New energy motor input shaft press-fitting device

A press-fitting device and input shaft technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of not using rotary press-fitting, failing to meet the quality requirements of the press-fitting process, and not having two-step press-fitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

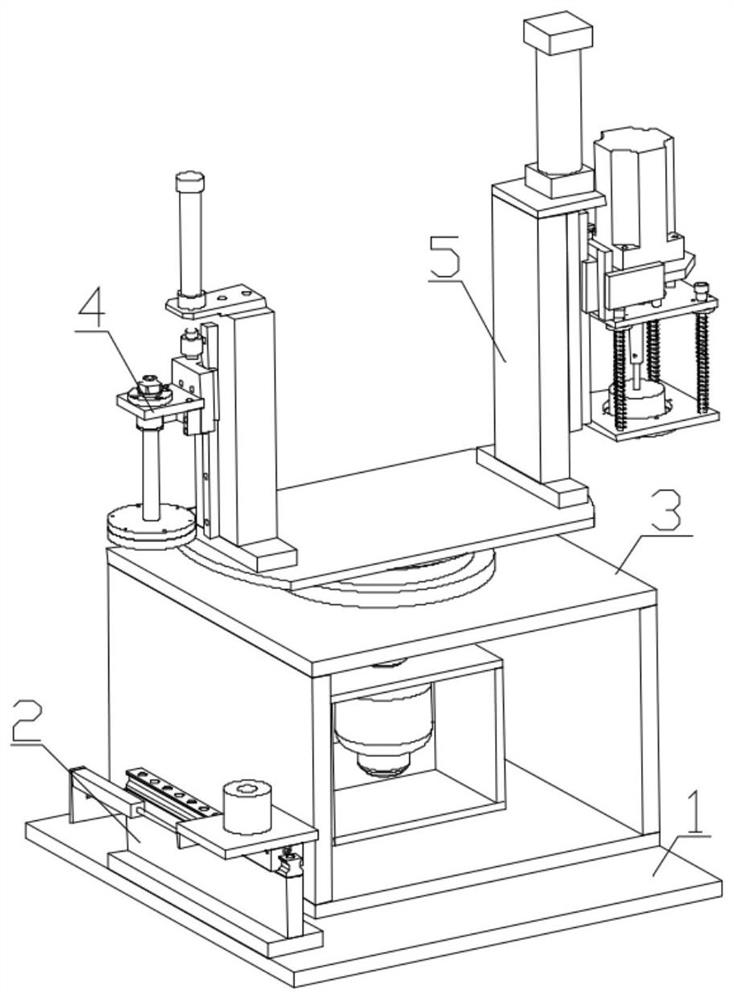

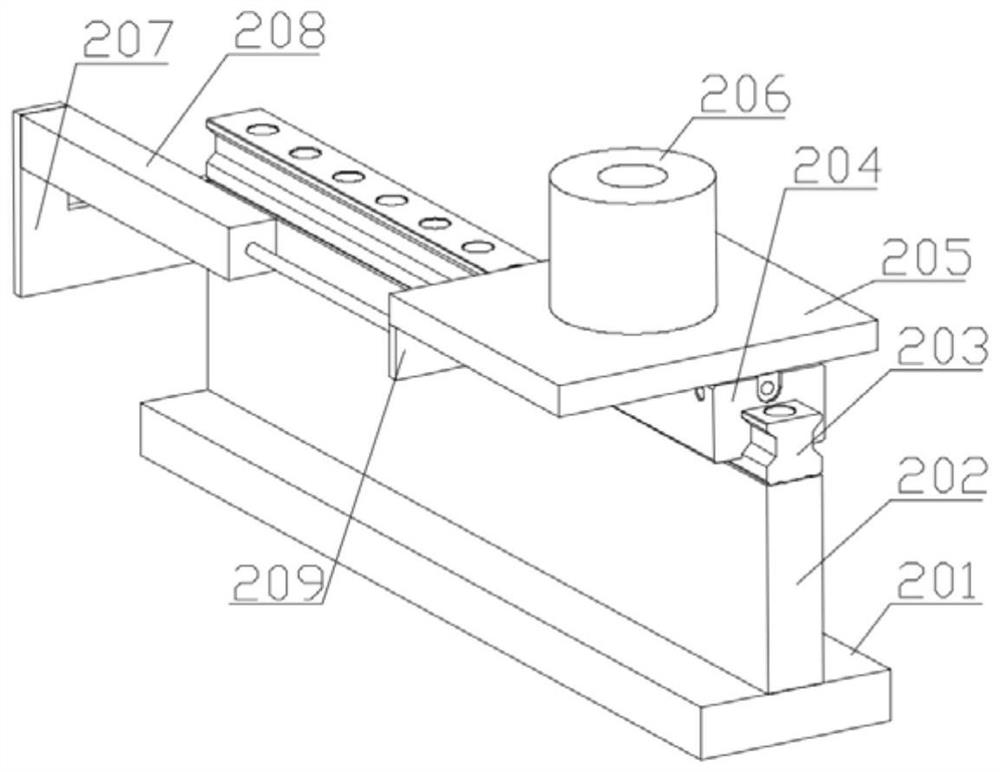

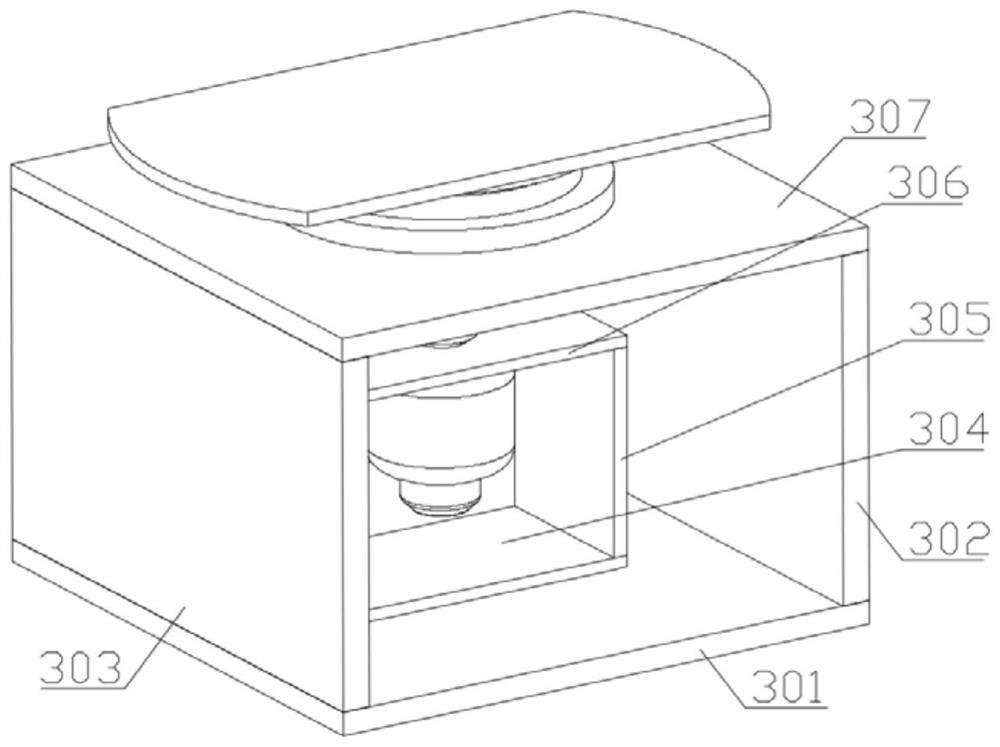

[0027] Attached below Figure 1-8 The present invention is described in detail below.

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, a new energy motor input shaft press-fitting device includes an equipment base plate 1, the upper mounting surface of the equipment base plate 1 is installed together with the lower mounting surface of the workpiece transporting device installation base plate 201 in the workpiece transporting device 2, and the workpiece transporting device The left edge of the installation base plate 201 is aligned with the left edge of the upper mounting surface of the equipment base plate 1, the upper mounting surface of the equipment base plate 1 is installed together with the lower plane of the rotating device base plate 301 in the rotating device 3, and the rotating device base plate 301 The right edge is aligned with the right edge of the upper mounting surface of the equipment b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com