Patents

Literature

1182 results about "Isophorone diisocyanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

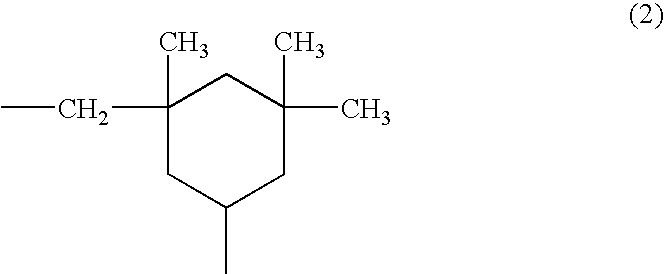

Isophorone diisocyanate (IPDI) is an organic compound in the class known as isocyanates. More specifically, it is an aliphatic diisocyanate. It is produced in relatively small quantities, accounting for (with hexamethylene diisocyanate) only 3.4% of the global diisocyanate market in the year 2000. Aliphatic diisocyanates are used, not in the production of polyurethane foam, but in special applications, such as enamel coatings which are resistant to abrasion and degradation from ultraviolet light. These properties are particularly desirable in, for instance, the exterior paint applied to aircraft.

High-toughness photosensitive resin for 3D printing and preparation method thereof.

The invention provides a high-toughness photosensitive resin for 3D printing and a preparation method thereof. The photosensitive resin comprises a photosensitive resin (maleable photosensitive resin and rigid photosensitive resin), an active diluent, a light initiator and an additive. The method first synthesizes the toughness photosensitive resin (maleable polyurethane acrylate and epoxy modified polyurethane), and then the maleable photosensitive resin is mixed with the rigid photosensitive resin, active diluent, light initiator and additive. The maleable photosensitive resin is prepared from a polymer soft segment, which is a mixture of one or more selected from of polypropyleneoxide glycol ether, PTMG, hydroxyl-terminated polybutadiene, hydroxyl-terminated styrene butadiene rubber, hydroxyl-terminated butadiene acrylonitrile rubber and hydroxyl-terminated polysiloxane, and a polymer hard segment of toluene diisocyanate or isophorone diisocyanate, through hydroxyethyl acrylate or epoxypropanol termination. The photosensitive resin is applicable to DLP or SLA type 3D printers for modification of the existing 3D printing photosensitive resin, has excellent bending strength, and can directly print out elastic models.

Owner:QINGDAO UNIV OF SCI & TECH

Clear coating composition having improved early hardness and water resistance

InactiveUS6472493B1Improve efficiencyRemove blemishesLiquid surface applicatorsPolyurea/polyurethane coatingsPolyesterOrganic fluid

A fast hardening clear coating composition for repairing a clearcoat / colorcoat finish of a vehicle, which composition is capable of being wet sanded, buffed or polished to a high gloss finish on the same day of application, comprising a film forming binder and an organic liquid carrier, where the binder contains a hydroxyl component comprising a hydroxyl-containing acrylic polymer and a hydroxyl-terminated polyester oligomer, and an organic polyisocyanate crosslinking component, at least portion of which comprises a trimer of isophorone diisocyanate, where the composition further contains, as a combined curing catalyst, at least one dialkyl tin aliphatic carboxylate, at least one tertiary aliphatic mono or diamine, and at least one aliphatic carboxylic acid, in an effective amount such that the clear coating composition on curing at ambient temperatures is in a water spot free and sufficiently hard state for sanding or buffing within about 4 hours after application or on cool down when baked under normal conditions.

Owner:AXALTA COATING SYST IP CO LLC

Preparation method and application of graphene oxide-polyurethane foam material

InactiveCN103408718AImprove adsorption capacityGood removal effectOther chemical processesWater contaminantsMalachite greenPolymer science

The invention belongs to the field of high polymer material synthesis, and relates to preparation of a graphene oxide-polyurethane foam material, in particular to a preparation method and application of the graphene oxide-polyurethane foam material. The preparation method of the graphene oxide-polyurethane foam material comprises the following steps: firstly, preparing graphene oxide by adopting an improved Hummers method, then mixing and stirring graphene oxide, polyether glycol NJ-330, foaming agent, foam stabilizer and catalyst at room temperature, adding isophorone diisocyanate, and finally, foaming further to obtain the graphene oxide-polyurethane foam material. The graphene oxide-polyurethane foam material prepared through the method can be applied to absorption of coloring matters or heavy metal ions in waste water, and has better absorption and removal effects as shown in a test by taking a solution containing malachite green and Cd (II) as the absorption object. The application of the foam material to treatment of the coloring matters and the heavy metal ions in sewage has the characteristics of simplicity in operation and high absorption rate, and has a certain practical value.

Owner:JIANGSU UNIV

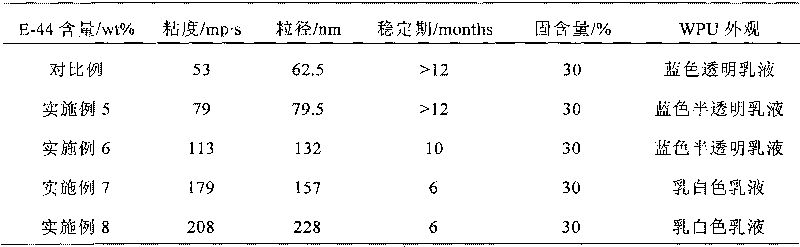

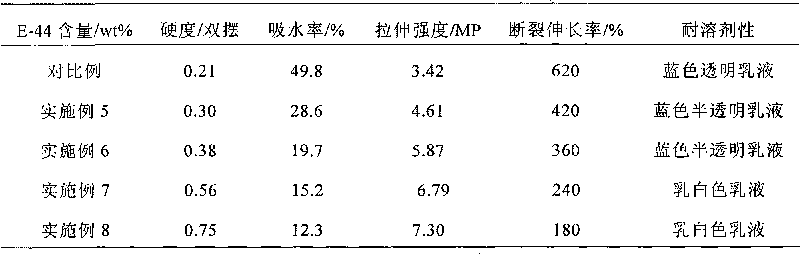

Epoxy resin modified water-based polyurethane emulsion and preparation method thereof

InactiveCN101717488AHigh molecular weightImprove cohesive energyPolyurea/polyurethane coatingsPolyesterWater based

The invention relates to an epoxy resin modified water-based polyurethane emulsion and a preparation method thereof. The emulsion comprises the following components in percentage by weight: 20 to 40 percent of isophorone diisocyanate, 20 to 40 percent of polyester, 5 to 10 percent of hydrophilic chain extender, 2 to 10 percent of chain extender, 1 to 3 percent of crosslinker, 3 to 10 percent of neutralizing agent, 2 to 10 percent of epoxy resin and 10 to 20 percent of acetone. The preparation method comprises the steps of feed preparation, polyester dehydration, the synthesis and neutralization of prepolymer, and chain extension and emulsification. Compared with the prior art, the epoxy resin modified water-based polyurethane emulsion has the advantages of high hardness of film, good water resistance and solvent resistance and the like, and is widely applied in the field of packaging coatings.

Owner:SHANGHAI WEIKAI CHEM

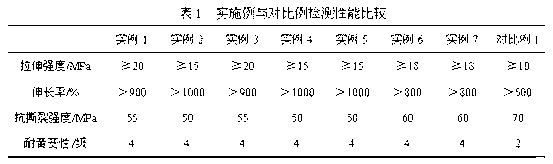

Aqueous polyurethane dispersoid for coating yellowing-resistant leather and preparation method thereof

InactiveCN102924683AGood yellowing resistanceEasy to preparePolyurea/polyurethane coatingsLeather surface finishingPolyurethane dispersionPolymer science

The invention discloses an aqueous polyurethane dispersoid for coating yellowing-resistant leather. The aqueous polyurethane dispersoid is prepared through the following steps: performing reaction on polyalcohol, a diisocyanate mixture and a crosslinking agent to generate a prepolymer with -NCO terminal group, wherein the diisocyanate mixture consisting of dicyclohexylmethane diisocyanate and isophorone diisocyanate is taken as a starting material; adding a hydrophilic chain extender into the prepolymer, further reacting and extending the chain by micromolecular dihydric alcohol; and neutralizing by using triethylamine and dispersing into water to obtain the aqueous polyurethane dispersoid. According to the aqueous polyurethane dispersoid prepared by the method, the yellowing-resistant level can reach more than level 4, the tensile strength is more than or equal to 15 MPa, the elongation ratio is more than or equal to 800 percent and the tearing strength is more than or equal to 50 MPa. The coated leather has soft and natural luster and plump and moist handfeel.

Owner:山西省应用化学研究所

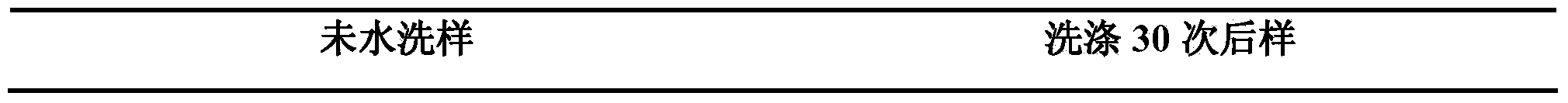

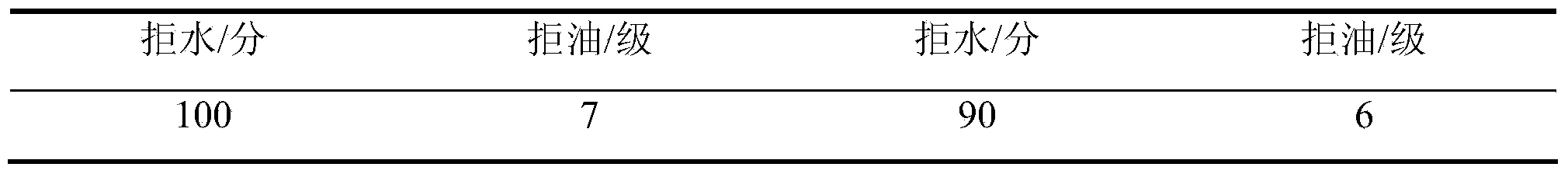

Preparation method of organic fluorosiloxane modified polyurethane emulsion containing short fluoroalkyl chain

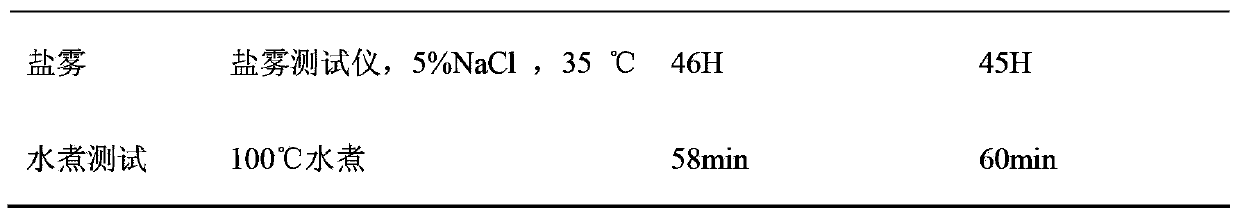

ActiveCN103865026ANot easy to corrodeImprove water resistancePolyurea/polyurethane coatingsPolymer scienceSolvent

The invention relates to a preparation method of an organic fluorosiloxane modified polyurethane emulsion containing a short fluoroalkyl chain. The method comprises the following steps: by taking isophorone diisocyanate as a hard segment and a mixture of polytetrahydrofuran ether diol and hydroxyl silicone oil as a soft segment, heating to 70-110 DEG C to react for 1-8 hours; then, adding dimethylolpropionic acid and fluorine-containing diol as a chain extender for primary chain extension for 1-6 hours; cooling to 25-60 DEG C, adding a neutralizer, stirring for 0.5-1.5 hours, and transferring to a high speed disperser; adding neutralizer and a secondary chain extender, and dispersing for 0.5-3 hours at a high speed to obtain the emulsion which is uniform and stable in grain size. The prepared modified polyurethane emulsion coating not only has better temperature resistance, water resistance, solvent resistance and corrosion resistance, but also has good water repellency and oil repellency.

Owner:SHANDONG UNIV

Environment-friendly polyurethane adhesive, and preparation method and applications thereof

ActiveCN106634778AOrderly rowsGood physical propertiesPolyureas/polyurethane adhesivesPolyurethane adhesiveOperability

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

UV curing resin, preparation method thereof and application of UV curing resin in UV curing colored paint

ActiveCN103421156ASolve technical problems that are difficult to cureGuaranteed color uniformityInksPolyurea/polyurethane coatingsPolyolFoaming agent

The invention discloses a UV curing resin, a preparation method thereof and the application of the UV curing resin in a UV curing colored paint. The preparation method comprises the following steps: mixing polyalcohol, polyacid and fatty acid at first, adding a reflow solvent to prepare alkyd resin, then mixing an ester compound and isophorone diisocyanate, adding a polymerization inhibitor and a catalyst, reacting to obtain acrylic acid modified polyurethane, reacting the acrylic acid modified polyurethane and the alkyd resin for 2-3 h at the temperature of 60-100 DEG C to obtain the YV curing resin, and performing reaction of the UV curing resin, an acrylic acid alkyl oxidation polyol ester active diluent, a pigment, thermoplastic acrylic resin, a photoinitiator, an alkyd resin drier, a dispersant, a foam agent and a flattening agent to obtain the UV curing colored paint. The invention solves the problems that as a pigment in a conventional ultraviolet light curing colored paint system shields ultraviolet light, the paint system can not be completely cured, and as the UV curing resin can not well moisten the pigment, and the coating adhesive force is poor.

Owner:SOUTH CHINA UNIV OF TECH

Aqueous polyurethane dispersion with high solid content and low activation temperature, preparation method and application thereof

InactiveCN101649039AHigh solid contentHigh solids content by weightPolyureas/polyurethane adhesivesPolyesterAdhesive

The invention relates to an aqueous polyurethane dispersion with high solid content and low activation temperature prepared by a solvent-free preparation method, which is generated on the basis of a preformed polymer generated by reacting isophorone diisocyanate or a mixture of the isophorone diisocyanate and one or two other isocyanates with polyester glycol or a mixture of the polyester glycol and poly (ester-ether) glycol and / or polyether glycol, and hydroxycarboxylic acid, and selectively reacting with aliphatic polyols of which the molecular weight is between 60 and 400 under the condition without the existence of any organic solvents, wherein the preformed polymer is neutralized and dispersed in warm water to react with the water and / or a chain extender, and the solid content of theaqueous polyurethane dispersion reaches up to about 50 percent. The activation temperature of the aqueous polyurethane dispersion is as low as about 50 DEG C, thus the aqueous polyurethane dispersionis suitable to be used as an adhesive which can adhere polar base materials (such as PVC, ABS and the like) and nonpolar base materials (such as PE, PP, PET and the like).

Owner:上海倍力新材料有限公司

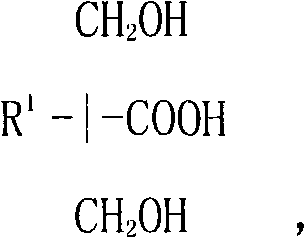

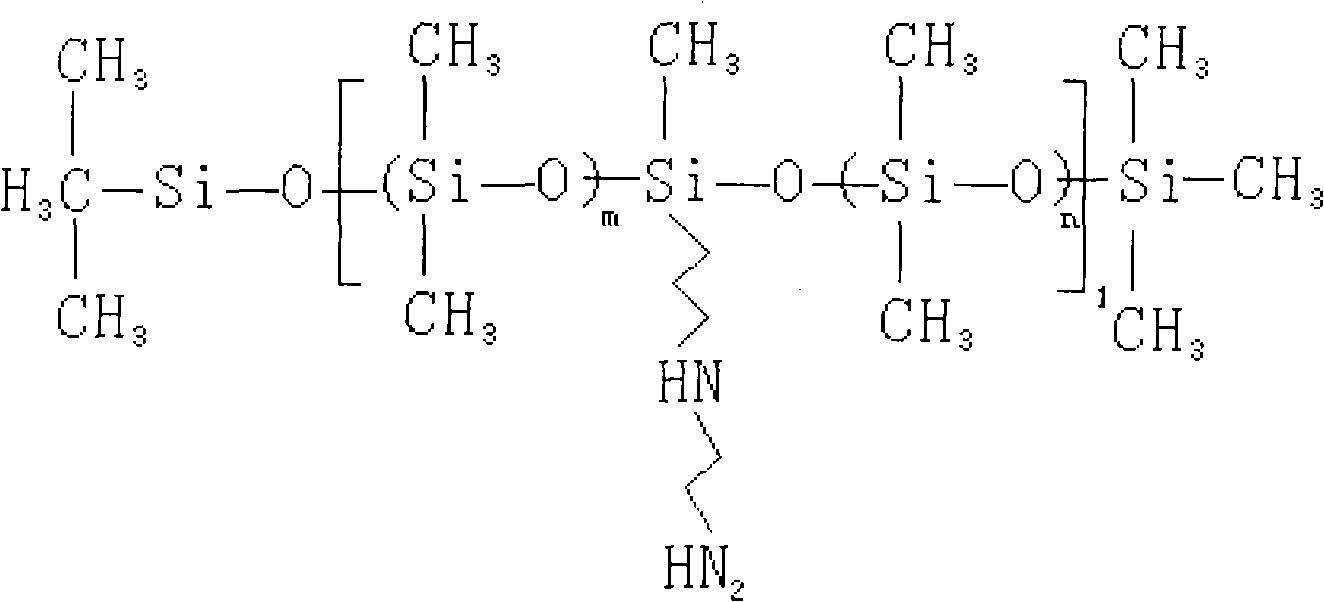

Preparation method of polyurethane modified organic silicon multipolymer fabric softening agent

ActiveCN103951809AImprove hydrophilicityImprove wearing moisture absorptionGrip property fibresEpoxyPolyethylene glycol

The invention discloses a preparation method of a polyurethane modified organic silicon multipolymer fabric softening agent. The preparation method comprises the following steps: firstly preparing a polyurethane prepolymer by using polyethylene glycol 2000 and isophorone diisocyanate; then preparing alkylhydroxyl-containing silicone oil by using di-n-butyl amine, epoxy 1,3-bis(3-glycidoxypropyl)-1,1,3,3-tetramethyldisiloxane and octamethyl cyclotetrasiloxane; reacting the polyurethane prepolymer with the alkylhydroxyl-containing silicone oil so as to obtain a polyurethane organic silicon multipolymer; and finally adding deionized water, and emulsifying so as to obtain the polyurethane modified organic silicon multipolymer fabric softening agent. The preparation method of the polyurethane modified organic silicon multipolymer fabric softening agent has the beneficial effects that urethane groups and urethane are introduced into organic silicon and serve as hard chain segments for generation of physical crosslinking, meanwhile, polyether is introduced and serves as a hydrophilic chain segment, the problem that as an amino silicon oil softening agent is easy to yellow and demulsify, oil patches are formed on fabrics, is solved, the hydrophilic performance of the fabrics subjected to soft finish is improved, the wearing hygroscopicity of the fabrics is improved, and the durability of the fabrics is good.

Owner:佛山市澳棉纺织有限公司

Optical resin composition having excellent impact resistance and method for fabricating optical lens using the same

Disclosed herein are an optical resin composition with superior impact resistance and a method for producing an optical lens from the composition. More specifically, the optical resin composition for a plastic optical lens has superior impact resistance as well as light-weight, superior moldability, excellent dyeing ability, a high Abbe number and good transparency. The optical lens produced from the composition exhibits superior impact resistance even after multi- coating. The optical resin composition with superior impact resistance has a solid refractive index (nD) of 1.53 to 1.57, an Abbe number of 35 to 48, a liquid specific gravity of 0.97 to 1.25 and a solid specific gravity of 1.10 to 1.35, by which the composition comprises a mixture of isophorone diisocyanate and hexamethylene diisocyanate, pentaerythritol tetrakis(3-mercaptopropionate), a UV absorber, a release agent and a polymerization initiator. The optical lens is produced by thermally curing the composition.

Owner:KOC SOLUTION

Yellowing-resistant transparent polyurethane elastomer combined material and using method thereof

ActiveCN101096408ALow costOvercome the disadvantage of poor yellowing resistancePolyurethane elastomerAlcohol

The invention provides a yellowed-resistance type transparent urethane elastomer combination material, wherein the polyatomic alcohol part comprises 3 functionality and 4000-6000 molecular weight polyether polyol, 2 functionality and 2000-4000 molecular weight polyether polyol, aromatic, chain expansion agent and accelerant; the prepolymer part (NCO%=12%-17%)is made by 1000-2000 molecular weight, 2 functionality polyether polyol and isophorone diisocyanate at 70-90Deg. The use method comprises the following steps: mixing prepolymer with polyatomic alcohol part according to 2:1-1:1 at 25Deg. C-40Deg. C, pouring; vulcanizing at 25Deg. C-70Deg. C. The product avoids the low yellowed resistance problem of the urethane elastomer product, which is used to manufacture the armoured glass, the neon sign board, the shoe sign and the nameplate of the household electrical appliance.

Owner:SHANDONG INOV POLYURETHANE

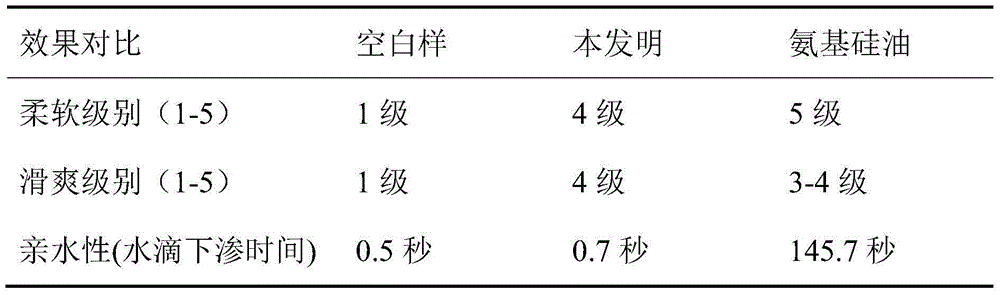

Coating compositions having improved early hardness

InactiveUS20070190257A1Improve efficiencyHigh glossPolyurea/polyurethane coatingsSpecial surfacesIsophorone diisocyanateAcrylic polymer

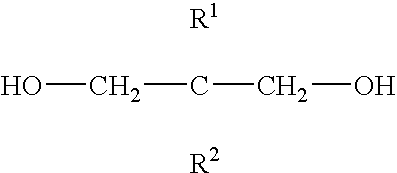

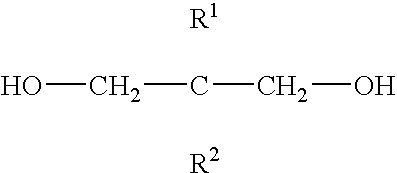

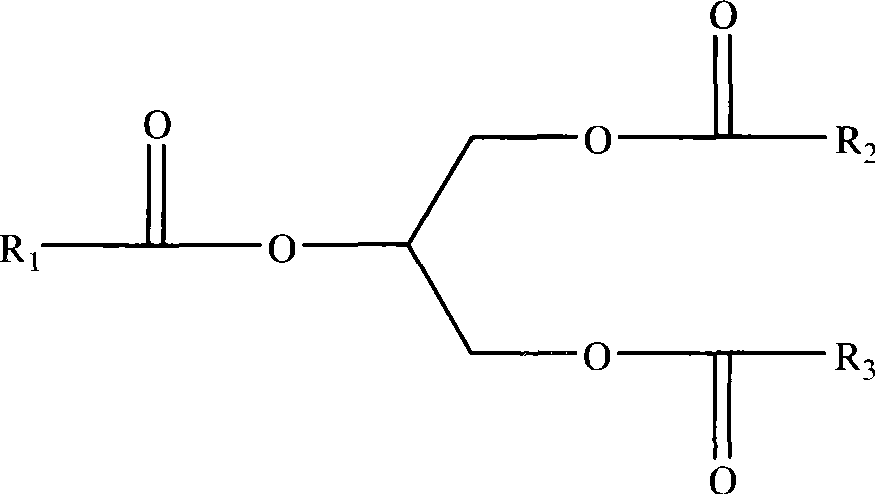

A fast hardening clear coating composition for repairing a clear coat / color coat finish or a pigmented mono-coat of a vehicle comprising a film forming binder and an organic liquid carrier, where the binder contains a hydroxyl polymer component comprising (A) hydroxyl-containing acrylic polymer, (B) at least one hydroxyl-terminated component selected from the group consisting of (1) an organic diol having the formulawhere R1 and R2 are individually selected from the group of hydrogen and an alkyl group having 1, 3-5 carbon atoms and (2) a hydroxyl terminated reaction product of trimethylol propane and a lactone; (C) an organic polyisocyanate crosslinking component, at least portion of which comprises a trimer of isophorone diisocyanate or hexamethylene diisocyanate and the composition further contains, a curing catalyst, of a dialkyl tin aliphatic carboxylate, a tertiary aliphatic mono or diamine, an aliphatic carboxylic acid, and optionally, a zinc or calcium organic acid salt in an effective amount such that the coating composition on curing at ambient temperatures is in a water spot free and sufficiently hard state for sanding or buffing within about 2 hours after application or on cool down when baked under normal conditions.

Owner:AXALTA COATING SYST IP CO LLC

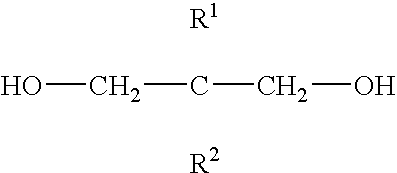

Vegetable oil based polyurethane acrylic ester, preparing process and use thereof

InactiveCN101497684AWide variety of sourcesEasy to makePolyurea/polyurethane coatingsSurface treatment compositionsAlkaneVegetable oil

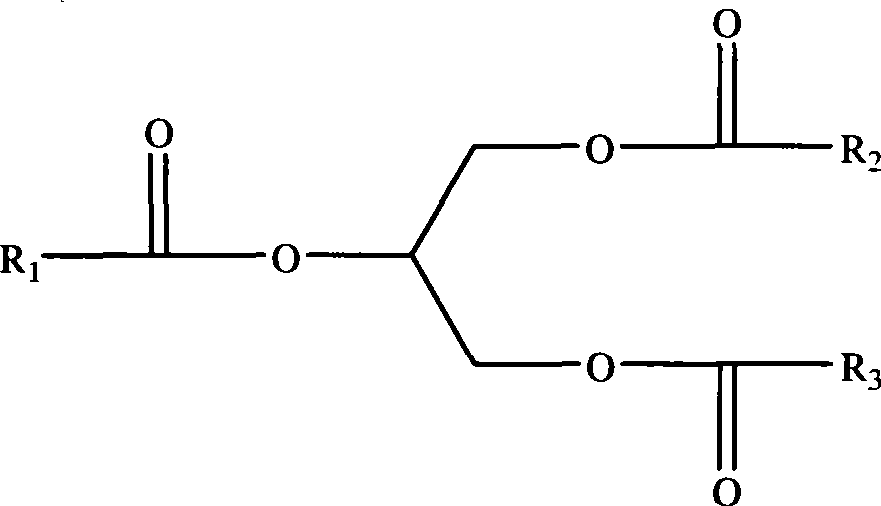

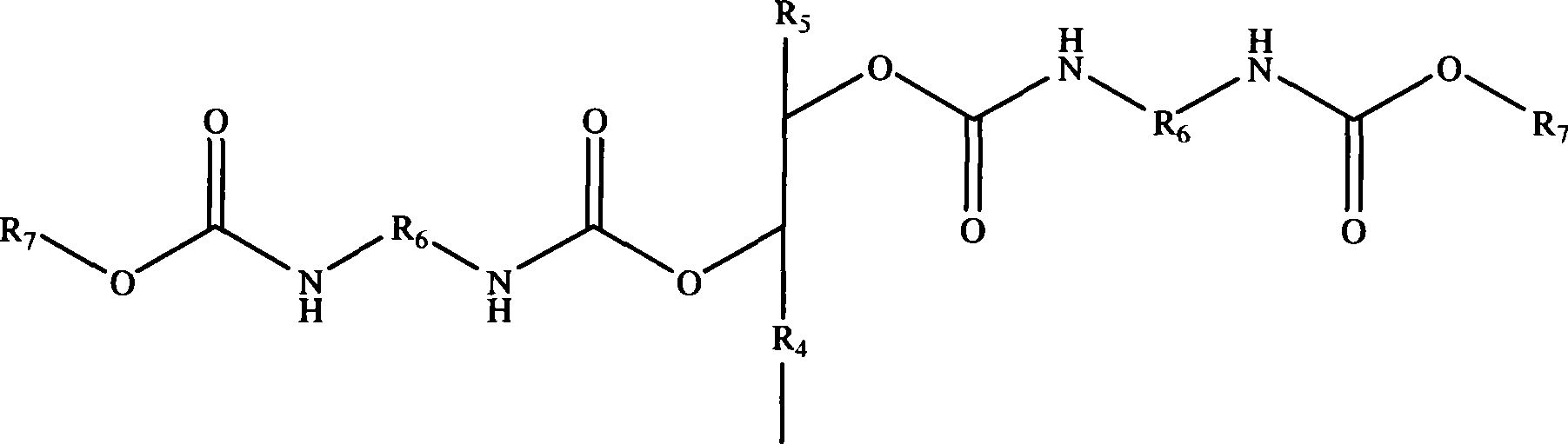

The invention relates to vegetable oil based polyurethane acrylic ester, belonging to the field of photosensitive polymer material. The vegetable oil based polyurethane acrylic ester is characterized in that the general chemical formula is Formula I, wherein R1, R2 and R3 are respectively chosen from alkane of C1-C18, at least one of the alkane is chosen from Formula II, R4 and R5 are respectively chosen from alkane of C1-C16, R6 is diphenyl methane-4,4'-diisocyanate, or hexamethylene diisocyanate, or isophorone diisocyanate or residue of 2,4-toluene diisocyanate with two isocyanate functional group removed, and R7 is 2-hydroxyethyl acrylate, or hydroxypropyl acrylate, or residue of pentaerythritol triacrylate with hydroxy functional group removed.

Owner:天津市天骄辐射固化材料有限公司

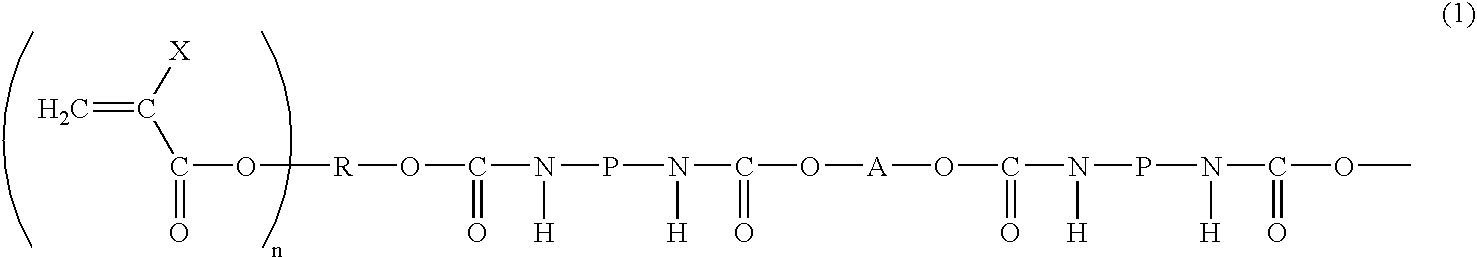

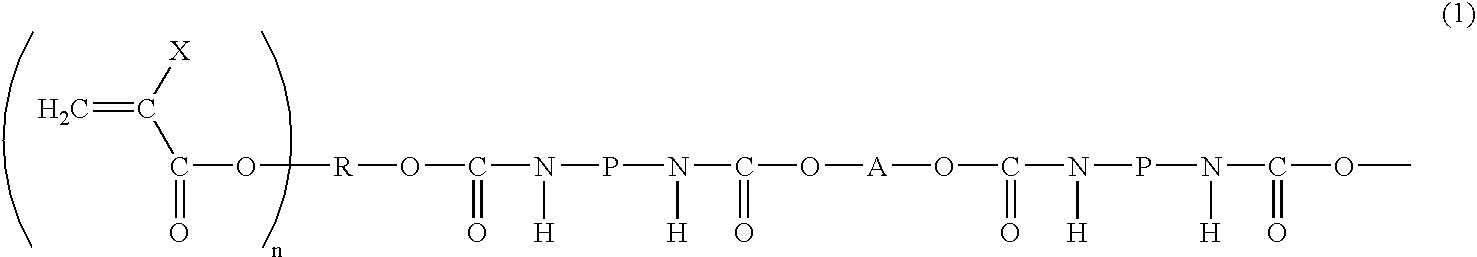

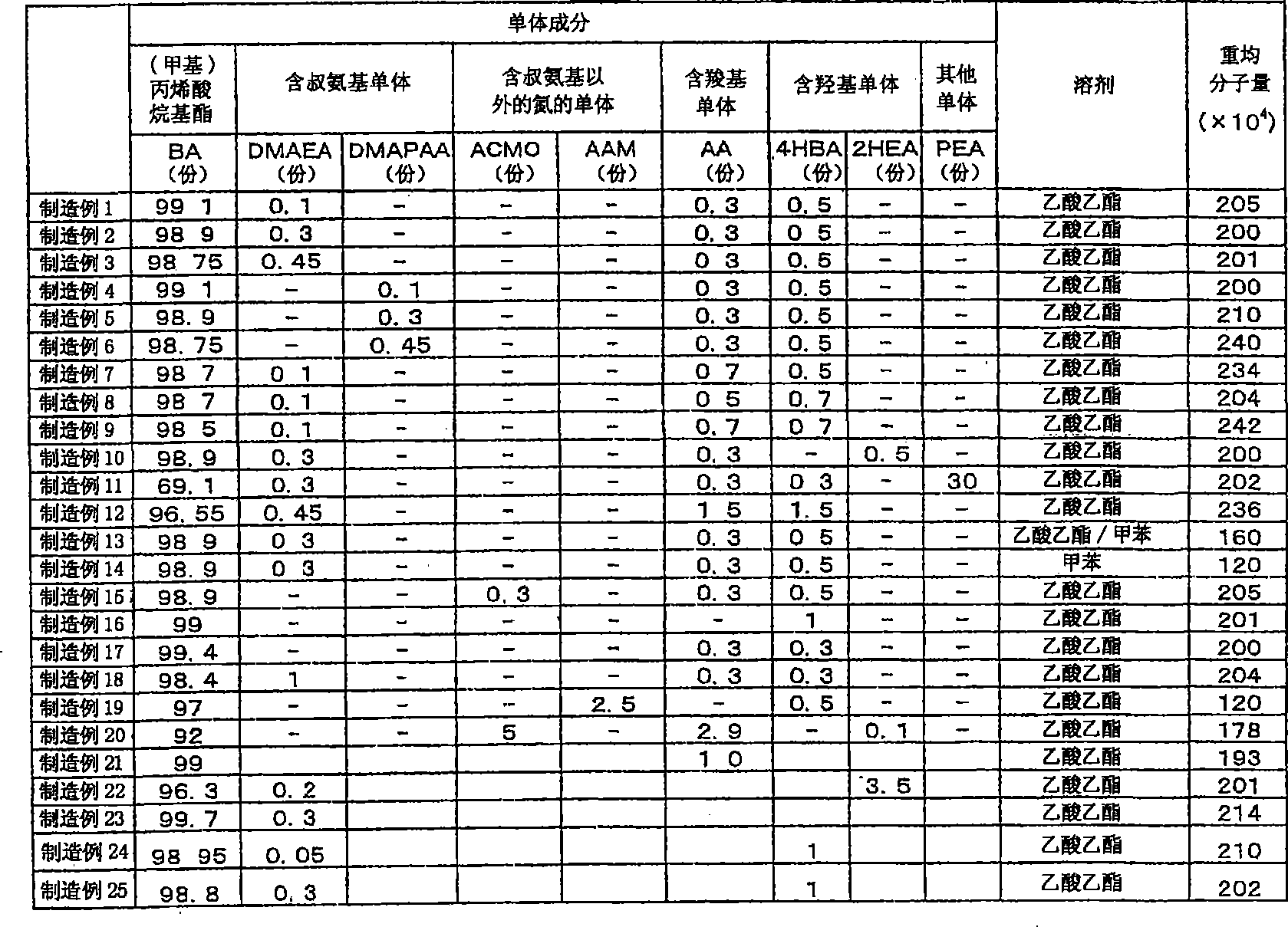

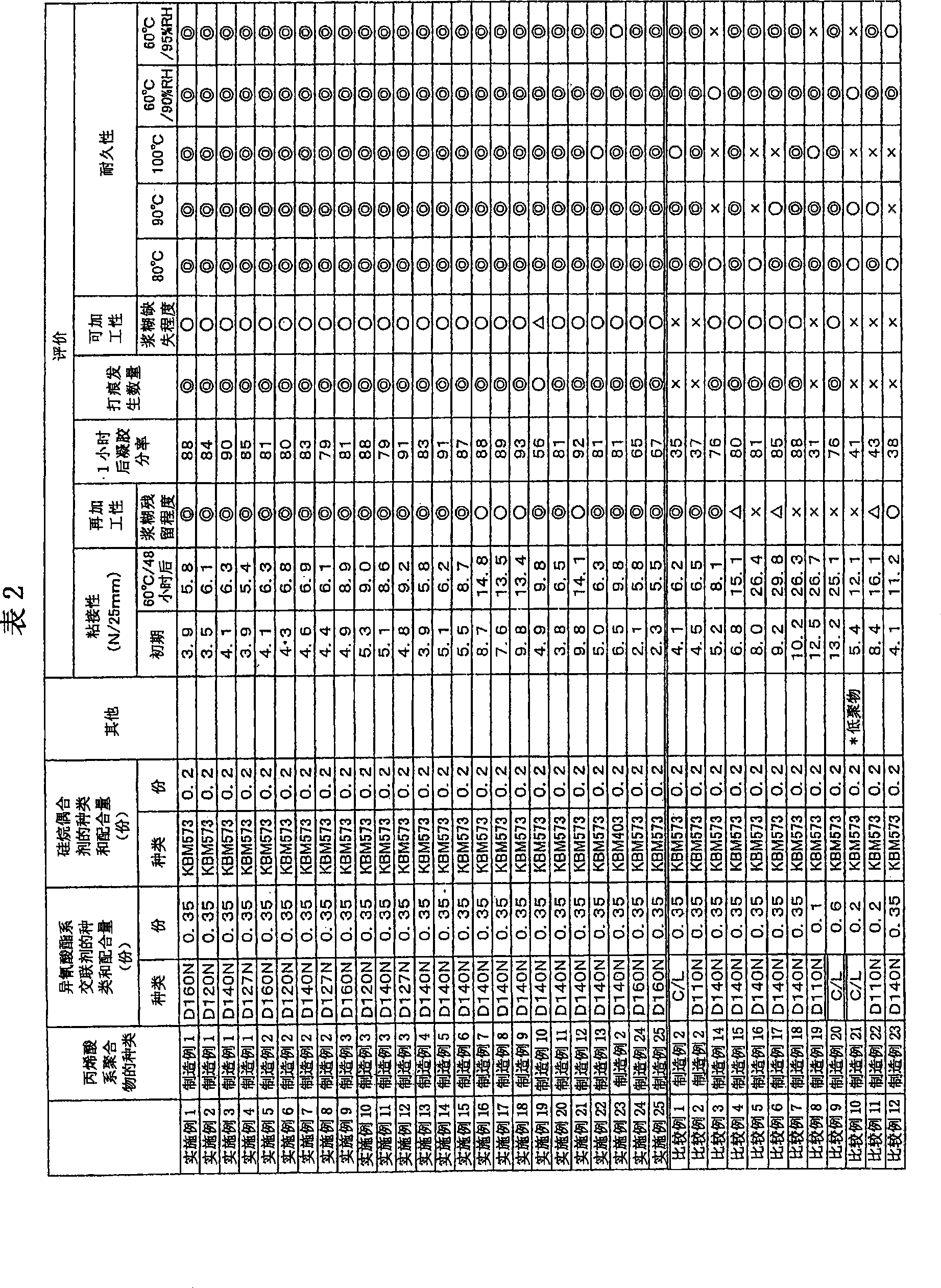

Pressure-sensitive adhesive composition for optical films, pressure-sensitive adhesive optical film and image display

InactiveUS20090162577A1Easy to processExcellent reworkabilityMonocarboxylic acid ester polymer adhesivesLiquid crystal compositionsXylyleneMeth-

There is provided an optical film pressure-sensitive adhesive composition capable of forming a pressure-sensitive adhesive layer that has reworkability such that optical films therewith can be easily separated from liquid crystal panels with no adhesive residue and also has satisfactory processability such that it can be processed without causing adhesive stain or dropout after it is formed on an optical film. The optical film pressure-sensitive adhesive composition includes 100 parts by weight of a (meth)acrylic polymer including, as monomer units, (a) 50 to 99.79% by weight of an alkyl (meth)acrylate monomer, (b) 0.01 to 0.45% by weight of a tertiary amino group-containing monomer, and (c) 0.1 to 3% by weight of a hydroxyl group-containing monomer; and 0.01 to 2 parts by weight of a crosslinking agent that is at least one selected from the group consisting of hexamethylene diisocyanate, hydrogenated xylylene diisocyanate, and isophorone diisocyanate, or a polyisocyanate compound derived therefrom.

Owner:NITTO DENKO CORP

Amino silicone modified waterborne polyurethane and preparation method thereof

InactiveCN102167795AReduce joinLower surface energyPolyurea/polyurethane coatingsPropanoic acidSide chain

The invention discloses amino silicone modified waterborne polyurethane. The waterborne polyurethane is prepared from the following raw materials in parts by weight: 150-220 parts of polyether, 100-150 parts of isophorone diisocyanate, 15-20 parts of dimethylol propionic acid, 0.5-0.8 part of catalyst, 0-5 parts of trimethylolpropane, 15-30 parts of 1,4-butanediol, 4-5 parts of acetone, 10-15 parts of triethylamine, 5-10 parts of side chain amino silicone oil and 620-630 parts of deionized water. The preparation method of the amino silicone modified waterborne polyurethane is that side chain amino silicone oil is introduced in the aqueous phase chain extending process for modification; and the waterborne polyurethane has low preparation cost and good water resistance and adhesive force, is environmentally friendly and has no security threat.

Owner:王奇

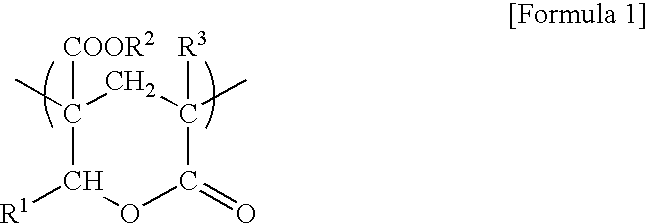

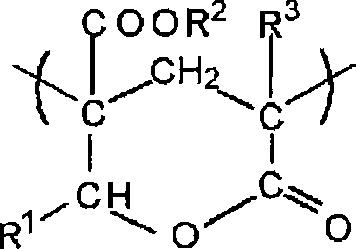

Photosensitive resin composition, image forming material and image forming method using thereof

InactiveUS20070099115A1Improve curing effectSuppressing polymerization inhibitionPhotosensitive materialsRadiation applicationsMeth-Side chain

There is devised a novel acryl resin in which an unsaturated group introduced in an alkali soluble resin is placed at a longer distance from the resin skeleton of the alkali soluble resin, the mobility of the unsaturated group is promoted and the number of the unsaturated double bonds is increased; therefore it allows crosslinking reaction to occur easily and a functional resin portion which imparts a specific function, in particular, function of suppressing polymerization inhibition due to oxygen by introduction of an active methylene group is provided at a resin portion existing between the acryl resin skeleton and the unsaturated double bond, and a photosensitive resin composition containing thereof is to be provided. A photosensitive resin composition comprising an alkali soluble resin, an ethylenically unsaturated compound, a near infrared absorbing dye, a compound containing a halomethyl group and a compound containing an organoboron anion, wherein the alkali soluble resin comprises an acryl resin having one or more of pendant groups in which both terminals of a diol compound have been blocked with isophorone diisocyanates and then (meth)acryloyl has been added, and, an image forming material comprising a substrate, and a photosensitive layer formed by the photosensitive resin composition on the substrate, as well as an image forming method.

Owner:NIPPON PAINT CO LTD

Water-resisting, oil-proof, antifouling agent for fabric and production process thereof

The present invention is waterproof, oilproof and anti-fouling agent for fabric and its production process. The waterproof, oilproof and anti-fouling agent is the mixture of emulsion polymerized fluoric acrylate polymer and pyrolytic closed polyurethane cross-linking agent. Its components include N-ethyl-N-hydroxyethyl perfluoro octyl sulfonamide 80-100 weight portions, isophorone diisocyanate 8-11 weight portions, hydroxyethyl acrylate 4-6 weight portions, acrylic acid 7-10 weight portions, acrylate 650-800 weight portions, and N-hydroxymethyl acrylamide 20-30 weight portions. It is used in the step of high temperature stoving and settling of fabric, and has the advantages of obvious effect, simple production process and lowered production cost.

Owner:LIAONING FIXED STAR FINE CHEM

Waterborne polyurethane grouting material and preparation method thereof

InactiveCN102093537AConvenient sourceAvoid poisoningOther chemical processesIsophorone diisocyanatePolymer chemistry

The invention discloses a preparation method of a waterborne polyurethane grouting material. The method is as follows: isocyanate, retarding agent and hydrophilic polyether polyol are mixed to react and obtain the finished product, wherein isocyanate is selected from diphenylmethane diisocyanate, liquefied diphenylmethane diisocyanate, polymethylene polyphenyl isocyanate isophorone diisocyanate, dicyclohexylmethylmethane-4,4'-diisocyanate, hexamethylene diisocyanate and polymethylene polyphenyl isocyanate or the mixture of toluene diisocynate and the isocyanates; and the degree of functionality of hydrophilic polyether polyol is 2-6, the ratio of ethylene oxide to propylene oxide is 99 / 1-60 / 40 and the molecular weight is 1000-20000. The invention also relates to the hydrophilic polyurethane grouting material prepared by the method. The preparation method of the invention is simple and convenient and has wide raw material sources; the prepared hydrophilic polyurethane grouting material does not contain organic solvent, thus avoiding the damage on the health of the constructor and promoting environmental protection; and the grouting material can have lower viscosity and good permeability and waterproof and leaking stoppage effect.

Owner:SHANGHAI DONGDA CHEM

Prepn process of water thinned polyurethane emulsion

The preparation process of water thinned polyurethane emulsion includes the reaction of polyester polyols, polyether polyols and isophorone diisocyanate in the molar ratio between isophorone diisocyanate and the sum of polyester polyols and polyether polyols equal to 2.7-3.2 in the presence of dibutyl tin laurate catalyst at 75-80 deg.c for 1 hr to obtain pre-polymer; adding dihydroxymethyl propionic acid containing hydrophilic group and co-solvent N-methyl pyrrolidone to reaction for further 2 hr; neutralizing with triethylamine, dropping into water while adding amine chain expander, defoaming, and filtering to obtain the water thinned polyurethane emulsion. The water thinned polyurethane emulsion has solid content of 30-35 wt%, pH value of 6.5-8.0, viscosity of 10-50 MPa.S, etc.

Owner:SHANGHAI PLASTICS RES INST CO LTD

Water-soluble polyurethane for wood lacquer and preparation method thereof

ActiveCN102070768AGood yellowing resistanceHigh molecular weightPolyurea/polyurethane coatingsEthylenediaminePropanoic acid

The invention discloses water-soluble polyurethane for the wood lacquer and a preparation method thereof. The water-soluble polyurethane comprises the following raw materials in parts by weight: 165-175 parts of polycarbonate diol, 131-132 parts of isophorone diisocyanate, 0.4-0.6 part of catalyst, 16.5-17.5 parts of dihydromethyl propionic acid, 2.7-3 parts of dihydroxyacetone, 18.5-19.5 parts of 1,4-butanediol, 4-5 parts of acetone, 12.5-13 parts of triethylamine, 6-7 parts of ethylenediamine, 628-638 parts of deionized water and 5-6 parts of adipic acid dihydrazide. The preparation method adopts the preparation technology combining the acetone method with pre-polymer dispersion method, thus effectively reducing the dosage of acetone and increasing the molecular weight of the generated polyurethane; and when the prepared water-soluble polyurethane dispersion forms a film, with the volatilization of water and the reduction of the pH value, the self-crosslinking reactions of ketonic carbonyl and hydrazide group can be performed, thus the after crosslinking density of the film can be increased and the hardness and water resistance of the the film can be increased.

Owner:安徽好思家涂料股份有限公司

Polyurethane retanning filler

InactiveCN103030769APromote environmental protectionImprove hydrophobicityTanning treatmentPolymer scienceEmulsion

The invention relates to a polyurethane retanning filler. The preparation method of the polyurethane retanning filler comprises the following steps: preparing a prepolymer from raw materials IPDI (isophorone diisocyanate), PEG (polyethylene glycol), castor oil and DMBA (dimethylbenzanthracene); adding triethylamine to carry out neutralization reaction to generate salt; and adding an ethylenediamine water solution to carry out emulsification and chain extension to prepare the water-based polyurethane emulsion. The coated film of the water-based polyurethane emulsion has favorable water resistance and yellowing resistance.

Owner:QINGDAO WINCHANCE TECH

Adhesive composition for optical films, adhesive optical film and image display

ActiveCN101463234AInhibit sheddingPollution suppressionNon-macromolecular adhesive additivesFilm/foil adhesivesXylyleneMeth-

The present invention provides an optical film pressure-sensitive adhesive composition, pressure-sensitive optical films and an image display device. The invention particularly provide an optical film pressure-sensitive adhesive composition capable of forming a pressure-sensitive adhesive layer that has reworkability such that optical films therewith can be easily separated from liquid crystal panels with no adhesive residue and also has satisfactory processability such that it can be processed without causing adhesive stain or dropout after it is formed on an optical film. The optical film pressure-sensitive adhesive composition includes 100 parts by weight of a (meth)acrylic polymer including, as monomer units, (a) 50 to 99.79% by weight of an alkyl (meth)acrylate monomer, (b) 0.01 to 0.45% by weight of a tertiary amino group-containing monomer, and (c) 0.1 to 3% by weight of a hydroxyl group-containing monomer; and 0.01 to 2 parts by weight of a crosslinking agent that is at least one selected from the group consisting of hexamethylene diisocyanate, hydrogenated xylylene diisocyanate, and isophorone diisocyanate, or a polyisocyanate compound derived therefrom.

Owner:NITTO DENKO CORP

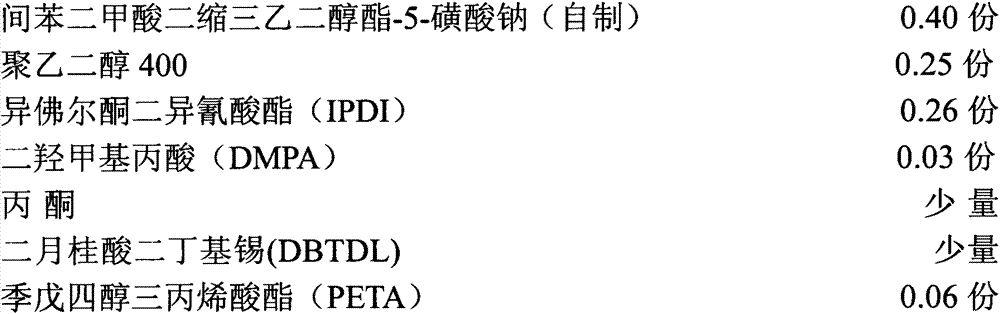

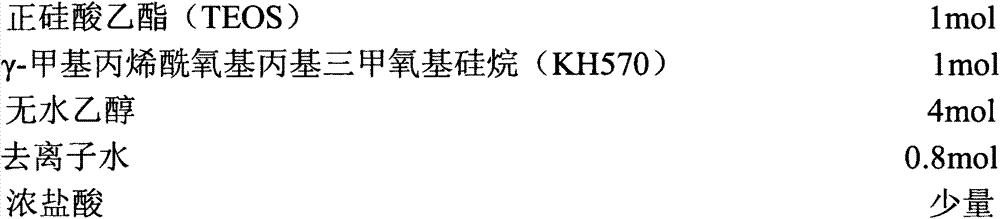

Preparation method for antifogging thin film coating with high light transmission

ActiveCN103709927APolyurea/polyurethane coatingsPigment treatment with organosilicon compoundsSolventDibutyltin dilaurate

Provided is a preparation method for an antifogging thin film coating with high light transmission. M-phthalic acid triethylene glycol ester-5-sodium sulfonate (self made), polyethylene glycol 400, isophorone diisocyanate and pentaerythritol triacrylate are employed as main raw materials, dibutyltin dilaurate is employed as a catalyst, dimethylolpropionic acid is employed as a chain extender, acetone is employed as a solvent, and hydrophilic UV prepolymers are prepared; ethyl orthosilicate is employed as a precursor, gamma-methacryloxy propyl trimethoxysilane is employed as a modifier, a sol-gel method is employed, and uniform and stable modified SiO2 sol is prepared; the hydrophilic UV prepolymers and the modified SiO2 sol are subjected to hybridization through a UV curing way, and a thin film coating is obtained. The prepared thin film coating has good hardness and adhesive force, water resistance and high light transmission and good antifogging effects, and can be used for antifog of surfaces of glass and eyeglass. The preparation technology of the thin film coating accords with green environmental protection concepts, curing and film forming are fast, and comprehensive performances are good. The antifogging thin film coating has good market prospect and is suitable for popularization and application.

Owner:JIANGNAN UNIV

Water-based polyurethane composite emulsion and preparation method thereof

ActiveCN102838713ASpeed up evaporationLower glass transition temperatureGraft polymer adhesivesWater basedPolyester

The invention discloses a water-based polyurethane composite emulsion and a preparation method thereof. The preparation method is characterized by comprising the following steps: by using acetone or butanone and acrylic monomer as solvents, polymerizing diisocyanate (HDI), isophorone diisocyanate (IPDI), mixed polyester polyalcohol, dihydroxymethylpropionic acid, 1,4-butanediol, trimethylolpropane monoene propyl ether, 2-hydroxypropyl acrylate and 2-hydroxyethyl acrylate to obtain carboxylic polyurethane; neutralizing with tertiary amine, and removing the solvents to obtain a self-emulsified double-bond-containing water-based polyurethane anionic emulsion; and by using the emulsion as a seed, adding acrylate monomer and a right amount interpenetrating-network crosslinking agent monomer to carry out pre-emulsification, and carrying out seed emulsion polymerization to obtain the composite emulsion in an interpenetrating network structure. The invention has the advantages of energy saving, environmental protection, high early bonding force, safe and reliable technique and stable product quality.

Owner:广东多正树脂科技有限公司

Polyurethane resin

InactiveCN101381447ANo yellowing phenomenonGuaranteed softnessFibre treatmentAnti freezingOrganic solvent

The invention relates to polyurethane resin, which consists of the following components in weight percentage: 4 to 5 percent of polyethylene glycol adipate, 11 to 13 percent of polytetrahydrofuran glycol, 0.4 to 0.6 percent of ethylene glycol, 1.8 to 1.9 percent of isophorone diamine, 6 to 8 percent of isophorone diisocyanate, 0.08 to 0.1 percent of antioxidant and 73 to 80 percent of organic solvent. The polyurethane resin is applied to produce instep leather of top-grade travel shoes and has good ultraviolet ray yellow stain resistant performance; and under the sunlight, the leather color can be kept unchanged for a long time, and no yellow stain occurs; meanwhile, the polyurethane resin also has good anti freezing property, and no crack generates when the polyurethane resin is used at low temperature for a long time.

Owner:XUCHUAN CHEM KUNSHAN

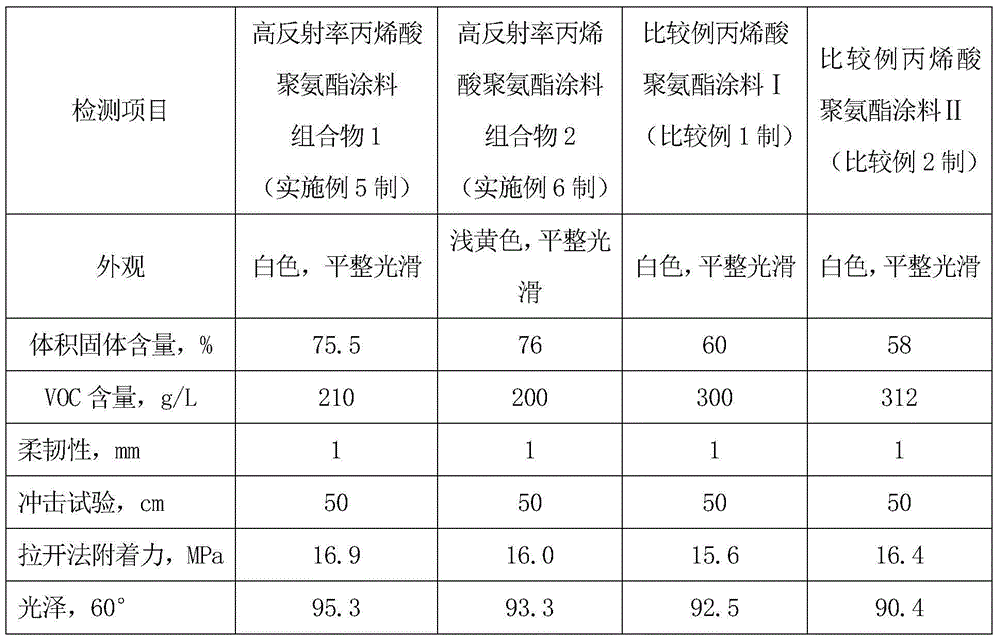

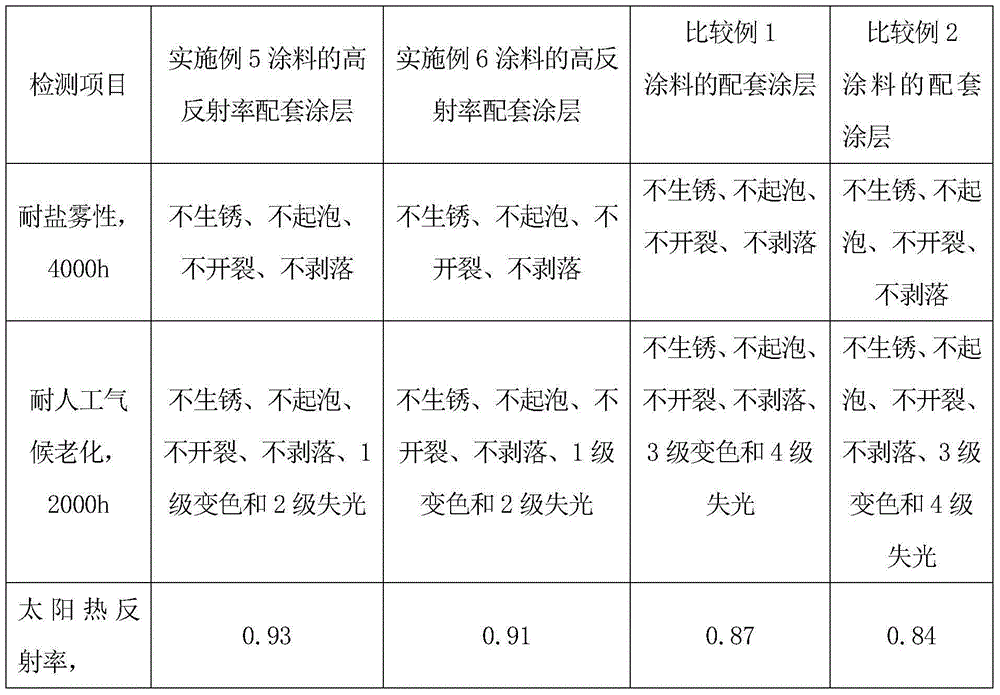

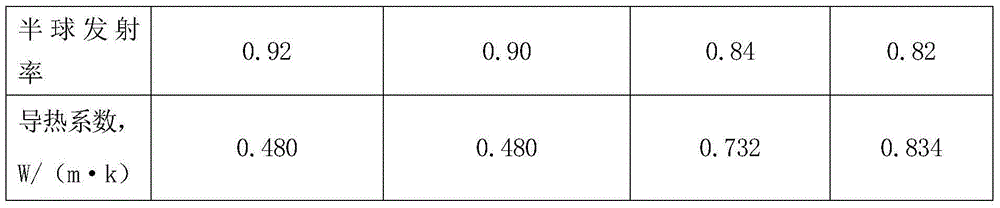

High-reflective acrylic polyurethane coating composition

ActiveCN104371531AHigh solid contentGood weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinIsophorone diisocyanate

The invention relates to a high-reflective acrylic polyurethane coating composition which comprises a component A and a component B in a mass part ratio of 20;3. The component A in 100 parts by mass comprises the following materials in part by mass: 30-50 parts of modified hydroxyl acrylic resin, 2-6 parts of auxiliaries, 35-45 parts of heat reflective pigments, 4-8 parts of aerogel and 10-15 parts of organic solvent. The component B in 100 parts by mass comprises the following materials in part by mass: 75-90 parts of polyisocyanate and 10-25 parts of organic solvent. The modified hydroxyl acrylic resin is obtained by cold-blending modified resin and hydroxyl acrylic resin in a mass part ratio of 1-3: 1; the solid content of the modified hydroxyl acrylic resin is greater than or equals to 75wt%; the particle size of heat reflective pigments ranges from 0.55 micron to 1.2 microns; the particle size of the aerogel ranges from 1 micron to 80 microns; the pore size of the aerogel ranges from 10 nanometers to 20 nanometers; and the heat conductivity coefficient of the aerogel is less than or equals to 0.015W / (m k). The polyisocyanate is one or more of HDI (hexamethylene diisocyanate) biuret, HDI trimer and IPDI (isophorone diisocyanate) trimer curing agents. The high-reflective acrylic polyurethane coating composition is high in reflective insulation quality; and the quantity of VOC (volatile organic compounds) of the high-reflective acrylic polyurethane coating component is low.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Polyurethane cured acrylic resin anti-fogging and abrasion-resistant paint and preparation method thereof

InactiveCN102086348AStrong anti-fogHigh transparencyPolyurea/polyurethane coatingsAcrylic resinPolypropylene glycol

The invention discloses polyurethane cured acrylic resin anti-fogging and abrasion-resistant paint and a preparation method thereof. The paint is prepared from the following components in parts by weight: 130-190 parts of hydrophilic acrylic resin, 210-525 parts of blocked polyether-isocyanate used as curing agent and 2.00-5.00 parts of butyltin dilaurate used as catalyst, wherein the blocked polyether-isocyanate curing agent uses polypropylene glycol and isophorone diisocyanate as raw materials. The preparation method of the paint comprises the following steps: reacting to obtain polyether-isocyanate prepolymer and then reacting with methyl ethyl ketoxime used as sealing agent. The test result shows that the paint prepared by the method has high anti-fogging property, good transparency and abrasion resistance and low production cost; and under the premise of ensuring the good anti-fogging property of the paint, the surface wear resistance can be increased and the application prospectis wide.

Owner:上海旺俊化工有限公司

Preparation method of polysiloxane modified polyurethane water dispersion

The invention relates to a preparation method of polysiloxane modified polyurethane water dispersion. According to the preparation method, IPDI (isophorone diisocyanate) is melted, then, polyether 210 and polyether 220 are added, and the mixture reacts for 25-30 min at the temperature of 70 DEG C-80 DEG C; a polysiloxane modifying agent is added, and the mixture reacts for 30 min; a dimethylol propionic acid solution is added, and the mixture reacts for 25-30 min at the temperature of 70 DEG C-80 DEG C; ethylene glycol is added, the mixture reacts for 40-60 min, and a modified polyurethane prepolymer is obtained; and the prepolymer is cooled to the room temperature, acetone is added, the mixture is uniformly stirred at the normal temperature, then, triethylamine is added, an acetone solution of the prepolymer is obtained and added into a water solution of diethylenetriamine after 15-30 minutes, the mixture is stirred and subjected to emulsification chain extension, acetone is removed, and the polysiloxane modified polyurethane water dispersion is obtained. The prepared polysiloxane modified polyurethane water dispersion has excellent water resistance, ageing resistance, weather resistance, high-low temperature resistance and chemical solvent resistance.

Owner:DONGHUA UNIV +1

Phase-change material microcapsule with aromatic odor and preparation method thereof

ActiveCN103805143AHave stored energyHas an aromatic smellHeat-exchange elementsMicroballoon preparationOil phaseIsophorone diisocyanate

The invention relates to a phase-change material microcapsule with an aromatic odor and a preparation method thereof. The raw material comprises the following components by mass percent: an oil-phase component, including 7.0-24.0% of phase-change material, 6.0-16.0% of essence and 2.5-4.5% of diisocyanate, a water-phase component, including 0.5-4.0% of emulsifier, 0.5-2.5% of diamine and 50.0-85.0% of deionized water, wherein the sum of all components by mass fraction is 100%. The preparation method comprises the following steps: mixing an oil phase with a water phase, forming an emulsion after shearing at a high speed by a homogenizer; carrying out polymerization reaction on diisocyanate and diamine on a water-oil interface of the emulsion to generate a polyurea shell; cladding a core material to form the microcapsule. The essence is added to the phase-change material microcapsule, so that the defect that the traditional phase-change material microcapsule has a peculiar smell can be overcome, the problem that isophorone diisocyanate is insoluble to paraffin hydrocarbon is solved, and the phase-change material microcapsule can be applied to the fields such as textile and clothing, building materials, refrigeration and the like.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com