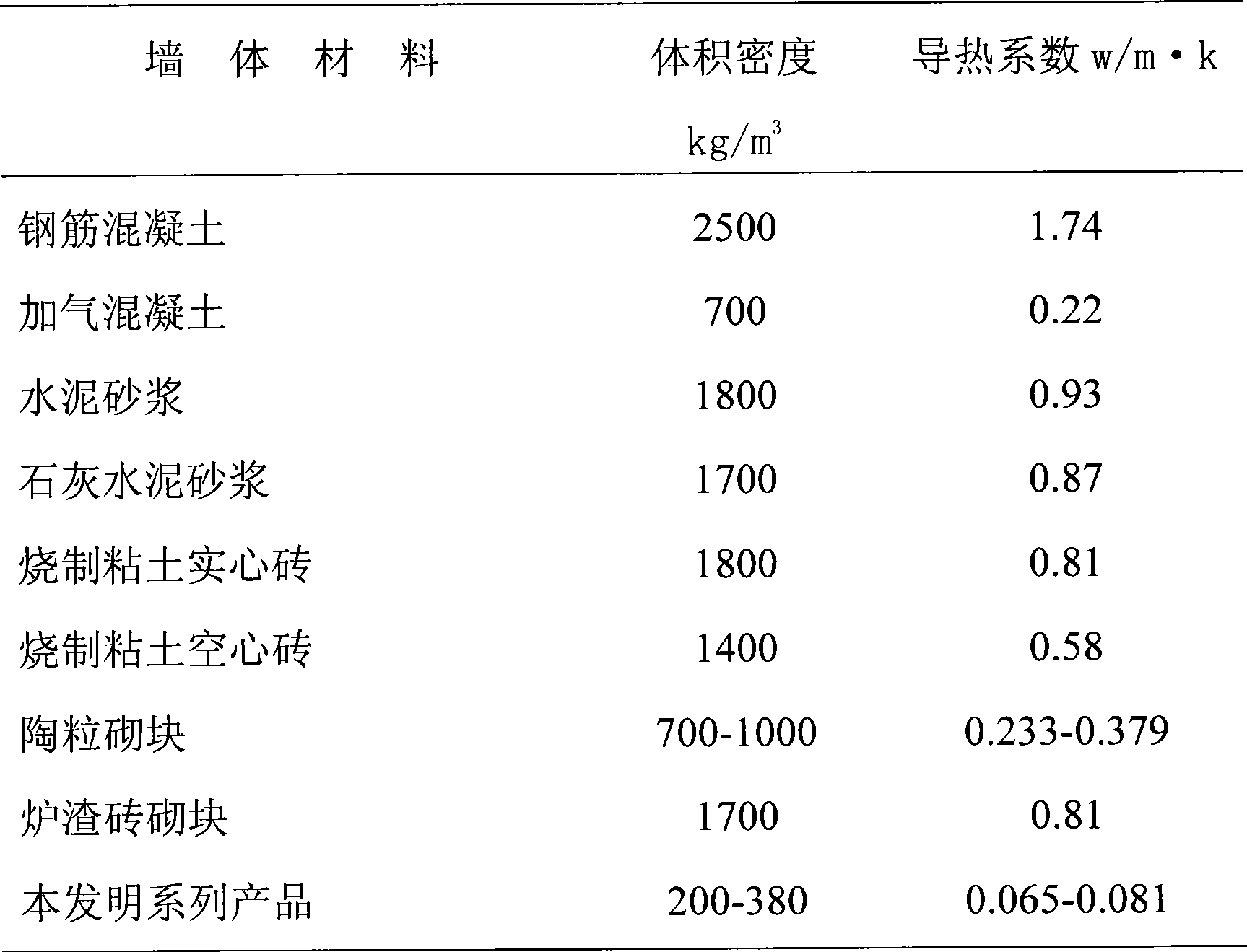

Light energy conservation insulating concrete

A kind of thermal insulation concrete and lightweight technology, applied in the field of building materials, can solve the problems of affecting popularization and use and high cost, and achieve the effect of strong decoration, weight reduction and load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Including master batches and auxiliary materials in the following proportions by weight:

[0052] a. Masterbatch:

[0053] The cementitious material is Portland cement: 30 parts;

[0054] Filling material: 25 parts of blast furnace slag powder;

[0055] Strength activator: 5 parts of sulfoaluminate series cement clinker;

[0056] b. Accessories:

[0057] Waterproofing agent: 1 part of calcium stearate;

[0058] Bleeding agent: 2.0 parts of talc;

[0059] Suspending agent: 2.0 parts of light calcium carbonate;

[0060] Foam stabilizer: 0.1 part of oleic acid;

[0061] Honeycomb agent: 38 parts, which is 1.5% hydrogen peroxide:triethanolammonium=100:1;

[0062] Rust inhibitor: 0.5 part of sodium nitrite;

[0063] Enhancer: 0.02 part of ultra-fine silica fume powder;

[0064] Early strength agent: 0.003 part of lithium carbonate;

[0065] Expansion agent: 1.2 parts of UEA expansion agent;

[0066] Acid and alkali resistant fiber: 0.6 parts of polypropylene fiber...

Embodiment 2

[0070] Including master batches and auxiliary materials in the following proportions by weight:

[0071] a. Masterbatch:

[0072] Cementitious material: 50 parts of ordinary Portland cement;

[0073] Filler: 42 parts of fly ash;

[0074] Strength activator: 8 parts of iron aluminate series cement clinker;

[0075] b. Accessories:

[0076] Waterproofing agent: 2 parts of zinc stearate;

[0077] Bleeding agent: 2.5 parts of talc;

[0078] Suspending agent: 3.5 parts of light calcium carbonate or quicklime;

[0079] Foam stabilizer: 0.3 part of oleic acid or polyvinylamide powder;

[0080] Honeycomb agent: 2.0% hydrogen peroxide: triethanolammonium = 100:1, 49 parts;

[0081] Rust inhibitor: 1.0 part of sodium nitrite;

[0082] Enhancer: 5 parts of ultrafine wollastonite powder;

[0083] Early strength agent: 0.01 part of lithium chloride;

[0084] Expansion agent: 2.7 parts of CSA expansion agent;

[0085] Acid and alkali resistant fiber: 1.0 part of 9mm acrylic;

[...

Embodiment 3

[0089] Including master batches and auxiliary materials in the following proportions by weight:

[0090] a. Masterbatch:

[0091] Cementitious material: 70 parts of slag Portland cement;

[0092] Filling material: 60 parts of coal dry stone powder;

[0093] Strength activator: 10 parts of sulfoaluminate series cement clinker;

[0094] b. Accessories:

[0095] Waterproofing agent: 3 parts of magnesium stearate;

[0096] Bleeding agent: 3.0 parts of talc;

[0097] Suspending agent: 5.0 parts of light calcium carbonate;

[0098] Foam stabilizer: 0.5 part of polyvinylamide powder;

[0099] Honeycomb agent: 2.5% hydrogen peroxide: triethanolammonium = 100:1, 60 parts;

[0100] Rust inhibitor: 1.5 parts of sodium nitrite;

[0101] Enhancer: 10 parts of ultrafine quartz powder;

[0102] Early strength agent: 0.021 part of lithium carbonate;

[0103] Expansion agent: 4.2 parts of bentonite;

[0104] Acid and alkali resistant fiber: 1.4 parts of 12mm nylon;

[0105] The pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com