Patents

Literature

655results about How to "Good anti-adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-shrinkable multi-layer film

InactiveUS6146726AImprove sealingLow-temperature sealabilityWrappers shrinkageShrinkage connections1-OcteneCLARITY

The invention provides a heat-shrinkable multi-layer film comprising at least a thermoplastic resin layer as the outermost layer (A), a gas barrier resin layer as a core layer (B) and a sealing resin layer as the innermost layer (C), and optionally an adhesive layer between the individual layers, wherein (1) the sealing resin layer of the innermost layer (C) is a layer formed of a resin material (b) comprising a linear ethylene-1-octene copolymer (a) obtained by using a constrained geometry catalyst and having an 1-octene content not lower than 1 wt. % but lower than 20 wt. % and a density higher than 0.885 g / cm3 but not higher than 0.960 g / cm3, and (2) an intermediate layer (D1) formed of at least one resin (c) selected from the group consisting of polyamide resins, thermoplastic polyester resins and ethylene copolymer resins is provided between the outermost layer (A) and the core layer (B). The film has excellent sealing properties, clarity, mechanical strength, stretchability and bag-making property.

Owner:KUREHA KAGAKU KOGYO KK

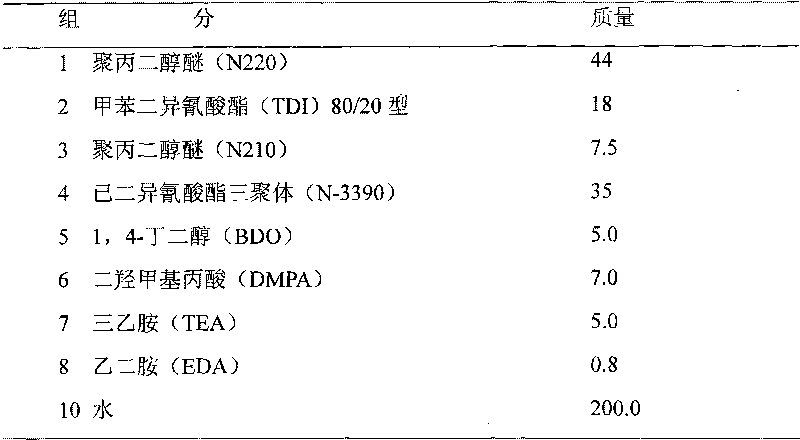

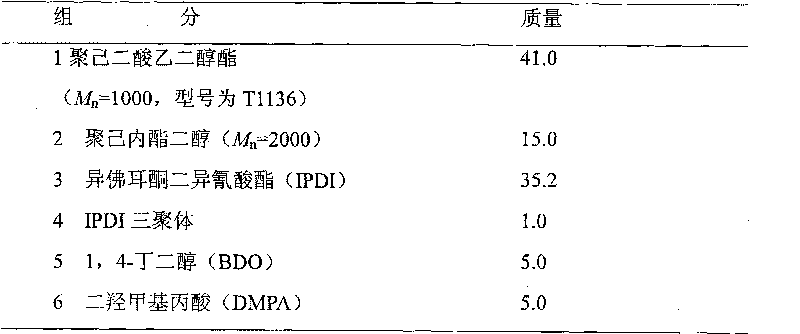

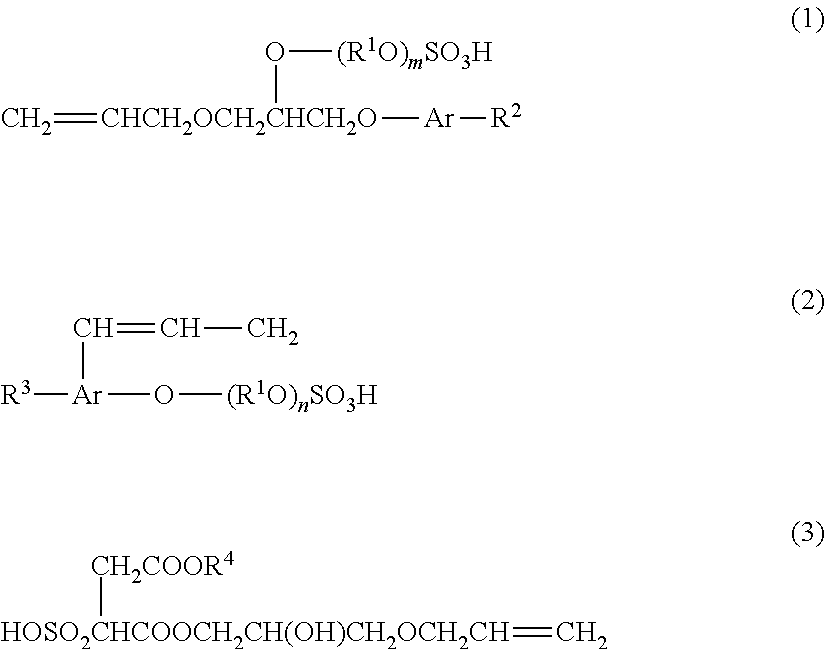

Preparation method and application of modified polyurethane aqueous dispersions of polyisocyanate curing agents

InactiveCN101696262ASimple processEasy to operatePolyurea/polyurethane coatingsLeather surface finishingPolyesterSolvent

The invention discloses a preparation method and application of modified polyurethane aqueous dispersions of polyisocyanate curing agents. The preparation method comprises the following steps of: carrying out prepolymerization reaction by using polyester polyol, vulcabond monomer and a polyisocyanate curing agent; reacting with a hydrophilic chain-extending agent and a micro-molecule chain-extending agent to obtain polyurethane prepolymer containing hydrophilic groups (carboxyl or sulfonic groups) and isocyanate(NCO)-terminated groups; neutralizing the polymer into salt, and then dispersing the salt into water; and preparing the modified polyurethane aqueous dispersions of the polyisocyanate curing agents by the chain extending of a polyamine chain-extending agent. The modified polyurethane aqueous dispersions of the polyisocyanate curing agents have self-crosslinking function at room temperature, and the self-crosslinking density is over 85%. Compared with non-modified polyurethane aqueous dispersions prepared under the same condition, the modified polyurethane aqueous dispersions have superior film forming property, water resistance, alcohol resistance, pollution resistance, cold resistance, dry / wet rubbing resistance and chemical solvent resistance; and coating films have especially high drying speed, high hardness increment speed and high final hardness.

Owner:SOUTH CHINA UNIV OF TECH

Biaxially stretched multilayer polypropylene film and use thereof

InactiveCN101160209ALow densityLow surface smoothnessSynthetic resin layered productsCoatingsPolymer scienceFilm base

Disclosed is a biaxially stretched multilayer polypropylene film wherein a front layer and back layer composed of a propylene polymer (a1) are respectively arranged on both sides of a biaxially stretched polypropylene film base layer (B) which is composed of a propylene polymer composition (A) obtained by adding an inorganic compound powder (a2) to the propylene polymer (a1). This biaxially stretched multilayer polypropylene film is characterized in that the front and back layers have a surface roughness (three-dimensional center plane average roughness SRa) of less than 0.08 [mu]m and a glossiness (incident angle: 60 degrees) of not less than 114%, and the multilayer polypropylene film has a total light transmittance of not more than 20% and a density of 0.40-0.65 g / cm<3>.

Owner:TOHCELLO CO LTD (JP)

Degradable compound biomaterial membrane for medical purpose

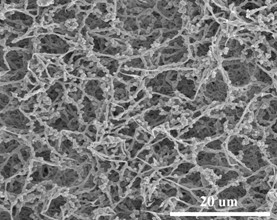

InactiveCN1994476AHigh porosityLarge specific surface areaAbsorbent padsBandagesFiberElectrospinning

The invention relates to a method for preparing composite biological medical material used to avoid adhering organisms, wherein said film is formed by two layers; the layer used as base material is formed by degradable composite macromolecule polylactic acid, glycolic acid, or their copolymer, treated by static spin technique, to make film fiber into nanometer level; then coats one layer of degradable natural macromolecule chitose or relative derivant on the base film, to be treated to obtain the degradable composite biological medical film; and the invention can add different amounts of medical elasticizer between two layers to adjust the degrade speed. The invention can improve immunity with haemostasis function, etc.

Owner:BEIJING HUASHI BENQUAN TECH

Acrylate micro-emulsion with high solid content, its preparation method and use

The invention refers to a high-solid content acrylate micro-latex, its making method and its application to carpentry dope. It adopts the technique of half-continuous starvation feeding, and is obtained by the polymerizing method of seed latex. It leads into cross-linking groups in the course of polymerization such as amidogen, acetoacetyl and amido, depends on the reaction of the groups of form film, gets painting film with cross-linking construction, and improves the water and solvent resistance of the painting film.

Owner:SOUTH CHINA UNIV OF TECH

Medical anti-sticking membrane and preparation method thereof

The invention provides a medical anti-sticking membrane and a preparation method thereof. The anti-sticking membrane comprises a nanometer frame and hydrosol attached thereon. The hydrosol is internally packed with one or several kinds of styptic medicament or / and anti-sticking medicament. The invention also provides a preparation method of the anti-sticking membrane, comprising the following steps of: preparing electro-spinning solution, styptic medicament and / or anti-sticking medicament-containing hydrosol solution and crosslinker solution; receiving static spinning with the crosslinker solution to obtain the nanometer frame; printing the styptic medicament and / or anti-sticking medicament-containing hydrosol solution onto the nanometer frame by an ink-jet printer, and solidifying the hydrosol solution to obtain the anti-sticking membrane. The anti-sticking membrane has good capability and biological compatibility, and nontoxicity as well as nonirritant, can be completely degraded and absorbed, is compounded with controllably released styptic medicament or / and anti-sticking medicament, has controllable degrading time and speed, and conquers defects of the prior art.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

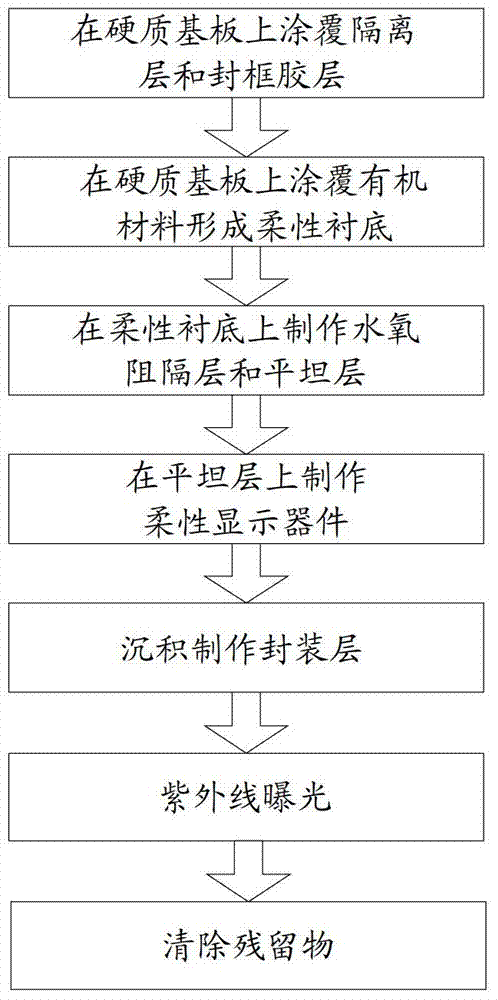

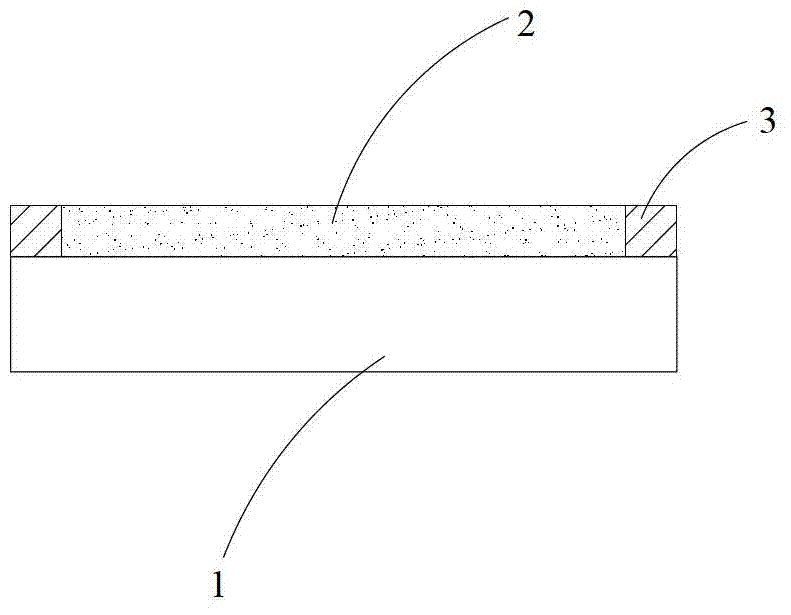

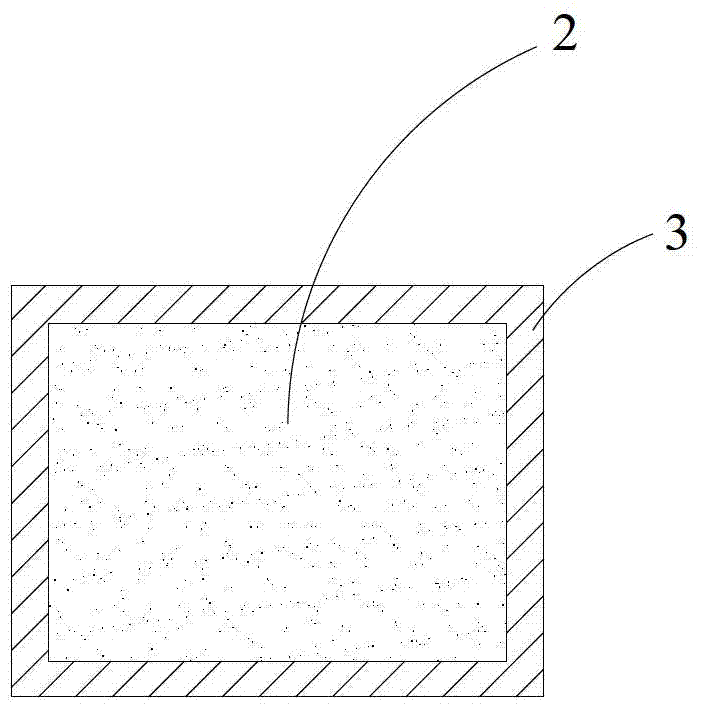

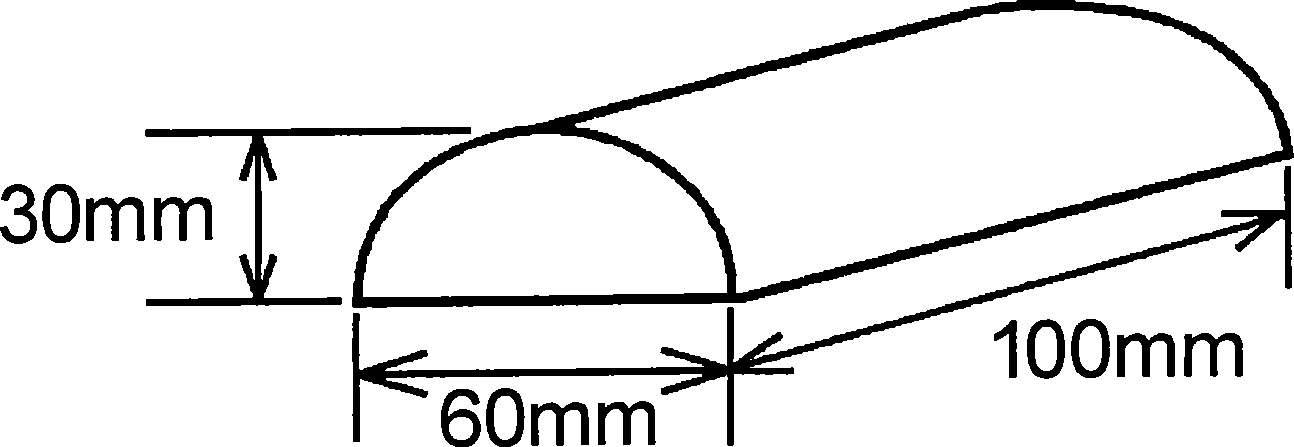

Manufacturing method of flexible display device

ActiveCN103325731AGood flexibilityImprove display qualitySolid-state devicesSemiconductor/solid-state device manufacturingIsolation layerUltraviolet

The invention belongs to the field of displayers, and discloses a manufacturing method of a flexible display device. The manufacturing method of the flexible display device comprises the following steps that a rigid substrate is coated with an isolation layer and a frame sealing glue layer, the rigid substrate is coated with organic materials to form a flexible substrate, a flexible display device is manufactured on the flexible substrate, ultraviolet exposure is conducted, and residues are removed. According to the manufacturing method of the flexible display device, radical group matter is added to enable the isolation layer to have anti-adhesion performance, the periphery of the isolation layer is coated with the modified frame sealing glue layer, the frame sealing glue layer has good anti-adhesion performance, the ultraviolet exposure is conducted, the frame sealing glue layer is resolved, and therefore the flexible substrate is naturally separated from the rigid substrate. According to the manufacturing method of the flexible display device, separating performance is good, the residues are few, technological process is simple, and the manufactured flexible display device is good in flexibility, and good in display quality.

Owner:TCL CORPORATION

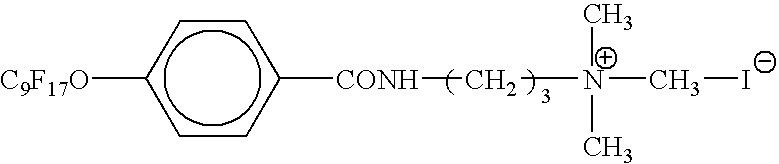

Water-proof moisture-permeation coating agent composition and application thereof

InactiveCN101104752AGood hygroscopicityGood anti-adhesionNatural rubber coatingsPolyurea/polyurethane coatingsFiberHigh resistance

The invention relates to a waterproof and moisture-permeable coating agent composition, wherein, a certain amount of microporous lignocellulose fine powder is added into the coating agent with waterproof function, so that the coating agent has moisture permeable performance. The waterproof and moisture-permeable coating agent composition which is used as the coating agent for non-woven fabric, knitted fabric or woven fabric can be made into coated fabric and synthetic leather with waterproof and moisture permeable performances. Compared with the prior at, the invention has the advantages that: 1. the raw material is easy to be added, the process is available with high adaptability, no need to add new equipment; 2. on the premise that the waterproof performance is not decreased, the amount of moisture permeated is increased obviously and the anti-adhesion is improved; 3. the coated fabric and superfine fiber and artificial cover synthetic leather made by the invention has the advantages of fine moisture permeability, high resistance to water pressure and that the physical performance does not decrease.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

Organic siloxane modified phenylethylene-acrylic ester nano-emulsion and preparing method thereof

InactiveCN1456577AHigh glass transition temperatureLow minimum film forming temperatureHigh resistanceSolid component

An organic siloxane modifier nano-class styrene-acrylate emulsion used for paint or adhesive is prepared from the functional silane monomer with multifunctional vinylalkoxy groups and the monmers of styrene, alkyl methylacrylate, hydroxyalkyl methylacrylate, alkyl acrylate and (methyl) acrylic acid through copolymerization in the manner that under the action of organic silaxane as hydrolysis inhibitor the emulsion polymerizing is inhibited. Its advantages are low content of emulsifier, high content of solid component and storage stability (more than one year), high resistance to weather, dirt, water, chemical solvent and alkali, and high adhesion and tension strength.

Owner:SOUTH CHINA UNIV OF TECH

Ink composition, inkjet recording method, printed material, and molded printed material

ActiveCN101503587AExcellent curabilityGood flexibilityDuplicating/marking methodsInksMethacrylateDouble bond

An ink composition of the invention is characterized by comprising the following componets: (A) a compound having an ethylenically unsaturated double bond and a silicone chain, (B) a polymerizable monomer, and (C) a radical polymerization initiator, at least 75 wt % of the polymerizable monomer being a monofunctional polymerizable monomer selected from the group consisting of a monofunctional acrylate, a monofunctional methacrylate, a monofunctional vinyloxy compound, a monofunctional N -vinyl compound, a monofunctional ethylenically unsaturated carboxylic acid compound, a monofunctional acrylamide, and a monofunctional methacrylamide. Furthermore, the inkjet recording method, the printed material and molded printed material of the invention uses the ink composition according to the invention.

Owner:FUJIFILM CORP

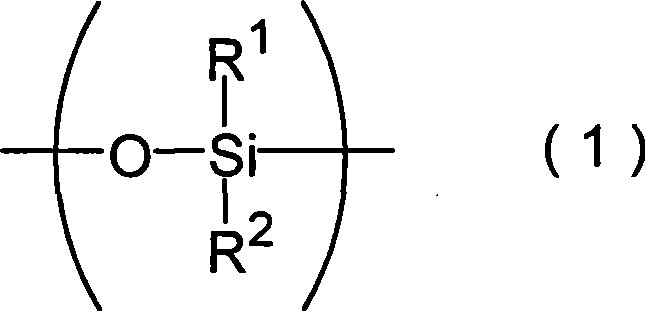

Optical diffusion barrier with covering power and light transmittance compatibility and preparation method thereof

InactiveCN105589117AGuaranteed light transmittanceImprove scratch resistanceDiffusing elementsInorganic particleOptical transmittance

The invention discloses an optical diffusion barrier with covering power and light transmittance compatibility, comprising a transparent PET base material, a diffusion layer coating the upper surface of the base material, and a back coating layer coating the lower surface of the base material. The diffusion particle of the diffusion layer comprises composite particle size organic particles composed of large particle size organic particles with a particle size range of 10-20 mu m, middle particle size organic particles with a particle size range of 5-8 mu m, and small particle size organic particles with a particle size range of 1-3 mu m, and small particle size inorganic particles with a particle size range of 20-500 nm. The arrangement format, particle size and mass percent of organic particles in the diffusion layer and the thickness of the diffusion layer are controlled, thereby realizing the covering power and light transmittance compatibility of the diffusion barrier; in addition, anti-adhesion inorganic particles are arranged in the back coating layer, so as to enhance scraping resistance performance, and to allow the diffusion barrier to possess better antistatic and anti-adhesion performance. The invention also discloses a preparation method of the optical diffusion barrier with covering power and light transmittance compatibility, which meets market demands, possesses simple processes and is easy to operate.

Owner:FSPG HI TECH

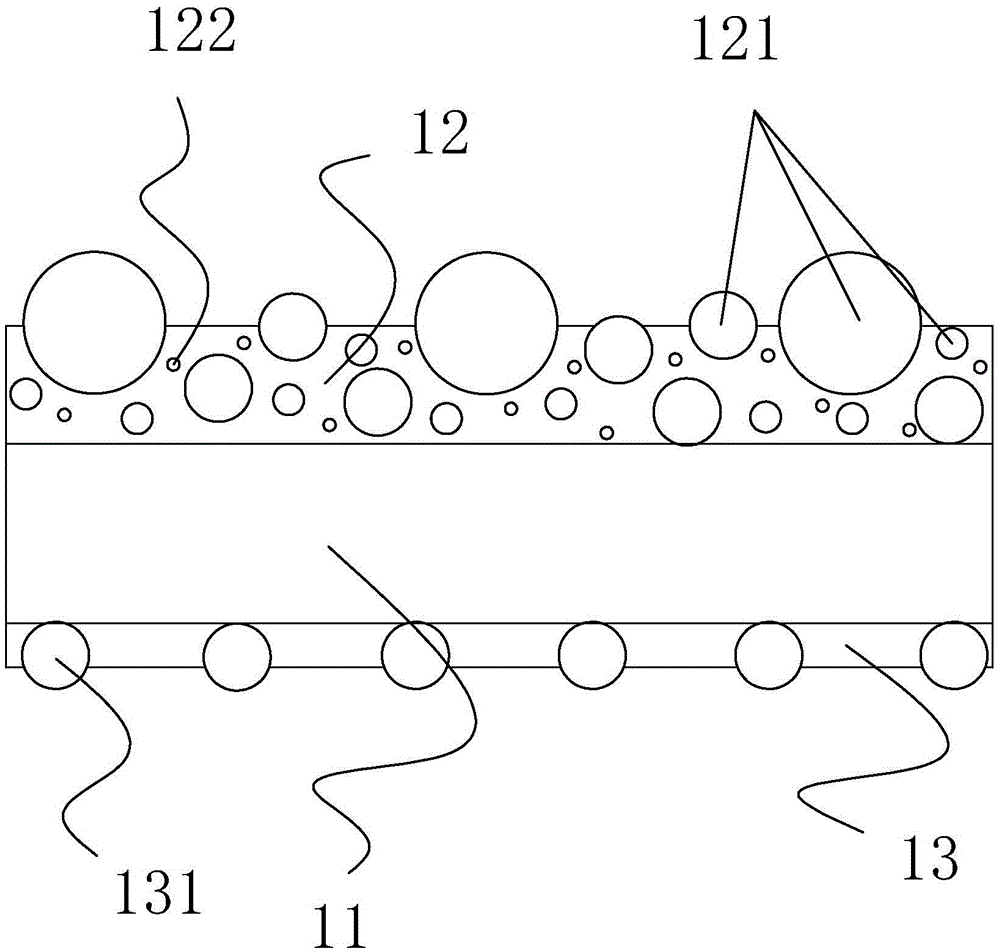

Medical nano-fiber sponge material and preparation method and application thereof

ActiveCN102657893AExcellent healing propertiesImproves anti-adhesion and cell viabilityAbsorbent padsBandagesFreeze dryNanofiber

The invention relates to a medical nano-fiber sponge material, of which the porosity is 90-98 percent and the diameter of a nano-fiber is 50-1,000 nanometers. The medical nano-fiber sponge material consists of the following components in percentage by mass: 0.5-8.5 percent of bioactive glass fine particles, 65-88 percent of gelatin, 0.2-5.0 percent of hyaluronic acid, 0.2-5.0 percent of chitosan and the balance of water. A preparation method of the medical nano-fiber sponge material comprises the following steps of: adding bioactive glass fine particles and ethanol into a gelatin aqueous solution, and stirring uniformly; performing low-temperature phase separation and freeze drying to obtain nano-fiber sponge obtained by compounding gelatin and bioactive glass fine particles; and performing soaking, refrigerating and freeze drying with a hyaluronic acid solution and a chitosan solution in sequence under a negative pressure condition to obtain a porous composite sponge material in which nano-fibers are crosslinked and coated statically with hyaluronic acid and chitosan. The nano-fiber sponge has excellent bioactivity, bacteriostasis and mechanical property, and can be widely applied in the fields of regenerative repair of various skin wounds and skin tissue engineering.

Owner:ZHEJIANG UNIV

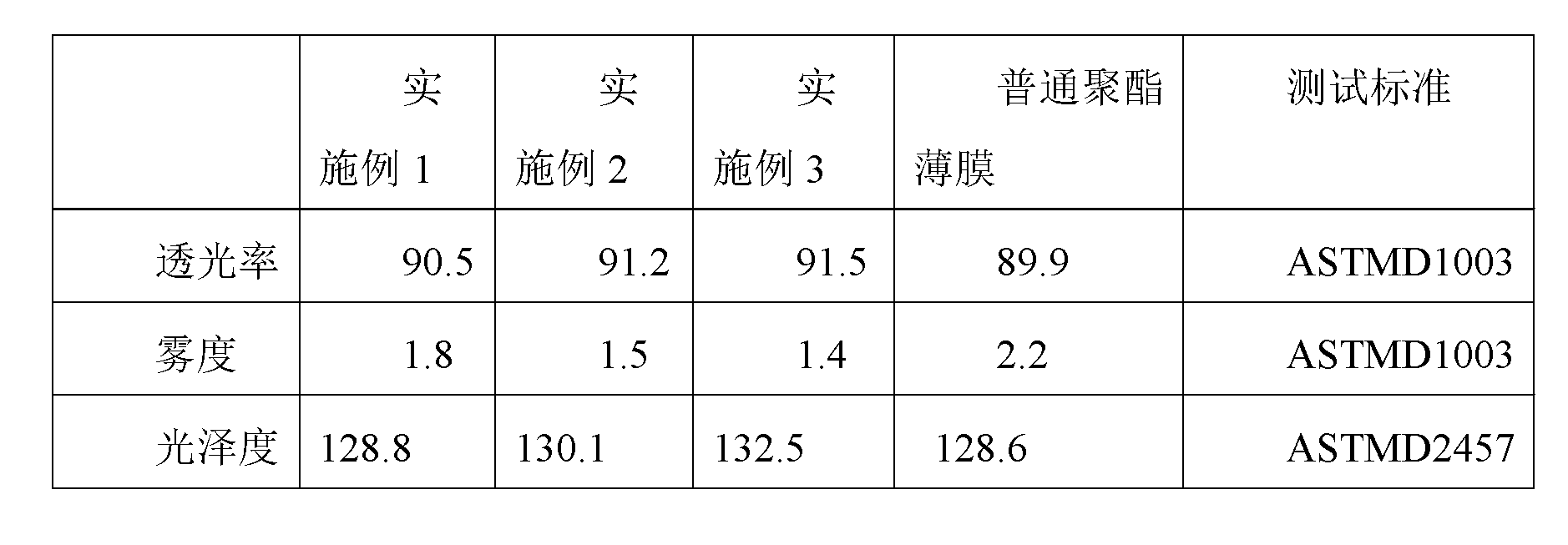

Bidirectional-stretching online-coating optical base film and its making method

InactiveCN103171223AGood anti-adhesionImprove smoothnessSynthetic resin layered productsPolyesterSurface layer

The invention relates to a bidirectional-stretching online-coating optical base film and its making method. The optical base film comprises a three-layer co-extruded bidirectional-stretching polyester film, and a coat having a thickness of 1-10mum and coated on at least one surface of the polyester film. The three-layer co-extruded polyester base film has an A / B / A structure and is formed by two co-extruded surface layers (the A layers) and a core layer (the B layer) positioned between the two surface layers. The coat adopts an aqueous polyurethane coating liquid, and includes a silica colloid having a particle size of 40-50mum, and micron-sized silica having a particle size of 1-6mum. The optical base film having the above structure has the characteristics of high light transmittance, low haze, good adhesion resistance and the like, and is suitable for the use in optical films comprising diffusion films, whitening films and protection films for the optical use.

Owner:CHANGZHOU BAIJIA NIANDAI FILM TECH CO LTD

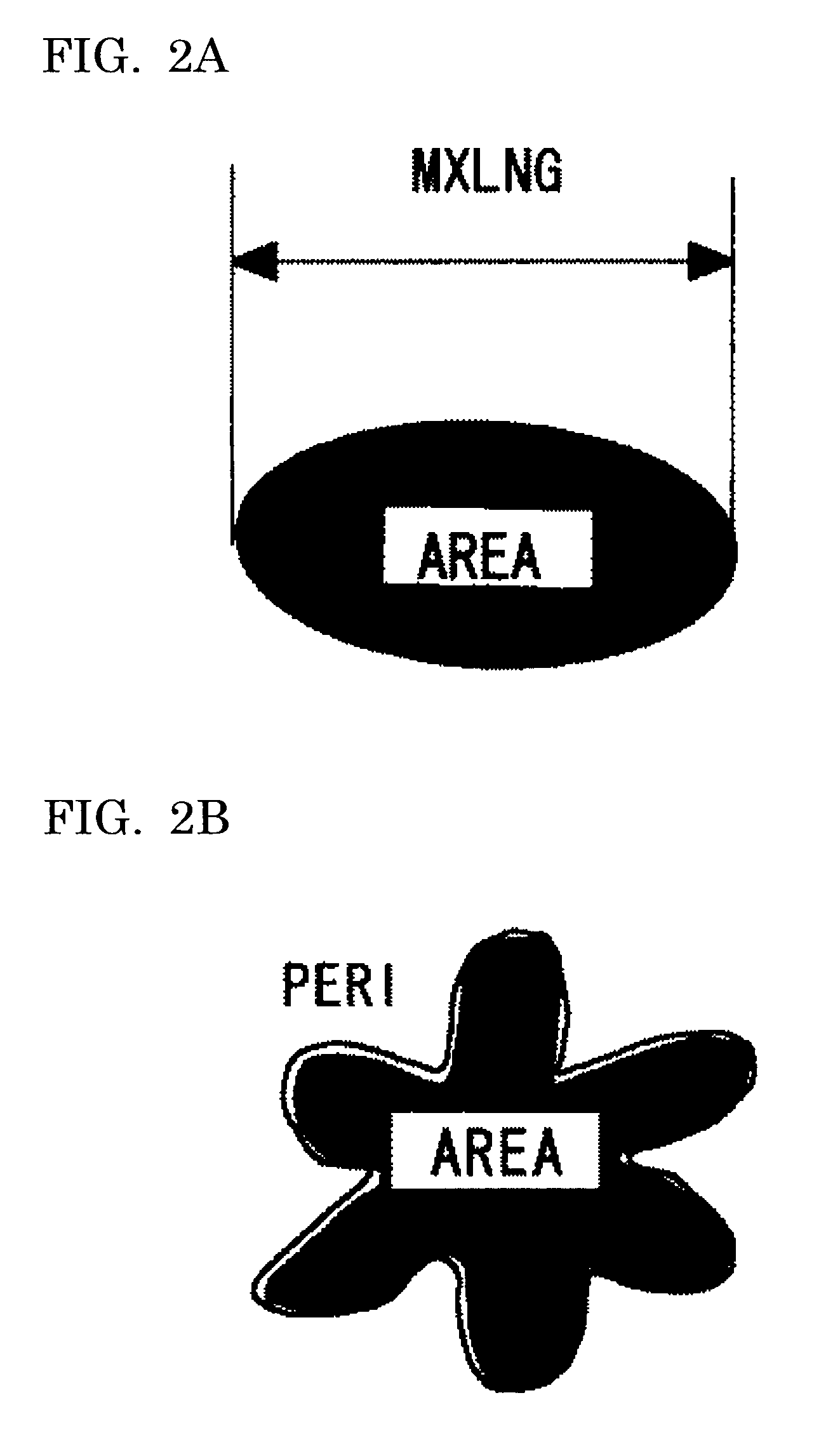

Electrostatic image developing toner and image forming apparatus using the same

InactiveUS20090011356A1Good anti-adhesionElectrographic process apparatusDevelopersPolymer sciencePtru catalyst

Provided is an electrostatic image developing toner excellent in blocking resistance at high temperature and humidity, as well as in low temperature-fixing property, having a polyester resin toner binder. Provided is the electrostatic image developing toner containing at least one noncrystalline polyester resin and a crystalline polyester resin, wherein the polyester resins are formed in the presence of at least one titanium-containing catalyst expressed in the following Formulas:Ti(—X)m(—OH)n O═Ti(—X)p(—OR)q where X is a residue resulting from removing an H atom in one hydroxyl group from (poly)alkanolamine having 2 to 12 carbon atoms, R represents an H atom or an alkyl group that has 1 to 8 carbon atoms and may contain 1 to 3 ether bonds, m, n, p, and q are integers; m, n, p, and q are 1-4, 0-3, 1-2, 0-1, respectively; and the sum of m and n, and p and q are 4 and 2, respectively.

Owner:RICOH KK

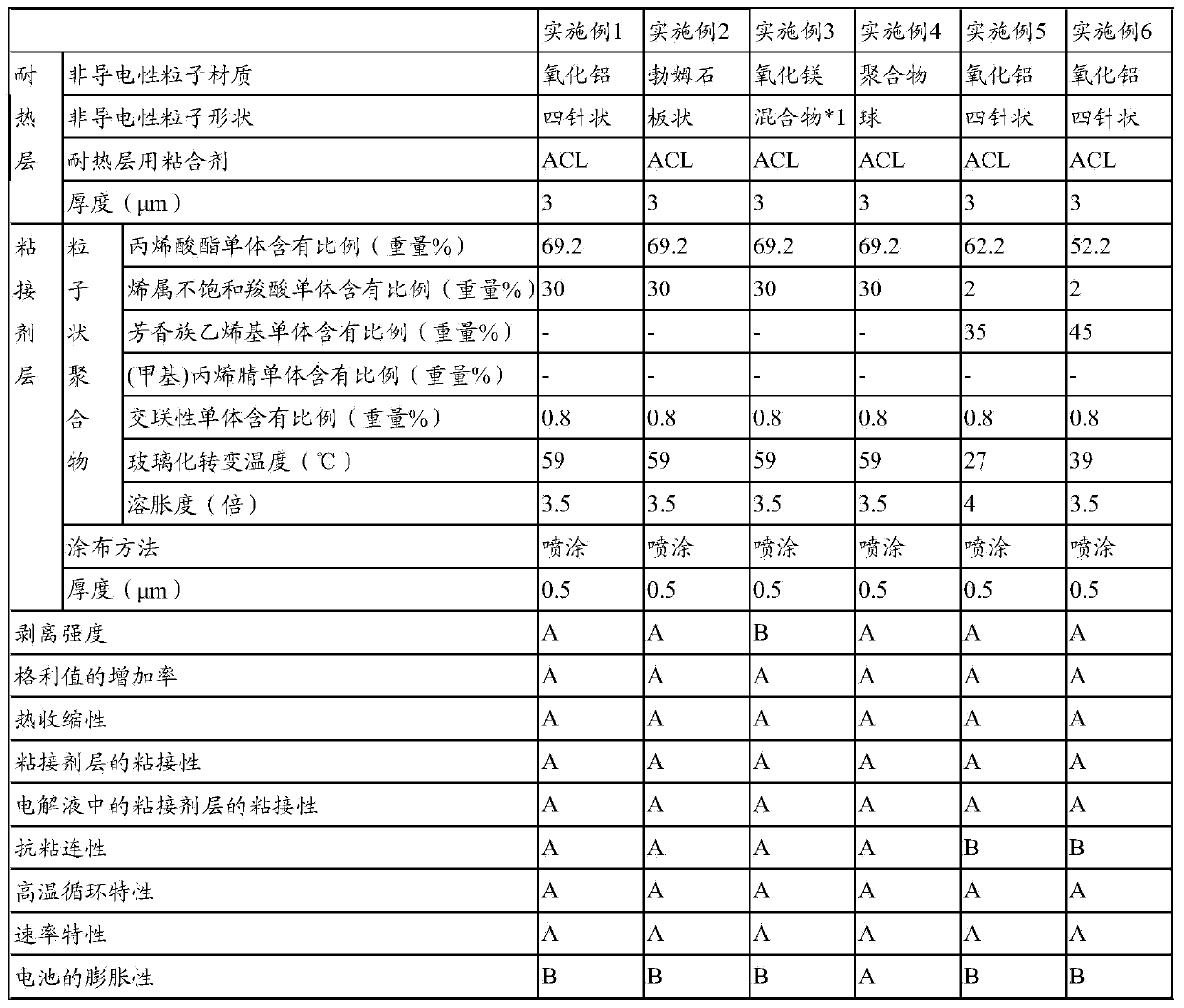

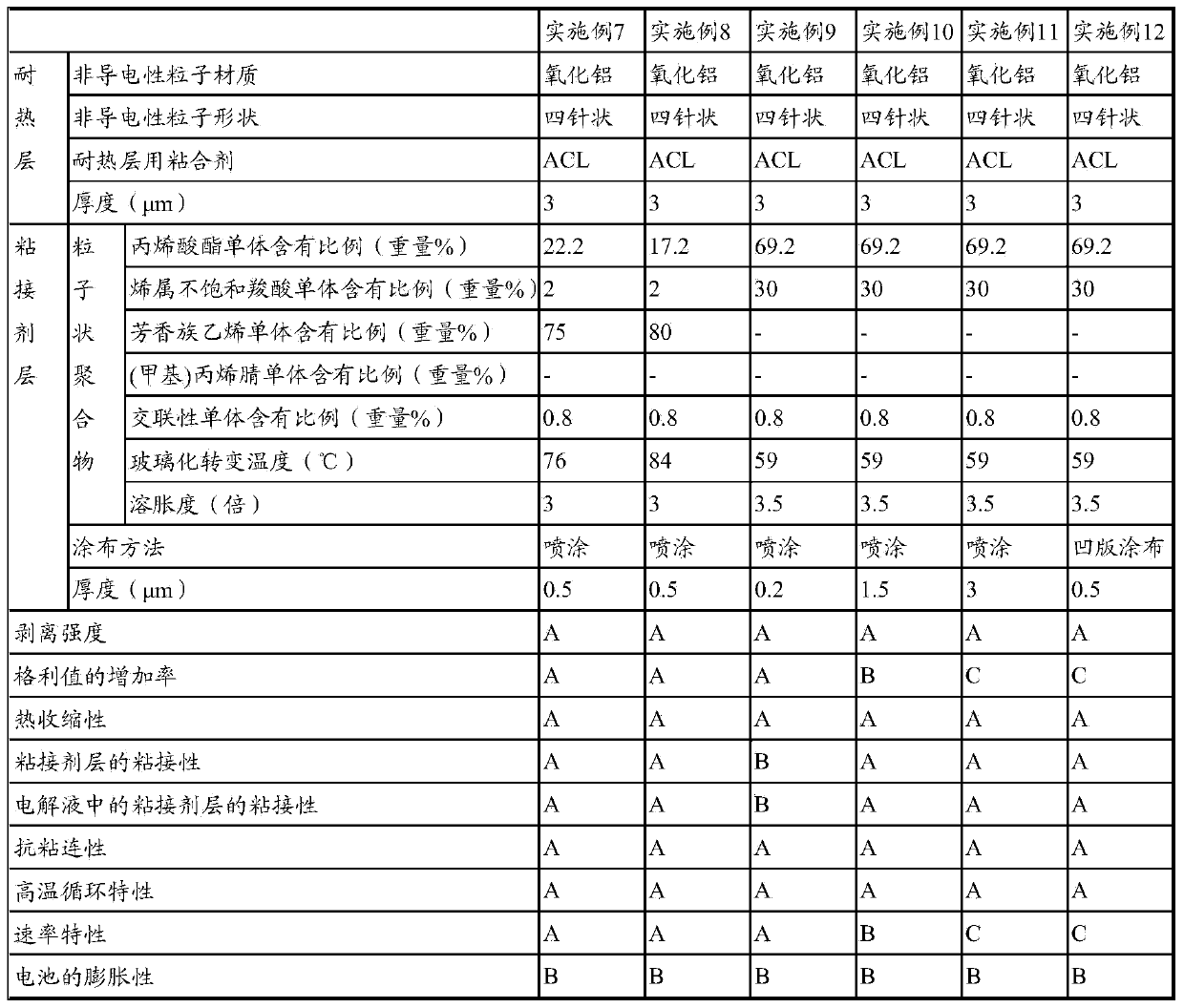

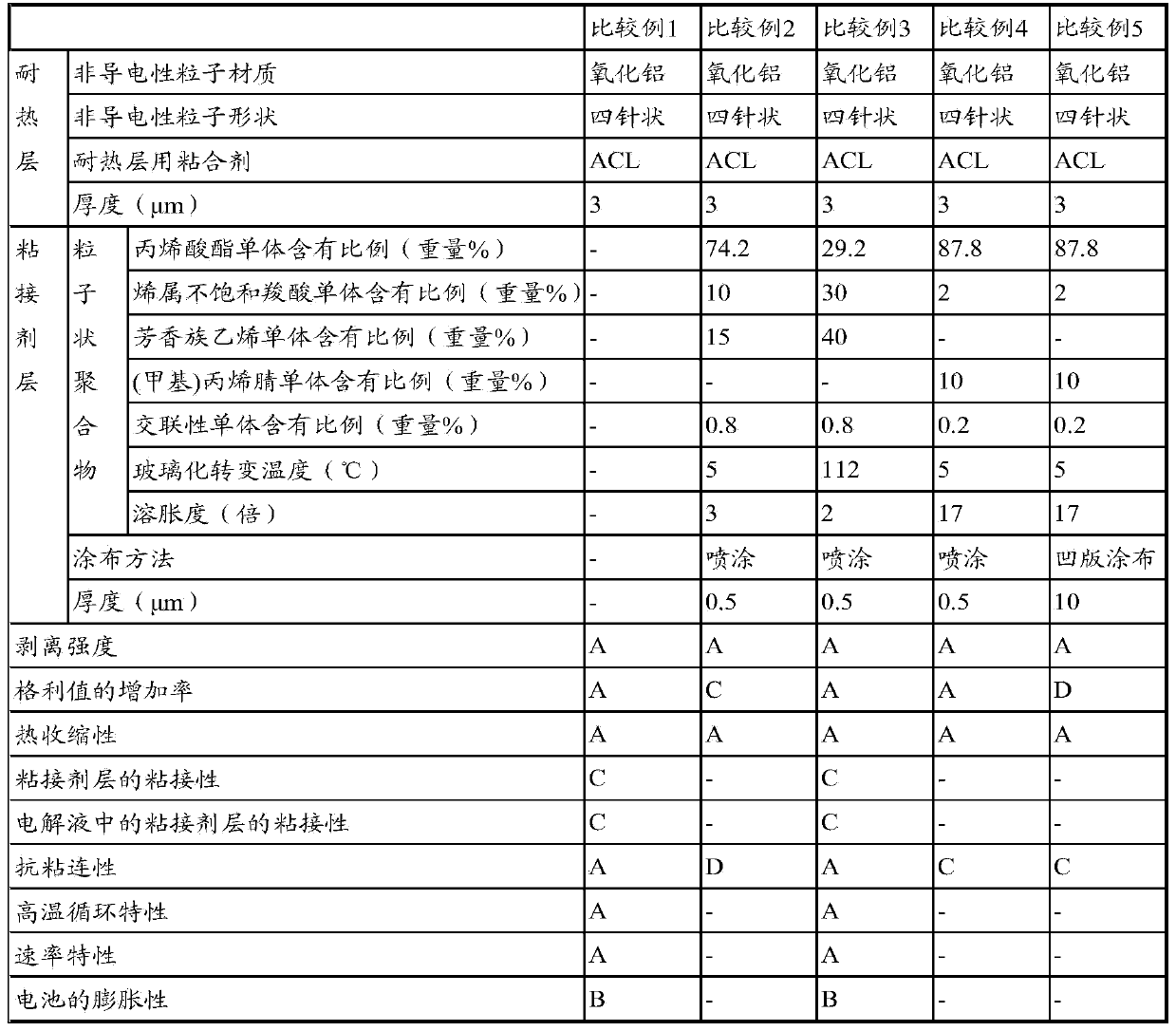

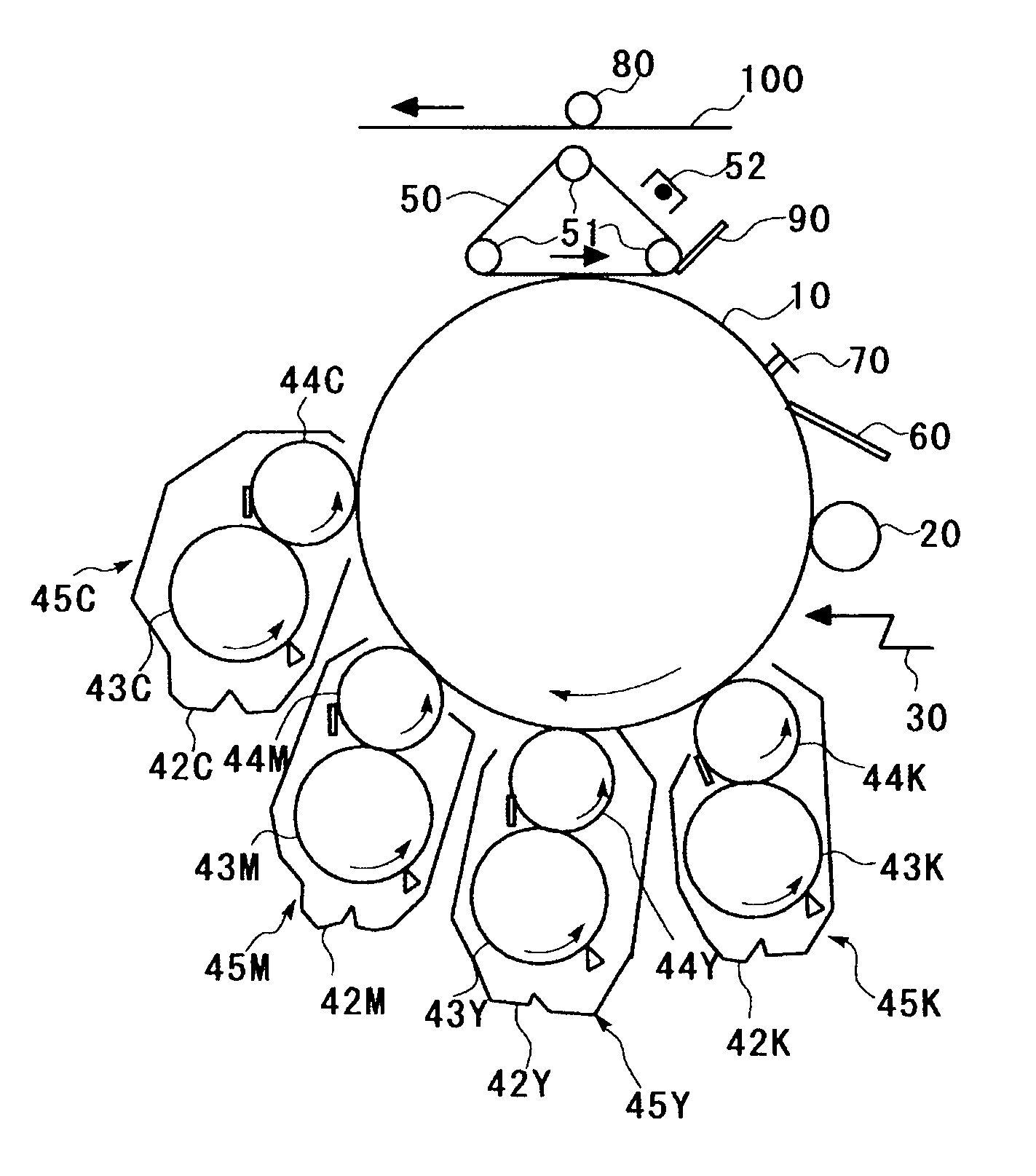

Separator for secondary cell

ActiveCN104221184AImprove featuresImprove heat resistanceCell seperators/membranes/diaphragms/spacersLi-accumulatorsParticulatesVitrification

Provided are: a separator for a secondary cell, the separator having good heat resistance, high adhesion to an electrode active material layer laminated on the collector, and high blocking resistance; and a secondary cell having the separator for a secondary cell. This separator for a secondary cell has an organic separator layer, a heat resistance layer formed adjacent to at least one surface of the organic separator layer, and an adhesive layer formed on the heat resistance layer, the heat resistance layer containing non-conductive particles and a binder, and the adhesive layer including a particulate polymer having a glass transition temperature (Tg) of 10 to 100 DEG C.

Owner:ZEON CORP

Electrostatic image developing toner, toner kit and image forming apparatus

ActiveUS20090123186A1Excellent blocking resistanceLow temperature fixabilityDevelopersElectrographic process apparatusHydrogen atomEther

A toner is provided that comprises a colorant and a binder resin, wherein the binder resin comprises a polyester resin that is prepared by a polycondensation reaction in the presence of at least a titanium-containing catalyst expressed by General Formula (II) or (II), the toner has a volume average particle diameter of 2.0 μm to 10.0 μm and a ratio Dv / Dn within a range of 1.00 to 1.40, in which Dv represents a volume average particle diameter and Dn represents a number average particle diameter,Ti(—X)m(-OH)n General Formula (I)O═Ti(—X)p(-OR)q General Formula (II)in General Formulas (I) and (II), X represents a residue of a mono-alkanolamine of 2 to 12 carbon atoms or a polyalkanolamine from which a hydrogen atom of one hydroxyl group is removed; other hydroxyl group(s) and still other hydroxyl group(s), within the polyalkanolamine molecule that has a directly bonding Ti atom, may polycondense to form a ring structure; other hydroxyl group(s) and still other hydroxyl group(s) may polycondense intermolecularly to form a repeating structure; and the polymerization degree is 2 to 5 in a case of forming the repeating structure; R represents one of a hydrogen atom and alkyl groups of 1 to 8 carbon atoms that may have 1 to 3 ether bonds; “m” is an integer of 1 to 4; “n” is an integer of 0 to 3; the sum of “m” and “n” is 4; “p” is an integer of 1 or 2; “q” is an integer of 0 or 1; the sum of “p” and “q” is 2; and in a case that “m” and “p” is 2 or more, the respective Xs may be identical or different each other.

Owner:RICOH KK

Toner binder and resin particle

Provided is a toner binder that is excellent in heat resistant storage properties and hot offset resistance properties and also affords excellent anti-blocking properties of paper when printing continuously. The present invention is directed to a toner binder comprising a crystalline resin (A), wherein the crystalline resin (A) comprises two or more crystalline resins (a) and the endothermic peak temperature group that is composed of all of the endothermic peak temperatures of the respective two or more crystalline resins (a) has two or more different endothermic peak temperatures; and a resin particle containing the toner binder.

Owner:SANYO CHEM IND LTD

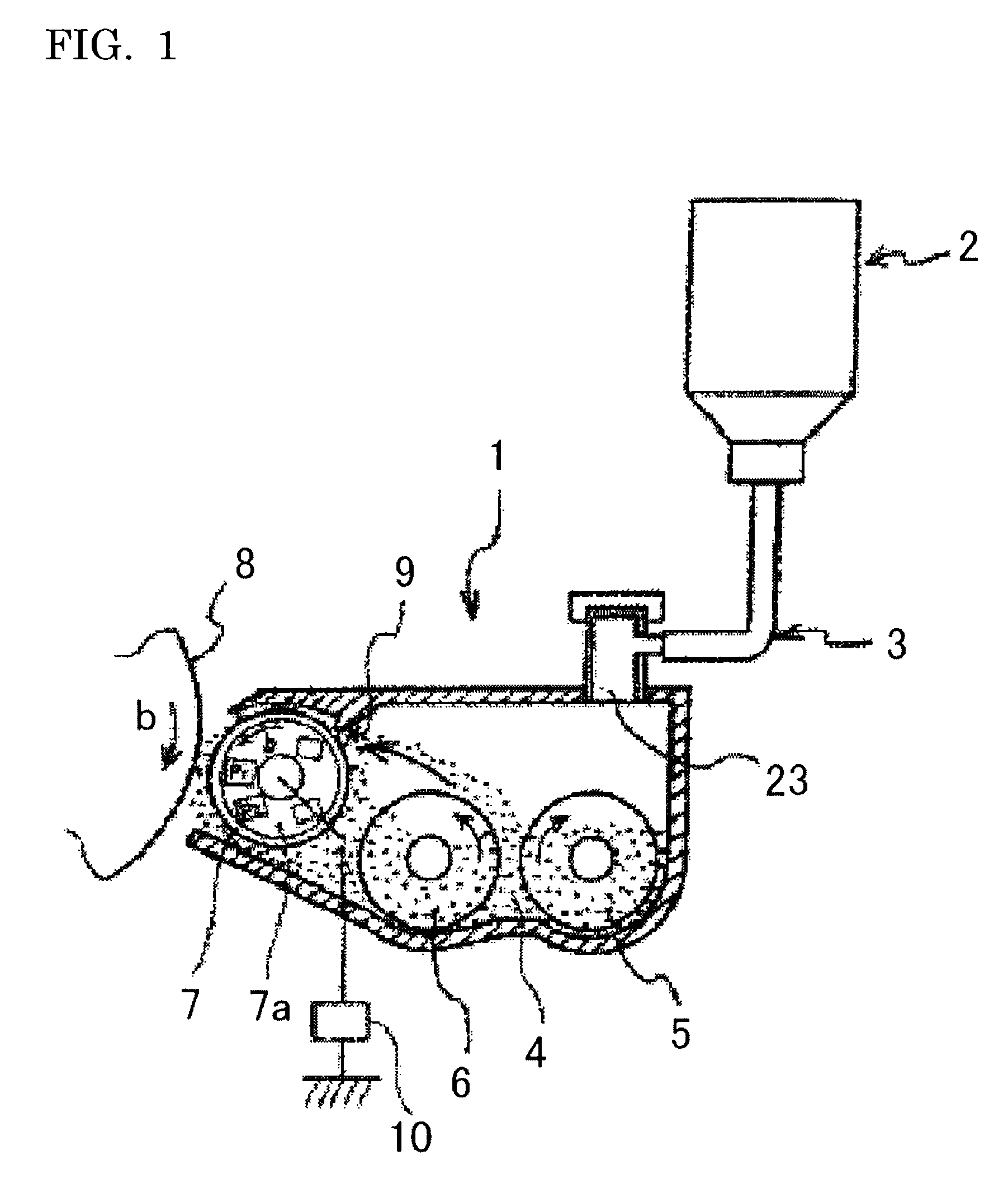

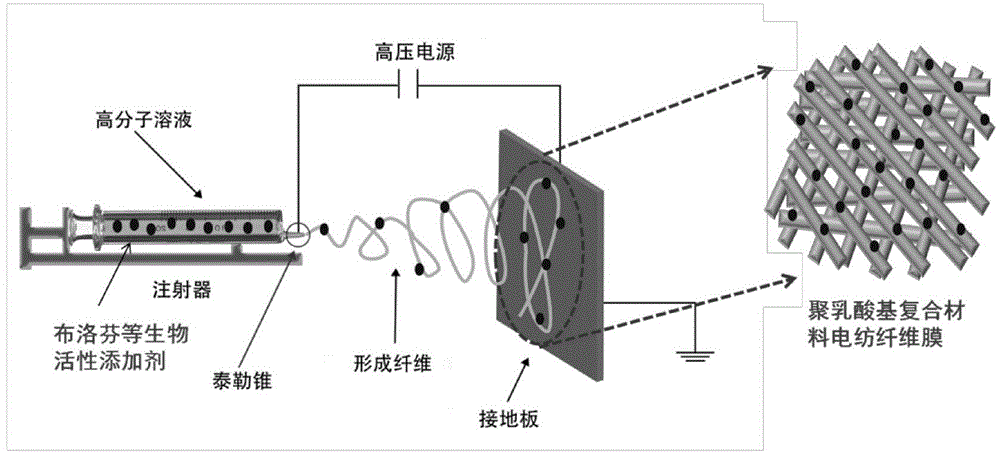

Polylactic acid-based composite material surgical medical film and preparation method thereof

InactiveCN104056297AImprove performanceGood flexibilityAbsorbent padsNon-woven fabricsFiberEnvironmental resistance

The invention discloses a polylactic acid-based composite material surgical medical film and a preparation method thereof. By adopting electrostatic spinning equipment and exploring proper technological parameters, different types of polylactic acid-based composite material macromolecular fiber thin films are finally formed and are applied to the field of biomedicine. In addition, by regulating and controlling composition of a macromolecular composite material system and thickness of an electro-spinning thin film, the surgical medical film which has good flexibility, high tensile strength, controllable degradation rate as well as excellent waterproof, antibacterial and air permeable performances is obtained finally. The surgical medical film is applicable to the field of various biomedicines such as healing film, wound surface dressing and anti-adhesion medicine; the medical film not only can be better adhered to tissues and avoid biotoxicity, but also can effectively promote transmission functions of blood, nutrients and growth factors in a human body due to the nature of semipermeable membrane. The process of the invention is simple and environment-friendly; the preparation method is easy to operate, low in cost, applicable to large-scale production and good in controllability, and is expected to be widely applied to various medical fields.

Owner:SICHUAN UNIV

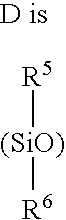

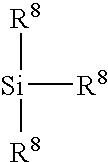

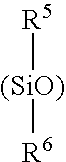

Monofunctional branched polysiloxanes, compositions and processes of preparing the same

InactiveUS7074488B2Good anti-adhesionImprove protectionElectrographic process apparatusThin material handlingPhotochemistryHydrocarbon

Branched monofunctional polysiloxanes are disclosed having the general formula:X-(Da)-(DbTc),wherein X-(Da) is a linear moiety and (DbTc) is a branched moiety; X a substituted or unsubstituted, monovalent or divalent hydrocarbon having a functional group;R5 and R6 are independently halogenated or unhalogenated monovalent hydrocarbon or substituted or unsubstituted divalent hydrocarbon;T is (R7)dSiO(4-d) / 2 R7 is a substituted or unsubstituted monovalent hydrocarbon; wherein the branched polysiloxane is end-capped byR8 is a substituted or unsubstituted monovalent hydrocarbon; a is 1 to 300, b is 25 to 5000, c is 1 to 100, d is 0 or 1; and Tc is randomly distributed in the branched polysiloxane. Additionally, processes for preparing such polysiloxanes, and coating compositions comprising the same is provided. A fuser member and substrate comprising a branched monofunctional polysiloxane of the above formula are also disclosed.

Owner:EASTMAN KODAK CO +2

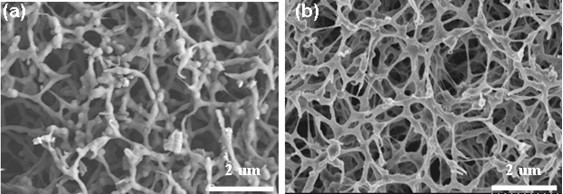

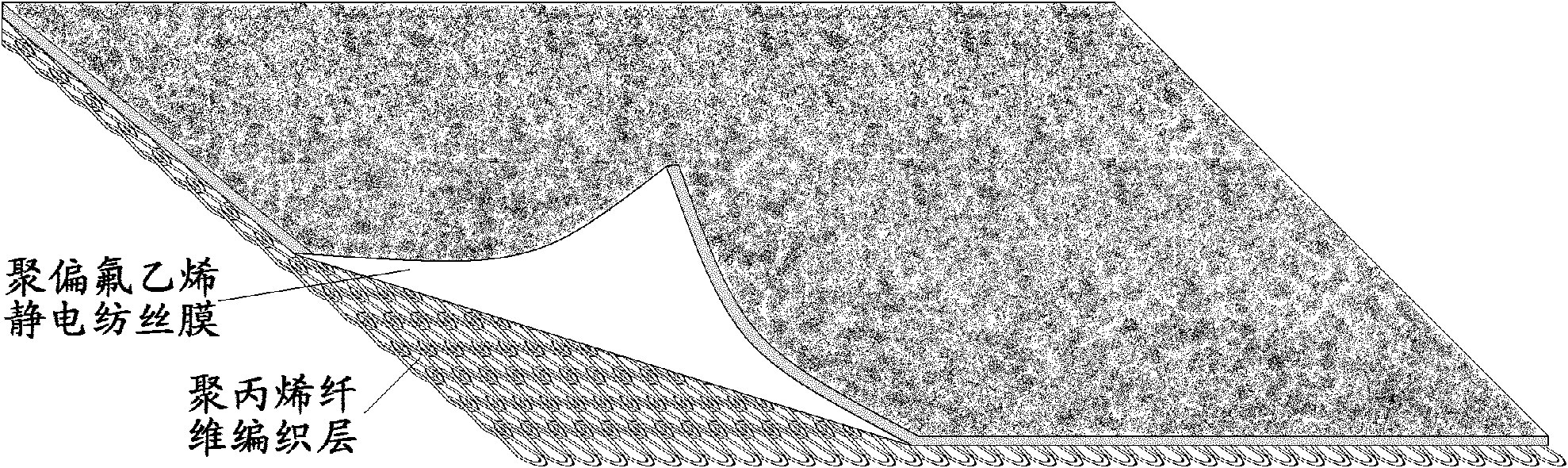

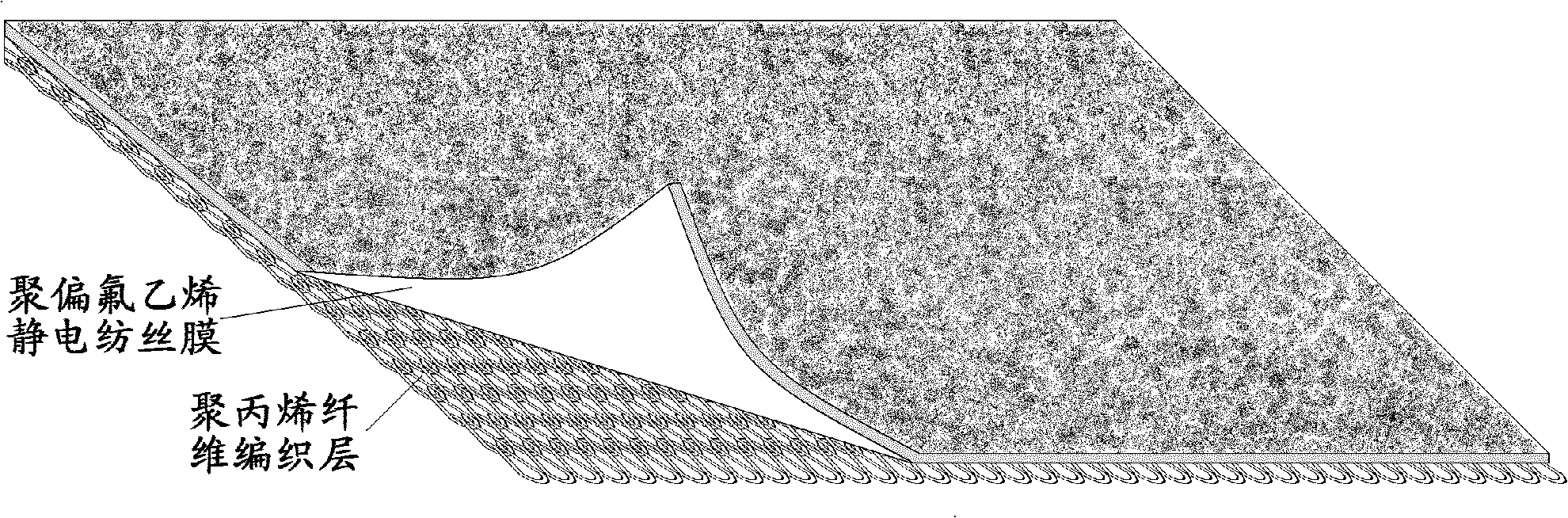

Polypropylene/polyvinylidene fluoride composite hernia patch and preparation method thereof

InactiveCN102085122AEasy to stickNot easy to stickProsthesisBiocompatibility TestingMechanical property

The invention relates to a polypropylene / polyvinylidene fluoride composite hernia patch and a preparation method thereof. The composite hernia patch has a bilayer structure, wherein the bottom layer is a plasma modified polypropylene braid and the surface layer is a polyvinylidene fluoride electrospinning film. The preparation method comprises the following steps: (1) dissolving polyvinylidene fluoride in the mixed solution of dimethylformamide and acetone to prepare polyvinylidene fluoride solution; (2) performing plasma modification to the polypropylene fiber braid; (3) adopting the electrospinning method to spray the polyvinylidene fluoride solution on the modified polypropylene fiber braid; and (4) shaping the composite fabric and drying. The hernia patch of the invention has stable structure and good mechanical properties and biocompatibility; by utilizing the good anti-adhesion property of polyvinylidene fluoride, the problem that the polypropylene hernia patch prepared from a single material is easy to be adhered with intestinal tissues can be overcome; and the preparation method is simple and is suitable for industrial production.

Owner:DONGHUA UNIV

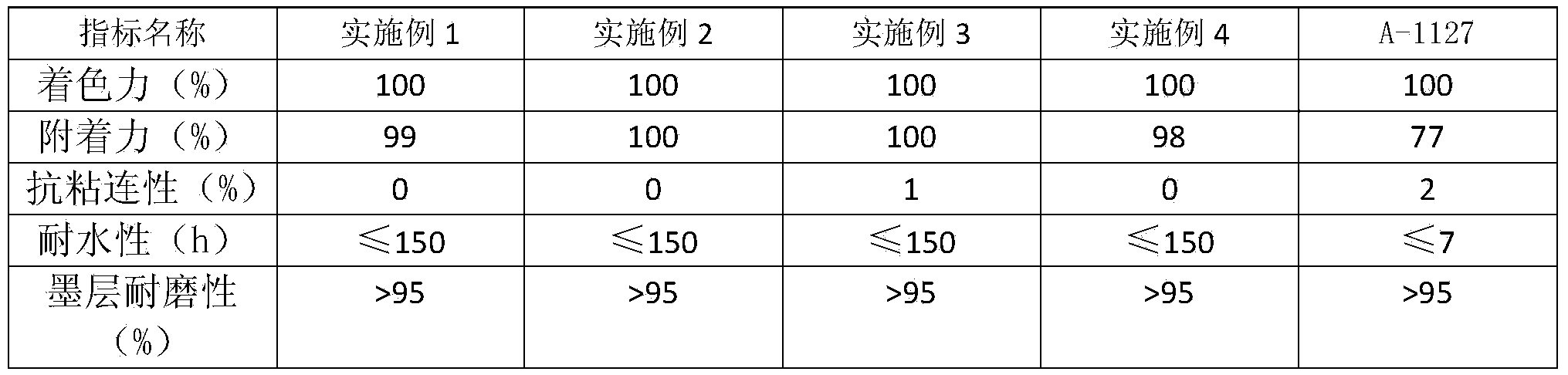

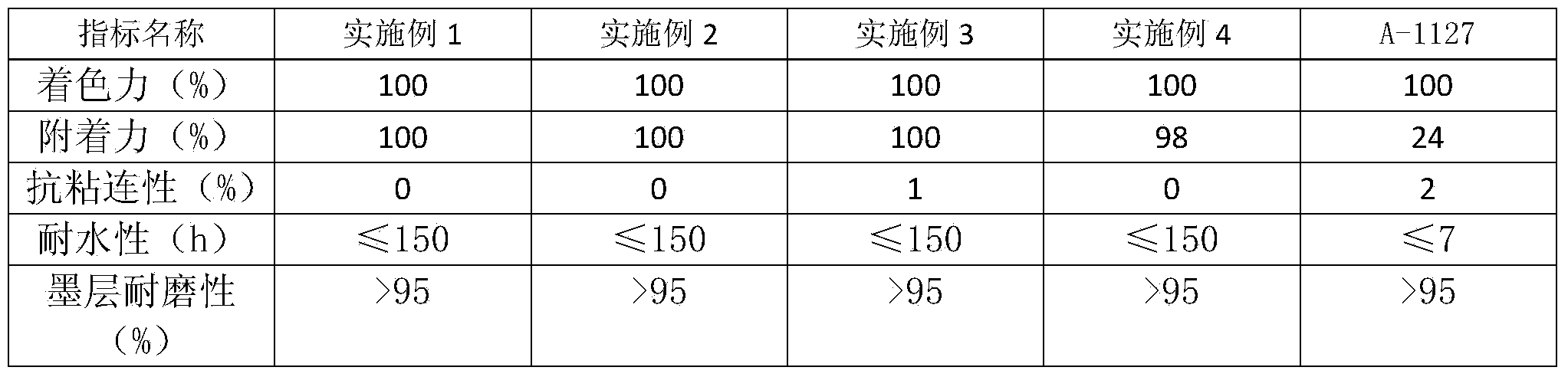

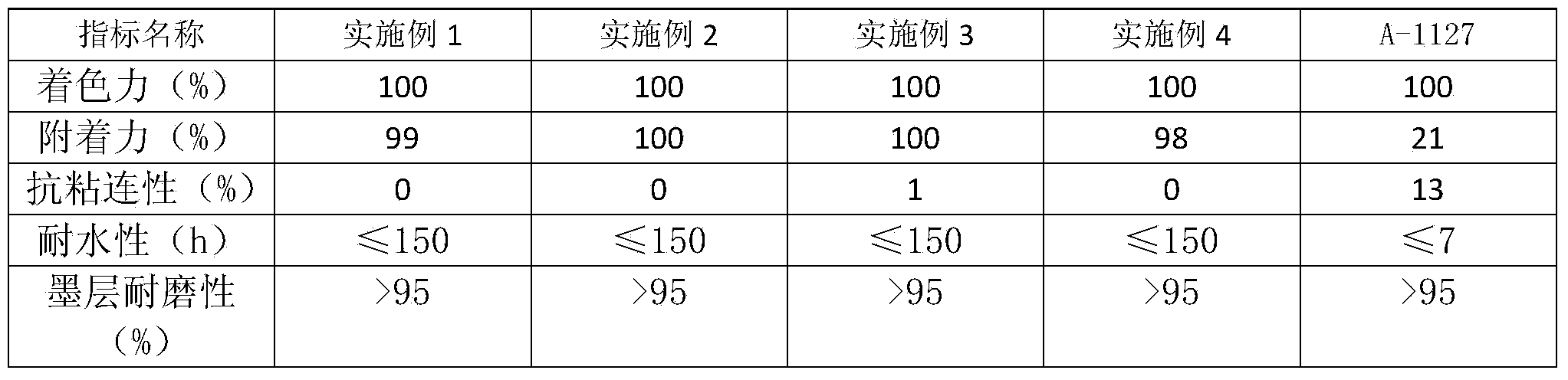

Low-temperature self-crosslinking acrylate emulsion with core-shell structure as well as preparation method and application thereof

The invention discloses a low temperature self-crosslinking acrylate emulsion with a core-shell structure as well as a preparation method and application thereof. The preparation method comprises the following steps: weighing the following materials in parts by weight: 30-40 parts of shell monomer, 0.8-1.2 parts of emulsifier and 7-14 parts of deionized water, and dispersing the materials to prepare a pre-emulsified shell monomer; weighing 0.2-0.5 parts of initiator and 10-18 parts of deionized water to prepare a shell initiator liquid, keeping temperature at 70-80 DEG C, simultaneously dropwise adding the pre-emulsified shell monomer and the shell initiator liquid into a core-layer emulsion within 2-3 hours so as to prepare a shell-layer emulsion, reacting at the constant temperature for 2-4 hours, cooling, and regulating the pH value. The acrylate emulsion prepared by the invention is environment-friendly, low in cost and simple in production process, and has the characteristics of self-crosslinking at a low temperature (40DEG C), high adhesion, good water tolerance, excellent anti-adhesion and the like; the emulsion can be used as a water-based ink binder so as to be compounded with a water-based color paste to obtain PP / PE (Propen Polymer / Poly Ethylene) film water-based ink.

Owner:SOUTH CHINA UNIV OF TECH

Water-based woodenware matte varnish

InactiveCN101186773AGood chemical resistanceImprove grinding effectLiquid surface applicatorsCoatingsWater basedCross-link

The invention discloses matte transparent finish paint for the surface of wooden ware which is used for family decorates and furniture production. The formula and mixture ratio are that self-cross linking acrylic resin is 75-85, polysiloxane antifoaming agent is 0.3-0.6, organic silicon flatting and slipping agent is 0.3-0.6, polyether modified wetting agent is 0.3-0.5, macromolecular dispersant is 0.3-0.5, silica matting agent is 1.5-3, Dipropylene Glycol Methyl Ether is 5-8, propyleneglycol monobutyl ether is 5-8, polyurethane associated rheological additives are 1-3, and water is 4-6. The invention is characterized by 1, good chemical resistance, 2, excellent blocking resistance, 3, good sanding ability, 4, high hardness, 5, good waterproof property, 6, excellent fullness and hand feeling.

Owner:GUANGDONG SANVO CHEM IND TECH

Water soluble acrylic resin and its prepn

The present invention relates to one kind of water soluble acrylic resin for ink, polish oil and paint and its preparation process. The organic silicone oil modified acrylic resin is prepared with acrylic acid monomer 15-57 wt%, organic silicone oil with double bond 1-15 wt%, organic solvent 20-60 wt% and initiator 0.1-10 wt%, and through free radical solution polymerization at 60-160 deg.c to obtain organic silicone oil modified acrylic resin, adding neutralizing agent and water through stirring, distilling to eliminate organic solvent, further adding neutralizing agent and water to reach solid content of 20-60 wt%. The organic silicone oil modified acrylic resin has high vitrification point, low filming temperature, high water tolerance and other advantages.

Owner:JIANGSU SANMU GROUP CORPORATION

Water-based matt handfeel oil and preparation method thereof

ActiveCN103031050AImprove performanceStrong adhesionAntifouling/underwater paintsPaints with biocidesPolyesterPolymer science

The invention relates to the technical field of preparation of handfeel oil, in particular to water-based matte handfeel oil and a preparation method thereof. The water-based matt handfeel oil consists of the following raw materials in part by weight: 72 to 87 parts of matt resin, 7 to 14 parts of bright resin, 2 to 5 parts of alcohol, 1 to 4 parts of water, 1 to 4 parts of handfeel agent, 0.5 to 1.5 parts of anti-sticking agent, 2 to 4 parts of flatting agent, 2 to 8 parts of wear-resistant agent, 0.1 to 1.5 parts of mildew preventive, 0.2 to 0.6 part of defoaming agent, 0.2 to 0.8 part of thickening agent and 0.5 to 1.4 parts of handfeel crosslinking agent. By adoption of polyester polyol and aziridine crosslinking agent, the wear resistance, the attachment fastness and the chemical resistance of the handfeel oil are greatly improved and high practicability is achieved. The preparation method is simple in process, low in production cost and favorable for popularization and application.

Owner:广东佳景科技股份有限公司

Water-soluble copolyester and preparation method thereof

The invention discloses water-soluble copolyester and a preparation method thereof. Caprolactone, dicarboxylic acid or ester thereof, m-benzene sulfonate and dihydric alcohol are adopted as raw materials, and the method comprises the following steps of: raising the temperature to catalyze quick ring opening; and raising the temperature for esterification and polycondensation. The polyester resin has good water solubility and better adhesion; and when used for textile sizing, the polyester resin can well adhere to hairs to greatly reduce the end breakage of warp yarns in the weaving process; therefore, the production efficiency and the quality of textiles are improved.

Owner:中瀚新材料科技有限公司

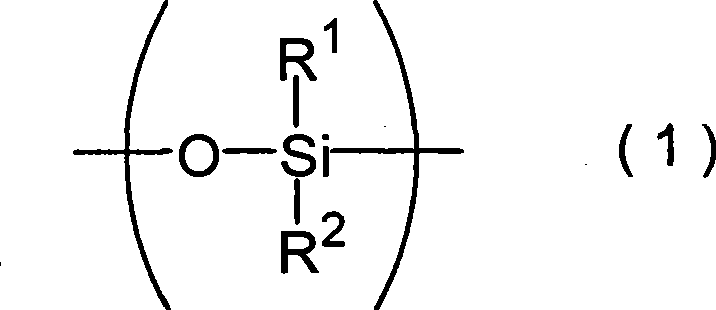

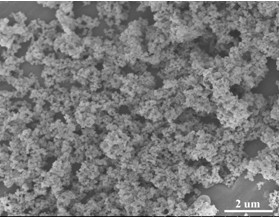

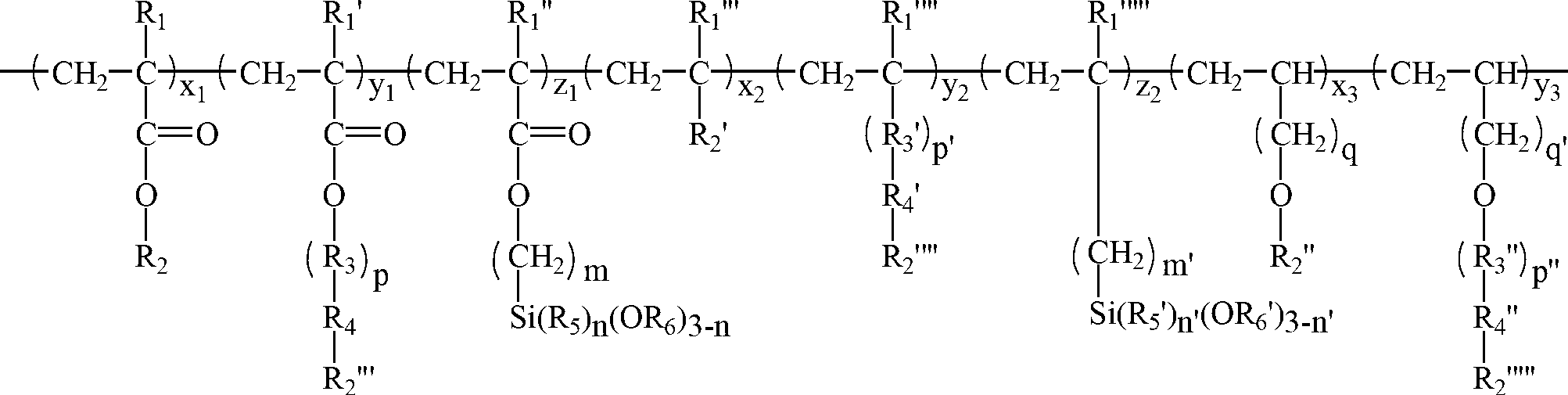

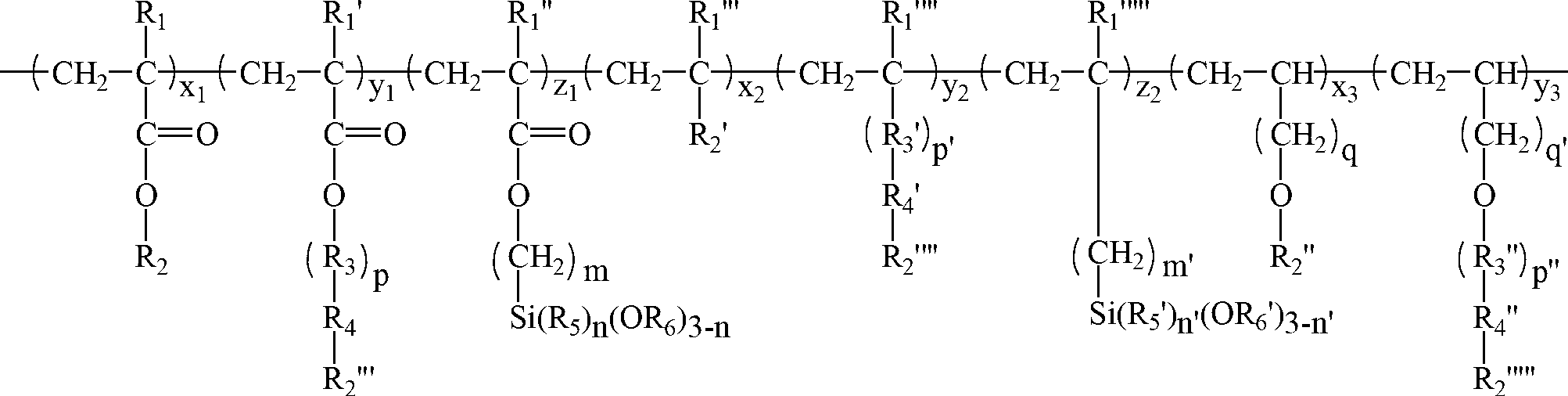

Ultraviolet cross-linked organosilicone modified acrylate copolymer emulsion

The invention discloses an ultraviolet cross-linked organosilicone modified acrylate copolymer emulsion which belongs to the field of high-molecular compounds. The ultraviolet cross-linked organosilicone modified acrylate copolymer emulsion is formed by constitutional repeating units and is a modified acrylate copolymer with a side chain containing an ultraviolet active group and an alkoxy siloxane group. The ultraviolet cross-linked organosilicone modified acrylate copolymer emulsion is obtained through the copolymerization reaction of an ultraviolet active single-functionality degree monomer, an alkoxy siloxane single-functionality degree monomer and a third single-functionality degree monomer. According to the ultraviolet cross-linked organosilicone modified acrylate copolymer emulsion, the side chain of the copolymer contains the ultraviolet active group and the alkoxy siloxane group, double crosslinking is realized, i.e. ultraviolet self-crosslinking and organosilicone self-crosslinking, and a high elastic material with good flexibility is formed, has high surface smoothness, strong contamination resistance, excellent adhesion resistance and no residual small molecules.

Owner:邯郸市瑞斯达乳胶科技有限公司

Process for producing powdery linear polymer having improved powder properties

InactiveUS20050049332A1Avoid cloggingPreventing excessive coagulationSynthetic resin layered productsCellulosic plastic layered productsVitrificationPolymer science

A powdery linear polymer having a narrow particle size distribution with little dusting and excellent in anti-blocking property is recovered from a latex of a linear polymer containing a large proportion (35-75 wt. %) of soft polymer (S) component through a two-step coagulation process including a first (moderate coagulation) step causing 70-98 wt. % of the coagulation. The linear polymer in the latex has a multilayer structure comprising a linear polymer (S) having a glass transition temperature below 40° C. and a linear polymer (H) having a higher glass transition temperature disposed in totally at least two layers and containing 35-75 wt. %, as a whole, of the linear polymer (S) with the proviso that the linear polymer (S) cannot be contained in excess of 30 wt. % in an outermost layer of the multilayer structure.

Owner:ROHM & HAAS CO

Organosilicon-modified acrylate emulsion and preparation method of coating agent for powder-free gloves

InactiveCN101575398ALow costImprove unevennessAntifouling/underwater paintsPaints with biocidesEmulsionSolid content

The invention relates to an organosilicon-modified acrylate emulsion and a preparation method of a coating agent for powder-free gloves. The preparation method comprises the following steps of: preparing the organosilicone-modified acrylate emulsion; adding the organosilicon-modified acrylate emulsion into a stirred tank; adding a wetting agent for base materials, a germicide and deionized water under constant mixing; then adding a foam killer, a thickening agent, a pH value conditioner after evenly mixing; and discharging after evenly mixing. The solid content of the coating agent of the organosilicon-modified acrylate emulsion is between 10% and 30%; the surface tension is not more than 35mN / m; and the viscosity is between 100 mPa.s and 1000mPa.s; and the pH value is between 7 and 9. The coating agent is diluted with the deionized water according to a rate of 1:19, is leached by a hand model coated with a disposable glove and then is dried at the temperature between 100 DEG C and 150 DEG C. Finally the powder-free gloves processed by the coating agent are formed after demolding.

Owner:天津碧海蓝天水性高分子材料有限公司

Preparation method of medical hemostatic occlusion dressing

The invention discloses a preparation method of a medical hemostatic occlusion dressing. The preparation method comprises the following steps: (1), taking and pouring deionized water into a reactor, heating the reactor, slowly adding lemon peel pectin and gelatin, and mechanically stirring at the same time; (2), after the addition of the lemon peel pectin and gelatin, stirring continuously, then adding other components into the reactor, and carrying out mechanical stirring uniformly at the same time; (3), after the mixing of the materials, cooling hydrogel to be at a room temperature, so as to obtain the medical hemostatic occlusion dressing. The medical hemostatic occlusion dressing prepared through the method provided by the invention is high in bleeding stopping speed, has auxiliary functions of promoting wound surface healing, preventing adhesion and the like, is also better in biomechanics and air permeability, and has an important clinical application value; the preparation method provided by the invention has the advantages that the process is simple, requirements for equipment are relaxed, raw materials are low in cost and readily available, the cost is low, and industrialization is easy to realize.

Owner:SUZHOU BEC BIOLOGICAL TECH

Glass fibre reinforced plastic and anti-fouling corrosion resistant protecting agent for surface of high molecular products thereof

InactiveCN101338039AExcellent water repellencyExcellent weather resistance and durabilityCoatingsIonCorrosion resistant

The invention relates to a surface antifouling corrosion-resistant protectant for glass fiber reinforced plastic and other polymer products. The surface antifouling corrosion resistant protectant for glass fiber reinforced plastic and other polymer products, which is provided by the invention, is composed of fluoro-alkyl silane, long-chain alkyl silane, nanometer SiO2, alkyl silicate, alcohol, inorganic acid catalysts and de-ionized water or distilled water. The surface antifouling corrosion resistant protectant for glass fiber reinforced plastic and other polymer products, which is provided by the invention, can form a layer of low surface water-repellent, oil-proof, antifouling, anti-sticking, anti-ultraviolet and corrosion-resistant coat film on the surfaces of the glass fiber reinforced plastic and the other polymer products, the water contact angle can reach as high as 149 DEG, the purposes of effective reduction of rain accumulation as well as the attachment of atmospheric dust, guano, etc. on the surfaces of the glass fiber reinforced plastic and the other polymer products, acid rain corrosion damage resistance, salt mist corrosion damage resistance, ultraviolet corrosion damage resistance and reduction of use and maintenance cost are achieved.

Owner:SHANGHAI NALE MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com