Patents

Literature

451 results about "Dioctyl adipate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dioctyl adipate (DOA) is an organic compound with the formula (CH₂CH₂CO₂C₈H₁₇)₂. It is a colorless oily liquid. As well as related diesters derived from 2-ethylhexanol, decanol, isodecanol, etc, it is used as a plasticizer.

Environment-friendly cold-resistant polyvinyl chloride cable material and preparation method thereof

InactiveCN102653618AImprove performanceHeat resistantPlastic/resin/waxes insulatorsAntioxidantDioctyl terephthalate

The invention provides an environment-friendly cold-resistant polyvinyl chloride cable material and a preparation method thereof. The environment-friendly cold-resistant polyvinyl chloride cable material is prepared from the following raw materials in percentage by mass: 40-60% of polyvinyl chloride, 5-25% of dioctyl terephthalate, 5-25% of dioctyl adipate, 1-10% of chlorinated polyethylene, 5-25% of light activated calcium carbonate, 1-3% of lubricant, 2-8% of Ca-Zn composite stabilizer, 0.1-1% of antioxidant and 0.1-4% of pigment. The environment-friendly cold-resistant polyvinyl chloride cable material is mainly compounded from dioctyl terephthalate and dioctyl adipate. The cable material can be normally used in a low-temperature environment of -40 to -65 DEG C, has favorable shock resistance under low-temperature conditions, does not contain ortho-benzoic ether compounds, and is environment-friendly, thereby solving the problem that the existing polyvinyl chloride cable material is not environment-friendly and has poor shock resistance under low-temperature conditions.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD +1

Medical polyvinyl chloride plastic and preparation process thereof

Owner:上海新上化高分子材料有限公司

PET (polyethylene glycol terephthalate) fiber/teflon fiber composite sound absorbing cotton and preparation method of PET fiber/teflon fiber composite sound absorbing cotton

InactiveCN102965843AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsNon-woven fabricsDiphenyl phosphatePolymer science

The invention discloses PET (polyethylene glycol terephthalate) fiber / teflon fiber composite sound absorbing cotton, which is prepared from the following ingredients in parts by weight: 70 to 80 parts of PET fibers, 40 to 50 parts of teflon fibers, 10 to 15 parts of emulsifying agents OP-30, 5 to 10 parts of peregal O-20, 80 to 100 parts of PP (propene polymer), 30 to 40 parts of HIPS (high impact polystyrene), 15 to 20 parts of activated clay, 10 to 15 parts of modified kieselguhr, 2 to 3 parts of stearic acid, 5 to 8 parts of dioctyl adipate, 4 to 6 parts of cresyl diphenyl phosphate, 2 to 3 parts of liquid paraffin, 1 to 2 parts of 3-aminopropyltrimethoxysilane, 2 to 3 parts of calcium stearate, 1 to 2 parts of barium stearate, 0.5 to 1.5 parts of anti-aging agents RD and 1 to 2 parts of antioxidants DLTP (dilauryl thiodipropionate). The sound absorbing cotton prepared by the invention has the advantages that the appearance evenness is good, the thickness is uniform, the hand feeling is soft, the product bonding degree is good, the tensile performance is high, the sound absorbing performance is excellent, the flame retardant effect is good, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

High-performance complex calcium sulfonate grease and preparation method thereof

InactiveCN101824357AImprove high temperature resistanceGood mechanical stabilityLubricant compositionAntioxidantDioctyl sebacate

The invention discloses high-performance complex calcium sulfonate grease and a preparation method thereof. The complex calcium sulfonate grease comprises the following components: 35 to 80 percent of base oil, 10 to 40 percent of ultrahigh-base-number synthetic calcium sulfonate, 0.5 to 2 percent of antioxidant and 0.5 to 20 percent of transforming agent, wherein the base oil is dicarboxylic acid diester, dioctyl sebacate, dioctyl adipate and the like; the ultrahigh base number of the ultrahigh-base-number synthetic calcium sulfonate is between 380 and 420mgKOH / g; and the synthetic calcium sulfonate comprises the following complex components: 0.5 to 8 percent of C12 to C24 hydroxy fatty acid, 0.5 to 4 percent of boric acid and 0.5 to 2 percent of calcium hydroxide. The complex calcium sulfonate based grease has high-temperature resistance, high mechanical stability and high extreme-pressure abrasion resistance, reduces the using amount of the transforming agent such as alcohol, ether and the like and environmental pollution in the production process, and improves the efficiency of transforming Newtonian high-base-number calcium sulfonate into non-Newtonian high-base-number calcium sulfonate completely, so that the production technology is simpler.

Owner:李墨菊

No-cleaning leadless solder and preparation method thereof

InactiveCN101391350AAffect physical propertiesImprove liquidityWelding/cutting media/materialsSoldering mediaBenzyl benzoatActive agent

The invention relates to a no-clean lead-free tin welding wire and a preparation method thereof, wherein the lead-free welding wire is composed of 2 to 3 percent of flux and 97 to 98 percent of lead-free solder. The lead-free solder is composed of 0.5 to 0.7 percent of Cu, 0.03 to 0.05 percent of Ni, 0.01 to 0.02 percent of P, 0.005 to 0.01 percent of Ga and the remnant amount of Sn. The No-clean flux is composed of 1.0 to 4.0 percent of organic acid active agent, 0.5 to 5.0 percent of halogenated derivative active solvent, 2.0 to 5.0 percent of heat-resistant resin , 1.0 to 4.0 percent of cosolvent, 2.0 to 5.0 percent of high boiling point solvent and the remnant amount of modified rosin. The cosolvent belongs to ester compound and the high boiling point solvent is the mixed solvent of one or more of the SAF-25, dioctyl sebacate, benzyl benzoate, dioctyl adipate. In the preparation of the welding wire, the key point is first to form the alloys of Sn with other metals, and then the alloys can be added to the tin for melting. The lead-free welding wire of the invention has good heat resistance without halogen, low flux spattering, low odor, non-corrosive flux residue, strong practical feature, good electrical insulation after being welded, crack-free flux residue and high reliability.

Owner:太仓市首创锡业有限公司

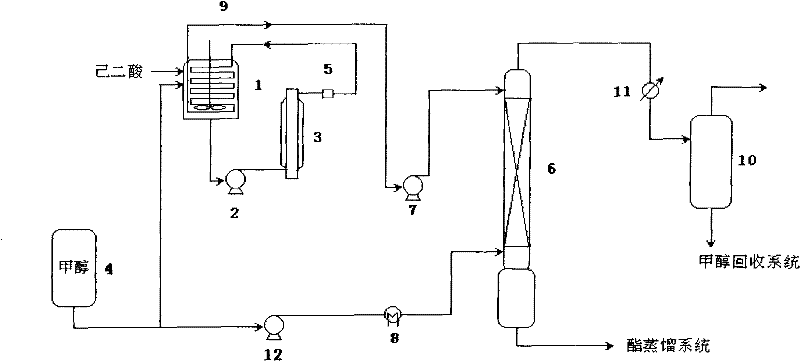

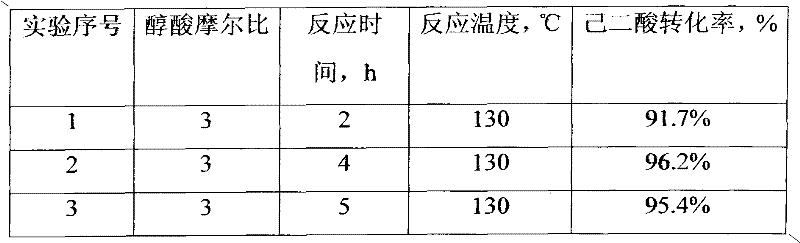

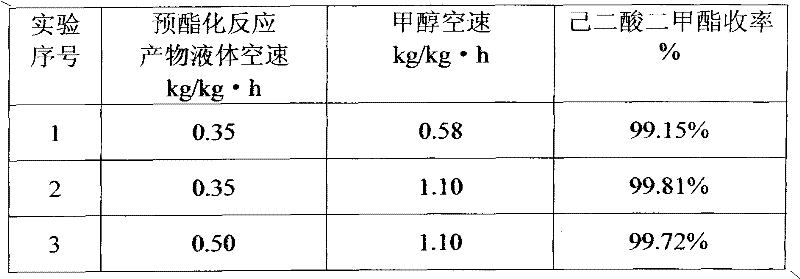

Method for preparing dimethyl adipate by continuous esterification

ActiveCN102442905AImprove conversion rateReduce reaction loadOrganic compound preparationCarboxylic acid esters preparationAdipic acid dimethyl esterEsterification reaction

The invention discloses a method for preparing dimethyl adipate by continuous esterification, comprising the steps of (1) pre-esterifying mixture of adipic acid and methanol in a tubular reactor with an inner component on the catalyst-free condition, wherein the temperature is 90-180 degrees centigrade and the pressure is 0.05-3 MPa; (2), sending the pre-esterified product to upper part of a continuous catalytic rectifying tower; enabling the dried methanol to enter the lower part of the catalytic rectifying tower after being vaporized; enabling the pre-esterified material to contact the methanol steam in the catalytic rectifying tower in a counter-current manner; and further performing esterifying. The method overcomes the problems that the traditional process has device corrosion and pollution problem caused by the sulphuric acid catalyst, and has no continuous pre-esterification and large catalyst consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

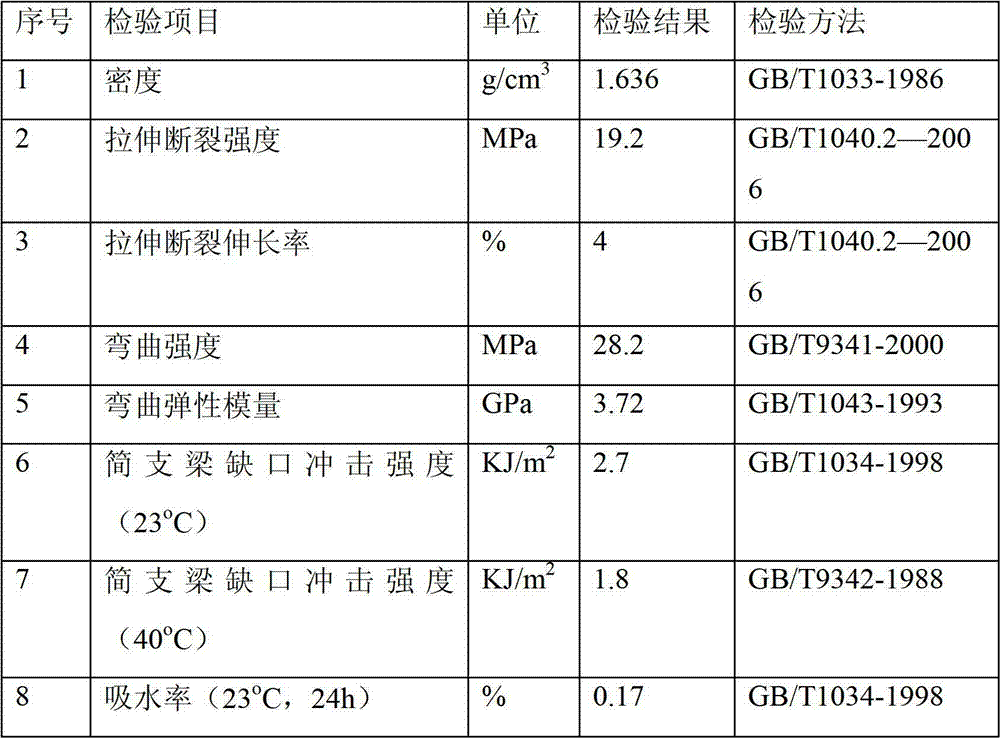

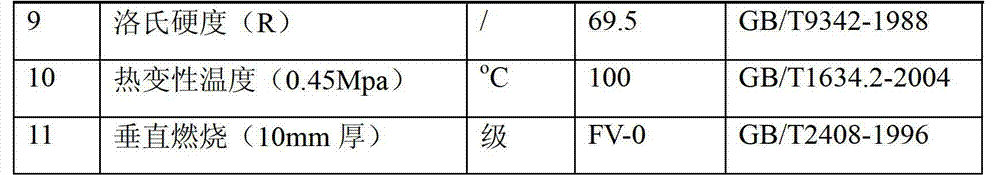

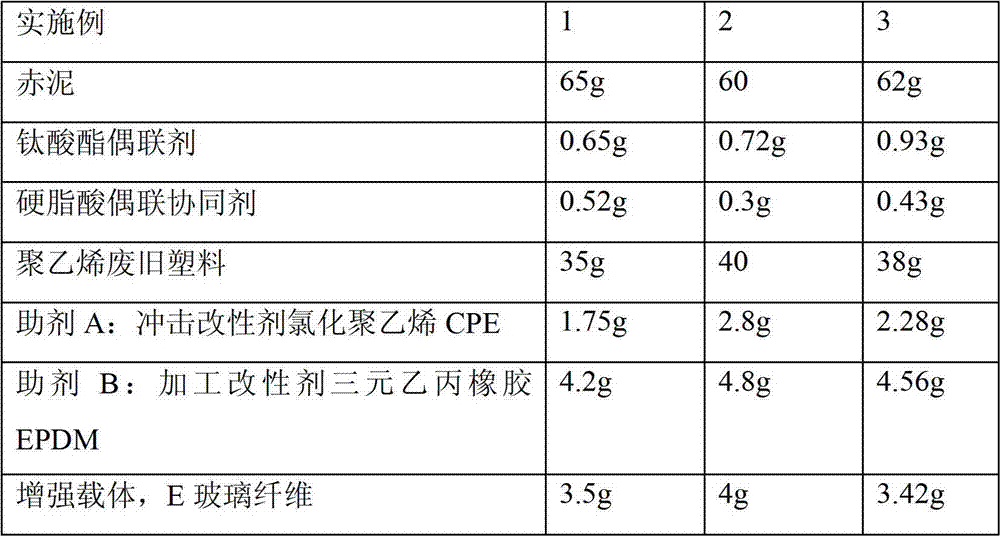

Floor, manufacture method and application thereof

ActiveCN102757590ANo radioactive contaminationMeet the testing standardsFlooringRed mudPolyvinyl chloride

The invention provides a floor with industrial residues as main materials. The materials for manufacturing the floor include red mud, functional additives and enhancing carriers. The component includes, by weight, 55 to 70 parts of red mud, 30 to 45 parts of plastic, 0.05 to 4 parts of functional additives A, 3 to 5 parts of functional additives B and 3 to 5 parts of enhancing carriers, wherein the plastic is selected from polyethylene, polrvinyl chloride or polypropylene; the functional additives A are selected from impact modifier chlorinated polyethylene (CPE), plasticizer dioctyl adipate (DOA), and nucleating agent beta crystal form nucleating agent tetramethylbenzidine (TMB)-5; the functional additives B are selected from a processing modifier ethylene propylene diene monomer (EPDM), and an impact modifier methyl methacrylate-butadiem-styrene (MBS) copolymer resin; and the enhancing carriers are E glass fibers. The floor has good corrosion resistance, firmness and light quality, water proofing, fire proofing, electricity proofing properties, sound insulation and heat insulation performances, no radioactive contamination or harmful gas, and good market prospects and use values.

Owner:湖北声荣再生资源利用有限公司

High-strength wear-resisting nitrile butadiene rubber cable material

InactiveCN103554570AImprove performanceHigh strengthInsulated cablesInsulated conductorsLow-density polyethyleneLinear low-density polyethylene

The invention relates to a cable material, and in particular relates to a high-strength wear-resisting nitrile butadiene rubber cable material. The cable material is prepared from the following raw materials in parts by weight: 35-40 parts of nitrile butadiene rubber (3304), 1-2 parts of sulphur, 4-5 parts of polyacrylonitrile, 6-8 parts of ABS (Acrylonitrile Butadiene Styrene) high rubber powder, 30-34 parts of metallocene linear low-density polyethylene, 12-14 parts of butadiene rubber, 3-4 parts of stearic acid, 1-2 parts of oxalic acid, 25-28 parts of N330 carbon black, 5-8 parts of dioctyl adipate, 5-7 parts of triethyl citrate, 6-8 parts of zinc oxide, 2-4 parts of magnesium oxide, 28-32 parts of N550 carbon black, 1-2 parts of accelerant DM and 4-5 parts of auxiliary. According to the cable material, the advantages of the raw materials of nitrile butadiene rubber, butadiene rubber, ABS high rubber powder, metallocene linear low-density polyethylene and the like are combined, the properties of the conventional nitrile butadiene rubber cable material are improved, the cable material is enabled to have the advantages of high strength, good tension property, external impact resistance, wear resistance and the like, can meet the application requirements in special situations, is harmless to environment and human bodies, and is wide in application prospect.

Owner:安徽文峰电子科技集团有限公司

Low-temperature-resistant and ageing-resistant modified fluororubber cable sheath material

The invention discloses a low-temperature-resistant and ageing-resistant modified fluororubber cable sheath material prepared form the following raw materials in parts by weight: fluororubber, butadiene rubber, ethylene-vinyl acetate copolymers, rear-earth complexes, white carbon black, modified carbon nano-tubes, nanometer kaolin, castor oil, rapeseed oil, stearic acid, zinc oxide, sulphur, dicumyl peroxide, triallyl isocyanurate, dioctyl adipate, epoxidized triglyceride, inositol hexaphosphate, a silane coupling agent, an accelerant M, an accelerant DM, an anti-aging agent RD and an anti-aging agent 4010NA. The low-temperature-resistant and ageing-resistant modified fluororubber cable sheath material disclosed by the invention is good in ageing resistance and low temperature resistance; and the prepared cable sheath is good in comprehensive performance and long in service life.

Owner:ANHUI HUIYI CABLE GROUP

Insulation electrical engineering bushing plastic and preparation method thereof

InactiveCN103289247AHigh strengthHigh impactPlastic/resin/waxes insulatorsInsulated cablesPhosphorous acidPolymer science

The present invention relates to an insulation electrical engineering bushing plastic and a preparation method thereof. The plastic comprises the following components, by mass, 70-90 parts of a PVC resin, 10-17 parts of an acrylonitrile-butadiene-styrene copolymer, 30-45 parts of dioctyl phthalate, 3-8 parts of dioctyl adipate, 0.5-3 parts of epoxy soybean oil, 1-4.5 parts of calcined kaolin, 1.5-2.7 parts of dibasic lead phosphite, 1.2-1.8 parts of fatty acid ester, 5-10 parts of aluminum hydroxide, 2-5 parts of zinc borate, 1.5-3 parts of barium stearate, 1-3.5 parts of an organotin stabilizer, and 1.5-4 parts of PE wax. The insulation electrical engineering bushing plastic has characteristics of high strength, high impact resistance, high toughness, good insulation and good fire retardation, and can provide good protection effects for electric wires, electric cables and the like.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

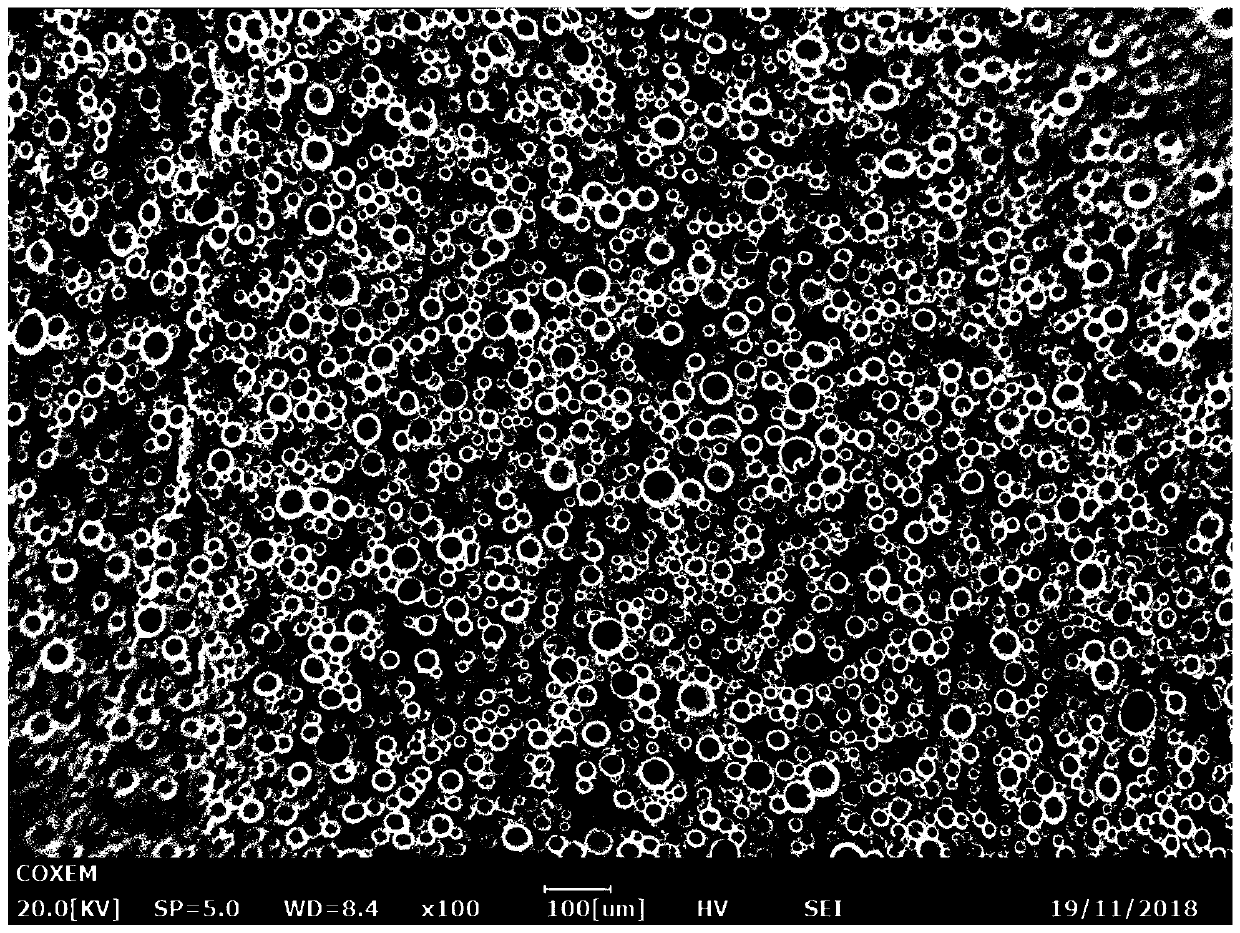

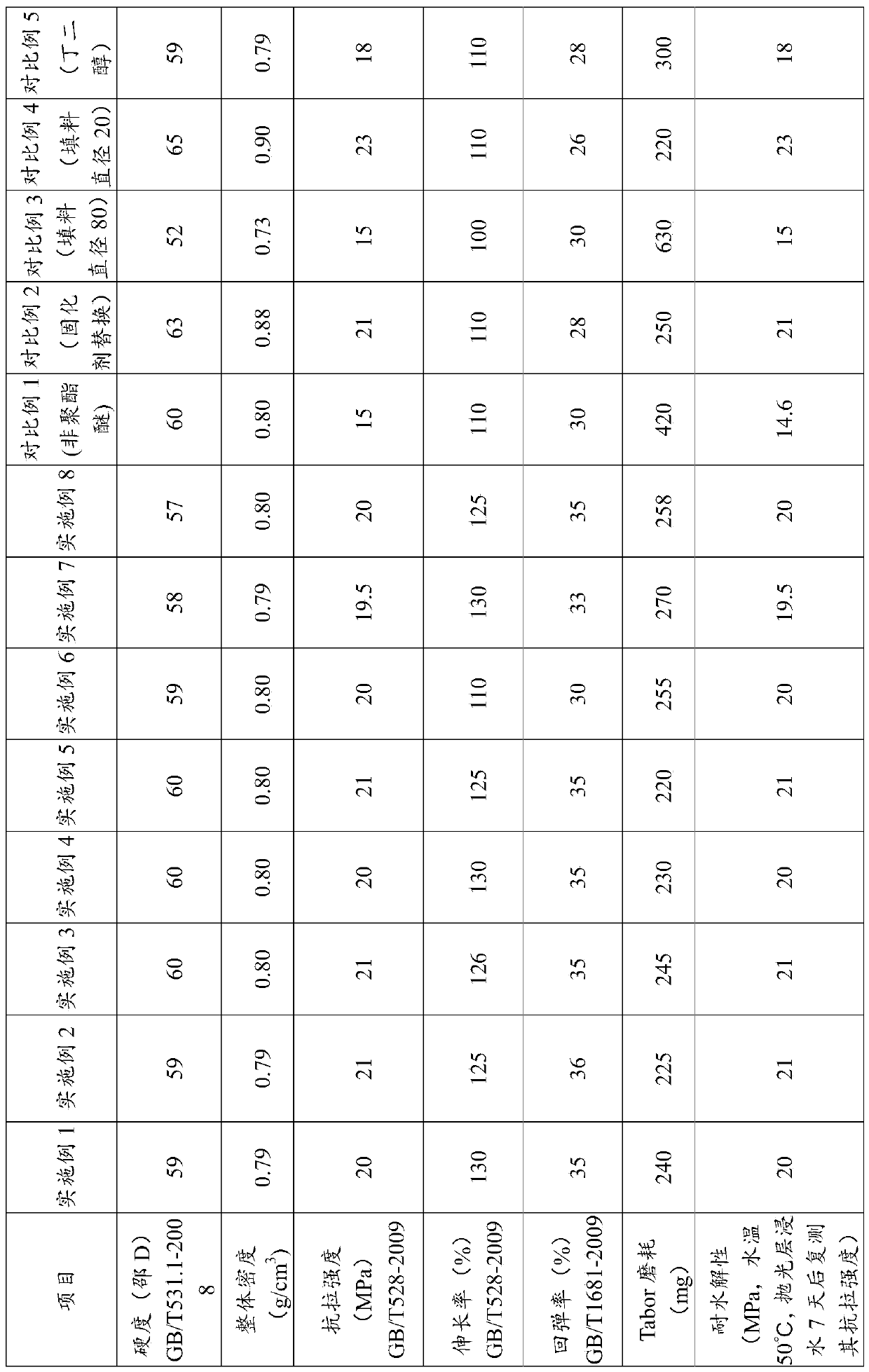

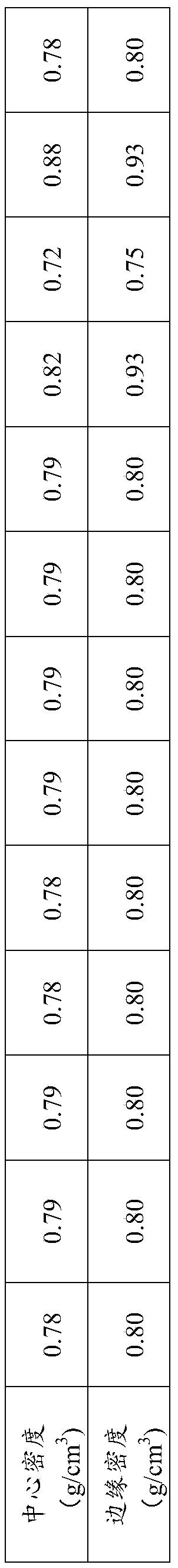

Polishing layer of chemical-mechanical polishing pad and application of polishing layer

ActiveCN110977756AImprove mechanical propertiesImprove wear resistanceSemiconductor/solid-state device manufacturingLapping toolsPolymer sciencePolyol

The invention provides a polishing layer of a chemical-mechanical polishing pad and application of the polishing layer. The polishing layer is prepared by the reaction of isocyanate prepolymer, a curing agent and functional filling; the isocyanate prepolymer is prepolymer prepared by the reaction of raw materials including diisocyanate, polyether ester polyol and optional small molecular polyol; the curing agent is dispersion liquid formed in dioctyl adipate by a complex of diamine compound and sodium chloride, wherein concentration of the complex is 40 wt%-50 wt%; and the functional filling is expanded polymer hollow microspheres. The polishing layer has higher mechanical strength and abrasive resistance while having high elasticity and hydrolysis resistance, so that the durability of thepolishing layer is good.

Owner:万华化学集团电子材料有限公司

Outer rubber resistant to low temperature of minus 55 DEG C for hydraulic rubber hose

The invention discloses outer rubber resistant to a low temperature of minus 55 DEG C for a hydraulic rubber hose. The outer rubber is prepared from the following raw materials in parts by weight: 35 to 45 parts of nitrile rubber with low acrylonitrile content, 35 to 45 parts of composite materials of nitrile rubber and polyvinyl chloride, 15 to 25 parts of chlorosulfonated polyethylene rubber, 4.9 to 7.1 parts of anti-aging agents, 3.8 to 5.2 parts of activating agents, 5 to 7 parts of light magnesium oxides, 3.5 to 4.5 parts of anti-ozone wax, 15 to 25 parts of reinforcing filling agents, 70 to 100 parts of reinforcing agents, 4.3 to 6.7 parts of adhesives, 15 to 25 parts of plasticizing agents dioctyl adipate (DOA), 1 to 2 parts of vulcanizing agents, and 1.3 to 2.3 parts of accelerating agents. A vulcanized rubber material is obvious in physical property, low temperature resistance and effect, and a gray hydraulic rubber pipe made from the above materials has the low temperature resistance which is up to minus 55 DEG C, and is intact in the conditions of 50ppm of ozone in 72 hours at a temperature of 40 DEG C.

Owner:LUOHE LETONE RUBBER

Formula of nitrile rubber pad for sealing transformer oil

InactiveCN102807690AImprove aging resistanceMeet the requirements of 30-year service lifeOther chemical processesPolymer scienceNitrile rubber

The invention relates to a formula of a nitrile rubber pad for sealing transformer oil, and belongs to the technical field of rubber sealing materials for transformers. The formula adopts the following technical scheme: the nitrile rubber pad comprises the following components by weight percent: 65-68% of carbon black N330, 5-17% of dioctyl adipate DOA, 10-13% of zinc oxide, 1-1.5% of stearic acid, 1-2% of antioxidant RD, 1-2% of antioxidant MB, 3-5% of vulcanizing agent DCP (dicumyl peroxide) and 2-4% of vulcanizing agent TAIC (triallyl isocyanurate), based on 100% of nitrile rubber 3365. All the materials in the formula are conventional materials which can be purchased in the market. The nitrile rubber pad for the production process and the background technology is not changed but the added raw materials and the proportions are different. The formula has the positive benefits as follows: the ageing-resistant performance of the materials is improved on the premise of guaranteeing the physical performance, the service life is prolonged, the requirement of the 30-year service life of a transformer is met, and the problem of leakage caused by ageing of the nitrile rubber pad is solved.

Owner:保定市新科橡胶制品研究所

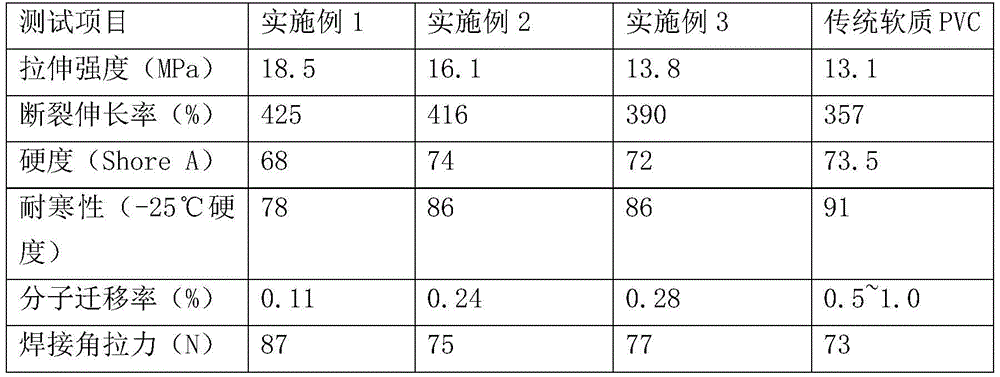

Modified polyvinyl chloride door seal and preparation method thereof

The invention belongs to the technical field of door seal materials, and relates to a modified polyvinyl chloride door seal and a preparation method thereof. The door seal is prepared from, by weight, 40-50 parts of polyvinyl chloride resin powder, 5-15 parts of anti-yellowing thermoplastic elastomer, 0-5 parts of 1,2-cyclohexane dicarboxylic acid di-isononyl ester, 5-20 parts of trioctyl trimellitate, 0-5 parts of dioctyl adipate, 5-10 parts of epoxidized soybean oil, 5-10 parts of polyester oligomer, 10-15 parts of filler, 1-3 parts of a stabilizer, 1-3 parts of a compatilizer, 1-3 parts of a lubricating agent and 0.1-1 part of pigment. Fat diisocyanate is two of hexamethylene diisocyanate (HDI), isophorone diisocyanate (IPDI) and hexamethylene diisocyanate (HMDI). The defects that the hardness of a traditional soft PVC door seal is sharply increased at low temperature and elasticity becomes poor are overcome, the tensile strength and the breaking elongation of the door seal are improved, the welding angle pull force of the door seal is increased, and the service life of the door seal is prolonged.

Owner:QINGDAO NEW MATERIAL TECH IND PARK DEV

Transparent embossing table mat

ActiveCN103724886AHigh transparencyStrong three-dimensional embossingLamination ancillary operationsSynthetic resin layered productsPolymer sciencePlasticulture

The invention relates to the technical field of home decoration articles, and particularly relates to a transparent embossing table mat which is prepared from PVC (polyvinyl chloride) resin and an assistant and has a specific formula as follows: 100 parts of PVC resin, 43-50 parts of dioctyl phthalandione, 2-5 parts of dioctyl adipate, 2-3 parts of epoxidized soybean oil, 2-3 parts of barium and zinc composite stabilizing agent and 0.05-0.08 part of coloring agent. The transparent embossing table mat is prepared by adopting the steps: fully mixing materials in a high-speed mixing machine, sending the mixed materials to a planet machine for being preplasticized, then conveying to a filter machine, repeatedly plastifying, filtering and plasticizing, calendaring in a calendaring machine, further plastifying and calendaring the calendered blank to form a film with a certain thickness after continuous calendaring, then introducing the film outside through an introducing roller, drying moisture on the film by warming, coiling to obtain a product, sending the product into a refrigeration house, cooling for 6-8 hours, and discharging outside from the refrigeration house. The transparent embossing table mat has the characteristics of high transparency, good embossing effect, good heat resistance and cold resistance, no toxicity and taste, and environmental friendliness.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Improved polyvinyl chloride granula for cable

InactiveCN1962744AExtended operating temperature rangeSatisfy frequent transfer useInsulated cablesInsulated conductorsAcetic acidUltraviolet

The invention discloses a polychloroethylene cable material for torrid zone and frigid zone, which comprises the following parts: 40-70%wt polychloroethylene resin and 30-60%wt ethylene-acetic acid ethyenyl ester copolymer composition or 70-95%wt vinyl chloride and 5-30%wt maleate copolymer, 20-35%wt dioctyl sebacate and or adipate dioctyl plasticizer, 0.3-1.6%wt ultraviolet adsorbent and 0.5-2.0%wt anti-fungus agent. The temperature scale of cable material is -50+80 Deg C, which is fit for frequent transmitting utility.

Owner:WUXI HUANCABLE

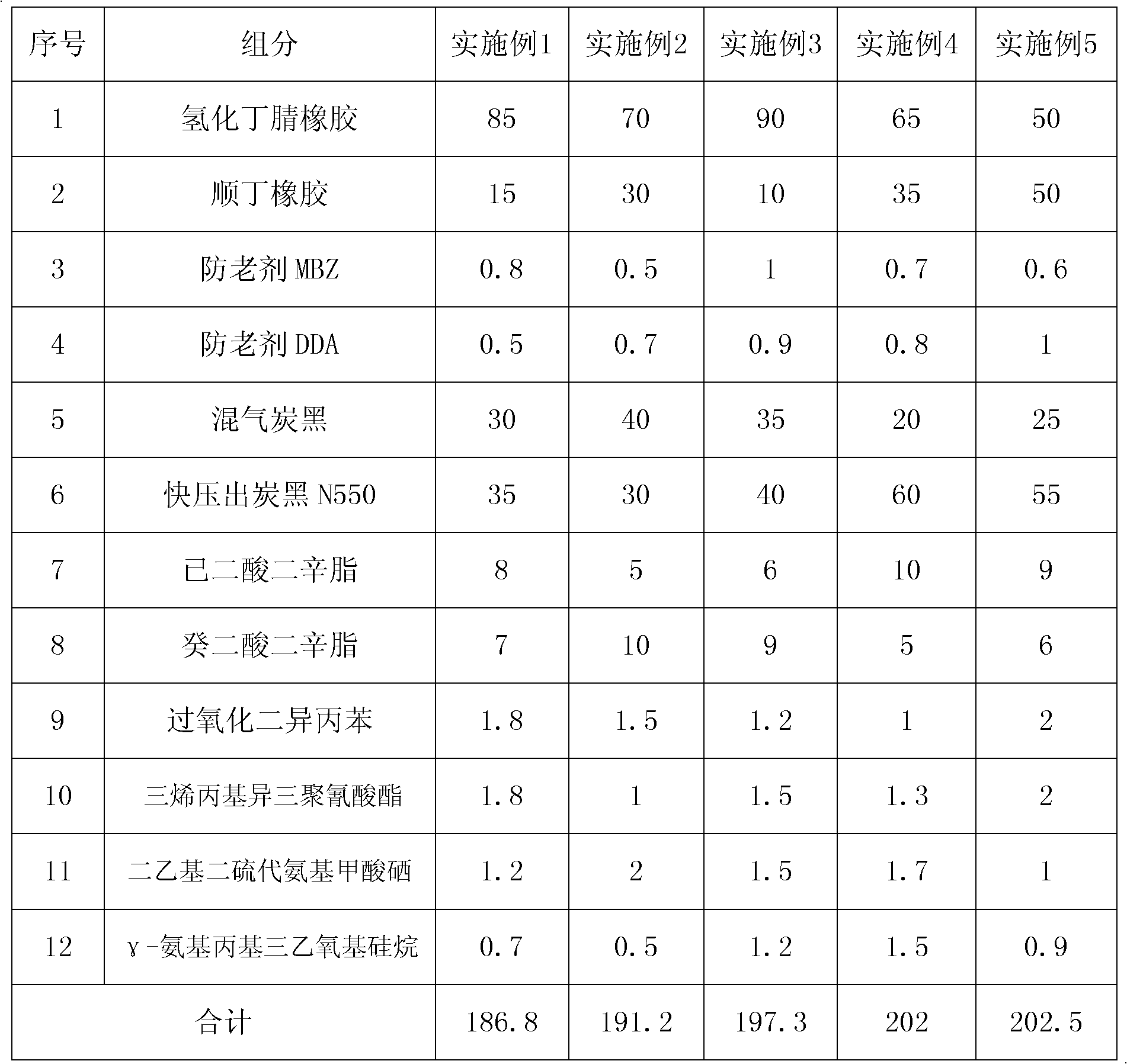

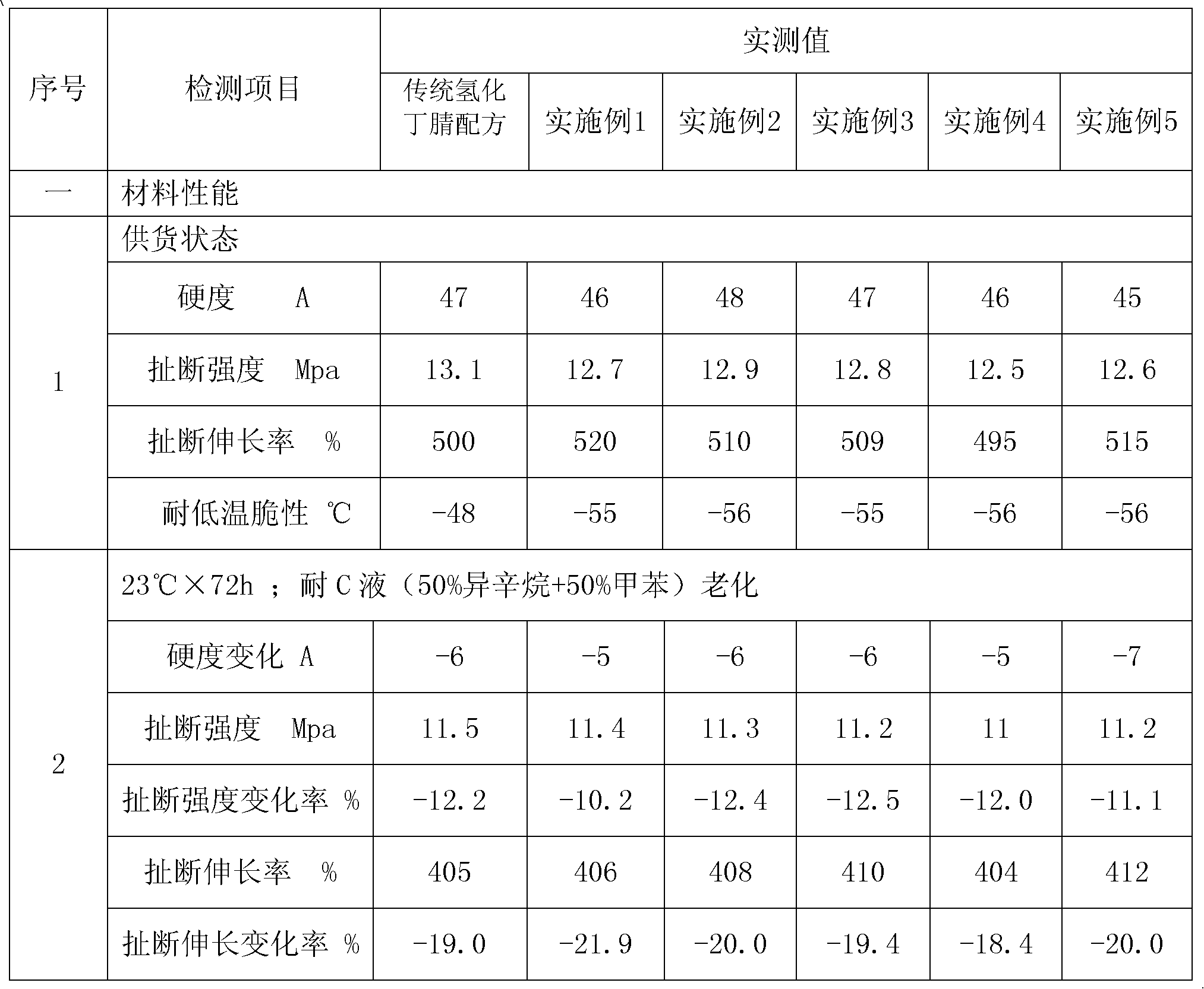

Hydrogenated nitrile-butadiene rubber composition

The invention relates to a hydrogenated nitrile-butadiene rubber composition. The composition comprises hydrogenated nitrile-butadiene rubber, butadiene rubber, an anti-aging agent MBZ, an anti-aging agent DDA, mixed gas carbon black, quick pressed-out carbon black N550, dioctyl adipate, dioctyl sebacate, dicumyl peroxide, triallyl isocyanurate, selenium diethyl dithiocarbamate and gamma-amino propyl triethoxysilane. The low-temperature resistance of the hydrogenated nitrile-butadiene rubber is further enhanced by using the hydrogenated nitrile-butadiene rubber and the butadiene rubber together under the combined action of auxiliary agents such as the dioctyl adipate, the dioctyl sebacate and like; the hydrogenated nitrile-butadiene rubber has the brittleness temperature of up to -56 DEG C, no breakage and still good oil resistance; and other performance of the rubber is not changed obviously. The low-temperature resistance of the hydrogenated nitrile-butadiene rubber is improved and simultaneously the use value of the rubber is improved, which has great significance for better use of the hydrogenated nitrile-butadiene and products thereof in automobile industry, petrochemical industry and the like. Moreover, the safety insurance of the products is improved and the service life of the products is prolonged.

Owner:TIANJIN PENGYI GRP CO LTD

PVC cable material formula

InactiveCN105086196AImprove low temperature resistanceImprove cold resistancePlastic/resin/waxes insulatorsPhosphorous acidPhysical chemistry

The invention relates to the field of cables and concretely relates to a PVC cable material formula. The PVC cable material formula comprises, by weight, 98-102 parts of PVC resin, 3.6-4.4 parts of a stabilizing agent, 18-22 parts of a plasticizer, 5-7 parts of a filler, 17-19 parts of a lubricant, 1-1.4 parts of an anti-oxidant and 4-6 parts of a coloring agent. The PVC resin is loose PVC resin obtained by a suspension method. The stabilizing agent is calcium carbonate. The plasticizer is dioctyl adipate. The filler is calcined clay. The lubricant is chlorinated paraffin. The anti-oxidant is a mixture of lead stearate and calcium stearate. The coloring agent is a mixture of tribasic calcium sulfate and dibasic phosphorous acid. The PVC cable material formula improves low temperature resistance of a cable material. Through a mixture of lead stearate and calcium stearate, low temperature resistance of the cable material is improved, weatherability is good and hardness, tensile strength and elongation are greatly improved.

Owner:HEFEI XUANMING INFORMATION TECH

Flame-retardant cold-resistant impact-resistant rubber cable sheath and preparation method thereof

InactiveCN104194171AIncreased dispersionGood compatibilityRubber insulatorsPlastic/resin/waxes insulatorsFiberShock resistance

The invention discloses a flame-retardant cold-resistant impact-resistant rubber cable sheath which is prepared from the following raw materials in parts by weight: 55-65 parts of chlorinated polyethylene, 10-15 parts of ethylene-propylene rubber, 3-4 parts of sulfur powder, 1.5-2.5 parts of accelerator DM, 1-2 parts of accelerator TMTM, 5-8 parts of trioctyl trimellitate, 3-4 parts of tributyl citrate, 12-14 parts of pretreated fiber powder, 15-20 parts of barite powder, 6-9 parts of magnesium oxide, 35-40 parts of meerschaum powder, 12-16 parts of hard clay, 8-10 parts of red phosphorus, 5-8 parts of aluminum hydroxide, 10-15 parts of magnesium hydroxide, 5-8 parts of diisooctyl phthalate, 7-11 parts of phenyl petroleum sulfonate, 2-3 parts of anti-aging agent RD, 2.1-2.4 parts of anti-aging agent, 25-35 parts of dioctyl adipate and 5-7 parts of stearic acid. The lame-retardant cold-resistant impact-resistant rubber cable sheath has the advantages of favorable flame-retardant effect, high cold resistance and high shock resistance.

Owner:ANHUI LAND GRP

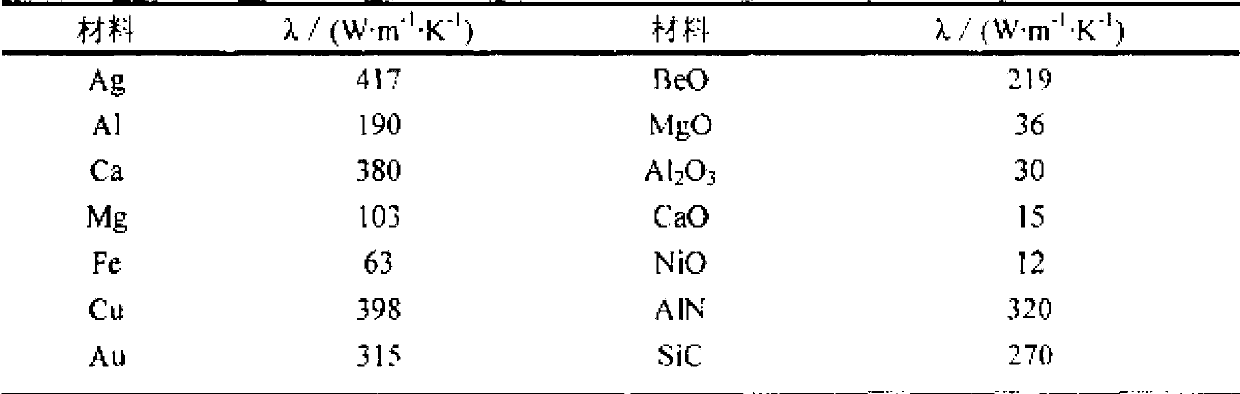

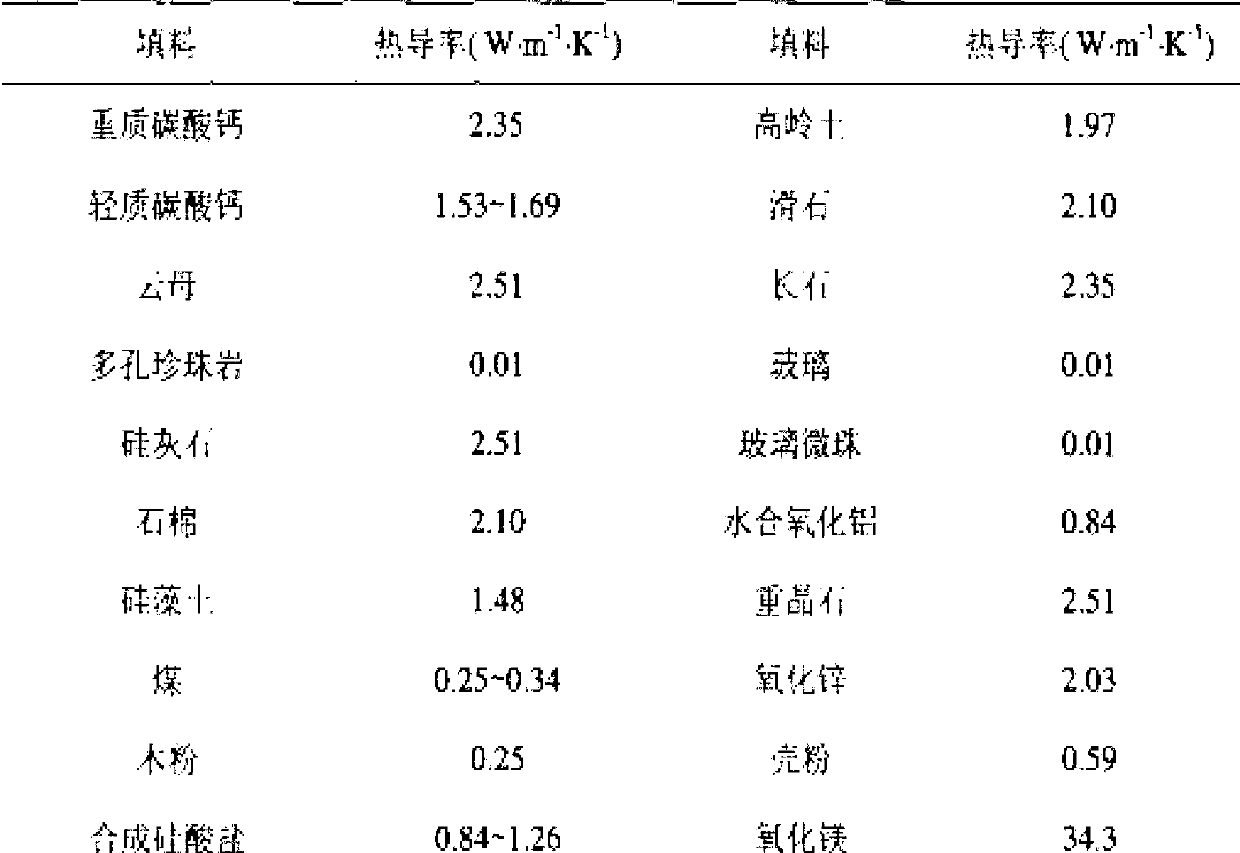

Ethylene propylene diene monomer heat-conducting rubber

The invention discloses ethylene propylene diene monomer heat-conducting rubber. A plasticizer of the ethylene propylene diene monomer heat-conducting rubber is one or more of the following reagents: dioctyl phthalate, polyol benzoate, dioctyl adipate, dihexyl adipate, butyl benzyl phthalate and di-2-ethylhexyl sebacate; and a dispersant of the ethylene propylene diene monomer heat-conducting rubber is one or more of the following reagents: triethylhexyl phosphoric acid, lauryl sodium sulfate, methyl anyl alcohol, cellulose derivative, polyacrylamide, guar gum and polyethylene glycol fatty acid. When an inorganic particle filler is ultrafine and even nanometer-sized, the heat conductivity of the inorganic particle filler is qualitatively changed due to the change of atomic distances and structures in particles. The heat conducting coefficient of high-purity fine magnesium oxide is not less than 50 w / (m.K) and is equivalently 4 times that of silicon oxide and 3 times that of aluminum oxide.

Owner:天津瑞艾化工科技股份有限公司

Antibacterial and antistatic tear-resistant thin-film material

The invention discloses an antibacterial and antistatic tear-resistant thin-film material. The antibacterial and antistatic tear-resistant thin-film material is prepared from the following raw materials in parts by weight: 40-50 parts of polypropylene, 10-20 parts of polyethylene, 10-15 parts of polyester, 2-5 parts of polyurethane, 1-3 parts of 2,2-dimethylol propionic acid, 5-8 parts of 1,2-dimethylcyclohexane, 4-8 parts of dioctyl adipate, 2-6 parts of 2-methyl-1,3-propylene glycol, 0.5-3 parts of a natural antibacterial agent, 1.5-2.5 parts of a concentrated anti-blocking agent, 0.5-1.5 parts of an anti-fog agent, 1-3 parts of an anti-sticking agent, 2.5-4 parts of a slipping agent, 1-5 parts of an antistatic agent, 3-5 parts of zinc oxide whiskers and 1-5 parts of electro-conductive fibers. The antibacterial and antistatic tear-resistant thin-film material has the advantages of being economical, environment-friendly, antistatic, antibacterial, stretch-proof, tear-resistant, anti-fog, wide in application, safe, reliable and the like.

Owner:桐城市人和包装有限公司

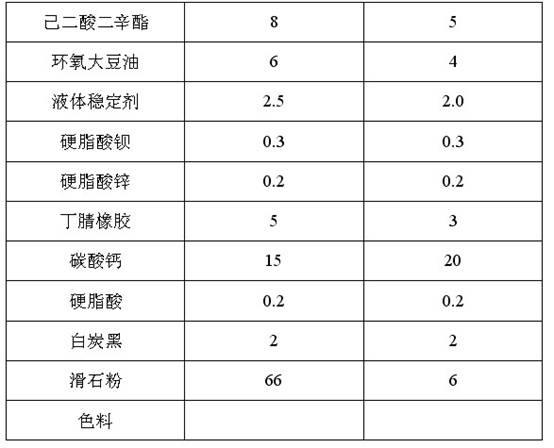

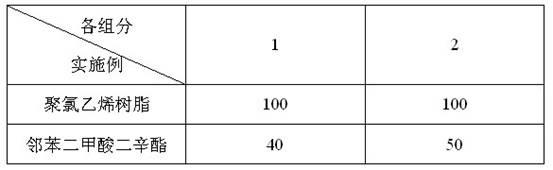

Polyvinyl chloride geomembrane modified by nitrile-butadiene rubber

InactiveCN101864129AHigh tensile strengthHigh impact strengthMarine site engineeringNitrile rubberGeomembrane

The invention relates to a polyvinyl chloride geomembrane modified by nitrile-butadiene rubber, belonging to the technical field of the geomembrane. The polyvinyl chloride geomembrane modified by the nitrile-butadiene rubber is characterized in that the mixture ratio composition of the geomembrane takes polyvinyl chloride resin 100 as reference, and the geomembrane comprises the components based on parts by weight: 20-50 dioctyl phthalate, 2-10 dioctyl adipate, 2-10 epoxidized soybean oil, 2-5 heat stabilizer, 1-5 nitrile-butadiene rubber, 10-20 calcium carbonate, 0.1-0.5 stearic acid, 1-5 white carbon black and 1-6 talcum powder. The modified polyvinyl chloride geomembrane has the advantages of good hand feeling of rubber, high toughness and strength, excellent sealing performance, saving cost, being beneficial to environmental protection, being long in service life, and the like.

Owner:TIANJIN TIANSU SCI & TECH GROUP

No-cleaning lead-free solder soldering flux

InactiveCN101391353AGood welding performanceImprove insulation performanceWelding/cutting media/materialsSoldering mediaActive agentSolvent

The invention relates to a no-clean lead-free solder flux which is composed of following components by weight ratio: 1.0 to 4.0 percent of the organic acid active agent, 0.5 to 5.0 percent of halogenated derivative active solvent, 2.0 to 5.0 percent of heat-resistant resin, 1.0 to 4.0 percent of cosolvent, 2.0-5.0 percent of high boiling point solvent and the remnant amount of modified rosin. The cosolvent belongs to ester compound and the high boiling point solvent is the mixed solvent of one or more of the SAF-25, dioctyl sebacate, benzyl benzoate, and dioctyl adipate. The flux can effectively work with the lead-free solder to form the lead-free welding wire. The invention has good welding property without amine odor, good electrical insulation and heat resistance, and low ion contamination level, and particularly has no halogenated ionic residues after be welded.

Owner:太仓市首创锡业有限公司

Rubber damper for automobiles

The invention discloses a rubber damper for automobiles. The rubber damper comprises raw materials in parts by weight as follows: 40-60 parts of nitrile rubber, 20-50 parts of natural rubber, 1-3 parts of zinc oxide, 1-3 parts of sulfur, 1.2-3 parts of an accelerant TE, 1-1.8 parts of tetramethyl thiuram disulfide, 0.5-1.5 parts of N-cyclohexyl-2-benzothiazole sulfonamide, 20-30 parts of light calcium carbonate, 20-40 parts of white carbon black, 40-60 parts of modified calcium sulfate, 1-2 parts of microcrystalline wax, 1-2 parts of dioctyl adipate, 2-7 parts of dioctyl terephthalate, 0.5-2.5 parts of stearic acid, 0.5-2.5 parts of an anti-aging agent 4020 and 1.5-2.3 parts of an anti-aging agent RD. The product is light in mass and good in elasticity and has excellent high-temperature-resistant performance and good anti-shocking performance.

Owner:宁国天运橡塑制品有限公司

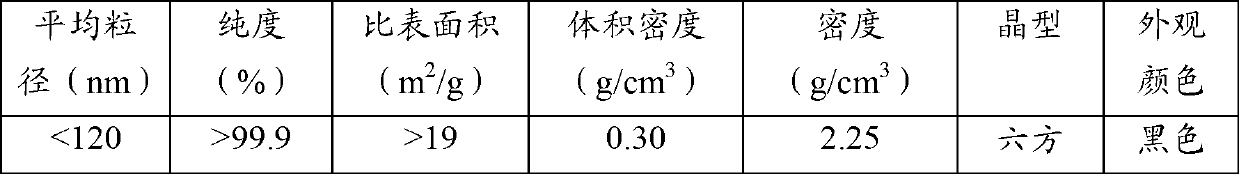

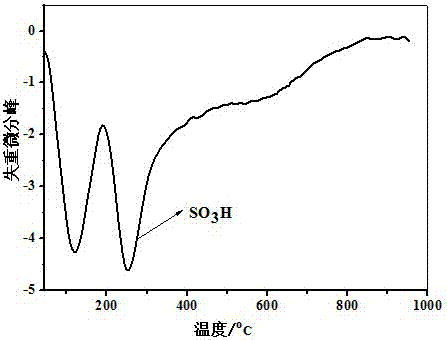

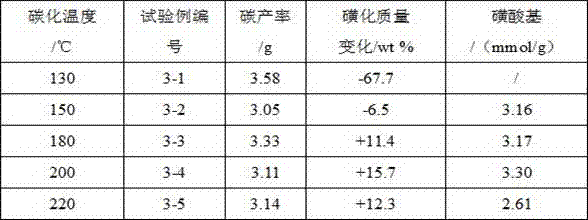

Preparation method of ultrahigh-sulfonic-acid-density biomass carbon solid acid

ActiveCN106861719AHigh yieldReduce energy consumptionPhysical/chemical process catalystsOrganic compound preparationFiberBiomass carbon

The invention relates to the field of catalytic material synthesis, and discloses a preparation method of ultrahigh-sulfo-group-density biomass carbon solid acid HBC-SO3H and a method for synthesizing dioctyl adipate by catalytic esterification. The preparation method of HBC-SO3H comprises the following steps: carrying out hydrothermal carbonization on wood fiber biomass under the catalytic actions of Lewis acid and phenol, and sulfonating by using concentrated sulfuric acid or fuming sulfuric acid. The preparation method of HBC-SO3H has the advantages of short procedure, mild reaction conditions, low cost, high catalyst yield and low environmental pollution, and is simple to operate. The sulfo-group density of the HBC-SO3H is generally 3 mmol / g or above, and can reach 5 mmol / g at the maximum. When being used for catalyzing the synthesis of dioctyl adipate, the HBC-SO3H has excellent catalytic esterification activity and excellent recoverability and reusability.

Owner:HUNAN NORMAL UNIVERSITY

Silver-carrying antibacterial hydrocolloid dressing and preparation method thereof

InactiveCN106362195AGood antibacterial effectReduce concentrationAbsorbent padsBandagesWound healingAntioxidant

The invention discloses silver-carrying antibacterial hydrocolloid dressing and a preparation method thereof. The silver-carrying antibacterial hydrocolloid dressing is sequentially provided with a backing, a hydrocolloid functional dressing core and an isolation layer from top to bottom; the hydrocolloid functional dressing core is prepared from the following raw materials including sodium carboxymethylcellulose, an SIS thermoplastic elastomer, liquid paraffin, tackifying resin, an antioxidant, dioctyl adipate as a plasticizer, a bacteriostatic agent and a collaborative bacteriostatic agent. In a preparation process, the silver ion bacteriostatic agent and the plant extract collaborative bacteriostatic agent are added; with addition of the plant extract collaborative bacteriostatic agent, the addition concentration of the silver ion bacteriostatic agent is lowered when the antibacterial activity of the dressing is effectively improved; with addition of the silver ion bacteriostatic agent, the antibacterial wide adaptability and the antibacterial durability are both improved; and as the two bacteriostatic agents are used in a matching manner, a wound can be effectively prevented from being infected, and the silver-carrying antibacterial hydrocolloid dressing also has the advantages of blocking bacteria, absorbing exudate, avoiding wound adhesion, supplying an ideal wet healing environment for a wound, promoting healing of the wound and reducing formation of scars.

Owner:HENAN HUIBO MEDICAL CO LTD

EPE pearl wool and preparation method thereof

InactiveCN107880347AEasy to operateShorten the timeLow-density polyethyleneLinear low-density polyethylene

The invention provides EPE pearl wool. The EPE pearl wool is prepared from the following raw materials in parts by weight: 70-80 parts of low density polyethylene, 30-40 parts of high density polyethylene, 10-15 parts of an ethylene-vinyl acetate copolymer, 12-16 parts of azodicarbonamide, 3-5 parts of dicumyl peroxide, 3-5 parts of zinc oxide, 20-30 parts of titanate modified calcium carbonate, 5-7 parts of isobutyl triethoxysilane, 1-2 parts of magnesium stearate, 4-6 parts of butyl stearate, 4-5 parts of hexamethylenetetramine, 3-5 parts of polycarbonate, 5-7 parts of aluminum hydroxide, 8-9 parts of bamboo charcoal powder, 6-8 parts of dioctyl adipate, 3-5 parts of ethanol amine, 8-9 parts of dicyclohexyl phthalate and 7-9 parts of kaolin. The EPE pearl wool provided by the invention has good elasticity, buffering capability, thermal stability and mechanical properties. The invention also provides a preparation method of the EPE pearl wool.

Owner:HEFEI LANGSHENG NOVEL MATERIAL CO LTD

Fiber reinforced thermoplastic compound pipeline and manufacturing technology thereof

ActiveCN104534187AHigh tensile strengthImprove bending strengthFlexible pipesRigid pipesManufacturing technologyAntioxidant

The invention discloses a fiber reinforced thermoplastic compound pipeline and a manufacturing technology of the pipeline. The compound pipeline comprises an inner lining layer, a fiber reinforced layer and an outer surface layer. The inner lining layer and the outer surface layer are made of the same material comprising, by weight, 170-180 parts of polypropylene, 20-28 parts of polytetrafluoroethylene, 10-12 parts of linoleic acid, 3-4 parts of dibutyltin maleate, 4-6 parts of barium stearate, 2-3 parts of wollastonite, 5-7 parts of white carbon black, 1-3 parts of barium sulfate, 7-9 parts of alkyl phosphoric acid, 3-5 parts of ethylene propylene rubber, 5-7 parts of glyceryl monostearate, 6-8 parts of silane coupling agents, 4-5 parts of dioctyl adipate, 2-3 parts of phosphite antioxidants, 4-6 parts of titanium oxide fine powder and 10-12 parts of assistant master batches. The pipeline has high tensile strength, bending strength, modulus and impact resistance. The manufacturing method of the pipeline is simple and easy to operate, and pipes of different specifications and with different function can be manufactured to meet social requirements through different pipe moulds.

Owner:JIANGSU RUNSOO PIPELINE TECH CO LTD

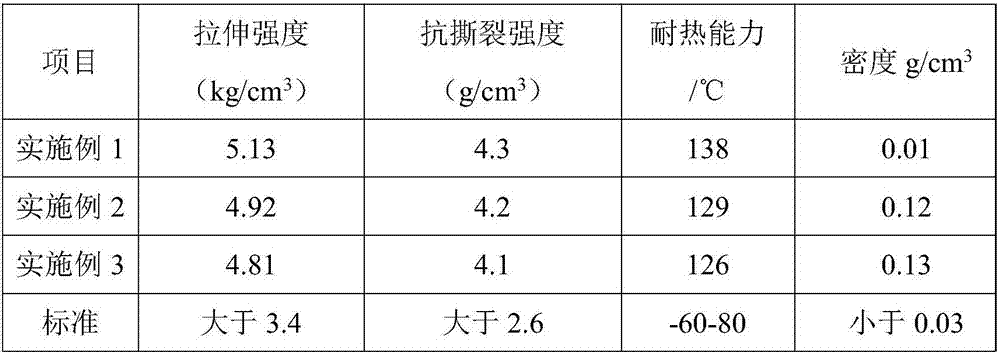

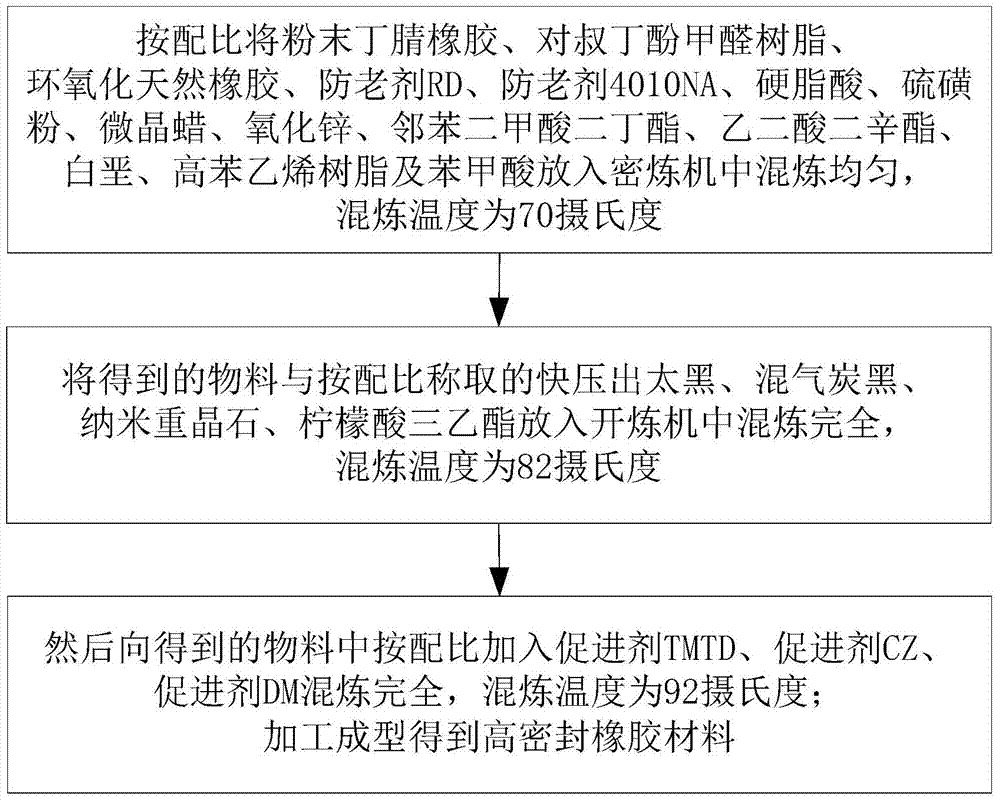

Highly sealing rubber material and preparation technology thereof

The invention discloses a highly sealing rubber material. The rubber material comprises the following raw materials in parts by weight: 75-90 parts of powdery nitrile rubber, 20-40 parts of para-tertiary butyl phenol formaldehyde resin, 20-40 parts of epoxidized natural rubber, 0.8-1.7 parts of antiager RD, 0.5-1.3 parts of antiager 4010NA, 0.4-0.8 part of stearic acid, 0.4-0.6 part of sulphur powder, 0.9-1.3 parts of microcrystalline wax, 3-4 parts of zinc oxide, 40-60 parts of fast extruding furnace black, 30-40 parts of mixed gas carbon black, 20-25 parts of triethyl citrate, 1.2-2.7 parts of phthalic acid dibutyl ester, 0.4-0.9 part of dioctyl adipate, 1.2-1.4 parts of accelerator TMTD, 1-1.3 parts of accelerator CZ, 1.1-1.3 parts of accelerator DM, 1-3 parts of nanometer barite, 1-2 parts of chalk, 1.5-2.3 parts of high styrene resin, and 2.2-2.8 parts of benzoic acid. The invention also discloses a preparation technology for the highly sealing rubber material. The highly sealing rubber material has excellent bonding and sealing performances, good elasticity and warping strength, and long service life.

Owner:ANHUI SHENGDONG CHEM

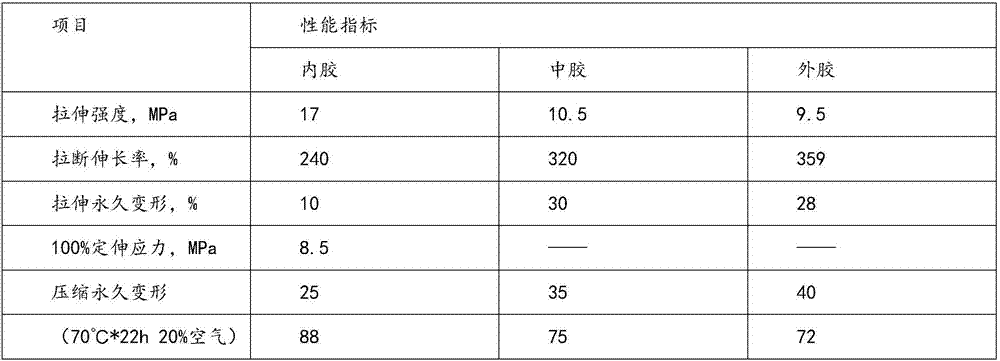

Steel wire braided rubber hose

The invention discloses a steel wire braided rubber hose. The rubber hose comprises an inner rubber layer, two steel wire layers which are braided outside the inner rubber layer, a middle rubber layerbetween the two steel wire layers and an outer rubber layer outside the two steel wire layers, and inner rubber of the inner rubber layer comprises, by weight, 90-120 parts of nitrile rubber, 100-120parts of carbon black, 5-10 parts of white carbon black, 15-25 parts of dioctyl adipate, 5-10 parts of zinc oxide, 1-5 parts of stearic acid, 3-5 parts of antioxidants, 1-3 parts of sulfur, 0.3-0.8 part of a vulcanizing agent, 3-8 parts of adhesives, 0.5-1.5 parts of accelerants, 0.3-0.7 part of an anti-scorching agent and 3-8 parts of organic montmorillonite. According to the steel wire braidedrubber hose, pulse stress deformation is small, the rubber hose is light in weight, the bending radius is small, pulse performance is stable, and furthermore, pulse frequency breaks through 0.3 million times, so that the service life of the rubber hose is greatly prolonged.

Owner:T RUBBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com