Numerical control end-face and excircle grinding machine

A cylindrical grinding machine and end face technology, which is used in grinding machines, grinding machine parts, machine tools designed for grinding workpiece rotating surfaces, etc. One-time accuracy and other problems, to ensure one-time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

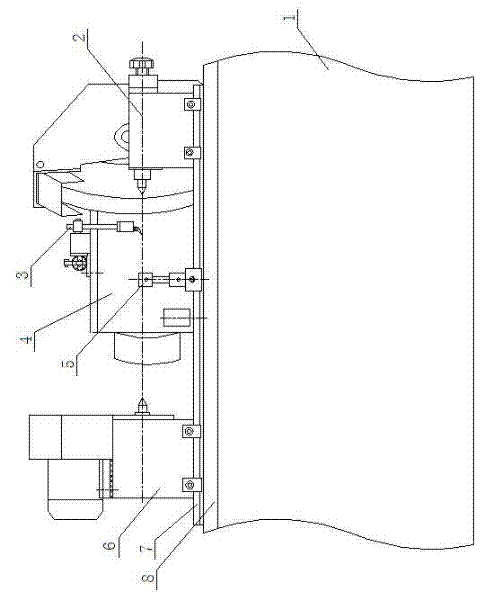

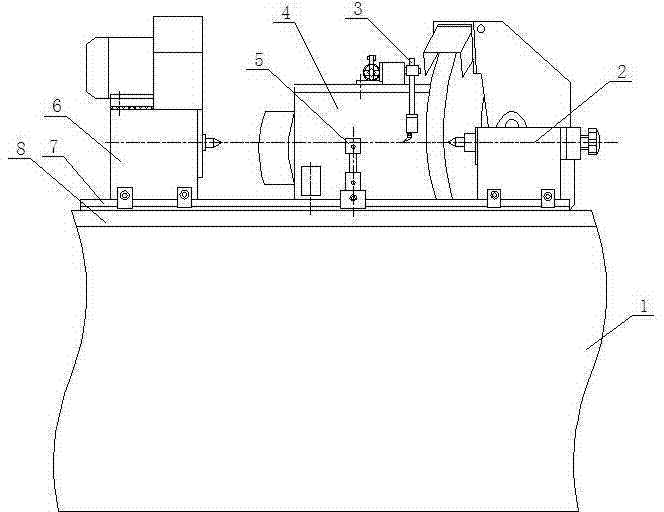

[0007] As shown in Figure 1, it is a CNC end face cylindrical grinding machine, including a bed 1, a carriage 8 is set on the bed 1, a guide rail 7 is set on the carriage 8, a headstock 6 and a tailstock 2 are arranged on the guide rail 7, and a carriage 8 The outer circle detector 5 is connected on the top, and the outer circle detector 5 is arranged between the headstock 6 and the tailstock 2 . A grinding wheel spindle frame 4 is arranged on the bed 1, and the grinding wheel spindle frame 4 is arranged on a side between the headstock 6 and the tailstock 2, and the grinding wheel spindle frame 4 is connected with an end face detector 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com