Patents

Literature

2789 results about "Polyurethane coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for forming a two-coat electrodeposited composite coating the composite coating and chip resistant electrodeposited coating composition

InactiveUS6248225B1Electrolysis componentsVolume/mass flow measurementPolyurethane coatingAqueous dispersion

A process for applying two electrodeposited coatings, one on top of the other, to an electrically conductive substrate is provided. An electrically conductive first coating is applied to provide for corrosion resistance and a second polyurethane-based coating is applied to the first coating to provide chip resistance. Also, aqueous dispersions of the polyurethane coating compositions are disclosed.

Owner:PPG IND OHIO INC

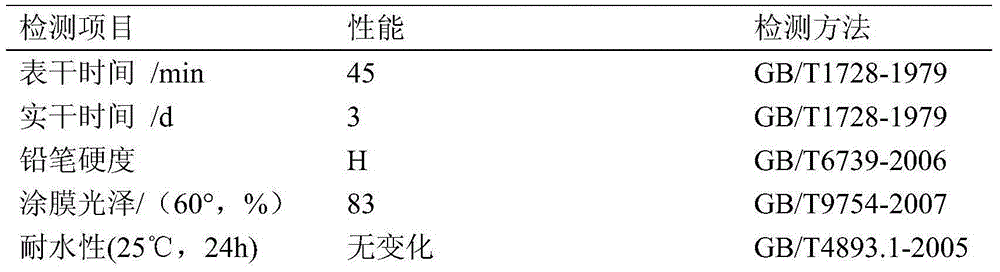

Aquosity bi-component polyurethane coloured paint and method of manufacturing the same

InactiveCN101108951AReduce pollutionPolyurea/polyurethane coatingsEmulsion paintsOrganic solventDisinfectant

The invention discloses a two-component waterborne polyurethane colored paint and the preparation method. The components of the paint are 5 to 15 water, 0.2 to 0.5 dispersant, 0.1 to 0.3 antifoamer, 0.1 to 0.3 wetting agent, 3 to 25 paints, 0 to 50 fillers, 10 to 80 film forming resins, 0 to 5 film forming additives, 0.1 to 0.3 disinfectant, 0.1 to 0.3 antiflash rust agent, 0.5 to 2 thickeners, 1 to 20 hydrophilically-modified polyisocyanate. The preparation method is that water, dispersant, antifoamer, wetting agent, paints and fillers are dispersed evenly by a sand mill, a ball mill or a high-speed stirrer after stirring, and are added with film forming resins, film forming additives, disinfectant, antiflash rust agent and thickeners to gain the product-component A. The hydrophilically-modified polyisocyanate is component B. The component A and component B are mixed uniformly when using. The invention is characterized in that the invention does not adopt organic solvents, does not contain toxic paints and has no harm on the human body and environment, and the properties can reach the solvent two-component polyurethane paint, which can be produced to the primer, intermediate coat and finishing coat, and can be applied in the surface of the wooden ware, cement and metals.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

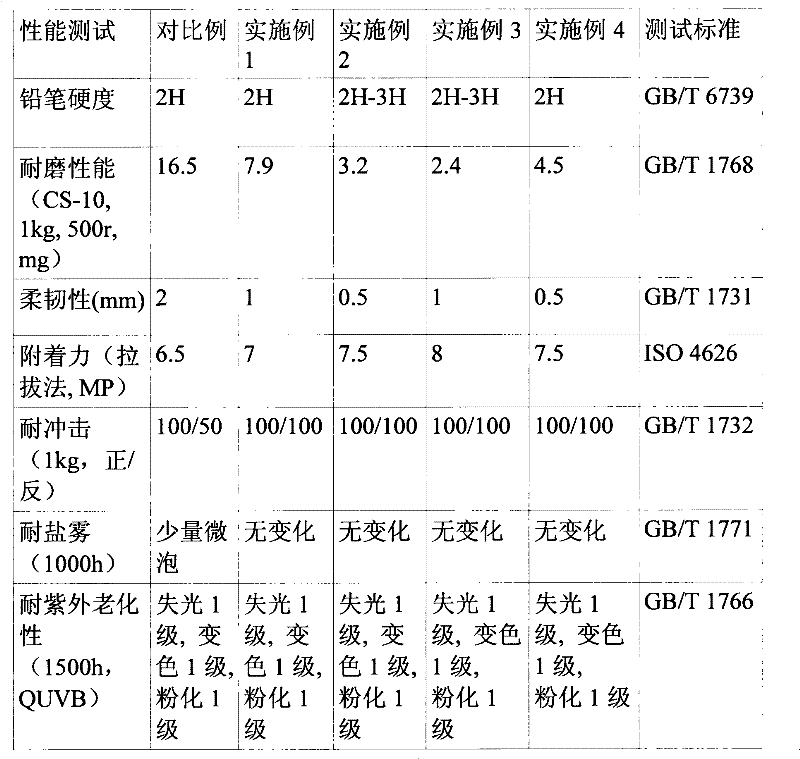

Wear-resisting scratch-resisting weather-proof polyurethane coating and preparation method thereof

ActiveCN101792639AImprove scratch resistanceGood weather resistancePolyurea/polyurethane coatingsPolyester coatingsScavengerAcrylic resin

The invention relates to a double-component polyurethane coating and a preparation method thereof. The coating comprises a component A and a component B, wherein the component A comprises hydroxyl-containing acrylic resin, fluorocarbon resin, polyester resin, non-nanoscale titanium white, nanometer titanium dioxide, nanometer silicon dioxide and various auxiliary agents; and the component B comprises polyisocyanate curing agent, solvent and moisture scavenger. The component A and the component B are mixed at the weight ratio of 4:1-5:1 to obtain the polyurethane coating. The coating has excellent wear resistance, scratch resistance and weather proofness, has favorable decoration, and is suitable for coating the surfaces of rapid trains, automobiles and the like which have higher requirements on decoration and physiochemical performance.

Owner:DE LAITTERN ENVIRONMENTAL COATING BEIJING

Bi-component polyurethane coating and preparation method thereof

ActiveCN102757722AGuaranteed viscosityGuaranteed mechanical propertiesPolyurea/polyurethane coatingsPlasticizerShock resistance

The invention relates to a bi-component polyurethane coating which is prepared from a component A and a component B in a weight ratio of 1:(1-3), wherein the component A comprises the following materials in parts by weight: 40-80 parts of polylol, 20-50 parts of polyisocyanates, 1-10 parts of plasticizer and 0-5 parts of storage stabilizing agent; and the component B comprises the following materials in parts by weight: 10-40 parts of polylol, 10-40 parts of liquid filler, 5-10 parts of crosslinking agent, 30-60 parts of solid filler, 3-15 parts of plasticizer, 0.1-8 parts of thixotropic agent, 0-5 parts of pigment and 0.2-5 parts of additive. The bi-component polyurethane coating is suitable for water prevention, permeability resistance, corrosion resistance and protection of a horizontal plane, can be thickly coated and constructed (>3mm / turn) on complex parts such as a vertical surface and an incline, does not generate sagging and bubble phenomena in a construction process, is full in color, and has the advantages of excellent mechanical property, shock resistance, water resistance and corrosion resistance.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Production method for liner gloves aqueous polyurethane coating connection material

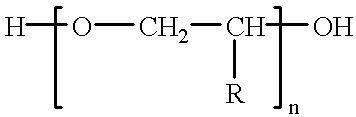

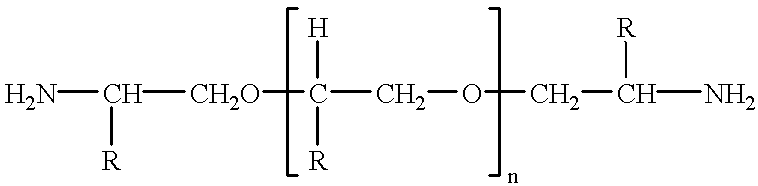

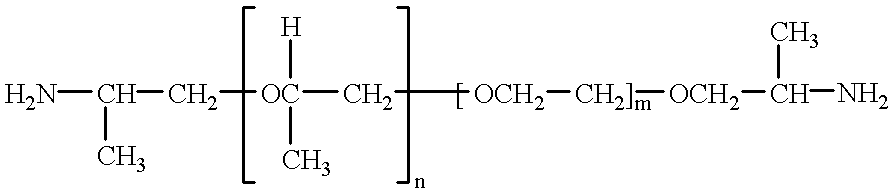

InactiveCN101328383ABreathableGood moisture permeabilityPolyurea/polyurethane coatingsWater basedPropanoic acid

The invention discloses a production method for insert gloves water-based polyurethane coating bonding materials. The method comprises the following steps of: under the protection of dry nitrogen, adding polyether glycols (including polyether diatomic alcohol and / or polyether triatomic alcohol) having undergone vacuum dewatering and isocyanate into a reaction vessel; heating the mixture up to between 80 and 100 DEG C for reaction after even mixing; then adding a hydrophilic chain extender such as dihydromethyl propionic acid (DMPA) and a catalyst for reaction at a temperature of between 80 and 100 DEG C; finally adding the chain extender and a solvent into the mixture for reaction at a temperature of between 55 and 65 DEG C until the NCO content of the isocyanate group does not change; discharging the reactant after temperature reduction to obtain an ionomer; neutralizing a preformed polymer with triethylamine or diethanolamine or triethanolamine and then adding water the mixed solution for emulsification to obtain water-based polyurethane latex; and carrying out reduced pressure distillation to remove the solvent and obtain the product. The synthesized water-based polyurethane resin which serves as a gloves coating has the advantages of good air and moisture permeability, excellent mechanical performance, solvent resistance, ageing resistance, resistance to corrosion caused by chemical mediators, oil resistance, resistance to hooking, cutting and piercing, excellent abrasion resistance, odorlessness, innocuous and nondestructive for contacting with skin, etc.

Owner:ANHUI UNIVERSITY +1

Coating compositions for glass substrates

InactiveUS20110045219A1Synthetic resin layered productsPolyurea/polyurethane coatingsPolyurethane dispersionPolyol

The present invention relates to an aqueous polyurethane coating composition comprising:1) 1 to 99 wt. % of the reaction product of:a) a polyol component, which is soluble or dispersible in water and is the reaction product of a polyisocyanate component containing 50 to 100 wt. % of an aliphatic diisocyanate, a polyol component containing one or more polyether polyols and having an OH number of 25 to 350 mg KOH / g solids and an isocyanate-reactive component containing at least one group capable of salt formation; andb) polyisocyanate component, which is soluble or dispersible in water, has blocked isocyanate groups and is the reaction product of one or more polyisocyanates having an isocyanurate group content of 2 to 30 wt. %, a reversible, monofunctional blocking agent for isocyanate groups, a nonionic hydrophilic component and a stabilizing component which has 1 to 2 hydrazide groups and a molecular weight of 70 to 300; and2) 1 to 99 wt. % of an aqueous polyurethane dispersion prepared from at least one polycarbonate polyol,wherein the total wt. % of components 1) and 2) add up to 100%.

Owner:COVESTRO LLC

Heat reflective coated structural article

InactiveUS6872440B1Energy efficiencyLow costRecord information storageCeramic layered productsElastomerCeramic coating

The present invention relates to a heat reflective coated structural article comprising a heat reflective component and a coated structural article component which comprises a substrate having an ionic charge coated with a coating having essentially the same ionic charge. The coating of the coated structural article consists essentially of a filler material and a binder material wherein the binder material bonds the filler material together and to the substrate and wherein the coating does not bleed through the substrate. Nonlimiting examples of the heat reflective component include, elastomeric coatings, aluminum fiber coatings, acrylic and polyurethane coating systems, ceramic coatings insulating paints, metal pigment paints, metal pigment pastes and aluminum flakes. The heat reflective coated structural article of the present invention may be incorporated into commercial roofing products.

Owner:ELK PREMIUM BUILDING PROD

Coating for fertilizer

InactiveUS20050076687A1Maintain reaction temperatureImparts physical strengthBiocideGas treatmentVegetable oilPolymer chemistry

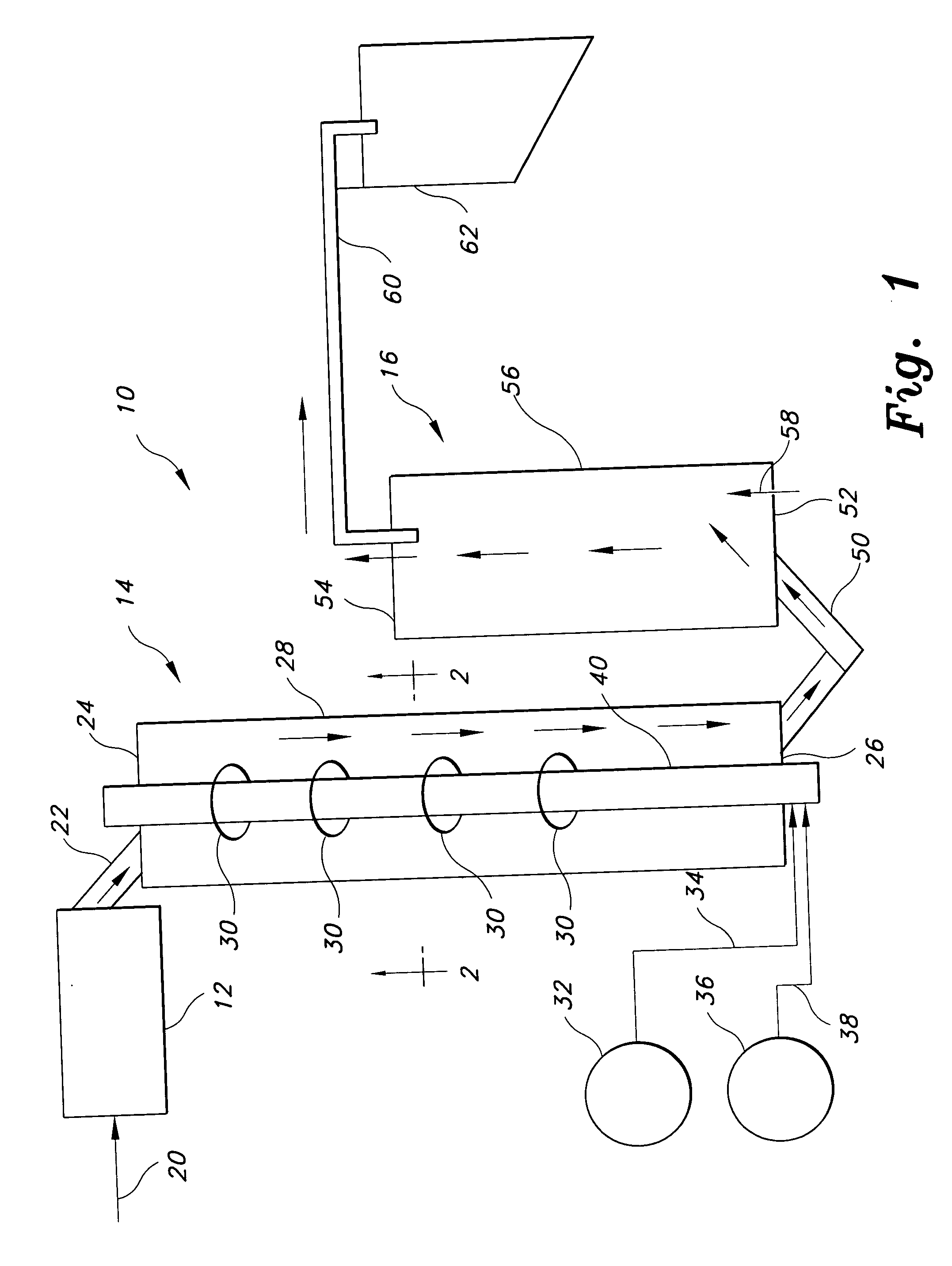

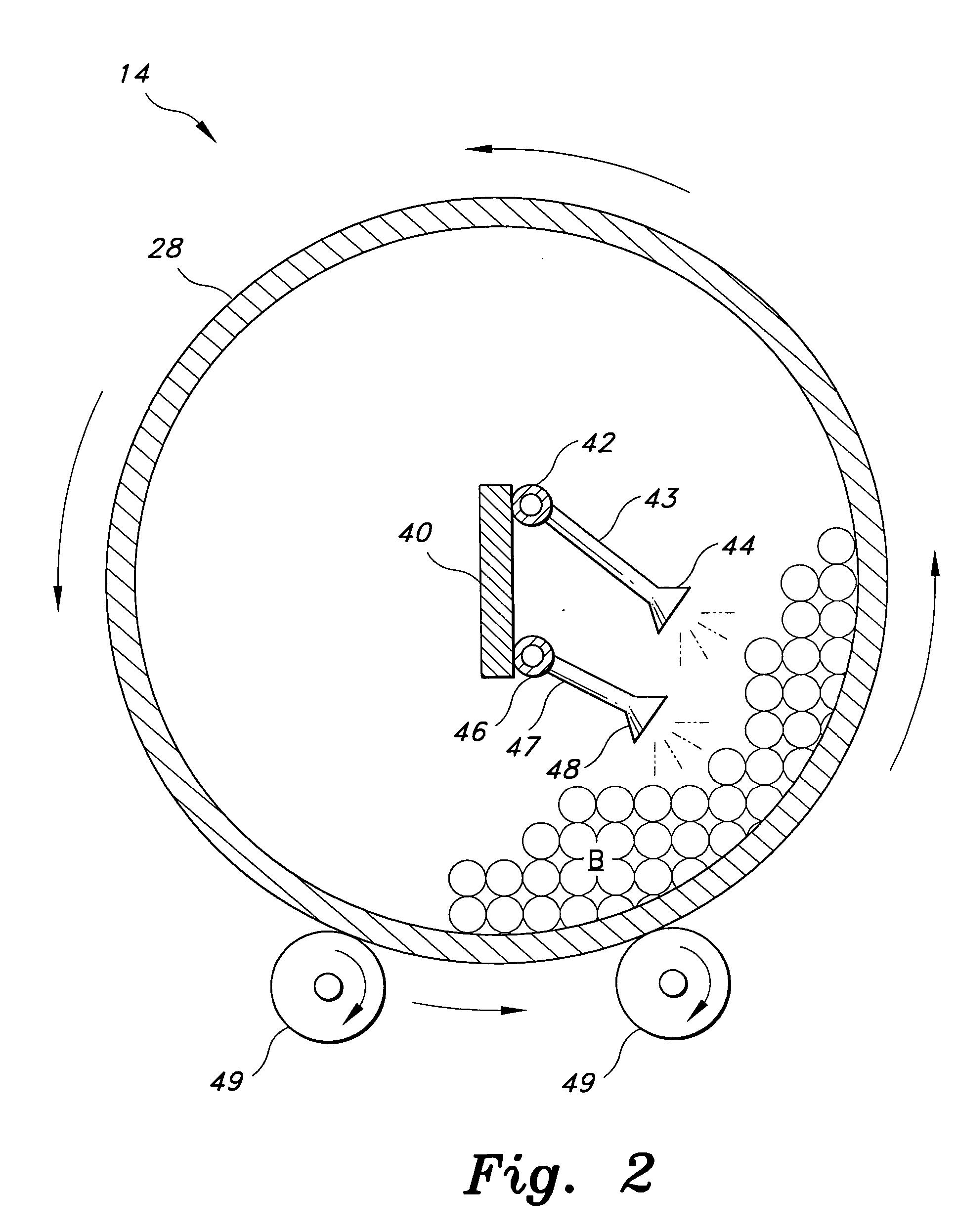

Method and apparatus for coating fertilizer in pellet or other form to impart time-release characteristics and the resulting coated pellet product. The polyurethane coating encapsulates fertilizer particles, forming a hydrophobic coating for slow-release qualities. The urethane polymer coating is formulated with an isocyanate and a combined fluid of a polyether polyol, a methyl ester derivative of plant or vegetable oil, a T-12 curing catalyst, barium sulfate, and an oil-based dye. The barium sulfate imparts physical strength to and enhances color quality of the polyurethane coating, and acts as a detackifier and maintains temperature in the coating reactor. The inventive formulation is effective in the practical polymer coating of sulfate-based or other fertilizer pellets in an inventive time-release fertilizer product. An apparatus is provided for carrying out the coating process.

Owner:WHITTINGTON PATSIE A

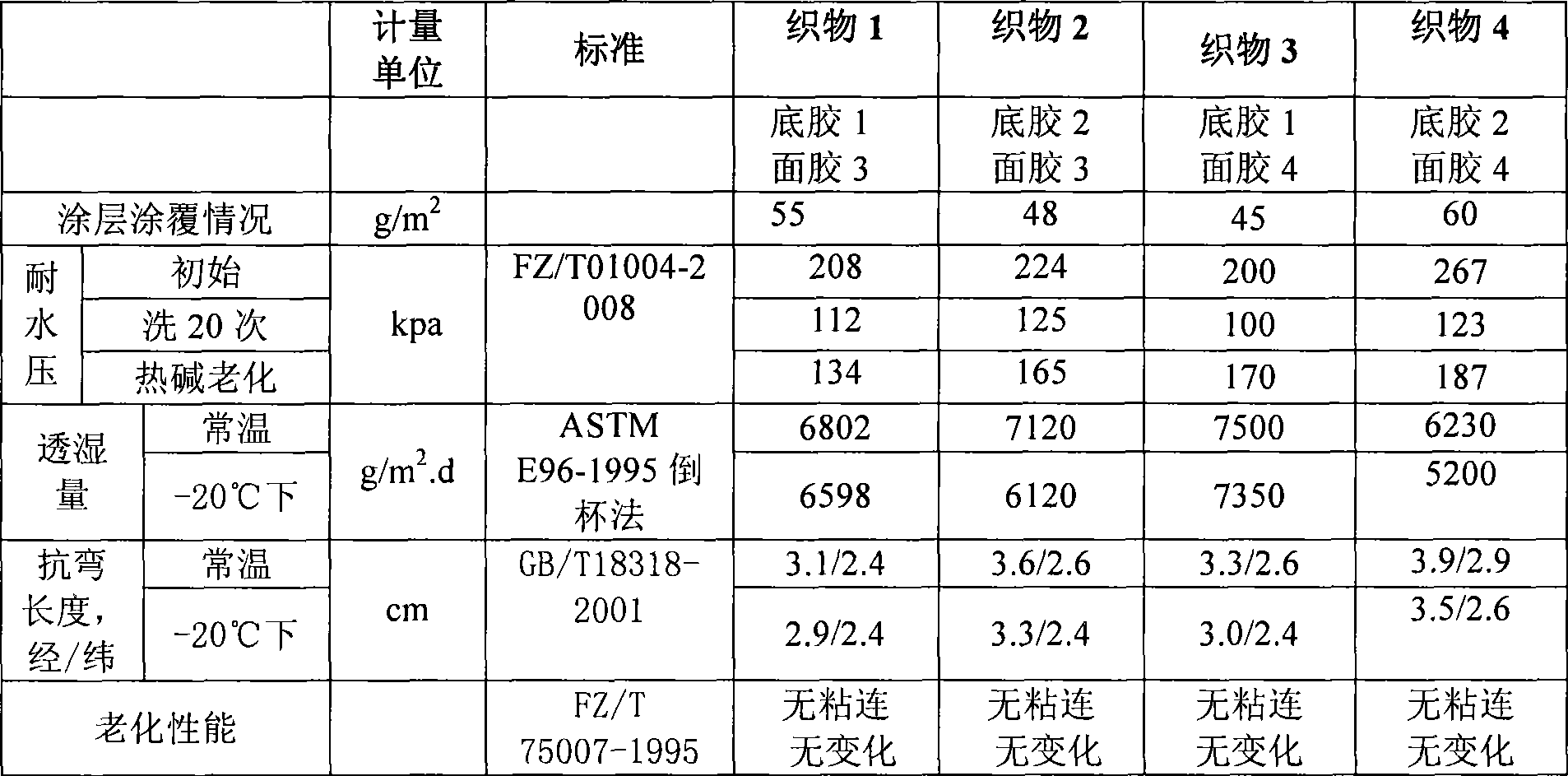

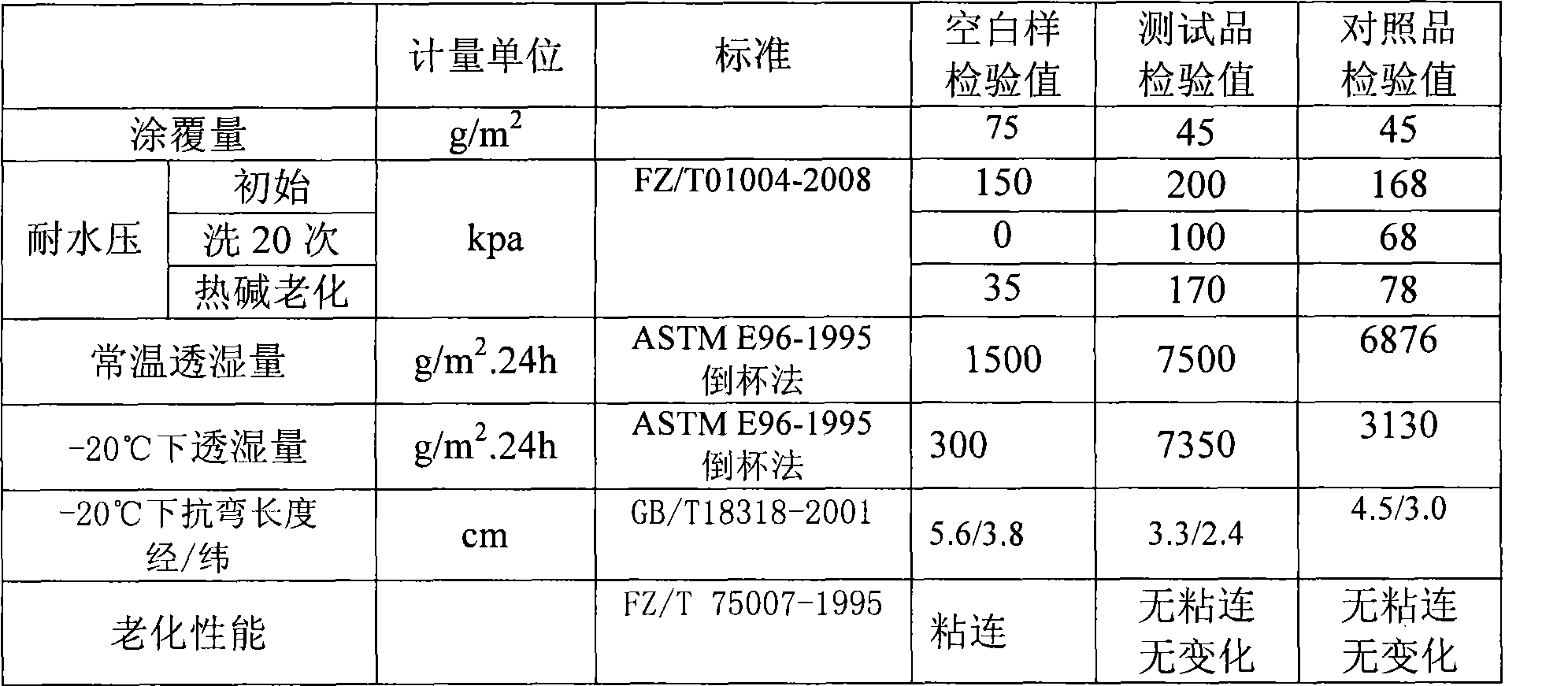

Waterproof moisture permeable modified polyurethane coating glue and preparation thereof

InactiveCN101481579AEasy to addWorkmanship is feasiblePolyurea/polyurethane coatingsTextiles and paperAdhesiveMoisture permeability

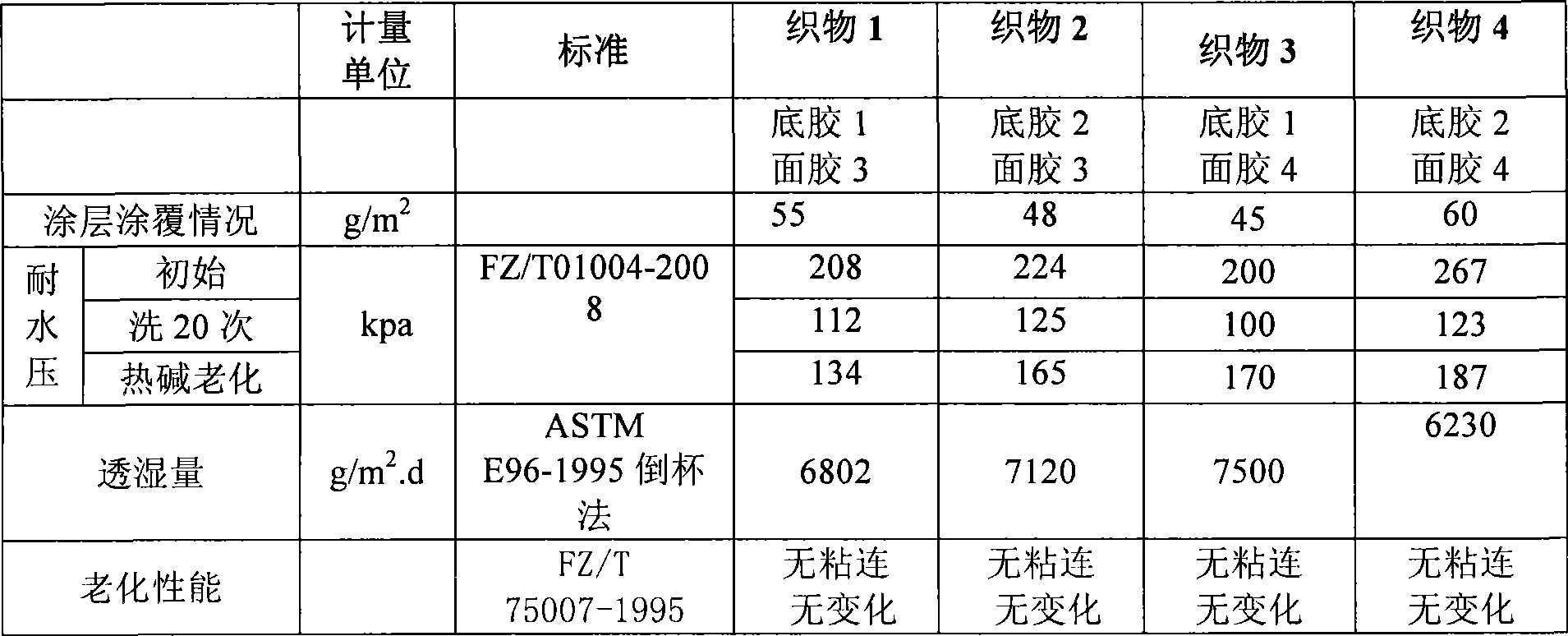

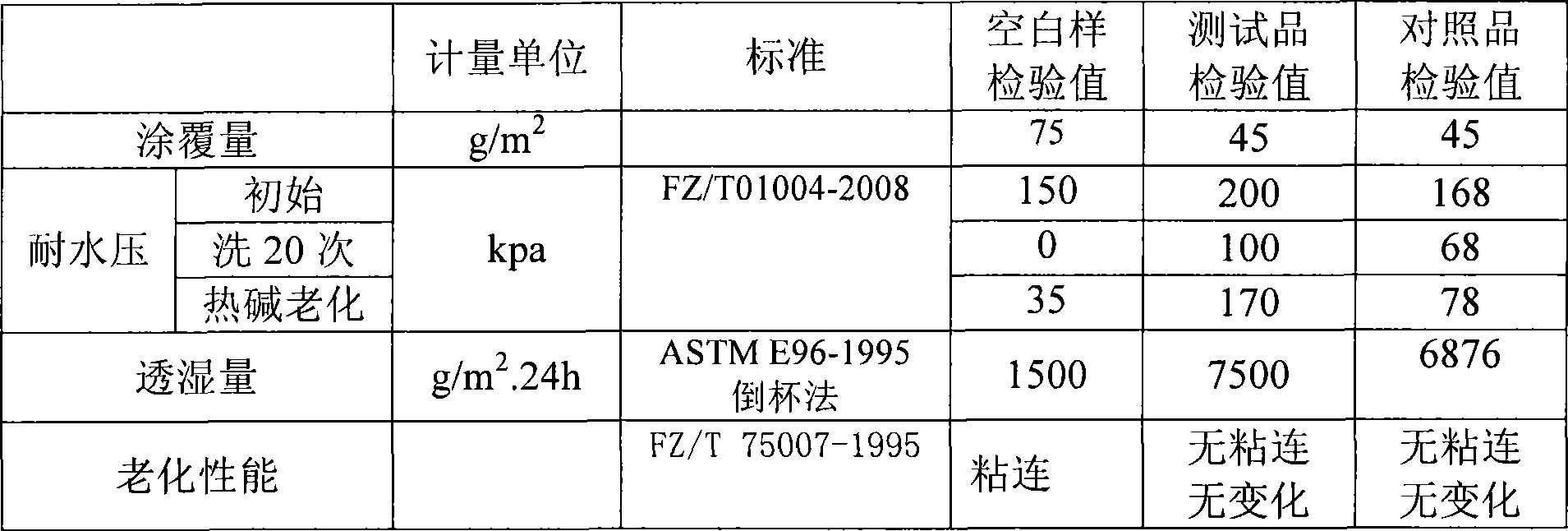

The invention provides a water-proof and moisture-permeable advanced polyurethane coating adhesive, which is prepared by mixing three components of coating agent, crosslinking agent and crosslinking promoter with a solvent when in use; the coating agent contains 500 to 1000 mesh of lignocellulose micropowder; the amounts of the crosslinking agent and crosslinking promoter are 2-5wt% of that of the coating agent; and the viscosity of the coating adhesive is 8000 to 15000 mPa.s. The advanced polyurethane coating adhesive in the invention is coated on a base fabric so as to prepare a water-proof and moisture-permeable coated fabric; the moisture permeability is greater than 7000 g / m.d; the water pressure resistance is greater than 200 kPa; the aging resistant performance is enhanced; the blocking resistance is obviously improved; and the coated fabric can be used as a coating material of clothes having water-proof and moisture-permeable functions.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +2

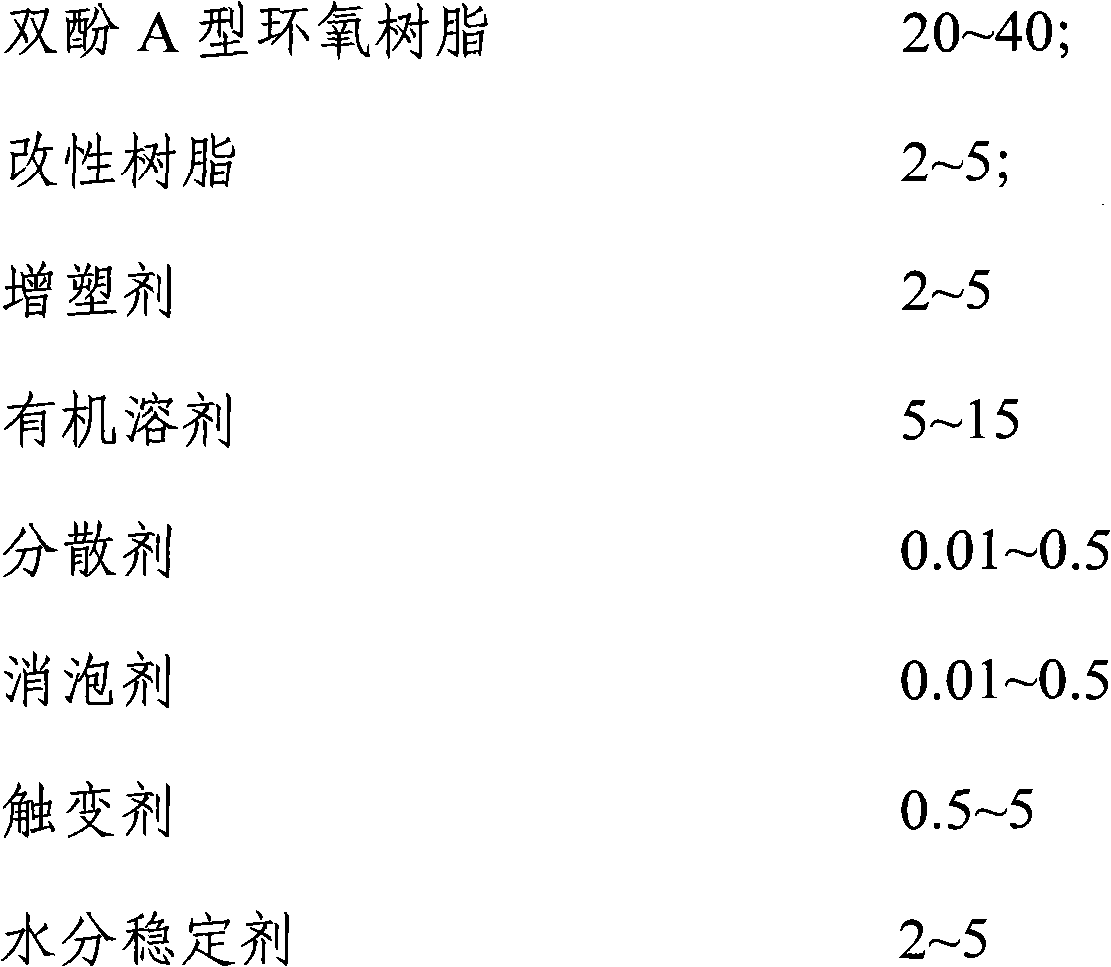

Epoxy coating and preparation method and application thereof

ActiveCN102618148AImprove the shortcomings of hard and easy to crack and poor flexibilityHigh mechanical strengthRosin coatingsAnti-corrosive paintsResin coatingPolyurethane coating

The invention provides a novel epoxy coating and a preparation method thereof. The coating not only has excellent corrosion resistance, but also has excellent compatibility with a base material or a lower coating film, particularly an epoxy coating, a polyurethane coating, a fluorocarbon coating or an alkyd resin coating. The epoxy coating comprises a main paint and a curing agent, wherein the main paint contains bisphenol A epoxy resin and modifying resin for modifying the bisphenol A epoxy resin; and the curing agent contains polyamino amide and cardanol modified phenolic amine.

Owner:北京红狮科技发展有限公司

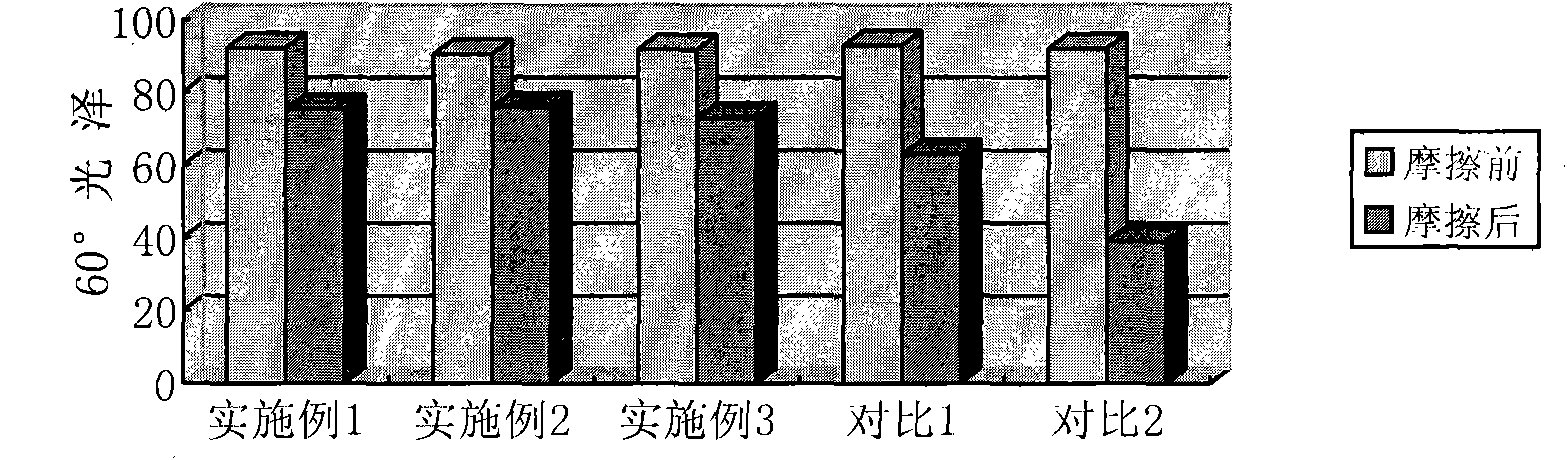

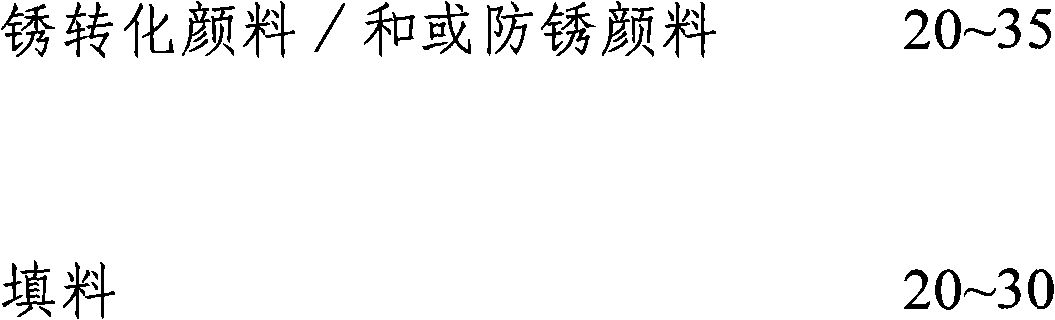

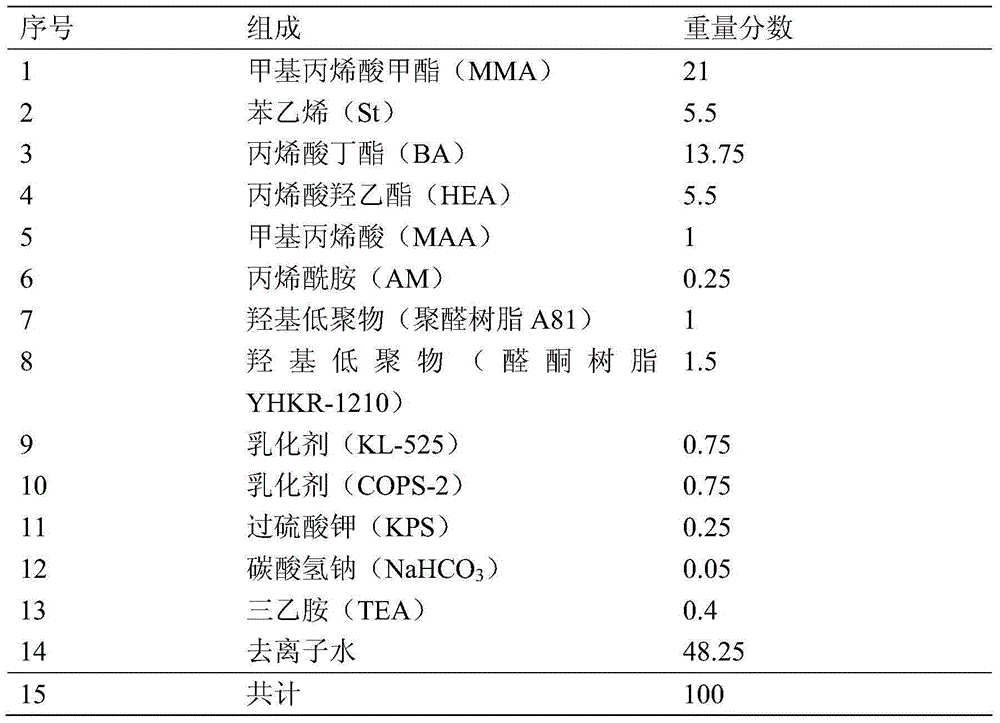

Hydroxypolyacrylate emulsion, and preparation method and application thereof

ActiveCN105061665AHydroxyl content is easy to adjustLarge adjustment rangePolyurea/polyurethane coatingsSodium bicarbonateMethacrylate

The invention discloses a hydroxypolyacrylate emulsion, and a preparation method and an application thereof. The preparation method comprises the following steps: weighing an acrylate monomer and / or a metacrylate monomer, a hydroxyacrylate monomer, an acrylic monomer, an acrylate function monomer and a hydroxy oligomer, uniformly mixing to prepare a monomer mixture, weighing 10-15% of the monomer mixture, and emulsifying by using an emulsifier to prepare a seed pre-emulsion for later use; and adding the emulsifier, sodium bicarbonate and deionized water into a reaction kettle, stirring, rising the temperature of a reaction system, adding an initiator, stabilizing, adding the seed pre-emulsion in a dropwise manner, stabilizing, adding the remaining monomer mixture and the remaining initiator in a dropwise manner, heating, slaking, cooling, neutralizing, carrying out heat insulation, cooling, and discharging to obtain the hydroxypolyacrylate emulsion. A film made by using an aqueous dual-component polyurethane coating prepared from the hydroxypolyacrylate emulsion and an aqueous polyisocyanate curing agent has the advantages of high hardness, high luster and excellent chemical resistance.

Owner:SOUTH CHINA UNIV OF TECH +1

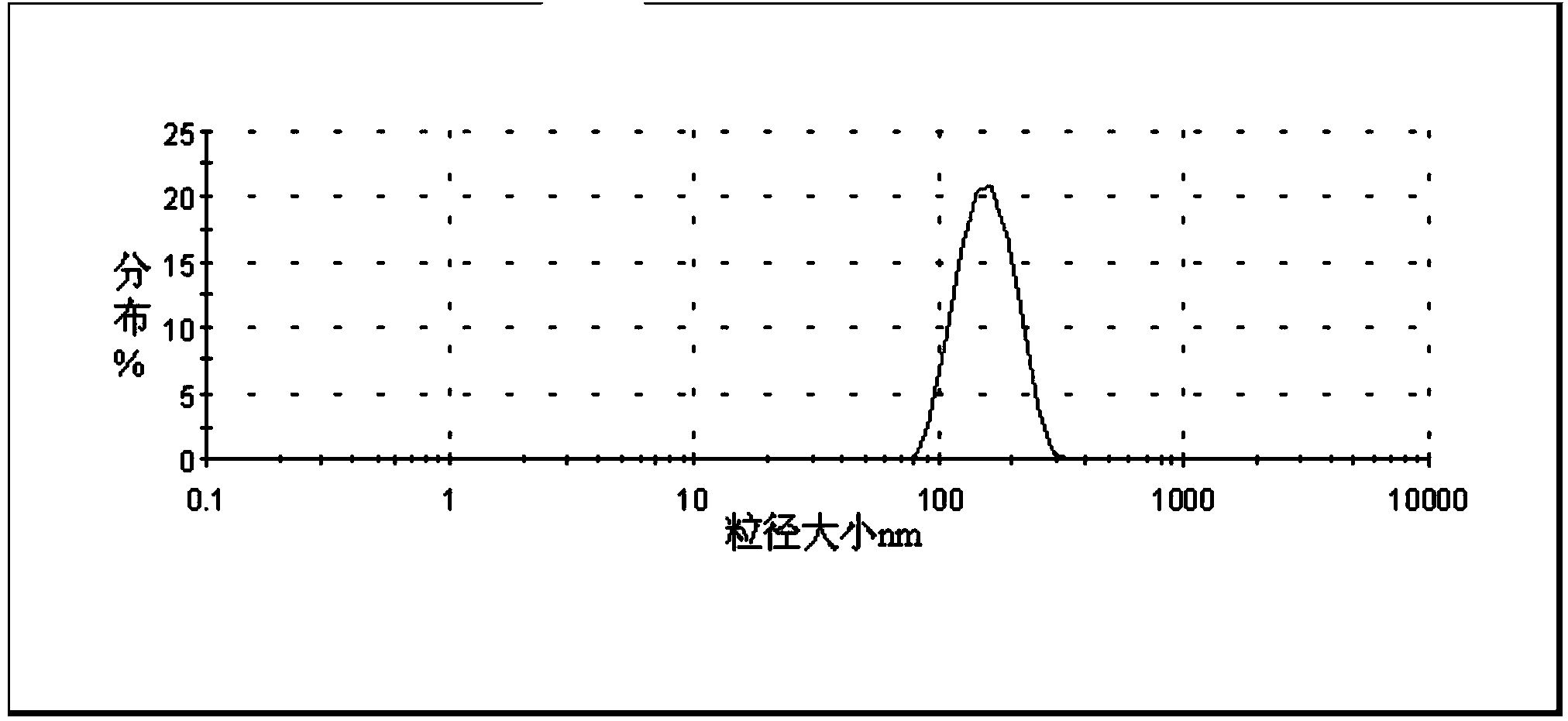

Preparation method of matting leather water-based polyurethane coating agent

ActiveCN103740250AGood light stabilityGood compatibilityFibre treatmentPolyurea/polyurethane coatingsWater basedCross-link

The invention provides a preparation method of a matting leather water-based polyurethane coating agent. According to the preparation method, a polyurethane A component with a cross-linked structure and a large particle size is synthesized, and is mixed with a B component with a small particle size. The A component possesses many molecular branched chains, size of micellar particles is relatively large, and specific gravity of the A component is less than that of the component B; so that the A component will float on film surface, roughness of the film surface is relatively high, delustering effect is achieved, no delustering agent is needed, excellent transparency is obtained after coating, and no influence on leather substances is caused as the delustering effect is achieved.

Owner:SICHUAN DOWELL SCI & TECH INC

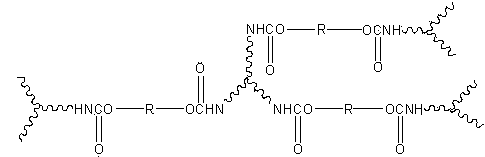

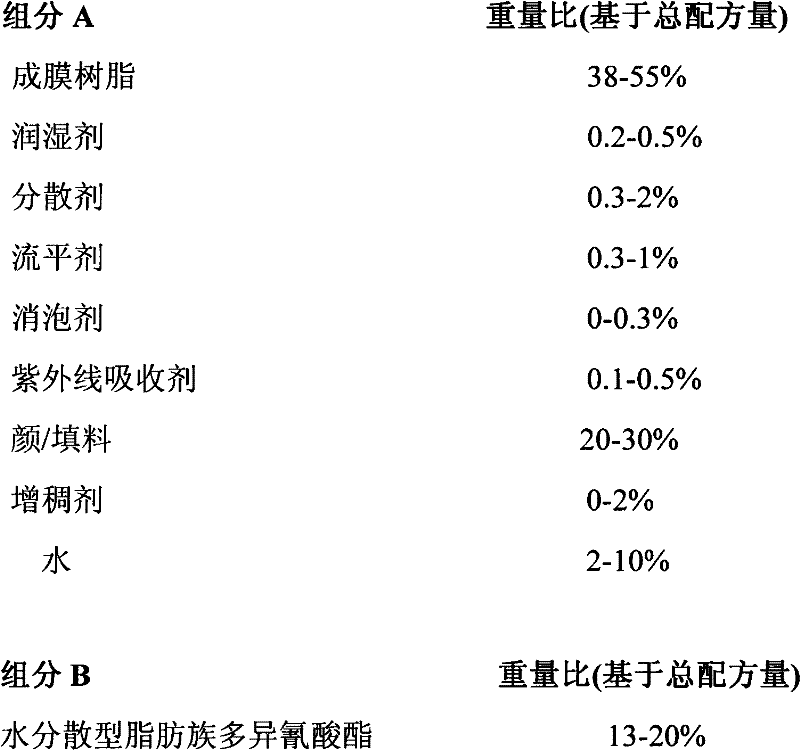

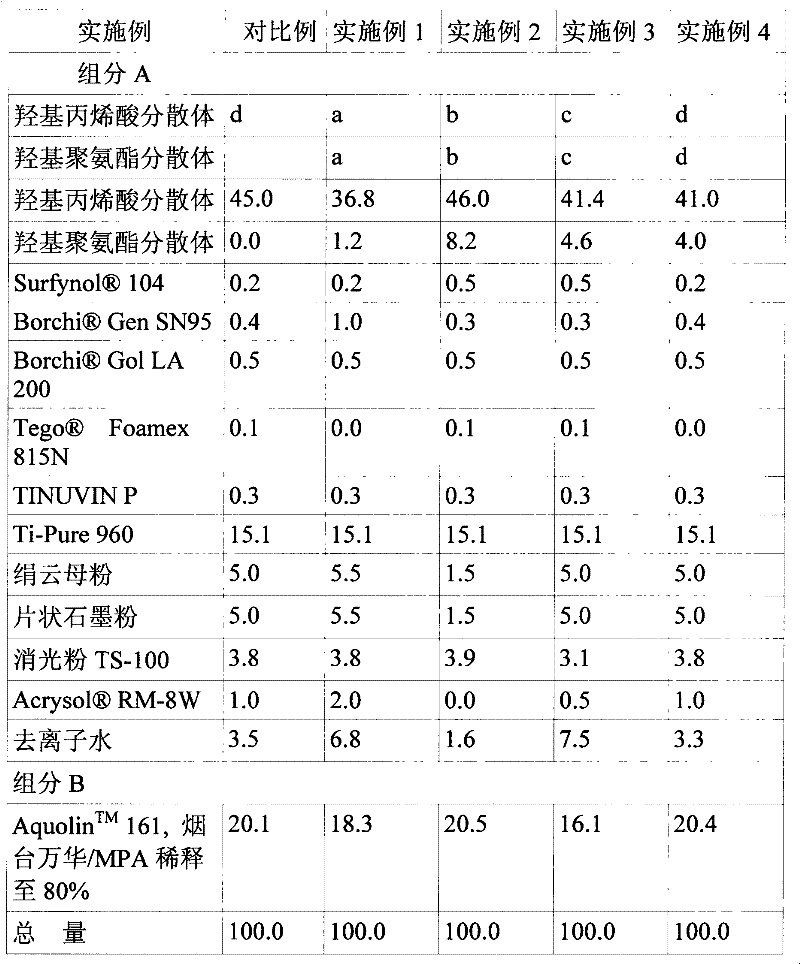

Water-based coating and preparation method and application thereof

ActiveCN102533078AGood UV aging resistanceImprove wear resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedPolyurethane dispersion

The invention discloses a water-based coating and a preparation method and an application thereof. The water-based coating belongs to a water-based two-component polyurethane coating for a wind turbine blade, and can be taken as priming paint and finishing paint. Film forming resin consists of a hydroxyl acrylic acid dispersion and a hydroxyl polyurethane dispersion; due to the adoption of a acrylic acid structure and a polyurethane structure, excellent ultraviolet ray resistance and high wear resistance can be provided respectively; and water-dispersible aliphatic diisocyanate is taken as a curing agent. The coating has excellent adhesive ability on the wind turbine blade, has excellent tolerance, and can be used for effectively prolonging the service life of wind power equipment.

Owner:WANHUA CHEM GUANGDONG +2

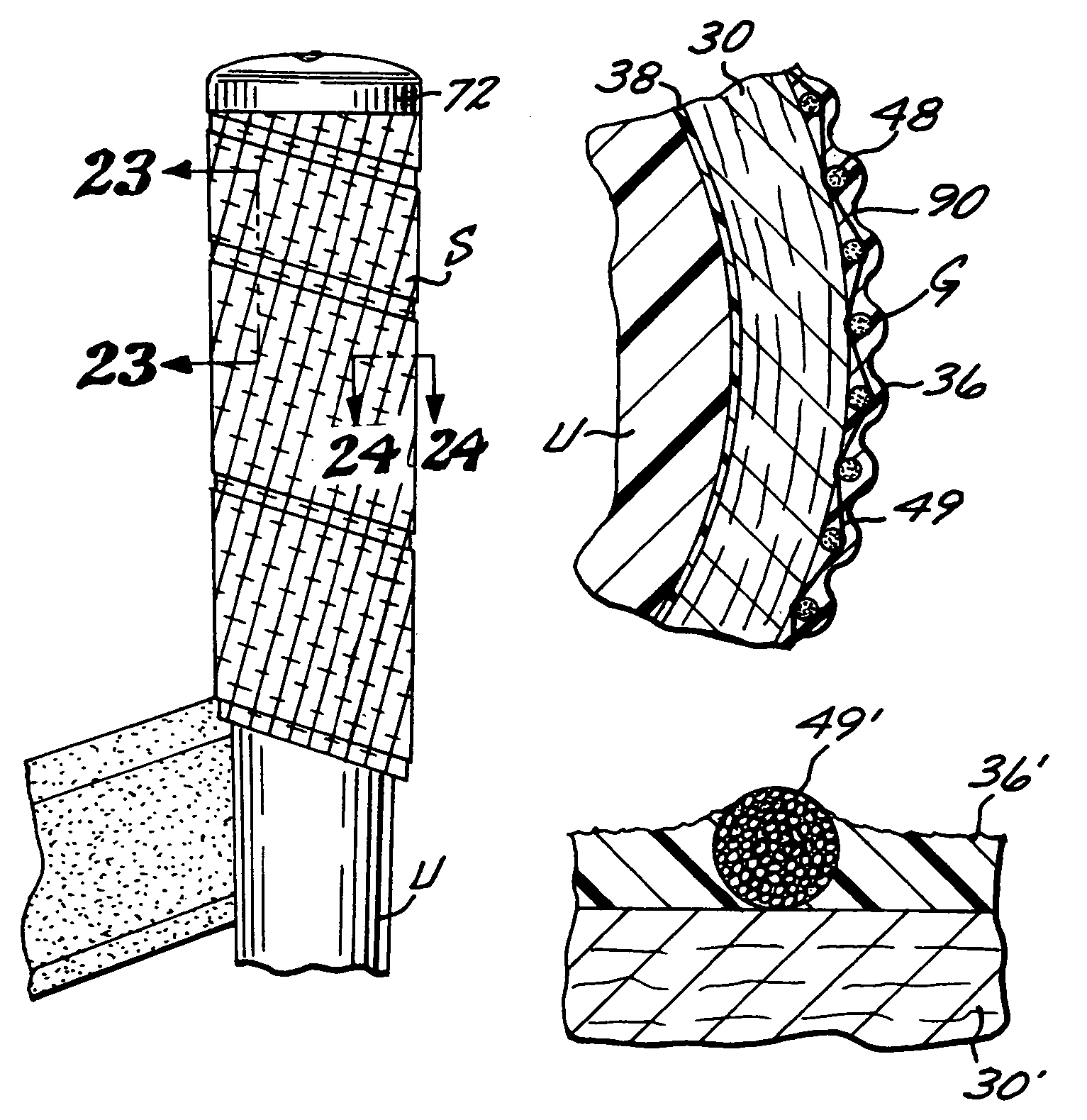

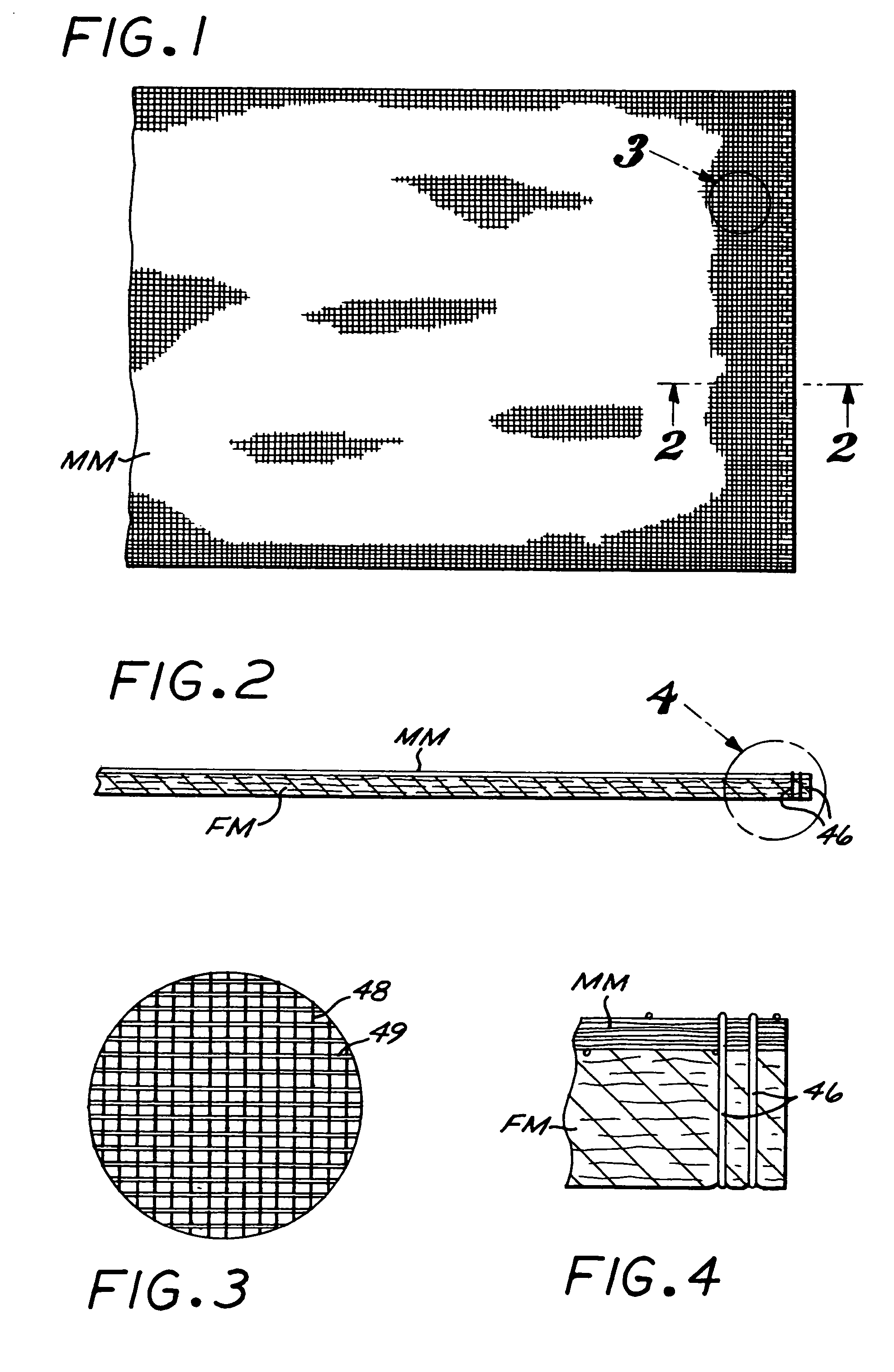

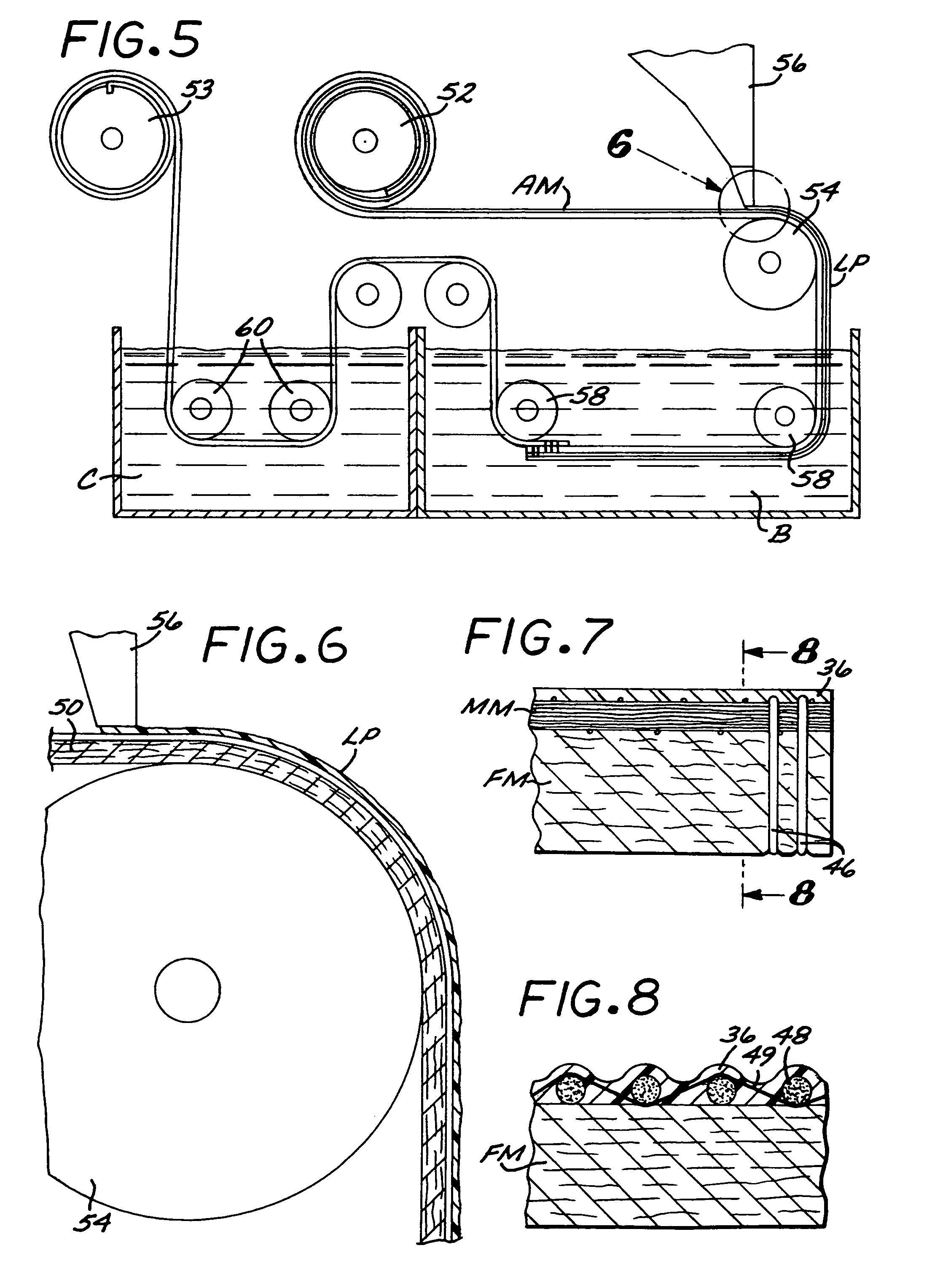

All-weather golf club grip

InactiveUS7374498B2Improve the immunityMinimizes slippage effectLamination ancillary operationsSynthetic resin layered productsFiberEngineering

A slip-resistant shock absorbing golf club grip that includes a felt layer, a fabric mesh formed of fibers and a polyurethane coating covering the mesh and felt, the fibers of the mesh defining grooves in the surface of the slip-resistant polyurethane which are engaged by a golfers' hands, with the polyurethane coating being buffed to partially expose the fibers.

Owner:HUANG BEN

Waterproof moisture permeation polyurethane paint used for textiles and preparation method

The invention relates to waterproof moisture permeation polyurethane paint used for textiles and a preparation method. The waterproof moisture permeation polyurethane paint is prepared from methyl diphenylene diisocyanate, toluene di-isocyanate, polyether glycol (with the molecular weight of 2000), linear dihydroxylated alkylsiloxane (with the molecular weight of 1000), polyester dihydric alcohol (with the molecular weight of 2000), trimethylolpropane, chain extending agents, sealing compounds, dibutyl tin laurate and solvents through the processes of pre-polymerization reaction, chain extension reaction and sealing reaction. The production process is simple, and the products have the advantages of self-crosslinking effect, soft hand feeling, good cold resistance performance, high moisture permeation performance, high water pressure resistance and little reduction after water pressure resistance washing.

Owner:郯城丰润粮机配件有限公司

Waterborne polyurethane coating and preparation method thereof

ActiveCN102010650AHigh strengthImprove wear resistancePolyurea/polyurethane coatingsPolyesterPolycarbonate

The invention discloses a novel waterborne polyurethane coating which comprises the following components in parts by weight: 50-80 parts of poly (propylene carbonate) polyols, 10-30 parts of polyisocyanates, 3-8 parts of hydrophilic chain extender, 1-4 parts of cross-linking agent and 170-270 parts of deionized water. The invention also discloses a preparation method of the waterborne polyurethane coating. In the invention, polyatomic alcohol is used as polycarbonate (PC), so the coating not only has the advantages of a polyester polyurethane coating such as stronger abrasive resistance, scratch resistance and high bonding strength, but also does not generate hydrolysis and has strong storage stability and weather fastness. In addition, the poly (propylene carbonate) polyols can be prepared by using carbon dioxide as a raw material, thereby having low cost. The coating prepared by the preparation method has wide market prospects.

Owner:HUIZHOU DAYAWAN DAZHI FINE CHEM

Anti-icing and anti-frosting polyurethane coating and preparation method thereof

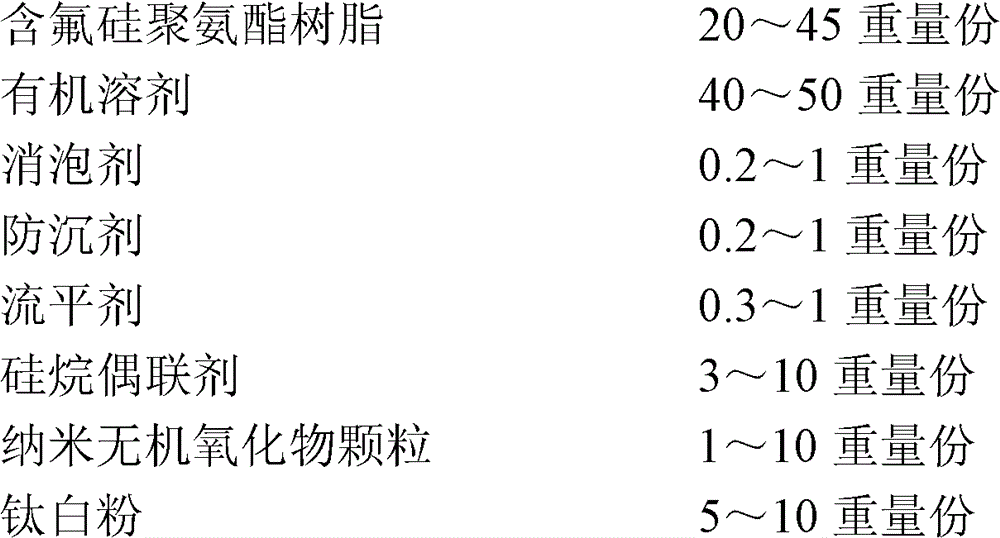

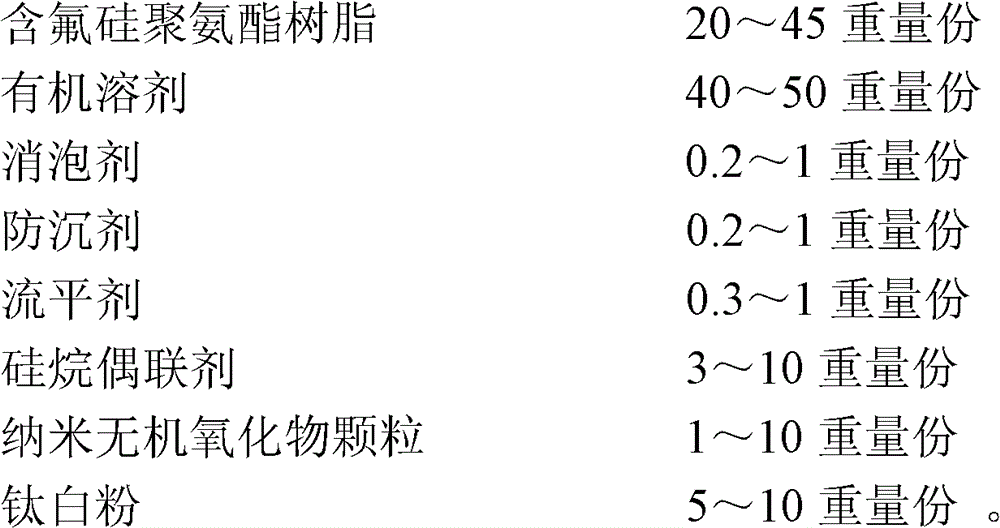

ActiveCN102746782AImprove hydrophobicityImprove adhesionPolyurea/polyurethane coatingsAir conditioningInorganic oxide

The invention belongs to the fields of aerospace, low temperature refrigeration and heat pump air-conditioning and relates to an anti-icing and anti-frosting polyurethane coating and a preparation method thereof. The anti-icing and anti-frosting polyurethane coating has good film forming properties, low temperature resistance and high hydrophobicity. The preparation method comprises that based on weight parts of a fluorosiloxane-containing polyurethane resin, 20 to 45 parts by weight of the fluorosiloxane-containing polyurethane resin, 40 to 50 parts by weight of one or more organic solvents, 0.2 to 1 part by weight of one or more defoamers, 0.2 to 1 part by weight of one or more anti-settling agents and 0.3 to 1 part by weight of one or more flatting agents are mixed into a mixed solution; 3 to 10 parts by weight of one or more silane coupling agents, 1 to 10 parts by weight of nanoscale inorganic oxide particles and 5 to 10 parts by weight of titanium dioxide are added into the mixed solution; and the mixture is subjected to ball-milling to form the anti-icing and anti-frosting polyurethane coating. Through utilization of the fluorosiloxane-containing polyurethane resin, the anti-icing and anti-frosting polyurethane coating has good adhesion with a base and has good surface hydrophobicity.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Super-hydrophobic acrylic polyurethane coating and preparation method thereof

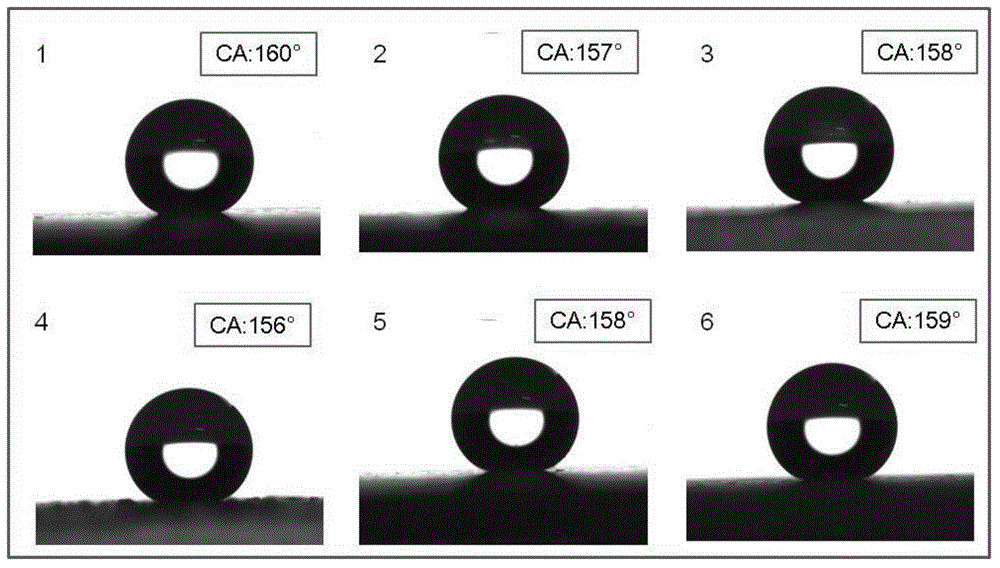

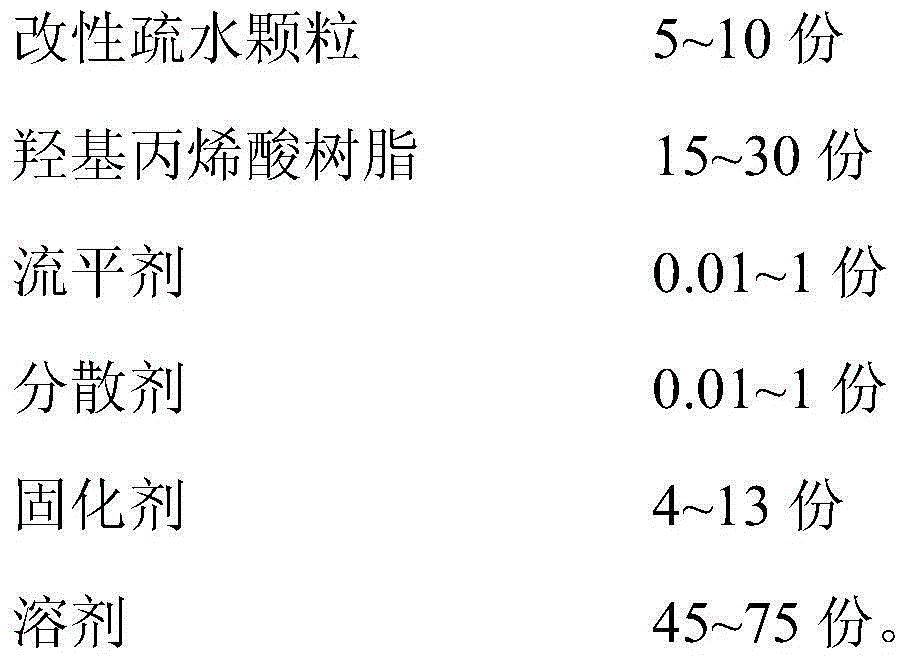

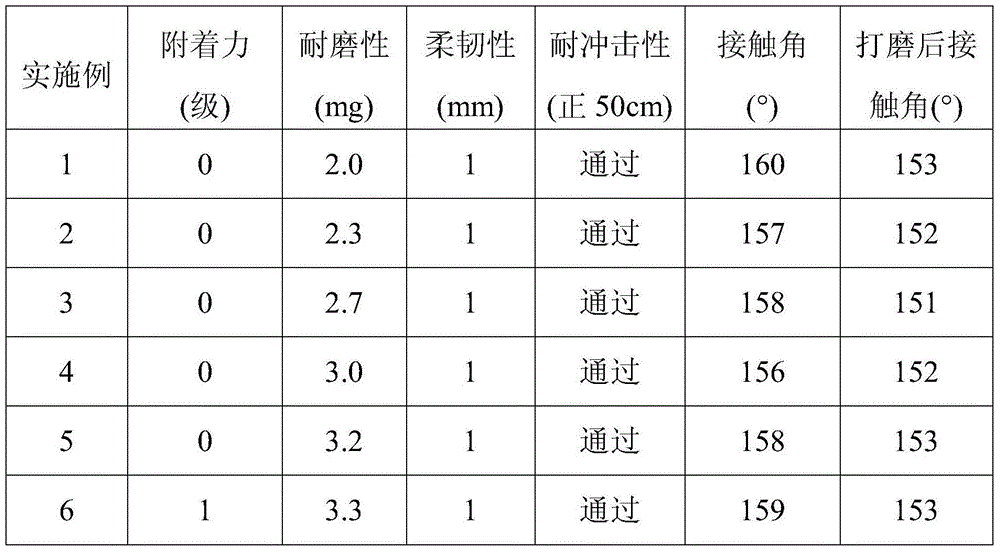

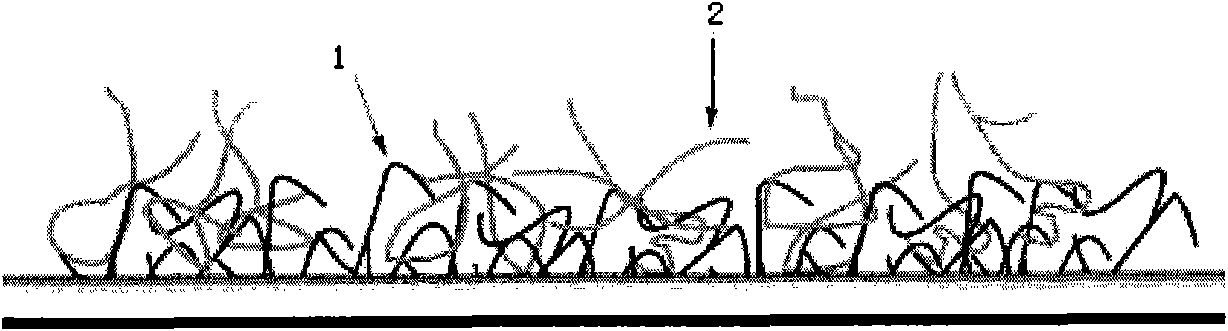

ActiveCN104910779AStrong adhesionImprove impact resistancePolyurea/polyurethane coatingsAcrylic resinPliability

The invention discloses a super-hydrophobic acrylic polyurethane coating and a preparation method thereof, and belongs to the technical field of chemical materials. The super-hydrophobic acrylic polyurethane coating is prepared from the following raw materials in parts by weight: 5-10 parts of modified hydrophobic particles, 15-30 parts of hydroxyl acrylic resin, 0-1 part of a leveling agent, 0-1 part of a dispersant, 4-13 parts of a curing agent and 45-75 parts of a solvent by virtue of spray coating and curing. The water contact angle of the super-hydrophobic acrylic polyurethane coating disclosed by the invention can be as high as 160 degrees, the roll angle is less than 10 degrees, a water drop falling on the coating tumbles off extremely easily, the adhesive force of the coating can reach a 0 level, and the coating is marvelous in flexibility and impact resistance. The preparation method of the coating disclosed by the invention is simple and feasible, the used raw materials are convenient and easy to obtain, the process condition is easy to realize industrial large-scale production, and the super-hydrophobic acrylic polyurethane coating has a broad application prospect.

Owner:浙江国能科技有限公司

Hydrophilic coating for surface of medical apparatus and preparation method thereof

InactiveCN101934101AHigh mechanical strengthExcellent coating mechanical propertiesSurgeryPolyurea/polyurethane coatingsHydrophilic coatingNetwork structure

Owner:BEIJING DEMAX MEDICAL TECH

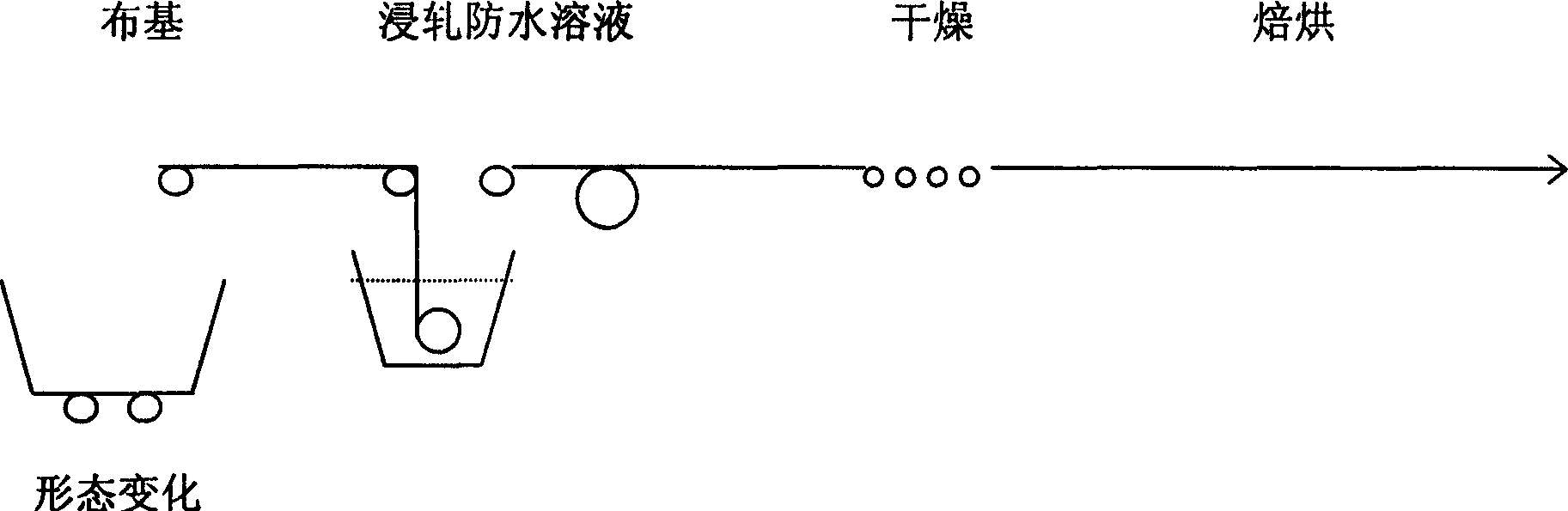

Method for preparing waterproof moisture-permeable coated fabric

InactiveCN101736595ASimple manufacturing methodScalable productionFibre treatmentMoisture permeabilityPolyurethane coating

The invention discloses a method for preparing a waterproof moisture-permeable coated fabric. The moisture permeability of a polyurethane coated fabric is improved by adding modified cellulose powder which accounts for 5 to 50 percent of the weight of polyurethane and is modified by a silane coupling agent into a polyurethane coating agent, and the waterproof property of the polyurethane is improved by adding inorganic powder which accounts for 0.5 to 5 percent of the weight of the polyurethane and is modified by the silane coupling agent, wherein the silane coupling agent accounts for 0.5 to 1 percent of the weight of the modified cellulose powder; and the silane coupling agent accounts for 0.5 to 1 percent of the weight of the inorganic powder. The modified polyurethane which accounts for 15 to 50 percent of the weight of a base fabric is coated on the base fabric of a knitted fabric, a woven fabric or a non-woven fabric to prepare the waterproof moisture-permeable coated fabric with good performance. The method is simple and easy, and can perform mass production; and the prepared fabric has excellent waterproof and moisture-permeable abilities, solves the contradiction between the waterproof capacity and the moisture-permeable capacity of the fabrics, and can be applied to coated fabrics for functional clothing, shoes, tents and buildings in a large quantity.

Owner:ZHEJIANG SCI-TECH UNIV

Two-package curing type polyurethane paint and preparation thereof

InactiveCN101565590ALow viscosityImprove the level ofFibre treatmentPolyurea/polyurethane coatingsApparent viscosityPolyol

The invention relates to a two-package curing type polyurethane paint and preparation thereof. The raw material system of the paint comprises a polyether polyol, a isocyanate, a small molecular chain expander and a solvent, wherein polydihydrofuran ether glycol with molecular weight between 700 to 1500 is used as the plyether polyol; methyl diphenylene diisocyanate is used as the isocyanate, 1,4-butanediol is used as the small molecular chain expander, dimethylformamide is used as the solvent. Weight proportion between the plyether polyol, the small molecular chain expander and the solvent is 1:0.7 - 0.85:8 - 15. Colloidal viscosity of the polyether polyol at 25 DEG C. is between 3000 and 2000cps. The paint is obtained by primarily charging DMF as the solvent, the polyether polyol and the chain expander into the reaction container simultaneously at one time, and then gradually charging the isocyanate for the reaction. By using MDI to substitute TDI for preparation of the polyurethane paint preparation, the invention is low in viscosity, great in levelability, easy for hardness adjustment, low in cost, safe and environment friendly in use.

Owner:顾建荣

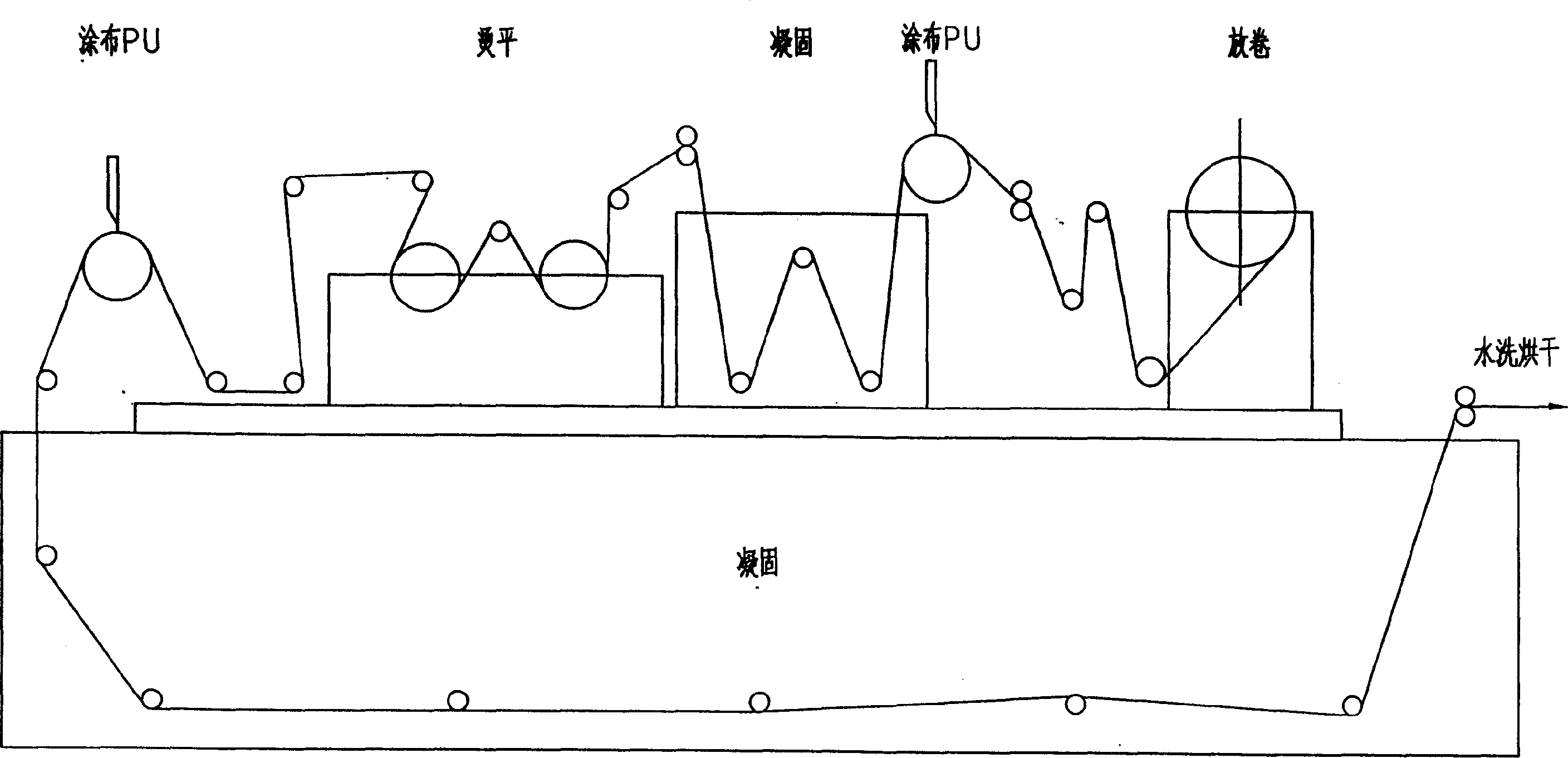

Waterborne polyurethane coating transfer synthetic leather and manufacturing method

InactiveCN101666043ASimple production processExpand technical routeSynthetic resin layered productsTextiles and paperOrganic solventSolvent based

The invention relates to waterborne polyurethane coating transfer synthetic leather and a manufacturing method, belonging to the technical field of synthetic leather and manufacturing methods. The manufacturing method of the waterborne polyurethane coating transfer synthetic leather is characterized in that the waterborne polyurethane coating transfer synthetic leather is manufactured by sequentially including the following steps: base cloth, surface formation by dry coating transfer, curing, separation of paper and leather, inspection and storage. Compared with solvent based polyurethane, thewaterborne polyurethane coating transfer synthetic leather has equivalent physical properties of the product, meets the requirement of application, uses the environmentally friendly waterborne polyurethane so that organic solvent which is harm to environmental protection is not contained in the product, and simplifies the production process because the working procedure of DMF recycling needed bysolvent-based products is reduced in a production process, thereby saving energy, protecting environment, meeting the restrictive requirements of foreign countries on the environmentally friendly polyurethane leather, reducing the quantity demand on production personnel, alleviating harm to human bodies, lowering the production cost and enabling the market competitiveness of the product to be strong.

Owner:烟台万华超纤股份有限公司

Bicomponent polyurethane coating and preparation thereof

ActiveCN101469248AImprove interlayer adhesionEnhanced stone chip resistancePolyurea/polyurethane coatingsPolyesterInter layer

The invention discloses a bicomponent polyurethane coating, which comprises a component A and a component B. The component A comprises a hydroxy acrylic acid resin, a filler, an auxiliary agent, a solvent, and linear saturated polyester, and the component B comprises an isocyanate curing agent, a solvent, a water absorber (containing or not containing) and a drier (containing or not containing), wherein a hydroxyl value of the linear saturated polyester is between 20 and 36mgKOH / g, and an acid value is between 10 and 30mgKOH / g. The bicomponent polyurethane coating is particularly applicable to a middle coating for the coating of the surfaces of automobiles, further solves the problem of inter-layer adhesion of the middle coating and an anti-corrosive primer and a finishing coat, and strengthens the stone chip resistance and the shock resistance of coatings at the same time.

Owner:ANHUI SANCAI IND & TRADE

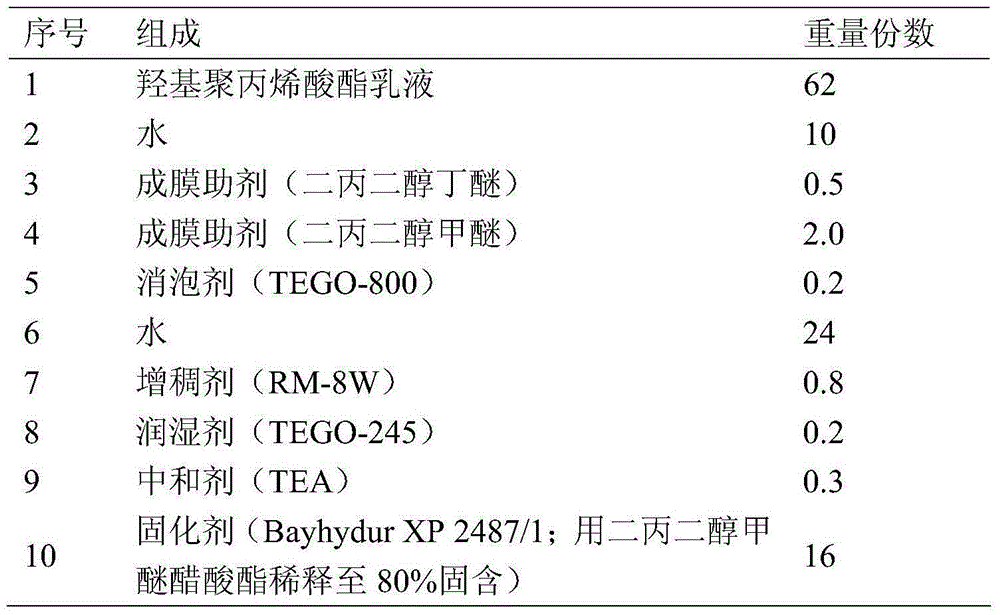

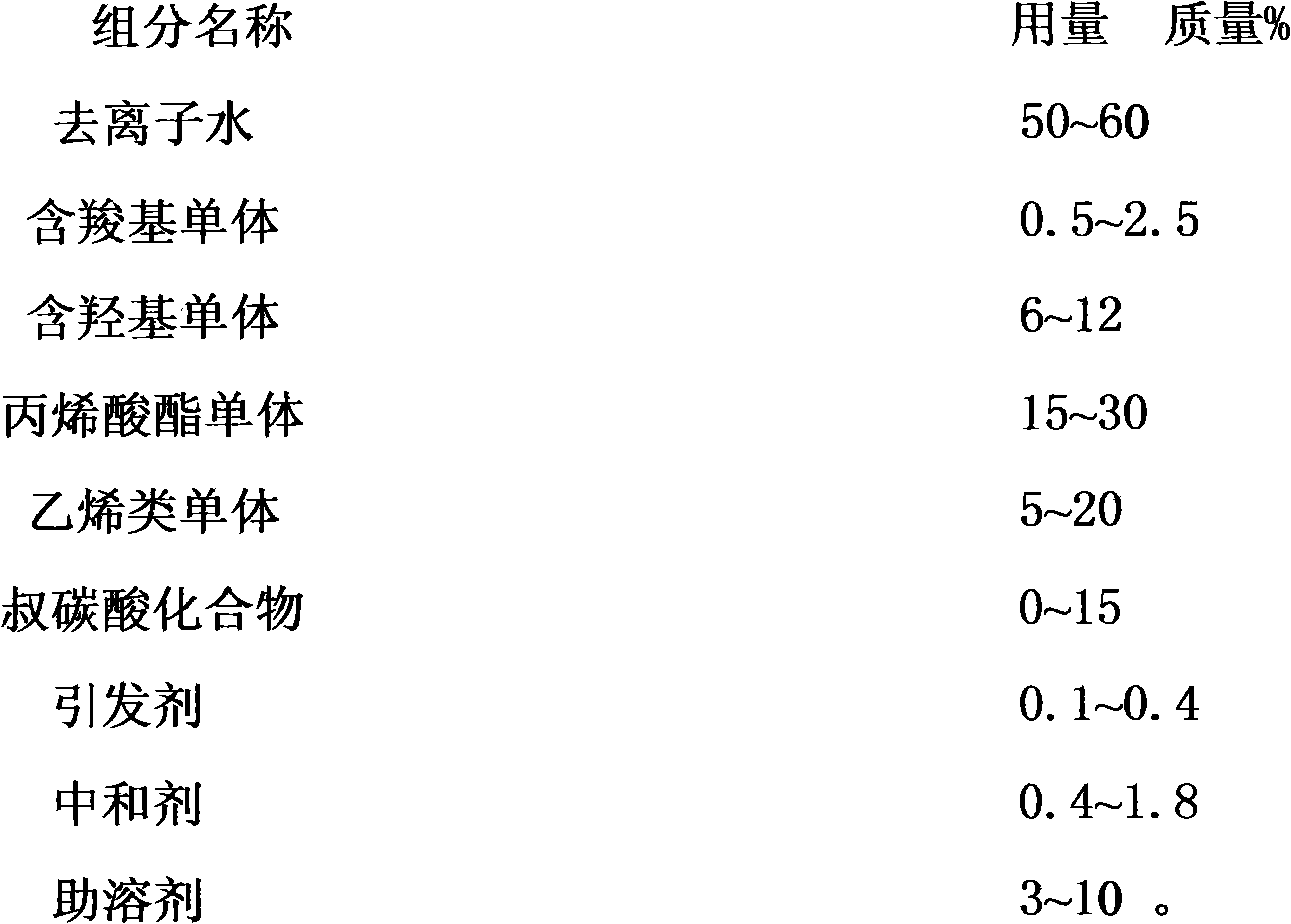

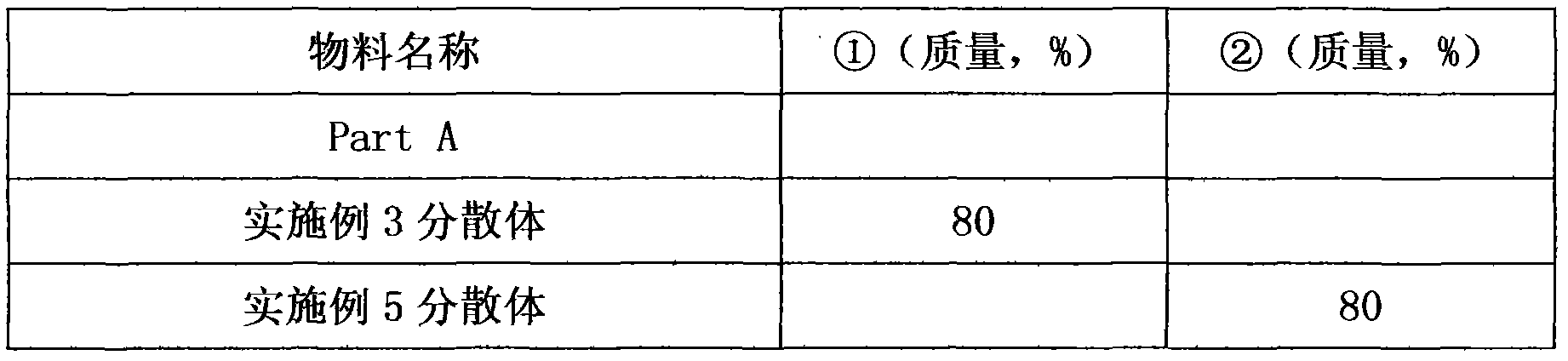

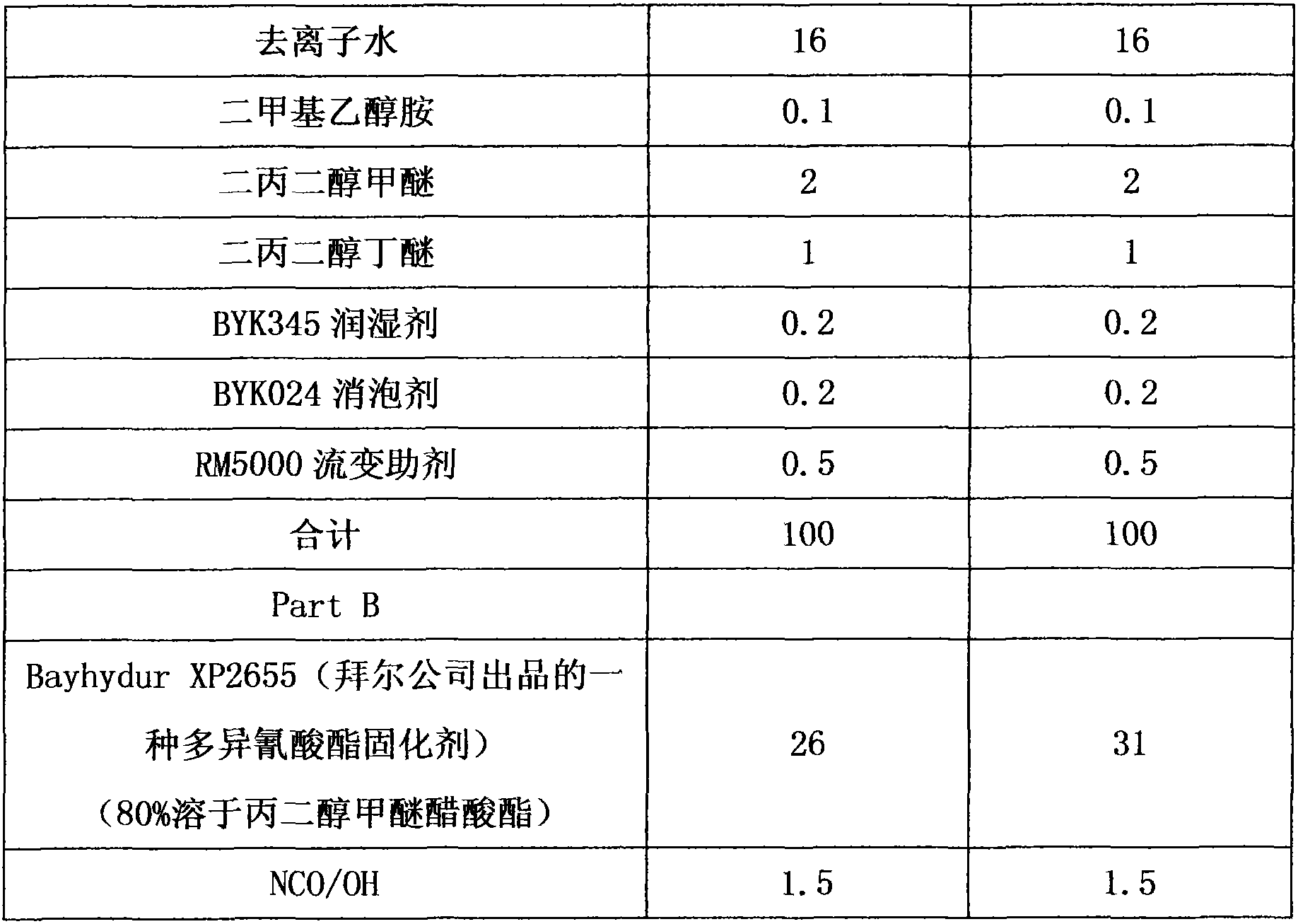

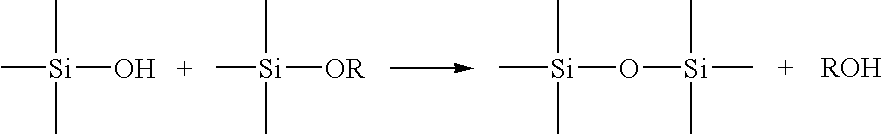

Preparation method of organosilicone modified hydroxy acrylic resin aqueous dispersion

The invention belongs to the field of chemical coatings, and particularly relates to a preparation method of an organosilicone modified hydroxy acrylic resin aqueous dispersion. The method comprises the following steps: preparing an organosilicone modified hydroxy acrylic resin by orderly dropwise adding different mixed liquids; removing part of solvents in the organosilicone modified hydroxy acrylic resin, and carrying out a neutralized salifying reaction; and finally, dispersing the obtained product into water so as to prepare the organosilicone modified hydroxy acrylic resin aqueous dispersion. The method mainly solves a problem that the storage stability of previous organosilicone modified acrylic emulsions is poor, and the stability of the prepared dispersion is significantly improved. A two-component waterborne polyurethane coating prepared through the combination of the dispersion and a waterborne polyisocyanate curing agent has the characteristics of high gloss, good mechanical properties, and good water resistance, weather resistance, corrosion resistance, and the like, and can be applied to the decoration and protection and the like of ocean engineering steel structures, electronic products, transportation facilities and furniture.

Owner:浙江纳宝莱化工科技有限公司

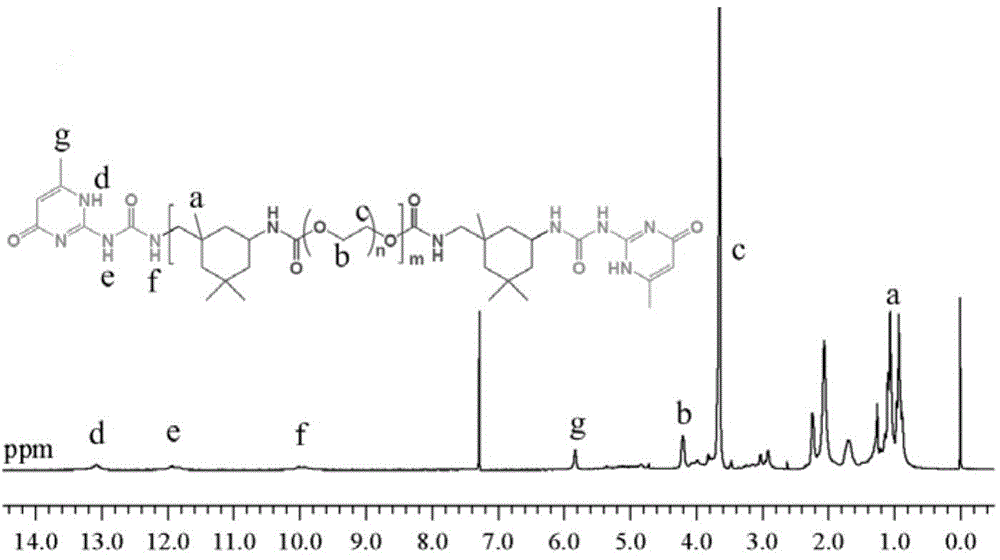

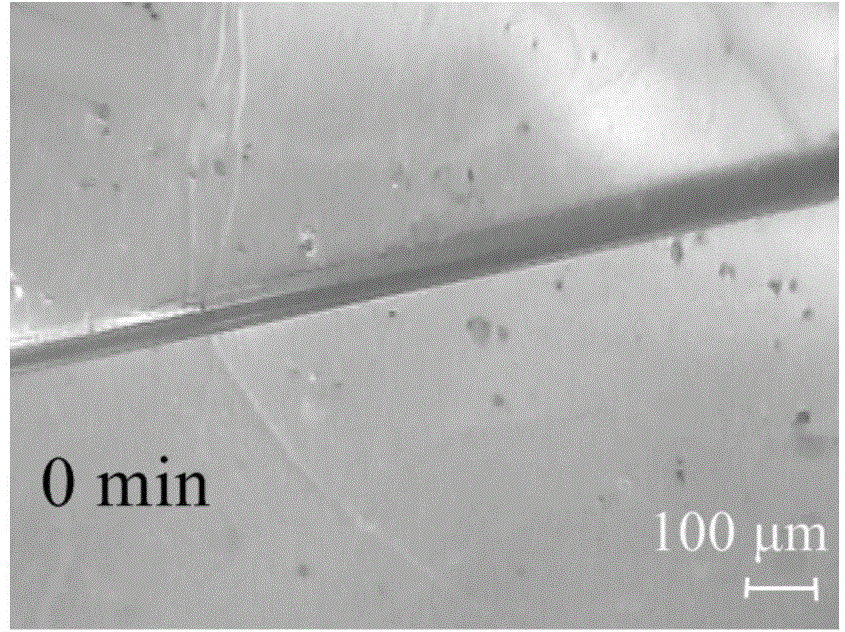

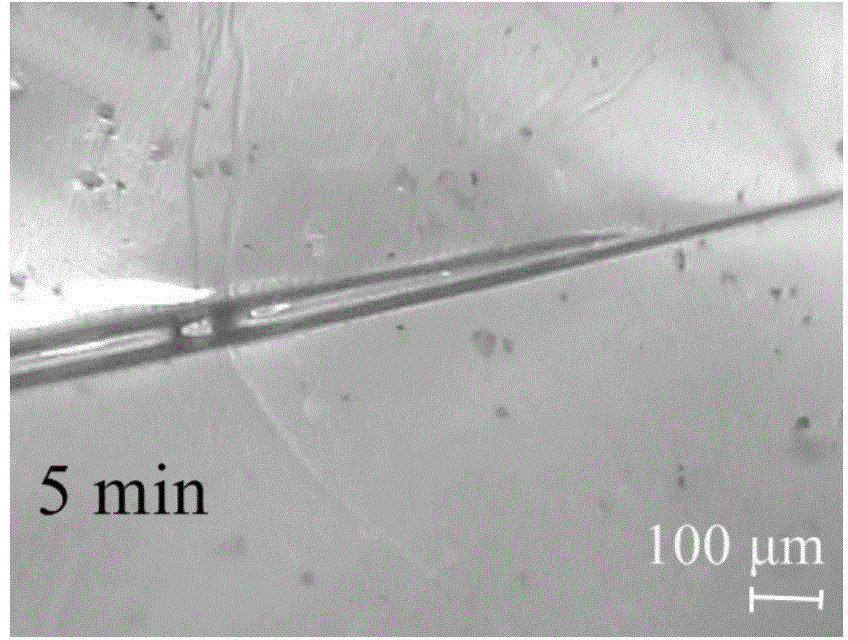

Self-repairing polyurethane coating and preparation method thereof

ActiveCN104356338ARepair damageGood physical and mechanical propertiesPolyurea/polyurethane coatingsPolyesterPolyol

The invention discloses a self-repairing polyurethane coating and a preparation method thereof. The polyurethane coating comprises the following raw materials in parts by mass: 15-20 parts of polyisocyanates, 40-60 parts of hydrophilic polyester polyol or polyether polyol, 2-3 parts of a chain extender and 7-15 parts of methylcystein. The preparation method comprises the following steps: preparing a hydrophilic polyurethane prepolymer from hydrophilic polyester polyol or polyether polyol and the chain extender, and reacting the isocyanate group in the hydrophilic polyurethane prepolymer with methylcystein, so as to obtain a polyurethane material of which the tail end or the main chain contains 2-urea-4-pyrimidone units; spraying or coating the polyurethane material on the surface of a substrate, thereby obtaining the self-repairing polyurethane coating. The self-repairing of the self-repairing polyurethane coating disclosed by the invention can be completed without external repairing agent or requirements of special environment, the coating is good in transparency, high in strength, good in filming property, simple in process and low in cost, and the function of repeated repairing in same positions can be achieved.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing hydroxy-containing polyacrylate secondary aqueous dispersion

ActiveCN102850703AImprove "hydrophilic efficiencyReduce viscosityPolyurea/polyurethane coatingsAcid valueNitrogen

A method for preparing hydroxy-containing polyacrylate secondary aqueous dispersion includes dropping mixed monomer not containing carboxyl monomer in cosolvent under the condition of introducing nitrogen gas, to generate hydrophobic long chain free radical; dropping mixed monomer containing carboxyl monomer in the generated hydrophobic long chain free radical, and synthesizing to obtain copolymer with its molecular chain tail end containing hydrophilic group; and adding neutralizer in the obtained copolymer, and dropping deionized water. The obtained hydroxy-containing polyacrylate secondary aqueous dispersion has low acid value, small particle diameter, uniform distribution, and good storage stability; and coated film of prepared aqueous two-component polyurethane coating has high gloss and fullness, and good leveling property.

Owner:上海华谊涂料有限公司

Preparation method of polyester acrylate hybrid aqueous dispersion

InactiveCN101824209AAchieve chemical modificationImprove stabilityPolyurea/polyurethane coatingsPolyesterOrganic solvent

The invention relates to a preparation method of polyester acrylate hybrid aqueous dispersion, which belongs to the field of chemical coatings, and the preparation method comprises four steps of synthesizing hydroxyl acrylate resin, preparing an intermediate, preparing polyester acrylate resin and dispersing with deionized water. The preparation method effectively combines the advantages of polyester and acrylic resin, the prepared stable dispersion can be used as the hydroxyl resin component of a dual-component polyurethane coating for preparing a high-performance waterborne dual-component polyurethane coating with hydrophilic polyisocyanate, and a coating film has excellent performance; in addition, the preparation of the dispersion does not use amine as a neutralizer, thereby avoiding the smell caused by the amine and simplifying the process; and only a small amount of cosolvent is adopted in the dispersion, and the content of an organic solvent in the coating is low.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

Waterproof, low temperature resistant, soft and moisture permeable coating glue and preparation thereof

InactiveCN101481580AGood flexibilityImprove waterproof performancePolyurea/polyurethane coatingsTextiles and paperCelluloseAdhesive

The invention provides a water-proof, cold-resistant, flexible and moisture-permeable coating adhesive, which is prepared by mixing three components of coating agent, crosslinking agent and crosslinking promoter with a solvent when in use; the coating agent is organosilicone polyurethane copolymer containing 500 to 1000 mesh of advanced lignocellulose micropowder; the amounts of the crosslinking agent and crosslinking promoter are 2-5wt% of that of the coating agent; and the viscosity of the coating adhesive is 8000 to 15000 mPa.s. The advanced organosilicone polyurethane coating adhesive in the invention is coated on a base fabric so as to prepare a coated fabric; the moisture permeability is greater than 5000 g / m.d; the water pressure resistance is greater than 100 kPa; the aging resistant performance is good; the blocking resistance is obviously improved; the moisture permeability is less than 20% reduced and the bending length is basically unchanged at a low temperature; and the coated fabric has good flexibility and very good low temperature resistant characteristic, and is in particular applied to being used as a coating material of clothes having water-proof and moisture-permeable functions at a low temperature.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +2

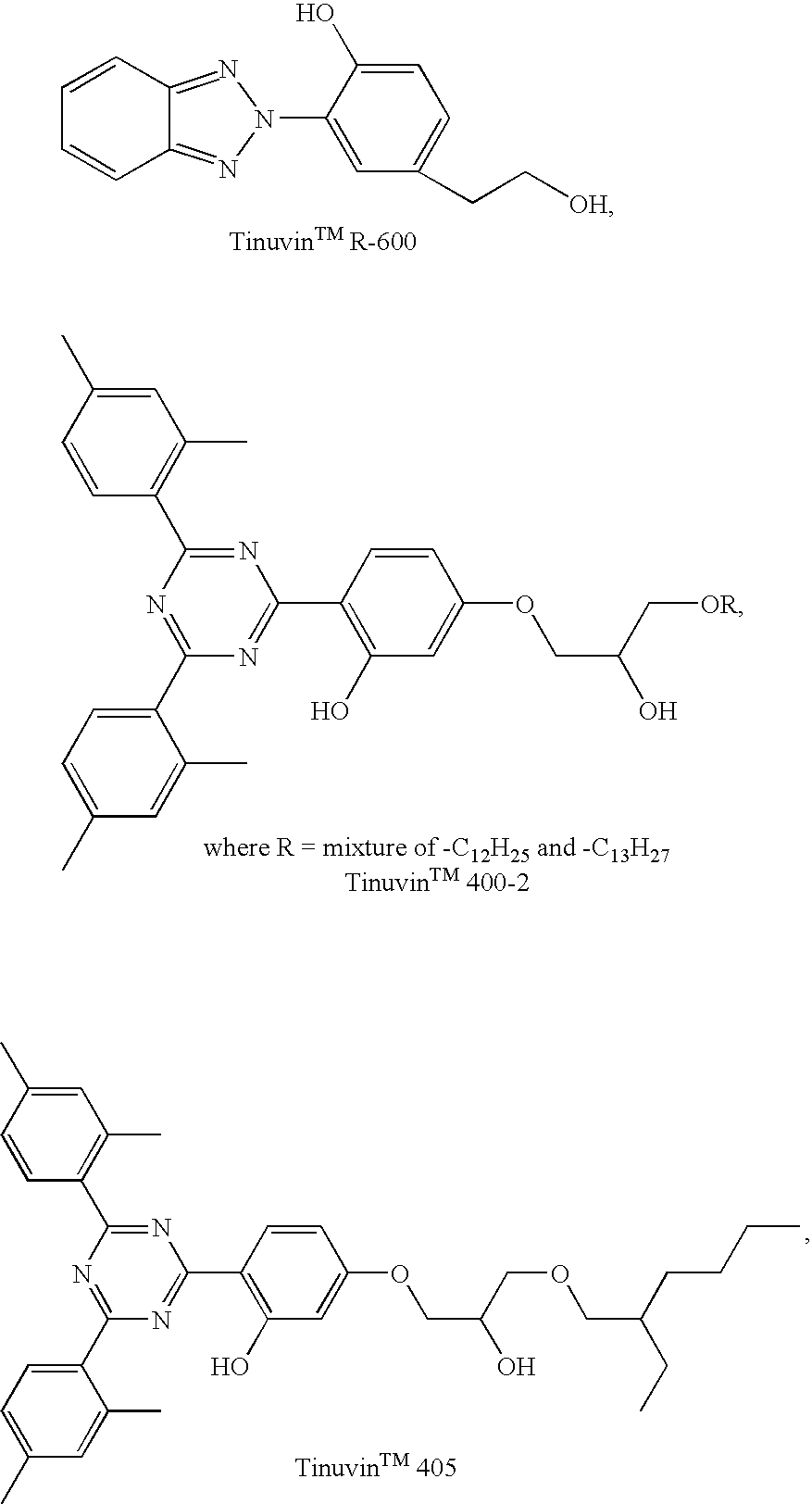

Stain resistant polyurethane coatings

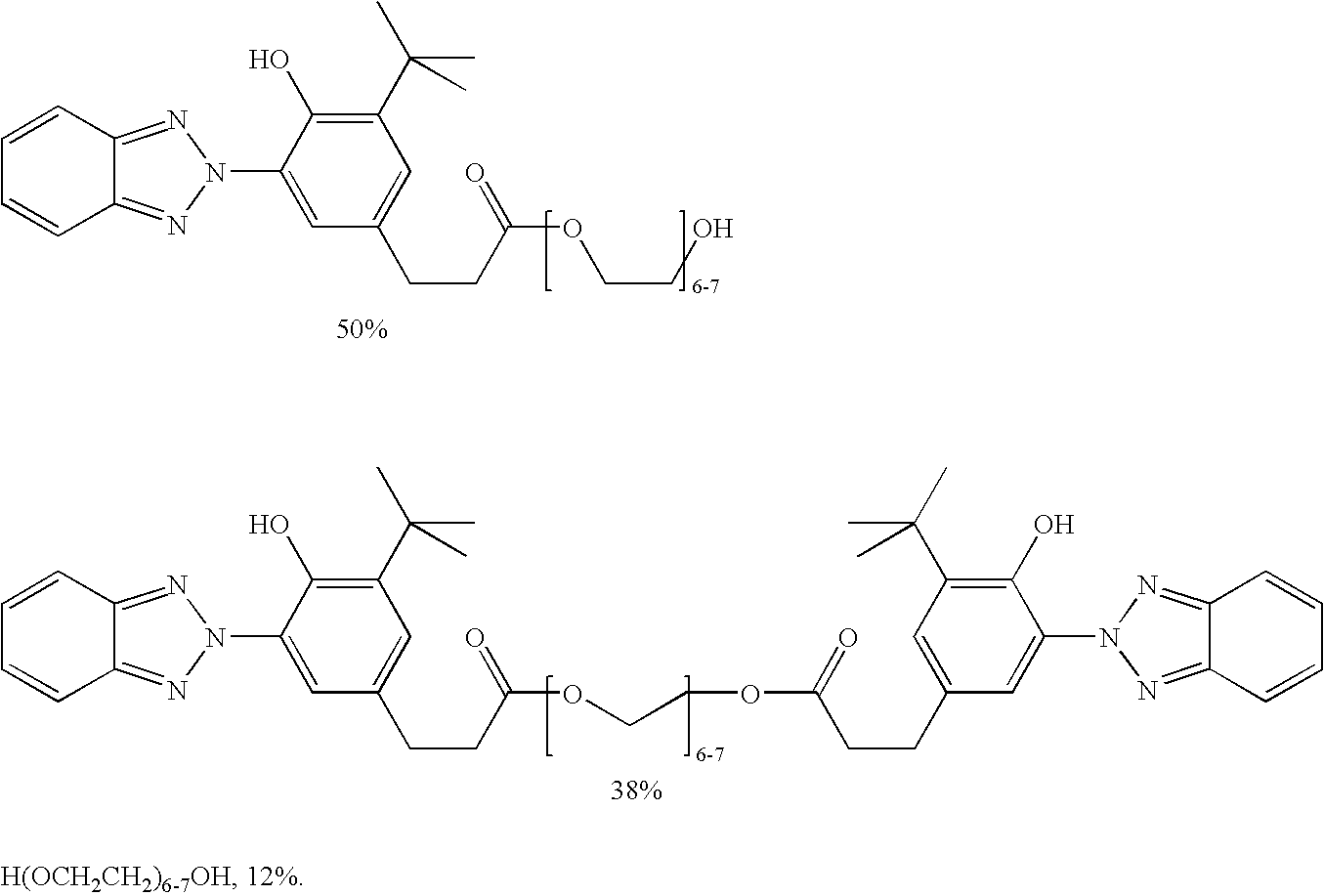

ActiveUS20050075471A1Improve the immunitySilicon organic compoundsFibre treatmentPolymer scienceCarbamate

A chemical composition comprises one or more urethane oligomers of at least two polymerized units selected from the group consisting of fluorine-containing urethane oligomers and long-chain hydrocarbon-containing urethane oligomers, wherein said oligomers comprise the reaction product of (a) one or more polyfunctional isocyanate compounds, (b) one or more polyols, (c) one or more monoalcohols selected from the group consisting of fluorocarbon monoalcohols, optionally substituted long-chain hydrocarbon monoalcohols, and mixtures thereof, (d) one or more silanes, and (e) one or more stabilizers comprising one or more reactive groups.

Owner:3M INNOVATIVE PROPERTIES CO

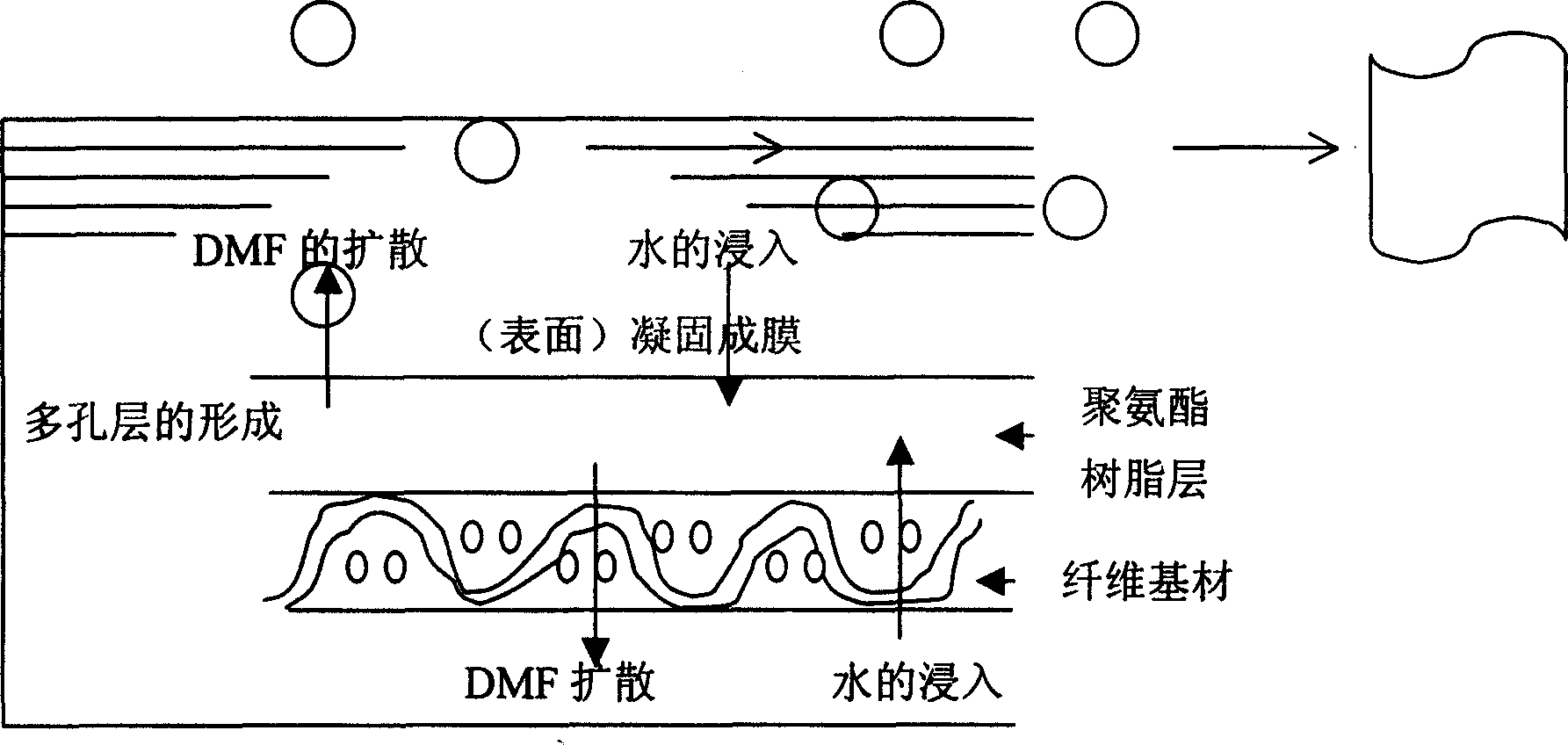

Water-proof, cold-proof and moisture permeable polyurethane coating cloth and its producing process

InactiveCN1554822ANo crackPlay the role of waterproof and breathableTextiles and paperPolyurethane coatingMoisture

The production process of polyurethane coating cloth includes the waterproof the of base cloth, wet painting to form film, printing or post-painting treatment and inspection. The wet painting to form film includes twice painting polyurethane mixture liquid, solidifying to form film, water washing and ironing; stoving; cooling and winding and forms microporous film. The composite polyurethane coating structure has in its inside micro pores of diameter between water drop diameter and water molecule owing to the replacement of water and DMF and the special micro pore regulating effect during the twice water washing. The present invention can meet the requirement of resisting water, resisting cold, permeating moisture and being light for easy carrying about.

Owner:长沙中园科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com