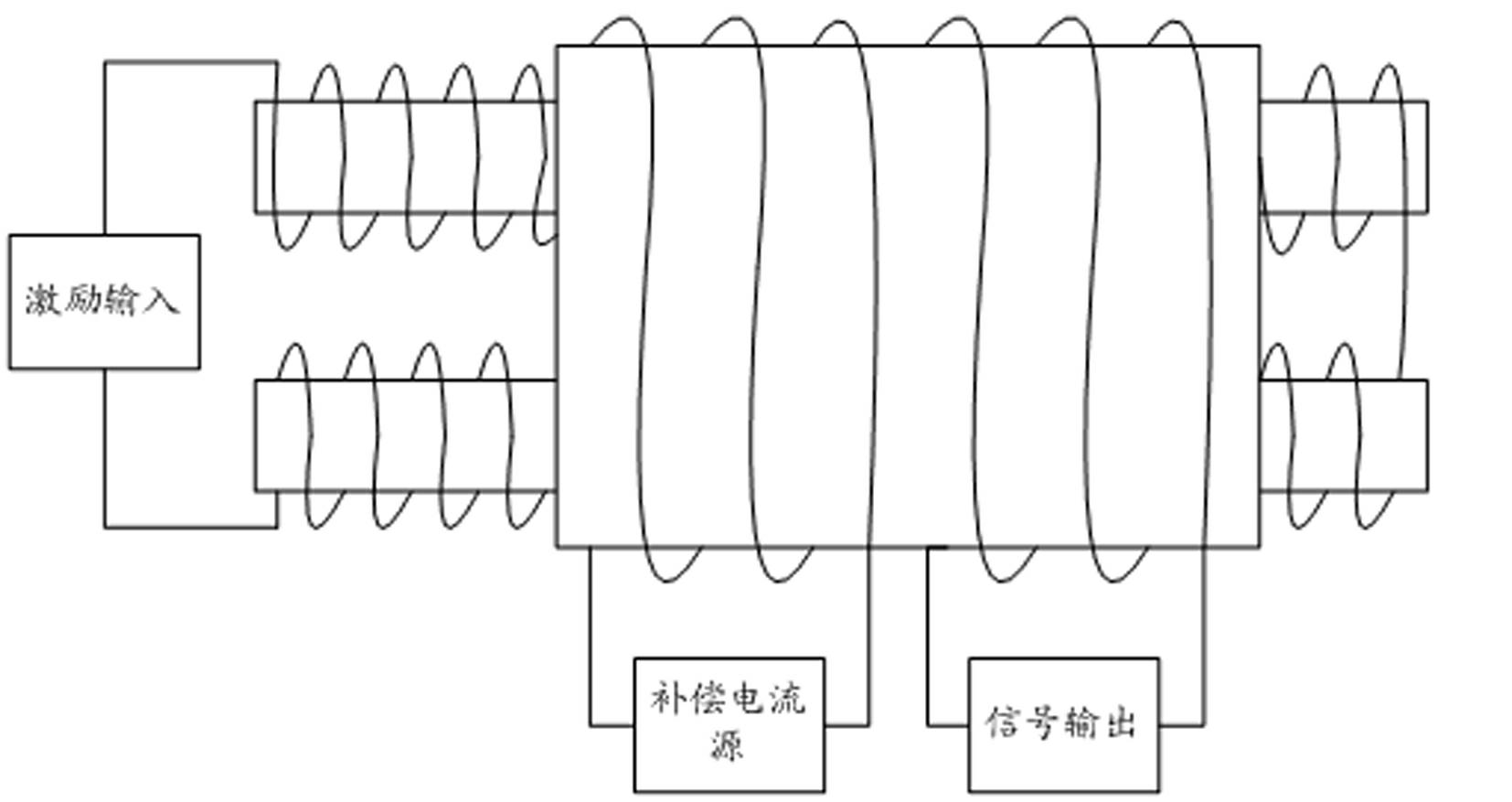

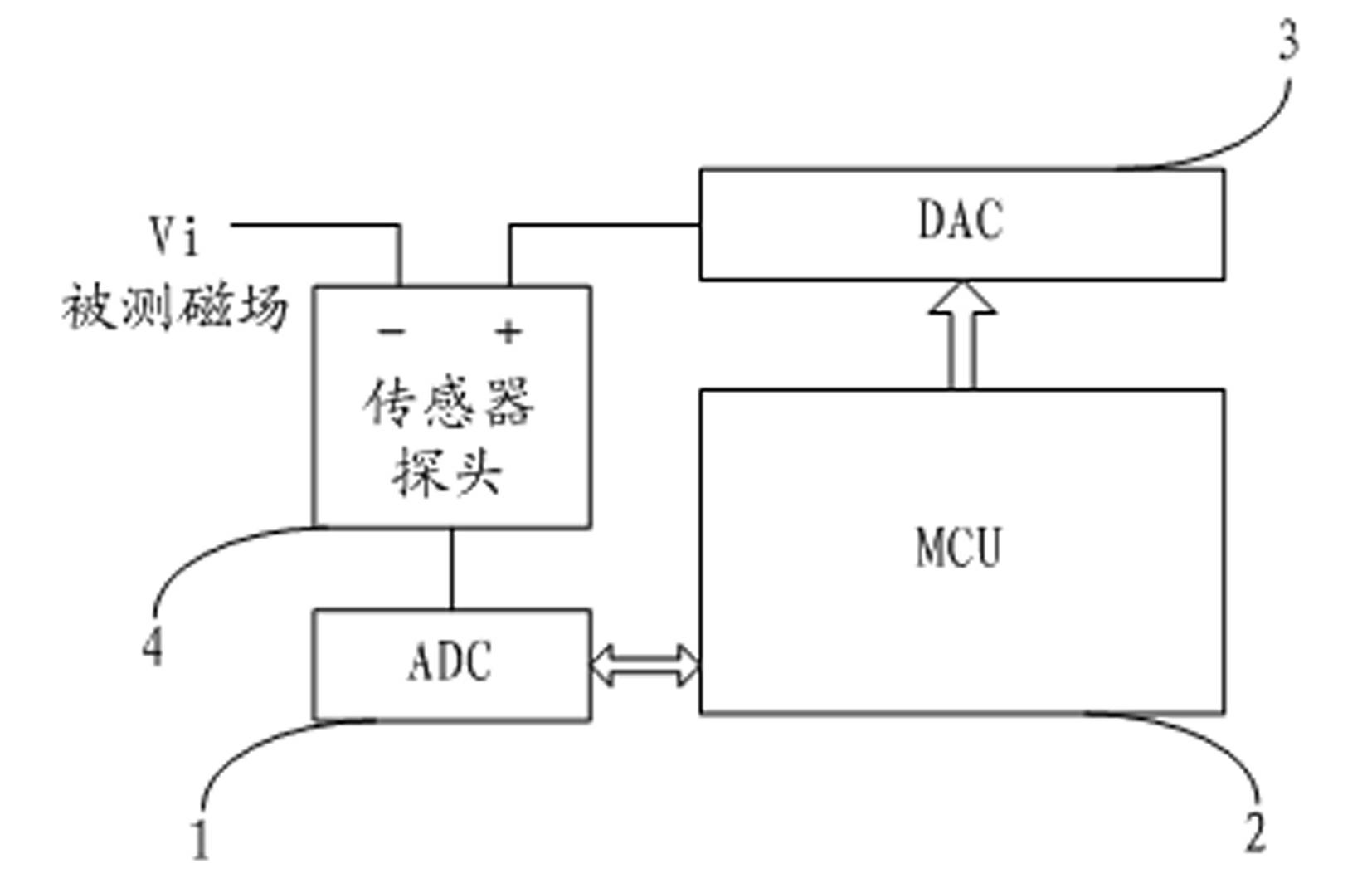

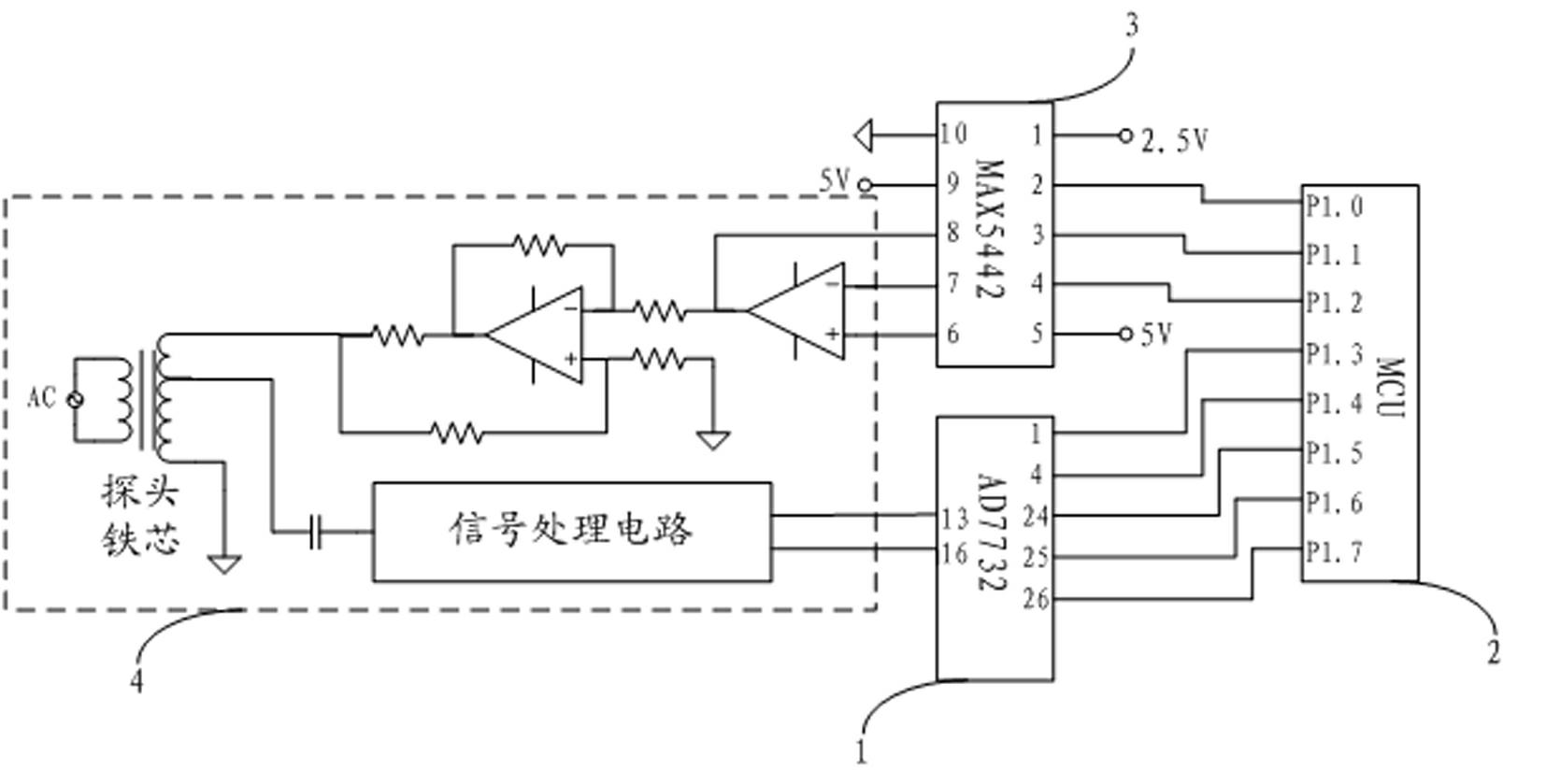

Automatic compensation device and method for background field of fluxgate magnetometer

InactiveCN102129051AImprove compensation efficiency and accuracyRealize automatic compensationMagnetic field measurement using flux-gate principleZero fieldVoltage

The invention relates to an automatic compensation device and method for a background field of a fluxgate magnetometer. The device comprises an analog / digital (A / D) converter, a micro control unit (MCU) and a D / A converter; the A / D converter acquires the measurement value of the fluxgate magnetometer from a sensor probe of the fluxgate magnetometer, converts the measurement value into a digital signal in real time and provides the digital signal for the MCU for operation; and a digital compensation signal obtained by operation of the MCU is converted into an analog voltage signal through the D / A converter, and the analog voltage signal is coupled to a compensation coil in the sensor probe of the fluxgate magnetometer. The method comprises the following steps of: acquiring signals by the A / D converter; judging whether compensation is needed and giving the magnitude and the direction of an initial compensation value by the MCU, and outputting compensation current by the D / A converter; repeating the compensation cycle; and placing the sensor probe in a quasi-zero field by a plurality of compensation cycles. In the invention, manpower for operating instruments on site is not needed, compensation efficiency and precision are improved, and the device and the method can be used for deep well observation and remote monitoring and intelligent measurement of the instruments.

Owner:INST OF GEOPHYSICS CHINA EARTHQUAKE ADMINISTRATION

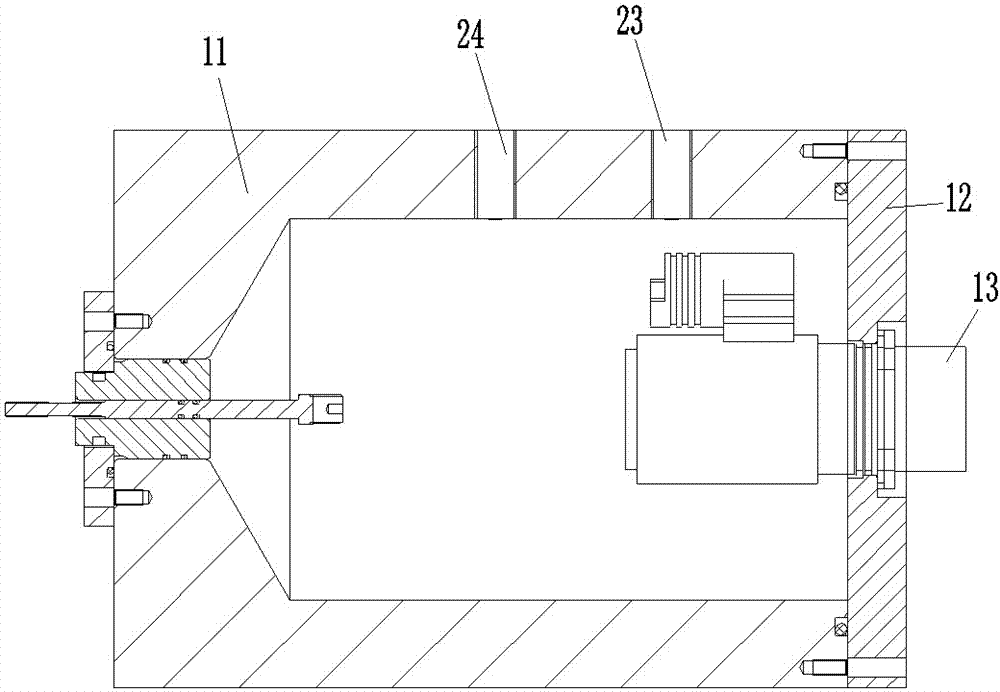

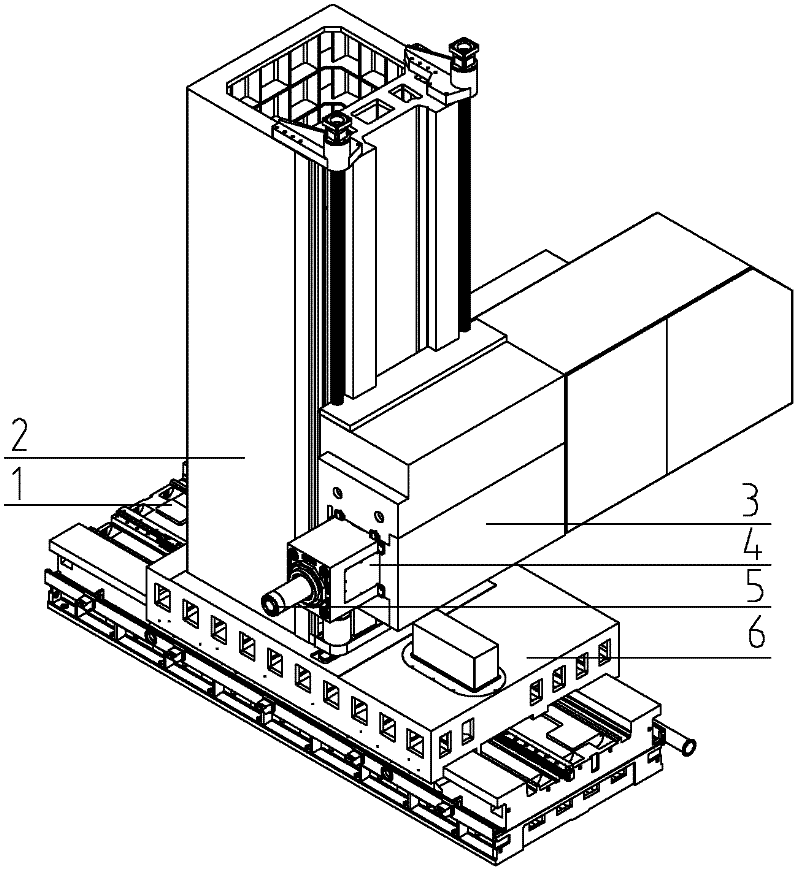

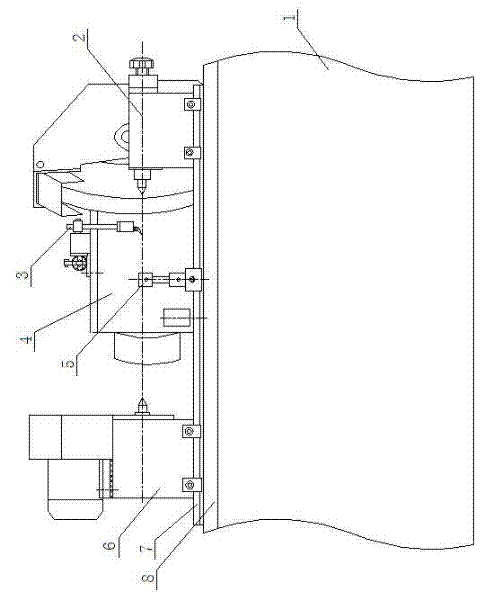

Ram flexibility compensation mechanism of heavy numerical control floor type milling and boring machine

InactiveCN102528566ARealize automatic compensationIncrease deflectionOther manufacturing equipments/toolsNumerical controlPull force

The invention discloses a ram flexibility compensation mechanism of a heavy numerical control floor type milling and boring machine. Flexible deformation is compensated by using a pull rod. The ram flexibility compensation mechanism is characterized in that: two elongated pull rods are arranged at two corners above the internal space of a ram; a hydraulic oil cylinder for providing pull force is fixed at the rear end of the ram; after being serially assembled by the pull rods, the ram, the pull rods and the oil cylinder are fixed by using a sleeve screw cap at the rear end of the hydraulic oil cylinder; a sleeve is designed between the pull rods and a piston for connecting the piston and the pull rods; the sleeve is integrally fixed to the pull rods at the rear ends of the pull rods through screw caps; no relative motion exists between the pull rods and the piston; baffle rings are embedded between the sleeve and the piston in pair to fix the sleeve and the piston; and the pull rods are driven by the piston to produce backward pull force by the cam, so that bending deformation caused by gravity of the cam is compensated. According to the designed sleeve, the strict process of machining an annular groove is saved, and a supercharging oil cylinder meets the requirement of small size. According to the design, automatic compensation for the motion straightness of the cam can be realized, meanwhile, motion straightness of the main shaft can also be obviously improved.

Owner:ZHONGJIE MACHINE TOOL

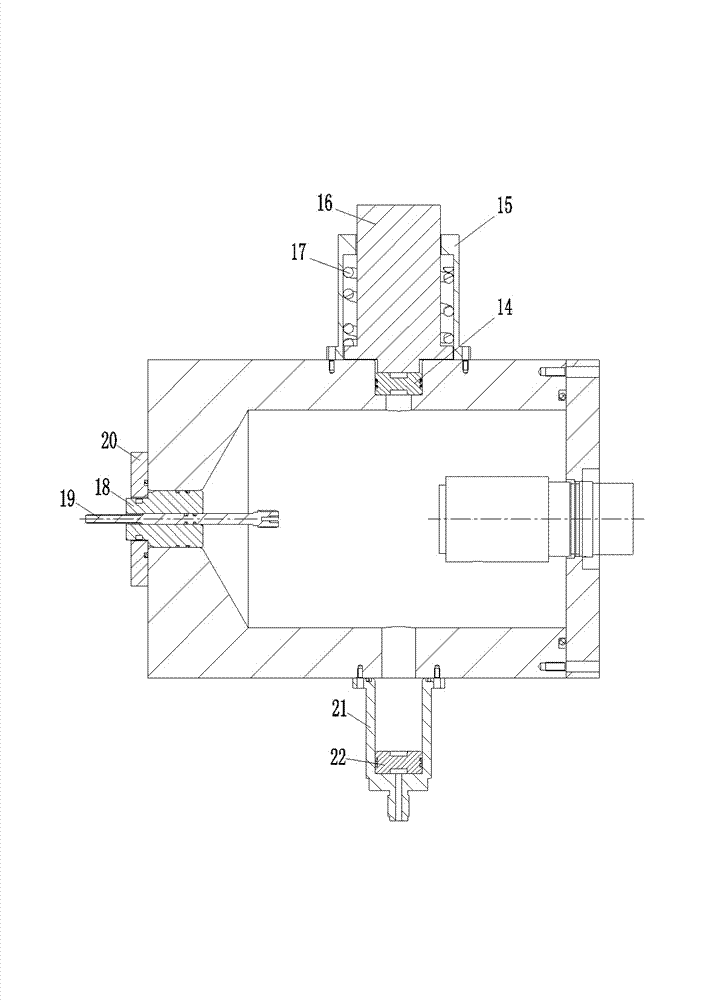

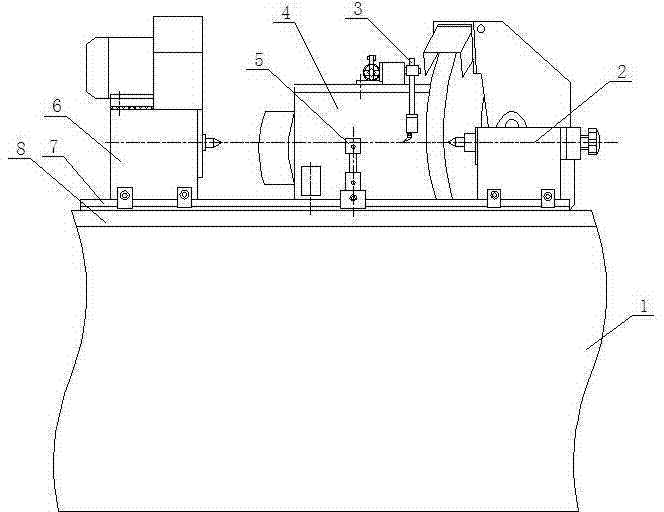

Numerical control end-face and excircle grinding machine

InactiveCN102240929AGuaranteed one timeRealize online detectionRevolution surface grinding machinesGrinding feed controlNumerical controlEngineering

The invention discloses a numerical control end-face and excircle grinding machine and relates to machining equipment, in particular to the technical field of structures of grinding machines. The numerical control end-face and excircle grinding machine comprises a machine body; the machine body is provided with a carriage which is provided with a guide rail; the guide rail is provided with a headstock and a tailstock; the machine body is provided with a grinding wheel main shaft frame which is arranged on one side between the headstock and the tailstock; the carriage is connected with an excircle detector which is arranged between the headstock and the tailstock; and the grinding wheel main shaft frame is connected with an end-face detector. By arranging the excircle detector and the end-face detector, on-line detection, on-line tracking, automatic compensation, and automatic finishing can be realized, so that the one time of the accuracy of a workpiece is guaranteed.

Owner:扬州博斯达精密机床有限公司

Numerical control type universal polishing unit

InactiveCN104608039AImprove performanceHigh control precisionPolishing machinesGrinding machinesNumerical controlEngineering

The invention relates to a numerical control type universal polishing unit. A portal frame is fixed to a machine base, the machine base is provided with a product clamping mechanism, a polishing mechanism is installed on the portal frame, and the product clamping mechanism and the polishing mechanism are controlled to act by an electric control device. The polishing mechanism comprises polishing wheels, an up-and-down moving assembly, a 360-degree rotating assembly, a polishing wheel swing assembly and a spray gun assembly. The product clamping mechanism comprises a product installation jig, a jig front-and-back moving assembly, a jig left-and-right moving assembly and a jig rotating assembly. Quality is stable, and the production efficiency is high.

Owner:南通金庆美术图案设计有限公司

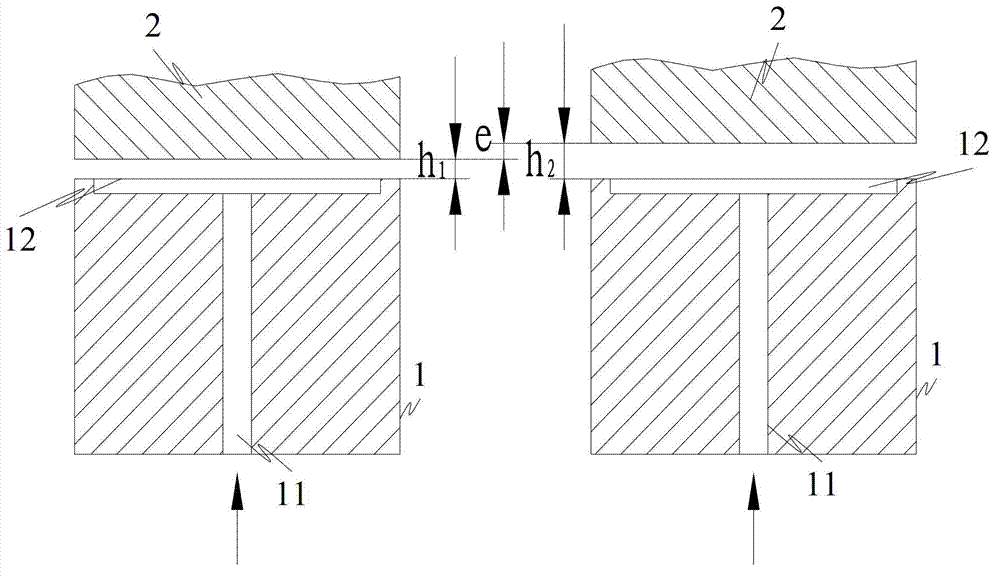

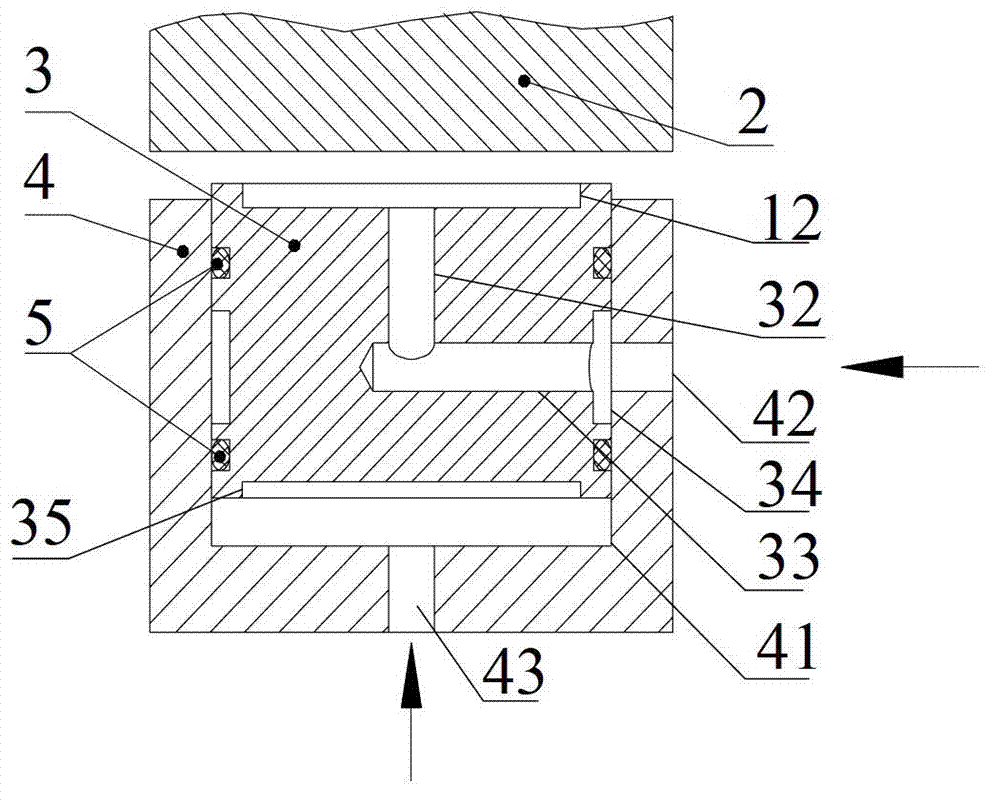

Thickness automatically-compensating device for multi-oil-chamber static pressure oil film, and system thereof

ActiveCN102777496AGuaranteed uniformityEnsure consistencyEngine sealsBearingsCylinder blockHydraulic pressure

The invention discloses a thickness automatically-compensating device for a multi-oil-chamber static pressure oil film, and system thereof, wherein the device is composed of a cylinder, and a piston which can move up and down in the cylinder and which is not separated from the cylinder by action of hydraulic oil, wherein an inner cavity which has an opening on the top and depth greater or equal to height of the piston is arranged in the cylinder, and the piston is arranged in the inner cavity; the cylinder is provided with a hydraulic oil supply channel of a closed space formed by communicating the inner cavity or communicating the piston with the inner cavity; a side wall of the cylinder is provided with a static pressure oil supply port; a top surface of the piston is provided with at least one oil chamber closed on a circumference; and a static pressure oil supply channel for communicating the oil chamber with the static pressure oil supply port is arranged in the piston. The piston can axially move up and down and can be not separated from the cylinder by common action of hydraulic oil and static pressure oil to automatically compensate thickness of oil-chamber oil films, thereby ensuring thickness of the multi-oil-chamber oil film is consistent, and loads are distributed uniformly.

Owner:SINOVEL WIND GRP

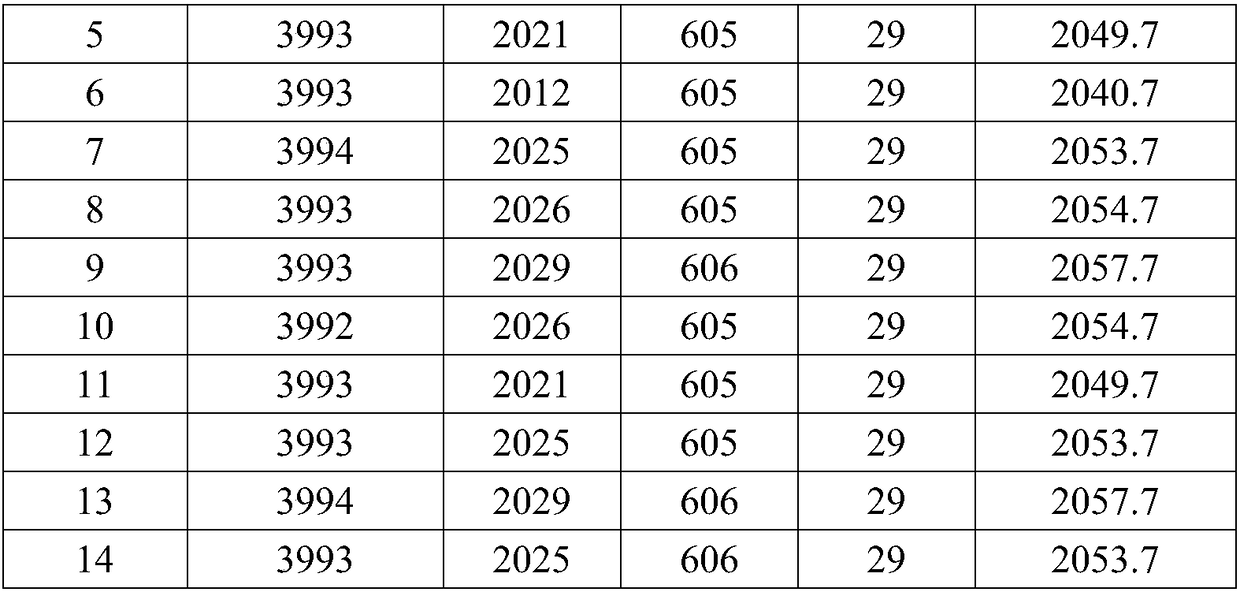

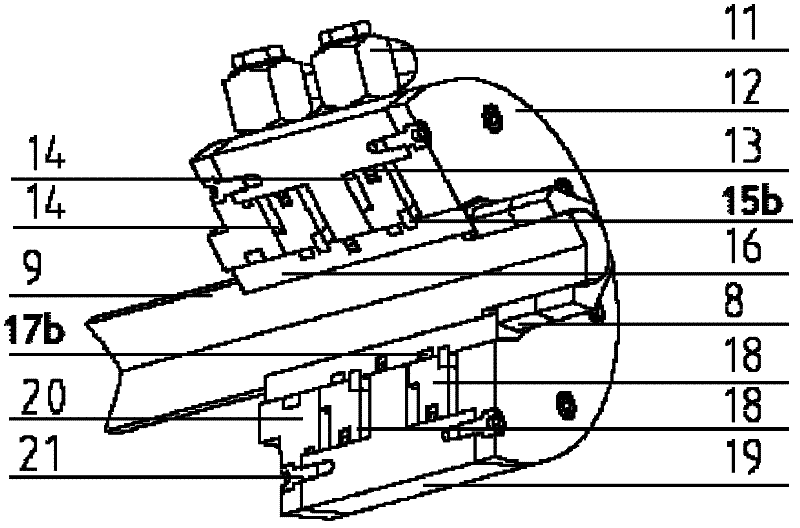

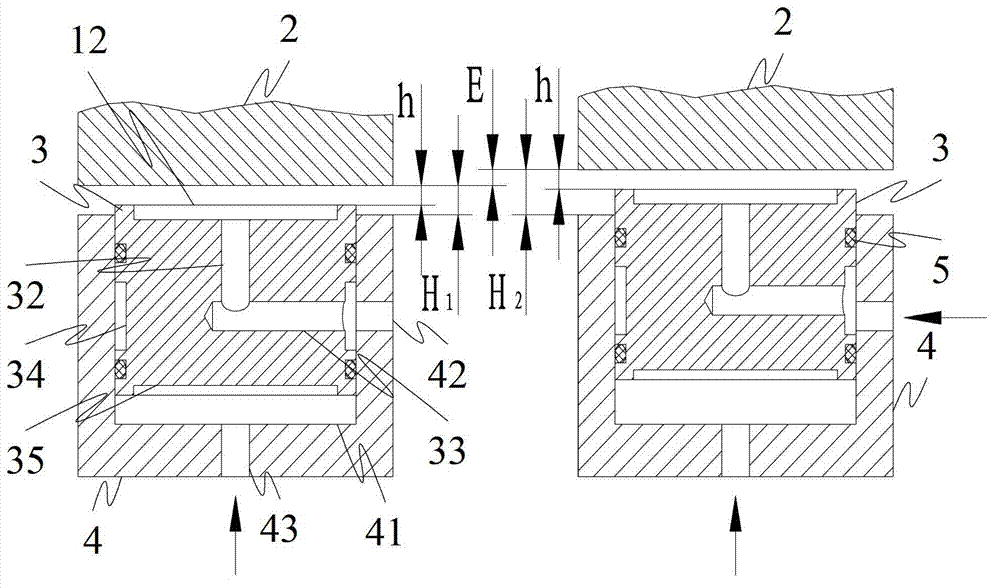

Brake shoe wear automatic compensation device for hydraulic disc brake

ActiveCN103185093ABrake shoe back distance is constantRealize automatic compensationSlack adjustersDisc brakeBrake shoe

The invention discloses a brake shoe wear automatic compensation device for a hydraulic disc brake, which comprises a rack. An oil cylinder is arranged on the rack; a cylinder cover is arranged on the end surface of one side of the oil cylinder; a brake shoe is arranged outside the end surface of the other side of the oil cylinder; the brake shoe mainly consists of a brake seat and a brake rubber block; the brake rubber block is arranged on the brake seat; a piston is arranged in the middle position of the oil cylinder; one end of the piston is provided with a rotating rod, and the other end of the piston is mounted with a piston rod; the brake seat is connected with the piston rod in a sleeving way; a brake spring is arranged between the piston and the brake seat; the front end of the cylinder cover is provided with an end cover; an automatic detection mechanism is arranged between the end cover and the oil cylinder; a transmission mechanism is arranged on the end cover; and one end of the transmission mechanism is in contact with the automatic detection mechanism, and the other end of the transmission mechanism is connected with the rotating rod. The brake shoe wear automatic compensation device for the hydraulic disc brake avoids brake failure caused by continuous wear to the brake shoe in the operating process.

Owner:SHANDONG KEDA ELECTROMECHANICAL TECH CO LTD

Rubber extruder

The invention discloses a rubber extruder. The rubber extruder comprises a feeding cylinder, bearings, a shell and a rotation shaft. Two ends of the rotation shaft are each provided with a section of a thread. The inner walls of the two ends of the feeding cylinder are each provided with a first isolation plate and a second isolation plate. The first isolation plates and the second isolation plates are disposed between the corresponding bearings and the threads. An annular column is arranged between each first isolation plate and the corresponding second isolation plate, and a tapered face is arranged on the inner wall of each annular column. A seal ring is arranged in each annular column and in fit with the annular column through the corresponding tapered face, and a spring is arranged between each seal ring and the corresponding first isolation plate. One end of the shell is fixedly connected with a die sleeve, and a through hole is formed in the center of the die sleeve. An annular cylinder fixedly connected with the inner wall of the shell is arranged in the shell, and a die core is in thread fit connection with the interior of the annular cylinder and penetrates through the shell. A discharging hole is formed between the inner surface of the die sleeve and the outer surface of the die core. A thread is arranged on the outer circular face of the die core, and a die core sleeve in thread fit connection with the die core is arranged on the outer circular face of the die core. By means of the extruder, the extrusion quality of rubber materials and work efficiency can be improved.

Owner:山西丛鑫液压科技集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com