Method for pressing winding stator iron core of pole motor in machine base

A stator core and winding technology, which is applied in the field of assembly of the stator core with windings and the motor base, can solve the problems of inconvenient threading of lead wires, many coil breakdowns, and high labor intensity, so as to improve work efficiency, The effect of reducing breakdown rate and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

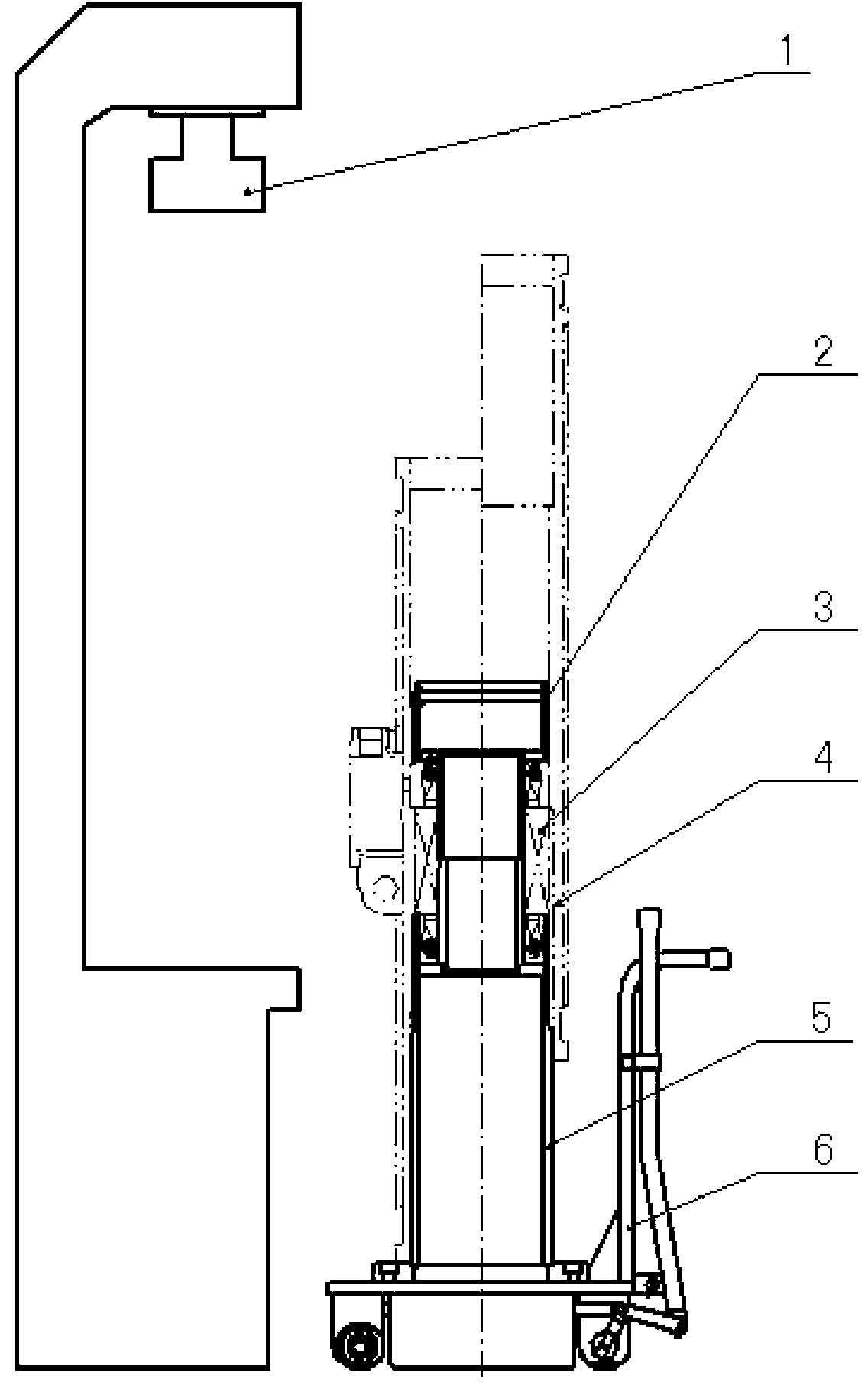

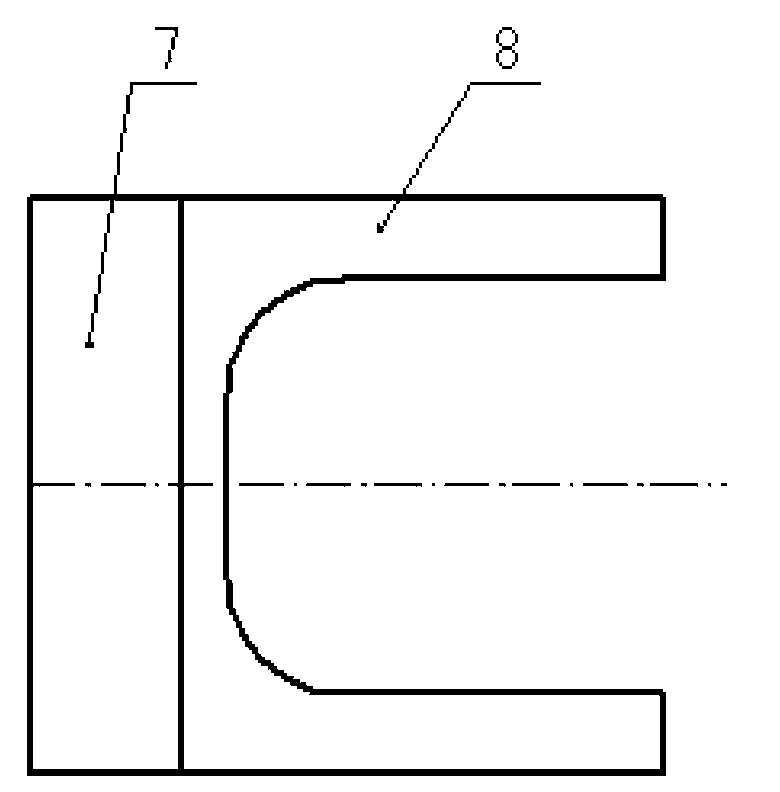

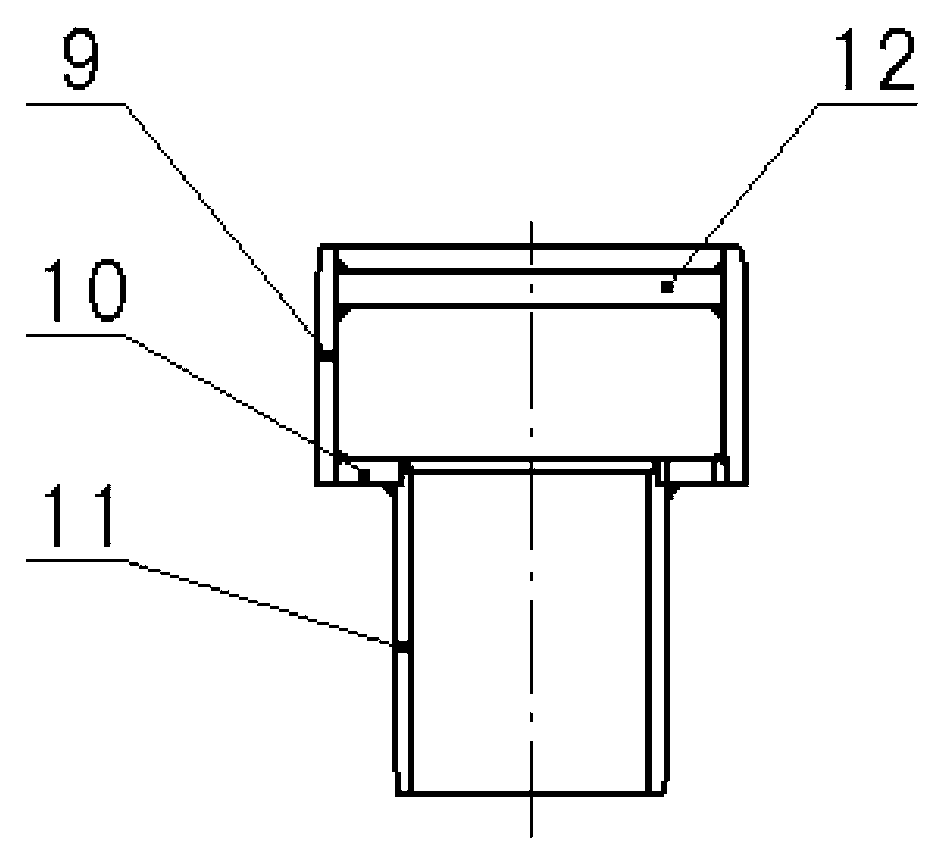

[0030] The method for pressing the winding stator core of the long rod motor into the machine base provided by the present invention is realized by using a special pressing die, a pushcart and a reformed single-column vertical hydraulic press. The method is: see figure 1 , cut the square workbench of the single-column vertical hydraulic press into a "U"-shaped workbench with an opening outward, and install the lower pressing mold assembly 5 of the special tooling with the winding stator core pressed into the machine base on the self-made pusher On the car 6, put the winding stator core 3 on the lower press-fitting mold assembly 5 (the end with the lead wire is placed on the top), and then put the upper press-fitting mold assembly 2 on the winding stator core 3, Pull out the lead wire from the waist-shaped hole of the upper press-fitting die assembly 2 and put it therein, then set the support 4 on the press-fitting die assembly, and finally push the trolley 6 with tooling and wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com