Patents

Literature

53results about How to "Enhanced destructive strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

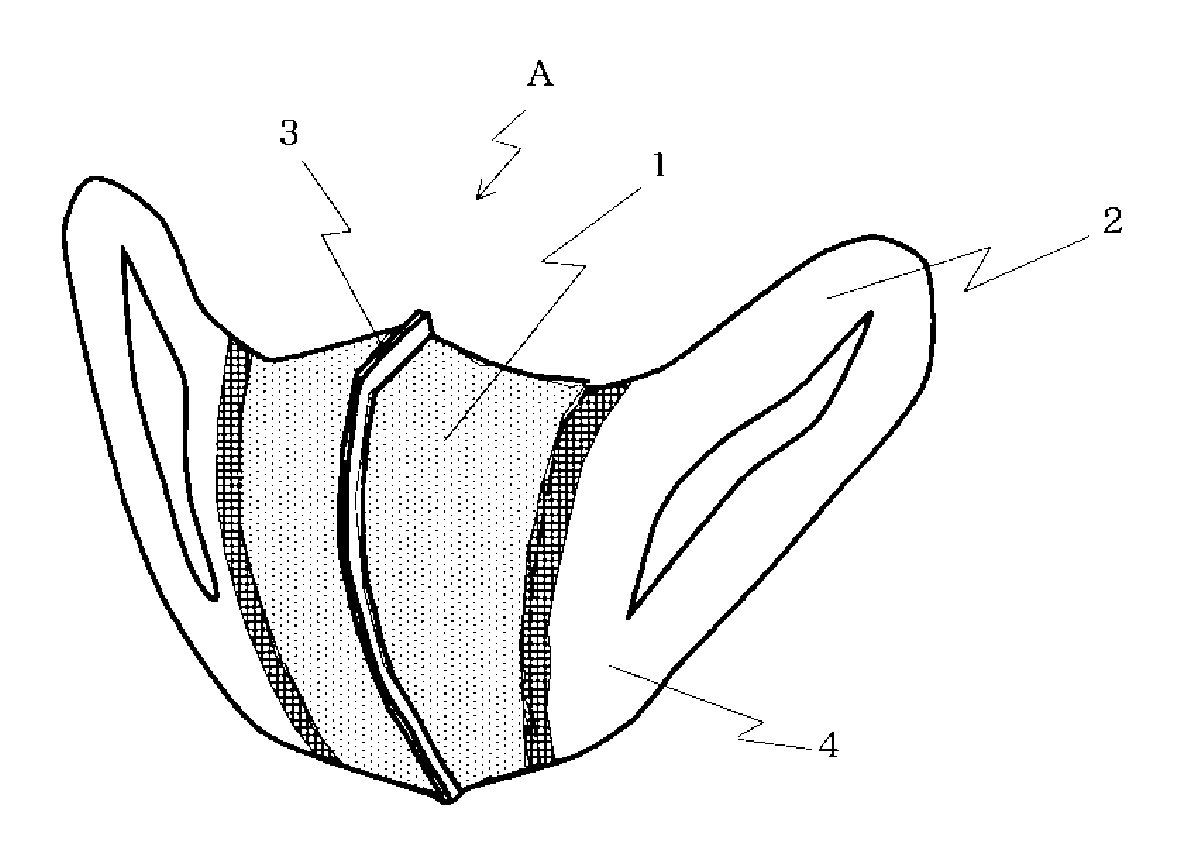

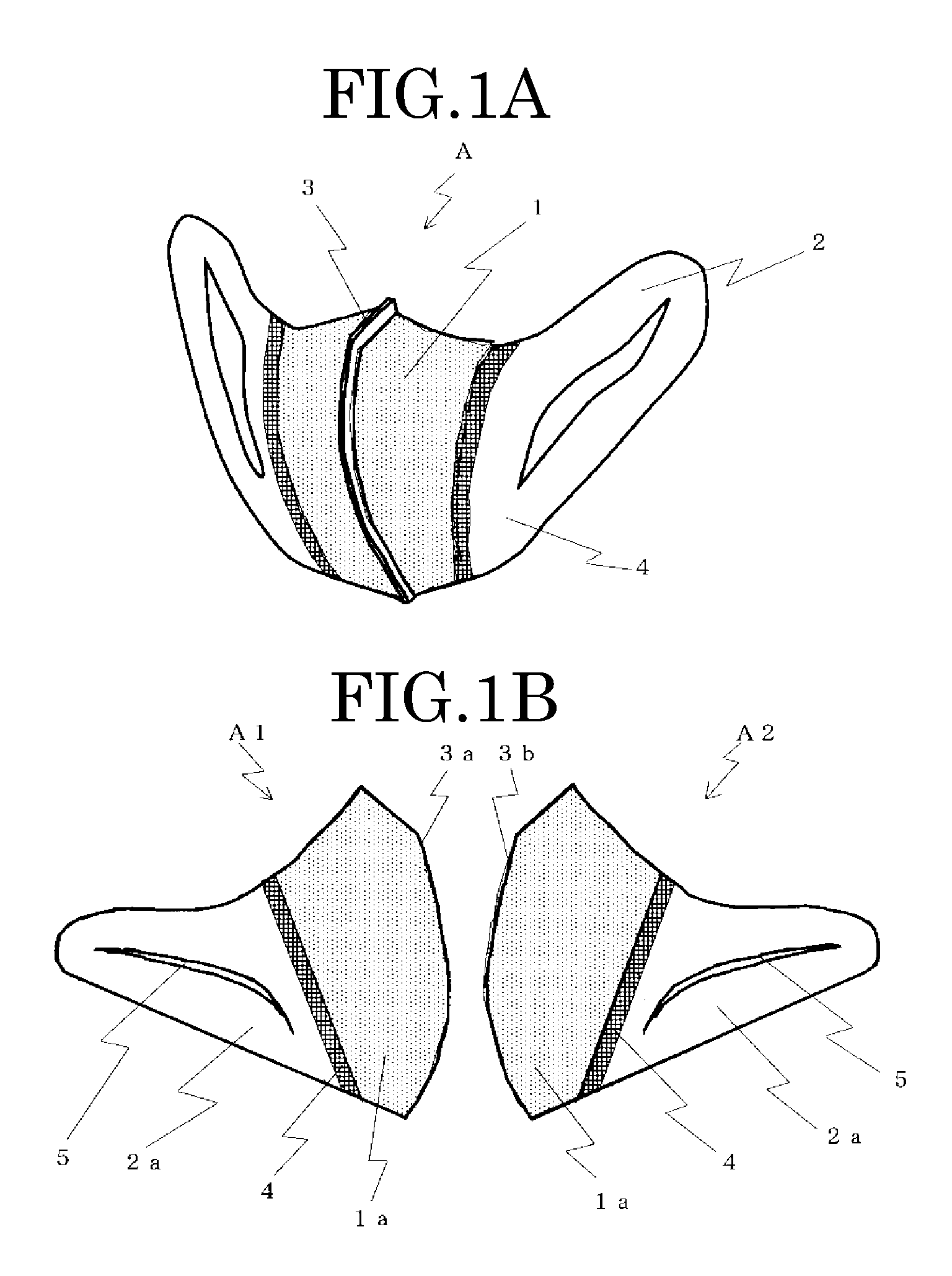

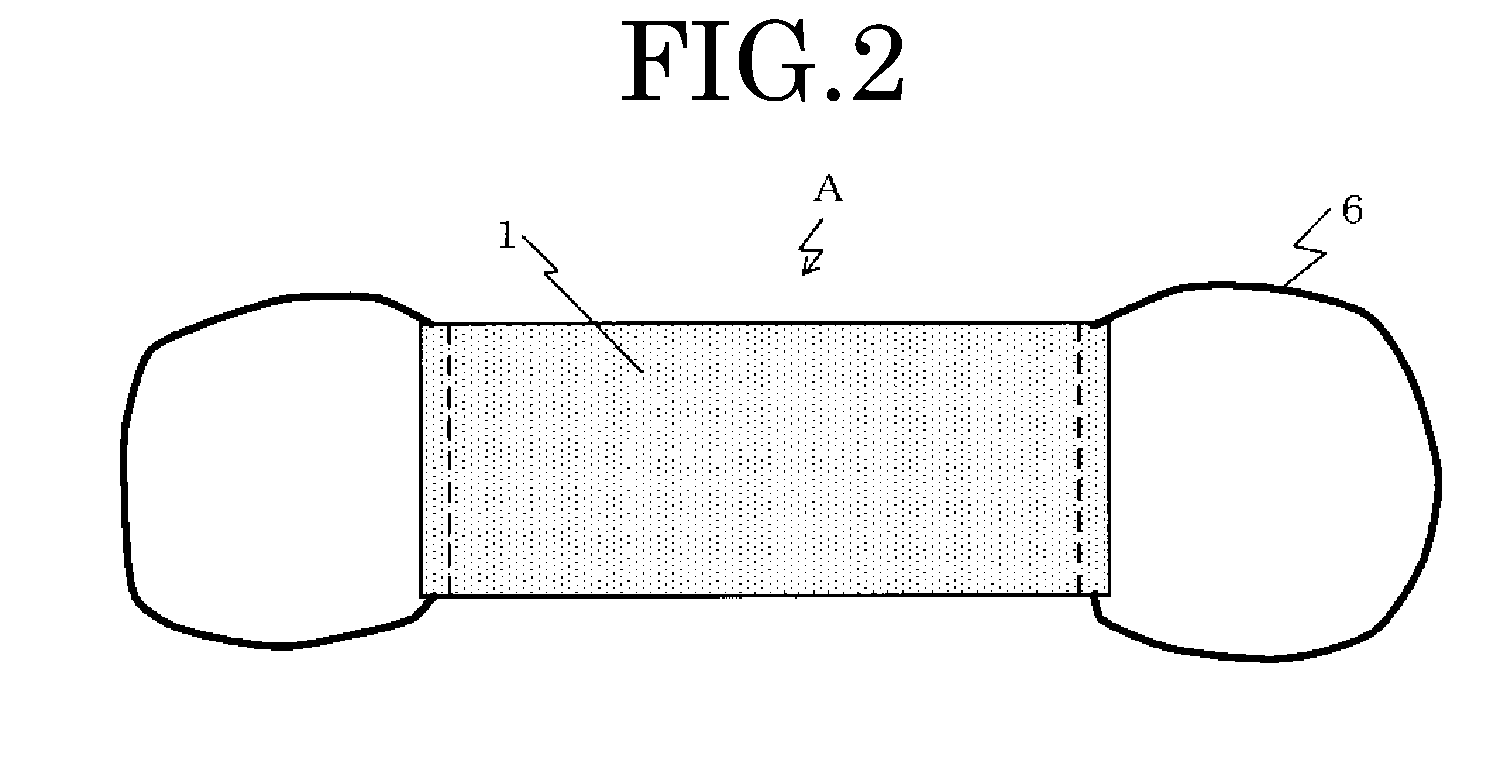

Mask filter and mask produced using the same

InactiveUS20100307503A1Improve antibacterial propertiesEfficient activationBreathing filtersProtective equipmentPolymer sciencePolyolefin

The present invention provides a mask filter exhibiting a high antimicrobial / antiviral activity, a high dust filtration ability, a high ventilation characteristic, a high failure-strength and a high workability into a mask and the mask produced using such mask filter. An antimicrobial polyolefin fiber sheet is provided wherein the polyolefin fiber sheet has one or more spots in which 1 / 100 or more by volume of individual inorganic antimicrobial agent particles are exposed on surfaces of polyolefin fibers per fiber sheet area of 1.0×10−2 mm2 or has one or more spots in which the inorganic antimicrobial agent particles are exposed on the surfaces of polyolefin fibers each occupying an area of 0.01 μm2 or larger per fiber sheet area of 1.0×10−2 mm2. Such polyolefin fiber sheet is arranged as the core layer and this core layer is sandwiched between upper and lower layers of dry nonwoven fabric to form the mask filter in the form of a laminated sheet. Such mask filter is used to form the mask.

Owner:UNI CHARM CORP

High-strength semitransparent ceramic sheet and preparation method thereof

The invention relates to a high-strength semitransparent ceramic sheet and a preparation method for the high-strength semitransparent ceramic sheet. The high-strength semitransparent ceramic sheet is prepared by sintering the formula components: 20-25% of sodium sand, 15-20% of potassium feldspar, 9-13% of high potassium sand, 20-25% of potassium sodium feldspar, 1-3% of barium carbonate, 12-15% of calcined kaolin, 5-15% of bone meal, and 1-3% of sheet aluminum oxide in percentage by weight at high temperature. The preparation method comprises the following steps: (1) preparing powder; (2) forming by punching; (3) drying and sintering; (4) polishing to make the high-strength semitransparent ceramic sheet. Sheet aluminum oxide particles are added in an original semitransparent ceramic material, an inorganic peroxide crystal whisker is further added, the water absorption of the semitransparent ceramic material is reduced, the breaking strength is improved, and then the semitransparent ceramic material is applied in the ceramic sheet, so that the water absorption of the ceramic sheet is reduced, and the breaking strength of the ceramic sheet is improved.

Owner:FOSHAN HECAI TECH SERVICE

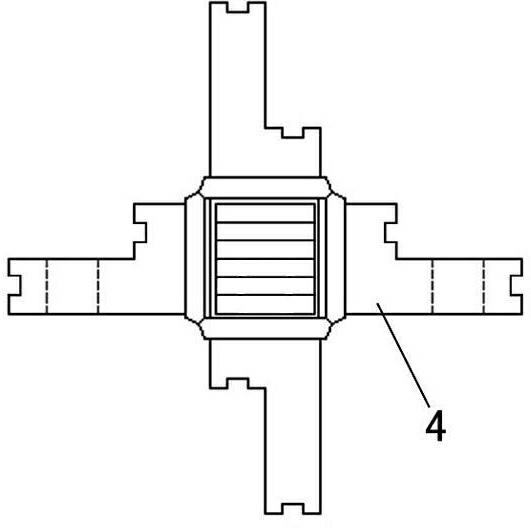

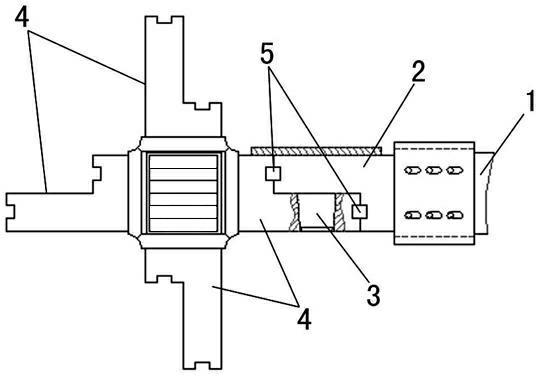

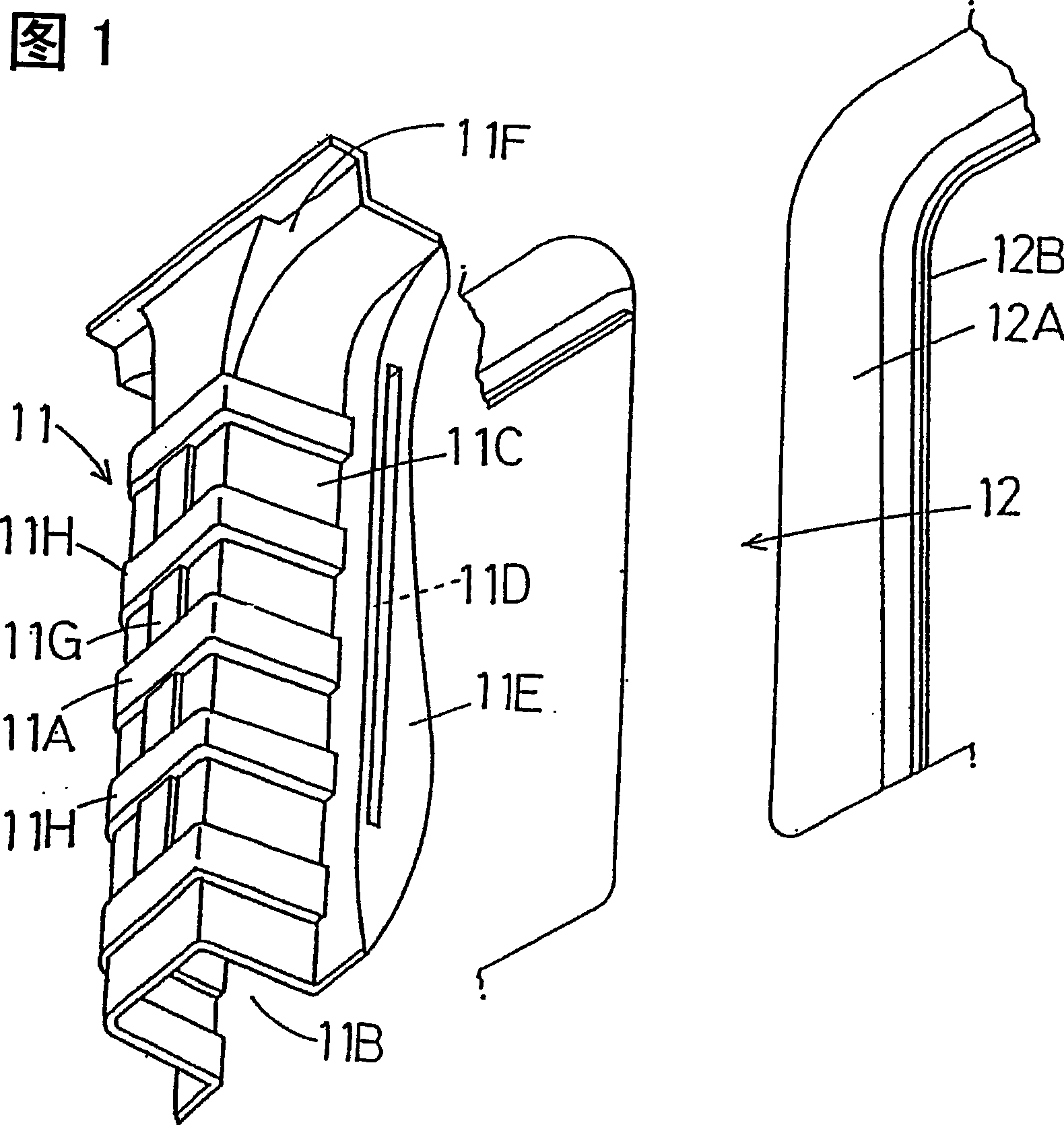

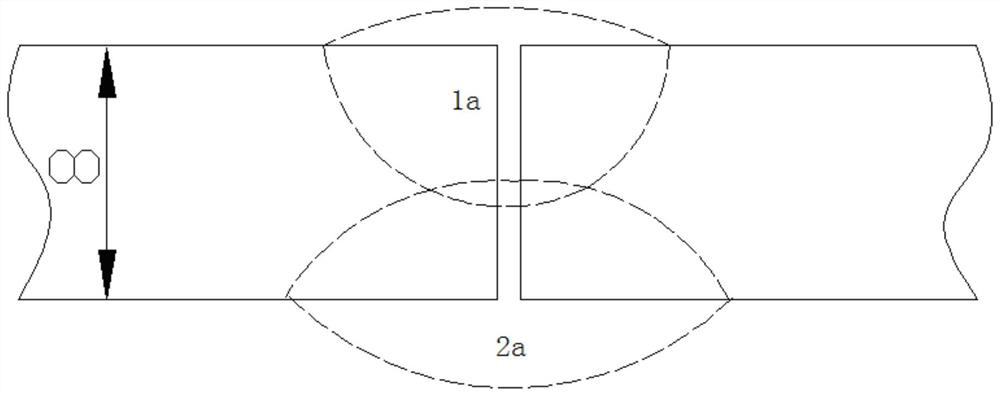

Steel structure building beam or pillar node interface

InactiveCN102561527AImprove bearing capacityHigh longitudinal tensile strengthBuilding constructionsBreaking strengthButt joint

The invention relates to a steel structure building beam or a steel structure pillar node interface, which is used for connecting convergent nodes of a steel structure building beam or a steel structure pillar and overcoming the shortages of toilsome assembly, bad accuracy, low connection strength, and the like in the existing connection mode. The steel structure building beam or pillar node interface is composed of joints of the end part of the beam or the pillar and joint seats converged on the node, wherein the joints lack a half at the end part in the horizontal direction to form a ladder shape. The shape and the size of the joint seats are the same with that of the joints. A connection insertion tenon is arranged on a mutual faying surface formed when the joint is butt jointed with the joint seat, the connection insertion tenon is vertical to the faying surface and a fastening structure for preventing the joint and the joint seat from horizontally separating is arranged at the faying position of the joint and the joint seat. According to invention, the steel structure building beam or pillar node interface has the beneficial effects that the faying mode bearing of the interface has large bearing capacity; the steel structure building beam-pillar node interface has high longitudinal tensile strength, is provided with the fastening member for preventing the joint and the joint seat from horizontally separating so that the connection of the node of the beam and the pillar has multi-directional higher anti-breaking strength, has a simple structure, and is convenient to manufacture and install; and with the adoption of the steel structure building beam or pillar node interface, the conditions are created for modularization, standardization and serialization of steel structure housing construction.

Owner:罗大威

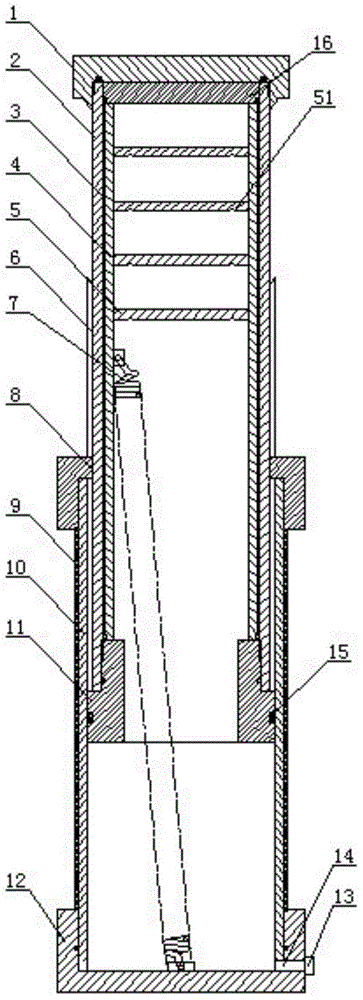

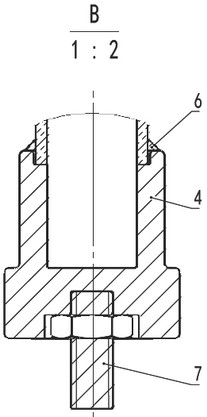

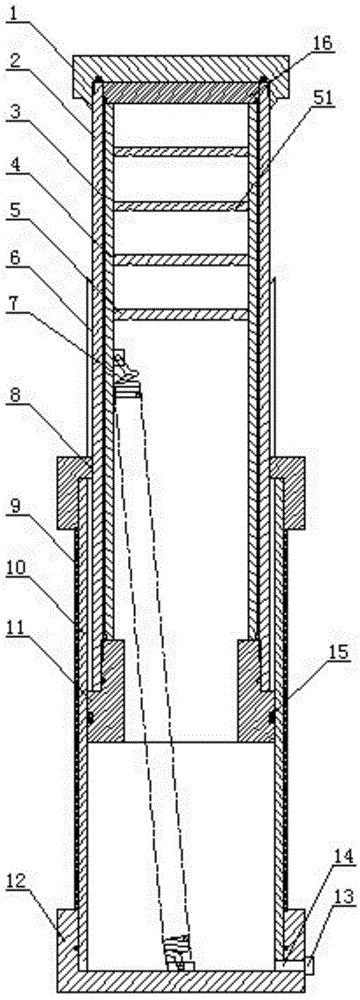

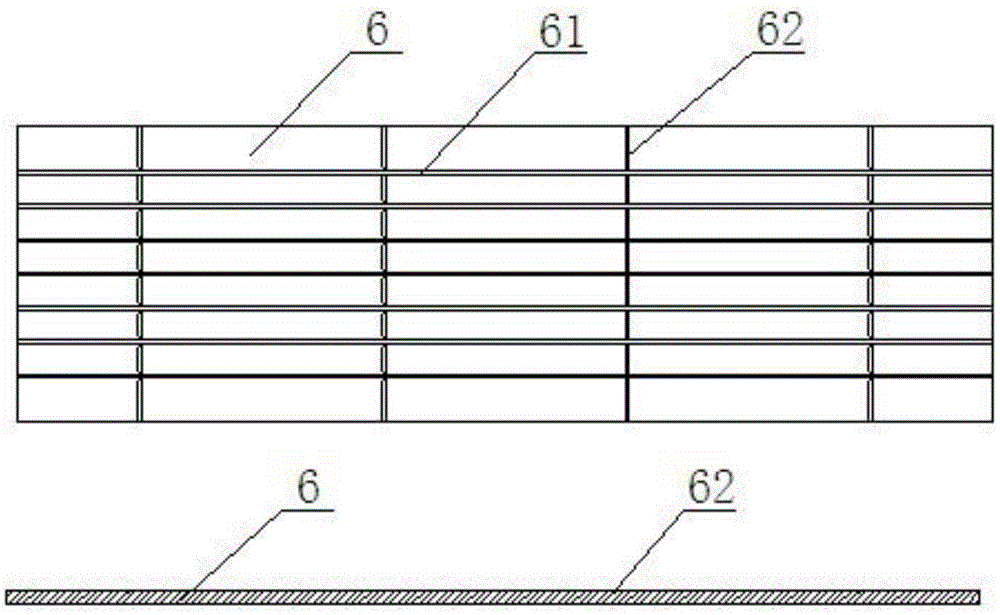

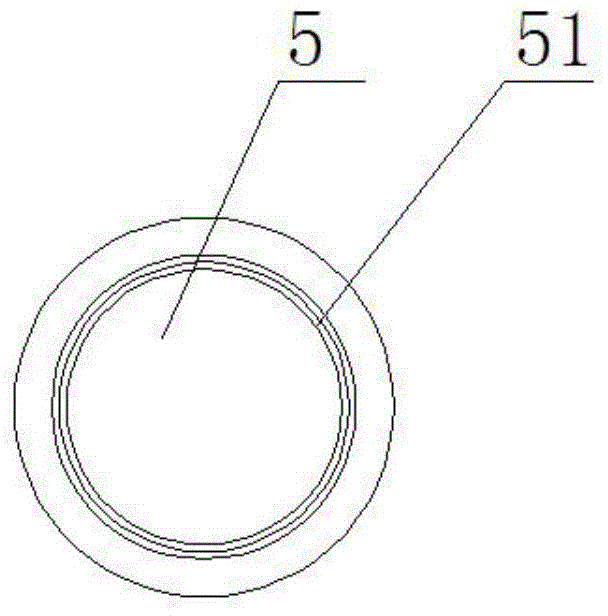

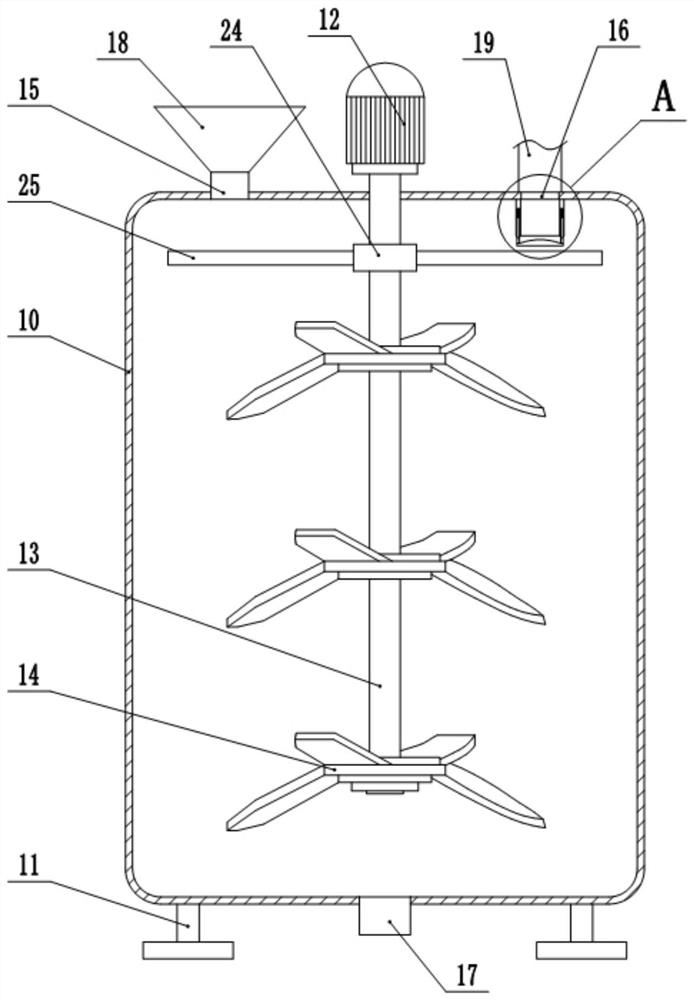

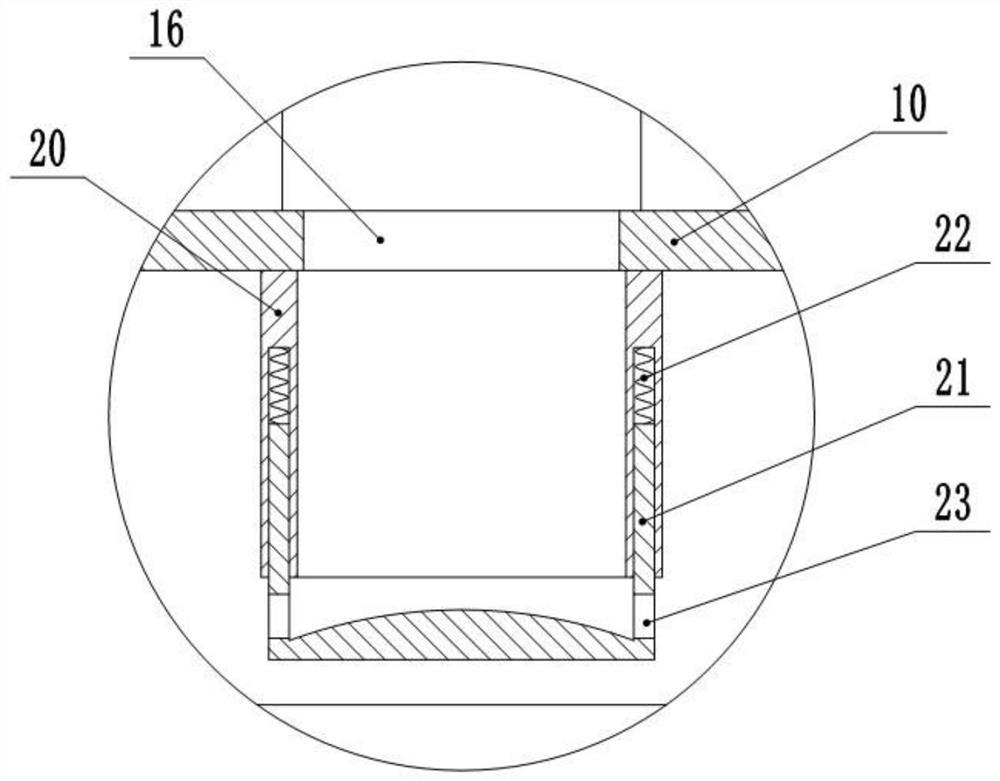

Multi-stage anti-impact supporting column

InactiveCN103557016AEnhanced destructive strengthStrong energy absorption and shock resistanceProps/chocksPistonGround pressure

The invention discloses a multi-stage anti-impact supporting column which comprises a top cover, an energy absorption barrel top cover, hydraulic columns, a multi-stage liquid energy absorption barrel, a trench energy absorption barrel, a hydraulic cylinder top cover, an alloy hydraulic cylinder, a piston, a hydraulic cylinder base, a three-purpose valve and the like, wherein the multi-stage liquid energy absorption barrel is sleeved in the hydraulic columns; the hydraulic columns are sleeved in the prefabricated trench energy absorption barrel; the prefabricated trench energy absorption barrel is sleeved in a light-weight and high-intensity hydraulic cylinder; under a condition of high dynamic load, the multi-stage liquid energy absorption barrel is used for performing quick abdication and energy absorption to prevent the phenomenon that inner elements of the three-purpose valve and column bodies of the hydraulic columns are damaged due to dramatic increasing of pressure in a hydraulic cylinder at the moment of impact and implement quick absorption of the energy which is caused by impact ground pressure and is applied to the supporting column; furthermore, the remote three-purpose valve is used for realizing a function of remotely lifting the supporting column, so that the injuries to people caused by surrounding rock collapse during column falling are avoided, and the safety of workers is guaranteed.

Owner:LIAONING TECHNICAL UNIVERSITY

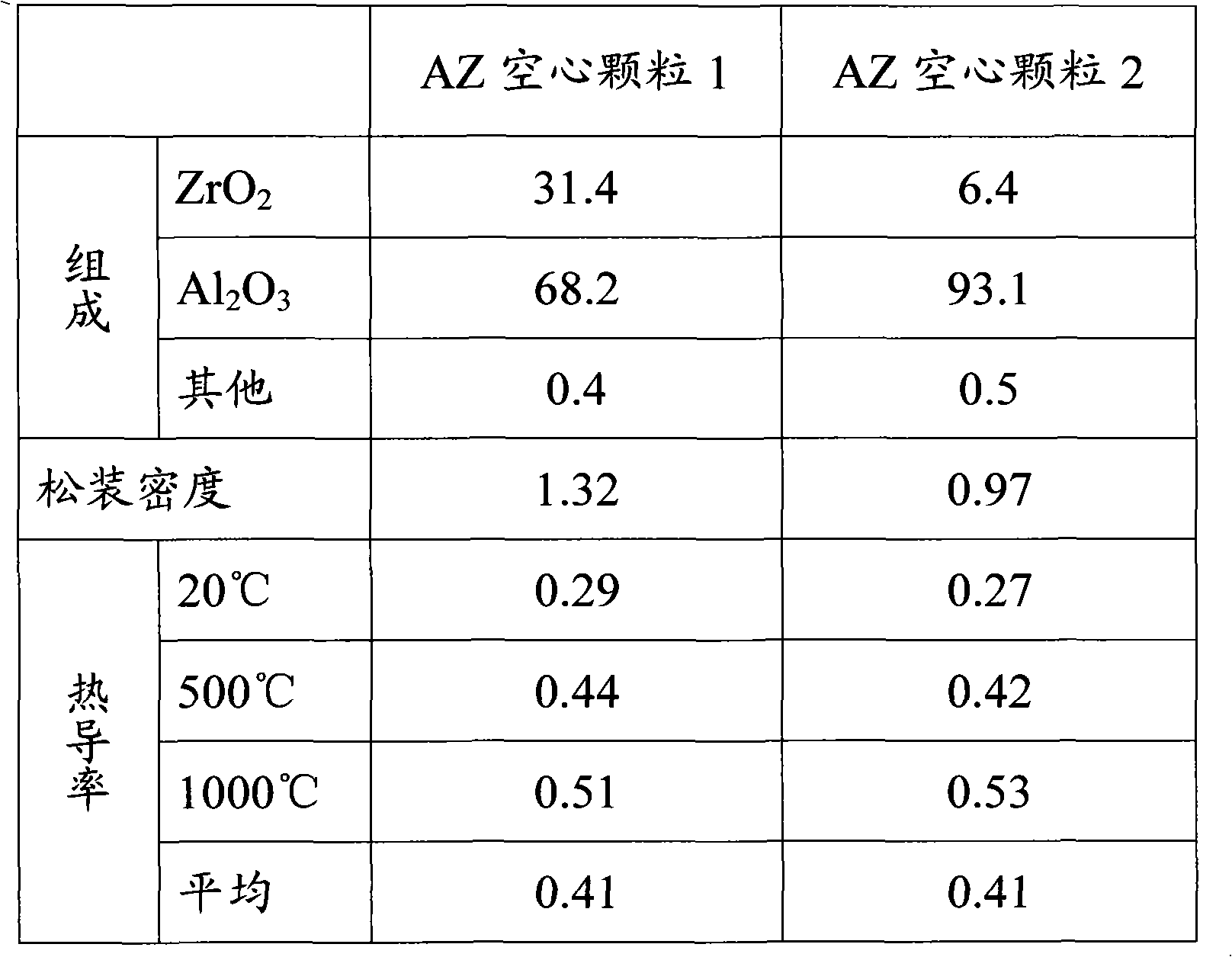

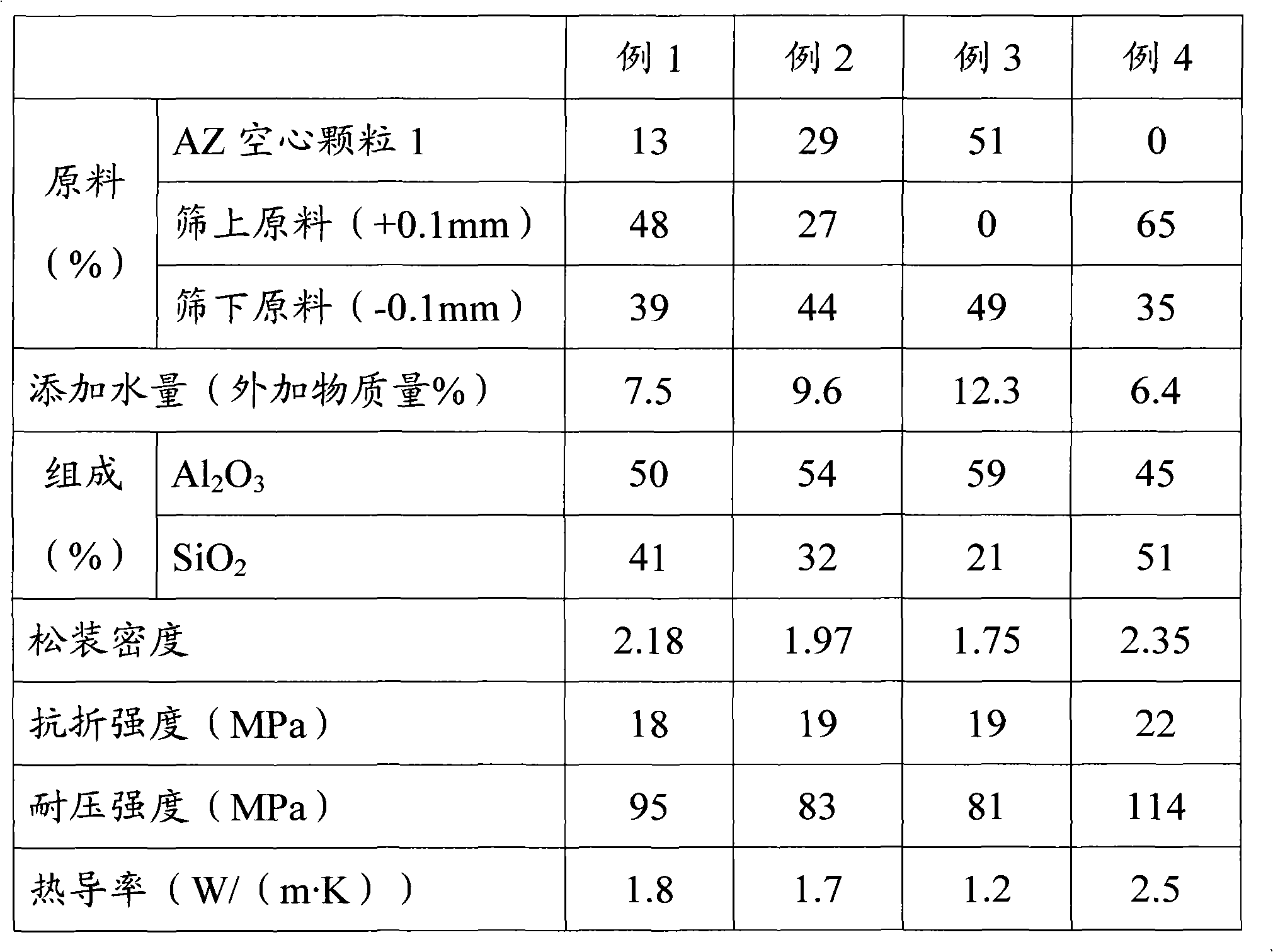

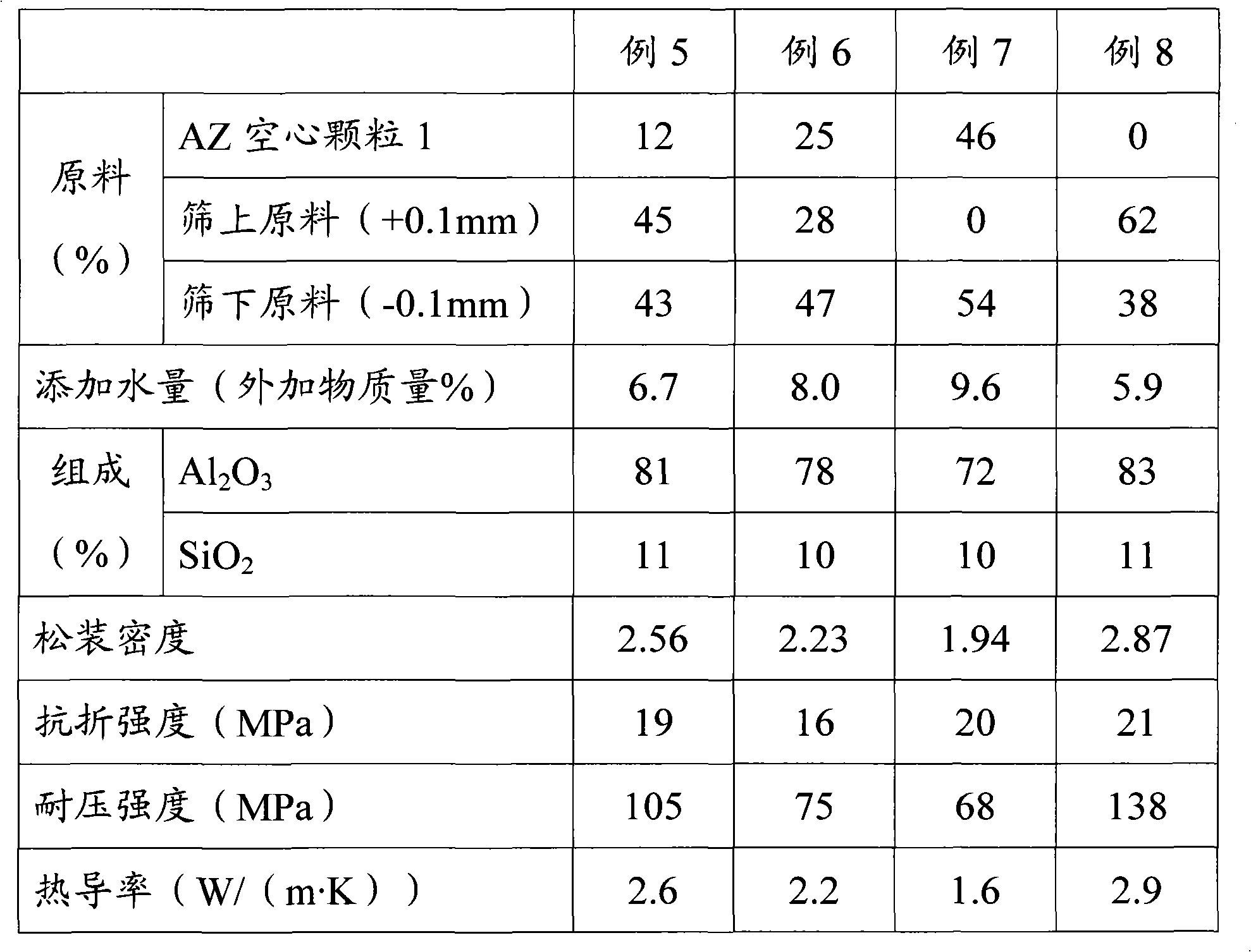

Powder composition for refractory castable and refractory castable equipped therewith

InactiveCN102432307AEnhanced destructive strengthLow thermal conductivityThermal conductivityAluminium oxide

The invention provides the powder composition for a refractory castable and a refractory castable equipped therewith. The powder composition for refractory castable is high in breaking strength, light in weight and low in thermal conductivity. Alumina-zirconia hollow particles are adopted as the essential ingredients of the powder composition for a refractory castable. The alumina-zirconium hollow particles comprise 67-99 % of Al2O3 by mass and 1-33 % of ZrO2 by mass with the total mass thereof over 96%.

Owner:旭硝子セラミックス株式会社

Preparation process for ultrathin ceramic brick

The invention discloses a preparation process for an ultrathin ceramic brick. Blank raw materials comprise the following components in percentage by weight: 35-40% of clay, 25-30% of feldspar, 8-13% of lithium chinastone, 5-10% of aluminum ore and 15-20% of white sand; the preparation process comprises the following steps: preparing materials, pulping, preparing powder, forming and drying, biscuiting, glazing and printing, carrying out glaze firing, carrying out fine trimming and packaging. Through the adoption of the preparation process disclosed by the invention, the dosage of raw materials is reduced, the ball-milling time and sintering time are shortened to some extent, and the sintering temperature is reduced to some extent, so that sewage discharge, exhaust emission and consumption of energy and raw materials are reduced greatly and manpower resources are saved greatly.

Owner:SICHUAN BAITA XINLIANXING CERAMIC GROUP

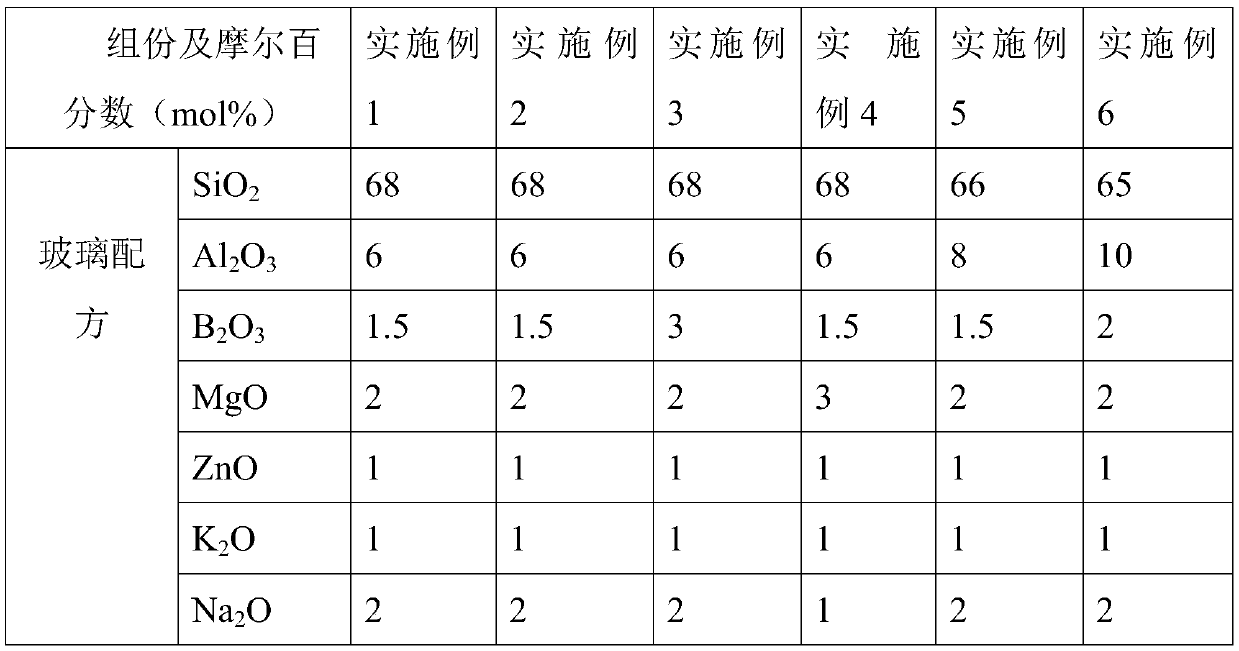

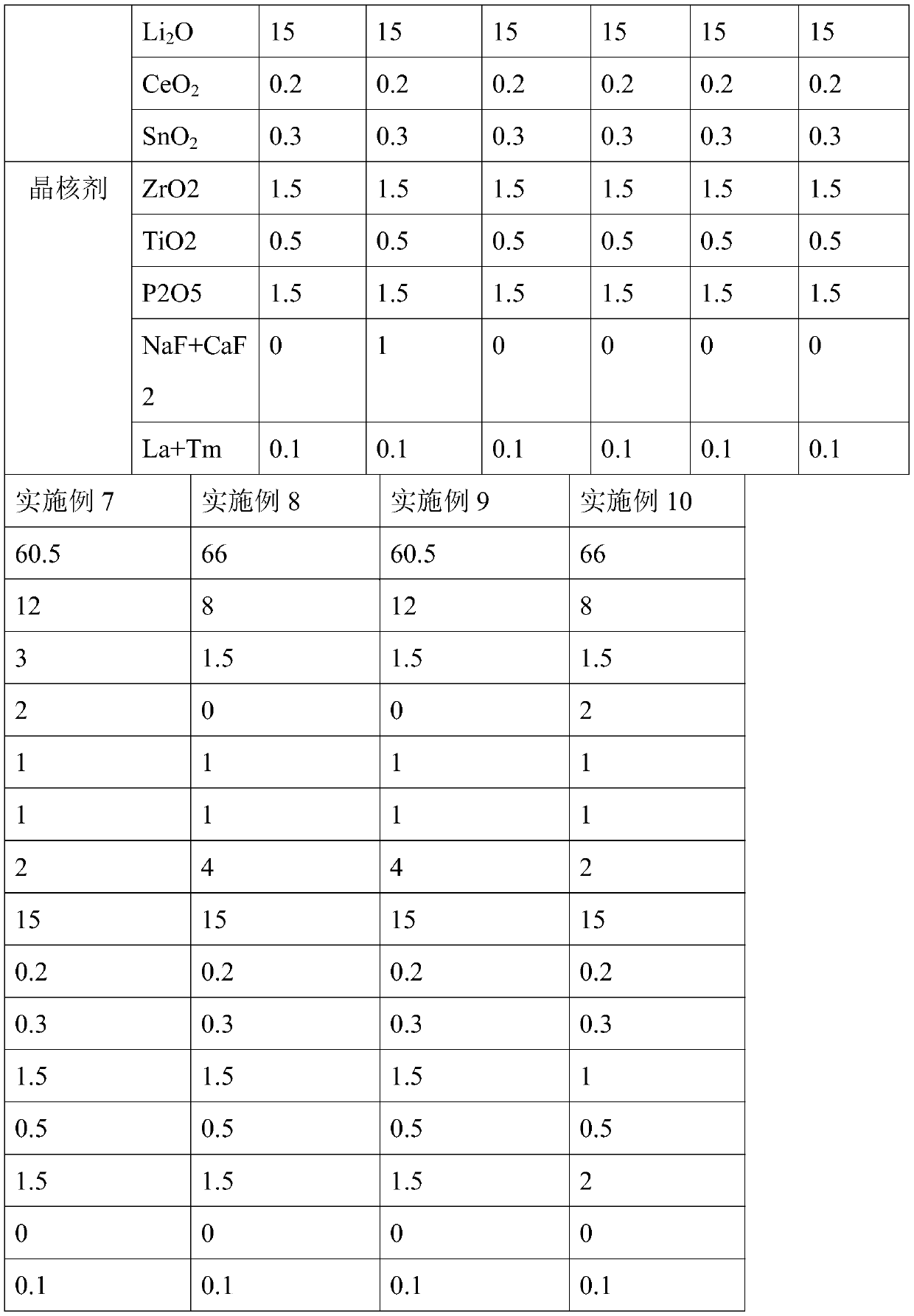

Multi-crystal-nucleus composite transparent glass ceramic and preparation method thereof

ActiveCN110981206AImprove resistance to damageHigh fracture toughnessMaterial nanotechnologyGlass meltingGlass-ceramic

The invention discloses multi-crystal-nucleus composite transparent glass ceramic and a preparation method thereof. The preparation method of the multi-crystal-nucleus composite transparent glass ceramic comprises the following steps that: S1, multiple nucleating agents are added during glass melting; S2, plain glass with a certain boundary dimension is obtained after processing; S3, the plain glass obtained in S2 is placed under the condition that the temperature is T1 and heated for 1-6 hours for annealing treatment, after annealing treatment is completed, the plain glass is placed under thecondition that the temperature is T2 and is heated for 1-6 hours and subjected to nucleation treatment, after nucleation treatment is completed, the plain glass is placed under the condition that thetemperature is T3 and heated for 0-3 hours for crystallization treatment, and T1 is smaller than T2. According to the invention, the glass ceramic containing various crystal nucleuses and crystal phases of lithium disilicate and petalite is prepared, the nucleation and crystallization energy required by the crystal precipitation is reduced through the multiple crystal nucleuses, the heat treatment temperature and the heat treatment time can be reduced, the crystal ratio can be adjusted, and the glass ceramic prepared through the preparation method has characteristics of enhanced damage resistance, good fracture toughness and wide application range.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

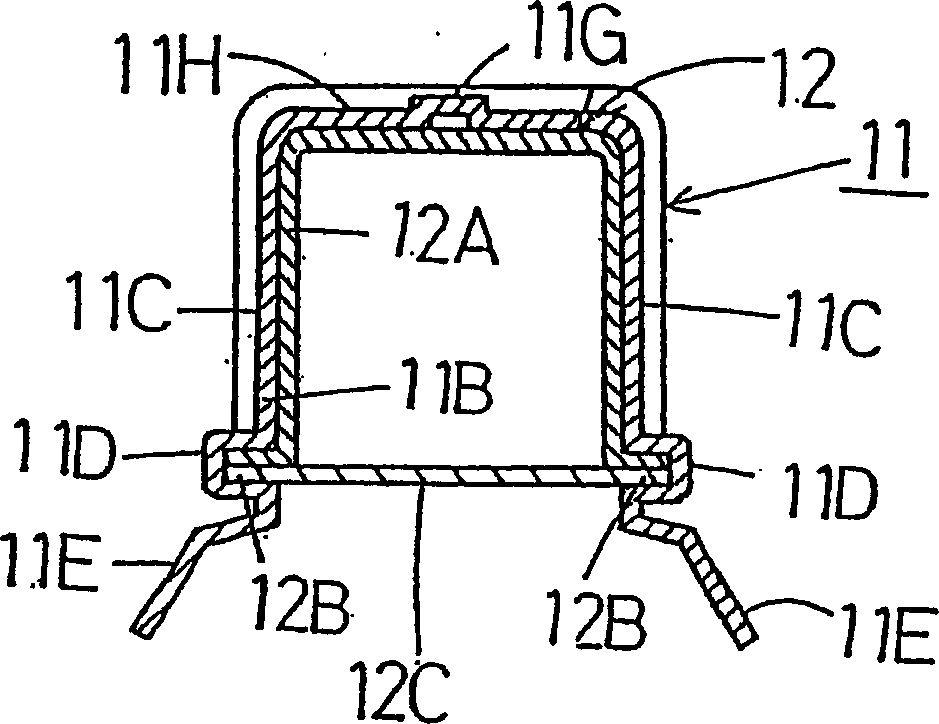

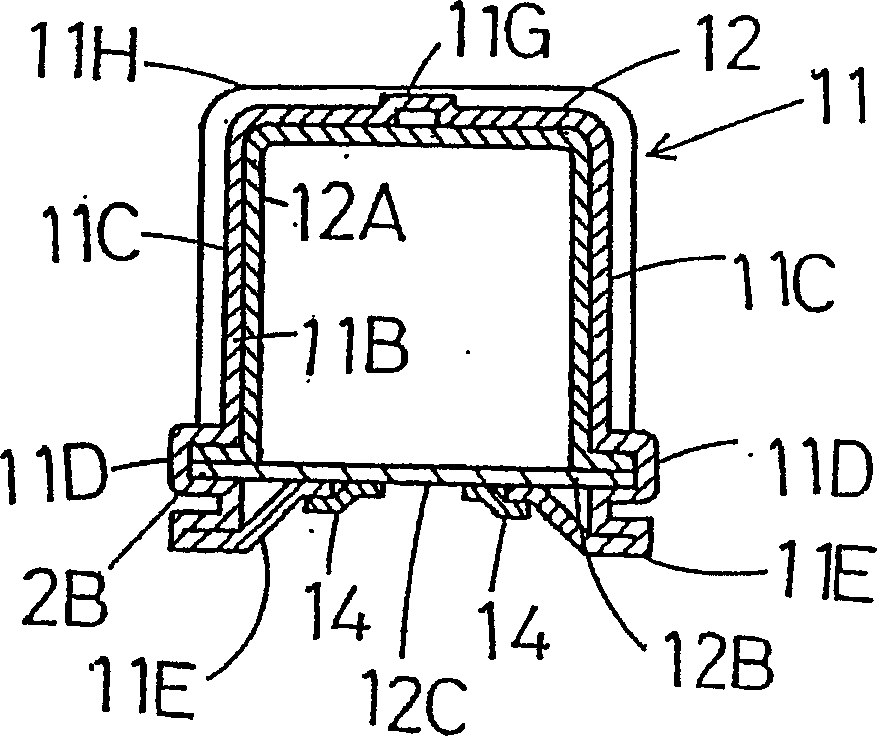

Masking material

The invention provides a heat-resistant and reusable shielding material (11). The shielding material (11) is made of a polymer alloy with a sea-island structure, and polyolefin is used as a continuous phase in the sea-island structure. And use engineering plastics selected from methylpentene copolymer, polysulfone, polyethersulfone, polyphenylene sulfide, polyphenylene ether, polyamideimide, polyetherimide, polyetheretherketone resin One, two or more are dispersed phases.

Owner:NAGOYA OIL CHEM CO LTD

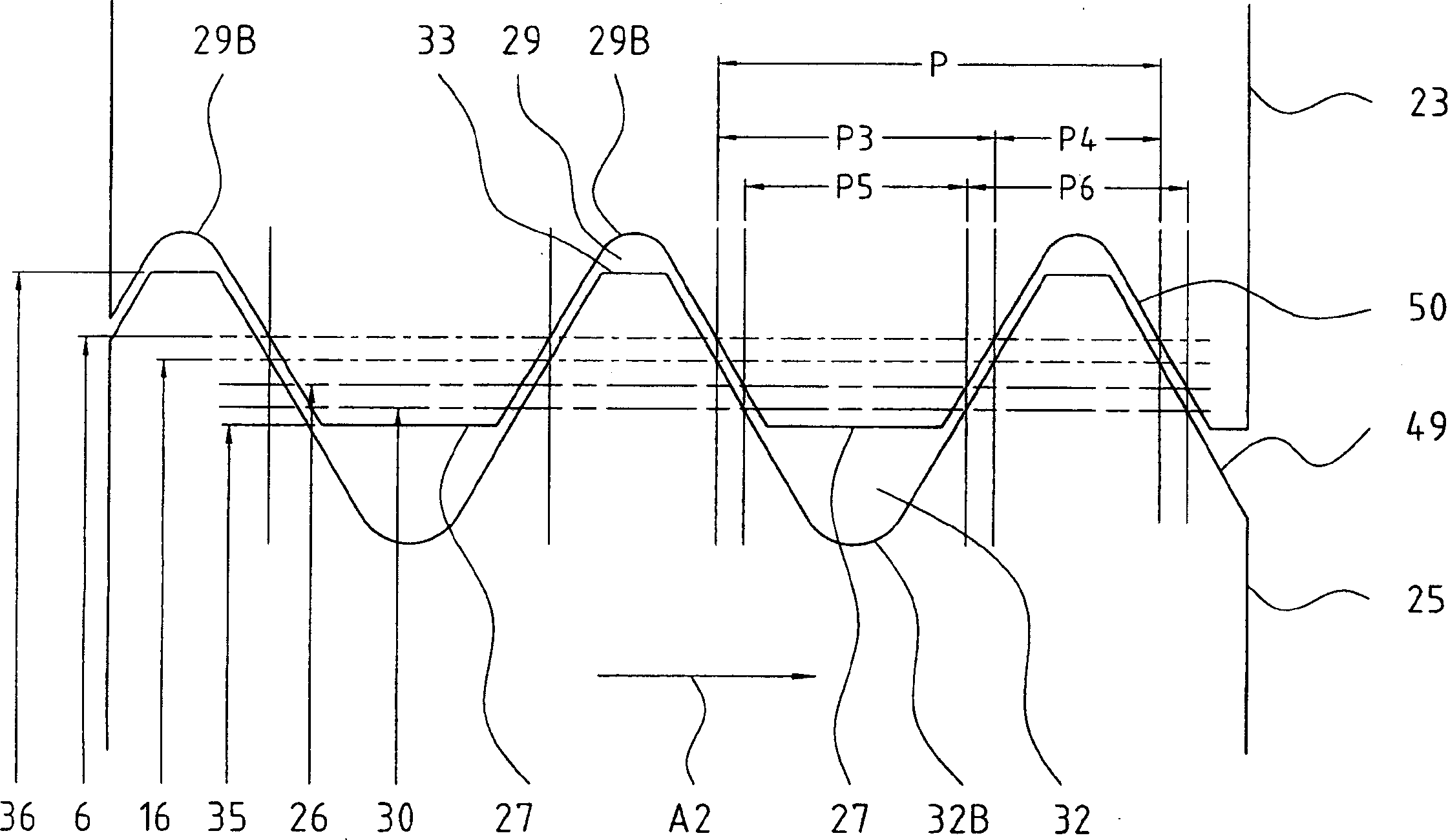

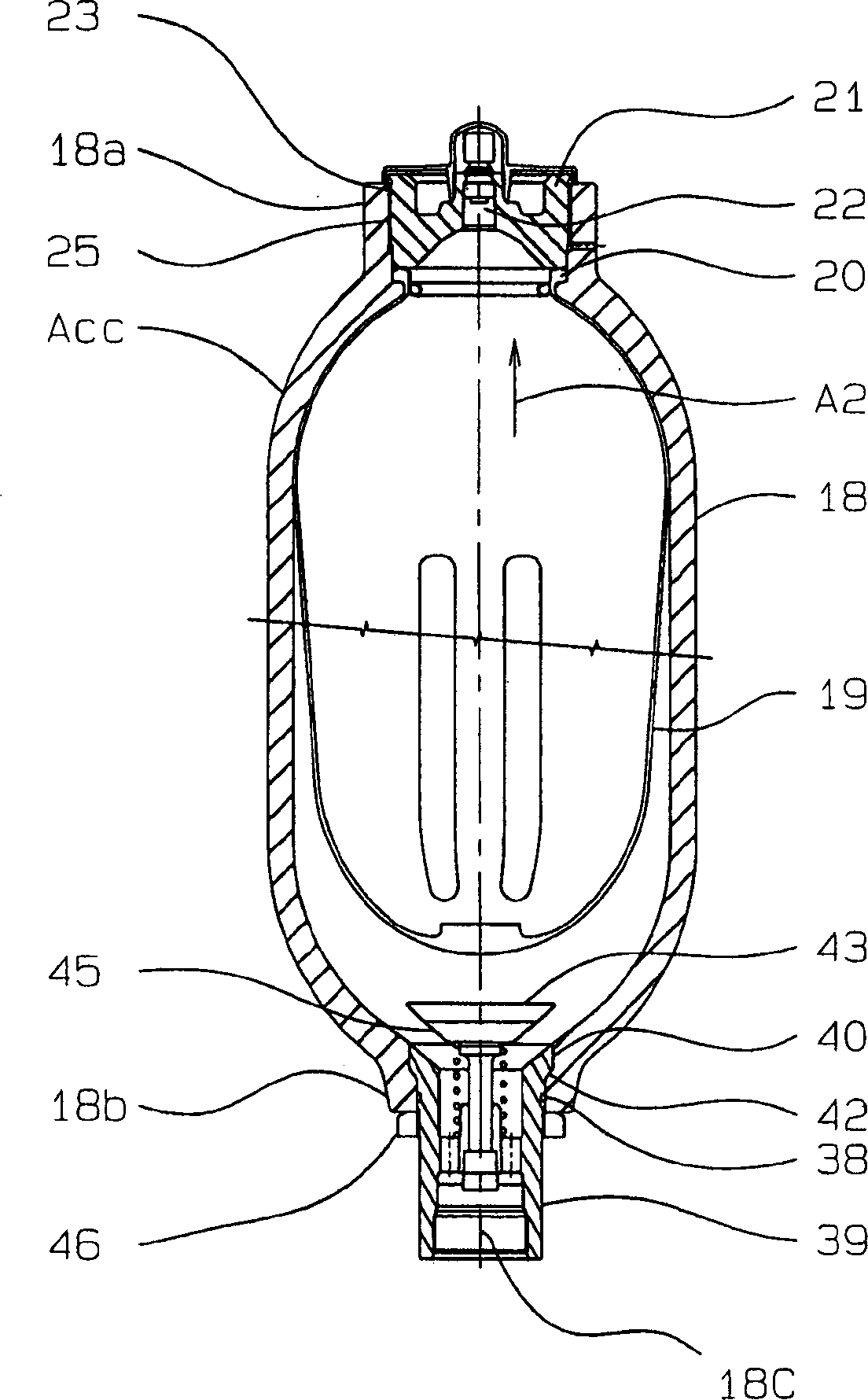

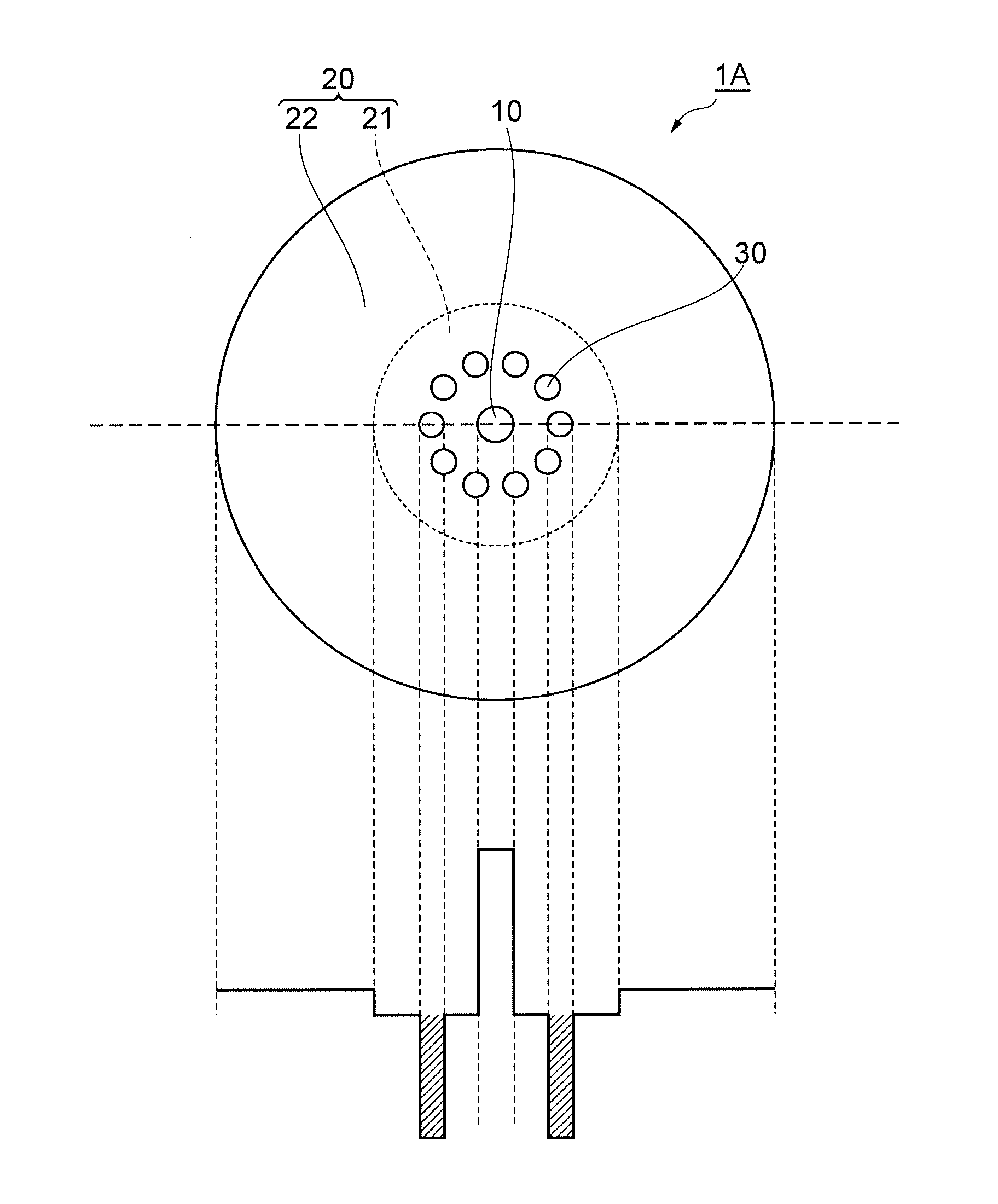

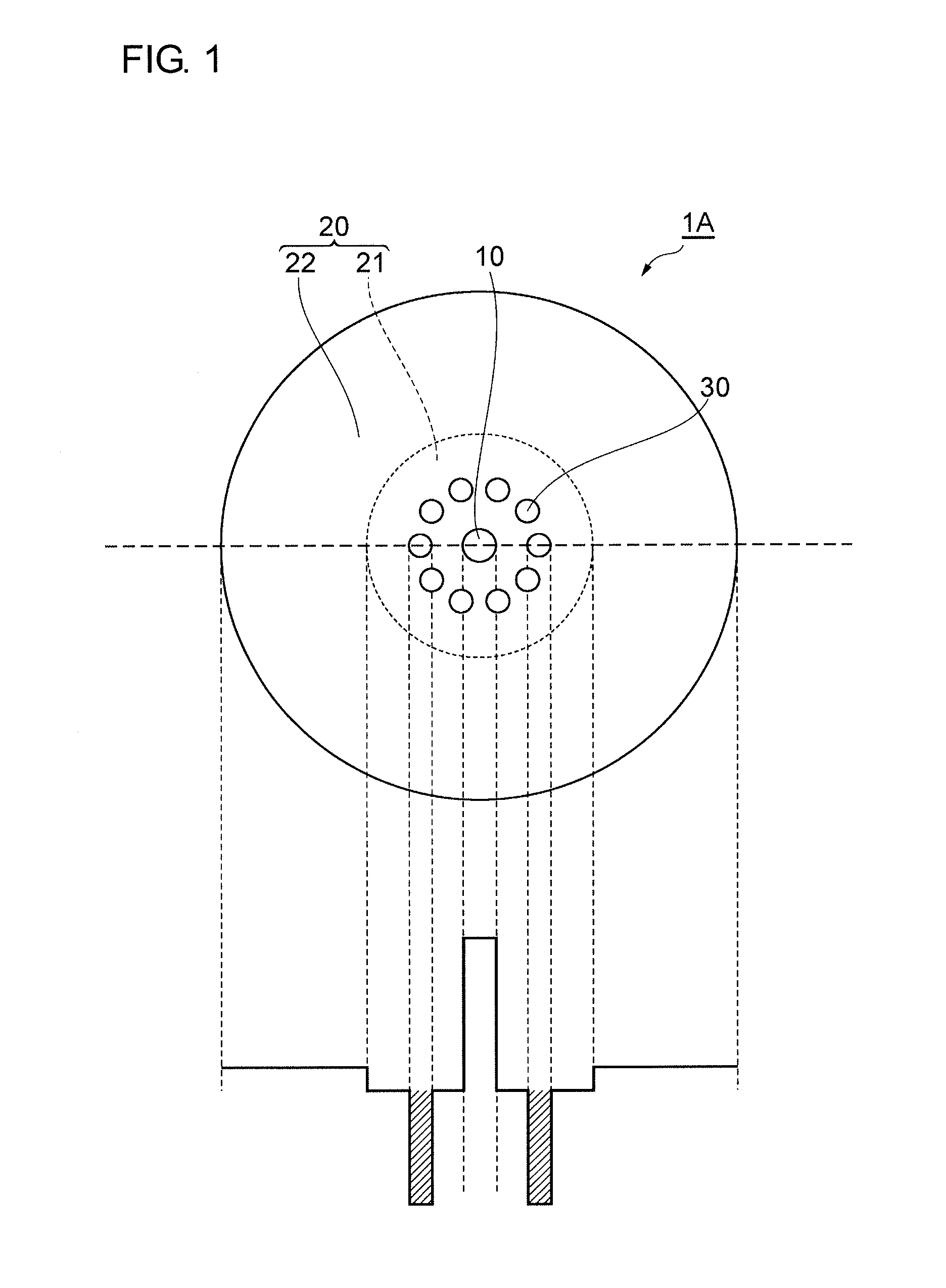

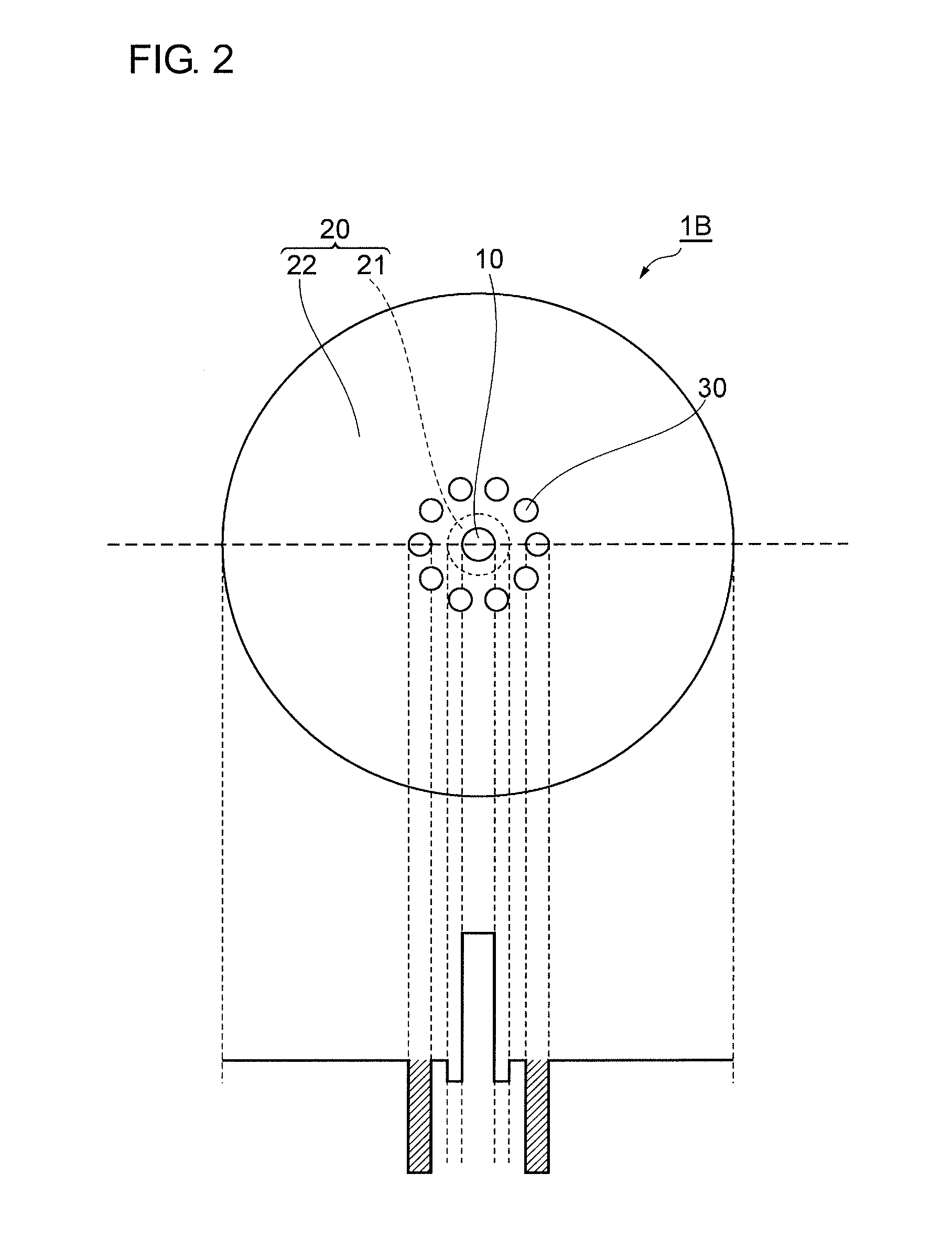

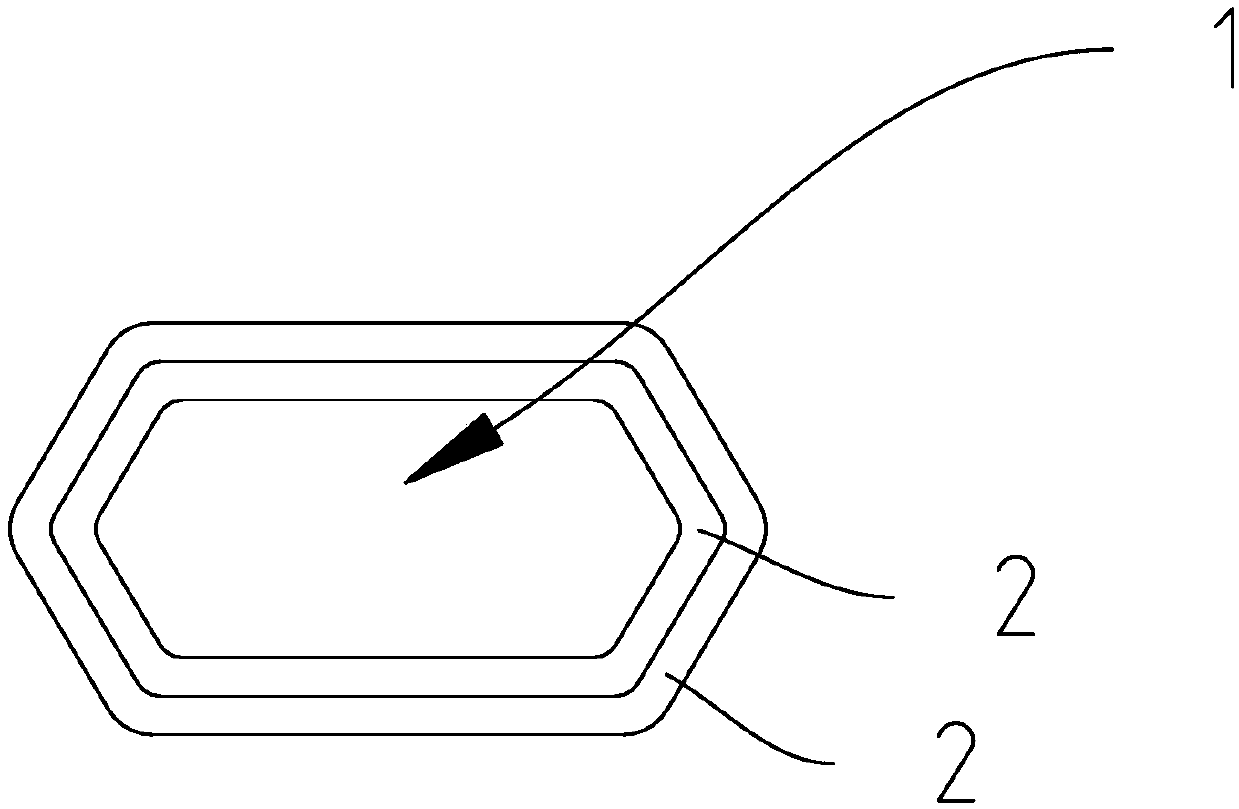

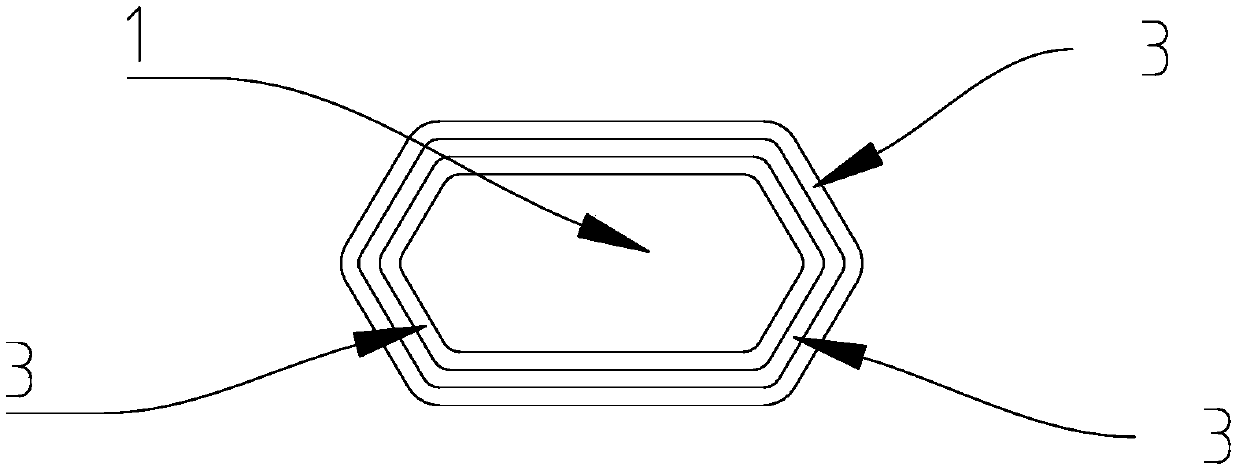

Optical fiber

InactiveUS20130064513A1Enhanced destructive strengthSmall transmission lossCladded optical fibreOptical waveguide light guideFiberEngineering

An optical fiber has a plurality of holes in a cladding around a core, and has a high failure strength and small transmission loss. The core is made of glass. The cladding surrounds the core, and the holes are formed in the cladding so as to extend along a central axis of the fiber. The holes are formed with constant intervals therebetween along a circle centered on the core, and each hole has a substantially circular cross section. The cladding is sectioned into two claddings. A residual stress in an inner region that is inside a circumcircle of the holes is a compressive stress.

Owner:SUMITOMO ELECTRIC IND LTD

Method for treating nickel-iron slag and ceramic brick

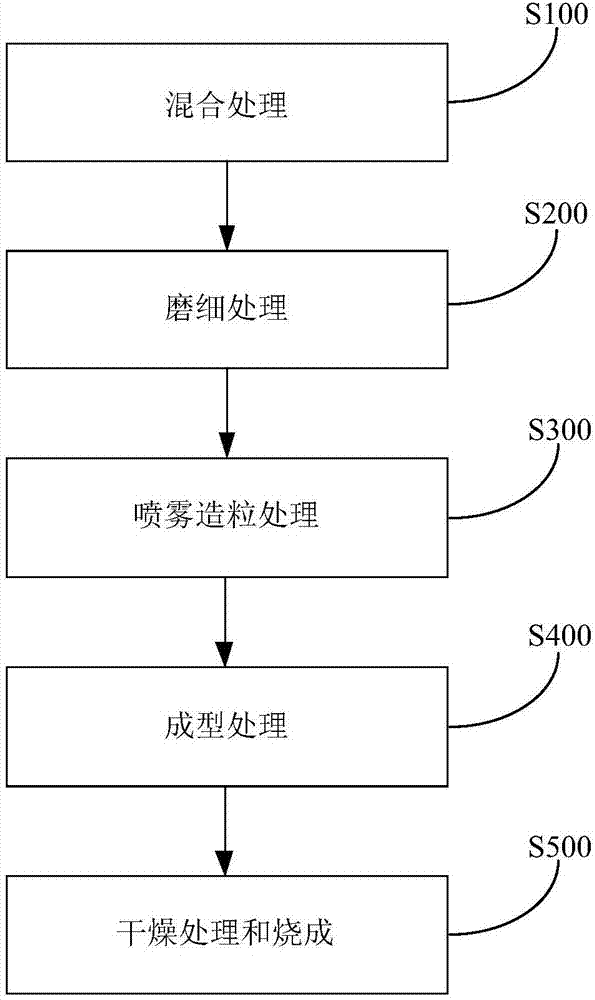

PendingCN107827439AEnhanced destructive strengthBroaden the way of resource utilizationCeramic materials productionClaywaresBrickSodium Bentonite

The invention discloses a method for treating nickel-iron slag and a ceramic brick. The method comprises the following steps: (1) mixing nickel-iron slag, bentonite, silica and red mud molten slag toobtain a mixed material; (2) finely grinding the mixed materials to obtain a powder material; (3) performing spraying pelletizing treatment on the powder material to obtain a granular material; (4) performing molding treatment on the granular material to obtain raw material plates; (5) performing drying treatment and sintering on the raw material plates sequentially, thereby obtaining ceramic bricks. By adopting the method, high-quality ceramic bricks can be prepared from metallurgy wastes, namely nickel-iron slag, a novel way for resource utilization of the nickel-iron slag is developed, andremarkable economic benefits and environment benefits are made.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

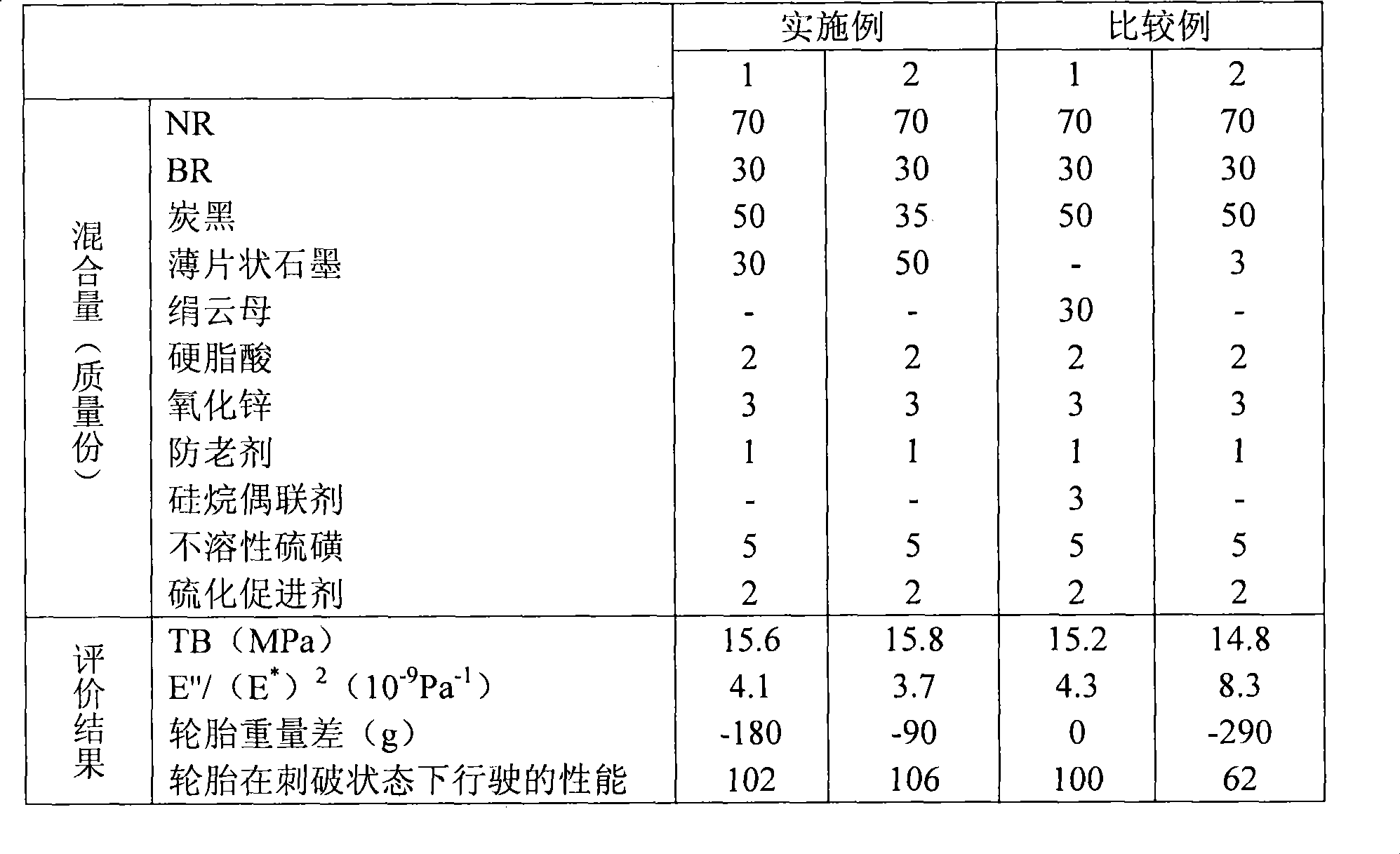

Rubber composition and run flat tire using the same

InactiveCN101415765AReduce fuel consumptionIncreased durabilitySpecial tyresTyre sidewallsBreaking strengthEngineering

Disclosed is a rubber composition containing 5-120 parts by weight of a flake graphite, which has an average aspect ratio of 3-80 and an average particle size of 2-80 mu m, per 100 parts by weight of a diene rubber component. This rubber composition is improved in all of breaking strength, low heat generation property, run flat durability and low fuel consumption property. Also disclosed is a run flat tire using such a rubber composition.

Owner:SUMITOMO RUBBER IND LTD

High-stability battledore frame and manufacturing process thereof

InactiveCN109603117AImprove symmetric distributionIncrease the number of lapsStringed racketsWeight distributionRaw material

The invention discloses a high-stability battledore frame and a manufacturing process thereof. The manufacturing process comprises the following steps: 1) preparing raw materials; 2) coiling a battledore frame; 3) fixing; 4) molding. By reducing the FAW, the battledore frame is manufactured through coiling according to an overlapped symmetric increase method, symmetric distribution of overlapped layers is improved, coils of the battledore frame can be effectively increased, the wall thickness of the cross section of the battledore frame can be reduced, the weight distribution uniformity consistence of the cross section of the battledore frame can be improved, and the battledore frame has stable rigidity, high strength and good playing performance.

Owner:南京源威复合材料科技有限公司

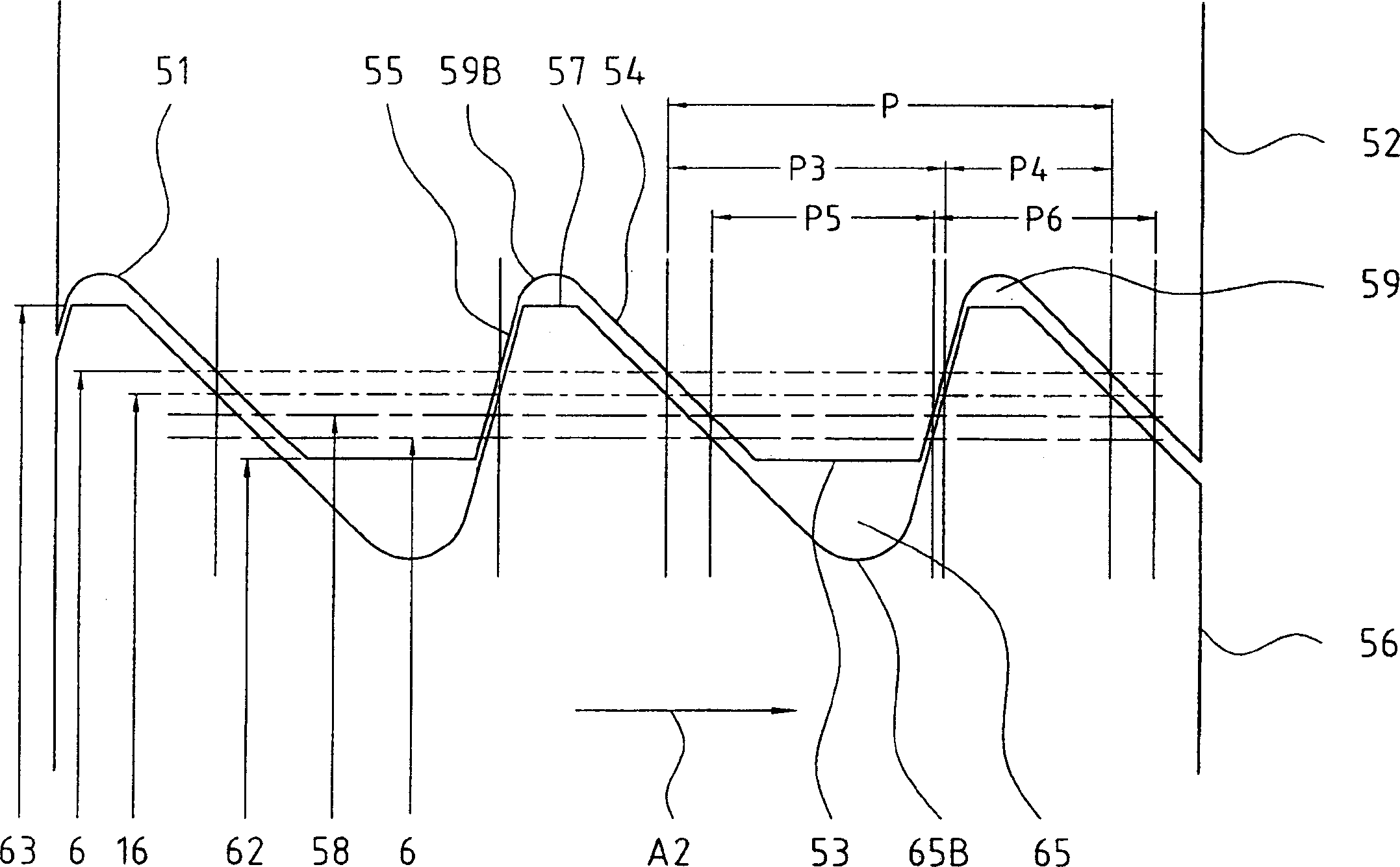

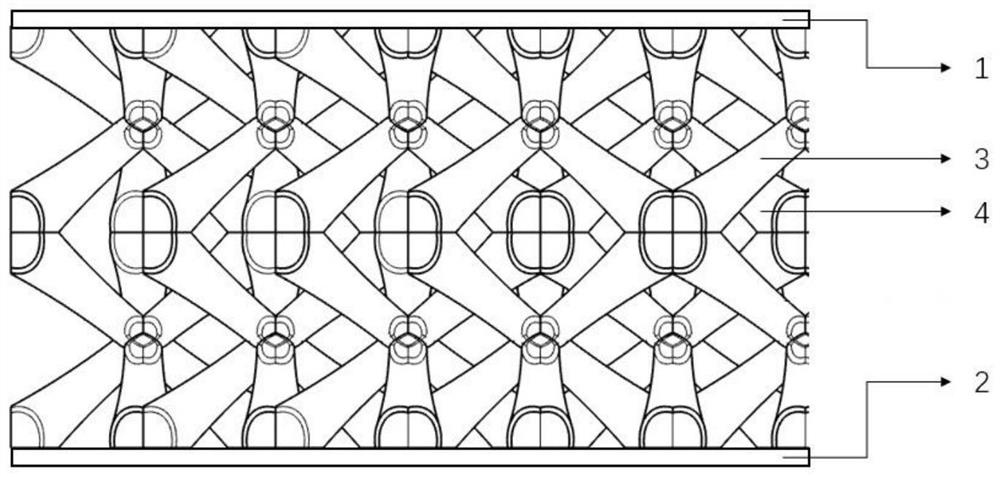

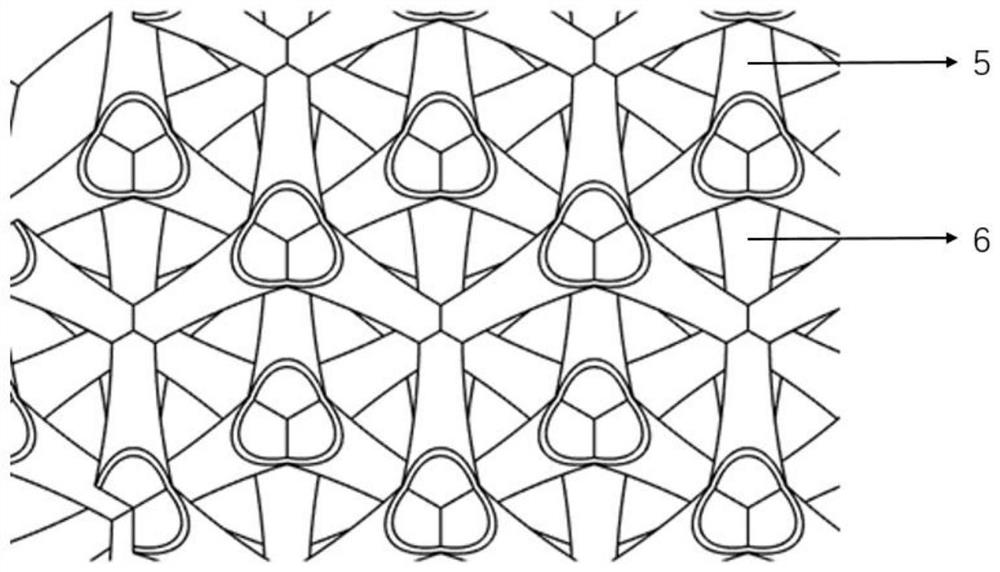

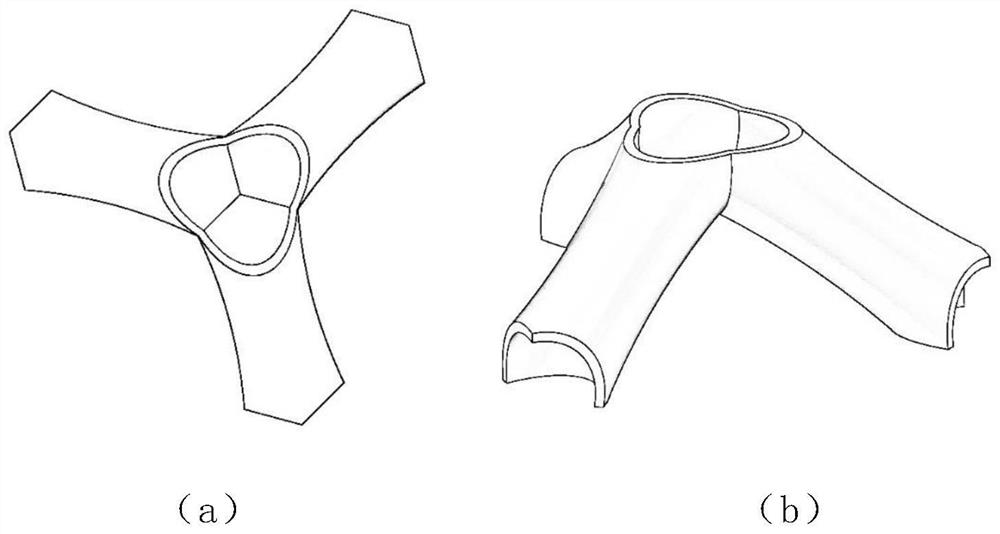

Additive-manufacturing-oriented pulmonary alveolar bionic super heat exchanger structure and production method thereof

ActiveCN113720193AIncrease the heat exchange areaImprove heat transfer effectAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringMechanical engineering

The invention discloses an additive-manufacturing-oriented pulmonary alveolar bionic super heat exchanger structure and a production method thereof. The upper side and the lower side of a super heat exchanger structure core are correspondingly connected with an upper panel and a lower panel, wherein the super heat exchanger structure core comprises multiple super heat exchanger structure unit cells, the multiple super heat exchanger structure unit cells are periodically arranged between the upper panel and the lower panel, and liquid to be cooled is arranged in the super heat exchanger structure core, between the super heat exchanger structure core and the upper panel and between the super heat exchanger structure core and the lower panel. According to the additive-manufacturing-oriented pulmonary alveolar bionic super heat exchanger structure and the production method thereof, an additive-manufacturing-technology-oriented pulmonary alveolar bionic super heat exchanger is produced, the pulmonary alveolar bionic super heat exchanger structure is obtained, and has the advantages of being efficient in heat exchange, compact in structure and high in breaking strength, the designability is high, production is flexible, and the pulmonary alveolar bionic super heat exchanger structure has wide application prospects in the fields of aerospace, ships, high-end equipment and national defense military.

Owner:XI AN JIAOTONG UNIV

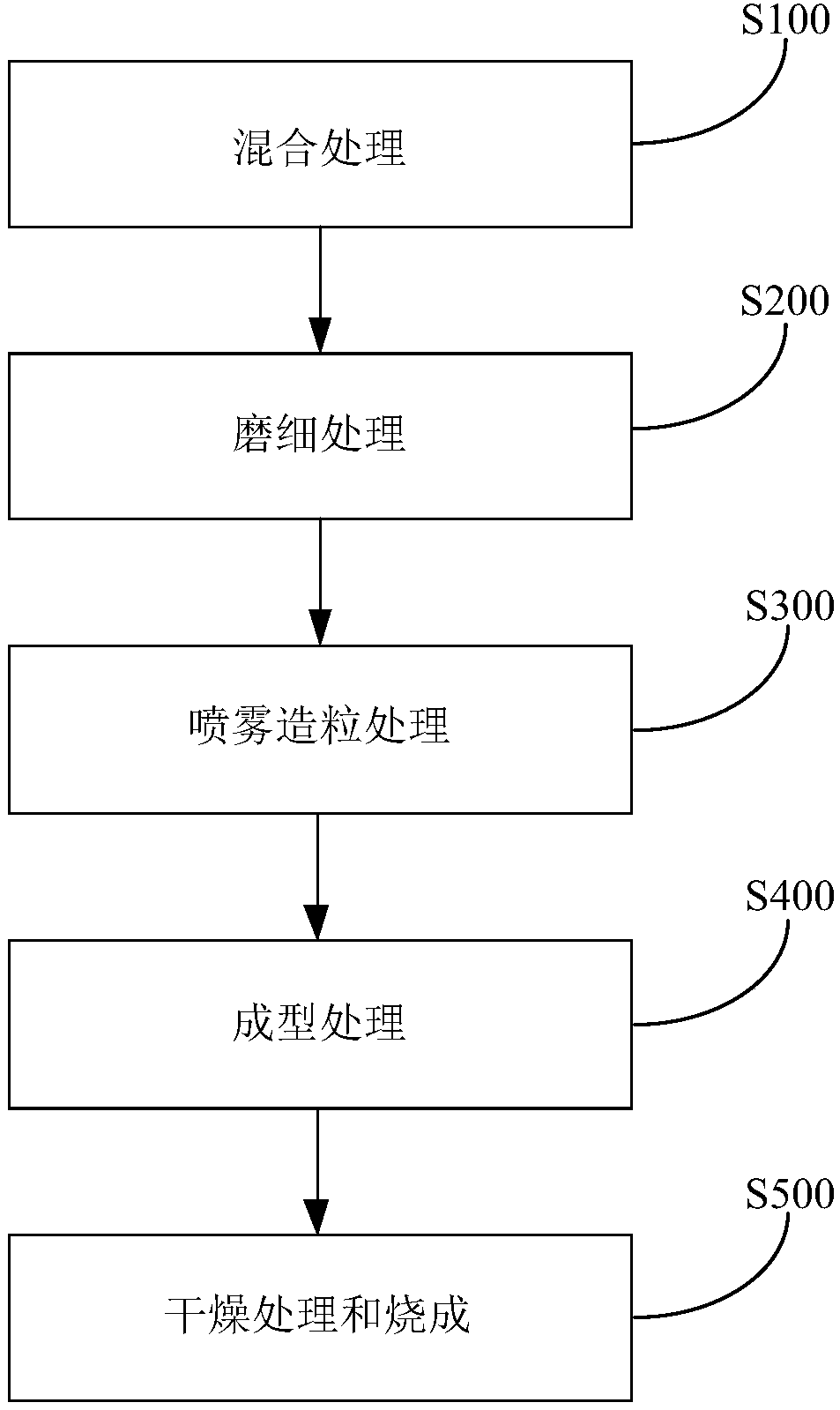

Chromium iron slag processing method and ceramic tiles

PendingCN107973586AEnhanced destructive strengthBroaden the way of resource utilizationCeramic materials productionClaywaresSpray GranulationBrick

The invention discloses a chromium iron slag processing method and ceramic tiles. The method comprises the following steps: (1) performing mixing on the chromium iron slag, clay and sandstone to obtain a mixture; (2) performing fine grinding treatment on the mixture to obtain a powdery material; (3) performing spraying granulation treatment on the powdery material to obtain a particle material; (4) performing molding treatment on the particle material to obtain raw material boards; and (5) performing drying treatment and firing on the raw material boards to obtain the ceramic tiles. Accordingto the method, high-quality ceramic tiles can be prepared by effectively using metallurgical scrap chromium iron slag, so that a new way for resource utilization of the chromium iron slag is opened up, therefore, the method has significant economic and environmental benefits.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

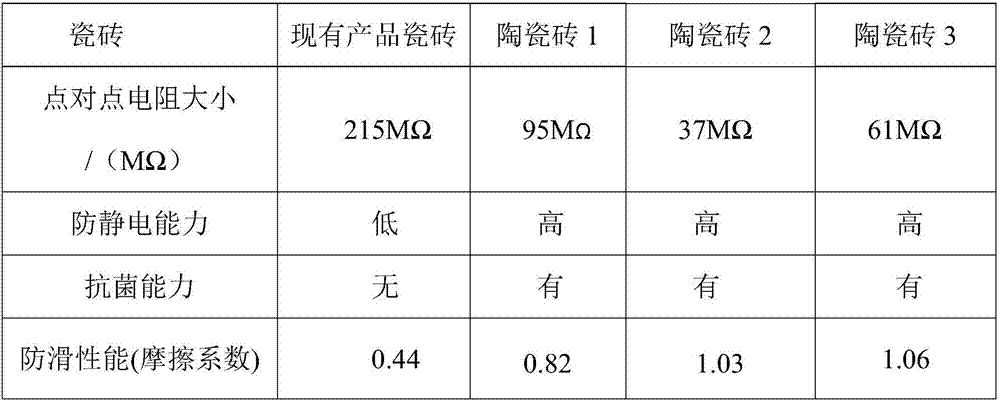

Antibacterial and antistatic ceramic glaze with high wear resistance and preparation method for ceramic tile

InactiveCN107417118AUniform and stable flow distributionStable anti-static effectCeramic glazeFineness

The invention discloses an antibacterial and antistatic ceramic glaze with high wear resistance and a preparation method for a ceramic tile. Glaze materials for the ceramic glaze comprise an antistatic glass frit, a composite antibacterial nanoparticle, an inorganic oxide whisker and stamp-pad ink, wherein the mass ratio of the antistatic glass frit, the composite antibacterial nanoparticle, the inorganic oxide whisker and the stamp-pad ink is (1-1.5):(0.5-0.8):(0.5-2):(2-2.5); the fineness of the antistatic glass frit is 60 to 125 meshes. The antibacterial and antistatic ceramic glaze with high wear resistance has the characteristics of stable antistatic effect, good antiskid effect and antifouling peroperty and high high-temperature resistance; a process for preparing an antibacterial and antistatic ceramic tile with high wear resistance from the ceramic glaze is simple and convenient to operate.

Owner:陆洁容

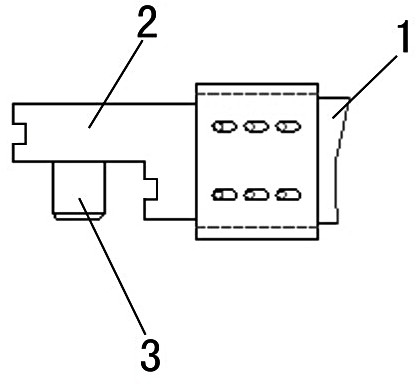

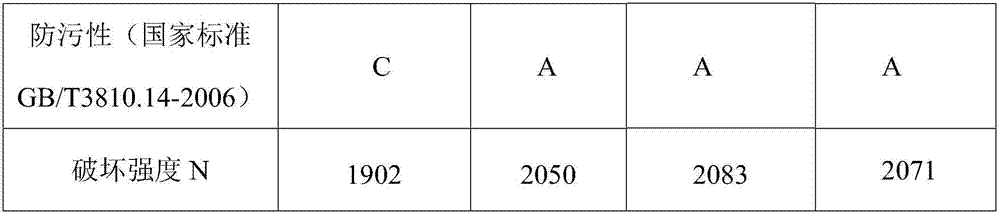

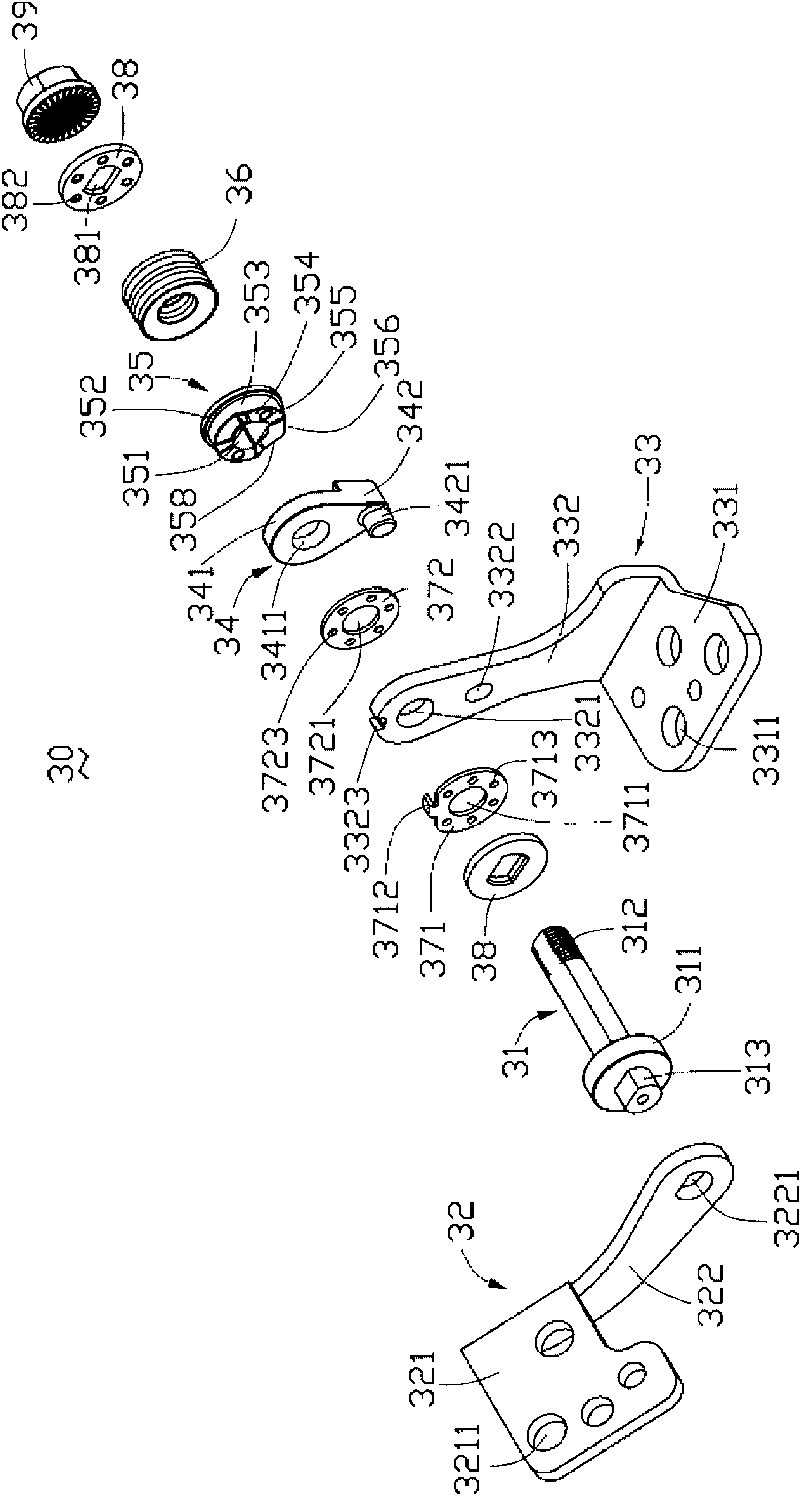

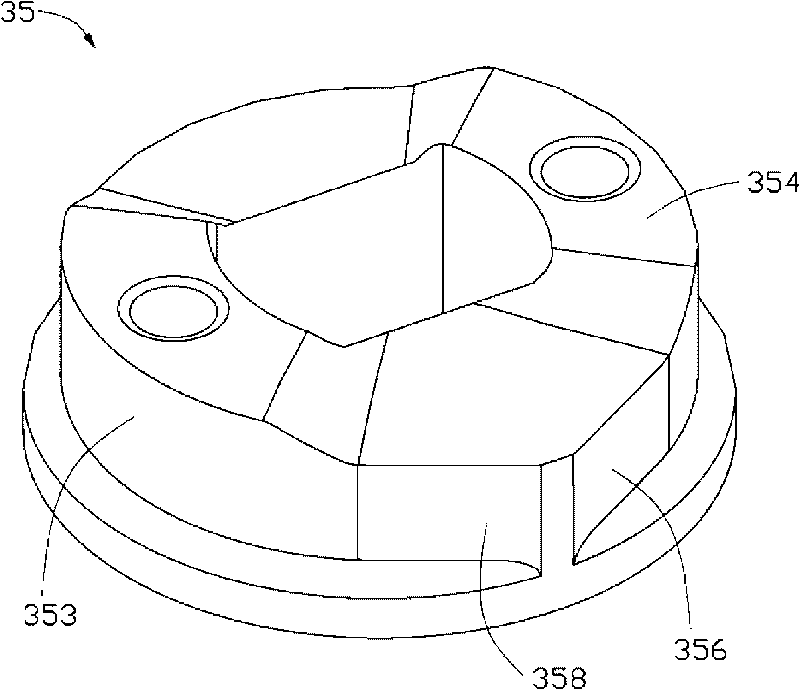

Hinge structure

InactiveCN101725626AImprove impact resistanceSuitable for meeting the development trend of light, thin and smallCasings/cabinets/drawers detailsDetails for portable computersBiomedical engineeringSurface fitting

The invention provides a hinge structure. The hinge structure comprises a pivot shaft, a rotating bracket, a fixed bracket, a fixing element and a limiting member, wherein the rotating bracket and the limiting member are connected with the pivot shaft in a non-rotating way; the fixed bracket and the fixing element are rotatably connected with the pivot shaft; the fixing member is fixedly connected with the fixed bracket; the fixing element is provided with a limiting step; a limiting surface fitting the limiting step is formed on the circumference of the limiting member; and one of the fixing element and the limiting member is provided with a positioning bump while the other is correspondingly provided with a positioning groove fitting the positioning bump. The limiting member includes a column body of which the periphery projects outwards and forms a limiting surface and an adjacent surface, wherein the limiting surface and the adjacent surface are all planes, one ends of the limiting surface and the adjacent surface are connected to each other through an outer periphery surface of a small segment of the column body, and the other ends of the limiting surface and the adjacent surface are respectively transited with the periphery of the column body in an arc state. The hinge structure has the beneficial effects of good limiting effect and low manufacturing cost.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Antique ceramic exterior wall tile subjected to sand blasting treatment and preparation method thereof

The invention discloses an archaized ceramic exterior wall tile subjected to sand blasting treatment and a preparation method of the archaized ceramic exterior wall tile. The preparation method comprises the following steps: firstly, mixing a bottom blank and a pigment to prepare a fabric base material; performing ball milling and pelleting on the mixture to obtain a pelletized bottom blank, pelletized imitation metal glaze powder and a pelletized fabric base material; according to a two-time material distribution process, firstly, applying imitation metal glaze powder and then applying a surface material basic material and a bottom blank; press-shaping a green body by using a pressing machine through a reverse beating process, and then overturning the green body; drying the green body; carrying out sand blasting treatment on the surface of the blank body by using a sand blasting machine; blending color paste and spraying the color paste; and sintering the green body to obtain the antique ceramic exterior wall tile. A silver color is presented after the imitation metal glaze powder is sintered, holes in the surface of a green body and the color of color water are integrated, and avivid antique effect is presented. The breaking strength and breaking modulus of the ceramic exterior wall tile are far higher than the national standard, and the water absorption rate is far lower than the national standard.

Owner:广宁广陶陶瓷有限公司

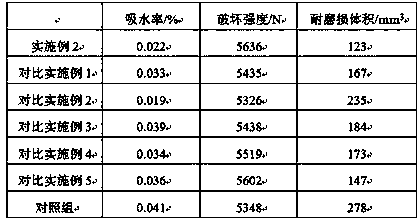

Preparation method of high-performance vacuum stone

The invention discloses a preparation method of high-performance vacuum stone, and belongs to the technical field of vacuum stone preparation. The preparation method comprises the following steps: (1)preparing a modified filler; (2) weighing raw materials; (3) preparing a mixture; (4) carrying out material distribution; (5) forming. The preparation method is invented to avoid the defects of the existing vacuum stone. The preparation method of the high-performance vacuum stone is researched and developed; by adding the modified composite filler and improving the preparation process, the waterabsorption and wear-resistant volume of the vacuum stone are effectively reduced, the water resistance and wear resistance of the vacuum stone are remarkably improved, the breaking strength of the vacuum stone is improved, the mechanical property of the vacuum stone is improved to a great extent, the comprehensive performance is excellent, and the application range is wide.

Owner:安徽力峰建材科技有限公司

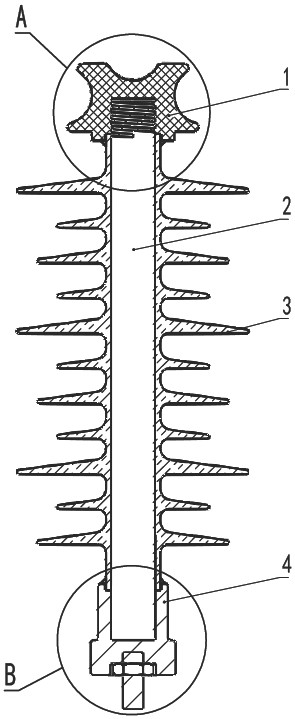

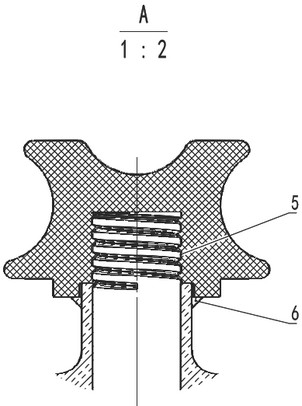

Porcelain head type pin composite insulator and porcelain head bonding process thereof

The invention provides a porcelain head type pin composite insulator and a porcelain head bonding process. The porcelain head bonding process comprises the following steps: preparation of an adhesive:mixing epoxy resin after heat preservation and a curing agent according to a mass ratio of 1: 0.8-1.2, and defoaming under negative pressure to obtain the adhesive; treatment of bonded parts: dippingabsolute ethyl alcohol into a clean rag for cleaning one end of the core rod with the external thread and the interior of the small hole I of the porcelain head, smearing a silane coupling agent after the ethyl alcohol is completely volatilized, and airing at room temperature for later use; bonding of the porcelain head: quantitatively injecting the prepared adhesive into the small hole I of theporcelain head, then uniformly smearing the adhesive into a threaded groove in the threaded end of the core rod, then screwing the upper end part, combined with the porcelain head, of the core rod into the small hole I, and then manually cleaning the adhesive overflown from the combined part of the porcelain head and an umbrella tray string; and heating curing: placing the bonded porcelain head composite insulator into an oven at the temperature of 130 DEG C to 170 DEG C to be subjected to heat preservation curing, so that the cost of the pin type composite insulator is reduced, and the electrical performance is improved.

Owner:XIANGYANG GUOWANG COMPOSITE INSULATORS

A multi-stage anti-shock pillar

InactiveCN103557016BEnhanced destructive strengthRealize segmental energy absorptionProps/chocksHydraulic cylinderEnergy absorption

The invention discloses a multi-stage anti-impact supporting column which comprises a top cover, an energy absorption barrel top cover, hydraulic columns, a multi-stage liquid energy absorption barrel, a trench energy absorption barrel, a hydraulic cylinder top cover, an alloy hydraulic cylinder, a piston, a hydraulic cylinder base, a three-purpose valve and the like, wherein the multi-stage liquid energy absorption barrel is sleeved in the hydraulic columns; the hydraulic columns are sleeved in the prefabricated trench energy absorption barrel; the prefabricated trench energy absorption barrel is sleeved in a light-weight and high-intensity hydraulic cylinder; under a condition of high dynamic load, the multi-stage liquid energy absorption barrel is used for performing quick abdication and energy absorption to prevent the phenomenon that inner elements of the three-purpose valve and column bodies of the hydraulic columns are damaged due to dramatic increasing of pressure in a hydraulic cylinder at the moment of impact and implement quick absorption of the energy which is caused by impact ground pressure and is applied to the supporting column; furthermore, the remote three-purpose valve is used for realizing a function of remotely lifting the supporting column, so that the injuries to people caused by surrounding rock collapse during column falling are avoided, and the safety of workers is guaranteed.

Owner:LIAONING TECHNICAL UNIVERSITY

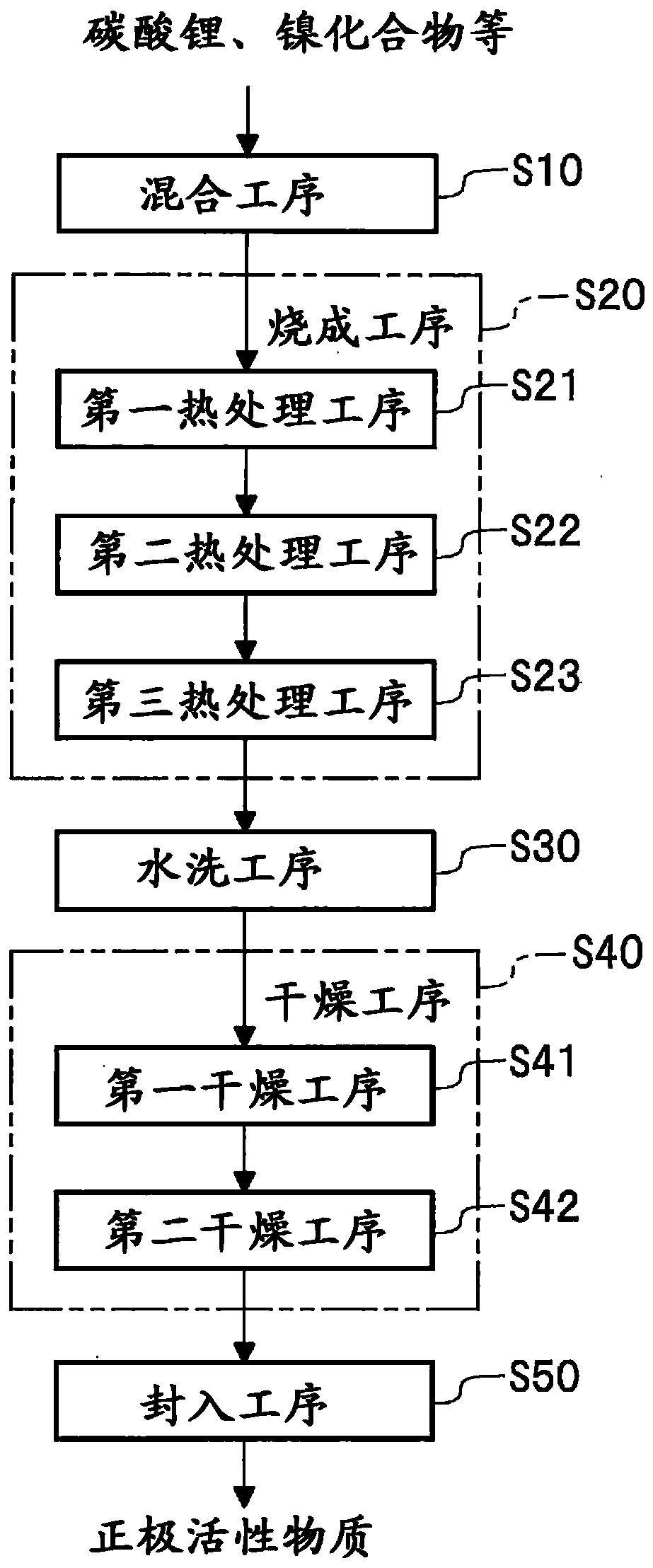

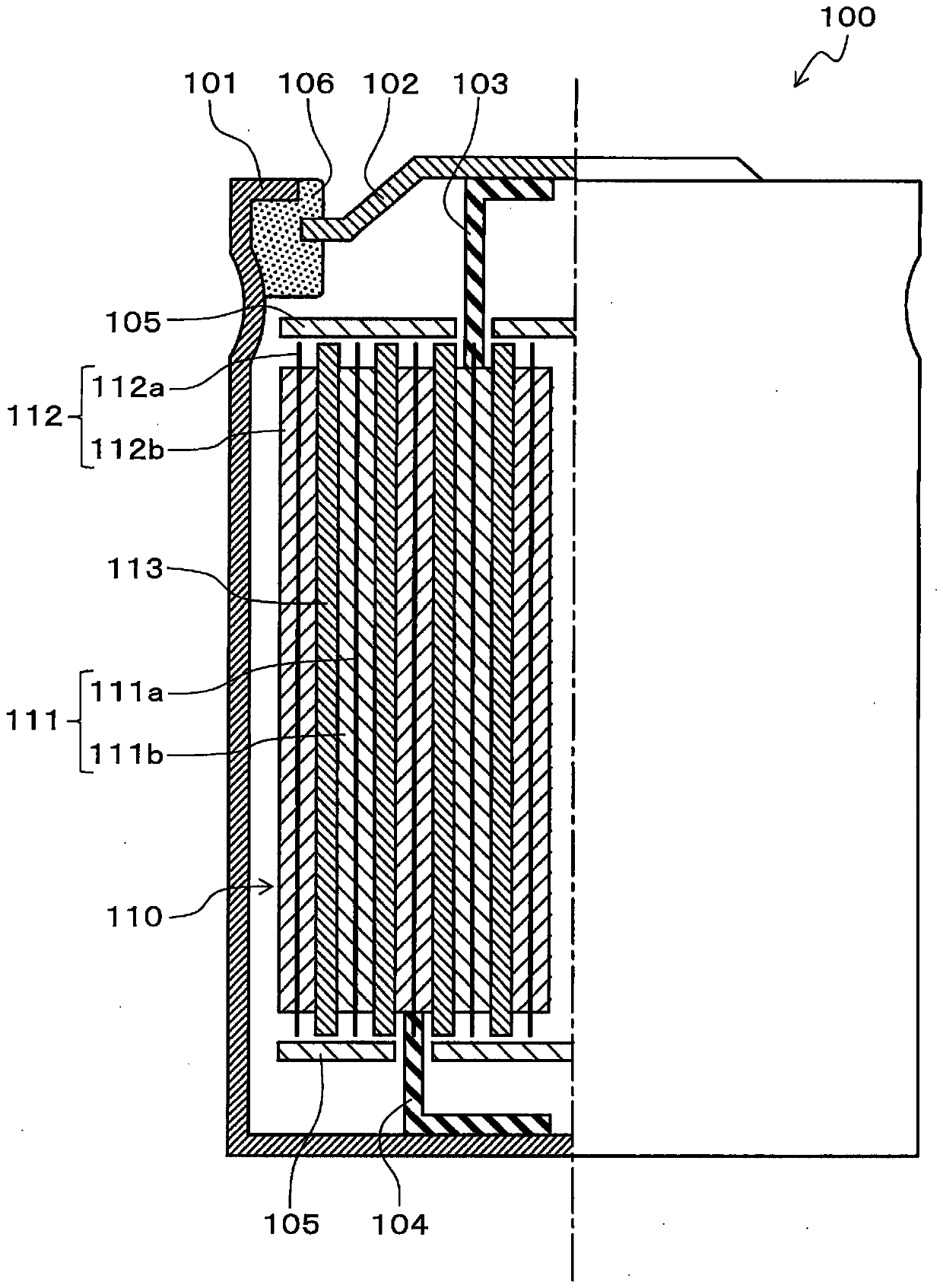

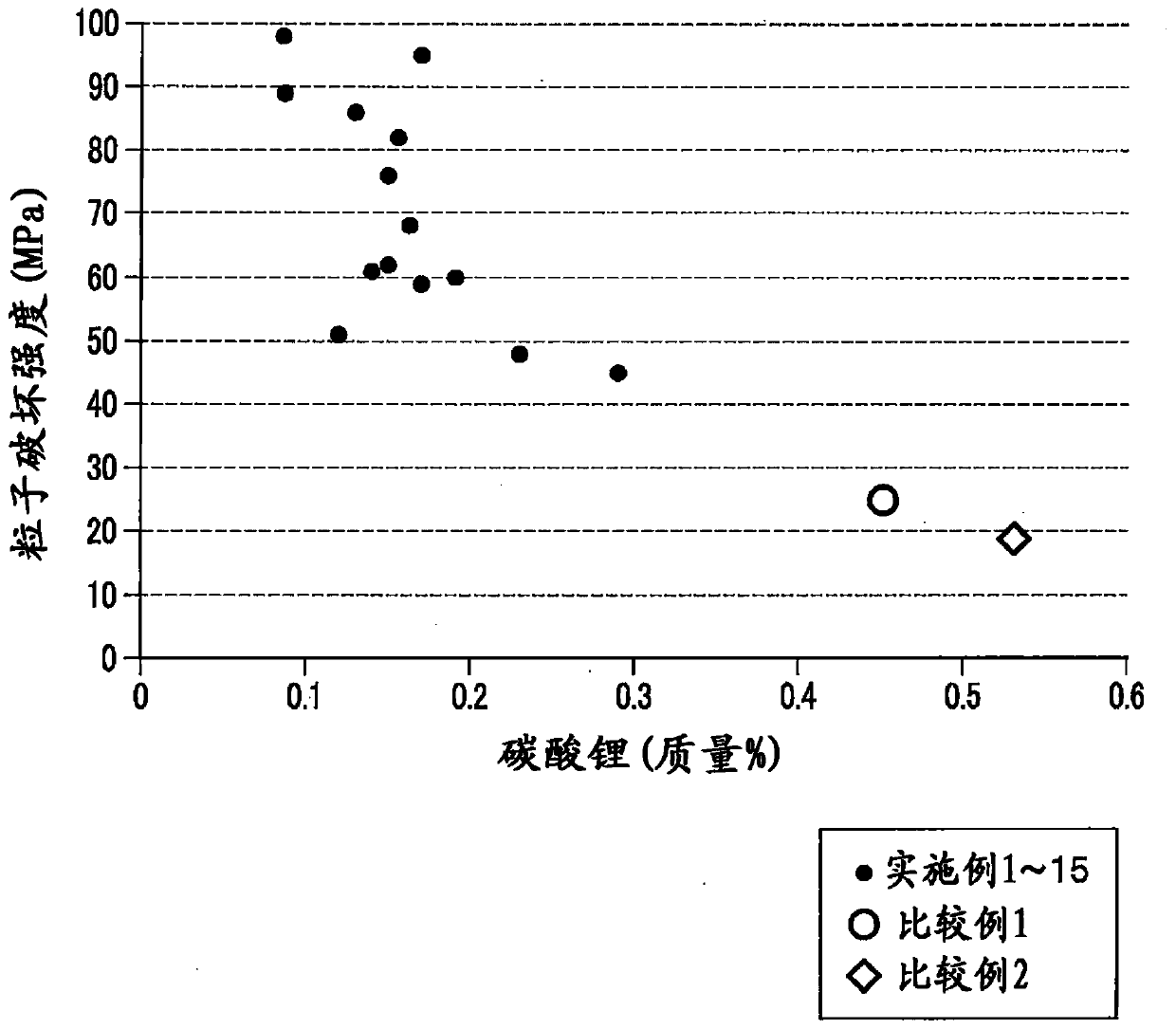

Positive electrode active material for lithium ion secondary batteries, method for producing the positive electrode active material for lithium ion secondary batteries, and lithium ion secondary battery

ActiveCN111052463AEnhanced destructive strengthConvenient coatingPositive electrodesLi-accumulatorsElectrical batteryPhysical chemistry

The present invention provides: a positive electrode active material for lithium ion secondary batteries, which has good coating workability, and wherein secondary particles that constitute a powder have high breaking strength; a method for producing a positive electrode active material for lithium ion secondary batteries; and a lithium ion secondary battery. The positive electrode active materialfor lithium ion secondary batteries according to the present invention contains primary particles of a lithium composite compound represented by formula (1) and secondary particles, in each of whichthe primary particles aggregate; the ratio of the average particle diameter of the primary particles to the average particle diameter of the secondary particles is from 0.006 to 0.25 (inclusive); theamount of lithium carbonate is 0.4% by mass or less; and the breaking strength of the secondary particles is 30 MPa or more. The formula (1) is Li<1+a>NixCoyM1<1-x-y-z>M2<z>O<2+alpha>, wherein M1 represents at least one element selected from the group consisting of Mn and Al; M2 represents at least one element selected from the group consisting of Mg, Ti, Zr, Mo and Nb; -0.1 <= a <= 0.2; 0.7 <= x< 1.0; 0 <= y < 0.3; 0 <= z <= 0.25; 0 < 1-x-y-z< 0.3; and -0.2 <alpha<= 0.2.

Owner:HITACHI METALS LTD

A kind of preparation technology of ultra-thin ceramic brick

A preparation process for ultra-thin ceramic bricks. The raw material of the blank is composed of 35-40% clay, 25-30% feldspar, 8-13% lithium china stone, 5-10% aluminum ore, and 15-20% white sand. %, including batching, pulping, powder making, forming and drying, biscuit firing, glaze printing, glaze firing, finishing packaging and other steps. The amount of raw materials used in the process of the invention is reduced, and the ball milling time, firing temperature and firing time are all shortened to a certain extent, resulting in great savings in sewage discharge, waste gas discharge, energy and raw material consumption, and human resources.

Owner:SICHUAN BAITA XINLIANXING CERAMIC GROUP

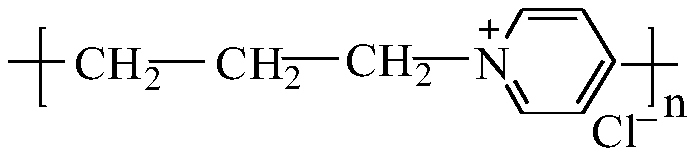

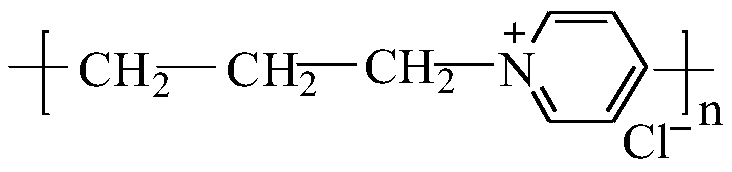

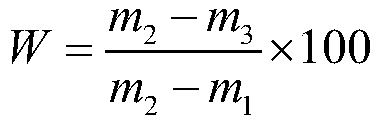

Wall fixing agent modified resin polymer for drilling fluid

The invention discloses a wall fixing agent modified resin polymer for drilling fluid. The wall fixing agent is prepared from the following raw materials: 200 to 220 parts of clear water, 20 to 30 parts of starch, 8 to 10 parts of 40% sodium hydroxide aqueous solution, 5.0 to 10.0 parts of 2-chloroethyl trimethyl ammonium chloride, 20 to 30 parts of acrylamide, 10 to 20 parts of methacryloyloxyethyl trimethyl ammonium chloride, 0.5 to 1 part of initiator, 10 to 20 parts of potassium nitrohumate, 10 to 20 parts of pseudo-boehmite, 0 to 12 parts of poly(1,3-propylidene pyridine chloride) and 20to 30 parts of adjuvant. The performance of the wall fixing agent is as follows: the water content is less than or equal to 10.0%, the low-temperature medium-pressure filtration loss is less than or equal to 10 mL, the wall fixing agent is aged for 16 h at normal temperature, high temperature of 150 DEG C and 180 DEG C, and the high-temperature high-pressure filtration loss is less than or equal to 30.0 mL. The drilling fluid can resist the high temperature of 180 DEG C or above, the filter loss is effectively reduced, the cementing force between rocks is enhanced, and the breaking strength isimproved, so that the well wall is stabilized, collapse is avoided, the safety of drilling engineering is ensured, and the drilling fluid also has the advantages of environmental friendliness and good biodegradability.

Owner:石家庄华莱鼎盛科技有限公司

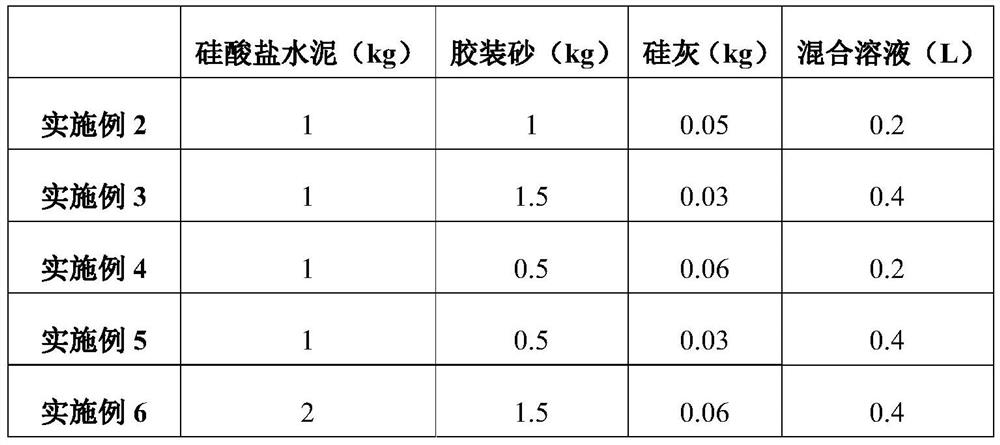

Adhesive for insulator

The invention relates to the technical field of insulator production materials, and particularly discloses an adhesive for insulators. The adhesive comprises the following raw materials in parts by weight: 1-2 parts of Portland cement, 0.5-1.5 parts of cementing sand, 0.03-0.06 part of silica fume and 0.2-0.4 part of a mixed solution, and the mixed solution comprises a defoaming agent, a water reducing agent and water. By adopting the adhesive obtained according to the proportion in the patent, the problems that in the prior art, the breaking strength of an insulator is reduced and the breakdown rate is increased due to the fact that the shrinkage rate is increased while high breaking strength is generated by increasing the lime-sand ratio are solved.

Owner:CHONGQING PIGEON ELECTRIC PORCELAIN CO LTD

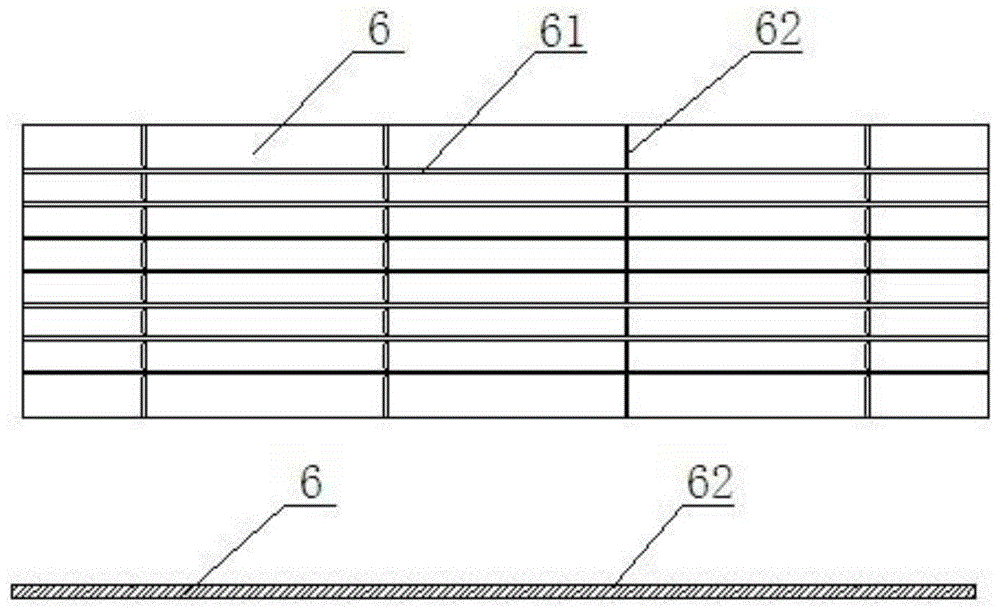

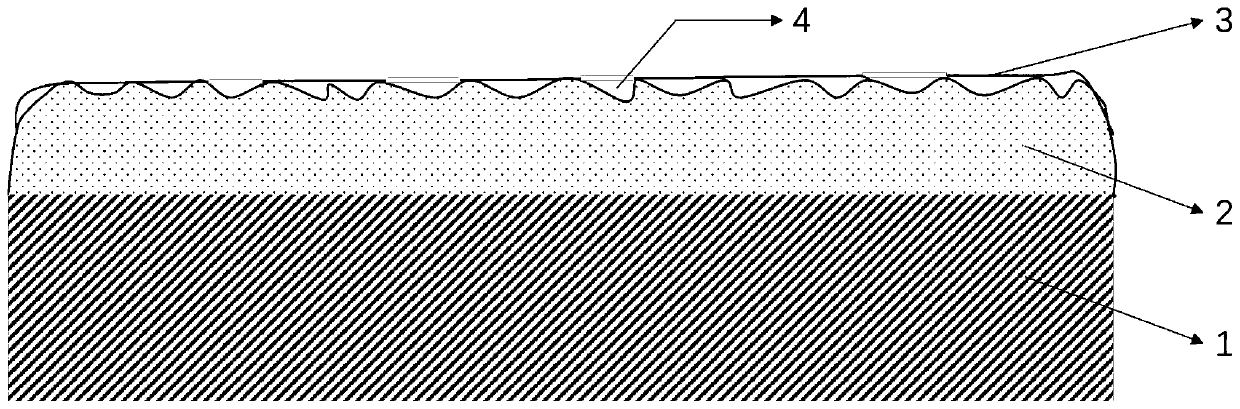

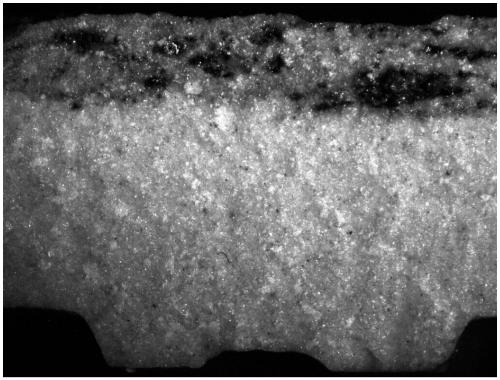

High strength ceramic thin plate and preparation method thereof

The invention discloses a high strength ceramic thin plate and a preparation method thereof, and the high strength ceramic thin plate is prepared from the following components by mass: 8-12% of stone chips soil, 12-25% of potassium sand, 10-15% of sodium stone powder, 10-15% of potassium sodium stone particles, 22-27% of calcined kaolin, 3-5% of lithium feldspar and 5-10% of flaky alumina grains. The method includes the steps of (1) mixing and ball milling of all the raw materials; (2) spray pulverization; (3) 24 hours of ageing and rotting of the material prepared by the step (2), and pressing; and (4) drying and final firing. The preparation method is simple, and by adding of the flaky alumina grains, water absorption rate of the ceramic thin plate is reduced, and the breaking strength is improved.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

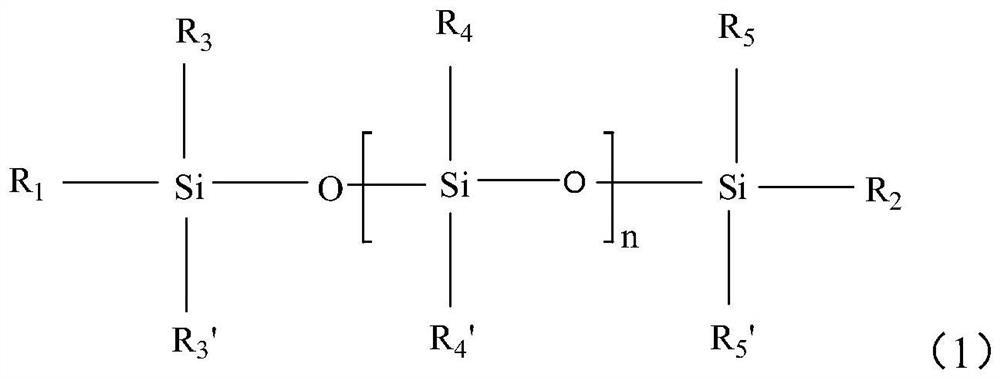

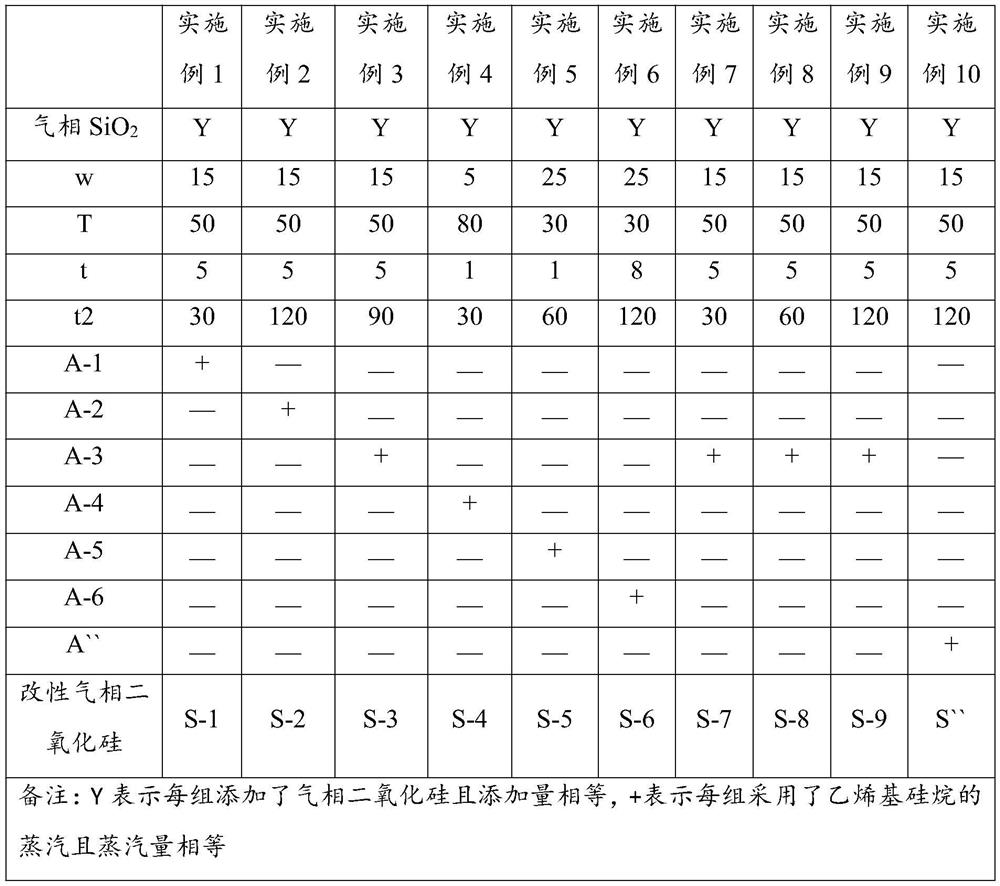

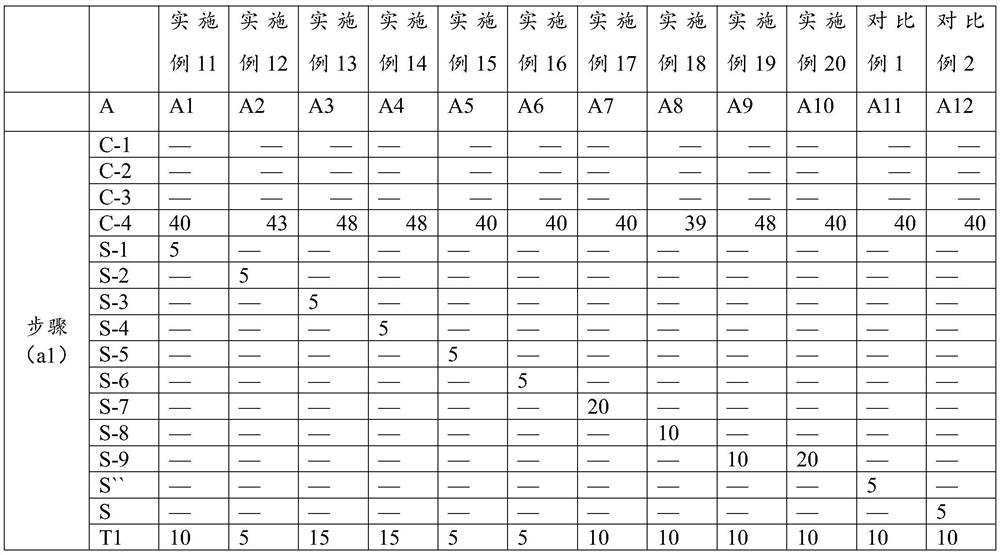

Dam adhesive and preparation method thereof, and fumed silica and preparation method thereof

PendingCN111876127AImprove adhesionHigh destructive strengthNon-macromolecular adhesive additivesPigment treatment with organosilicon compoundsPhotoinitiatorSilicone resin

The invention is applicable to the field of high polymer materials, and provides dam adhesive, a preparation method of the dam adhesive, fumed silica and a preparation method of the fumed silica. Thedam adhesive includes a component A and a component B, wherein the component A is prepared from 30 to 50 parts of vinyl silicone oil, 5 to 40 parts of vinyl silicone oil, 10 to 50 parts of silicon resin, 5 to 20 parts of modified fumed silica and 0.1 to 2 parts of photoinitiator; the component B comprises the following components in parts by weight: 30-50 parts of vinyl silicone oil, 5-40 parts ofvinyl silicone oil, 10-40 parts of hydrogen-containing silicone oil, 5-20 parts of modified fumed silica, 5-20 parts of silicon resin, 0.1-2 parts of an adhesive and 0.01-2 parts of a thixotropic agent; during use, the component A and the component B are mixed according to the weight ratio of 1 : (0.8-1.2). The dam dam adhesive has the advantages of moderate viscosity, low curing temperature, easiness in application, good compatibility with a base material and an organic silicon liquid optical adhesive and the like, can be stored at normal temperature and has good storage stability.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

Self-cleaning super-hydrophilic ceramic material and preparation method thereof

ActiveCN113979788AFlat surfaceImprove self-cleaning abilityCoatingsCeramic materials productionKaolin clayPotassium feldspar

The invention provides a self-cleaning super-hydrophilic ceramic material and a preparation method thereof. The self-cleaning super-hydrophilic ceramic material comprises a first coating and a second body layer, wherein the first coating comprises nano titanium dioxide, nano aluminum trioxide and nano silicon dioxide; and the second body layer comprises quartz, kaolin, aluminum oxide, potassium feldspar, zinc oxide and magnesian mud. The first coating on the surface of the self-cleaning super-hydrophilic ceramic material is thin and can be closely associated with the second body layer, and the nano titanium dioxide in the first coating has photocatalytic activity, so that the self-cleaning of the ceramic material can be realized, and the combination of the first coating, the nano titanium dioxide and the second body layer has super-hydrophilic performance and is beneficial to the removal of oil stains.

Owner:亚细亚新材料科技股份公司

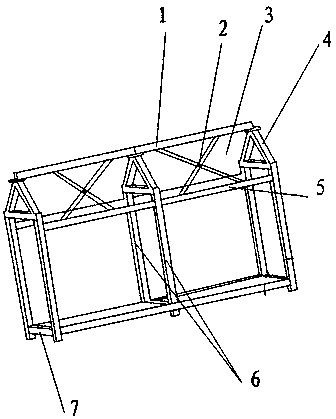

Simple steel-frame structure

InactiveCN109667345AHigh strengthEasy splicing combinationBuilding roofsHeat proofingBreaking strengthSteel frame

The invention discloses a simple steel-frame structure which comprises top beams, roof support rods, heat-insulating plates, roof tripods, horizontal support beams, vertical columns and longitudinal support beams; the roof tripods, the vertical columns and the longitudinal support beams are connected with each other by end part connectors, so as to form support components of a simple house; threeor more support components are fixedly connected into an overall steel-frame structure of the house through the top beams and the horizontal support beams. In the simple steel-frame structure providedby the invention, original joints are changed; all the components are matched and spliced with each other so as to realize multidirectional higher breaking strength of connection at joints; all the joints are conveniently and quickly spliced and assembled, are high in strength and can be easily detached; conditions are created for standardization, universalization and higher safety of construction of the simple house; when the simple house is not required, the simple house can be quickly detached; all the components after detaching can be reused, so that waste is reduced and economical and environment-friendly effects are achieved.

Owner:丹阳市俊腾五金有限公司

Submerged arc sintering flux for ferrite-austenite duplex stainless steel and preparation method thereof

ActiveCN109926758BGood sealing and moisture-proof effectHigh breaking strengthWelding/cutting media/materialsSoldering mediaFerrosiliconSS - Stainless steel

A submerged arc welding sintering flux (F-A for short) for ferritic-austenitic duplex stainless steel used for welding chemical tankers disclosed by the invention is prepared from solder and potassium sodium water glass, wherein the solder by Al 2 o 3 , CaF 2 、BaF 2 , MgO, SiO 2 、TiO 2 、K 2 O, ferrosilicon, ferromanganese and ferromolybdenum are mixed. The invention also discloses a preparation method of the above-mentioned F-A duplex stainless steel submerged arc sintering flux for chemical transport ships. The composition formula of the present invention has good mechanical properties of the weld metal, high low-temperature impact toughness at -20°C, especially the ratio of ferrite to austenite can be kept at about 1:1, and has excellent corrosion resistance; the welding arc is stable, Smoke and dust, the slag removal in the groove is good, the weld shape is beautiful, and the weld bead transition is smooth and tidy.

Owner:上海纪好旺造船科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com