Adhesive for insulator

An adhesive and insulator technology, which is applied in the field of insulator production materials, can solve the problems of decreased anti-destructive strength and increased breakdown rate of insulators, and achieve the effect of improving bonding force and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] An adhesive for insulators, including 1kg of Portland cement, 0.5kg of colloidal sand, 0.03kg of silica fume and 0.2L of mixed solution, wherein the mixed solution is made of pure water, defoamer and water reducer ; Portland cement chooses brand PI52.5, which is an ultrafine powder material, and the particles with a fineness of ≤0.09mm are 100%; the cementitious sand includes SiO with a mass fraction of 95% 2 and 5% Fe 2 o 3 , the fineness of 0.3-1mm particles in the colloidal sand is more than 80%, the pH value of the pure water in the mixed solution is 7.0-7.2, and the fineness of the silica fume is greater than 250 mesh.

[0031] The preparation method of the above-mentioned adhesive for insulators comprises the following steps:

[0032] S1: Weigh 1kg Portland cement, 0.5kg gelatinous sand and 0.03kg silica fume and mix them evenly;

[0033] S2: Mix the defoamer, water reducer and water to obtain a mixed solution. In this example, when preparing the mixed solution...

Embodiment 2~6

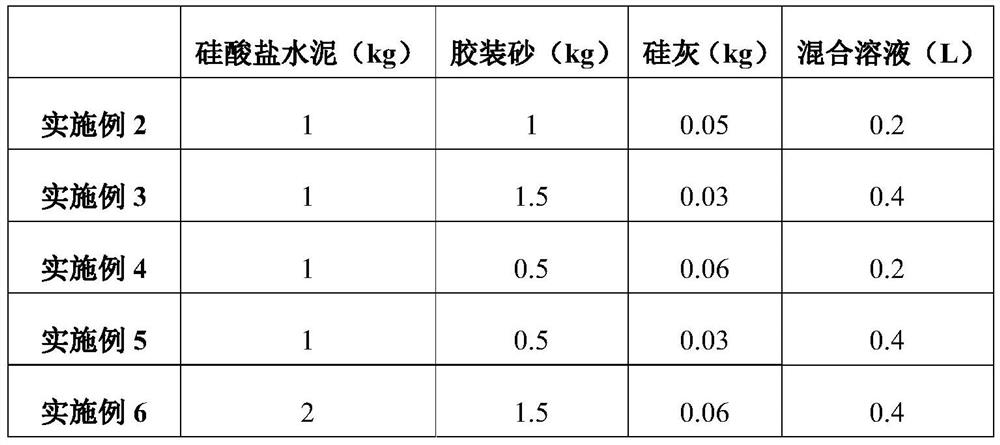

[0035] Embodiment 2~6 and comparative example 1~5:

[0036] The difference from Example 1 is that the proportions of raw materials are different, and the proportions are shown in Table 1.

[0037] Table 1 is the raw material proportion table of embodiment 2~6 and comparative example 1~5

[0038]

[0039]

Embodiment 7

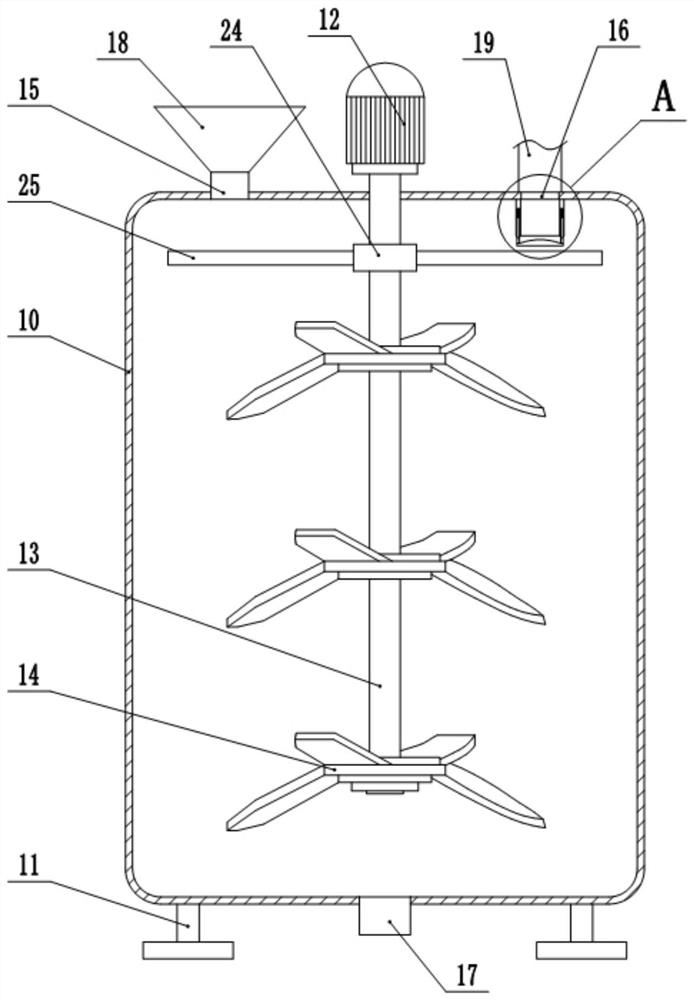

[0041] The difference with Example 1 is that an improved cement mixer is used in step S3 of Example 7, and the cement mixer combines figure 1 with figure 2 As shown, a mixing bucket is included, a supporting foot 11 is set at the bottom of the mixing bucket, and the top of the mixing bucket is closed, and a stirring mechanism is arranged in the mixing bucket, wherein the stirring mechanism includes a motor 12, a stirring shaft 13 and a stirring paddle 14, wherein the motor 12 is fixed on the mixing bucket, the stirring shaft 13 is connected to the top of the mixing bucket in rotation, the stirring shaft 13 is fixedly connected with the output shaft of the motor 12, and the stirring paddle 14 is fixed on the stirring shaft 13.

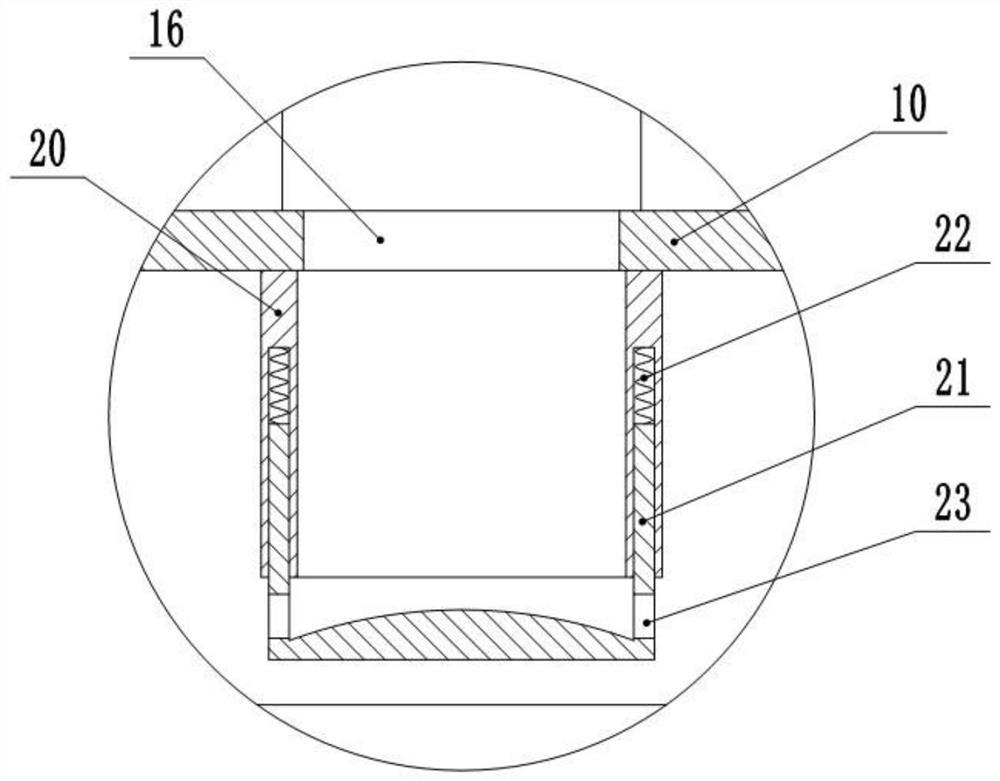

[0042] The top of the mixing bucket is provided with a feed inlet 15, a liquid inlet 16 and a cleaning port, and the bottom of the mixing bucket is provided with a discharge valve 17, wherein a feed hopper 18 is fixed at the feed inlet 15, in order to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| curing time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com