Patents

Literature

2382results about How to "Moderate viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

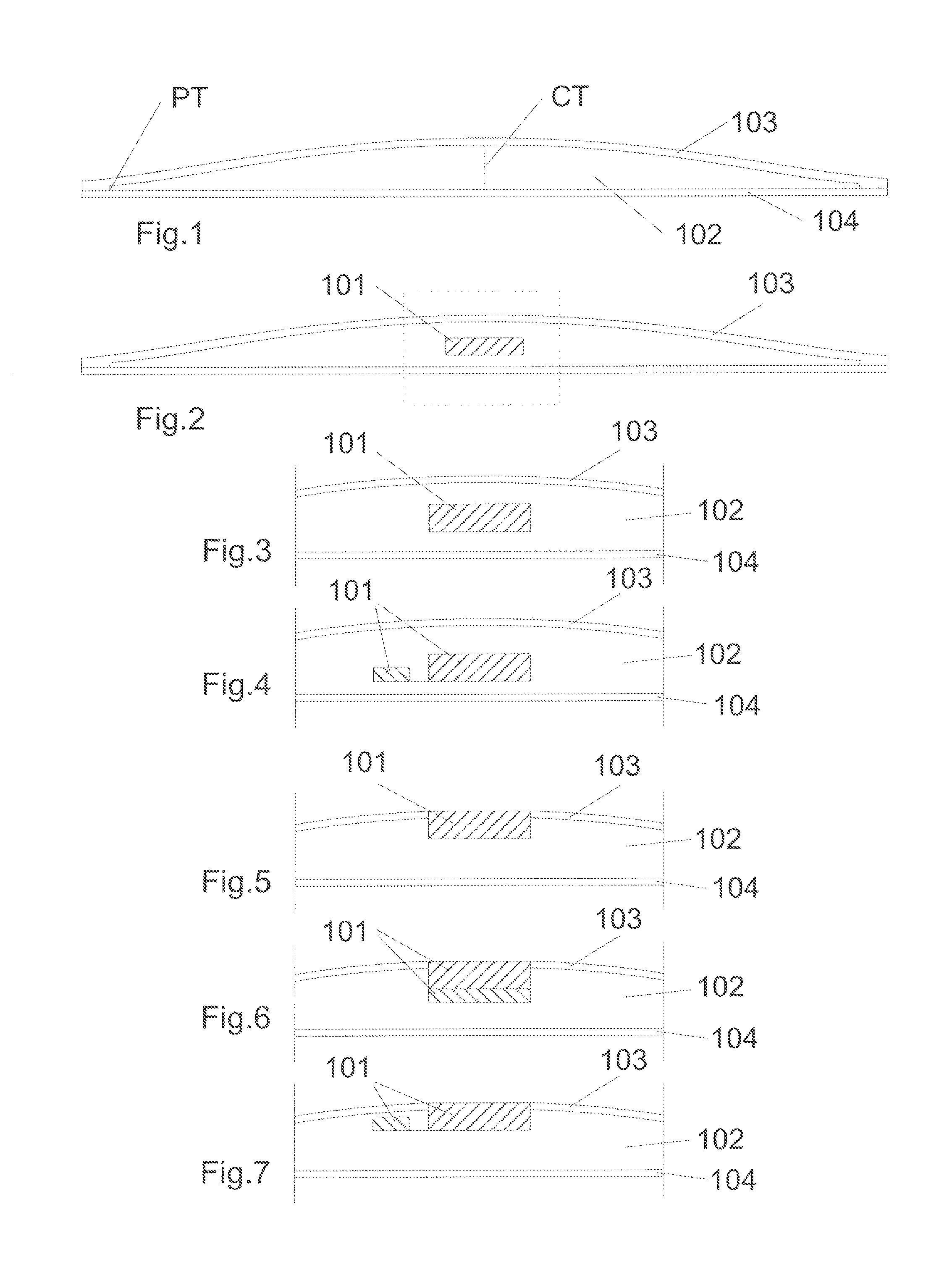

Three-Dimensional Adhesive Device Having a Microelectronic System Embedded Therein

InactiveUS20080275327A1Simple and inexpensive wayModerate viscosityWave amplification devicesLayered productsCapacitanceElectronic systems

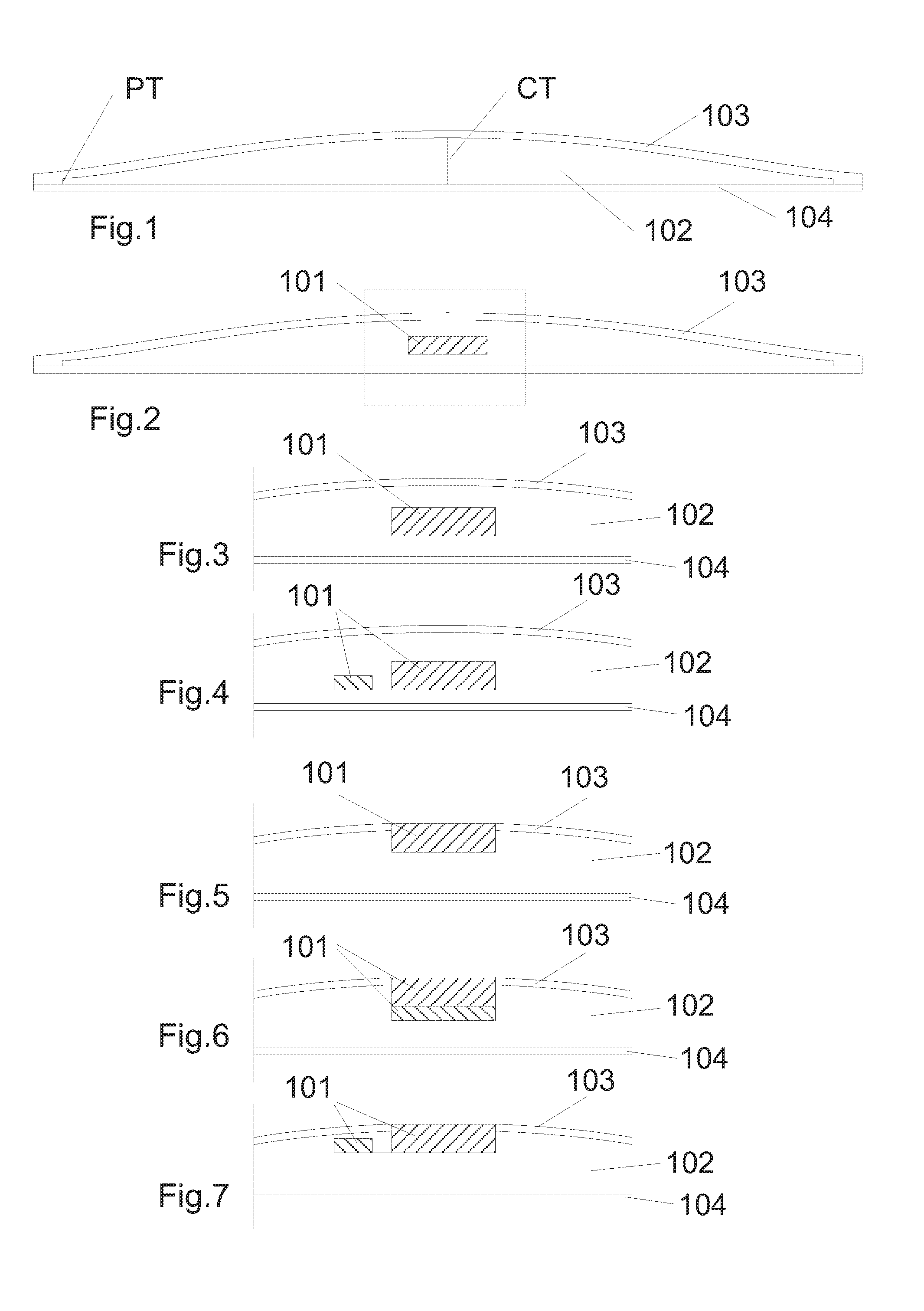

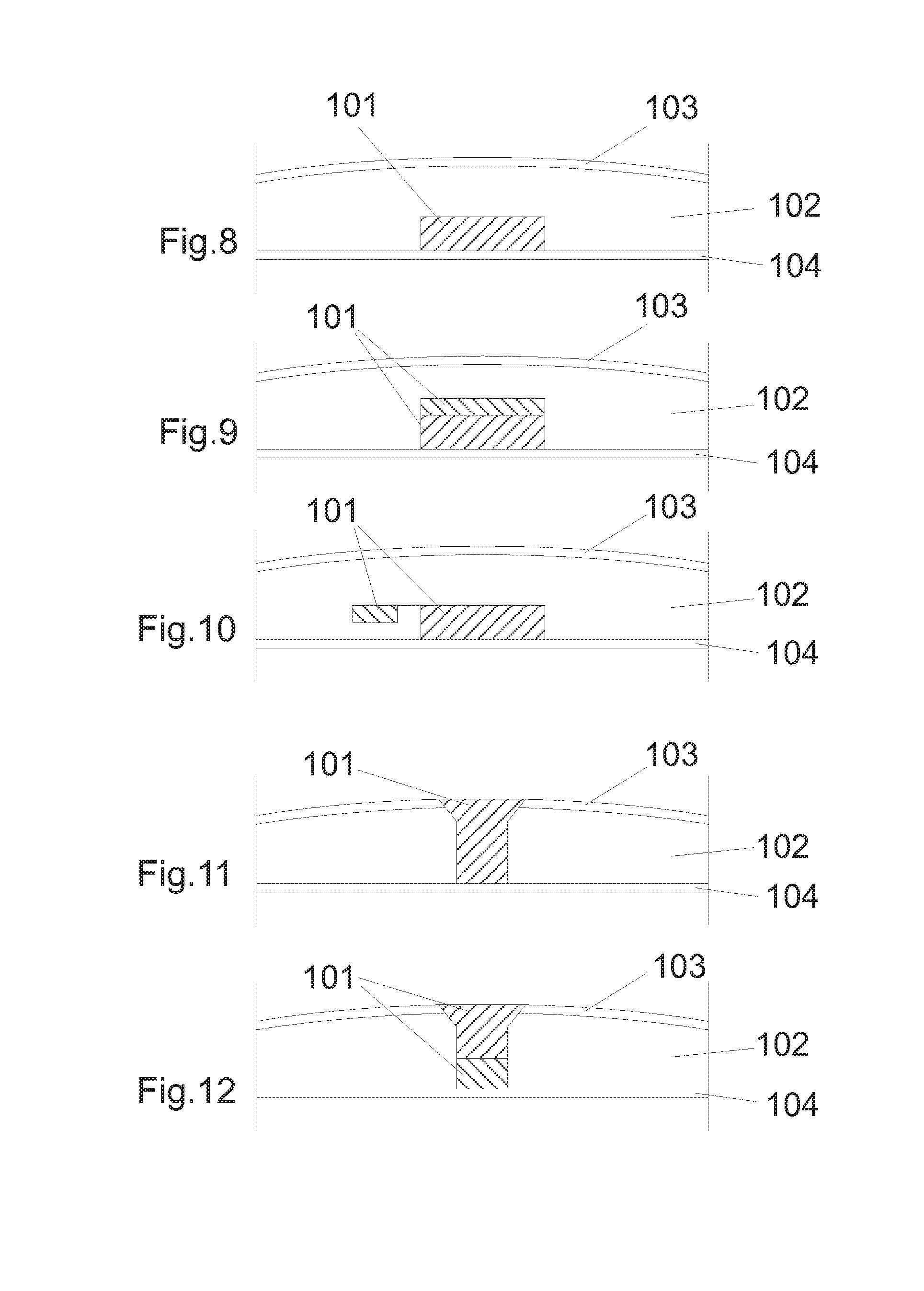

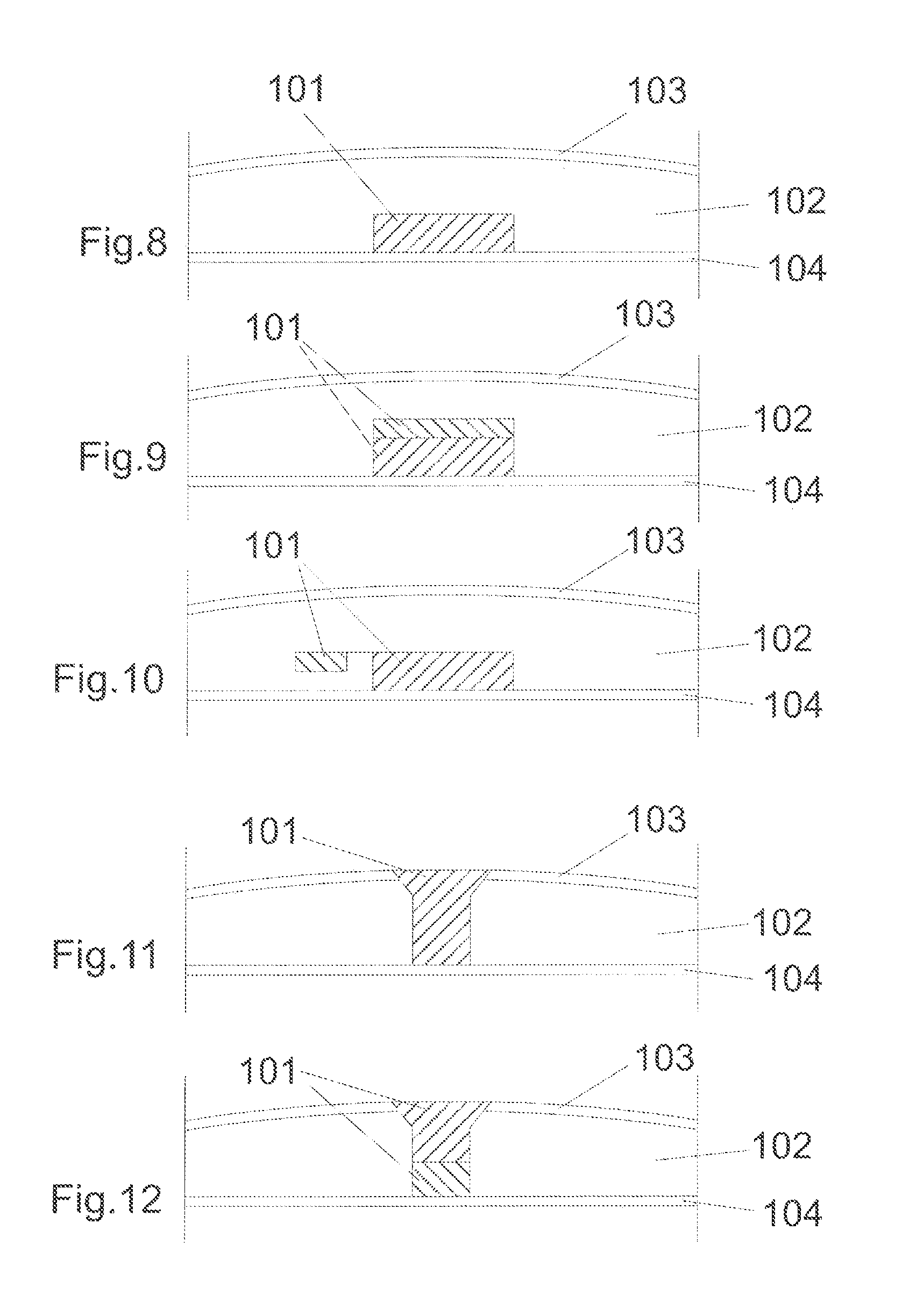

Accordingly, the present invention relates to a three-dimensional adhesive device to be attached to the body surface of a mammal comprising a microelectronic sensing system characterized by(a) a three-dimensional adhesive body made of a pressure sensitive adhesive having an upper surface and a bottom surface;(b) a microelectronic system embedded in the body of the pressure sensitive adhesive;(c) one or more cover layer(s) attached to the upper surface; and(d) optionally a release liner releasable attached to the bottom surface of the adhesive device.Suitably the microelectronic system is a microelectronic sensing system capable of sensing physical input such as pressure, vibration, sound, electrical activity (e.g. from muscle activity), tension, blood-flow, moisture, temperature, enzyme activity, bacteria, pH, blood sugar, conductivity, resistance, capacitance, inductance or other chemical, biochemical, biological, mechanical or electrical properties.

Owner:BRAEMAR MFG +2

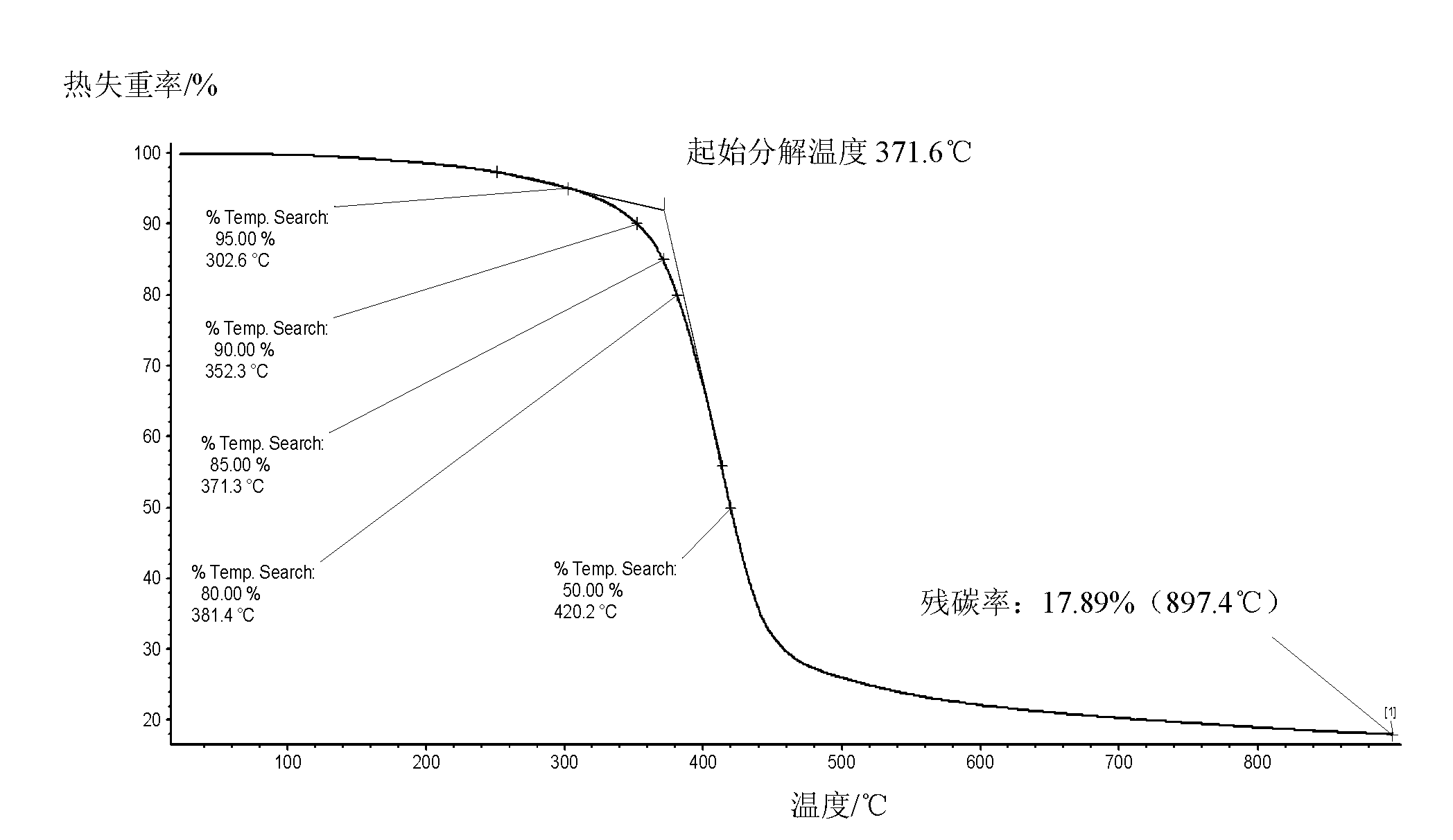

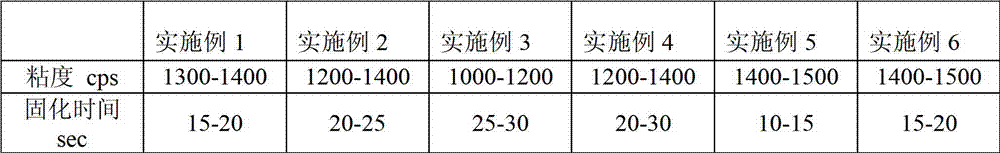

Epoxy resin adhesive modified by unsaturated polyimide and preparation method thereof

InactiveCN102181251AModerate viscosityGood workmanshipEpoxynovolac adhesivesMicroelectronicsChemistry

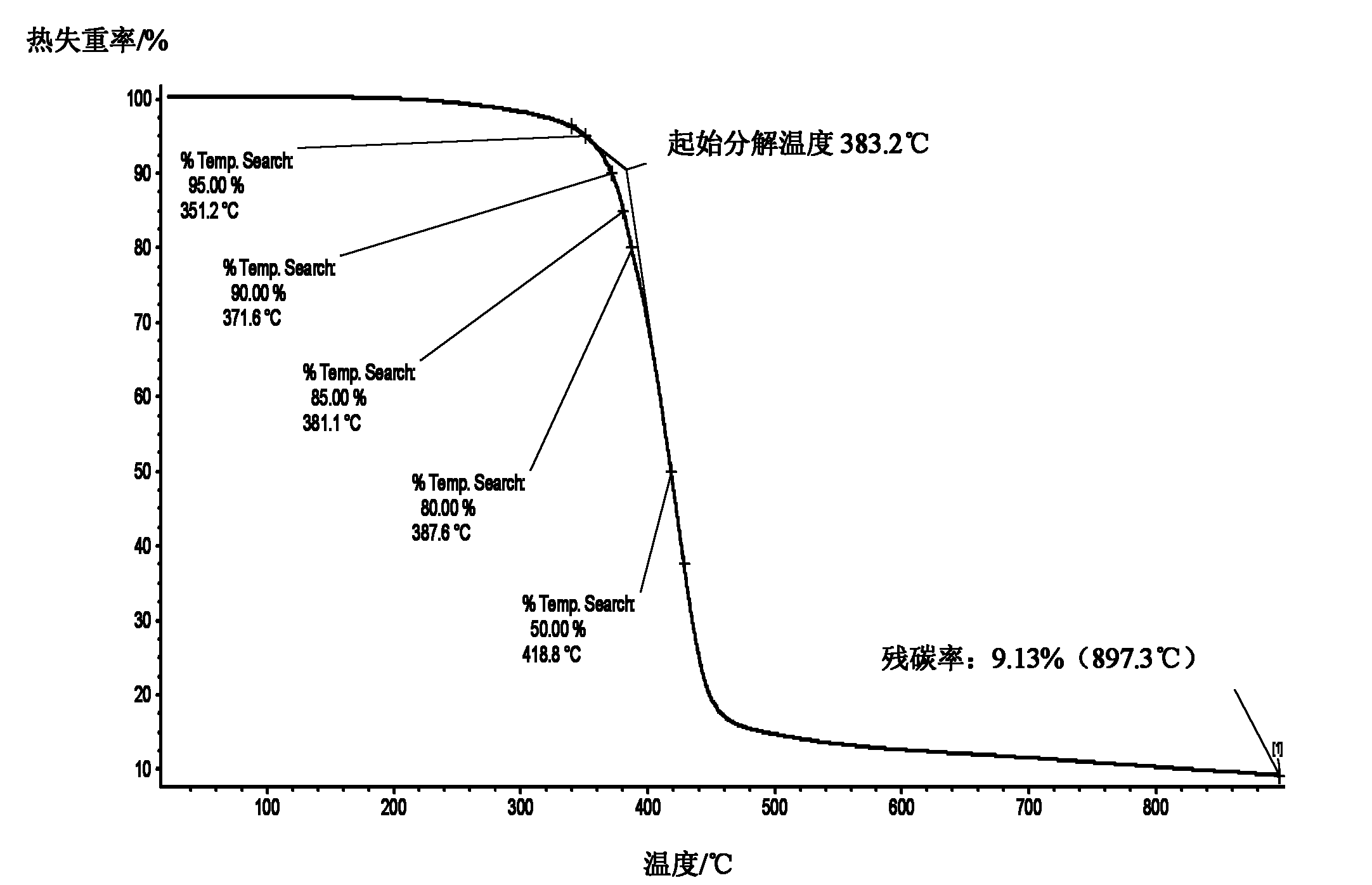

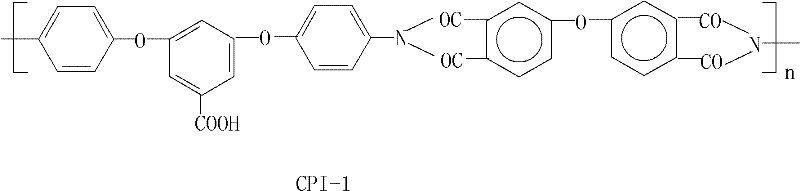

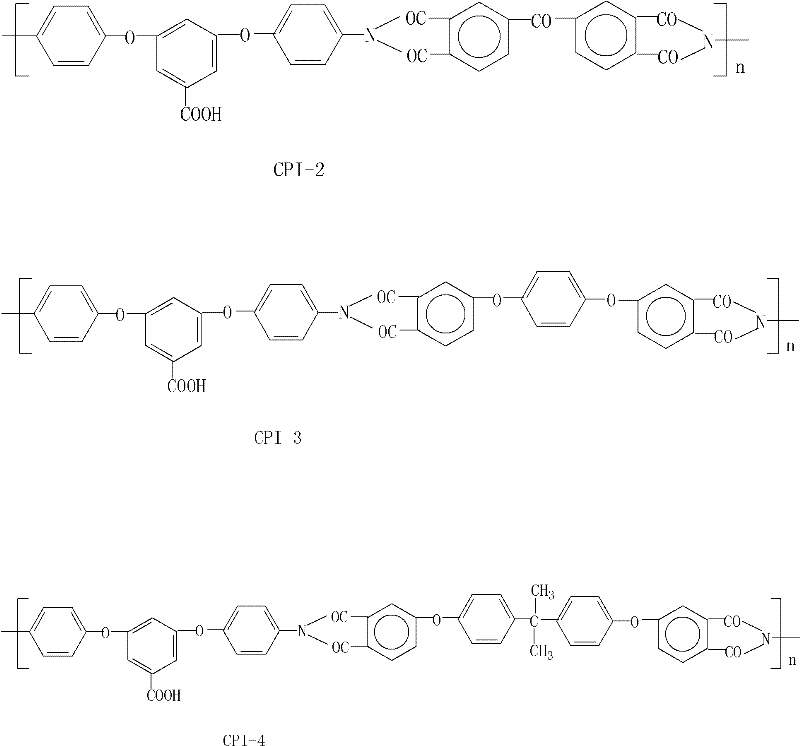

The invention relates to an epoxy resin adhesive modified by unsaturated polyimide and a preparation method thereof. A formula of the adhesive contains 80-85% of epoxy resin, 8-10% of unsaturated polyimide resin and 7-10% of curing agent in percentage by mass. By using the invention, the strength of the adhesive is effectively increased, the tensile shear strength at room temperature reaches up to 17.3 MPa and the brittleness of condensate is reduced; the epoxy resin adhesive provided by the invention is of very high practical value to the development of the adhesive industry, is favorable for realizing industrial production and has the advantages of simple preparation process and low cost. Broad application prospects are obtained in the fields of electronics, microelectronics, flexible copper clad laminates, flexible printed circuit boards, hard copper clad laminates, motors, aerospace and the like.

Owner:DONGHUA UNIV +1

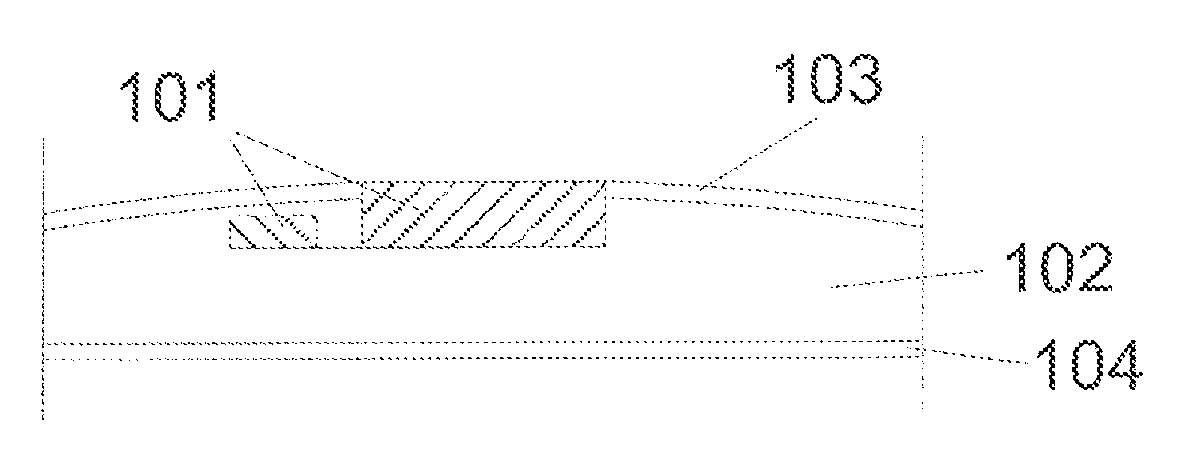

Three-dimensional adhesive device having a microelectronic system embedded therein

InactiveUS20140288381A1Simple and inexpensive wayModerate viscosityCatheterSensorsCapacitanceBlood sugar

A three-dimensional adhesive device to be attached to the body surface of a mammal including a microelectronic sensing system. The system includes (a) a three-dimensional adhesive body made of a pressure sensitive adhesive having an upper surface and a bottom surface; (b) a microelectronic system embedded in the body of the pressure sensitive adhesive; (c) one or more cover layer(s) attached to the upper surface; and (d) optionally a release liner releasably attached to the bottom surface. Suitably the microelectronic system is capable of sensing physical input such as pressure, vibration, sound, electrical activity (e.g. from muscle activity), tension, blood-flow, moisture, temperature, enzyme activity, bacteria, pH, blood sugar, conductivity, resistance, capacitance, inductance or other chemical, biochemical, biological, mechanical or electrical purposes.

Owner:BRAEMAR MFG +1

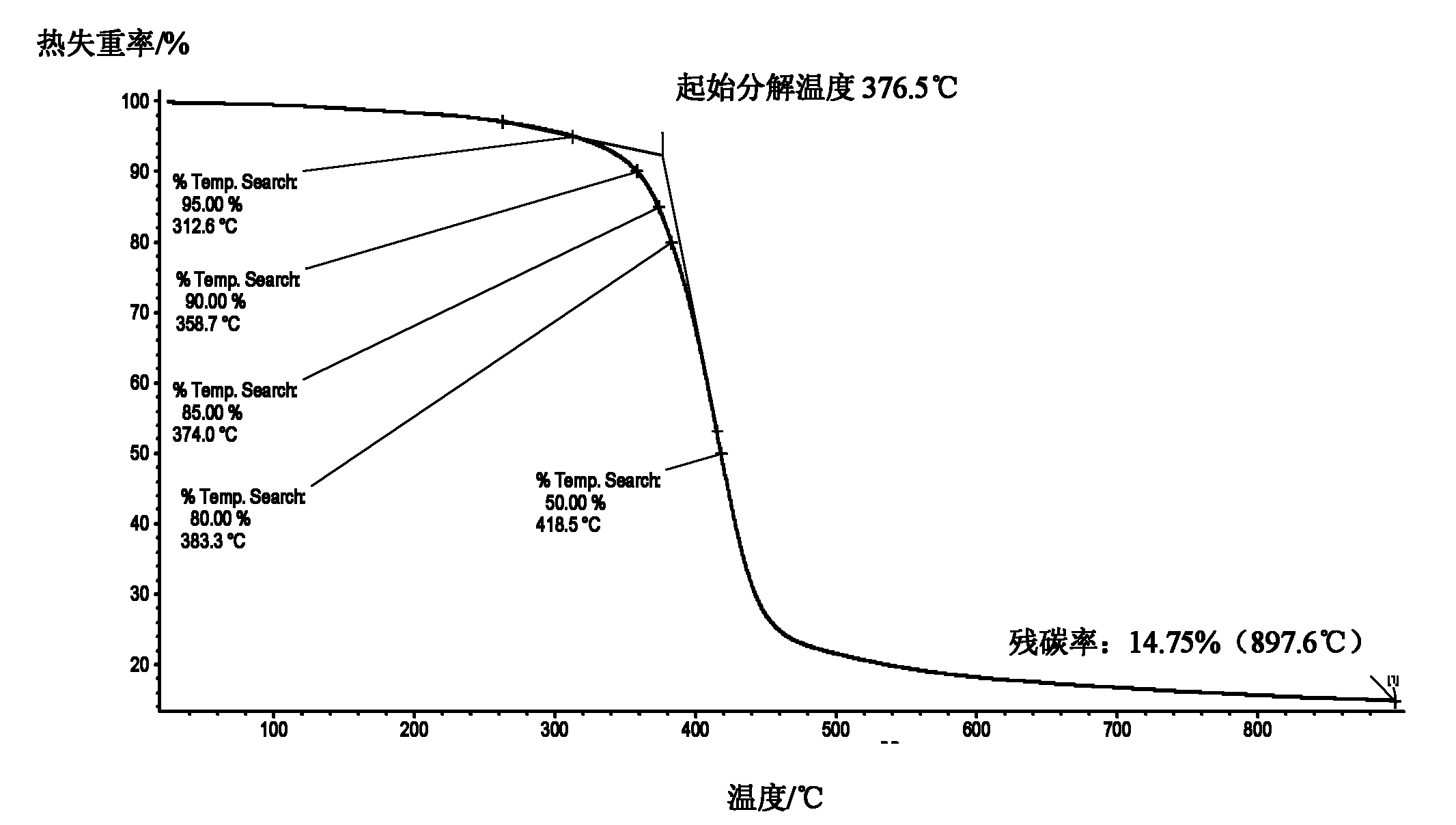

A kind of high temperature resistant modified epoxy resin adhesive and preparation method thereof

InactiveCN102260480AModerate viscosityGood workmanshipCarboxyl rubber adhesivesEpoxy resin adhesivesMicroelectronicsChemistry

The invention relates to a high-temperature-resistant modified epoxy resin adhesive and a preparation method thereof. The high-temperature-resistant modified epoxy resin adhesive comprises the following formula components by weight percent: 55%-58% of epoxy resin, 1%-6% of carboxyl-containing polyimide powder, 3.8%-4% of curing agent, 28.7%-30.5% of diluent and 6.3%-6.8% of terminal carboxyl nitrile rubber. The formula components are mixed evenly to obtain the adhesive. According to the preparation method, carboxyl-containing polyimide is added in an epoxy resin substrate, thereby effectivelyimproving the strength of the adhesive and reducing the brittleness of the cured material of the adhesive; the preparation method has the advantages of simple process and low cost, and is convenient for operation; and the preparation method has a high practicable value for the development of the adhesive industry and has a wide application prospect in multiple fields, such as electronics, microelectronics and the like.

Owner:DONGHUA UNIV +1

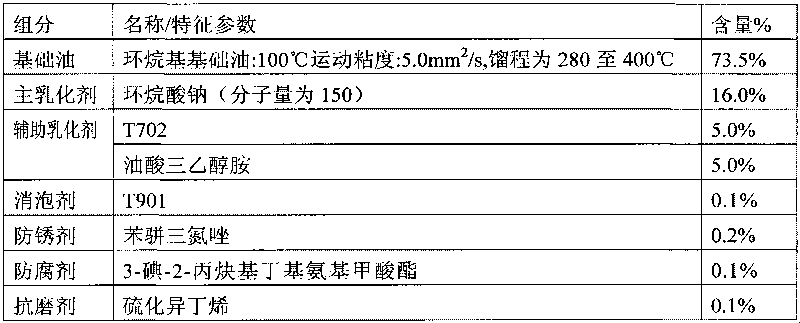

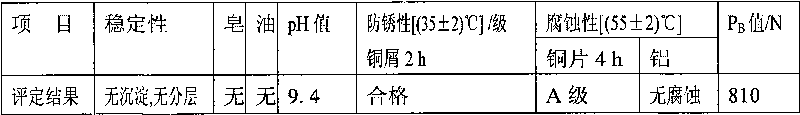

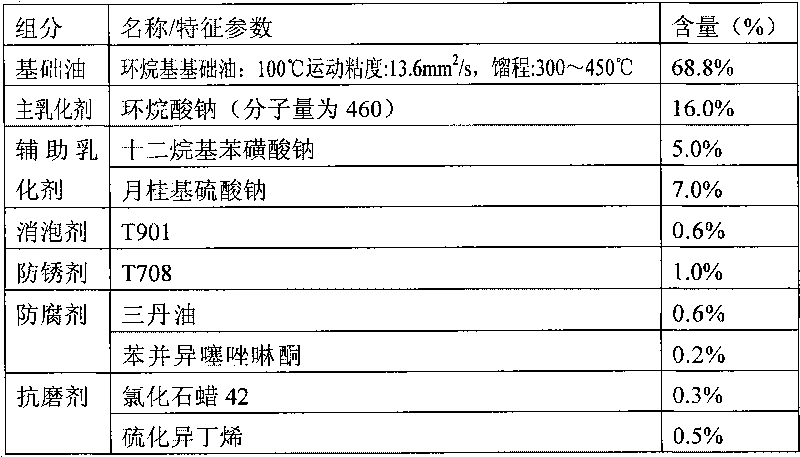

Water-based copper and aluminum wiredrawing oil composite and preparation method thereof

The invention relates to an oil-based lubricating composite and a preparation method thereof, in particular to a water-based copper and aluminum wiredrawing oil composite and a preparation method thereof. The water-based copper and aluminum wiredrawing oil composite comprises base oil, an emulsifier, an auxiliary emulsifier, a defoaming agent, a rust-proof agent, an antiseptic and an antiwear agent. The preparation method comprises the following steps of: configuring the water-based copper and aluminum wiredrawing oil composite into 3 percent to 45 percent water-based emulsion according to weight percentage; and spraying the water-based emulsion into a wiredrawing die cavity in the copper and aluminum wiredrawing process. The water-based copper and aluminum wiredrawing oil composite has the advantages of excellent lubricating property, great optimal light stability and storage stability, low cost, good cooling effect, fast heat transfer, little temperature increase in the using process, difficult combustion and easy cleaning and ensures the safety of the service environment; and in addition, a copper wire and an aluminum wire drawn by the method have the advantages of uniform wireshape, bright surfaces, difficult corrosion, good ultraviolet and storage stability and good stability.

Owner:PETROCHINA KARAMAY PETROCHEMICAL CO LTD

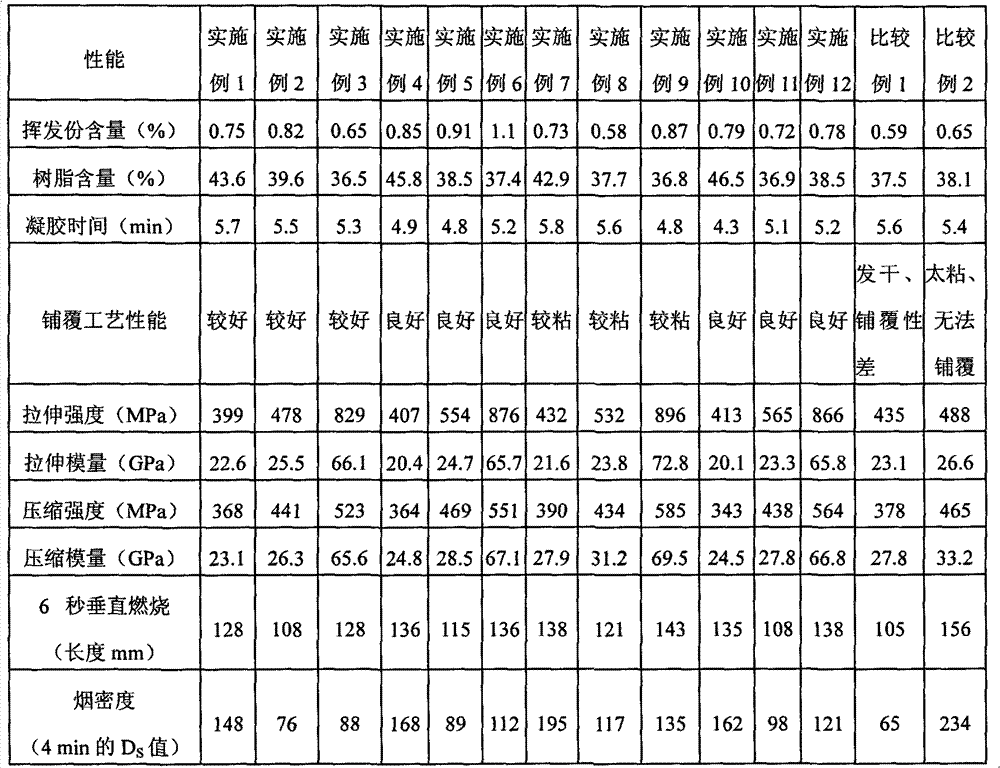

Flame retardant epoxy prepreg composite material and its preparing method and its use

ActiveCN102731969AImprove toughnessImprove flame retardant performanceCabin furnitureEfficient propulsion technologiesTetrabromobisphenol AResin matrix

The present invention relates to a flame retardant epoxy prepreg composite material and its preparation method and its use, the composite material contains 20 to 70% of epoxy resin matrix and 30-80% of fiber reinforced materials; wherein the epoxy resin matrix comprises the following components by mass part: 100 parts of an F type epoxy resin, 10-50 parts of an E type epoxy resin, 5-40 parts of tetrabromobisphenol A, 5-20 parts of a curing agent, 1-10 parts of a curing accelerator, 5-25 parts of a toughening agent, 1-10 parts of antimonous oxide and 20-80 parts of an organic solvent. According to the invention, F46 type epoxy resin containing a rigid frame structure is taken as a main component, the flame retarding and toughening modification are carried out on the resin matrix by a combination technology, the epoxy composite material with high toughness, high flame retardancy and good overlaying manufacturability can be realized, the flue gas density is obviously decreased when the flame is carried out, and the epoxy prepreg composite material possesses important popularization and application prospects in the fields of large aircraft, ships, high-speed rails and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Monocomponent moisture cure urethanes adhesive

InactiveCN101629061AModerate viscosityEasy to operateNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterAntioxidant

The invention provides a monocomponent moisture cure urethanes adhesive. The adhesive comprises the following compositions in portion by weight: 100 portions of isocyanate terminated polyurethane prepolymer, 0.025 to 0.25 portion of composite catalyst, 0.001 to 0.3 portion of stabilizer, 0.5 to 2 portions of coupling agent, 0.05 to 0.30 portion of antioxidant and 0 to 25 portions of diluting agent which react and are mixed, wherein the isocyanate terminated polyurethane prepolymer is prepared by reactions of polyisocyanates which is mixed by carbodiimide modified methyl diphenylene diisocyanate or 4,4'-methyl diphenylene diisocyanate and polyaryl polymethylene isocyanate, and polyester polyol with number average molecular weight of Mn of between 400 and 2,500 or polyether polyol with number average molecular weight of Mn of between 400 and 4,000 and a chain extender. The adhesive has higher curing speed and longer applicable time, can be bonded with an aluminum alloy with shearing strength more than or equal to 8MPa after curing at room temperature, has plump fluff and good hand feeling in electrostatic flocking products with abrasion resistance of a spinning machine roller reaching over 10,000 times.

Owner:SHANGHAI XINGUANG CHEM

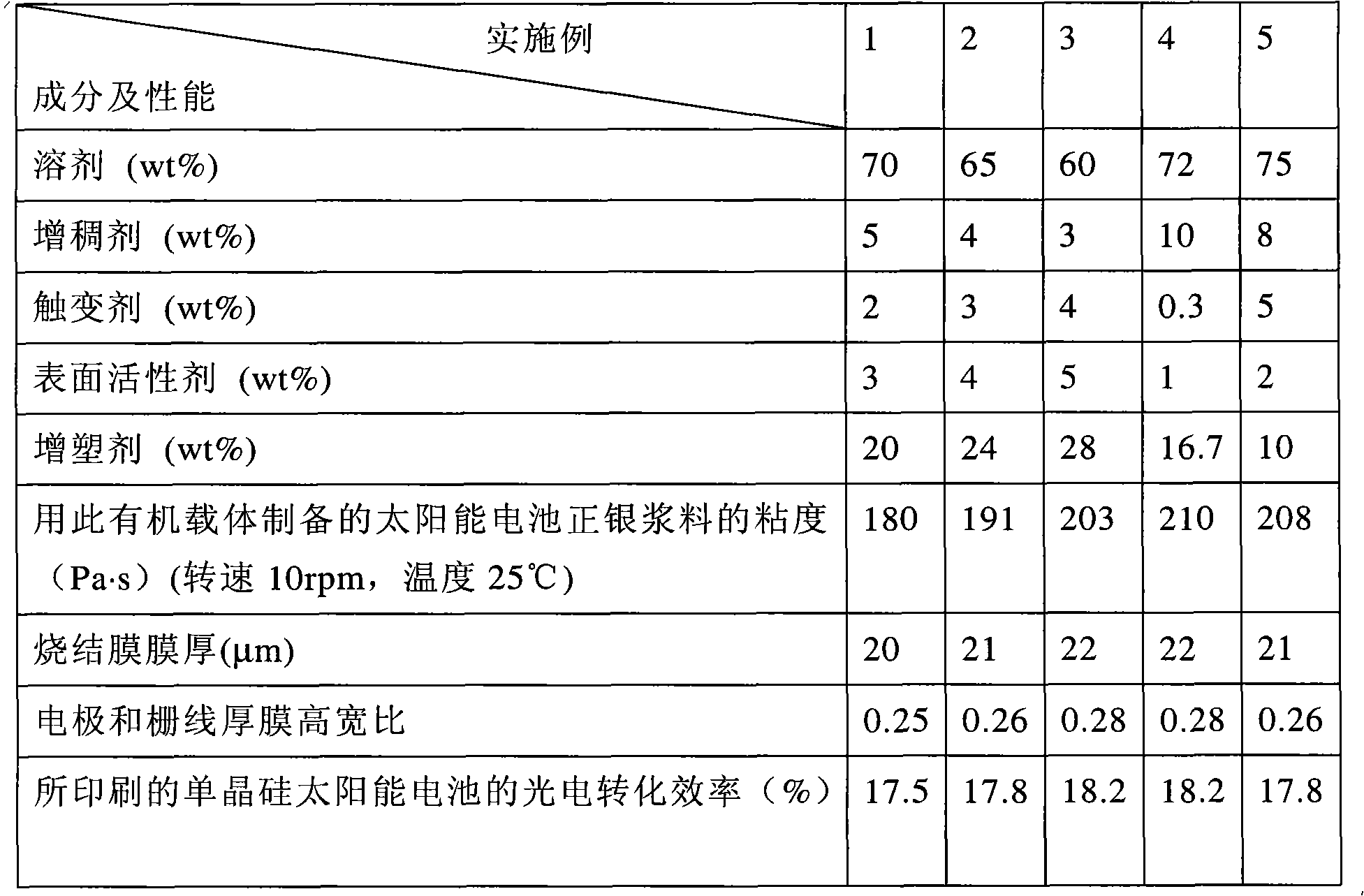

Organic carrier for silver paste and preparation method thereof as well as silver paste containing organic carrier and solar cell manufactured from silver paste

InactiveCN102136308AModerate viscositySuitable ThixotropyNon-conductive material with dispersed conductive materialSemiconductor devicesSolventChemical stability

The invention discloses an organic carrier for conductive silver paste applied to a front face electrode and a grid line of a solar cell, a preparation method of the organic carrier, silver paste containing the organic carrier and a solar cell manufactured from the silver paste. The organic carrier comprises the following components in percentage by weight: 60-75 percent of solvent, 1-10 percent of thickener, 0.3-5 percent of thixotropic agent, 1-5 percent of surfactant and 10-30 percent of plasticizer. The preparation method of the organic carrier comprises the following steps of: weighing various raw materials; adding various aids into a solvent respectively; and heating and stirring until the aids are dissolved completely. The organic carrier has proper viscosity and a simple preparation process. Paste prepared from the organic carrier has proper viscosity, fineness, leveling property, thixotropy and chemical stability. After the paste is subjected to screen printing and sintering on a cell substrate, the thicknesses of a front face electrode and a grid line thick film of a cell panel can be over 20 micros, and the prepared electrode and the grid line thick film can obtain a higher height-width ratio.

Owner:湖南威能新材料科技有限公司

High temperature anti-oxidation coating and slurry for same of Cf/SiC composite material and preparation method thereof

InactiveCN101613209AThe coefficient of thermal expansion is close toSmall coefficient of thermal expansionCeramic layered productsMass ratioViscous flow

The invention discloses a slurry for high temperature anti-oxidation coating of Cf / SiC composite material and a preparation method thereof; the slurry is suspension liquid containing solid-phase components and organic carrier in a mass ratio of (1-4):1, the solid-phase components comprise BaO-Al2O3-SiO2 glass powder and oxide mixed powder in a mass ratio of (0-1):1 and the oxide mixed powder comprises Y2O3 powder and SiO2 powder in a molar ratio of 1:2. The invention also discloses a high temperature anti-oxidation coating of Cf / SiC composite material which is prepared from the slurry and a specific preparation method thereof. The coating is yttrium silicate composite coating or multilayer composite coating which is superimposed with various yttrium silicate composite coatings. The coating prepared by the method of the invention has low expansion coefficient and sufficient consistency, suitable high temperature viscous flow property and strong chemical bond with the protected composite material.

Owner:NAT UNIV OF DEFENSE TECH

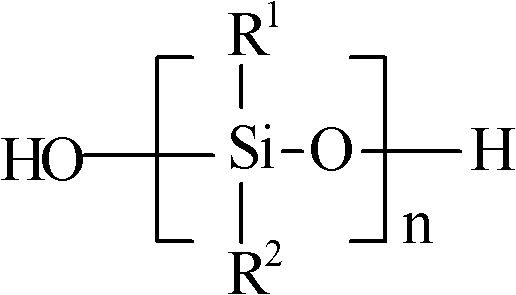

Room-temperature cured phenyl silicon resin conformal coating

The invention discloses a room-temperature cured phenyl silicon resin conformal coating which comprises components A) a segmented copolymer of phenyl silicon resin and linear polyorganosiloxane or methyl phenyl silicon resin and linear polyorganosiloxane, B) alkoxy silane, C) a silane coupling agent containing amino or epoxy group, D) an organic titanium compound, E) organic phosphate flame retardant synergist, and (F) an organic hydrocarbon solvent or low molecular weight siloxane, wherein the organic hydrocarbon solvent is one or multiple of methylbenzene, dimethylbenzene, petroleum ether, cyclohexane and normal heptane; and the low molecular weight siloxane is a mixture of octamethyl-trisiloxan, octamethyl cyclotetrasiloxane or methyl cyclosiloxane. A product produced by the cured resin conformal coating of the invention has the advantages of very high transparency, good elasticity, tough and wearable surfaces as well as excellent high / low temperature performance, waterproofing, heat resistance, cold resistance, weathering resistance, ultraviolet ray resistance, medium resistance, irradiation resistance, flame retarding and the like.

Owner:MIANYANG WELLS ELECTRONICS MATERIAIS

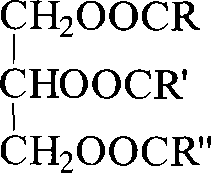

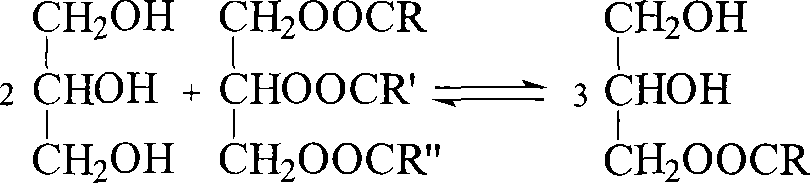

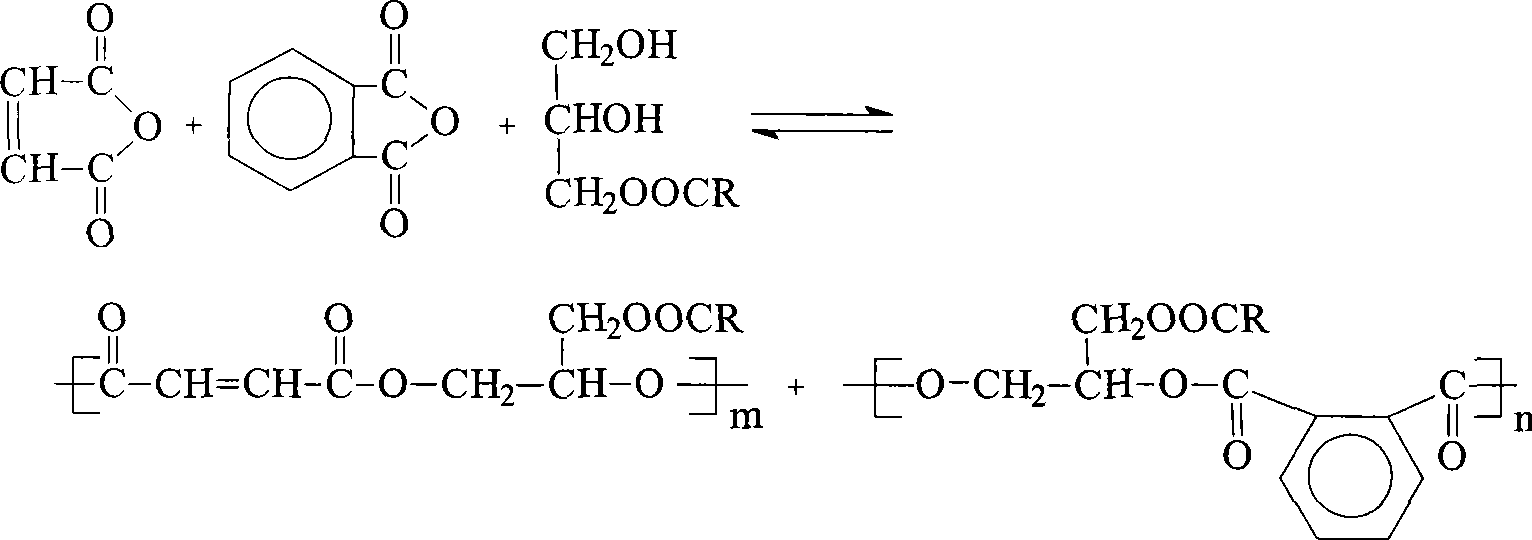

Method for synthesizing unsaturated polyester resin

The invention relates to a process for synthesizing unsaturated polyester resin with renewable vegetable fat, which comprises generating acid ester through conducting alcoholysis reaction for vegetable oil and organic polyatomic alcohol, using as modified dihydric alcohol and being leading to the typical synthesis formulation of unsaturated polyester resin, completely replacing conventional dihydric alcohol, using for synthesizing unsaturated polyester, and then mixing with cross-linking monomer. The resin which is synthesized has excellent hue, appropriate viscosity, excellent heat stability, favorable alkali resistivity, wonderful flexible property and low shrinking rate, which is suitable for various composite material shaping technology such as hand lay-up, winding and spraying and the like. Renewable raw material of vegetable oil with cheap price is applied in the synthesis process of the invention, and the stability of product is excellent.

Owner:江苏大力士云石护理材料有限公司

Solid dust suppressant

InactiveCN104817997AHigh bonding strengthGuaranteed moisture contentOther chemical processesBursting strengthMoisture absorption

A solid dust suppressant is prepared by mixing 40-90% of a water-soluble high molecular polymer, 5-40% of water-soluble high molecular glue, 0-25% of a moisture absorption humectant, 0.5-5% of a flexibilizer, 1-5% of an antiseptic and 3-10% of an osmotic agent, and has the characteristics of high film forming strength, low brightness and moderate viscosity. The viscosity (at 25DEG C), the pH value, the wind loss rate (under 30mm / s wind speed 5mins, %), the cured layer thickness, the film tensile strength, the film elongation at break and the material bursting strength of the solid dust suppressant are not lower than 8.0mPa.s, 6.0-7.0, not greater than 0.40, not lower than 11.25mm, greater than 11mpa, greater than 13% and greater than 0.05mpa respectively, and the solid dust suppressant realizes difficult brittle rupture after film formation, has a long effective dust suppression time and an ideal dust suppression effect.

Owner:INNER MONGOLIA BORAN TECH CO LTD

Printing strippable protective ink, and preparation method and application thereof

The invention discloses a printing strippable protective ink, and a preparation method and application thereof. The ink comprises the following components in parts by weight: 50-80 parts of thermoplastic film-forming resin, 20-50 parts of low-viscosity plasticizer, 1-10 parts of filler and pigment, and 1-3 parts of functional assistant. The printing strippable protective ink has 100% solid rate, does not volatilize any solvent, is a green environment-friendly material, and satisfies the increasingly higher ecological environmental requirements. The ink has the advantages of no irritating smell, moderate viscosity and no voids, is not sticky to the printing screen, and is easy for printing operation; the ink can form a film by thermosetting at medium / low temperature, so the energy consumption is low; the thermosetting film has high flexibility, favorable heat resistance, favorable insulativity and favorable acid / alkali resistance, and effectively solves the influence on the resistance when etching the circuit on a transparent conductive film with acid and alkali in the touch screen manufacturing process; and after the conductive film protecting technique is finished in the touch screen manufacturing process, the protective ink layer can be easily stripped, and does not leave any residue, thereby effectively solving the problem of protection of the conducting film in the existing touch screen manufacturing process.

Owner:PANYU NANSHA YAN TIN CHEM

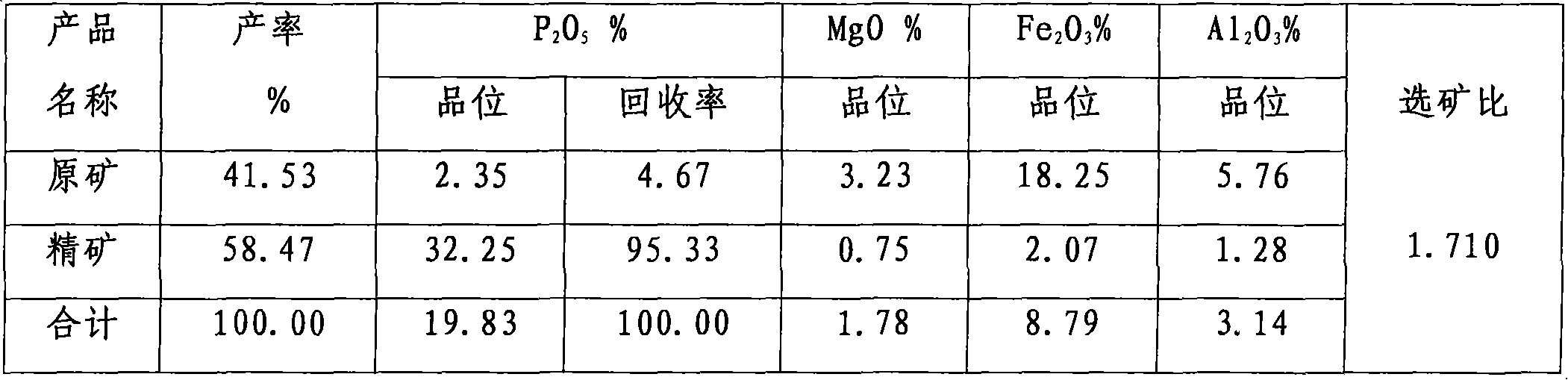

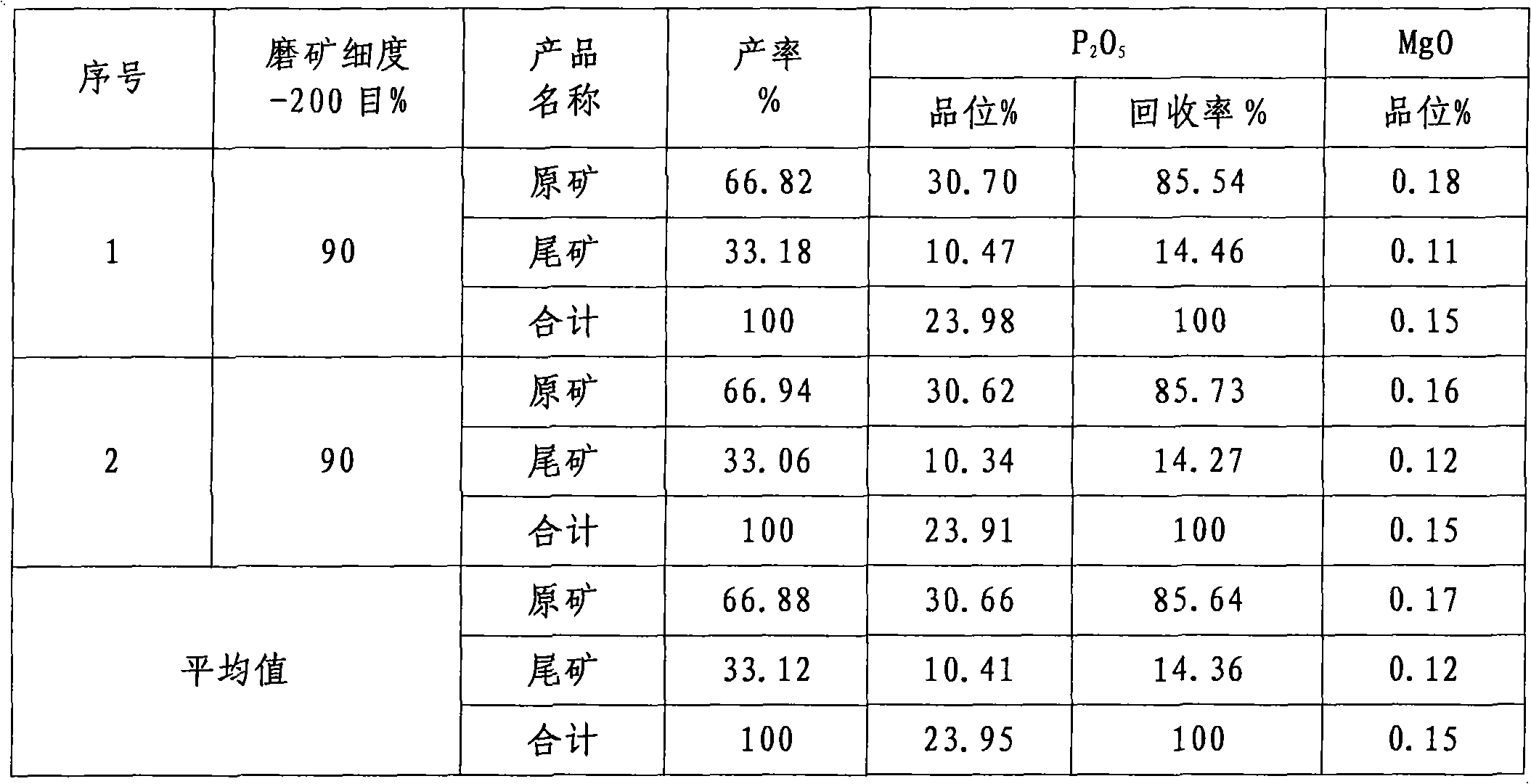

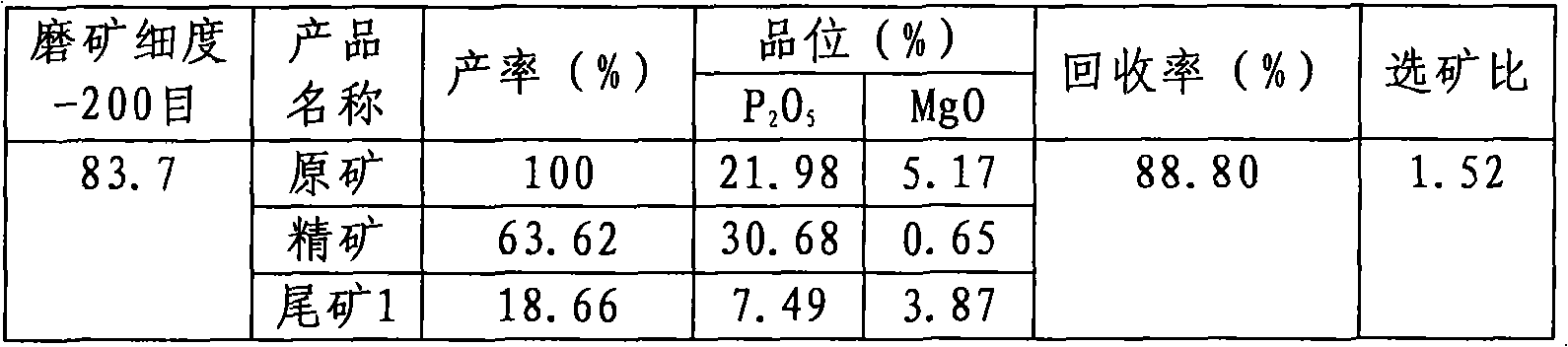

Collophanite flotation collector and method for preparing same

ActiveCN101797536AStable chemical propertiesGood water solubilityFatty acids production/refiningFlotationSolubilityFatty acid

The invention relates to a collophanite normal-temperature flotation collector, in particular to collophanite flotation collector prepared from natural rubber seed oil fatty acid, belonging to the collector. The invention also relates to a method for preparing the collophanite flotation collector. The collophanite flotation collector comprises natural rubber seed oil fatty acid, tall oil, tributyl phosphate, tween 80, dodecyl benzene sulfonic acid, inorganic base and water. The collophanite flotation collector has stable chemical performance, good water solubility, high flotation speed, suitable viscosity and strong selectivity and collection performance, is easy to diffuse in collophanite pulp, can be used for obverse floatation and reverse flotation and can generate uniform bubbles, obviously shorten the floatation time, improve the concentrate grade and reduce the content of impurities in the concentrate product.

Owner:YUNNAN CHEM RES INST

Modified dry oil alkyd resin for protective paint for metal coating on the back of the mirror and the curtain coating paint

InactiveCN1621430AImprove drynessImprove water resistancePolyester coatingsOptical elementsEpoxySolvent

The modified drying alkyd resin for curtain coated paint protecting metal coating in the back of mirror includes medium oil content drying alkyd resin in 55-70 wt%, acrylate monomer in 20-30 wt% and epoxy resin as modifier in 10-15 wt%. The medium oil content drying alkyd resin and the acrylate monomer form copolymer resin, and the copolymer resin is reacted with epoxy resin to form the modified drying alkyd resin with final viscosity of 150-300 s, acid value lower than 5 mg KOH / g and solid powder content over 50 wt%. The modified drying alkyd resin, selected cross-linking resin, pigment and solvent constitute curtain coated paint capable of well attaching to the surface of smooth metal coating.

Owner:徐金龙

Ultraviolet curing liquid optical clear adhesive and preparation method thereof

InactiveCN103031105ASmall smellModerate viscosityPolyureas/polyurethane adhesivesAdhesiveToluene diisocyanate

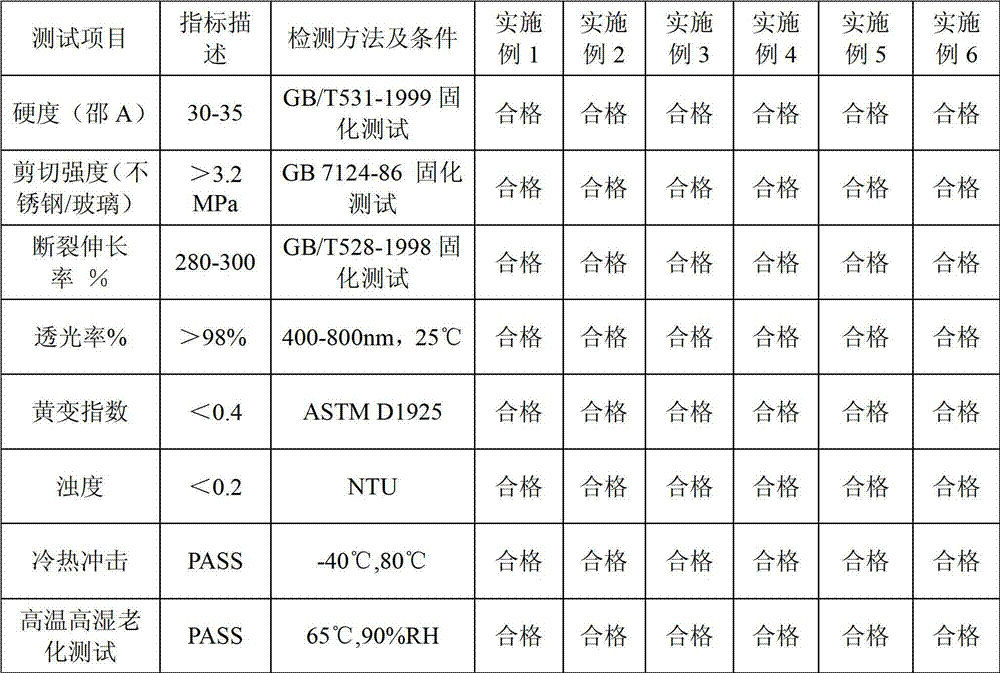

The invention relates to an ultraviolet curing liquid optical clear adhesive and a preparation method thereof, and belongs to the field of bonding adhesives. The method comprises the steps that toluene diisocyanate, polyethylene glycol and hydroxyethyl acrylate are taken as raw materials; a urethane acrylate prepolymer is synthesized through polystep reaction by a bulk method; the prepolymer is taken as a main body; a photoinitiator, a composite reactive diluent and other assistants are added; and then the ultraviolet curing liquid optical clear adhesive is prepared. The ultraviolet curing liquid optical clear adhesive prepared by the preparation method has the characteristics that the ultraviolet curing liquid optical clear adhesive is low in smell, moderate in viscosity, good in flexibility, high in light transmittance and refractive index, high in bonding strength, waterproof, and good in cold and heat shock resistance, weather resistance and ageing resistance. The ultraviolet curing liquid optical clear adhesive is completely transparent after being cured, and can keep stable high transparency and is free from yellowing, whitening and degumming for a long term in high-temperature and high-humidity environments.

Owner:SHENZHEN JINLIAN TECH

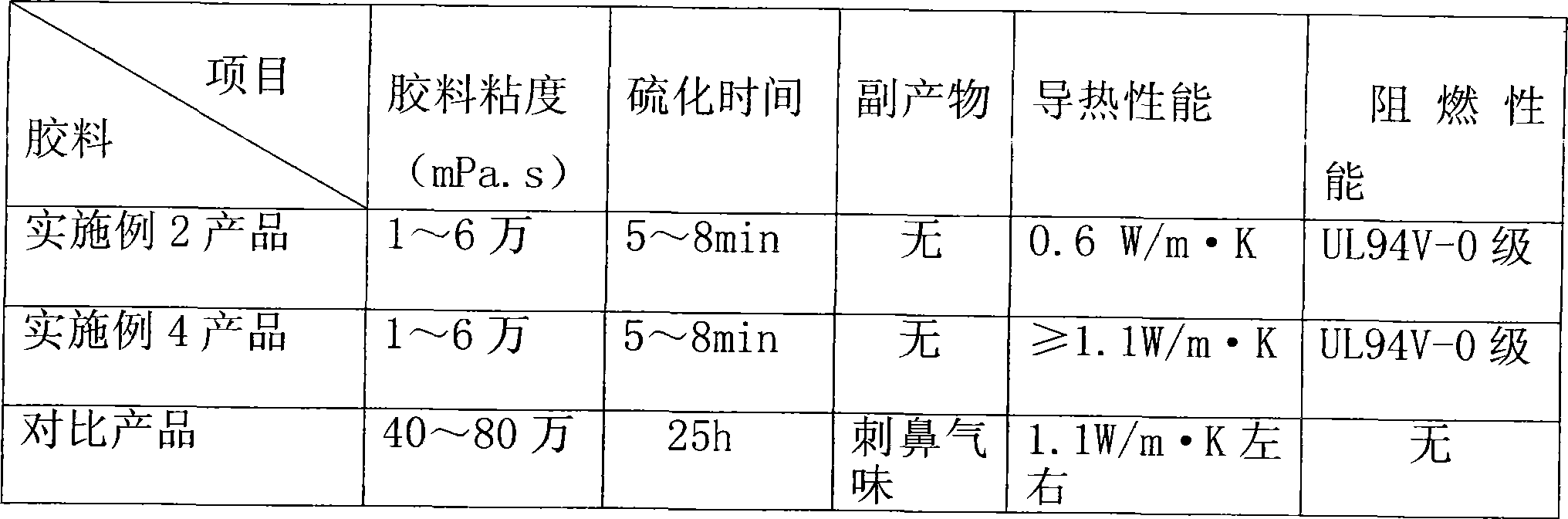

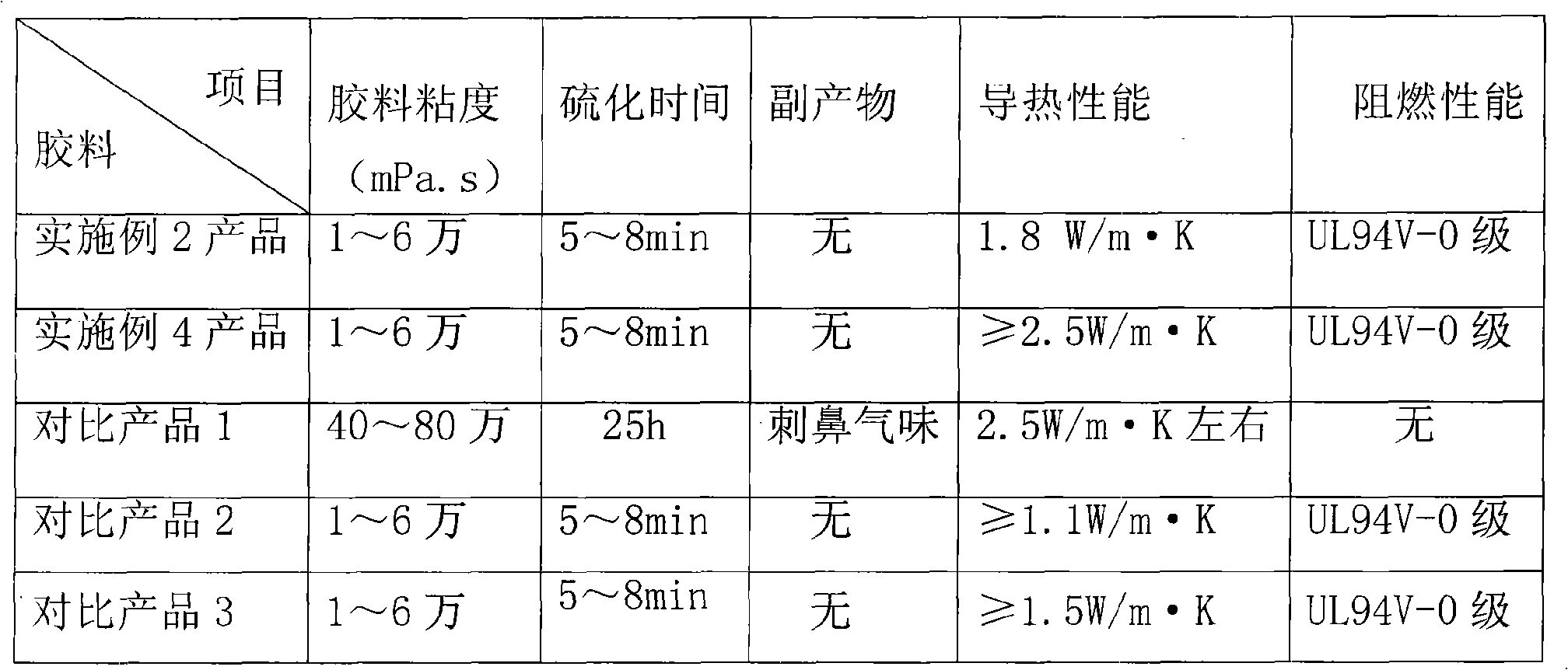

Heat-conducting anti-flaming liquid silicon rubber and preparation method thereof

InactiveCN101168620AReduce consumptionIncrease demandHeat-exchange elementsVulcanizationHeat conducting

The invention discloses heat conduction flame retardant liquid silica gel, which comprises components with the following parts by weight: 10 to 40 parts of vinyl end organopolysiloxane with 500 to 5000 mPa.s polymeric viscosity in 25 DEG C, 10 to 40 parts of vinyl end organopolysiloxane with 10000 to 50000 mPa.s in 25 DEG C, and 1 to 5 parts of hydrogen-containing polymethylsiloxane, 2 to 8 parts of alkyl disilazane, 20 to 50 parts of surface hydrophobicity Al2O3 powder with average particle diameter of 5 to 20 microns, 10 to 50 parts of Al(OH)3 powder with average particle diameter of 5 to 20 microns, 0.3 to 2 parts of addition solidification catalyst, 0.01 to 0.06 part of alkynol depressant and 0.5 to 2 parts of distilled water, wherein, R is methyl, ethyl, propyl or butyl. The invention is prepared by the way of addition type heat vulcanization, toxic substance or irritant gas is not produced in the production process, the vulcanization rate is quick, and the energy saving, the consumption decreasing and the environmental protection requirements are conformed. The storage stability of the product is good, the viscosity is moderate, the operability is good, the product integrates the heat conduction, insulation and flame retardant performances into a whole, and the performance-price ratio is high.

Owner:兆舜科技(广东)有限公司

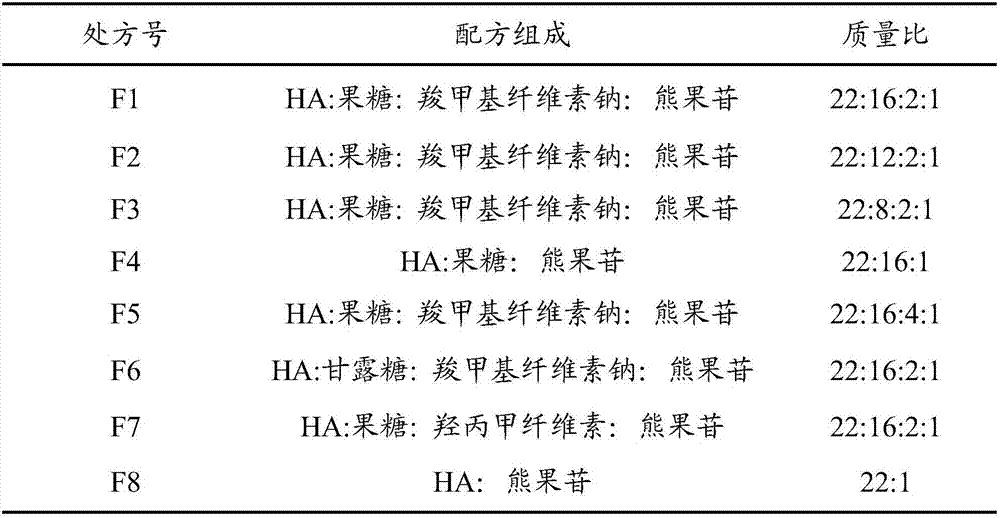

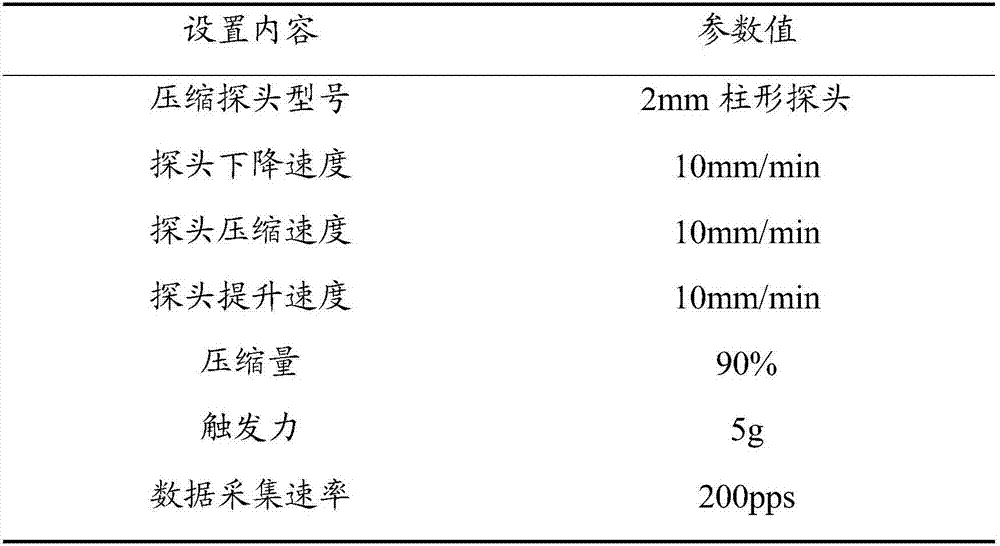

Soluble microneedle patch used for skin whitening and preparation method thereof

ActiveCN107375008AHigh mechanical strengthSolve the lack of hardnessCosmetic preparationsToilet preparationsSolubilitySodium hyaluronate

The invention relates to a soluble microneedle patch used for skin whitening and a preparation method thereof. The soluble microneedle patch comprises a needle point and a substrate, the needle point comprises the following raw materials in parts by weight: 1 part of arbutin, 15-30 parts of hyaluronic acid or its salt, and 5-25 parts of a forming material; wherein the hyaluronic acid or its salt is hyaluronic acid or sodium hyaluronate; and the forming material is selected from at least one of fructose, mannose, carboxymethylcellulose sodium and hydroxypropyl methylcellulose. The soluble microneedle patch has good mechanical strength, hardness and dissolvability, avoids the disadvantage that a traditional skin-caring mode cannot perform arbutin advantage, and has obvious effects for lightning color spots and whitening skin.

Owner:GUANGZHOU NEWORLD PHARMA CO LTD +1

Water-based calcium stearate dispersion for papermaking and preparation method thereof

InactiveCN102094356AImprove performanceSmall particle sizeDefoamers additionCoatings with pigmentsWater basedRoom temperature

The invention relates to a water-based dispersion and a preparation method thereof, wherein the water-based dispersion takes calcium stearate as the main component and is used for papermaking; and the dispersion is mainly used as an auxiliary, a functional auxiliary and a coating lubricant in the papermaking and coating processes. The dispersion is formed by processing the calcium stearate, an emulsifier A, an emulsifier B, an auxiliary, a dispersing agent, a defoamer, a fungicide and water; and the production comprising the steps of: adding the calcium stearate, the emulsifier A, the emulsifier B, the auxiliary, the dispersing agent, the defoamer, the fungicide and the water into a high-pressure reaction kettle according to a certain proportion; sealing the high-pressure reaction kettle and heating to 160-190DEG C; mixing the materials at a constant temperature for 1h; and then rapidly cooling to the room temperature so as to obtain the target product. According to the proportion and the method, the viscosity range of the prepared water-based calcium stearate dispersion is 90-680mPa.S, the particle size range is 0.45-5.0 microns and the solid content is 39-75wt%. The water-based calcium stearate dispersion has the advantages of simple process, high efficiency, no color reversion of the product, no odor, no pollution and the like; and the particle size, the solid content and the viscosity are adjustable.

Owner:DONGGUAN CHNV TECH CO LTD

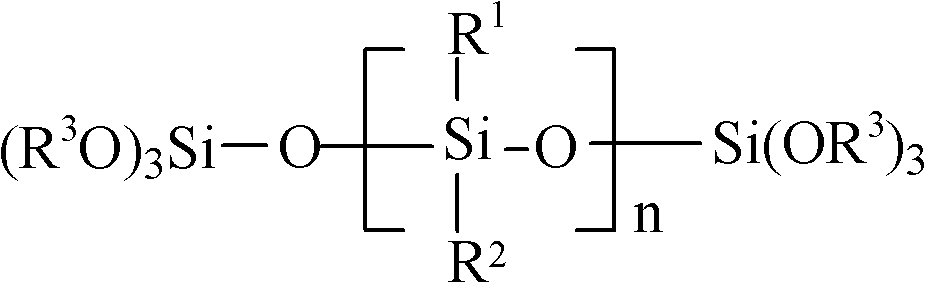

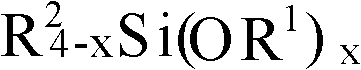

Heat conduction flame-proof liquid silicon rubber for electron and method of producing the same

The invention discloses a heat-conductive anti-flaming liquid silicone rubber used for electrons, which comprises the components with the following parts by weight: ethylene group dead-end organic polysiloxane which has polymer viscosity of 500 to 5000mPa.s and 10000 to 50000mPa.s when reaching 25 DEG C and has a general formula R2SiO(SiRR'O)nSiR2; hydric polysiloxane which has a general formula R'R2SiO(SiR HO)nSiR2R'; alkyldisilazane which has a general formula R3SiNHSiR3; a mixed-powder of Al2O3 and MgO with the surface hydrophobic particle size being respectively 5 Mum and 2 Mum and with the ratio of 4:1between Al2O3 and MgO; an Al(OH)3 powder which has an average particle size of 2 to 10 Mum; an additive solidified catalyst; an alkynol solidified inhibitor; and distilled water. The silicone rubber generates no toxic substance or irritative gas and has no side product and high efficiency; the product obtained is characterized by high thermal conductivity, good storage stability, moderate viscosity and good operability, and can integrate heat conduction, insulation and anti-flaming properties together, thereby meeting higher requirements of electrical appliances industry and having high cost performance.

Owner:兆舜科技(广东)有限公司

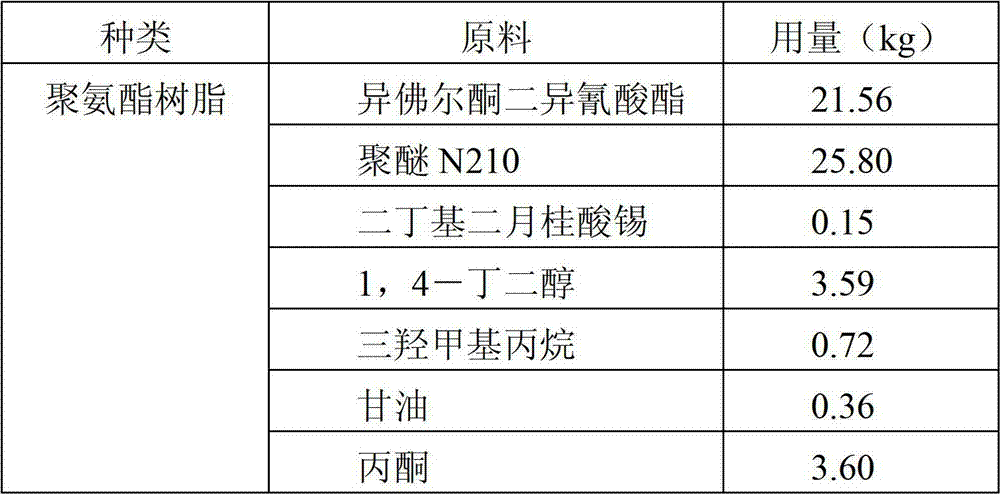

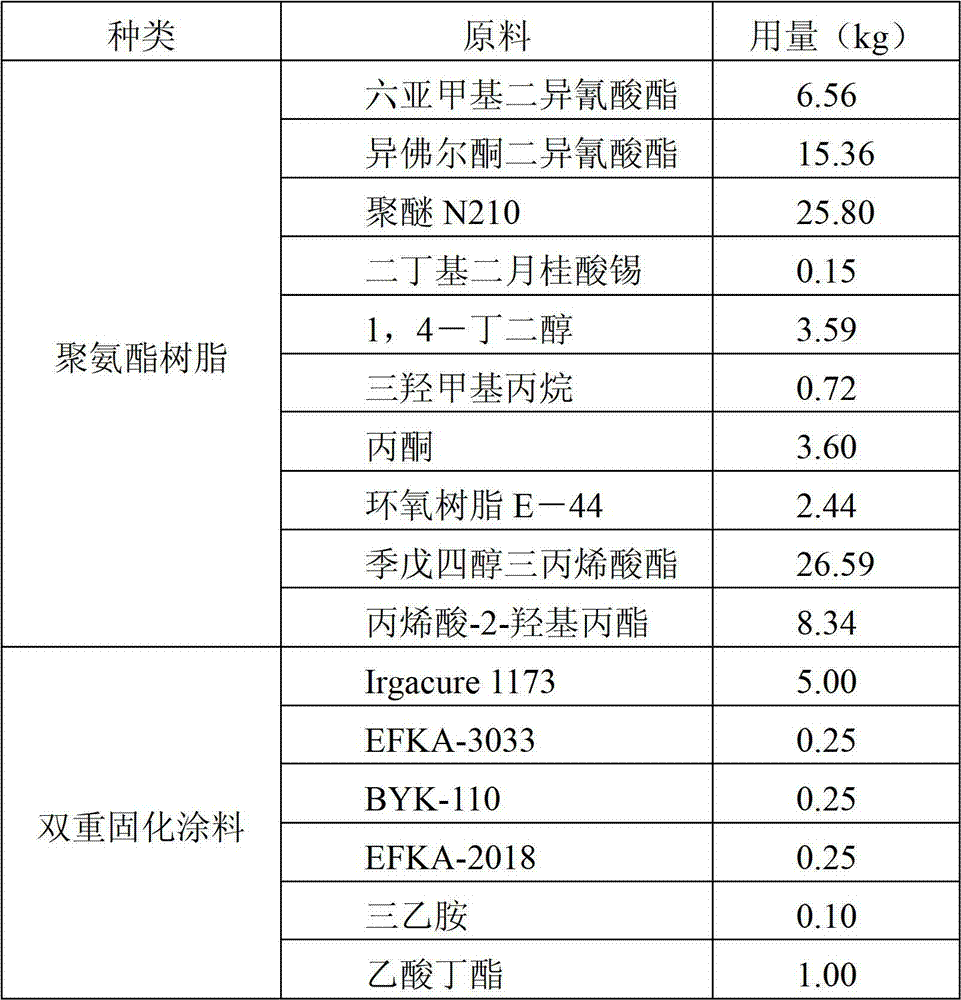

Humidity and ultraviolet dual-cured polyurethane woodware coating and preparation method thereof

The invention discloses humidity and ultraviolet dual-cured polyurethane woodware coating and a preparation method thereof. A synthesis method includes synthesizing initial polyurethane polymer I, polyurethane pre-polymer II, polyurethane pre-polymer III, polyurethane acrylate oligomer and ultraviolet cured woodware coating. The humidity and ultraviolet dual-cured polyurethane woodware coating is mainly prepared by aliphatic diisocyanate, dihydric alcohol pre-polymer, polyhydroxy acid, epoxy resin and hydroxy acrylic ester and the like, and by adding auxiliaries such as photoinitiators, flatting agents, defoamers, substrate wetting agents and catalysts, the ultraviolet cured woodware coating is prepared. The ultraviolet cured woodware coating can form films and be cured under irradiation of ultraviolet, also can be cured by humidity in the air within 5 hours at the room temperature, and has the advantages of high solid, NCO (isocyanate) group content and adhesion force, fine resistance to chemical corrosion, high film coating hardness and fine storage stability and the like, can be used for irregular coating surfaces, hone finished UV (ultraviolet) paint and UV colored paint and the like where cannot be irradiated by the ultraviolet.

Owner:广州常圣新材料科技有限公司

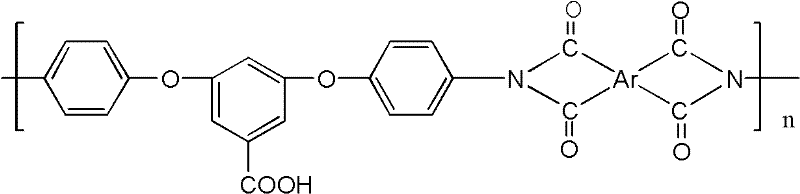

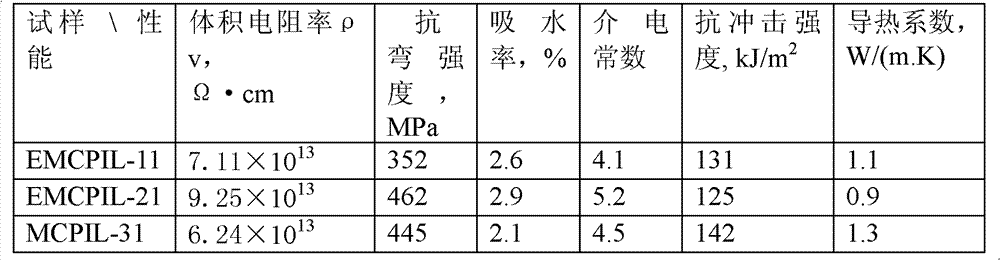

High-toughness high-heat-conduction epoxy-imine resin system and preparation method and application thereof

The invention relates to a high-toughness high-heat-conduction epoxy-imine resin system and a preparation method and application thereof. The high-toughness high-heat-conduction epoxy-imine resin system comprises epoxy resin, carboxyl-containing polyimide resin solution, firming agent, filler and organic solvent in a weight ratio of 100:100-200:30-50:30-50:150-250. The preparation method includes sequentially adding the epoxy resin, the carboxyl-containing polyimide resin solution, the firming agent, the filler and the organic solvent into a mixer, and mixing well to obtain the high-toughness high-heat-conduction epoxy-imine resin system. The high-toughness high-heat-conduction epoxy-imine resin system is applicable to preparation of glass cloth reinforced composite material. The high-toughness high-heat-conduction epoxy-imine resin system is moderate in viscosity and fine in usability. The preparation process is simple and convenient to operate. The glass cloth enhanced composite is high in impact resistance, fine in heat conductivity, high in heat resistance, and fine in electrical insulation.

Owner:DONGHUA UNIV +1

Coating and suspending chocolate with sweet potato powder added

The invention relates to a coating chocolate, wherein, every 1000 weight portions of chocolate comprises raw materials of 220 to 250 weight portions of sugar, 30 to 80 weight portions of sweet potato powder, 180 to 280 weight portions of milk solid, 340 to 430 weight portions of oil, 70 to 110 weight portions of cocoa powder and 0.5 to 1 weight portion of emulsifier. The sweet potato powder is cheap, full of nutriments, rich in cellulose, pectin and protein and relatively expensive raw materials such as milk powder, whey powder, etc., are replaced in the current coating chocolate, thus guaranteeing the quality of the coating chocolate and greatly saving cost. The coating chocolate provided by the invention can be applied to producing ice cream with surface coated with particles, can improve the adhesive capacity of particles by 5 to 10 percent, thereby not only improving the flavor and taste of ice cream, but also reducing the waste of particles.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

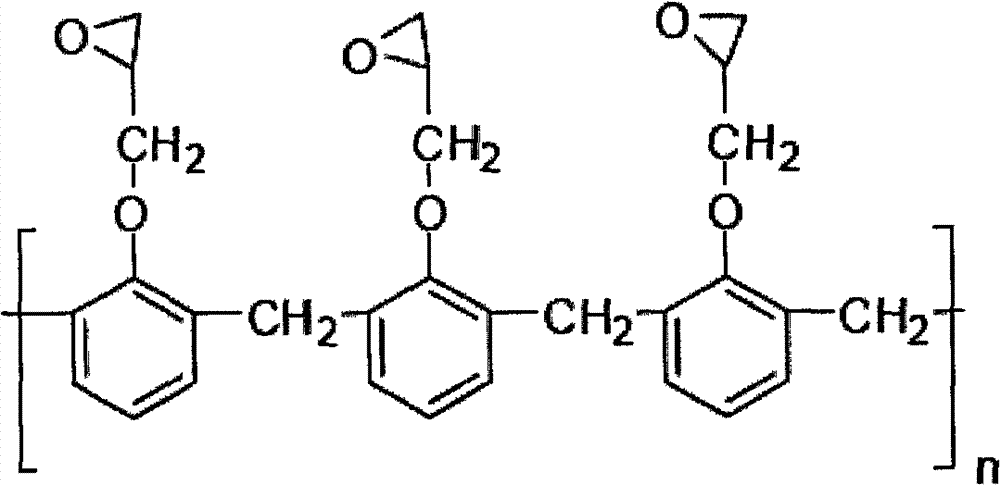

Method for preparing self-emulsifying carbon fiber sizing agent component

InactiveCN101880967AGood compatibilityGood static stabilityCarbon fibresCarbon fibersSelf emulsifying

The invention discloses a method for preparing a self-emulsifying carbon fiber sizing agent component, which comprises the following steps of: performing graft polymerization reaction on epoxy resin by adopting an emulsion polymerization method to prepare modified epoxy emulsion; and standing the modified epoxy emulsion at 80 DEG C for two hours, adding dropwise ammonia water into the solution after demulsification to make the solution alkaline, standing the solution at 95 DEG C in a sealing way, stirring and hydrolyzing the solution for 3 hours, taking the solution out, acidifying and neutralizing the redundant ammonia water, drying and rinsing the solution to produce modified bisphenol A epoxy resin, placing the synthesis product in the step and the bisphenol A epoxy resin into a container according to a certain weight ratio, and performing phase-inversion emulsification on the mixture at 70 DEG C to prepare a modified epoxy emulsion sizing agent component with certain solid content. The prepared carbon fiber sizing agent component has the characteristics of storage time longer than 12 months, high high-temperature stability, and high dilution stability, so that the method has huge breakthrough compared with the prior art. Carbon fibers sized by the sizing agent have high machining performance and improved inter-layer shear strength.

Owner:BEIHANG UNIV

Synthetic method of thermocuring polyurethane elastomer composite material for sealing materials

The invention discloses a synthetic method of a thermocuring polyurethane elastomer composite material for sealing materials. The synthetic method comprises the following steps of reacting predehydrated polyhydric alcohols with diisocyanate to synthesize an isocyanate-terminated quasi-prepolymer; uniformly mixing the predehydrated polyhydric alcohols, a small molecule chain extender, a catalyst and an assistant to prepare a chain extender; uniformly mixing the isocyanate-terminated quasi-prepolymer and the chain extender according to a metering ratio, and performing casting, mold pressing thermal curing forming and vulcanization. The thermocuring polyurethane elastomer composite material disclosed by the invention has the advantages of good mechanical property, small compression permanent deformation, as well as good rebound resilience, wear resistance and processing property.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

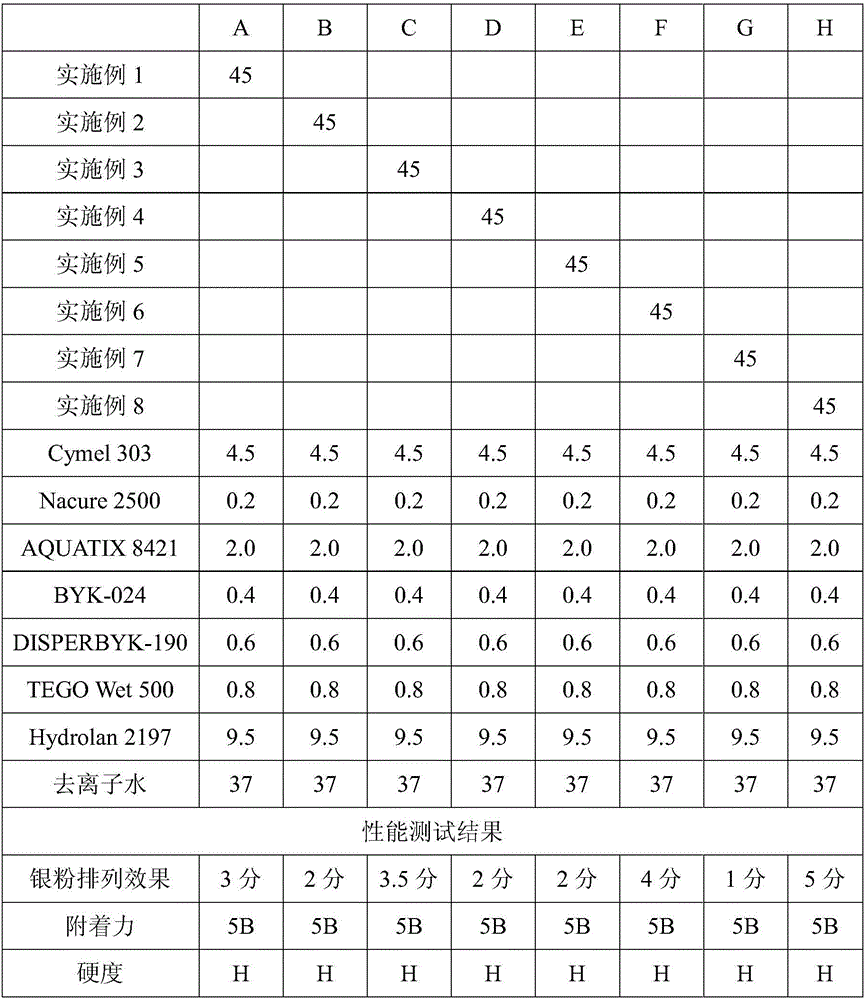

Directive water-based acrylic resin with excellent aluminite powder and preparation and coating thereof

InactiveCN106478860AStrong adhesionGood orientation of aluminum powderAnti-corrosive paintsChemistryAluminium

The invention belongs to the technical field of resin coating, and discloses a directive water-based acrylic resin with excellent aluminite powder and a preparation method, aluminite powder coating based on it and an application in aluminum profile water-based coating. Resin is prepared from the following components (1) 60-99% of acrylic acid monomers of all monomers, including 5-10% of carboxyl acrylic monomers by total weight of all monomers, 15-25% of hydroxyl acrylic monomers of all monomers and other acrylic acid monomers; (2) 0-25% of ethylene aromatic monomers of all monomers; (3) 0.5-3% of initiator of all monomers; (4) 5-40% of cosolvent of all monomers; (5) 0.5-2% of neutralizer of all monomers; (6) water; all monomers consist of (1) to (3). The aluminite powder coating based on the resin is good in directive property, excellent in adhesive force, strong in film metal sense, good in glossiness, and strong in corrosive resistance.

Owner:GUANGZHOU HUMAN CHEM

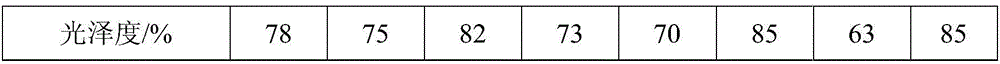

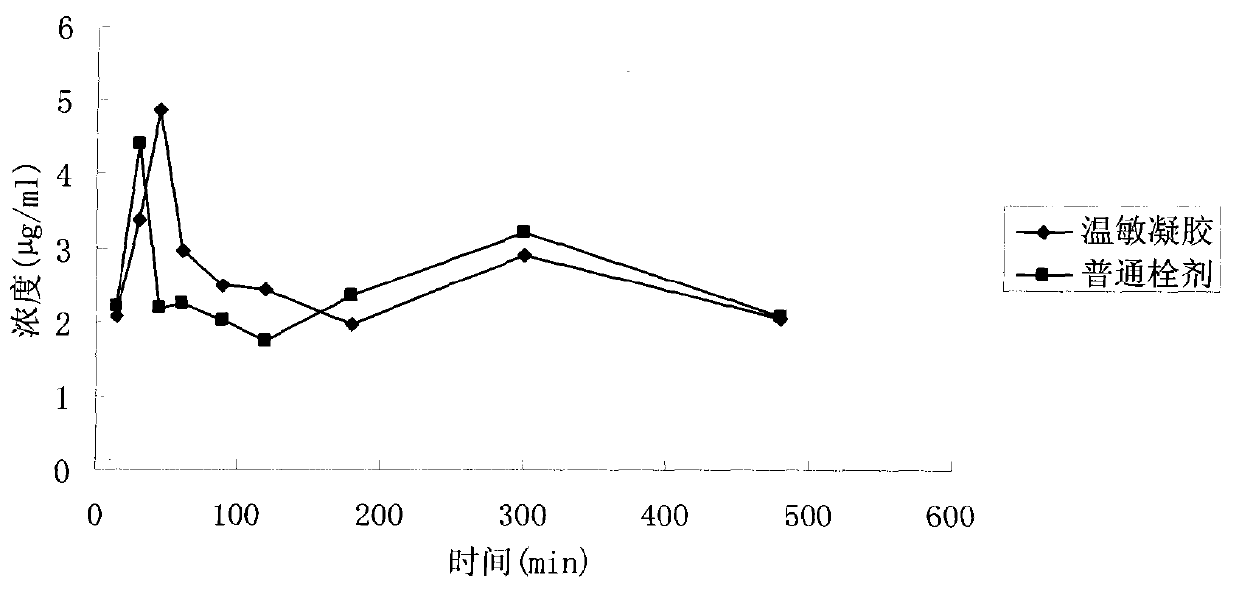

Baicalin thermosensitive gelatin and preparation method and use thereof

InactiveCN101732237AImprove temperature-sensitive propertiesAdjustable release rateAntibacterial agentsOrganic active ingredientsPreservativeDrug release

The invention discloses a baicalin thermosensitive gelatin and a preparation method and use thereof. The baicalin thermosensitive gelatin is prepared by the following steps: (1) taking the following components in percentage by weight: 0.6 to 15 percent of baicalin, 10 to 24 percent of poloxamer 407, 1 to 10 percent of poloxamer 188, 55.8 to 81.17 percent of solvent, 0 to 5 percent of viscosity modifier, and 0 to 0.2 percent of preservative; and (2) dissolving the baicalin and the preservative into the solvent, slowly adding the poloxamer 407 and the poloxamer 188 with stirring, mixing uniformly, adding the viscosity modifier, mixing uniformly, and placing the mixture into freely flowable semitransparent solution to prepare the baicalin thermosensitive gelatin. The baicalin thermosensitive gelatin is flowable liquid at normal temperature, which generates reversible phase change if affected by the body temperature after contacting with a mucous membrane or body fluid. Therefore, the medicament is tightly attached to the mucosal tissue, which is hard to leak. After the phase change is generated in the body fluid, the release rate of the medicament can be controlled.

Owner:LOGISTICS UNIV OF CAPF

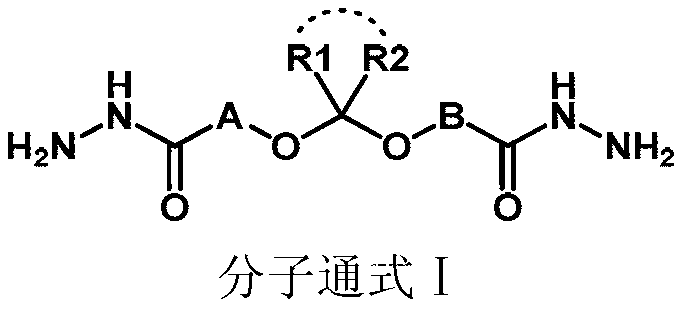

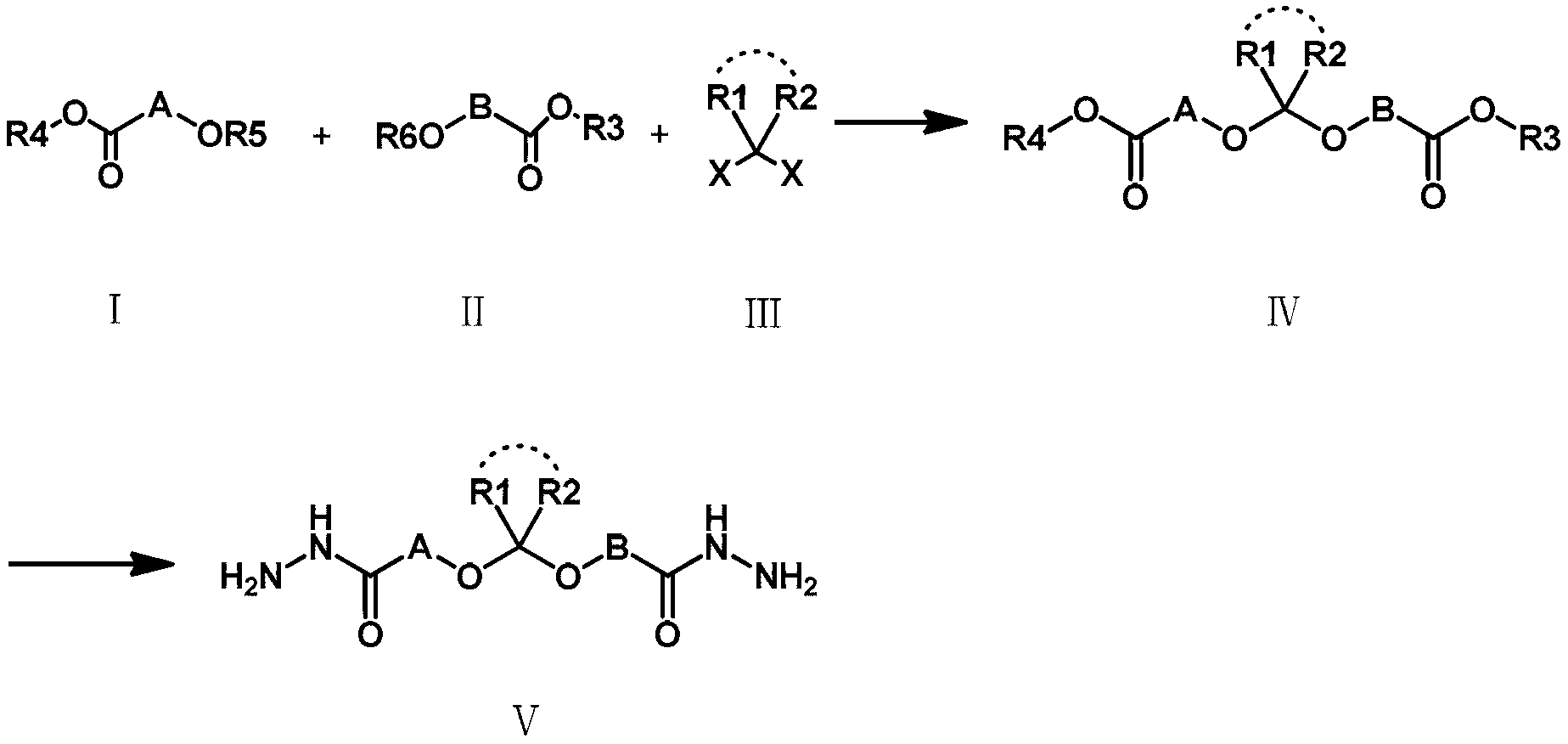

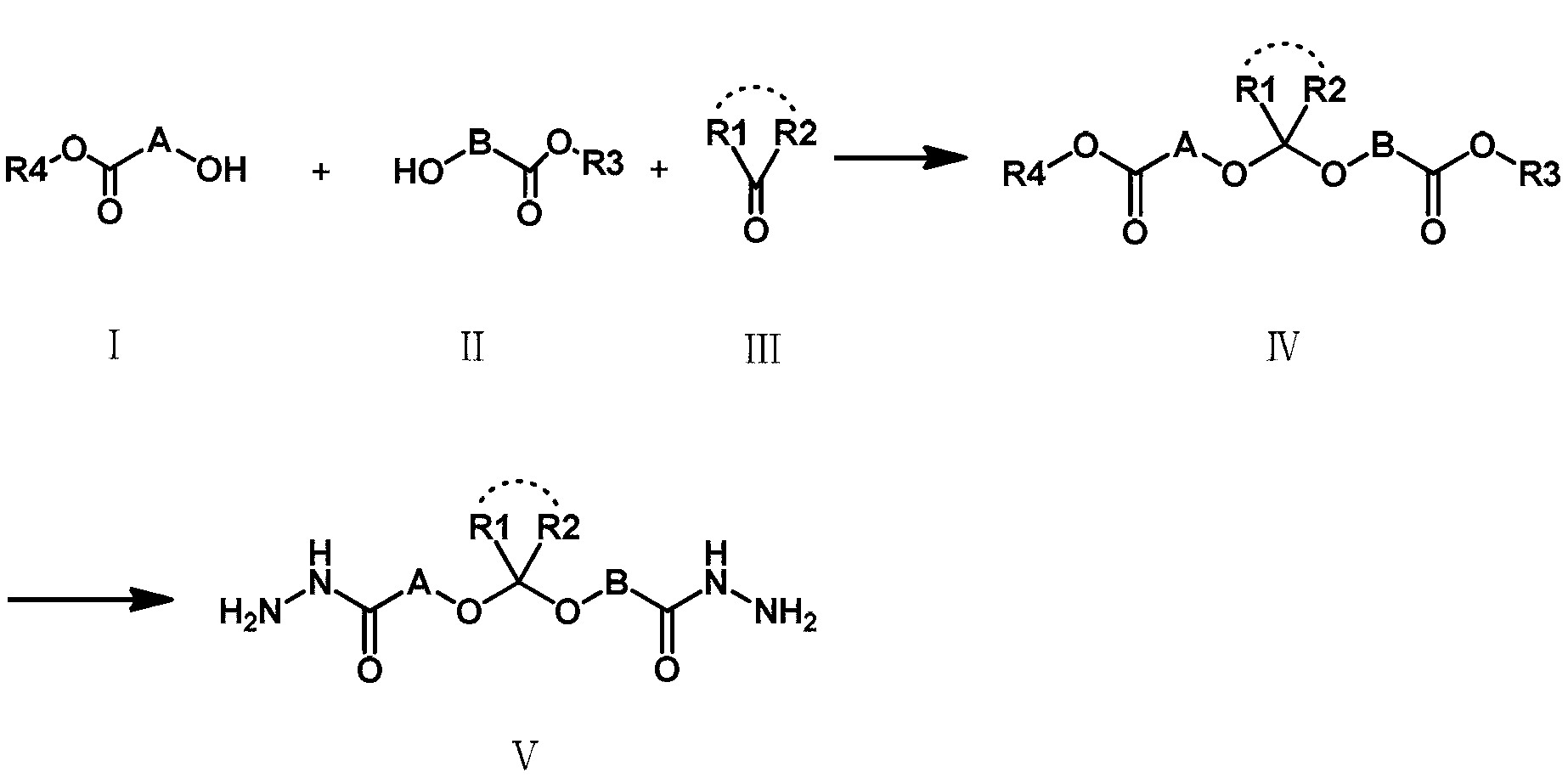

Degradable hydrazide latent epoxy resin curing agent and application thereof

ActiveCN103193959AOptimize operating timeModerate viscosityHydrazide preparationPlastic recyclingEpoxyCrosslinked polymers

The invention provides a degradable hydrazide latent epoxy resin curing agent. The curing agent can be polymerized with epoxy resin to generate a degradable crosslinked polymer; and the degradable crosslinked polymer can be degraded in a mixed system of an acid and a solvent under the conditions of heating and stirring. The invention also provides a prepreg, consisting of the curing agent, the epoxy resin, an auxiliary material and a reinforcing material. The invention also provides a reinforcing composite material which is prepared from the curing agent, the epoxy resin, the auxiliary material and the reinforcing material. The reinforcing composite material can be prepared by a prepreg forming method. The reinforcing composite material can be degraded in the mixed system of the acid and the solvent under the conditions of heating and stirring, and can be recycled and reused after being neutralized. The reinforcing composite material has excellent mechanical property and is suitable for the field of application of different composite materials; and the degrading and recycling method of the reinforcing composite material is simple, economic, mild in condition and easy to control.

Owner:芜湖天道绿色新材料有限公司

Preparation method of water-based coating for lost foam casting

The invention discloses a preparation method of a water-based coating for lost foam casting. A coating prepared by the preparation method has excellent performances, good suspensibility, thixotropy and permeability, and high surface strength. The preparation method overcomes the defects that refractory powder adopted by the conventional casting coating preparation technology is very expensive and a coating production cost of the conventional casting coating preparation technology is high. A casting coating obtained by the preparation method is smooth and has appropriate viscosity. Through the preparation method, a high-quality casting coating can be prepared from cheap raw materials through simple production processes. Therefore, the preparation method reduces a coating production cost and realizes good finished product quality.

Owner:南通江海港建设工程有限公司

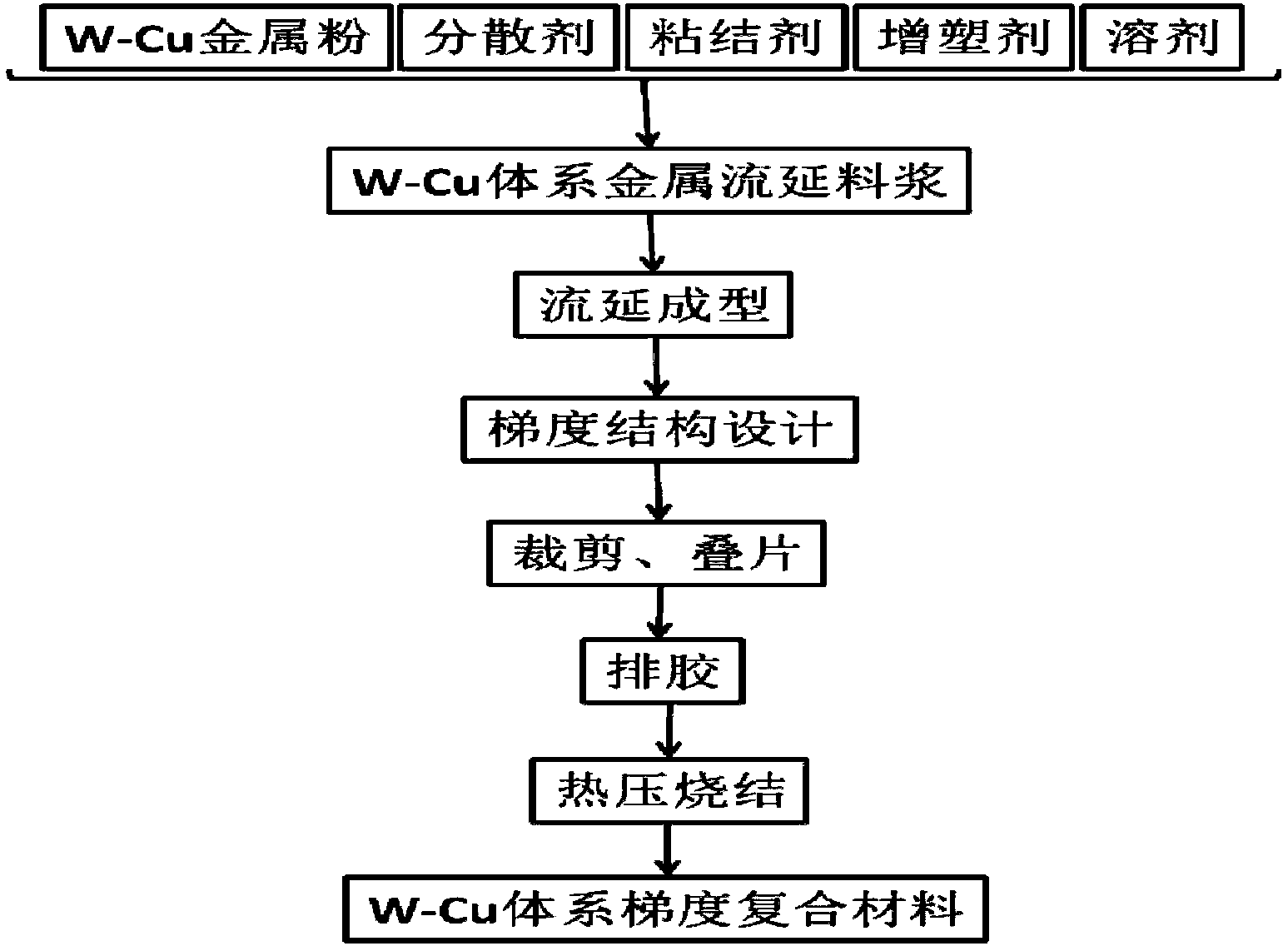

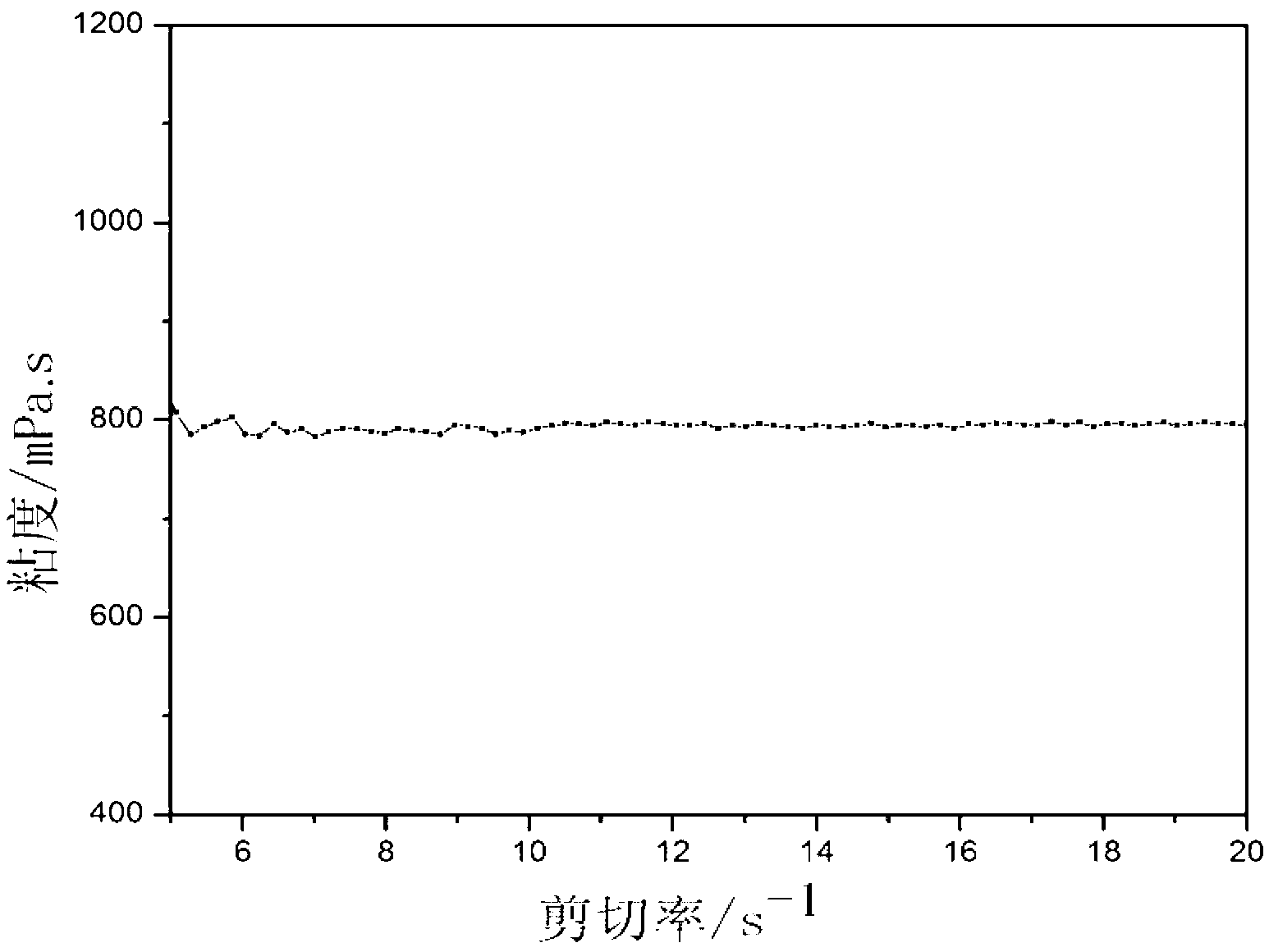

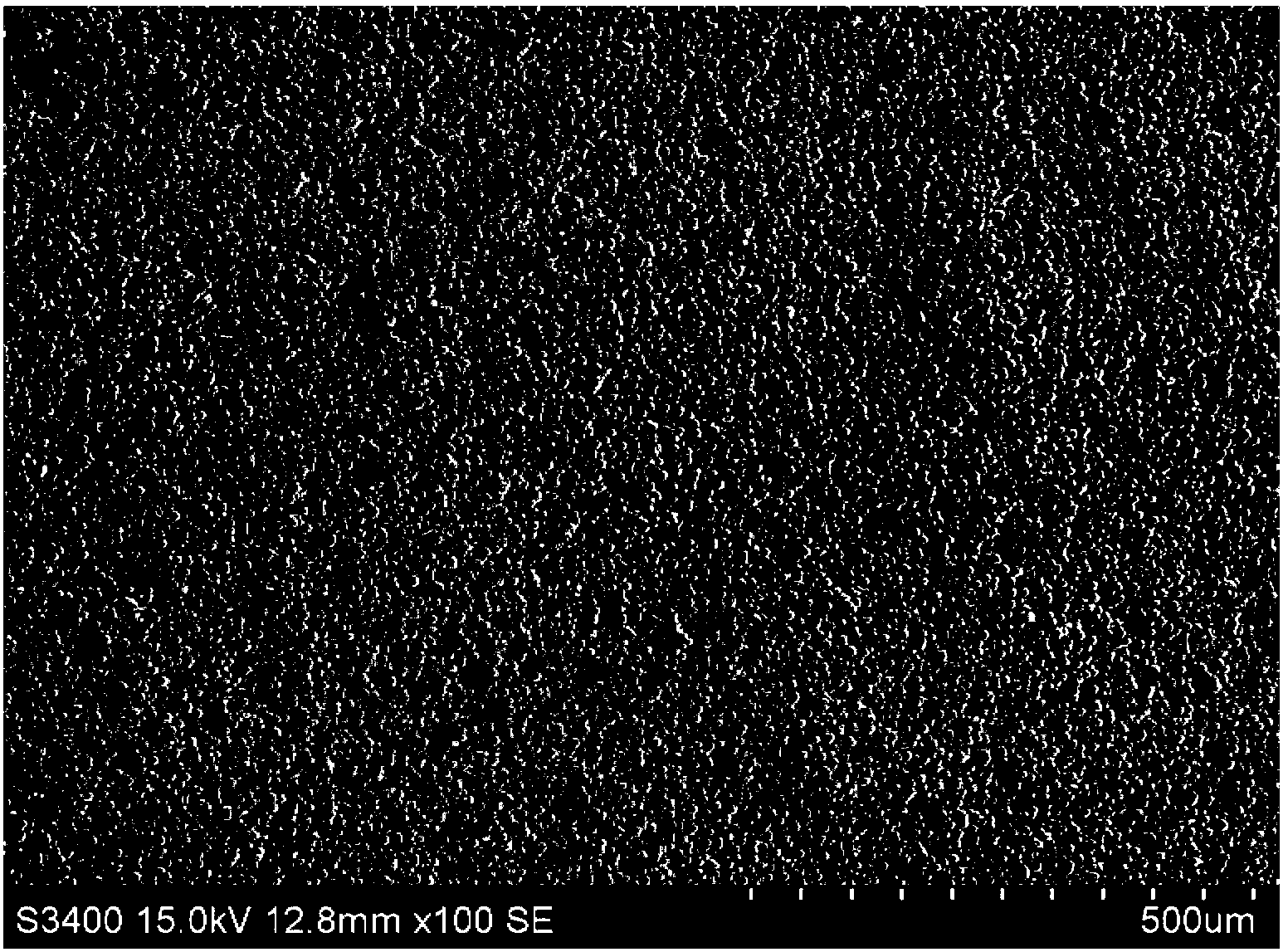

Method for manufacturing gradient composite of W-Cu system by aid of tape casting process

The invention relates to a method for manufacturing a gradient composite of a W-Cu system by the aid of a tape casting process. The method includes steps of (1), manufacturing metal powder non-water-based tape casting slurry and performing tape casting: defoaming and filtering metal powder non-water-based slurry which is mixed by means of ball milling, then performing tape casting on the metal powder non-water-based slurry a tape casting machine, and drying the metal powder non-water-based slurry in air to obtain a single-component metal tape casting membrane; (2), designing, cutting and laminating a gradient structure: cutting tape casting diaphragms with different W-Cu components according to a design of a thickness-direction distribution function C=C<0>+AXx of copper contents, and laminating the cut tape casting diaphragms to form a green body with the gradient structure; (3), removing adhesive of the green body and performing hot pressed sintering: removing the adhesive of the green body in nitrogen and hydrogen mixed atmosphere, and then performing hot pressed sintering on the green body in a vacuum hot press furnace. The method has the advantages that a technology is simple, the cost is low, the thickness of a single-component layer of the composite manufactured by the method can reach a micron dimension, variation of a component is gentle, a transitional layer is smooth and continuous, and the gradient composite is excellent in electro-thermal performance and can be applied to the thermoelectric fields of electric contacts, electronic packaging and the like.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com