Three-dimensional adhesive device having a microelectronic system embedded therein

a three-dimensional adhesive and microelectronic technology, applied in the field of micro electronic systems, can solve the problems of occlusion of adhesives, inability to disclose constructs, and several major drawbacks of known microelectronic systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0332]Three batches of adhesive were produced. The adhesives were prepared by standard hot melt procedure in a Herman Linden z-blade mixer (Machine type LK 110.5), by mixing the components of elastomer (Kraton), one third of the plasticiser (DOA) and the resin (Arkon) at 130 degree C. until a homogeneous mixture was achieved (30-50 minutes). The rest of the plasticiser and the hydrocolloid filler (CMC) was added and the mixture was blended for 20 minutes.

Recipe 1Recipe 2Recipe 3Kraton 116118.019.015.0(Shell)Arkon P9032.036.0(ArakawaDOA (Dioctyl adipate)5.67.5Vistanex ® LM-MH45.0(Exxon)CMC: Blanose44.437.54009H4XF (Hercules)

example 2

Moulded Bodies of the Adhesives of Example 1

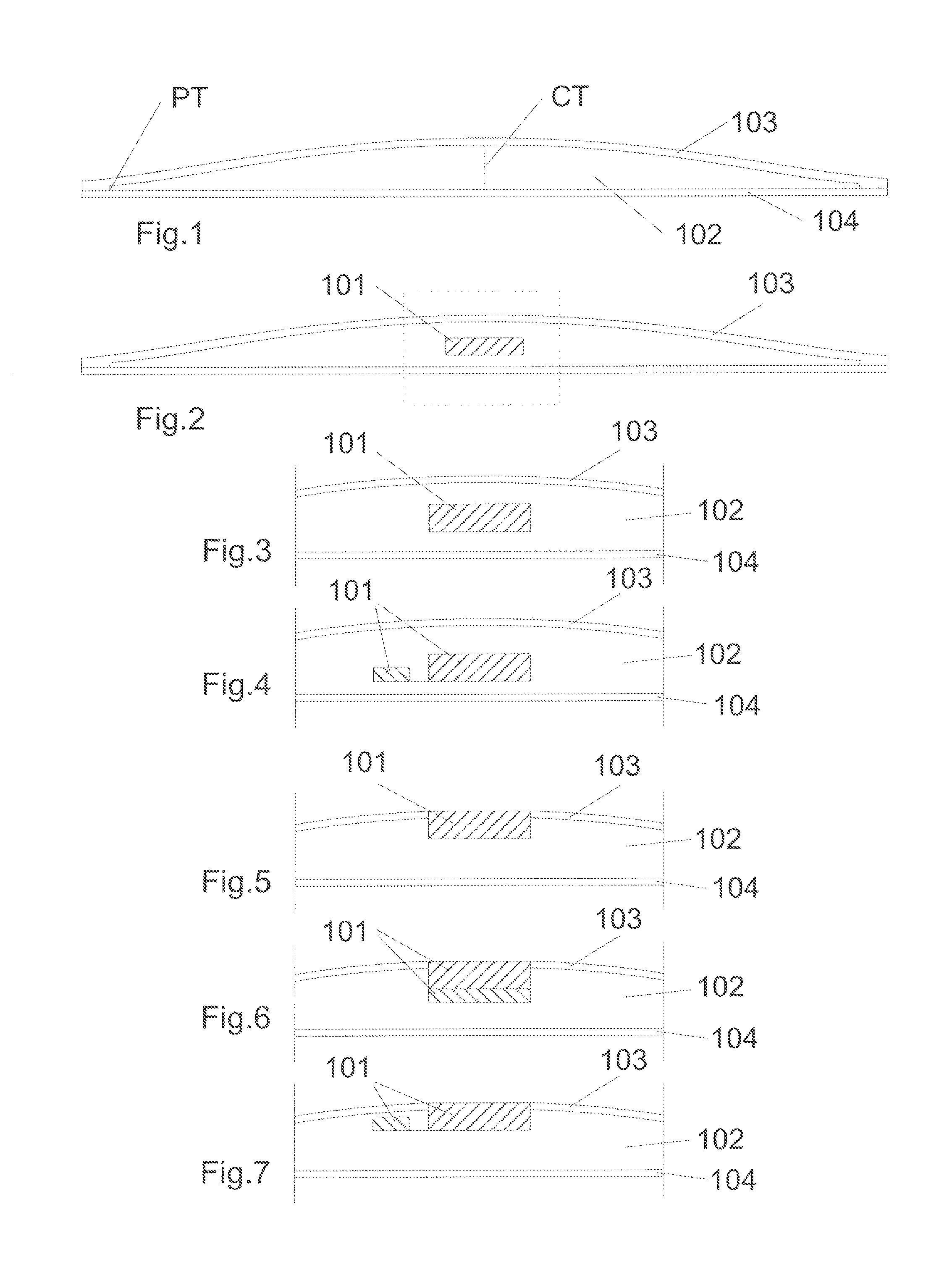

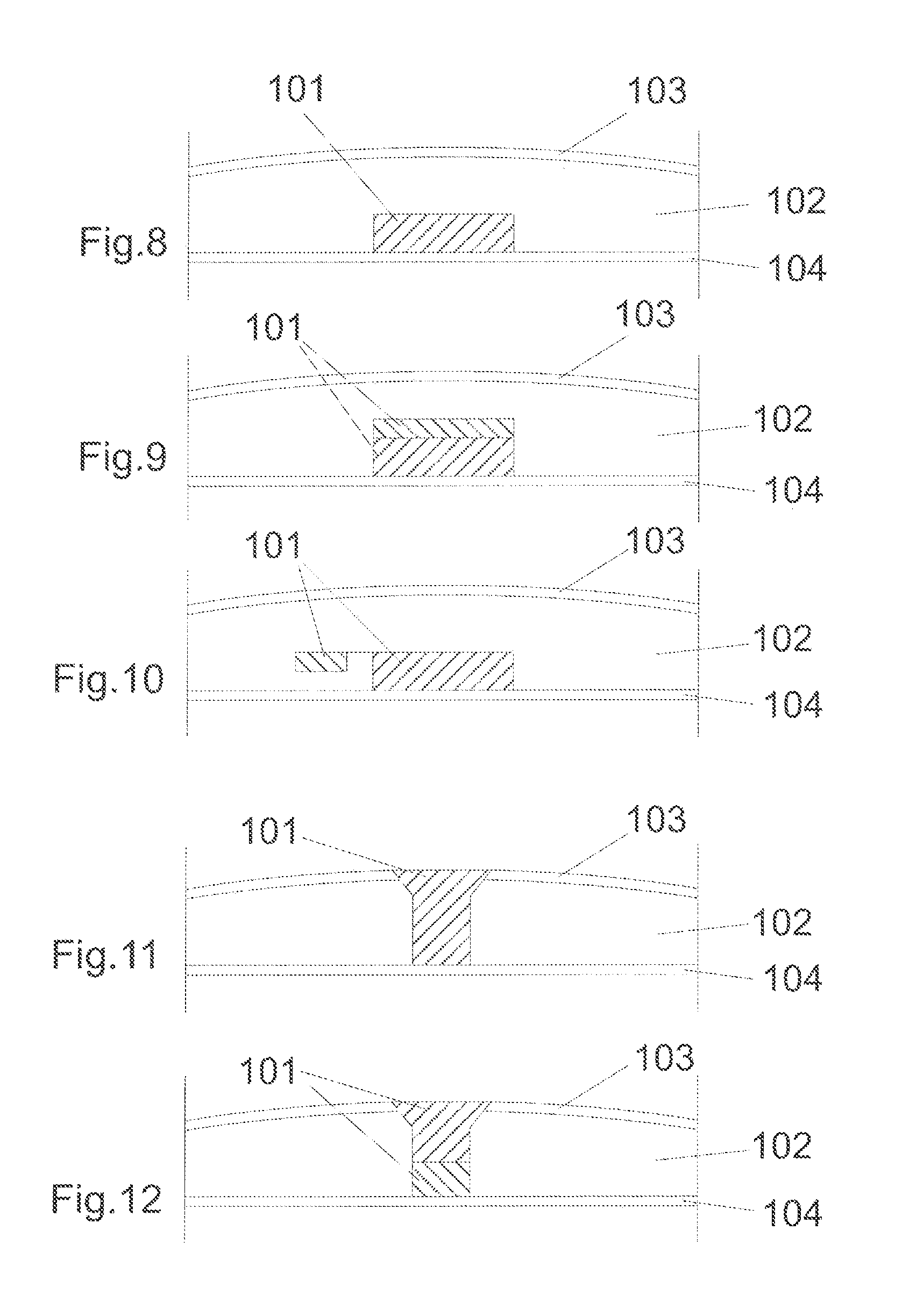

[0333]Each of the adhesives according to claim 1 were applied on to a 35 micrometer thick cover film of polyethylene and a siliconised polyethylene liner was applied to the opposite side of the adhesive patch and pressed to the desired shape according to any of the illustrations 1-3 in a for the shape designed mould at 90 degree C. by altering the non-cavity holding mould to give the shape of the recess. The centre of the adhesive device was 3.4 mm and the thickness of the outer rim 0.4 mm.

example 3

Moulded Silicone Pressure Sensitive Adhesive Body

[0334]Dow Corning 7-9800 A&B (mixing ration between A and B is 1:1 by weight) were used for production of a PDMS based adhesive body. A mould having a triangular shape (each side of the triangular mould having a distance of 300 mm, the center part having a thickness of 0.5 mm and the edge having a thickness of 0.1 mm) was used. The components were thoroughly mixed and applied on a 50 μm cover layer of silicone rubber lining in the female part of a triangular mould and a male mould part was placed on top, said part lined with a low density polyethylene release liner. The adhesive was cured in an oven at 100 degree C. for 15 minutes. After curing the adhesive was punched out of the mould and a dent in the centre of the adhesive body device for embedment of an electronic sensing system was punched out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com