High-reflective acrylic polyurethane coating composition

An acrylic polyurethane, high reflectivity technology, used in polyurea/polyurethane coatings, reflective/signal coatings, anti-corrosion coatings, etc., can solve the problems of reduced heat reflection effect, low resin solid content, low solid content, etc., to achieve VOC release Small, high solids content, the effect of increasing the solids content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

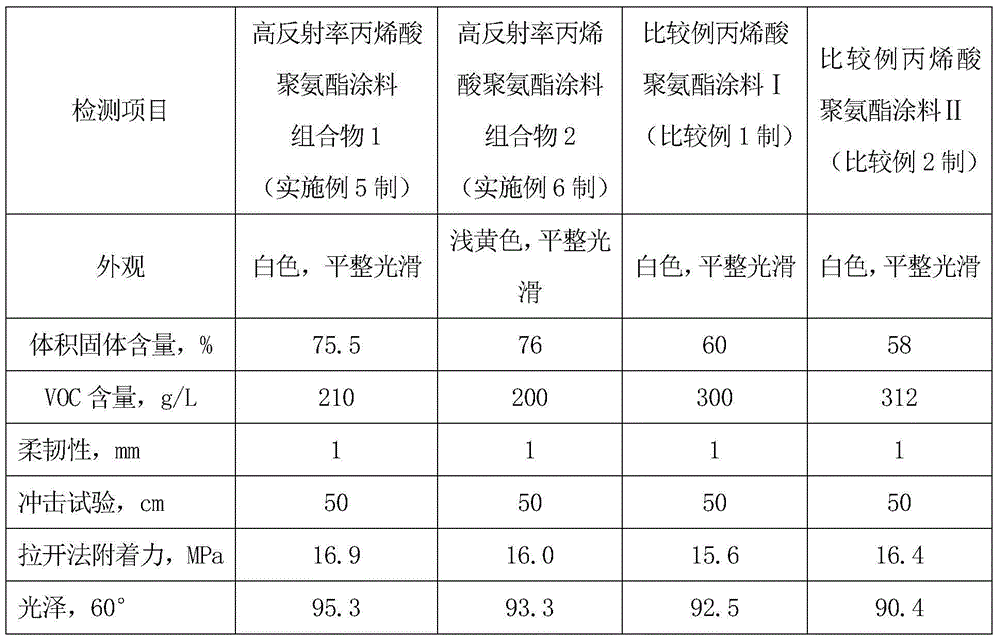

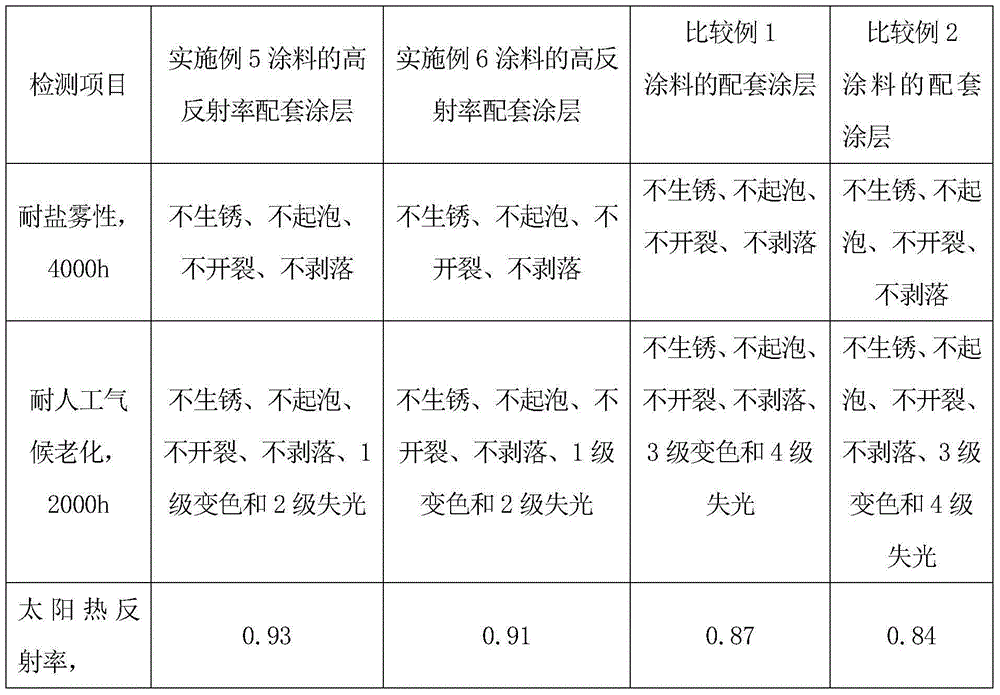

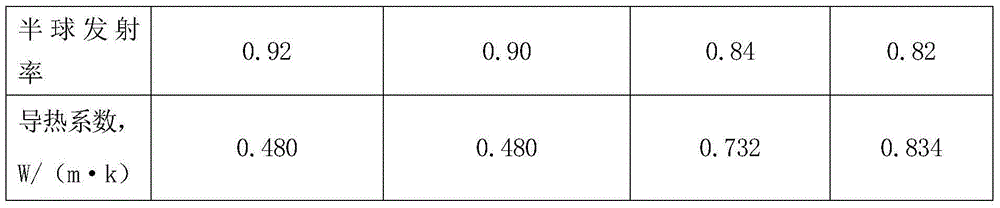

Examples

Embodiment 1

[0025] The preparation modified hydroxyacrylic resin of embodiment 1

[0026] ① Formula

[0027] In the modified hydroxyacrylic resin of every 100 mass parts, 25 mass parts of hydroxyacrylic resin S1196, 75 mass parts of modified resin CTR 6275, wherein: hydroxyacrylic resin S1196 is the product of Nuplex (China) company, and its weight-average molecular weight is 4000-5000, the solid content is 55-60wt%, the hydroxyl content is 2.3-2.6wt%, the viscosity measured by the rotational viscometer is 2400-3800mPa·s; the modified resin CTR 6275 is a product of CNOOC Changzhou Environmental Protection Coatings Co., Ltd., they It is made of functional monomers such as isobornyl methacrylate, cyclohexyl acrylate and glycidyl tert-carbonate as comonomers, with a weight average molecular weight of 2000-2500, a solid content of ≥80wt%, and a hydroxyl content of 4.0- 4.2wt%, the viscosity measured by the rotational viscometer is 2500-3000mPa·s.

[0028] ② Preparation method

[0029] In t...

Embodiment 2

[0030] Embodiment 2 prepares A component 1 (white, pigment base ratio 1.5)

[0031] ① Formula

[0032] In every 100 parts by mass of the A component, 40 parts of modified hydroxyacrylic resins made in Example 1, 39 parts of heat-reflecting pigments (including 26 parts of rutile TiO 2 ALTIRIS 550 and 13 parts rutile TiO 2ALTIRIS 800), 6 parts of airgel SJ 1800, 3 parts of additives (including 1 part of dispersant BYK 163, 0.5 parts of defoamer DF-220.5 parts of anti-sagging agent PLUS and 1 part of leveling agent EFKA 3777), 12 parts Parts of organic solvents (including 6 parts of xylene and 6 parts of butyl acetate).

[0033] ② Preparation method

[0034] In the dispersion tank, add modified hydroxyacrylic resin, organic solvent, dispersant, defoamer, stir evenly, add anti-sag agent PLUS, stir at high speed for 15 minutes, make anti-sag agent PLUS fully wet and disperse, then add Heat-reflecting pigments and aerogels are stirred evenly, then moved into a sand mill, and are...

Embodiment 3

[0035] Embodiment 3 prepares A component 2 (light yellow, pigment base ratio 1.5)

[0036] ① Formula

[0037] In every 100 parts by mass of the A component, 40 parts of modified hydroxyacrylic resins made in Example 1, 39 parts of heat-reflecting pigments (including 26 parts of rutile TiO 2 ALTIRIS 550, 13 parts of nickel titanium yellow PY-53), 6 parts of airgel SJ 1800, 3 parts of additives (including 1 part of dispersant BYK 163, 0.5 parts of defoamer DF-22, 0.5 parts of anti-sagging agent PLUS , 1 part of leveling agent EFKA 3777), 12 parts of organic solvents (including 6 parts of xylene and 6 parts of butyl acetate).

[0038] ② Preparation method

[0039] In the dispersion tank, add modified hydroxyacrylic resin, organic solvent, dispersant, defoamer, stir evenly, add anti-sag agent PLUS, stir at high speed for 15 minutes, make anti-sag agent PLUS fully wet and disperse, then add Heat reflective pigments and aerogels are stirred evenly, then moved into a sand mill, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com