EPE pearl wool and preparation method thereof

A technology of pearl cotton and low density polyethylene, applied in the field of packaging materials, can solve the problems of poor bending strength, elasticity and heat resistance, poor recovery, deformation, etc., and achieve the effects of low cost, high work efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

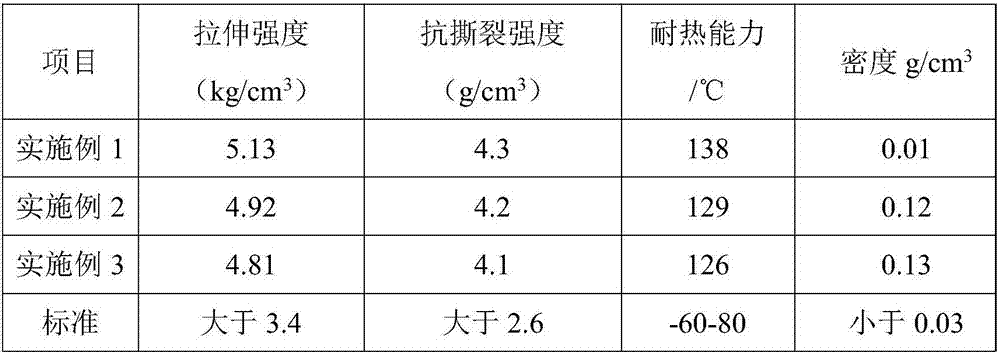

Examples

Embodiment 1

[0016] An EPE pearl cotton, made of the following raw materials in parts by weight: 75 parts of low-density polyethylene, 36 parts of high-density polyethylene, 12 parts of ethylene-vinyl acetate copolymer, 15 parts of azodicarbonamide, diisoperoxide Propylbenzene 4 parts, zinc oxide 3 parts, titanate modified calcium carbonate 25 parts, isobutyltriethoxysilane 6 parts, magnesium stearate 1 part, butyl stearate 5 parts, hexamethylene 4 parts of tetramine, 5 parts of polycarbonate, 6 parts of aluminum hydroxide, 7.5 parts of bamboo charcoal powder, 7 parts of dioctyl adipate, 4 parts of ethanolamine, 8 parts of dicyclohexyl phthalate and 8 parts of kaolin.

[0017] The preparation method of the EPE pearl cotton described in the present embodiment may further comprise the steps:

[0018] (1) Put low-density polyethylene, high-density polyethylene and ethylene-vinyl acetate copolymer in a mixer for 4 minutes, and then add zinc oxide, titanate-modified calcium carbonate, isobutylt...

Embodiment 2

[0022] An EPE pearl cotton, made of the following raw materials in parts by weight: 70 parts of low-density polyethylene, 40 parts of high-density polyethylene, 10 parts of ethylene-vinyl acetate copolymer, 12 parts of azodicarbonamide, diisoperoxide 5 parts of propylbenzene, 3 parts of zinc oxide, 30 parts of titanate modified calcium carbonate, 7 parts of isobutyltriethoxysilane, 1 part of magnesium stearate, 4 parts of butyl stearate, hexamethylene 5 parts of tetramine, 5 parts of polycarbonate, 7 parts of aluminum hydroxide, 9 parts of bamboo charcoal powder, 8 parts of dioctyl adipate, 3 parts of ethanolamine, 9 parts of dicyclohexyl phthalate and 9 parts of kaolin.

[0023] The preparation method of EPE pearl cotton of the present invention may further comprise the steps:

[0024] (1) Put low-density polyethylene, high-density polyethylene and ethylene-vinyl acetate copolymer in a mixer for 5 minutes, and then add zinc oxide, titanate-modified calcium carbonate, and isob...

Embodiment 3

[0028] An EPE pearl cotton, made of the following raw materials in parts by weight: 80 parts of low-density polyethylene, 30 parts of high-density polyethylene, 15 parts of ethylene-vinyl acetate copolymer, 16 parts of azodicarbonamide, diisoperoxide 3 parts of propylbenzene, 5 parts of zinc oxide, 30 parts of titanate modified calcium carbonate, 5 parts of isobutyltriethoxysilane, 2 parts of magnesium stearate, 6 parts of butyl stearate, hexamethylene 4 parts of tetramine, 5 parts of polycarbonate, 7 parts of aluminum hydroxide, 9 parts of bamboo charcoal powder, 6 parts of dioctyl adipate, 5 parts of ethanolamine, 8 parts of dicyclohexyl phthalate and 7 parts of kaolin.

[0029] The preparation method of EPE pearl cotton of the present invention may further comprise the steps:

[0030] (1) Put low-density polyethylene, high-density polyethylene and ethylene-vinyl acetate copolymer in a mixer for 2-5 minutes, and then add zinc oxide, titanate modified calcium carbonate, isobu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com