Patents

Literature

382results about How to "Workmanship is feasible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-proof moisture-permeation coating agent composition and application thereof

InactiveCN101104752AGood hygroscopicityGood anti-adhesionNatural rubber coatingsPolyurea/polyurethane coatingsFiberHigh resistance

The invention relates to a waterproof and moisture-permeable coating agent composition, wherein, a certain amount of microporous lignocellulose fine powder is added into the coating agent with waterproof function, so that the coating agent has moisture permeable performance. The waterproof and moisture-permeable coating agent composition which is used as the coating agent for non-woven fabric, knitted fabric or woven fabric can be made into coated fabric and synthetic leather with waterproof and moisture permeable performances. Compared with the prior at, the invention has the advantages that: 1. the raw material is easy to be added, the process is available with high adaptability, no need to add new equipment; 2. on the premise that the waterproof performance is not decreased, the amount of moisture permeated is increased obviously and the anti-adhesion is improved; 3. the coated fabric and superfine fiber and artificial cover synthetic leather made by the invention has the advantages of fine moisture permeability, high resistance to water pressure and that the physical performance does not decrease.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

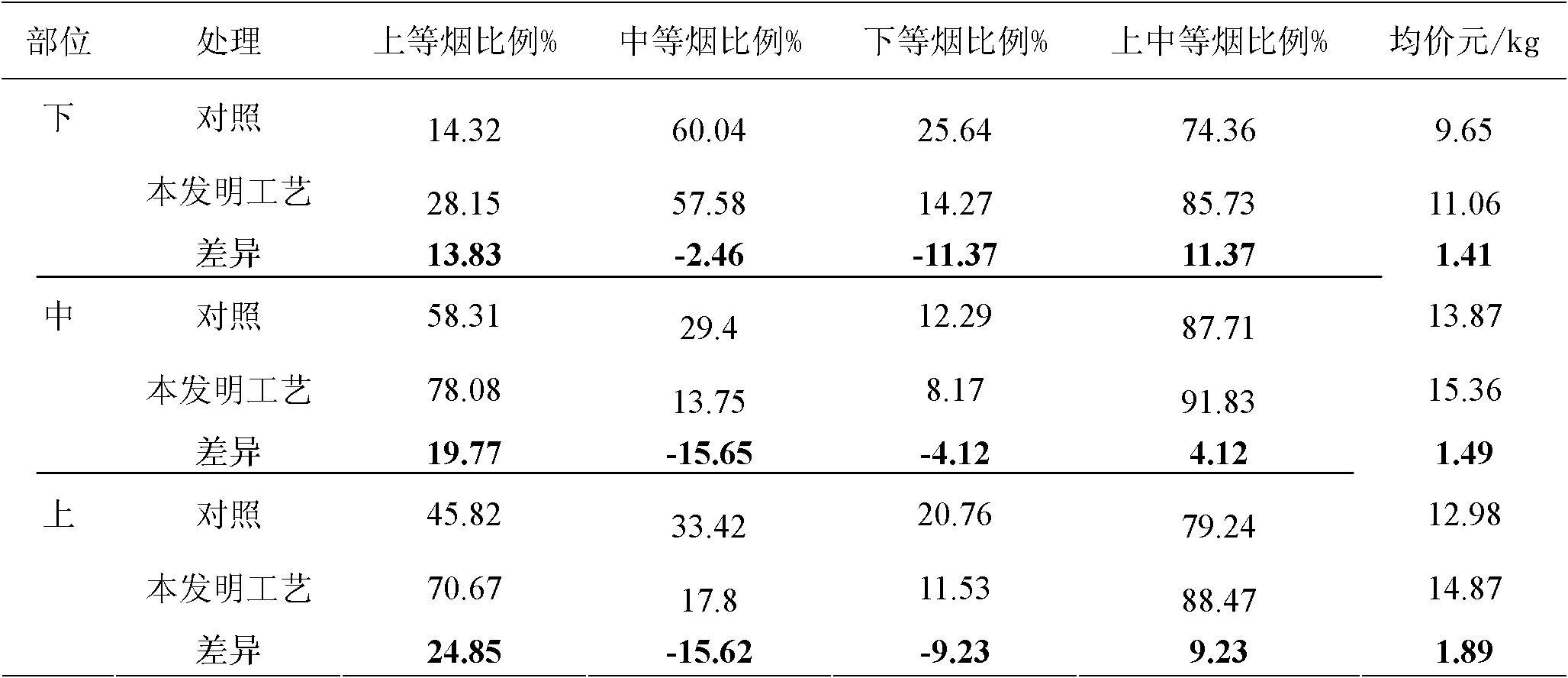

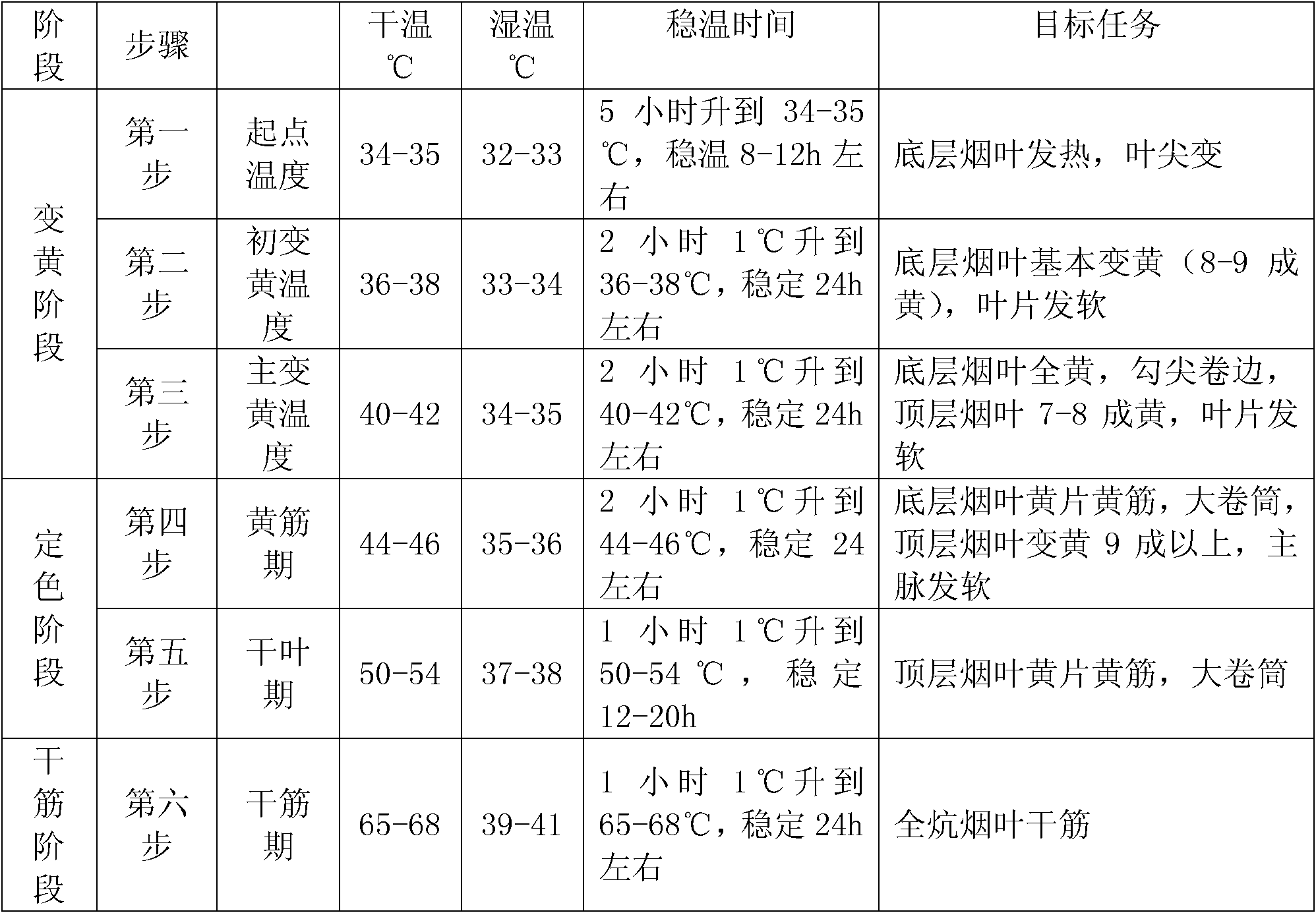

Three-stage six-step baking technology for flue-cured tobacco in common flue-curing barn

InactiveCN102488311AImprove roast qualityEasy to masterTobacco preparationCooking & bakingThree stage

The invention discloses a three-stage six-step baking technology for flue-cured tobacco in a common flue-curing barn, and belongs to the technical field of modulation of flue-cured tobacco. The technology mainly comprises three baking stages, namely a yellowing stage, a color fixing stage and a stem drying stage. The technology is characterized in that: the yellowing stage comprises three key temperature and humidity steps; the color fixing stage comprises two key temperature and humidity steps; and the stem drying stage has a key temperature and humidity step. The whole braking process has the three baking stages and the six key temperature and humidity steps, and the temperature and the humidity in the flue-curing barn are controlled in the temperature and humidity ranges required by the corresponding steps of the six key temperature and humidity steps according to the change conditions of tobacco leaves, so that the aim of regulating and controlling the baking process of the flue-cured tobacco is fulfilled, a good effect is achieved, the destroyed tobacco such as green impure tobacco and the like is obviously reduced, the proportion of orange tobacco and high-grade tobacco is improved, the flue-cured tobacco has a loose structure, the oil content of the flue-cured tobacco is increased, and the inner and outer view quality and the availability of the tobacco leaves are remarkably improved.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD +2

Method for laser hardening gear part

ActiveCN102021568AImprove wear resistanceImprove anti-corrosion performanceMetallic material coating processesLaser beam welding apparatusWear resistantLaser scanning

The invention discloses a method for laser hardening gear part, which comprises the following steps: 1) machining a gear part according to the prior art, wherein the thickness of the gear is required to be 1.5 mm less than the design value; 2) laser scanning the gear part by a laser hardening equipment with a laser output power of 5 kw, a scanning speed of 480 mm / min, and a powder feed rate of 18 g / min, performing the powder feeding and the laser cladding simultaneously in one work step, and cladding the gear surface with metal powder containing wear resistant materials to form a laser hardening layer with a cladding thickness of 3 mm and with polishing allowance reserved, wherein the laser beam is a broadband rectangular spot of 15X2.5; the metal powder material comprises, by weight: 48.4% of Fe, 0.077% of C, 0.85% of Si, 0.368% of Mn, 17.02% of Cr, 24.4% of Ni, and 2.68% of Mo; 3) processing the laser-clad mating surface to achieve a design size. The laser-clad gear of the present invention has an average micro-hardness of HV800, a Rockwell hardness of HRC65, and the wear resistance of the gear surface is enhanced.

Owner:SHANDONG ENERGY HEAVY EQUIP GRP DAZU REMANUFACTURING CO LTD +1

Water-based ink for cork paper bobbin intaglio printing and preparation method thereof

The invention discloses a water-based ink for cork paper bobbin intaglio printing, which is characterized by comprising the components in parts by weight as follows: 23 to 50 parts of watercraft acrylic resin, 10 to 40 parts of pigment, 5 to 25 parts of curling preventing auxiliary, and 0.05 to 2 parts of defoamer, wherein the curling preventing auxiliary is polyatomic alcohol or ester. The water-based ink for cork paper bobbin intaglio printing has the advantages of feasible matching process, high inking performance, stability in storage, high on-machine printing effect, high printability, high post-printing adaptability and high cigarette performance, and can completely meet the requirements on design and printing, and is completely suitable for intaglio printing at a high speed, and has an extremely good effect.

Owner:山西精华科工贸有限公司 +2

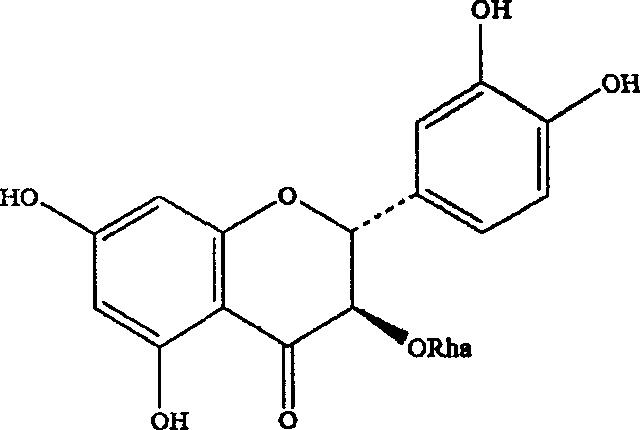

Preparation method of astilbin

InactiveCN1724552AHigh purityIncrease contentSugar derivativesSugar derivatives preparationAlcoholPolyamide

The invention provides a process for preparing astilbin which comprises the steps of disintegrating medicinal materials, extracting with aqueous solutions of ethanol with two concentrations, degreasing the 90-95 wt% water raffinate of ethanol with petroleum ether, condensing into concrete, alcohol-depositing the concrete, merging the mother liquid with 20-80 wt% water raffinate of ethanol, concentrating and extracting with ethanol-containing acetic ester liquid, alcohol-depositing the extract and mixing with the precipitation, dissolving then passing through macro-porous absorption resin or polyamide columns, eluting with 20-80 wt% aqueous solution of ethanol, finally recrystallizing the eluent. The extraction rate of astilbin is over 50%, and the content of astilbin is over 90%.

Owner:CHIA TAI TIANQING PHARMA GRP CO LTD +1

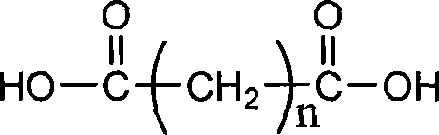

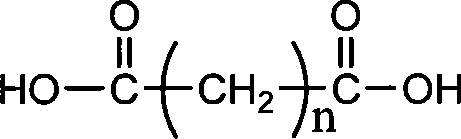

Preparation method of full biodegradation polyester copolymer

The invention belongs to the technological field of the polymer material, particularly relating to a preparation method of the completely biodegradable polyester copolymer. The invention uses the method of the fusion and direct polymerization to prepare the carboxyl-terminated lactic acid prepolymer and then copolymerize with the aliphatic polycarbonate; then the reaction is done in the twin-screw extruder to screw out the extension chain and the good polylactic acid copolymer is made. The concrete steps are: the lactic acid and small-molecule dicarboxylic acid react under the condition with the presence of the catalyst to directly polymerize the carboxyl-terminated lactic acid prepolymer; then the aliphatic polycarbonate diol and the catalyst are added; with the presence of the N2, the reaction is kept for 1 to 10 hours at the temperature of 150 to 200 Celsius system to get the poly lactic acid and polycarbonate copolymer of the low molecular weight; then the reaction is done in the twin-screw extruder at the temperature of 150 to 190 Celsius system to screw out the extension chain; finally the polylactic copolymer of the high molecular weight, toughness and heat resistance is made. The process of the method of the invention is simple and easy in the industrialized production; the copolymer resin product produced by the method is completely biodegradable and the application scope is wide.

Owner:TONGJI UNIV

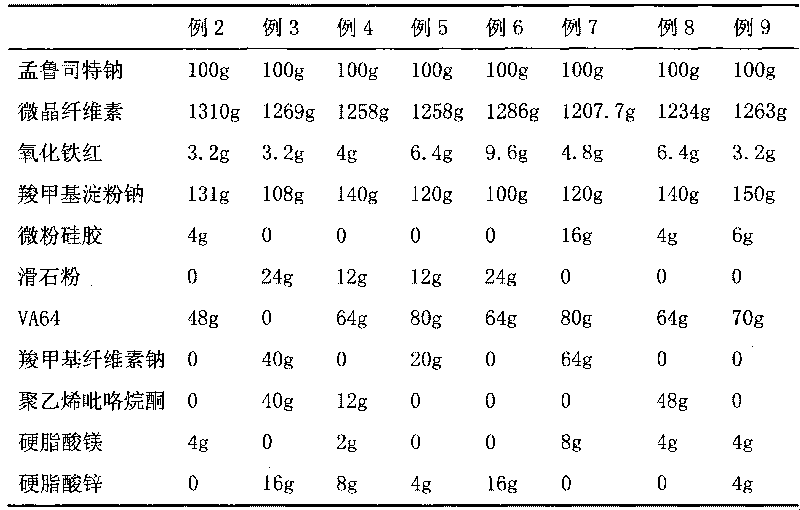

Montelukast sodium tablet and preparation method thereof

ActiveCN101732268AWell mixedSolve production problems that require dark operationPill deliveryPharmaceutical non-active ingredientsTemperature controlAdhesive

The invention belongs to the field of medicine preparations, in particular to a montelukast sodium tablet and a preparation method thereof. Because the montelukast sodium tablet adopts a wet method granulation process and has the problems of long drying time, difficult temperature control and easy causing of content difference, content descent and relevant substance increase between particles, the invention provides the montelukast sodium tablet and the preparation method thereof in order to enhance the stability and the operability of the montelukast sodium tablet. The montelukast sodium tablet provided by the invention comprises montelukast sodium, a filling agent, a disintegrating agent, an adhesive, a colorant, a lubricant and a flow aid. The preparation method of the montelukast sodium tablet provided by the invention adopts direct tabletting after dry method granulation and uses the colorant, the colorant can act as a very good light shielding function in the operational process, the operation is convenient, the influence of a drying process and moist heat to the product quality is avoided, and the product stability is enhanced.

Owner:LUNAN PHARMA GROUP CORPORATION

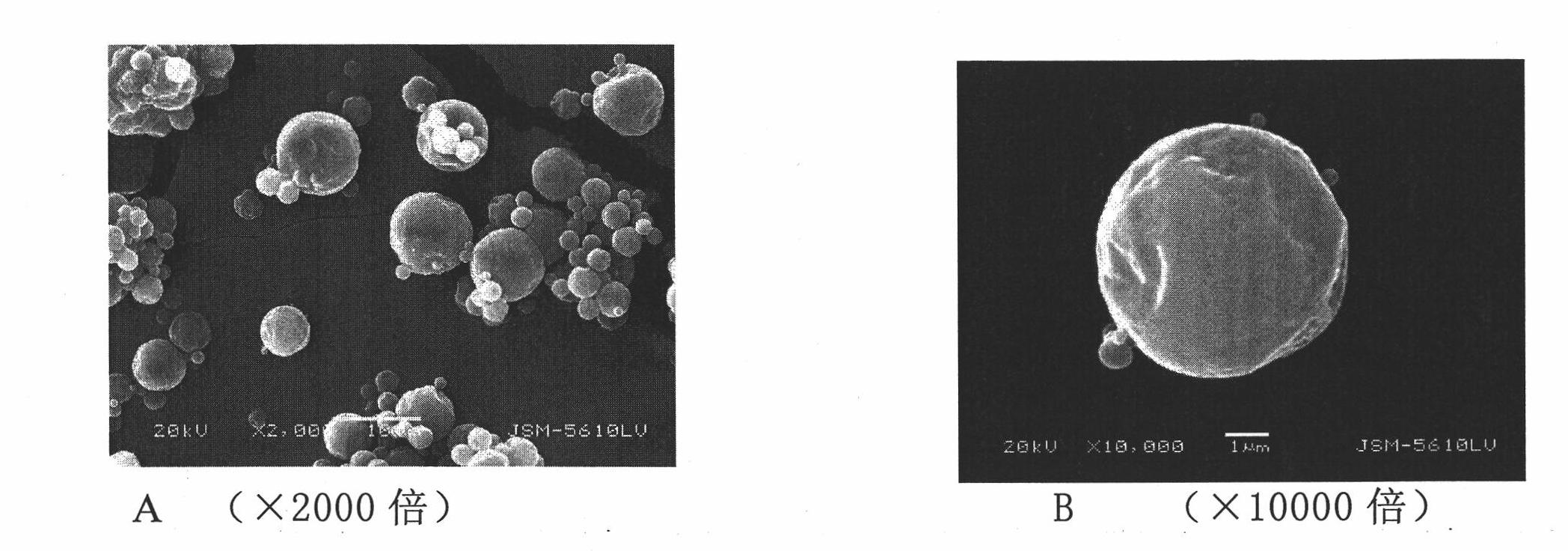

New type slightly soluble oral medicine self-emulsification preparation and preparation method thereof

InactiveCN101862306AImprove solubilityHigh dissolution rateOrganic active ingredientsPill deliverySolubilityOral medicine

The invention provides a new type slightly soluble oral medicine self-emulsification preparation. The preparation comprises a self-emulsification medicine-releasing part and a water-soluble solid carrier, wherein the self-emulsification medicine-releasing part contains slightly soluble medicine, oil phase, surface active agent, cosurfactant and oversaturation matter. The invention also provides a preparation method for the self-emulsification preparation, which comprises a spray drying method or a solvent melting method. After the self-emulsification preparation is taken orally, the self-emulsification preparation can form the emulsion with a grain size smaller than 1mum emulsion with a grain size smaller than 100nm in body, so as to promote the solubility and digestion degree of the slightly soluble medicine, improve the absorption and bioavailability of the medicine and reduce the influence of the food on the medicine absorption as well as reduce the dose of the surface active agent and the cosurfactant in the self-emulsification preparation, enhance the stability and safety of the self-emulsification preparation and be suitable for industrializing production.

Owner:WUHAN GENERAL HOSPITAL OF GUANGZHOU MILITARY

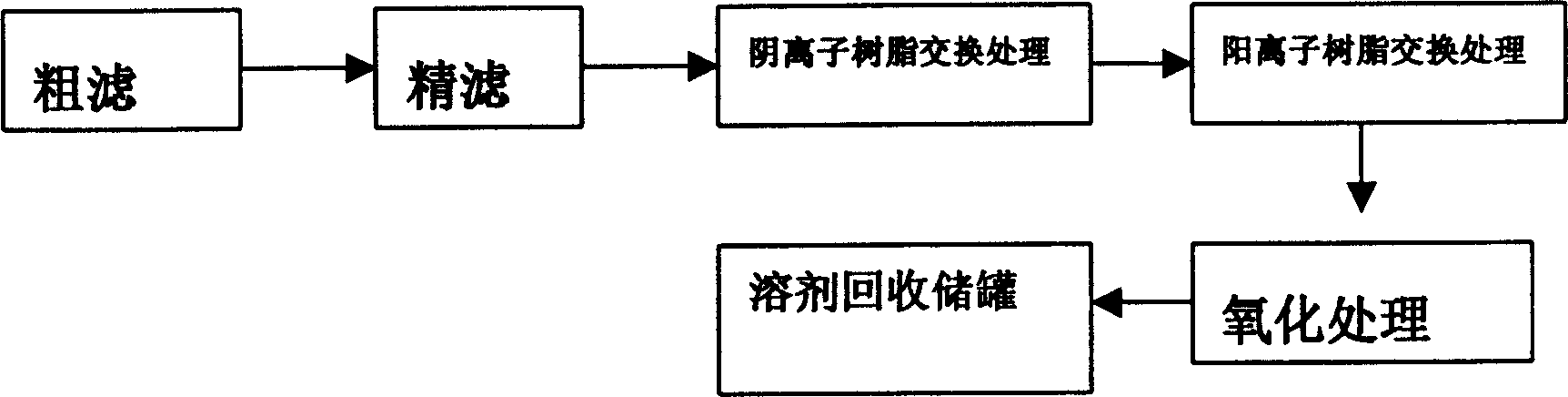

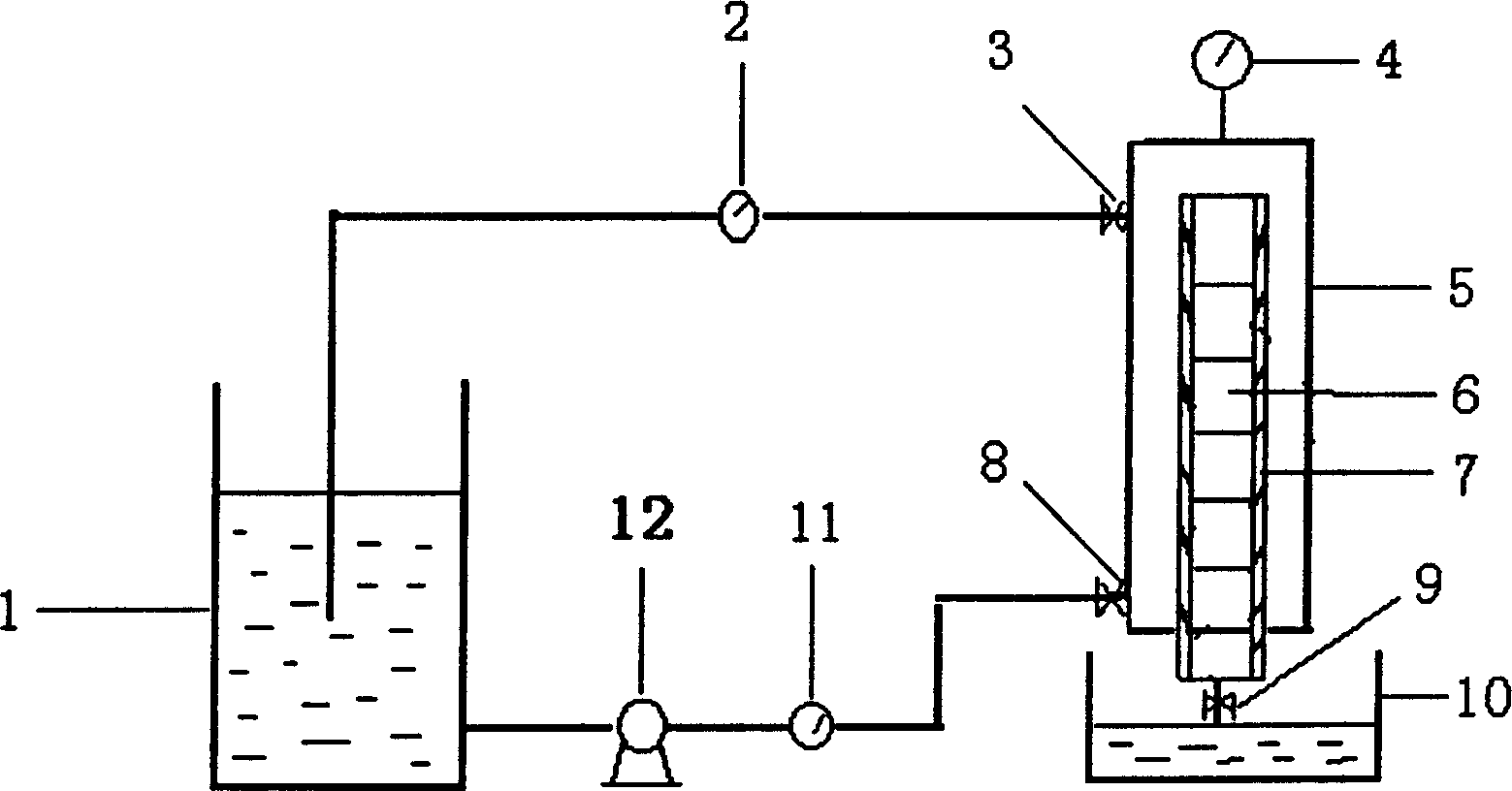

Solvent recovery process for solvent method cellulose fiber preparation

InactiveCN1603479AEfficient removalWorkmanship is feasibleArtificial filament recoveryTextile/flexible product manufactureSolventIon

In the chemical fiber manufacturing industry solvent extraction cellulose textile fiber preparation process the solvent recovery craft, first uses the spinning productive cycle waste liquid thickly filters out eliminates is bigger than 9um the aerosol impurity; The zirconium oxide membrane essence which again if the outer wall spreads through the pore ceramics tube which has the process agglutinates round trip to filter the system to eliminate is bigger than 1um the shot; Then uses the anion resin to remove the colored decomposition matter; Then through the reasonable choice cation exchange resin, uses it adsorptive attraction to be bigger than according to the metallic ion was equal to Maring is bigger than NMM to be bigger than NMMO the choice exchange order characteristic, removes the metallic ion and Maring; Finally turns into the NMM oxygen NMMO. The above five processing sequence synthesis composes a recycling systems engineering, has removen the many kinds of impurities, and effectively has recycled solvent NMMO, improved the textile fiber quality and the craft security, this craft is feasible, highly effective.

Owner:DONGHUA UNIV

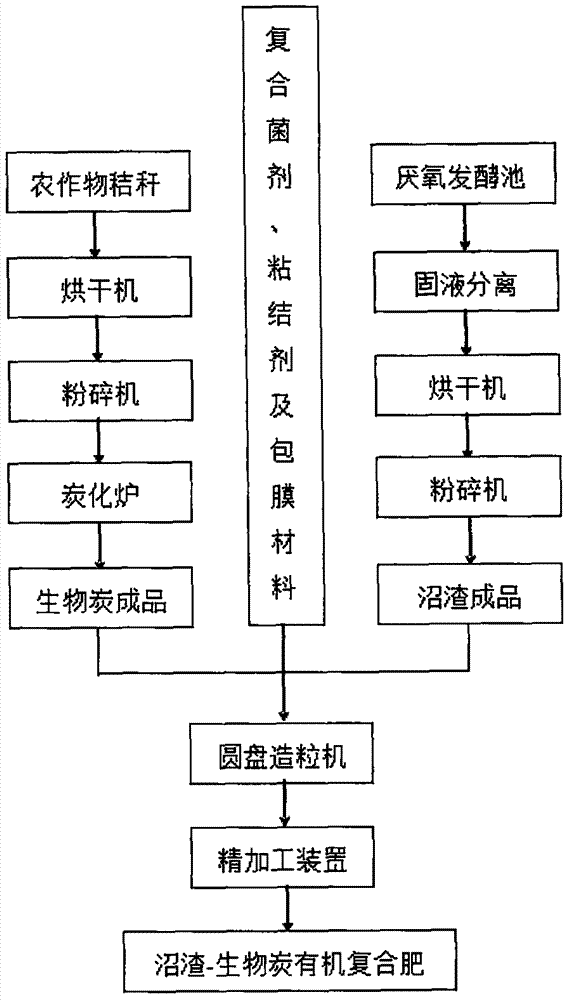

Biogas residue-biological carbon organic compound fertilizer and preparation method thereof

InactiveCN107285846AMeet different nutritional needsIncrease pHAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAdhesiveCarbon.organic

The invention provides biogas residue-biological carbon organic compound fertilizer and a preparation method thereof. The biogas residue-biological carbon organic compound fertilizer is prepared from the following raw materials: biogas residue, biological carbon, conventional fertilizer, a mineral powder adhesive, a compound microorganism bacterium agent, a granulation adhesive and a film coating material; the preparation method of the compound fertilizer comprises the following steps: carrying out high-temperature cracking on straws to prepare the biological carbon; collecting the biogas residues which are generated in an anaerobic fermentation process of organic wastes; after mixing the prepared biological carbon with the biogas residues and the conventional fertilizer and melting, granulating; carrying out screening and film coating on grains to prepare the biogas residue-biological carbon organic fertilizer. The organic compound fertilizer provided by the invention sufficiently utilizes the residual straws and biogas residues and has the advantages of slowly releasing the fertilizer, improving soil, fixing carbon and reducing emission and the like; the biogas residue-biological carbon organic compound fertilizer is nutritional and is scientifically matched; when the biogas residue-biological carbon organic compound fertilizer is matched with conventional chemical fertilizer and then is applied, the fertilizer efficiency and the utilization rate can be further improved and the yield and quality of crops are remarkably improved. The method provided by the invention has the advantages of relatively low cost, a simple and feasible proces, and is suitable for large-scale popularization.

Owner:NORTHWEST A & F UNIV

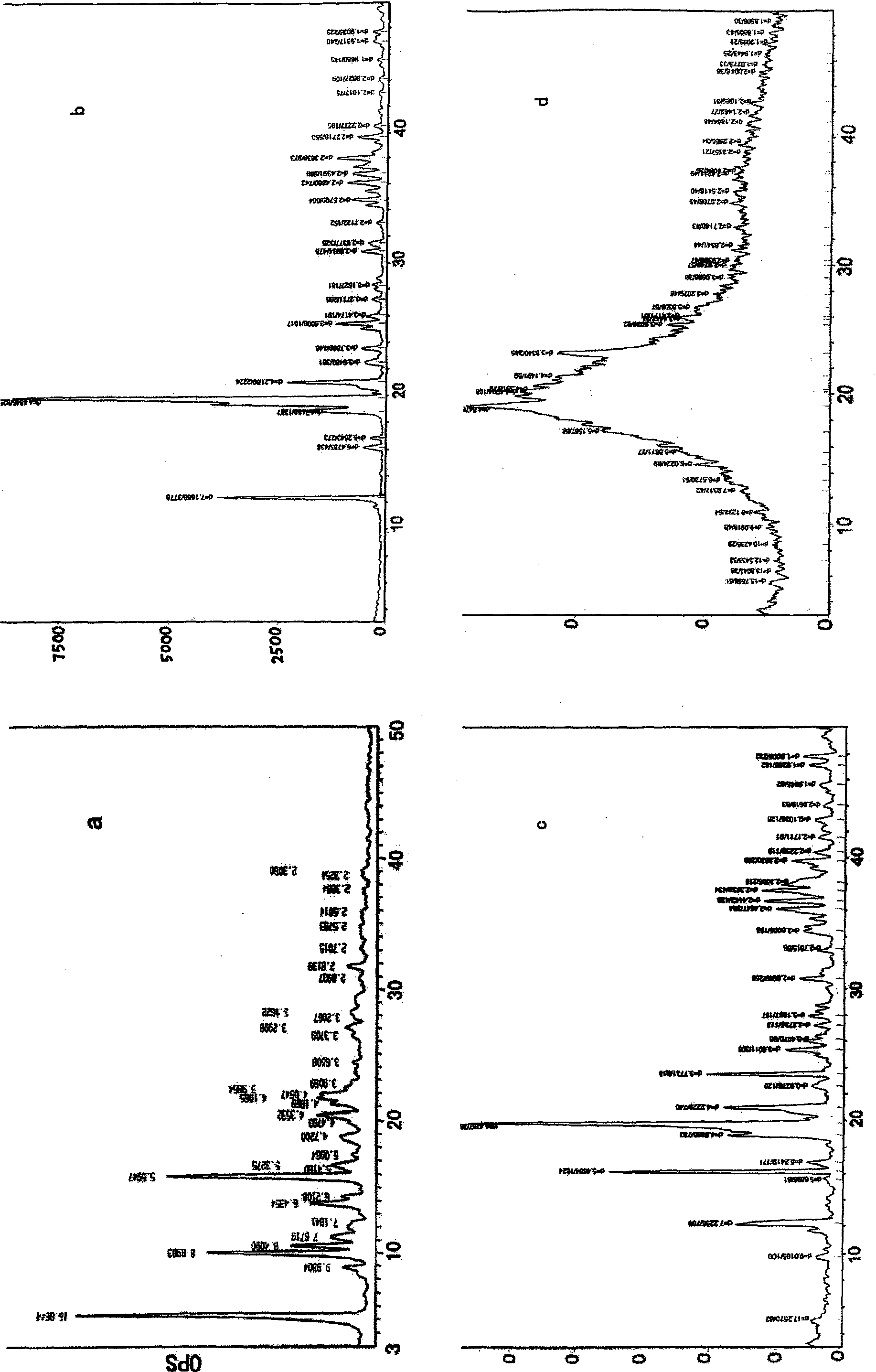

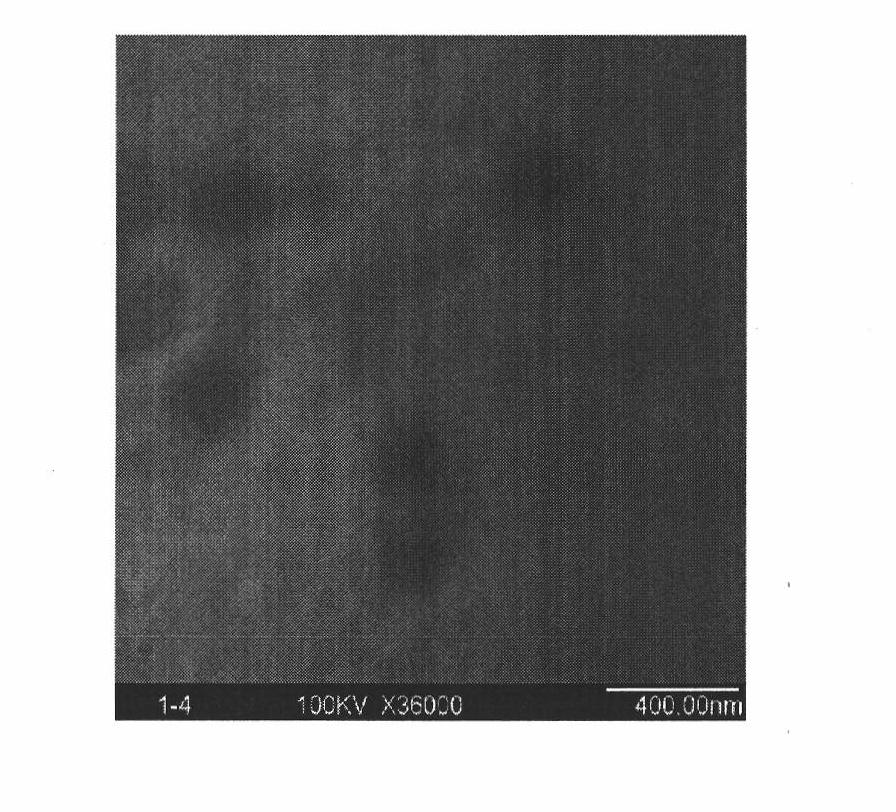

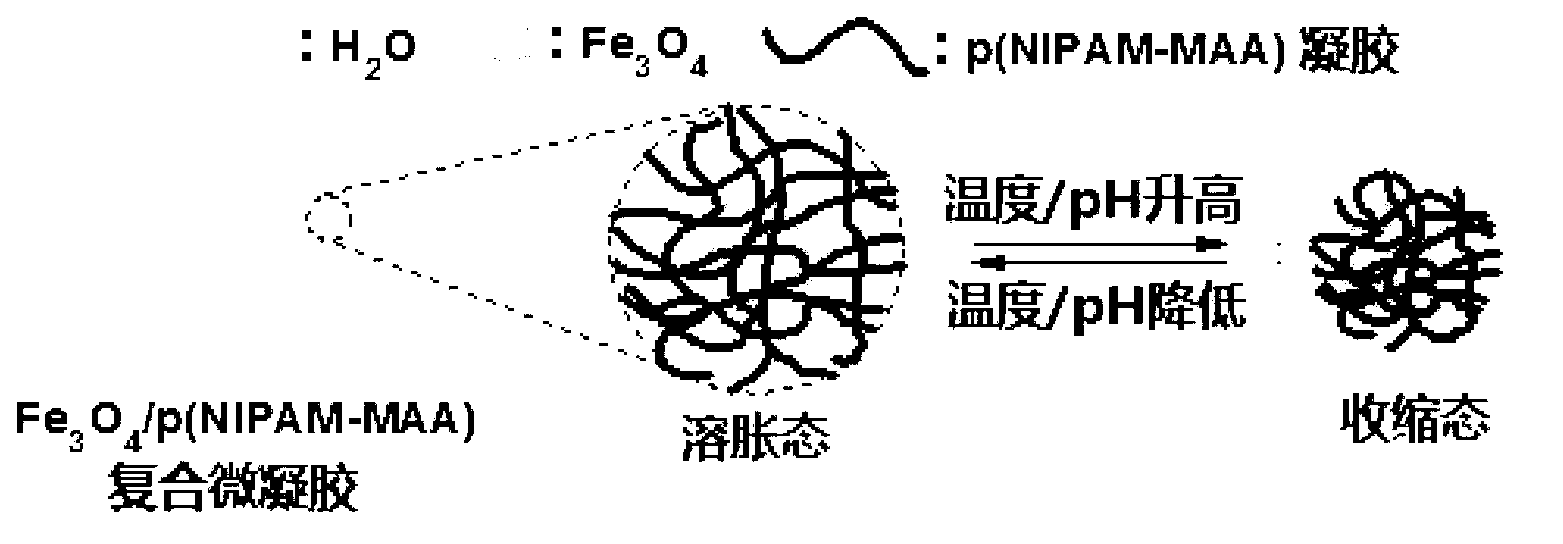

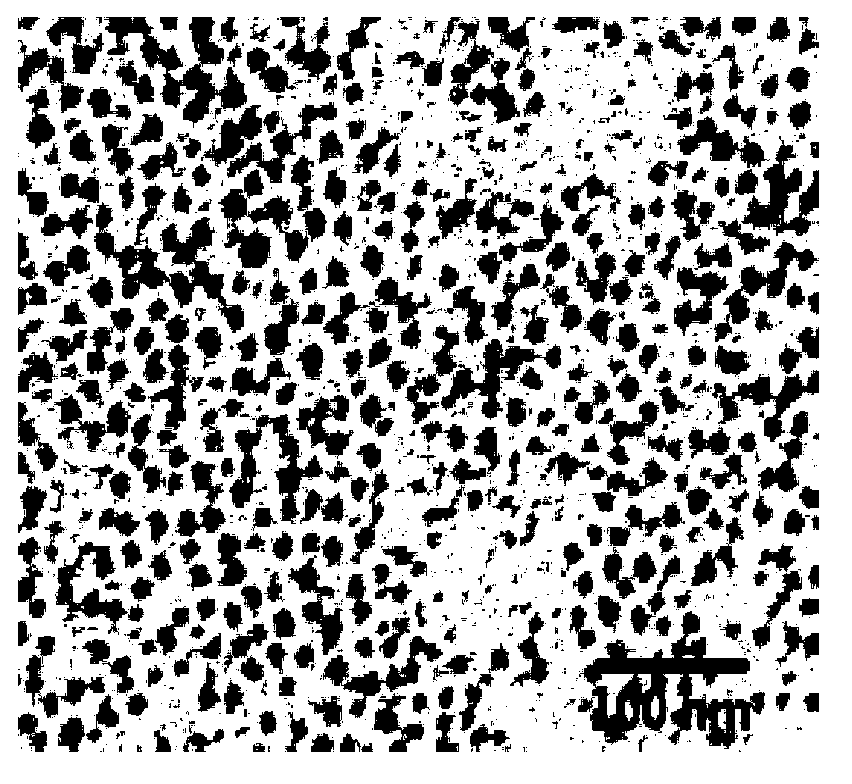

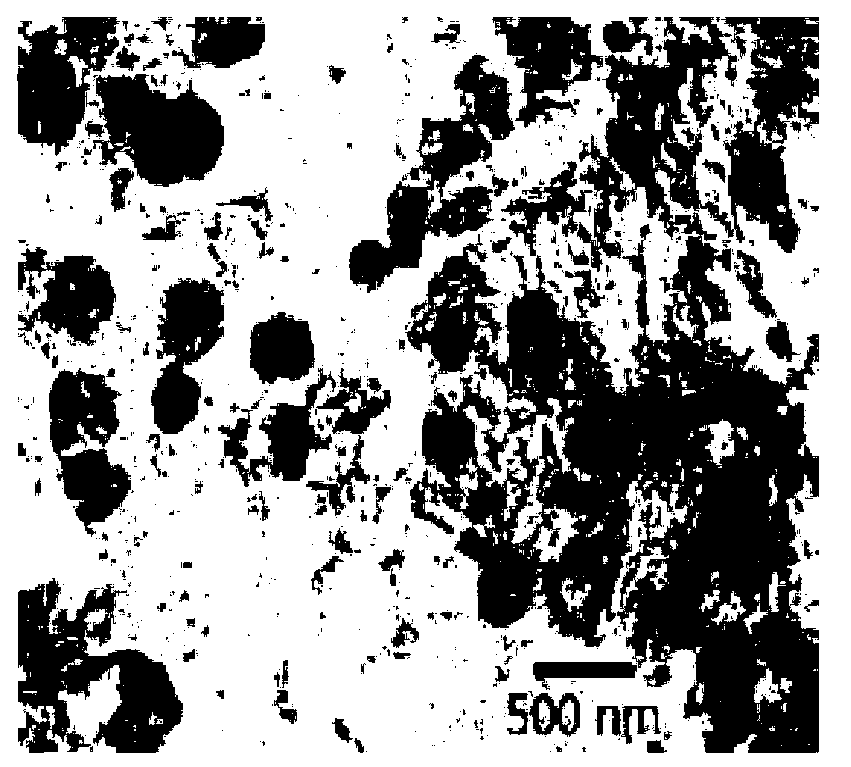

Preparation method of composite microgel with temperature, pH and magnetic field sensitivities

The invention relates to a preparation method of a composite microgel with temperature, pH and magnetic field sensitivities. The method specifically comprises the following steps of: firstly, hydrolyzing a mixed divalent / trivalent inorganic iron salt in an alkaline aqueous solution by taking thioalcohol as a stabilizing agent and adopting a coprecipitation method to prepare nano ferroferric oxide particulates with superparamagnetism; and secondly, carrying out a sedimentation polymerization reaction under the combined action of an initiator, a crosslinking agent and a surfactant by taking N-isopropyl acrylamide as a temperature-sensitive monomer and methacrylic acid as a pH-sensitive monomer to prepare a magnetic nano ferroferric oxide coated poly(N-isopropyl acrylamide-methacrylic acid) composite microgel with the temperature, pH and magnetic field sensitivities. Compared with the prior art, the preparation method has the advantages of reasonable design, feasible process, simple operation, easily-controllable reaction and the like, and the prepared product has three sensitivities, and has wide application values in the biological medical material fields of medicament controlled release, chemical separation and the like.

Owner:SHANGHAI JIAO TONG UNIV

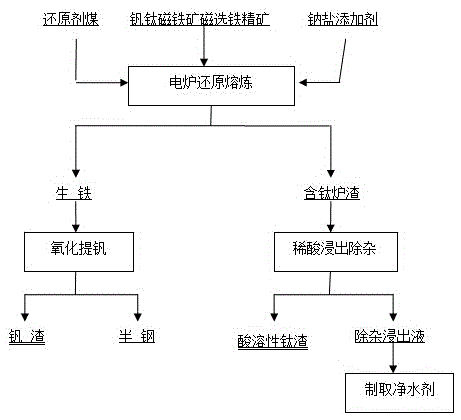

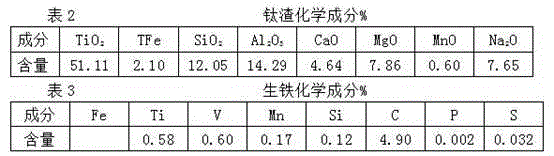

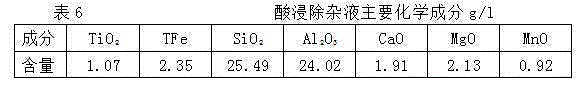

Method for extracting titanium from vanadium-titanium magnetite

InactiveCN105112689AEfficient and reasonable useSolve the technical problems of efficient separation and extractionProcess efficiency improvementElectric furnaceAluminateSmelting process

The invention discloses a method for extracting titanium from vanadium-titanium magnetite. The method comprises the following steps: adding sodium or potassium salt additive in the reduction smelting of an iron ore concentrate electric stove to obtain liquid iron and titanium-containing slag, wherein vanadium and iron are reduced to enter liquid iron, under a smelting high temperature condition, silicon and aluminum impurities form sodium aluminosilicate capable of being dissolved in dilute acid with the sodium or potassium salt additive, and enabling the sodium aluminosilicate and titanium and aluminum magnesium impurities to remain in the titanium-containing slag; purifying the titanium-containing slag by virtue of a wet-method metallurgical impurity removal method, to acquire a titanium slag product with TiO2 content more than 75 percent. For the application problem of titanium in the iron ore concentrate, the slag modification additive is added in the reduction smelting process, so that not only is the mobility of the slag improved, but also a condition is created for removing the later silicon-aluminum impurities of the slag, the high-efficiency separation and extraction problem of the titanium in the iron ore concentrate can be well solved, the resource utilization rate of the iron, titanium and vanadium is greatly increased, and the utilization rate of the titanium is increased about 3 times compared with the flow of a blast furnace.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Method for preparing polylactic acid group block copolymer

The invention belongs to the technological field of polymer material, particularly relating to a preparation method of the poly-lactic acid block copolymer. The invention uses the melting and direct polymerization method to prepare the lactic acid prepolymer, and then uses the chain extension method to prepare the poly lactic acid multi-block copolymer with the high molecular weight. The concrete steps are: first the lactic acid and aliphatic polycarbonate diol are used to react under the condition of the presence of the catalyst and to direct polycondensate to synthesize the hydroxyl-terminated p lactic acid prepolymer; then the chain extender and catalyst are added; with the presence of N2, vacuum; the reaction is kept for 10 to 50 minutes at the temperature of 150 to 300 Celsius system; finally the poly lactic acid multi-block copolymer with the high molecular weight can be made. The process of the method of the invention is simple and easy for the industrialized production; the copolymer resin product produced in the invention is completely biodegradable and the application scope is wide.

Owner:TONGJI UNIV

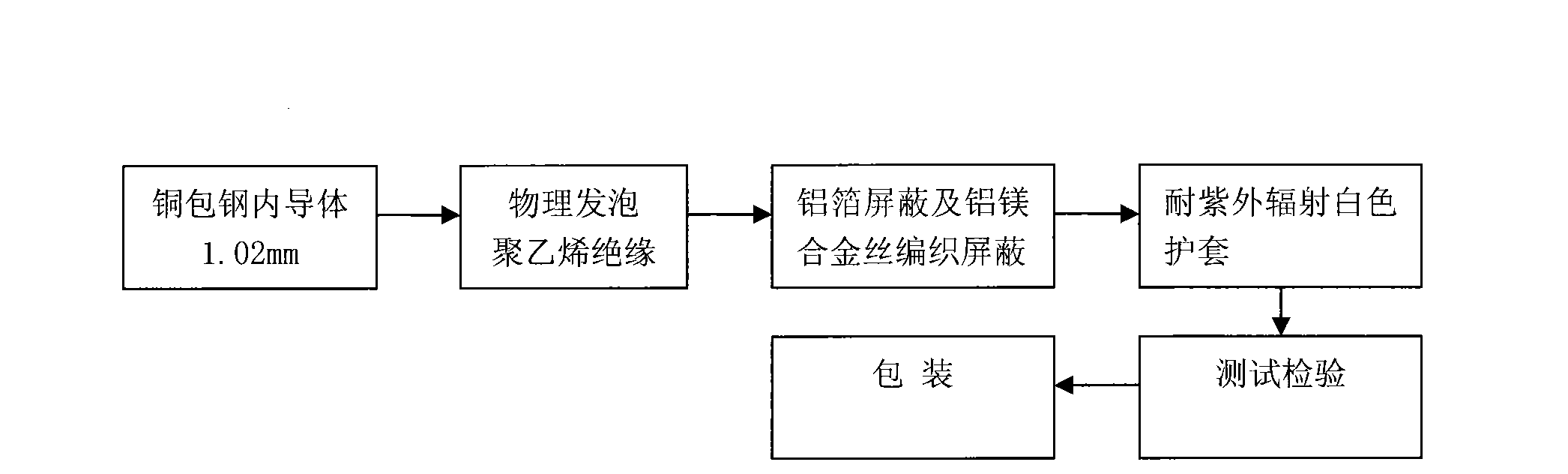

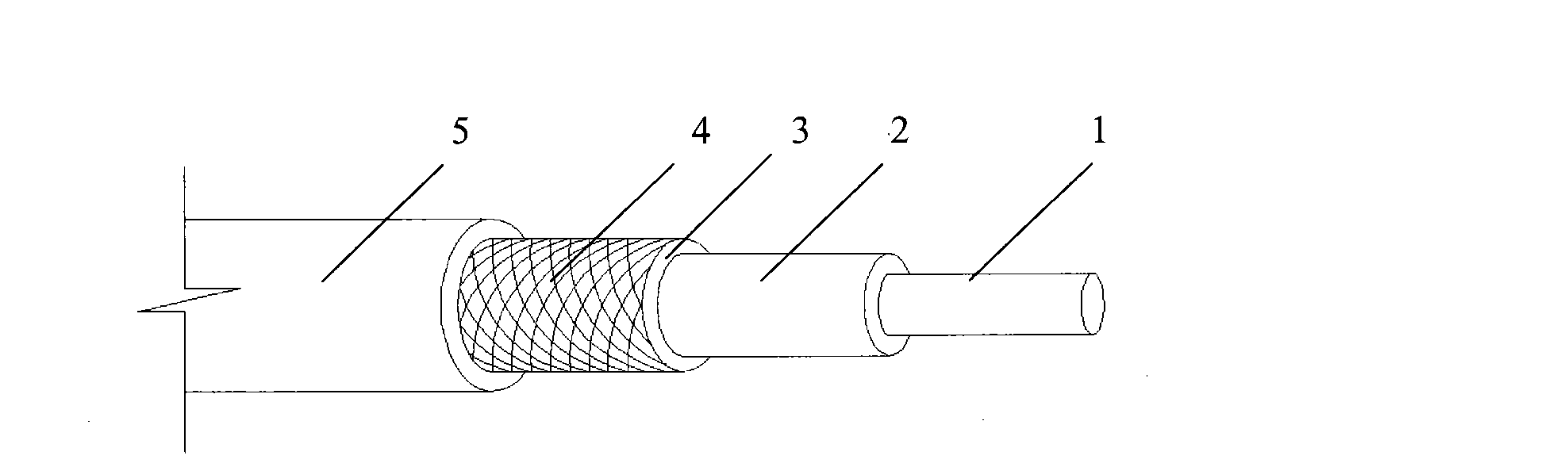

Ultraviolet light resistant ring protective cover material and white concentric cable produced thereof

InactiveCN101492557AExcellent resistance to UV radiationEnvironmental protection is goodPlastic/resin/waxes insulatorsUltraviolet lightsSocial effects

An ultra violet radiation resistant environmental protection sheathing material is mainly prepared by the following materials according to the parts by weight: 40-50 pars of polyvinyl chloride resin, 6-8 parts of trioctyl trimellitate, 4-6 parts of dioctyl sebacate, 7-9 parts of dioctylphthalate, 4-6 parts of ca-zn composite stabilizer, 1-1.5 parts of epoxidized soybean oil, 1-1.5 parts of diantimony trioxide, 1-1.5 parts of diantimony trioxide, 10-13 parts of magnesium hydrate, 8-10 parts of refined calcium carbonate, 8-10 parts of titanium dioxide, and 0.3-0.5 parts of ultraviolet absorbent. The invention technically solves the difficult point of compound formulation of the ultra violet radiation resistant white sheathing material, greatly increases the resistance to ultra violet radiation performance of the product, has strong practicability and lays the material foundation for the design and development of resistance to ultra violet radiation coaxial-cables. Based on the resistance to ultra violet radiation white polyvinyl chloride sheathing material, the resistance to ultra violet radiation environmental protection sheathing material technically solves the technical difficulties of resistance to ultra violet radiation performance, softness, UL mechanical physical property, ROHS environment requirements and the like which are difficult to be achieved completely, meets the strict requirements of the application of products on tropical and subtropical regions and has remarkable social effect.

Owner:ZHEJIANG WANMA GRP SPECIAL ELECTRONCABLE

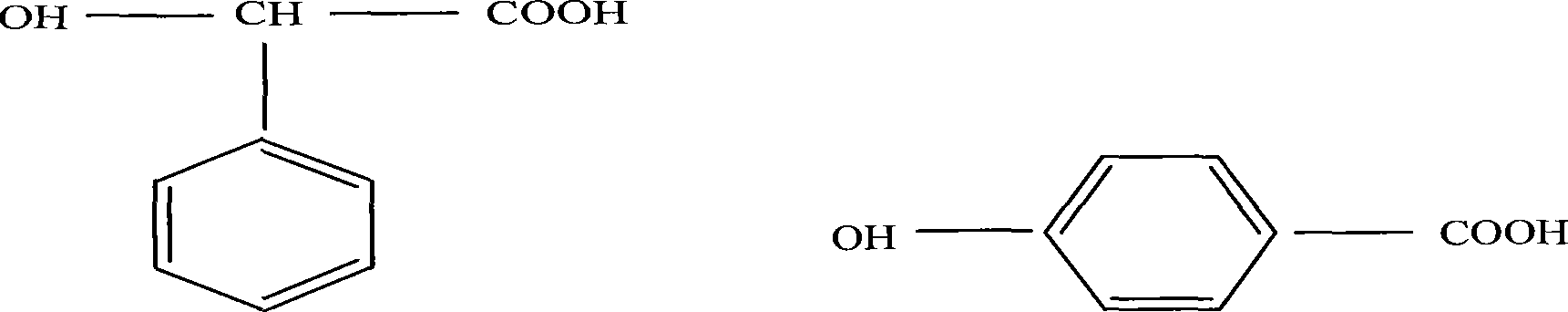

Method for preparing polylactic acid-polycarbonate copolymers

Production of poly-lactic acid-poly-ester carbonate is carried out by reacting lactic acid with small molecular acid containing phen-cyclic and small molecular binary acid under catalyst condition, condensation polymerizing to synthesize carboxy-capping lactic acid pre-polymer directly, adding into fatty polycarbonate dibasic alcohol and catalyst, vacuum supplying under N2 atmosphere, and reacting for 5-10 hrs at 150-200 deg. C. It's simple and biologically degradable, has high molecular weight and better toughness and heat resistance and can be used for industrial production.

Owner:TONGJI UNIV

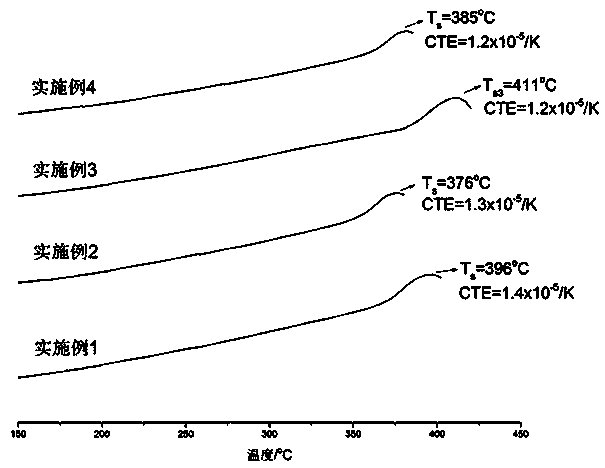

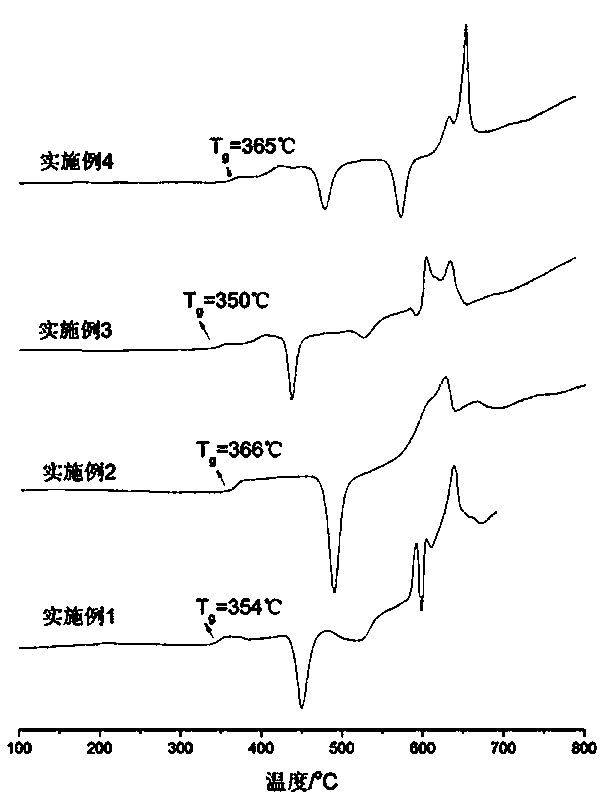

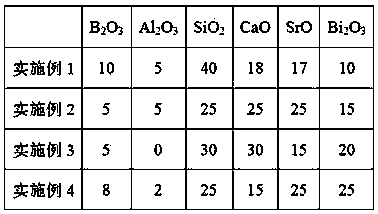

Devitrification type lead-free low-temperature sealing glass as well as preparation method and application method thereof

The invention discloses devitrification type lead-free low-temperature sealing glass as well as a preparation method and application method thereof. The devitrification type lead-free low-temperature sealing glass includes the following raw materials with the molar ratio of (0-10):(0-5):(20-40):(30-60):(5-30): B2O3, Al2O3, SiO2, MO (one or a mixture of MgO, CaO, SrO and BaO), and Bi2O3. Through the synergy between the Bi2O3 and the B2O3, the softening temperature range of the glass is reduced to 370-420 DEG C, and the coefficient of thermal expansion within the range of 150-300 DEG C reaches 1.2 minus 1.4*10<-5> / K, so that the sealing performance of the glass is remarkably improved; meanwhile, the sealing glass has good stability while being placed in hot water with the temperature of 80 DEG C for 1,000 hours, so that the sealing glass is applicable to electronic material and other low-temperature sealing fields. The raw materials for preparation of the sealing glass are simple and easy to get, the process is stable, simple and feasible, the cost is low, and the requirements for practicality and industrialization are met.

Owner:FUZHOU UNIV

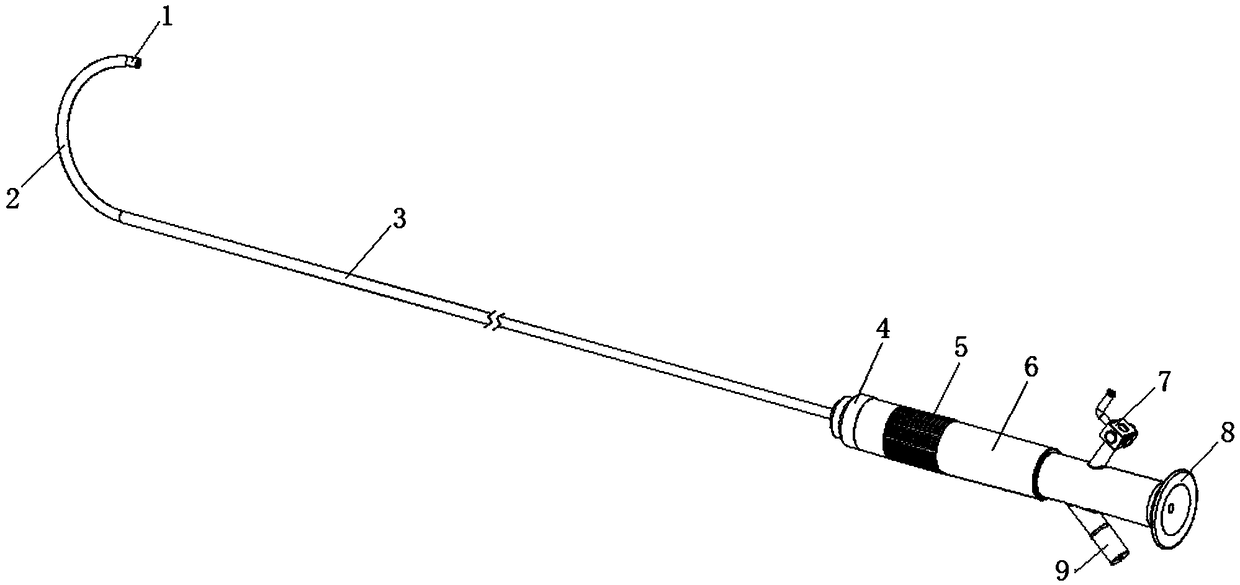

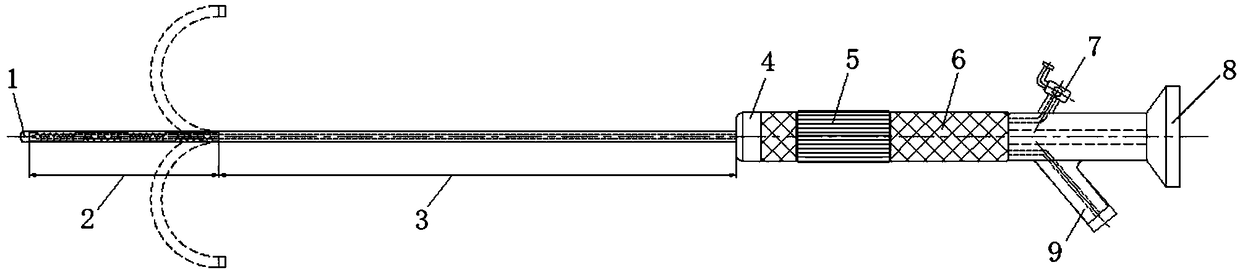

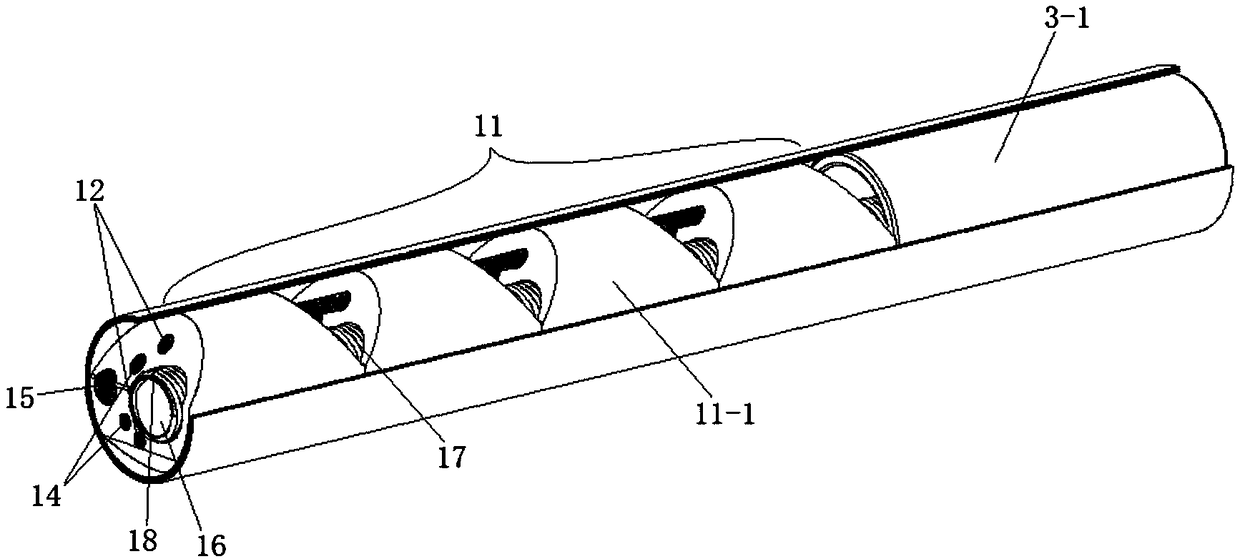

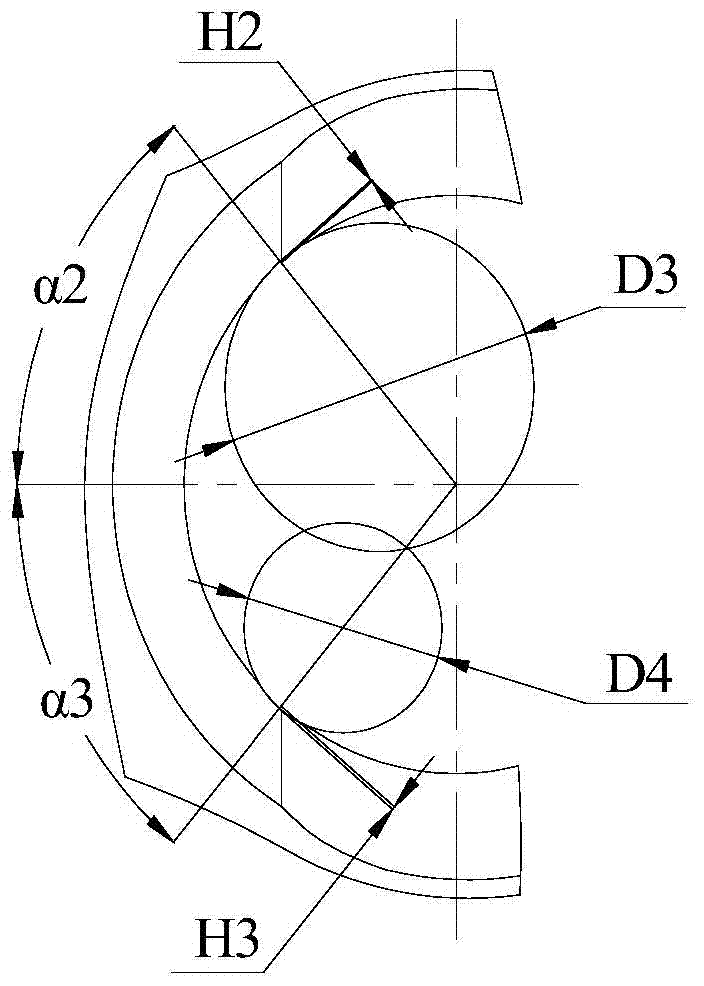

Bidirectional bend-adjusting endoscope

The invention discloses a bidirectional bend-adjusting endoscope, which comprises a front end part, an adjustable bending part, a hard insert part, an operation handle, and a light guide beam, an eyepiece component and an operation channel which can orderly penetrate through the operation handle, the hard inserting part, the adjustable bending part and the front end part. The adjustable bending part comprises several joints sleeved on the elastic supporting body and pull ropes penetrated at the inner part of the joint; there are two groups of pull ropes, the joint bending spaces closing to both sides between the joints can pass through the inner part of the joint; the front end of the pull ropes and the end joints fixedly connected with the front end part are fixed to form a stress anchorpoint; the tail end is fixedly connected with a reciprocating operation mechanism on the operation handle; the adjustable bending part can be controlled to vertically bend through the operation handle. The endoscope pipe body has straight state and bending state; the pipe body in straight state can insert to the patient body conveniently, the front end angle is adjustable when the pipe body is under the bending state; through the eyepiece component and the light guide beam, the touring location can be realized exactly, and the observing blind zone is reduced.

Owner:HUNAN HANDLIKE MINIMALLY INVASIVE SURGERY CO LTD

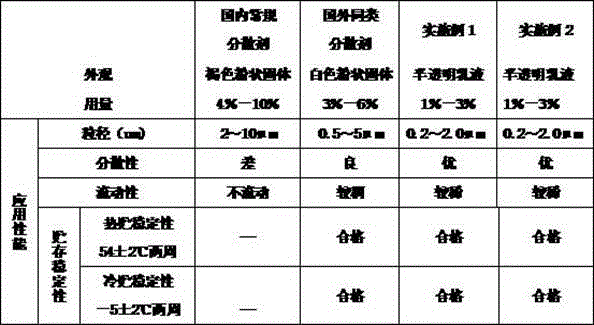

Pesticide suspension concentrate dispersing agent and novel preparation method thereof

InactiveCN102911321AReduce manufacturing costWorkmanship is feasibleBiocideAnimal repellantsPolymer sciencePolyethylene oxide

The invention discloses a pesticide suspension concentrate dispersing agent which is a polymer with a comb-shaped structure, wherein a main chain of the polymer is connected by C-C bonds; and a side chain containing polyethylene oxide or polypropylene oxide and a carboxyl strong polar group capable of being ionized are connected to a side chain of the polymer. The pesticide suspension concentrate dispersing agent is prepared according to the method that unsaturated macromonomers A of the long chain containing the polyethylene oxide or the polypropylene oxide, unsaturated carboxylic acid or derivative monomers B thereof and other copolymer monomers C containing ethylenic bonds are mixed and dissolved in water, wherein the total amount of the A, the B and the C is 100 percent by mass; then a pH (potential of hydrogen) regulator is added to a reaction system so as to enable a solution to be electrically neutral; a cross-linking agent for controlling the molecular weight of a product and a surfactant are added to the solution, and the solution is stirred and heated to a reaction temperature under the protection of N2; a free radical initiator is dripped to the solution to initiate an emulsion polymerization reaction; after the reaction is finished, the solution is vacuumized to remove unreacted monomers and small molecular polymers, and then the dispersing agent of the pesticide suspension concentrate is obtained. The molecular weight of the pesticide suspension concentrate dispersing agent is 5000 to 500000.

Owner:JIANGSU ZHONGSHAN CHEM

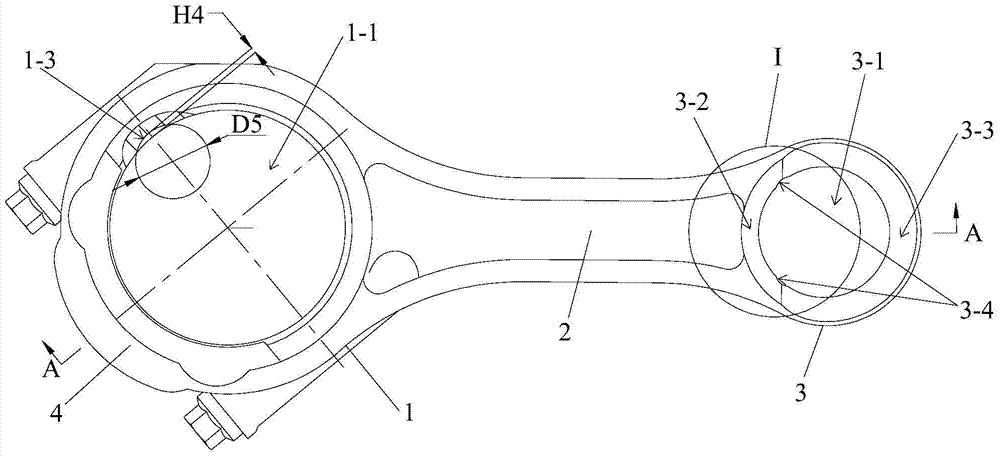

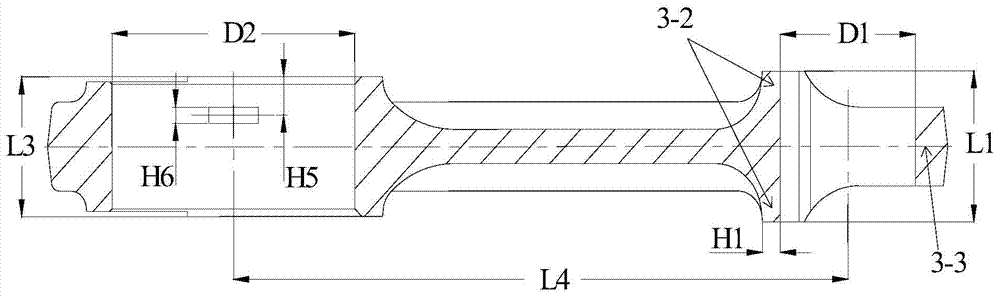

Manufacturing method of hard-base soft-structure internal combustion engine connecting rod

ActiveCN103921097AThe principle is simpleSimple and reliable manufacturing processMetal working apparatusBatch productionEngineering

The invention discloses a manufacturing method of a hard-base soft-structure internal combustion engine connecting rod. The method includes the following steps of forging of a blank, coarse grinding of end faces, boring, rough boring of a large-head hole and a small-head hole, chamfering of the large-head hole, threaded hole machining, fracture splitting of a large-head end and assembling, accurate grinding of the end faces, semi-fine boring of the large-head hole and the small-head hole, tegular groove milling and oil groove boring, fine boring of the large-head hole and the small-head hole, flat grinding of the large-head end, parkerizing of the small-head hole, and cover removing, cleaning and assembling. The connecting rod comprises the large-head end, a rod body and a small-head end, the large-head end and the small-head end are arranged at two ends of the rod body respectively, the connecting rod is of an integral structure, and a connecting rod cover is arranged at the large-head end of the connecting rod. The manufacturing method is simple in principle, a manufacturing technique of a traditional internal combustion engine connecting rod is improved to provide a feasible and reliable manufacturing technique for the hard-base soft-structure internal combustion engine connecting rod, and particularly precision and performance of a soft structure of the small-head end of the connecting rod are guaranteed. Meanwhile, the method has the advantages of simple technique and low manufacturing cost, and is convenient for batch production.

Owner:广东四会实力连杆有限公司

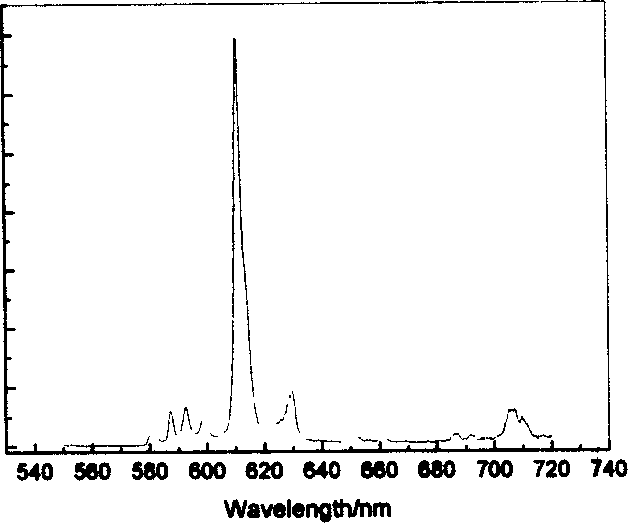

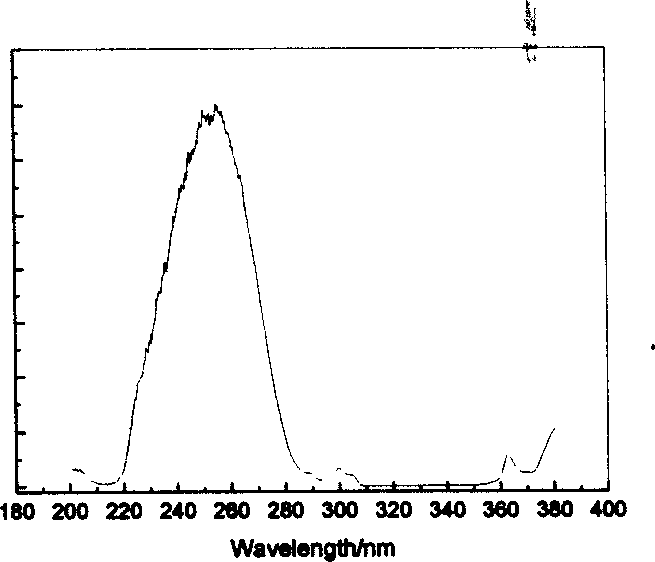

Prepn of red phosphor

InactiveCN1637115AChange coordination environmentSmall particle sizeLuminescent compositionsAlkaline earth metalPhosphate

The preparation process of red phosphor includes: mixing Eu2O3, Y2O3 and MgO, Al(NO3)3 or Sb2O3 to form mixture, adding HNO3 solution and citric acid and heating at 60-100 deg.c to prepare red phosphor mother liquid; compounding oxalic acid solution with oxalic acid and deionized water, adding ethanol and heating to 80 deg.c; mixing red phosphor mother liquid with H2O2 at 25-30 deg.c and heating to 80 deg.c, adding the oxalic acid solution to produce precipitate, filtering, washing the precipitate with deionized water and stoving at 90 deg.c in stove for 2 hr; initial roasting of the precipitate in high temperature furnace and cooling; adding to the roasted product with one or two kinds of fluoride, chloride, phosphate or carbonate of alkali metal and alkali earth metal, secondary roasting in high temperature furnace, cooling, washing with dilute nitric acid, washing with deionized water and stoving to obtain the red phosphor.

Owner:SHAANXI NORMAL UNIV

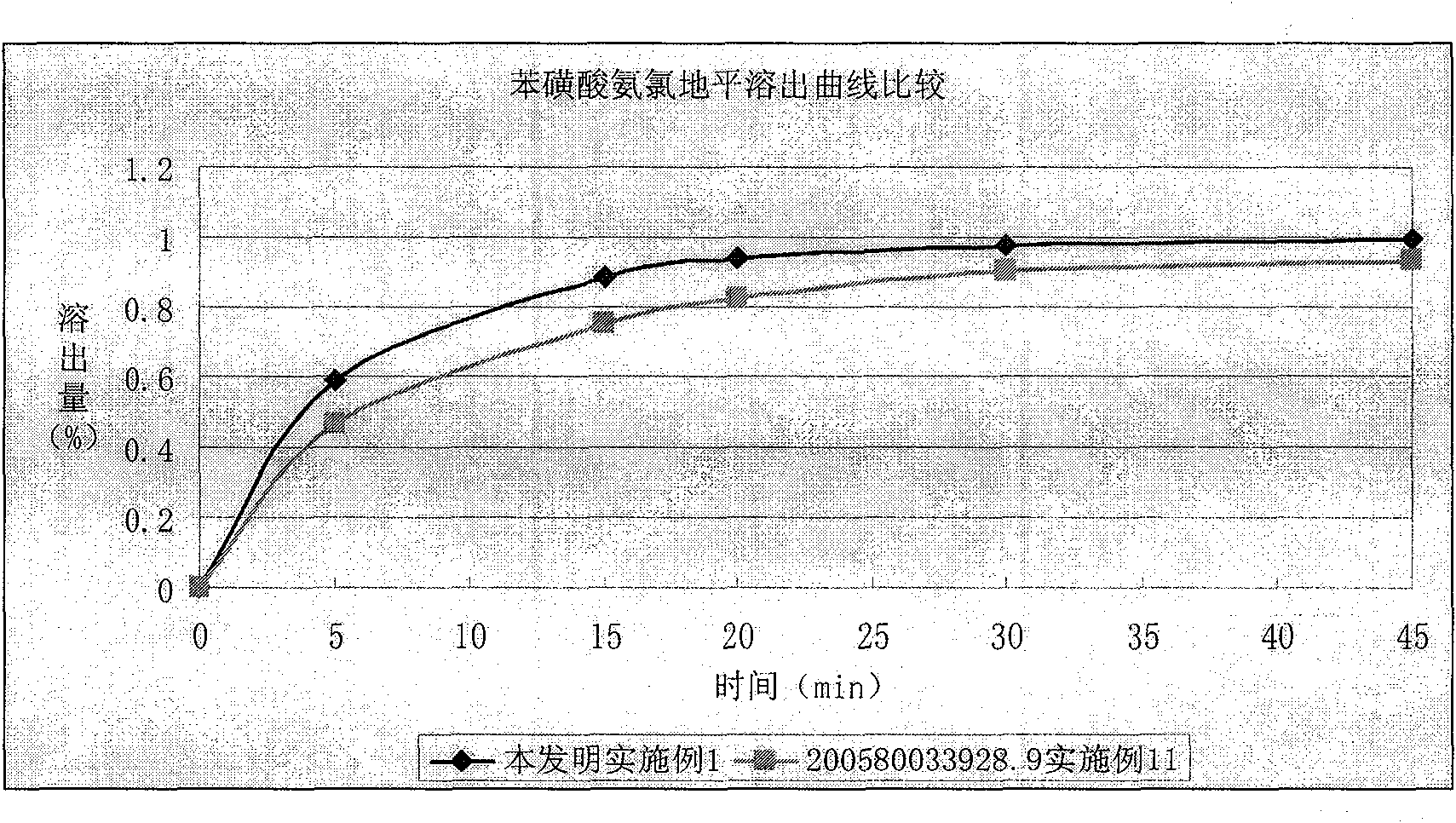

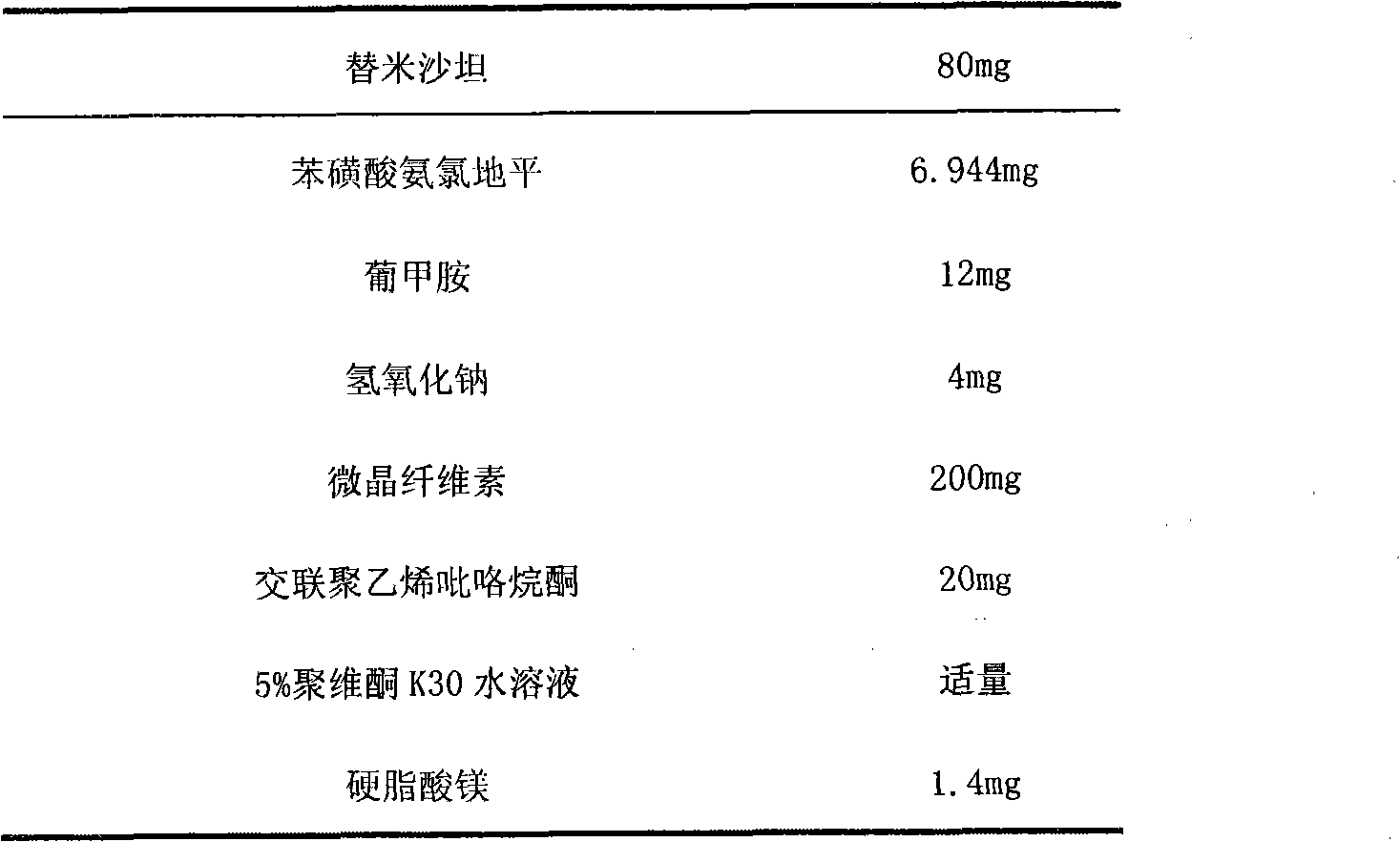

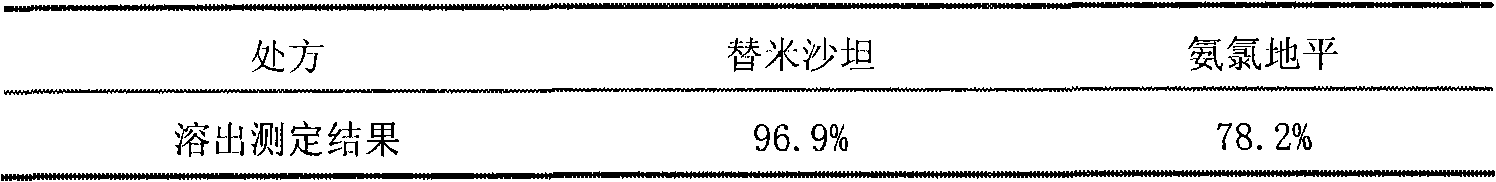

Compound telmisartan amlodipine besylate medicinal composition and preparation method thereof

ActiveCN101947219APrescription stableReasonable prescriptionOrganic active ingredientsPill deliveryDrugSolubility

The invention discloses a compound telmisartan amlodipine besylate medicinal composition. The composite is a tablet which is prepared by the following steps: preparing amlodipine besylate into amlodipine besylate solid dispersion by a solid-state dispersion technology; and preparing the amlodipine besylate solid dispersion and telmisartan into the composite. The tablet improves the dissolubility of primary medicine, promotes the medicament to be quickly disintegrated, prevents dissolution influence of meglumine to the amlodipine besylate, simultaneously improves the absorptivity in blood, and improves the bioavailability of the primary medicine. The tablet has excellent curative effect to hypertension symptoms.

Owner:天津汉一医药科技有限公司

Compound niclosamide parasite-expelling tablet used for pet and preparation method thereof

ActiveCN101601670ASmooth appearanceDisintegrates quicklyOrganic active ingredientsPharmaceutical non-active ingredientsOral medicationPolyethylene glycol

The invention relates to a compound niclosamide parasite-expelling tablet used for pet. The compound niclosamide parasite-expelling tablet used for pet is characterized by comprising the following components according to the mass percent respectively: 68 to 80 of niclosamide, 3 to 5 of hydrochloric acid levamisole, 13 to 20 of starch, 0.1 to 1 of polyethylene glycol 4000 used for preparing aqueous ethanol solution, 3 to 6 of sodium carboxymethyl starch and 0.5 to 1 of magnesium stearate. In preparation, the niclosamide is weighed, the starch is added, and a mixture is prepared by mixing, pulverization and sieving; and the hydrochloric acid levamisole is dissolved in the aqueous ethanol solution, the polyethylene glycol 4000 is dissolved, then the aqueous ethanol solution is added into the mixture, a soft material is prepared, granulated by using a sieve and dried at 50 DEG C to 70 DEG C, the obtained dry particles are granulated by the sieve, the magnesium stearate and the sodium carboxymethyl starch are added, and the obtained mixture is evenly mixed and tabletted to obtain a product. The tablet has bright and clean appearance, rapid disintegration, good parasite-expelling effect after oral administration, simple technology and low cost, is feasible and is suitable for industrialized production, and each index of the tablet reaches optimization.

Owner:QINGDAO VLAND BIOTECH INC

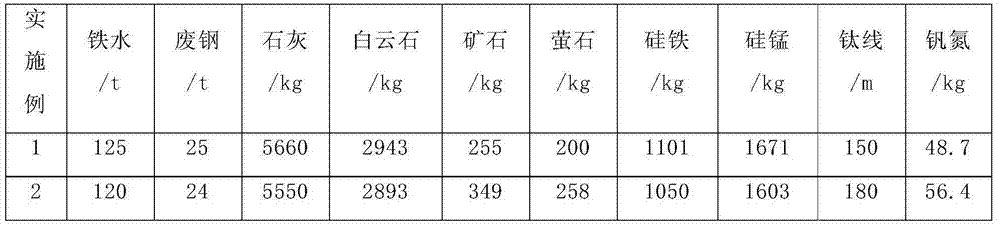

Low-temperature resistant hot rolling H section bar with low compression ratio and super-thick specification and production method thereof

The invention discloses a low-temperature resistant hot rolling H section bar with low compression ratio and super-thick specification and a production method thereof and belongs to the field of hot rolling H section bars. The H section bar is prepared from the following chemical components in percentage by weight: 0.11-0.19% of C, 0.15-0.30% of Si, 1.30-1.55% of Mn, less than or equal to 0.02% of P, less than or equal to 0.008% of S, 0.008-0.020% of Ti, 0.015-0.055% of V and the balance of Fe and inevitable impurities. The production method of the H section bar sequentially comprises the following steps: smelting in a converter or electric furnace; LF (ladle furnace) refining; full protection continuous casting of a beam blank; heating; rolling; and cooling to finally obtain the low-temperature hot rolling H section bar, wherein the flange is over 30mm thick, the compression ratio is less than 3, and the surface is good in quality. The vertical average ballistic work at -20 DEG C is over 150J, so that the H section bar has a wide market application prospect.

Owner:LAIWU IRON & STEEL GRP

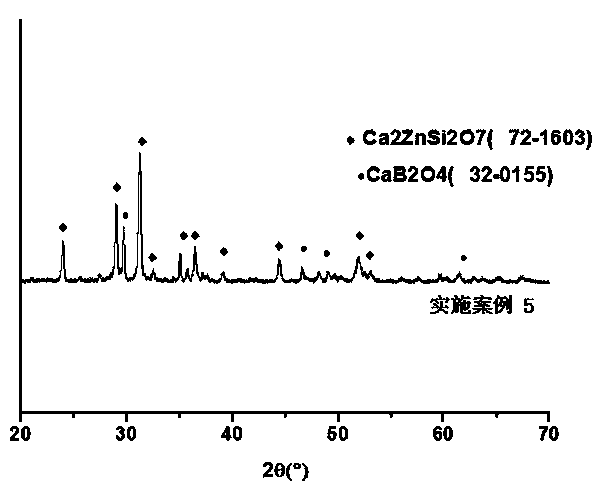

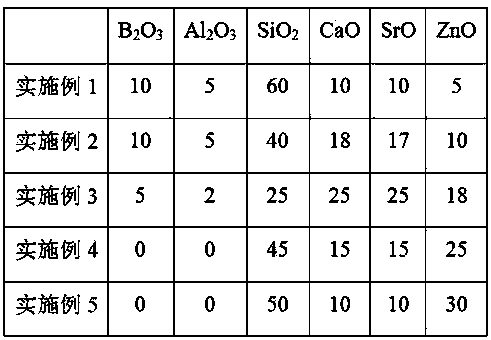

ZnO-containing sealing microcrystalline glass, and preparation and using methods thereof

The invention discloses ZnO-containing sealing microcrystalline glass, and preparation and using methods thereof. The ZnO-containing sealing microcrystalline glass comprises the following raw materials: B2O3, Al2O3, SiO2, MO (one or more of MgO, CaO, SrO and BaO) and ZnO with the molar ratio of (0-10): (0-5): (25-60): (20-50): (5-30). As the ZnO is added, the formation of CaB2O4 crystals in the glass can be promoted, the volatilization of a B-containing substance in the sealing glass in a working environment can be significantly reduced, and the thermal stability of the sealing glass and the chemical compatibility of the sealing glass with a cathode are further improved; and simultaneously, by adding the ZnO, the formation of Ca2ZnSi2O7 crystals in the glass can also be promoted so as to be conductive to improving the thermal expansion coefficient matching degree of the sealing glass with other SOFC (solid oxide fuel cell) components. The ZnO-containing sealing microcrystalline glass disclosed by the invention has the advantages of simple preparation raw materials, easiness in obtainment of the raw materials and stable process, an invert glass grid structure taking SiO2 as a main body is obtained, the cost is low, the process is simple and feasible, and practical and industrial conditions are further achieved.

Owner:FUZHOU UNIV

Formula of instant sour and sweet fresh asparagus lettuce slices and preparation method

The invention discloses a formula of instant sour and sweet fresh asparagus lettuce slices and a preparation method. The preparation method comprises the following steps of: removing hard skin of asparagus lettuce, cleaning, soaking the asparagus lettuce into disinfectant for 3 to 5 minutes for disinfection in a semi-sterile hygienic and clean plant, fishing out the asparagus lettuce, flushing the asparagus lettuce by using fresh purified water, cutting the asparagus lettuce into strips, salting the strip asparagus lettuce for 60 minutes by using salt, filtering to remove a salt solution, adding edible D-sodium isoascorbiate, table vinegar, edible sugar, cooking wine, ginger, raw garlic, sorbic acid for food, chili powder, pricklyash peel powder and the like, mixing uniformly, continuously salting for 60min*8, packing, and sealing to obtain the fresh vegetable subsidiary foodstuff suitable to being stored for a long term and directly eaten in trip, in field, on construction sites and the like. The instant sour and sweet fresh asparagus lettuce slices keep natural nutritional components and have a unique flavor.

Owner:曾正

Preparation technology and purpose of citrus grandis peel flavones

InactiveCN102302592AProcess stabilityIncrease profitMetabolism disorderFood preparationCardiovascular functionsBlood lipids

The invention belongs to the technical field of the preparation of active substances in traditional Chinese medicines, and especially relates to a preparation technology and a purpose of citrus grandis peel flavones. The preparation technology comprises steps of (1) pre-treating, wherein peels of fresh ripe fruits are cut into strips for later use; (2) extracting, wherein an ethanol solution is added to the citrus grandis peel strips, the peels are dipped, heated until boiled, and an extract is obtained; (3) condensing, wherein the extract is condensed until a total flavonoid content is higher than 38.33mg / mL, and the condensate is obtained; (4) separating and purifying; and (5) drying. The invention is advantaged in that: the preparation technology of citrus grandis peel flavones provided by the invention is stable and applicable; the flavones content of the product is higher than that obtained with prior technologies; the utilization rate of the raw materials is improved, and the extraction rate of effective components is improved; the citrus grandis peel flavones can be used for treating hyperlipidemia, reducing blood fat, treating cardiovascular diseases and enhancing cardiovascular functions.

Owner:ZHEJIANG CHINESE MEDICAL UNIVERSITY

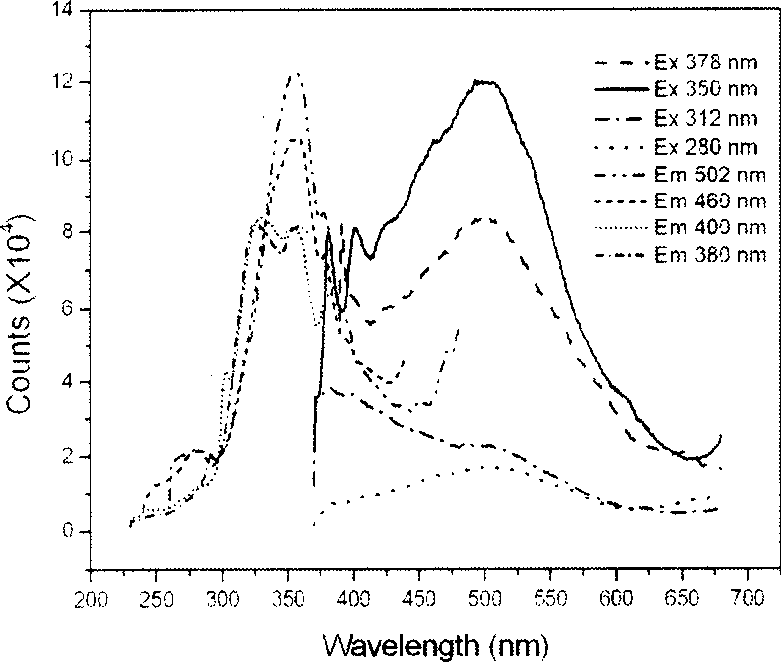

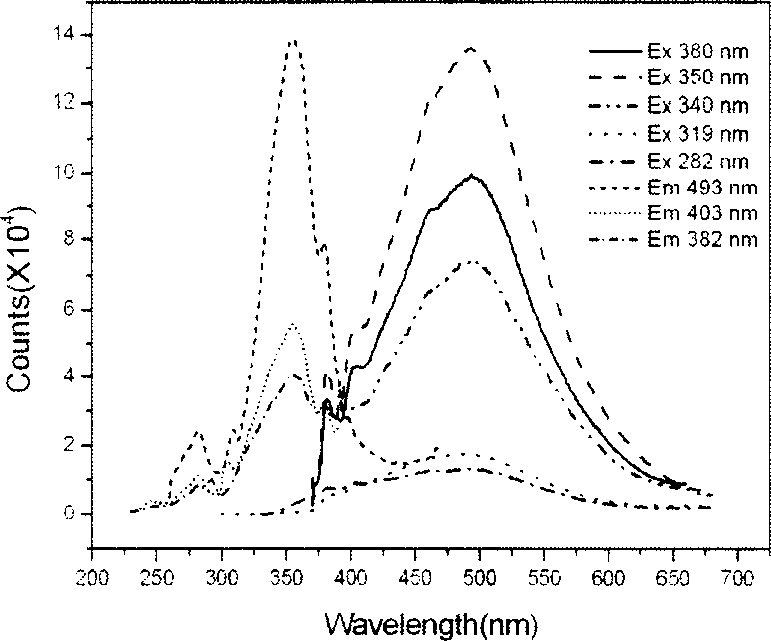

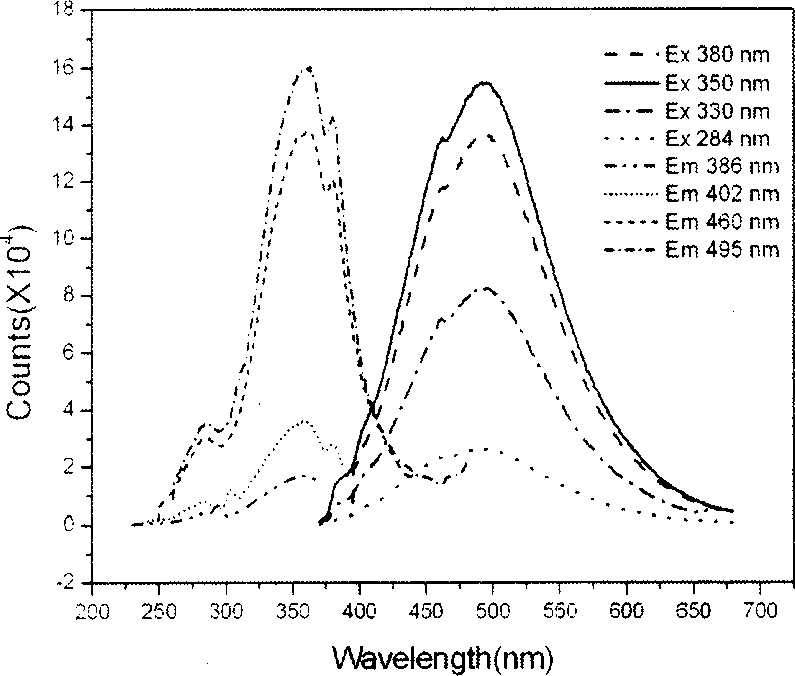

Preparation method of pyrene functionalized sensing film and its application in nitryl arene detection

InactiveCN1837793AExtended service lifeHigh sensitivityChemiluminescene/bioluminescenceFluorescenceSilanization

This invention relates to a preparation method of pyrene functionalized sensing film and its application in nitryl arene detection, which comprises: substrate-lotion-activated substrate-silanizated substrate-trichoromethane solution for four pyrene sulfamoyl derivatives-target. This design is reasonable and practical, and the product has well stability, long lifetime and high sensitivity.

Owner:SHAANXI NORMAL UNIV

Anti-oxidation method used for preparing magnesium alloy artificial bone by laser

InactiveCN106337180AEffective dispersionEvenly dispersedMetallic material coating processesSelective laser meltingAlcohol

The invention relates to an anti-oxidation method used for preparing a magnesium alloy artificial bone by laser, which solves the problem of easy oxidation during a magnesium alloy artificial bone laser sintering process, and provides graphene for consumption and protection of residual oxygen in atmosphere, and reduces the oxidized magnesium alloy, and graphene is used as the nano-phase enhanced magnesium alloy artificial bone. The method comprises the following steps: 1) mixing graphene and Mg-Zn alloy powder in straight alcohol and performing ultrasonic processing; 2) compositing powder and performing ball milling; and 3) performing selective laser fusing.

Owner:CENT SOUTH UNIV

High interlaminar shear strength epoxy resin base composite material and preparation method thereof

The invention provides a high interlaminal shear strength epoxy resin based composite material, which consists of the following materials in mass portion: 75 to 95 portions of epoxy resin, 5 to 25 portions of phenolic resin and 80 to 120 portions of acetone, hardening agent and carbon fiber, wherein the adding amount of the hardening agent is 30 percent of the total weight of the epoxy resin and the phenolic resin, and the adding amount of the carbon fiber is 60 to 70 percent of the total weight of the epoxy resin and the phenolic resin. The epoxy resin, the phenolic resin, the acetone and the hardening agent are mixed and dissolved into homogeneous matrix solution, and the carbon fiber is soaked in the matrix solution to prepare one-way laid fabric, and the one-way laid fabric is hardened. The material has the advantages of high interlaminal shear strength and simple process.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

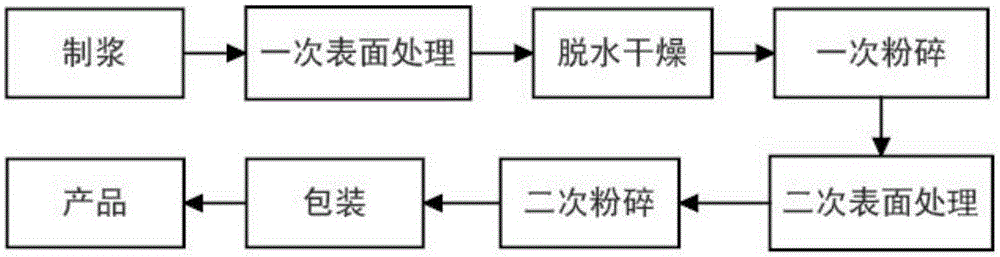

Surface treatment method of special nanometer calcium carbonate for polyurethane sealant

ActiveCN105255218AShorten drying timeGood compatibilityPigment treatment with organosilicon compoundsPigment physical treatmentDrying timeSealant

The invention discloses a surface treatment method of special nanometer calcium carbonate for polyurethane sealant. The surface treatment method includes the steps that 1, paste making is performed; 2, in primary surface treatment, a mixed saponification solution of fatty acid and lysine is added for stirring; 3, in dehydration and drying, modified nanometer calcium carbonate is dehydrated and dried; 4, in primary crashing, powder is crashed; 5, in secondary surface treatment, nanometer calcium carbonate is added into a stirring machine to be stirred in a heating mode, when material temperature is increased to 80 DEG C-90 DEG C, a mixed modifying agent of dimethicone and 3-(3- aminophenoxy) propyl trimethoxy silane is added, and when the material temperature is increased to 100 DEG C-110 DEG C, stirring is stopped, and discharging is performed; 6, in secondary crashing, nanometer calcium carbonate is crashed again. The polyurethane sealant is filled with nanometer calcium carbonate modified through the method, and therefore the mechanical property of the polyurethane sealant is remarkably improved, and surface drying time is shortened. The preparation method is simple, the production cost is low, and good economic benefits are achieved.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com