Dam adhesive and preparation method thereof, and fumed silica and preparation method thereof

A technology of fumed silica and dams, applied in adhesives, dyed organosilicon compound treatment, fibrous fillers, etc., can solve the problems of difficult sizing, poor wettability of substrates, poor bonding of substrates, etc., and achieve destructive strength High, improved adhesion, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

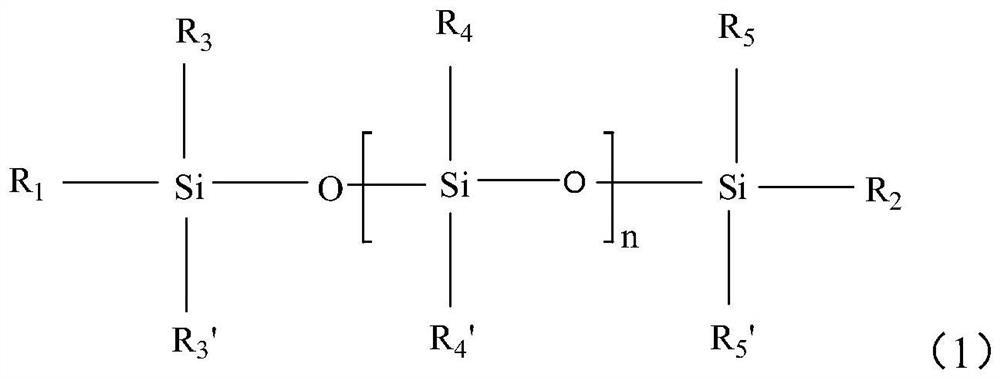

[0048] The embodiment of the present invention also provides a kind of preparation method of said dam glue, comprising:

[0049] 30-50 parts of vinyl silicone oil with a viscosity of 50,000-120,000 mPa.s and 5-20 parts of modified fumed silica are placed in a vacuum state and mixed to obtain the first base rubber;

[0050] Put the first rubber base, 5-40 parts of vinyl silicone oil with a viscosity of 100-50000 mPa.s, 0.1-2 parts of initiator and 10-50 parts of silicone resin in a high-speed shear mixer, shear and mix, Get component A;

[0051] Put 30-50 parts of vinyl silicone oil with a viscosity of 50,000-120,000 mPa.s and 5-20 parts of modified fumed silica in a vacuum state, and mix them to obtain the second base rubber;

[0052] The second rubber base and 10-40 parts of hydrogen-containing silicone oil, 0.1-2 parts of binder, 0.01-2 parts of thixotropic agent, 5-20 parts of silicone resin and 5-40 parts of silicone resin have a viscosity of 100-50000mPa.s Place the vin...

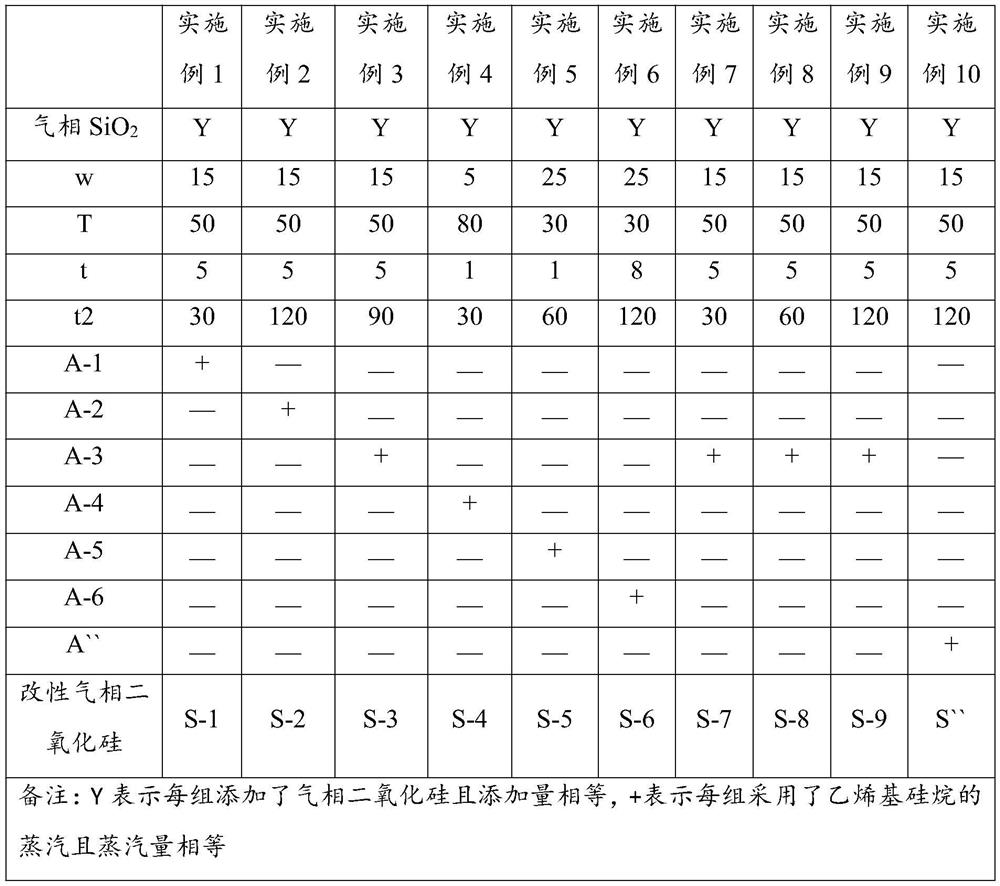

Embodiment 1~10

[0077] The preparation of embodiment 1~10 modified fumed silica

[0078] S1: Soak fumed silica with hydrochloric acid solution under heating conditions;

[0079] S2: Rinse the fumed silica soaked in step S1 repeatedly with pure water, adjust the pH to 7, and dry it to obtain pretreated fumed silica;

[0080] S3: The pretreated fumed silica obtained in step S2 is placed under the vapor of a siloxane coupling agent to contact and react in a fluidized bed to obtain modified fumed silica.

[0081] Wherein, the heating temperature in step S1 is 30°C-80°C; the mass percentage of HCl in the hydrochloric acid solution is 5%-25%; the soaking time is 1h-8h.

[0082] Wherein, the baking time in step S3 is 30min to 120min; the siloxane coupling is a vinylsilane coupling agent, specifically tetramethyltetravinylcyclotetrasiloxane, hexamethylhexavinylcyclohexasiloxane One or more of alkane, vinyltriethoxysilane, vinyltrimethoxysilane, vinyltris(β-methoxyethoxy)silane, vinyltriacetoxysilan...

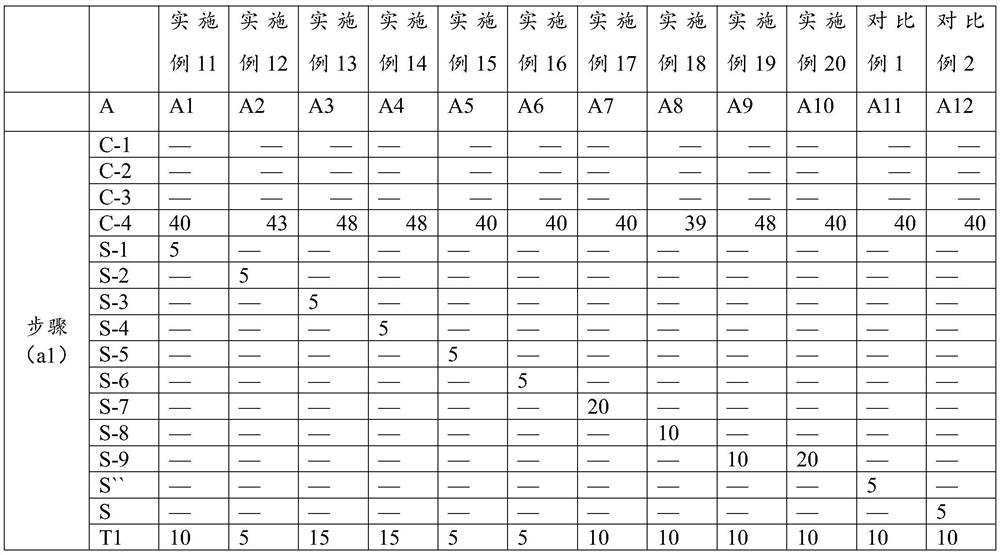

Embodiment 11~20、 comparative example 1

[0090] The preparation of embodiment 11~20, comparative example 1~2 dam glue

[0091] Preparation of component A:

[0092](a1) Put 30-50 parts of vinyl silicone oil with a viscosity of 100000mPa.s and 5-20 parts of modified fumed silica in a vacuum state, mix at high speed, and then continue to ultrasonicate the mixed product in a vacuum state Treat for 5-15 minutes to obtain the base rubber;

[0093] (a2) Take the base rubber obtained in step (a1), 5-40 parts of vinyl silicone oil with a viscosity of 100-50000mPa.s, 0.1-2 parts of initiator and 10-50 parts of silicone resin in a high-speed shear mixer , shear and mix to obtain component A;

[0094] Preparation of component B:

[0095] (b1) Put 30-50 parts of vinyl silicone oil with a viscosity of 100000mPa.s and 5-20 parts of modified fumed silica in a vacuum state, mix at high speed, and then continue to sonicate the mixed product in a vacuum state Treat for 5-15 minutes to obtain the base rubber;

[0096] (b2) Take the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com