Patents

Literature

104results about How to "Guarantee the quality of pressing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

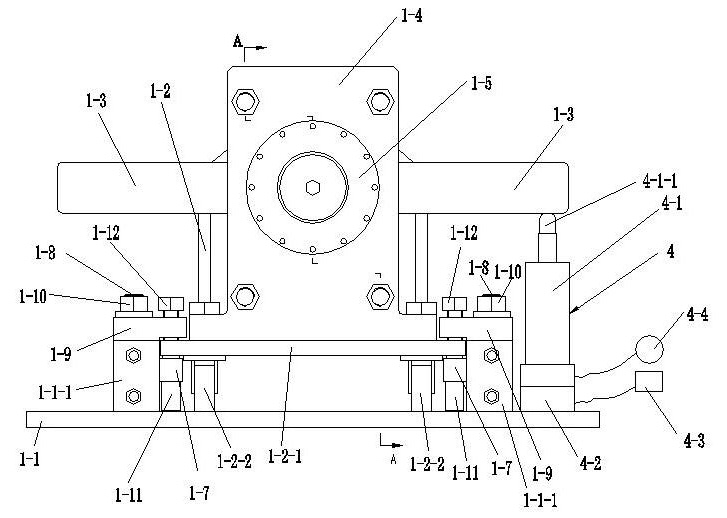

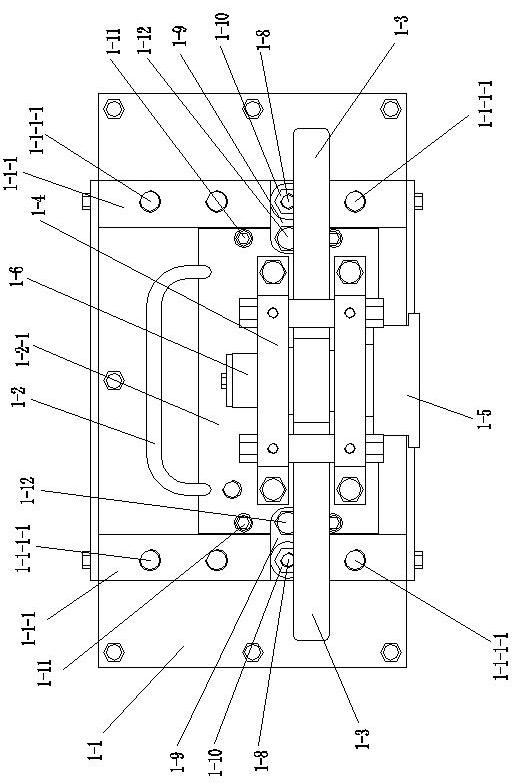

Copper bush press-mounting machine

ActiveCN102059540AGuarantee the quality of pressingReduce labor intensityMetal working apparatusHydraulic cylinderCopper

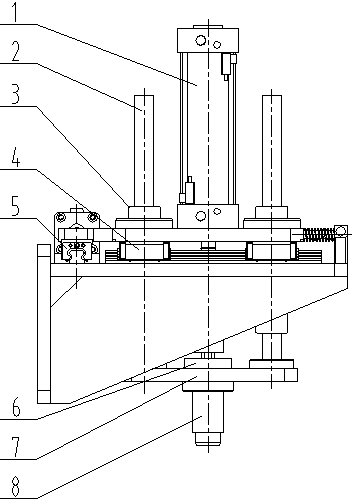

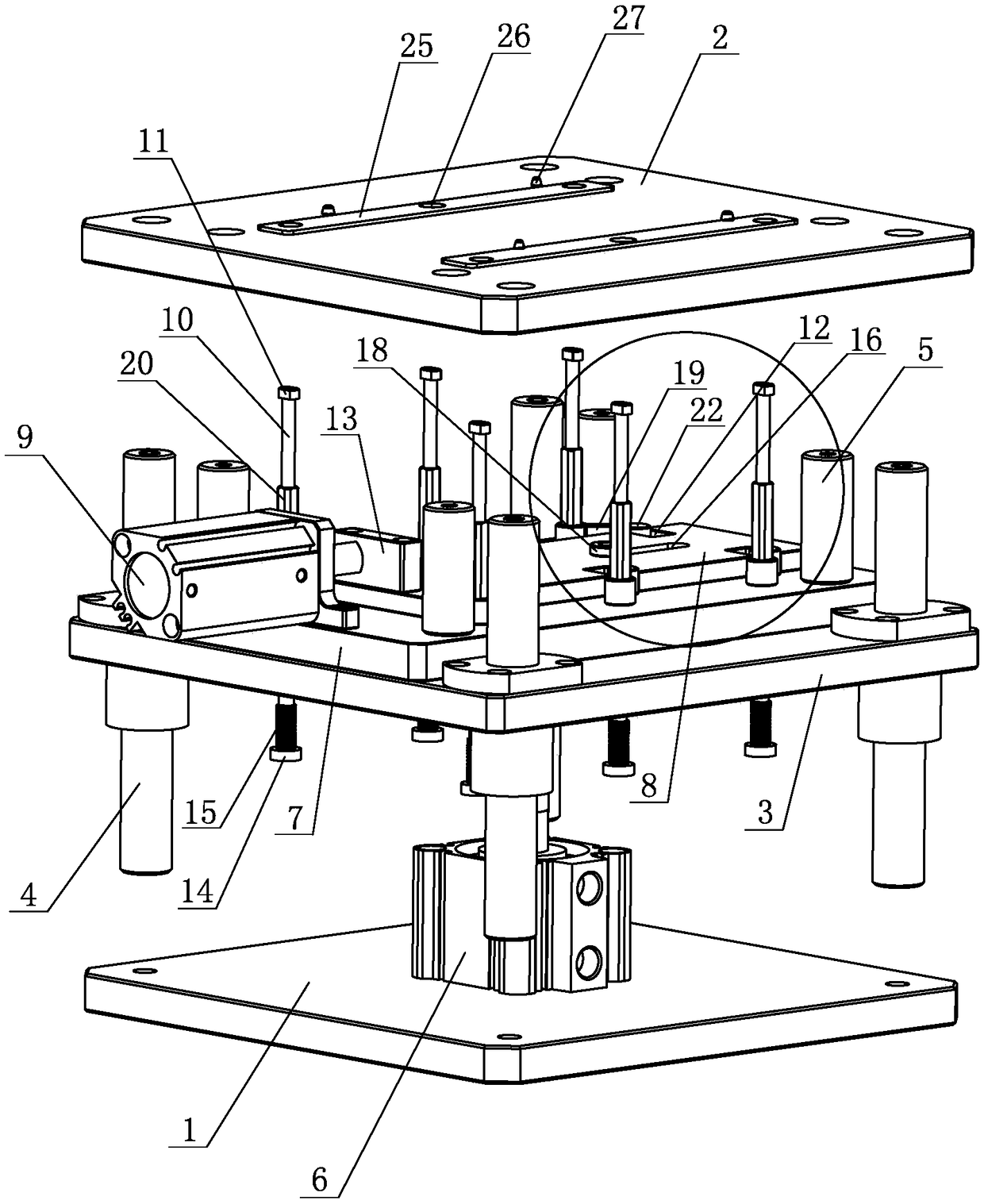

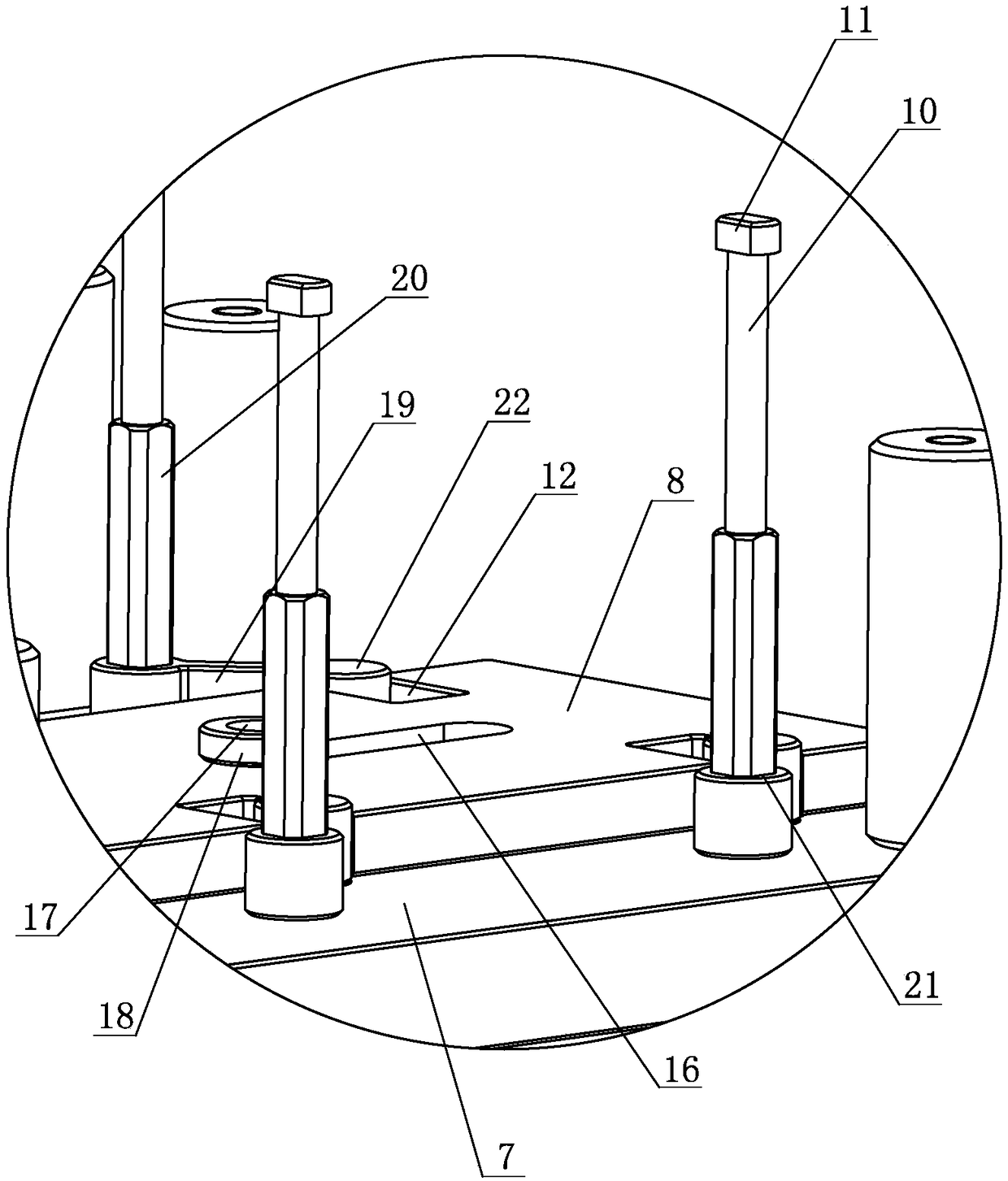

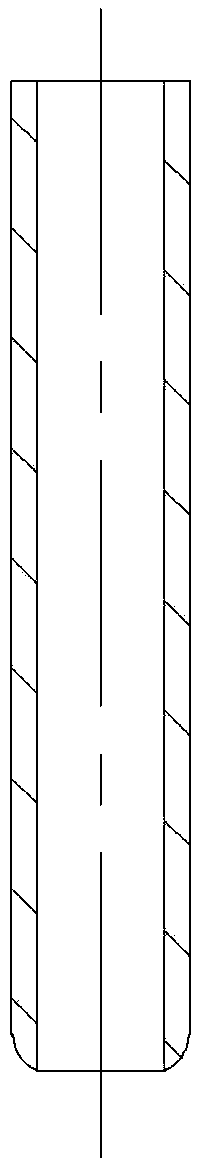

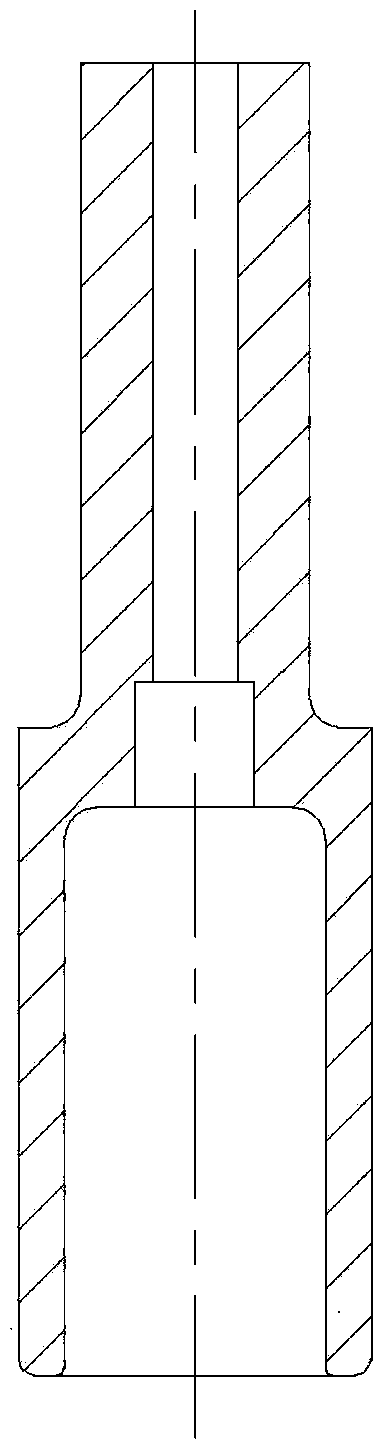

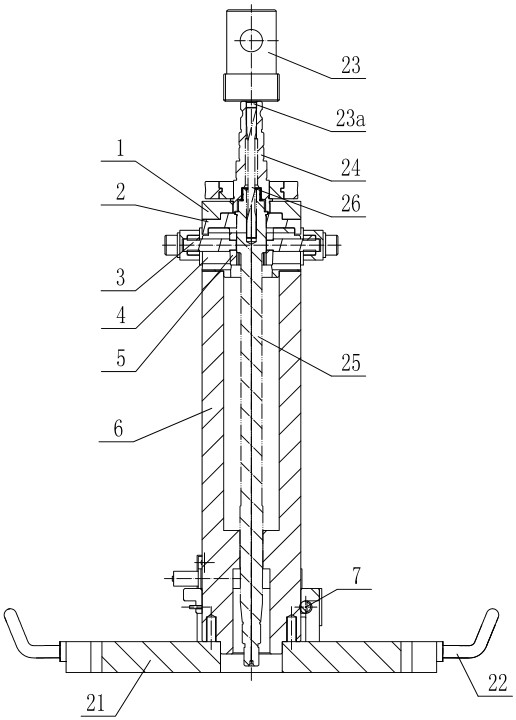

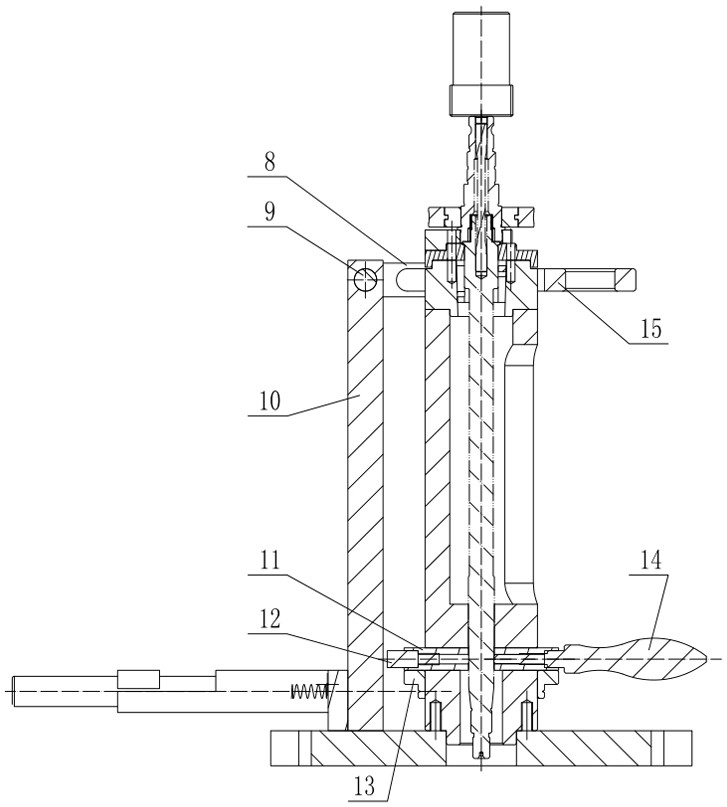

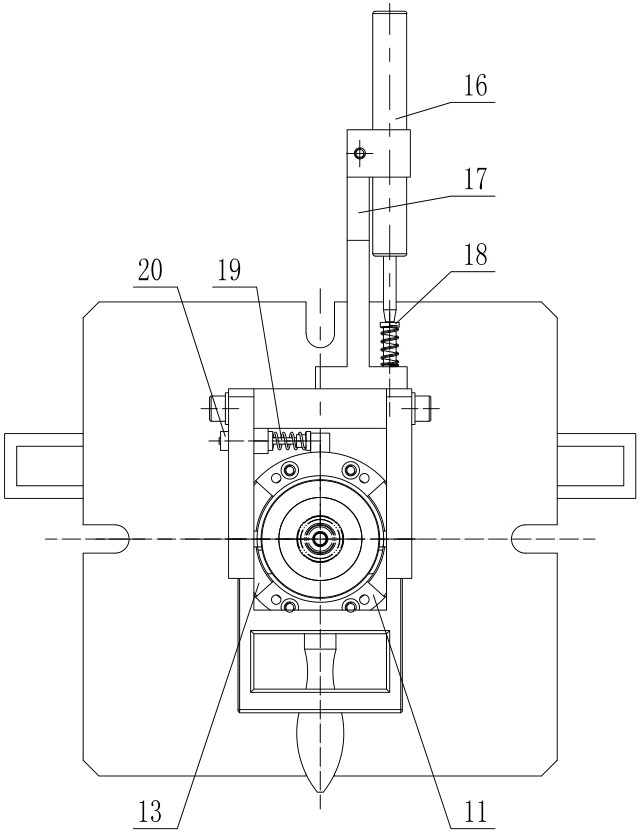

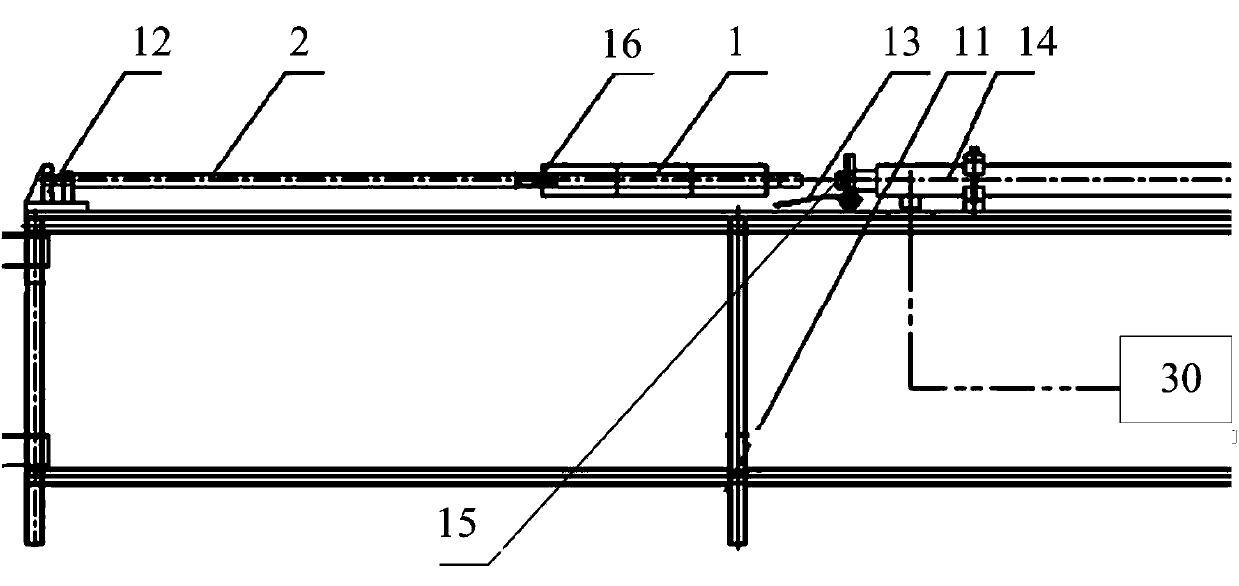

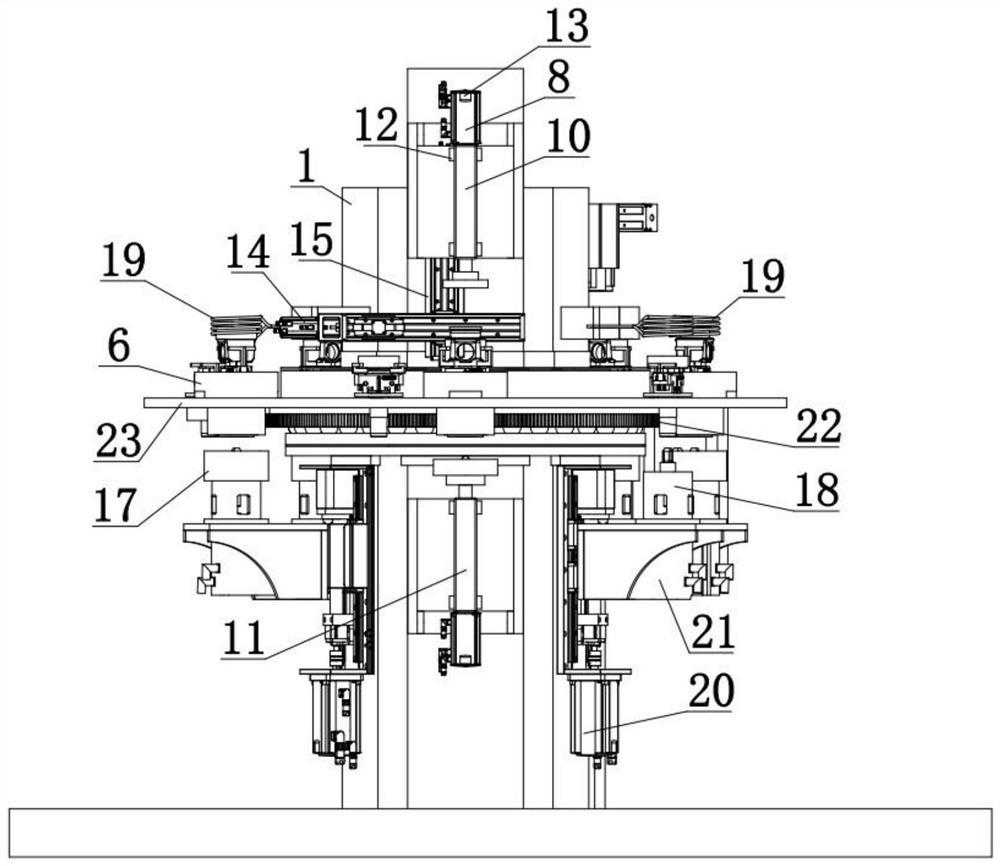

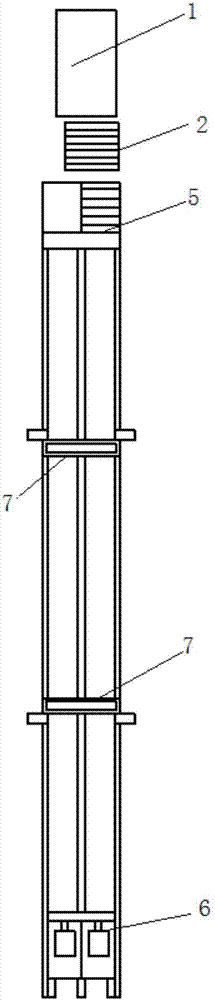

The invention discloses a copper bush press-mounting machine, which comprises a top plate and a bottom plate, wherein the top plate is connected with the bottom plate to form a whole through an upright post; the inner side of the bottom plate is provided with a workpiece conveying device, the workpiece conveying device is in drive connection with a first hydraulic cylinder, one end of the outer side of the bottom plate is provided with a workpiece pre-positioning device, and the workpiece pre-positioning device is in drive connection with a second hydraulic cylinder; a workpiece process hole positioning mechanism and a workpiece bottom surface positioning block are arranged above the bottom plate, and the workpiece process hole positioning mechanism is in drive connection with a third hydraulic cylinder; a special hydraulic cylinder is arranged on the top plate, and the special hydraulic cylinder is provided with piston rods of double-rod structure and formed by sleeving the large piston rod on the small piston rod; and a press-sleeving mechanism is connected on the large piston rod of the special hydraulic cylinder, and a press rod mechanism is connected on the small piston rod of the special hydraulic cylinder. The copper bush press-mounting machine is convenient to operate, and has the advantages of reliable press-mounting quality, high production efficiency and the like.

Owner:GUANGXI YUCHAI MASCH CO LTD

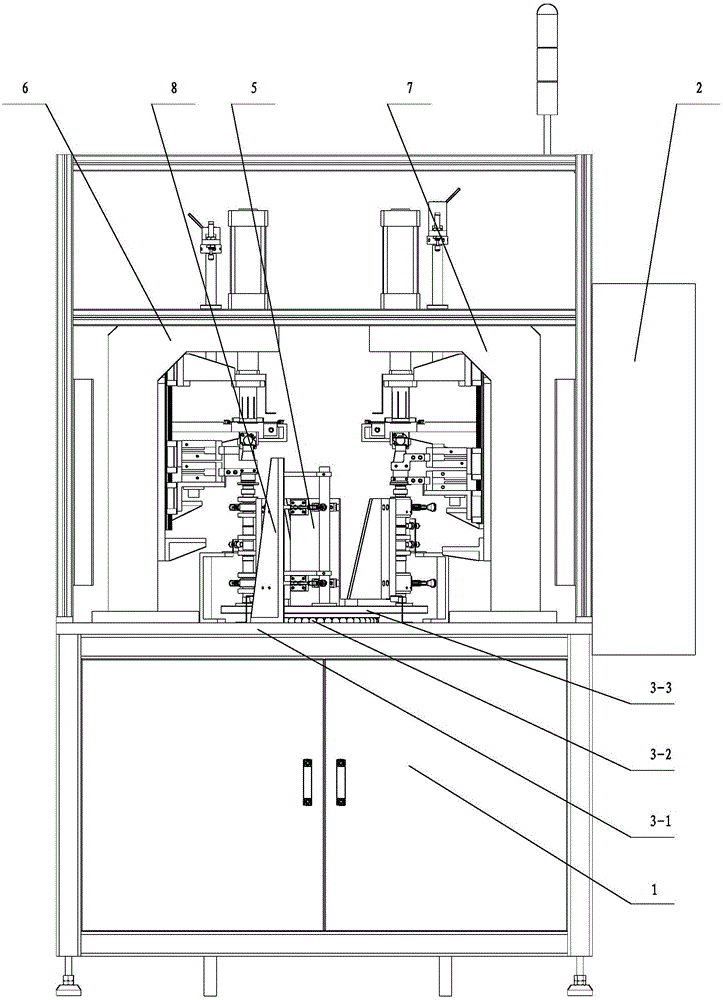

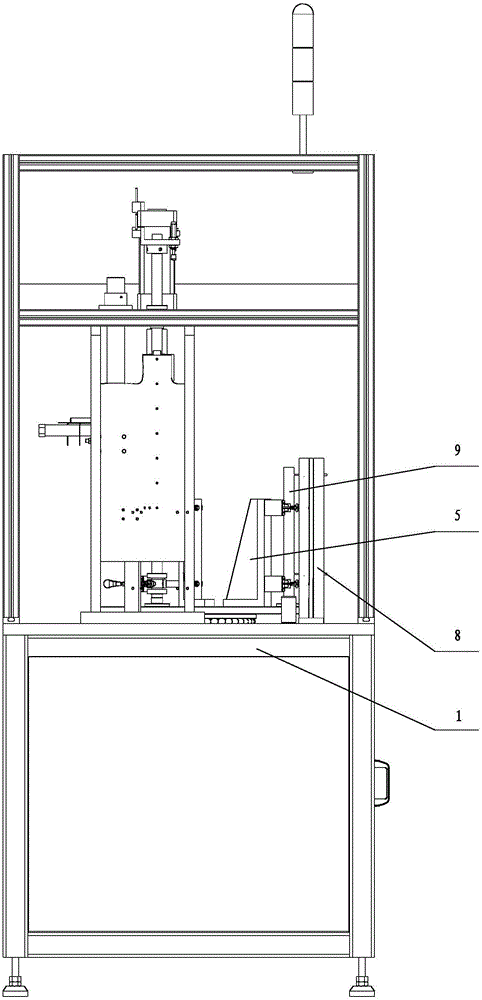

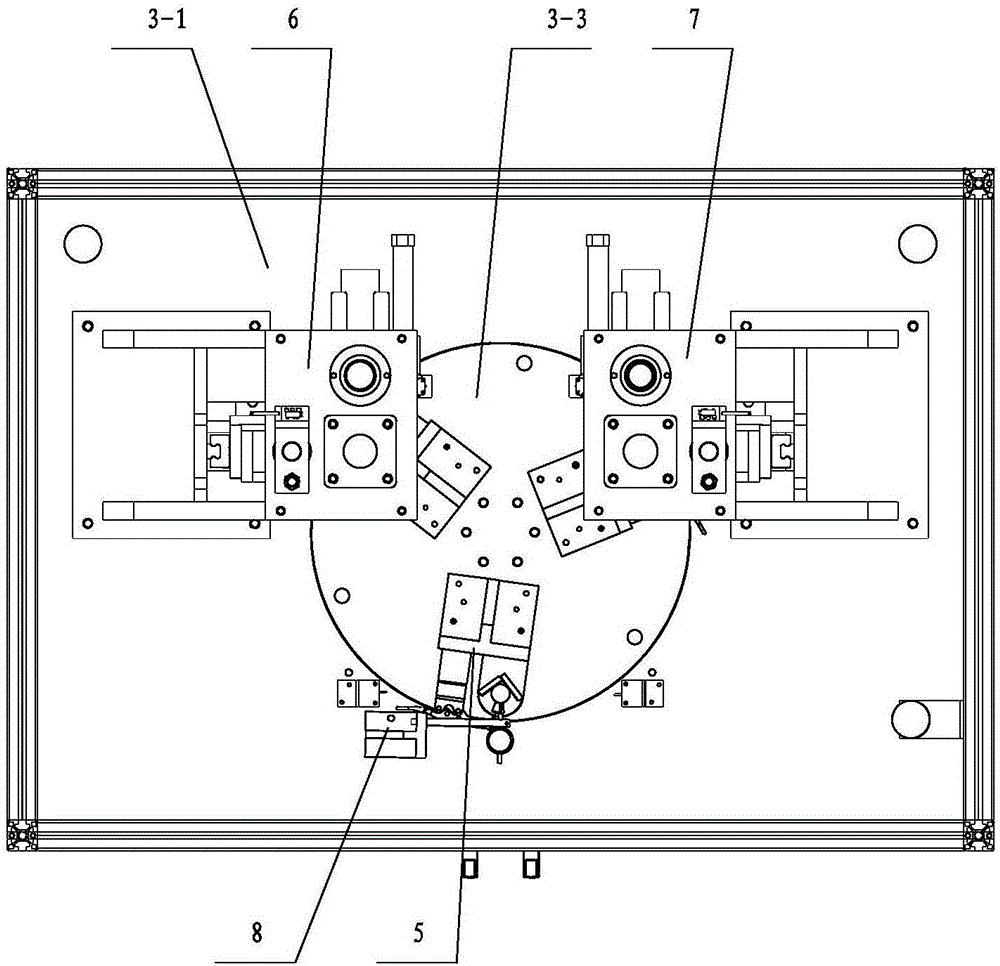

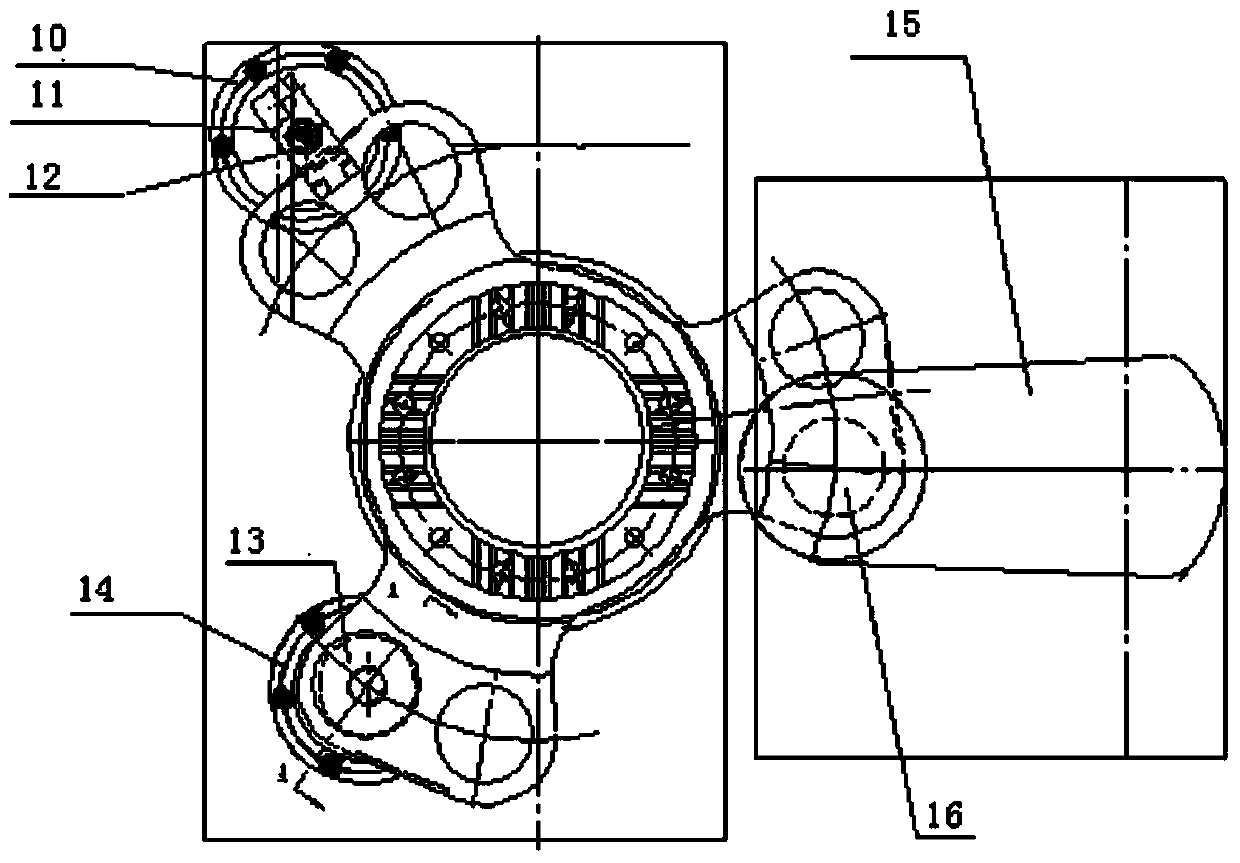

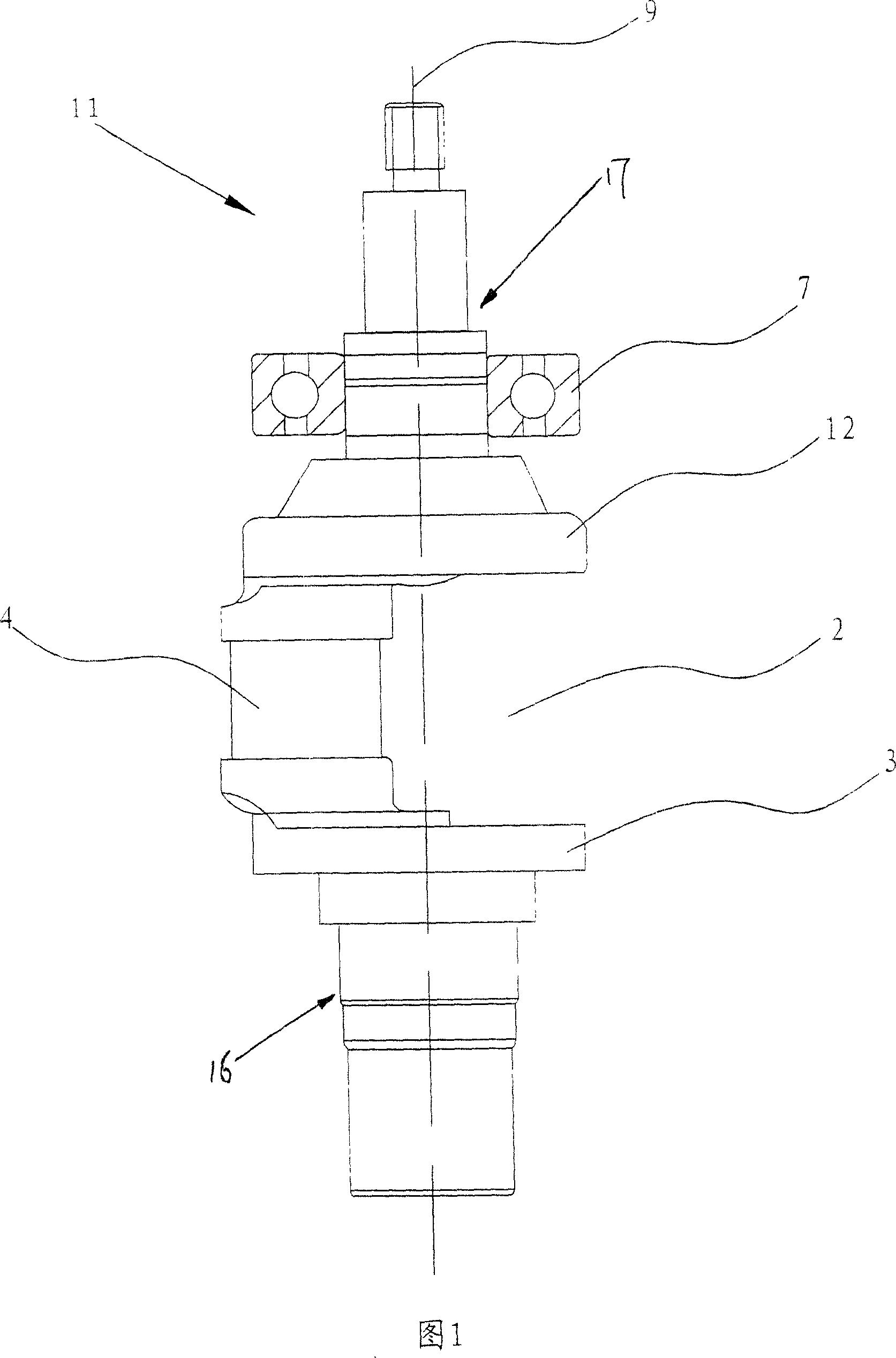

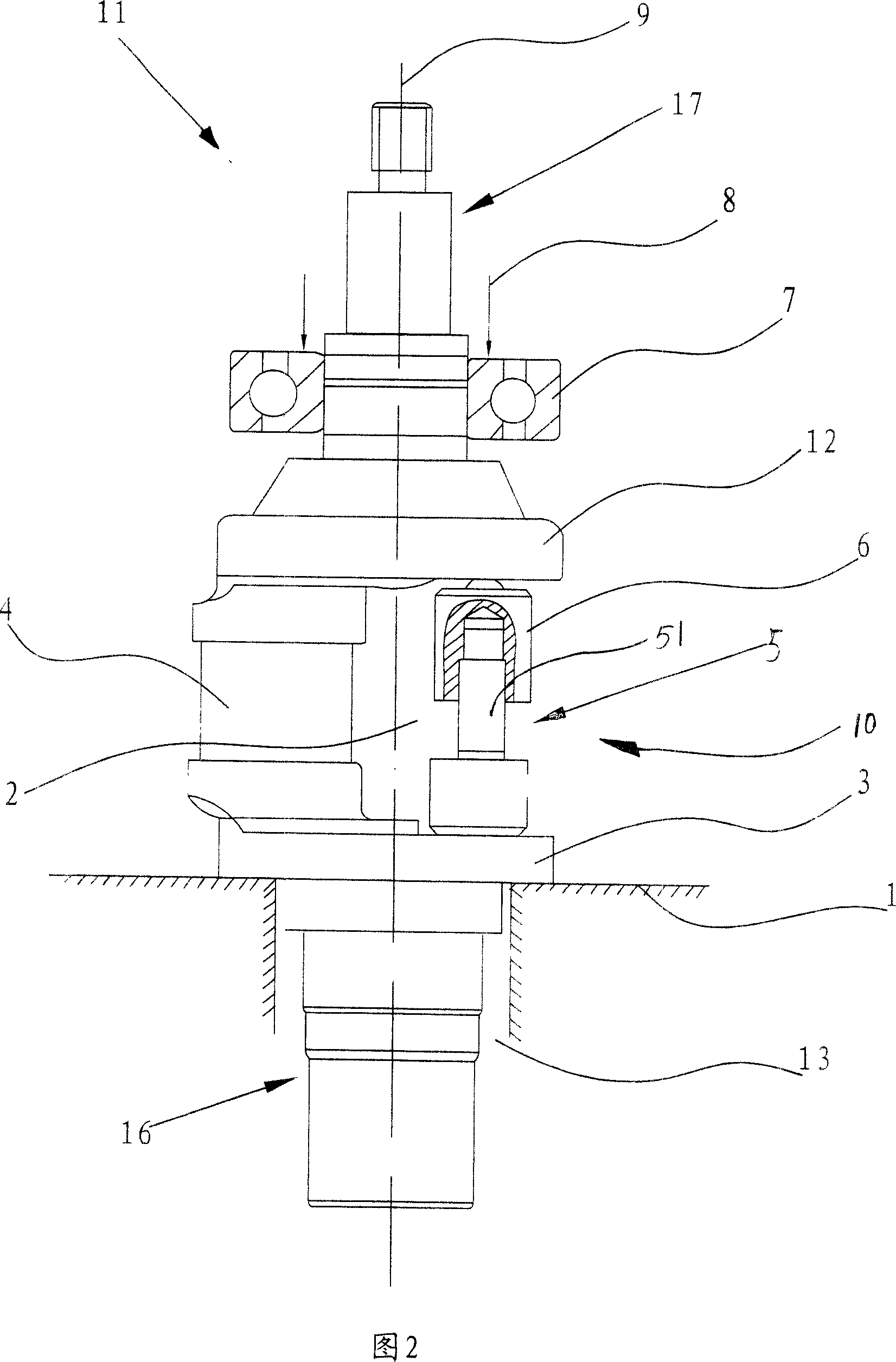

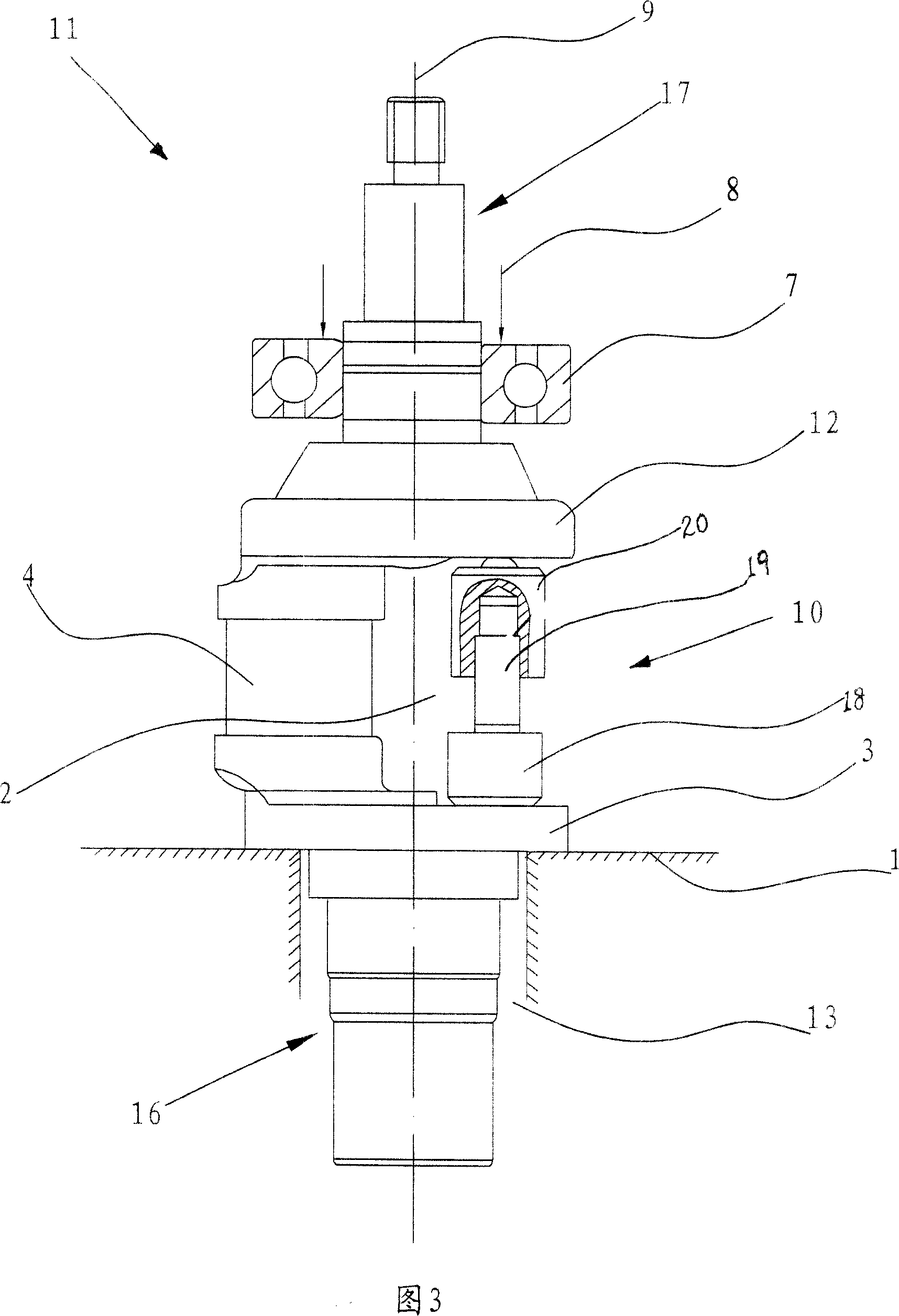

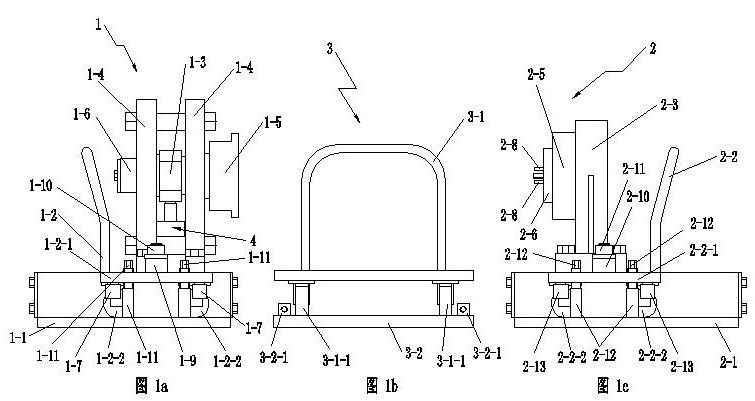

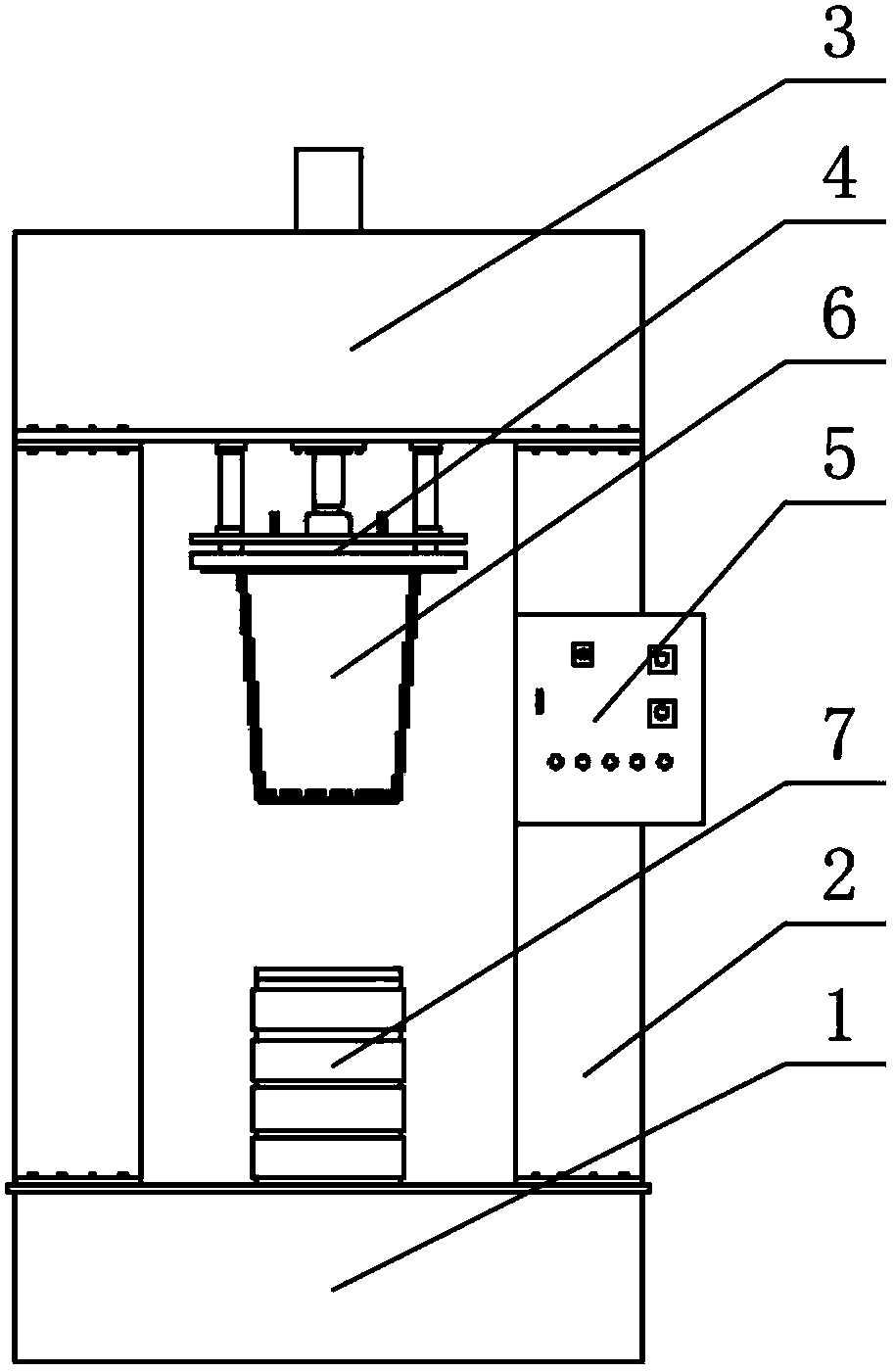

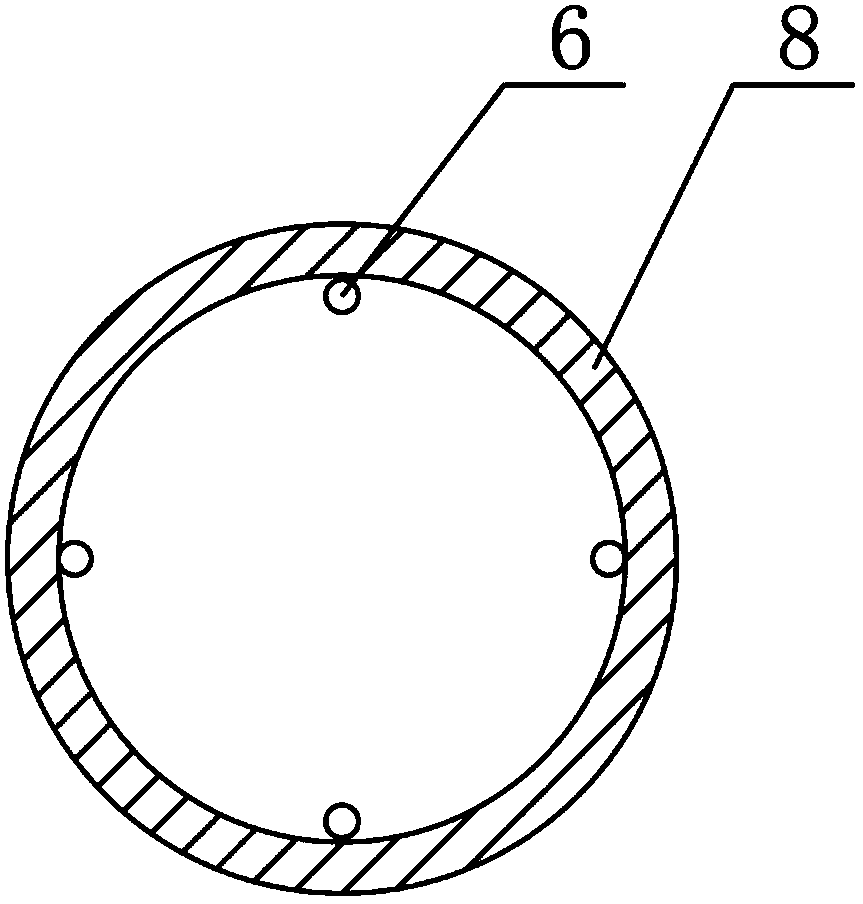

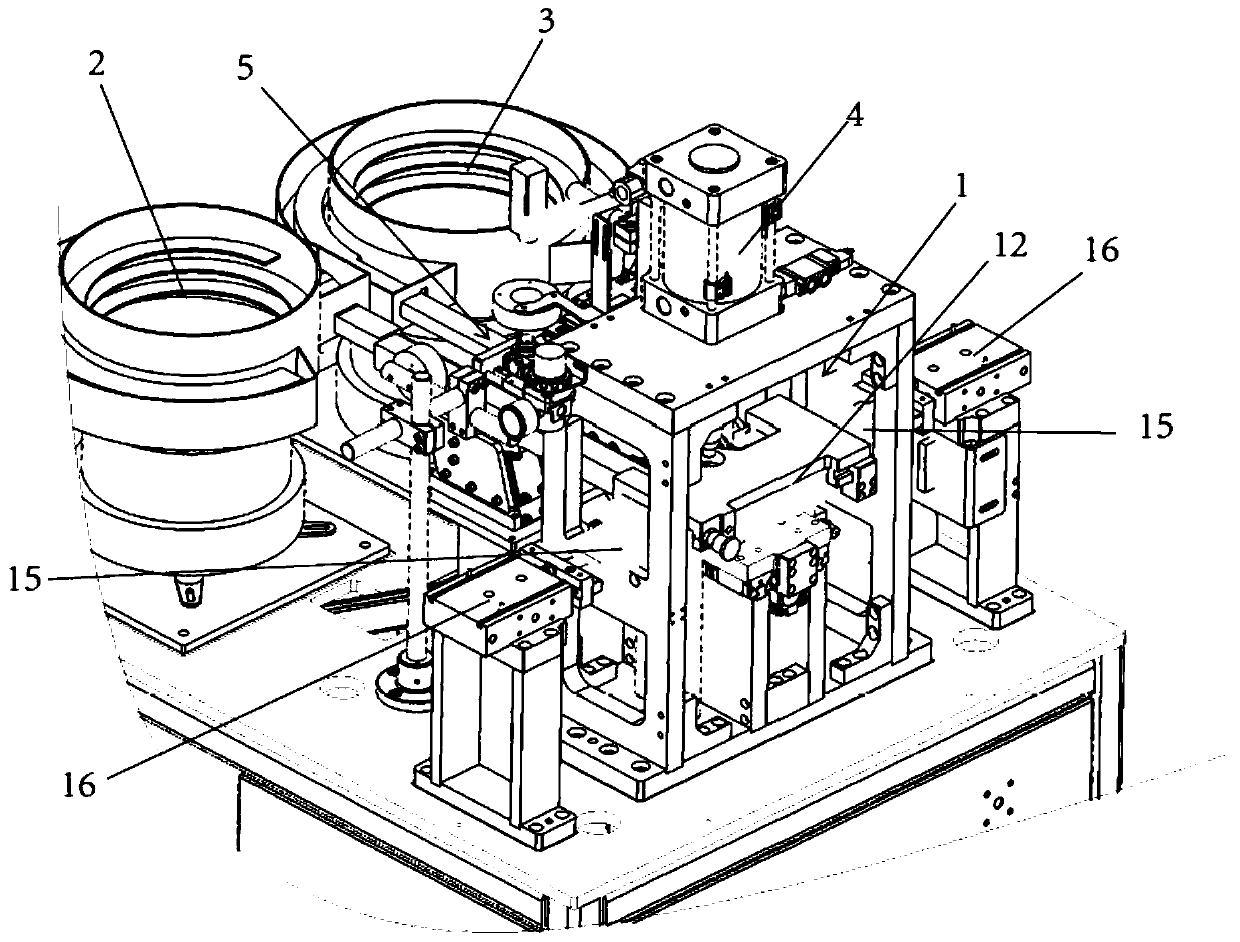

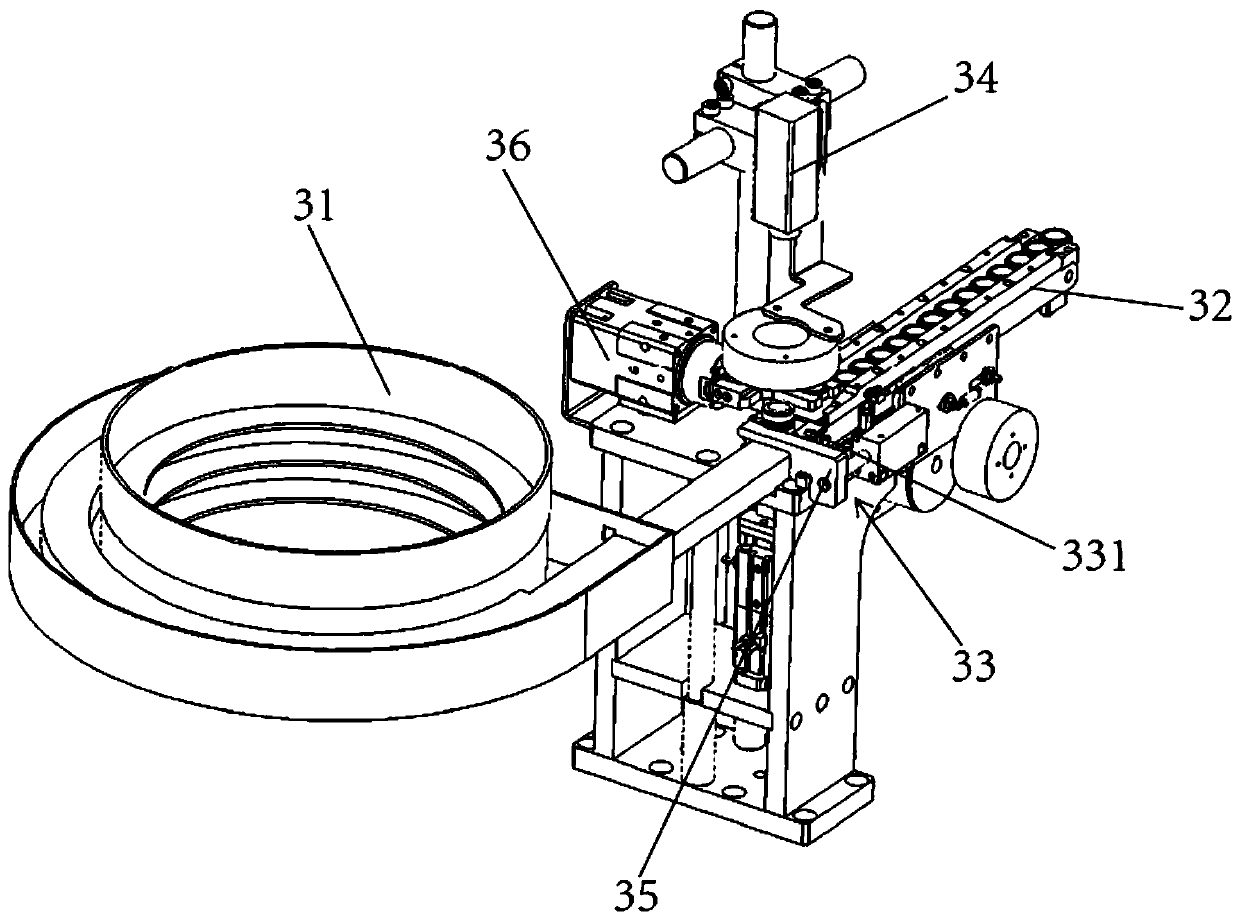

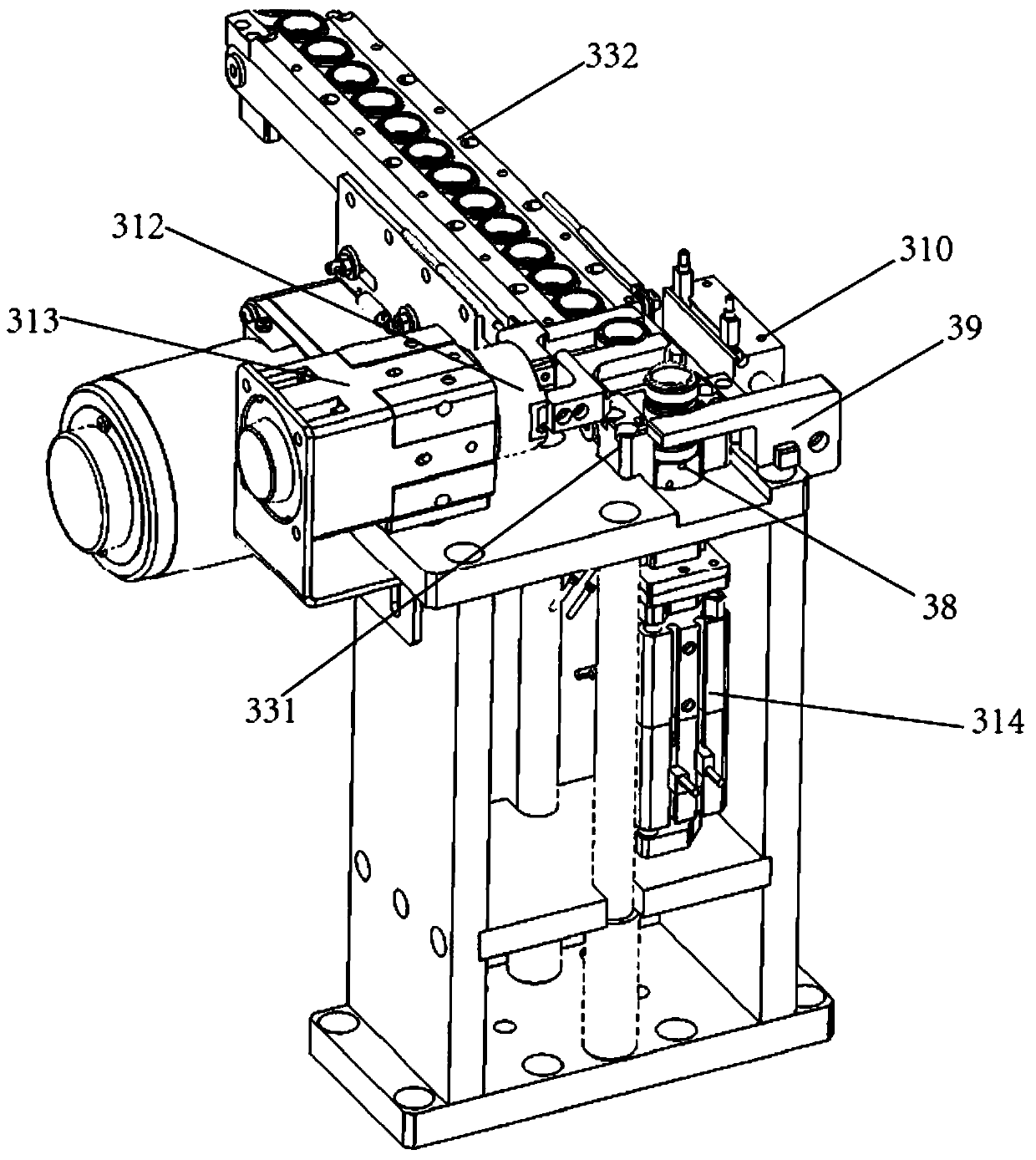

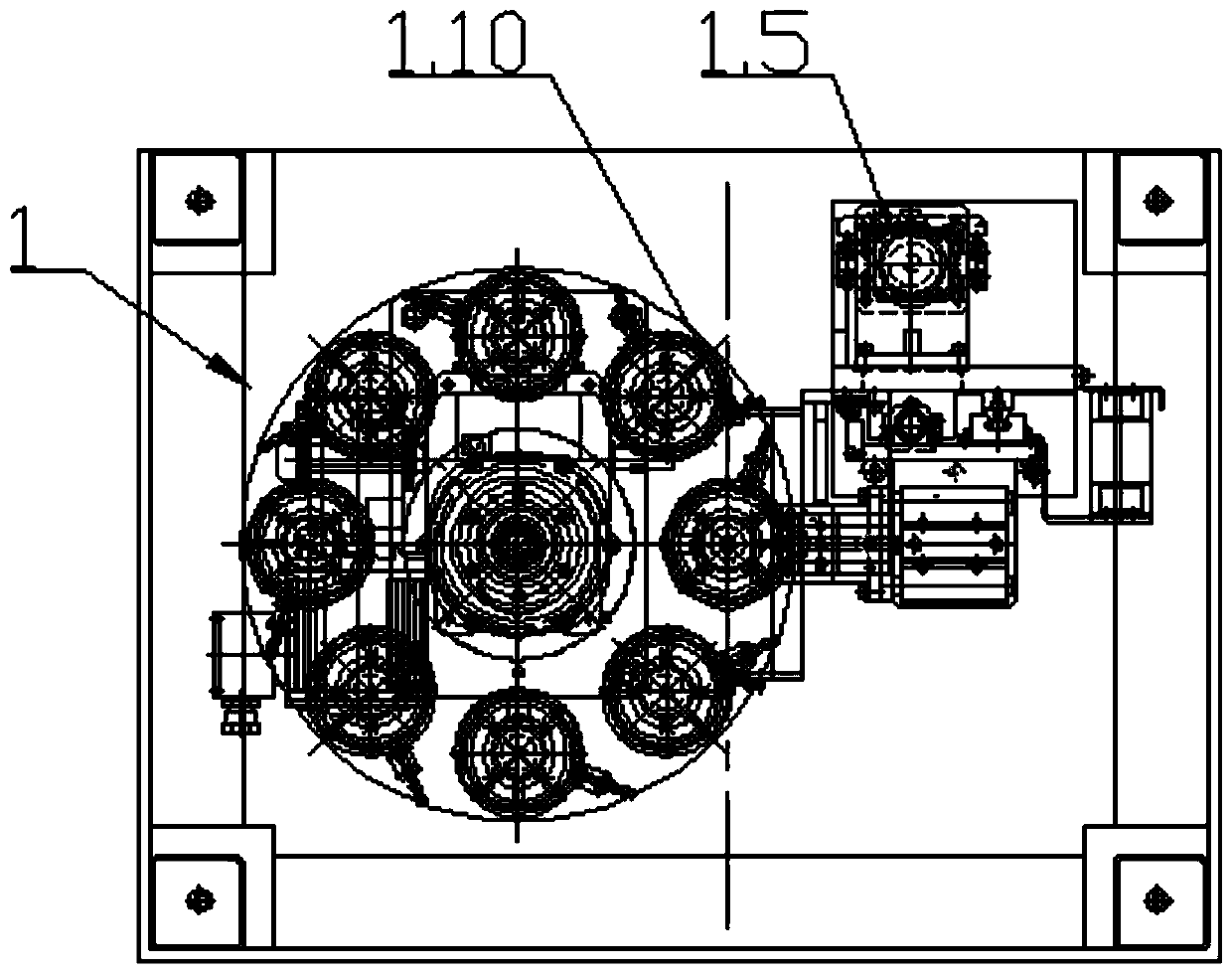

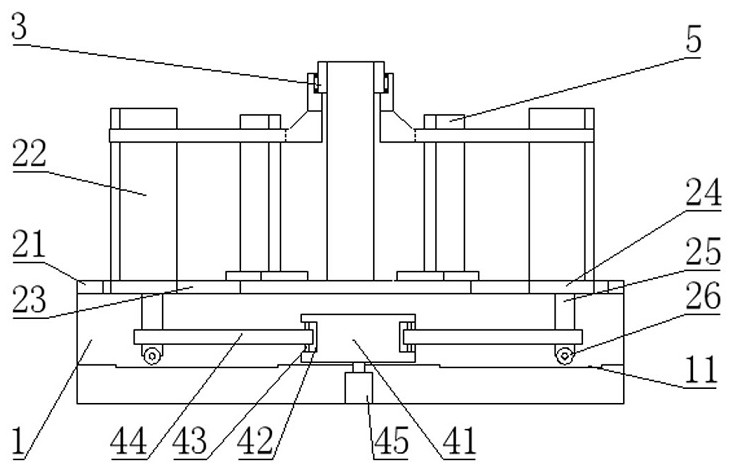

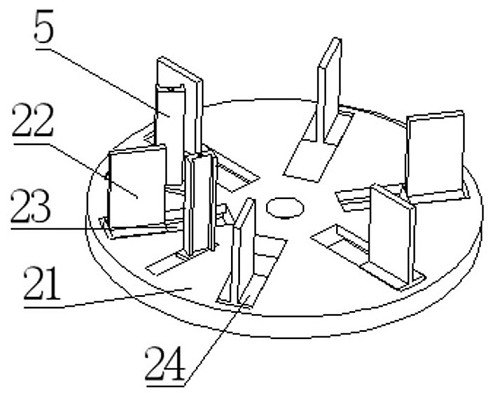

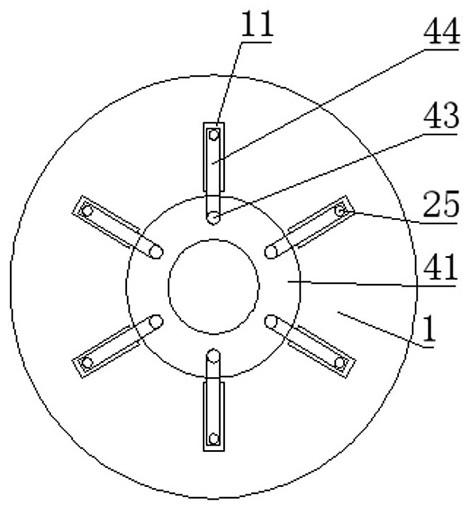

Cam shaft sealing ring pressing machine

ActiveCN106181860AEasy to operateIncrease productivityMetal-working hand toolsEngineeringElectric control

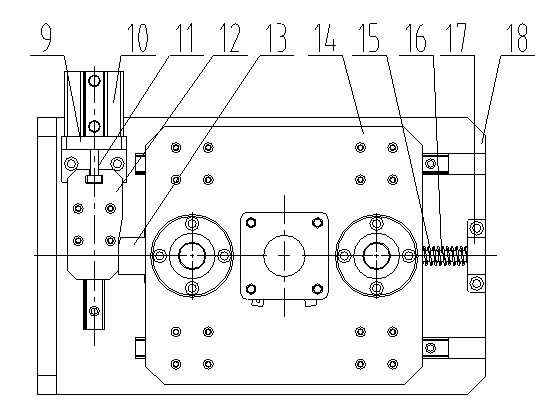

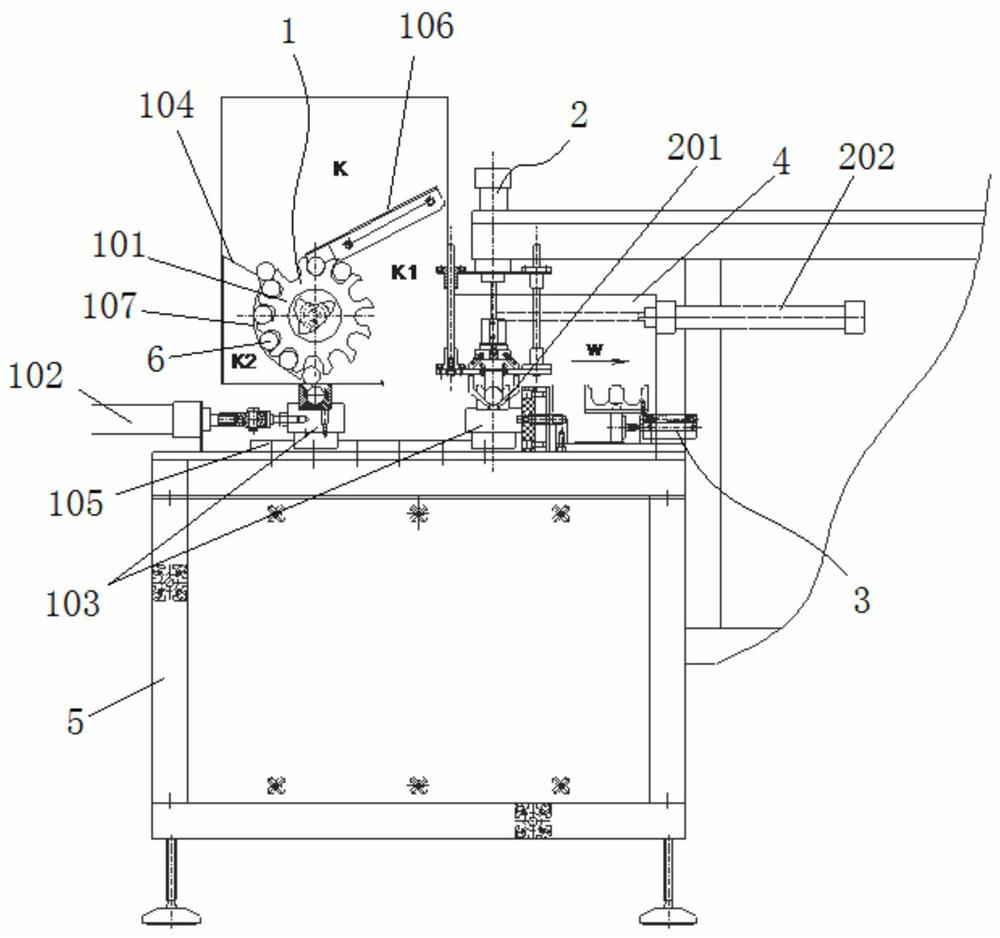

The invention discloses a cam shaft sealing ring pressing machine. The cam shaft sealing ring pressing machine comprises a rack (1), an electric control cabinet (2), a rotary table type workbench, cam shaft clamping devices, a head sealing ring pressing device and a tail sealing ring pressing device. The three sets of cam shaft clamping devices are arranged and connected to a rotary table (3-3). The head sealing ring pressing device and the tail sealing ring pressing device are arranged on a workbench plate (3-1). The installing position of the head sealing ring pressing device and the installing position of the tail sealing ring pressing device correspond to the positions of the cam shaft clamping devices on the rotary table (3-3). Drive mechanisms of the rotary table type workbench, the head sealing ring pressing device and the tail sealing ring pressing device are electrically connected with the electric control cabinet (2). After the above structure is adopted, cam shaft clamping only needs to be conducted at the position of a feeding clamping station, the pressing machine is started, the station automatically rotates to a head sealing ring pressing station or a tail sealing ring pressing station, operation is very convenient, and therefore the production efficiency is greatly improved.

Owner:宁波圣龙智造凸轮轴有限公司

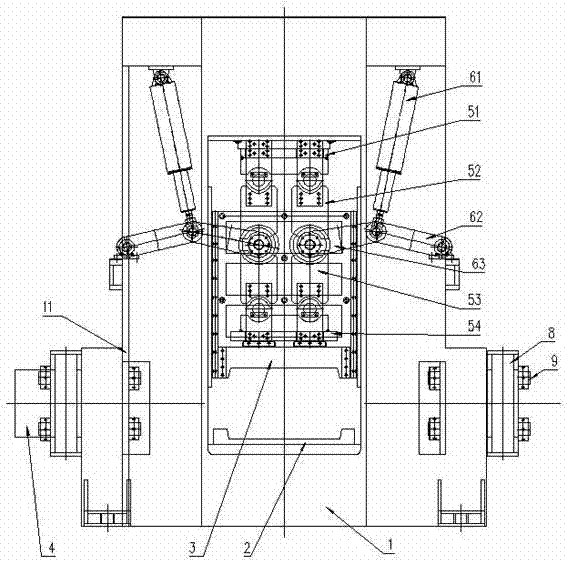

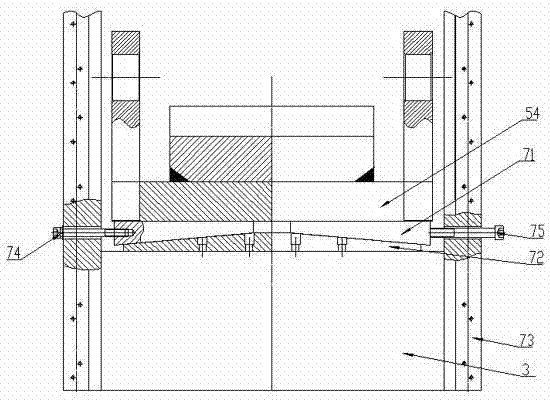

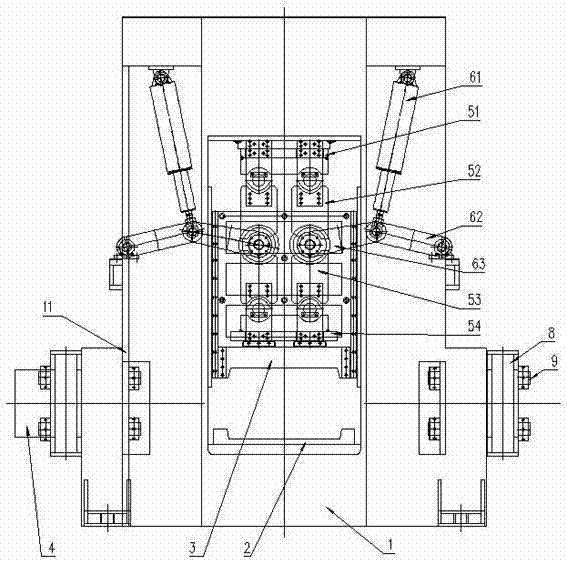

Toggle lever metal extruder

ActiveCN102343377AImprove mechanical performanceSlow and smooth working strokeHydraulic cylinderMechanical engineering

The invention discloses a toggle lever metal extruder, which comprises a framework-type rack and is creatively characterized in that a workbench is arranged at the lower part of the rack, a sliding block is arranged above the workbench and can reciprocate on the rack along a vertical direction, and two sides of the work bench are provided with lateral pressing cylinders; a toggle lever mechanism is arranged on the upper part of the rack and mainly comprises an upper support, an upper toggle lever, a lower toggle lever and a lower support; and a driving mechanism is arranged outside the togglelever mechanism and comprises a hydraulic cylinder, a first connecting lever and a second connecting lever. A hydraulic cylinder and the lateral pressing cylinder act to drive an upper die, a left male die and a right male die to move to a lower die on the workbench for pressing. The driving mechanism drives the toggle lever mechanism to move the sliding block, the sliding block is fast in a return downward trip, and a working stroke is slow and stable; in addition, in the working stroke, the stamping pressure has long duration, the pressing efficiency is high, the stress bearing effect of the rack is good, so that the installed power is reduced and the production cost is lowered.

Owner:NANTONG RUNDE MECHANICAL TECH

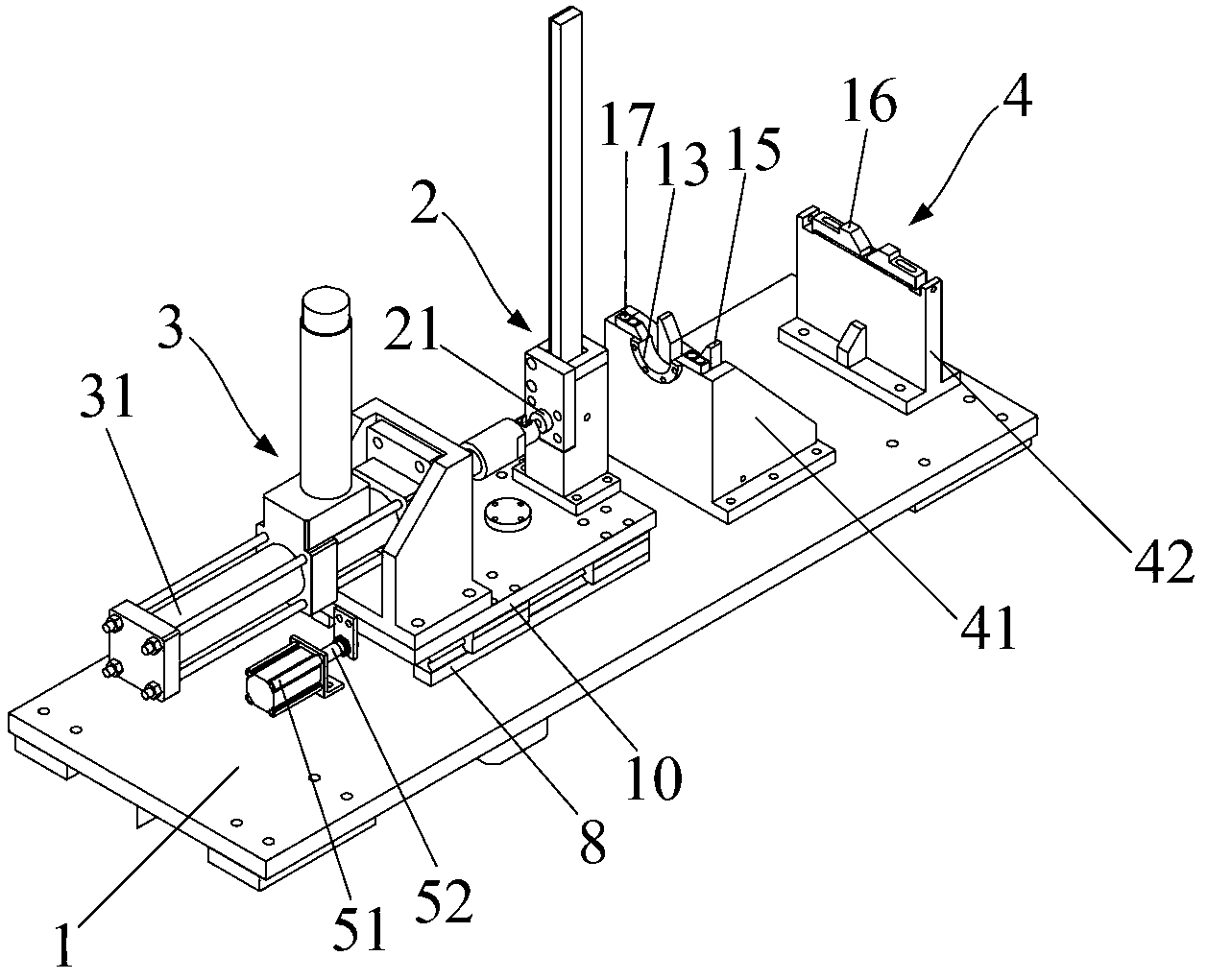

Crankshaft positioning pin pressing-mounting tool

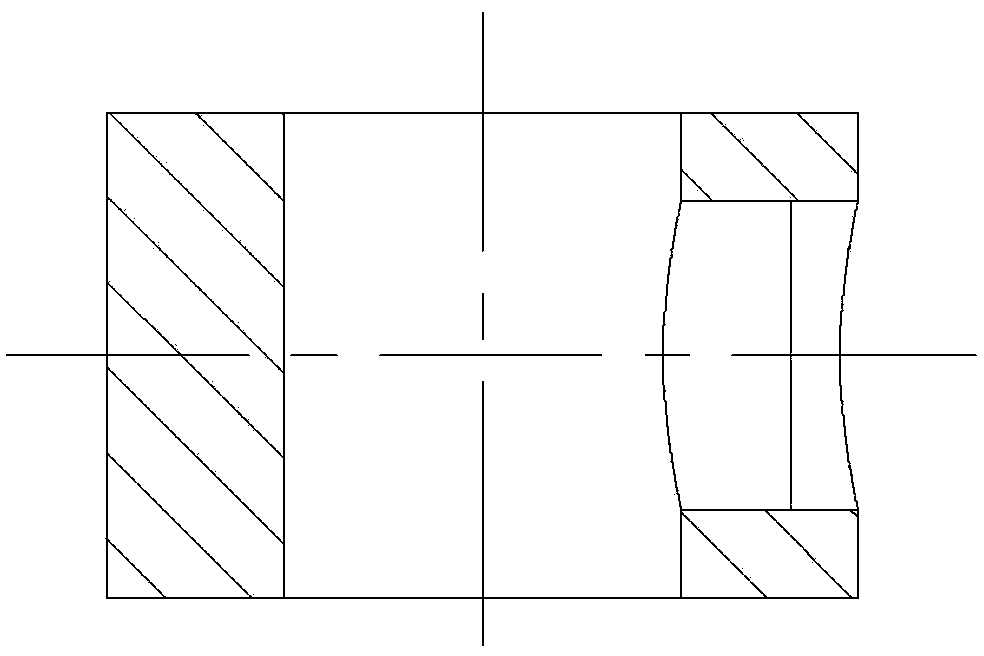

ActiveCN103231238AGuarantee the quality of pressingDoes not destroy roundnessMetal working apparatusReciprocating motionEngineering

The invention relates to the technical field of automobile production tools and discloses a crankshaft positioning pin pressing-mounting tool. The crankshaft positioning pin pressing-mounting tool comprises a guiding mechanism, a pressing-mounting mechanism and a fixing mechanism, wherein the pressing-mounting mechanism comprises a pressing-mounting piston cylinder and is used for substituting for manpower and providing pressing-mounting force, accordingly the requirements for manual skills are reduced, and labor intensity is reduced. A guiding through hole is arranged on the guiding mechanism and is matched with a piston rod of the pressing-mounting piston cylinder to enable the piston rod of the pressing-mounting piston cylinder to perform reciprocating motion on one straight line and not to be influenced by self weight. When a positioning pin is pressed and mounted, a crankshaft is fixedly placed on the fixing mechanism. The guiding mechanism is installed between the fixing mechanism and the pressing-mounting mechanism to enable the piston rod of the pressing-mounting piston cylinder to press the positioning pin into a pin hole along the axis direction of the pin hole, the roundness of an excircle face of a crankshaft flange is not damaged, and the pressing-mounting quality of the crankshaft positioning pin is ensured.

Owner:长城汽车股份有限公司平湖分公司

Oil seal press-fitting device

PendingCN108655702ACheck flatnessEffective detection of flatnessMetal working apparatusEngineeringMechanical engineering

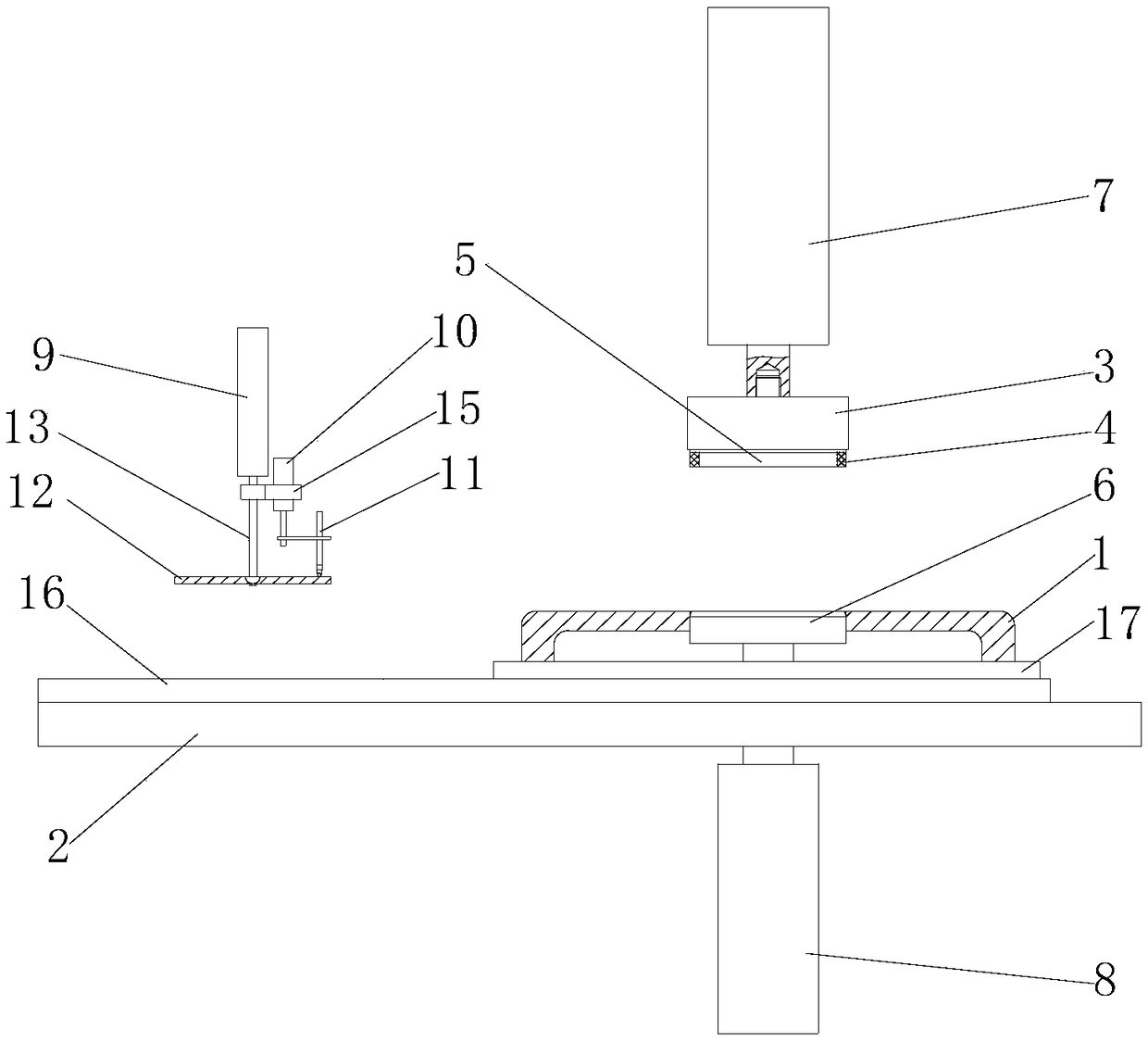

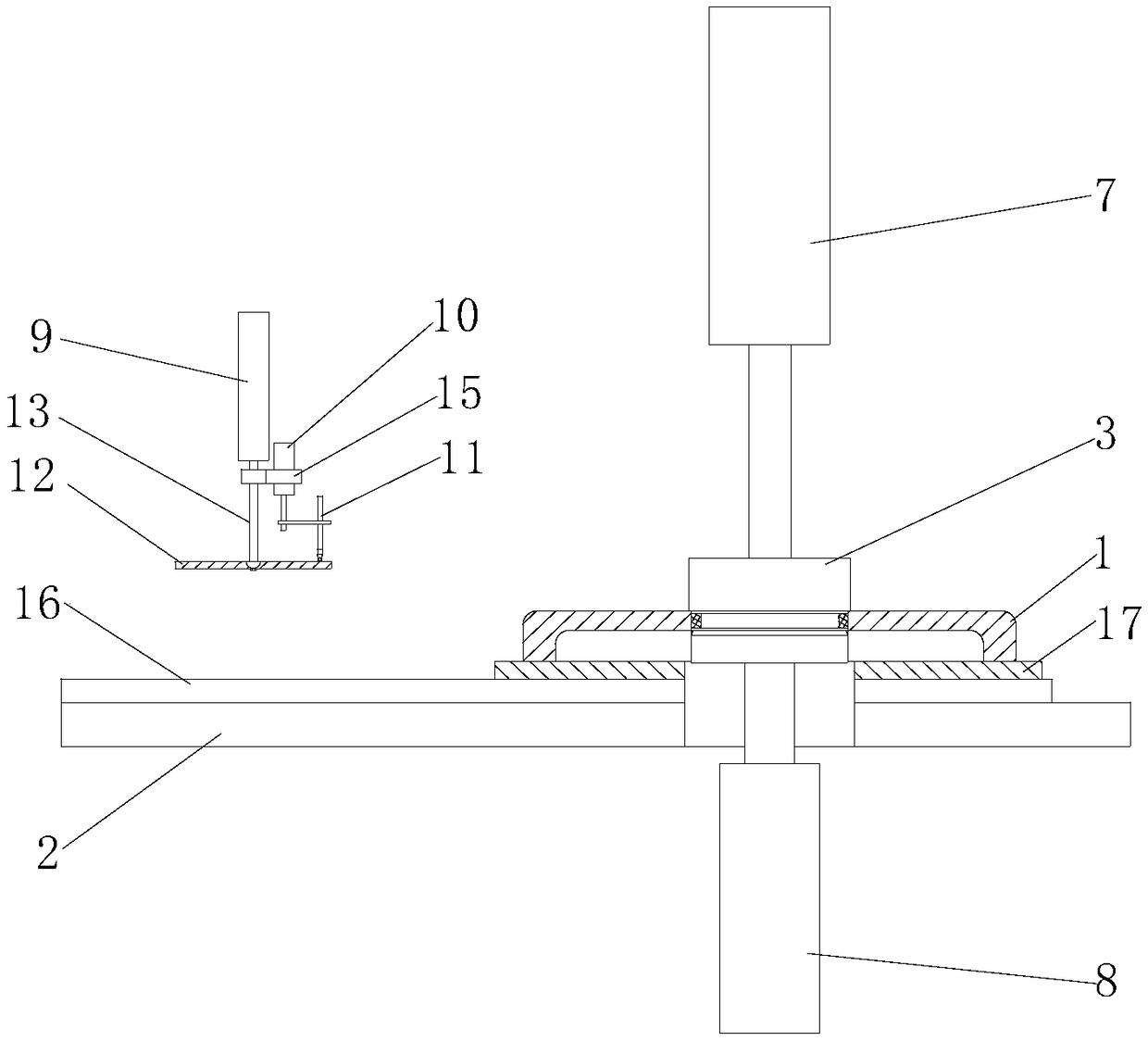

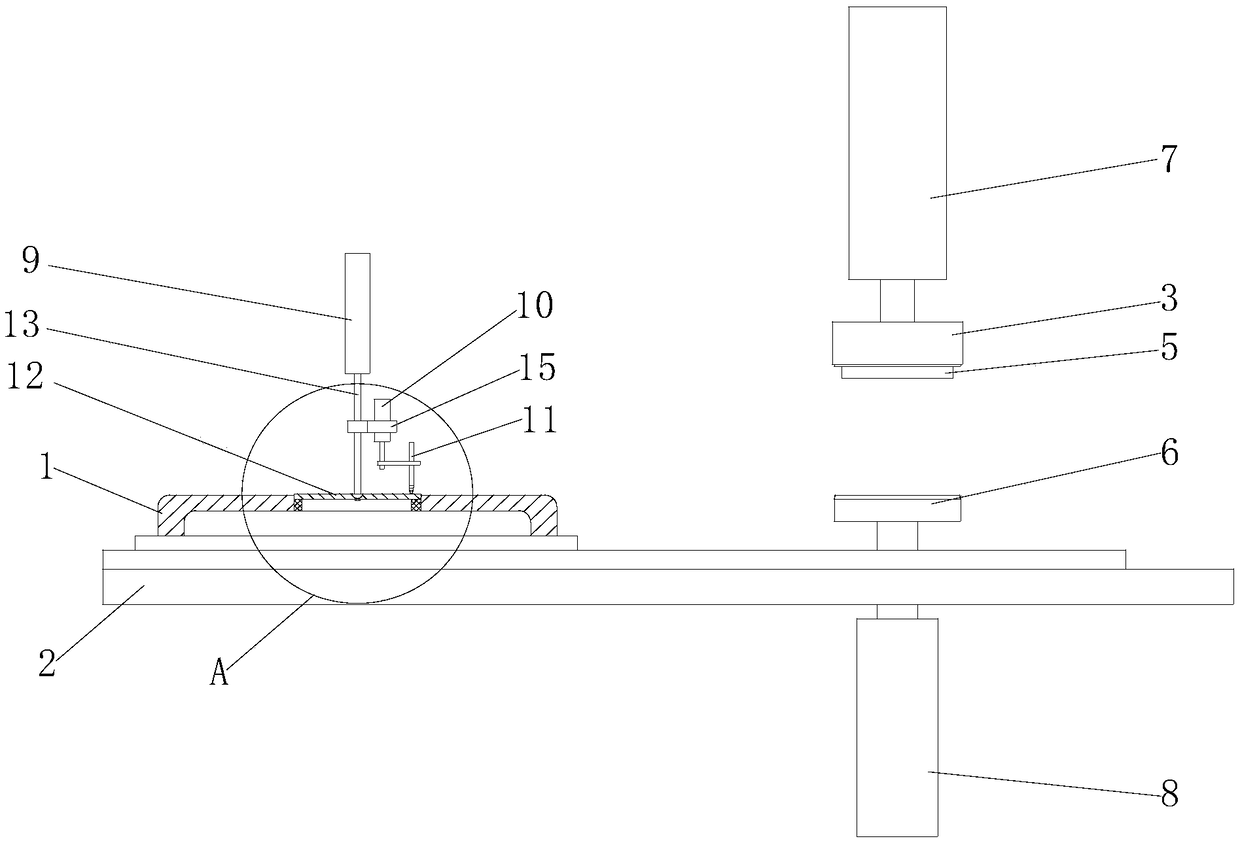

The invention discloses an oil seal press-fitting device. The oil seal press-fitting device comprises a workbench used for allowing a workpiece to be contained, an oil seal pressing head capable of moving up and down is arranged above the workbench, an inserting connection port is arranged on the oil seal pressing head and is used for allowing an oil seal to be installed, a positioning block capable of moving up and down is arranged below the workbench, and the axis line of the oil seal pressing head, the axis line of the positioning block and the axis line of an oil seal hole of the workpiececoincide; the oil seal press-fitting device further comprises a plane detection mechanism and a conveying mechanism, wherein the plane detection mechanism is located above the workbench and is used for detecting the flatness of the oil seal, and the conveying mechanism is used for conveying the workpiece to the position below the plane detection mechanism. According to the oil seal press-fittingdevice, the press-fitting force and the stroke of the oil seal can be monitored in real time, moreover, the flatness of the oil seal after press-fitting can be detected, the press fitting quality of the oil seal is ensured, and the faults of oil seal oil leakage and oil seal loosening are avoided, and the situation of a large amount of cost caused by reworking of an engine is avoided.

Owner:GUANGXI YUCHAI MASCH CO LTD

Locomotive hollow shaft rubber joint press-mounting method

InactiveCN103624527APrecise positioningEasy to operateWork holdersMetal working apparatusEngineeringSacroiliac joint

The invention provides a locomotive hollow shaft rubber joint press-mounting method. A rotary mandrel is arranged on a platform surface of a work platform, and positioning pin bases, pressing plate bases and press-mounting mechanical devices are arranged on the platform surface and the platform side according to distribution angles of rubber joint installation holes in a hollow shaft. The large-end hole of the hollow shaft is formed in the rotary mandrel, the hollow shaft is rotated so that after one installation hole is aligned to one positioning pin base, one positioning pin is inserted into the corresponding installation hole and clamp a pressing plate on the corresponding pressing plate base, and the installation hole at the corresponding angle is located in the station of the corresponding press-mounting mechanical device. Then press-mounting is carried out on a rubber joint by means of the press-mounting mechanical devices. Positioning and aligning are accurate, operations are easy, what is needed is poking and rotating, manual transportation for adjustment is needless, tools are needless to be adjusted, labor intensity is low, one worker can operate, work efficiency is improved by three times, and press-mounting quality is effectively guaranteed.

Owner:CRRC DALIAN CO LTD

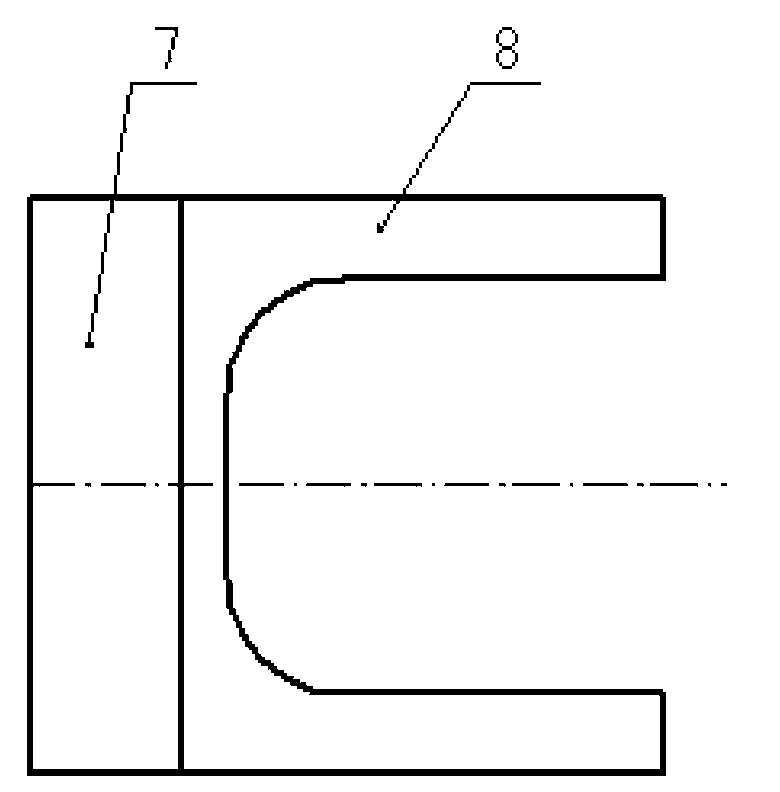

Method of pressing bearing on crankshaft

InactiveCN100999047AAvoid force deformationGuarantee the quality of pressingWork holdersMetal working apparatusCrankshaftSupport plane

The present invention relates to a method for press-mounting bearing on crankshaft. Said method includes the following steps: firstly, fixing the crankshaft on a supporting frame; then making the bearing to be mounted by cover-placed on the upper side of mounting portion of said crankshaft and making axis of bearing be coincident with axis of said crankshaft; in the notch position of said crankshaft placing a pusher along the axial direction of said crankshaft and making two end portions of pusher be respectively tightly contacted with first main shaft neck and second main shaft neck; finally applying pressure to said bearing until the described bearing is fixed on the mounting portion of said crankshaft.

Owner:JIANGSU WANGONG TECH GRP CO LTD

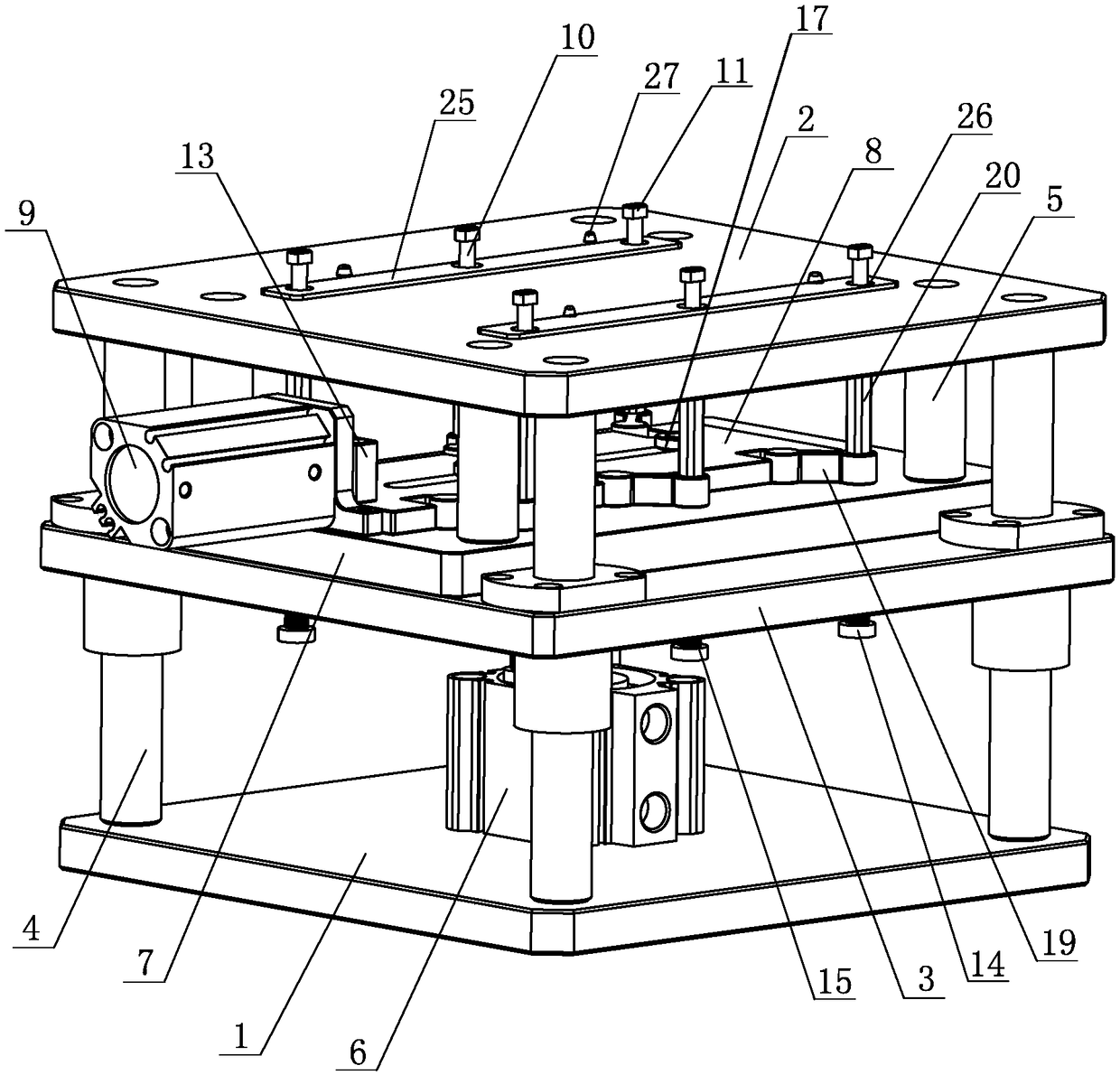

Small-displacement high-precision pitch-change mechanism

InactiveCN104029011ARealize automatic precise positioningGuarantee the quality of pressingAssembly machinesMetal working apparatusSlide plateEngineering

The invention provides a small-displacement high-precision pitch-change mechanism which comprises an oil cylinder, guide rods, an air cylinder, a stop block and a fixing seat, wherein a pair of cross shaft slide rails is arranged on the fixing seat; a slide plate is mounted on the cross shaft slide rail; the oil cylinder and linear bearings are fixed on the slide plate; the guide rods is fixed with a pressure plate together; the inner end of a floating joint is connected with an oil cylinder rod of the oil cylinder; the air cylinder is fixed with the fixing seat together via an air cylinder seat; and the air cylinder drives a step locating block to move back and forth via an air cylinder joint.The mechanism can achieve automatic and accurate location of a pressure head, achieve that middle shafts of every gearbox can be subjected press mounting coaxially, and ensure press mounting quality, the position of the mechanism cannot be changed due to leakage of compressed air or a hydraulic station, and the mechanism is stable, reliable, low in cost, simple in structure and convenient to maintain.

Owner:ANHUI GSTONE AUTOMATION EQUIP

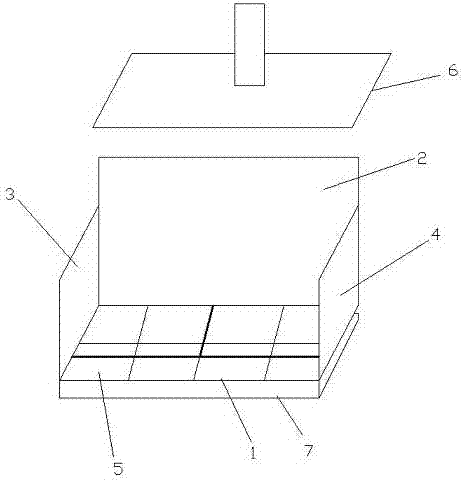

Brick tea pressing die

ActiveCN105494708AGuaranteed pressing qualityAvoid pollutionPre-extraction tea treatmentBrickEngineering

The invention discloses a brick tea pressing die which is used for pressing and molding brick tea. The brick tea pressing die comprises a base, an aluminum-made brick-shaped die body, a movable plate, a top plate and a feeding hole, wherein the base is used for providing supporting for the pressing and molding of the brick tea; the aluminum-made brick-shaped die body is arranged above the base and is used for providing a processing space for the pressing and molding of the brick tea; the movable plate is detachably connected onto one side of the aluminum-made brick-shaped die body and is used for controlling the opening and closing of the side part of the aluminum-made brick-shaped die body; the top plate is detachably connected to the top of the aluminum-made brick-shaped die body and is used for controlling the opening and closing of the top of the aluminum-made brick-shaped die body; and the feeding hole is formed in the top plate and is used for inputting brick tea raw materials. With the adoption of the structural design of the brick tea pressing die, the heat dissipation effect can be effectively improved and the brick tea pressing quality is ensured; the service life of the die also can be prolonged; and the die is relatively convenient to operate, and pollution or damages on the brick tea also can be avoided.

Owner:YIYANG SHENGXI MACHINERY EQUIP MFG

Clamping device for computer shell machining

PendingCN108747516AGuarantee the quality of pressingImprove clamping efficiencyPositioning apparatusMetal-working holdersEdge surfaceMachining

The invention discloses a clamping device for computer shell machining. The clamping device is characterized by comprising a support, a fixed plate, a product bearing plate and a pressing plate; a raised block is arranged on the top surface of the product bearing plate, a product placing groove is formed in the top face of the raised block, and the periphery of the bottom surface of the pressing plate is arranged on the top outer edge surface of the raised block; a left side through hole and a right side through hole are formed in the fixed plat, a first vacuum connector is installed in the left through hole, and a second vacuum connector is installed in the right through hole; a sealed first groove and a sealed second groove are formed in the bottom of the product bearing plate, the leftthrough hole communicates with the first groove, and the right through hole communicates with the second groove; a plurality of breathable holes and ventilation holes are formed in the product placinggroove, suction holes communicate with the first groove, and the ventilation holes communicate with the second groove. The clamping device for computer shell machining improves the clamping efficiency and the clamping quality of products.

Owner:江苏匠准精密组件有限公司

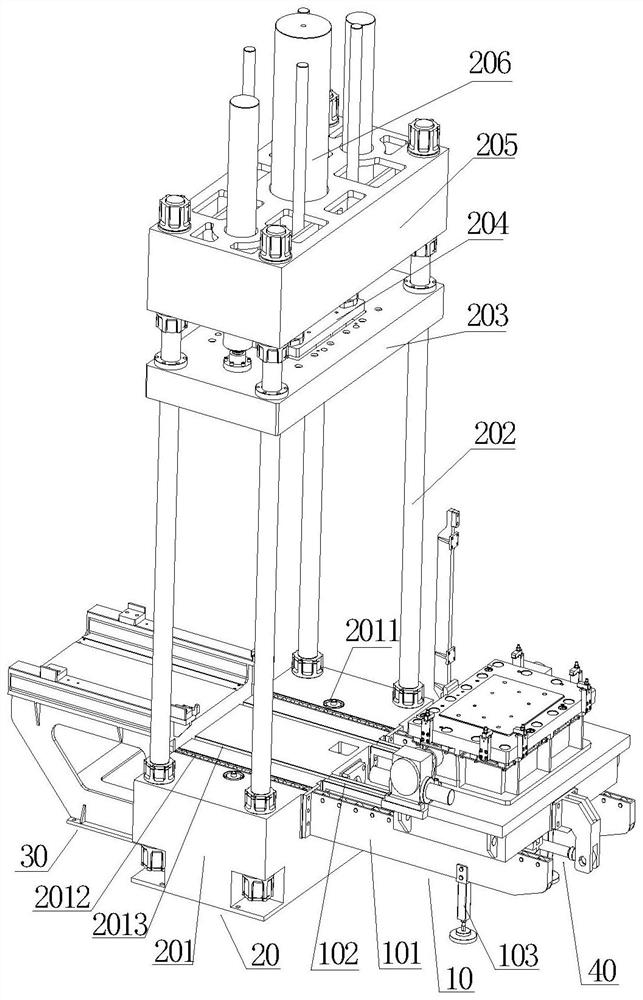

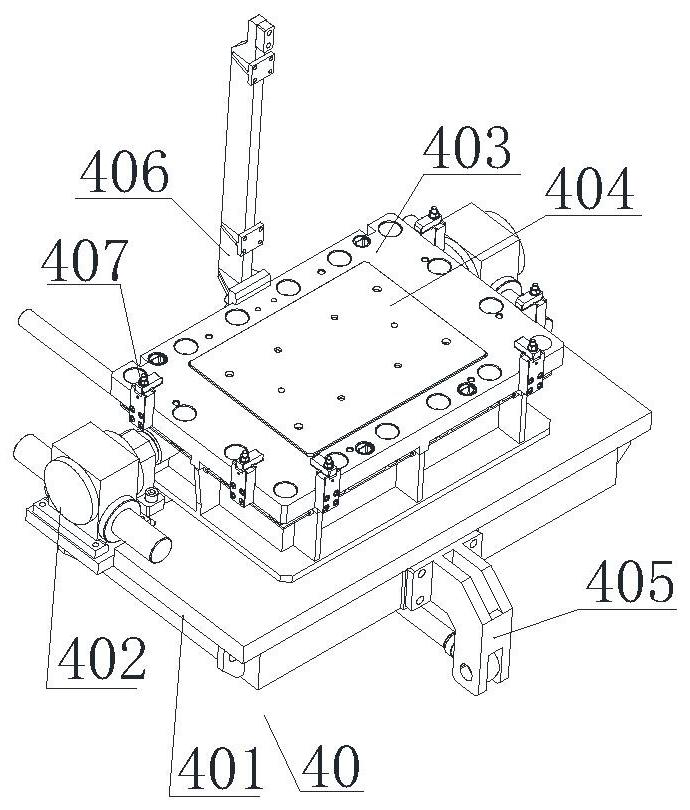

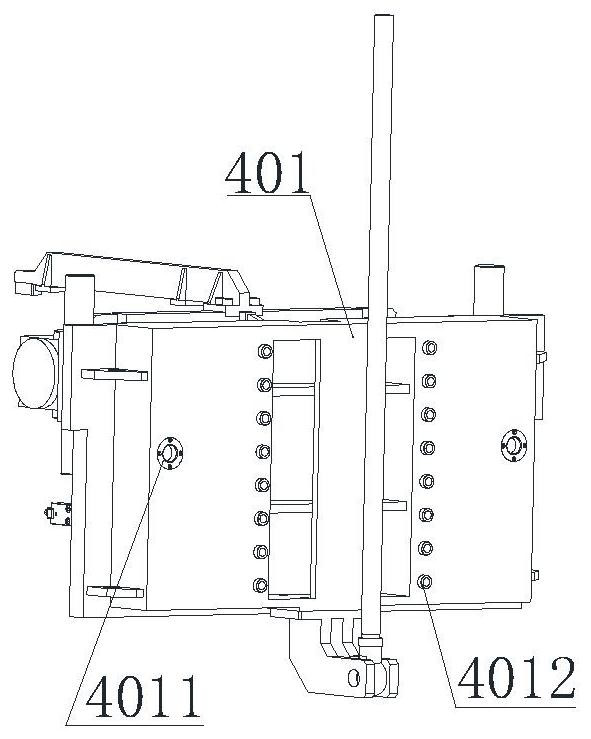

Battery stack press-fitting equipment

ActiveCN113422095AEven by forceGuarantee the quality of pressingRegenerative fuel cellsElectrical batteryEngineering

The invention provides battery stack press-fitting equipment. The battery stack press-fitting equipment comprises a stacking supporting table (10), a moving mechanism (40) and a press machine (20), the press machine (20) comprises a base (201), a guide column (202), a pressing head (204) and a driving mechanism (206), the guide column (202) is fixed to the base (201), the pressing head (204) can slide along the guide column (202) under the driving action of the driving mechanism (206), the moving mechanism (40) can move to the base (201) from the stacking supporting table (10), the battery stack can be stacked on the moving mechanism (40) when the moving mechanism (40) is located on the stacking supporting table (10), and the pressing head (204) is used for pressing the battery stack arranged on the moving mechanism (40). According to the battery stack press-fitting equipment disclosed by the invention, the overall stress of the stack can be uniform, and the press-fitting quality of the stack is ensured.

Owner:湖南钒谷新能源技术有限公司

Multi-point clamping device for product

PendingCN108714805AImprove efficiencyQuality improvementPositioning apparatusMetal-working holdersSlide plateEngineering

Owner:江苏匠准精密组件有限公司

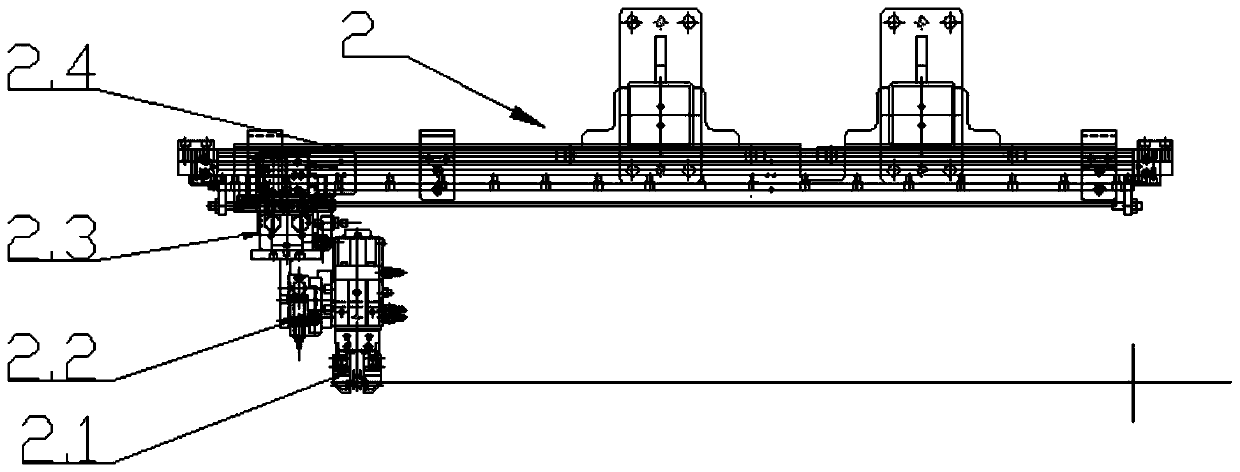

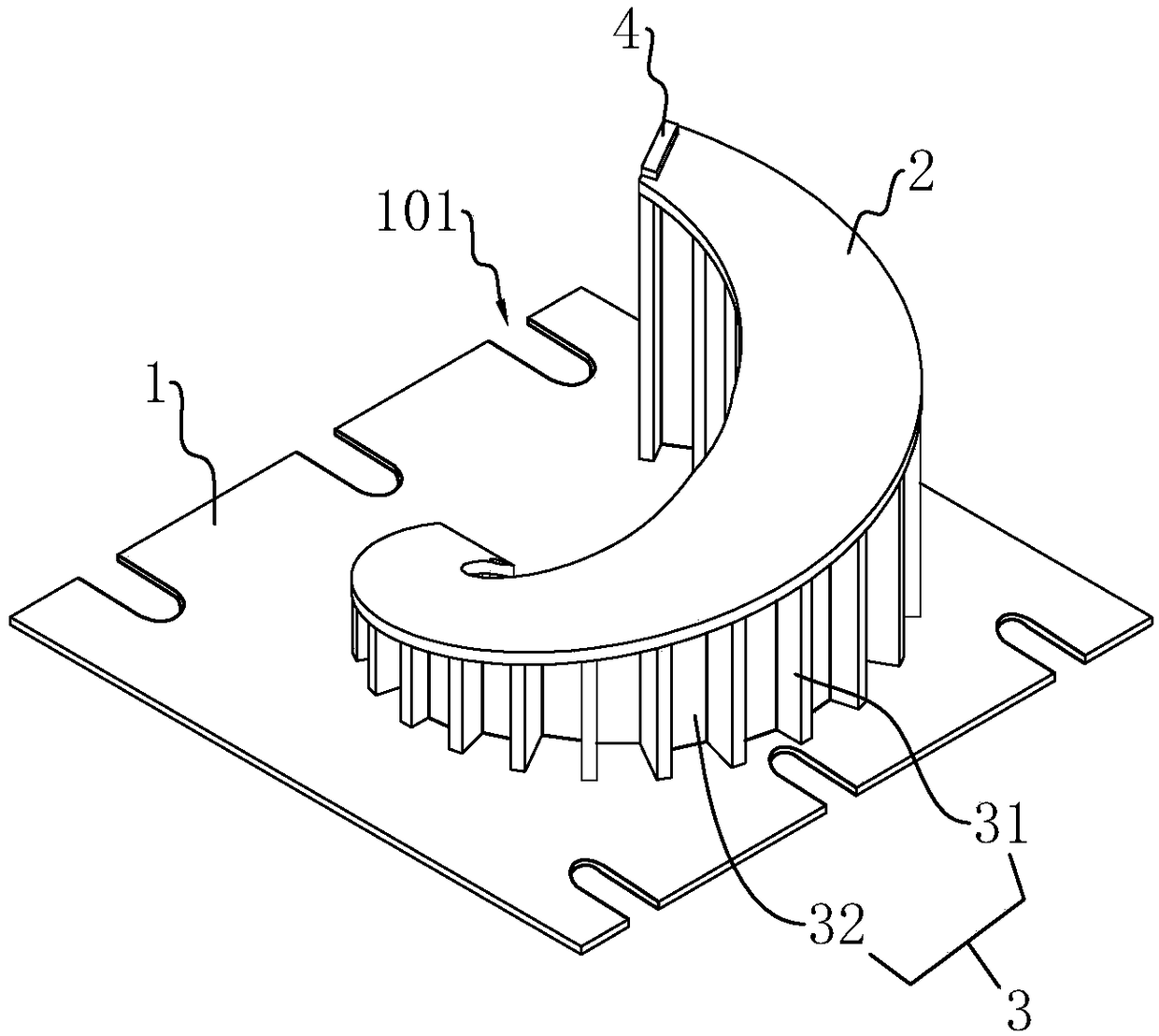

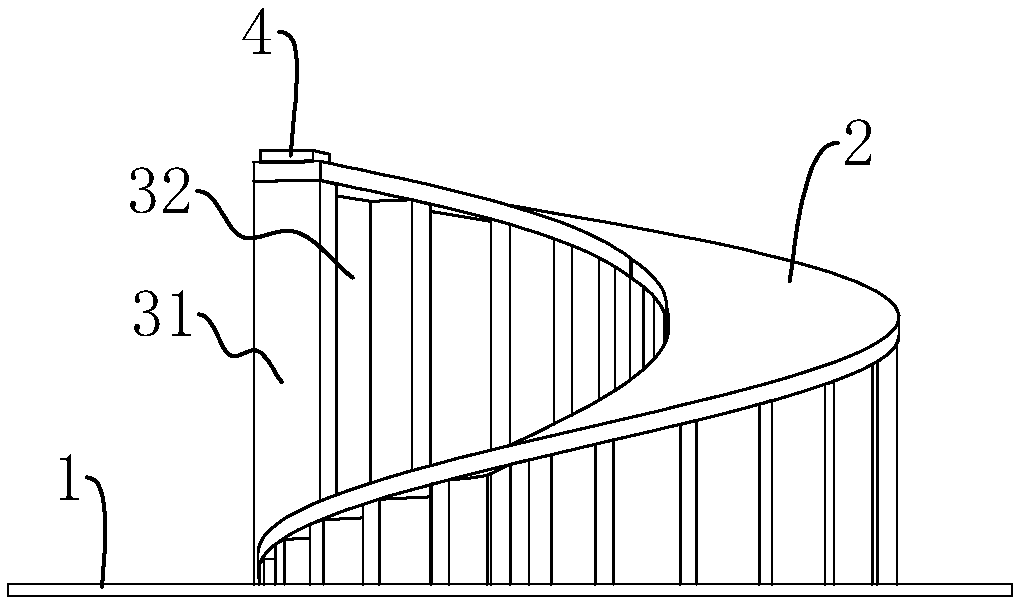

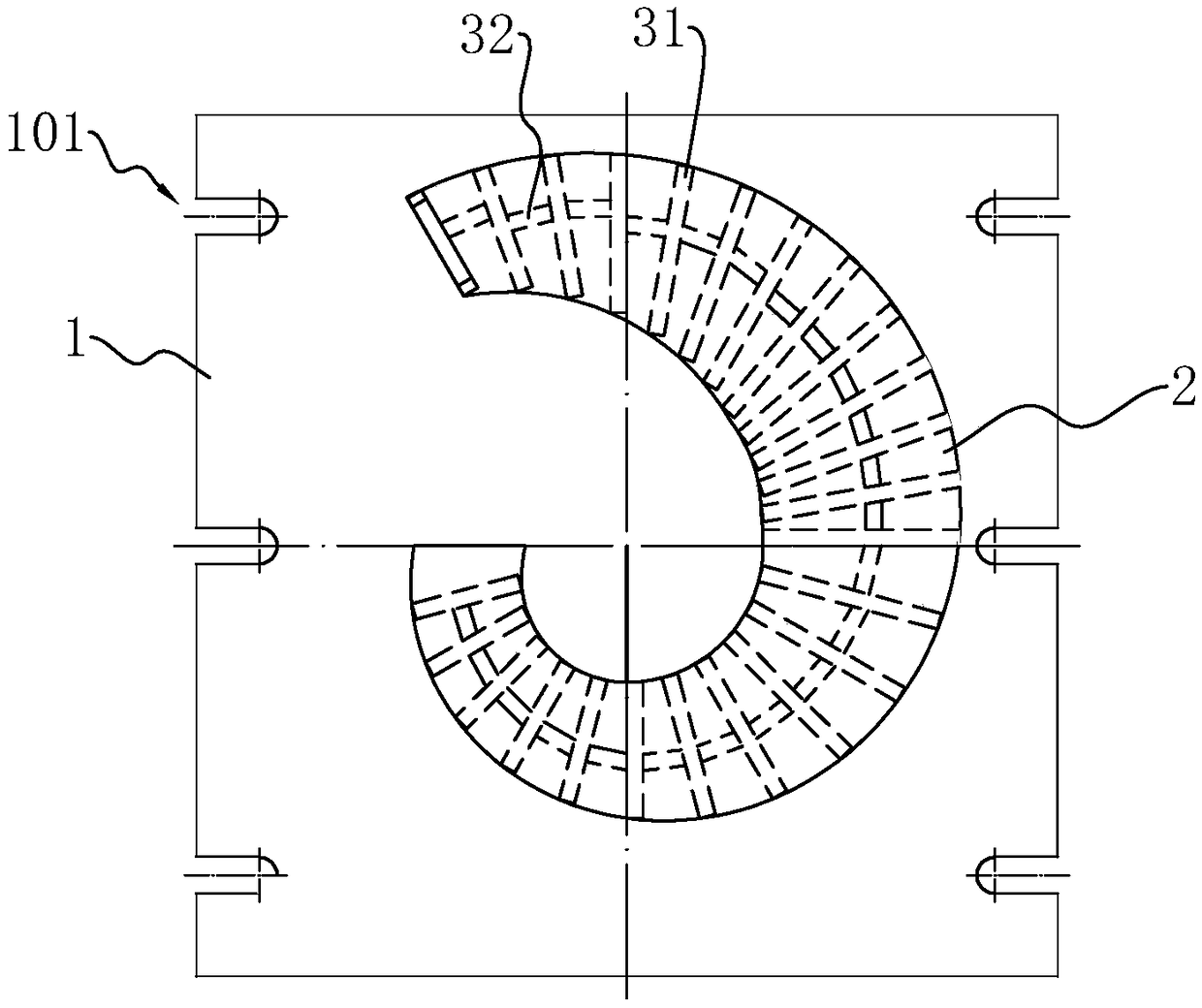

Automatic press fitting equipment for automobile brake tube fittings

ActiveCN104015051AReduce assembly stepsAccelerateAssembly machinesMetal working apparatusEngineeringMechanical engineering

Automatic press fitting equipment for automobile brake tube fittings is characterized by comprising a working table (1), a cylinder (2), a controller and a pressing die (3); the cylinder (2) and the controller are installed on the working table (1); the pressing die (3) is installed on the working table (1) and located at one end of a cylinder piston rod (2.1); a core tube clamping cavity (3.1), a buckling-pressing tube clamping cavity (3.2) and a sealing connecting tube clamping cavity (3.3) are connected and sequentially formed in the end, opposite to the cylinder piston rod (2.1), of the pressing die (3); the core tube clamping cavity (3.1) is throughout the end, opposite to the cylinder piston rod (2.1), of the pressing die (3); the cylinder piston rod (2.1), the core tube clamping cavity (3.1), the buckling-pressing tube clamping cavity (3.2) and the sealing connecting tube clamping cavity (3.3) are coaxial and are all arranged parallel to the working table (1); the cylinder (2) is further in electric connection with the controller. The automatic press fitting equipment facilitates assembly of a core tube, a buckling-pressing tube and a sealing connecting tube, assembly efficiency is high, and quality is excellent.

Owner:宁波名古屋工业有限公司

Torque measuring system for motor coupling

ActiveCN102589988AThe test data is accurateThe test data is reliableMachine gearing/transmission testingStrength propertiesMobile vehicleElectric machine

The invention discloses a torque measuring system for a motor coupling, which includes a lever device, a locked rotor device and a coupling moving device, wherein the coupling moving device is arranged between the lever device and the locked rotor device; the lever device includes a first base, a first traveling vehicle, a lever, a first bracket and a first flange; the first bracket is mounted on the first traveling vehicle, and a pin shaft is rotationally mounted on the first bracket in a matched manner; one end of the pin shaft is connected with the first flange, and the lever is fixed on the pin shaft; a stress application testing device is also mounted on the first base, and is located below the lever body of the lever; the locked rotor device includes a second base, a second moving vehicle and a second bracket, wherein the second bracket is mounted on the second moving vehicle and is provided with a second flange; a third flange is mounted on the second flange, and a rolling stopper pin is mounted on the third flange; and the moving vehicles are glidingly matched with the bases. The torque measuring system not only has the advantages of simple structure and high measuring accuracy, but also is convenient to operate and low in investment cost.

Owner:BOMBARDIER NUG PROPULSION SYST CO LTD

Improved corrugated paper pressing machine

InactiveCN103753867AGuarantee the quality of pressingReduce space consumptionMechanical working/deformationStructural engineeringMechanical engineering

The invention provides an improved corrugated paper pressing machine. The improved corrugated paper pressing machine comprises a frame, wherein a fixed plate is arranged above the frame; an air cylinder is arranged above the fixed plate, and is provided with a fixed plate through which a telescopic rod passes; the lower end of the telescopic rod is provided with a pressing plate; a positioning plate is arranged below the pressing plate, and comprises a panel, and a front side baffle plate, a left side baffle plate and a right side baffle plate which are arranged on the panel; the panel is provided with a plurality of holding areas which are formed in an array from; a buffer cushion is arranged below the panel. The improved corrugated paper pressing machine has the beneficial effects that during use, large paper packages are directly placed onto the panel, and can be pressed after accumulating to a certain height; small paper packages can be positioned accurately through the baffle plates and the holding areas on the panel, and can flattened after accumulating to a certain height. By adopting the pressing machine, the pressing quality of large and small paper packages is ensured, the cost is reduced, and the space occupied by a workshop is reduced.

Owner:ANHUI JIAXIN PACKAGING & PRINTING

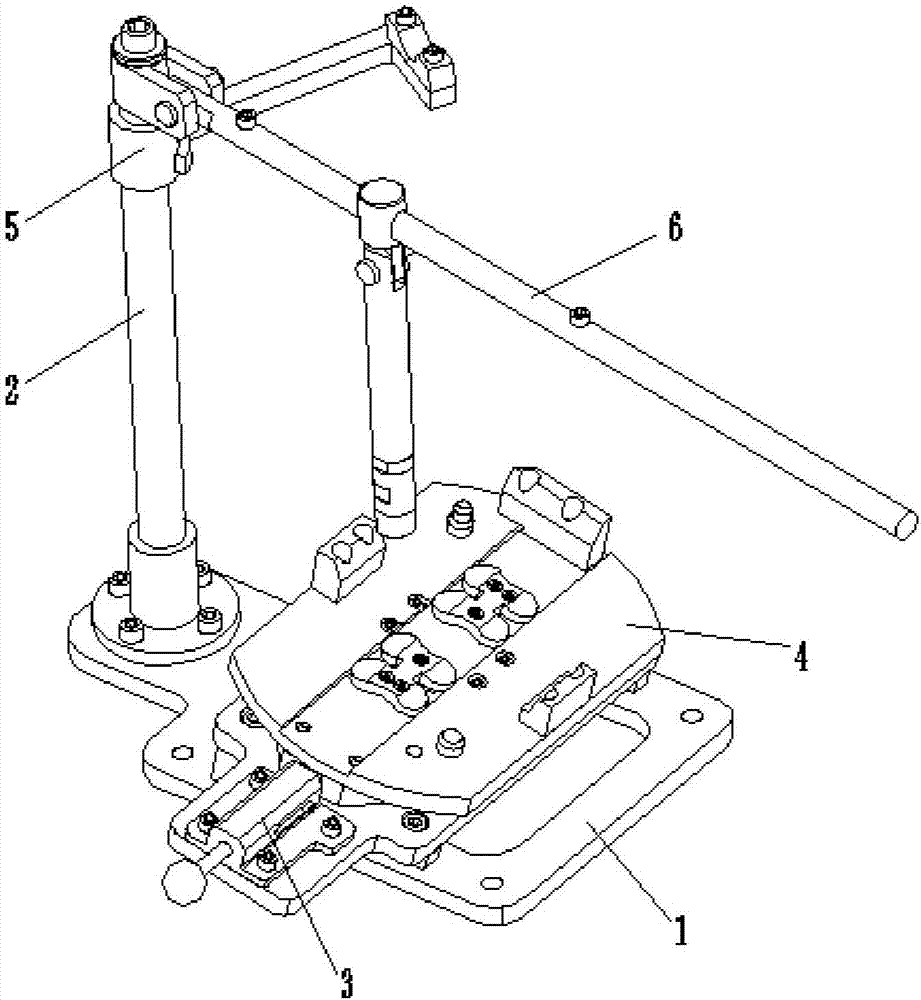

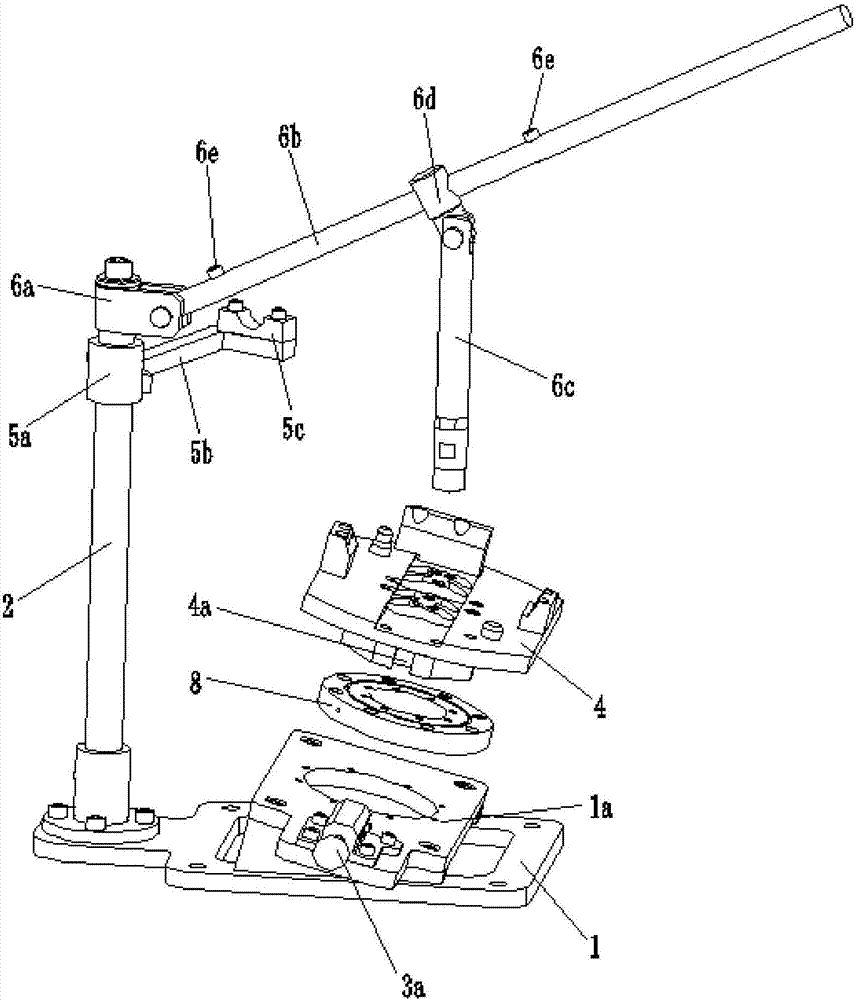

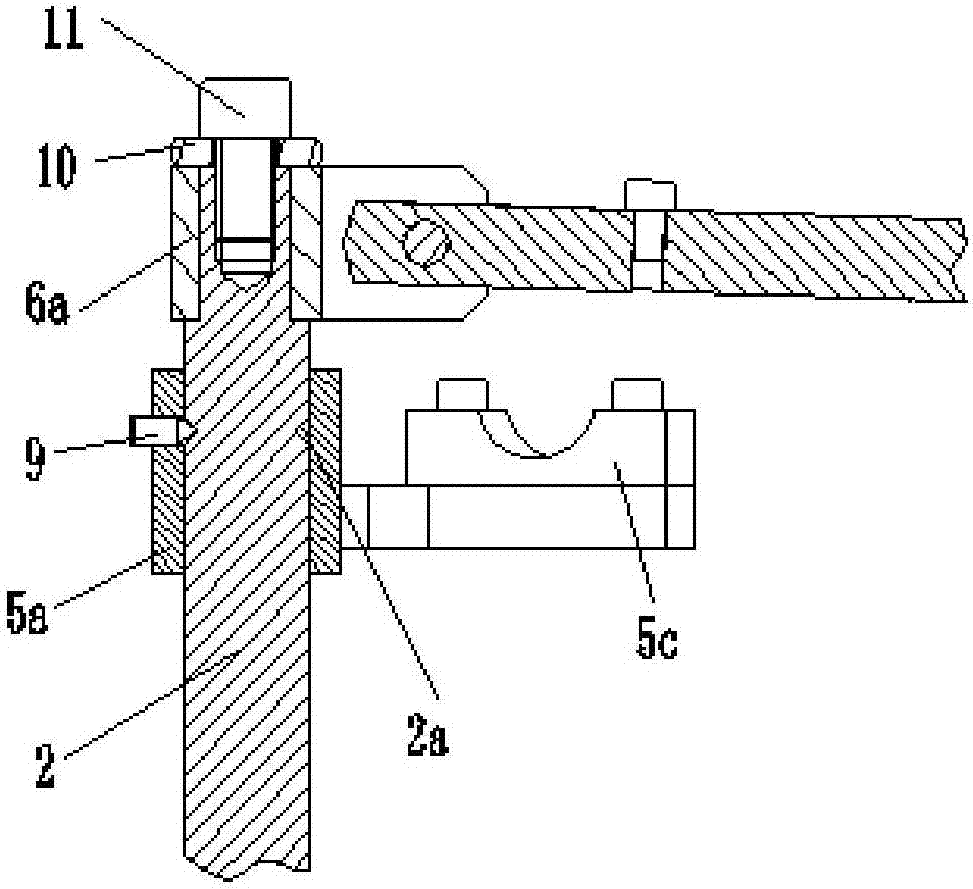

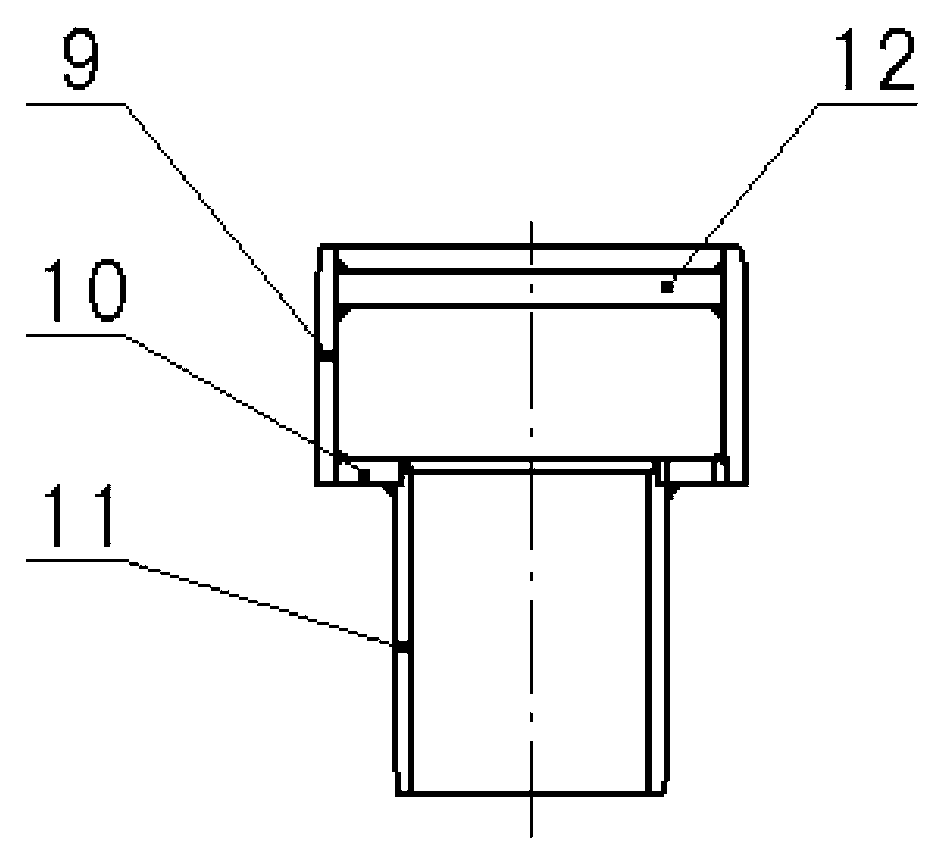

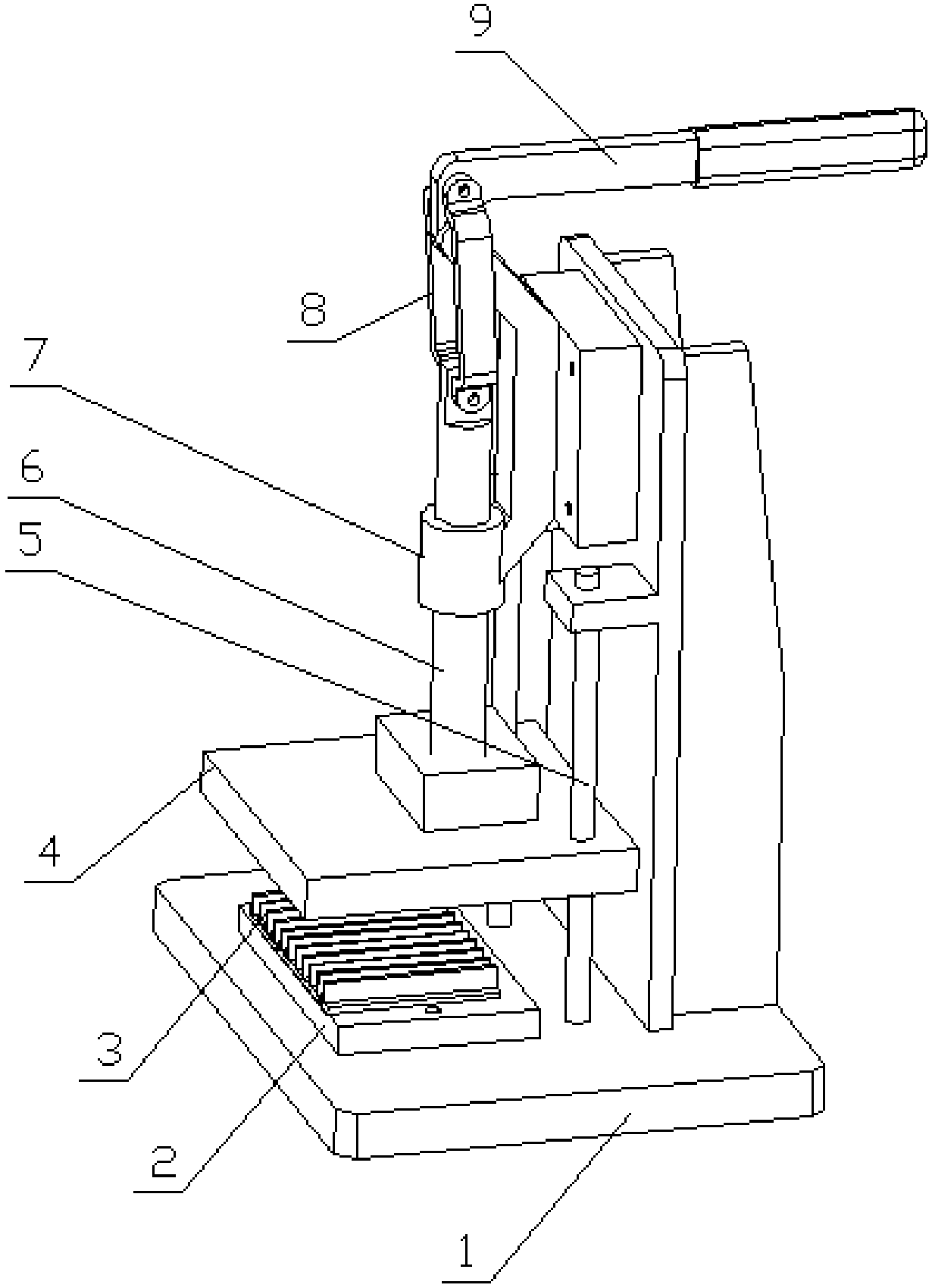

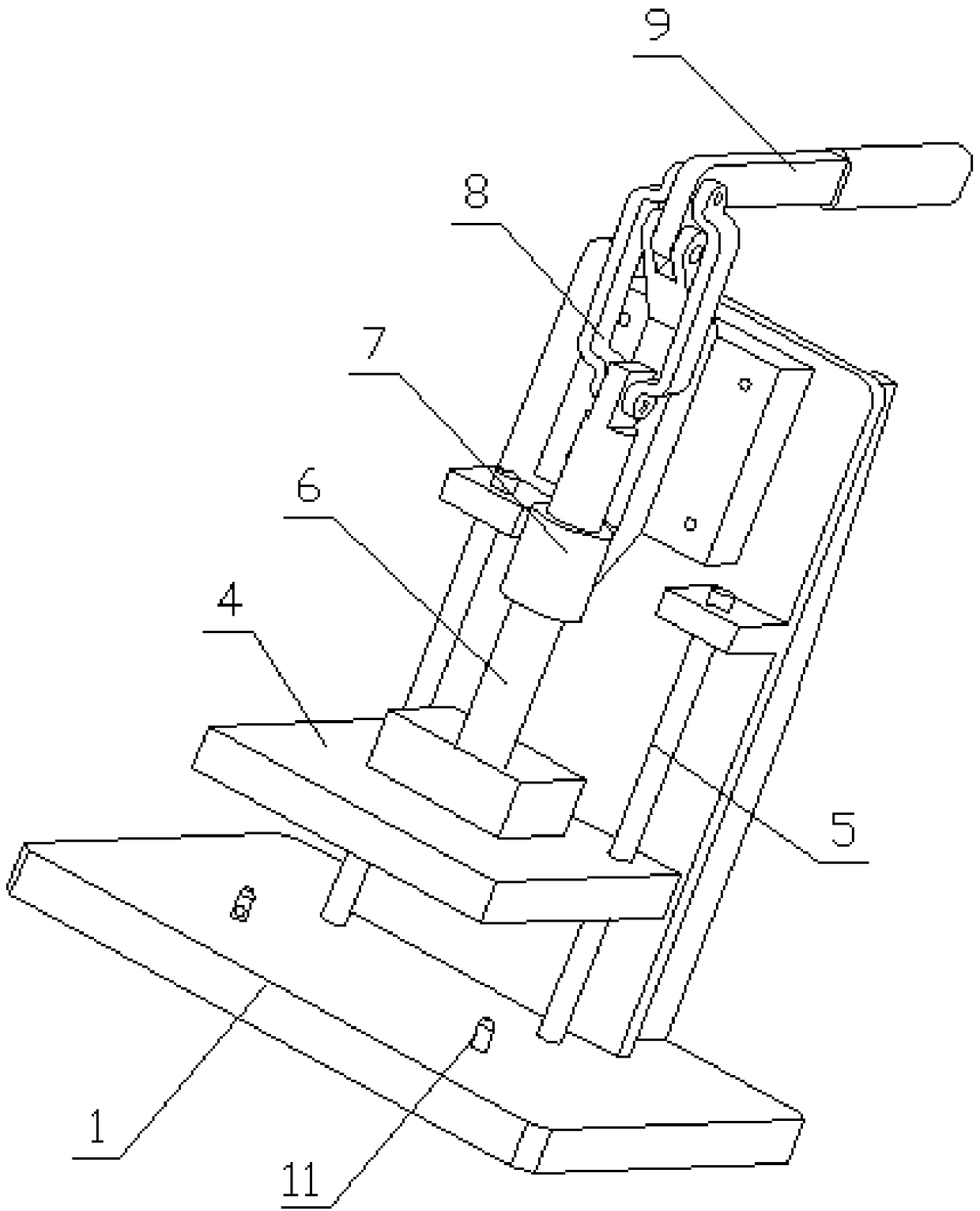

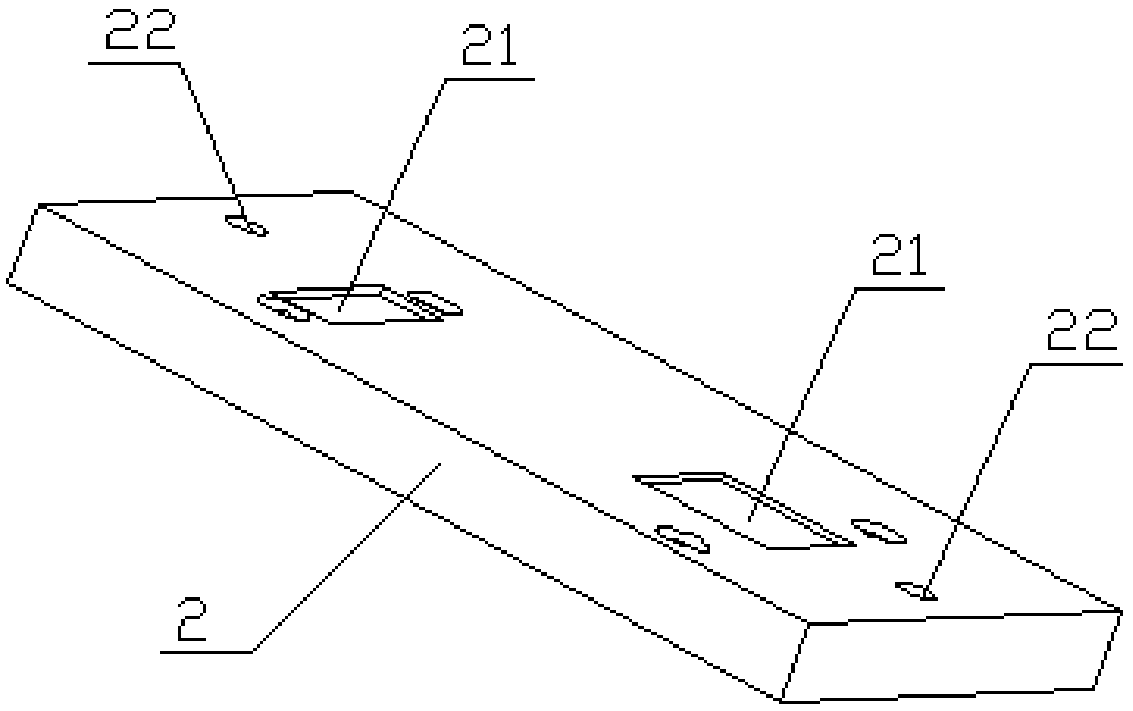

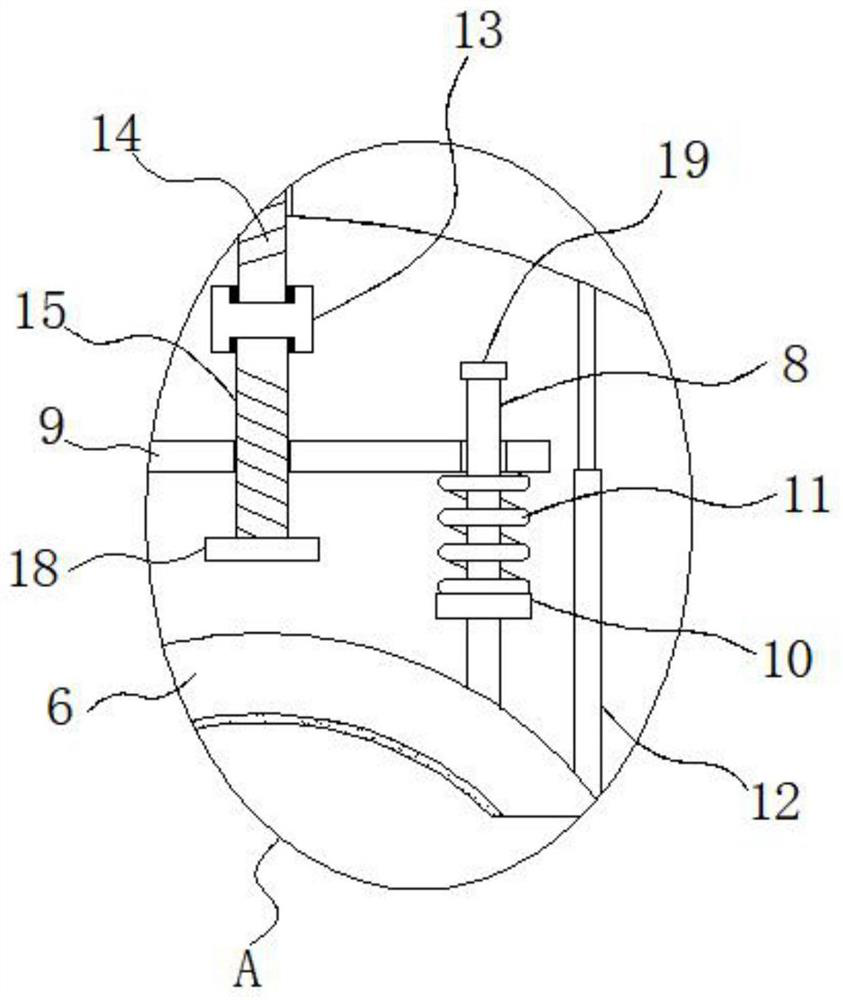

Air door lock block press-mounting tool

The invention discloses an air door lock block press-mounting tool. A vertical column, a turntable locking mechanism and an inclined turntable assembly are mounted on a bottom plate; the turntable assembly is used for clamping and positioning a cylinder cover; the turntable assembly can be locked through the turntable locking mechanism in a first press-mounting position and a second press-mounting position after being rotated by 180 degrees correspondingly; a pressing rod supporting assembly and a pressing rod assembly are sequentially mounted on the vertical column in a sleeving mode; the pressing rod supporting assembly comprises a mounting sleeve, a connecting rod and a pressing rod supporting block; the mounting sleeve is axially and fixedly mounted on the vertical column in a sleeving mode; the pressing rod assembly comprises a rotating block, a horizontal rod, a pressing head and a hinged block; the rotating block is rotatably mounted on the vertical column in a sleeving mode; one end of the horizontal rod is hinged on the rotating block in an up-down swinging mode; and the hinged block is mounted on the horizontal rod in a sleeving mode and hinged to the upper end of the pressing head together. Press-mounting of an air inlet door lock block and an air outlet door lock block can be completed through one-time clamping, the clamping frequency is decreased, the press mounting efficiency is improved, easiness and labor saving are achieved, and through replacement of the turntable assembly, press-mounting of cylinder cover air door lock blocks of different types and different positions can be met.

Owner:CHONGQING SOKON IND GRP CO LTD

Solid wood bending and hot pressing former

The invention provides a solid wood bending and hot pressing former comprising a base, a main frame, a driving device and the like. The main frame is arranged on the base, the driving device is located on the main frame and connected with a down-pressing plate, an upper die is located under the down-pressing plate and connected with the same, and a lower die is fixed on the base and matched with the upper die in use. The solid wood bending and hot pressing former is characterized by further comprising heating units which are respectively located in the upper die and the lower die, and each heating unit is connected with a control box through a wire. The solid wood bending and hot pressing former is short in preheating time, only takes 20 minutes to complete preheating, and is low in energy consumption, high in heating speed and fast in formation. The heating units are uniformly distributed in the upper die and the lower die, so that wood is heated uniformly and stable in quality. According to difference of wood processing shapes, the upper die and the lower side are selected appropriately, bending and pressing of the wood can be realized, application range is wide, and practicality is high.

Owner:MEXARTS HOME TIANJIN

Electric steering gear torsion bar press-fitting tool

ActiveCN112247528AGuaranteed axial clearanceControl axial playMetal working apparatusInterference fitPhysics

The invention relates to the technical field of electric steering gears, in particular to an electric steering gear torsion bar press-fitting tool. According to a previous common press-fitting mode, atorsion bar is connected with an input shaft in an interference fit mode first, and then the torsion bar is inserted into an output shaft and fixedly connected with the output shaft through a stop pin, wherein the input shaft is formed by welding an upper shaft and a lower shaft. The product structure and the press-fitting mode are improved, the upper shaft and the lower shaft of the input shaftare integrally formed, the torsion bar is connected with the input shaft and the output shaft in an interference fit mode, the axial gap between the input shaft and the output shaft and the left-rightcentering of a flat square and a flat groove are controlled firstly, then press-fitting is carried out on the torsion bar, the input shaft and the output shaft, but a tool for the press-fitting modeis not available at present. According to the electric steering gear torsion bar press-fitting tool, the axial gap between the input shaft and the output shaft can be effectively controlled, and left-right centering of the flat square and the flat groove can be effectively controlled, so that the press-fitting quality can be guaranteed, and the product quality can be improved.

Owner:HUNAN INST OF TECH

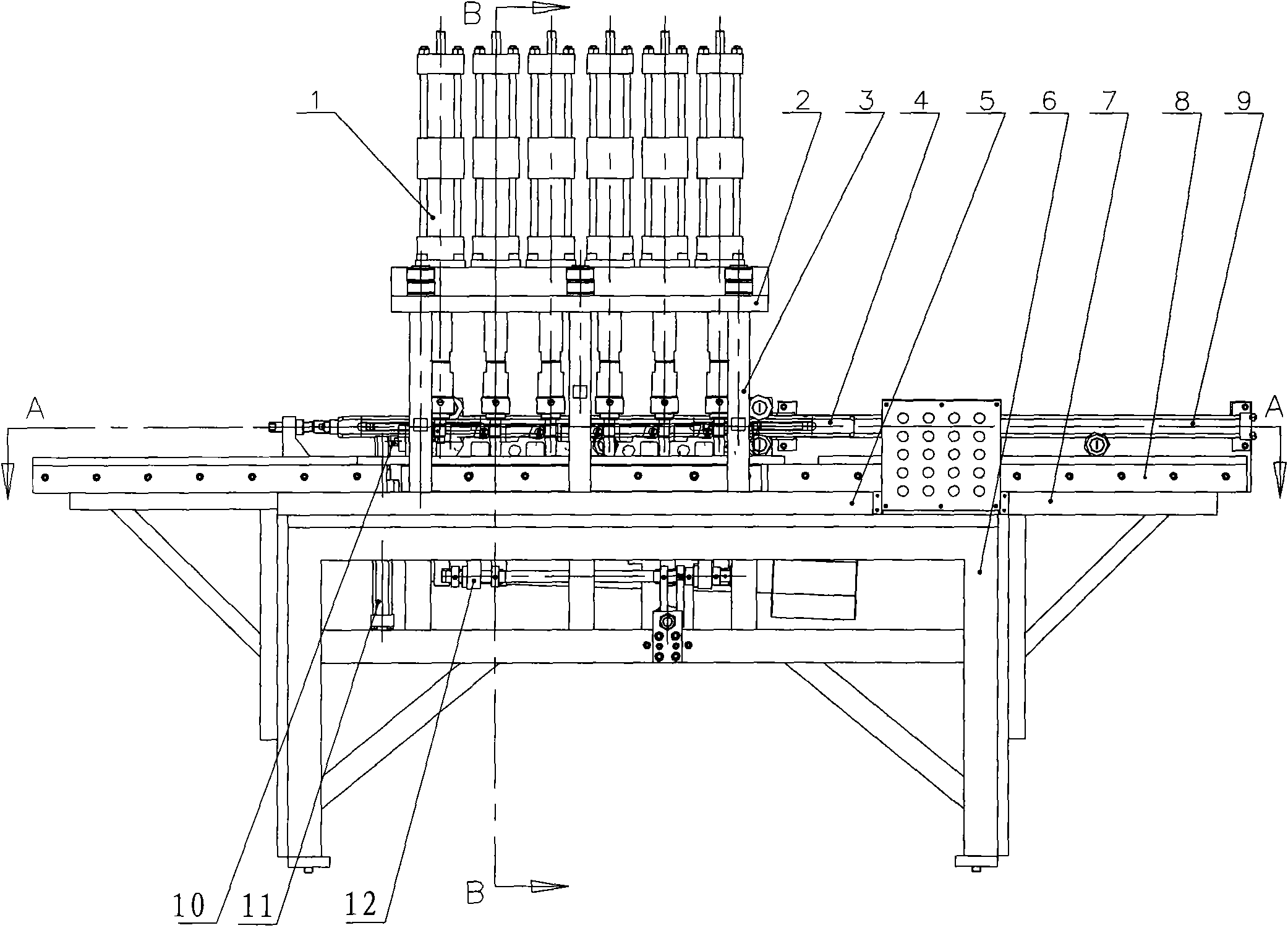

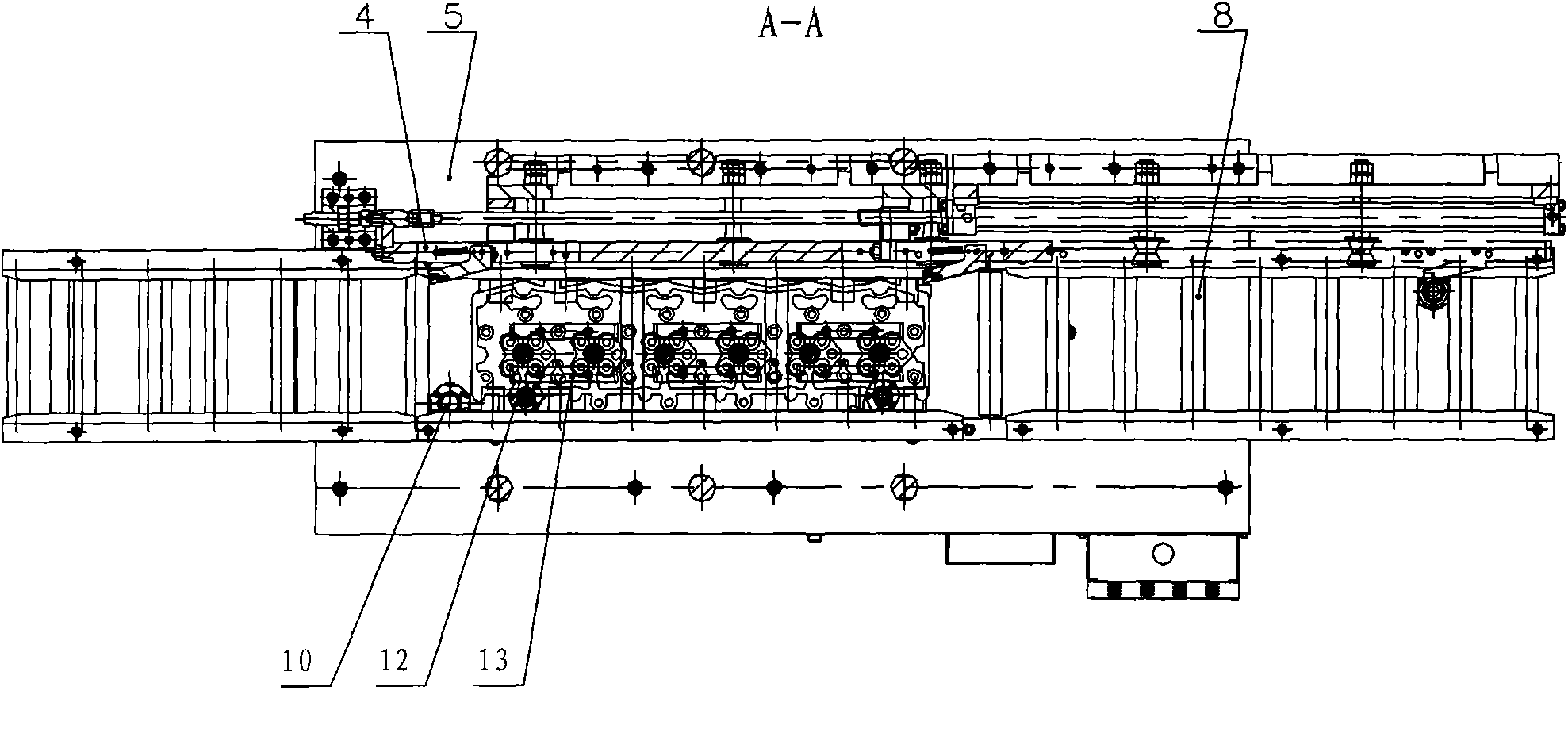

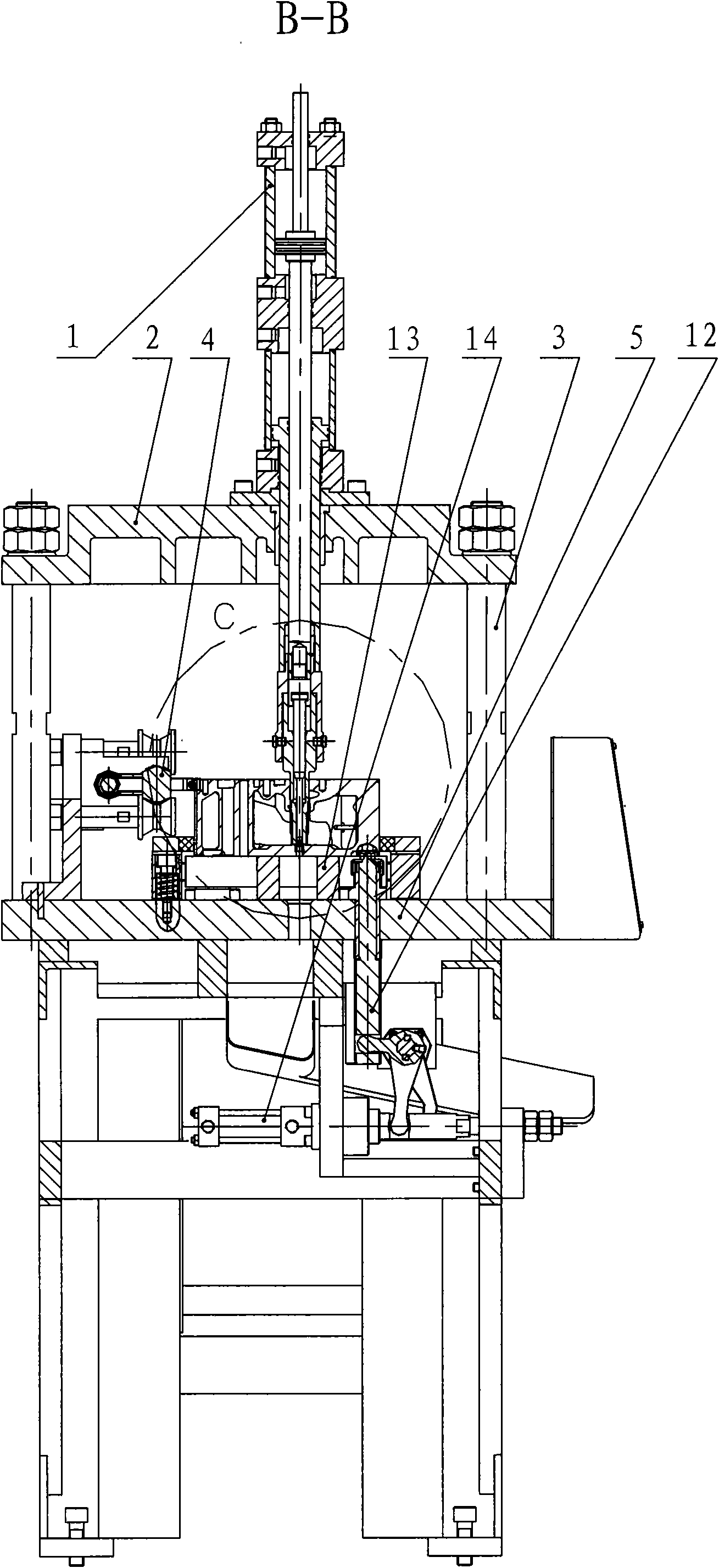

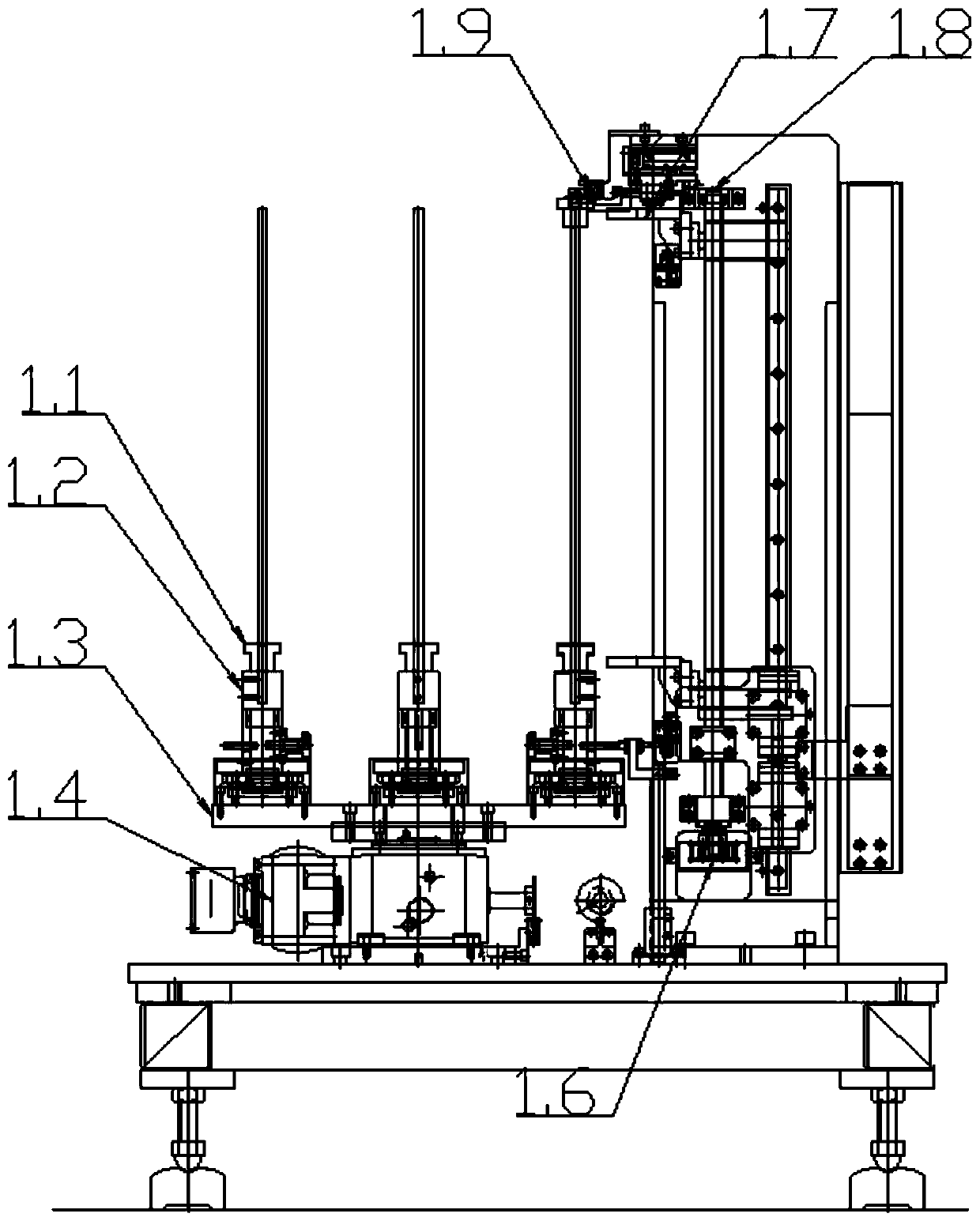

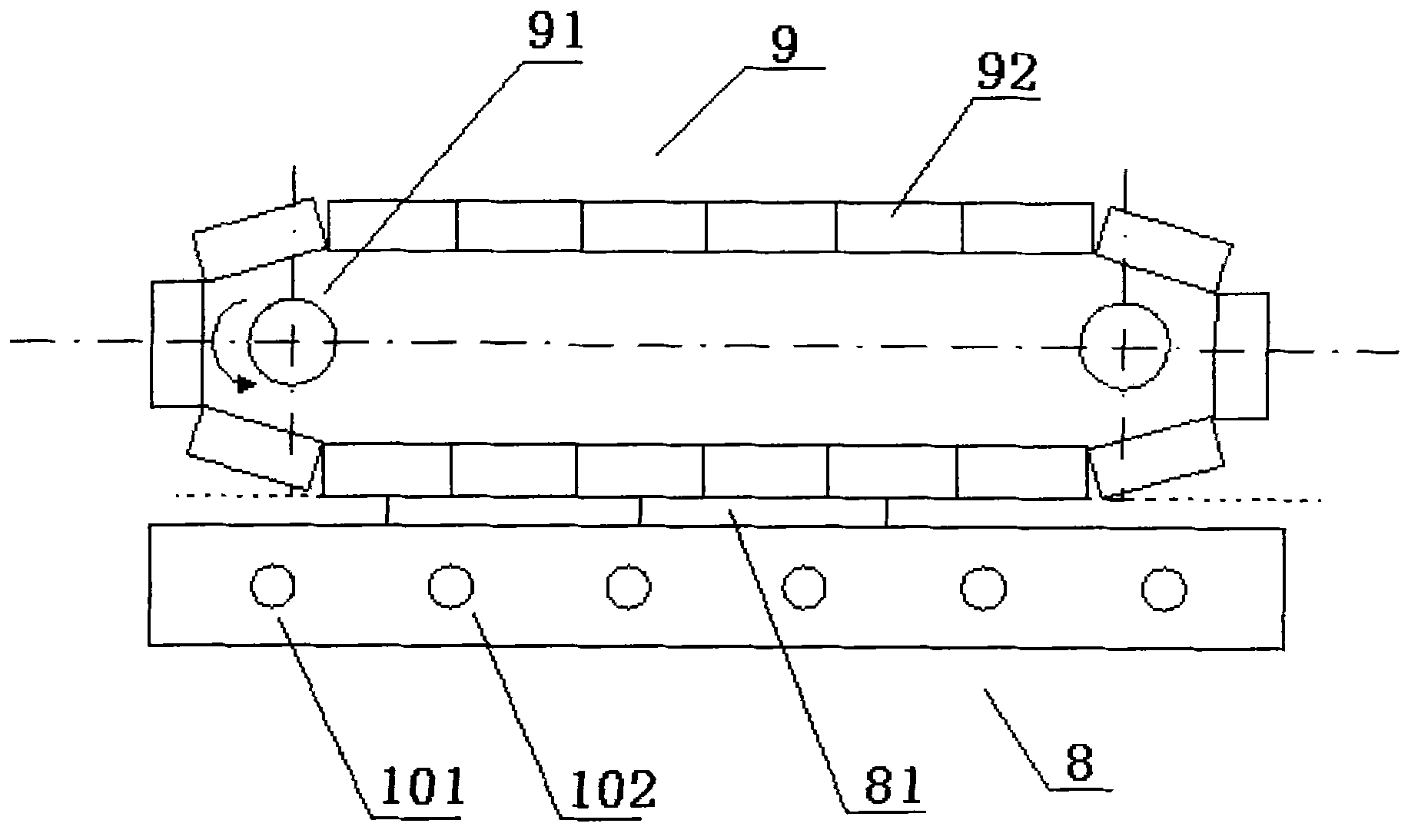

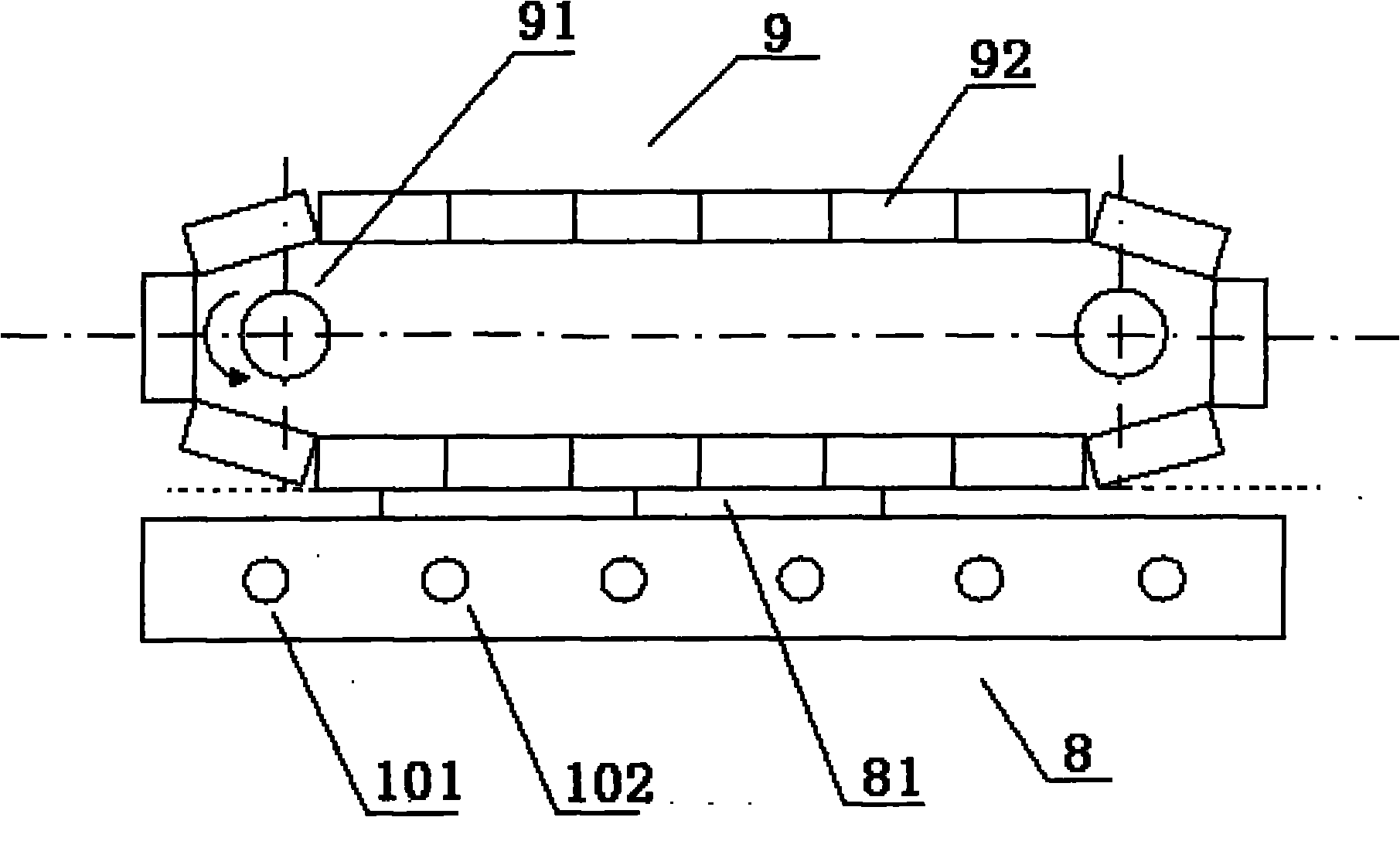

Combined press-mounting table for peeling roller of corn harvesting machine

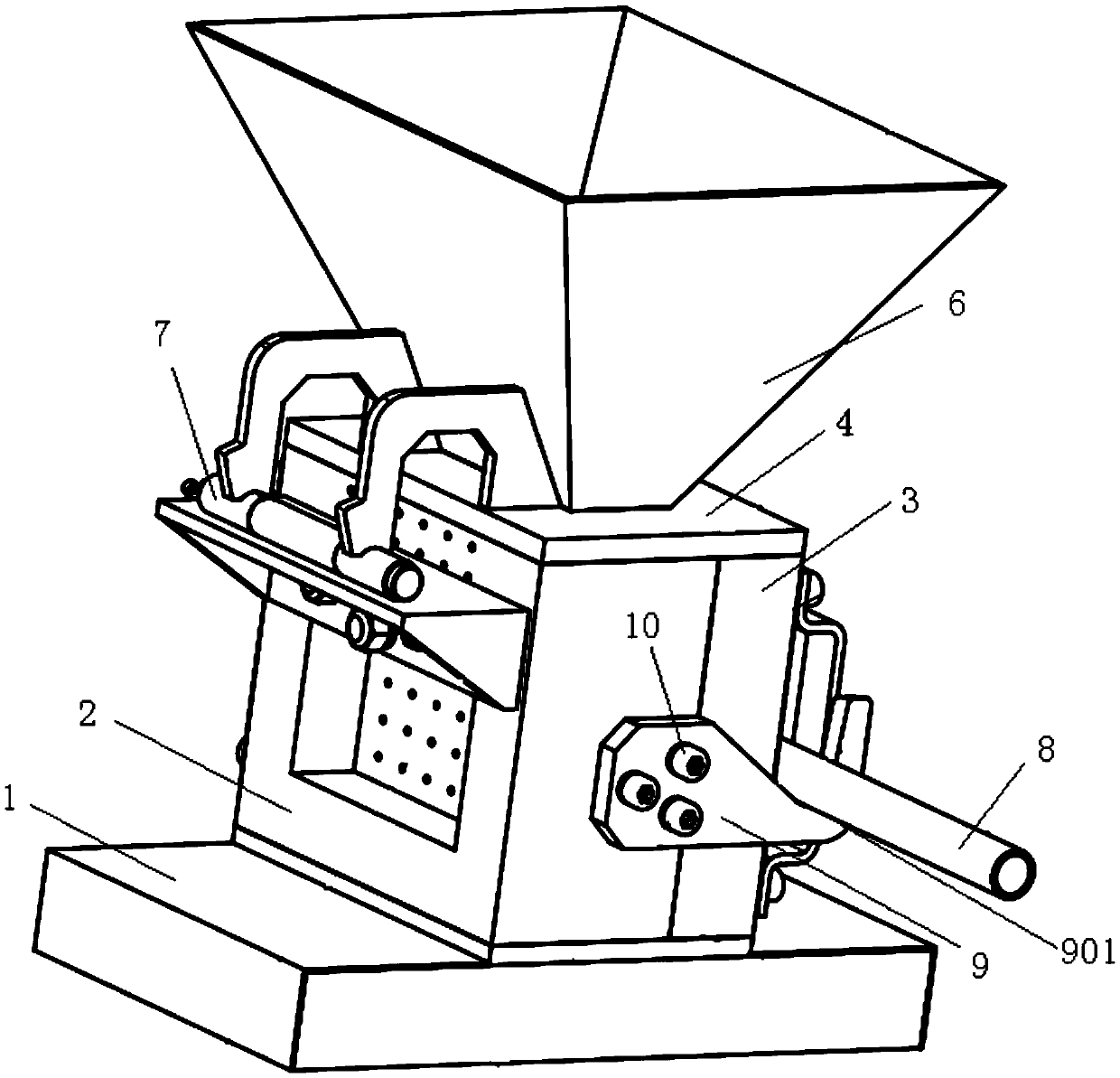

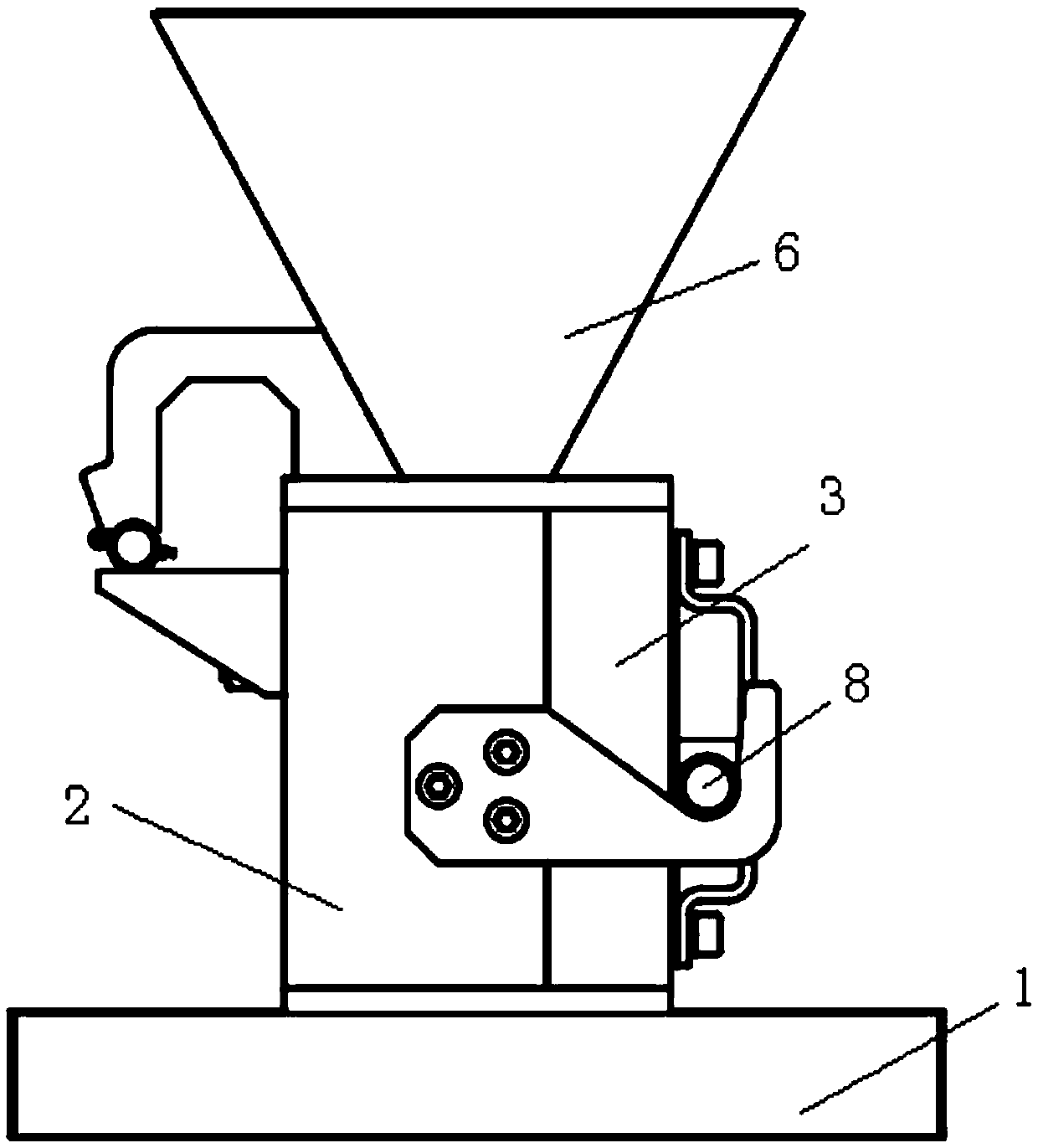

ActiveCN104067775AGuarantee the quality of pressingReduce turnaround timeHarvestersThreshersTurnover timeAgricultural engineering

The invention discloses a combined press-mounting table for a peeling roller of a corn harvesting machine. The combined press-mounting table comprises a peeling roller rubber sleeve press-mounting table, a duplex-bearing block press-mounting table and a hydraulic station, wherein the peeling roller rubber sleeve press-mounting table comprises first positioning seats, aligning devices and pressure heads, the first positioning seats are horizontally arranged on a first frame in sequence, and the pressure heads are fixed at one ends of long-stroke oil cylinders; the duplex-bearing block press-mounting table comprises second positioning seats and a duplex pressure head, the second positioning seats are vertically arranged on a second frame in sequence, and the duplex pressure head is fixed at one end of an oil cylinder; the long-stroke oil cylinders and the oil cylinder are connected with the hydraulic station respectively; the peeling roller rubber sleeve press-mounting table can guarantee the quality of press mounting of peeling roller rubber sleeves, the duplex-bearing block press-mounting table can guarantee the quality of press mounting of duplex-bearing blocks; manual operation is replaced by mechanical operation, and the peeling roller rubber sleeve press-mounting table and the duplex-bearing block press-mounting table are combined together to form a workflow, so as to facilitate line production, shorten the turn-over time of workpieces and improve the assembly efficiency of the peeling roller of the corn harvesting machine.

Owner:ZOOMLION HEAVY MASCH CO LTD

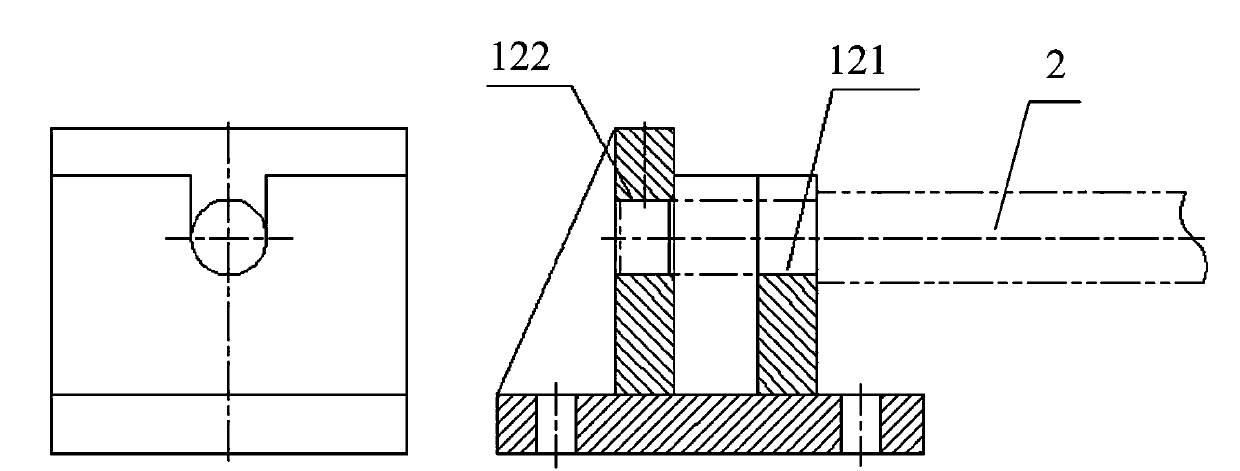

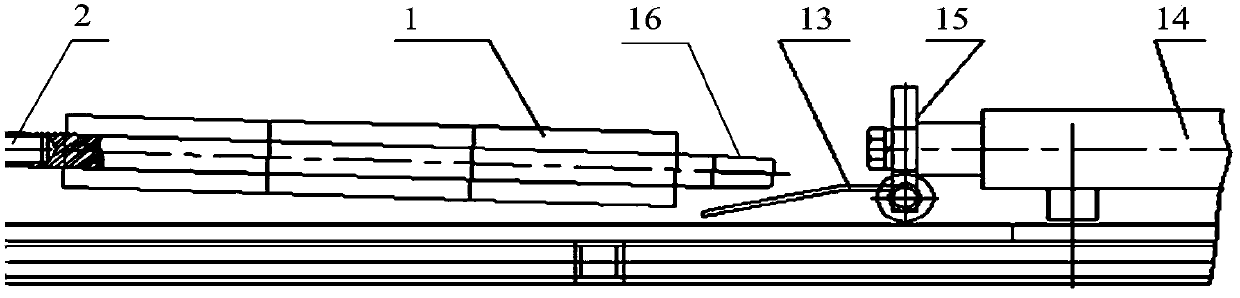

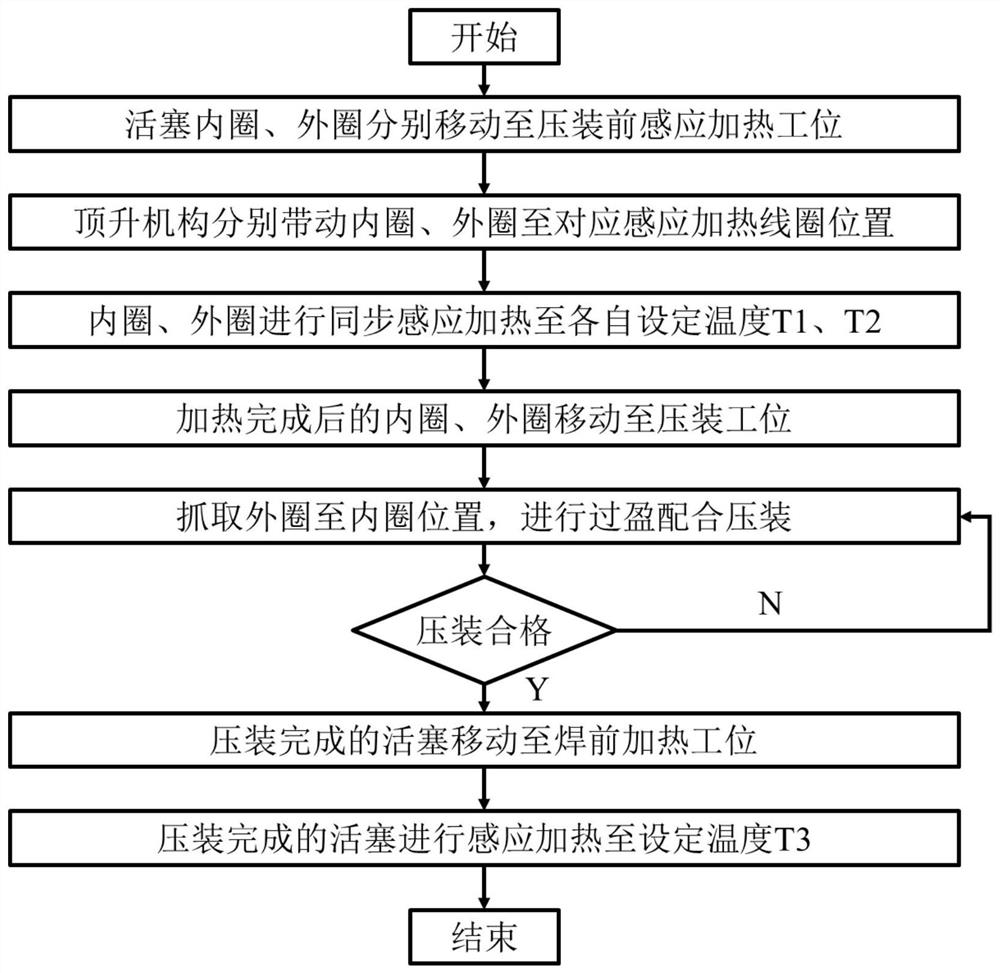

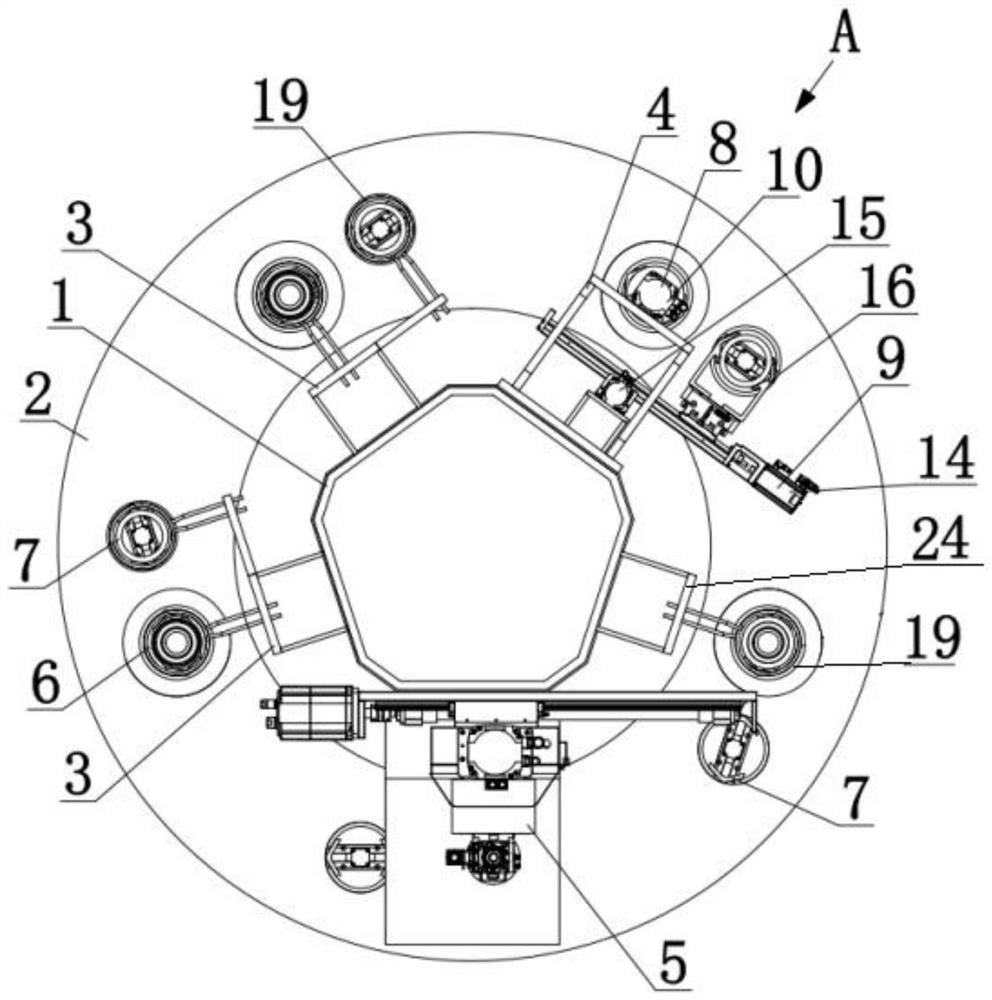

Pre-welding sectional type heating and press-fitting method and device

PendingCN112222759AImprove processing efficiencyEfficient heatingMetal working apparatusLaser beam welding apparatusInterference fitEngineering

The invention discloses a pre-welding sectional type heating and press-fitting method and device which are are used for heating and press-fitting of interference fit of an inner ring and an outer ringof an automobile engine steel piston. The method comprise the following steps that S1, the inner ring and the outer ring of the steel piston are moved to induction heating stations before press-fitting, the number of the induction heating stations is multiple, gradient heating is synchronously carried out on the inner ring and the outer ring, the temperature uniformity of the inner ring and the outer ring is guaranteed, and the temperature difference is reduced; S2, the heated inner ring and the heated outer ring are moved to a press-fitting station, and a steel piston is formed through press-fitting; and S3, the steel piston formed through press-fitting is moved to a pre-welding preheating station, and the steel piston is integrally heated to the temperature needed by welding. The multiple induction heating stations are adopted, the pre-welding heating time (only 1 / 4 of the time needed by single-station induction heating) can be greatly shortened, the temperature difference (within + / -10 DEG C) of the inner ring and the outer ring is further reduced, the steel piston part achieves the more efficient heating process, and the overall machining efficiency of the steel piston is improved.

Owner:武汉光谷航天三江激光产业技术研究院有限公司

Automatic cap pressing mechanism of fuse

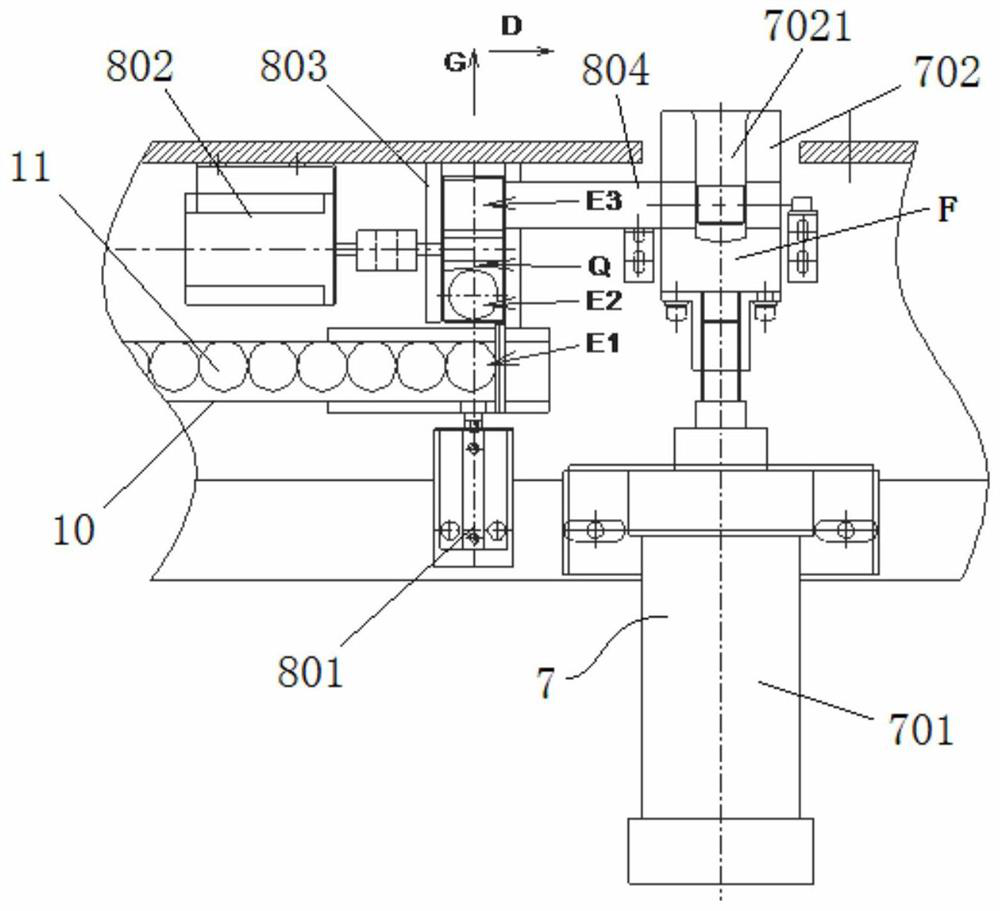

PendingCN111681916AGuaranteed production beat matchingRealize fully automatic productionFuse device manufactureElectric machineGear wheel

The invention relates to the technical field of fuse production, in particular to an automatic cap pressing mechanism of a fuse. The mechanism comprises a fusion tube input mechanism, an end cap overturning input mechanism, a cap pressing mechanism, a discharging mechanism and a transition mechanism. The fusion tube input mechanism comprises an input gear disc and an input cylinder; a to-be-pressed fusion tube is fed into the cap pressing station through the fusion tube input mechanism; the end cap overturning input mechanism comprises an end cap pushing-in air cylinder, an end cap overturningmotor, an overturning base and an end cap roller path; the end cap is pushed into the overturning notch of the overturning base through the end cap pushing-in cylinder; the overturning base is drivenby the end cap overturning motor to overturn, after overturning, an inclined face Q in the overturning notch is connected with the input end of the end cap roller path, the cap pressing mechanism isprovided with a cap pressing base, when the cap pressing base retreats, the notch in the cap pressing base is connected with the output end of the end cap roller path, and the fusion tube completing cap pressing is conveyed into the transition mechanism through the discharging mechanism. The mechanism can be matched with automatic gluing equipment to achieve automatic cap pressing operation, and the purpose of full-automatic production of fuses is achieved.

Owner:大连北方真空开关有限公司

Small-sized bearing press-fitting equipment

PendingCN110238629AAvoid placing risksImprove automated production capacityMetal working apparatusEngineeringMechanical engineering

The invention discloses small-sized bearing press-fitting equipment. The small-size bearing press-fitting equipment comprises a press-fitting positioning assembly, wherein two feeding inlets are formed in the press-fitting positioning assembly, the two feeding inlets are respectively connected with an outer ring feeding conveying line and an inner ring feeding conveying line, a stamping device is further arranged on the press-fitting positioning assembly, a detection correction unit is arranged on the inner ring feeding conveying line, the detection correction unit is used for adjusting the conveying state of the inner ring, the press-fitting positioning assembly comprises a guide bracket and two positioning plates in the guide bracket, the two positioning plates are arranged in an overlapped mode and are both connected with corresponding dislocation power devices, the two positioning plates are provided with feeding positioning openings on the same side edge respectively, and after the two positioning plates move in a staggered mode, the feeding positioning openings of the two positioning plates can be overlapped and are supplied to the stamping device to be processed. According to the small-sized bearing press-fitting equipment, accurate feeding can be realized, the press fitting is stable and reliable, and the production efficiency is greatly improved.

Owner:苏州康克莱自动化科技有限公司

Automatic bushing assembling equipment

PendingCN110744280AImprove assembly efficiency and assembly qualityAvoid manual feedingMetal working apparatusTransfer mechanismStructural engineering

The invention discloses automatic bushing assembling equipment. The automatic bushing assembling equipment comprises an automatic bushing conveying mechanism, a bushing transferring mechanism and a bushing press-fitting mechanism, wherein the automatic bushing conveying mechanism comprises a rotating disc, a plurality of material collecting mechanisms, a carrying guide sleeve and a carrying ascending mechanism, the material collecting mechanisms are uniformly mounted on the rotating disc in the circumferential direction, and the rotating disc is driven by a rotating air cylinder to rotate fora fixed angle; bushings are fetched from the automatic bushing conveying mechanism and transferred to press-fitting positions by the bushing transferring mechanism; and the bushing press-fitting mechanism comprises a linear driver and a presser head and grip jaw assembly, the presser head and grip jaw assembly comprises presser heads and grip jaws, the grip jaws are used for clamping the bushings,the presser heads are used for pressing the bushings, and the presser head and the grip jaw assembly is driven by the linear driver to move upwards and downwards. The automatic bushing assembling equipment realizes the automatic conveying and press-fitting of bushing class accessories and can increase the assembling efficiency and improve the assembling quality.

Owner:ZHEJIANG ASIA PACIFIC MECHANICAL & ELECTRONICS

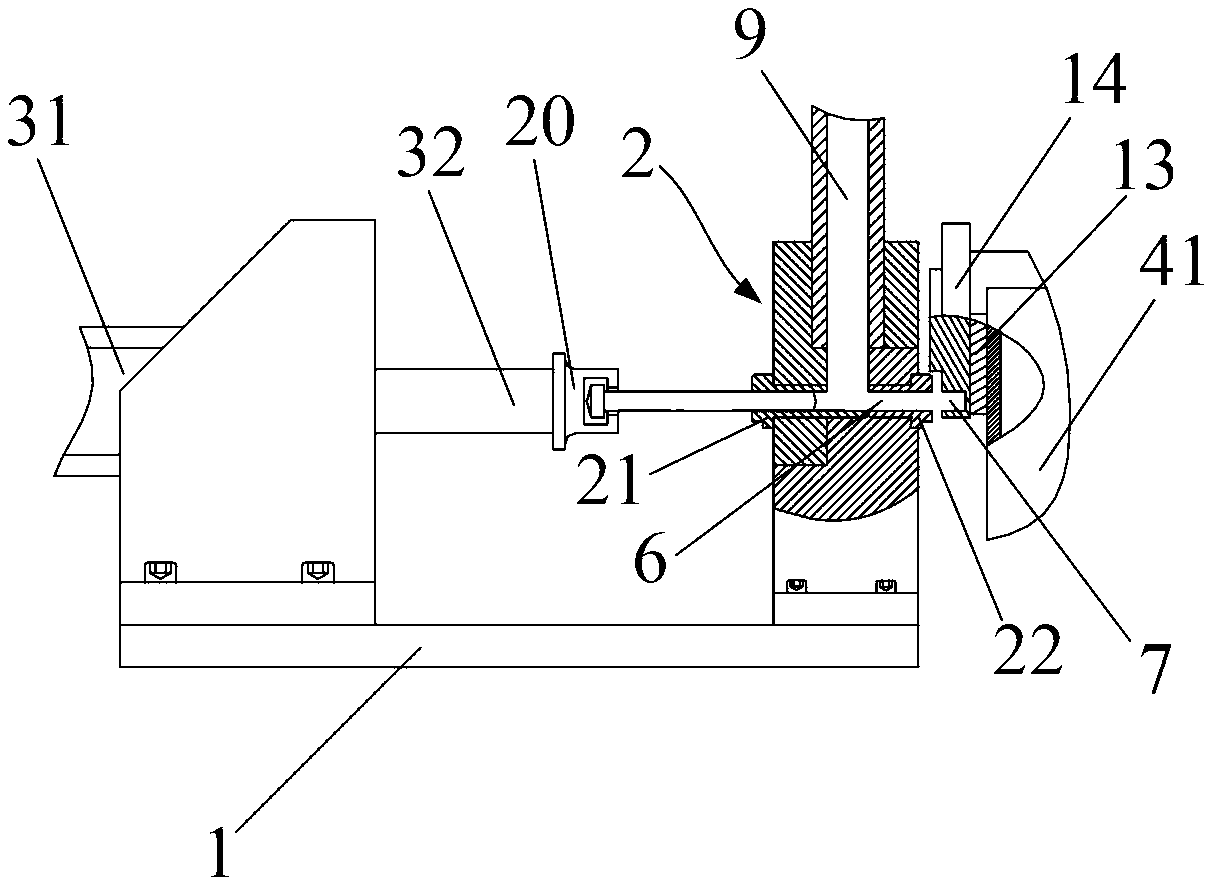

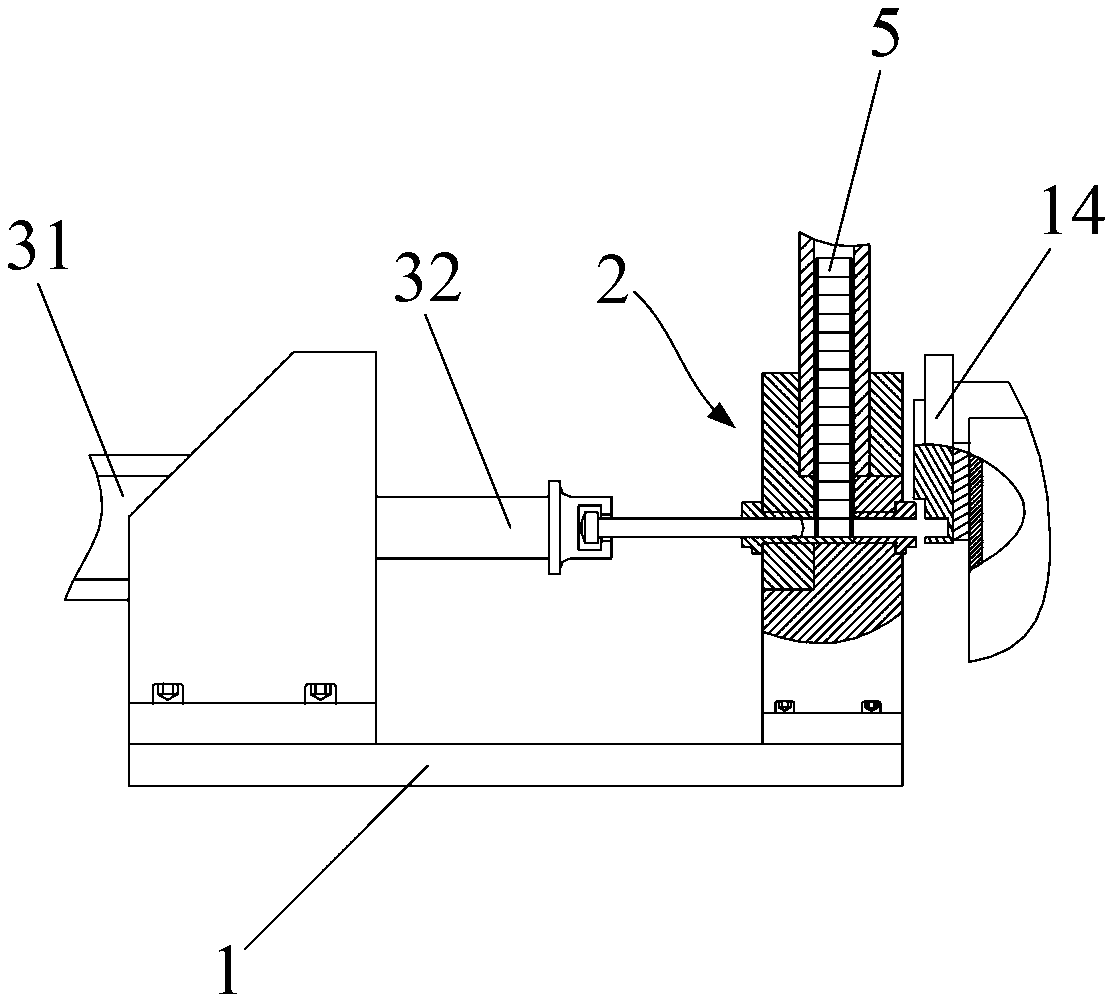

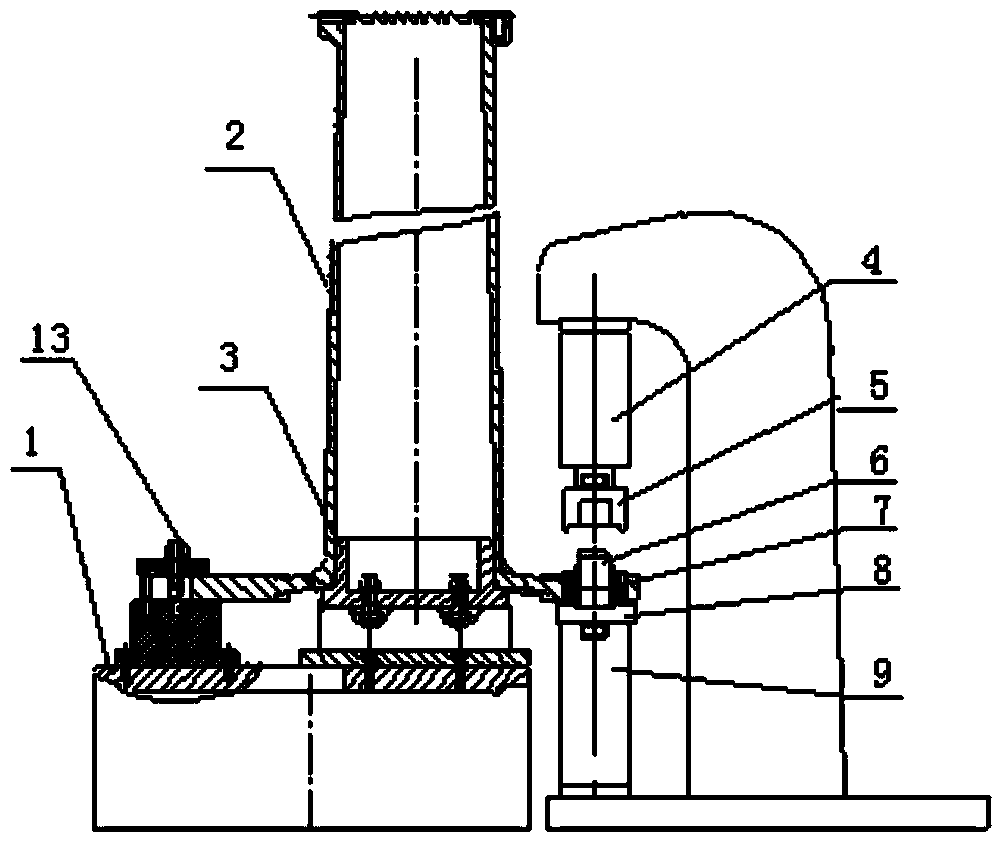

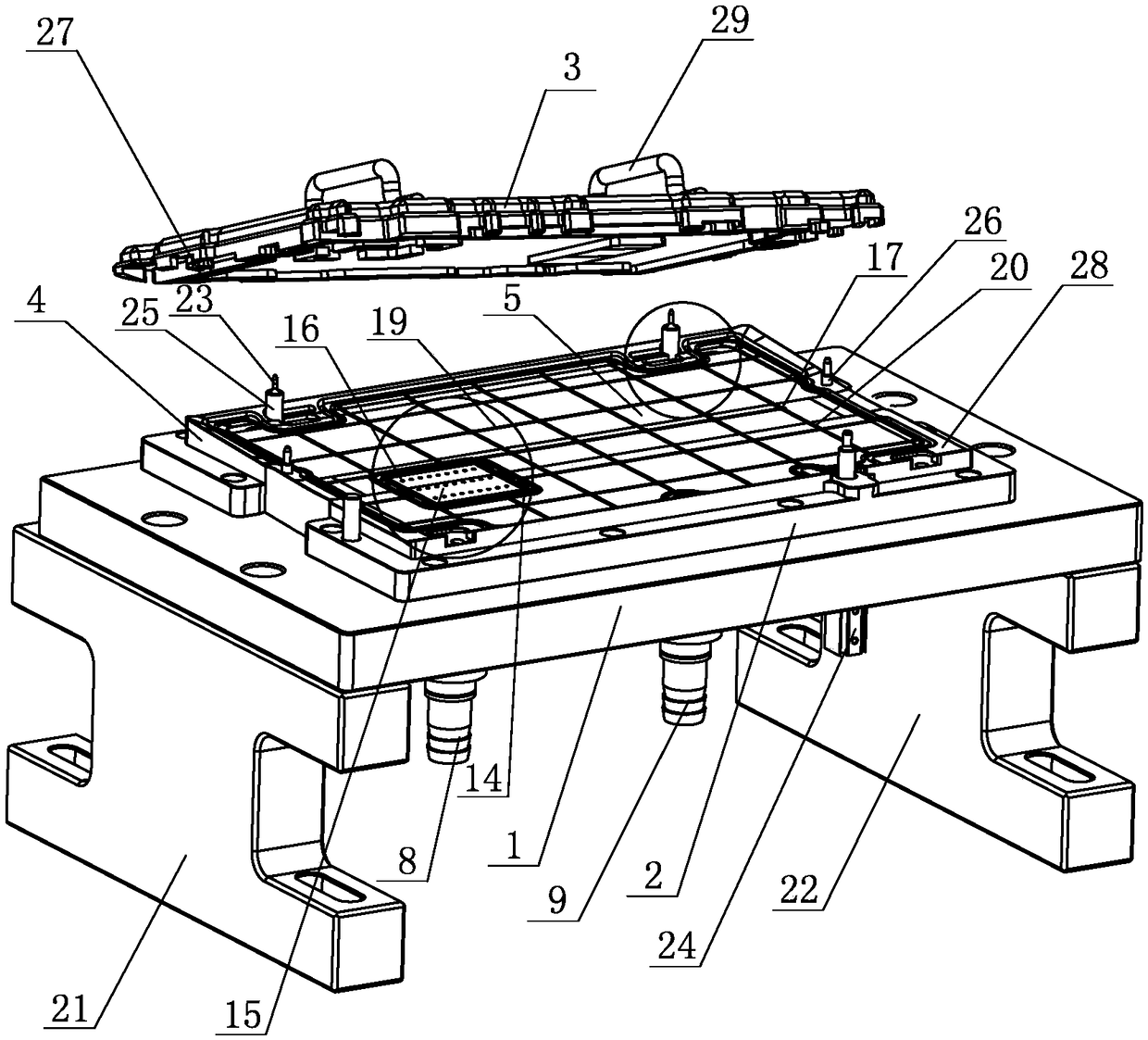

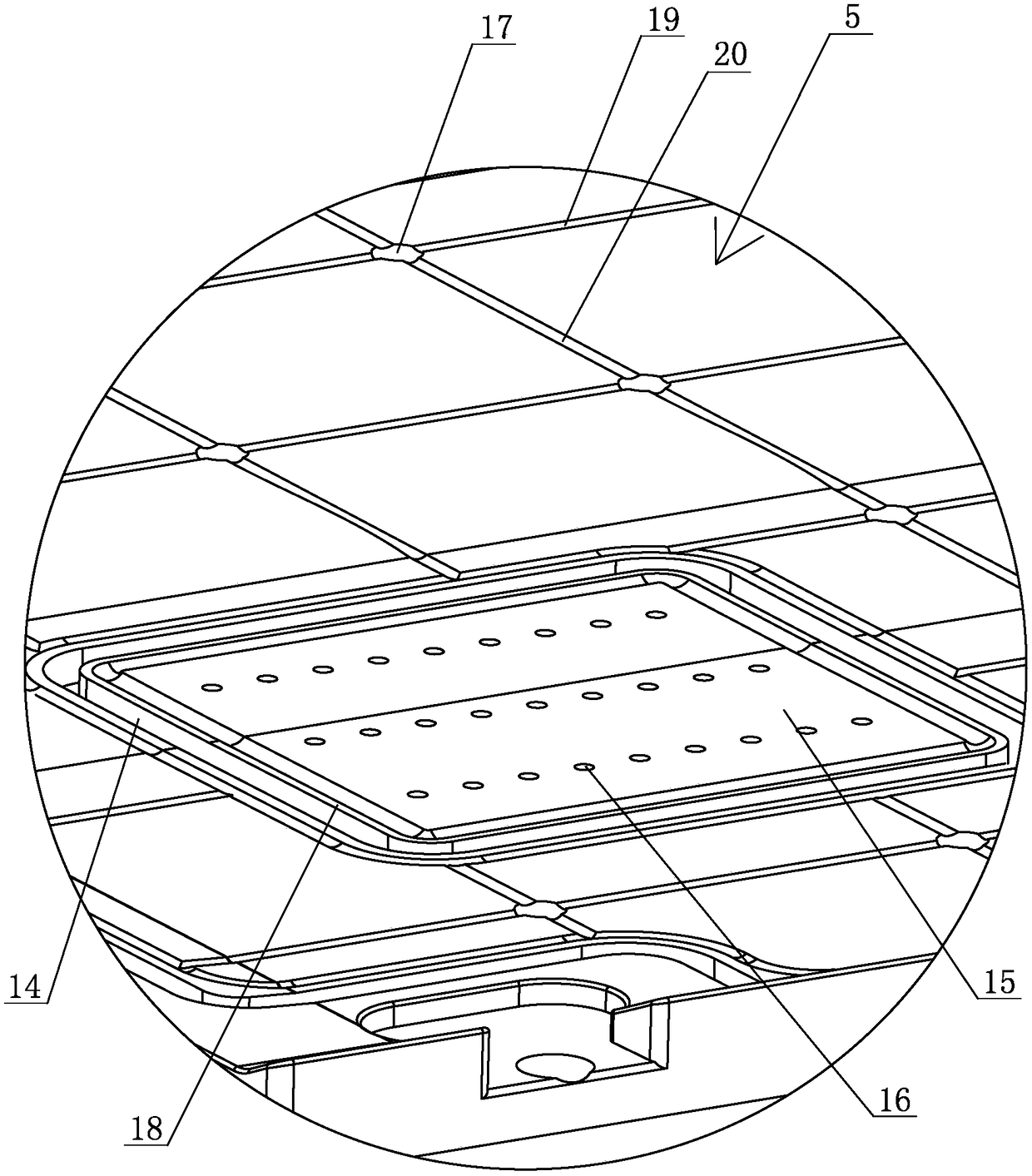

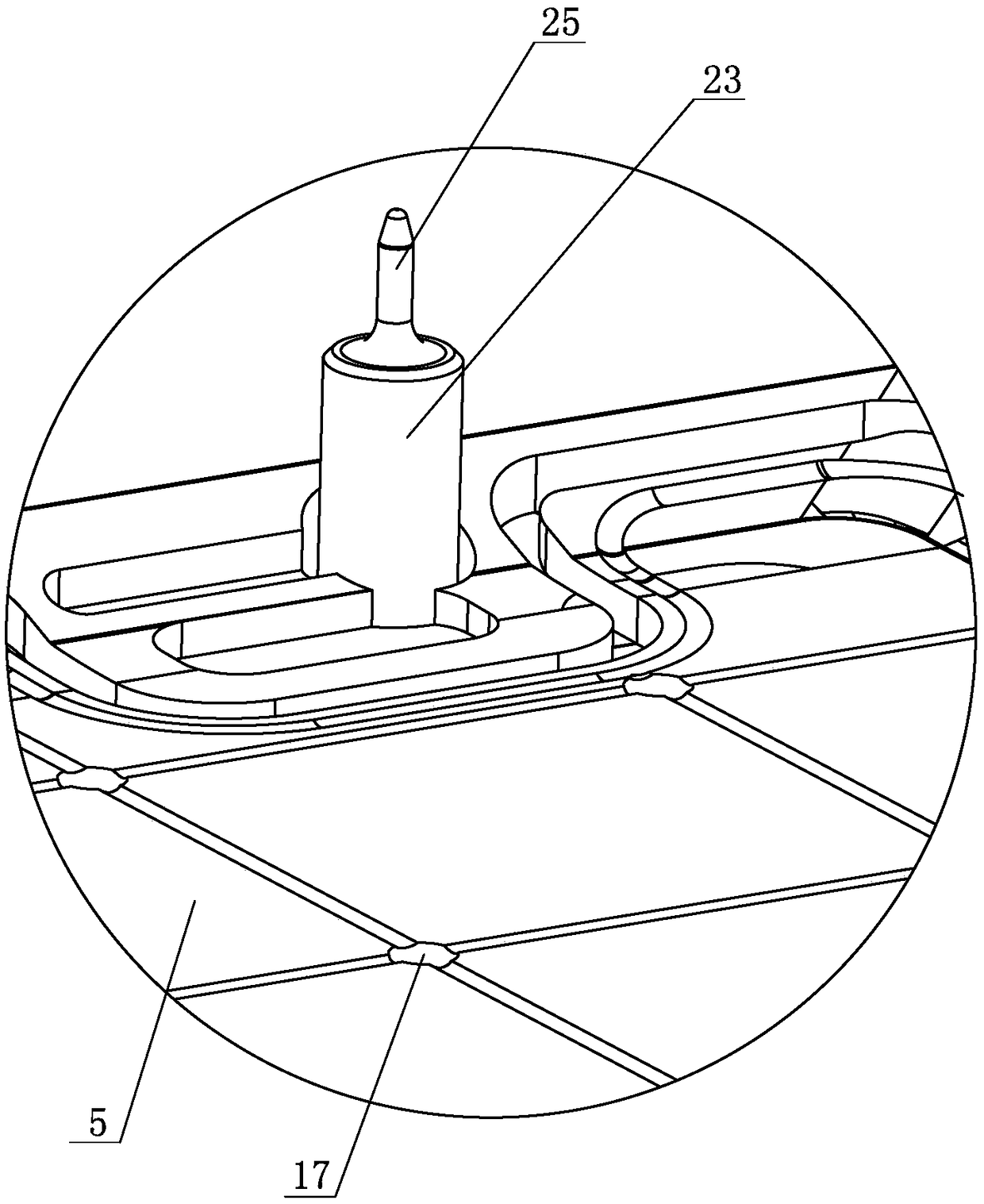

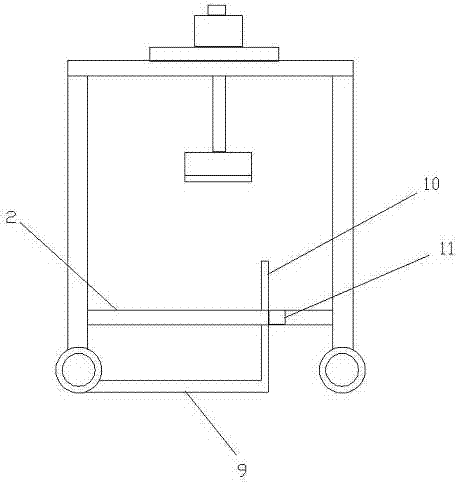

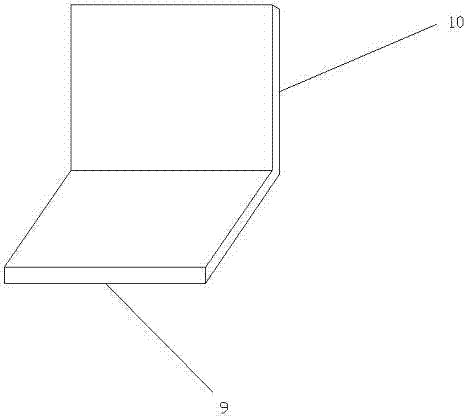

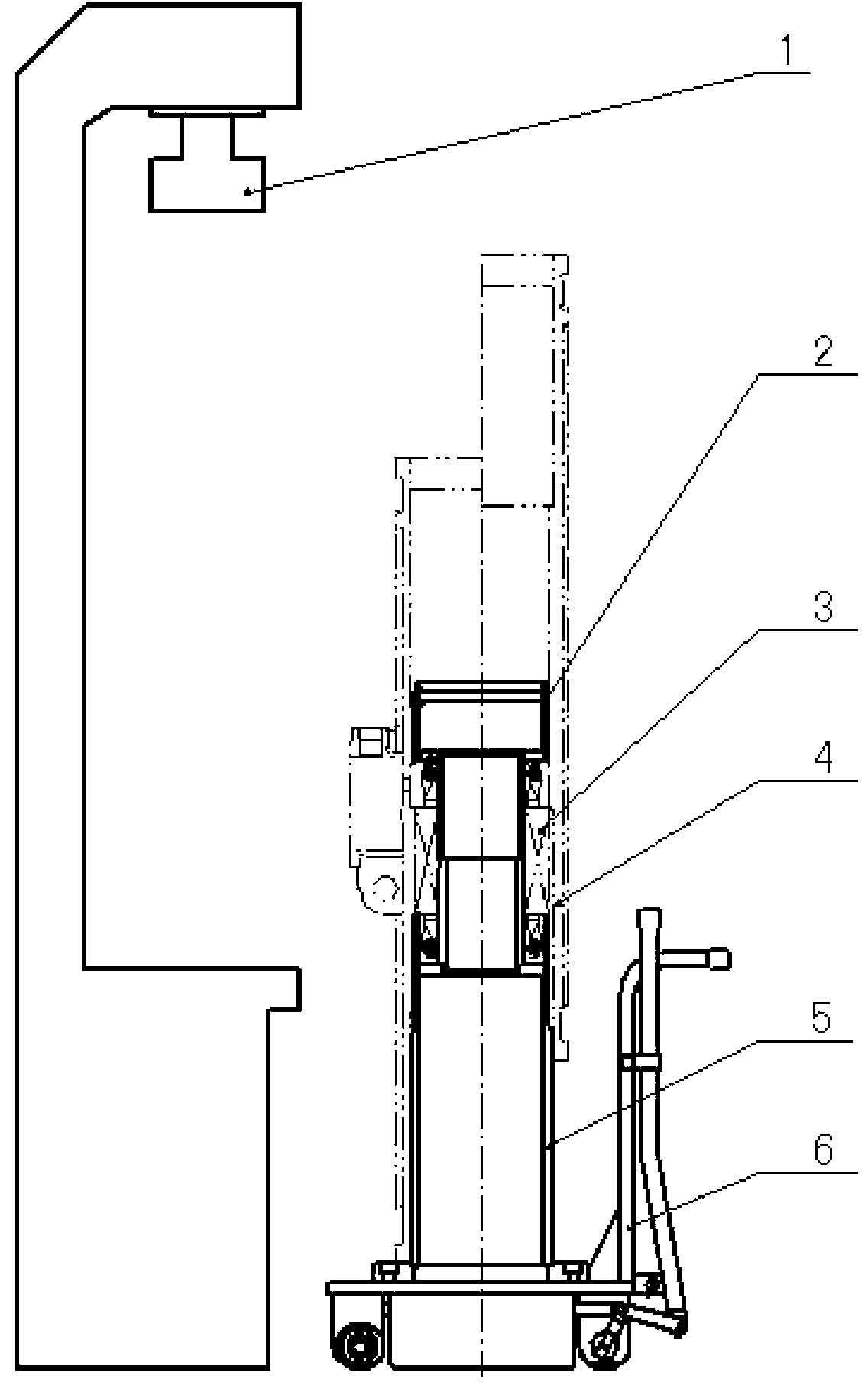

Method for pressing winding stator iron core of pole motor in machine base

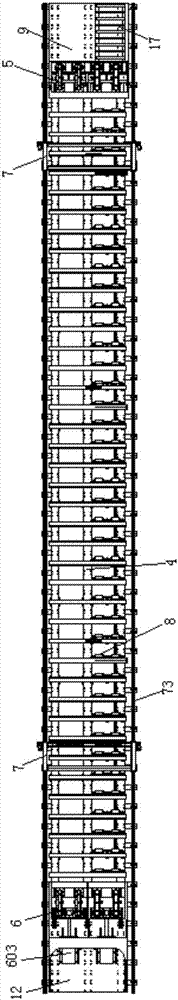

ActiveCN103326516AReduce breakdown rateGuarantee the quality of pressingManufacturing dynamo-electric machinesStatorEngineering

The invention discloses a method for pressing a winding stator iron core of a pole motor in a machine base. Specifically, a lower press mounting die assembly (5) is arranged on a push trolley (6); in a press mounting process, the winding stator iron core (3) is placed on the lower press mounting die assembly, then an upper press mounting die assembly (2) is placed on the winding stator iron core (3), a lead wire is pulled out of the kidney-shaped hole of the upper press mounting die assembly (2) and placed in the upper press mounting die assembly (2), the machine base (4) is sleeved on the press mounting die assemblies, and finally the push trolley provided with a tool and a workpiece is pushed below a single column vertical hydraulic machine (1) to be pressed and mounted. Due to the fact that in the press mounting process, an upper locating guide structure and a lower locating guide structure are adopted and the machine base is pressed towards the winding stator iron core, the breakdown rate generated in the process is zero, the assembling quality that the winding stator iron core of the pole motor is pressed in the machine base is greatly improved, therefore, the performance of the generated motor is made to be capable of meeting design requirements, meanwhile, production efficiency is improved, and the labor intensity of workers is reduced.

Owner:钟祥新宇机电制造股份有限公司

Board card radiator heat transfer cement pressing device

ActiveCN108513495AAvoid deformationGood thermal conductivityModifications by conduction heat transferPress ramMaterials scienceHeat spreader

The invention discloses a board card radiator heat transfer cement pressing device; one board card is provided with one radiator; a pressed heat transfer cement block can fill gaps between each electronic element and the radiator on the board card; the heat transfer cement pressing device comprises a frame; the frame is horizontally provided with a cement die; the top surface of the cement die isprovided with a cement cavity used for placing the cement and a radiator fixing structure used for fixing the radiator; the frame is provided with a press block arranged above the cement die and usedfor pressing the radiator on the cement die, and a press block lift driving device used for driving the press block to lift. The cement thickness and shape requirements can be satisfied, thus ensuringthe heat transfer cement pressing quality.

Owner:ZHEJIANG UNIV +1

Automatic uncoiling and tensioning equipment for rail car body skin

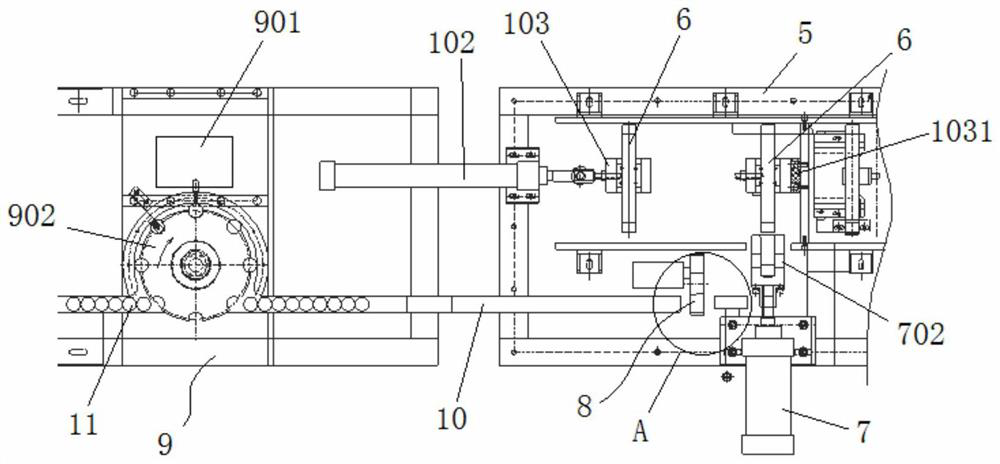

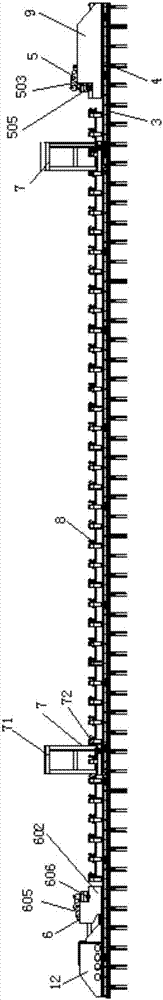

ActiveCN107398736ASmall footprintEase of workOther manufacturing equipments/toolsAutomatic controlControl system

The invention provides automatic uncoiling and tensioning equipment for a rail car body skin. A shearing and tensioning assembly comprises a base longitudinal beam, a movable platform, shearing and pressing devices, pressing and tensioning devices and framework locating and pressing devices. The pressing and tensioning devices are arranged at the left end of the movable platform. The two sets of position-adjustable framework locating and pressing devices are arranged between the shearing and pressing devices and the pressing and tensioning devices. A leveling machine and an uncoiling machine are sequentially arranged on the right sides of the shearing and pressing devices. After a PLC control system is used for controlling all parts to cooperatively work, automatic tensioning, locating before welding and dragging before hoisting of steel plates are achieved. According to the automatic uncoiling and tensioning equipment, uncoiling, leveling, tensioning and welding assembly are integrated on the same work platform for operation; the occupied area of a plant is greatly reduced; steel plate hoisting work after uncoiling and leveling is omitted; the steel plate tensioning work efficiency is improved; the steel plate tensioning quality and the flatness after steel plate tensioning are greatly improved; uncoiling, leveling and tensioning are all completed through automatic control; and the manual cost is reduced.

Owner:宝鸡市亿丰德工贸有限公司

Urea pipe forming press-fitting tool

InactiveCN111761543AEasy to pressGuarantee the quality of pressingMetal-working hand toolsStructural engineeringIndustrial engineering

The invention relates to the technical field of urea pipes, and discloses a urea pipe forming press-fitting tool. The urea pipe forming press-fitting tool comprises a fixed arc-shaped plate and a movable arc-shaped plate of the same structure, the movable arc-shaped plate and the fixed arc-shaped plate are rotationally connected through a rotating pin, supporting columns are symmetrically and fixedly connected to the lower surface of the fixed arc-shaped plate, and the other ends of the two supporting columns are jointly and fixedly connected with a base; a lower arc-shaped press-fitting plateand an upper arc-shaped press-fitting plate which are the same in structure are symmetrically arranged on the opposite sides of the fixed arc-shaped plate and the movable arc-shaped plate, the upperarc-shaped press-fitting plate is connected with the movable arc-shaped plate through a regulation and control mechanism, the lower arc-shaped press-fitting plate is fixedly connected with the inner side wall of the fixed arc-shaped plate through a plurality of fixing columns, and the regulation and control mechanism comprises two sliding rods which are symmetrically and fixedly connected to the upper surface of the upper arc-shaped press-fitting plate. According to the urea pipe forming press-fitting tool, urea pipes of different models can be conveniently press-fitted, and the pressure during press-fitting can be regulated and controlled as required, so that the press-fitting quality is effectively ensured.

Owner:十堰铁马汽车零部件有限公司

Arc-shaped radiator assembly tool

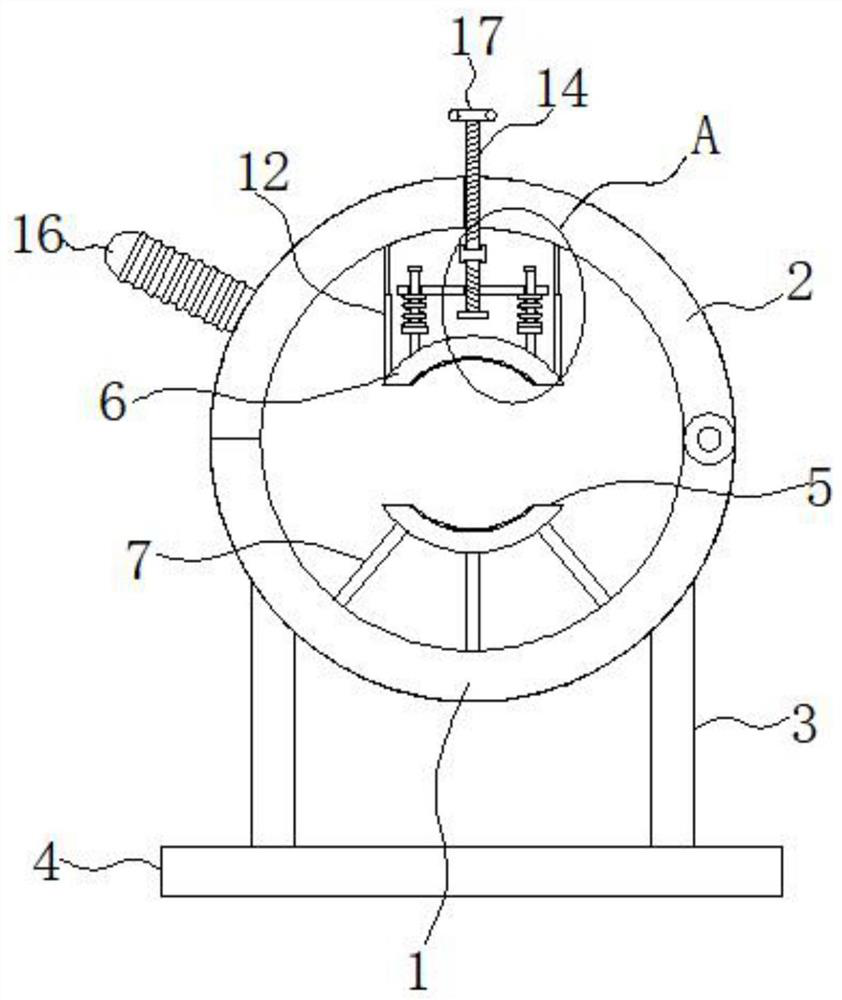

ActiveCN113275823AUniform pressureAvoid skewWelding/cutting auxillary devicesAuxillary welding devicesEngineeringScrew thread

The invention is suitable for the technical field of tools, and provides an arc-shaped radiator assembly tool which comprises a peripheral limiting mechanism, a pressing mechanism and an end limiting mechanism are arranged in the peripheral limiting mechanism, and the bottom of the peripheral limiting mechanism is movably connected with an adjusting mechanism. The adjusting mechanism comprises a rotary disc with an annular groove formed in the periphery, a plurality of stand columns are arranged in the annular groove, each stand column is rotationally connected with an adjusting rod in a sleeved mode, the end, away from the corresponding stand column, of each adjusting rod is rotationally connected with a connecting rod in a sleeved mode, and each connecting rod is connected with a limiting plate of the peripheral limiting mechanism. The pressing mechanism comprises a lead screw connected to the middle of the peripheral limiting mechanism, a threaded sleeve is rotationally connected to the lead screw, a bearing is fixedly connected to the periphery of the threaded sleeve, a pressing block is fixedly connected to the periphery of the bearing, a pressing disc is fixedly connected to the bottom of the pressing block, and a penetrating groove capable of allowing the pressing disc to penetrate through the limiting plate is formed in the pressing disc. Thus, the arc-shaped radiator assembly tool can be used for assembling radiators of various sizes, the practicability of the tool is improved, the assembling quality is guaranteed, and the cost is saved.

Owner:WEIFANG HUALONG RADIATOR

Mixing blade pressing tool and pressing process

InactiveCN109127819AImprove processing efficiencyEasy to control shapeEngineeringMechanical engineering

The invention discloses a mixing blade pressing tool and pressing process and relates to the technical field of mixing blade processing. The mixing blade pressing tool comprises a base and a tool blade arranged on the base. The tool blade is of a helical structure. A supporting assembly used for supporting the tool blade is further fixed to the base. The tool blade is fixed to the top of the supporting assembly. The supporting assembly comprises a plurality of supporting rib plates vertically fixed to the base. A reinforcing plate is fixedly connected between any two adjacent supporting rib plates. The mixing blade pressing tool and pressing process provided by the invention can improve the processing efficiency of mixing blades and can also greatly improve the processing quality of the mixing blades.

Owner:中化学华谊装备科技(上海)有限公司

Production process of relief type pattern floor and relief pattern printing equipment

InactiveCN102140833AGuarantee the quality of pressingEliminate Bubble ProblemsFlooringLacquerEngineering

The invention relates to a production process and equipment of a floor, relating to the field of floor manufacture. The production process of a relief type pattern floor comprises the following steps of: manufacturing a blank plate of the floor with a flexible upper surface; pressing three-dimensional patterns on the blank plate of the floor, and solidifying the blank plate of the floor; abrading the pressed three-dimensional patterns by adopting an abrasive tool; coating base paint on the upper surface of the blank plate of the floor; polishing the base paint; coating the base paint again on the processed base paint; and then coating finish paint on the base paint. The relief pattern printing equipment comprises a floor blank plate shaping mould system and a three-dimensional pattern printing module system, wherein the floor blank plate shaping mould system comprises a shaping mould and a shaping mould cooling system; and the three-dimensional pattern printing module system comprises a three-dimensional pattern printing module and a printing module acting system, wherein the three-dimensional pattern printing module is positioned above the shaping mould. By adopting the production process of the relief type pattern floor and the relief pattern printing equipment, the floor with relief patterns can be produced.

Owner:上海金喆机械厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com